Patents

Literature

536results about "Artificial filament recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

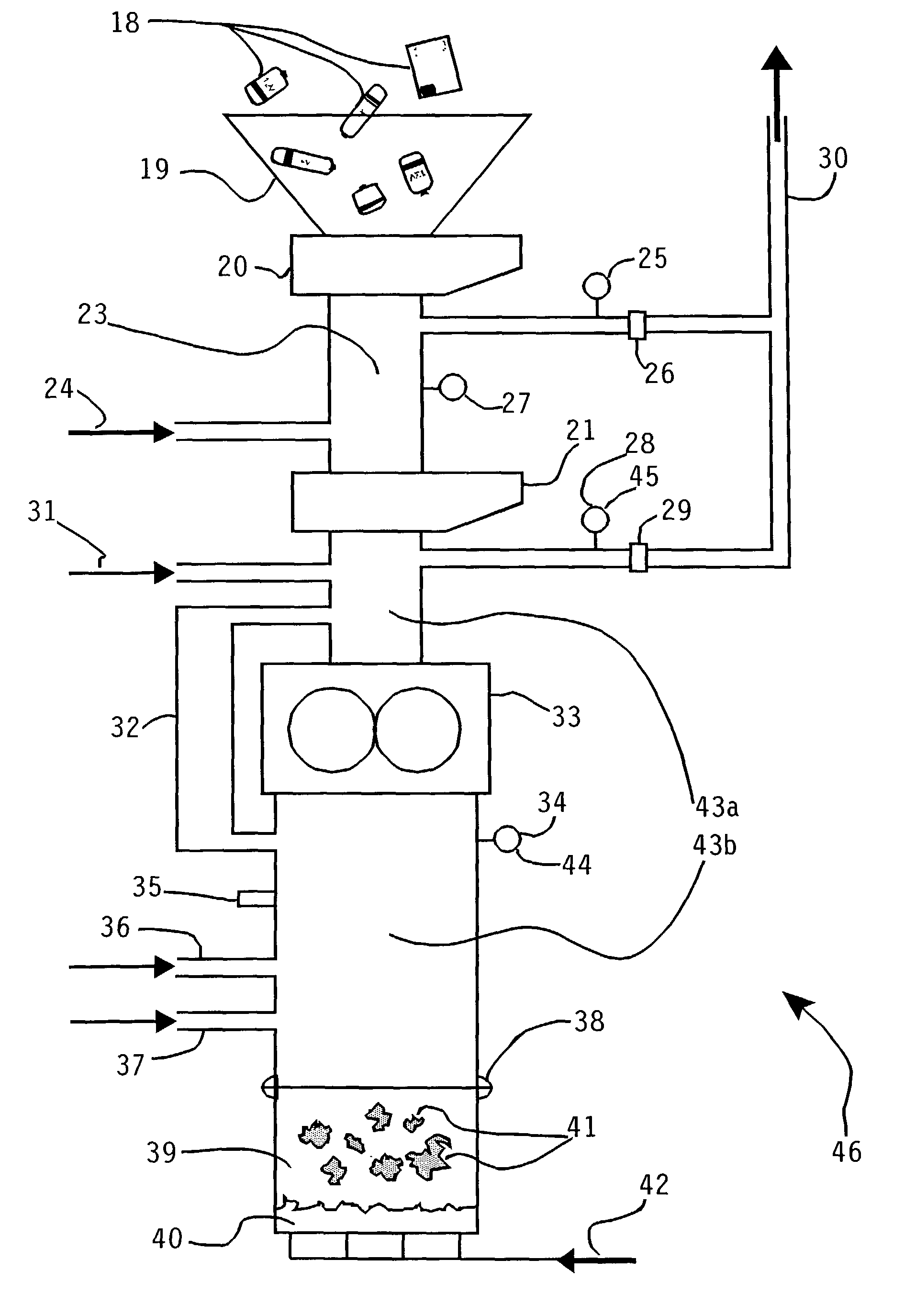

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

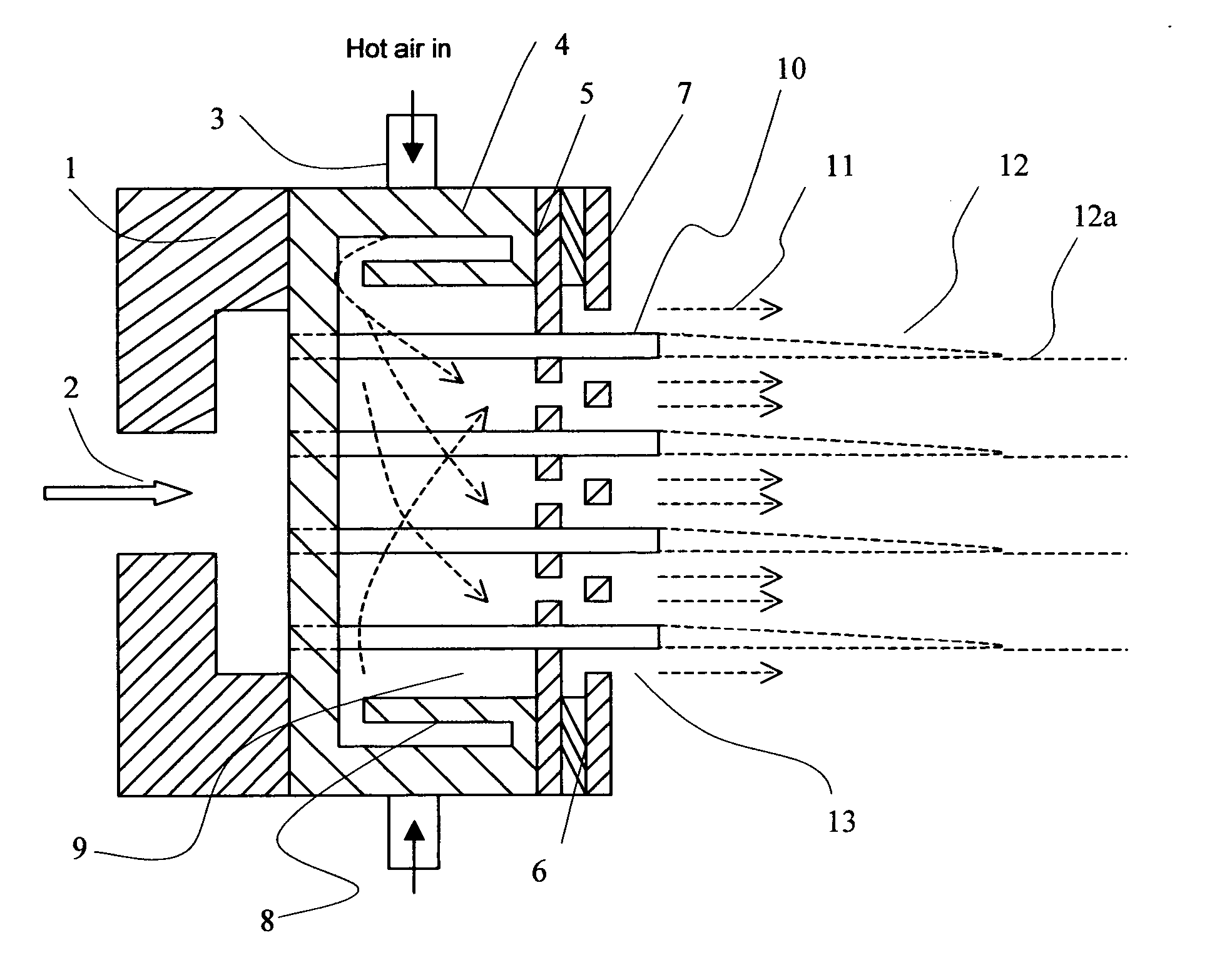

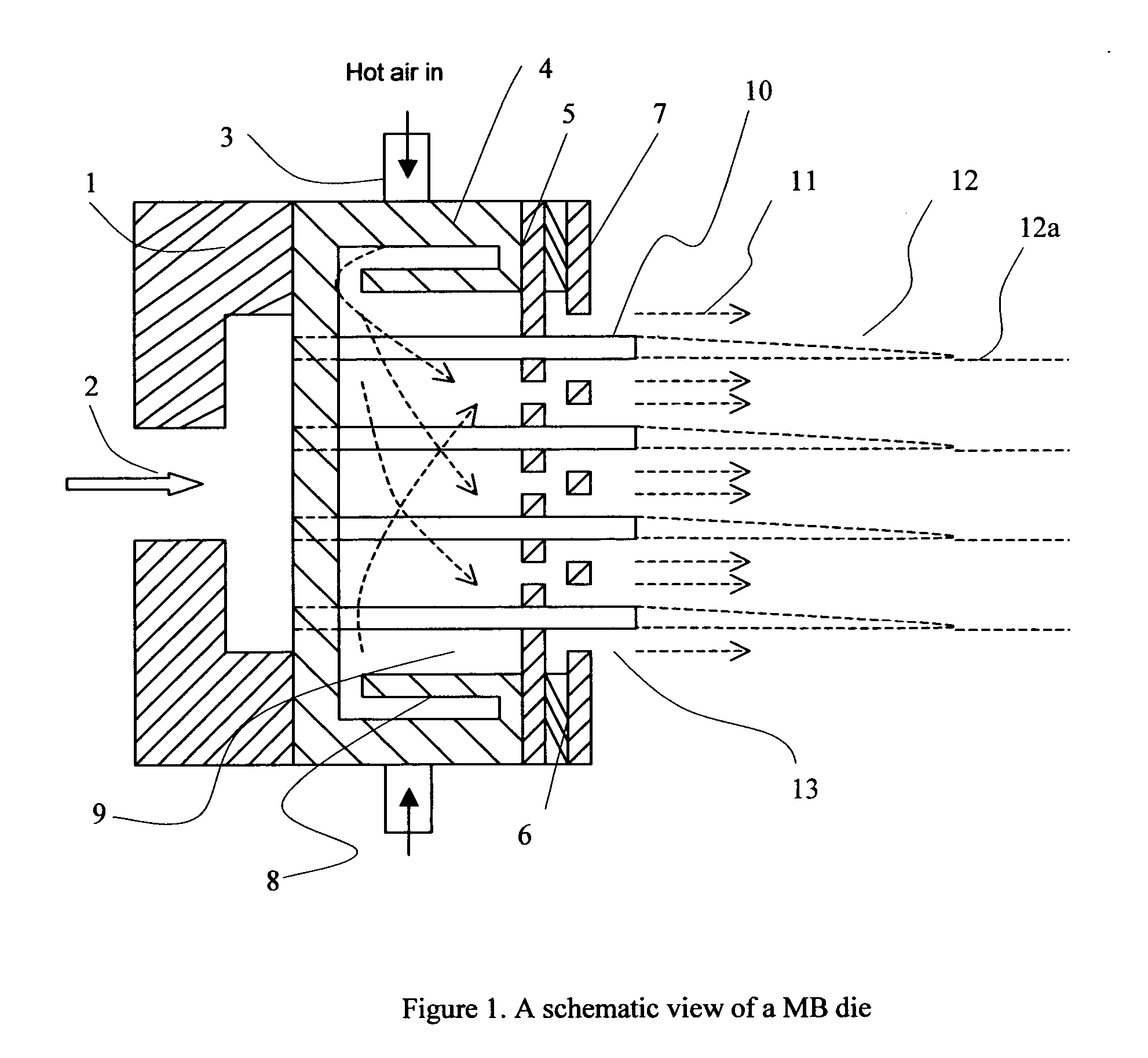

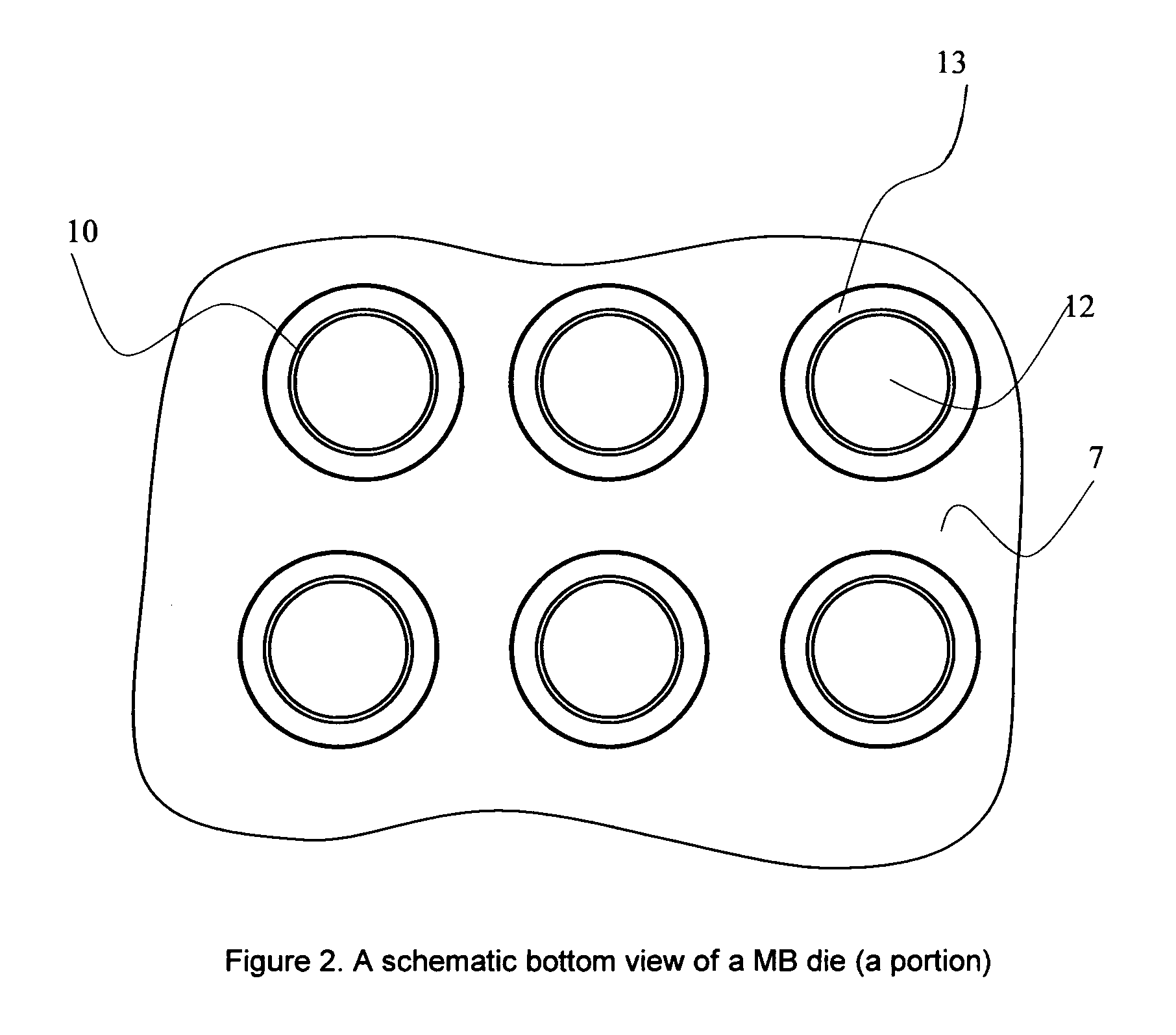

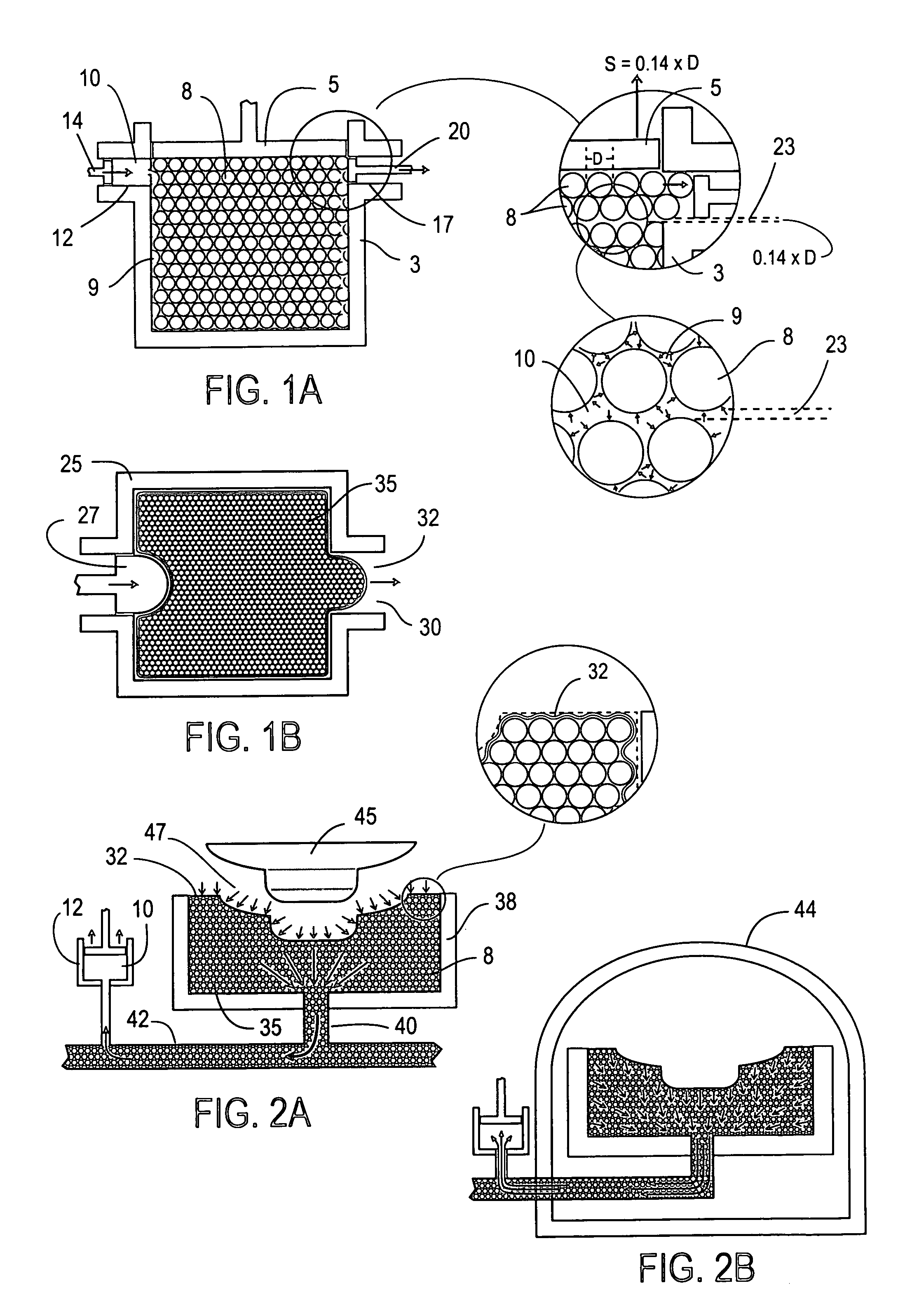

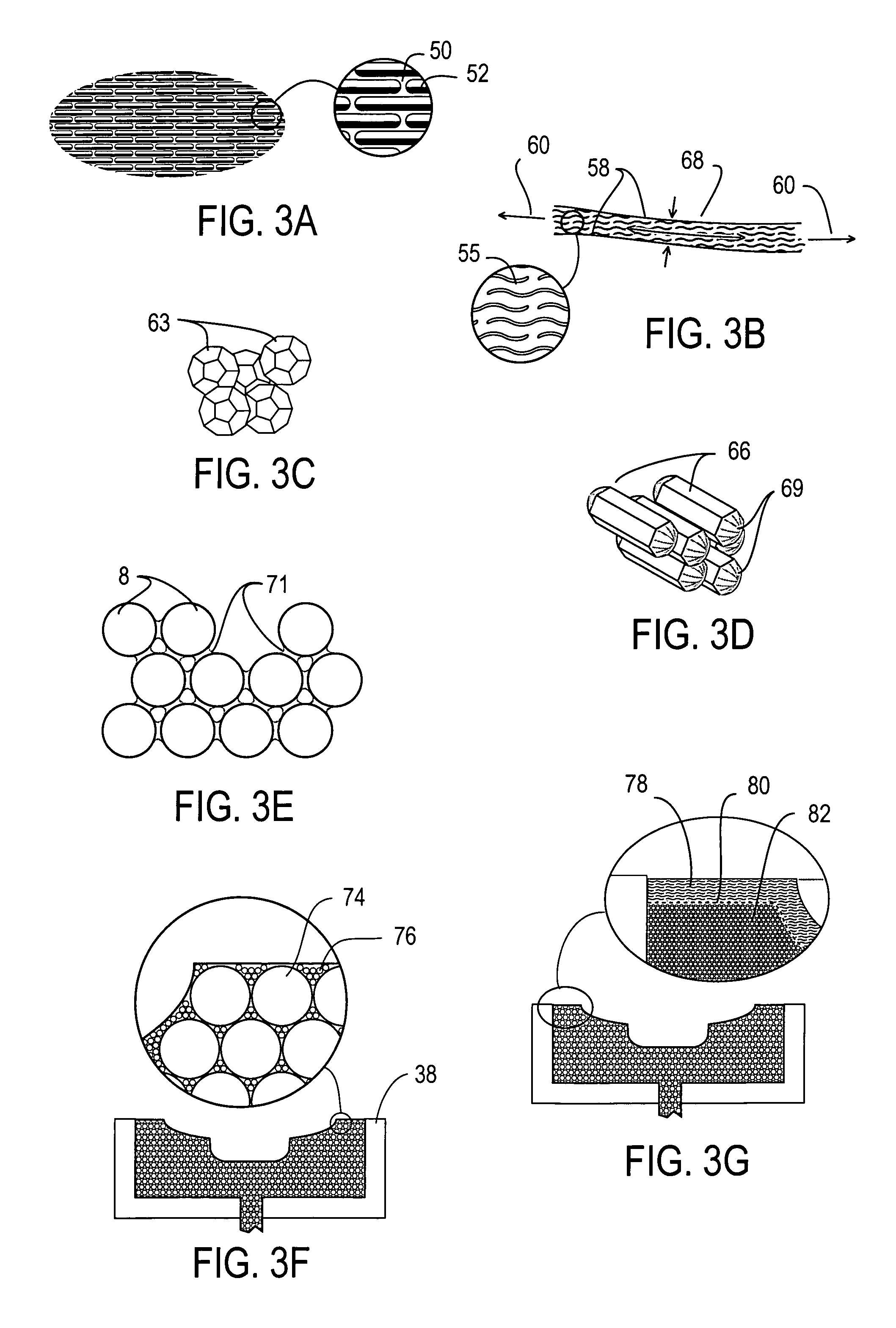

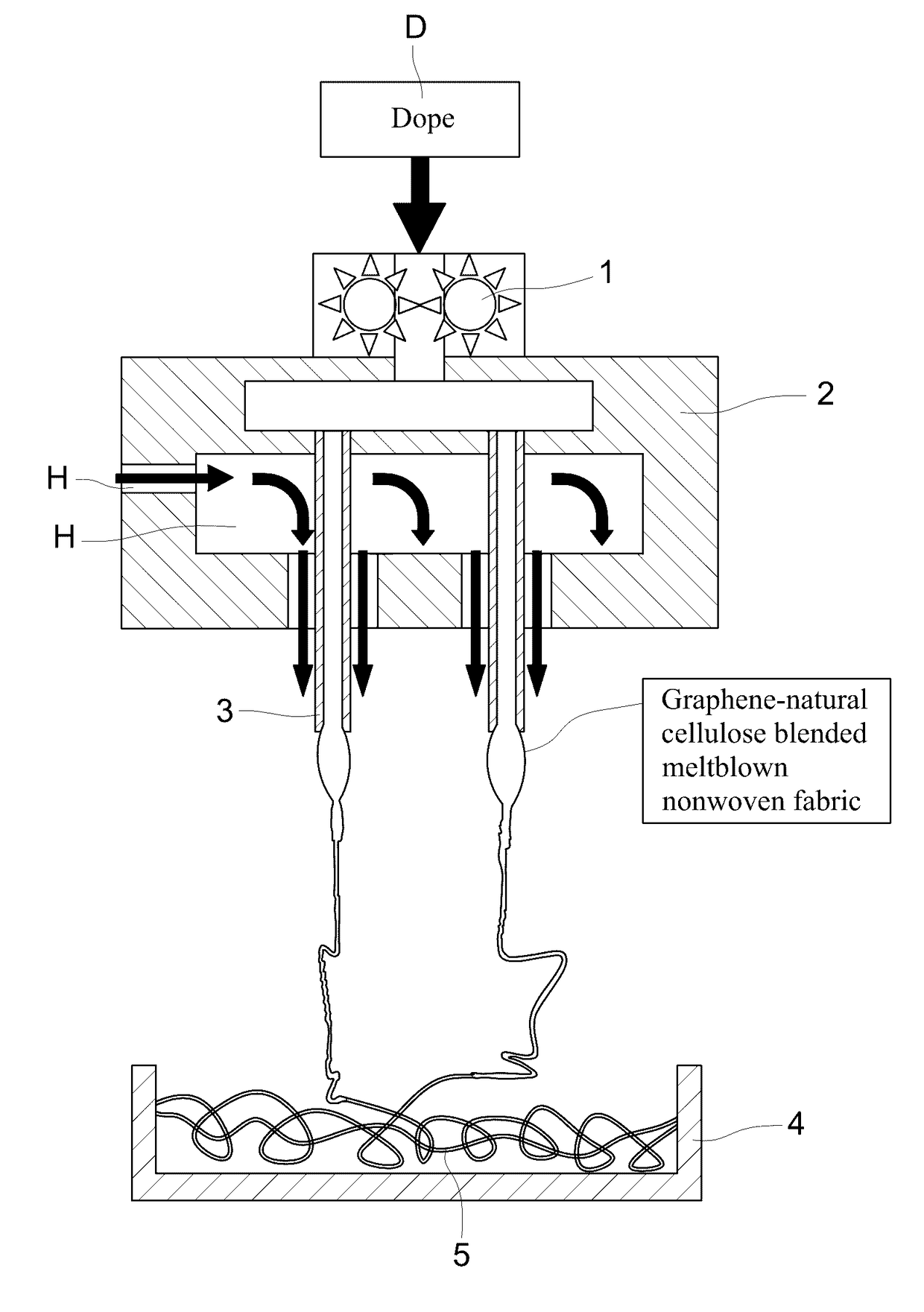

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

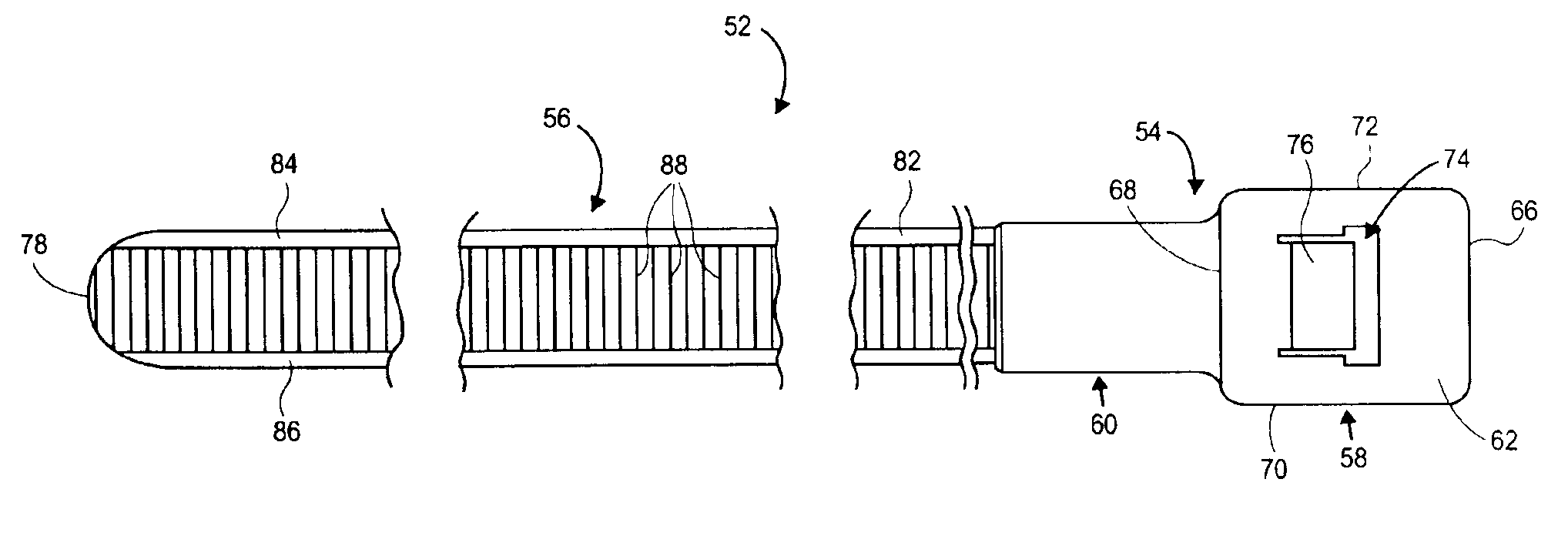

Use of state-change materials in reformable shapes, templates or tooling

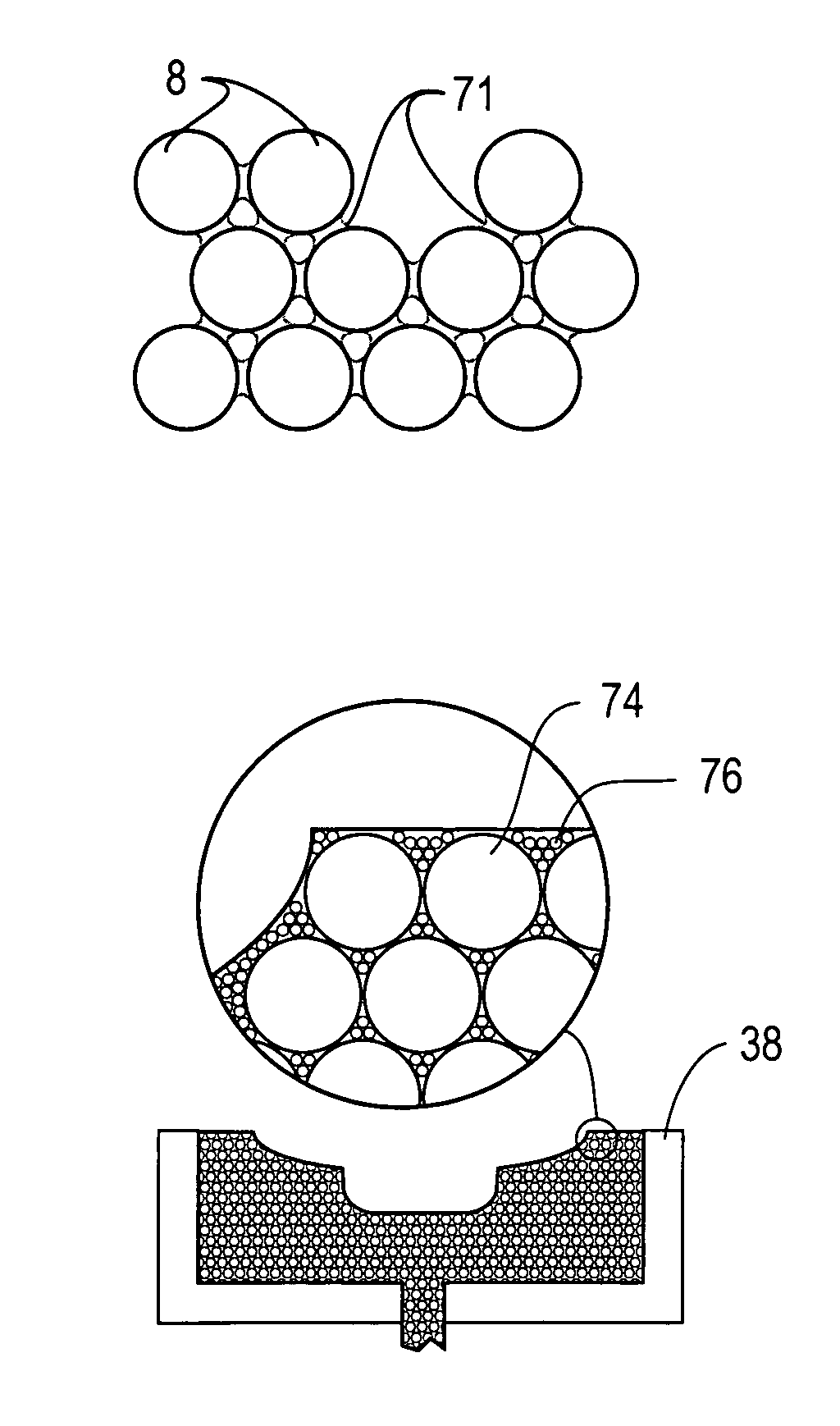

Techniques for generating a stable, force-resisting positive or negative representation of a shape. A state-changeable mixture includes uniform, generally ordered, closely-spaced solid bodies and a liquid carrier medium, with the liquid filling any voids or interstices between the bodies and excluding air or gas bubbles from the mixture. Within the mixture, the solid bodies can be caused to transition from a near-liquid or fluent condition of mobility to a stable, force-resisting condition. To create mobility, a small excess quantity or transition liquid is introduced to create a fluent condition by providing a slight clearance between the bodies which permits the gently-forced introduction of at least two simultaneous slip planes between ordered bulk masses of the bodies at any point in the mixture. Transition to the stable condition is caused by extraction of the transition liquid, removing the clearance between bodies and causing them to make stable, consolidated contact.

Owner:TRAN BAO

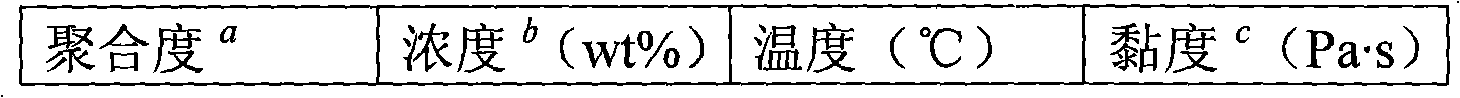

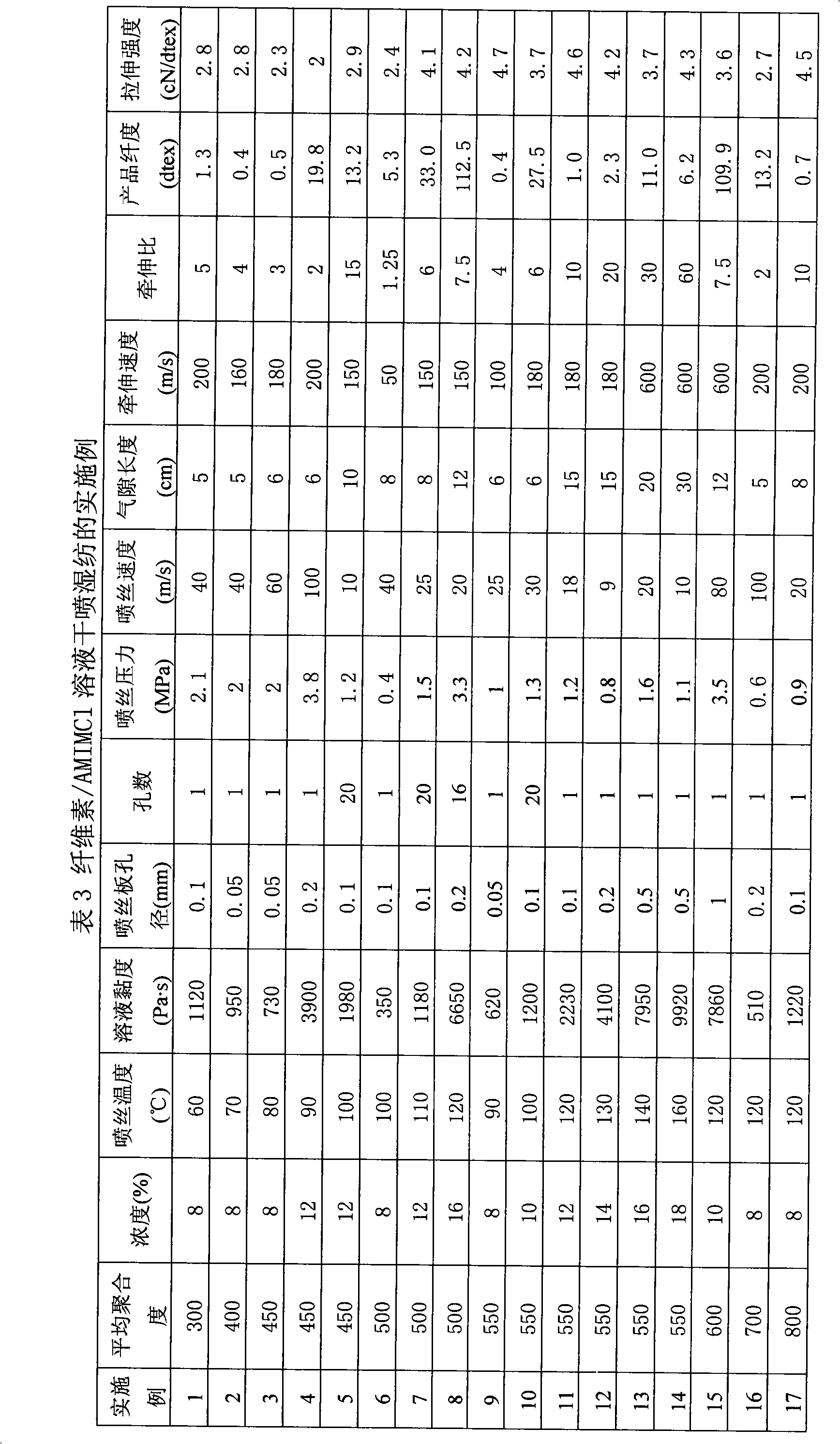

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Three-dimensional object forming apparatus and method for forming three-dimensional object

InactiveUS20100247742A1Avoid pollutionLiquid surface applicatorsConfectioneryComputer moduleEngineering

Owner:MICROJET TECH

Process for the preparation of transparent, shaped articles containing polyesters comprising a cyclobutanediol

ActiveUS20060235167A1Easy to passGood active barrier propertyEnvelopes/bags making machineryFilament/thread formingPolyesterPolymer science

Disclosed is a process for the preparation of shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles, having high transparency and low haze, and comprising immiscible blends of at least one polyester comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce shaped articles having oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

Process for the preparation of transparent shaped articles

ActiveUS20060197246A1Improve claritySuitable for preparationEnvelopes/bags making machineryFilament/thread formingPolyesterPolymer science

Disclosed is a process for the preparation of shaped articles such as, for example, sheeting, films, tubes, bottles, preforms and profiles, having high transparency and low haze comprising immiscible blends of one or more thermoplastic polymers selected from polyesters, polycarbonates, and polyarylates, and a copolyamide or a transamidized, homogeneous blend of a least two polyamides. The components of the immiscible blend which have refractive indices which differ by about 0.006 to about −0.0006. The small difference in the refractive indices enable the incorporation of regrind into the polymer composition to produce transparent shaped articles. These articles may have one or more layers and can exhibit improved excellent barrier properties and good melt processability while retaining excellent mechanical properties. Metal catalysts can be incorporated into the compositions to produce shaped articles having oxygen-scavenging properties.

Owner:EASTMAN CHEM CO

Graphic image fusion

InactiveUS7166249B2Satisfactory abrasion resistanceSatisfactory fade resistancePaper/cardboard articlesArtificial filament recoveryThermoplasticGraphics

An in-mold and in-line decorating method is disclosed which, using a single sheet layer, allows the placement of the highest possible quality graphics into the surface of products made from a variety of moldable thermoplastic, thermoset, and vulcanizable materials using a variety of molding processes. The methods also provide new or improved capabilities for product identification, safety, and serialized tracking.

Owner:TAYLOR COMM INC

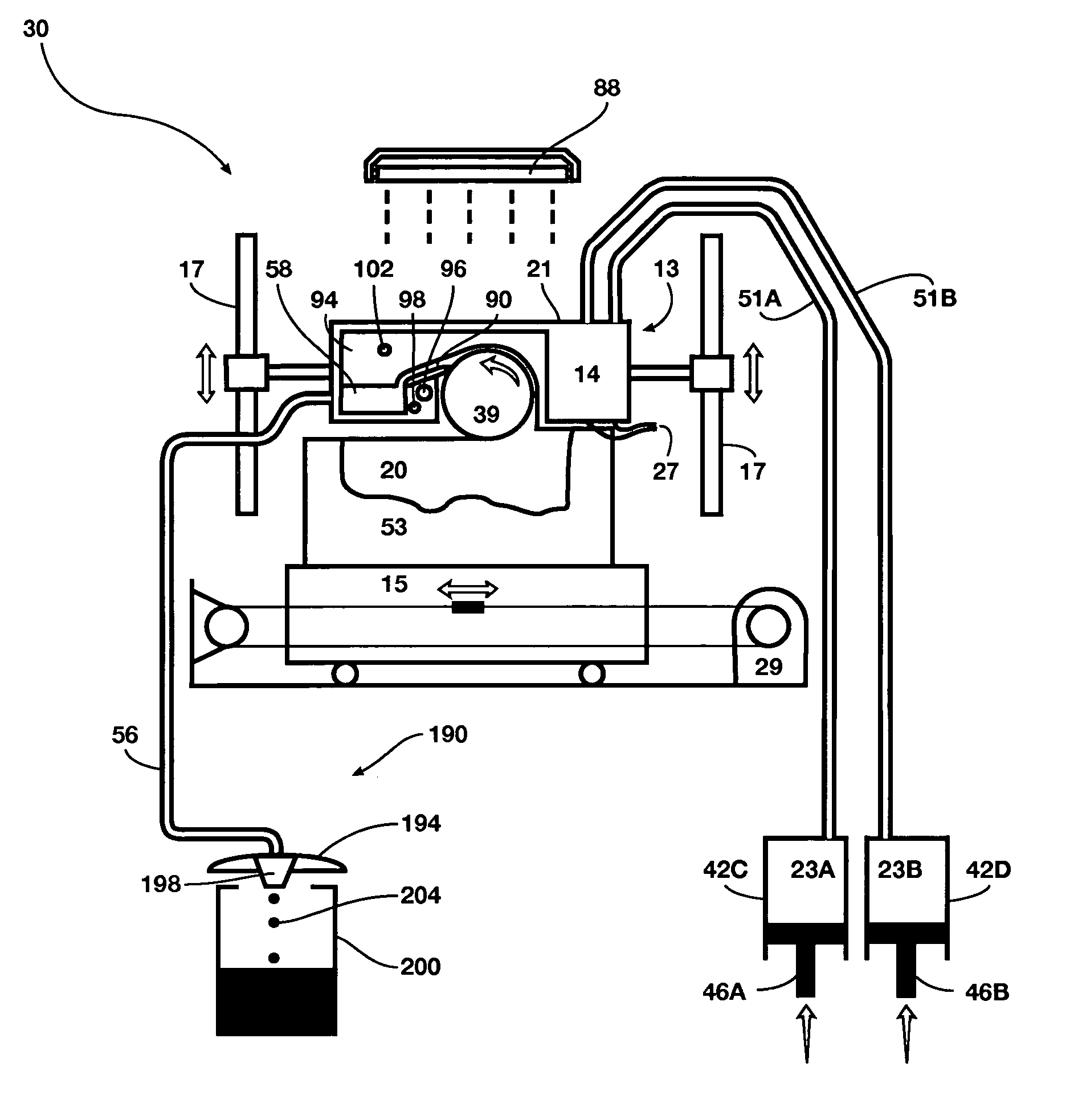

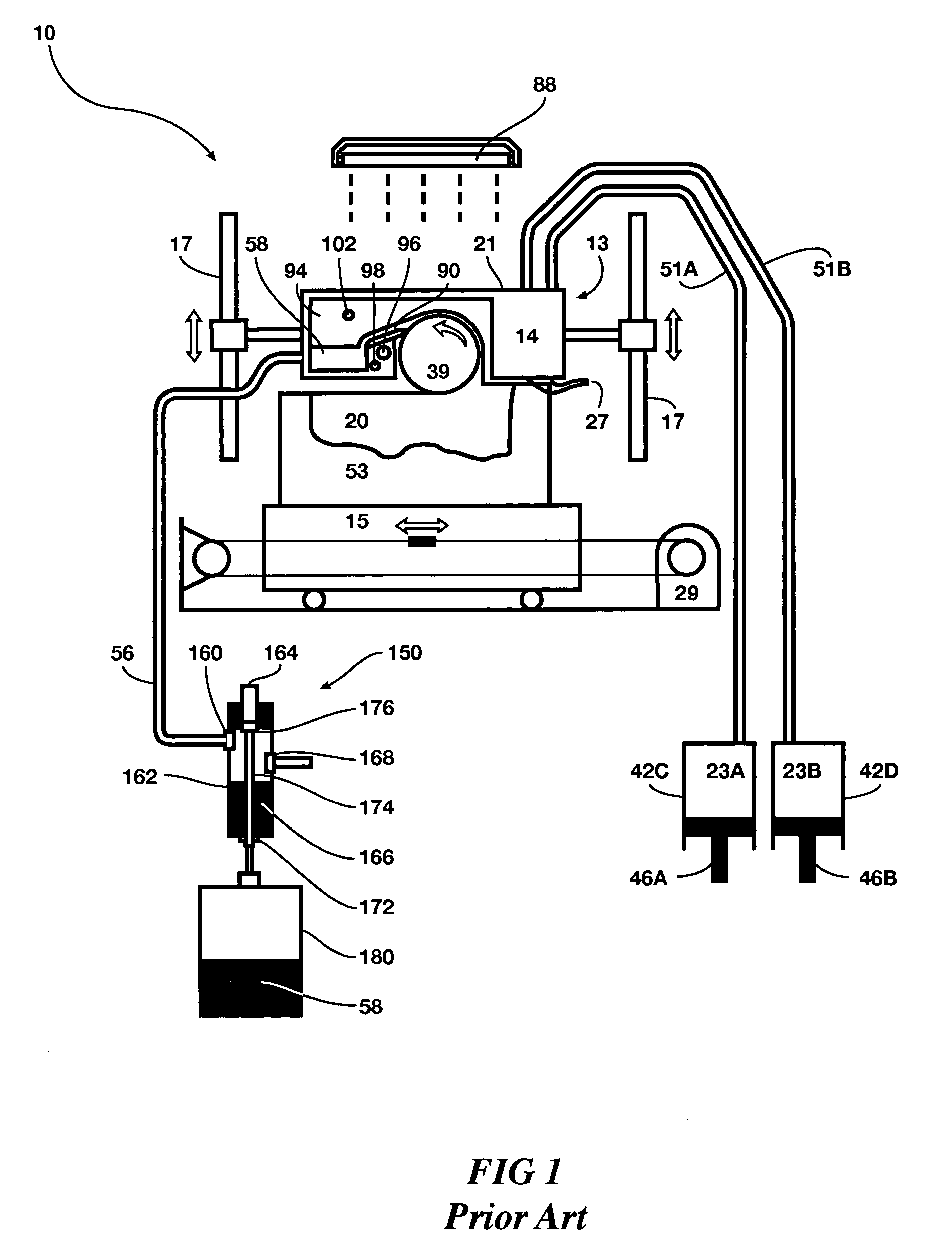

Removal of fluid by-product from a solid deposition modeling process

InactiveUS20070063366A1Reliable and low costLow costArtificial filament recoveryAuxillary shaping apparatusWaste managementMechanical system

A by-product waste material removal system for solid deposition modeling. As excess build and support material is removed during the build as a by-product waste the removal system collects the by-product waste material into a waste receptacle for disposal. The by-product waste material removal system requires no mechanical systems.

Owner:3D SYST INC

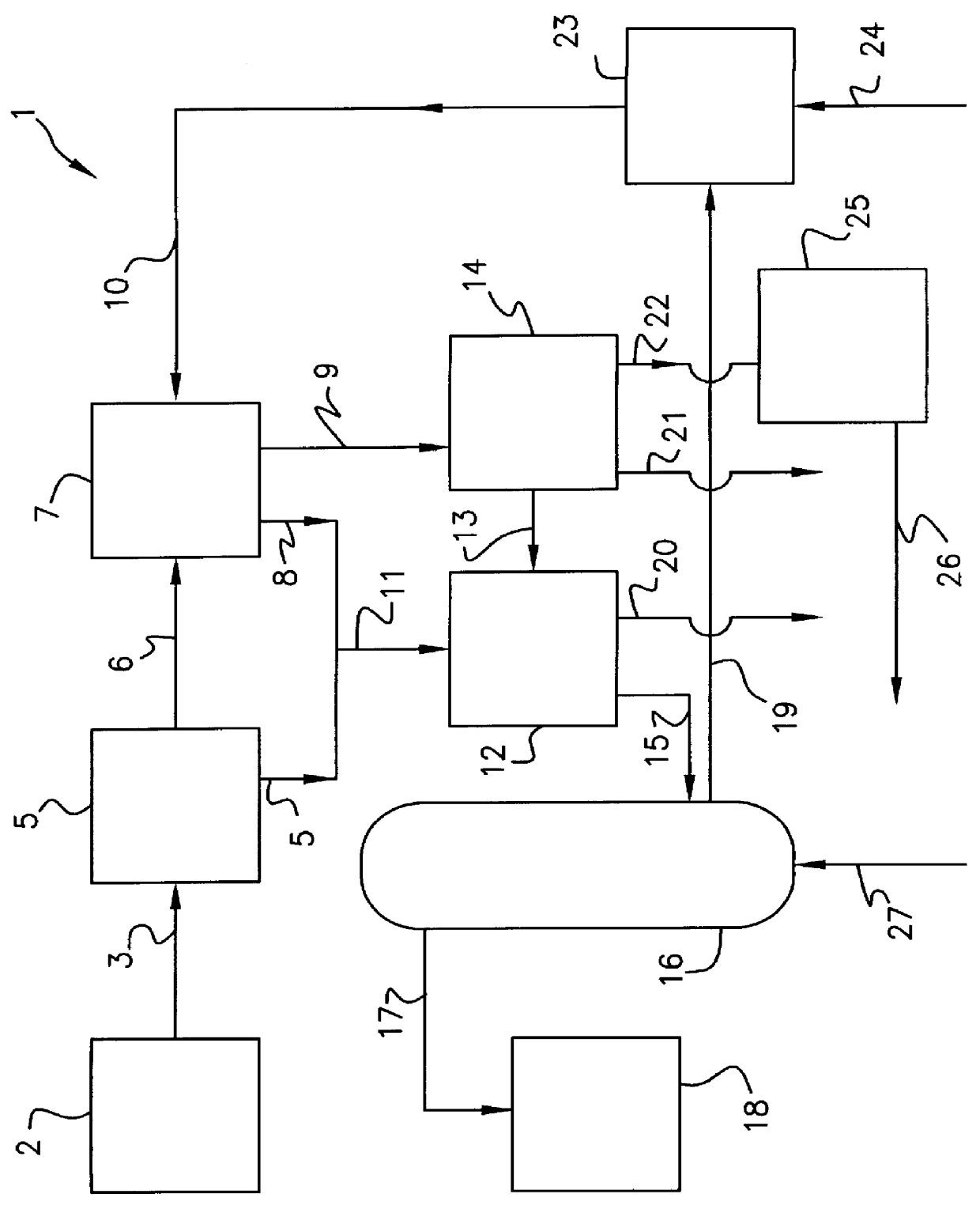

Methods and systems for manufacturing the manufacture of layered three-dimensional forms

ActiveUS20080237933A1Efficiently reclaim and re-useEfficient use ofAdditive manufacturing apparatusArtificial filament recoveryParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

Plastic reclamation process

A plastic article or plastic container reclamation process if provided in which plastic containers are divided into relatively large pieces, then washed, agitated and separated using an aqueous solvent to remove residual materials. The residual materials such as motor oil are reclaimed for reuse and the aqueous solvent is regenerated for reuse in the process. Residual materials such as dirt, labels and adhesives from the plastic containers is recovered for recycling or passed to waste for disposal or reuse.

Owner:DOONAN BILLIE ODELL

Preparation method of p-aramid nanofiber

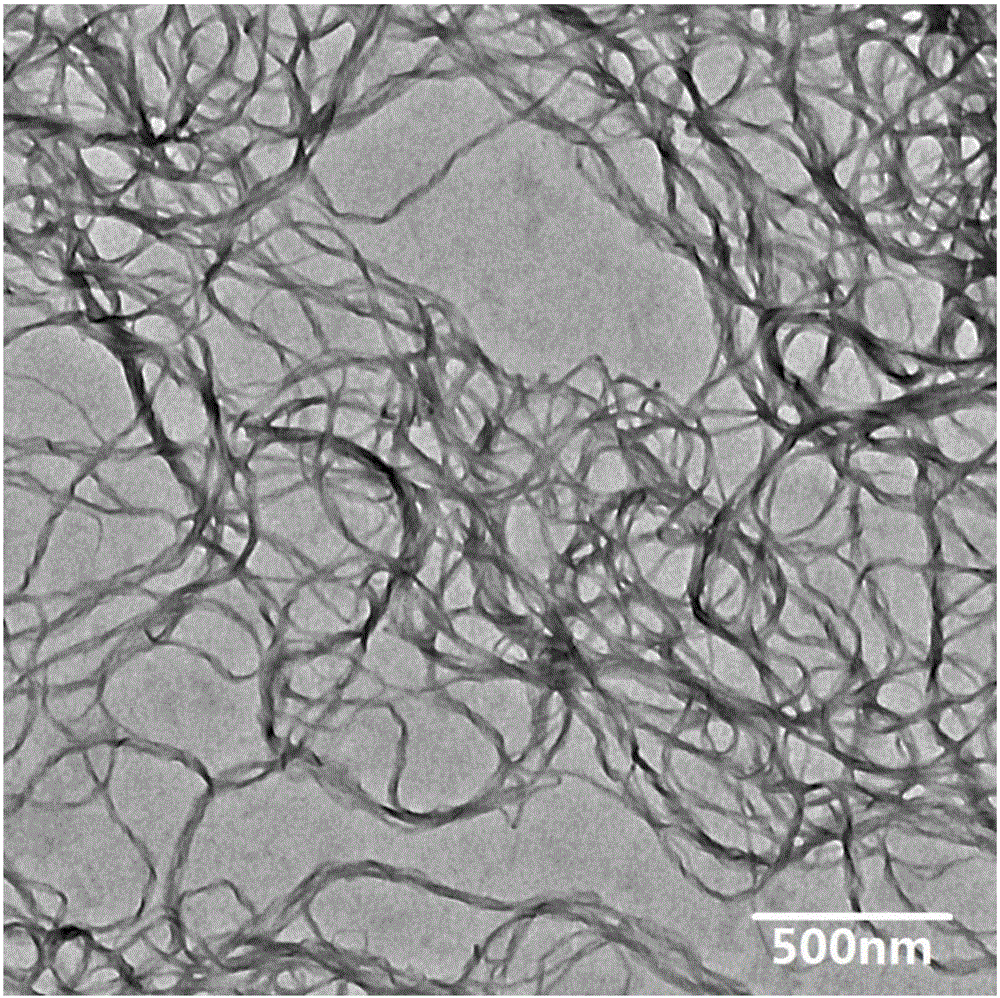

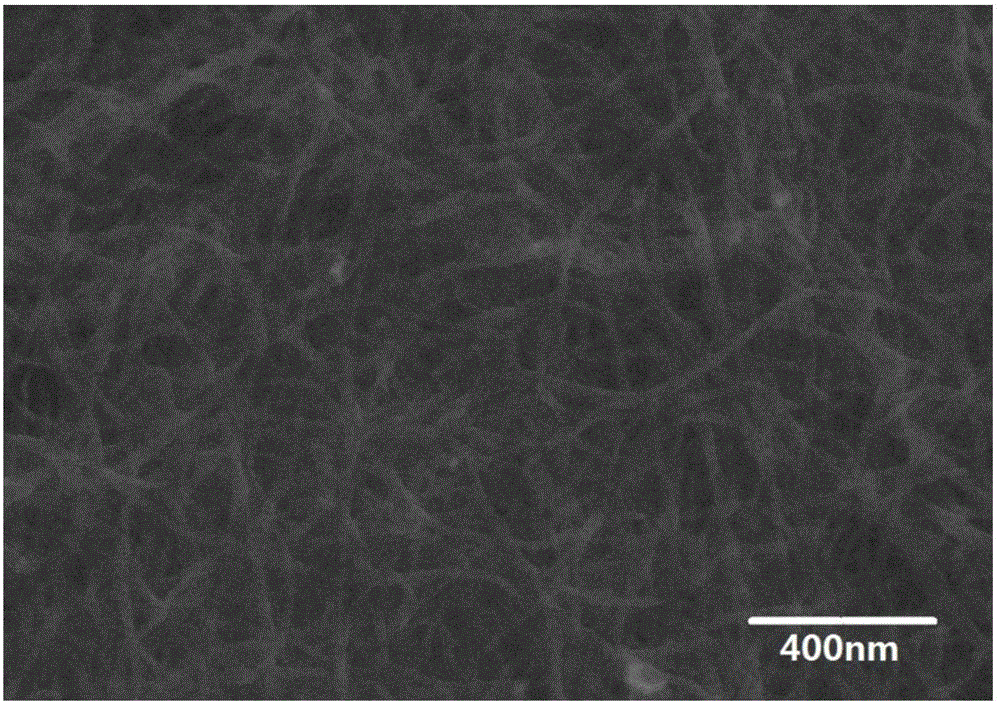

ActiveCN105153413AReduce usageSimple processArtificial filament recoveryArtificial filament washing/dryingMicrometerNanofiber

The invention relates to a preparation method of p-aramid nanofiber, and belongs to the technical field of polymer new materials. The diameter of the prepared p-aramid nanofiber ranges from tens of nanometers to hundreds of nanometers, and the length of the prepared p-aramid nanofiber ranges from hundreds of nanometers to tens of micrometers. According to the preparation method, a certain amount of surface active agents are added in the PPTA low-temperature polymerization process, aggregation of PPTA molecules is controlled while PPTA molecule chains are lengthened, and the p-aramid nanofiber which is uniform in size and has the diameter capable of being regulated within the range between nanometer and submicron can be prepared under the auxiliary effect of other means (for example, precipitator and high-speed shearing and dispersing). The preparation method is short in production flow, devices are simple, batched and stable production can be achieved, and therefore the requirement for industrially producing the p-aramid nanofiber on a large scale is met; the preparation method has wide application prospects and can be used for preparing lithium-ion battery separators and high-performance composites.

Owner:SHANDONG JUFANG NEW MATERIAL CO LTD

Method for recovering alkali and hemicellulose from chemical fibre waste liquid

InactiveCN1450001AEfficient separationEfficient purificationArtificial filament recoveryTextile/flexible product manufactureLiquid wasteFiltration

The method for recovering alkali and hemicellulose from waste liquor produced by producing optical fibre includes the folloiwng steps: making the pressed liquor containing alkali and hemicellulose undergo the processes of prefiltration and fine filtration, and feeding it into membrane separation equipment to obtain the penetrated liquor containing alkali and concentrate containing hemicellulose, and the alkaline liquor concentration in the obtained penetrated liquor can be up to 80-250 g / l, and the final alkali content in the concentrate is 5-30 g / l, and the hemicellulose content is 100-200 g / l. Said technological process is simple, can effectively separate and purify hemicellulose and alkali liquor.

Owner:凯能高科技工程(上海)有限公司

Method for making product from fiber glass waste

InactiveUS20050242477A1Reduce wasteSave energyCovering/liningsArtificial filament recoveryGlass fiberNatural resource

The invention provides a method to transform large quantities of fiber glass waste into useful ceramic products by a low-cost manufacturing process. The method consists of reducing the fiber glass waste into a glass powder; mixing the glass powder with additives into a glass-additives mixture; granulating the glass-additives mixture into granulated particles; forming the granulated particles into a green ceramic article; and heating the green ceramic article into the ceramic product. Water and clay can be included in the processing. Only one firing step is needed with a low peak firing temperature of about 700° C. to about 1000° C. The method conserves energy and natural resources compared to clay-based traditional ceramic manufacturing. High-quality impervious ceramic products can be produced by the invention.

Owner:HAUN MICHAEL J

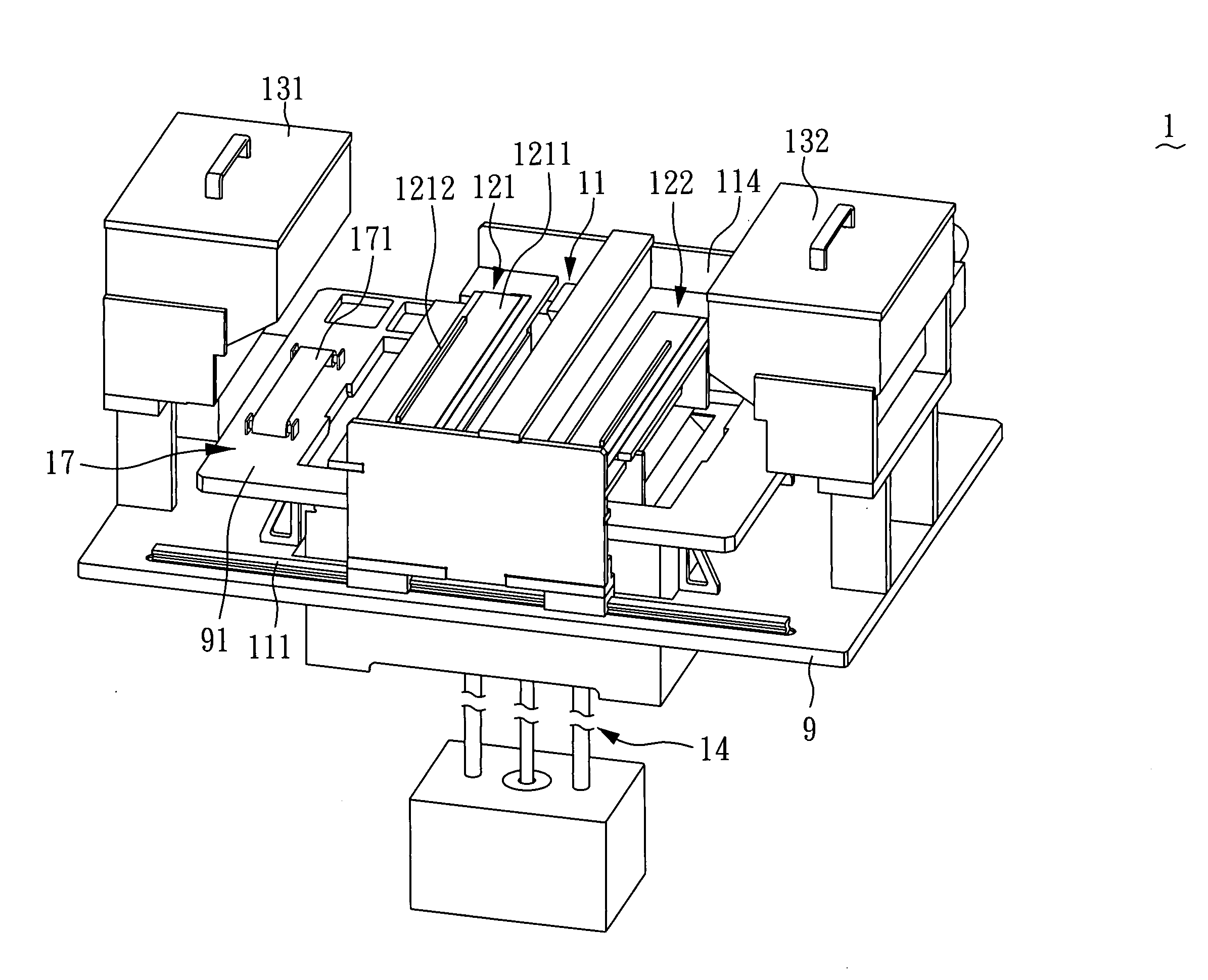

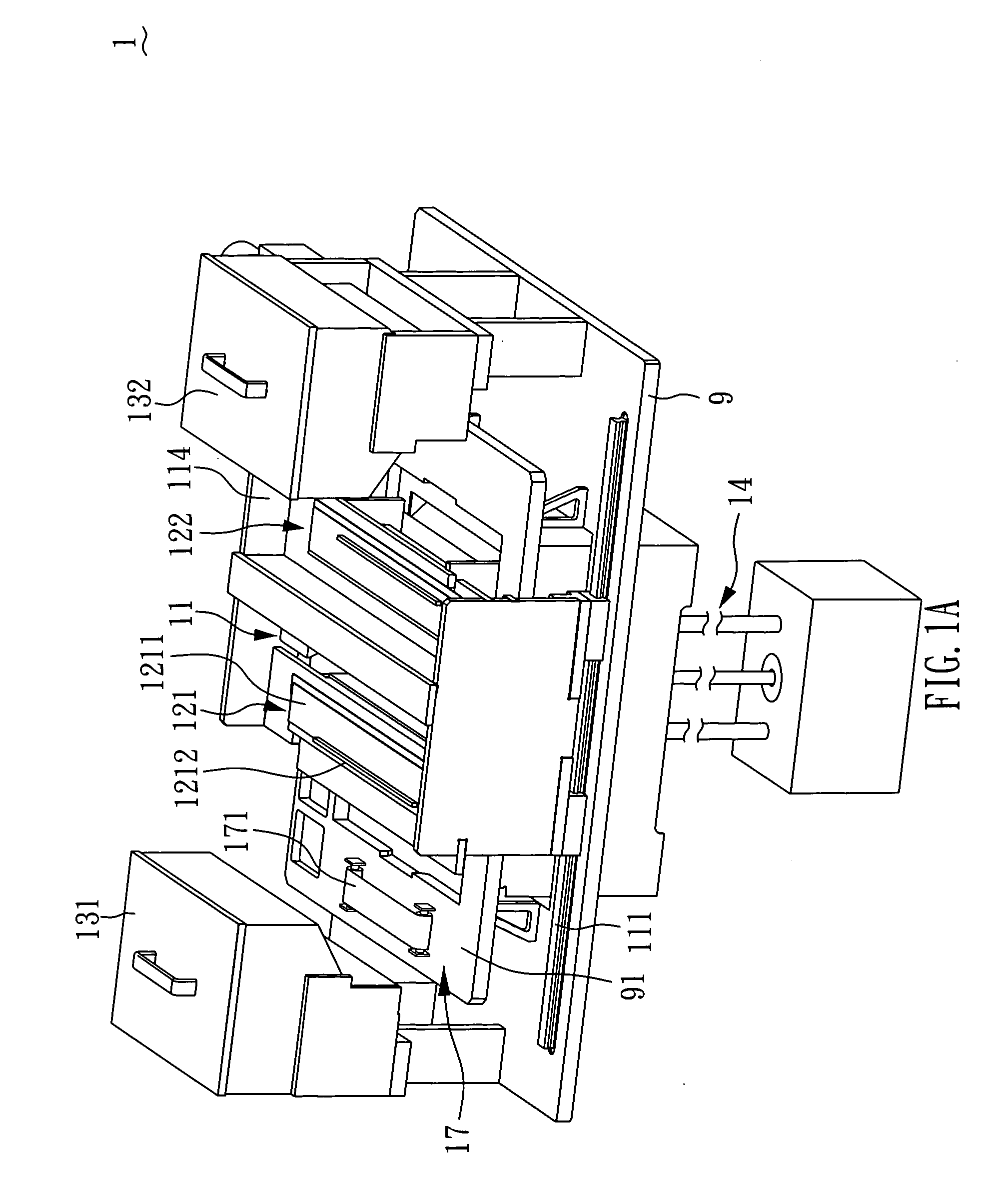

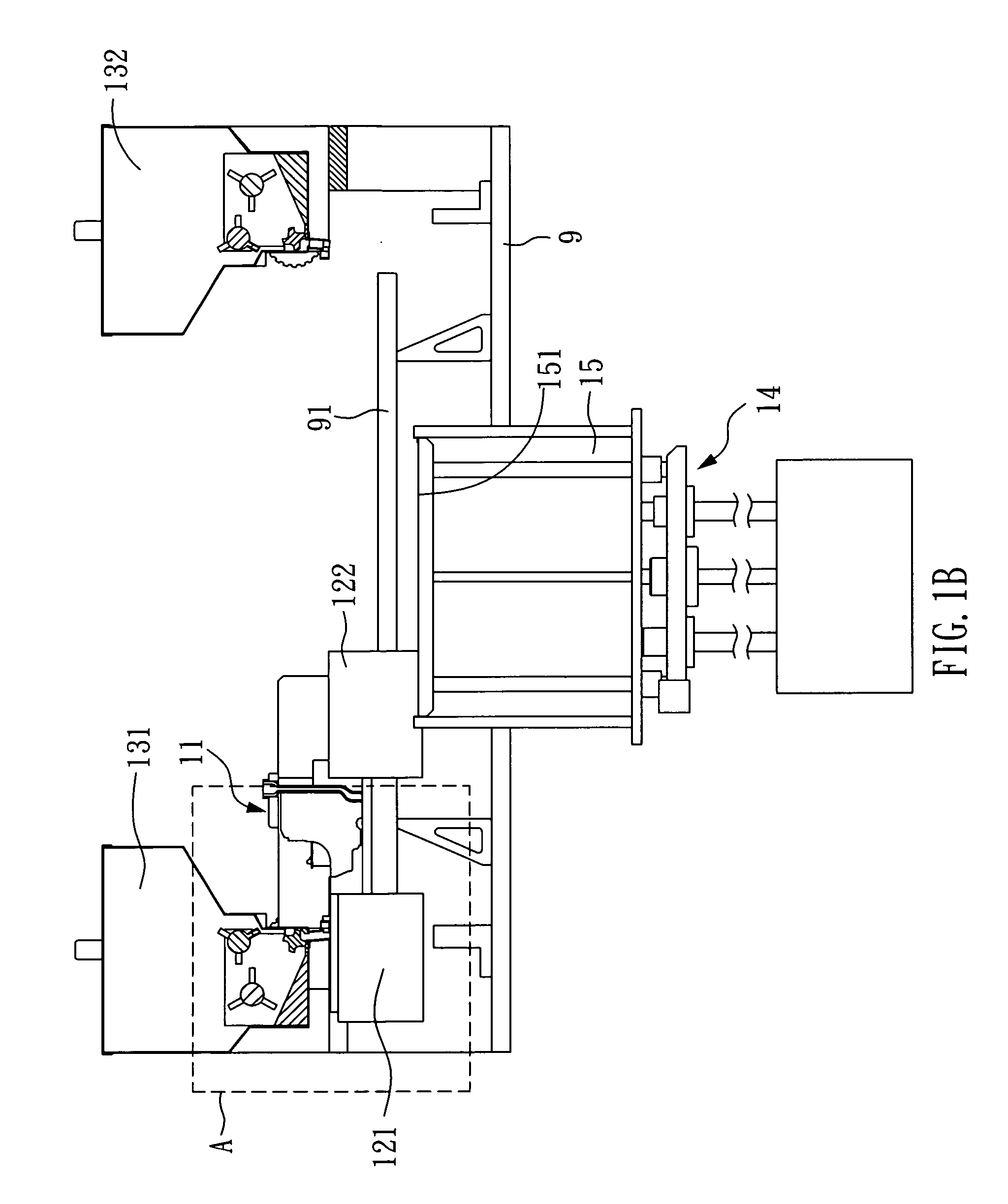

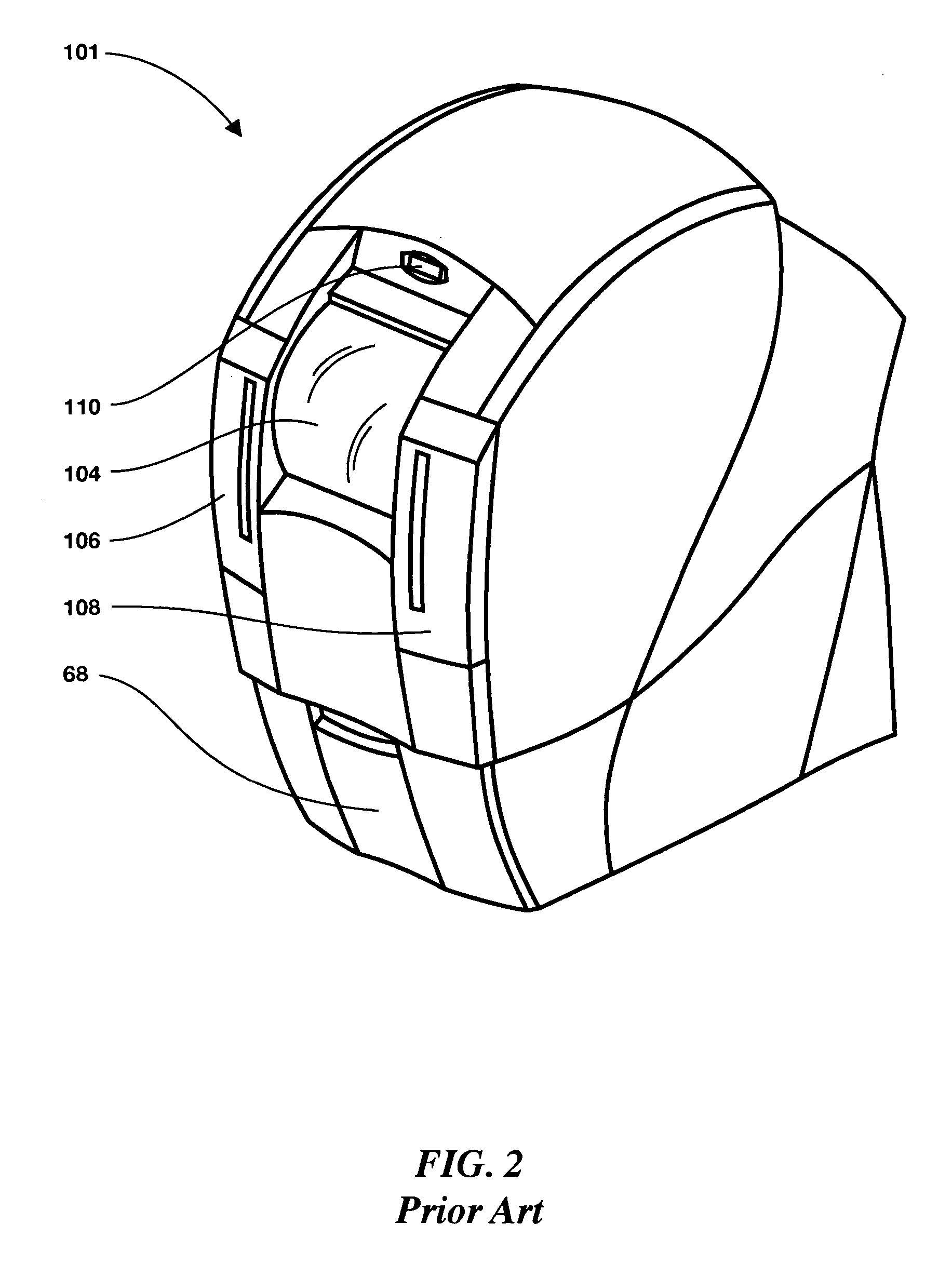

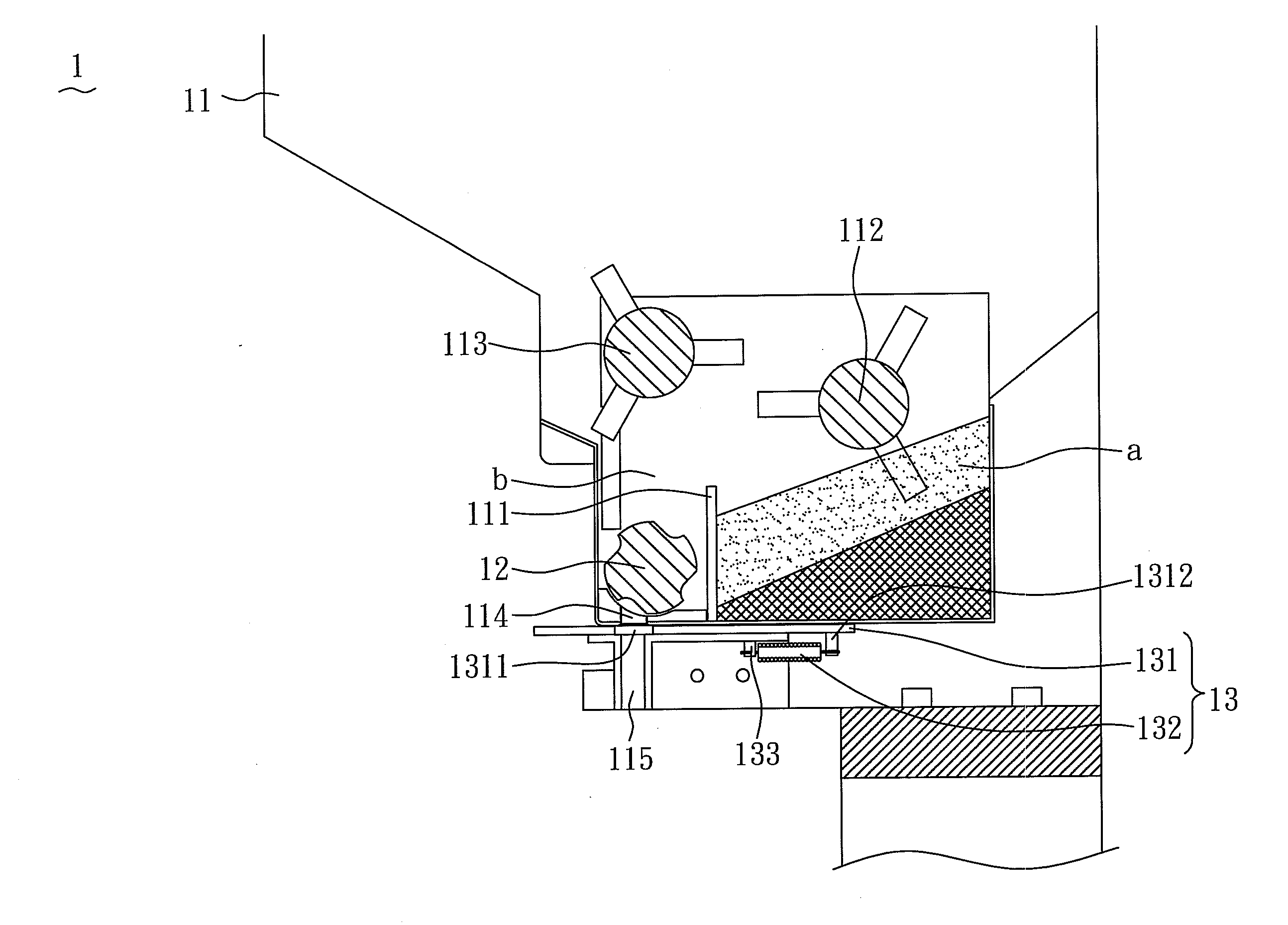

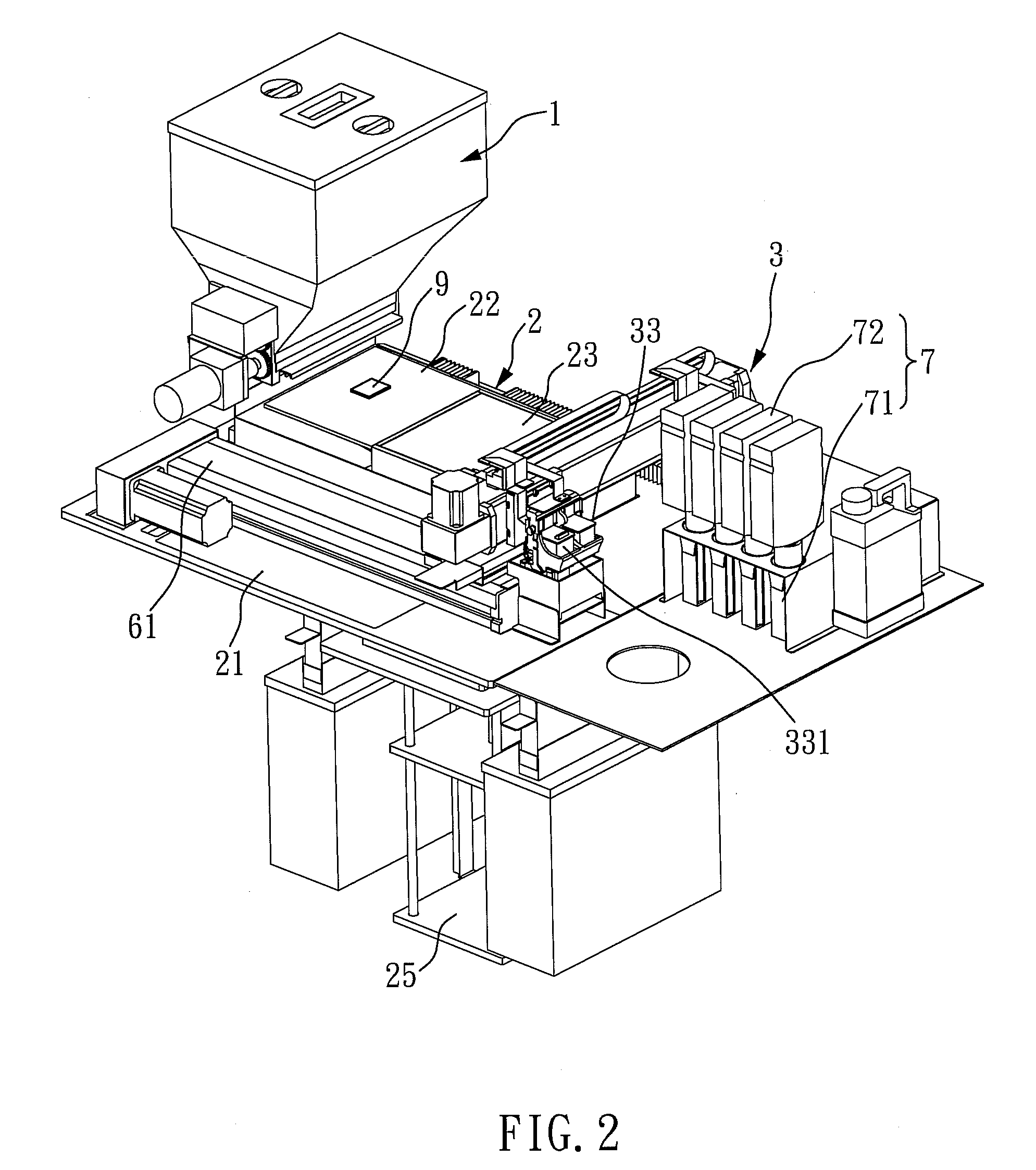

Three-dimensional object-forming apparatus

ActiveUS20110300248A1Avoid wastingLow production costManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

Recycled rubber products

InactiveUS6821623B2Increase ratingsReduce the amount requiredArtificial filament recoverySynthetic resin layered productsPolymer scienceShell molding

Recycled rubber products are made in a two step process. In the first step, ground rubber is treated with a polyurethane binder to make a treated rubber. In the second step, the treated rubber is mixed with additional polyurethane binder and molded into finished products. This method uses less polyurethane binder than the conventional process, but the products have higher tensile strengths. The molding time is also reduced because of the reduced amount of polyurethane binder used.

Owner:RYVEC

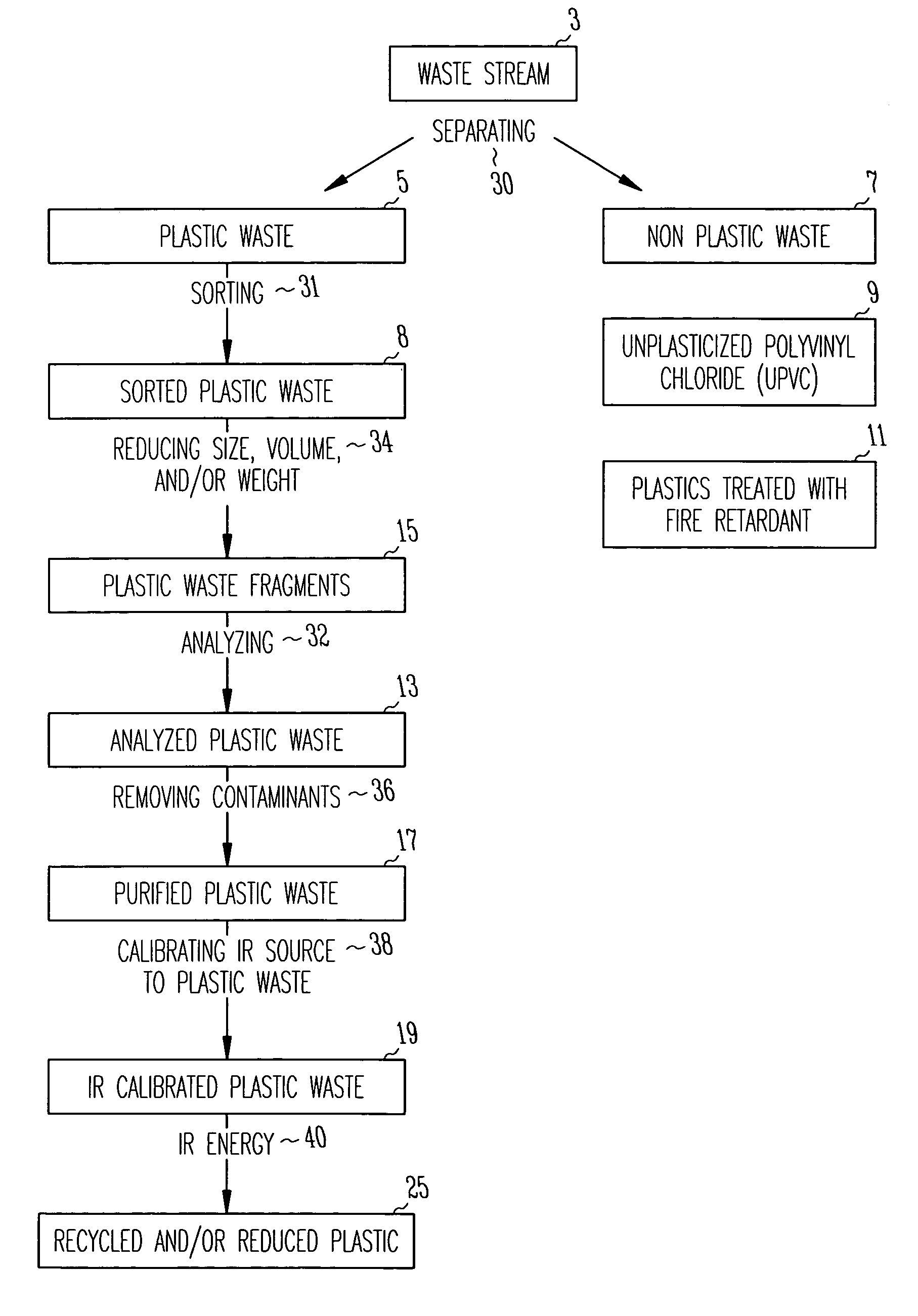

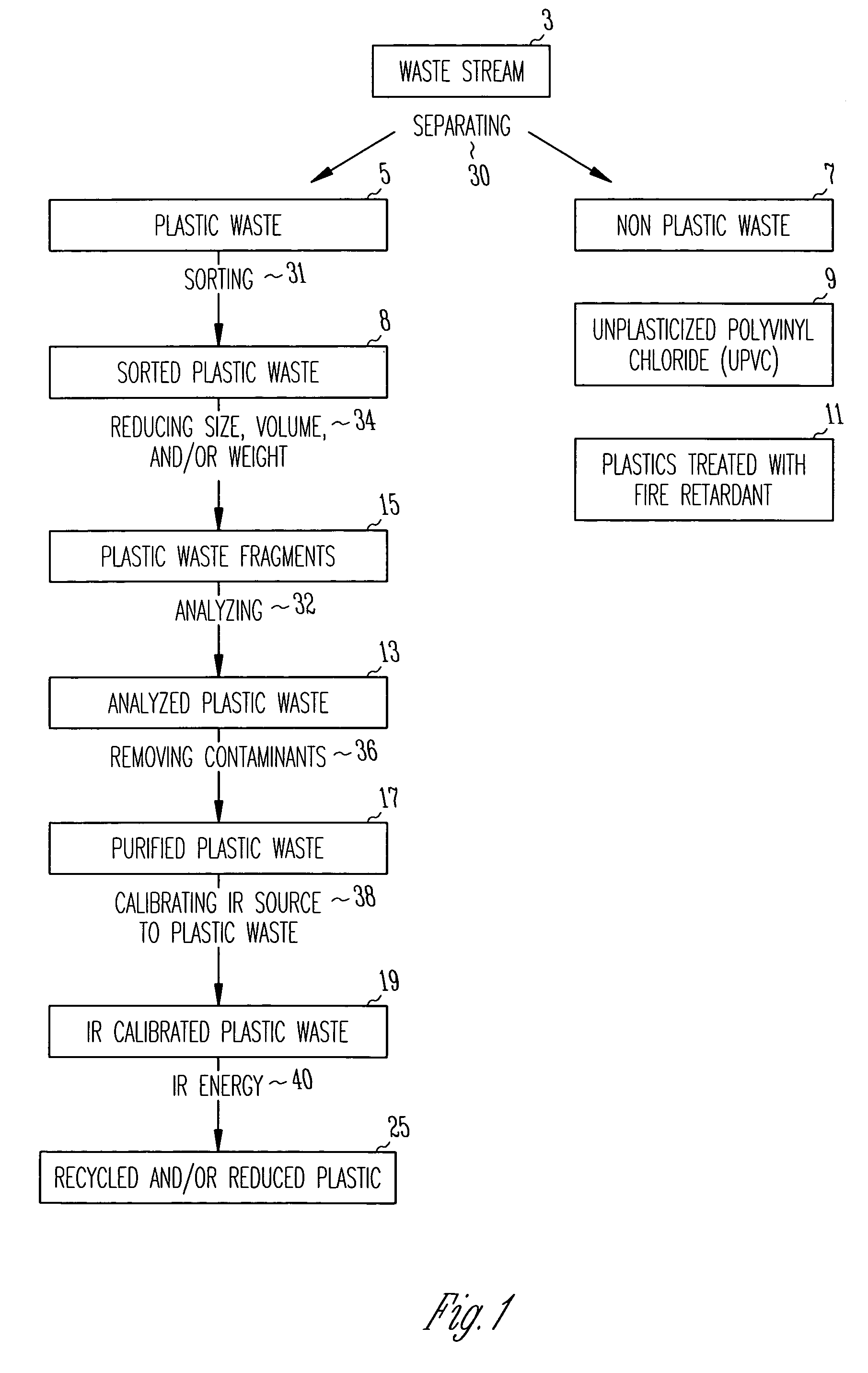

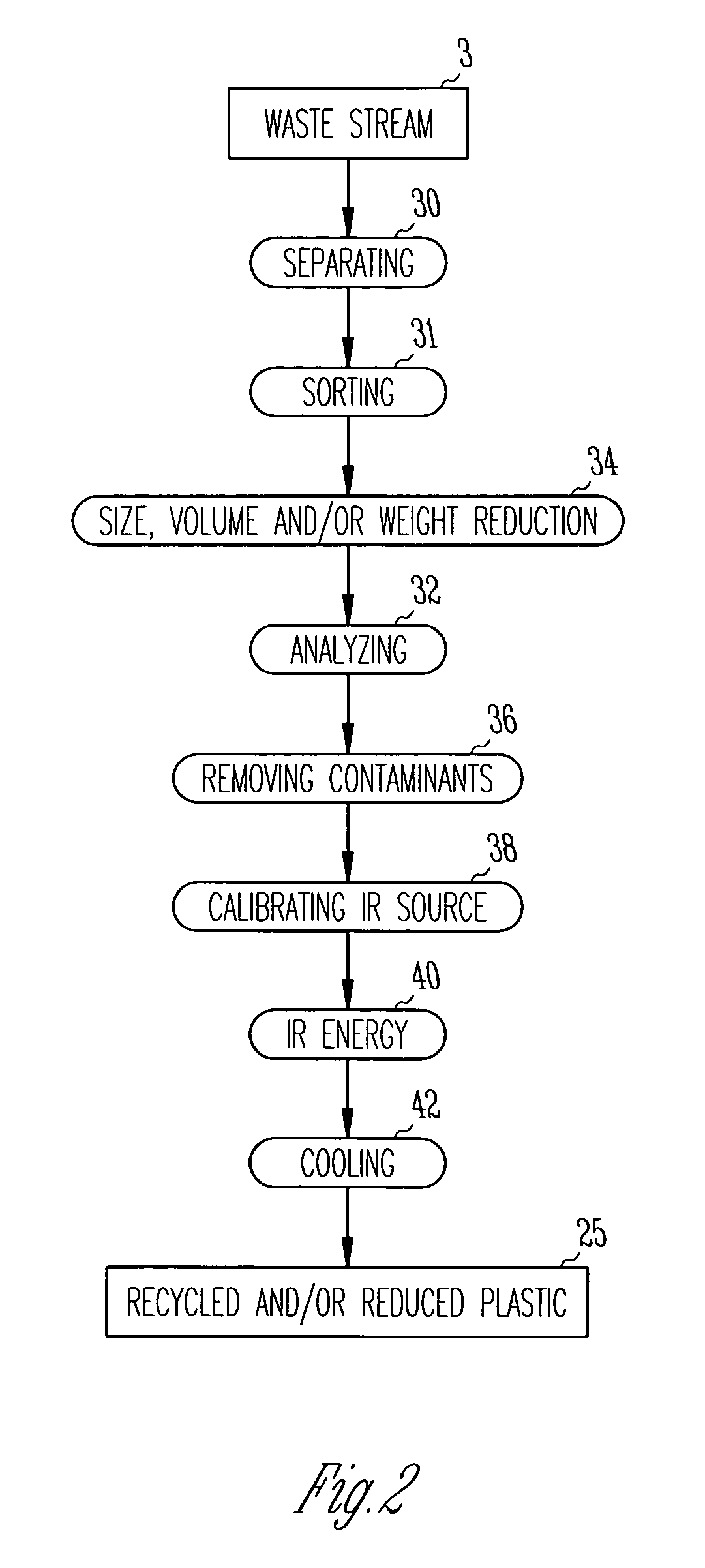

Recycling and reduction of plastics and non-plastics material

InactiveUS7799835B2Small sizeChange volumeRadiation pyrometryMangetographic processInfraredWaste stream

The present invention provides, e.g., methods to recycle and / or reduce plastic, non-plastic, or a combination thereof, from a waste stream. The methods of the present invention include contacting the plastic waste with infrared (IR) energy at one or more frequencies and at one or more intensities, over a period of time effective to heat plastic present in the plastic waste.

Owner:NEXTTEC

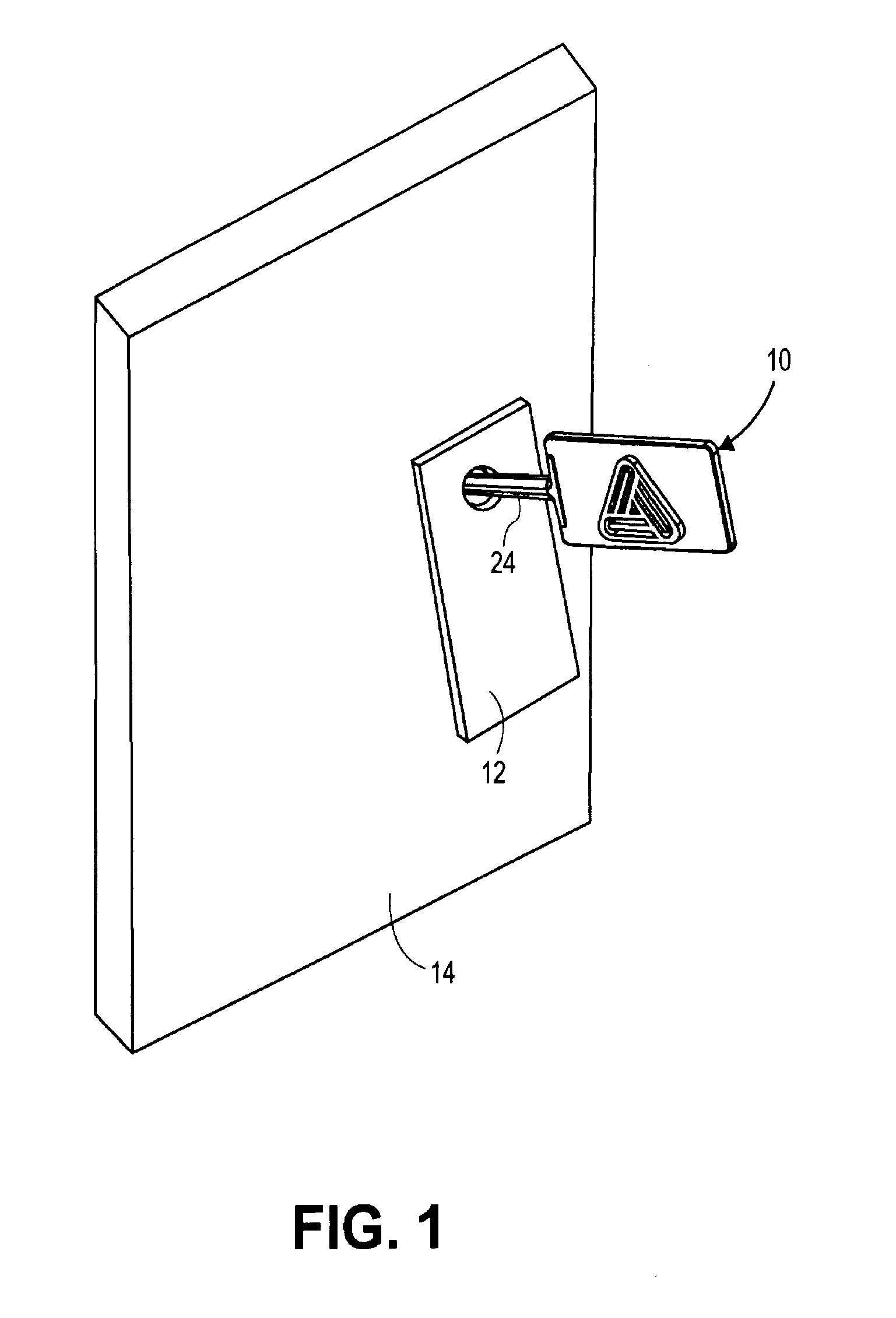

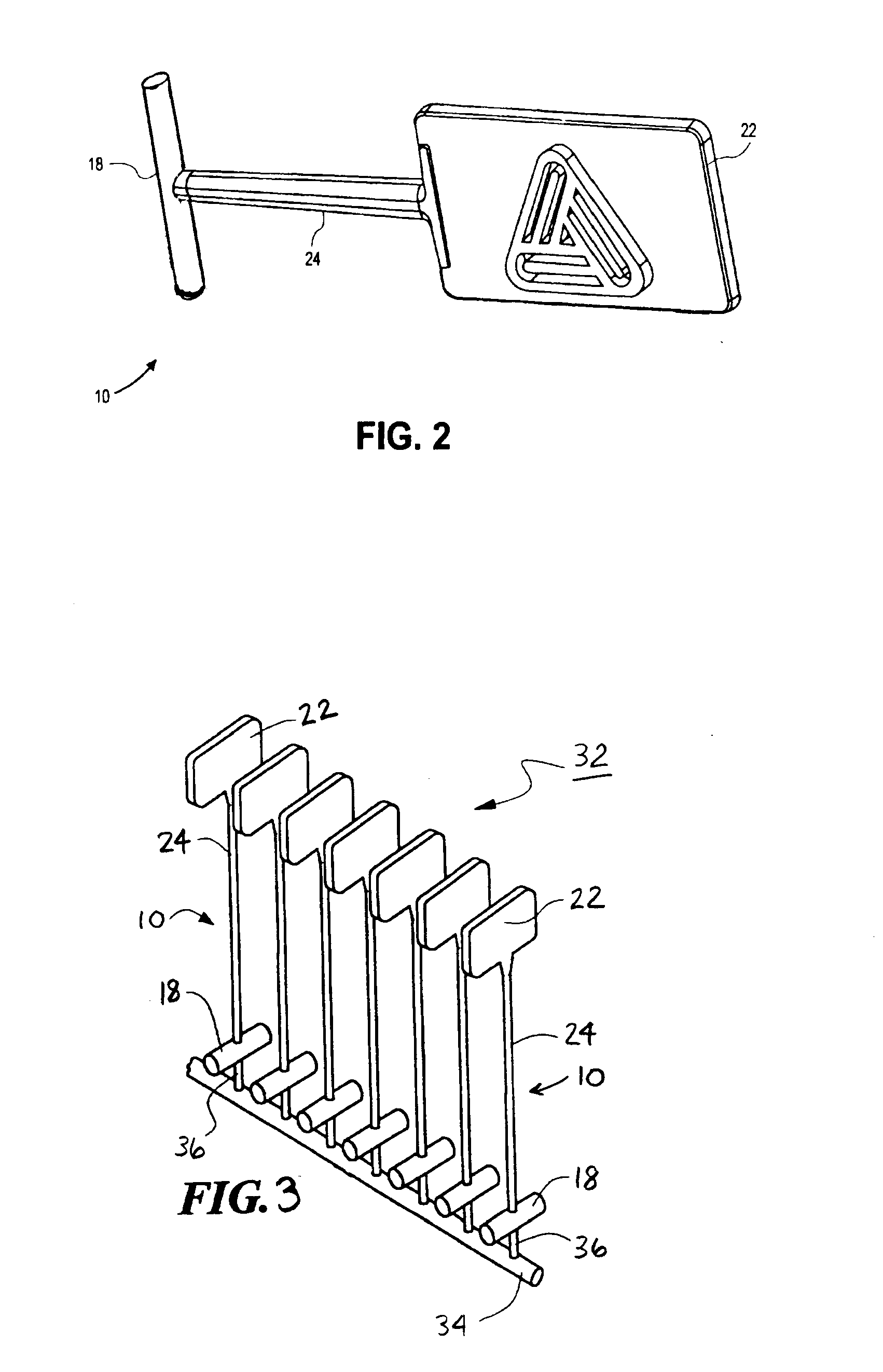

Plastic Fastening Device Comprising a Recycled Thermoplastic Resin

InactiveUS20120279023A1Improve compatibilityStampsArtificial filament recoveryLow-density polyethyleneThermoplastic

A plastic fastening device that includes a recycled material. In one embodiment, at least a portion of the fastening device includes a blend of two or more thermoplastic resins, at least one of which is a recycled material. The blend may include, for example, a fresh thermoplastic resin and a recycled thermoplastic resin. The fresh thermoplastic resin may include, for example, one or more of a polyethylene (PE), a polyamide (PA), or a polycarbonate (PC). The recycled thermoplastic resin may include, for example, a recycled polyethylene terephthalate (rPET). In a preferred embodiment, the blend of two or more thermoplastic resins includes a blend of (i) rPET and (ii) one of a low-density polyethylene (LDPE), a LDPE / LLDPE (linear low-density polyethylene) blend and LLDPE, (iii) wherein the rPET constitutes about 88% to 98% of the total material content and the LDPE, the LDPE / LLDPE blend, or the LLDPE constitutes the balance.

Owner:AVERY DENNISON CORP

Solvent recovery method for cellulose fiber preparation with ion liquid as solvent

InactiveCN1804161AImprove protectionGood for healthArtificial filament recoveryTextile/flexible product manufactureRecovery methodFiltration

The invention provides a solvent recovery method in the cellulose fiber preparation process by using ionic liquid as the solvent, which comprises subjecting coagulating bath components to precipitation, filtration, vacuum distillation and normal atmosphere distillation.

Owner:DONGHUA UNIV

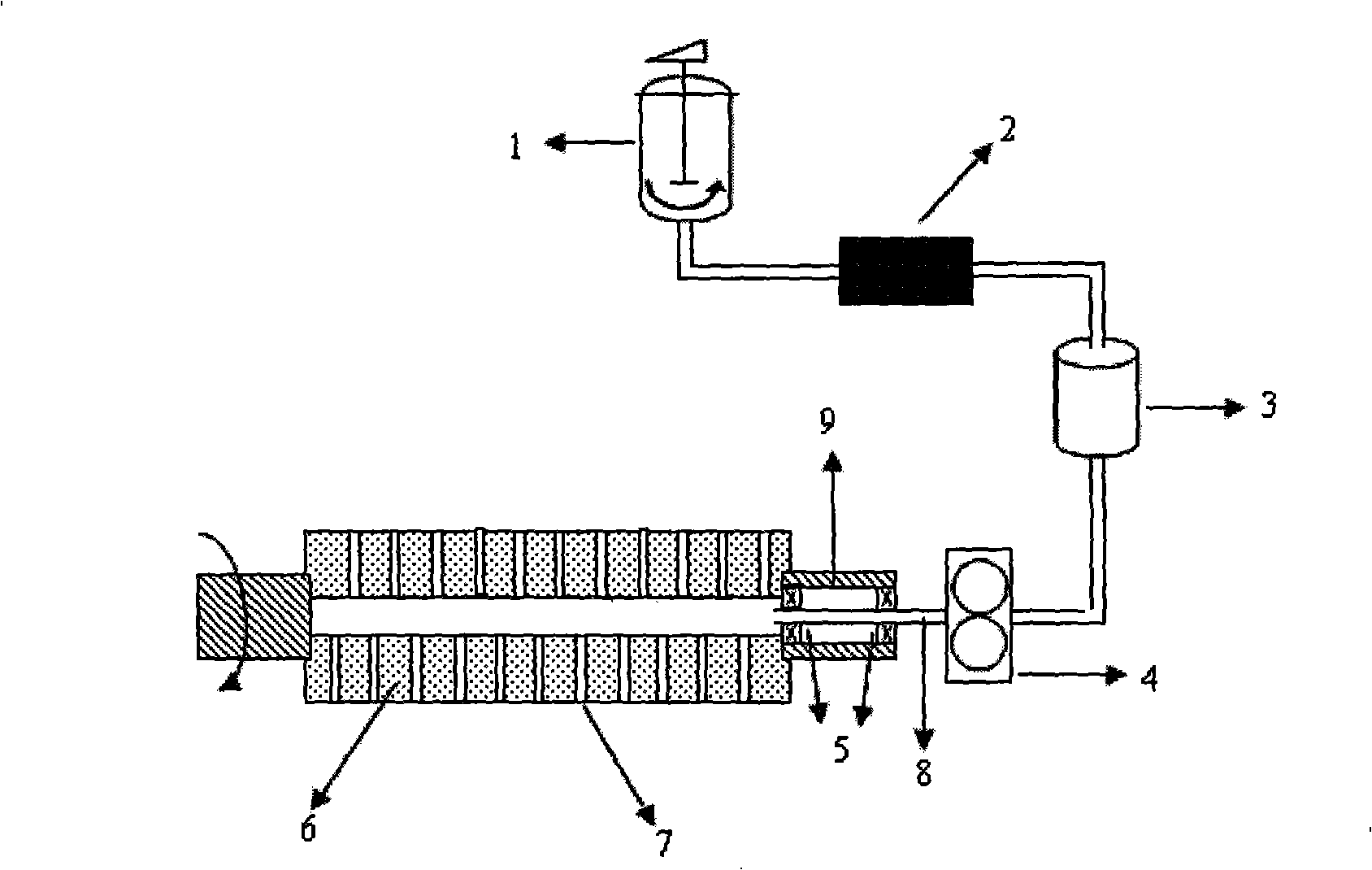

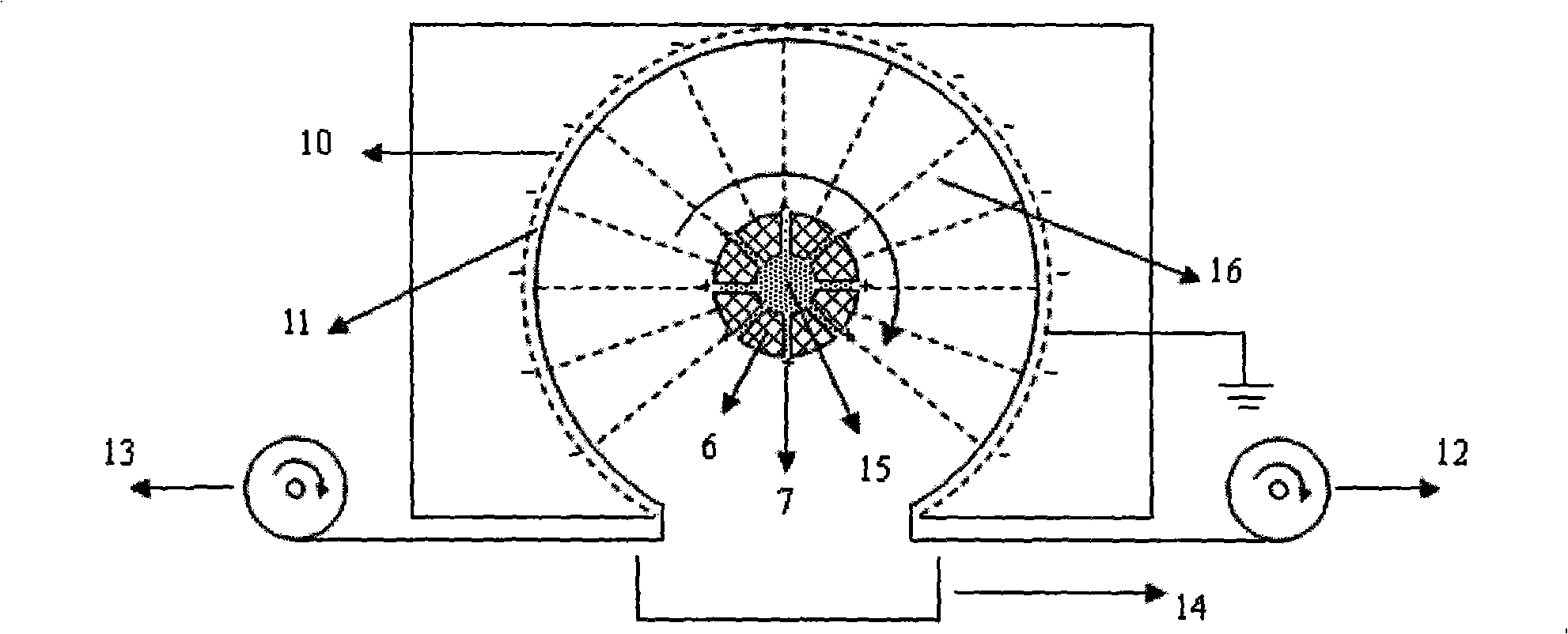

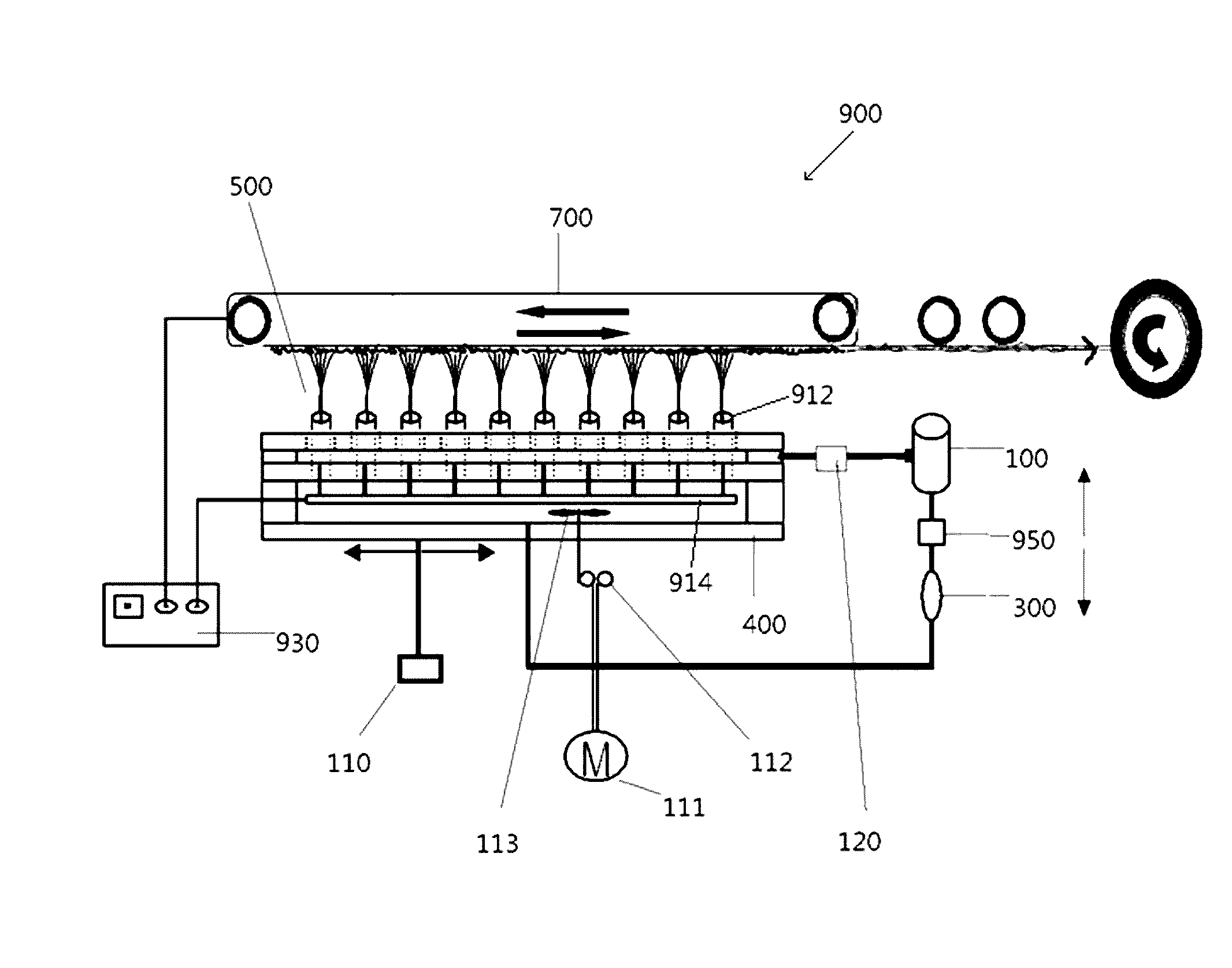

Method for producing continuous high-efficiency nano fibre nonwoven fabric and production device thereof

InactiveCN101298724AEvenly distributedAvoid uneven distribution of the jet (16) on the surface of the metal drumSpinnerette packsArtificial filament recoveryElectrospinningNanofiber

The invention relates to continuous high efficiency nano spinning solution (15), a nanofiber nonwovens manufacturing method and a manufacturing device which not only has high manufacturing efficiency but form better thickness of the nanofiber nonwovens. The manufacturing device comprises a solution supply system, a solution feeding pipe (8), a connecting mechanism and a metal roller (6); a metal strainer (10) and a fiber receiving web (11) which have the same shaft with the metal roller are sequentially arranged on the outside of the metal roller (6), an unreel roller (12) and a winding roller (13) are arranged on the fiber receiving web (11), and pores (7) are cut on the hollow metal roller (6). The manufacturing method includes the steps: (1), polymer spinning solution (15) is prepared; (2), an electric field is arranged between the metal roller (6) and metal strainer (10); (3), the metal roller (6) is revolved at a certain speed; (4) a measuring pump (4) is led to the metal roller (6) for even internal inputting; (5), the nanofiber is received. The invention is good for the scale manufacturing of static spinning.

Owner:DONGHUA UNIV

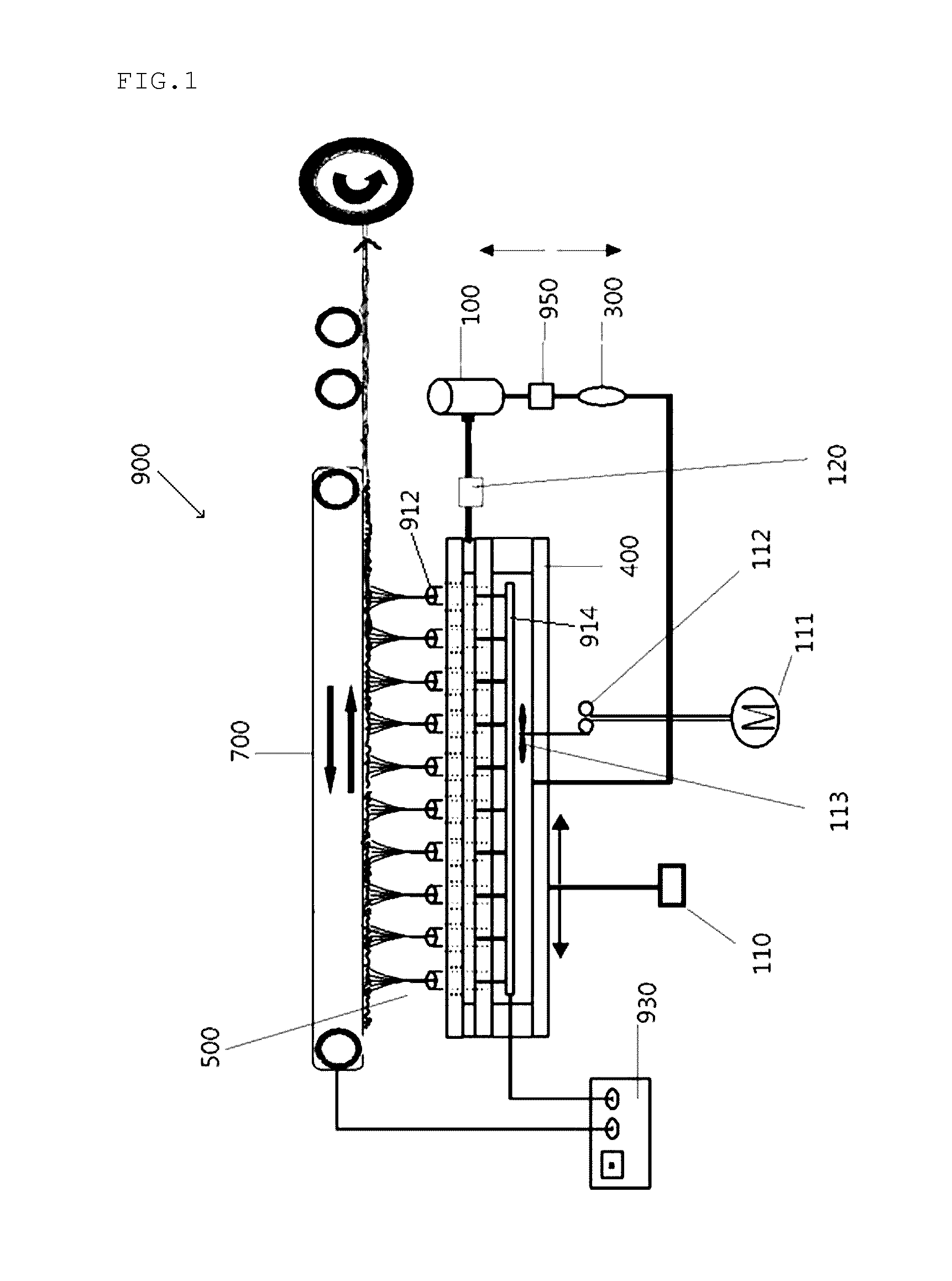

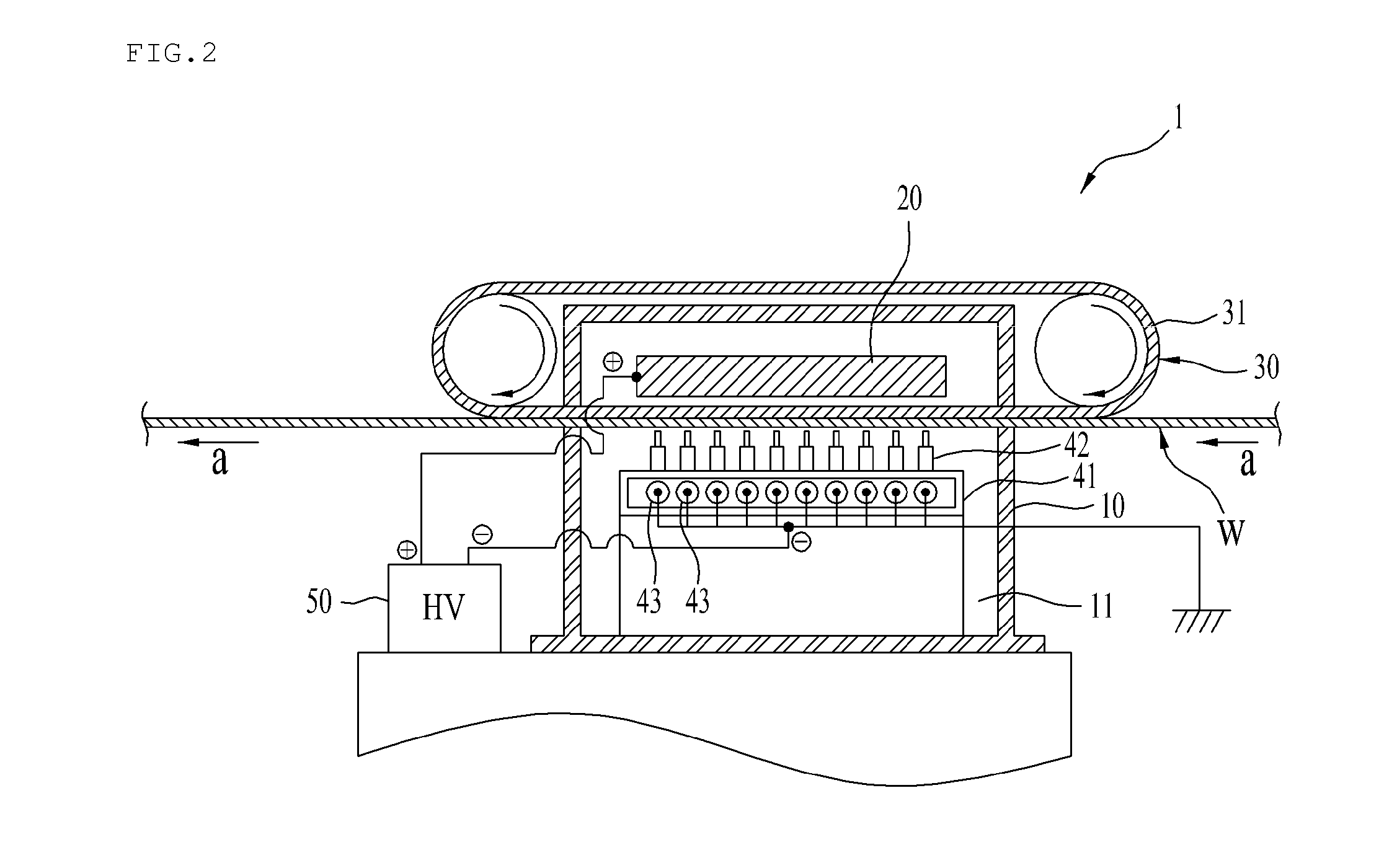

Electrospinning apparatus

InactiveUS20160083868A1Uniform qualitySimple manufacturing processSpinning solution filteringArtificial filament recoveryHigh volume manufacturingElectrospinning

The present invention relates to an electrospinning apparatus, and the purpose of the present invention is to provide an electrospinning apparatus capable of producing nanofiber having various ingredients and thicknesses by controlling the temperature of at least one solution discharged from nozzles mounted on the tubular bodies of a nozzle block and thus controlling the viscosity of the solution which is electrospun; producing nanofiber having uniform quality without applying a density difference and a voltage difference by disposing the front end portions of the nozzles in a flare shape; and mass-producing nanofiber at a low cost as well as reducing the amount of the solution used by removing an overflow prevention system and using a metering pump alone or by using the metering pump and the overflow prevention system alternatively or in a hybrid manner.

Owner:FINETEX ENE

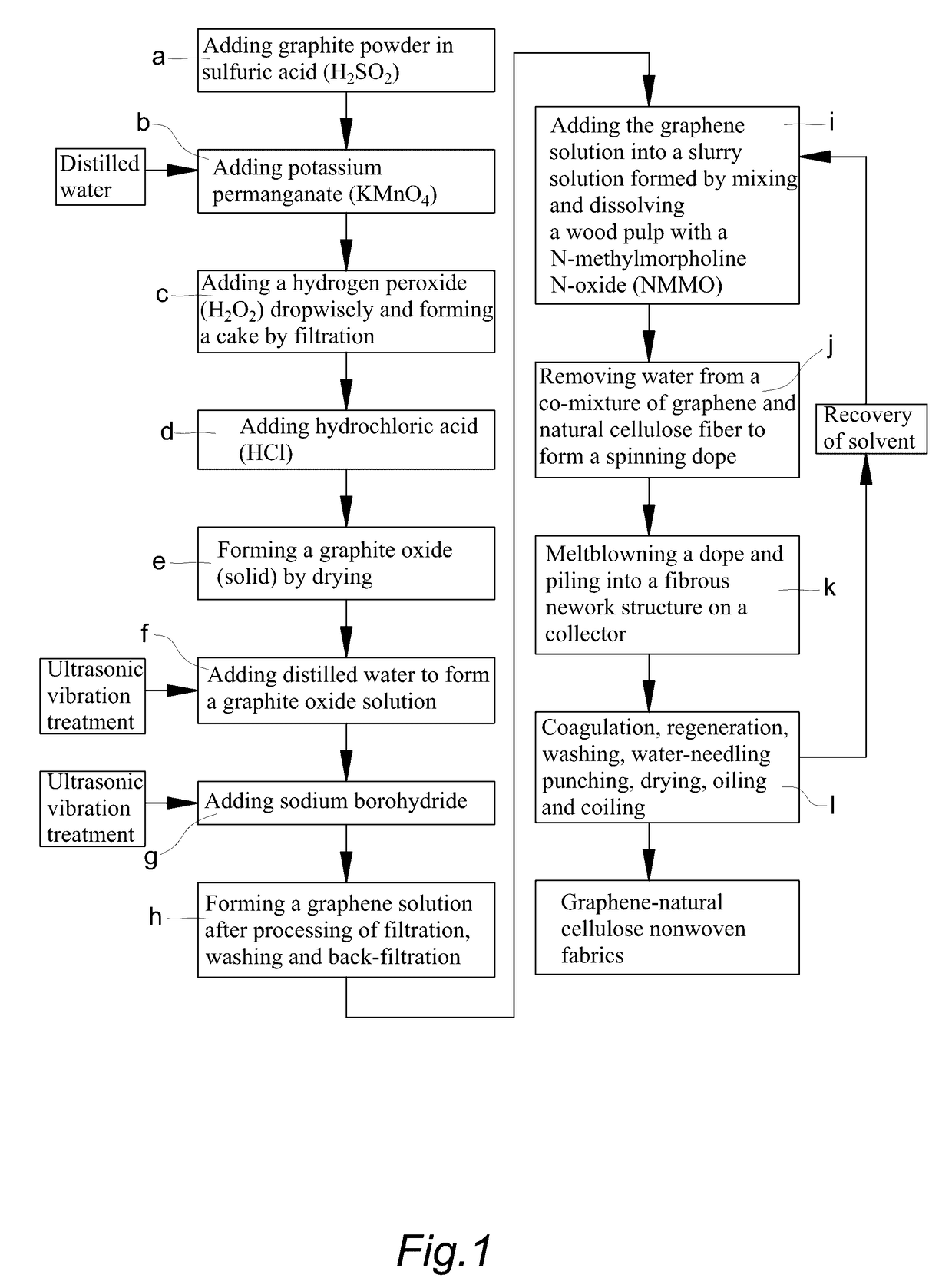

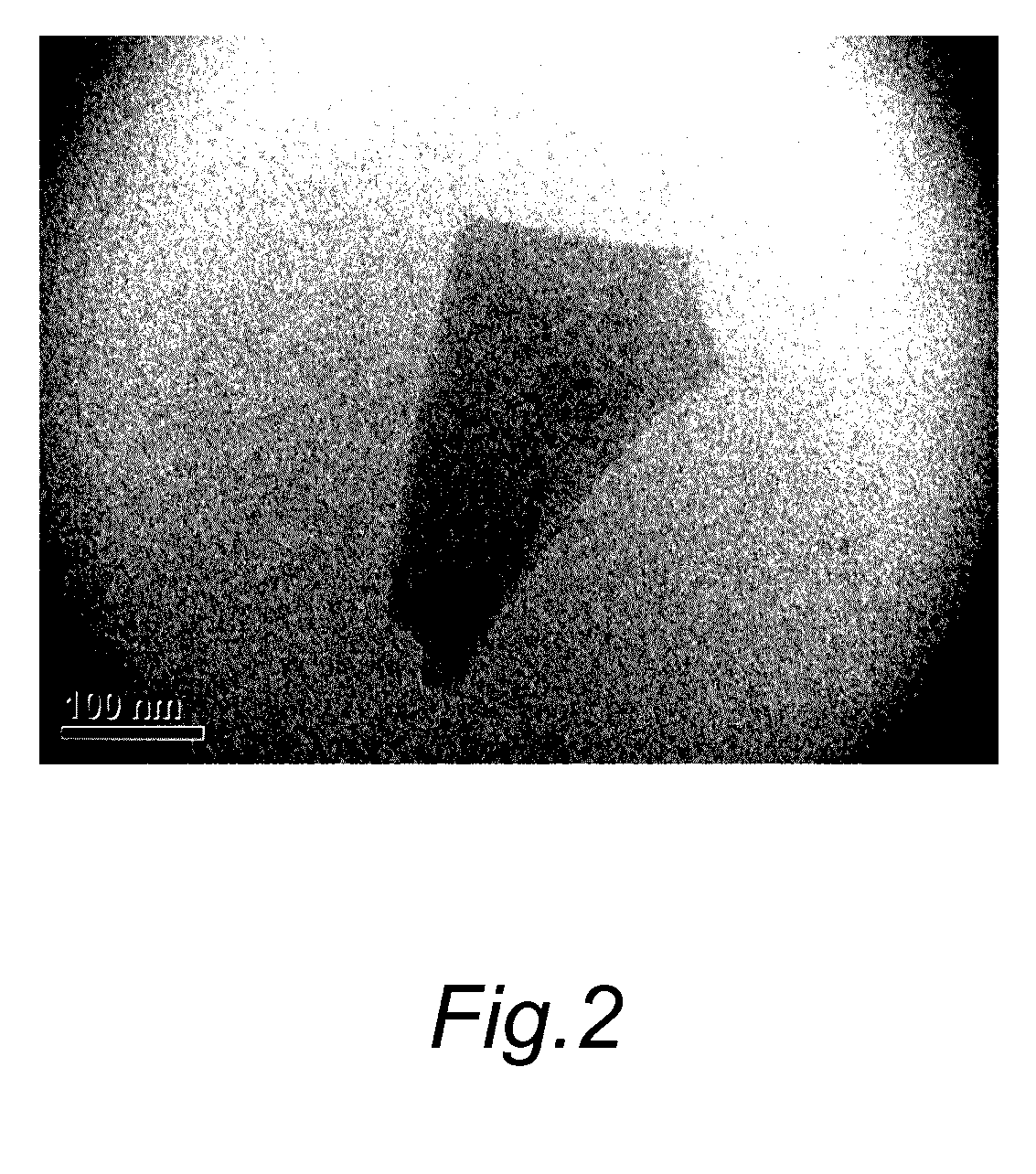

Method of Preparing of Natural Graphene Cellulose Blended Meltblown Nonwoven Fabric

ActiveUS20170107650A1Avoiding health hazard associated with solutionAltered propertyArtificial filament recoveryGraphitePresent methodSlurry

This application describes a method of preparation of a natural graphene cellulose blended meltblown nonwoven fabric, which comprises using a graphite powder as a raw material for preparing a graphene solution, adding the graphene solution to a slurry formed by mixing and dissolving a wood pulp with N-methylmorpholine N-oxide (NMMO), removing the water content thereof to form a spinning dope, and then directly preparing the natural graphene cellulose blended meltblown nonwoven fabric by a meltblown process. The present method does not require a highly toxic hydrazine hydrate solution. Further, by increasing the adding ratio of the graphene solution in the manufacturing process, control of the antistatic properties and thermal transferring function can be achieved, and thereby various requirements of different consumers can be satisfied. Besides, the fabric can decompose naturally after being used, and thus the product is harmless, natural, and environmentally friendly.

Owner:LIN CHIH HSIN

Process for the production of ceramic tiles

InactiveUS20030183988A1Low costSpeed up the processArtificial filament recoveryCeramic shaping apparatusSlagFly ash

Owner:COUNCIL OF SCI & IND RES

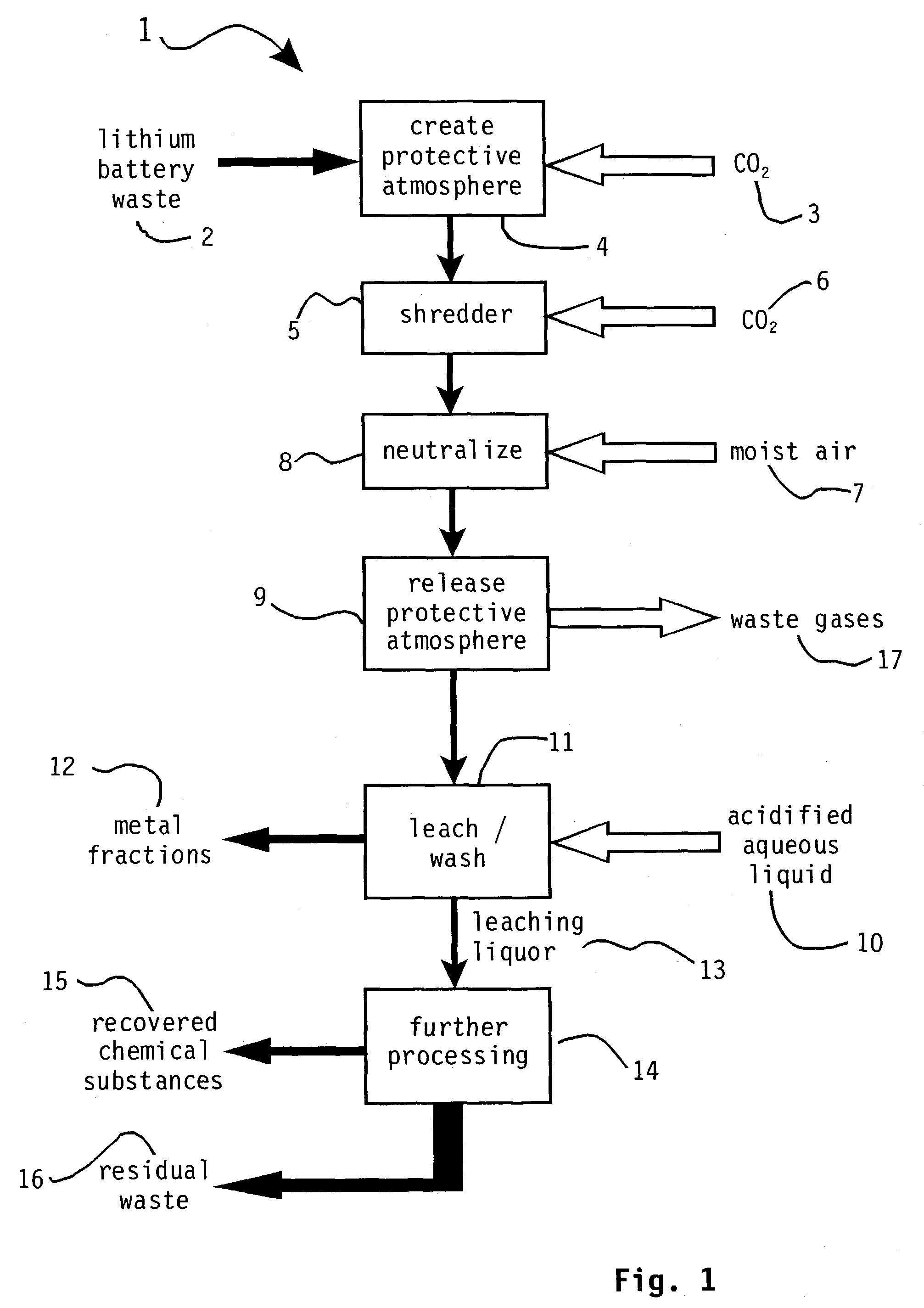

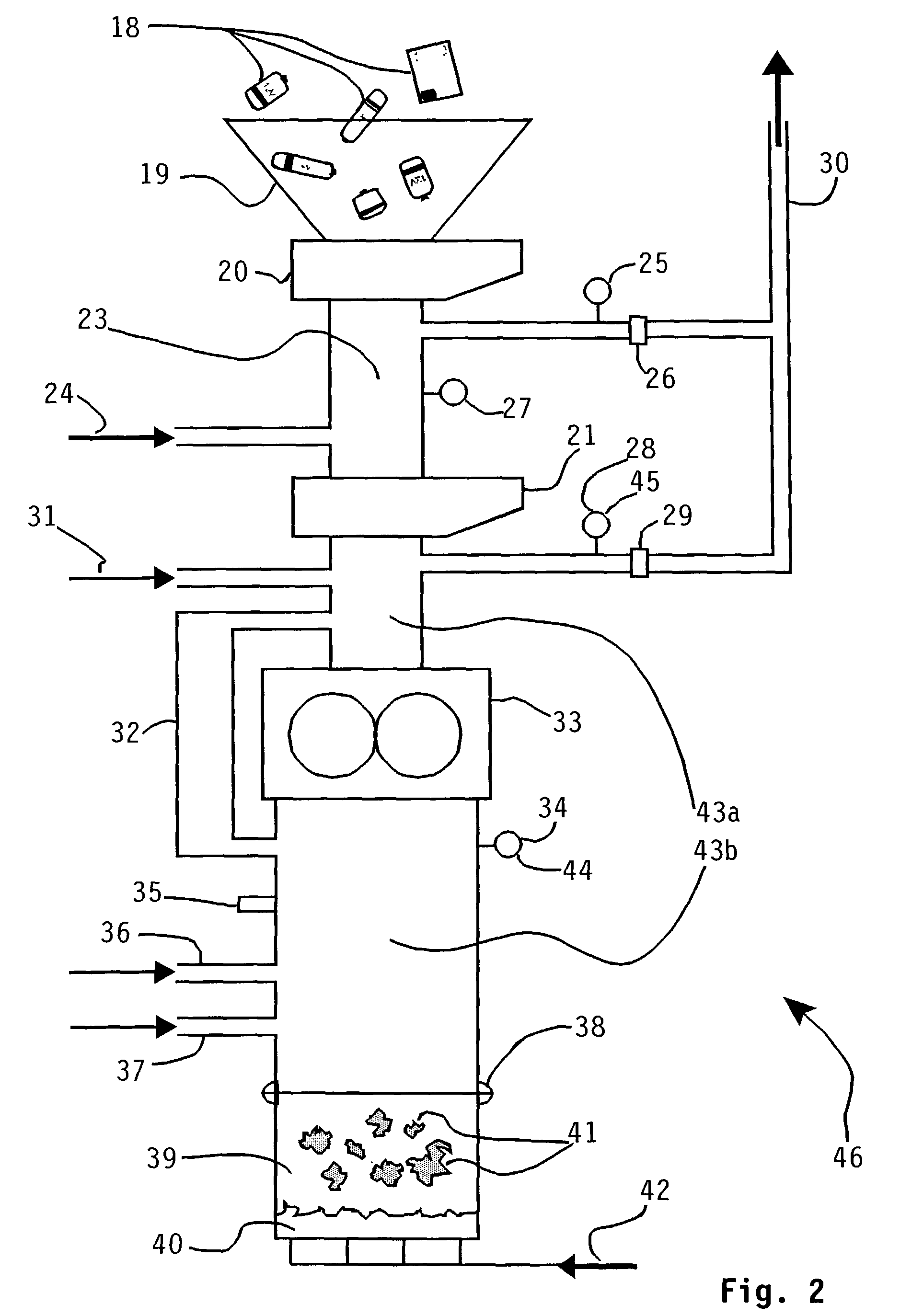

Method of and apparatus for dismantling and storage of objects comprising alkali metals, such as alkali metal containing batteries

InactiveUS7833646B2Cost effectiveEasy to separateNon-aqueous electrolyte accumulatorsArtificial filament recoveryProduct gasMetal

There is disclosed a method of and an arrangement for dismantling and storage of objects comprising alkali metal containing substances, in particular lithium containing batteries, in the presence of a protective atmosphere, wherein the protective atmosphere is carbon dioxide. The arrangement comprises a gas-tight chamber for bringing the objects under a protective environment, and a gas-tight chamber for dismantling the objects within the protective atmosphere of carbon dioxide gas.

Owner:BATREC IND

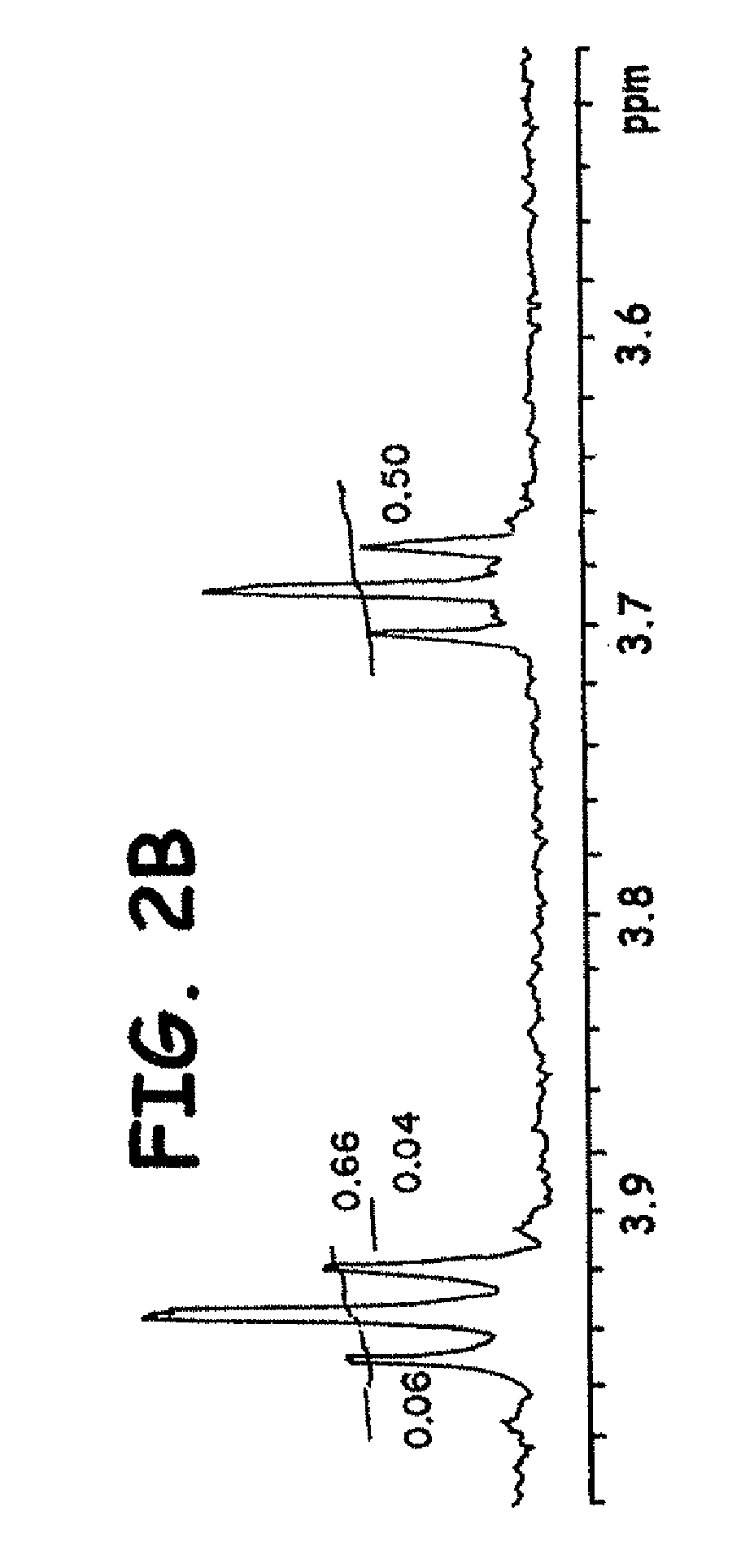

Recovery method for NMMO solvent in fibre production by solvent method

ActiveCN101280476AReduce concentrationHigh recovery rateArtificial filament recoveryTextile/flexible product manufactureFiberRecovery method

The invention relates to a recycling method of NMMO waste liquor, which provides a recycling method of NMMO in the waste liquor of fiber production with solvent method. According to the specific method of the invention, after passes through in sequence the cation resin exchange column and the anion resin exchange column, the NMMO waste liquor is in decompression and evaporation to the refractive index of 1.480 and cooled, thus the NMMO containing a crystallization water is produced. The cation resin is the macroreticular type or gel-type strong acid polystyrene cation exchange resin, and the anion resin is the macroreticular type or gel-type alkalescence acrylic acid anion resin. Compared with the prior recycling method, in the method of the invention, the recovery rate of the NMMP waste liquor is increased from 95% to 99.5%. In the discharged wastewater after the recycling, the concentration of NMMO is reduced and the steam is saved. Therefore, the textile production costs are greatly reduced.

Owner:YIBIN GRACE GROUP CO LTD

Method for recovering useful components from dyed polyester fiber

InactiveUS7959807B2Efficient and economical componentHigh purityArtificial filament recoveryPreparation by ester-hydroxy reactionFiberRecovery method

To establish an efficient and economical useful component recovery method capable of recovering high purity useful components from a dyed polyester fiber.A method for recovering useful components from a dyed polyester fiber, includes a dye extraction step, a solid liquid separation step, a depolymerization reaction step, an ester interchange reaction step, and a useful component separation step, for recovering useful components from the dyed polyester fiber, wherein the dye extraction step includes a step of extracting and removing a dye at the glass transition temperature of the polyester or higher and at 220° C. or less with a xylene extracting solvent and an alkylene glycol extracting solvent in combination.

Owner:TEJIN FIBERS LTD

Method for producing aramid fiber pulp by aramid fiber waste material

InactiveCN101250771AIncrease productivityShort processArtificial filament recoveryPlastic recyclingSlurryFibrillation

The invention discloses a method for manufacturing aramid pulp by using aramid waste materials, which comprises the following steps: shredding the aramid waste materials by directly arranging the aramid waste materials in a multi-tool mechanical cutter, enabling the average length of the shredded fiber to be 0.1- 5.0mm, dispersing the shredded fiber in water, forming suspending liquid with concentration of 0.1-8.0%, arranging the suspending liquid in a multi-tool bilateral beater, wherein beating time is 0.5-2h, then arranging the beat suspending liquid in a two-plate lapping machine, carrying out the knocking fibrillation, wherein knocking time is 20-300s, forming steady serous fluid, then dehydrating by arranging the serous fluid into a continuous filter and drying by arranging the serous fluid into a continuous drier, then opening, and obtaining the aramid pulp, wherein the aramid waste materials are made of aramid cloth rim leftovers, aramid yarn leftover bits and pieces and aramid filament waste materials, and the aramid waste materials are obtained by recycling used aramid textile such as aramid old gloves and the like. The method of the invention has the advantages of simple process, high manufacturing efficiency and less pollution to environment, simultaneously the method can satisfy the requirements of industrialization.

Owner:上海依极科技有限公司

Method for extracting xylose from viscoce chemical fiber squeezed alkali liquor

InactiveCN104099431ASave resourcesReduce pollutionArtificial filament recoveryTextile/flexible product manufactureFiberHydrolysate

The invention relates to a method for extracting xylose from viscoce chemical fiber squeezed alkali liquor. According to the technical scheme, the method comprises the following steps: pre-filtering to obtain pre-concentrated liquor; filtering the pre-concentrated liquor through a nanofiltration membrane to obtain concentrated liquor; adding hydrochloric acid to the concentrated liquor to obtain hydrolysate; adding hydrolysate to NaOH until being neutral; decolorizing; regulating the concentration of NaCl; cooling at constant speed until reaching room temperature; enabling glucose in hydrolysate to cocrystallize with NaCl to remove glucose; treating filtrate through ion exchange columns to obtain purified liquor; crystallizing and purifying the purified liquor for the second time to obtain coarse xylose; refining the coarse xylose to obtain final xylose. With the adoption of the method, the resource is saved, the economic benefit is brought to enterprises, and the environment is protected.

Owner:沈阳新华环保技术有限公司

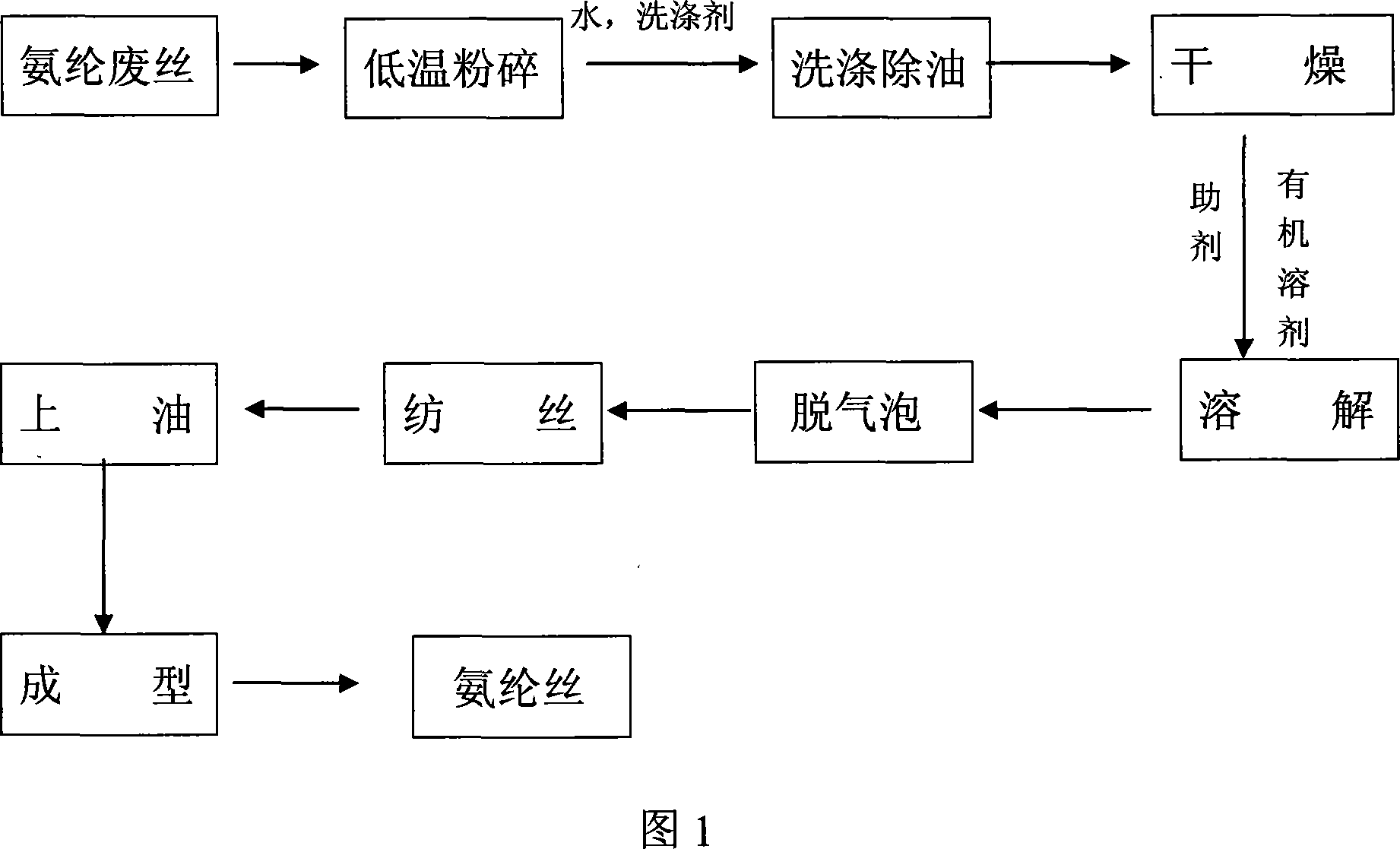

Method for regenerating normalization spandex fibre from dry spinning spandex waste silk

ActiveCN101096781ASolve pollutionThe operation process is simple and convenientMonocomponent polyurethanes artificial filamentArtificial filament recoveryFiberOrganic solvent

The invention discloses a method to regenerate dry-spun spandex waste silk to normal spandex silk in spandex silk preparing technique domain, which comprises the following steps: (1)adopting cryogenic breaking technology; changing the long fiber to short fiber; (2)removing oil solution on the surface of the spandex waste silk with water and detergent; (3)drying the water on the spandex waste silk; (4)adding into spandex waste silk, organic solvent and aids into reactor; reacting for 6-12 h at 45-100 deg. c; getting spinning raw liquid with proper viscosity; (5)removing bubble; spinning; oiling; modeling; getting spandex silk. This invention possesses simple operating course and little investment, which can get bigger economical benefit.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

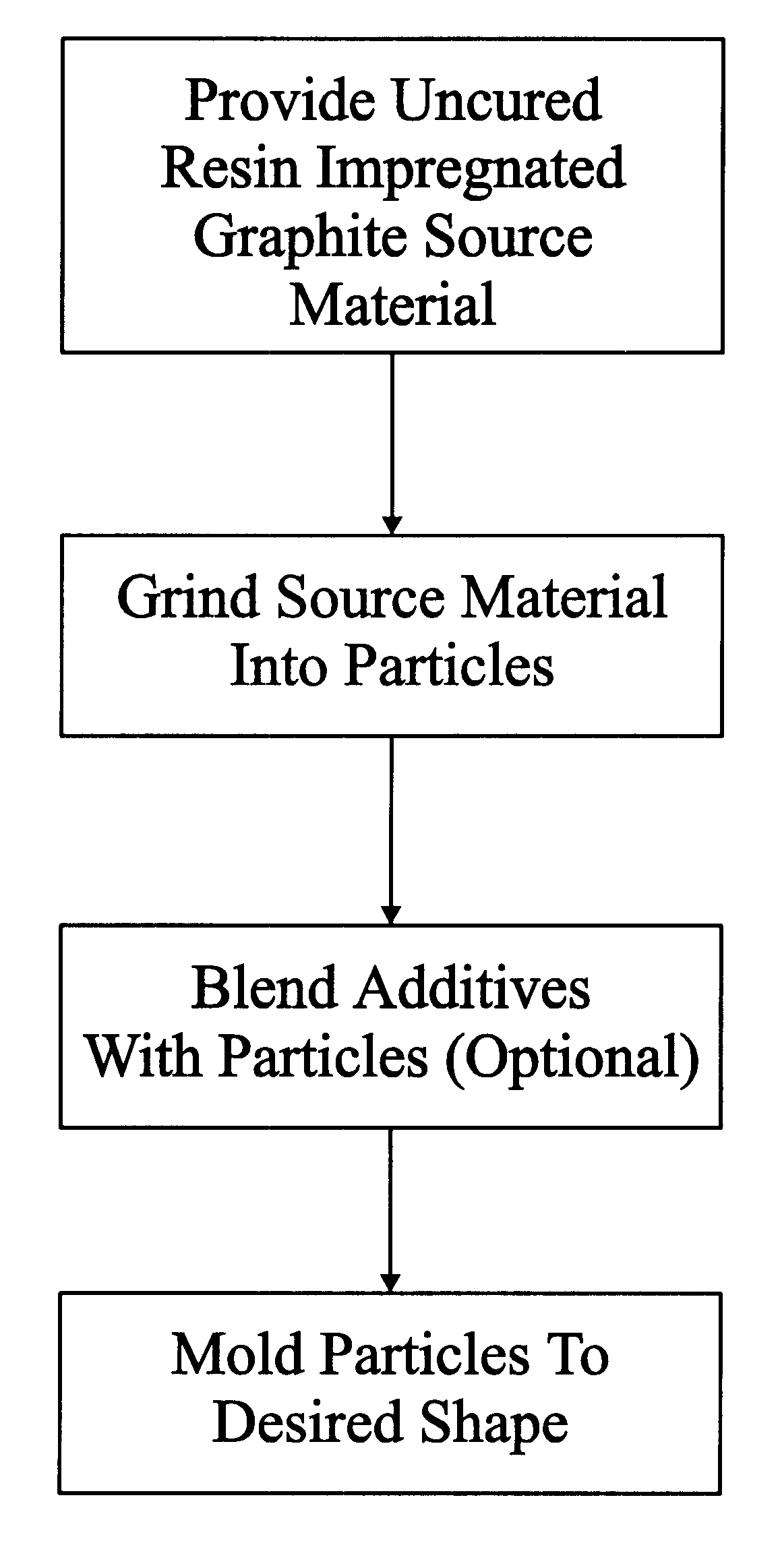

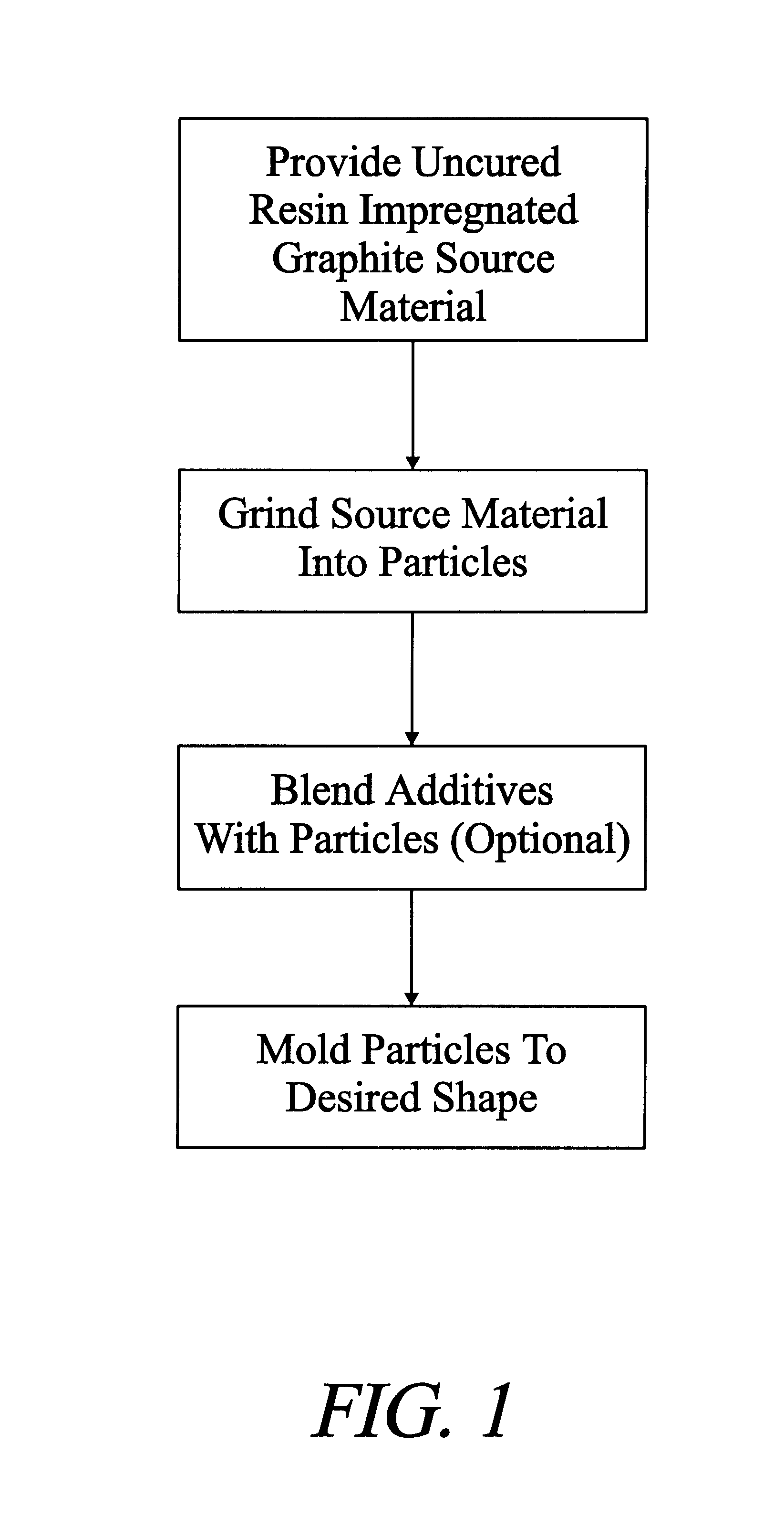

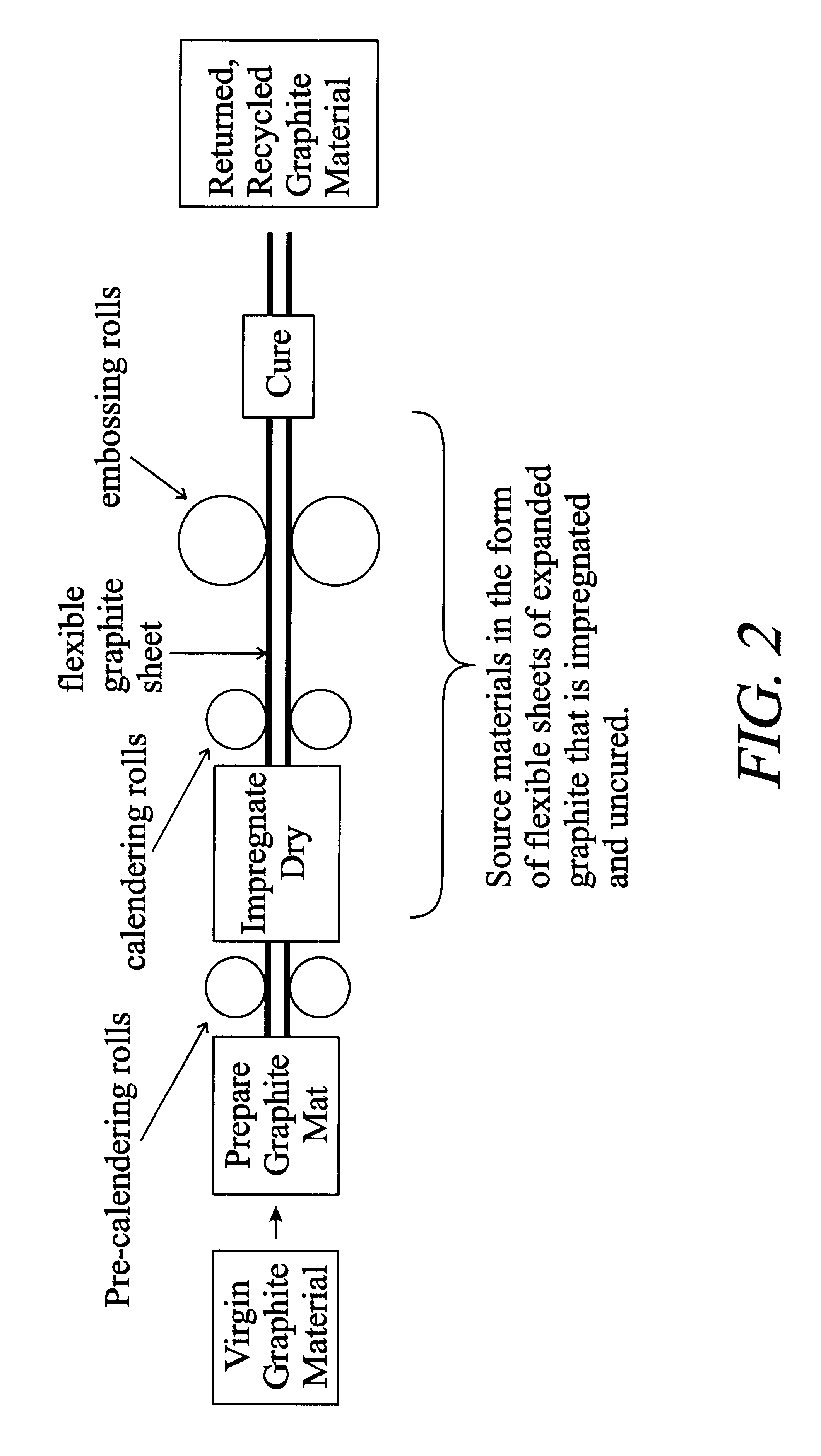

Molding of materials from graphite particles

InactiveUS6613252B2Good electrical and thermal conductivityReduce disposal costsMaterial nanotechnologyArtificial filament recoveryPolymer scienceFuel cells

A method of manufacturing material suitable for the construction of a component of a fuel cell, such as a flow field plate or electrode. Uncured resin impregnated flexible graphite sheet is ground into particles. Without re-expanding the particles, and without adding further resin to the particles, the particles are molded into the form of the desired material. The material is then cured. Additives may be mixed with the particles to improve the properties of the material.

Owner:GRAFTECH INT HLDG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com