Food wrap base sheet with regenerated cellulose microfiber

a technology of regenerated cellulose and food wrap, which is applied in the field of paper-containing products, can solve the problems of aggravate processing difficulties and high cost of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0103]The present disclosure can be more fully described according to the following non-limiting examples.

Hand Sheet Study #1

[0104]A hand sheet study was conducted with southern softwood and fibrillated lyocell fiber. FIG. 3 is a photomicrograph of stock lyocell fiber of 1.5 denier (e.g., 16.6 mg / 100 m) by 4 mm in length, which was fibrillated until the freeness was less than about 50 CSF. FIG. 4 shows a photomicrograph of 14 mesh refined regenerated cellulose, and FIG. 5 shows a photomicrograph of 200 mesh refined regenerated cellulose fiber. It will be appreciated from FIGS. 4 and 5, that the fibrillated fiber has a much lower coarseness than the stock fiber.

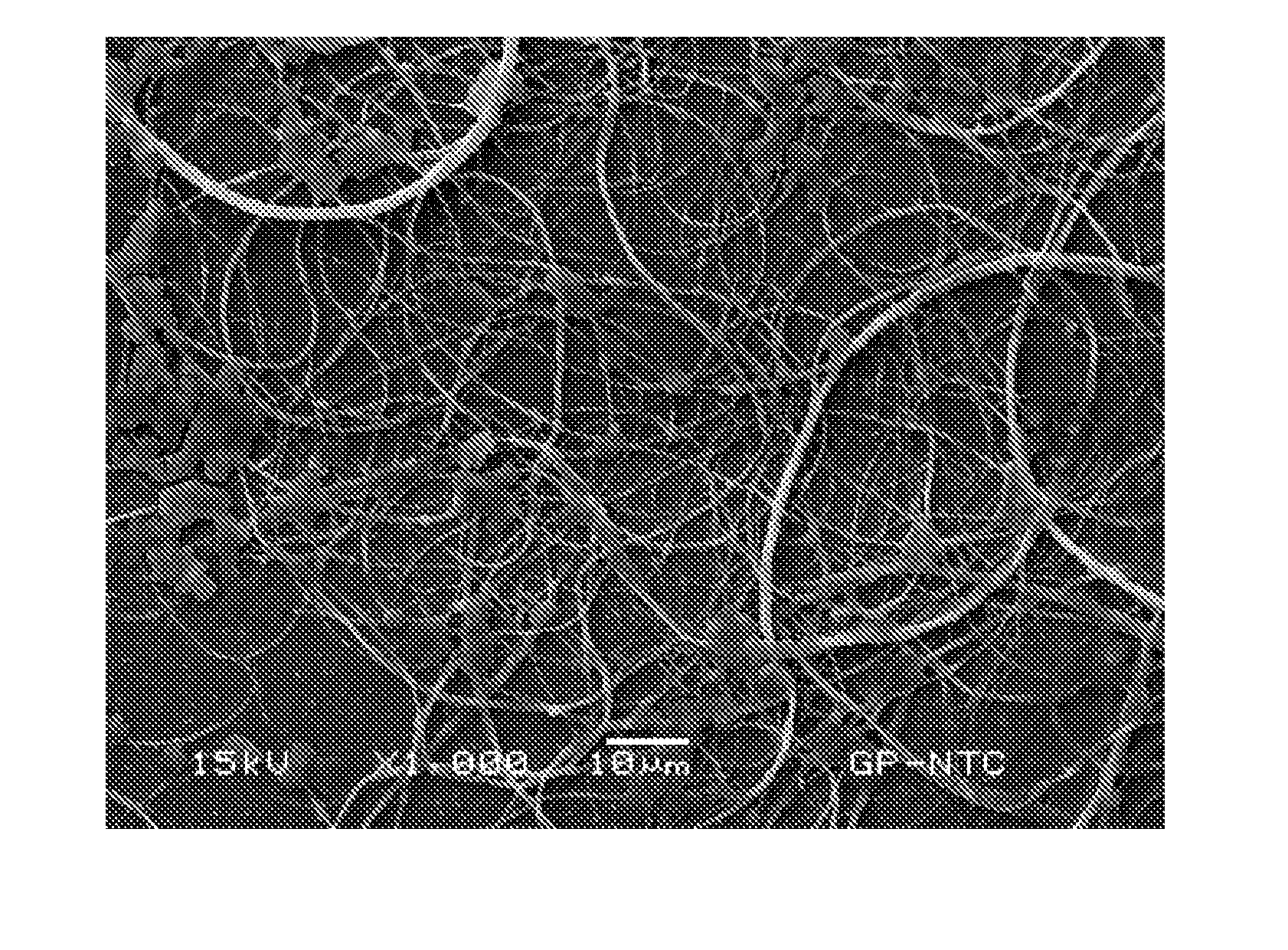

[0105]FIGS. 6-10 show photomicrographs of fibrillated lyocell material at increasing magnification, wherein the fibrillated lyocell material has been passed through the 200 mesh screen of a Bauer-McNett classifier. This material can be referred to as “fines.” In wood pulp, fines are mostly particulate rather than fibrous. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average diameter | aaaaa | aaaaa |

| weight average length | aaaaa | aaaaa |

| weight average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com