Patents

Literature

460results about How to "Smooth edges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

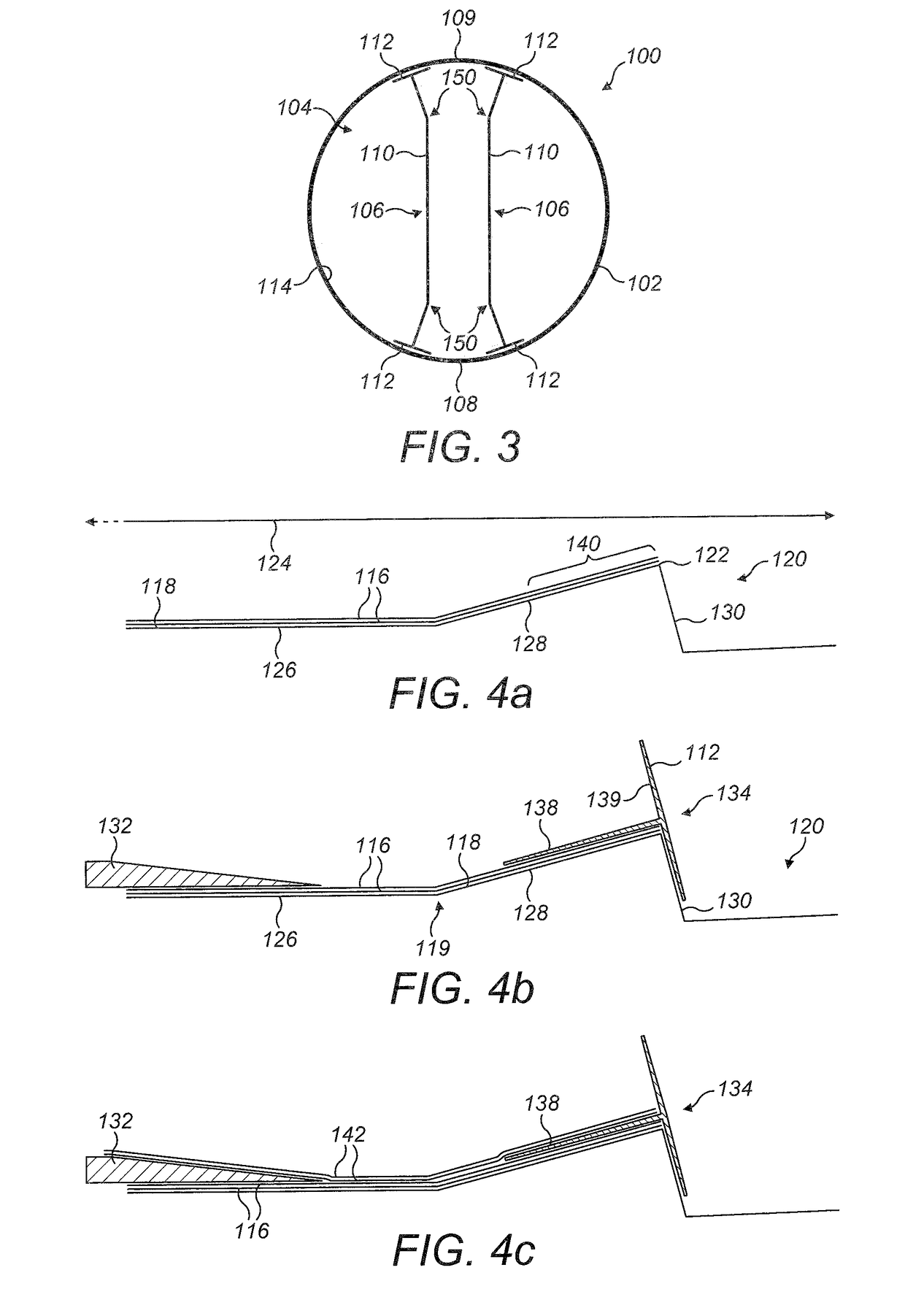

Diffractive lenses for vision correction

ActiveUS7156516B2Smooth edgesEasy to manufactureSpectales/gogglesIntraocular lensSquare waveformDiffraction order

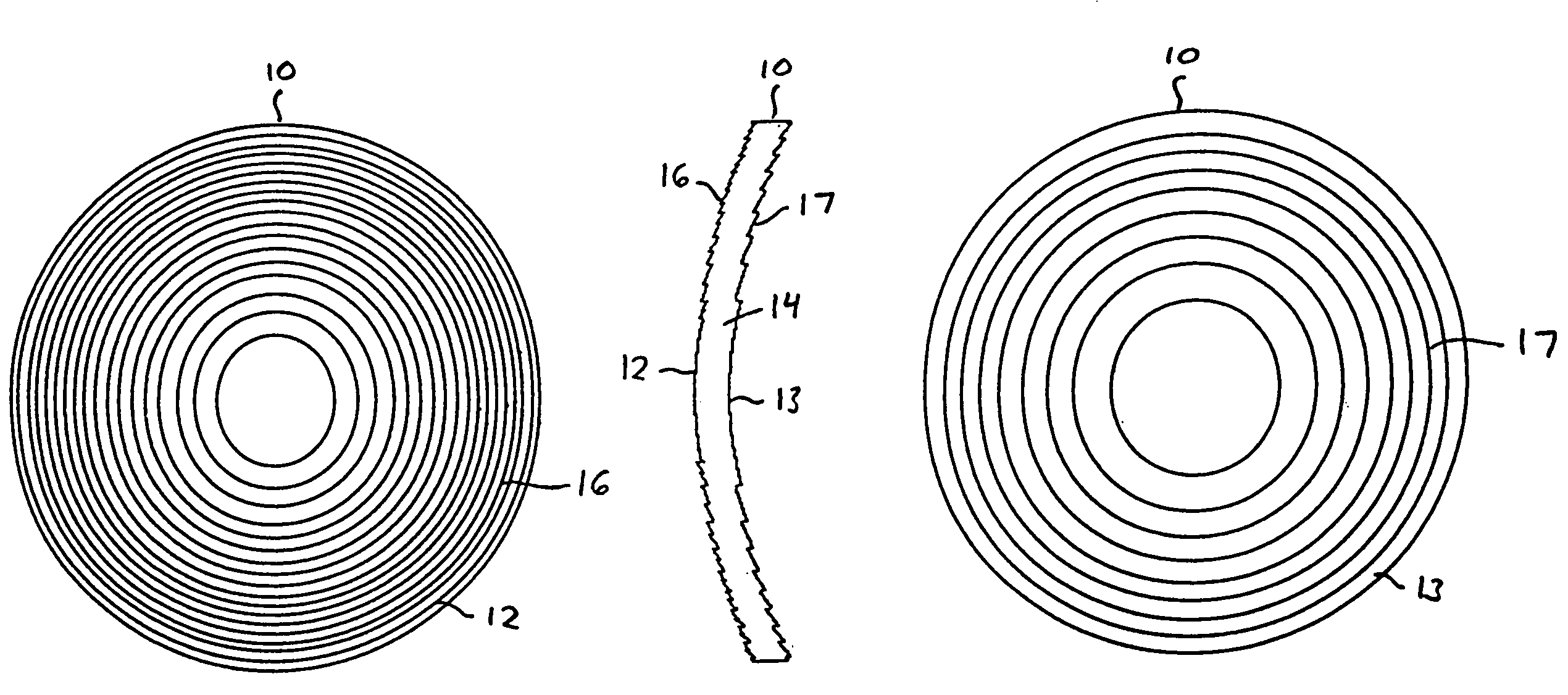

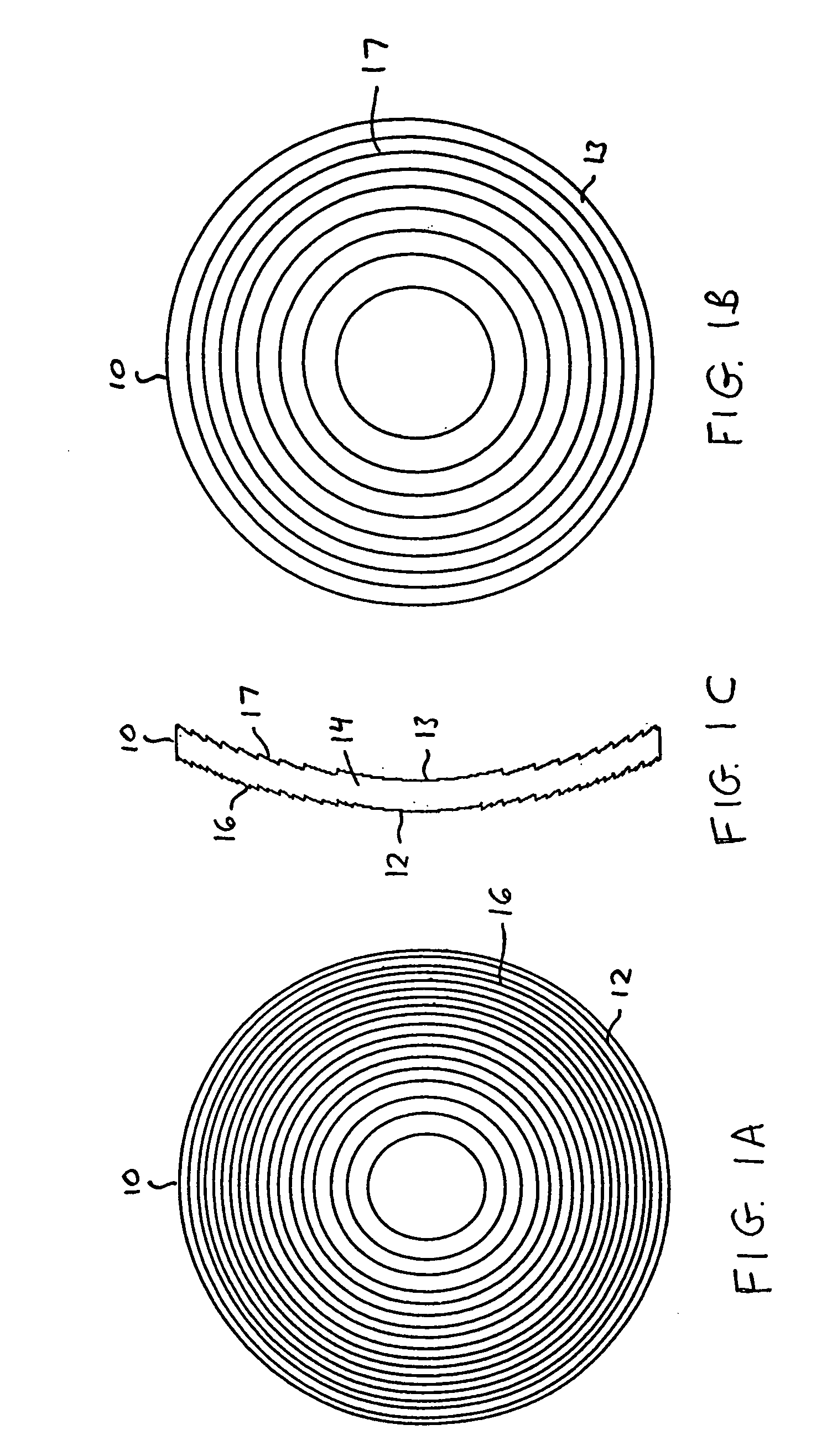

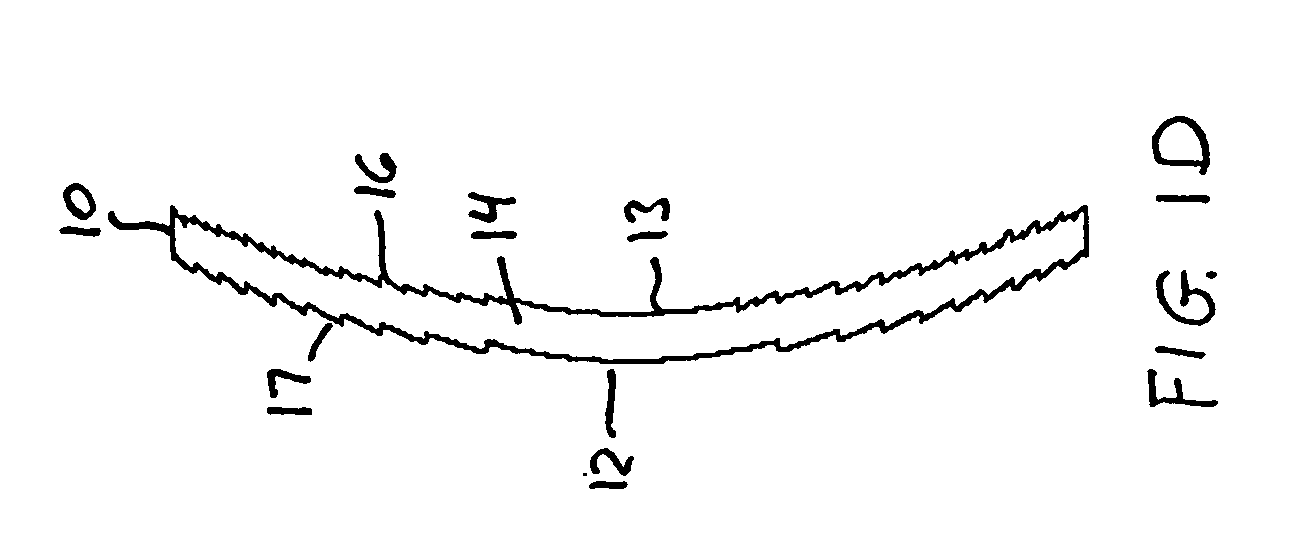

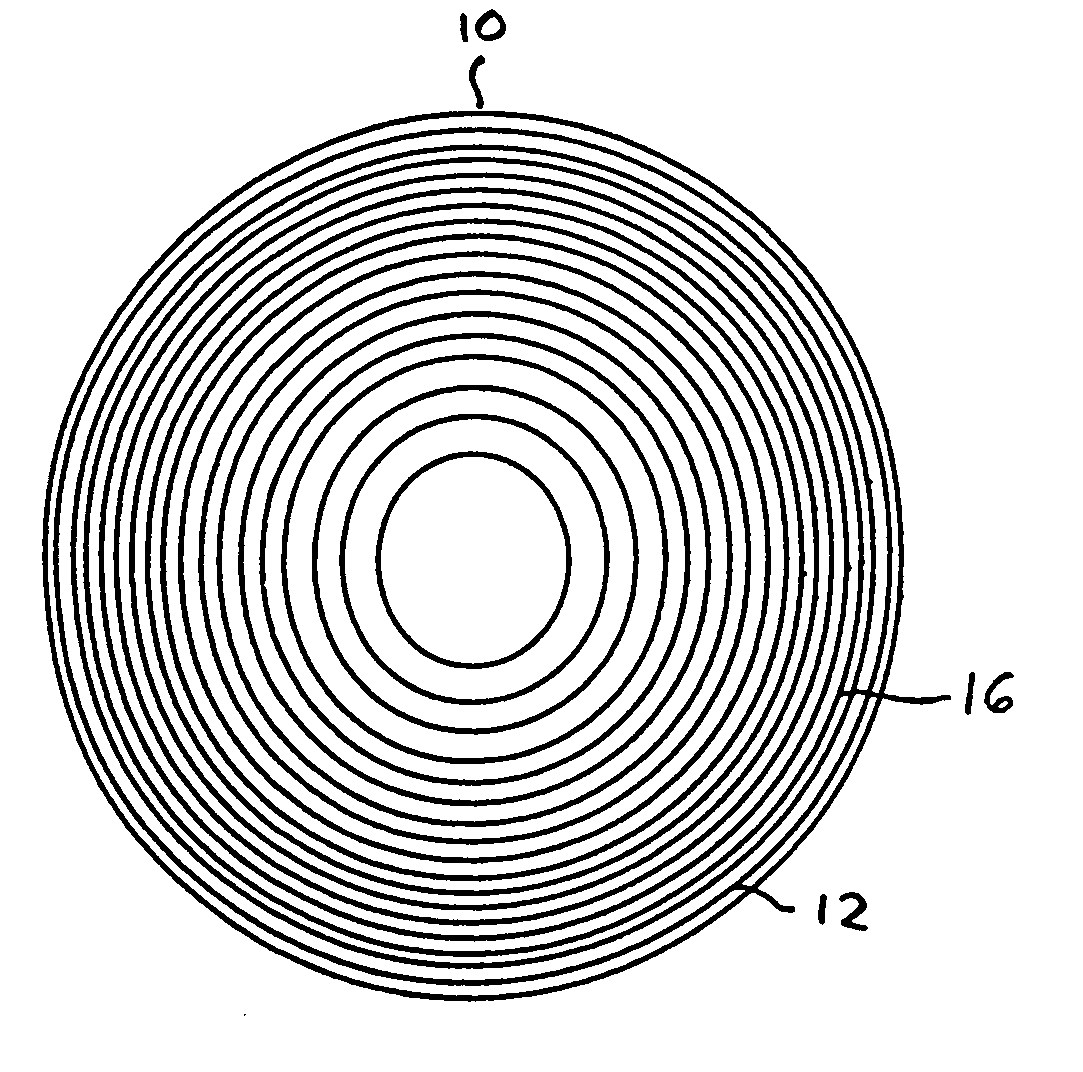

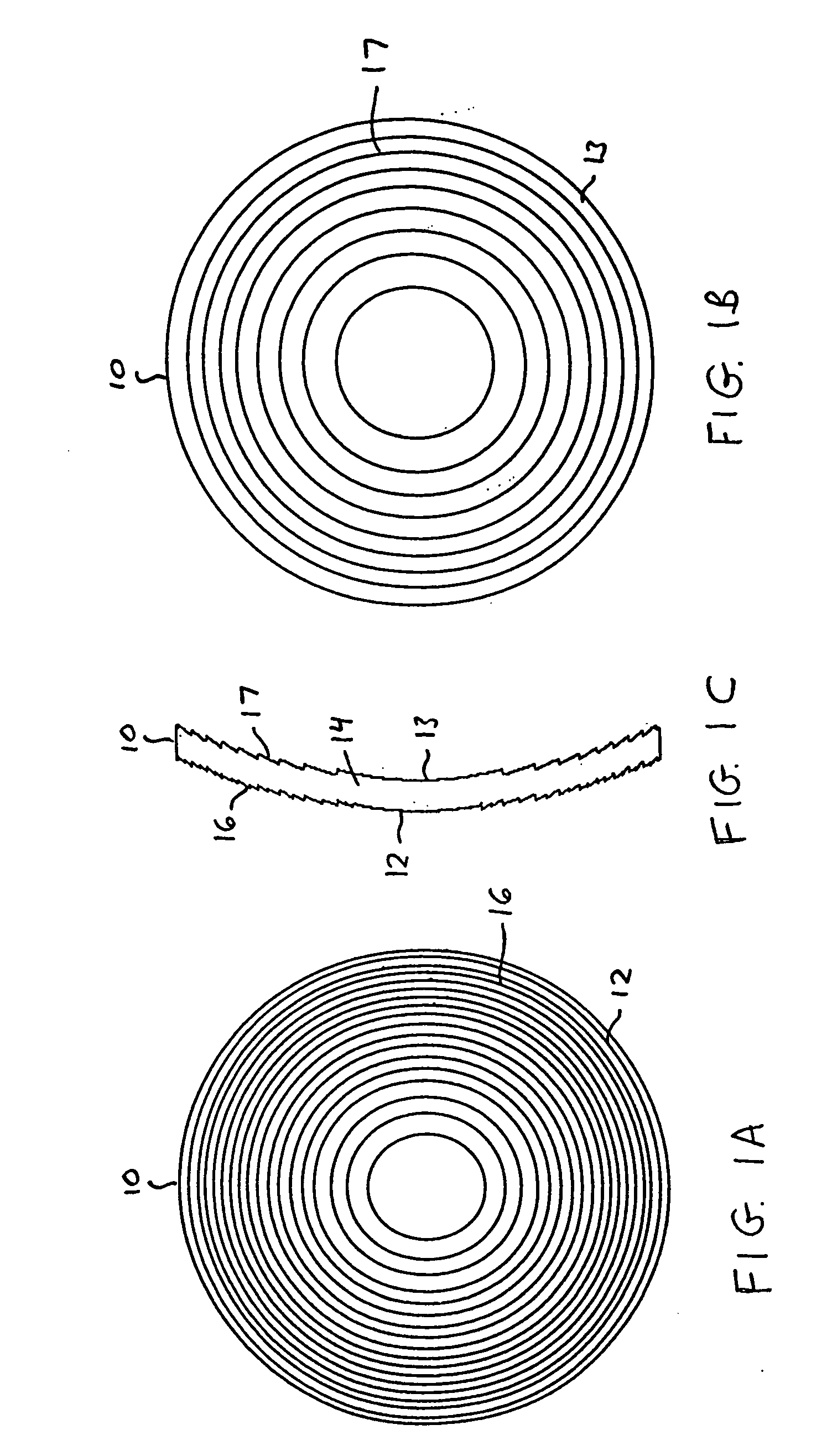

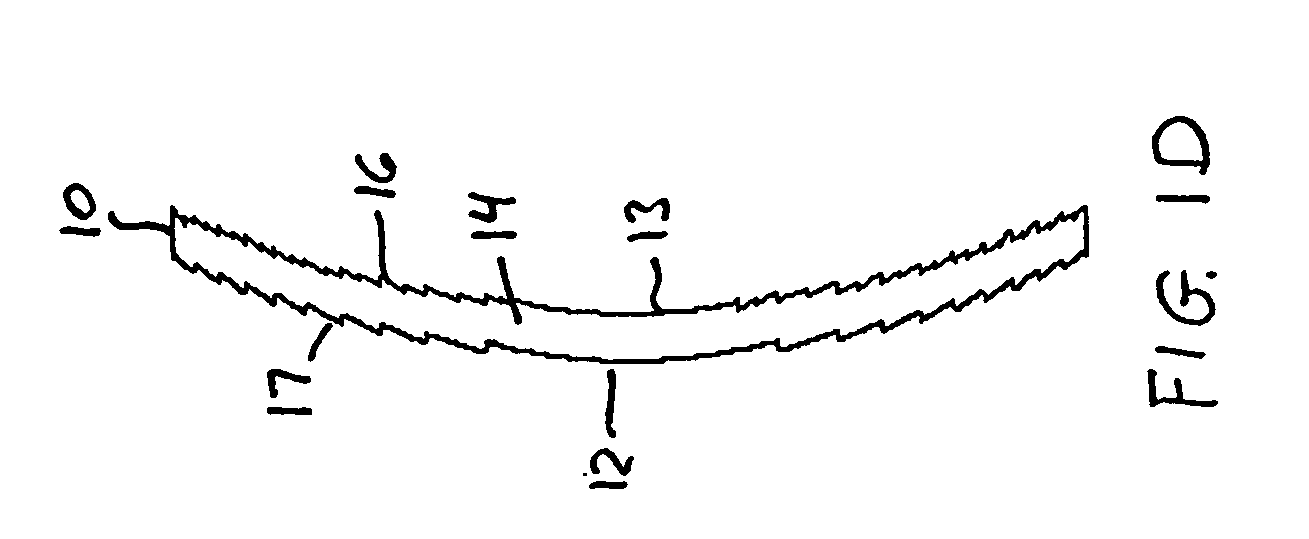

Diffractive lenses for vision correction are provided on a lens body having a first diffractive structure for splitting light into two or more diffractive orders to different focal distances or ranges, and a second diffractive structure, referred to as a multiorder diffractive (MOD) structure, for diffracting light at different wavelengths into a plurality of different diffractive orders to a common focal distance or range. In a bifocal application, the first and second diffractive structures in combination define the base power for distance vision correction and add power for near vision correction of the lens. The first and second diffractive structures may be combined on the same surface or located on different surfaces of the lens. The first diffractive structure may have blazed (i.e., sawtooth), sinusoidal, sinusoidal harmonic, square wave, or other shape profile. A sinusoidal harmonic diffractive structure is particularly useful in applications where smooth rather than sharp edges are desirable.

Owner:APOLLO OPTICAL SYST

Diffractive lenses for vision correction

ActiveUS20060055883A1Smooth edgesEasy to manufactureSpectales/gogglesIntraocular lensSquare waveformDiffraction order

Diffractive lenses for vision correction are provided on a lens body having a first diffractive structure for splitting light into two or more diffractive orders to different focal distances or ranges, and a second diffractive structure, referred to as a multiorder diffractive (MOD) structure, for diffracting light at different wavelengths into a plurality of different diffractive orders to a common focal distance or range. In a bifocal application, the first and second diffractive structures in combination define the base power for distance vision correction and add power for near vision correction of the lens. The first and second diffractive structures may be combined on the same surface or located on different surfaces of the lens. The first diffractive structure may have blazed (i.e., sawtooth), sinusoidal, sinusoidal harmonic, square wave, or other shape profile. A sinusoidal harmonic diffractive structure is particularly useful in applications where smooth rather than sharp edges are desirable.

Owner:APOLLO OPTICAL SYST

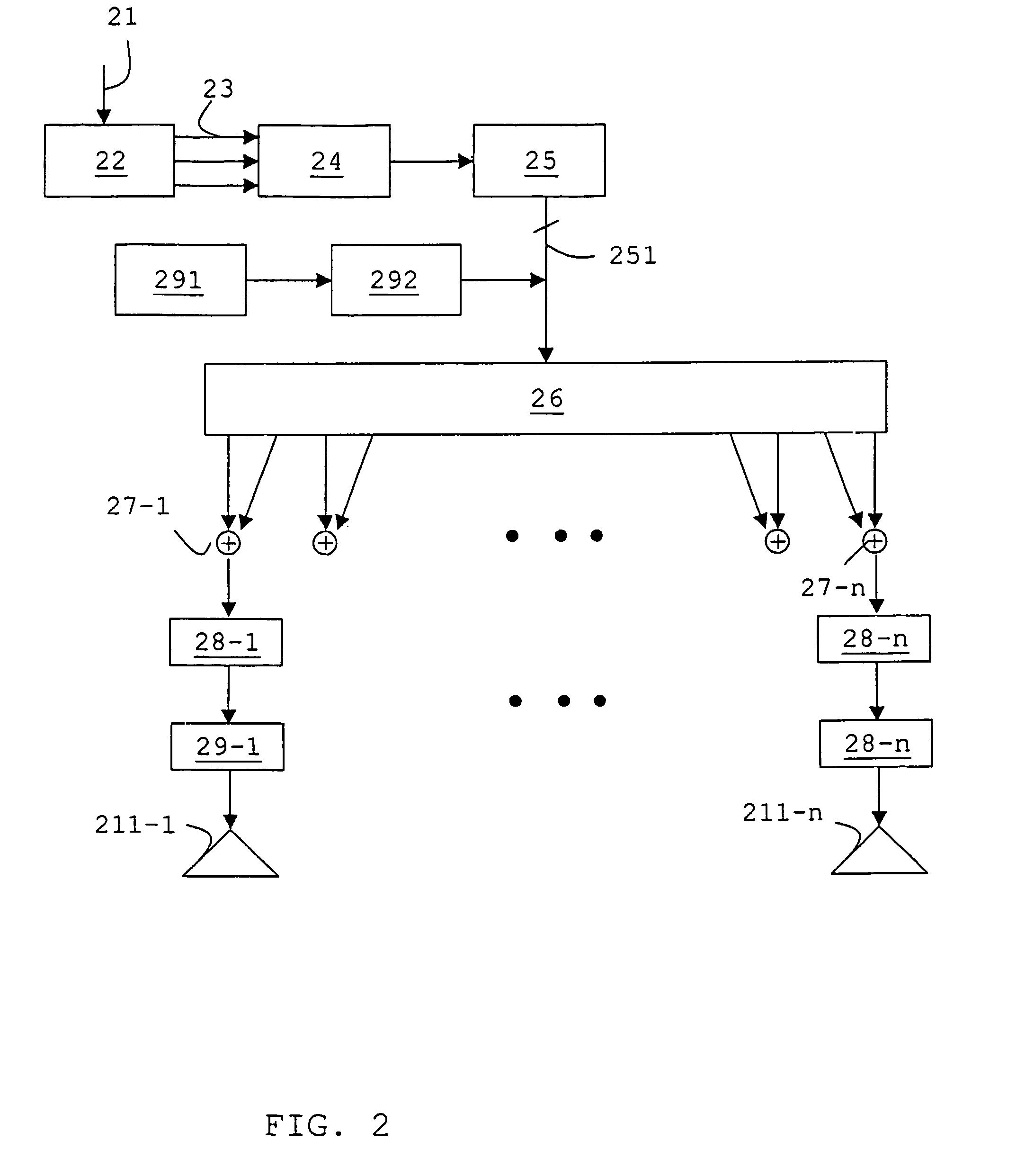

Signal processing device for acoustic transducer array

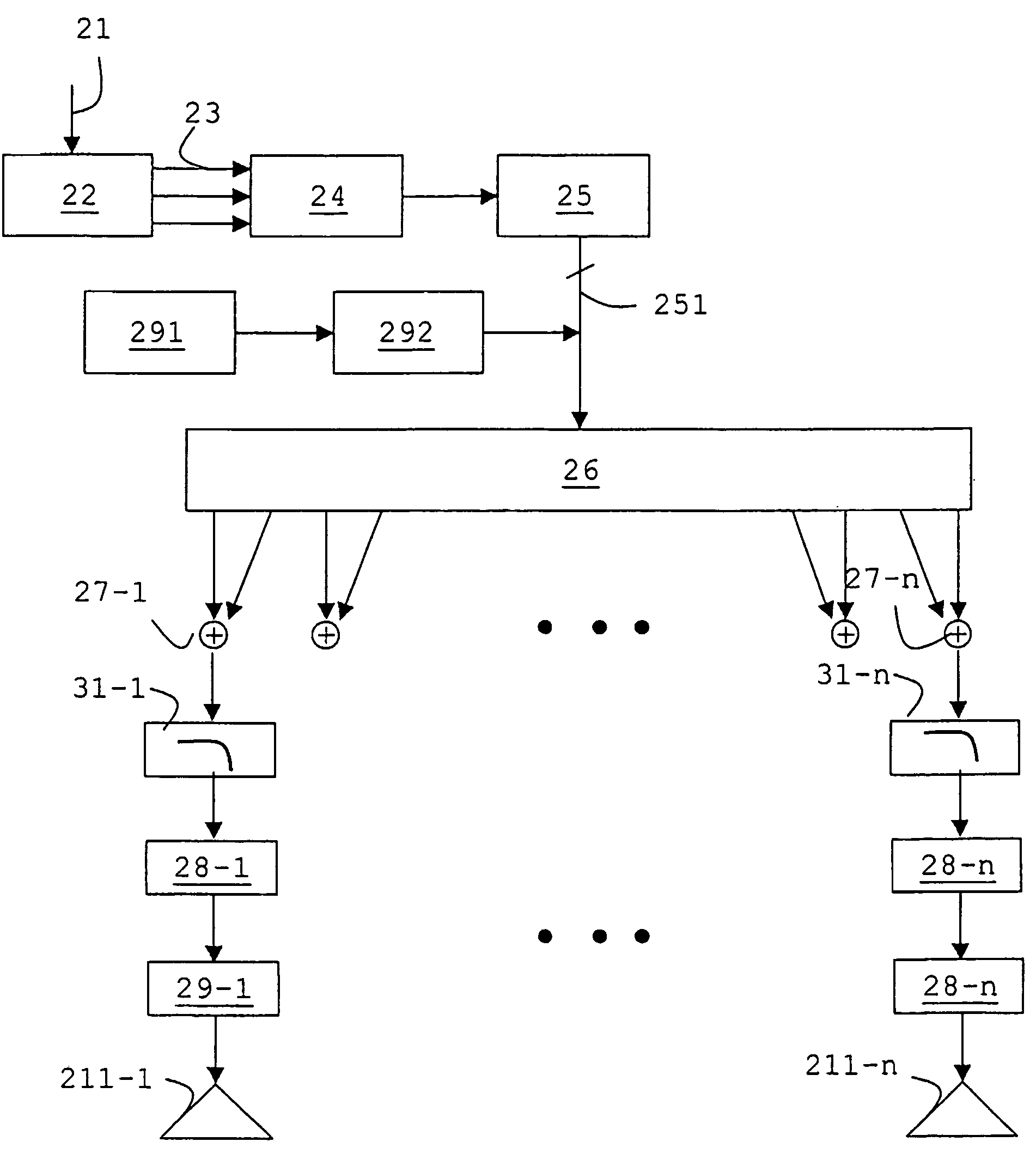

InactiveUS7319641B2Weaken energySmooth edgesMicrophonesTransducers for sound channels pluralityTransducerSide lobe

The invention provides transducer arrays which are capable of outputting sound beams having a relatively constant width, and with minimal sidelobes, across a range of frequencies. This is achieved by utilising one or more digital signal modifiers within the signal path between the input sound signal and the array of transducers. Variable window functions are also disclosed.

Owner:YAMAHA CORP

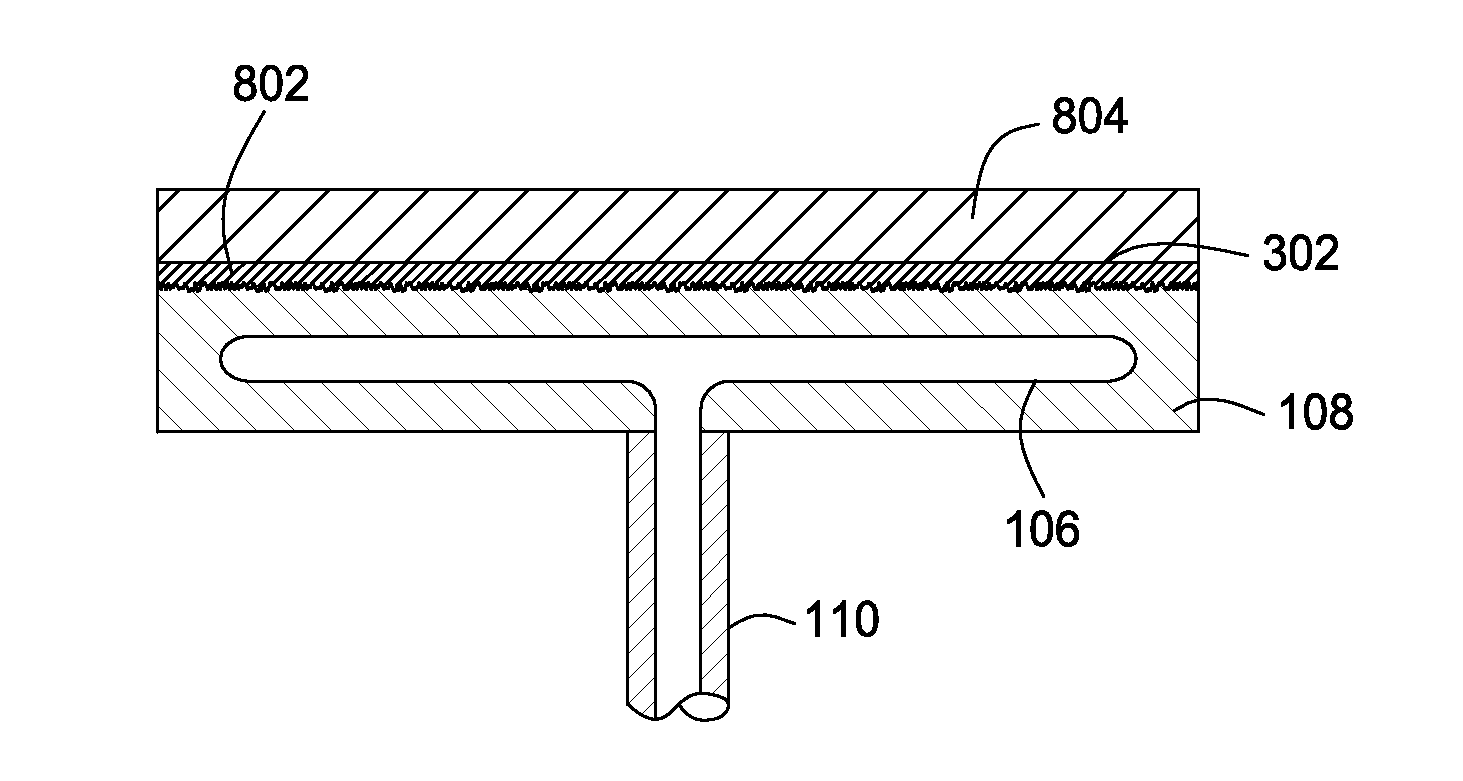

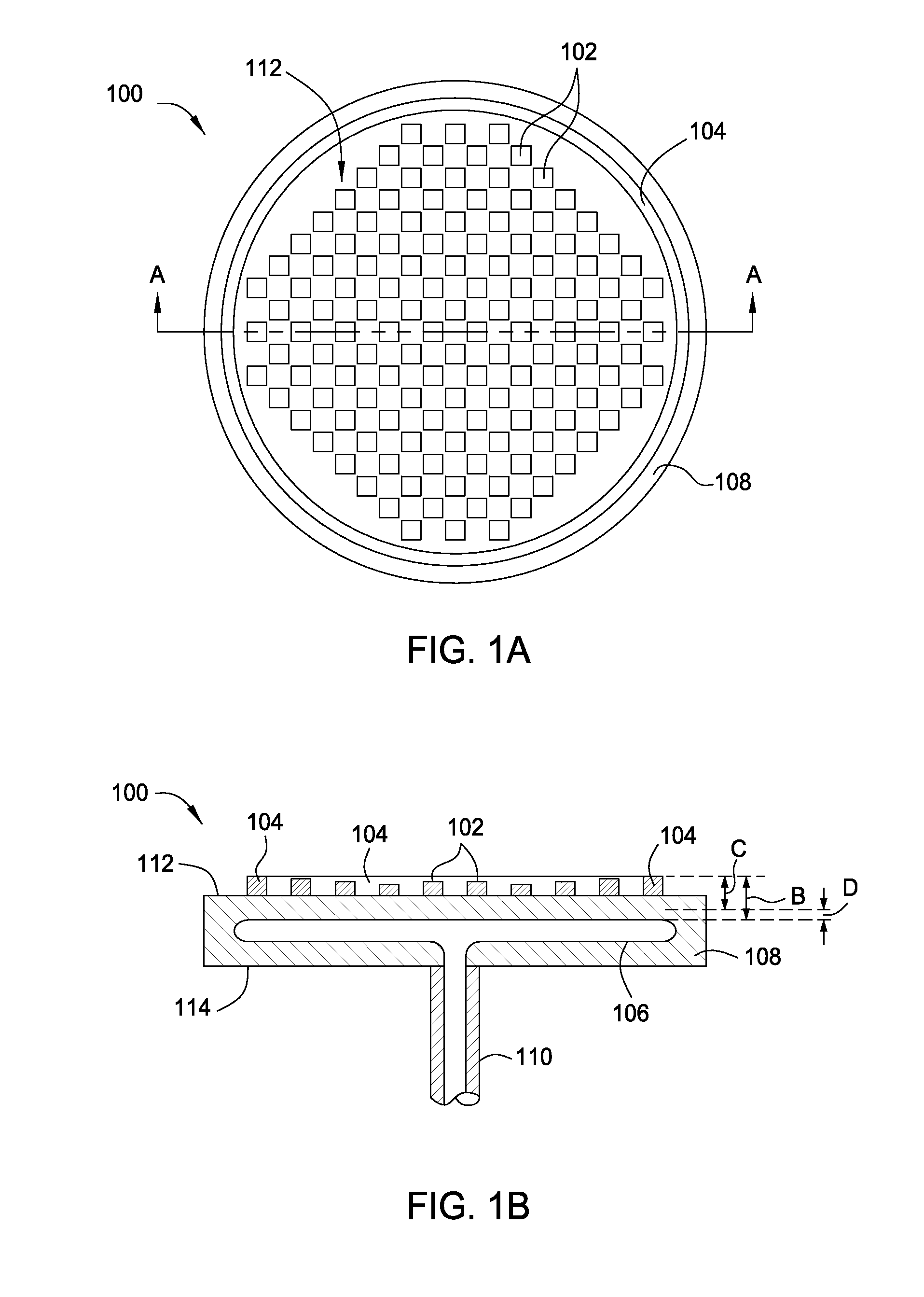

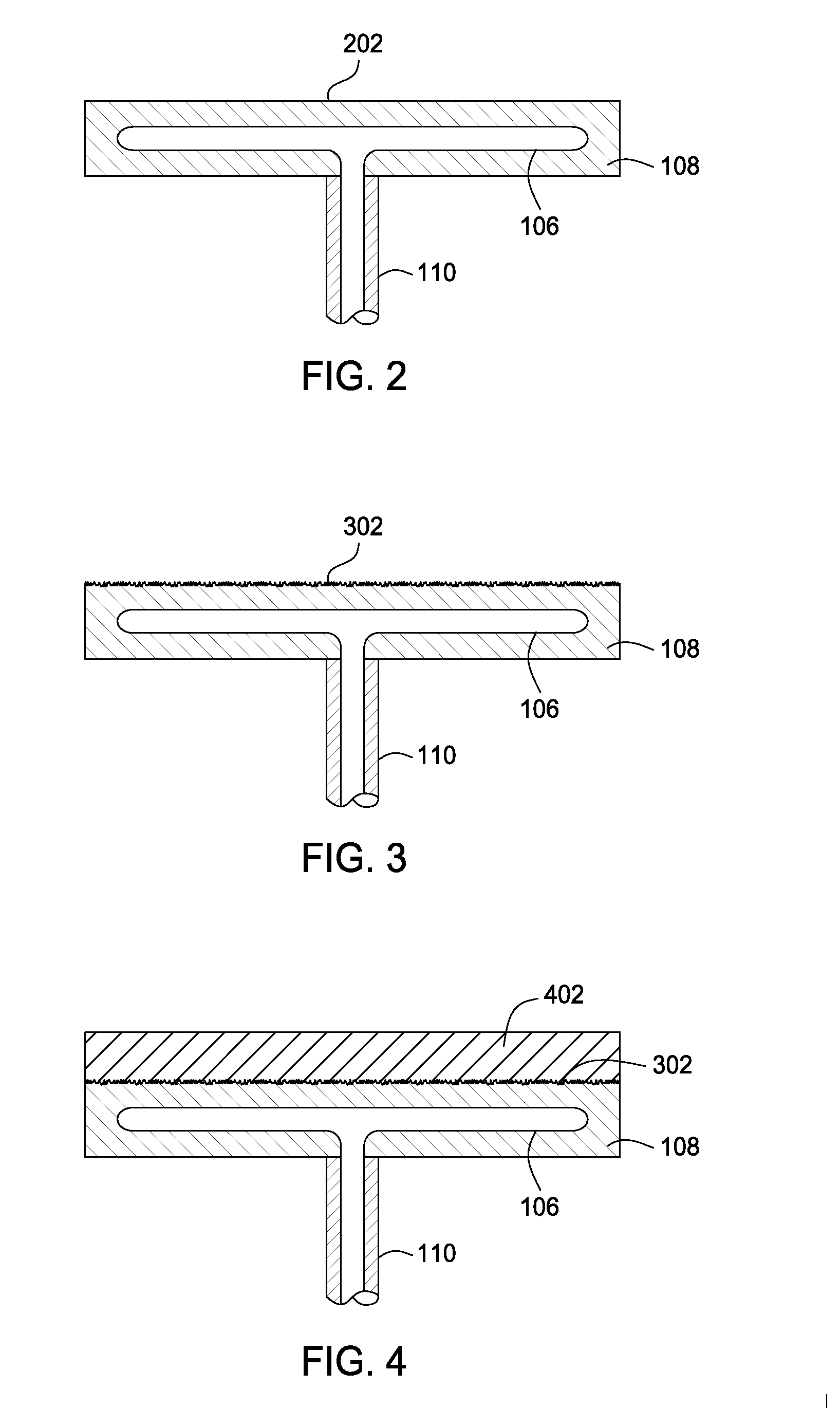

Electrostatic chuck aln dielectric repair

ActiveUS20120307412A1Improve adhesionSmooth edgesSemiconductor/solid-state device manufacturingArc welding apparatusEngineeringDielectric layer

The present invention generally relates to a refurbished electrostatic chuck and a method of refurbishing a used electrostatic chuck. Initially, a predetermined amount of dielectric material is removed from the used electrostatic chuck to leave a base surface. Then, the base surface is roughened to enhance the adherence of new dielectric material thereto. The new dielectric material is then sprayed onto the roughened surface. A mask is then placed over the new dielectric material to aid in the formation of mesas upon which a substrate will sit during processing. A portion of the new dielectric layer is then removed to form new mesas. After removing the mask, edges of the mesas may be smoothed and the refurbished electrostatic chuck is ready to return to service after cleaning.

Owner:APPLIED MATERIALS INC

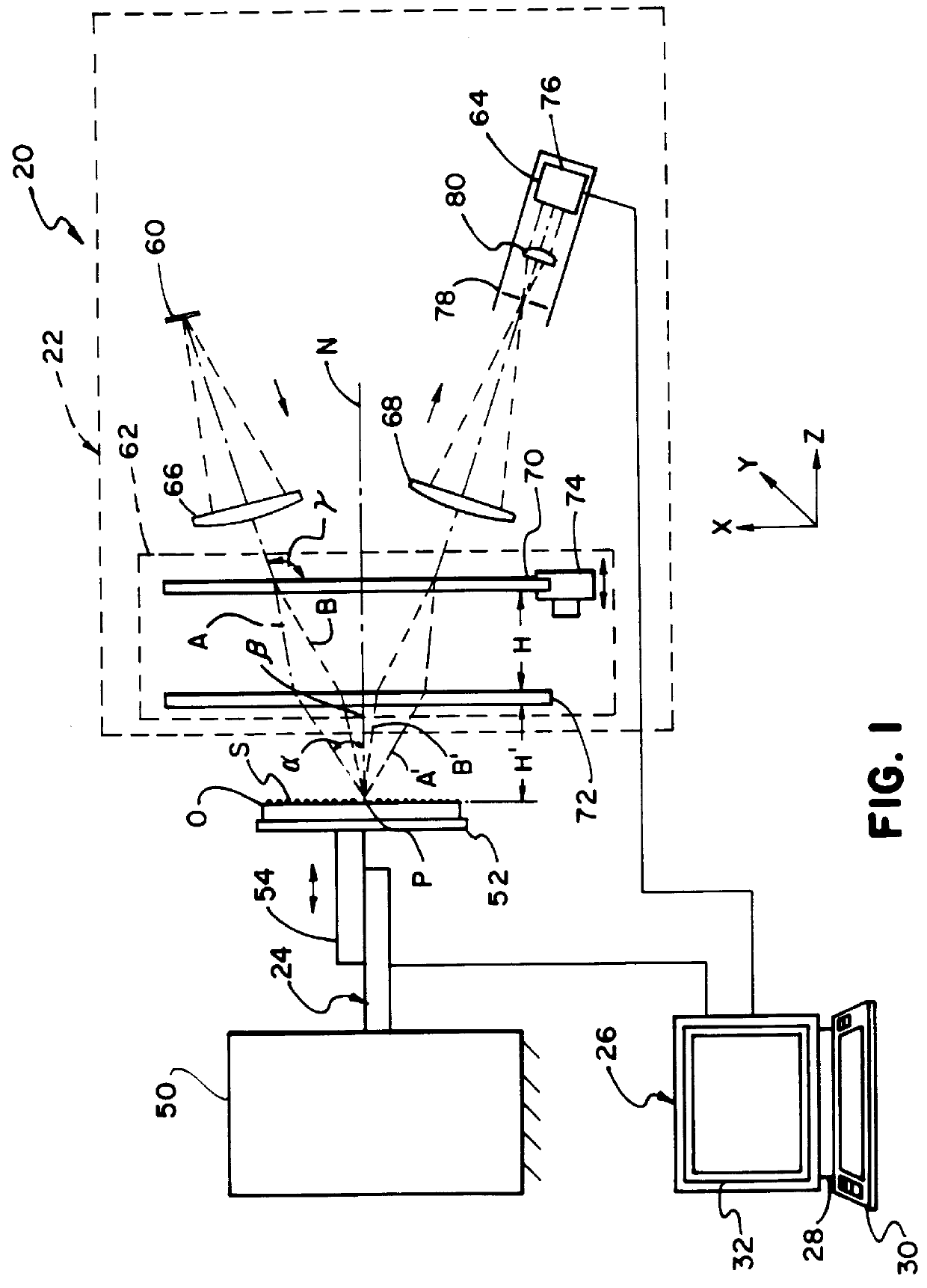

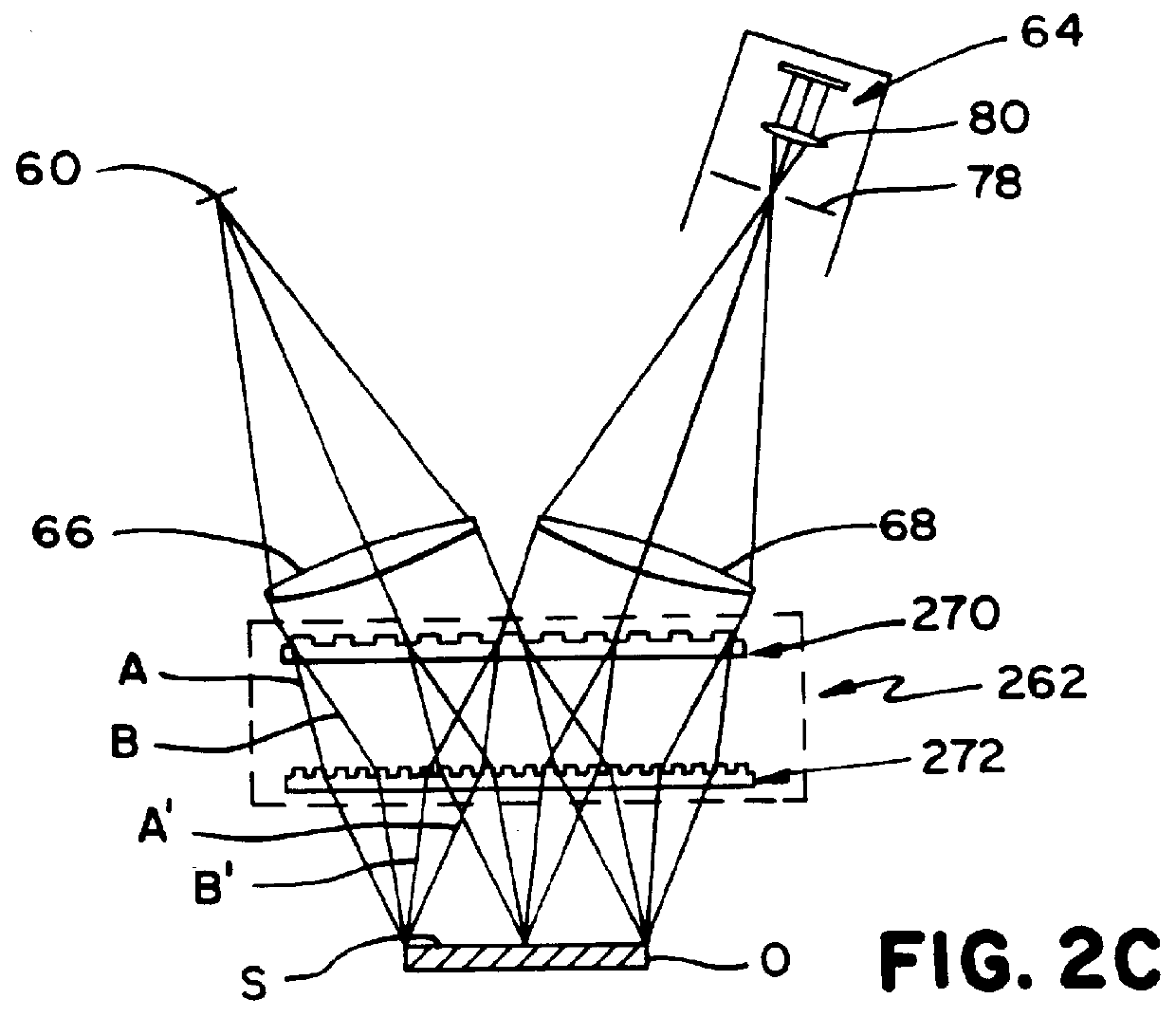

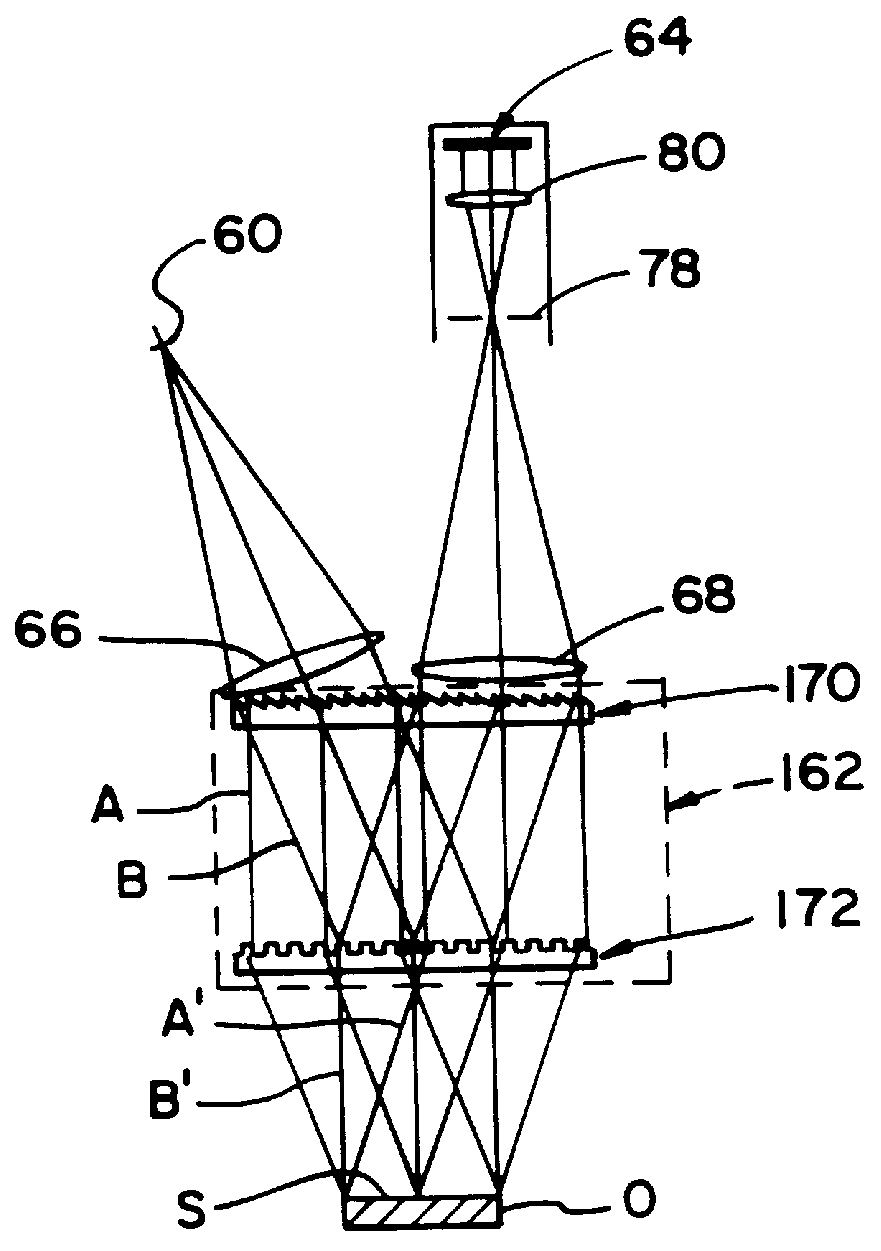

Geometrically-desensitized interferometer incorporating an optical assembly with high stray-beam management capability

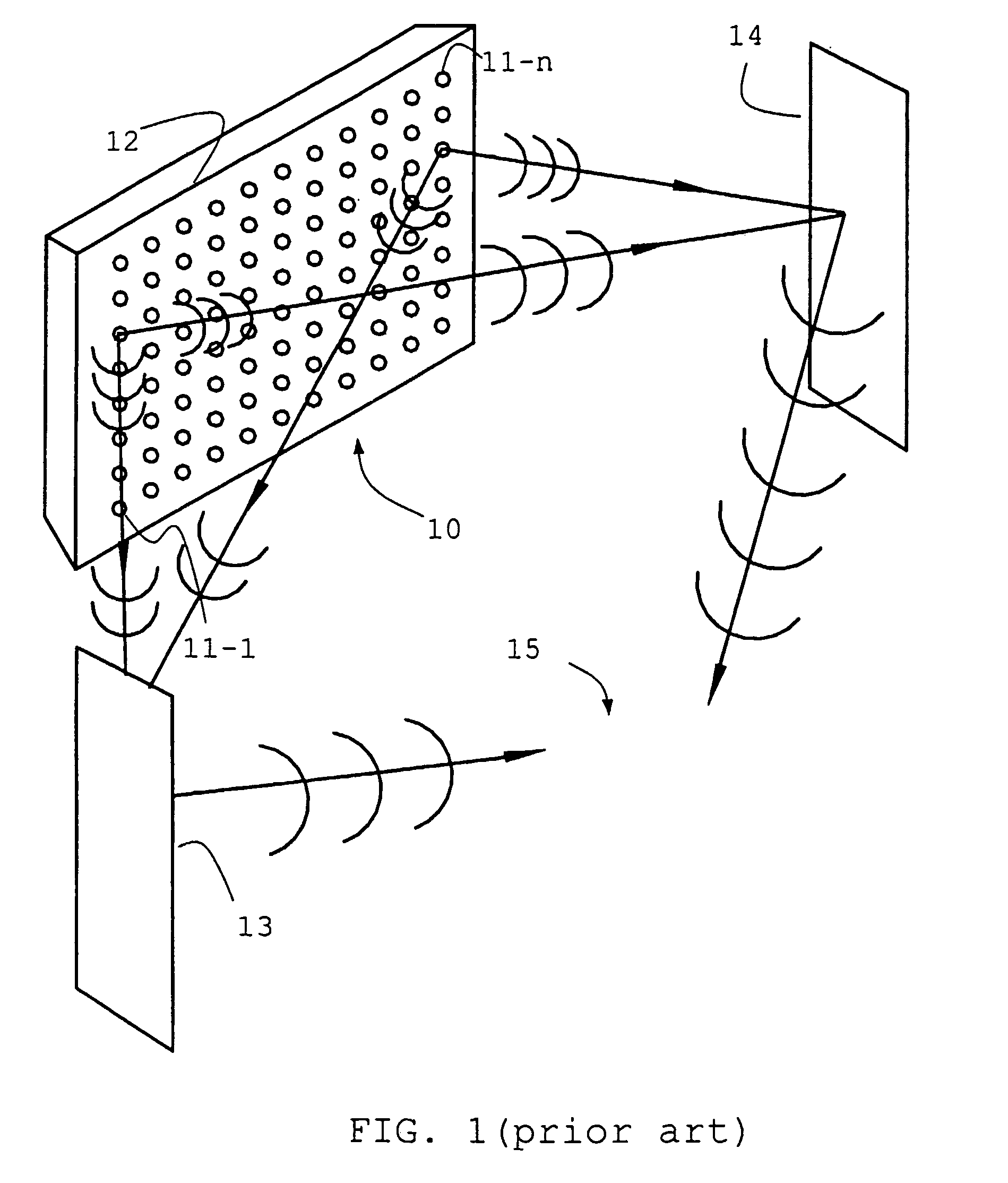

InactiveUS6072581AReduce in quantityHigh measurement accuracyDiffraction gratingsUsing optical meansMetrologyDiffraction order

The optical assembly of a GDI instrument is configured to deviate or steer stray beams away from the pupil of the instrument's imaging device and / or to suppress stray beams. Stray beam deviation is optimized by selecting particular wedge and / or tilt configurations that achieve the desired stray beam deviation while avoiding or at least minimizing phase offset at the optimum metrology plane. Stray beam suppression can be achieved by providing the diffractive groove profile of the instrument's optical assembly with smooth edges. The resultant profile facilitates effective diffraction order management as well as a reduction in back reflection. The invention is particularly well-suited for use with a GDI instrument in which the optical assembly comprises first and second diffraction gratings. In this case, any average phase offset that remains after setting wedge and / or tilt can be eliminated by inserting a suitable compensating plate between the first and second diffraction gratings or between the second diffraction grating and the object.

Owner:ZYGO CORPORATION

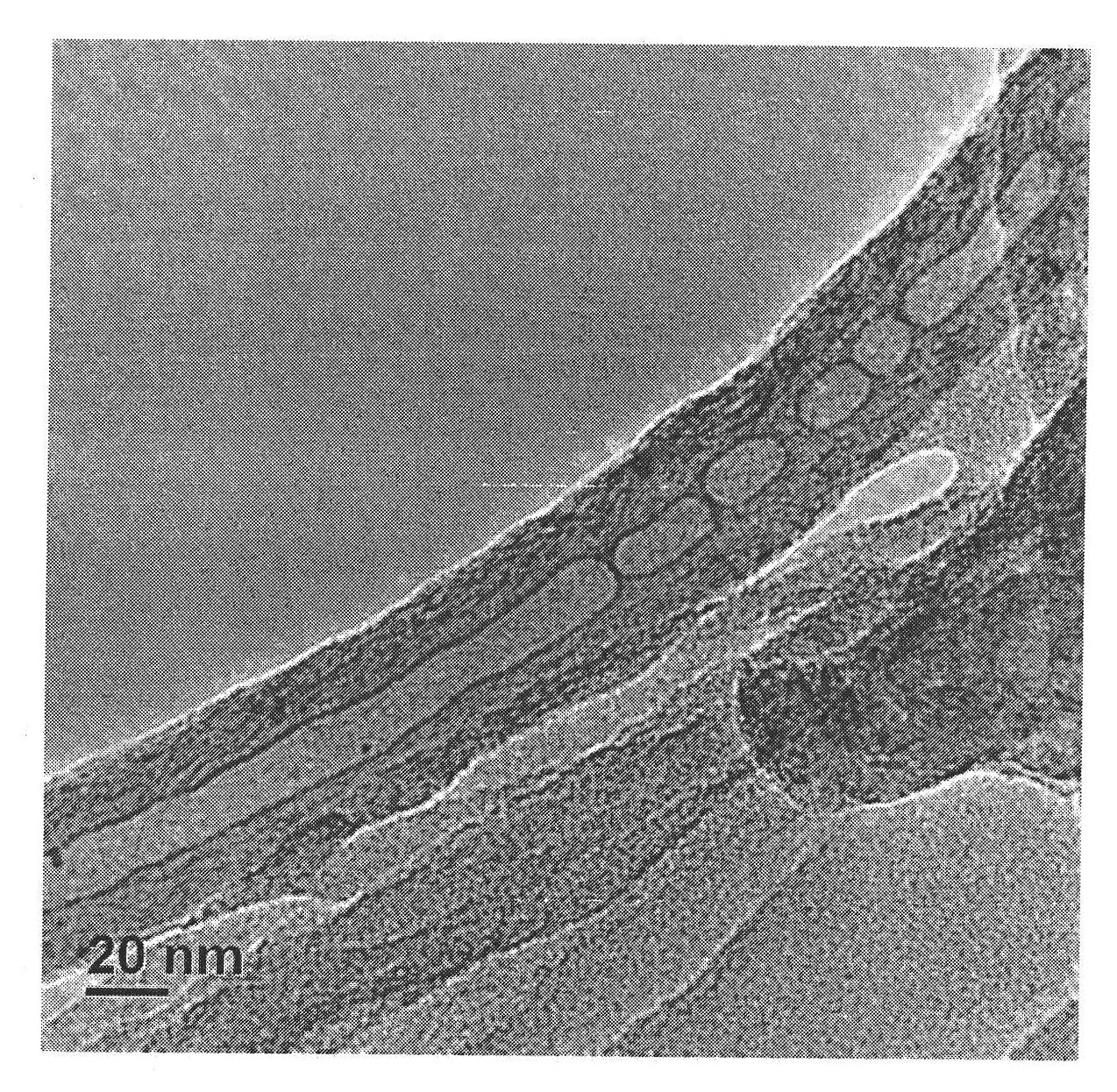

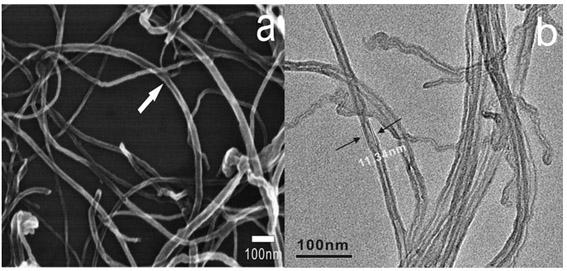

Method for preparing graphene nanobelt

The invention relates to a method for preparing a graphene nanobelt. The method comprises the following steps of: (1) placing a carbon nano tube in air and calcining the carbon nano tube at the temperature of 400 DEG C for 1 hour, then placing the calcined product in a tube furnace with argon-hydrogen gas mixture and heating the calcined product at the temperature of 900 DEG C for 1 hour; (2) adding well treated carbon nano tube into 12mol / L concentrated hydrochloric acid for refluxing for 4 hours at the temperature of 100 DEG C, making the carbon tube neutral by filtering and cleaning and drying the neutral carbon tube at the temperature of 800 DEG C; (3) mixing alkali metals and the carbon nano tube in a mass ratio of 2:1, and reacting the mixture with solvents by an alkali metal melting method or an electrochemical process; and (4) filtering and cleaning the product and drying the product at the temperature of 80 DEG C to obtain the graphene nanobelt. The method is simple and easy to apply and is suitable for mass production. The prepared graphene nanobelt has the advantages of smooth edge and a small number of defects.

Owner:DONGHUA UNIV

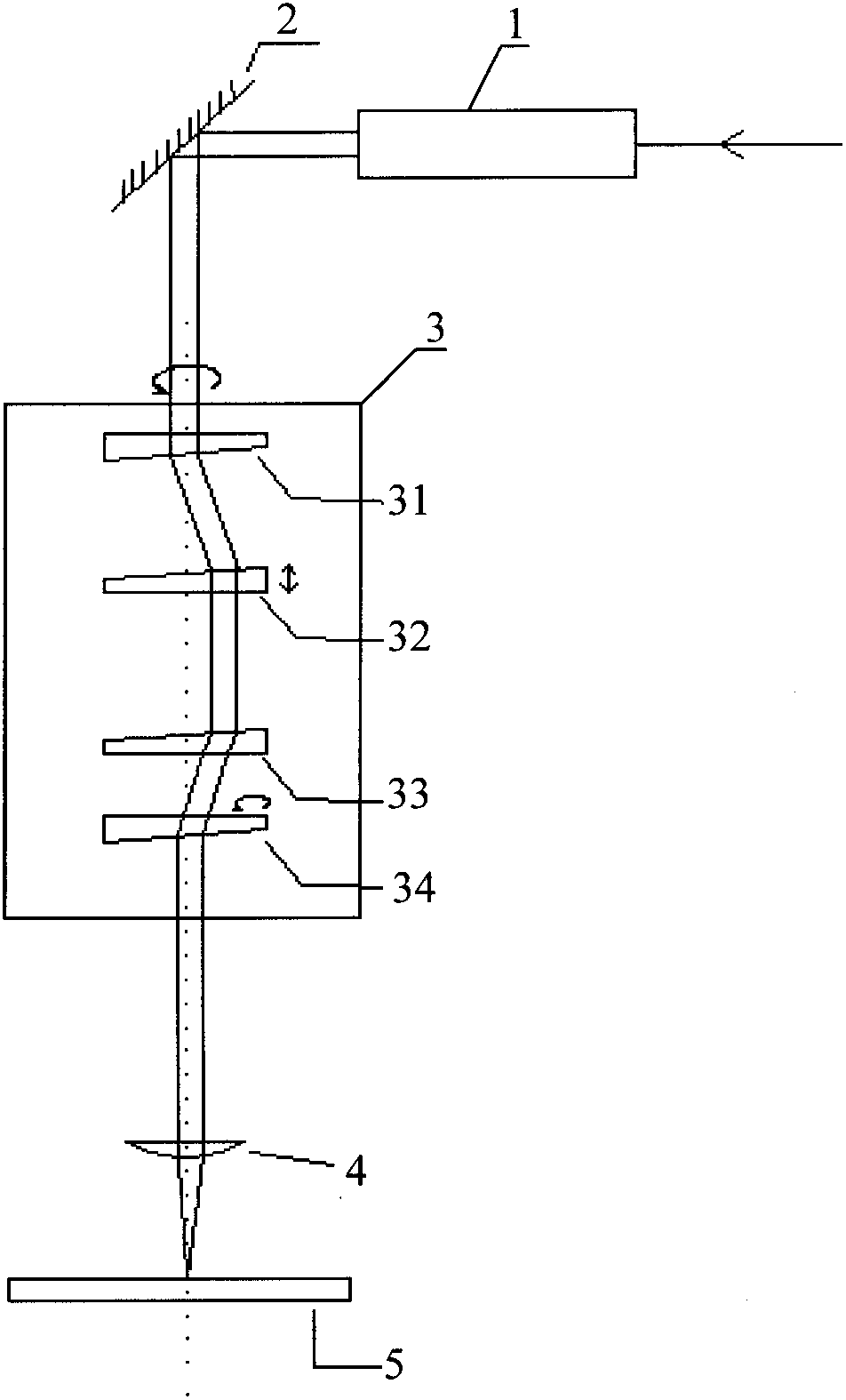

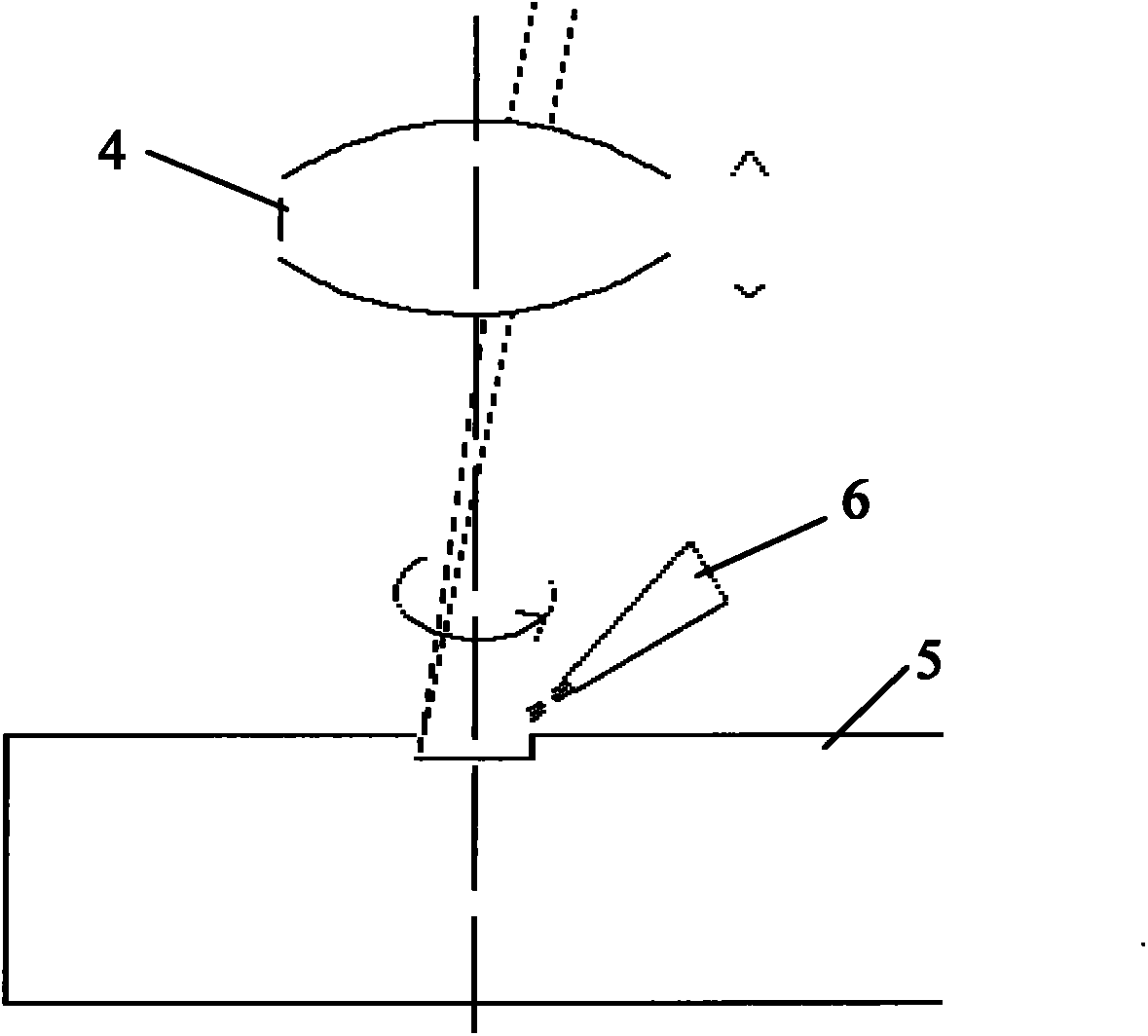

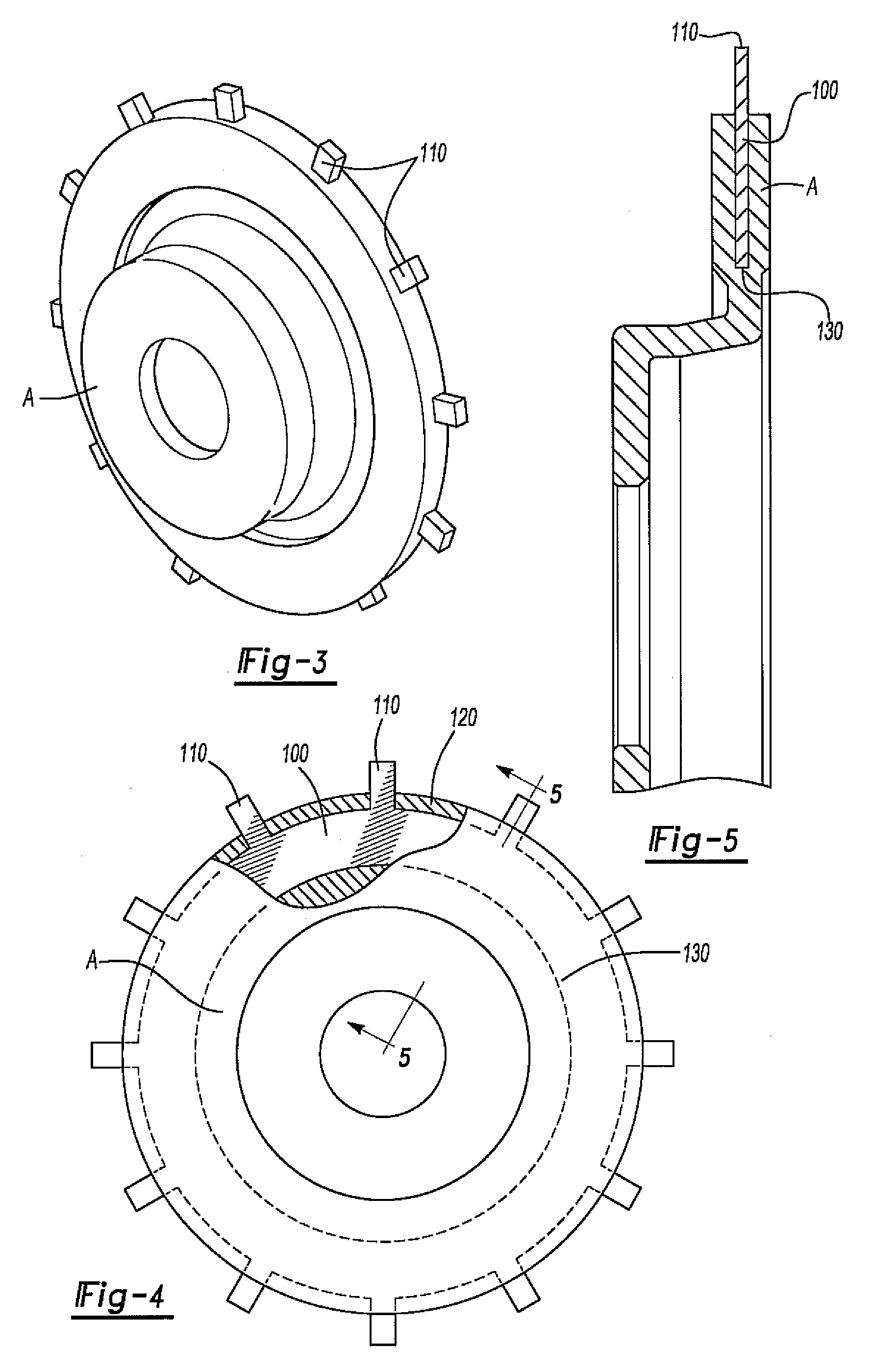

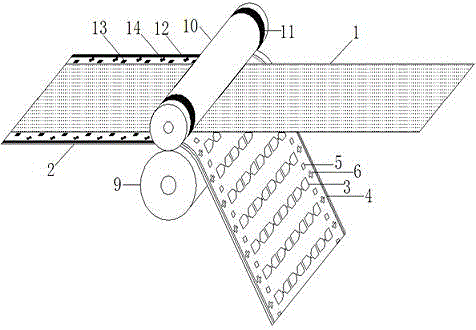

Laser rotary-cut drilling device

InactiveCN102218605AVariable sizeControllable taperLaser beam welding apparatusWedge angleBeam expander

The invention relates to a laser rotary-cut drilling device. The output end of a laser is provided with a beam expander; the output end of the beam expander is provided with a 45-degree total reflection mirror; the output end of the 45-degree total reflection mirror is provided with an optical rotation system; the optical rotation system comprises a first wedge prisma, a second wedge prisma, a third wedge prisma and a fourth wedge prisma; the first wedge prisma and the second wedge prisma have the same wedge angles; the first wedge prisma or the second wedge prisma is connected with a vertical straight-line motion mechanism; the third wedge prisma and the fourth wedge prisma have the same wedge angles; the third wedge prisma or the fourth wedge prisma is connected with a rotation mechanism; the output end of the optical rotation system is provided with a focus lens; and the focus lens is just opposite to a processing platform. The device is used for performing laser rotary-cut drilling on a workpiece, and can process straight holes, variable taper holes and irregular taper holes, so a laser drilling effect of variable sizes, controllable taper and smooth edges is achieved.

Owner:SUZHOU DELPHI LASER +1

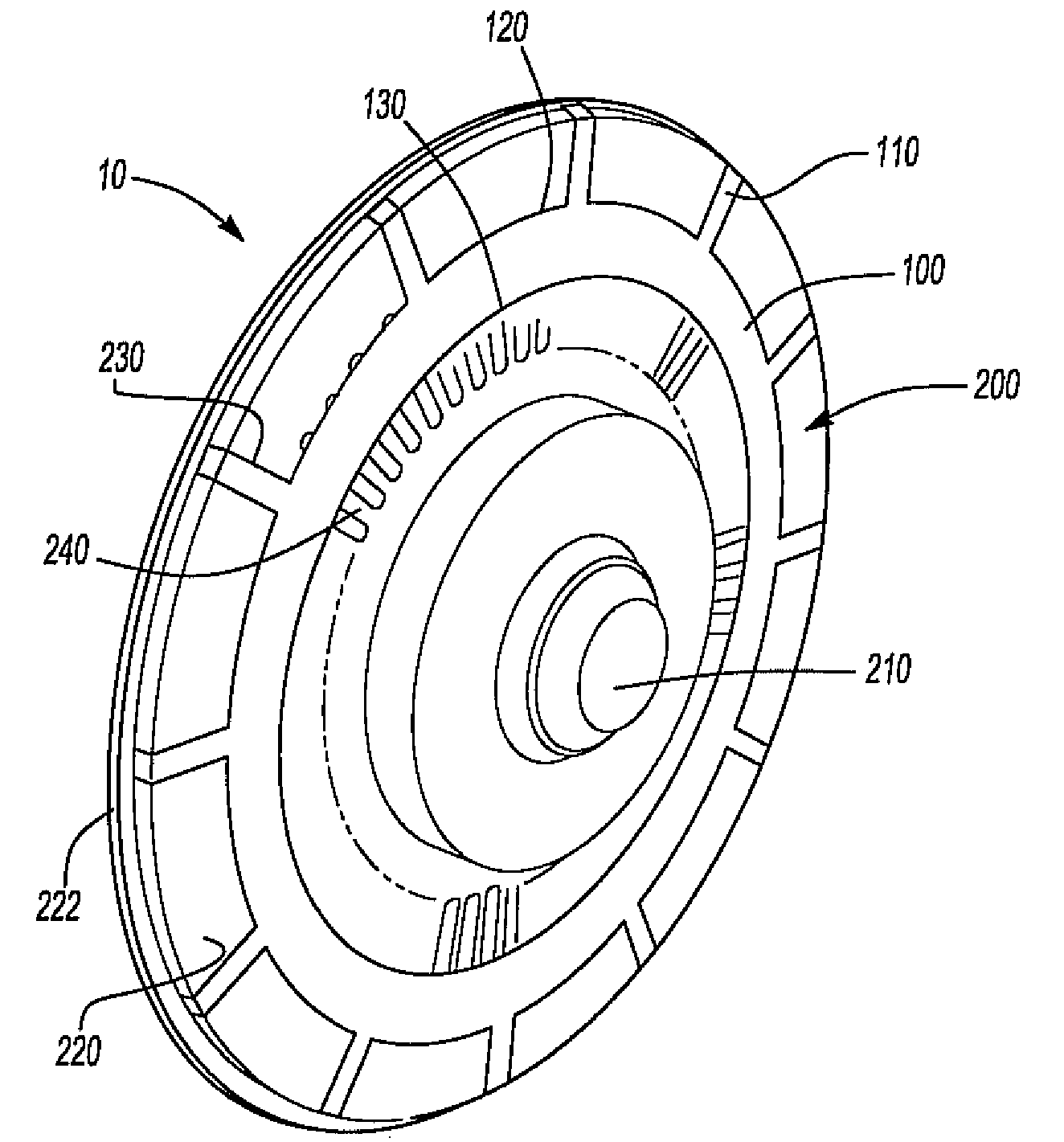

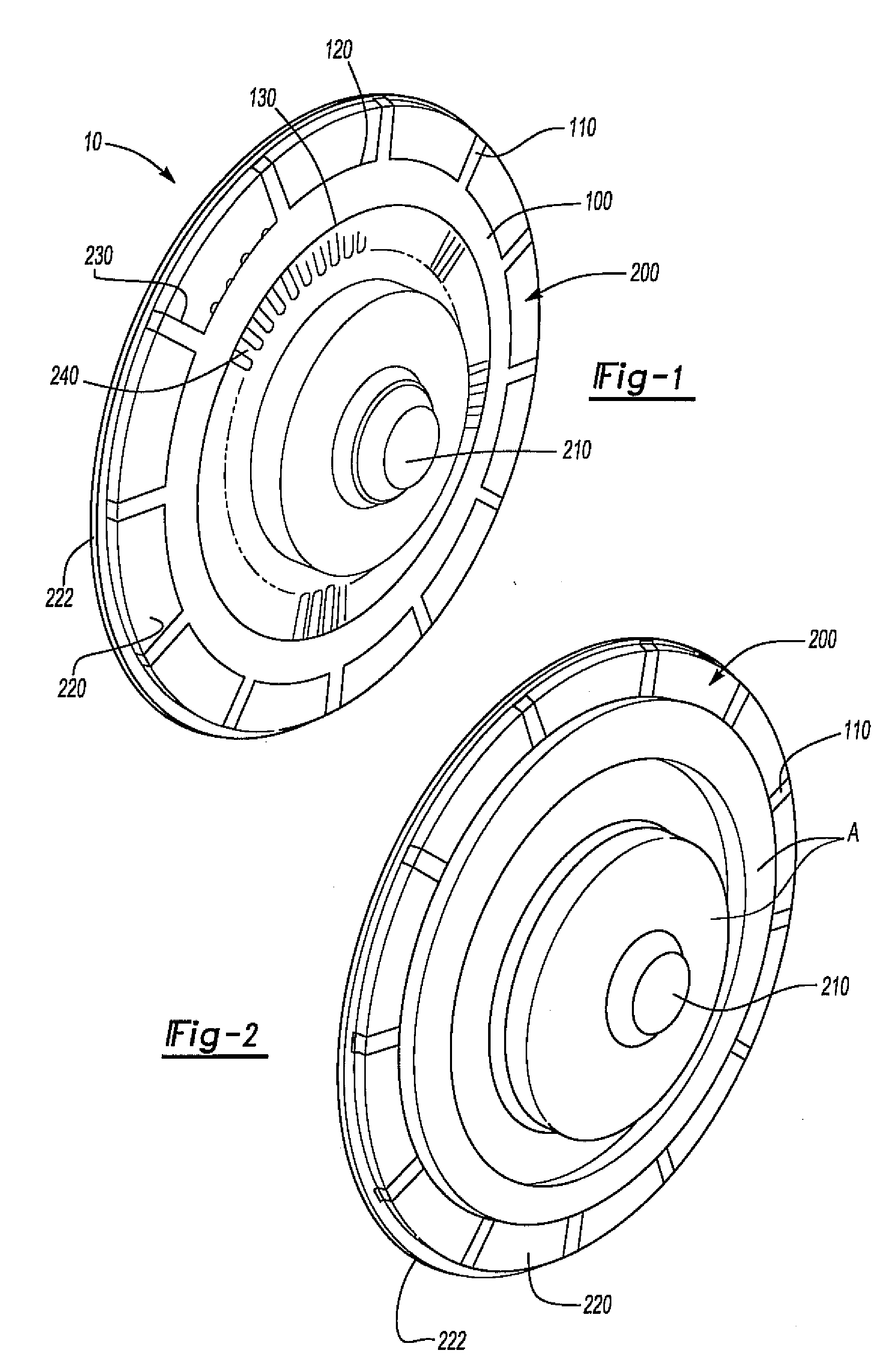

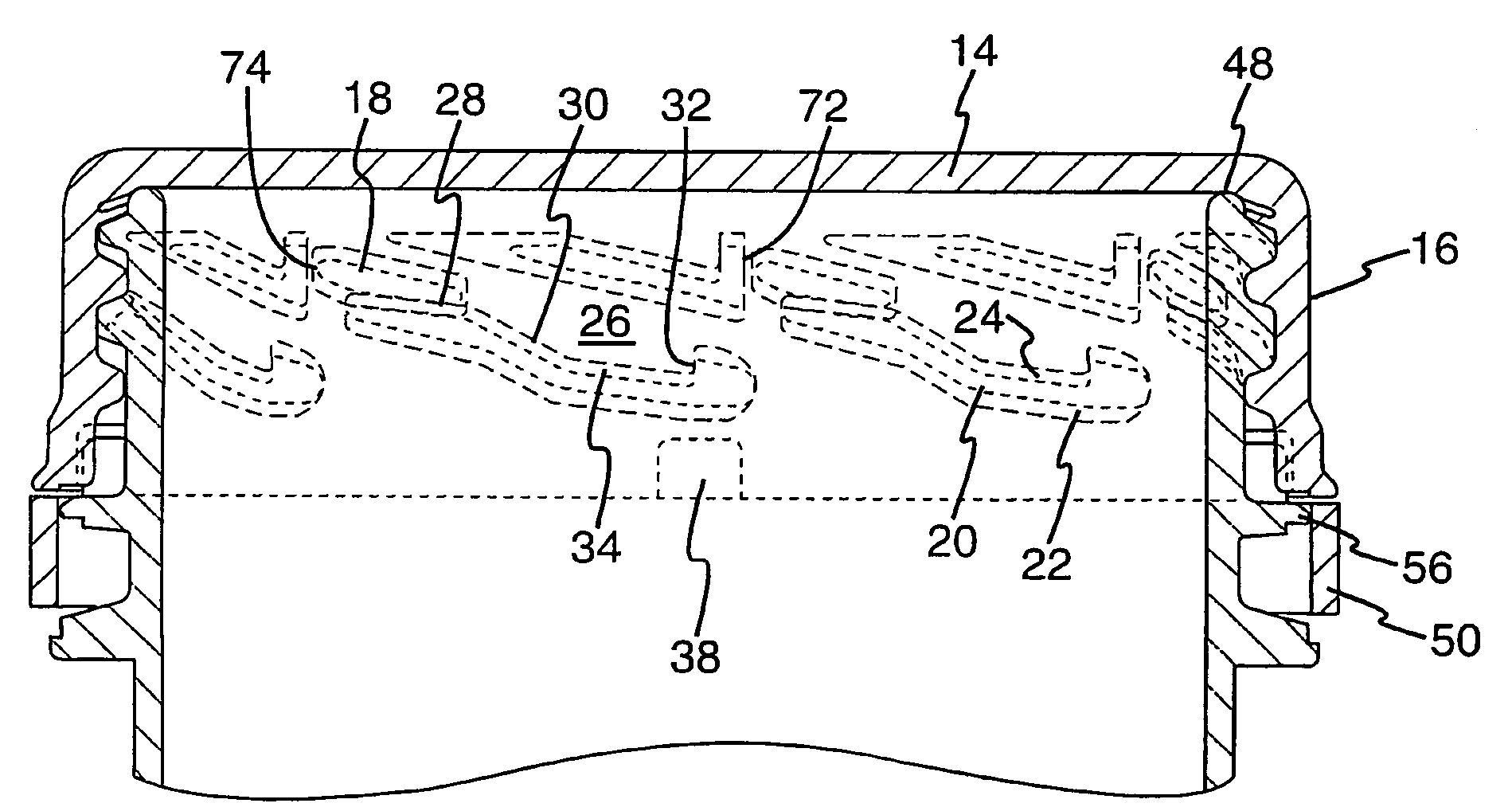

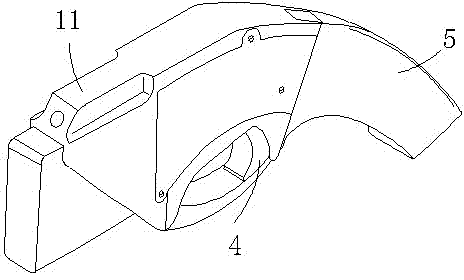

Insert for manufacture of an enhanced sound dampening composite rotor casting and method thereof

InactiveUS20070235270A1High melting pointIncrease expansionNoise/vibration controlBraking discsCasting moldCalipers

An insert for a casting mold used to produce a sound dampening rotor of a caliper disc brake is provided. The insert includes a ring having an inner diameter, an outer diameter and at least one tab. The insert also includes an inner core made from a refractory material, the inner core being adjacent to the ring. The tab of the ring is operable to position the ring relative to the inner core. Furthermore, the ring and the inner core together can be placed within the casting mold and afford for the desirable and accurate placement of the sound dampening ring within a cast sound dampening composite rotor of a caliper disc brake.

Owner:THYSSENKRUPP WAUPACA DIV

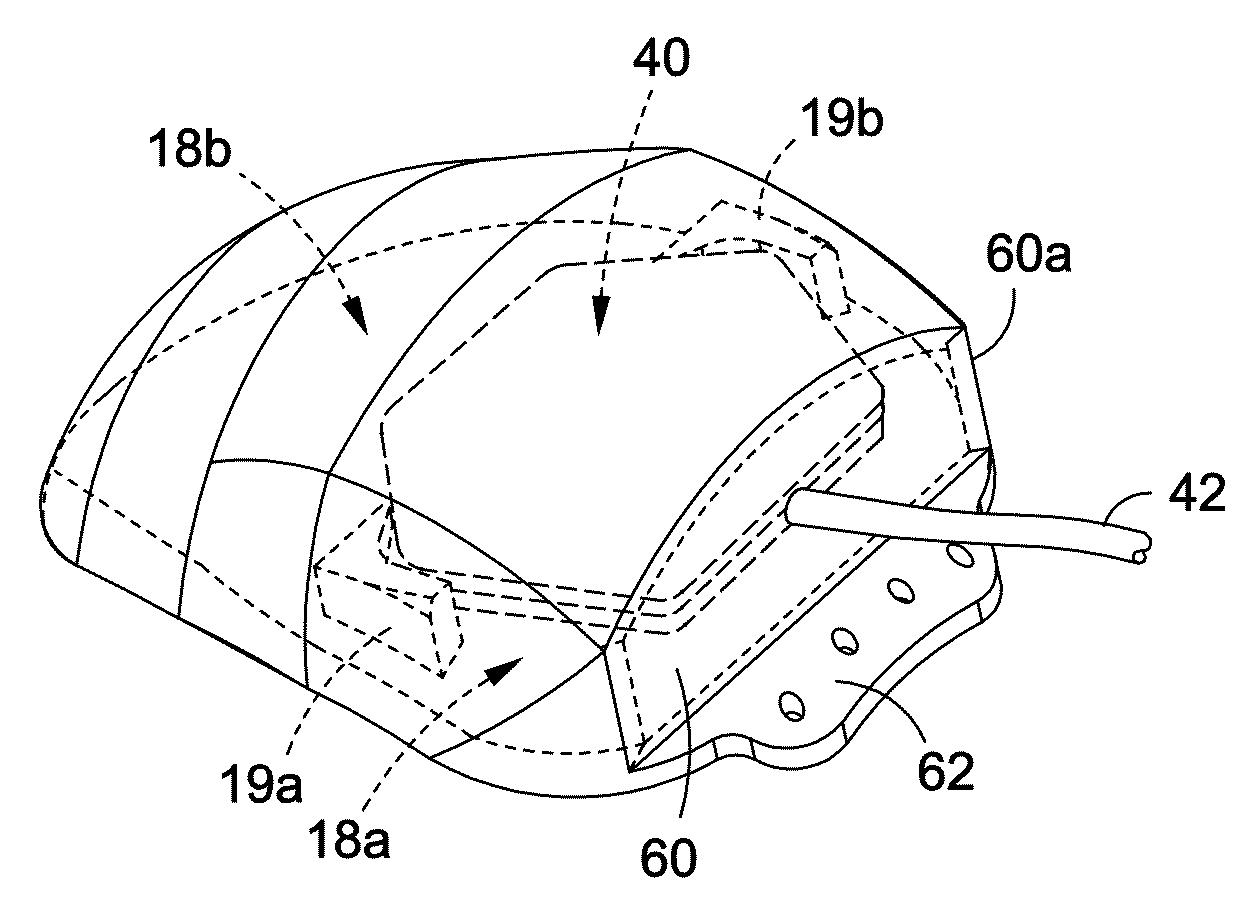

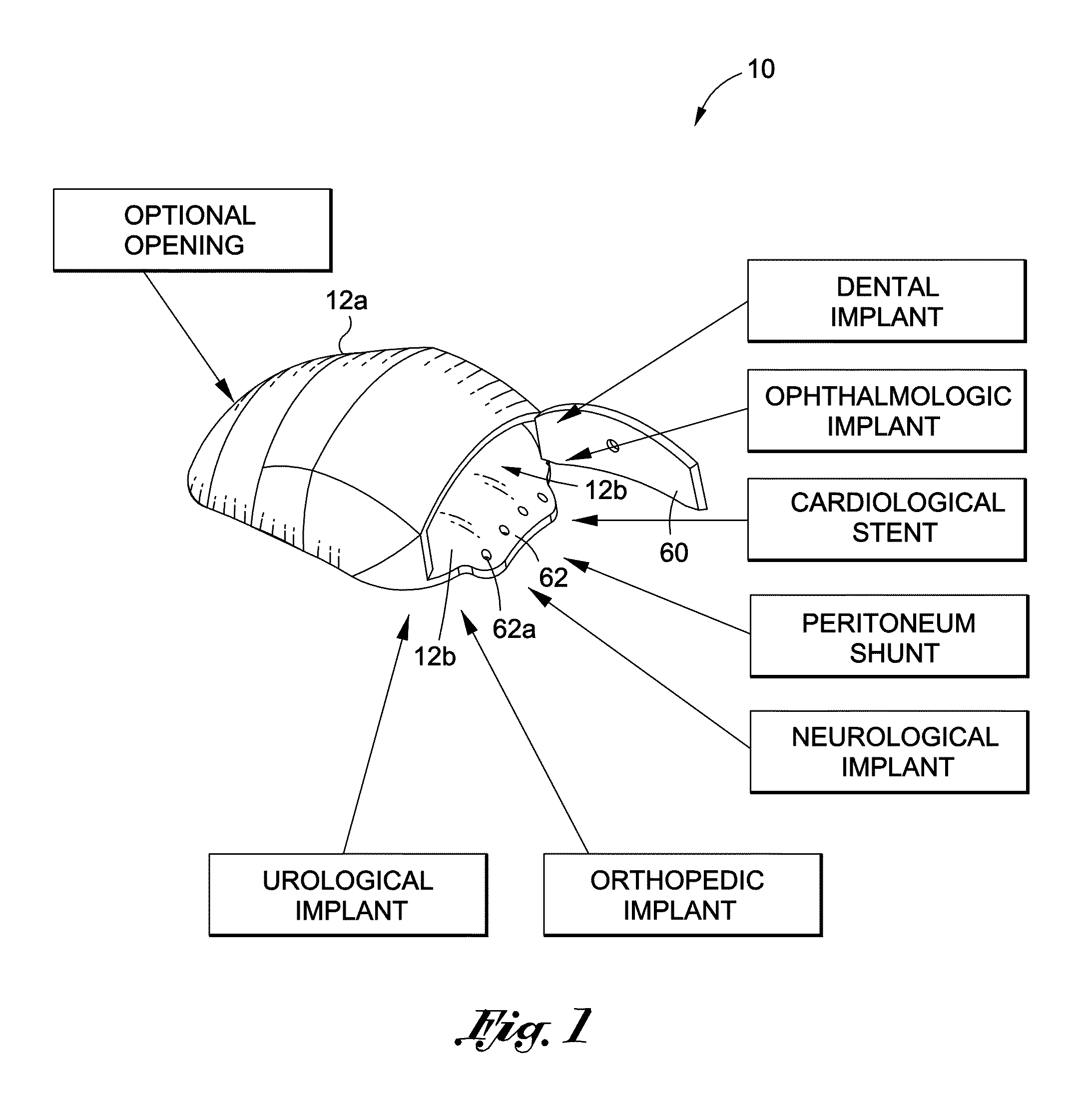

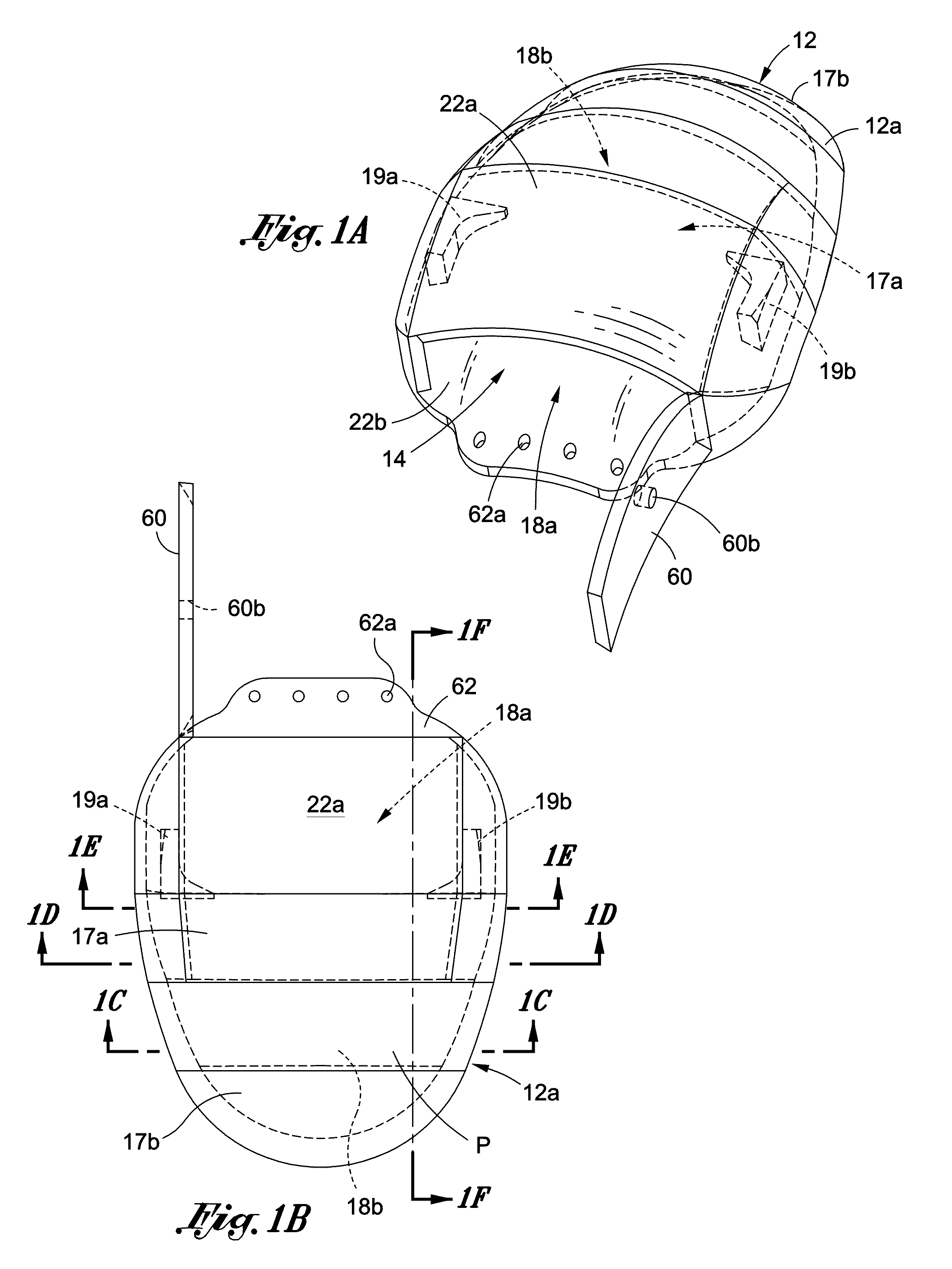

Implantable medical assembly and methods

ActiveUS8632489B1High speedReduce resistanceAdditive manufacturing apparatusEye surgeryBody fluidMedical device

An implantable medical assembly includes a cover having a porous chamber. Enclosed within the chamber is a medical device through which aqueous body fluid flows from an outlet of the device into the chamber. The chamber is formed at least in part from a porous material that promotes vascularization and inhibits fibrotic encapsulation upon implantation and that allows aqueous body fluid in the chamber to flow through the porous material into body tissue in which the assembly is implanted. The chamber has a pair of walls that are spaced apart at a first portion of the chamber at or near the outlet and converge at a second portion of the chamber downstream of the outlet.

Owner:AHMED A MATEEN

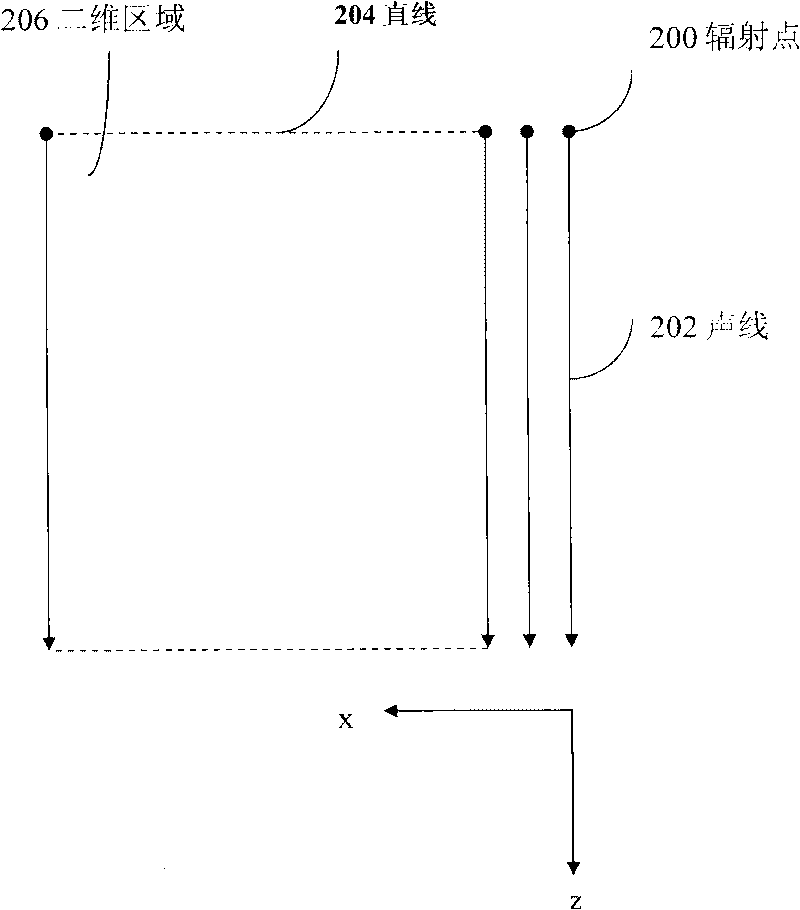

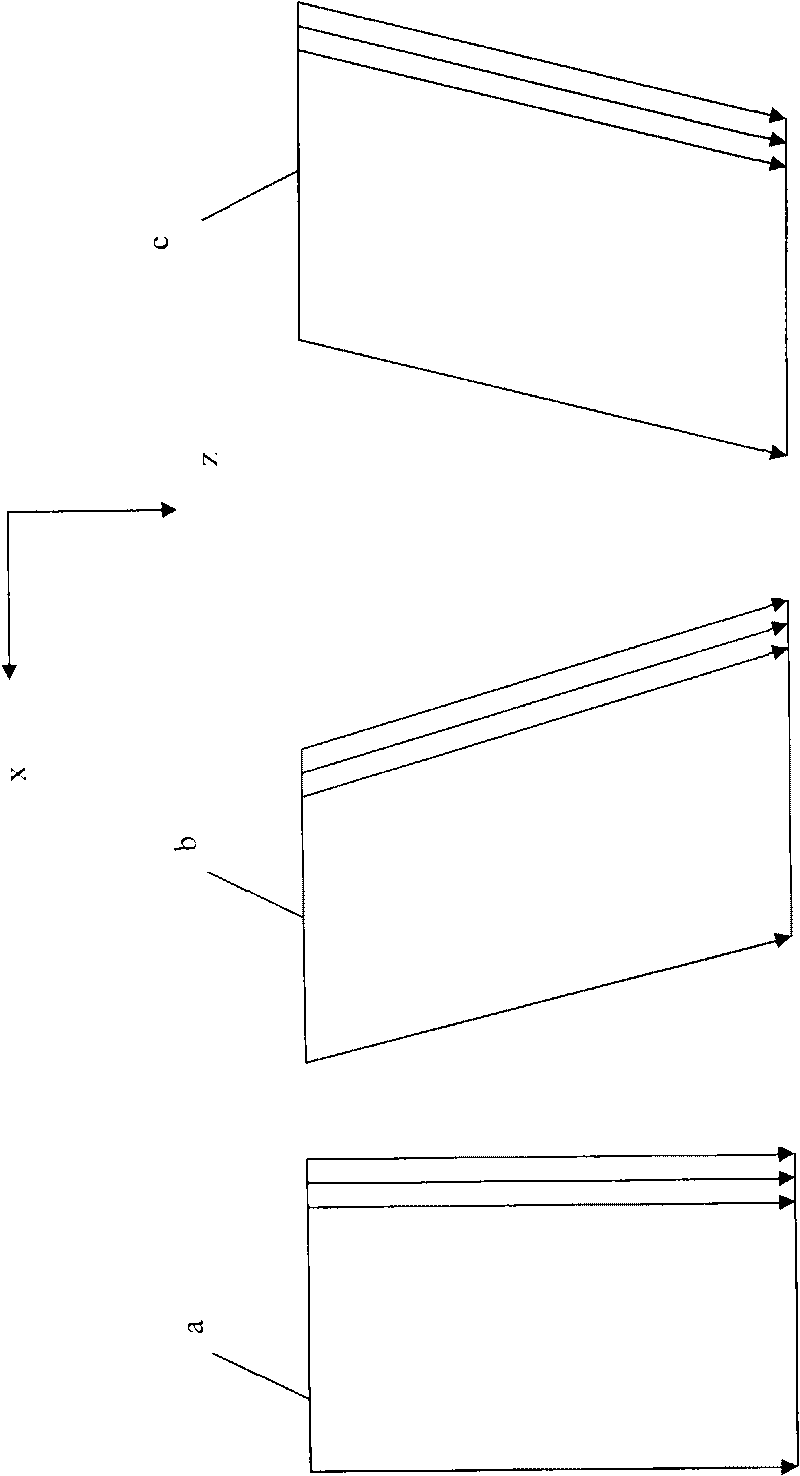

Ultrasonic imaging method and device

InactiveCN101744639AHigh resolutionGood mirror reflection profileUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsMirror reflectionSignal-to-quantization-noise ratio

The invention relates to ultrasonic imaging method and device, in particular to ultrasonic imaging method and device for acquiring a composite ultrasonic image by using a space and frequency composite technology. By using the space and frequency composite technology, frames observable from a plurality of angles are acquired by a Tx / Rx frequency and beam deflection angles which can be configured by a user and the frames are compounded to form a composite image with high resolution and favorable mirror reflection contour. Because the frequency in the invention can be flexibly configured along with the deflection angles, the invention can further widen the allowable range of the beam deflection angles and lower less resolution to a certain extent to restrict the side lobes and the grating lobes of the deflection frames and weaken spot noise and clutter, thereby improving the visibility, the signal-to-noise ratios of the tested tissue and needle and the texture appearance and smoothening the edges.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

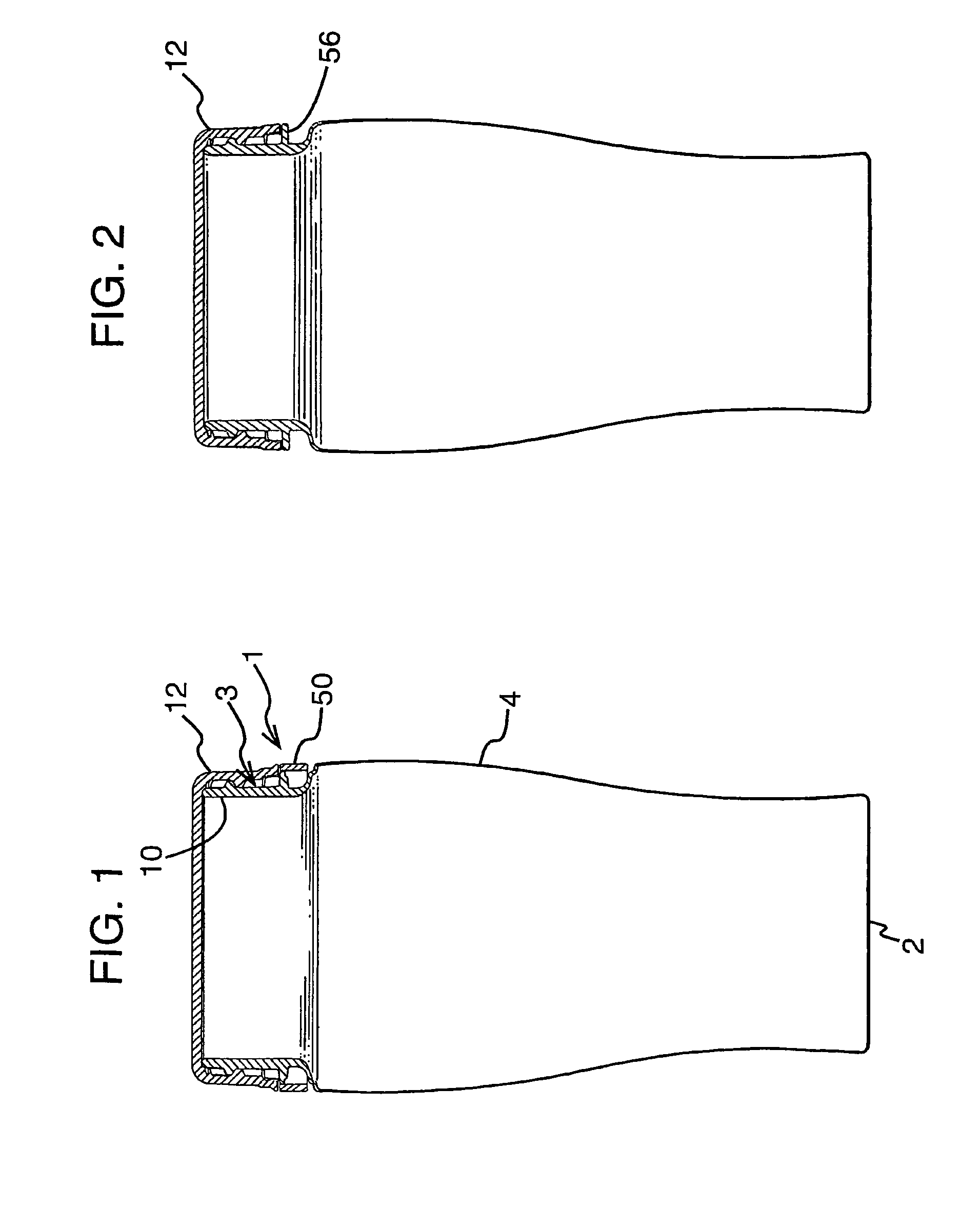

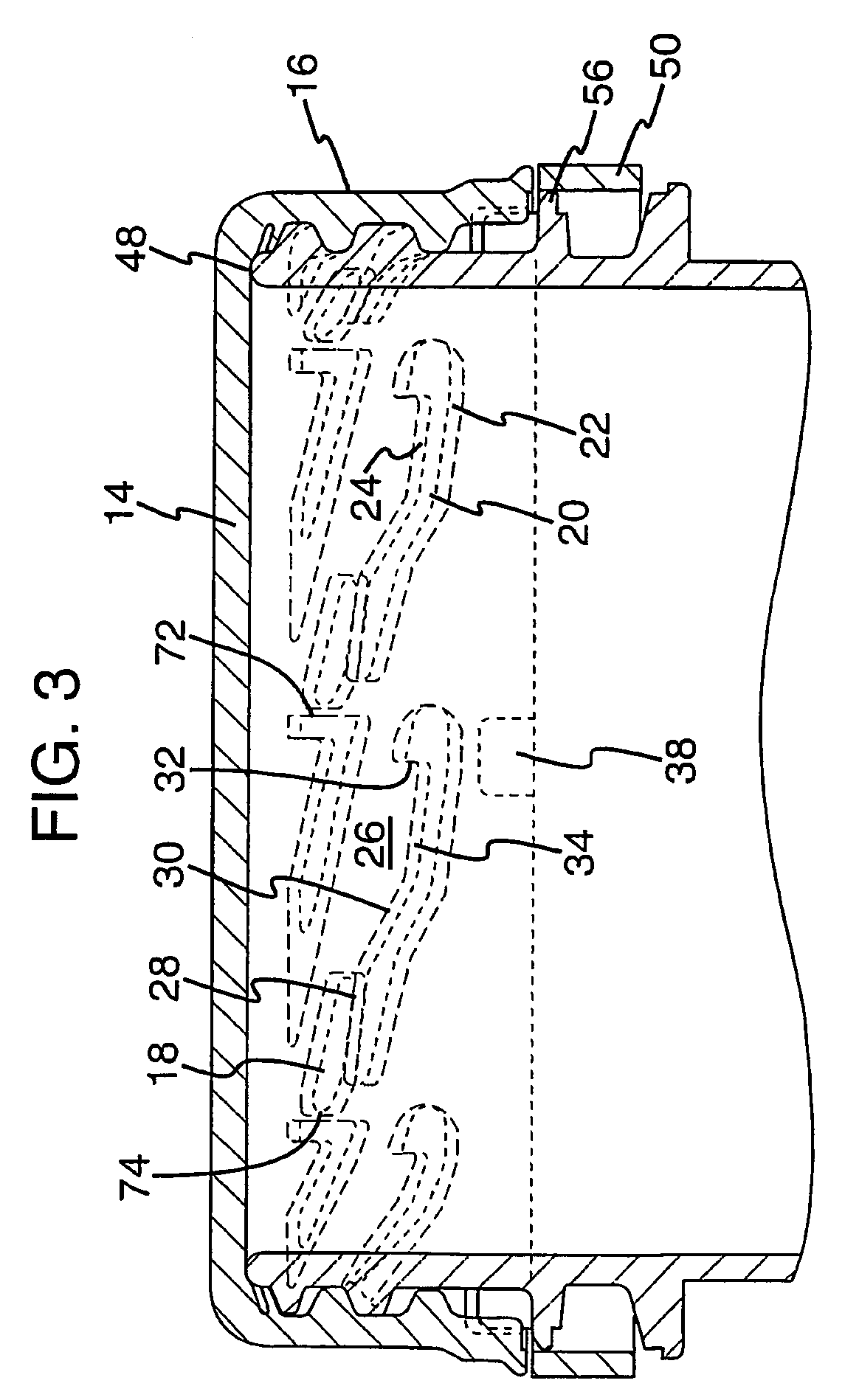

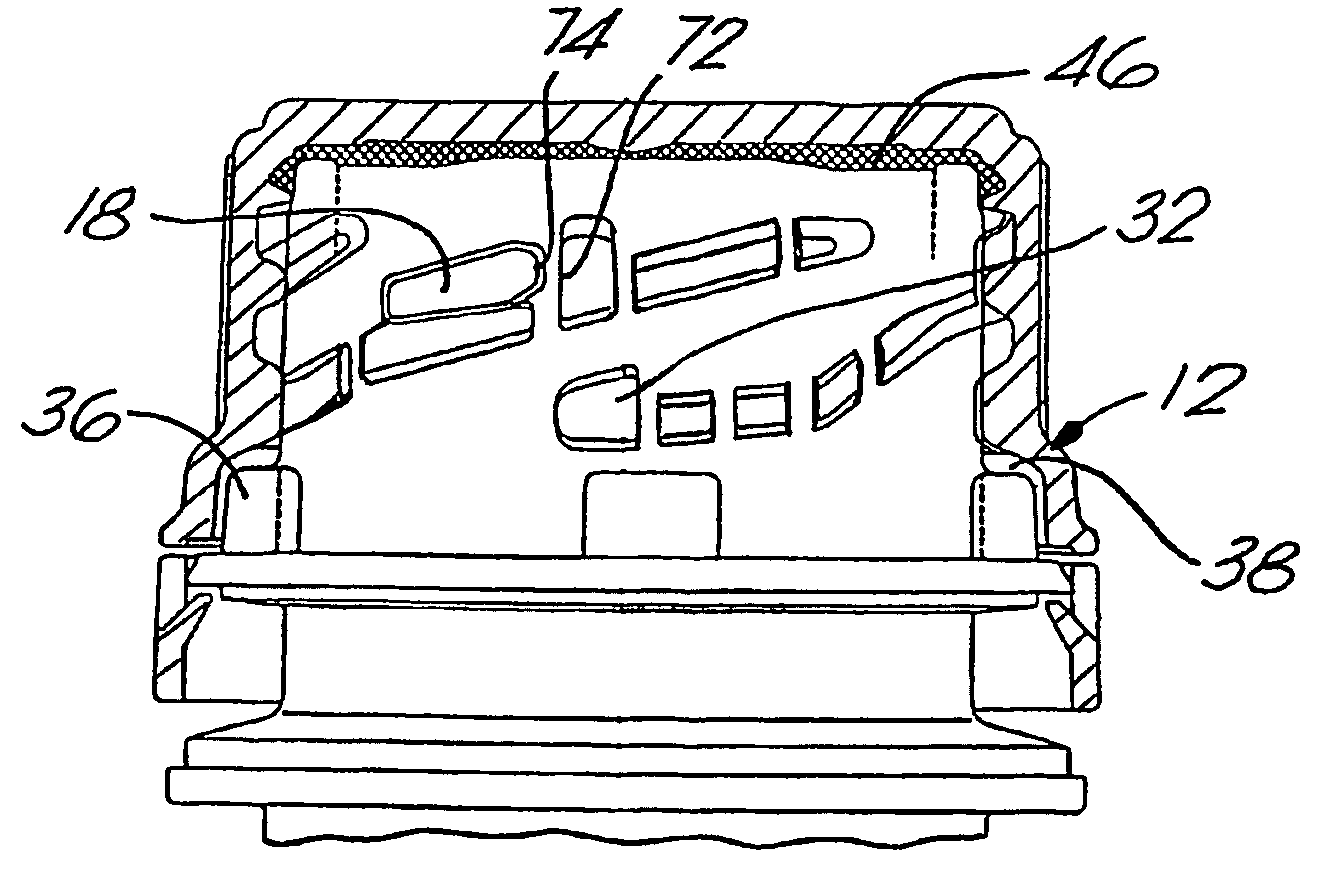

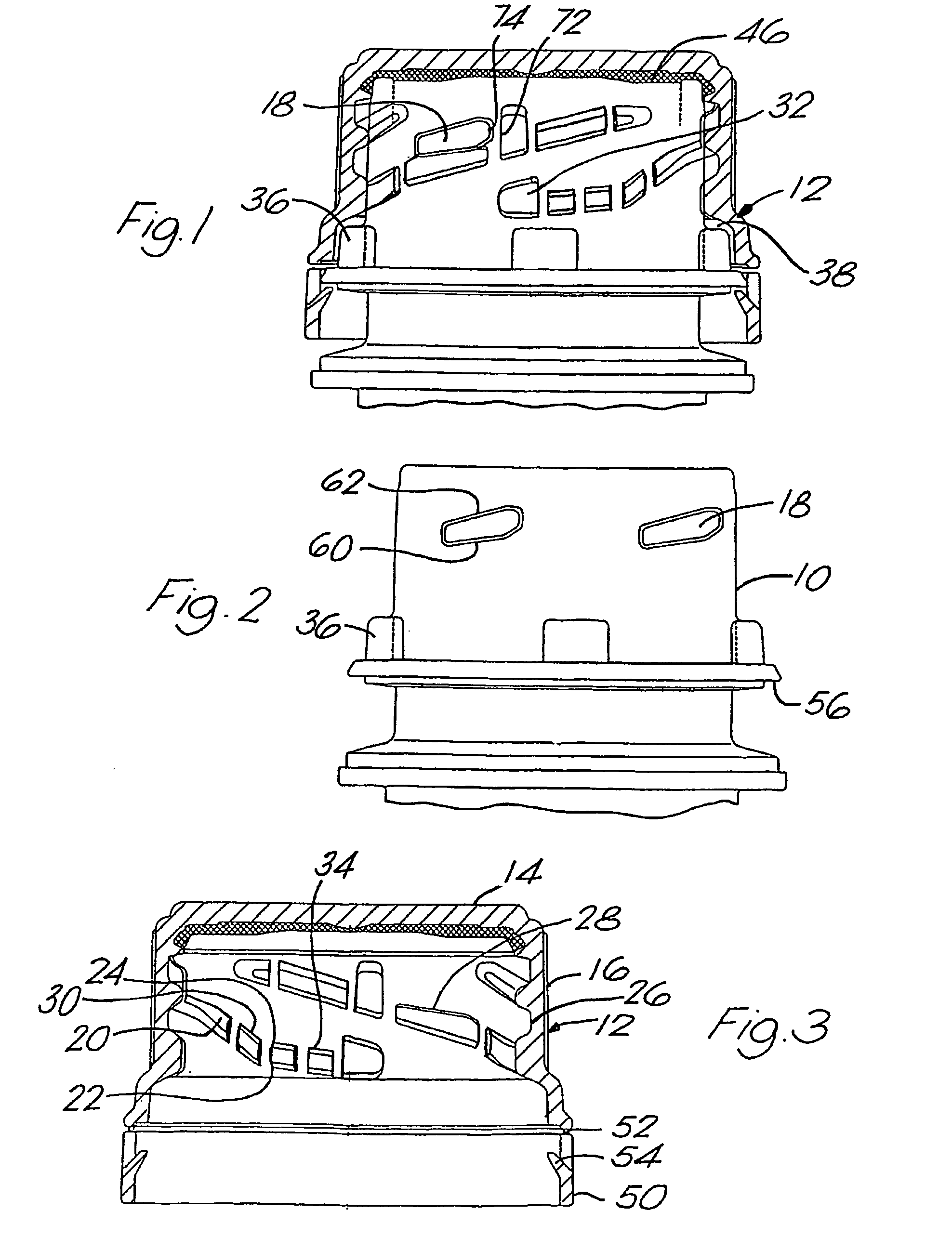

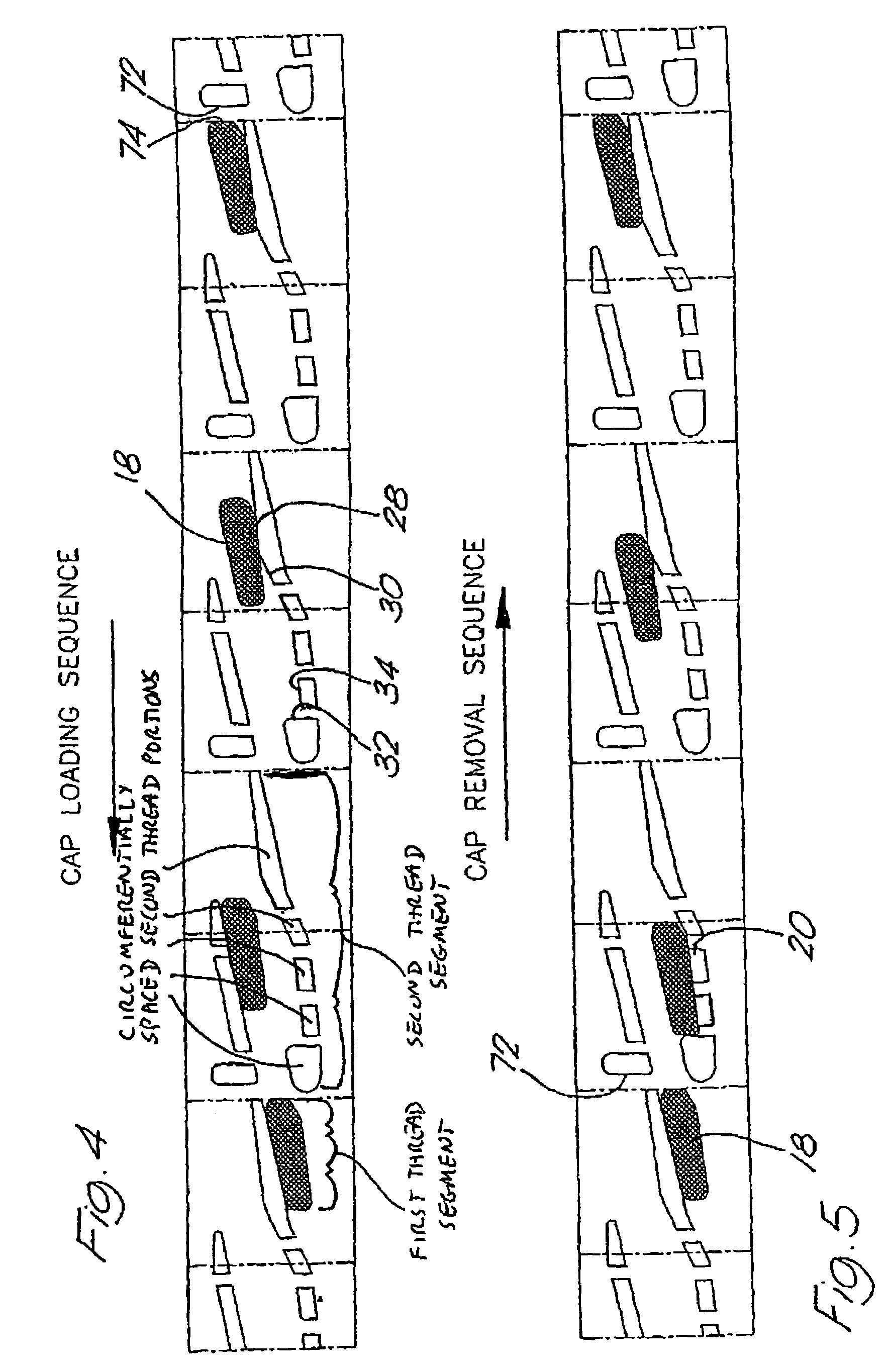

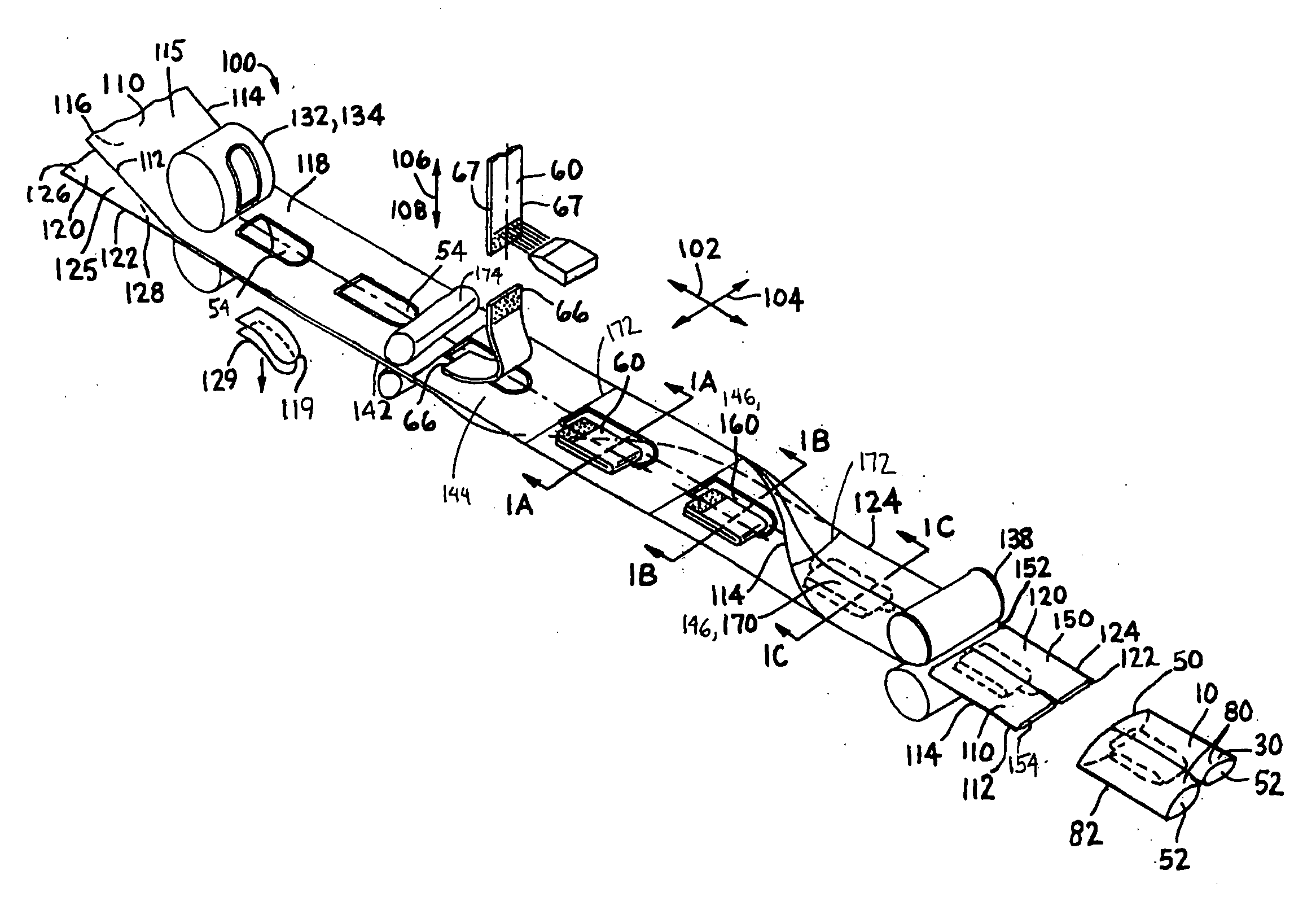

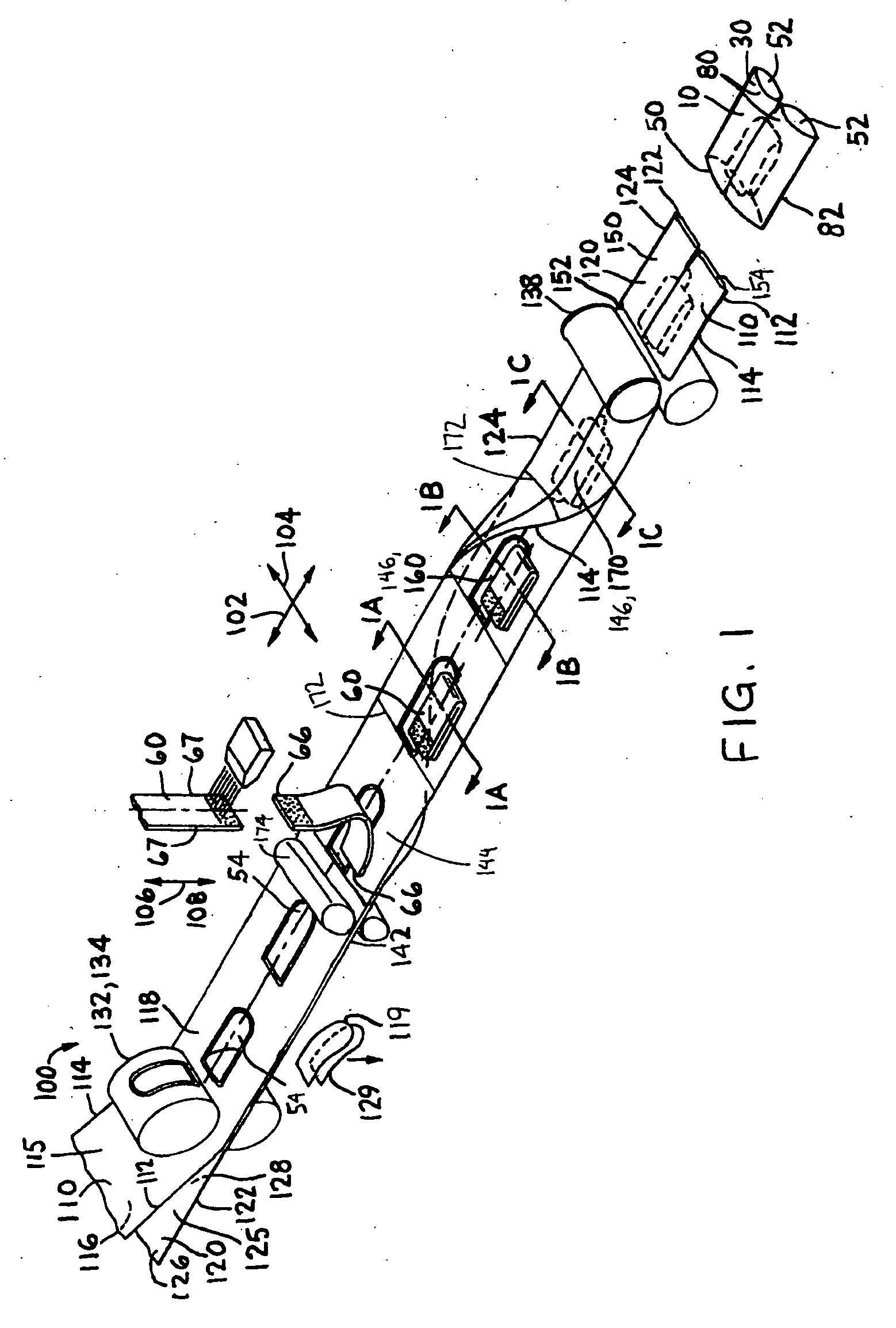

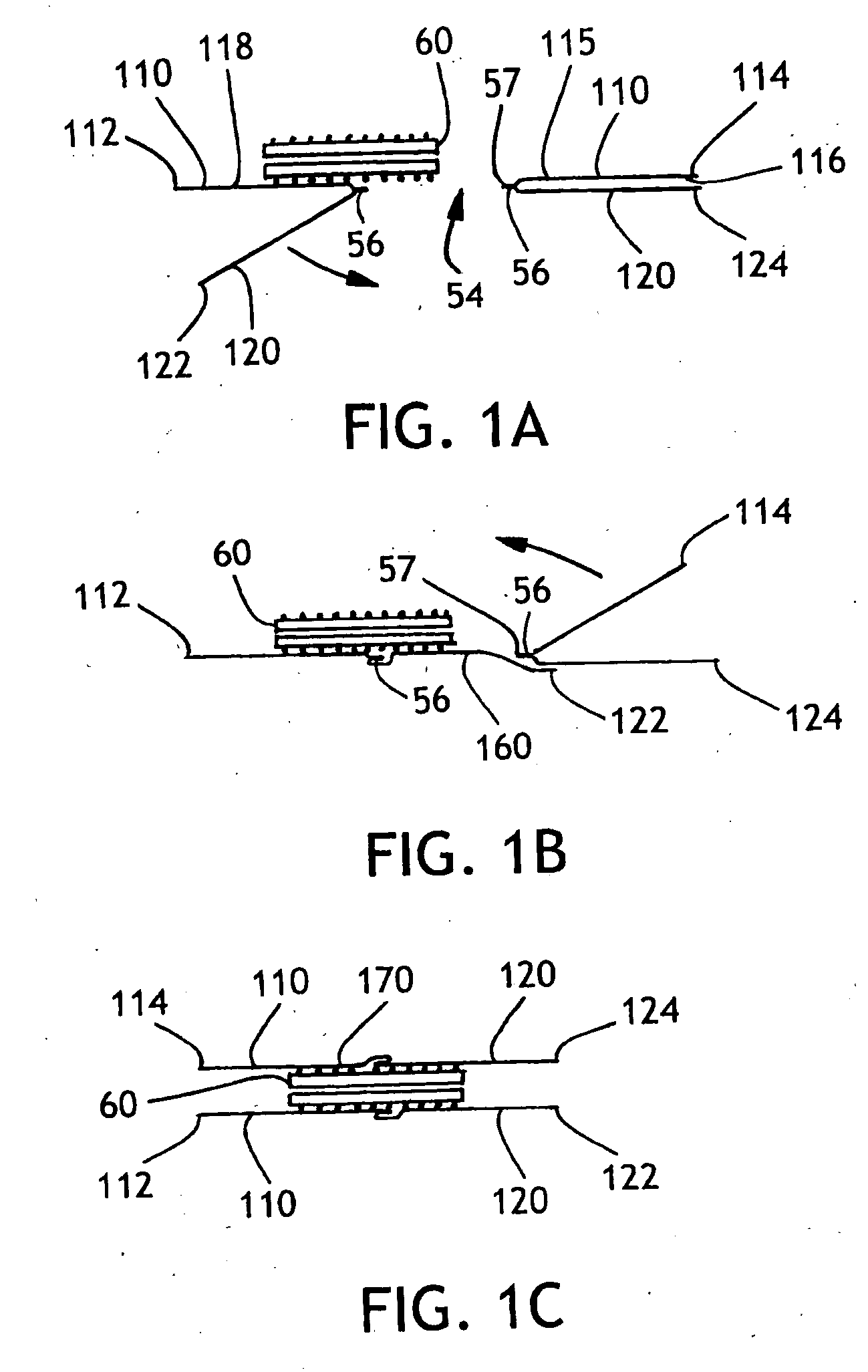

Closure assembly for a wide mouth vessel

InactiveUS7182213B2Improve user friendlinessIncreased radius of curvatureCapsClosure capsWide mouthEngineering

A closure assembly includes: a vessel opening; a closure for said opening, the closure having a base portion and a skirt portion; a first screw thread on the opening, said first screw thread having one or more first thread segments; a second screw thread on an inner surface of the skirt of the closure, said second screw thread having one or more second thread segments; said first and second screw threads being configured to enable a user to secure, remove and resecure the closure into a sealing position on the opening by rotation of the closure on the opening; wherein the first thread segments are shorter than said second thread segments; and wherein the second thread segments are each made up of one or more radially spaced projecting portions, each said portion extending radially no more than about 60° around the closure skirt.

Owner:BEESON & SONS

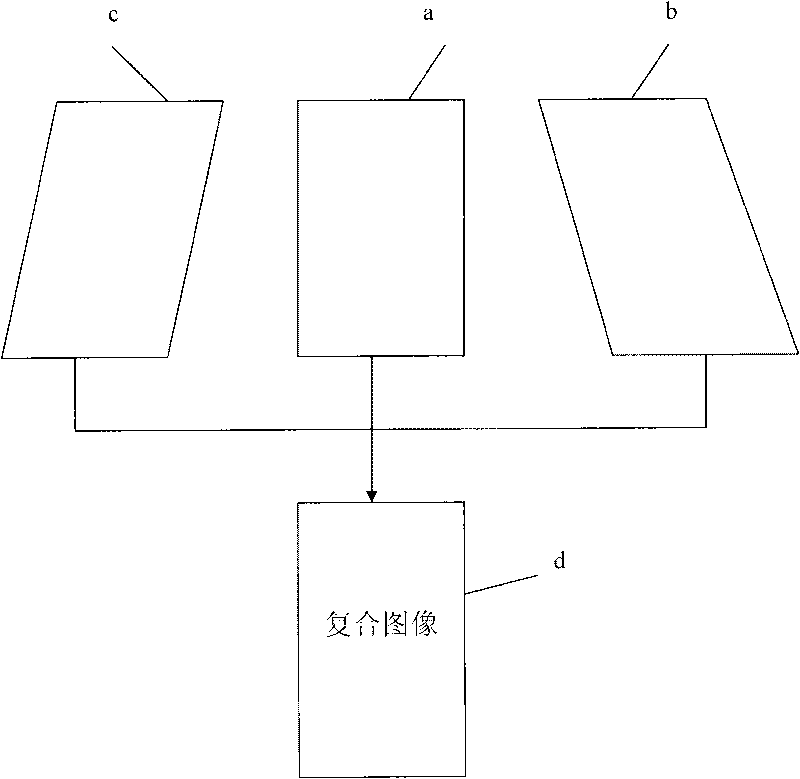

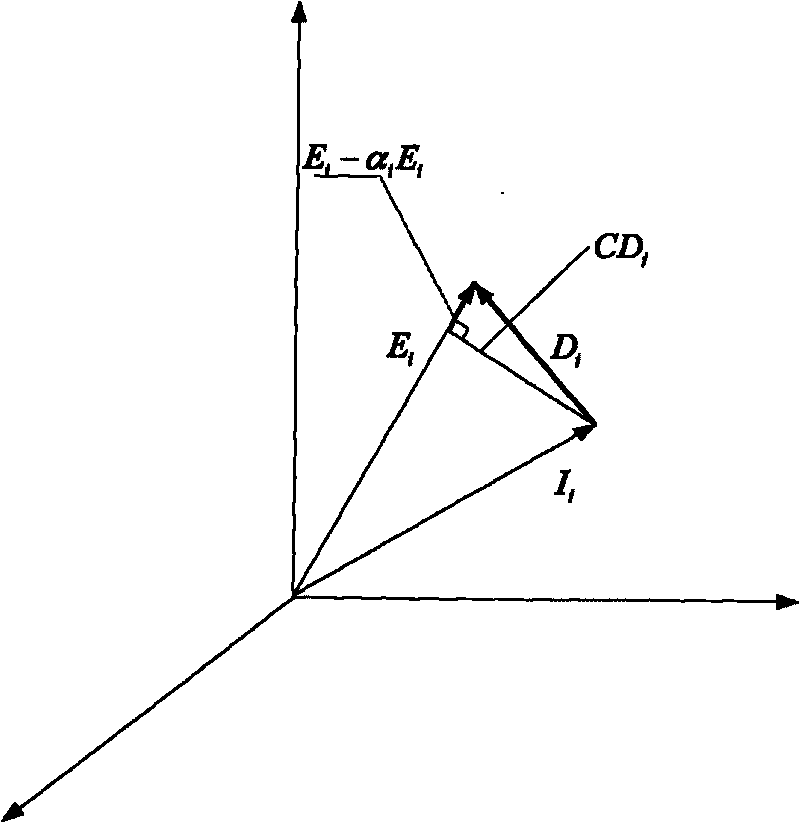

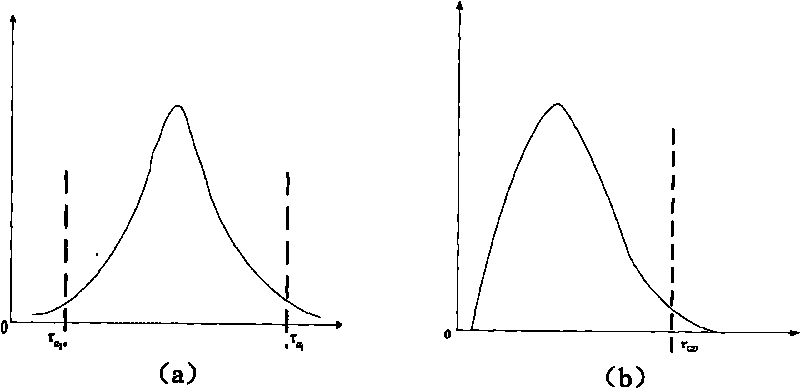

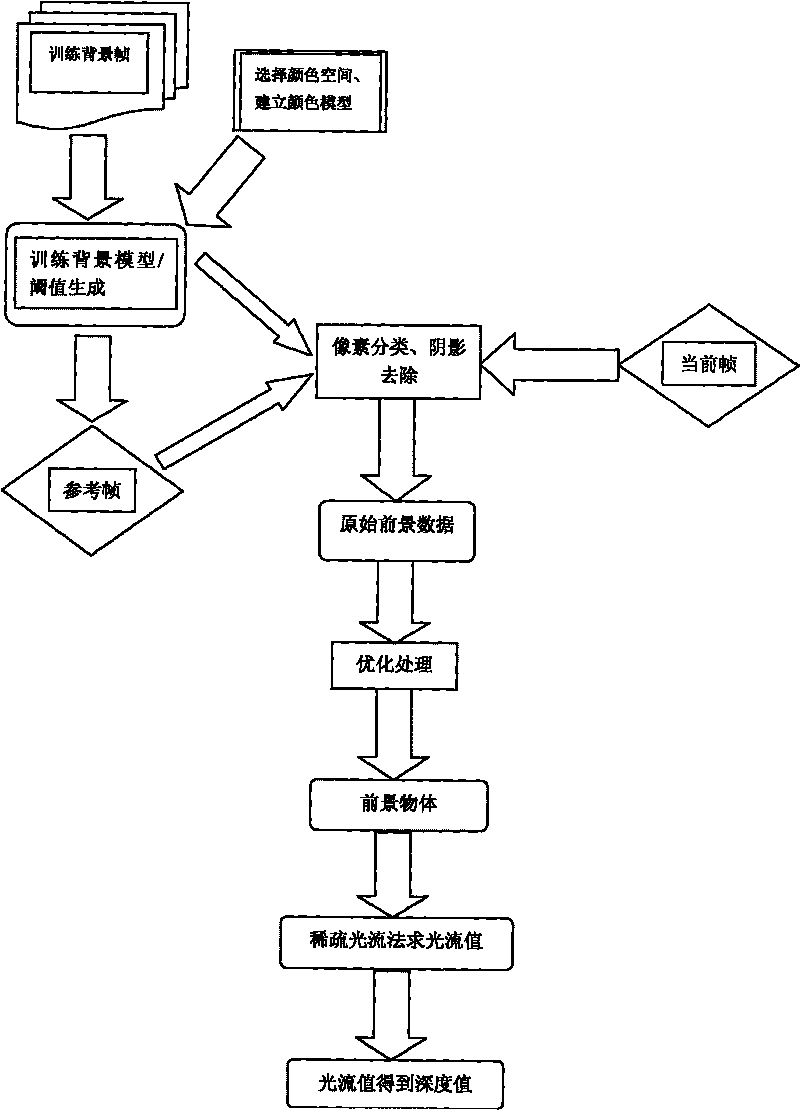

Depth generating method based on background difference sectional drawing and sparse optical flow method

InactiveCN101699512AImprove classification resultsSmooth edgesImage analysisVideo sequenceOptical flow

The invention relates to a depth generating method based on a background difference sectional drawing and a sparse optical flow method. The depth generating method comprises the following steps: selecting suitable colour space and establishing a colour model; establishing a background model fast and effectively so as to exactly describe the background of a video sequence; classifying each pixel point according to the background model; optimizing the classified result of the pixel; evaluating an optical flow value of a feature point by the sparse optical flow method; evaluating the optical flow values of all the points by interpolation; and obtaining a depth value by the optical values. The invention has the advantages as follows: the sheltering problem which cannot be solved by singly using the optical flow method can be avoided; and the generation of the depth of the video sequence can be automatically realized.

Owner:无锡景象数字技术有限公司

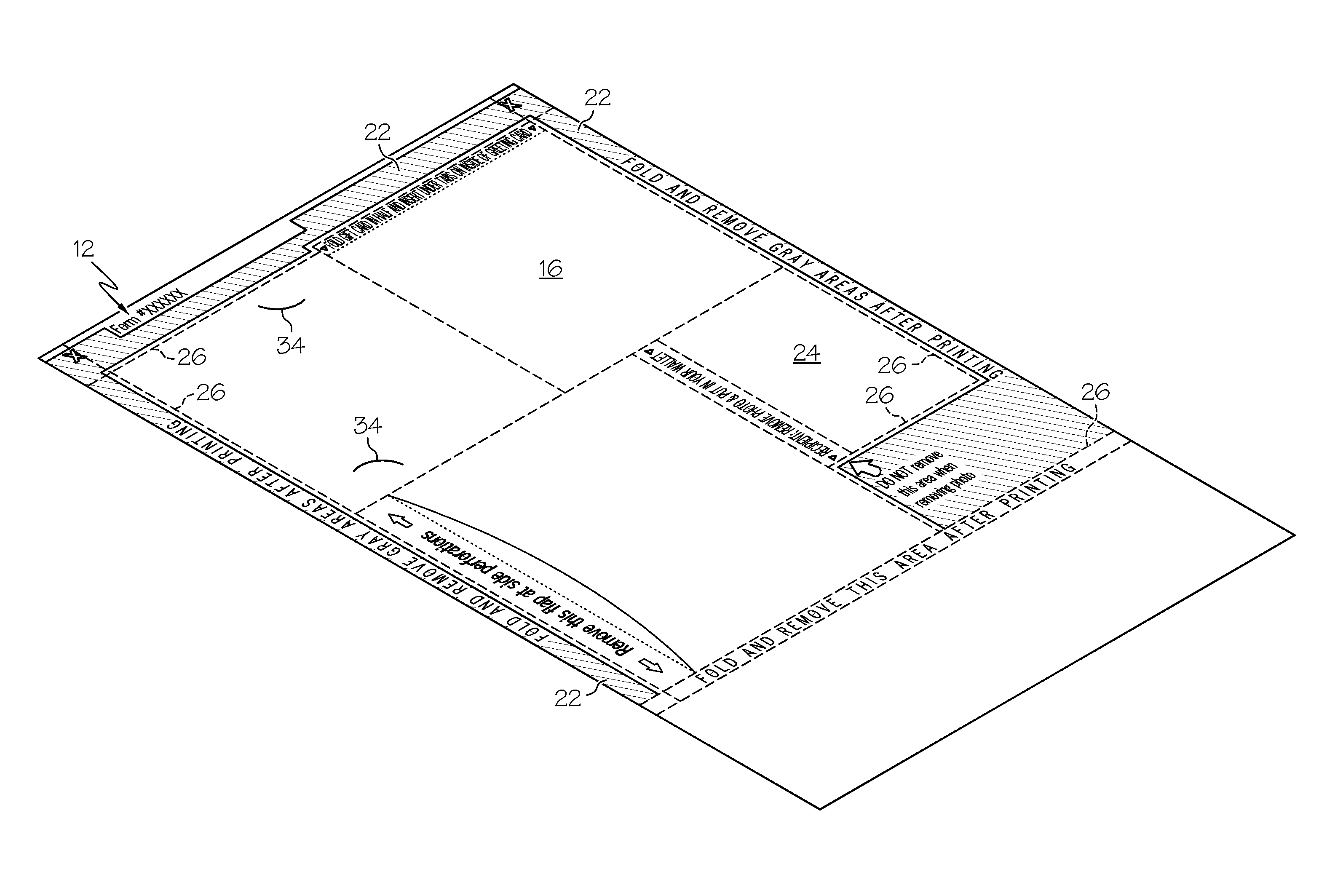

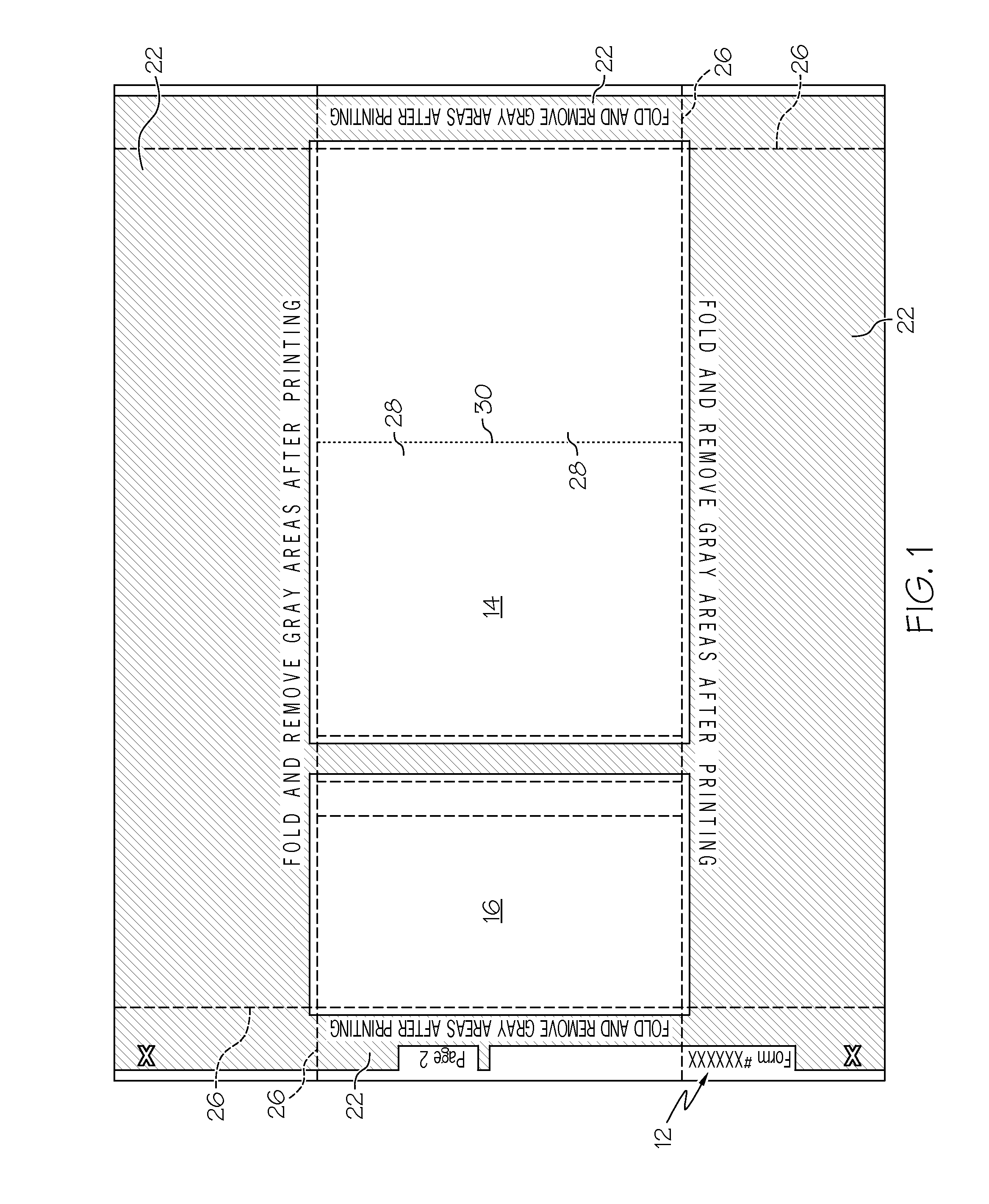

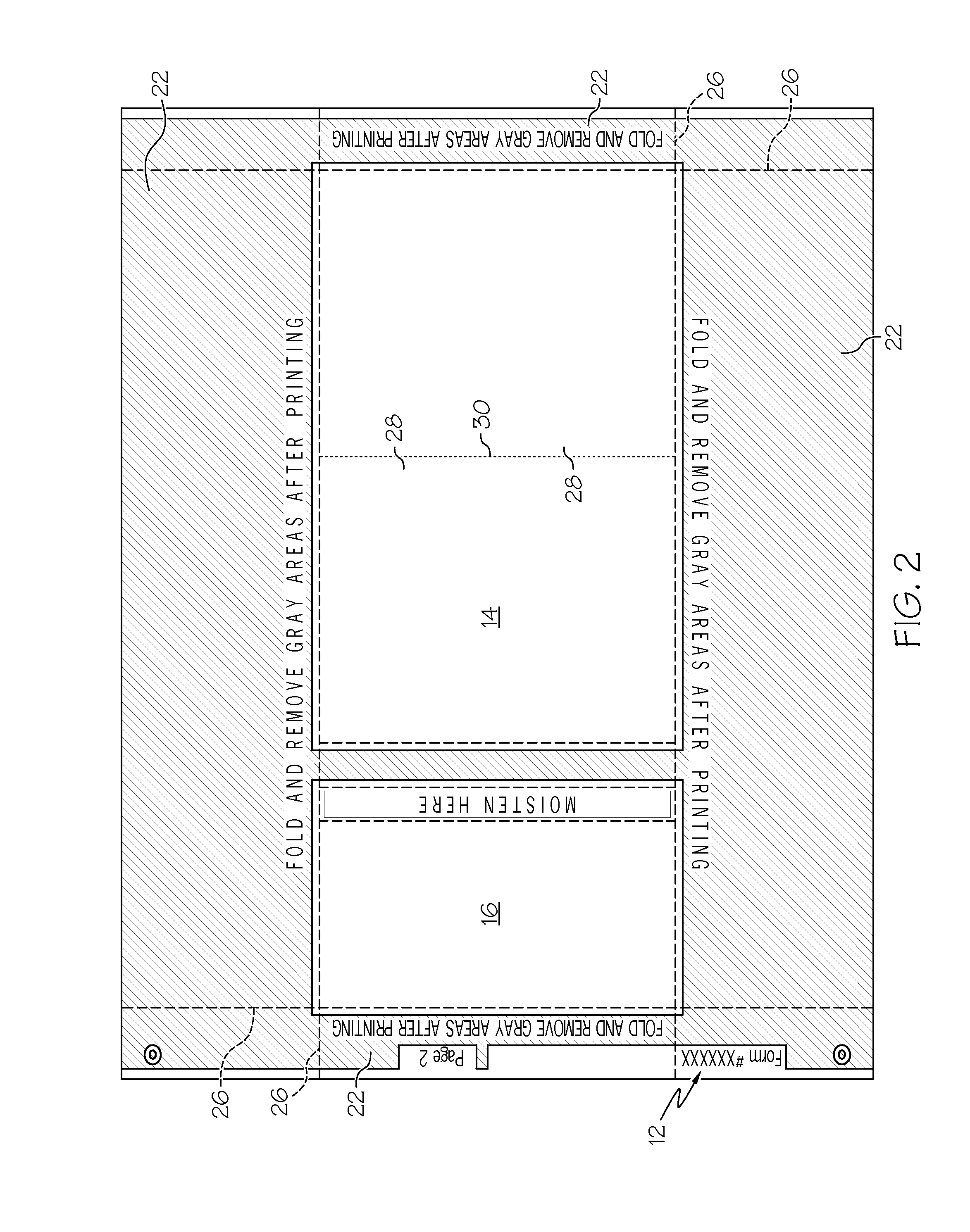

Multi-component forms

A printable and imprintable multi-component form is described that features detachable components including a correspondence piece, an envelope, and a variable element. The multi-component form is formed from two plies of material such as paper, plastic, foil, or paperboard. The correspondence piece can be a greeting card or a post card. The variable element can be a scrip, a customizable component, e.g., a wallet-sized photograph, or a product stamp. The scrip can be any non-monetary certificate exchangeable for currency, goods, or services including, for example, a gift card or a gift certificate. The assembled envelope can be used to mail the correspondence piece and variable element to a recipient. The detachable components can be separated from one another and from the sheet of material of the form at a plurality of lines of separation such as perforations.

Owner:WILOPEN PRODS LC

Channel catfish ictalurus punctatus deepfreezed fillets and processing technique

InactiveCN101032337AIncrease incomeGreat tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsLeiocassis longirostrisIce water

The present invention discloses one kind of fast frozen white delicious fish fillet of spotted forked-tail Leiocassis longirostris and its production process. The production process includes the steps of temporarily raising, killing to eliminate blood, slicing, eliminating skin, trimming, soaking to sterilize, loading into tray and quick freezing, grading, coating with ice, packing, etc. The production process features complete elimination of blood, low temperature of fish fillet in icy water at 0-4 deg.c, soaking fish fillet in ozone icy water and ultralow temperature quick freezing at below -35 deg.c. The production process has high fish fillet yield and less nutrient loss, and the produced fish fillet is white, translucent and delicious.

Owner:YIYANG YIHUA AQUATIC PRODS

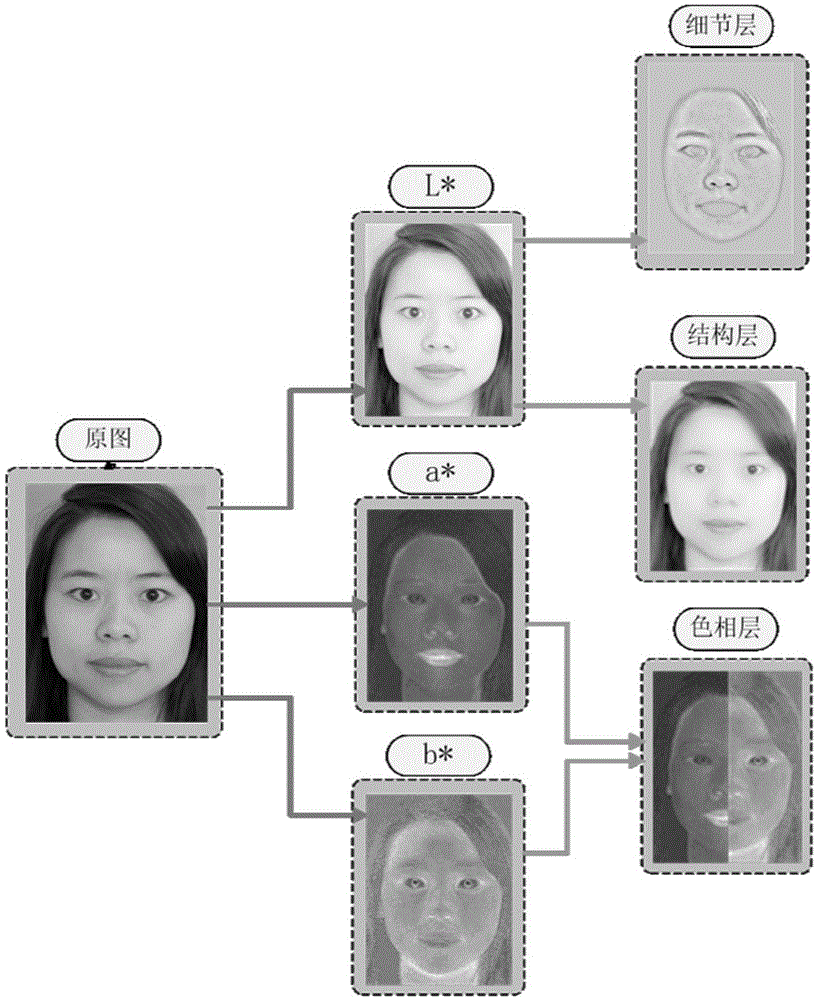

Facial image layer decomposition method based on improved guide filter

ActiveCN105469407ASmooth edgesSmall time complexityImage enhancementImage analysisPattern recognitionInformation layer

The invention provides a facial image layer decomposition method based on an improved guide filter, and the method comprises the steps: carries out the improved guide filtering of a facial image brightness channel, obtaining a human face structure information layer, further carrying out differential operation, and obtaining a texture detail layer. According to the invention, the method carries out the regularization factor adaptive adjustment optimization of a guide filter and Gaussian blurring and corrosion processing of a parameter matrix image, and obtains different filtering effects of a facial image in different regions. The method is used for a digital makeup system, obtains an excellent layer decomposition effect, and remarkably reduces the time complexity of layer decomposition.

Owner:SOUTH CHINA UNIV OF TECH

User-friendly bottle and closure thread assembly

The invention provides a threaded container closure assembly includes: a container neck having an opening; a closure for said neck, the closure having a base portion and a skirt portion; a first screw thread on the neck, said first screw thread comprising one or more first thread segments; a second screw thread on an inner surface of the skirt of the closure, said second screw thread comprising one or more second screw thread segments; said first and second screw threads being configured to enable a user to secure, remove and resecure the closure into a sealing position on the neck by rotation of the closure on the neck; and wherein said first thread segments are shorter than said second thread segments; and wherein the second thread segments are each made up of one or more radially spaced projecting portions, each said portion extending radially no more than about 60° around the closure skirt.

Owner:BEESON & SONS

Process for separating a product web into discrete products

ActiveUS20070044608A1Improve processing speedSmooth edgesLamination ancillary operationsLaminationEngineeringProcess engineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for forming circuit board without location holes

ActiveCN105338746ASimple forming methodFlat edgePrinted circuit manufactureMolding machineEngineering

The invention discloses a method for forming a circuit board without location holes. A circuit board to be processed with two technological edge is included, and each technological edge is provided with two location holes. The method comprises the following concrete steps: S1, carrying out a primary milling formation to prepare semi-finished product circuit boards A; S2, carrying out an electric test; S3, successively aligning the semi-finished product circuit boards A and overlapping the semi-finished product circuit boards A on the bench surface of a formation machine, one technological edge of the multiple semi-finished product circuit boards A is fixed by use of a positioning pin, and boring is performed at board edge positions of the multiple semi-finished product circuit boards A, and the semi-finished product circuit boards A are fixed by use of positioning pins; S4, carrying out secondary milling to prepare semi-finished product circuit boards B; S5, boring is performed at positions, close to board edges, of the semi-finished product circuit boards B after the technological edges are milled, and the semi-finished product circuit boards B are fixed by use of the positioning pins; S6, carrying out third-time milling to prepare a finished product circuit board; and S7, cleaning, and performing drying processing. According to the invention, milling formation is used for three times, a circuit board formation method is optimized, the board edge of the circuit board is enabled to be flat and smooth, splicing application is facilitated, the quality of the circuit board is improved, the production time is reduced, and the production efficiency is improved.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

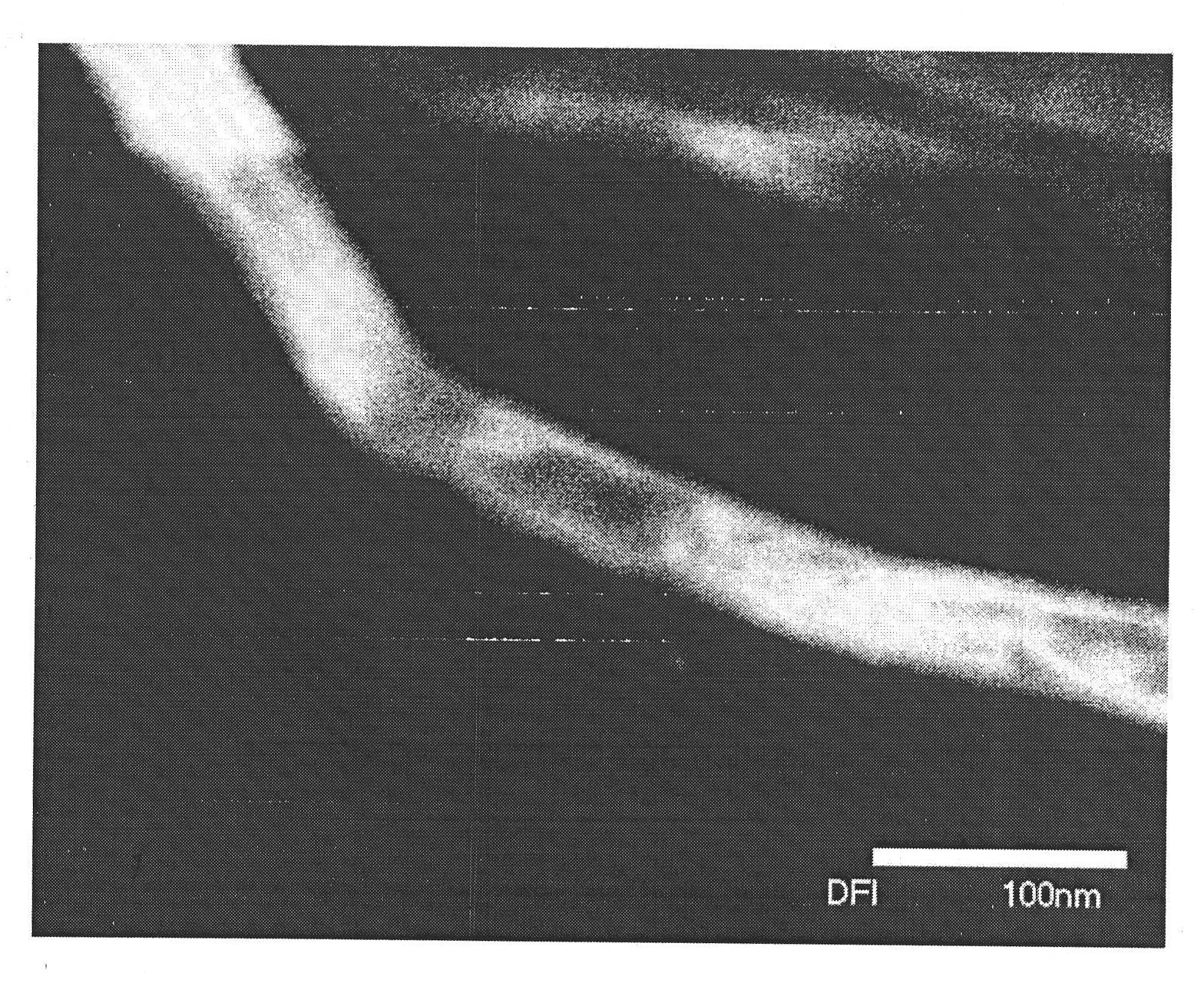

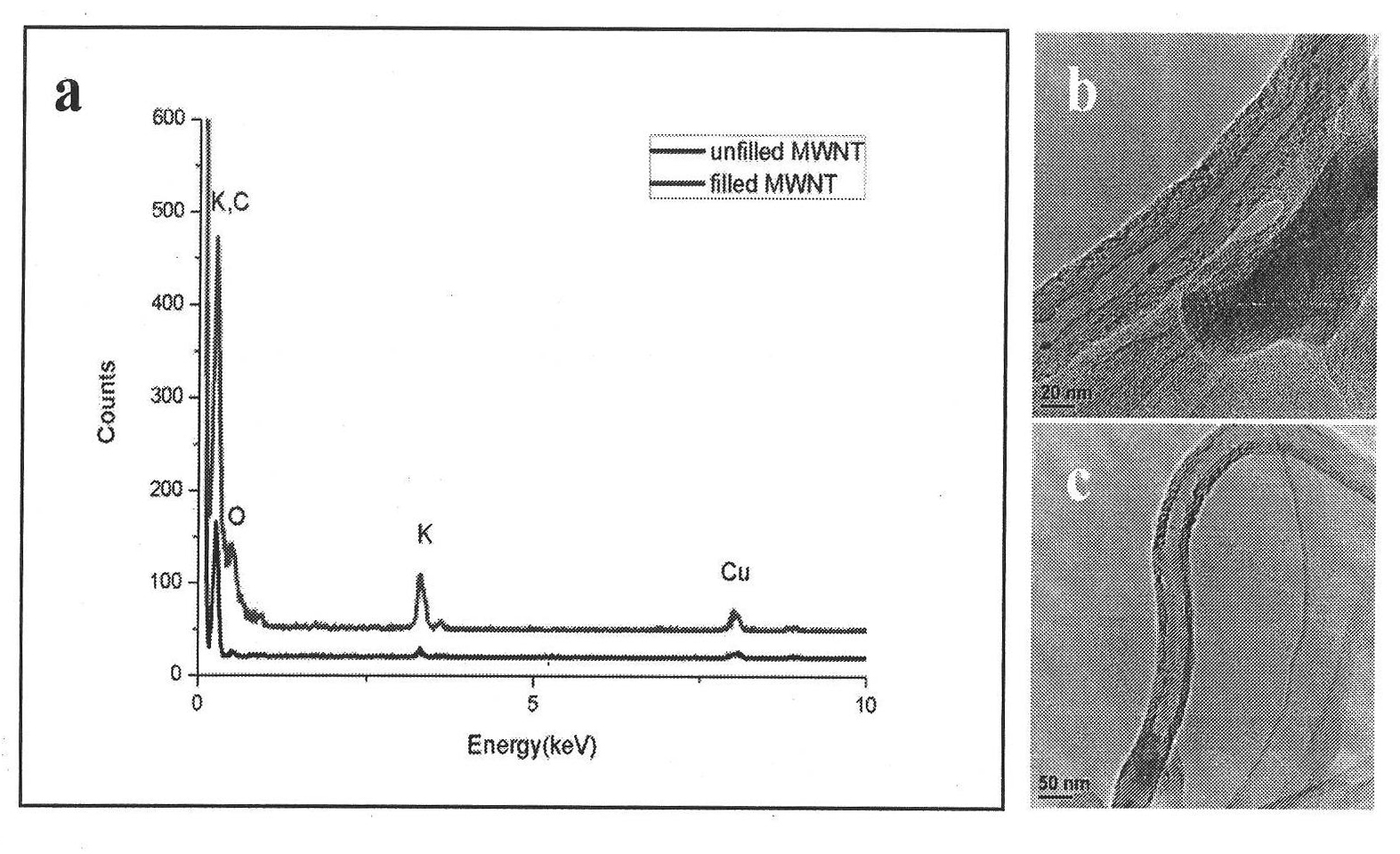

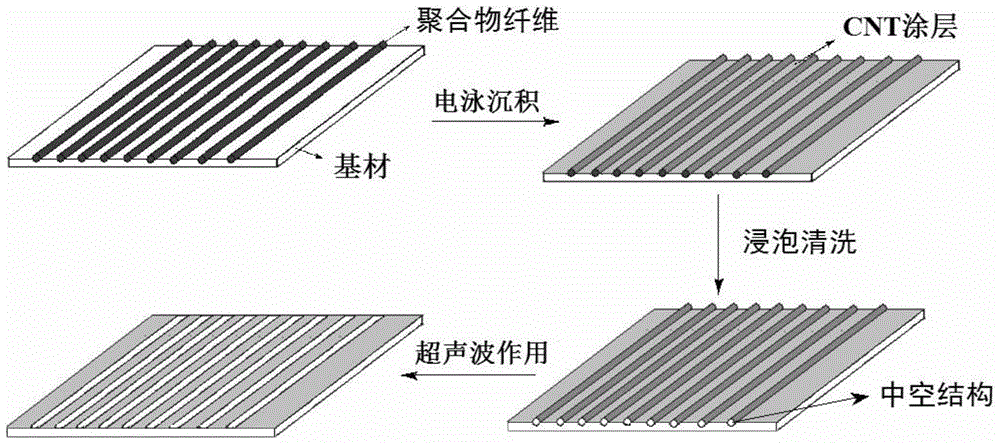

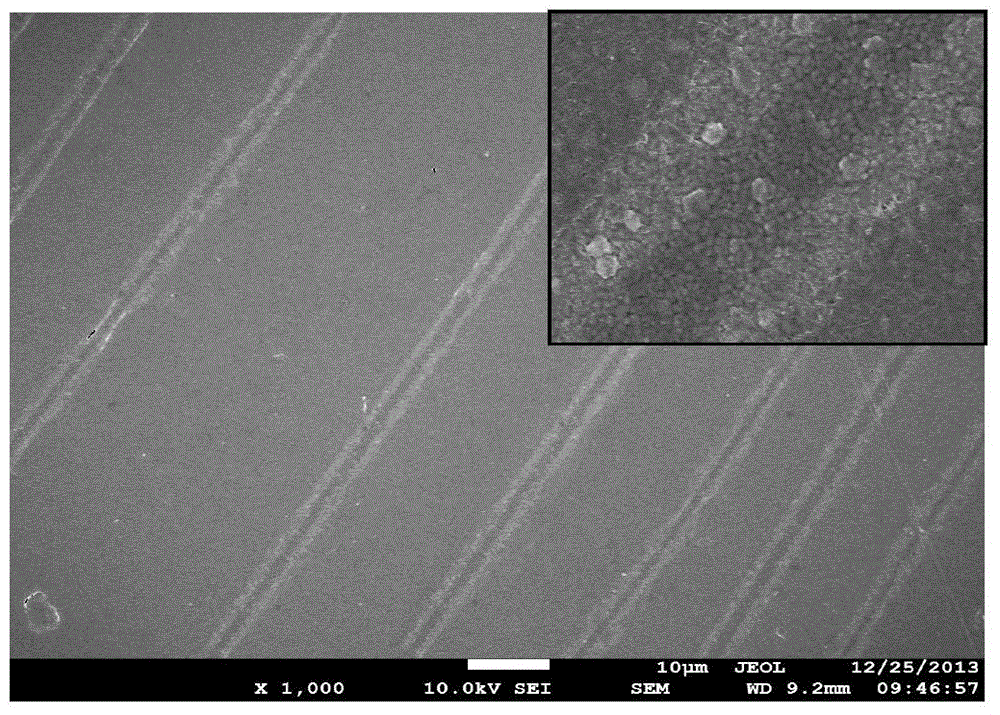

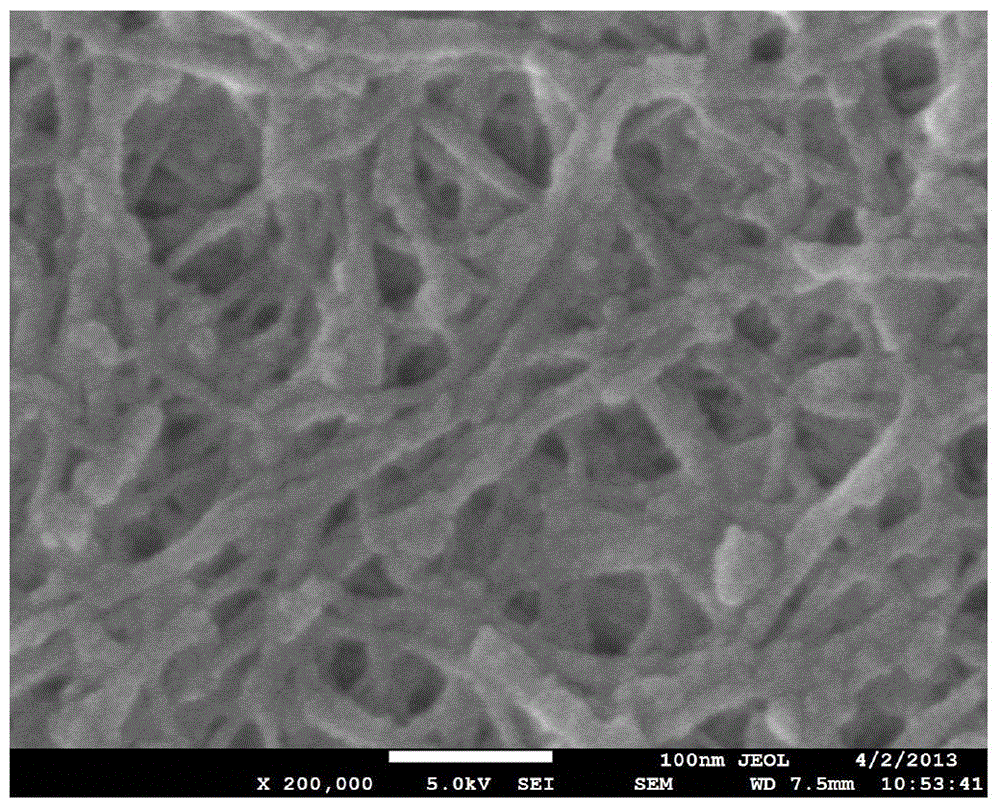

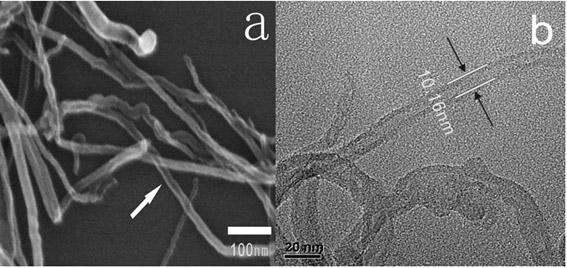

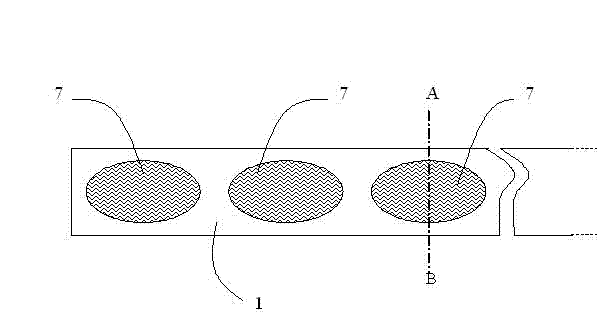

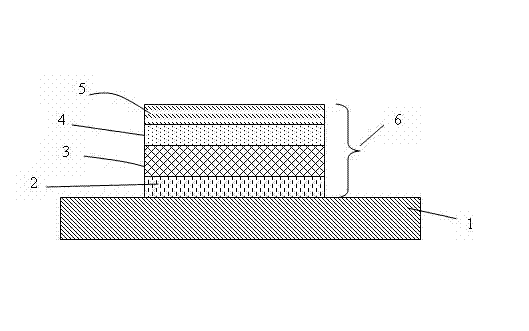

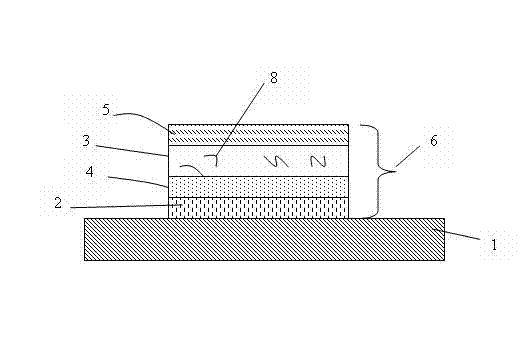

Nerve conduit material having topological structure and modified by CNT/conducting polymer composite coating and preparation method of nerve conduit material

The invention provides a nerve conduit material having a topological structure and modified by a CNT (Carbon Nano Tube) / conducting polymer composite coating and a preparation method of the nerve conduit material. With electro-spun polymer fibers as templates, CNTs are deposited on the surface of a substrate by use of an electrophoresis method so as to form a three-dimensional porous network CNT coating, next, solvent cleaning and ultrasonic stripping are carried out to form the CNT coating with a directional groove structure, then a conducting polymer is deposited by use of electro-chemical impulse polymerization, and the conducting polymer is coaxially wound around the surface of the CNT bundle to form the nerve conduit material modified by the CNT / conducting polymer composite coating having the directional groove structure. The surface of the nerve conduit material has two layers in the topological structure: at micrometer scale, the coating is provided with a patterned micrometer-scale groove for guiding the rearrangement of a neural cytoskeleton; at nanometer scale, the coating is provided with a nanometer-scale porous network structure for guaranteeing the physical conditions for the attachment and growth of nerve cells and excellent electrochemical properties of the nerve conduit.

Owner:NANJING NORMAL UNIVERSITY

Manufacturing method of strong twinkling aluminium pastes

ActiveCN101735671ASmooth surfaceNarrow particle size distributionPigment pastesPigment physical treatmentSurface finishingBall mill

The invention discloses a manufacturing method of strong twinkling aluminium pastes. The manufacturing method comprises the following steps: in a vertical stirring mill, adopting glass beads with the diameter being 1.0-5.0mm to serve as milling medium of a ball mill; mixing uniformly the ultrafine spherical aluminium powder with d50 being greater than 8mu m and less than 10mu m, organic solvent and dispersing agent according to the ratio of 20-50:80-200:1-5; ball milling for 20-50h under the rotating speed being 50-200rpm, discharging, filter pressing, introducing the filter liquor to the ball milling procedure for recycling; classifying through fine screening; filter pressing the screened material at each stage by the filter press; blowing dry and reusing; filter pressing and washing through; carrying out surface treatment on the filter cakes entering the mediating procedure; controlling the thickness of the aluminium particles to be 1-2mu m; and packaging to obtain the finished products.

Owner:长沙族兴新材料股份有限公司

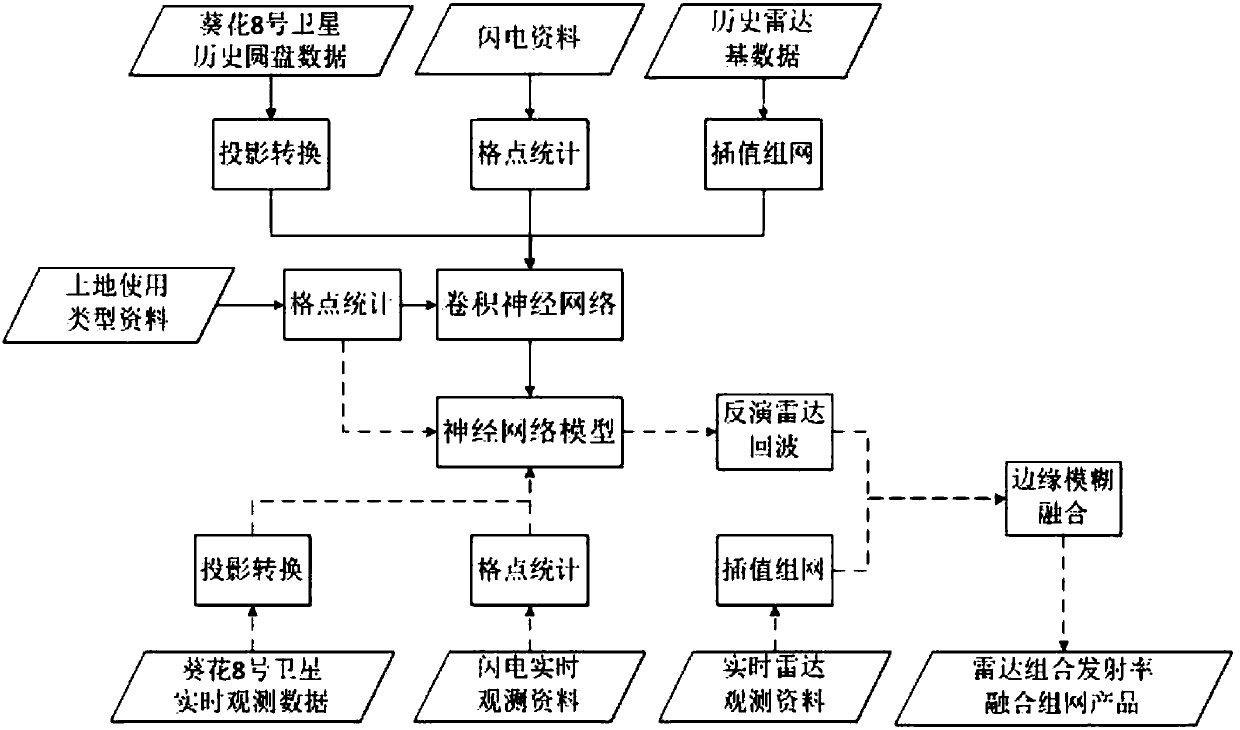

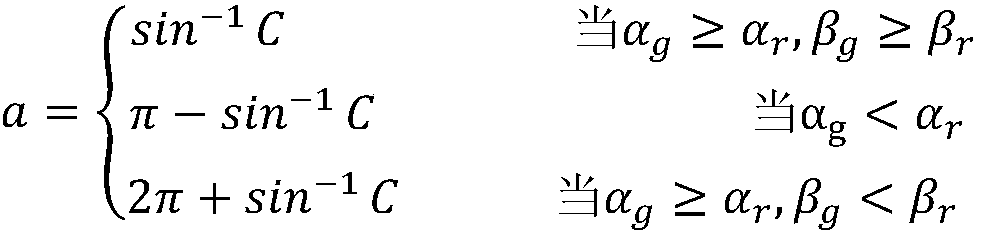

Satellite radar inversion fusion method based on NRIET machine learning

ActiveCN108445464AFill in unobservable areasImprove accuracyWave based measurement systemsNeural architecturesSatellite dataEmissivity

The invention discloses a satellite radar inversion fusion method based on NRIET machine learning. The method comprises a training phase and an inversion phase. The training phase includes satellite data and processing: subjecting the disc projection data of four waveband including B08, B10, B13 and B15 of a sunflower No. 8 geostationary satellite to projection conversion and interpolating the same to a spatial grid point of 0.02*0.02 degree; lightning data and processing; radar data and radar data networking; land use type data and processing; and model training. The inversion phase includes:data preprocessing: subjecting the sunflower No. 8 geostationary satellite data obtained by real-time observation and the lightning data to the same processing as the training phase, the land use type data using the data processed in the training phase; the radar data networking: subjecting the radar-base data observed in real time to networking according to the networking steps in the training phase to calculate the combined emissivity; radar echo inversion; and satellite radar data fusion.

Owner:NANJING NRIET IND CORP

Method of separating non-metallic material using microwave radiation

InactiveUS20090078370A1Improve cut qualityEasy to adaptGlass severing apparatusAdhesivesHost materialMetallic materials

A method of high speed cutting of non-metallic materials (14), preferably glass, is described. In the inventive method a concentrated microwave radiation (1) with appropriate frequency and power density is chosen so as to accomplish heating of at least one selected area (2) of the body at the required separating propagation path (3) to required temperature in a selected short time while ensuring that this temperature is large enough to create a thermal stress (6) through the thickness of the selected area that results in the separating of the body material.

Owner:GYROTRON TECH

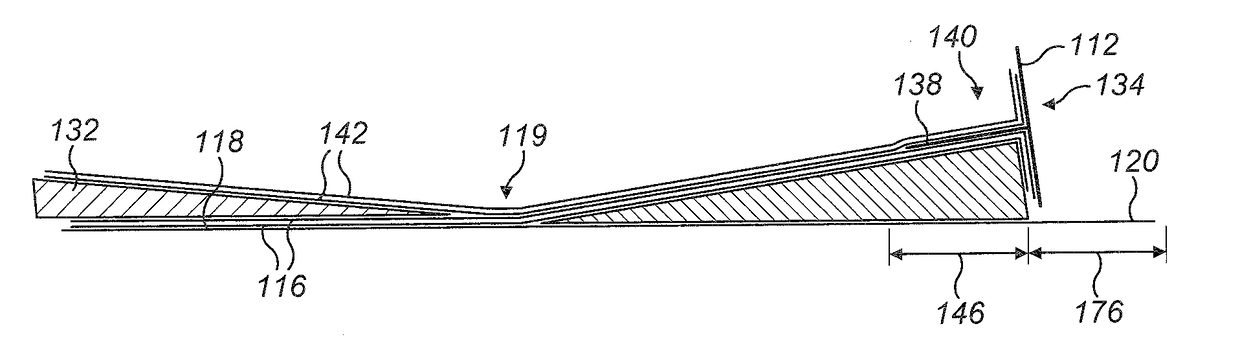

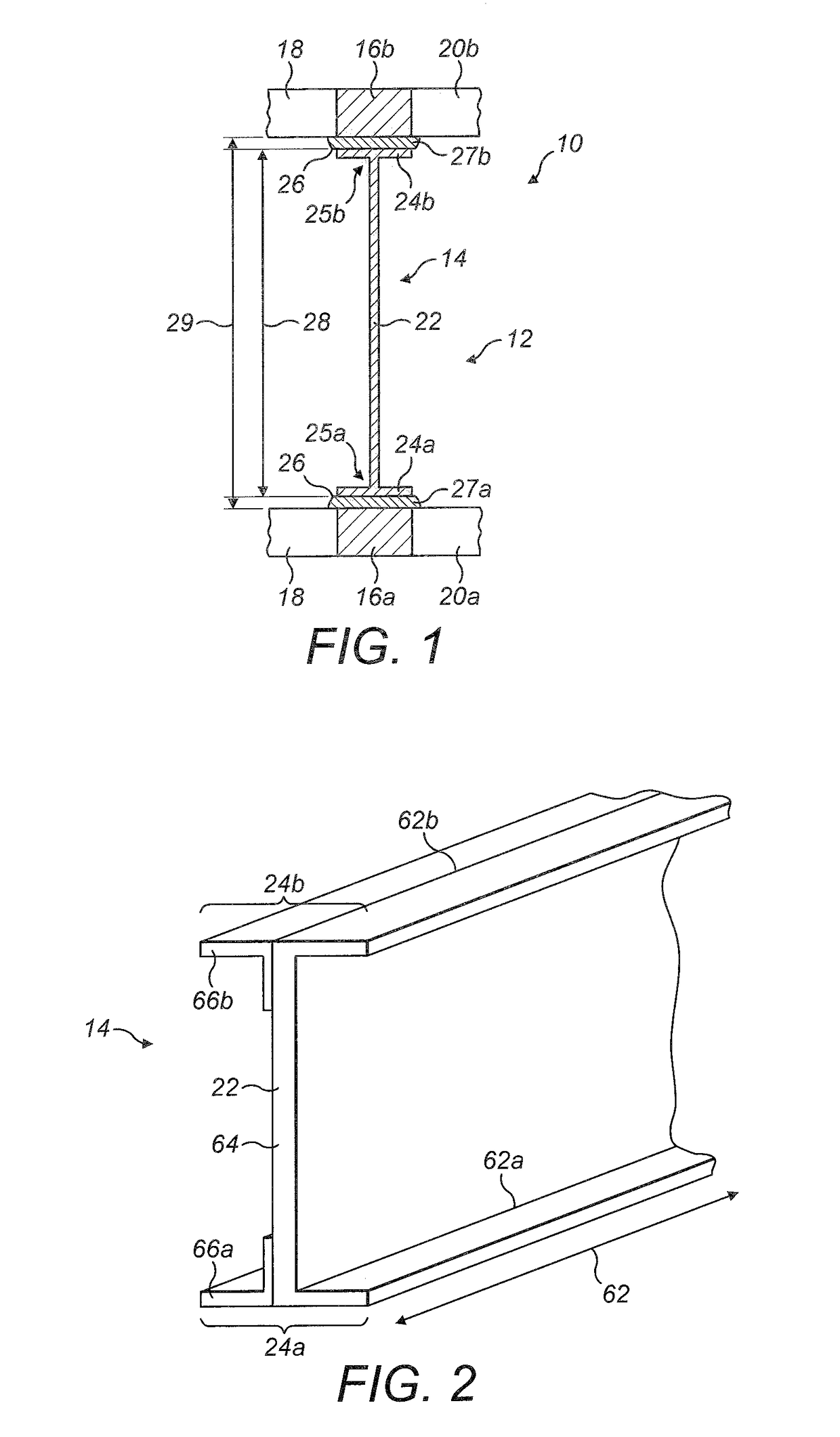

Reinforcing structure for a wind turbine blade

ActiveUS20180283349A1Few process stepsReduces factory footprintFinal product manufactureMachines/enginesTurbine bladeWind force

A method of making an elongate reinforcing structure, such as a shear web, for a wind turbine blade is described. The reinforcing structure comprises a longitudinally-extending web and a longitudinally-extending flange. The flange extends along a longitudinal edge of the web and is arranged transversely to the web. The method involves providing a flange structure comprising a flange portion, and a projecting portion that extends along the length of the flange portion and projects transversely from a surface of the flange portion. The projecting portion is bonded between laminate layers of the web. The flange structure is preferably a pultruded component having a T-shaped cross-section. The method allows a simple, inexpensive and reconfigurable mould tool to be used. In preferred embodiments the mould tool has a flat surface without sidewalls.

Owner:VESTAS WIND SYST AS

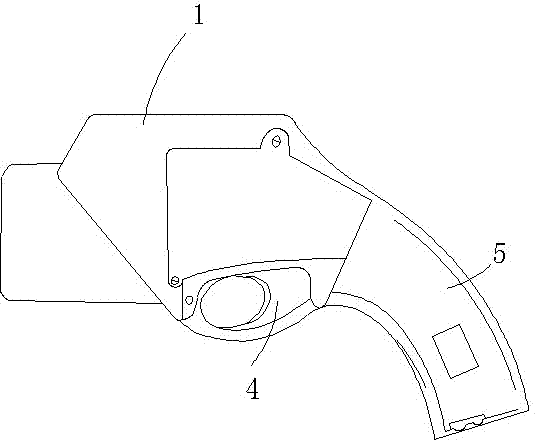

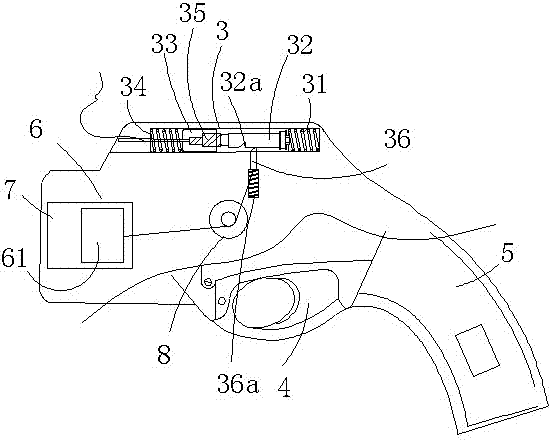

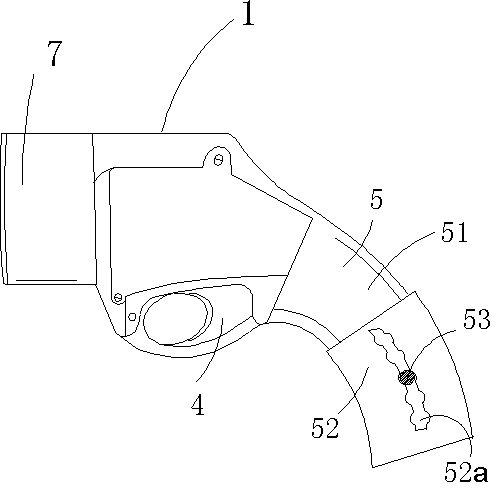

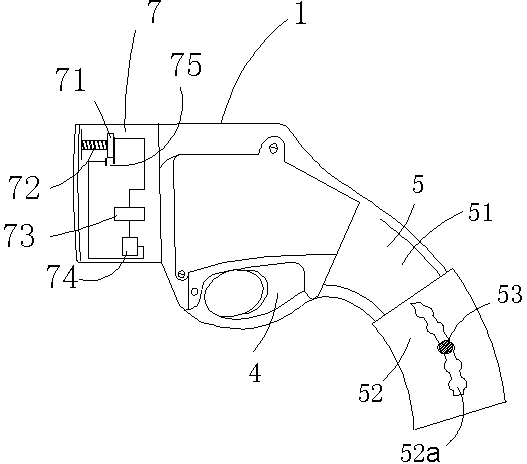

Magneto-electric induction type cattle left displaced abomasum repositor

The invention discloses a magneto-electric induction type cattle left displaced abomasum repositor. The magneto-electric induction type cattle left displaced abomasum repositor comprises a repositor needle transmitting device and a repositor needle with a thread binding hole, wherein the outer edge of the repositor needle transmitting device is round and smooth and comprises a transmitting tube, a catapulting part and a magneto-electric induction device, the repositor needle is a straight needle, the rear end of the repositor needle is arranged in the catapulting part, the rest of the repositor needle is arranged in the transmitting tube, the catapulting part comprises a hitting head provided with a position clamping shoulder, the repositor needle transmitting device is further provided with a limiting device capable of being clamped to the position clamping shoulder, the magneto-electric device comprises an electromagnet which is arranged in a sliding mode, and the electromagnet is in linkage match with the limiting device. Due to the magneto-electric induction type cattle left displaced abomasum repositor, an operation can be simplified, an opening is only formed in one side, the survival rate of a serious-disease cattle is improved, the repositor needle can be conveyed to a target position conveniently and effectively protected, the accident that the viscera is punctured by the repositor needle is reduced, magneto-electric induction automatic positioning is achieved, an assistant does not need to give assistance from the right side, and one person can complete the cattle left displaced abomasum operation.

Owner:广州市九星生物科技有限公司

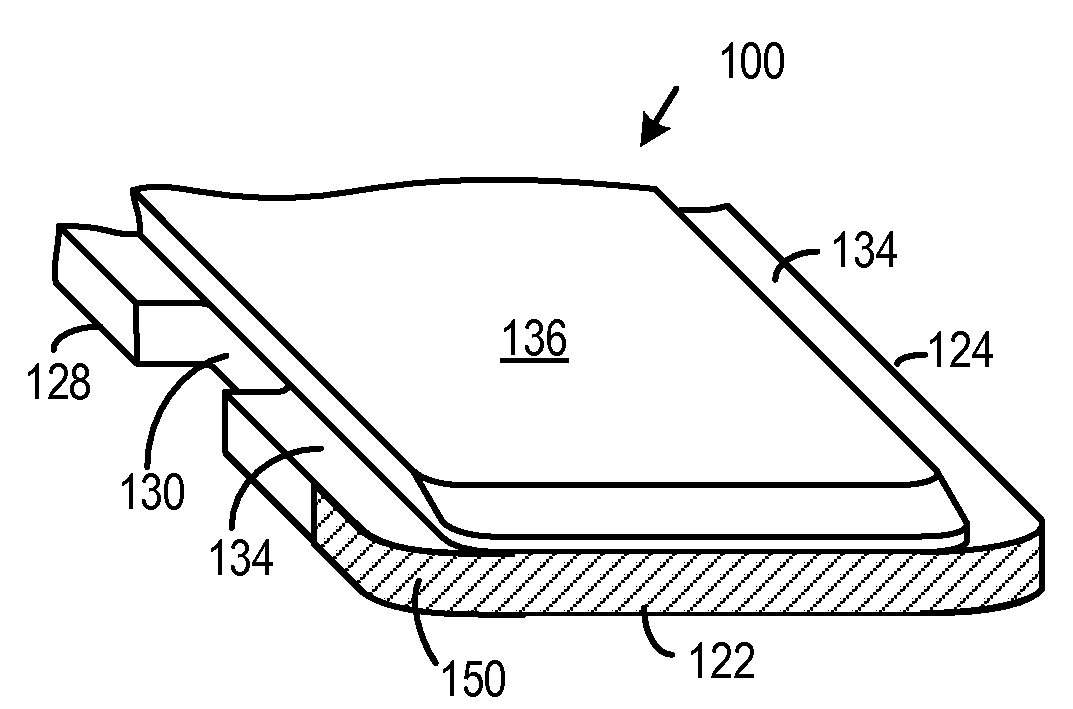

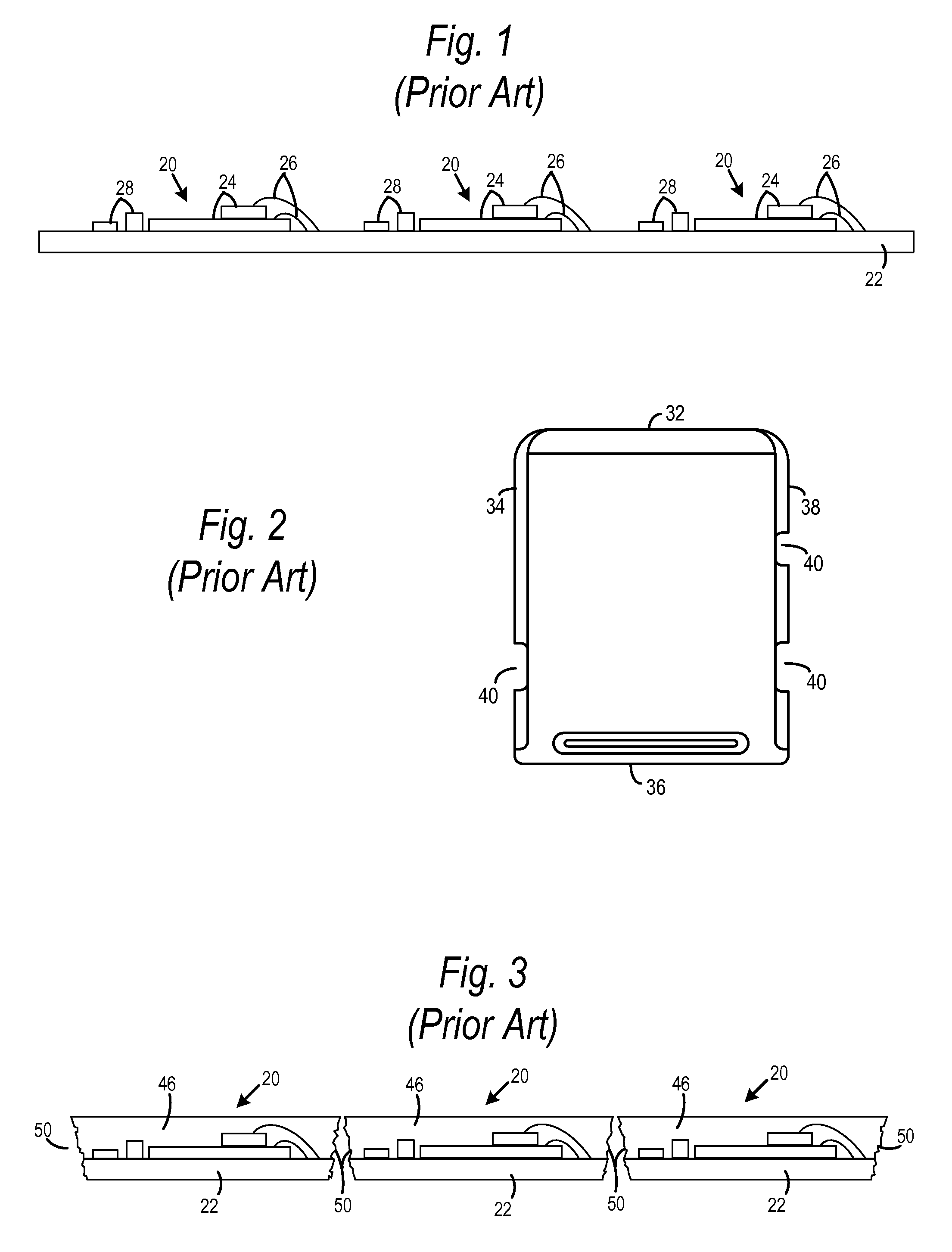

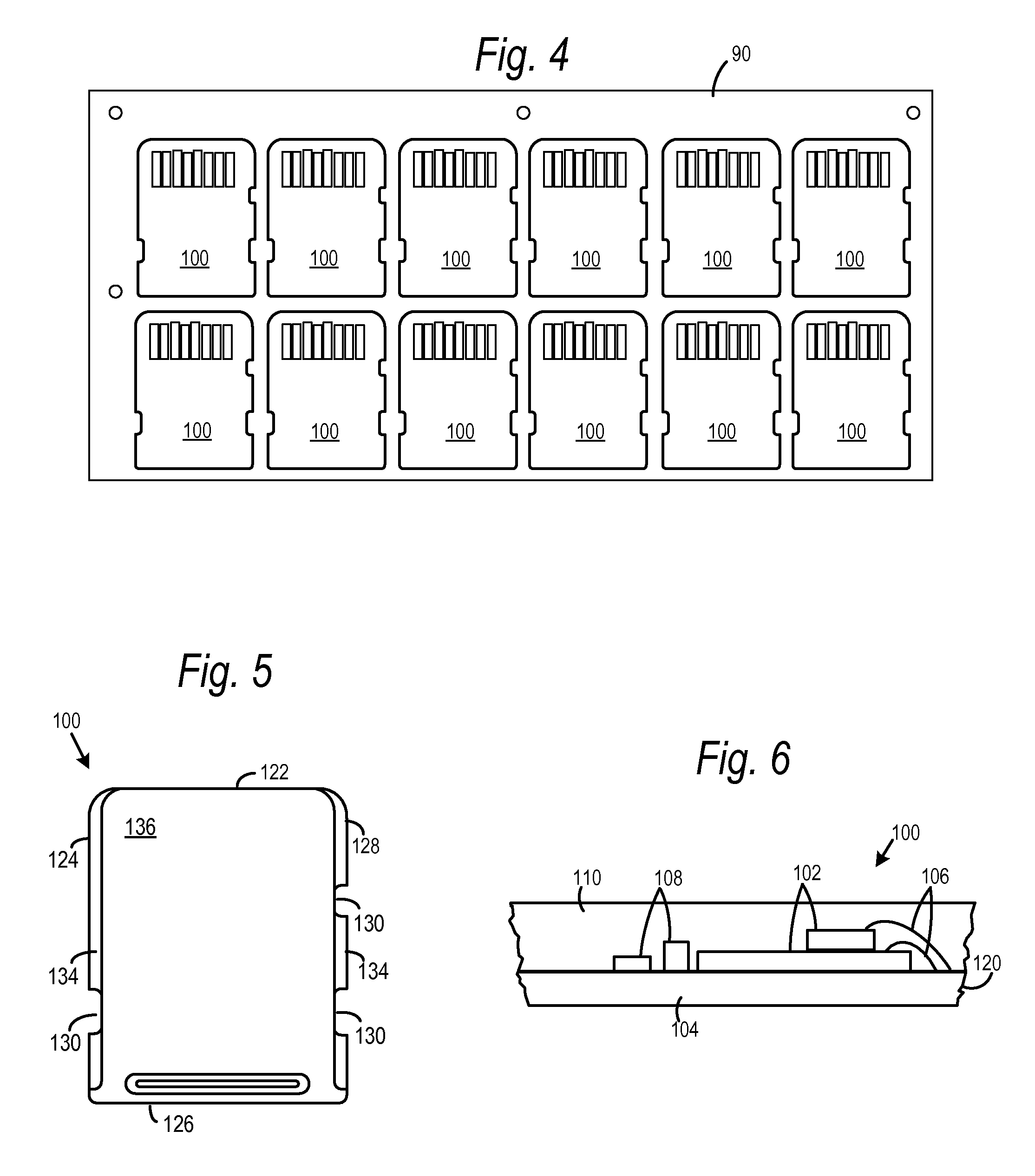

Method of reducing memory card edge roughness by edge coating

InactiveUS20090085232A1Smooth edgesSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A method of forming a semiconductor package with smooth edges, and a semiconductor package formed thereby is disclosed. In embodiments, after encapsulation, the semiconductor packages may be at least partially singulated from the panel by making one or more cuts through the panel to define one or more edges of the semiconductor package. The one or more edges may be smoothed by applying a laminate to the edges. The edges receiving the laminate may include any edge between a top and bottom surface of the package.

Owner:SANDISK TECH LLC

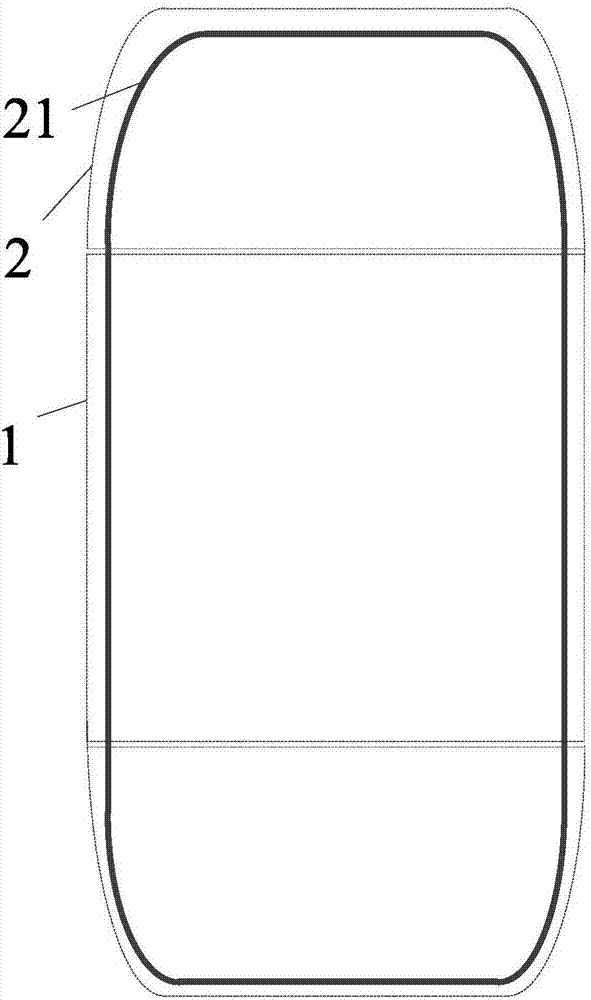

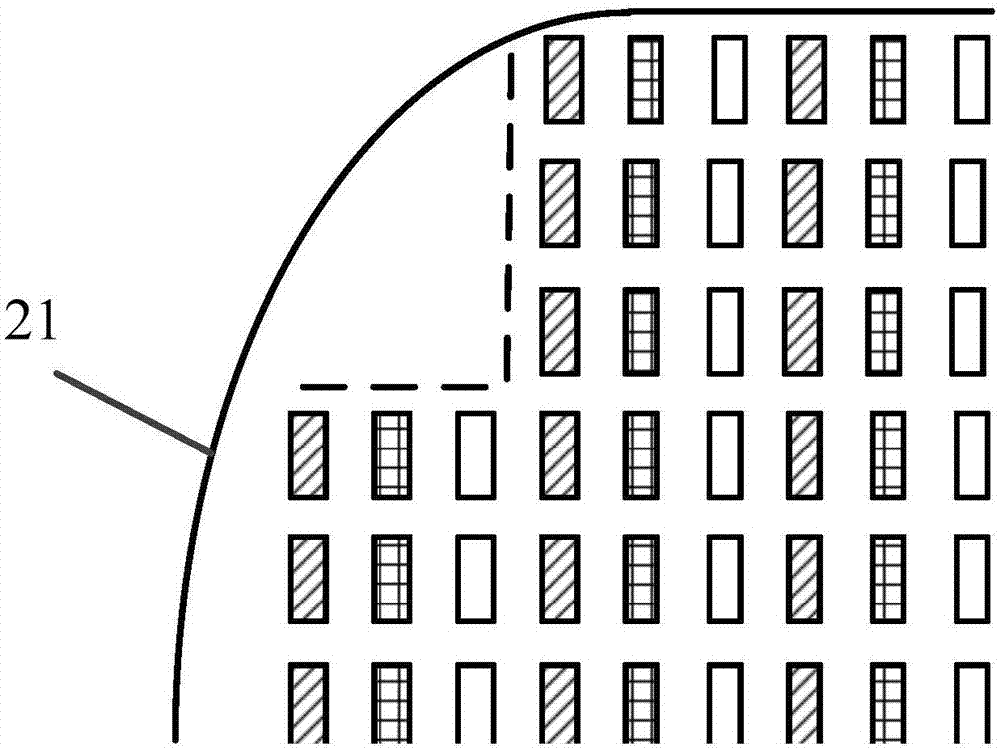

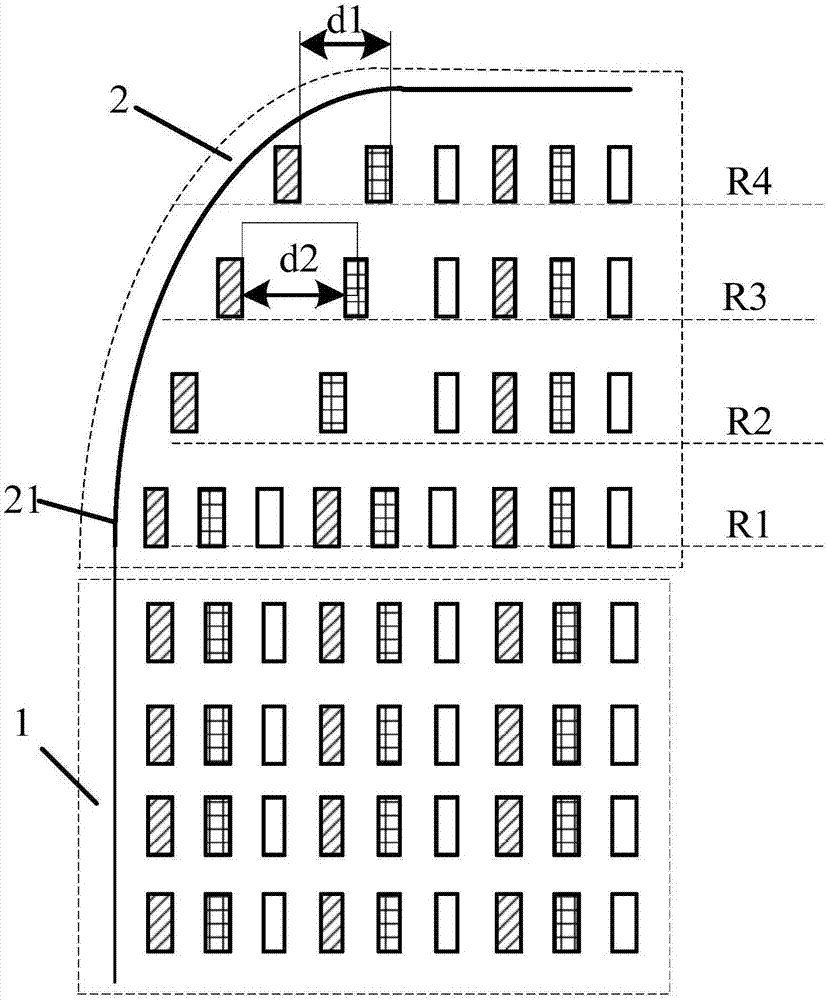

Special-shaped display panel and display device

ActiveCN107886850ASmooth edgesImprove aliasingStatic indicating devicesIdentification meansDisplay deviceComputer vision

The invention provides a special-shaped display panel and a display device, and relates to the technical field of displaying. The technical purpose is to avoid the sawtooth phenomenon occurring in edges of the display panel. The special-shaped display panel is provided with subsidiary pixel arrays. At least two adjacent rows of subsidiary pixels exist in the subsidiary pixel arrays of a special-shaped display area of the special-shaped display panel, and two subsidiary pixels in the same side edge of the two adjacent rows of subsidiary pixels are staggered in the line direction, wherein the distance of at least two adjacent subsidiary pixels in one row of subsidiary pixels is different from that of at least two adjacent subsidiary pixels in the other row of subsidiary pixels; and / or, in the special-shaped display area, the two subsidiary pixels located at the same side edge of at least two adjacent lines of subsidiary pixels in the subsidiary pixel arrays are staggered in the row direction, and in the two adjacent lines of subsidiary pixels, the distance of at least two adjacent subsidiary pixels in one line of subsidiary pixels is different from that of at least two adjacent subsidiary pixels in the other line of subsidiary pixels. The special-shaped display panel and the display device are mainly used for picture displaying.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

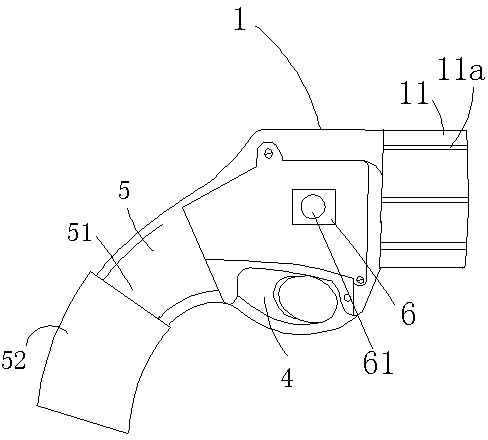

Left abomasal displacement operative reduction apparatus for cattle

InactiveCN103690268AWon't scratchIncreased surgical distanceSurgical veterinaryAbdominal wallOperative instrument

The invention discloses a left abomasal displacement operative reduction apparatus for cattle. The left abomasal displacement operative reduction apparatus is applied to the field of animal medicine and is an operative instrument for treating left abomasal displacement for the cattle. The operative reduction apparatus comprises a reduction needle transmitting device and reduction needles with line binding holes. The reduction needle transmitting device comprises three transmitting tubes and a sensing positioning device. The left abomasal displacement operative reduction apparatus has the advantages that abomasal fixing lines can be accurately, efficiently and stably conveyed to target positions on the right sides of abomasal walls of the ill cattle without opening the right sides of the abomasal walls of the cattle; the probability of injury to the cattle due to reduction needle conveying errors can be eliminated; the conveying distances of the reduction needles can be increased owing to a retractable handle, so that the abomasa of the cattle with different body sizes can be assuredly reduced to perfect positions; potential risks caused after the reduction needles penetrate the abomasal wall of the cattle and fly out can be prevented; only one operative person is required for performing left abomasal displacement on the cattle by the aid of the operative reduction apparatus and can independently complete operation without assistants.

Owner:王侨侨 +4

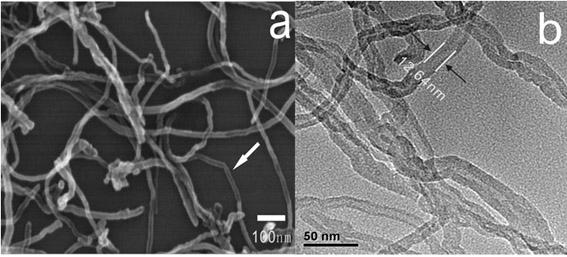

Method for preparing grapheme nano belts by etching carbon nano tubes through water vapor

InactiveCN102616770AQuality improvementHigh yieldGrapheneNanotechnologyWater vaporGraphene nanoribbons

The invention discloses a method for preparing grapheme nano belts by etching carbon nano tubes through water vapor. The method comprises the steps of putting multi-wall carbon nano tubes into a polyfluortetraethylene inner liner, adding a certain amount of distilled water into the inner liner, vibrating to ensure that the nano tubes are uniformly dispersed, then putting the polyfluortetraethylene inner liner into a reaction kettle, heating to 150 to 225 DEG C, keeping constant temperature for 5 to 20 h, so as to ensure that the multi-wall carbon nano tubes are longitudinally cracked to form high-quality grapheme nano belts. The grapheme nano belts prepared through the method have the advantages of less folds, uneasiness in aggregation, controllable number of layers, high yield and the like, at the same time, the preparation process is simple and easy to operate and can be accomplished at one step, a surface active agent is not required to be adopted for dispersing, and the process ispollution-free and environmental-friendly. The method overcomes the disadvantages of complex process, severe pollution, low yield and the like during the grapheme preparation through other methods.

Owner:FUZHOU UNIV

Self adhesive label and special film thereof

InactiveCN102163386ALow costPromote environmental protection and low carbonStampsLayered productsEngineeringRough surface

The invention provides a self adhesive label and a special film thereof. The self adhesive label is composed of a baseband layer and a transfer layer, wherein, the transfer layer comprises a disengaging layer, a paper / film layer, a printing information layer and a hot melt adhesive layer. The transfer layer undergoes die cutting and is discharged waste to become label units separated from each other. The self adhesive label and special film thereof solve the disadvantages that the base paper, the face material and the adhesive layer of the self adhesive label are thick, the self adhesive label is convenient to uncover, the formula needs to be adjusted in accordance with the season climates and the release force needs to be adjusted in accordance with the thickness of material; and solve the disadvantages that the thermal transfer label can not be used as a product sealing label, and is not suitable for using on uneven rough surfaces; and the special film of the self adhesive label is convenient for users to produce self adhesive label.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

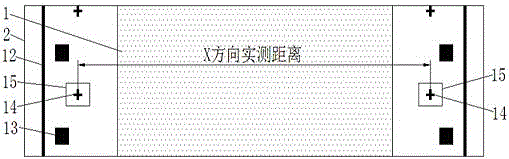

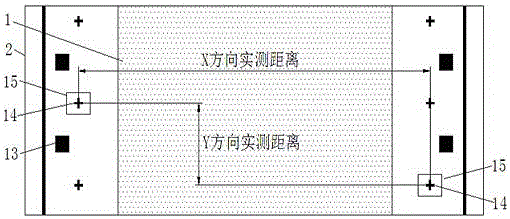

Laser production technology for radio frequency identification antenna capable of easily discharging waste

ActiveCN105789869ASolve the problem of waste dischargeGood waste discharge effectRadiating elements structural formsLaser beam welding apparatusAntenna designTime transformation

The invention discloses a laser production technology for a radio frequency identification antenna capable of easily discharging waste. In the laser production technology for the radio frequency identification antenna, changes of positions and dimensions of positioning marks at two sides of a radio frequency antenna substrate in X and Y directions are detected; real-time transformation is carried out on the shape, the dimension, the position and the angle of an engraved pattern through an adaptive algorithm according to the materials, the thicknesses, the composite temperatures, the environment temperatures and the humidities of a used metal film and the antenna substrate and the antenna design pattern and composition condition; meanwhile, laser engraving is compensated according to the monitored working temperature in a laser scanning system; and the influence of a temperature drift of the laser scanning system on the dimension and the position of the engraved pattern is reduced, so that the error of the system for overlapping positioning of the engraved pattern and a printed pattern is controlled within 20 microns or to be smaller than 1 / 2 laser spot size; the waste discharge technology is relatively easy to implement; the key problems of pattern positioning and edge tracking in the industrial process of the laser production technology for the radio frequency identification antenna are solved; and the industrialization process of the laser antenna production technology is pushed.

Owner:SUZHOU ZUENS IOT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com