Patents

Literature

1501 results about "Regenerated cellulose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Regenerated cellulose is a class of materials manufactured by the conversion of natural cellulose to a soluble cellulosic derivative and subsequent regeneration, typically forming either a fiber (via polymer spinning) or a film (via polymer casting).

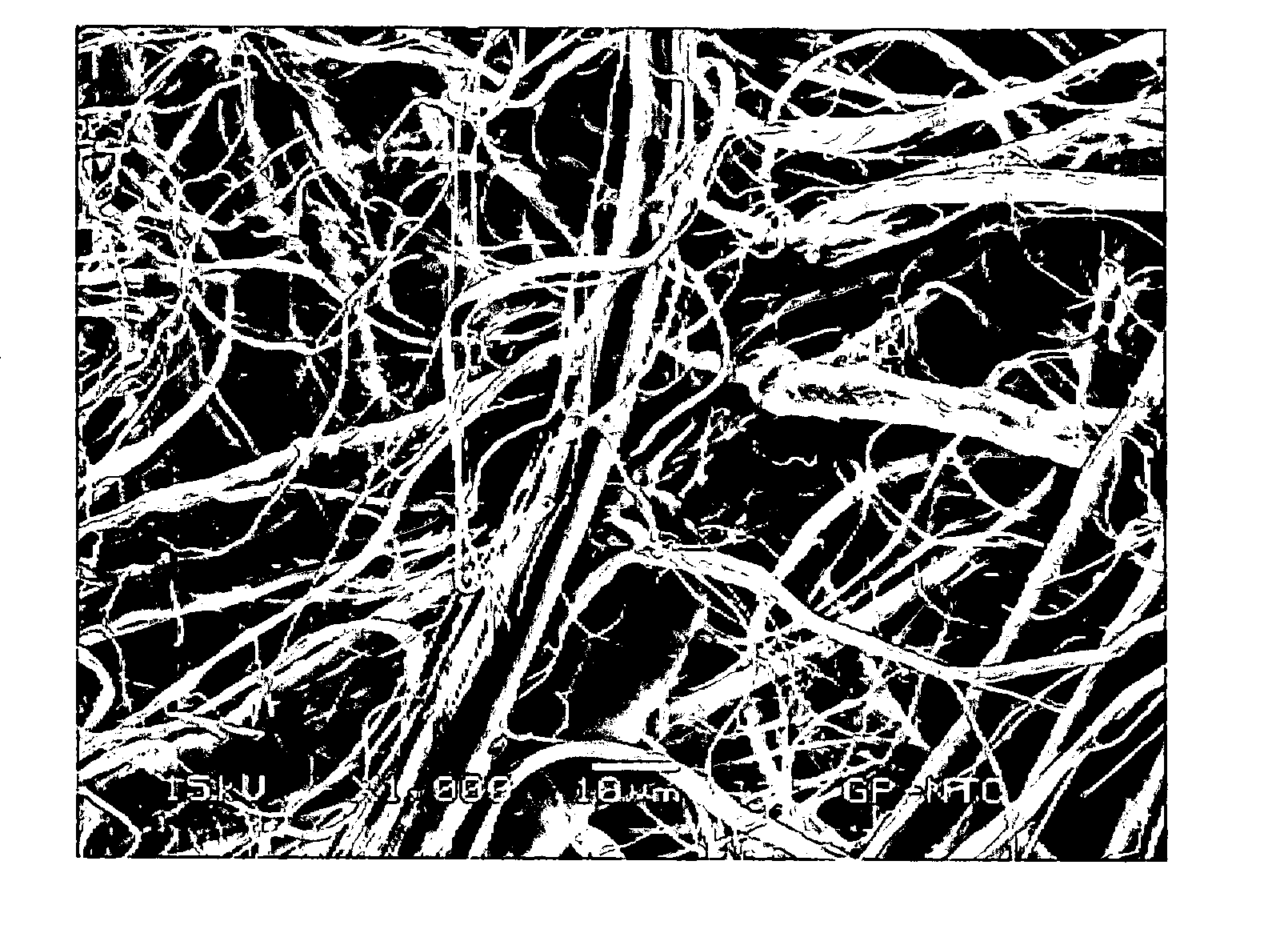

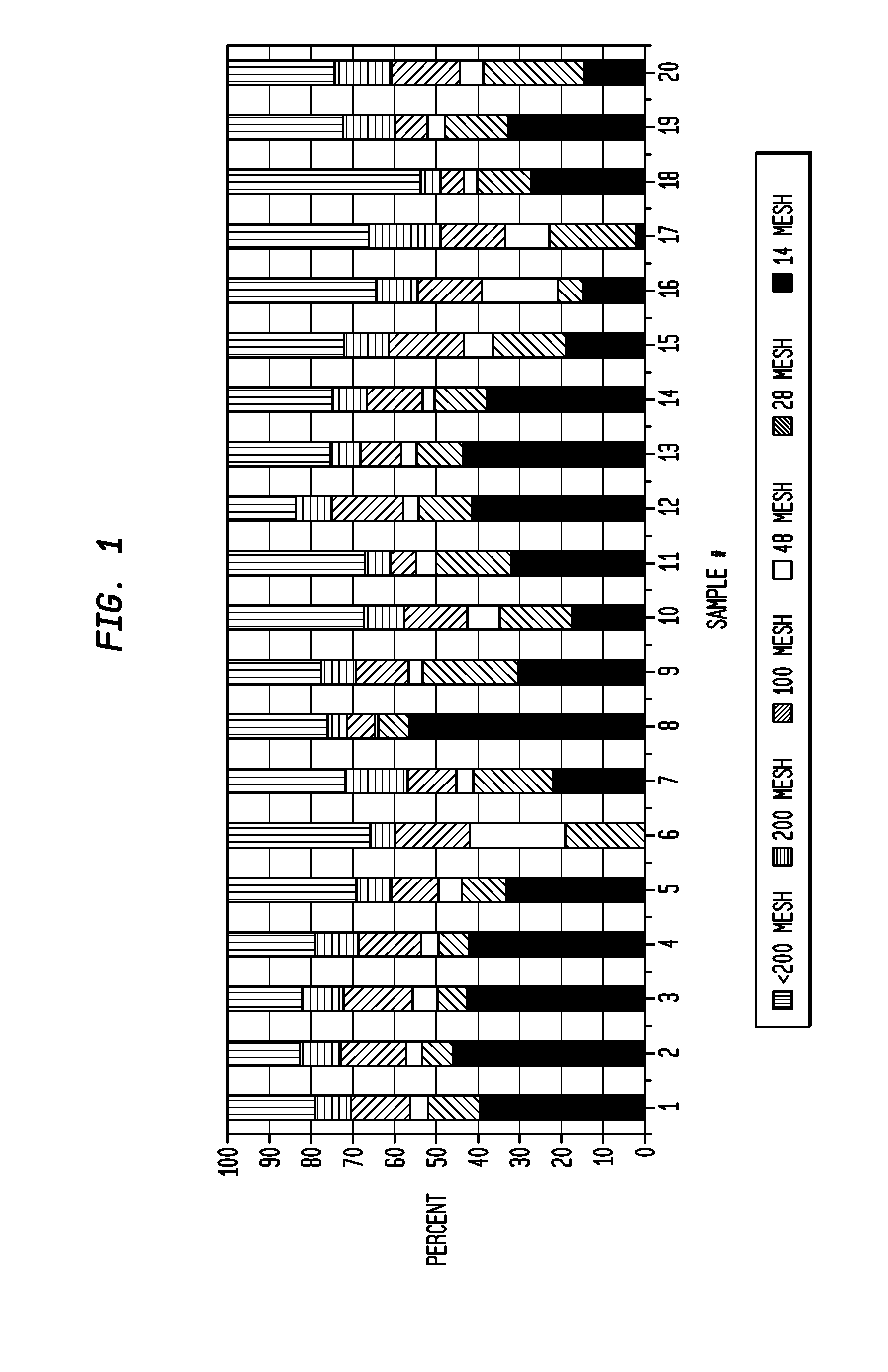

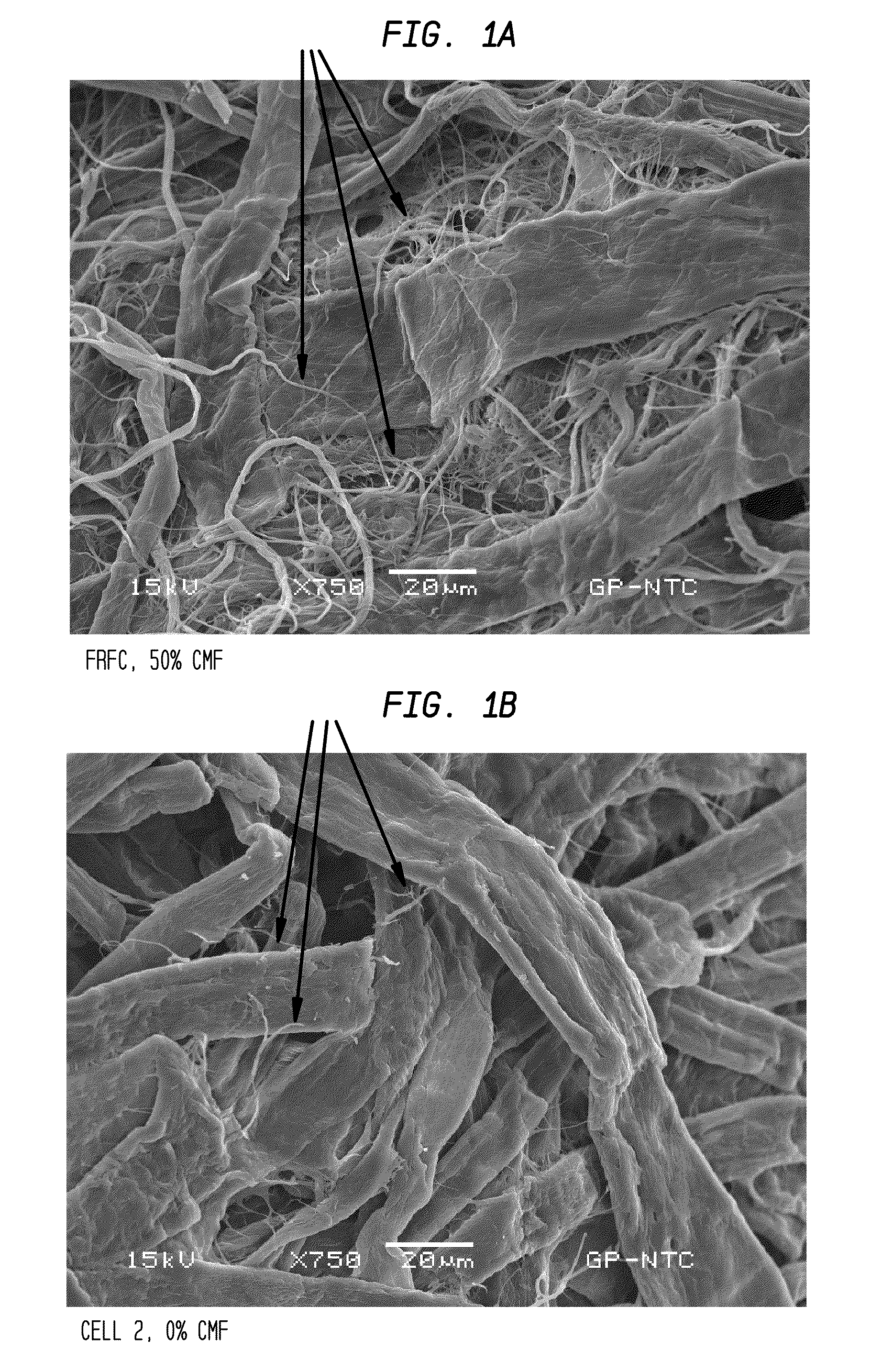

Absorbent sheet having regenerated cellulose microfiber network

ActiveUS20070224419A1High wet/dry tensile ratioImprove consistencyNon-fibrous pulp additionPaper after-treatmentPolymer sciencePapermaking

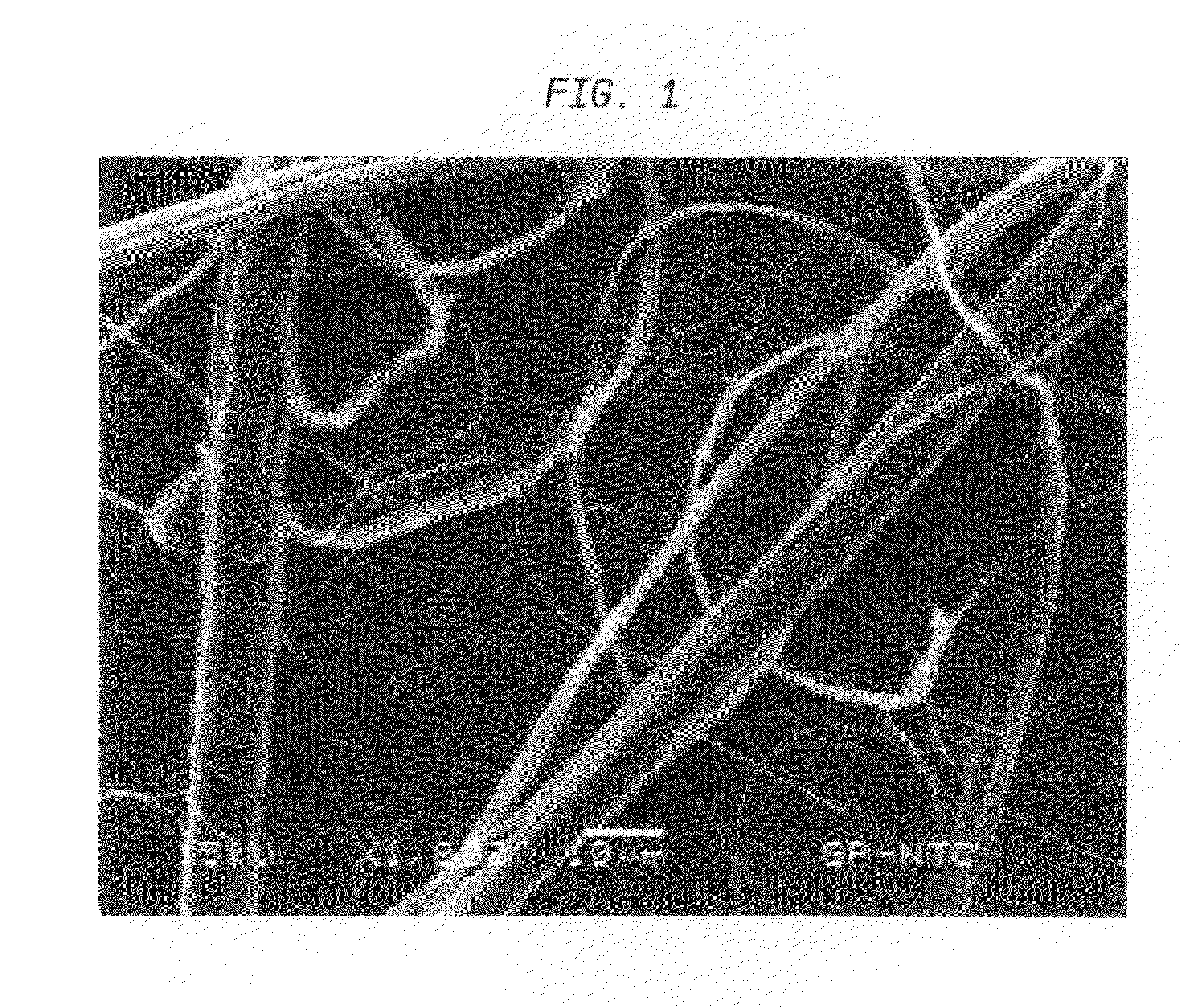

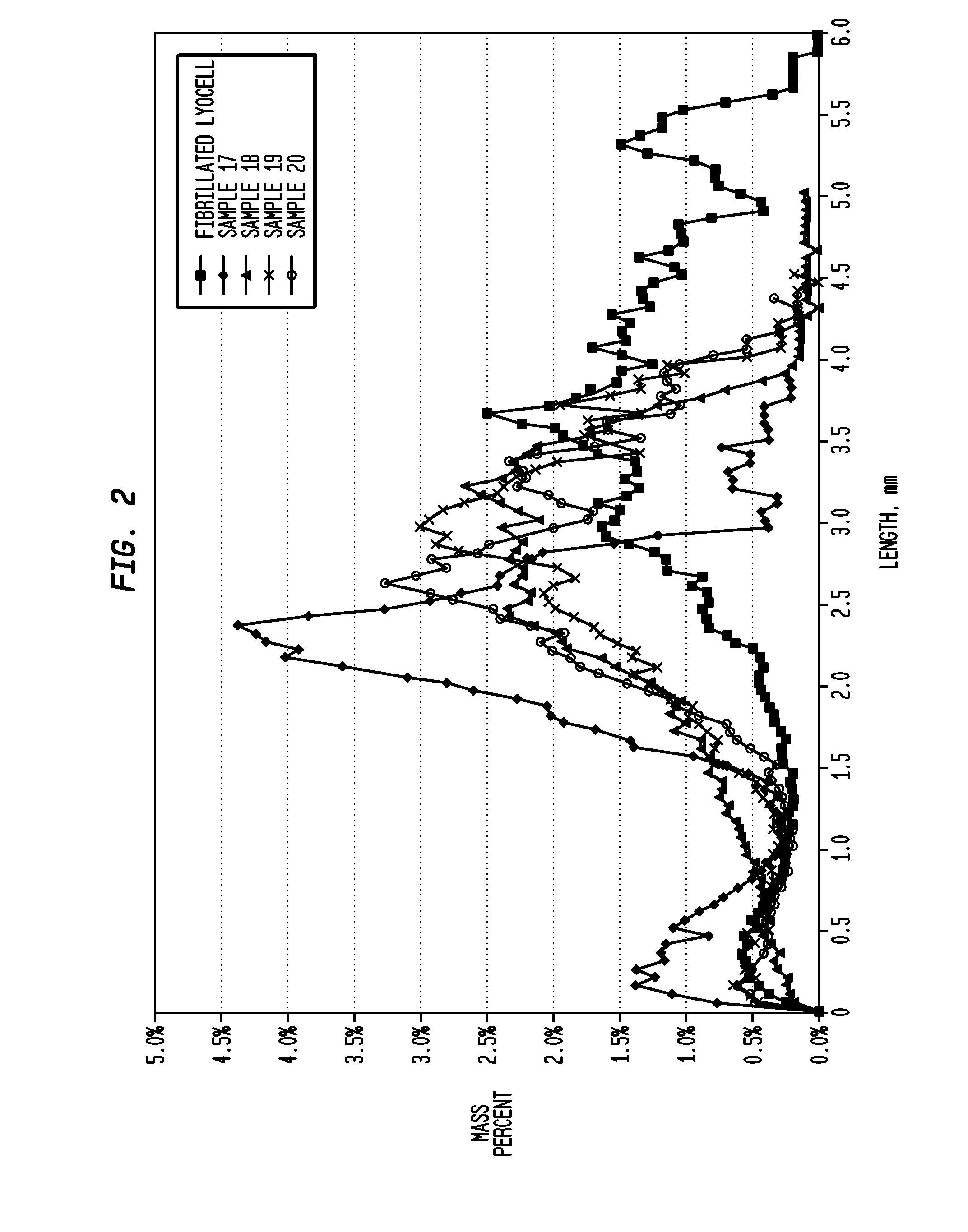

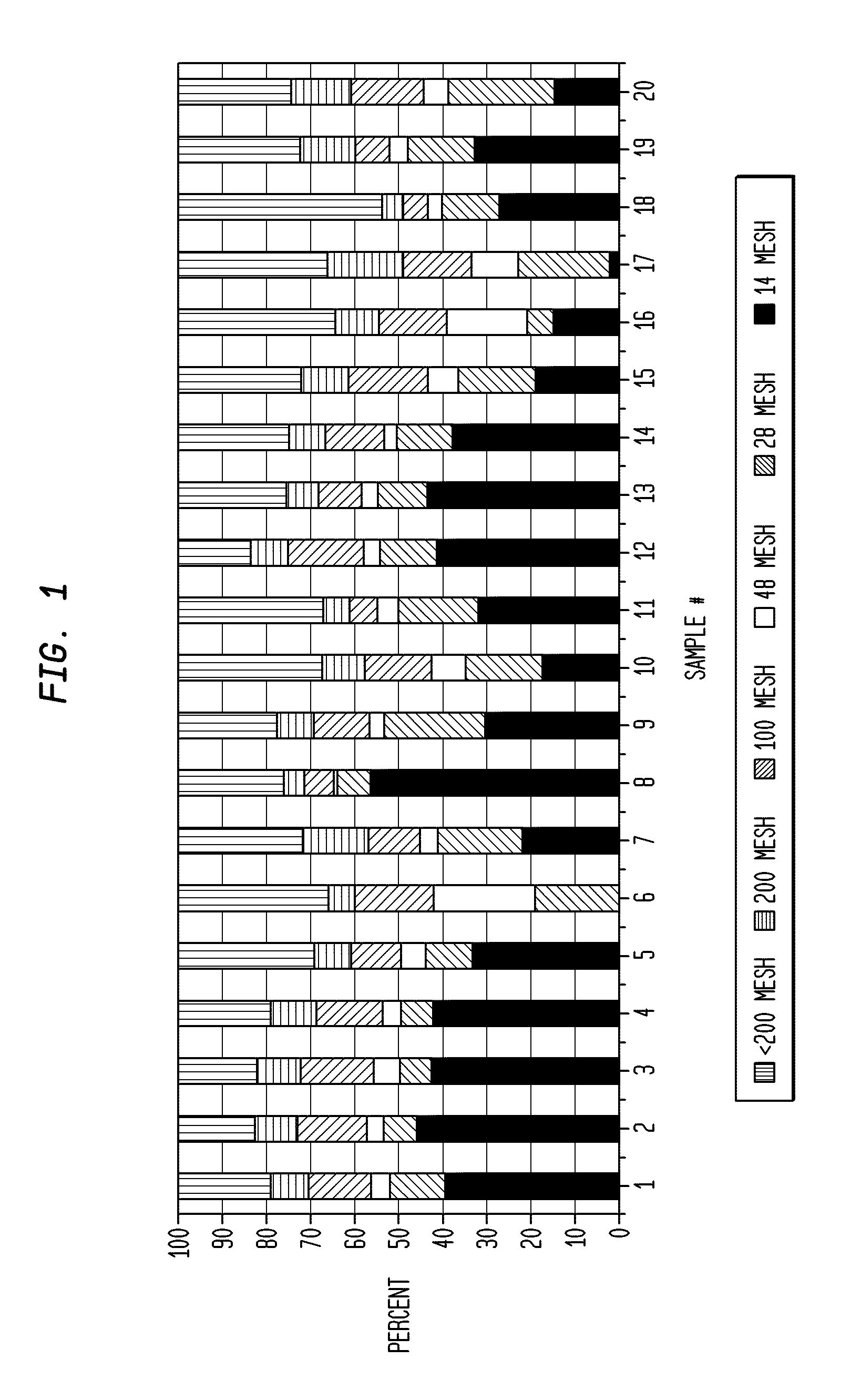

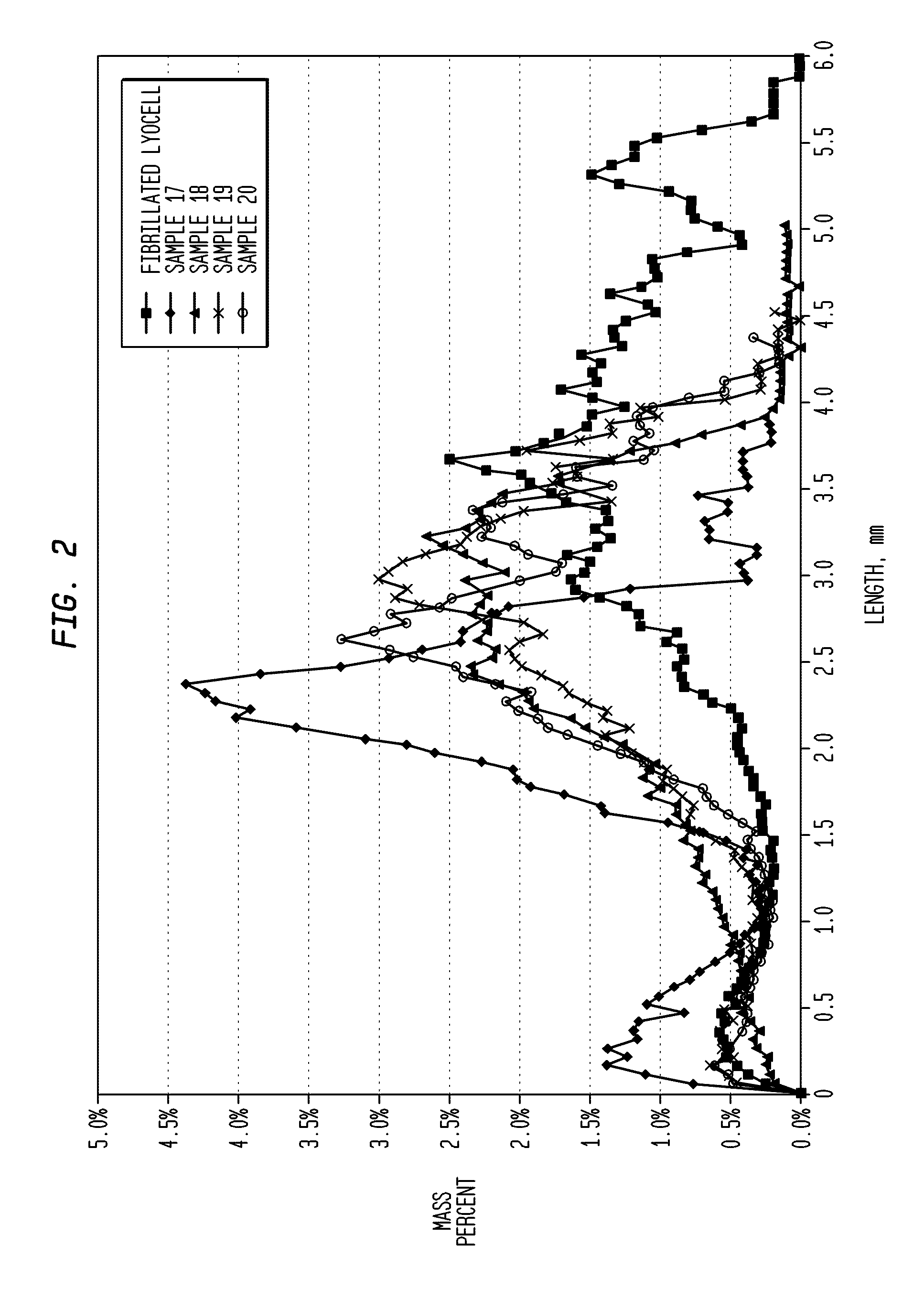

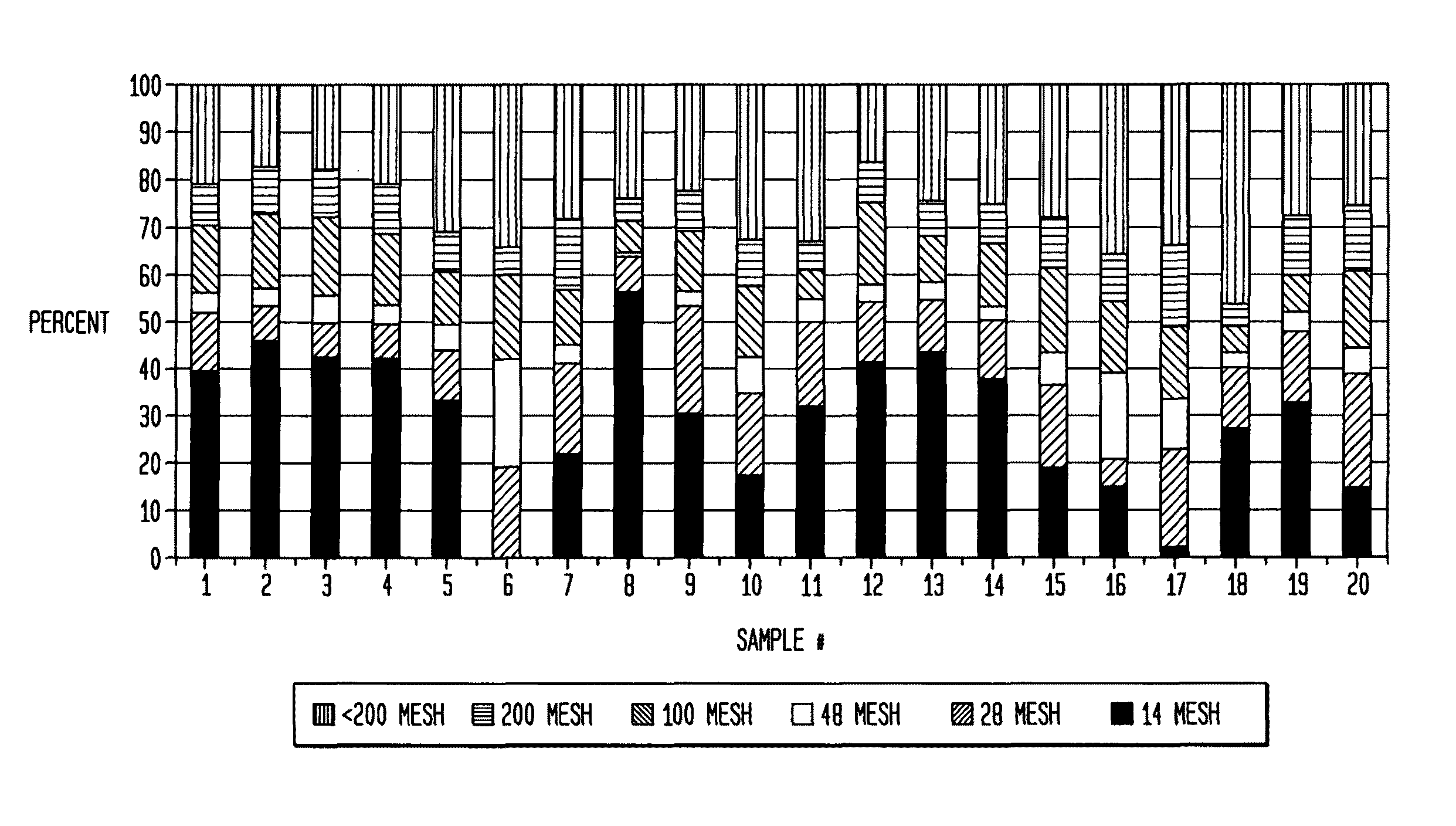

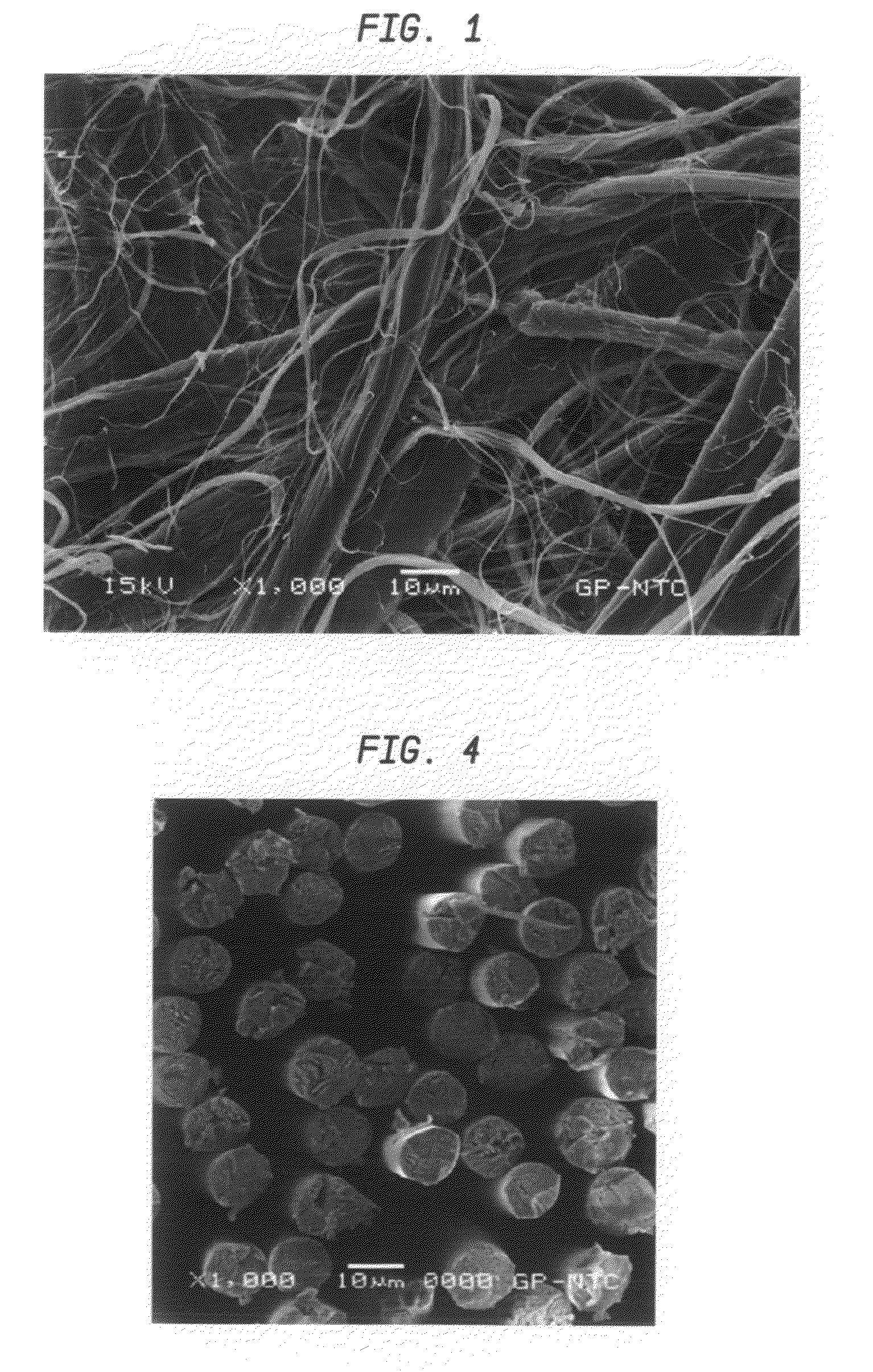

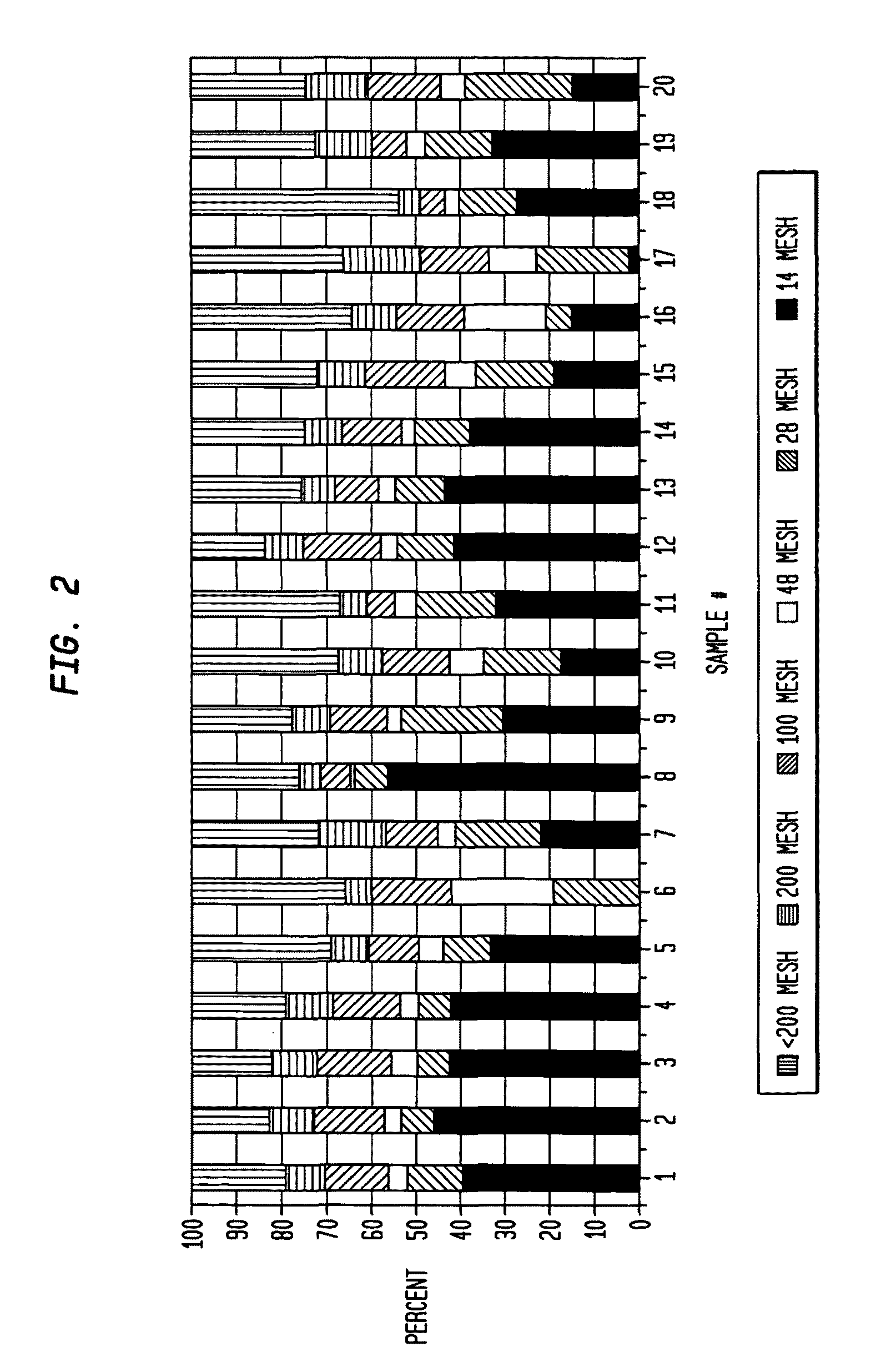

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Cellulose solution and its preparing method

The cellulose solution consists of ionic liquid and cellulose in the weight ratio of 3-8 to 100. The ionic liquid is ionic liquid of 1-ethyl 3-methyl imidazol acetate, 1-allyl 3-methyl imidazol chlorate, 1-allyl 3-methyl imidazol acetate or 1-butyl 3-methyl imidazol acetate. The cellulose material is insoluble wood pulp fiber. The preparation process of the cellulose solution is also disclosed. The cellulose solution is used in producing various regenerated cellulose products.

Owner:山东中科恒联生物基材料有限公司

Absorbent sheet having regenerated cellulose microfiber network

An absorbent paper sheet for tissue or towel includes from about 99 percent to about 70 percent by weight of cellulosic papermaking fiber and from about 1 percent to about 30 percent by weight fibrillated regenerated cellulose microfiber which was regenerated form a cellulosic dope utilizing a tertiary amine N-oxide solvent or an ionic liquid. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber. In some embodiments, the pulp is pre-treated with debonder to enhance the wet / dry CD tensile ratio of the sheet.

Owner:GPCP IP HLDG LLC

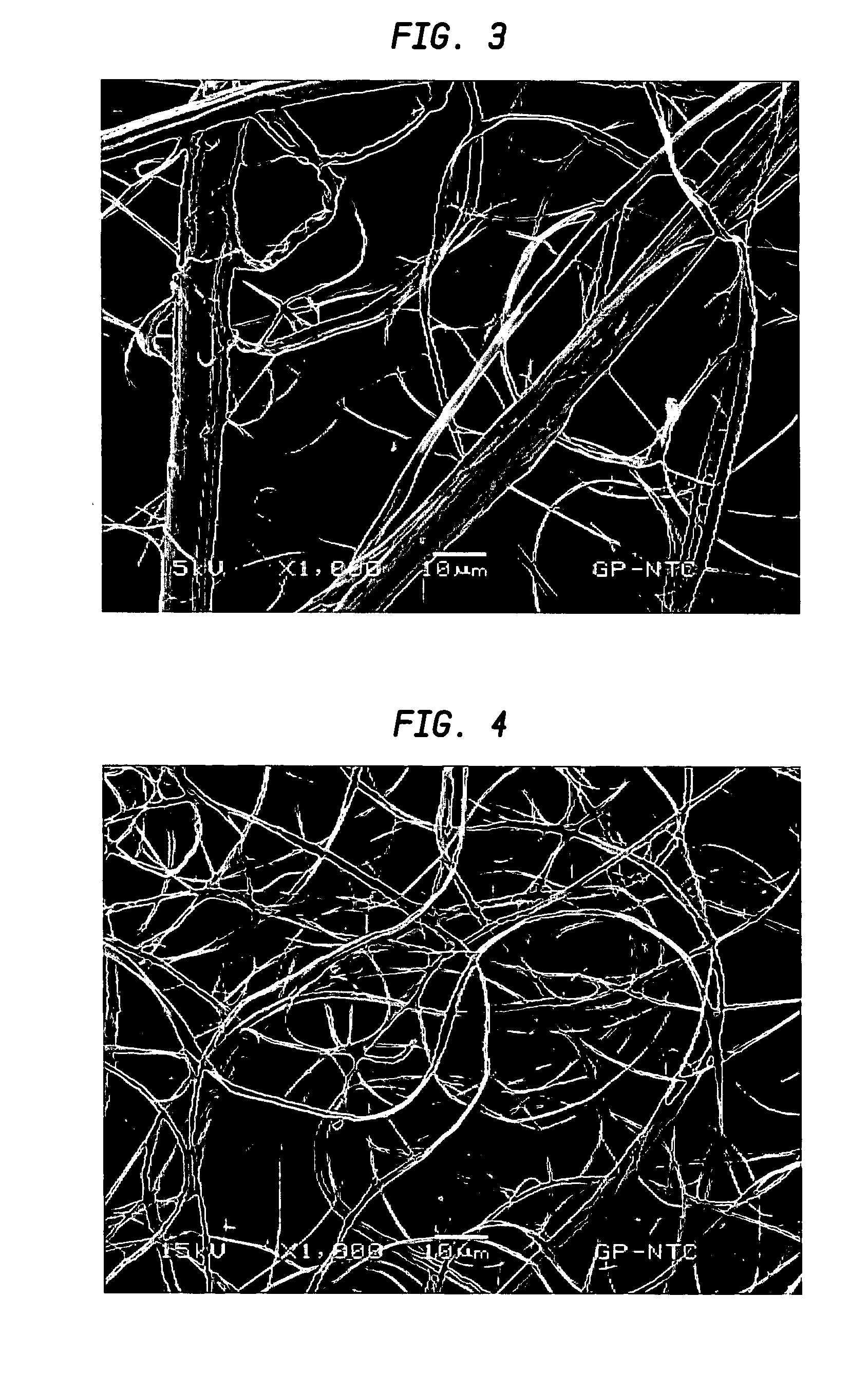

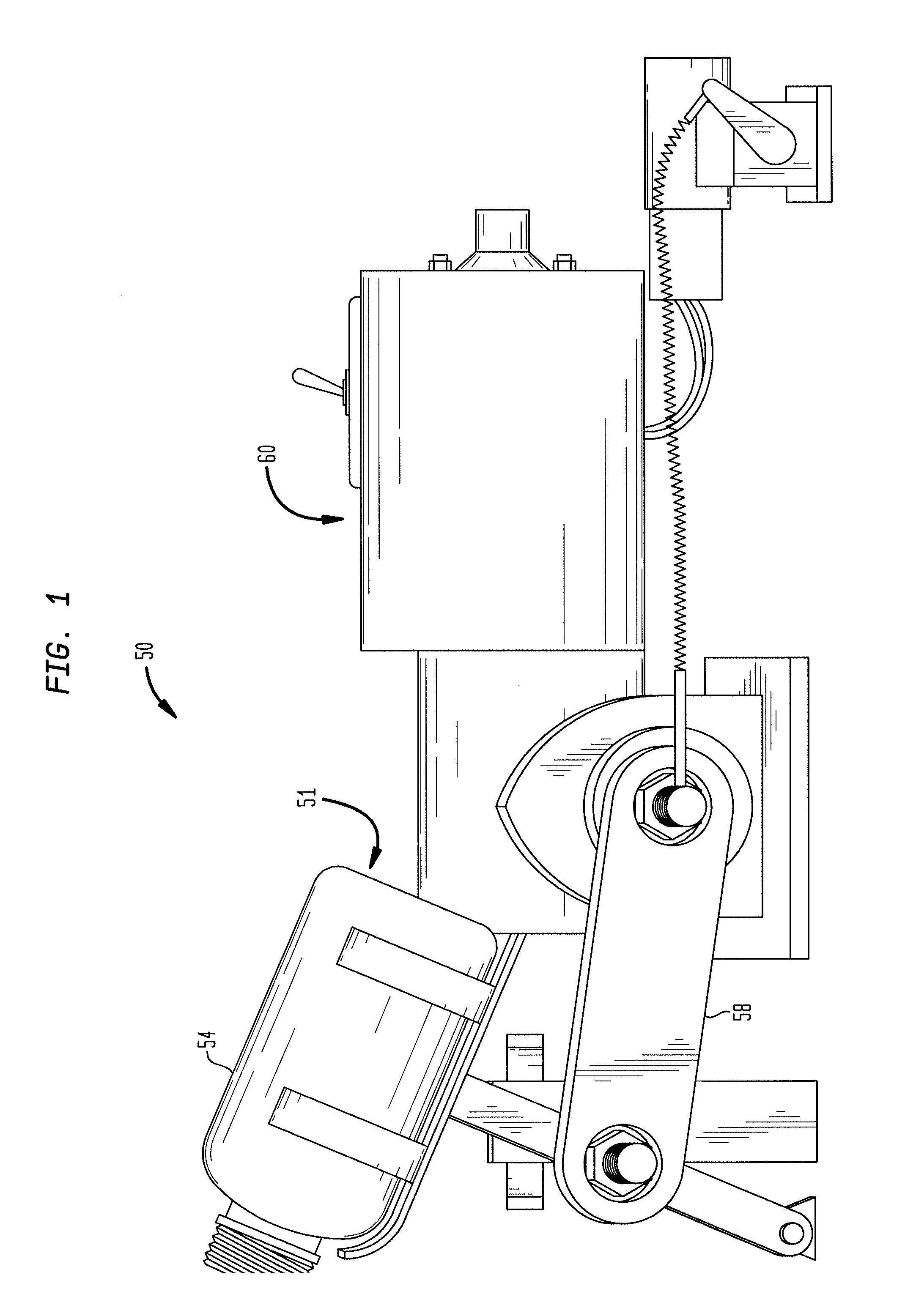

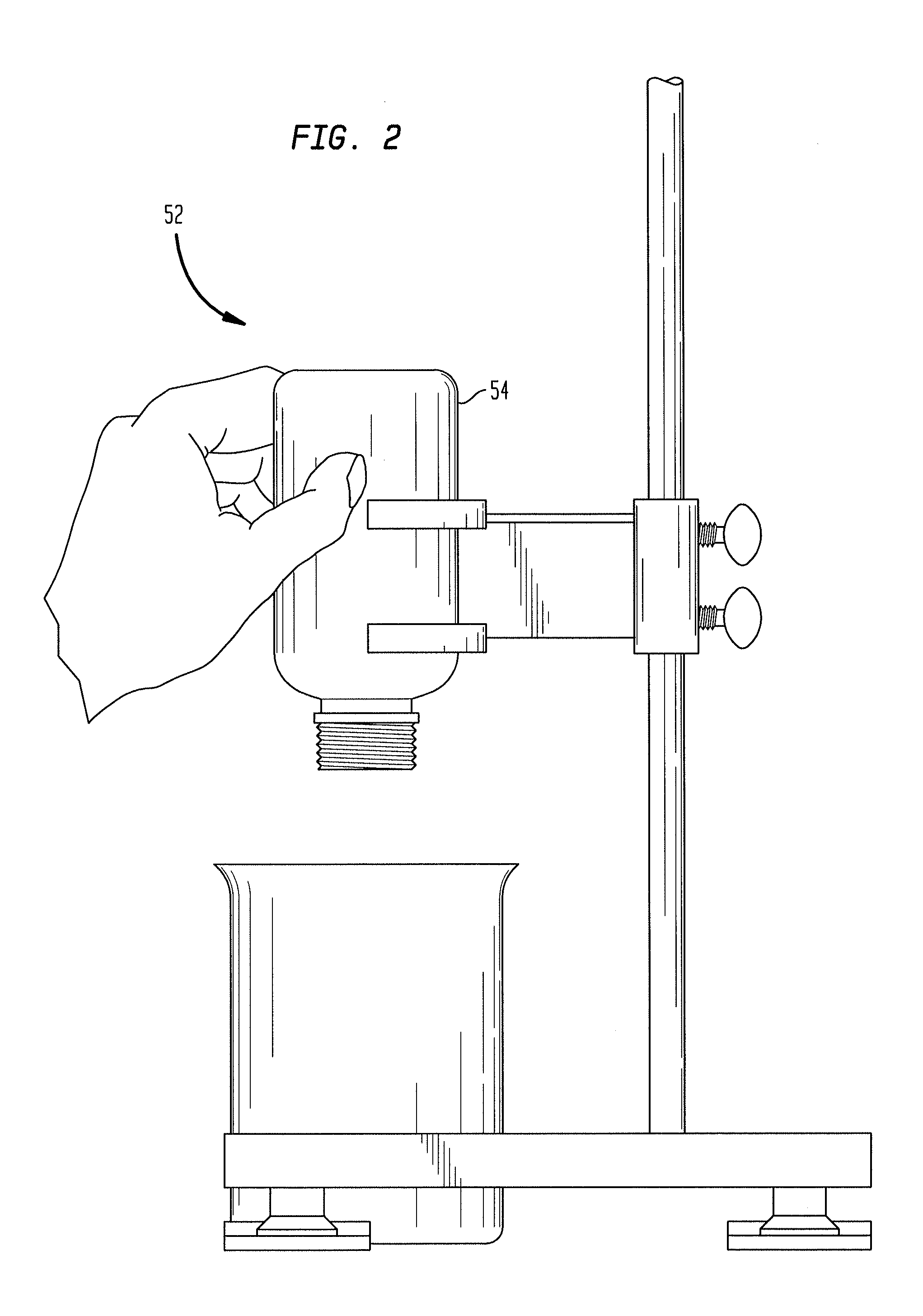

Method of making regenerated cellulose microfibers and absorbent products incorporating same

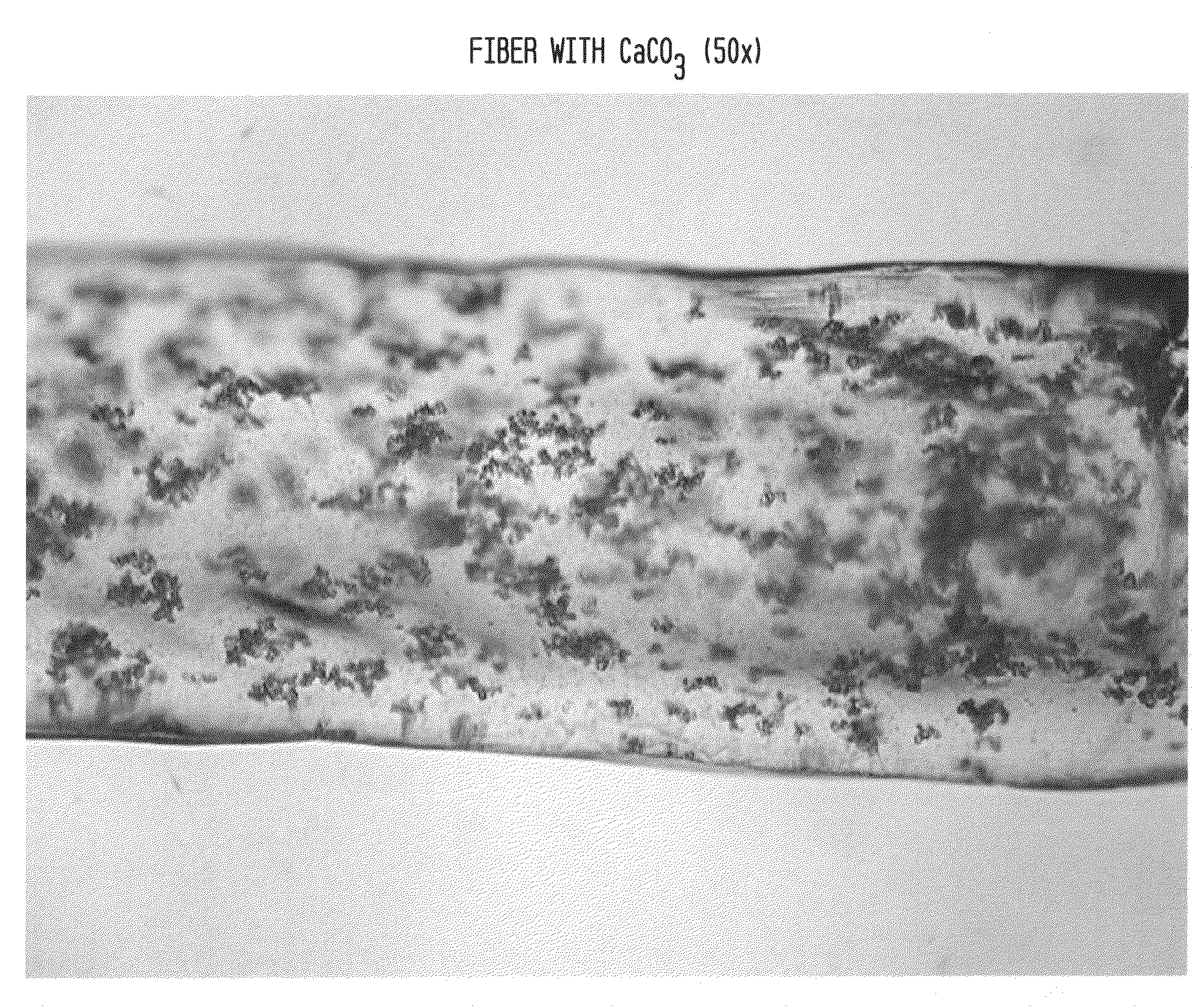

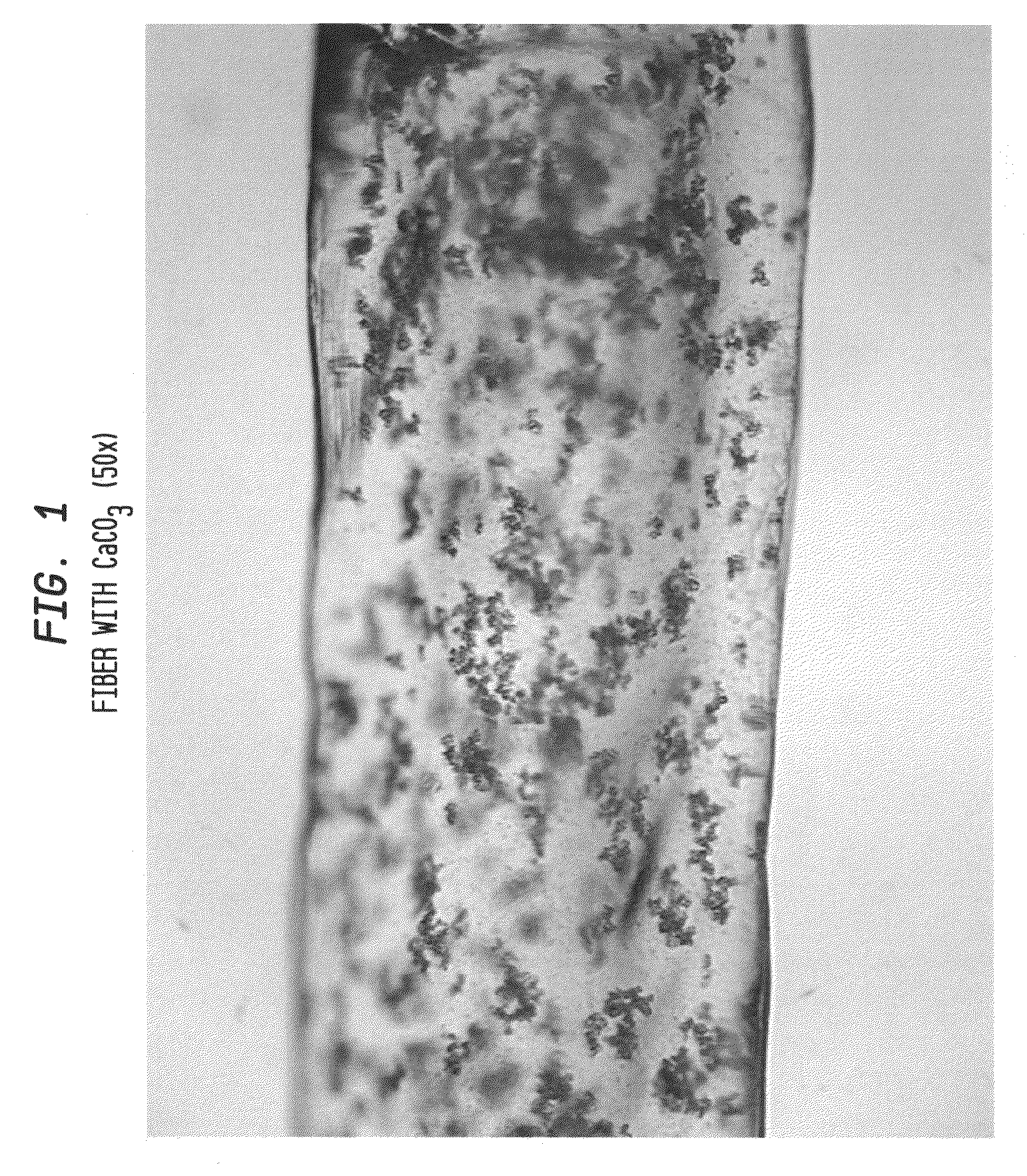

ActiveUS20080173419A1High yieldLow costNon-fibrous pulp additionElectric discharge heatingPolymer sciencePersonal Care Product

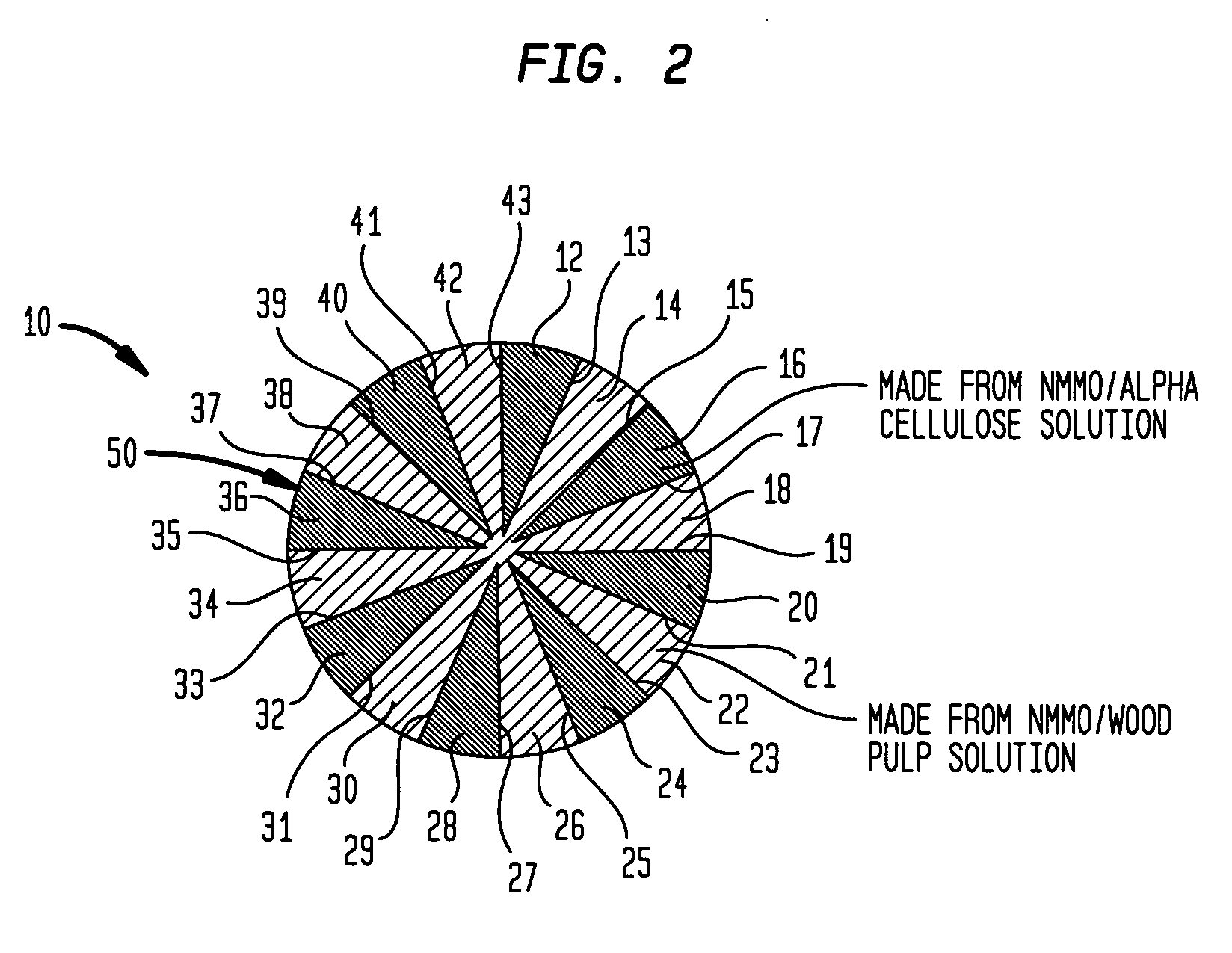

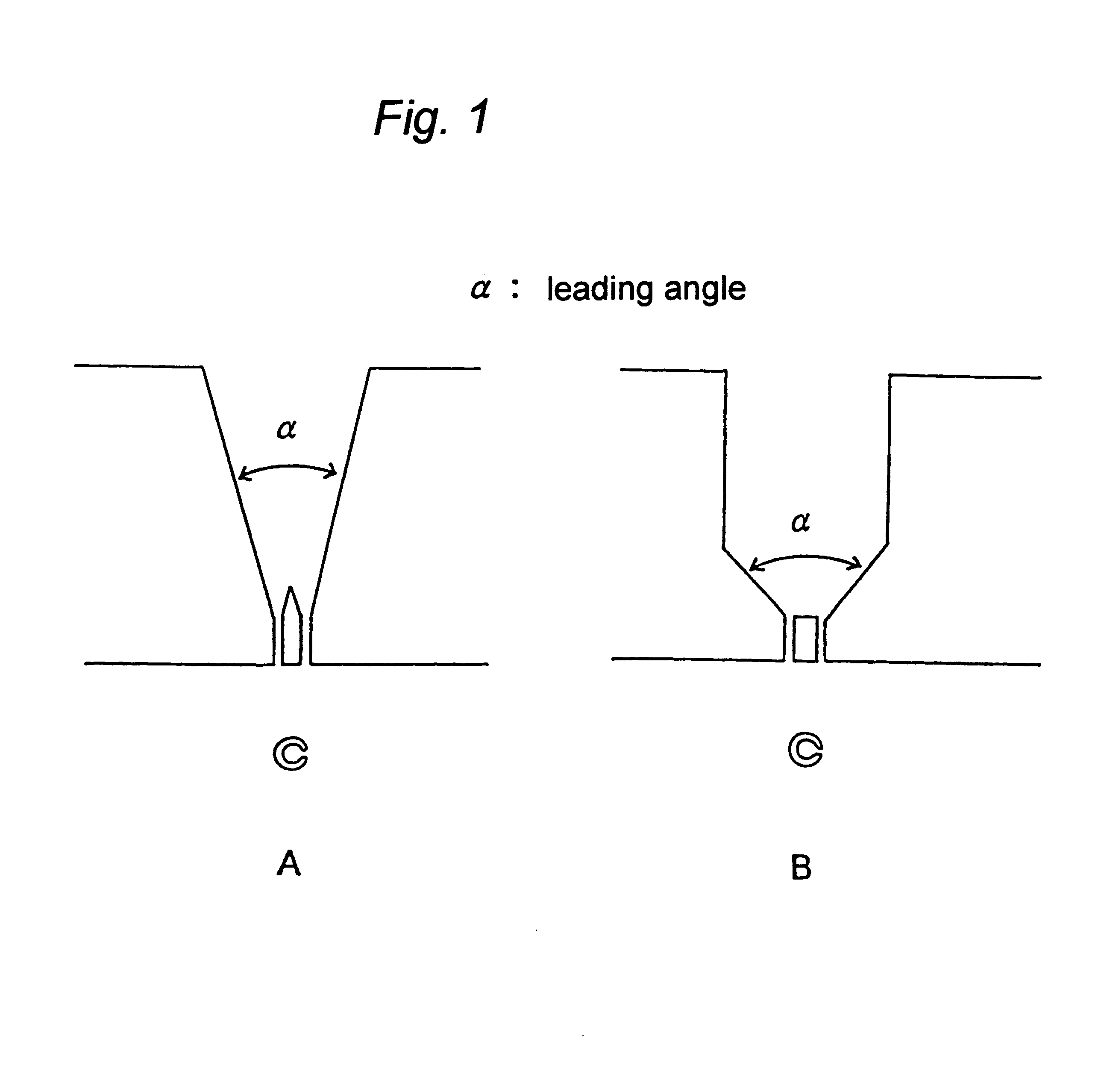

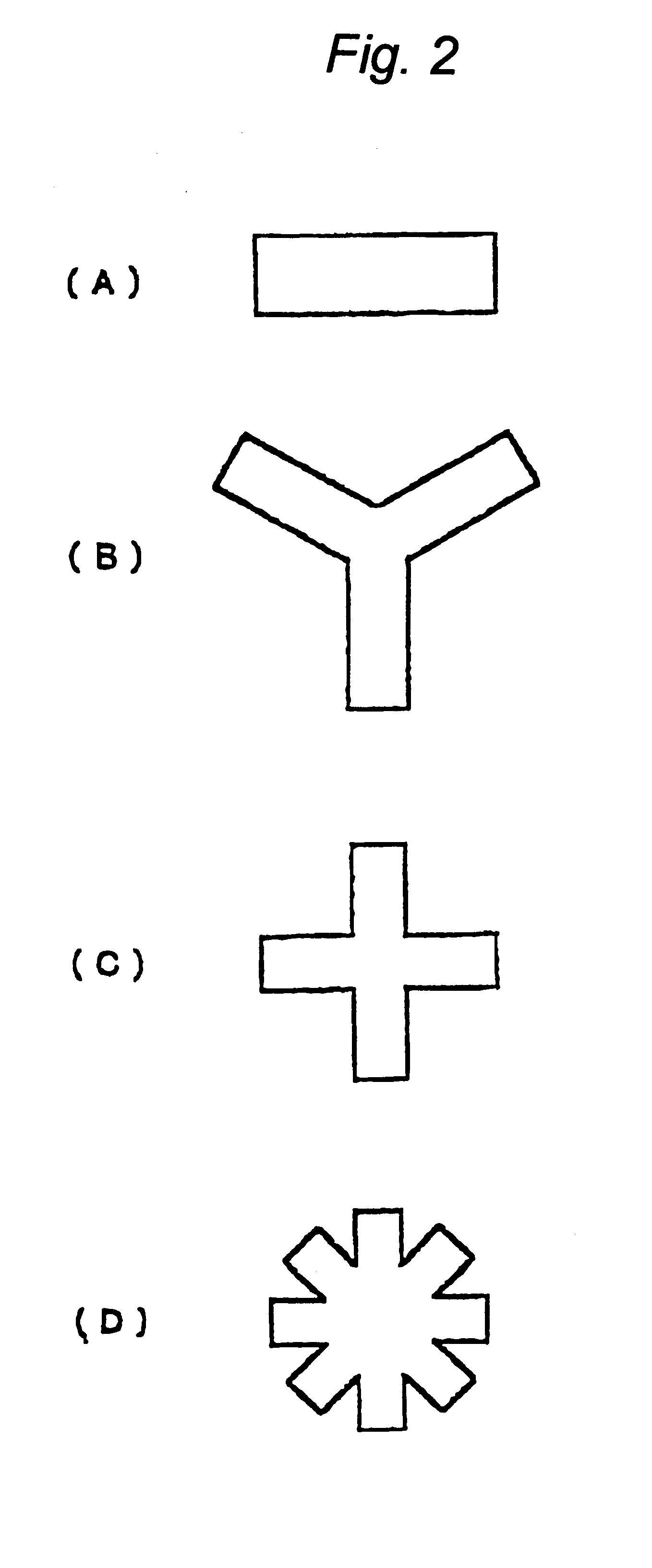

A method of making regenerated cellulose microfibers includes forming segmented fibers with multiple longitudinally-extending segments of slightly different composition such that there is defined splittable interfaces between juxtaposed segments of the fibers which are then split into microfibers at yields of greater than 50%. Fibers so produced may be incorporated into absorbent sheet with other papermaking fibers to provide strength, softness, bulk and absorbency to tissue, towel, and personal care products.

Owner:GPCP IP HLDG LLC

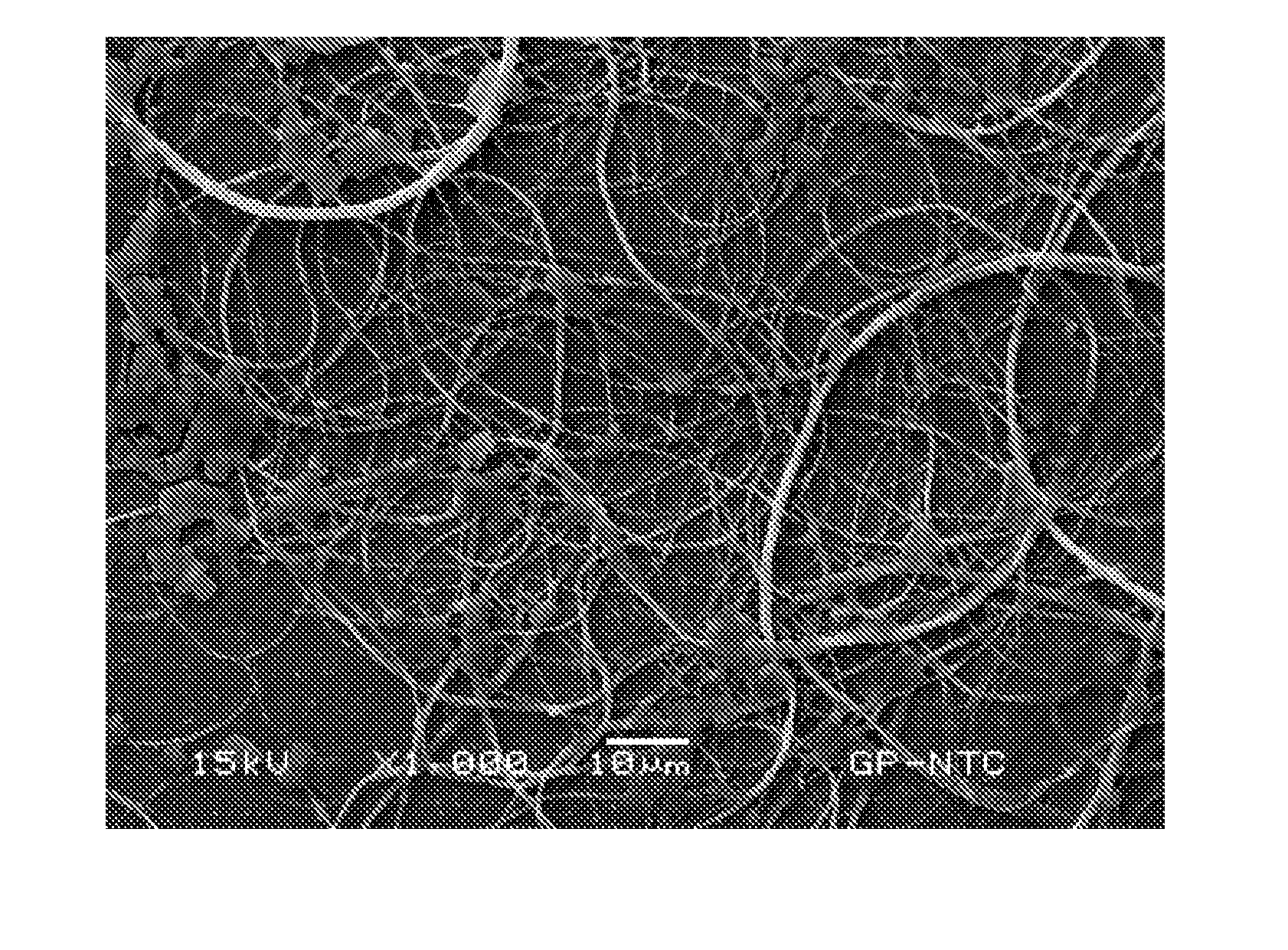

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

Endoglucanases and cellulase preparations containing the same

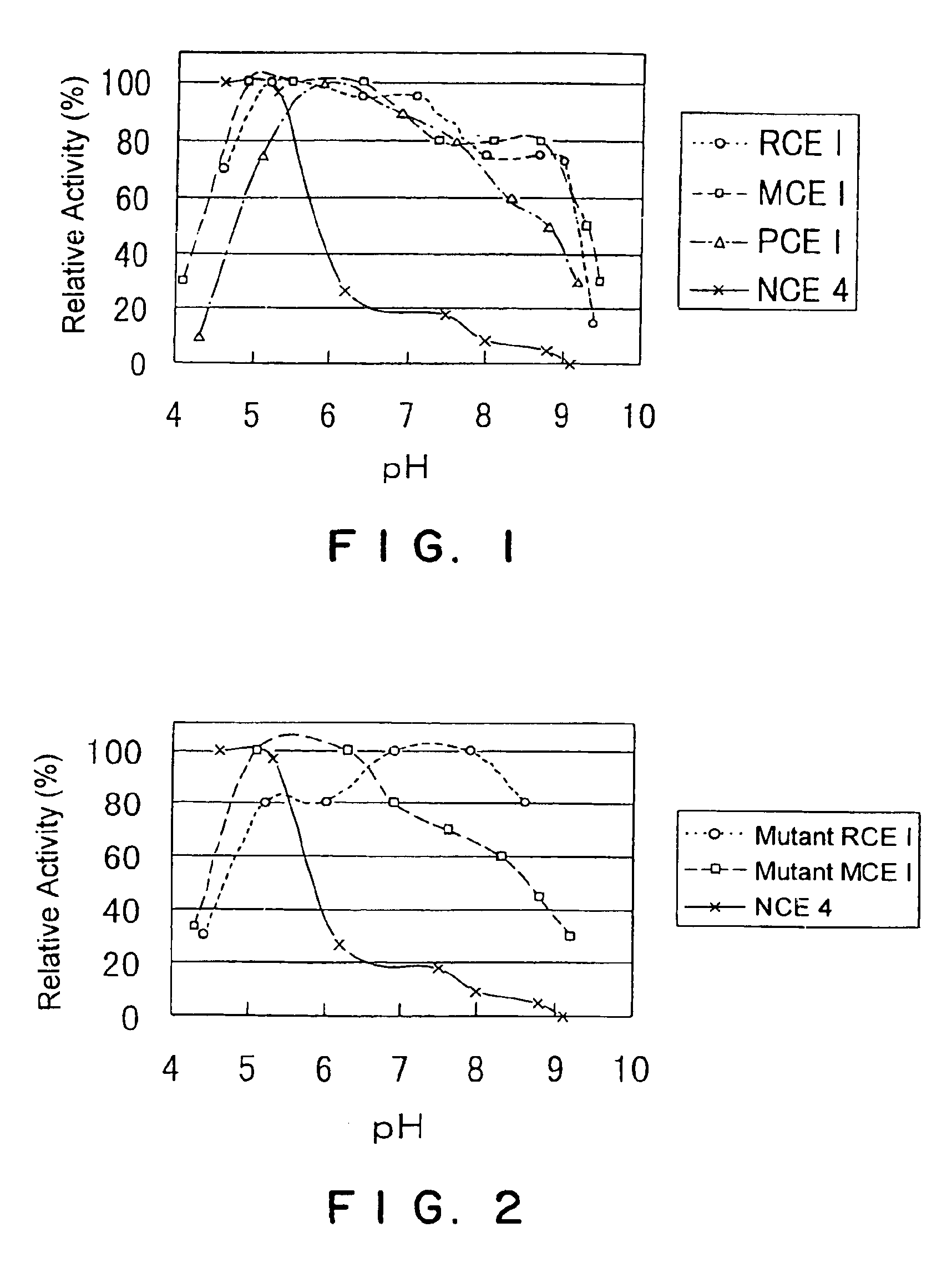

InactiveUS6921655B1High whitenessImprove freeness (drainage)Organic detergent compounding agentsBacteriaGlucanaseEndoglucanase activity

It is an object of the present invention to provide enzymes that have high endoglucanase activity and yet exhibit high activity even under alkaline conditions, and genes encoding the same. The enzyme according to the invention has the following properties: a) exhibiting endoglucanase activity; and b) capable of completely removing fuzz from regenerated cellulose fabrics at a concentration of 1 mg of the protein / L or below. The enzyme of the invention having endoglucanase activity is a protein comprising the amino acid sequence as shown in SEQ ID NO: 1, 3, 5, 7, 9 or 11; a modified protein thereof exhibiting endoglucanase activity; or a homologue of the protein or the modified protein.

Owner:MEIJI SEIKA PHARMA CO LTD

Method for preparing functional material of regenerated cellulose

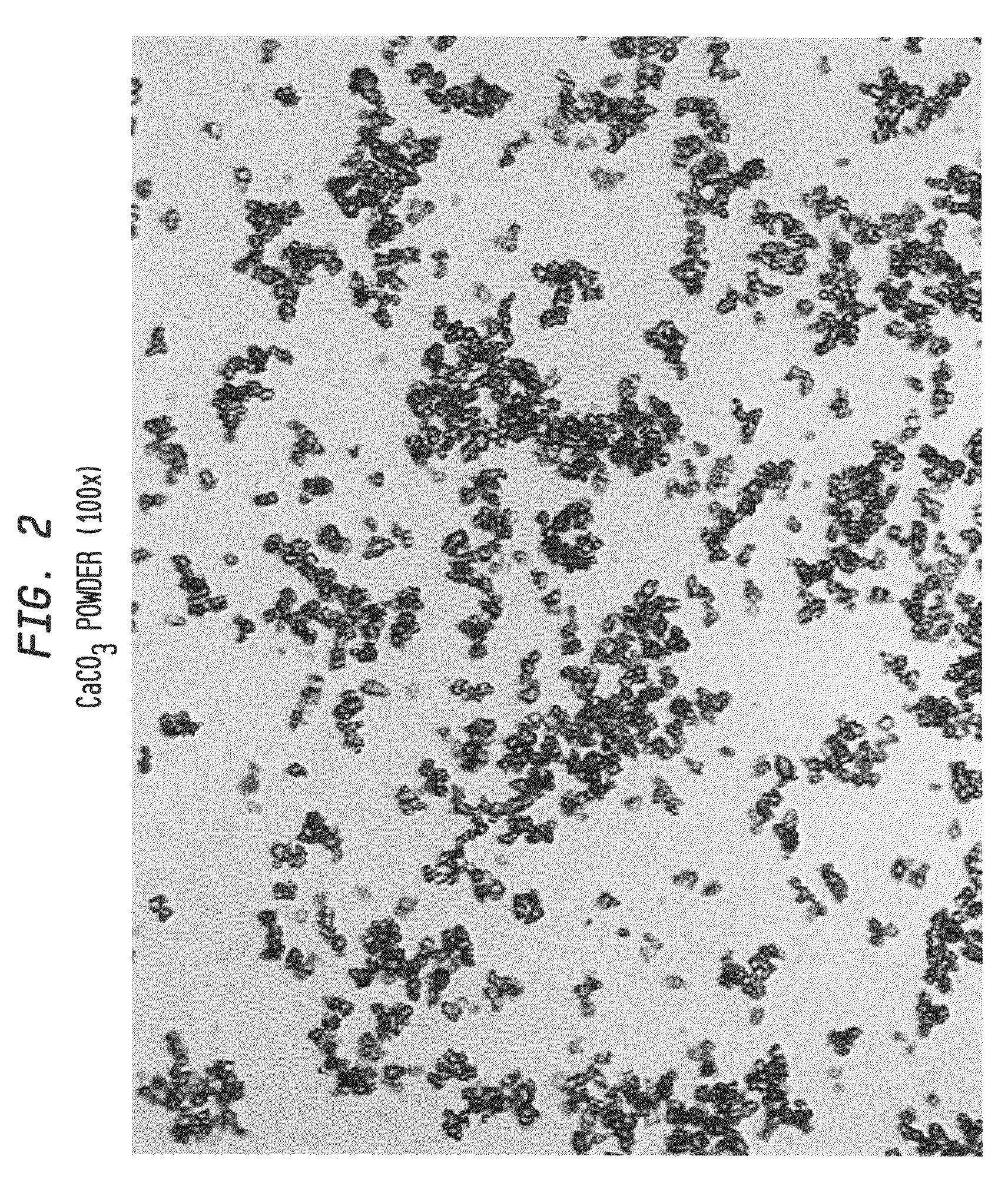

This invention publishes a preparation method for functionalized regenerated cellulose materials. Natural cellulose raw materials are dried and mixed with cellulose solvents, and the mixture is heated and stirred or mechanically kneaded until complete dissolution of cellulose. Functionalized fillers are added into the consequent homogeneous and transparent cellulose solution and stirred. The consequent solution is defoamed in vacuum, regenerated in coagulation bath, washed with water and dried or spun so as to obtain functionalized regenerated cellulose materials.

Owner:山东中科恒联生物基材料有限公司

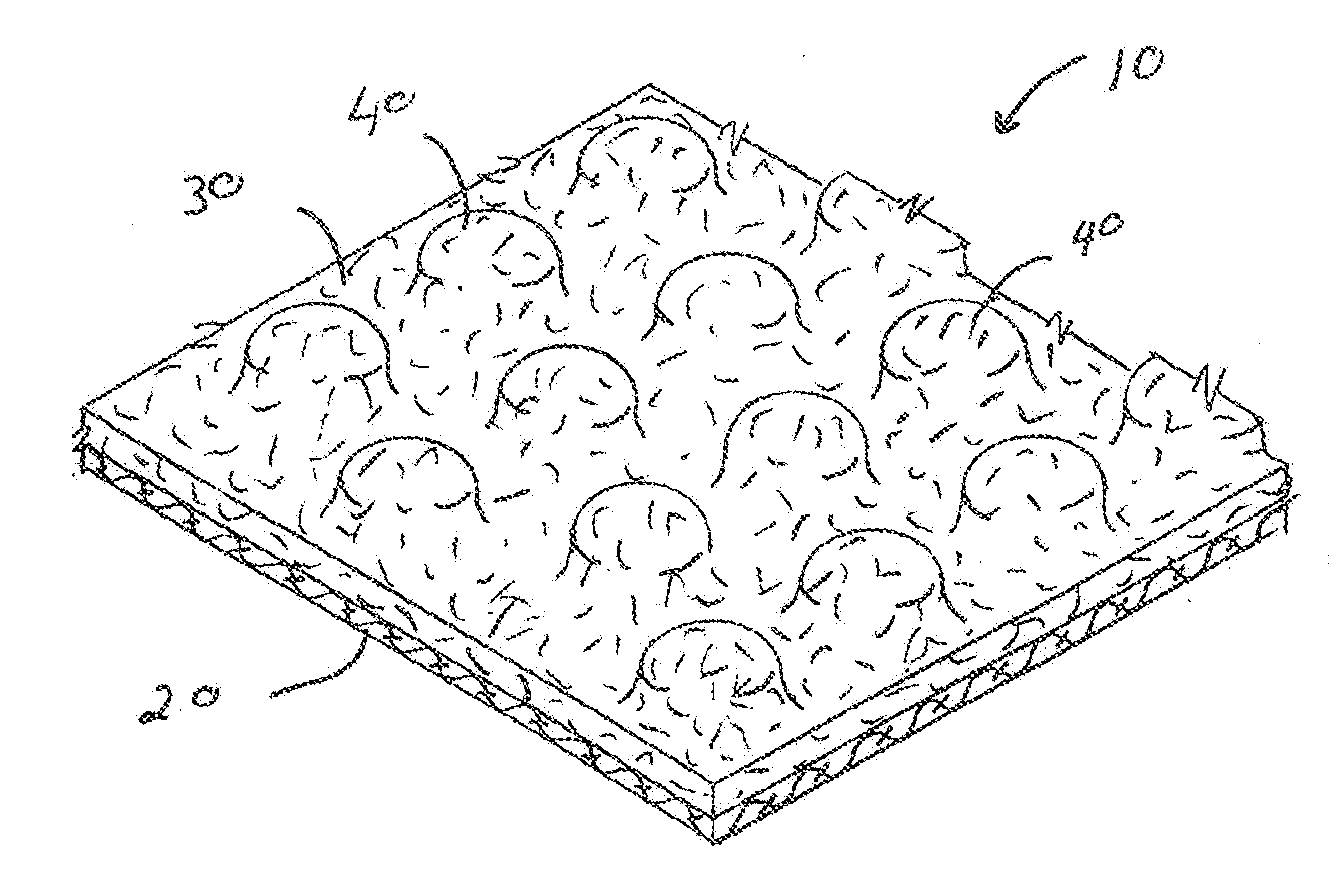

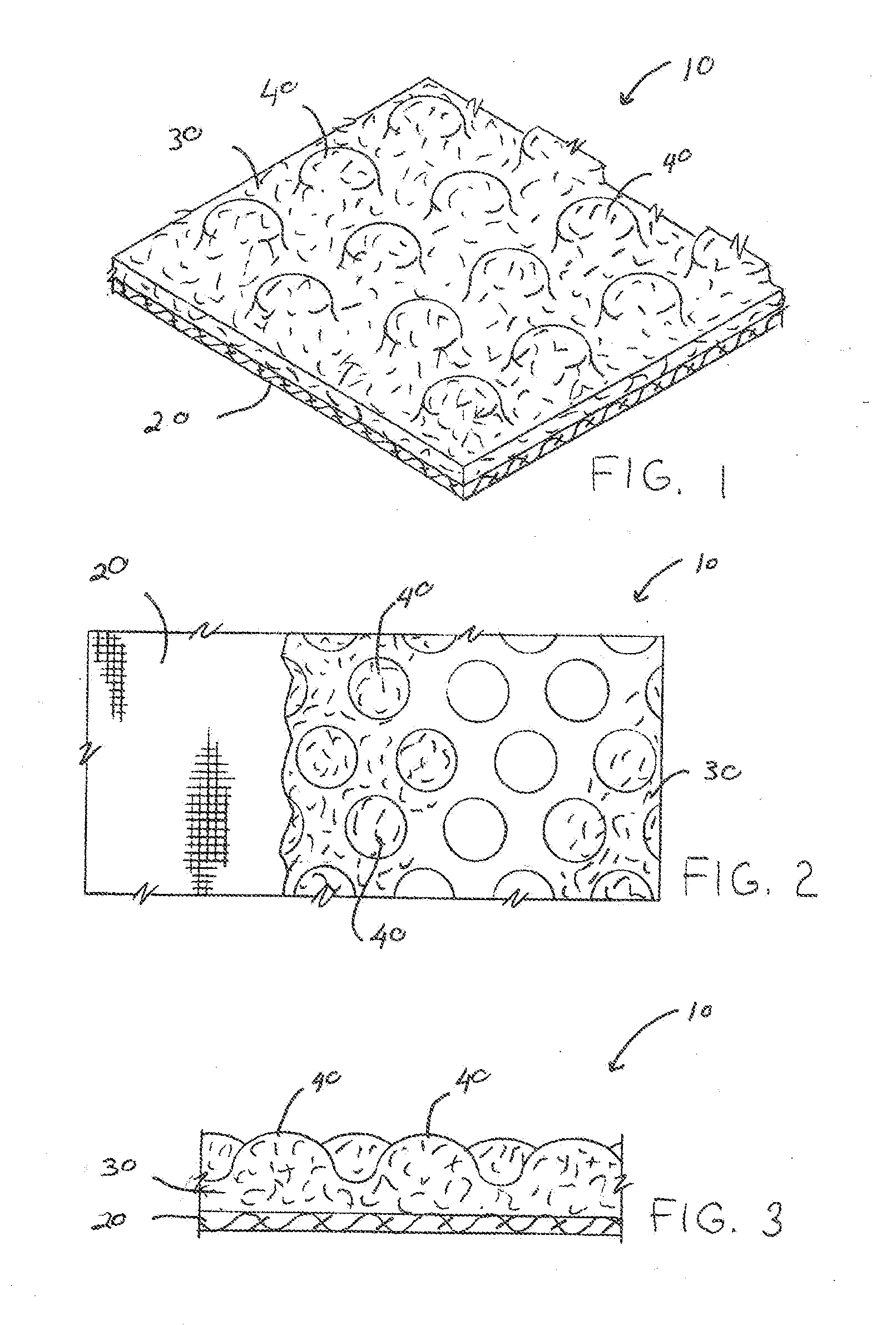

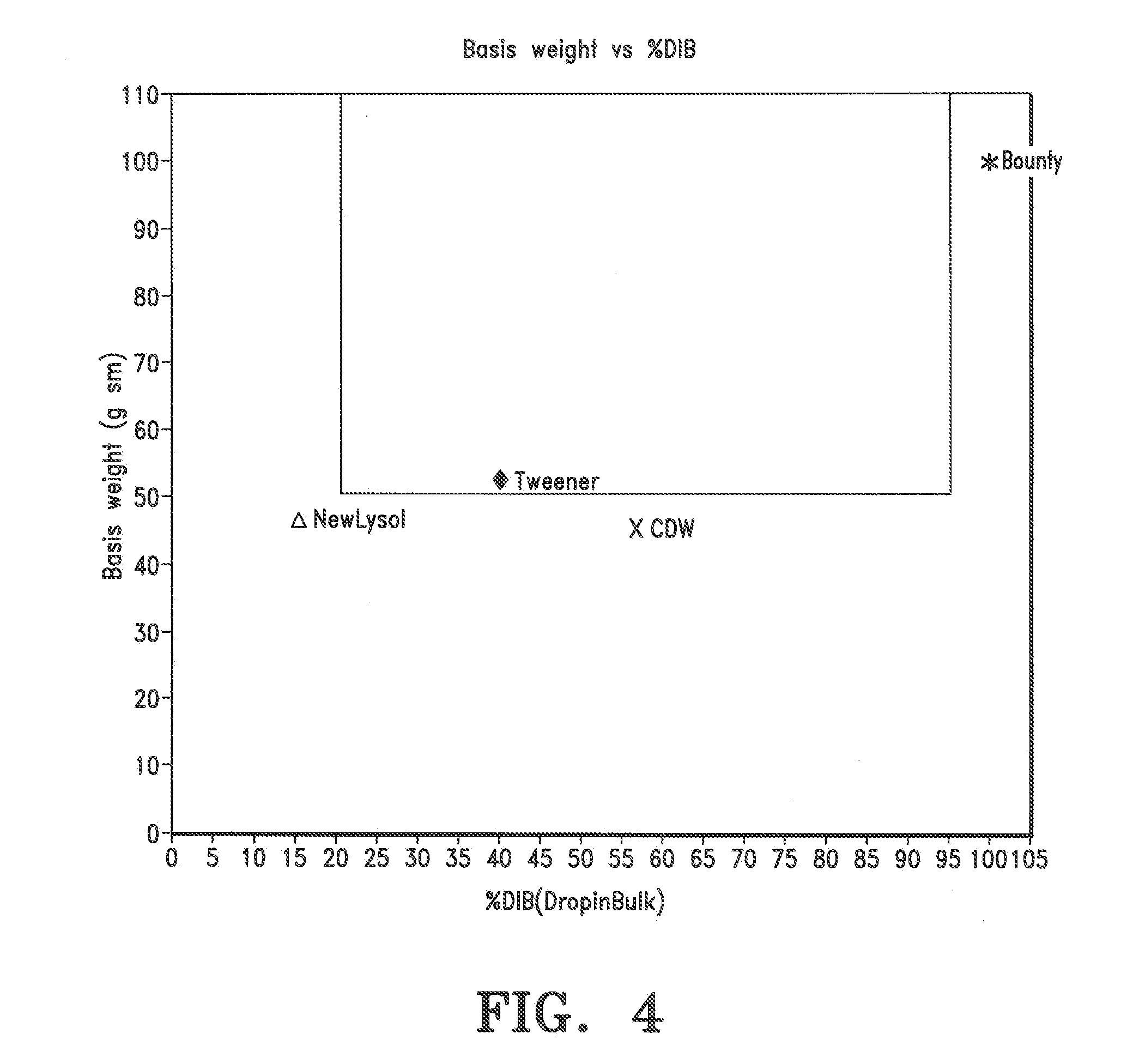

Textured wipes

InactiveUS20120227203A1Reduce material usageHigh strengthBoard cleaning devicesCarpet cleanersEngineeringSecondary layer

A wipe formed of a base layer and a secondary layer. The wipe has an initial caliper of at least about 0.5 mm, a basis weight of less than about 55 gsm and a % DIB of about 20-95%. The base layer is formed of a non-biodegradable material such as thermoplastic polymer and the secondary layer is formed of a biodegradable material such as wood pulp, cellulose and / or regenerated cellulose. The top surface of the secondary layer generally includes a non-uniform distribution of fibers.

Owner:THE CLOROX CO

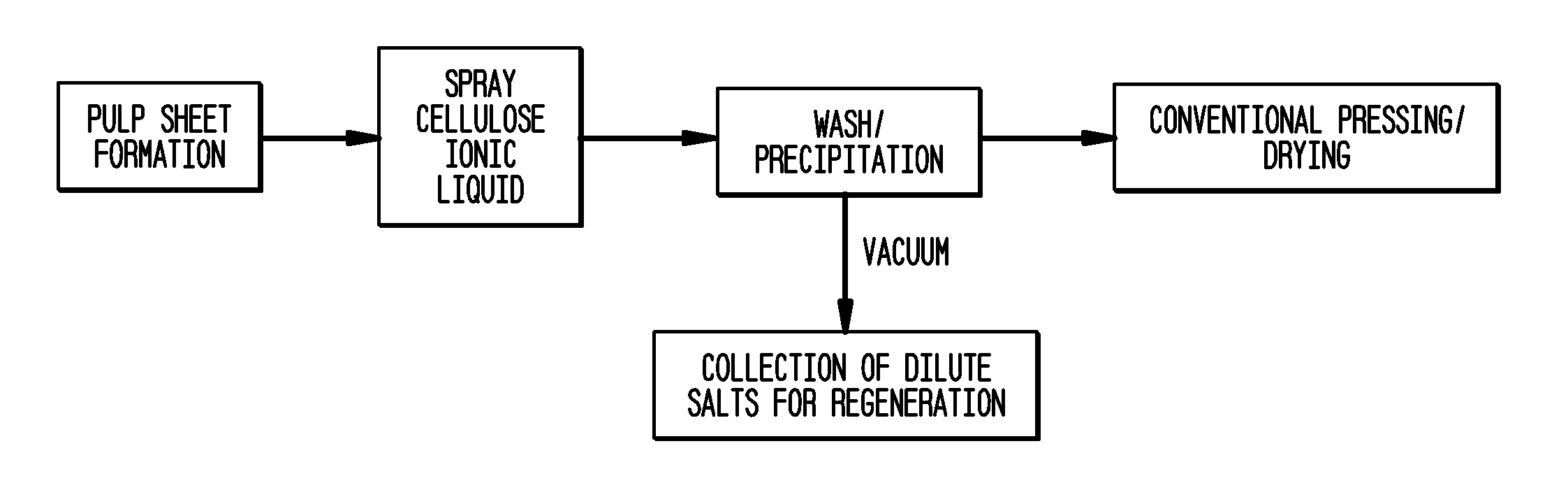

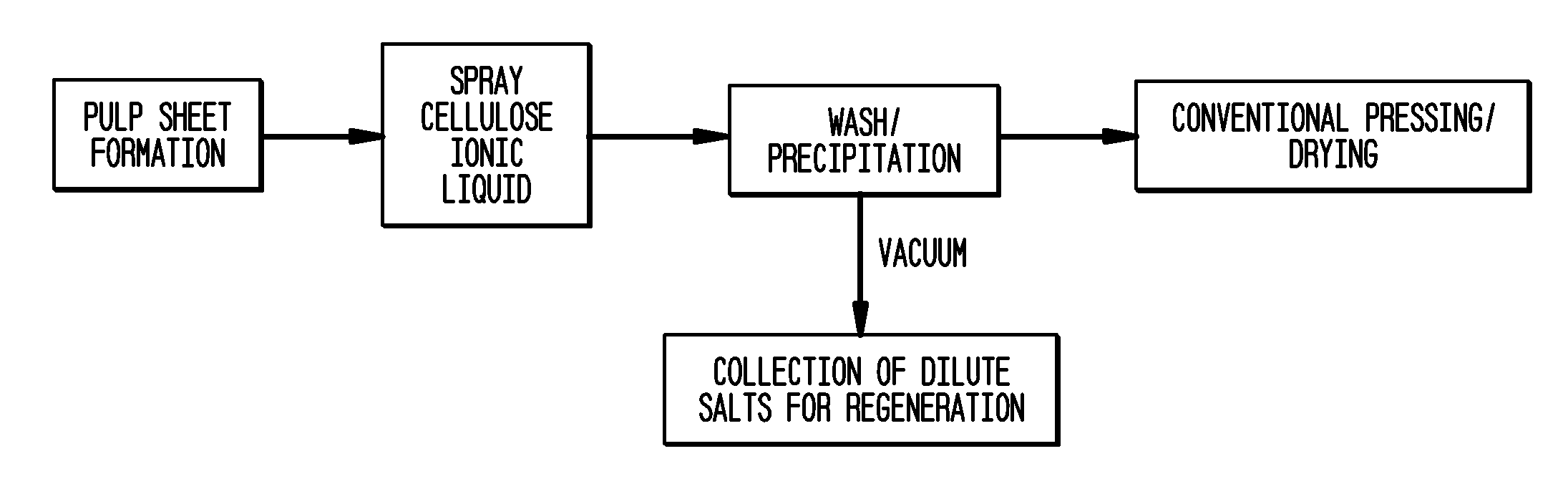

Absorbent cellulosic products with regenerated cellulose formed in-situ

ActiveUS7951264B2Non-fibrous pulp additionPaper after-treatmentPulp and paper industryRegenerated cellulose

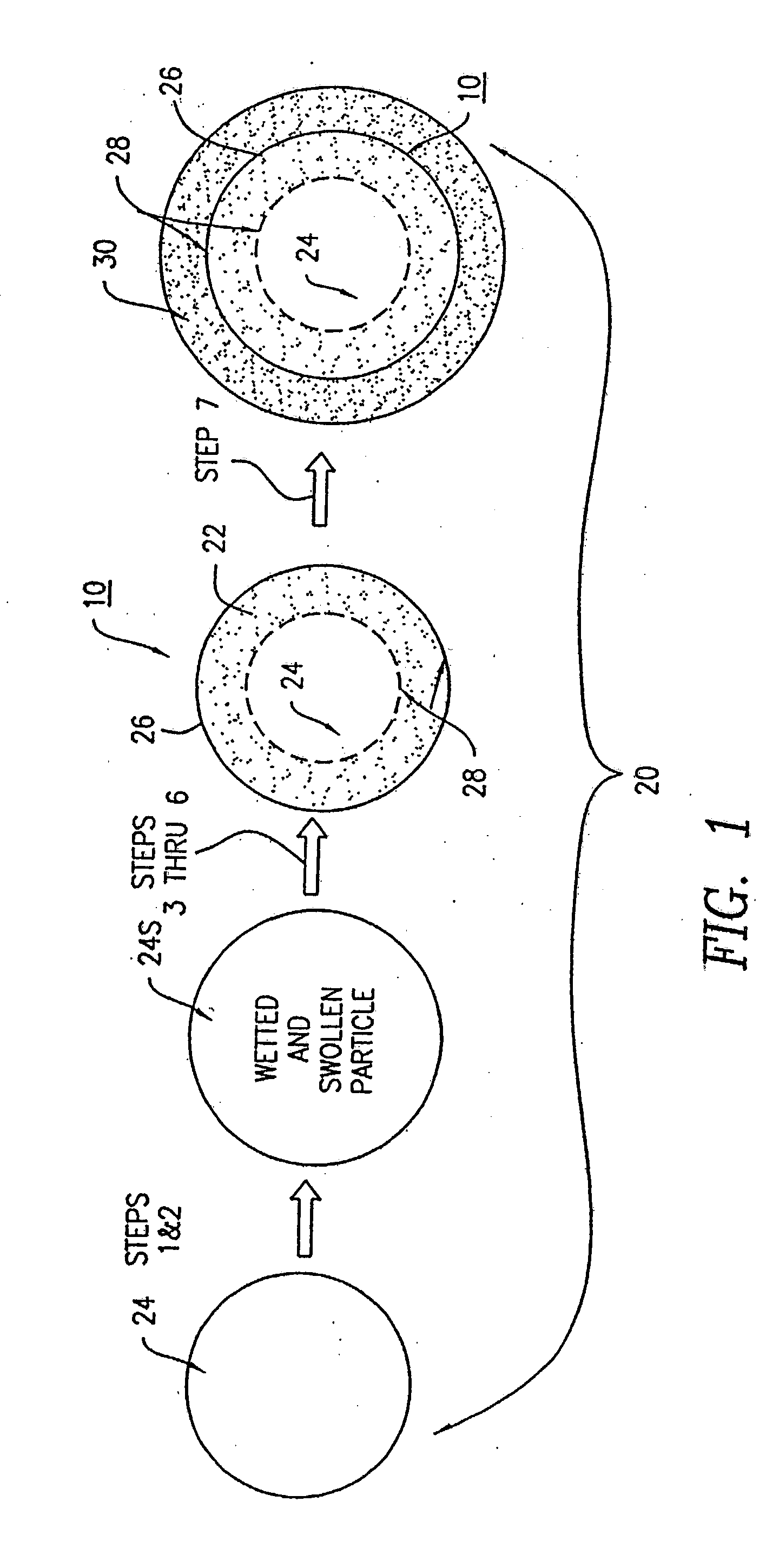

A method of making absorbent cellulosic sheet includes forming a web of papermaking fibers, extruding a cellulosic dope of underivatized cellulose, disposing the dope upon the web and regenerating the cellulose in-situ. Regenerated filaments may have a denier of from about 0.05 to about 20.

Owner:GPCP IP HLDG LLC

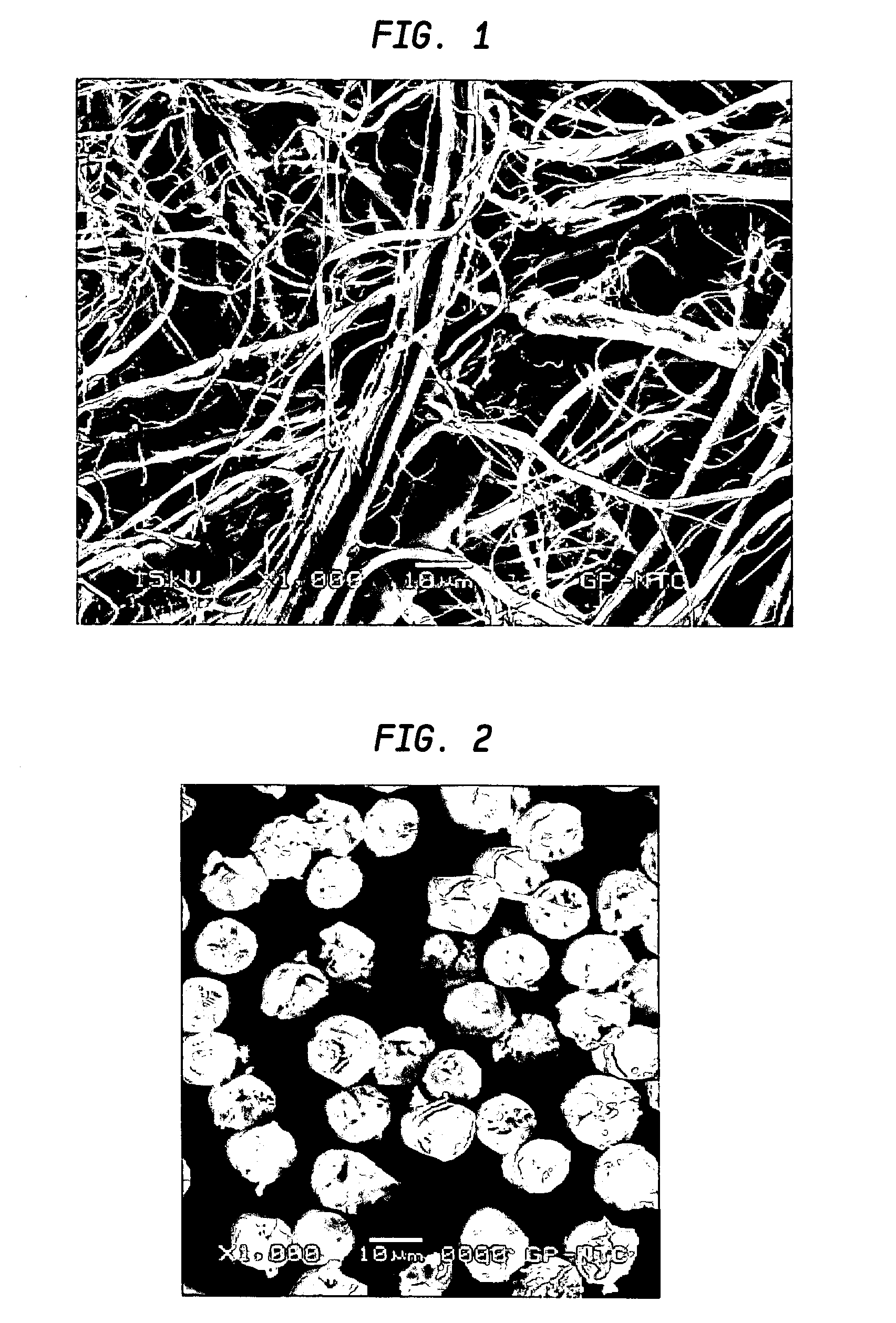

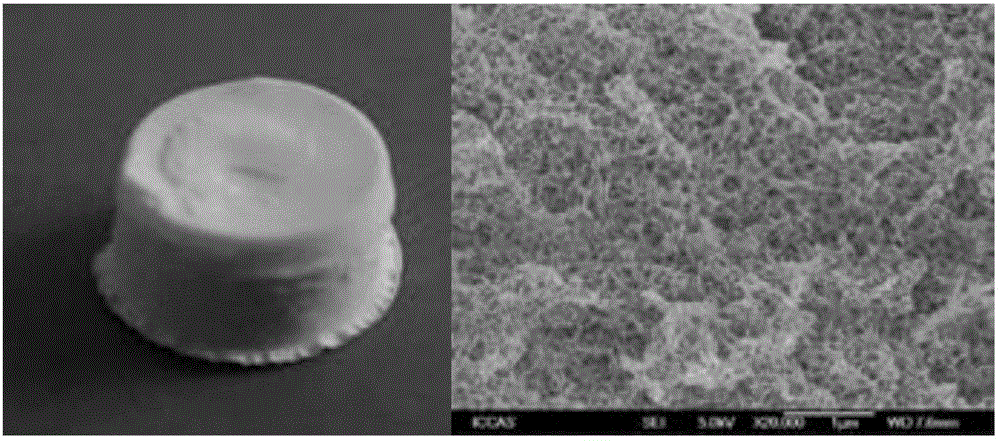

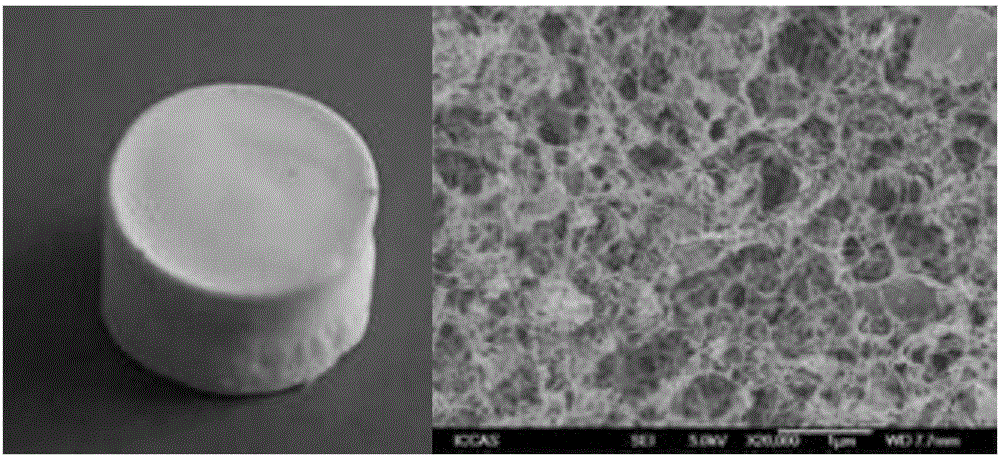

Cellulose aerogel and preparation method for hybrid aerogel thereof

The invention discloses low-cost green cellulose aerogel and a preparation method for hybrid aerogel thereof. The preparation method for the hybrid aerogel of the cellulose aerogel comprises the following steps that cellulose is dissolved into a zinc chloride aqueous solution, centrifugal deaeration is performed, and a uniform and transparent cellulose solution is obtained; the cellulose solution is formed, then the formed cellulose solution is placed into a coagulating bath to be regenerated, in addition, the regenerated cellulose solution is fully washed by use of a solvent, and cellulose solvent gel is obtained; the solvent in the cellulose solvent gel is removed by use of supercritical carbon dioxide drying or freeze drying, and the cellulose aerogel is obtained. Functional filler can be added into the cellulose solution to obtain the hybrid aerogel. By the adoption of different solution forming methods, the cellulose aerogel and the hybrid aerogel thereof in the shapes of sheets, fibers, particles and the like can be prepared. The preparation method is low in cost and is environmentally friendly, and the prepared aerogel is provided with a uniform nano-grade net porous structure.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Sublimation Printing Processes and Fabric Pretreatment Compositions for Ink Jet Printing onto Arbitrary Fabrics

InactiveUS20110169901A1Outstanding washfastness to repeated launderingImprove washing fastnessTransfer printing processDyeing processTextile fiberEngineering

An ink jet printing process for sublimation printing of arbitrary textile fiber substrates, wherein the fiber materials are pretreated with an aqueous coating composition, enabling ink jet printing of natural and regenerated cellulosic fibers and blends thereof with synthetic fibers, by direct sublimation or sublimation transfer printing, applying to said fibers a novel textile coating or fabric pretreatment composition, wherein said textile coating or fabric pretreatment comprises: an aqueous dispersion of fluoropolymer particles and a non-fluoropolymer binder.

Owner:ADVANCED COMM SOLUTIONS

Solvent composite and preparation method and use thereof

The solvent composition consists of sodium hydroxide 5-12 wt% and urea 8-20 wt% except water. The preparation process of the solvent composition is also provided. Water solution of sodium hydroxideand water solution of urea are mixed to compound the solvent composition; or sodium hydroxide is first compounded into water solution and urea is then added to compound the solvent composition. The solvent composition may be used in directly dissolving natural cellulose and regenerated cellulose to obtain transparent cellulose solution with high dissolubility and high concentration.

Owner:WUHAN UNIV

Food wrap base sheet with regenerated cellulose microfiber

A base sheet for food wrap products. The base sheet can include a pulp-derived papermaking fiber and a fibrillated regenerated cellulose microfiber having a CSF value of less than about 175 mL.

Owner:GPCP IP HLDG LLC

Absorbent Cellulosic Products with Regenerated Cellulose Formed In-Situ

A method of making absorbent cellulosic sheet includes forming a web of papermaking fibers, extruding a cellulosic dope of underivatized cellulose, disposing the dope upon the web and regenerating the cellulose in-situ. Regenerated filaments may have a denier of from about 0.05 to about 20.

Owner:GPCP IP HLDG LLC

Inflated filbers of regenerated cellulose formed from ionic liguid/cellulose dope and related products

Inflated fibers of regenerated cellulose and other regenerated structures are formed from ionic liquid / cellulose dope. Fibers so produced may be incorporated into absorbent sheet with other papermaking fibers to provide softness, bulk and absorbency.

Owner:GPCP IP HLDG LLC

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

Water disintegratable fibrous sheet

InactiveUS20120080155A1High strengthResistant to tearingNon-fibrous pulp additionSpecial paperPolymer scienceWet strength

To provide a water disintegratable fibrous sheet with high water disintegratability and wet strength, that can be used as a cleaning sheet. A prescribed water disintegratable fibrous sheet comprising 30-50% by mass of unbeaten pulp (a) with a beating degree of 700 cc or greater; 20-40% by mass of beaten pulp (b) with a beating degree of 400-700 cc; 15-45% by mass of regenerated cellulose (c) with a beating degree of 700 cc or greater; and 2-15% by mass of fibrillated purified cellulose (d) with a beating degree of 0-400 cc.

Owner:UNI CHARM CORP

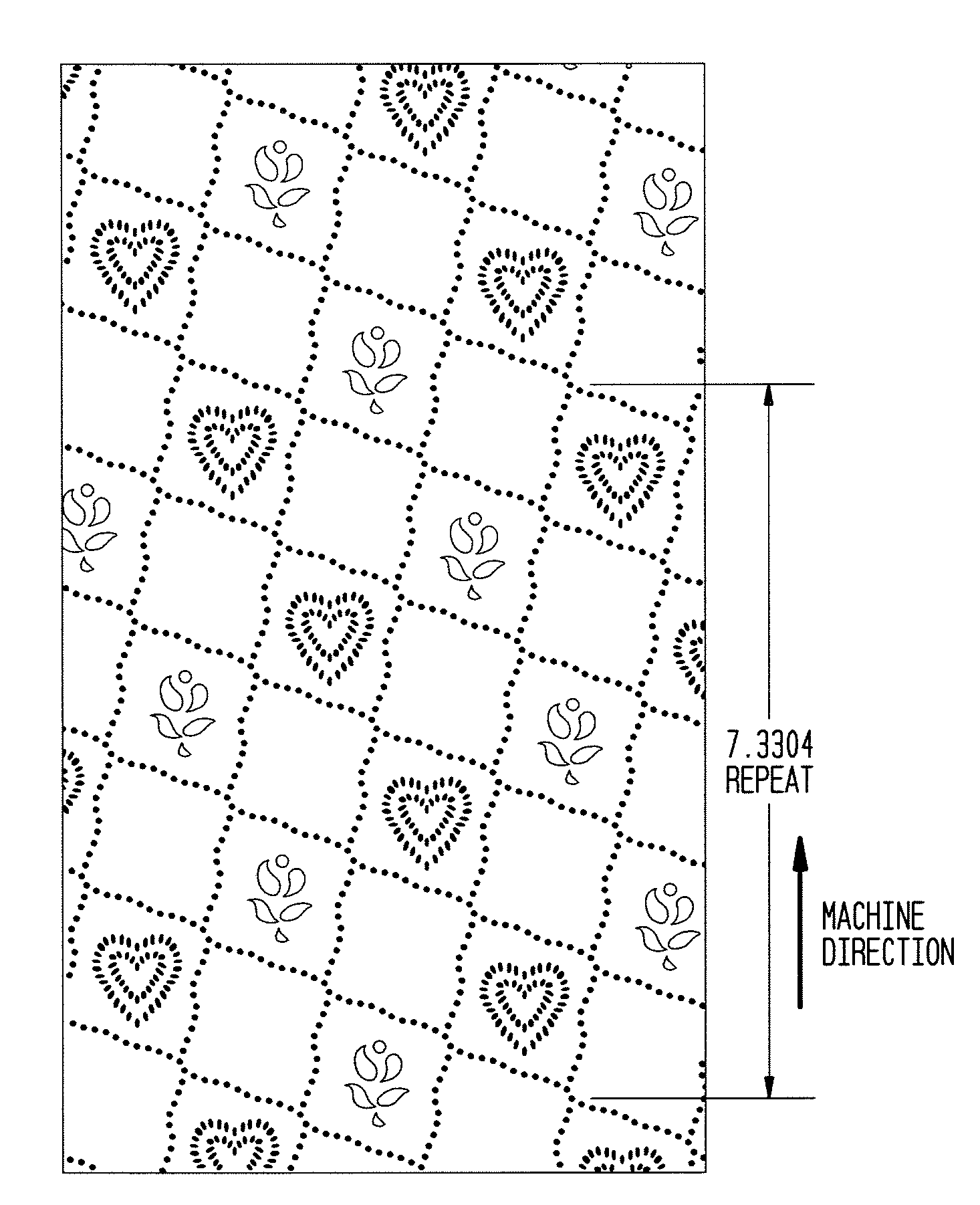

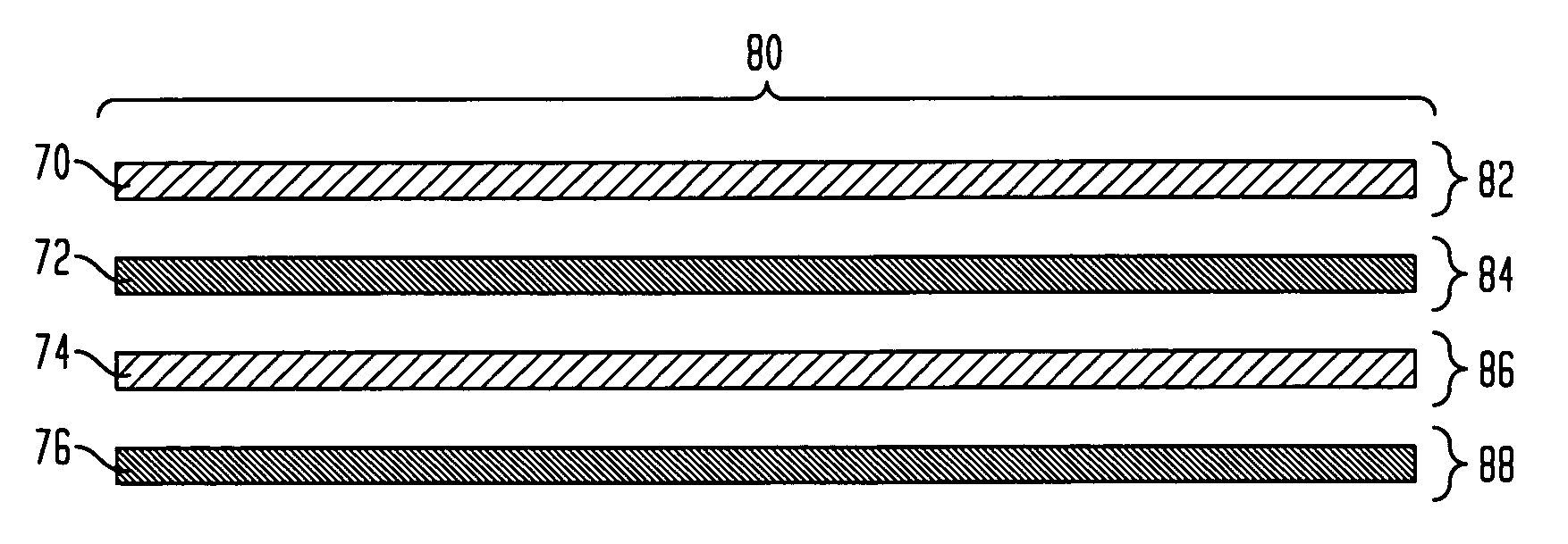

Belt-creped, variable local basis weight multi-ply sheet with cellulose microfiber prepared with perforated polymeric belt

ActiveUS20120021178A1High absorbency (SAT)Eliminate needMechanical working/deformationLayered productsPaper towelEngineering

A multi-ply absorbent sheet includes at least a first and second ply bonded together. In one construction, the first and second ply are provided with from about 90% by weight to about 25% by weight pulp-derived papermaking fiber and from about 10% to about 75% by weight fibrillated regenerated cellulosic microfiber having a characteristic CSF value of less than 175 ml; the sheet having a caliper of from 180-250 mils / 8 sheets and exhibiting a wipe-dry time of less than 20 seconds, an SAT capacity in the range of 350-500 g / m2, an SAT rate in the range of 0.05-0.25 g / s0.5, a CD wet tensile in the range of 400-2500 g / 3″ and a wet / dry CD tensile ratio of from 35% to 60%. The multi-ply sheets are efficient, high capacity wipers and have enough absorbent capacity to be used as ordinary paper towels. Preferred wiper towel products exhibit a differential pore volume for pores under 5 microns in diameter of at least about 75 mm3 / g / micron.

Owner:GPCP IP HLDG LLC

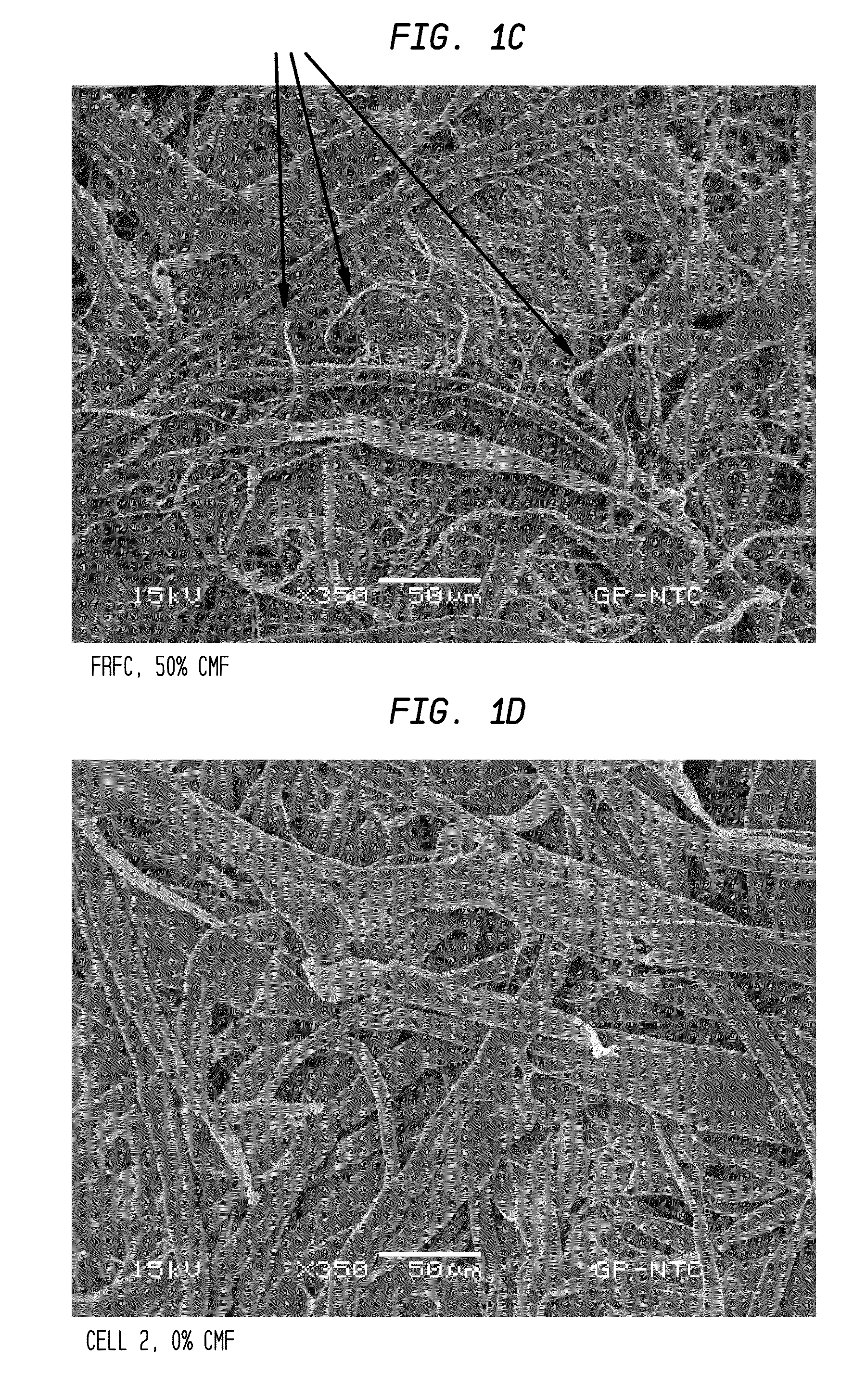

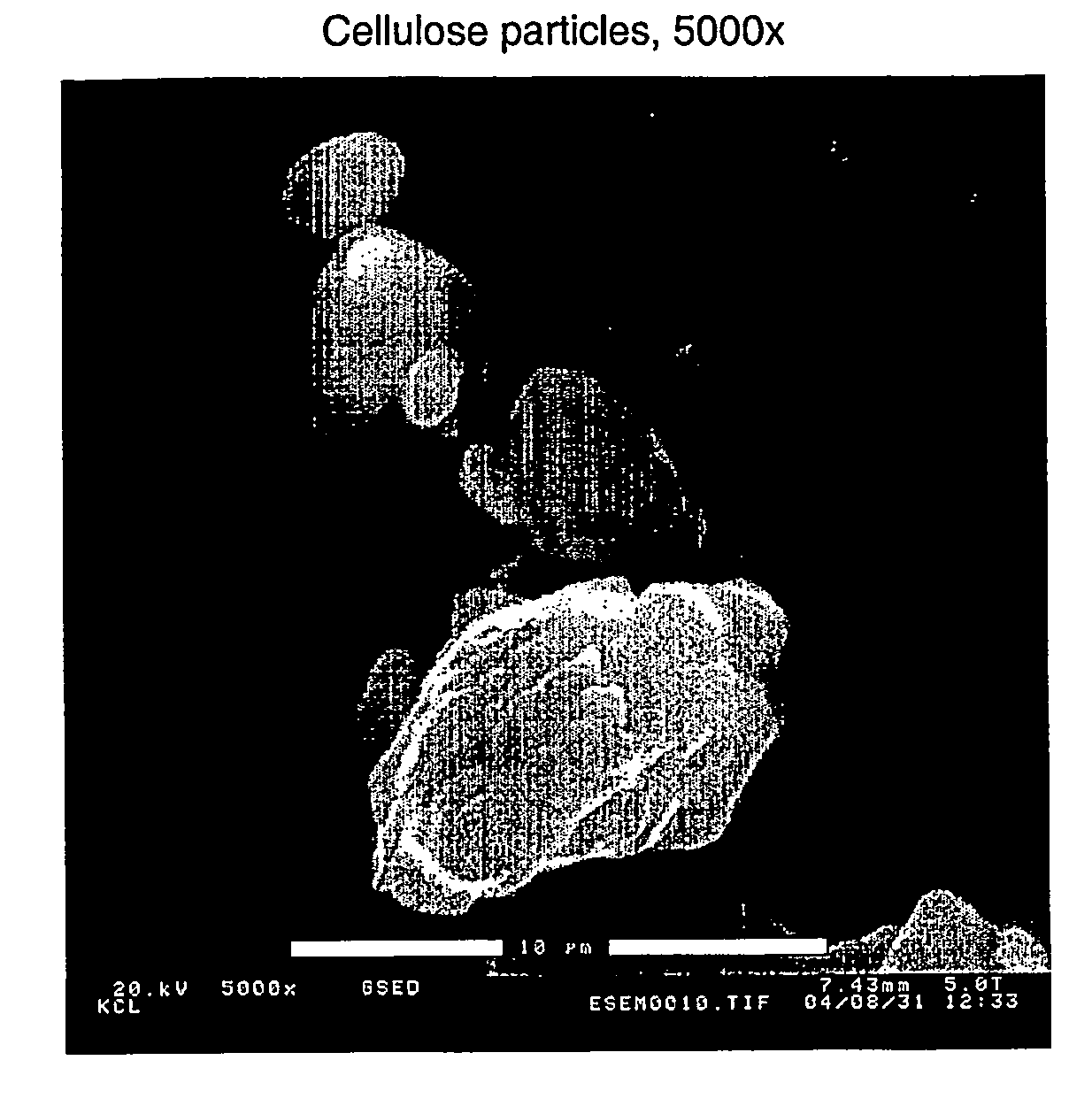

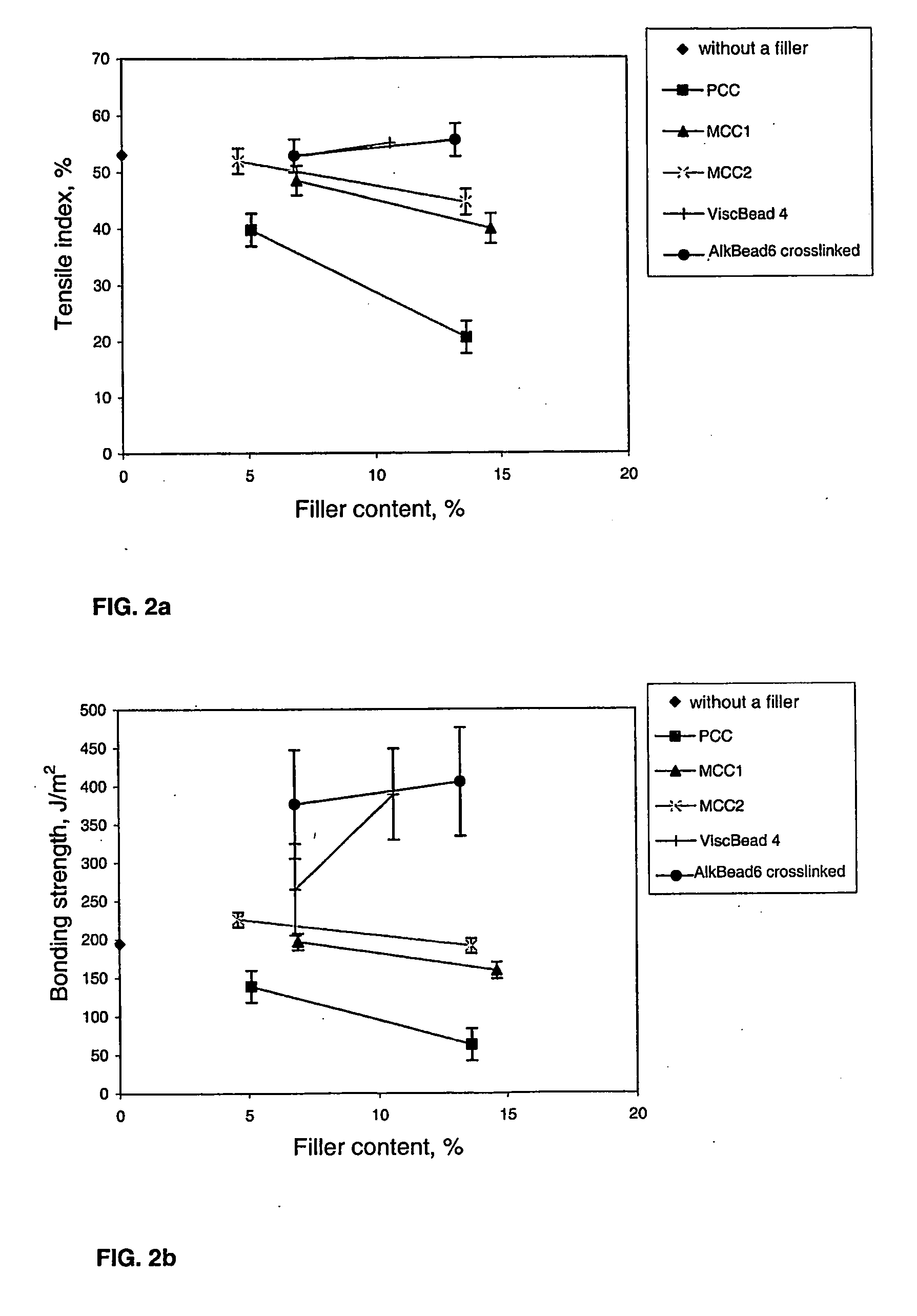

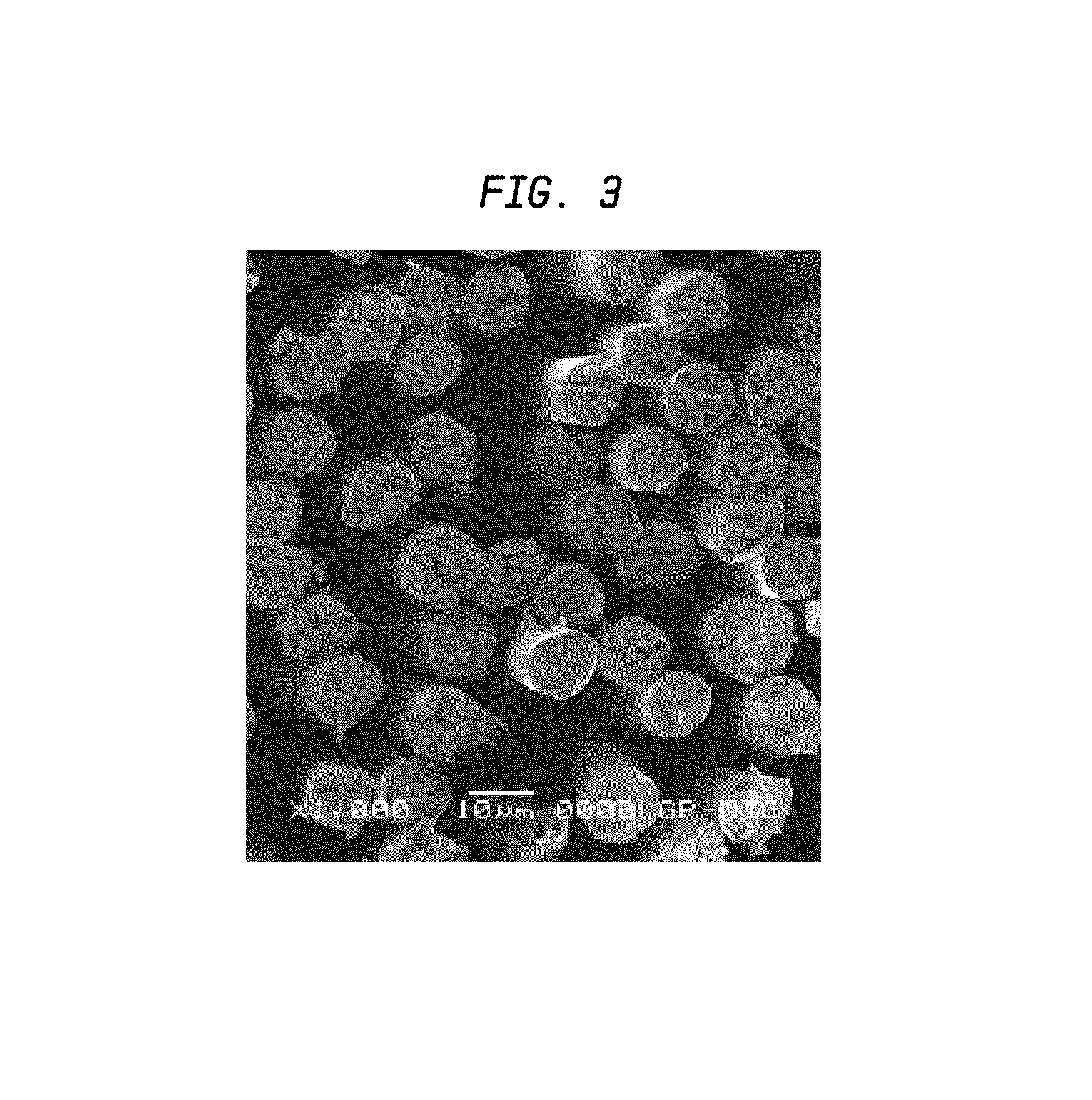

Method for Dissolving Cellulose and for Producing Cellulose Particles

InactiveUS20090014902A1Improve strength propertiesNon-fibrous pulp additionPaper coatingCardboardPigment

The invention relates to a method for dissolving cellulose e.g. for the production of regenerated cellulose products such as films, fibres, particles and the like. In said method, the cellulose material is dissolved using an enzymatic treatment, followed by a base treatment. The invention is also directed to a method for producing cellulose particles wherein cellulose dissolved as described above is sprayed or mixed into a regenerating solution for precipitating cellulose particles. Moreover, the invention relates to the use of said cellulose particles produced with this method as a filler and / or coating pigment of paper and board. The invention is also directed to methods for producing and coating paper and board.

Owner:SAPPI NETHERLANDS SERVICES

Food wrap base sheet with regenerated cellulose microfiber

A base sheet for food wrap products. The base sheet can include a pulp-derived papermaking fiber and a fibrillated regenerated cellulose microfiber having a CSF value of less than about 175 mL.

Owner:GPCP IP HLDG LLC

Absorbent sheet incorporating regenerated cellulose microfiber

ActiveUS8187421B2Good flexibilityHigh strengthCellulosic pulp after-treatmentNon-fibrous pulp additionPolymer sciencePapermaking

An absorbent paper sheet includes cellulosic papermaking fiber and up to about 75 percent by weight fibrillated regenerated cellulose microfiber which may be regenerated from a cellulosic dope utilizing a tertiary amine N-oxide solvent or selected ionic liquids. Fibrillation of the microfiber is controlled such that it has a reduced coarseness and a reduced freeness as compared with unfibrillated regenerated cellulose microfiber from which it is made and provides at least one of the following attributes to the absorbent sheet: (a) the absorbent sheet exhibits an elevated SAT value and an elevated wet tensile value as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (b) the absorbent sheet exhibits an elevated wet / dry CD tensile ratio as compared with a like sheet prepared without fibrillated regenerated cellulose microfiber; (c) the absorbent sheet exhibits a lower GM Break Modulus than a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber; or (d) the absorbent sheet exhibits an elevated bulk as compared with a like sheet having like tensile values prepared without fibrillated regenerated cellulose microfiber.

Owner:GPCP IP HLDG LLC

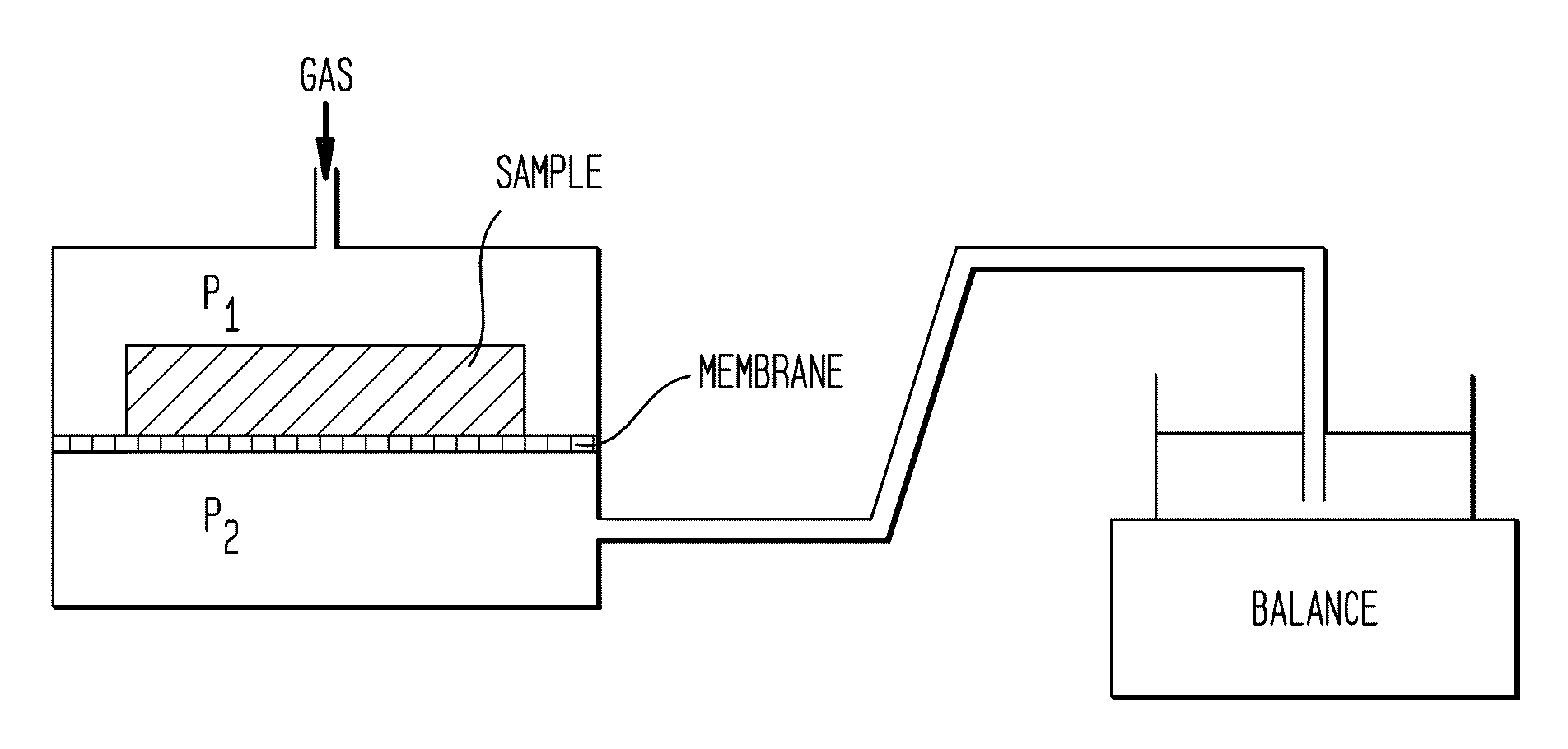

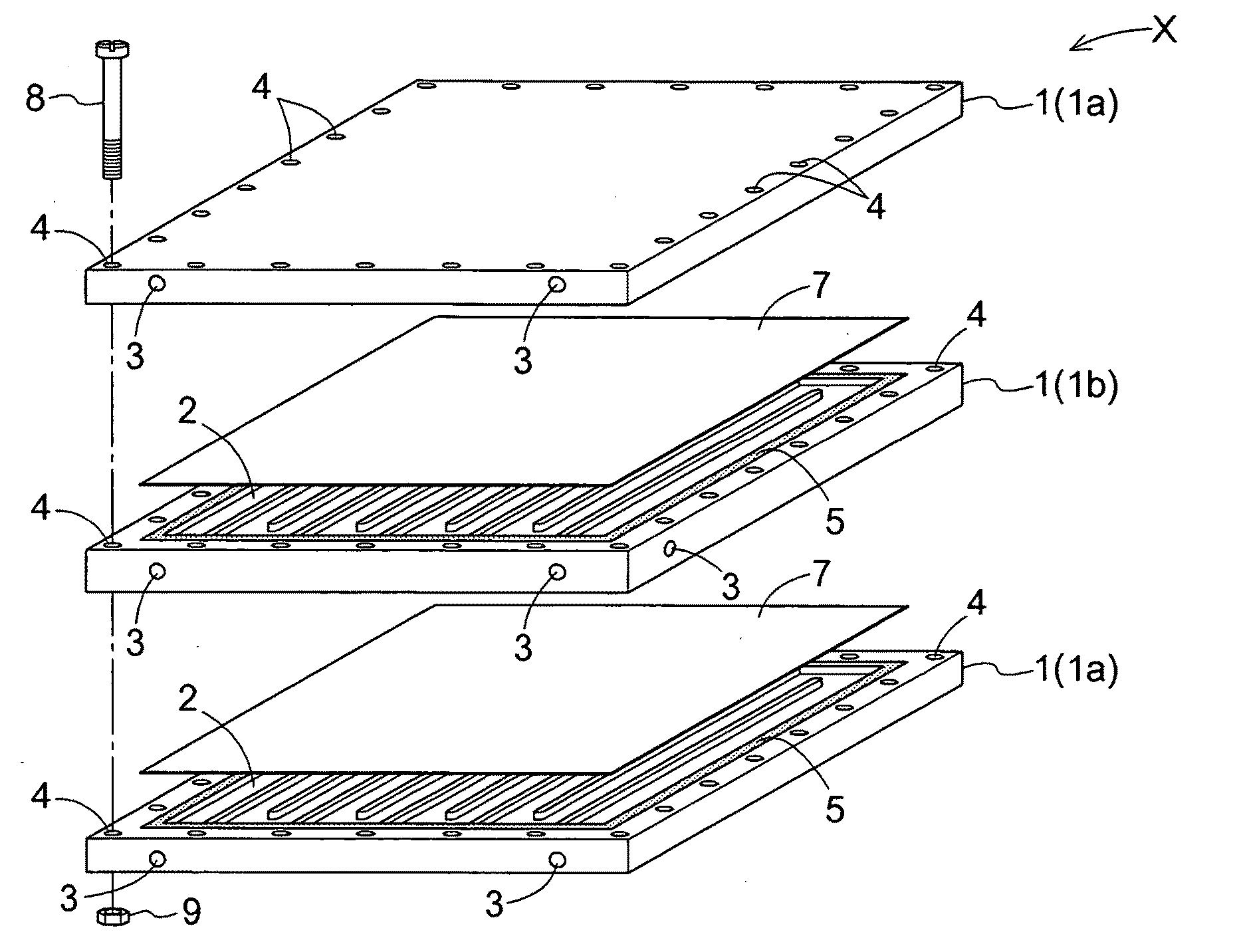

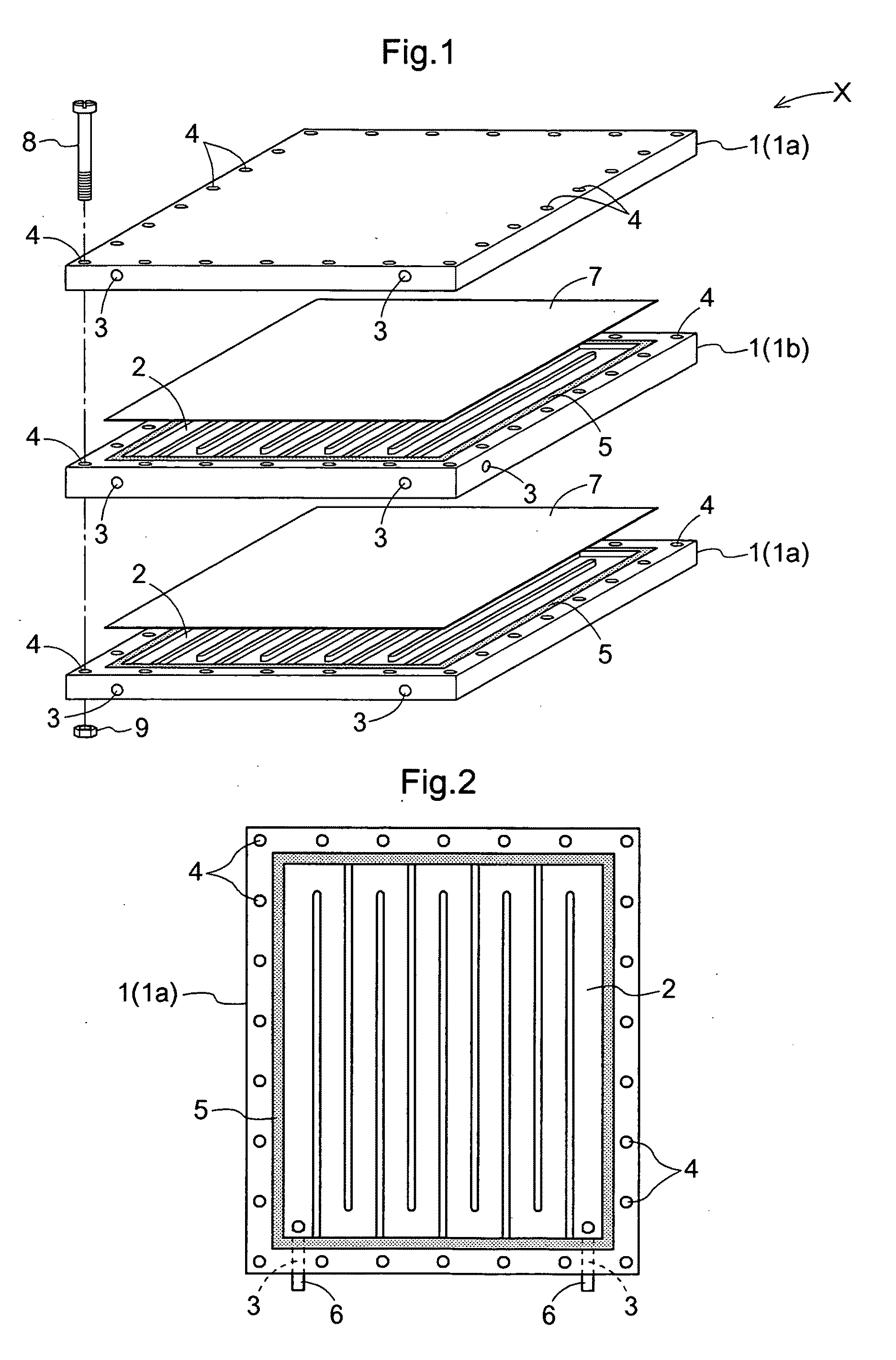

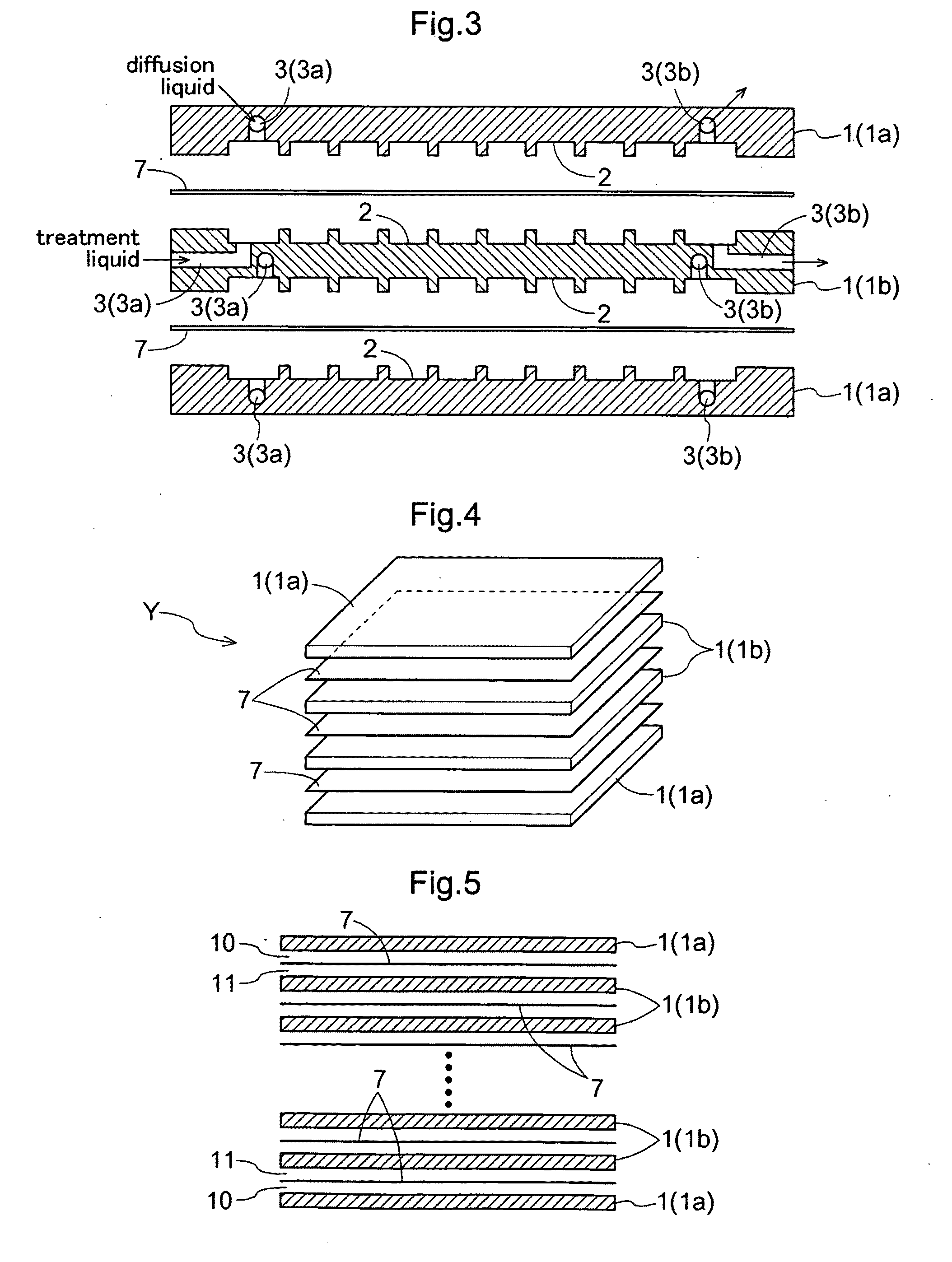

Pore Diffusion Type Flat Membrane Separating Apparatus, Flat Membrane Concentrating Apparatus, Regenerated Cellulose Porous Membrane for Pore Diffusion, and Method of Non-Destructive Inspection of Flat Membrane

A pore diffusion type flat membrane separation apparatus X including a plurality of flat membranes 7 and a plurality of flat plate-like supports 1 arranged alternately with each other, each flat membrane 7 defining a plurality of pores and configured to separate a predetermined dispersed substance contained in a solution by a pore diffusion technique, each flat plate-like support 1 having a flow conduit 2 on one or both faces thereof. A ratio between a spatial volume of the flow conduit 2 and a membrane area of the flat membrane 7 is set from 0.04 to 0.4 cm. The flat plate-like support 1 includes, in at least two positions in a lateral face thereof water conduits 3 in communication with the flow conduit 2, so that flow directions of the solution in the flow conduits 2 of upper and lower flat plate-like supports 1 across the flat membrane 7 may be substantially same directions. The flat plate-like support 1 and the flat membrane 7 can be assembled with and disassembled from each other.

Owner:MANABE SEI ICHI

Solvent for solving cellulose and its application

The invention relates to a dissolvent for quick-speed direct dissolution of cellulose which comprises sodium-hydroxide and the water solution of sulfourea, wherein sodium-hydroxide amounts to 8.1-12.0% of the total water solution weight in the dissolvent, and sulfourea amounts to 3.0-6.0A% of the total water solution weight. The invention also provides a process for quick-speed direct dissolution of cellulose.

Owner:WUHAN UNIV +1

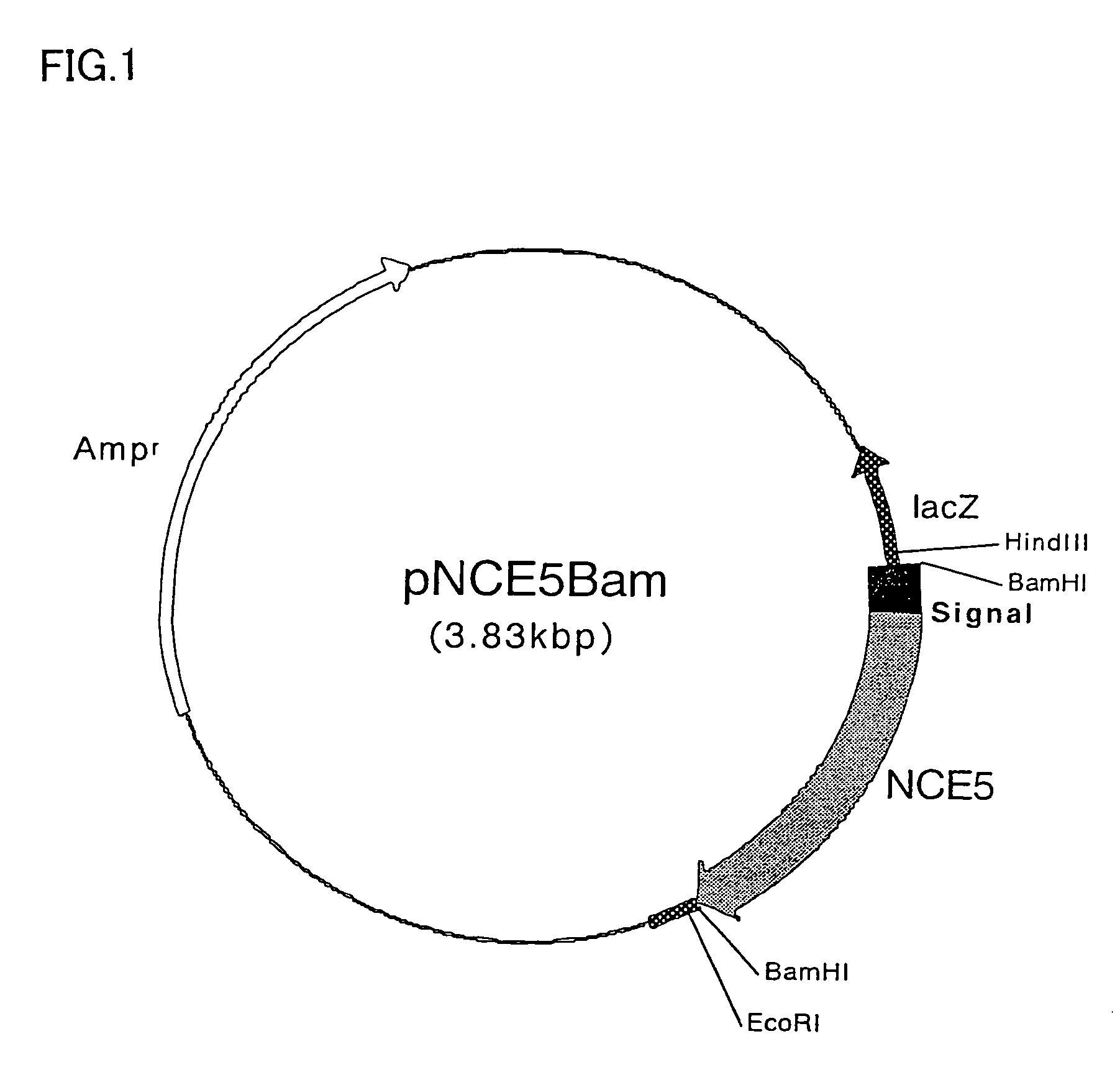

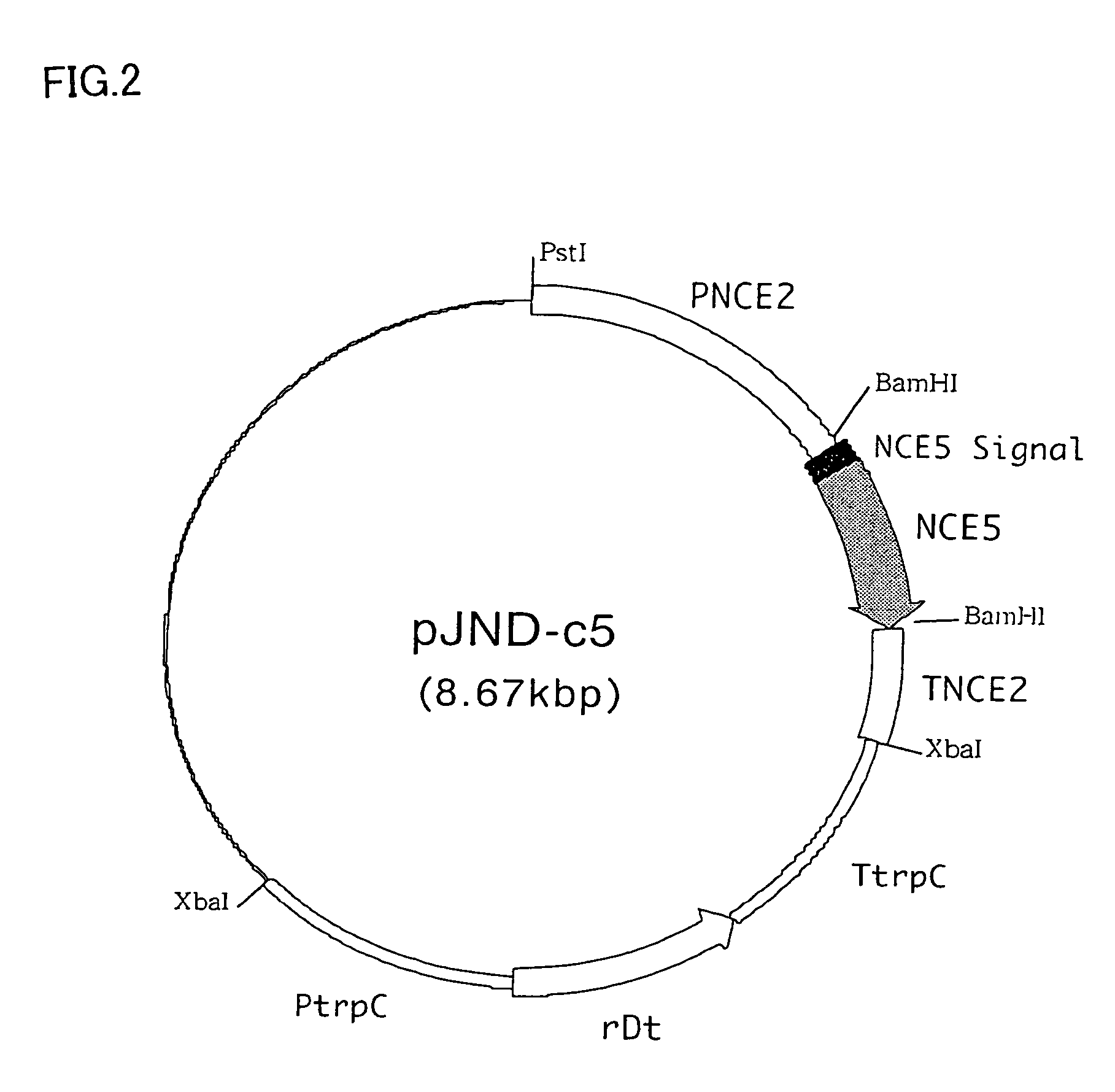

Endoglucanase enzyme NCE5 and cellulase preparations containing the same

InactiveUS7138263B2Efficient and inexpensive treatmentLow degreeFungiOrganic detergent compounding agentsBiotechnologyCellulase

There is provided an endoglucanase enzyme, which is useful for reducing fuzz of regenerated cellulose-containing fabrics, improving the touch and appearance, color clarification, localized variation in color, reducing stiffness and using it as components of a detergent, as well as deinking waste paper and improving freeness of paper pulp. A cDNA coding for the endoglucanase enzyme NCE5 was cloned and its DNA sequence and amino acid sequence derived from it were determined.

Owner:MEIJI SEIKA KAISHA LTD

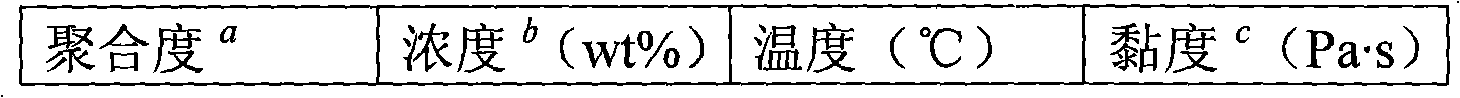

Regenerated cellulosic fibers and process for producing the same

InactiveUS6183865B1Reduce stretchImprove the immunityMonocomponent cellulose artificial filamentCellulosic plastic layered productsLiquid crystallinePolymer science

It is an object of the present invention to overcome the problem of fibrillation which is a drawback found in solvent-spun regenerated cellulosic fibers and to thereby provide high-quality regenerated cellulosic fibers. The regenerated cellulosic fibers are produced by the use of a spinning dope of cellulose dissolved in a solvent containing N-methylmorpholine N-oxide under the conditions that the average degree of polymerization of cellulose contained in the spinning dope is held to 400 or lower and 5% to 30% by weight of the cellulose is adjusted to a degree of polymerization of 500 or higher. Thus a pseudo-liquid-crystalline phenomenon can be allowed to occur in the stretched filaments during spinning, so that the resulting regenerated cellulosic fibers have improved resistance to fibrillation as well as improved dyeability and feeling.

Owner:TOYOBO CO LTD

Active carbon fibre and preparation thereof

InactiveCN101348952ALarge specific surface areaPore structure highOther chemical processesAlkali metal oxides/hydroxidesActivated carbonPolyvinyl alcohol

The invention relates to an activated carbon fiber and a preparation method thereof. The compositions in weight percentage of the activated carbon fiber are: 80 to 95 percent of fiber-forming polymer, and 20 to 5 percent of functional additive component, wherein the fiber-forming polymer can be polyacrylonitrile, modified polyacrylonitrile, polyvinyl alcohol or regenerated cellulose fiber; and the functional additive component can be a superfine absorbent of supporting metal with the average diameter of between 0.01 and 20 mu meter; and the supporting metal can be one of a silver ion, a copper ion or a zinc ion. The preparation method comprises the following steps: a base material fiber-forming polymer fiber containing the functional additive component is prepared first, wherein the base material fiber can be a polyacrylonitrile fiber, a modified polyacrylonitrile, a polyvinyl alcohol fiber or a regenerated cellulose fiber base fiber; and different physical activation treatments or / and chemical activation treatments are carried out according to different base material fibers to produce the activated carbon fiber corresponding to the base material.

Owner:TIANJIN POLYTECHNIC UNIV

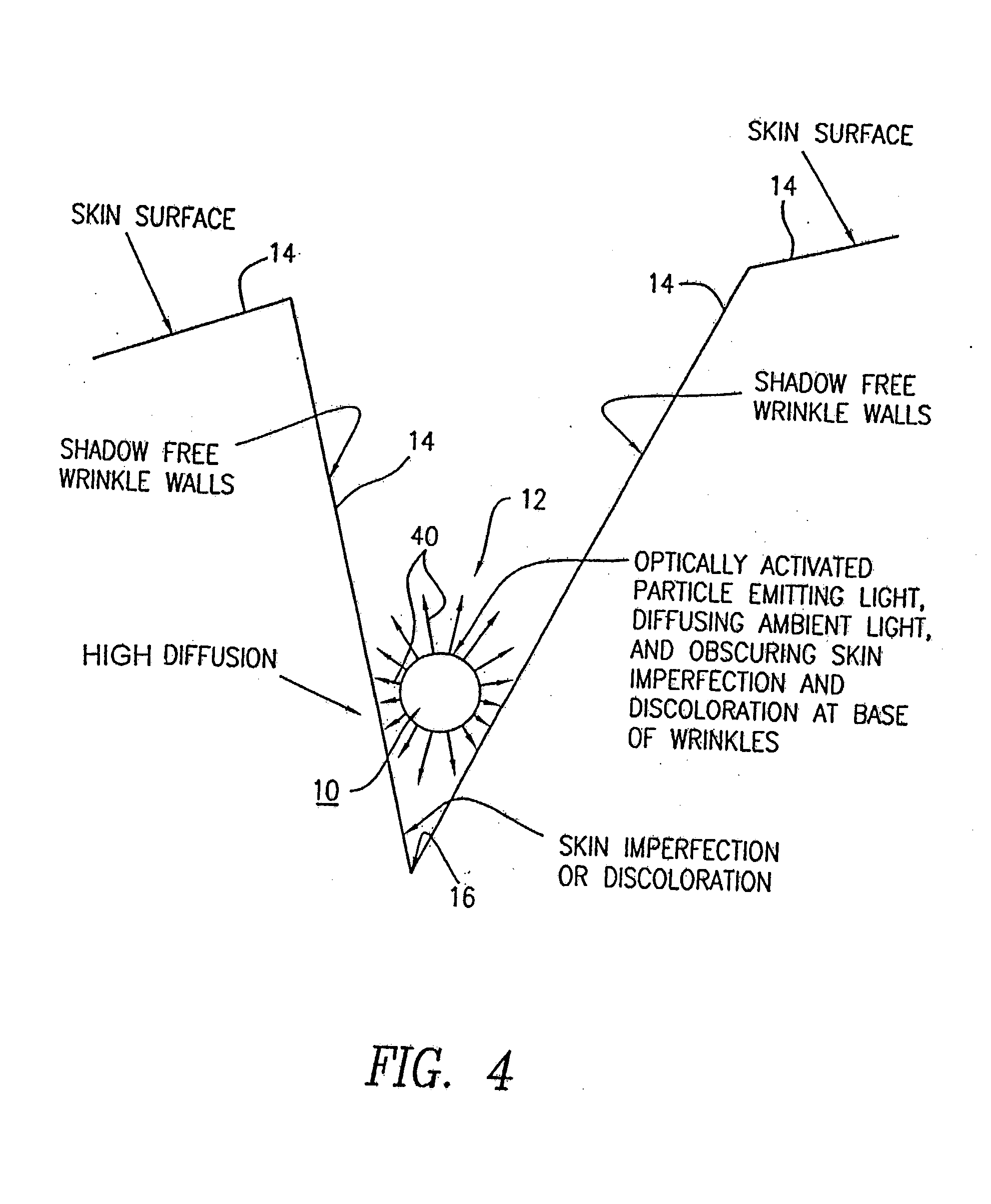

Method of using optically-activ ated particles in cosmetic preparations

Optically-activated particles for use in cosmetic preparations. The optically-activated particles include a plurality of substrate particles selected from the group consisting of nylons, acrylics, polyesters, other plastic polymers, natural materials, regenerated cellulose, metals and minerals; an optical brightener chemically bonded to each of the plurality of substrate particles to form integral units in the form of optically-activated particles for diffusing light to reduce the visual perception of skin imperfections, including cellulite, shadows, skin discolorations, and wrinkles; and each of the optically-activated particles are encapsulated with a UV transparent coating to increase the diffusion light to further reduce the visual perception of the skin imperfections. The encapsulated optically-activated particles are able to absorb ultraviolet radiation and emit visible light; and the encapsulated optically-activated particles are able to both scatter and absorb light in a diffuse manner in order to reduce the visual perception of skin imperfections, including cellulite, wrinkles, shadows, and skin discolorations, when the optically-activated particles are applied to the skin surface. The encapsulated optically-activated particles are used in the making of cosmetic preparations such as skin lotions, creams, shampoos, body and skin rinses, bath gels, soaps, hair conditioners, color conditioners and rinses, hair color solutions, foundation powders (compressed or loose), tooth pastes, oral rinses, and any acceptable cosmetic vehicle or medium.

Owner:PNC BANK NAT ASSOC

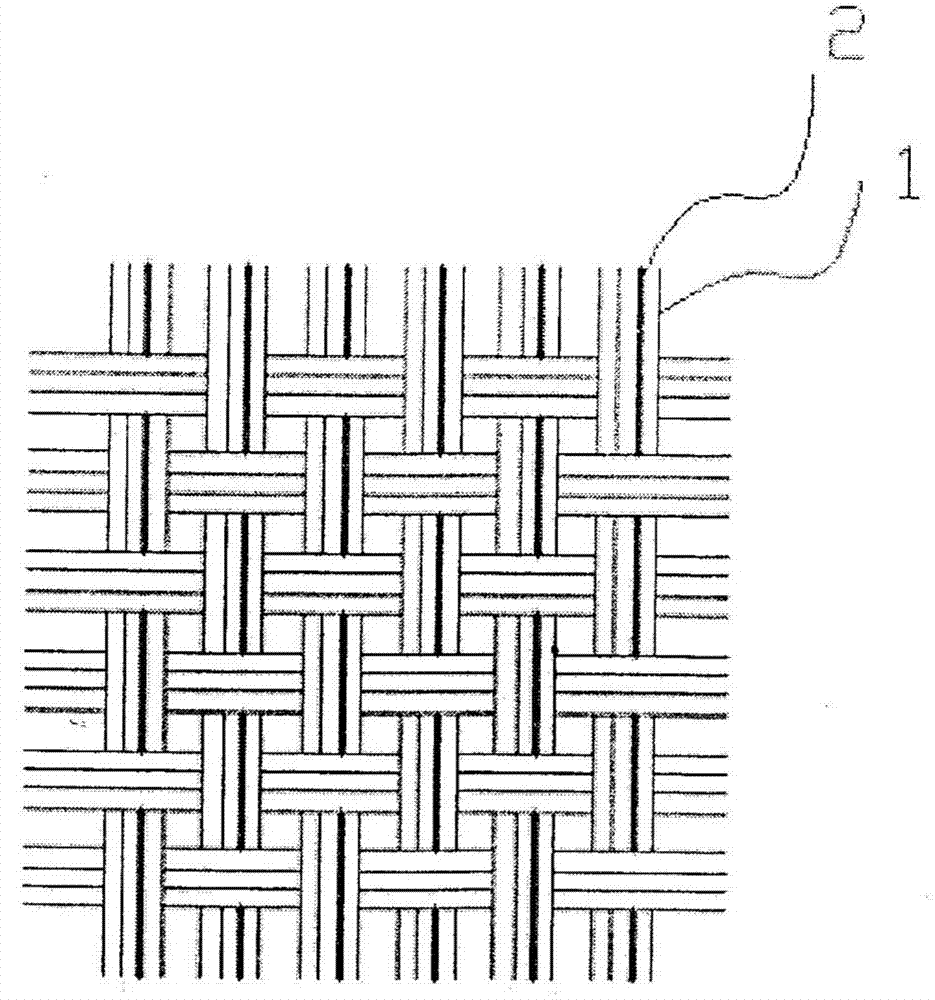

Permanent flame-retardant multifunctional fabric and making method thereof

ActiveCN104499161AImprove flame retardant propertiesReduce investmentWoven fabricsYarnPolymer scienceNatural fiber

The invention discloses permanent flame-retardant multifunctional fabric and a making method thereof and belongs to the technical field of protecting fabric and processing thereof. The permanent flame-retardant multifunctional fabric is formed by interweaving warp yarn and weft yarn. The permanent flame-retardant multifunctional fabric is characterized in that a raw material by which each of the warp yarn and the weft yarn is made is a mixture of high-temperature-resistant natural flame-retardant fibers and natural fibers or regenerated cellulose fibers, the high-temperature-resistant natural flame-retardant fibers account for 40-90% of the fabric, the natural fibers or the regenerated cellulose fibers account for 8-58% of the fabric, and antistatic filaments are woven in the warp yarn at intervals and account for 1-3% of the fabric. The permanent flame-retardant multifunctional fabric can permanently maintain ideal flame-retardant characteristics which do not decline with passage of time or increase of washing times, demonstrates high environment friendliness, breathability and wearing comfortability and has safety, and excellent antistatic performance can be guaranteed lastingly; processes are simplified, so that the above advantages of the fabric can be demonstrated comprehensively.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com