Patents

Literature

166results about "Fibre cleaning and opening machine combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High ratio blended spinning technique for ultrashort low-density fibre based on cotton spinning device

InactiveCN101148797ARaise the ratioReasonable workmanshipFibre cleaning and opening machine combinationsCarding machinesYarnPolymer science

The present invention discloses the process of producing blended cheese yarn with high content of ultra short low density fiber in cotton spinning apparatus. A punching with high homogeneity and great cohesion is first produced through mixing ultra short low density fiber and other fiber in an opening and picking step much loosening and less beating; and then produced into cheese through the steps of combing, drawing, roving, spinning and coning. The blended cheese yarn consists of ultra short low density fiber 51-95 wt%, natural fiber 5-49 wt% and chemical fiber 5-49 wt%. The blended cheese yarn with high content of ultra short low density fiber is light, soft, lofty and high in strength, and its produced fabric has high color fastness.

Owner:DONGHUA UNIV +1

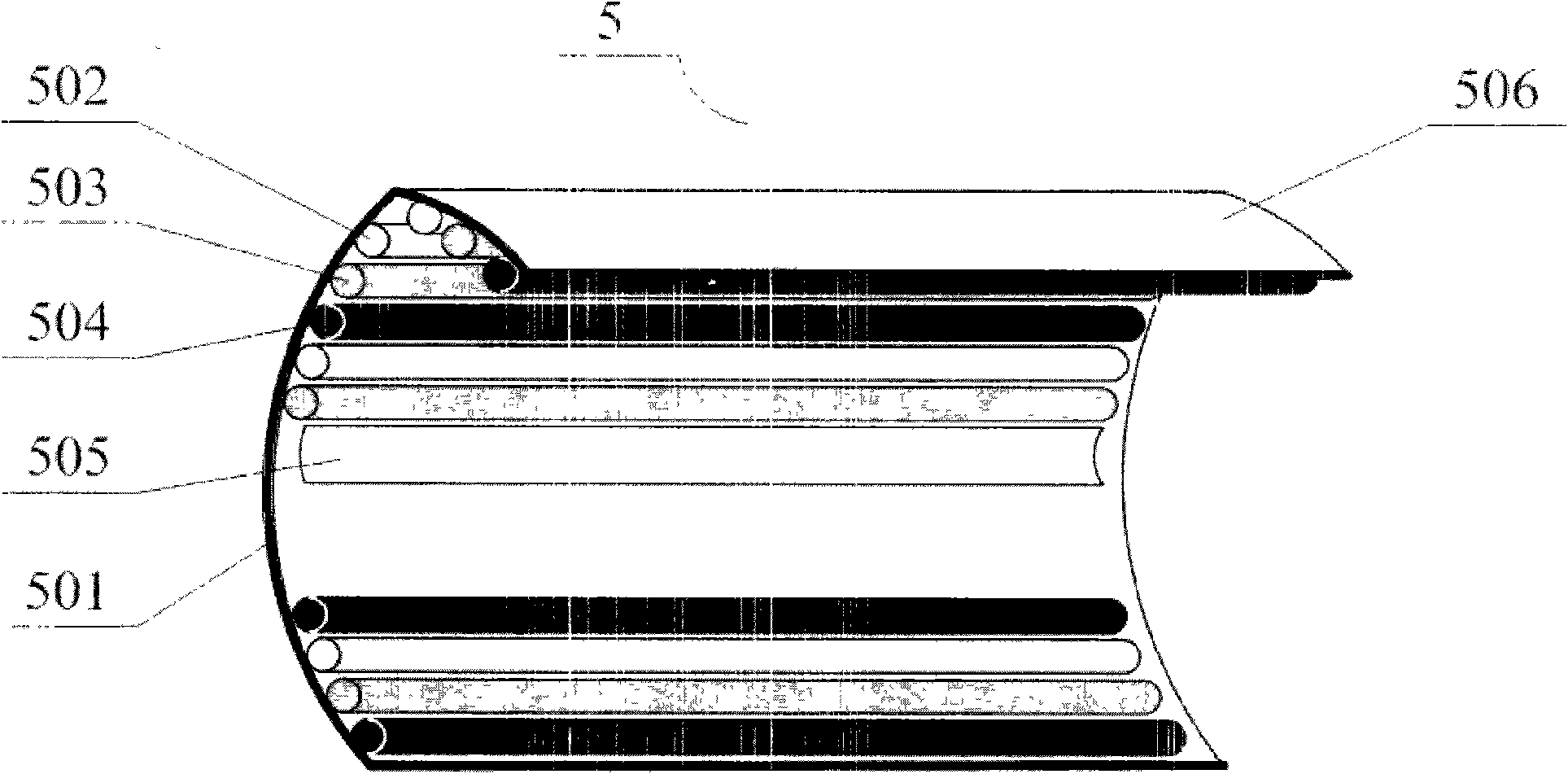

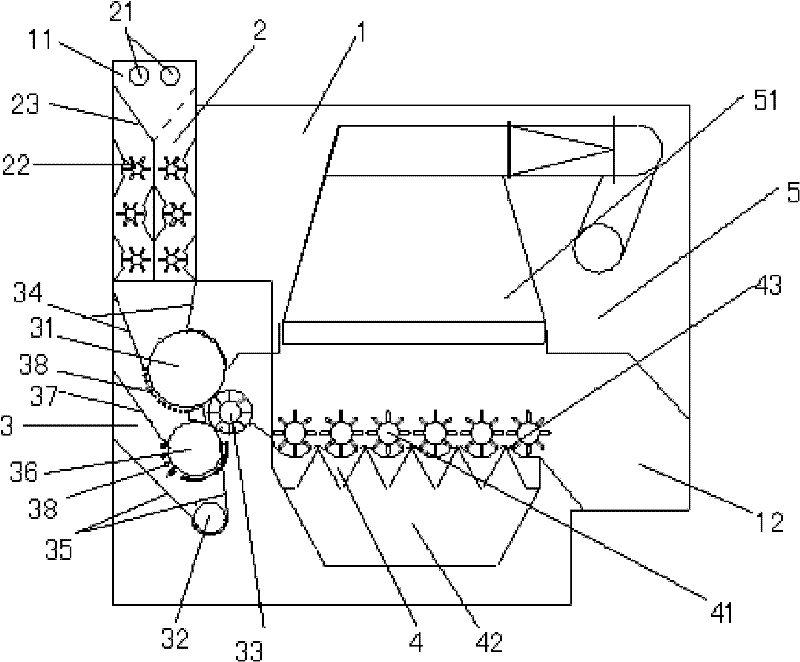

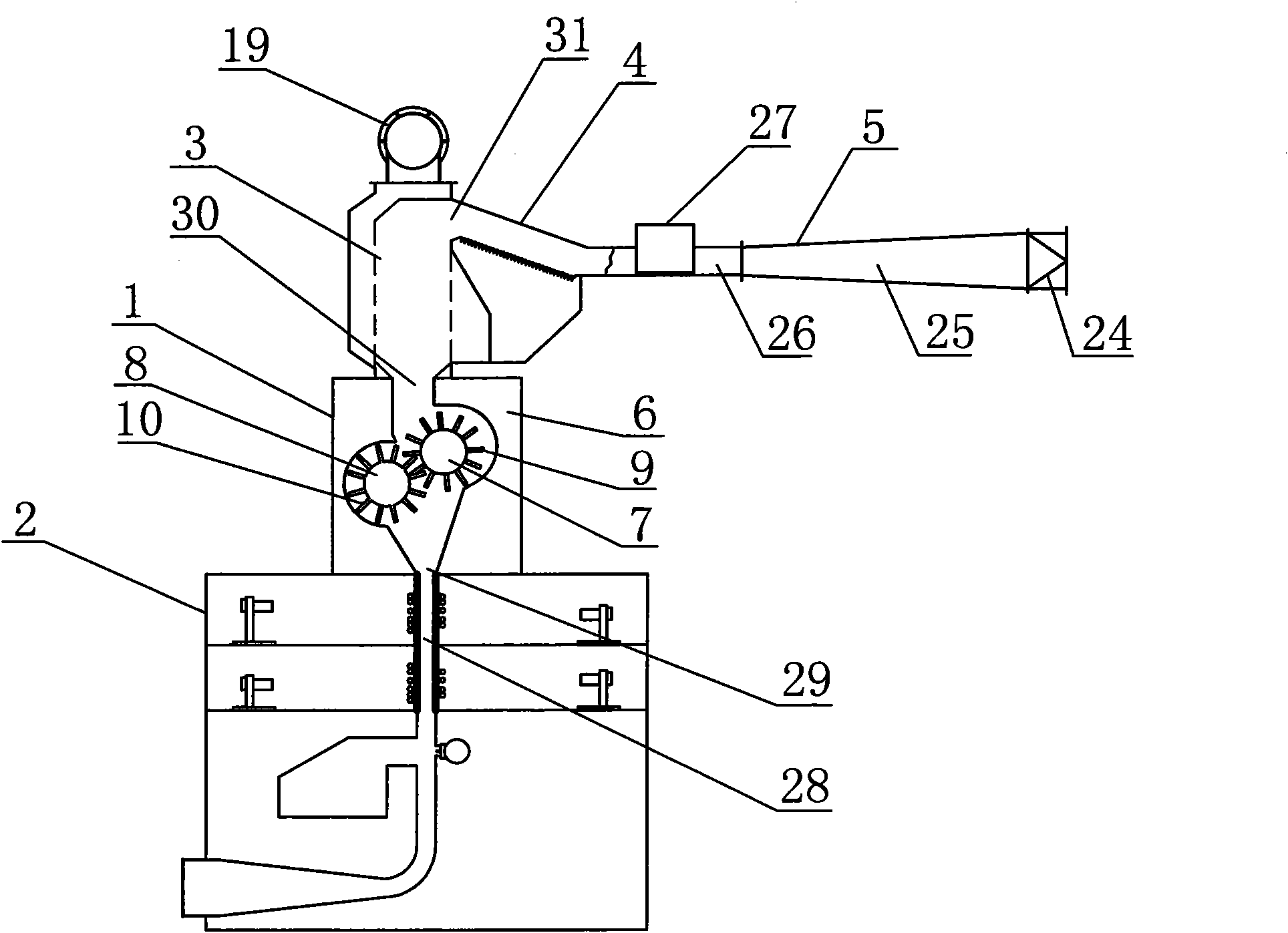

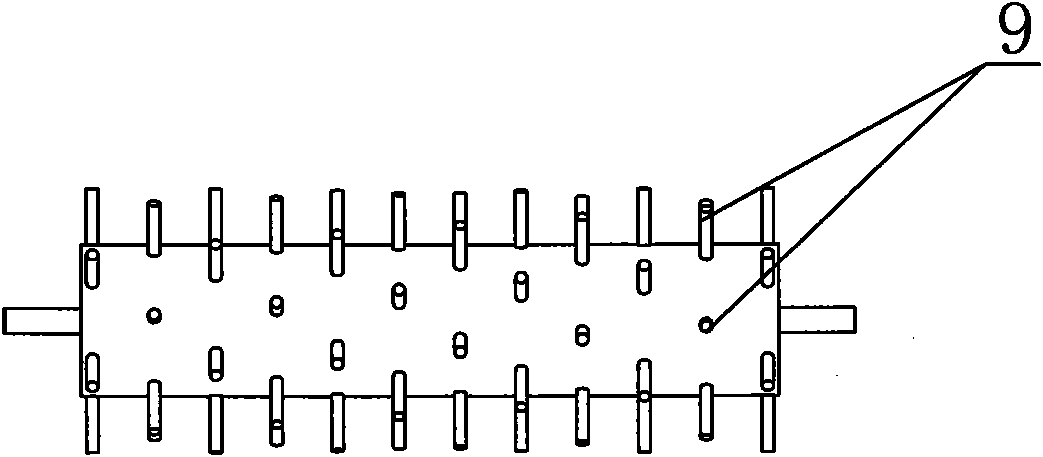

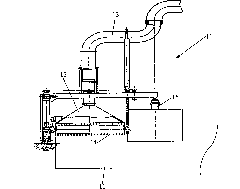

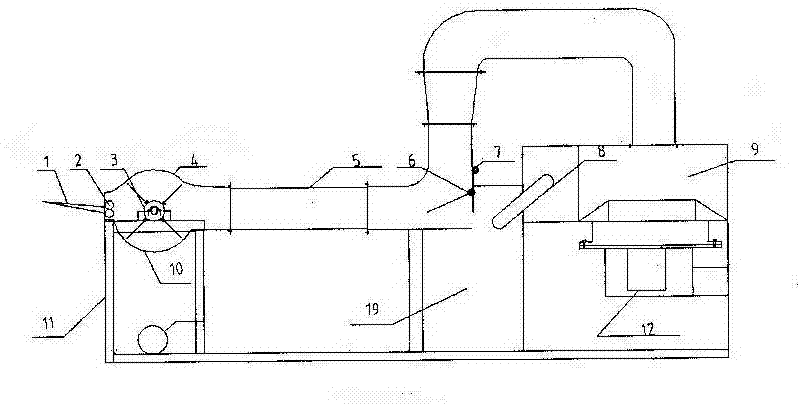

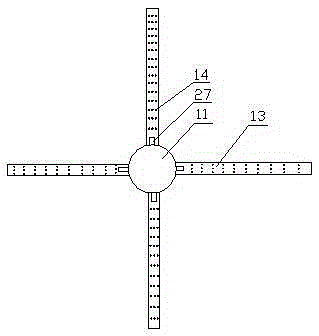

Method and device for online detection of foreign fiber in cotton

InactiveCN101629336AStrong discriminationLow costFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberFrequency conversion

The invention provides a method and a device for online detection of foreign fiber in cotton. The device comprises a cotton opener, channels, windows, a CCD (Charge Coupled Device) camera, an illumination light source, a background plate, a nozzle array, a foreign fiber channel, a foreign fiber collecting unit, a computer, an electrical equipment cabinet, operating buttons, a frequency conversionfan and a cotton conveyance pipe. The method comprises the following steps: opening lint cotton; feeding the lint cotton into the detection area of the CCD camera through the channels; performing theillumination and CCD camera sampling in three steps, and further collecting the detection results of the three steps for identifying the foreign fiber; calculating the time for nozzles in the corresponding positions to the foreign fiber to open and close by combining the action delay time of each nozzle; controlling the corresponding nozzles to operate, so as to remove the foreign fiber; and meanwhile, outputting clean cotton with the foreign fiber being removed from the clean cotton output channel, wherein, by combining the performance parameters of the CCD camera, the cotton flow rate in the corresponding area of each nozzle can be calculated from the data obtained through infrared LED illumination and sampling, and the average cotton flow rate can be further calculated; and then, the cotton flow rate in the channels can be stabilized within a per-determined range by controlling the frequency conversion fan.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

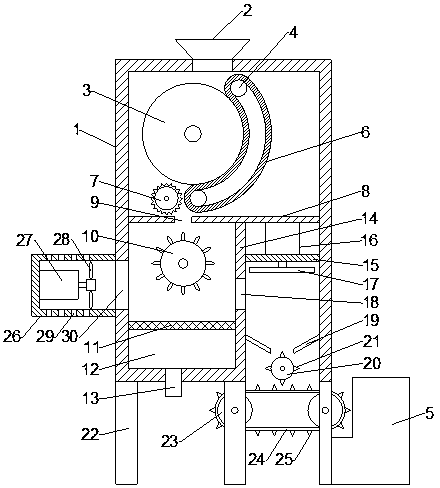

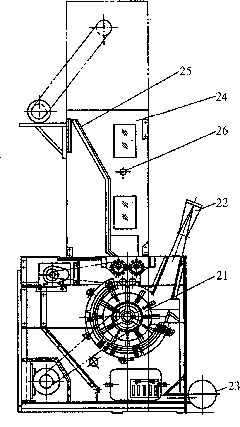

Opener with impurity removal function

InactiveCN102586955AAvoid breakingAvoid damageFibre cleaning and opening machine combinationsFibre cleaning/opening machinesWindow openingMechanical engineering

The invention discloses an opener with an impurity removal function, belonging to the field of non-woven textile machinery. The opener comprises a left case, a right case, an upper baffle, a lower baffle, a rear baffle, a cotton outlet box, an opening roller, a first roller and a second roller, wherein the left and right cases are opposite to each other; the left case is provided with an opening roller drive mechanism; the right case is provided with a roller drive mechanism; the upper, lower and rear baffles are fixed between the left and right cases; the cotton outlet box is fixed at the top between the left and right cases; an opening roller half shaft is arranged at the left and right ends of the opening roller respectively; the first and second rollers are matched with each other. The opener is characterized in that a window opening is arranged in the length direction of the lower baffle; a window door is arranged on one side of the lower baffle, back on to an opening cavity; a metal piece absorption component is arranged on one side of the window door, facing the window opening; a block rod and a block roller are arranged in the opening cavity; an impurity lead-out channel is formed between the lower part of the rear baffle and the lower part of the lower baffle; and a garbage accumulation disc is arranged below the impurity lead-out channel and fixed at the bottom between the left and right cases. The opener disclosed by the invention has the advantages that the production efficiency is improved, the working intensity is reduced, and the using cost is lowered.

Owner:常熟市伟成非织造成套设备有限公司

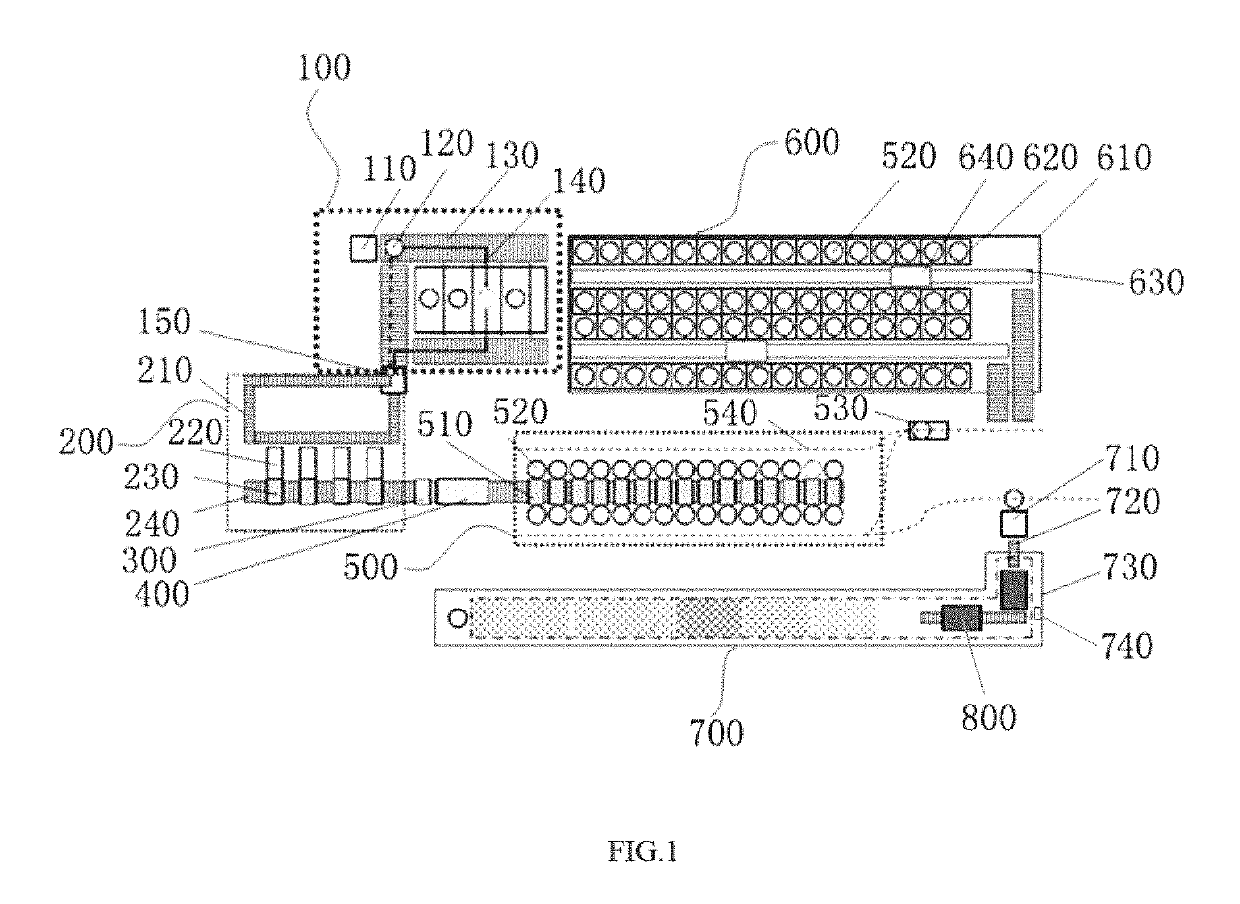

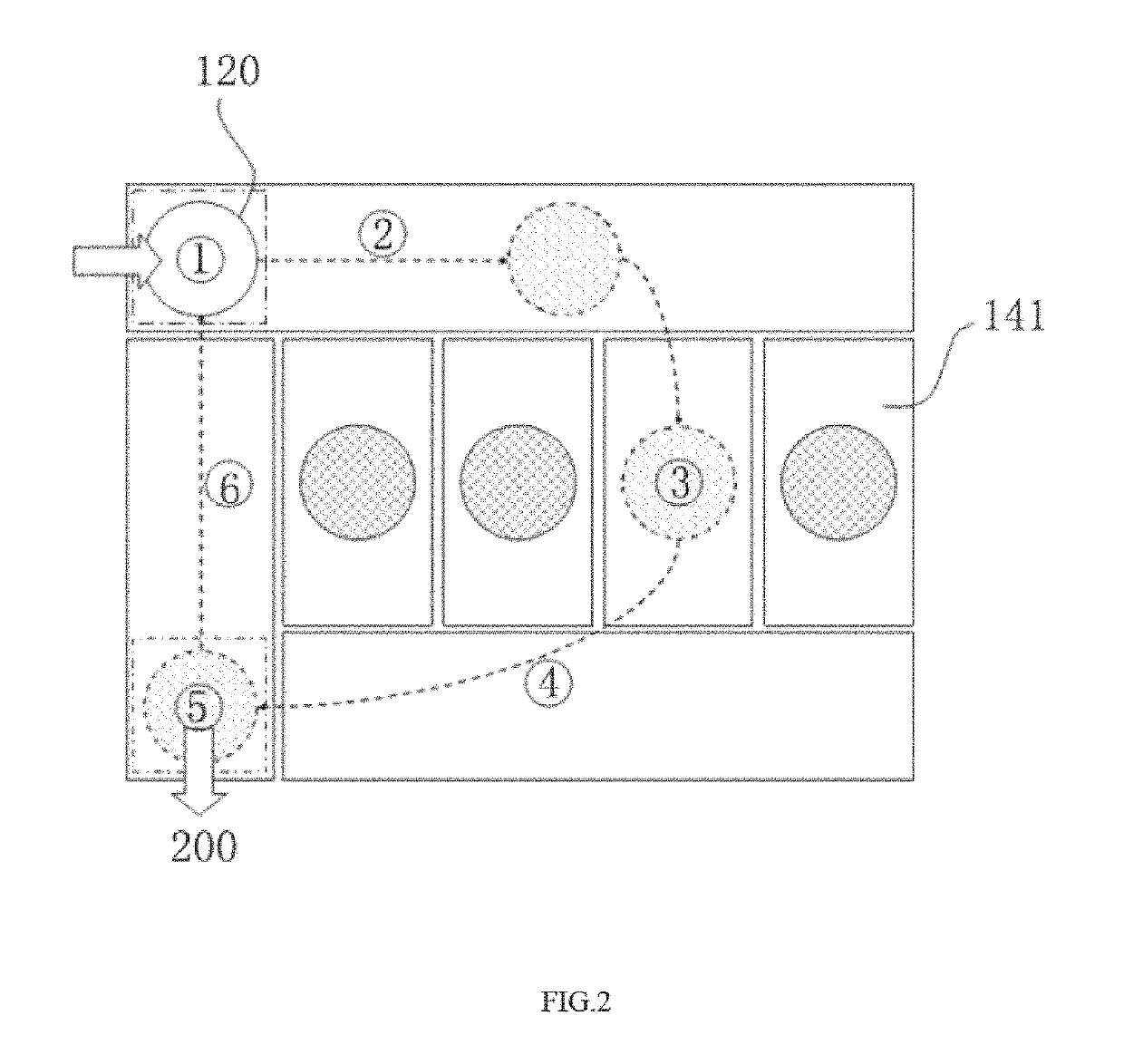

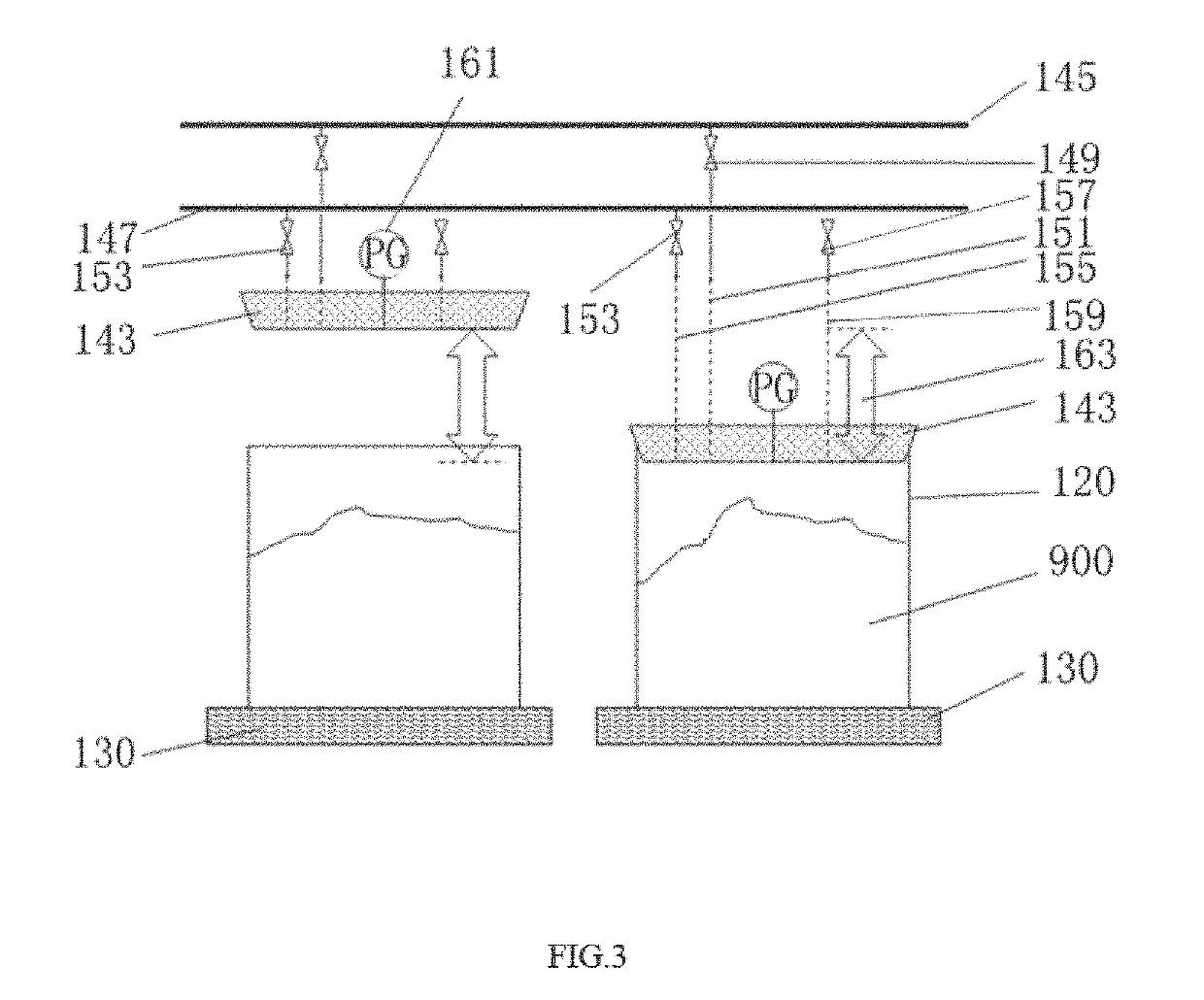

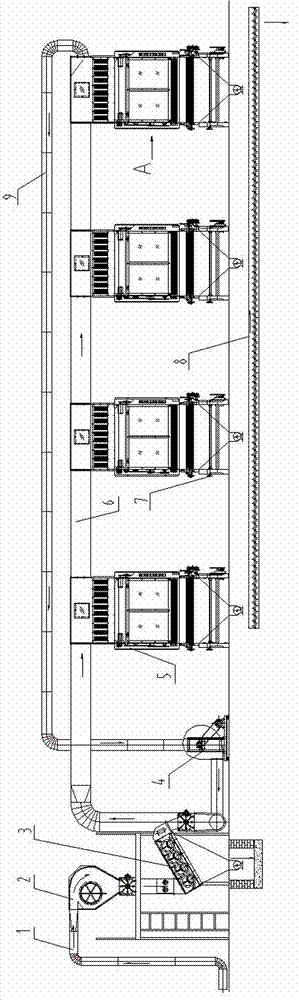

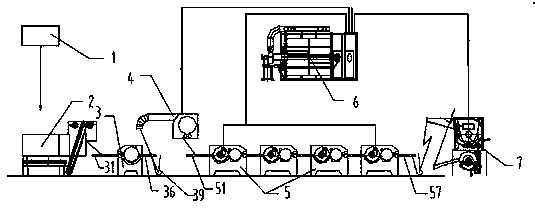

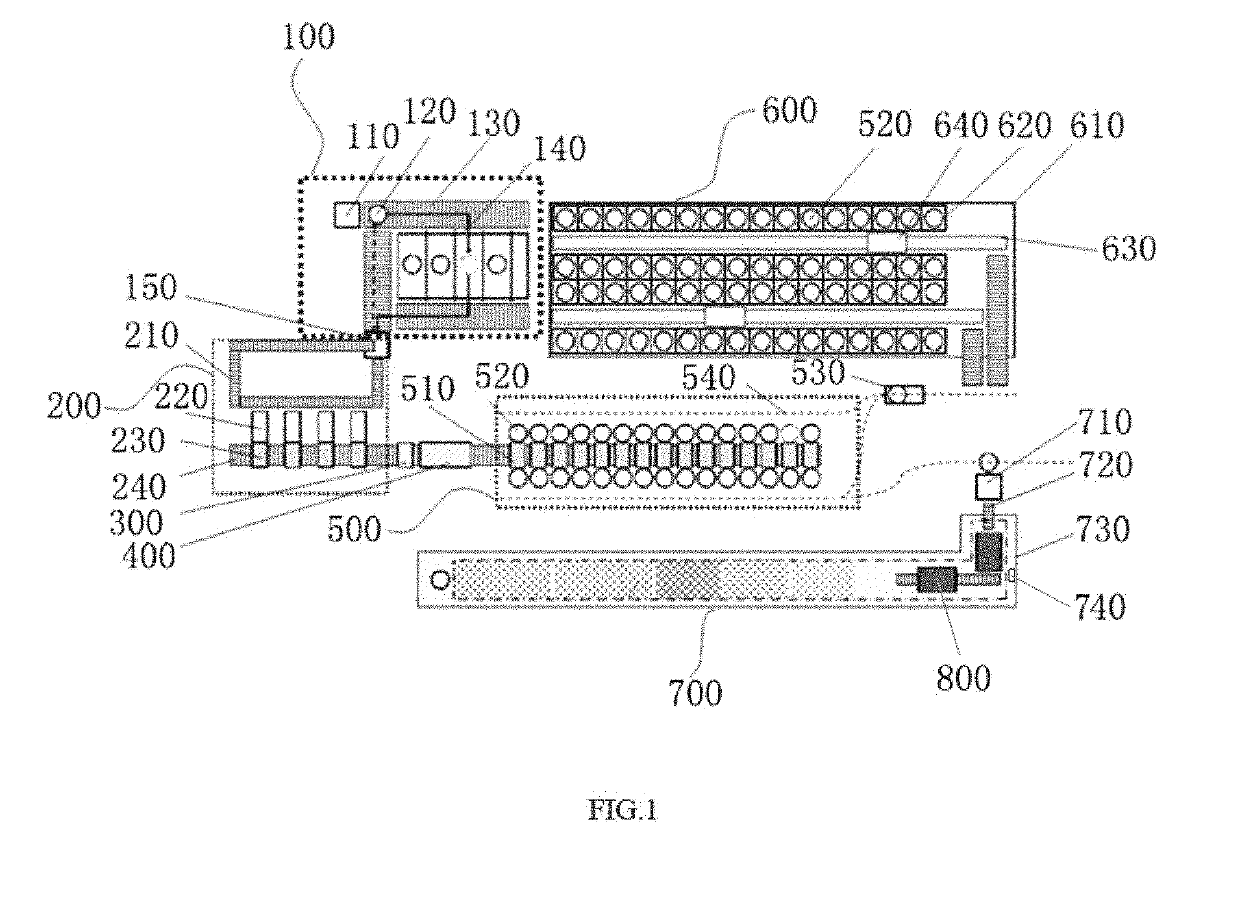

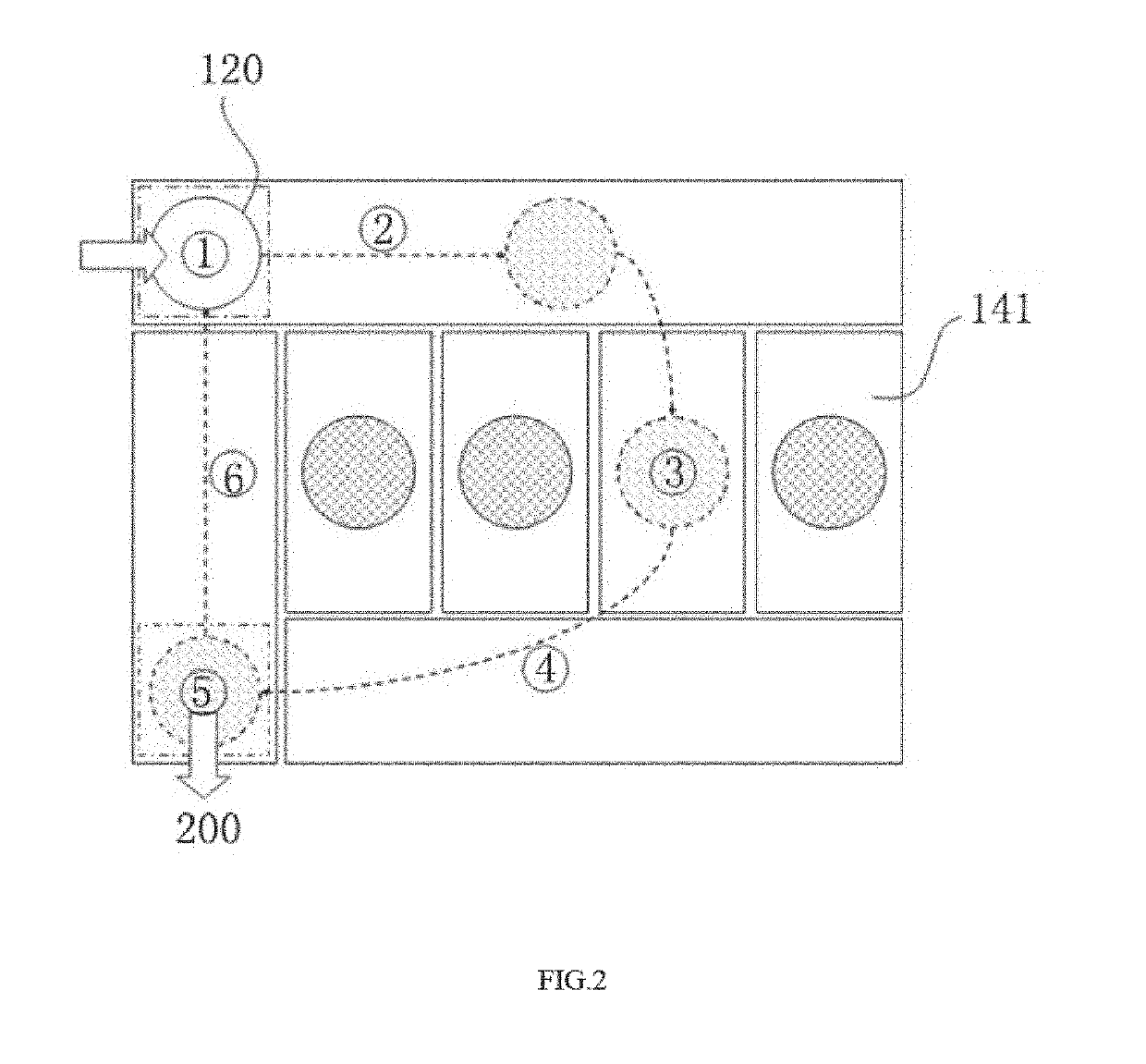

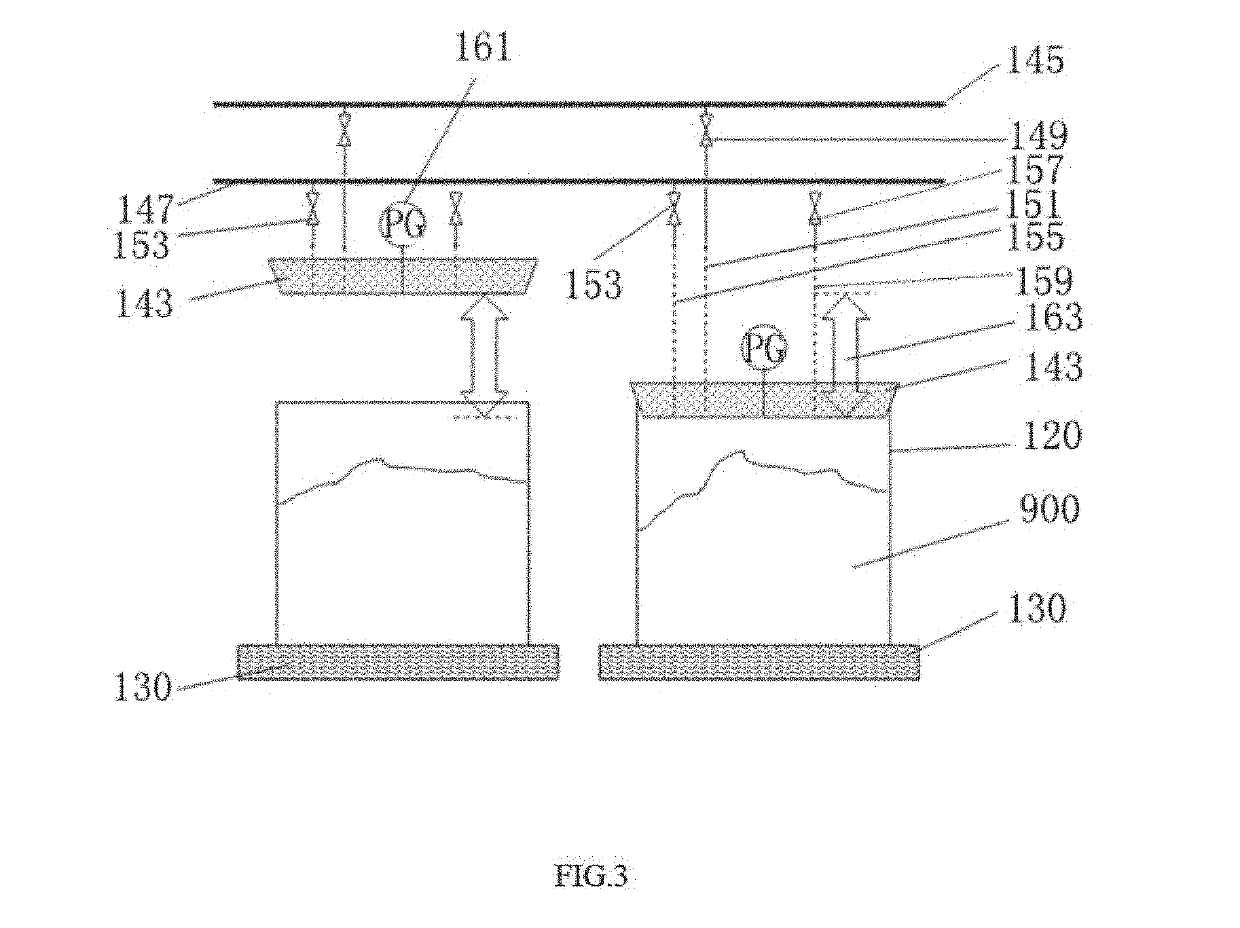

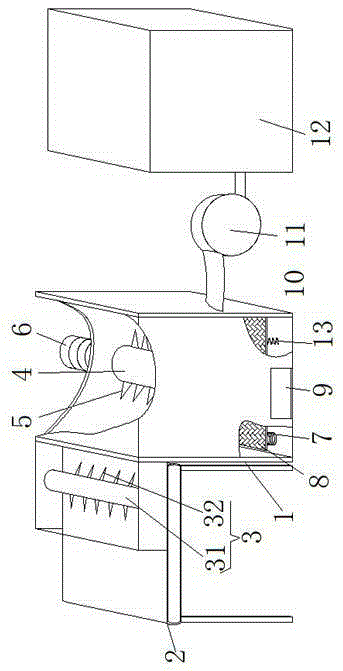

System and method for recycling fibers from textiles waste

ActiveUS10458047B2Fibre cleaning and opening machine combinationsSolid waste disposalFiberPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

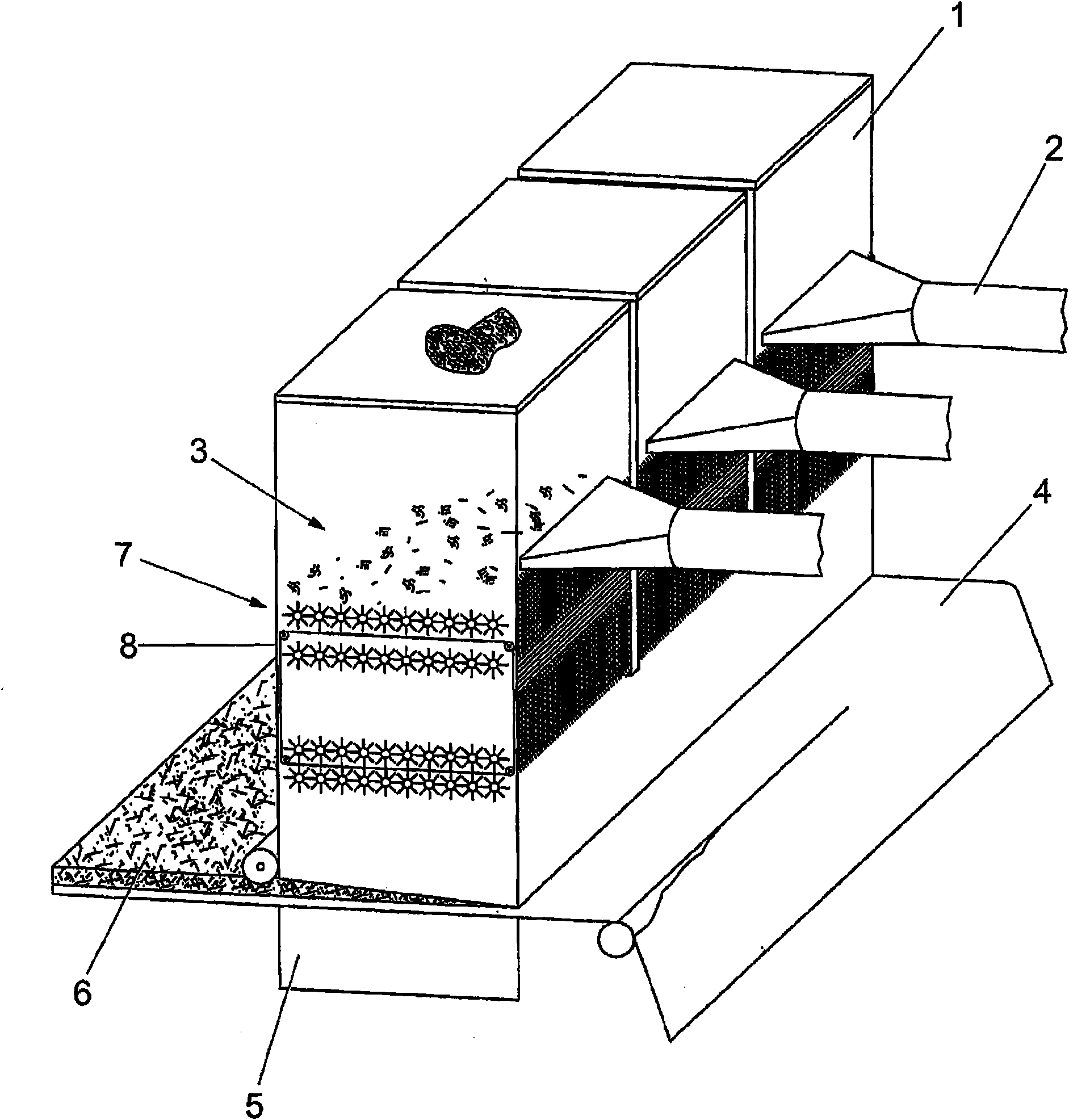

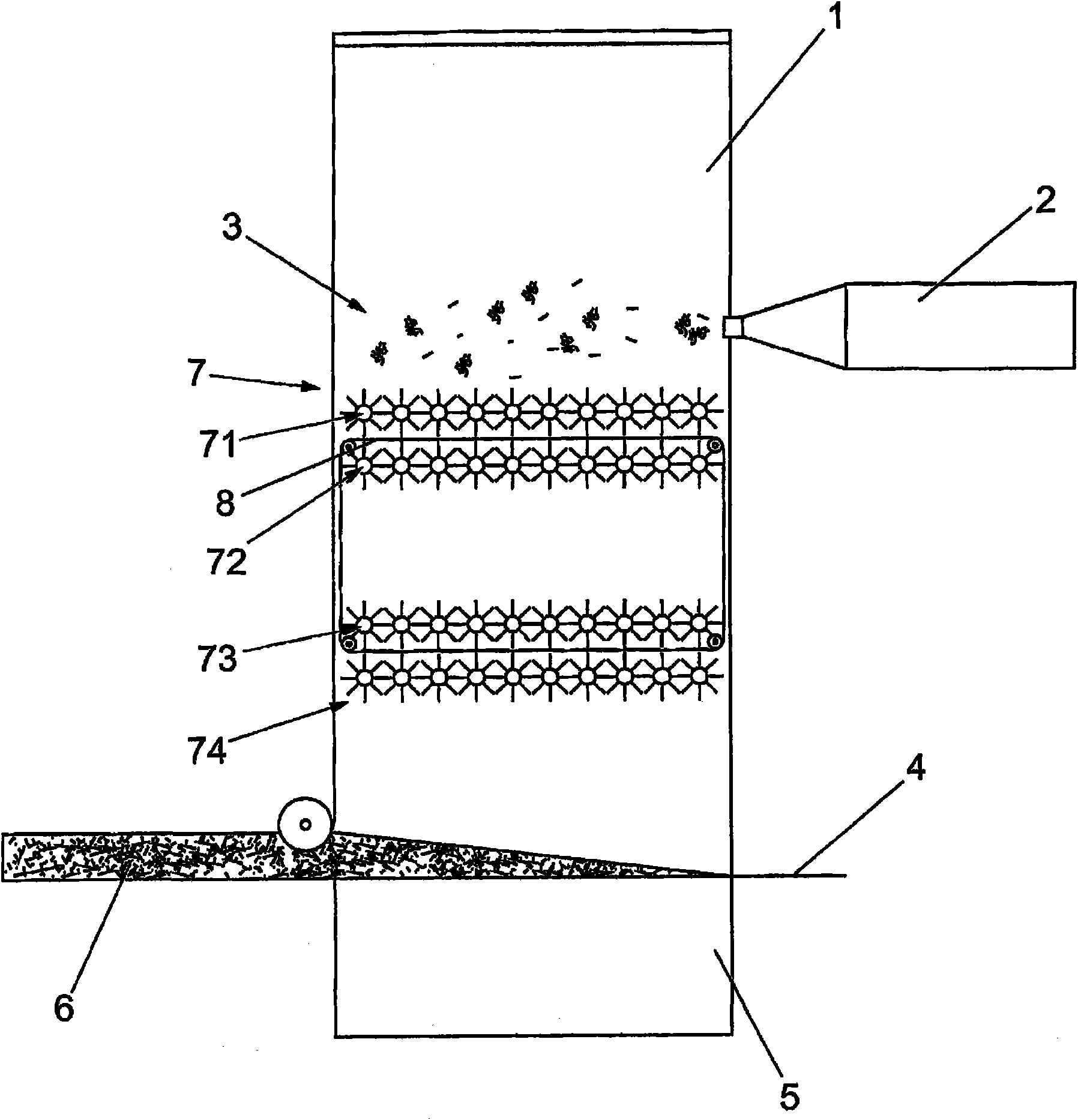

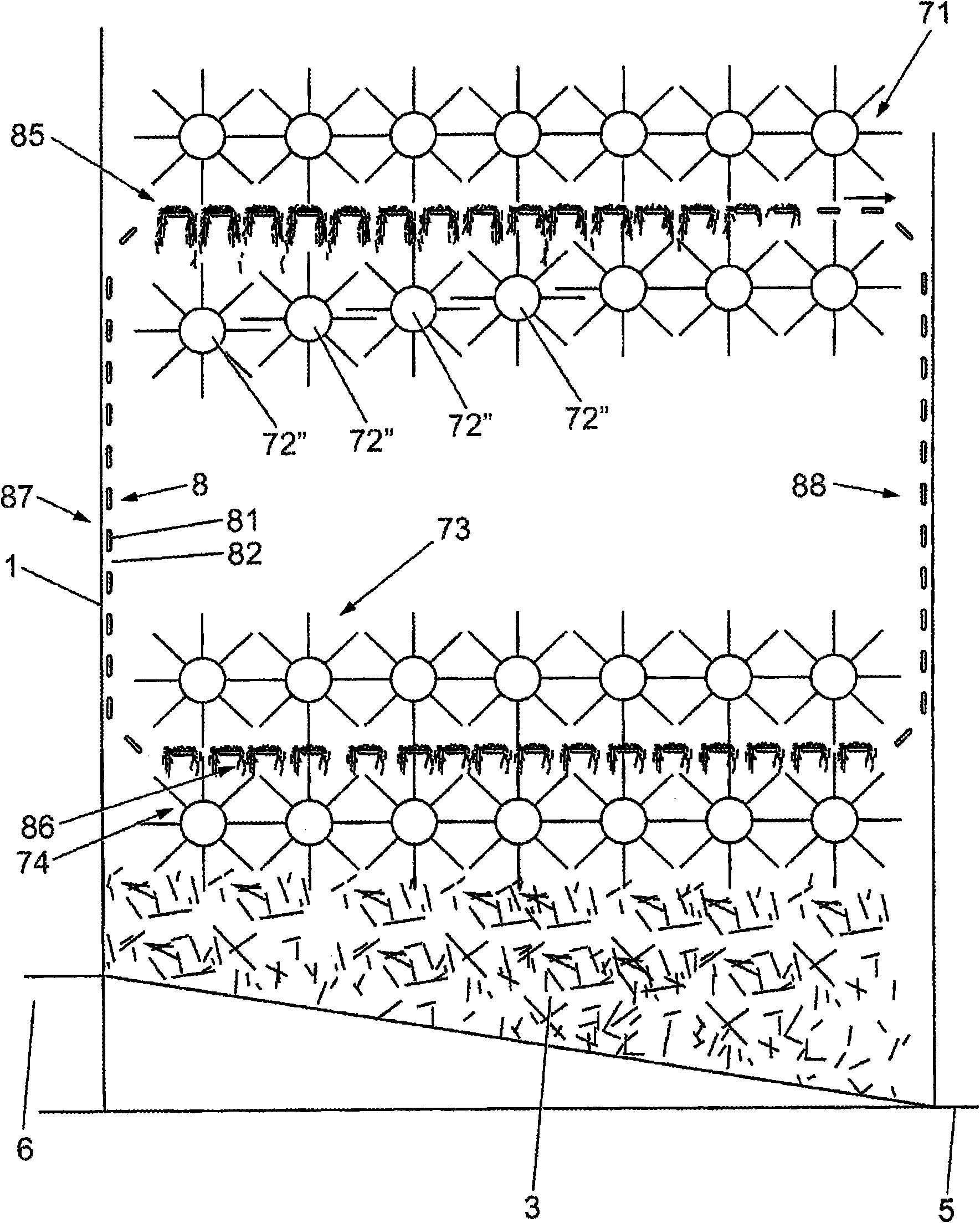

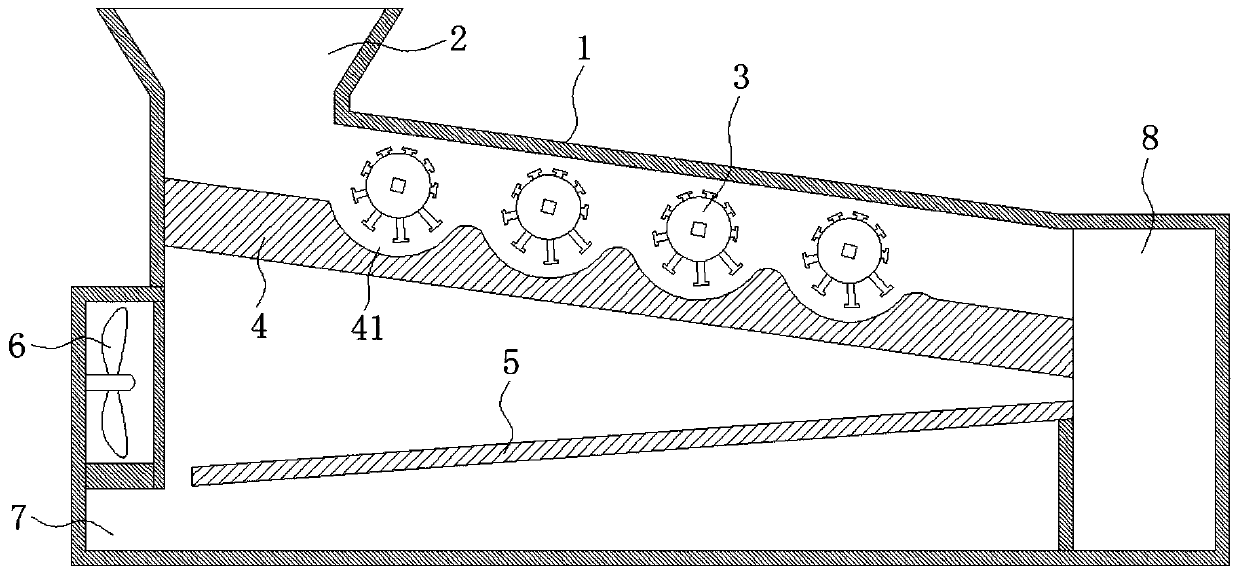

Method of making mounting mats for mounting pollution control element

InactiveCN101821070AEasy to prepareEasy to manufactureFibre cleaning and opening machine combinationsSilencing apparatusFiberMechanical engineering

The present invention relates to a method of making mounting mats for use in pollution control device. The method comprises the steps of: (i) supplying inorganic fibers through an inlet of a forming box having an open bottom positioned over a forming wire to form a mat of fibers on the forming wire, the forming box having a plurality of fiber separating rollers arranged in at least one row in the housing between the inlet and housing bottom for breaking apart clumps of fibers and an endless belt screen; (ii) capturing clumps of fibers on a lower run of the endless belt beneath fiber separating rollers and above the forming wire; (iii) conveying captured clumps of fibers on the endless belt above fiber separating rollers to enable captured clumps to release from the belt and to contact and be broken apart by the rollers; (iv) transporting the mat of fibers out of the forming box by the forming wire; and (v) compressing the mat of fibers and restraining the mat of fibers in its compressed state thereby obtaining a mounting mat having a desired thickness suitable for mounting a pollution control element in the housing of a catalytic converter.

Owner:3M INNOVATIVE PROPERTIES CO

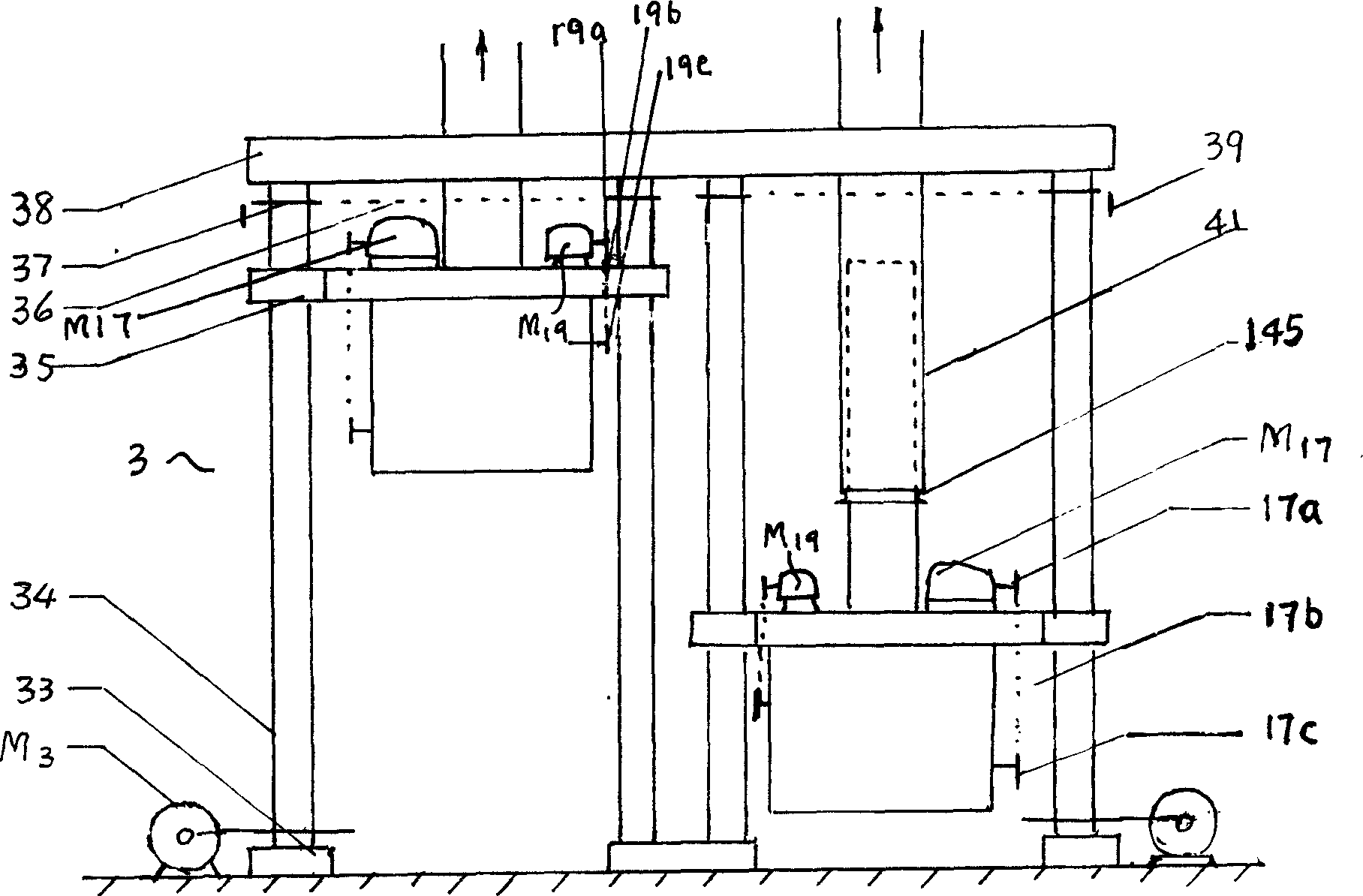

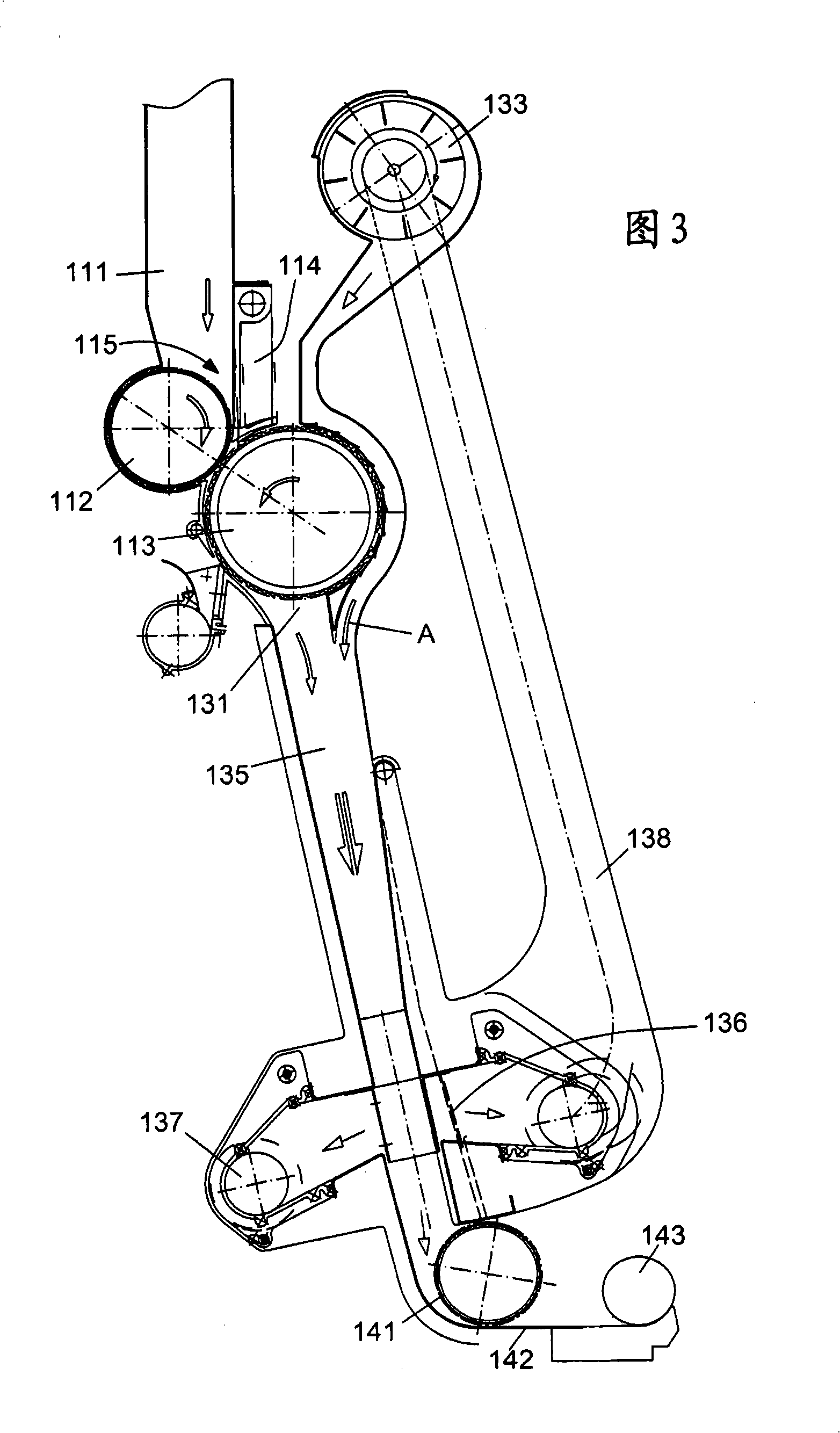

Procedure and system for opening and proportioning synthetic material

ActiveUS7752715B2Avoid Level FluctuationsDensity of fiber uniformFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberSynthetic materials

A method and a device for opening and dosing fiber feeds the fiber material via a feeding shaft of an opening device. The fiber material is processed in a first opening step of a dosing opener and is fed without an interconnecting pneumatic means to the feeding shaft of a second opening step. A large-volume feeding shaft has been placed before the first opening device from which the fiber material is delivered to a feeding shaft with a considerably smaller volume that delivers the fiber material to a second opening device. Both opening devices and their associated feeding shafts are placed on top of one other.

Owner:TEMAFA MASCHFAB

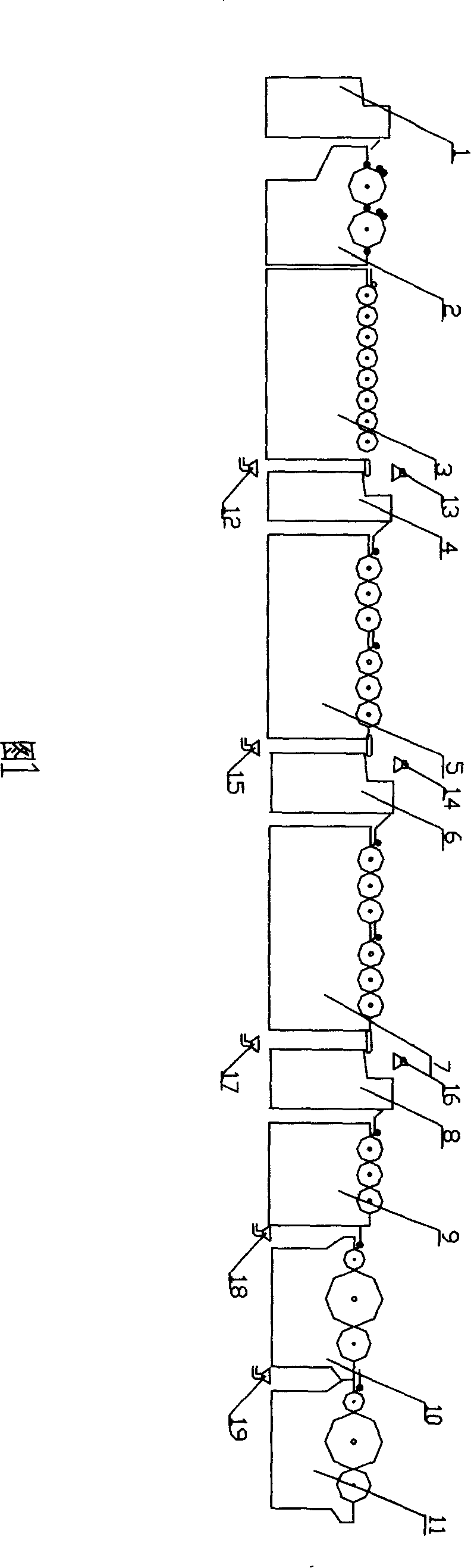

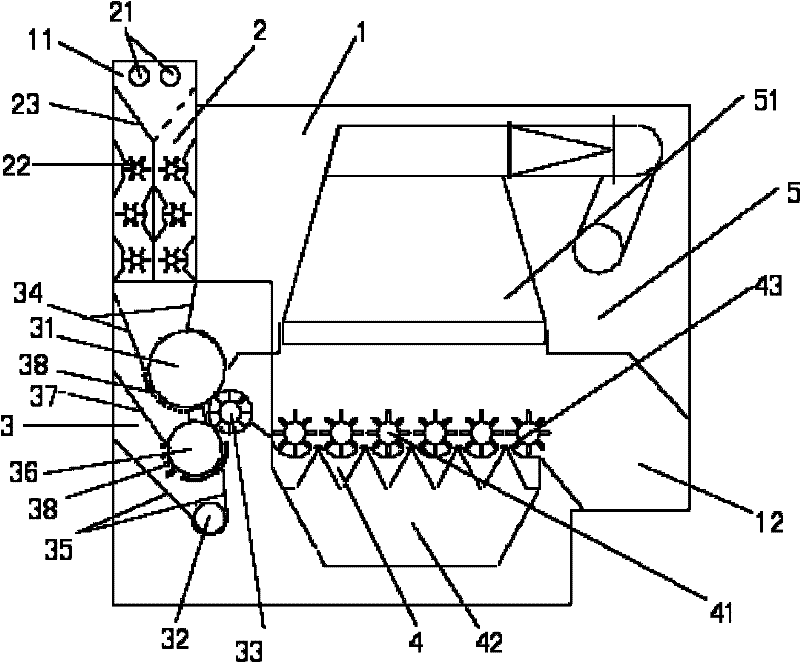

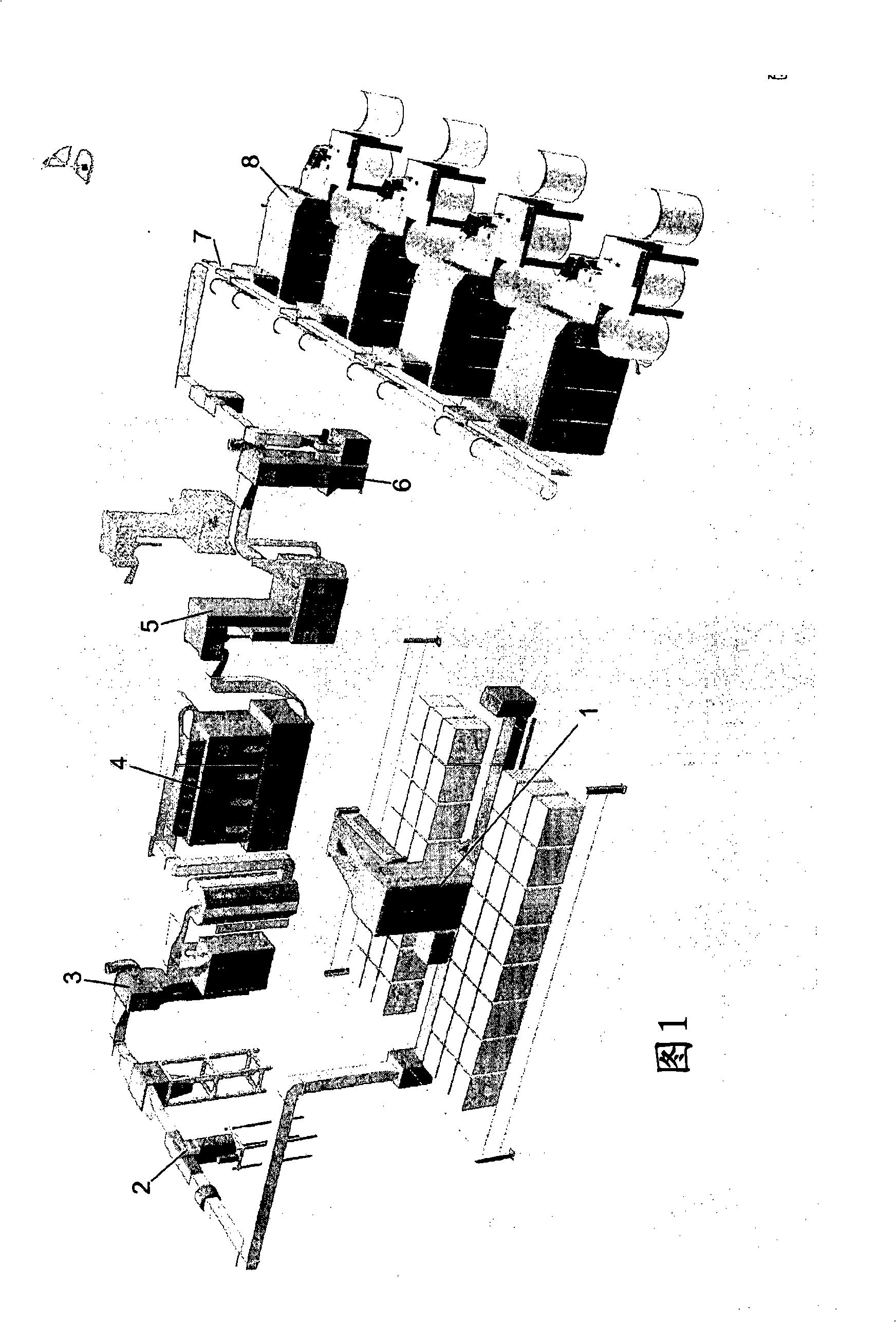

Cashmere carding combination machine

InactiveCN101205644AFibre cleaning and opening machine combinationsContinuous processingAssembly linePulp and paper industry

The invention is a cashmere separating joint machine which relates to a textile mechanical device used for cashmere carding process. The cashmere separating joint machine is composed of feeders, refining machines and carding machines. The invention is characterized in that: the cashmere separating joint machine adopts an sequential arrangement of a feeder, an open refining machine, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a feeder, a refining machine, a carding machine and a carding machine, which are all combined in a way of assembly line. A blanking recovery hopper is arranged under each feeder, a blanking outlet is arranged at a feed port of each feeder, and a delivery device is arranged between the blanking recovery hopper and the blanking outlet. Each carding machine is provided with a blanking collecting hopper which allows the recovered crushed materials to be delivered to a blanking port to be feed into a feeder again. The cashmere separating joint machine is high in separating efficiency, suitable for large amount separation, applicable to various sorts of cashmere, low in damage to cashmere, and high in cashmere utilization rate.

Owner:孙贤功

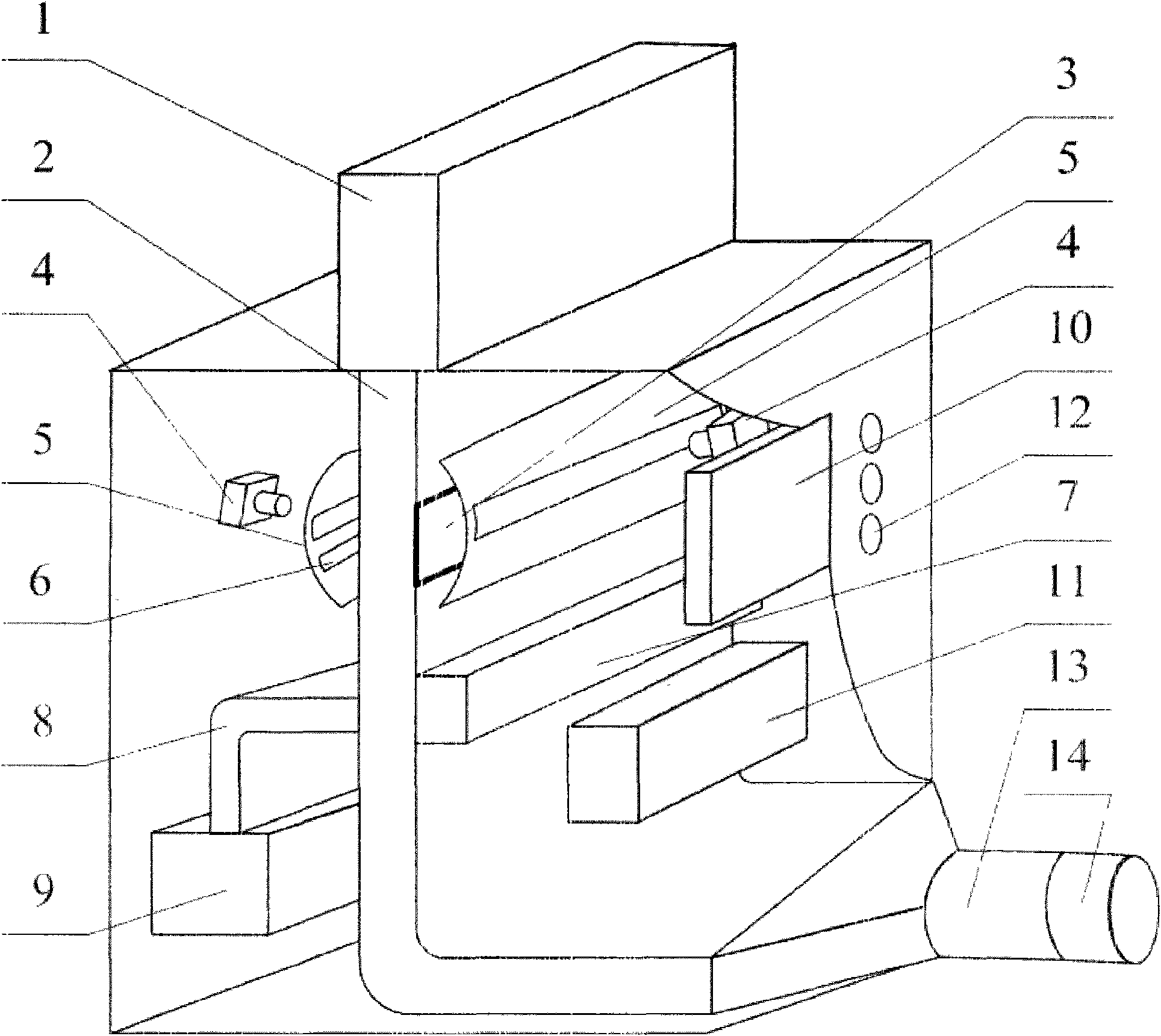

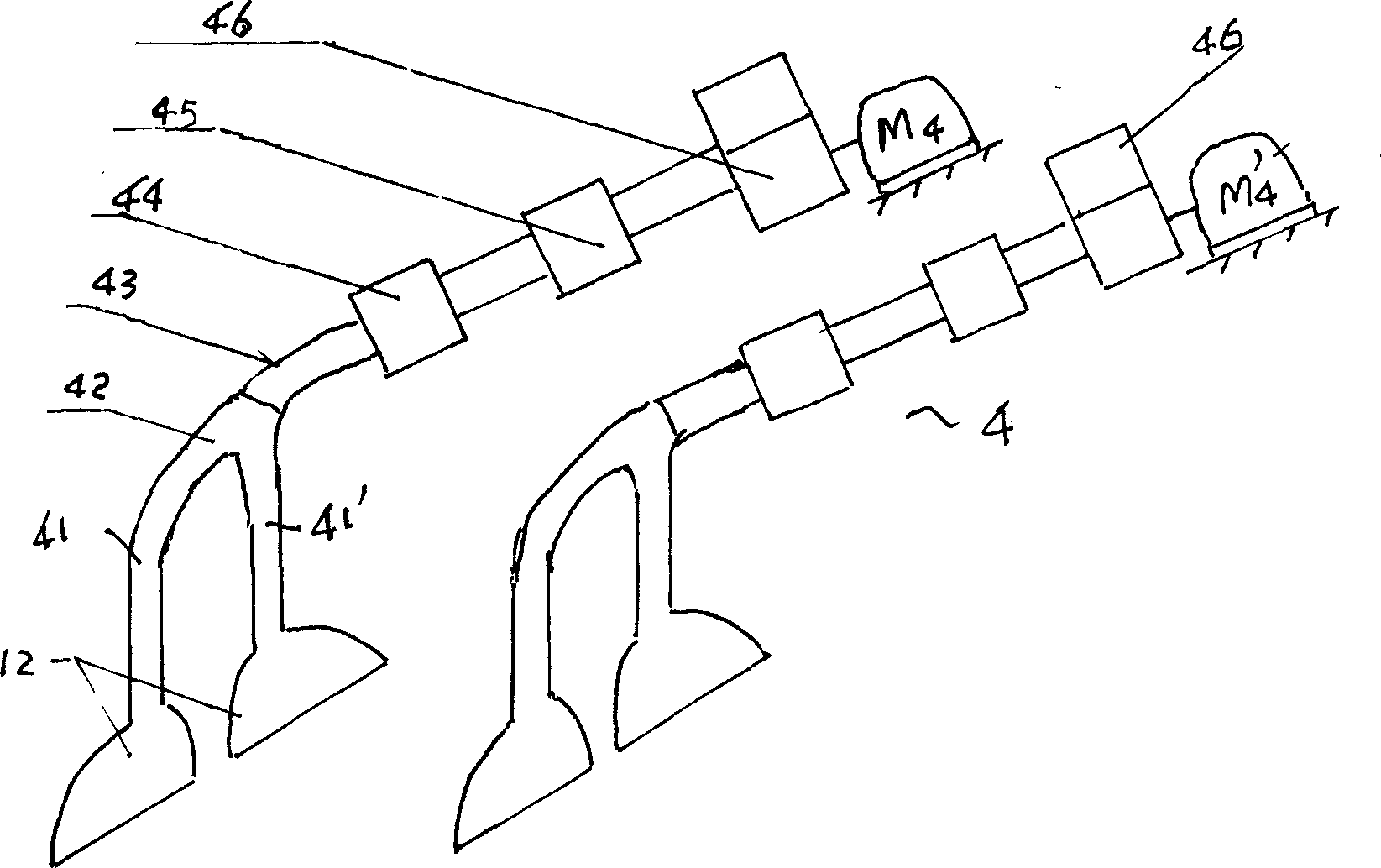

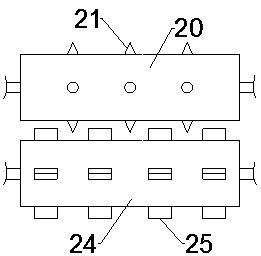

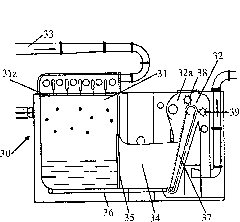

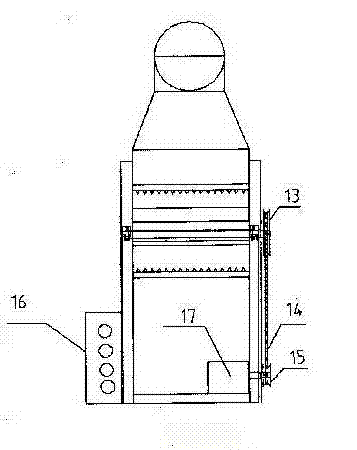

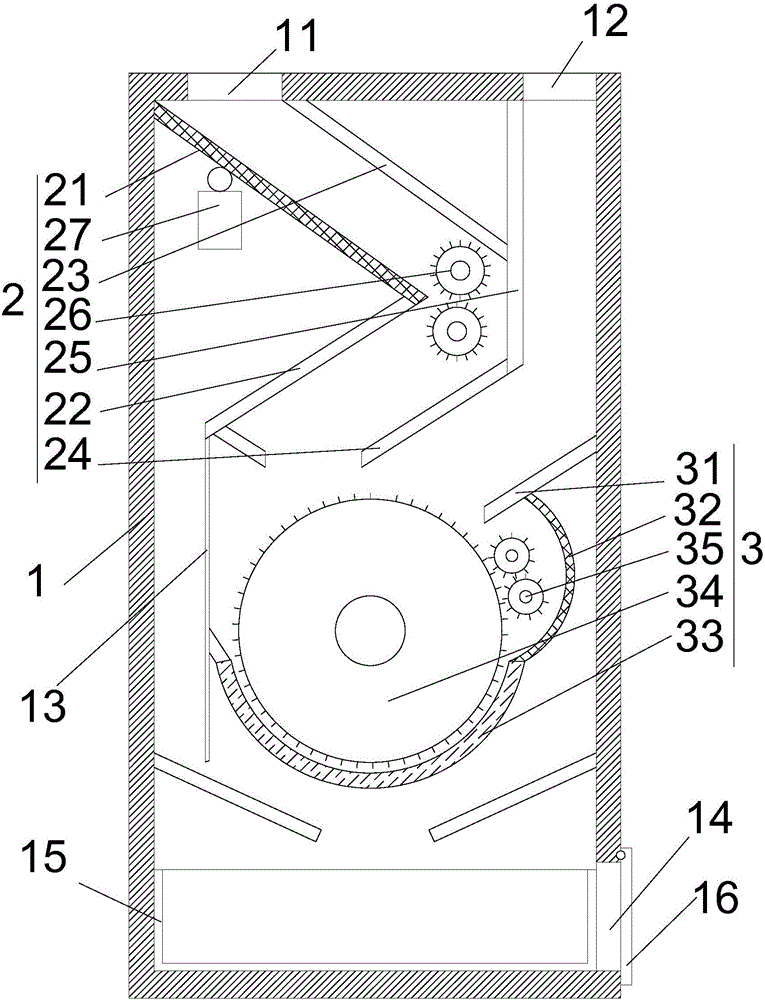

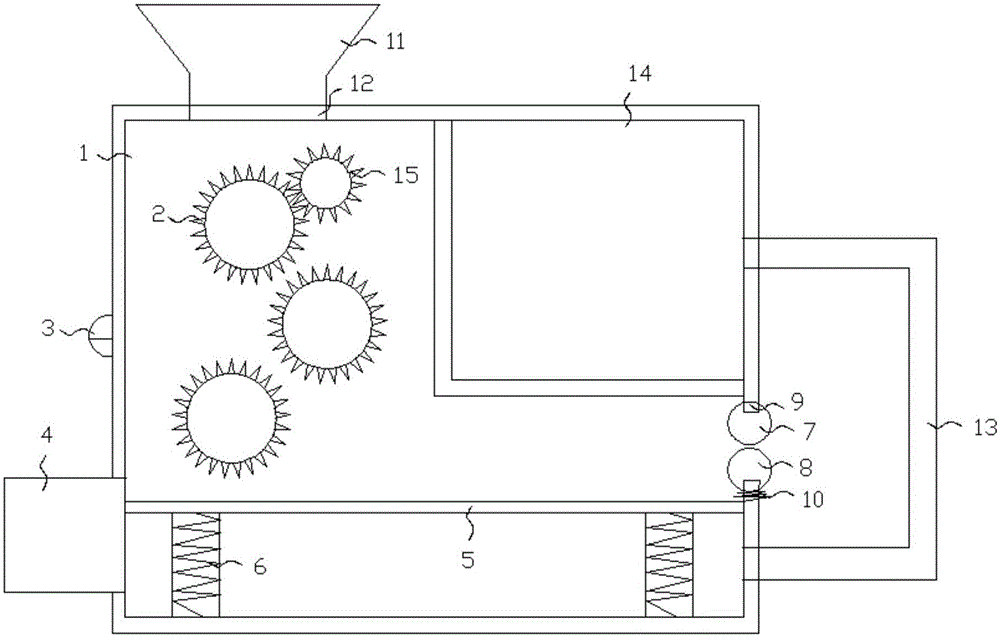

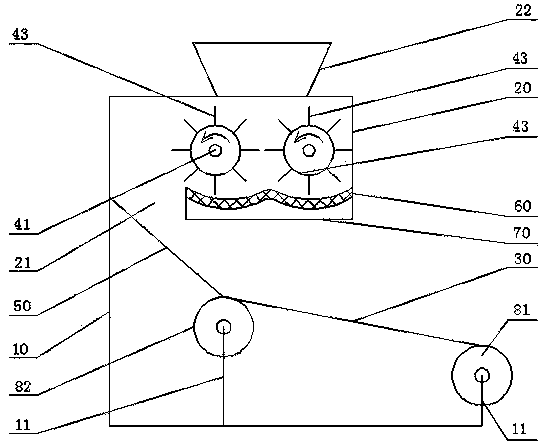

Seed-cotton foreign fiber cleaning machine

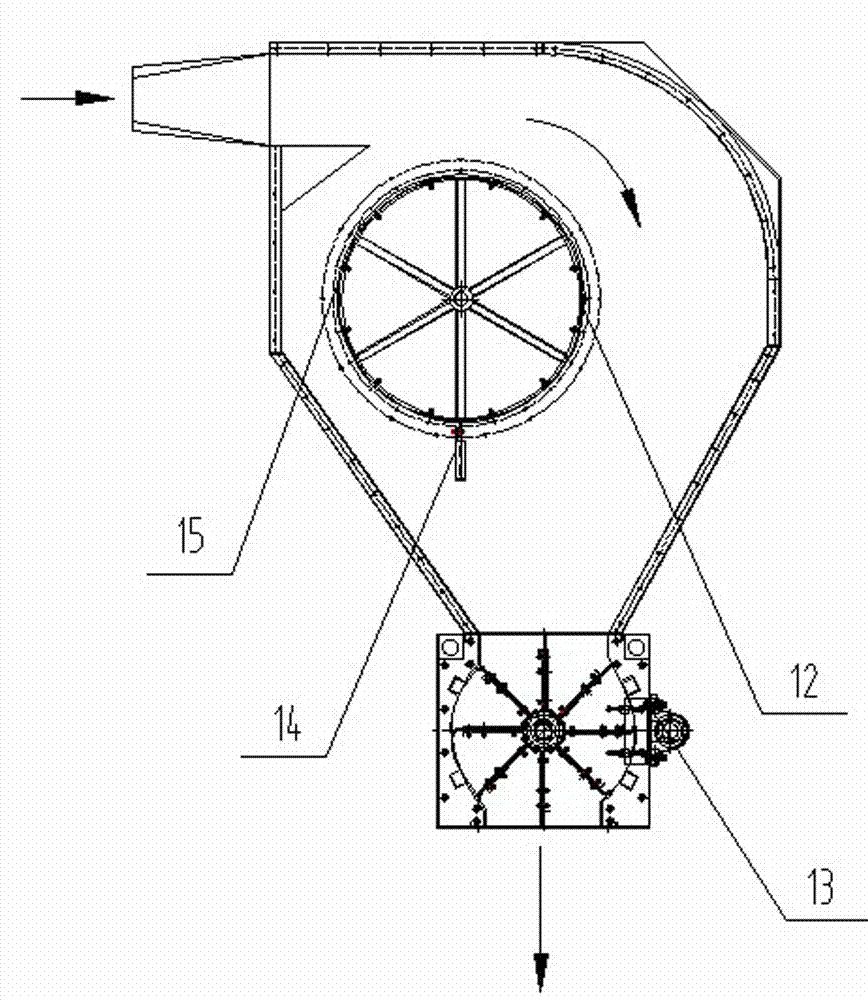

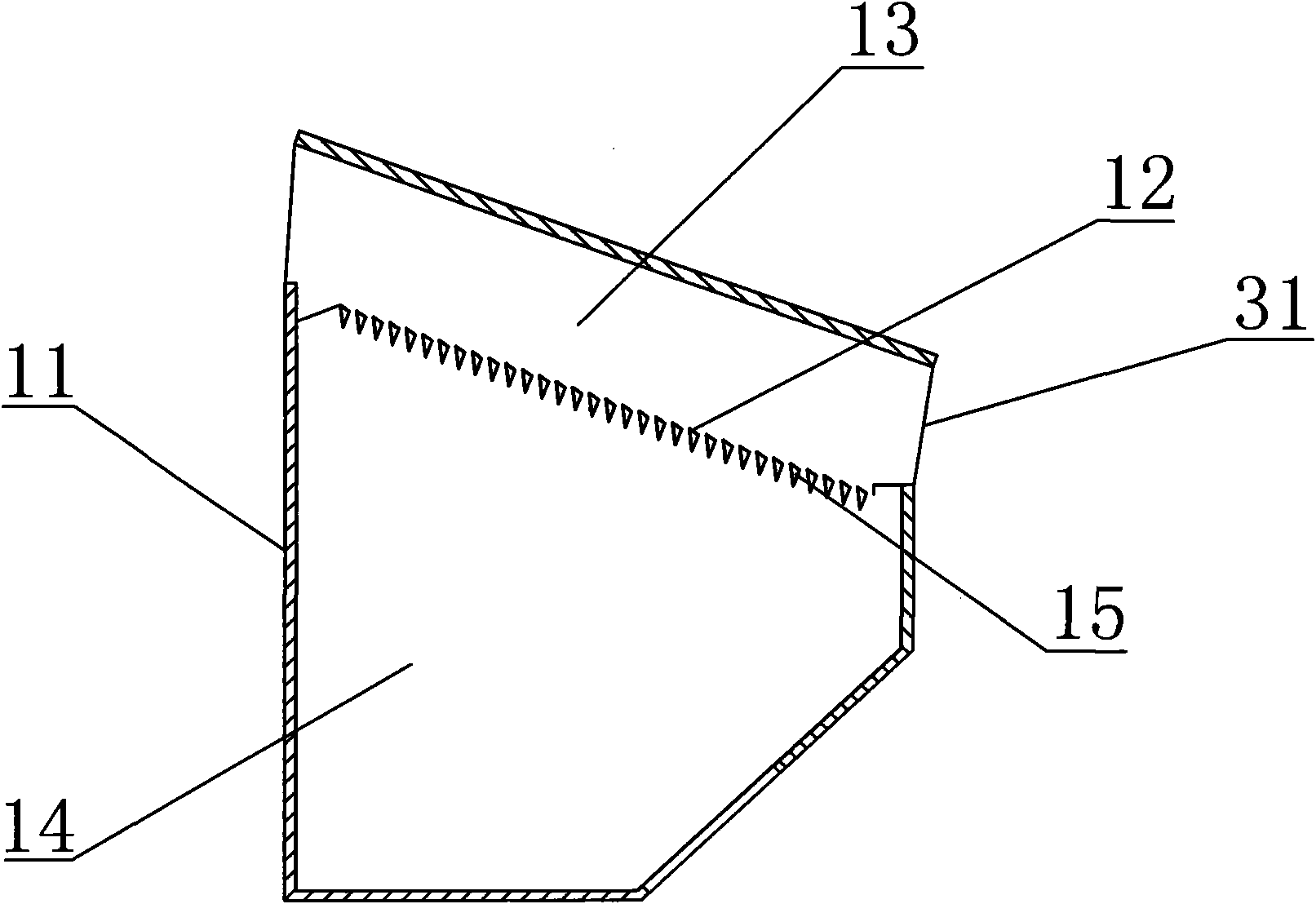

ActiveCN102191589AEasy to cleanImprove cleaning efficiencyFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention relates to a combined-type seed-cotton foreign fiber cleaning machine which is characterized by comprising a tank body which is internally provided with a winding and cleaning device, a hook-pull purification cleaning device, a boiling and opening device and a wind power cleaning device, wherein the winding and cleaning device comprises two pattern feeding rollers; two groups of winding rollers are arranged under the two pattern feeding rollers; a regulating plate is arranged at a passageway dividing place of the two groups of winding rollers; the hook-pull purification cleaning device comprises at least one rack roller, one auger and one doffing roller, wherein the auger is arranged under the rack roller; the doffing roller is arranged slantwise under the rack roller; the boiling and opening device comprises a row of opening rollers; an air bellows which is connected with a fan is arranged under the opening rollers; a plurality of seam-type blast nozzles are arranged on the tops of the air bellows; each seam-type blast nozzle is arranged between any two adjacent opening rollers; and the wind power cleaning device comprises a gettering cover which is connected with the fan. The seed-cotton foreign fiber cleaning machine has a good seed-cotton cleaning effect and high cleaning efficiency and can be widely applied to cotton processing factories for cleaning various foreign fibers in seed cotton.

Owner:北京智棉科技有限公司

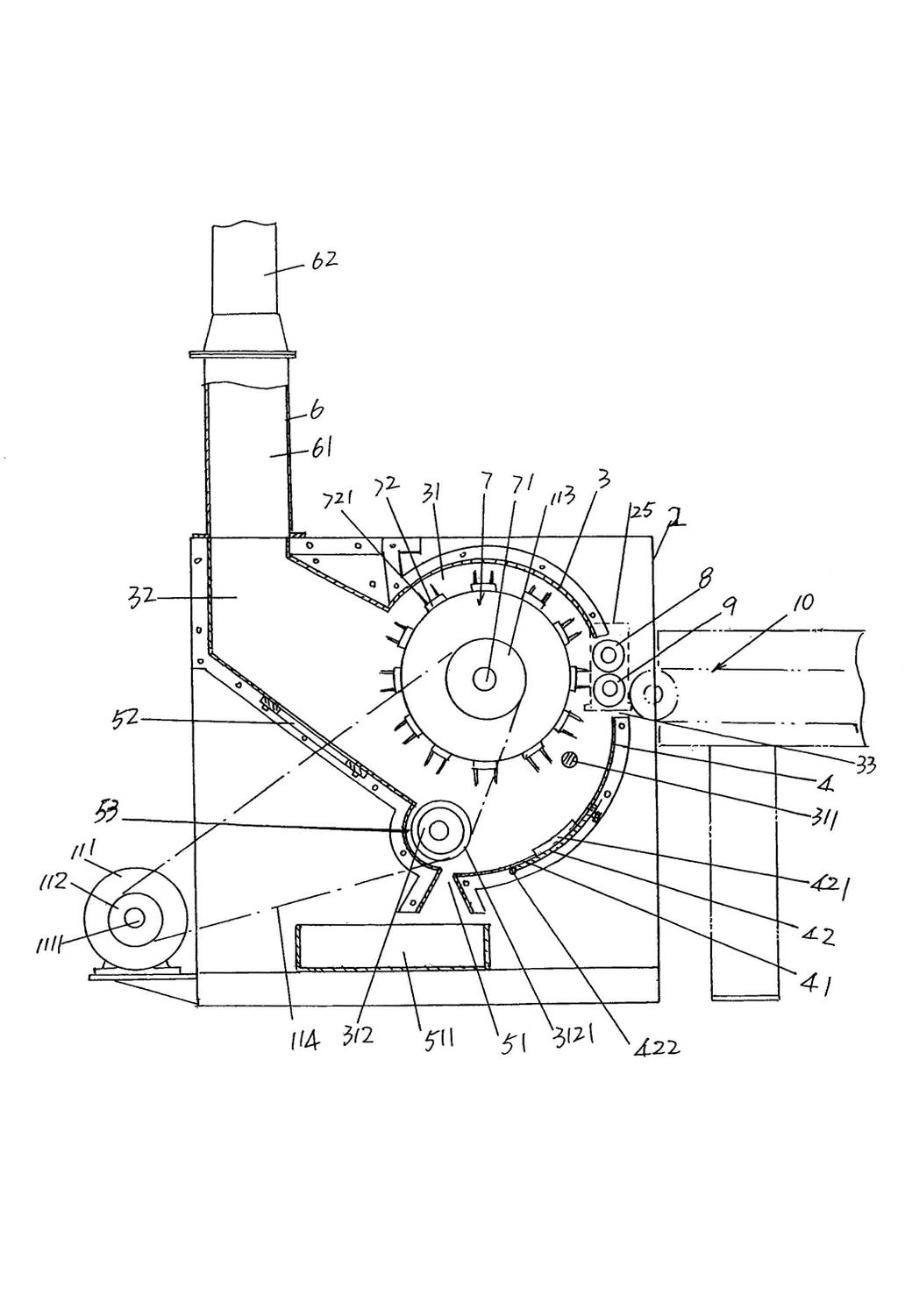

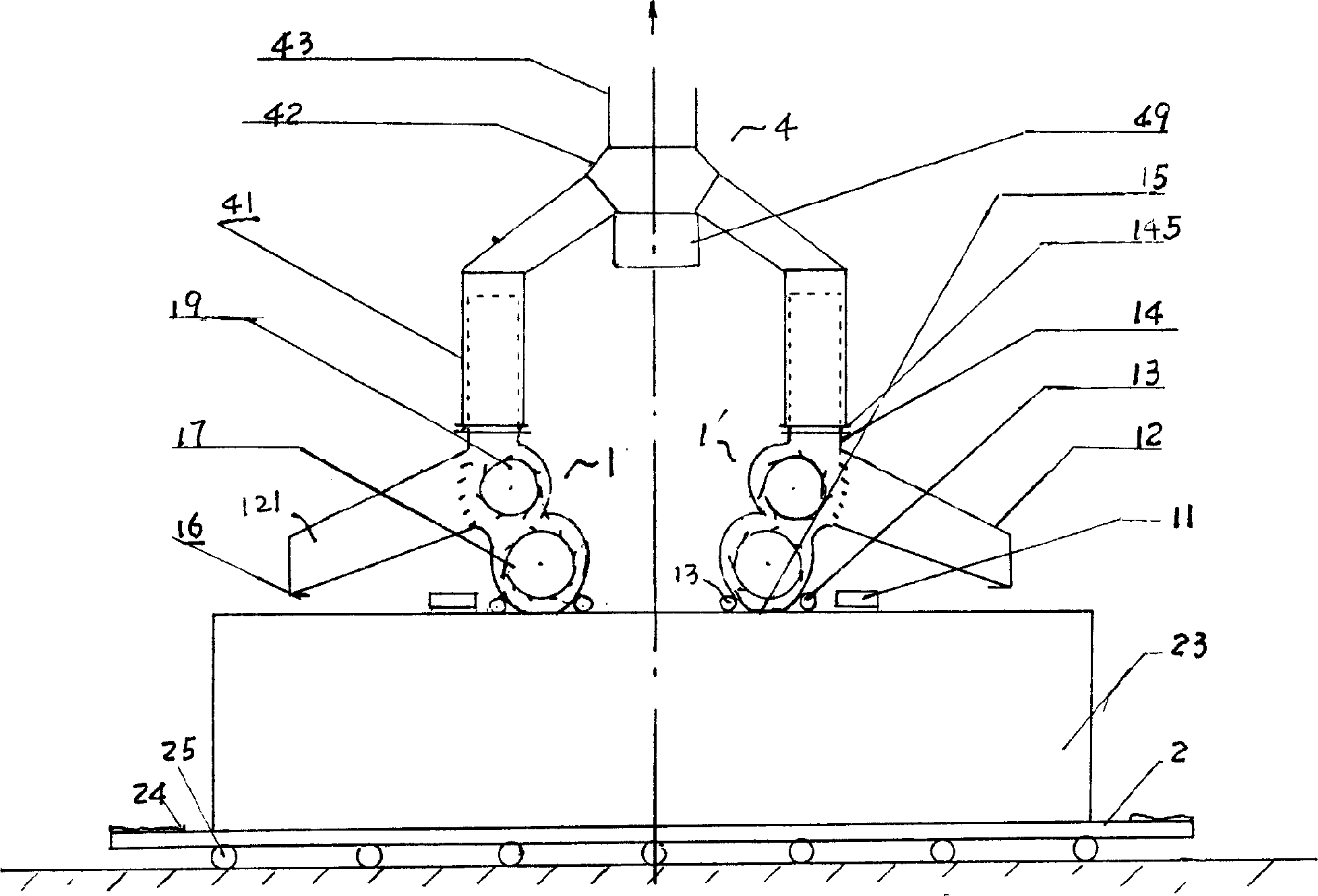

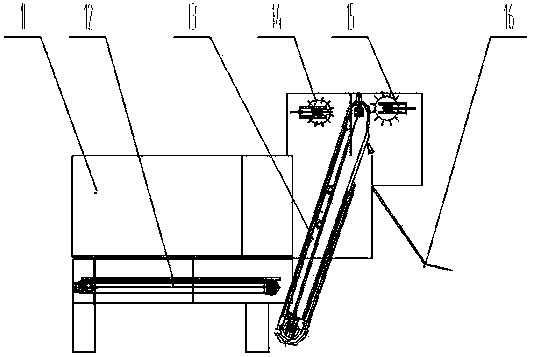

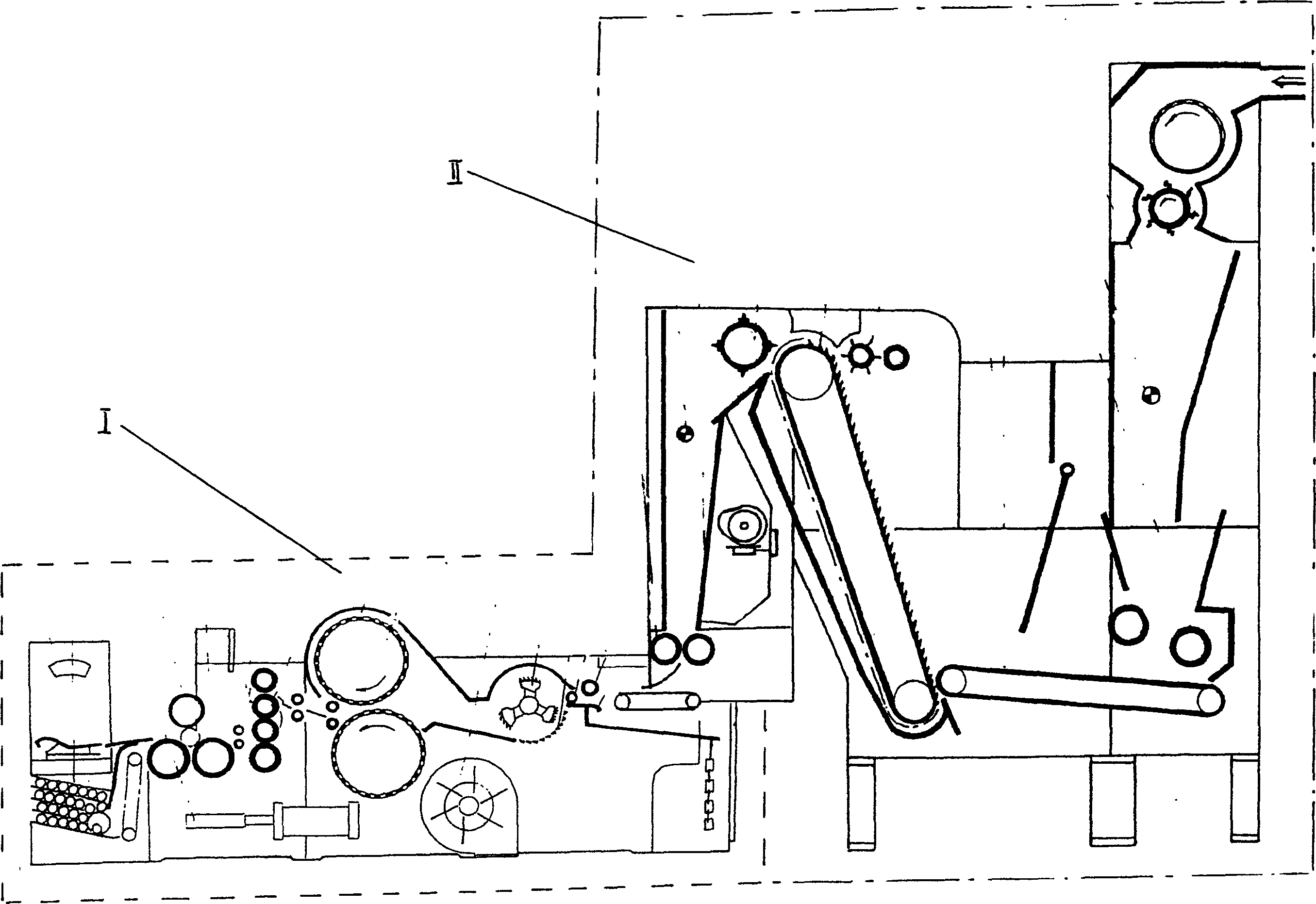

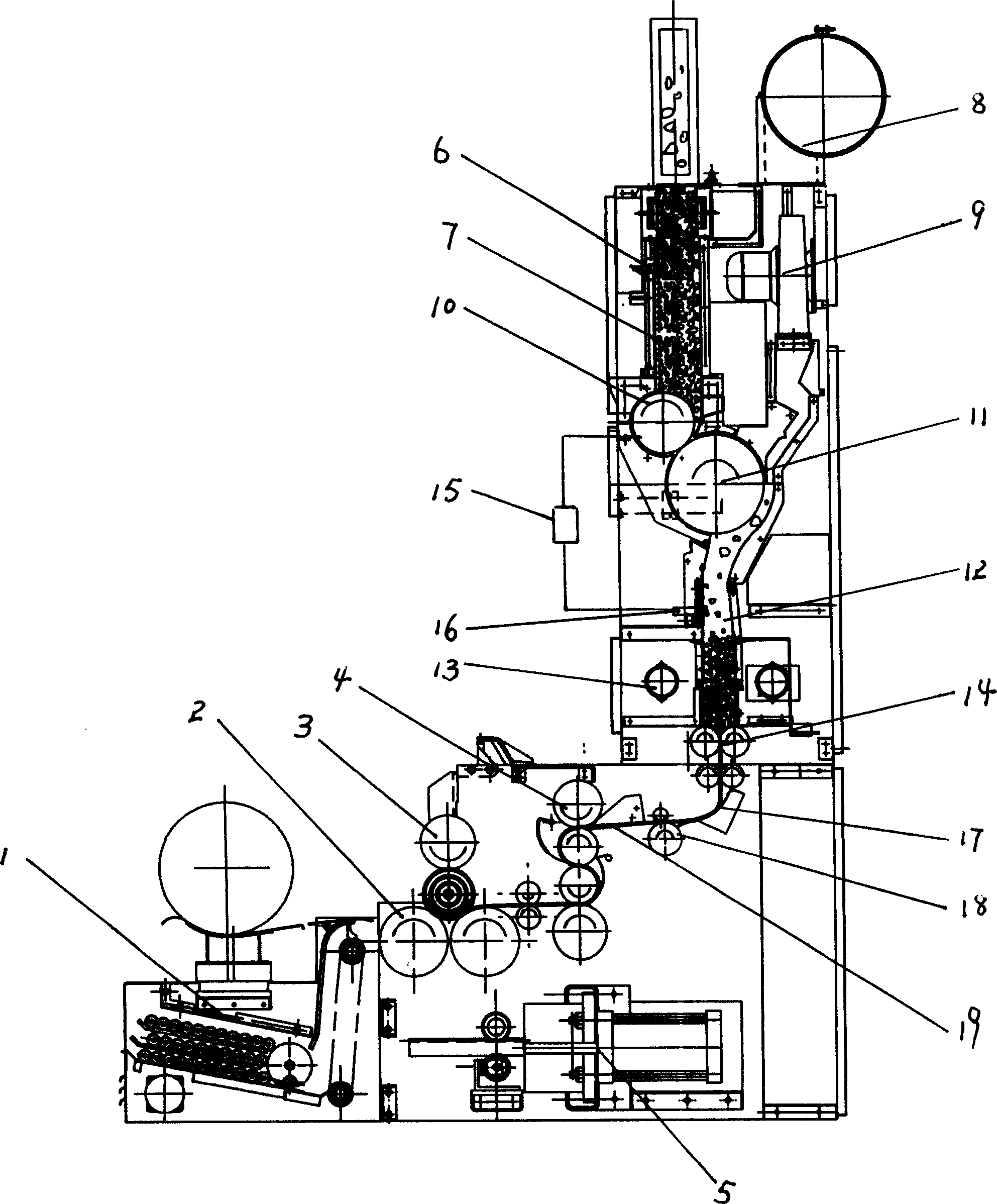

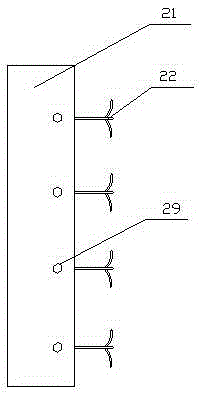

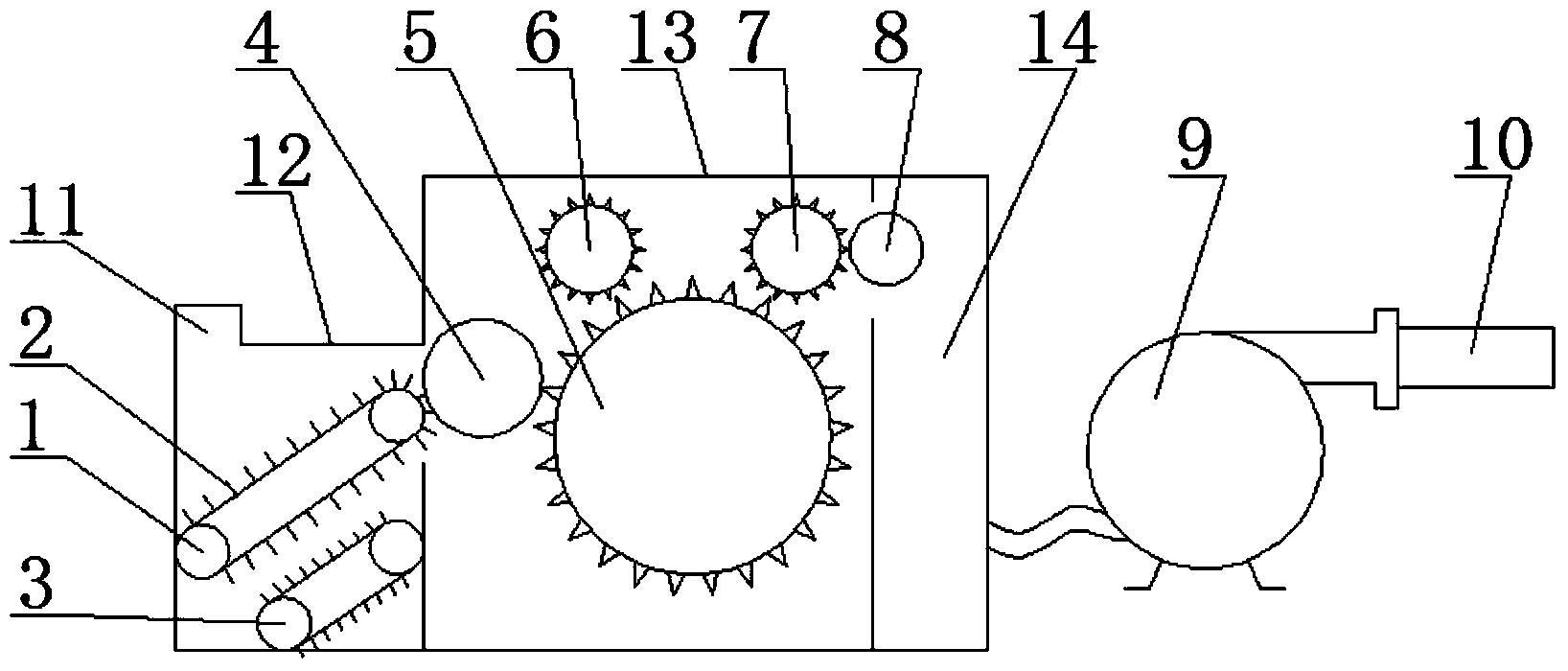

Bale plucker

InactiveCN1508304ASignificant advantagesSignificant beneficial effectFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsFiberReciprocating motion

The invention is a package catcher, composed of the cotton catching head group linked by cotton table and cotton feeding pipe, and the riser, the cotton catching head only making lift motion and the cotton table able to move back and forth on the trolley wheel; two cotton catching heads become a group, the cotton beam output pipe and two down-inclining dropping boxes set on the case of the cotton catching head, and the cotton catching beater and purifying beater set inside the cotton catching head. The purifying beater can make on-line elimination of the impurities carried by the cotton beam such as cotton seeds, cotton scraps and so on.

Owner:吕恒正

Comb needle cotton slitting machine

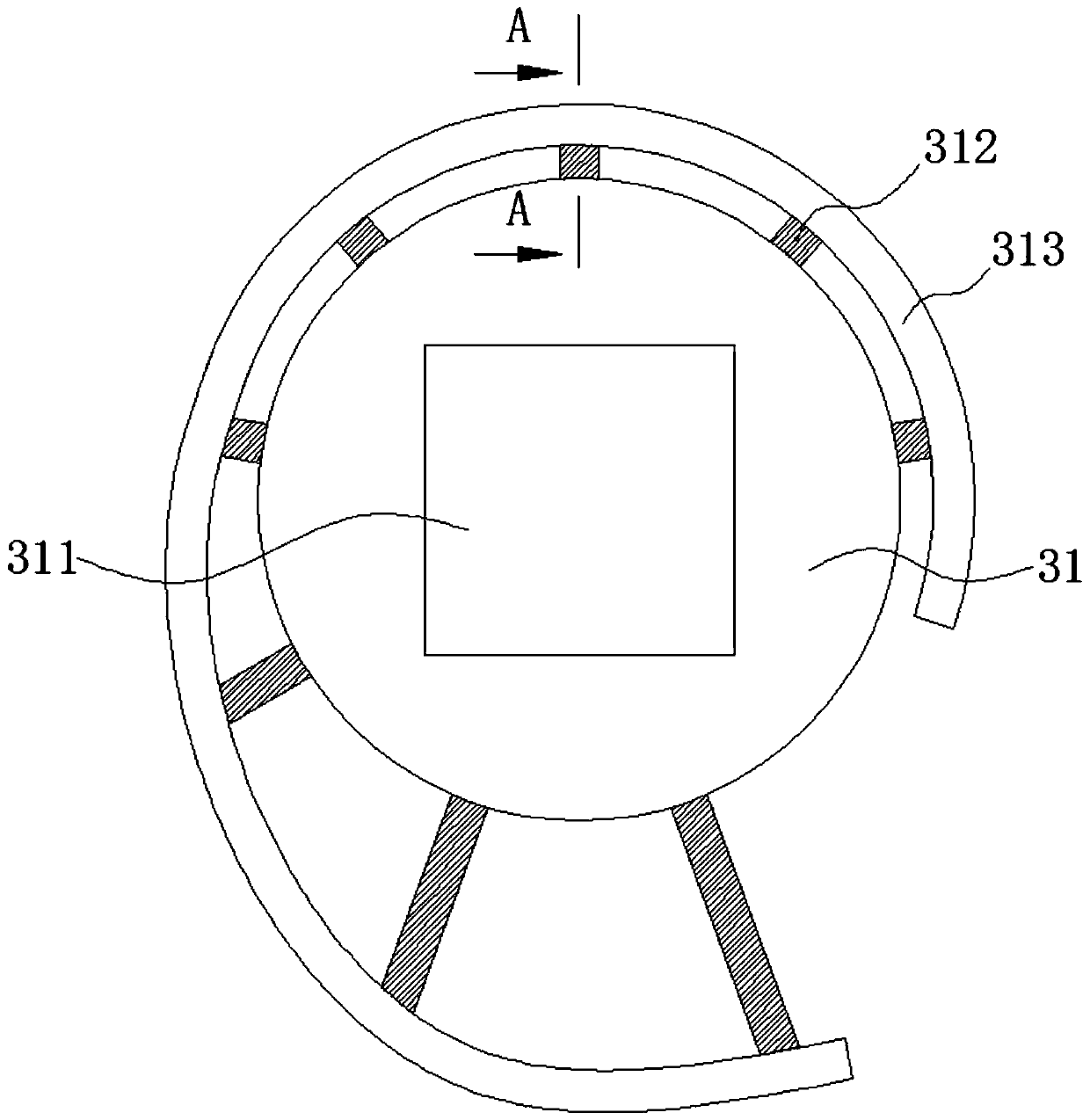

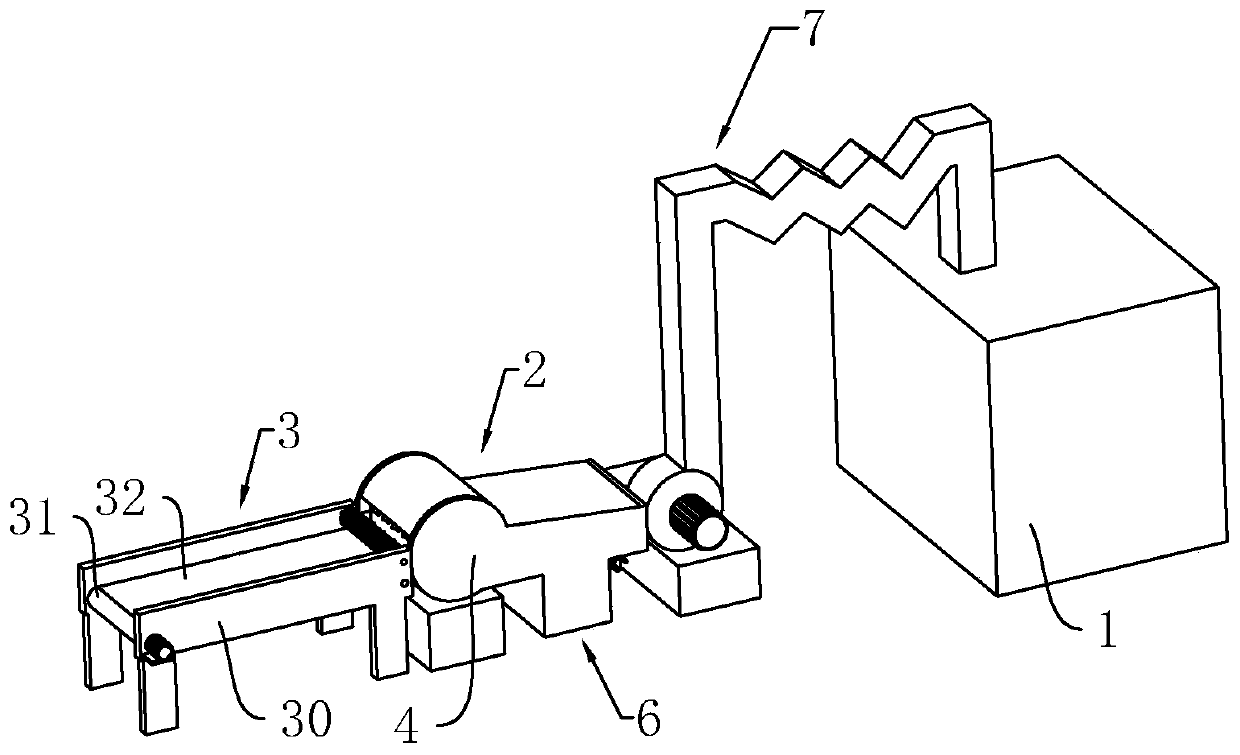

PendingCN107164846AWon't hurtAvoid cloggingFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberEngineering

The invention discloses a comb needle cotton slitting machine which comprises a cotton condenser, a transfer cotton box and a cotton outlet box; a dust cage and a cotton stripping beater are arranged in the cotton condenser; the transfer cotton box is provided with a cotton conveying channel; the cotton outlet box comprises a woolen roller, a cotton feeding roller, a comb needle beater, a flow guide plate, a dust removal device and a cotton outlet channel; the cotton feeding roller is arranged under the wooden roller; the comb needle beater is arranged under the cotton feeding roller, and dust grids are arranged outside three fourths of circumference of the comb needle beater; the cotton outlet channel is formed above the flow guide plate; the dust removal device comprises a vibrating sieve, a conveying belt and a dust collector and is arranged under the comb needle beater; the vibrating sieve is arranged above the conveying belt; the dust collector is arranged at one end of the conveying belt. The comb needle cotton slitting machine disclosed by the embodiment of the invention has the benefits that with the adoption of the comb needle beater, fibers cannot be damaged; small particle of dust passing through the vibrating sieve can be conveyed to the vicinity of the dust collector through the conveying belt; the dust collector can suck dust to ensure inside cleanness of the comb needle cotton slitting machine, and the cleanness of the fibers is ensured.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

Impurity-removal automatic feeding device for carding machine

PendingCN109183205AEfficient removal of impuritiesSimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsDrive wheelEngineering

The invention discloses an impurity-removal automatic feeding device for a carding machine. The device includes an outer box, an inner box, supporting legs, a motor, a stirring shaft, a feeding port,a discharging port, a sliding baffle plate, a spring, a heating wire, an air distribution plate, an induced draft fan and a drying box, wherein the bottom of the outer box is provided with multiple supporting legs, the inner box is located inside the outer box, bottom plates of the inner and outer boxes are overlapped, the motor is arranged on the left side of the outer box, a rotating shaft of the motor penetrates through the outer box and is connected with a driving wheel, the stirring shaft is arranged inside the inner box, a left end of the stirring shaft penetrates through the inner box,the stirring shaft is connected with a driven wheel, the driven wheel and a driving wheel are engaged with each other, the inner box is further provided with the feeding port penetrating through the top of the outer box, the discharging port is arranged below the inner box, the sliding baffle plate is arranged at the discharging port, the spring is arranged between a right end of the sliding baffle plate and the outer box, the air distribution plate is further disposed above the inner box inside the outer box, the air distribution plate is provided with the heating wire, and an air inlet pipeis arranged at a top plate of the outer box above the heating wire.

Owner:湖州萌星服饰有限公司

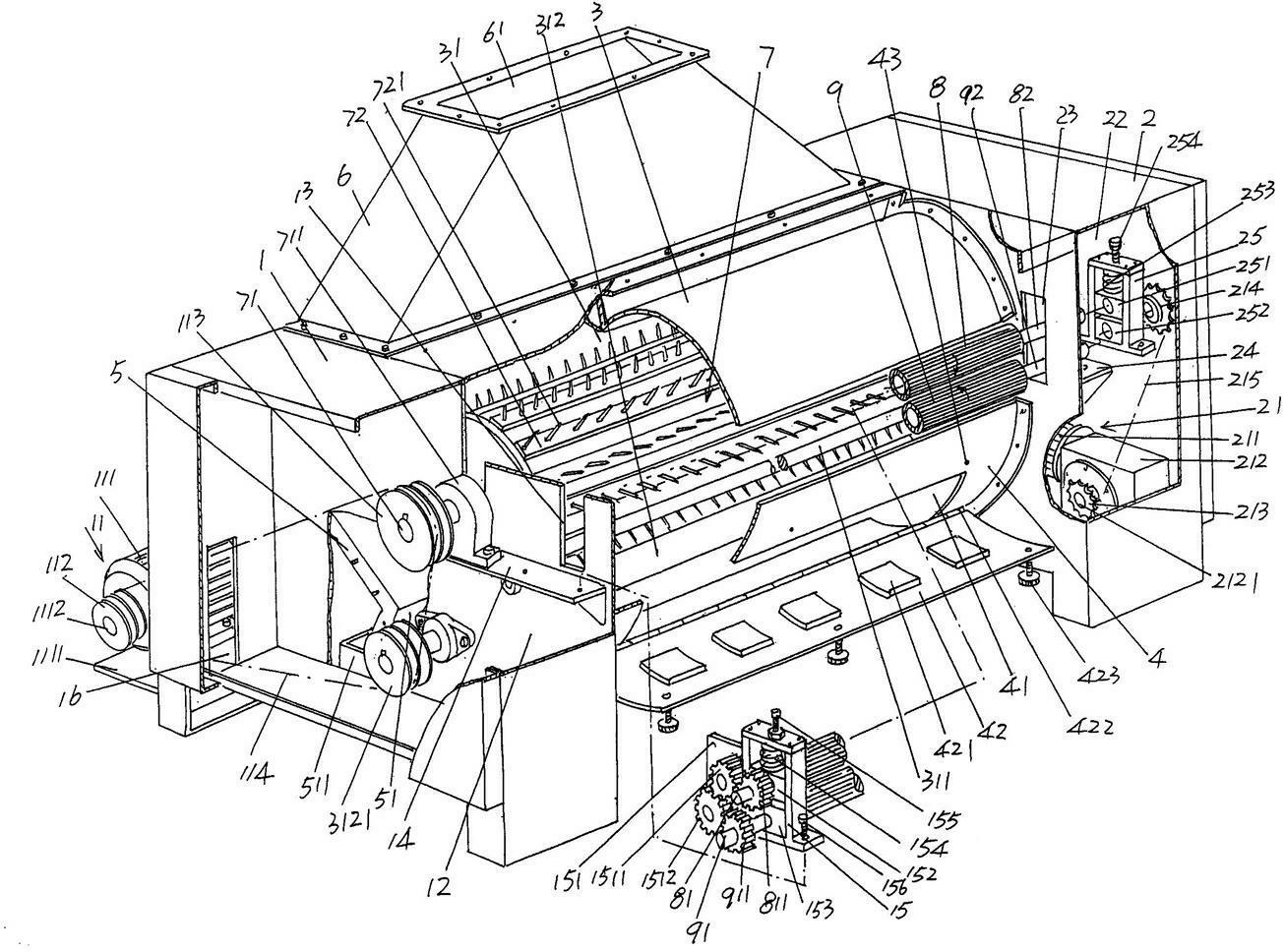

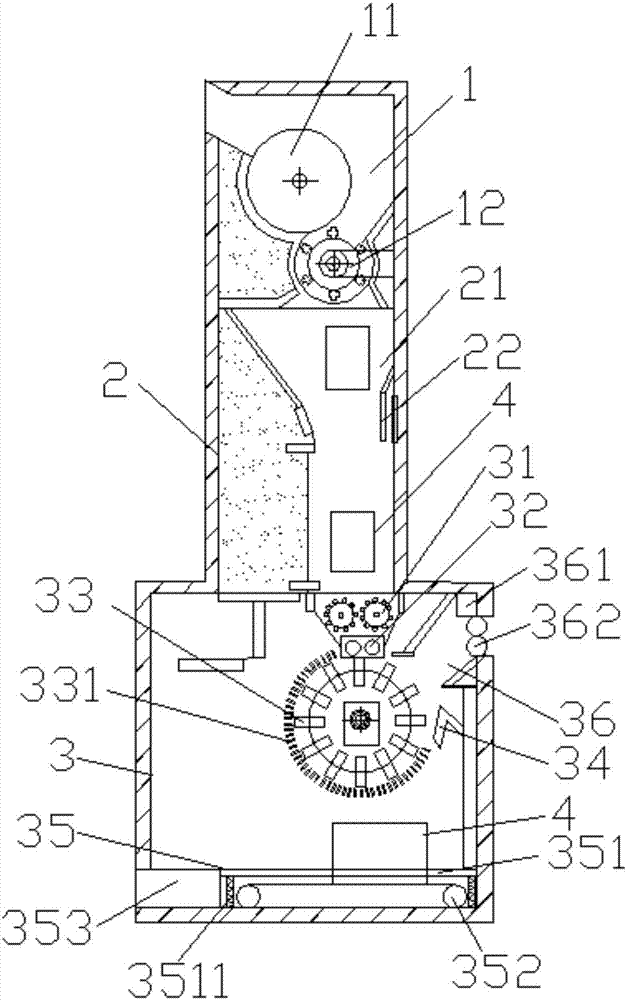

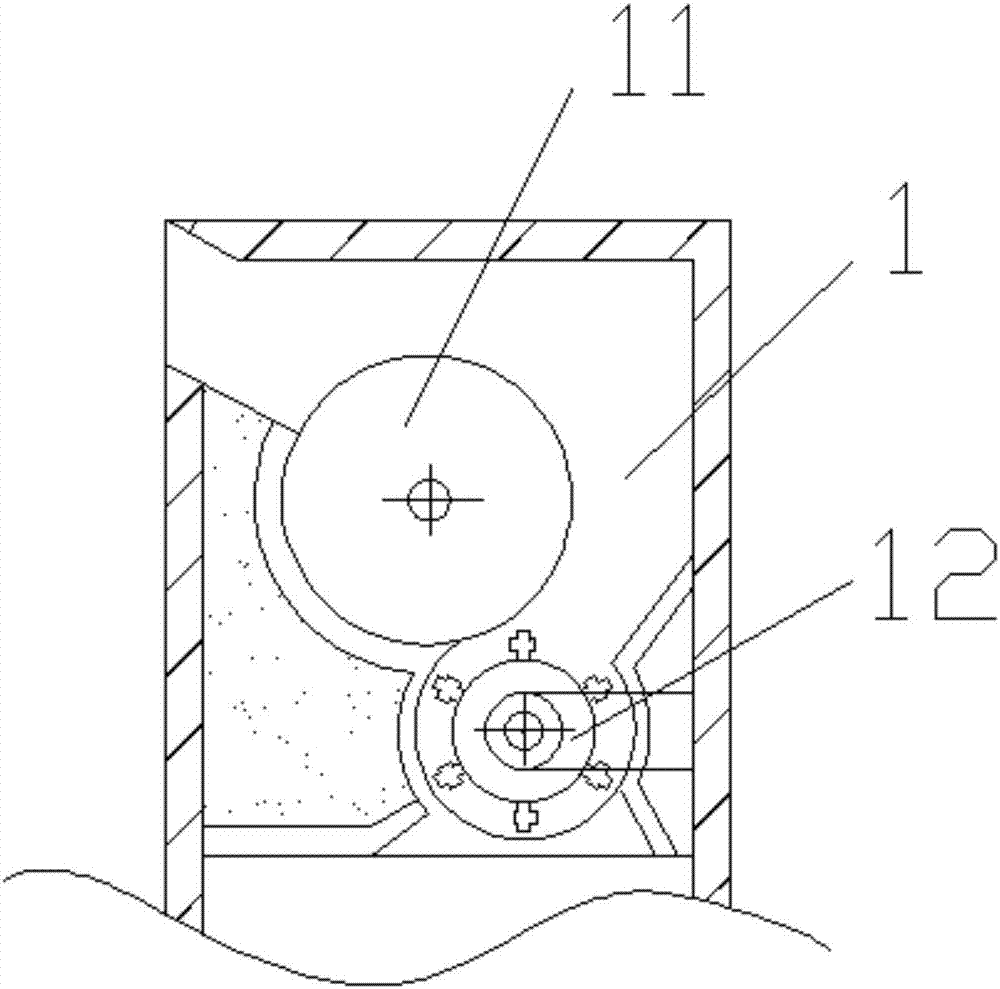

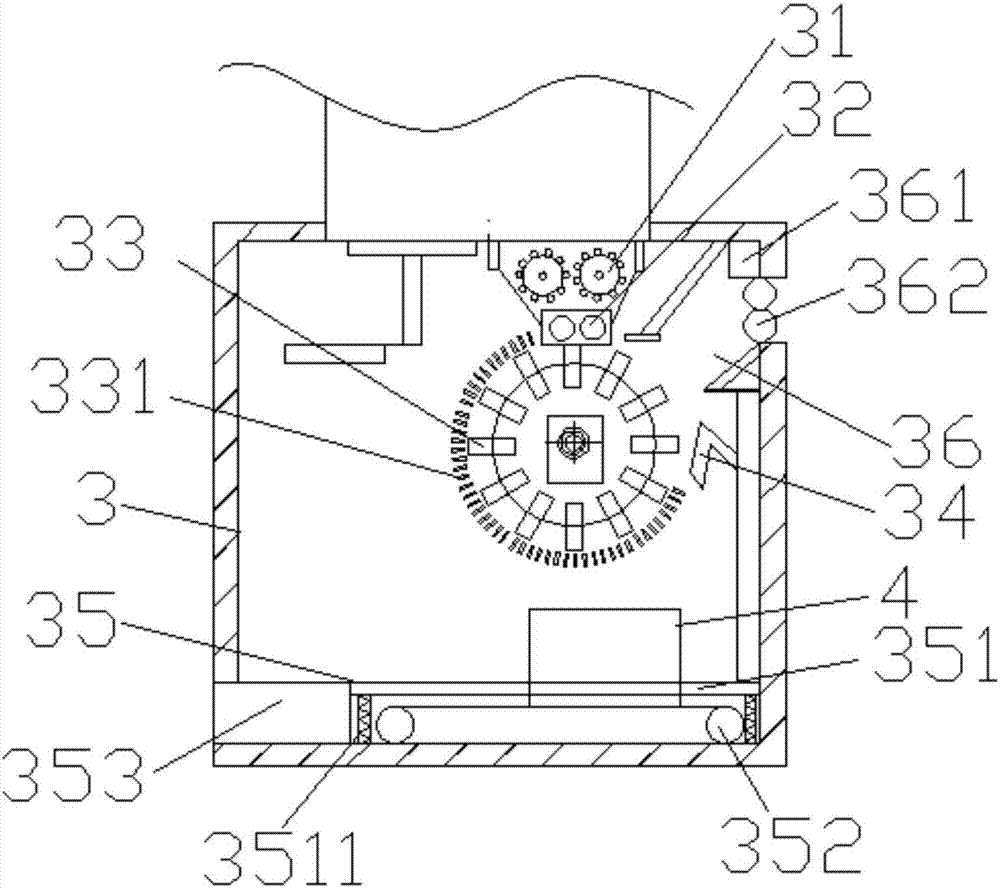

Clearing and recovering method and device for fibers in sterile seeds

ActiveCN103088469AIncrease throughputEasy to cleanFibre cleaning and opening machine combinationsFibre cleaning/opening machinesCross-linkBiotechnology

The invention discloses a clearing and recovering method and a device for fibers in sterile seeds. Compared with an existing clearing and recovering method for the fibers in the sterile seeds, opening and carding are further carried out on the sterile seeds before scutching sterile seeds after being cleared so that the sterile seeds can be in a good state, and namely, the fibers of the sterile seeds are not cross-linked to be pressed into bats and sent to a scutcher. By means of the clearing and recovering method and the device for the fibers in the sterile seeds, clearing effects can be effectively improved, and besides, processing capacity of the scutcher can be effectively improved.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

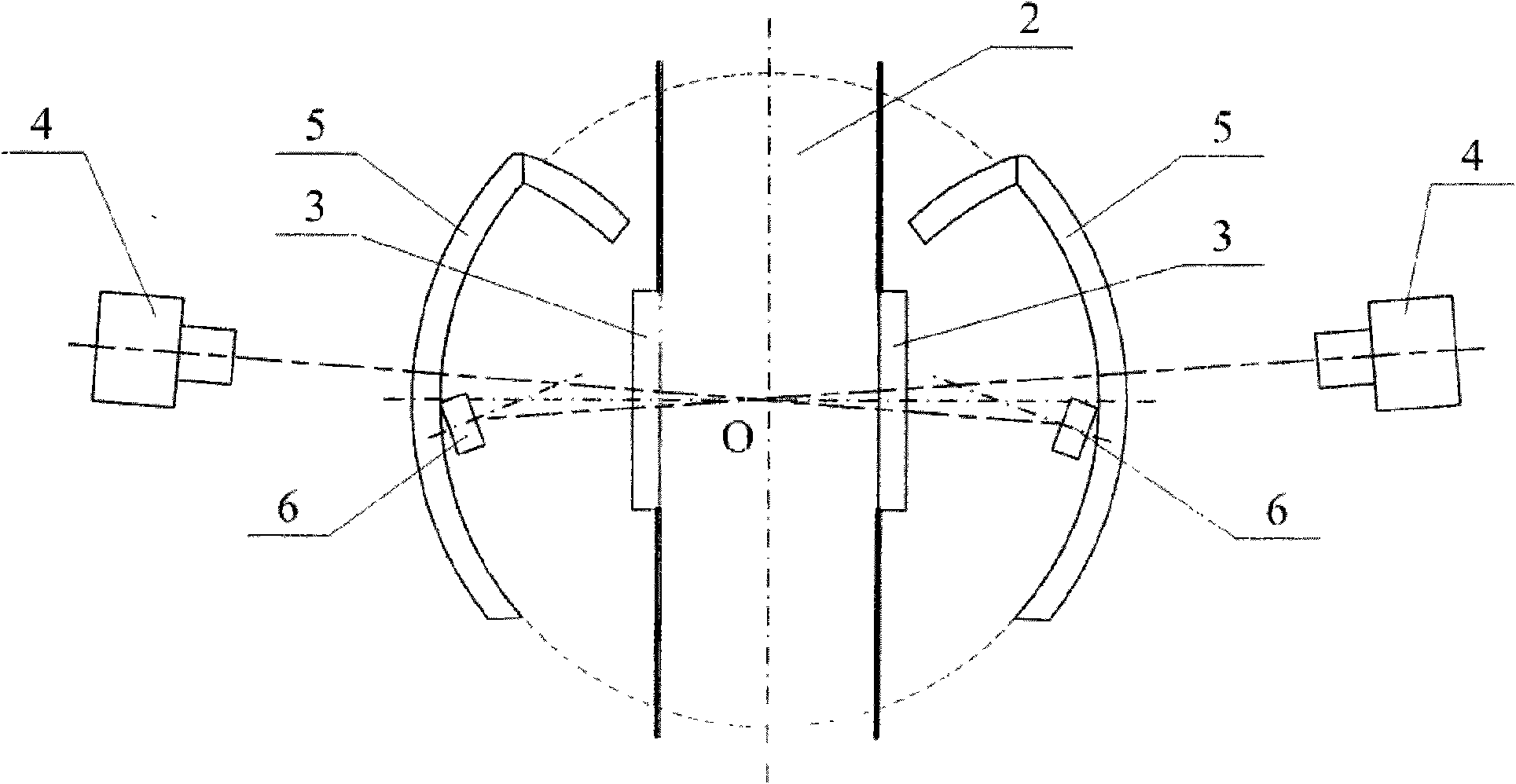

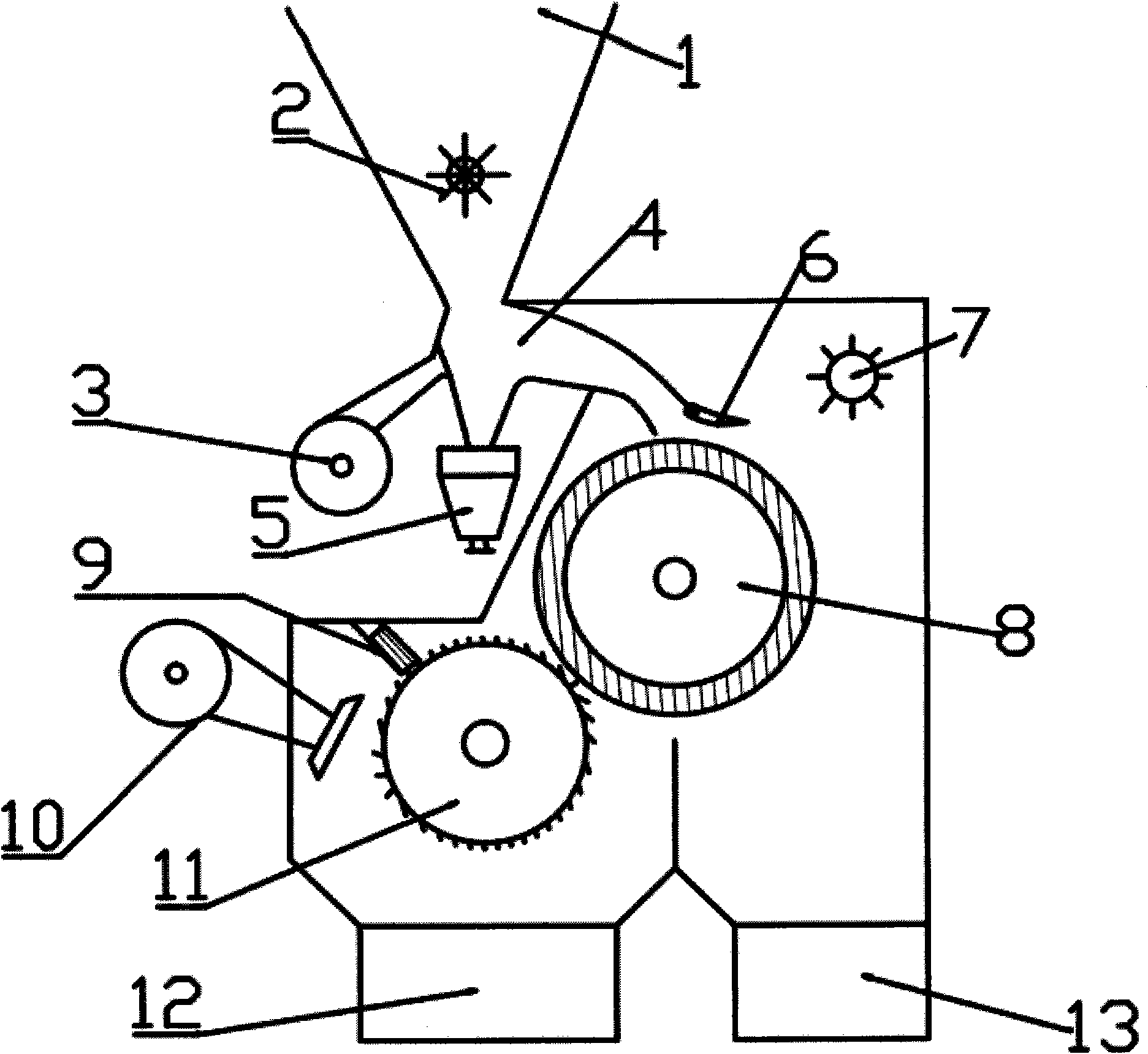

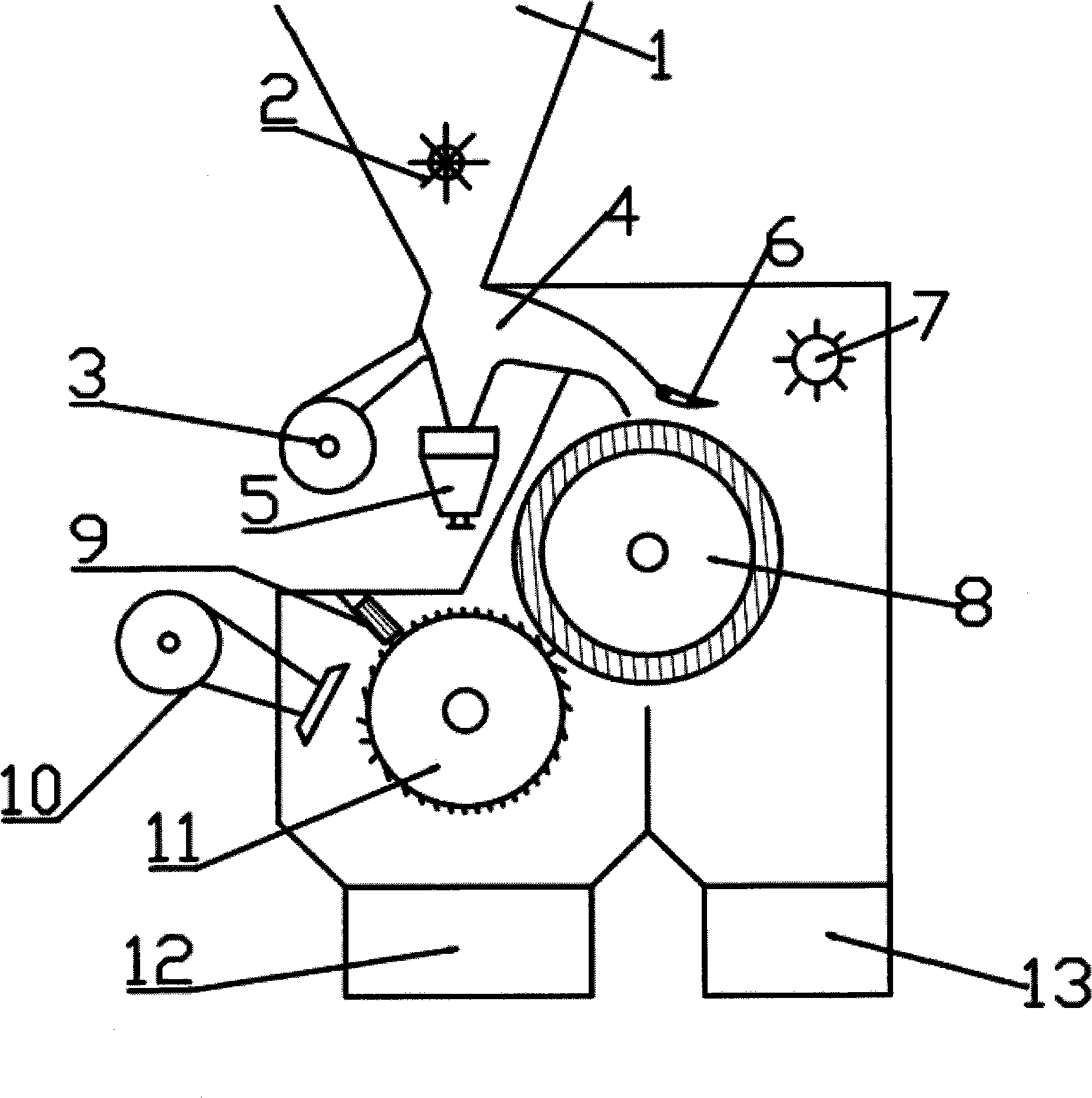

Seed cotton foreign fiber cleaner

InactiveCN101979729AFully clearSufficient separationFibre cleaning and opening machine combinationsFibre cleaning/opening machinesFiberEngineering

The invention discloses a seed cotton foreign fiber cleaner, and relates to equipment for cleaning impurities in seed cotton. The equipment consists of a seed cotton loosening device, a charge coupled device (CCD) image detecting and cleaning device, a fine dust cleaning device, an impurity separating device and a seed cotton diffuser, wherein the seed cotton loosening device is arranged at the upper end of the CCD image detecting and cleaning device; a lower opening of the seed cotton loosening device is communicated with a detection channel of the CCD image detecting and cleaning device; the fine dust cleaning device is arranged at the upper end of the seed cotton loosening device; a seed cotton passage of the fine dust cleaning device is communicated with an upper opening of the seed cotton loosening device; and the seed cotton diffuser is communicated with a feed port of the fine dust cleaning device through the impurity separating device. The cleaner can fully eliminate and separate heavy impurities and suspended fine dust which are mixed in the seed cotton and ensure the detection accuracy of the foreign fiber and equipment safety. The seed cotton loosening device can quickly loosen the dense seed cotton to a puff state, so that the cleaner is favorable for foreign fiber detection, reduces the amount of seed cotton carried when the foreign fiber is cleaned and has high cleaning accuracy.

Owner:LUOYANG FANGZHI MEASUREMENT & CONTROL

Fiber mixed device and fiber mixed method

InactiveCN101824673AAvoid damageGood for colorFibre cleaning and opening machine combinationsFibre mixingFiberEngineering

The invention provides a fiber mixed device, which comprises a first mixed unit, an opening and carding unit and a second mixed unit. The first mixed unit is arranged at the initiating terminal of the fiber mixed device, and comprises a storage component for accommodating different fiber materials in proportion, a grab component arranged above the storage component, and a transfer channel which is connected with the grab component and leads to the downstream units; the opening and carding unit is arranged at the downstream of the first mixed unit, and comprises a breaking component for breaking up the fibers; and the second mixed unit is arranged at the downstream of the opening card unit, and comprises a fiber collecting cabinet for collecting the fibers and a mixed component for mixing the collected fibers so as to mix the sent fibers by way of planking smoothly and lifting vertically.

Owner:江阴市霞客彩纤有限公司

Wool vegetable matter removing device

InactiveCN104018250AEfficient removalAvoid environmental pollutionFibre cleaning and opening machine combinationsFibre cleaning/opening machinesFiberVegetable matter

The invention discloses a wool vegetable matter removing device. The device comprises a wool humidifier, a wool feeder, a gas fiber separator, a card wire roller opener, a single-licker-in cleaning opener, a wool cleaner and a dust collector, wherein a discharging hole of the wool humidifier is formed above a feeding hole of the wool feeder, a discharging hole of the wool feeder is connected with a second flat conveying curtain on a feeding hole of the card wire roller opener through a material flowing plate, the gas fiber separator is arranged above a third flat conveying curtain of the card wire roller opener, the discharging end of the gas fiber separator is arranged over a fourth flat conveying curtain of a sawtooth roller tooth opener, and a discharging hole of the sawtooth roller tooth opener is connected to a feeding hole of the wool cleaner through a fifth flat conveying curtain. According to the wool vegetable matter removing device, the vegetable matter contained in wool can be effectively and mechanically removed as a whole, and therefore the negative effects that the environment is polluted and the native quality of wool is damaged when the vegetable matter contained in wool is removed with a traditional carbonization technology can be avoided.

Owner:ZHENGZHOU COTTON & JUTE ENG TECH & DESIGN RES INST

Cotton cleaning method and processing device thereof

InactiveCN101929002AFewer ticksImprove product gradeFibre cleaning and opening machine combinationsFibre cleaning/opening machinesFiberAir separation

The invention relates to a cotton cleaning method and a processing device thereof and is characterized by creating a method for removing impurities by a cleaning processing unit. The processing unit is composed of a feed tank, an opening beater, an air blower, an air separation chamber, an impurity hopper, a baffle plate, an electrode emitter, an electrode roller, a hairbrush, a stripping air blower, a licker-in, an impurity cabin and a fiber storage vault which are connected. The method of combining air separation and electric separation is adopted to clean cotton, separation accuracy is controlled by adjusting angle of the baffle plate, small fiber damage is caused in the whole cleaning process, impurity cleaning is thorough, and has a carding function, thus facilitating subsequent processes.

Owner:杨洪举

System and method for recycling fibers from textiles waste

ActiveUS20190226125A1Fibre cleaning and opening machine combinationsSolid waste disposalFibre treatmentPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

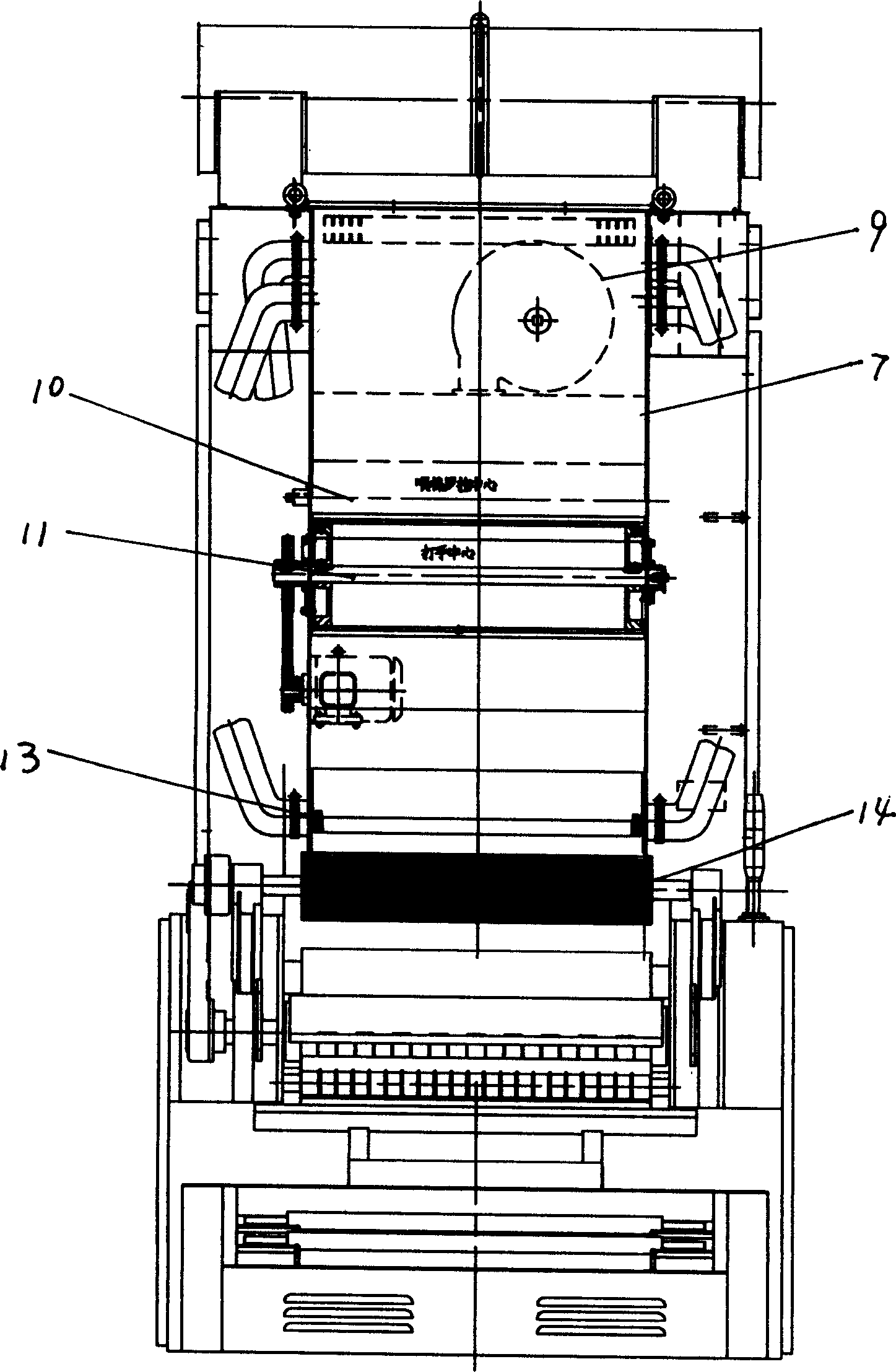

Cotton basket coiler

InactiveCN1464083AUniform thicknessContinuous feeding guaranteedFibre cleaning and opening machine combinationsBogiePunching

The cotton box lap machine includes punching mechanism comprising lap bogie, lap roller and lap pressing roller and features vertical cotton box set behind the punching mechanism comprising upper cotton box with ventilating and dedusting unit, dedusting pipeline, circulating fan, cotton feeding roller, opening beater, lower cotton box, hydrostatic pressure diffusing box, and cotton discharge roller, as well as continuous cotton feeder, pressure sensor, controller to receive the signal from the pressure sensor for the control of cotton feeding speed. The present invention has compact and reasonable structure, and its cotton box and punching mechanism may be combined together.

Owner:ZHENGZHOU HONGDA NEW TEXTILE MACHINERY +1

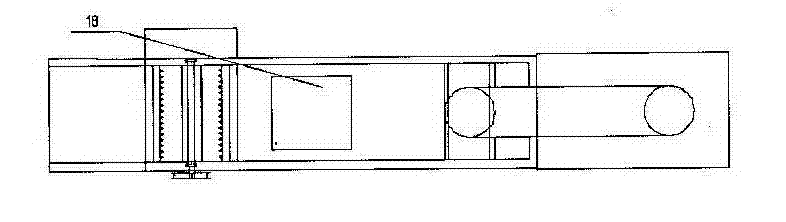

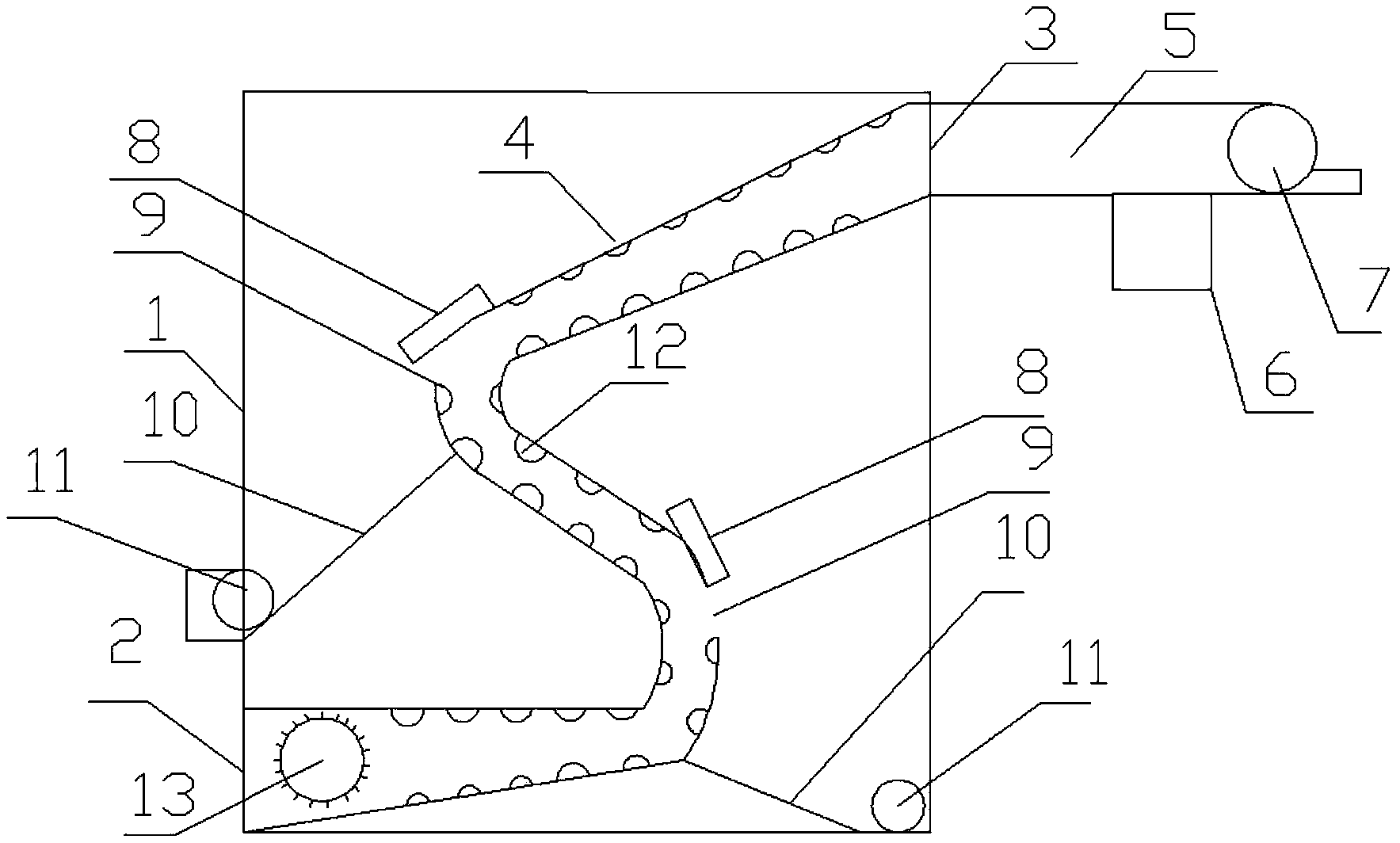

Impurity removing device special for separating calotropis gigantean fiber capsule seeds

ActiveCN103031625AAvoid damageSave unique featuresFibre cleaning and opening machine combinationsFibre cleaning/opening machinesFiberLow speed

The invention discloses an impurity removing device special for separating calotropis gigantean fiber capsule seeds. The impurity removing device comprises a feeding device, a transmission system and a cotton conveying pipe, and is characterized in that the feeding device consists of a cotton feeding plate, a cotton feeding roller, a dust rod and four-wing beaters, and is mounted at the upper part of the front end of a rack; the transmission system is fixed at the lower part of the front end of the rack; a cotton conveying pipeline is arranged at the middle part of the rack; two adjusting plates in an upper and lower manner and a negative pressure air pipe are arranged inside the pipeline; a capsule seed dust chamber is arranged at the lower part of the pipeline; and a cotton storage box and a negative pressure fan are arranged at the rear part of the rack. According to the impurity removing device, elastic metal sheets are adopted as the beaters; a plurality of beaters are adopted and operated in low speed, so that the fiber is less damaged, the whole set of device structure is small in physical beating effect, impurities are removed with the combination of airflow, and the unique characteristics of the fibers are better maintained; compared with manual sorting, the separation effect is increased by 26 times, so that the industrial batch production of the calotropis gigantean fiber is facilitated; and the dirt percentage is reduced to 3%, so that the impurities in the fibers is effectively removed.

Owner:湖南云锦集团股份有限公司

Sliding rail type dust-free fiber wool opener

InactiveCN105386161AWon't tangleReduce the burden onFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberEngineering

The invention discloses a sliding rail type dust-free fiber wool opener which comprises an auger conveyor and a housing. A feeding port is formed in the upper portion of the housing, a discharging port is formed in the lower portion of the housing, and the housing is internally divided into a coarse opening area and a collecting area. A second motor is arranged on one side of the feeding port and connected with a stirring shaft, a stirring paddle is arranged on the stirring shaft and provided with protruding circular wool opening balls, an air channel is formed in the stirring shaft, air outlet holes are formed in the side face of the stirring shaft, an impurity area is arranged below the coarse opening area, at least two sets of wool outlet holes in the vertical direction are formed in the side face of the coarse opening area, vertical rails are arranged on the side face of the collecting area, wool loosening blocks are connected to the rails, wool loosening hooks are arranged on the side faces of the wool loosening blocks and are in an anchor type, air nozzles facing inwards are arranged on the side face of the housing, a suction fan is arranged on the outer side of the discharging port, and a control box is arranged on the outer side of the housing. Materials produced through the sliding rail type dust-free fiber wool opener are fluffy, fine and soft, the burden of equipment is small, production efficiency is high, the phenomenon that many materials are wound on the inner wall of the wool opener can be avoided, and thus the service life is long.

Owner:盐城瑞德棉业有限公司

Fine scutching machine

InactiveCN105970363AEasy to cleanEasy to stackFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersEngineeringMechanical engineering

The present invention proposes a fine cotton cleaning machine, comprising a cleaning box, a first dismantling mechanism and a second dismantling mechanism; the opposite sides of the upper part of the cleaning box are respectively provided with a material inlet and a material outlet, and the first dismantling The cleaning mechanism includes the first filter screen, the first dividing plate, the second dividing plate, the third dividing plate, the fourth dividing plate, a plurality of first small beating rollers and a vibrating motor, the first filtering net, the first dividing plate, the second dividing plate The second partition, the third partition and the fourth partition cooperate with the feed inlet and the box wall of the cleaning box to form a cotton feeding channel in the cleaning box; a partition is installed in the cleaning box corresponding to the lower end of the first partition Dust plate; the second dismantling mechanism includes the fifth partition, the second filter screen, a dust removal knife, a large beater roller and a plurality of second small beater rollers; the fourth partition, the third partition and the fifth partition are connected with the outlet The material outlet and the box wall of the cleaning box cooperate to form a cotton outlet channel in the cleaning box; the cleaning box is provided with a miscellaneous outlet and is located below the second dismantling mechanism. The invention can effectively avoid the problem that a large amount of cotton bundles are entangled on needle punching.

Owner:WANGJIANG RUNHUA TEXTILE

Cotton opener

InactiveCN106381579AAvoid influenceQuality improvementFibre cleaning/opening by air draught arrangementsFibre cleaning and opening machine combinationsFiberCoupling

The invention discloses a cotton opener comprising a machine body; the feed inlet of the machine body is provided with a conveyer and a pre-opening unit; the pre-opening unit comprises a licker-in and a roller; an opening roller is arranged in the machine body; the surface of the opening roller is provided with opening thorns; one end of the opening roller is connected with a motor arranged outside the machine body through a coupling; the bottom in the cavity of the machine body is provided with a vibrator connected with one end of a screen plate; the other end of the screen plate is hinged to the inner wall of the machine body; the machine body below the screen plate is provided with a slag removal port; one side of the machine body is connected with a negative pressure tube; the negative pressure tube is connected with one end of a drawing fan; the other end of the drawing fan is connected with a cotton storage room through a pipeline; the vibrator and the screen plate of the cotton opener can separate the impurities from the cotton, so the impurities can be discharged, thus improving cotton fiber quality; the cotton storage room can collect opened cottons, thus preventing mess conditions caused by random stacking of the cottons.

Owner:华巧波

Four-roller raw cotton opening and impurity removal device for textiles

ActiveCN110396734AHave the effect of hittingAvoid wrappingFibre cleaning and opening machine combinationsFibre cleaning/opening by beater armsPulp and paper industryImpurity

The invention provides a four-roller raw cotton opening and impurity removal device for the textiles and relates to the technical field of cotton thread spinning. The four-roller raw cotton opening and impurity removal device for the textiles comprises a frame, opening stirring rollers are fixedly connected into the frame, and a first filtering plate is fixedly installed on the portion, below theopening stirring roller, in the frame; a second filtering plate is fixedly connected to the portion, below the first filtering plate, in the frame, a draught fan is fixedly connected to the left sideof the frame, a dust collection box is arranged at the bottom of the second filtering plate, and a finished product collection box is arranged at the right side of the frame. According to the four-roller raw cotton opening and impurity removal device for the textiles, when raw cotton is stirred and pulled, the effect of hitting the raw cotton can also be achieved, the opening effect is improved, separation of impurities from dust is accelerated, in the rotation process, stirring rods can retract, the situation is avoided that the raw cotton winds the stirring rollers, cotton batting which leaks down can be recycled again, and waste of the raw cotton is avoided.

Owner:杭州余杭丝绸制造有限公司

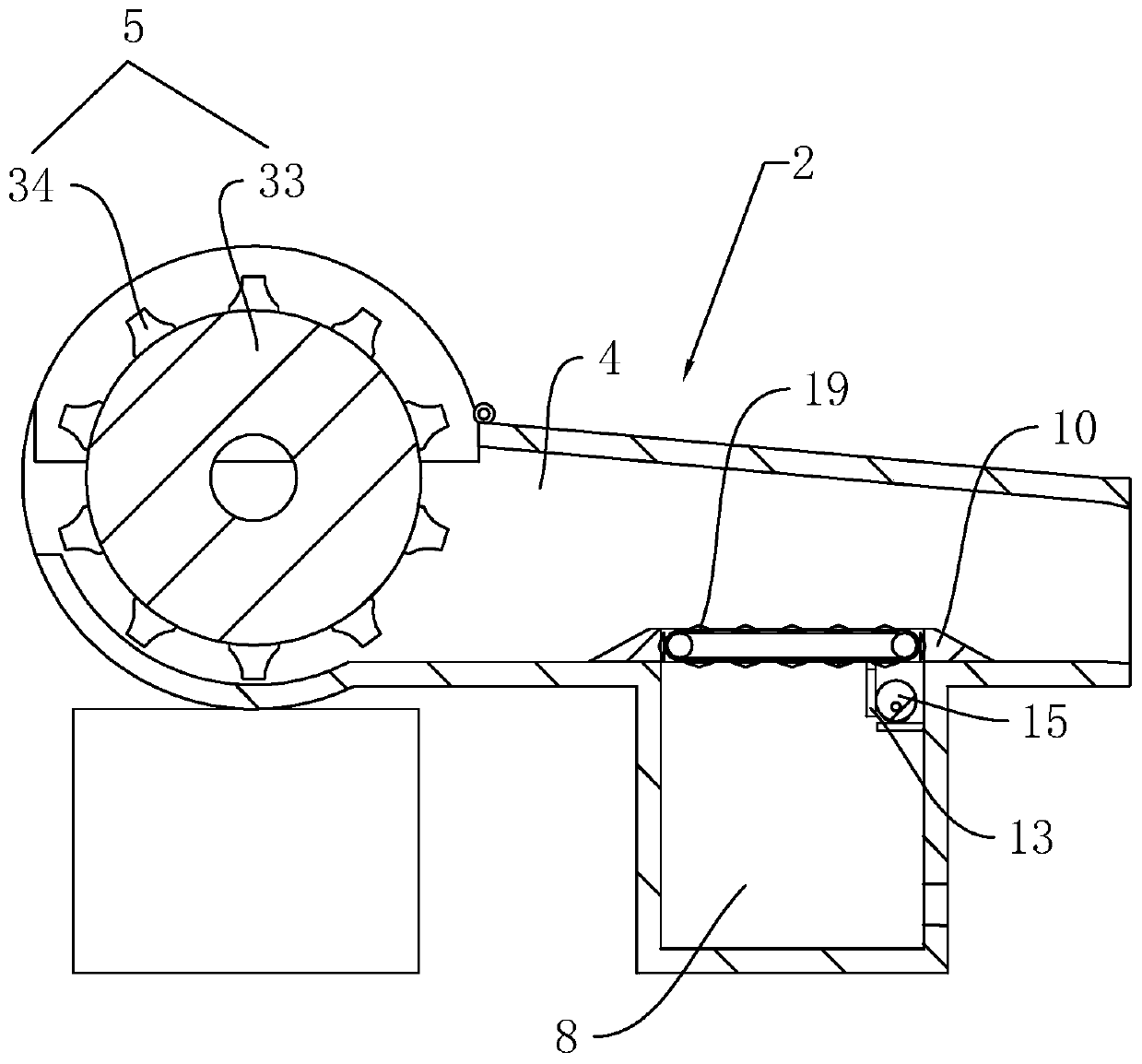

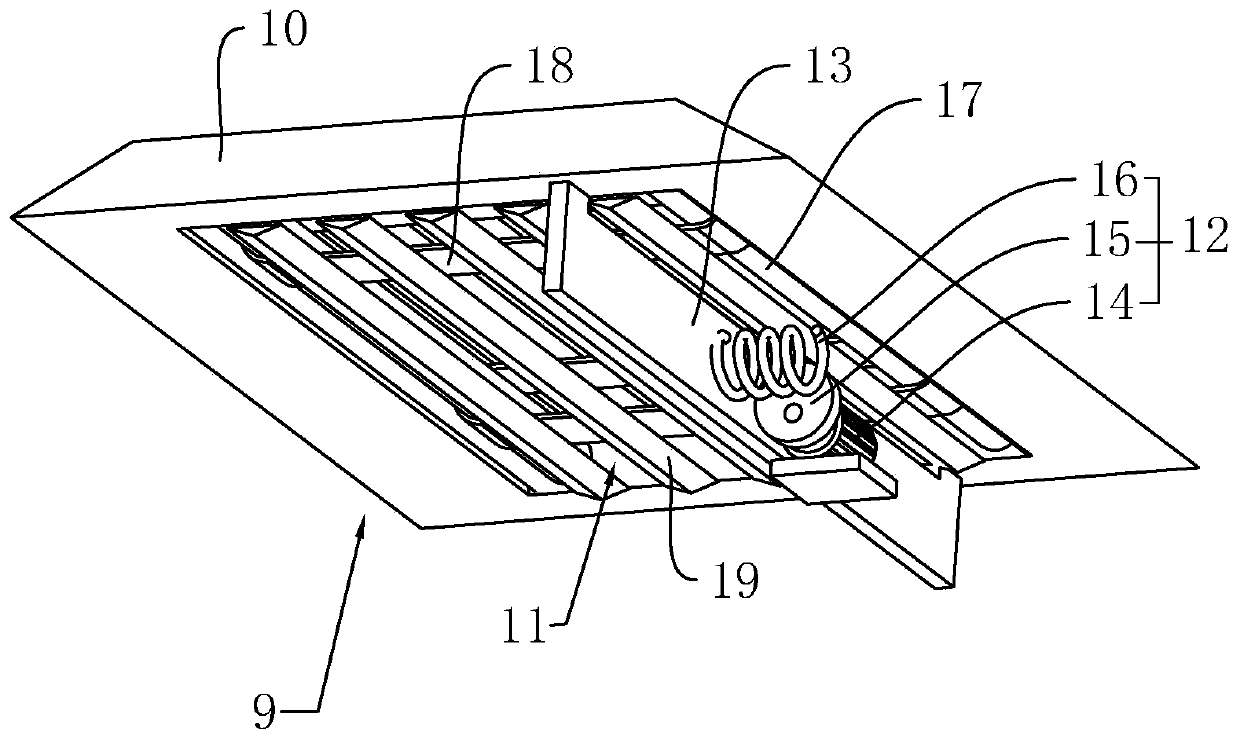

Cotton carding scattering device for home textiles and cotton carding process applying the scattering device

PendingCN110983507AFall into smoothImprove the effect of impurity removalFibre cleaning and opening machine combinationsContinuous processingFiberPolymer science

The invention relates to a cotton carding scattering device for home textiles. The cotton carding scattering device comprises a cotton storage box, wherein the front of the cotton storage box is connected with a scattering device, the scattering device comprises a cotton opening box, a cotton opening mechanism arranged in the cotton opening box and an impurity removing mechanism connected behind the cotton opening mechanism; and the impurity removing mechanism is connected with a feeding mechanism used for feeding fibers to the cotton storage box, the impurity removing mechanism comprises an impurity removing box connected to a bottom surface of the cotton opening box and provided with an opening at an upper end, and a vibrating screen component is arranged at an opening at the top of theimpurity removing box. The cotton carding scattering device disclosed by the invention has the advantage of improving carding and spinning effects by removing impurities from the fibers.

Owner:沈建华

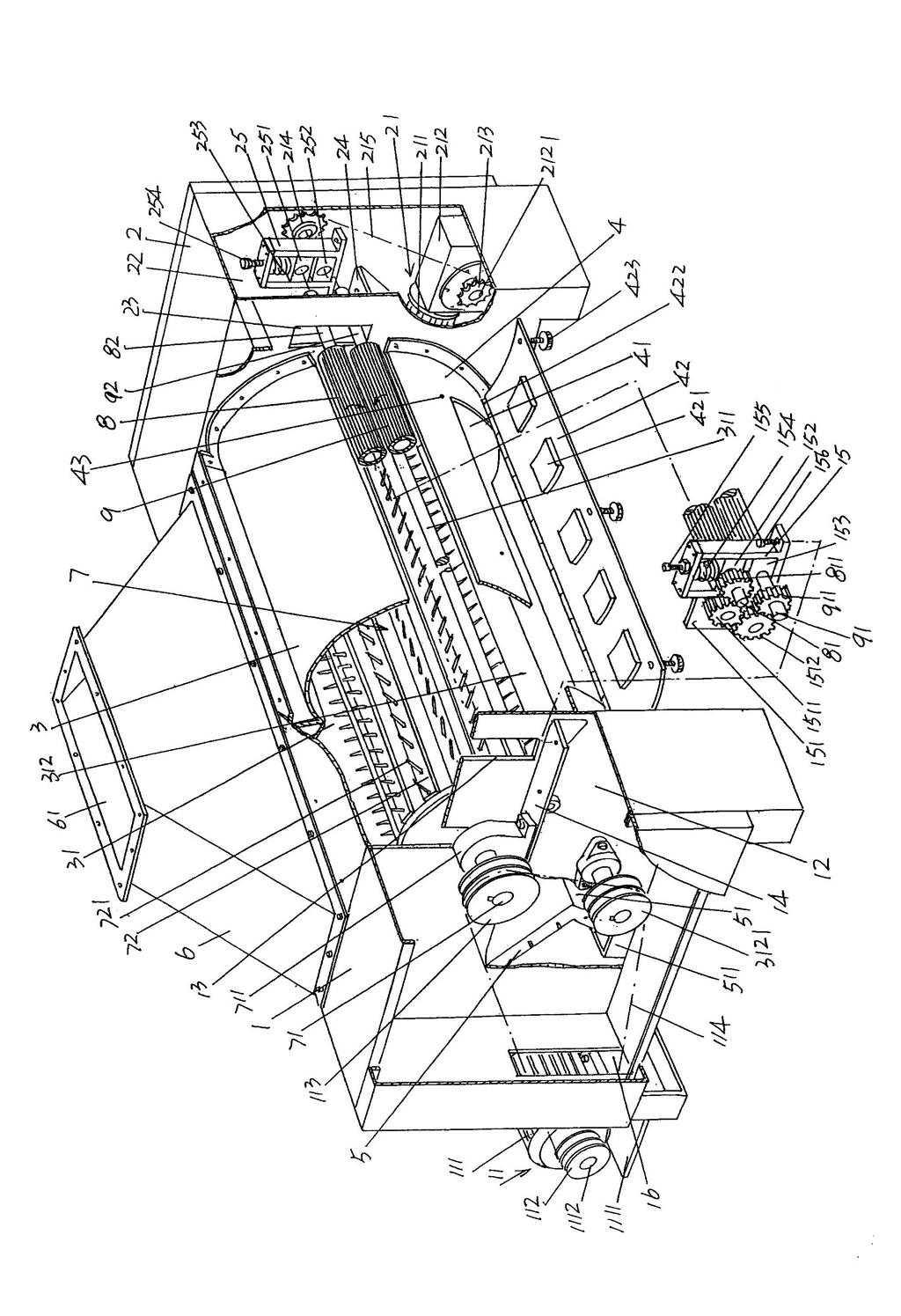

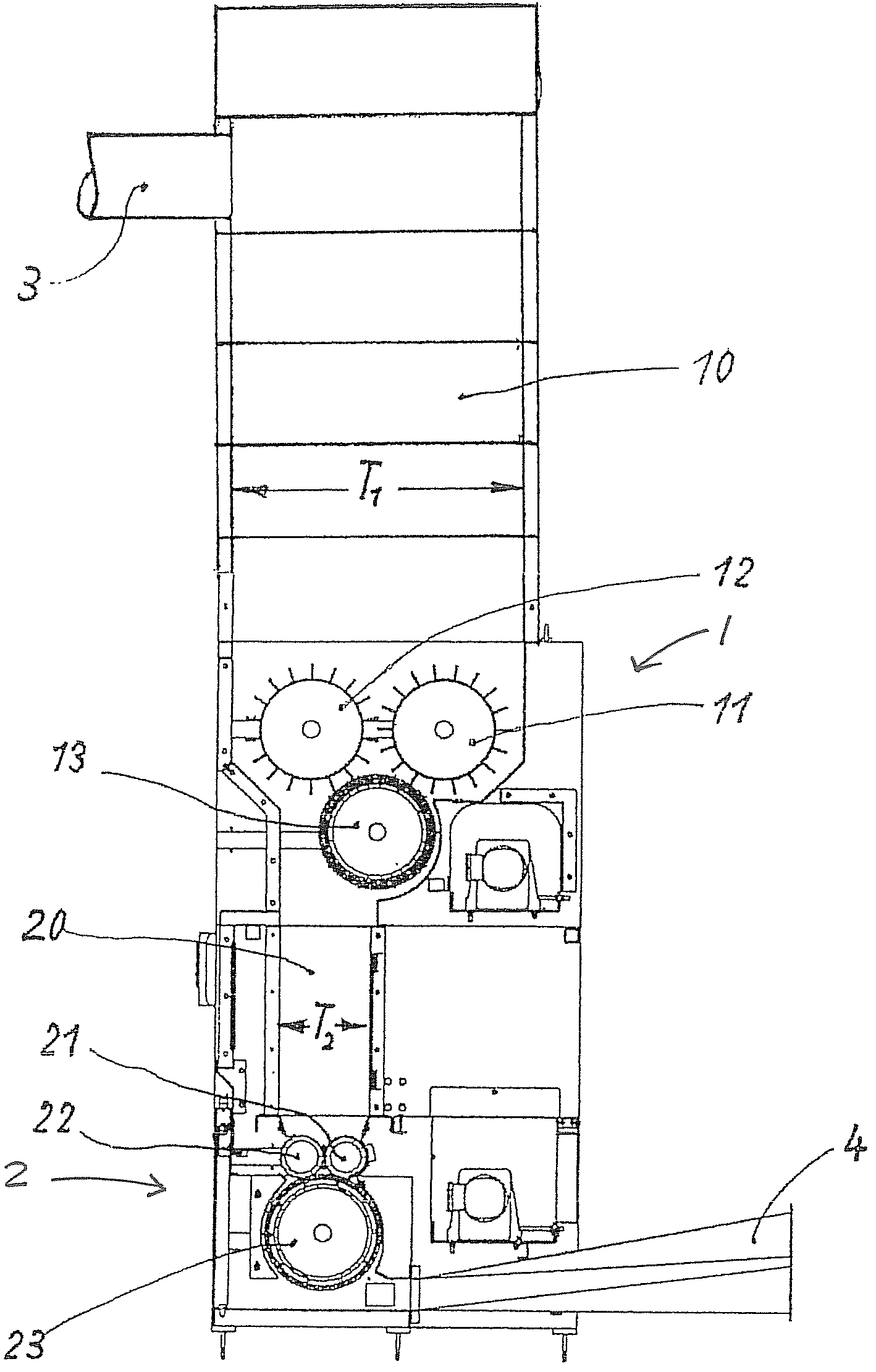

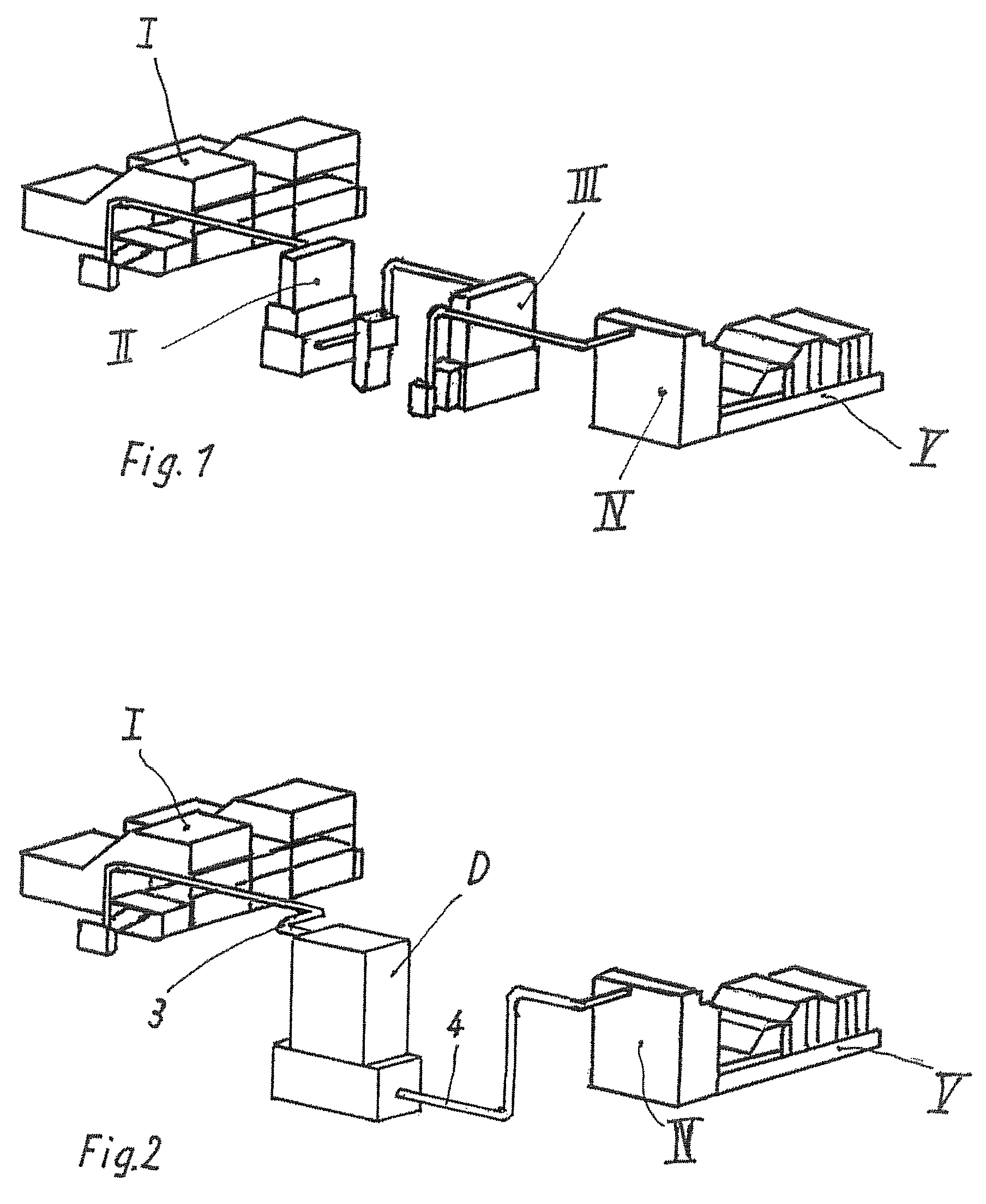

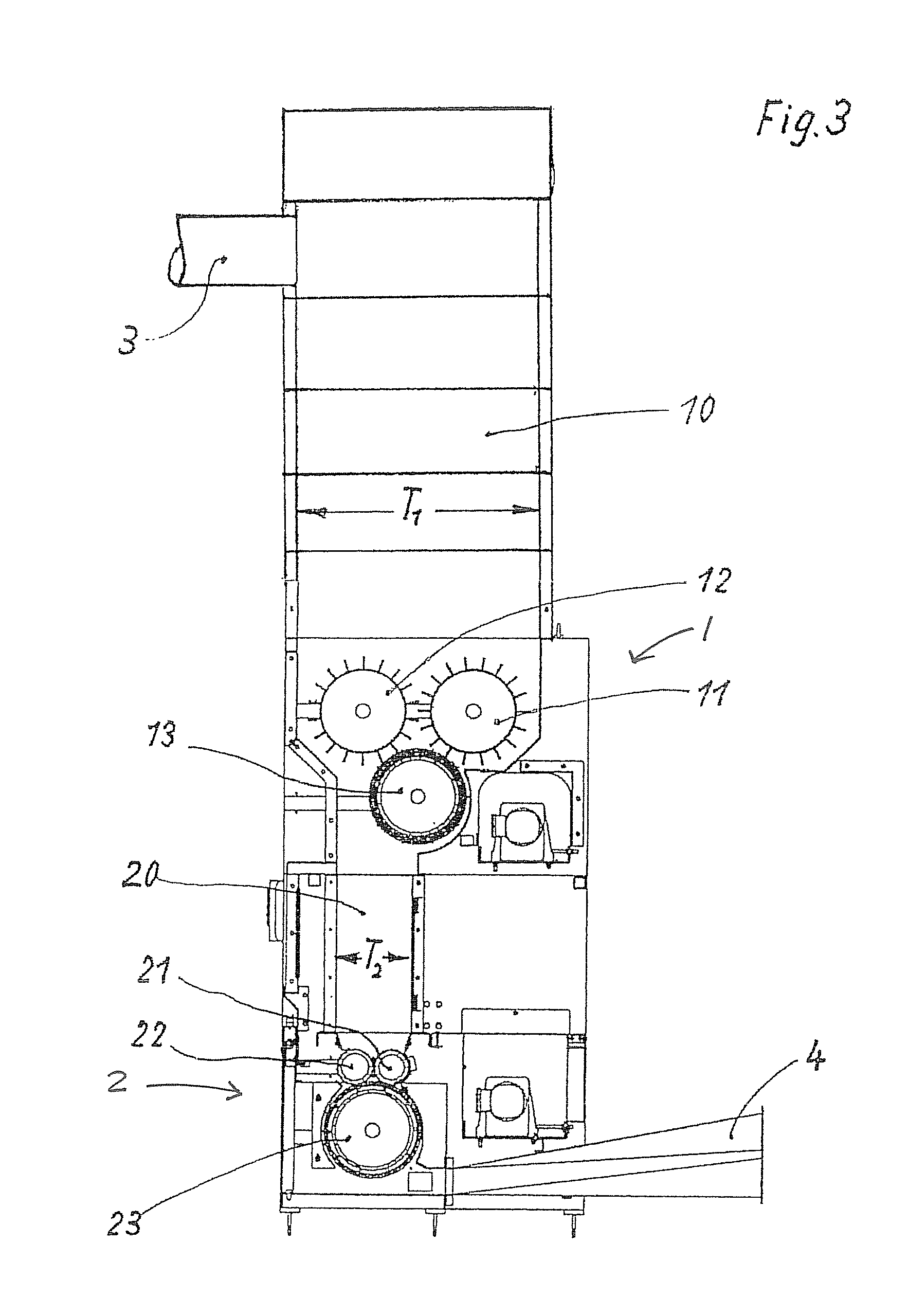

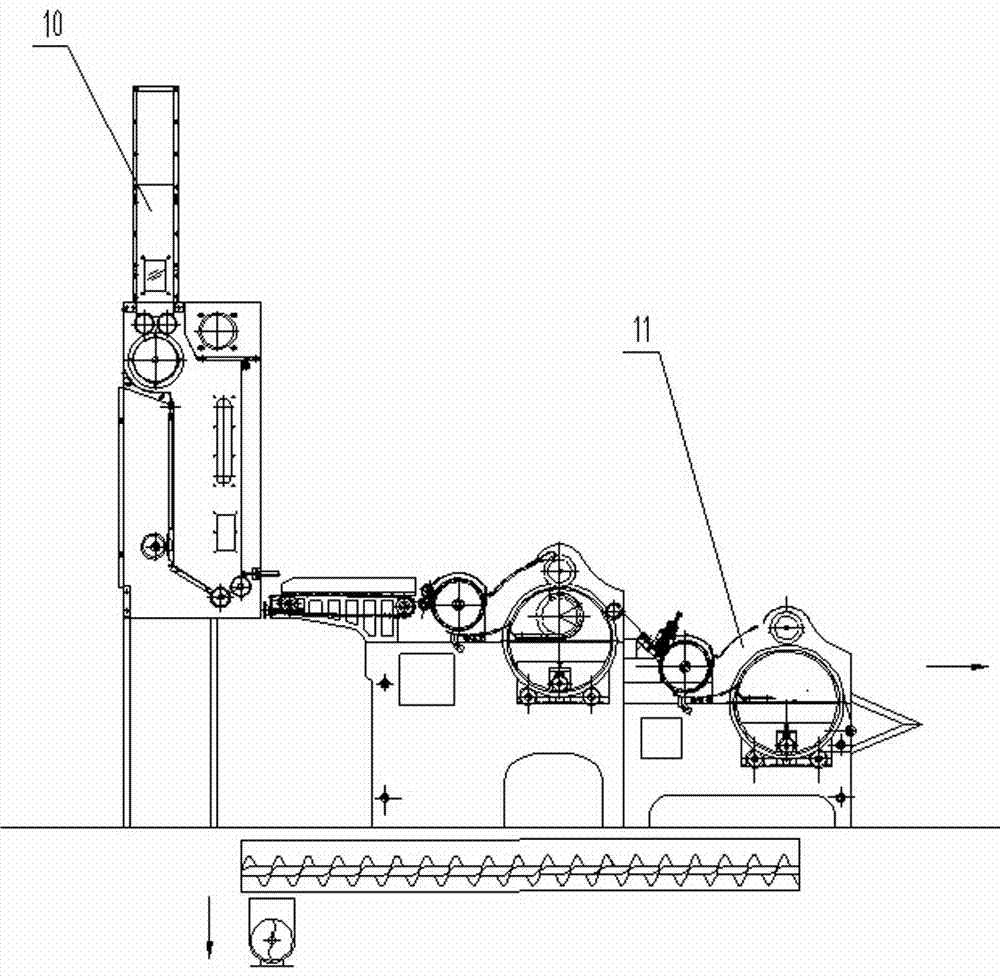

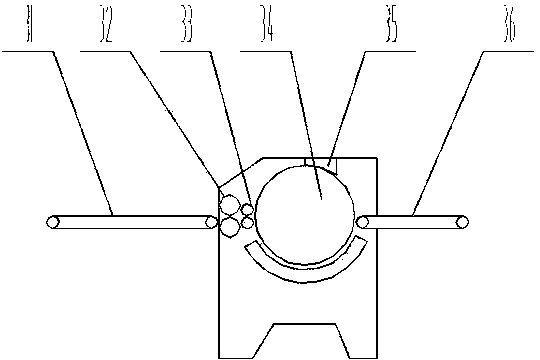

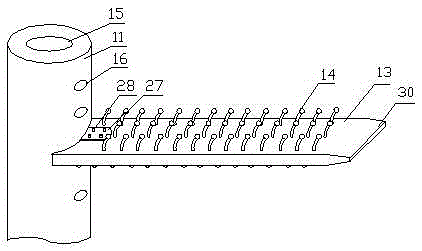

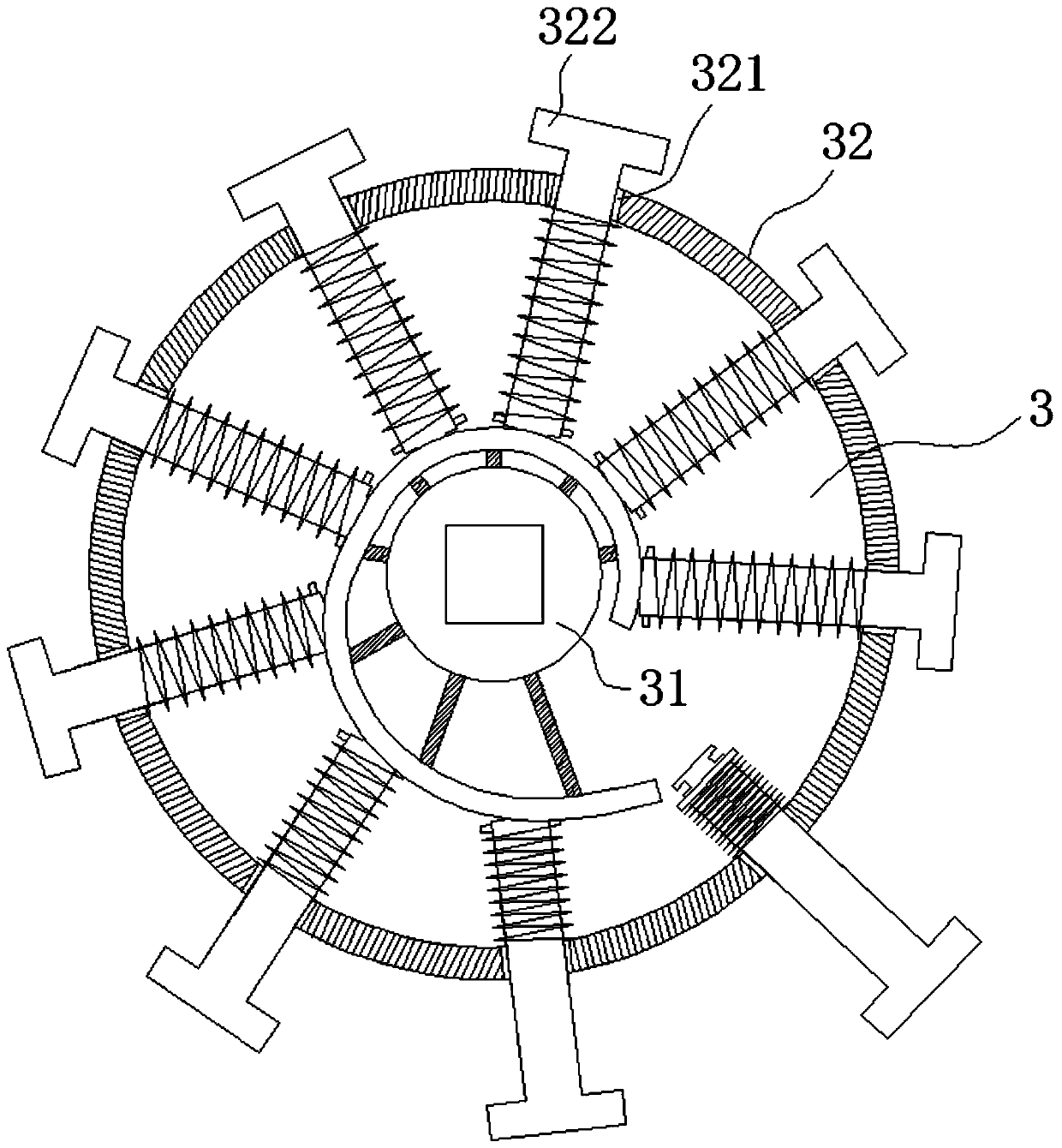

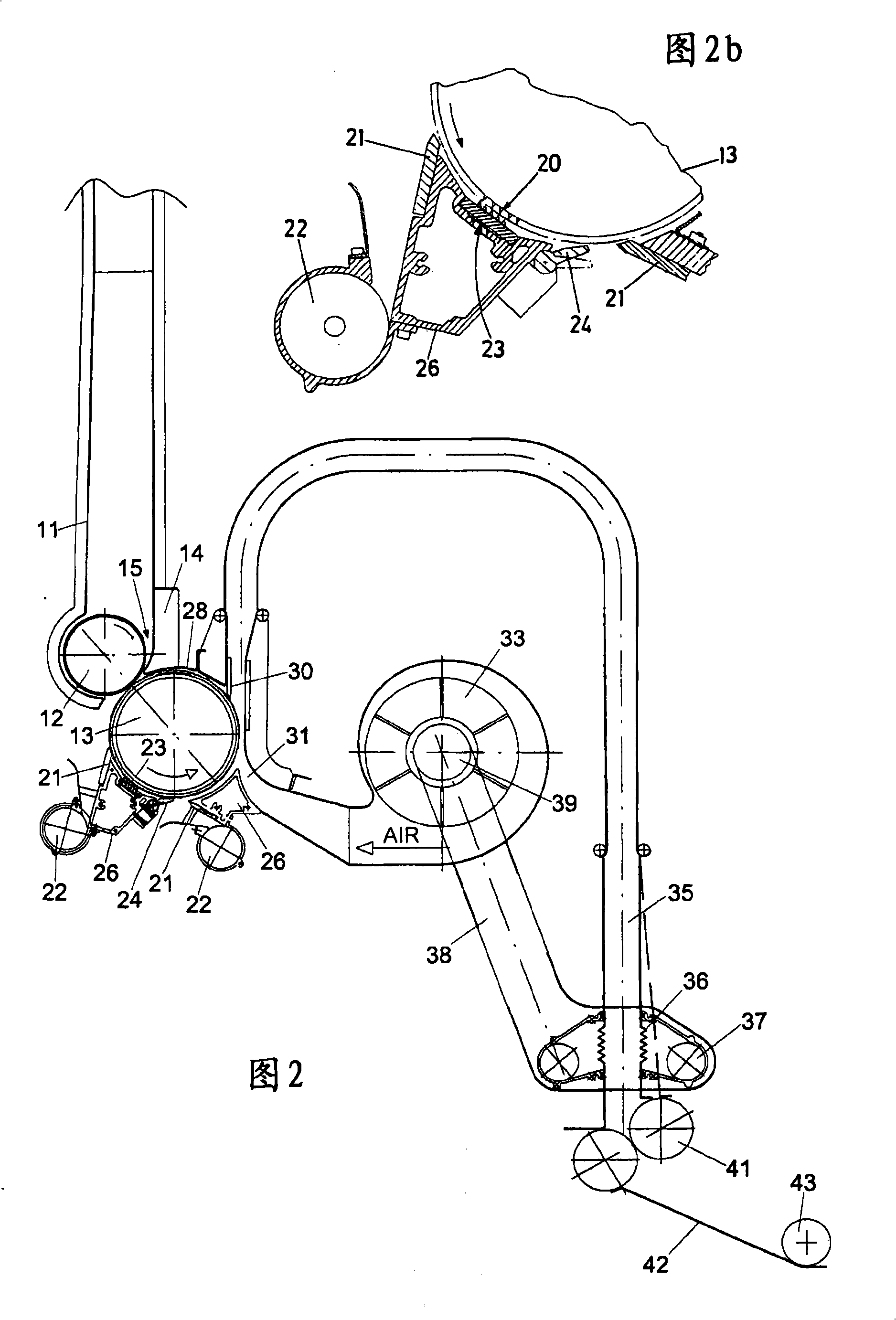

Aggregate unit for bundle fiber and feeding bundle fiber into carding machine

The invention provides a combination device used for opening a bundle fiber and feeding the bundle fiber into a single carding machine, comprising a vertical silo. The vertical silo feeds the bundle fiber into one or more rollers with card clothing to open and clean the bundle; the roller is provided with a treatment element group; the treatment element group comprises a separating knife for cleaning and opening a fiber material, a suction nozzle and a fixed carding section; and then, the fiber material is delivered to a second silo which feeds the fiber material to the carding machine by a pad mode.

Owner:MARZOLI

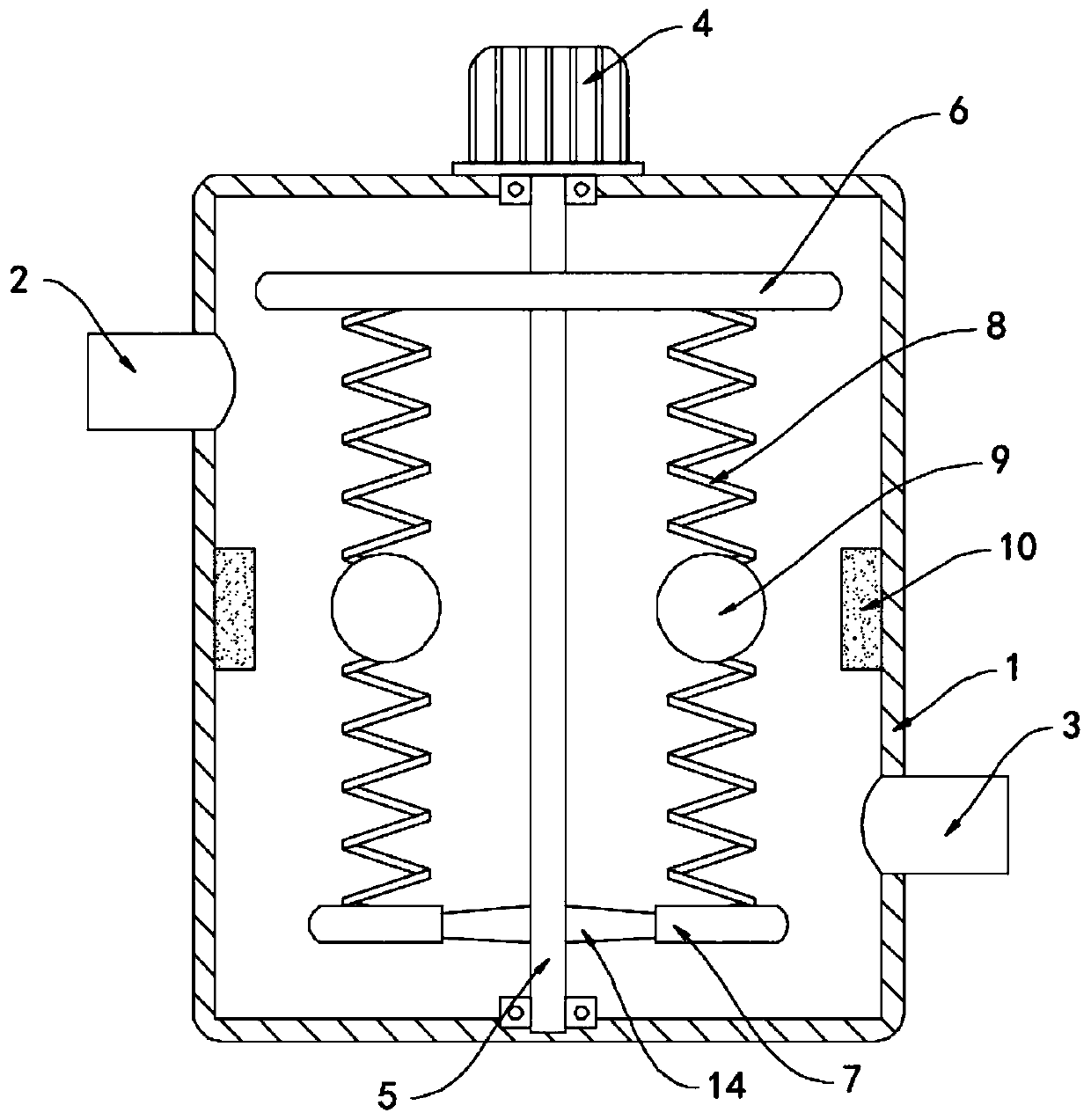

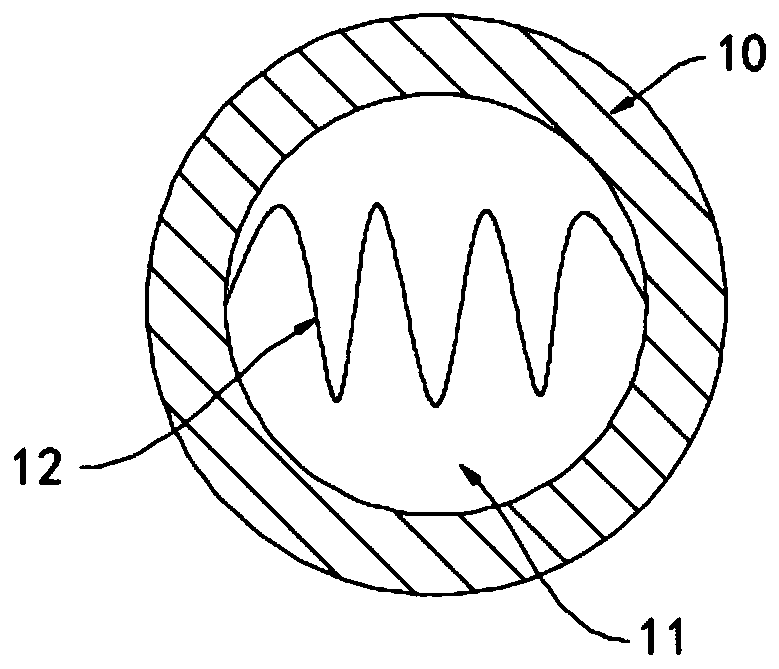

Vibrating spring type efficient cotton opening knocking device

InactiveCN111206306AImprove efficiencyImprove the opening effectFibre cleaning and opening machine combinationsFibre cleaning/opening machinesElectric machineryEngineering

The invention belongs to the technical field of textile machinery, and particularly relates to a vibrating spring type efficient cotton opening knocking device. The device comprises a shell, wherein afeeding pipe and a discharging pipe are fixedly communicated with the side wall of the shell respectively, a motor is fixedly installed on a top surface of the shell, an output shaft of the motor extends into the shell and is coaxially and fixedly connected with a rotating shaft, an upper supporting plate and a lower supporting plate which are horizontally arranged are arranged in the shell respectively, the rotating shaft sequentially penetrates through the upper supporting plate and the lower supporting plate and is rotatably connected with an inner bottom surface of the shell, the rotatingshaft is fixedly connected with the upper supporting plate and the lower supporting plate, a plurality of vibrating springs are fixedly connected between the upper supporting plate and the lower supporting plate, and magnetic flapping balls are fixedly installed on the vibrating springs. The cotton opening knocking device disclosed by the invention can drive the magnetic flapping balls to performhigh-frequency knocking on the cotton in the shell through the high-frequency vibration of the vibrating springs, the cotton opening effect is good, the efficiency is high, and a heating coil is closed to heat and dehumidify the cotton, thereby preventing the cotton from absorbing moisture in air and being agglomerated.

Owner:王珂欣

Opener capable of improving opening speed and quality and dedusting

InactiveCN105040174AEasy to detectSimple structureFibre cleaning and opening machine combinationsFibre cleaning/opening machinesEngineeringMechanical engineering

The invention provides an opener capable of improving opening speed and quality and dedusting. The opener comprises a box body and a dust collector arranged in the box body, multiple opening rollers are fixedly arranged in the box body, the opening rollers are fixedly connected with a speed control wheel for transmission, a speed switch and a vibrating motor are fixedly arranged on one side of the box body, an upper cotton discharging roller and a lower cotton discharging roller are fixedly arranged on the other side of the box body through struts, a vibrating screen is arranged at the bottom of the box body, the vibrating screen is fixedly connected with the vibrating motor, and cotton feeding port is formed in the top end of the box body. According to the opener capable of improving the opening speed and quality and dedusting, the structure is simple, the operation is easy, the practicability is strong, the speed of the speed control wheel is controlled through the speed switch, therefore, the speed of the opening rollers is controlled to control the opening speed, the detection process of a humidity sensor is convenient and fast, cotton bales with appropriate humidity are detected, appropriate opening speed is adopted, the efficiency is high, and the work efficiency and the work quality are greatly improved.

Owner:SUZHOU XINGYUAN TEXTILE

Improved airflow type lint cleaning machine

InactiveCN104357960ASimple structureImprove trash removalFibre cleaning and opening machine combinationsFibre cleaning/opening machinesPulp and paper industryAirflow

The invention relates to the technical field of cotton processing and discloses an improved airflow type lint cleaning machine. The improved airflow type lint cleaning machine comprises a shell, a lint inlet and a lint outlet which are formed in the shell, a lint channel is arranged between the lint inlet and the lint outlet and is provided with at least one sharp turning position, impurity removal notches and lint supporting plates are arranged at the sharp turning position, and impurity dripping plates and impurity removal augers are arranged at the lower ends of the impurity removal notches; a blowing licker-in is arranged at the lint inlet, the lint outlet is connected with an air pipe, and the air pipe is connected with a fan and a discharging device. The improved airflow type lint cleaning machine has the advantages of simple structure, good impurity removal effect and high working efficiency.

Owner:QUANJIAO XINYU COTTON PROD

Integrated cotton material processing equipment

InactiveCN104342761AIncrease filling volumeReduce manufacturing costFibre cleaning and opening machine combinationsVegetable fibre separation from seedsEngineeringAir blower

The invention provides integrated cotton material processing equipment. The integrated cotton material processing equipment comprises a feeding box, a working box, a material collecting box, an air blower and a discharging opening, wherein the feeding box, the working box and the material collecting box are sequentially connected and provided with communicating holes, a main conveyor belt is arranged in the feeding box, barbs are arranged on the main conveyor belt, a guide-in roller, an auxiliary licker-in, a main licker-in, a guide-out roller and a cotton collecting beam are arranged in the working box, the guide-in roller is in contact with the barbs on the main conveyor belt, the guide-in roller, the auxiliary licker-in and the guide-out roller are tangent with the main licker-in, the auxiliary licker-in and the guide-out roller are arranged on the two sides of the main licker-in, the guide-in roller and the auxiliary licker-in are arranged on the same side of the main licker-in, the cotton collecting beam is placed at the communicating hole between the working box and the material collecting box, one end of the air blower is connected with the material collecting box, and the other end of the air blower is connected with the discharging opening. The integrated cotton material processing equipment has the positive effects that working equipment are highly integrated, the structure is simple, cotton loosening processing can be fully realized, raw silk is effectively reduced, the filling content of cotton spinning products is improved, and the production cost of enterprises is directly reduced.

Owner:天津市沃琦家具有限公司

Device for cleaning up hybrid fibers

InactiveCN103741268ASimple structureImprove the efficiency of removing trash fibersFibre cleaning and opening machine combinationsFibre cleaning/opening by toothed membersFiberEngineering

The invention relates to a device for cleaning up hybrid fibers. The device comprises a machine frame, wherein the machine frame is provided with a cotton feeding box, a conveyer belt is arranged on an outlet of the cotton feeding box on the machine frame, a cotton inlet is arranged in the end portion of the cotton feeding box, the inside, right opposite to the cotton inlet, of the cotton feeding box is provided with a pair of barbed nail rollers which are the same in rotation direction, and an oblique guide plate extending to the conveyer belt is arranged on one side of the cotton feeding box in the rotation direction of the barbed nail rollers. The device for cleaning up the hybrid fibers is simple in structure, raw cotton is preprocessed through the barbed nail rollers in a cotton feeding machine so that the raw cotton can be opened, and the hybrid fibers are exposed; meanwhile, particles, dust, impurities and the like in the raw cotton can be removed, the opened raw cotton is smoothly guided into the upper conveying edge on the conveyer belt through the guide plate, operation staff pick and choose the hybrid fibers, and removing efficiency of the hybrid fibers is greatly improved.

Owner:WUJIANG DAYE SILK FINISH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com