Manufacture method of room temperature stored conditioning instant flavor fish cake with high elasticity

A high-elasticity, fish cake technology, used in food preparation, food science, applications, etc., can solve the problems of quality degradation such as elasticity, unsuitable for storage at room temperature, etc., achieve long shelf life, eliminate the effects of nutrients and flavor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

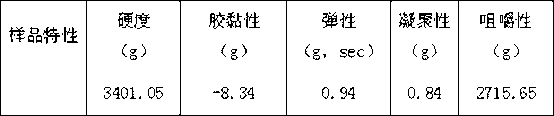

[0032] Example 1: Preparation of high-quality prepared ready-to-eat flavored fish cakes with high proportion of eels

[0033] (1) Use eel and fresh surimi, mix according to the ratio of 1:1.2, the beating process is divided into three steps: 1) Empty beating, the mixed fish meat is beating for 5 minutes; 2) Salt beating, after empty beating, add 0.2 The combination of %Tg enzyme and ratio is sodium pyrophosphate: sodium tripolyphosphate: sodium hexametaphosphate in the ratio of 0.8:0.54:0.66, and the optimal concentration is 0.5g / 100g. Boil with salt for 10 minutes to increase the water holding capacity and tenderness of the fish. Then add 1% salt to dissolve the salt-soluble protein in the fish, and finally add 7% egg white liquid and beat for 5 minutes. At this time, the water holding capacity and tenderness of the fish are at the best; 3) Mix and beat, add 1.5% soybean protein isolate, 6.7% cornstarch, 6.7% fat pork, 0.3% monosodium glutamate, 3% water and mix and beat So...

Embodiment 2

[0046] Example 2: Preparation of high-quality prepared ready-to-eat flavored fish cakes with medium proportion of eel

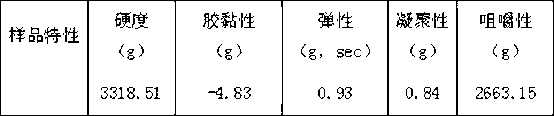

[0047] (1) Use eel and fresh surimi, mix according to the ratio of 1:1.5, the beating process is divided into three steps: 1) Empty beating, the mixed fish meat is beating for 5 minutes; 2) Salt beating, after empty beating, add 0.2 The combination of %Tg enzyme and ratio is sodium pyrophosphate: sodium tripolyphosphate: sodium hexametaphosphate in the ratio of 0.8:0.54:0.66, and the optimal concentration is 0.5g / 100g. Boil with salt for 10 minutes to increase the water holding capacity and tenderness of the fish. Then add 1% salt to dissolve the salt-soluble protein in the fish, and finally add 7% egg white liquid and beat for 5 minutes. At this time, the water holding capacity and tenderness of the fish are at the best; 3) Mix and beat, add 1.5% soybean protein isolate, 6.7% cornstarch, 6.7% fat pork, 0.3% monosodium glutamate, 3% water and mix and beat S...

Embodiment 3

[0056] Embodiment 3: the preparation of the high-quality conditioning ready-to-eat flavor fish cake of low eel ratio

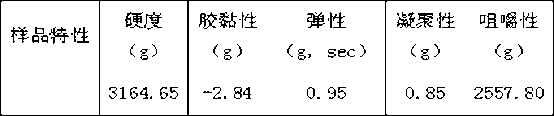

[0057] (1) Use eel and surimi, mix according to the ratio of 1:1.8, the grinding process is divided into three steps: 1) Empty grinding, the mixed fish meat is empty for 5 minutes; 2) Salt grinding, add 0.2% after empty grinding The combination of Tg enzyme and ratio is sodium pyrophosphate: sodium tripolyphosphate: sodium hexametaphosphate in the ratio of 0.8:0.54:0.66, and the optimal concentration is 0.5g / 100g. Boil with salt for 10 minutes to increase the water holding capacity and tenderness of the fish. Then add 1% salt to dissolve the salt-soluble protein in the fish, and finally add 7% egg white liquid and beat for 5 minutes. At this time, the water holding capacity and tenderness of the fish are at the best; 3) Mix and beat, add 1.5% soybean protein isolate, 6.7% cornstarch, 6.7% fat pork, 0.3% monosodium glutamate, 3% water and mix and beat Soak fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com