Method for continuously preparing regenerated cellulose fibre

A technology of regenerated cellulose and cellulose, applied in fiber processing, fiber chemical characteristics, sustainable manufacturing/processing, etc., can solve the problems of low cellulose concentration, high melting point and viscosity, low production efficiency, etc., and achieve the spinning process. The effect of mild conditions, wide process range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17

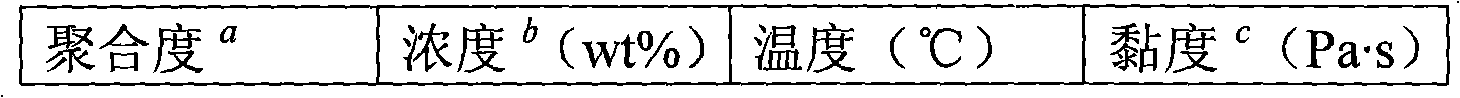

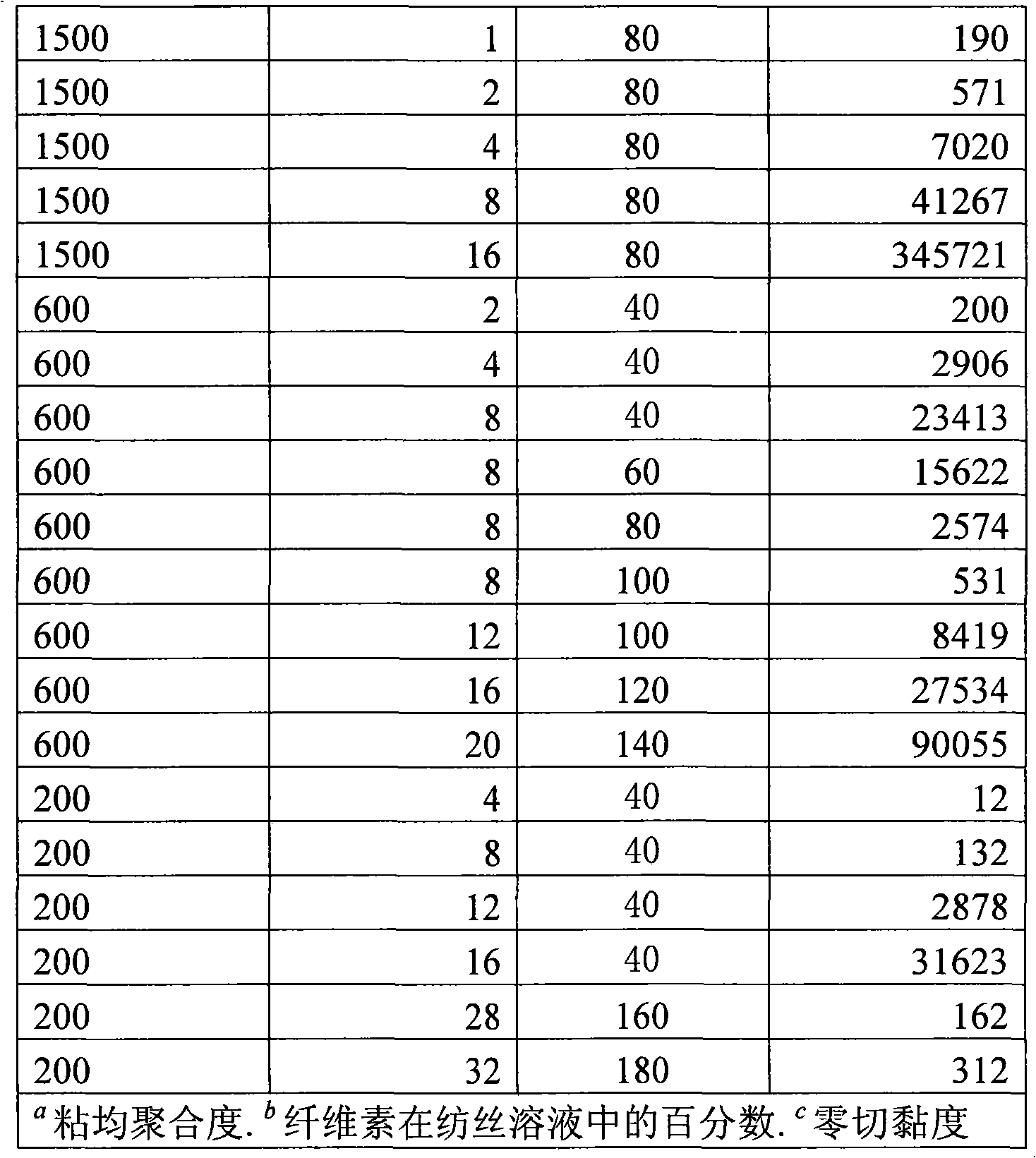

[0054] Using microcrystalline cellulose, wood pulp, and absorbent cotton as three raw materials, a cellulose / AMIMCl solution with an average molecular weight of 300-800 and a concentration of 8-18% was prepared, and it was filtered and defoamed under various conditions. For dry jet wet spinning, the coagulation bath is AMIMCl aqueous solution with a concentration of 0-20% (weight). The as-spun fibers were washed with deionized water six times, and dried at 80-150°C. The tensile properties of the product fibers were measured after being placed in a constant temperature room for 48 hours. Each sample was measured 10 times and the average value was taken. The specific spinning conditions, product fineness and tensile strength are shown in Table 3.

[0055] Experiments have proved that the cellulose / low-viscosity ionic liquid system is suitable for spinning by dry-jet wet spinning technology. It has the advantages of wide process range, mild temperature conditions, moderate press...

Embodiment 18~35

[0058] According to basically the same process as AMIMCl, other low-viscosity ionic liquids such as 1-ethyl-3-methylimidazolium acetate were used to carry out cellulose spinning experiments. Typical experimental data and results are listed in Table 4.

[0059] It can be seen from these examples that, like using AMIMCl as a cellulose solvent, using these low-viscosity ionic liquids can also spin regenerated cellulose fibers at a relatively low temperature, and the resulting fibers have good properties.

Embodiment 36~40

[0061] According to the substantially same process as in Examples 1-5, using 1-allyl-3-methylimidazolium chloride salt ionic liquid as a solvent, adding different contents of carbon nanotubes into the cellulose solution, the cellulose spinning experiment was carried out. Typical experimental data and results are listed in Table 5, among them, cellulose concentration: 8%, cellulose polymerization degree: 550, spinning temperature: 80 ℃, air gap length: 5cm, spinning pressure: 2MPa; Spinning speed : 40m / s, drawing speed: 160m / s, number of spinneret holes: 1, spinneret hole diameter: 0.1mm.

[0062] It can be seen from these examples that, like using AMIMCl as a cellulose solvent, adding carbon nanotubes to cellulose / ionic liquid can spin regenerated cellulose fibers with antistatic properties, and the obtained fibers have good mechanical properties.

[0063] The embodiment of the cellulose / AMIMCl solution dry jet wet spinning that table 5 contains carbon nanotubes

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com