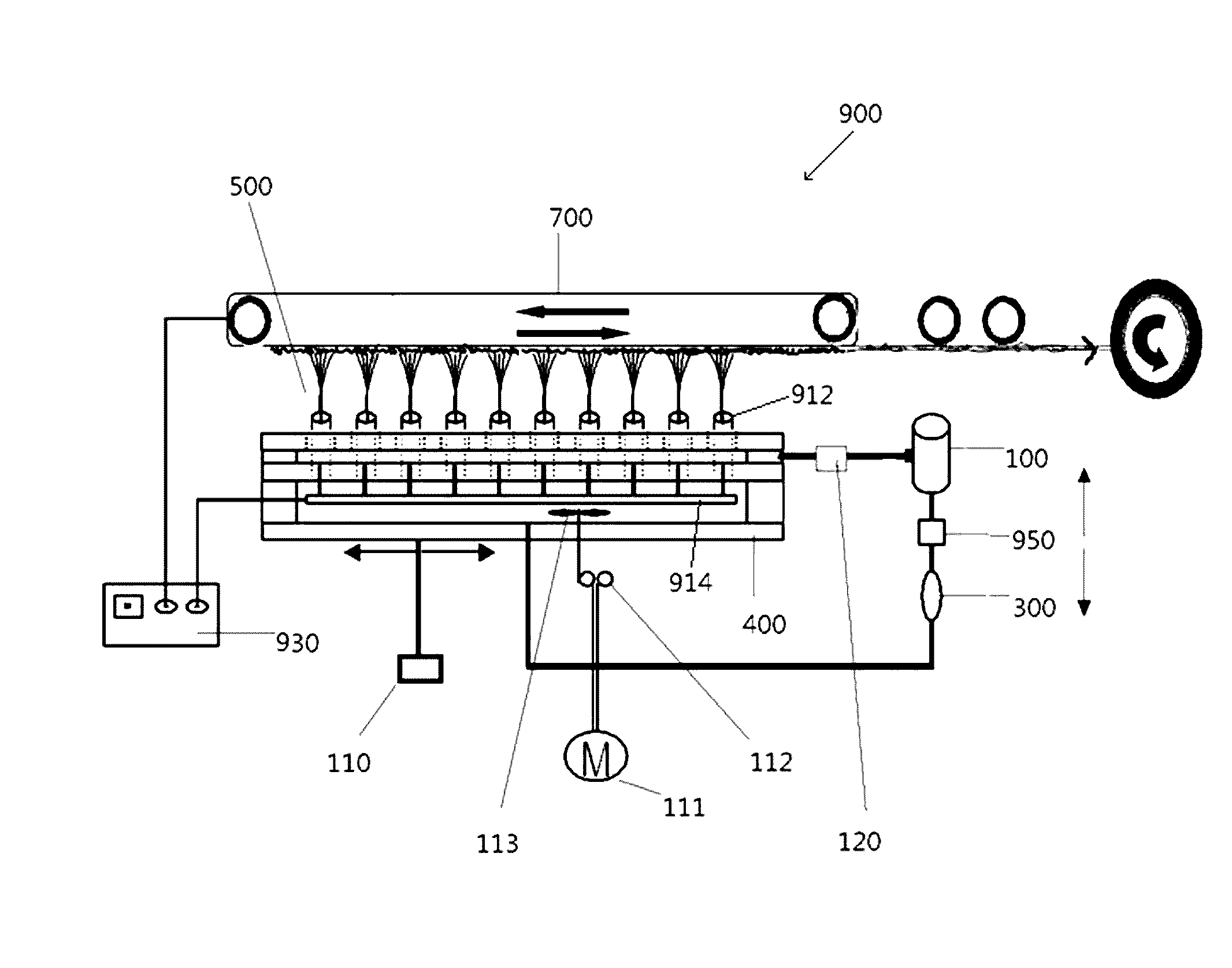

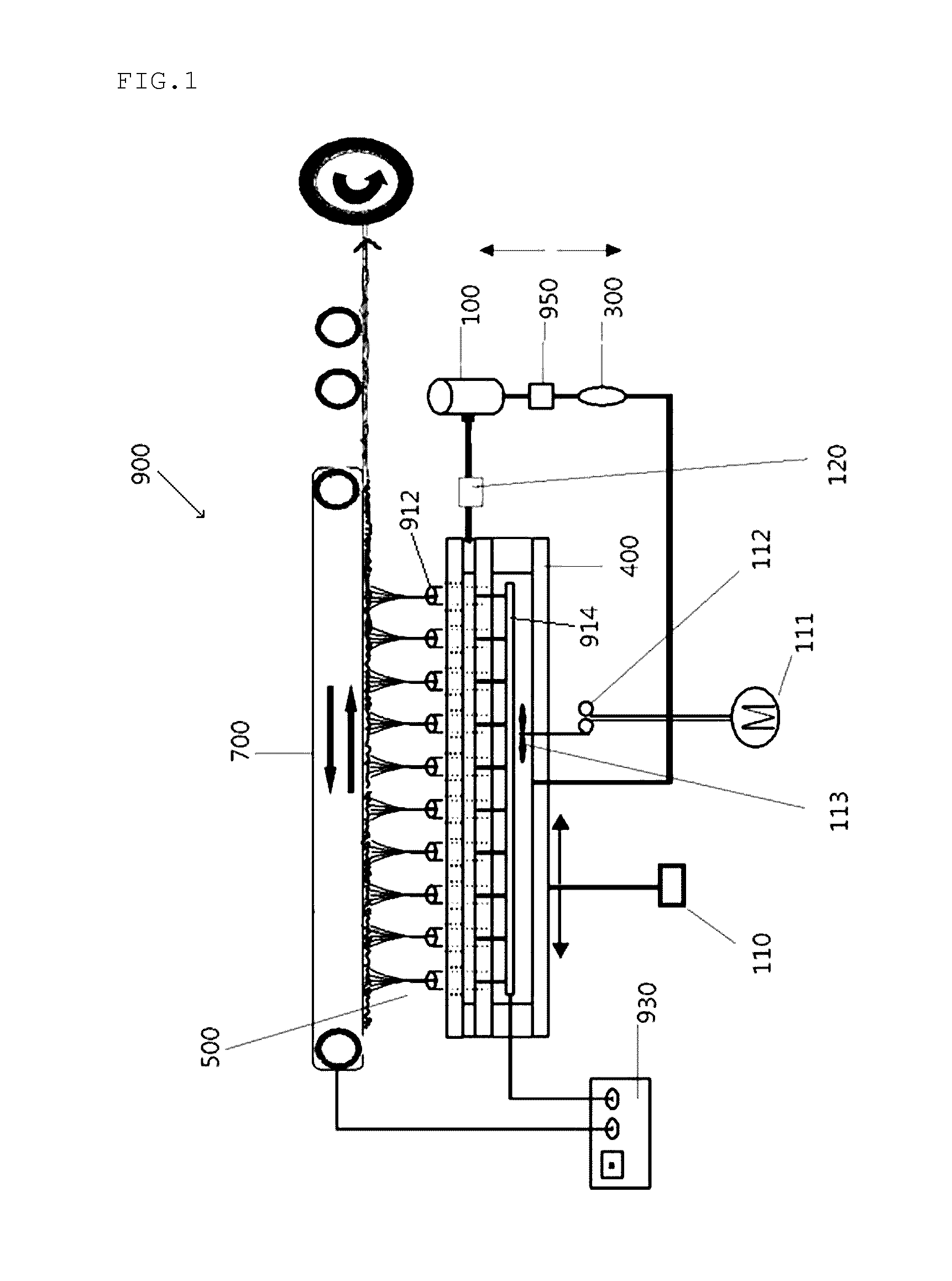

Electrospinning apparatus

a technology of electropinning apparatus and spherical plate, which is applied in the direction of spinning solution filtering, final product manufacturing, artificial filament recovery, etc., can solve the problems of long manufacture line, high installation cost and energy expense, and high equipment and energy expense, so as to reduce manufacturing cost and simplify manufacturing process , the effect of uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0164]According to a nanofiber manufacture device which features 20% of front-end of nozzle of nozzle block in flare shape, distance between electrode and nozzle is 40 cm, applied voltage is 20 kV, spinning solution flow is 0.1 mL / h, temperature is 22° C., humidity is 20% and produces nanofiber nonwoven by electrospinning.

[0165]In this case, as there is no interference among nozzles, nanofiber non-fabric collected in predetermined discharging amount on a collector could be produced.

[0166]Meanwhile, the electrospinning apparatus (1) of the present invention, as illustrated in FIGS. 13 and 14, provided a metering pump, or provided a metering pump and overflow system, controlling polymer solution amount, not integrated to the collector, minimize amount attached to the nozzle, simultaneously minimize polymer solution consumption.

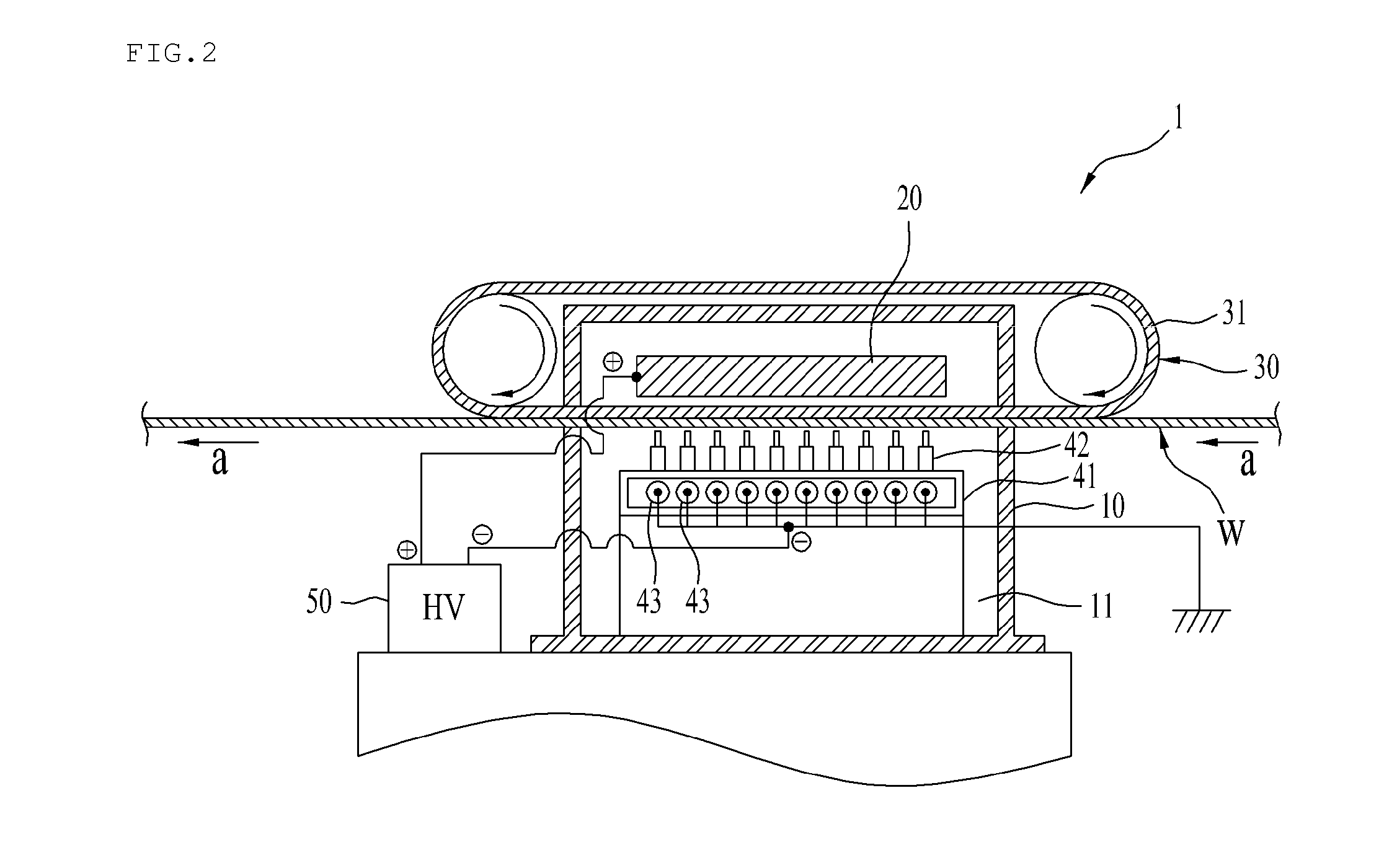

[0167]In other words, as illustrated in FIG. 13, the collector (20) of the electrospinning apparatus (1) comprising an electric conductor, through an insulator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| humidity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com