Patents

Literature

1319 results about "Green production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

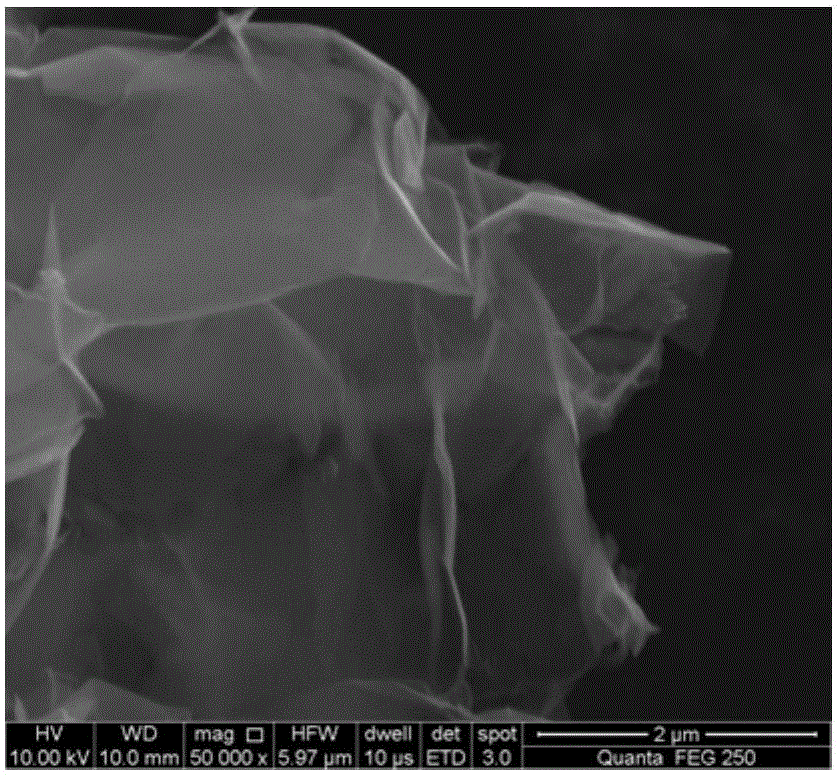

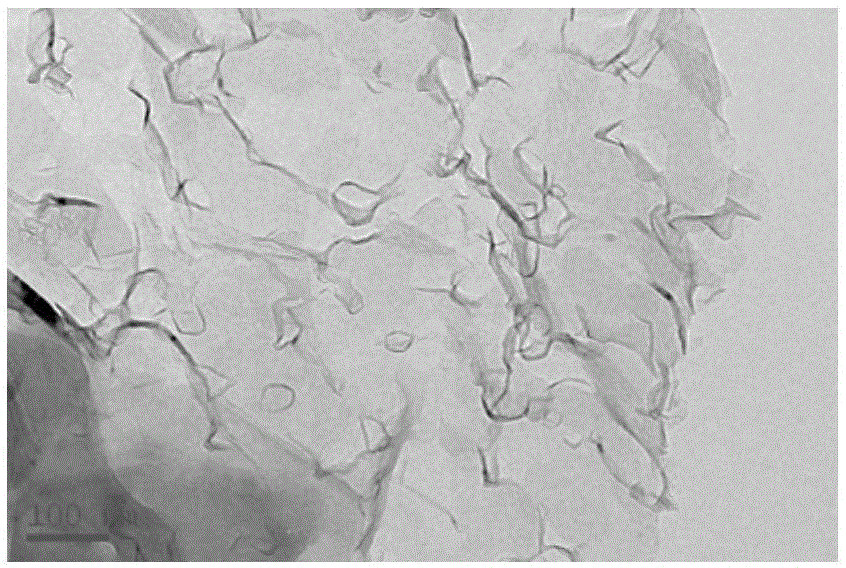

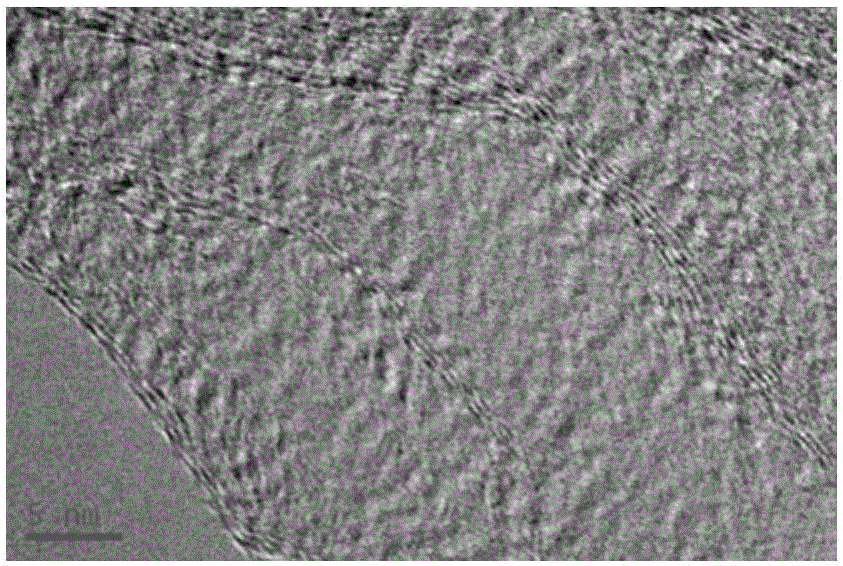

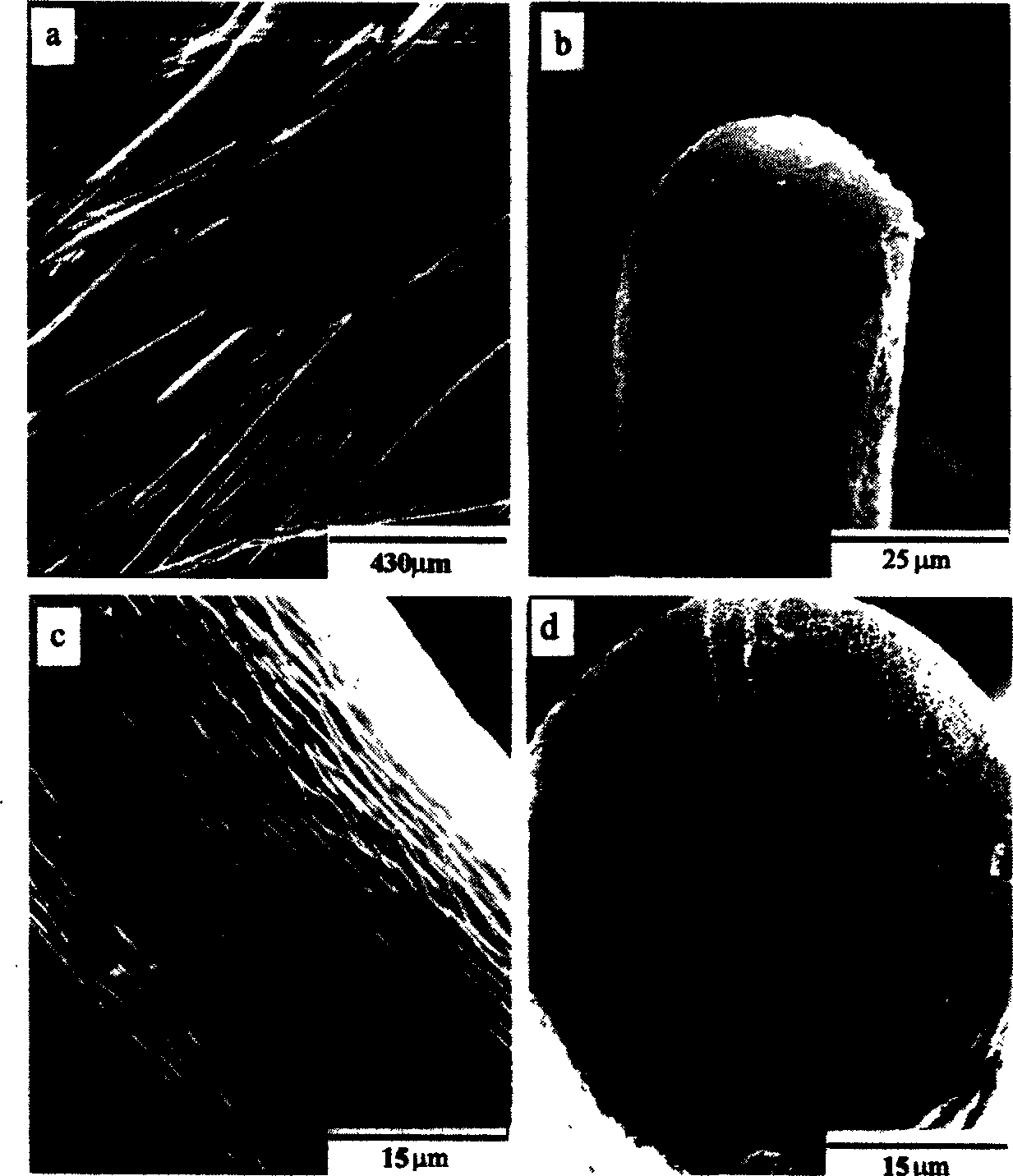

Method for preparing fewer-layer graphene on basis of biomass waste

ActiveCN105060289AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerArgon atmosphere

The invention discloses a method for preparing fewer-layer graphene on the basis of biomass waste, which comprises the following steps: carrying out hydrothermal treatment on the biomass waste, and carrying out carbonization by heating and calcination, thereby obtaining a carbonization material; immersing the carbonization material in an acid solution to remove impurities, thereby obtaining biomass carbon; and quickly heating the biomass carbon in an argon atmosphere, and carrying out high-temperature graphitization to obtain the biomass fewer-layer graphene. The hydrothermal process is combined with the high-temperature graphitization to directly strip the biomass waste, and the carbonization and high-temperature graphitization are carried out. Thus, the prepared biomass fewer-layer graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The method is simple to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production. The prepared biomass fewer-layer graphene can be used in the fields of lithium ion batteries, supercapacitors and the like, is beneficial to green production of battery industry, and has important practical value and favorable application prospects.

Owner:湖南宸宇富基新能源科技有限公司

Method for preparing 5-hydroxymethylfurfural by solid acid catalysis

InactiveCN102399201AAccelerated precipitationEasy to separateCatalyst carriersOrganic chemistrySolid acidCarbonization

The invention discloses a method for preparing 5-hydroxymethylfurfural by solid acid catalysis. The method comprises the following steps of taking lignin residue hydrolyzed by biomass as carrier raw material of solid acid; synthesizing the raw material into solid acid through a two-step way of carbonization and sulfonation, so that the waste material is recycled and the problem of disposal of pollutants is solved. In the dehydration reaction of lignin-based solid acid catalyzed fructose and glucose, the yield of 5-hydroxymethylfurfural can be respectively 84% and 68%; after the dehydration reaction, the lignin-based solid acid is easy to separate and reusable, the acid density of the solid acid can be reduced after being reused five times, and the yield of the 5-hydroxymethylfurfural is still higher than 75%. The method provided by the invention can be used for realizing emission without pollution, and is helpful for realizing environment-friendly producing process of 5-hydroxymethylfurfural.

Owner:XISHUANGBANNA TROPICAL BOTANICAL GARDEN CHINESE ACAD OF SCI

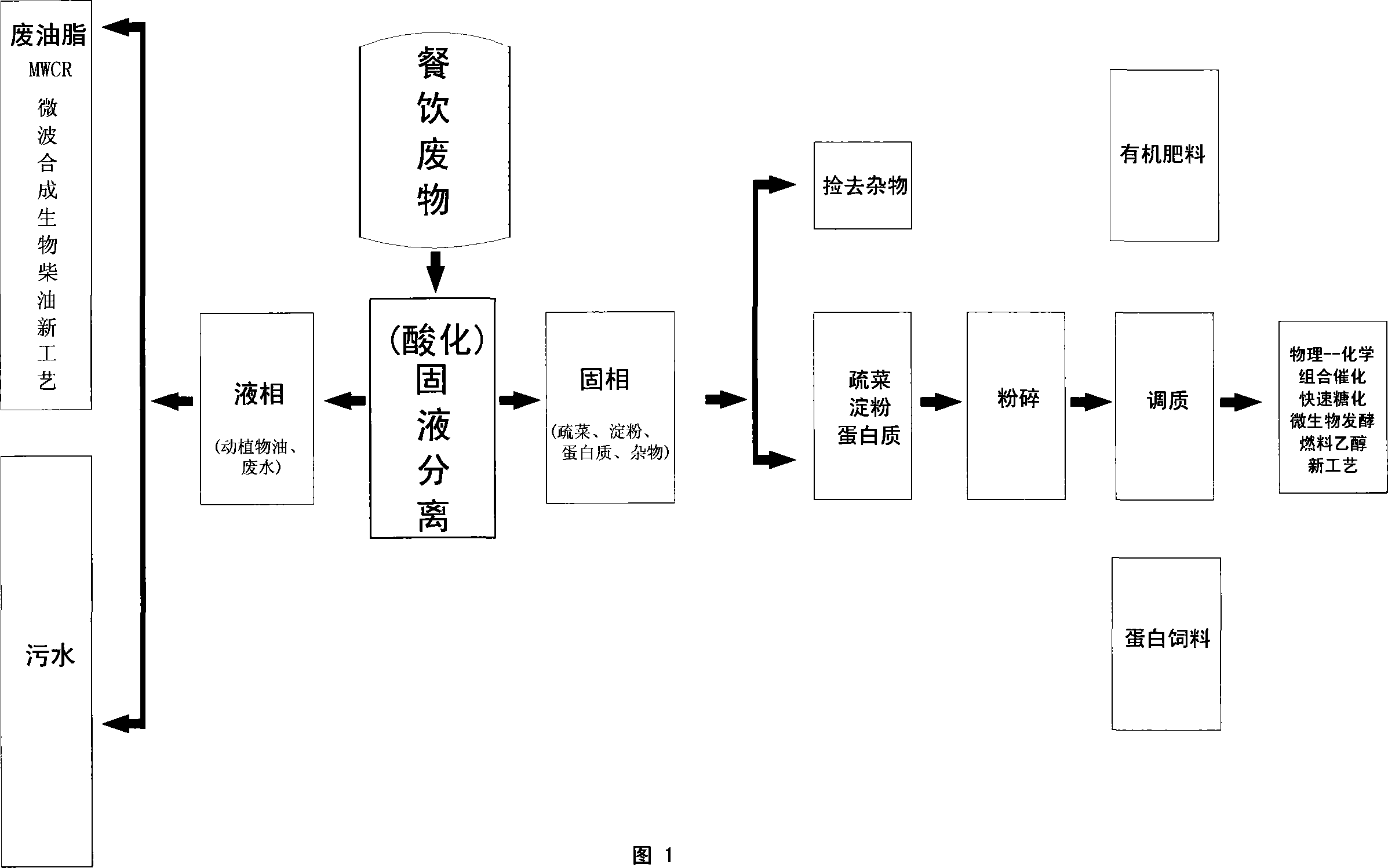

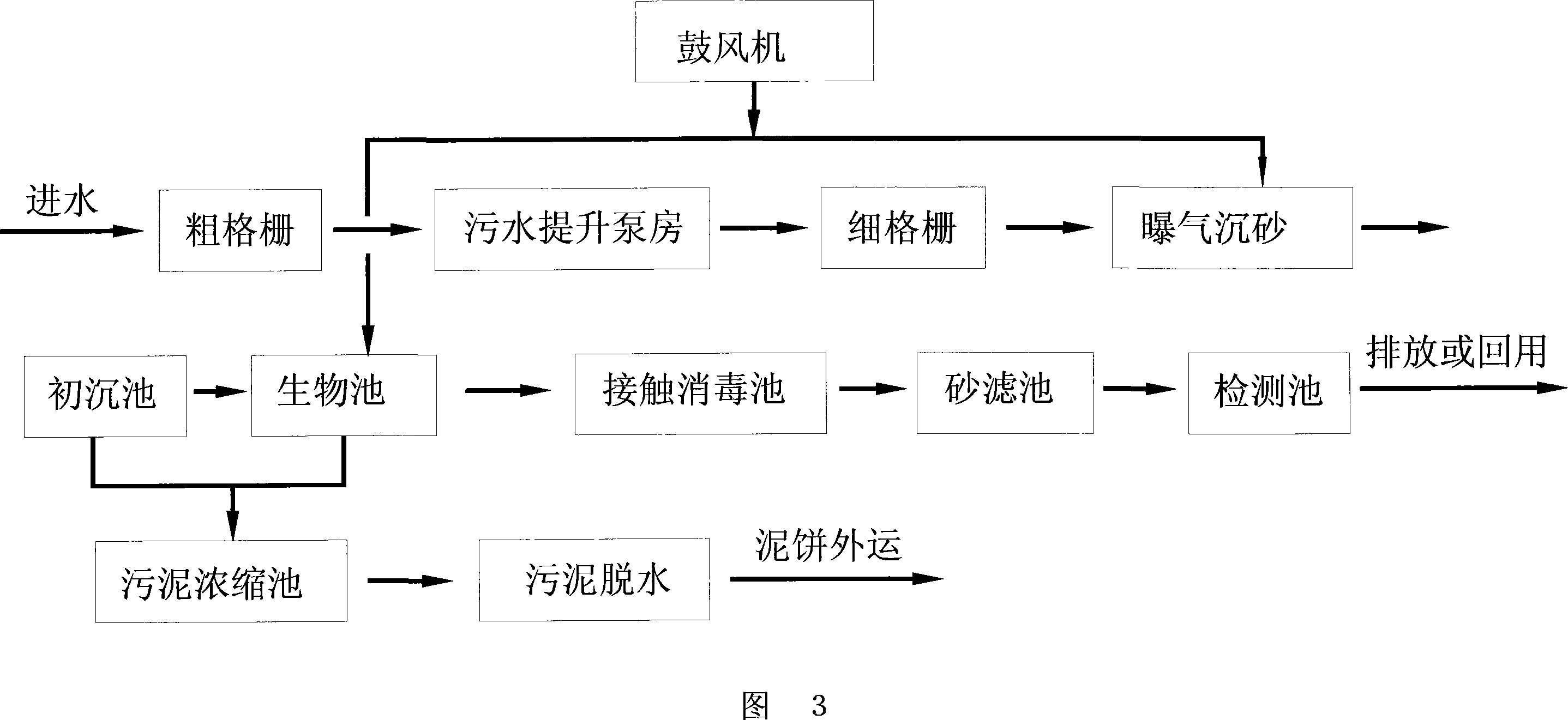

Resource using method for food and drink garbage

InactiveCN101058097AImprove conversion rateImprove efficiencyFood processingSolid waste disposalEngineeringWaste oil

The invention relates to a catering garbage reutilization method. It separates the liquid and the solid garbage and acidify them, then separate oil and water to get waste oil grease and sewage, using the waste grease synthesizing into biological diesel, processing the sewage to the required standard, crushing and grinding the solid, which are mixed with water to generate alcohol, batching, sterilizing, fermenting and drying the animal fodder. In this way, it can realize harmless processing of food waste, with zero discharge and enclosed green production.

Owner:中船重工(西安)东仪环保科技有限公司

Method for producing propylene oxide

ActiveCN101735177AReduce investmentAchieve recyclingOrganic chemistryDispersed particle separationProcess designSodium hydroxide

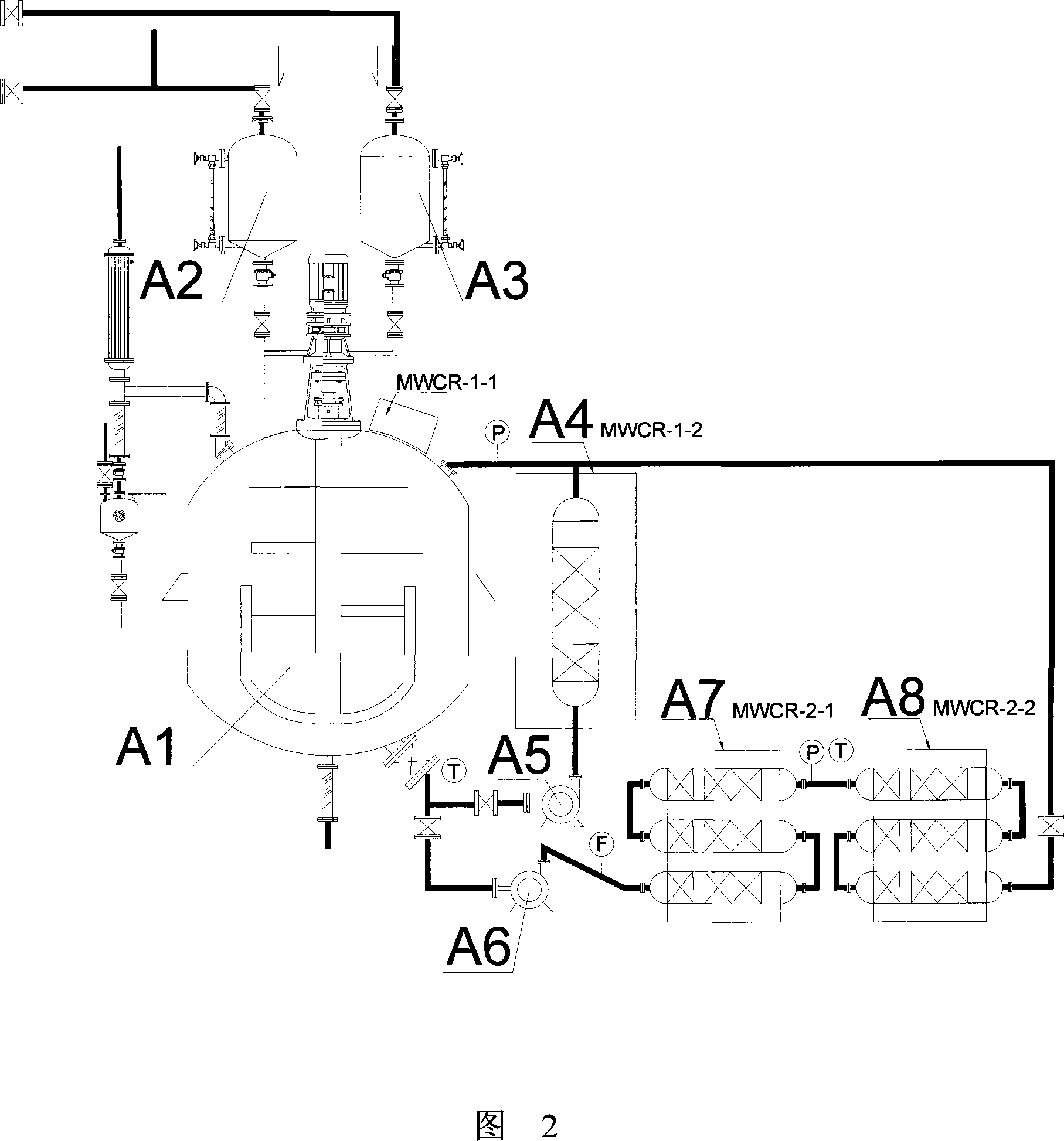

The invention discloses a chemical production method, in particular a novel green production process for propylene oxide. In the method, the process design is carried out by using bipolar membrane, electrodialysis, antiosmosis, air flotation, heat exchange, oxidation, and other technology. In the production process, sodium hydroxide replaces the conventional calcium hydroxide and generates sodium chloride through reaction; the sodium chloride generates hydrochloric acid and sodium hydroxide by the bipolar membrane technology; and the hydrochloric acid is recovered, and the sodium hydroxide and water can be recycled. Therefore, no new sodium hydroxide is needed and no wastewater is discharged in the production of the propylene oxide. The sodium hydroxide is added at the preliminary stage of the production of the propylene oxide, and the input amount of the sodium hydroxide is controlled between 5 and 15 percent. The novel green production process for the propylene oxide has the advantages that: the recycling of the water, sodium chloride and sodium hydroxide is realized, the effects of zero discharge and input reduction of production materials are substantially achieved, and finally better social and economic benefits are achieved. The novel green production process for the propylene oxide can be widely applied to the chlorohydrin production in China.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Process for preparing regenerated cellulose films and wires

The invention discloses a method for manufacturing cellulose film and silk. The cellulose is dissolved in mixed liquid 5-12wt% natrium oxyhydrogen and 8-20wt% ureophil, gets the cellulose liquid, then carries on film scratching and silk spraying to the cellulose, they are solidified in the solidifying bath, then the regenerated cellulose film and silk will be got after being cleaned. The cellulose thick liquid has excellent fiber textile performance and compactibiity of film, the regenerated cellulose has excellent light transmission and mechanical performance, the silk also has good mechanical performance. The method can obtain cellulose thick liquid by dissolving cellulose in room temperature. It has no contamination and its price is low, it is a kind of green manufacturing process.

Owner:WUHAN UNIV

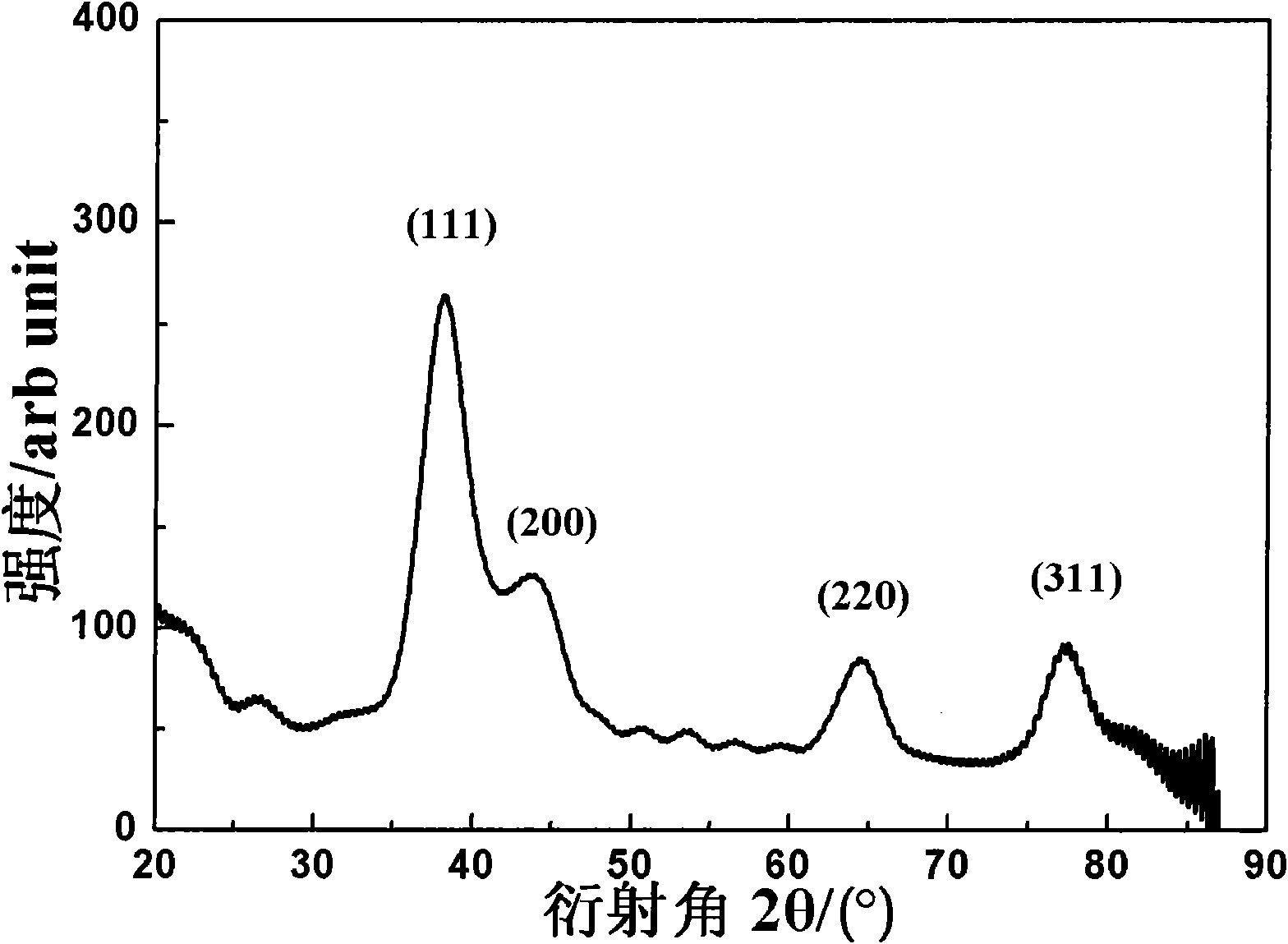

Novel and large-scale preparation method of nano-cuprous oxide

InactiveCN102167388AReduce consumptionNo generationNanostructure manufactureCopper oxides/halidesSolventReducing agent

The invention discloses a novel and large-scale preparation method of nano-cuprous oxide. The method comprises the steps of: fully dissolving copper salt and an organic protective agent in a dissolvent; gradually warming to 20-70 DEG C; adding a reducing agent into a reaction system after the temperature is stabilized; reacting for 20-30min by continuously stirring; gradually cooling; standing the cooled solution and centrifuging; and repeatedly washing by alcohol, deionized water and acetone sequentially in sequence to obtain stable cuprous oxide. The method is simple in technology, simple in operation, moderate in reaction, short in reaction time, and high in efficiency, thereby being suitable for large-scale production; the product is good in performance, the grain size of the nano-cuprous oxide is less than 20nm, and the product has good secondary dispersibility in various oil agents; the method is low in preparation cost, low in energy consumption, and free of the generation of harmful wastes, and meets the modern production requirement of 'green protection, environment protection and energy saving'.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

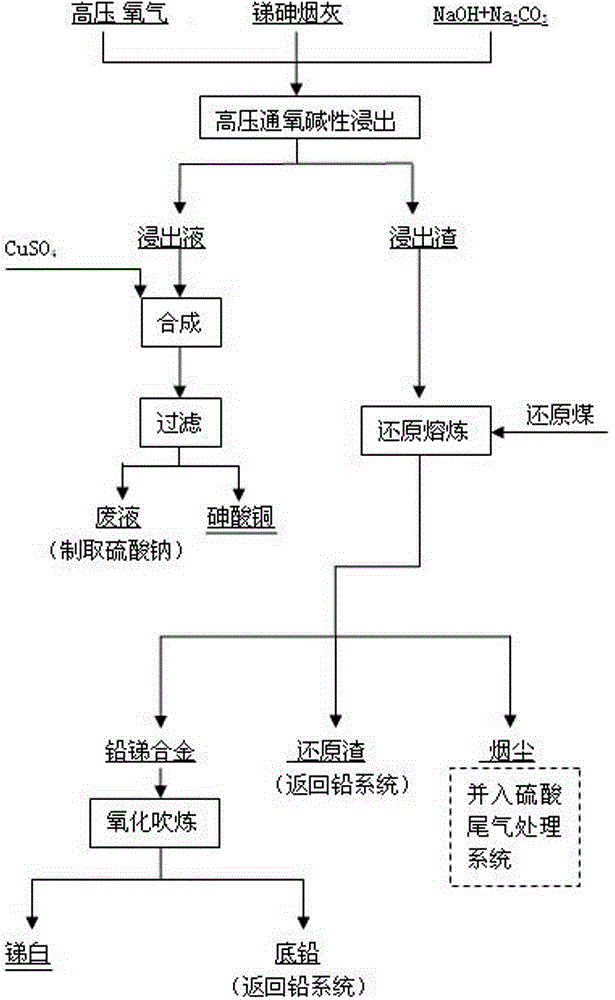

Environment-friendly and high-efficiency production method of antimony white by using Sb and As-containing ash

ActiveCN104911364AImprove energy efficiencyAvoid harmProcess efficiency improvementLiquid wasteChemical industry

The invention relates to an environment-friendly and high-efficiency production method of antimony white by using Sb and As-containing ash, belonging to the fields of nonferrous metallurgy and chemical industry. The production method comprises the following steps: putting Sb and As-containing ash into a high-pressure reactor, adding sodium hydroxide and sodium carbonate and performing high-pressure alkaline oxygen bleaching; reacting leachate with copper sulfate to generate a copper arsenate product and preparing sodium sulfate by using waste liquid; burdening leaching residue and reducing coal and adding to an internal smelter for reduction smelting to generate lead-antimony alloy; and burdening the produced lead-antimony alloy in an oxidizing kettle and performing oxidizing blowing to obtain antimony white with purity of 99.5% or above, wherein reduction residue obtained through reduction smelting returns to a lead system to be subjected to burdening and bottom lead obtained through oxidizing blowing also returns to the lead system to be subjected to burdening. The production method has the beneficial effects that As comes into leachate and Sb comes into leaching residue so that As and Sb in the Sb and As-containing ash can be effectively separated; moreover, the Sb and As-containing ash can be converted into high-purity antimony white, harm of As in the Sb and As-containing ash can be eliminated and As can be converted into a valuable copper arsenate product; latent heat in the production process is used sufficiently. The production method has the advantages of high raw material adaptability, large handling capacity, high energy efficiency and the like; moreover, environment pollution is avoided and green production is realized.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Preparation method for regenerated cellulose fiber

InactiveCN1594680AGood fiber spinnabilityReduce consumptionMonocomponent cellulose artificial filamentWet spinning methodsCellulose fiberAqueous solution

The invention discloses a preparation method for regenerated cellulose fiber, comprising: dissolving the cellulose in 5-12 wt.% of sodium hydroxide and 8-20 wt.% of urea mixed water solution, agitating, producing dense cellulose solution, spinning on the spinning machine by wet spinning method and regenerating solidification in the coagulating bath, drawing, drying, getting the regenerated cellulose fiber. The method is simple, short-processed, unpolluted and cheap. The method is hopeful to replace the rayon and non-woven cloth produced by the adhesive method which is high-pollution.

Owner:WUHAN UNIV +1

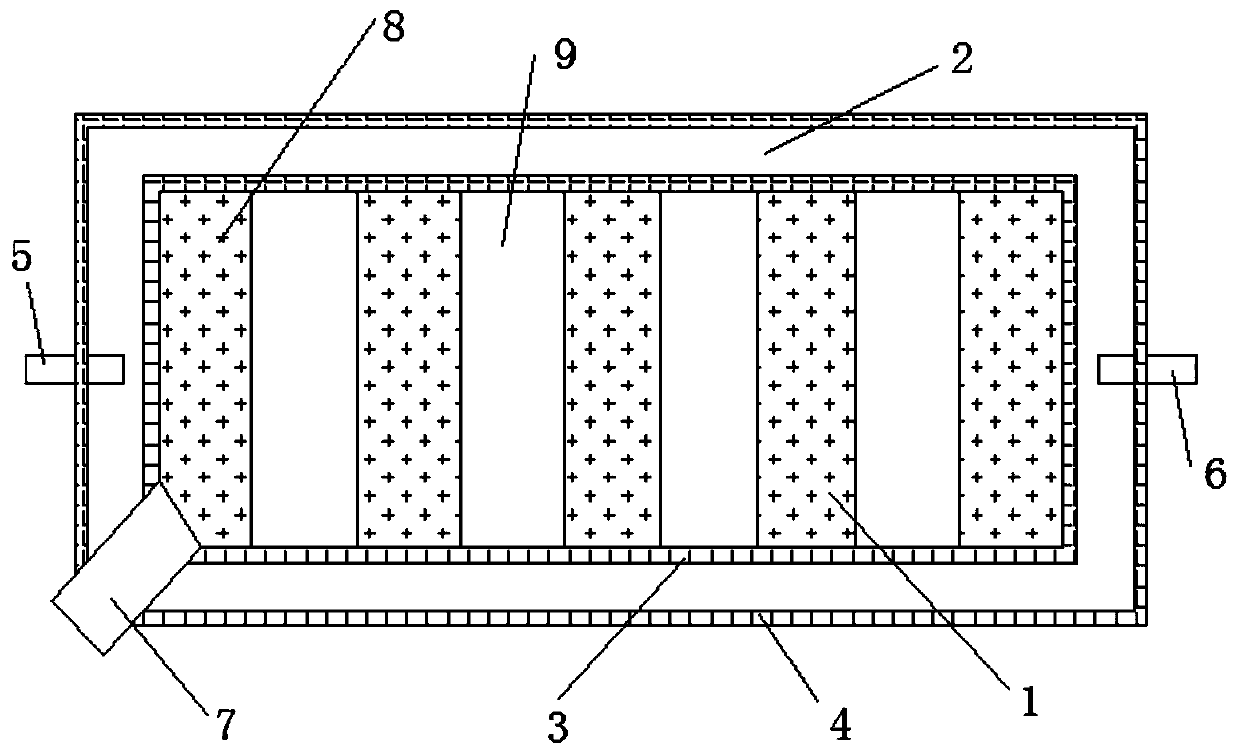

Nano-copper conductive ink preparation method

InactiveCN101608077ASimple processMild reaction conditionsInksNon-conductive material with dispersed conductive materialDistillationSolvent

The invention belongs to the nanometer material technical field, in particular to a nano-copper conductive ink preparation method, comprising the following steps: dissolving copper salt and organic protective agents in a solvent, heating the solution to 30-100 DEG C, simultaneously adding reducing agent in the reaction system to react while stirring for 20-30min, then cooling gradually; finally obtaining stable nano-copper conductive ink through electrodialysis separation and reduced pressure distillation. The invention has simple process, mild reaction conditions and short reaction time; the conductibility of the product is good, the particle size of nano-copper is 20-70nm, the nano-copper can not be oxidized for one month in the air; the production cost is low and no hazardous waste can be generated, thus meeting the demand of 'green production'.

Owner:FUDAN UNIV

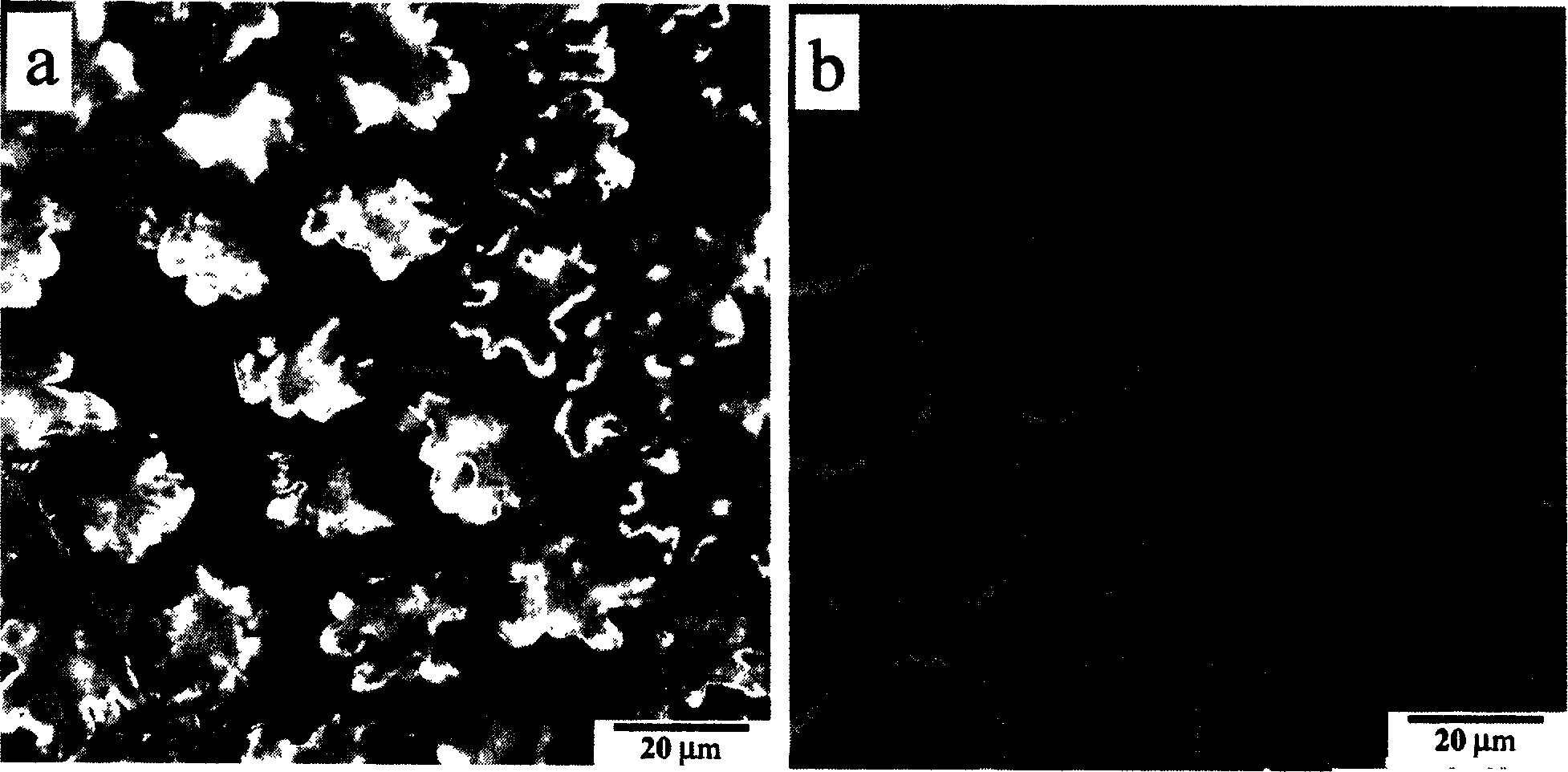

Method for synthesizing superfine Y-type molecular sieve

InactiveCN101891221AEasy to operateSuitable for large-scale productionFaujasite aluminosilicate zeoliteMolecular sieveHydrothermal synthesis

The invention discloses a method for synthesizing a superfine Y-type molecular sieve by using FCC spent catalyst fine powder, and belongs to the field of solid waste recycling. The method comprises the following steps of dissolving an FCC spent catalyst by using alkali for activation, and preparing the superfine Y-type molecular sieve by utilizing structure-oriented hydrothermal synthesis technology under the condition of adding a silicon source. The particle size of the obtained molecular sieve is controlled by a synthetic condition, particularly the activation condition of raw materials, and the particle size of the product can reach about 200 nm. Besides, the obtained product has a larger specific surface and a stable structure, and has a lamellar structure. In the method, the greening production process of the FCC is optimized, and the high-efficiency recycling of waste resources is realized, so that the method has good industrialized application prospect.

Owner:PETROCHINA CO LTD +1

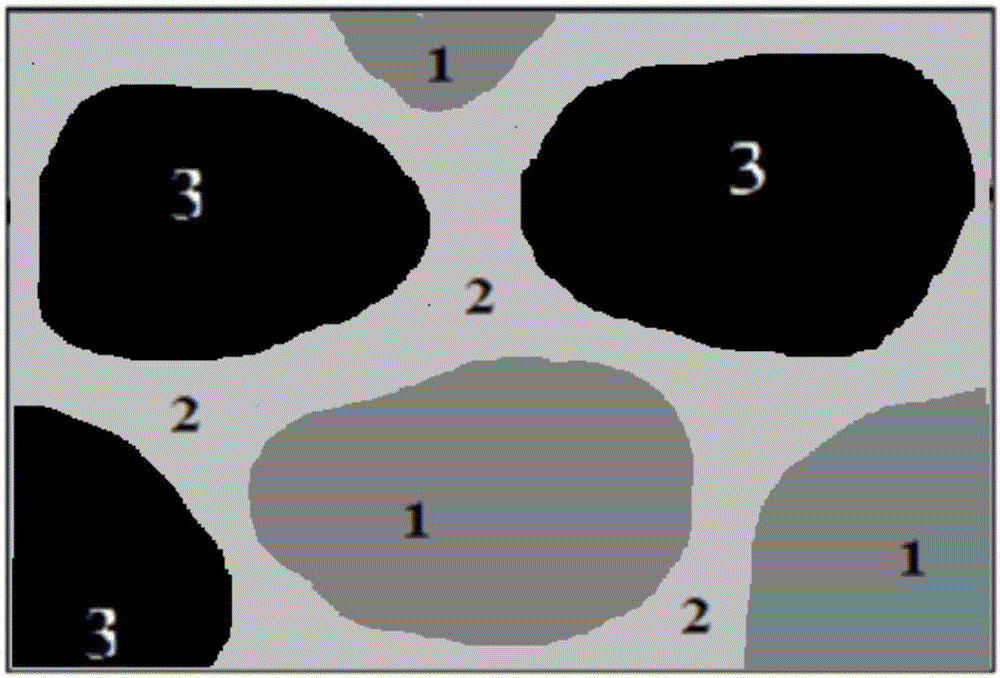

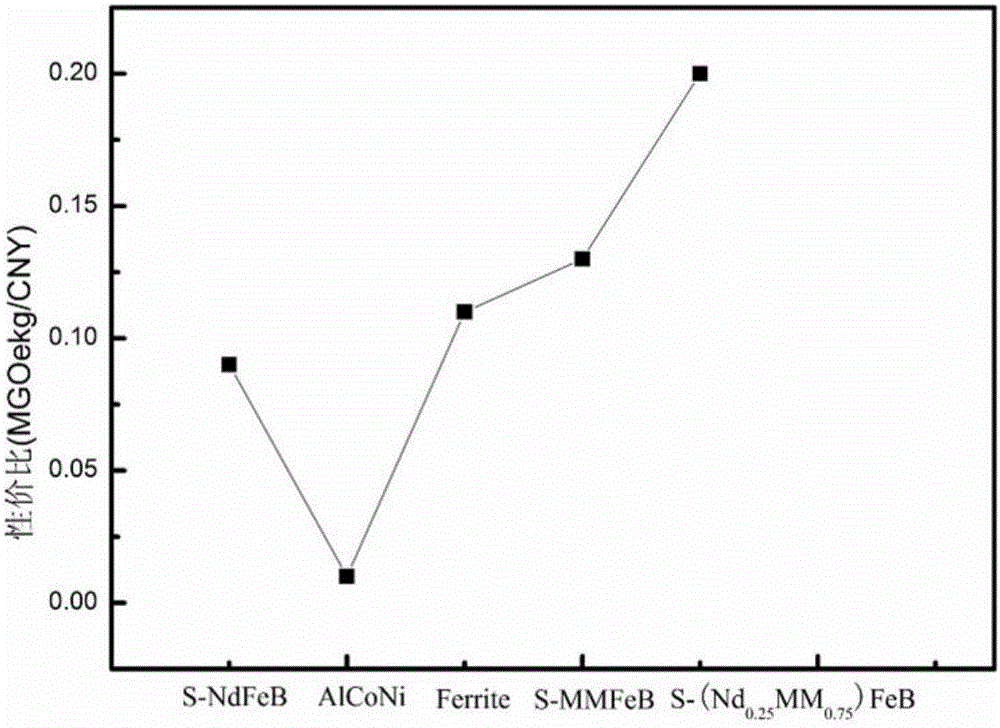

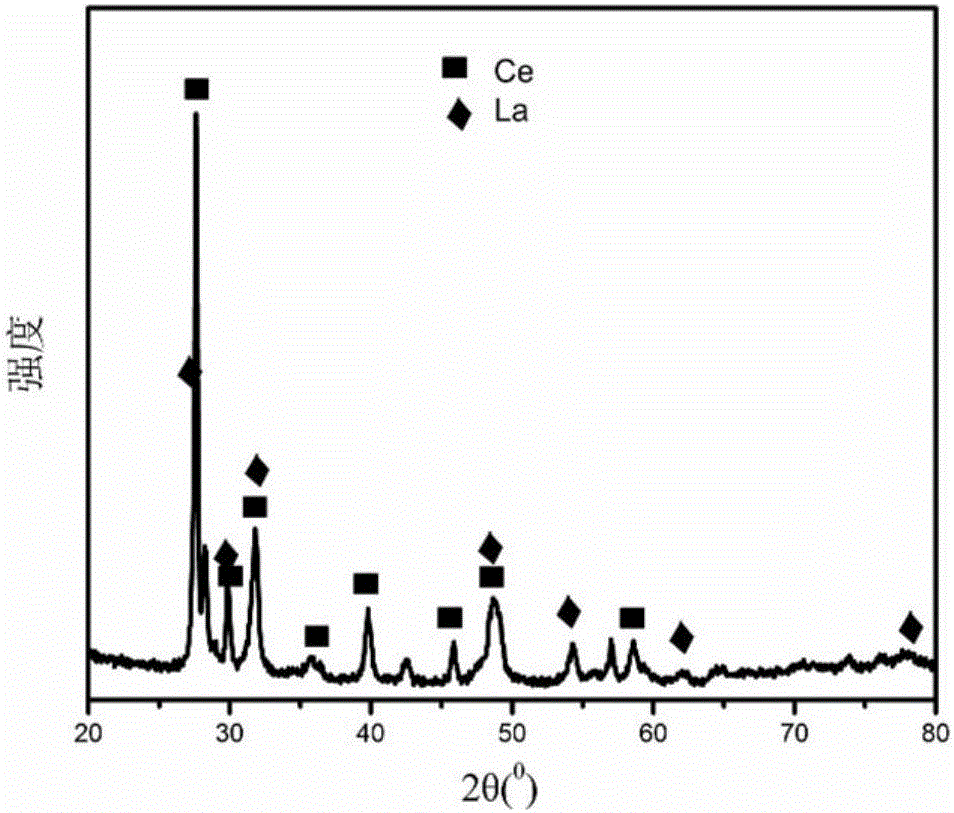

Double-hard magnetic main phase mixed rare-earth permanent magnet and preparation method thereof

ActiveCN106128674ANo wasteNo pollution in the processInductances/transformers/magnets manufactureMagnetic materialsChemical compositionCerium

The invention relates to a double-hard magnetic main phase mixed rare-earth permanent magnet and a preparation method thereof. The permanent magnet comprises double hard magnetic main phases and a rear-earth-rich phase, wherein the double hard magnetic main phases are MM<2>Fe<14>B and (PrNd)<2>Fe<14>B respectively; the permanent magnet is prepared from the following chemical component in percentage by mass: [MM<x1>(PrNd)<1-x1>]<x>Fe<100-x-y-z>B<y>TM<z>; x is smaller than or equal to 31 and greater than or equal to 27; x1 is smaller than or equal to 1 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0.9; z is smaller than or equal to 1.5 and greater than 0; TM is a composition of more of the elements Al, Cu, Co, Nb, Ga, Tb and Zr; and MM is a mixed rare-earth alloy which is directly separated from raw ore and contains La, Ce, Pr and Nd. The anisotropic sintered mixed rare-earth permanent magnet with high cost performance within a range of 10-48MGOe can be prepared by adjusting the content of PrNd. A basic rare-earth raw material used by the permanent magnet is cheap mixed rare earth, so that a separation and purification technology for the rare earth can be reduced, efficient utilization of lanthanum-cerium rare earth is achieved and the double-hard magnetic main phase mixed rare-earth permanent magnet meets the requirements of low carbon economy on green production technology innovation of a rare-earth permanent magnet product.

Owner:CENT IRON & STEEL RES INST

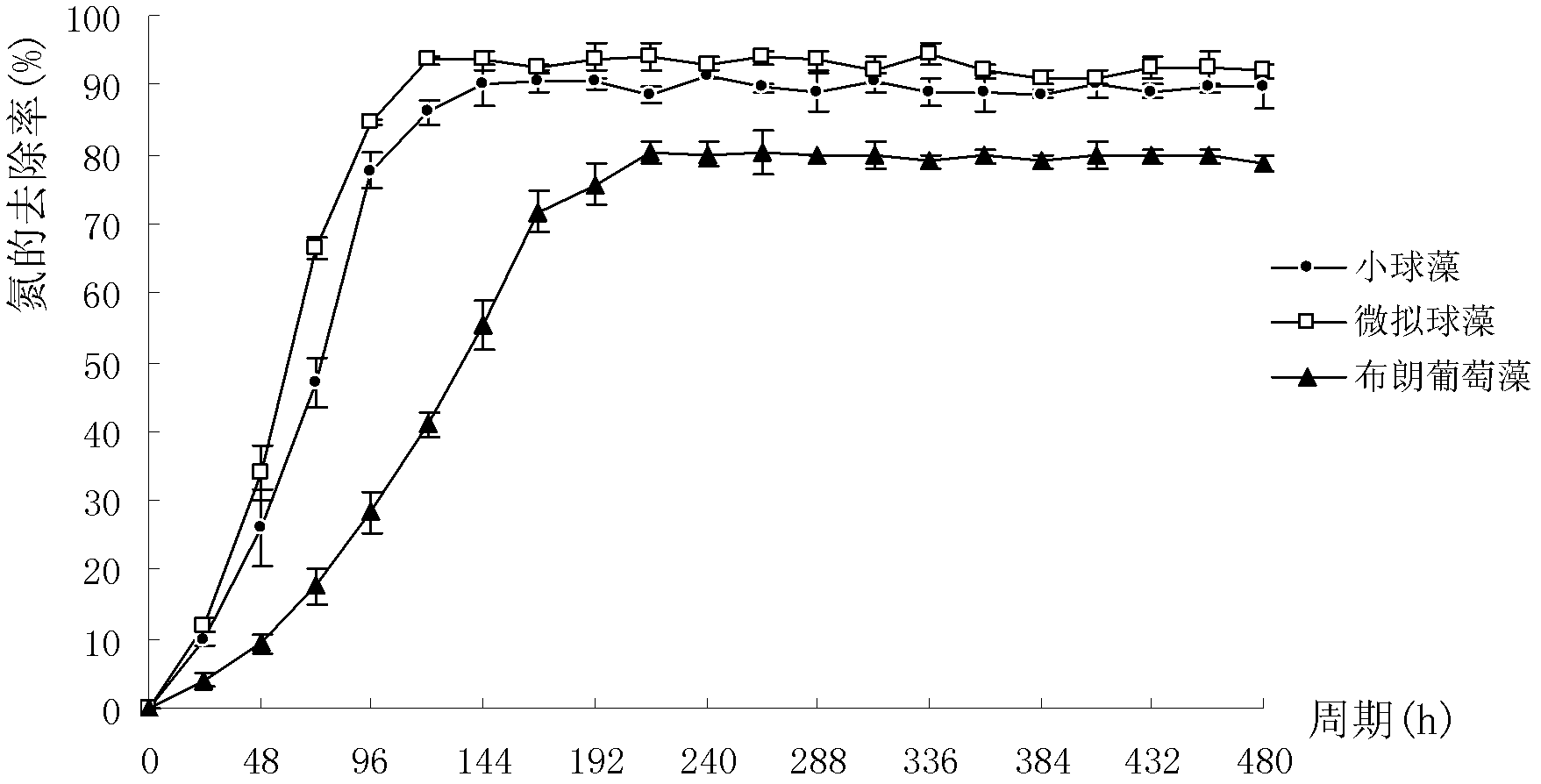

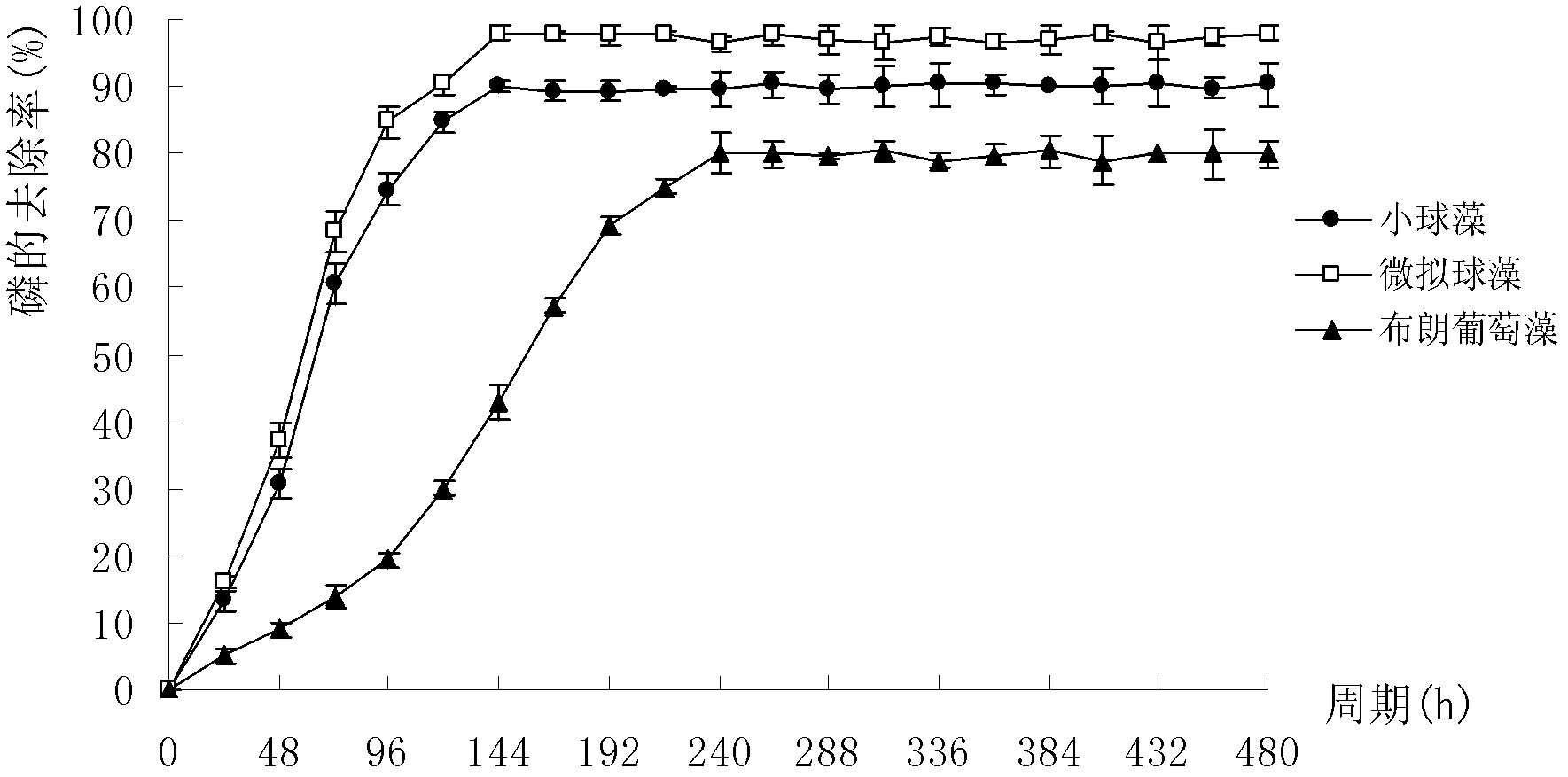

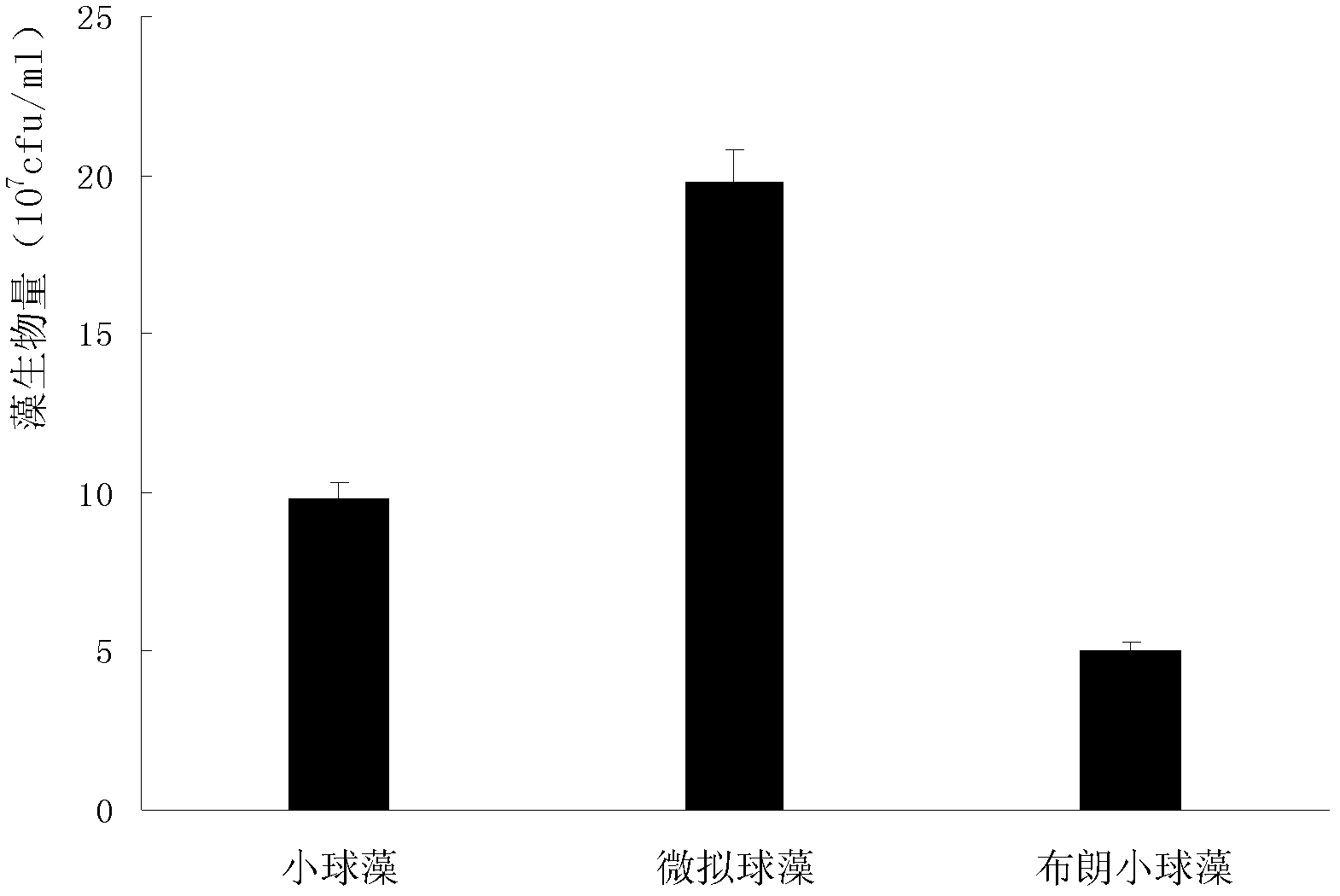

Method for treating fermentation industry waste water and producing algae powder by using microalgae

ActiveCN102863115AAchieve comprehensive utilizationAchieve emission reductionMultistage water/sewage treatmentEnergy based wastewater treatmentHydrogenPhotobioreactor

The invention provides a method for treating fermentation industry waste water and producing algae powder by using microalgae. The method comprises the following steps of: (1) carrying out pre-treatment on the fermentation industry waste water; (2) adding the microalgae to treat; (3) collecting the microalgae; and (4) preparing the algae powder. Preferentially, the pre-treatment step comprises: diluting the fermentation industry waste water and adjusting a pH (Potential Of Hydrogen) value of the fermentation industry waste water to be suitable for growth of the microalgae, wherein CO2 gas which is collected from released gas of a fermentation factory serves as a main carbon source of microalgae cultivation, treatment is carried out in a bioreactor, and a transparent groove-type closed bioreactor is preferentially selected. The method for treating the fermentation industry waste water and producing the algae powder by using the microalgae achieves emission reduction of CO2 and production of the algae powder while treating the fermentation industry waste water, so that the cost of production can be reduced, the comprehensive utilization of waste resources can be achieved, and the energy-saving and emission-reduction green production can be realized. The method is suitable to the microalgae cultivation in a laboratory and industrial large-scale microalgae cultivation, is clever and unique in design, and is suitable to large-scale popularization and application.

Owner:JIANGNAN UNIV

Method for preparing conductive cellulose fibers

InactiveCN102102231AEvenly dispersedImprove conductivityMonocomponent cellulose artificial filamentWet spinning methodsCarbon nanotubeAcid washing

The invention discloses a method for preparing conductive cellulose fibers, which comprises the following steps of: mixing nano carbon black and carbon nano tube in a certain ration, performing acid washing and purification, and then grinding and dispersing the mixture of carbon and ionic liquid under the condition of an infrared lamp; obtaining nano carbon / cellulose spinning solution containing 8 to 15 weight percent of carbon by using the carbon-containing ionic liquid as a cellulose solvent; and preparing carbon-containing cellulose composite fibers by using a dry-jet wet-spinning or wet-spinning process and using deionized water as a coagulation bath. The method can simply and feasibly realize uniform dispersion of the carbon nano tube and the carbon black in the cellulose fibers, andgreatly improves the electric conductivity of the cellulose fibers; and the obtained carbon-containing cellulose composite fibers can be widely applied in the antistatic field of materials for clothes or industries. The solvent used for the process production is nontoxic and can be repeatedly reclaimed and used, and the whole process realizes green production.

Owner:福建省纤维检验局

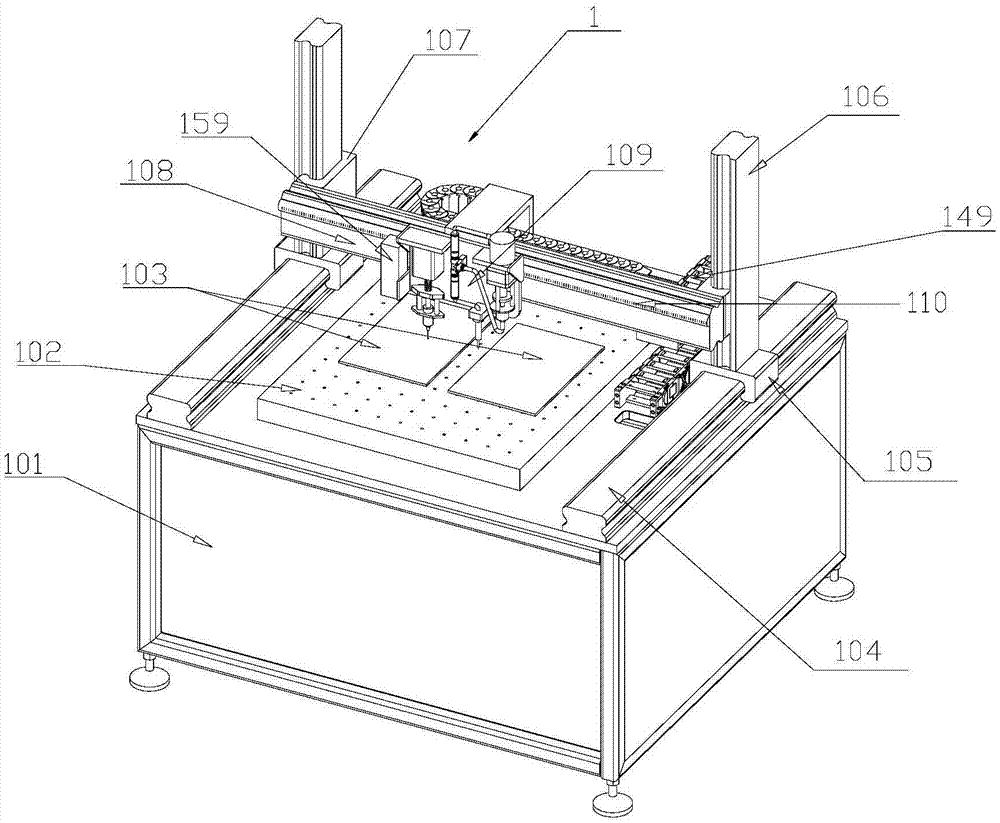

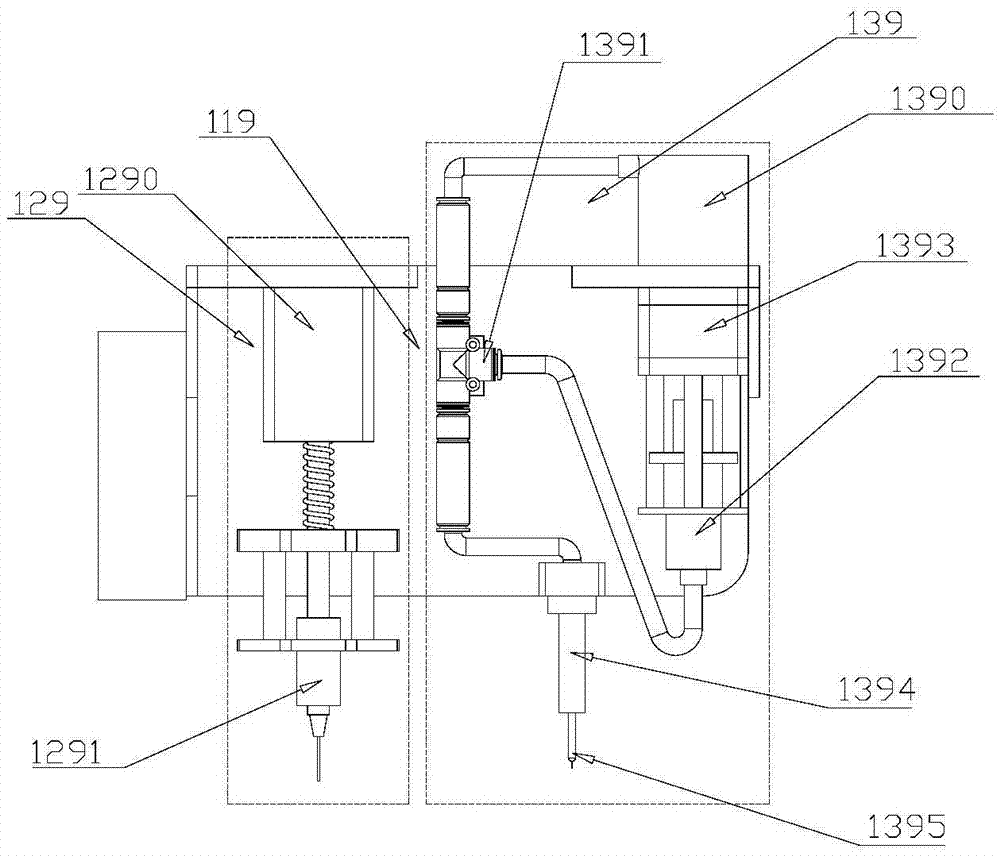

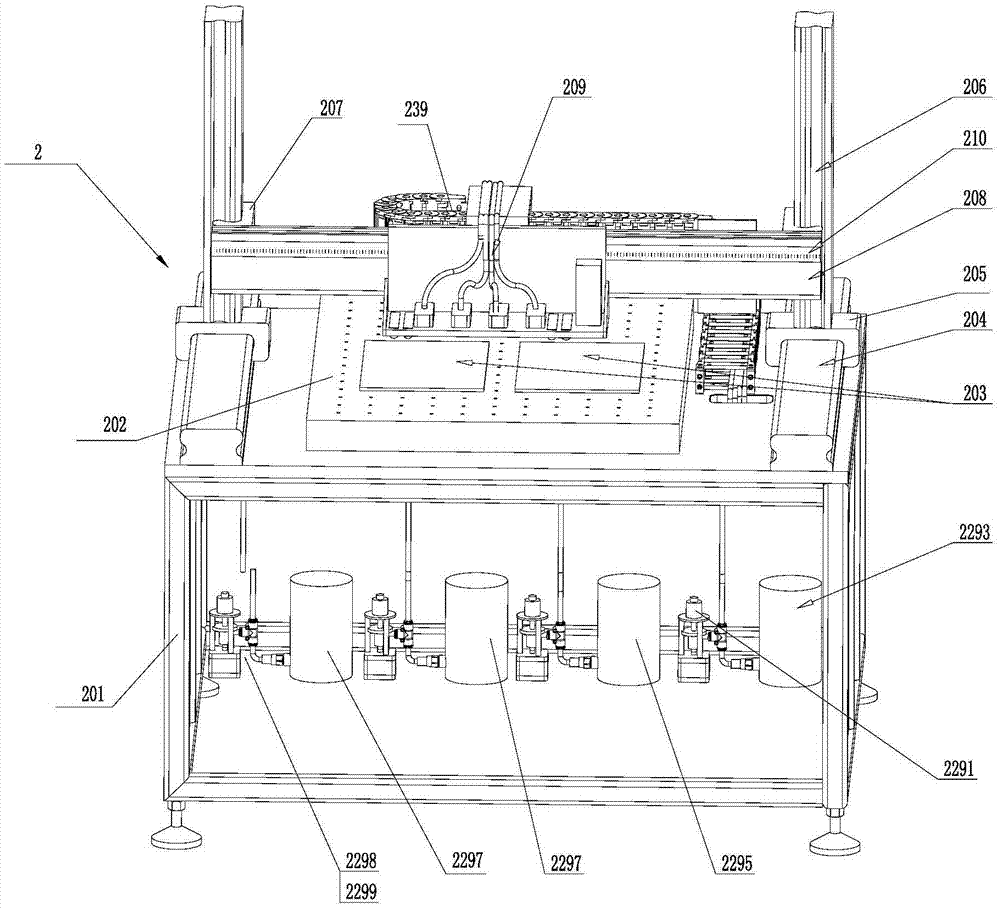

3D printer set for quickly manufacturing PCB (printed circuit board)

InactiveCN105437769AIncrease the areaEasy to produceLaminationLamination apparatusPrinting inkEngineering

The invention relates to a 3D printer set for quickly manufacturing a PCB (printed circuit board). The 3D printer set comprises three-dimensional drilling spray needle equipment, three-dimensional ink-jet character equipment and three-dimensional press fit equipment. Novel 3D printing equipment based on a digital inkjet technology uses materials such as nano liquid metal, photosensitive resin and the like to manufacture the PCB. The 3D printer set is integrated with punching, silver depositing, line spraying, coating and lettering, so that the whole producing and manufacturing process of the PCB can be completed by only needing one set of equipment, and therefore, the producing process is greatly simplified; ink-jet printing speed is greater than electroplating and etching speed by more than 20 times, so that total process time is saved by more than 60%, producing and manufacturing time is greatly shortened, and reliability is also remarkably improved; functional printing ink is used for jet printing so as to obtain a printed line, a resistance welding layer and a character layer for manufacturing the PCB, and therefore, a material utilization rate is close to 100%, energy consumption is lower, cost is lower, and green production is realized; and the functional printing ink is adopted to directly carry out jet printing on an insulated base plate so as to obtain the printed line, the resistance welding layer and the character layer, so that a printing ink utilization rate is close to 100%, and almost no-pollution emission is realized.

Owner:TIANJIN XITONG ELECTRONICS EQUIP CO LTD

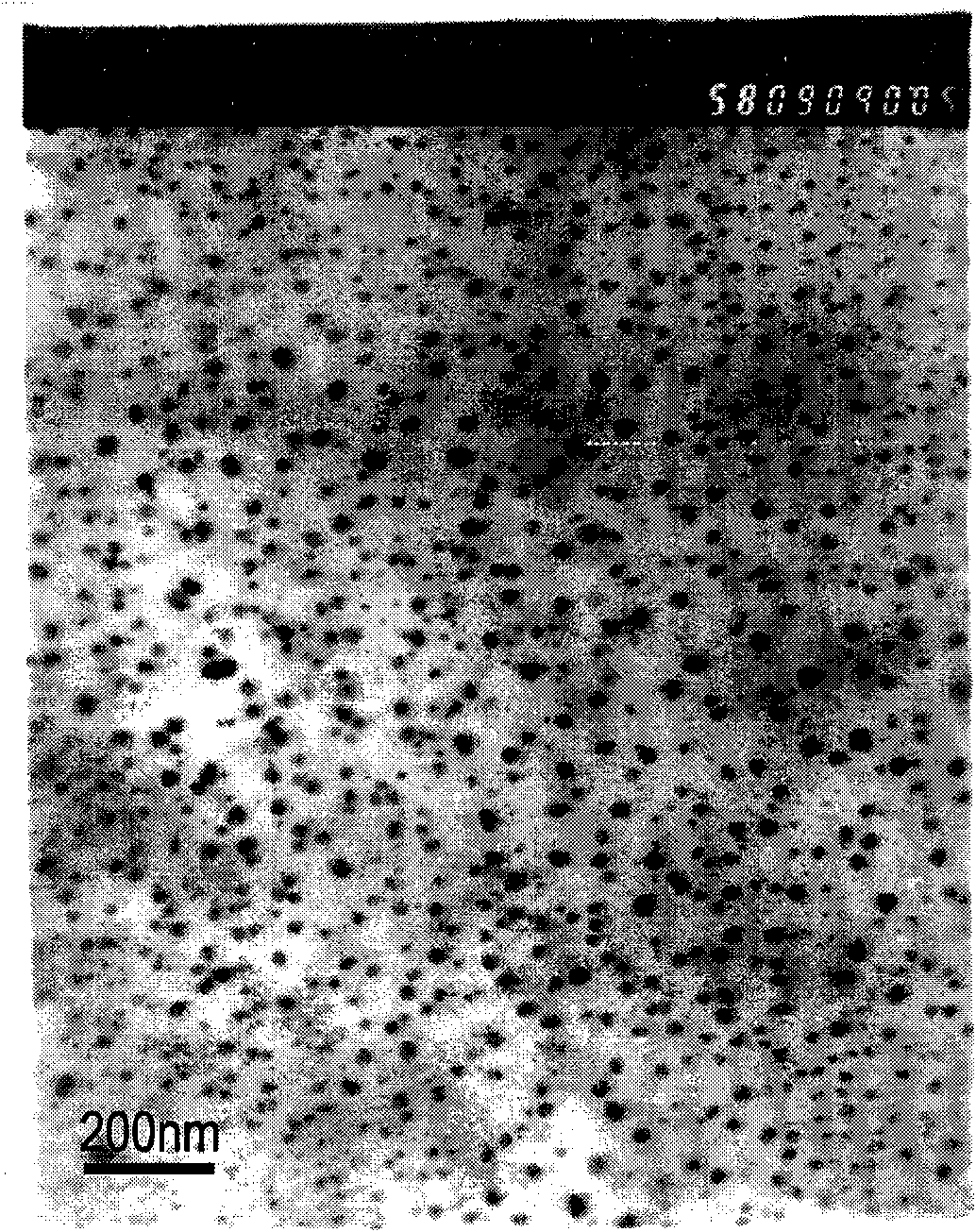

Preparation method of biomass-based colloidal carbon

The invention discloses a preparation method of biomass-based colloidal carbon and in particular relates to a colloidal carbon ball using xylose or glucose as a precursor. The colloidal carbon ball is prepared by hydrolyzing biomass by using dilute acid or concentrated acid respectively to obtain saccharic acid solution of xylose and glucose and performing in-situ polycondensation and carbonization on the saccharic acid solution. The preparation method particular comprises the following steps of: hydrolyzing the biomass by using dilute acid at a certain concentration; filtering to obtain xylosic acid solution and filter residues; adjusting the concentration of the saccharic acid solution and performing polycondensation and carbonization to prepare the colloidal carbon ball with grain size of 160 to 1,800 nm; performing alkali boiling on the residues to remove lignin; performing hydrolysis reaction on the residues and the concentrated sulfuric acid; filtering to obtain acid solution of the glucose; and performing in-situ polycondensation and carbonization to prepare the colloidal carbon ball with grain size of 180 to 2,000 nm. The method for preparing the colloidal carbon from the biomass is a green production route of sustainable development.

Owner:JILIN UNIV

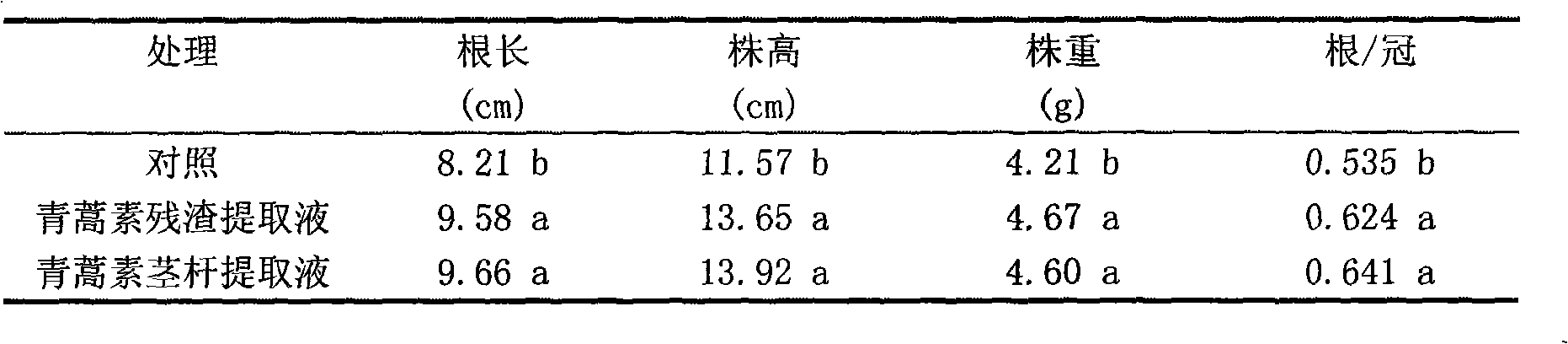

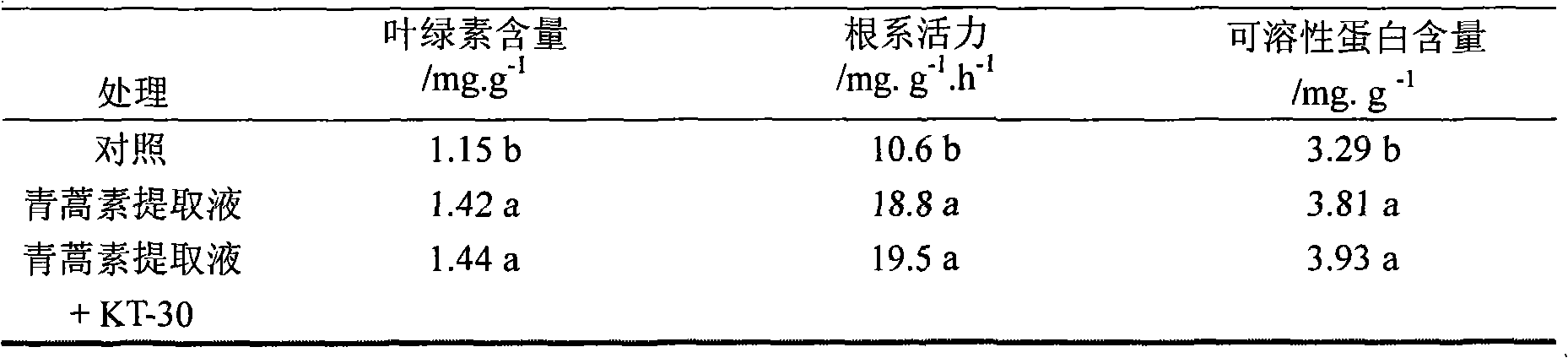

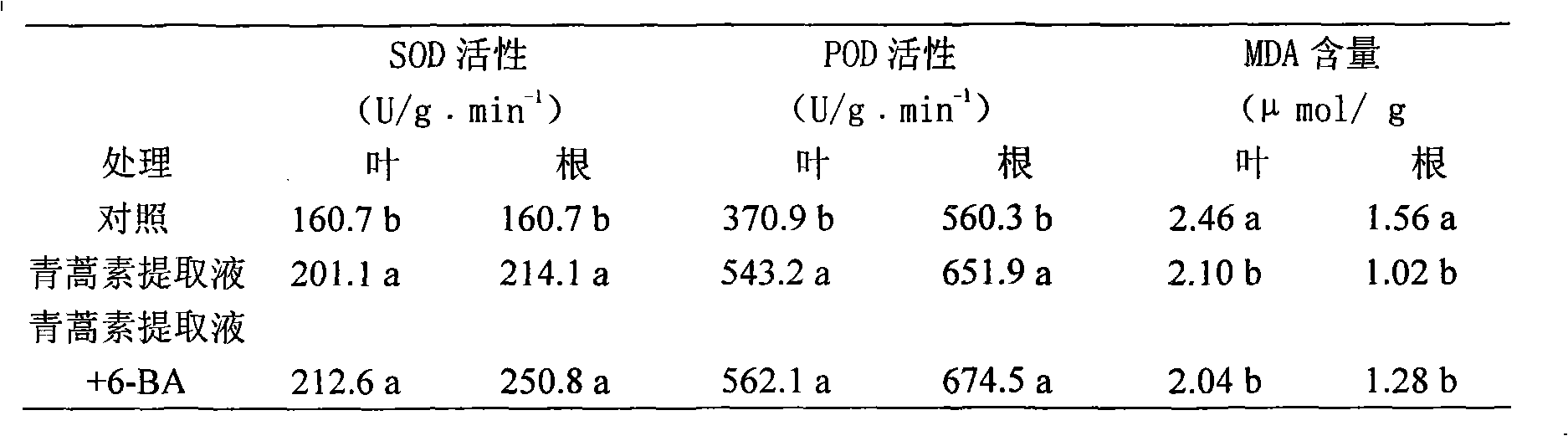

Use of southernwood extract as plant growth regulator and adverse-resistant agent

InactiveCN101258861AMake up for the defect of single ingredientAdjustable growthBiocidePlant growth regulatorsSOUTHERNWOOD ExtractAmbrosia artemisiifolia extract

The invention relates to a control agent and an anti-adversity agent of plant growth, which adopts southernwood, a Chinese traditional medicine, namely Artemisia annua L, as raw material, or adopts the secondary substances (also containing small amount of the artemisinin which is not completely extracted) which are abundant in the large amount of residues and concentrated mother solution after artemisinin is extracted by organic solvent. On the one hand, the invention does not influence the extraction of the artemisinin used for pharmaceuticals, on the other hand, the invention enhances the added value of the products of the southernwood, turns wastes into benefits and is good for environment protection and green production. The product of the invention is characterized by wide physiological effect, being safe and innoxious, being no pollution, being environment-friendly, easy obtaining of raw materials and low cost.

Owner:SOUTHWEST UNIV

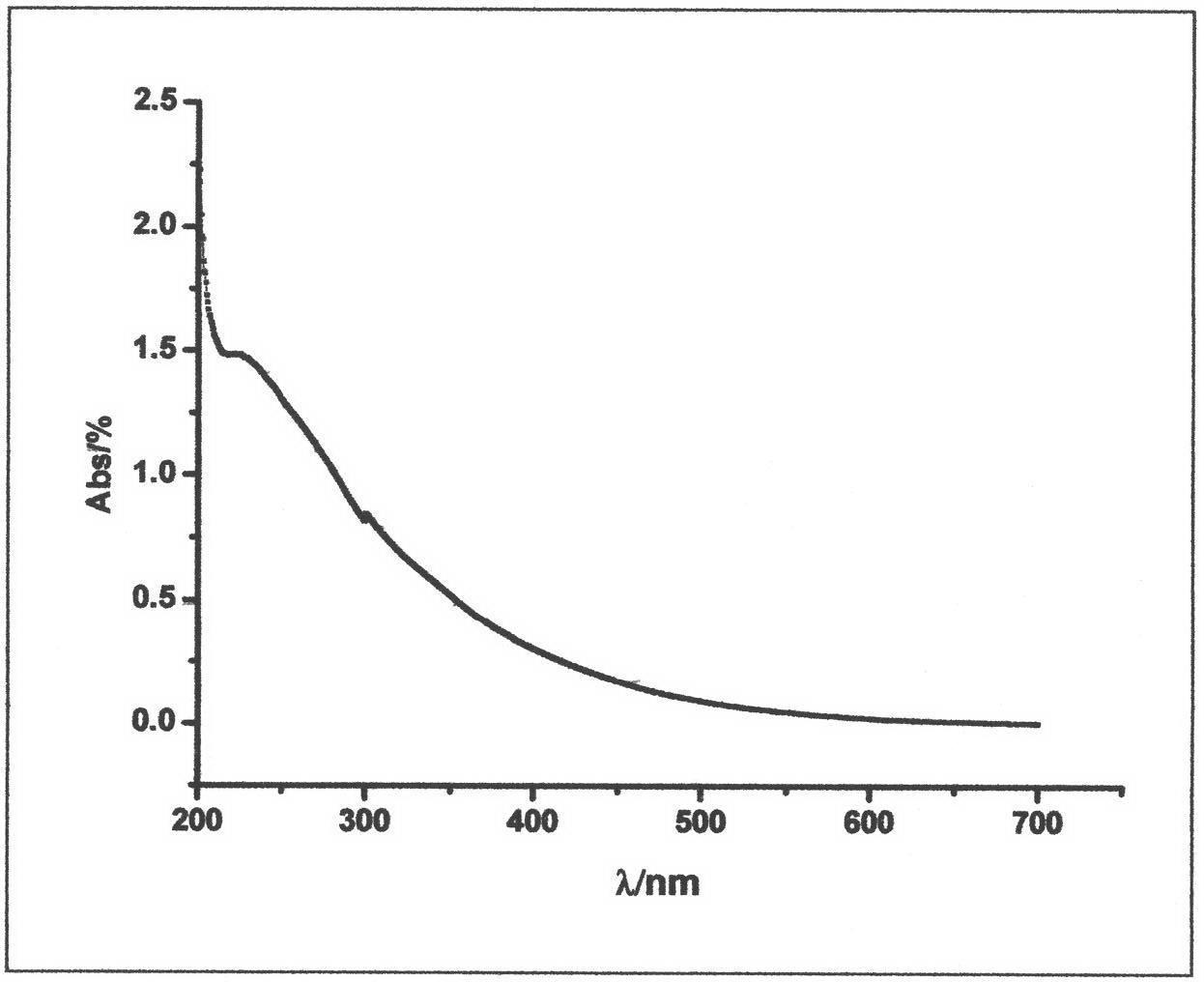

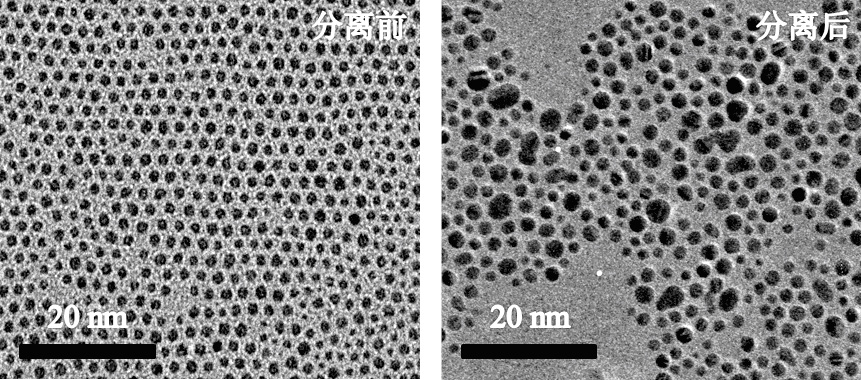

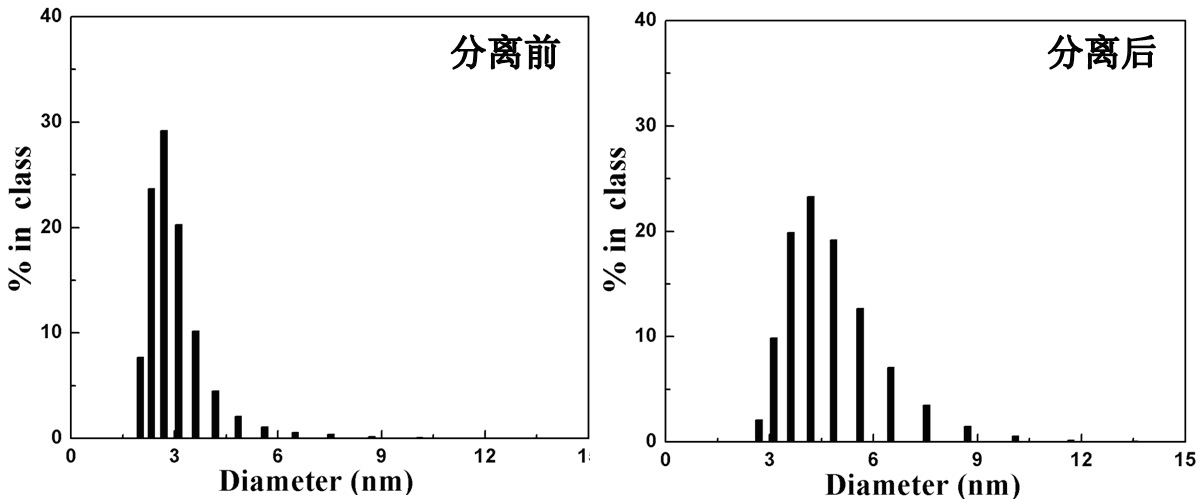

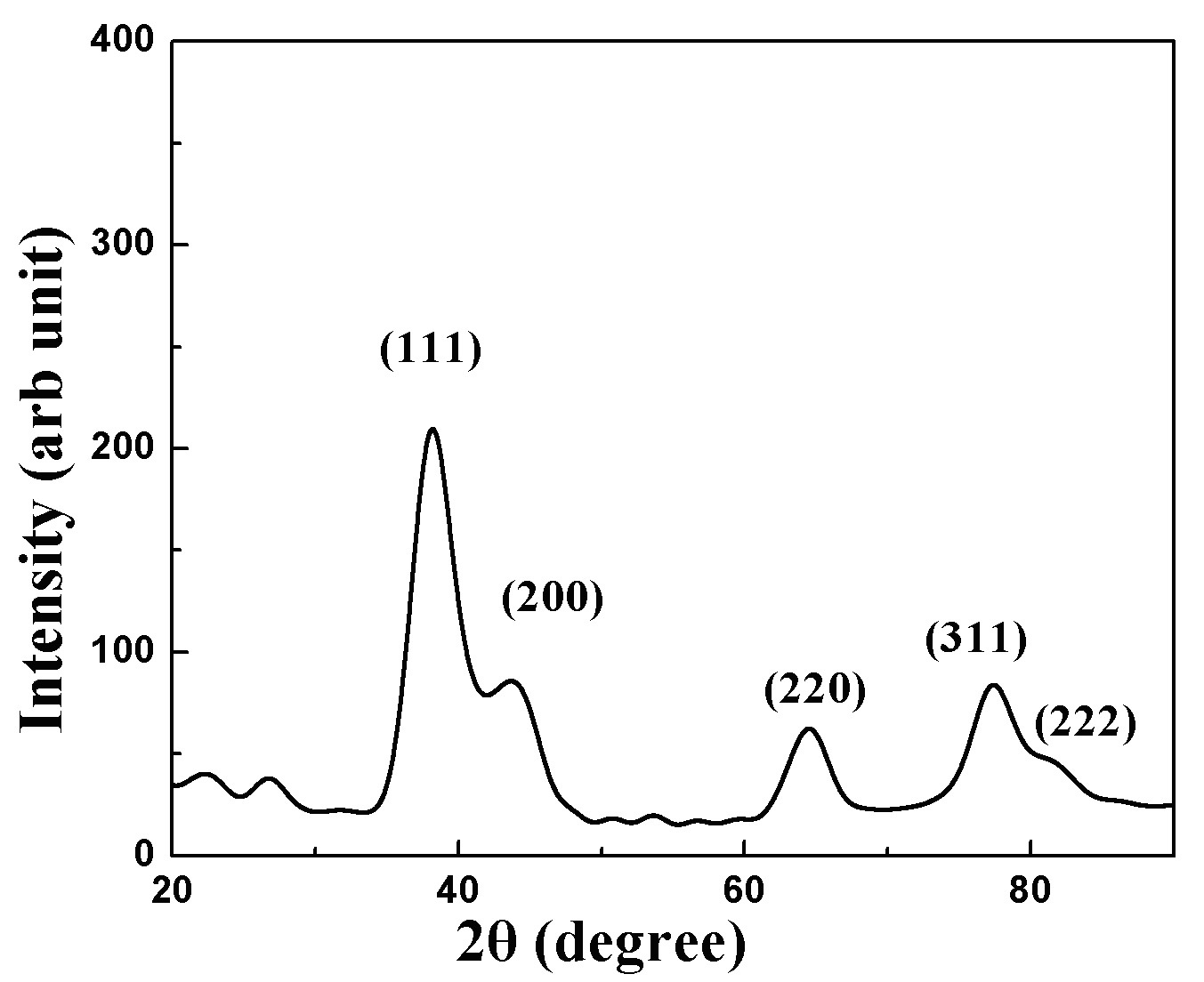

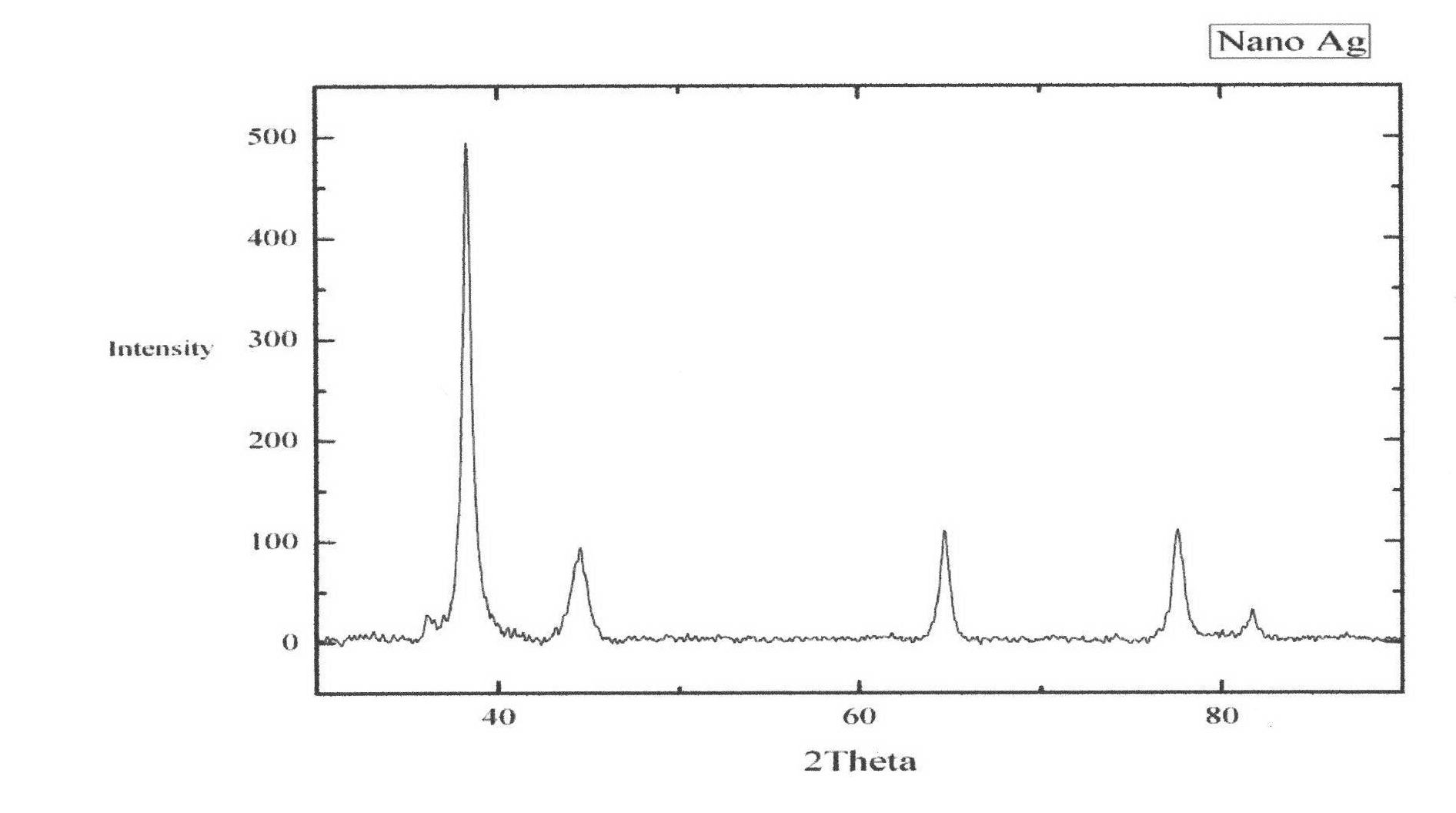

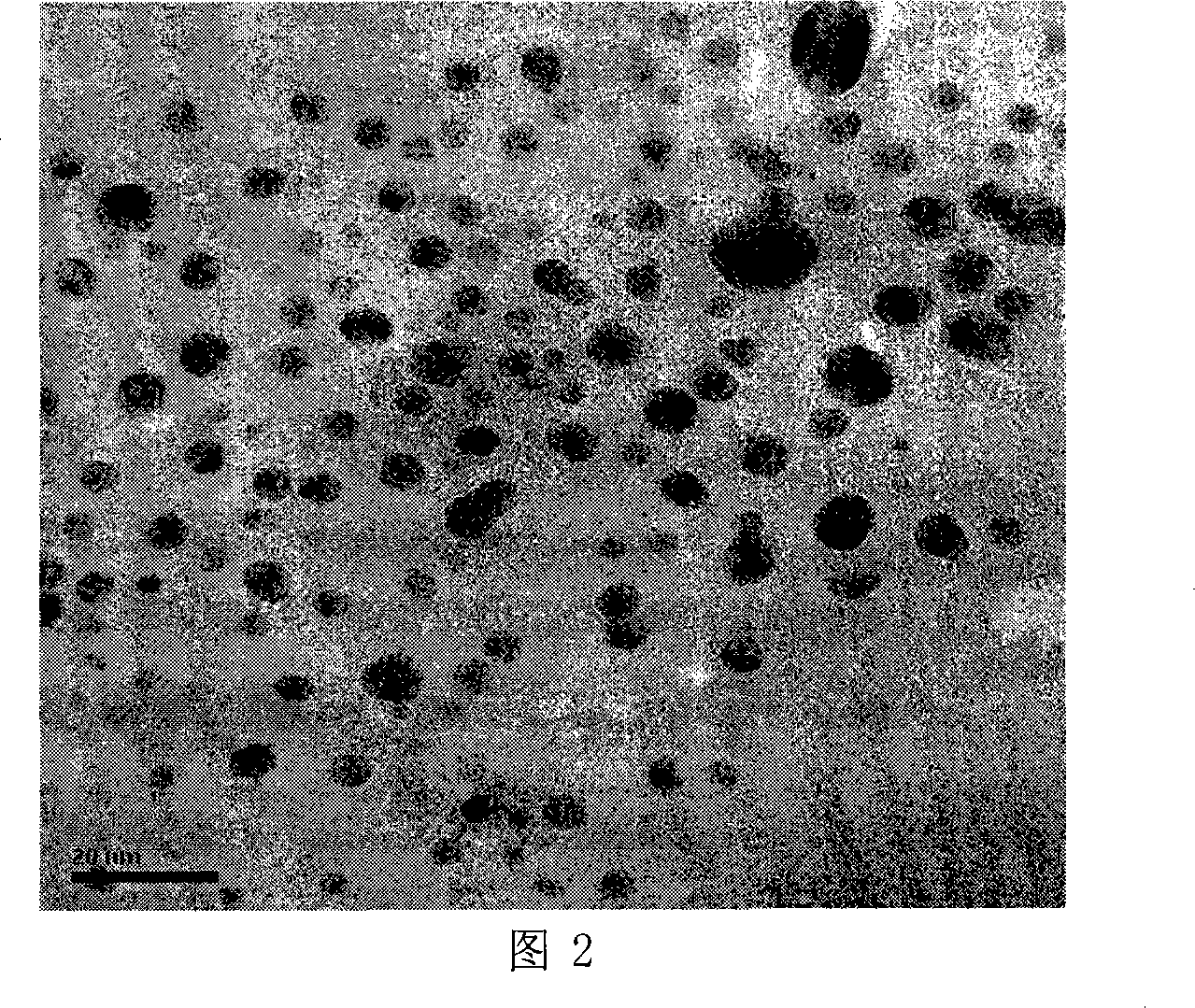

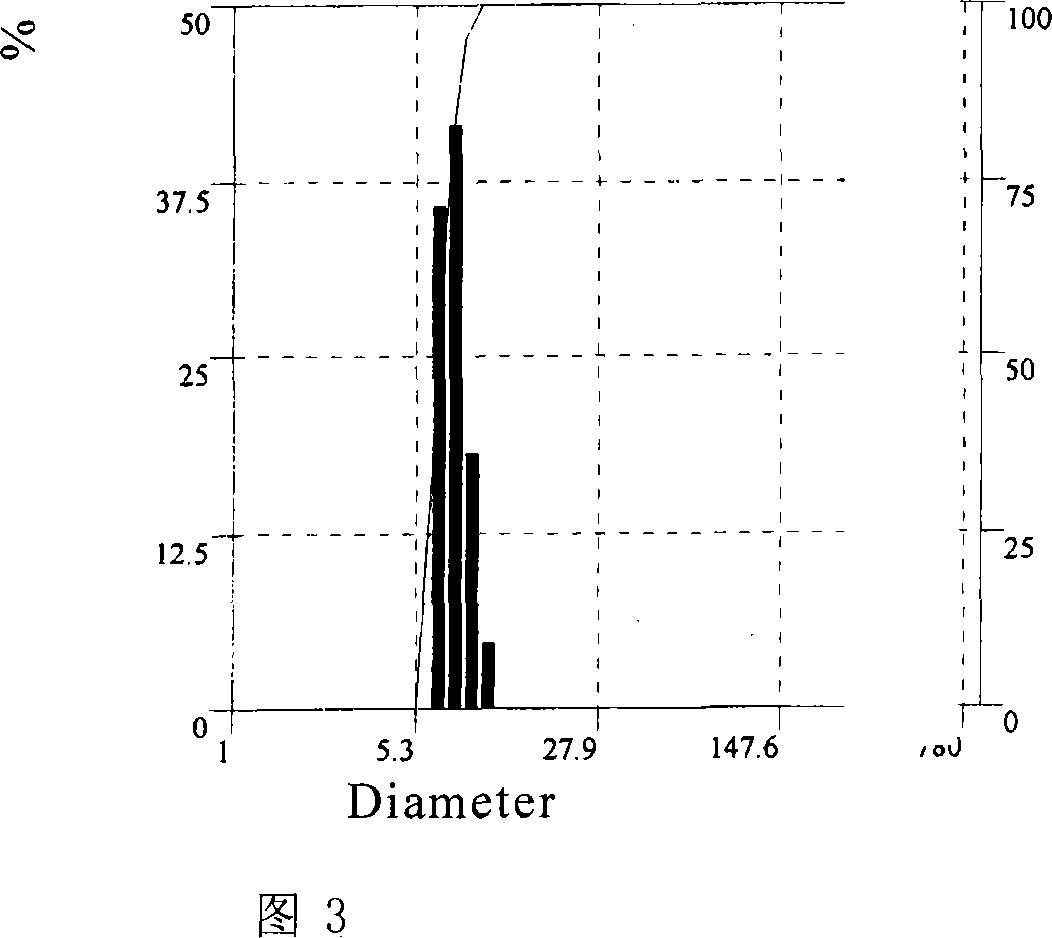

Original ecology separation and redispersion method of nano metallic colloid

The invention belongs to the technical field of nano, in particular to an original ecology separation and redispersion method of a nano metallic colloid. By taking spherical nano silver as an example, the method comprises the following steps: stirring and reacting silver salts under the existence of an organic protective agent and a reducing agent to obtain a nano silver colloid; adjusting the pH value of the nano silver colloid with acid, and continuously stirring and reacting until the colloid solution gradually appears flocks to obtain nano silver particles; and dispersing the nano silver particles in an organic solvent, and dispersing by ultrasonic to obtain the nano silver colloid dispersed in an original ecology mode. The invention can realize original ecology separation and redispersion repeatedly based on the interactive relationship among a dispersing agent, nano particles and the solution. The invention has the advantages of simple process, mild operation condition, short reaction time, little changes in particle size and appearance after repeated separation and dispersion, low preparation cost and no generation of harmful waste, and conforms to the requirement of green production.

Owner:FUDAN UNIV

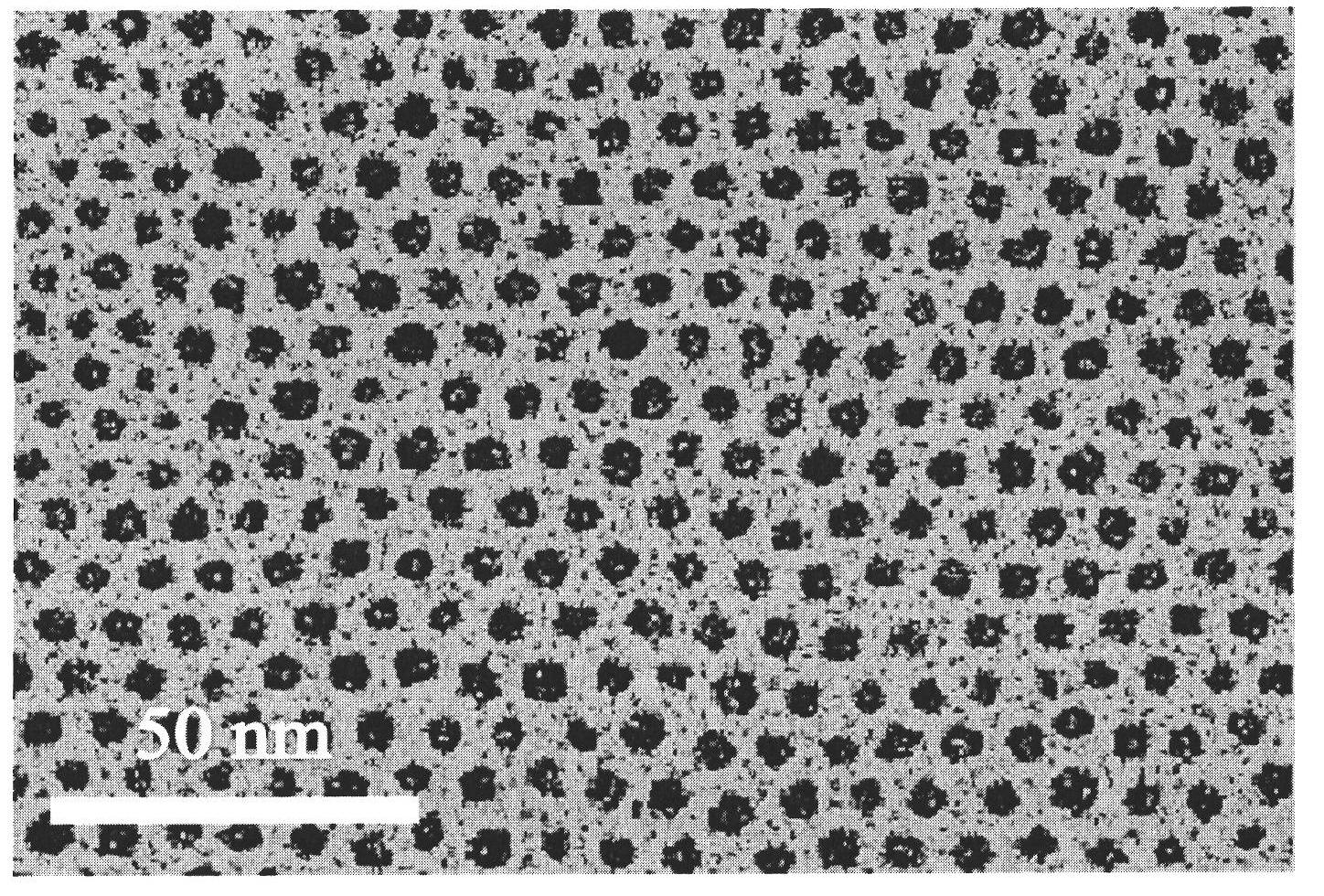

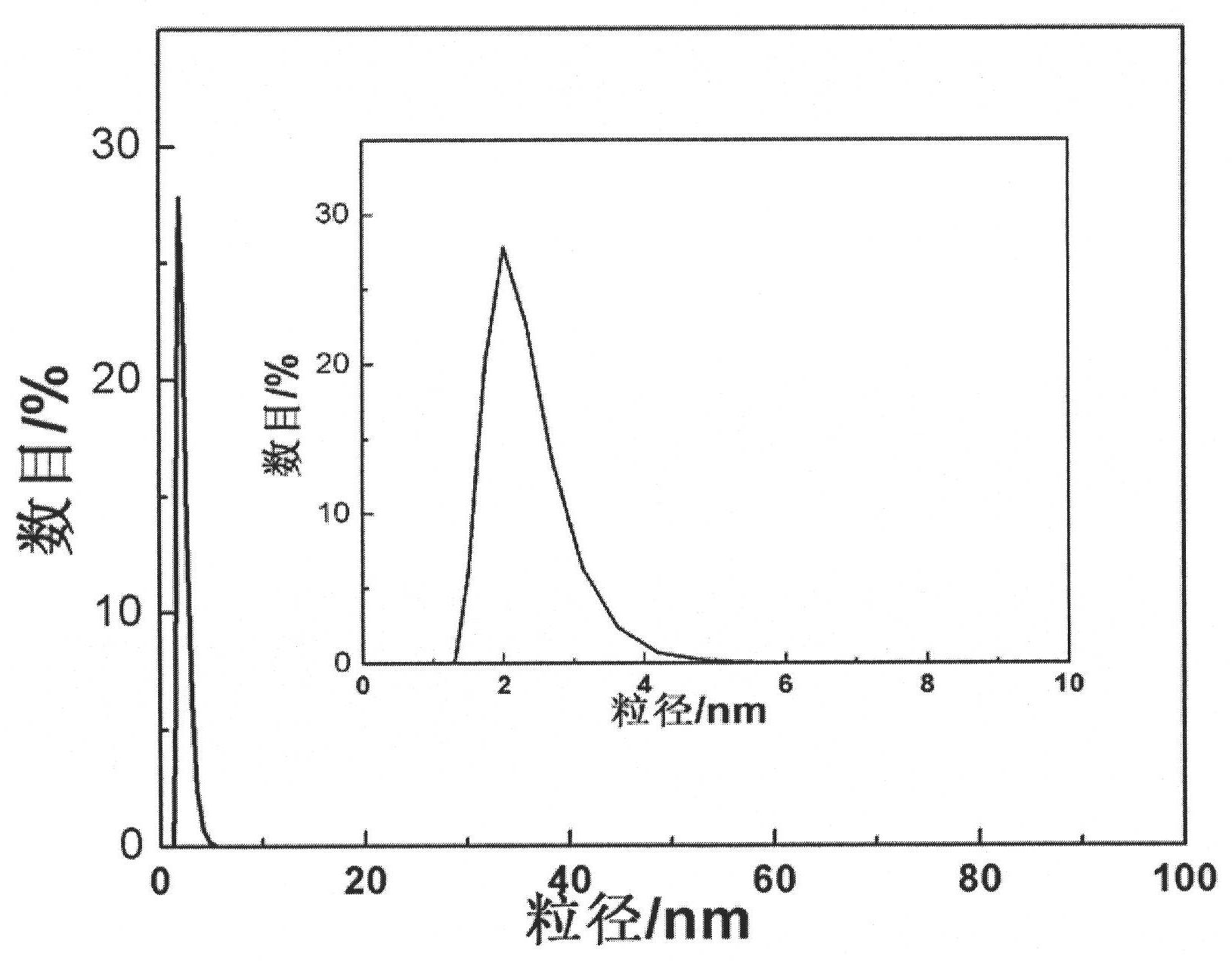

Method for preparing novel large-scale oil-soluble nano silver

The invention discloses a method for preparing novel large-scale oil-soluble nano silver. The method comprises the following steps of: completely dissolving silver salt and an organic protective agent into a solvent; gradually heating the solution to 20 to 70 DEG C; after the temperature is stabilized, adding a reducing agent into a reaction system; reacting for 20 to 30 minutes continuously under stirring; gradually cooling; standing and centrifuging the cooled solution; and washing sequentially with ethanol, deionized water and acetone for multiple times repeatedly to obtain the stable nano silver. The method is simple in process, simple and convenient in operation, mild in reaction, short in reaction time, high in efficiency and suitable for large-scale production; the product has high properties; the grain diameter of the nano silver is less than 20 nm; the nano silver has high secondary dispersibility in various oil agents; preparation cost and energy consumption are low; no harmful waste is generated; and the modernized production requirements, namely 'green production, environmental friendliness and energy conservation' are met.

Owner:SHANGHAI LANGYI FUNCTIONAL MATERIALS

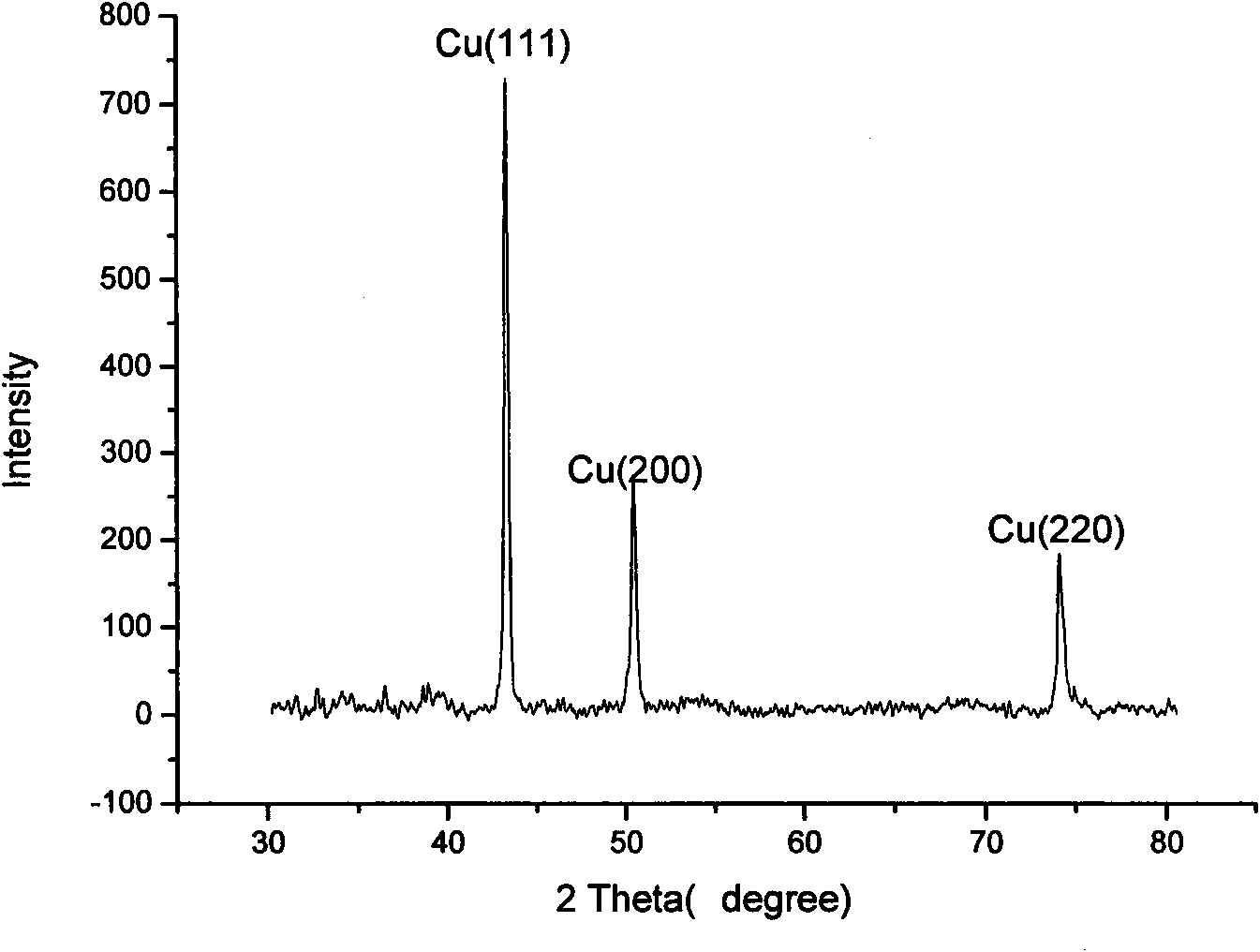

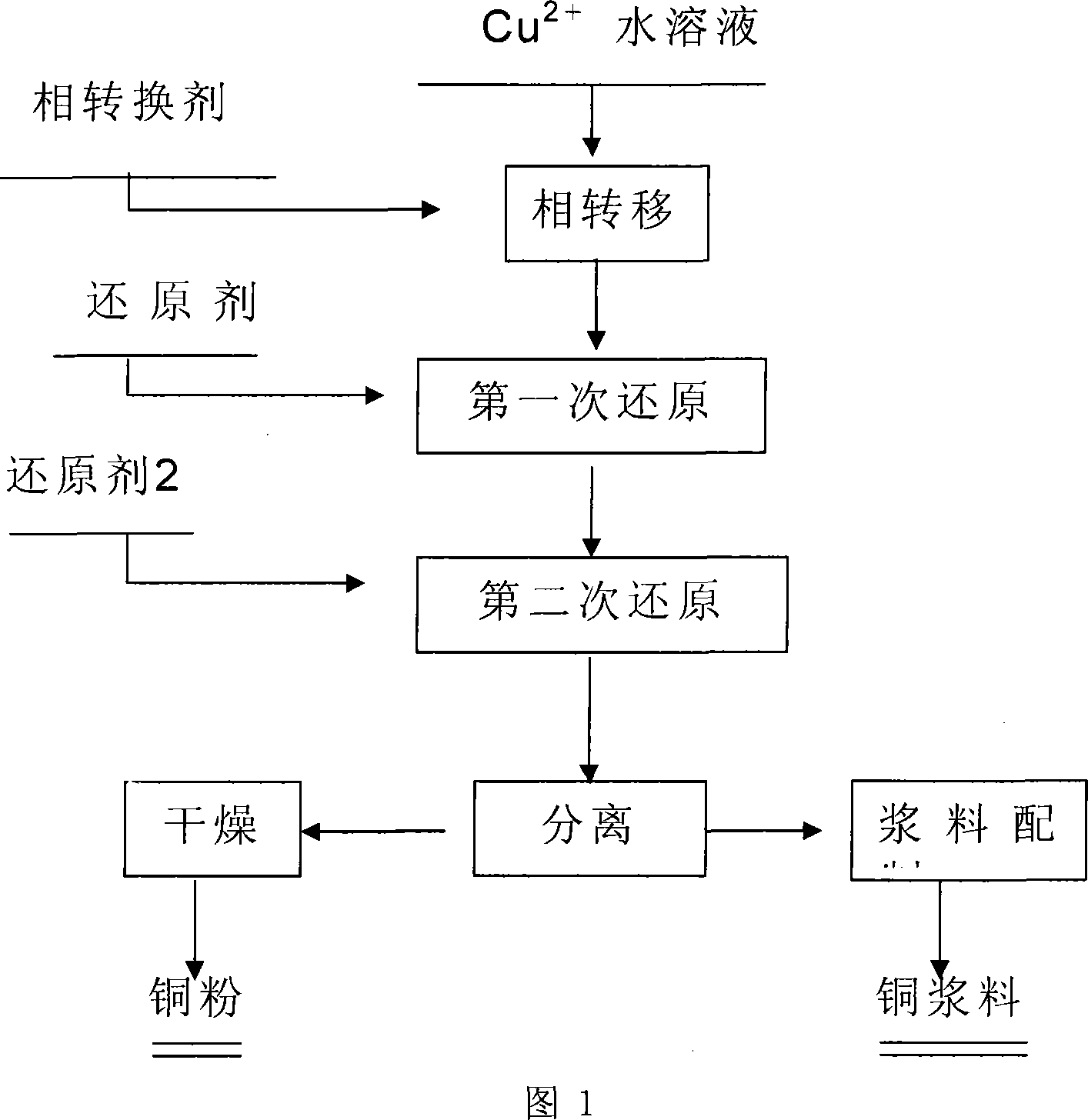

Method for preparing nano copper powder and copper slurry

InactiveCN101077529ASmall particle sizeImprove antioxidant capacityChemical compositionCeramic capacitor

The present invention is process of preparing nanometer copper powder and copper slurry with high antioxidant performance. The process includes solvent replacement, the first reduction, the second reduction, separation, drying and other steps. The present invention has the features of simple preparation process at normal temperature and normal pressure, low production cost, the effective protection of produced nanometer copper particle in organic phase, small copper powder size, environment friendly preparation process, etc. The prepared nanometer copper powder and copper slurry may be applied in producing large scale PCB, conducting ink, multilayer ceramic capacitor, etc.

Owner:CENT SOUTH UNIV +1

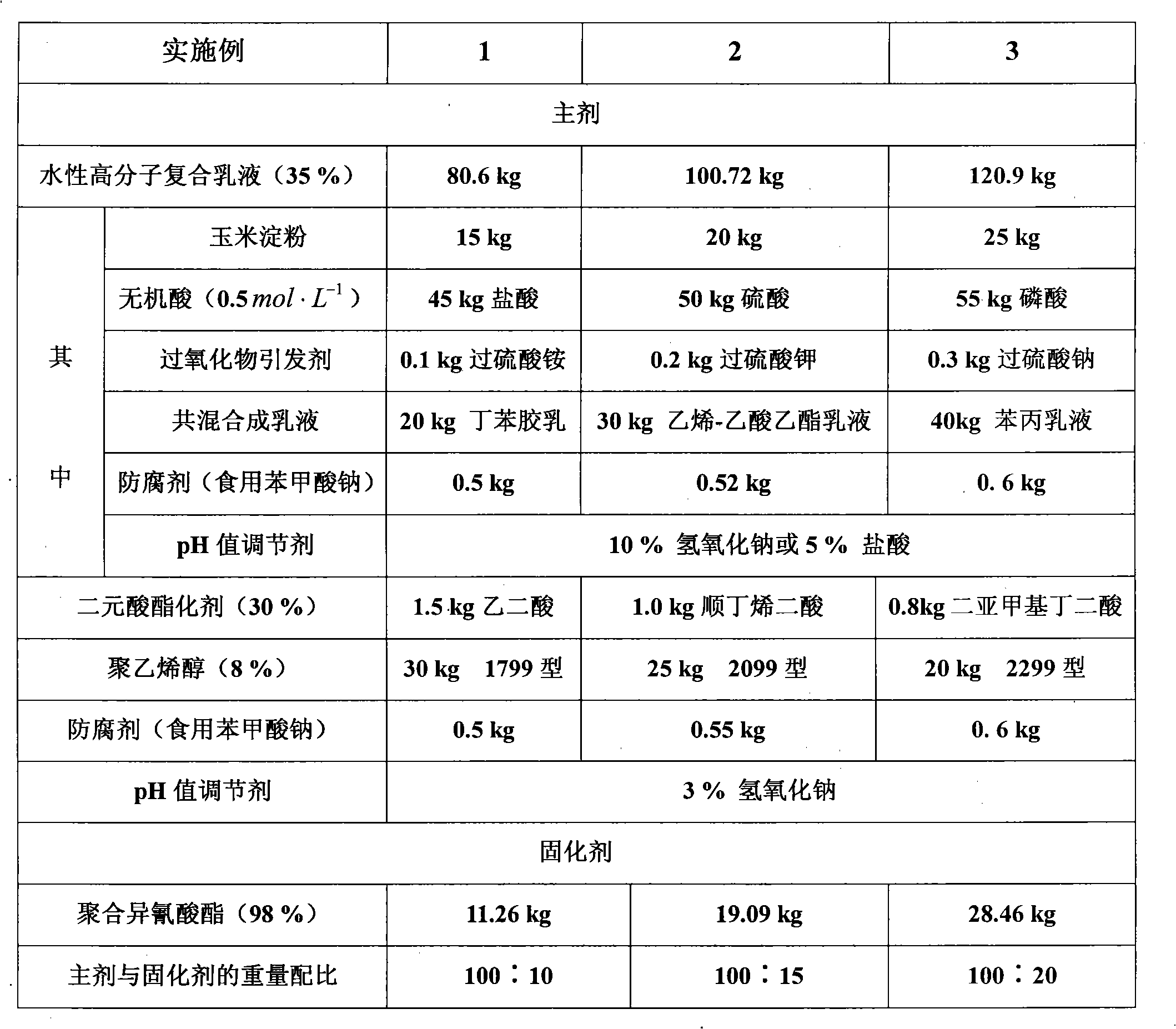

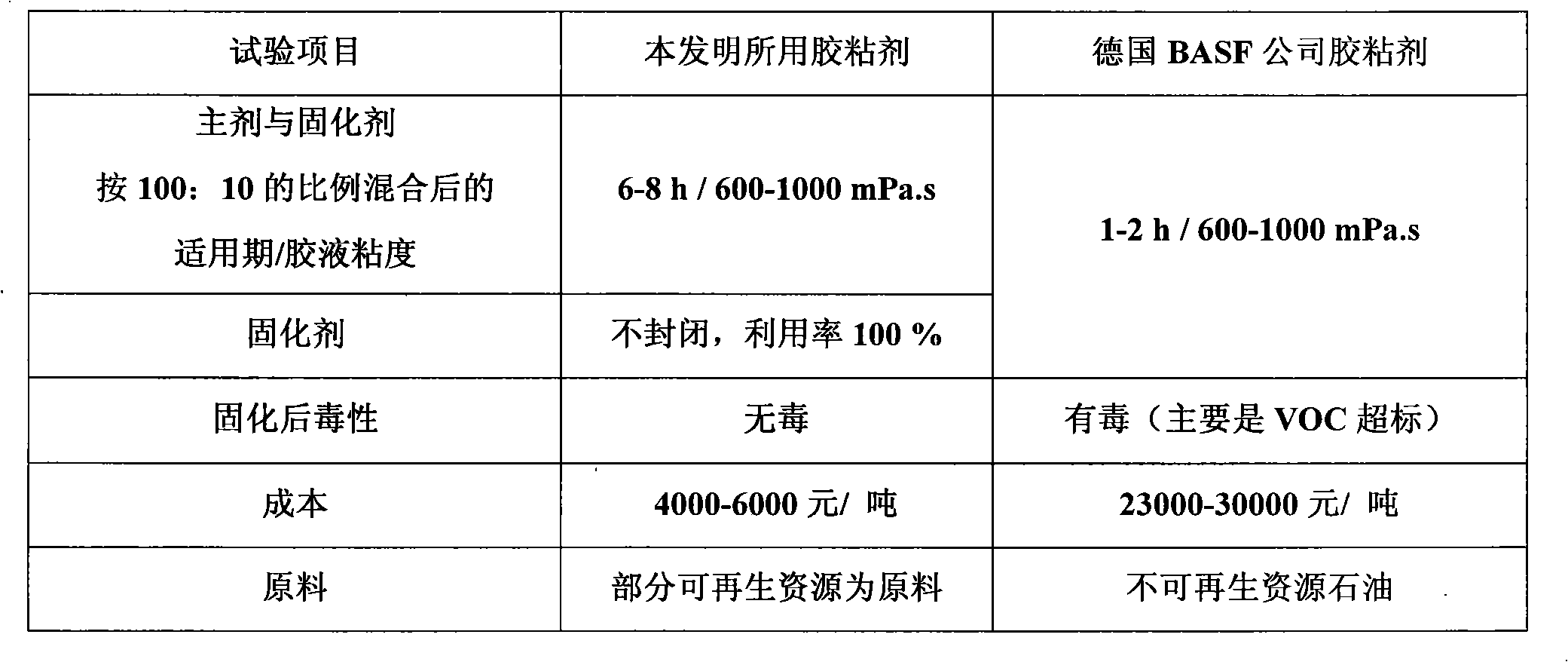

Aqueous macromolecule-isocyanic ester stalk artificial board and preparation thereof

ActiveCN101314235ARealize green productionGood workmanshipPolyureas/polyurethane adhesivesFlat articlesWater basedVolatiles

The invention relates to a water-based macromolecule-isocyanate straw hard board and a preparation method thereof. Straws of rice, wheat, corn or other crops, a water-based macromolecule-isocyanate adhesive and a straw interface performance modifying agent are used as raw materials, and the straws are treated by section cutting, kneading and modification, adhesive application and heat pressing to produce the water-based macromolecule-isocyanate straw hard board. A mixture ratio of the absolute dry straws to the water-based macromolecule-isocyanate adhesive to the straw interface performance modifying agent by weight is 100 to 10-16 to 0.05-0.15. The straw hard board uses the water-based macromolecule-isocyanate adhesive to replace a pure isocyanate adhesive, radically improves the problems of toxic organic volatiles, poor prepressing performance, adhesion on boards, etc., remarkably reduces cost and really realizes green production, and the raw materials after the treatment of kneading and modification have good prepressing and molding performances and high one-off qualified rate. The water-based macromolecule-isocyanate straw hard board has the characteristics of unique design, long active period, excellent aging, water and heat resisting performances, simple operation, easy availability of equipment, no environmental pollution, easy implementation, etc., and produces huge entironmental, social and economical benefits after the water-based macromolecule-isocyanate straw hard board is popularized.

Owner:BEIHUA UNIV

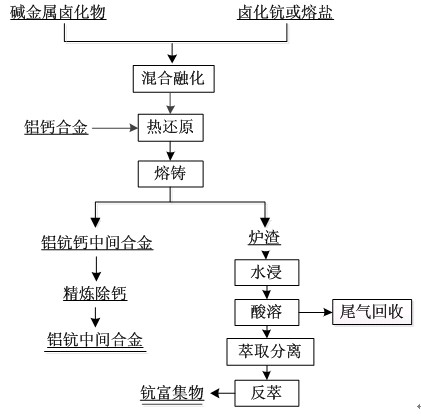

Method for preparing aluminum-scandium master alloy by thermal reduction of aluminum-calcium alloy

The invention discloses a method for preparing an aluminum-scandium master alloy by thermal reduction of an aluminum-calcium alloy. The method includes the steps as follows: firstly, by the contents of components in the aluminum-scandium master alloy, calculating the weight of the material aluminum-calcium alloy, the halide or the molten salt of scandium, and alkali chloride which are needed for smelting in every furnace; secondly uniformly mixing the halide or the molten salt of scandium with alkali chloride, adding the mixture into a crucible, raising temperature to 750-950 DEG C for melting the mixture, thus obtaining molten salt containing scandium; thirdly, adding the aluminum-calcium alloy into the molten salt containing scandium and after the aluminum-calcium alloy melts, keeping temperature and conducting thermal reduction for 20-200min; and fourthly, after the thermal reduction reaction finishes, adding excessive refining agent to remove calcium; and when the content of the calcium in the alloy is less than 50ppm, pouring and cooling a cast ingot, and then conducting water leaching for deslagging, thus obtaining the aluminum-scandium master alloy. The technology is simple and feasible in flow, high in metal yield, simpler and more environment-friendly than the traditional method and capable of realizing green production; and the method has the advantages of being simple in operation and equipment, low energy consumption in production, less pollution to the environment and economic stability.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Method for preparing ginseng and coix seed mixture and ginseng and coix seed paste

ActiveCN102415525AHigh total extraction rateNo pollution in the processFood preparationDigestionAbsorption rate

The invention provides a method for preparing a ginseng and coix seed mixture and a ginseng and coix seed paste. Raw materials comprise 1 to 10 parts of ginseng, 10 to 30 parts of coix seed, 2 to 10 parts of lotus seed, 10 to 35 parts of glutinous rice, 5 to 20 parts of black rice, 10 to 30 parts of flour, 2 to 15 parts of black sesame, 1 to 6 parts of walnut kernel, 1 to 10 parts of peanut kernel, 3 to 10 parts of malto dextrin, 1 to 4 parts of black soya bean, 1 to 4 parts of small red bean, 1 to 10 parts of edible modified starch and 2 to 10 parts of white granulated sugar. The ginseng is subjected to supercritical CO2 extraction, the green production process is really realized, and the total extraction rate of active substances such as ginsenoside and the like is over 90 percent. The obtained product is fine powder without cakes, is easy to store and convenient to use, has characteristics of fine and smooth texture, delicious taste and tasty mouthfeel, cleanness and faint scent, and high digestion and absorption rate of natural nutrients, and maintains natural nutrient components of the raw materials, and improves the mouthfeel and the nutrient component absorption rate.

Owner:TIANJIN UNIV

Method for preparing nano silver conductive ink

InactiveCN101870832ASimple processMild reaction conditionsInksMetallic pattern materialsSilver inkElectrolysis

The invention belongs to the field of nano technology and particularly relates to a method for preparing nano silver conductive ink. The method comprises the following steps: dissolving a silver salt and an organic protective agent in a solvent, adjusting the pH value of the solution to 9 to 10 with an alkaline complexing agent, and raising the temperature gradually to 30 to 100 DEG C till the reaction system is a transparent solution; and cooling the reaction system obtained by the previous step to room temperature, adding a reducer into the reaction system, and continuously stirring the reaction system for 20 to 30 minutes to obtain the nano silver conductive ink. The molar ratio of the organic protective agent to the silver salt is 0.01-3:1; each 0.01 mol of silver salt is dissolved in 5 to 50 milliliters of solvent; and the molar ratio of the reducer to the silver salt is 1-3:1. The nano silver prepared by the method has the advantages that: the particle size is less than 10 nanometers; the process is simple, the reaction conditions are mild and the reaction time is short; the raw materials are simple and the dose of the dispersant is small; the purity and concentration are high; and the conductive property is good. In addition, the preparation cost of the nano silver ink is low; no harmful waste is produced, so the requirements for 'green production' are met; and the nano silver ink can be widely used in fields of touch screens, electronic tags, thin film switches, flexible circuit boards, medical products, sensors, printing contact, radio frequency interference screening, electrolysis, multilayer circuit board hole filling and the like.

Owner:FUDAN UNIV

Clean preparation process for hexafluropropylene oxide

ActiveCN1634902ARealize green productionSolve the destructive effectOrganic chemistryBulk chemical productionHexafluoropropyleneAtmospheric ozone

The invention discloses an environmental protection method for preparing hexafluropropylene oxide from hexafluoropropylene by dioxygen liquid phase oxidation method. The method employs at least one supercritical fluid as solvent for replacing the CFCs with destructive effect to atmospheric ozone layer. The supercritical fluid as solvent is used in the invention which can reduce induction period of reaction and prevent the temperature raise in short time at the beginning of reaction.

Owner:SINOCHEM LANTIAN +1

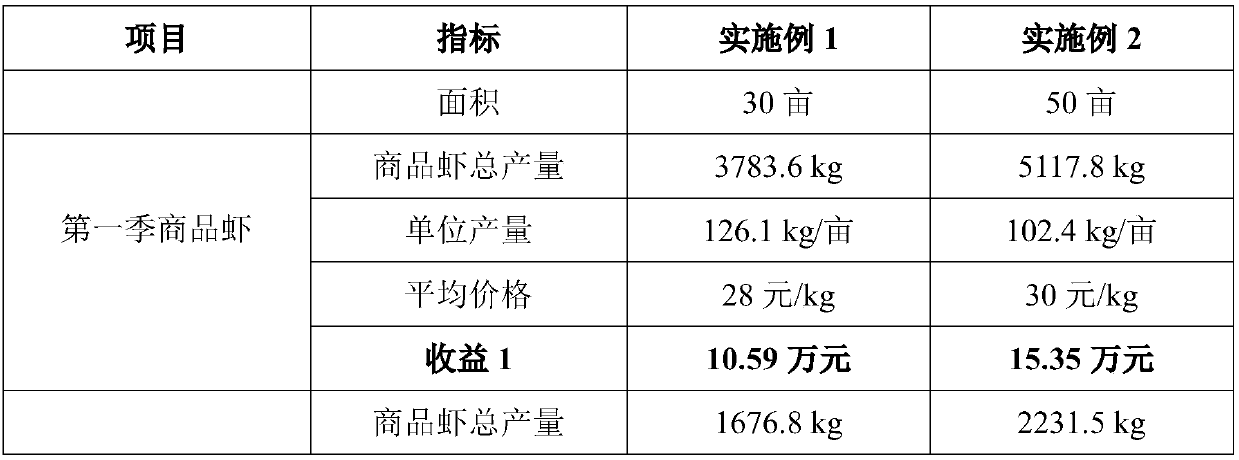

Green and efficient comprehensive shrimp-rice breeding method

InactiveCN109601292AIncrease productionIncrease specificationClimate change adaptationAccessory food factorsShrimpMortality rate

The invention discloses a green and efficient comprehensive shrimp-rice breeding method which comprises the following steps: (1) carrying out field engineering transformation and optimization; (2) carrying out rice field weeding and sterilization; (3) planting and maintaining aquatic plants; (4) carrying out early-stage natural feed biological culture; (5) launching shrimp fries and seed shrimps,harvesting commercial shrimps, and carrying out breeding circulation; (6) carrying out feeding and management; (7) carrying out water quality management and disease and insect prevention and control;(8) carrying out comprehensive planting and breeding management, and the like. By adopting the method, a first batch of shrimp fries are harvested in March to April, a first batch of commercial shrimps can be harvested in April to June, a second batch of commercial shrimps can be harvested in August to September, a batch of high-quality rice can be harvested at the middle and last ten days of October, the limit that sufficient mutualism of shrimps and rice cannot be achieved by using a conventional breeding mode can be avoided, meanwhile, ecological resources can be utilized, propagation and breeding of large-scale cray fries ahead of time can be promoted, the problems that a conventional shrimp-rice co-existence or continuous breeding is low in yield benefit and high in death rate can beavoided, a rice field ecological system is sufficiently utilized for comprehensive breeding and green production, and the benefits and the quality of cray and rice can be improved.

Owner:HUAZHONG AGRI UNIV

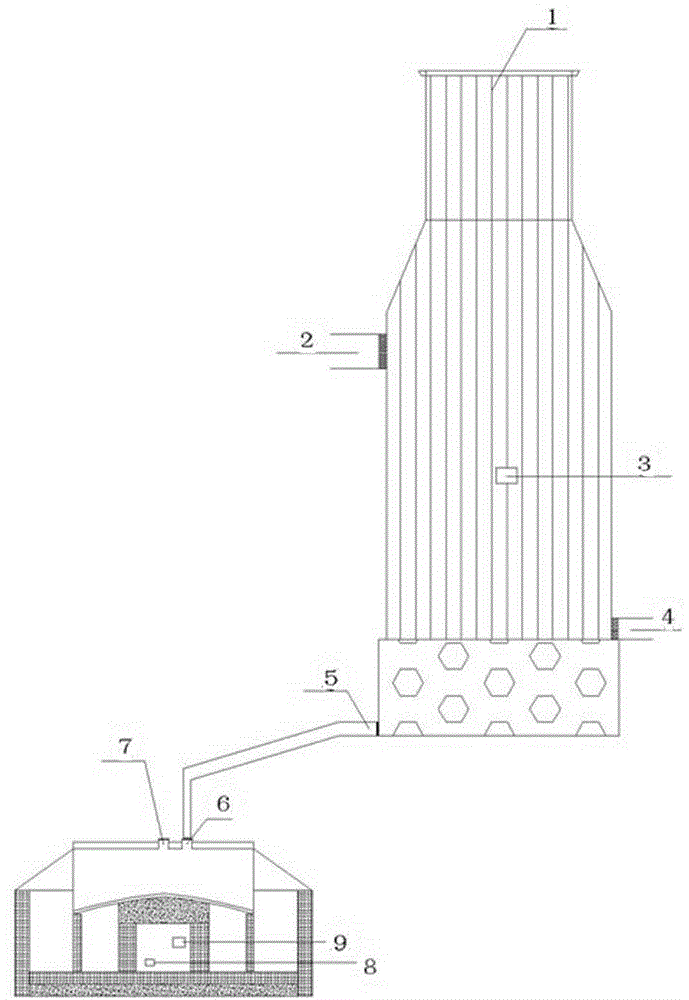

Application of coal modifier in shaft kiln incineration and producing technique thereof

A 'SHENZHOUSHENGLONG' coal modifier mainly consists of a grinding aid, a catalyst, an oxidant, a smoke suppressor and combustion improver, a smoke suppressor and igniter, a sulfur fixation agent, a bulking agent, a penetrating agent, etc. The coal modifier is a powdery material and can be added into coal (at a ratio of 0.1% the actual coal weight) to improve the combustion temperature and the combustion speed of the coal, thus achieving catalytic combustion and improving the coal combustion effect as well as the coal utilization rate. Accordingly, the invention performs the functions of saving coal, substituting high-quality coal by poor-quality coal, improving the hourly output of cement clinker stage, improving the grade of cement clinker, fixing sulfur and reducing the discharge of harmful gases such as SO2 in the smoke, thus protecting environment and indeed achieving the green production of cement.

Owner:哈尔滨绿万家环保科技有限公司 +5

Method for dissolving and processing wood/cotton bamboo hemp fibre by employing ionic liquid

InactiveCN101225552ANon-volatileEasy to recycleConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseTotal solid content

The invention relates to a dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid, which is characterized in that: (1) the pulverized wood or the pulverized cotton, the pulverized bamboo and the pulverized bast pulp are uniformly mixed with the ionic liquid; the spinning solution of the total solid content of 3 to 40% is formed through dissolving and deaerating for 1 to 120 hours at 35 to 160 degrees centigrade; wherein the weight ratio of the wood or the cotton, the bamboo and the bast is 30 to 80% : 7 to 60% : 10 to 60% ; (2) the spinning and the concreting bathing solidification are carried out after being filtered and deaerated; (3) the oiling and the drying process are carried out after being pulled, rinsed and bleached, so as to obtain a composite fiber. The dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid has the advantages that: due to use the ionic liquid, the productivity is high, the recovery is easy, the requirement of the green production is satisfied and the prepared composite fiber has good mechanical strength; simultaneously the different fiber characteristics of a plurality of materials such as the wood or the cotton, the bamboo and the bast are synthesized; the source of the material is wide; the cost is low; and the advantages of various natural celluloses can be synthesized according to the requirement.

Owner:DONGHUA UNIV

Method for producing fermented fish paste

The invention discloses a method for producing fermented fish paste. The method for producing the fermented fish paste mainly comprises the steps of low-value fish raw materials, pretreatment (removal of scales, head, tails, internal organs and vertebras), soaking in salt vinegar water, draining, soaking in ozone water, draining, defibrination, salt addition, in-jar fermentation, seasoning, mixedhomogeneity and obtaining of finished products. The method adopts a salt vinegar water soaking method to remove fishy-smell substance, is scientific, easy to operate and good in effect. The salt vinegar water is used for soaking fish slices, and acetic acid promotes solubility of the fishy-smell substance (trimethylamine oxide and dimethylamine oxide) in water with the assist of the salt water and enables the fishy-smell substance to be solved in the water, thereby achieving the removal purpose. Ozone solution produced by an electrolysis type ozone generator is used for soaking and disinfection, sundry fungus pollution and usage of preservatives are reduced, and the requirement for green production is met. Self enzyme of fishes is utilized to perform natural fermentation, thereby ensuringgood taste and special flavor of the fish paste.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

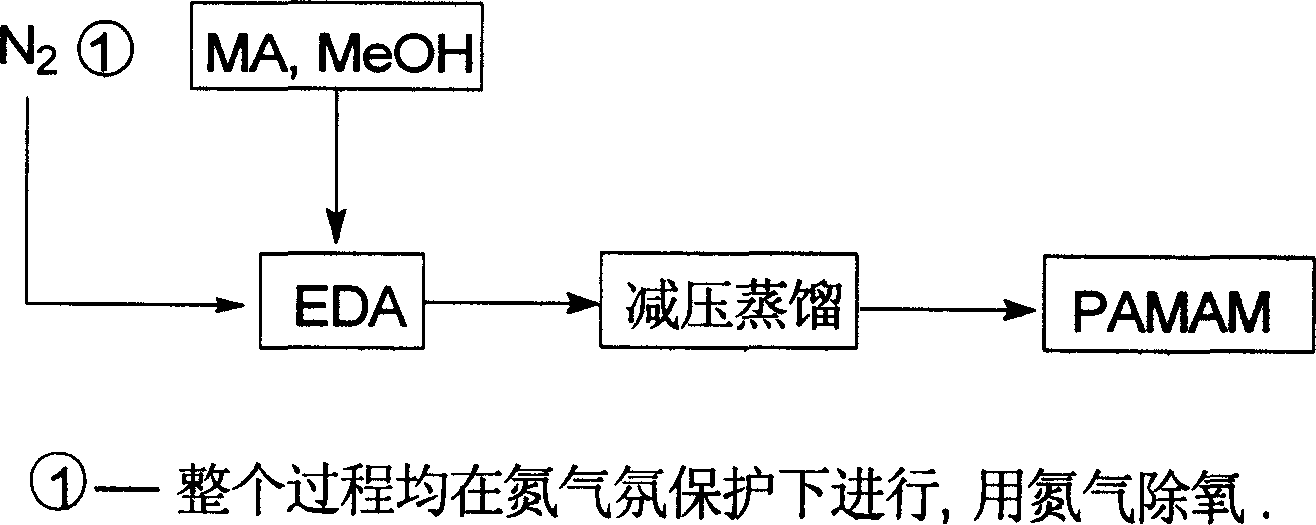

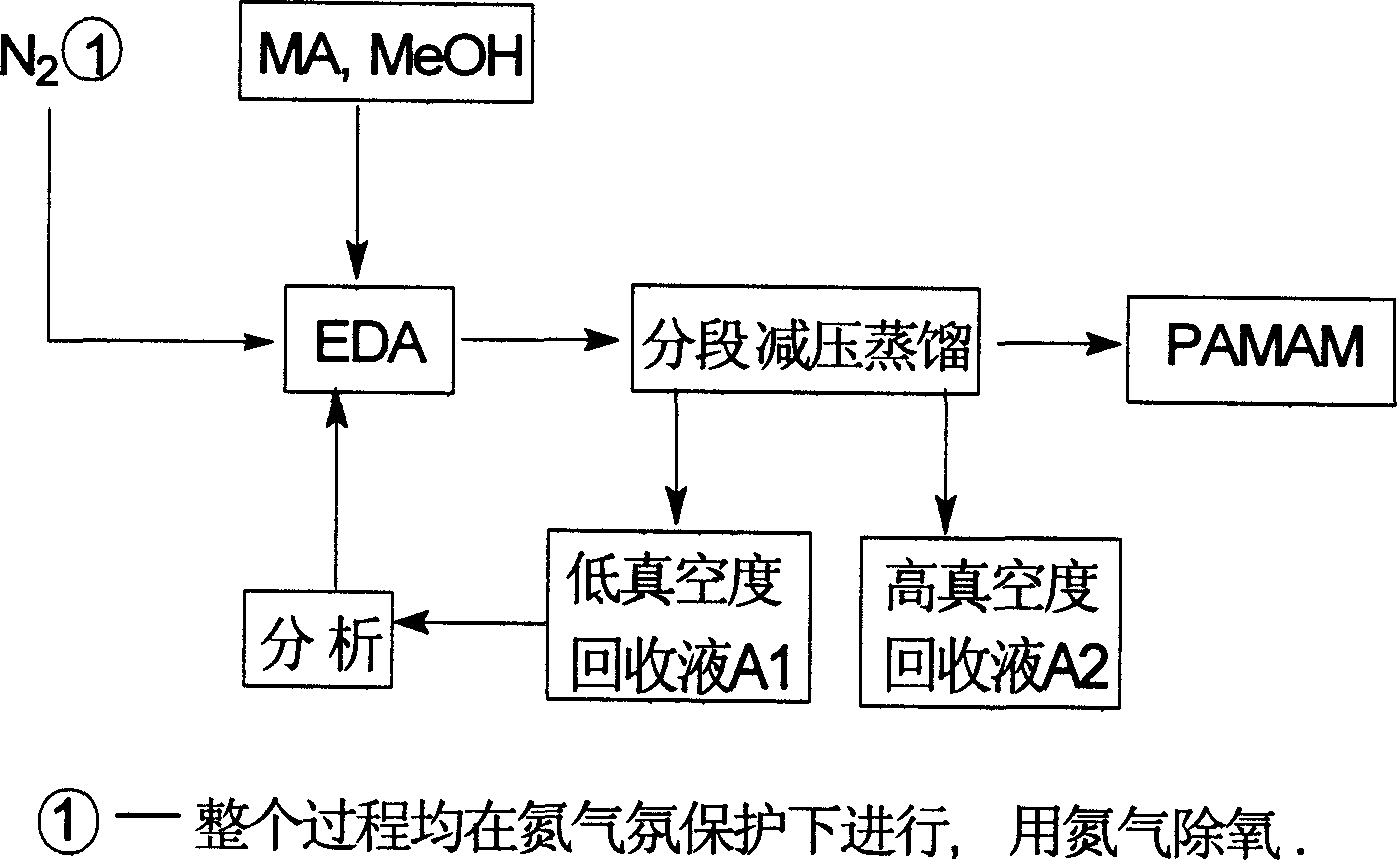

Green synthesis process of polyamide-dendritic amine polymer

The green synthesis process of dendritic polyamide-amine (PAMAM) polymer has material methyl acrylate (MA0 and ethylene diamine (EDA) in such amount that the ratio of MA or EDA to PAMAM end group matter is 5-8. The present invention has increased material amount to result in decreased reaction side product, raised purity of destination product, no polymerization in synthesizing high algebraic PAMAM and improved product quality. The present invention has high liquid recovering rate, less pollution, simplified technological process, low synthesis cost, low equipment cost and low power consumption, and reaches the aim of green production.

Owner:HUNAN UNIV OF SCI & TECH

Green production method of chilled fillets

ActiveCN101983570AGuaranteed qualityReduce the initial bacterial countMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyChlorine dioxide

The invention provides a green production method of chilled fillets. The method mainly comprises the following steps: preparing raw material fish, temporarily cultivating fish in cold water, performing movement bloodletting in cold water, preprocessing (removing scales, heads, tails and internal organs), cleaning with cold water, cutting into slices, removing fish bones and repairing, grading, sterilizing with electrolyzed ozone water, dewatering, spraying for coating, drying the water on the surface of fish, sterilizing with ultraviolet, performing atmosphere packaging and transporting. The main characteristics of the method of the invention are as follows: 1) electrolyzed ozone water and ultraviolet are used to sterilize the fillets and reduce the initial microbial content of raw material, chlorine dioxide and preservative are not used so as to ensure that the production technology is green and environmentally friendly; 2) temporarily cultivating in cold water, low-temperature movement bloodletting and whole-process low temperature operation are adopted to effectively control the microbial spoilage of the chilled fillets, reduce fat oxidation and protein degradation and ensure the freshness of the product; and 3) the green composite film preservative is coated on the chilled and sterilized fillets, thus effectively prolonging the shelf life of the chilled fillets.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com