System for automatically cleaning tail yarns of roving bobbins

An automatic cleaning and roving bobbin technology, which is applied in the direction of opening and cleaning with a suction device, textiles and papermaking, etc., can solve the problems of labor-intensive, incomplete use, and increase of cotton fiber short-lint rate, so as to save manpower, improve efficiency, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

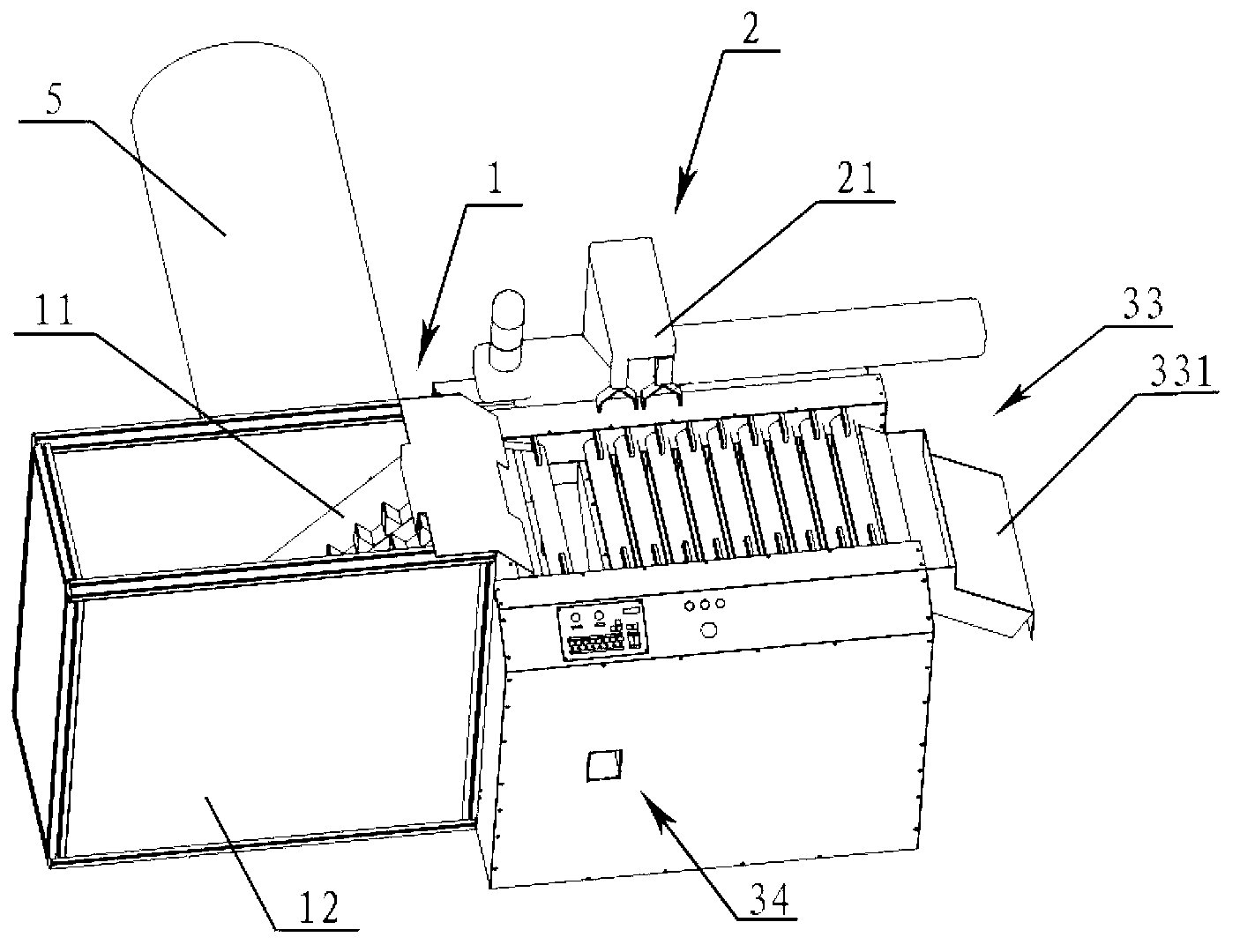

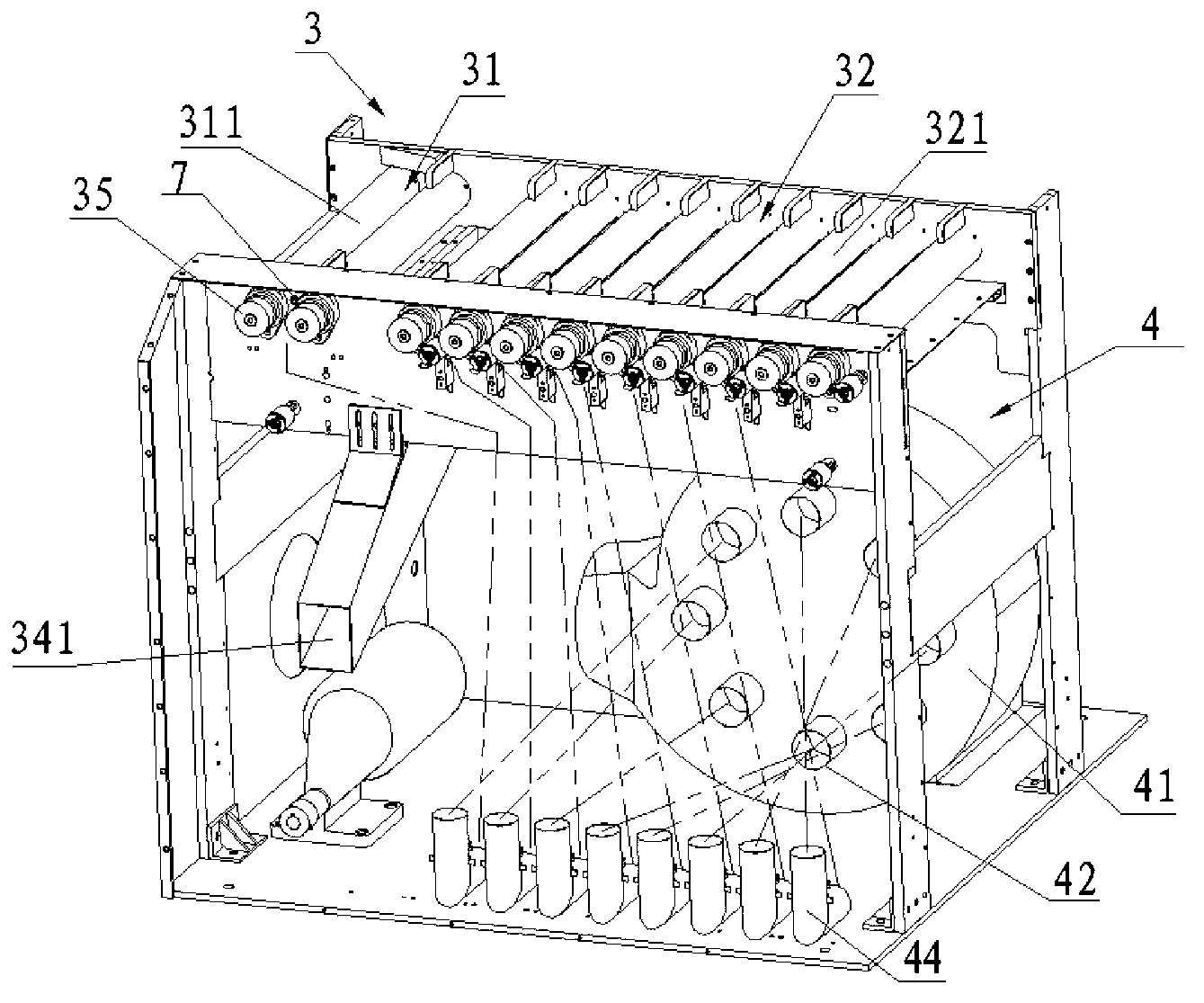

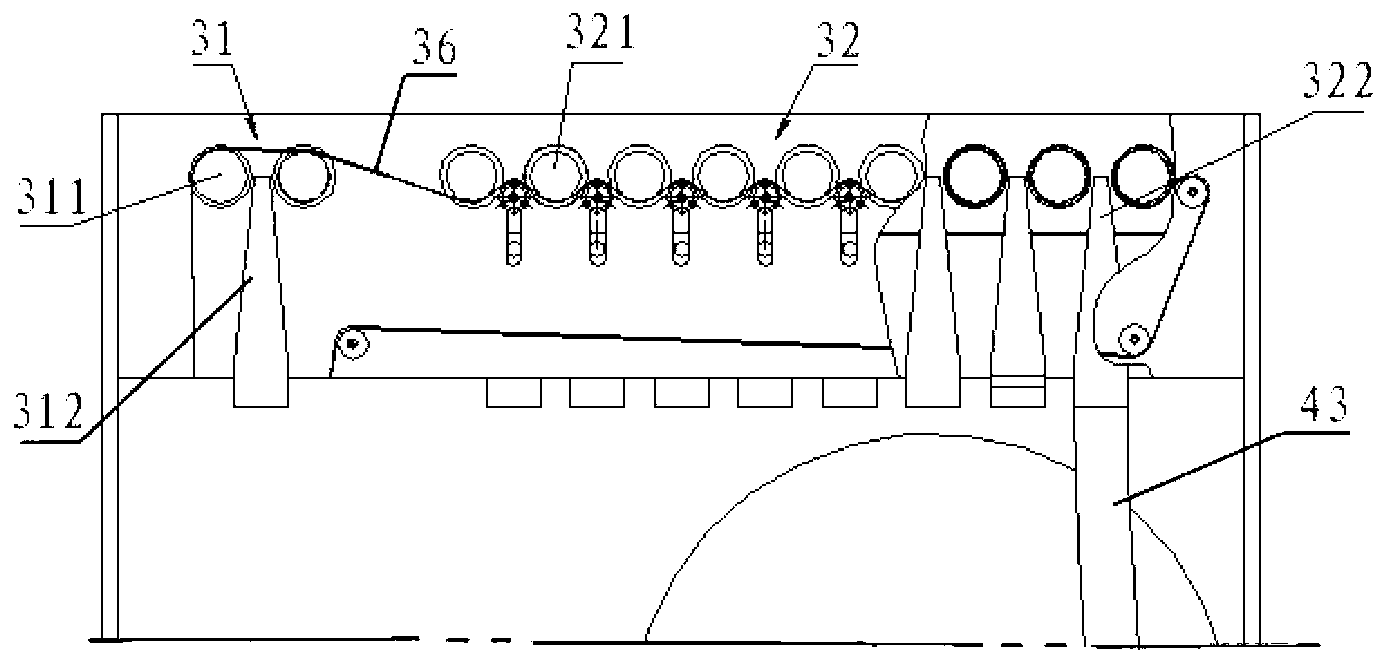

[0033] Combine below Figure 1 to Figure 7 The present invention is described in further detail:

[0034] This system includes a feeding device 1, a conveying device 2, an unwinding device 3, an opening device 4, a recovery device 5 and a control system (not shown in the figure); wherein the feeding device 1 can store several The roving bobbins 6 that are wound with tail yarns, and automatically convey the roving bobbins one by one to the unwinding device; the feeding device includes a storage box 12, and a belt 11 for conveying the roving bobbins is installed in the storage box, and the belt is located at the one The front side of the group shaft, the belt is a lifting belt, the staff should put the roving tubes with tail yarns into the storage box according to the requirements of the same size and direction, and then transport the roving tubes to the unwinding device one by one through the lifting belt.

[0035] The unwinding device 3 includes a turning-back sliver cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com