Centrifugal fan volute profile design method

A centrifugal fan and design method technology, applied in design optimization/simulation, calculation, instrument, etc., can solve the uneven distribution of flow parameters at the inlet of the volute, lack of distribution control, failure to determine the size of the volute tongue gap, assumptions Inconsistent with the actual situation and other problems, to achieve the effect of promoting the diffusion effect, simple design method, and reducing flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

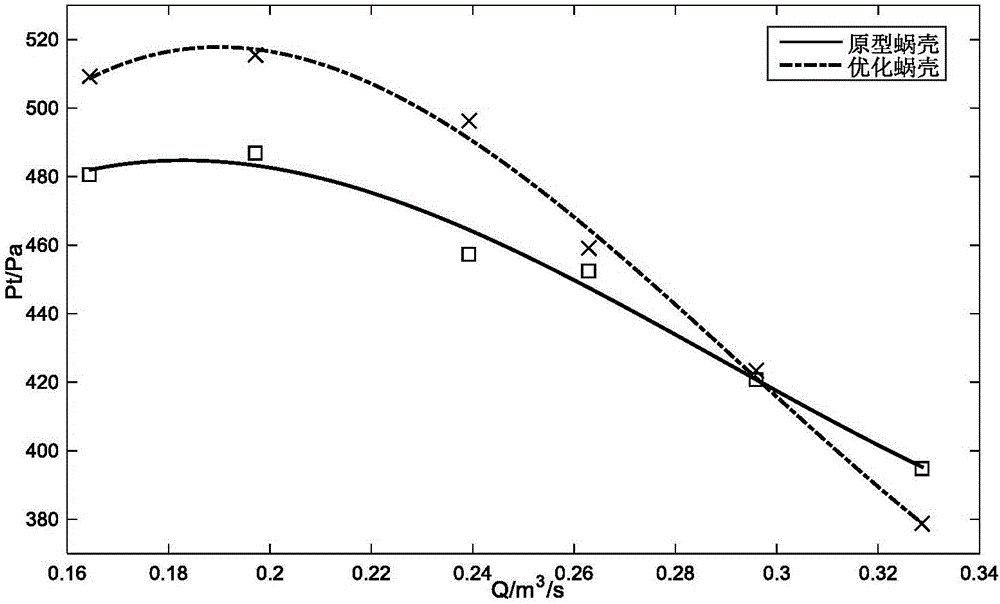

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

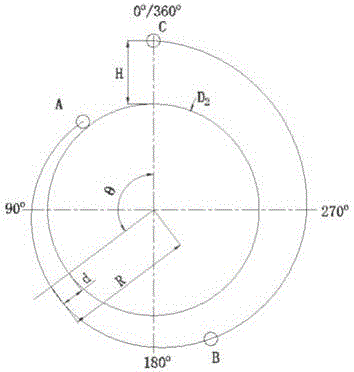

[0033] According to an embodiment of the present invention, the volute outer shape line of the forward curved centrifugal fan is drawn by the equilateral basis method, and the impeller diameter D 2 = 400mm.

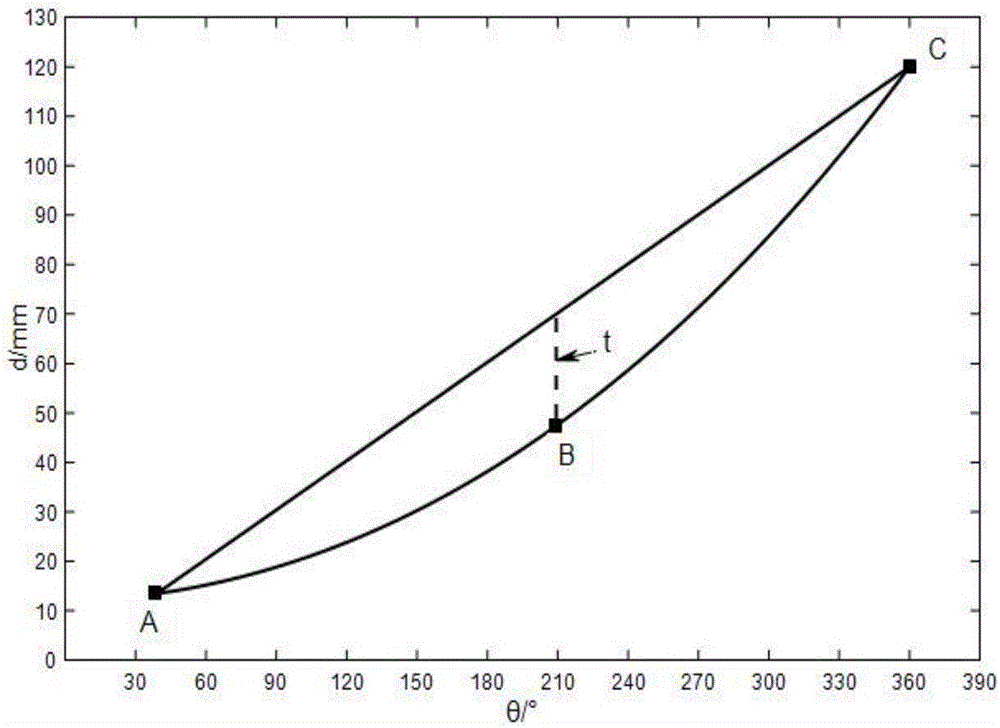

[0034] The starting point of the outer profile of the volute is the position of the volute tongue, and the ending point is the position of the opening of the volute outlet. For the centrifugal fan volute, its cross-sectional shape is rectangular, the volute width K remains unchanged, the distance d from the impeller outlet to the outer shape line in the radial direction and the radial cross-sectional area S (S=d*K) Proportional. Therefore, the angle θ-distance d image can vividly describe the distribution of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com