Acid rain-resistant antifouling aqueous nanometer polyurethane exterior wall finish

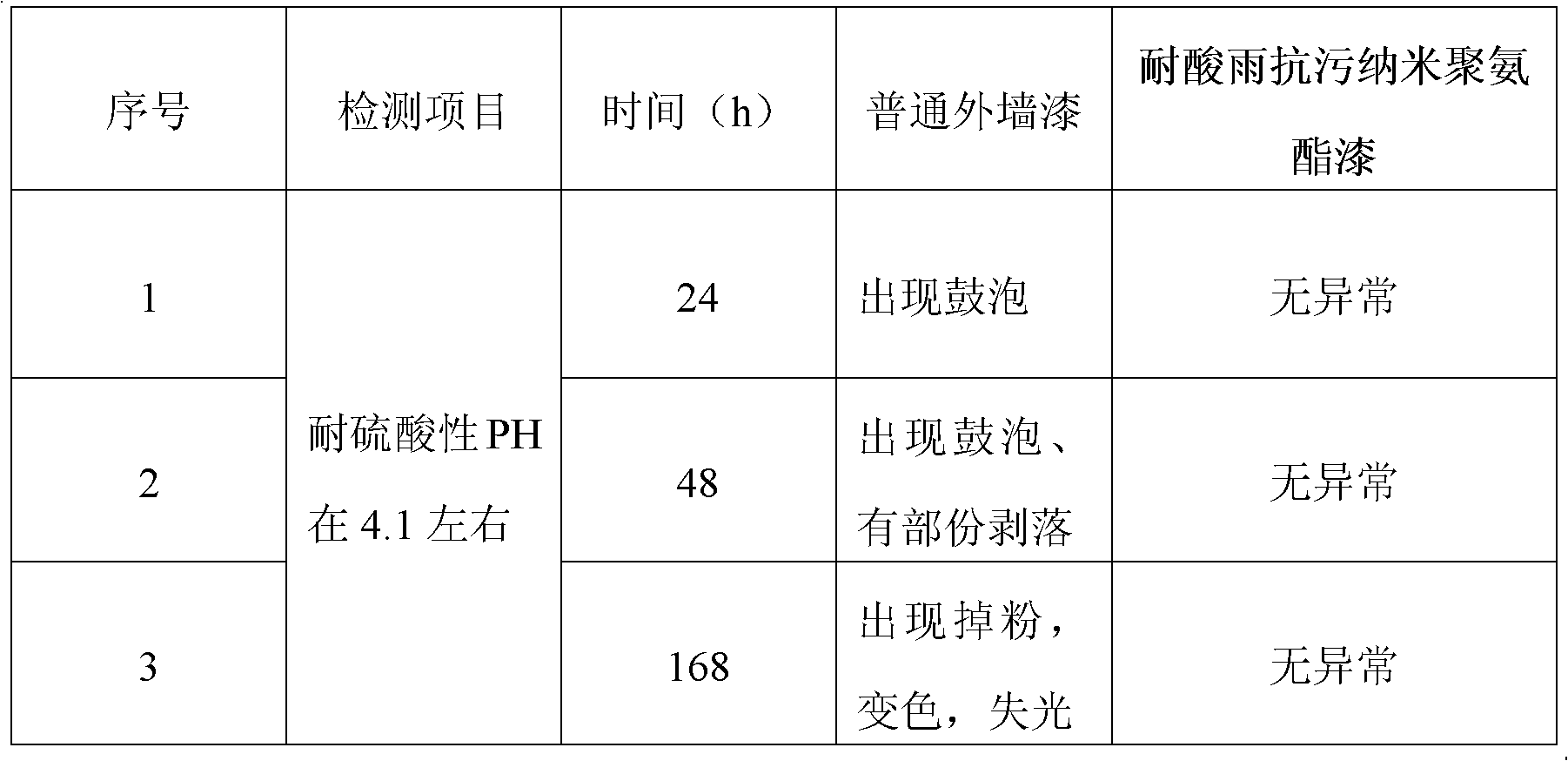

A water-based polyurethane and acid rain-resistant technology, which is applied in polyurea/polyurethane coatings, antifouling/underwater coatings, paints containing biocides, etc., can solve the problem of reducing building decoration requirements, reducing the decorativeness of paint films, and poor acid resistance. Good and other problems, to achieve excellent chemical properties such as acid and alkali resistance, increase strength and smoothness, and excellent gloss and color retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

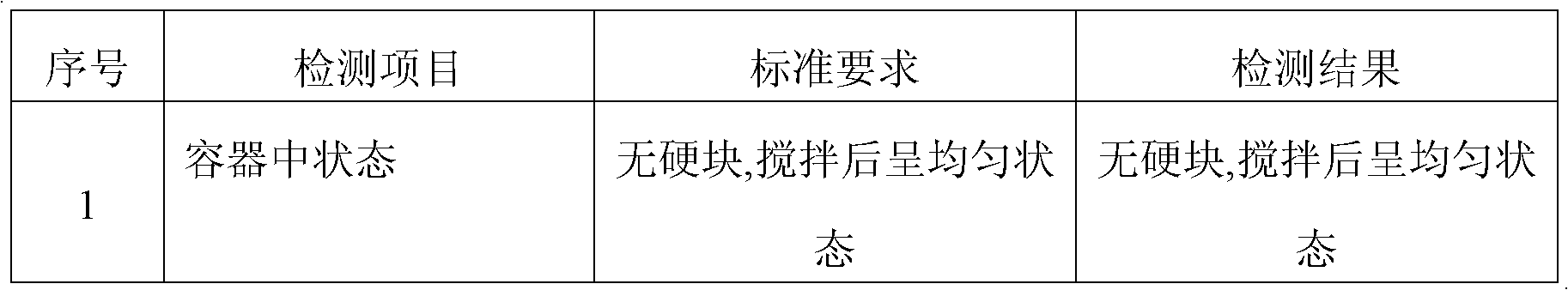

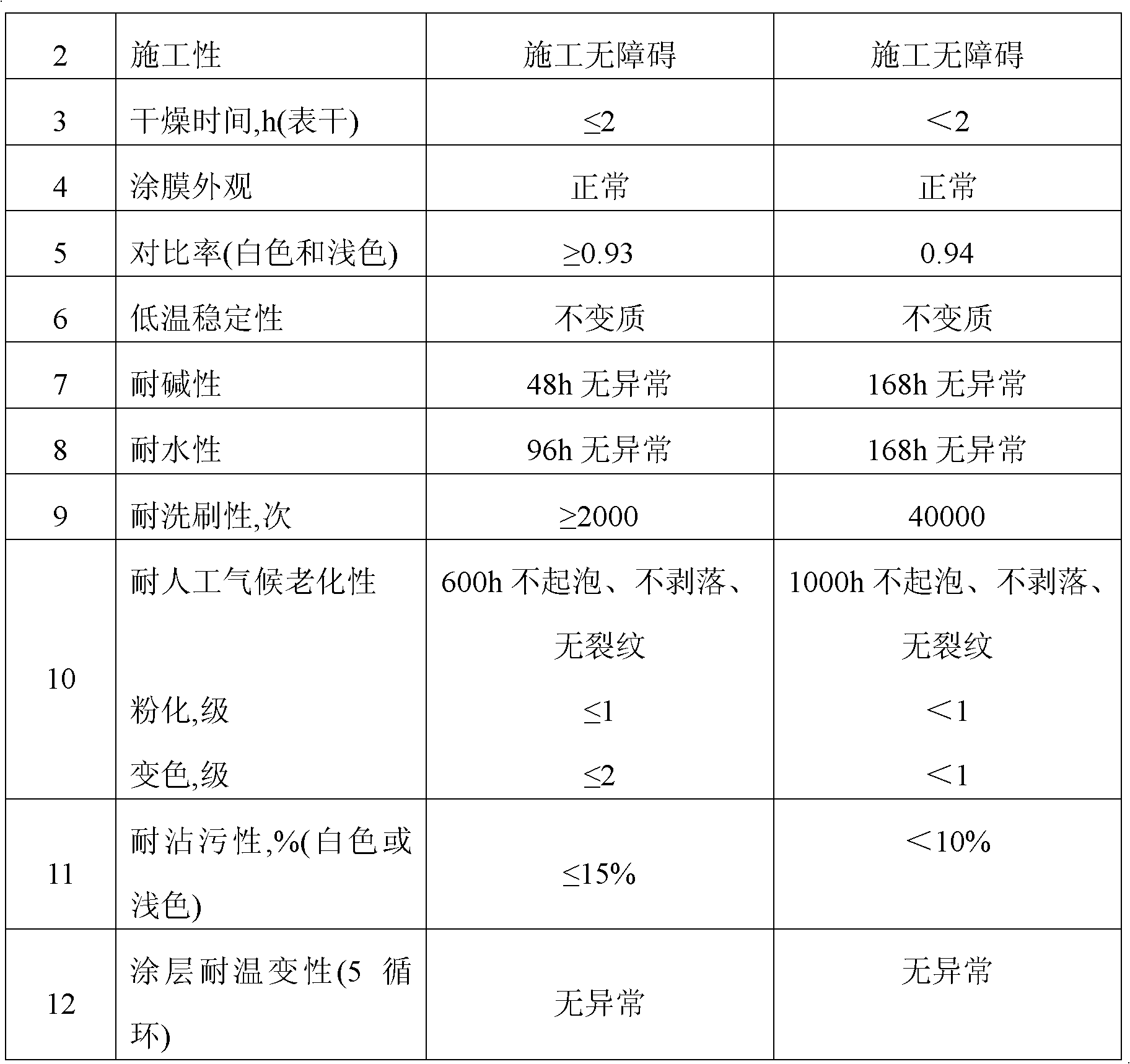

Examples

preparation example Construction

[0037] 1. Preparation of main paint: add water according to the weight of the example, and put in dispersant, thickener, wetting agent, propylene glycol, and defoamer in sequence at a speed of 300 to 500 rpm, and disperse for 6 minutes: At 500-900 rpm, add rutile titanium dioxide, chemically inert coatings, and nanomaterials; at 900-1400 rpm, disperse for 25-30 minutes: quality inspection sampling inspection fineness ≤ 60 microns; at 300 At a speed of ~500 rpm, add film-forming aids, preservatives, and antifungal agents in sequence. After dispersing for 6 minutes, add -OH-containing water-based polyurethane resin, PH regulator, defoamer, and thickener. Disperse for 6 minutes: take samples for quality inspection, filter and pack after passing the test.

[0038] 2. Preparation of curing agent:

[0039] (1) When the curing agent is pure -NCO-containing polyisocyanate, take the -NCO-containing polyisocyanate and stir for 5 minutes, and pack it after passing the quality inspection...

Embodiment 1

[0044] The preparation method of the above-mentioned acid rain and anti-fouling nano water-based polyurethane exterior wall paint is:

[0045] 1. Preparation of the main paint: add 210kg of water, and put in 5kg of dispersant successively at a speed of 300-500 rpm. The thickener at the place is preferably ACRYSOLRM-8W from Rohm and Haas China; 2kg wetting agent, preferably Hyoni PE-100 from Shenzhen Haichuan Chemical Technology Co., Ltd.; 18kg propylene glycol; 2kg defoamer, preferably Blackburn Chemicals Dilpelair CF247; disperse for 6 minutes: at 500-900 rpm, put in 180kg rutile titanium dioxide, rutile titanium dioxide is preferably TRONOX CR-828; 120kg chemically inert filler, preferably 1250 mesh barium sulfate; 9kg nanomaterials , selected from nm-SiO of Jiangsu Hehai Nano Technology Co., Ltd. 2 , where nm-SiO 2 The particle size is less than or equal to 20nm; at the speed of 900-1400 rpm, disperse for 25-30 minutes: after the quality inspection sampling inspection fin...

Embodiment 2

[0050] The preparation method of the above-mentioned acid rain and anti-fouling nano water-based polyurethane exterior wall paint is:

[0051] 1. Preparation of the main paint: add 300kg of water, and at a speed of 300-500 rpm, add 13kg of GA-40 selected from Ciba Specialty Chemicals China Co., Ltd., 8kg of GA-40 selected from Clariant Chemicals (China) ) Co., Ltd. HS30000YP2, 3kg of Emulsogen LCN407 selected from Clariant Chemical (China) Co., Ltd., 25kg of propylene glycol, 3kg of Dispelair CF550 selected from Blackburn Chemical, dispersed for 6 minutes: at 500-900 rpm, Put in 150kg TRONOX CR-828, 55kg of 1250 mesh barium sulfate, 15kg of nm-SiO selected from Jiangsu Hehai Nano Technology Co., Ltd. 2 , where nm-SiO 2 The particle size is less than or equal to 20nm; at the speed of 900-1400 rpm, disperse for 25-30 minutes: after the quality inspection sampling inspection fineness ≤ 60 microns; at the speed of 300-500 rpm, put in 35kg of Be selected from TEXANOL of Eastman C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com