Compressor stator cascade with constant depth grooves in end wall

A compressor and cascade technology, which is applied in the field of stator cascades of compressors, to achieve the effect of improving the diffusion capacity, reducing the total pressure loss coefficient, and not destroying the physical structure of the blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

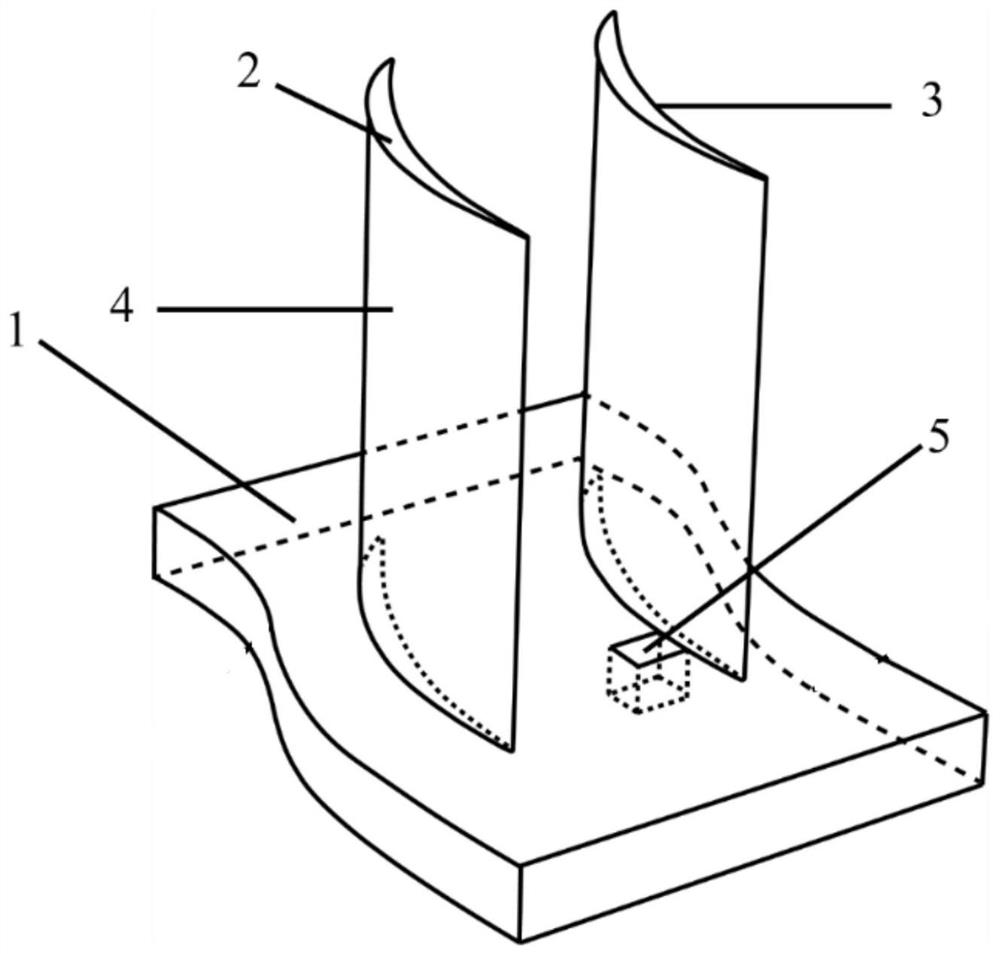

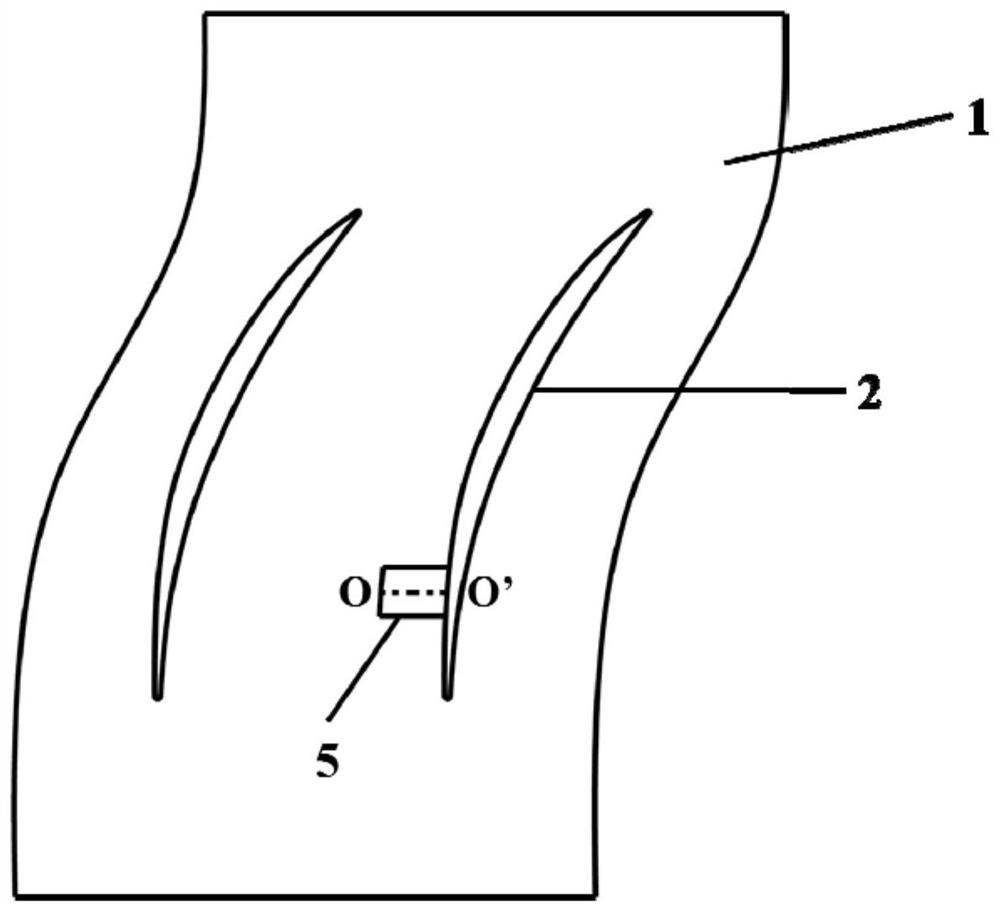

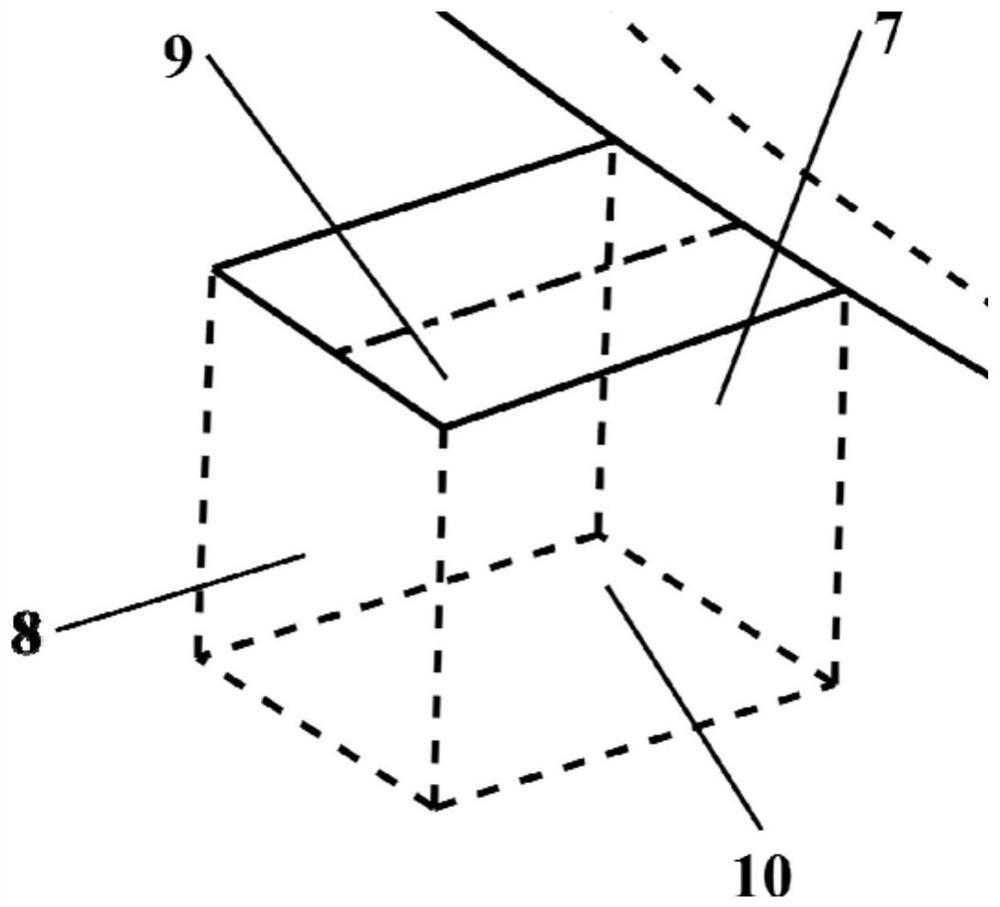

[0021] like Figure 1-Figure 3 As shown, the compressor stator blade cascade provided by the present invention with the end wall having equal depth grooves includes a lower end wall 1, an upper end wall and a plurality of blades 2 arranged side by side between the lower end wall 1 and the upper end wall; The space between the blades 2 is the cascade channel, the blade 2 is an arc-shaped plate, the inner arc surface is the pressure surface 3, the outer arc surface is the suction surface 4, and the inner arc surface and the outer arc surface have two intersections in the axial direction. The intersection line near the intake direction is the leading edge line, and the intersection line near the outlet direction is the trailing edge line, the distance between the leading edge line and the trailing edge line is the blade chord length, and the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com