Preparation method for regenerated cellulose fiber

A technology of regenerated cellulose and cellulose dissolving, applied in the direction of single-component cellulose rayon, fiber chemical characteristics, wet spinning method, etc., can solve the problems such as difficult to realize industrialization, achieve less raw material consumption, short production cycle, Effect of High Crystallinity and Molecular Weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

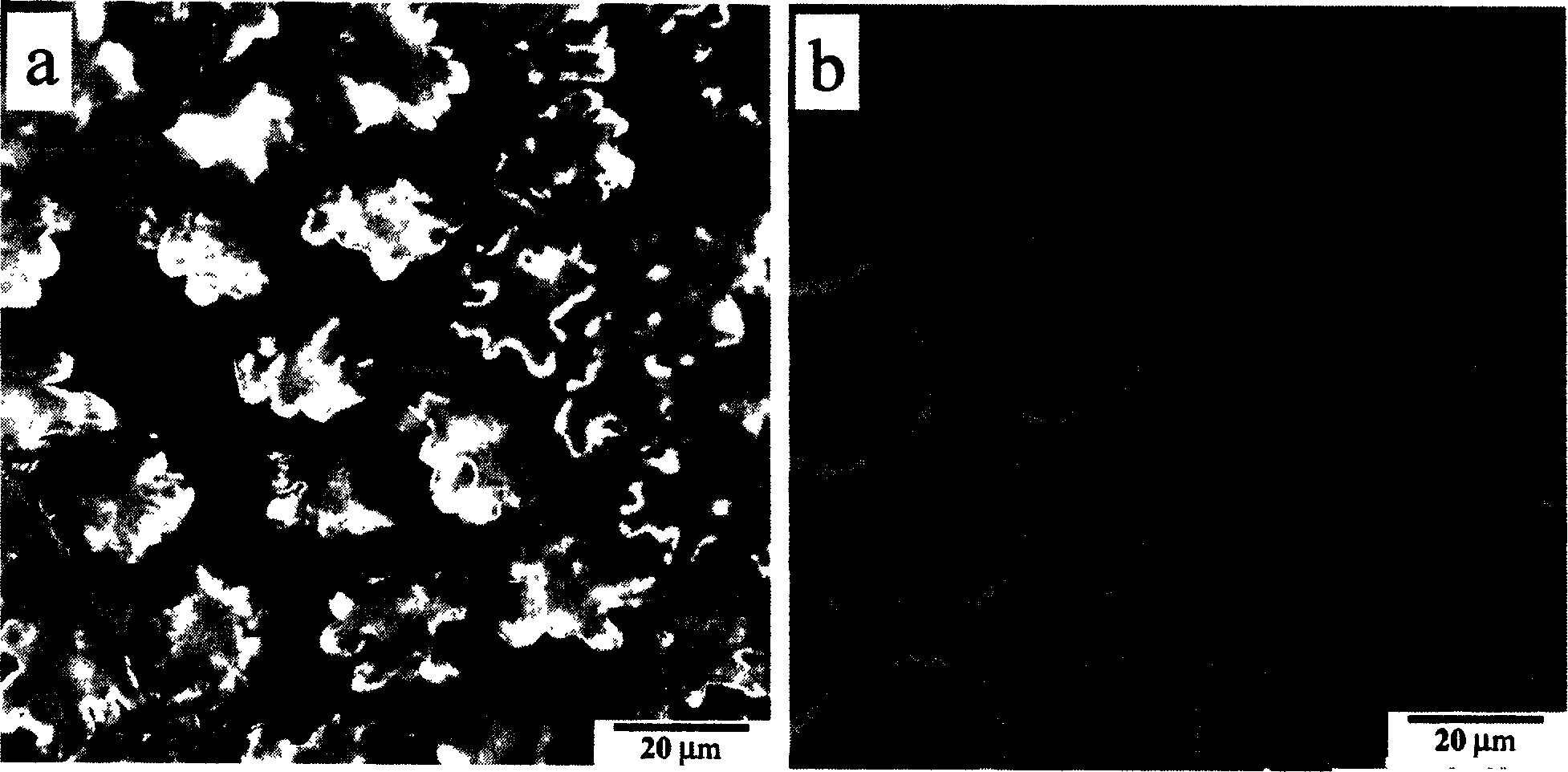

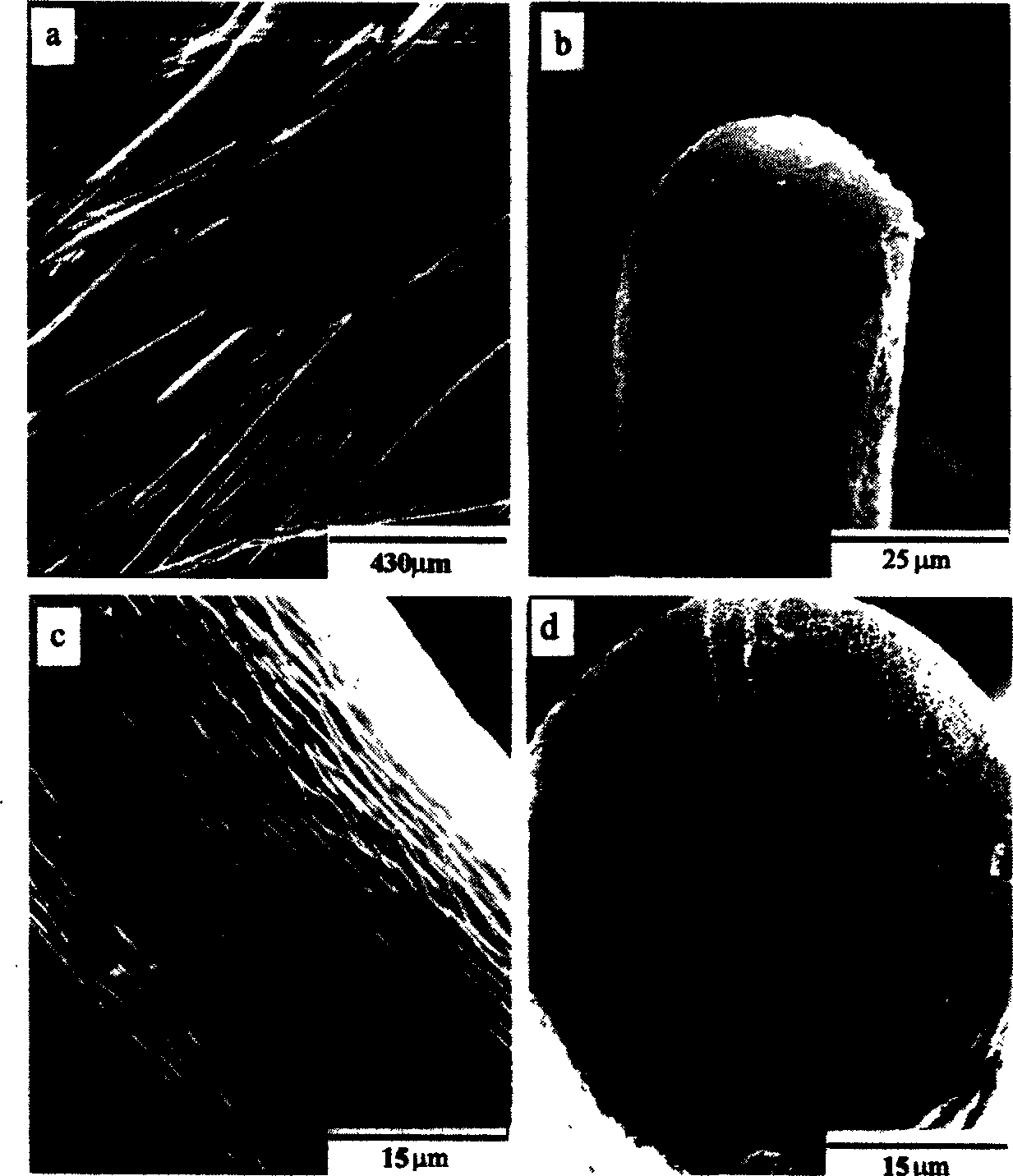

[0012] 200g of 5wt% NaOH / 20wt% urea mixed aqueous solution was pre-cooled to -10°C, then immediately added 12g of viscose staple fiber (polymerization degree 250), stirred at room temperature for 2 minutes, and the cellulose was completely dissolved. Use an ultracentrifuge at 8,000 rpm at 15°C for 30 minutes to degas it to obtain a transparent cellulose solution. Spinning into 3wt%H by spinning machine spinneret (30 holes, diameter 0.10mm) 2 SO 4 Coagulate and regenerate in an aqueous solution, rinse with water after stretching and orientation, and dry to obtain regenerated cellulose fibers. The fiber is white, soft and shiny, with high strength.

Embodiment 2

[0014] 200g of 12wt% NaOH / 8wt% urea mixed aqueous solution was precooled to -4°C, then immediately added 6.4g of cotton linter cellulose pulp (polymerization degree 800), stirred at room temperature for 2 minutes, and the cellulose was completely dissolved. Use an ultracentrifuge at 8,000 rpm at 15°C for 30 minutes to degas it to obtain a transparent cellulose solution. Spinning into 25wt%H by spinning machine spinneret (30 holes, diameter 0.10mm) 2 SO 4 Coagulate and regenerate in an aqueous solution, rinse with water after stretching and orientation, and dry to obtain regenerated cellulose fibers. The fiber is white, soft and shiny, with high strength.

Embodiment 3

[0016] 200g of 12wt% NaOH / 8wt% urea mixed aqueous solution was pre-cooled to -8°C, then immediately added 8.4g of non-woven fabric (polymerization degree 600), stirred at room temperature for 2 minutes, and the cellulose was completely dissolved. Use an ultracentrifuge at 8,000 rpm at 15°C for 30 minutes to degas it to obtain a transparent cellulose solution. Spinning into 25wt%H by spinning machine spinneret (30 holes, diameter 0.10mm) 2 SO 4 / 5wt%Na 2 SO 4 Coagulate and regenerate in an aqueous solution, rinse with water after stretching and orientation, and dry to obtain regenerated cellulose fibers. The fiber is white, soft and shiny, with high strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com