Preparation method of instant fish skin jelly food

A fish skin gel and food technology, applied in the field of preparation of instant fish skin jelly food, to achieve the effects of easy absorption by the human body, increased utilization value, and complete nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

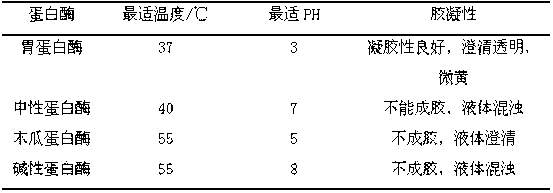

Image

Examples

Embodiment 1

[0025] 1. Cleaning: Put the raw fish skin in clean water to wash away mucus, impurities, etc.

[0026] 2. Degreasing: Degreasing the cleaned fish skin with lipase. Prepare an alkaline lipase solution with a solubility of 25.0u / ml (3000-3500U / g, Shandong Jienuo Bioenzyme Co., Ltd.), mix the fish skin with the lipase solution at a ratio of 1:4, and use Glycine-sodium hydroxide buffer was used to adjust the pH of the mixture to 9.0, and the mixture was kept at 40°C for 60 minutes to keep the fat content of the fish skin less than 2.0% (calculated on the basis of the wet basis of the fish skin).

[0027] 3. Enzymatic hydrolysis: pepsin (Beijing Suolaibao Technology Co., Ltd., 3 × 10 6 U / g) for enzymatic hydrolysis. Prepare a pepsin solution with a solubility of 30u / mL, mix the fish skin with the pepsin solution at a ratio of 1:4, adjust the pH of the mixture to 3.0 with 0.01mol / L citric acid-sodium citrate buffer solution, The mixture was incubated at 40°C for 200 min.

[0028...

Embodiment 2

[0034] A kind of preparation method of instant fish skin jelly food is as follows:

[0035] 1) Cleaning: wash the raw fish skin in clean water;

[0036] 2) Enzymatic degreasing: the washed fish skin is degreased with alkaline lipase, and the mass ratio of fish skin and enzyme solution is 1:3 for enzymolysis. The enzymatic hydrolysis conditions are: enzymatic hydrolysis pH=8.5, temperature 35°C, The enzymatic hydrolysis time is 75 minutes, the concentration of lipase solution is 20.0u / ml, and the fat content of fish skin after enzymatic hydrolysis and degreasing is less than 2.0%, calculated on a wet basis;

[0037] 3) Protease enzymatic hydrolysis: the degreased fish skin and pepsin solution are enzymatically hydrolyzed at a mass ratio of 1:3, the concentration of pepsin solution is 35u / mL, and the enzymatic hydrolysis conditions are: enzymatic hydrolysis pH 2, enzymatic hydrolysis time 180min, enzymatic hydrolysis temperature 40℃;

[0038] 4) Glue boiling: put the fish skin...

Embodiment 3

[0044] A kind of preparation method of instant fish skin jelly food is as follows:

[0045] 1) Cleaning: wash the raw fish skin in clean water;

[0046] 2) Enzymatic degreasing: the washed fish skin is degreased with alkaline lipase, and the mass ratio of fish skin and enzyme solution is 1:5 for enzymolysis. The enzymatic hydrolysis conditions are: enzymatic hydrolysis pH=9.5, temperature 45°C, The enzymatic hydrolysis time is 60 minutes, the concentration of lipase solution is 50.0u / ml, and the fat content of fish skin after enzymatic hydrolysis and degreasing is less than 2.0%, calculated on a wet basis;

[0047] 3) Protease enzymatic hydrolysis: the degreased fish skin and pepsin solution were enzymolyzed at a mass ratio of 1:5, the concentration of pepsin solution was 40u / mL, and the enzymatic hydrolysis conditions were: enzymatic hydrolysis pH 3, enzymatic hydrolysis time 240 min, enzymatic hydrolysis temperature 45°C;

[0048] 4) Glue boiling: put the fish skin after e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com