Patents

Literature

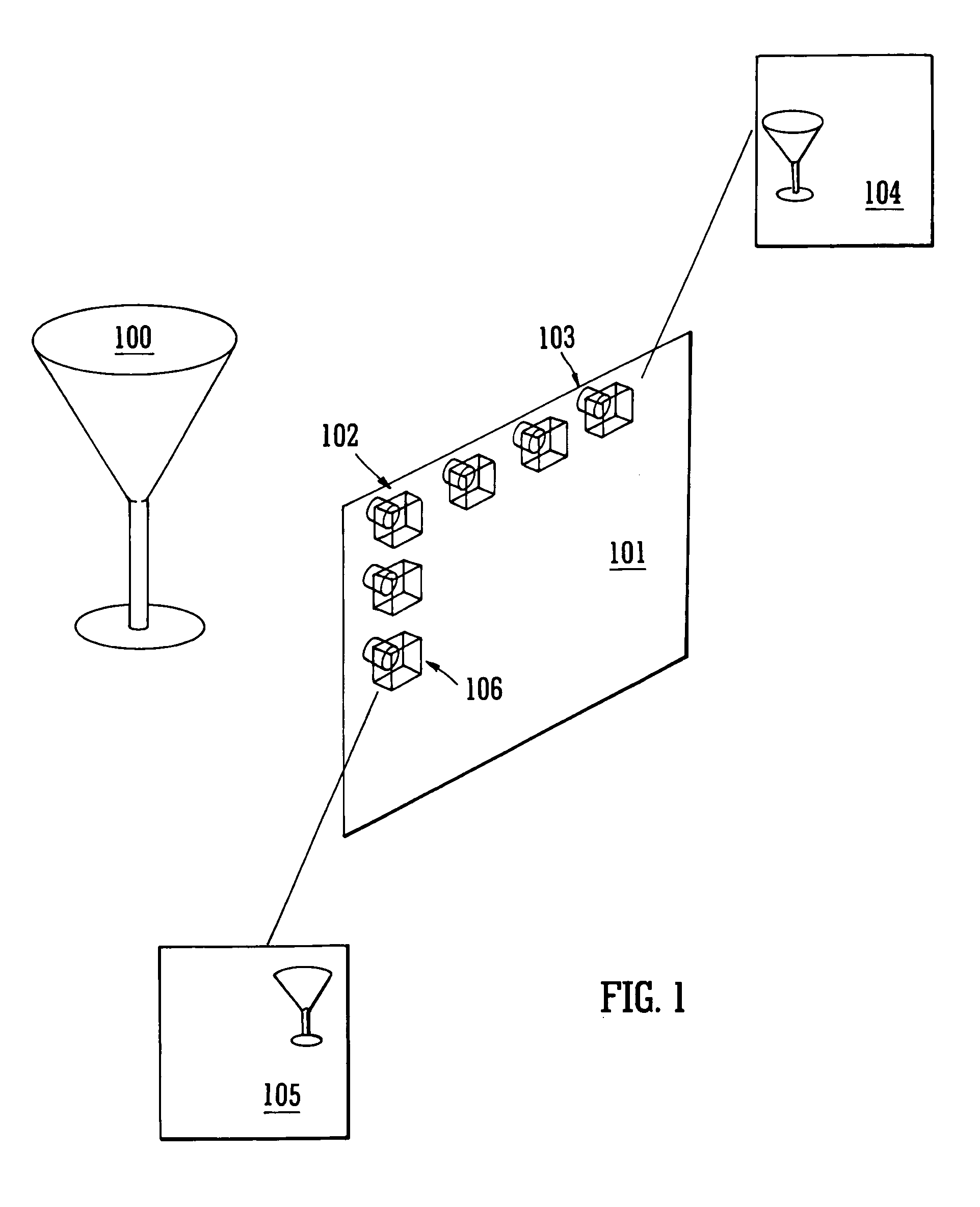

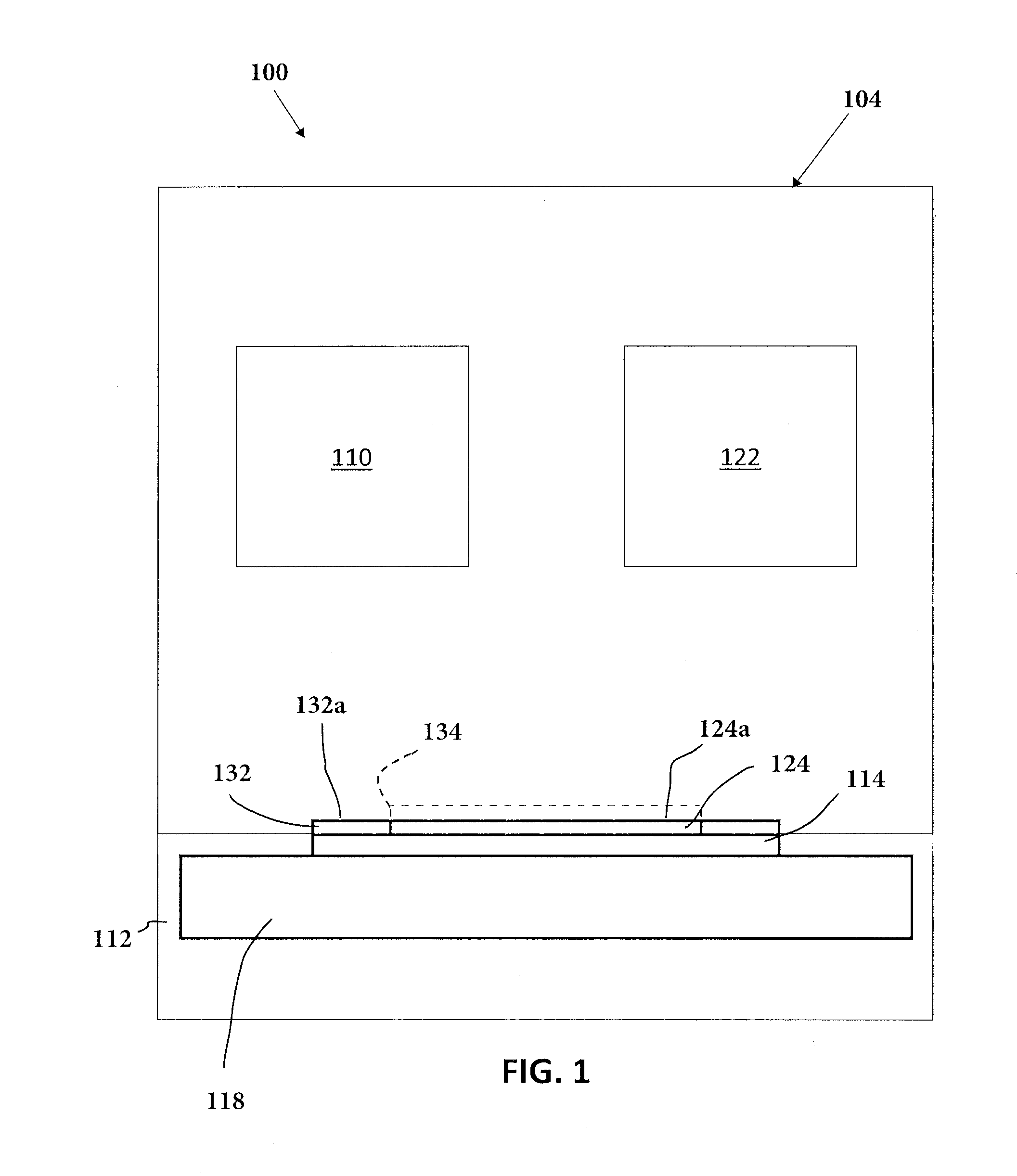

939 results about "Direct writing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Direct Writing. While automatic writing is produced by spirit using the arm and hand of the medium, direct writing (also known as independent writing) is produced purely by spirit. Direct writing can appear anywhere, on any substance. It has often appeared at the sites of poltergeist activity, written on walls, floor, or ceiling.

System and Method for Integrated Circuit Manufacturing

ActiveUS20150278429A1Photomechanical apparatusDesign optimisation/simulationMask inspectionIntegrated circuit manufacturing

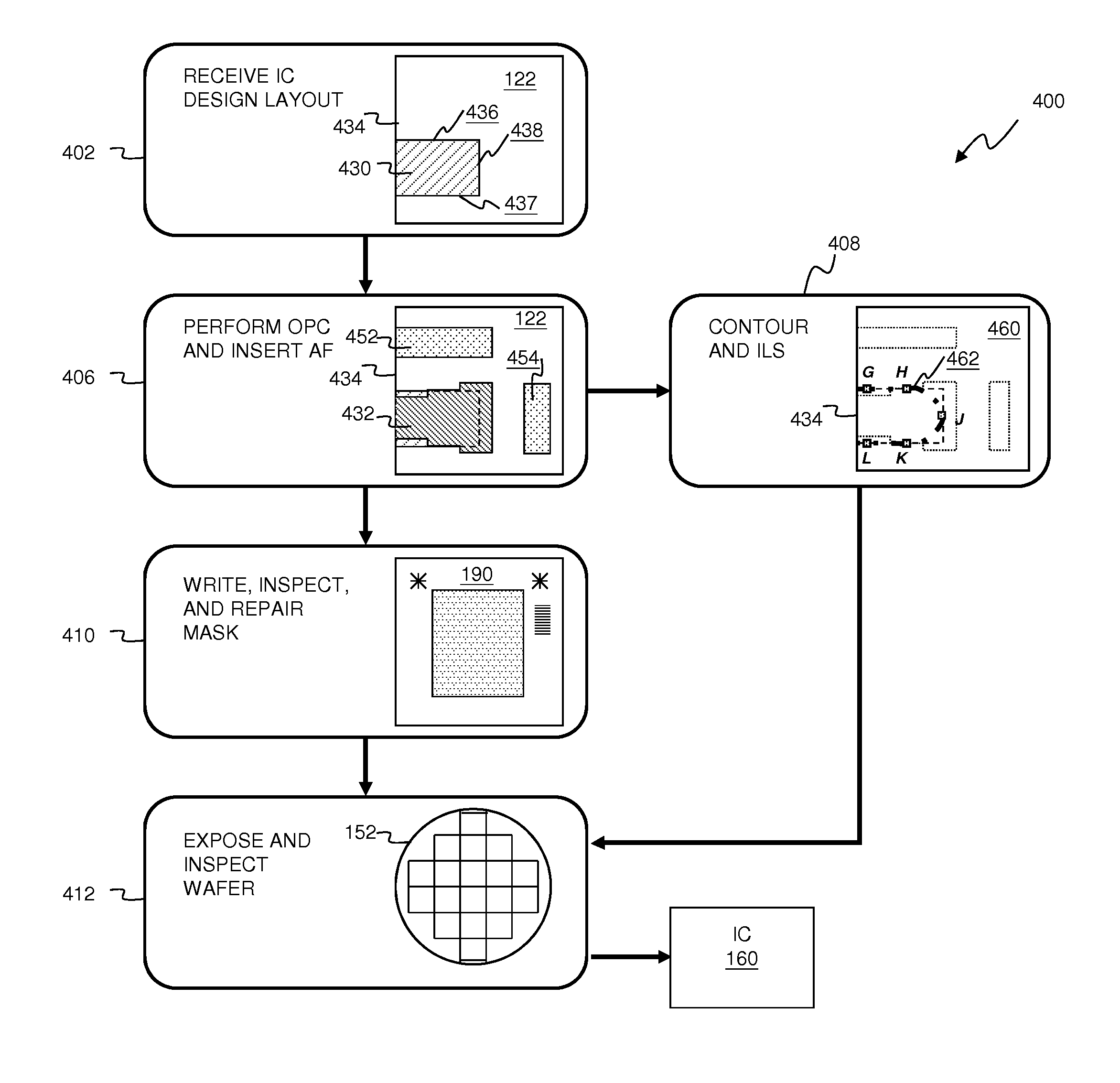

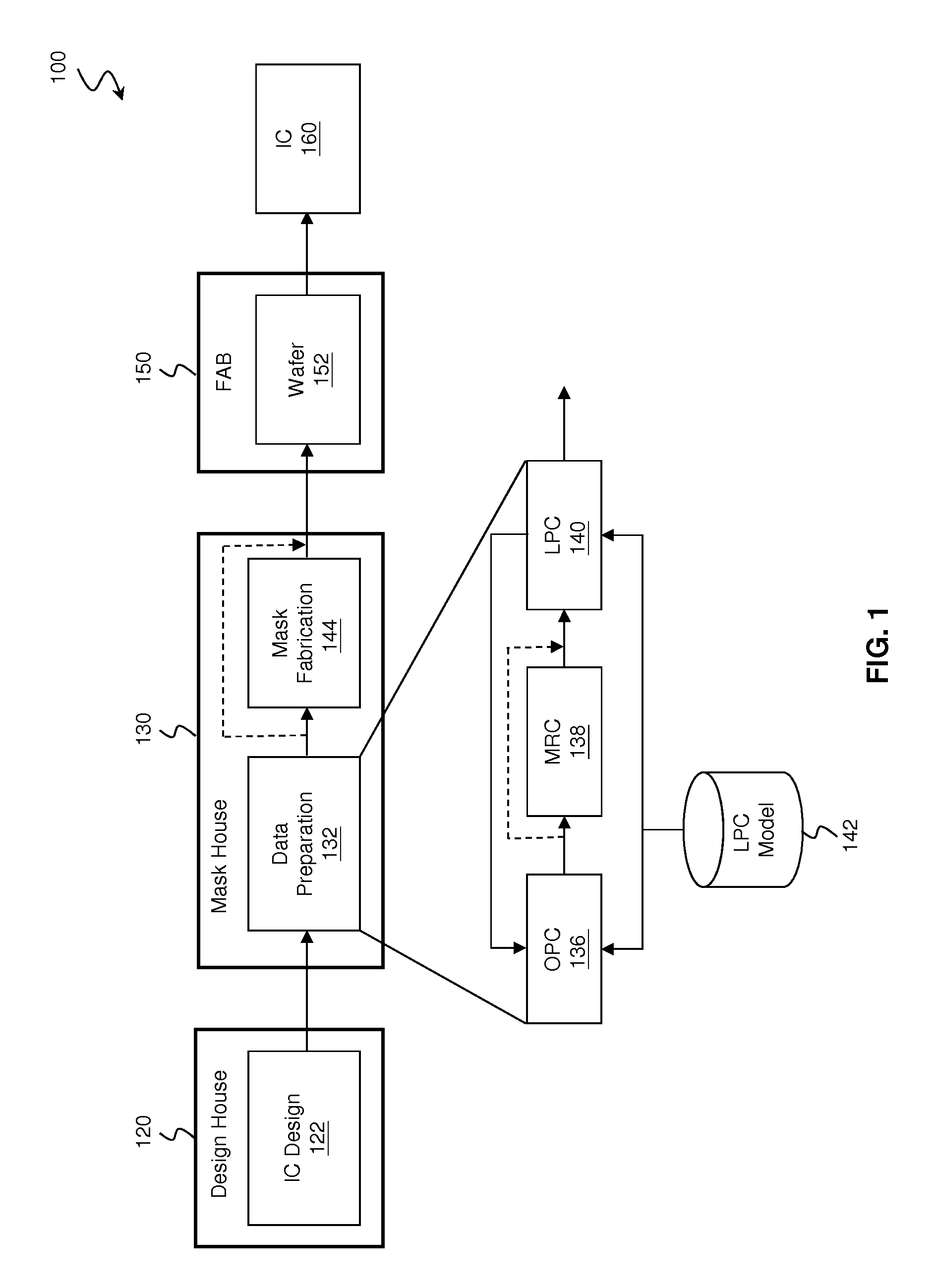

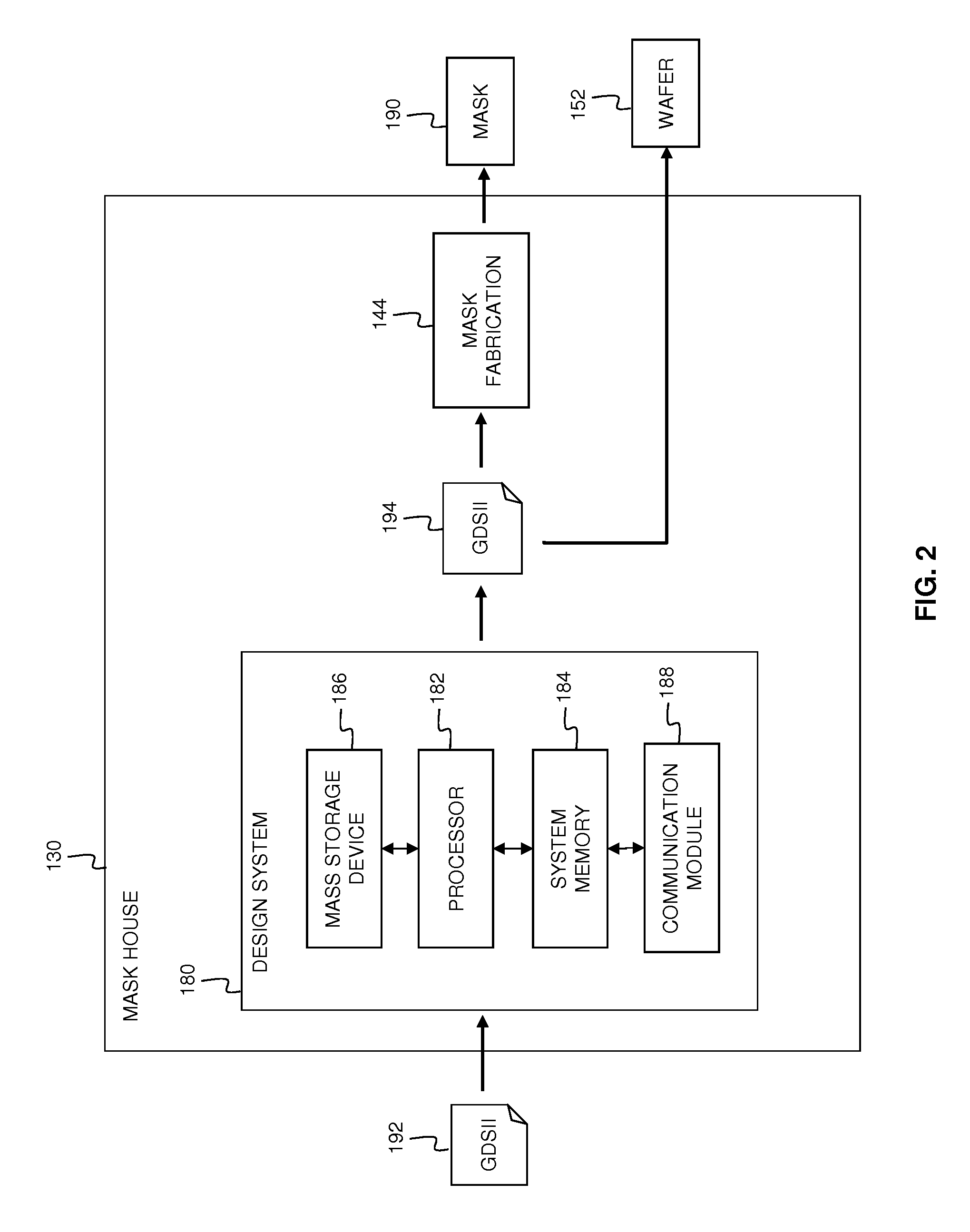

Provided is an integrated circuit (IC) manufacturing method. The method includes receiving a design layout of an IC, the design layout having a main feature; performing a process correction to the main feature thereby generating a modified main feature; using a computer, generating a simulated contour of the modified main feature, the simulated contour having a plurality of points; generating a plurality of assistant data in computer readable format, wherein each assistant data includes at least one process performance factor associated with one of the points; and keeping the simulated contour and the assistant data for use by a further process stage, such as mask making, mask inspection, mask repairing, wafer direct writing, wafer inspection, and wafer repairing.

Owner:TAIWAN SEMICON MFG CO LTD

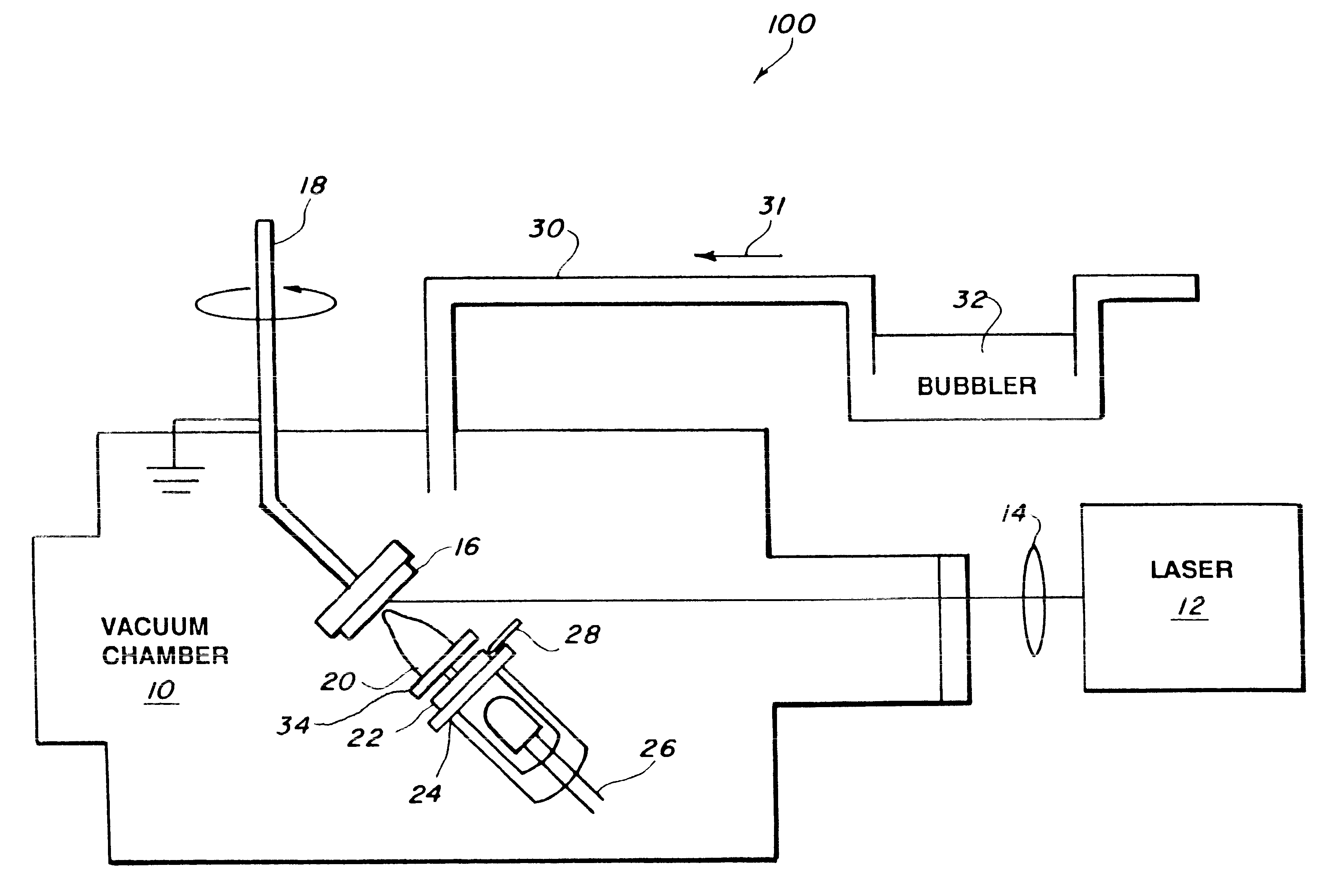

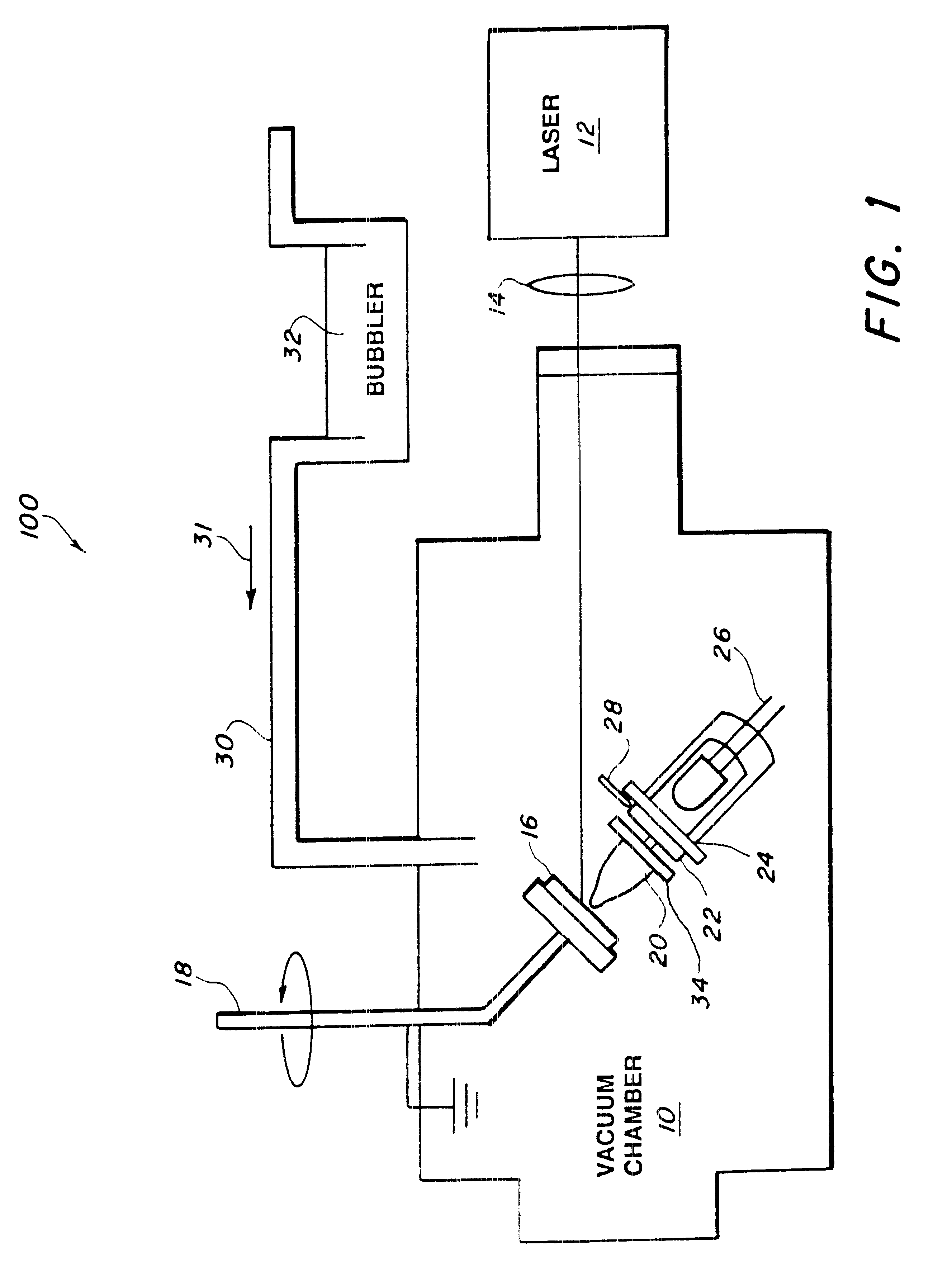

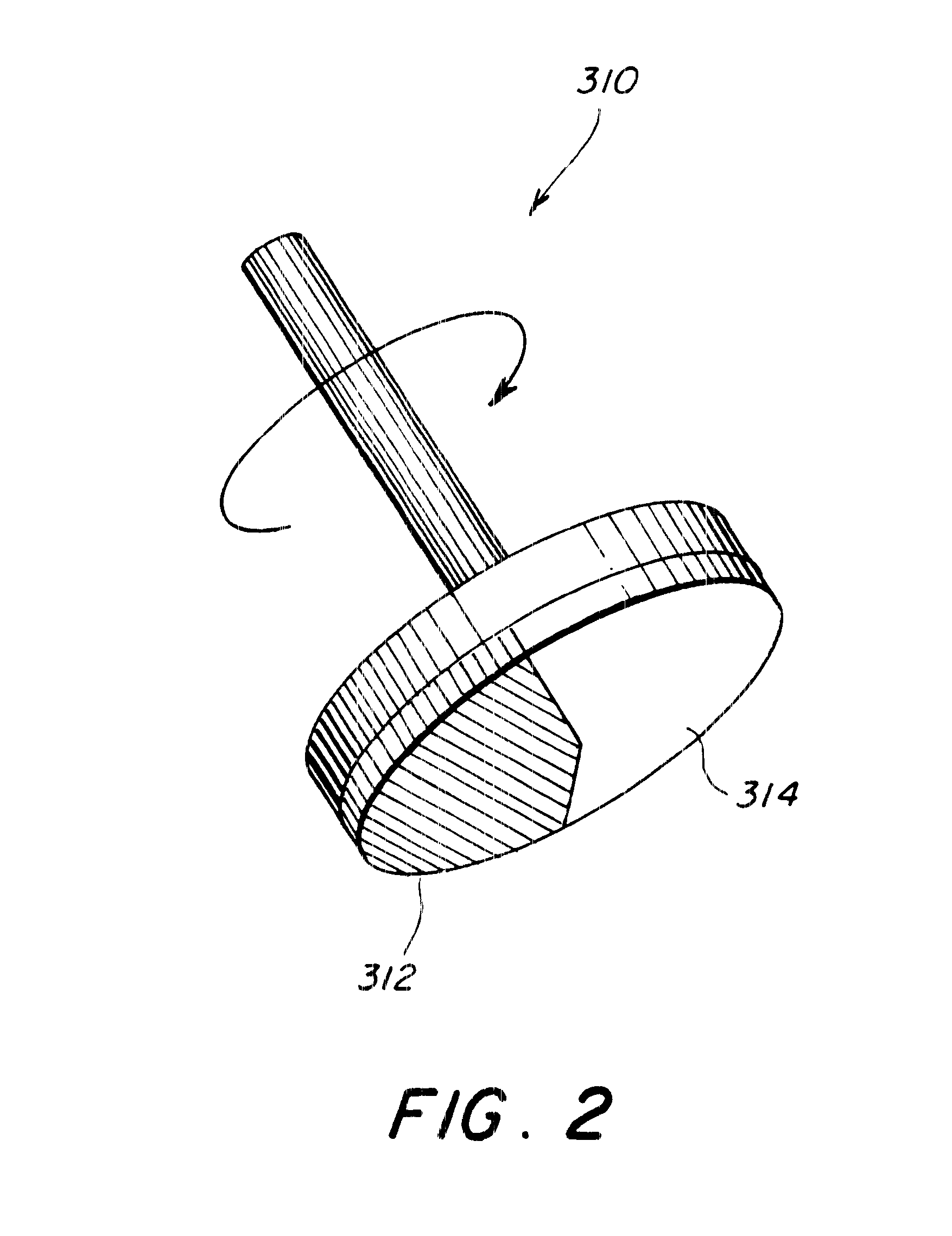

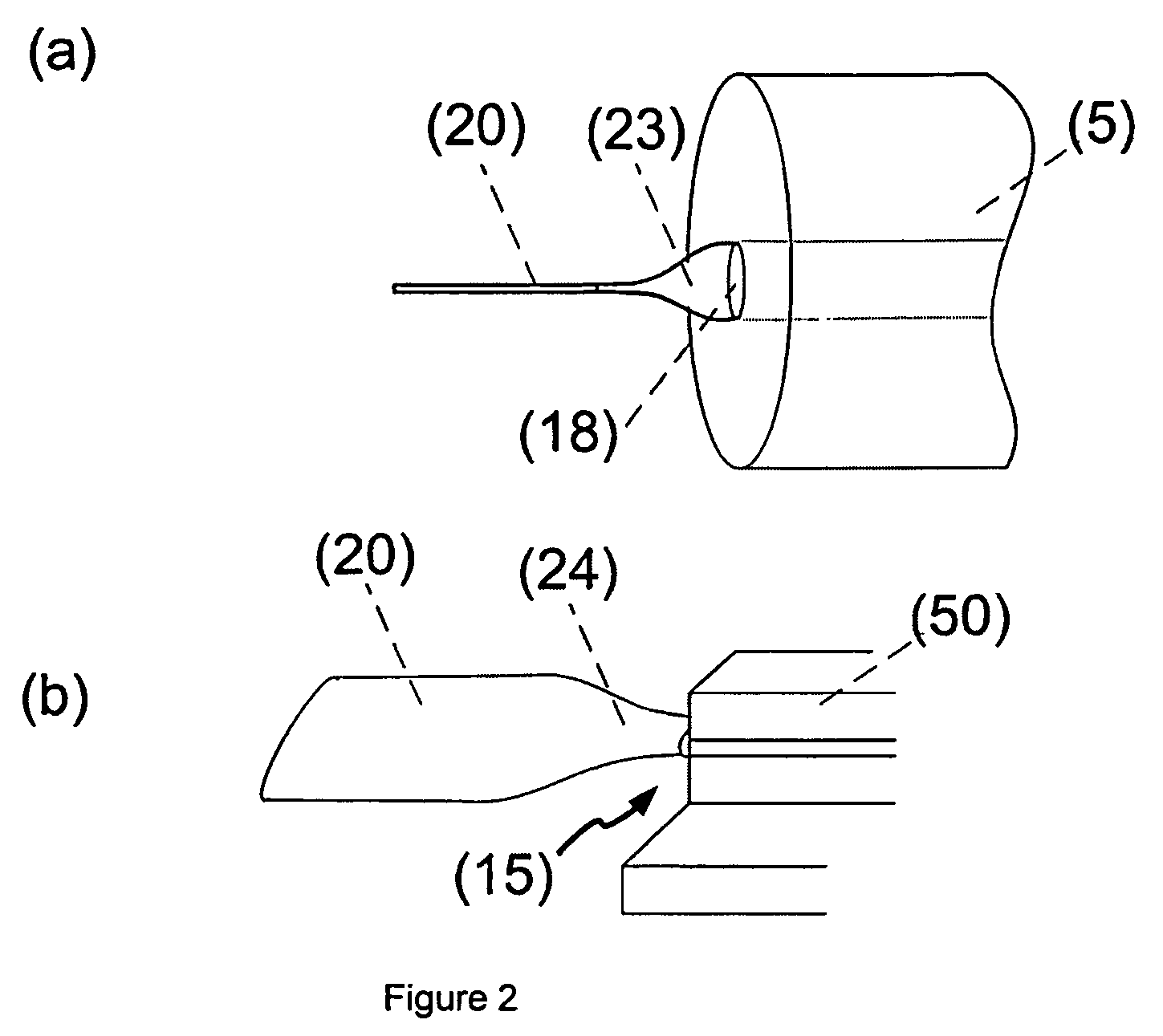

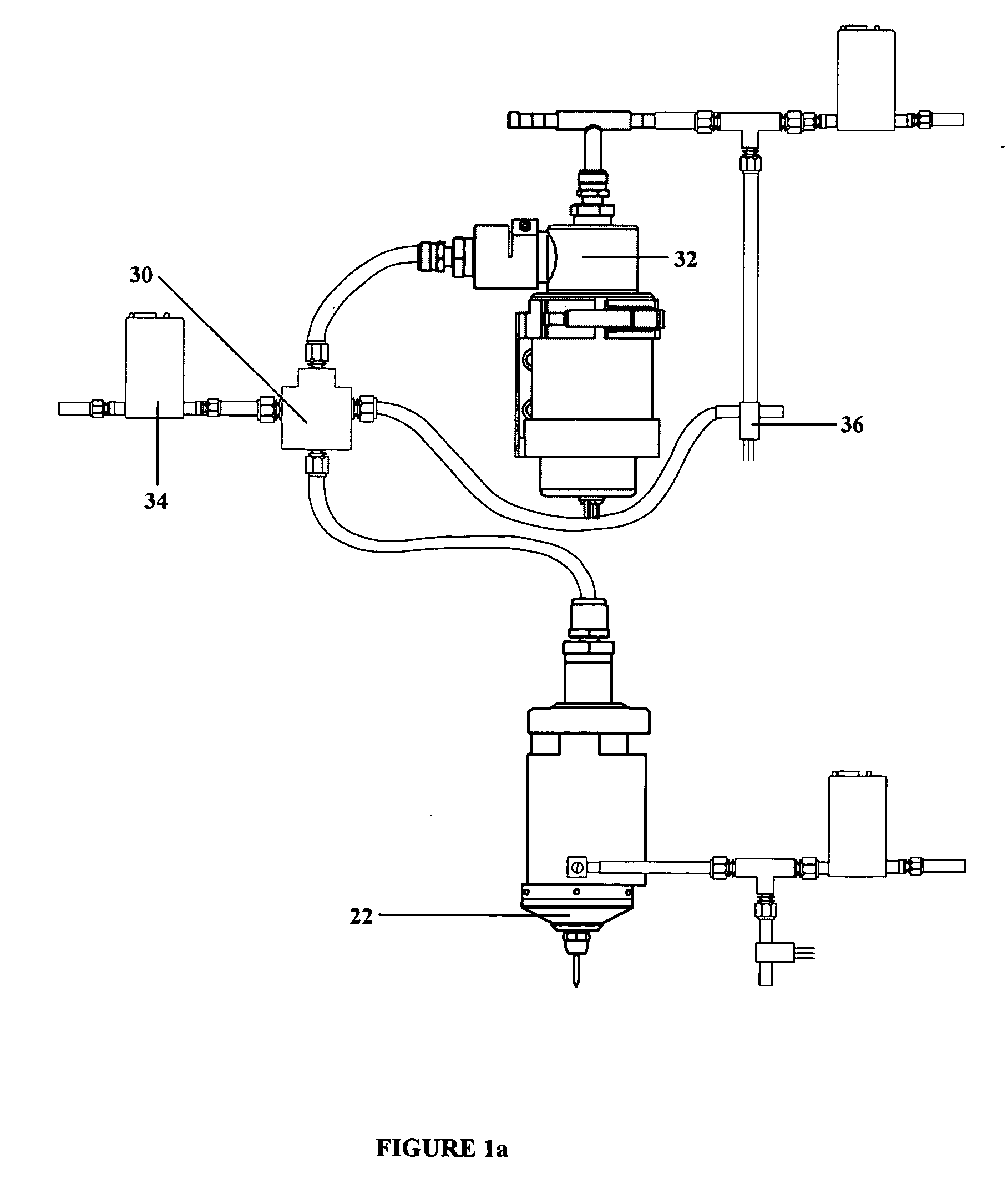

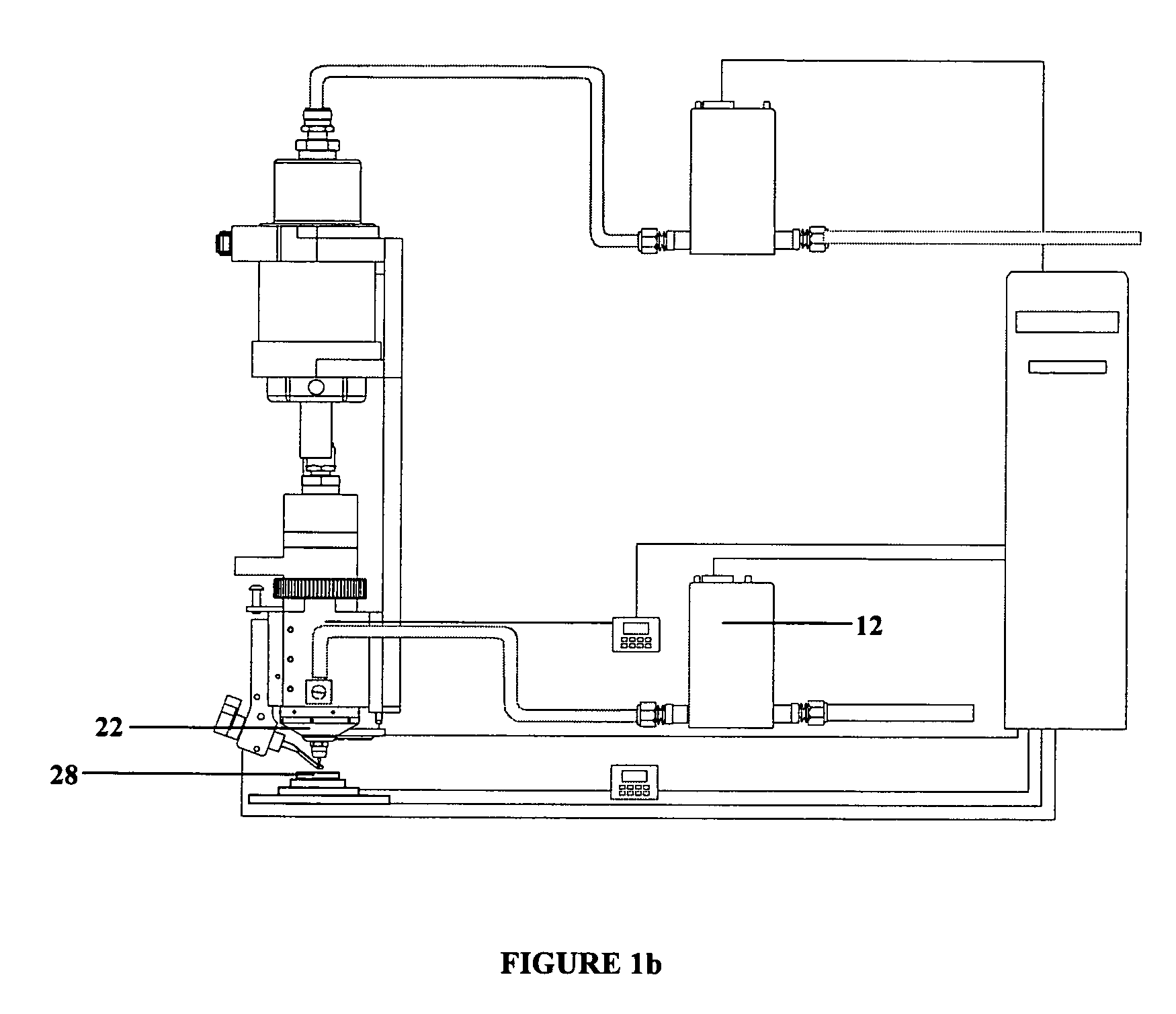

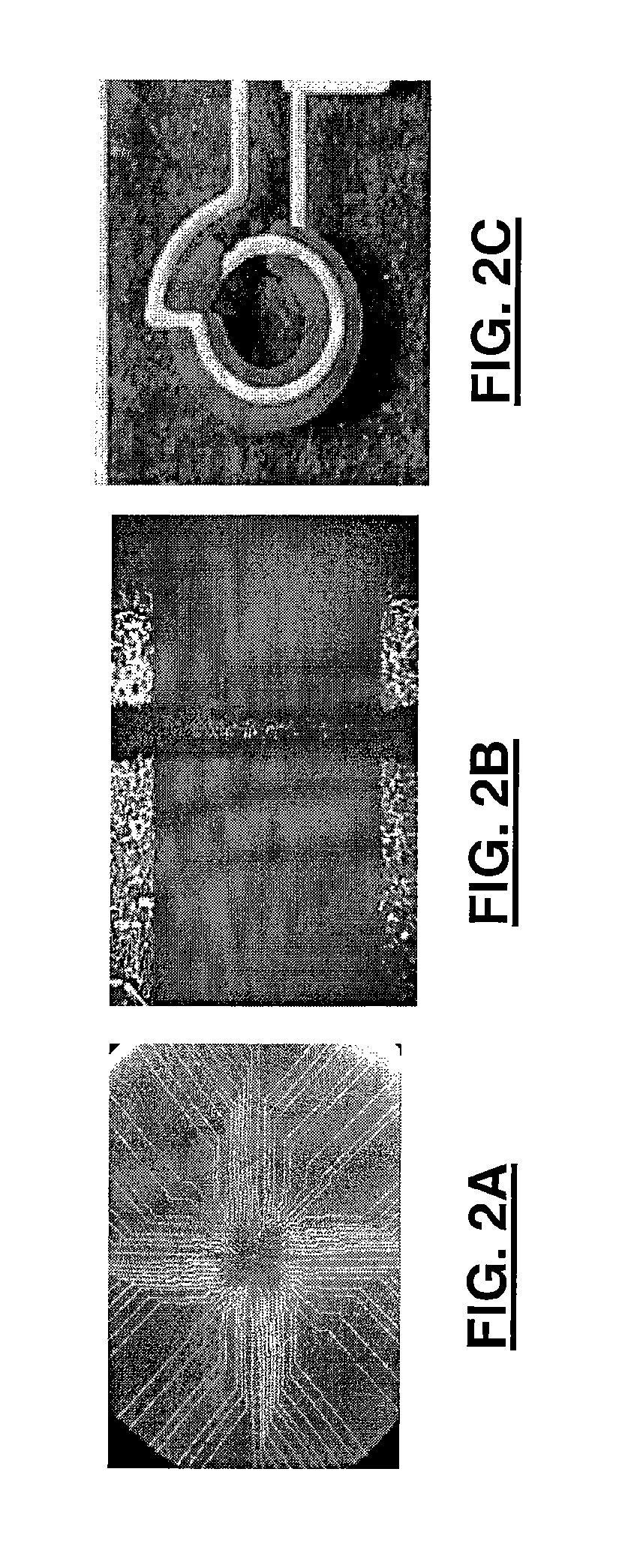

Aerodynamic jetting of aerosolized fluids for fabrication of passive structures

InactiveUS7674671B2Liquid surface applicatorsSemiconductor/solid-state device manufacturingOptical propertyDirect writing

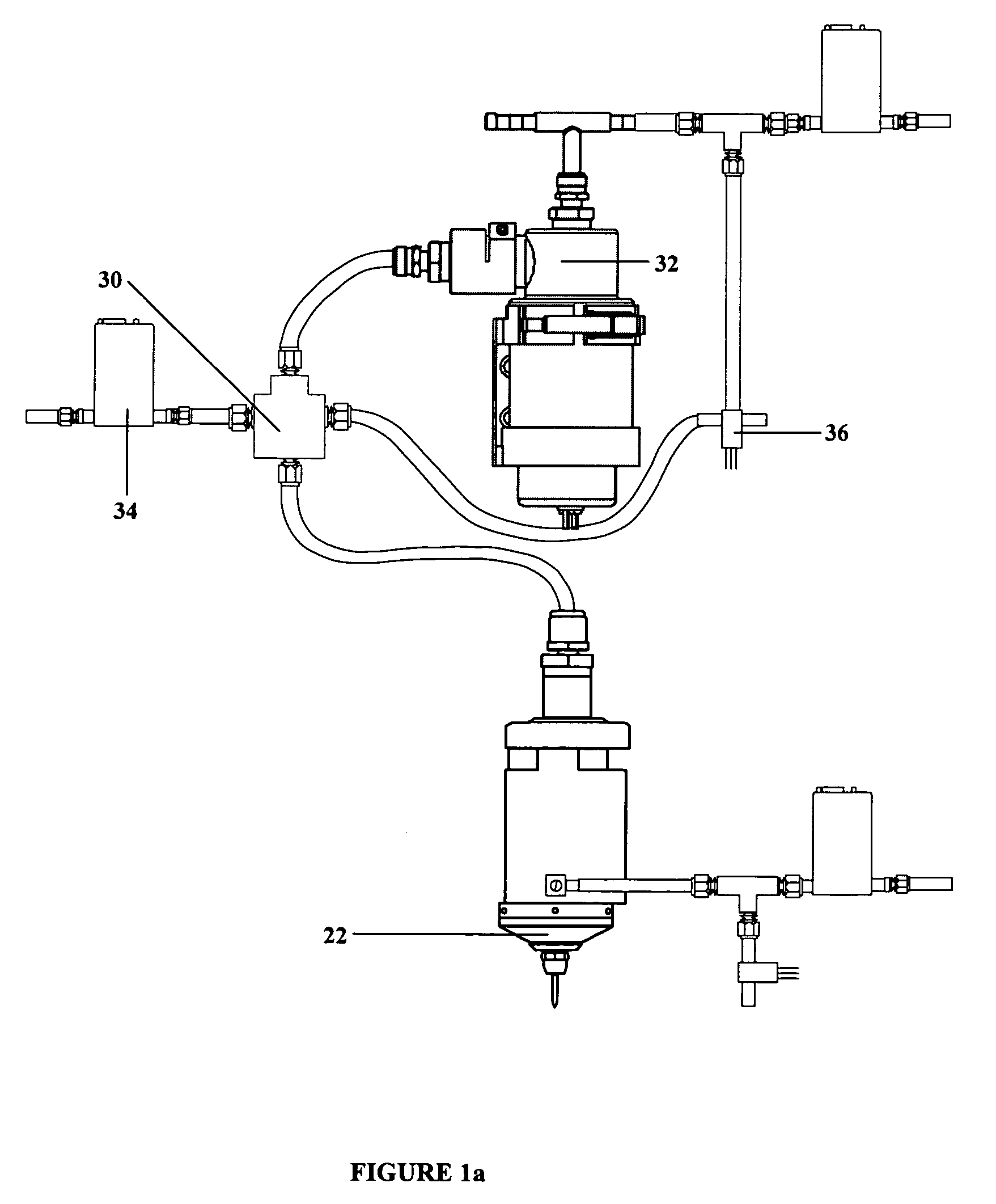

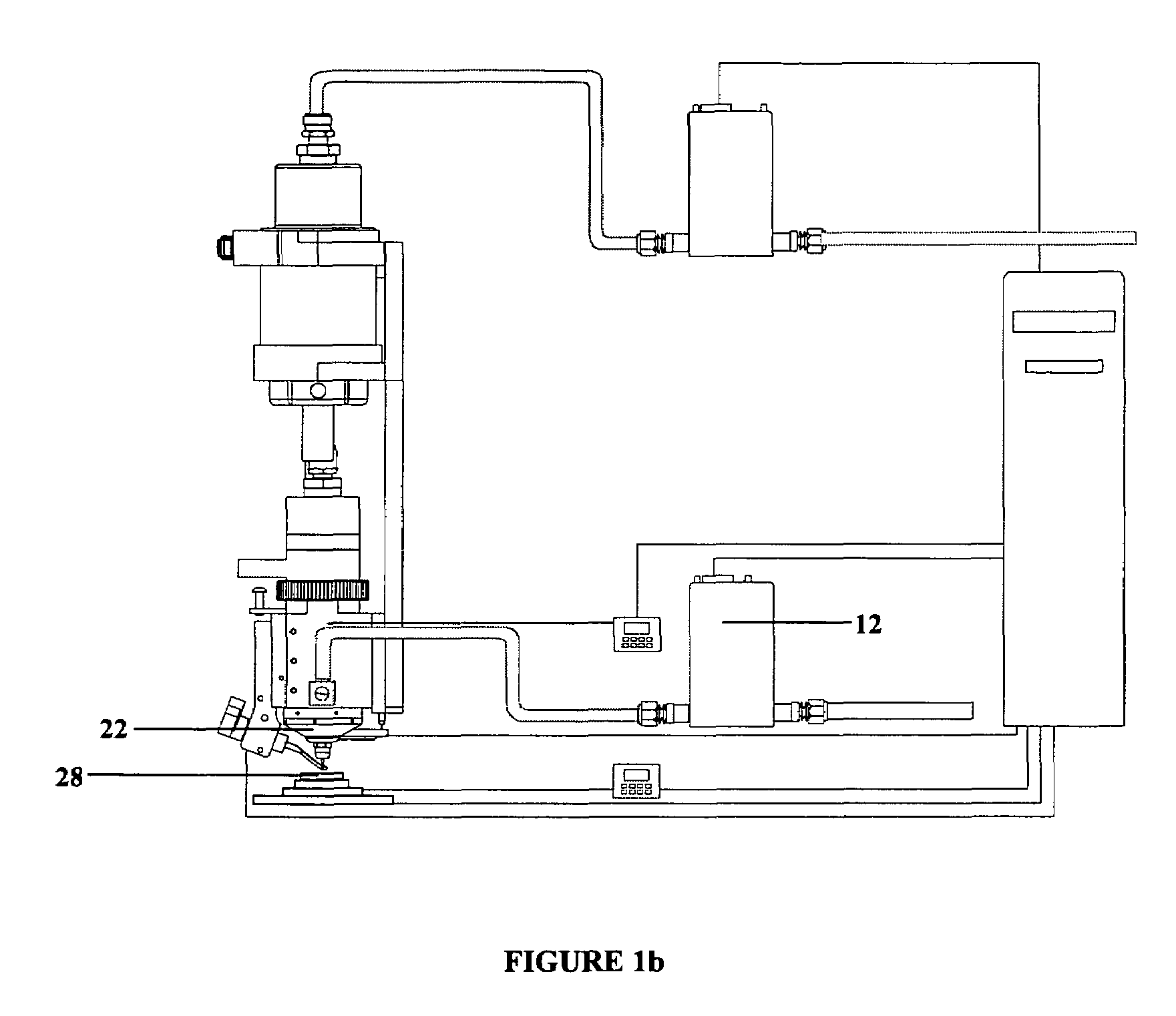

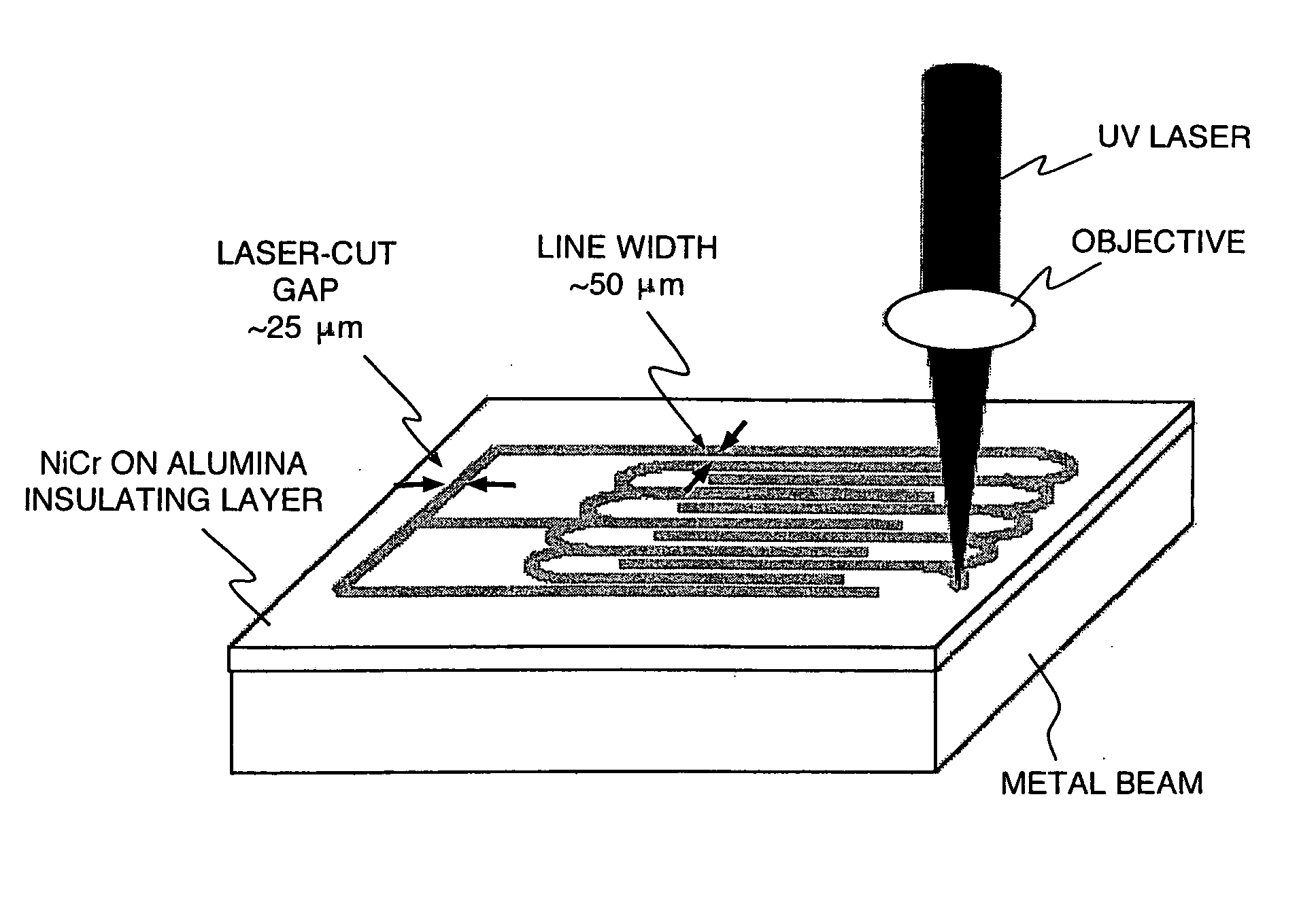

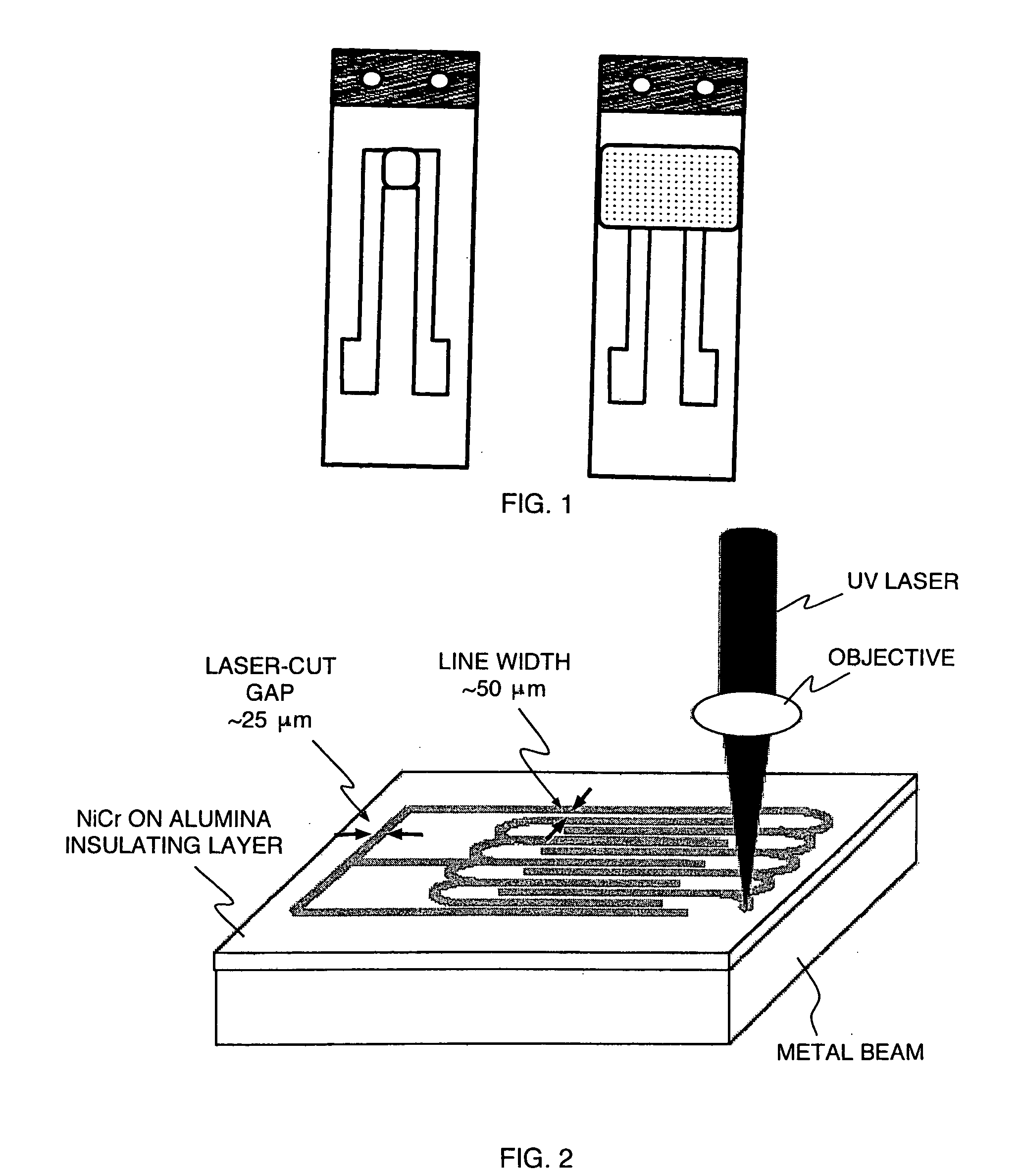

Method and apparatus for direct writing of passive structures having a tolerance of 5% or less in one or more physical, electrical, chemical, or optical properties. The present apparatus is capable of extended deposition times. The apparatus may be configured for unassisted operation and uses sensors and feedback loops to detect physical characteristics of the system to identify and maintain optimum process parameters.

Owner:OPTOMEC DESIGN CO

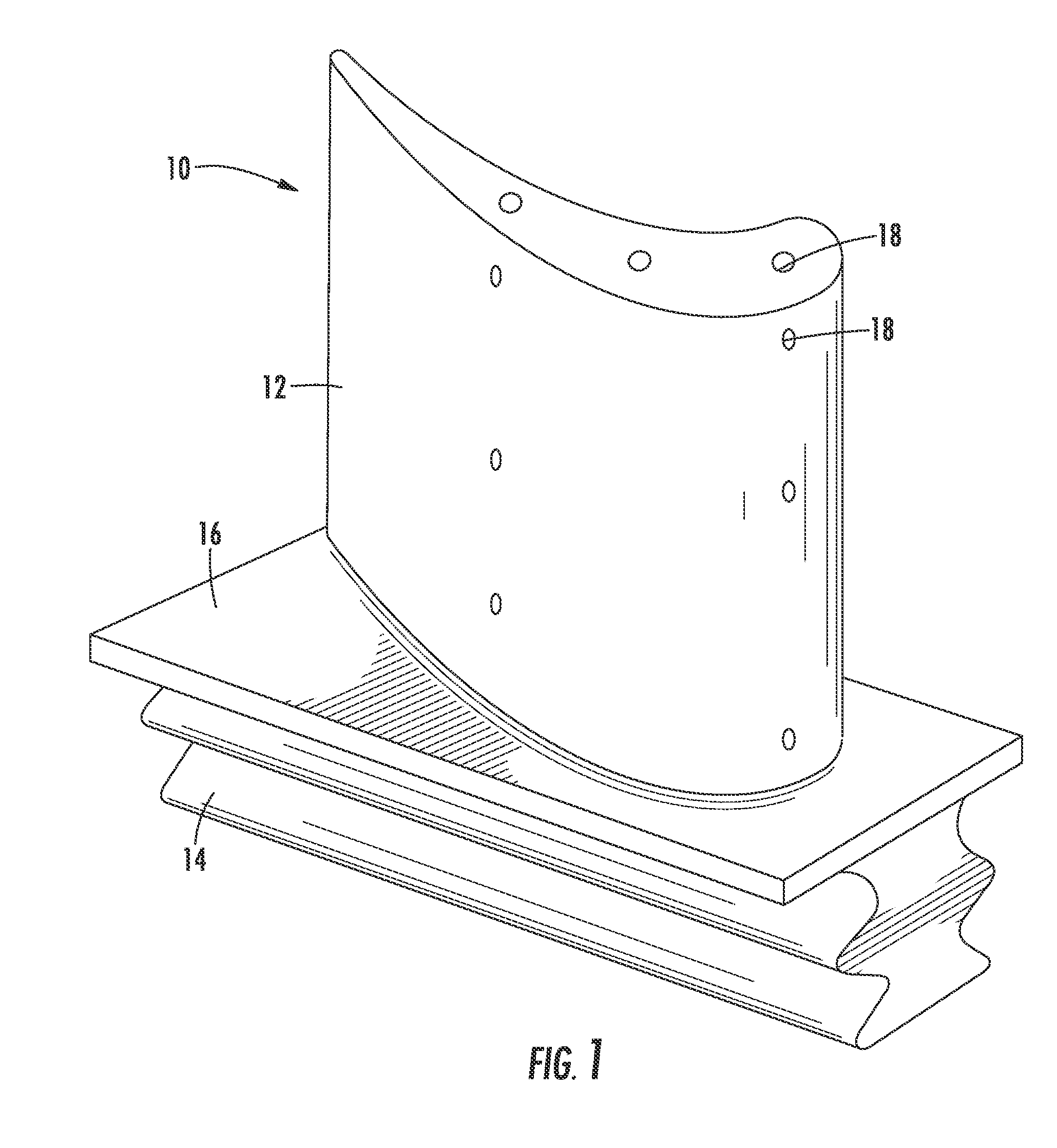

System and method for manufacturing embedded conformal electronics

ActiveUS20050029236A1Increase power generationMolten spray coatingThermoelectric device with peltier/seeback effectThermal sprayingEngineering

A method for fabricating an electronic device comprises providing a substrate (501), direct writing a functional material by a thermal spray on the substrate (502) and removing a portion of the function material to form the electronic or sensory device (503).

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Method and apparatus for laser machining relatively narrow and relatively wide structures

InactiveUS20110259631A1Increase energy densityConvenient ArrangementPrinted circuit aspectsPrinted circuit manufacturePolymer substrateDirect writing

The method uses a common optical, system and sequentially creates structures of different sizes in a polymer substrate by means of different laser processes is described. One process uses a laser beam that is tightly focussed on the substrate surface and is used for creating fine groove structures by semi-continuous direct write type beam movement. The second process uses a second laser beam that is used to form a larger size image on the substrate surface and is used to create blind pads and contact holes in the substrate in step and drill mode. A third optional process uses the second laser beam operating in direct writing mode to remove layers of the substrate over larger continuous areas or in a mesh type pattern.

Owner:M SOLV

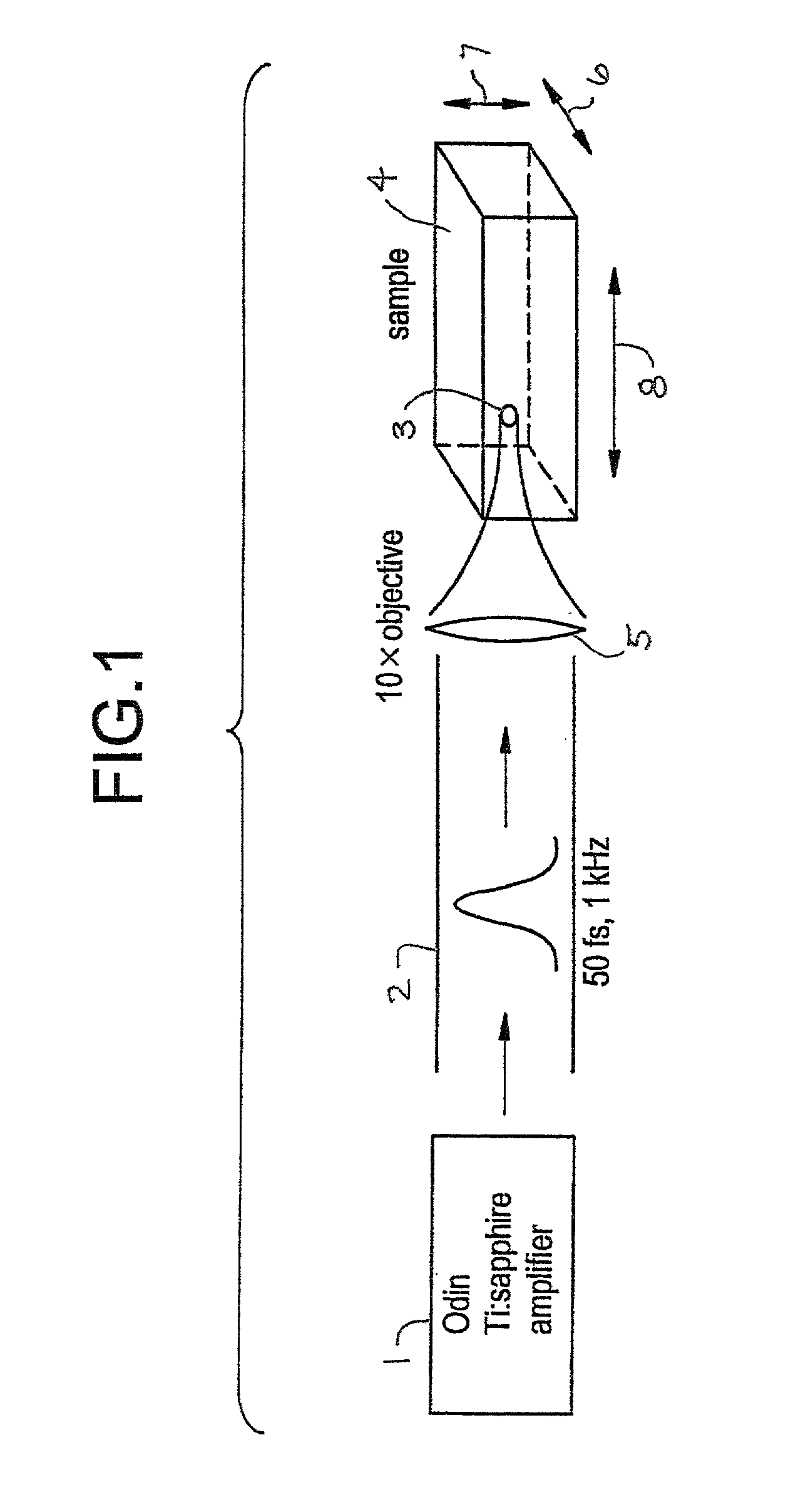

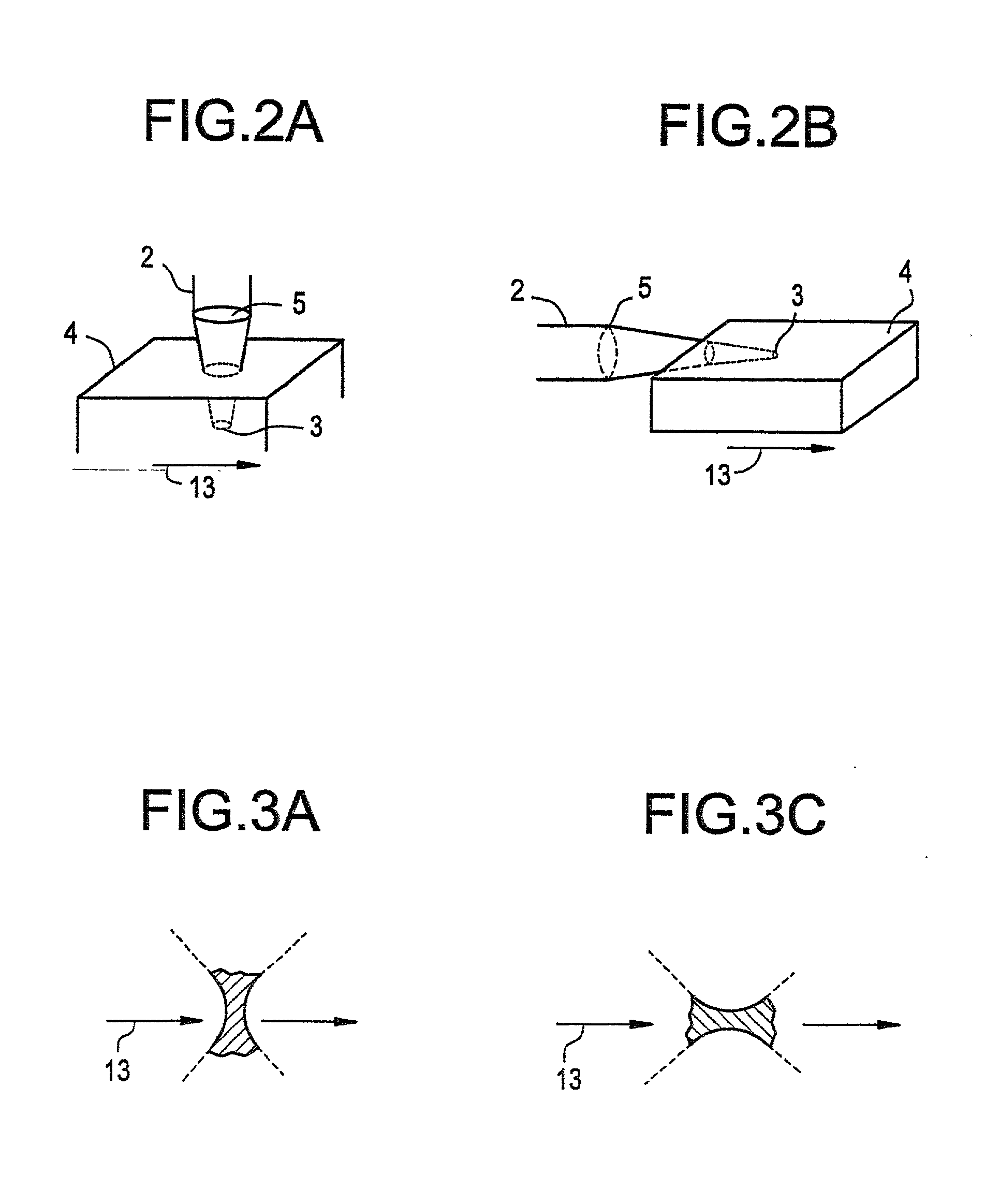

Direct writing of optical devices in silica-based glass using femtosecond pulse lasers

InactiveUS20020076655A1Efficient rateHigh sensitivityPhotography auxillary processesRadiation applicationsLight guideRefractive index

The invention relates to methods of writing a light-guiding structure in a bulk glass substrate. The bulk glass substrate is preferably made from a soft silica-based material having an annealing point less than about 1380°K. A pulsed laser beam is focused within the substrate while the focus is translated relative to the substrate along a scan path at a scan speed effective to induce an increase in the refractive index of the material along the scan path. Substantially no laser-induced physical damage of the material is incurred along the scan path. Various optical devices can be made using this method.

Owner:CORNING INC

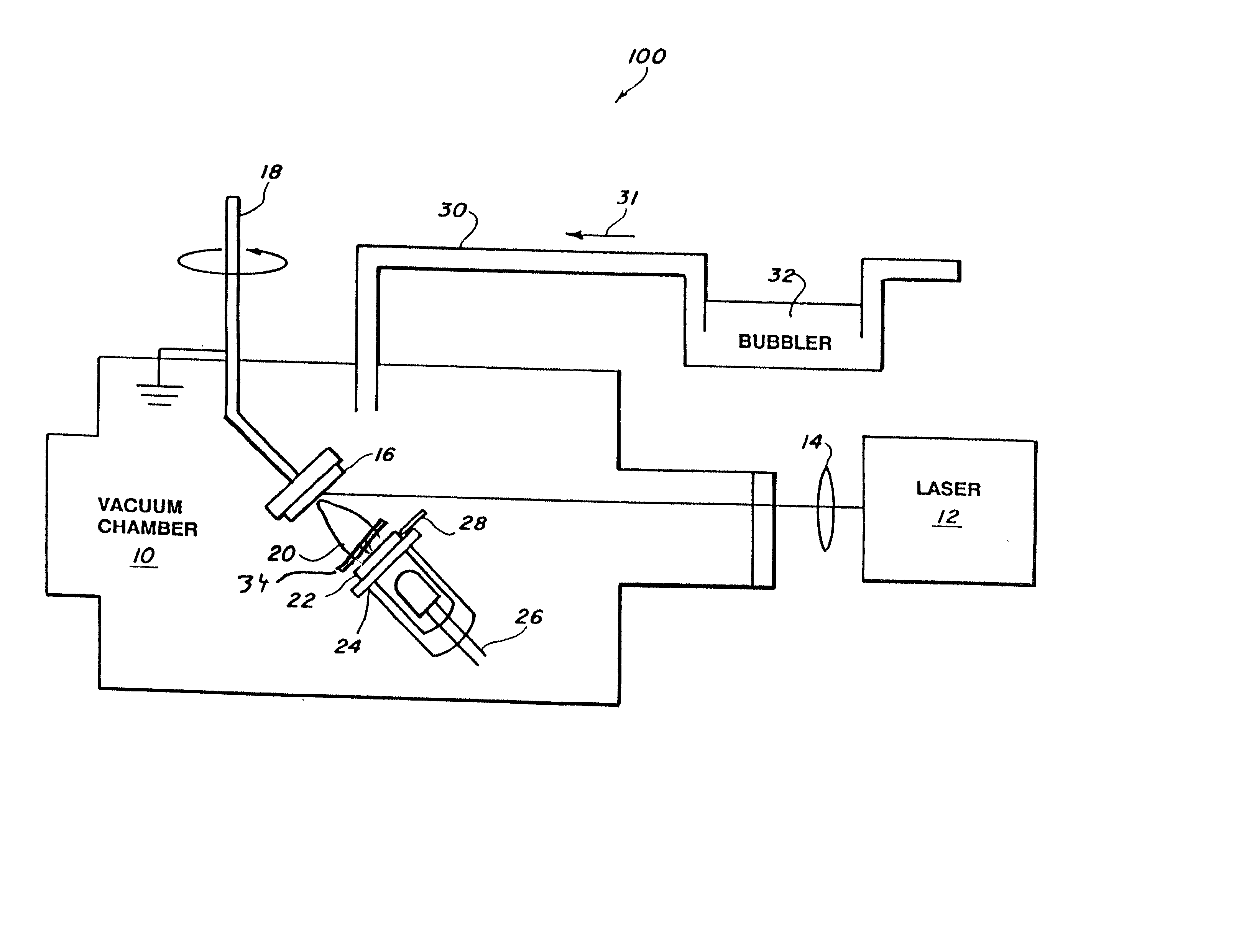

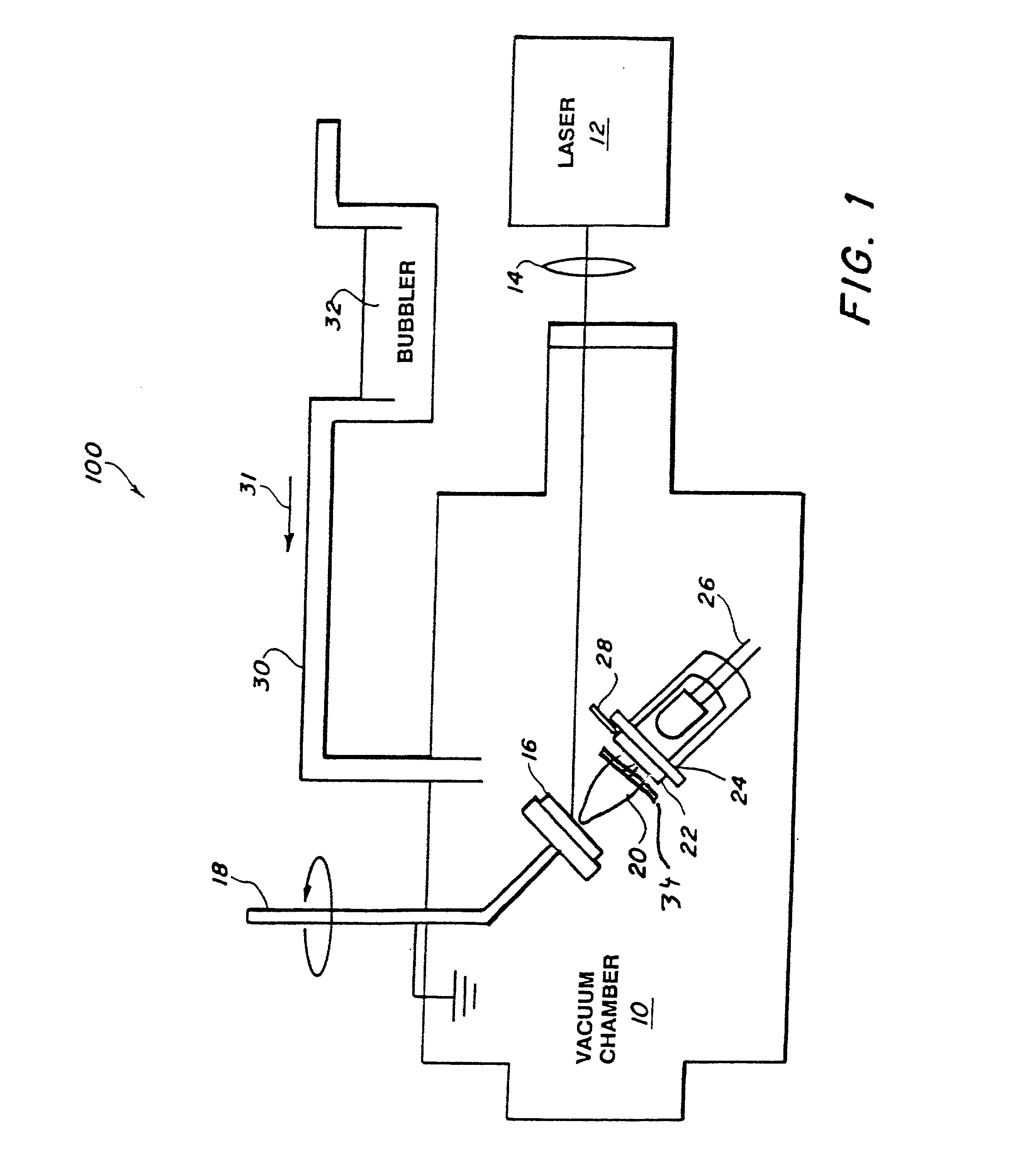

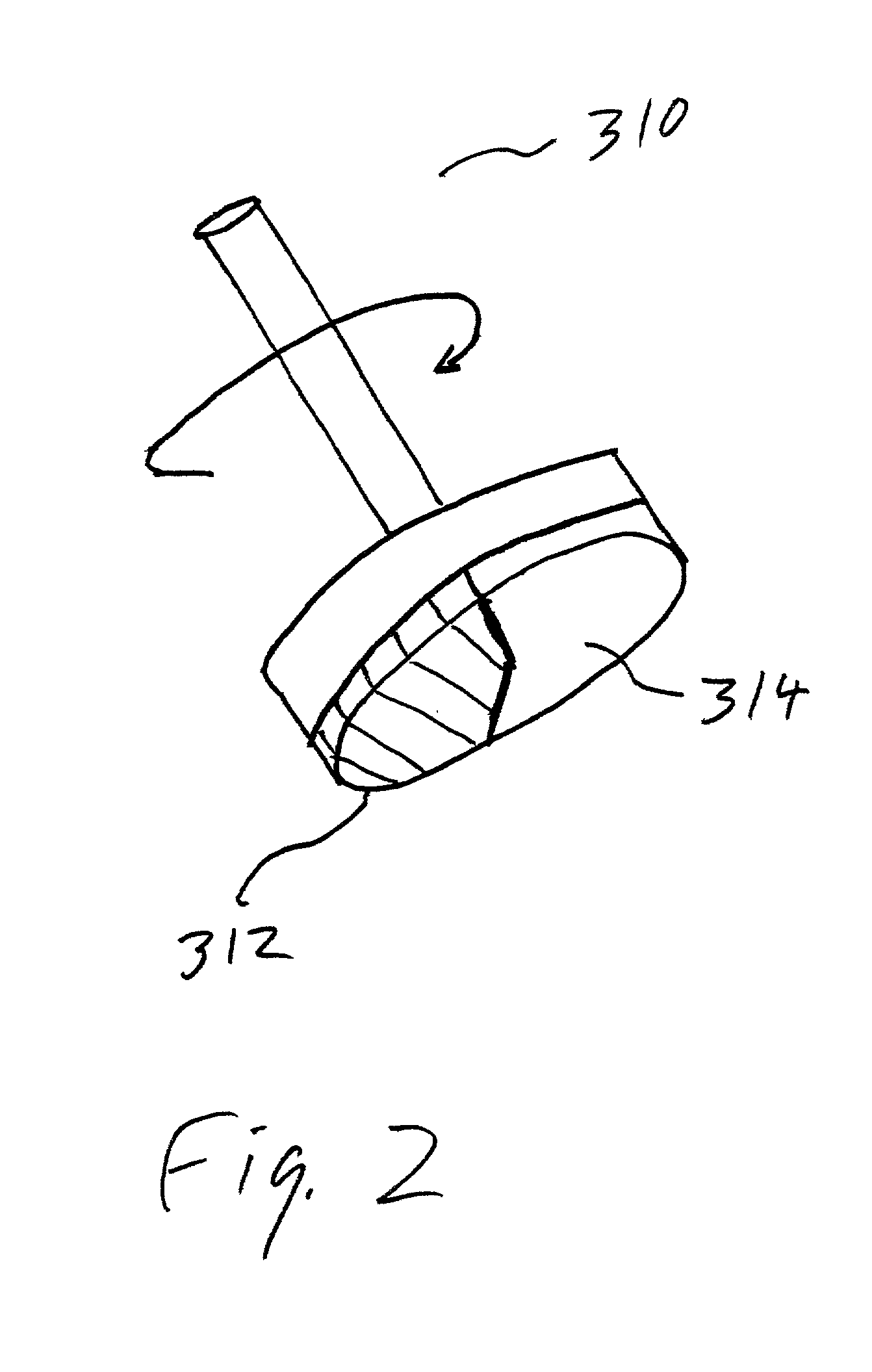

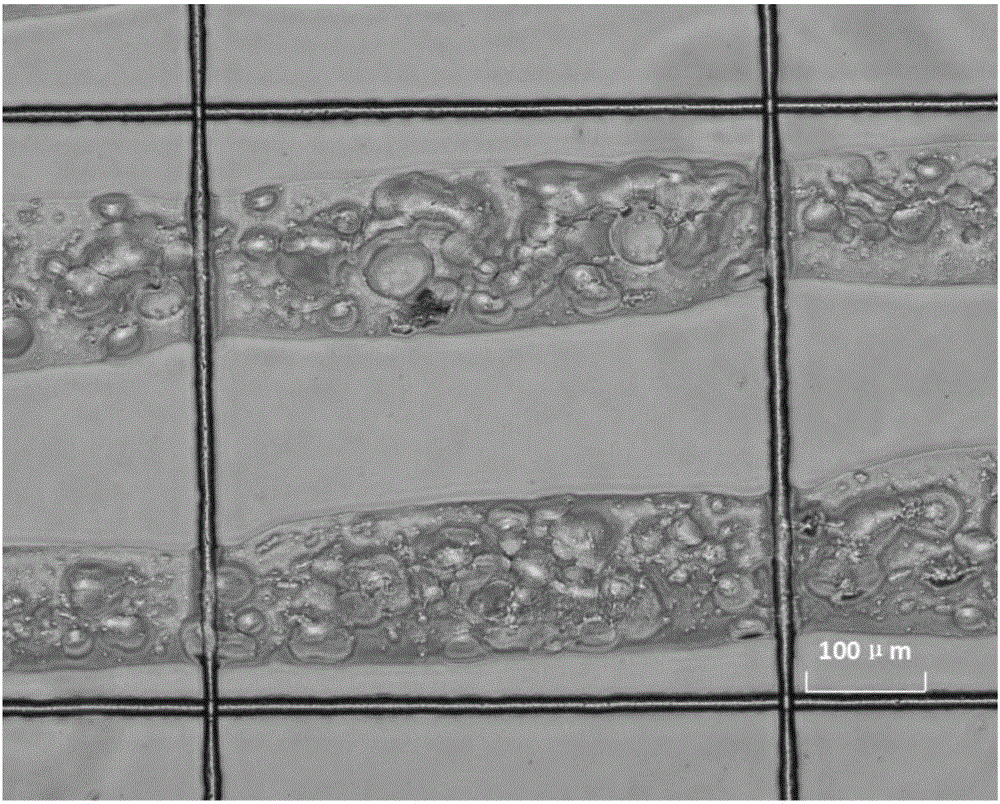

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

A composite layer of a sorbent, chemoselective, non-electrically-conducting polymer and nano-particles of an electrically conducting material dispersed throughout the polymer is formed on a substrate by pulsed laser deposition, matrix assisted pulsed laser evaporation or matrix assisted pulsed laser evaporation direct writing.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

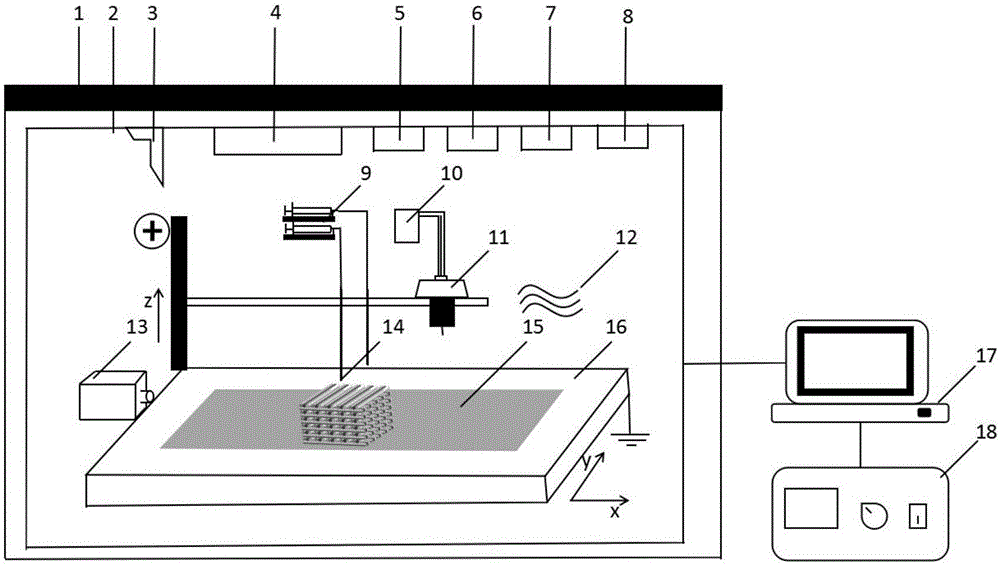

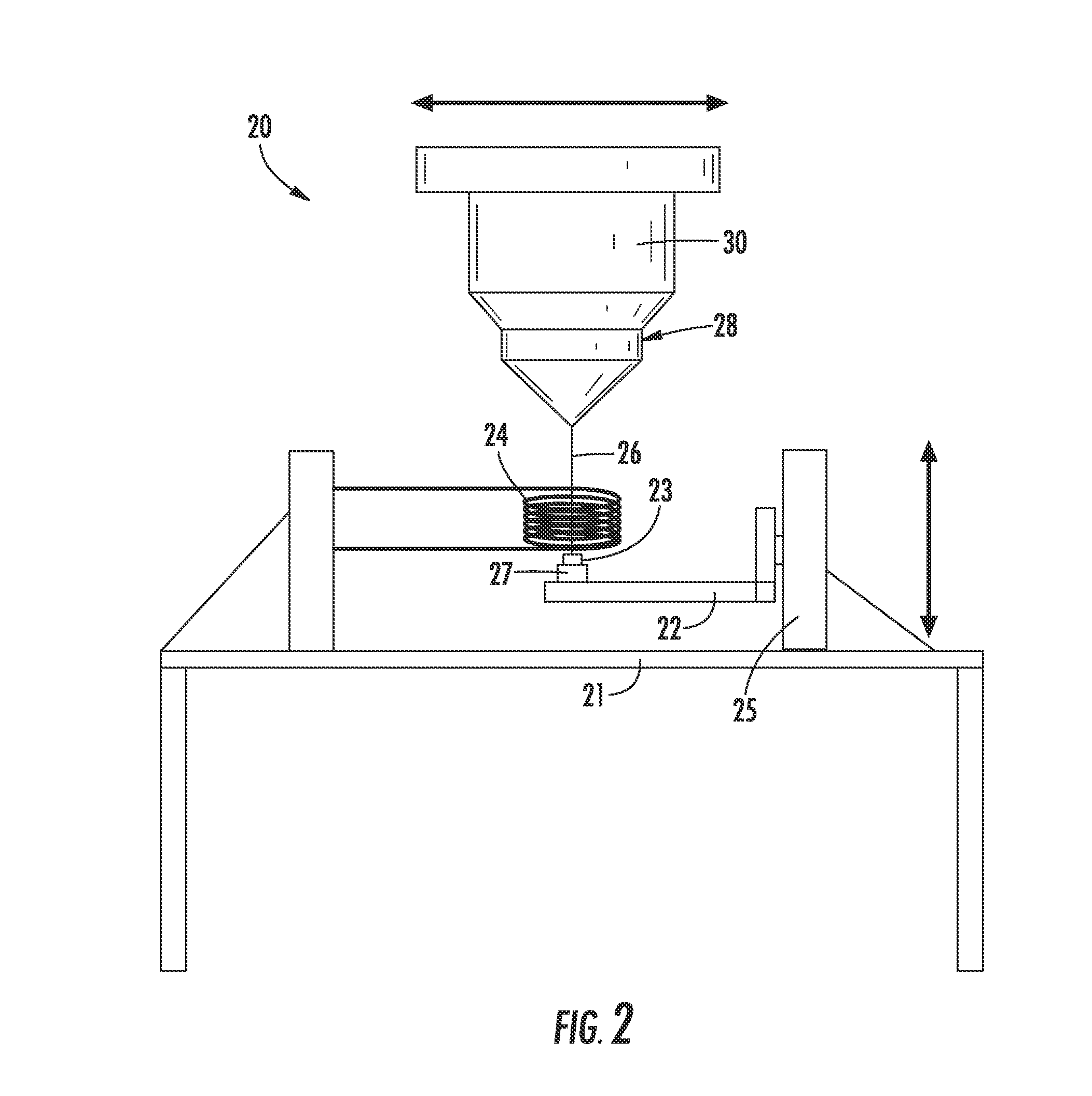

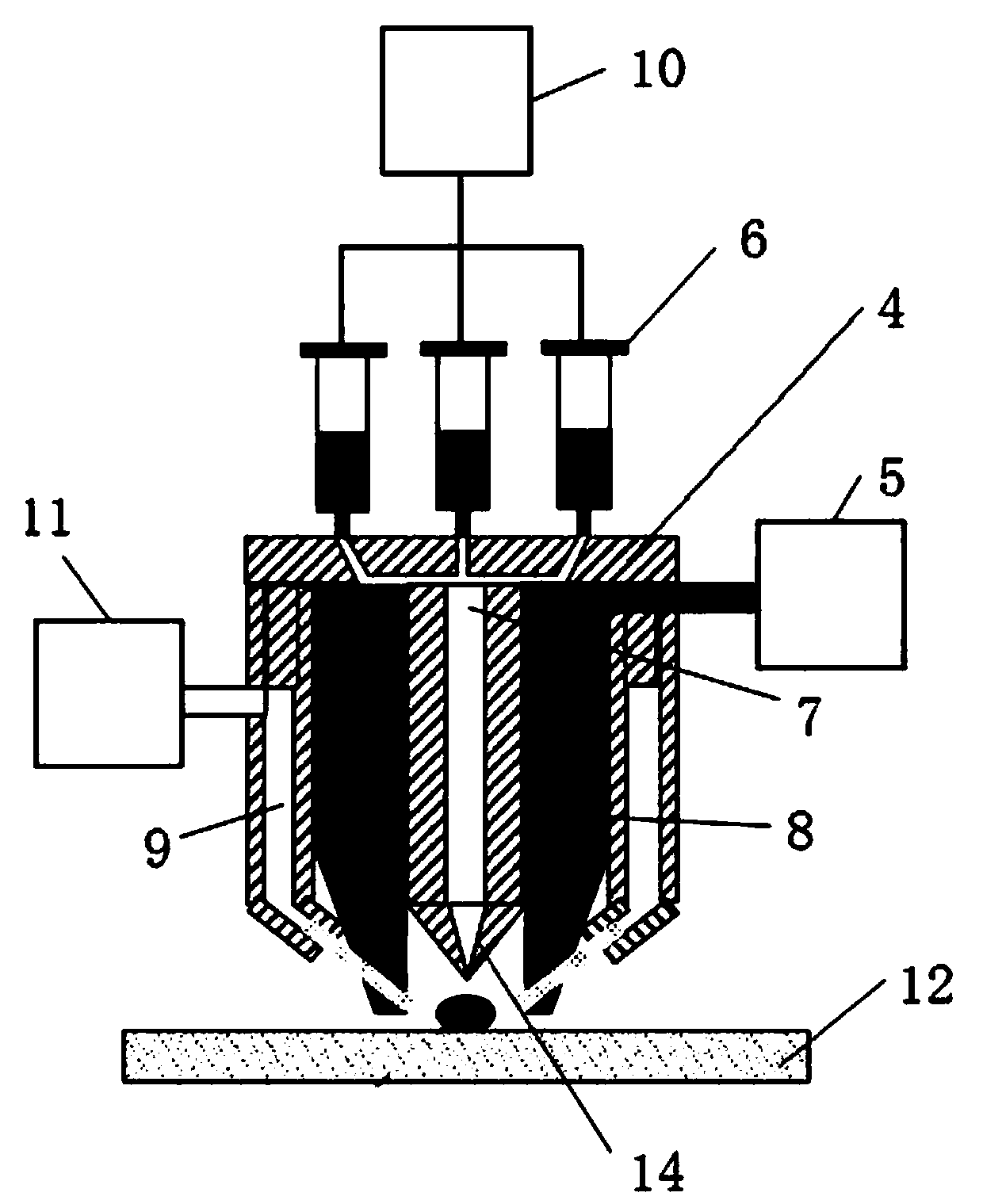

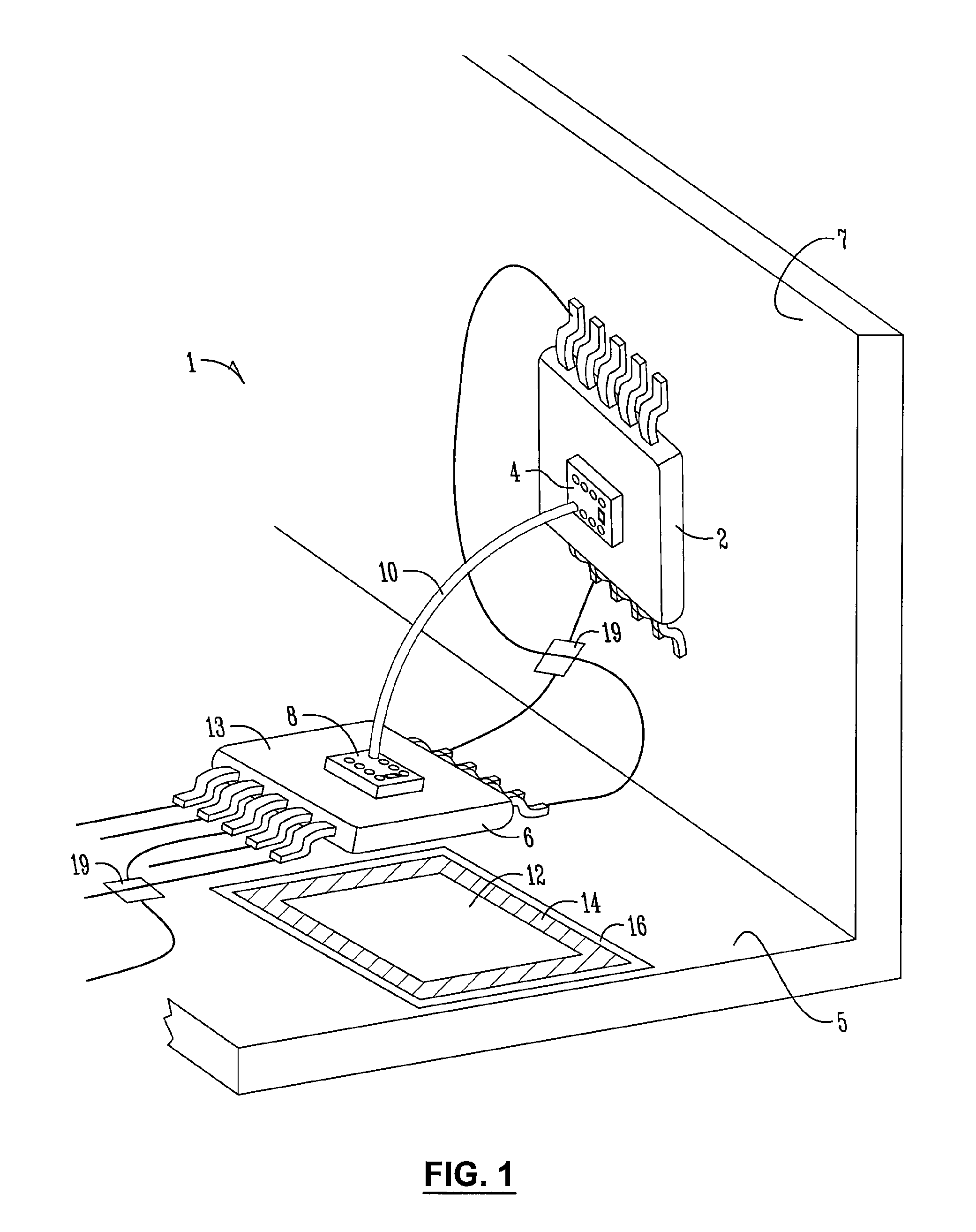

High-precision bio-compound 3D printing device and printing method

ActiveCN106222085AStable Composite PrintingHigh precisionAdditive manufacturing apparatusTissue/virus culture apparatusRefluxHigh-voltage direct current

The invention discloses a high-precision bio-compound 3D printing device and a printing method. The high-precision bio-compound 3D printing device comprises a cell printing spraying head and an electrostatic direct writing device which are arranged above a collection platform and are connected with a motion control module, wherein the cell printing spraying head is connected with an ultra-precision injection pump; the electrostatic direct writing device is connected with a reflux heating device; a main unit and a high-voltage direct current power supply are arranged outside an ultra-clean experiment table; the electrostatic direct writing device, the cell printing spraying head and the high-voltage direct current power supply are connected with the main unit. The printing method comprises the following steps: the main unit automatically switches the cell printing spraying head and the electrostatic direct writing device to print a cell-containing gel / biological scaffold / micro-channel compound structure; after the printing of one layer is completed, the cell printing spraying head and the electrostatic direct writing device move a distance equal to the thickness of one layer in the Z-axis direction for printing of the next layer, and repeating till all tissue organs to be printed are completed in printing. The high-precision bio-compound 3D printing device can stably and precisely print compounds of various cells and submicron or nano-level biological scaffolds.

Owner:XI AN JIAOTONG UNIV

Nano-silver conductive slurry

ActiveCN101710497AHigh resolutionLower maximum sintering temperatureNanostructure manufactureConductive materialDirect writingSlurry

The invention provides nano-silver conductive slurry, which comprises the following components in percentage by weight: 10 to 70 percent of nano-silver granules serving as a functional phase, and the balance of carrier phase. The nano-silver granules are uniformly dispersed in the carrier phase by methods of mechanical stirring, ultrasonic dispersion and the like to form the nano-silver conductive slurry; the slurry is molded by methods of spin coating, screen printing, micro thinning and micro-spray direct writing and the like, and then the molded slurry is thermally treated at the temperature of below 250 DEG C by a programmed heating method to form conductive patterns with good conductivity (the electrical resistivity is at a magnitude order of 0 to 50 ohm.cm) and high resolution (the maximum resolution is 30 mu m).

Owner:HUAZHONG UNIV OF SCI & TECH

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

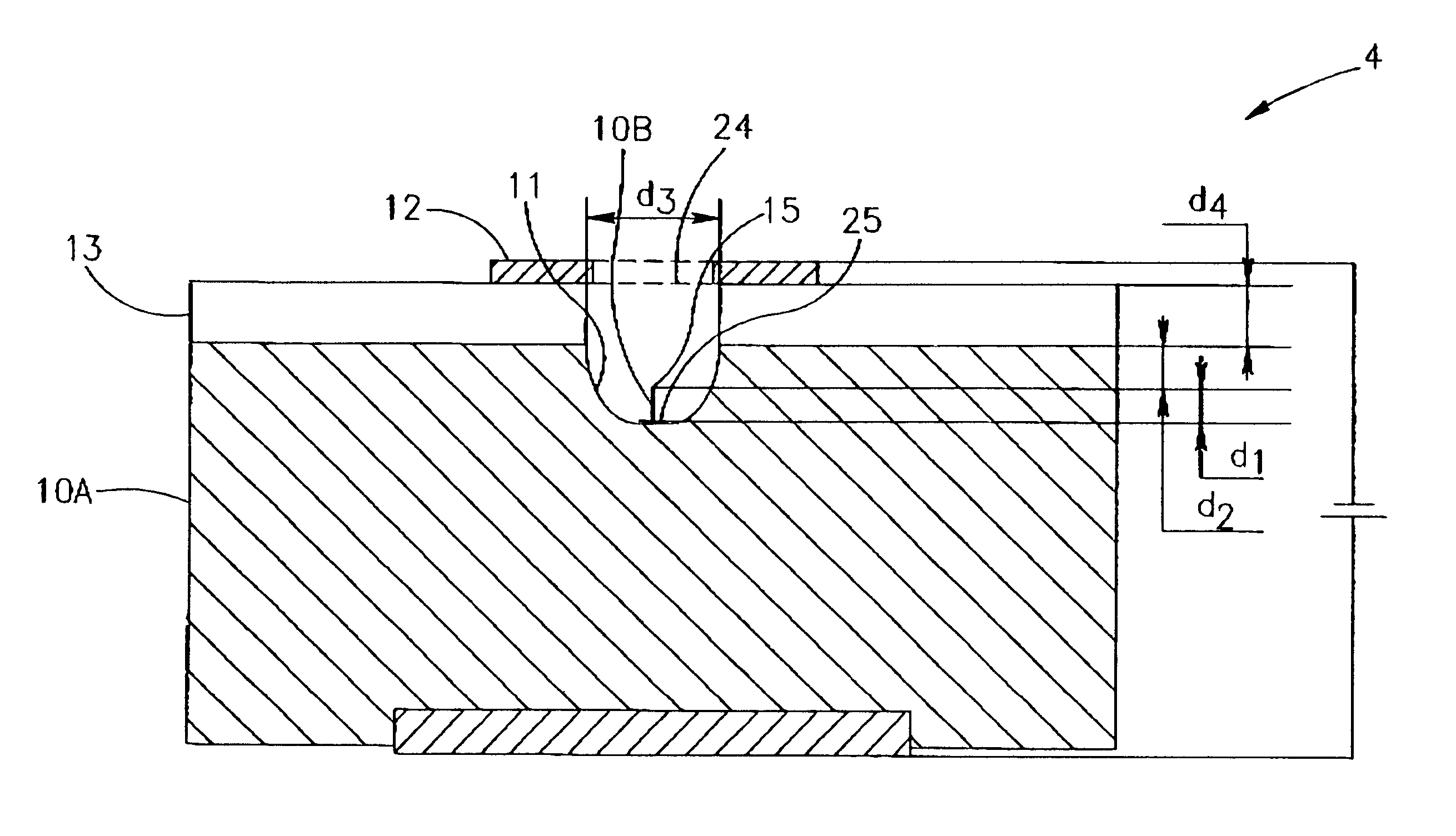

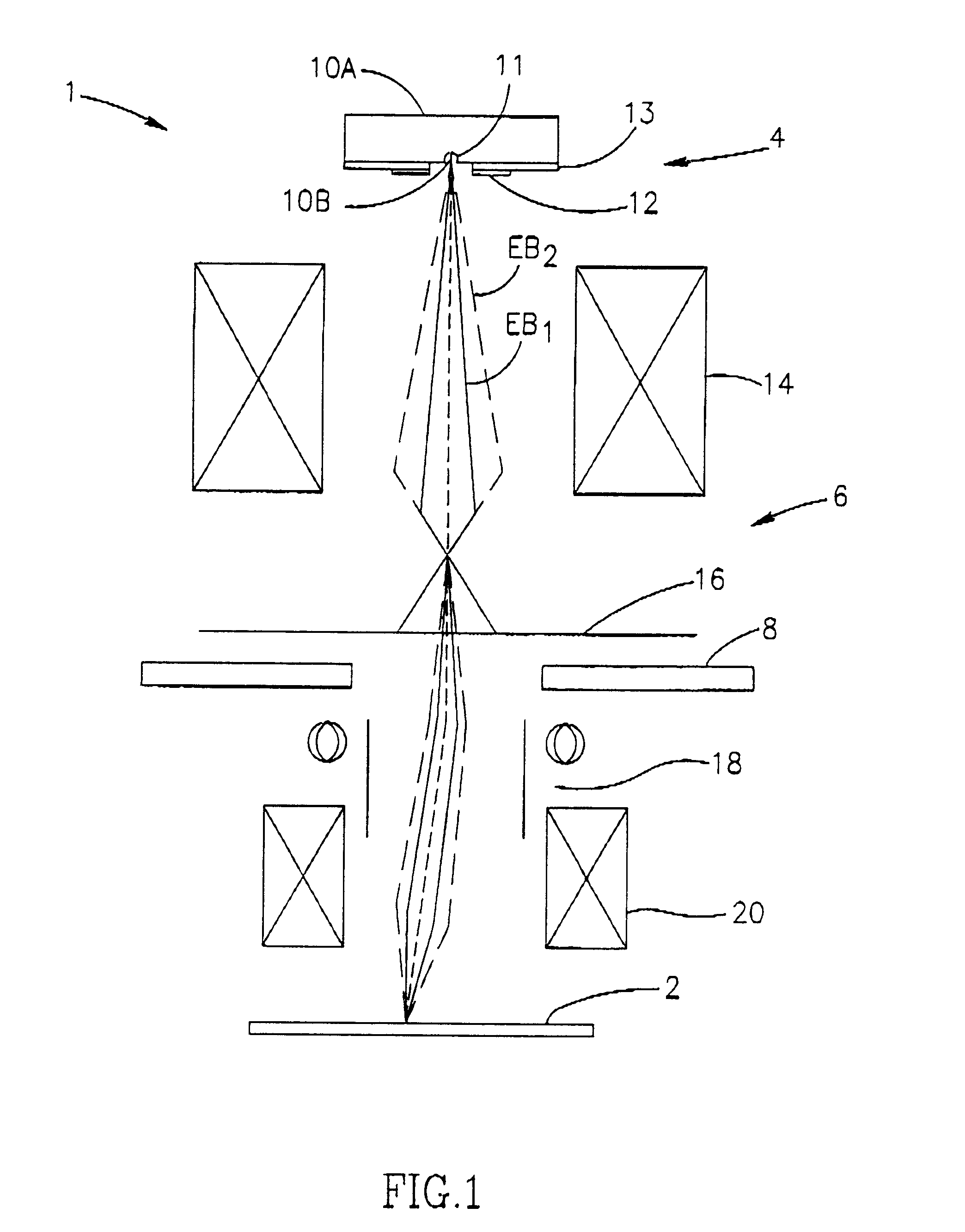

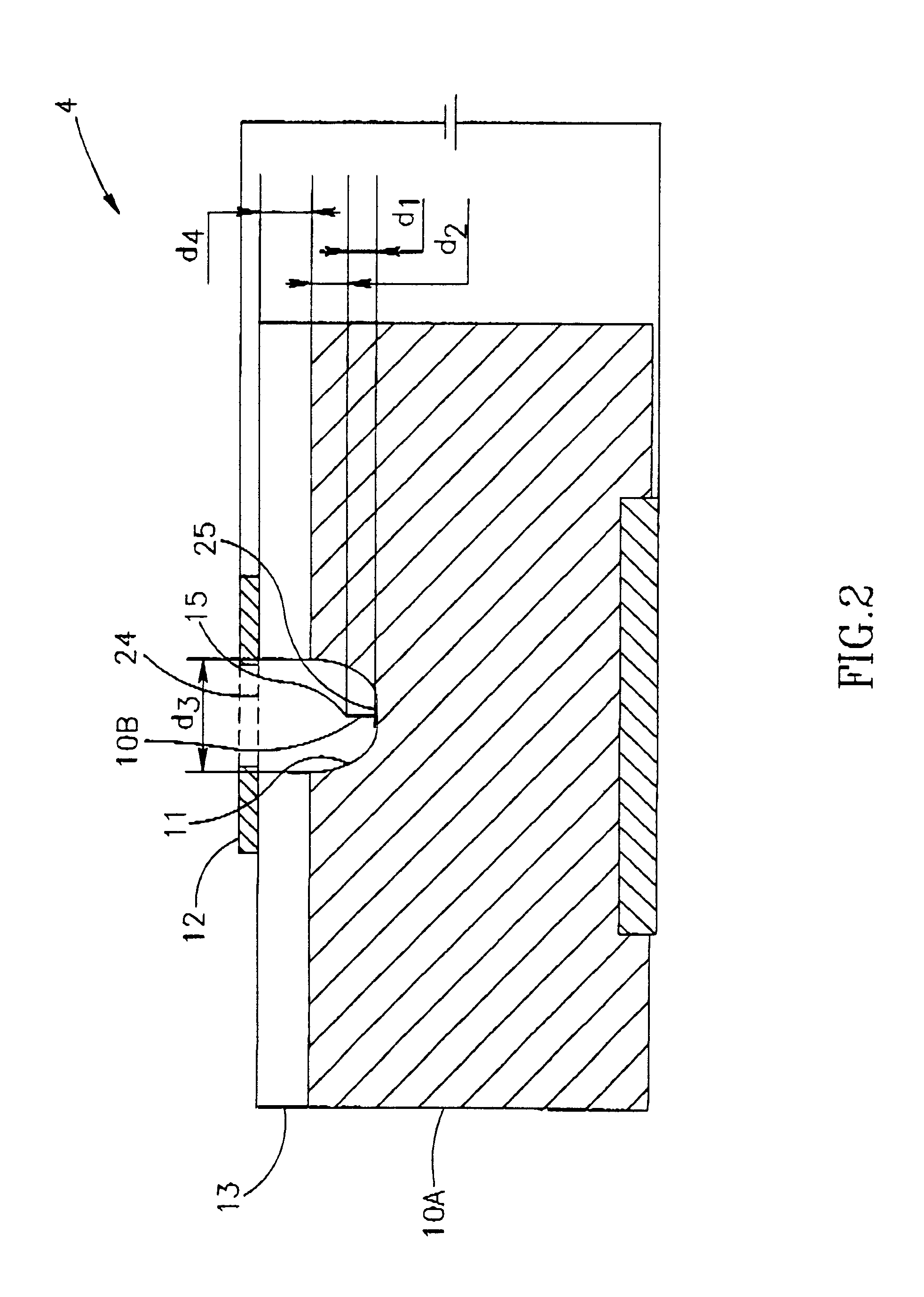

Nanotube-based electron emission device and systems using the same

InactiveUS6512235B1Minimizes angular divergence of beamLess sensitiveThermometer detailsNanostructure manufactureElectron sourceLithographic artist

A device that produces an electron beam with high optical quality for processing a sample, is presented. The optical quality is manifested by very high brightness and low energy spread. The device includes an electron source device comprising an electrode in the form of a shaped first layer, preferably in the form of a conducting crater carrying at least one nanotube, and an extracting electrode, which is formed with at least one aperture and is insulated from the firs layer. The source can be used in any column that requires such properties. The column according to the invention may be a full size or a miniature electron microscope, a lithography tool, a tool used for direct writing of wafers or a field emission display.

Owner:EL MUL TECH

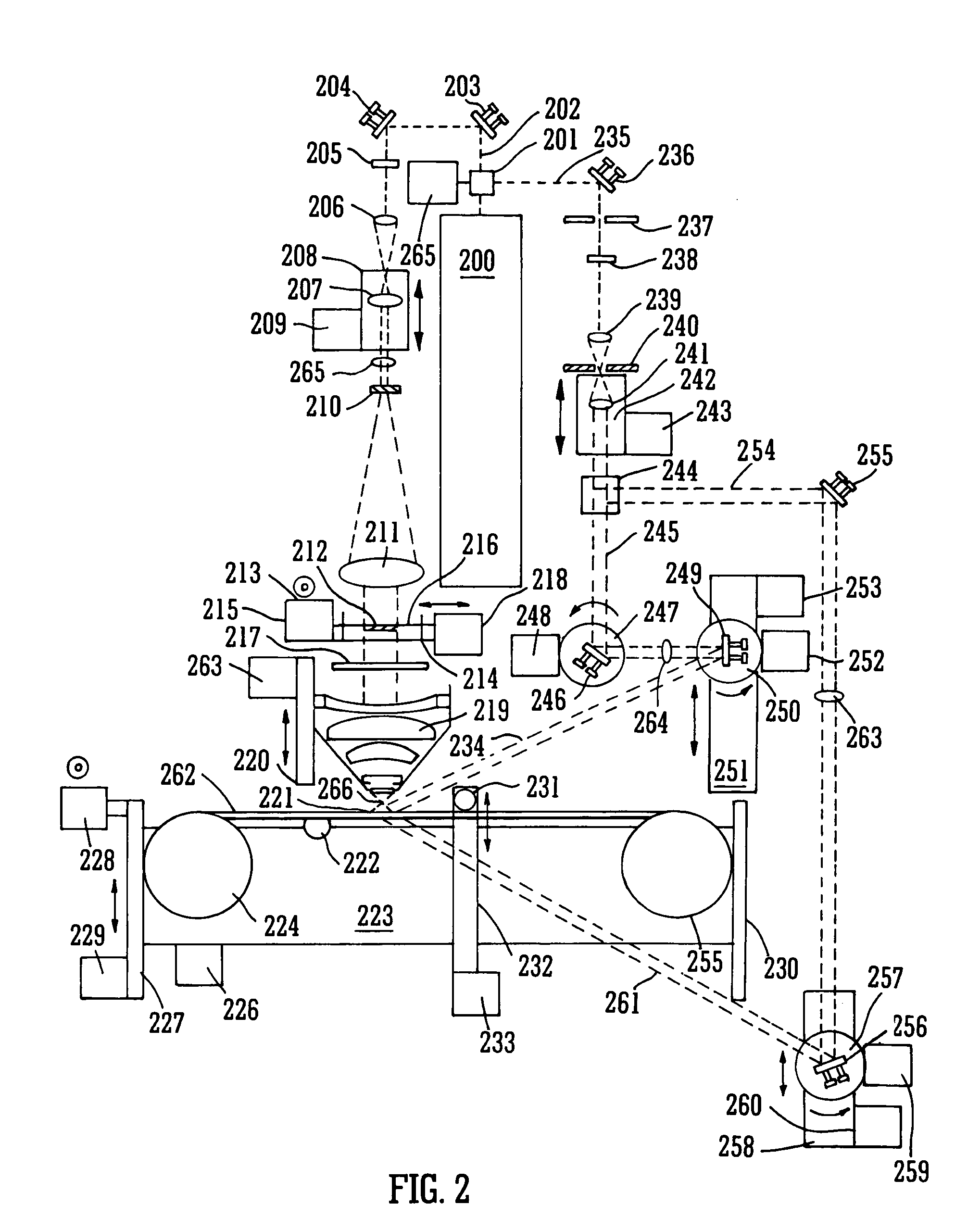

Holographic printer

InactiveUS7009742B2Increase printing speedGuaranteed uptimeHolographic light sources/light beam propertiesHolographic optical componentsCamera imageDigital data

Owner:XYZ IMAGING

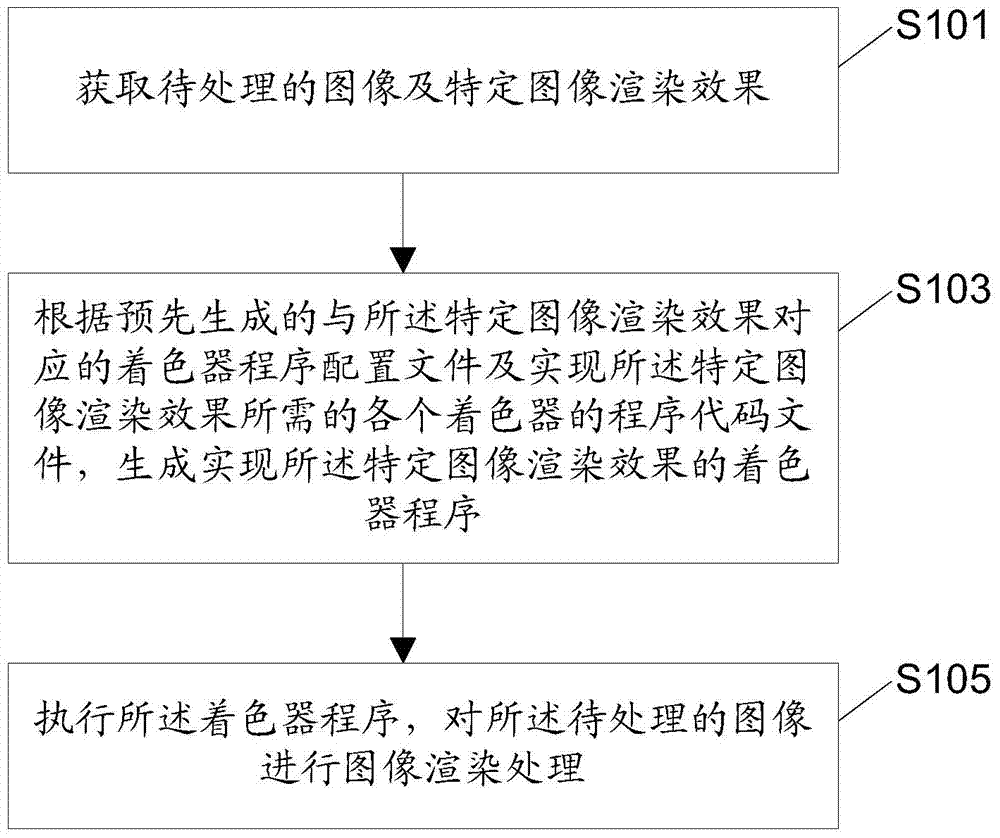

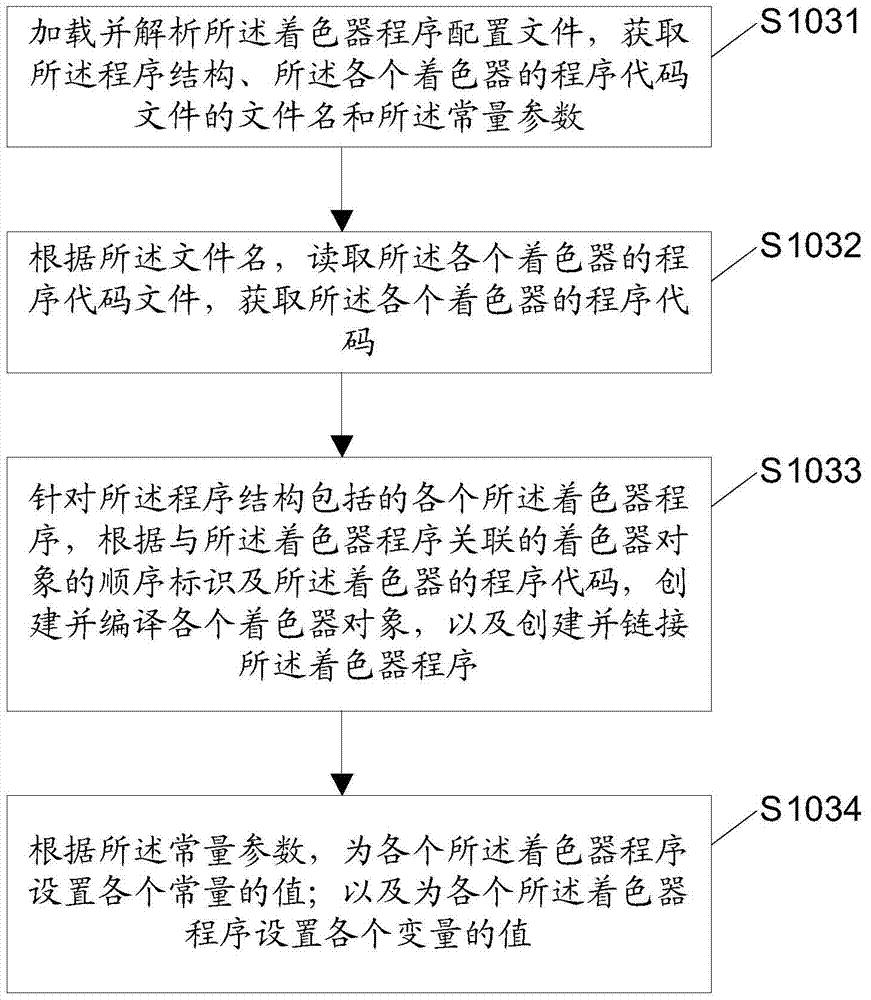

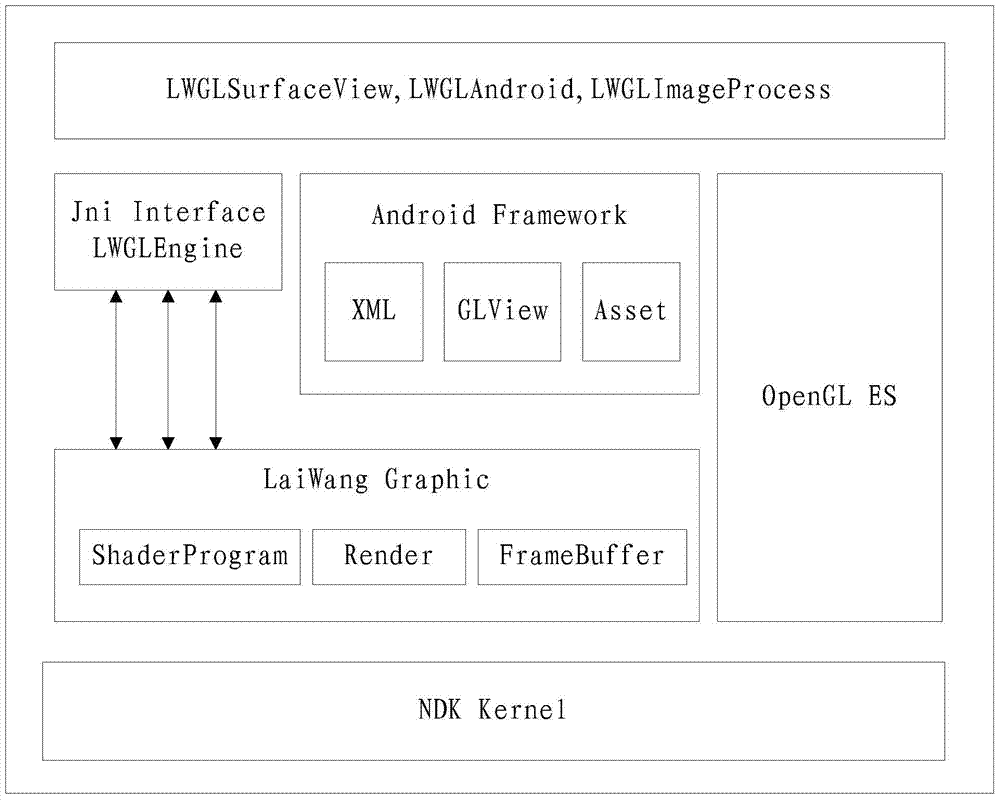

Image rendering method, image rendering device and electronic device

ActiveCN106997610AAvoid writing directlyImprove development efficiency3D-image renderingComputer graphics (images)Direct writing

Owner:ALIBABA GRP HLDG LTD

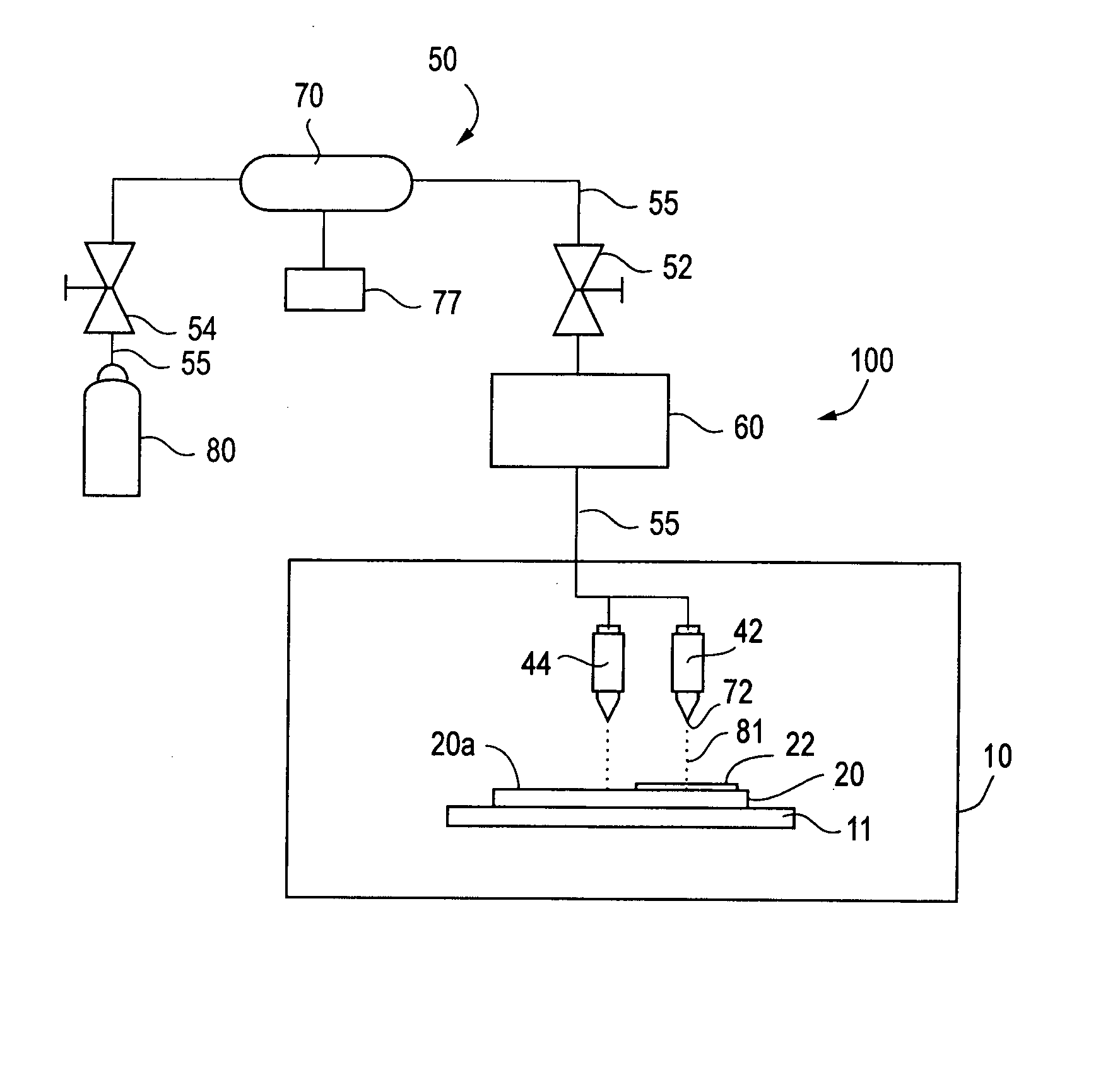

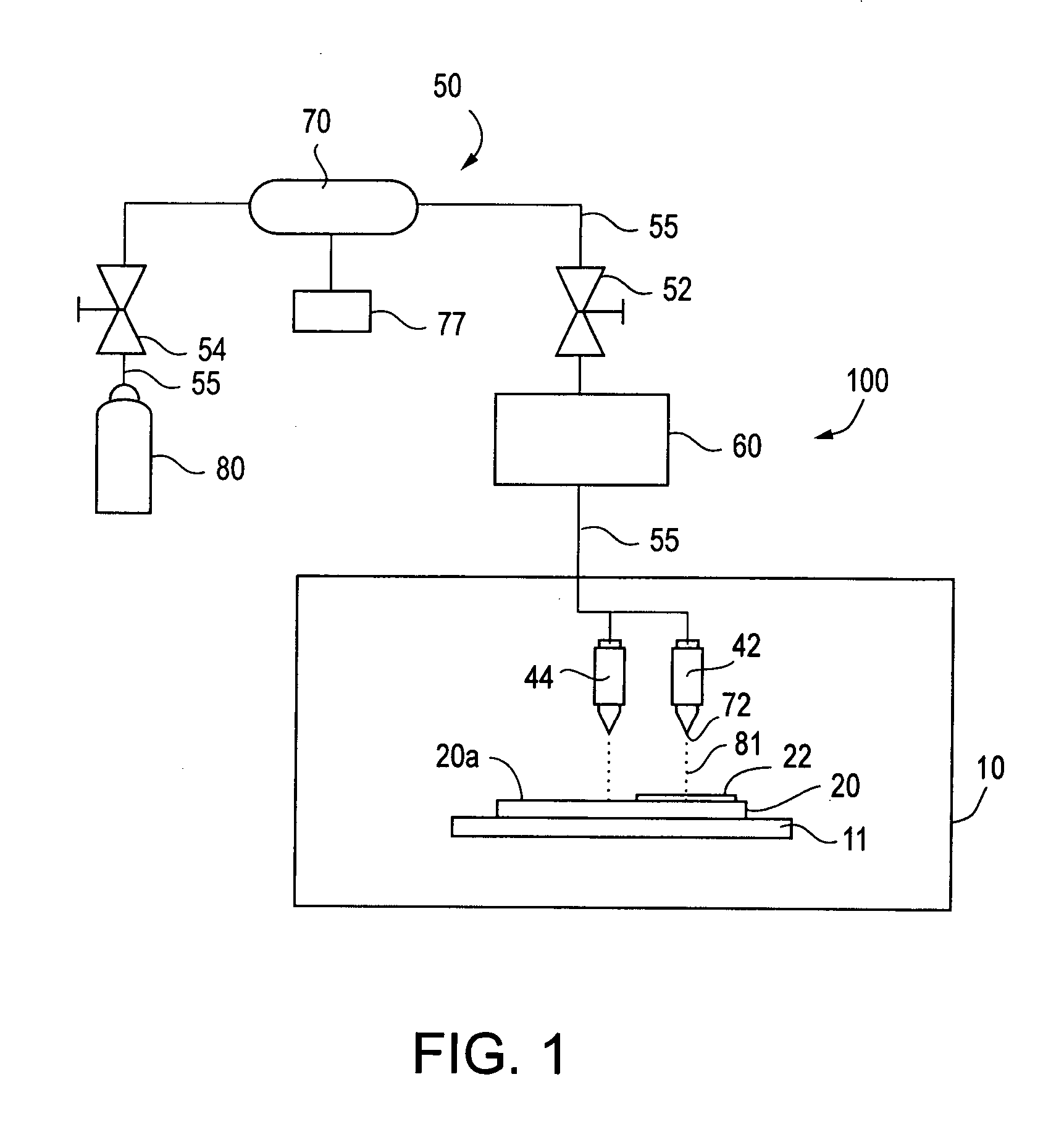

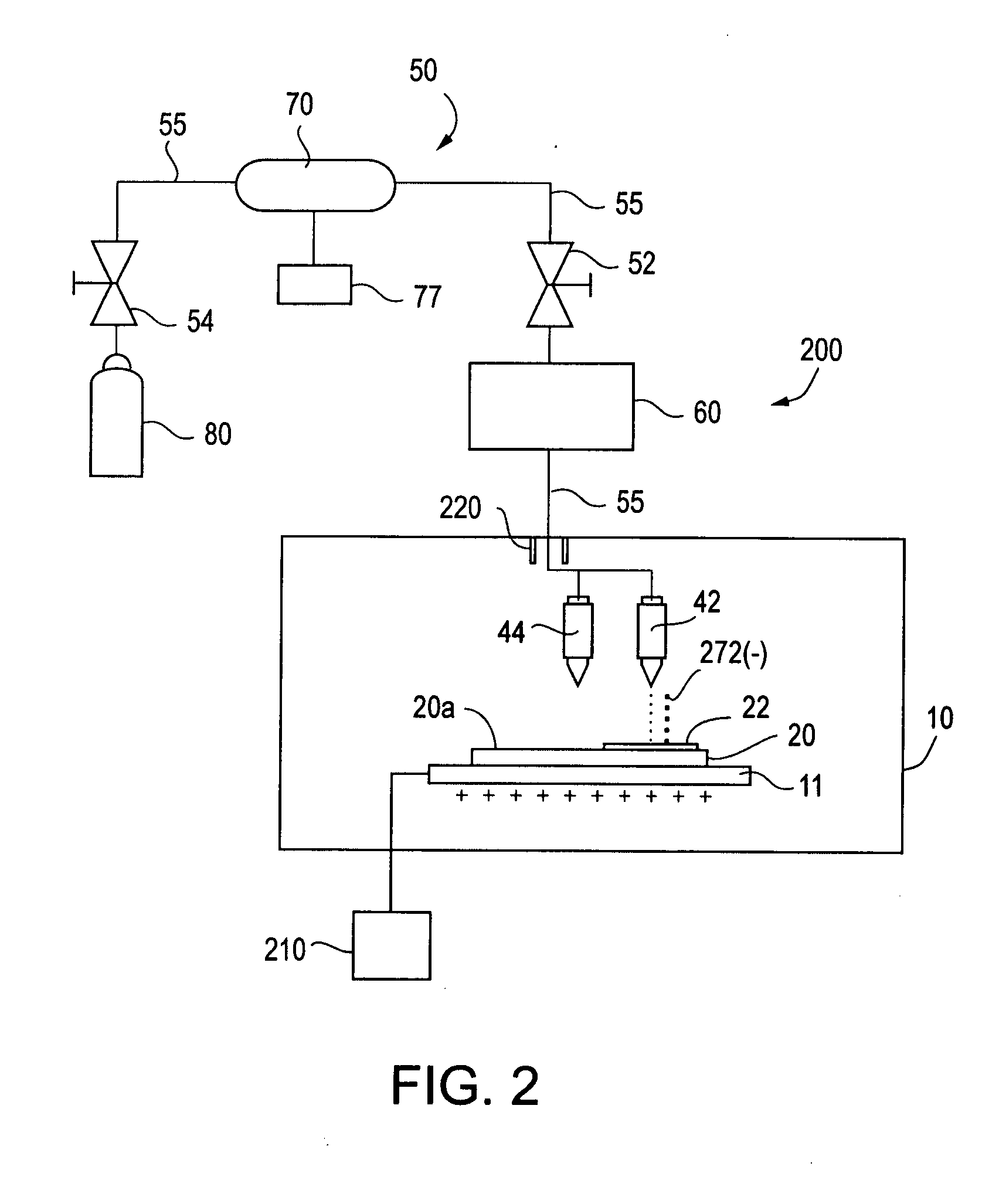

Supercritical fluid-assisted direct write for printing integrated circuits

InactiveUS20060266235A1High resolutionSemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

High resolution patterns provided on a surface of a semiconductor substrate and methods of direct printing of such high resolution patterns are disclosed. The high resolution patterns may have dimensions less than 0.1 micron and are formed by a direct writing method employing a supercritical fluid comprising nanometer-sized particles, which may be optionally electrically charged.

Owner:MICRON TECH INC

Method for chemical-mechanical jet etching of semiconductor structures

InactiveUS7037854B2Quickly and accurately removing large amounts of materialRapidly producing large-scale featuresDecorative surface effectsSemiconductor/solid-state device manufacturingSemiconductor structureCompound (substance)

A chemical-mechanical jet etching method rapidly removes large amounts of material in wafer thinning, or produces large-scale features on a silicon wafer, gallium arsenide substrate, or similar flat semiconductor workpiece, at etch rates in the range of 10–100 microns of workpiece thickness per minute. A nozzle or array of nozzles, optionally including a dual-orifice nozzle, delivers a high-pressure jet of machining etchant fluid to the surface of the workpiece. The machining etchant comprises a liquid or gas, carrying particulate material. The liquid may be a chemical etchant, or a solvent for a chemical etchant, if desired. The areas which are not to be etched may be shielded from the jet by a patterned mask, or the jet may be directed at areas from which material is to be removed, as in wafer thinning or direct writing, depending on the size of the desired feature or etched area.

Owner:APPLIED MATERIALS INC

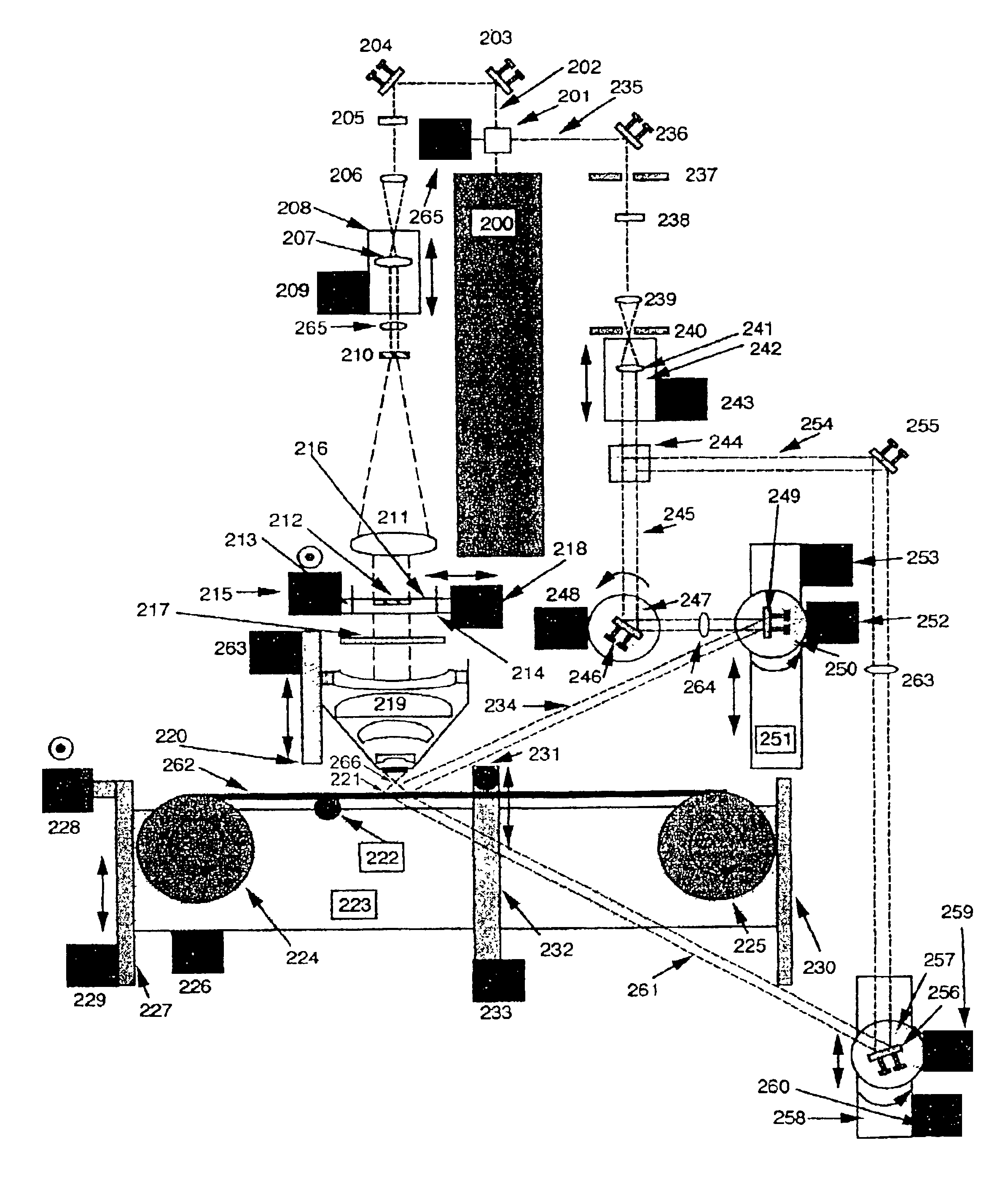

Holographic printer

InactiveUS6930811B2Increase printing speedGuaranteed uptimeHolographic light sources/light beam propertiesHolographic optical componentsDigital dataParallax

A single method and apparatus for producing many of the most common types of hologram from digital data is disclosed. The data are generated entirely by a computer as a 3-D (animated) model or from multiple 2-D camera images taken of a real 3-D (moving) object or scene from a plurality of different camera positions. The data are digitally processed and displayed on a small high resolution spatial light modulator (SLM). A compact low energy pulsed laser, is used to record composite holograms. The present invention permits the creation of restricted or full parallax master transmission or reflection type composite holograms, known as H1 holograms, that can be copied using traditional methods. Alternatively the same invention and apparatus permits the direct writing of hologram without the need to pass through the intermediate stage of the H1 transmission hologram.

Owner:COMPHARE TRUST COMPANY OF CANADA

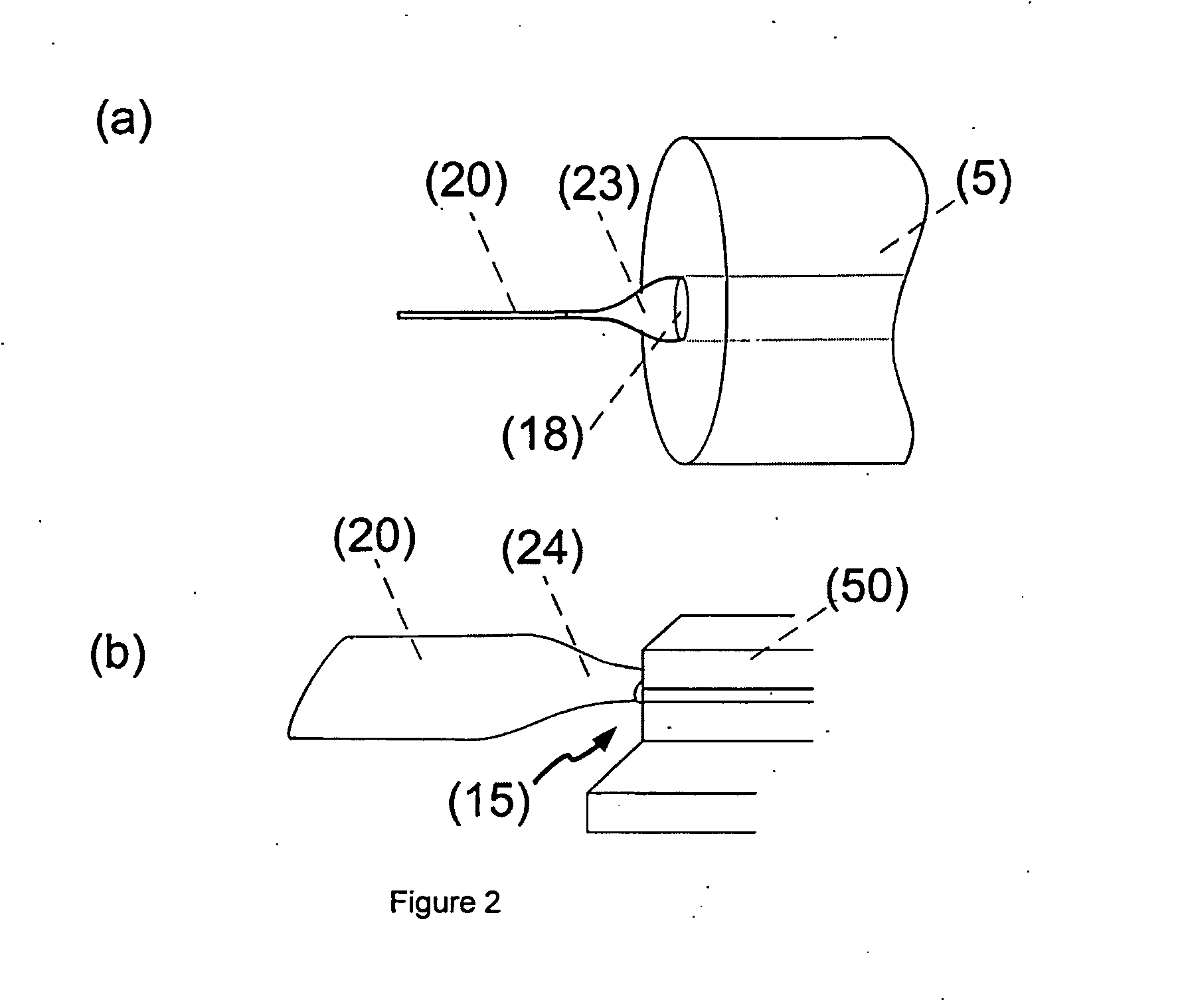

Method for producing photonic wire bonds

ActiveUS9034222B2Highly integratedIncrease the number ofOptical articlesCoupling light guidesResistLithographic artist

A method for making optical connections with optical waveguides includes mounting the optical waveguides or a device comprising the optical waveguides, on a component carrier. A partial region of the optical waveguides is embedded in a volume of resist material. Positions of the optical waveguides to be connected are detected with reference to a coordinate system using a measuring system. Favorable, three-dimensional geometries are determined for optical waveguide structures for connecting the optical waveguides to each other at predetermined connecting locations and the optical waveguide structure geometries are converted to a machine-readable dataset. The optical waveguide geometries in the volume of the resist material are three-dimensionally structured using a direct-writing lithography device operating on the basis of the machine-readable dataset. The structured resist material is treated using physical or chemical methods to form at least one optical waveguide structure having ends connected to predetermined connecting locations of the optical waveguides.

Owner:KARLSRUHER INST FUR TECH

Aerodynamic jetting of aerosolized fluids for fabrication of passive structures

InactiveUS20060163570A1Liquid surface applicatorsSemiconductor/solid-state device detailsOptical propertyEngineering

Method and apparatus for direct writing of passive structures having a tolerance of 5% or less in one or more physical, electrical, chemical, or optical properties. The present apparatus is capable of extended deposition times. The apparatus may be configured for unassisted operation and uses sensors and feedback loops to detect physical characteristics of the system to identify and maintain optimum process parameters.

Owner:OPTOMEC DESIGN CO

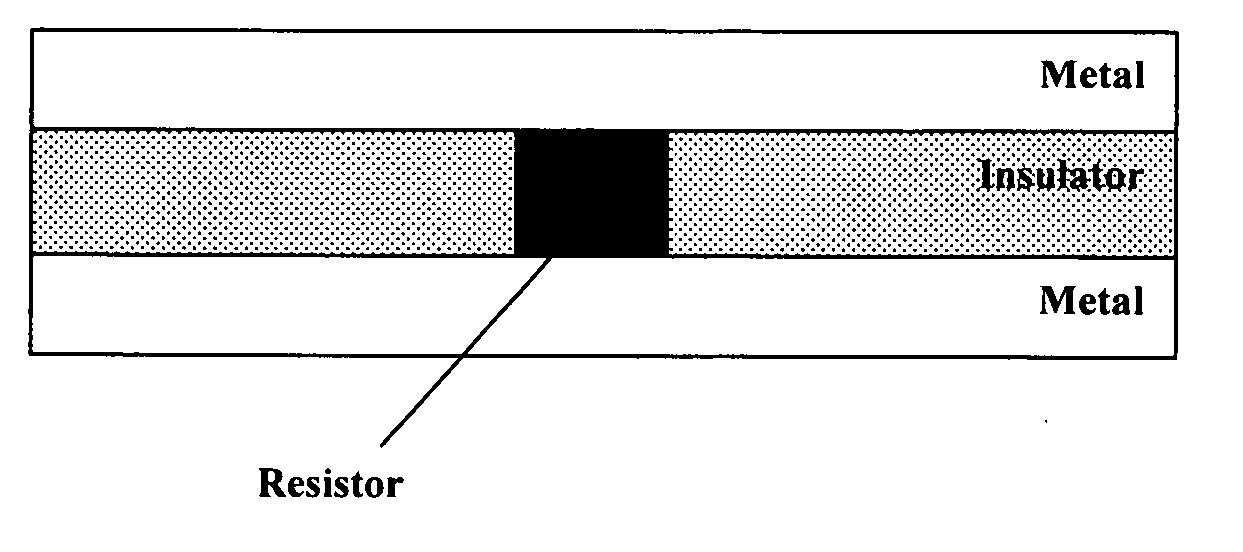

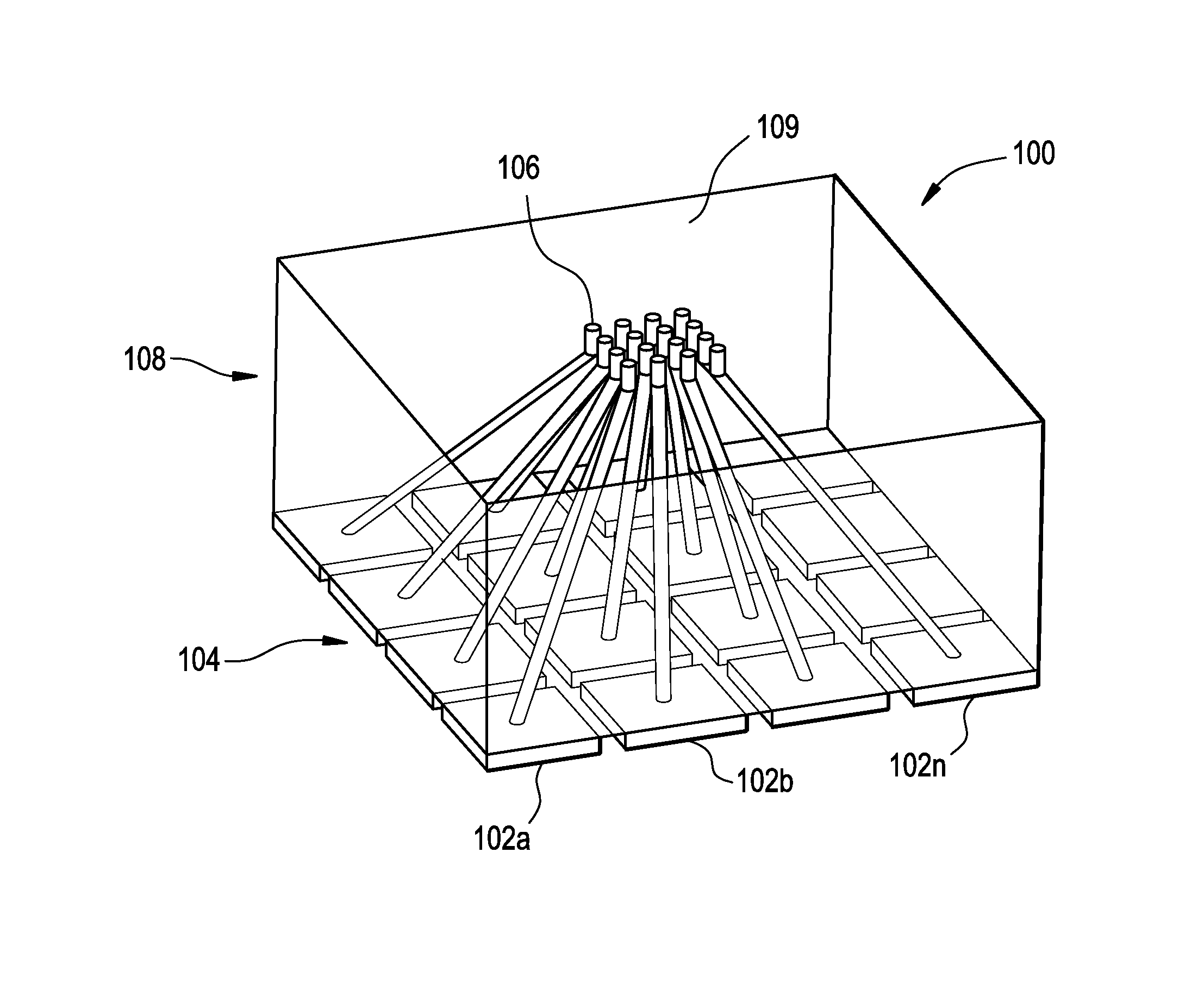

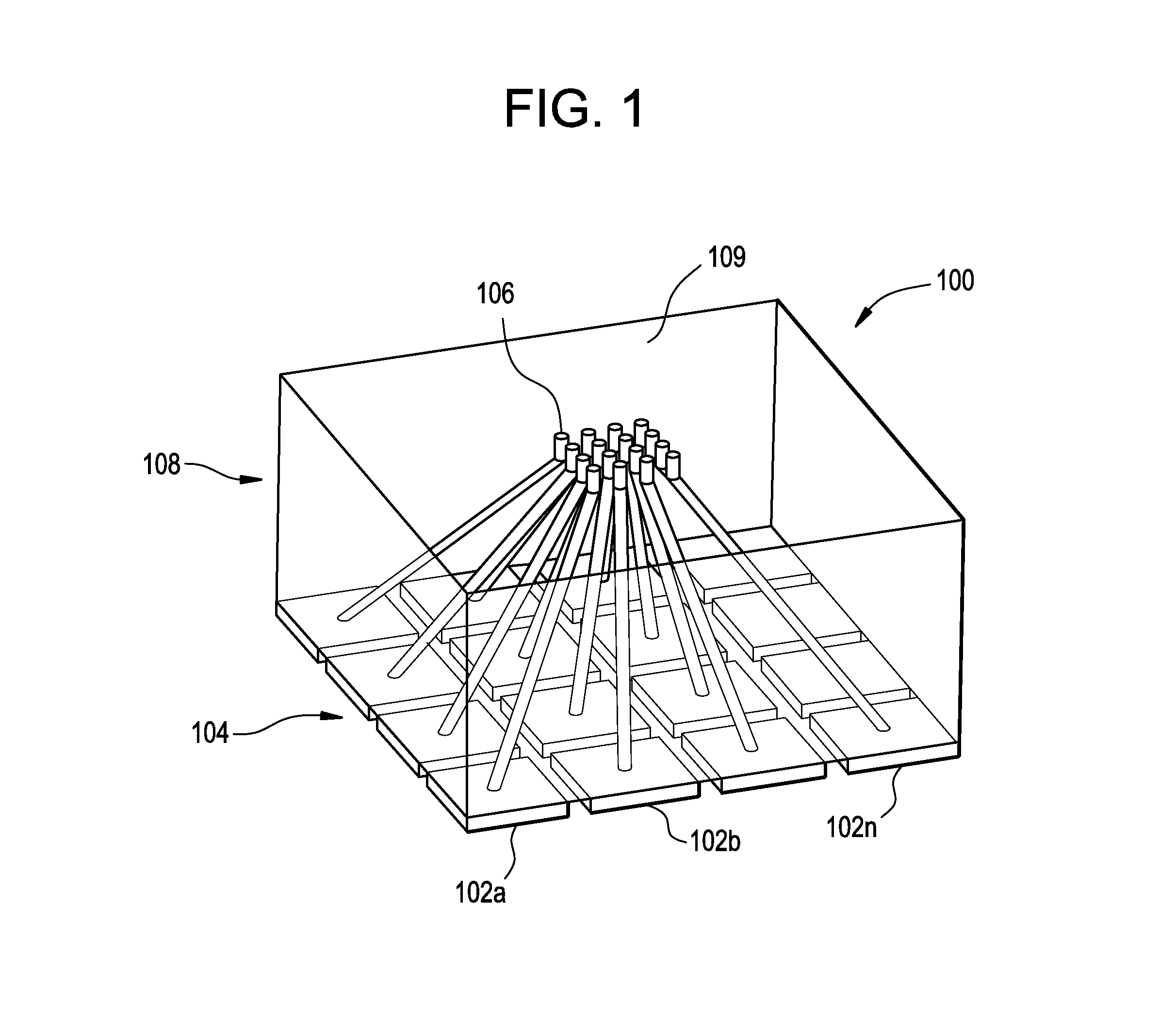

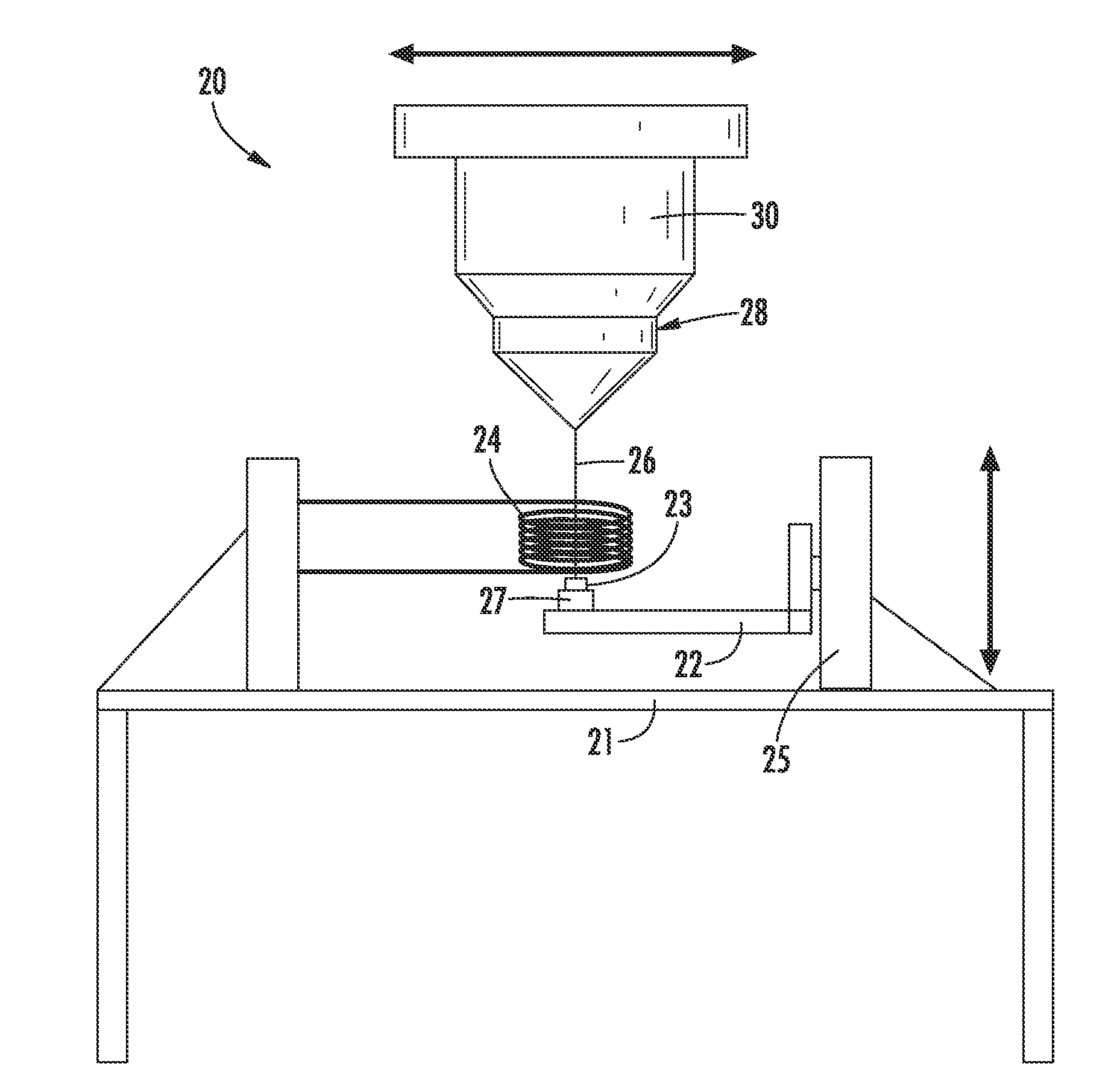

Direct writing of functionalized acoustic backing

ActiveUS20130088122A1Additive manufacturing apparatusPiezoelectric/electrostriction/magnetostriction machinesTransducerDirect writing

An acoustic transducer and method of making the acoustic transducer is disclosed. A transducer element for converting a signal between one of an electrical signal and an acoustic signal and the other of the electrical signal and the acoustic signal is provided. A backing to the transducer is additively fabricated to a side of the transducer element. The backing includes an electrically conductive path therein for conducting the electrical signal.

Owner:BAKER HUGHES INC

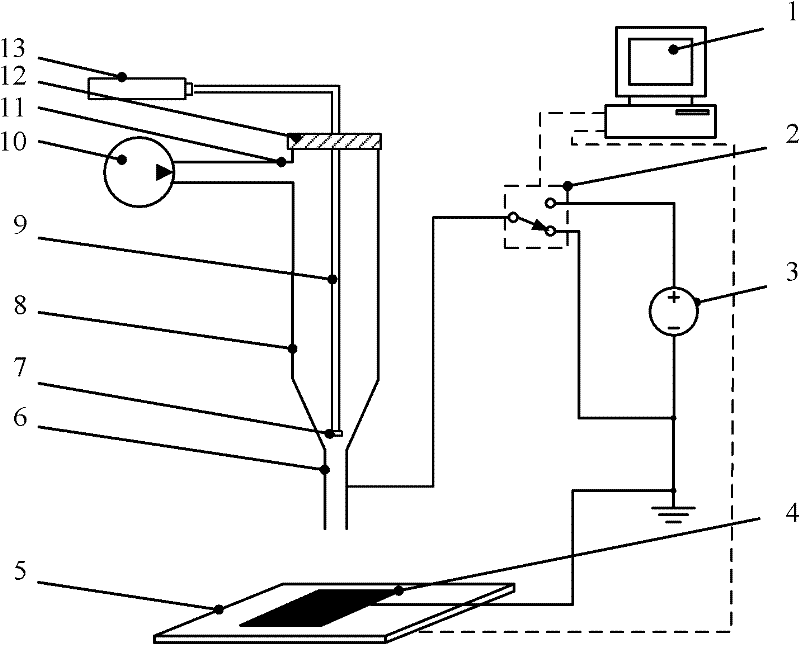

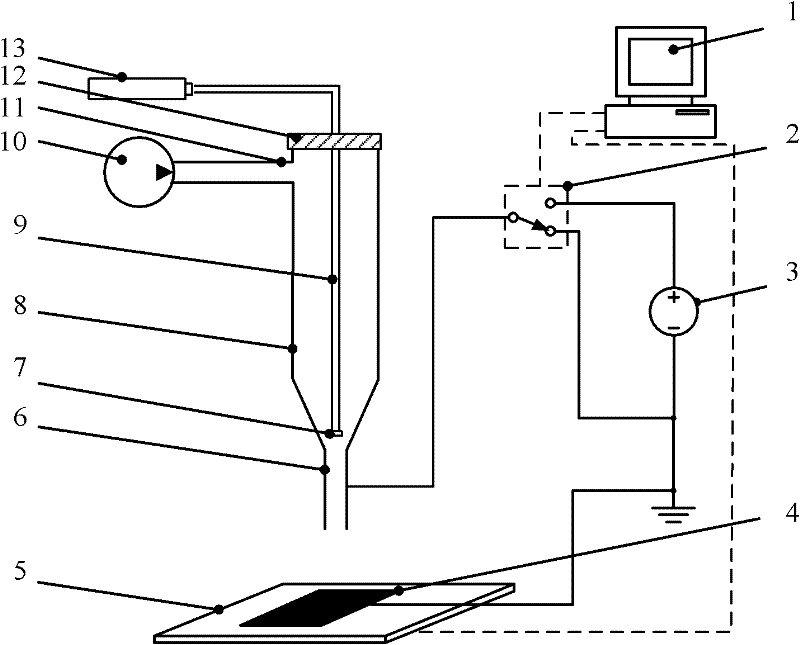

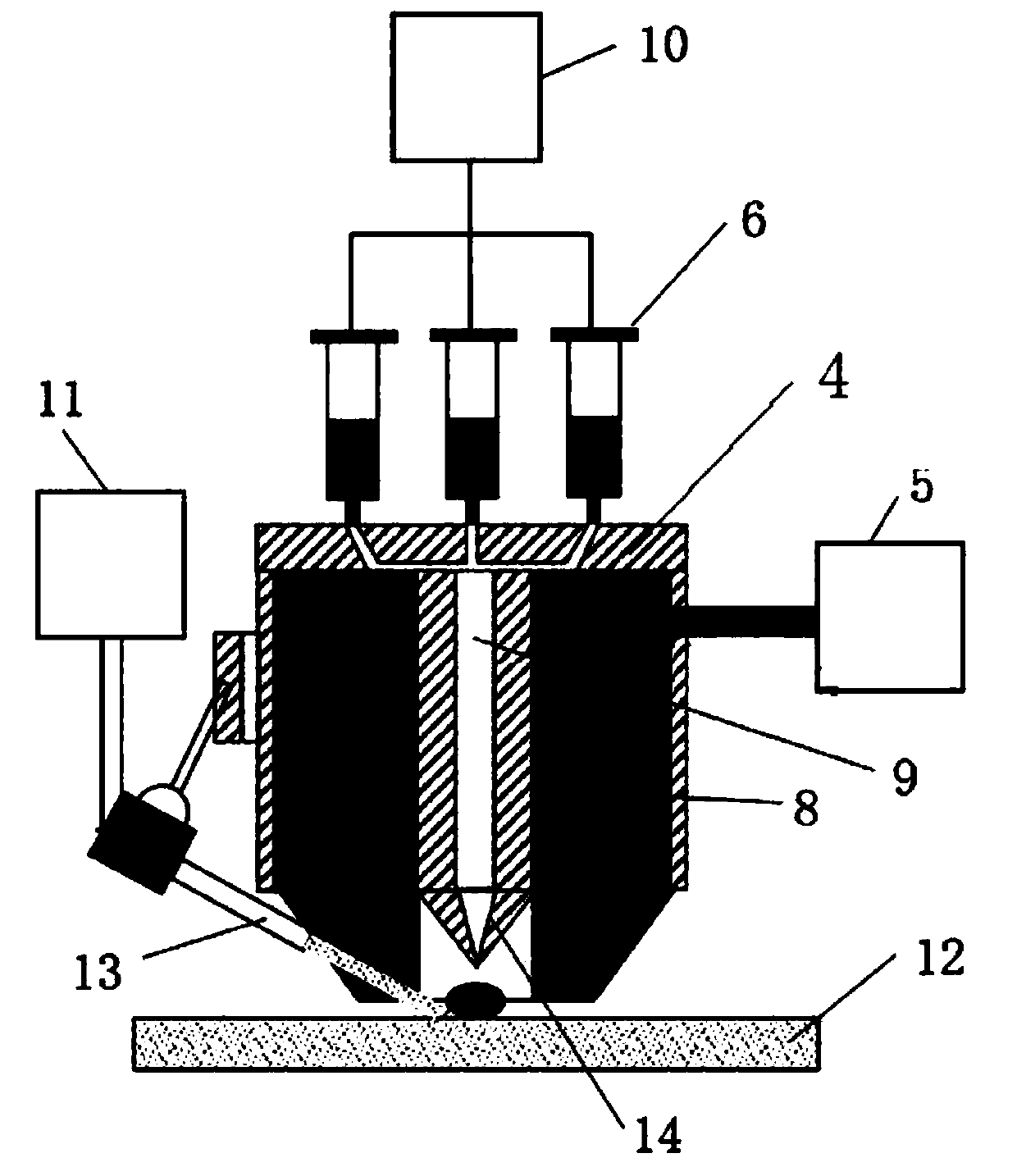

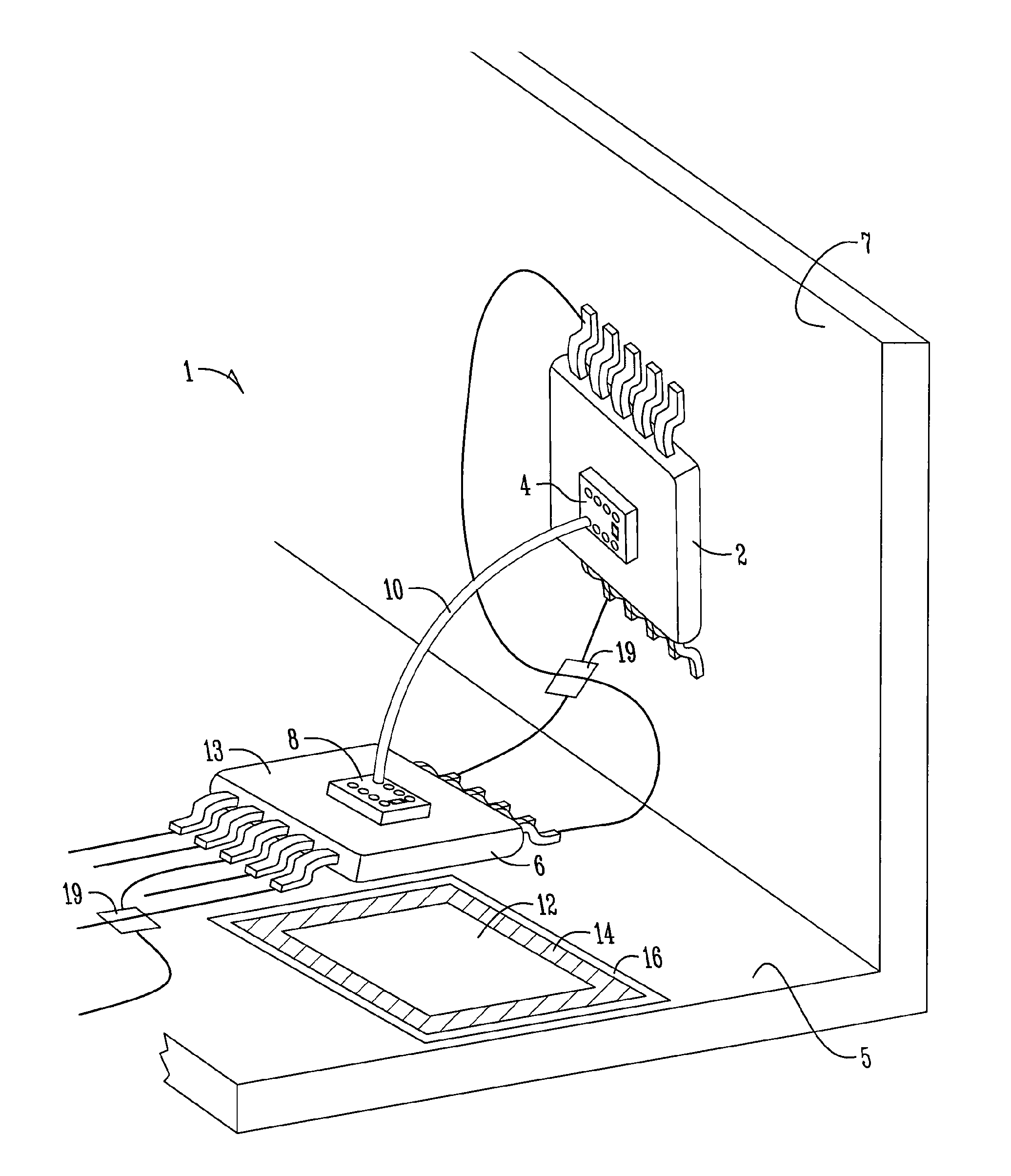

Laser-guided electrospinning direct writing device

InactiveCN102162175AImprove stabilityExtend exercise timeSpinnerette packsSpinning head liquid feederComing outElectrical conductor

The present invention provides a laser-guided electrospinning direct writing device capable of realizing long-time controllable preparation and precise positioning of single uniform micro / nanostructure. The device is provided with a controller, a high-voltage relay, an electrostatic high-voltage [power] source, a hollow nozzle, a collimating focusing lens set, optical fibers, a sealing adjusting part, a laser, a solution feed pump, a solution feed pipe, a collecting board and a motion platform, wherein the controller is connected with the high-voltage relay; ends of the high-voltage relay are respectively connected with the electrostatic high-voltage [power] source, the collecting board and a conductor nozzle arranged at the front end of the hollow nozzle; the sealing adjusting part is in a sealing connection with the rear end of the hollow nozzle; the optical fibers pass through the center of the sealing adjusting part and are fixedly connected with the sealing adjusting part; the collimating focusing lens set is arranged at the front end of the optical fibers; the rear end of the optical fibers comes out of the hollow nozzle and is connected with the laser; the solution feed pump is communicated with the hollow nozzle through the solution feed pipe; and the collecting board is fixed on the motion platform and faces the hollow nozzle. The laser constraints the disordered motion of spinning jet flow and guides the spinning jet flow to deposit at the laser spot of the collecting board.

Owner:XIAMEN UNIV

Apparatus and method for direct writing of single crystal super alloys and metals

InactiveUS20160258045A1TurbinesAdditive manufacturing apparatusTemperature controlSingle crystal superalloy

Apparatus and methods for direct writing of single crystal super alloys and metals are provided. In one method, a substrate is heated to a pretermined temperature below its melting point, and a laser is used to form a melt pool on a surface of a substrate. The substrate is positioned on a base plate, and the laser and the base plate are movable relative to each other, with the laser being used for direct metal deposition and the substrate is heated to a temperature below its melting point. A superalloy powder is introduced to the melt pool, and the temperature of the melt pool is controlled to maintain a predetermined thermal gradient on a solid and liquid interface of the melt pool so as to form a single crystal deposit on the substrate.

Owner:GENERAL ELECTRIC CO +1

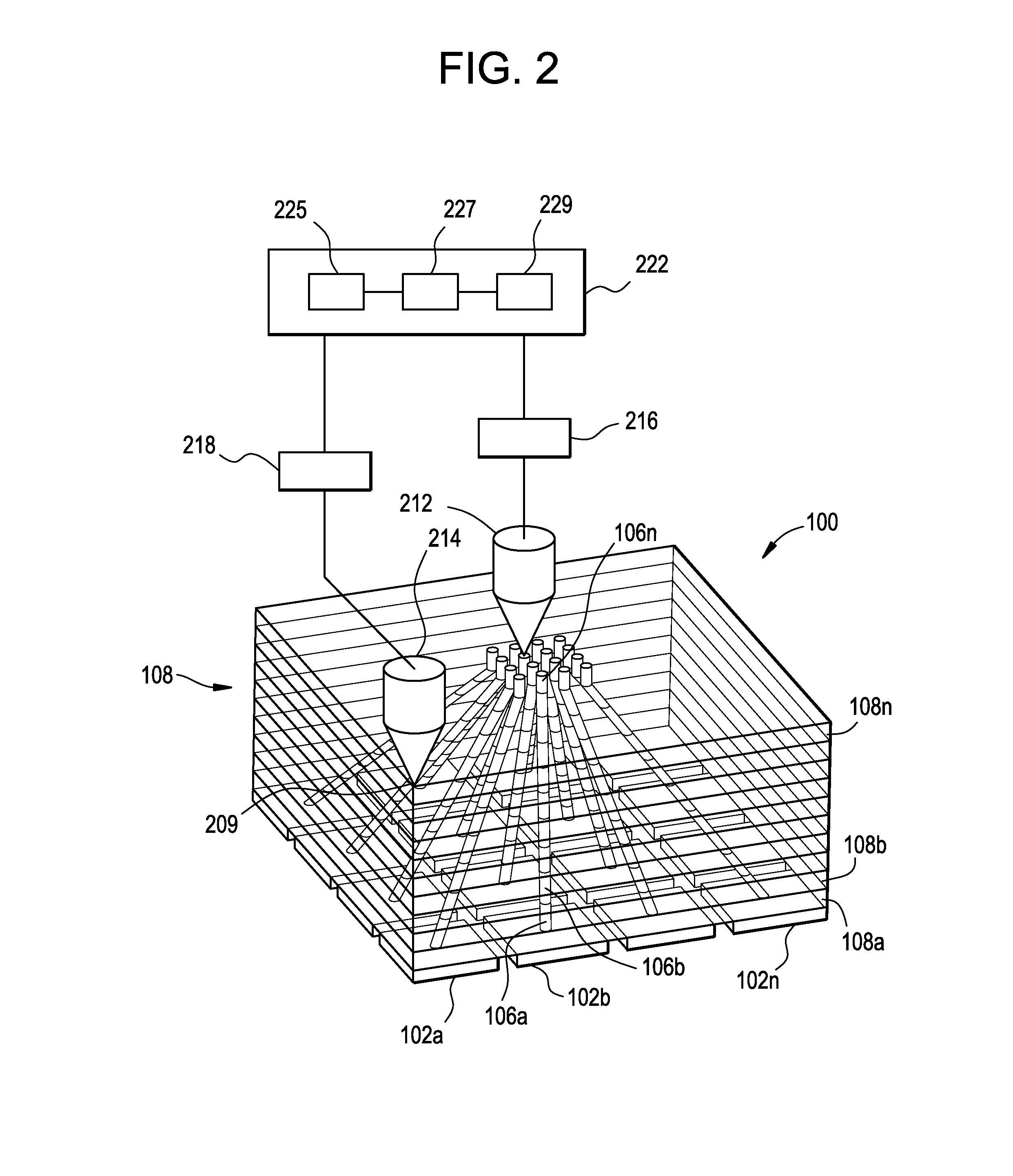

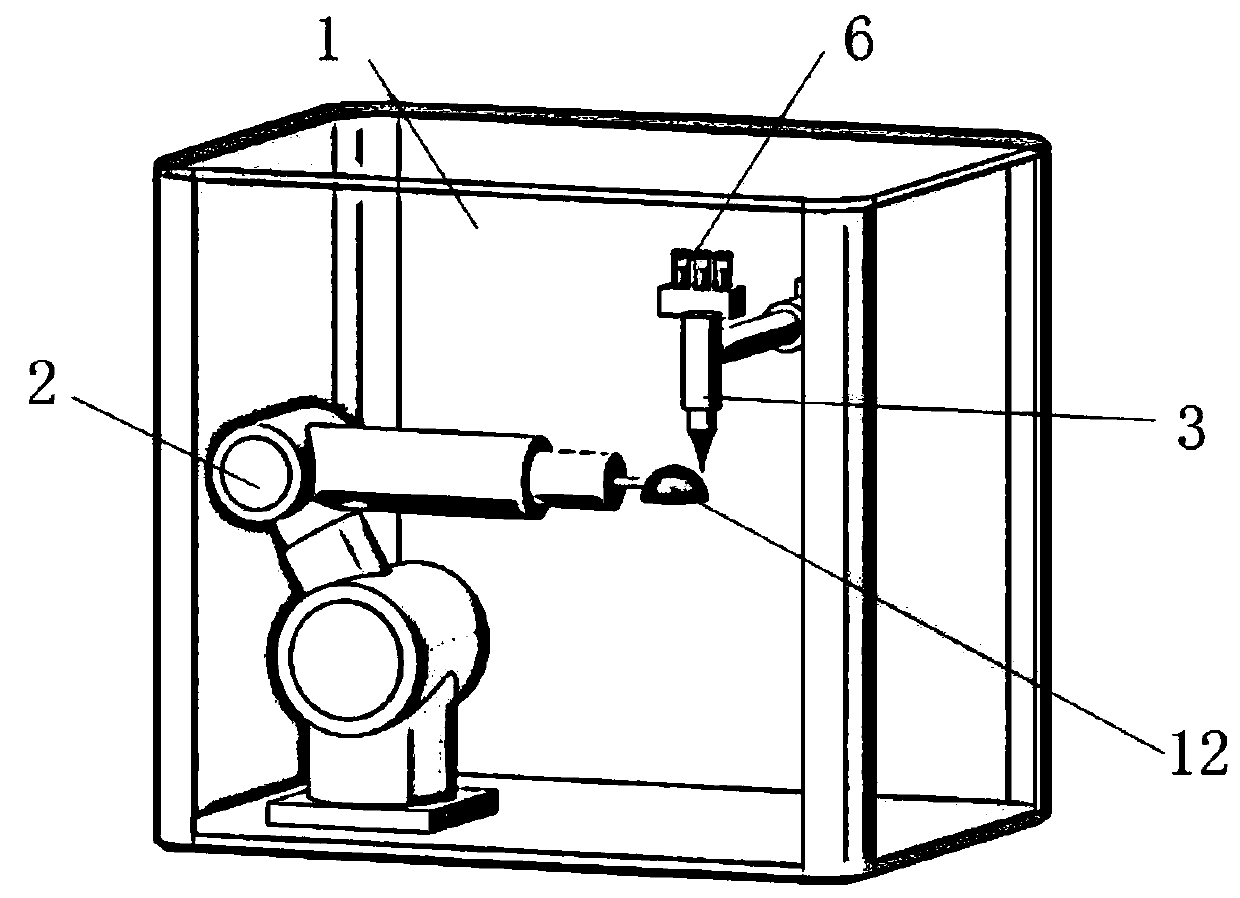

Multi-material laser direct writing conformal system and method

InactiveCN104260360ALarge adjustment rangeHigh repeat positioning accuracyMulti materialControl system

The invention discloses a multi-material laser direct writing conformal system and a method. The system comprises a vacuum seal case, a multi-joint mechanical arm, a multi-material laser direct writing head and a control system for controlling the constituent parts, wherein the mechanical arm and the laser direct writing head are arranged in the vacuum seal case; the laser direct writing head comprises a direct writing head body, a laser and at least two groups of material cylinders; a material channel and a laser focusing channel communicated with the laser and the material cylinders respectively are arranged on the direct writing head body; and the at least two groups of material cylinders are arranged on the direct writing head body in parallel. A particular process is as follows: the mechanical arm drives a workpiece to move along a set path; a material controller selects the corresponding material cylinders; a discharge head delivers and allows materials to be attached to the surface of the workpiece; and at the same time, laser light emitted from the laser focusing channel carries out solidifying or sintering forming on the attached materials. According to the invention, a control process is simple, the forming precision is high, continuous production is achieved, and production efficiency is improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

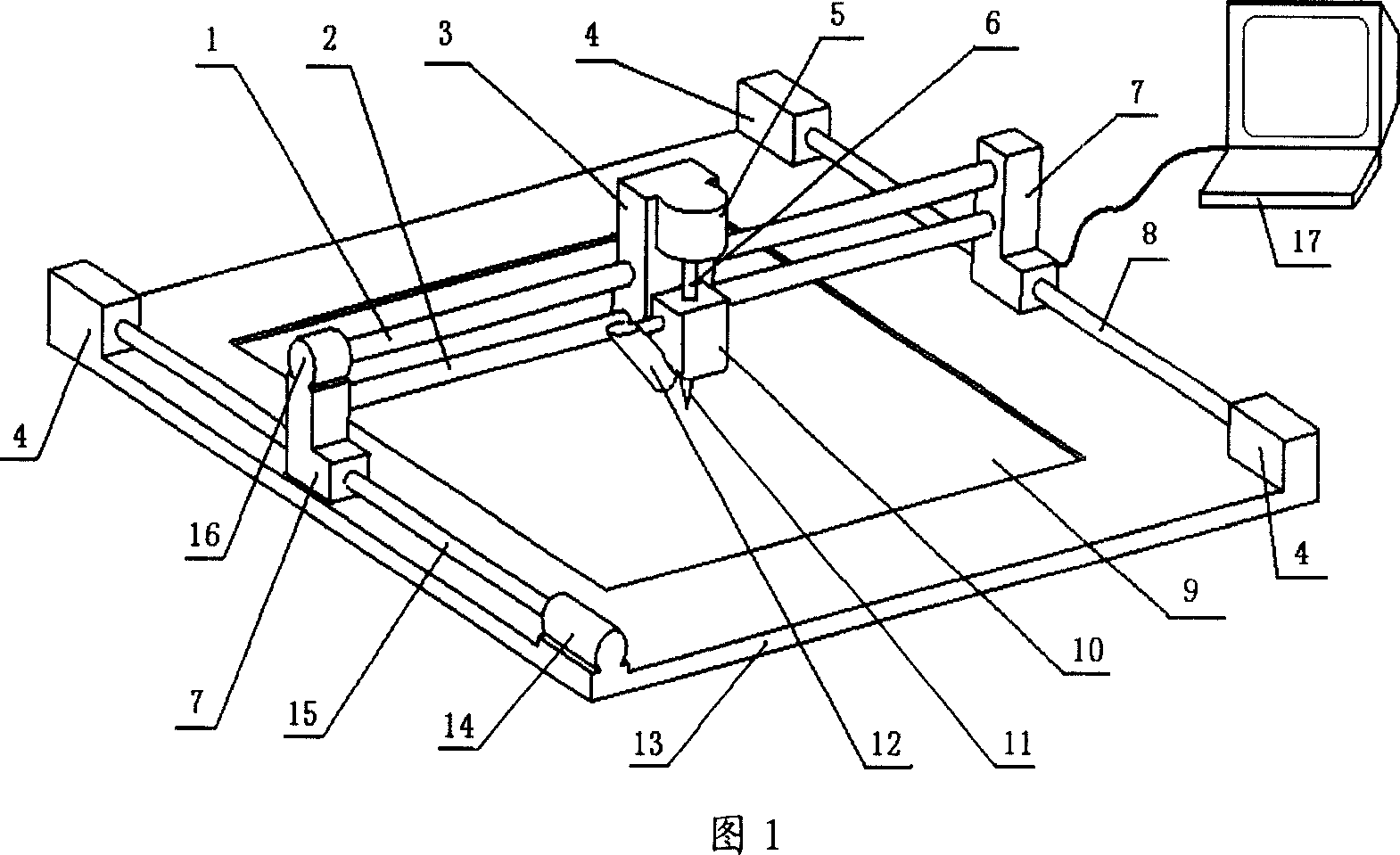

Micro nano structure direct-writing device

InactiveCN1966399AIncrease profitReduce development costsNanostructure manufactureFilament/thread formingMicro nanoMicrometer

The invention relates to a micrometer-nanometer structure writer of polymer material, wherein it is based on near-field static spinning technique, to quickly write adhesive material or macromolecule material, while the minimum diameter / line width is lower than 300nm / 20 mum. It has micro probe control platform, integrated high-voltage static power source, flux controller, X-Y platform, probe and CCD microscope; the integrated high-voltage static power source can power the probe, while its anode is connected to probe and cathode is connected to ground; the flux controller is fixed on the micro probe control platform, while it is connected to probe via tube; the probe is used as ejector of material, while it is mounted on micro probe control platform; the microscope is used to detect the spinning process and the writing effect, while it is arranged on micro probe control platform.

Owner:XIAMEN UNIV

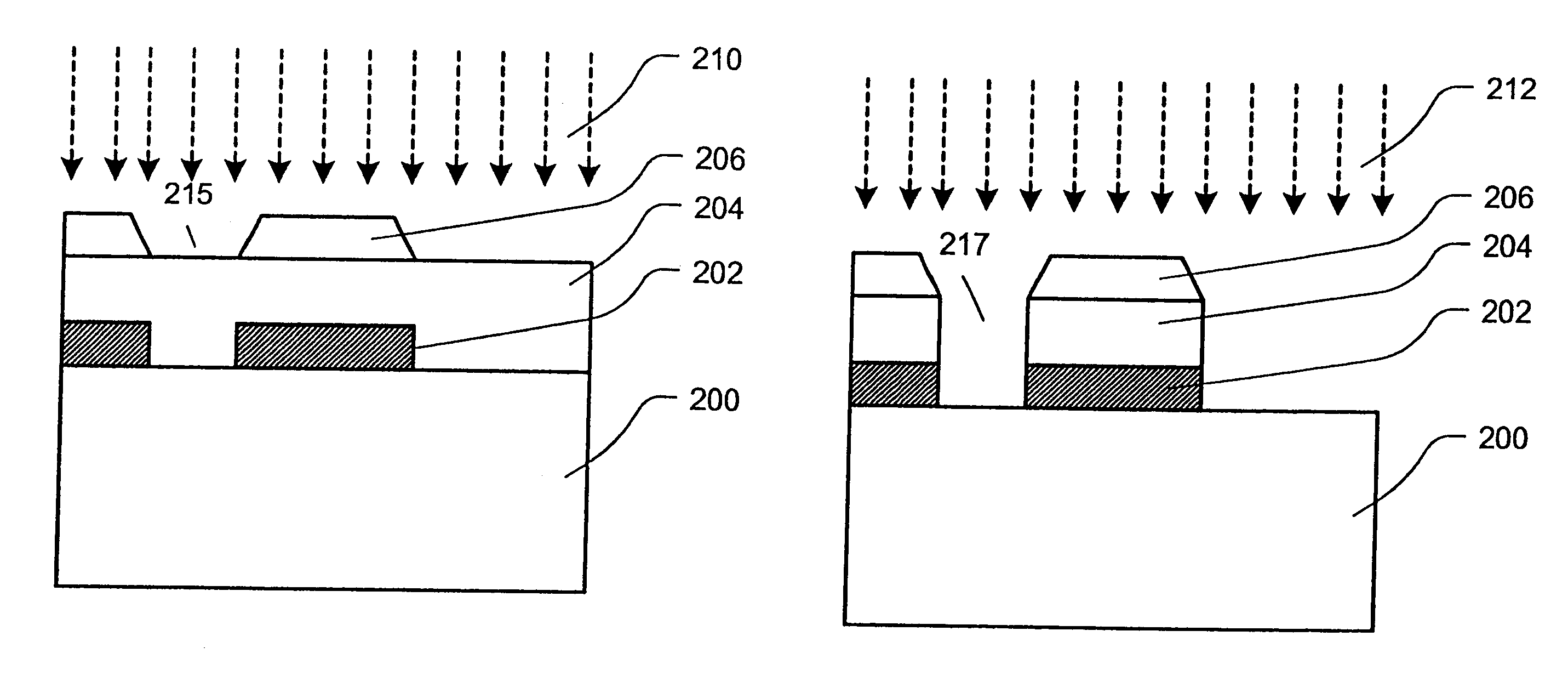

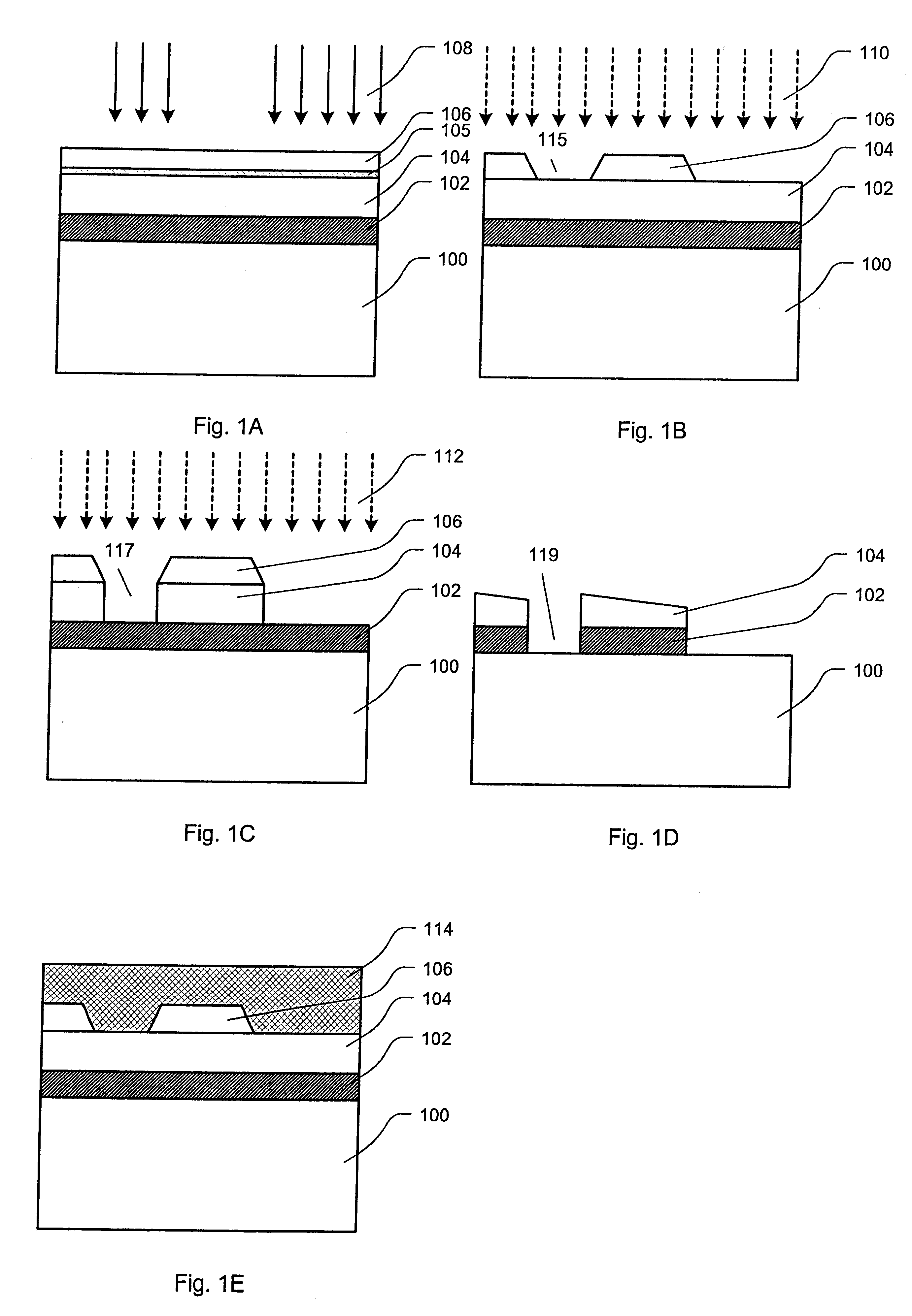

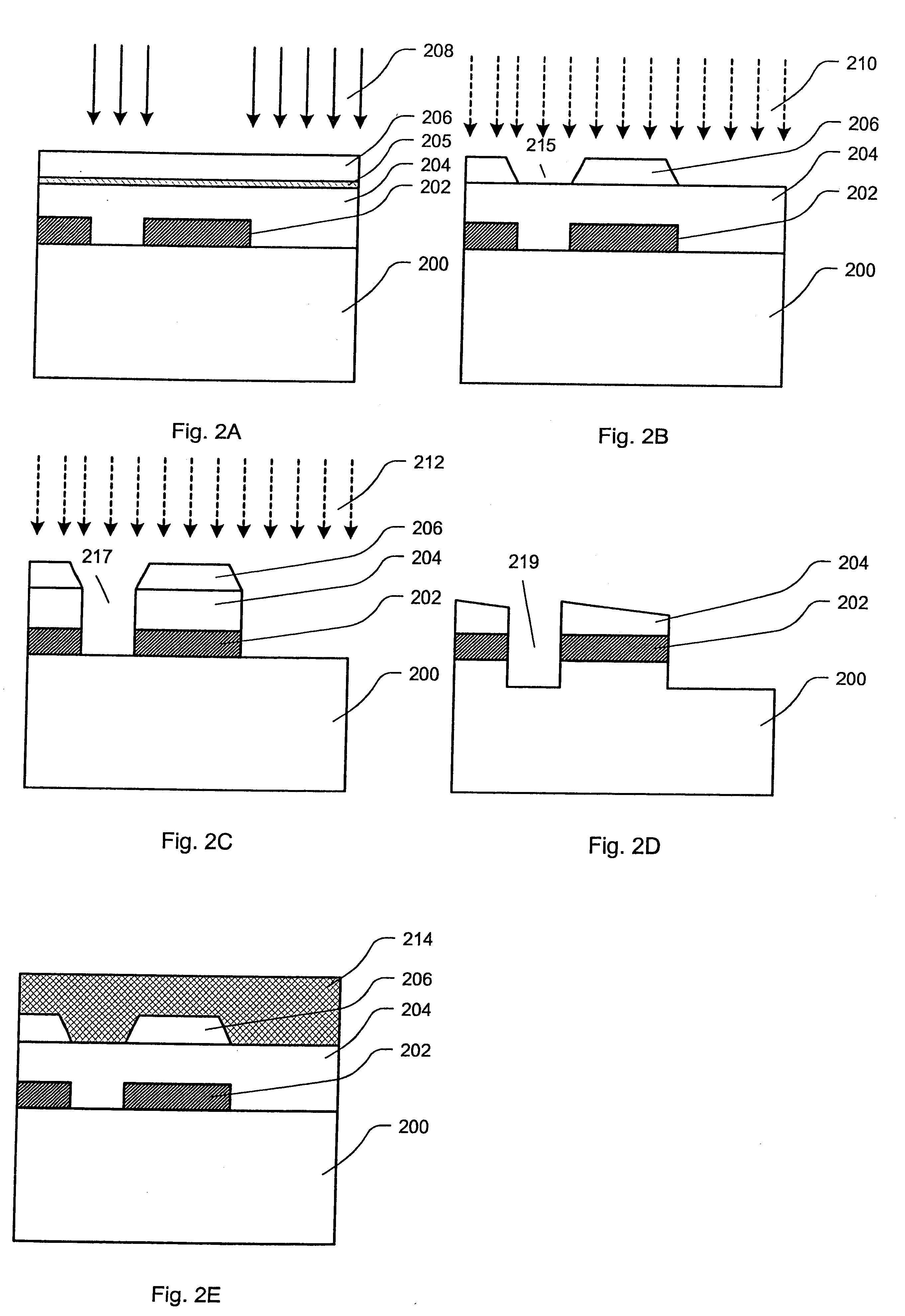

Reticle and direct lithography writing strategy

The present invention relates to preparation of patterned reticles to be used as masks in the production of semiconductor and other devices. Methods and devices are described utilizing resist and transfer layers over a masking layer on a reticle. The methods and devices produce small feature dimensions in masks and phase shift masks. The methods described for masks are in many cases applicable to the direct writing on other workpieces having similarly small features, such as semiconductor, cryogenic, magnetic and optical microdevices.

Owner:ASML NETHERLANDS BV

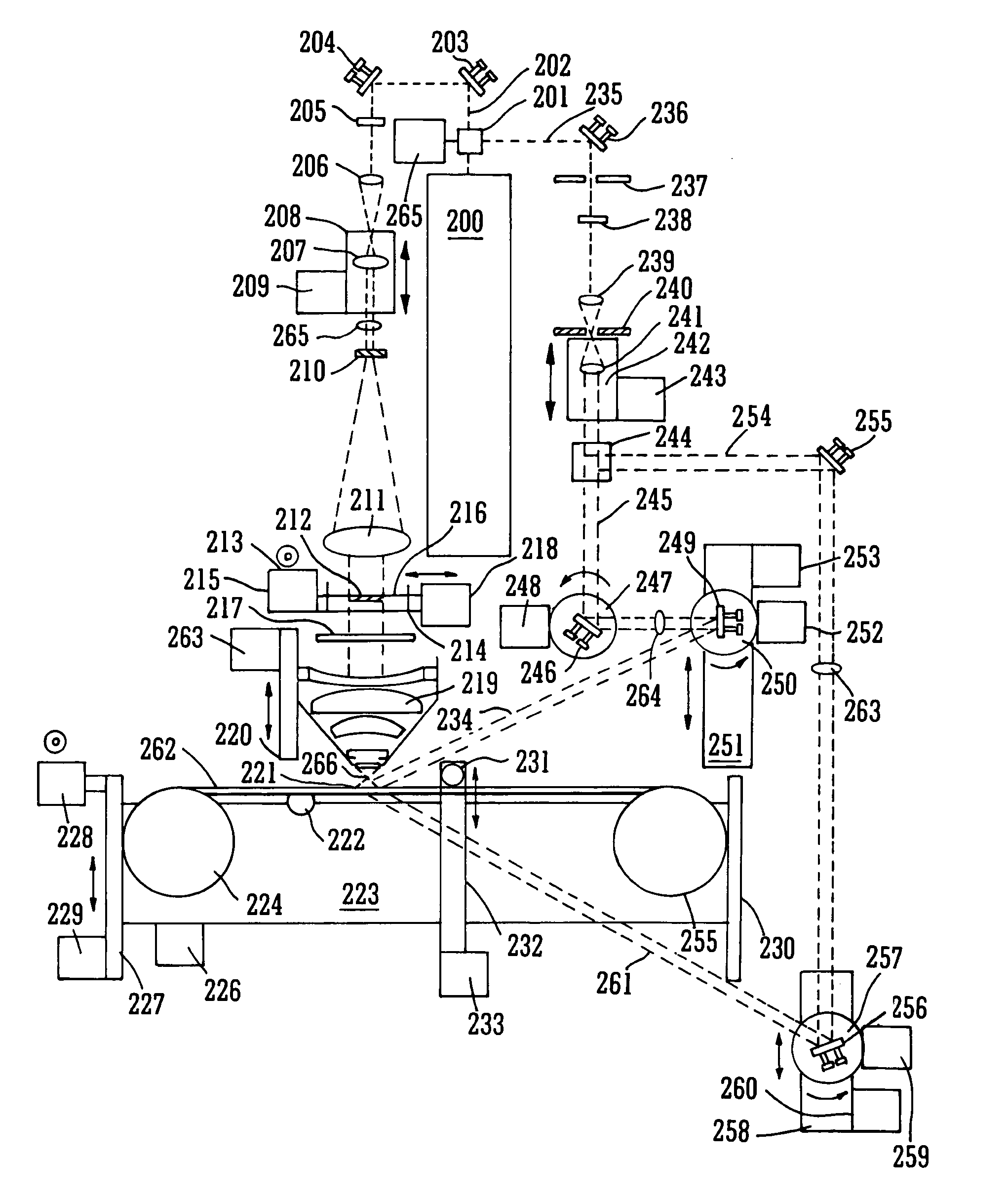

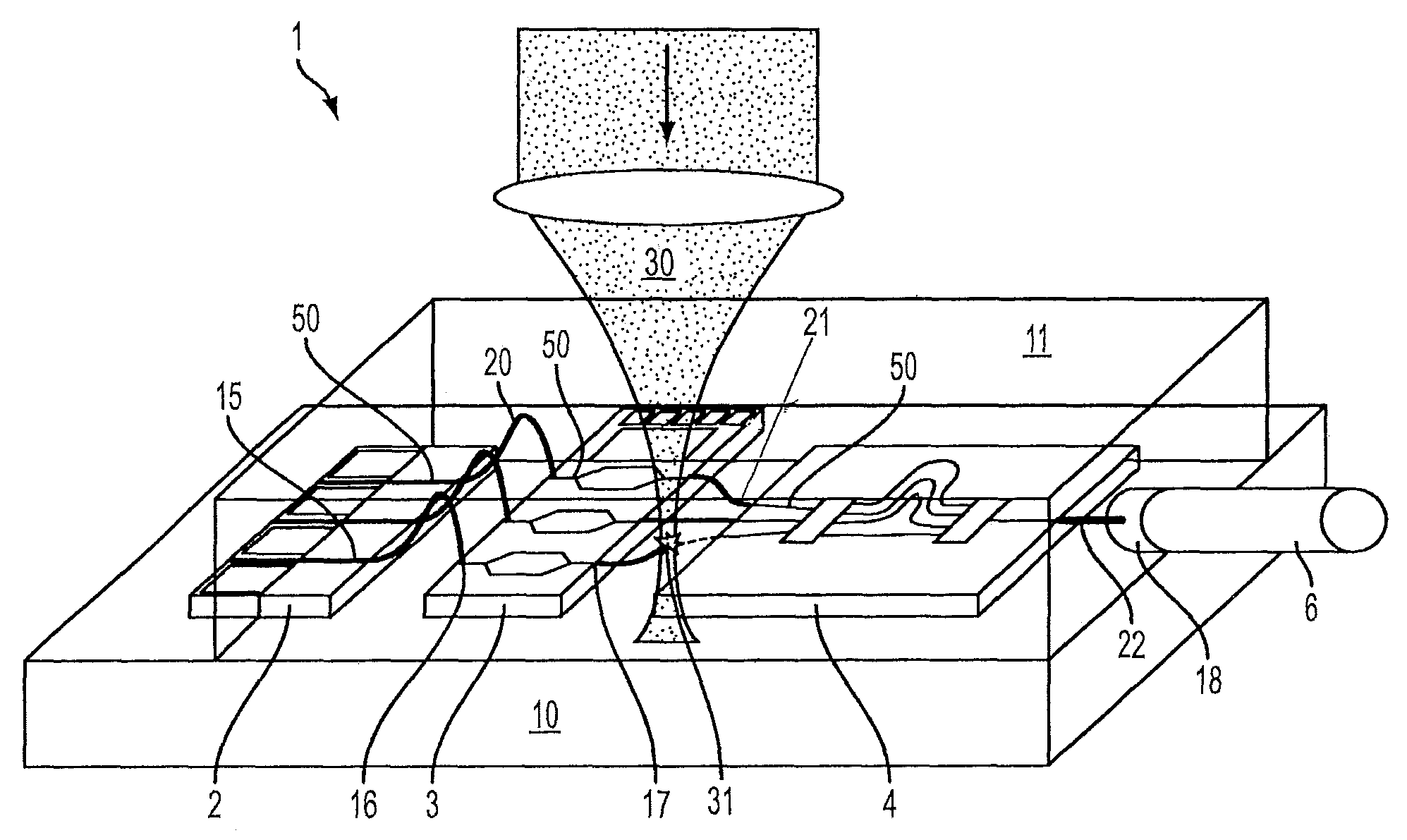

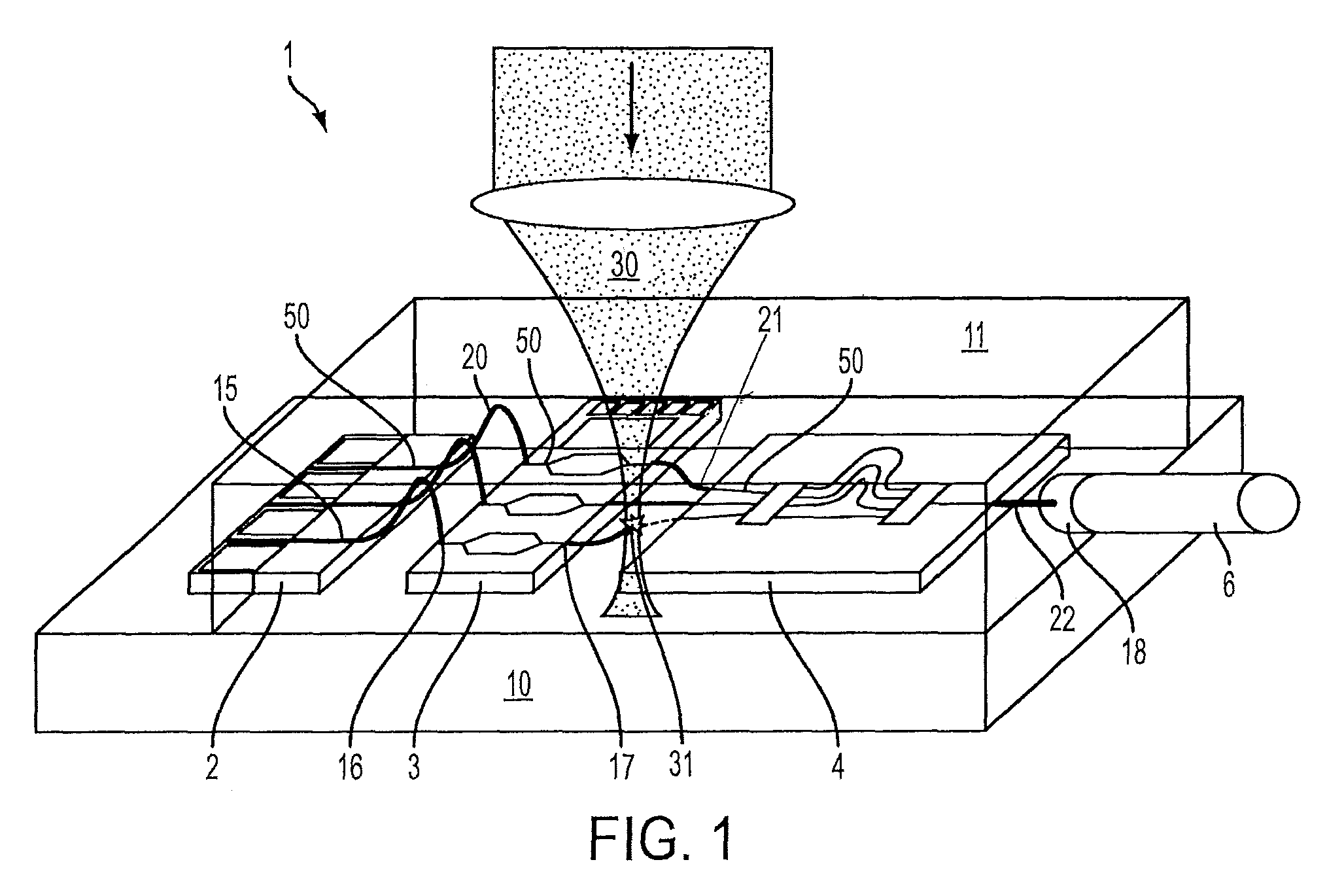

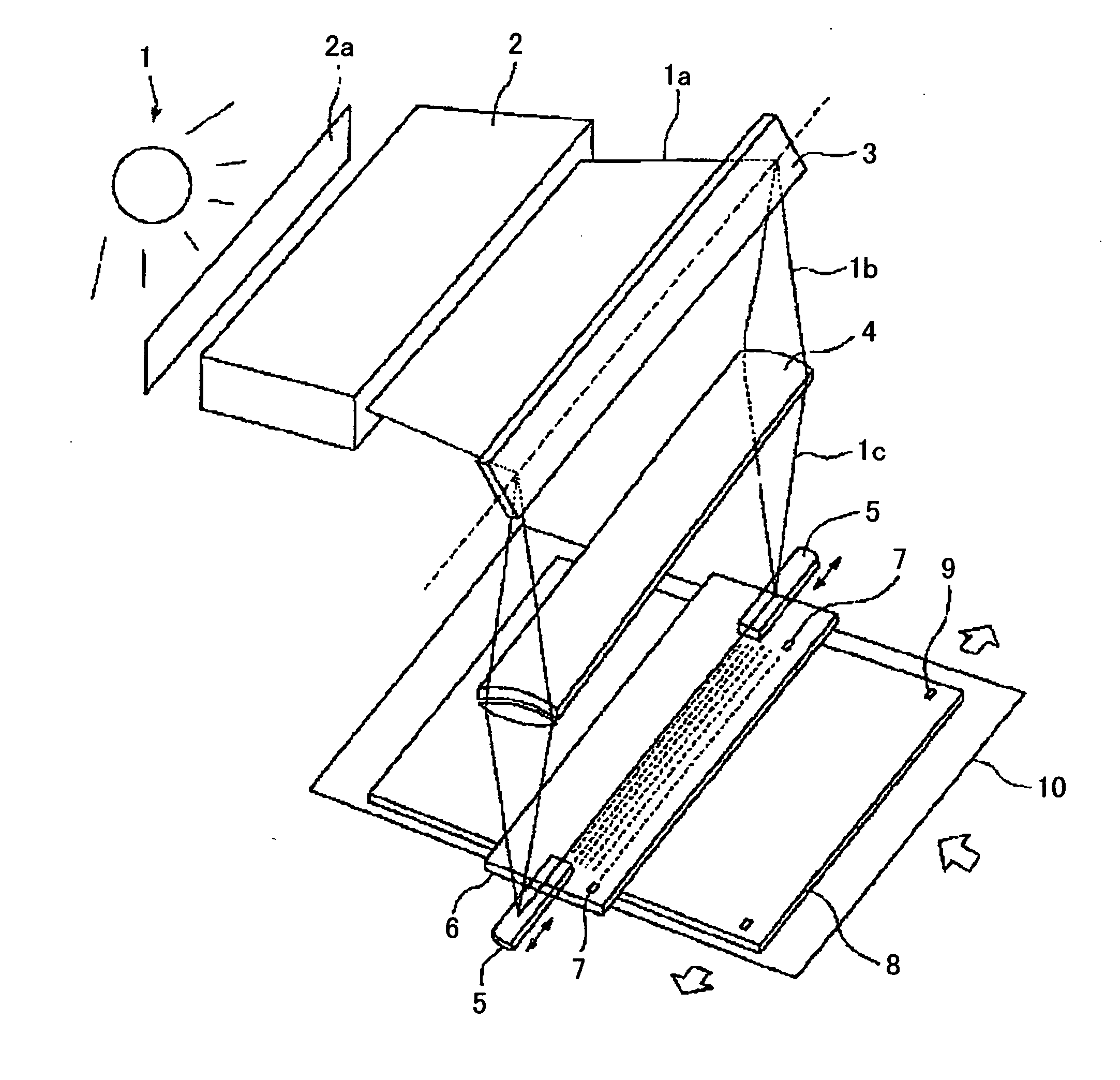

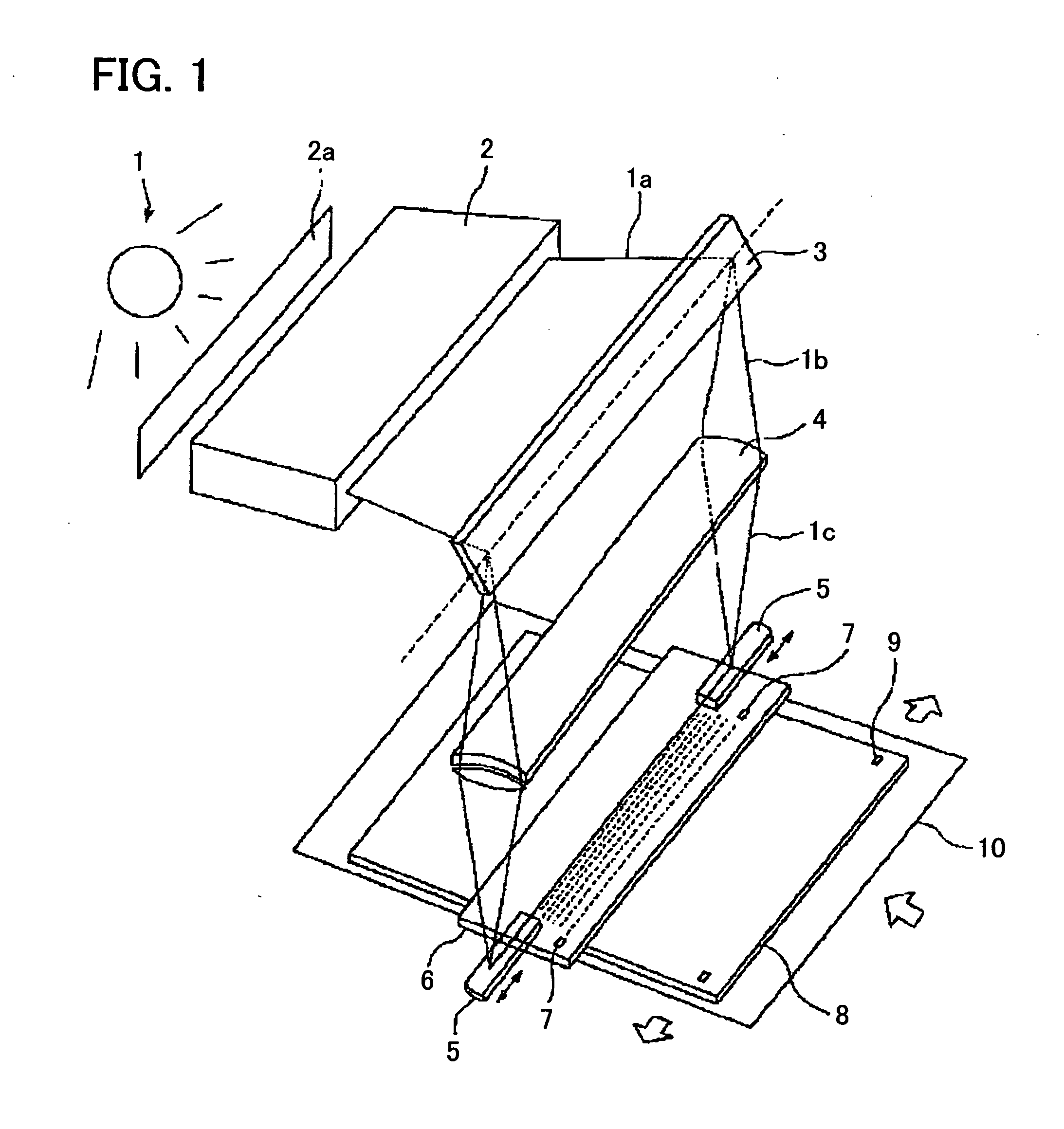

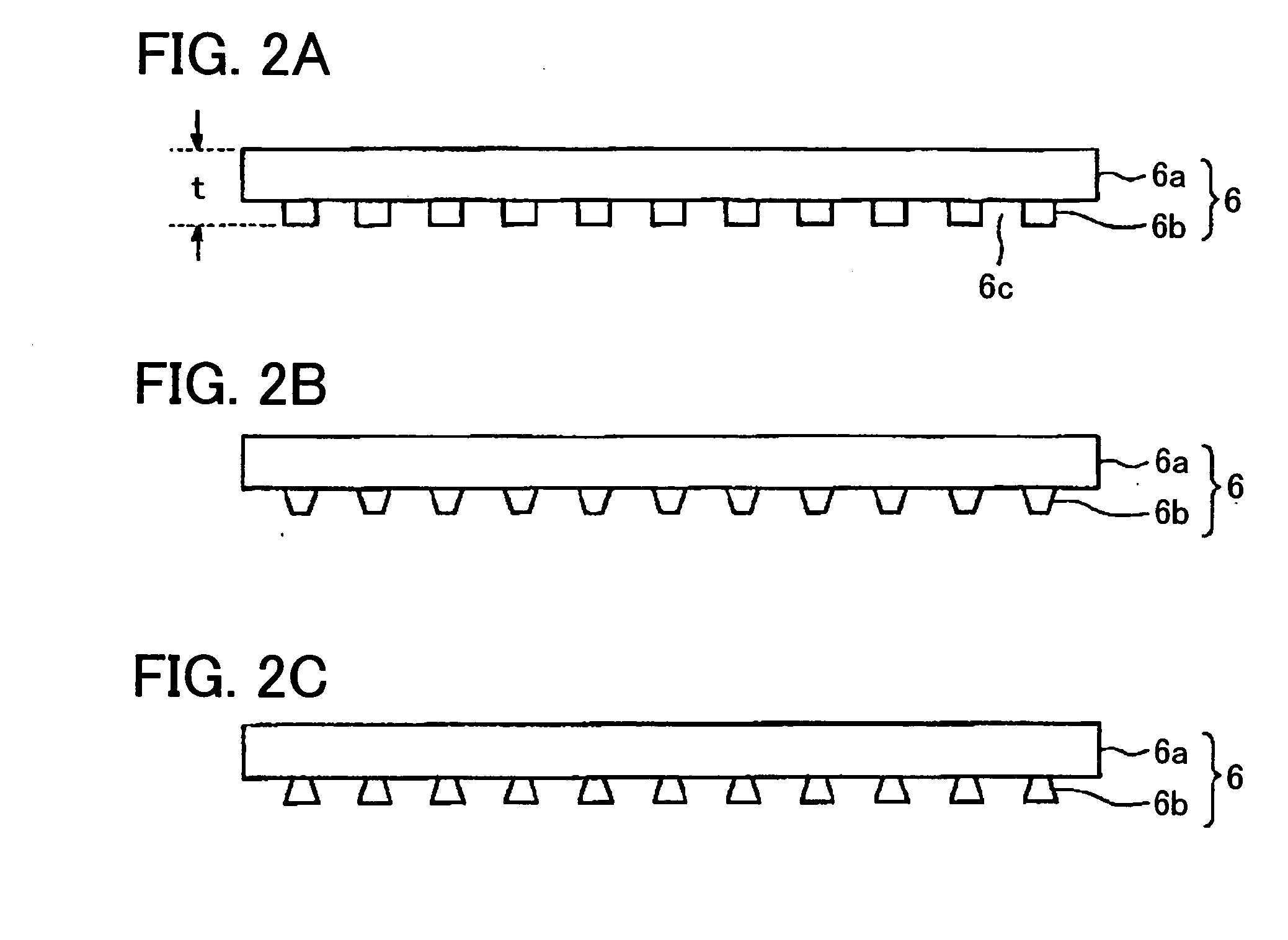

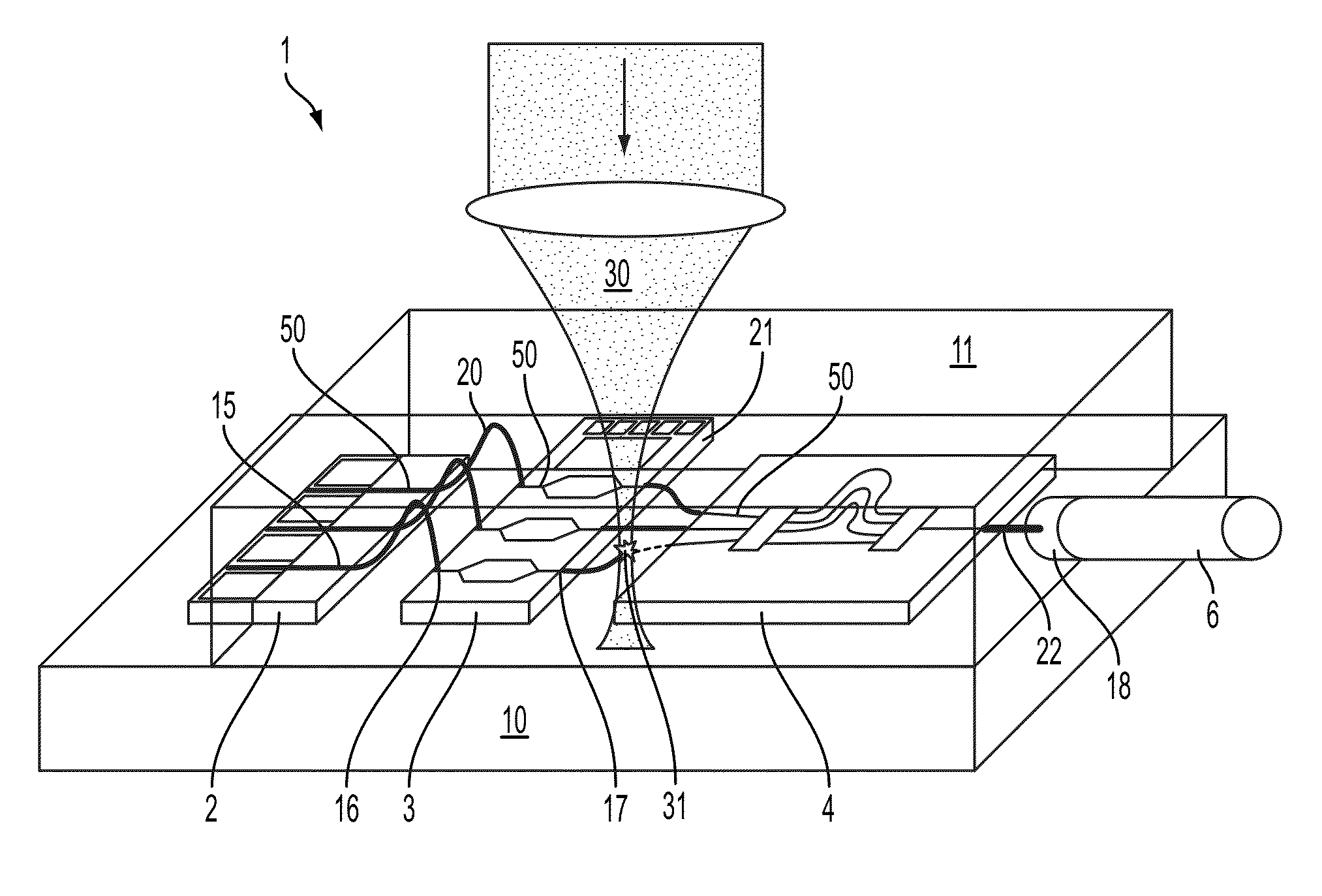

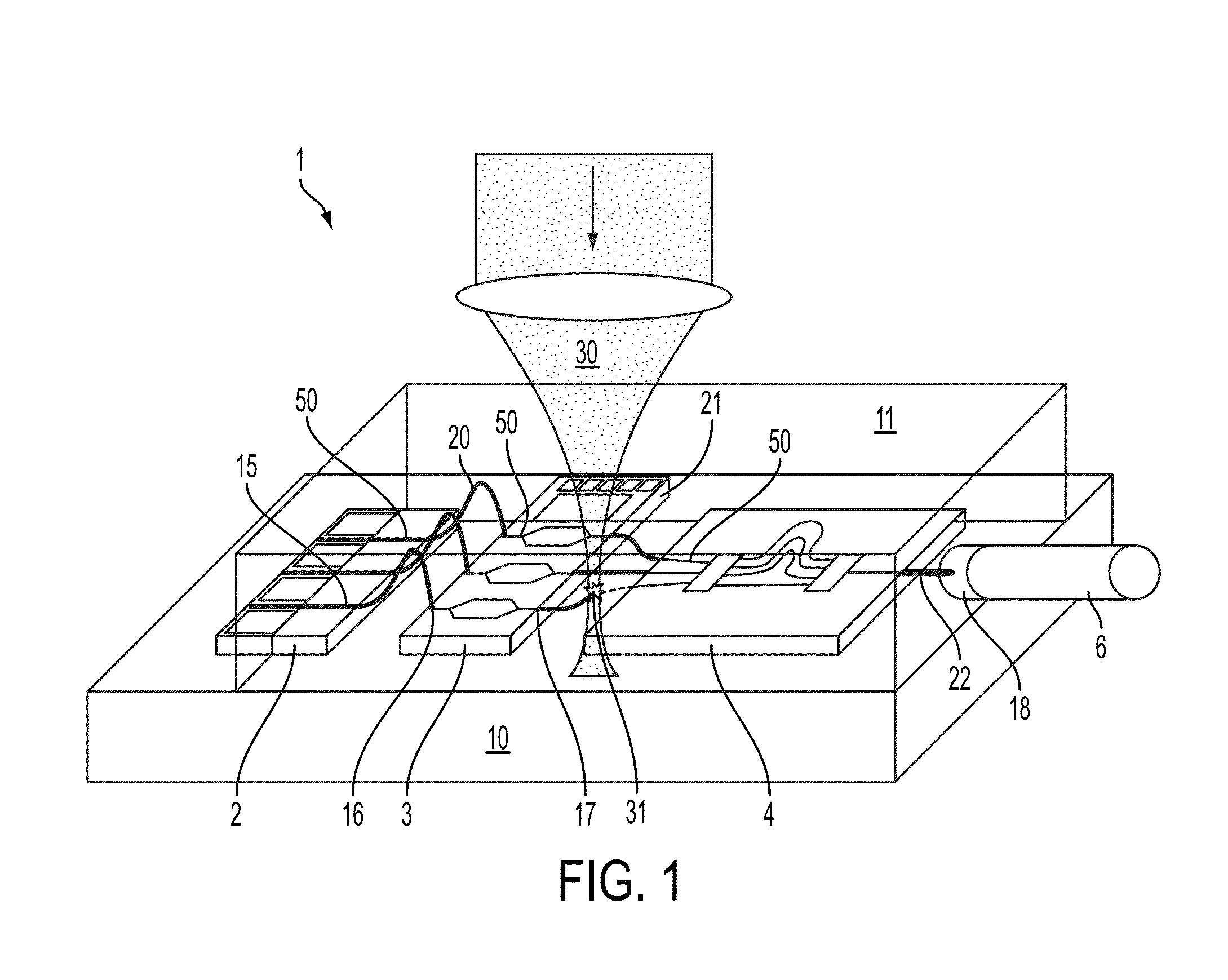

Laser processing apparatus, exposure apparatus and exposure method

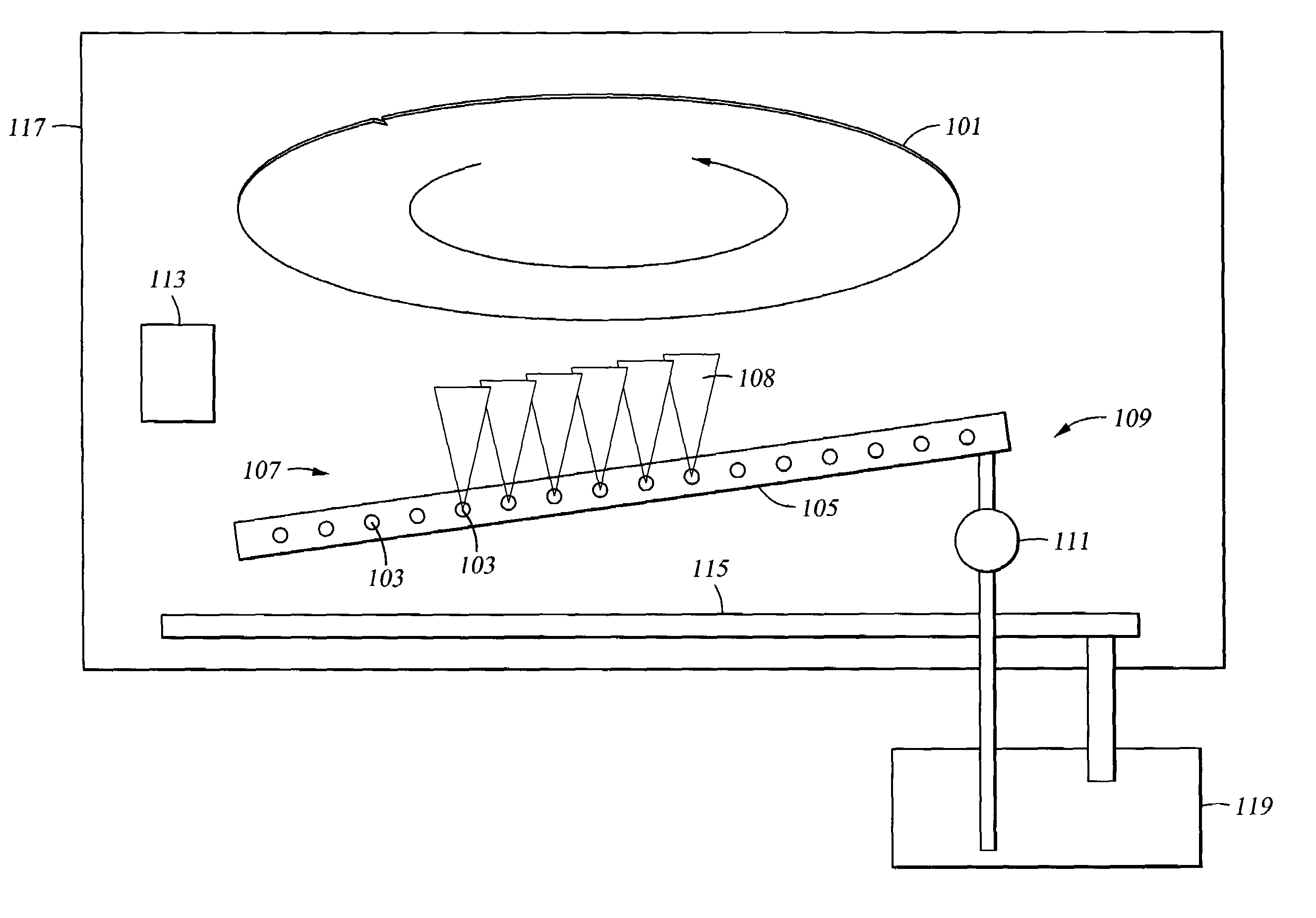

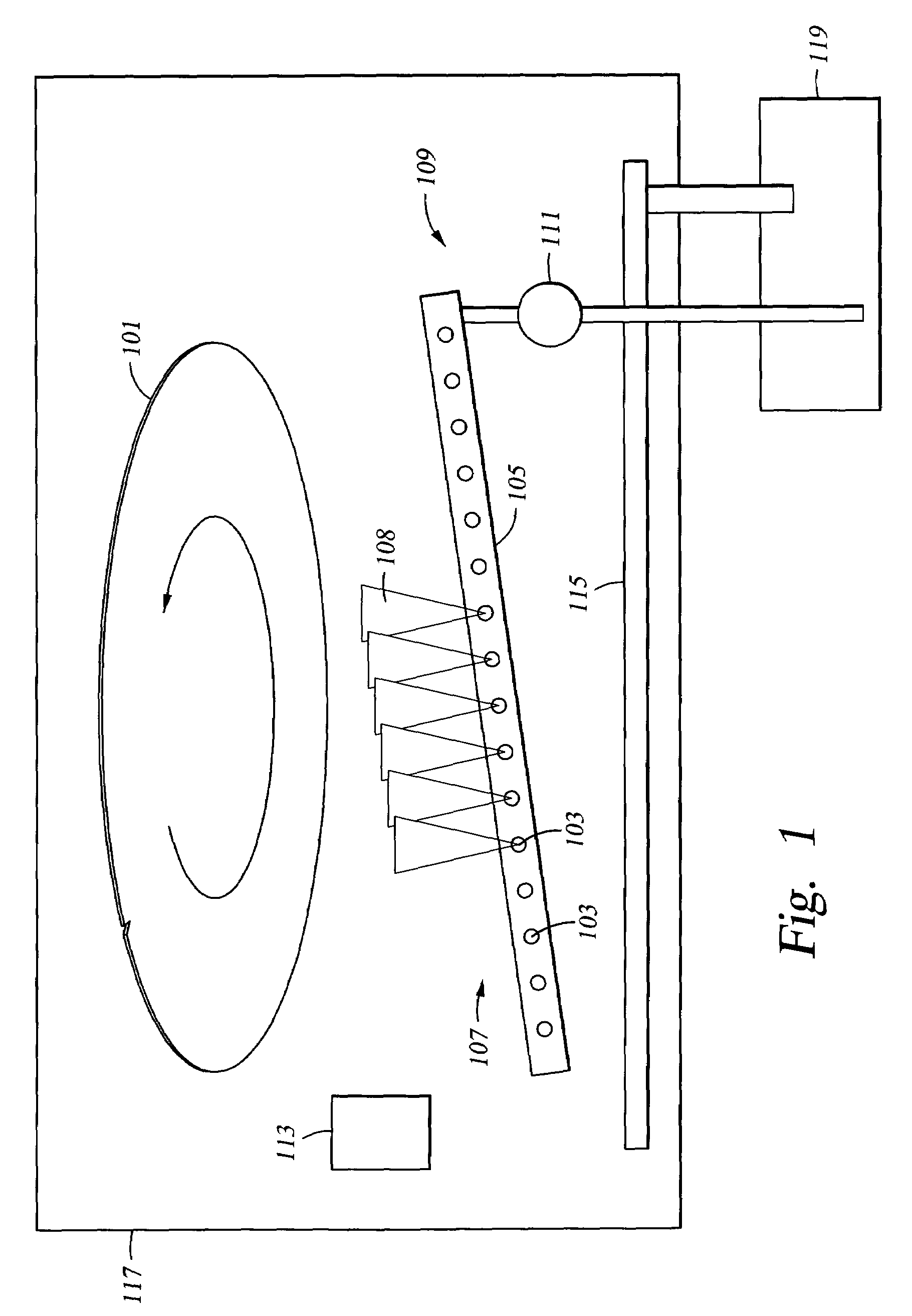

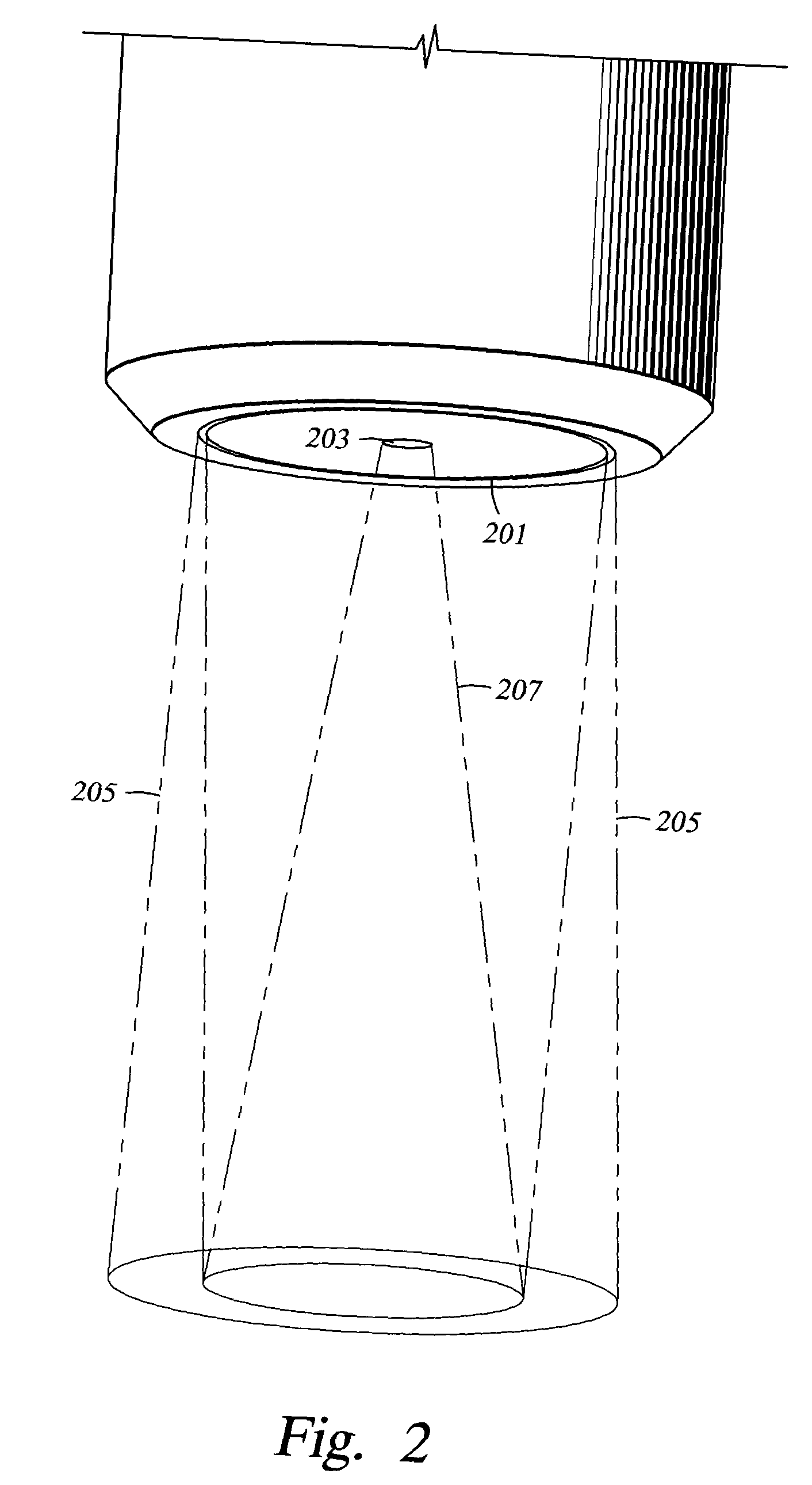

InactiveUS20070070319A1Increase speedLow costPhotomechanical apparatusPhotographic printingLaser processingLight beam

An exposure apparatus includes a stage 10 for holding a substrate 8 to be exposed; a direct writing mask 6 arranged above the substrate 8 to be exposed held by the stage 10; a repeated opening pattern in which a plurality of openings each having approximately the same size are arranged in a line at approximately the same interval, provided to the mask; an irradiation mechanism for irradiating with a linear laser beam 1c along the repeated opening pattern; and a movement mechanism for moving a relative position of a laser beam which is formed in such a way that the linear laser beam formed by the laser processing mechanism passes through the plurality of openings of the opening pattern and the substrate held by the stage.

Owner:SEMICON ENERGY LAB CO LTD

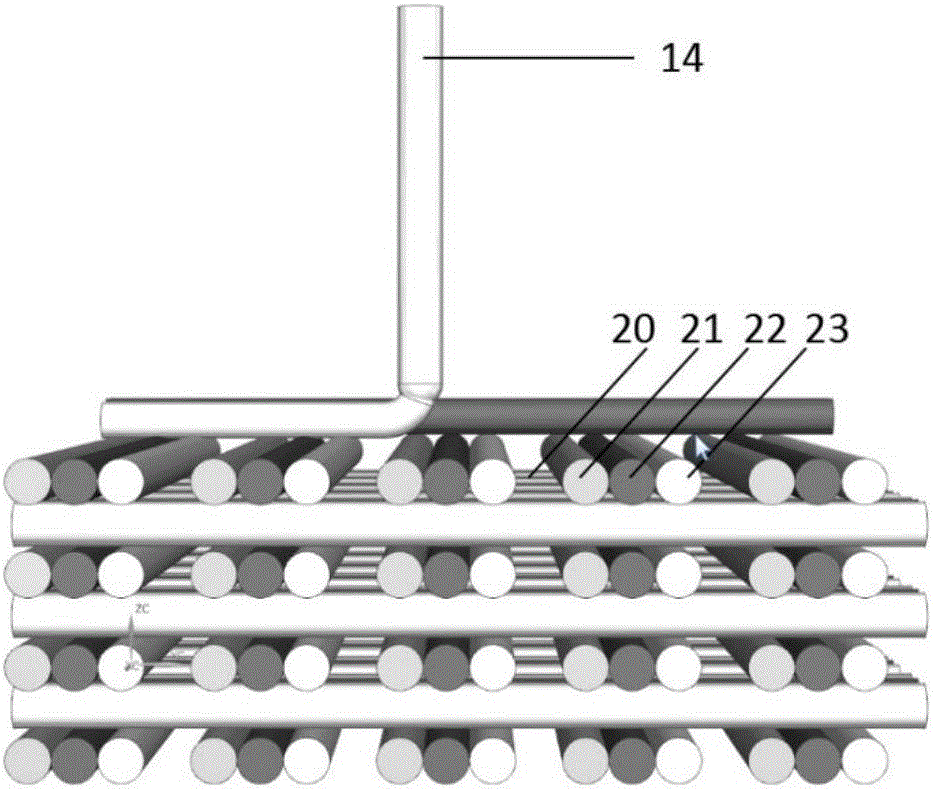

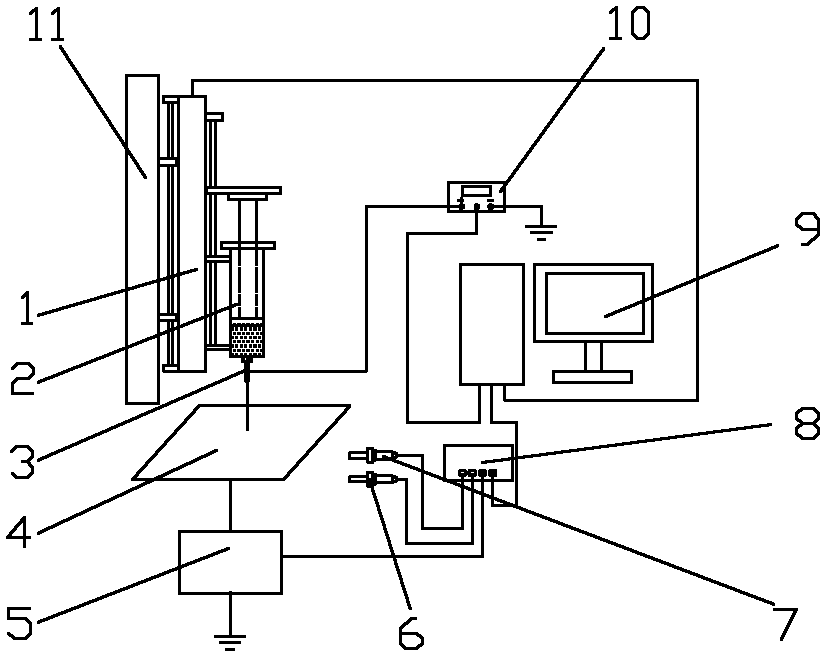

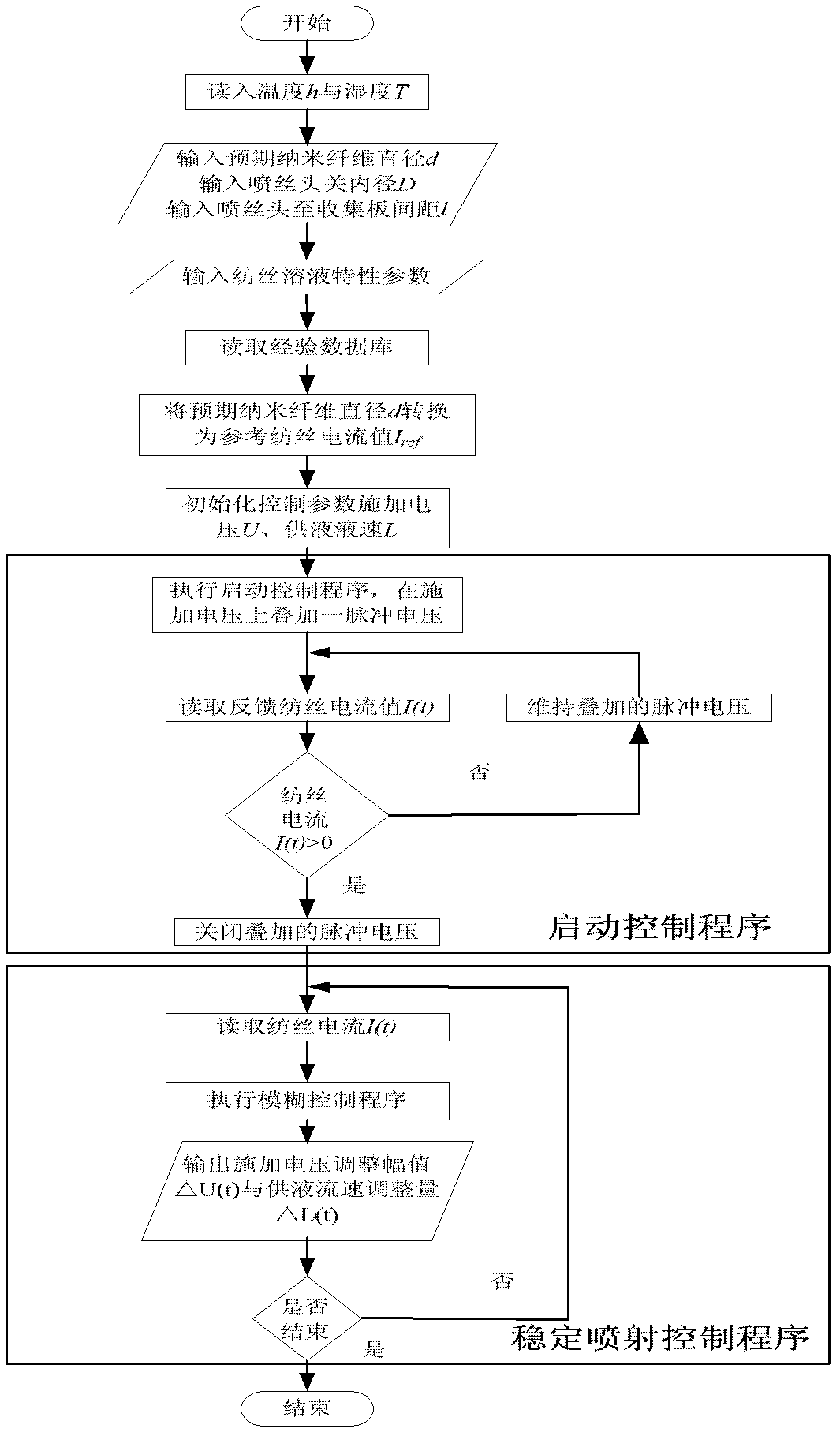

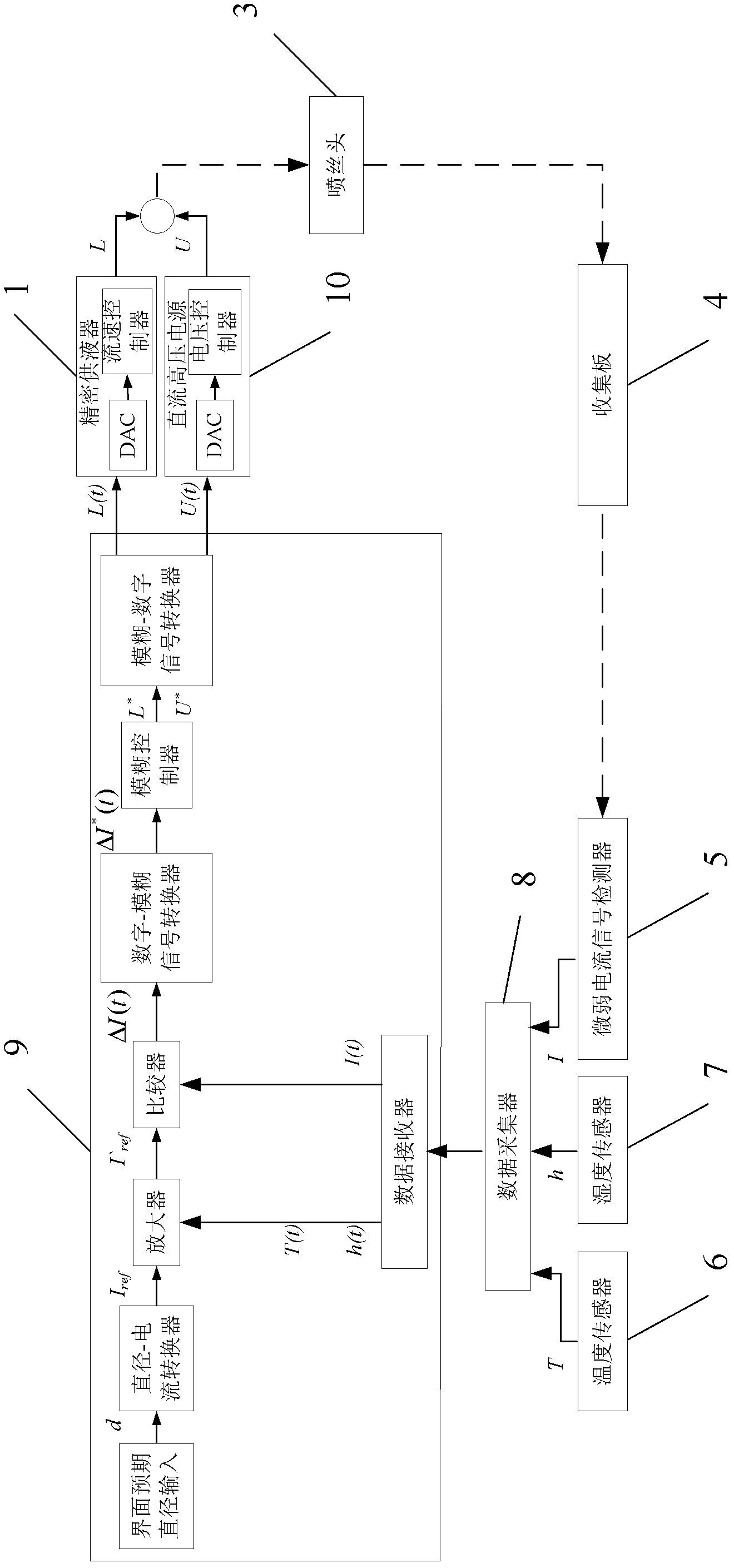

Electrospinning direct-writing closed-loop control system and control method

ActiveCN102582293ARealize controllable adjustmentImprove uniformityOther printing apparatusFiberLoop control

The invention relates to an electrospinning direct-writing closed-loop control system and a control method, which relate to electrospinning direct writing equipment. The invention provides the electrospinning direct-writing closed-loop control system which is capable of realizing the controllable adjustment of the electrospinning direct-writing nano fibre diameter and improves the jet injection stability of spinning and the uniformity of nano fibre diameter and the control method of the electrospinning direct-writing closed-loop control system. The system comprises a liquid storage tank, a liquid feeder, a spinning nozzle, a collecting plate, a weak current detector, a temperature sensor, a humidity sensor, a data collector, a control computer, a direct current high voltage power supply and an adjustable frame. The system establishes a fuzzy controller to obtain the jet injection state by detecting the spinning current, adjusts the applied voltage and the flow rate of the feeding liquid according to the change of the spinning current so as to avoid the influence of various interference factors and realize long time stable jet of the spinning jet flow. The set current of the fuzzy controller is adjusted to control the electrospinning direct-writing nano fibre diameter. The electrospinning direct-writing closed-loop control system is beneficial to improving the controllability of the electrospinning direct-writing nano fibre diameter and well promoting the industrialized application of the electrospinning direct-writing technology.

Owner:XIAMEN UNIV

Method for manufacturing 3D circuits from bare die or packaged IC chips by microdispensed interconnections

A method for manufacturing an electronic circuit in three-dimensional space provides for interconnecting electronic components within the circuit by directly writing conducting lines. The method may include observing a direct writing tool of a direct write system using a vision system, determining proper placement of the direct writing tool at least partially based on the step of observing, and directly writing conducting lines in three dimensions using the proper placement. The direct writing may be on a surface or in free space. The method may include stacking a plurality of chips to provide a stack having a top surface and edges extending away from the top and interconnecting connections of the chips by directly writing conducting lines along one of the edges.

Owner:SCIPERIO

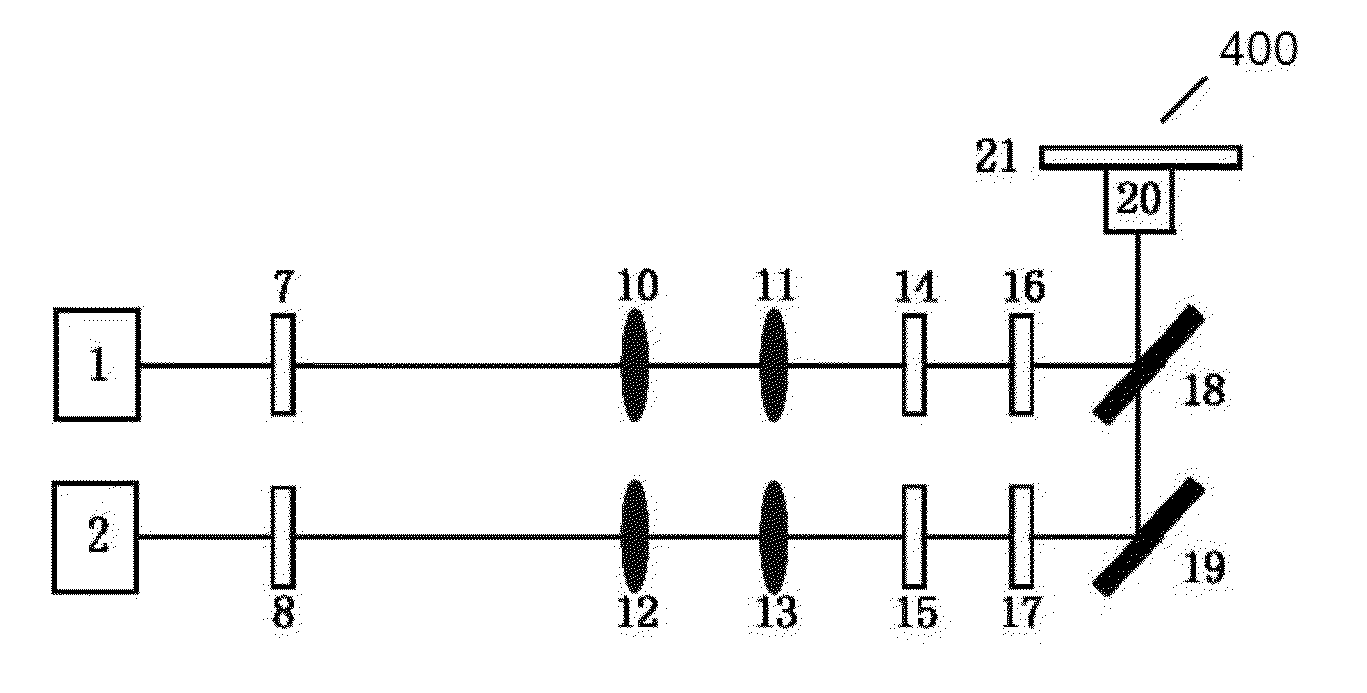

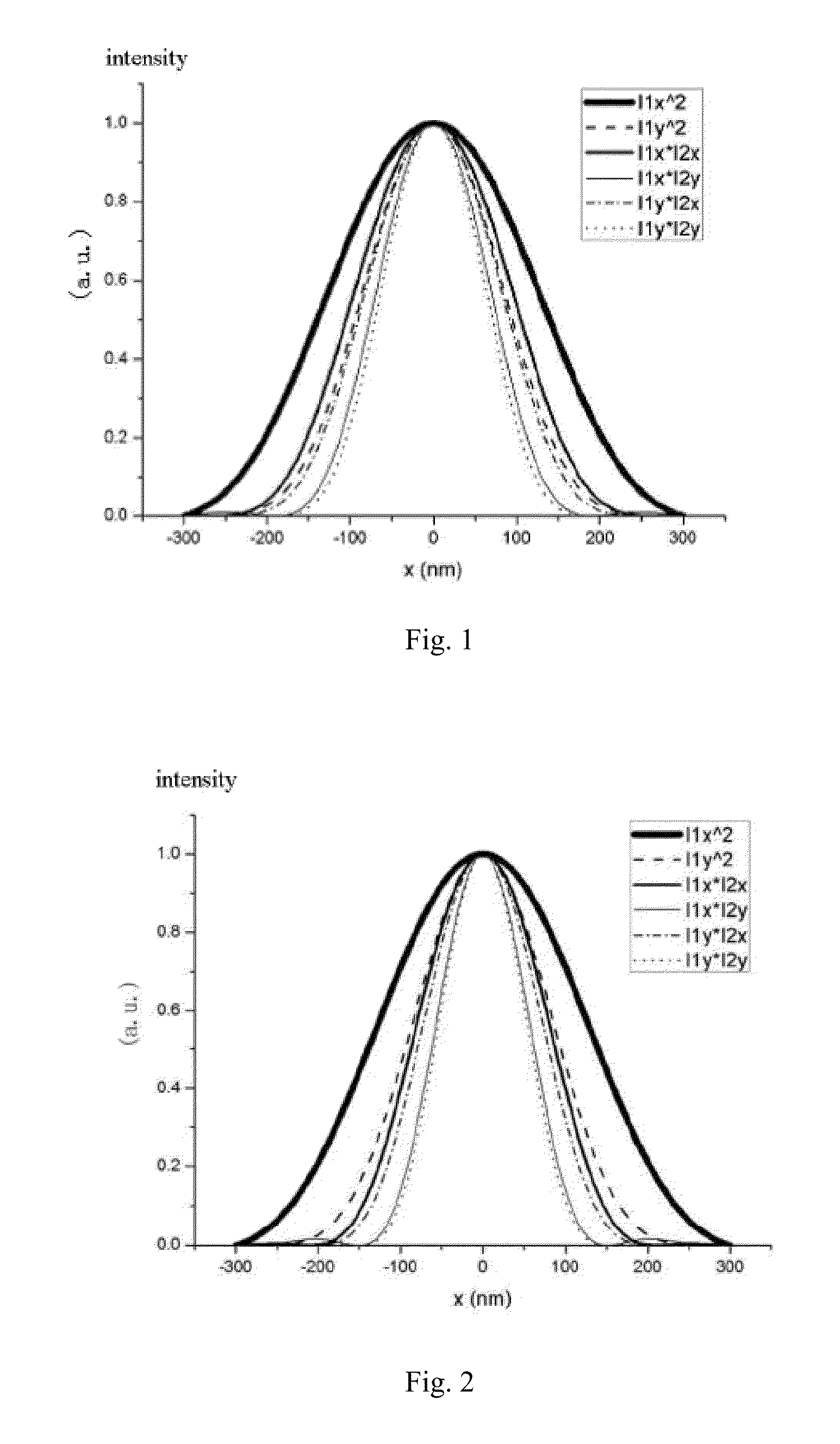

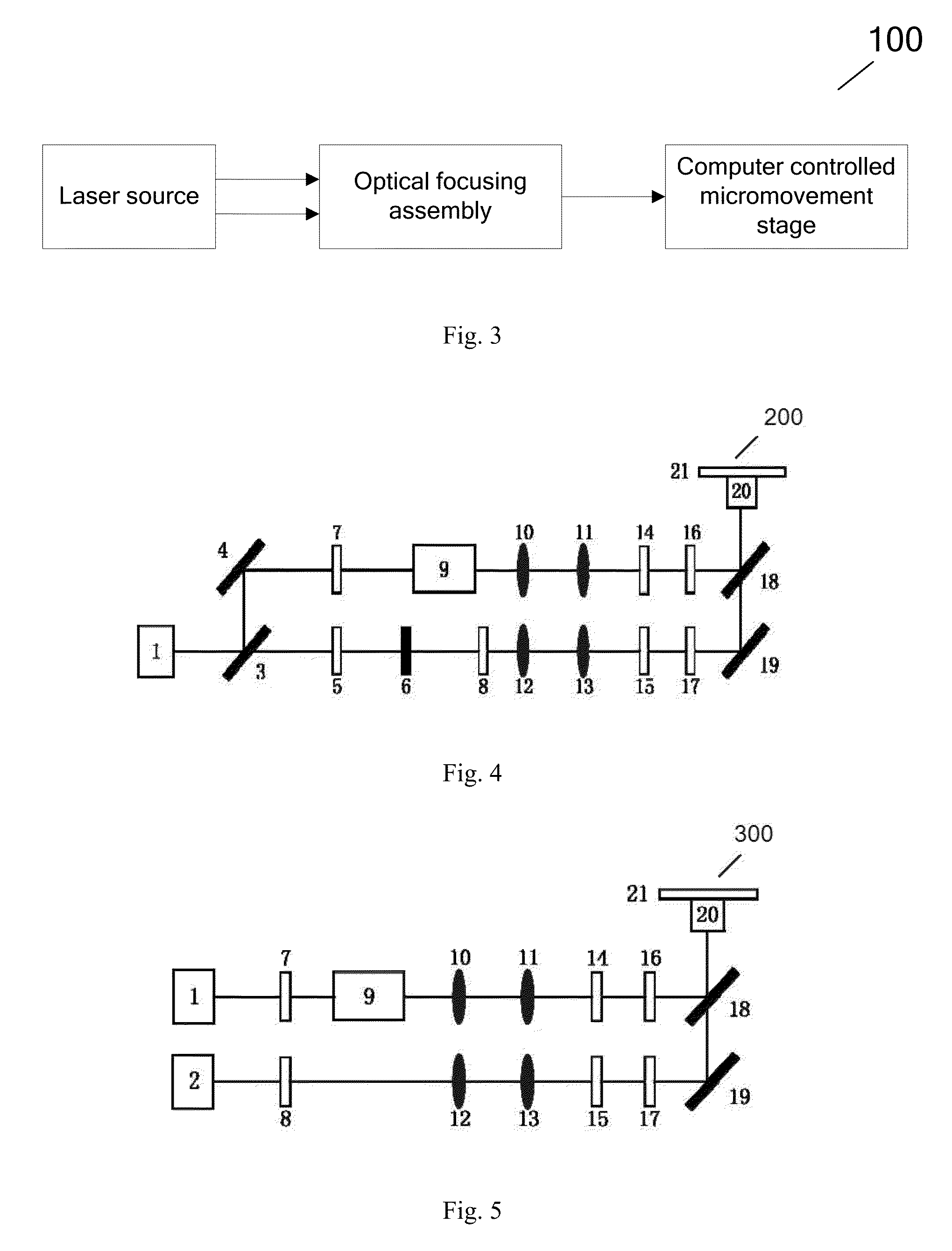

Laser micro/nano processing system and method

ActiveUS20130183833A1Improve accuracyLimited resolutionDecorative surface effectsPhotomechanical apparatusNano structuringNanosecond

A laser micro / nano processing system (100, 200, 300, 400) comprises: a laser light source used to provide a first laser beam having a first wavelength and a second laser beam having a second wavelength different from the first wavelength, with the pulse width of the first laser beam being in the range from a nanosecond to a femtosecond; an optical focusing assembly used to focus the first laser beam and the second laser beam to the same focal point; and a micro mobile platform (21) controlled by a computer. Also disclosed are a method for micro / nano-processing photosensitive materials with a laser and a method for fabricating a device with a micro / nano structure using laser two-photon direct writing technology. In the system and methods, spatial and temporal overlapping of two laser beams is utilized, so as to obtain a micro / nano structure with a processing resolution higher than that of a single laser beam, using an average power lower than that of a single laser beam.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Direct Writing For Additive Manufacturing Systems

ActiveUS20150352785A1Reduce weightPreferable functionNon-insulated conductorsLayered productsElastomerMulti material

There are provided techniques for direct printing material into parts made by additive manufacturing, such as parts made by laser sintering. The direct printed material may be a metal, elastomer, ceramic, or any other material. Further, the direct printed material is typically different than the laser sintering material. Other aspects of the invention include using direct printed materials in the laser sintered parts to improve part strength, provide multi-materials, selectively provide electrical conductivity, and / or provide other desirable features to the parts.

Owner:3D SYST INC

Method for producing photonic wire bonds

ActiveUS20130221550A1Bridging the gapHighly integratedOptical articlesCoupling light guidesResistDirect writing

A method for making optical connections with optical waveguides includes mounting the optical waveguides or a device comprising the optical waveguides, on a component carrier. A partial region of the optical waveguides is embedded in a volume of resist material. Positions of the optical waveguides to be connected are detected with reference to a coordinate system using a measuring system. Favorable, three-dimensional geometries are determined for optical waveguide structures for connecting the optical waveguides to each other at predetermined connecting locations and the optical waveguide structure geometries are converted to a machine-readable dataset. The optical waveguide geometries in the volume of the resist material are three-dimensionally structured using a direct-writing lithography device operating on the basis of the machine-readable dataset. The structured resist material is treated using physical or chemical methods to form at least one optical waveguide structure having ends connected to predetermined connecting locations of the optical waveguides.

Owner:KARLSRUHER INST FUR TECH

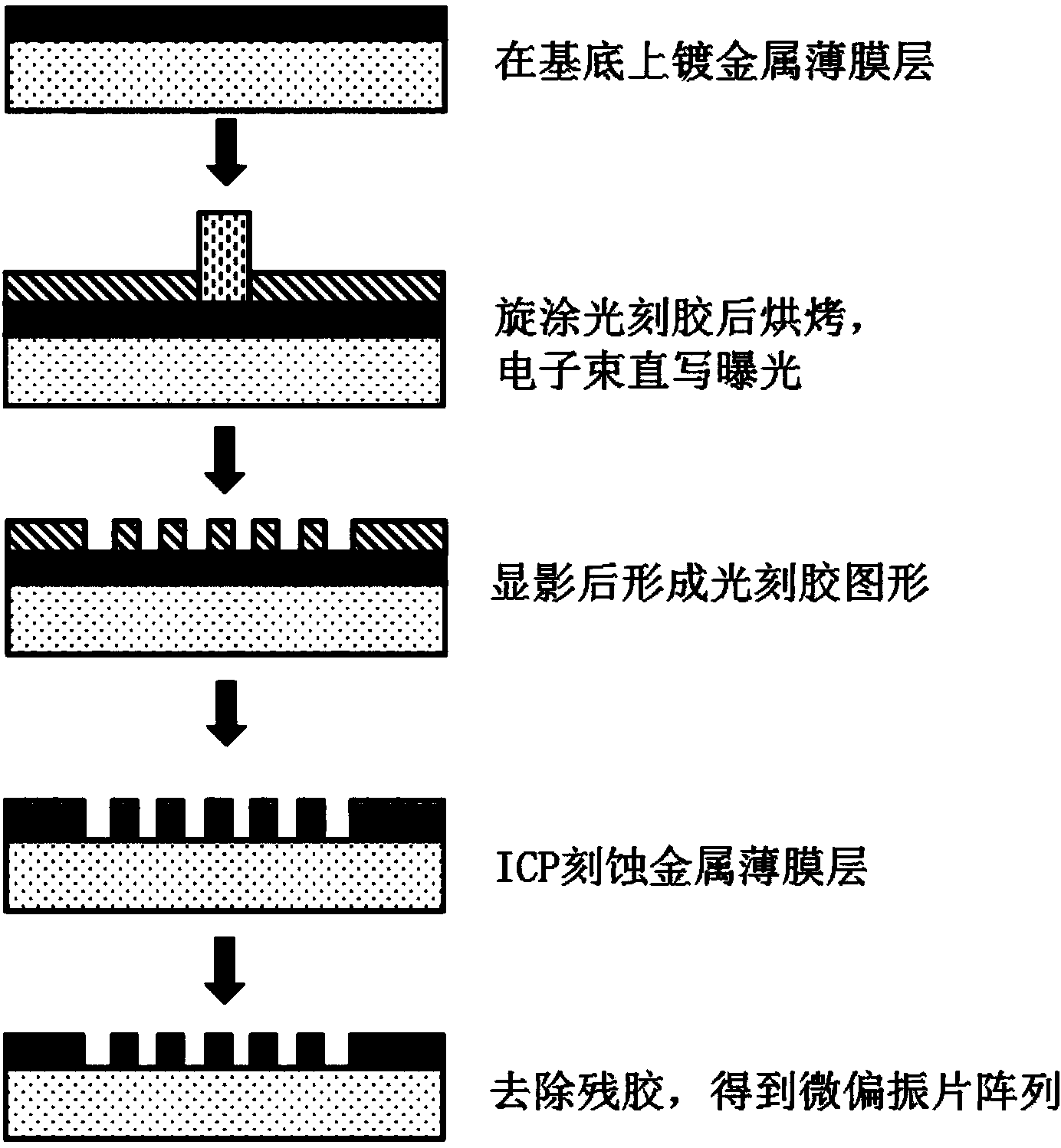

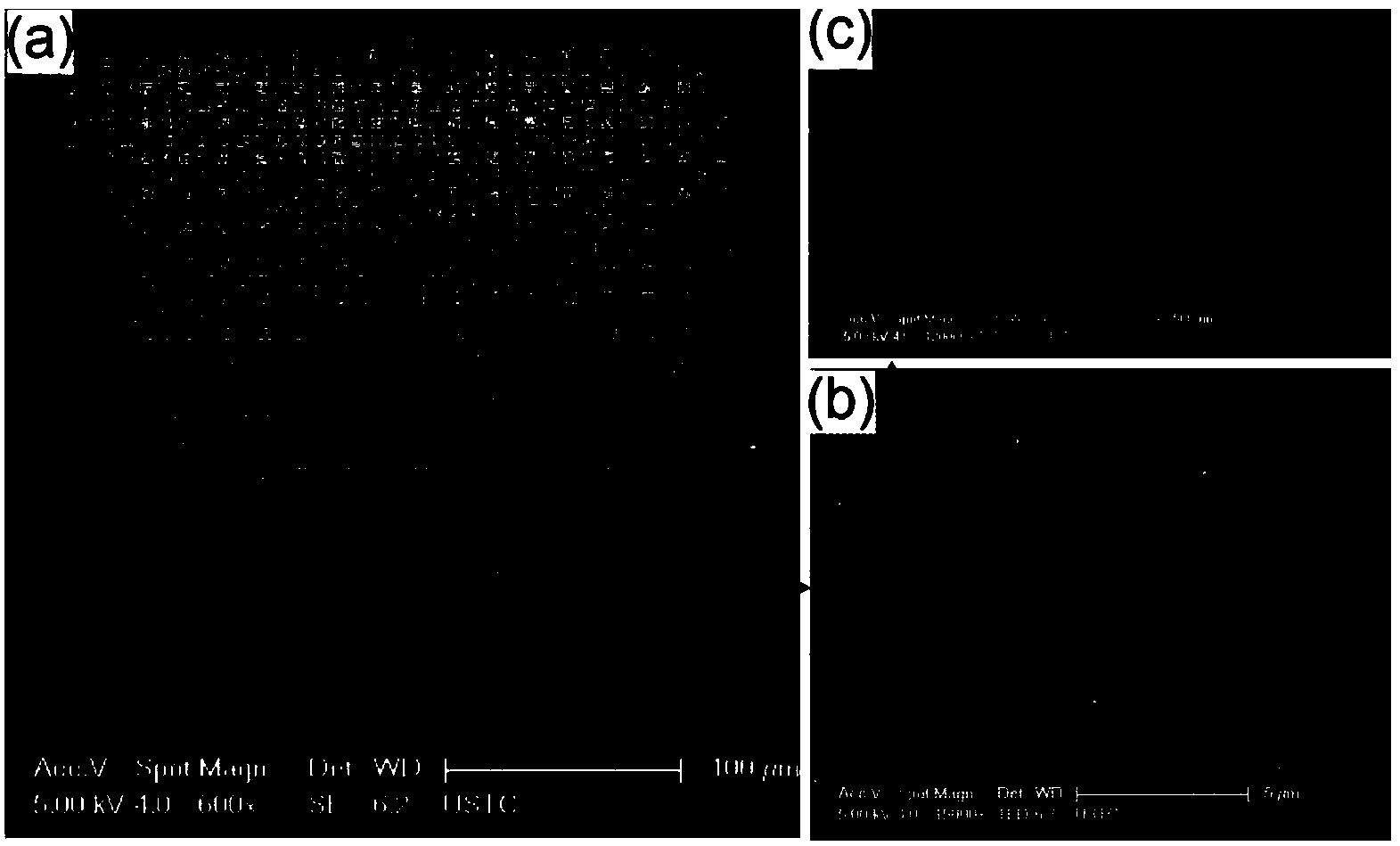

Method for manufacturing micro-polarizer array based on metal nanometer grating

ActiveCN103760681ASmooth edgesSmooth edges to ensure excellent polarization effect smoothPhotomechanical apparatusPolarising elementsGratingDirect writing

The invention relates to a method for manufacturing a micro-polarizer array based on a metal nanometer grating. The method comprises the steps that (1) a substrate is coated with a metal film layer, and the metal film layer is dried; (2) the metal film layer is coated with an electron beam positive photoresist layer in a spinning mode, and the electron beam positive photoresist layer is dried; (3) electron beam direct writing, exposure and developing are conducted on the photoresist layer, and then a photoresist nanoscale micro-polarizer array graph is obtained; (4) inductive coupled plasma is used for etching, wherein the photoresist layer with the image is used as a mask, the metal film layer is etched, and therefore the image is transferred to the metal film layer; (5) the photoresist layer is removed, and then the micro-polarizer array is obtained. The method for manufacturing the micro-polarizer array based on the metal nanometer grating is easy to implement. According to the method for manufacturing the micro-polarizer array based on the metal nanometer grating, the micro-polarizer array with multiple different polarization directions can be obtained through one-time exposure and developing; the polarization performance of the micro-polarizer array manufactured according to the method is high.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com