Patents

Literature

151 results about "Mask inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

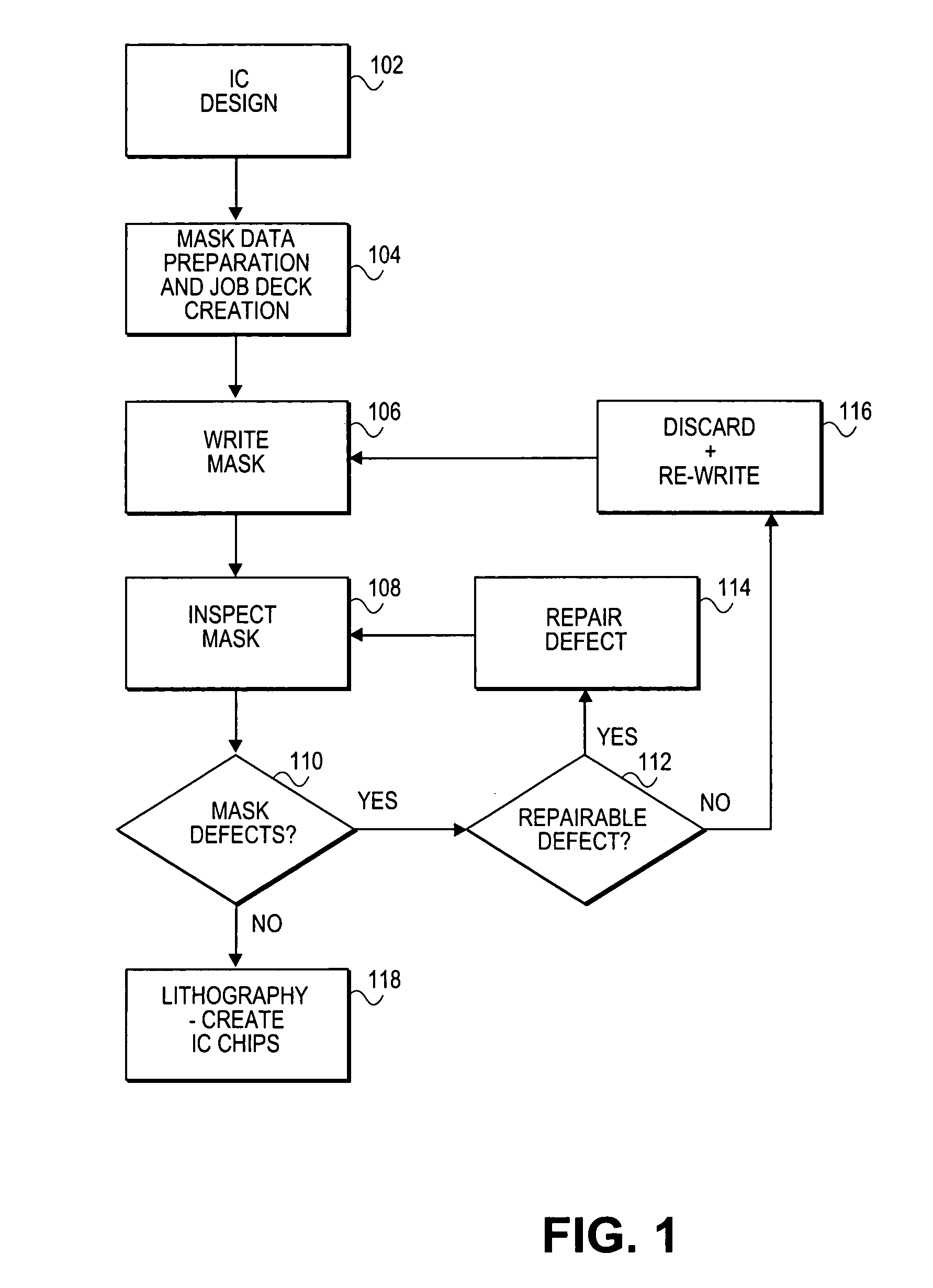

In microtechnology, mask inspection or photomask inspection is an operation of checking the correctness of the fabricated photomasks, used, e.g., for semiconductor device fabrication. Modern technologies for locating defects in photomasks are automated systems that involve scanning electron microscopy and other advanced tools.

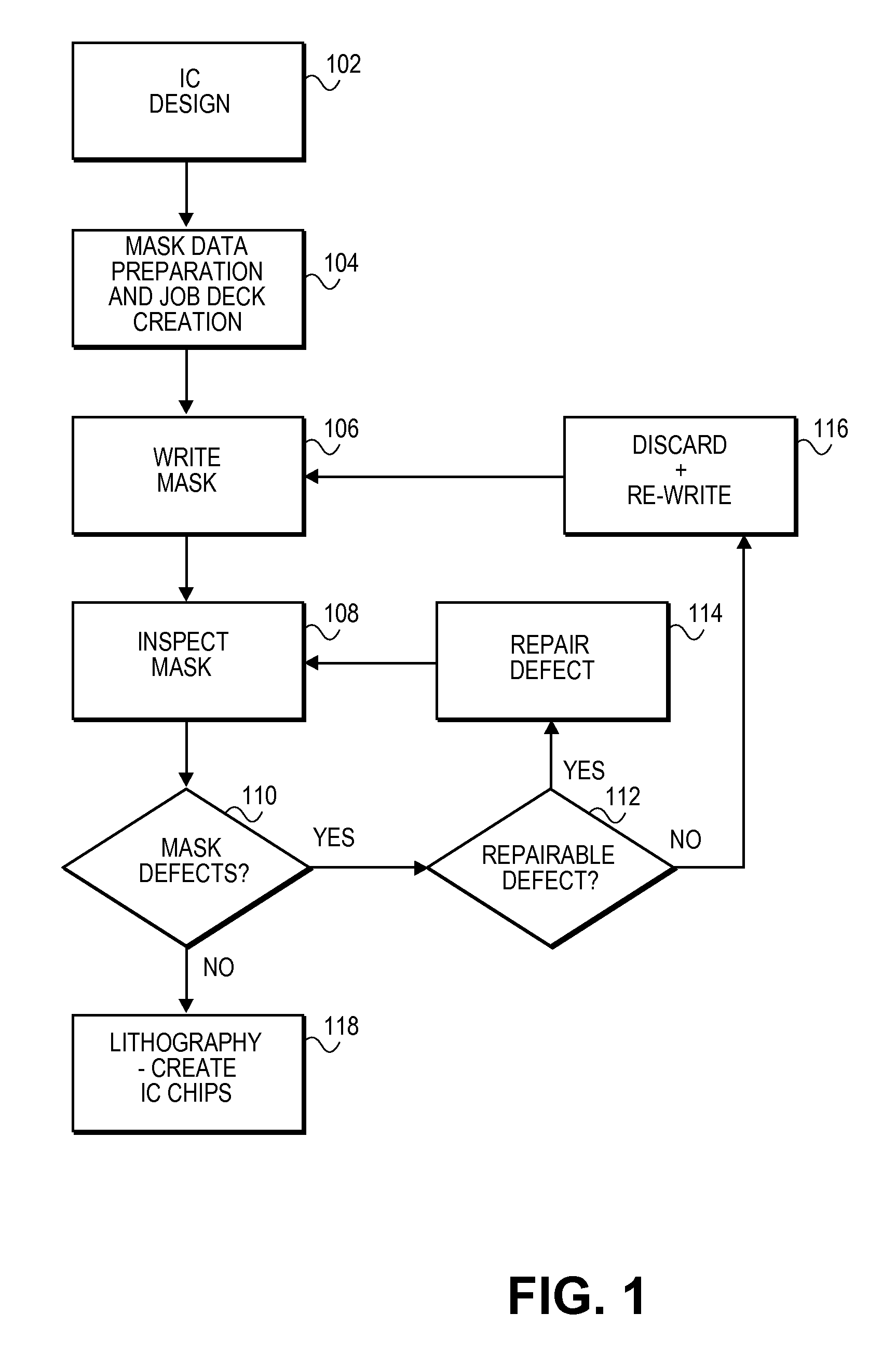

System and Method for Integrated Circuit Manufacturing

ActiveUS20150278429A1Photomechanical apparatusDesign optimisation/simulationMask inspectionIntegrated circuit manufacturing

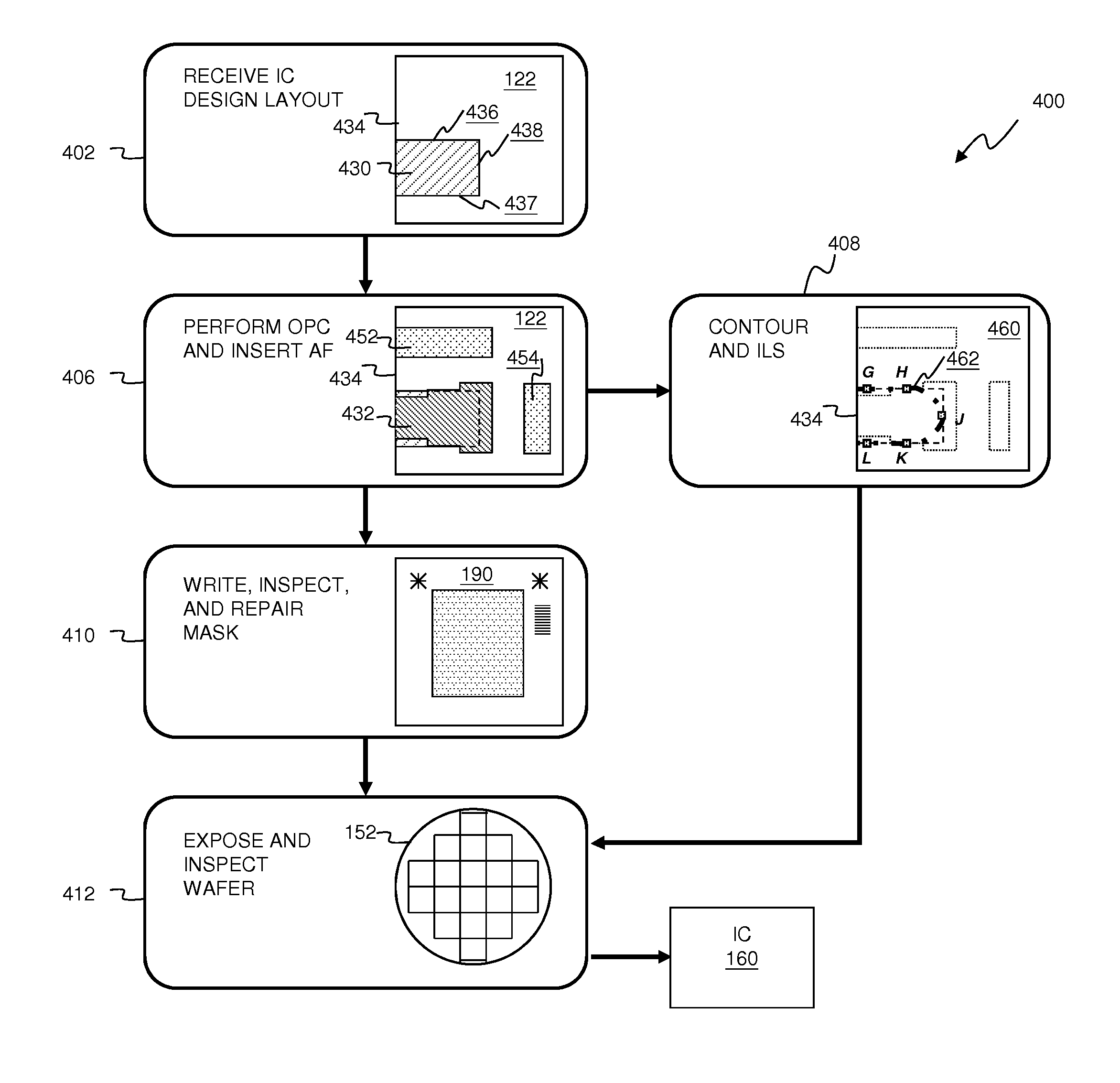

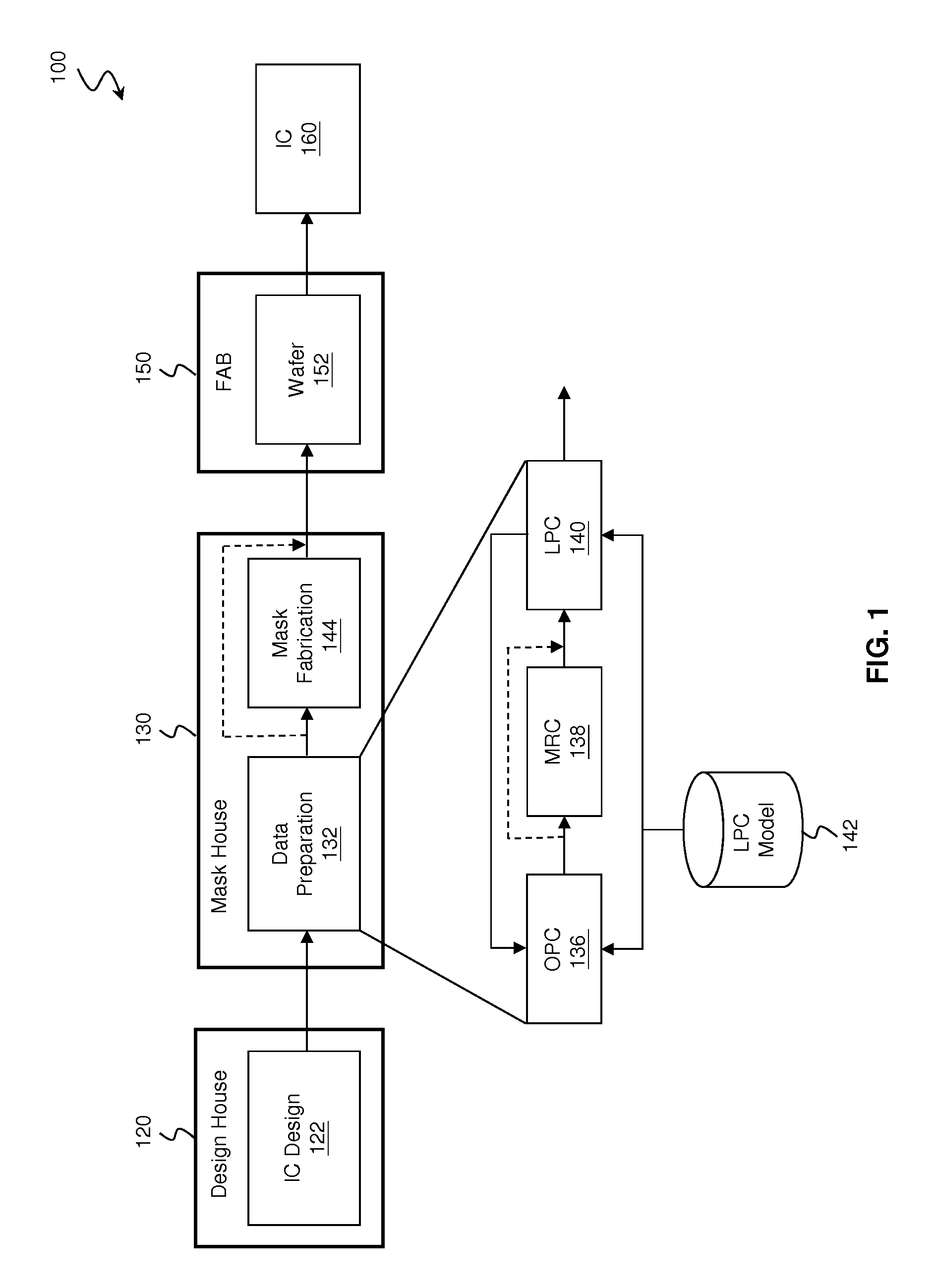

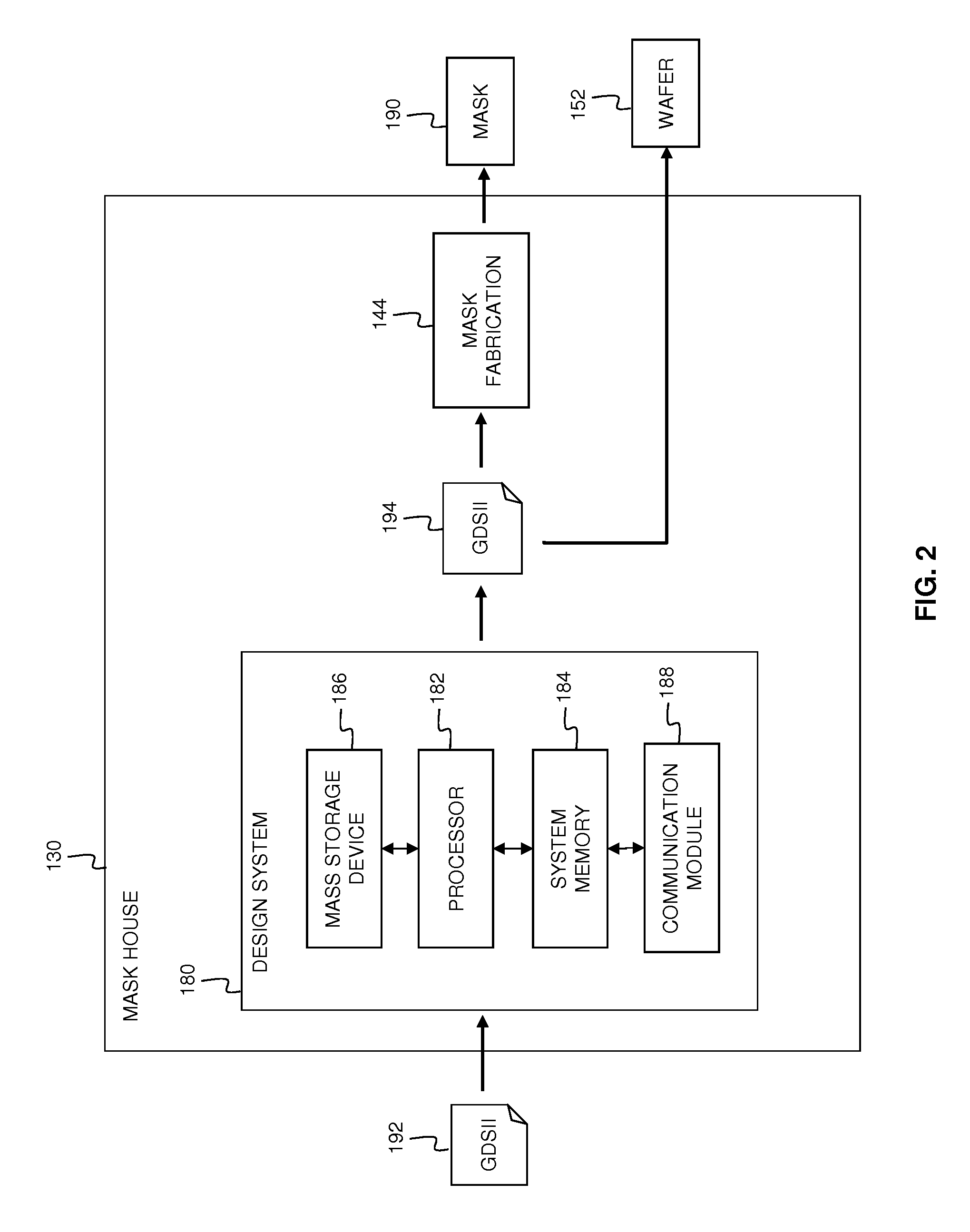

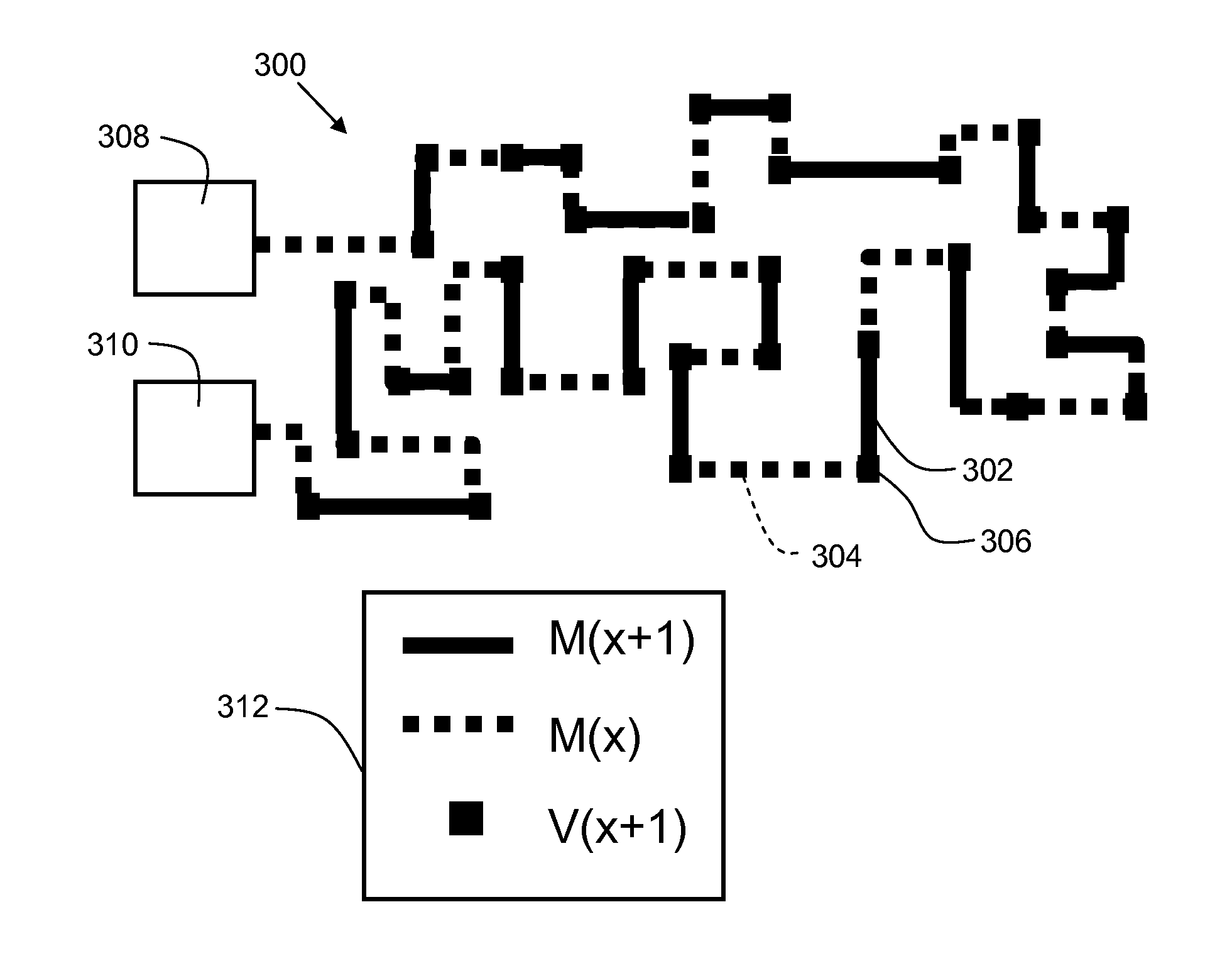

Provided is an integrated circuit (IC) manufacturing method. The method includes receiving a design layout of an IC, the design layout having a main feature; performing a process correction to the main feature thereby generating a modified main feature; using a computer, generating a simulated contour of the modified main feature, the simulated contour having a plurality of points; generating a plurality of assistant data in computer readable format, wherein each assistant data includes at least one process performance factor associated with one of the points; and keeping the simulated contour and the assistant data for use by a further process stage, such as mask making, mask inspection, mask repairing, wafer direct writing, wafer inspection, and wafer repairing.

Owner:TAIWAN SEMICON MFG CO LTD

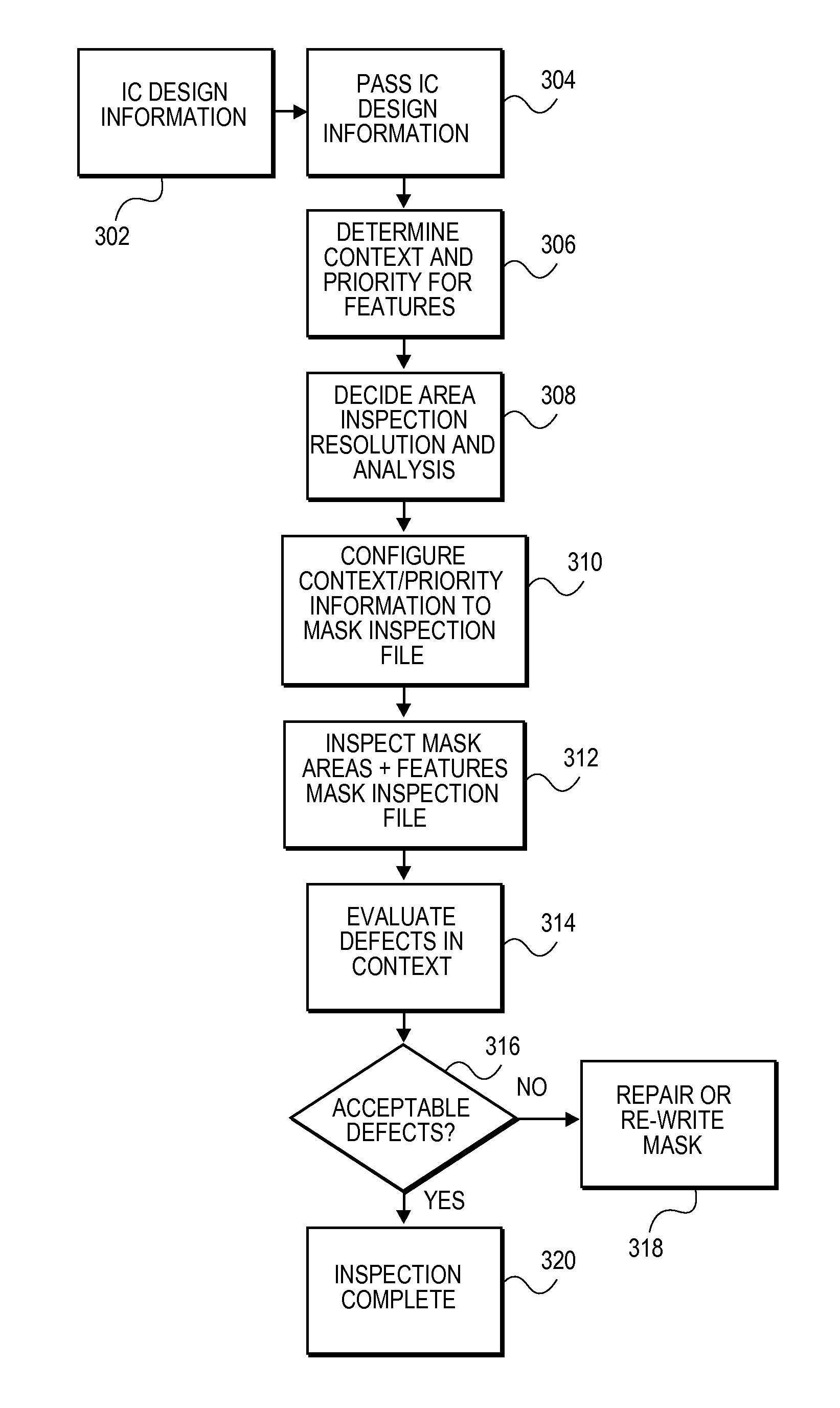

Method and system for context-specific mask inspection

InactiveUS7231628B2Electrical testingCharacter and pattern recognitionMask inspectionContext specific

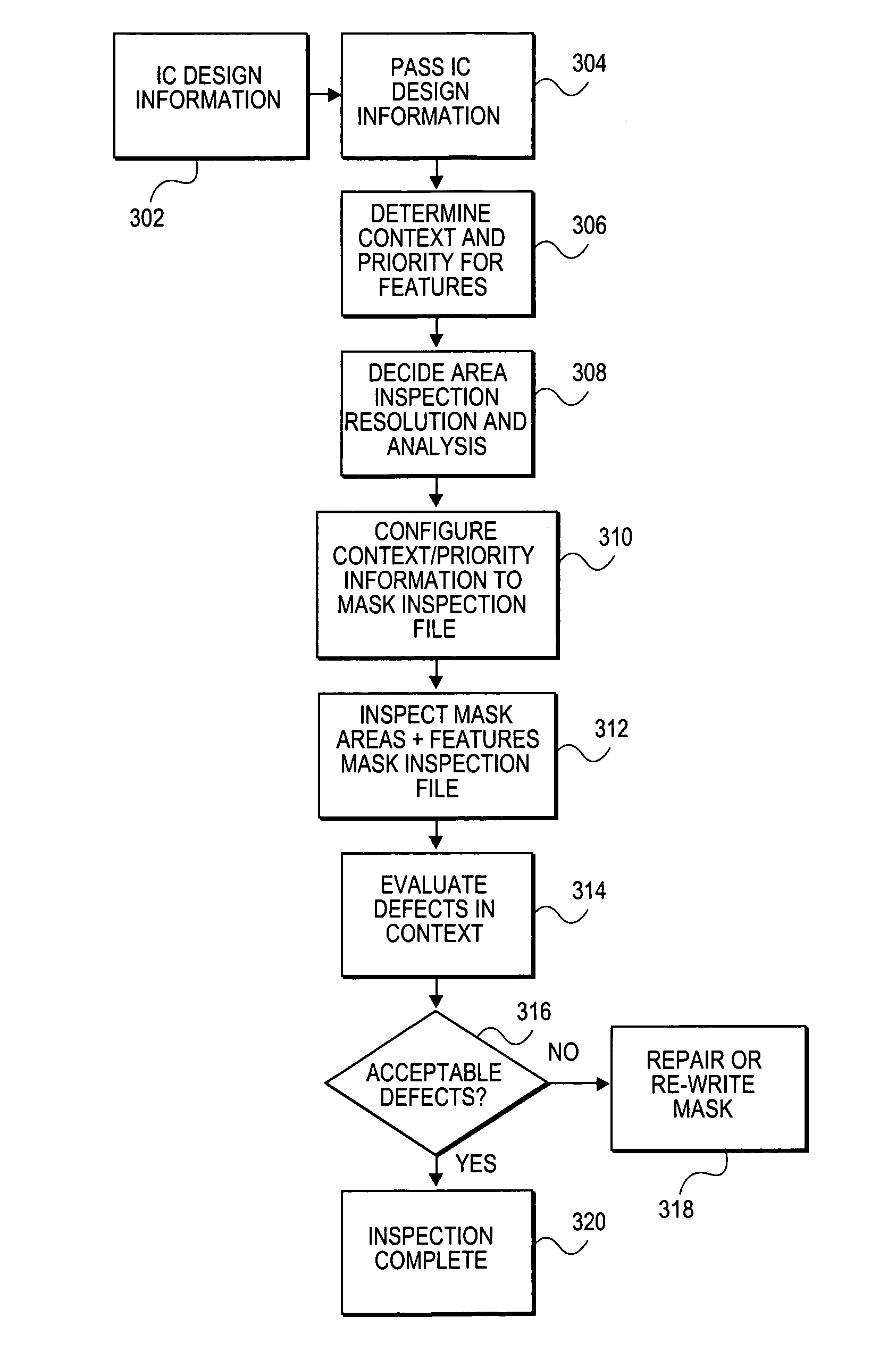

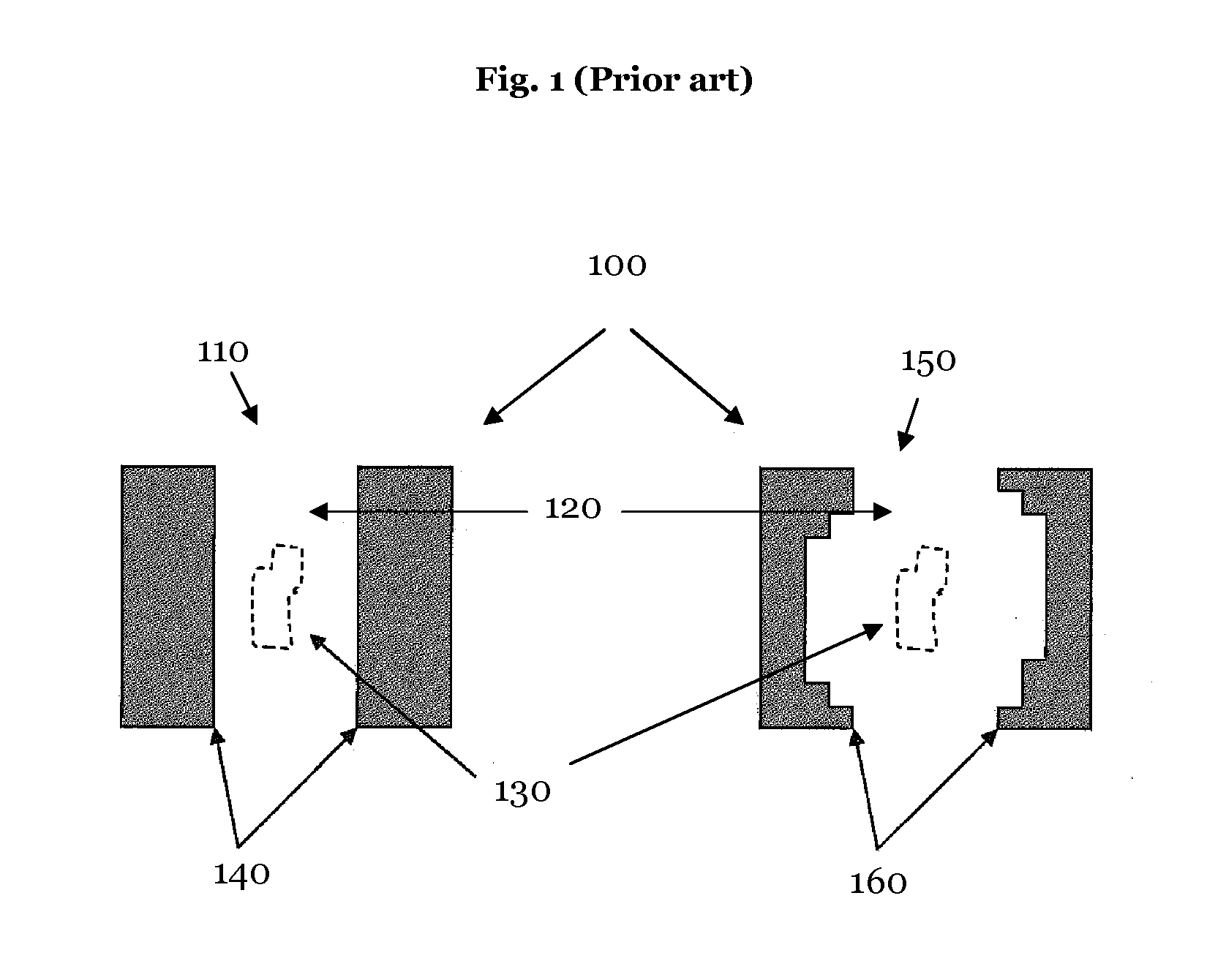

A method for inspecting lithography masks includes generating integrated circuit design data and using context information from the integrated circuit design data to inspect a mask.

Owner:CADENCE DESIGN SYST INC

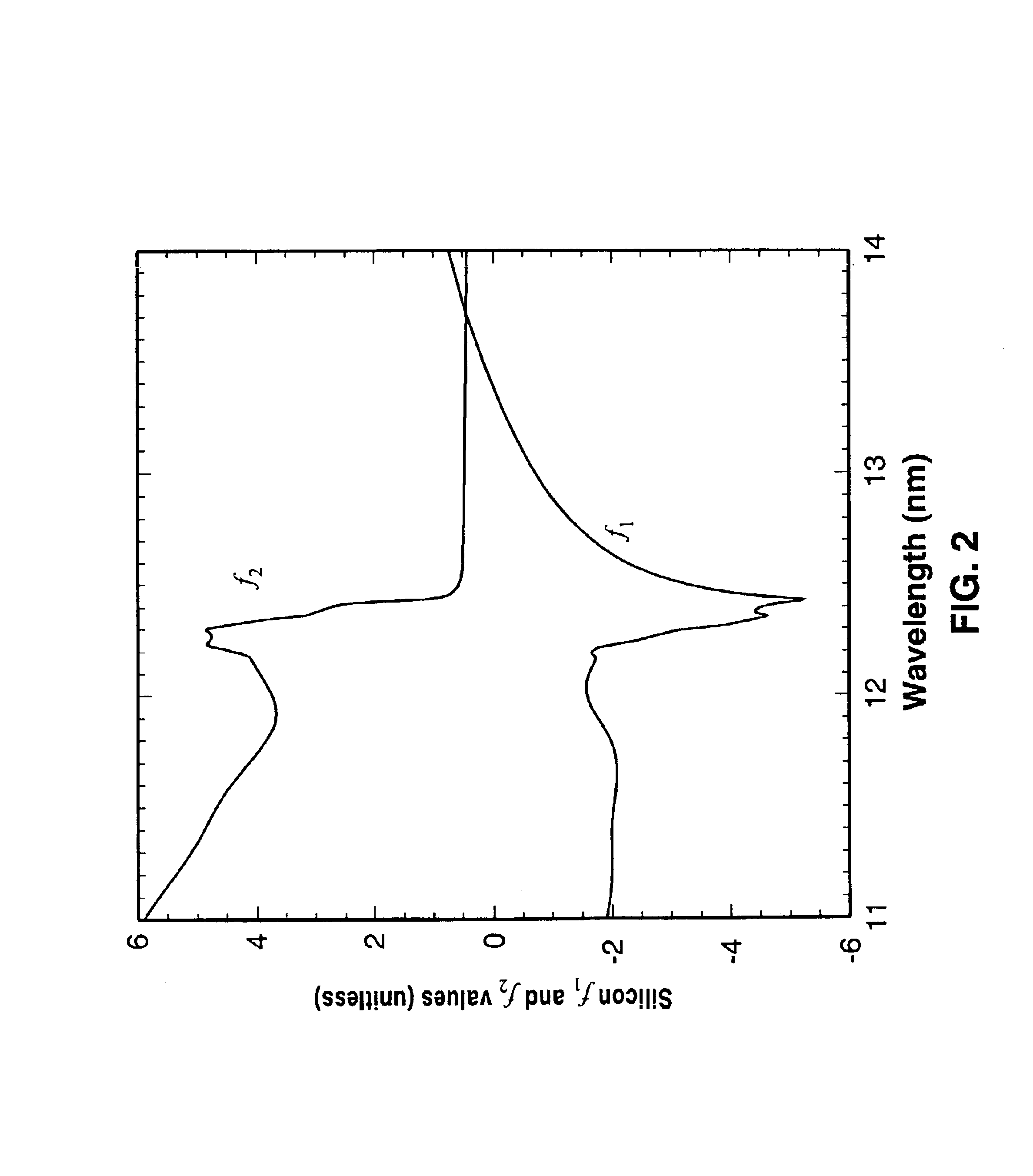

Reflective lithography mask inspection tool based on achromatic Fresnel optics

InactiveUS6914723B2High resolutionEfficient use ofOptical filtersMaterial analysis by optical meansFresnel lensMask inspection

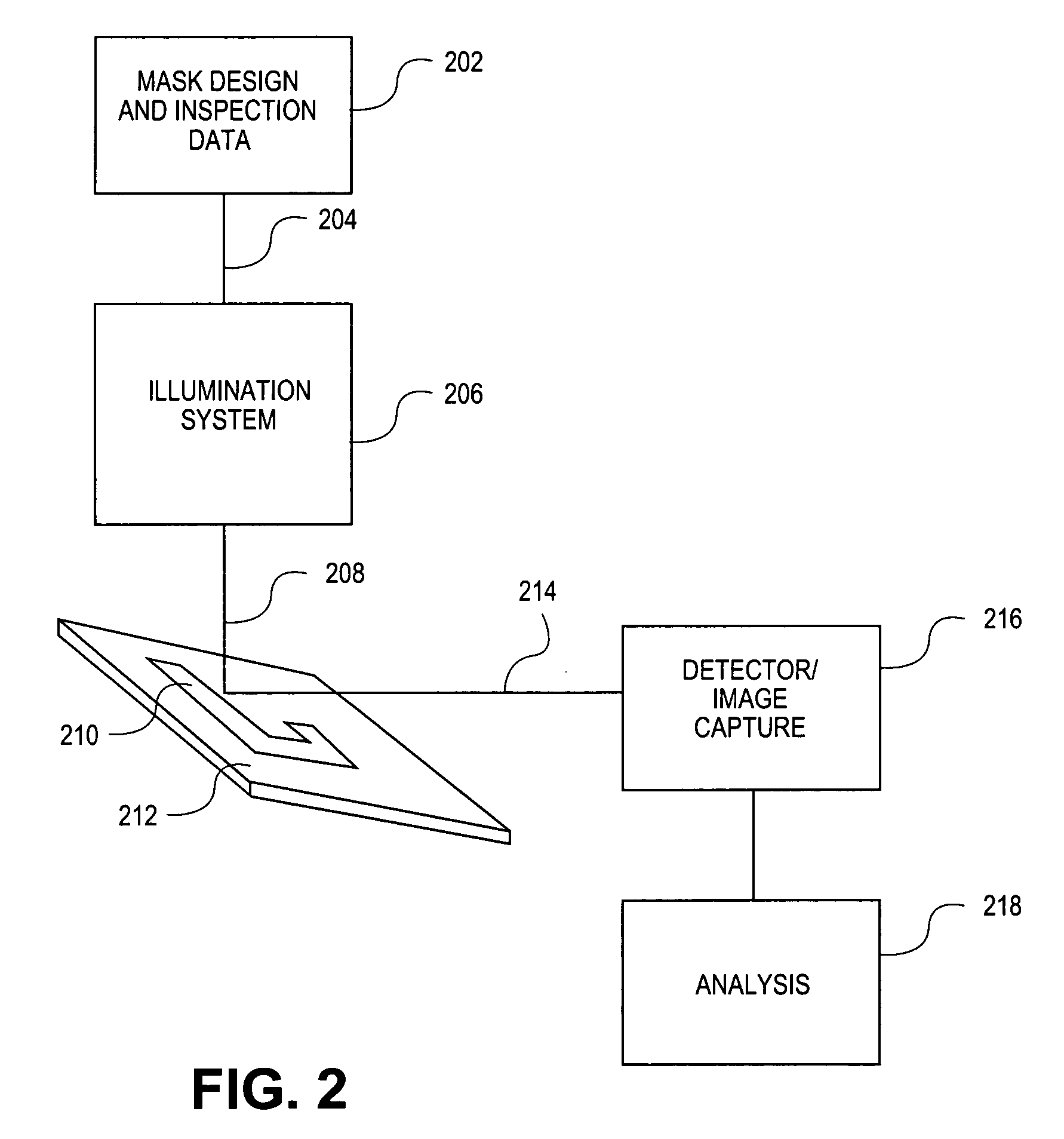

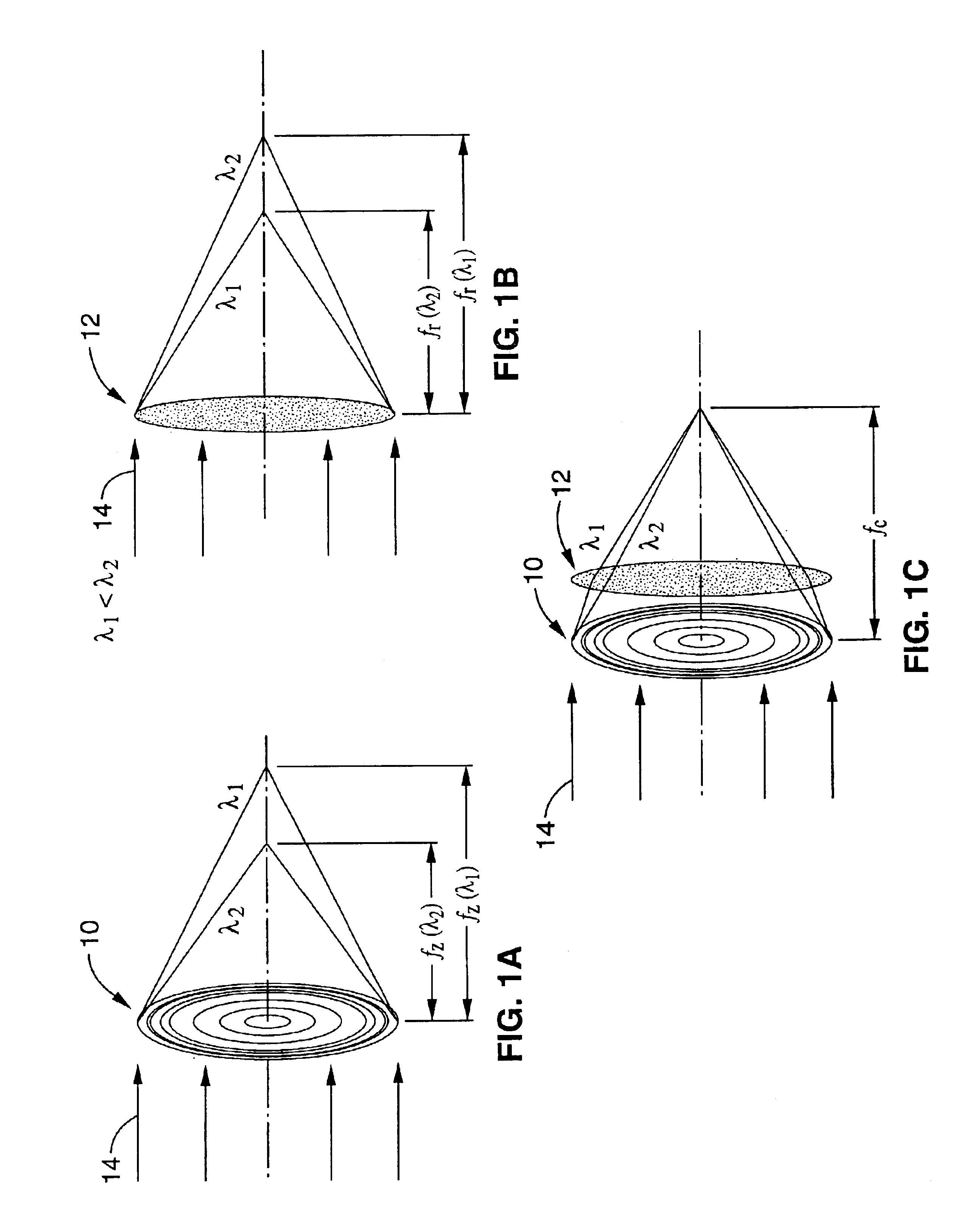

A mask blank inspection tool includes an AFO having a diffractive lens and a refractive lens formed on a common substrate. The diffractive lens is a Fresnel zone plate and the refractive lens is a refractive Fresnel lens. The AFO is used to image light from a defect particle on a multilayer mask blank or the surface of the multilayer mask blank to a detector.

Owner:XRADIA

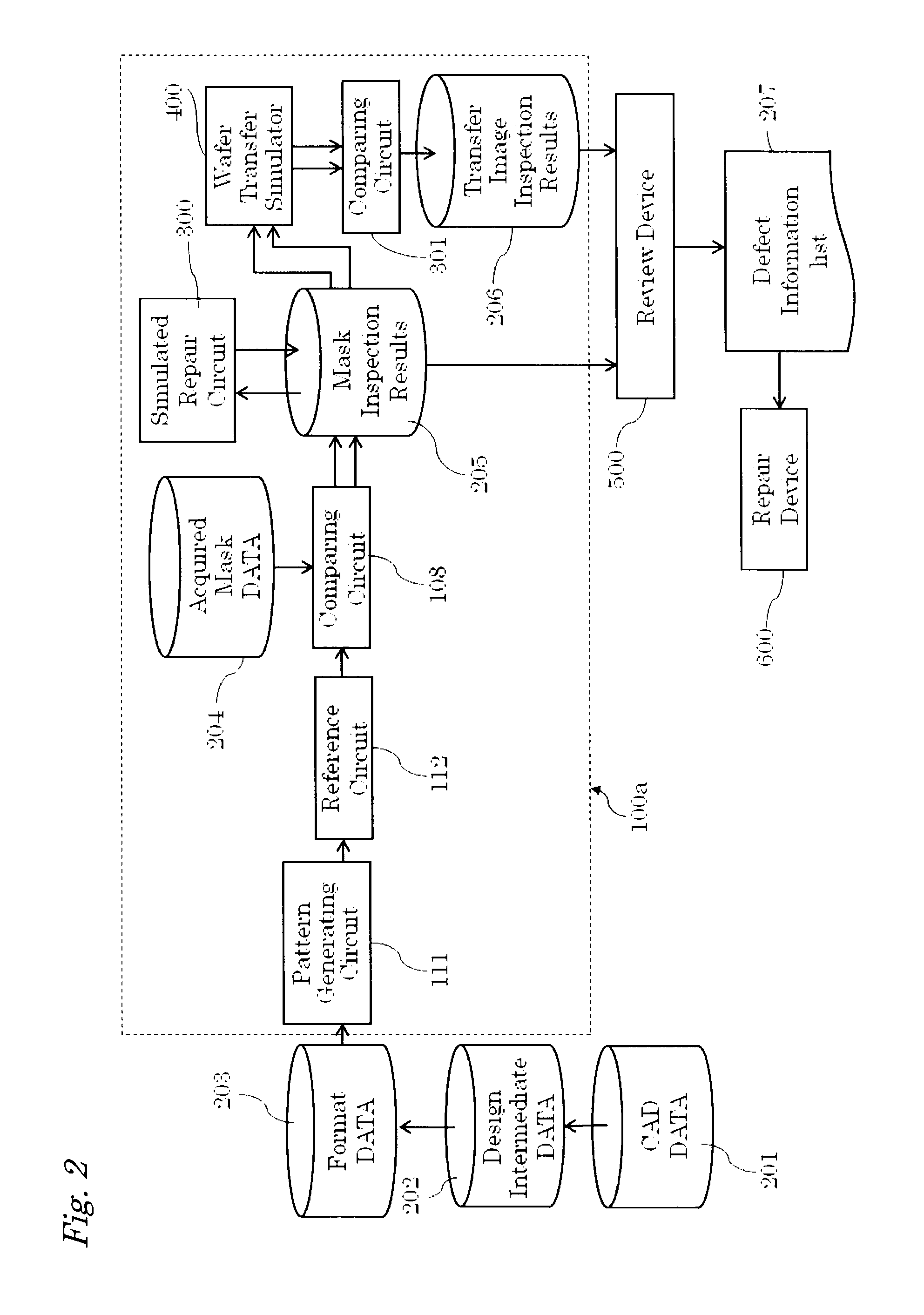

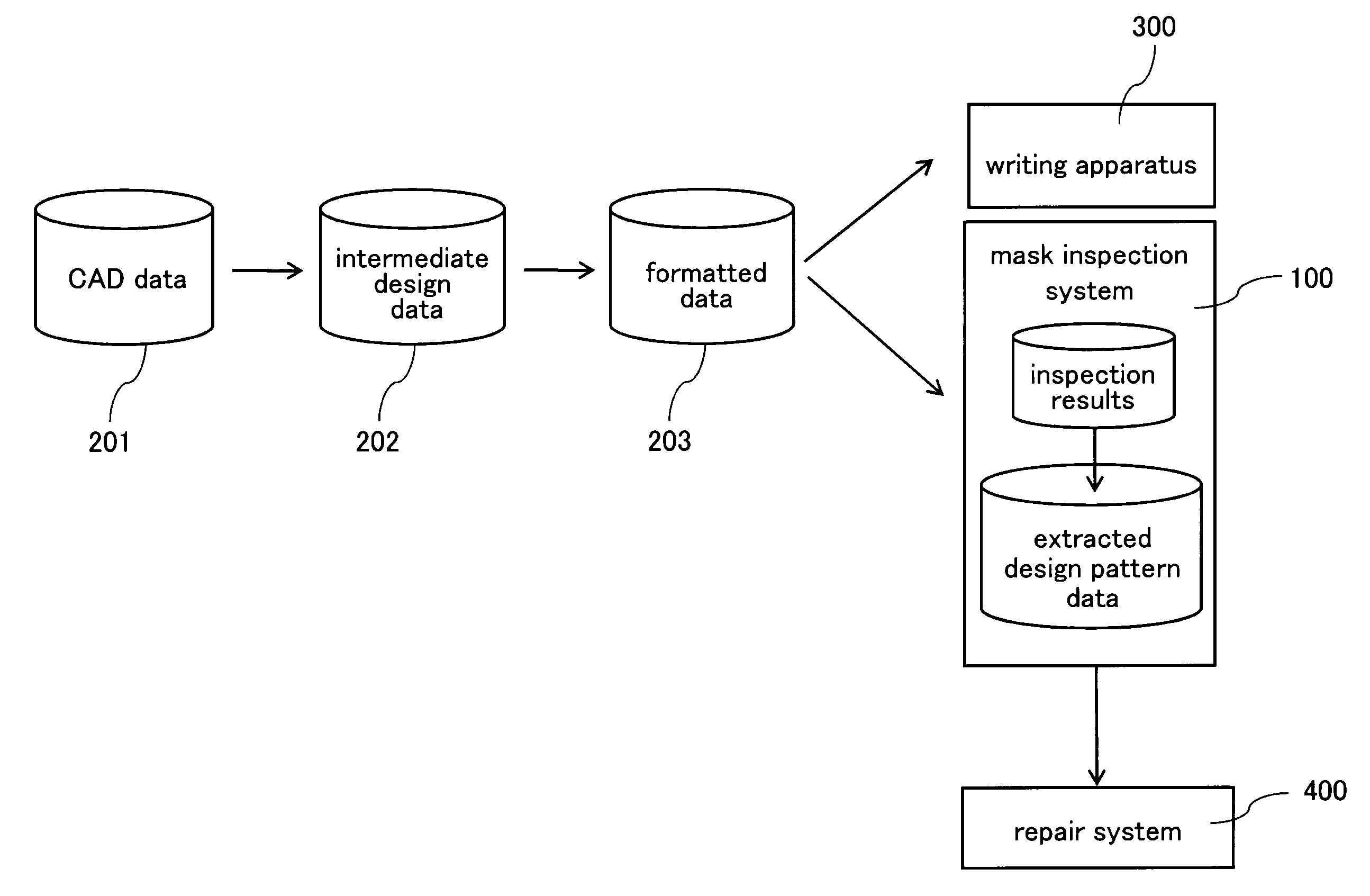

Defect estimation device and method and inspection system and method

Acquired mask data of a defect portion is sent to a simulated repair circuit 300 to be simulated. The simulation of the acquired mask data 204 is returned to the mask inspection results 205 and thereafter sent to a wafer transfer simulator 400 along with a reference image at the corresponding portion. A wafer transfer image estimated by the wafer transfer simulator 400 is sent to a comparing circuit 301. When it is determined that there is a defect in the comparing circuit 301, the coordinates and the wafer transfer image which is a basis for the defect determination are stored as transfer image inspection results 206. The mask inspection results 205 and the transfer image inspection result 206 are then sent to the review device 500.

Owner:NUFLARE TECH INC

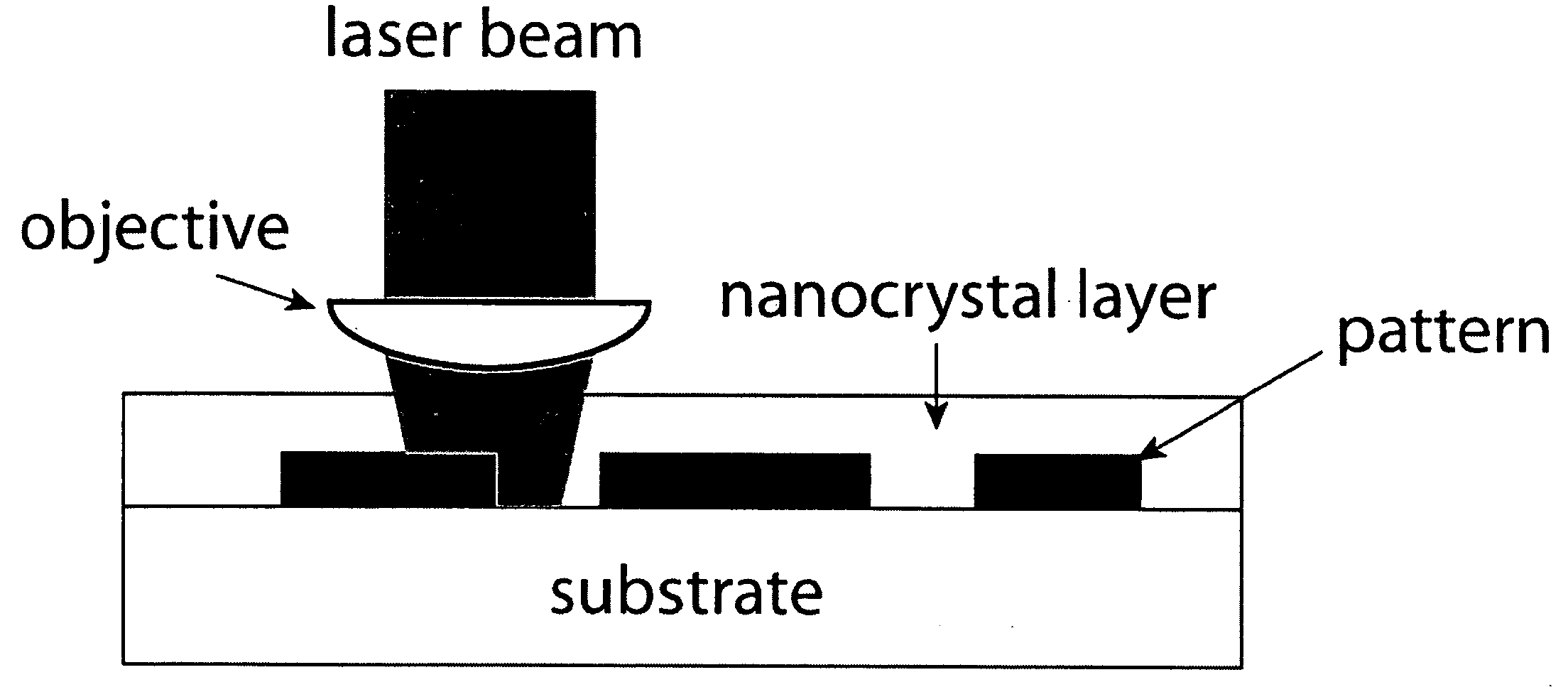

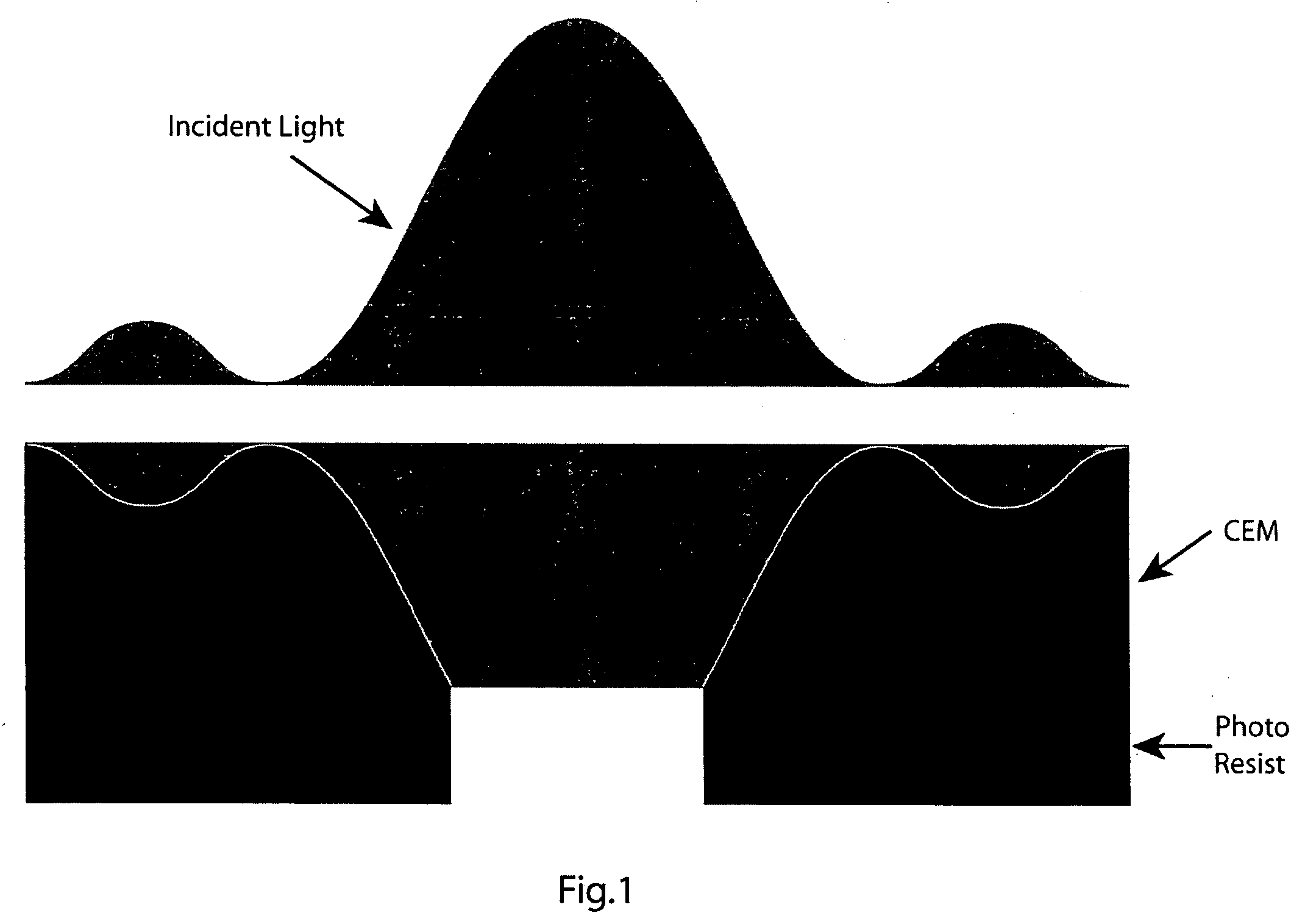

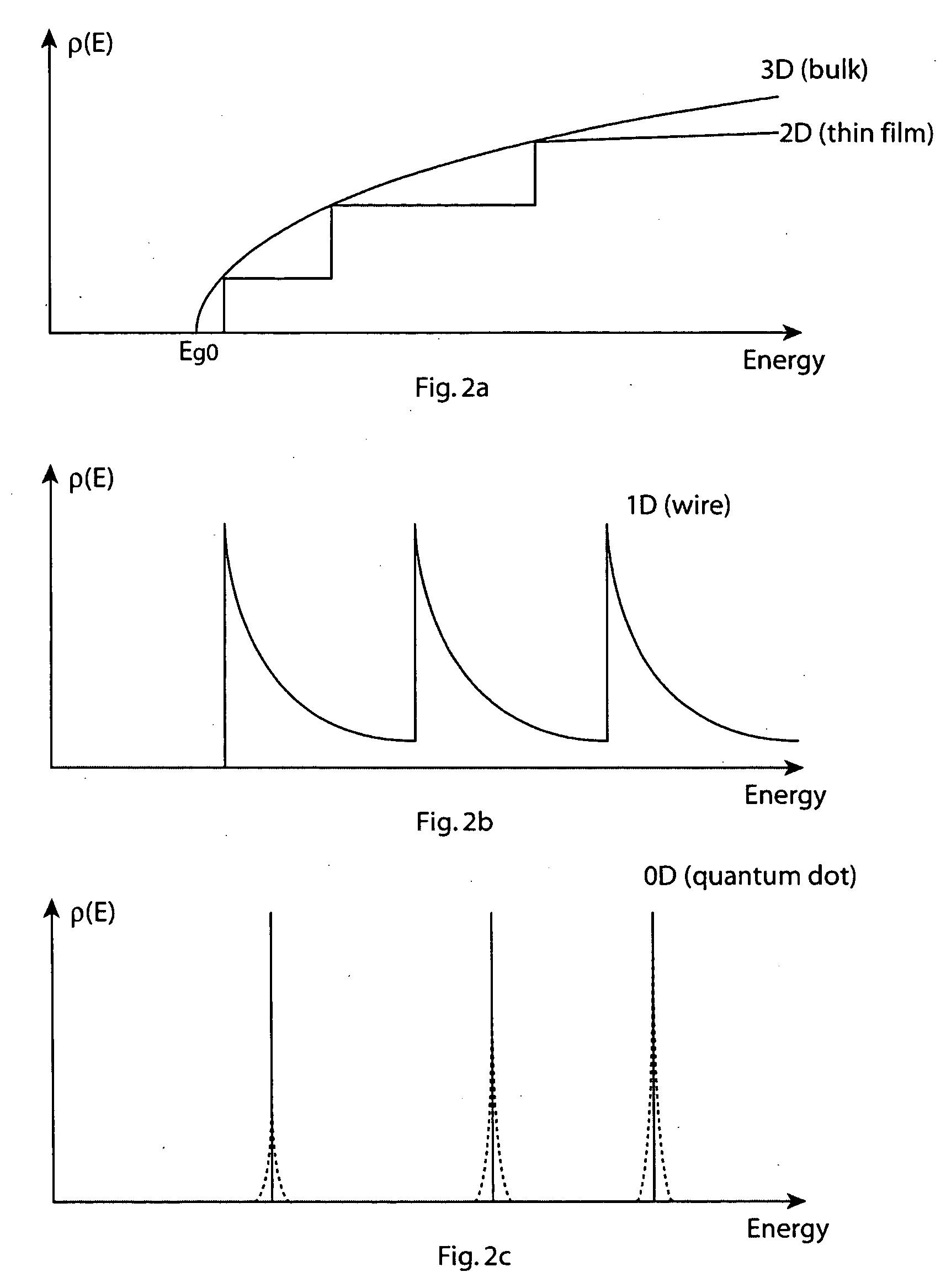

Reversible photobleachable materials based on nano-sized semiconductor particles and their optical applications

InactiveUS20040152011A1Improve image contrastReduce capacityPhotosensitive materialsRadiation applicationsMask inspectionLithographic artist

Semiconductor nano-particles, due to their specific physical properties, can be used as reversible photo-bleachable materials for a wide spectrum, from far infrared to deep UV. Applications include, reversible contrast enhancement layer (R-CEL) in optical lithography, lithography mask inspection and writing and optical storage technologies.

Owner:PIXELLIGENT TECH LLC

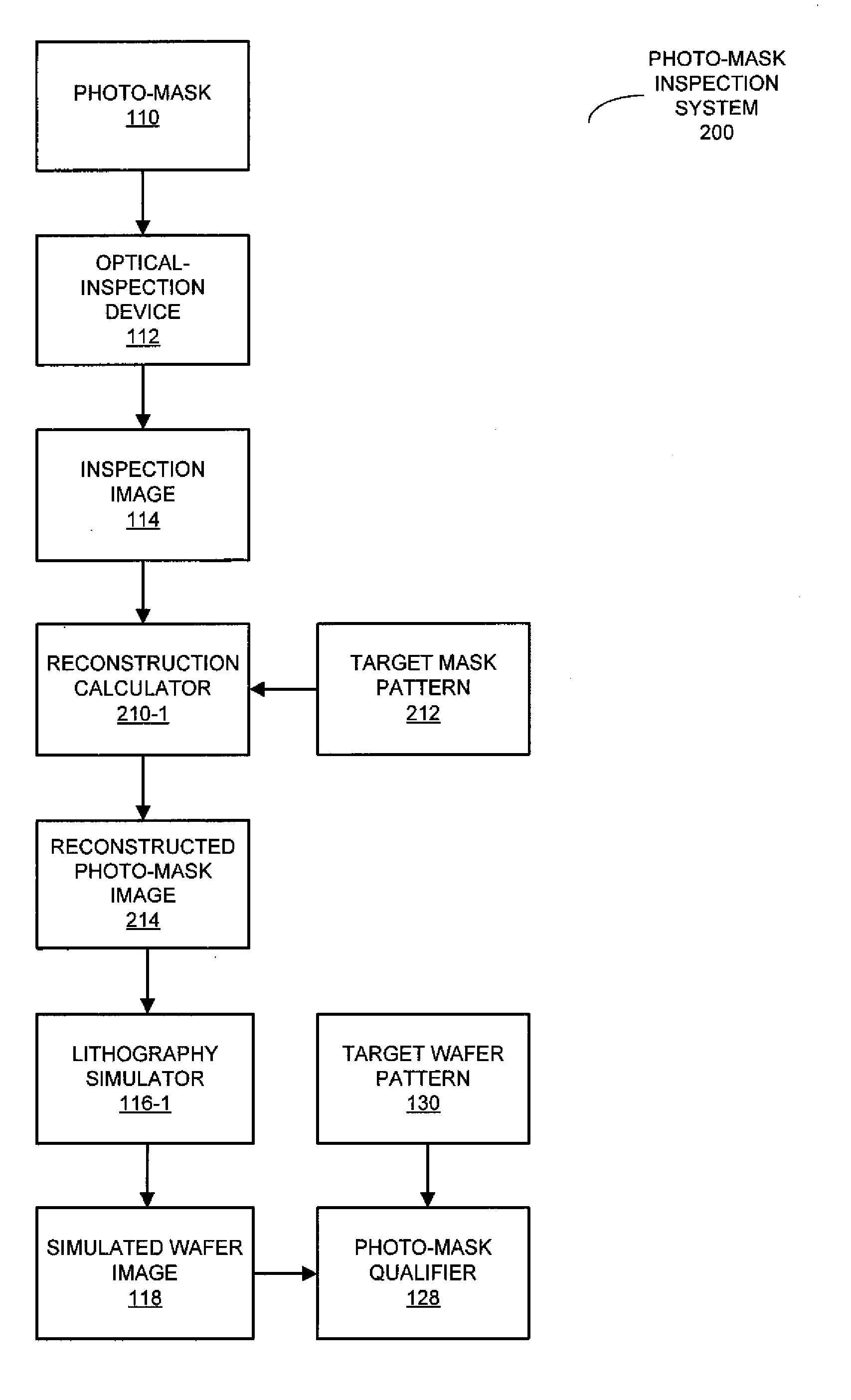

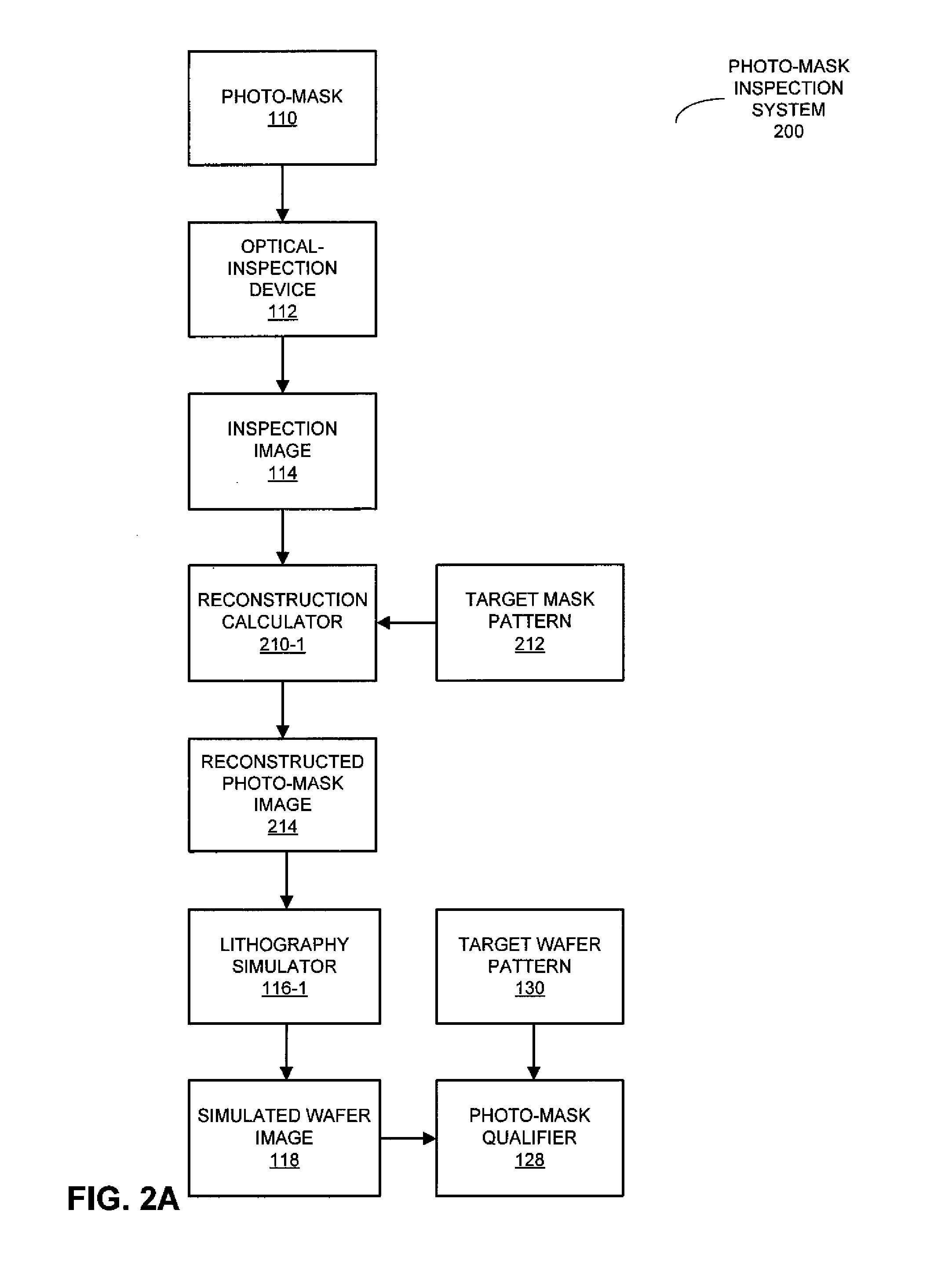

Extending the Field of View of a Mask-Inspection Image

ActiveUS20110194752A1Smooth transitionImage enhancementImage analysisPattern recognitionMask inspection

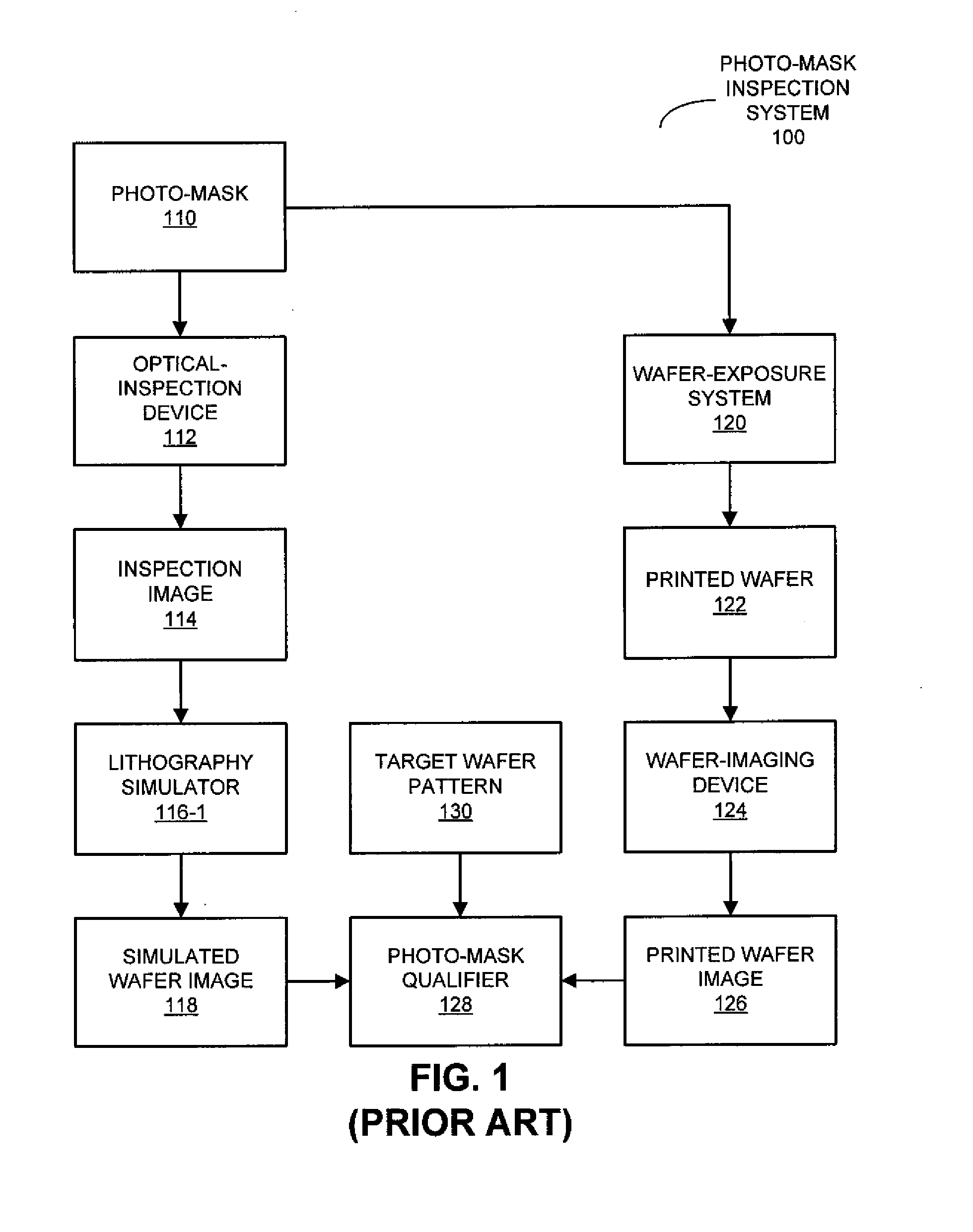

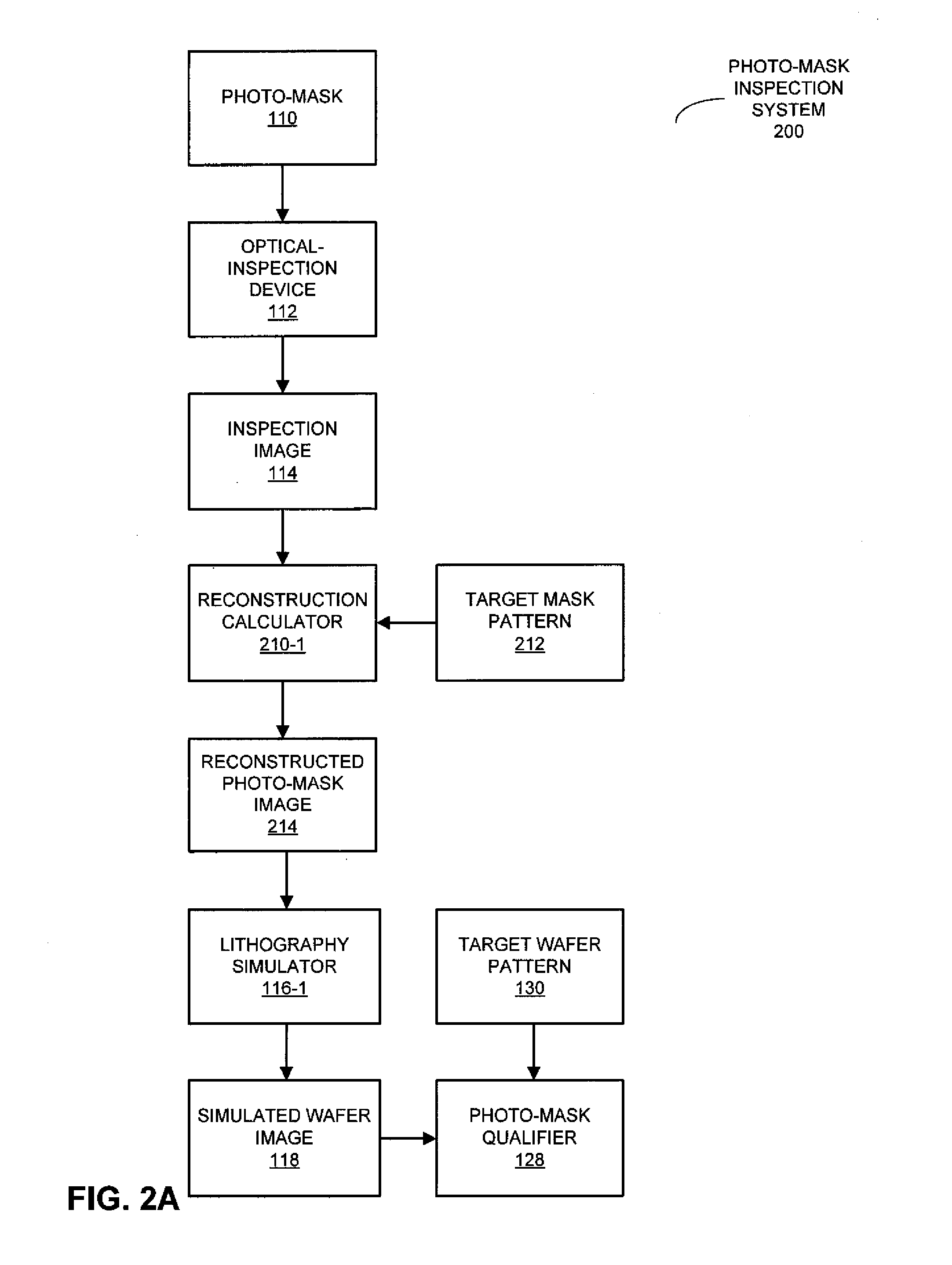

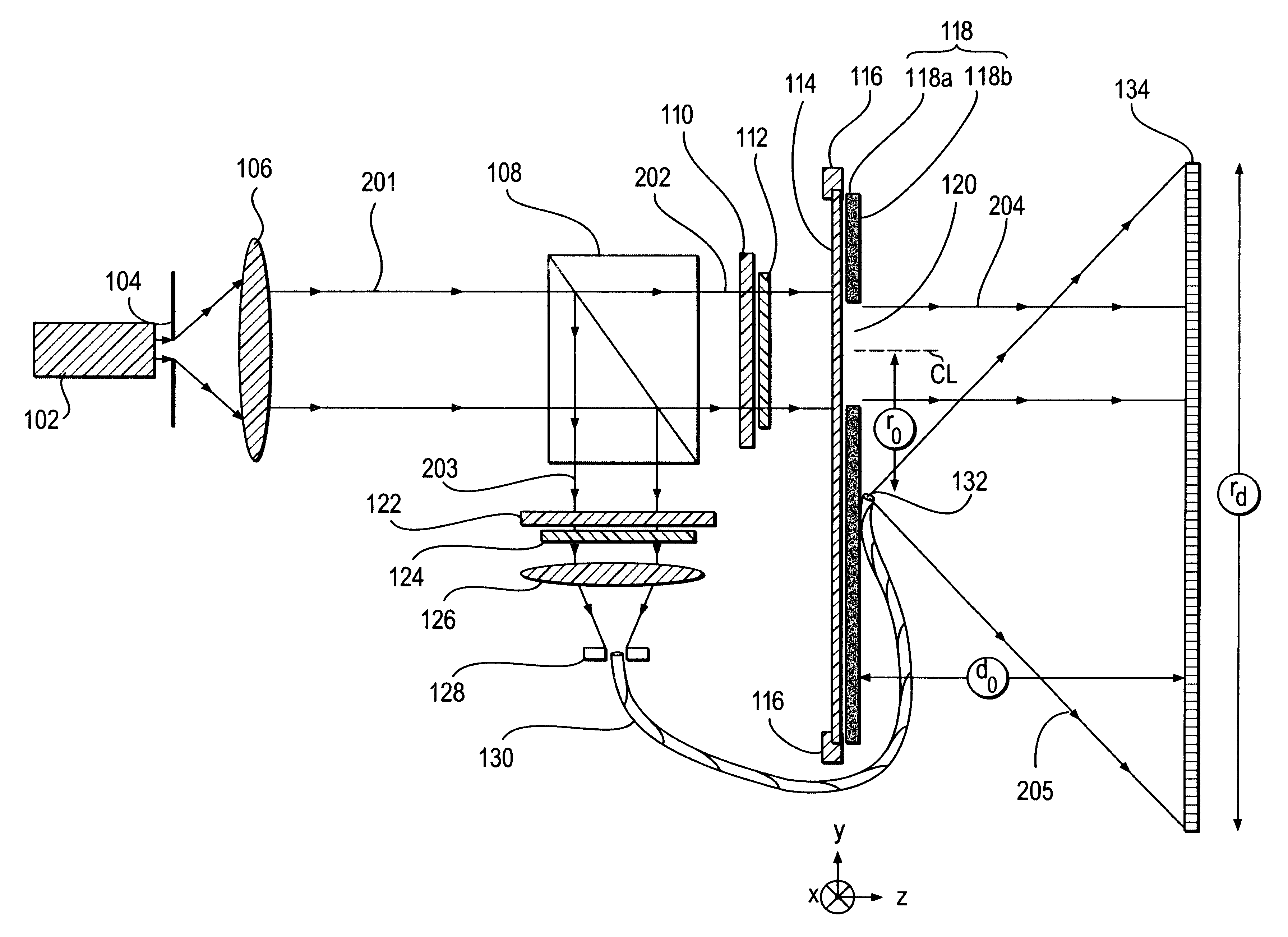

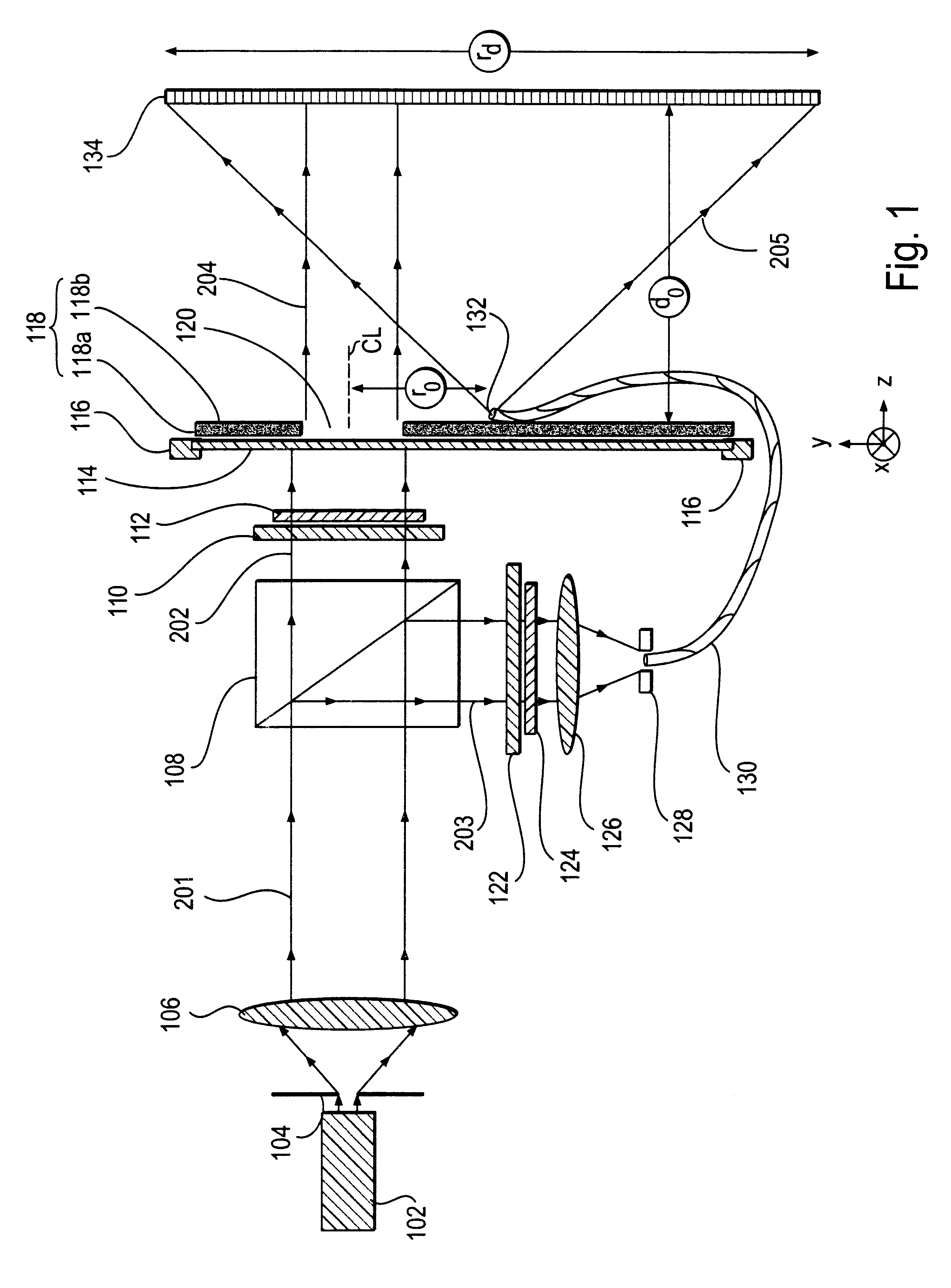

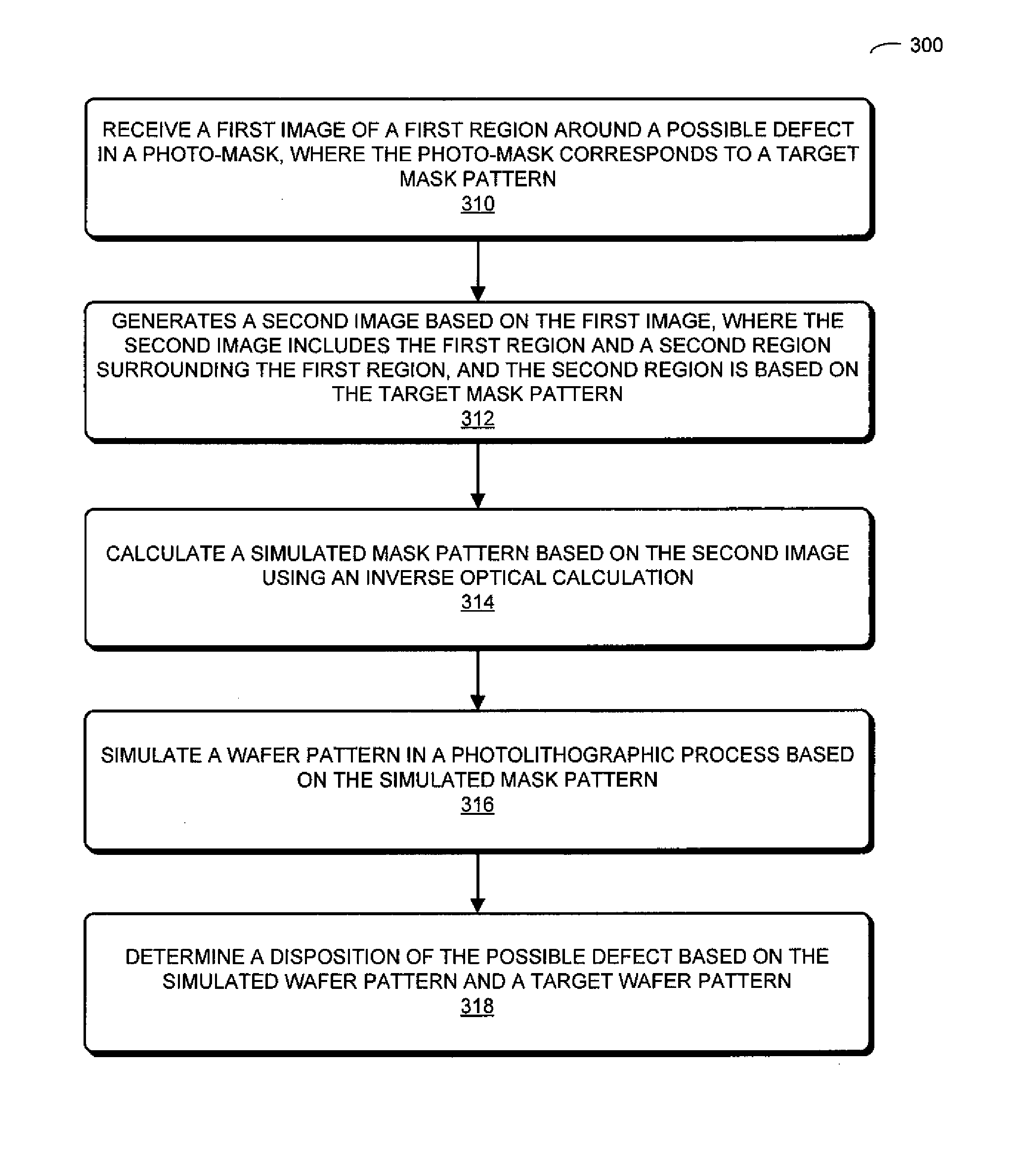

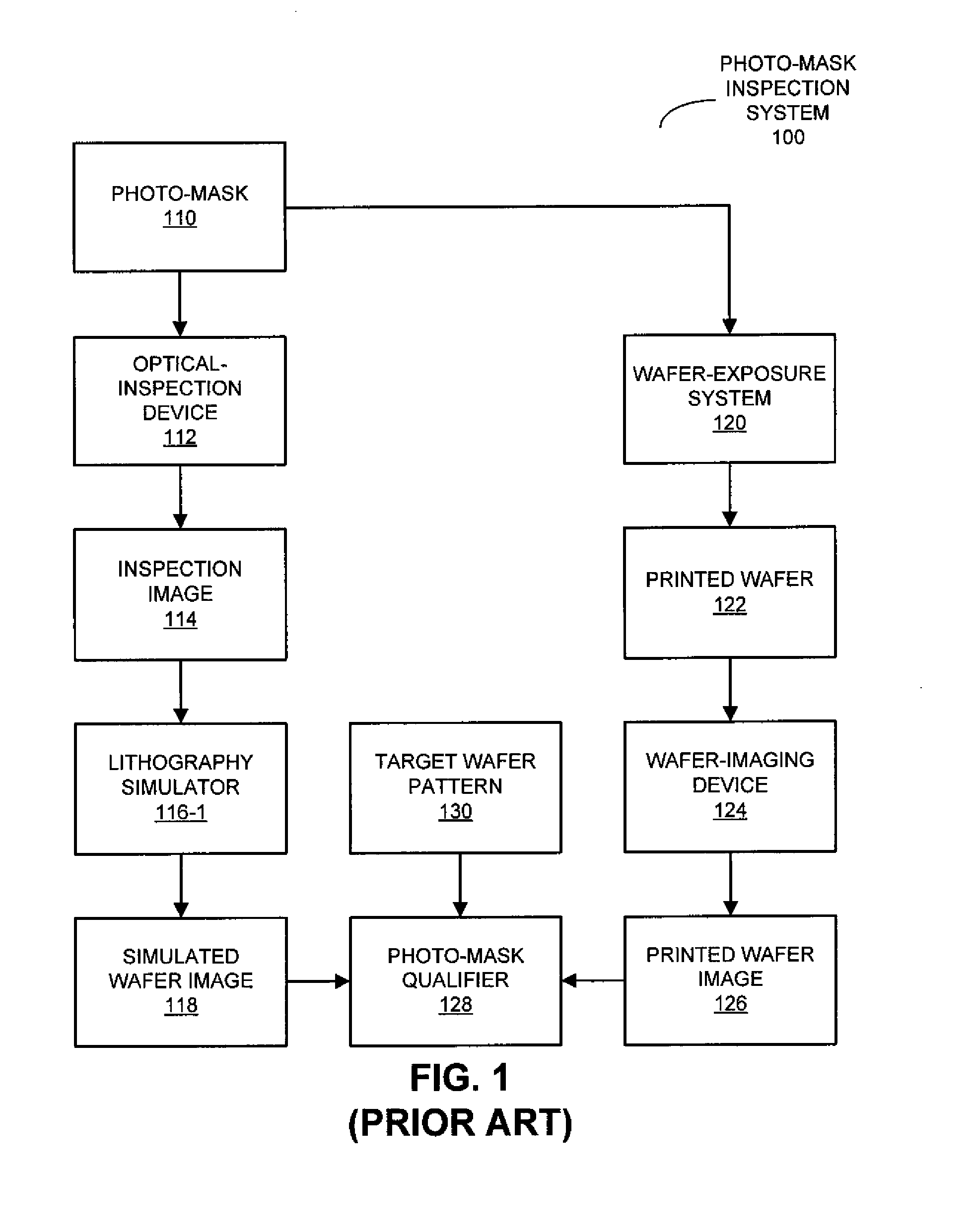

A technique for determining photo-mask defect disposition is described. In this technique, a target mask pattern is used to expand an initial region in a photo-mask that is included in an initial mask-inspection image. In particular, a revised mask-inspection image that includes the initial region and a region surrounding the initial region is generated based on the initial mask-inspection image and the target mask pattern. Then a corresponding simulated mask pattern is calculated in an inverse optical calculation using the revised mask-inspection image and an optical model of the mask-inspection system. This simulated mask pattern is used to simulate a wafer pattern in a photo-lithographic process, and disposition of a possible defect in the initial region is subsequently determined based on the simulated wafer pattern and a target wafer pattern.

Owner:KLA TENCOR TECH CORP

Point diffraction interferometric mask inspection tool and method

InactiveUS6559953B1Using optical meansOriginals for photomechanical treatmentMask inspectionBeam splitter

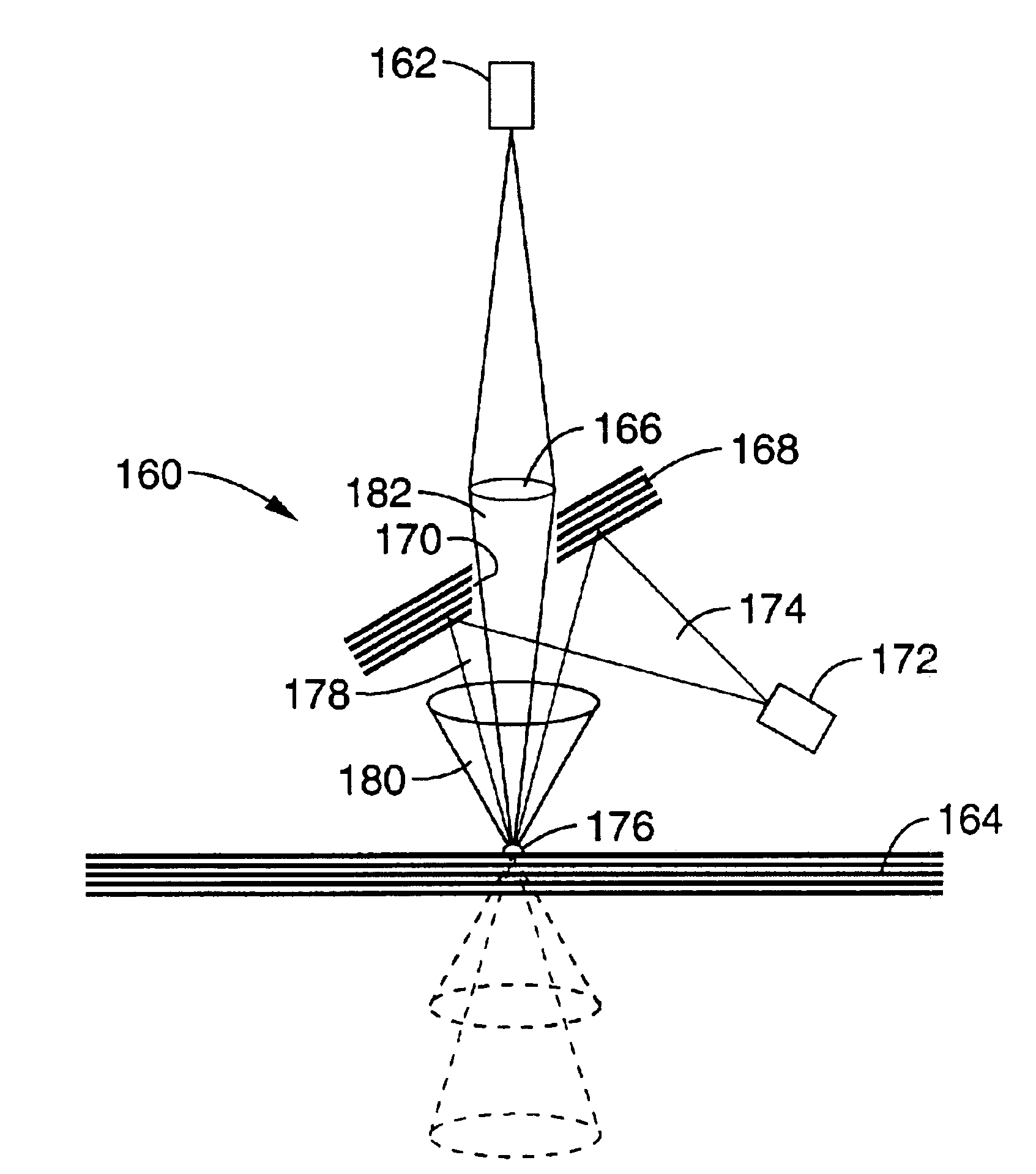

The present invention comprises a tool for and a method of inspecting a mask used in photolithography to determine errors in phase, amplitude, and pattern edges. An embodiment of the tool comprises a laser source, a polarizing beam splitter, a first shutter, a mask, a second shutter, a quarter wave retarder, a single-mode optical fiber, and a CCD detector array. An embodiment of the method comprises four independent measurements of light intensity, comprising: a pattern of a mask, a diffraction pattern of a reference pinhole, an interference pattern of the mask and the reference pinhole, and an interference pattern of the mask and the reference pinhole with a known phase difference. Calculations are performed to determine phase and amplitude information as a function of location on the mask. The phase and amplitude information is then compared with a design layout of the mask to determine pattern edge information and identify possible defects in the mask.

Owner:INTEL CORP

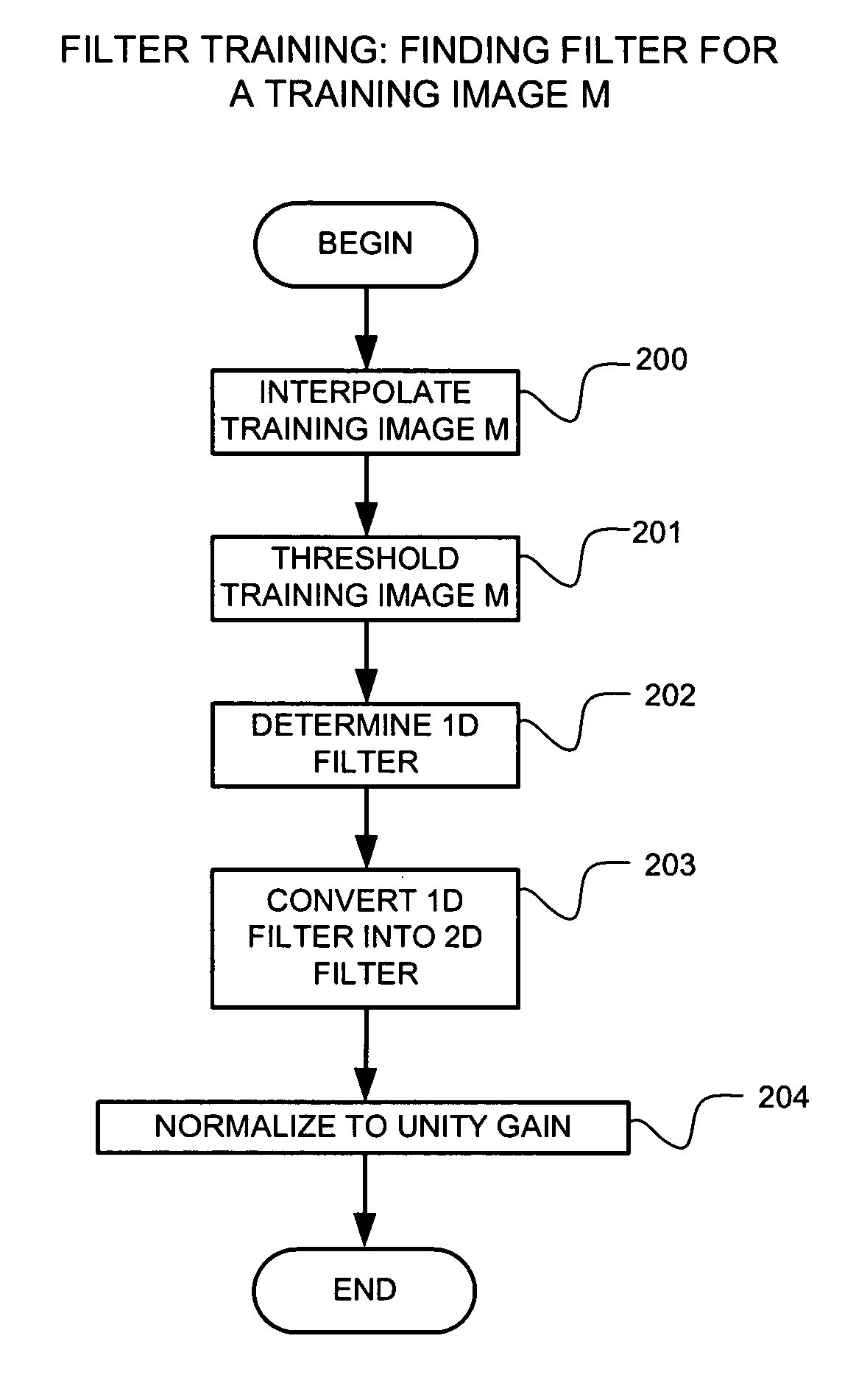

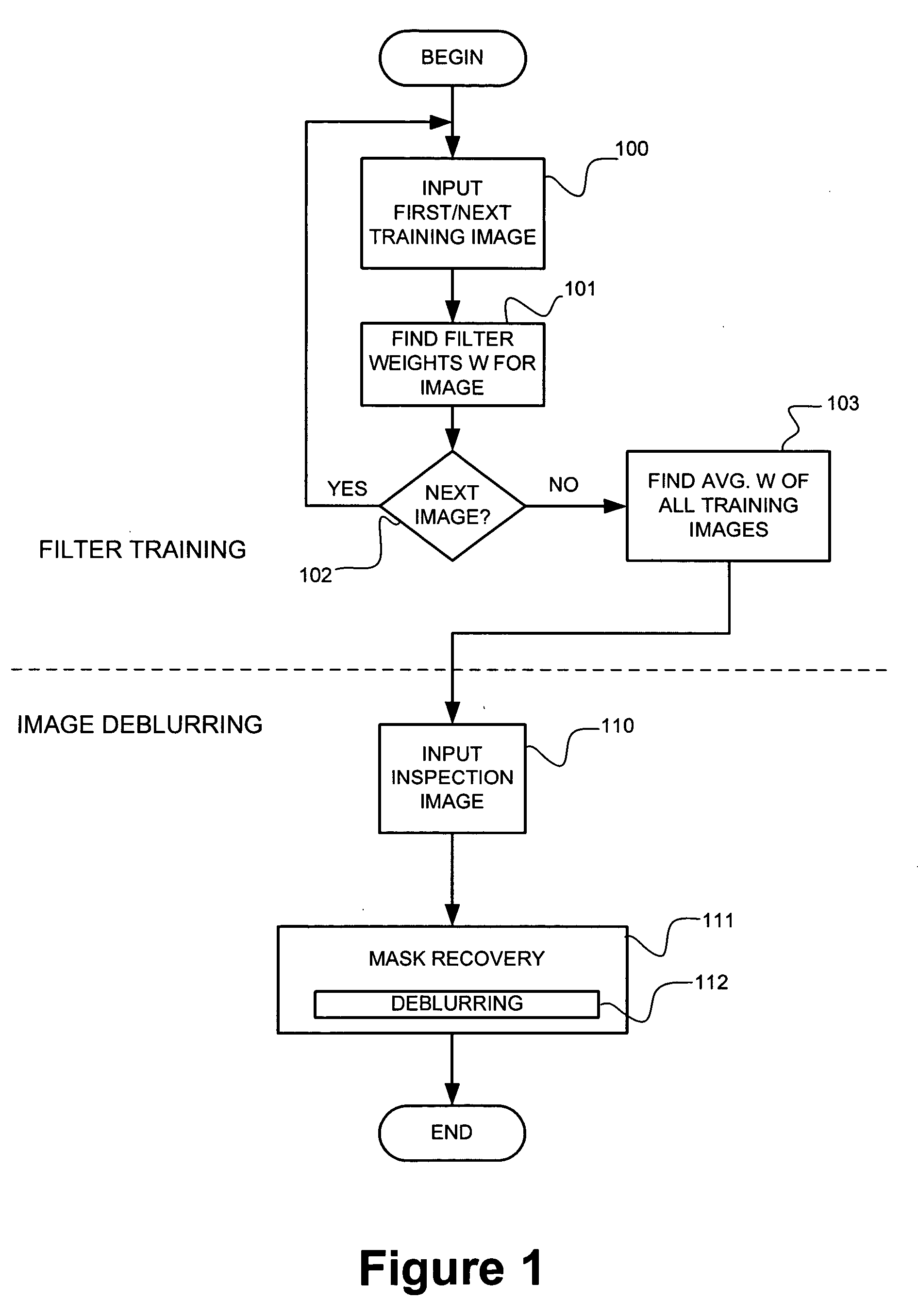

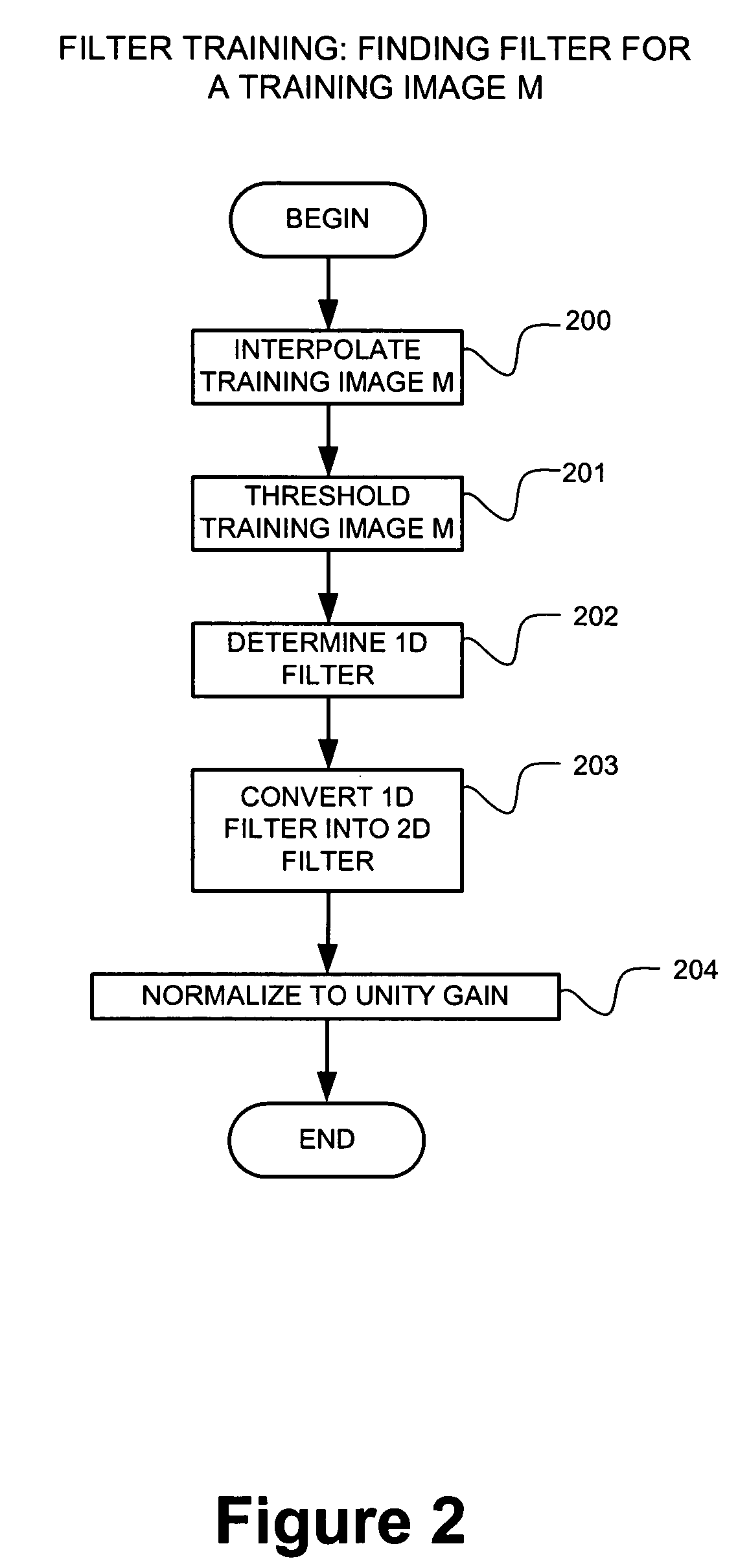

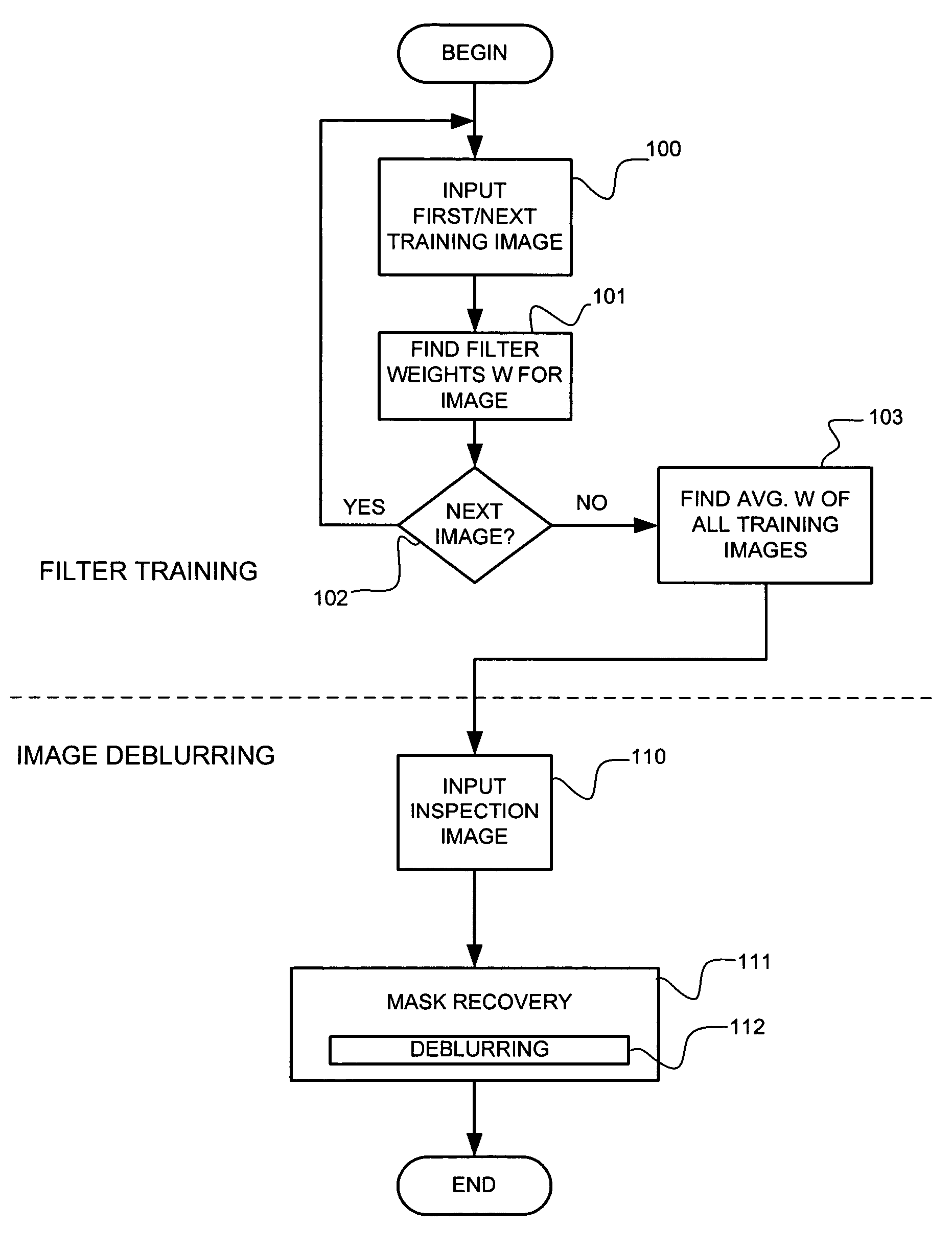

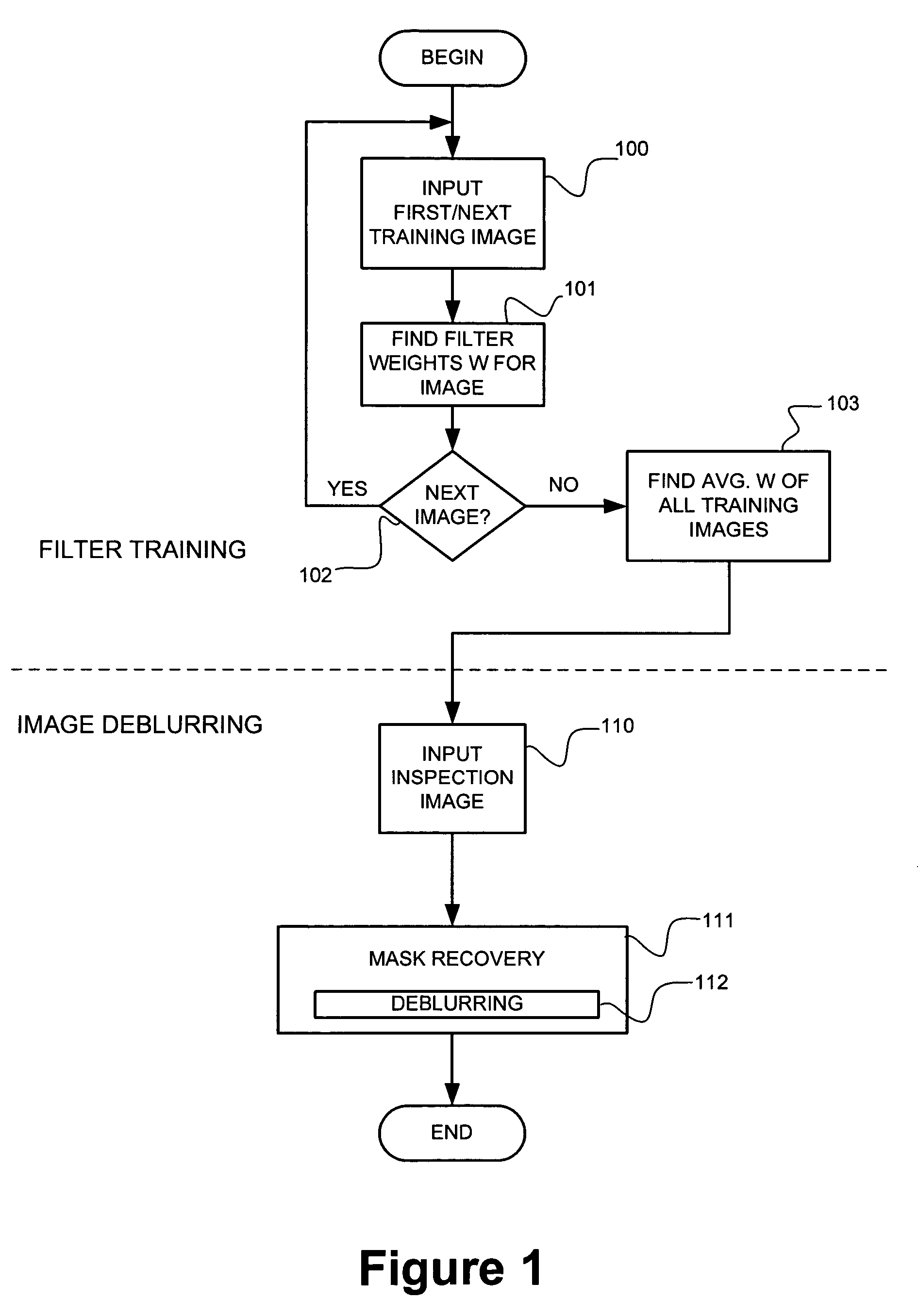

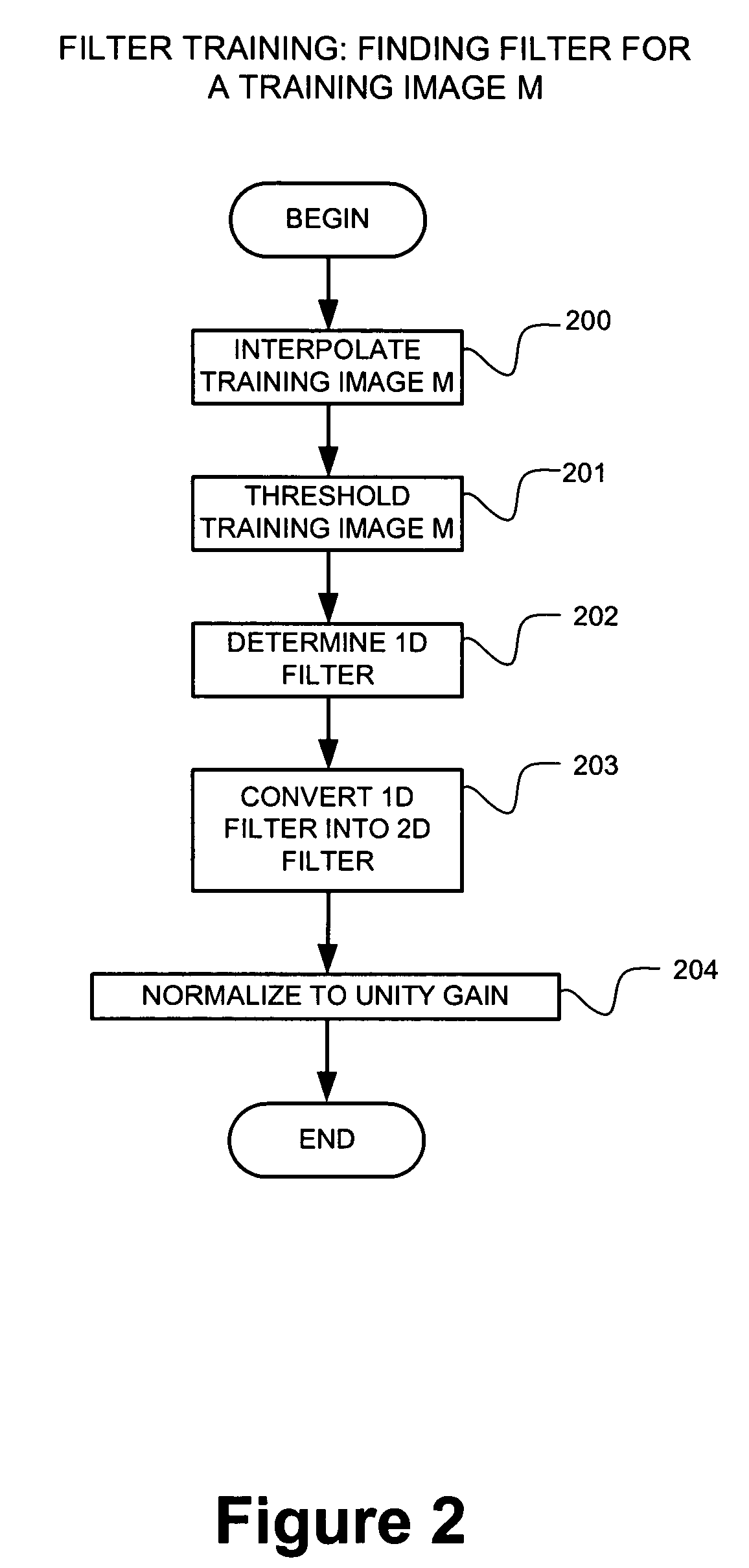

Method and apparatus for deblurring mask images

ActiveUS20060034505A1Reduce distortion problemsError minimizationImage enhancementImage analysisMask inspectionAdaptive filter

The invention comprises processes for determining and applying a deblurring filter that reduces inspection system distortion, of mask inspection images, by compensating for the non-uniform frequency response of the inspection system. In particular, an adaptive filter is determined empirically for an inspection system: one or more training images are obtained by the inspection system and the filter is determined from such images. In this way, the filter can adapt to the characteristics of each individual inspection system. An example adaptive filter, known as a Weiner filter, is determined and applied.

Owner:SYNOPSYS INC

Method and System for Context-Specific Mask Inspection

InactiveUS20070233419A1Measurement arrangements for variableDigital computer detailsMask inspectionLithographic artist

Owner:CADENCE DESIGN SYST INC

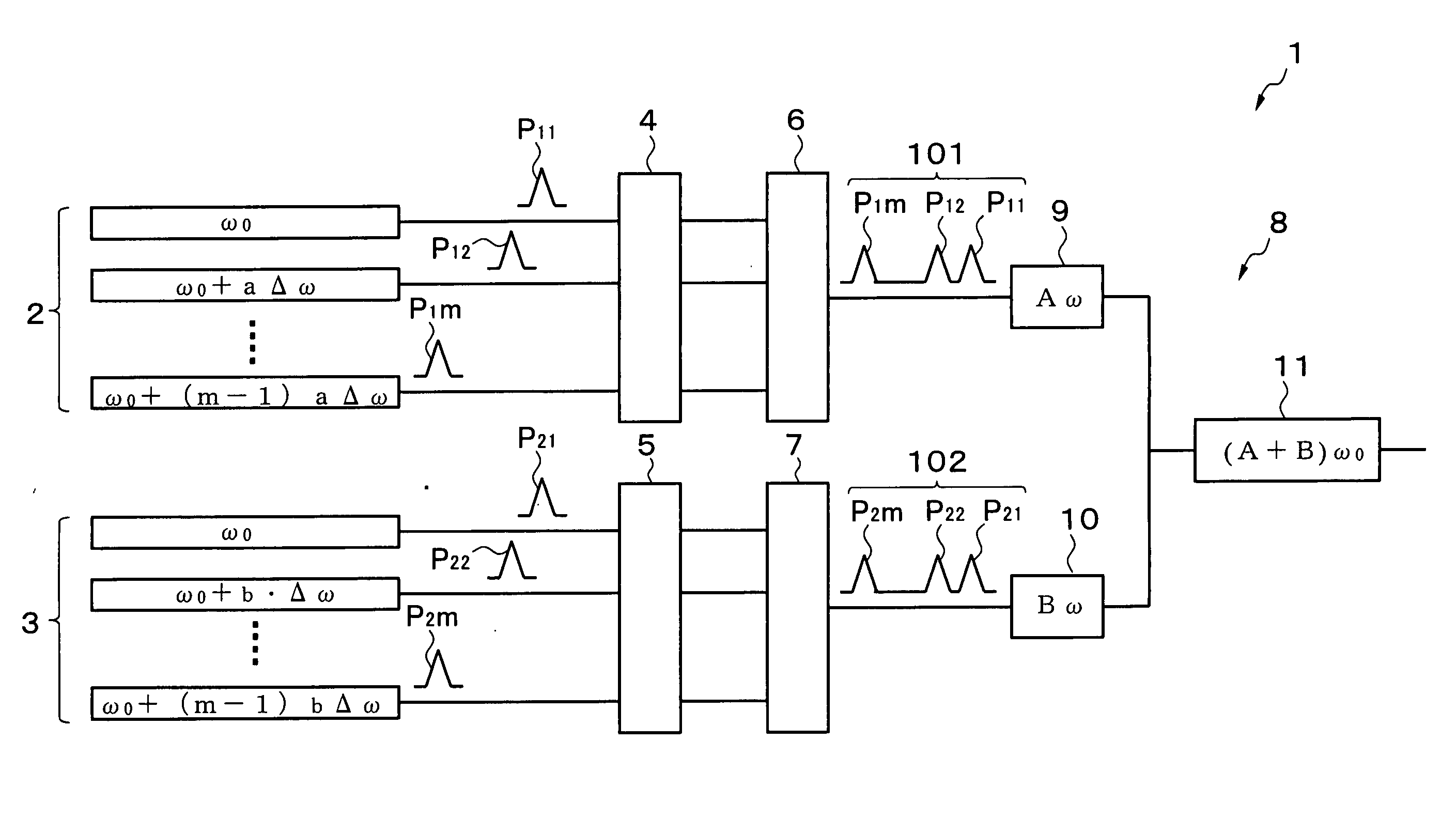

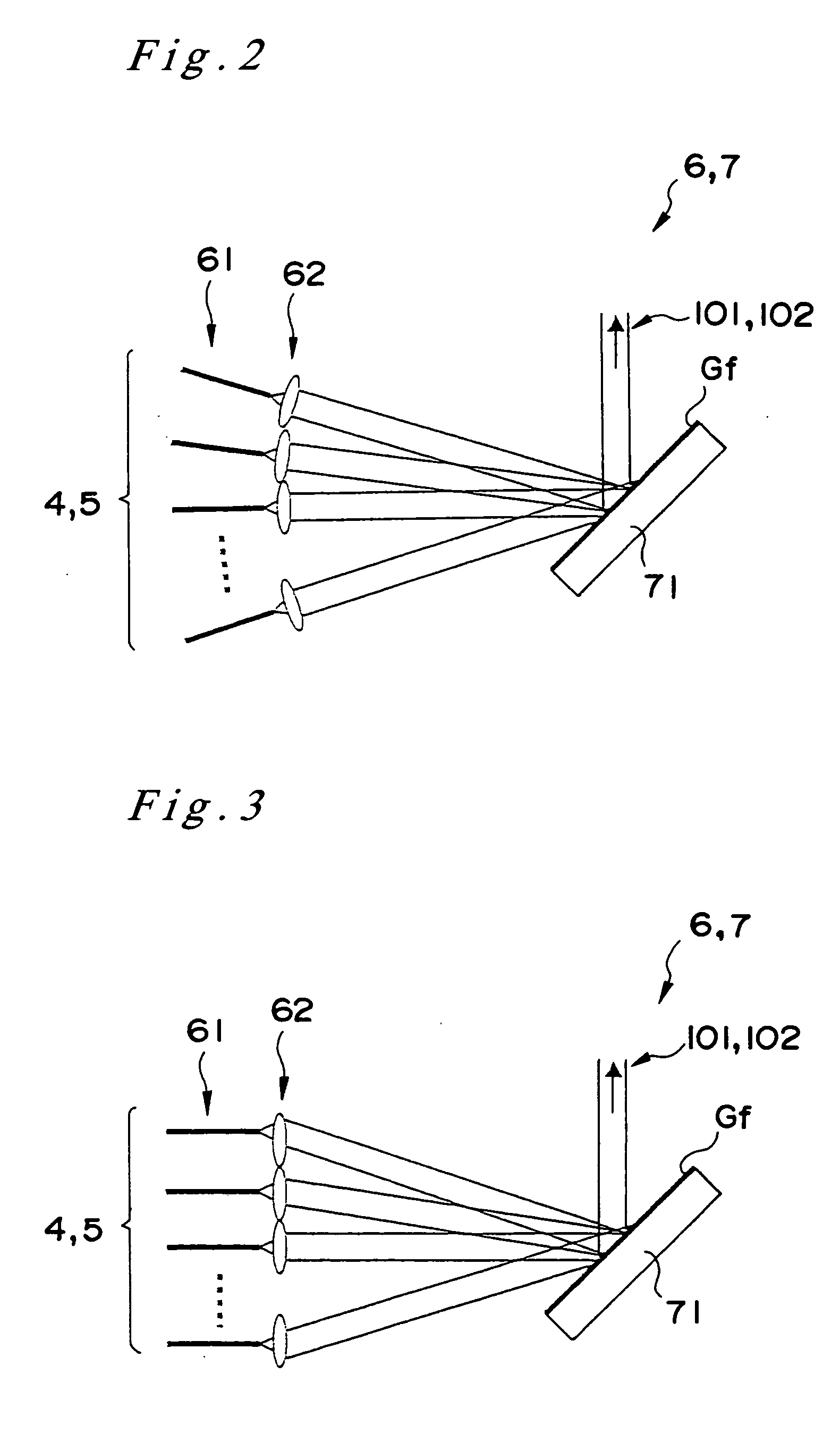

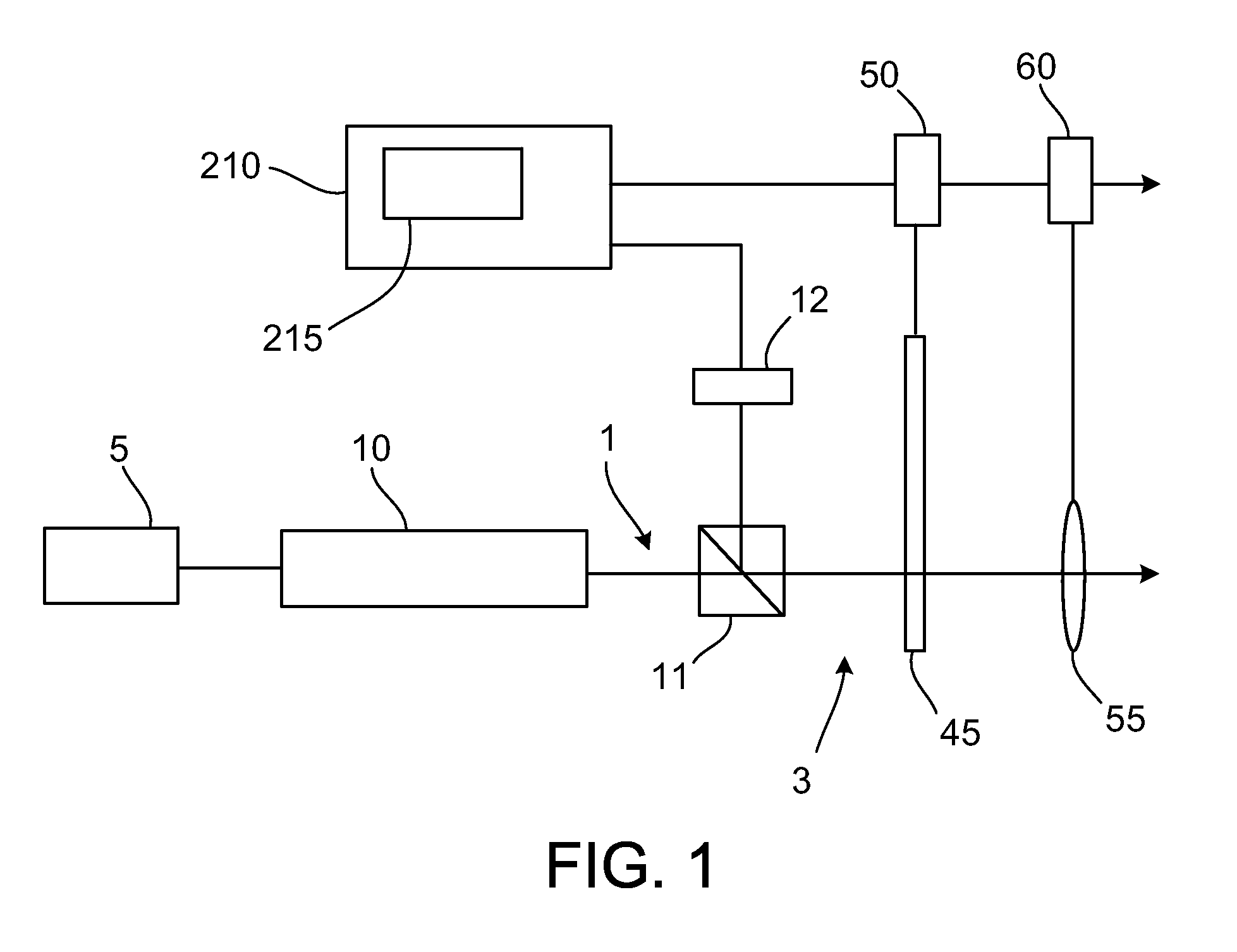

Laser light source device, exposure device, and mask inspection device using this laser light source device

InactiveUS20060291862A1Easy to integrateValid conversionTime-division optical multiplex systemsWavelength-division multiplex systemsMask inspectionMultiplexer

A laser light source device 1, comprising M number of laser light sources, of which frequency is shifted from a fundamental frequency by (m−1)·a·Δω, a first laser light source section 2 and a first fiber amplifier section 4 for amplifying these laser lights, a first optical multiplexer 6 for approximately coaxially superimposing the laser lights emitted from the first fiber amplifier section 4 and emitting the laser lights, a first wavelength conversion device 9 for multiplying the frequency of the laser lights emitted from the first optical multiplexer 6 by A, M number of laser light sources, of which frequency is shifted from the fundamental frequency by (m−1)·b·Δω, a second laser light source section 3 and a second fiber amplifier section 5 for amplifying these laser lights, a second optical multiplexer 7 for approximately coaxially superimposing the laser lights emitted from the second fiber amplifier section 5 and emitting the laser lights, a second wavelength conversion device 10 for multiplying the frequency of the laser lights emitted from the second optical multiplexer 7 by B, and a third wavelength conversion device 11 for simultaneously receiving the laser lights emitted from the first and second wavelength conversion devices 9 and 10 and converting the laser lights into laser lights, of which frequency is (A+B) times the fundamental frequency, the laser light source device 1 being characterized in that the expression A·a+B·b=0 is satisfied.

Owner:NIKON CORP

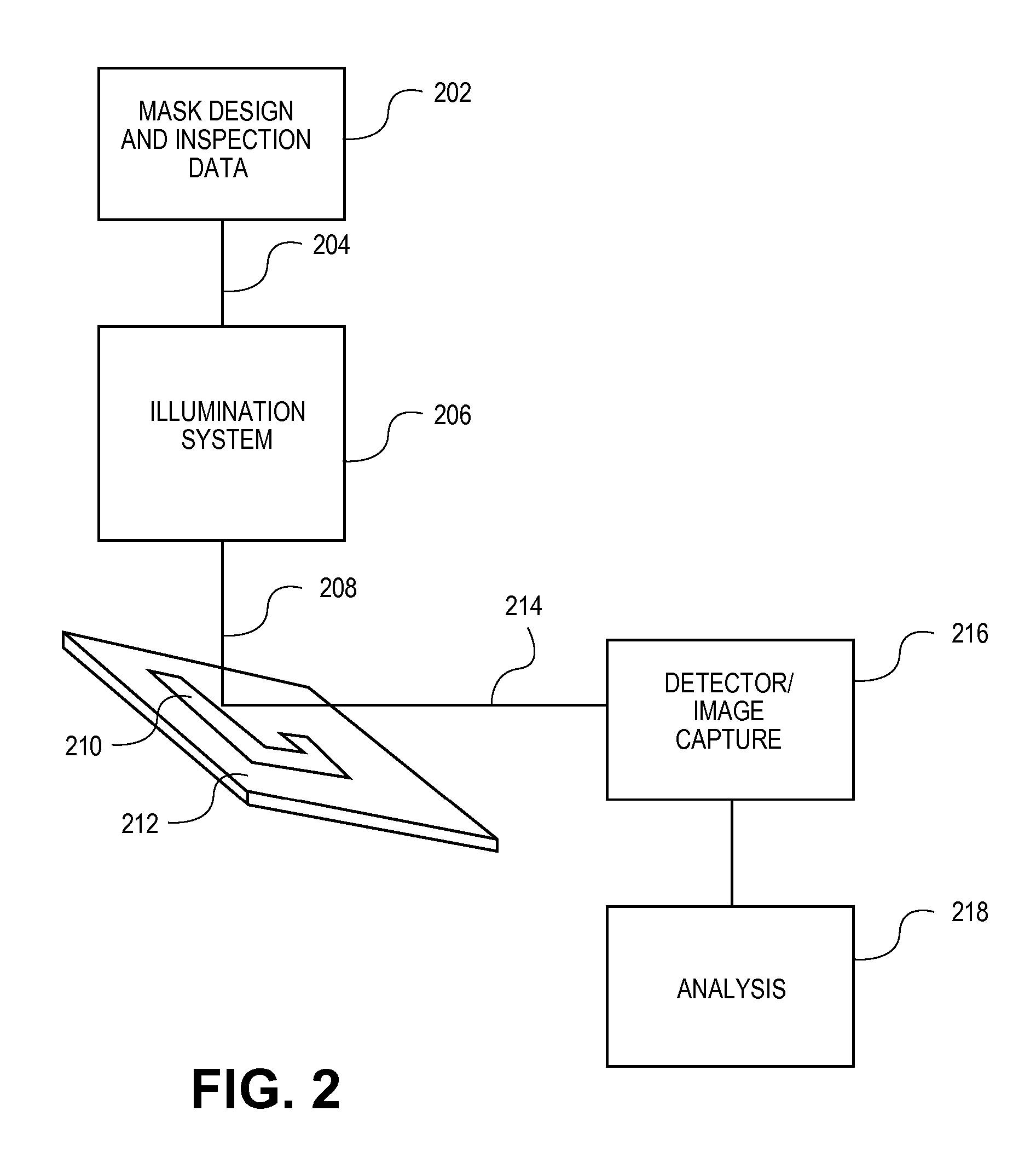

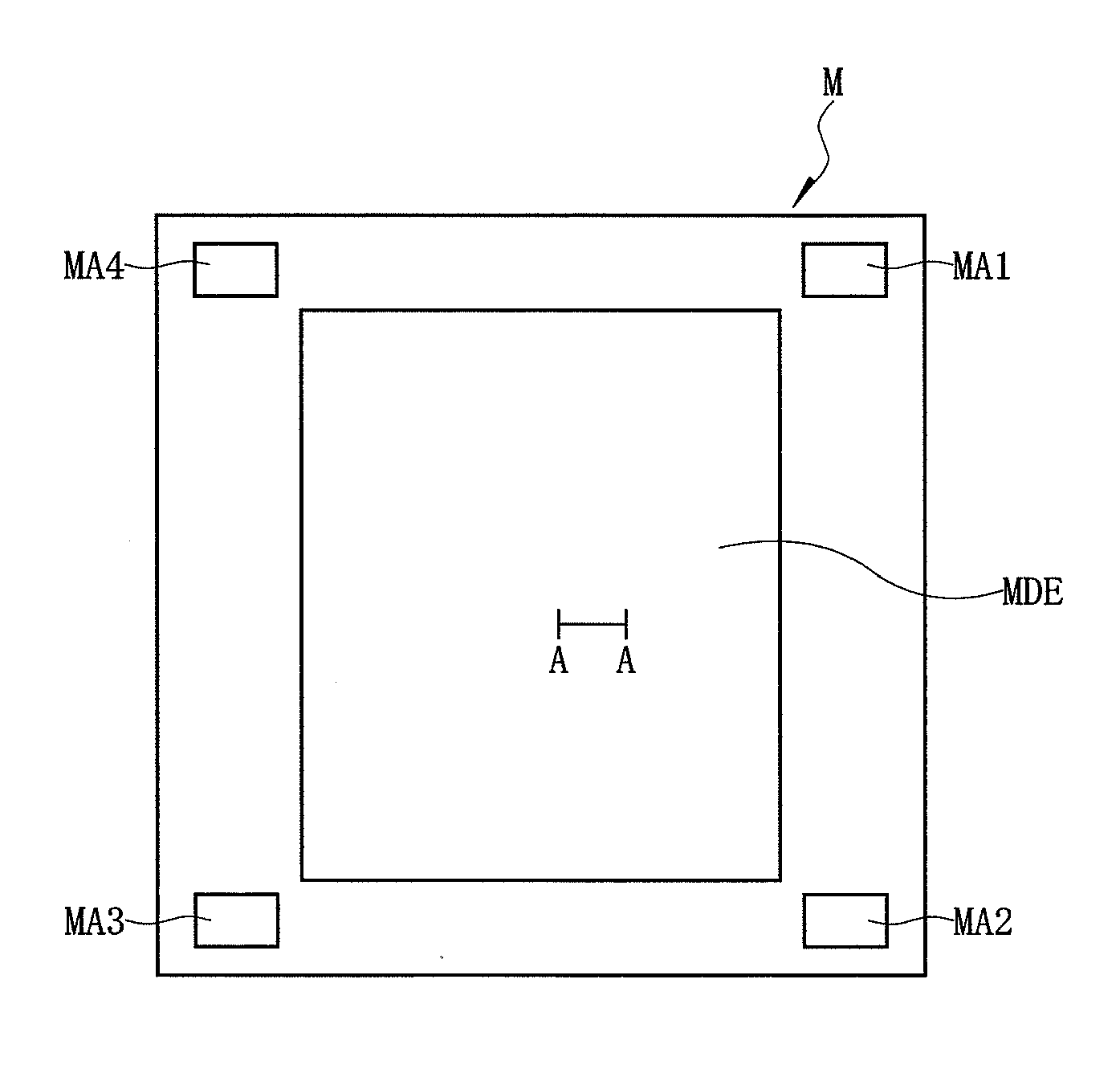

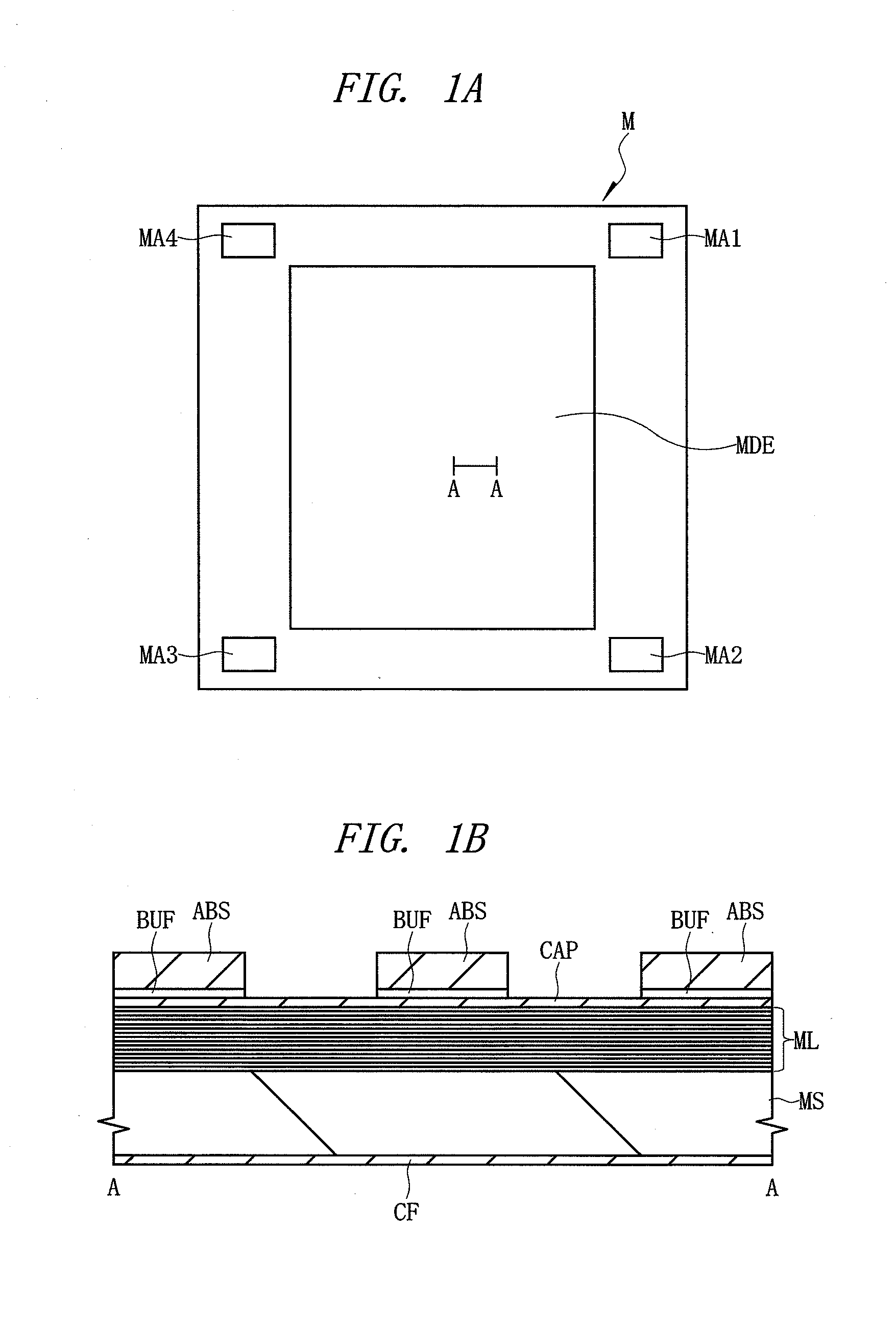

Method of inspecting mask, mask inspection device, and method of manufacturing mask

ActiveUS20130017475A1Increase background levelLow detection sensitivityOptically investigating flaws/contaminationOriginals for photomechanical treatmentMask inspectionIlluminance

There is provided a method of high-sensitively detecting both of a phase defect existing in a mask blank and a phase defect remaining after manufacturing an EUVL mask. When the mask blank is inspected, EUV light having illumination NA to be within an inner NA but a larger value is irradiated. When the EUVL mask is inspected, by using a dark-field imaging optical system including a center shielding portion for shielding EUV light and a linear shielding portion for shielding the EUV light whose width is smaller than a diameter of the center shielding portion, the center shielding portion and the linear shielding portion being included in a pupil plane, the EUV light having illumination NA as large as or smaller than the width of the linear shielding portion is irradiated.

Owner:RENESAS ELECTRONICS CORP

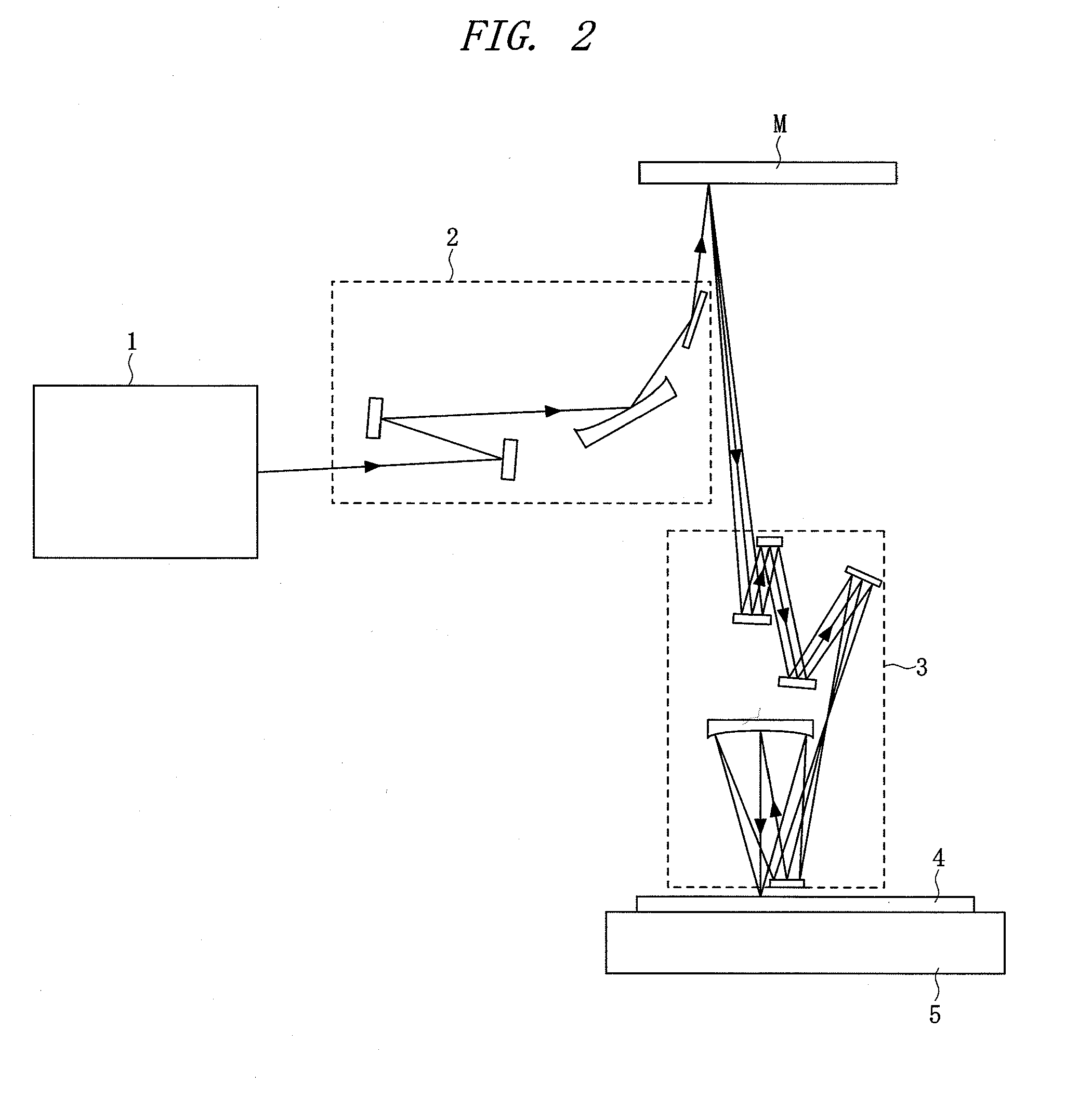

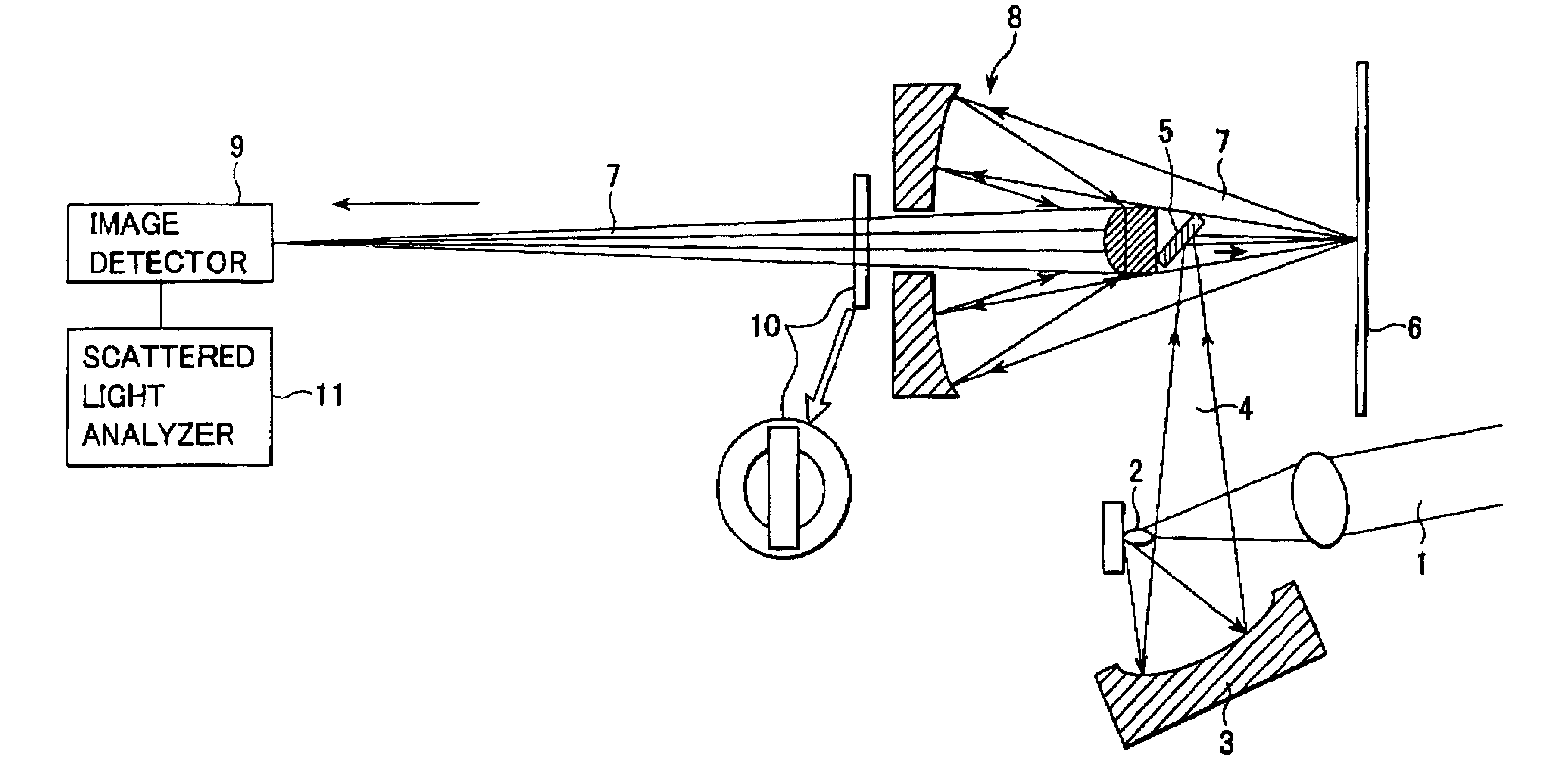

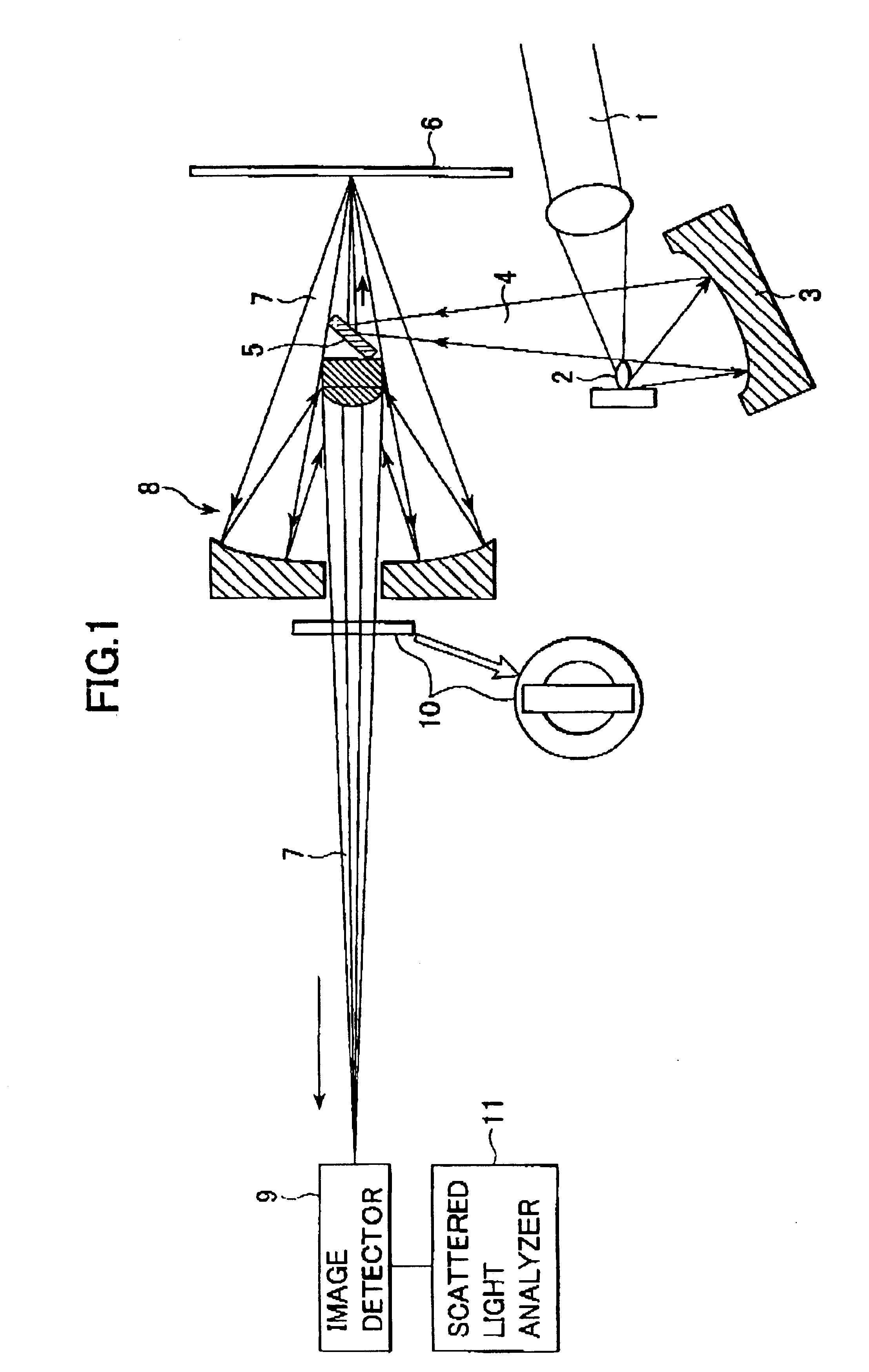

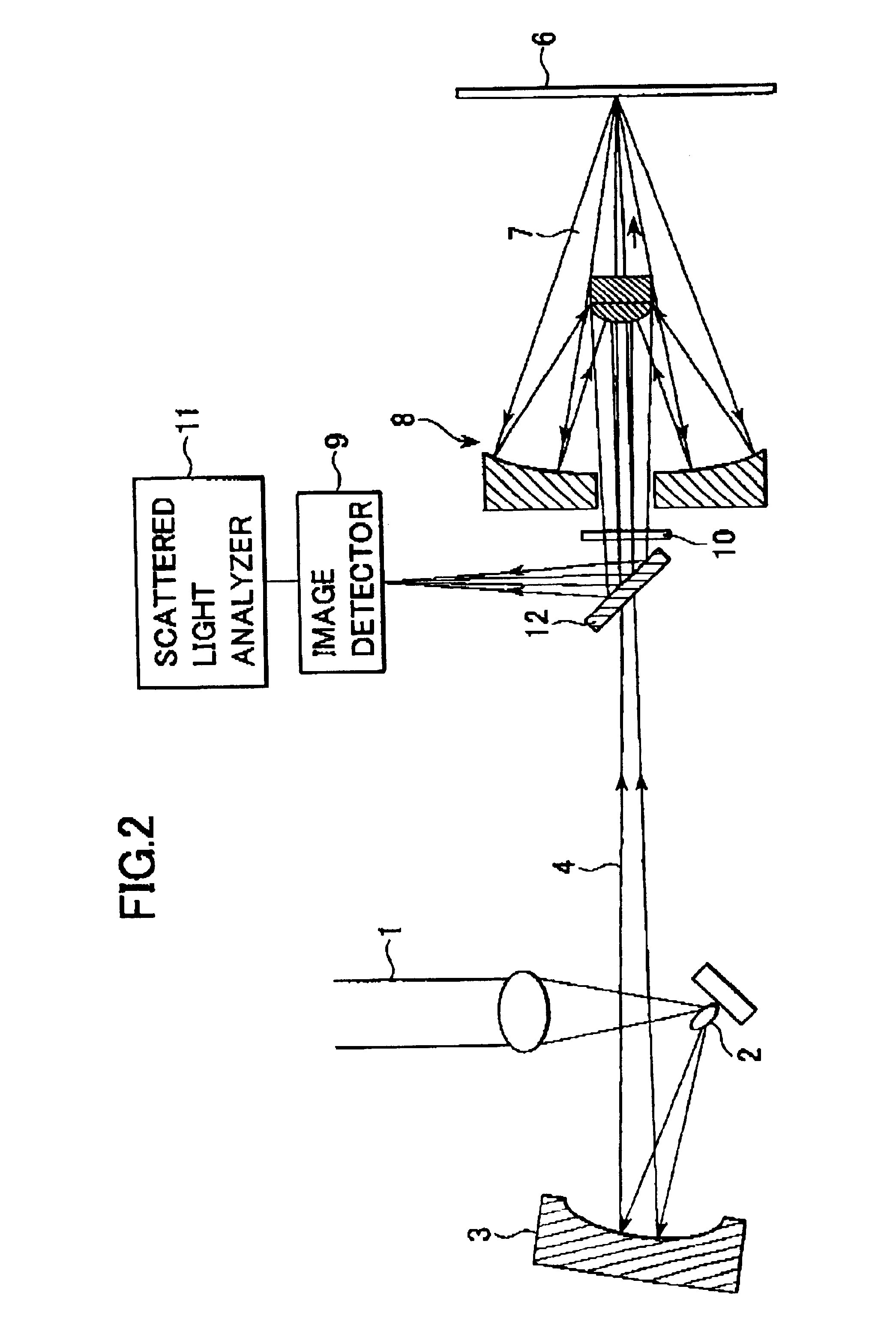

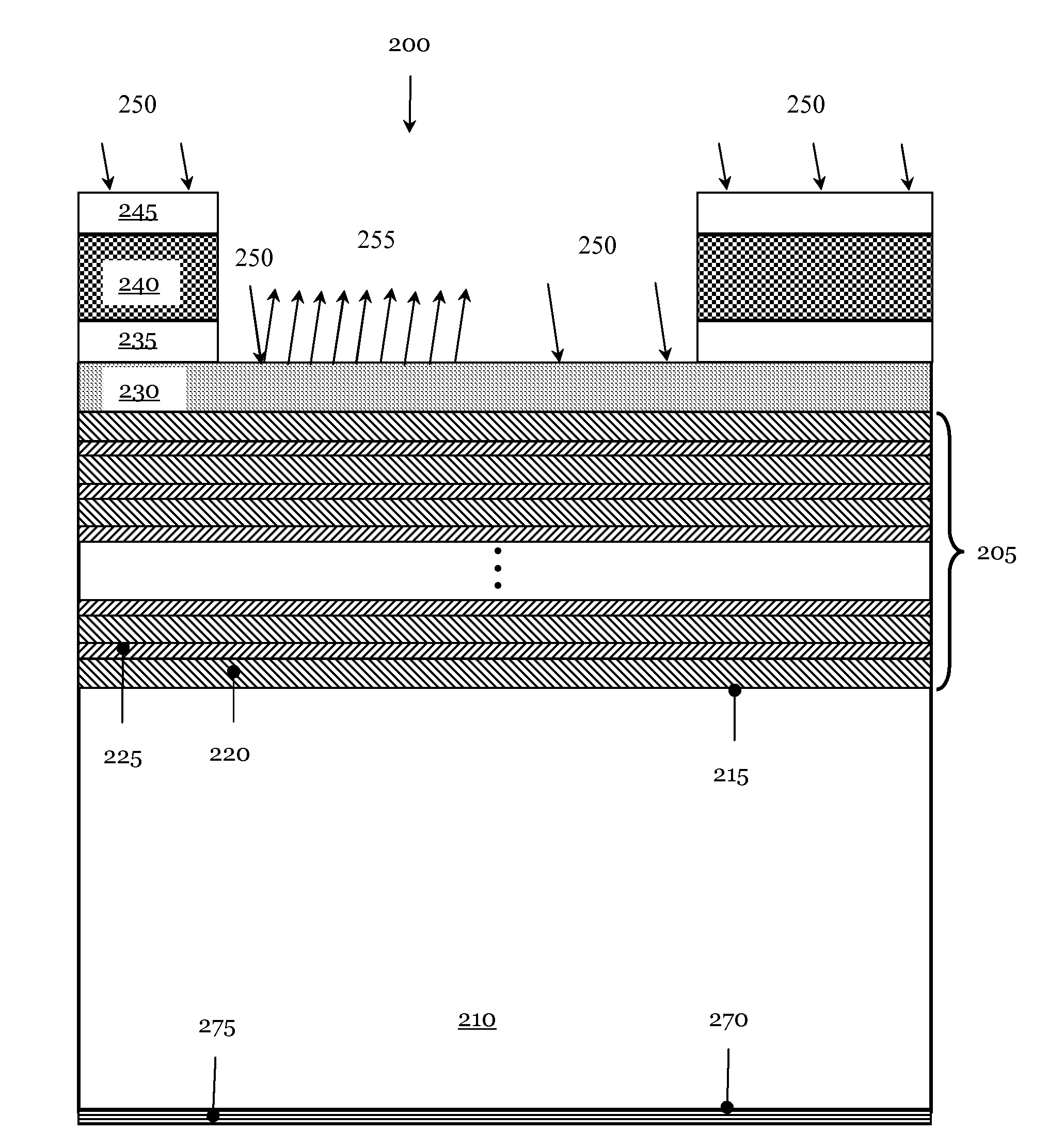

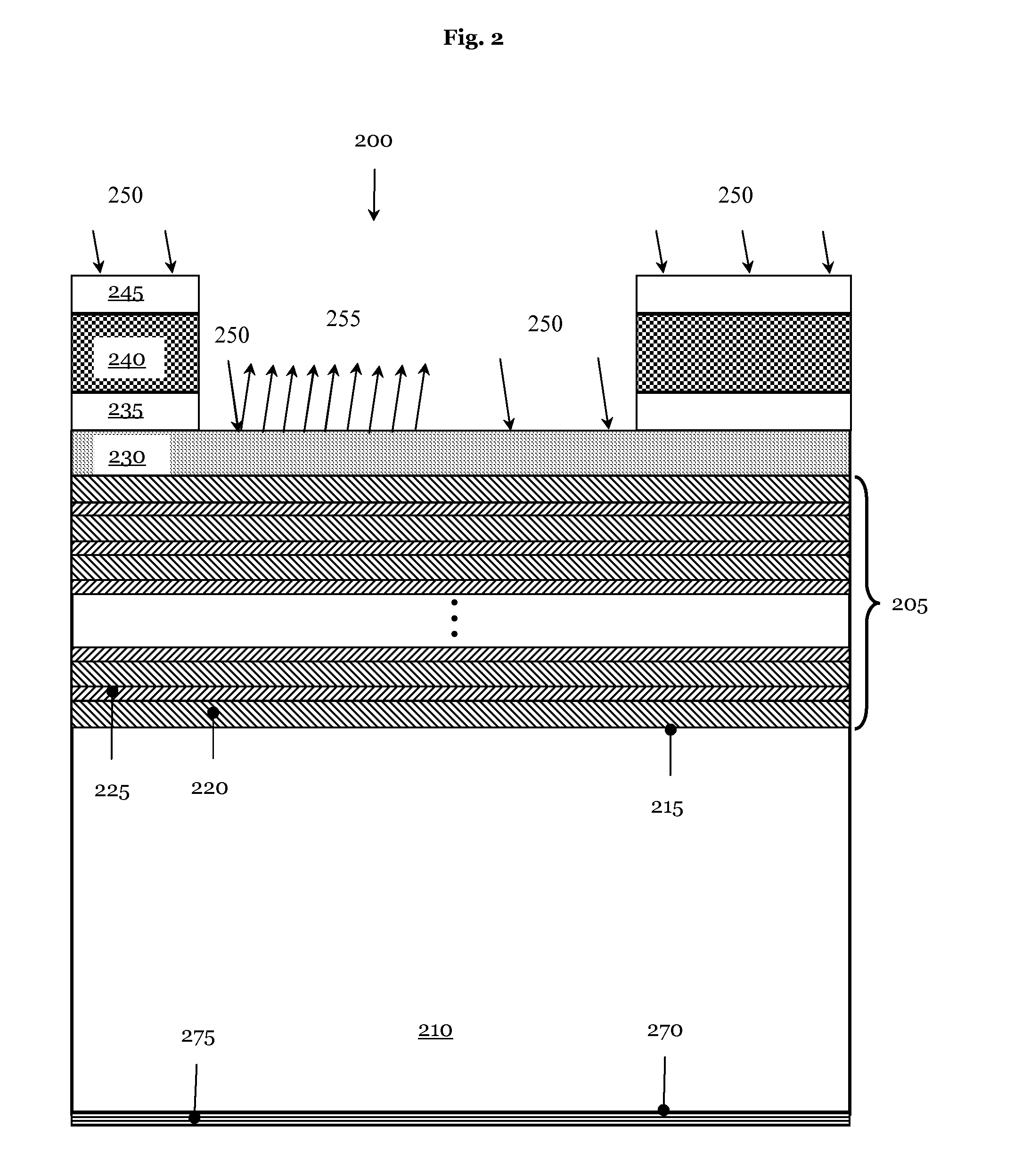

Method and apparatus for inspecting multilayer masks for defects

InactiveUS6954266B2MoreLarge magnificationPhotometrySemiconductor/solid-state device manufacturingMask inspectionImage formation

A method for inspecting multilayer masks to detect any defects includes illuminating a pixel region on a mask to be inspected, using illuminating light having a peak wavelength that is close to that of light reflected by the mask. The illuminating light specularly reflected by the mask is blocked. Scattered reflected illuminating light is collected and used to form an enlarged image. An image detector having a large plurality of pixels is used to observe the enlarged image to detect whether there are defects on the mask. The method is implemented using an mask inspection apparatus including a plasma light source for generating radiant rays, an illuminating light collecting optical system that collects radiated light from the light source for enlarged image formation illumination of a subject inspection region, a Schwarzschild optical system including convex and concave mirrors for collecting scattered light from the subject inspection region and forming an enlarged image of the inspection region, an image detector having a large plurality of pixels for recording the enlarged image that is obtained, and an analyzer that analyzes the images obtained to determine whether there is a defect.

Owner:NAT INST OF ADVANCED IND SCI & TECH

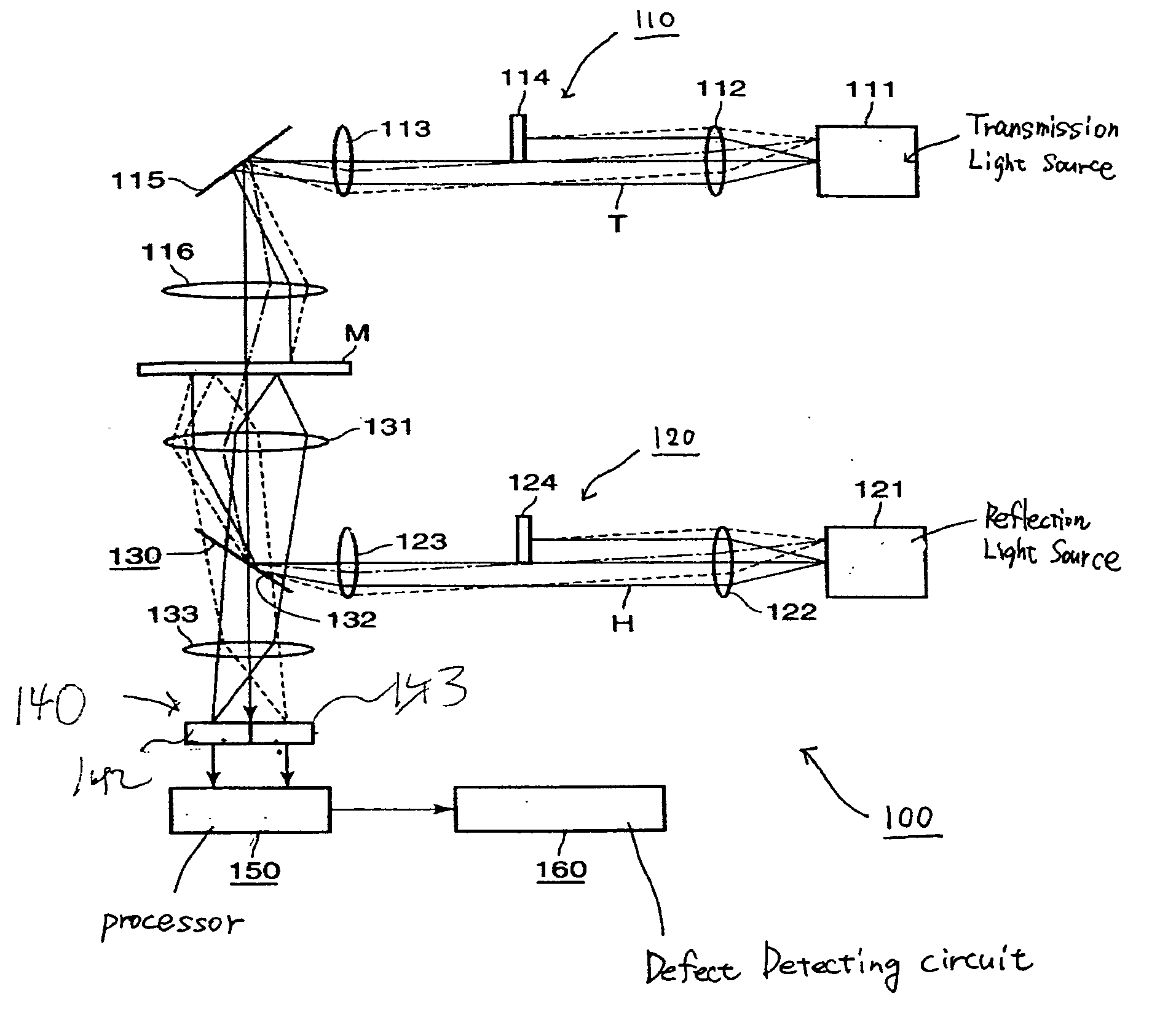

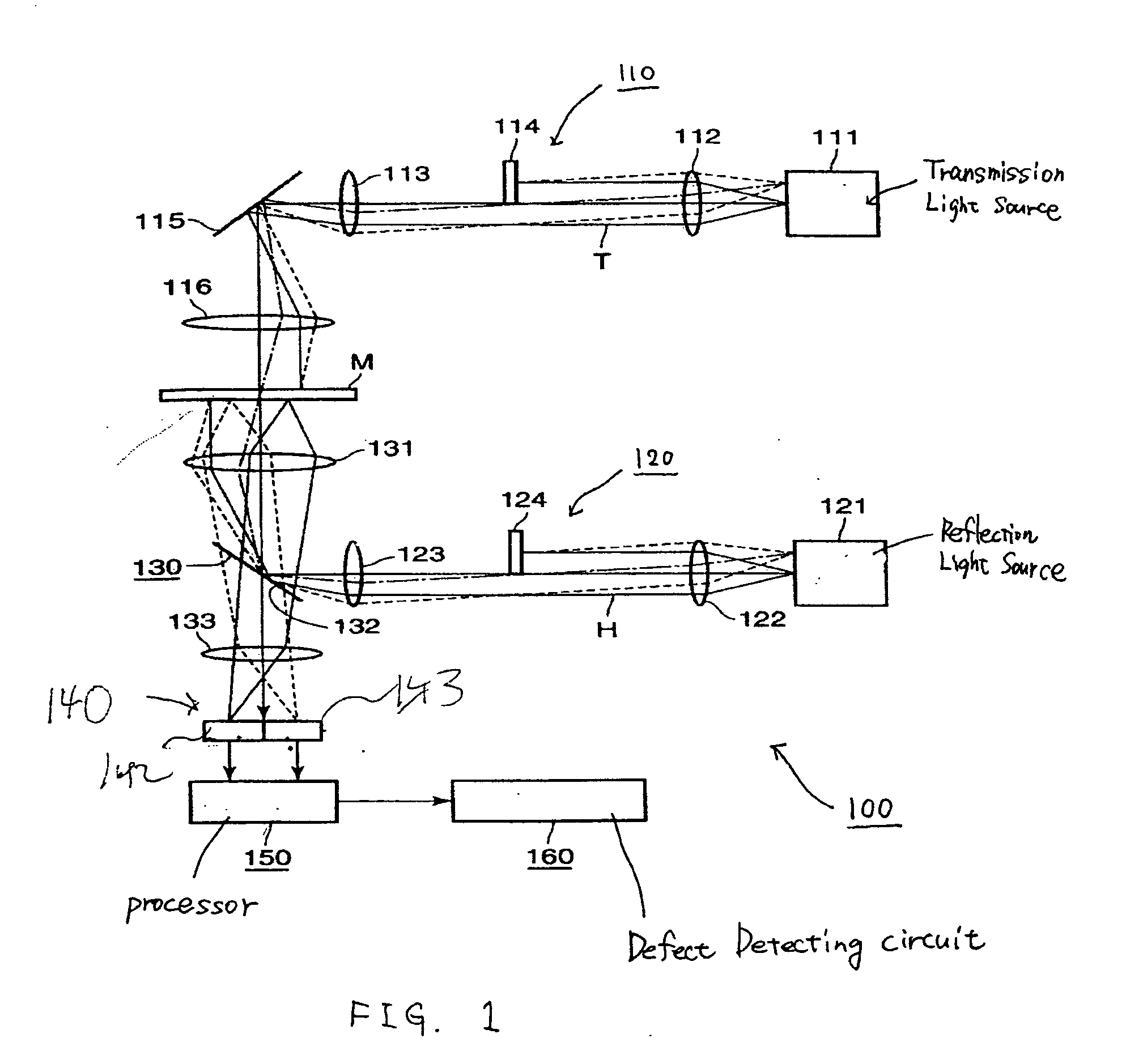

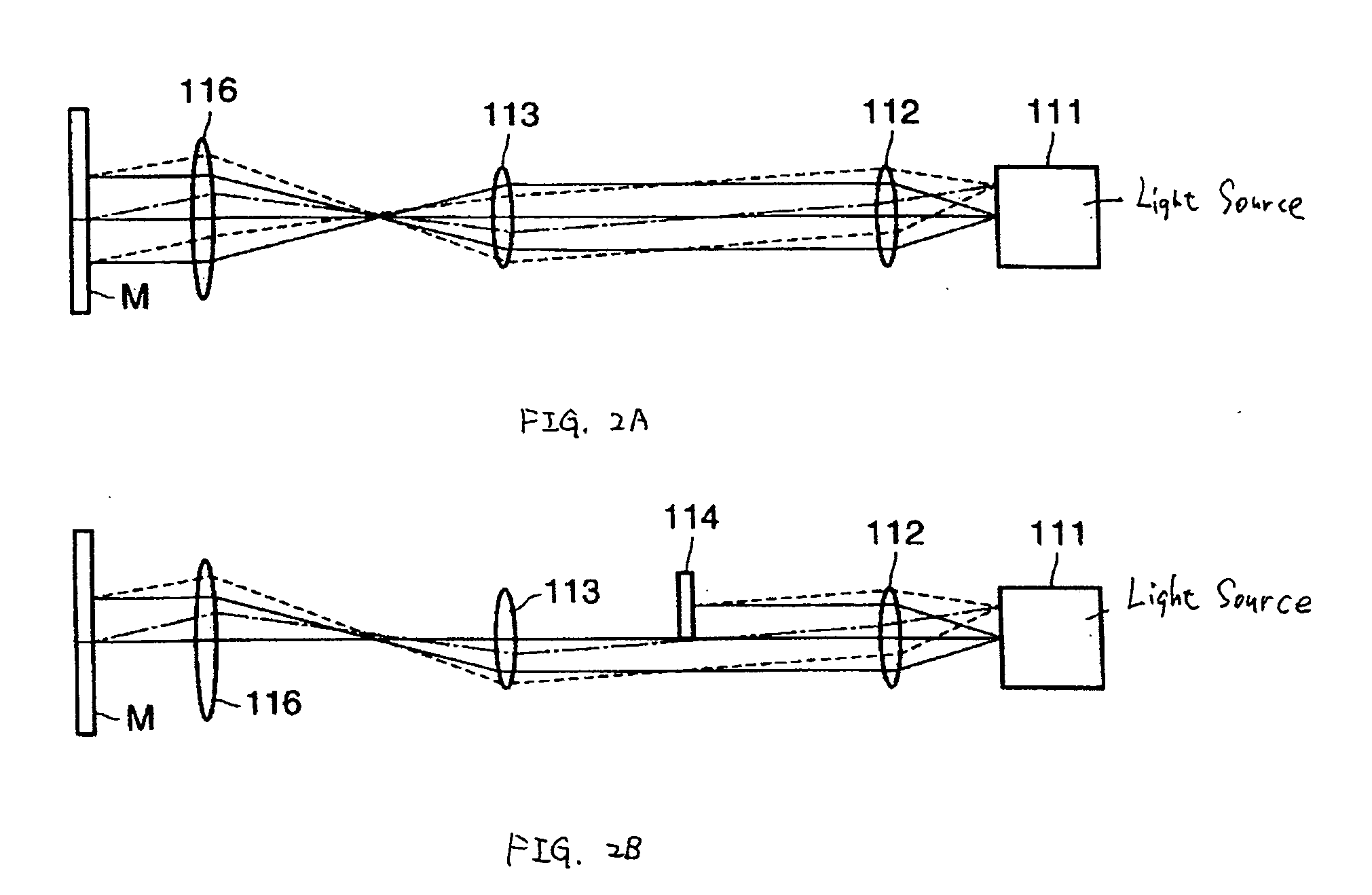

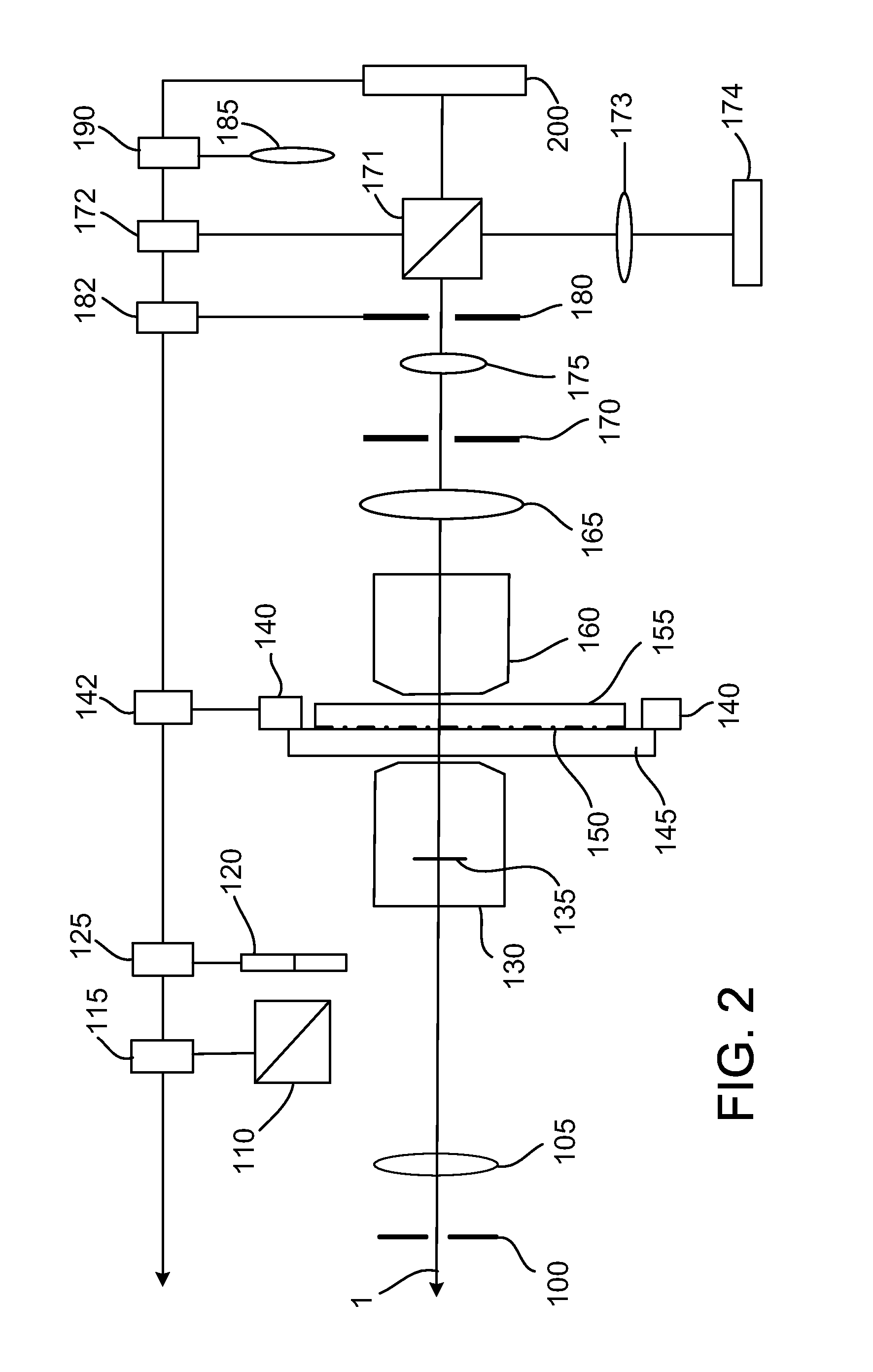

Inspection apparatus having two sensors, method for inspecting an object, and a method for manufacturing a photolithography mask

ActiveUS20050002020A1Semiconductor/solid-state device testing/measurementOptically investigating flaws/contaminationMask inspectionLight beam

A photolithography mask inspection apparatus has at least two sensors. One sensor is configured to sense light transmitted through an object to be inspected, and the other sensor senses light reflected off the object. A first optical system is arranged to expose a first portion of the object with a first light beam, and a second optical system is arranged to expose a second portion of the object, spaced form the first portion, with a second light beam. A third optical system focuses the transmitted light on to the first sensor, as well as the reflected light on to the second sensor. A defect detecting circuit is also provided to detect a defect of the object, based upon image data associated with the reflected and transmitted light.

Owner:KIOXIA CORP

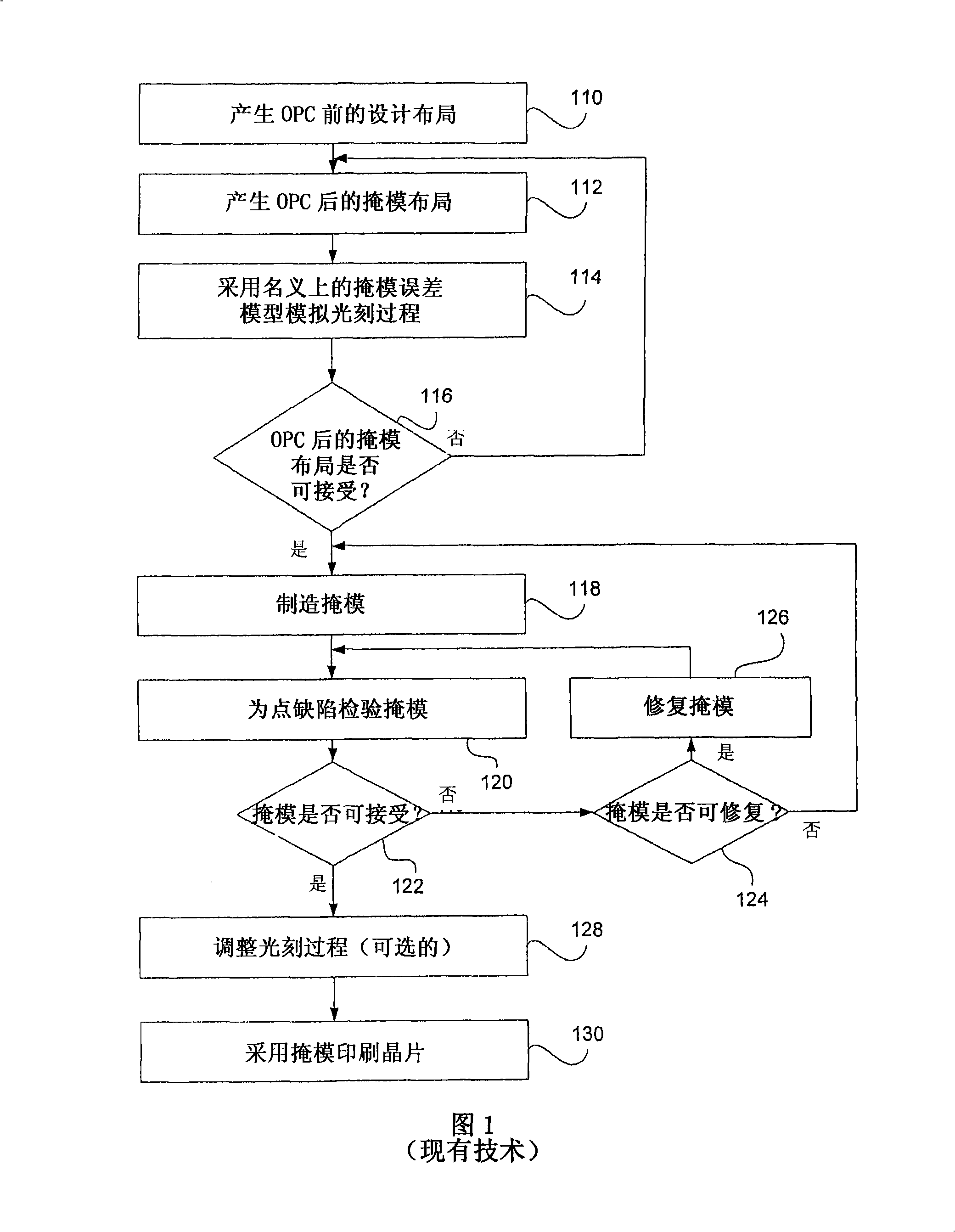

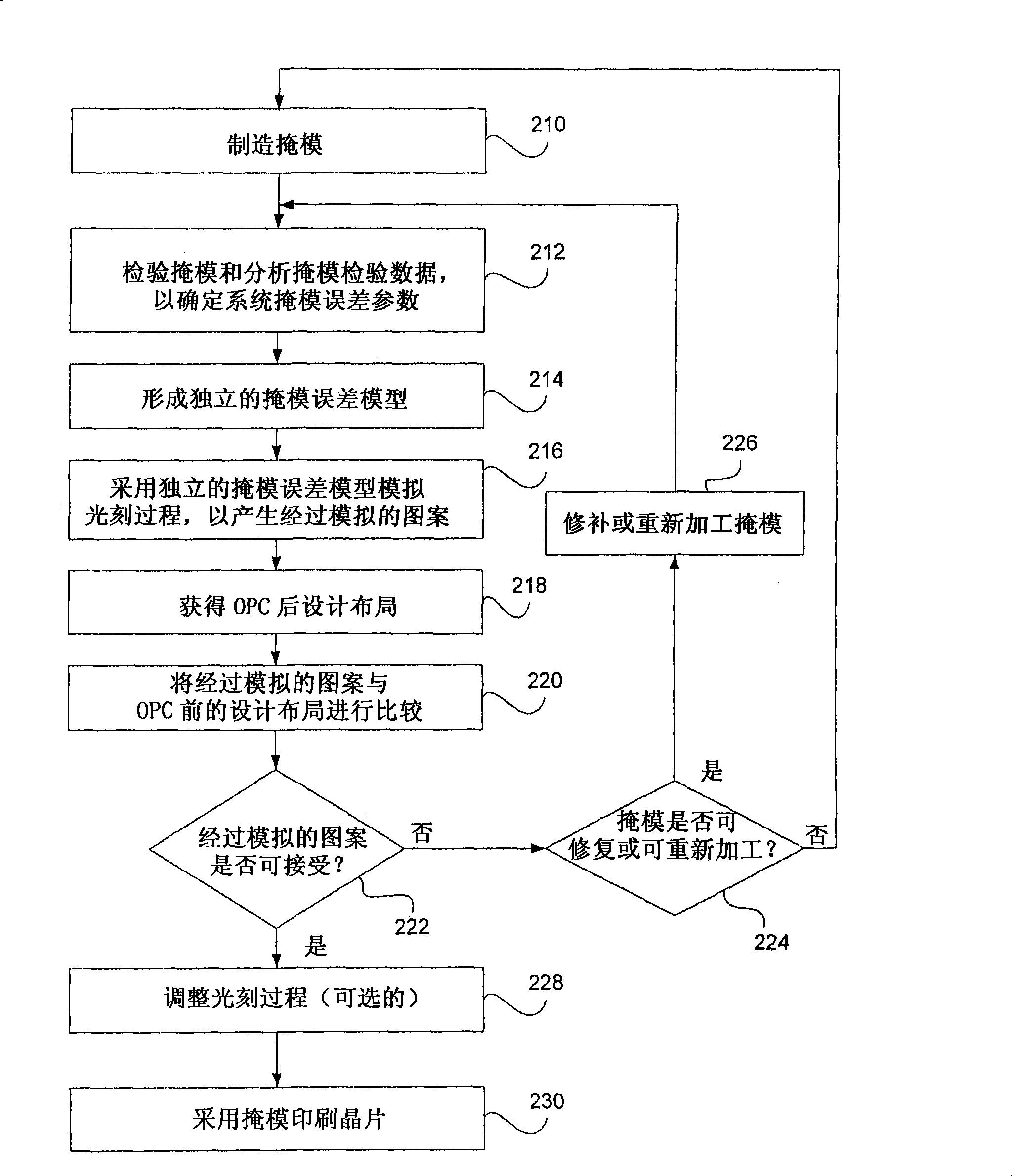

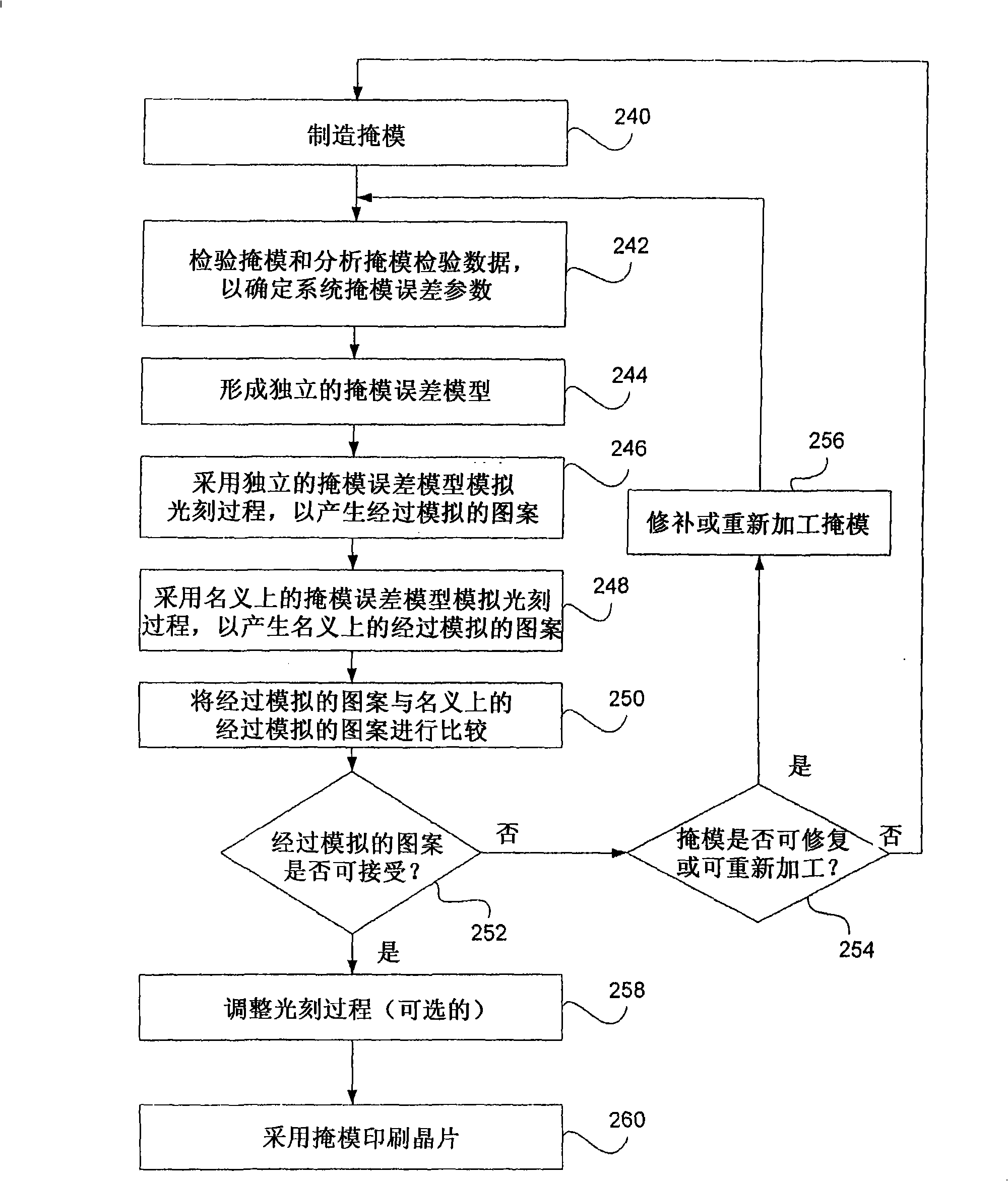

System and method for mask verification using an individual mask error model

InactiveCN101305320APhotomechanical apparatusOriginals for photomechanical treatmentMask inspectionModel method

Methods and systems are disclosed to inspect a manufactured lithographic mask, to extract physical mask data from mask inspection data, to determine systematic mask error data based on differences between the physical mask data and mask layout data, to generate systematic mask error parameters based on the systematic mask error data, to create an individual mask error model with systematic mask error parameters, to predict patterning performance of the lithographic process using a particular mask and / or a particular projection system, and to predict process corrections that optimize patterning performance and thus the final device yield.

Owner:ASML NETHERLANDS BV

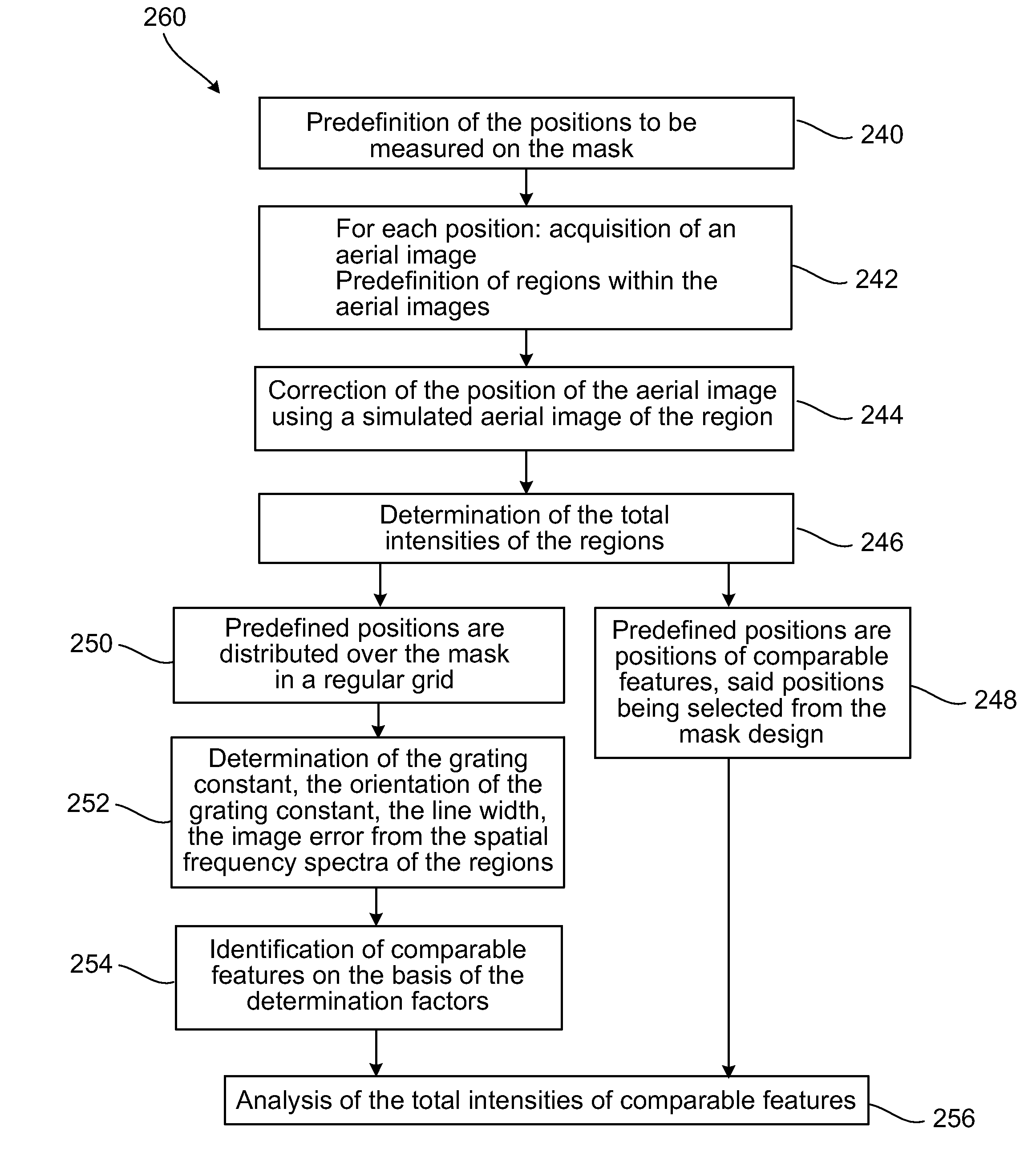

Method for characterizing a feature on a mask and device for carrying out the method

ActiveUS20120075456A1Improve accuracyFast and inexpensiveMaterial analysis by optical meansCharacter and pattern recognitionMask inspectionSpatially resolved

A mask inspection microscope is provided for characterizing a mask having a feature. The mask inspection microscope is configured to generate an aerial image of at least one segment of the feature of the mask, acquire a spatially resolved intensity distribution of the aerial image, and determine a total intensity from the intensities of at least one region of the aerial image.

Owner:CARL ZEISS SMT GMBH

Method and apparatus for analyzing and/or repairing of an EUV mask defect

ActiveUS20130156939A1Maximizes process windowImage analysisParticle separator tubesMask inspectionComputational physics

The invention relates to a method for analyzing a defect of a photolithographic mask for an extreme ultraviolet (EUV) wavelength range (EUV mask) comprising the steps of: (a) generating at least one focus stack relating to the defect using an EUV mask inspection tool, (b) determining a surface configuration of the EUV mask at a position of the defect, (c) providing model structures having the determined surface configuration which have different phase errors and generating the respective focus stacks, and (d) determining a three dimensional error structure of the EUV mask defect by comparing the at least one generated focus stack of the defect and the generated focus stacks of the model structures.

Owner:CARL ZEISS SMT GMBH

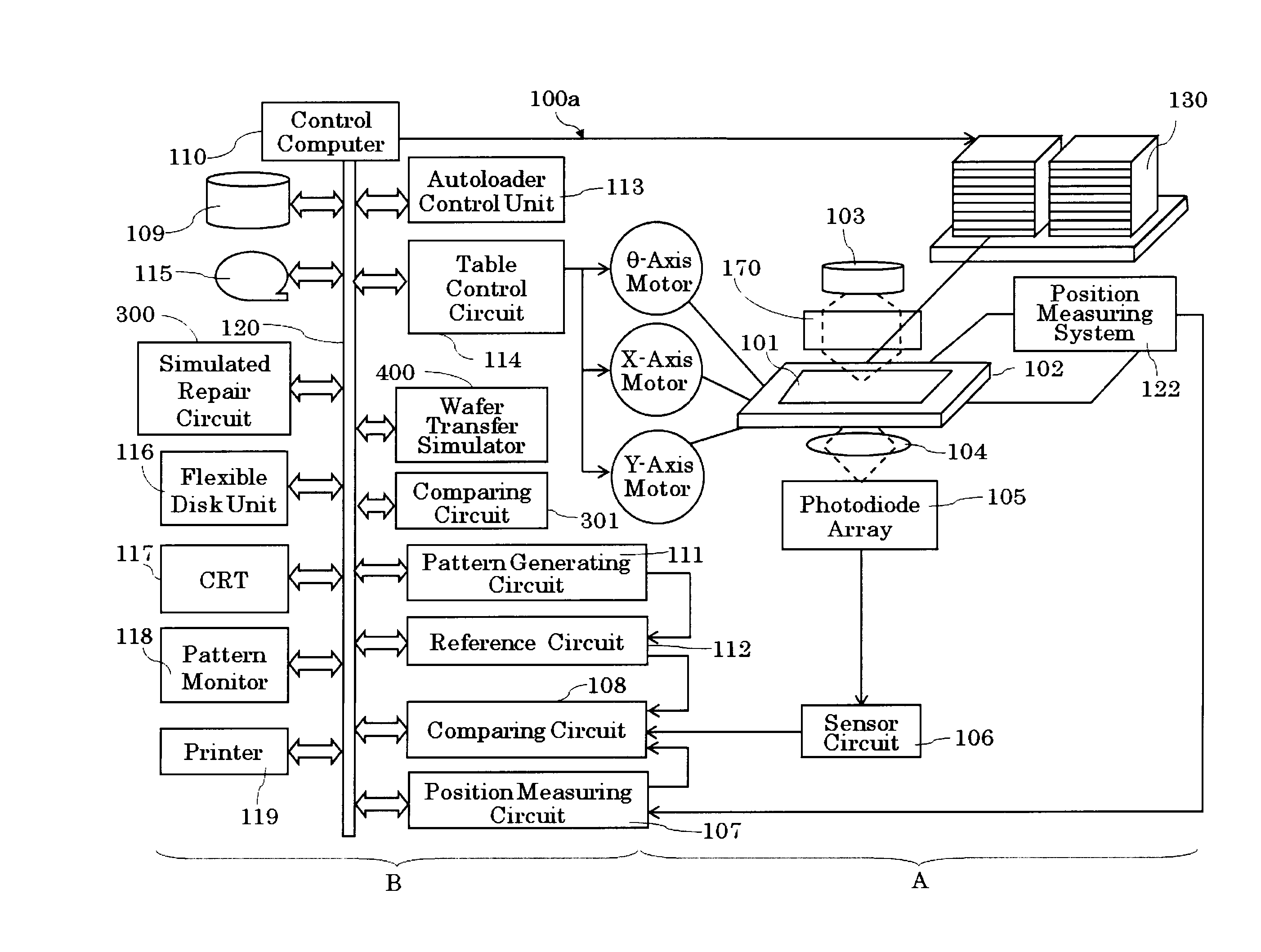

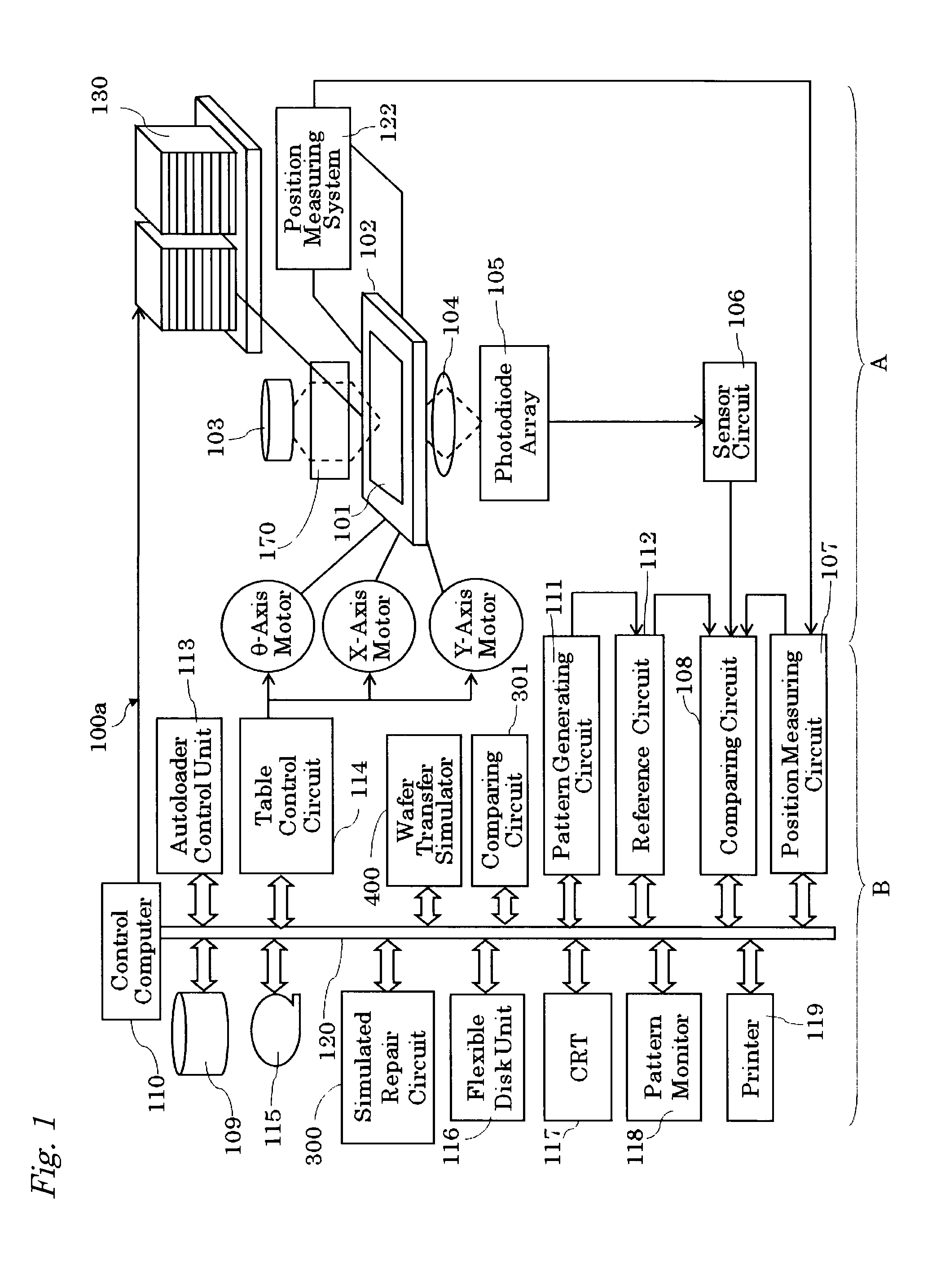

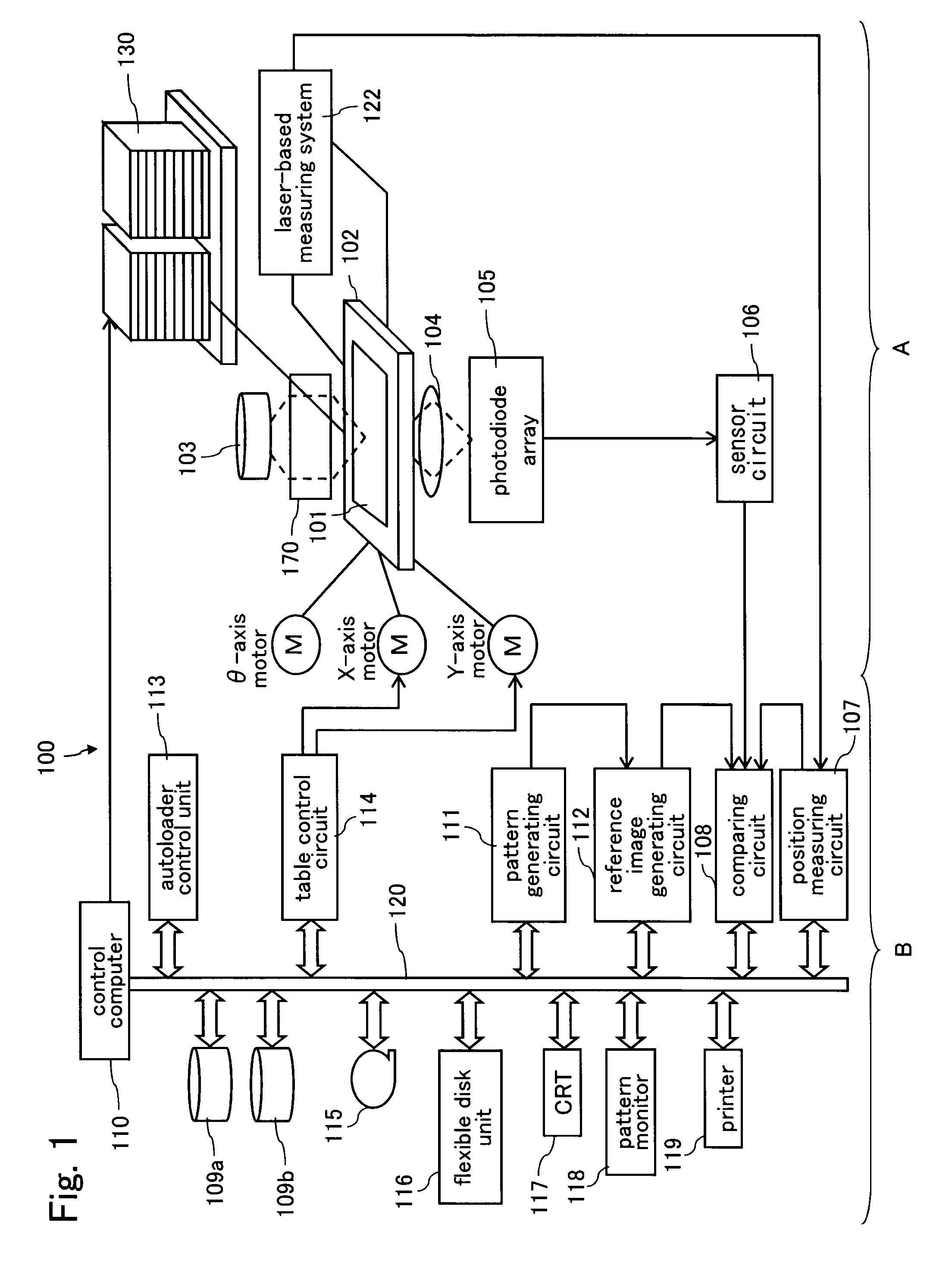

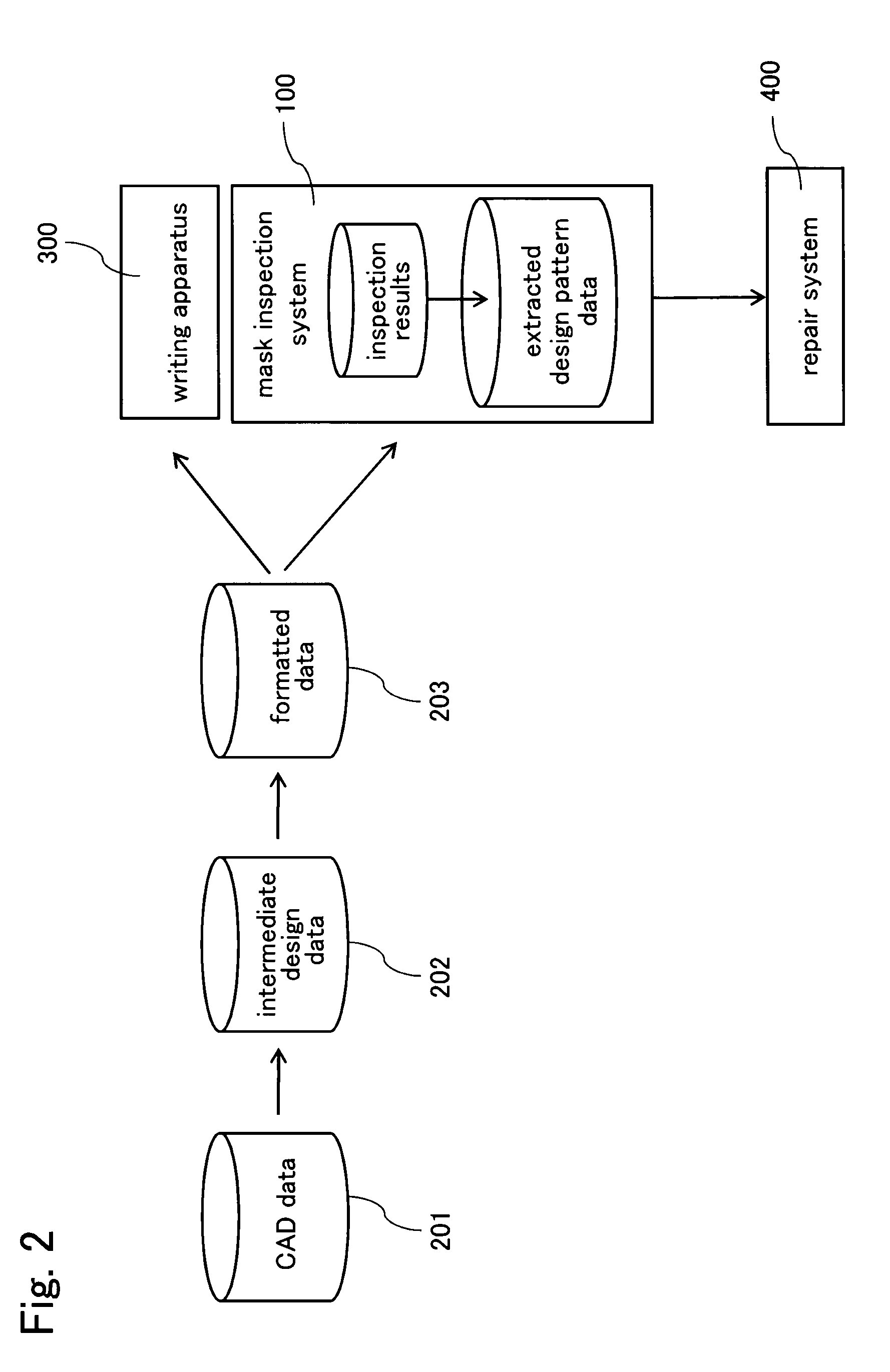

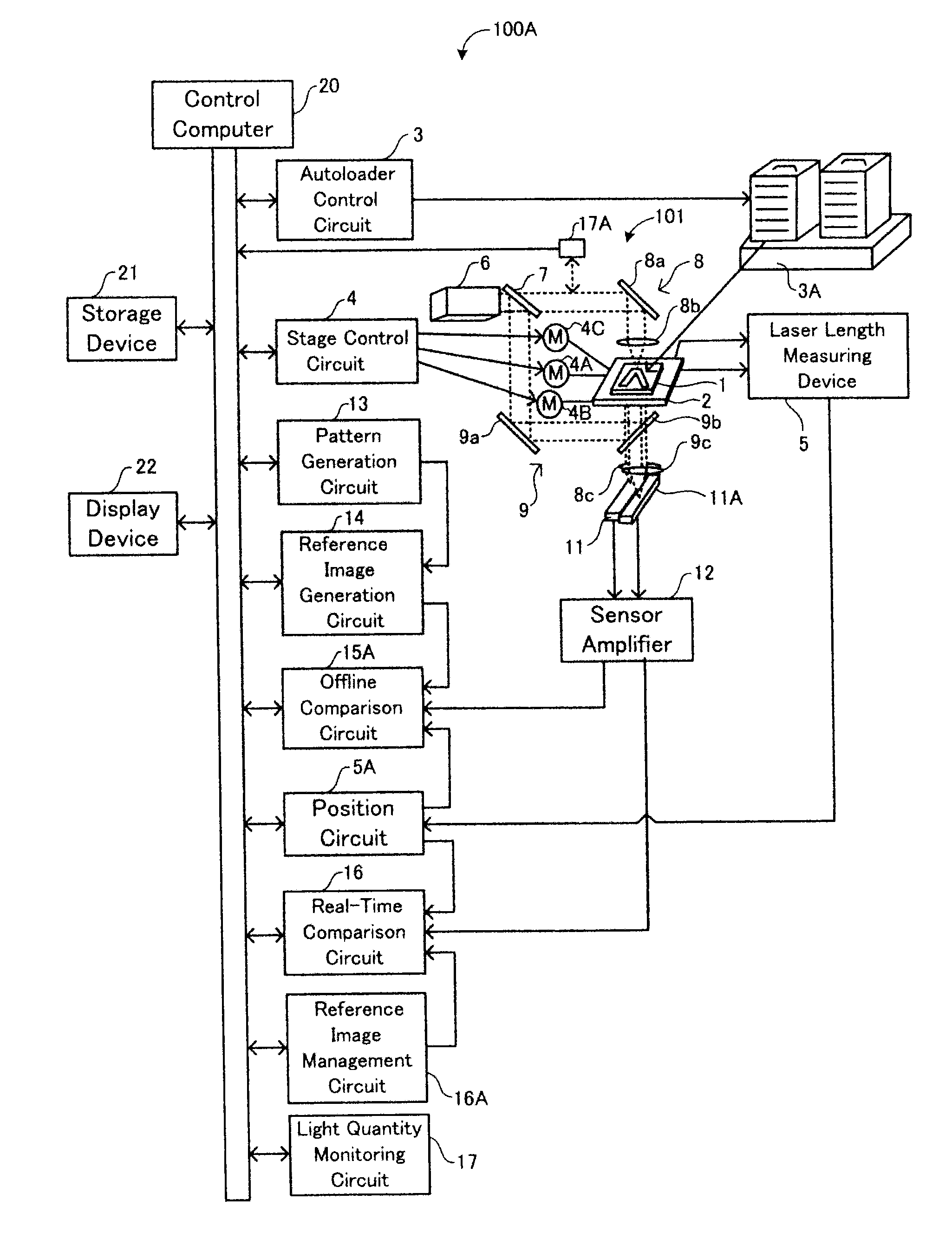

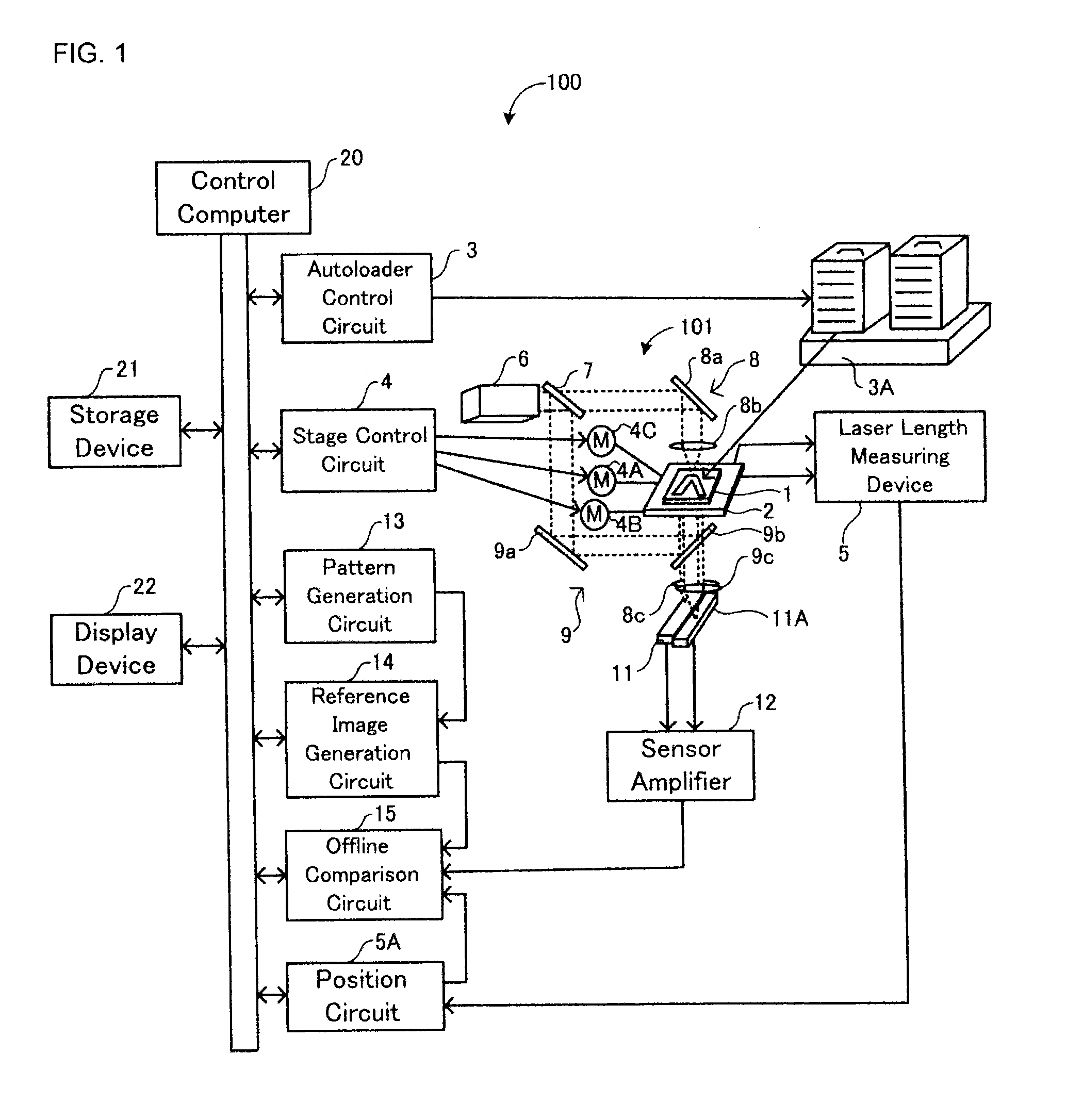

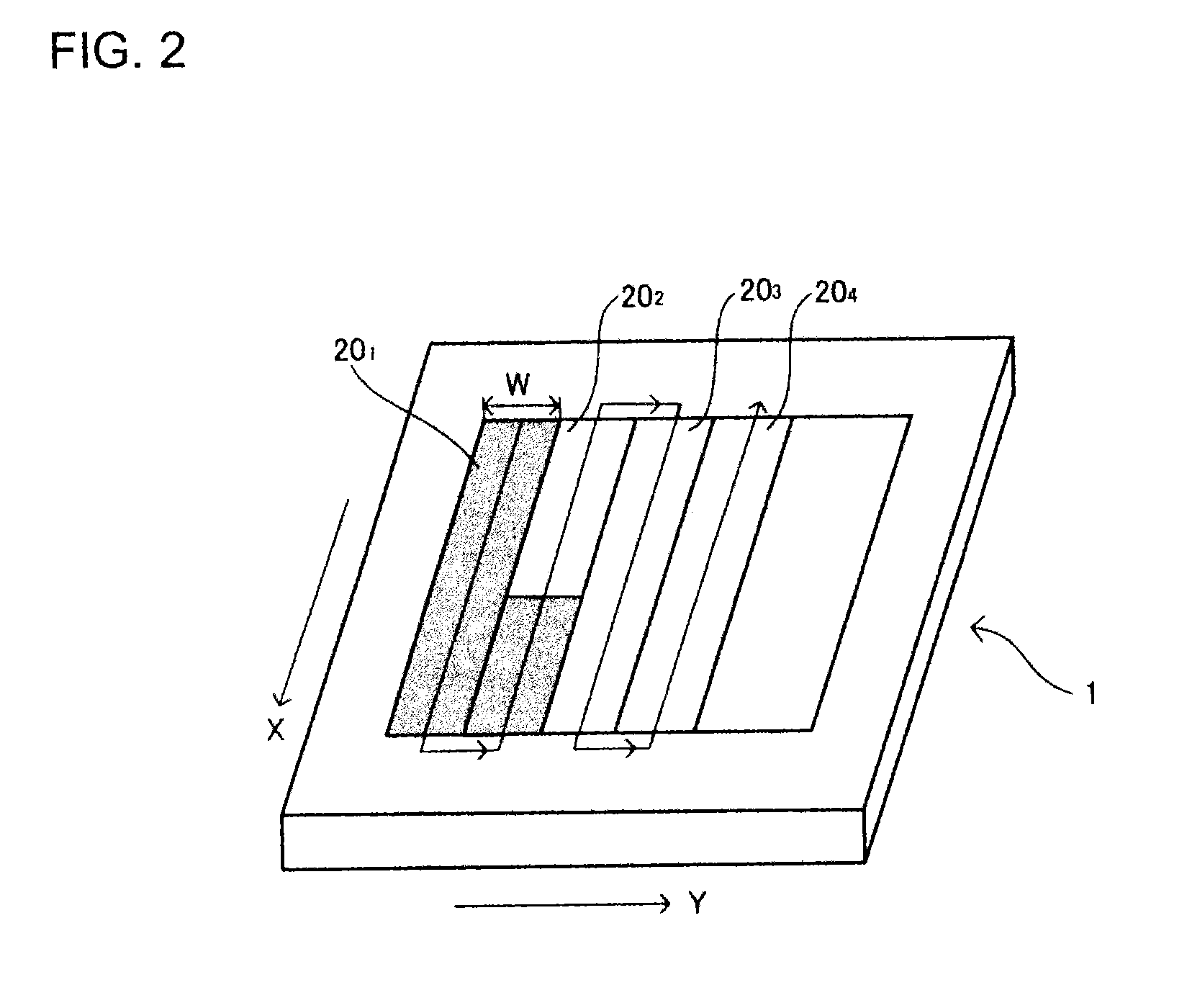

Inspection system and inspection method

A control computer 110 determines, for each detected pattern defect, a defect inspection pattern area of predetermined X and Y dimensions containing the coordinates of the defect, then determines the clusters or cells whose reference points are located within the defect inspection pattern area. Then extracts the data of these clusters or cells from design pattern data read from a first magnetic disk unit 109a. The control computer 110 then generates an output file containing the extracted data. The output file is then converted into the same format as the input design pattern data or into OASIS format, before it is output to a second magnetic disk unit 109b. The extracted pattern data specifying the clusters or cells within each defect inspection pattern area can be output from the mask inspection system 100 to external systems.

Owner:NUFLARE TECH INC

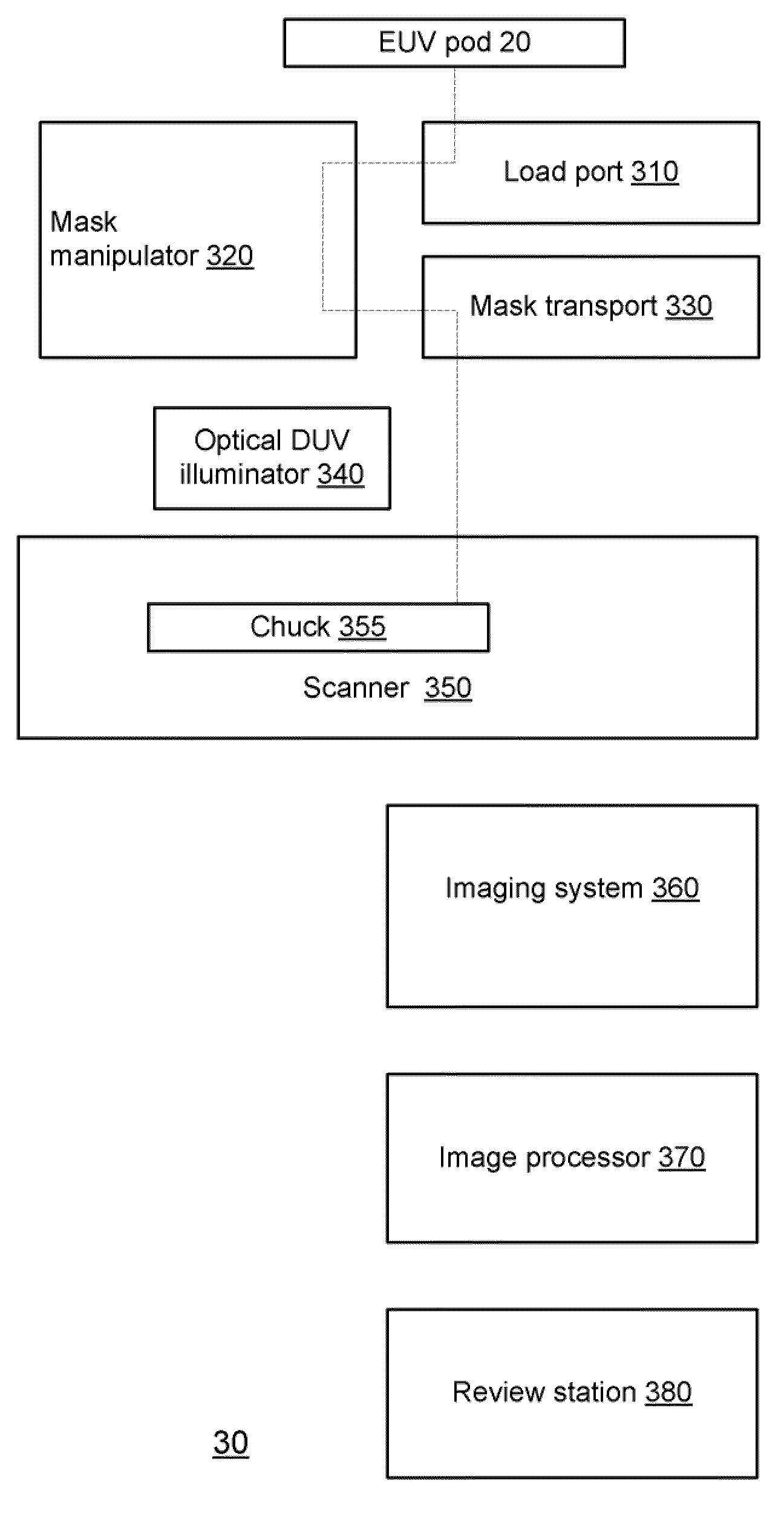

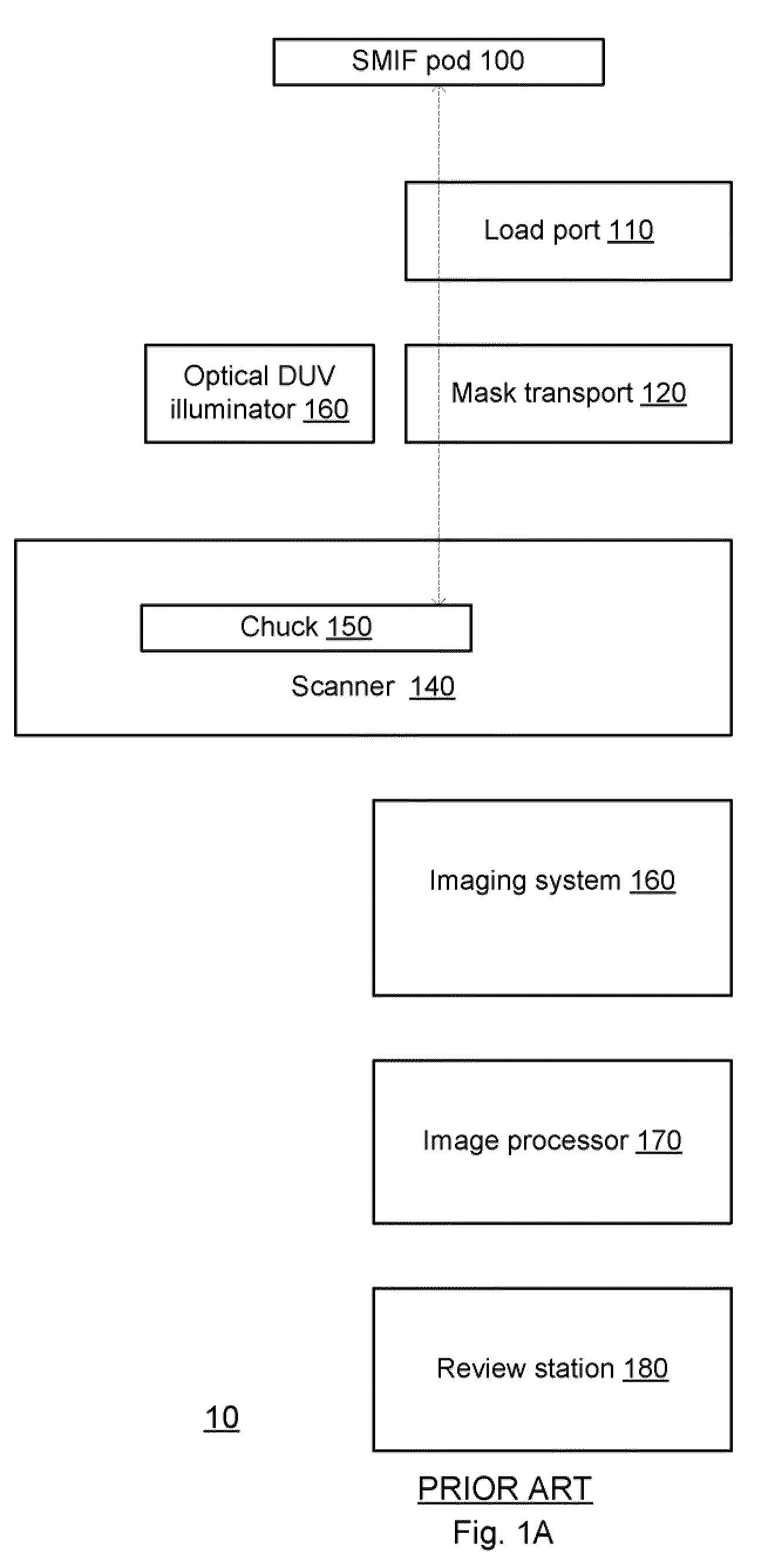

Inspection of EUV masks by a duv mask inspection tool

ActiveUS20110121193A1Material analysis using wave/particle radiationNanoinformaticsMask inspectionTransport system

A system that includes: (a) a mask manipulator, that is arranged to: receive an opaque EUV pod that encloses a EUV mask, extract, in a highly clean environment, the EUV mask from the outer pod and the inner pod of the EUV pod, and cover an upper face of the EUV mask with protective cover that is at least partially transparent to DUV radiation; (b) a scanner, arranged scan the EUV mask, using DUV illumination while maintaining in the scanner an environment that has a cleanliness level that is below a tolerable EUV mask cleanliness level; and a transport system arranged to transport the EUV mask and the protective cover between the scanner and the mask manipulator.

Owner:APPL MATERIALS ISRAEL LTD

Mask inspection apparatus and mask inspection method

ActiveUS20160019689A1Increase speedIncrease storage capacityImage enhancementTelevision system detailsComputer hardwareMask inspection

In a mask inspection apparatus, a defect detection unit includes a first memory region, a second memory region, an inspection condition reconfiguring unit, and a comparison unit. The inspection condition reconfiguring unit obtains a difference between gray scales of an optical image stored in the second memory region and a reference image stored in the first memory region. The existence of the defect is determined in the case where the difference is larger than a first threshold value. Further in the case where the number of defects is larger than a second threshold value, an inspection condition is re-estimated and configured and the reference image is regenerated. A comparison unit compares the stored reference image with the stored optical image in the case where the inspection condition is not reconfigured, and compares the regenerated reference image with the stored optical image in the case where the inspection condition is reconfigured.

Owner:NUFLARE TECH INC

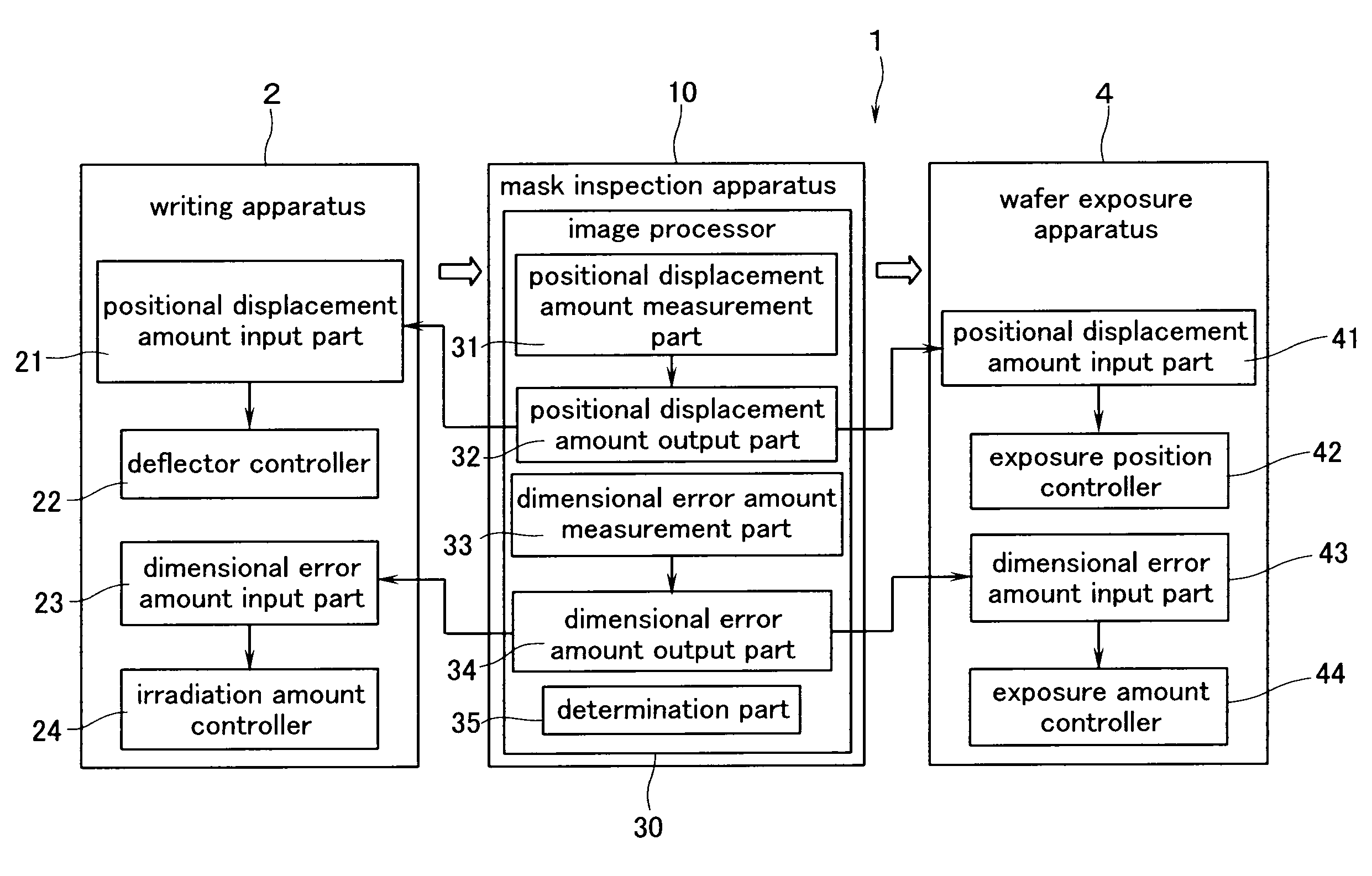

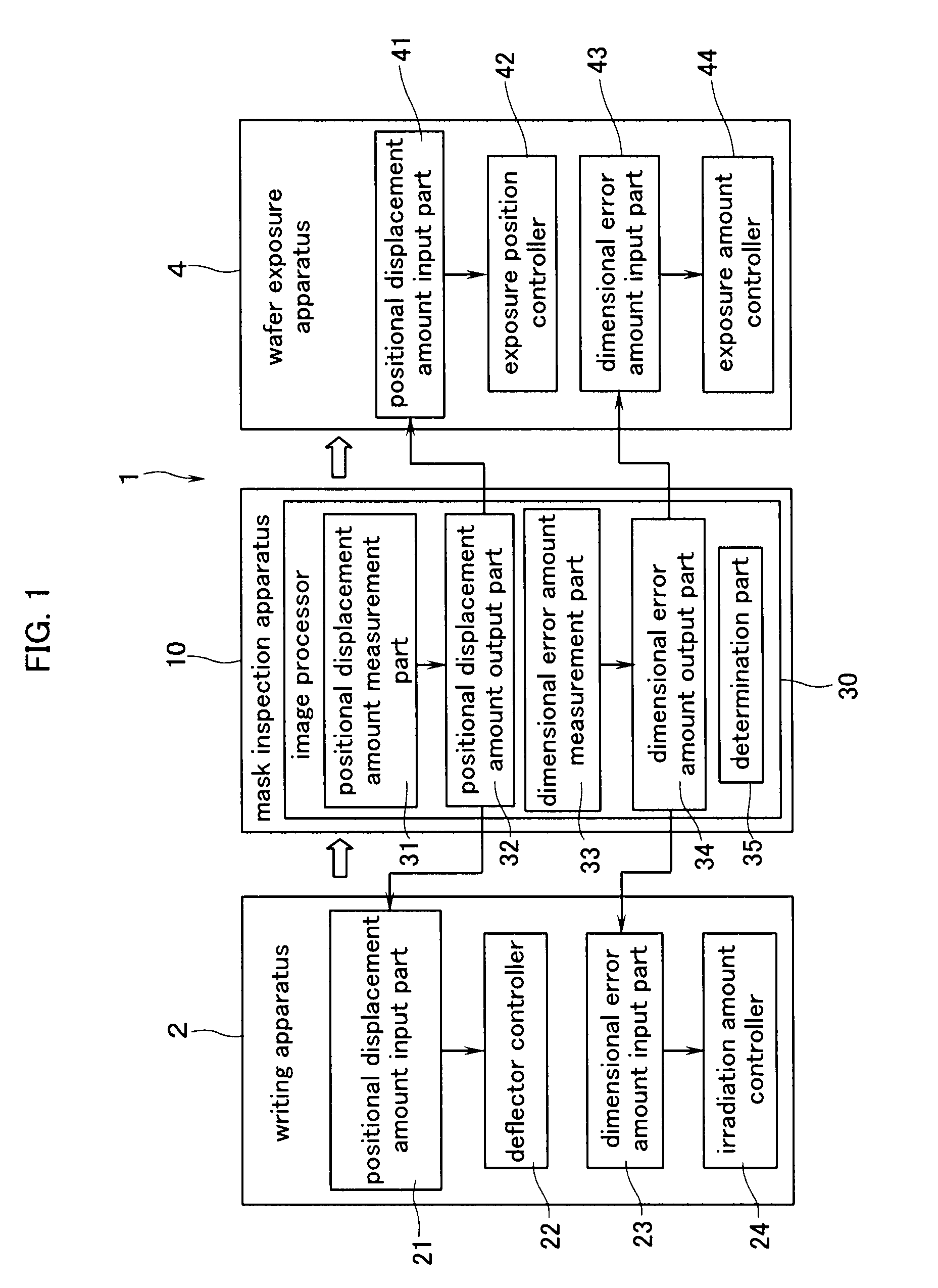

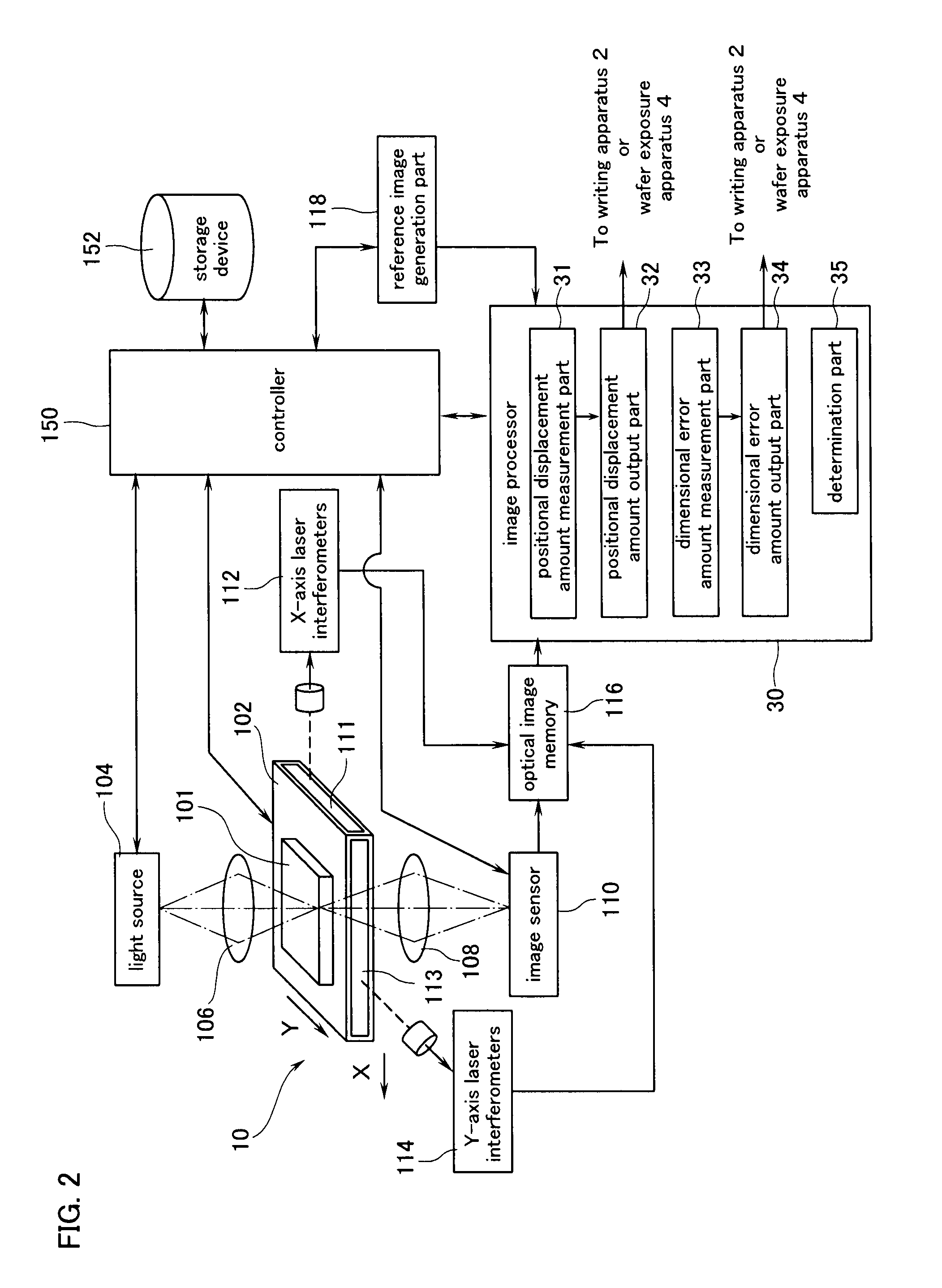

Mask inspection apparatus, and exposure method and mask inspection method using the same

The present invention provides a mask inspection apparatus and method capable of inspecting masks used in double patterning with satisfactory accuracy.Optical images of two masks are acquired (S100). The acquired optical images of the two masks are combined together (S102). Relative positional displacement amounts of patterns of the first mask and patterns of the second mask are measured at the combined image (S104). The measured relative positional displacement amounts are compared with standard values to thereby determine whether the two masks are good (S106).

Owner:NUFLARE TECH INC

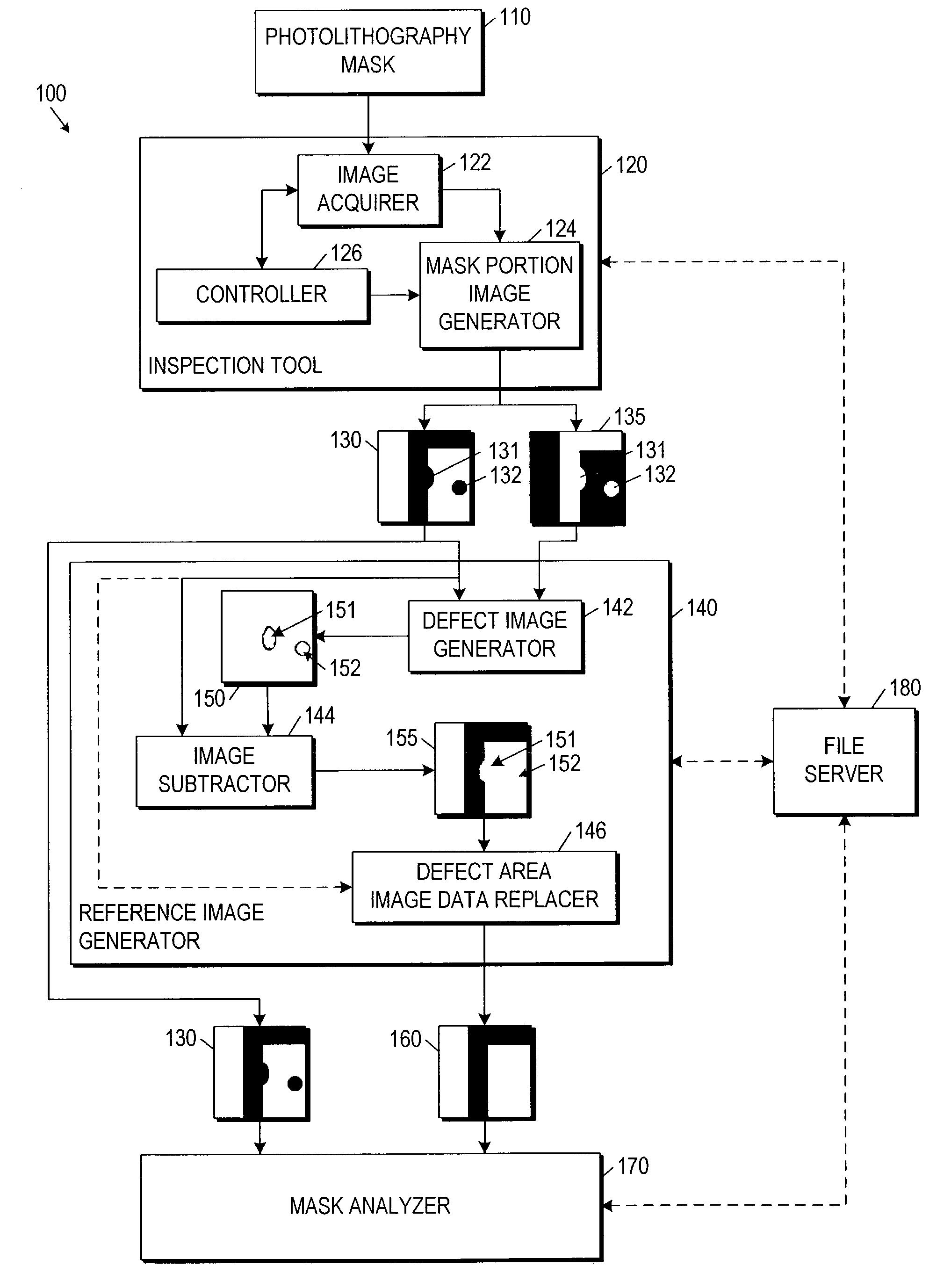

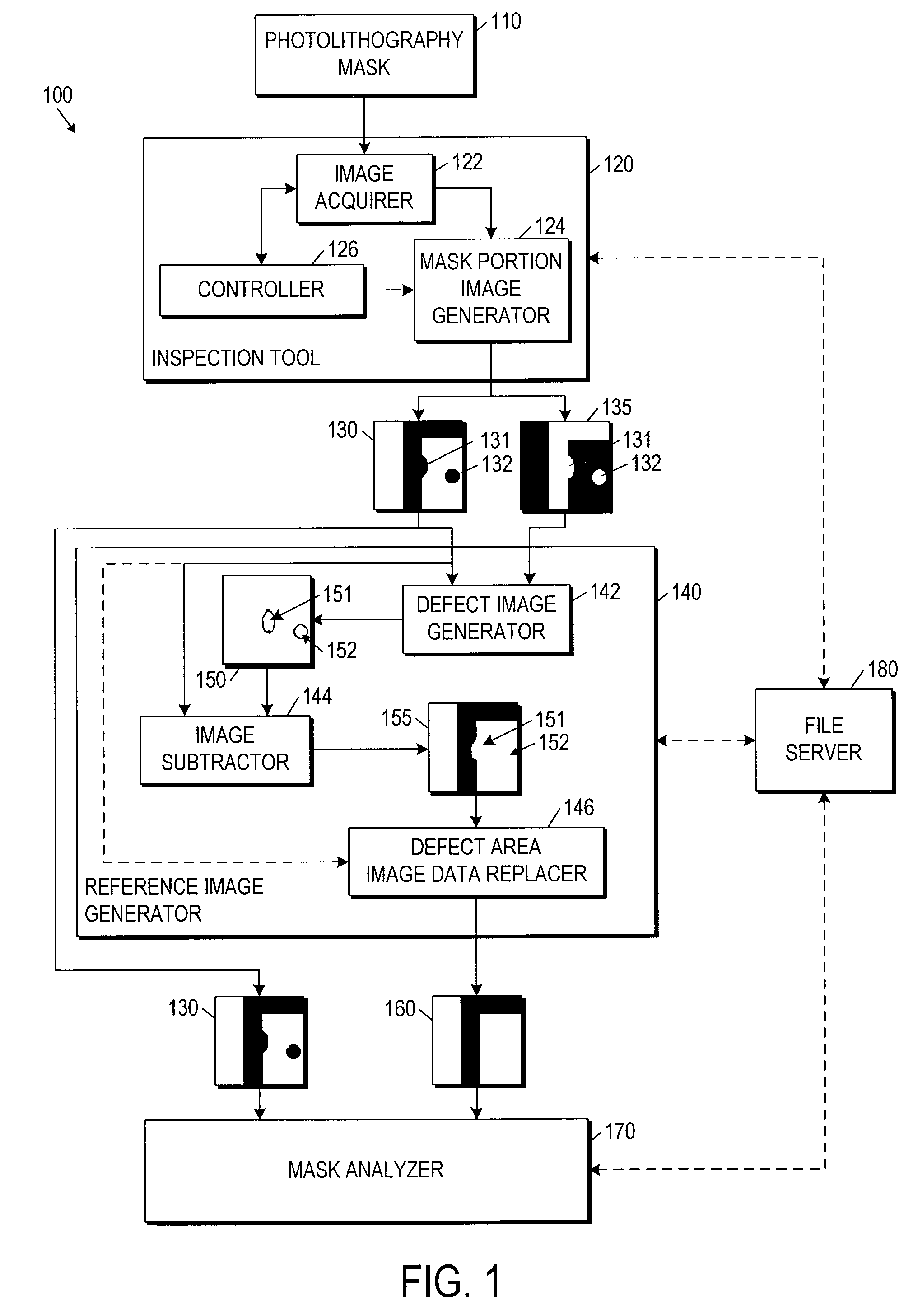

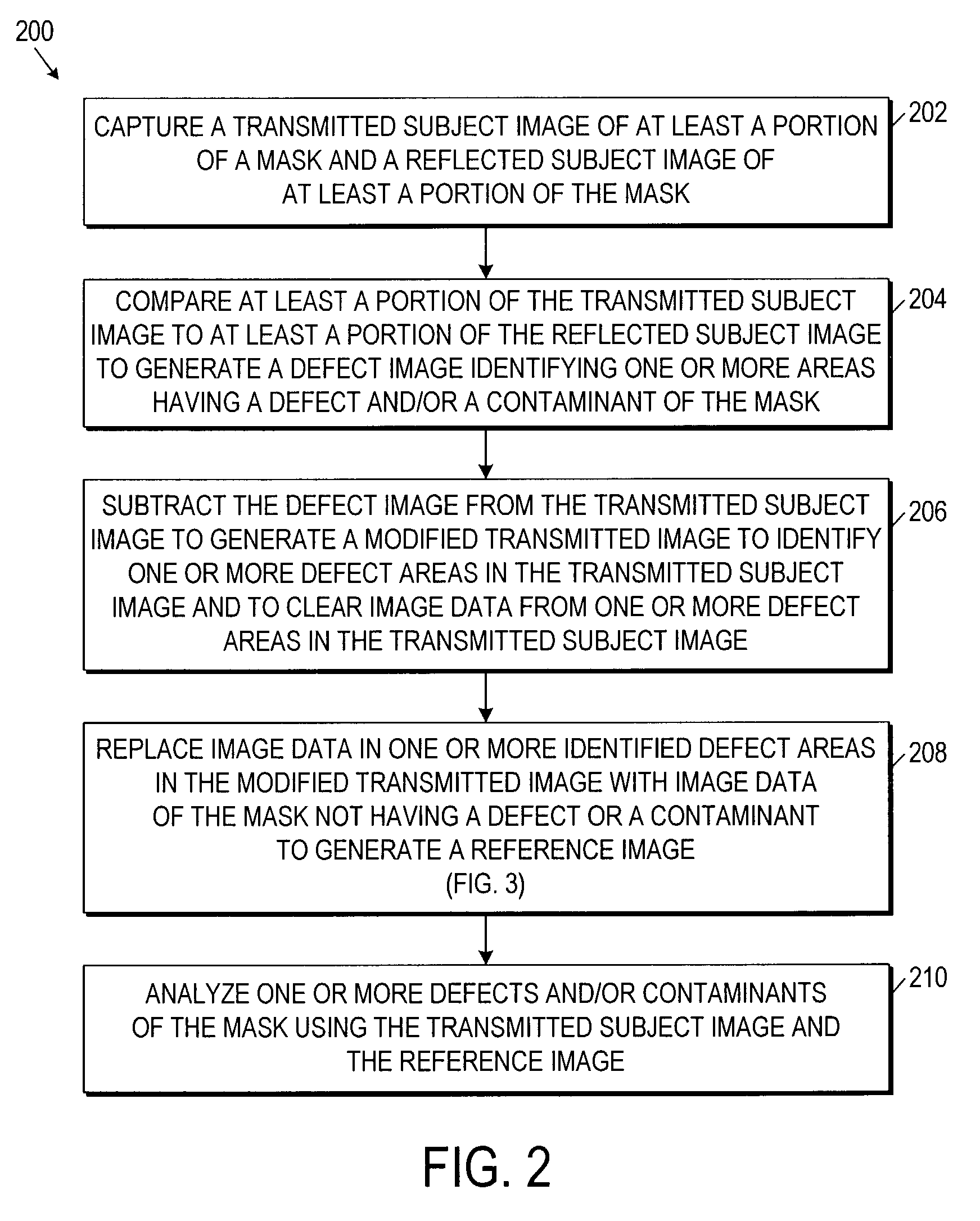

Reference image generation from subject image for photolithography mask analysis

A reference image is generated from a subject image of at least a portion of a photolithography mask to enable a photolithography mask inspection and analysis system that otherwise cannot generate a reference image from a reference die or digitized design data, for example, to perform a mask analysis using the reference image. A mask inspection and analysis system may then be enhanced to perform one or more additional mask analyses to analyze the mask. The reference image is generated by identifying a defect or contaminant of the mask in the subject image and modifying the subject image to remove the defect or contaminant from the mask to generate the reference image. For one embodiment, a system using a STARlight inspection tool that captures transmitted and reflected images of a portion of a mask may then be enhanced to perform one or more mask analyses that use a reference image.

Owner:SYNOPSYS INC

Extending the field of view of a mask-inspection image

Owner:KLA CORP

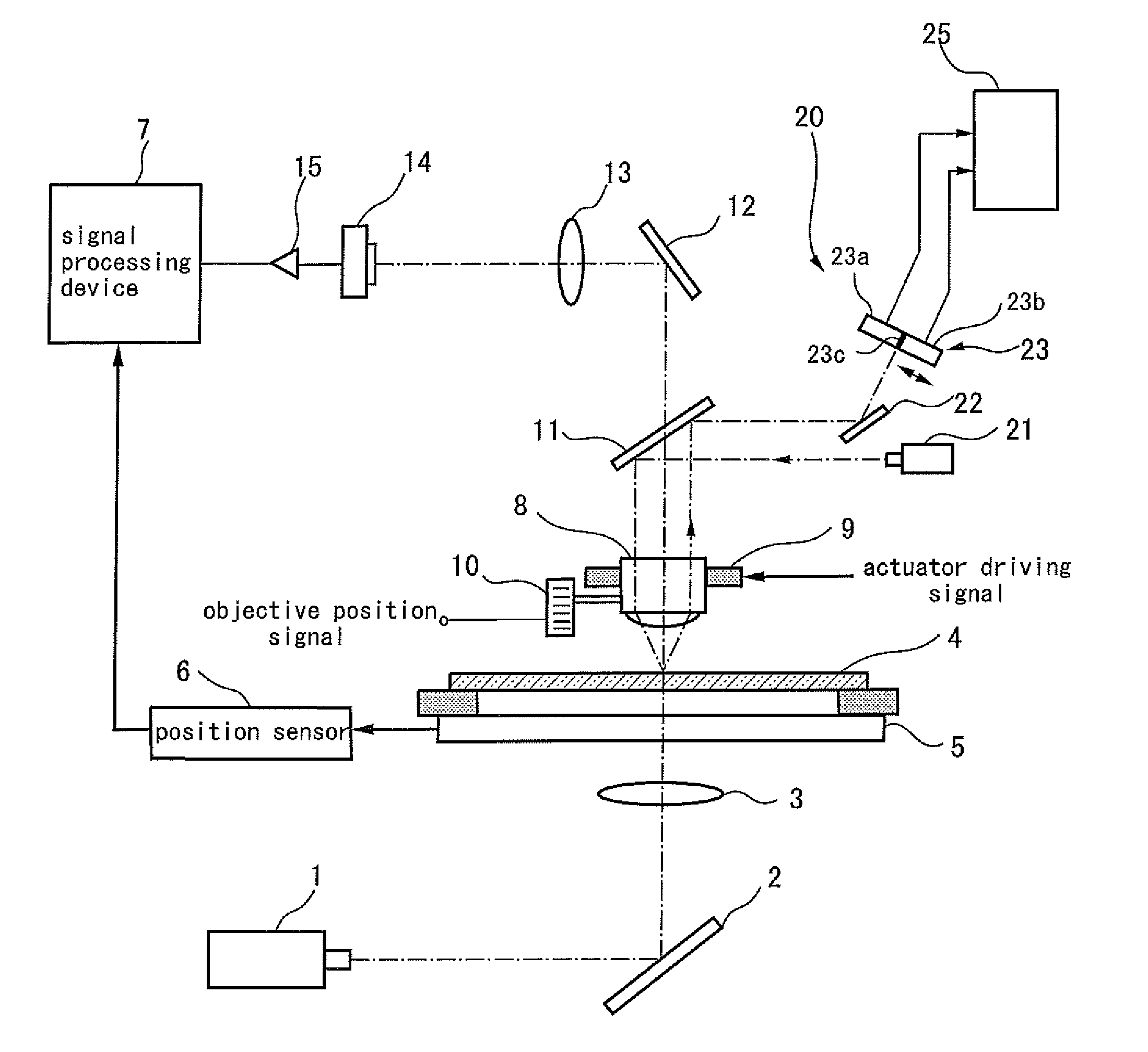

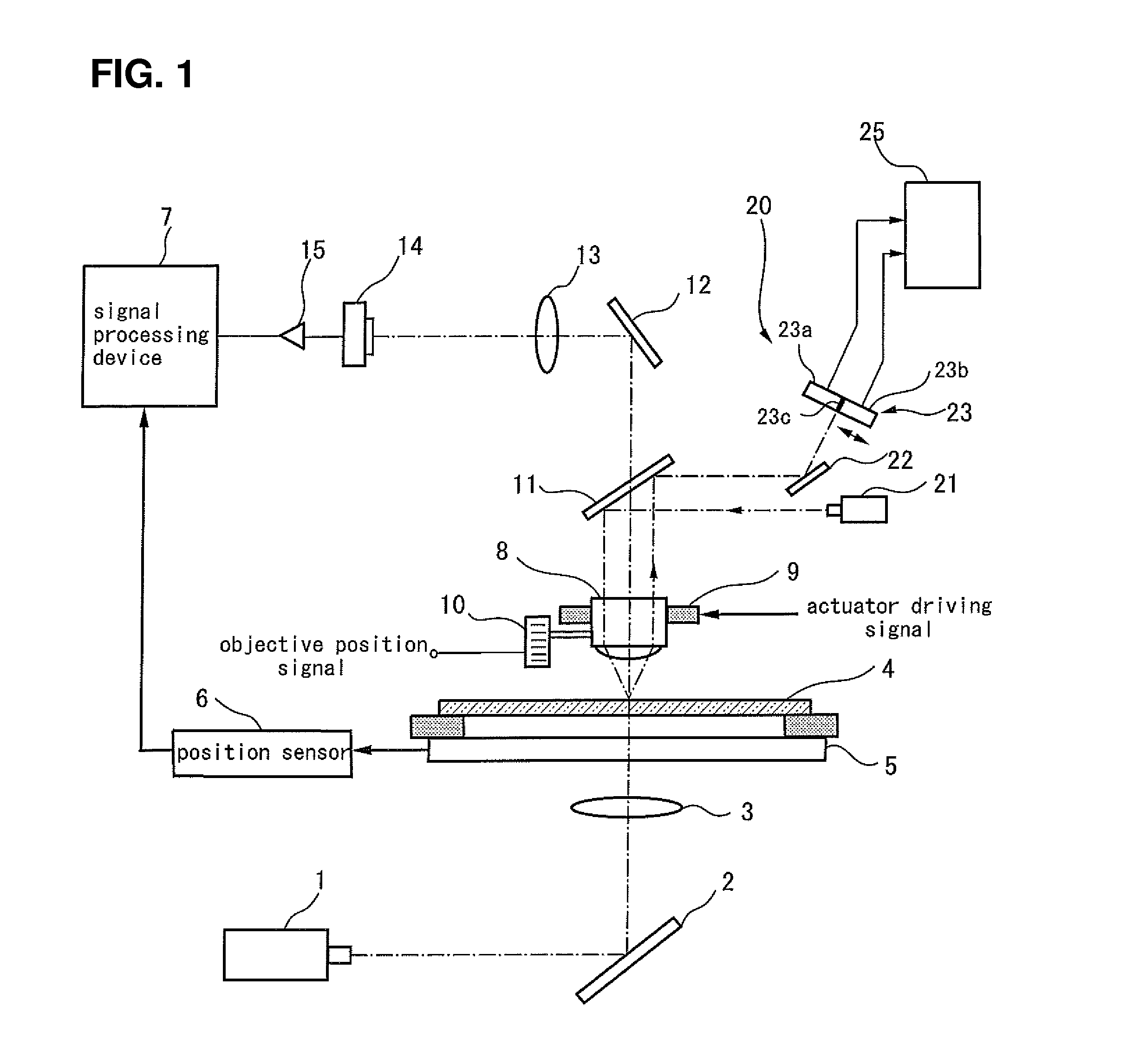

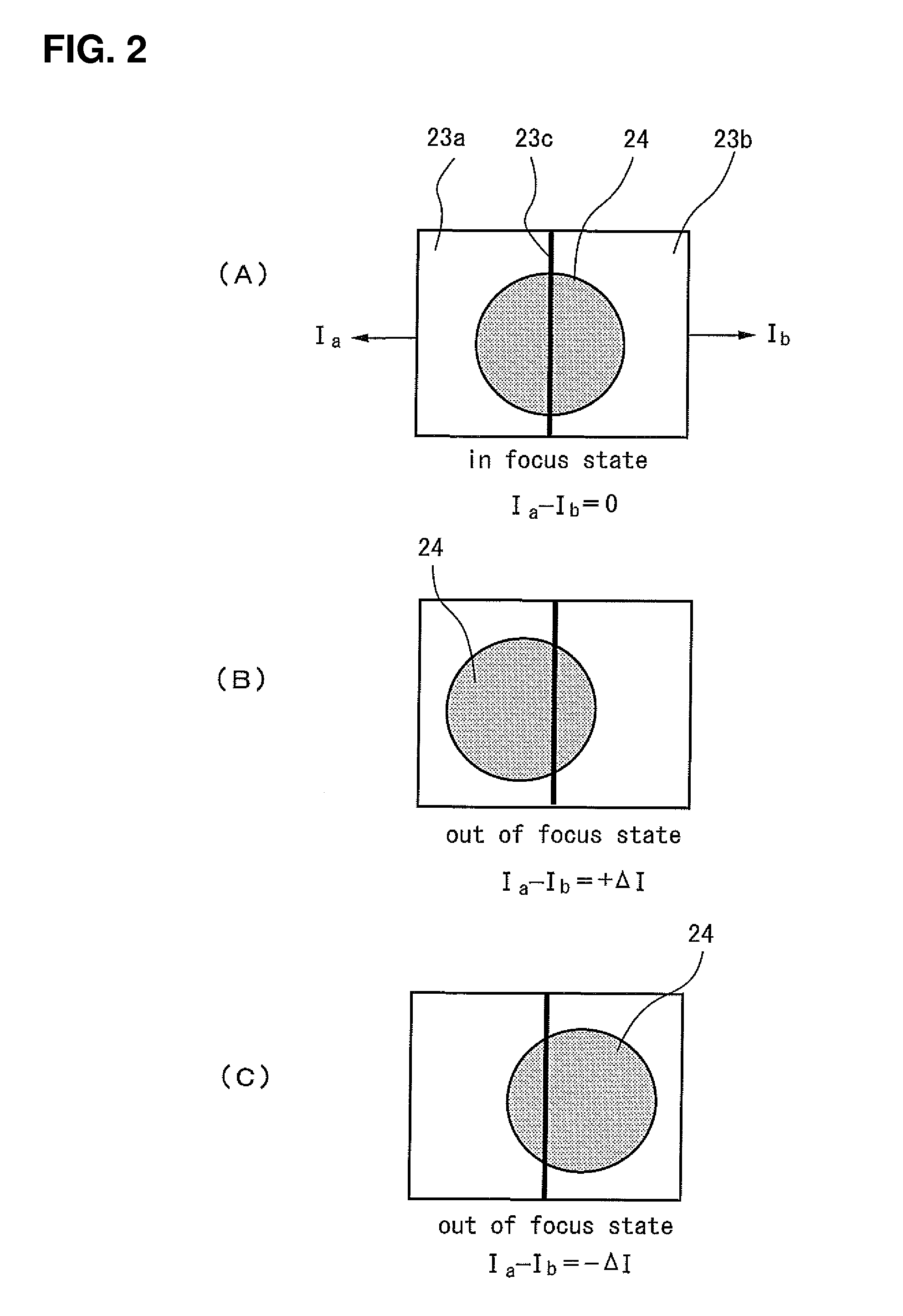

Substrate inspection apparatus and mask inspection apparatus

ActiveUS20120287424A1Accurate focus controlEnhance inspection throughputSemiconductor/solid-state device testing/measurementPhotomechanical apparatusMask inspectionOptical axis

Substrate inspection apparatus, in which the acquisition of the inspection data for a defect and the acquisition of the focus data of the objective lens are performed in parallel, includes an autofocus apparatus for controlling position of the objective lens along its optical axis. The autofocus apparatus includes a focus error detection unit and a focus control signal generation unit for generating a focus control signal for controlling the position of the objective lens for each scan line using a focus data signal composed of an objective position signal or the objective position signal to which a focus error signal is added. When “i” is assumed as a positive integer and “m” is as a natural number, the focus data signal which was acquired during the scanning period of i-th scan line is used to produce the focus control signal used to scan the (i+2m)-th scan line.

Owner:LASERTEC CORP

Method for inspecting mask

InactiveUS20050142455A1Suppress detectionShorten the timeImage enhancementImage analysisMask inspectionPattern recognition

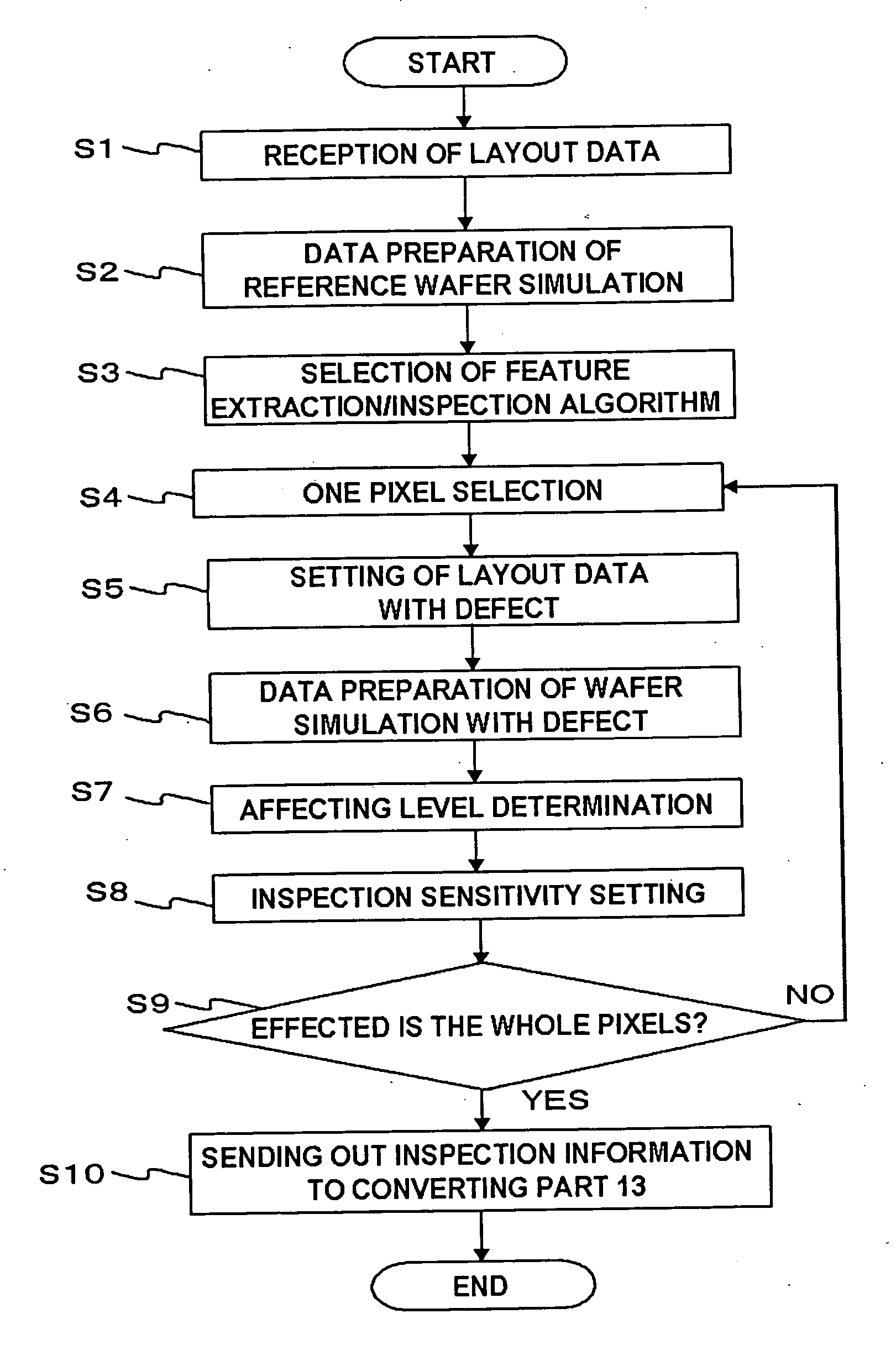

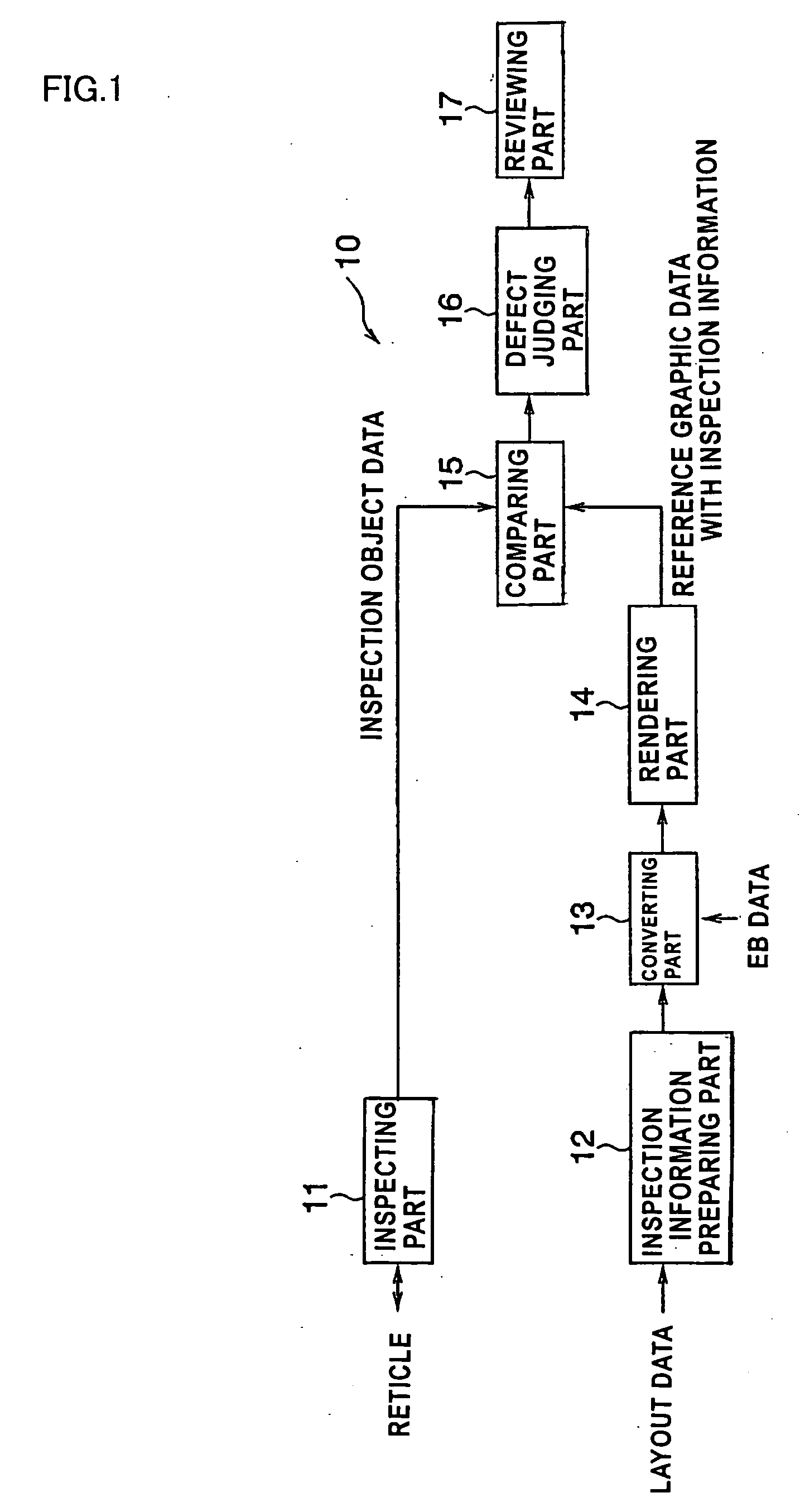

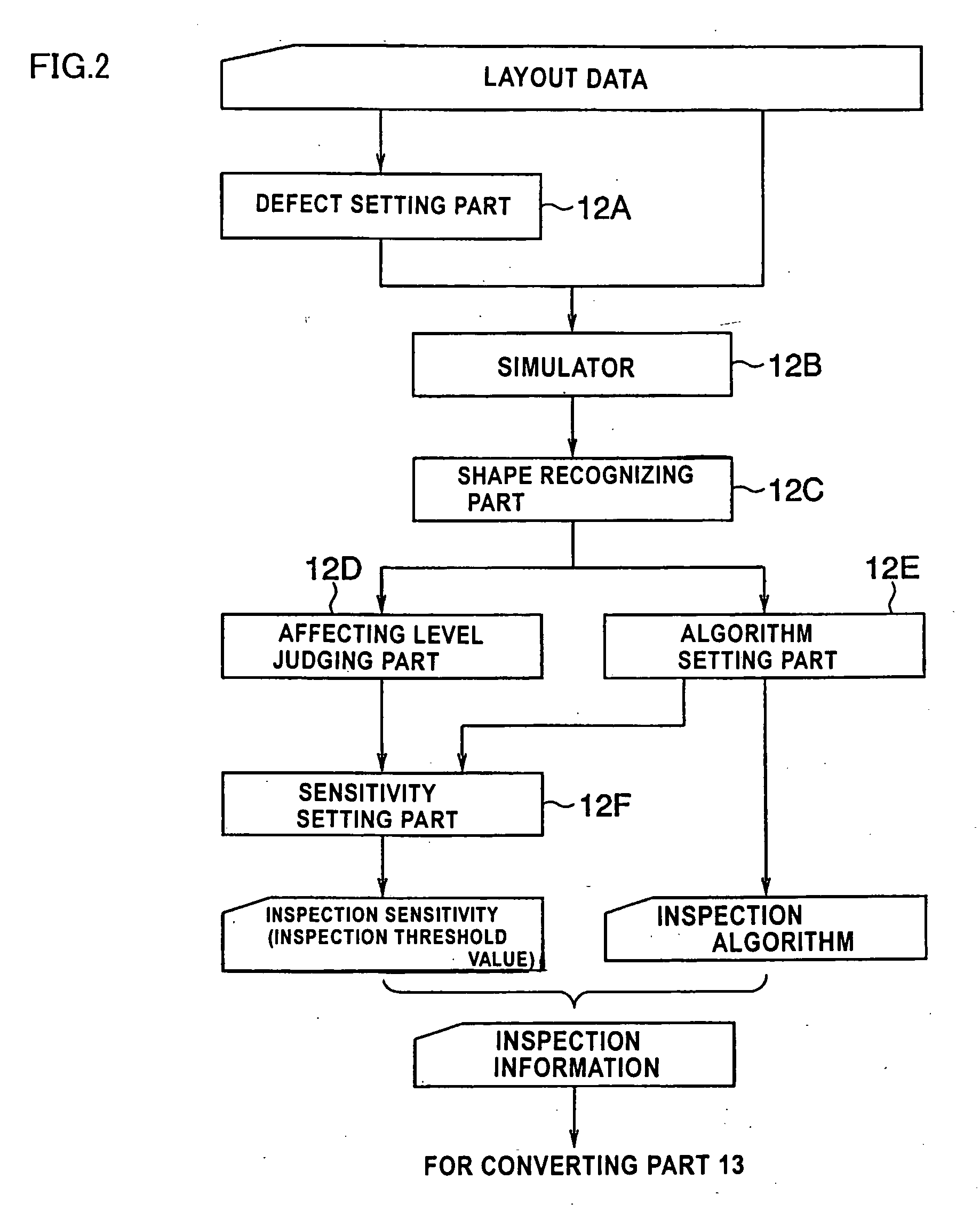

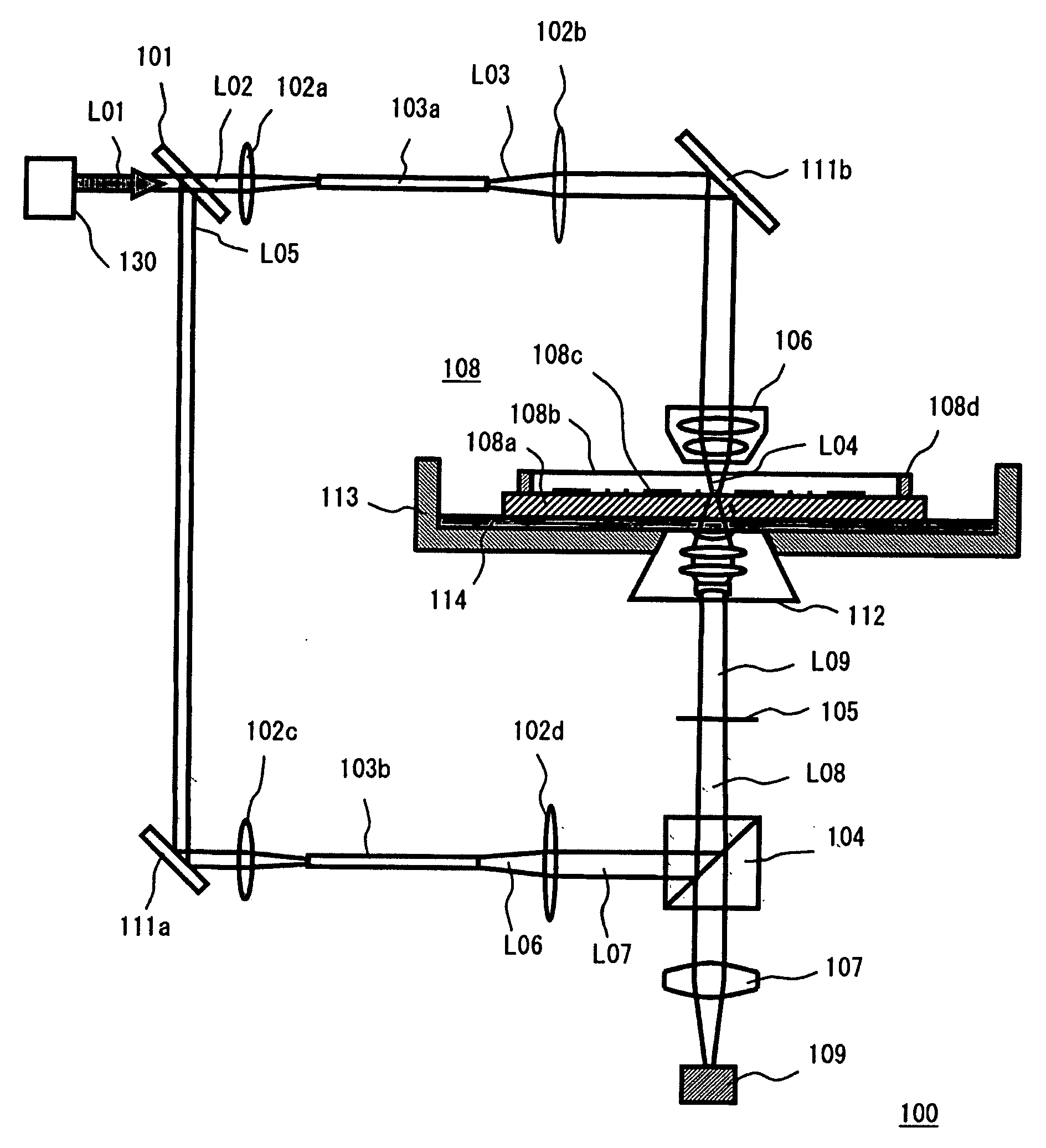

A mask inspection system 10 inspects an inspection object pattern while comparing an inspection object data obtained in such a way as to image the inspection object pattern with a reference pattern data. The mask inspection system 10 is provided with an inspection information preparing part 12 producing inspection algorithm and inspection sensitivity to the reference pattern data based on wafer simulation, a converting part 13 generating a reference graphic data with inspection information while adding the inspection information to the reference graphic data, and a defect judging part 16 judges propriety of an inspection object pattern data while comparing reference graphic data with an inspection object data in every pixel based on the inspection information added to the reference graphic data with inspection information.

Owner:RENESAS ELECTRONICS CORP

Photomask inspection apparatus

InactiveUS20090168191A1High resolutionEasy to disassembleMaterial analysis by optical meansOriginals for photomechanical treatmentMask inspectionPhysics

According to one aspect of the present invention, there is provided a photomask inspection apparatus which observes a pattern provided on a mask substrate of a mask to inspect the mask including an object lens, and a liquid that is present between a last lens in the side closer to the mask of the object lens and the mask.

Owner:LASERTEC CORP

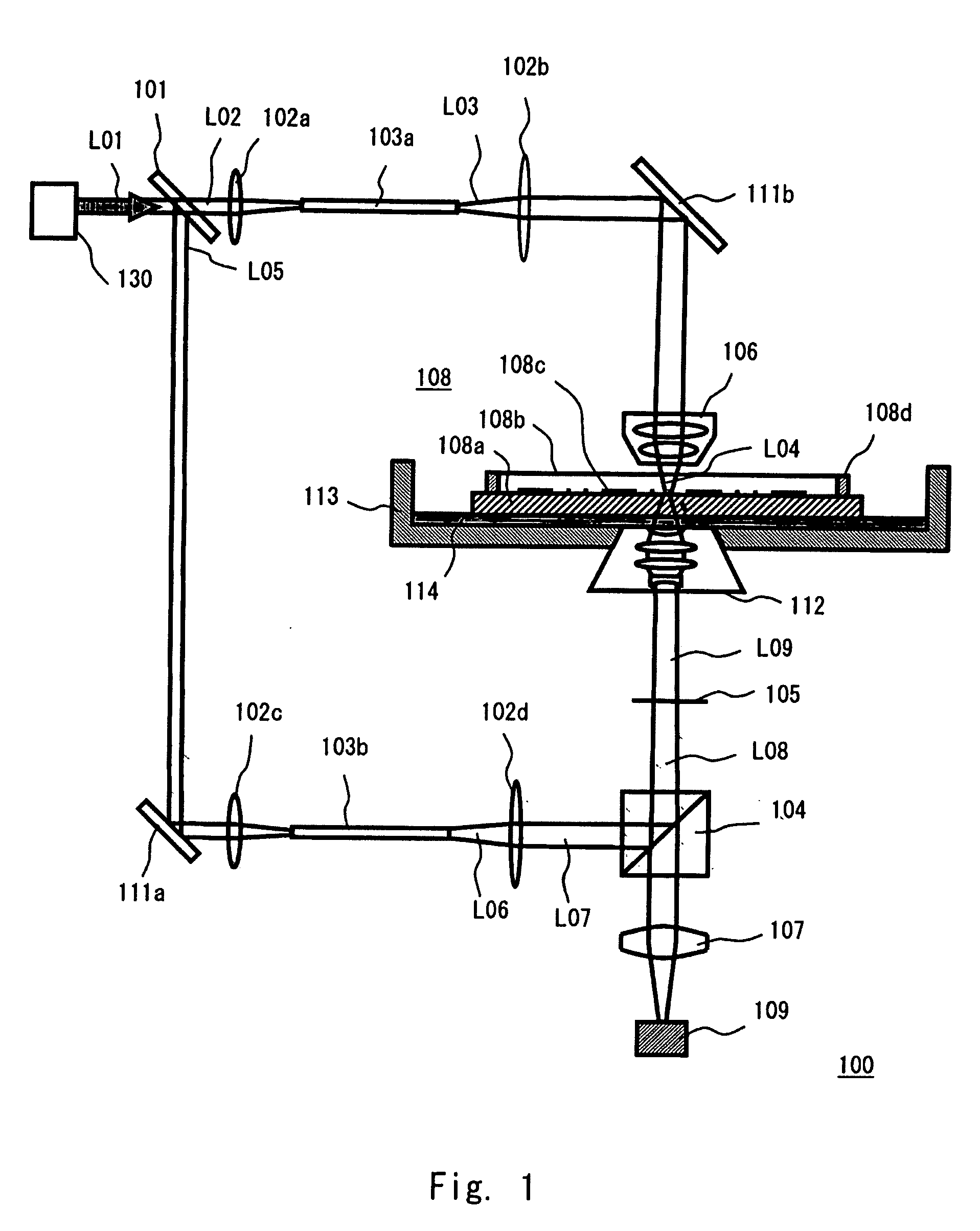

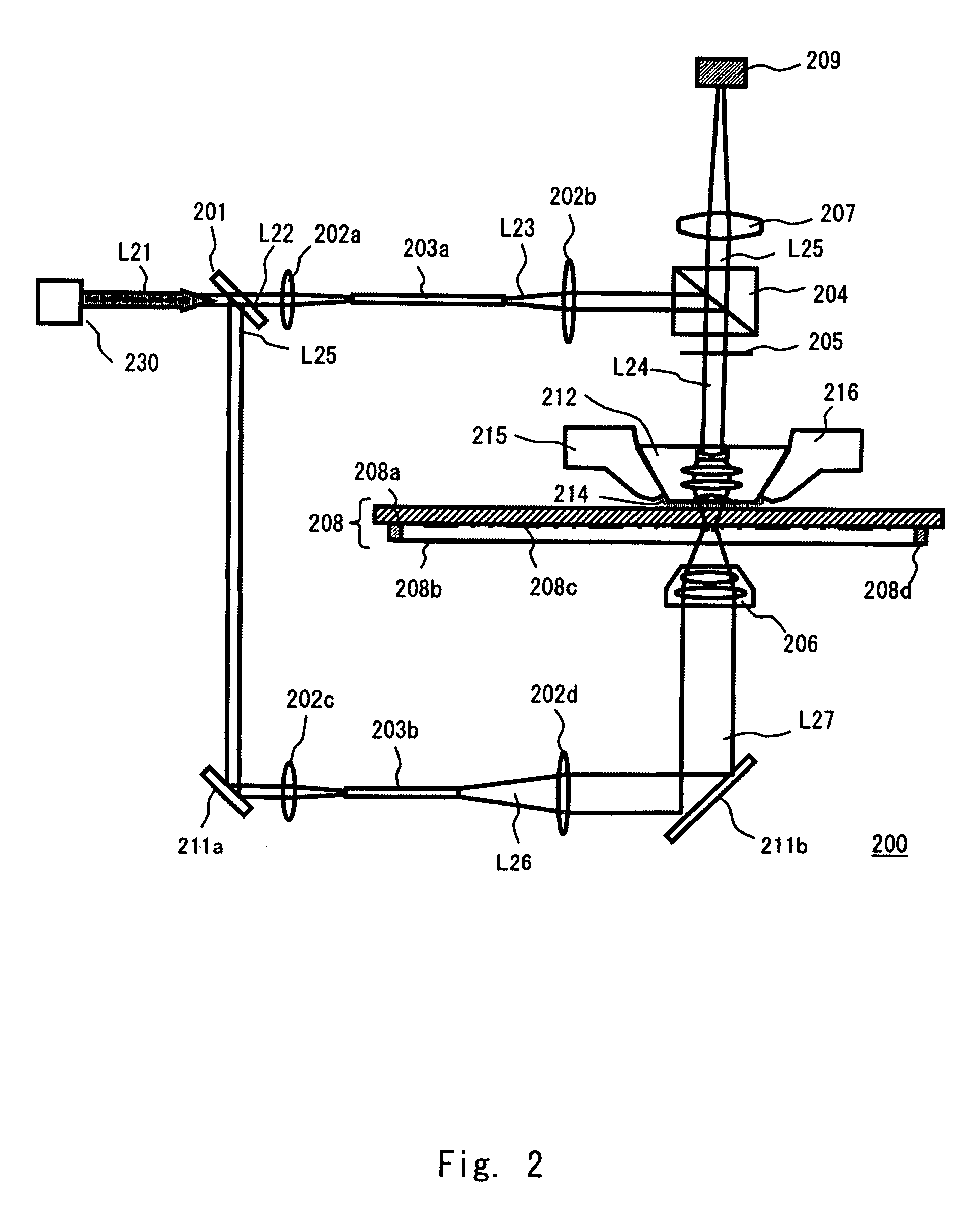

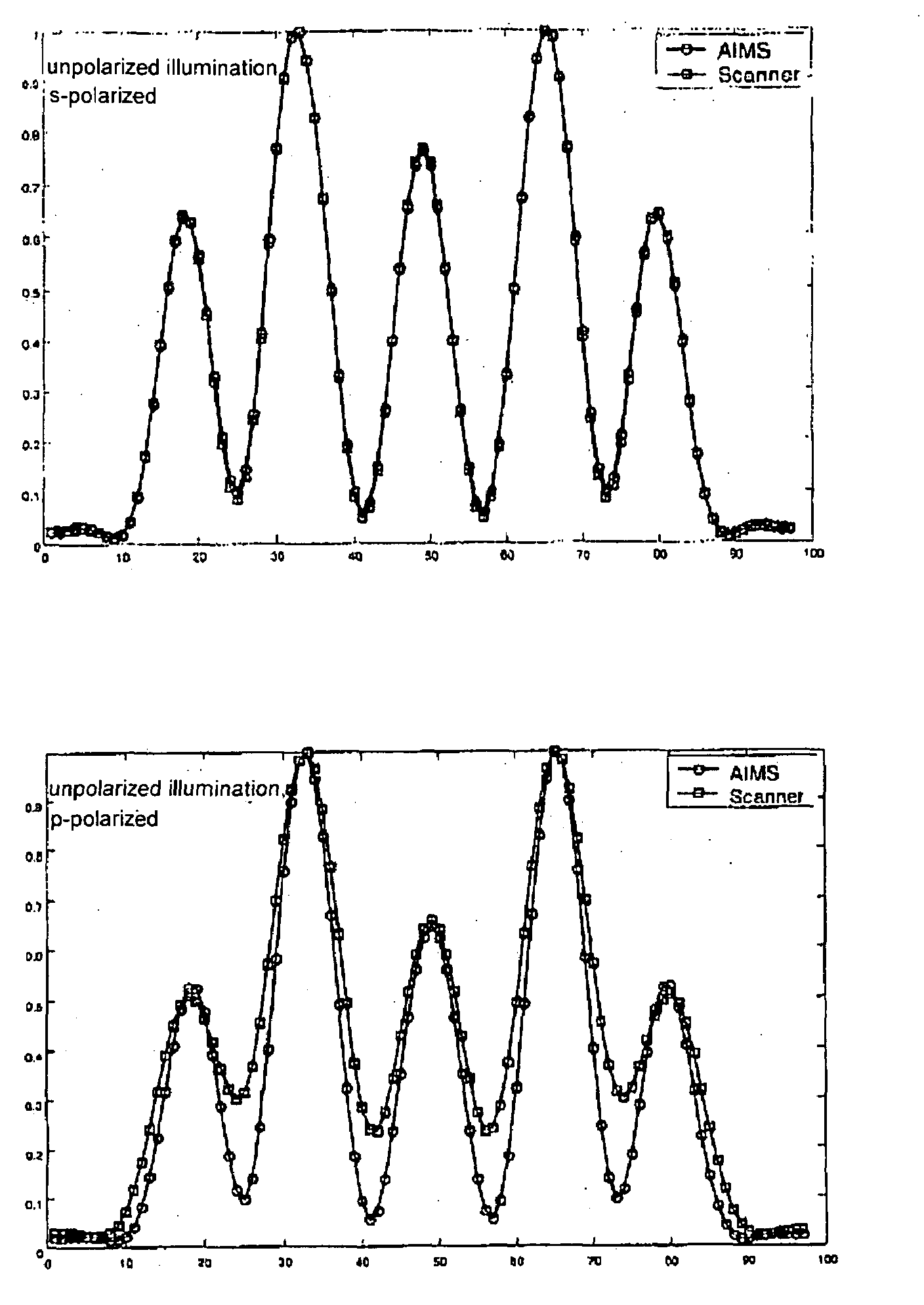

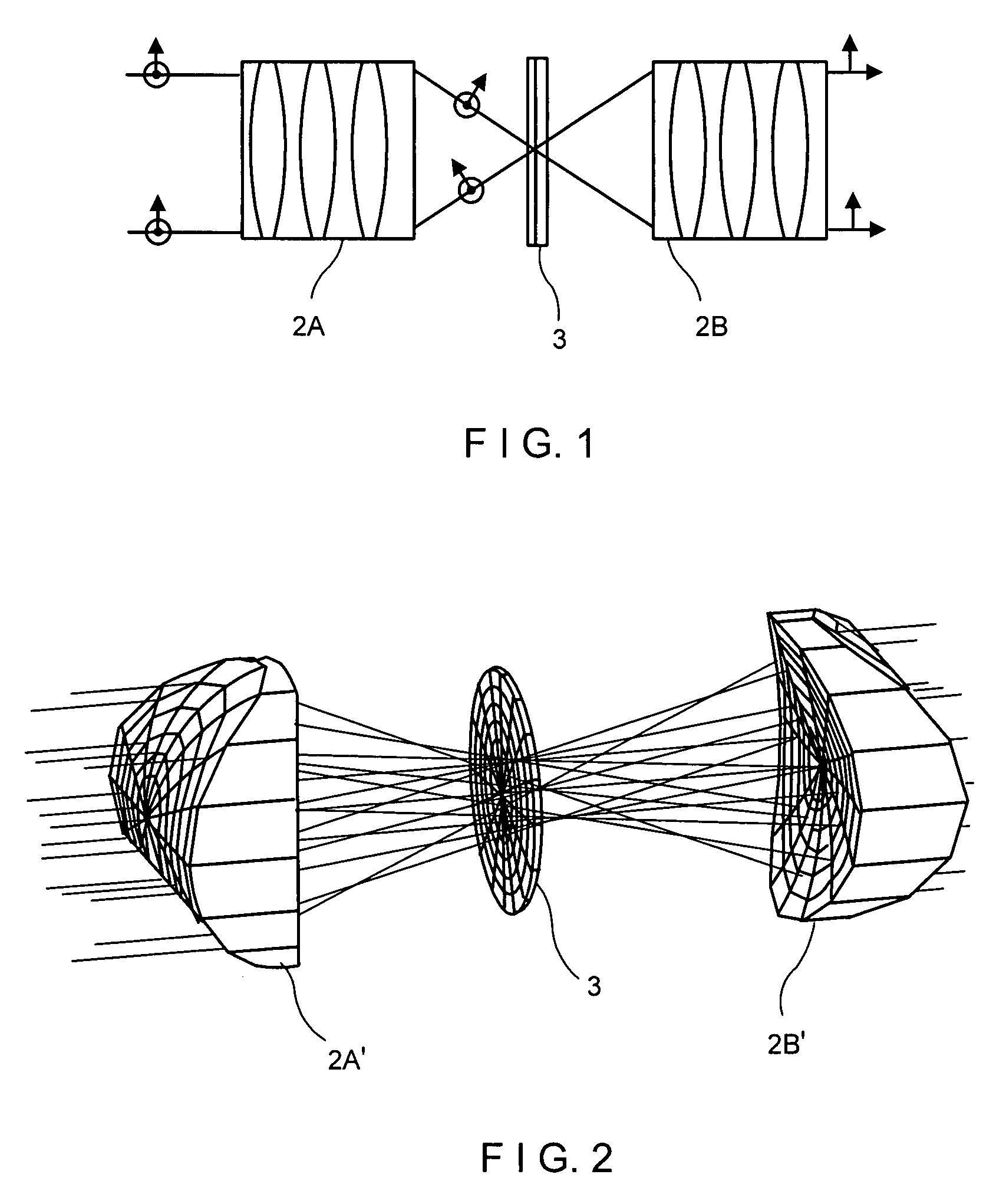

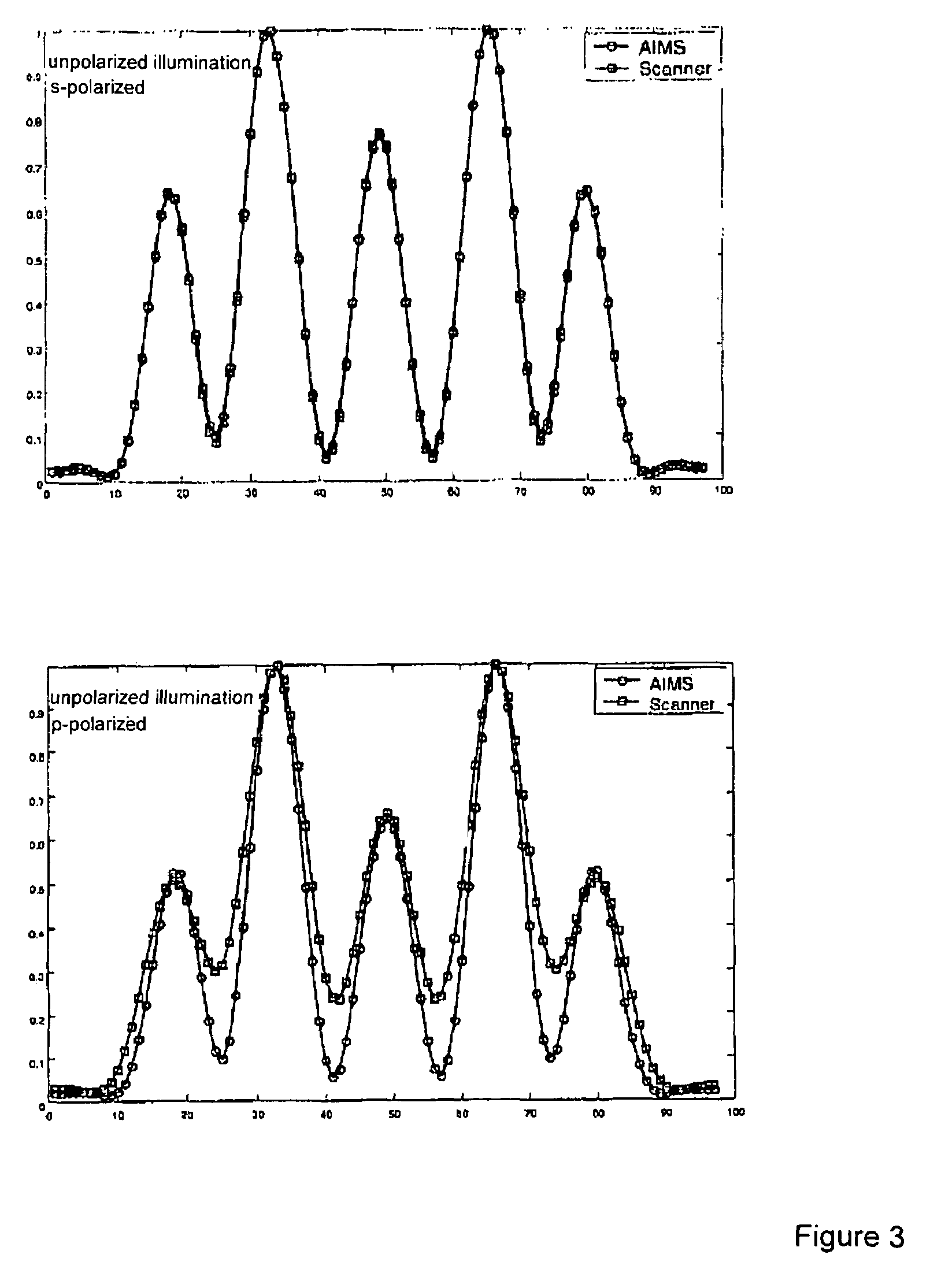

Microscope imaging system and method for emulating a high aperture imaging system, particularly for mask inspection

ActiveUS7286284B2Small structureIncrease the number ofPhotomechanical apparatusCharacter and pattern recognitionMask inspectionLithographic artist

An optical imaging system for inspection microscopes with which lithography masks can be checked for defects particularly through emulation of high-aperture scanner systems. The microscope imaging system for emulating high-aperture imaging systems comprises imaging optics, a detector and an evaluating unit, wherein polarizing optical elements are selectively arranged in the illumination beam path for generating different polarization states of the illumination beam and / or in the imaging beam path for selecting different polarization components of the imaging beam, an optical element with a polarization-dependent intensity attenuation function can be introduced into the imaging beam path, images of the mask and / or sample are received by the detector for differently polarized beam components and are conveyed to the evaluating unit for further processing.

Owner:CARL ZEISS SMT GMBH

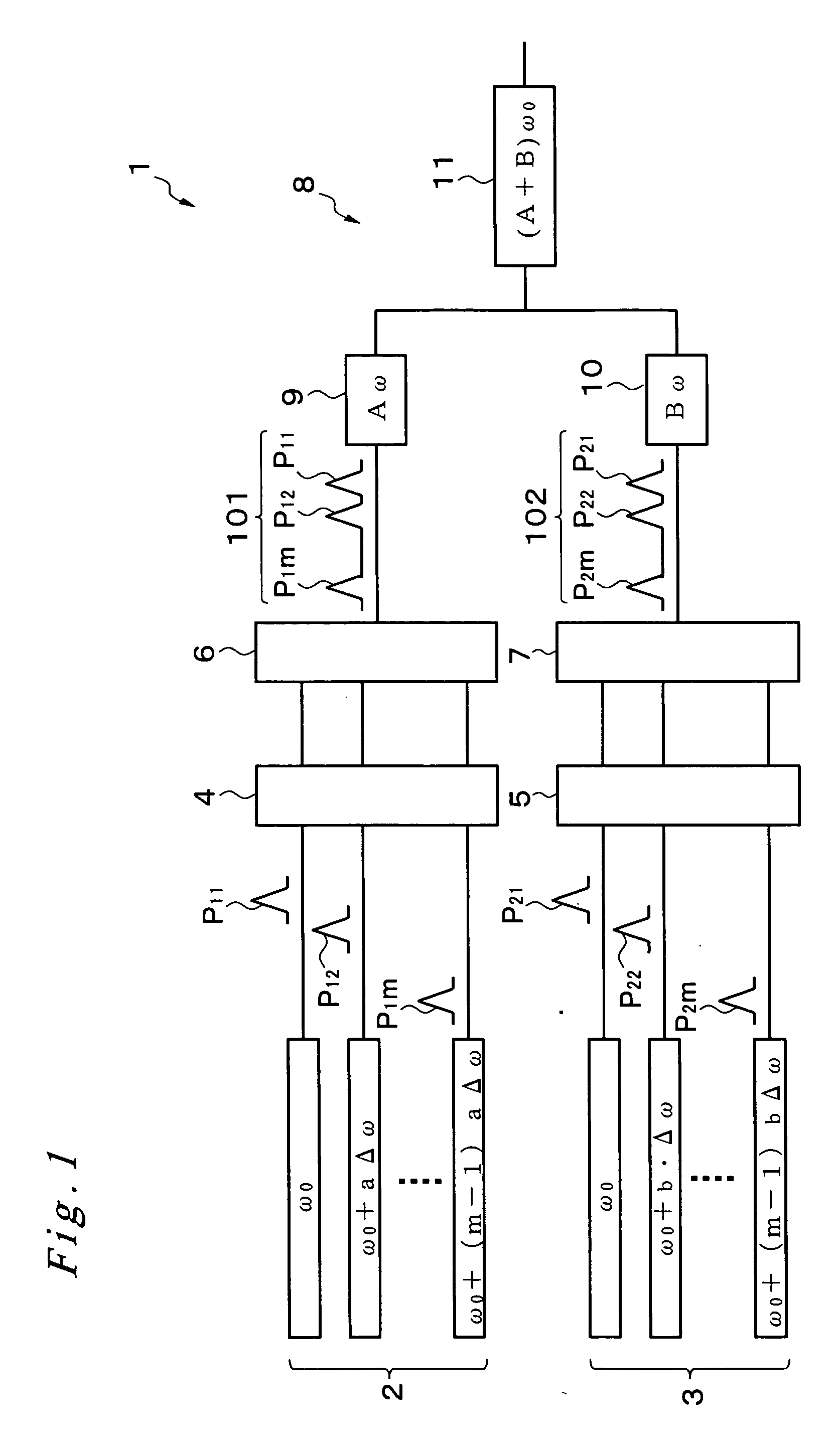

Laser light source device, exposure device, and mask inspection device using this laser light source device

InactiveUS20100073658A1Improve wavelength conversion efficiencyEasy to integrateTime-division optical multiplex systemsWavelength-division multiplex systemsMask inspectionMultiplexing

A laser light source device 1, comprising M number of laser light sources, of which frequency is shifted from a fundamental frequency by (m−1)·a·Δω, a first laser light source section 2 and a first fiber amplifier section 4 for amplifying these laser lights, a first optical multiplexer 6 for approximately coaxially superimposing the laser lights emitted from the first fiber amplifier section 4 and emitting the laser lights, a first wavelength conversion device 9 for multiplying the frequency of the laser lights emitted from the first optical multiplexer 6 by A, M number of laser light sources, of which frequency is shifted from the fundamental frequency by (m−1)·b·Δω, a second laser light source section 3 and a second fiber amplifier section 5 for amplifying these laser lights, a second optical multiplexer 7 for approximately coaxially superimposing the laser lights emitted from the second fiber amplifier section 5 and emitting the laser lights, a second wavelength conversion device 10 for multiplying the frequency of the laser lights emitted from the second optical multiplexer 7 by B, and a third wavelength conversion device 11 for simultaneously receiving the laser lights emitted from the first and second wavelength conversion devices 9 and 10 and converting the laser lights into laser lights, of which frequency is (A+B) times the fundamental frequency, the laser light source device 1 being characterized in that the expression A·a+B·b=0 is satisfied.

Owner:NIKON CORP

Method and apparatus for deblurring mask images

ActiveUS7483559B2Reduce distortion problemsError minimizationImage enhancementImage analysisMask inspectionFuzzy filter

The invention comprises processes for determining and applying a deblurring filter that reduces inspection system distortion, of mask inspection images, by compensating for the non-uniform frequency response of the inspection system.In particular, an adaptive filter is determined empirically for an inspection system: one or more training images are obtained by the inspection system and the filter is determined from such images. In this way, the filter can adapt to the characteristics of each individual inspection system.An example adaptive filter, known as a Weiner filter, is determined and applied.

Owner:SYNOPSYS INC

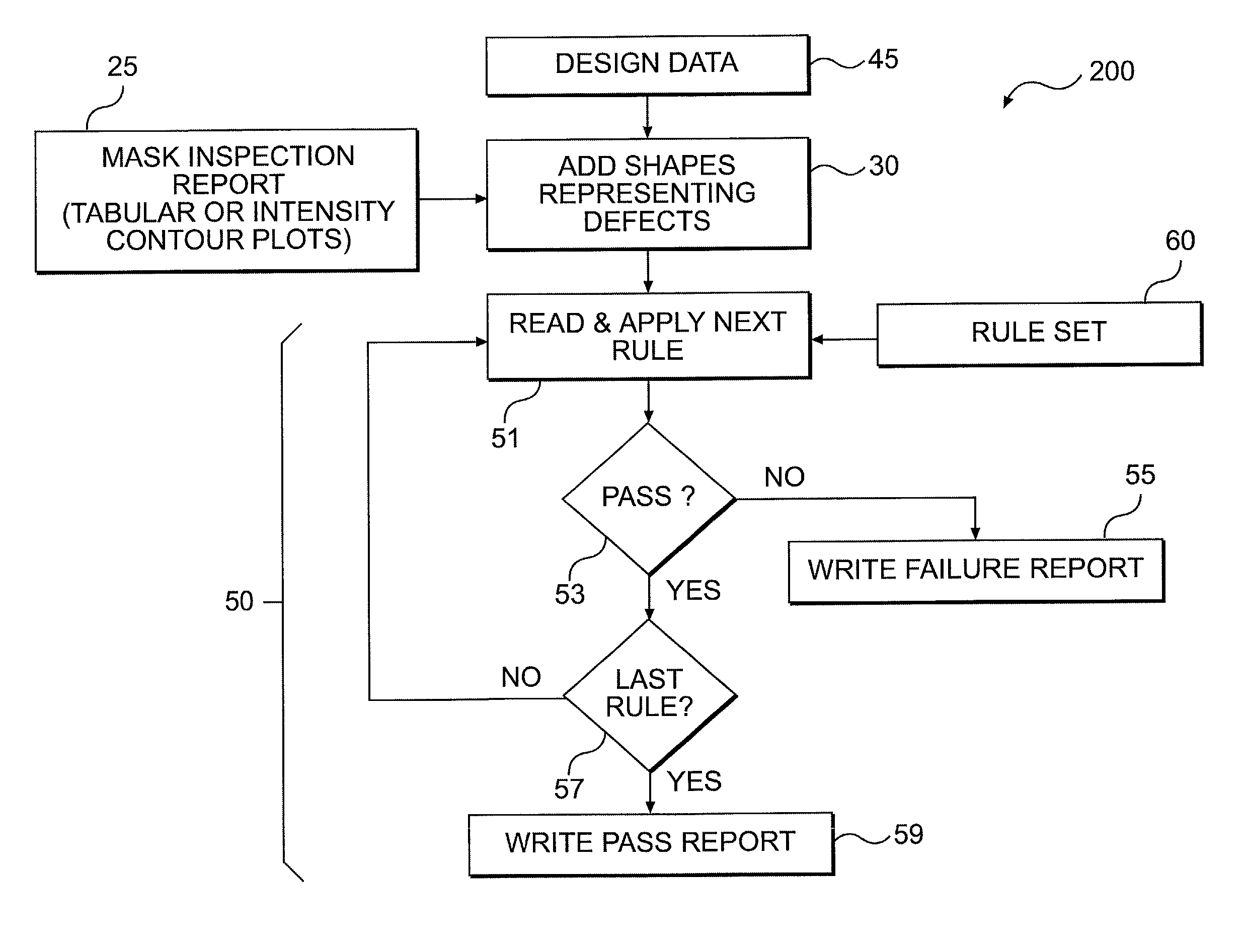

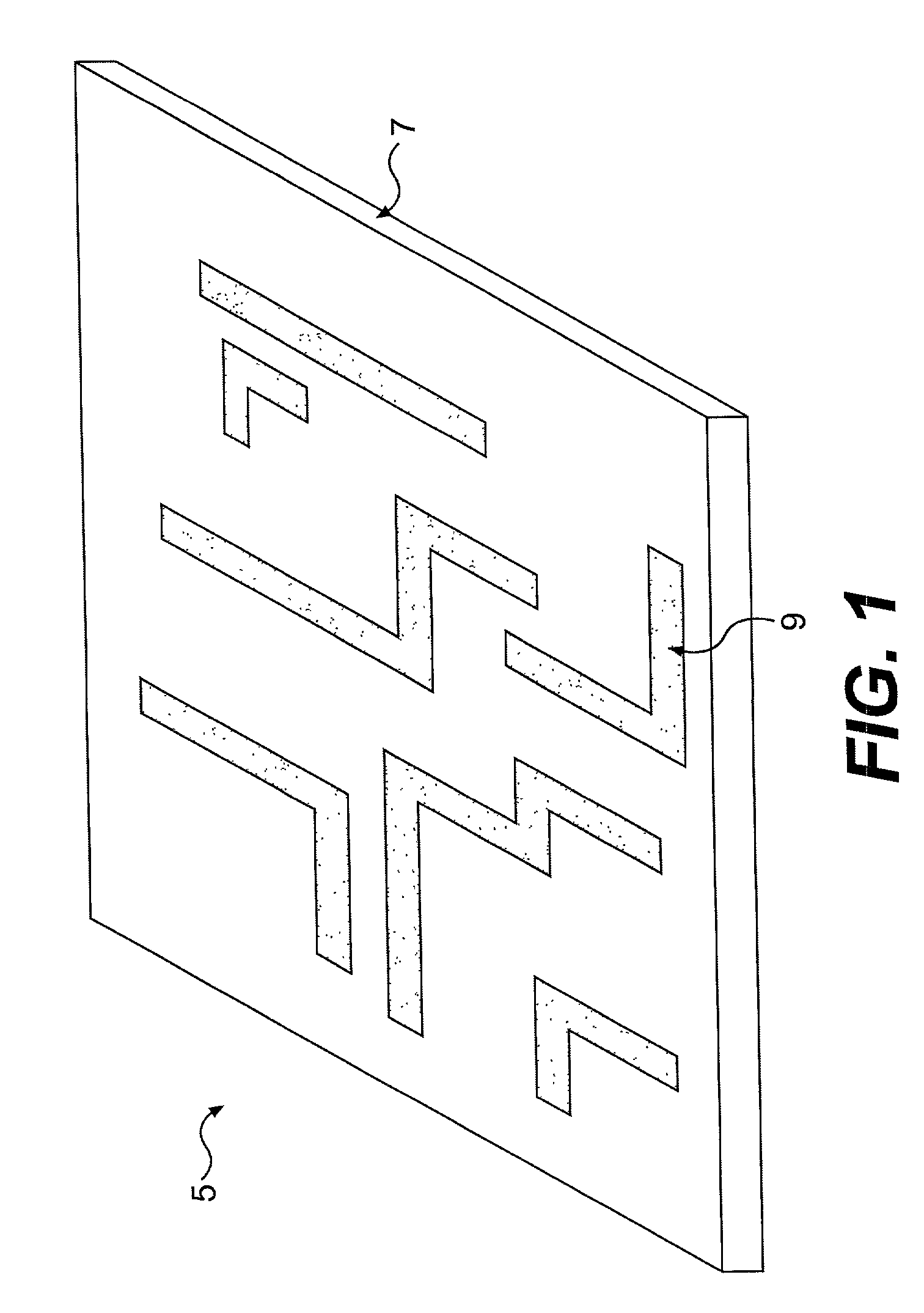

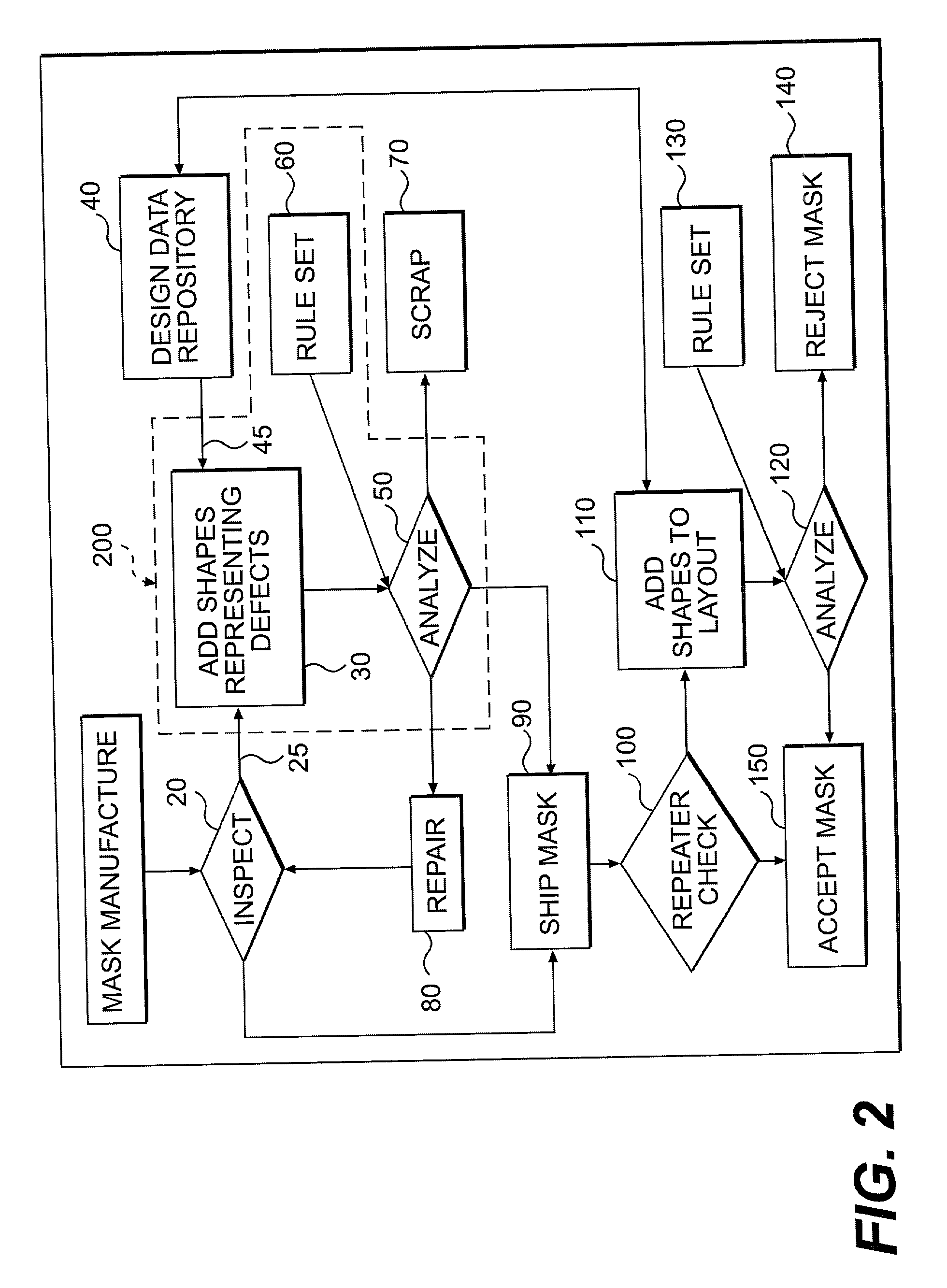

Mask defect analysis system

InactiveUS7257247B2Low costShorten the timeCharacter and pattern recognitionColor television detailsMask inspectionData application

An automated system for analyzing mask defects in a semiconductor manufacturing process is presented. This system combines results from an inspection tool and design layout data from a design data repository corresponding to each mask layer being inspected with a computer program and a predetermined rule set to determine when a defect on a given mask layer has occurred. Mask inspection results include the presence, location and type (clear or opaque) of defects. Ultimately, a determination is made as to whether to scrap, repair or accept a given mask based on whether the defect would be likely to cause product failure. Application of the defect inspection data to the design layout data for each mask layer being inspected prevents otherwise acceptable wafer masks from being scrapped when the identified defects are not in critical areas of the mask.

Owner:IBM CORP

Electrical mask inspection

InactiveUS20120068174A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsMask inspectionEngineering

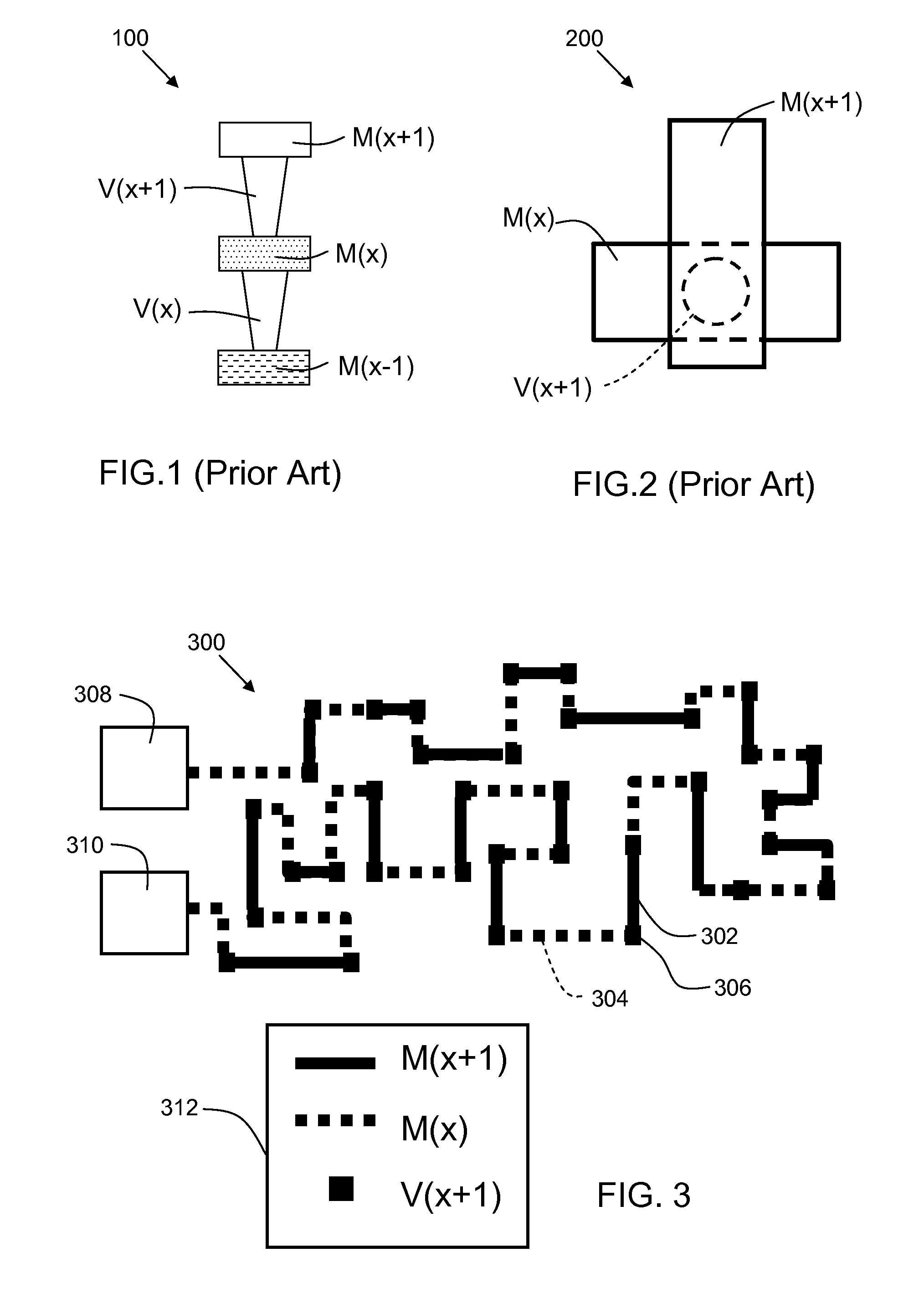

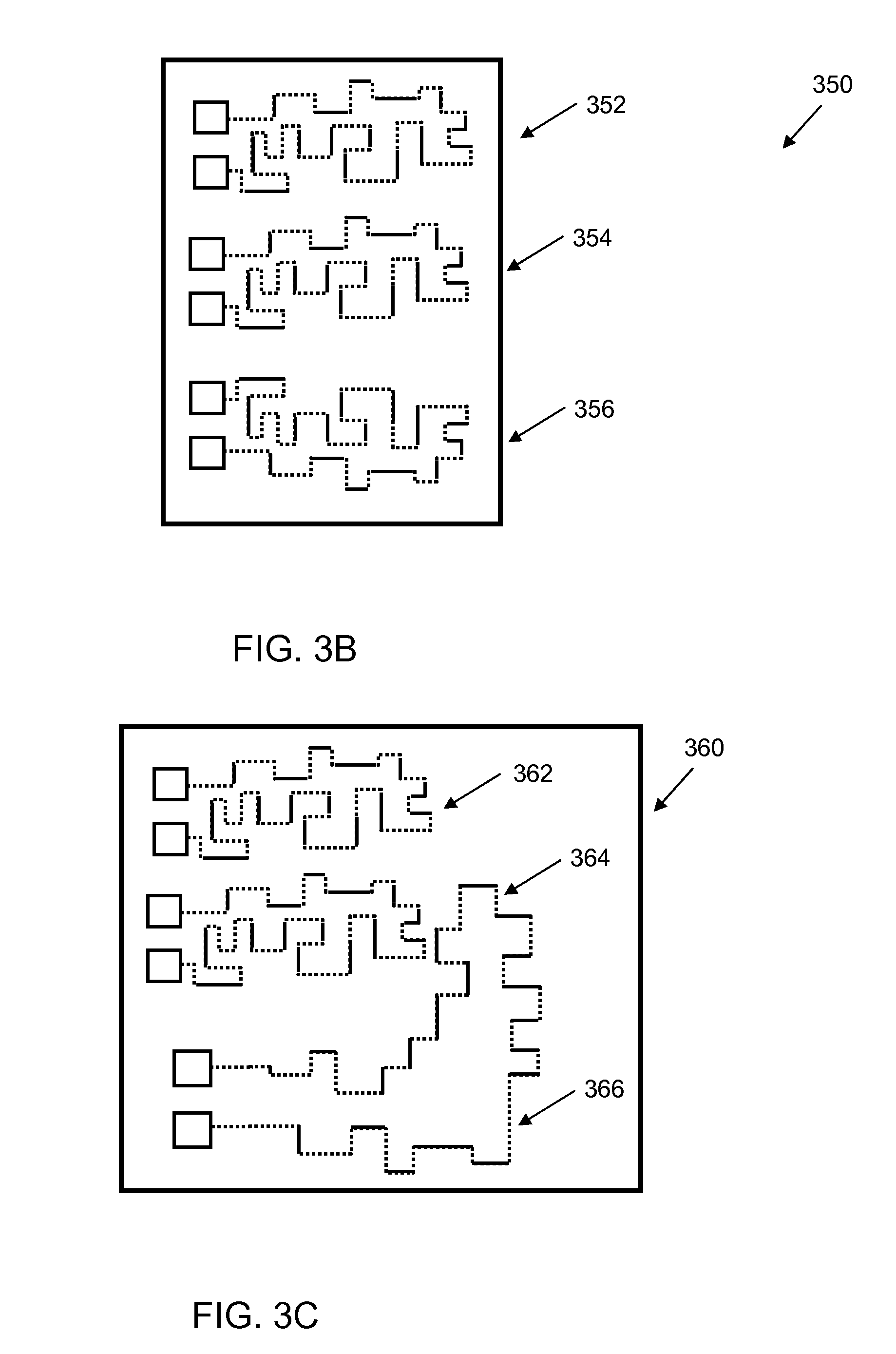

An apparatus and method for electrical mask inspection is disclosed. A scan chain is formed amongst two metal layers and a via layer. One of the three layers is a functional layer under test, and the other two layers are test layers. A resistance measurement of the scan chain is used to determine if a potential defect exists within one of the vias or metal segments comprising the scan chain.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com