Patents

Literature

134results about How to "Improve the opening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

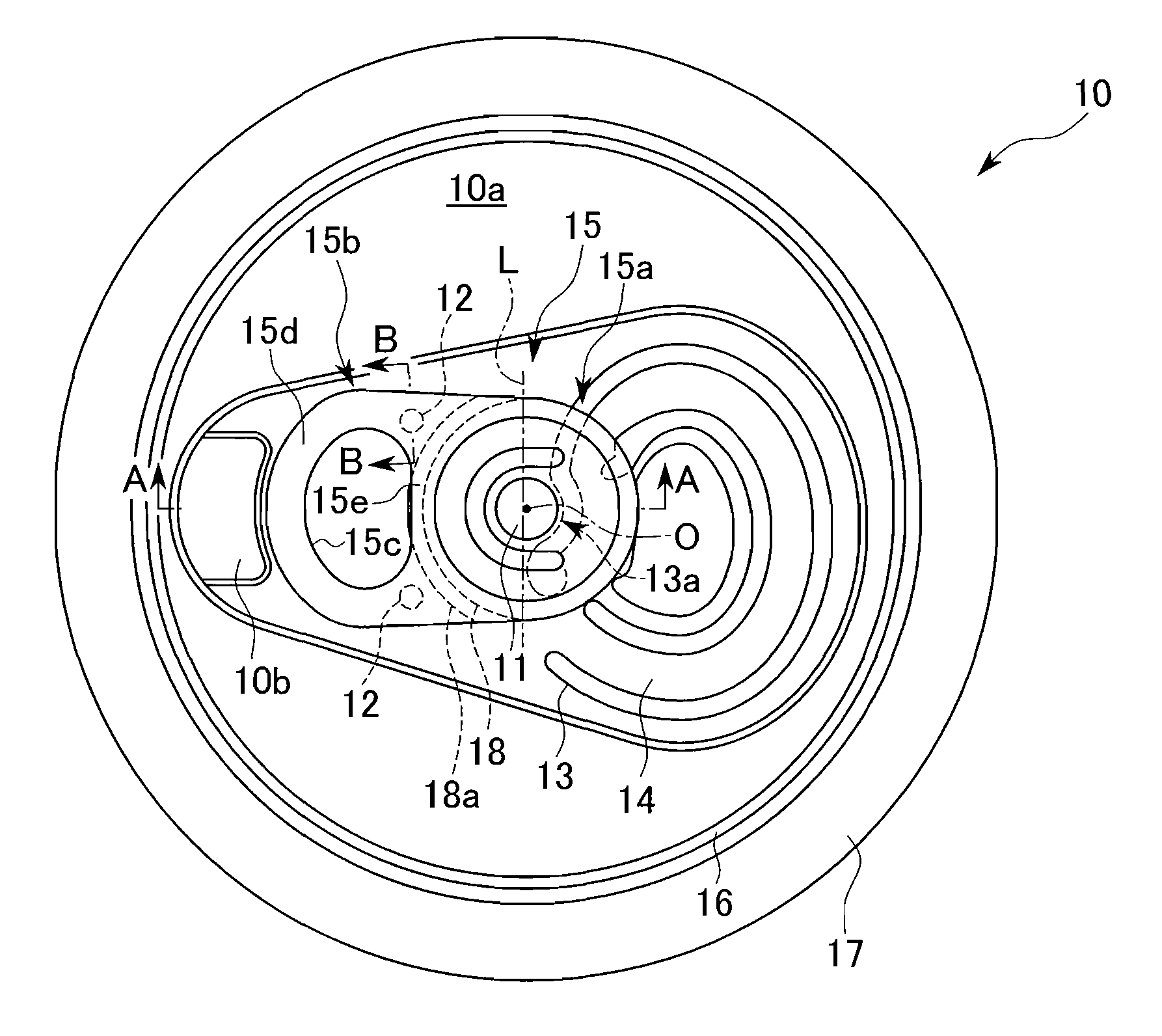

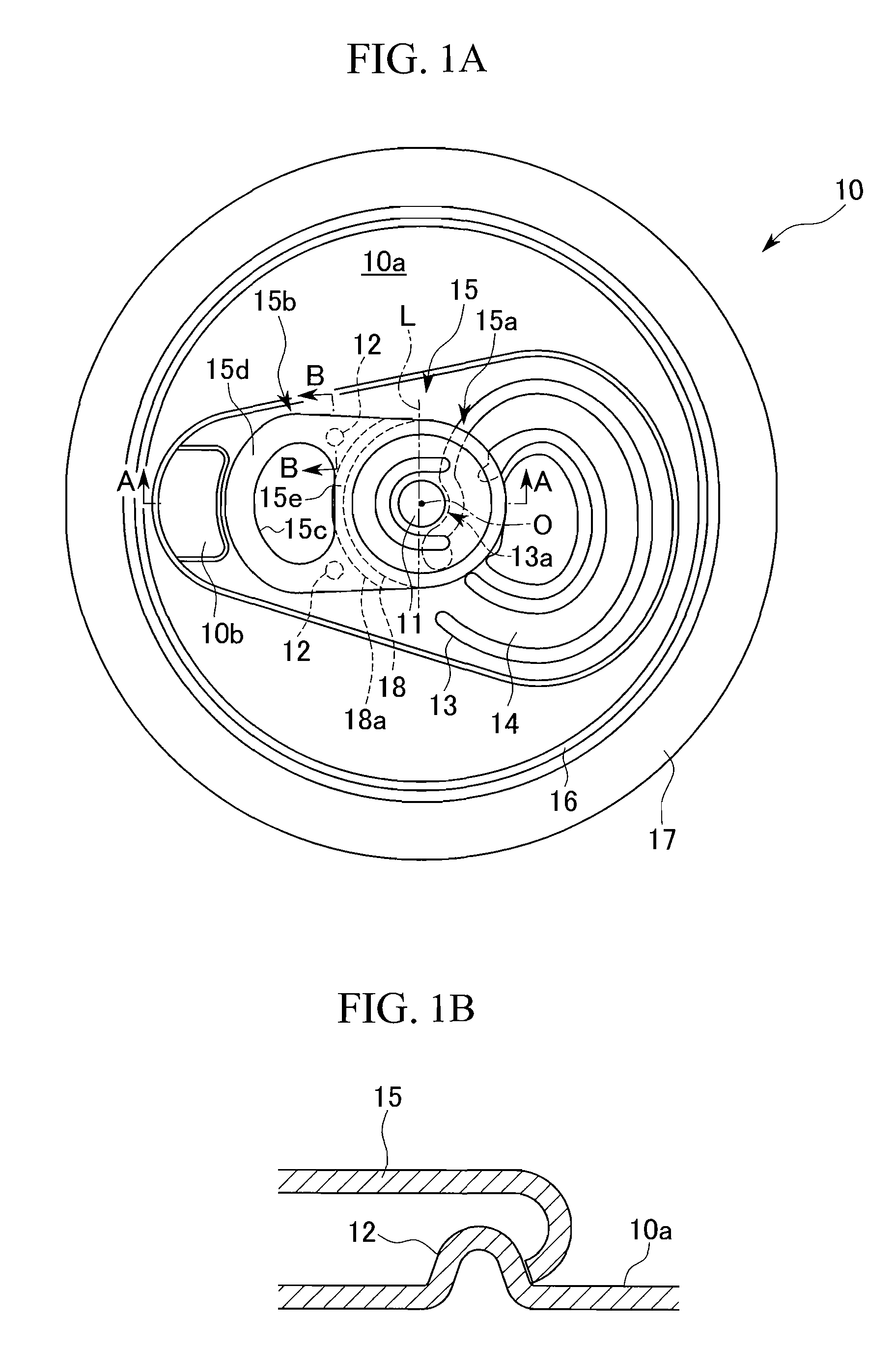

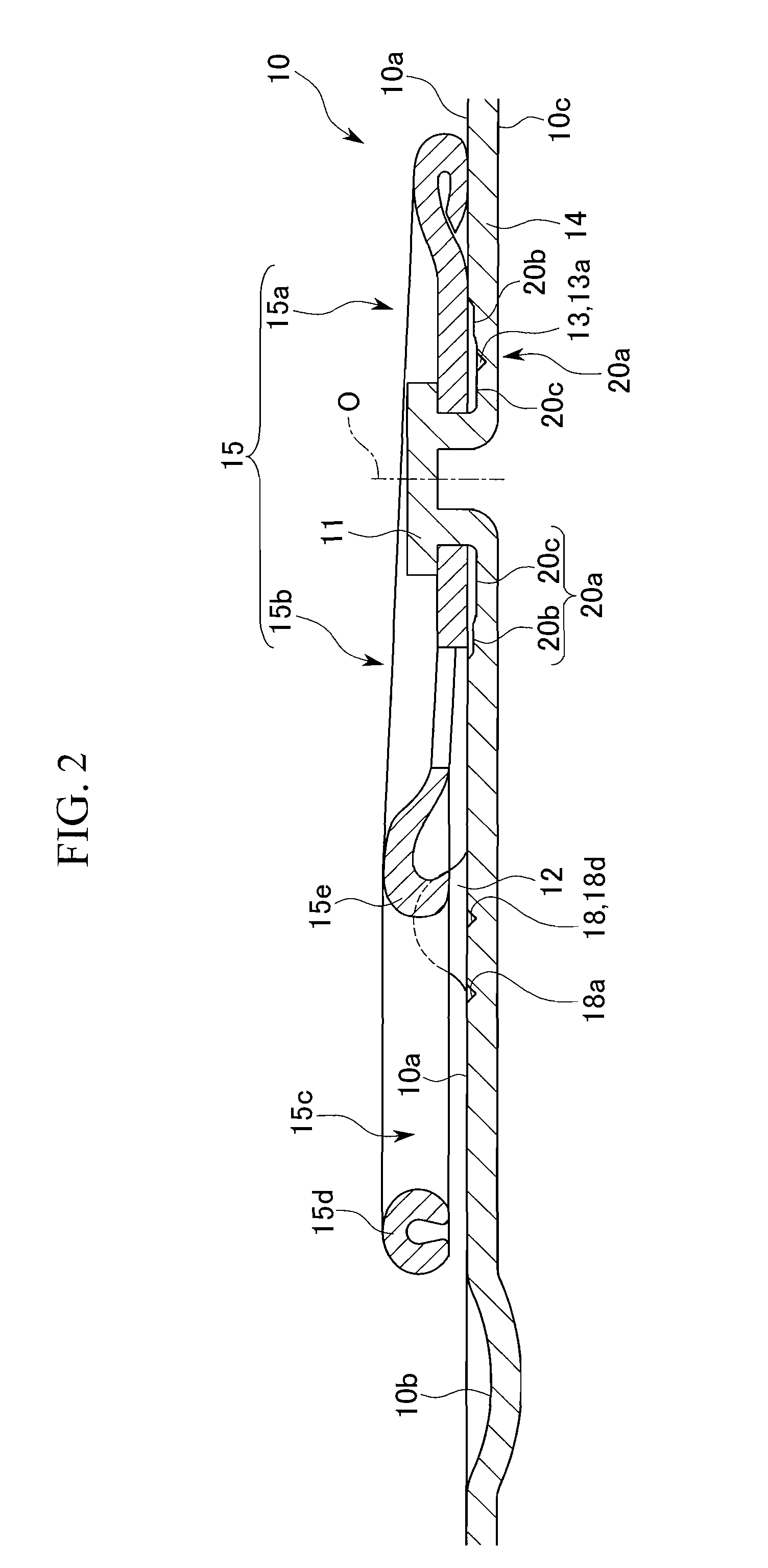

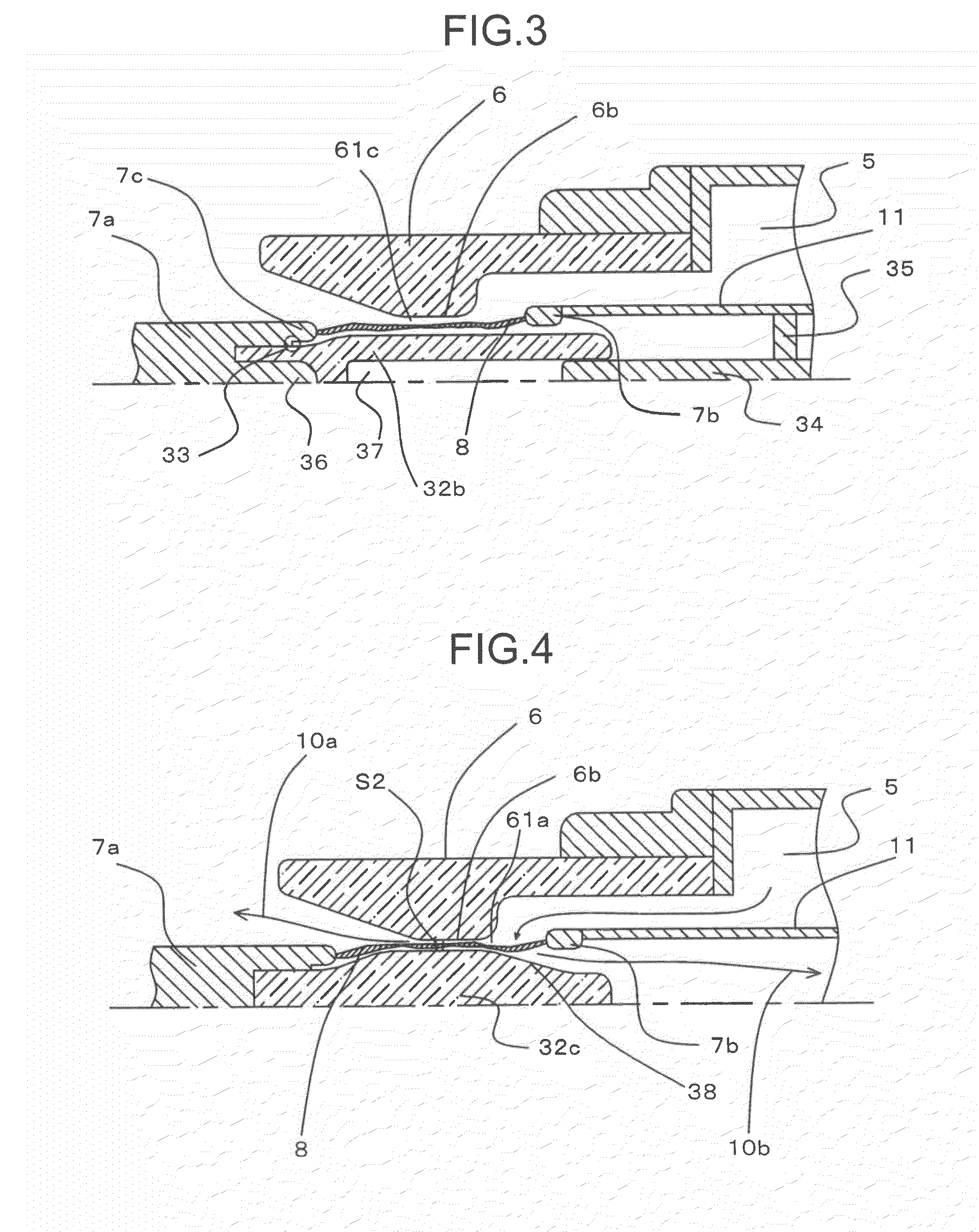

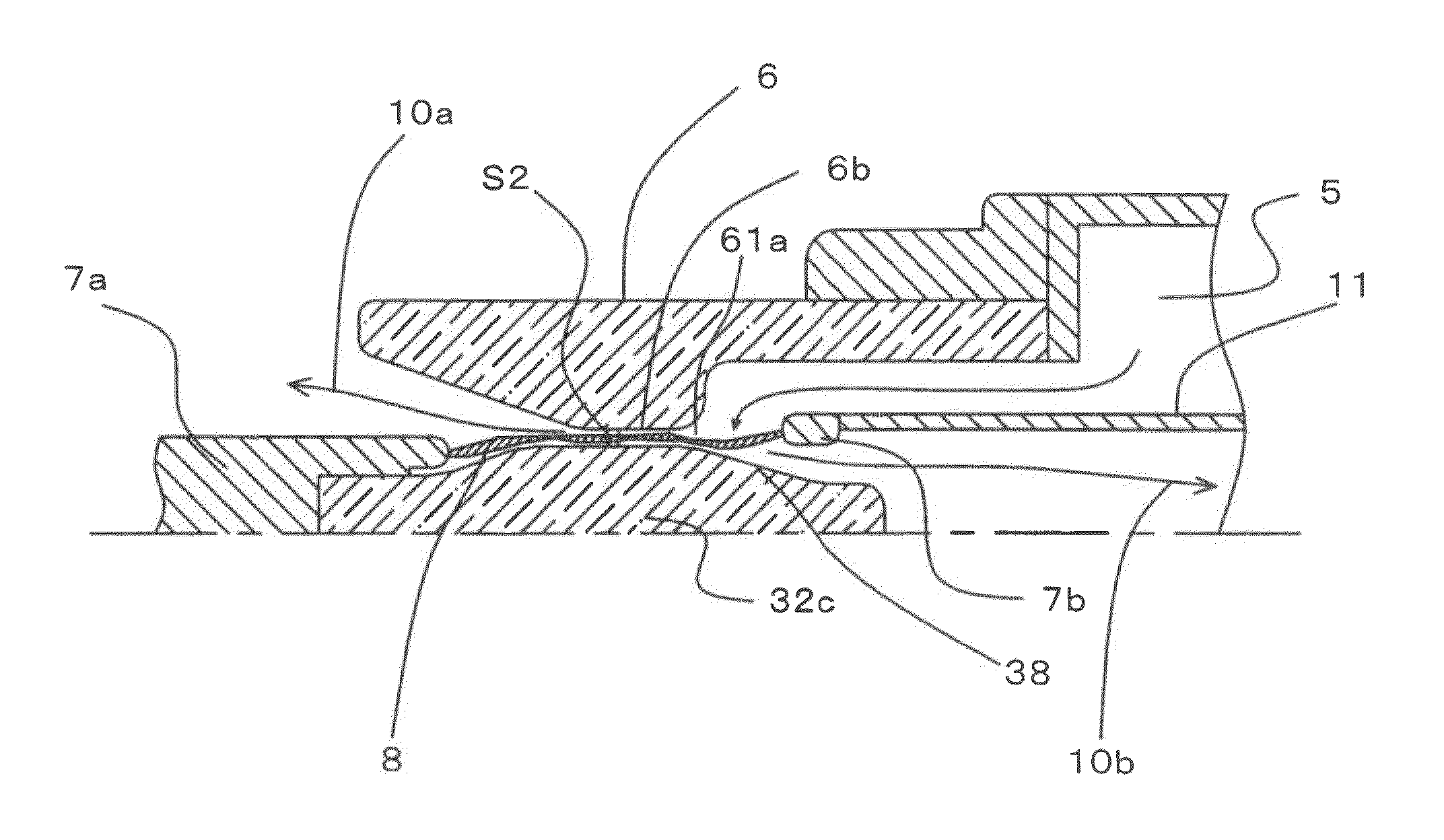

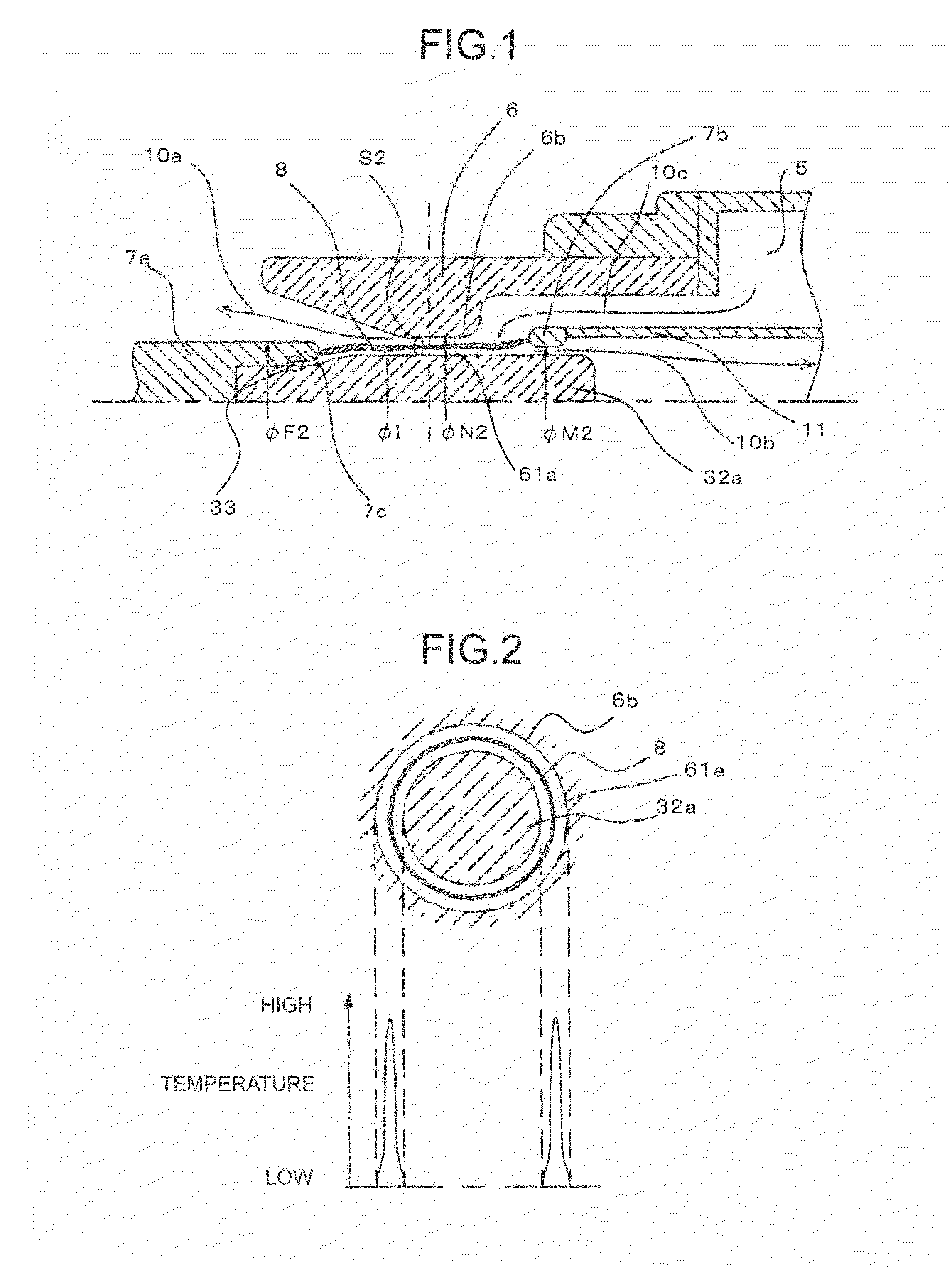

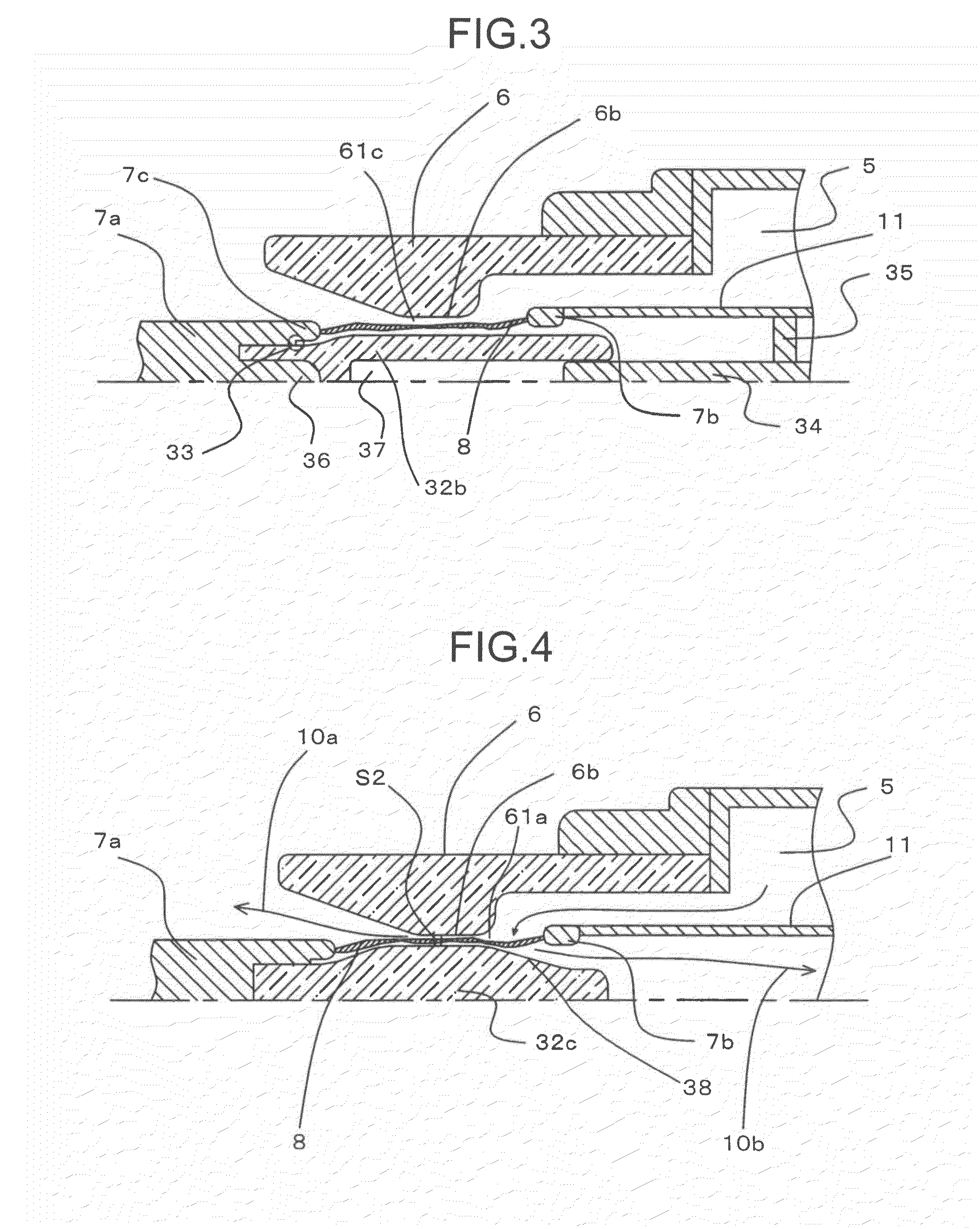

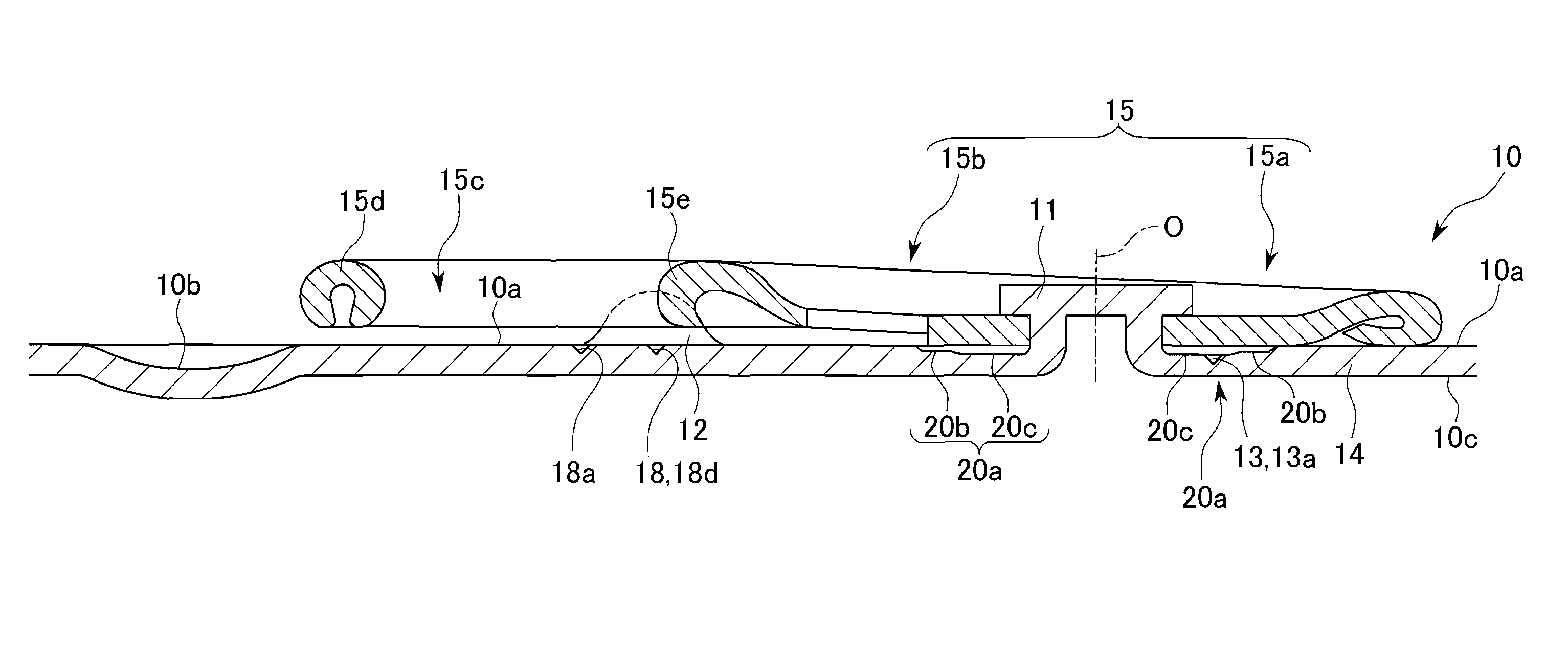

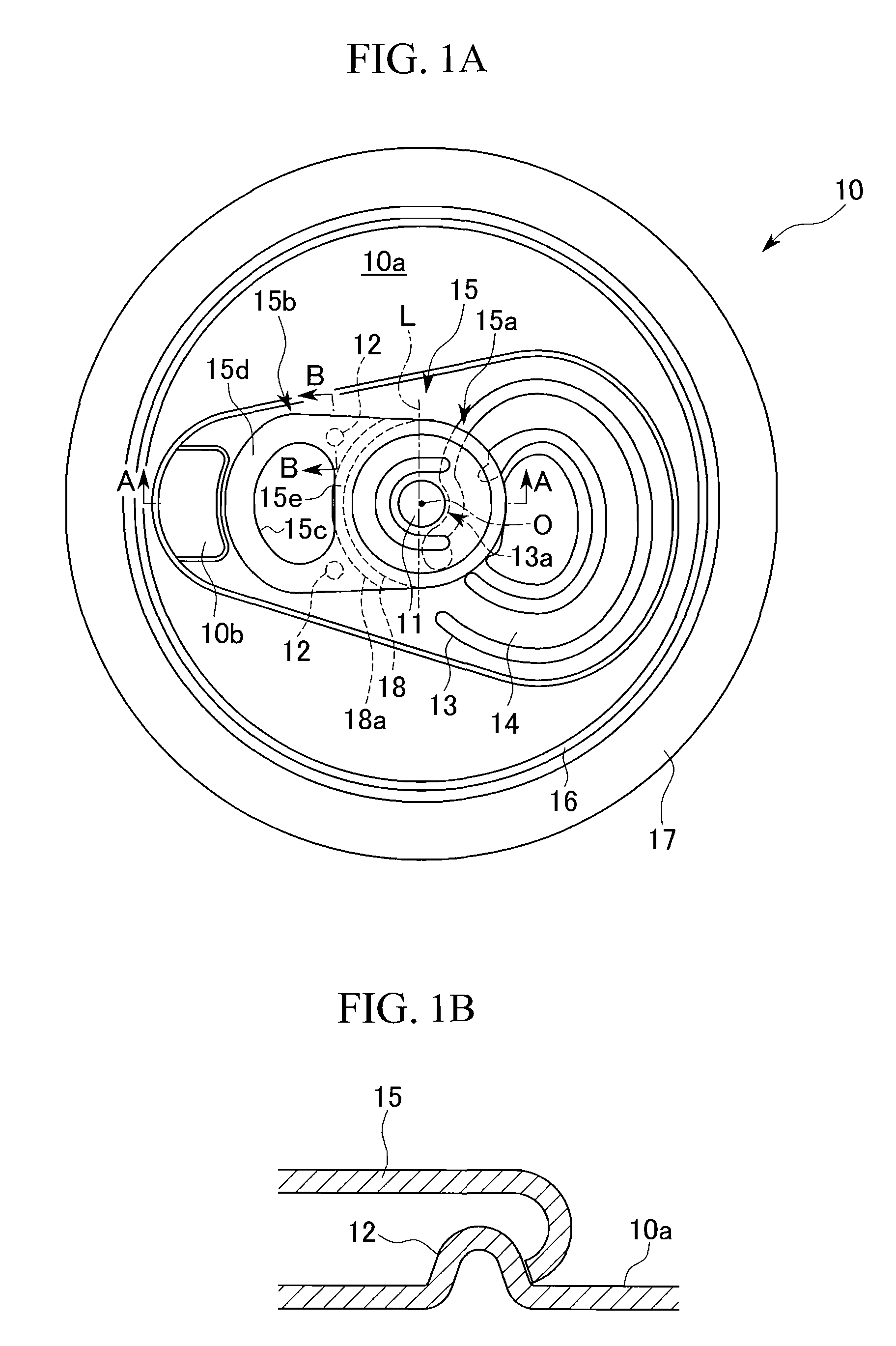

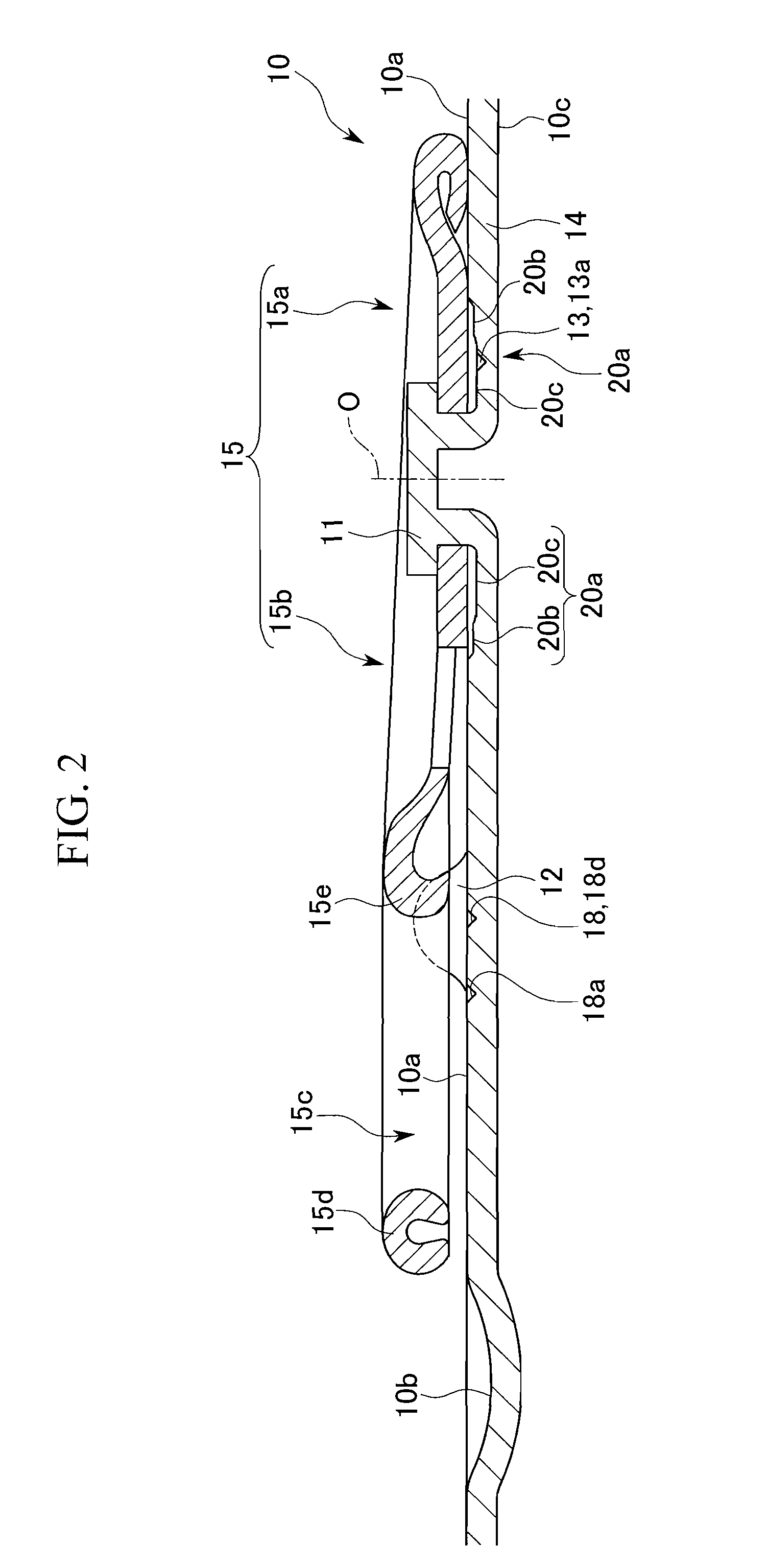

Can lid

ActiveUS20070215621A1Improve the opening effectDeteriorating impactRefuse receptaclesRigid containersEngineeringRivet

In this can lid, a rivet-slanting inhibitor which flows a metal of the can lid main body located between the rivet to the rivet side thereby correcting or preventing the slanting of the rivet is formed on a location in an opposite area which is opposed to an opening part across the rivet except for the coining part.

Owner:UNIVERSAL CAN CORP

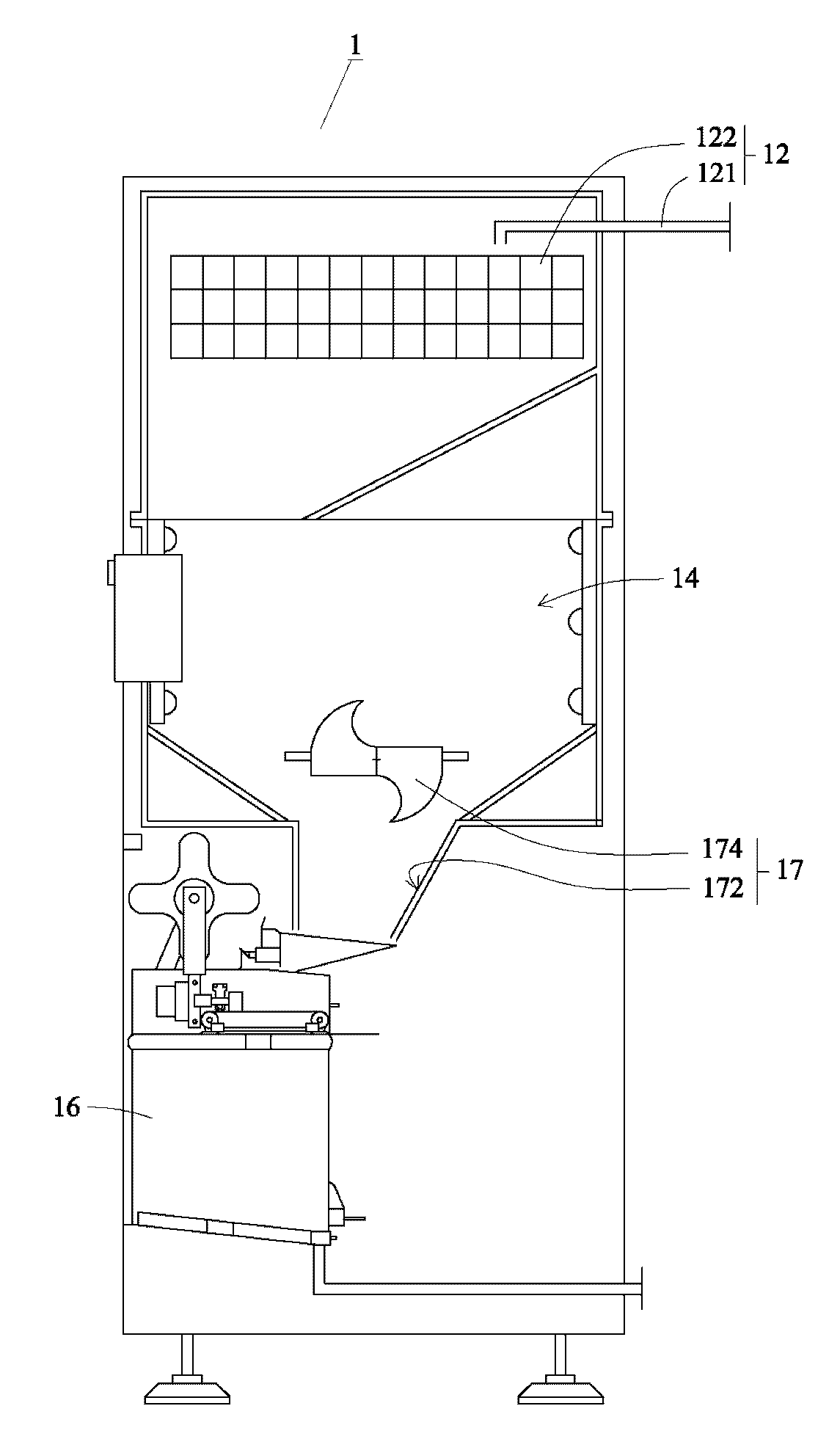

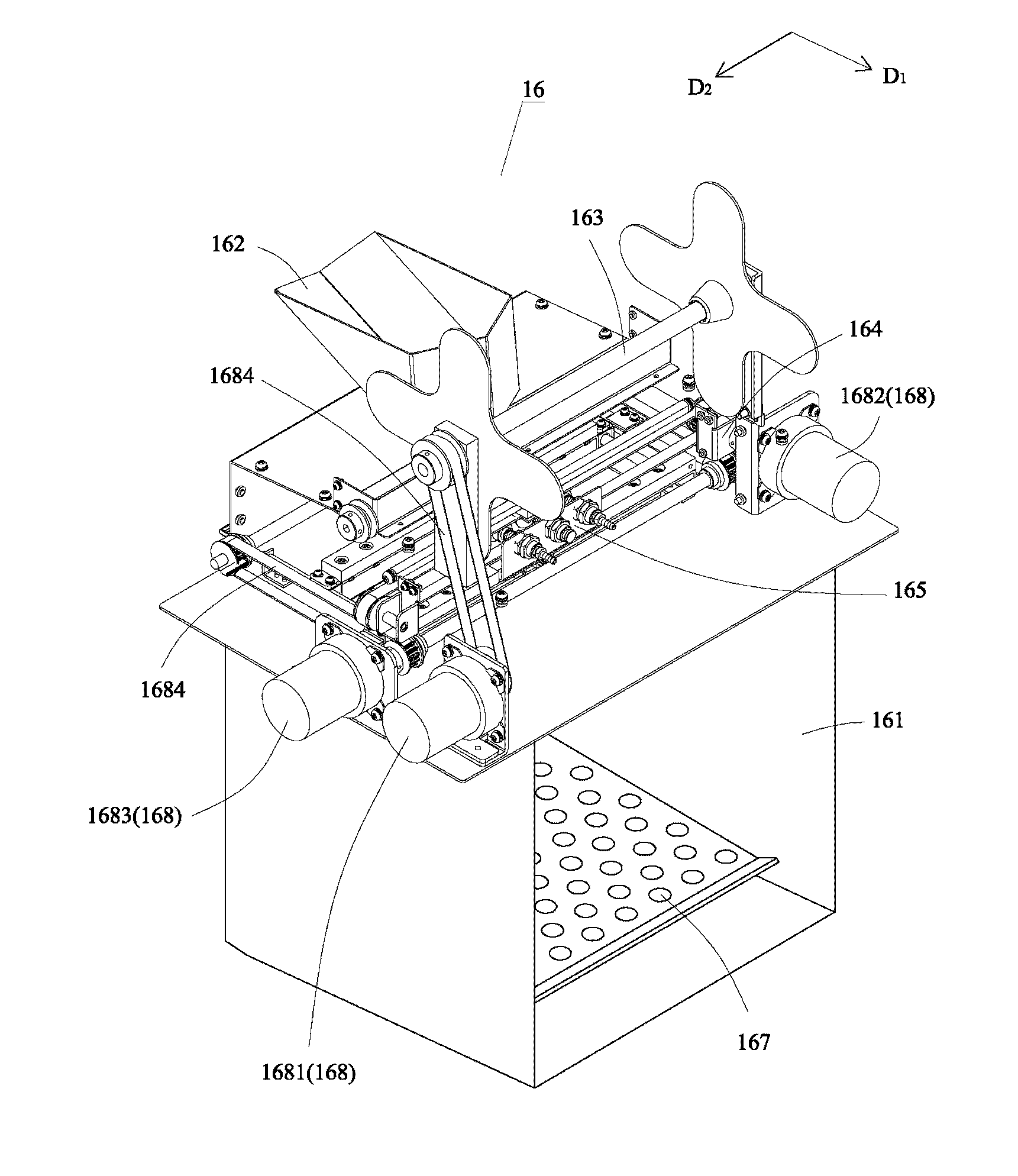

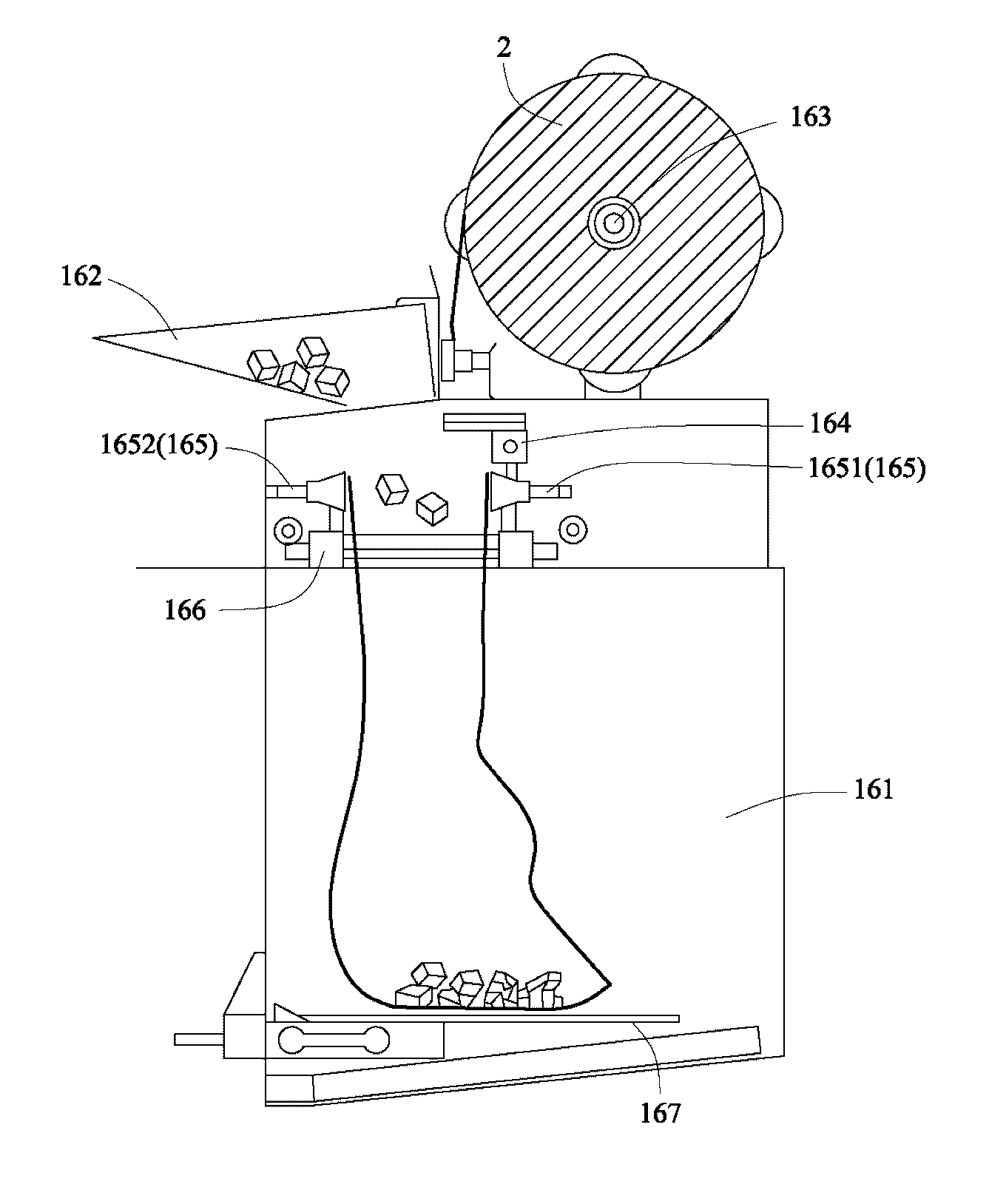

Bag closing machine and ice cake vending machine using same

InactiveCN102001456AThe volume can be made exquisiteOpen fastWrapping material feeding apparatusLighting and heating apparatusIce storagePlastic bag

The invention discloses a bag closing machine and an ice cake vending machine using the same. The ice cake vending machine comprises an ice making module, an ice storage barrel, the bag closing machine and an ice guide mechanism, wherein the ice storage barrel is positioned below the ice making module and is used for storing ice cakes made by the ice making module; and the ice guide mechanism is positioned between the ice storage barrel and the bag closing machine and is used for guiding the ice cakes in the ice storage barrel to the bag closing machine. A first electric heating component is adopted by a cutting machine of the bag closing machine for cutting drum plastic bags, so the volume of the bag closing machine can be made exquisite and the bag closing machine can be placed in the ice cake vending machine.

Owner:DONGGUAN JIAFENG MECHANICAL EQUIP

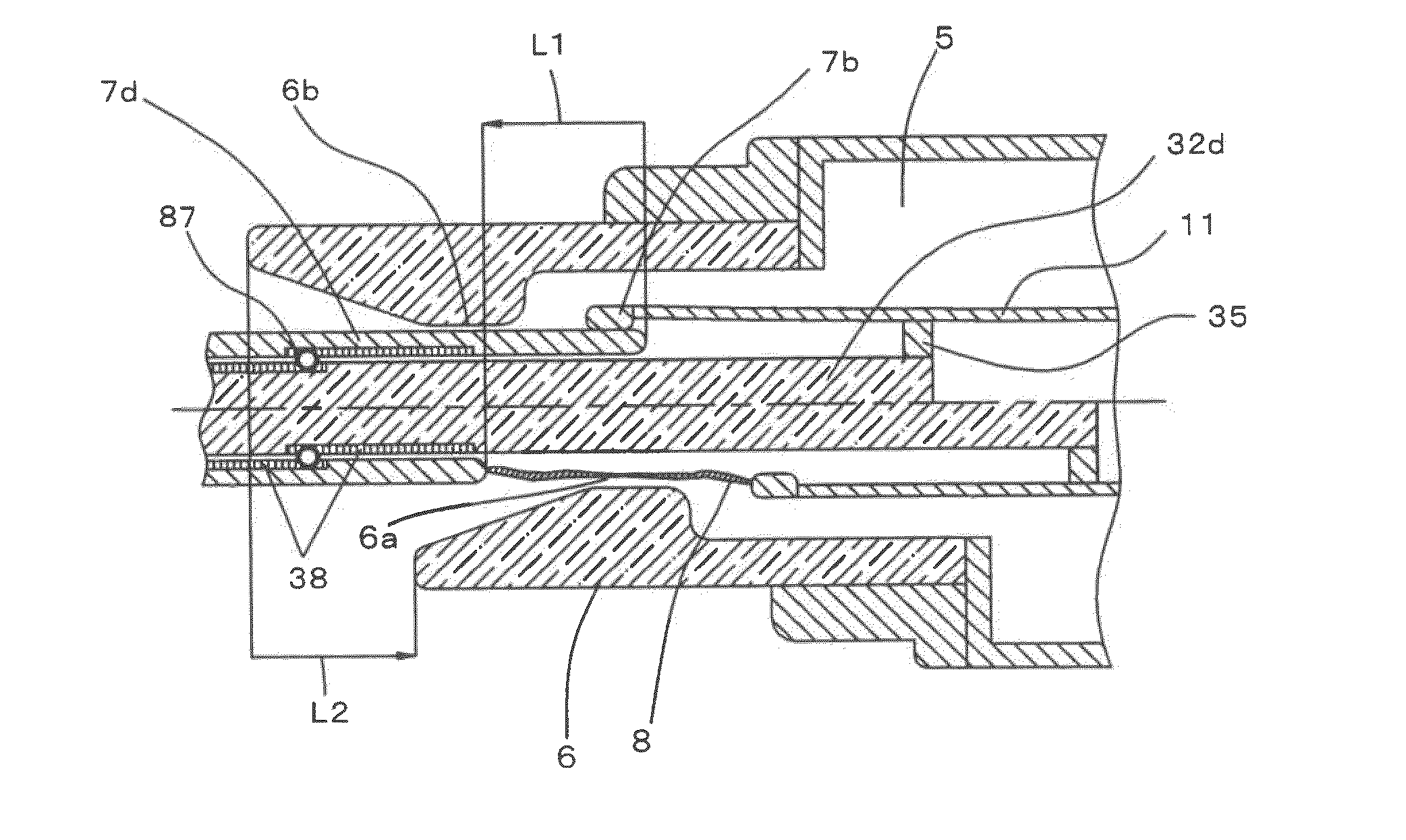

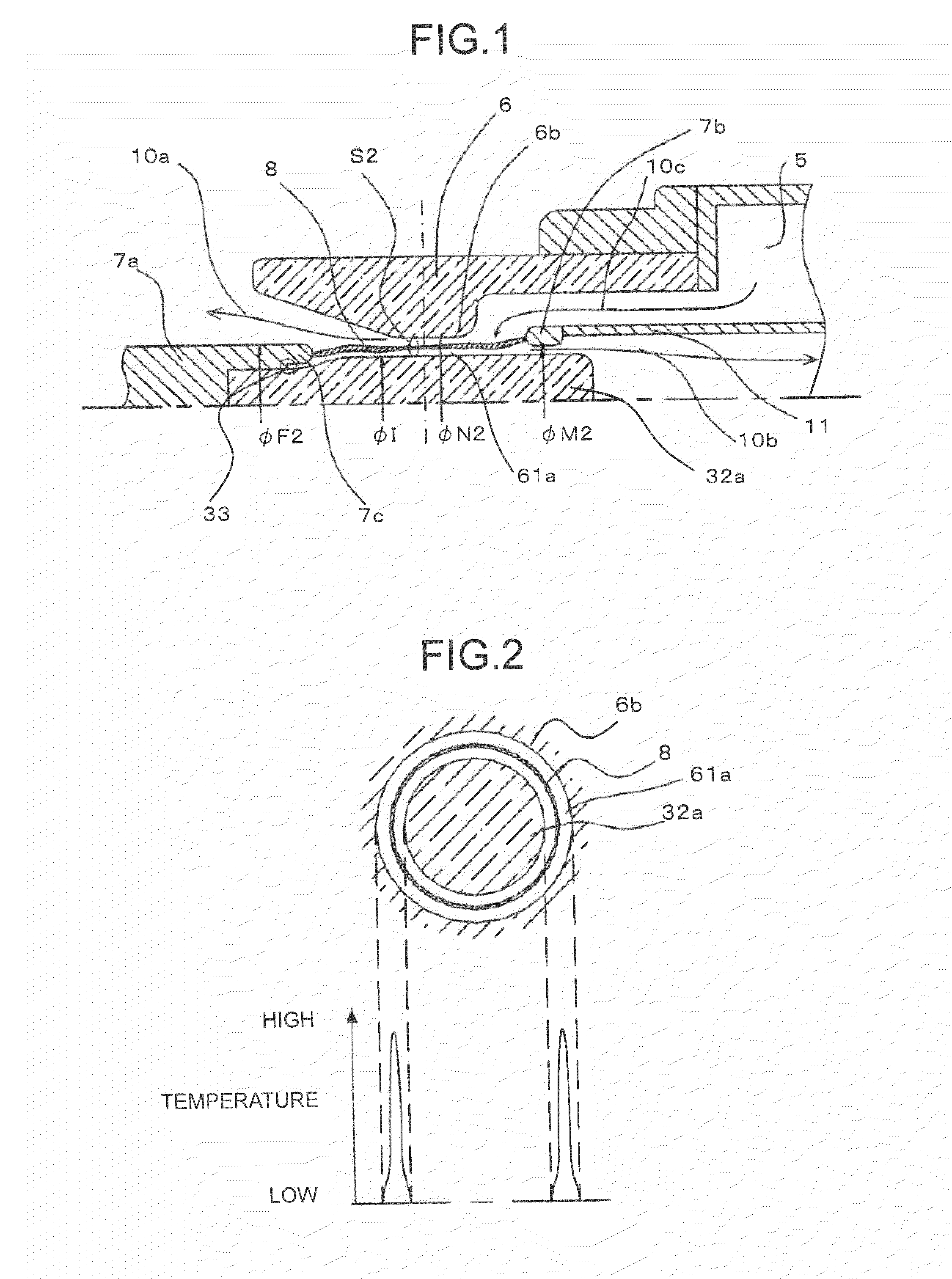

Gas-insulated circuit breaker

InactiveUS20100224594A1Reduce impactProlong lifeHigh-tension/heavy-dress switchesAir-break switchesCircuit breakerGas insulation

A gas-insulated circuit breaker has a sealed container filled with gas; a pair of contacts so constructed as to be connected and separated each other in the sealed container; gas flow generation means for blasting the gas on an arc generated when the contacts are separated, the gas flow generation means including: an accumulation space, pressure increasing means for increasing the pressure of the pressure accumulation space, a gas passage connecting the pressure accumulation space to the arc, and an insulating nozzle that controls the flow of the gas from the pressure accumulation space to the arc; an inside-nozzle insulating member disposed co-axially with the insulating nozzle. The arc is generated in a space between an inner wall section of the insulating nozzle and an outer wall section of the inside-nozzle insulating member, and the gas flows in the space.

Owner:KK TOSHIBA

Anti-aging heat radiation paint for LED lamp and preparation method thereof

The invention provides an anti-aging heat radiation paint for an LED lamp, wherein the paint is prepared by the raw materials by weight: 25-28 parts of aniline presence of formaldehyde resin, 20-25 parts of E-12 epoxy resin, 6-8 parts of 2-methyl methacrylate, 3-4 parts of tetraethylenepentamine, 15-18 parts of aluminum nitride powder, 1-2 parts of graphite alkene, 1-2 parts of carbon nanotube, 4-5 parts of titanium dioxide, 1-2 parts of barium sulfate, 2-3 parts of zinc oxide, 4-5 parts of glycol, 2-3 parts of silane coupling agent KH-550, 10-12 parts of phthalate, 1-2 parts of chromic oxide(Cr_2O_3), 12-14 parts of ethyl acetate, 8-10 parts of xylene, and 4-5 parts of film-forming auxiliary agent. Aluminum nitride powder is added to make the paint have advantages of high heat conductive rate and good heat radiation effect; titanium dioxide is added to make the paint have excellent anti-aging effect; under daylight irradiation, the paint has advantages of sunlight resistance, no cracking, no color change, and acid and alkali resistance; graphite alkene and carbon nanotube are added to make the paint have advantages of easy construction, greatly enhance the heat conduction effect of the paint, and improve the pot-opening effect of the paint.

Owner:天长市天泰光电科技有限公司

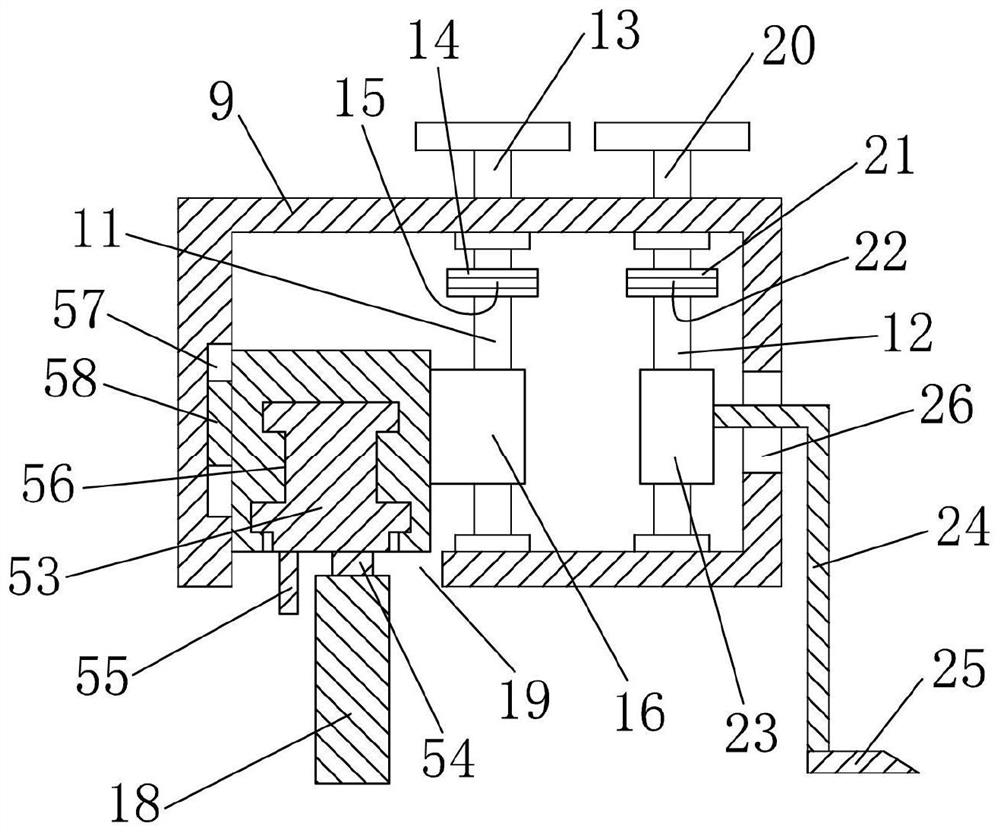

Automatic glass separating device

ActiveCN101863097AReduce labor intensitySolve the problem of easy pollutionProgrammable logic controllerEngineering

The invention relates to an automatic glass separating device, which comprises a cylinder, a sucker, a vacuum generator, an air pressure controller, a cylinder electromagnetic valve, a vacuum generator electromagnetic valve and a programmable logic controller. The cylinder consists of an upper cylinder and a lower cylinder; the sucker consists of an upper sucker and a lower sucker; the upper sucker is connected with the bottom of a piston rod of the upper cylinder, while the lower sucker is connected with the bottom of a piston rod of the lower cylinder; and the programmable logic controller controls the cylinder electromagnetic valve, the vacuum generator electromagnetic valve and the air pressure controller to enable the upper sucker and the lower sucker to absorb two glass molds respectively. In the invention, the upper cylinder and the lower cylinder are adopted to drive the upper sucker and the lower sucker to absorb the upper glass mold and the lower glass mold respectively, and meanwhile, the two glass molds are separated automatically under the action of the upper sucker and the lower sucker in an opposite direction so as to fill a material from a filling port; and the automatic glass separating device has the advantages of simple structure, high degree of automation, high work efficiency, no manual operation and low labor intensity, and solves the problem of pollution on the glass molds when the glass molds are prized up by a wedge crowbar in the traditional way.

Owner:TAIXING TOMSON ACRYLIC CO LTD

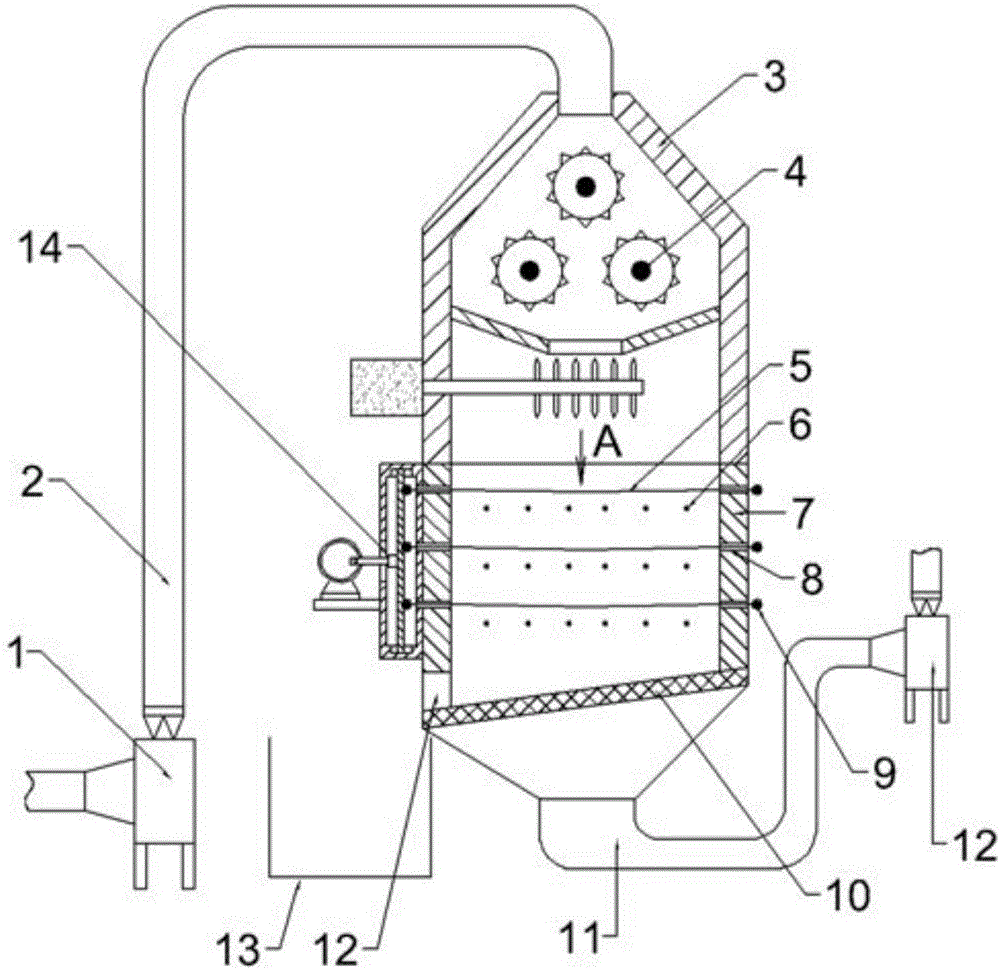

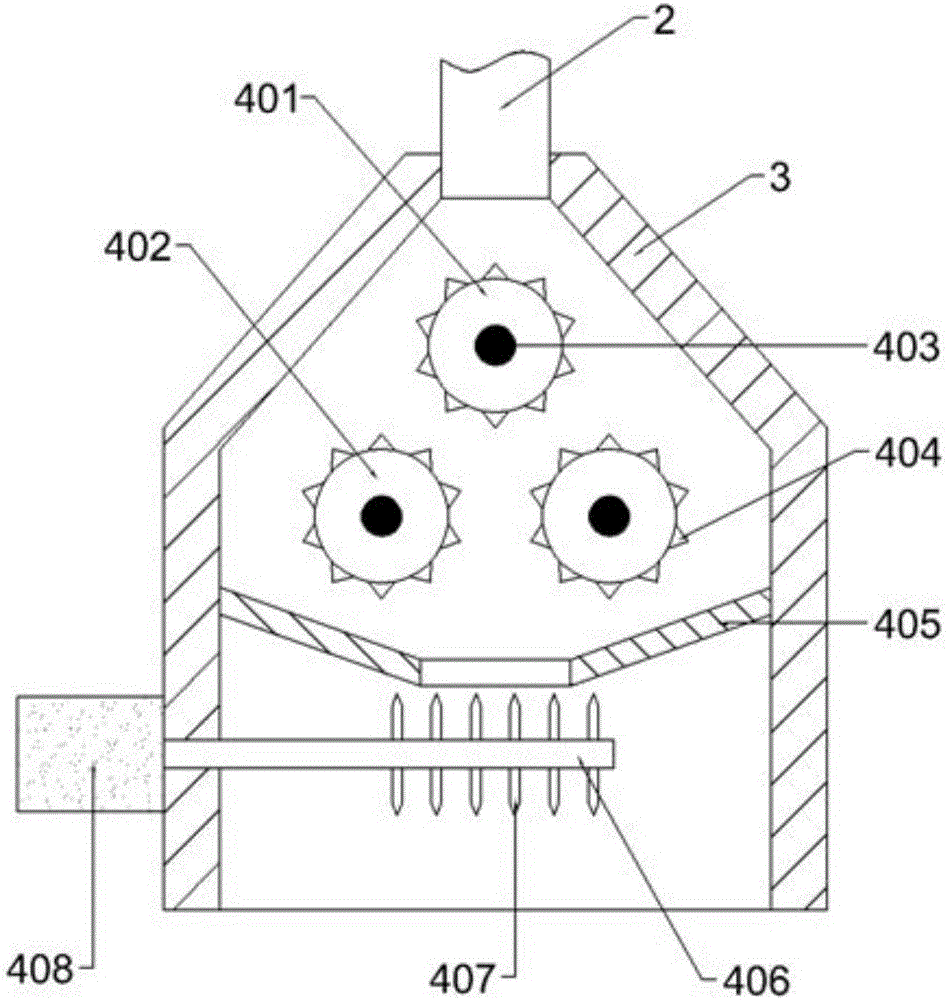

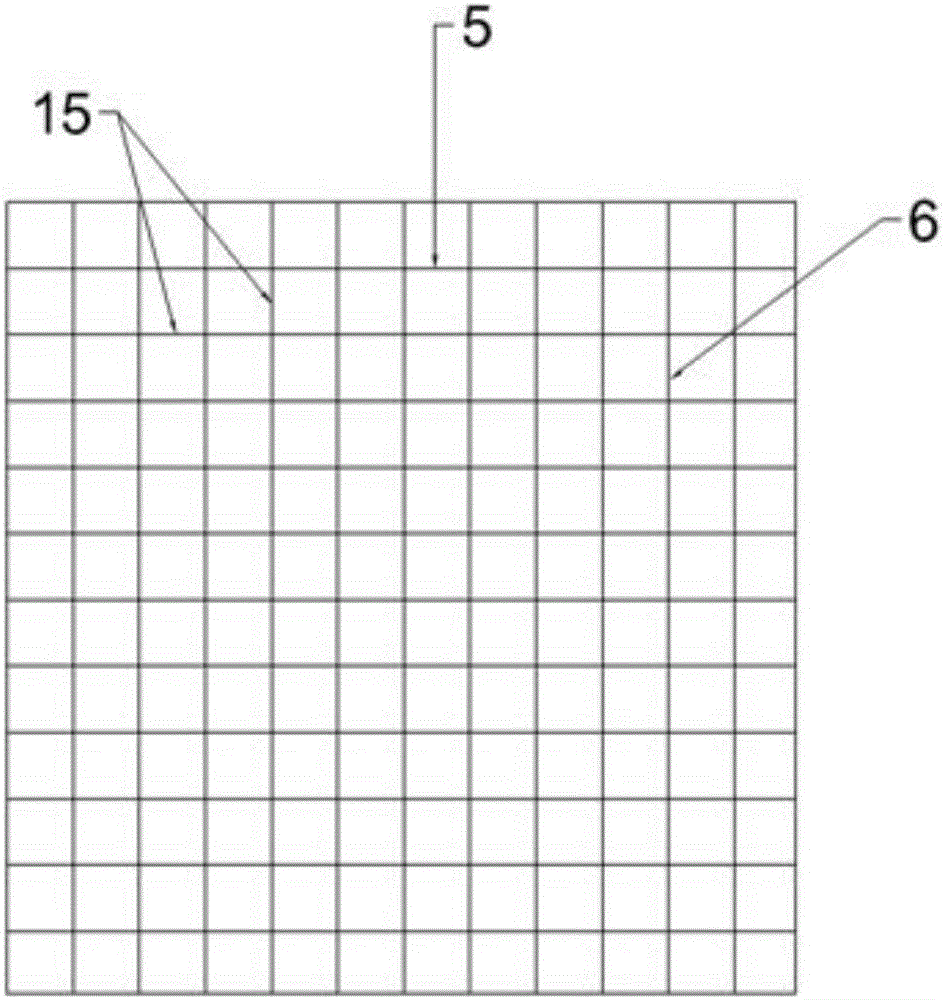

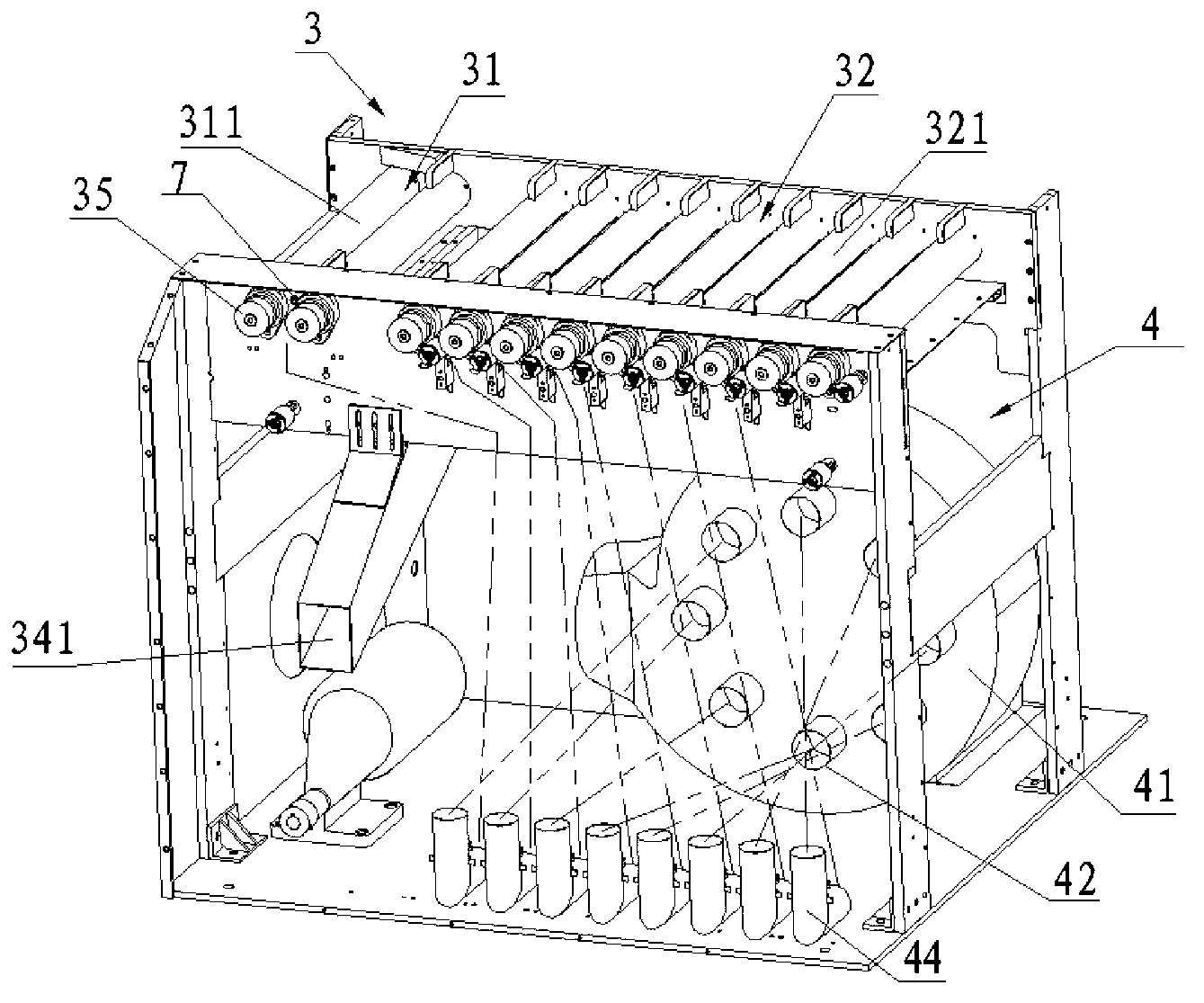

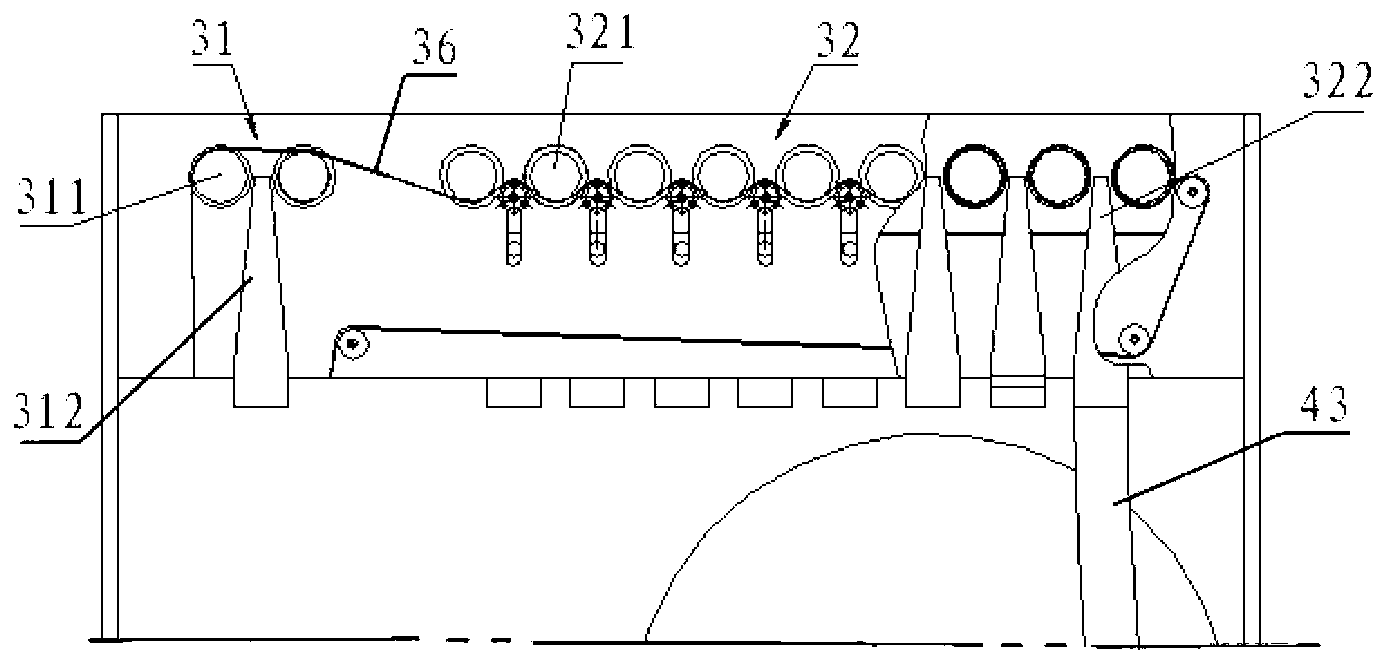

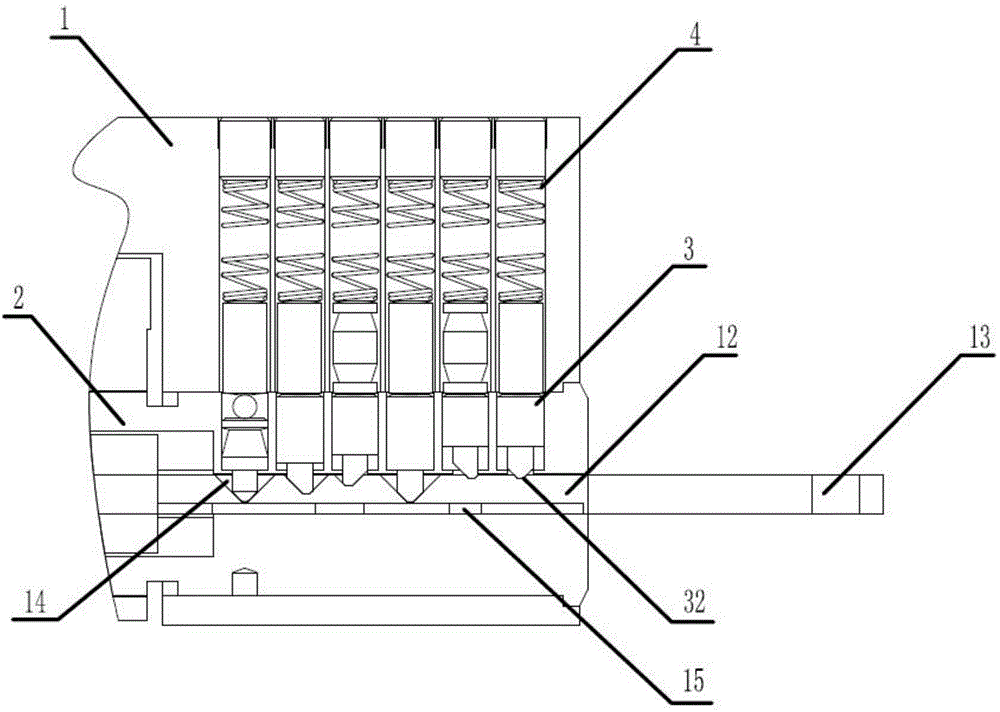

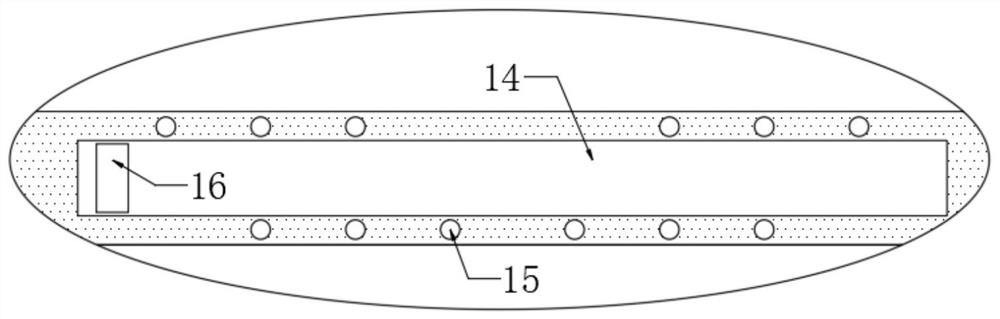

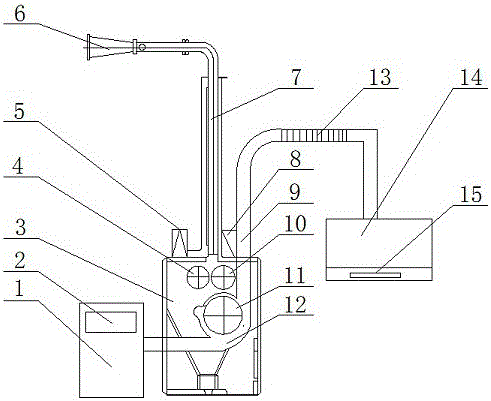

Fiber opening equipment

InactiveCN106835370AReduce damageImprove the opening effectFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention relates to a fiber opening device, comprising a cotton conveying fan, a conveying pipeline and a pre-opening box, the cotton conveying fan is connected to the top of the pre-opening box through a conveying pipeline, and the pre-opening box is an upper small The lower large round table and cylinder are composed of a pre-opening device in the pre-opening box; the lower end of the pre-opening box is fixedly connected with the opening box, and several layers of left and right vibrating opening layers are arranged in the opening box. A front and rear vibration opening layer is arranged below the left and right vibration opening layer. The beneficial effect of the present invention is that a pre-opening device is provided to pre-open the fiber raw materials, which improves the opening effect of the fiber raw materials; the vibration device is used to realize the oscillating wave on the silk thread, and quickly bounces the fiber raw materials, so that the fibers are fully Opening reduces the degree of damage to fibers. The invention has the advantages of reasonable structural design, convenient use, good opening effect, etc., and has certain popularization and application value.

Owner:安徽谢佑圣电子科技有限公司

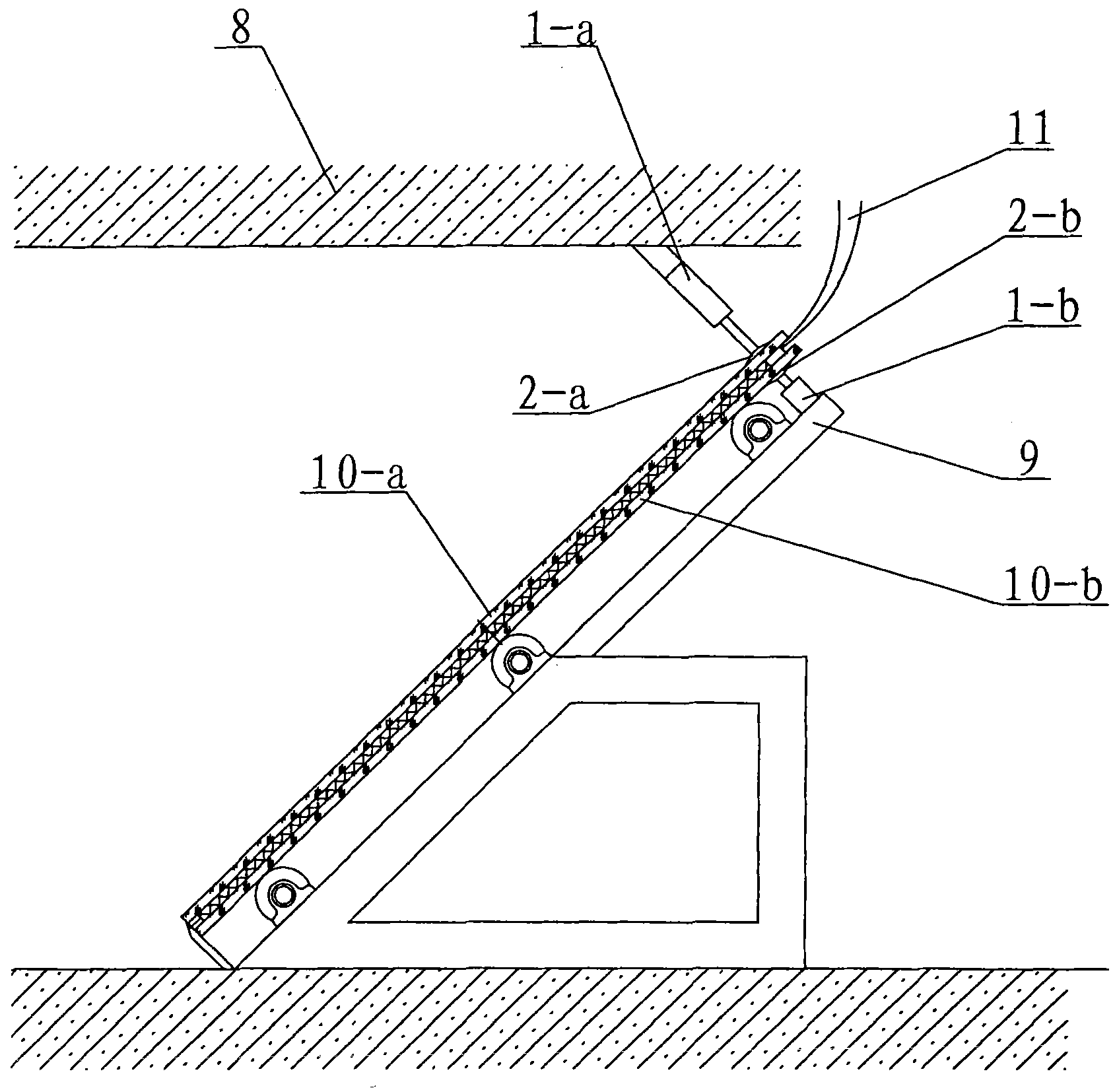

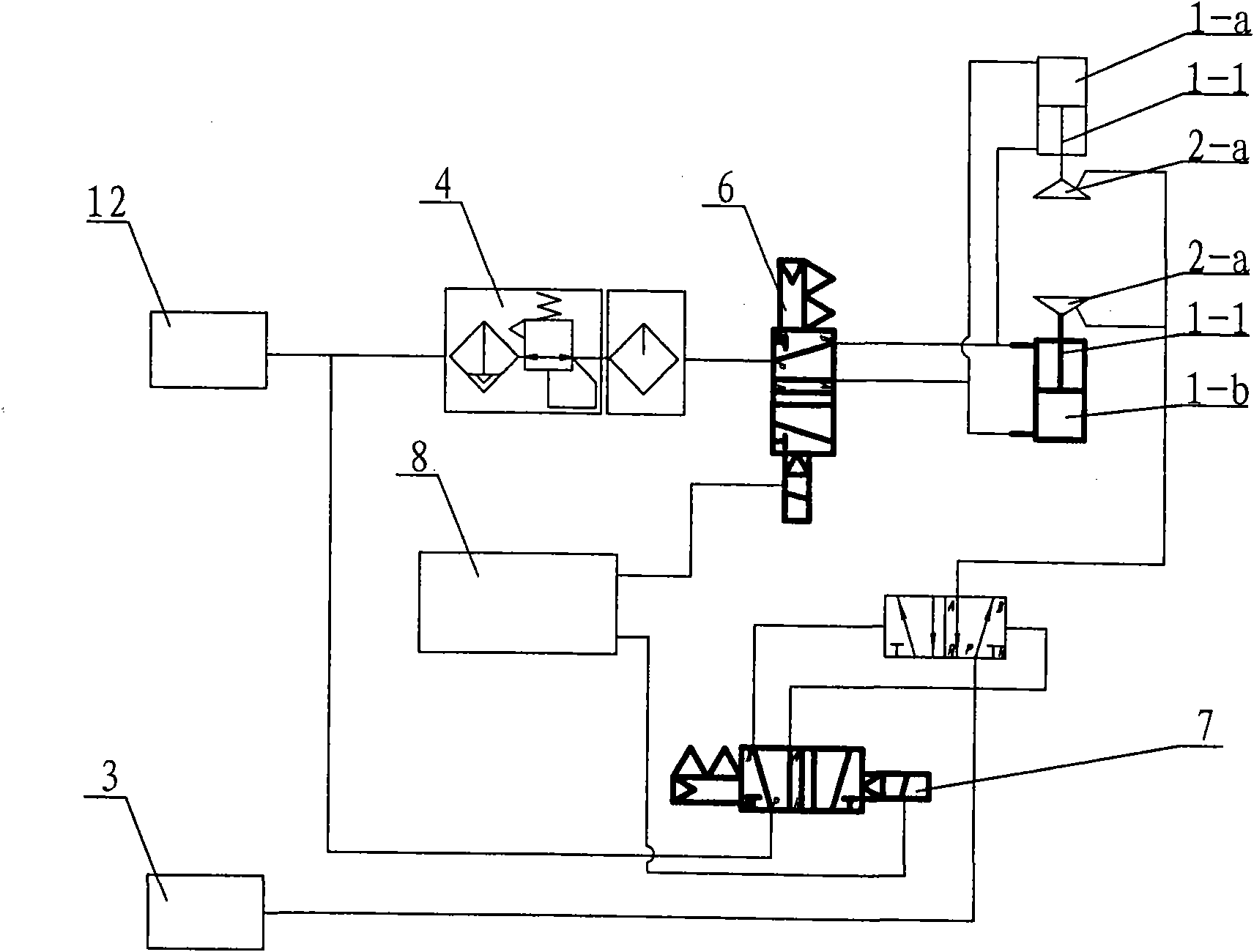

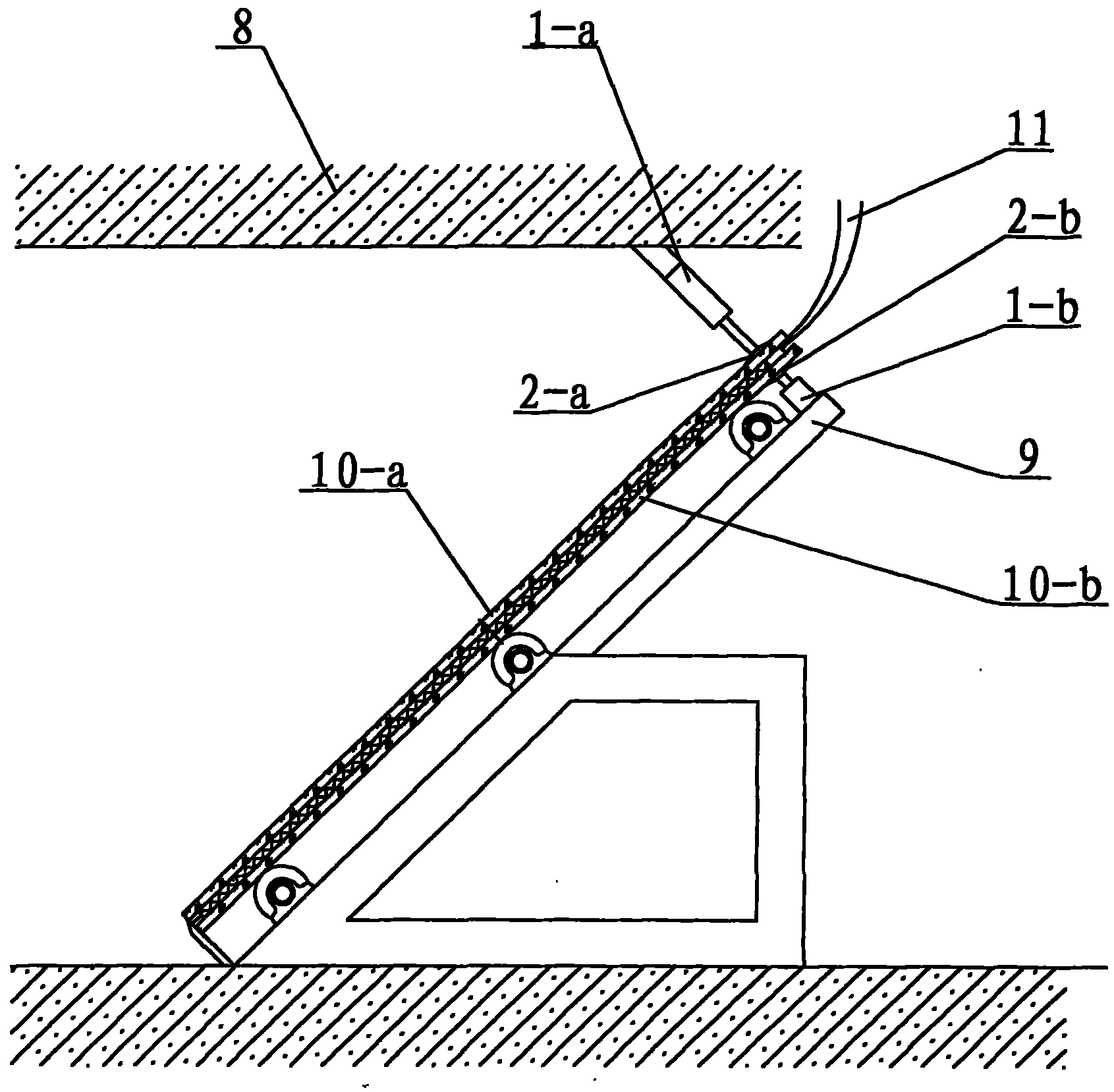

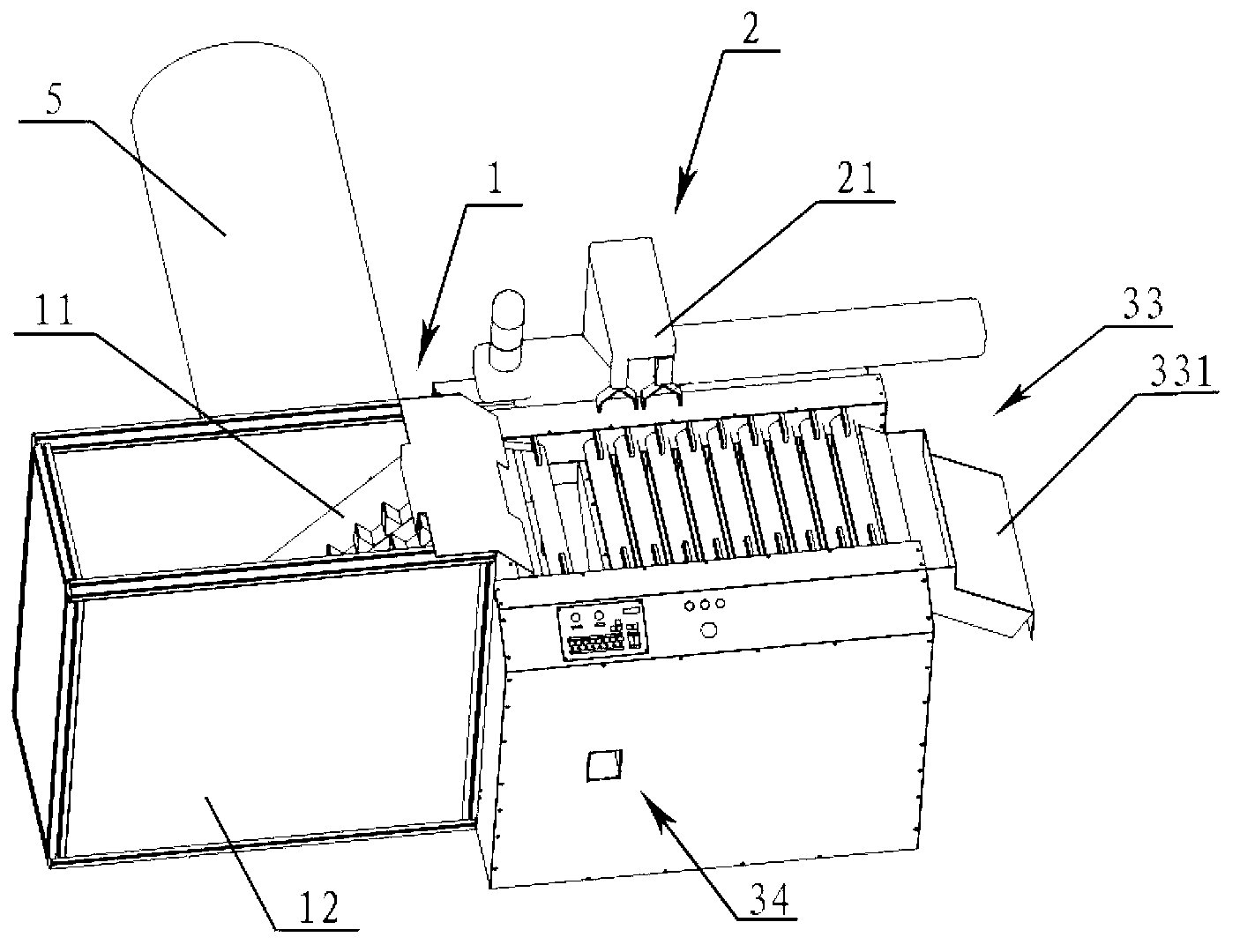

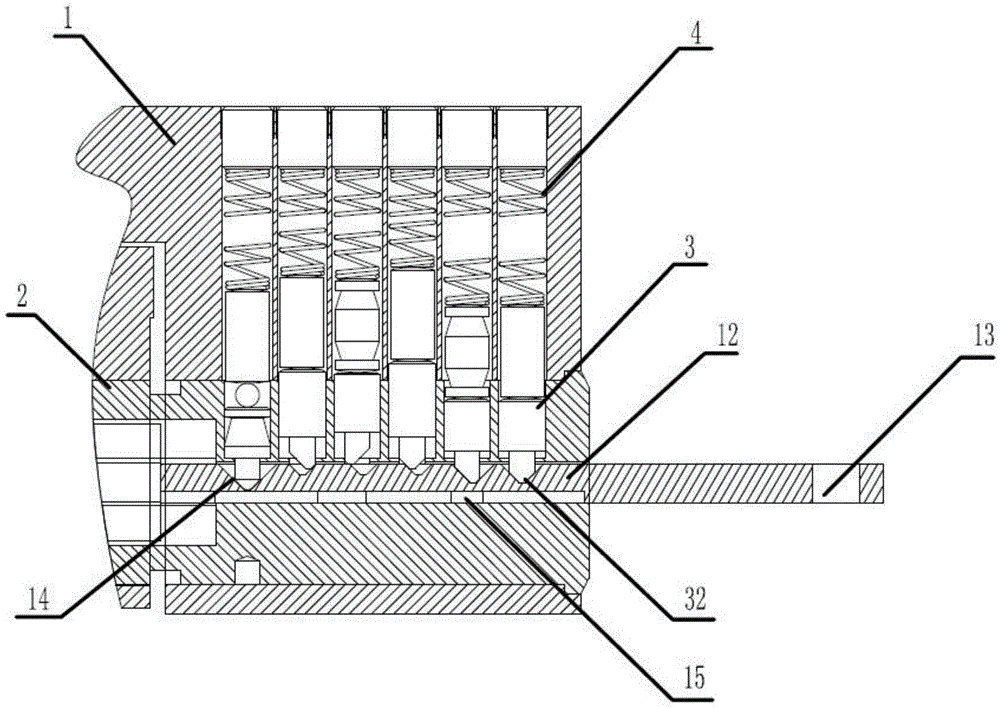

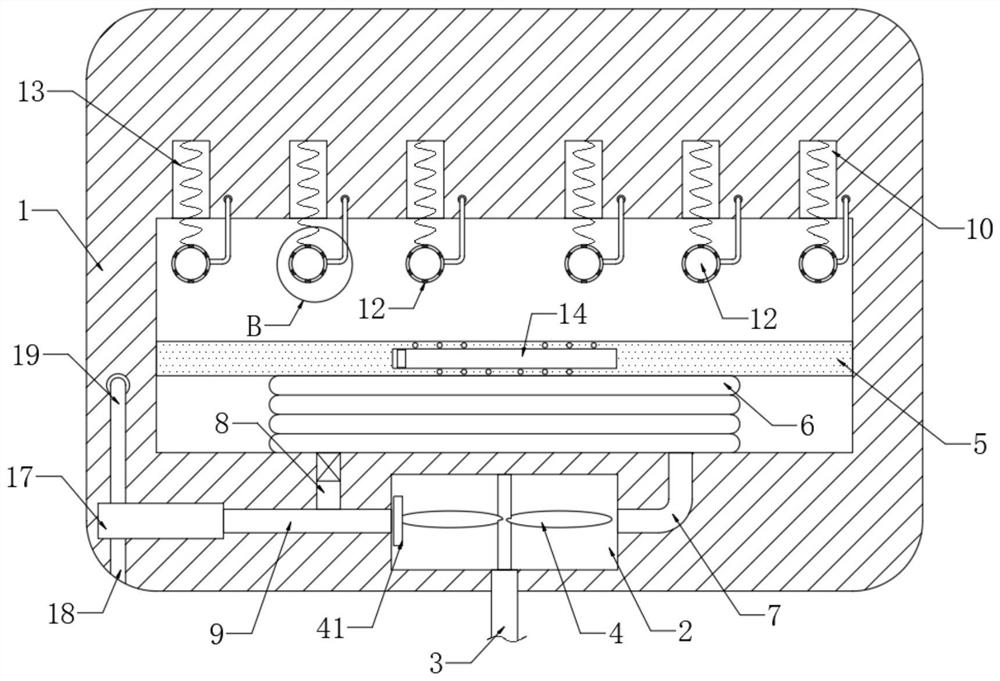

System for automatically cleaning tail yarns of roving bobbins

InactiveCN102704068AImprove the opening effectImplement automatic cleanupFibre cleaning/opening by air draught arrangementsYarnBobbin

The invention relates to a system for automatically cleaning tail yarns of roving bobbins. The system comprises a feeding device, a conveying device, an unwinding device, an opening device, a recovering device and a control system, wherein the feeding device is used for storing a plurality of roving bobbins of which large ends and small ends are respectively positioned in the same direction and which are wound with tail yarns and automatically conveying the roving bobbins to the unwinding device one by one; the unwinding device comprises a turnaround sliver cleaning mechanism, an unwinding mechanism, a successfully unwound roving bobbin collecting mechanism and an unsuccessfully unwound roving bobbin collecting mechanism; and the opening device is used for finding the ends of the tail yarns of the roving bobbins on the turnaround sliver cleaning mechanism and the unwinding mechanism and unwinding and opening the tail yarns. By matching the unwinding device, the opening device and the control system, the tail yarns of the roving bobbins are unwound and opened, the unwound roving bobbins are collected, or the roving bobbins which are not unwound or not completely unwound are collected, and the tail yarns are automatically cleaned in the whole process, so that a large amount of manpower is saved, and efficiency is improved.

Owner:CHANGDE TEXTILE MACHINERY

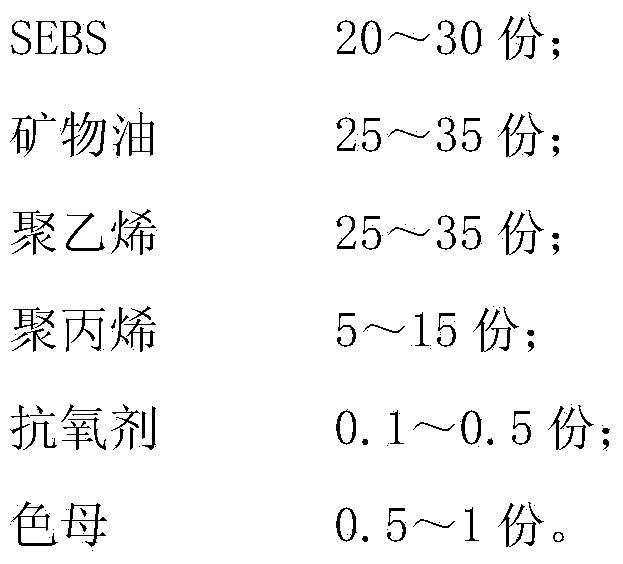

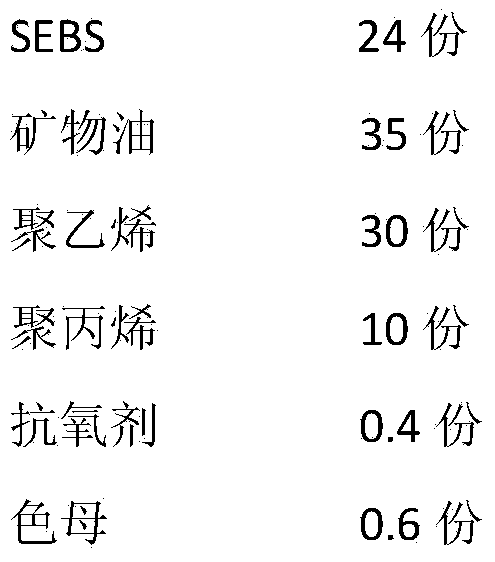

Bottle cap inner spacer material suitable for carbonated beverage

The invention relates to a bottle cap inner spacer material suitable for a carbonated beverage. The bottle cap inner spacer material mainly comprises the following materials in parts by weight: 20-30 parts of SEBS, 25-35 parts of mineral oil, 25-35 parts of polyethylene, 5-15 parts of polypropylene, 0.1-0.5 part of an antioxygen, and 0.5-1 part of a color mother. The bottle cap inner spacer material blends the SEBS, the mineral oil, the polyethylene, the polypropylene, the antioxygen and the color mother to extrude and pelletize, the 300% stretching strength of a prepared particle is more than 4 MPa, the 22-hour compression ratio at 70 DEG C is less than 0.5, the bottle cap inner spacer material can be used on a bottle cap inner spacer for the carbonated beverage, and provides an excellent gas tightness property and excellent performance of opening a bottle cap.

Owner:NANJING JINGJINYUAN TECHN IND

Gas-insulated circuit breaker

InactiveUS8115133B2Reduce impactProlong lifeHigh-tension/heavy-dress switchesAir-break switchesCircuit breakerElectric arc

A gas-insulated circuit breaker has a sealed container filled with gas; a pair of contacts so constructed as to be connected and separated each other in the sealed container; gas flow generation means for blasting the gas on an arc generated when the contacts are separated, the gas flow generation means including: an accumulation space, pressure increasing means for increasing the pressure of the pressure accumulation space, a gas passage connecting the pressure accumulation space to the arc, and an insulating nozzle that controls the flow of the gas from the pressure accumulation space to the arc; an inside-nozzle insulating member disposed co-axially with the insulating nozzle. The arc is generated in a space between an inner wall section of the insulating nozzle and an outer wall section of the inside-nozzle insulating member, and the gas flows in the space.

Owner:KK TOSHIBA

Foam pad and production method thereof

ActiveCN106317550AGood flexibilityIncrease elasticityClosure capsSynthetic resin layered productsHigh densityMicrometer

The invention provides a foam pad and the production method thereof. The foam pad comprises the base layer and the upper surface film and lower surface film covering the base layer. The base layer is the foam body, which is also the averagely distributed capillary pores, wherein the average diameter of the capillary pore is 1-100 micrometers; the film layer is evenly distributed with high density; the preparation method of the foam pad comprises the super-critical foaming process and the filming process. The foam pad has the advantages of excellent elasticity and softness and can be used as the plastic film for food. As the bottle cap gasket, the foam pad has excellent airtight features. The production method is also simple and can be easily industrialized.

Owner:JIANGSU JINHOU NEW MATERIAL TECH CO LTD

Can lid

ActiveUS8186532B2Improve the opening effectDeteriorating impactRefuse receptaclesRigid containersEngineeringRivet

Owner:UNIVERSAL CAN CORP

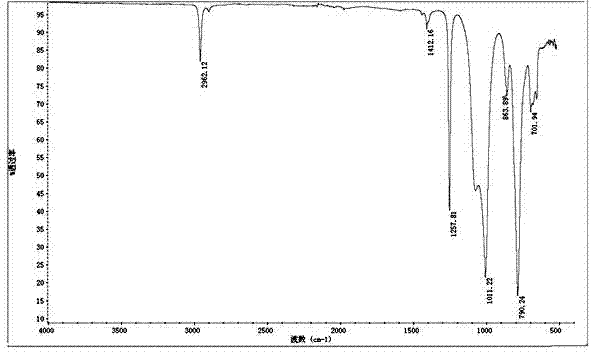

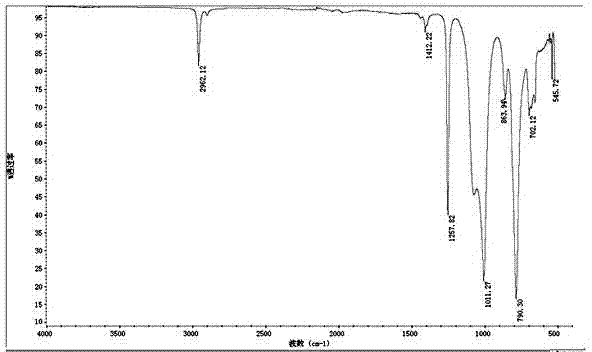

Modified attapulgite packing for coating and preparation method thereof

The invention discloses modified attapulgite packing for a coating. The modified attapulgite packing for the coating is prepared from the following raw materials in parts by weight: 1-2 parts of a titanate coupling agent, 3-5 parts of polyacrylamide, 2-3 parts of cellulose acetate butyrate, 4-5 parts of ethylene glycol, 1-2 parts of dimethylformamide, 2-3 parts of nanometer aluminium oxide, 1-2 parts of diethyl aminoethyl(methyl) acrylate, 1-2 parts of methacrylate, 0.2-0.4 parts of ammonium persulfate, 100-120 parts of attapulgite, a proper amount of water, 5-10 parts of an assistant, and 30-40 parts of 3-5% hydrochloric acid solution. According to the modified attapulgite disclosed by the invention, by high molecular polymeric modification, the surface lipophilicity is enhanced, the suspension property and the thixotropy of the coating are increased, and the modified attapulgite packing is good in thickening property, relatively full in film, and relatively good in can opening effect; by using the modified attapulgite packing, the wear-resisting property of the coating can be increased by addition of the nano aluminium oxide, the flowability of a powder coating can be improved, and the coating ratio is increased.

Owner:MINGGUANG GUOXING ATTAPULGITE CLAY

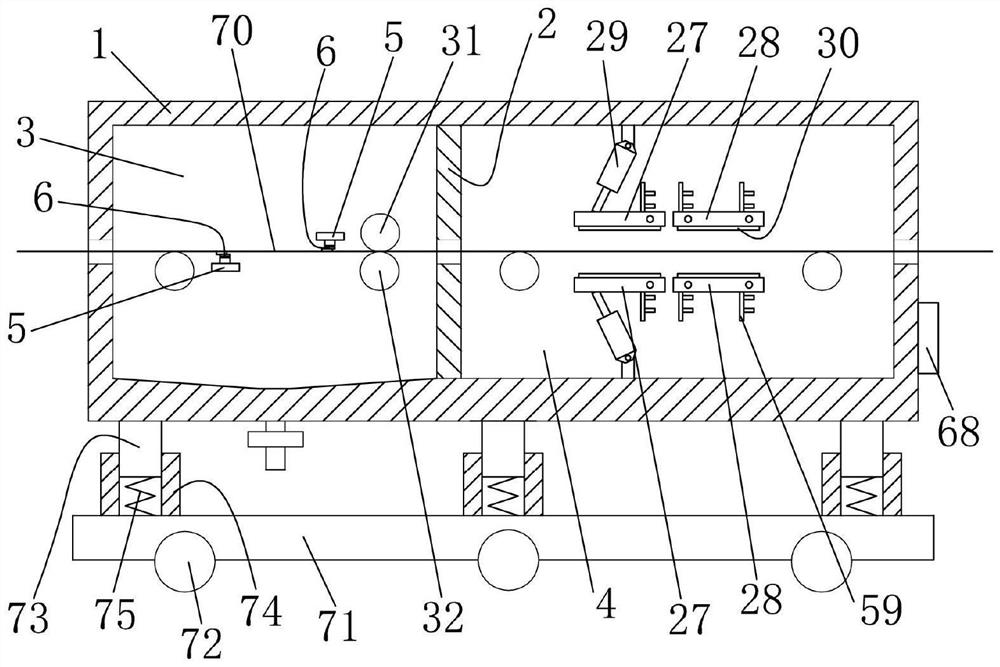

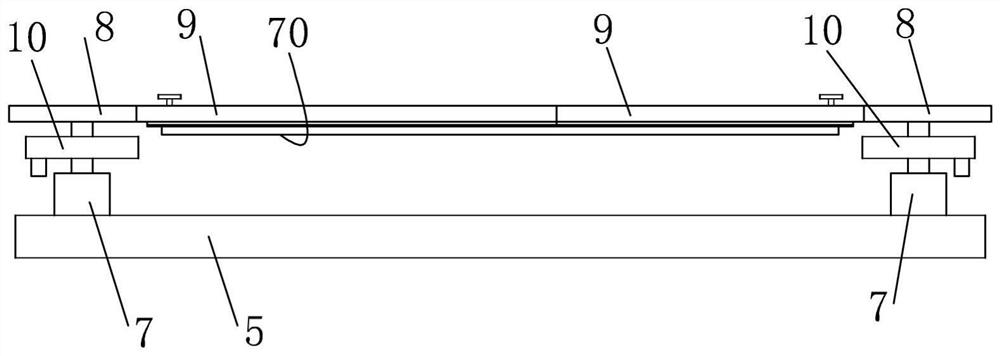

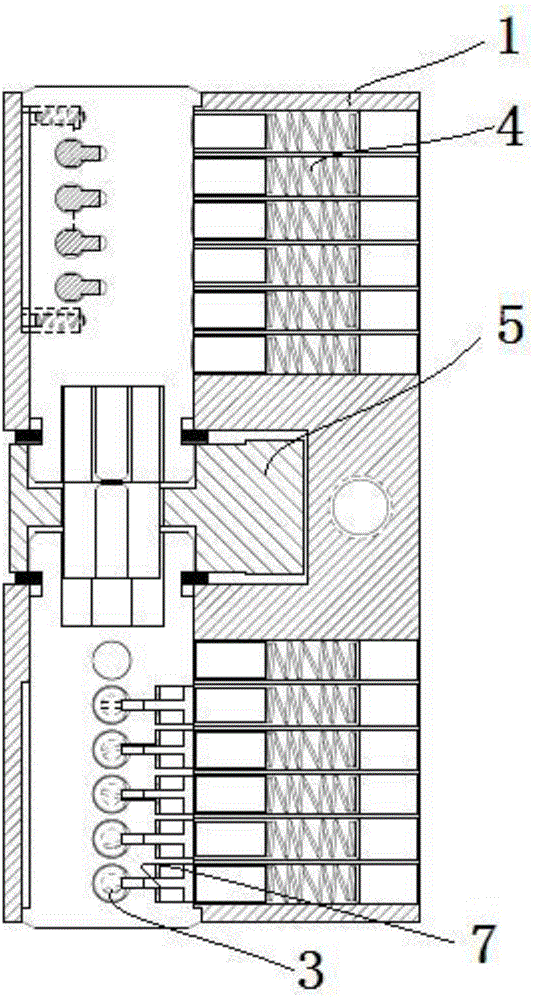

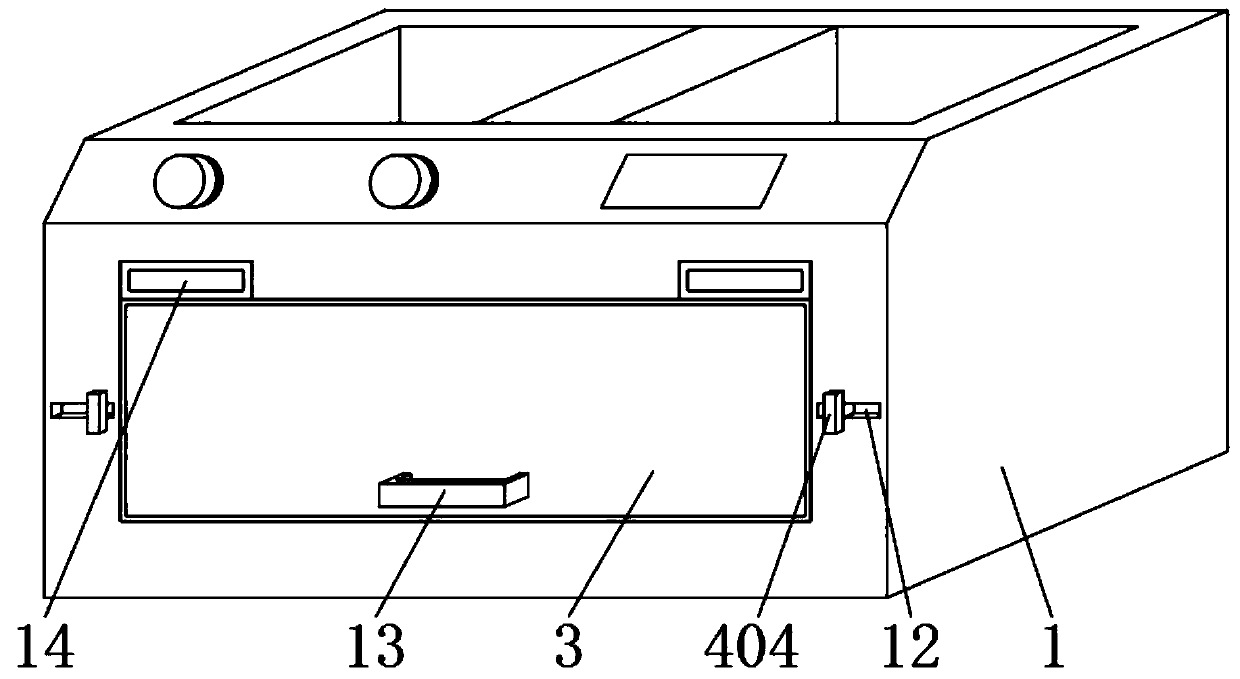

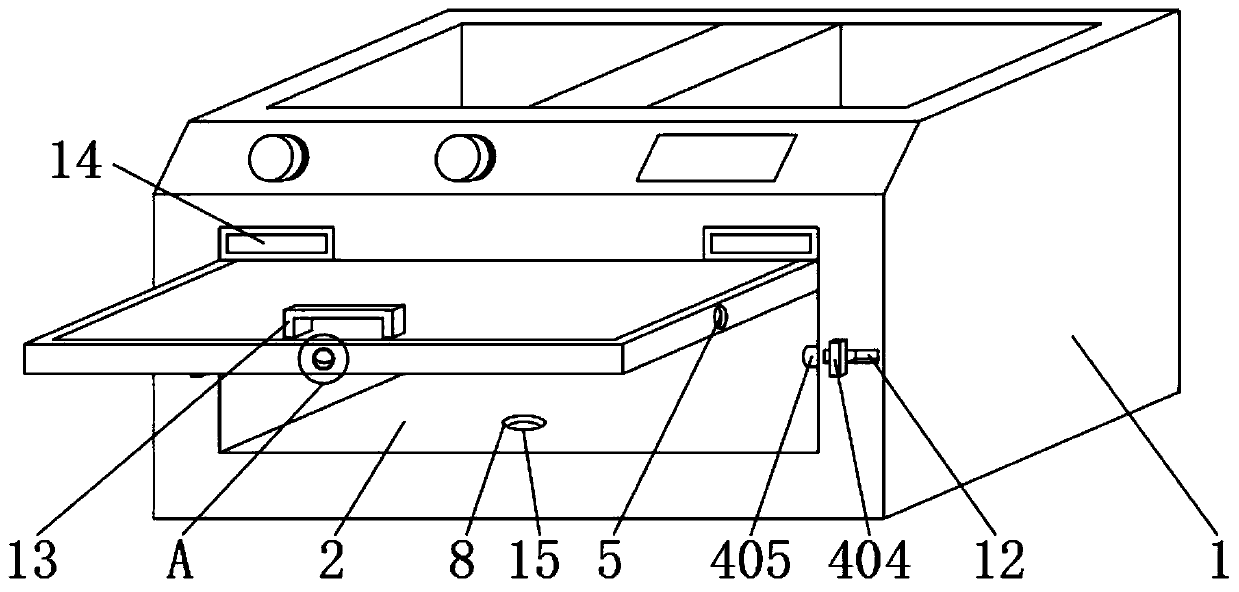

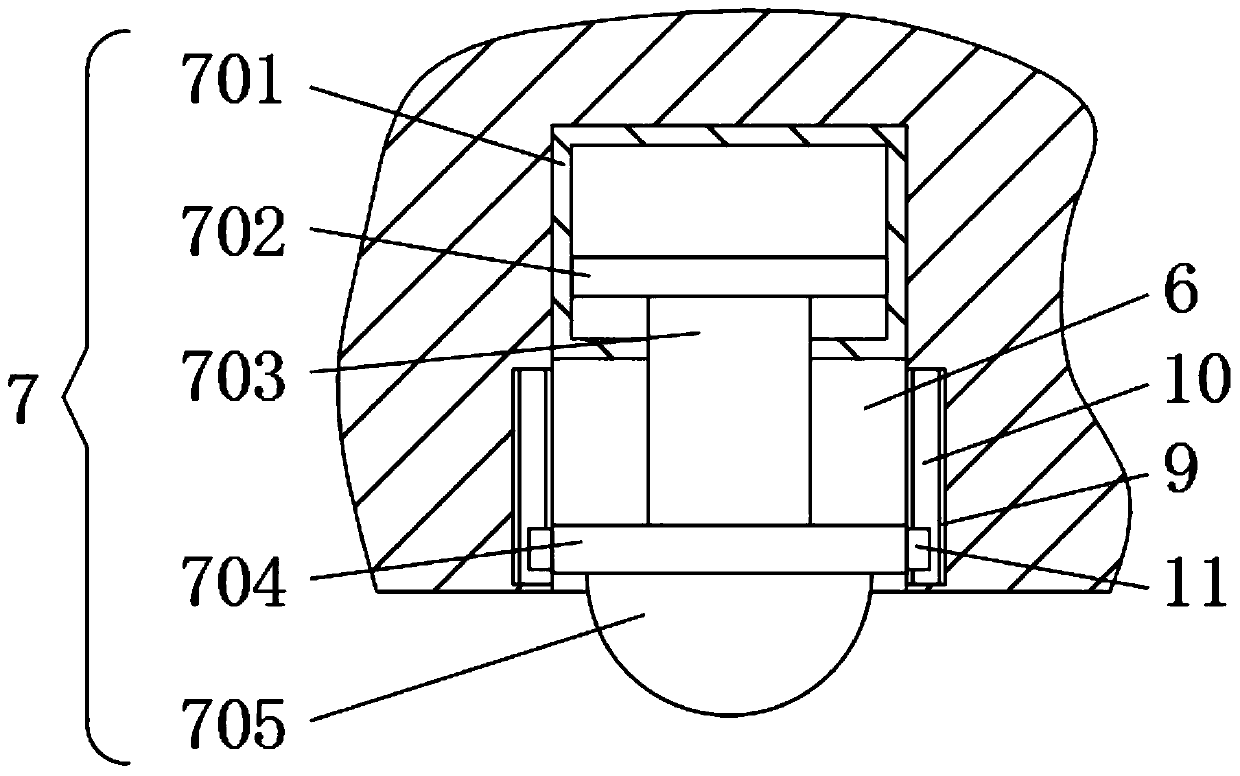

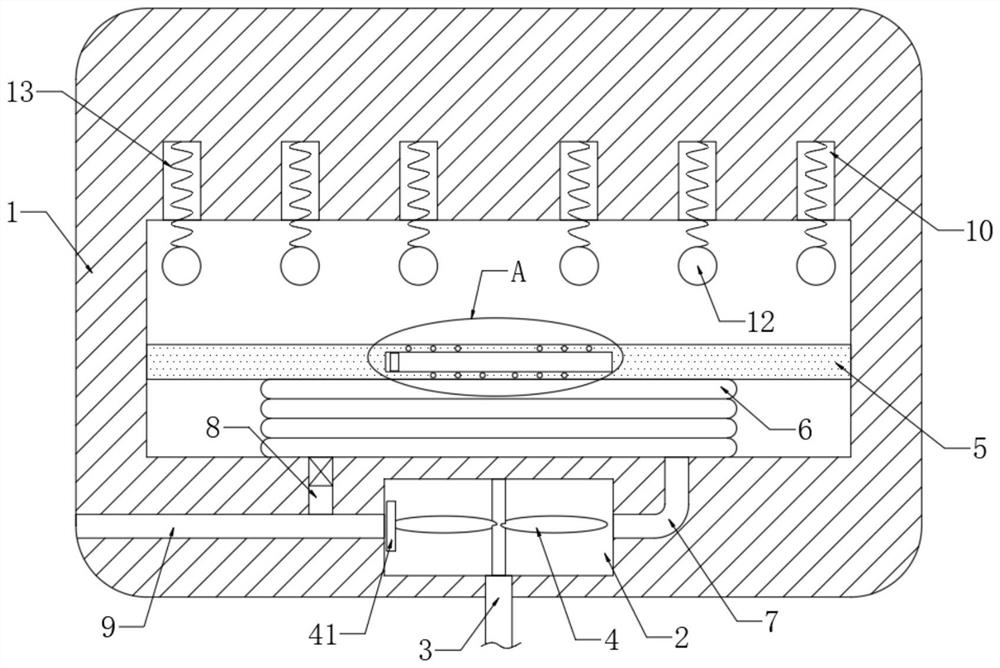

Textile fabric dewatering device

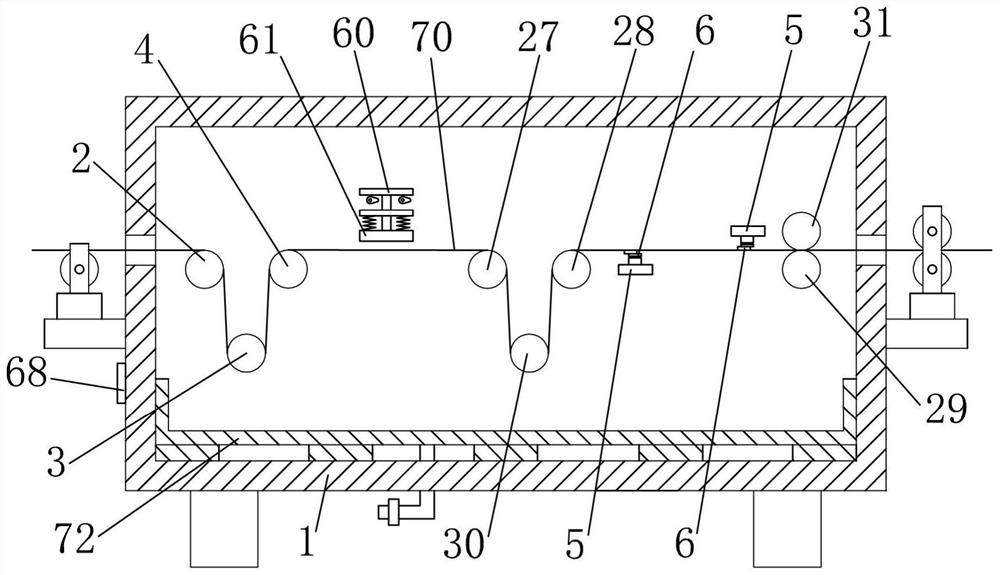

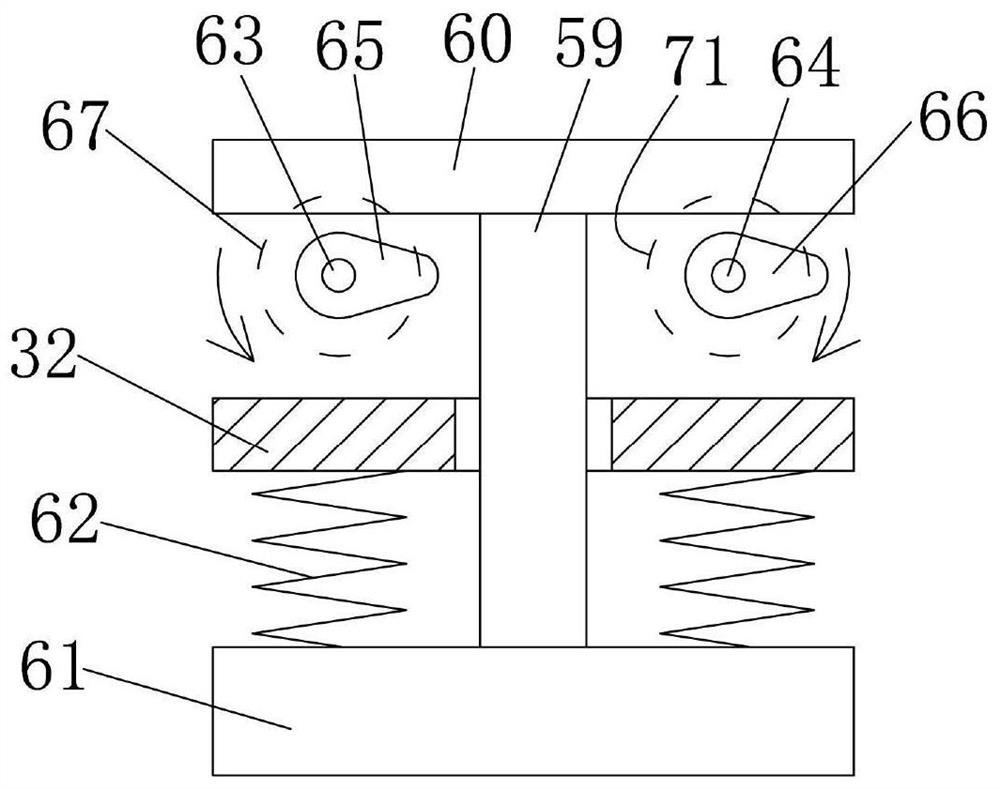

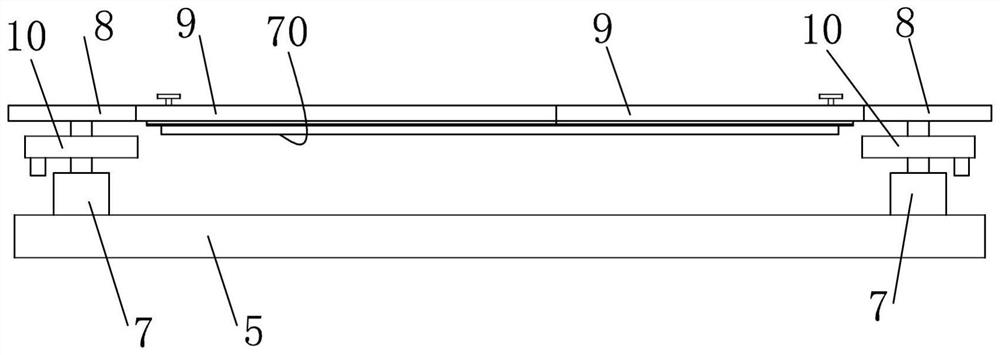

InactiveCN112981812AImprove the opening effectEasy to cleanMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention discloses a textile fabric dewatering device and belongs to the technical field of textile equipment. The textile fabric dewatering device comprises a box body, a first conveying roller, a first tensioning roller, a second conveying roller, a third conveying roller, a second tensioning roller, a fourth conveying roller and a fifth conveying roller are arranged in the box body, a supporting plate is arranged between the second conveying roller and the third conveying roller, a moving rod is arranged at the center of the supporting plate in a penetrating mode, one end of the moving rod is connected with a moving plate, the other end of the moving rod is connected with a beating plate, the bottom end of the supporting plate is connected with a spring, the other end of the spring is connected with the top end of the beating plate, a first rotating shaft and a second rotating shaft are arranged between the moving plate and the supporting plate, a first cam is installed on the first rotating shaft, and a second cam is installed on the second rotating shaft. Through mutual cooperation of the first cam, the second cam, the moving plate, the moving rod, the supporting plate, the spring and the beating plate, the surface of fabric can be beaten, beating dewatering treatment is conducted on the fabric, and the beating plate can beat the fabric once every time the fabric is rotated by 180 degrees.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

Coating with heat-resistant property

The invention relates to a coating with a heat-resistant property, which comprises the following components in parts by weight: 22-23.6 parts of a VAE emulsion (solid content: 55%), 18-20.084 parts of titanium dioxide (industrial grade), 38-41.163 parts of a styrene acrylic emulsion (solid content: 45%), 0.20-0.26 part of an emulsifier, 0.3-0.35 part of a composite dispersant, 1.35-1.59 parts of a composite thickener, 1.89-2.07 parts of a film-forming additive, 0.30-0.38 part of a composite defoaming agent, 11.35-11.55 parts of water, and the like. According to the invention, problems existing in traditional coatings are solved; due to the adoption of a new formula, the problems that coatings are swelled and embrittled after meeting water are solved fundamentally, and the gloss and heat resistance of the coating are improved. The coating disclosed by the invention is simple in process and good in effect and has certain development and utilization values, therefore, the coating has board market prospects.

Owner:ZIBO INTRUE LIGHT IND PROD CO LTD

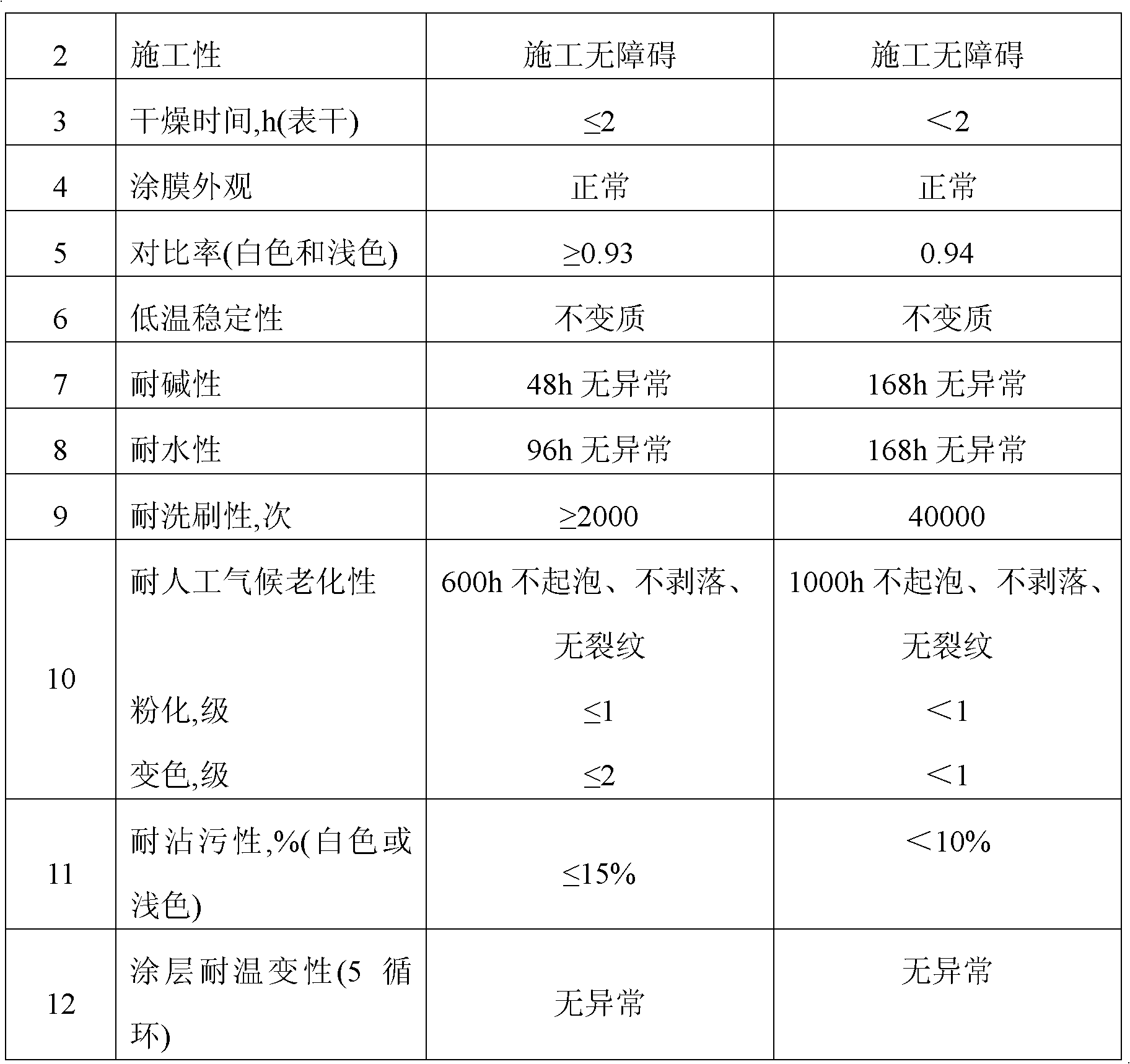

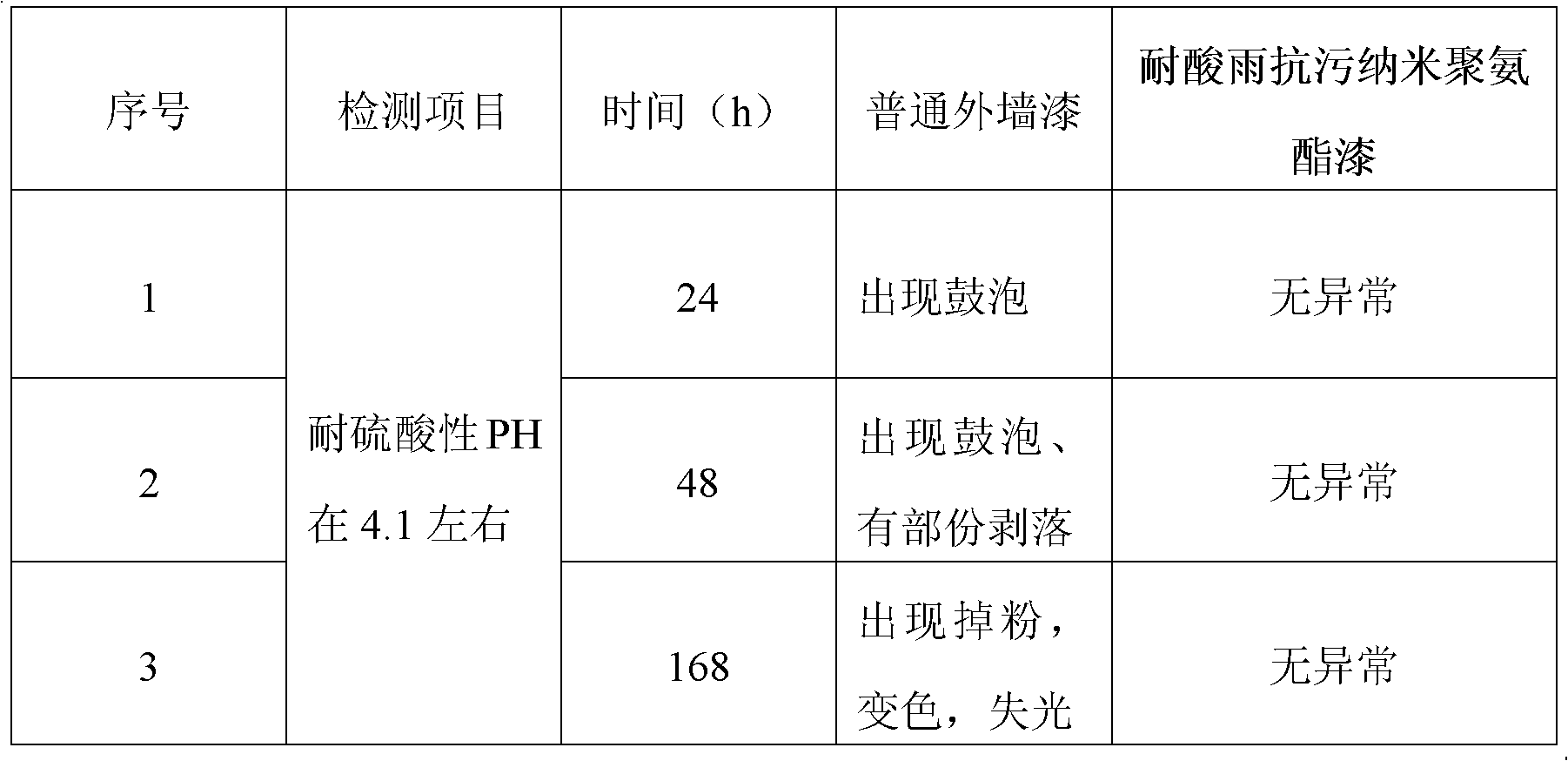

Acid rain-resistant antifouling aqueous nanometer polyurethane exterior wall finish

InactiveCN102504685AHigh strengthImprove the finishAntifouling/underwater paintsPaints with biocidesRutileAntiseptic

The invention discloses an acid rain-resistant antifouling aqueous nanometer polyurethane exterior wall finish. The finish is obtained by mixing a primary finish, a curing agent and water according to a weight ratio of 10:1:1, wherein the primary comprises water, a dispersant, a wetting agent, a defoamer, propylene glycol, rutile titanium dioxide, a nanomaterial with the particle size of equal to or less than 20nm, a chemical inert filler, an antiseptic, a mildew inhibitor, a pH conditioning agent, a film forming assistant, an aqueous polyurethane resin containing -OH, and a thickening agent; and the curing agent comprises polyisocyanate containing -NCO, and PMA (polymethyl acrylate). The exterior wall finish of the invention has the advantages of acid rain resistance and good antifouling performance.

Owner:肇庆千江高新材料科技股份公司

Drying device for cloth processing

InactiveCN112941874AImprove opening effectGood cushioning effectMechanical cleaningPressure cleaningPhysicsEngineering

The invention discloses a drying device for cloth processing and belongs to the technical field of textile equipment. The drying device comprises a box body and a base; rollers are arranged on the base; supporting columns are arranged at the bottom end of the box body; the bottoms of the supporting columns are sleeved with spring sleeves; the spring sleeves are connected with the base; springs are arranged in the spring sleeves; a partition plate is arranged in the box body, and the interior of the box body is divided into a cloth scutching cavity and a cloth drying cavity through the partition plate; supports are arranged in the cloth scutching cavity; the supports are located above and below the cloth respectively; scutching and cleaning mechanisms used for scutching and cleaning the cloth are symmetrically installed on the corresponding supports; drying mechanisms are arranged in the cloth drying cavity, and the drying mechanisms are located above and below the cloth respectively; and each drying mechanism comprises a first supporting plate, a second supporting plate, a telescopic air cylinder and an infrared heating assembly. By arranging the scutching and cleaning mechanisms, scutching, cleaning, leveling and dewatering treatment can be conducted on the upper surface and the lower surface of cloth, and multiple times of treatment on the same position of the cloth can be achieved.

Owner:ZHEJIANG IND POLYTECHNIC COLLEGE

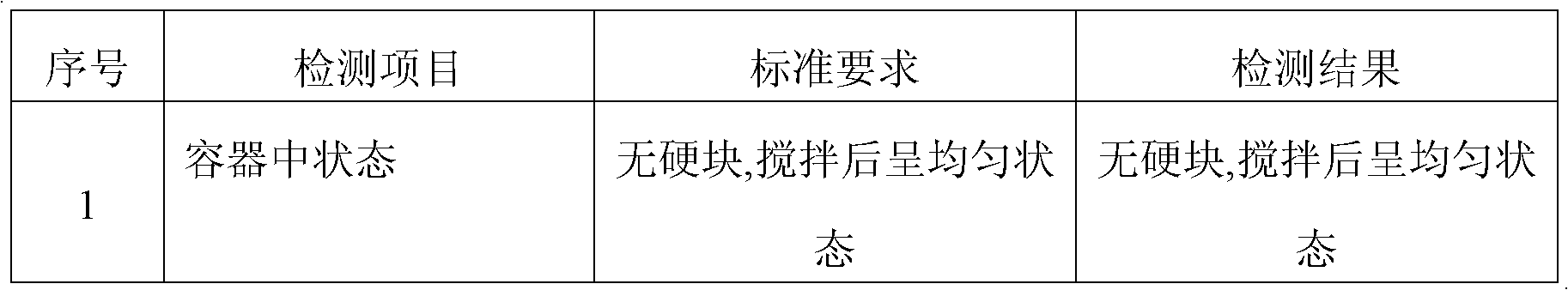

Water-based environment-friendly non-toxic and harmless elastic waterproof emulsion and preparation method thereof

The invention discloses a water-based environment-friendly non-toxic and harmless elastic waterproof emulsion and a preparation method thereof. The emulsion is characterized by comprising the following components in parts by weight: 1.5-2.5 parts of dispersant, 0.8-1.2 parts of defoamer, 8-13 parts of plasticizer, 190-220 parts of coarse whiting, 0-10 parts of rutile titanium dioxide, 80-120 parts of wollastonite powder, 450-550 parts of elastic emulsion, 3-5 parts of bactericide, 1-2 parts of edible high-gluten flour, 1.8-2.2 parts of thickener and 170-190 parts of water in manners of mixing and fully agitating. The ductility of the obtained product after film formation is 370-450%, and the tensile strength is 1.8-2.4Mpa by test detection. The product is innocuous and unpoisonous, strong in water tolerance, not easy to blister and fall off, and applicable to interior and exterior wall spaces, and the wall space of a toilet, can completely prevent the waterproof surface from leaking, and accords with the JC / T864-2008 executive standards (I type).

Owner:GUILIN HEXIN WATERPROOF DECORATION MATERIAL

Composite coating additive

InactiveCN102558932ACompatibility is simpleEasy to useCoatingsPolyethylene glycolSodium carboxymethyl starch

The invention discloses a composite coating additive, consisting of polyoxyethylene, polyethylene glycol and sodium carboxymethyl starch; the composite coating additive is prepared by normal methods such as preparing, mixing, stirring and filling, wherein compared with the prior art, the composite coating additive has simple compatibility, and is convenient in use and low in cost; when the additive is applied to the coating, the coating cost can be reduced; the can opening performance and coating performance are better; the additive plays a dispersing, thickening and flatting role; no stratification condition appears when the additive is stored for a long period and the fluidity is better; therefore, the composite coating additive can effectively overcome the disadvantages of bentonite in the coating.

Owner:张家港市惠发塑胶有限公司

Lock head and key

ActiveCN104453385ALarge amount of codingNot easy to openKeysCylinder locksElectrical and Electronics engineeringEccentric compression

The invention discloses a lock head. The lock head comprises a shell, a core, a number marble, a flat-end marble, a first eccentric compression piece and a dial wheel piece and further comprises a first positioning pin key, a first pin key groove formed in the inner wall of the shell, a second eccentric compression piece arranged between the first positioning pin key and the core, and a driving part arranged on the number marble, capable of being combined with the first positioning pin key when the number marble rotates along with the core and used for driving the first positioning pin key to be rotated out of the first pin key groove. The eccentric compression force of the second eccentric compression piece makes the first positioning pin key embedded and reset in the direction of the first pin key groove, the number marble can provide multiple secret key codes when axially rotating in the key insertion process and when the core axially moves in combination with the change of the length of the number marble, and therefore the extremely good technical opening preventing capacity is achieved.

Owner:四川王力安防产品有限公司

Electromechanical equipment with waste recovery function

PendingCN111466852AQuick clean upSolve problems that prevent quick cleanupTableware washing/rinsing machine detailsMechanicsWaste material

The invention discloses electromechanical equipment with a waste recovery function. The cleaning equipment comprises a cleaning equipment body, wherein a cleaning opening is formed in the front side of the cleaning equipment body, a sealing door is movably installed in the cleaning opening, circular containing grooves are formed in the left side and the right side of an inner wall of the cleaningopening, and positioning mechanisms are fixedly installed in the two circular containing grooves. The cleaning equipment is advantaged in that the cleaning equipment body is arranged, the cleaning opening, the sealing door, the positioning mechanisms, an extrusion spring, a circular stop block, a connecting block, a pushing handle, a circular fixing block, a circular fixing groove, a circular groove, a clamping mechanism, a pneumatic cylinder, a pushing piston, an extrusion rod, a circular limiting block, a circular clamping block, a circular clamping groove, a strip-shaped groove, a sliding rod, a sliding sleeve, a square through hole, a lifting handle, a hinge base and a circular block are matched for use, problems that existing internal cleaning is troublesome, and rapid cleaning is notfacilitated are solved, and the cleaning equipment is rapid in cleaning.

Owner:宁波科创助手科技服务有限公司

Efficient loosening and cotton opening knocking device

InactiveCN112522820AImprove cotton opening efficiencySave electricityFibre cleaning/opening machinesImpellerStructural engineering

The invention discloses an efficient loosening and cotton opening knocking device which comprises a processing box, wherein a driving groove is formed in the side wall of the processing box, an air inlet pipe is arranged at the inner bottom of the driving groove, a wind wheel is rotationally connected into the driving groove, a sealing piece is fixedly connected to one blade of the wind wheel, a supporting plate is slidably connected into the processing box, a telescopic air bag is fixedly connected between the lower end of the supporting plate and the inner bottom of the processing box, the telescopic air bag communicates with the driving groove through an air guide pipe, an exhaust groove is formed in the inner wall of the driving groove, and the exhaust groove communicates with the telescopic air bag through a one-way air outlet pipe. Under the combined action of an axial flow impeller, the sealing piece, the air guide pipe and the one-way air outlet pipe, the telescopic air bag continuously stretches out and draws back, so that the supporting plate moves up and down in a reciprocating mode, cotton can be bounced up when being knocked, the cotton at the bottom layer is preventedfrom being compacted, and the cotton opening efficiency is greatly improved.

Owner:宁波玻尔新材料科技有限公司

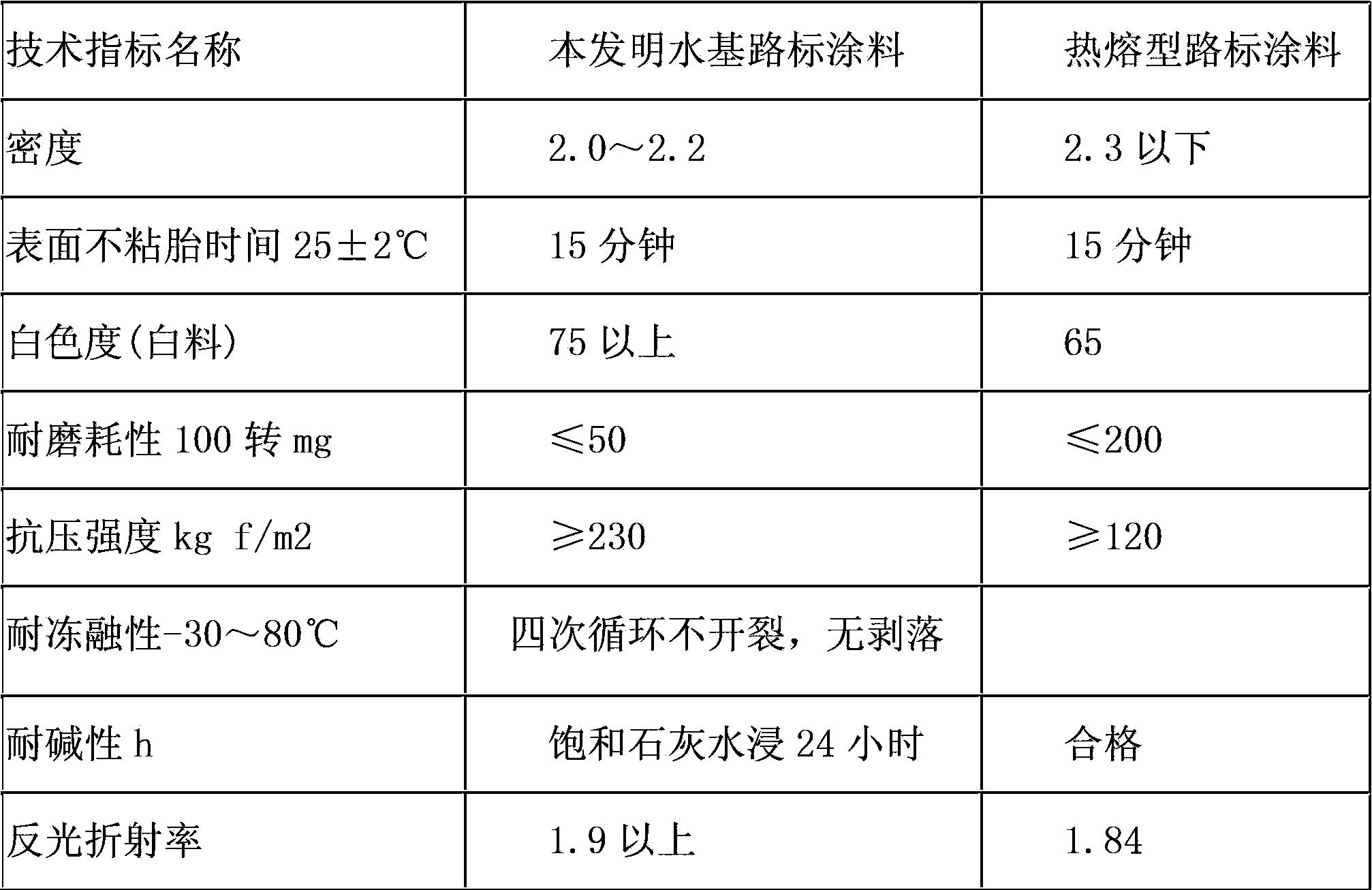

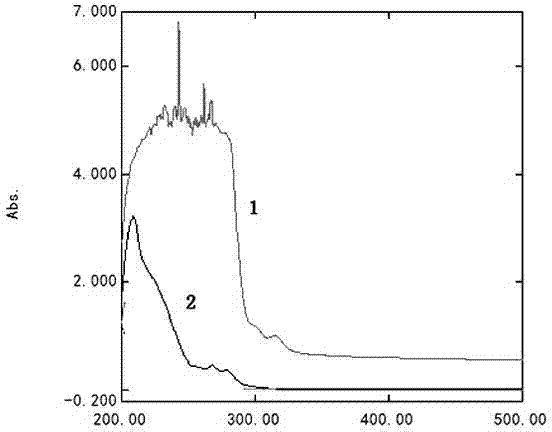

Preparation method of wear-resistant reflector marking coating for cement roads

The invention discloses a preparation method of a wear-resistant reflector marking coating for cement roads. The preparation method comprises the following steps: (1) weighing ingredients in percentage by weight; (2) putting sodium silicate into a reaction kettle, adding water to stir and dilute to relative density of 1.36-1.40, introducing steam in a jacket to heat, heating a liquid to 90 DEG C, with 5 DEG C plus or minus, slowly adding water-diluted sodium fluosilicate liquor under quick stirring, completing within 2 hours, then, adding zinc oxide, continuously reacting for 2 hours, and then cooling to 50 DEG C + / -5 DEG C; (3) adding water-soluble acrylic resin and silane while stirring, continuously reacting for 20-30 minutes, and then adding lauryl alcohol ester; (4) adding sodium hexametaphosphate and sodium polyacrylate while stirring, sequentially adding rutile titanium dioxide, talcum powder, attapulgite and ground calcium carbonate after uniformly mixing, and dispersing for 20-30 minutes; and (5) adding carboxymethylcellulose, ethylene glycol, glass beads and dimethyl silicone oil while stirring, and uniformly mixing to obtain a product.

Owner:JIANGSU WUXI TRAFFIC FACILITIES

Material for plastic twist-off cap, as well as preparation method and applications thereof

InactiveCN104119593AImprove the opening effectLight is not easy to decompose and goodPolypropylenePolyolefin

The invention discloses a material for a plastic twist-off cap. The material is prepared by the following components: polyolefin resin, an antioxidant, a heat stabilizer, and a silicone slipping agent according to the proportion in parts by weight of 100 to (0.01-0.5) to (0.05-0.5) to (0.1-5), wherein the polyolefin resin is high-density polyethylene with melt flow index of 1-20g / 10min, or polypropylene with the melt flow index of 1-20g / 10min; the antioxidant is 1010,1076 or 168 monocomponent antioxidant or a compound thereof; the heat stabilizer is metallic stearate; the silicone slipping agent is polydimethylsiloxane with molecular weight of more than or equal to 10000. The invention further discloses a preparation method and applications of the material for the plastic twist-off cap. The material for the plastic twist-off cap can be separately used for producing twist-off caps or compounded with master batch to produce twist-off caps, the capped twist-off caps are easily unscrewed, the reduction range of the twisting-off moment is small along with prolonging of time, the smell is low, and the twist-off caps are applicable to the fields of packing of food, beverage and the like which are directly contacted.

Owner:HANGZHOU WAHAHA TECH

Composite coating assistant

The invention discloses a composite coating assistant. The composite coating assistant comprises, by mass, 10-15 parts of sodium polystyrene sulfonate, 10-15 parts of methyl methacrylate, 10-15 parts of polyacrylic acid, 5-10 parts of diethylene glycol, 5-10 parts of monoglyceride stearate, 5-10 parts of carboxymethyl cellulose, 25-30 parts of disodium ethylene diamine tetraacetate and 25-30 parts of modified starch. The composite coating assistant has the advantages of simple formula, use convenience, low cost, reduction of the cost of a coating while being used in the coating, good tank opening effect and brushing performance, dispersing, thickening and leveling effects, no layering phenomenon after long-time storage, very good fluidity, and effective overcoming of the disadvantages of bentonite in the coating.

Owner:胡建辉

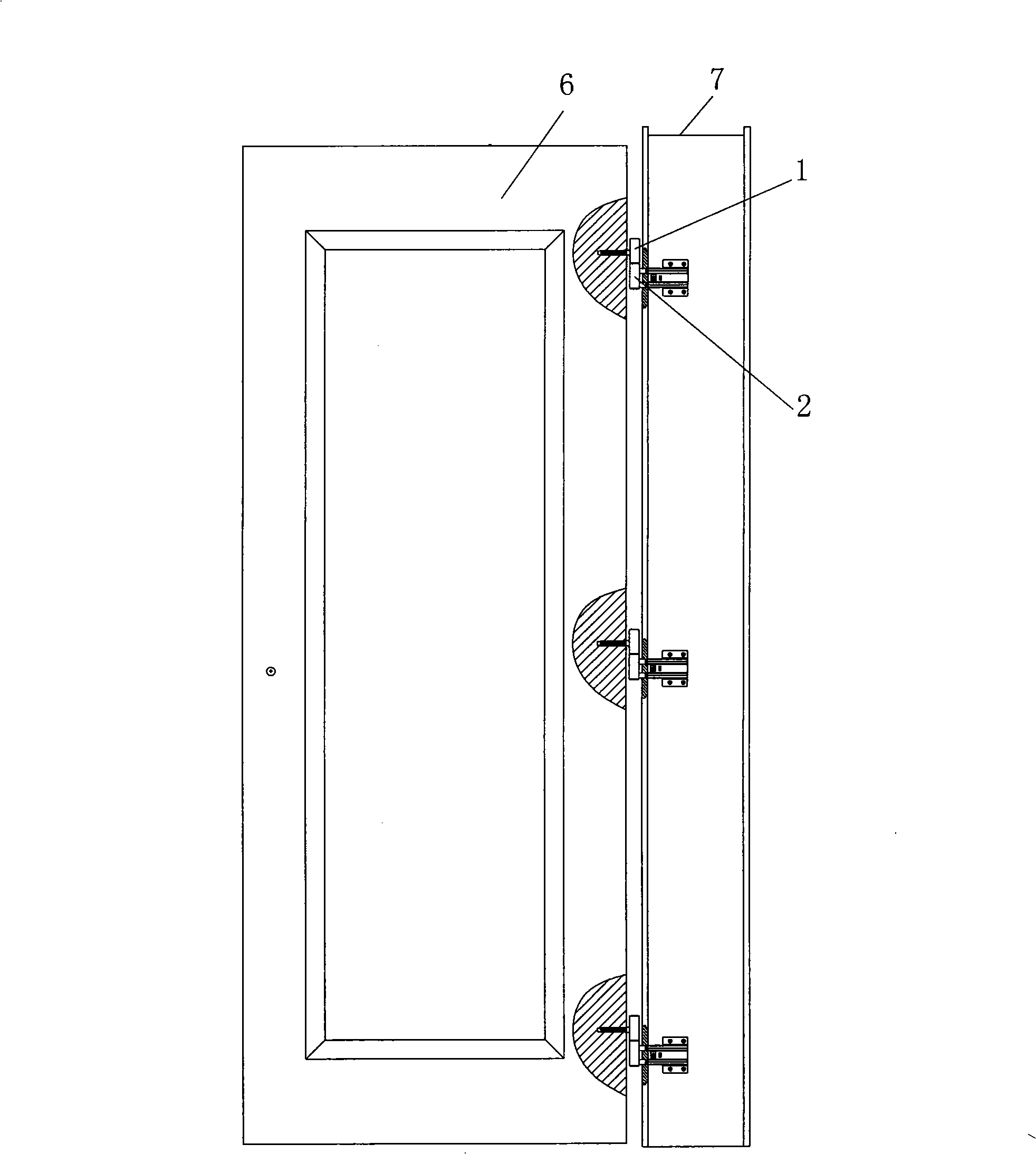

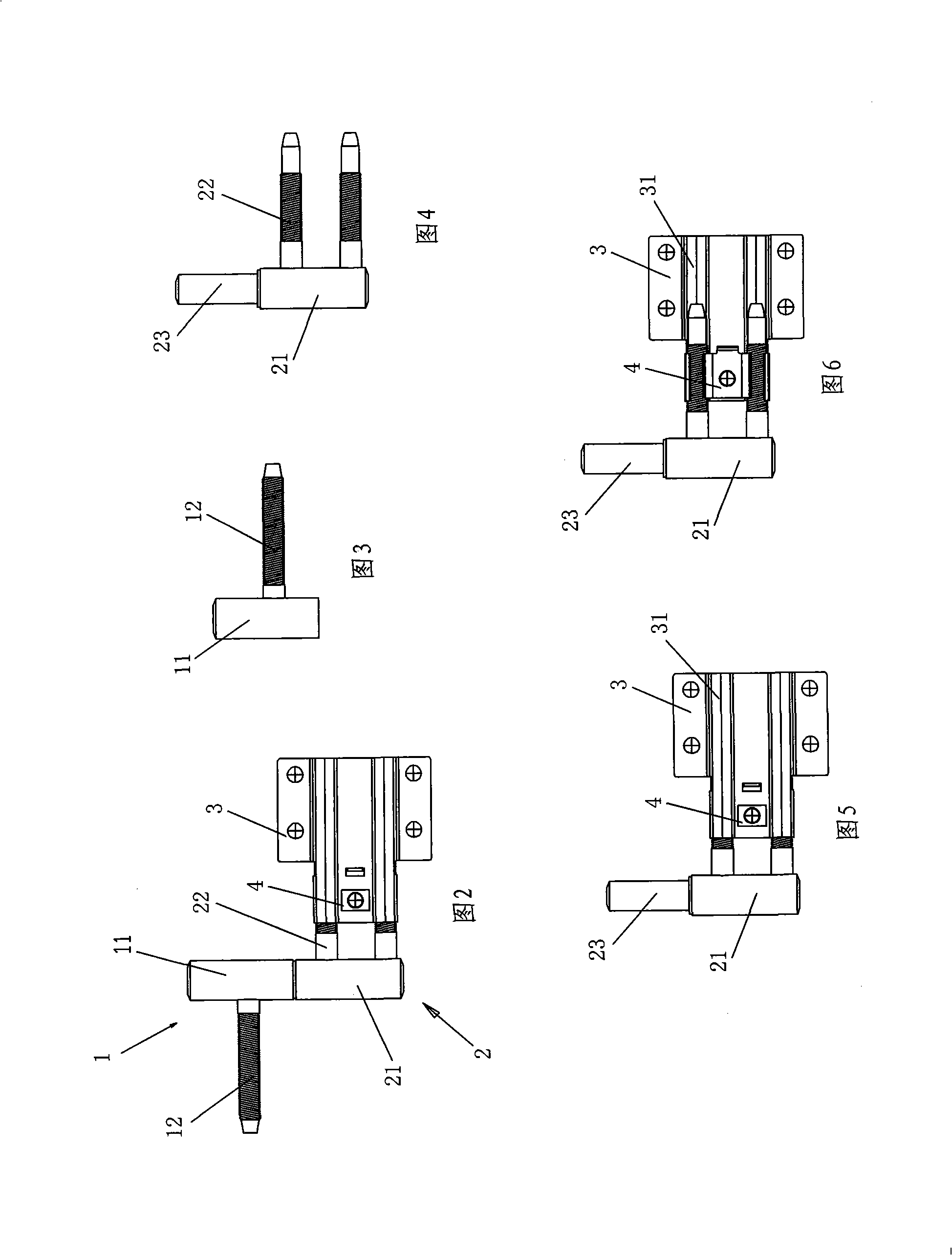

Adjustable three-fork hinge

An adjustable tripod type hinge is characterized in that the hinge presents a T-shape; and a single fork hinge and a double fork hinge are receptively arranged. In the single fork hinge, a push rod in the T-shaped structure is a tubular body; and a single rod connected with the middle part of the tubular body is a screw rod fixedly arranged in a door leaf through threads. In the double fork hinge, the push rod in the T-shaped structure takes double rods arranged in parallel as the supporting rods; a rotating shaft is respectively and coaxially arranged at one end of the push rod and the push rod; the tubular body on the single fork hinge is sleeved on the rotating shaft; the tubular body can be rotated relative to the rotating shaft; the double rods in the double fork hinge are arranged in a rod hole of a fixing plate through a metal pressing plate; and the fixing plate is fixedly arranged on a door pocket. The adjustable tripod type hinge has the advantages that the optimum opening effect can be obtained through the simple adjustment of each component; because the damping fit is arranged between the tubular body and the rotating shaft, the hinge can stop in arbitrary position, and the effect of the opening without noise can be achieved.

Owner:ANHUI FUHUANG STEEL STRUCTURE

High-levelling stain-resistant PVA inner wall antibacterial paint

InactiveCN108485404AImprove the level ofImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholSlurry

The invention provides high-levelling stain-resistant PVA inner wall antibacterial paint, which is prepared from the following raw material ingredients in parts by weight: 10 to 20 parts of polyvinylalcohol, 10 to 20 parts of nanometer titanium dioxide slurry, 4 to 6 parts of antibacterial nanometer titanium dioxide, 10 to 20 parts of titanium dioxide, 10 to 20 parts of ground limestone, 3 to 6 parts of light calcium carbonate, 8 to 10 parts of talcum powder, 3 to 6 parts of wollastonite powder, 3 to 6 parts of wax emulsion, 0.2 to 0.5 part of hydroxyethyl cellulose, 0.5 to 1.0 part of dispersants, 0.2 to 0.5 part of anti-foaming agents, 1.0 to 2.5 parts of coalescing agents, 1 to 3 parts of antifreezing agents and 40 to 60 parts of deionized water. The high-levelling stain-resistant PVAinner wall antibacterial paint has the advantages of good leveling performance, good coating hydrophobicity, antibacterial and bacteriostat performance, high leveling performance, stain resistance performance, high decoration performance, breath moisture regulation performance, green and environment-friendly performance, low cost and the like.

Owner:邹奇峰

Cotton opening mechanism for toy production

InactiveCN106245160ASmall footprintGood sealingFibre cleaning/opening machinesInlet channelEngineering

The invention discloses a cotton opening mechanism for toy production. The cotton opening mechanism comprises a fan box and an operation panel arranged on the surface of the fan box. The fan box is connected with a cotton opening box body through a cotton blowing channel; a cotton opening mechanism is mounted in the cotton opening box body and connected with a roller and a mote knife assembly; the mote knife assembly is connected with a dust discharging opening, and a falling cotton suction opening is formed in the top of the cotton opening box body; the cotton opening box body is connected with a cotton inlet channel, and a cotton inlet is formed in one end of the cotton inlet channel; the cotton blowing channel is connected with a cotton outlet channel, and an observation window is arranged on the surface of the cotton outlet channel. The tail end of the cotton outlet channel is connected with a collecting box, and an electronic balance is arranged at the bottom of the collecting box. The cotton opening mechanism is small in overall occupied area, good in sealing performance, low in power consumption and low in noise, feeding and discharging are optimized to be integrated, the cotton opening mechanism can be used singly, multiple cotton opening mechanism can be used in series, the operation panel is arranged for achieving photoelectric control, the feeding and discharging amount of raw cotton can be freely regulated and controlled, the situation of jam is avoided, and therefore the optimal cotton opening effect is achieved.

Owner:蓝灿玉

Preparation method of anti-aging exterior wall latex paint

InactiveCN112159612AImprove propertiesGood dispersionAntifouling/underwater paintsPaints with biocidesPolymer scienceMicroparticle

The invention relates to a preparation method of an anti-aging exterior wall latex paint, and belongs to the technical field of latex paints. The anti-aging exterior wall latex paint is prepared by adding modified silica sol. The silica sol is modified, so that the silica sol is better compatible with a polymer emulsion, and the application range of the silica sol can be expanded. The silica sol modified paint is more excellent in performance, the hardness and adhesive force of a film and the stain resistance, water resistance and aging resistance of the paint are obviously improved, particlesurface coordination in silica sol is vacant, and the anti-aging exterior wall latex paint has very high surface activity, has a certain adsorption effect on pigment, filler and other microparticles,and can reduce pigment attenuation caused by ultraviolet irradiation, so film chalking is reduced; and the silicon dioxide particles in the silica sol are dispersed to form a Si-O-Si network structure, so that the air permeability, the aging resistance and the like of the film can be improved.

Owner:廖莲英

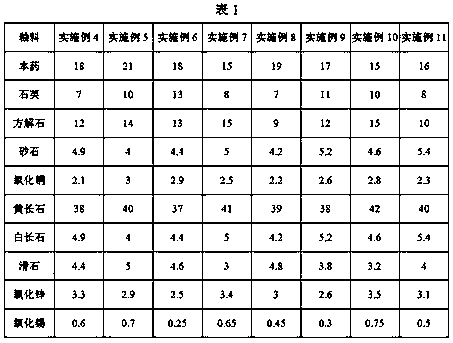

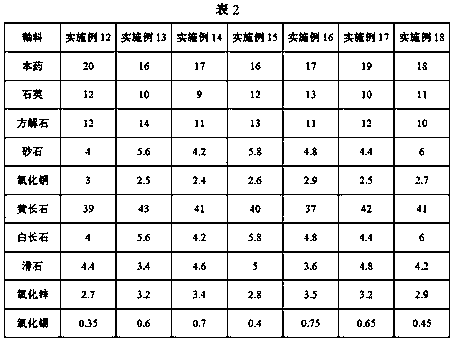

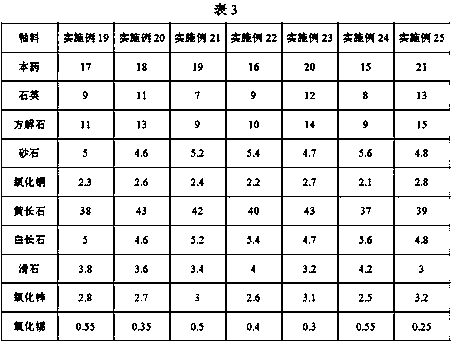

Cracked lujun glaze

The invention provides a cracked lujun glaze. The cracked lujun glaze is characterized by being prepared from the following raw materials in parts by weight: 15 to 21 parts of local feldspar from Yuzhou, Henan, China, 7 to 13 parts of quartz, 9 to 15 parts of calcite, 4 to 6 parts of gravel, 2 to 3 parts of copper oxide, 37 to 43 parts of melilite, 4 to 6 parts of white feldspar, 3 to 5 parts of talcum, 2.5 to 3.5 parts of zinc oxide and 0.25 to 0.75 parts of stannic oxide. Compared with the prior art, by scientifically and reasonably proportioning the raw materials and controlling a sinteringprocess, the sintered cracked lujun glaze disclosed by the invention has the advantages of natural color, has crackle, high jade texture, high rate of a finished product and rare floating light; in addition, a large kiln is adopted for firing, a firing method adopts a gas firing mode, and the rate of the finished product can reach 90 percent or above.

Owner:禹州市锦丰源瓷业有限公司

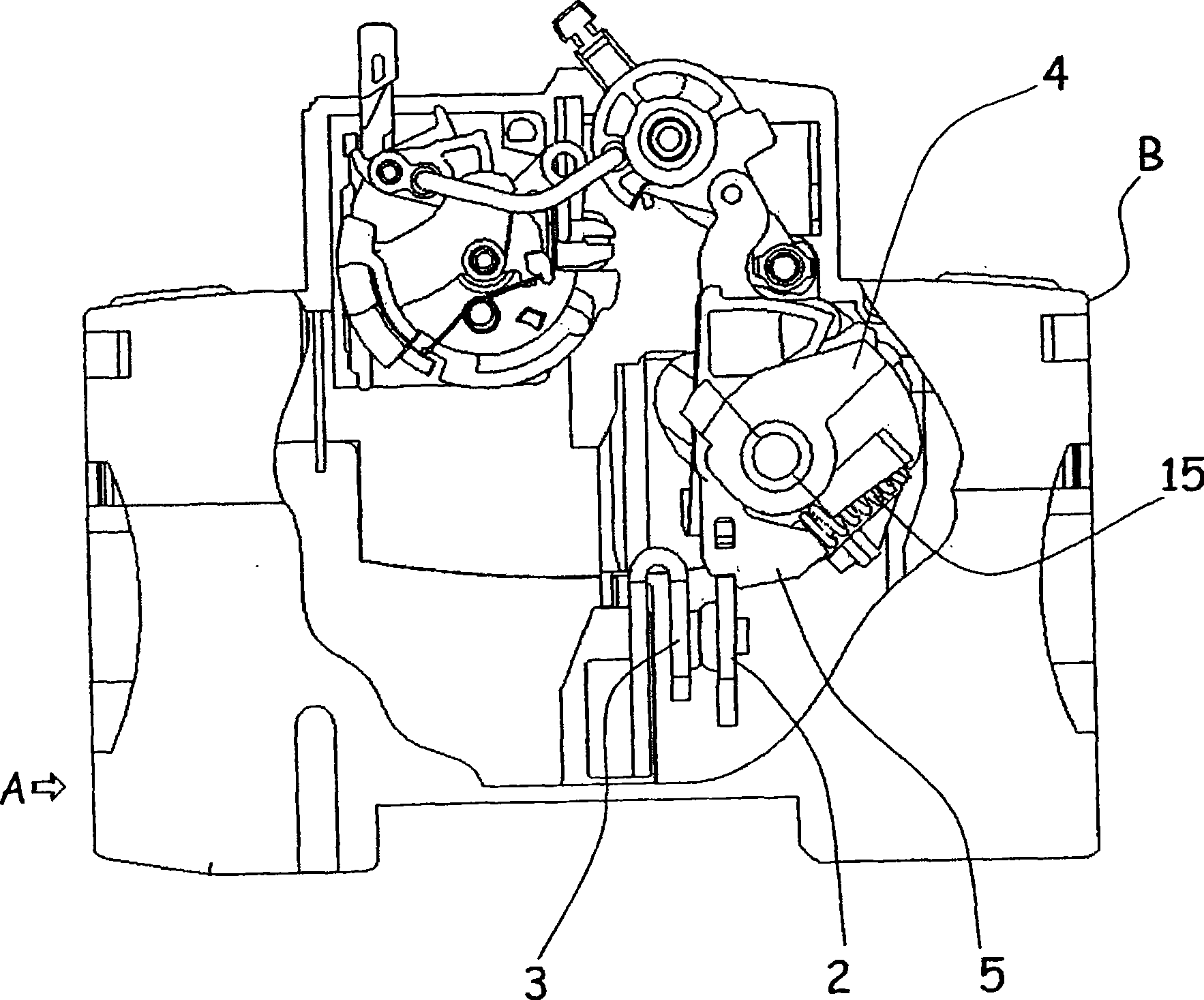

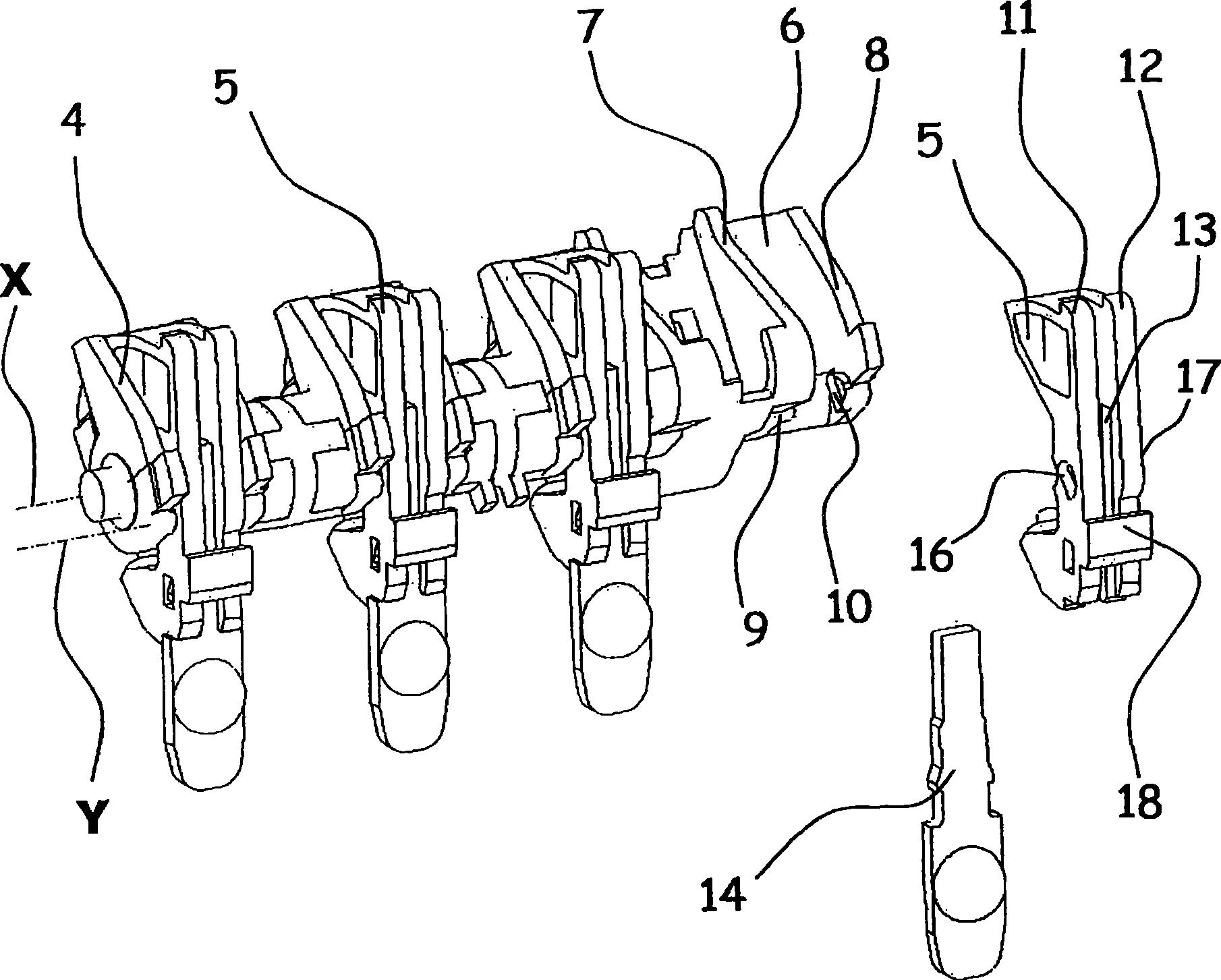

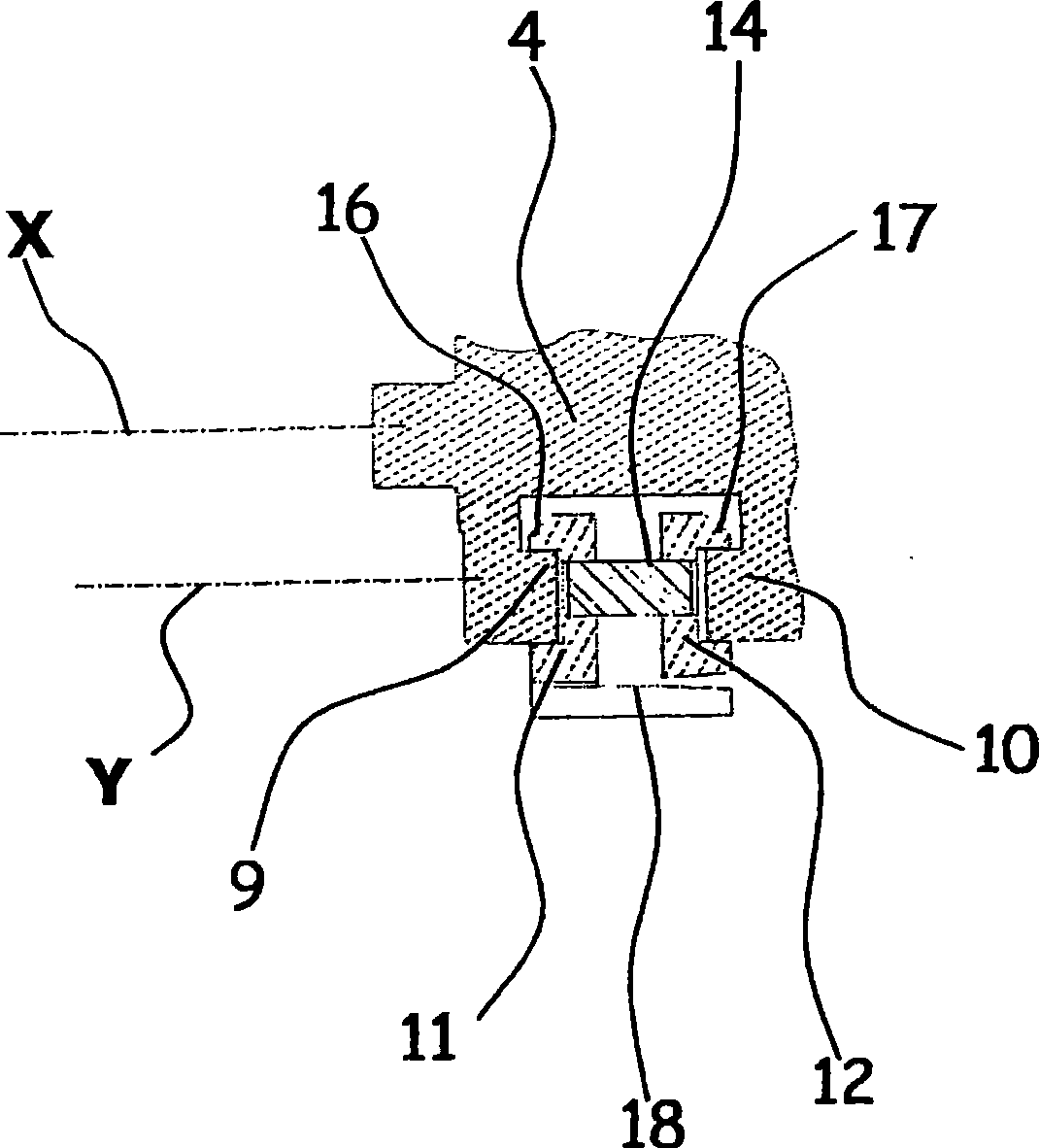

Electrical switchgear with rotating mobile contact(s)

ActiveCN101477923AGood reproducibilityEasy to closeProtective switch detailsContact engagementsEngineeringSwitchgear

The invention relates to an electrical switch unit A contained in an insulating housing B and comprising a contact bracket used for supporting at least a contact (2) called movable contact and for setting the movable contacts and each movable contact (2) to face to at least a contact (2) called still contact. The unit is characterized in that the contact (2) can be arranged in a bracket (5) called a second bracket (or movable contact are arranged brackets called second brackets respectively); the second bracket (5) is hinged with respect to the first bracket (4); and the unit comprises a device used for providing contact pressure between the movable contacts and the still contacts.

Owner:SCHNEIDER ELECTRIC IND SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com