Patents

Literature

376 results about "Fish fillet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fish fillet, from the French word filet ([filɛ]) meaning a thread or strip, is the flesh of a fish which has been cut or sliced away from the bone by cutting lengthwise along one side of the fish parallel to the backbone. In preparation for filleting, any scales on the fish should be removed. The contents of the stomach also need careful detaching from the fillet. Because fish fillets do not contain the larger bones running along the vertebrae, they are often said to be "boneless". However, some species, such as the common carp, have smaller intramuscular bones called pins within the fillet. The skin present on one side may or may not be stripped from the fillet. Butterfly fillets can be produced by cutting the fillets on each side in such a way that they are held together by the flesh and skin of the belly.

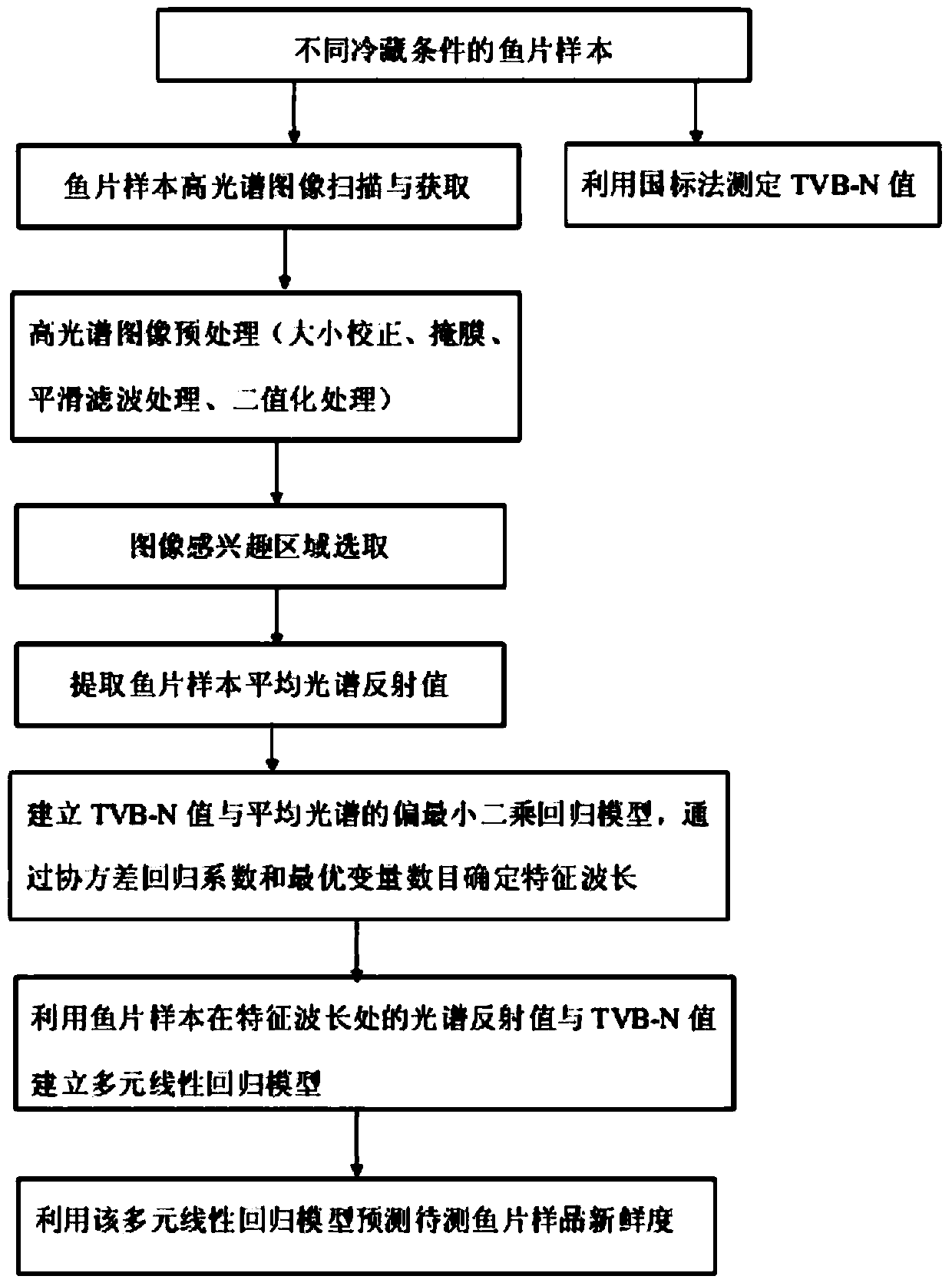

Fish fillet freshness detection method based on hyperspectral imaging

ActiveCN103439285AFast online detectionGuarantee quality and safetyColor/spectral properties measurementsNational standardFish fillet

The invention discloses a fish fillet freshness detection method based on hyperspectral imaging. The method comprises the following steps: measuring fish fillet samples stored for different days according to a traditional national standard method; scanning the hyperspectral information of the corresponding fish fillet samples by utilizing a hyperspectral imaging system, and preprocessing a hyperspectral image; establishing a regression equation between a freshness index TVB-N value and the fish fillet freshness with hyperspectral characteristic wavelength, detecting the fish fillet samples to be detected, and calculating the freshness of the fish fillet samples to be detected. The optimal wavelength is selected and the freshness of the fish fillet samples are rapidly and nondestructively detected by employing the hyperspectral imaging technology, the time required for a traditional method is obviously reduced, the detection efficiency is improved, and the purpose of rapid, nondestructive and online detection can be effectively fulfilled.

Owner:SOUTH CHINA UNIV OF TECH

Frozen tilapia mossambica slice and its processing method

InactiveCN1935029AImprove water holding capacityReduce denaturationMeat/fish preservation by freezing/coolingFood preparationTilapiaAquatic product

The present invention discloses a kind of frozen tilapia mossambica fish fillets containing freezing protective agent trehalose and its processing method. Said processing method includes the following steps: making the tilapia mossambica fish undergo the processes of cleaning dressing, boning, skinning and filleting treatments, then adding protective agent to treat fish fillets, taking out said fish fillets, draining to remove excess solution and freezing below-18 deg.C so as to obtain the invented frozen tilapia mossambica fish fillets. The described protective agent is an aqueous solution containing trehalose, glycine and sodium chloride.

Owner:南宁中诺生物工程有限责任公司 +2

Channel catfish ictalurus punctatus deepfreezed fillets and processing technique

InactiveCN101032337AIncrease incomeGreat tasteMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsLeiocassis longirostrisIce water

The present invention discloses one kind of fast frozen white delicious fish fillet of spotted forked-tail Leiocassis longirostris and its production process. The production process includes the steps of temporarily raising, killing to eliminate blood, slicing, eliminating skin, trimming, soaking to sterilize, loading into tray and quick freezing, grading, coating with ice, packing, etc. The production process features complete elimination of blood, low temperature of fish fillet in icy water at 0-4 deg.c, soaking fish fillet in ozone icy water and ultralow temperature quick freezing at below -35 deg.c. The production process has high fish fillet yield and less nutrient loss, and the produced fish fillet is white, translucent and delicious.

Owner:YIYANG YIHUA AQUATIC PRODS

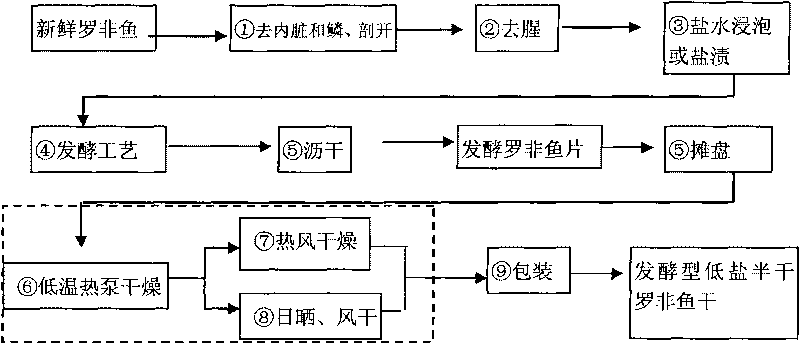

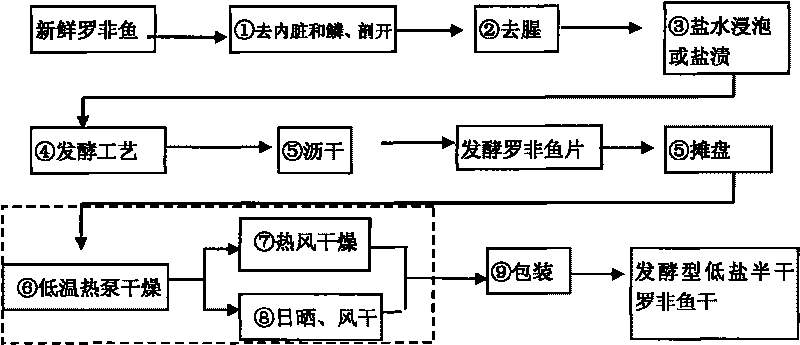

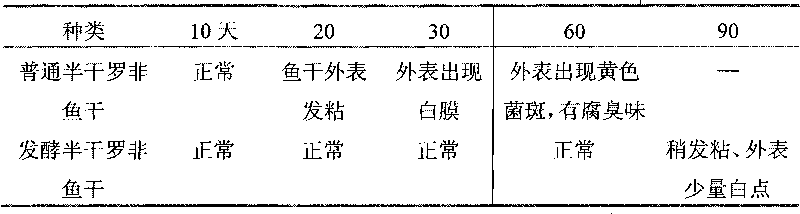

Fermented low-salt semi-dried tilapia mossambica, processing method thereof and application thereof

InactiveCN101744316AAchieving Controlled FermentationPromote dissolutionFood preparationSaline waterFlavor

The invention discloses a fermented low-salt semi-dried tilapia mossambica, a processing method thereof and application thereof. The processing method comprises the steps of: removing the internal organs and the scales of the tilapia mossambica; cutting along backside or abdomen; overturning; flatly pressing to form a symmetrical tilapia mossambica piece except the tail of the tilapia mossambica;washing with cleaning water; washing with salt water with 1%-4% of concentration to remove fishy smell and obtain the tilapia mossambica piece without the fishy smell; paving salt on the surface of the tilapia mossambica piece without the fishy smell, wherein the weight of the salt is equal to 3-8% of that of the tilapia mossambica; sousing for 8-24 hours; drying; or soaking for 8-24 hours with 5-10% of salt water to obtain the low-salt tilapia mossambica piece; spraying zymophyte on the surface of the tilapia mossambica piece, wherein the inoculum size of the zymophyte is 105-107 CFU / g fish meat; fermenting for 10-48 hours in a sealing way under the temperature of 12-20 DEG C; and drying the fermented tilapia mossambica piece to obtain the fermented low-salt semi-dried tilapia mossambicawith 30-60% of water content. The product has lubricating meat quality and typical flavor of dried meat. The processing method can be adapted to processing freshwater fishes.

Owner:汕尾市利群农业食品有限公司

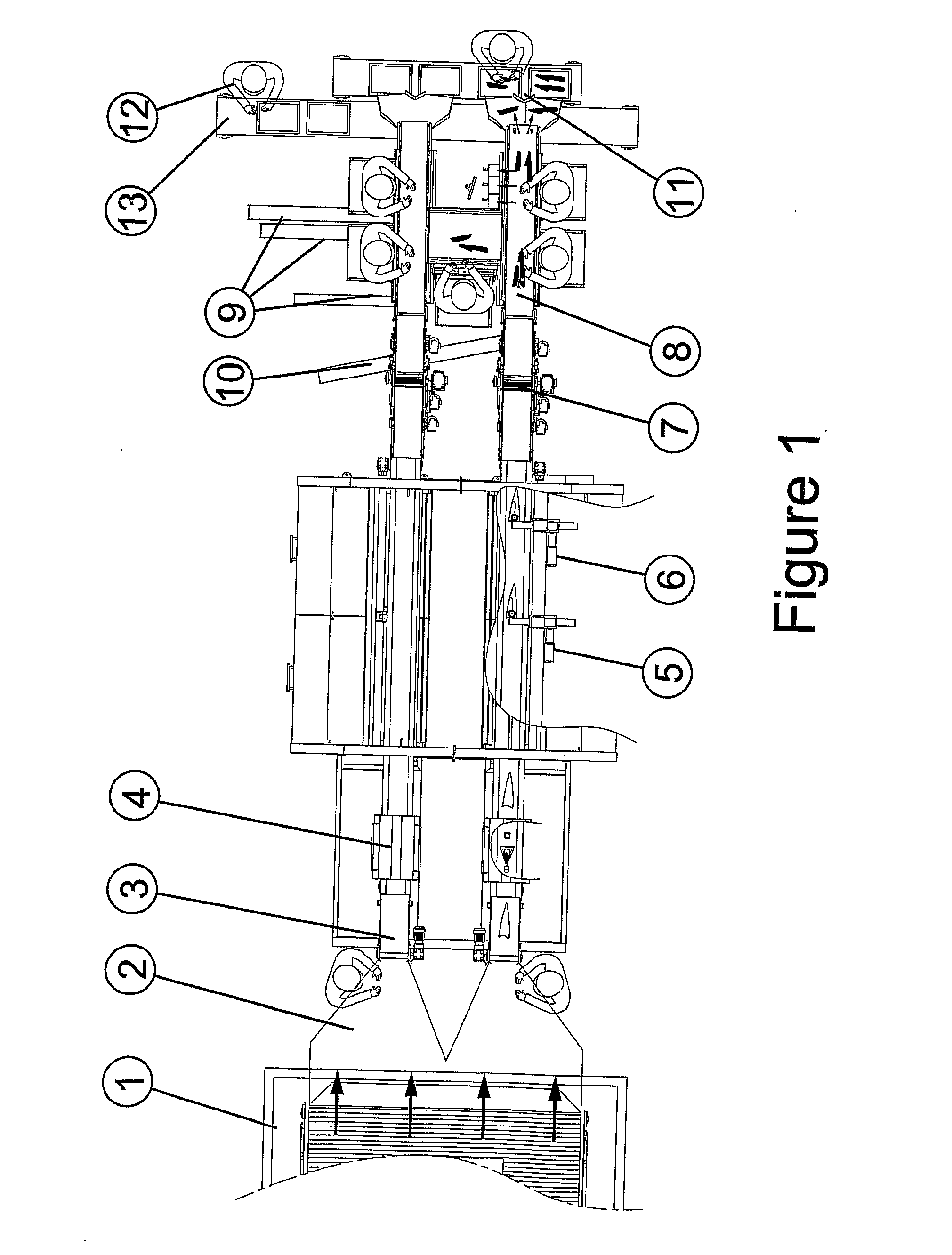

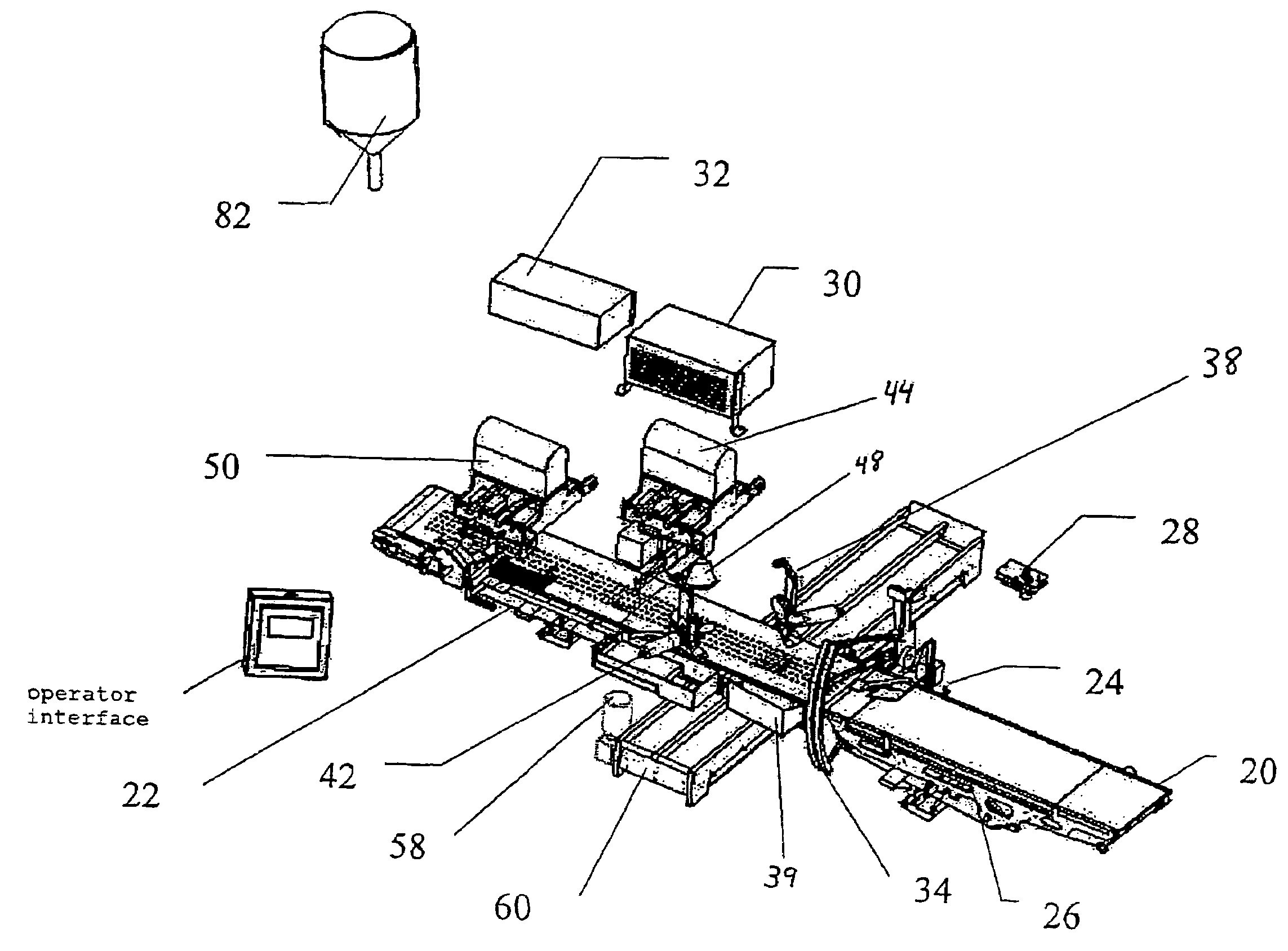

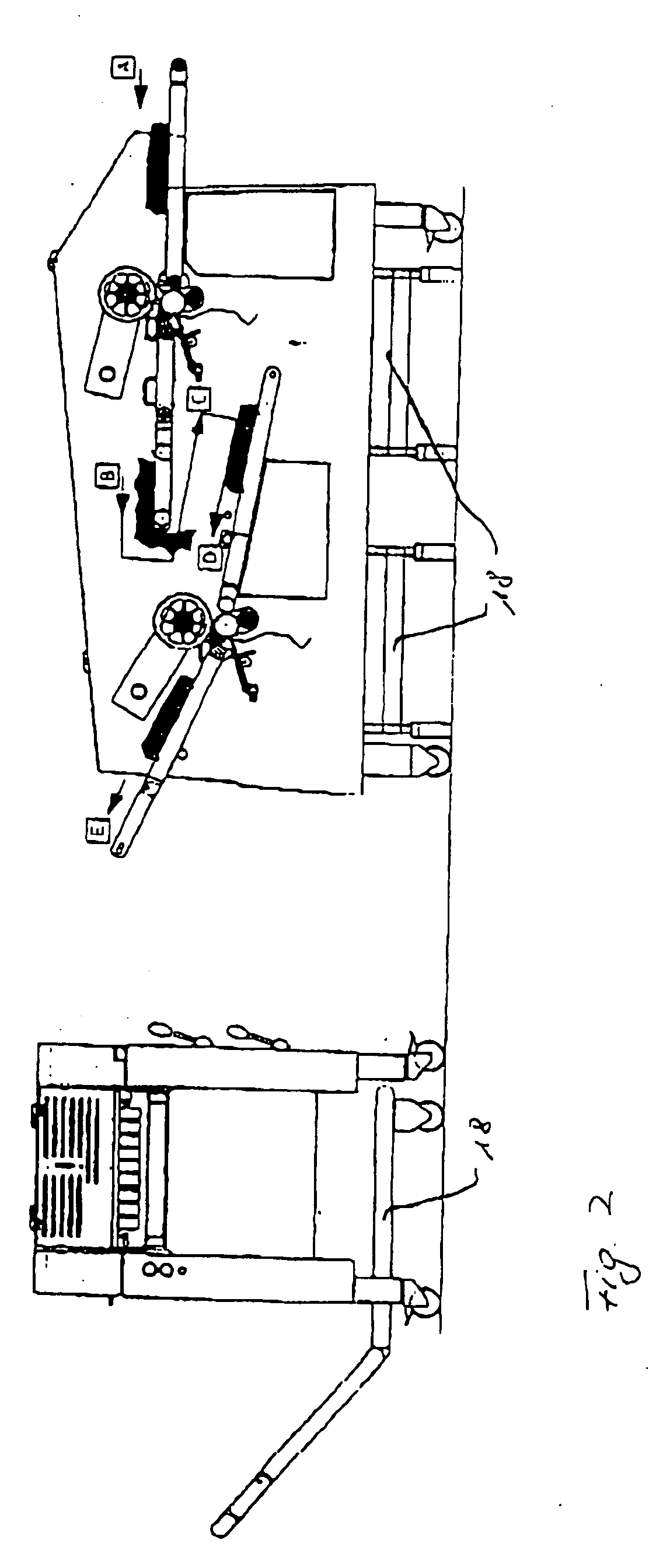

Method and an Apparatus for Automatic Bone Removal

ActiveUS20070293132A1Improve efficiencyIncrease valueMeat processing plantsPoultry processingDigital imagingFish fillet

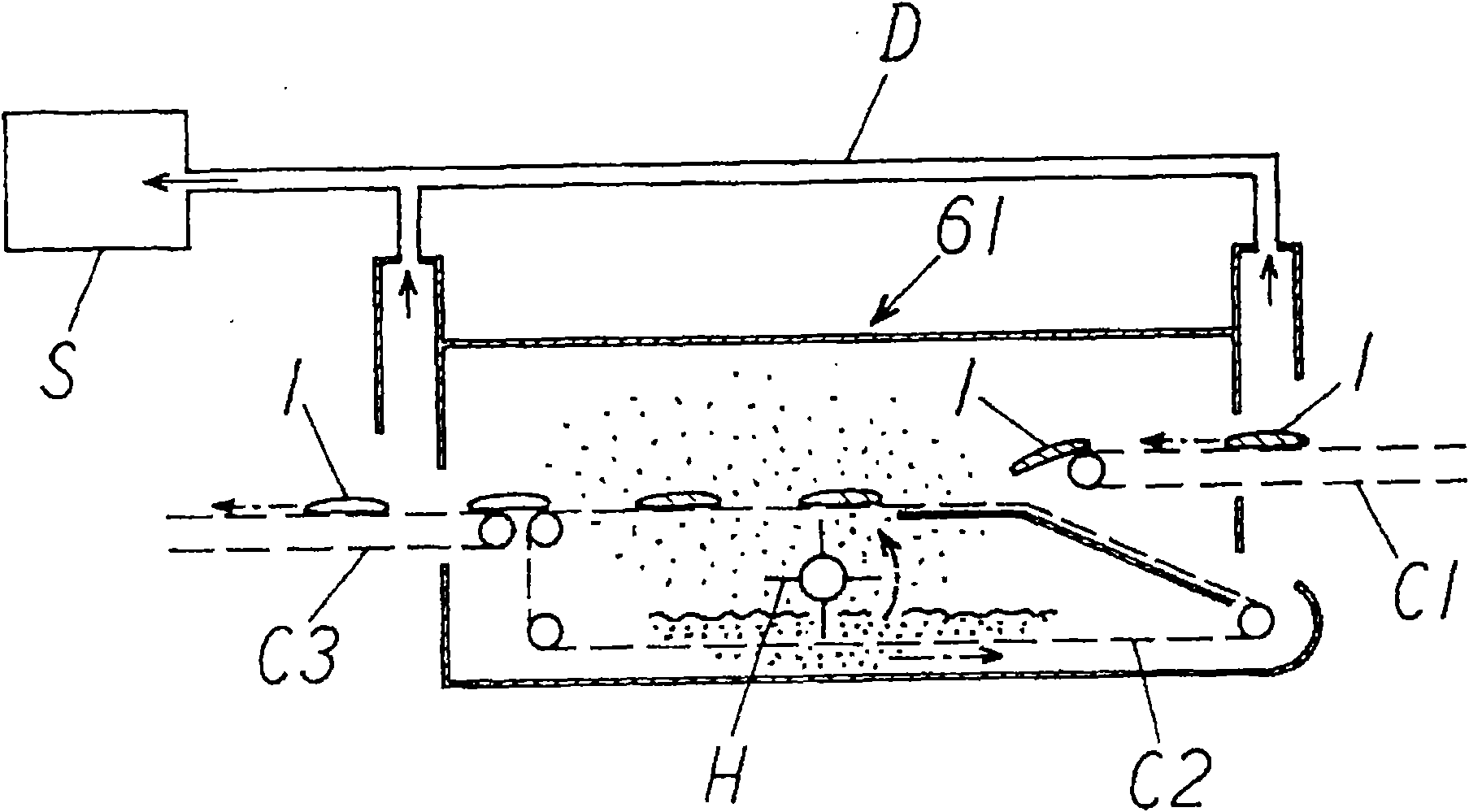

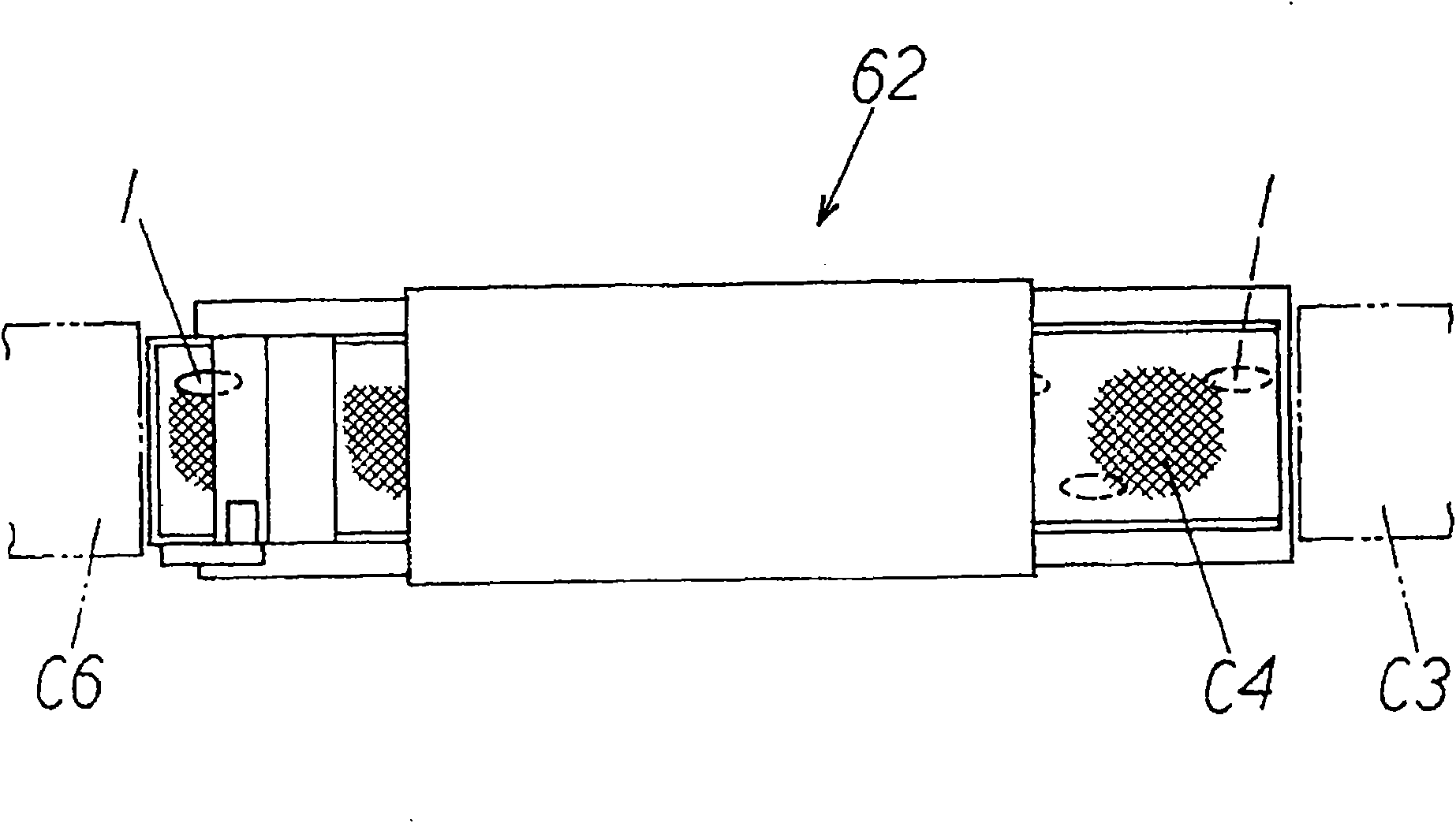

The present invention relates to a method for automatically removing bones and trimming a product such as fish fillets, where the fillets are in an under cooled state. The under cooling makes the fillets sufficiently stiff to remove pin pones and portion a fillet before or after skinning the fillet in a relative still position providing better cutting than conventional methods. This provides more efficiency than prior art methods as well as increasing the value of the product due to less gaping and dehydration of the product. The method of the present invention further provides possibilities for grading of products processed with the three dimensional scanning and digital imaging of the products.

Owner:LAMBHUSASUND EHF

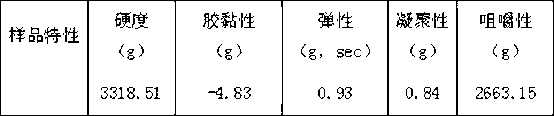

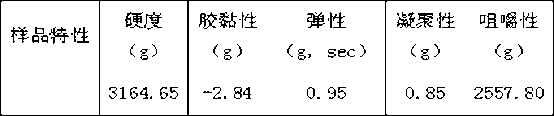

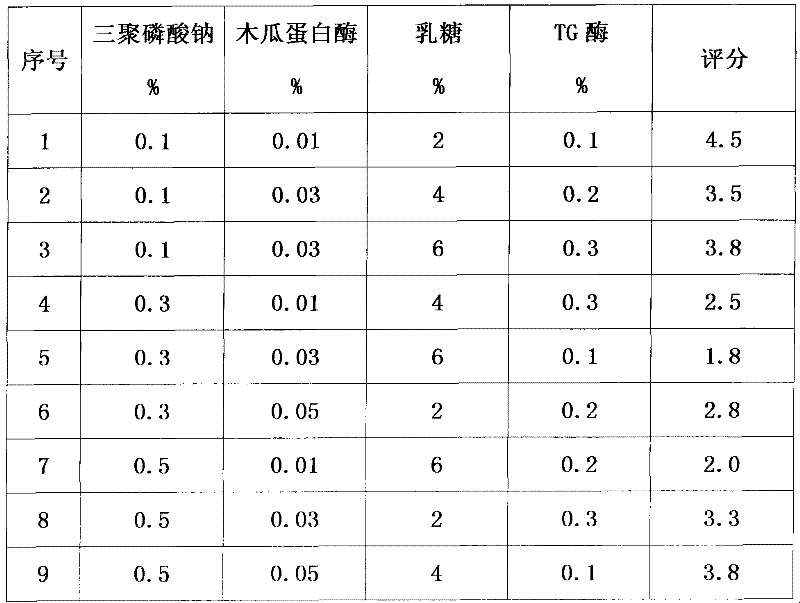

Preparation method for improving gel hardness of fish balls

The invention relates to a preparation method for improving the gel hardness of fish balls, which is characterized by comprising the following steps of: separating fish meat by using a meat separator, removing fish bones and black films, putting fish fillets into 5 to 8 percent salt solution and soaking for 20 to 40 minutes with continuous stirring; putting the fish meat from which fishy smell is removed into clear water in an amount which is 4 to 6 times that of fish meat, slowly stirring for 8 to 10 minutes, repeatedly washing by using circulating water, dissolving 2 to 4 percent of salt in water, adding into minced fillets, milling for 2 to 4 minutes, adding 0.1 to 0.6 percent of transglutaminase (TGase), milling for 6 to 10 minutes, adding seasonings into the minced fillets, and milling for 1 to 4 minutes; adding 3 to 6 percent of wheat gluten into the minced fillets, and milling for 2 to 5 minutes; putting the minced fillets into a 0 DEG C refrigerator for 1 to 3 hours, forming by using a ball making machine, and ensuring that the weight of each ball is 7 to 15g; and heating the fish balls to the temperature of between 37 and 45 DEG C, keeping for 15 to 25 minutes, putting into a 70 to 85 DEG C water bath for 20 to 30 minutes, fishing out, quickly cooling, quickly freezing, and packaging. The fish balls prepared by the method have smooth and mellow appearance, smooth mouthfeel, high elasticity and rich nutrition.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

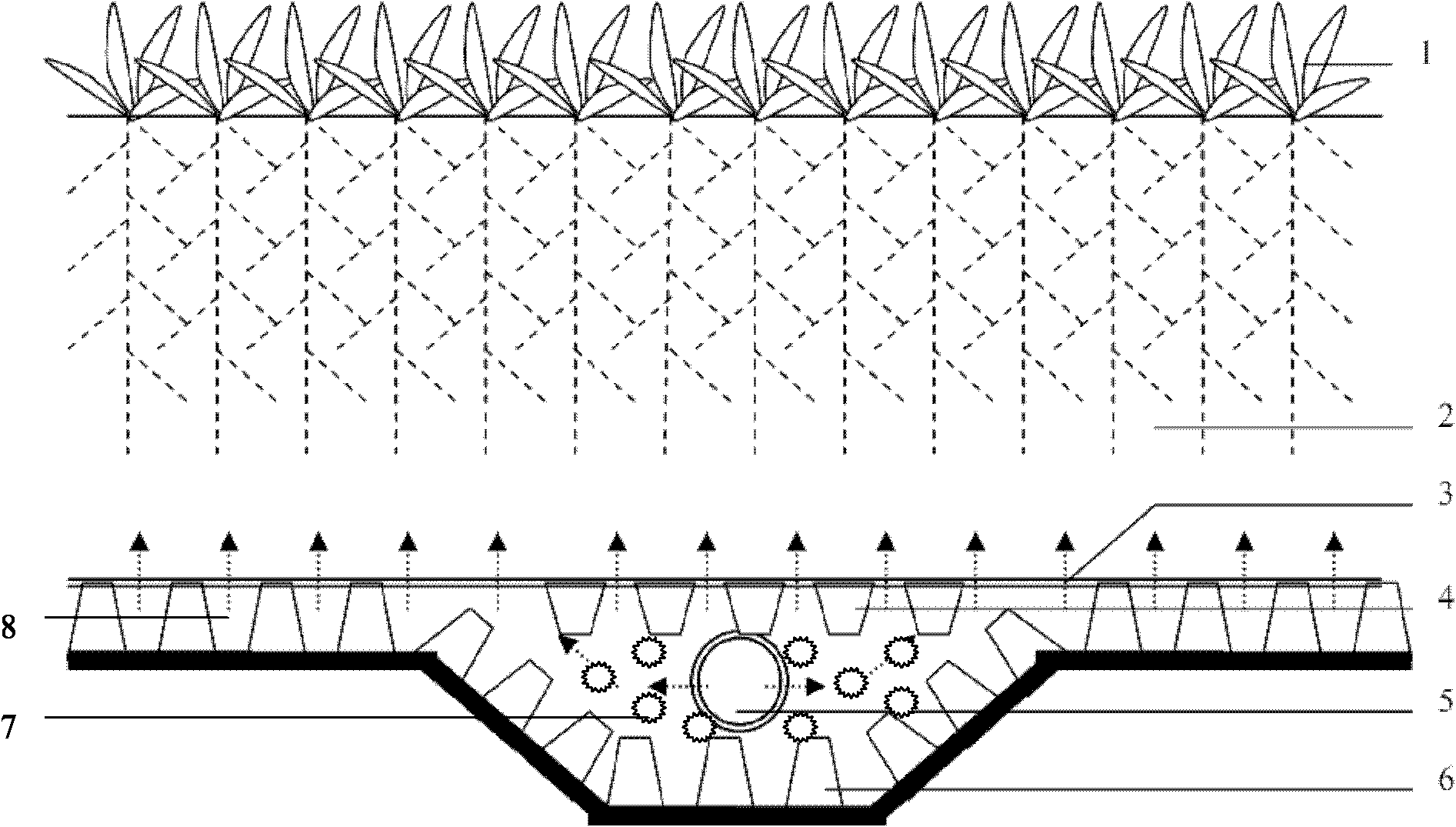

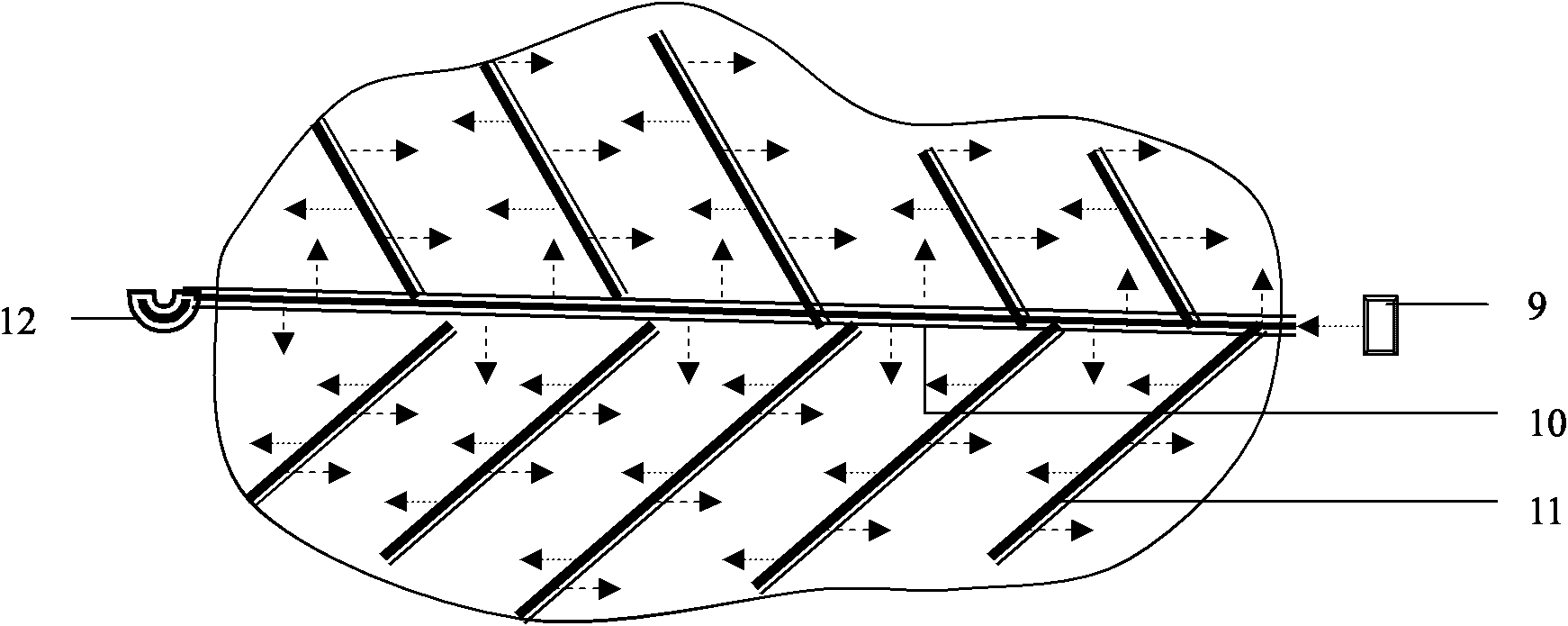

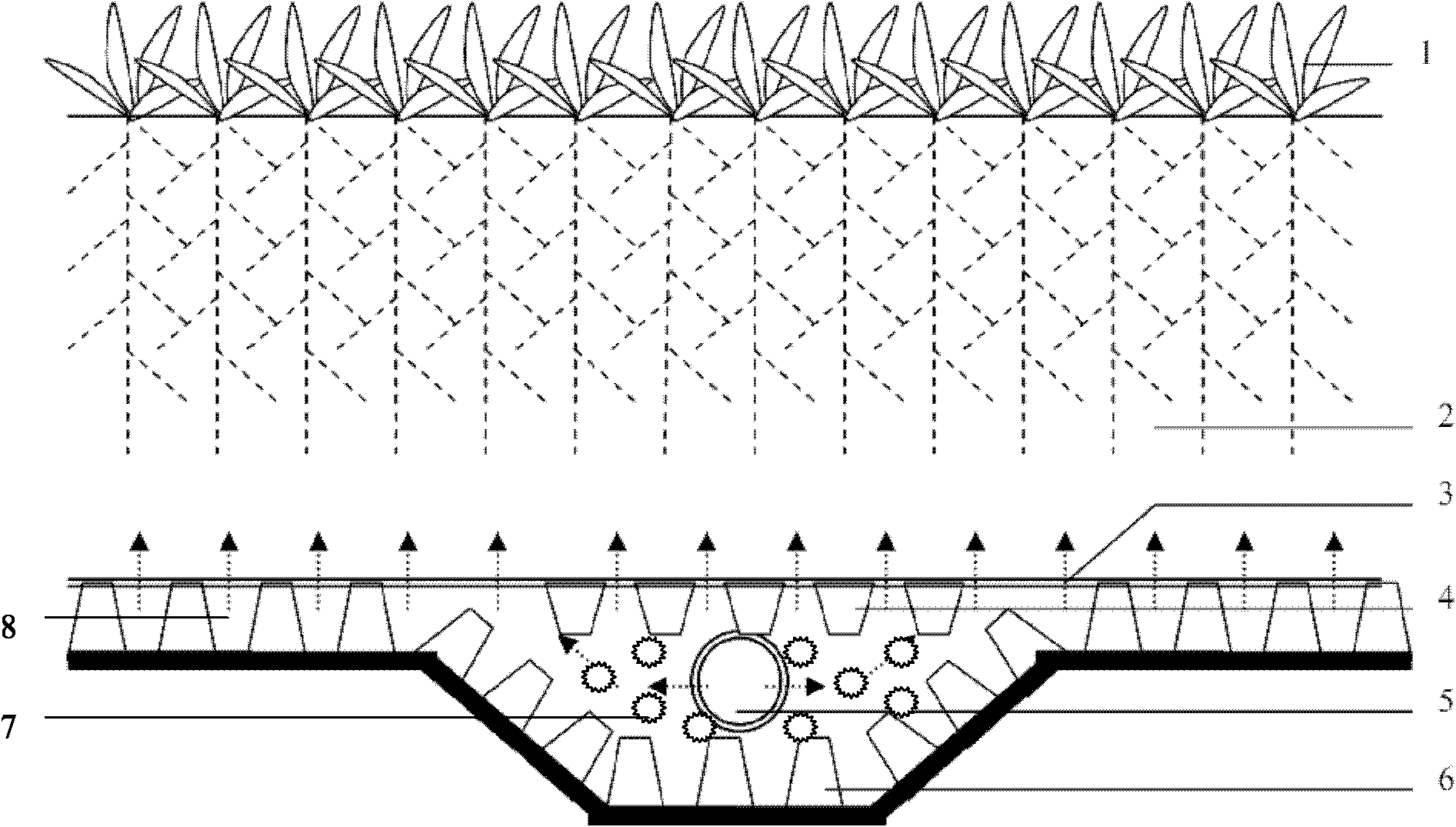

Regulation structure for temperature of lawn bed and construction method thereof

InactiveCN102172186AGuaranteed uniformityUniform temperature regulationClimate change adaptationGreenhouse cultivationTemperature controlWater storage

The invention discloses a regulation structure for temperature of a lawn bed and a construction method thereof, belonging to the field of building greening technology. The regulation structure comprises a drainage channel area and an original soil layer area, wherein the drainage channel area comprises drainage pipelines in fish fillet-shape or parallel distribution below the lawn bed, gravel filled around the pipelines and a water storage plate horizontally paved above; and the original soil layer area comprises a non-woven fabric horizontally paved below the lawn rhizosphere layer soil and a water storage / drainage plate. A port of each drainage pipeline is connected with an air outlet of an air conditioning system; cold / warm air flow of the air conditioning system enters the communicated concave / convex space in the water storage / drainage plate through holes on the wall of the drainage pipelines, and forms a stable temperature control layer below the lawn bed; and the cold / warm air flow enters the rhizosphere layer through gaps of the non-woven fabric to regulate the temperature of the rhizosphere layer. The regulation structure disclosed by the invention is suitable for various types of sports lawn and garden greening lawn such as golf course, football pitch and the like, and can regulate the bottom temperature of the lawn at a constant temperature.

Owner:SHANGHAI JIAO TONG UNIV

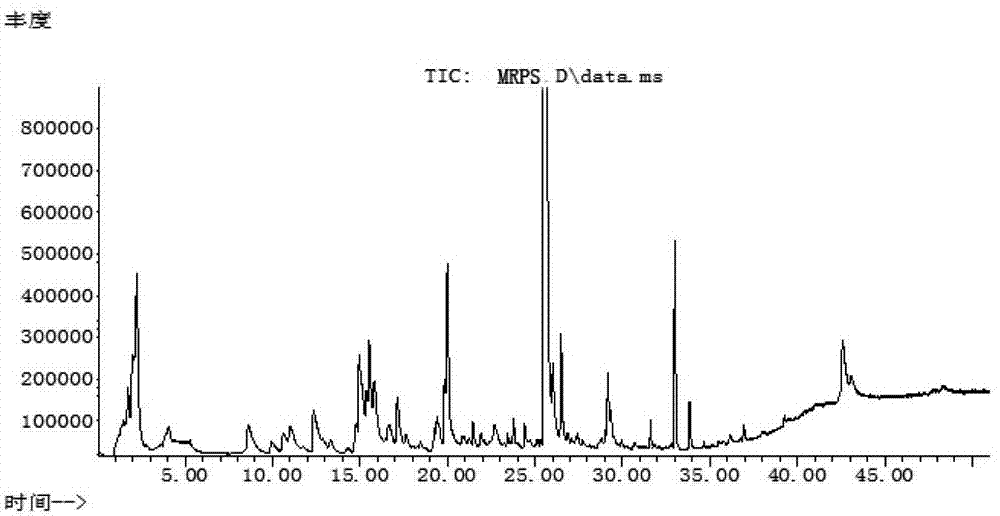

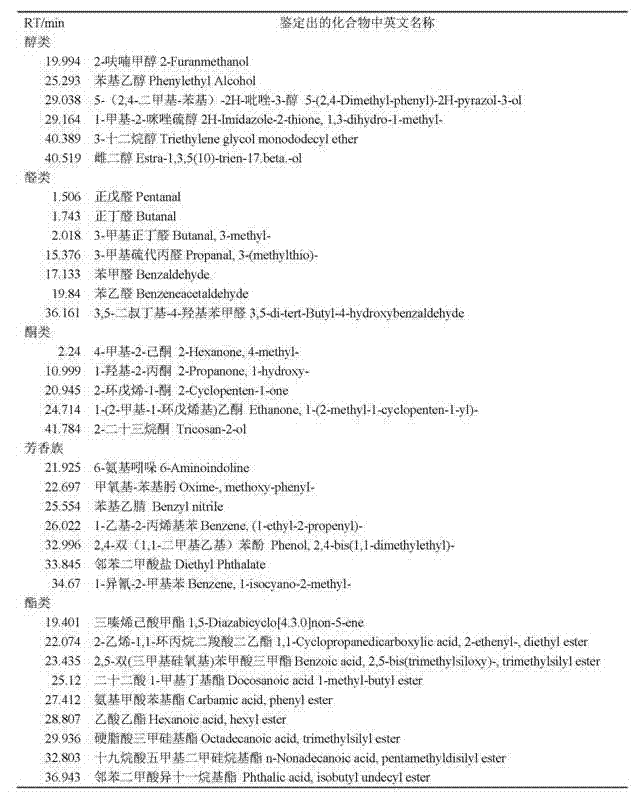

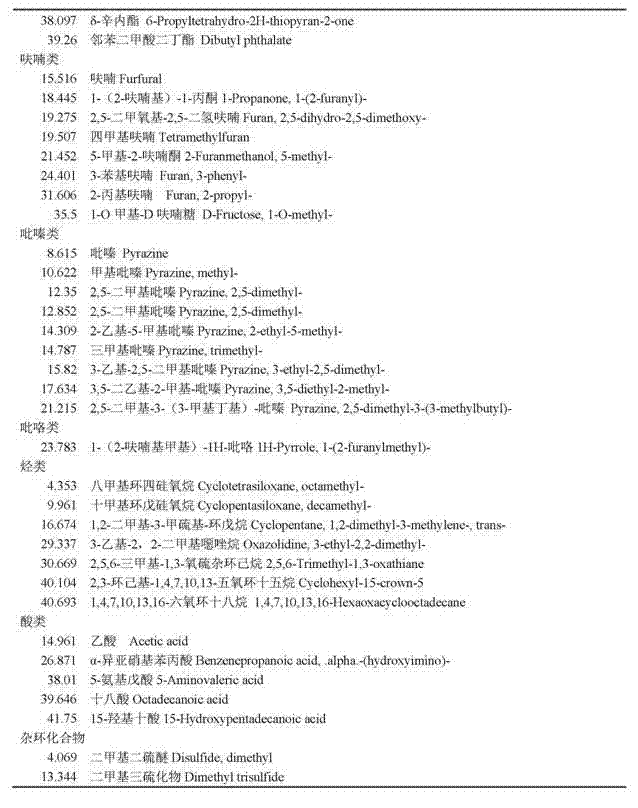

Method for preparing fish flavor nutritional condiment

ActiveCN102726700AEliminate fishy smellEliminate bitternessFood preparationFish FlavorMaillard reaction

The invention discloses a method for preparing fish flavor nutritional condiment. According to the method, the residual wastes fish fillet and ground meat generated in the Tilapia fillet producing process are used as the raw materials, then the raw materials are subjected to processes of pre-processing, protease composite enzyme solution, Maillard reaction, mixing, homogenizing, and spray drying, so as to obtain the fish flavor nutritional condiment. The protein in Tilapia fillet and ground meat are subjected to the protease composite enzyme solution, in order to generate small-molecular peptide and amino acid which are likely to digested and absorbed by human body; the Maillard reaction sweet process is used in order to remove fishy smell and bitter of enzyme resolution solution, so as to generate special fragrance and taste; the product is nutritional and delicious, can be directly used as a food condiment, and further can be used as the base material of other condiments.

Owner:JIMEI UNIV

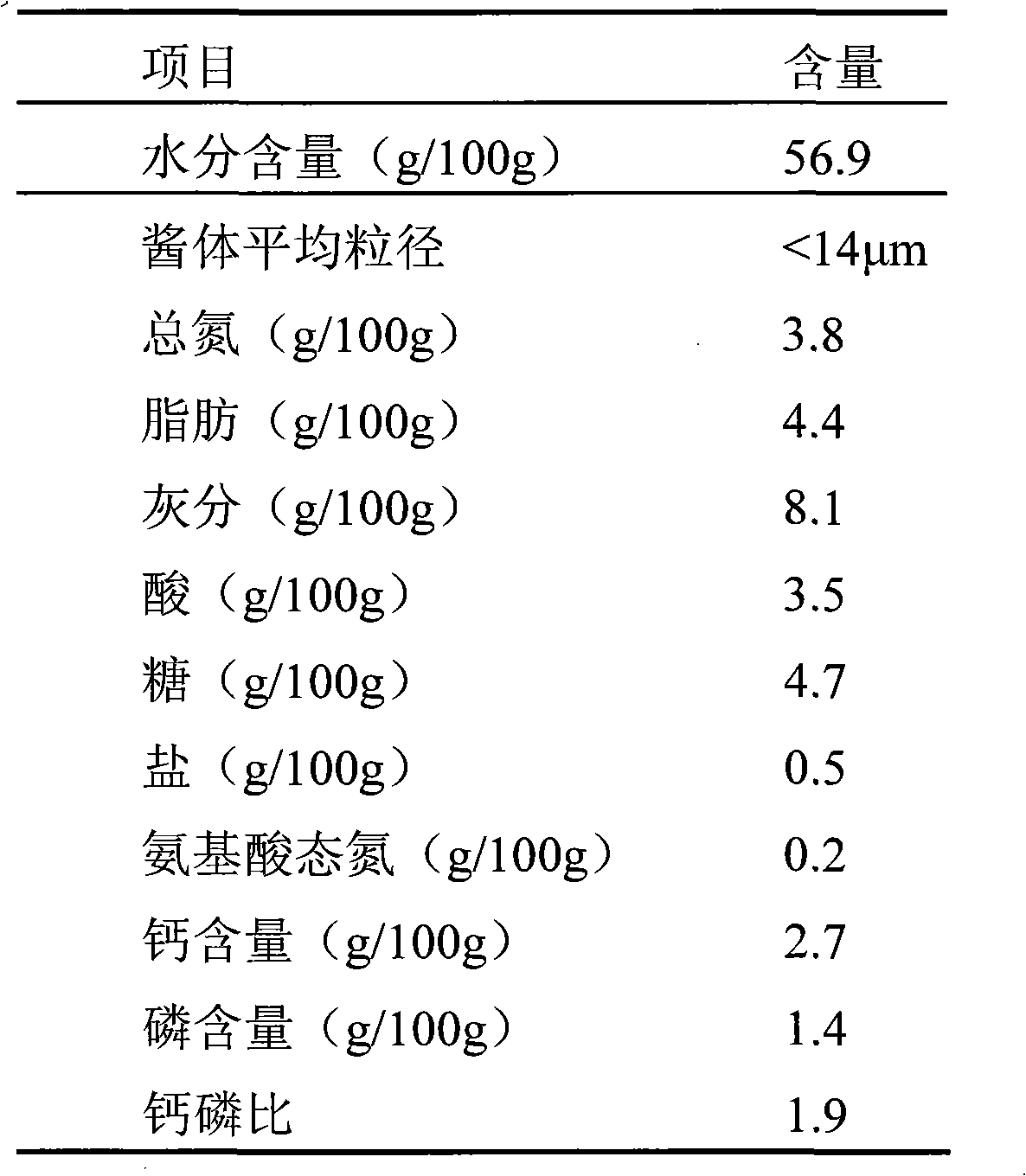

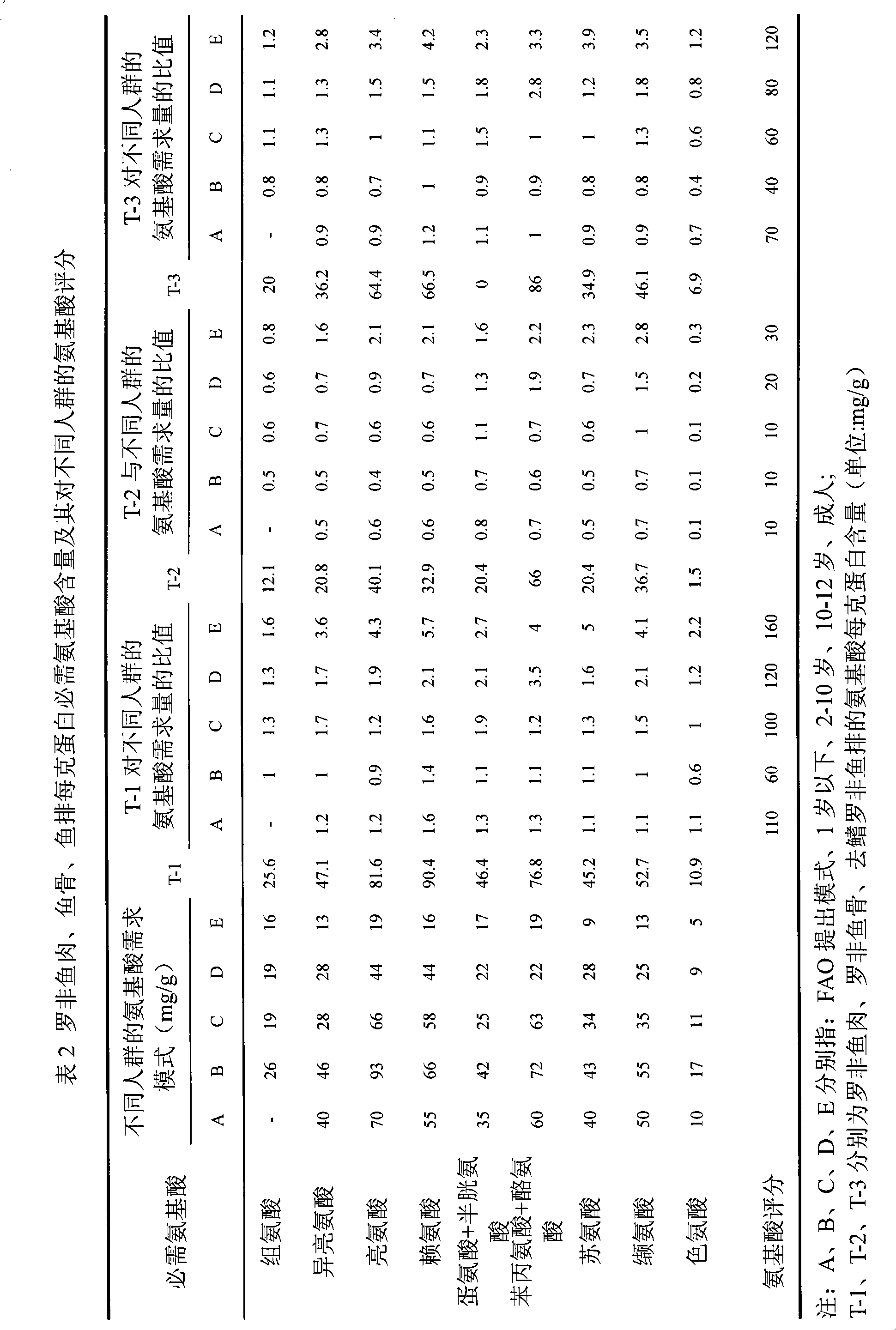

Fine and smooth tilapia mossambica bone and fish sauce and preparation method thereof

InactiveCN101919527AImprove softening effectShort holding timeFood preparationBiotechnologyMeat paste

The invention discloses a fine and smooth tilapia mossambica bone and fish sauce and a preparation method thereof. The preparation method comprises: taking tilapia mossambica processing leftovers fish fillet as raw material, and cleaning and mincing for standby; adding acetum into the minced raw material, and carrying out high-pressure cooking; after cooking and softening process, separating cooking liquid, and smashing solid bone and fish blocks by a meat grinder; then, mixing with the cooking liquid; adding clean water accounting for 50-100% of total weight of cooking liquid to adjust the denseness of size; then carrying out rubbing processing on the colloid; ensuring that colloid cycling time is 3-7 minutes; after degassing processing, processing material by a high-pressure microfluidics nanometer homogenizer at the pressure of 60-120MPa to obtain fine and smooth tilapia mossambica bone and fish pulp; and condensing and seasoning the fine and smooth tilapia mossambica bone and fishpulp to obtain the tilapia mossambica bone and fish sauce of different flavours. The invention can fully utilize the nutrition constituent of fish fillet raw material, has high processing speed and small average particle diameter of products and can meet the requirements of fine and smooth taste.

Owner:SOUTH CHINA UNIV OF TECH

Ready-to-eat osmanthus flower fragrance type fish meat particles and preparation method thereof

InactiveCN103907964AConvenience and leisureAroma harmonyFood ingredientsFood preparationBiotechnologyMonosodium glutamate

The invention discloses ready-to-eat osmanthus flower fragrance type fish meat particles and a preparation method thereof. The ready-to-eat osmanthus-fragrance type fish meat particles are prepared from following raw materials, by weight, 100 parts of fish slice, 1.2 to 1.8 parts of table salt, 6 to 14 parts of white granulated sugar, 1 to 1.4 parts of monosodium glutamate, 0.05 to 0.1 part of disodium 5'-ribonucleotide, 1 to 1.4 parts of five spices powder, 2 to 2.5 parts of chill oil, 0.8 to 1.2 parts of liquor, 1.5 to 2 parts of ginger powder, 3 to 5 parts of psyllium seed husk powder, 2 to 4 parts of gelidium amansii powder, 3 to 5 parts of soybean protein isolate, 0.5 to 0.8 part of xanthan gum, 0.5 to 1 part of osmanthus flower powder, and 0.05 to 0.08 part of capsanthin. According to the preparation method, the ready-to-eat osmanthus flower fragrance type fish meat particles are prepared via following steps: fish slice is washed, and is subjected to cooking, stir-frying, moulding, drying, packaging, sterilizing, and the like. Formability and organoleptic quality of the ready-to-eat osmanthus-fragrance type fish meat particles are excellent; the ready-to-eat osmanthus-fragrance type fish meat particles possess unique osmanthus flower fragrance; fragrance is harmonious; color is accretive; flavor is unique; mouthfeel is fresh and delicious; nutritional value is high; healthcare function is excellent; and deficiencies of freshwater fish that meat quality is poor, moulding is difficult, and earthy smell is heavy are avoided.

Owner:MINGGUANG YONGYAN AQUATIC GROUP CORP

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

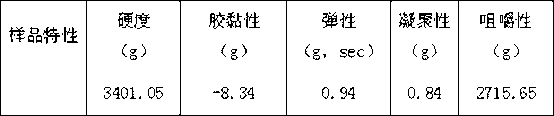

Manufacture method of room temperature stored conditioning instant flavor fish cake with high elasticity

The invention discloses a manufacture method of a room temperature stored conditioning instant flavor fish cake with high elasticity, belonging to the technical field of aquatic product processing. According to the manufacture method, excellent sea eel with good gelating property and high-quality frozen trash fish fillet are selected as raw materials. The manufacture method comprises the following steps of: blending, gelating, cooking and carrying out short-time high-temperature and high-pressure sterilization and nano zinc treatment. The industrialized production of a conventional fish cake is realized, and the instant fish cake which is rich in nutrients, slender, and high in elasticity and gloss is manufactured. The manufacture method has the advantages that firstly, on the basis of completely remaining the flavor and the specialties of the conventional fish cake, the defect that the qualities such as elasticity are reduced after the fish cake is sterilized at a high temperature is overcome; secondly, through short-time high-temperature and high-pressure sterilization and nano zinc treatment, the problem that the fish cake manufactured by a common manufacture method is not suitable for room-temperature storage is solved, and the safety of the room temperature stored instant fish cake is increased; thirdly, the room temperature quality guarantee period of the conditioning fish cake reaches 6 months and the elasticity of the conditioning fish cake reaches 0.936-0.949g / s; and fourthly, short-time high temperature and high pressure and nano zinc oxide are combined for sterilization, thus the defects of nutritional ingredient and flavor loss of the fish cake due to conventional high temperature sterilization are eliminated, and long quality guarantee period is ensured.

Owner:JIANGNAN UNIV +1

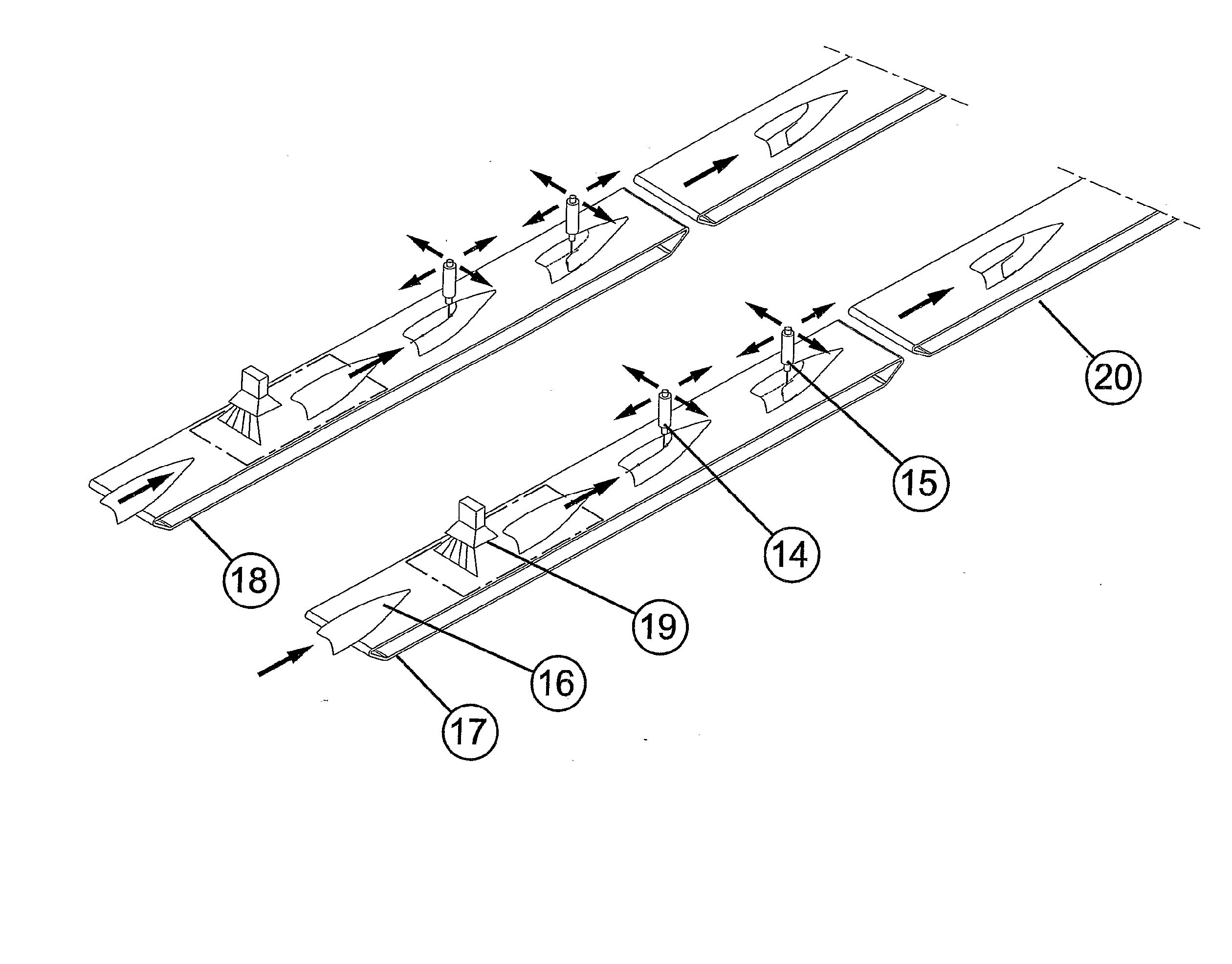

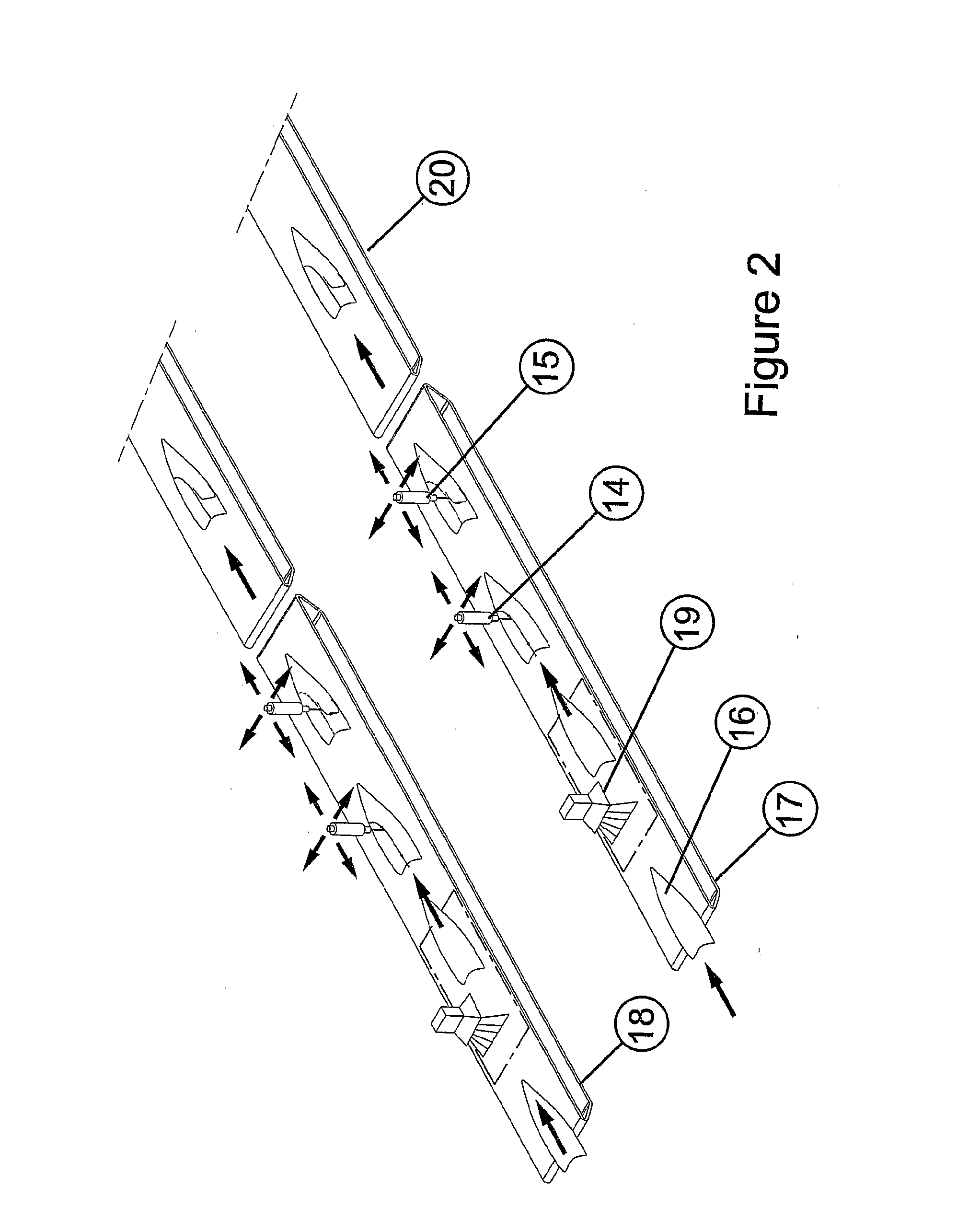

Apparatus and method for trimming of fish fillets

Owner:MAREL ICELAND EHF

Green production method of chilled fillets

ActiveCN101983570AGuaranteed qualityReduce the initial bacterial countMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyChlorine dioxide

The invention provides a green production method of chilled fillets. The method mainly comprises the following steps: preparing raw material fish, temporarily cultivating fish in cold water, performing movement bloodletting in cold water, preprocessing (removing scales, heads, tails and internal organs), cleaning with cold water, cutting into slices, removing fish bones and repairing, grading, sterilizing with electrolyzed ozone water, dewatering, spraying for coating, drying the water on the surface of fish, sterilizing with ultraviolet, performing atmosphere packaging and transporting. The main characteristics of the method of the invention are as follows: 1) electrolyzed ozone water and ultraviolet are used to sterilize the fillets and reduce the initial microbial content of raw material, chlorine dioxide and preservative are not used so as to ensure that the production technology is green and environmentally friendly; 2) temporarily cultivating in cold water, low-temperature movement bloodletting and whole-process low temperature operation are adopted to effectively control the microbial spoilage of the chilled fillets, reduce fat oxidation and protein degradation and ensure the freshness of the product; and 3) the green composite film preservative is coated on the chilled and sterilized fillets, thus effectively prolonging the shelf life of the chilled fillets.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Composite preservation method of hairtail slices

ActiveCN103229822AMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiotechnologyPolylysine

The invention discloses a composite preservation method of hairtail slices by partial freezing treatment in combination with a natural preservative, which comprises natural preservative dipping treatment and partial freezing low-temperature treatment. The invention can achieve the effects of inhibiting bacteria and lower the temperature of fish slices. The natural preservative comprises the following components in percentage by weight: 0.02-0.05% of nisin, 0.01-0.06% of epsilon-polylysine, 0.01-0.05% of lysozyme and the balance of water. The partial freezing process for preserving the product ensures the integrity of the product cells, can maintain the original color, freshness and flavor, greatly prolongs the shelf life of the product; and the product is still very fresh after being stored for 25 days.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

Preparation method of instant fish skin jelly food

The invention relates to a preparation method of instant fish skin jelly food. The preparation method comprises the following steps of: taking a by-product fish skin in a fish slice processing process as a raw material; and making the stink-free jelly food with adjustable flavor, various eating methods, rich nutrition and convenience by processes of cleaning, degreasing, carrying out enzymolysis, degelatinizing, filtering, destaining and deodorizing, concentrating, cooling type molding, preparing a seasoning bag and the like. The jelly food prepared by the invention not only contains the rich nutrient substance and various microelements, but also can be reduced for resource waste and environment pollution. Furthermore, better economical benefits and social benefits can be created.

Owner:FUJIAN AGRI & FORESTRY UNIV

Liquor-marinated fish processing technology

The invention discloses a liquor-marinated fish processing technology which is characterized by comprising the following steps: (1) cleaning: fresh grass carps are taken and processed through removal of scales, heads, tails and internal organs, the thickness is within 1.5 cm, part of which the thickness is larger than 1.5 cm is lightly scratched by a knife, without damaging the skin, black films and bloodiness are cleaned, fish slices are uniform, and the optimal weight of the grass carp is less than 3 kg; (2) curing to deodorize: salt, cooking wine and curing material are weighed, one layer of curing material, salt and cooling wine is scattered on each layer of fish slice in curing, the quantity of salt on the bottom layer is small, while the quantity of salt on the top layer is large, the curing time is 7 days, and tank overturning every day is carried out once. The liquor-marinated fish has the characteristics of moderate taste, fresh meat, fragrant flavor and chewing feeling. The fish meat has the effects of invigorating stomach to remove coldness, boosting immunization, clearing away heat and toxic materials, preventing cancer, reducing blood fat, assisting resisting computer radiation, and whetting the appetite, is good to the physical fitness, and is suitable for being eaten by populations sitting in the office too long.

Owner:安徽绍峰实业有限责任公司

Processing technology of half-dry seasoning tilapia fillet

InactiveCN102100372AOvercoming Perishability and DeteriorationOvercome the difficulty of not being easy to preserveFood preparationMeat/fish preservation by dryingMonosodium glutamateVegetable oil

The invention provides a processing technology of a half-dry seasoning tilapia fillet, which comprises the steps: preprocessing fresh tilapia; removing scales, internal organs and head and removing fishy smell; and carrying out microwave drying, seasoning and vacuum packaging and sterilizing to make the ready tilapia fillet, wherein the seasoning comprises salt, white spirit, monosodium glutamate, hot pepper, five spice powder, vegetable oil and the like. The ready tilapia finished product prepared by the method is a yellow and white fish fillet which has loose meat, delicious taste and strong fragrance, is hard and achieves the best taste between salty and tasteless. In addition, the product has unique flavor, suitable taste and long shelf life, has small possibility of deteriorating, and is convenient to transport and store, thereby being produced by qualified processing factories and having considerable benefits.

Owner:郑元平 +1

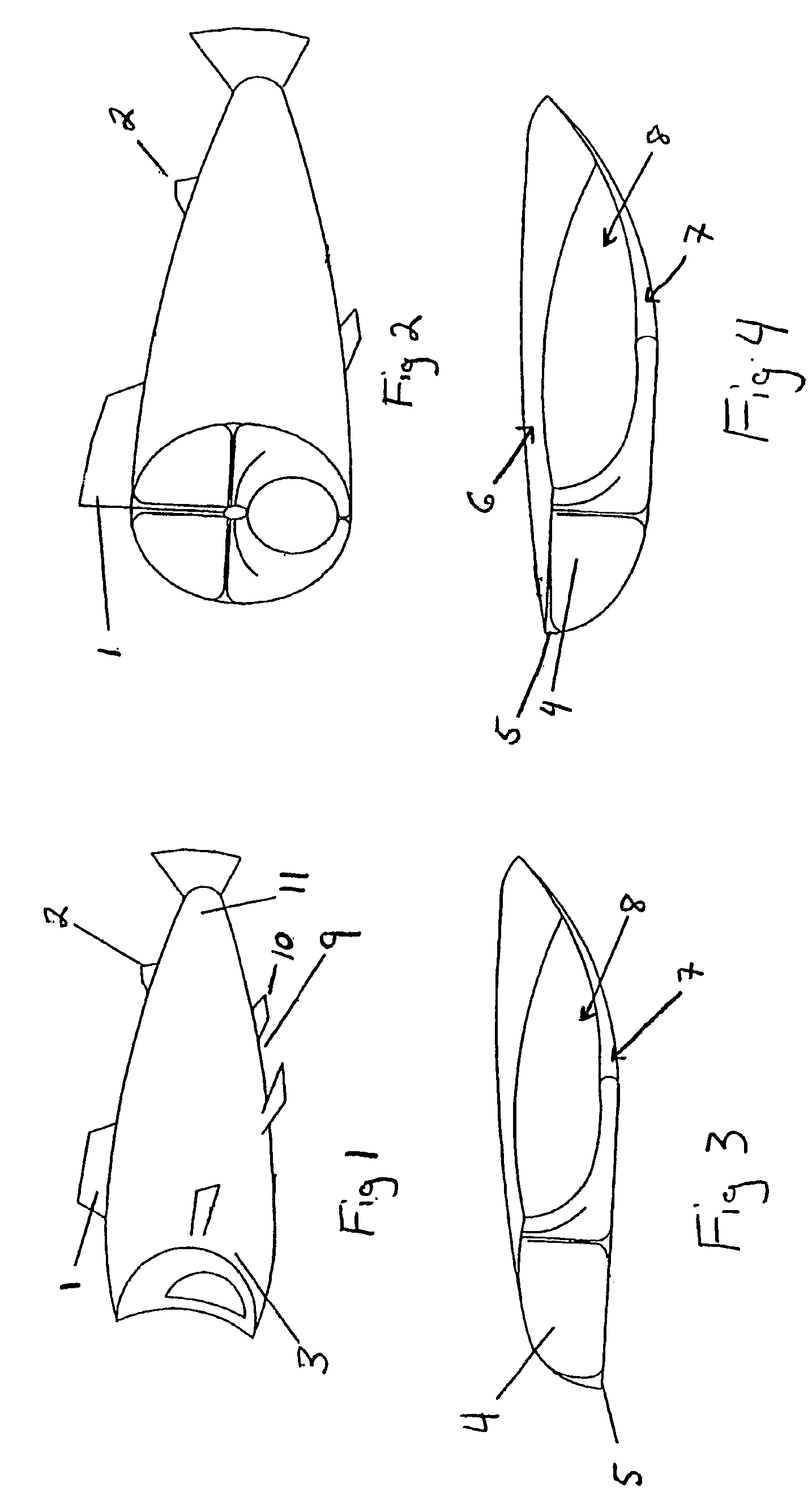

Device for de-rinding and skinning a product to be treated

InactiveUS20040248509A1Skinning instrumentsRind cutting-off apparatusFish filletMechanical engineering

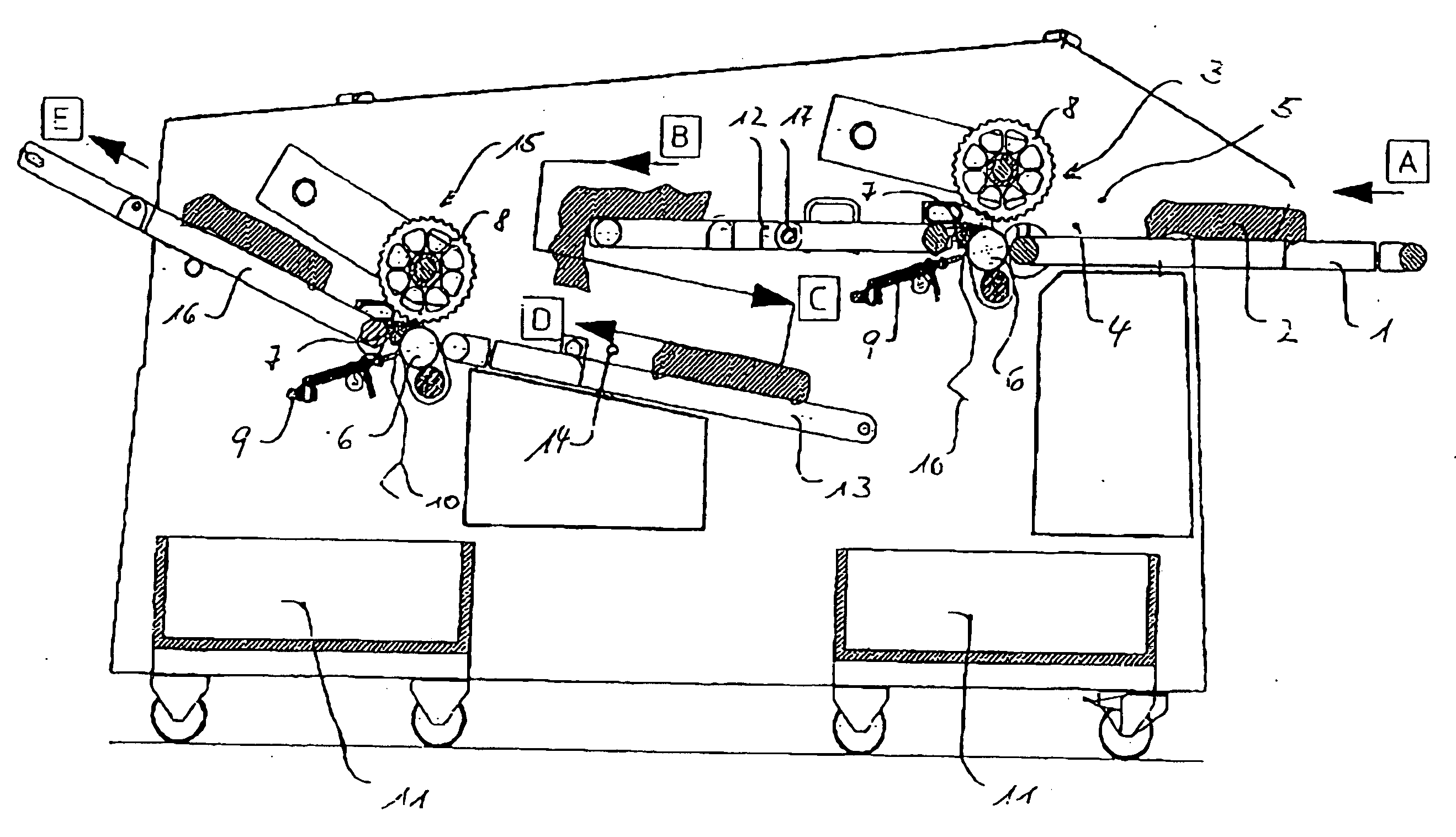

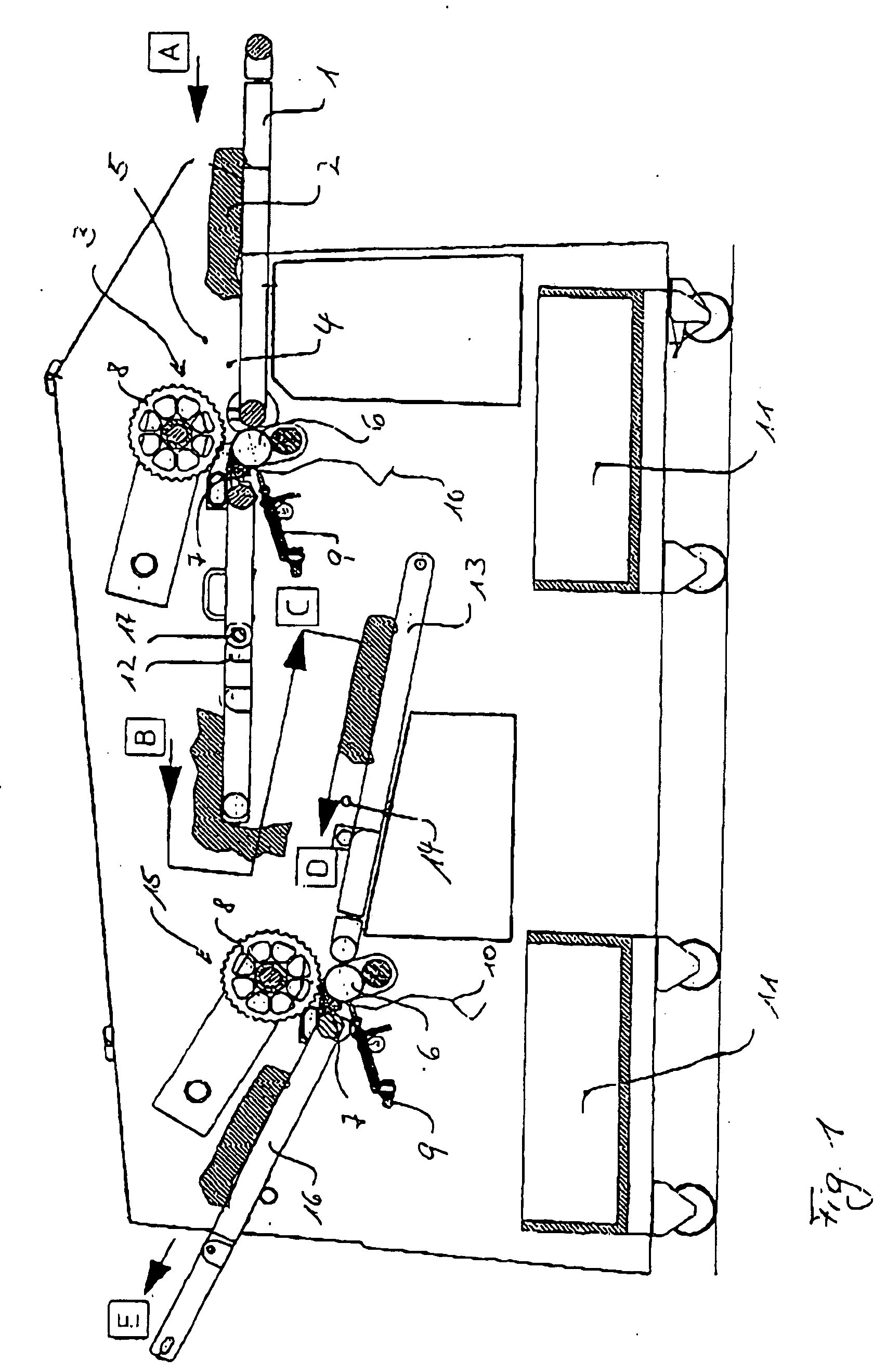

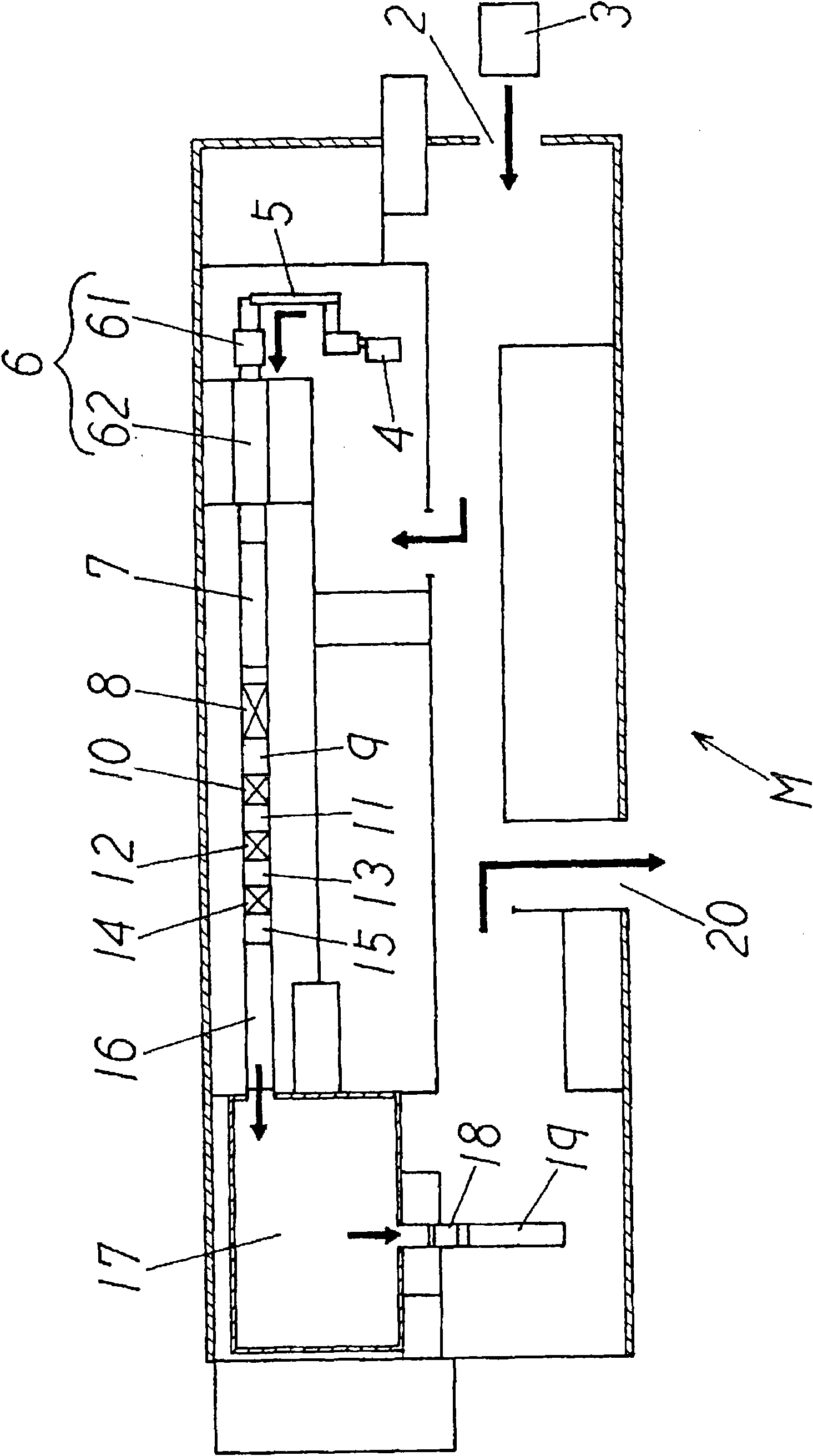

The invention relates to a device for skinning and de-rinding a product to be treated such as pieces of meat or fish and similar products (2), said product to be treated being first skinned from one side by means of a first skinning unit (3). A combination of a first conveyer belt (12) and a reversing belt (13) reverses the piece of meat. A second skinning unit (15 removes the remaining fat and skin (10) from the other side of the product (2) to be treated.

Owner:MAJA-MASCHINENFABRIK HERMAN SCHILL KG

Low value fresh water fish whole utilization process method

InactiveCN1557206AAchieve full utilizationReduce fatPeptide/protein ingredientsAnimal feeding stuffFresh water fishAquatic product

The present invention belongs to the field of aquatic product processing technology. Fresh water fish and leftover as material is processed into three kinds of product including crisp fish fillet, anti-fatigue amino acid oral liquid and pet food. Thin fish sheet is produced into crisp fish fillet through soaking in red tea and NaCl solution to eliminate fishy smell, drying, pickling to season, beating to loosen and soften and microwave embrittling. Fish leftover is produced into anti-fatigue amino acid oral liquid through enzymolysis with composite enzyme, killing enzyme, high speed centrifugating, filtering supernatant, bottling and sterilizing. The precipitate produced in the high speed centrifugating is produced into pet food via compounding with flour and other material, sterilizing and pelletizing. The present invention has high material utilization and low production cost.

Owner:JIANGNAN UNIV

Processing technique for roasted fish fillet

The invention relates to a processing technique for a roasted fish fillet, which belongs to the field of food processing, and more specifically, the invention relates to a processing technique for a roasted fish fillet. The processing technique for the roasted fish fillet, which is provided by the invention, has the advantages that: the processing technique is easy to operate, and the roasted fish fillet is rich in aroma. The process steps of the processing technique are as follows: a fish as material is unfrozen, preprocessed and cut into fillets, fishy smell is removed, and the fillets are flavored, roasted, inspected, packaged and finished.

Owner:龚岱

Processing method of quick-frozen Taiwan white sea bream fillets keeping fish meat fresh

InactiveCN102090443AImprove freshnessNice appearanceMeat/fish preservation by freezing/coolingRed mulletFish fillet

The invention discloses a processing method of quick-frozen Taiwan white sea bream fillets keeping fish meat fresh. The method comprises the following steps of: receiving and accepting raw material fishes, cultivating temporarily, laying cold with ice, bleeding, sectioning, peeling, buffing, trimming, quick freezing, quantitatively grading, coating an ice coat, vacuum packaging and refrigerating. The method comprises the following specific steps of: laying the fishes cold by using an ice laying machine; sectioning and bleeding in a current form; quickly freezing fillets, wherein the cooling central temperature is up to 18 DEG C below zero during quick freezing; and after machining, and refrigerating the processed fillets by using a scientific refrigerating method. By adopting a quick freezing processing method, Taiwan white sea bream fillets which are subjected to ice laying and current type bleeding can keep high freshness, have white color, high brightness, attractive appearance and good mouthfeel, and are not easy to infect by bacteria; after quick freezing, the nutrition of fillets does not loss and a higher nutritional value is achieved in comparison with the conventional quick freezing method; and a scientific refrigerating method is adopted, causes can be found easily and treatment is performed easily when the fillets are in a poor state.

Owner:福建铭发水产开发有限公司

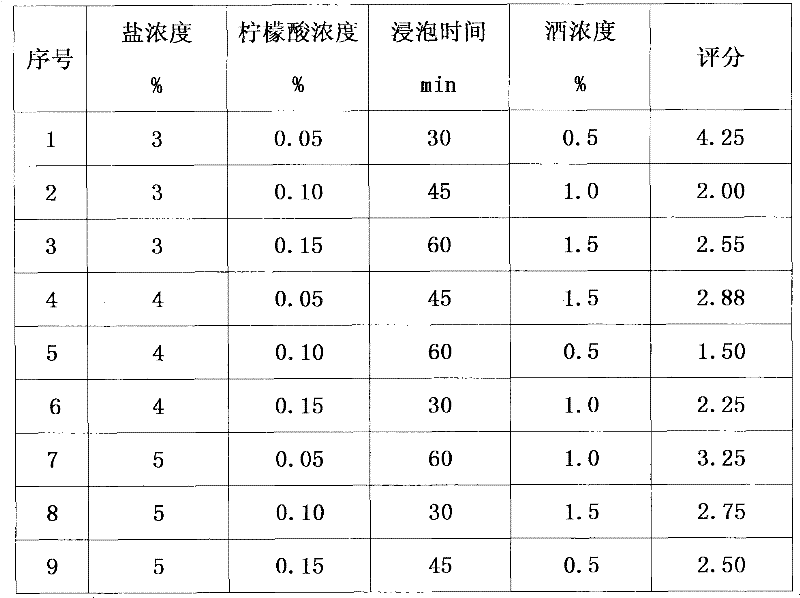

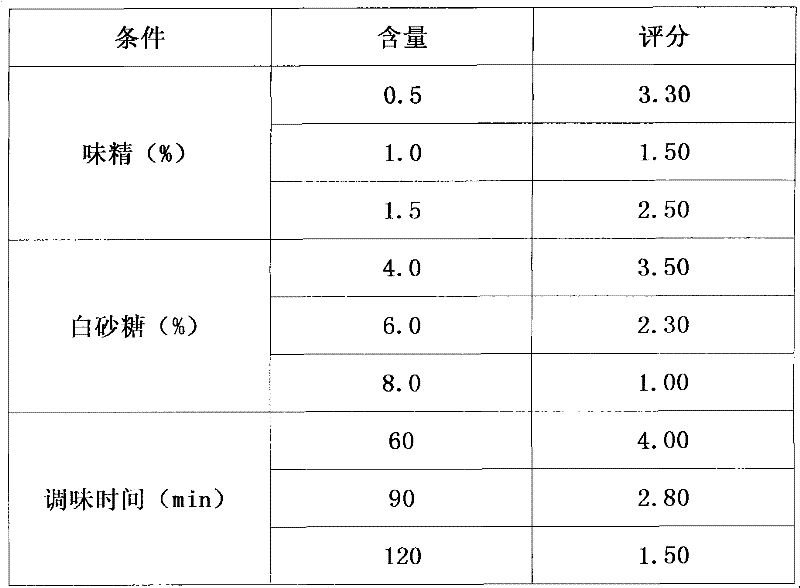

Processing technology of flavored roasted fish fillet

ActiveCN104055155AGood molding effectReduce nutrient lossFood preparationNutritionProcess engineering

The invention discloses a processing technology of a flavored roasted fish fillet and solves problems that a roasted fish fillet, processed through a processing technology of the flavored roasted fish fillet in the prior art, is liable to be crimped and crushed, is poor in formability, is thick in fishy smell, is dry and hard and is poor in mouth feel and taste. The processing technology mainly includes following steps: (1) cutting fish into fillets; (2) removing fishy smell; (3) forming the fillets; (4) soaking and flavoring the fillets; (5) primarily drying the fillets; (6) re-softening the fillets; and (7) enhancing fragrance of the fillets. According to the invention, overall optimization and improvement of the processing technology of the flavored roasted fish fillet is carried out, and optimizations and improvements of a fishy-smell-removing liquid formula, a soaking liquid formula and the primary drying process in the processing technology are especially carried out. The forming process, the re-softening process and the fragrance-enhancing process are added to the technology. The overall technology is simple in processes. The fish fillet is good in formability and is small in nutrition loss during the processes. An obtained fish fillet is complete in shape, is fluffy and soft in meat quality and is outstanding in taste. Quality of the fish fillet is greatly improved.

Owner:ZHEJIANG MARINE DEV RES INST

Making method for quick-frozen seasoned sliced Pneumatophorus japonicus food

ActiveCN103549493AExtended shelf lifeEasy to eatFood freezingFood thermal treatmentBiotechnologyPneumatophorus japonicus

The invention relates to a making method for quick-frozen seasoned sliced Pneumatophorus japonicus food. The method includes: selecting a fresh or frozen and saline thawed fresh Pneumatophorus japonicas as the raw material, subjecting the raw material fish to decapitating and evisceration treatment, then separating the fish body from a vertebra, removing the vertebra, fish blood and impurities, and cutting the fish body into fish slices; subjecting the fish slices to hot water rinsing to undergo protein modification, performing ice water cooling on the fish slices to inhibit microorganism propagation, draining the fish slices, then mixing them with the seasoning made of miso paste, olive oil, garlic essential oil, apple vinegar, granulated sugar, ginger juice, mashed garlic, lemon juice and water in proportion, then performing vacuum encapsulation, and then carrying out heating cooking and sterilization, cooling, quick-freezing treatment, and conducting packaging and inspection, thus obtaining the quick-frozen seasoned sliced Pneumatophorus japonicus food. The making method provided by the invention has the advantages of advanced technology, reasonable and strict processes, strong operability, and high making efficiency. The seasoned sliced Pneumatophorus japonicus food prepared by the method has the characteristics of rich nutrition, unique flavor, fresh and mellow taste, no peculiar or fishy smell, tender and soft mouthfeel, safety and sanitation, long shelf life, and convenient eating.

Owner:威海蓝谷海洋生物科技有限公司

Secondary liquid heat fuming preparation method for fresh water fish

InactiveCN101313761AFlexible and tightUniform fishMeat/fish preservation by heatingMeat/fish preservation using acidsFlavorFish quality

The invention relates to a method for preparing freshwater fish cans through two-time liquid hot smoking. The method comprises the following steps that: (1) drying treatment is carried out to fish fillets which are fermented with lactic acid and have fishy smell removed; (2) vacuum concentration is carried out to flavor agent prepared from freshwater fish leftovers; (3) dried fish fillets are canned, and the flavor agent is injected into a can; (4) liquid smoking flavor is injected into the can to carry out primary hot smoking; (5) the can after primary hot smoking is put into a full-automatic spraying type high-temperature pressure cooker to accept secondary hot smoking; (6) the can after secondary hot smoking is cooled to normal temperature. The can prepared through method is elastic and compact in fish quality and uniform in fish fillets, and has no broken fish fillet or fat layer.

Owner:林明

Method for processing grilled fish fillets

The invention provides a method for processing grilled fish fillets, which is developed to improve flavor and eliminate fishy smell. The processing method for grilled fish fillet is used for grilling one sliced eel, mackerel pike, sardine, eye-benefiting sardine, conger eel or loach. The method comprises the following steps of: coating the food material, frying the material, braising the fried food material, adding flavors onto the food material, and then grilling the food material.

Owner:YAMADA MARINE PRODS

Processing method of fumigated anchovy fillets

The invention relates to a processing method of fumigated anchovy fillets, which belongs to the processing technology of fumigated fillets and aims at solving the technical problem of improving color, aroma and taste of fumigated fillets made by a liquid fumigating agent. The processing method comprises the following technical schemes: processing raw materials, seasoning, drying, impregnating by the liquid fumigating agent and far-infrared thermal processing. The processing method is characterized in that the impregnating process by adopting the liquid fumigating agent comprises the following steps: dipping fish fillets after being seasoned and dried into 4-6 percent of liquid fumigating agent, picking the fish fillets out and resting about 4 hours and then carrying out the far-infrared thermal processing; far-infrared rays of 180-200 DEG C are adopted in the far-infrared thermal processing to bake the fish fillets about 4 minutes, and the color, the aroma and the taste of the liquid-fumigating products can be improved. The invention is used for fumigating the anchovy fillets.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Processing method of instant fish slices

The invention discloses a processing method of instant fish slices. The processing method comprises the following steps: (1) preprocessing; (2) removing the smell and slicing; (3) soaking; (4) steaming; (5) filming; (6) frying; (7) packaging in vacuum. According to the processing method, as the fish slices are soaked in soaking liquid, the taste completely permeates fish meat; due to the process of wrapping the fish slices with lotus leaves and steaming the fish slices wrapped with the lotus leaves, the original umami of the fish meat is retained, the faint scent of the lotus leaves is left on the fish meat, and the effects of improving the flavor and removing the grease are achieved; due to the filming process, the fish meat can be effectively prevented from being dispersed in the frying process, and the instant fish slices are guaranteed to be burnt outside and tender inside; flour is combined with mentha spicata, coriander leaves, crushed fennel leaves and garlic powder, so that the fish slices are relatively delicious in taste, golden yellow and jade green in appearance, marketable and capable of improving the appetite of eaters. The instant fish slices processed by the method is good in mouth feel, long in storage life, free of preservatives, safe and sanitary to eat and convenient to eat and carry. The processing method is simple and reasonable in process, high in operability and easy for industrialized production.

Owner:ZHEJIANG OCEAN UNIV

Method for preparing seasoning mackerel slice dried by cold air

InactiveCN104473230AGuaranteed qualityImprove stabilityFood ingredient functionsFood preparationBiotechnologyRed yeast rice

The invention relates to a method for preparing a seasoning mackerel slice dried by cold air. The method comprises the following steps: on the basis of optimized mackerel material, removing backstabs, heads and internal organs of the raw material fish; separating fish bodies from vertebras; taking the fishes bodies, and cutting into fish slices; cleaning the fish slices, and then putting into a seasoning liquid prepared from potherb mustard water decoction, mung bean water decoction, edible salt, vinegar, vitamin C, red yeast rice, fatty acid, lemon juice, fresh ginger, Chinese prickly ash, star anise, cinnamon and water at the ratio in a mixing manner, soaking, pickling, controlling liquid, and dishing up; supporting on a drying net of a drying car, and pushing into a cold air drying workshop to dry; and instantly freezing, packaging, and checking out, so as to obtain the finished product. The method for preparing the seasoning mackerel slice dried by cold air disclosed by the invention is reasonable and strict in process, high in operability, high in preparation efficiency, and suitable for industrialized production; the seasoning mackerel slice dried by cold air prepared by the method is abundant in nutrients, fresh and mellow in taste, free of a soybean odor, unique in flavor, tender and soft in mouthfeel, safe, sanitary, and long in quality guarantee period.

Owner:HENGMAO IND GRP

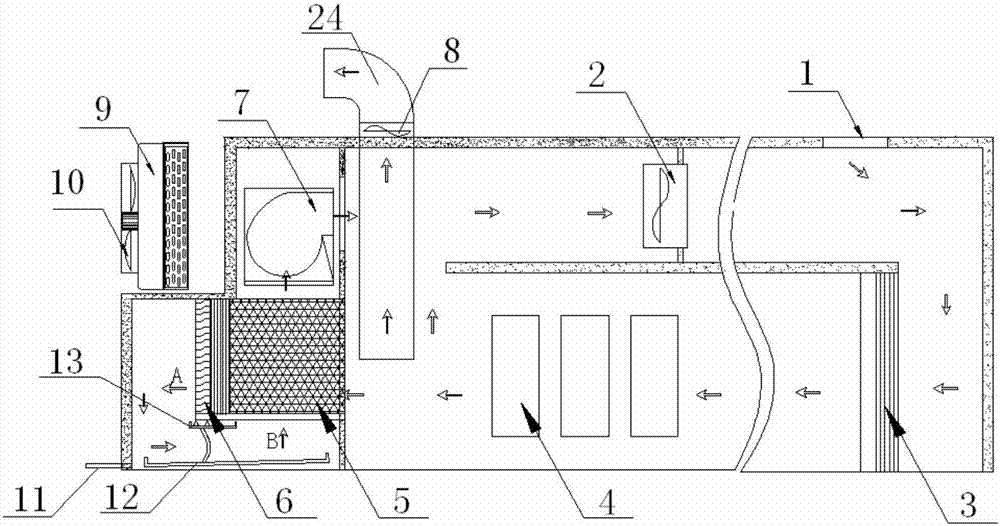

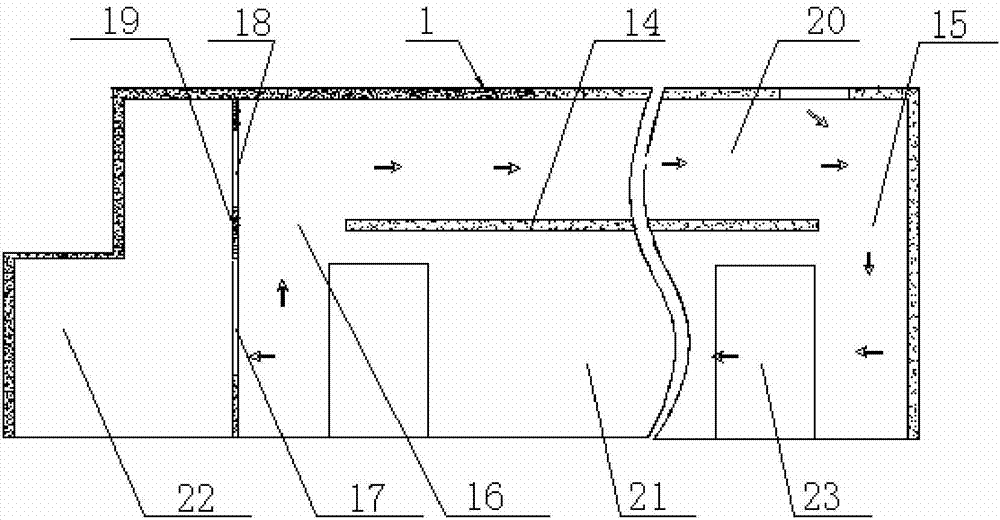

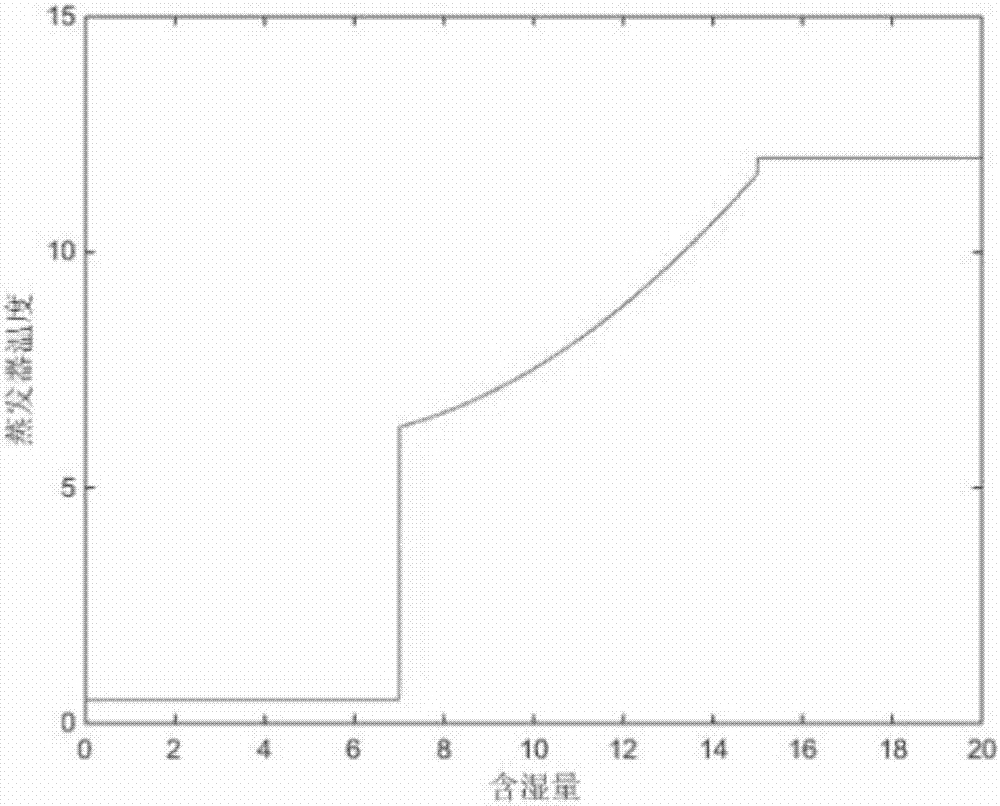

Dehumidification control method of fish fillet seafood tunnel drying system based on heat pump

ActiveCN107439661ALow costSimple methodFood processingMeat/fish preservation by dryingFrequency changerFish fillet

The present invention provides a dehumidification control method of a fish fillet seafood tunnel drying system based on a heat pump. The dehumidification control method comprises the following steps: 1) a circulation fan is turned on; 2) a compressor and a dehumidification fan are turned on, opening and closing of an outdoor condenser and regulation of an opening degree of an air door are used to control the temperature within a circulation air duct to be in a set range; if the moisture content x of the part, near an evaporator side, in the circulation air duct is large than or equal to 15, the target temperature y of fins of an evaporator is 12 DEG C; if the x is equal to or larger than 7 and less than 15, the y is 0.05215*x<2>-0.4749*x+7.059; and if x is less than 7, then the y is more than or equal to 0 DEG C; and 3) a frequency of a frequency changer of the dehumidification fan is controlled to enable the surface temperature of the fins of the evaporator to be rapidly close to the y value. The above steps are conducted to realize a maximum water discharging and dehumidification efficiency control of a whole machine system.

Owner:LUDONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com