Patents

Literature

89969results about "Design optimisation/simulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total joint arthroplasty system

ActiveUS20090131941A1Precise alignmentImprove visualizationMedical simulationProgramme controlJoint arthroplastyTotal hip arthroplasty

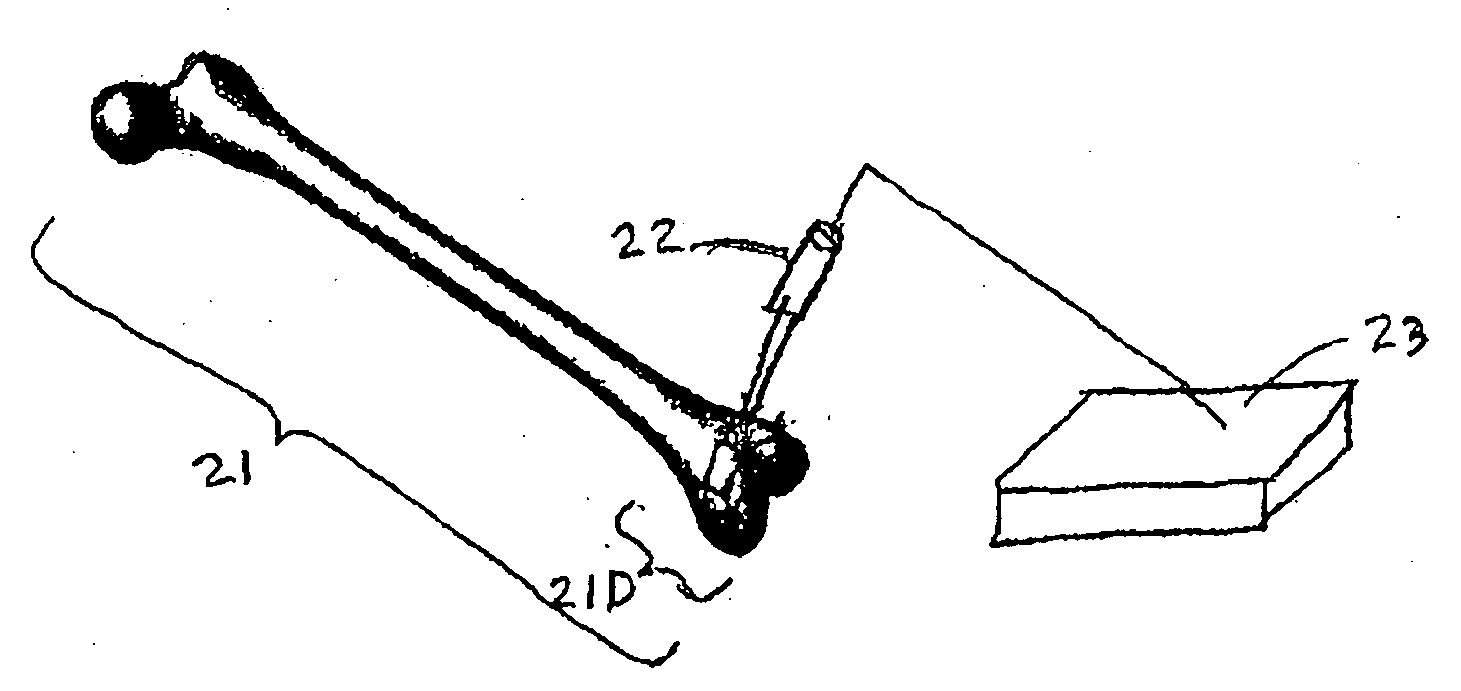

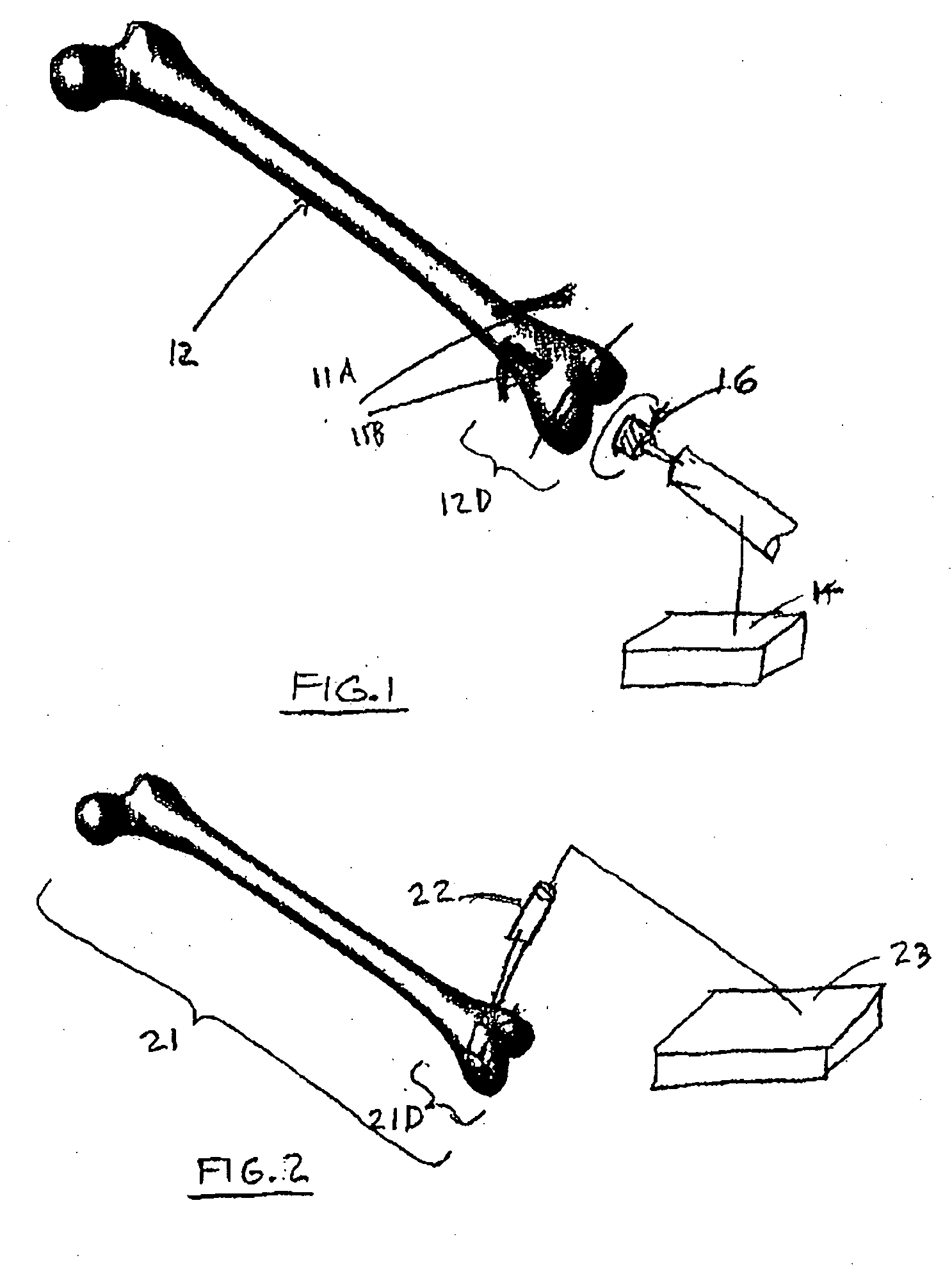

A method and system for performing a total joint arthroplasty procedure on a patient's damaged bone region. A CT image or other suitable image is formed of the damaged bone surfaces, and location coordinate values (xn,yn,zn) are determined for a selected sequence of bone surface locations using the CT image data. A mathematical model z=f(x,y) of a surface that accurately matches the bone surface coordinates at the selected bone spice locations, or matches surface normal vector components at selected bone surface locations, is determined. The model provides a production file from which a cutting jig and an implant device (optional), each patient-specific and having controllable alignment, are fabricated for the damaged bone by automated processing. At this point, the patient is cut open (once), the cutting jig and a cutting instrument are used to remove a selected portion of the bone and to provide an exposed planar surface, the implant device is optionally secured to and aligned with the remainder of the bone, and the patient's incision is promptly repaired.

Owner:HOWMEDICA OSTEONICS CORP

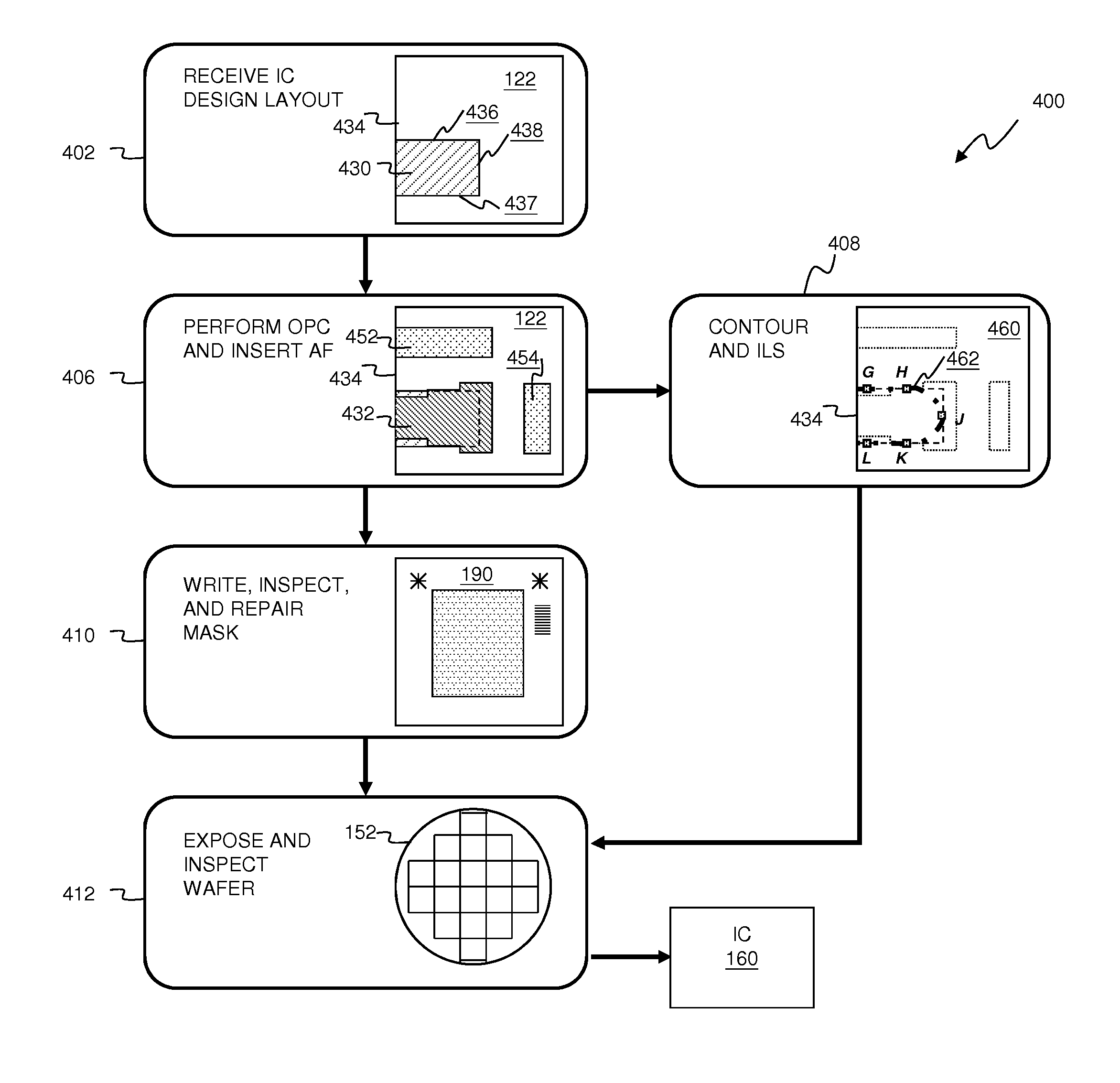

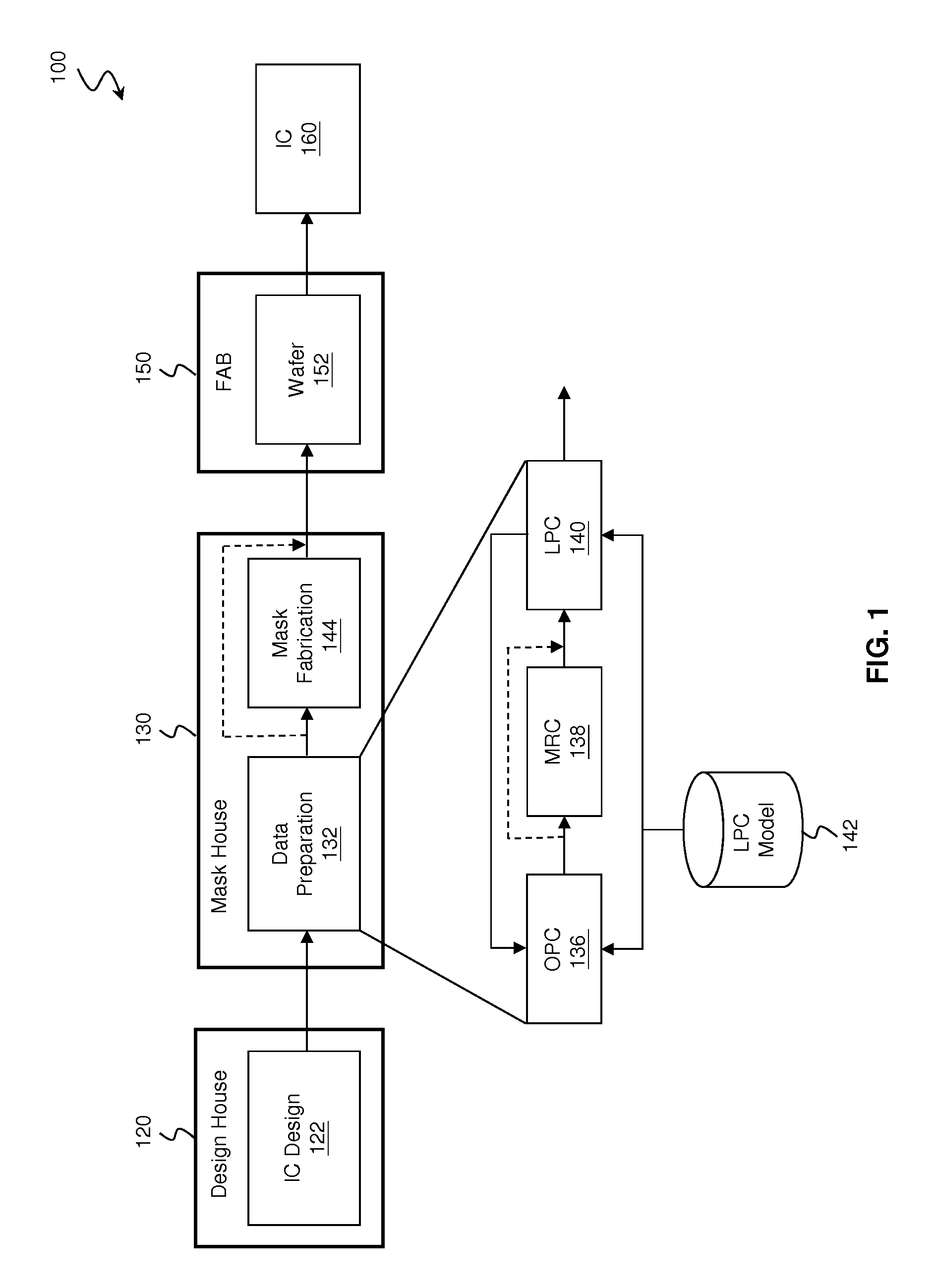

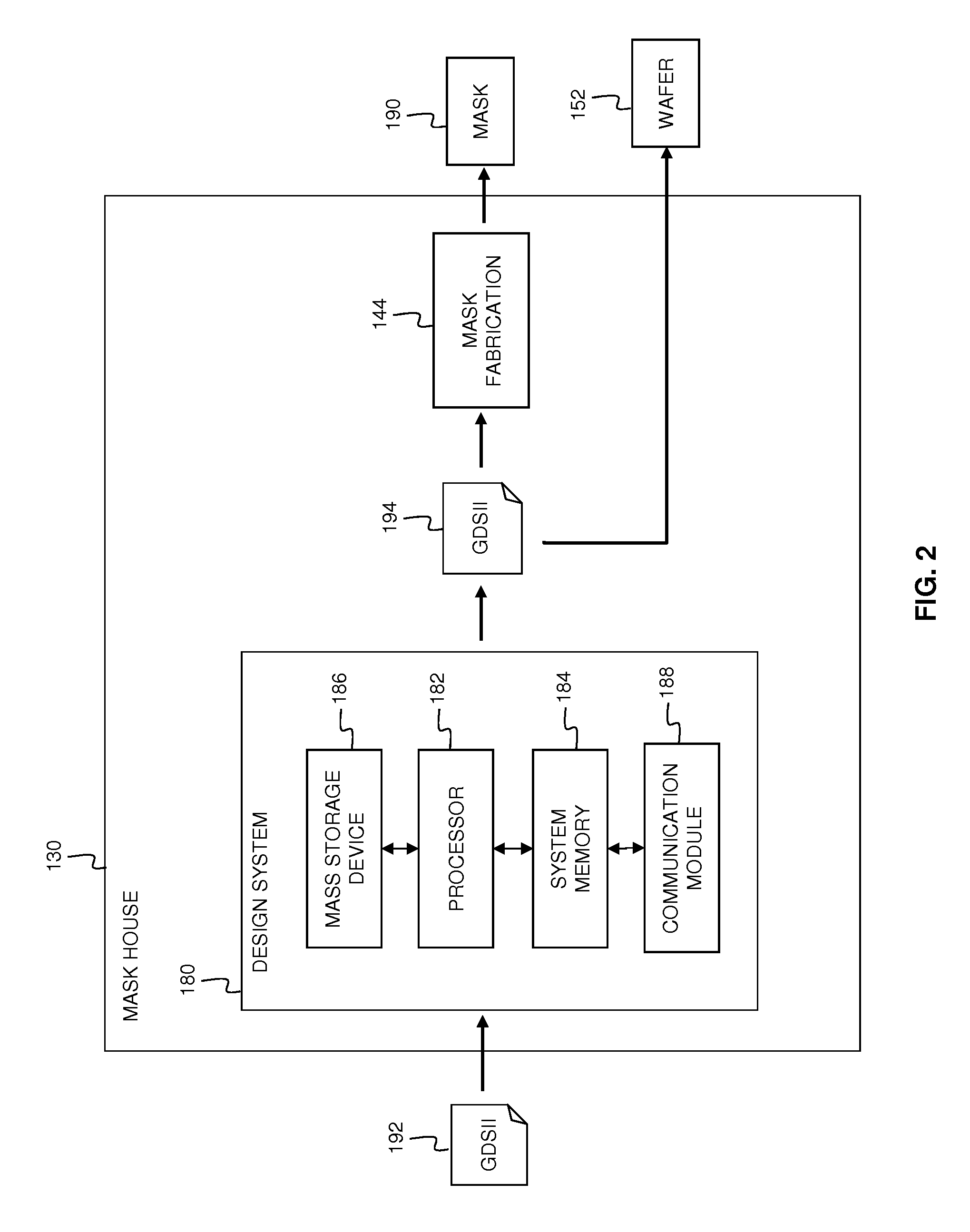

System and Method for Integrated Circuit Manufacturing

ActiveUS20150278429A1Photomechanical apparatusDesign optimisation/simulationMask inspectionIntegrated circuit manufacturing

Provided is an integrated circuit (IC) manufacturing method. The method includes receiving a design layout of an IC, the design layout having a main feature; performing a process correction to the main feature thereby generating a modified main feature; using a computer, generating a simulated contour of the modified main feature, the simulated contour having a plurality of points; generating a plurality of assistant data in computer readable format, wherein each assistant data includes at least one process performance factor associated with one of the points; and keeping the simulated contour and the assistant data for use by a further process stage, such as mask making, mask inspection, mask repairing, wafer direct writing, wafer inspection, and wafer repairing.

Owner:TAIWAN SEMICON MFG CO LTD

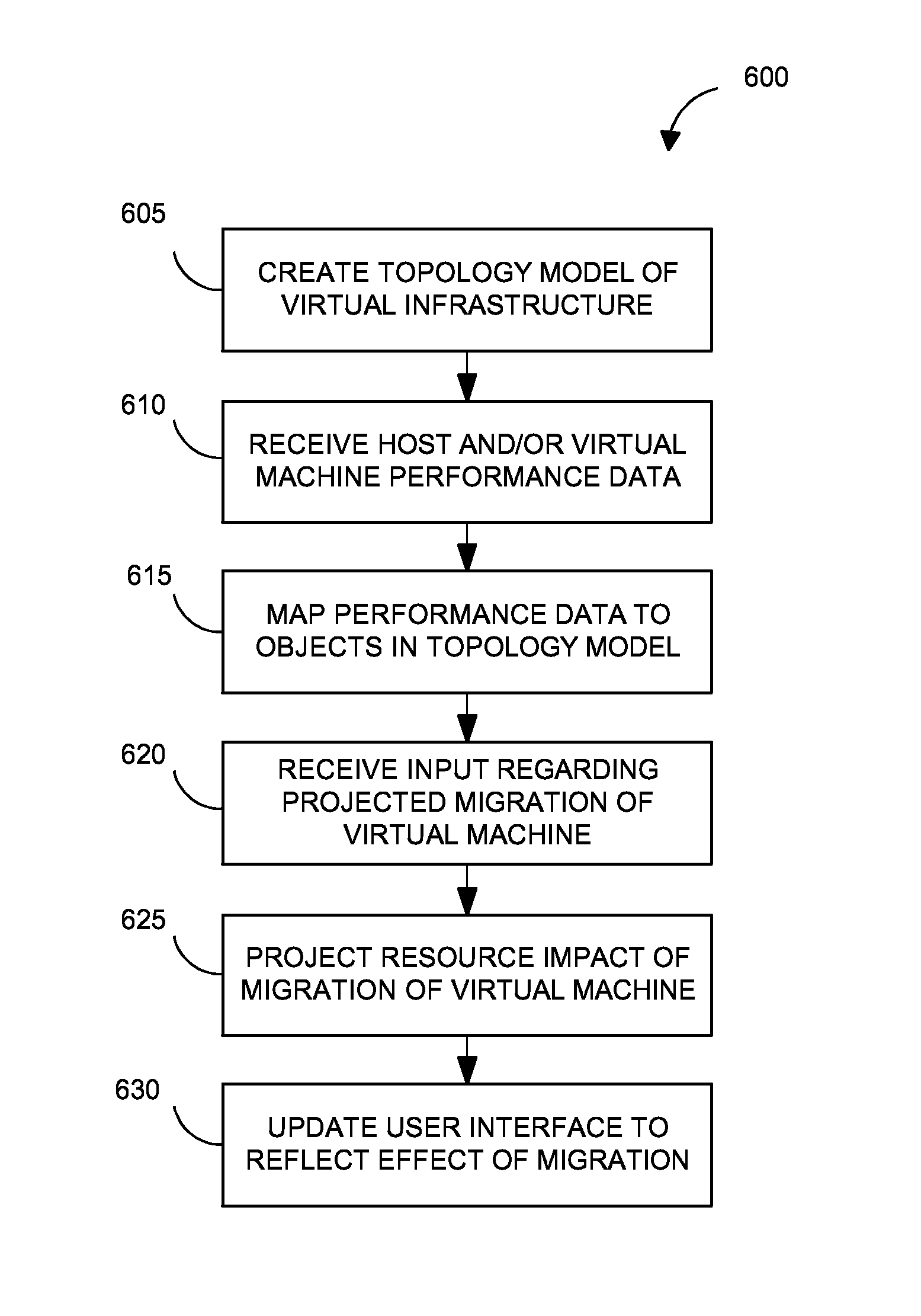

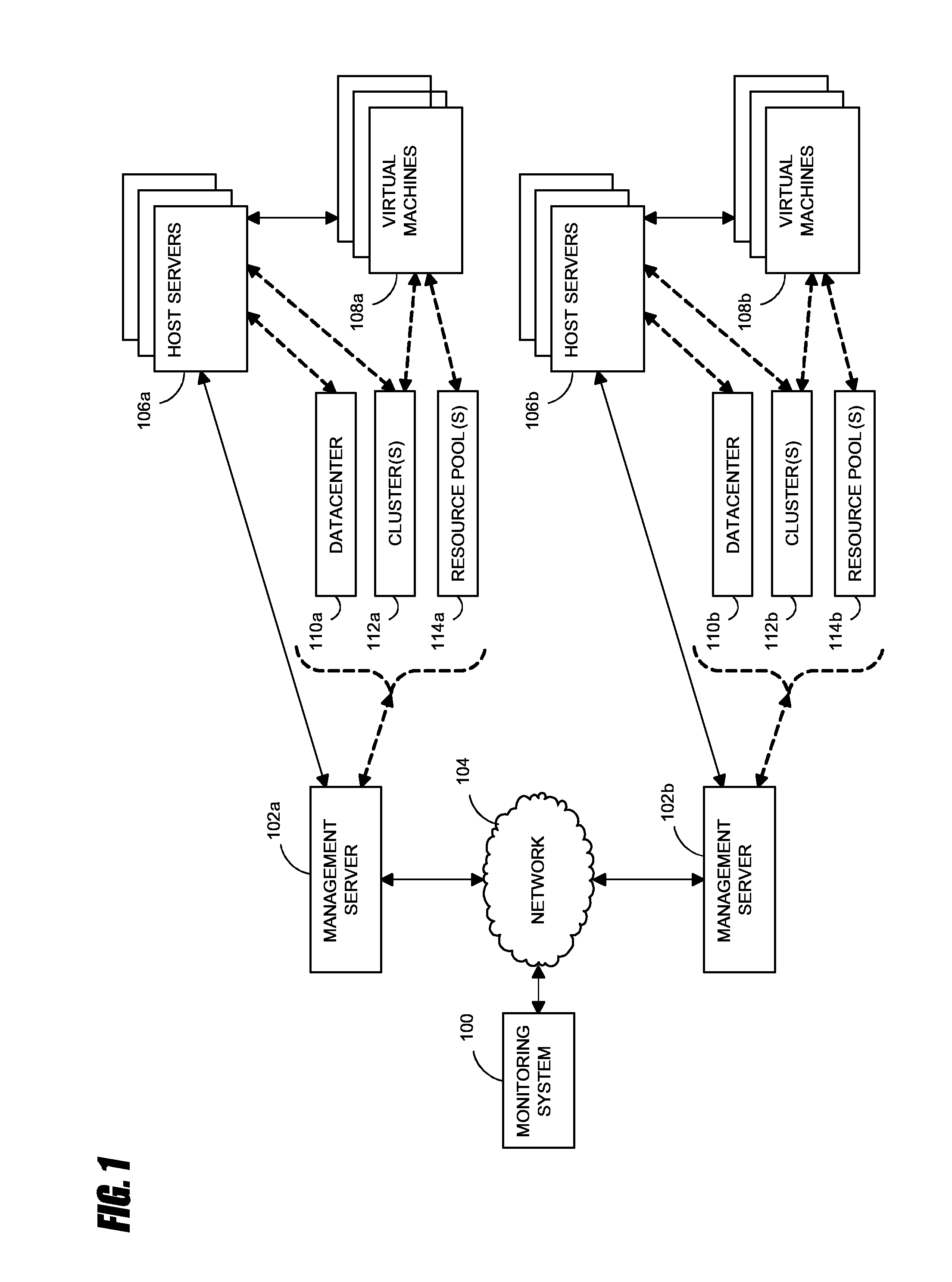

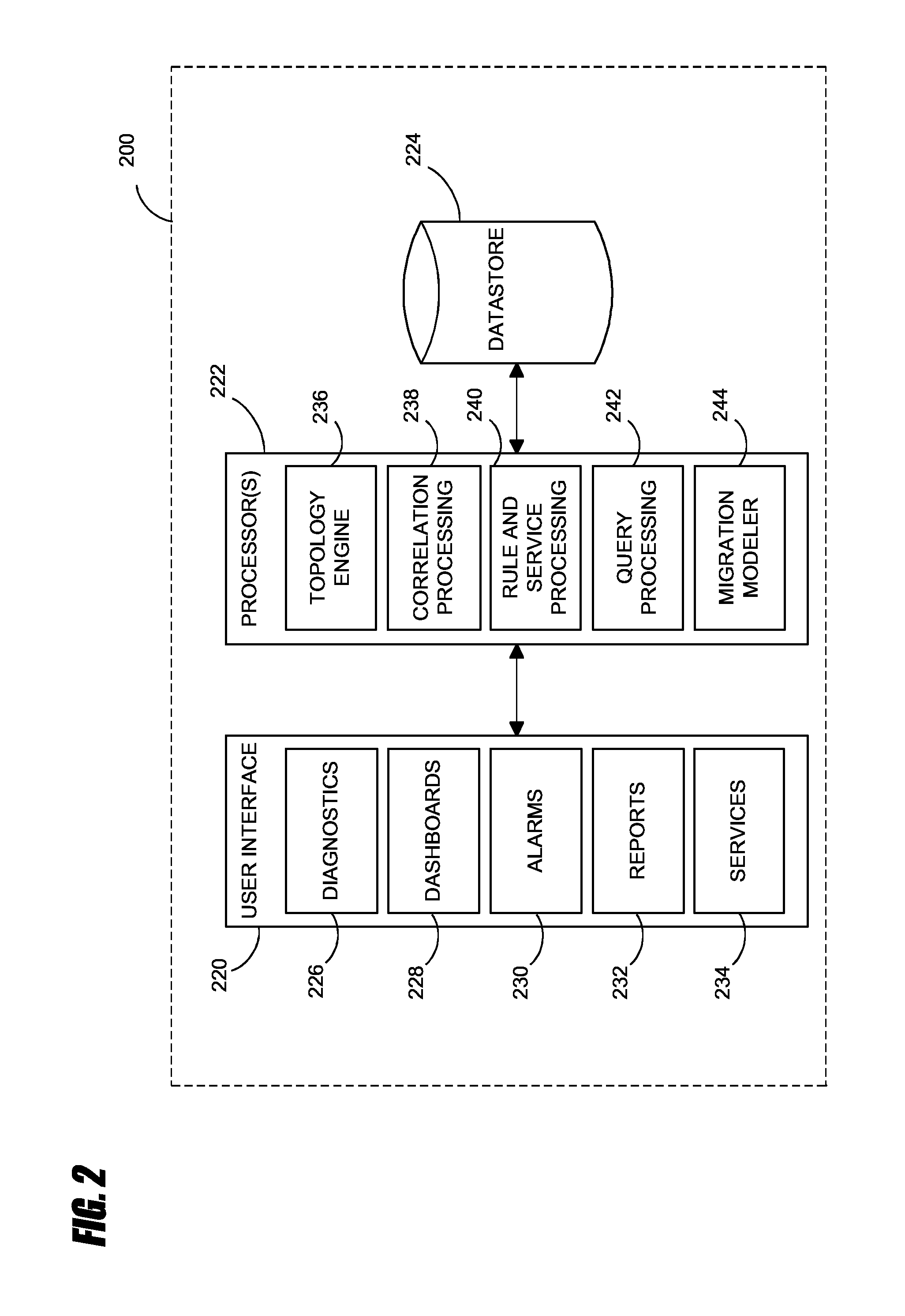

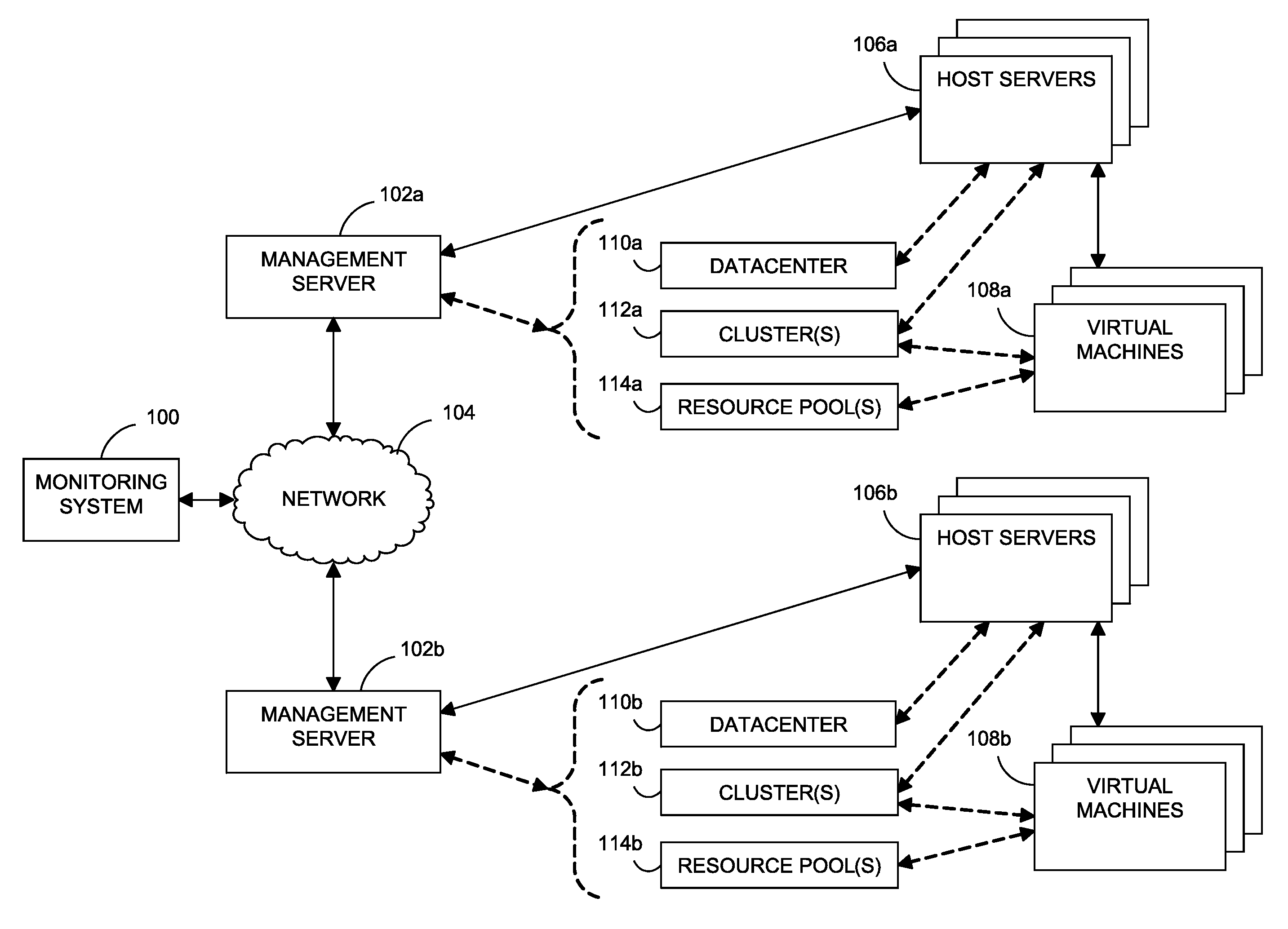

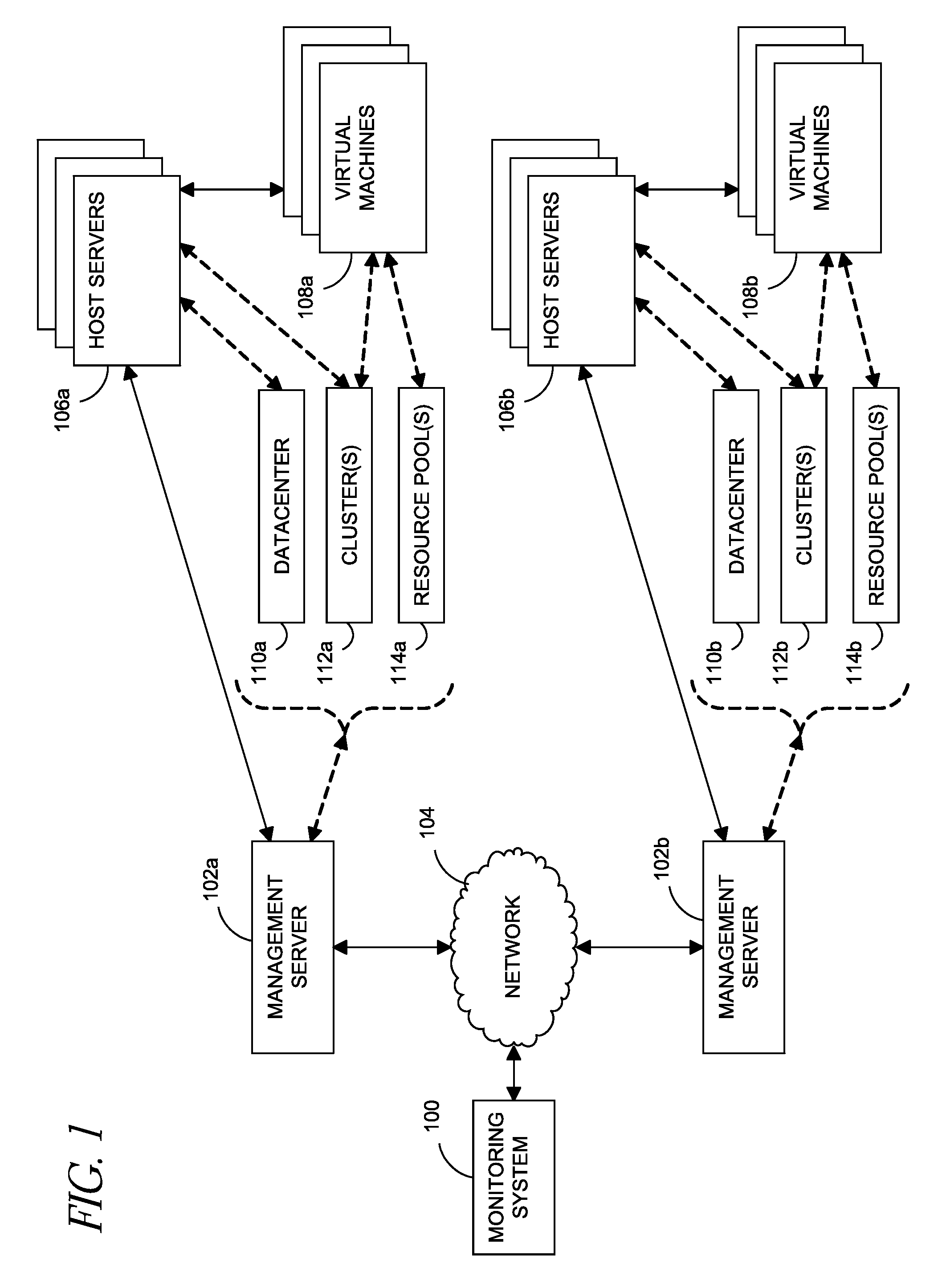

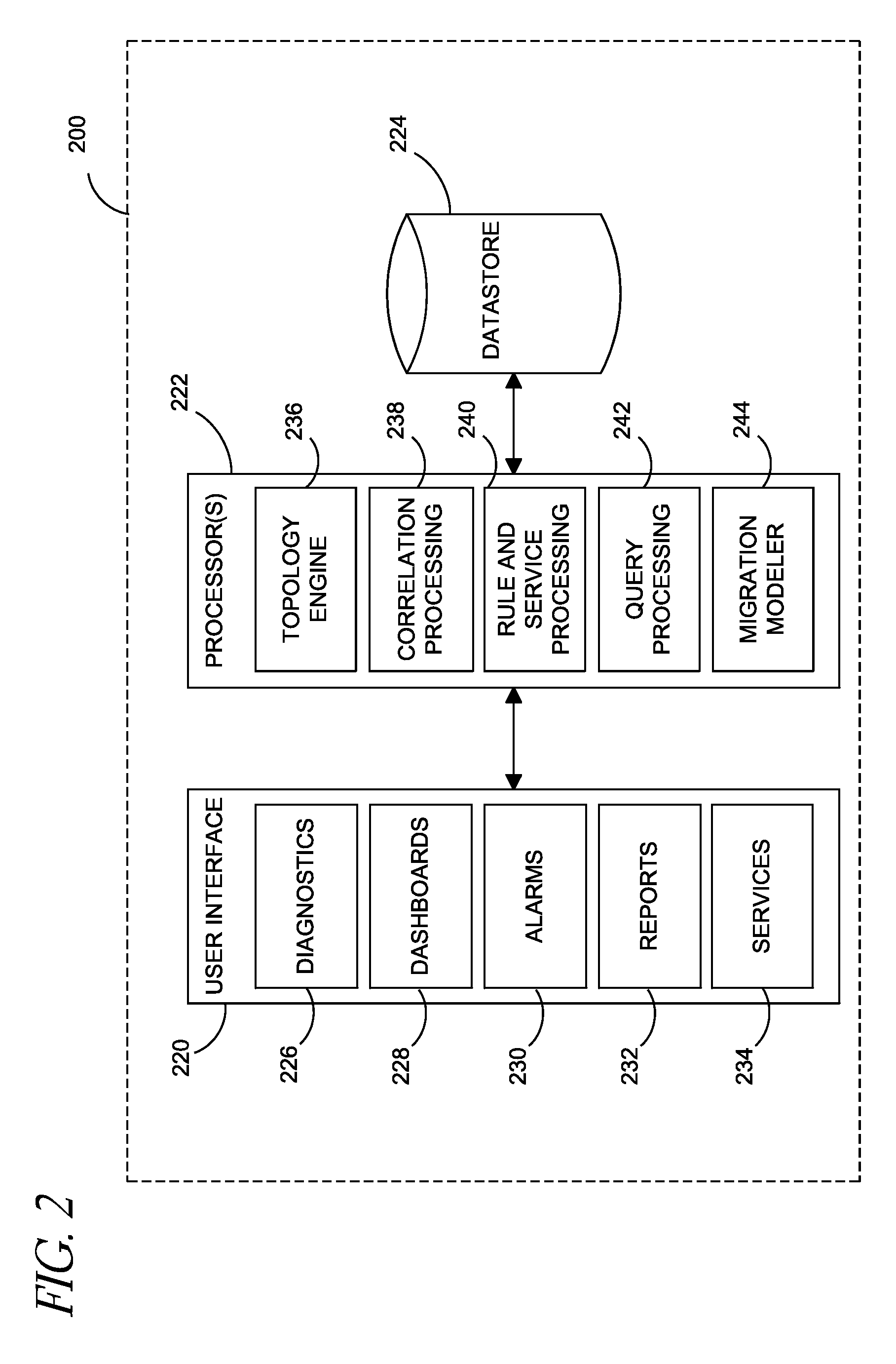

Systems and methods for analyzing performance of virtual environments

InactiveUS8175863B1Effective and efficient diagnosisResource allocationError detection/correctionMonitoring systemSmart surveillance

Intelligent monitoring systems and methods for virtual environments are disclosed that understand various components of a virtual infrastructure and how the components interact to provide improved performance analysis to users. In certain examples, a monitoring system assesses the performance of virtual machine(s) in the context of the overall performance of the physical server(s) and the environment in which the virtual machine(s) are running. For instance, the monitoring system can track performance metrics over a determined period of time to view changes to the allocation of resources to virtual machines and their location(s) on physical platforms. Moreover, monitoring systems can utilize past performance information from separate virtual environments to project a performance impact resulting from the migration of a virtual machine from one physical platform to another.

Owner:QUEST SOFTWARE INC

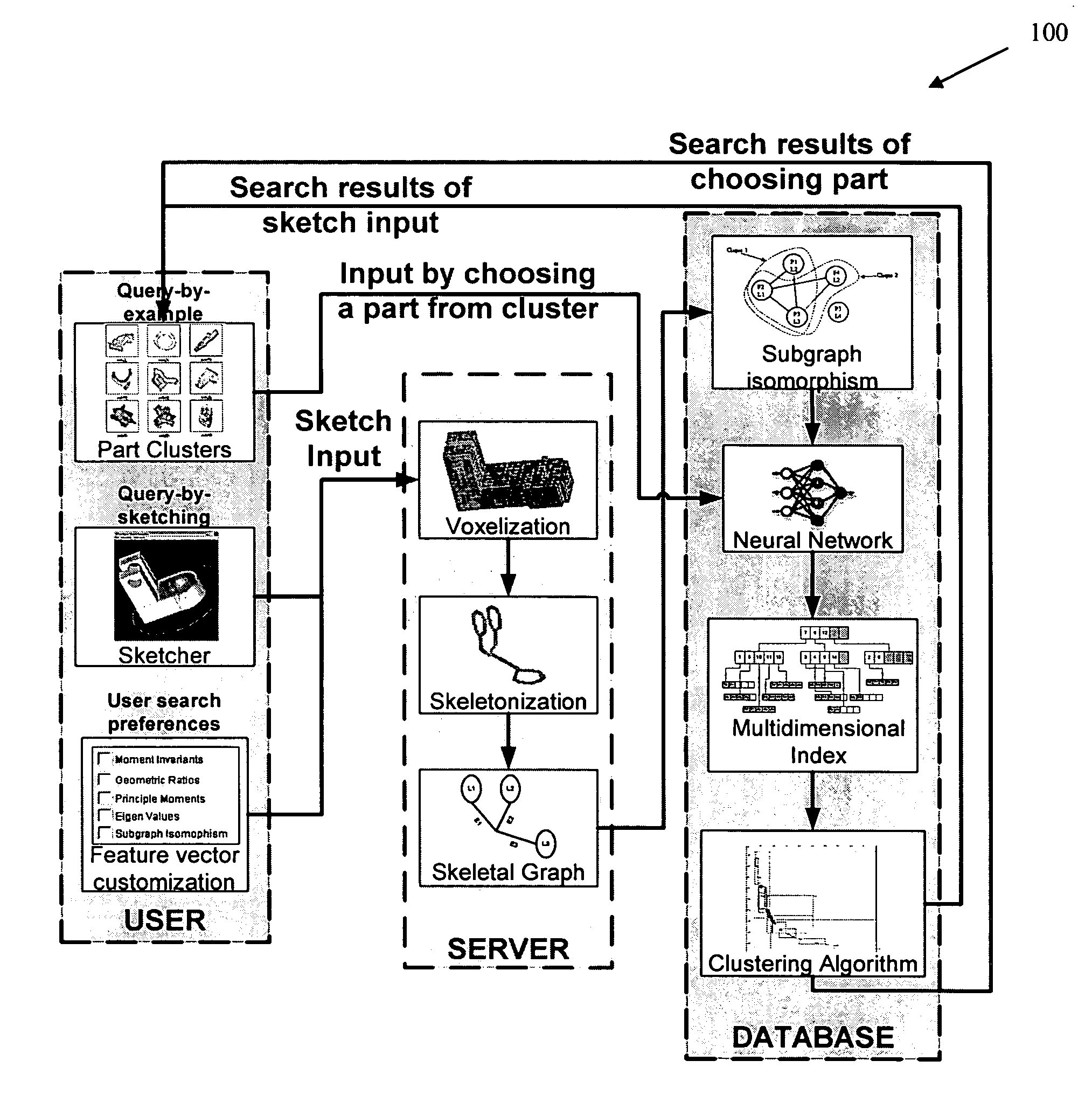

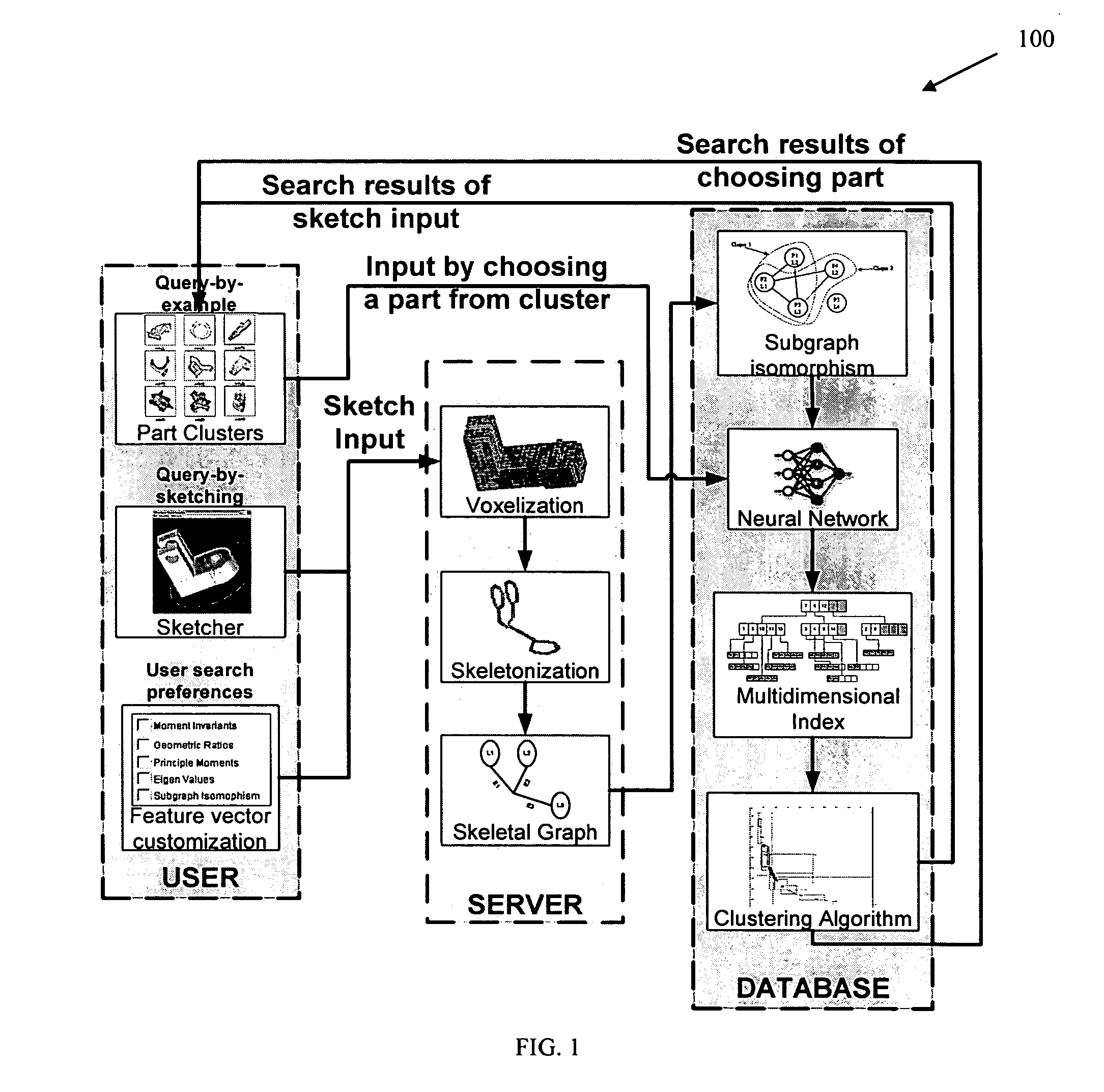

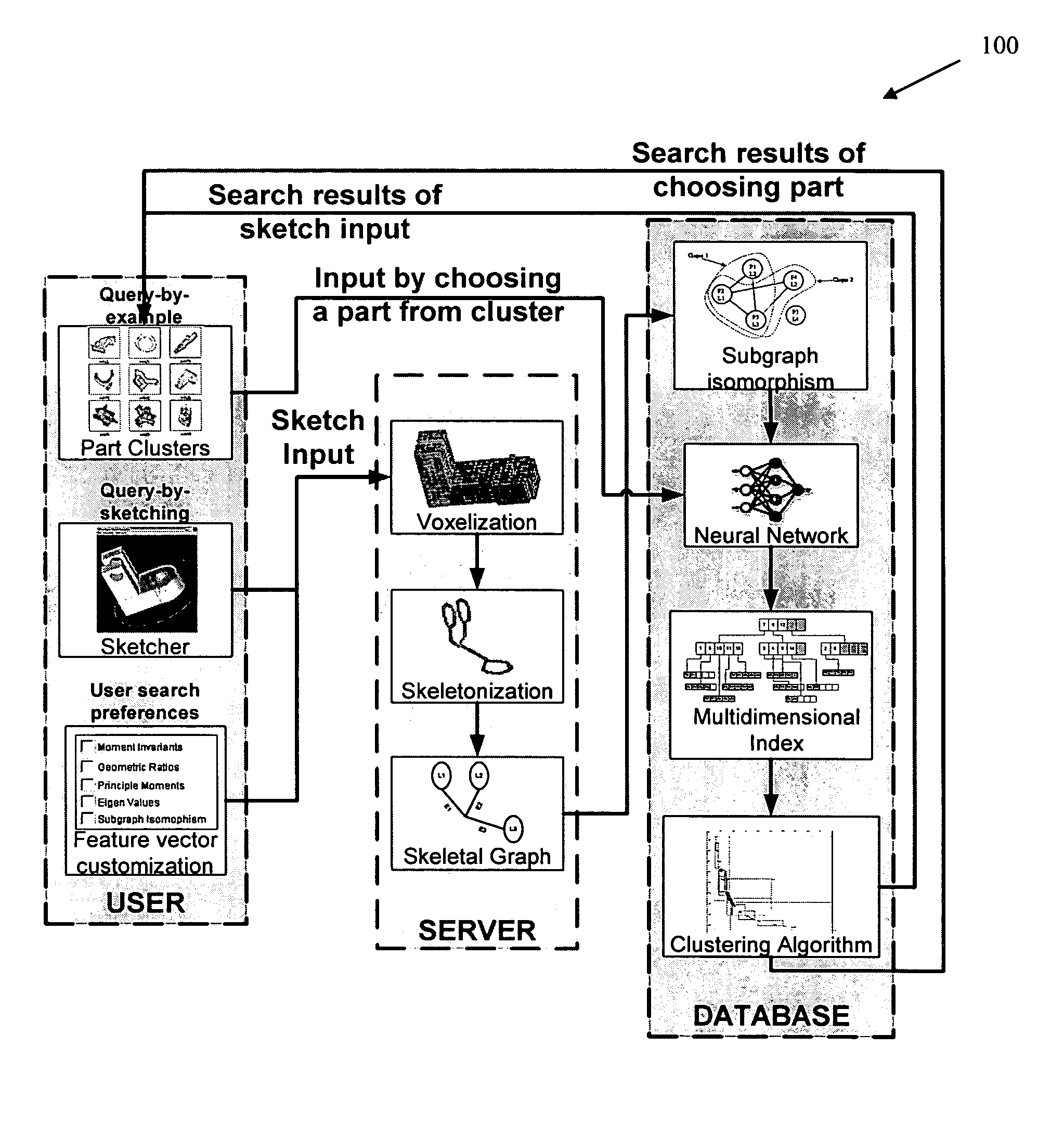

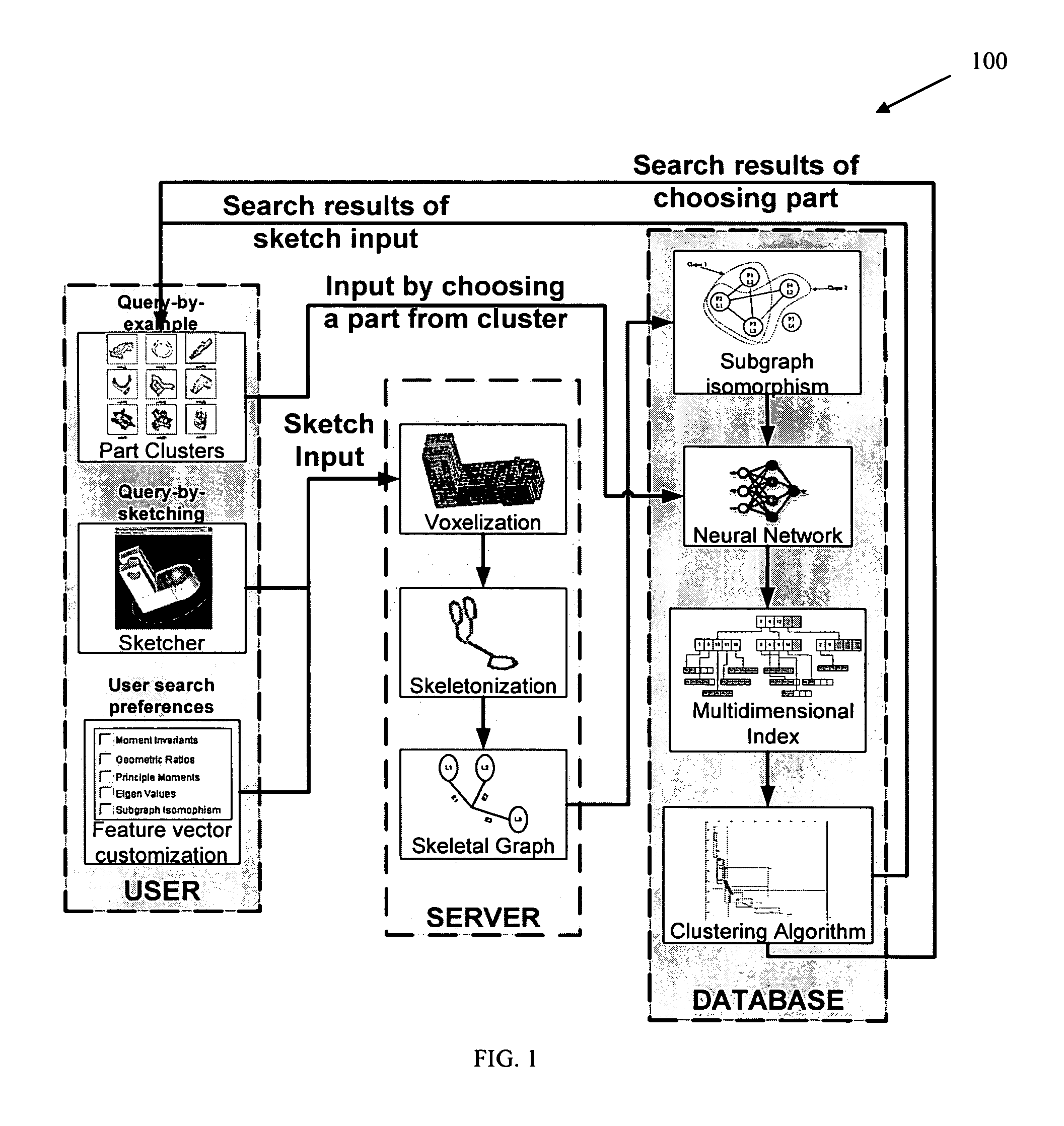

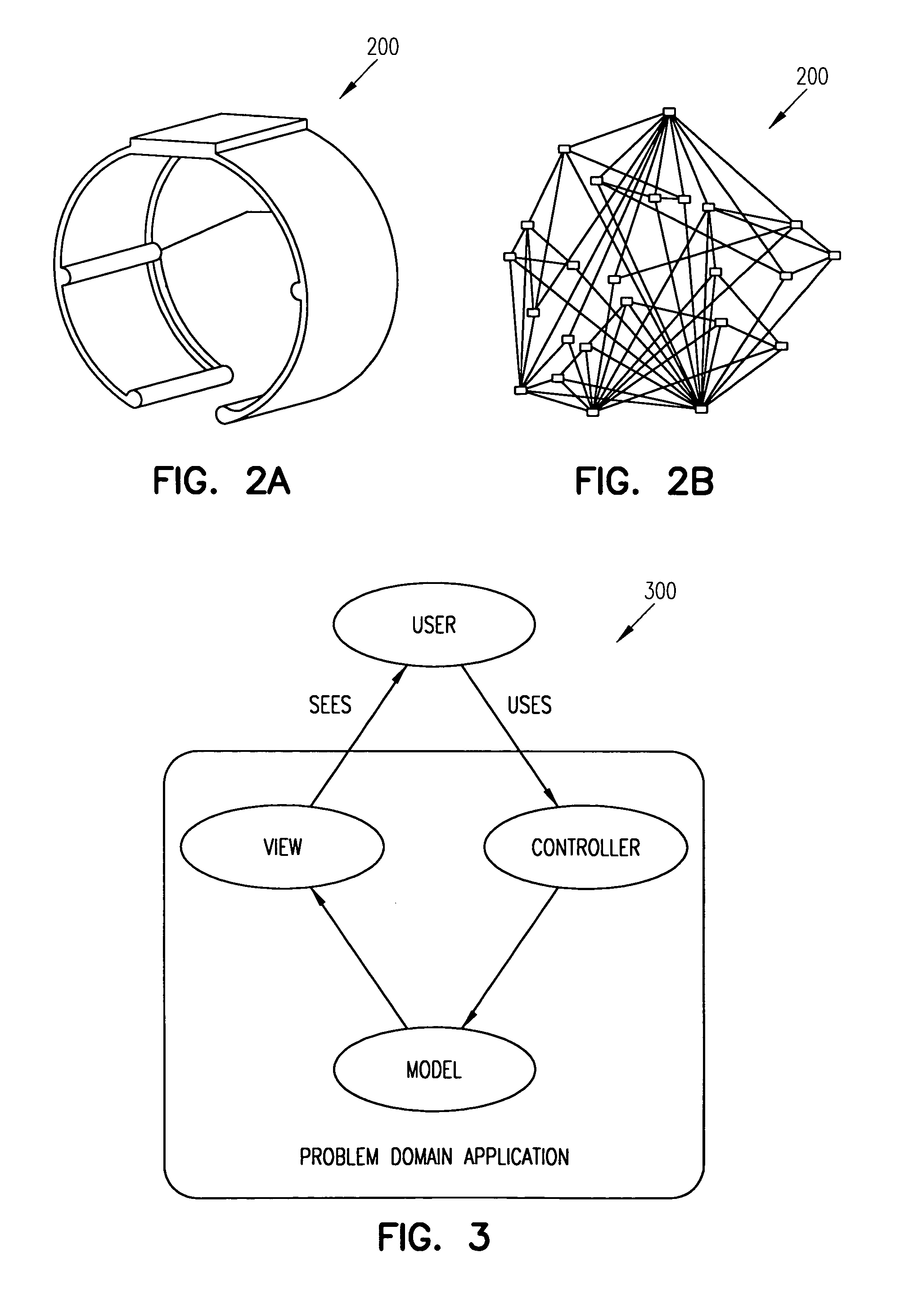

Methods, systems, and data structures for performing searches on three dimensional objects

Techniques are provided for searching on three dimensional (3D) objects across large, distributed repositories of 3D models. 3D shapes are created for input to a search system; optionally user-defined similarity criterion is used, and search results are interactively navigated and feedback received for modifying the accuracy of the search results. Search input can also be given by picking 3D models from a cluster map or by providing the orthographic views for the 3D model. Feedback can be given by a searcher as to which models are similar and which are not. Various techniques adjust the search results according to the feedback given by the searcher and present the new search results to the searcher.

Owner:PURDUE RES FOUND INC

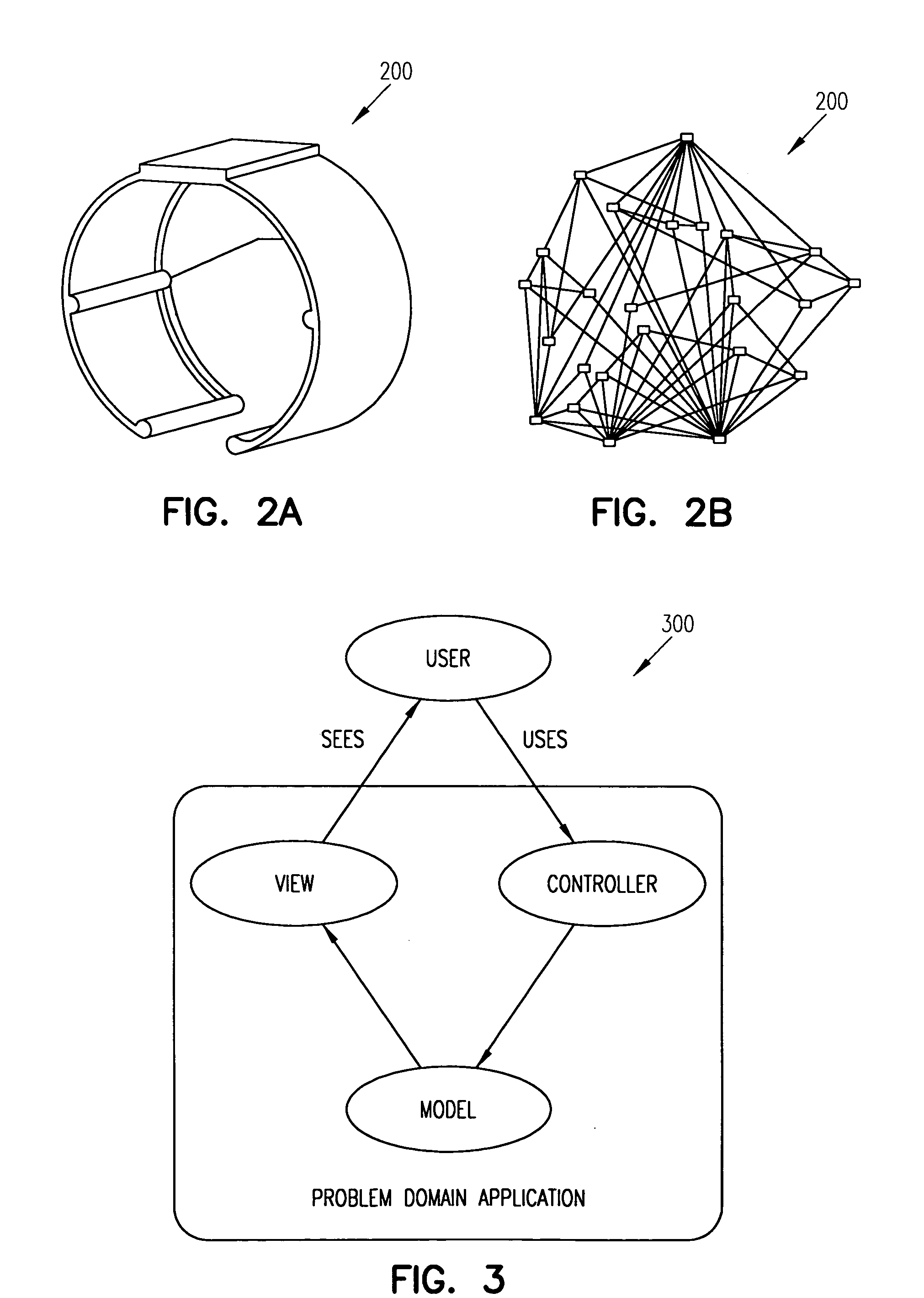

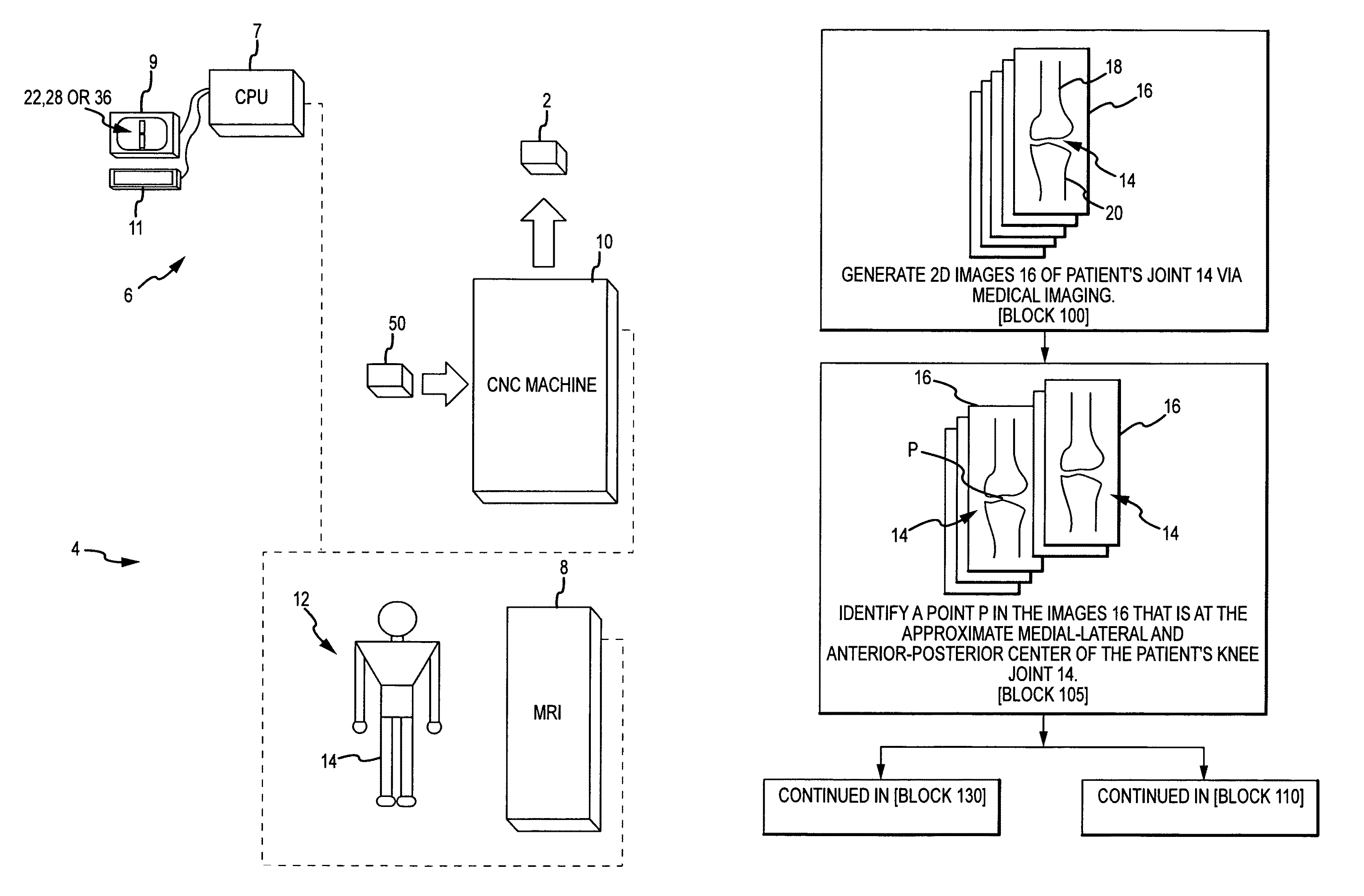

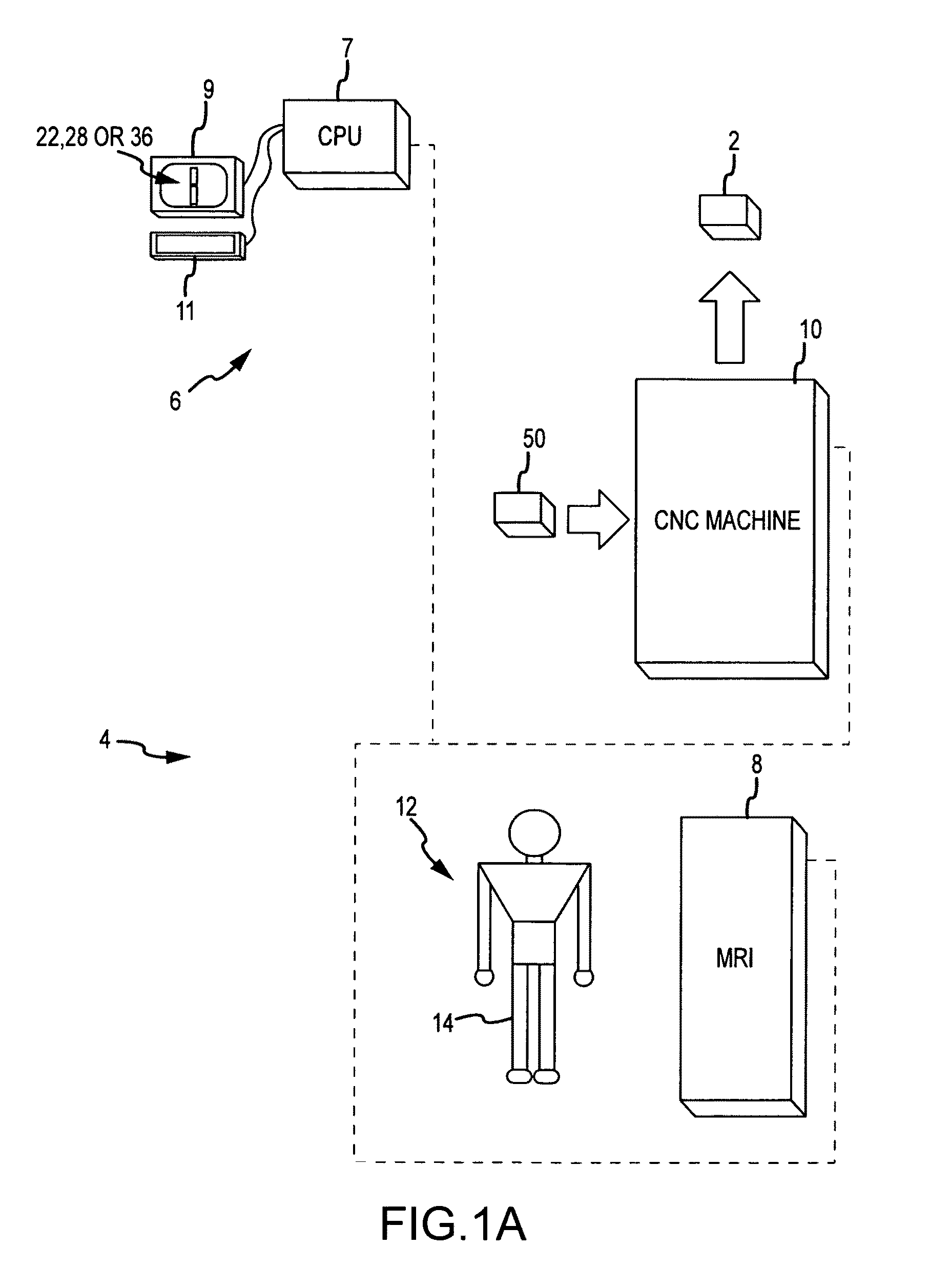

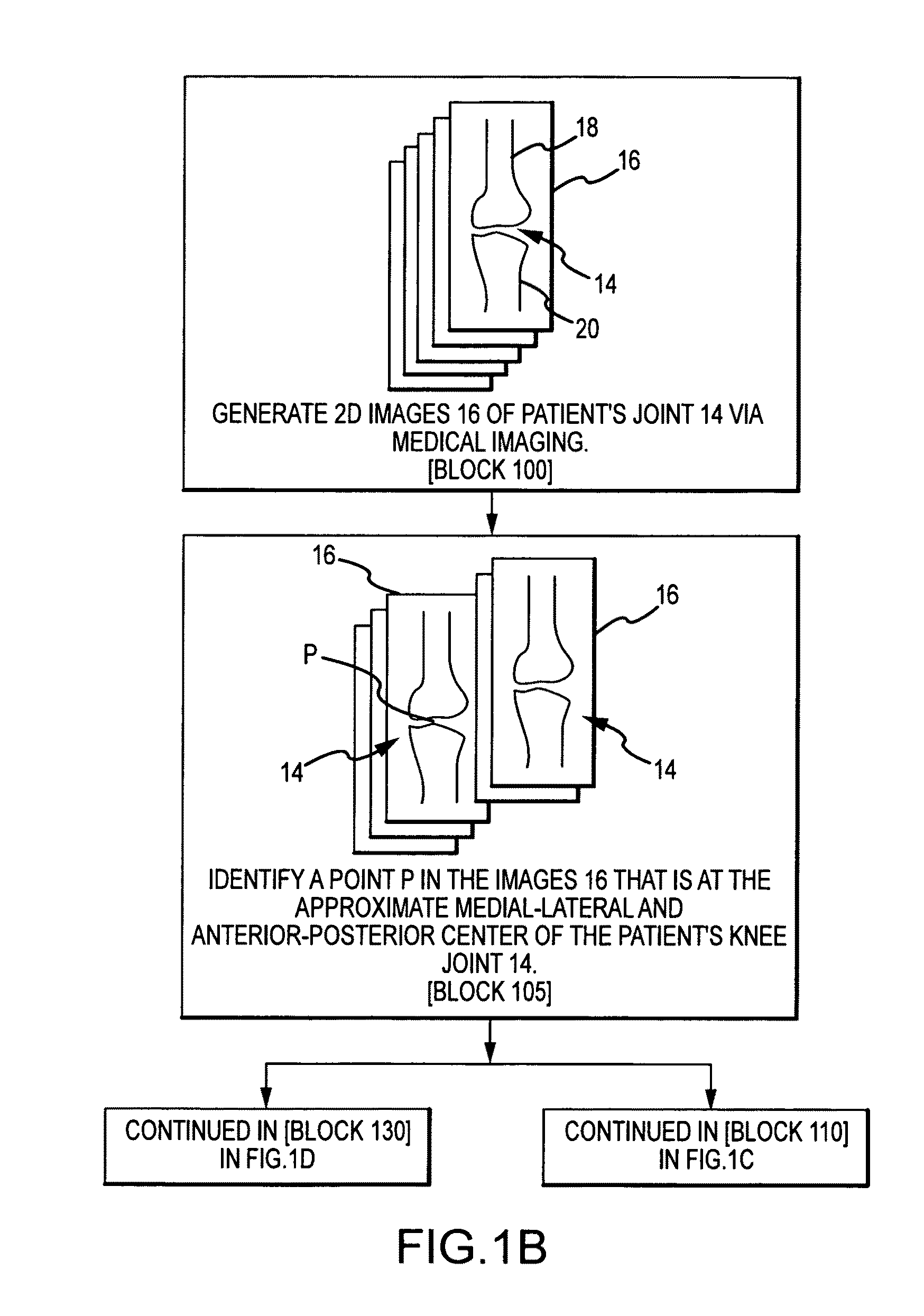

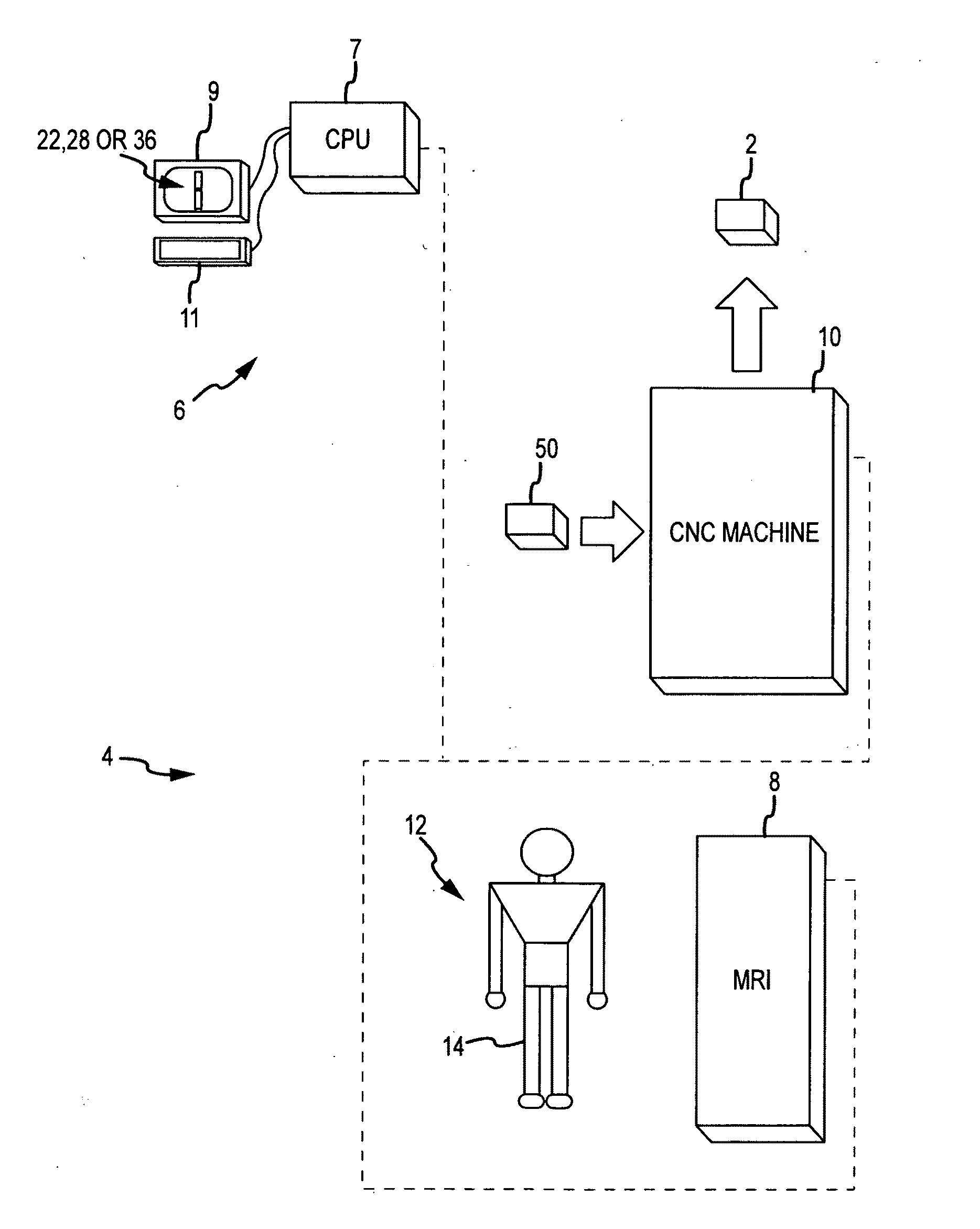

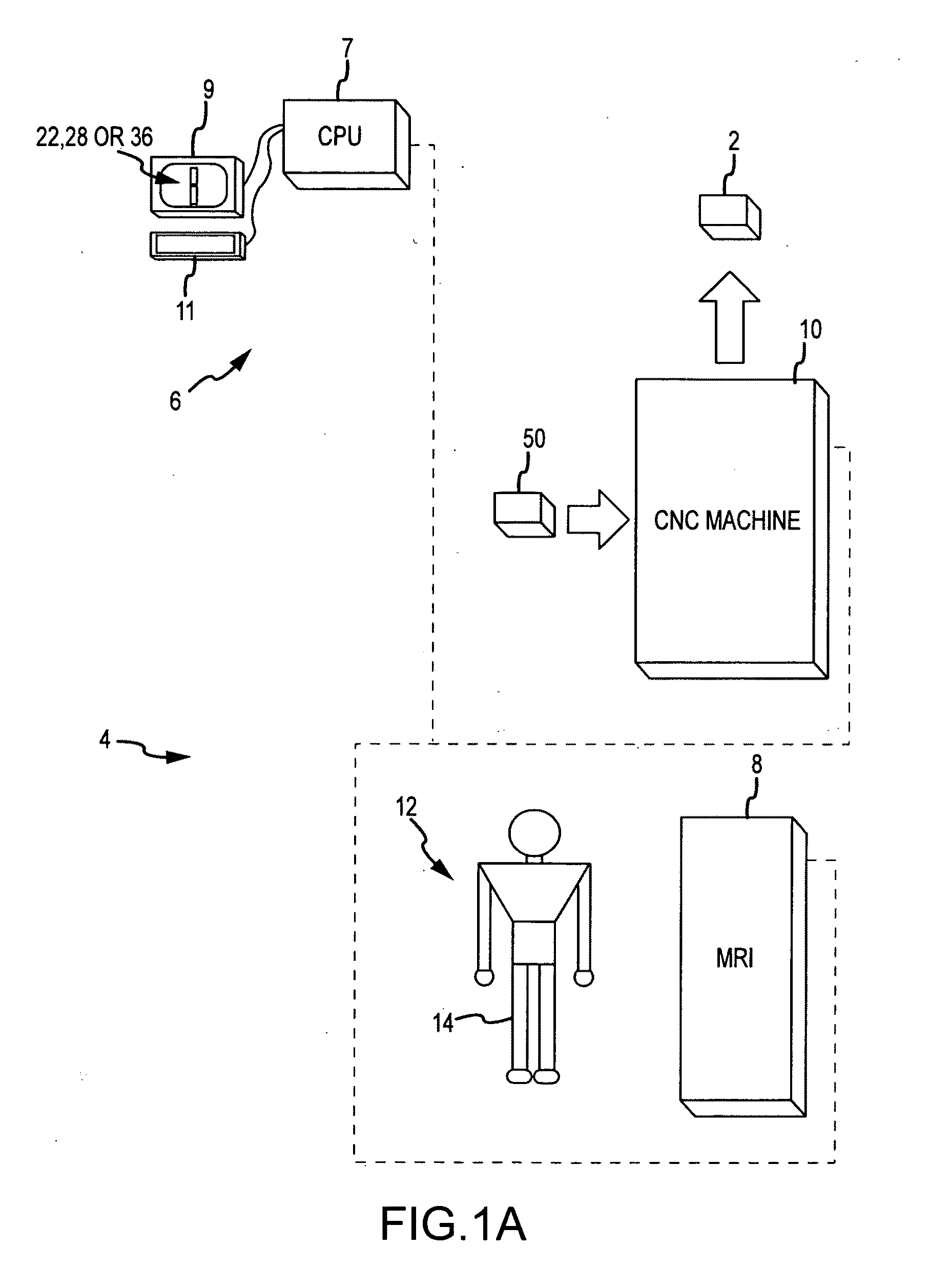

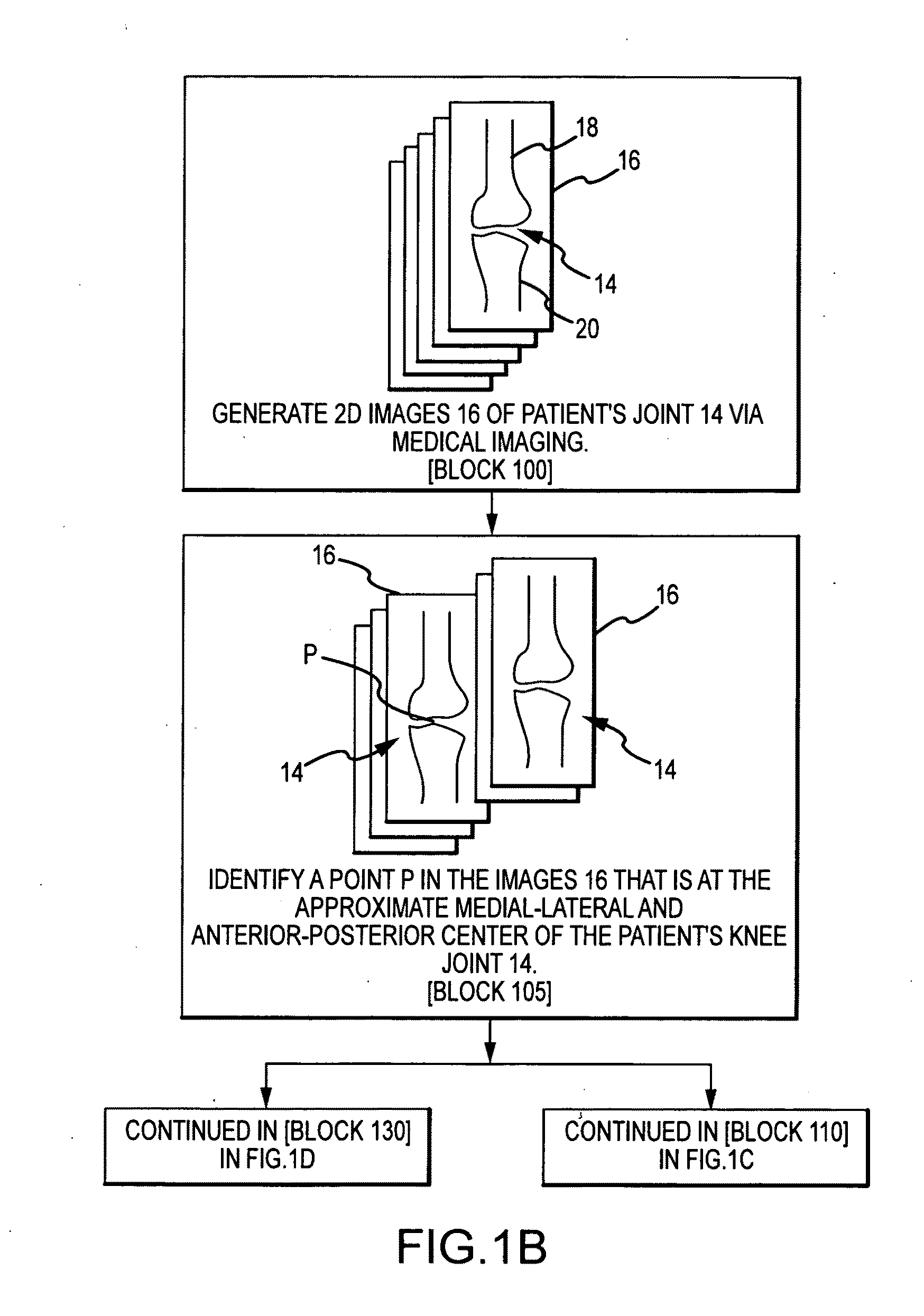

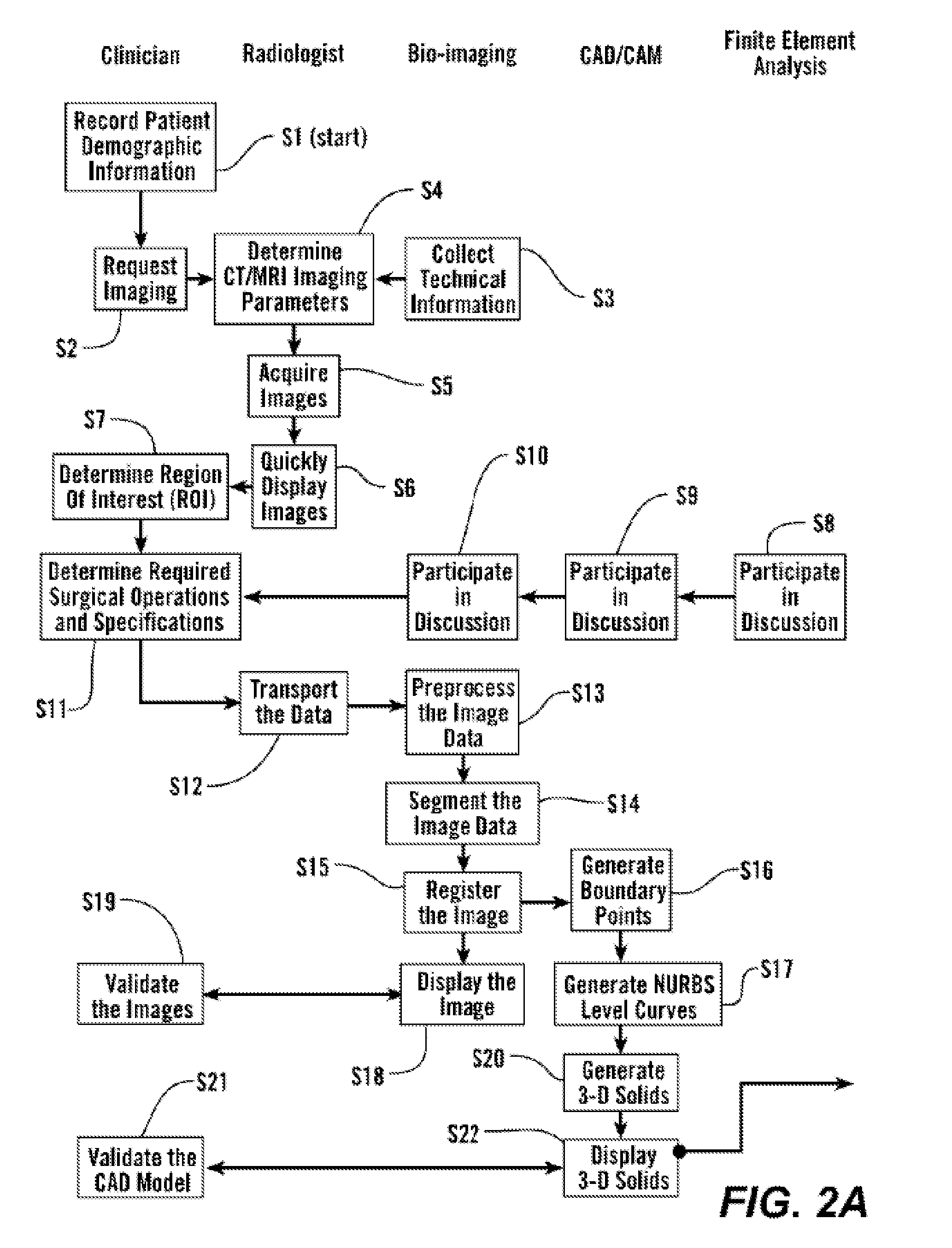

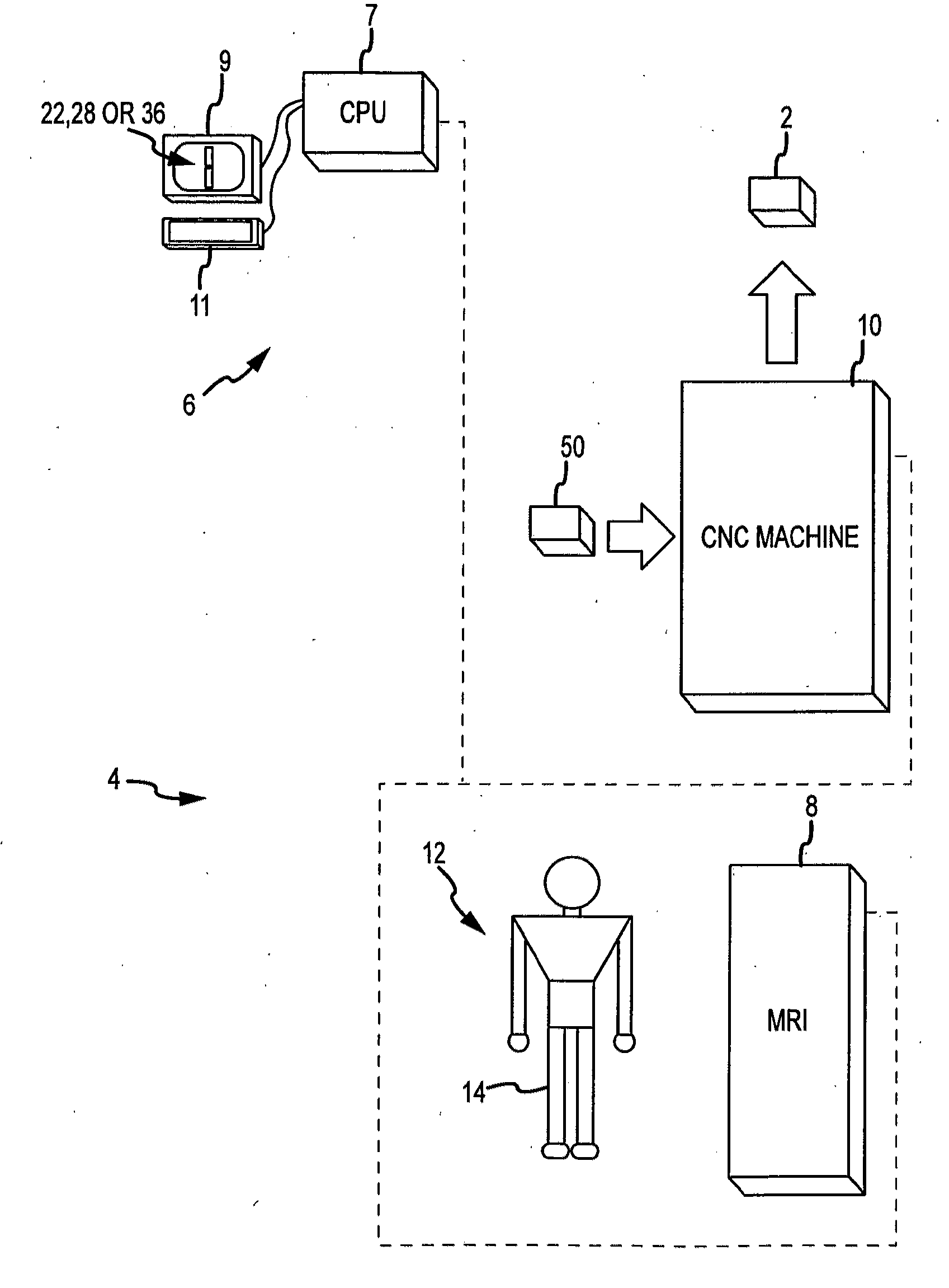

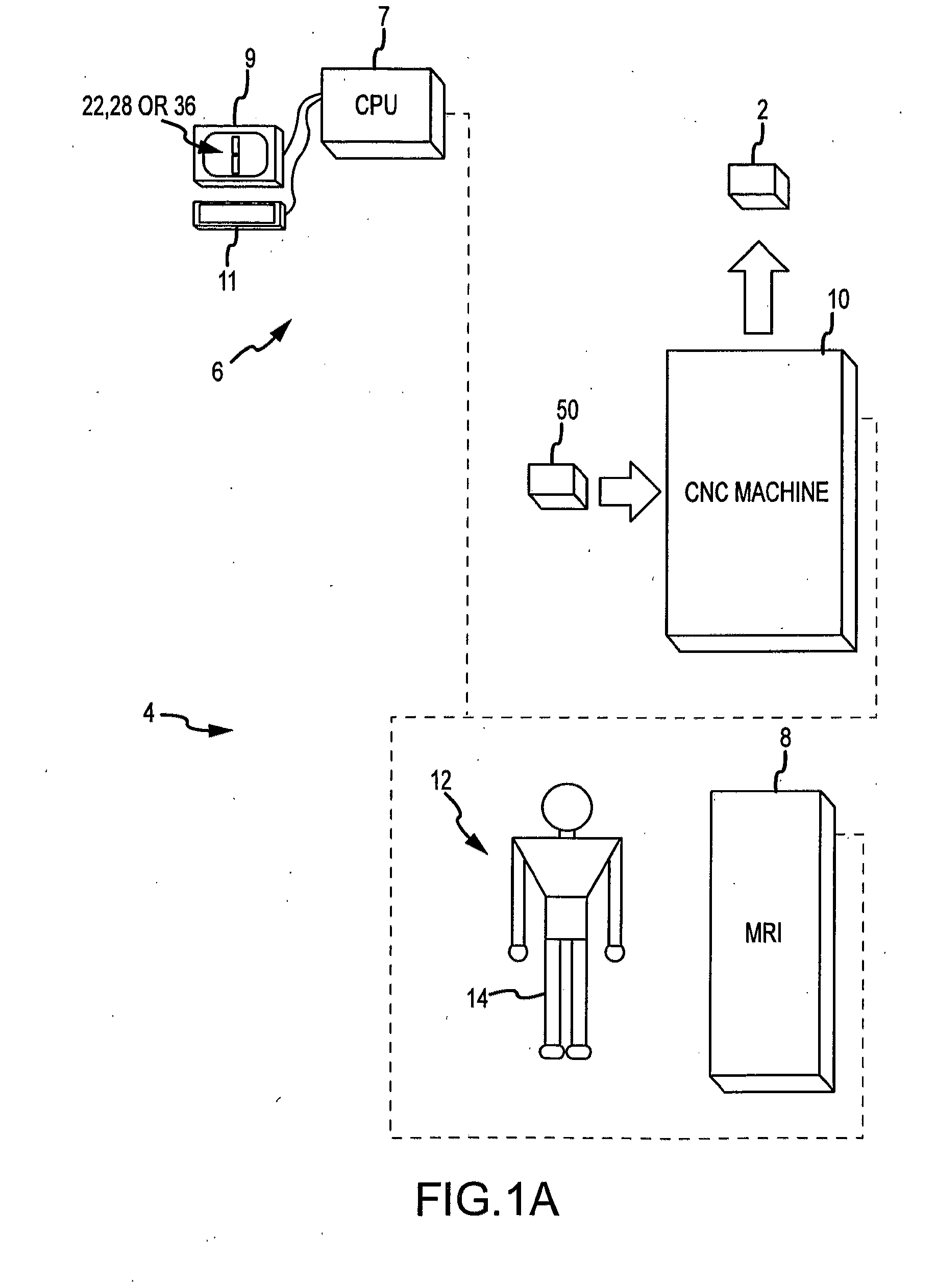

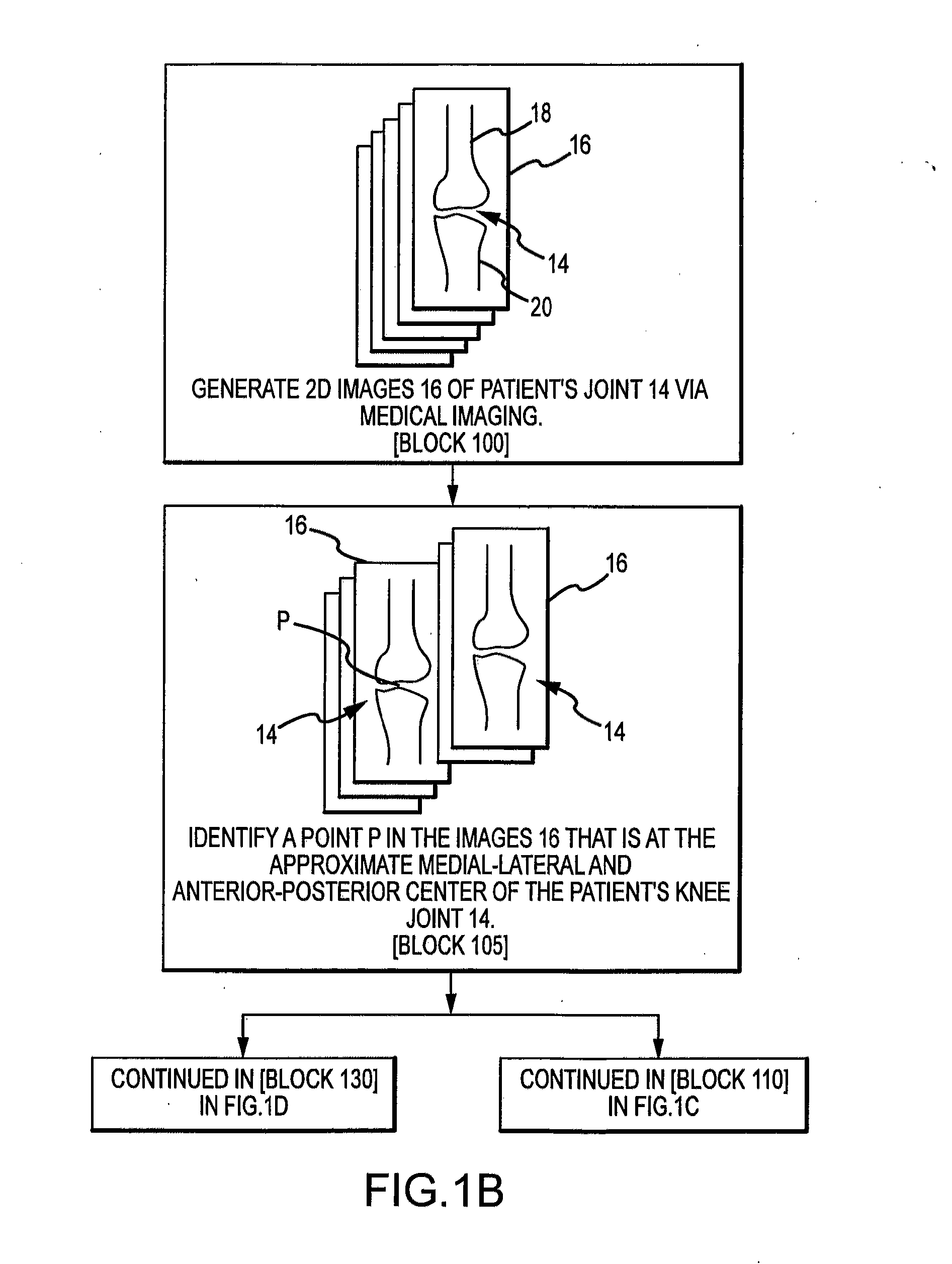

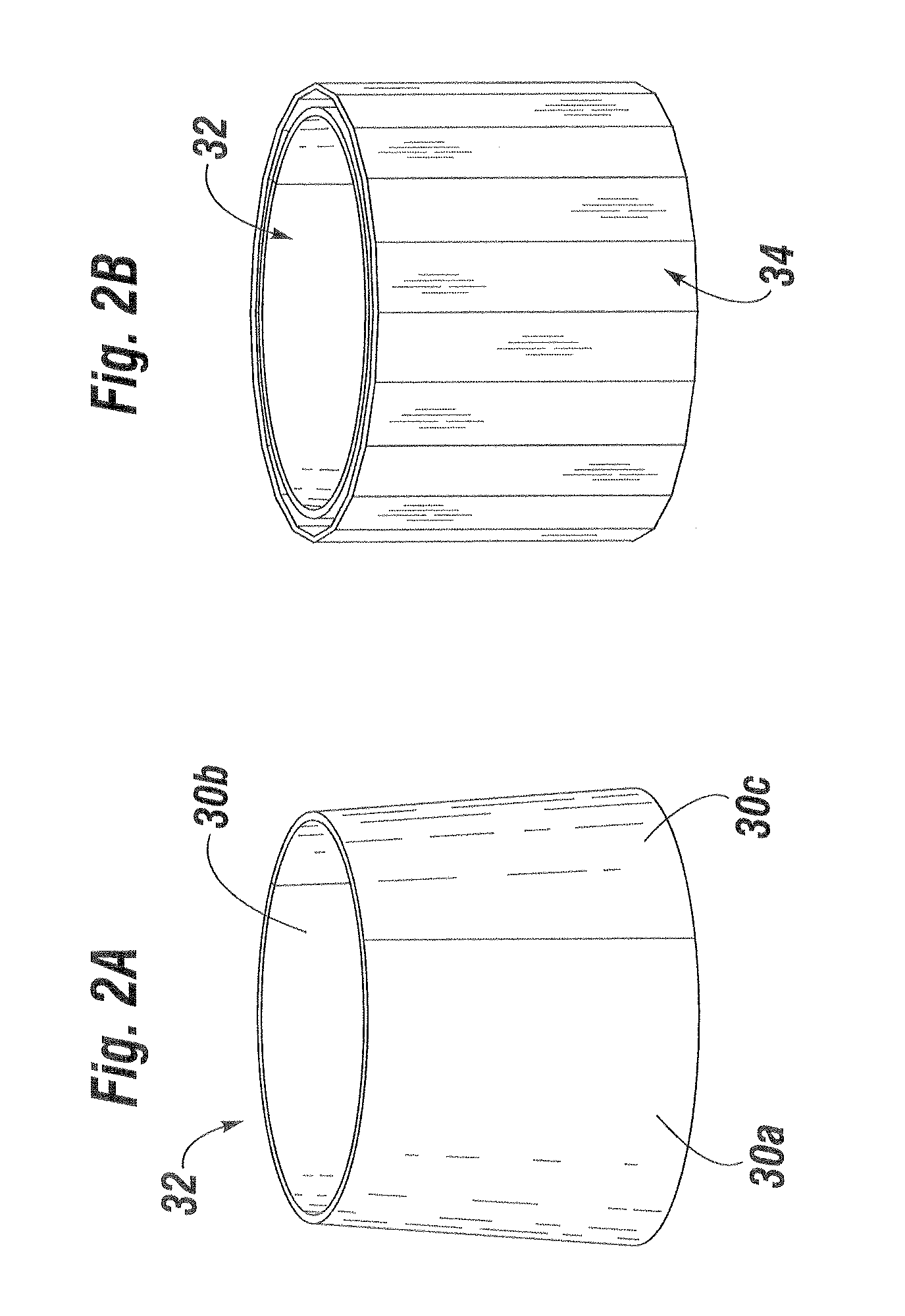

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS8160345B2Details involving processing stepsImage enhancementMedical imagingImage segmentation

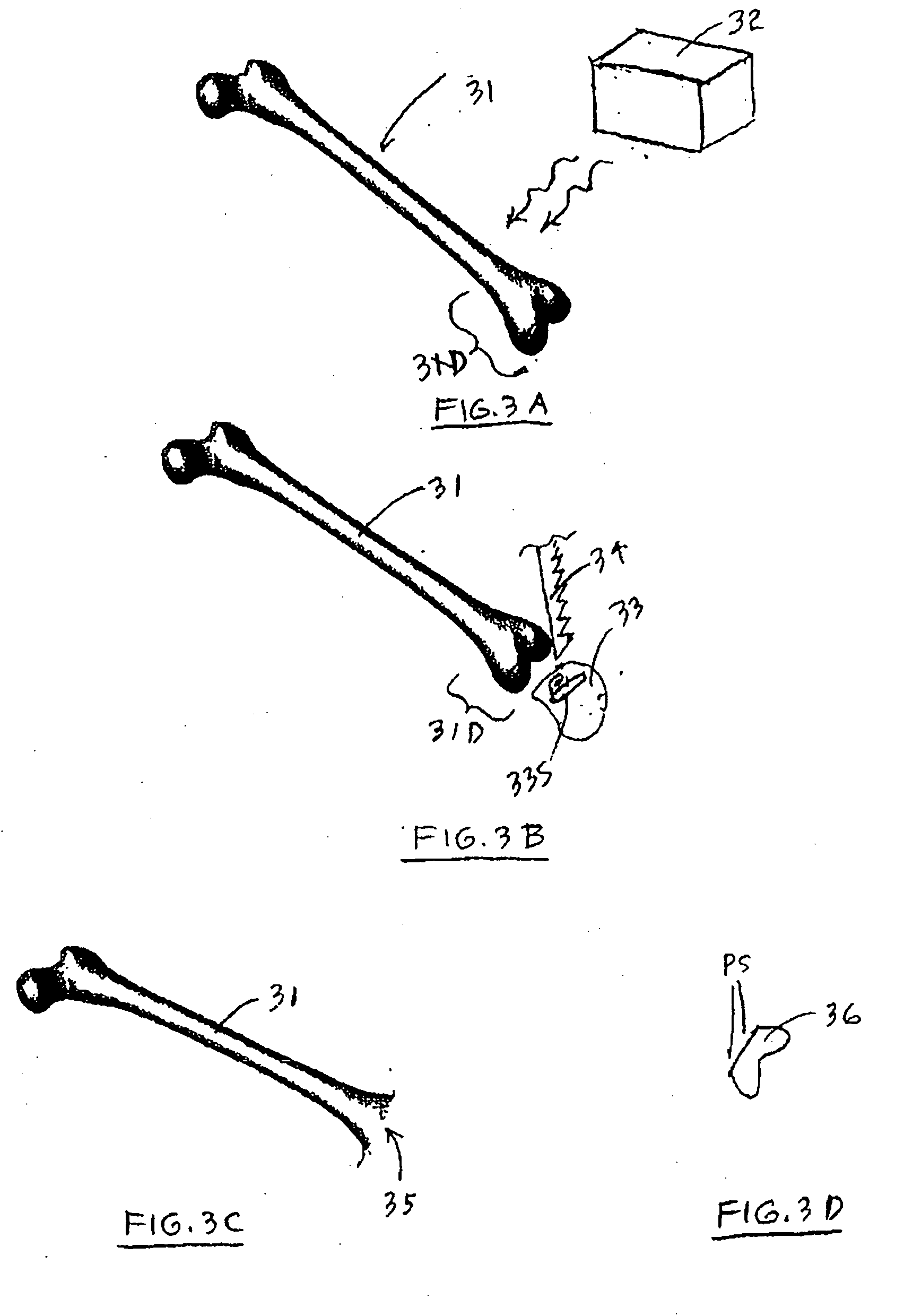

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The guide manufactured includes a mating region configured to matingly receive a portion of a patient bone associated with an arthroplasty procedure for which the custom arthroplasty guide is to be employed. The mating region includes a surface contour that is generally a negative of a surface contour of the portion of the patient bone. The surface contour of the mating region is configured to mate with the surface contour of the portion of the patient bone in a generally matching or interdigitating manner when the portion of the patient bone is matingly received by the mating region. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

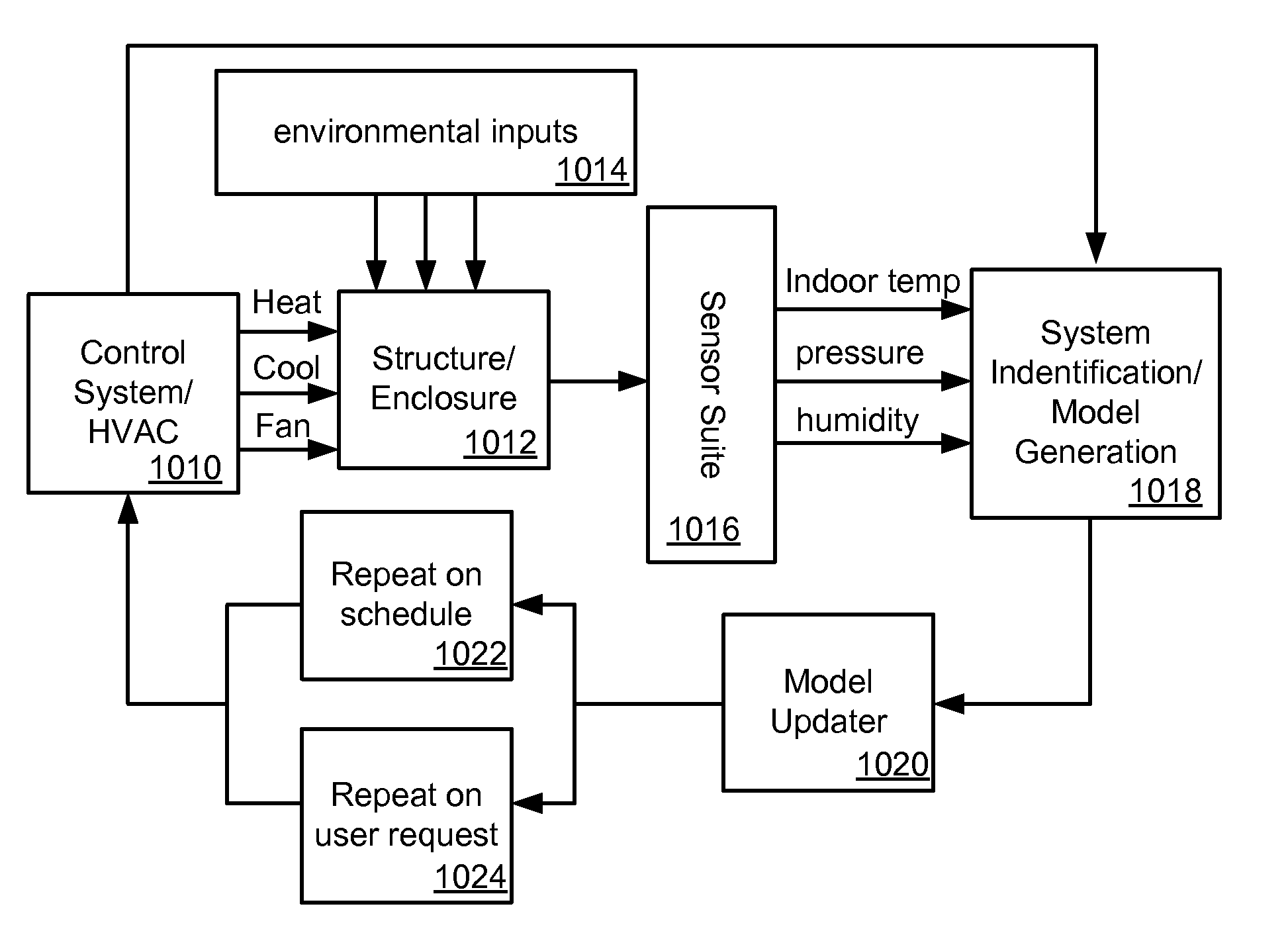

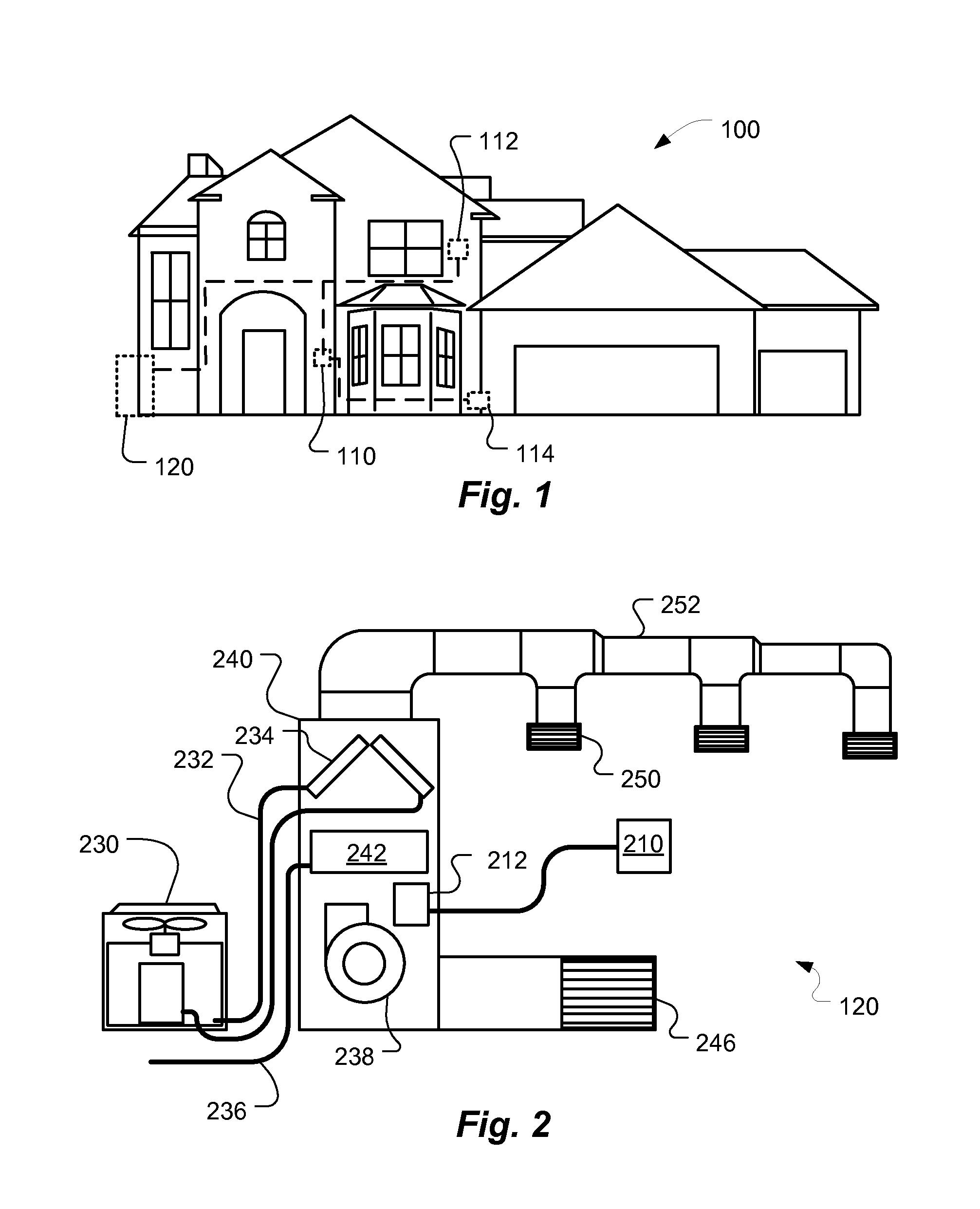

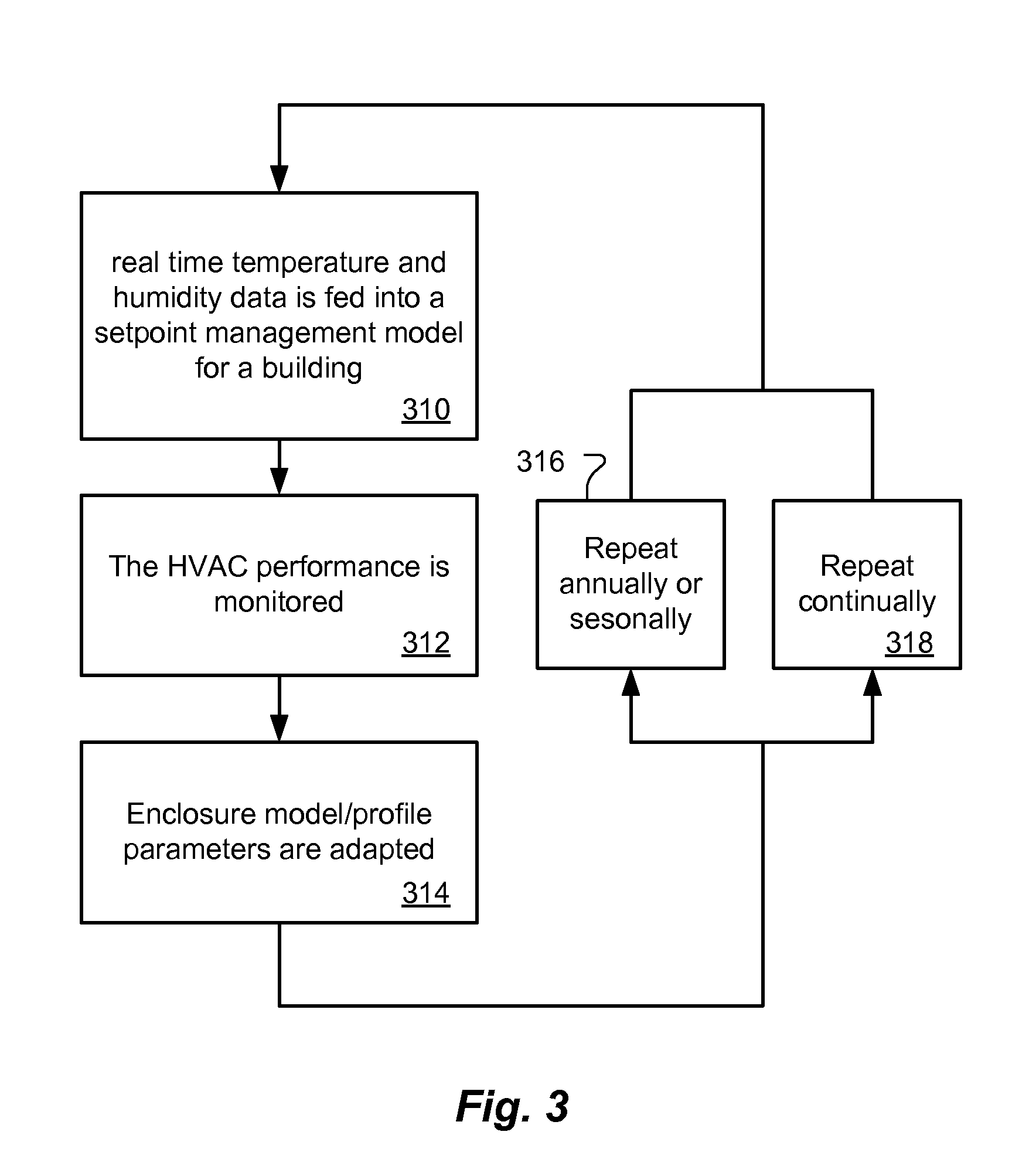

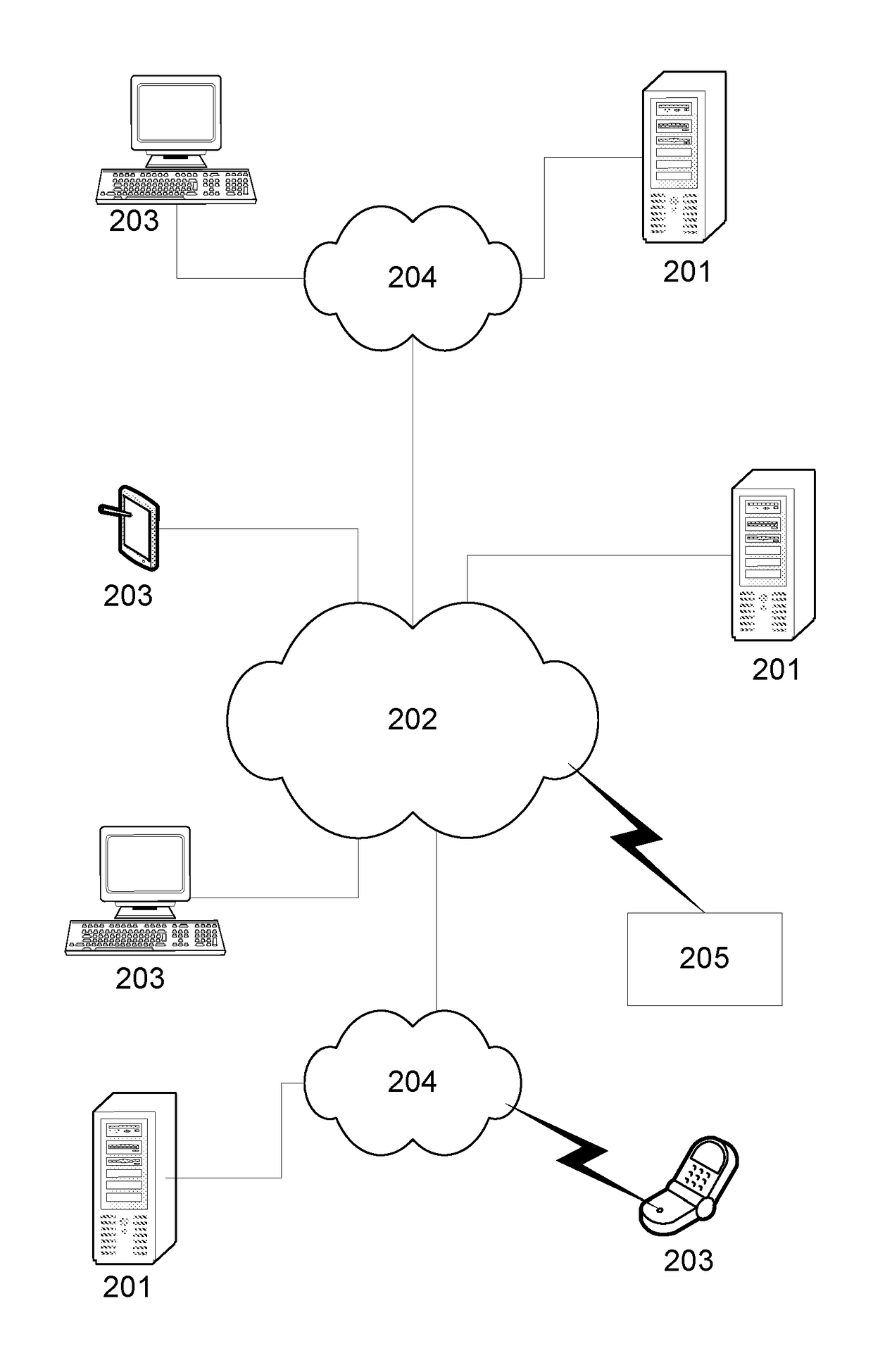

Thermodynamic modeling for enclosures

Systems and methods for modeling the behavior of an enclosure for use by a control system of an HVAC system are described. A model for the enclosure that describes the behavior of the enclosure for use by the control system is updated based on a weather forecast data. The weather forecast data can include predictions more than 24 hours in the future, and can include predictions such as temperature, humidity and / or dew point, solar output, precipitation. The model for the enclosure can also be updated based on additional information and data such as historical weather data such as temperature, humidity, wind, solar output and precipitation, occupancy data, such as predicted and / or detected occupancy data, calendar data, and data from the one or more weather condition sensors that sense current parameters such as temperature, humidity, wind, precipitation, and / or solar output. The model for the enclosure can be updated based also on an enclosure model stored in a database, and / or on enclosure information from a user. The model can be updated based on active testing of the enclosure which can be performed automatically or in response to user input. The testing can include heating and / or cooling the enclosure at times when the enclosure is not likely to be occupied.

Owner:GOOGLE LLC

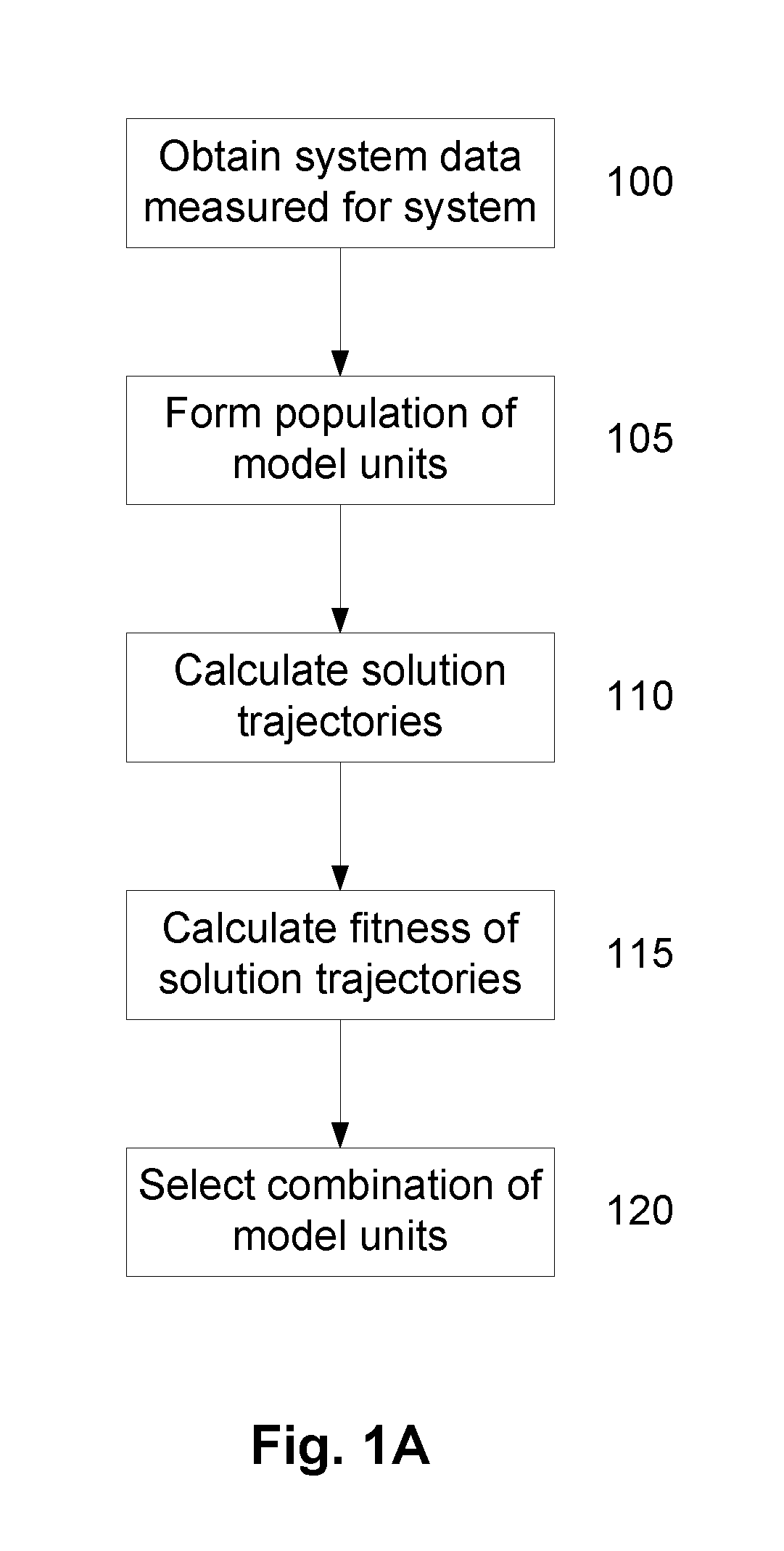

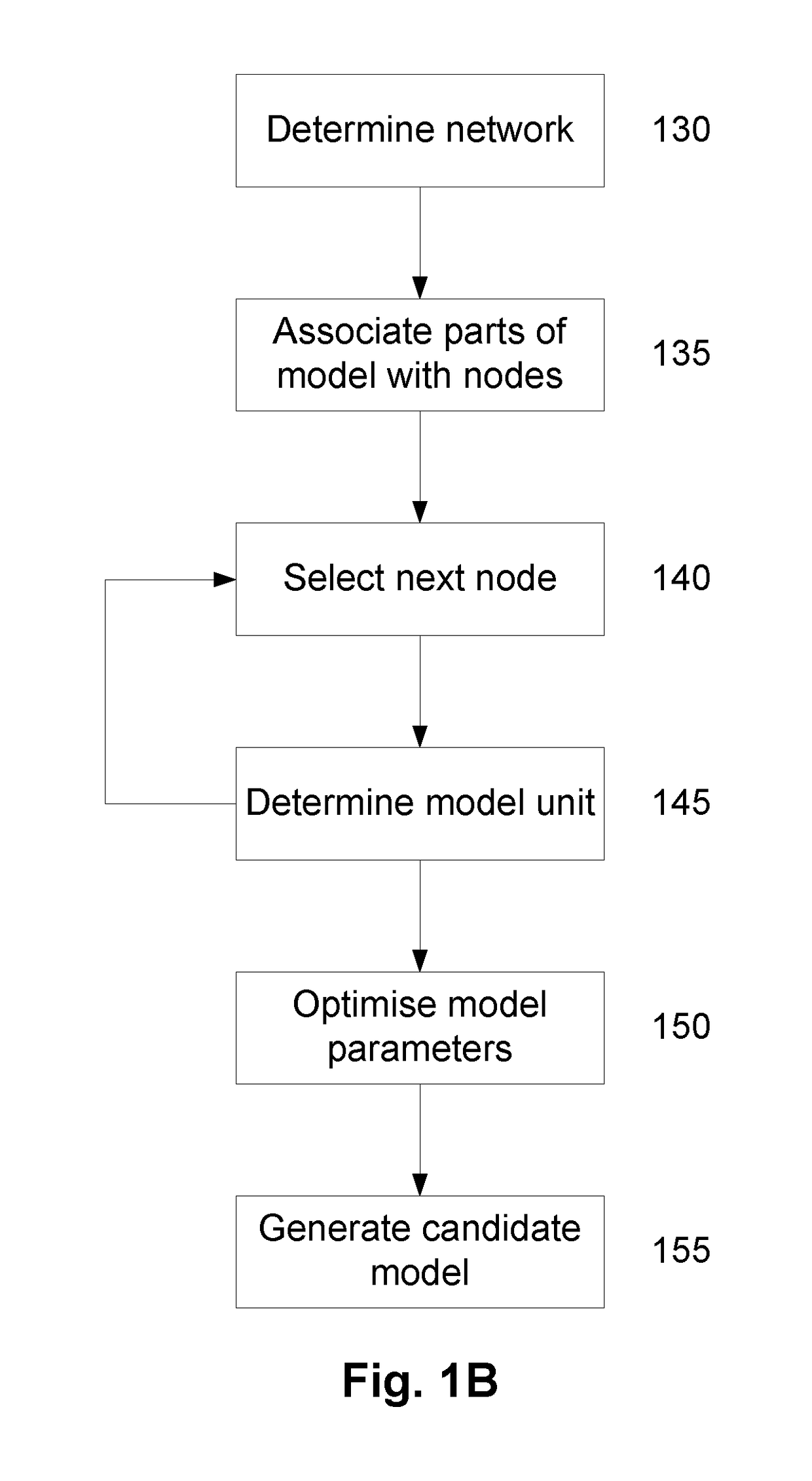

A System and Method for Modelling System Behaviour

ActiveUS20170147722A1Reduce the impactReduce impactMedical simulationDesign optimisation/simulationCollective modelModel system

A method of modelling system behaviour of a physical system, the method including, in one or more electronic processing devices obtaining quantified system data measured for the physical system, the quantified system data being at least partially indicative of the system behaviour for at least a time period, forming at least one population of model units, each model unit including model parameters and at least part of a model, the model parameters being at least partially based on the quantified system data, each model including one or more mathematical equations for modelling system behaviour, for each model unit calculating at least one solution trajectory for at least part of the at least one time period; determining a fitness value based at least in part on the at least one solution trajectory; and, selecting a combination of model units using the fitness values of each model unit, the combination of model units representing a collective model that models the system behaviour.

Owner:EVOLVING MACHINE INTELLIGENCE

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS20110282473A1Image enhancementDetails involving processing stepsImage segmentationMedical imaging

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The guide manufactured includes a mating region configured to matingly receive a portion of a patient bone associated with an arthroplasty procedure for which the custom arthroplasty guide is to be employed. The mating region includes a surface contour that is generally a negative of a surface contour of the portion of the patient bone. The surface contour of the mating region is configured to mate with the surface contour of the portion of the patient bone in a generally matching or interdigitating manner when the portion of the patient bone is matingly received by the mating region. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

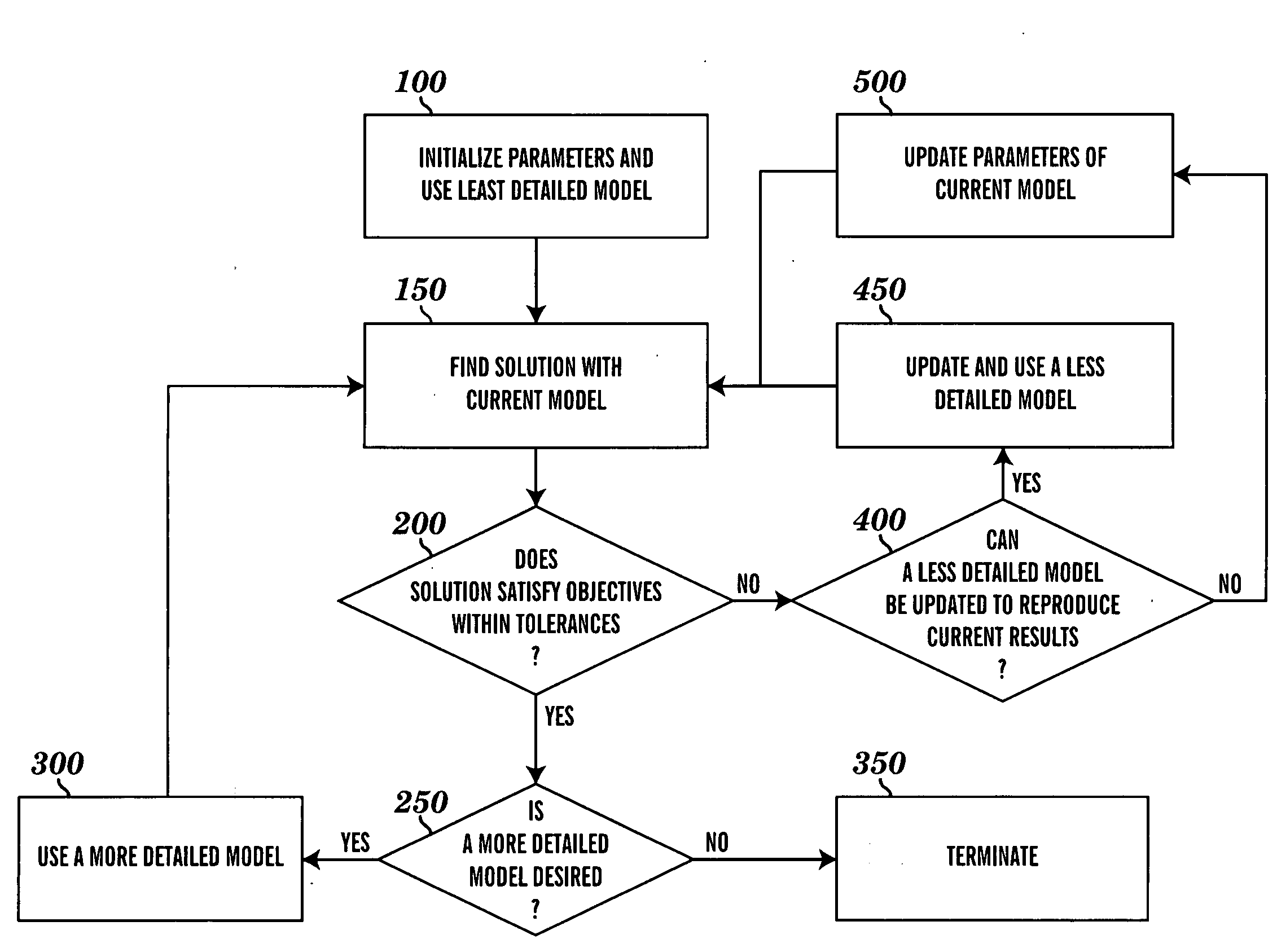

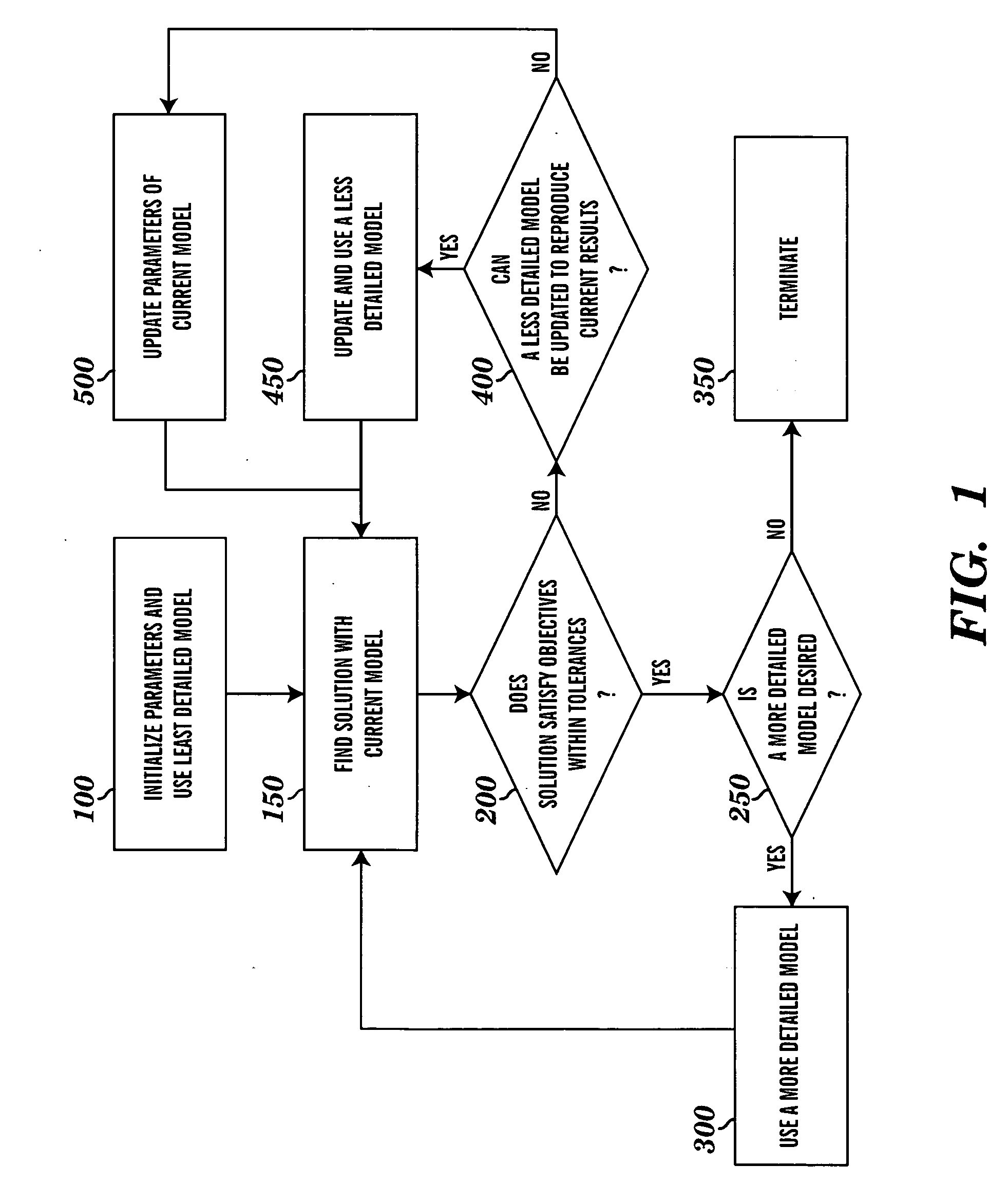

Method for tuning patient-specific cardiovascular simulations

ActiveUS20100017171A1Improve understandingImprove representationMedical simulationAnalogue computers for chemical processesReduced modelComputing Methodologies

Computational methods are used to create cardiovascular simulations having desired hemodynamic features. Cardiovascular modeling methods produce descriptions of blood flow and pressure in the heart and vascular networks. Numerical methods optimize and solve nonlinear equations to find parameter values that result in desired hemodynamic characteristics including related flow and pressure at various locations in the cardiovascular system, movements of soft tissues, and changes for different physiological states. The modeling methods employ simplified models to approximate the behavior of more complex models with the goal of to reducing computational expense. The user describes the desired features of the final cardiovascular simulation and provides minimal input, and the system automates the search for the final patient-specific cardiovascular model.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

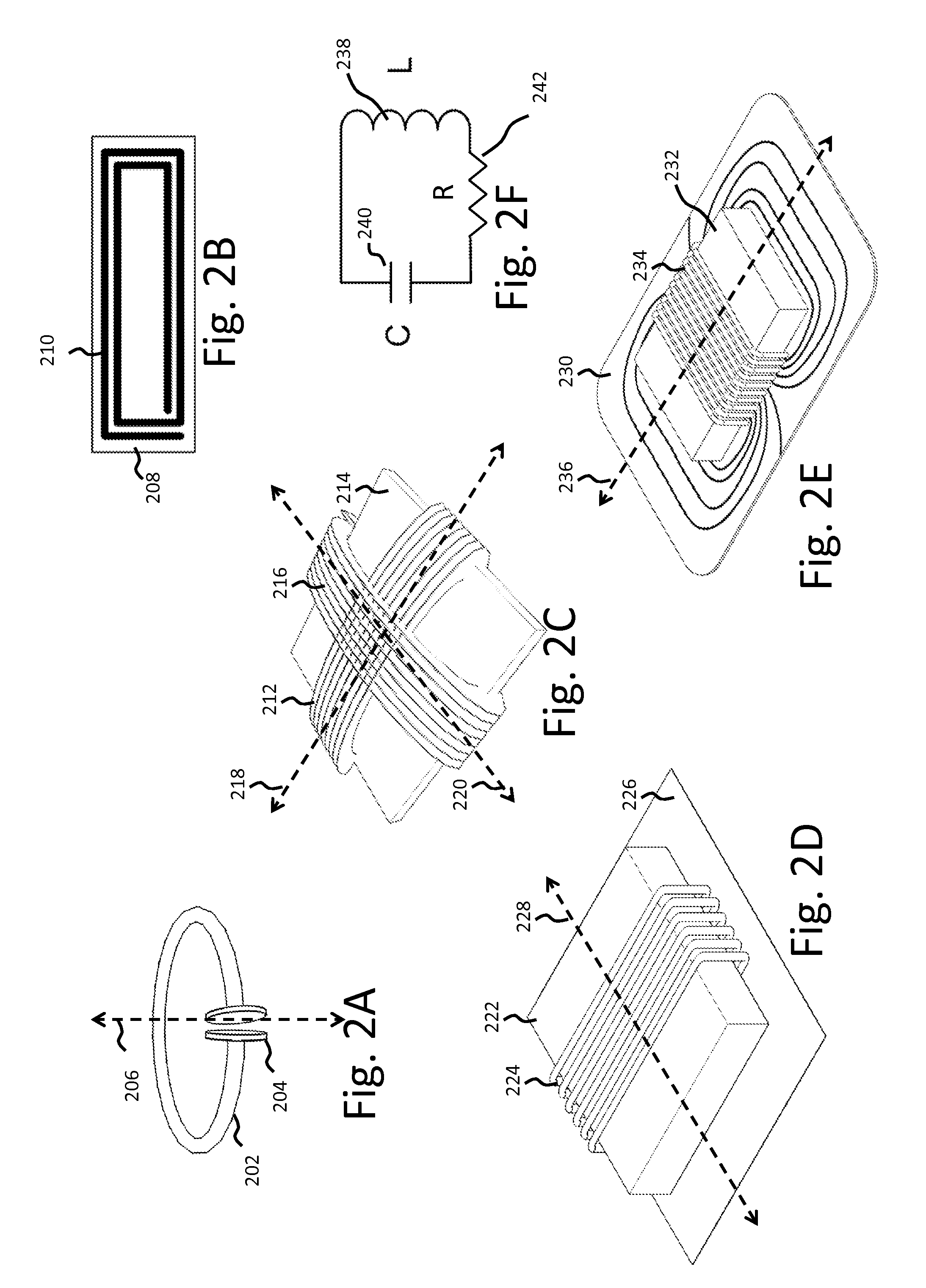

Wireless energy transfer modeling tool

ActiveUS20130159956A1Tune performanceCircuit arrangementsDesign optimisation/simulationEnergy transferElectromagnetic interference

A method includes defining and storing one or more attributes of a source resonator and a device resonator forming a system, defining and storing the interaction between the source resonator and the device resonator, modeling the electromagnetic performance of the system to derive one or more modeled values and utilizing the derived one or more modeled values to design an impedance matching network.

Owner:WITRICITY CORP

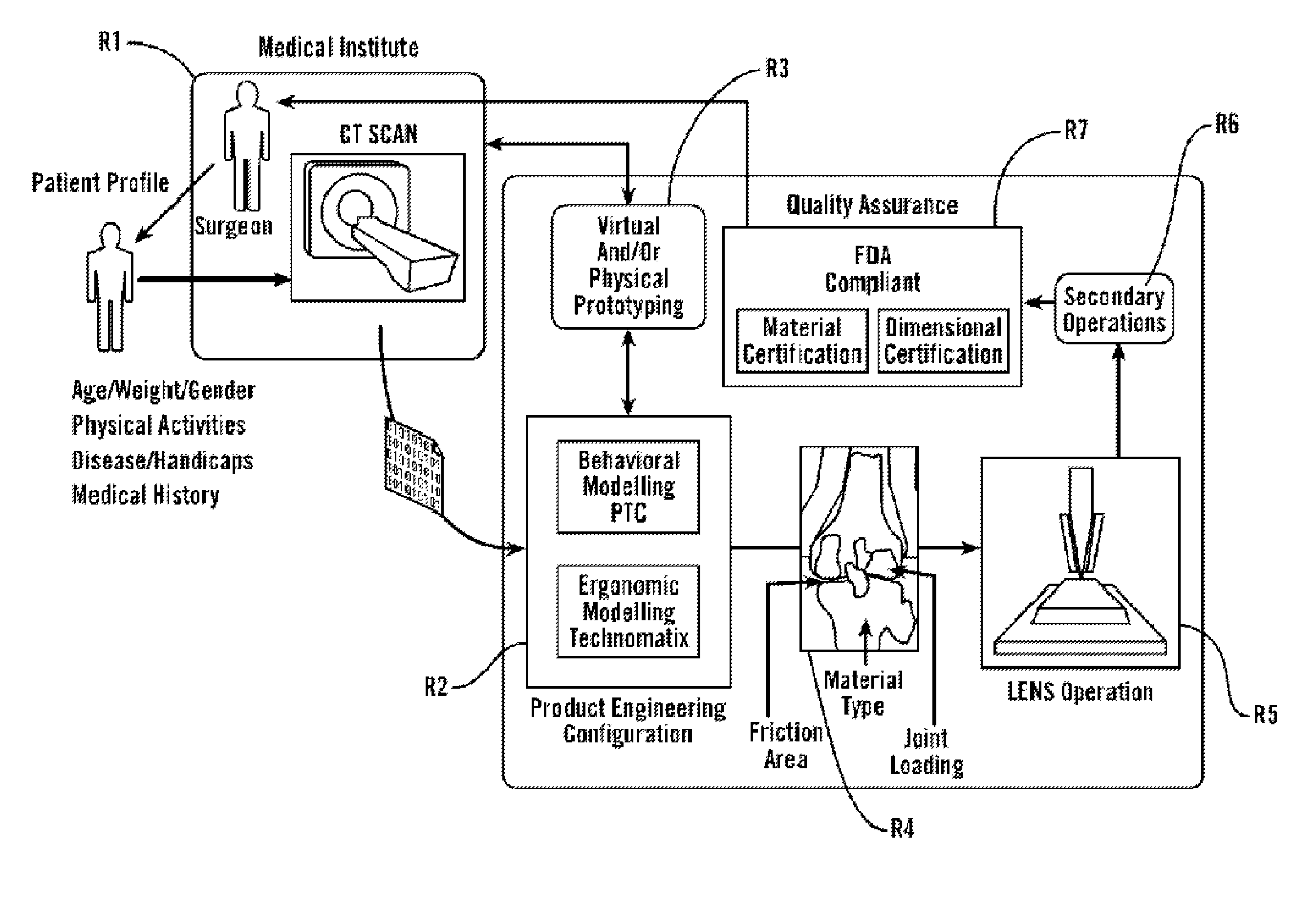

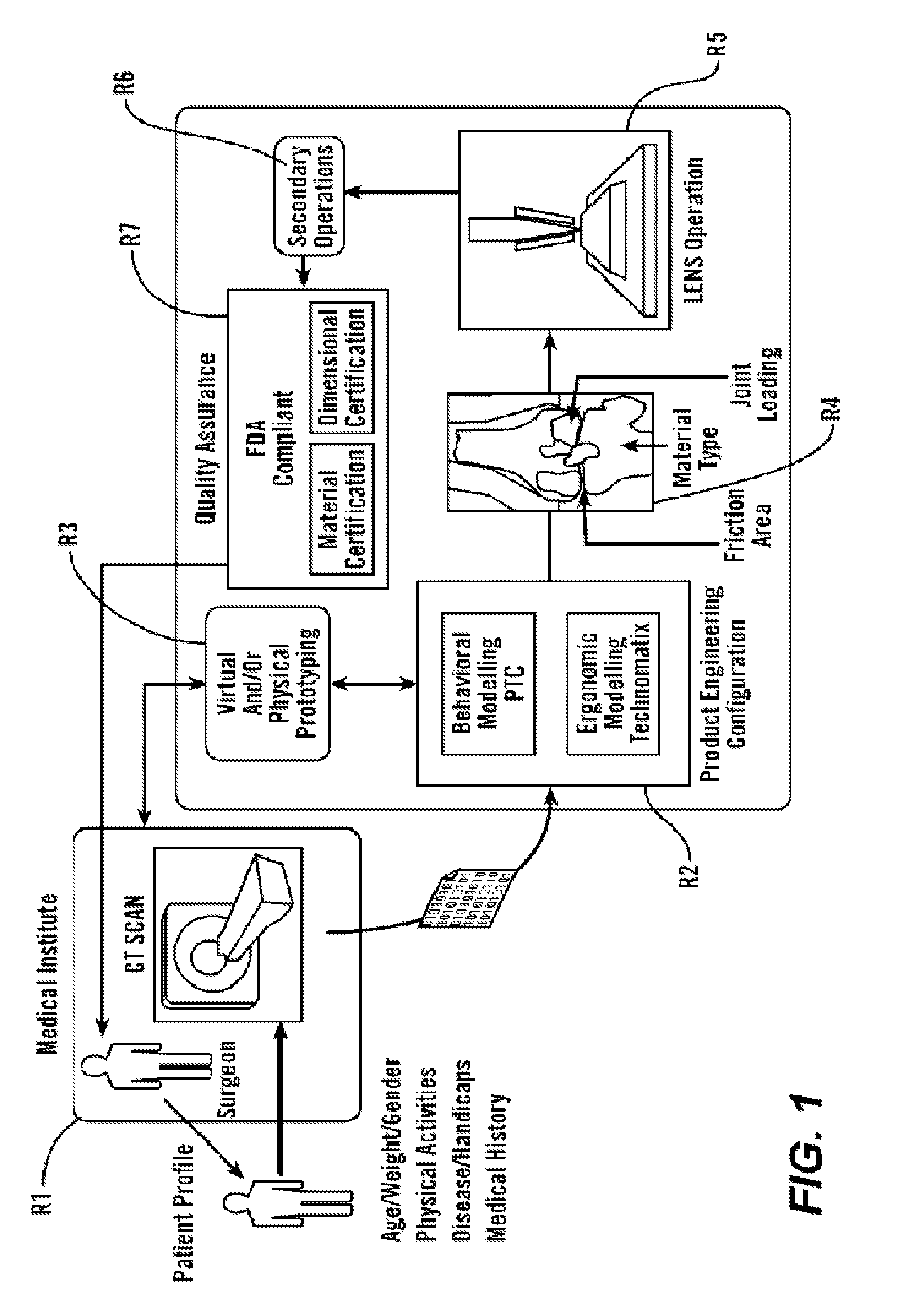

Personalized fit and functional designed medical prostheses and surgical instruments and methods for making

ActiveUS8457930B2Simple designFast learningMedical simulationAdditive manufacturing apparatusCamMedical treatment

Owner:SCHROEDER JAMES

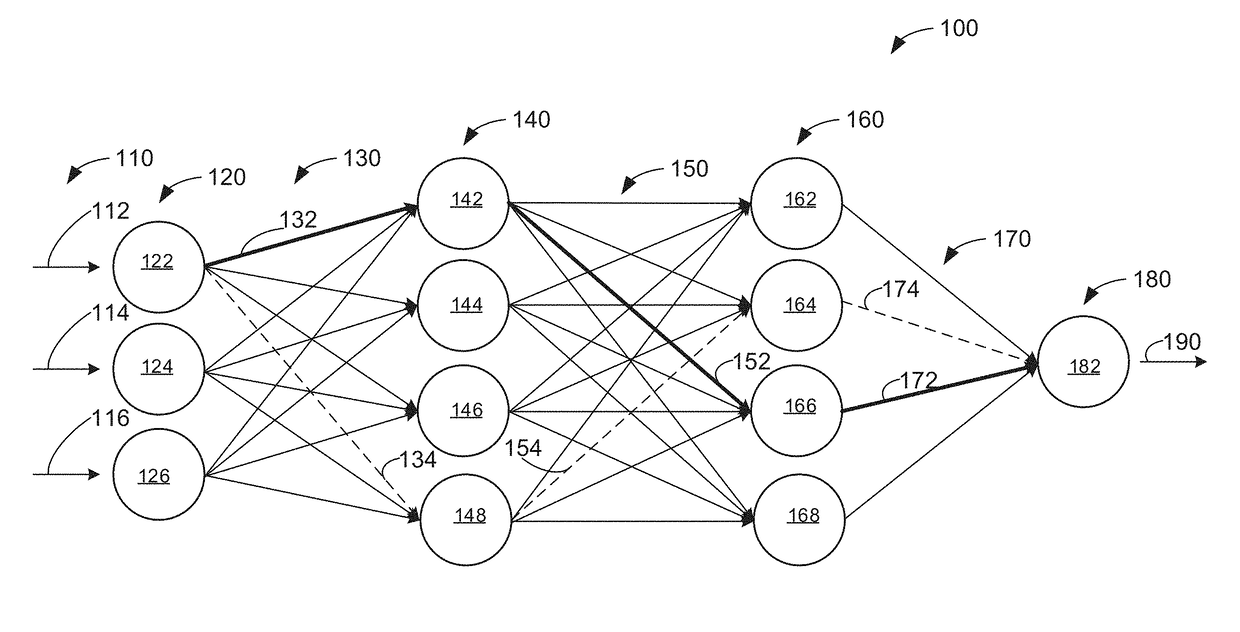

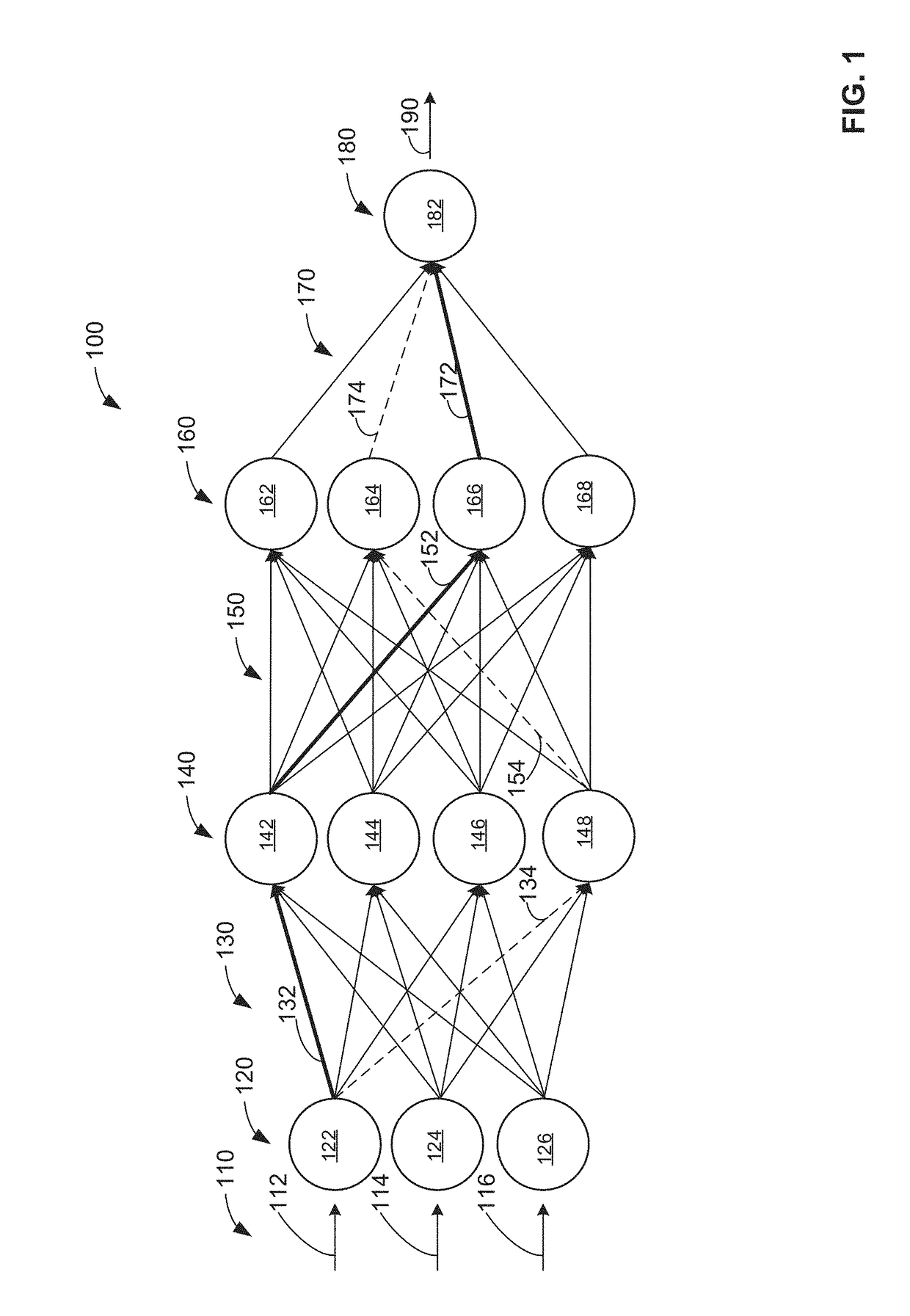

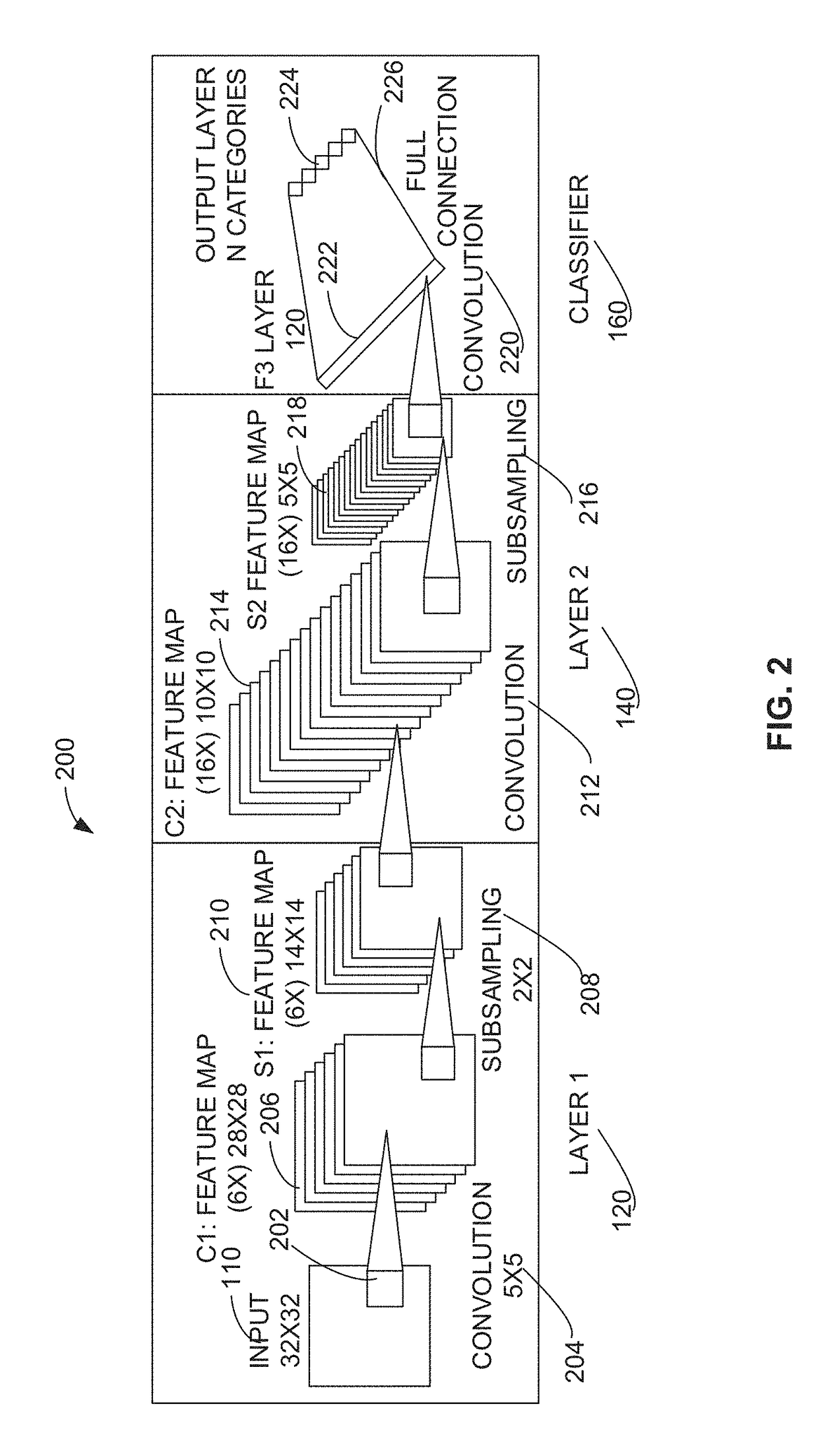

Hardware system design improvement using deep learning algorithms

Methods and apparatus for deep learning-based system design improvement are provided. An example system design engine apparatus includes a deep learning network (DLN) model associated with each component of a target system to be emulated, each DLN model to be trained using known input and known output, wherein the known input and known output simulate input and output of the associated component of the target system, and wherein each DLN model is connected as each associated component to be emulated is connected in the target system to form a digital model of the target system. The example apparatus also includes a model processor to simulate behavior of the target system and / or each component of the target system to be emulated using the digital model to generate a recommendation regarding a configuration of a component of the target system and / or a structure of the component of the target system.

Owner:GENERAL ELECTRIC CO

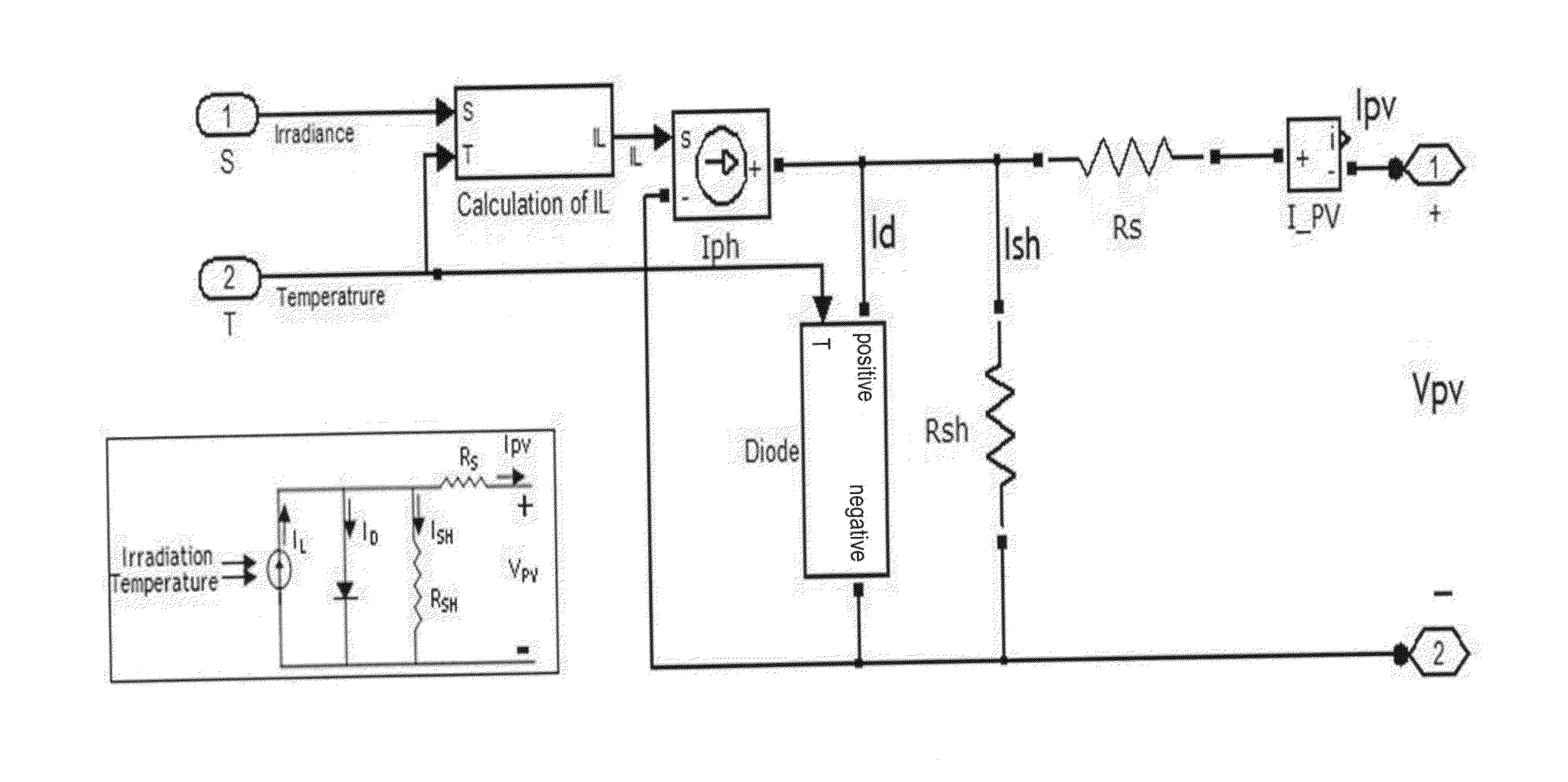

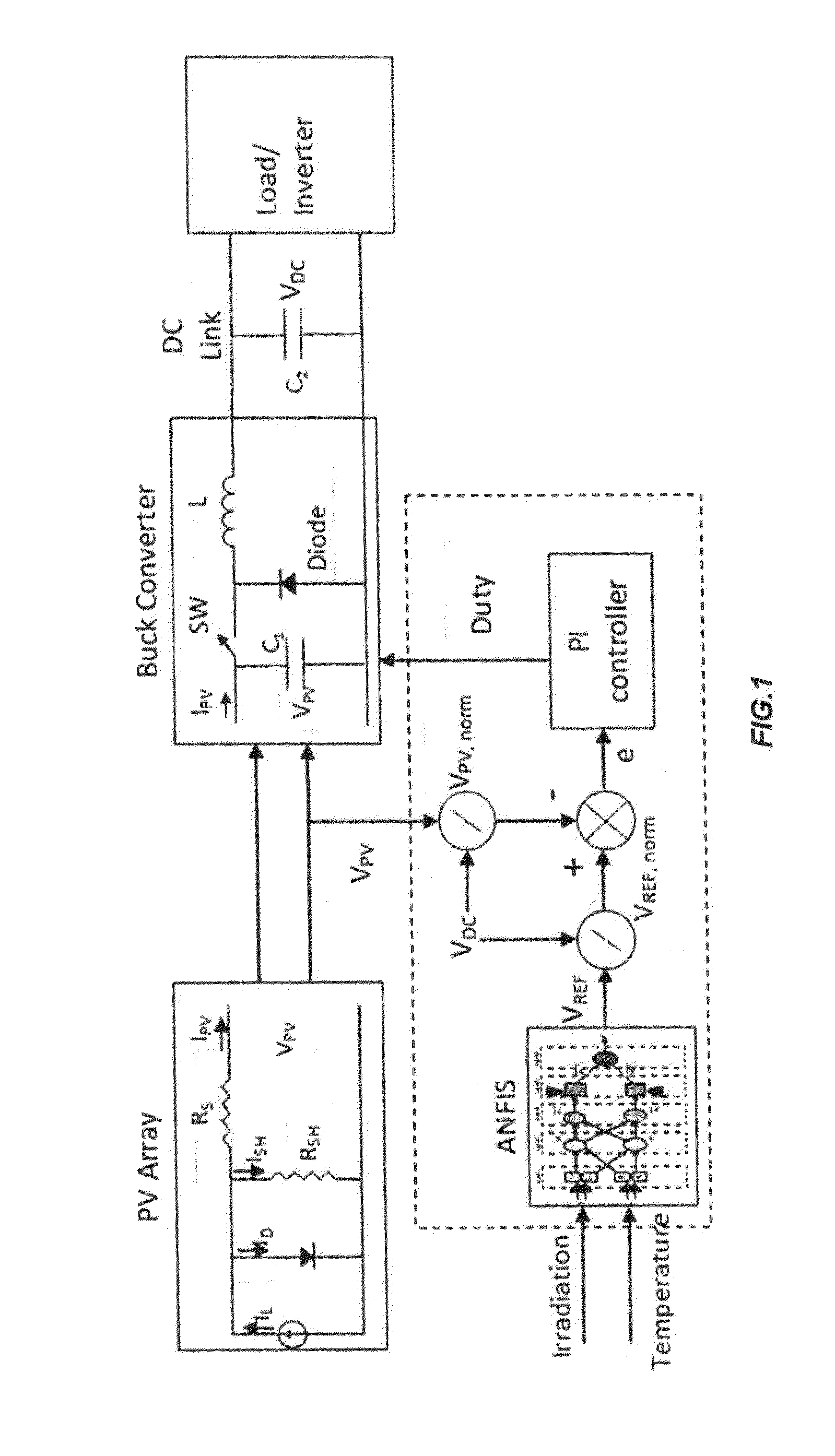

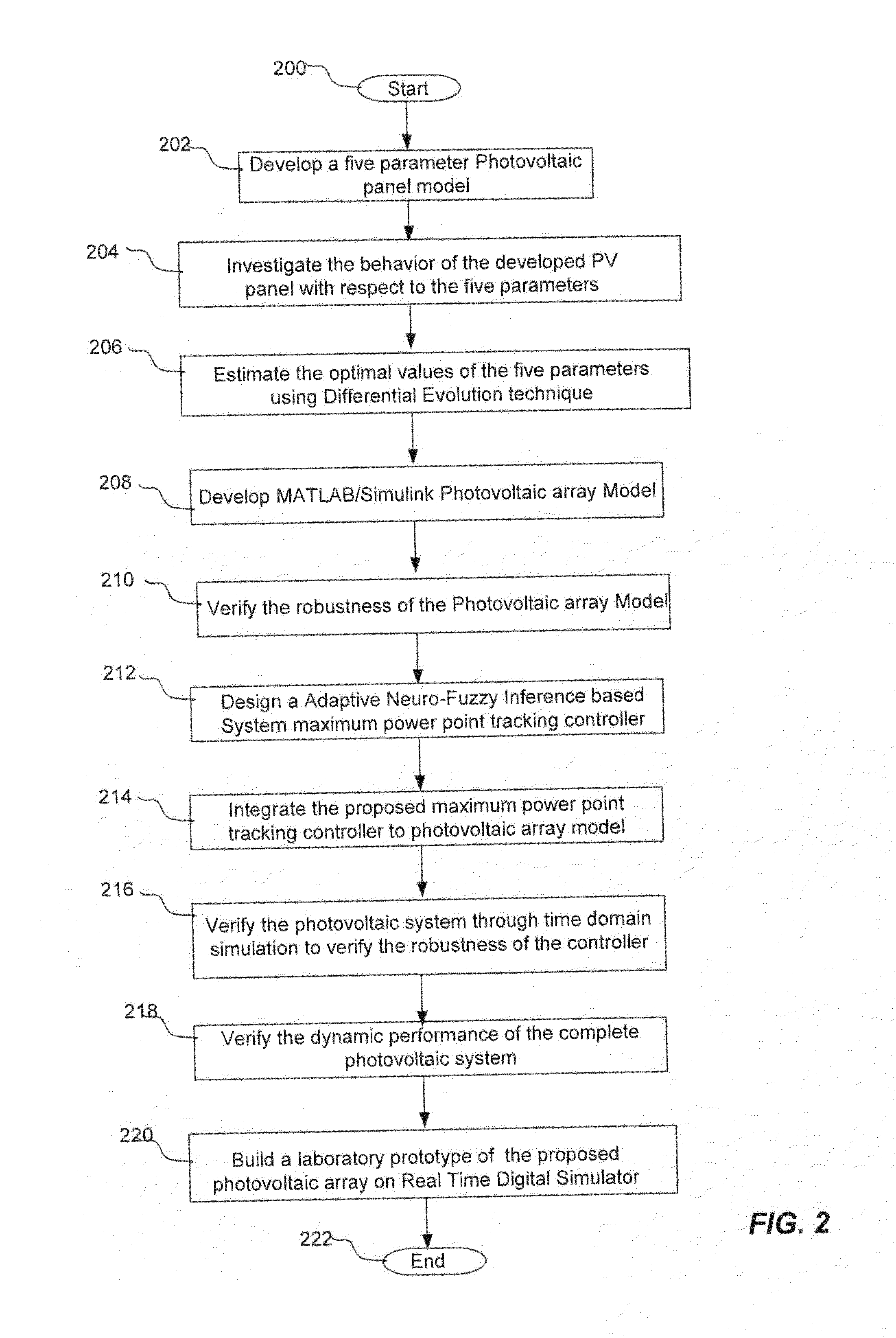

Photovoltaic systems with maximum power point tracking controller

ActiveUS20150188415A1Simulator controlAnalogue computers for nuclear physicsFuzzy inferenceEngineering

A system and a method provide a photovoltaic system which regenerates the output characteristics of the photovoltaic at different ambient condition with high precision under all environmental conditions. The photovoltaic system includes a photovoltaic array, a buck / boost converter, a DC link capacitor to connect the buck / booster converter to a load / inverter, an adaptive network-based fuzzy inference maximum power point tracking controller, a voltage control loop, a proportional integral controller to maintain the output voltage of the photovoltaic array to the reference voltage by adjusting the duty ratio of buck / boost converter.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

System and method for image segmentation in generating computer models of a joint to undergo arthroplasty

ActiveUS20120192401A1Image enhancementDetails involving processing stepsImage segmentationMedical imaging

A custom arthroplasty guide and a method of manufacturing such a guide are disclosed herein. The method of manufacturing the custom arthroplasty guide includes: a) generating medical imaging slices of the portion of the patient bone; b) identifying landmarks on bone boundaries in the medical imaging slices; c) providing model data including image data associated with a bone other than the patient bone; d) adjusting the model data to match the landmarks; e) using the adjusted model data to generate a three dimensional computer model of the portion of the patient bone; f) using the three dimensional computer model to generate design data associated with the custom arthroplasty guide; and g) using the design data in manufacturing the custom arthroplasty guide.

Owner:HOWMEDICA OSTEONICS CORP

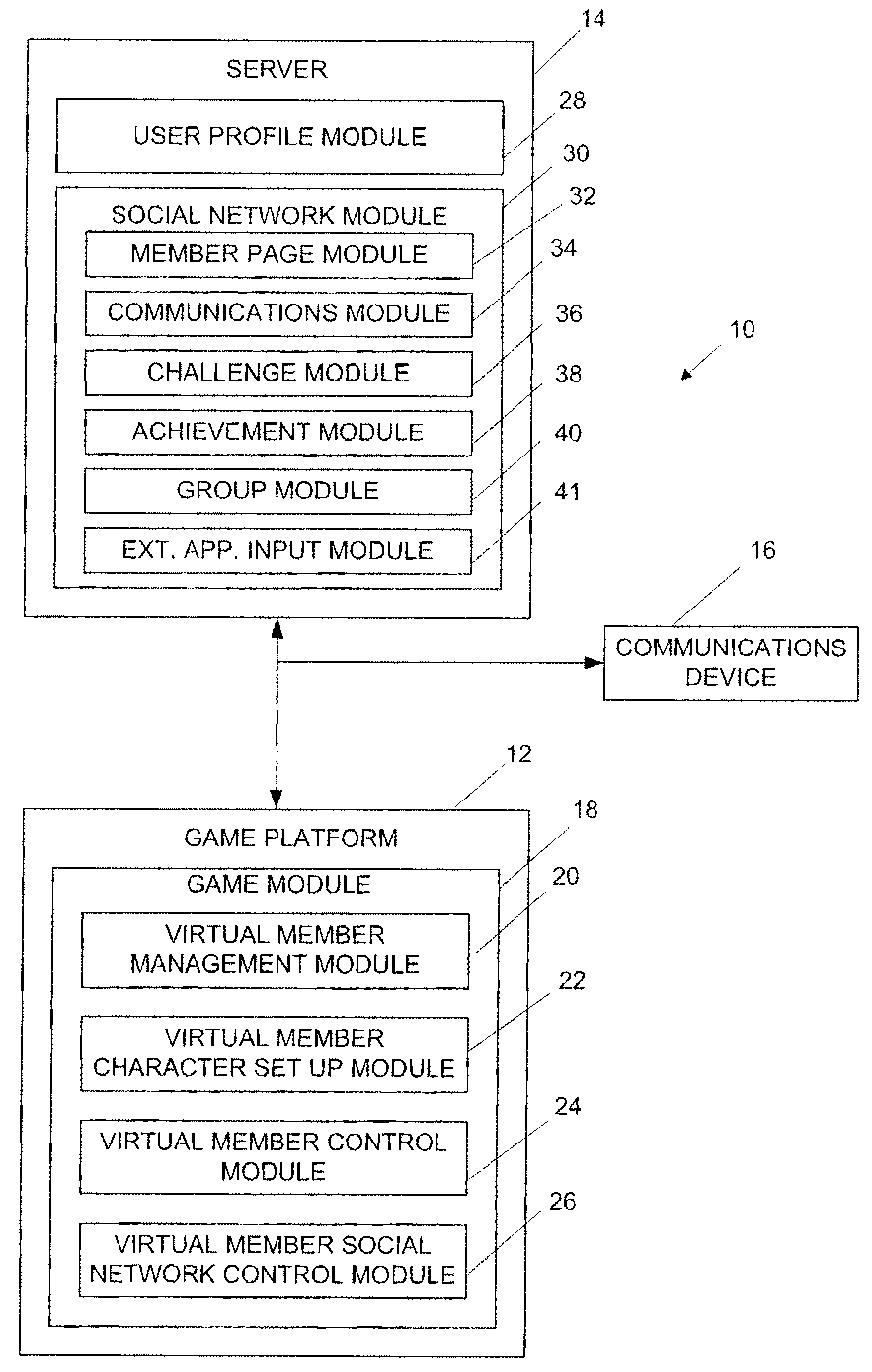

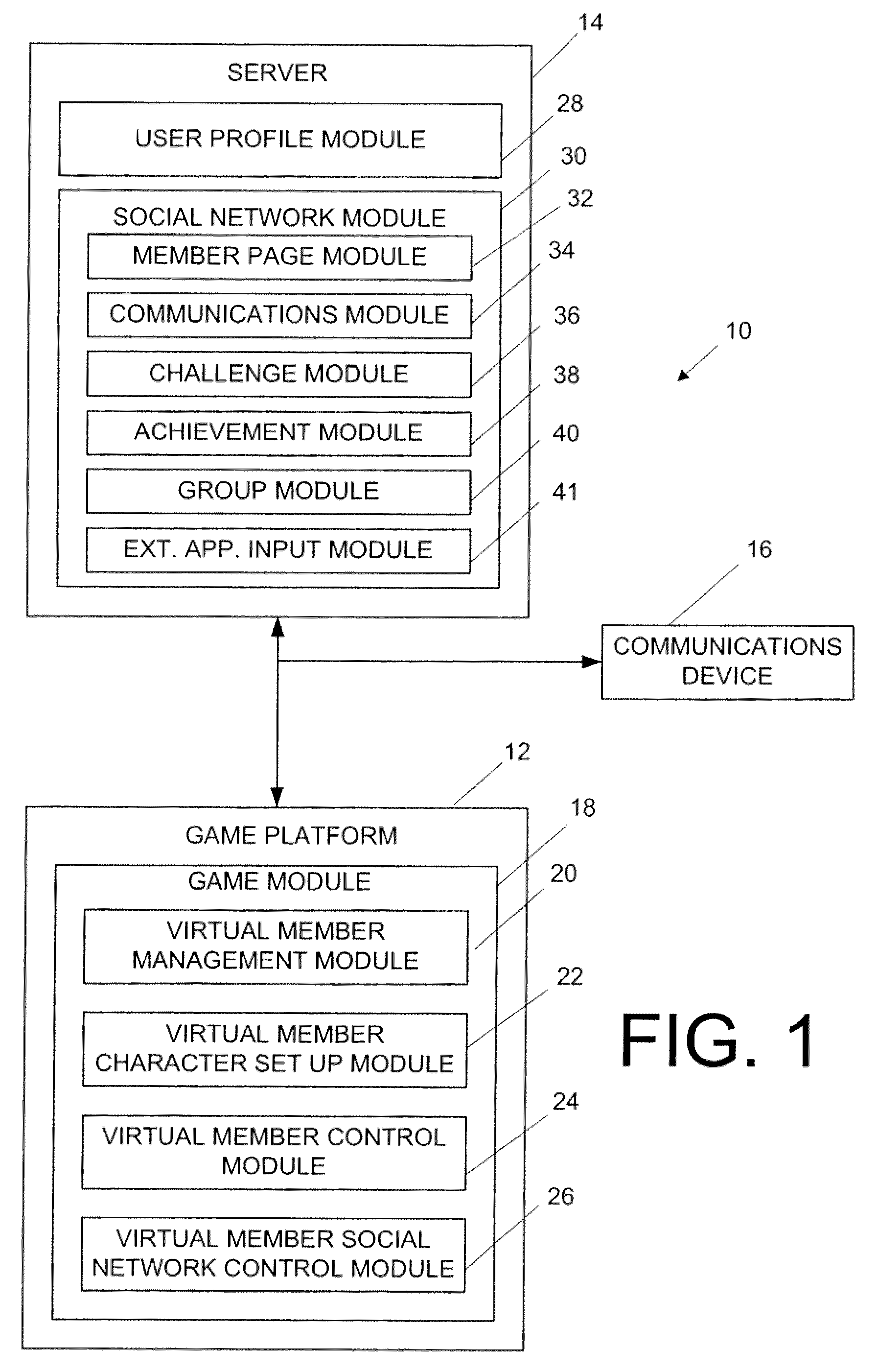

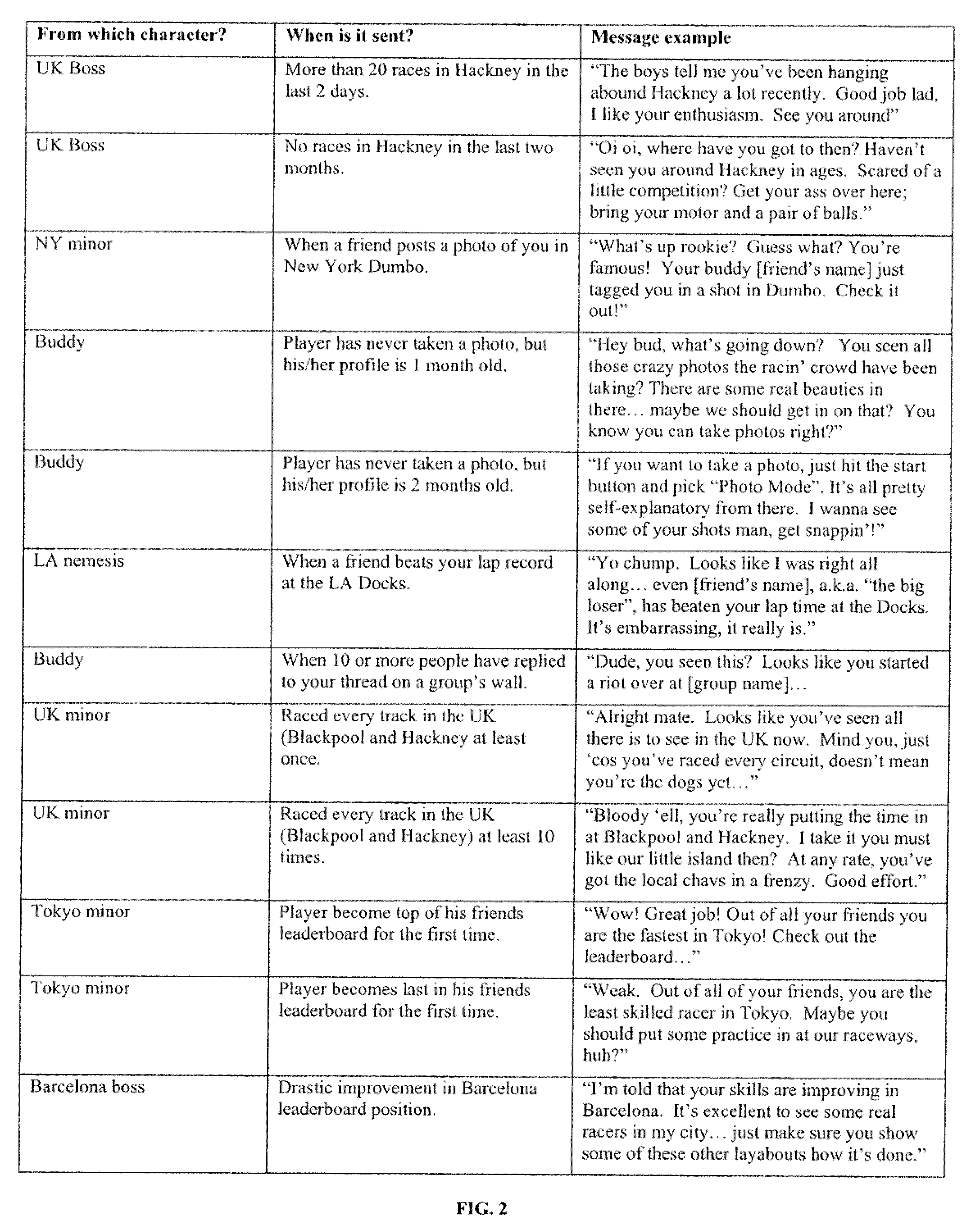

Social Network System and Method For Use With and Integration into a Video Game

ActiveUS20100216553A1Expand accessBuilds brand loyalty amongst usersDesign optimisation/simulationVideo gamesSocial webGame play

A centralized social network tool is configured to interface with and integrates into one or more videogames and / or videogame series. The social network tool may be integral to the theme of the games and be pervasive within game play. The social network may drive progression of the story and interaction between characters. According to another aspect of the invention, the members of the social network may include actual members (corresponding to real people) and virtual members (e.g., artificial intelligence controlled bot members). The virtual members may be part of the social network and may interact with real members within and outside of the game as part of the theme of the game.

Owner:ACTIVISION PUBLISHING

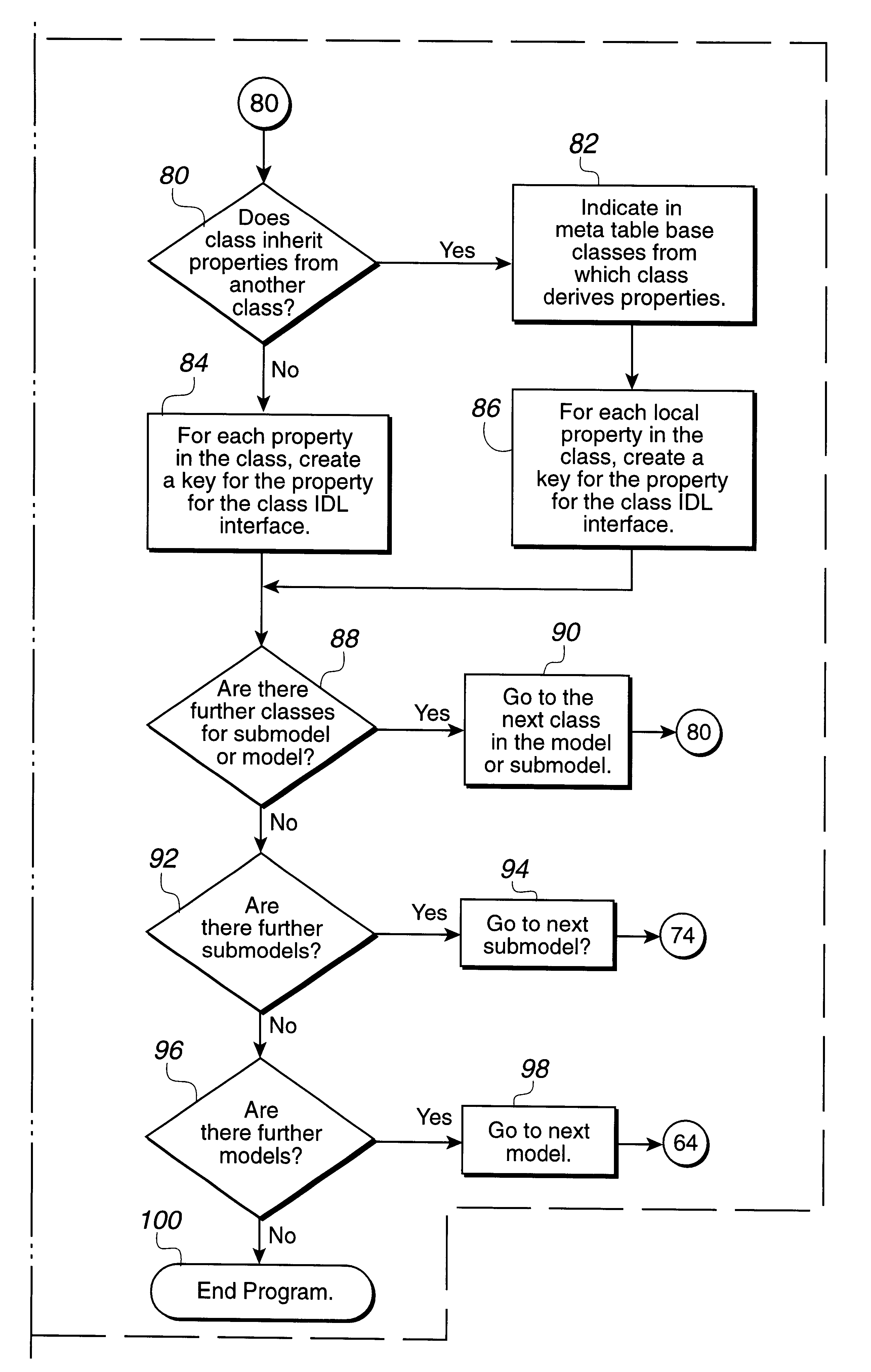

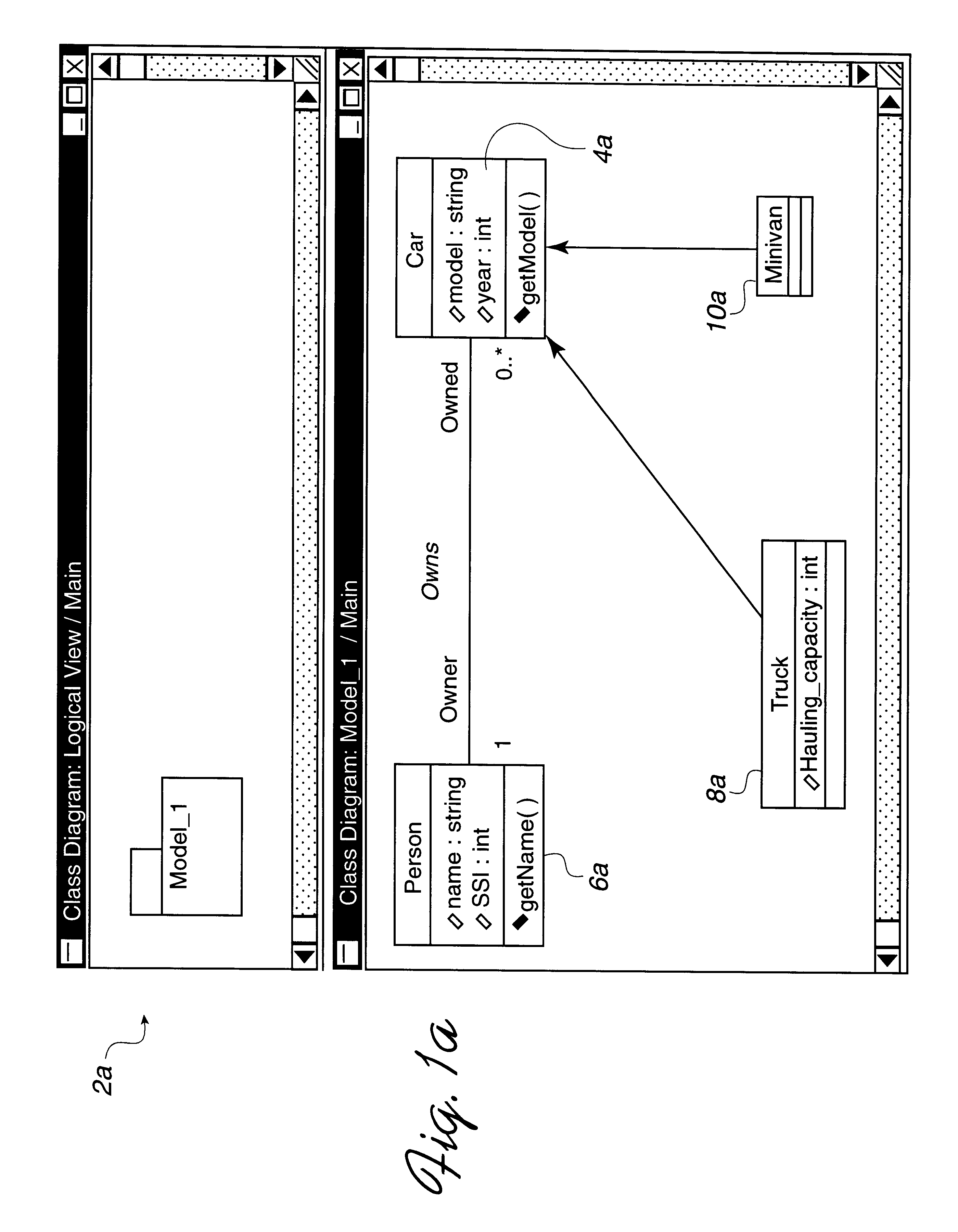

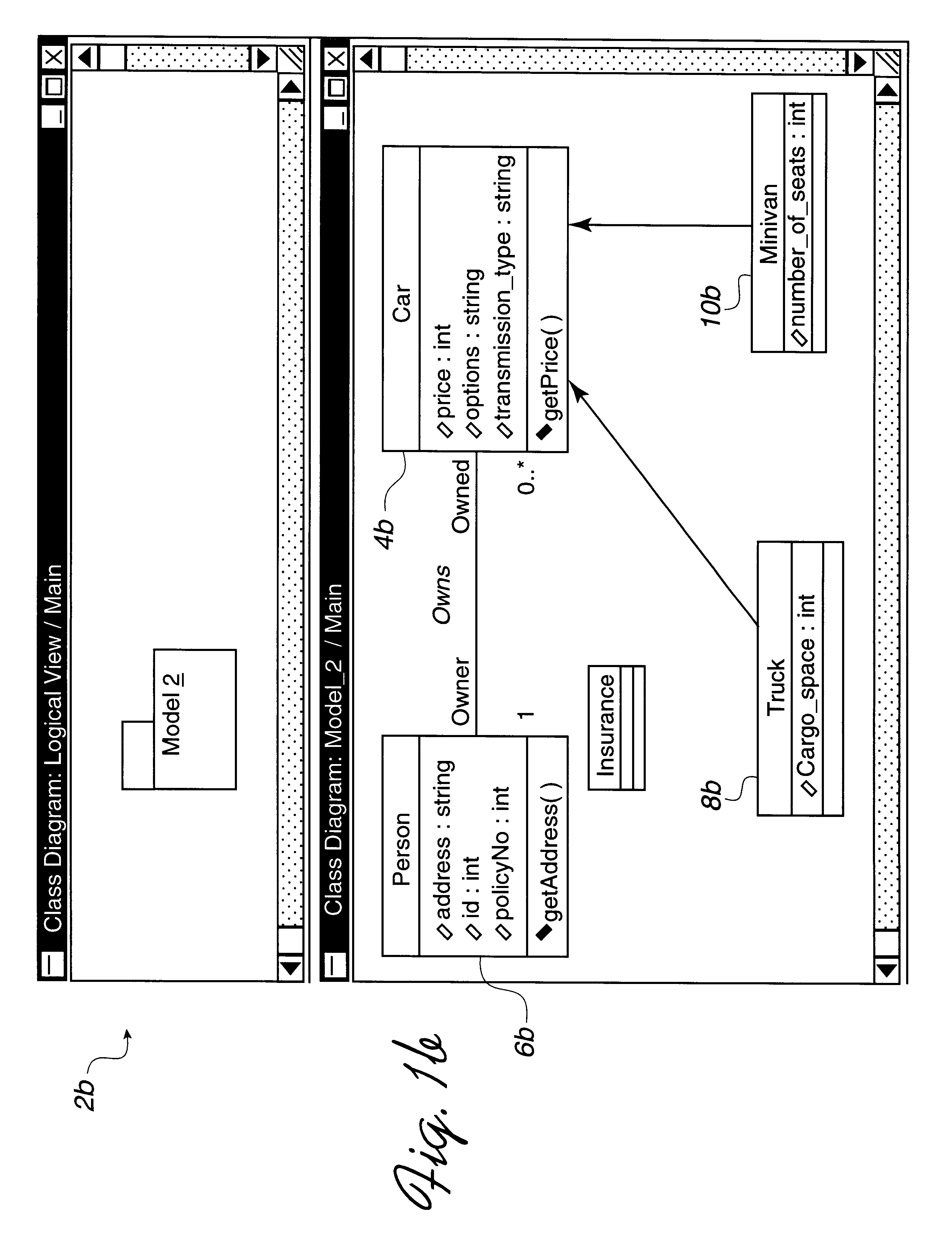

System and method for mapping a design model to a common repository with context preservation

InactiveUS6343265B1Improved GUIEasy to understandData processing applicationsSoftware designModeling languageData structure

Disclosed is a system for mapping objects defined in a design model, such as an object oriented design model defined using a design language such as the Universal Modeling Language (UML), to a data model accessible to an application development tool. A design model is provided that includes at least two models. A first model includes a first class and a second model includes a second class. The first class and second class have the same name, and the first class and second class have at least one different attribute and method. The first model, the first class, and attributes and methods therein are mapped to a first data structure that indicates that the first class is included with the first model. The second model, the second class, and attributes and methods therein are mapped to a second data structure that indicates that the second class is included with the second model. In this way, the first class and the second class are distinguished according to their model in the data structures.

Owner:IBM CORP

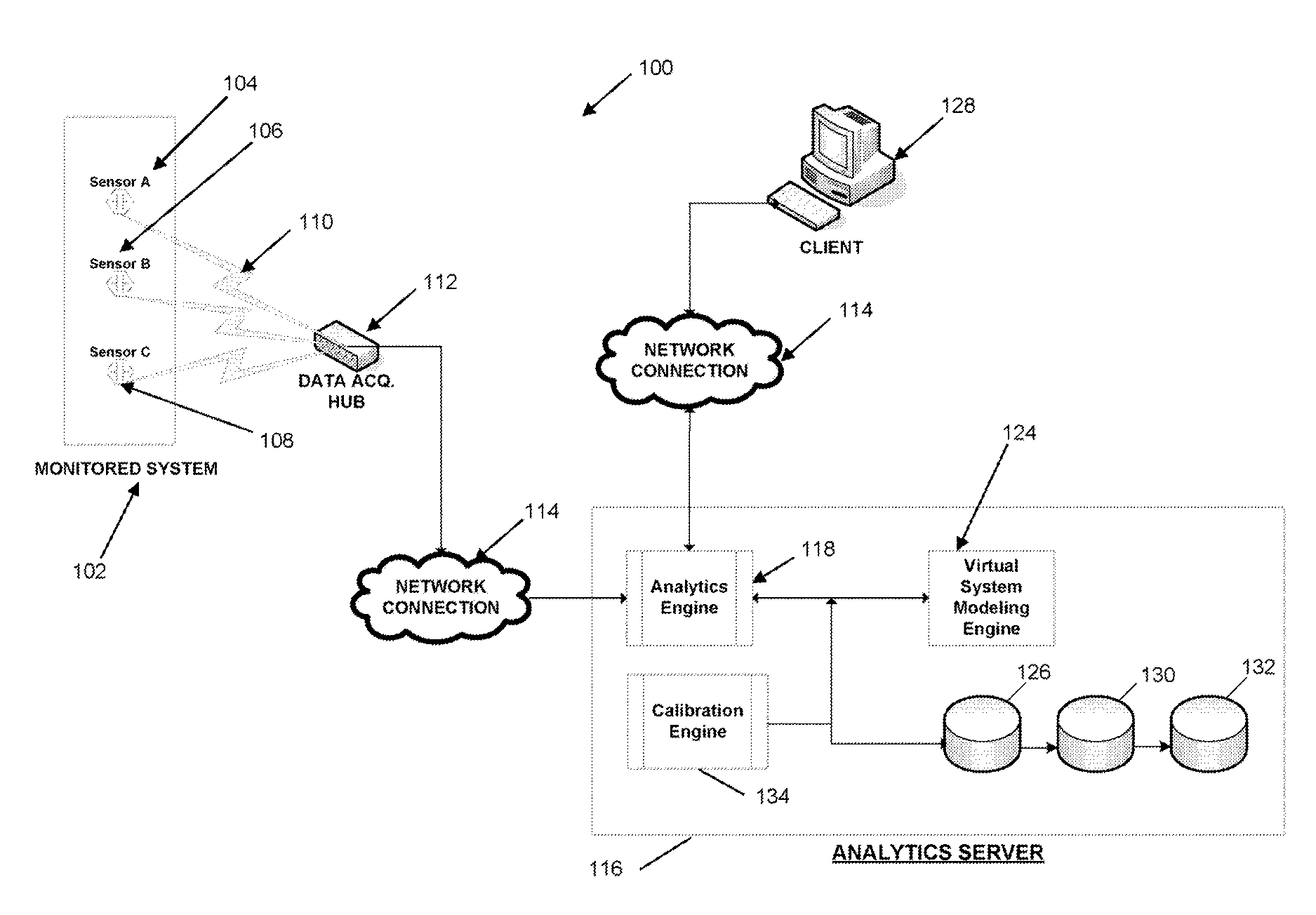

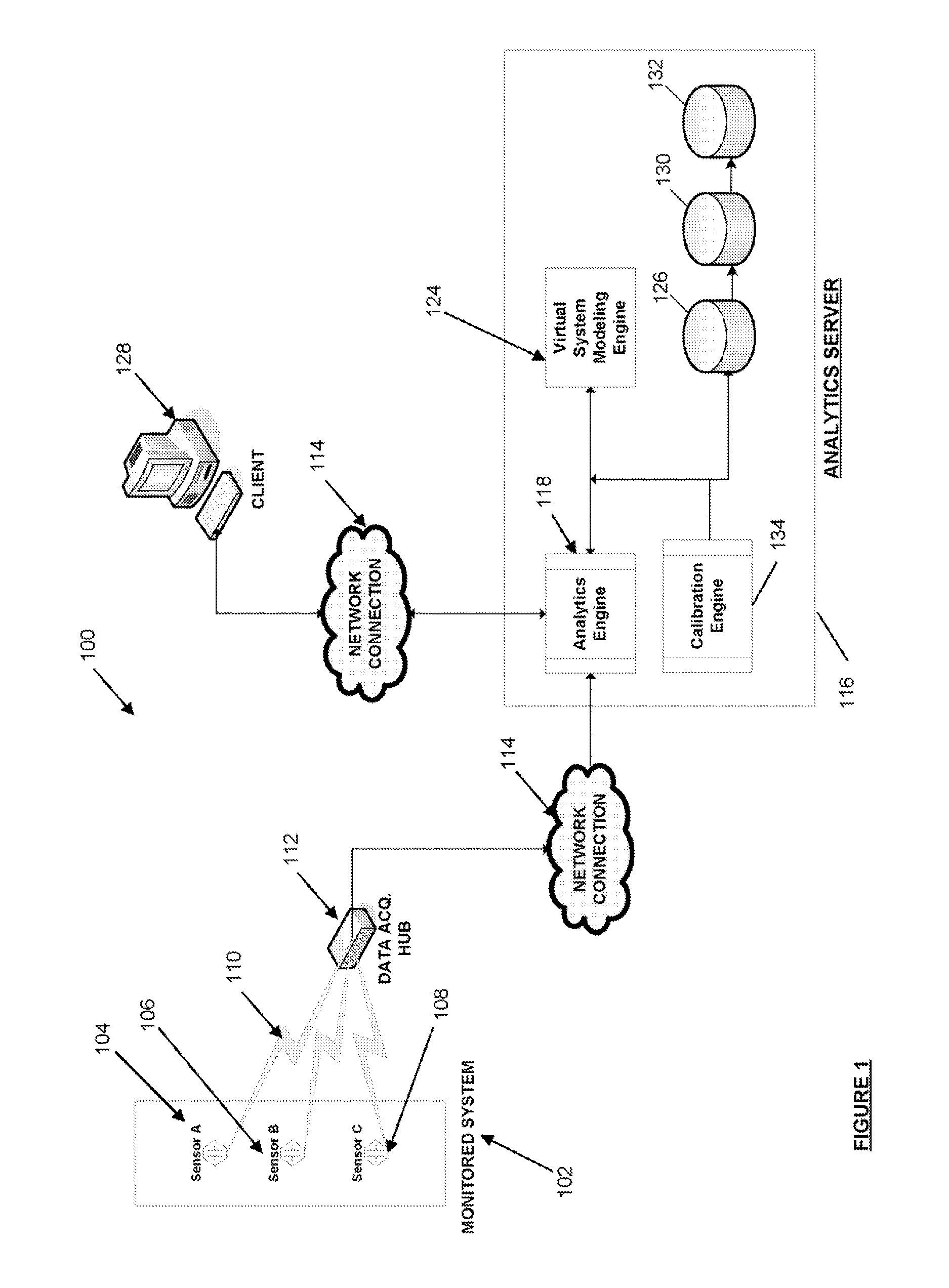

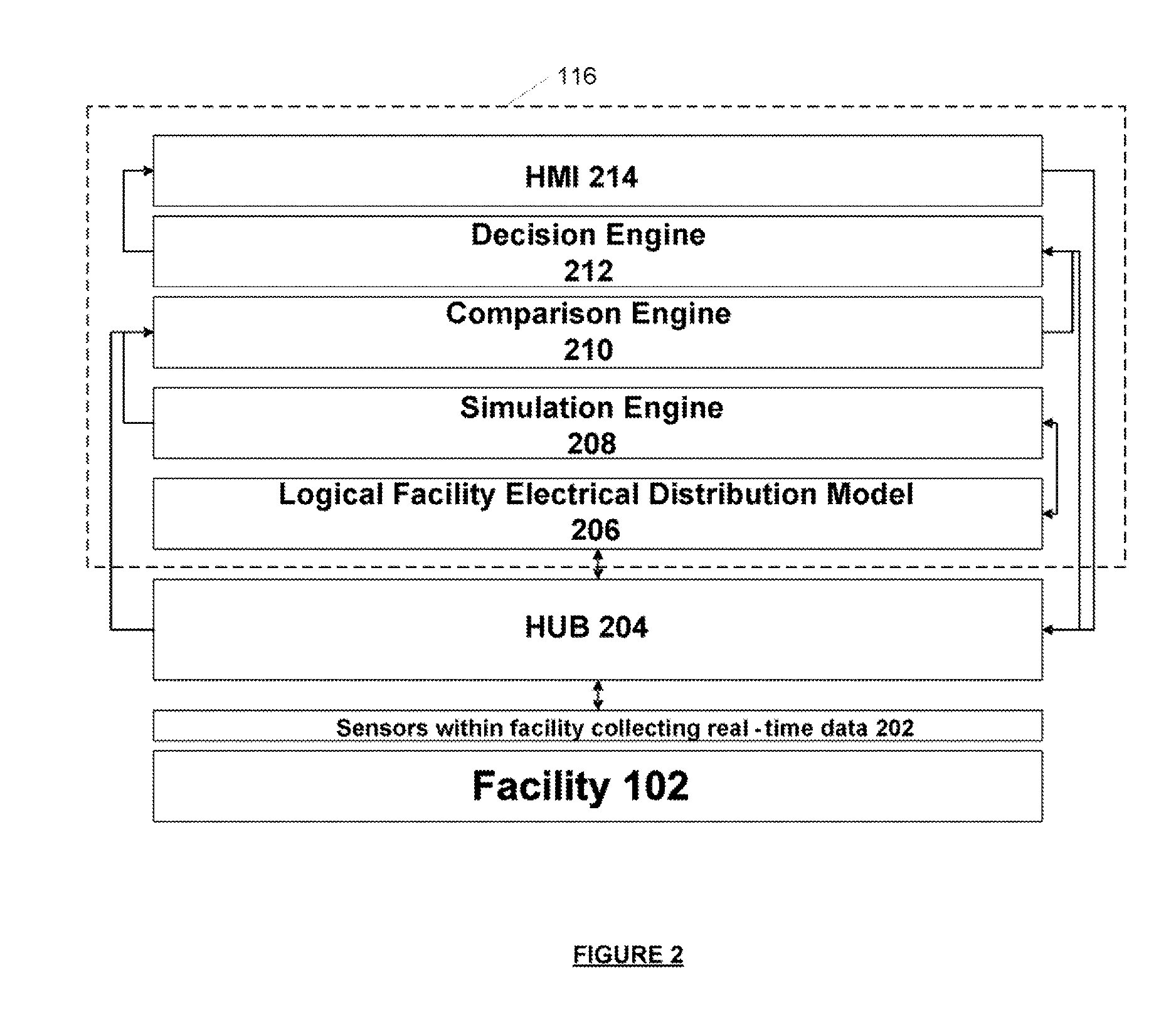

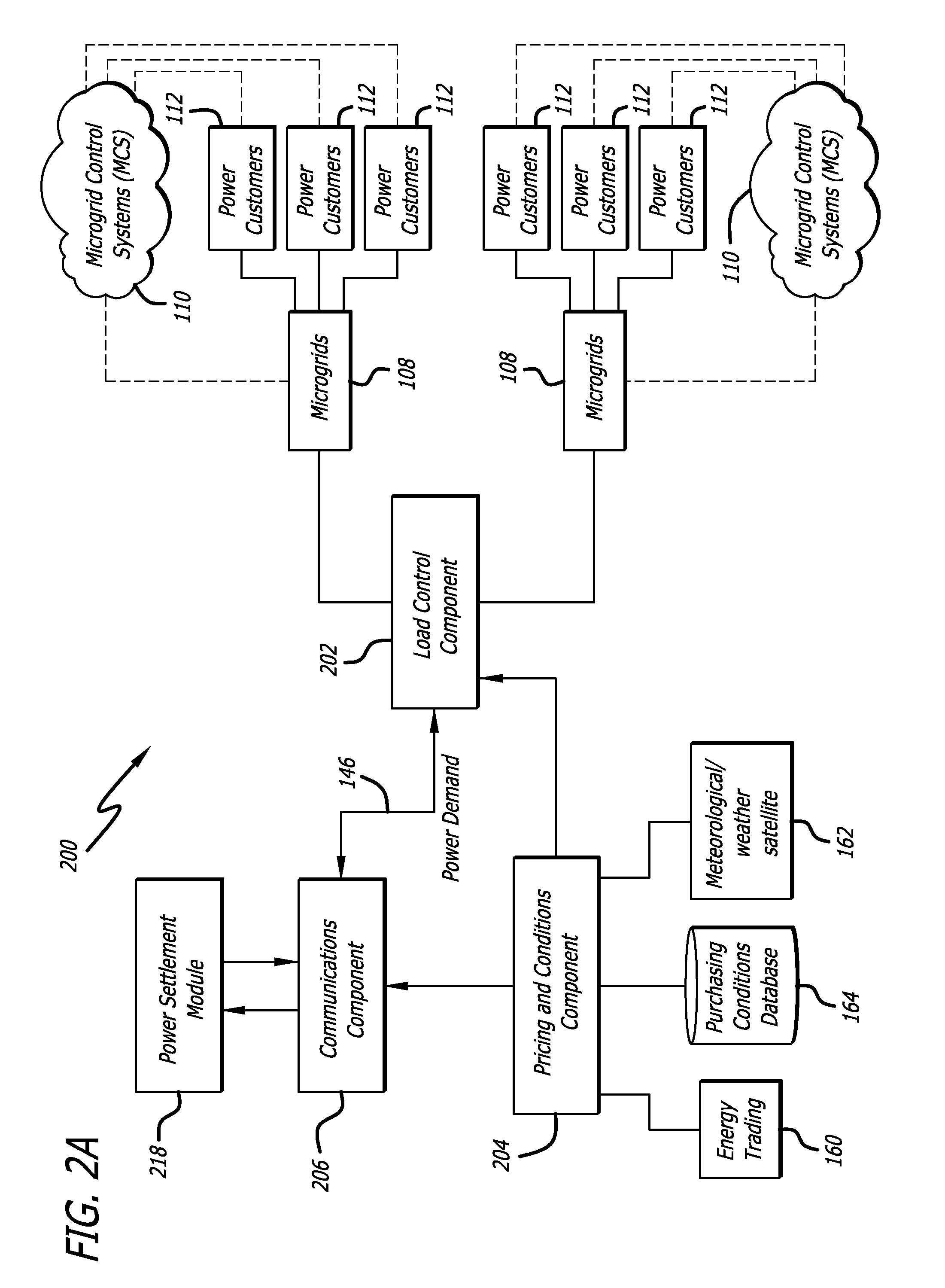

Systems and methods for real-time DC microgrid power analytics for mission-critical power systems

Systems and methods for performing power analytics on a microgrid. In an embodiment, predicted data is generated for the microgrid utilizing a virtual system model of the microgrid, which comprises a virtual representation of a topology of the microgrid. Real-time data is received via a portal from at least one external data source. If the difference between the real-time data and the predicted data exceeds a threshold, a calibration and synchronization operation is initiated to update the virtual system model in real-time. Power analytics may be performed on the virtual system model to generate analytical data, which can be returned via the portal.

Owner:POWER ANALYTICS CORP

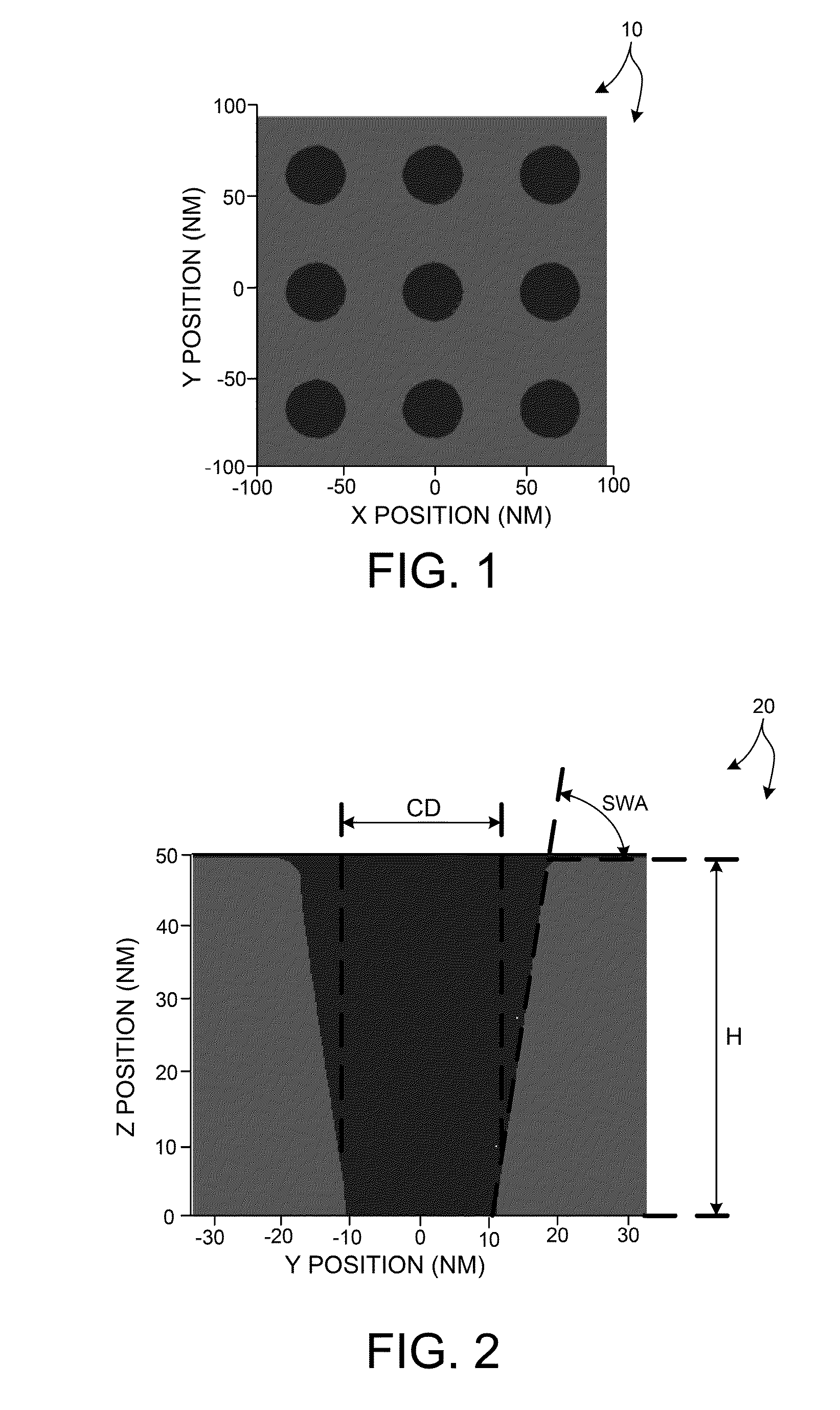

Integrated use of model-based metrology and a process model

ActiveUS20140172394A1Predictive result is improvedSimple processPhotomechanical apparatusDesign optimisation/simulationMetrologyModel method

Methods and systems for performing measurements based on a measurement model integrating a metrology-based target model with a process-based target model. Systems employing integrated measurement models may be used to measure structural and material characteristics of one or more targets and may also be used to measure process parameter values. A process-based target model may be integrated with a metrology-based target model in a number of different ways. In some examples, constraints on ranges of values of metrology model parameters are determined based on the process-based target model. In some other examples, the integrated measurement model includes the metrology-based target model constrained by the process-based target model. In some other examples, one or more metrology model parameters are expressed in terms of other metrology model parameters based on the process model. In some other examples, process parameters are substituted into the metrology model.

Owner:KLA TENCOR TECH CORP

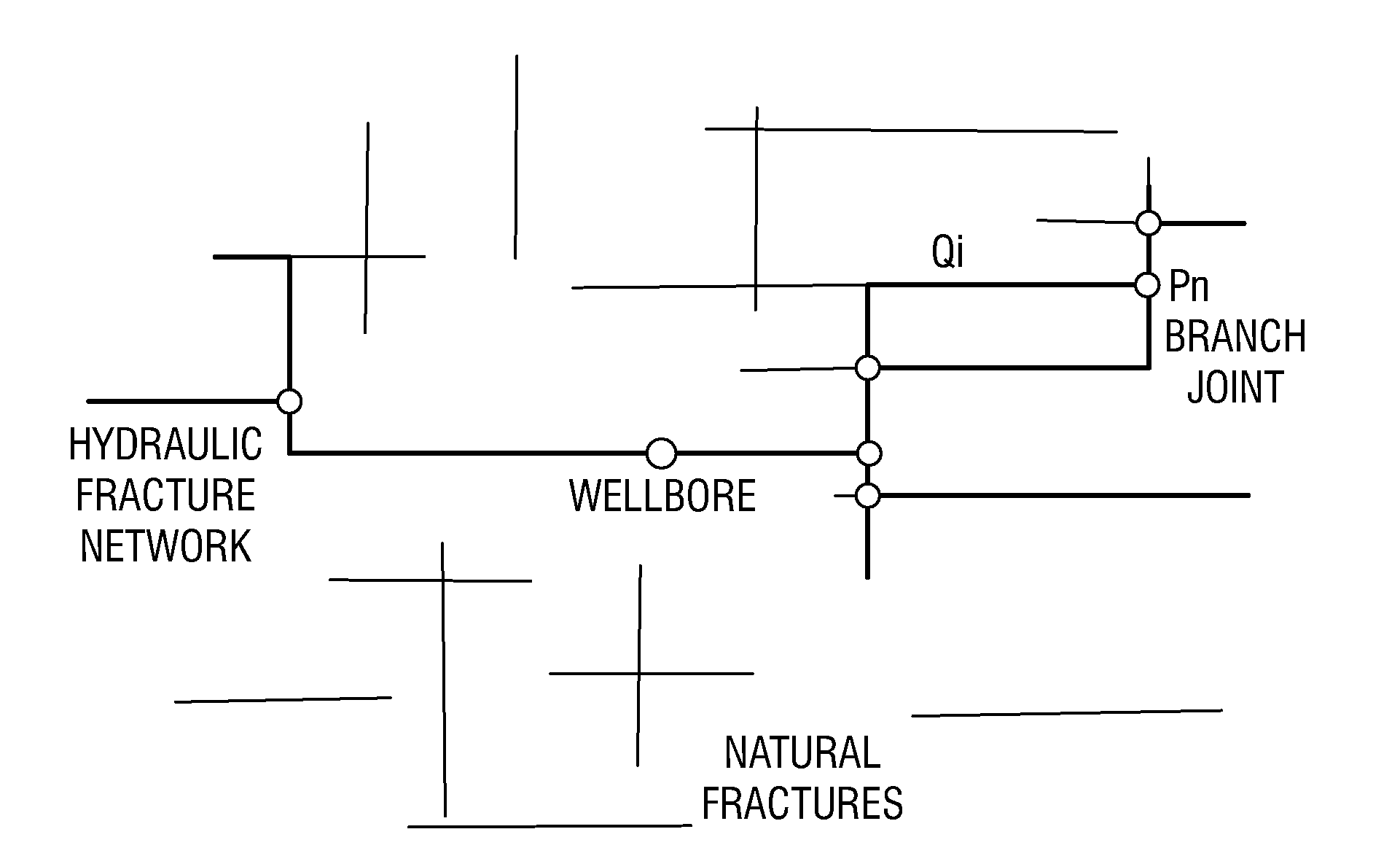

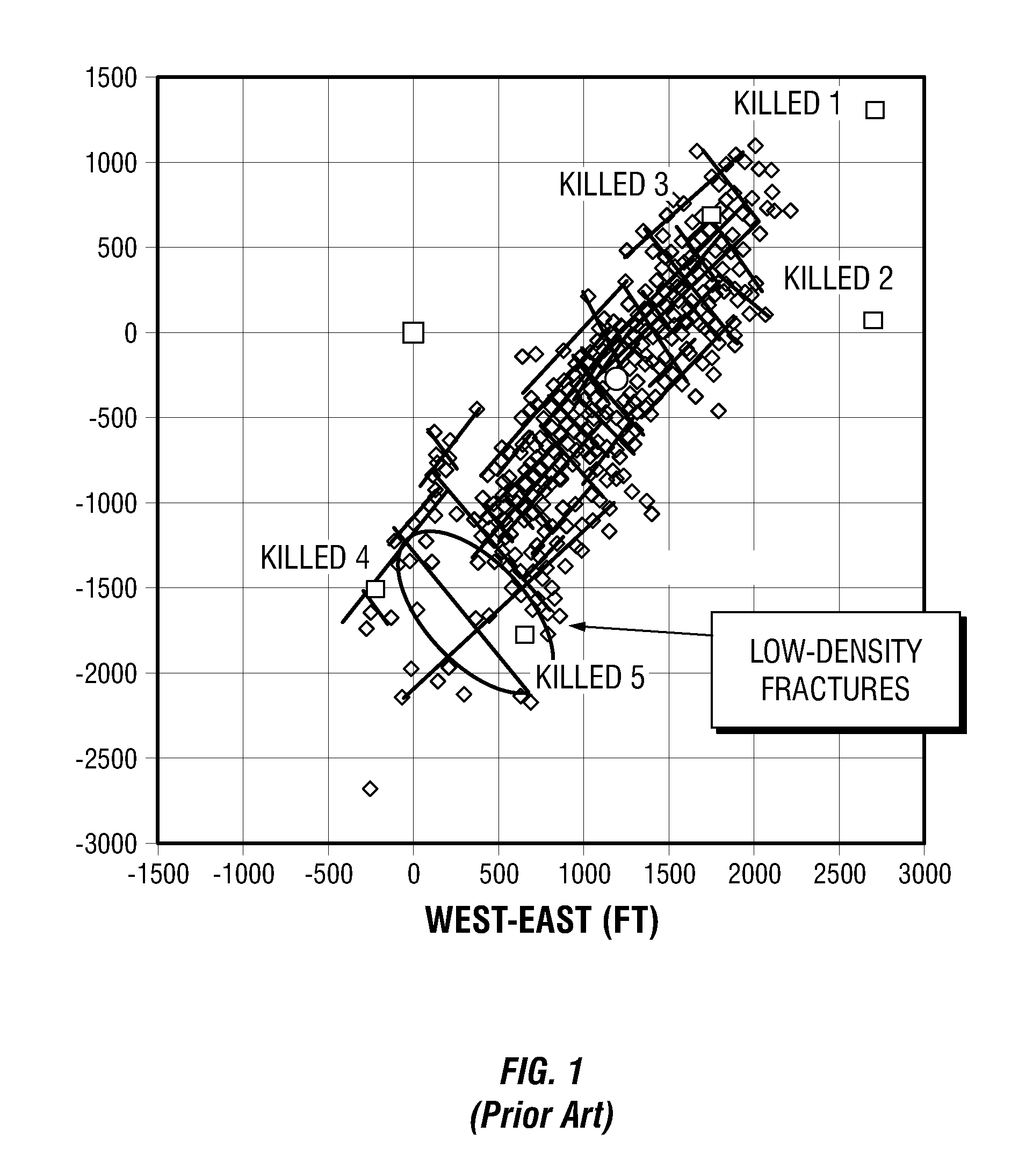

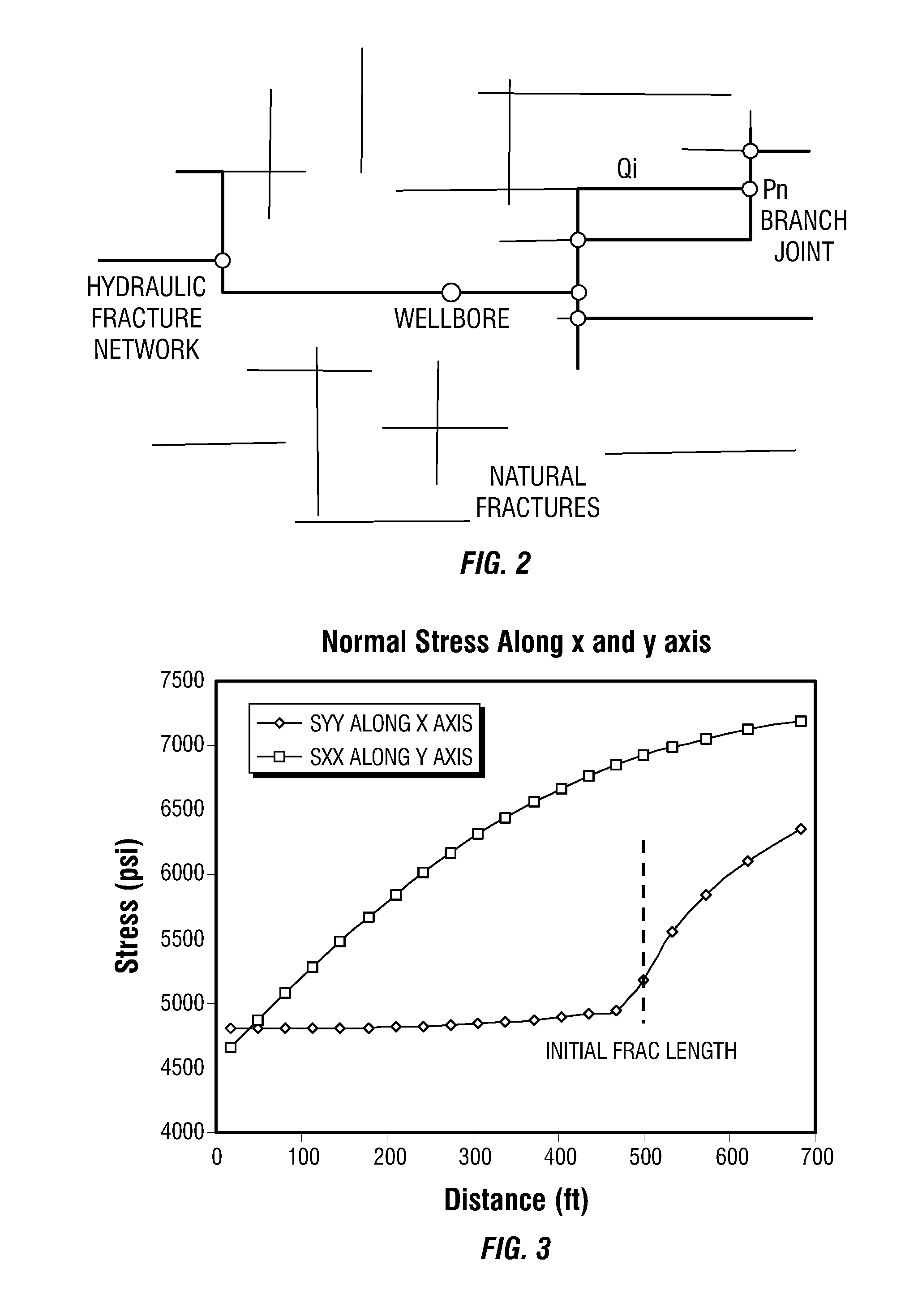

Simulations for Hydraulic Fracturing Treatments and Methods of Fracturing Naturally Fractured Formation

A hydraulic fracture design model that simulates the complex physical process of fracture propagation in the earth driven by the injected fluid through a wellbore. An objective in the model is to adhere with the laws of physics governing the surface deformation of the created fracture subjected to the fluid pressure, the fluid flow in the gap formed by the opposing fracture surfaces, the propagation of the fracture front, the transport of the proppant in the fracture carried by the fluid, and the leakoff of the fracturing fluid into the permeable rock. The models used in accordance with methods of the invention are typically based on the assumptions and the mathematical equations for the conventional 2D or P3D models, and further take into account the network of jointed fracture segments. For each fracture segment, the mathematical equations governing the fracture deformation and fluid flow apply. For each time step, the model predicts the incremental growth of the branch tips and the pressure and flow rate distribution in the system by solving the governing equations and satisfying the boundary conditions at the fracture tips, wellbore and connected branch joints. An iterative technique is used to obtain the solution of this highly nonlinear and complex problem.

Owner:SCHLUMBERGER TECH CORP

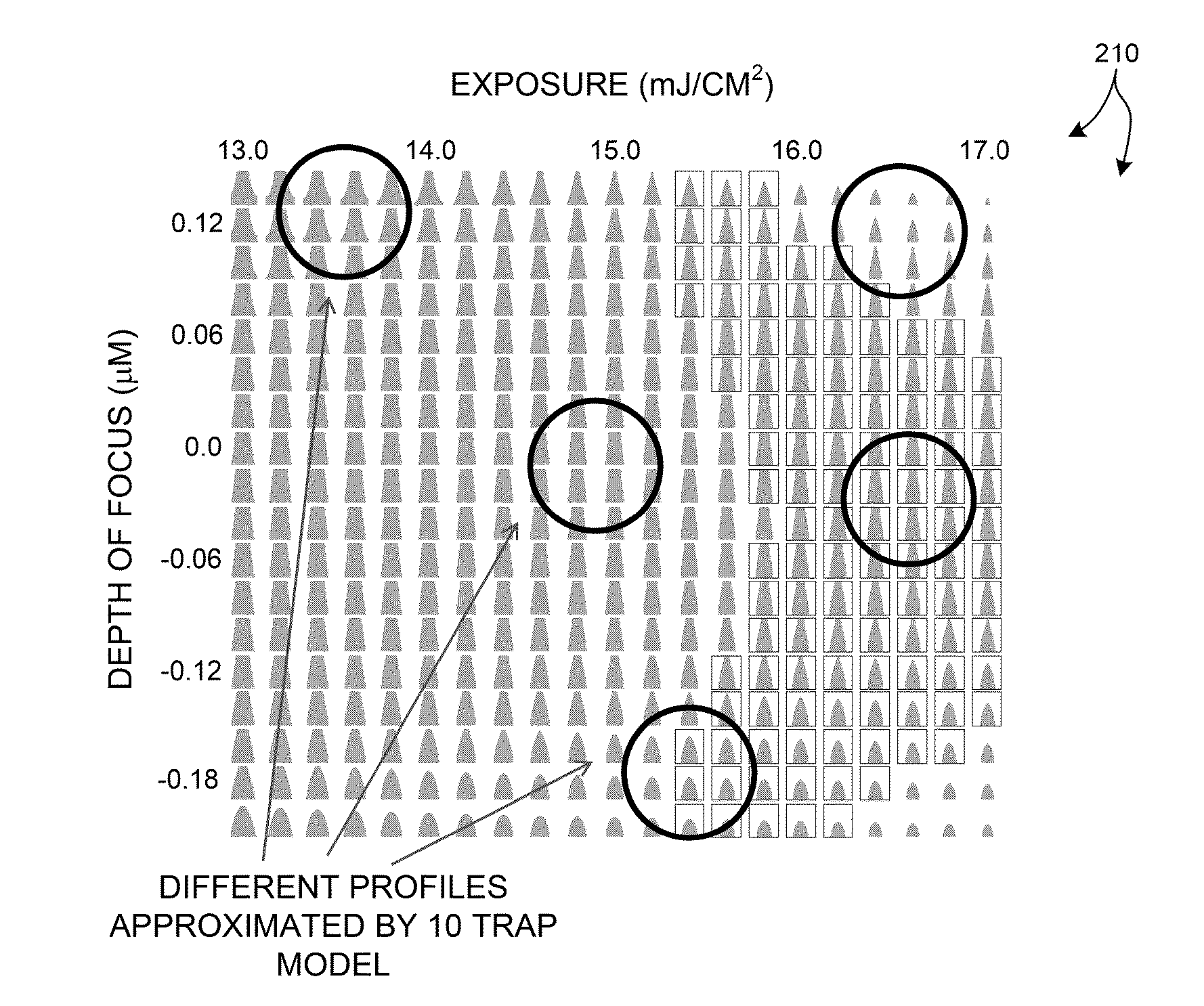

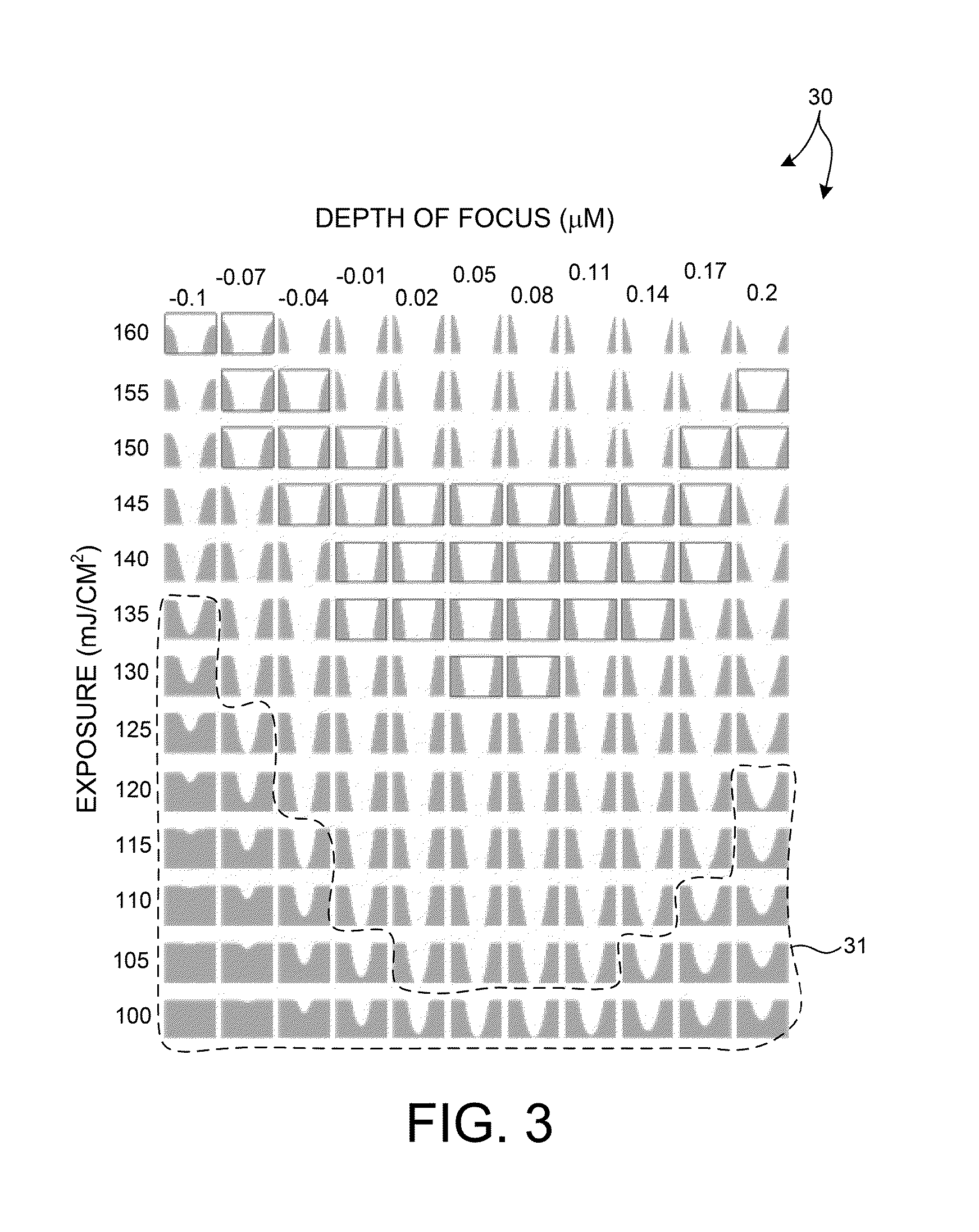

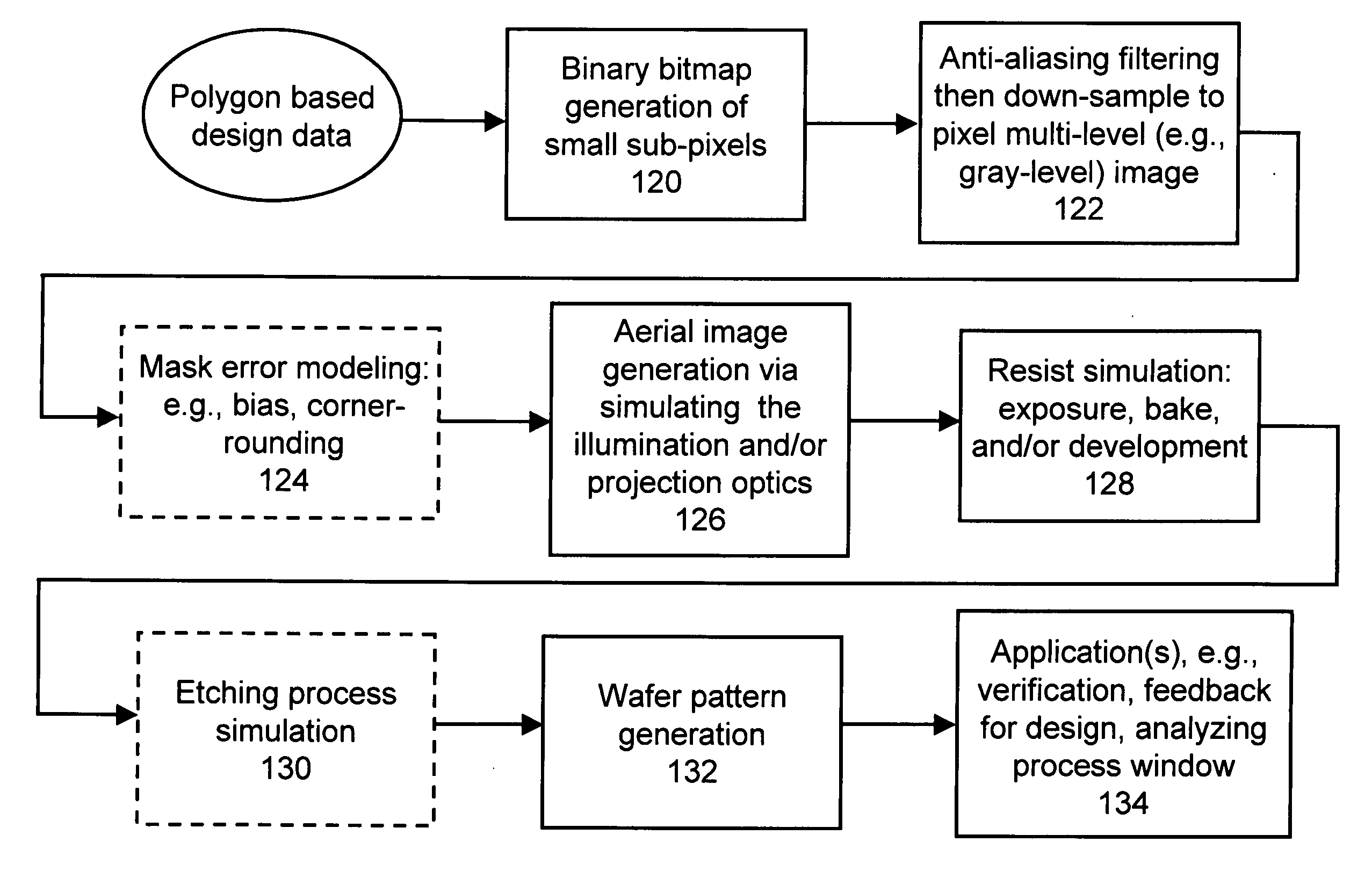

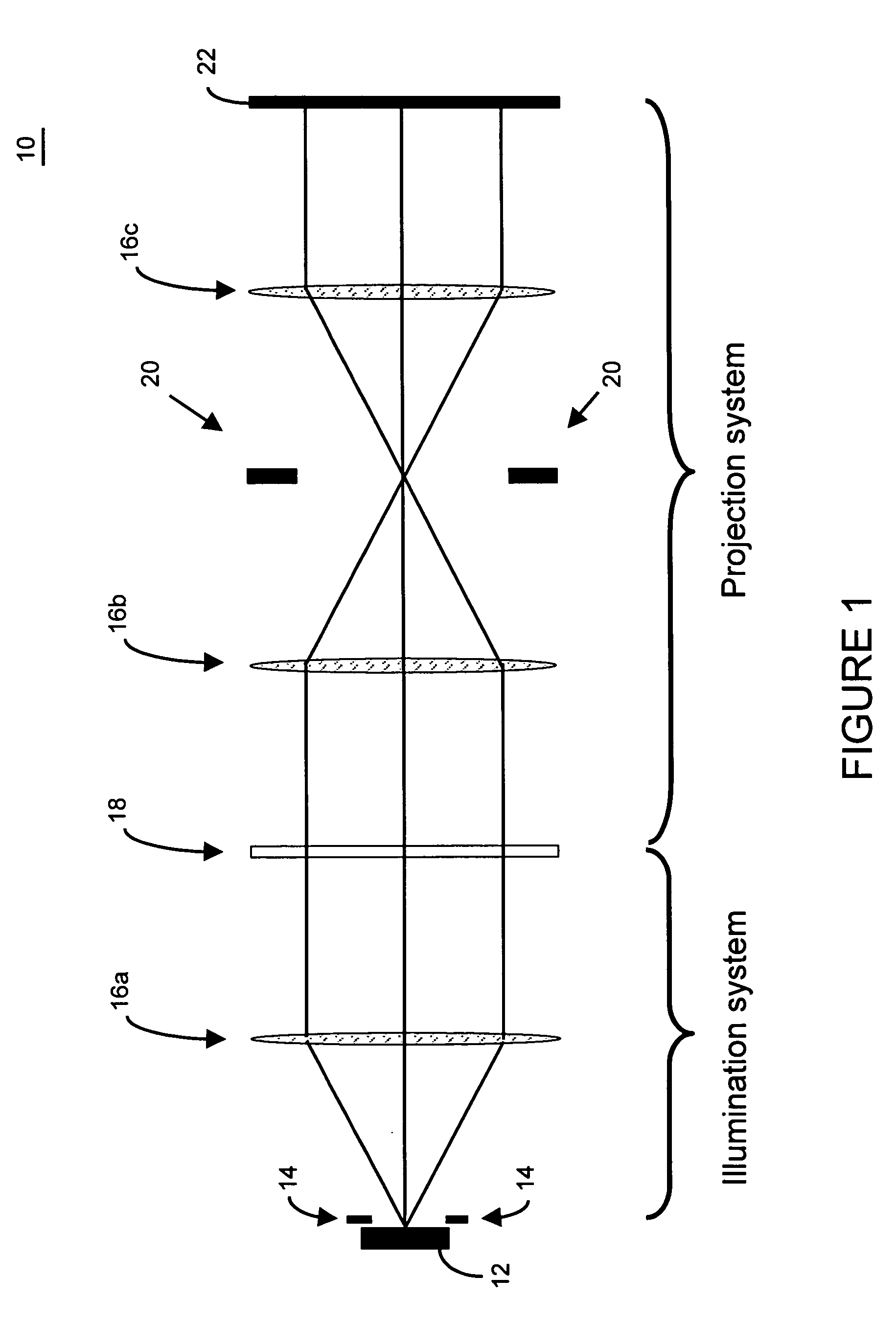

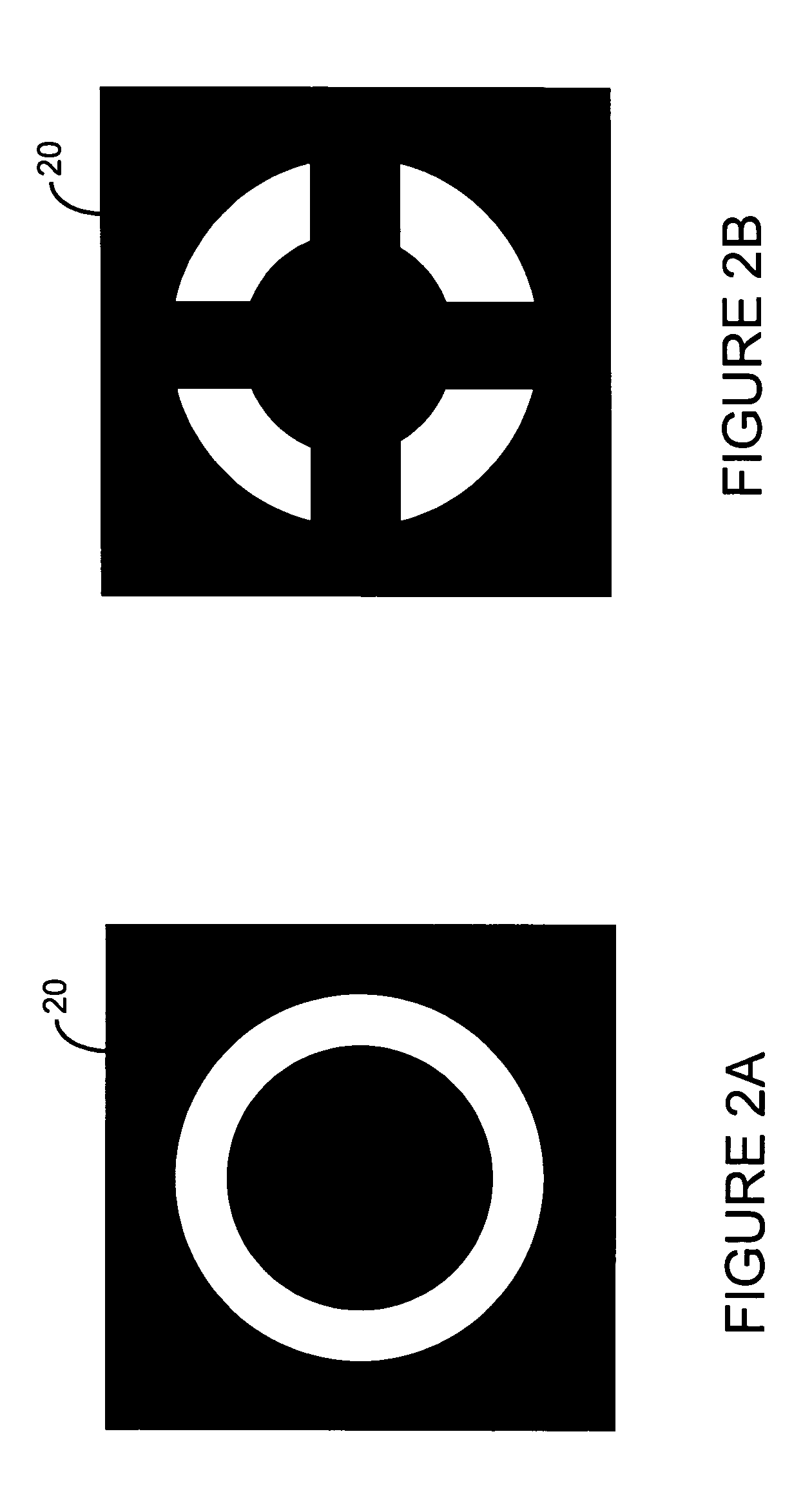

System and method for lithography simulation

There are many inventions described and illustrated herein. In one aspect, the present invention is directed to a technique of, and system for simulating, verifying, inspecting, characterizing, determining and / or evaluating the lithographic designs, techniques and / or systems, and / or individual functions performed thereby or components used therein. In one embodiment, the present invention is a system and method that accelerates lithography simulation, inspection, characterization and / or evaluation of the optical characteristics and / or properties, as well as the effects and / or interactions of lithographic systems and processing techniques. In this regard, in one embodiment, the present invention employs a lithography simulation system architecture, including application-specific hardware accelerators, and a processing technique to accelerate and facilitate verification, characterization and / or inspection of a mask design, for example, RET design, including detailed simulation and characterization of the entire lithography process to verify that the design achieves and / or provides the desired results on final wafer pattern. The system includes: (1) general purpose-type computing device(s) to perform the case-based logic having branches and inter-dependency in the data handling and (2) accelerator subsystems to perform a majority of the computation intensive tasks.

Owner:ASML NETHERLANDS BV

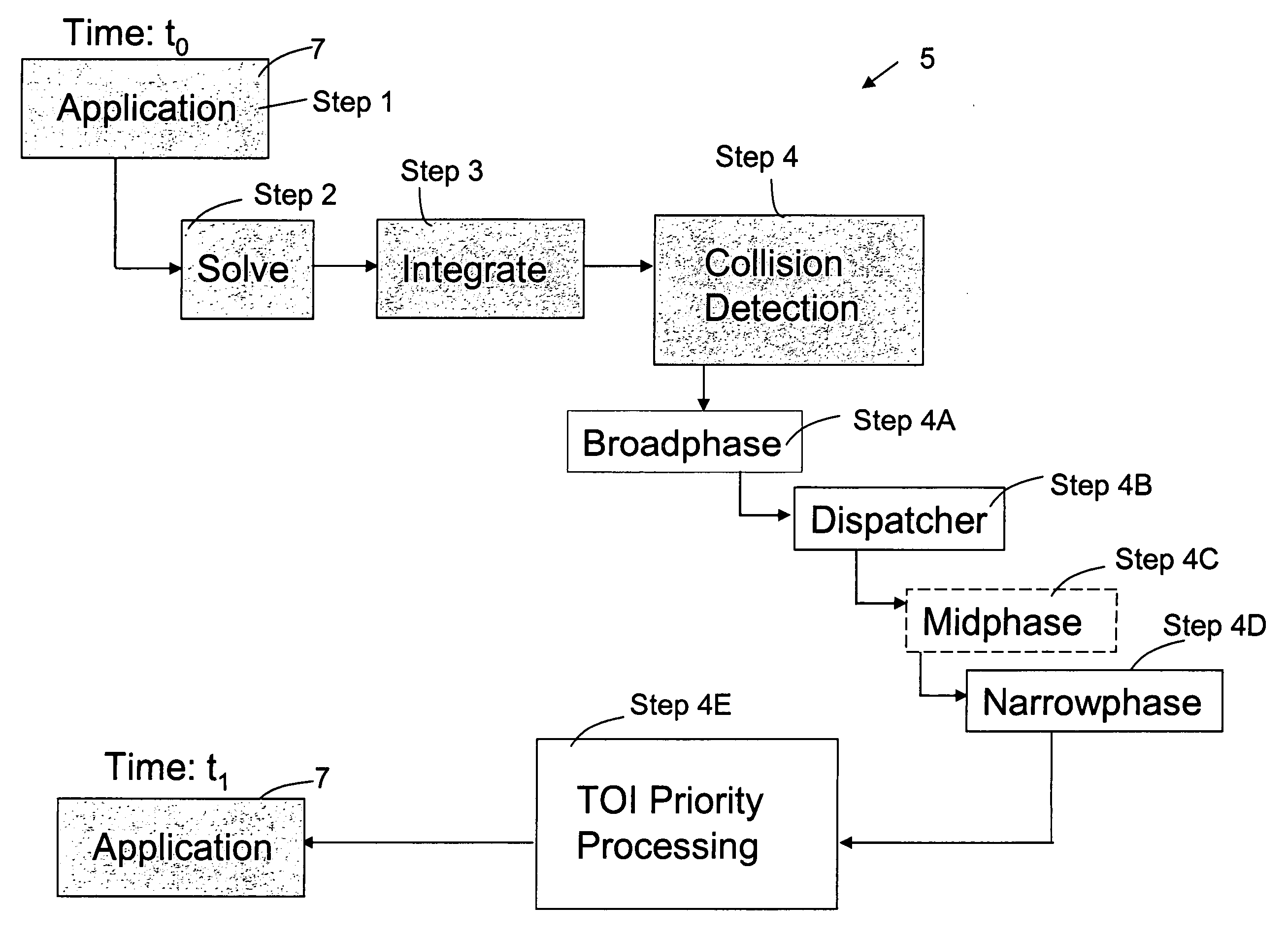

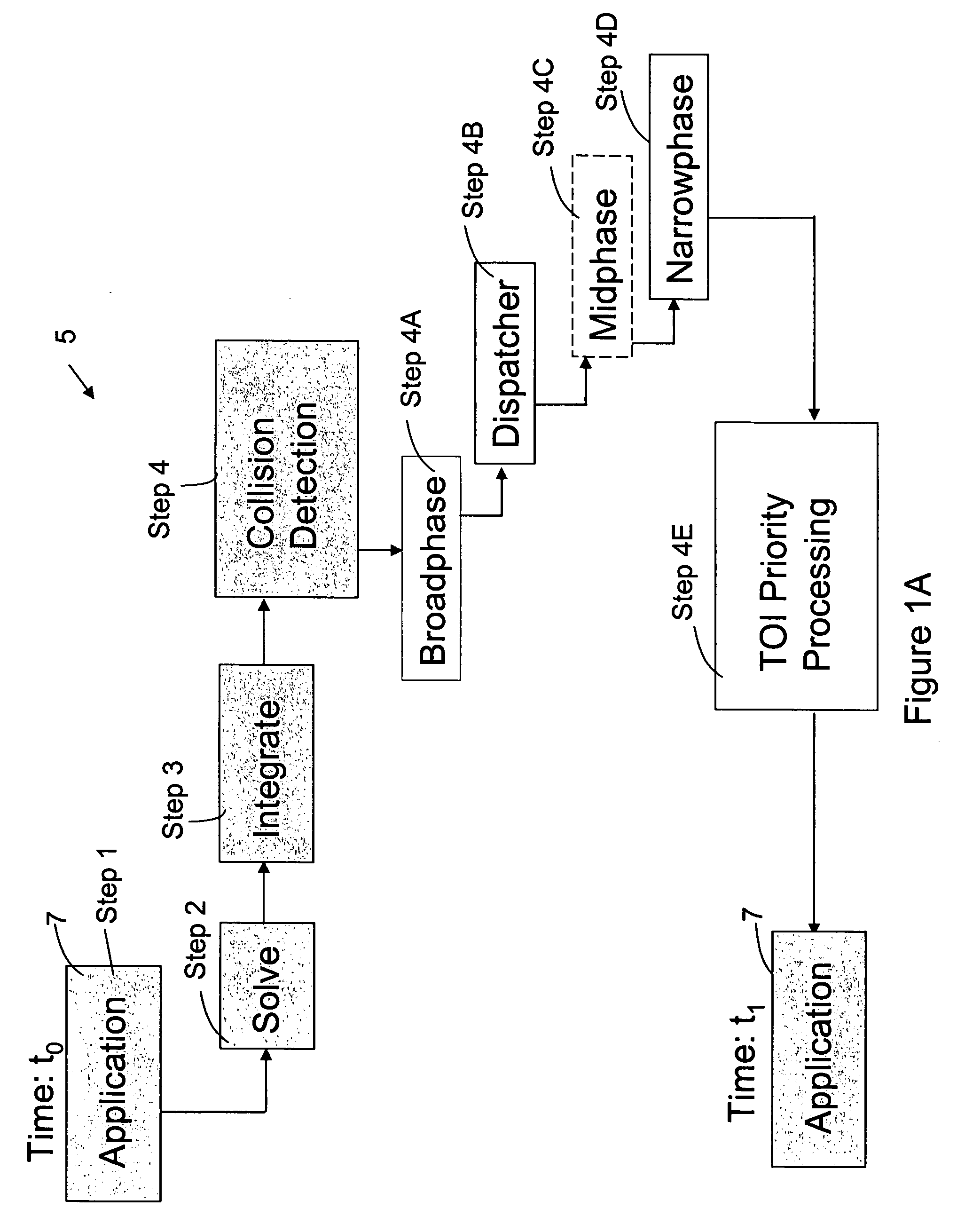

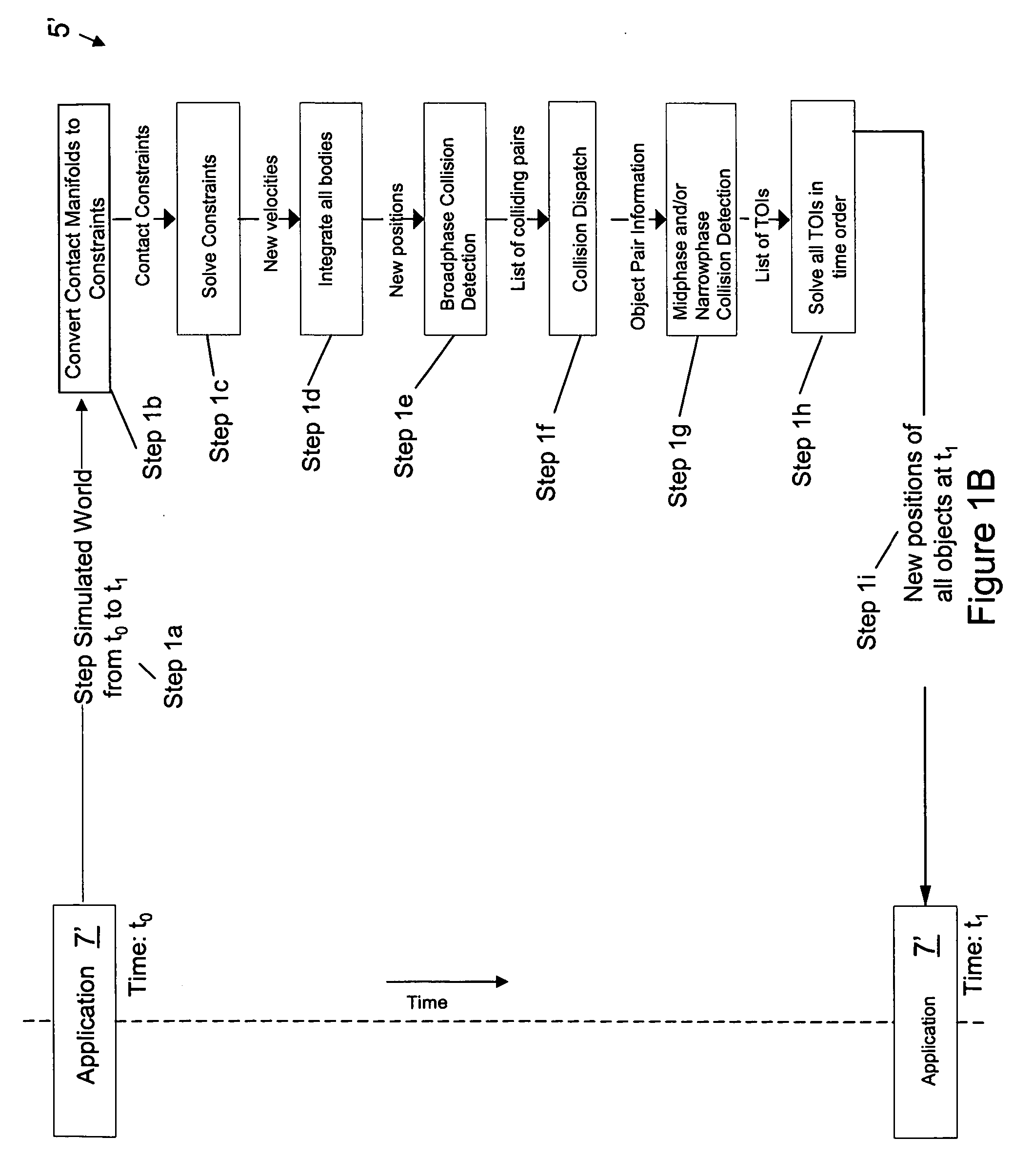

Physics simulation apparatus and method

InactiveUS20060149516A1Improve the level ofImprove stabilityGeometric CADDesign optimisation/simulationLevel of detailCollision response

A method and apparatus wherein complex physical interactions and collisions are modeled at a high level of detail while reducing the computational demands placed on the processing system. In one embodiment the method comprising the steps of defining a first object and a second object, each object adapted for colliding with the other object; assigning an interaction type for at least one of the first and second object in response to an object parameter; and selecting between a continuous simulation of a collision and a discrete simulation of the collision in response to the interaction type.

Owner:MICROSOFT TECH LICENSING LLC

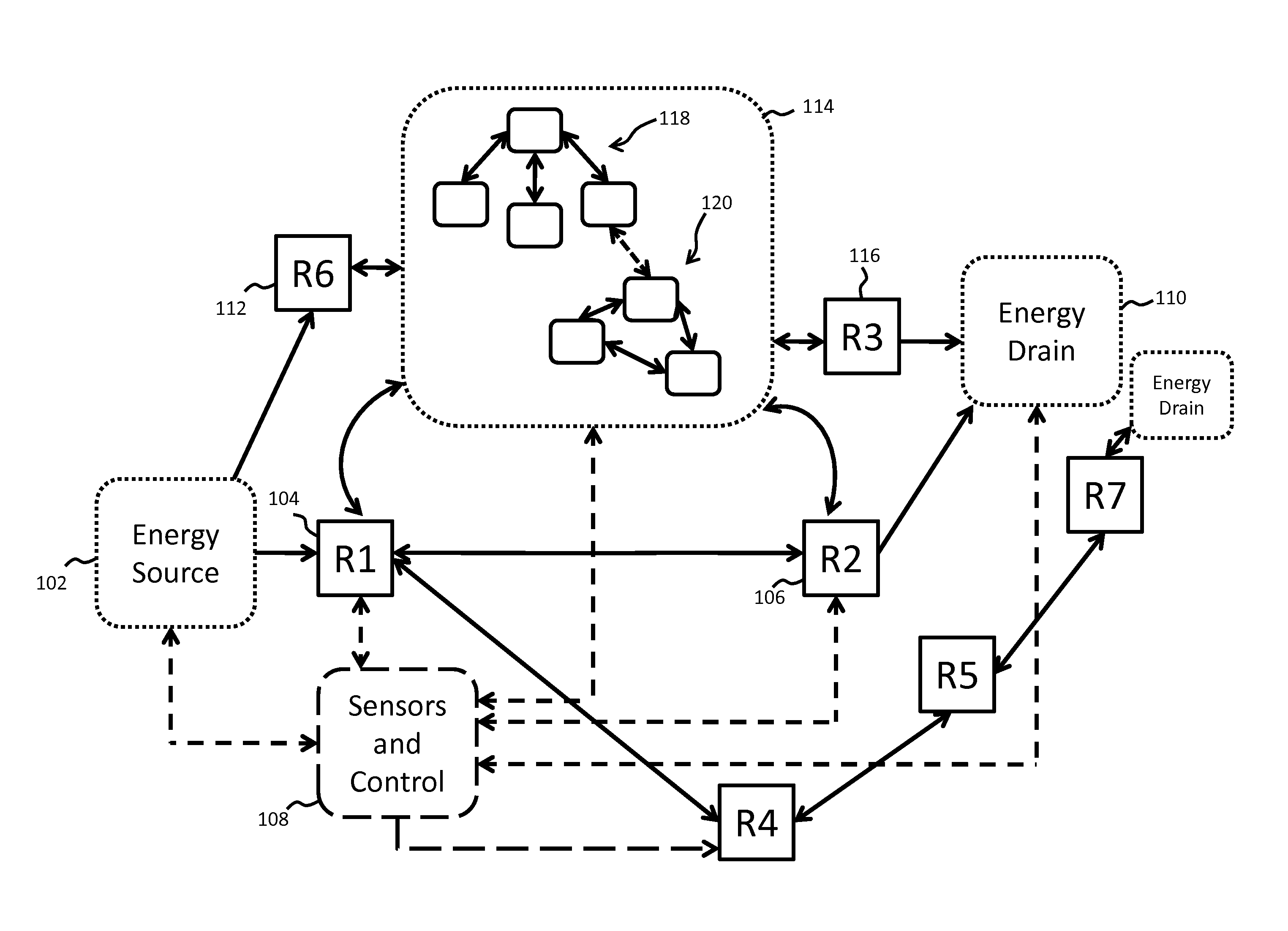

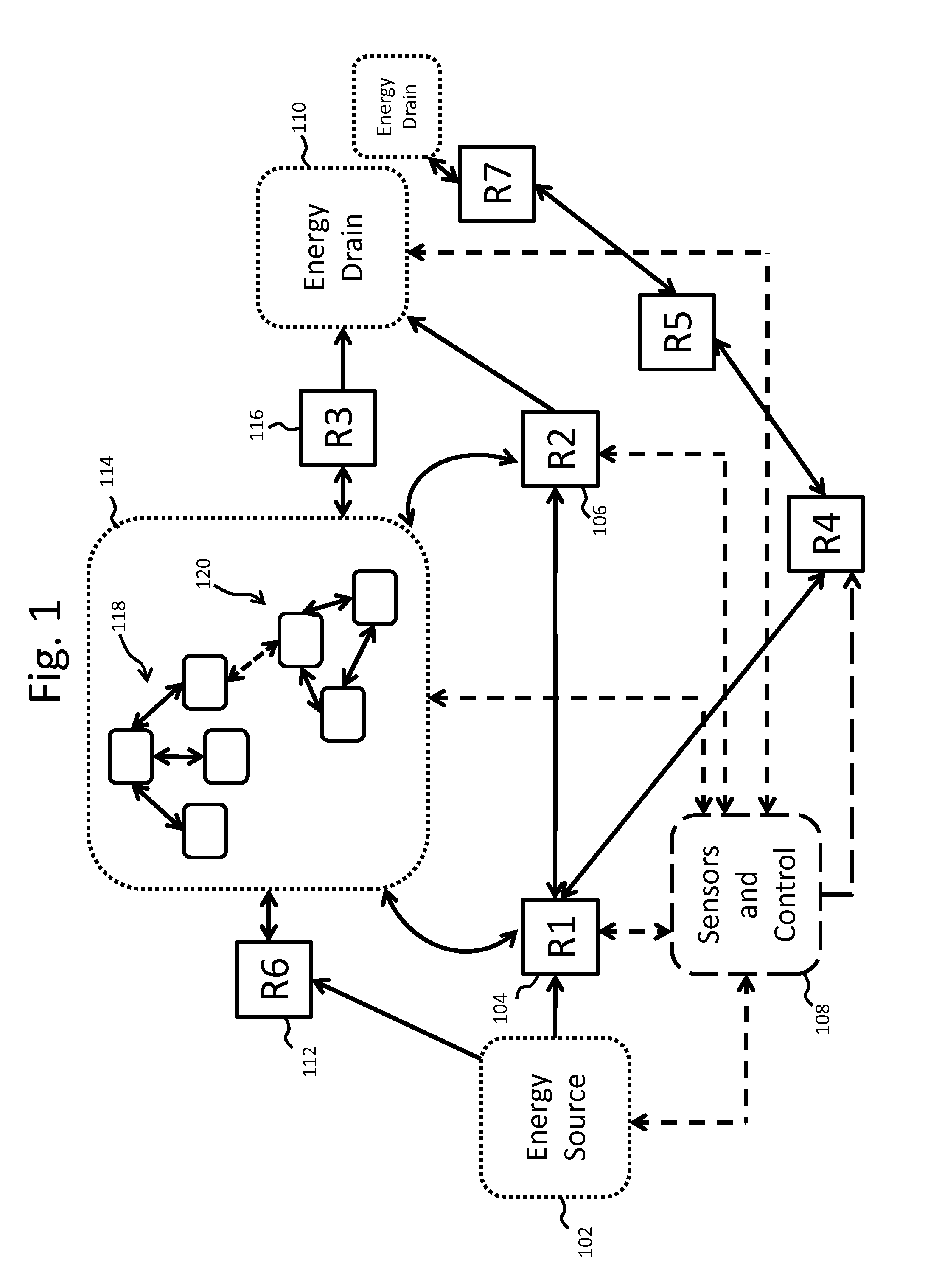

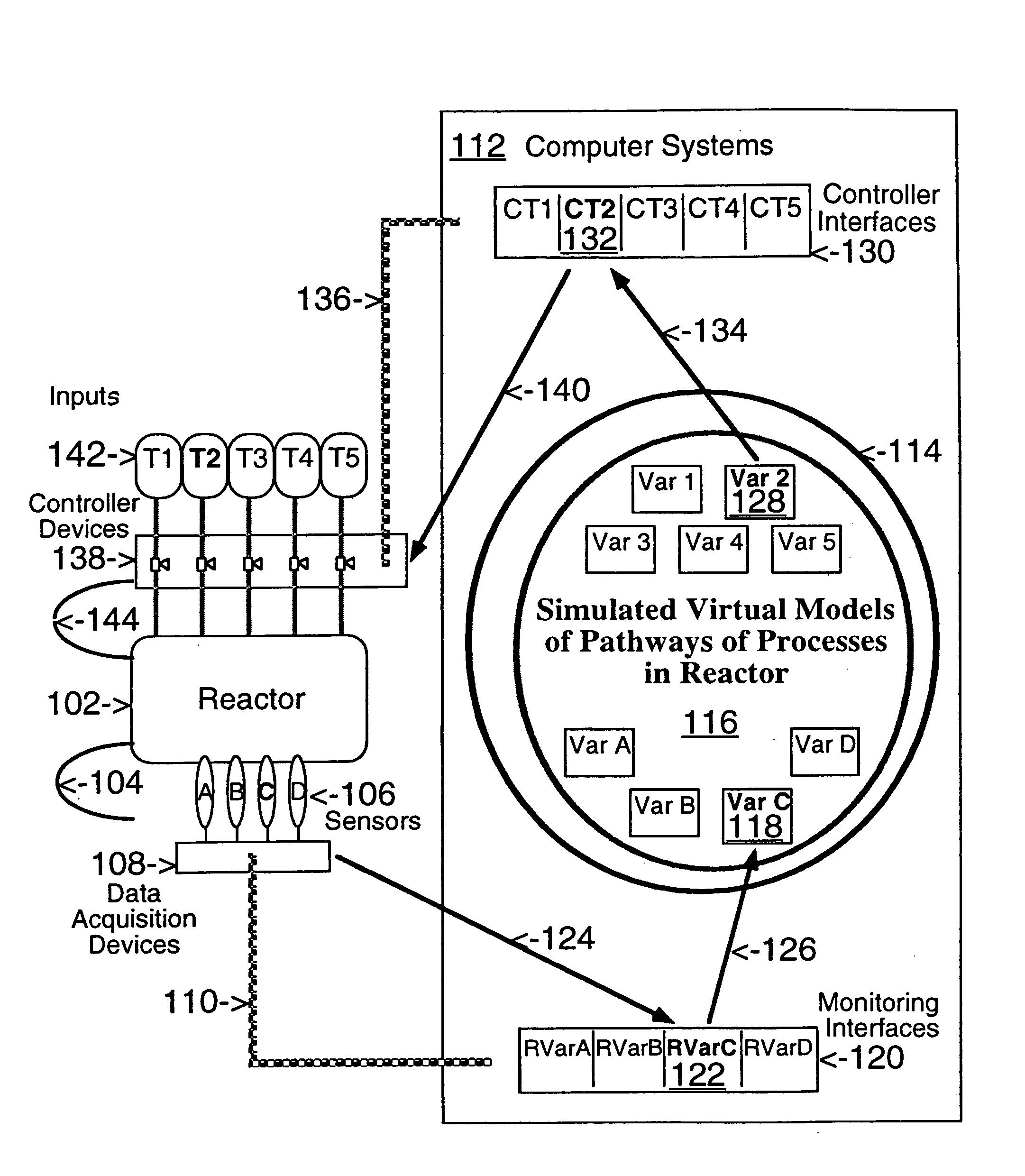

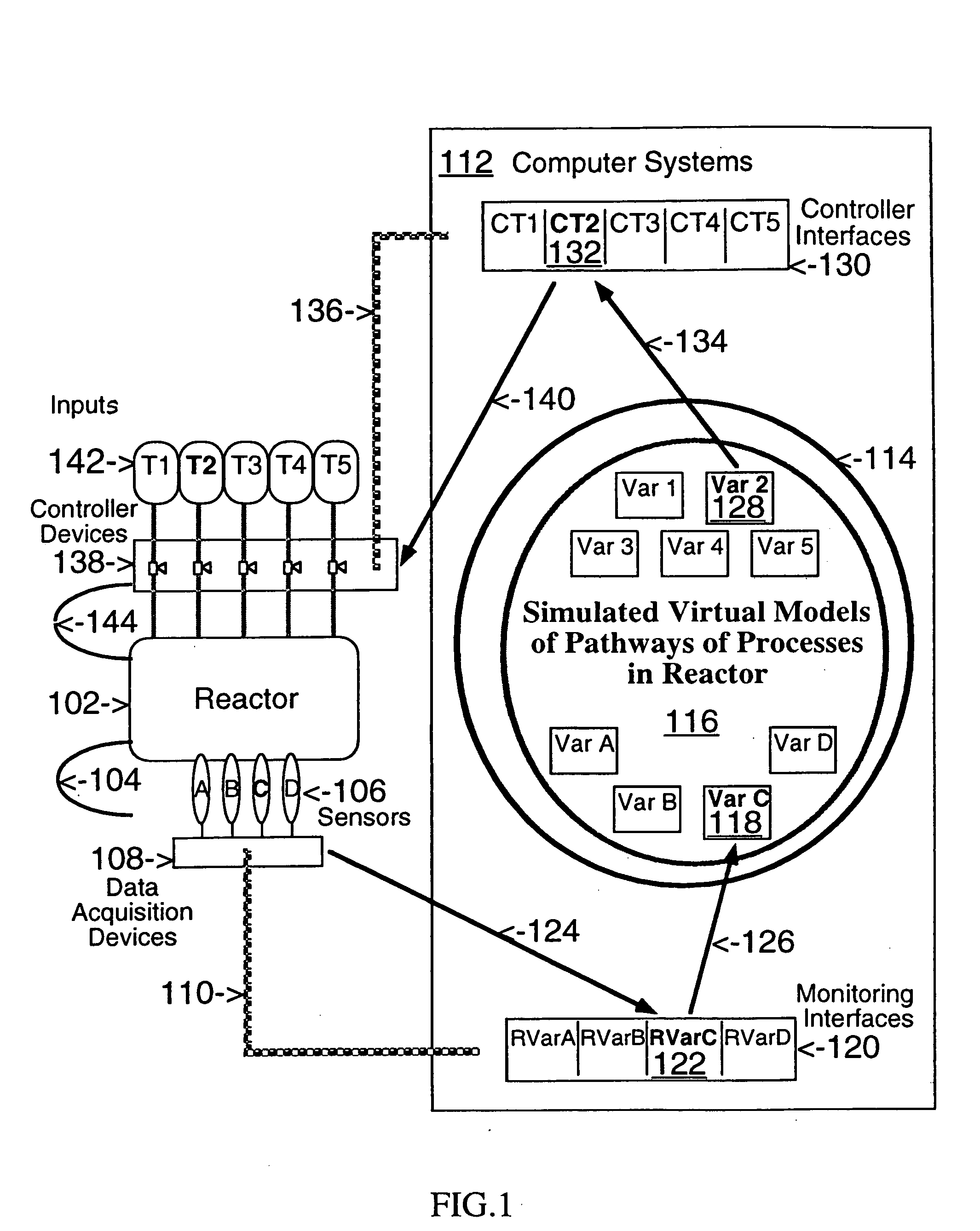

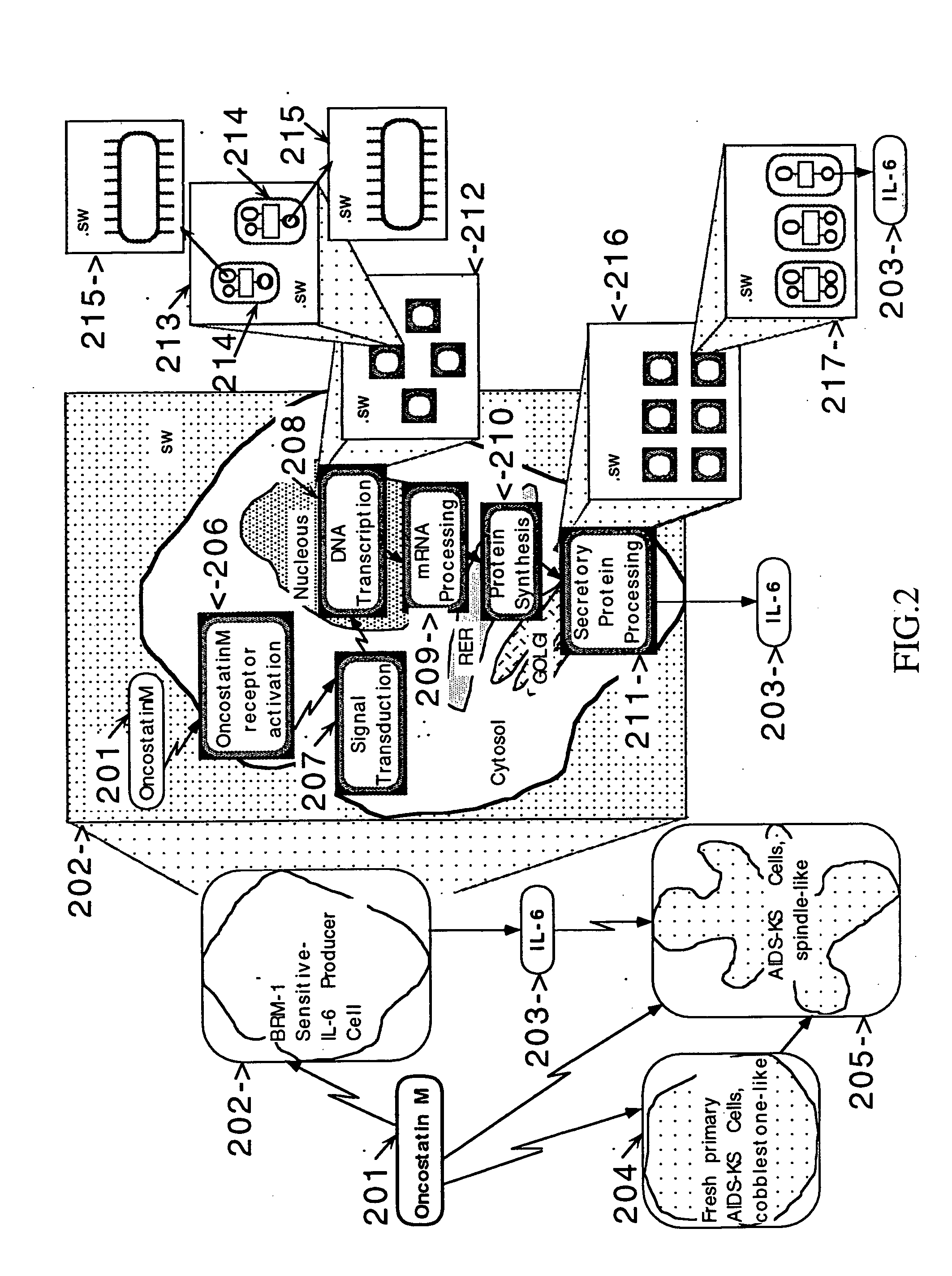

Network models of complex systems

This invention describes computer based virtual models of complex systems, together with integrated systems and methods providing a development and execution framework for visual modeling and dynamic simulation of said models. The virtual models can be used for analysis, monitoring, or control of the operation of the complex systems modeled, as well as for information retrieval. More particularly, the virtual models in the present implementation relate to biological complex systems. In the current implementation the virtual models comprise building blocks representing physical, chemical, or biological processes, the pools of entities that participate in those processes, a hierarchy of compartments representing time-intervals or the spatial and / or functional structure of the complex system in which said entities are located and said processes take place, and the description of the composition of those entities. The building blocks encapsulate in different layers the information, data, and mathematical models that characterize and define each virtual model, and a plurality of methods is associated with their components. The models are built by linking instances of the building blocks in a predefined way, which, when integrated by the methods provided in this invention, result in multidimensional networks of pathways. A number of functions and graphical interfaces can be selected for said instances of building blocks, to extract in various forms the information contained in said models. Those functions include: a) on-the-fly creation of displays of interactive multidimensional networks of pathways, according to user selections; b) dynamic quantitative simulations of selected networks; and c) complex predefined queries based on the relative position of pools of entities in the pathways, the role that the pools play in different processes, the location in selected compartments, and / or the structural components of the entities of those pools. The system integrates inferential control with quantitative and scaled simulation methods, and provides a variety of alternatives to deal with complex dynamic systems and with incomplete and constantly evolving information and data.

Owner:INTERTECH VENTURES

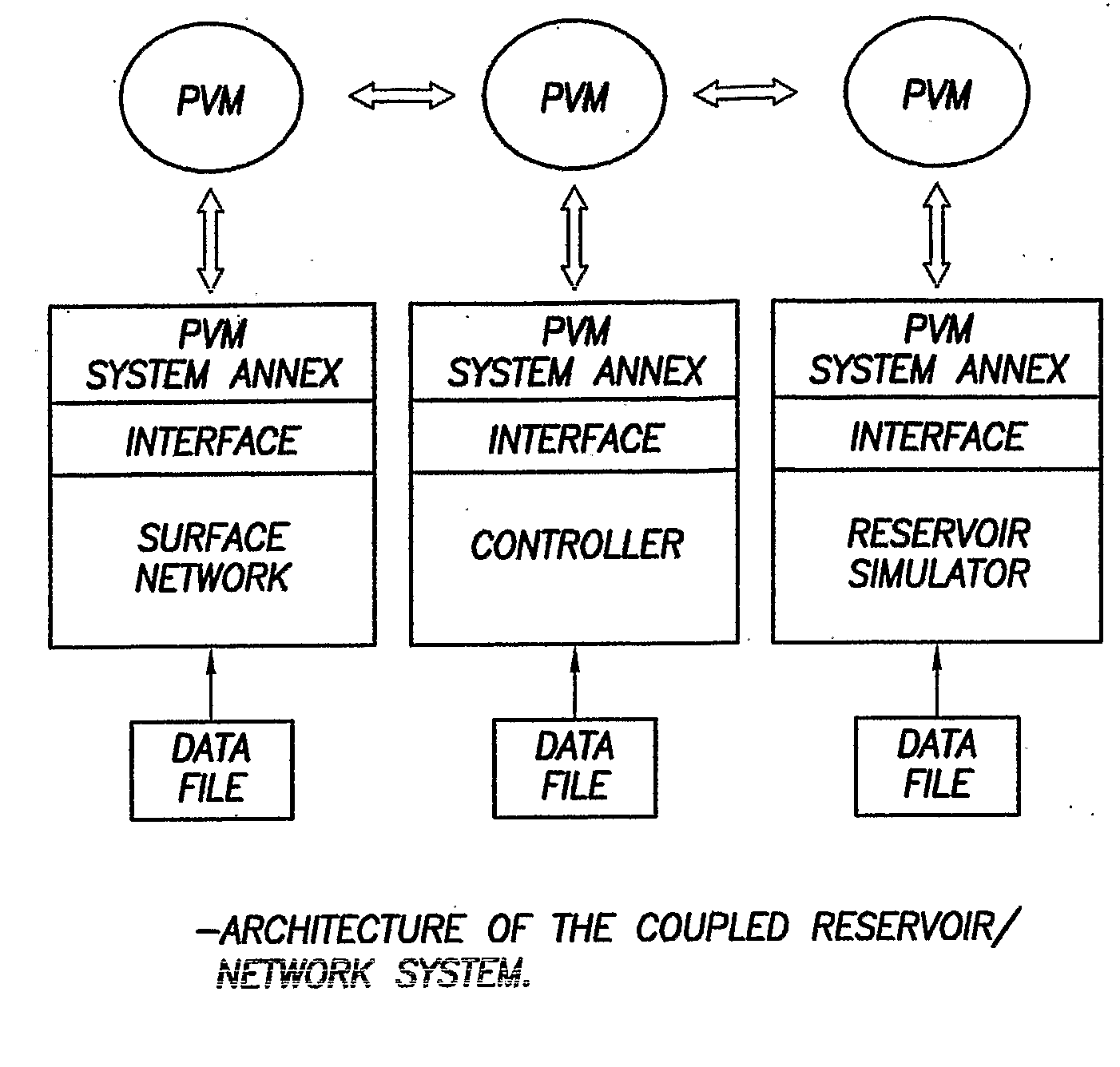

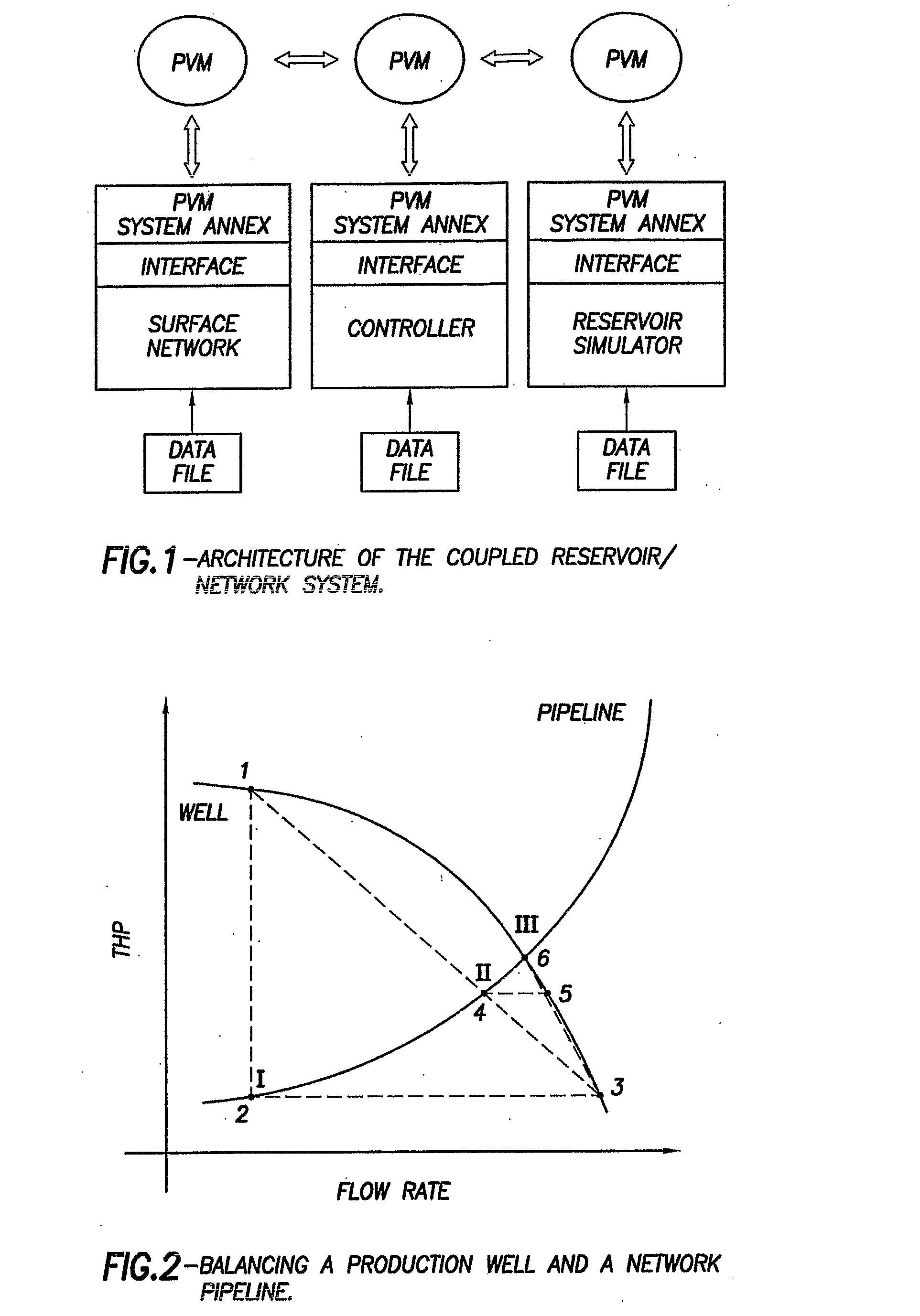

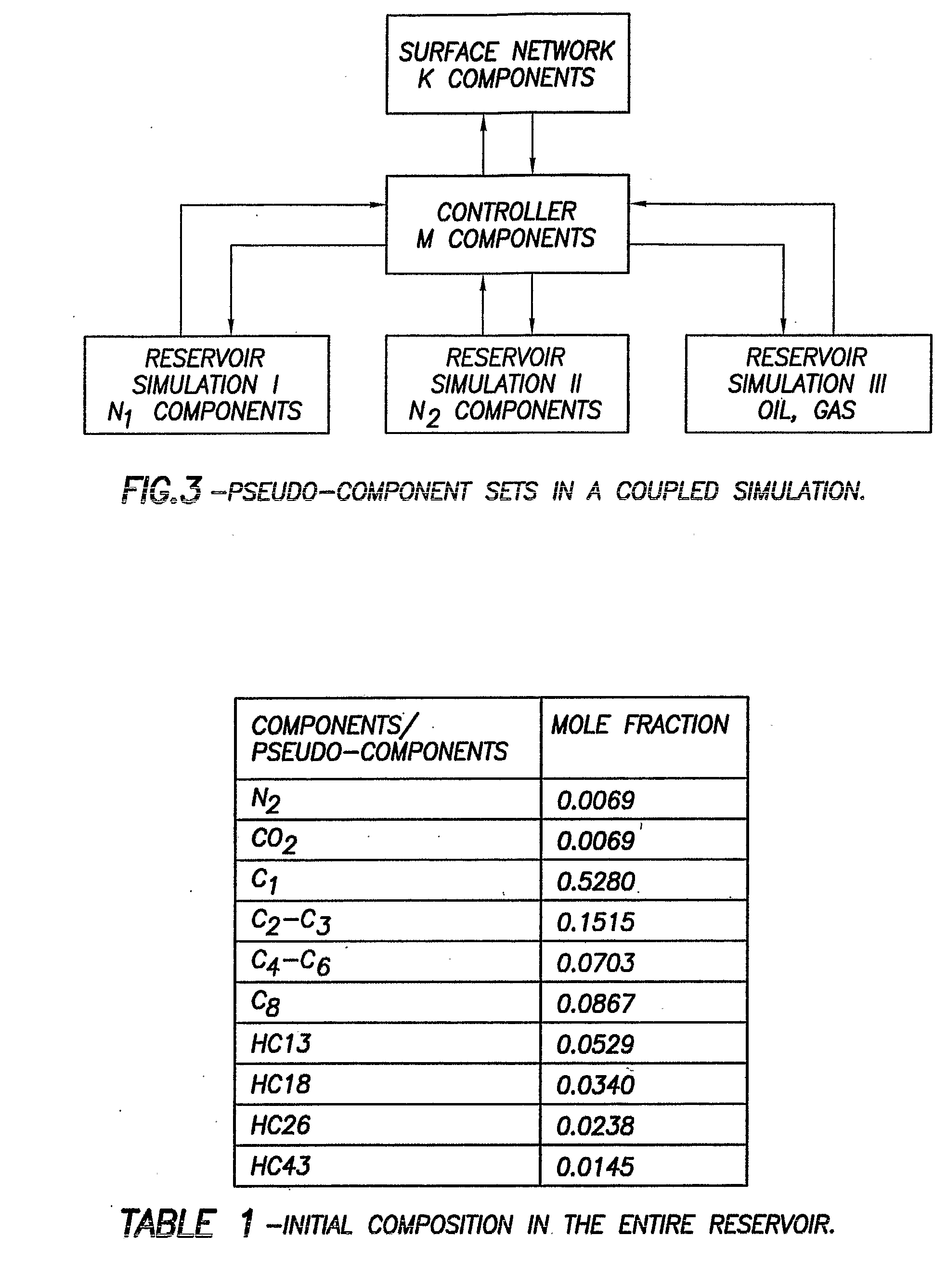

Method and system for integrated reservoir and surface facility networks simulations

InactiveUS20070112547A1Design optimisation/simulationConstraint-based CADMulti platformNetwork model

Integrated surface-subsurface modeling has been shown to have a critical impact on field development and optimization. Integrated models are often necessary to analyze properly the pressure interaction between a reservoir and a constrained surface facility network, or to predict the behavior of several fields, which may have different fluid compositions, sharing a common surface facility. The latter is gaining a tremendous significance in recent deepwater field development. These applications require an integrated solution with the following capabilities: * to balance a surface network model with a reservoir simulation model in a robust and efficient manner. * To couple multiple reservoir models, production and injection networks, synchronising their advancement through time. * To allow the reservoir and surface network models to use their own independent fluid descriptions (black oil or compositional descriptions with differing sets of pseudo-components). * To apply global production and injection constraints to the coupled system (including the transfer of re-injection fluids between reservoirs). In this paper we describe a general-purpose multi-platform reservoir and network coupling controller having all the above features. The controller communicates with a selection of reservoir simulators and surface network simulators via an open message-passing interface. It manages the balancing of the reservoirs and surface networks, and synchronizes their advancement through time. The controller also applies the global production and injection constraints, and converts the hydrocarbon fluid streams between the different sets of pseudo-components used in the simulation models. The controller's coupling and synchronization algorithms are described, and example applications are provided. The flexibility of the controller's open interface makes it possible to plug in further modules (to perform optimization, for example) and additional simulators.

Owner:SCHLUMBERGER TECH CORP

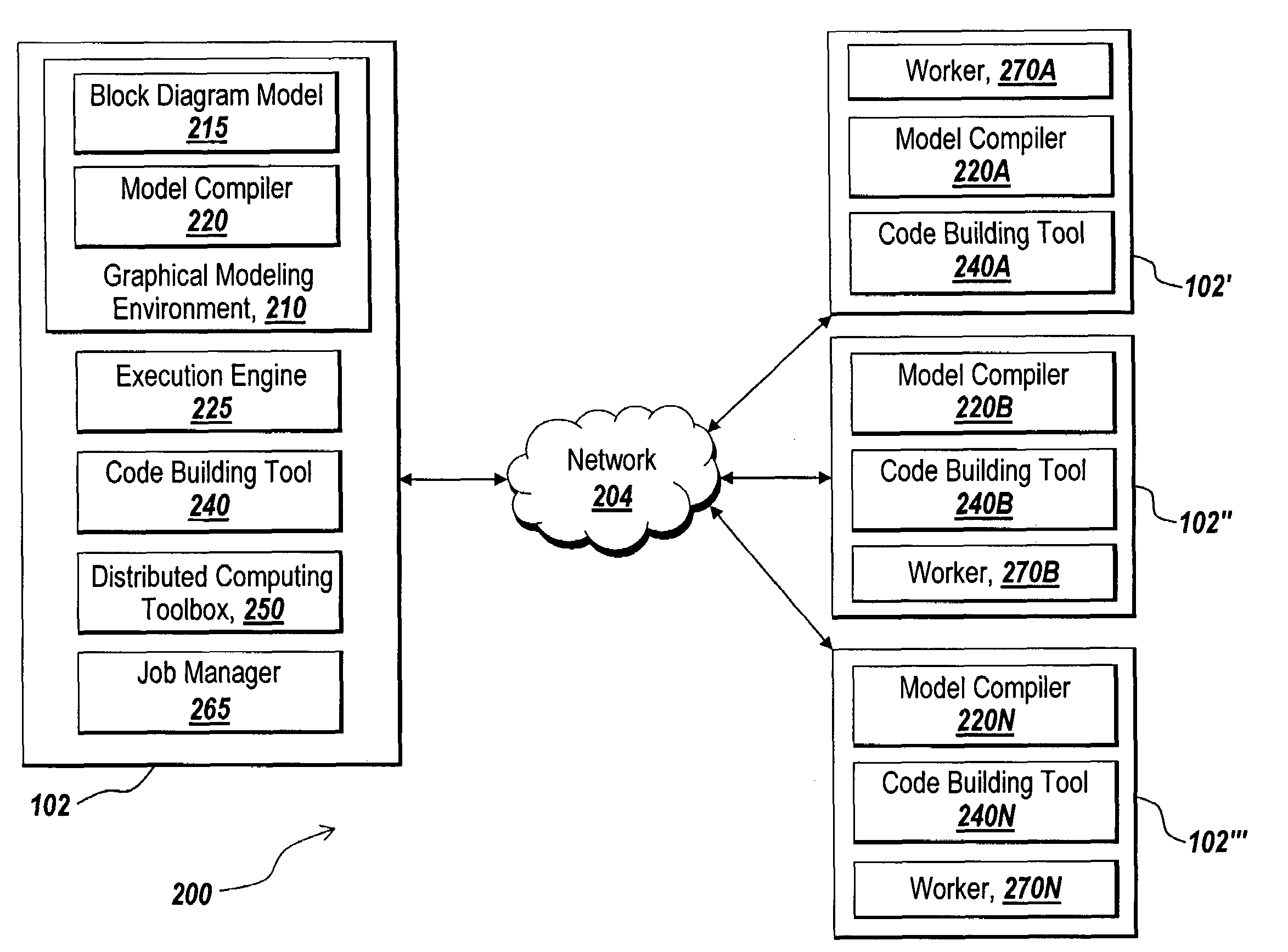

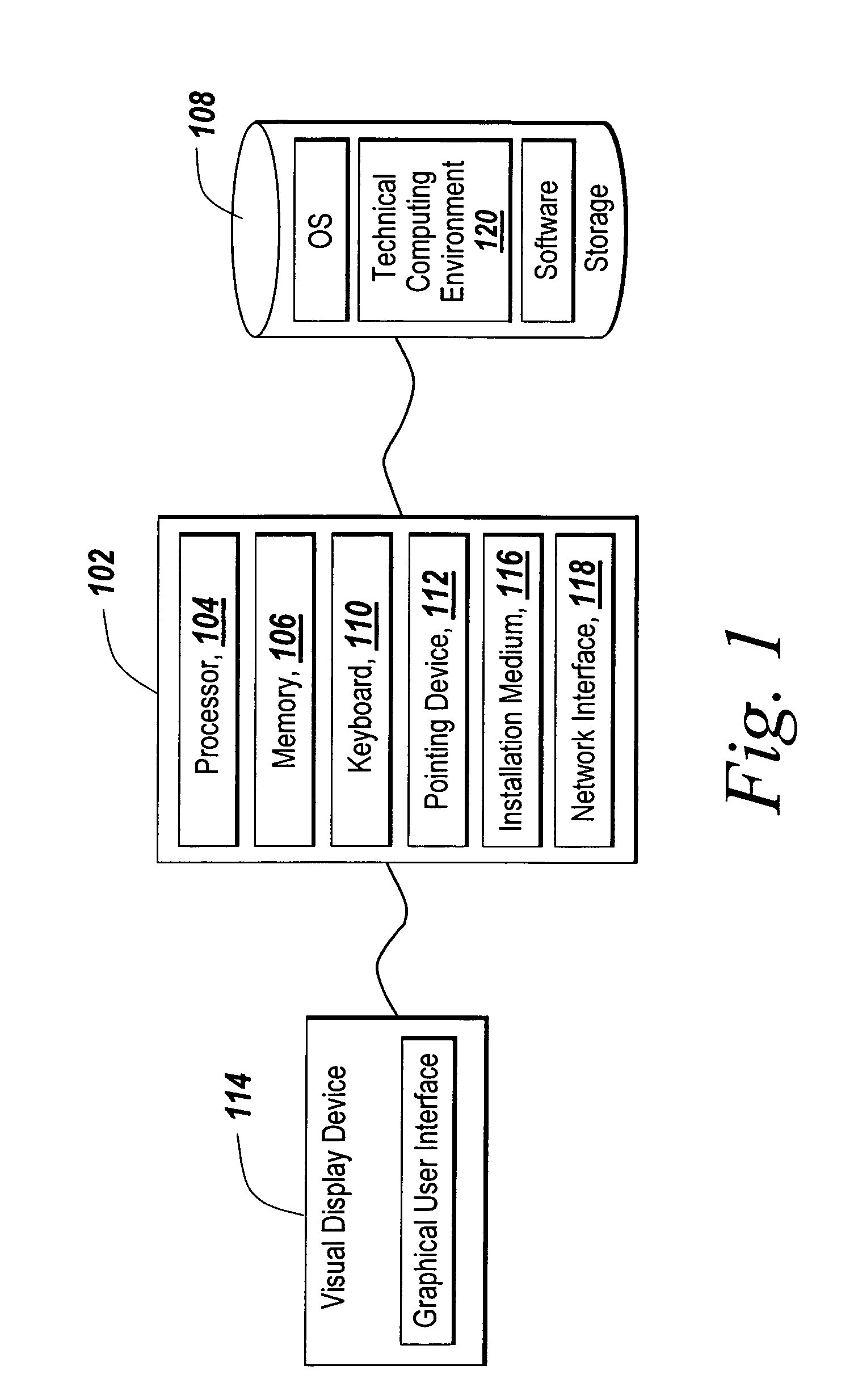

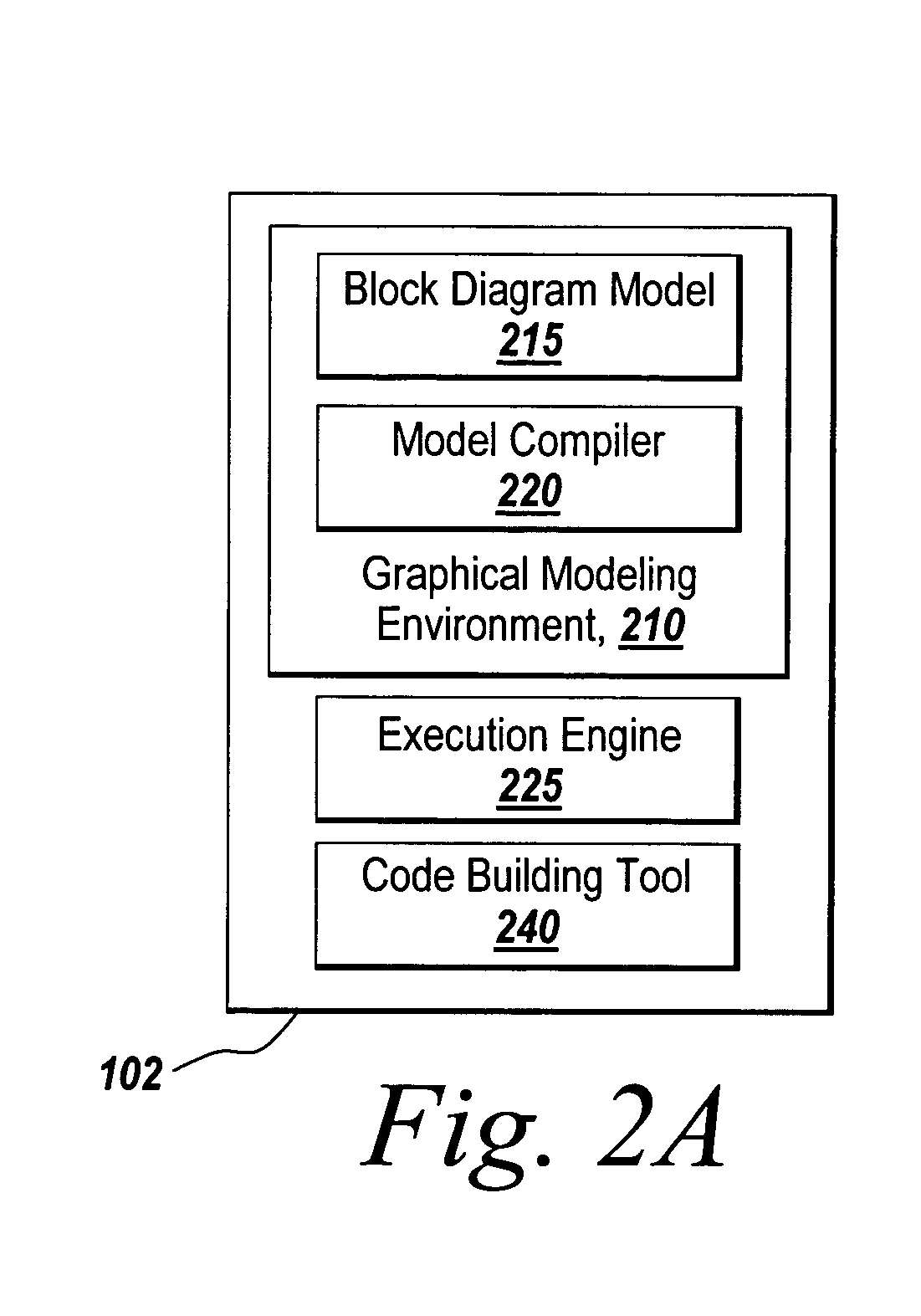

Distributed model compilation

ActiveUS7509244B1Shorten the timePromote generationAnalogue computers for electric apparatusComputation using non-denominational number representationGraphicsParallel computing

Methods and systems are provided for partitioning and distributing the model processing of a graphical model to provide an executable form of the graphical model. The methods and systems determine tasks of the model processing that can be processed separately and concurrently from other tasks. A distribution scheme for distributing the model processing tasks is determined that considers the characteristics of the model processing tasks in view of the characteristics of available computing resources. Variations of partitioning and distributing the model processing tasks can be determined to provide for distributed processing in an optimized or desired manner. The results of the distributed processing of the model processing tasks are obtained and combined to provide an executable form for the graphical model.

Owner:THE MATHWORKS INC

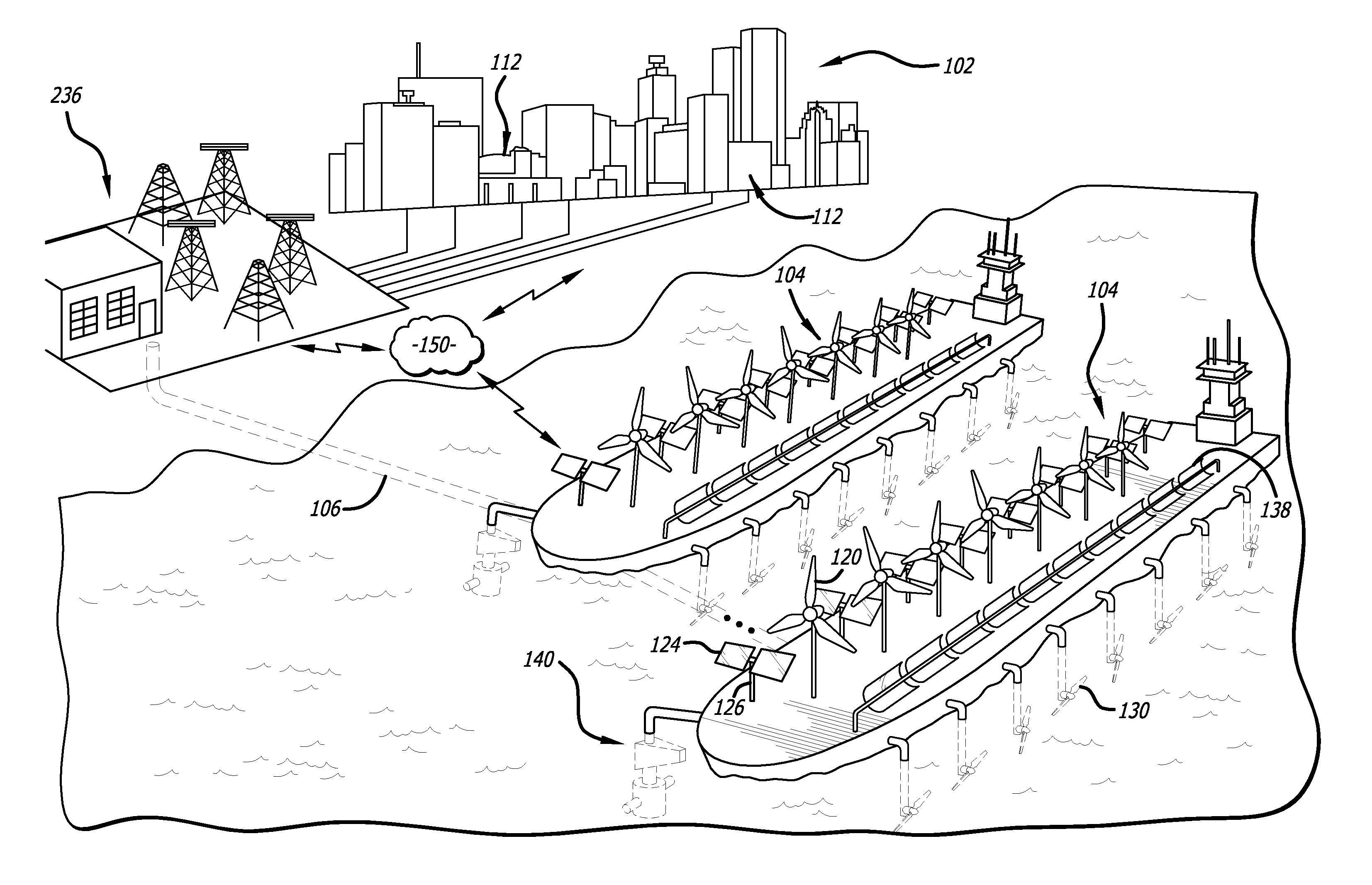

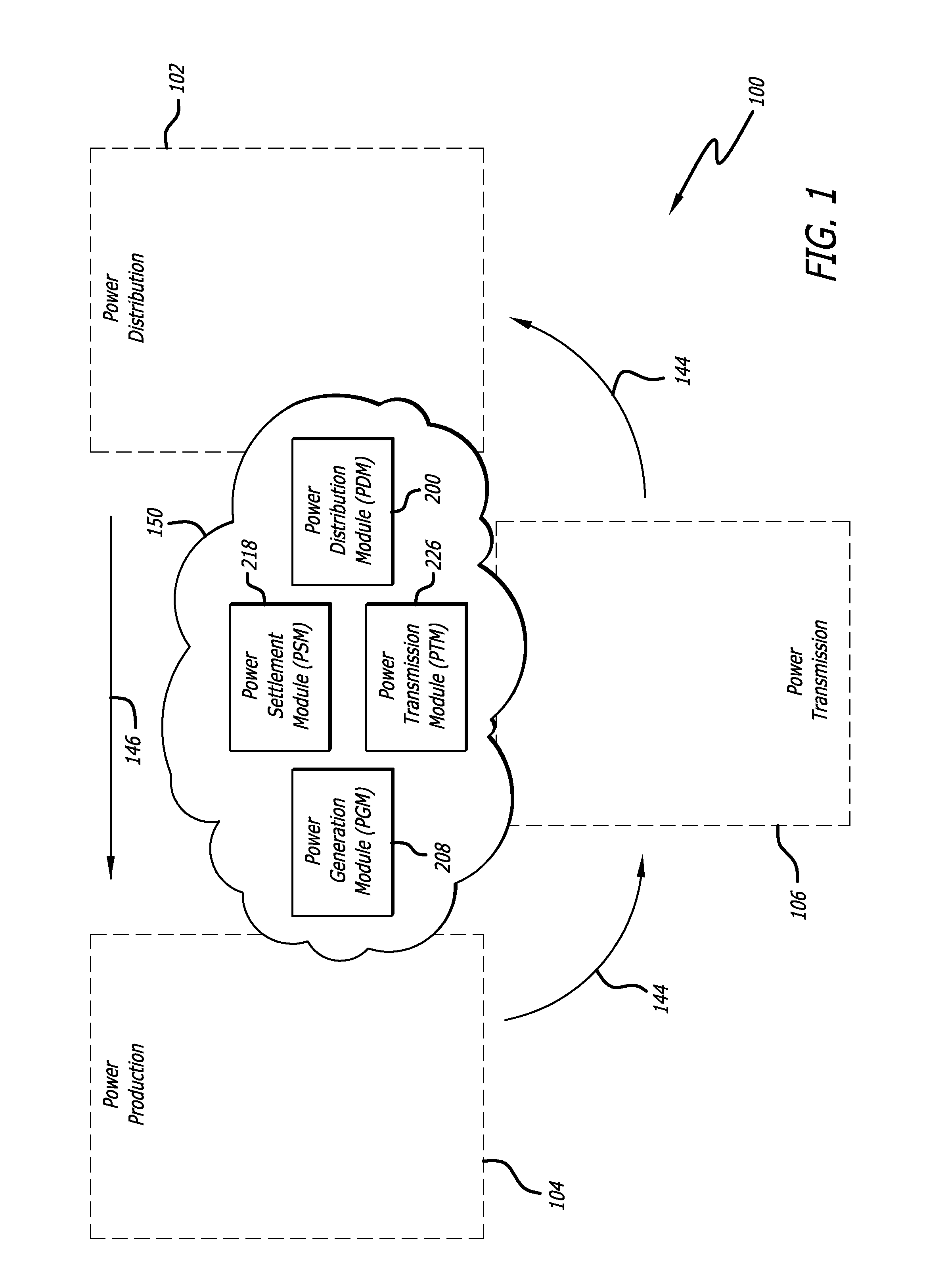

Energy management system for power transmission to an intelligent electricity grid from a multi-resource renewable energy installation

InactiveUS20120150679A1Balance power productionEfficiently and effectively respondGeneration forecast in ac networkMachines/enginesElectric power transmissionMicrogrid

A renewable energy resource management system manages a delivery of a power requirement from a multi-resource offshore renewable energy installation to an intelligent power distribution network. The installation includes multiple renewable energy resource components and is capable of variably and independently generating power from each to microgrids comprising the intelligent power distribution network so that the entire power requirement is satisfied from renewable energy resources. An electricity grid infrastructure is also disclosed in which power production is balanced with power consumption so that power storage requirements are minimized.

Owner:LAZARIS SPYROS J

Systems and methods for analyzing performance of virtual environments

ActiveUS20120284713A1Effective and efficient diagnosisDigital data processing detailsError detection/correctionMonitoring systemSimulation

Intelligent monitoring systems and methods for virtual environments are disclosed that understand various components of a virtual infrastructure and how the components interact to provide improved performance analysis to users. In certain examples, a monitoring system assesses the performance of virtual machine(s) in the context of the overall performance of the physical server(s) and the environment in which the virtual machine(s) are running. For instance, the monitoring system can track performance metrics over a determined period of time to view changes to the allocation of resources to virtual machines and their location(s) on physical platforms. Moreover, monitoring systems can utilize past performance information from separate virtual environments to project a performance impact resulting from the migration of a virtual machine from one physical platform to another.

Owner:QUEST SOFTWARE INC

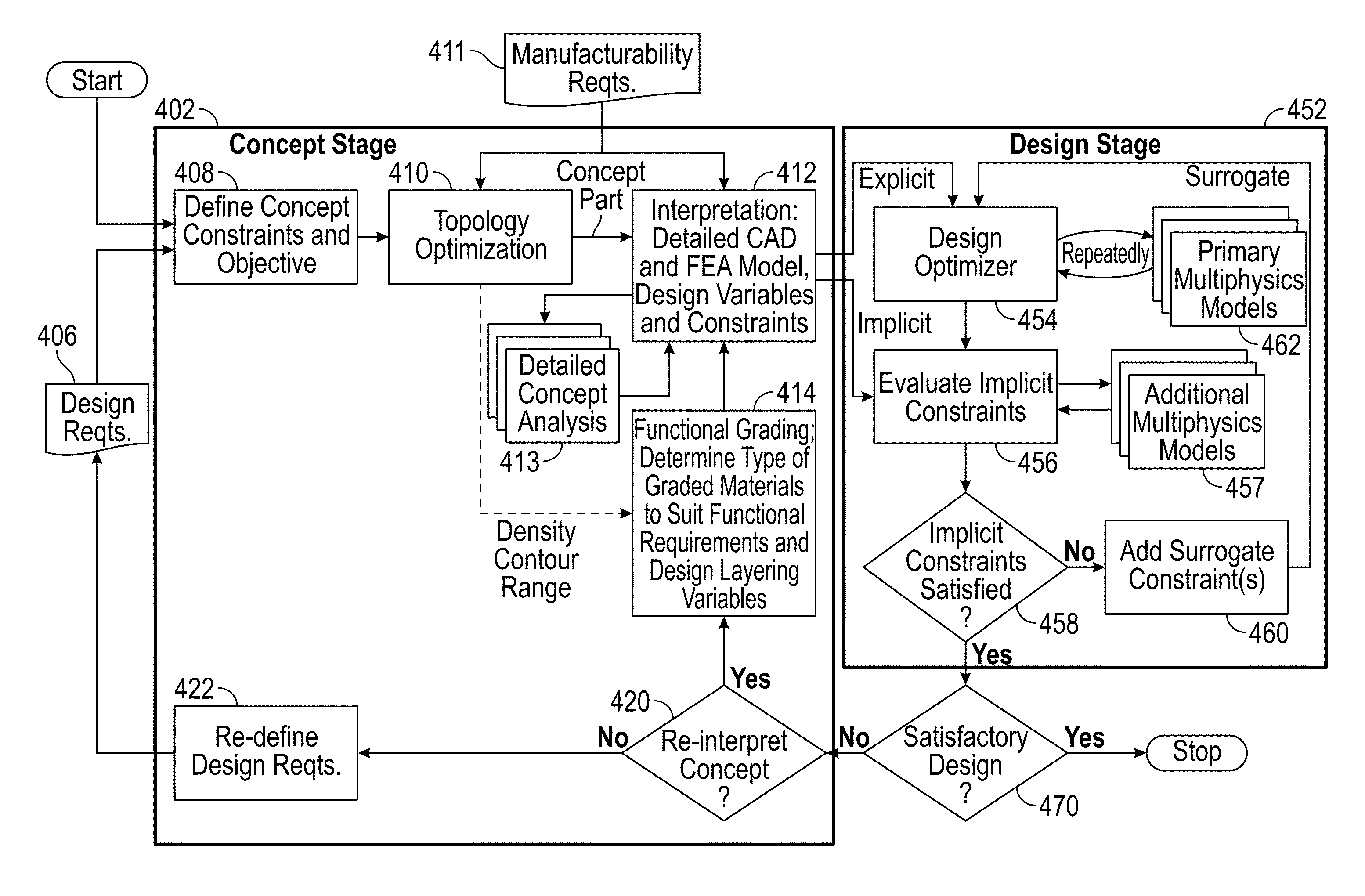

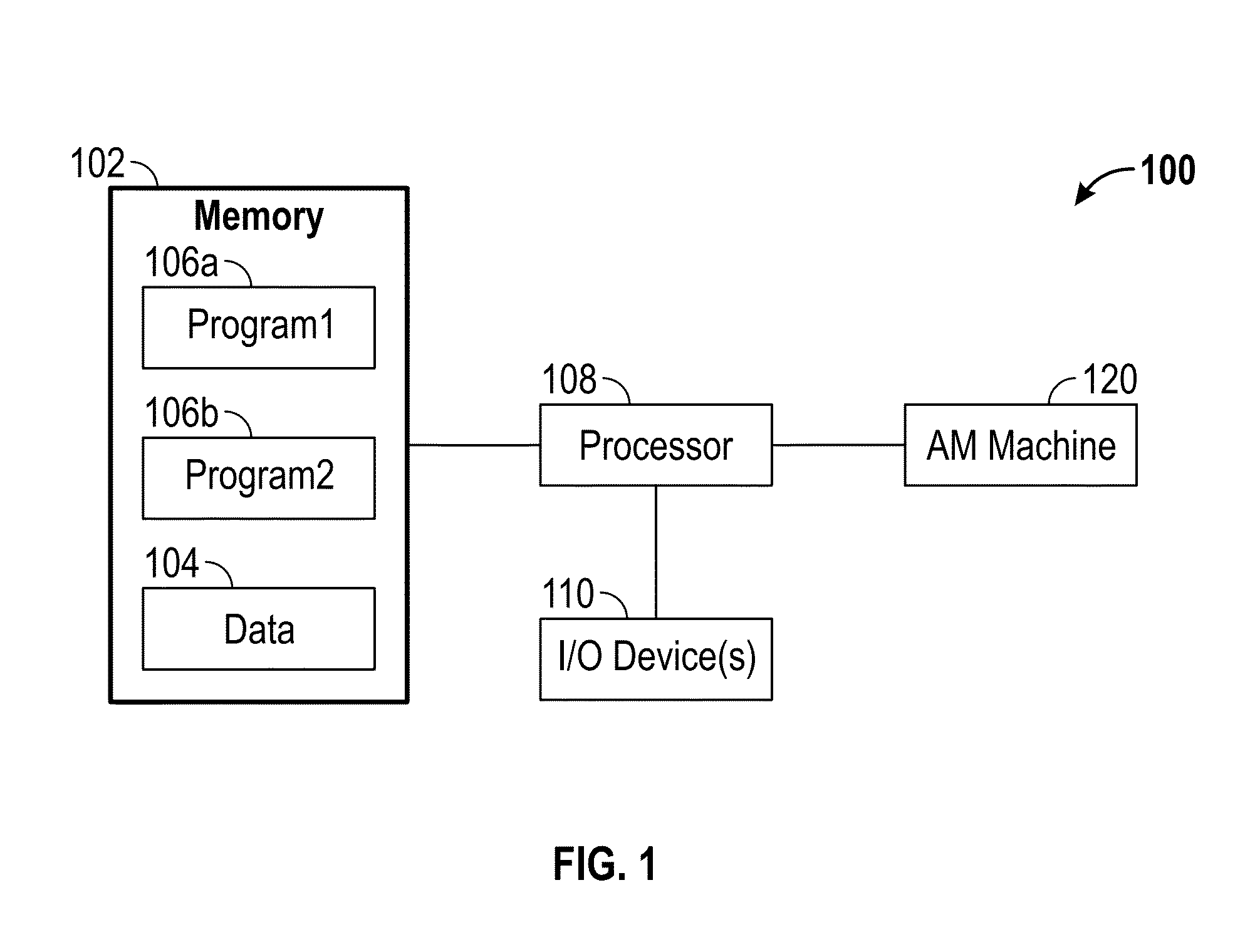

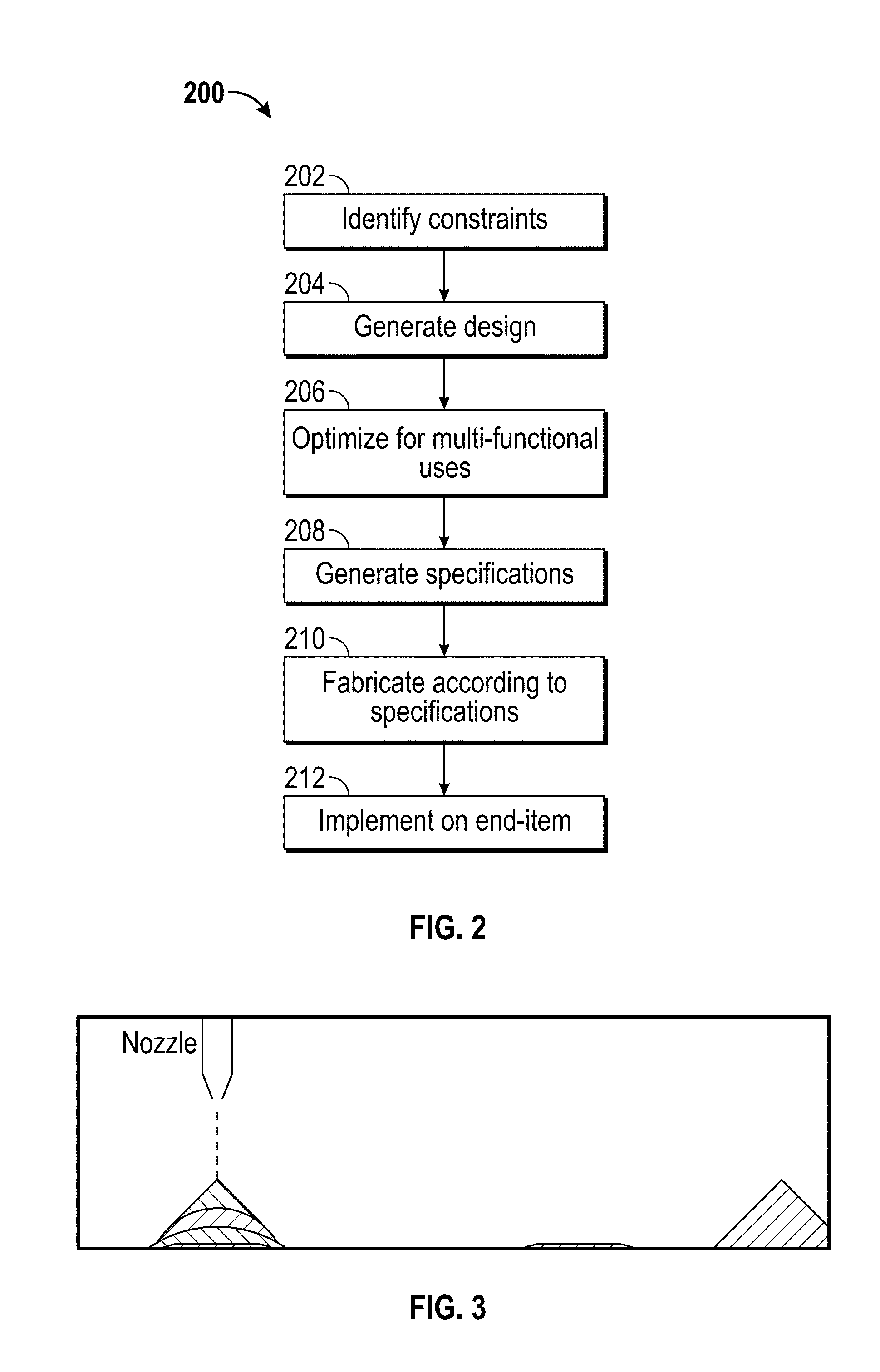

Additive topology optimized manufacturing for multi-functional components

InactiveUS20140277669A1Programme controlAdditive manufacturing apparatusTopology optimizationAdditive layer manufacturing

Owner:SIKORSKY AIRCRAFT CORP

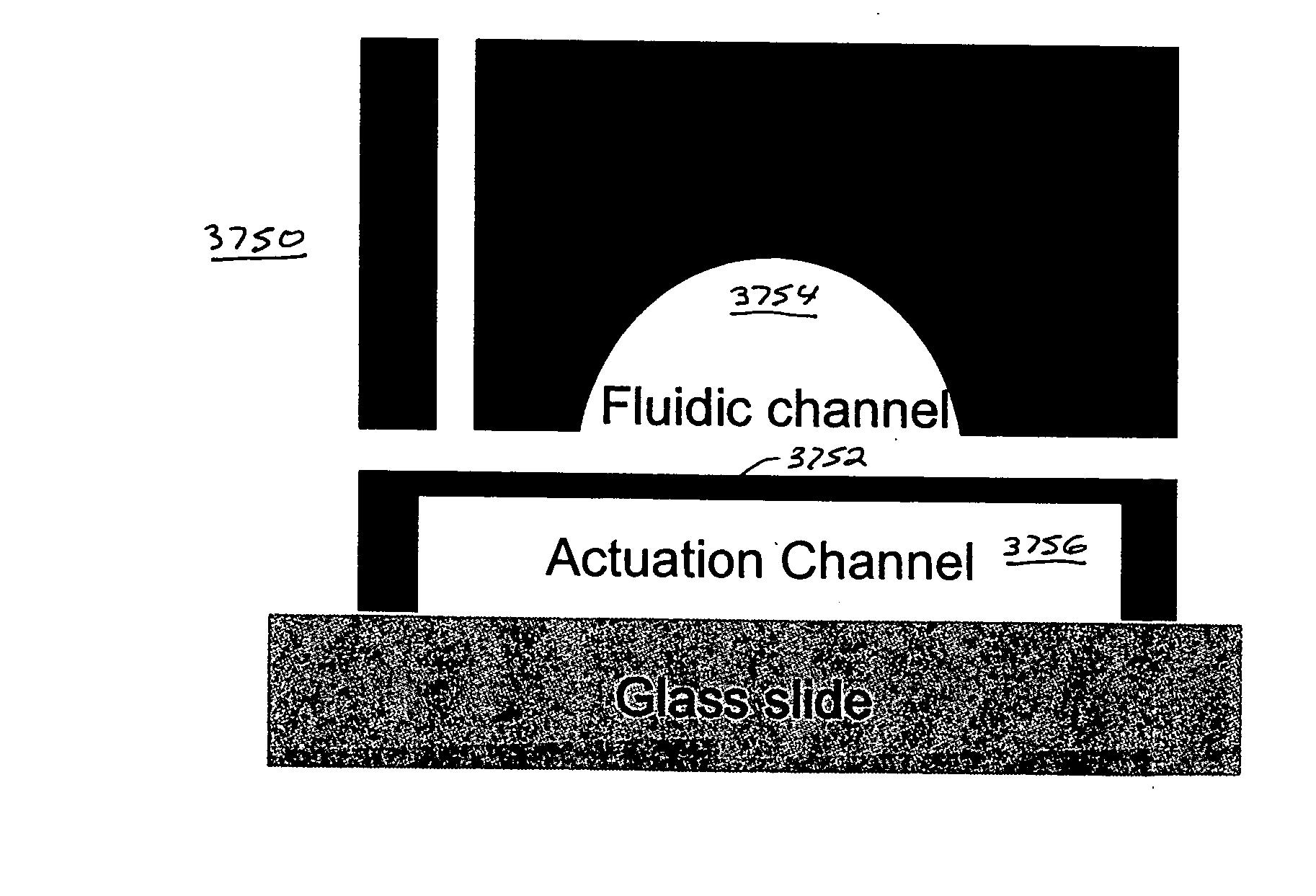

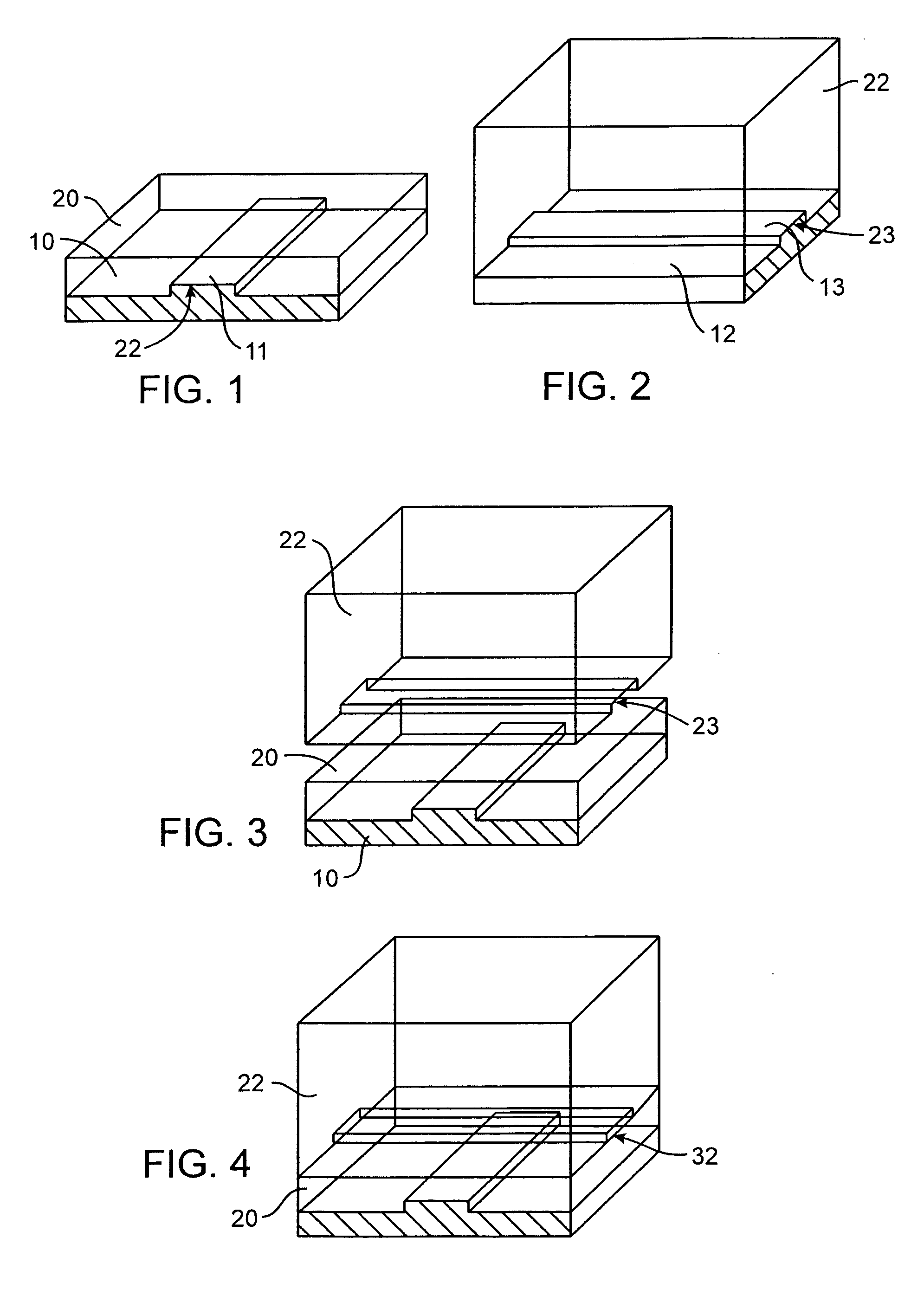

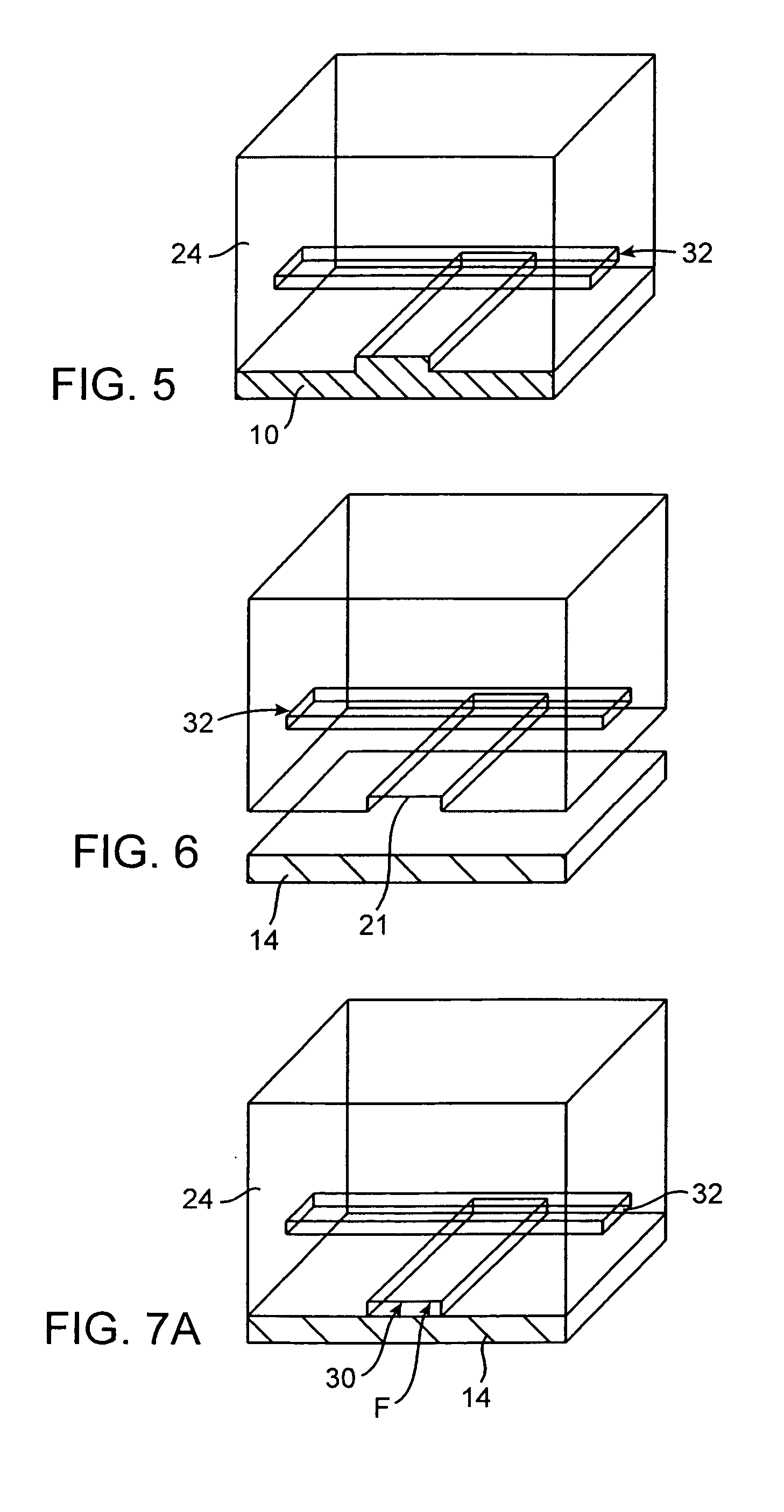

Microfluidic large scale integration

InactiveUS20050072946A1Operating means/releasing devices for valvesCircuit elementsElastomerFlow resistivity

Using basic physical arguments, a design and method for the fabrication of microfluidic valves using multilayer soft lithography is presented. Embodiments of valves in accordance with the present invention feature elastomer membrane portions of substantially constant thickness, allowing the membranes to experience similar resistance to an applied pressure across their entire width. Such on-off valves fabricated with upwardly- or downwardly-deflectable membranes can have extremely low actuation pressures, and can be used to implement active functions such as pumps and mixers in integrated microfluidic chips. Valve performance was characterized by measuring both the actuation pressure and flow resistance over a wide range of design parameters, and comparing them to both finite element simulations and alternative valve geometries.

Owner:CALIFORNIA INST OF TECH

Methods, systems, and data structures for performing searches on three dimensional objects

Techniques are provided for searching on three dimensional (3D) objects across large, distributed repositories of 3D models. 3D shapes are created for input to a search system; optionally user-defined similarity criterion is used, and search results are interactively navigated and feedback received for modifying the accuracy of the search results. Search input can also be given by picking 3D models from a cluster map or by providing the orthographic views for the 3D model. Feedback can be given by a searcher as to which models are similar and which are not. Various techniques adjust the search results according to the feedback given by the searcher and present the new search results to the searcher.

Owner:PURDUE RES FOUND INC

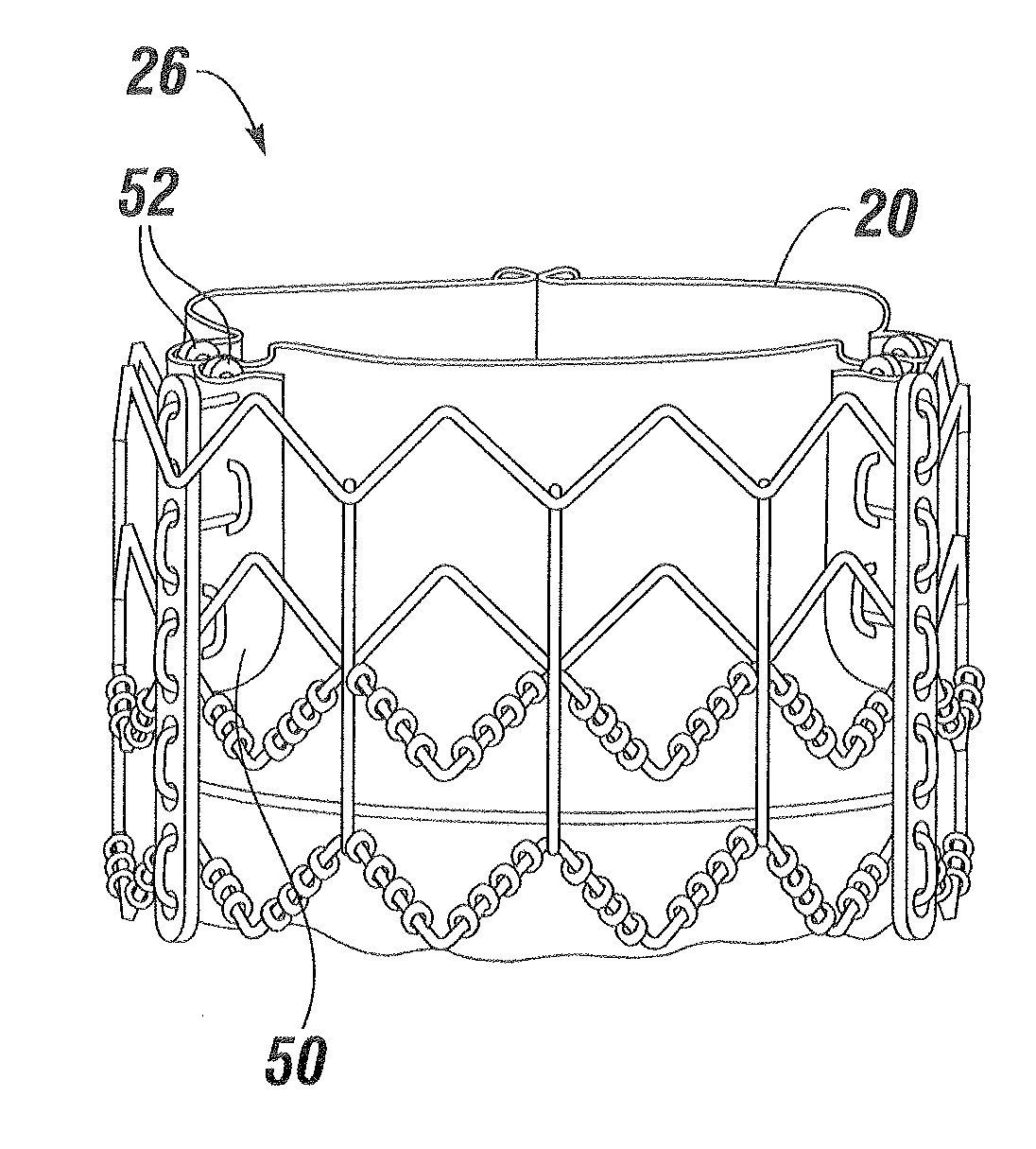

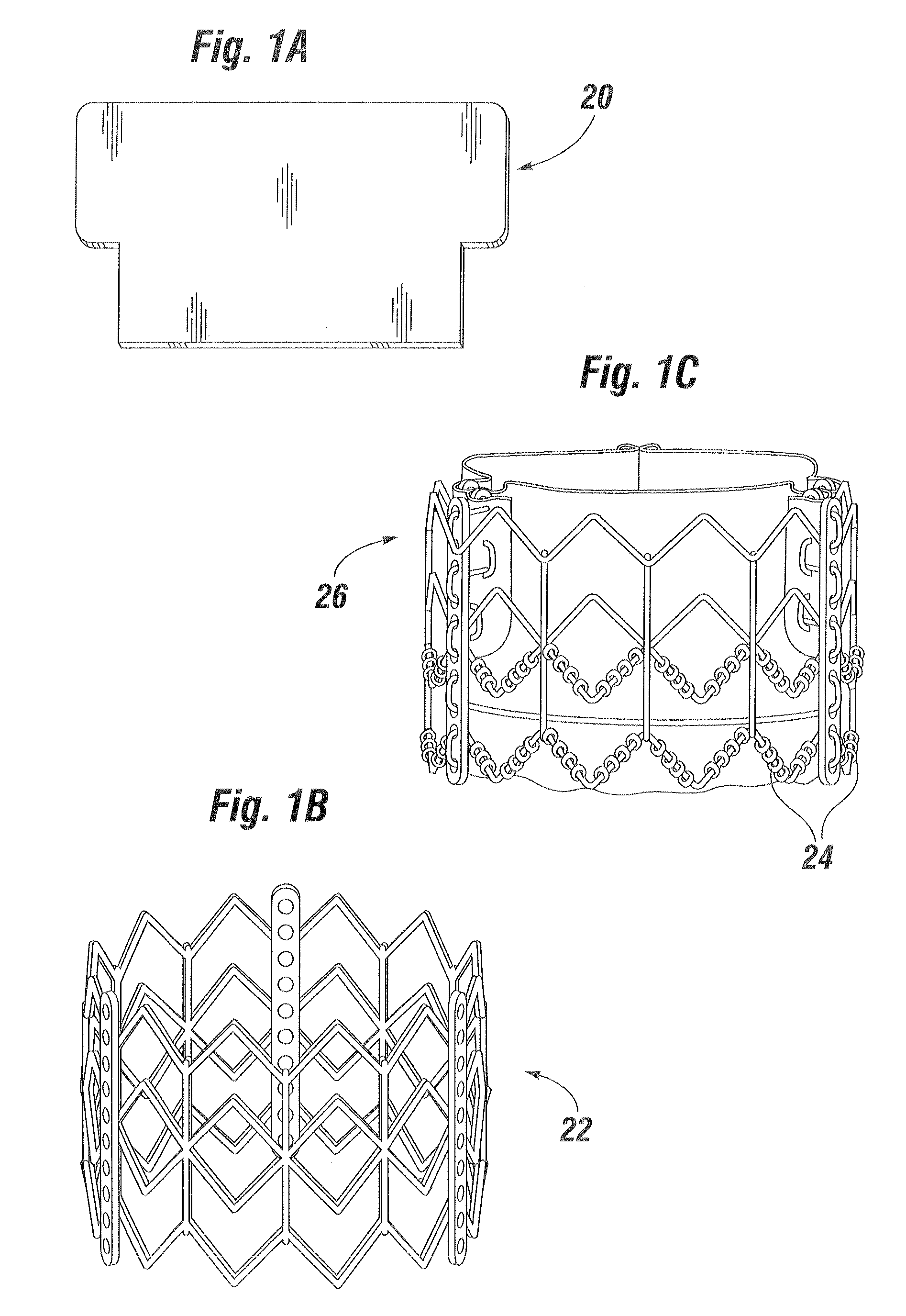

Virtual heart valve

ActiveUS20070208550A1Accurate measurementFast formingHeart valvesAnalogue computers for chemical processesPrincipal stressStress level

A computational technique to construct a 3-D valve leaflet geometry. The invention pertains to methodology to construct a 3-D heart valve leaflet geometry using finite element analysis (FEA) to simulate the manual assembly process or, in other words, provide a virtual assembly process as an input to a subsequent simulated valve testing step. The simulated valves may be subjected to simulated cyclic valve opening and closings and the stress levels induced therein monitored. Simulated valve designs with lower principal stresses can then be selected for prototyping. Proposed valves can be subjected to cyclic fatigue stress testing under simulated physiologic conditions to study valve durability.

Owner:EDWARDS LIFESCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com