Patents

Literature

857results about "Fibre cleaning/opening machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

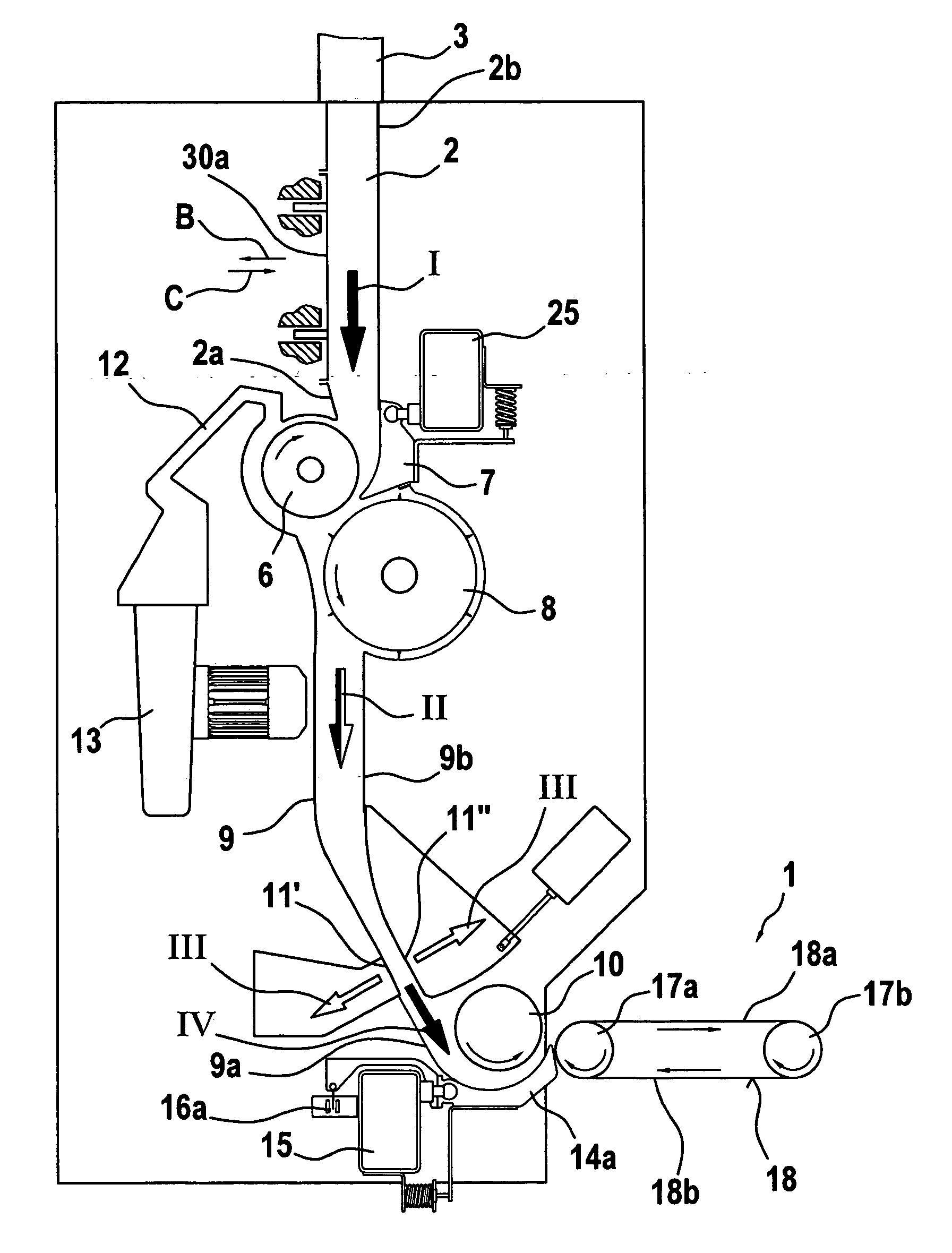

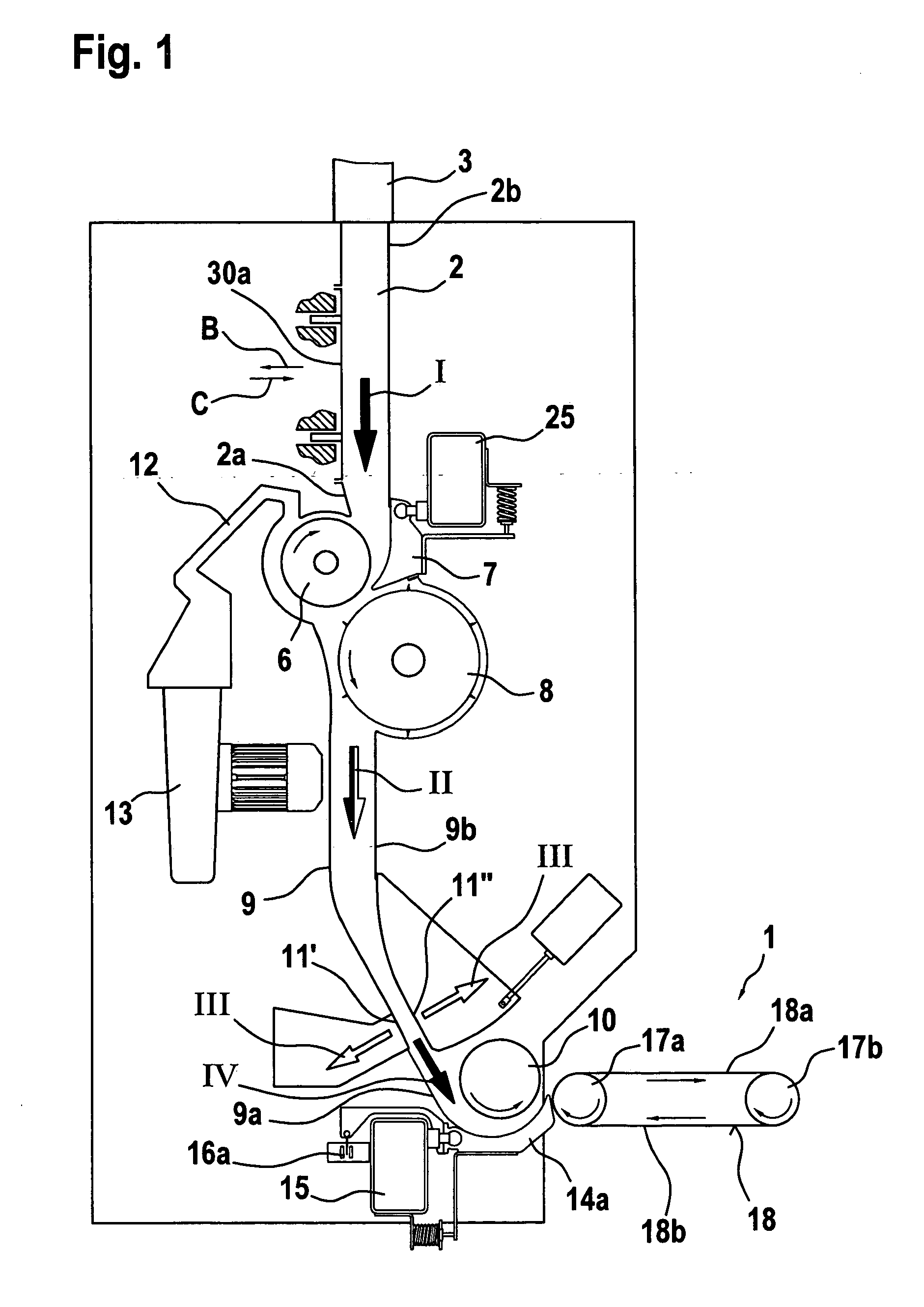

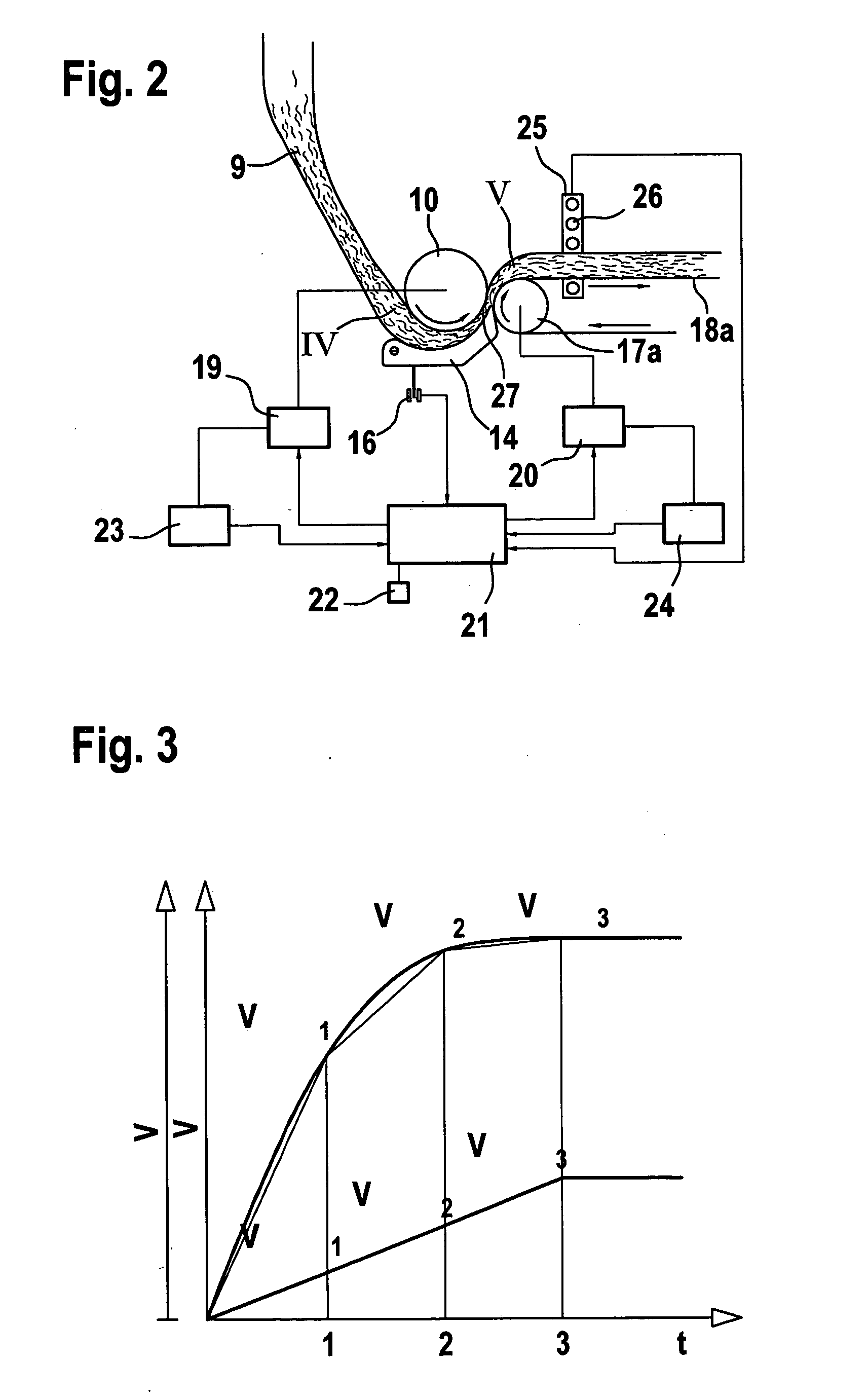

Device on a spinning preparation machine, for example a tuft feeder, having a feed device

A device on a spinning preparation machine, for example a tuft feeder, having a feed device comprising at least one slow-speed feed roller and a counter-element, for example a feed tray, with which fibre material can be supplied to a downstream transport device, has a driven transport element, for example a conveyor belt. In order to provide improved delivery from the feed device, or improved takeover by the downstream transport device, and to allow troublefree operation, for the purpose of determining setting values for the optimum speed of the transport element, a function between the measured values of the feed roller speed and the measured values of the transport speed is so determined that the fibre material lies on the moving surface of the transport element.

Owner:TRUETZSCHLER GMBH & CO KG

Process for making bamboo fiberfill and articles thereof

InactiveUS20090101294A1Small sizeNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

A process for producing bamboo fiberfill from raw bamboo fiber includes, obtaining a bale of the raw bamboo fiber, picking up and separating the raw bamboo bale fiber into tufts of bamboo fiber with a bale opener, feeding the bamboo fiber tufts into a blending hopper configured to blend the bamboo fiber tufts, feeding the blended bamboo fiber tufts into a beater configured to open the bamboo fiber tufts, and feeding the opened bamboo fiber tufts into a fine opener configured to reduce the size of the opened bamboo fiber tufts and refine the opened bamboo fiber tufts into the bamboo fiberfill, wherein the bamboo fiberfill has a fiber length of about 30 millimeters to about 60 millimeters and a linear density of about 0.5 denier to about 5.0 denier.

Owner:FAIRFIELD PROCESSING CORP

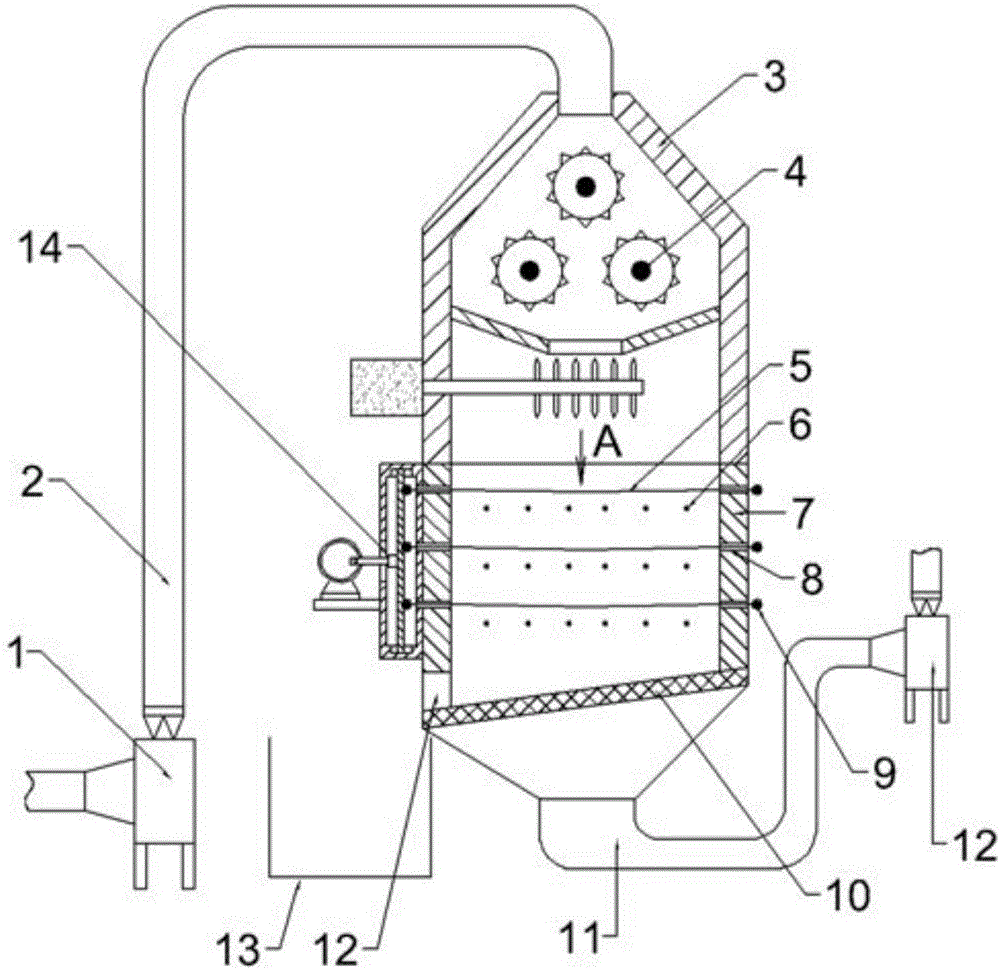

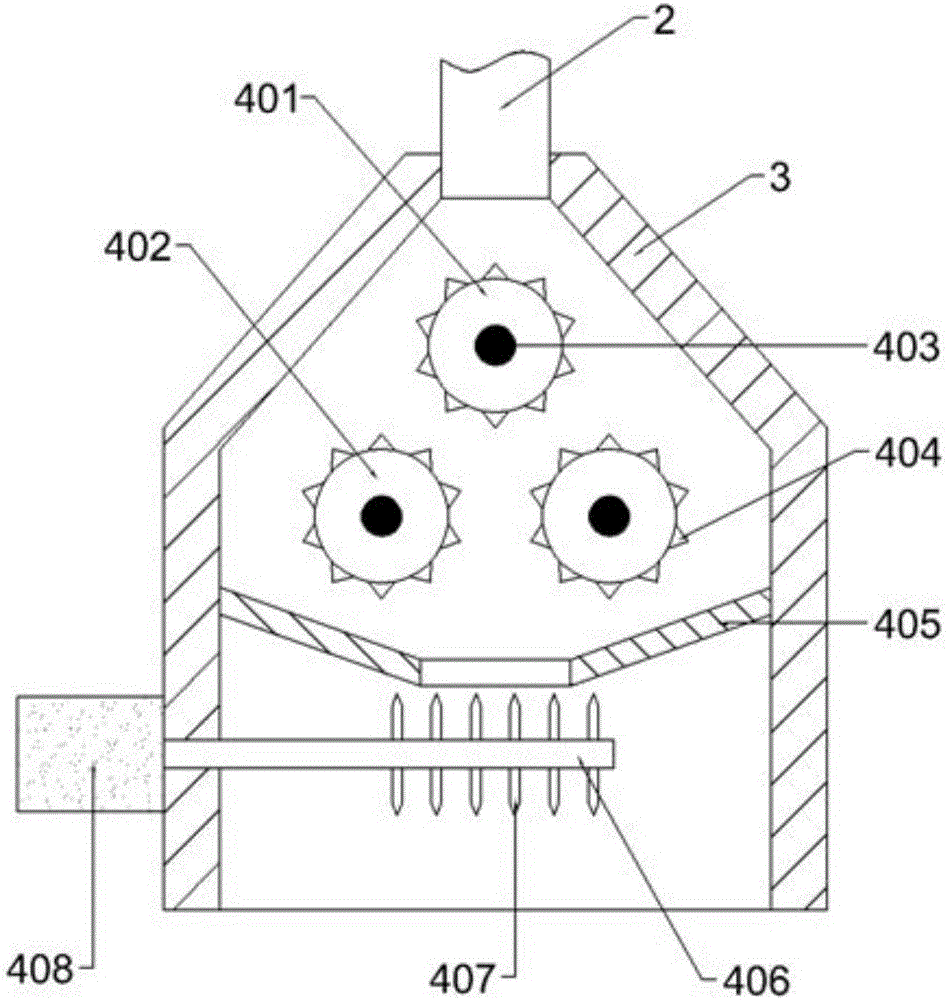

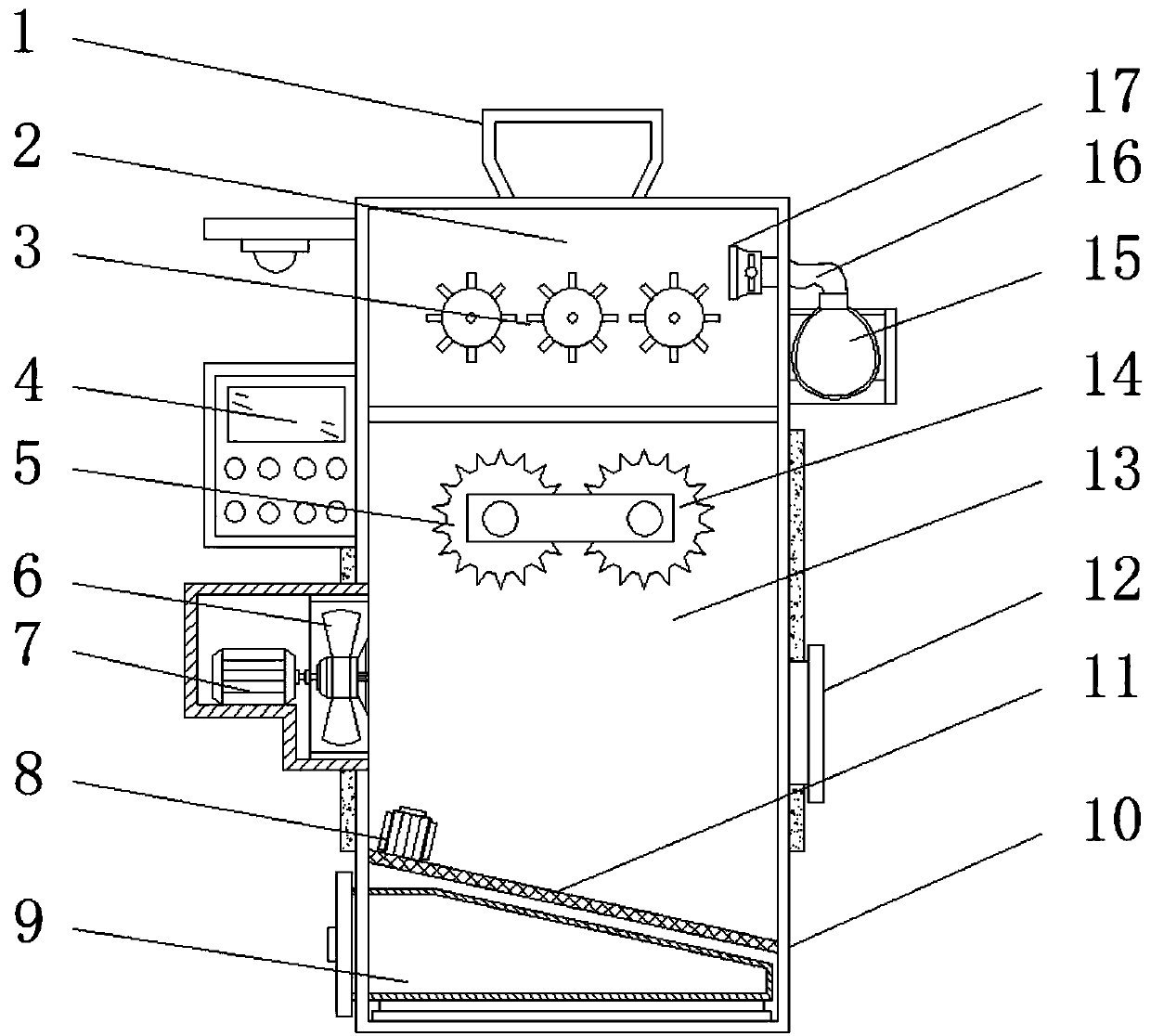

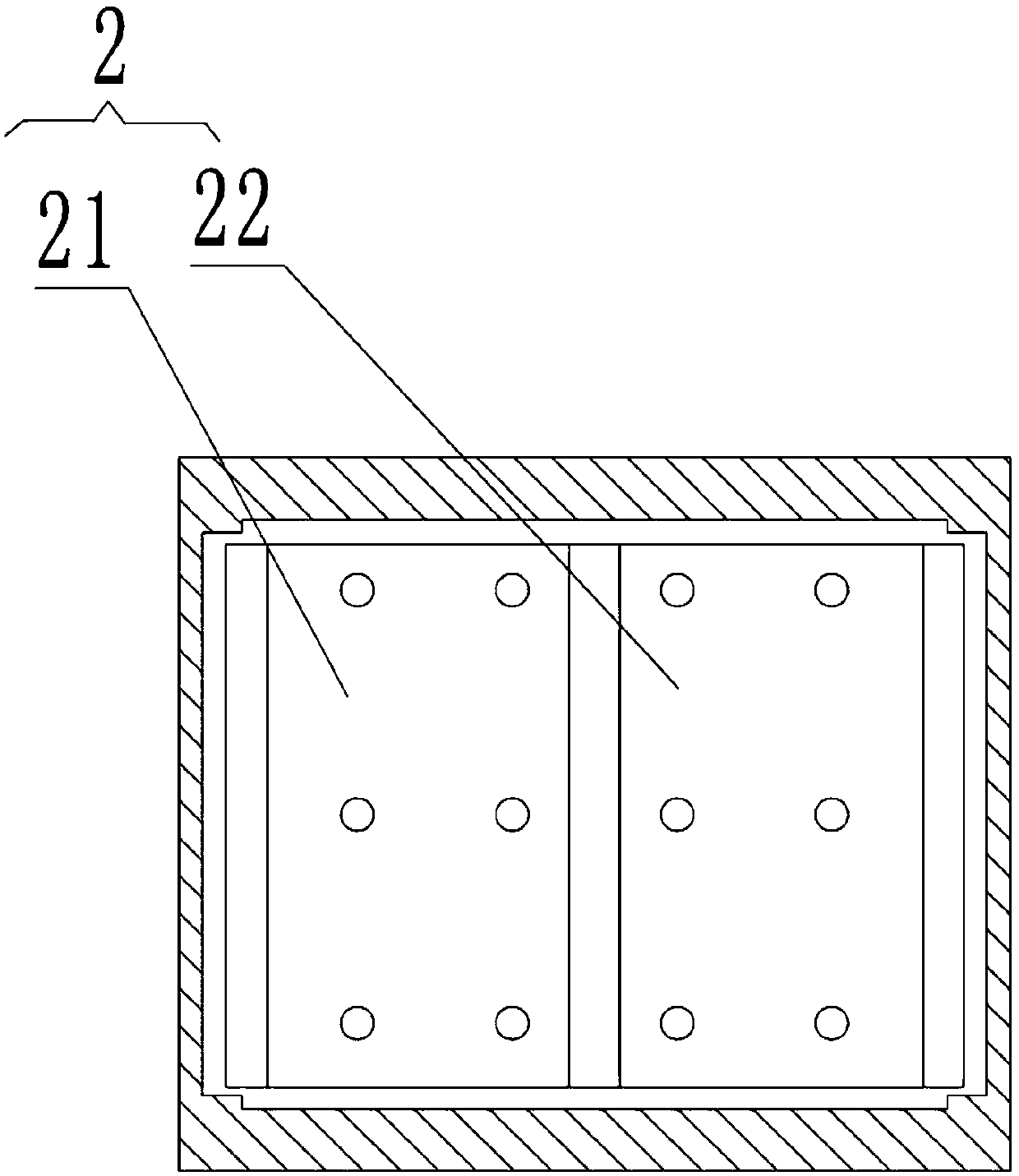

Opener with impurity removal function

InactiveCN102586955AAvoid breakingAvoid damageFibre cleaning and opening machine combinationsFibre cleaning/opening machinesWindow openingMechanical engineering

The invention discloses an opener with an impurity removal function, belonging to the field of non-woven textile machinery. The opener comprises a left case, a right case, an upper baffle, a lower baffle, a rear baffle, a cotton outlet box, an opening roller, a first roller and a second roller, wherein the left and right cases are opposite to each other; the left case is provided with an opening roller drive mechanism; the right case is provided with a roller drive mechanism; the upper, lower and rear baffles are fixed between the left and right cases; the cotton outlet box is fixed at the top between the left and right cases; an opening roller half shaft is arranged at the left and right ends of the opening roller respectively; the first and second rollers are matched with each other. The opener is characterized in that a window opening is arranged in the length direction of the lower baffle; a window door is arranged on one side of the lower baffle, back on to an opening cavity; a metal piece absorption component is arranged on one side of the window door, facing the window opening; a block rod and a block roller are arranged in the opening cavity; an impurity lead-out channel is formed between the lower part of the rear baffle and the lower part of the lower baffle; and a garbage accumulation disc is arranged below the impurity lead-out channel and fixed at the bottom between the left and right cases. The opener disclosed by the invention has the advantages that the production efficiency is improved, the working intensity is reduced, and the using cost is lowered.

Owner:常熟市伟成非织造成套设备有限公司

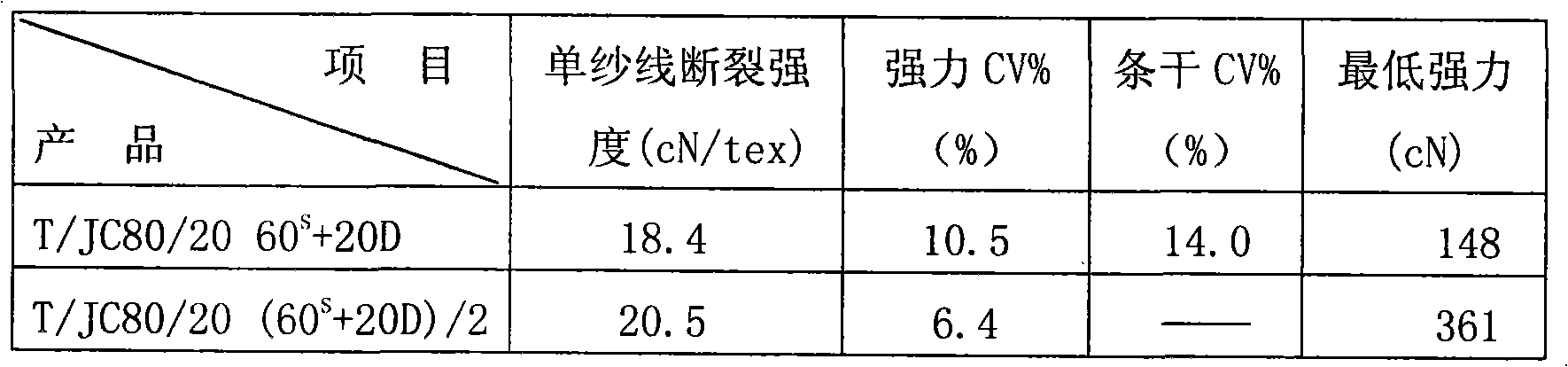

Production method of moisture-absorbing and sweat-discharging fabric

InactiveCN101962850AGood moisture absorption and quick drying effectSkinnyFibre cleaning/opening machinesWoven fabricsBreaking strengthPolyester

The invention relates to a production method of a moisture-absorbing and sweat-discharging fabric. In the method, the moisture-absorbing and sweat-discharging fabric is produced by using 80 percent of honeycomb moisture-absorbing and quick-drying fibers and 20 percent of cotton fibers as coating fibers and 20D common polyester filaments as core yarns. The method comprises the following steps: subjecting moisture-absorbing and sweat-discharging fibers to cotton opening and cleaning, cotton carding and primary combination, subjecting cotton fibers to cotton opening and cleaning, cotton carding and fine carding, and combining the moisture-absorbing and sweat-discharging fibers and cotton fibers primarily; combining secondarily; spinning a coarse yarn; spinning a fine yarn; winding single yarn; twisting; yarn strand winding; and producing T / JC80 / 20(60s+20D) single yarnbs and T / JC80 / 20(60S+20D) / 2 yarn stands, wherein the breaking strengths of the single yarn and the yarn strand are 18.4cN / tex and 20.5cN / tex respectively, the strength CV values of the single yarn and the yarn strand are 10.5 percent and 6.4 percent respectively, the lowest strength of the single yarn and the yarn strand are 148cN and 361cN respectively, and the yarn levelness of the T / JC80 / 20(60S+20D) single yarn is 14.0 percent; and weaving the yarn and yarn stand by warping, sizing, denting, weaving, finishing and producing a T / JC80 / 20(60s+20D) / 2*T / JC80 / 20(60s+20D) / 2 76*71 70.5''1 / 1. In the invention, the fabric produced by reasonable cotton cleaning and carding processes and proper sizing and weaving processes and by combining two combined yarns has high moisture-absorbing and rapid-drying effects and offers an excellent skinny effect.

Owner:JIHUA 3509 TEXTILE

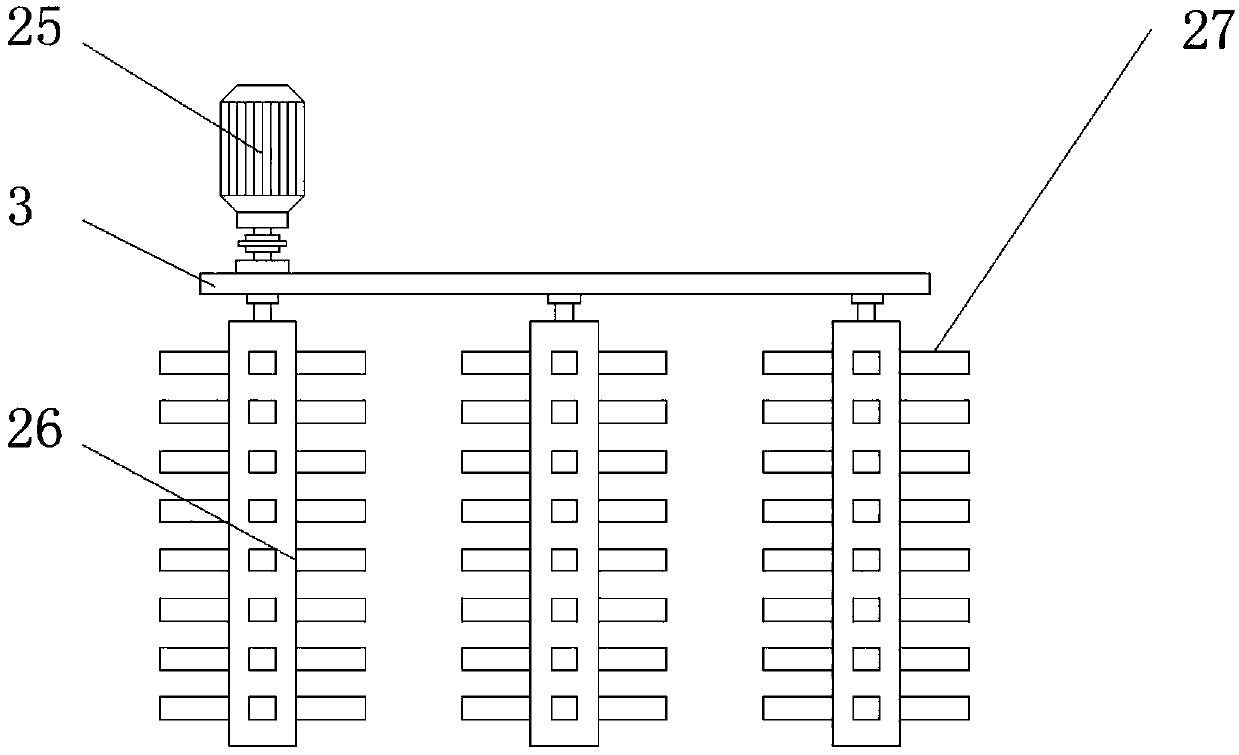

Vibration type opener

InactiveCN102181965AReduce damagePass smoothlyFibre cleaning/opening machinesSevering fibresCardingLongitudinal wave

The invention discloses a vibration type opener. The opener comprises a feeding mechanism and a vibrating opener, wherein a fiber feeding inlet is arranged at the top of the vibrating opener; a fiber outlet is arranged at the bottom of the vibrating opener; the feeding mechanism is connected with the fiber feeding inlet on the vibrating opener; a plurality of first opening layers and second opening layers are arranged in the vibrating opener; the first opening layers and the second opening layers are alternately arranged from top to bottom; each first opening layer is formed by a plurality ofsilk threads which can synchronously act similar to longitudinal wave amplitude shaped vibration and can be pulled up transversely; and each second opening layer is formed by a plurality of silk threads which can synchronously act similar to transverse wave amplitude shaped vibration and can be pulled up transversely. The opener has the following beneficial effects: the first opening layers and the second opening layers are arranged in the vibrating opener, thus changing the traditional card wire pin roller type opening or sawtooth clothing carding type opening and farthest reducing the degree of damage on the fibers in the fiber opening process; and when passing through the first opening layers and the second opening layers, the fibers are elastically hit by the silk threads repeatedly, thus fully opening the fibers.

Owner:青岛东佳纺机(集团)有限公司

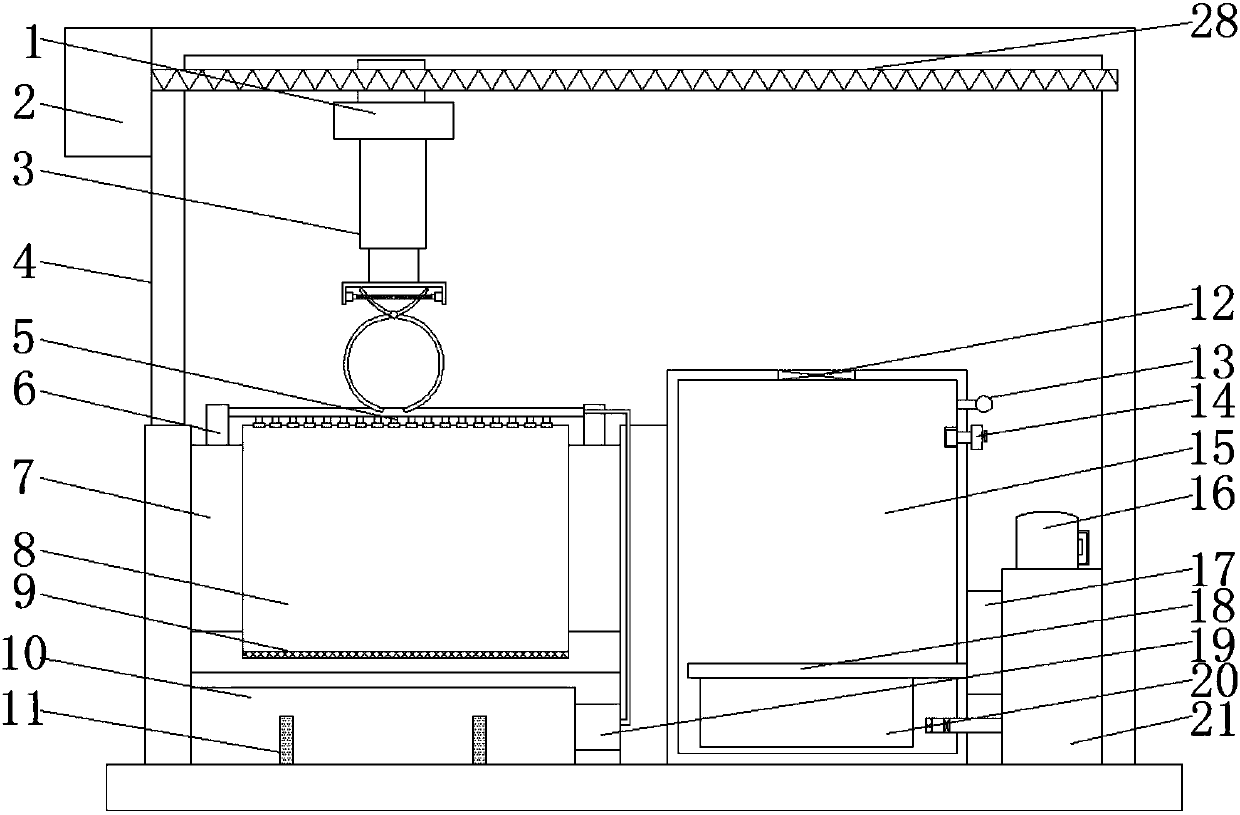

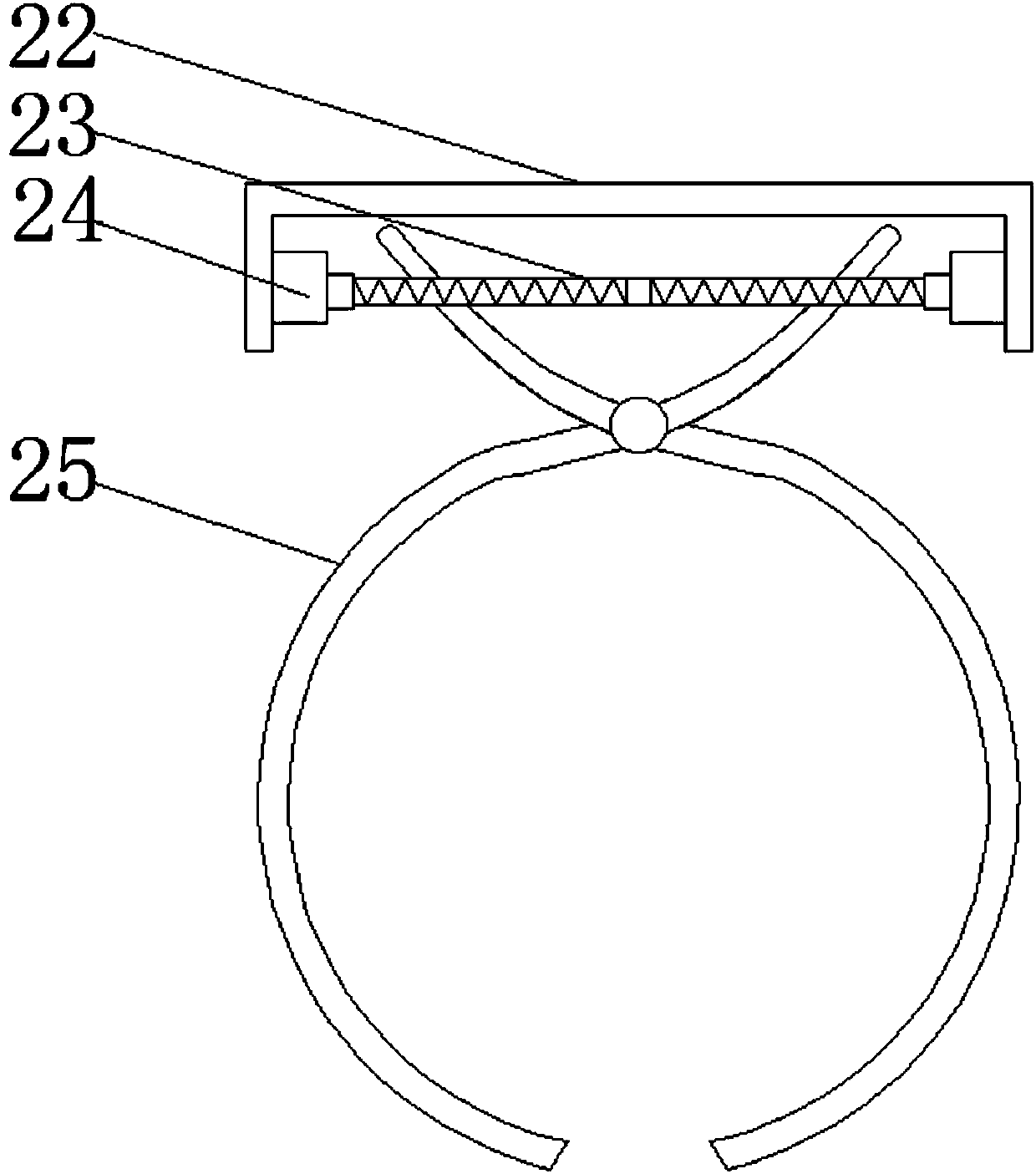

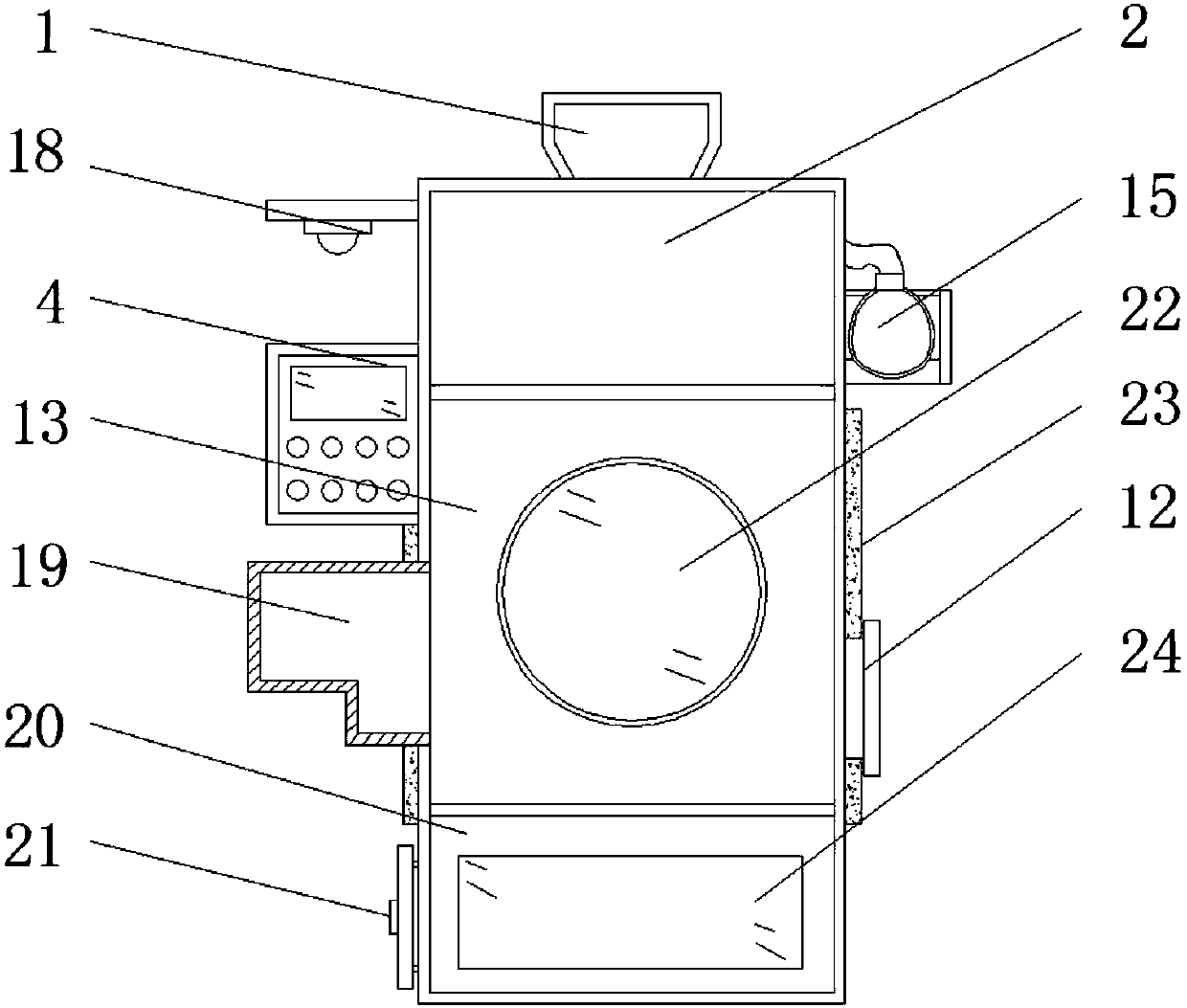

Down feather screening device

ActiveCN107587209ASpray evenlyAvoid enteringFibre cleaning/opening machinesTextile treatment machine arrangementsAir pumpAir compressor

The invention discloses a down feather screening device. The device comprises an air pump, a motor, a pneumatic retractable rod, a bracket, atomizing nozzles, a fixing rod, a vibration motor, a vibration box, a sieve net, a water tank, a drying box, an air compressor, a stirring motor, a water pump, a winch board, an air heater, a connecting frame, a miniature motor, a first screw rod, a fixture and a second screw rod; the motor and the second screw rod are utilized to control the movement of the fixture in the horizontal direction to make the fixture enter the drying box; down feathers are introduced into the drying box, a stirring motor, a stirring stick and the winch board are utilized to prevent the down feathers from accumulating at the bottom of the drying device, and drying is conducted more fully; a pressure gauge and a safety valve are utilized to control the safety of the drying box, and a filter net is utilized to prevent the down feather or impurities from entering the equipment. The down feather screening device is easy to operate, the down feathers can be screened to remove impurities and dust particles and then cleaned and dried, the production efficiency is improved, the resources are saved, and the cost is reduced.

Owner:安徽芙芮雅羽绒有限公司

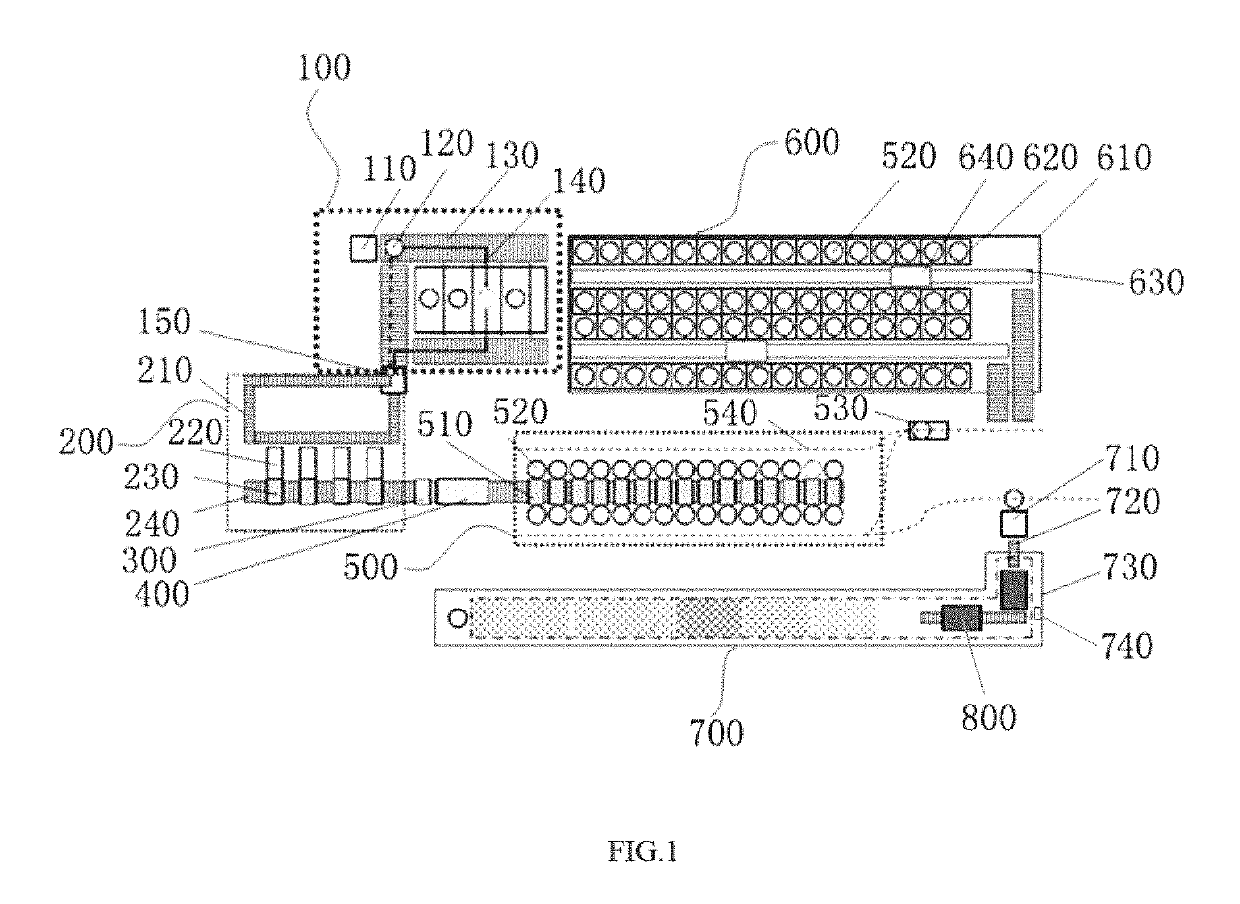

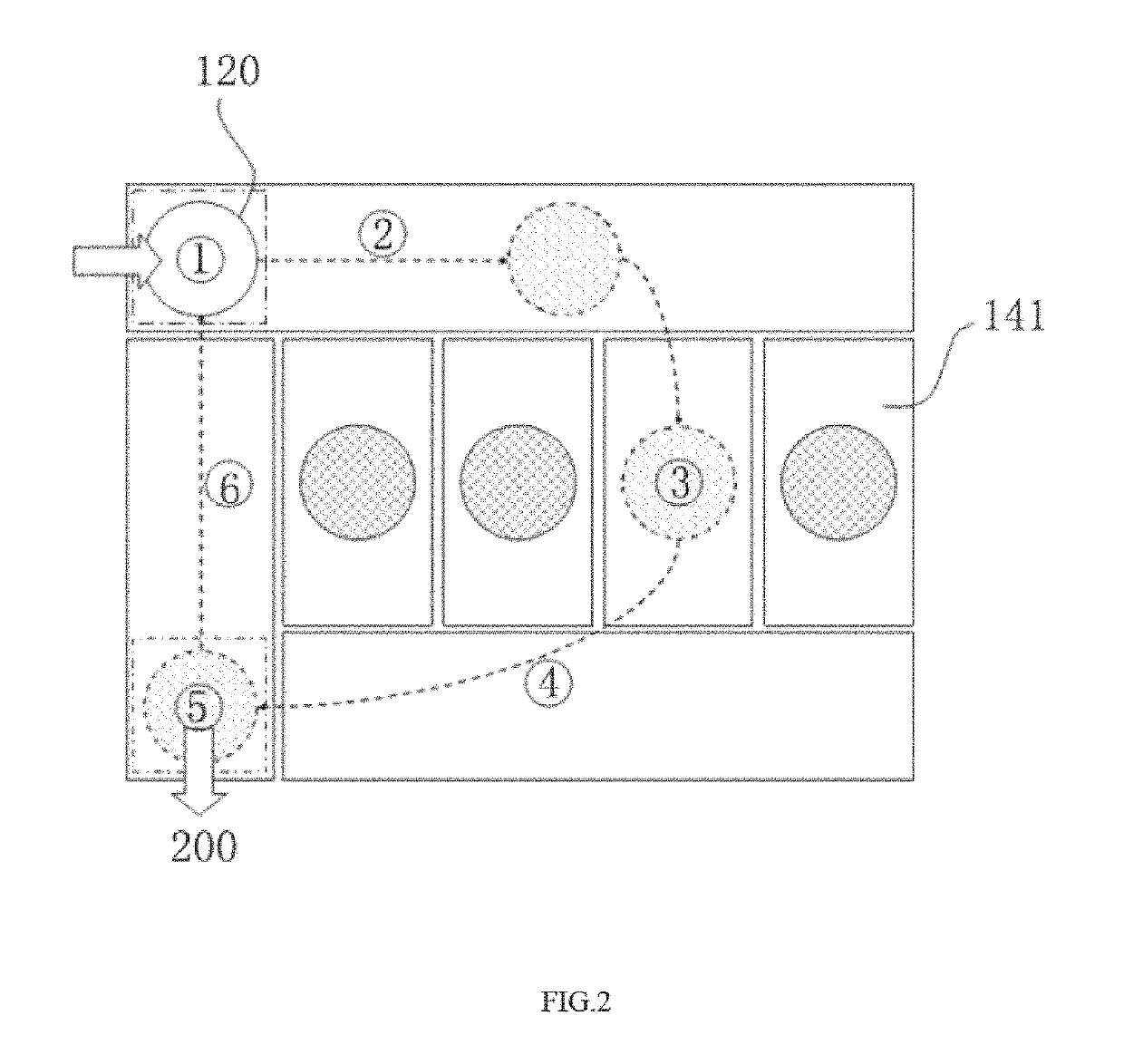

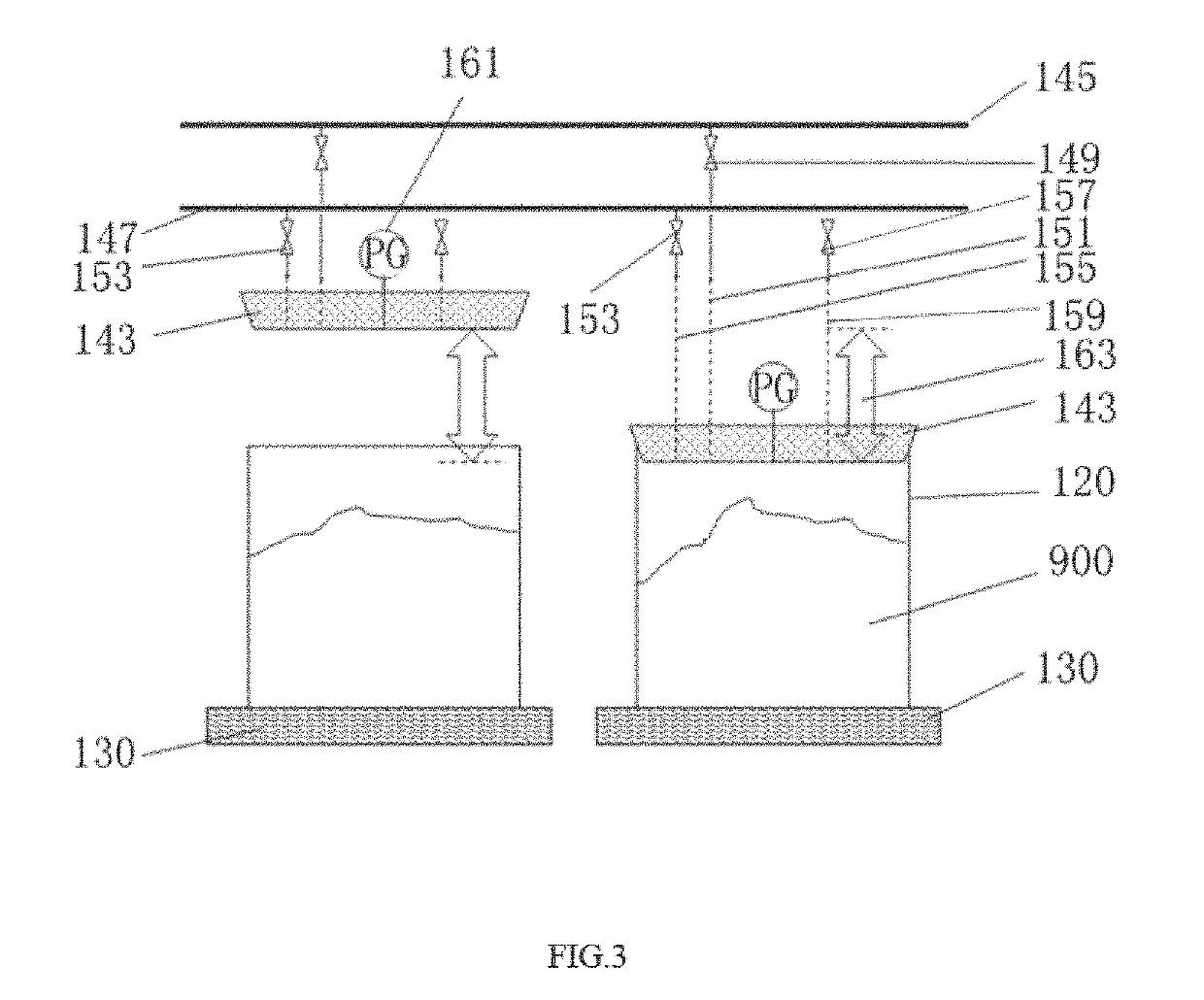

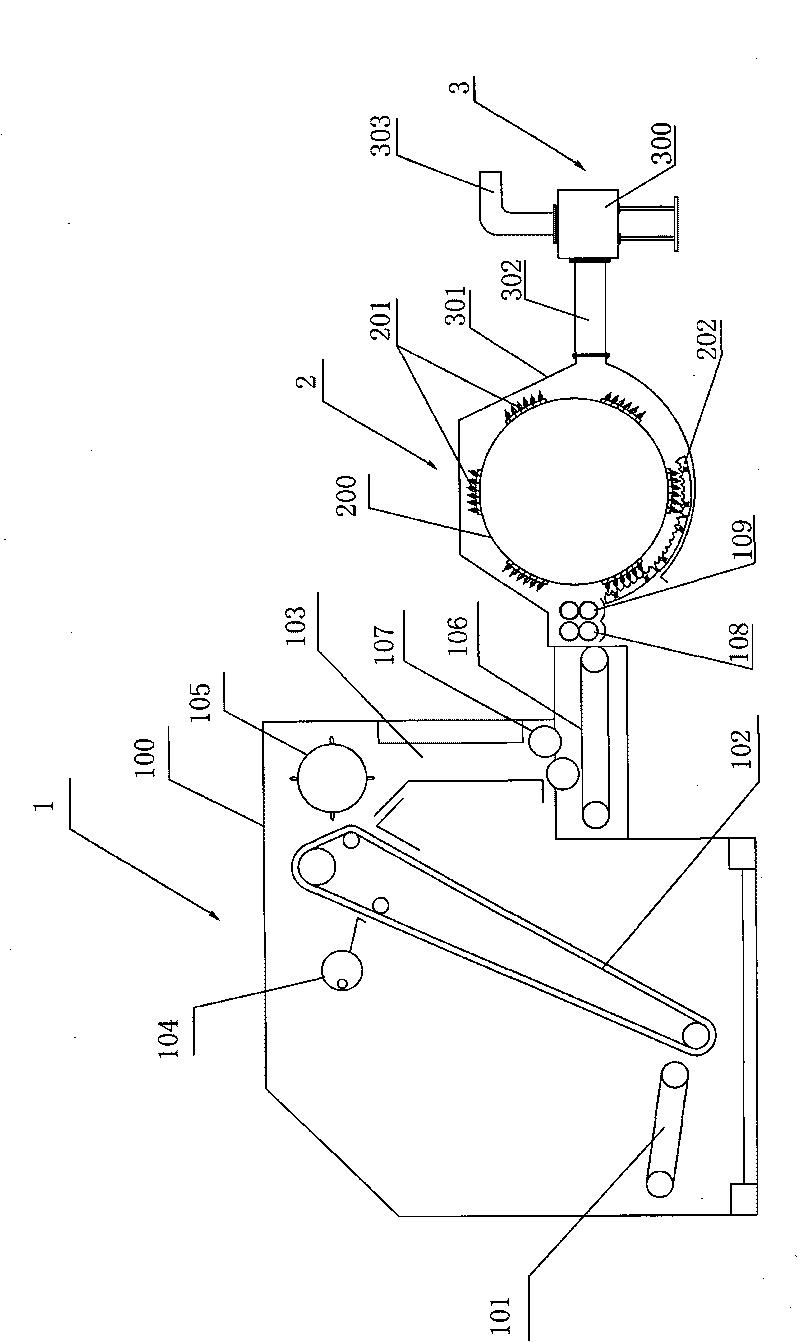

System and method for recycling fibers from textiles waste

ActiveUS10458047B2Fibre cleaning and opening machine combinationsSolid waste disposalFiberPre treatment

The present disclosure related to a system and method for recycling fibers from textiles waste. The system includes a first sanitization device; a pre-processing device; a fabric sorting device; a storage device; a fiber processing device; and a second sanitization device mounted in the fiber processing device. The first sanitization device, the pre-processing device, the fabric sorting device, the storage device and the fiber processing device are arranged along a transmission path of the textiles waste.

Owner:NOVETEX TEXTILES LTD

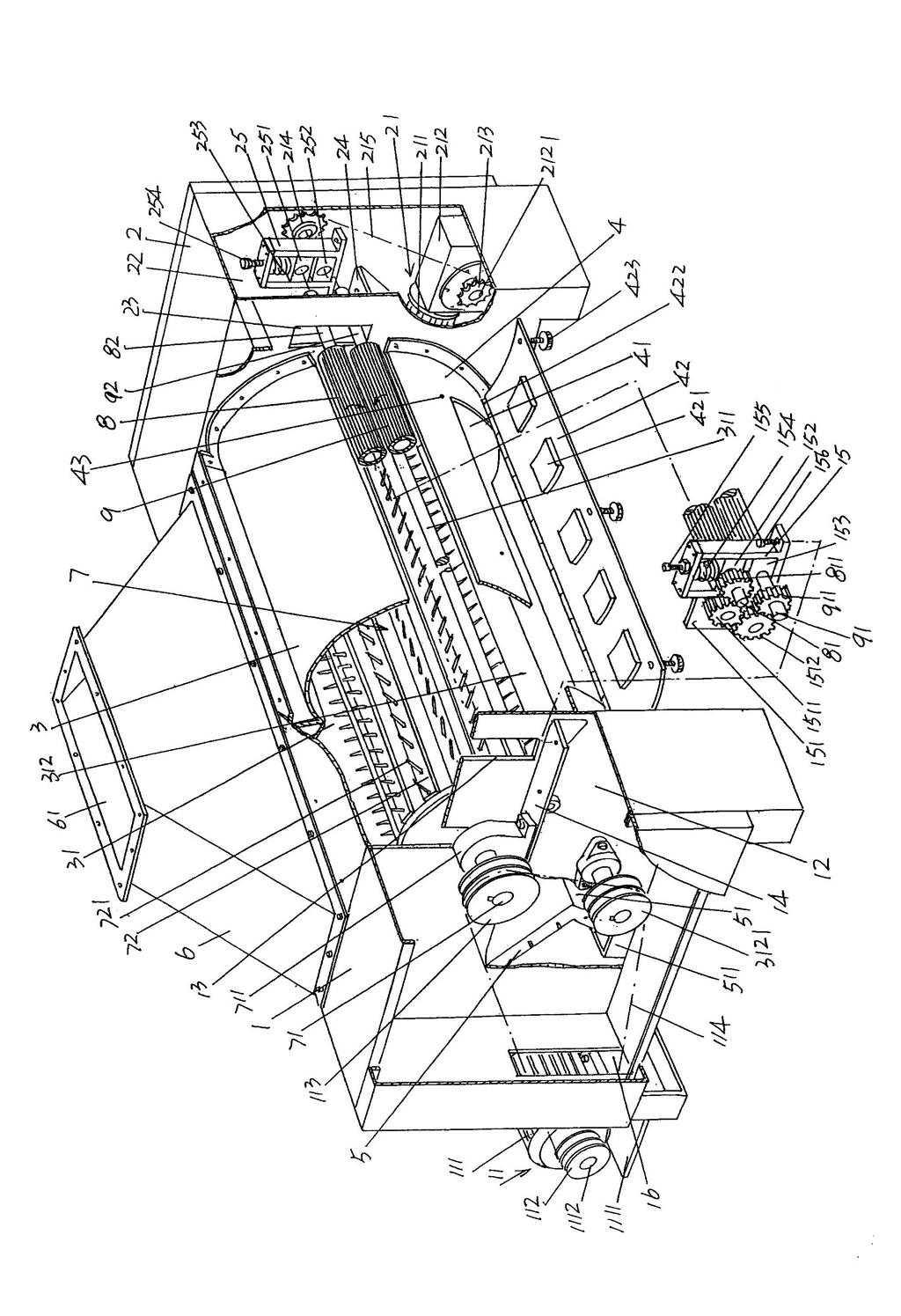

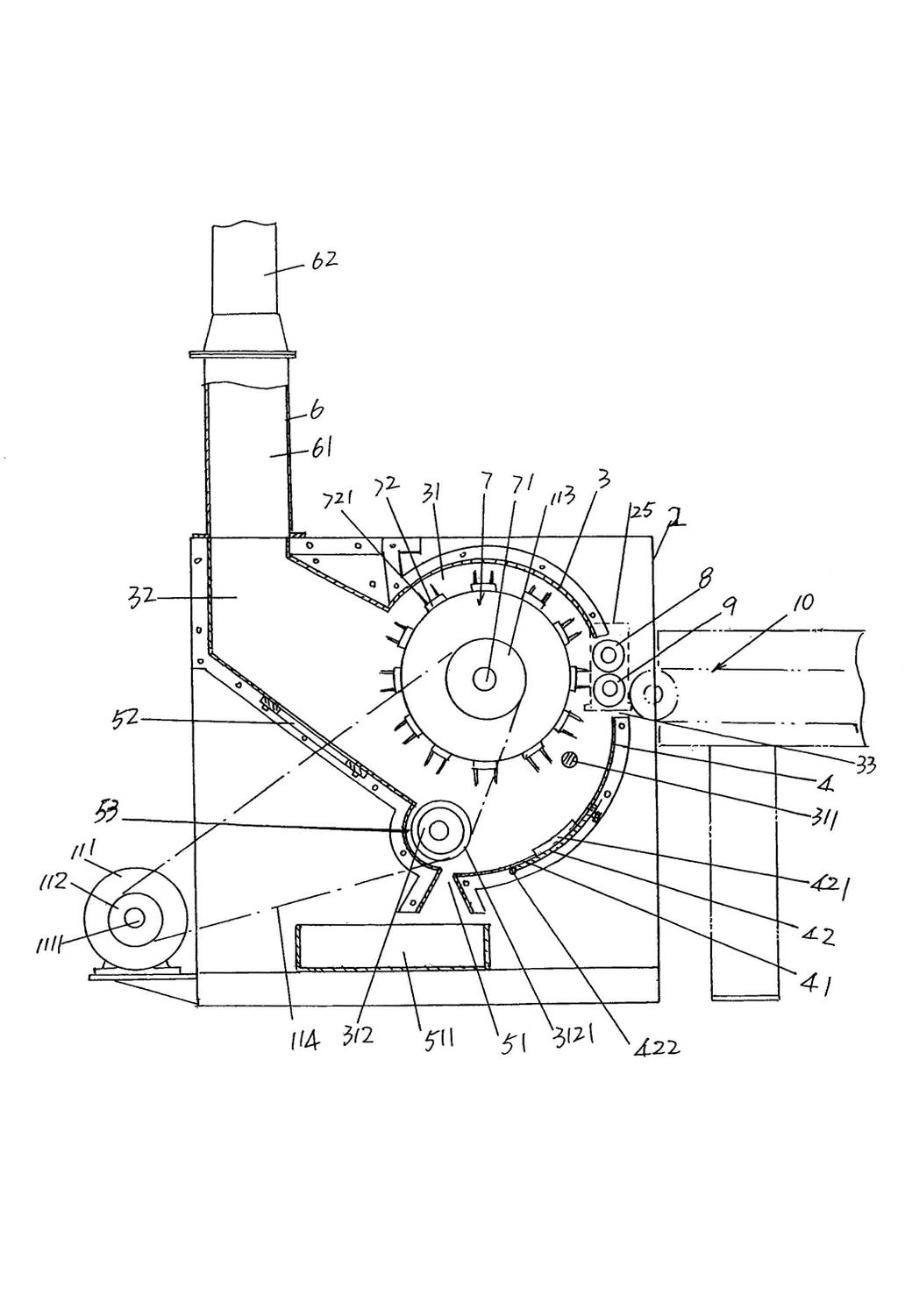

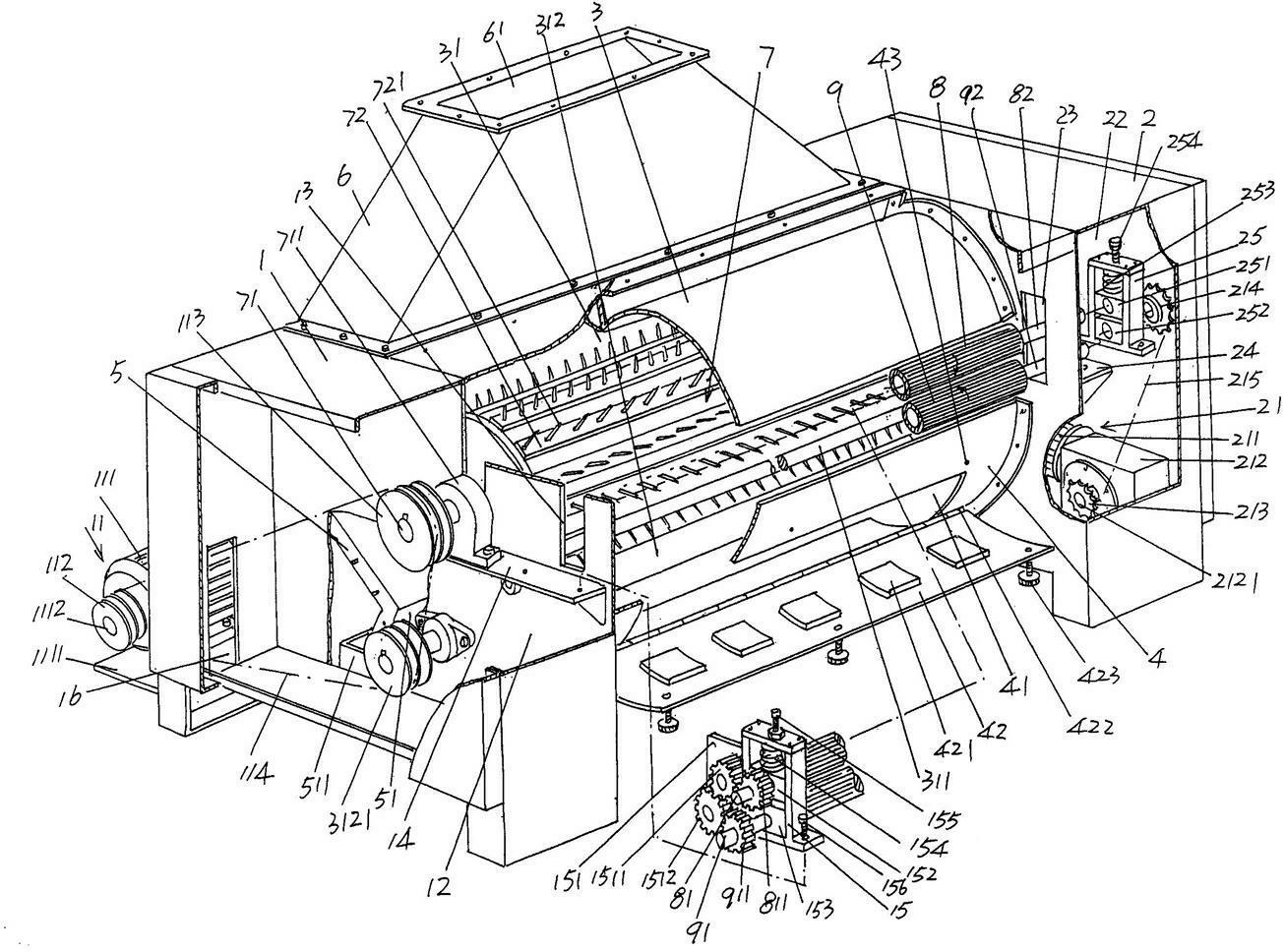

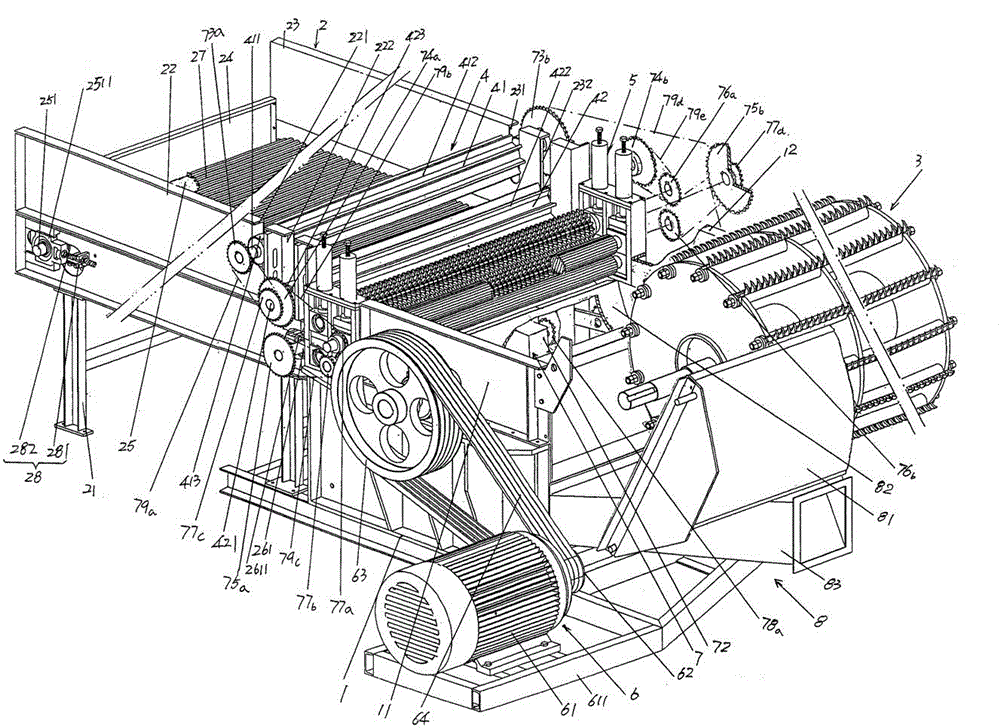

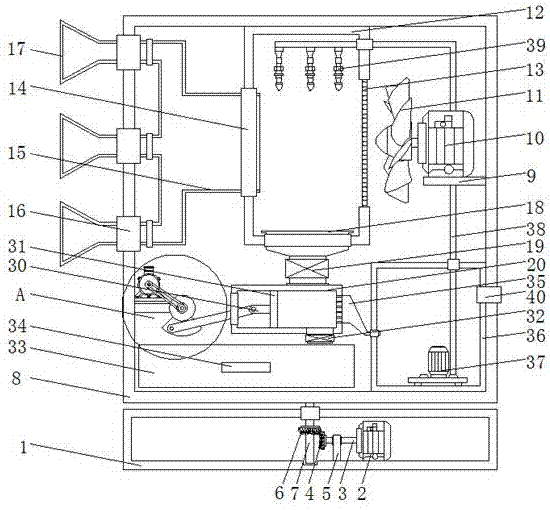

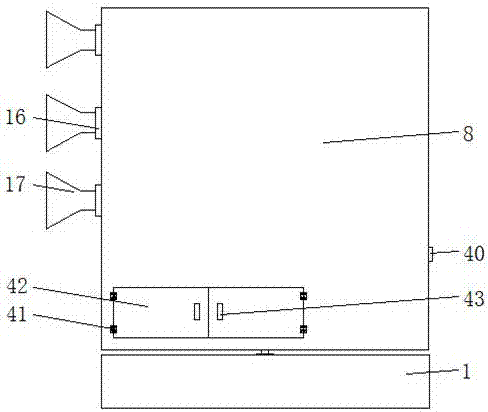

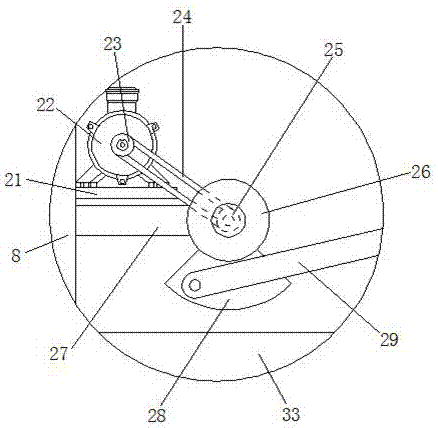

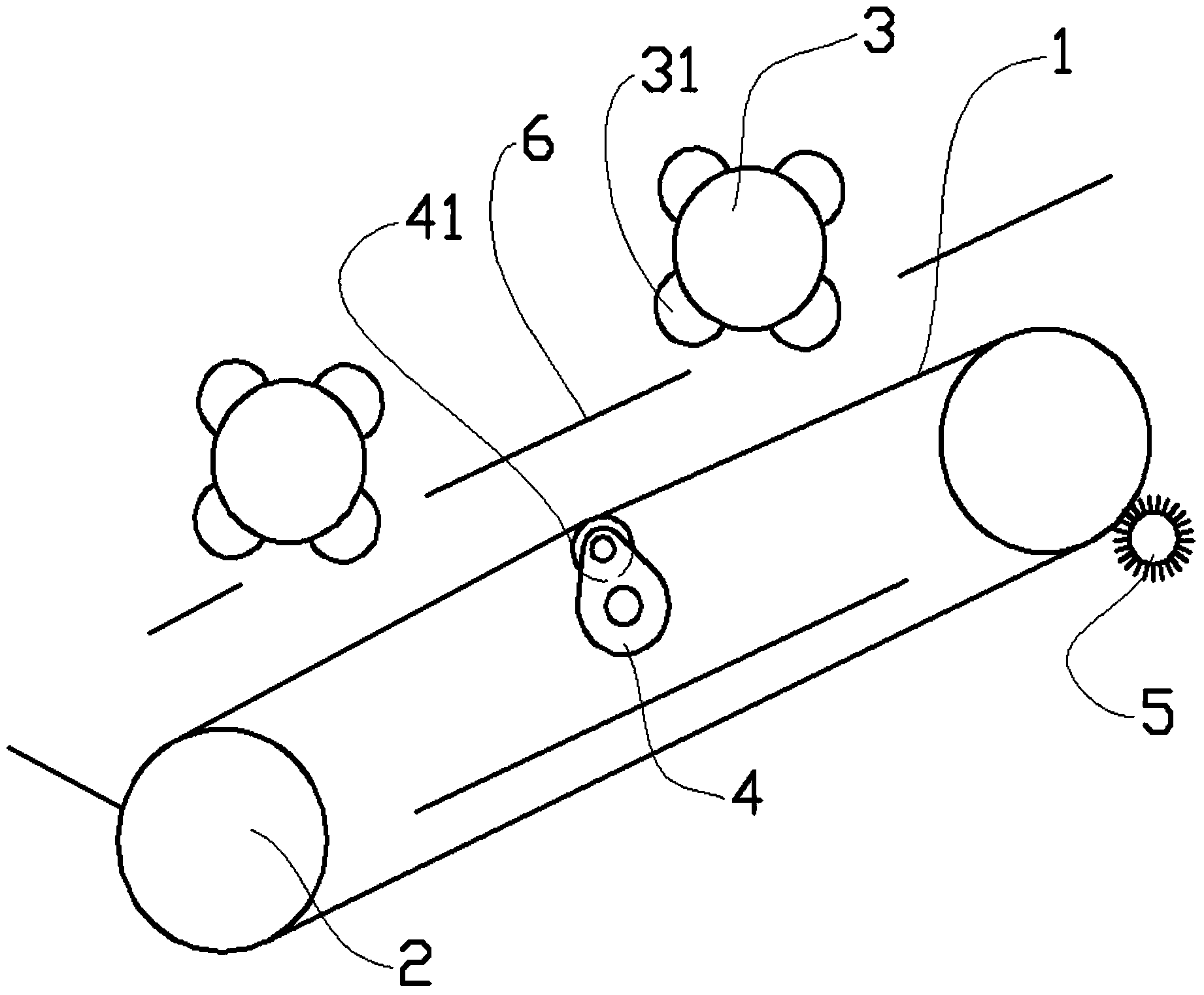

Waste fiber leftover pre-opener

ActiveCN103147172AMeet reuse requirementsReduce manufacturing costFibre cleaning/opening machinesTextile disintegration and recoveryFiberCircular economy

The invention relates to a waste fiber leftover pre-opener, belonging to the field of non-woven fabric machines. The waste fiber leftover pre-opener comprises a pre-opening roller rack, a waste fiber leftover conveying mechanism, a pre-opening roller, a pressing mechanism, a feeding mechanism, a pre-opening roller driving mechanism, a power transmission mechanism and a fiber leading-out mechanism, wherein a first wallboard is fixedly arranged above one side of the pre-opening roller rack and a second wallboard is fixedly arranged above the other side of the pre-opening roller rack; the waste fiber leftover conveying mechanism is connected with one end of the pre-opening roller rack; the pre-opening roller is supported between the first wallboard and the second wallboard; the pressing mechanism is arranged on the waste fiber leftover conveying mechanism; the feeding mechanism is arranged on the pre-opening roller rack and is arranged between the pre-opening roller and the pressing mechanism; the pre-opening roller driving mechanism is arranged on the pre-opening roller rack and is connected with the pre-opening roller; the power transmission mechanism is arranged on the pre-opening roller rack and is connected with the waste fiber leftover conveying mechanism, the pressing mechanism and the feeding mechanism; and the fiber leading-out mechanism is fixedly arranged on the pre-opening roller rack. The waste fiber leftover pre-opener has the advantages that the opening effect is good, the opening efficiency is ideal, the requirement on reuse of waste fibers can be satisfied, the resources are saved, the environment is protected, the circular economy is reflected and the manufacturing cost of automobile interior ornaments is reduced.

Owner:江苏常盛无纺设备有限公司

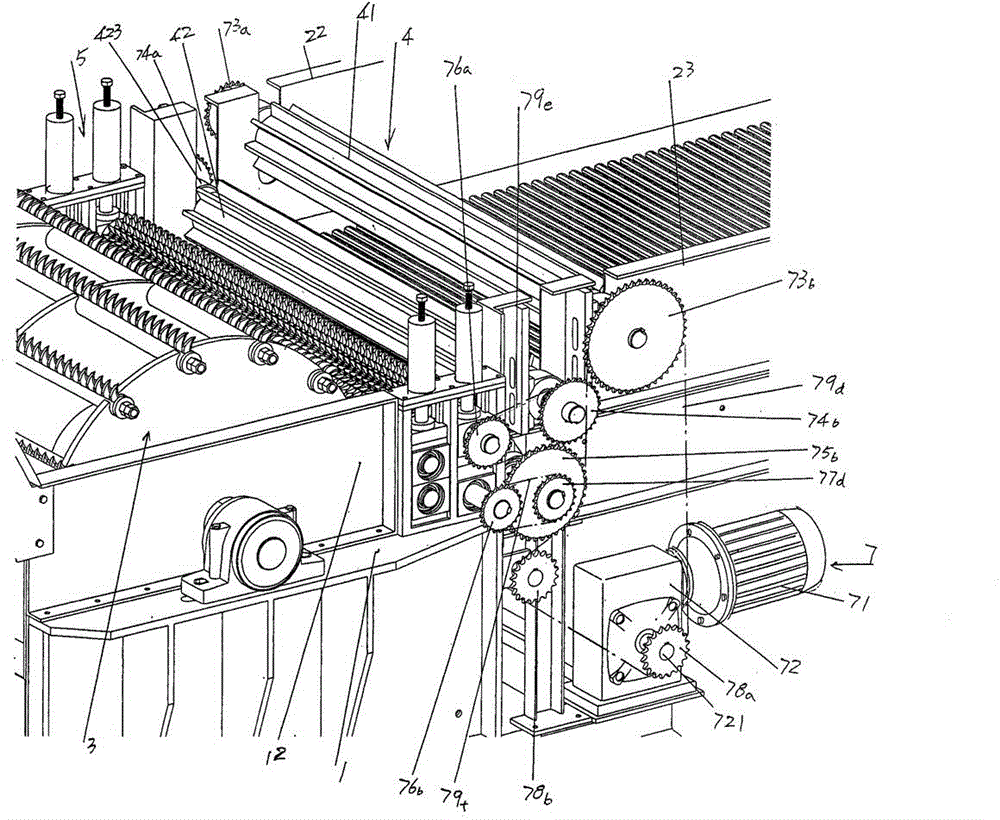

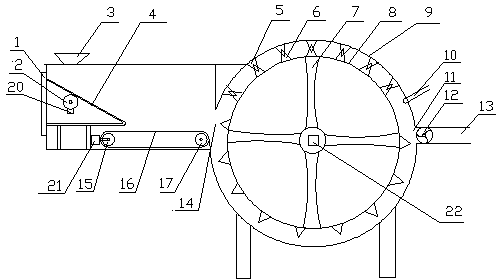

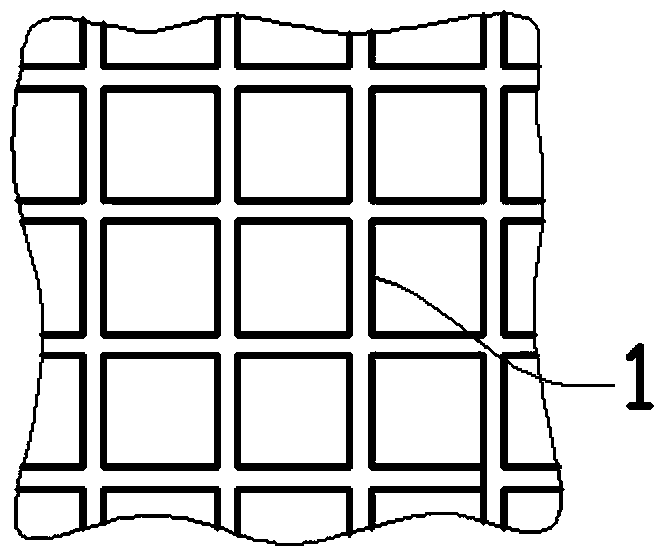

Fine opener with under screen and card clothing

ActiveCN101736446AImprove performanceReasonable useFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention discloses a fine opener with an under screen and card clothing, which comprises a feeding mechanism, an opening and carding mechanism, and an opened fiber output mechanism. The opening and carding mechanism is provided with a opening roller, a plurality of opening roller fallers are arranged in the circumferential direction of the opening roller, a card wire is arranged on each teasing roller faller, and the under screen is arrange below the opening roller. The fine opener is characterized in that the under screen comprises a supporting light panel, a plurality of under screen faller strips are arranged on the upper supporting surface of the supporting light panel, and each of the under screen faller strips is provided with the card clothing, and an opening and carding region is formed among the opening roller fallers and the under screen faller strips. The invention has a production efficiency increased by more than 20% by verification on condition that the rotating speed of the opening roller and the number of the opening roller fallers are not increased and the opening and carding effect is ensured.

Owner:青岛东佳纺机(集团)有限公司

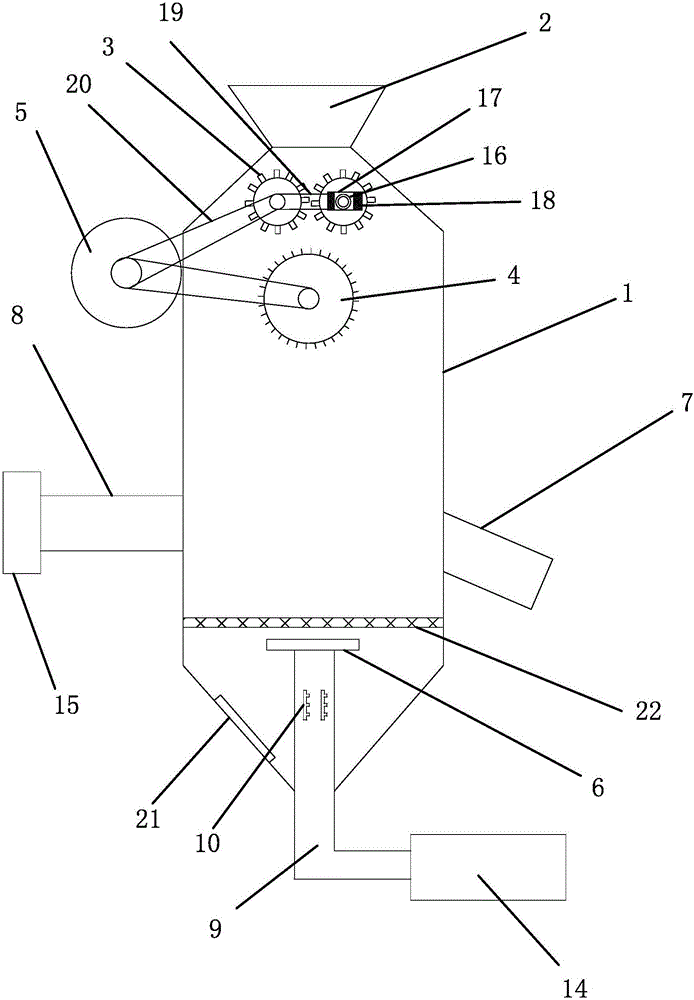

Cotton opener

InactiveCN103590144AIncrease contactEliminate static electricityFibre cleaning/opening by toothed membersFibre cleaning/opening machinesElectric machineryEngineering

The invention discloses a cotton opener and belongs to the technical field of textile machinery. The cotton opener is characterized by comprising a rack. A cotton inlet is formed in the rack, a pre-opening device is arranged on the cotton inlet, a cotton inlet box is arranged behind the pre-opening device, and an atomizing nozzle is arranged above the cotton inlet box. The atomizing nozzle is connected with a static electricity elimination agent through a pipeline with an electromagnetic valve. The underneath of the cotton inlet box is communicated with an opening cavity, an opening cylinder is arranged in the opening cavity, a driving chamber is formed below the rack, a motor is arranged in the driving chamber, a dust collection pipe is arranged on the outer side of the driving chamber, and a dust collection box is arranged above the dust collection pipe. The cotton opener is simple in structure and capable of eliminating the static electricity and improving working efficiency.

Owner:谭国华

Ecological heat preservation cotton and production technology thereof

ActiveCN105908360AImprove the bactericidal effectEasy to passLiquid surface applicatorsSevering textilesManufacturing technologyCarding

The invention provides ecological heat preservation cotton and a production technology thereof. The ecological heat preservation cotton has the good windproof and water-repellent effect and has the certain sterilization function, and the heat preservation effect is better. The ecological heat preservation cotton comprises a heat preservation cotton core, a waterproof breathable layer and a soft close-fitting layer, the heat preservation cotton core is manufactured by mixing 30% of Sorona polymer fiber, 30% of superfine heat preservation fiber, 30% of three-dimensional hollow heat preservation fiber and 10% of native cotton fiber, the waterproof breathable layer is manufactured by mixing 70% of collagenous fiber and 30% of meldable fiber, the waterproof breathable layer is coated with a nanometer silicon particle treatment layer, the treatment layer is coated with a fluorine quaternary amine silane coupling agent coating, a sterilization layer is arranged between the soft close-fitting layer and the heat preservation cotton core, the soft close-fitting layer is fixed to the inner side of the sterilization layer in a flocking mode, and the soft close-fitting layer is composed of short fiber with the length being 0.05-0.2 cm. The manufacturing technology of the ecological heat preservation cotton comprises the steps of automatic machine blending mixing, opening, carding, lapping, glue spraying, heat setting and lap formation..

Owner:广州泰达纤维制品有限公司

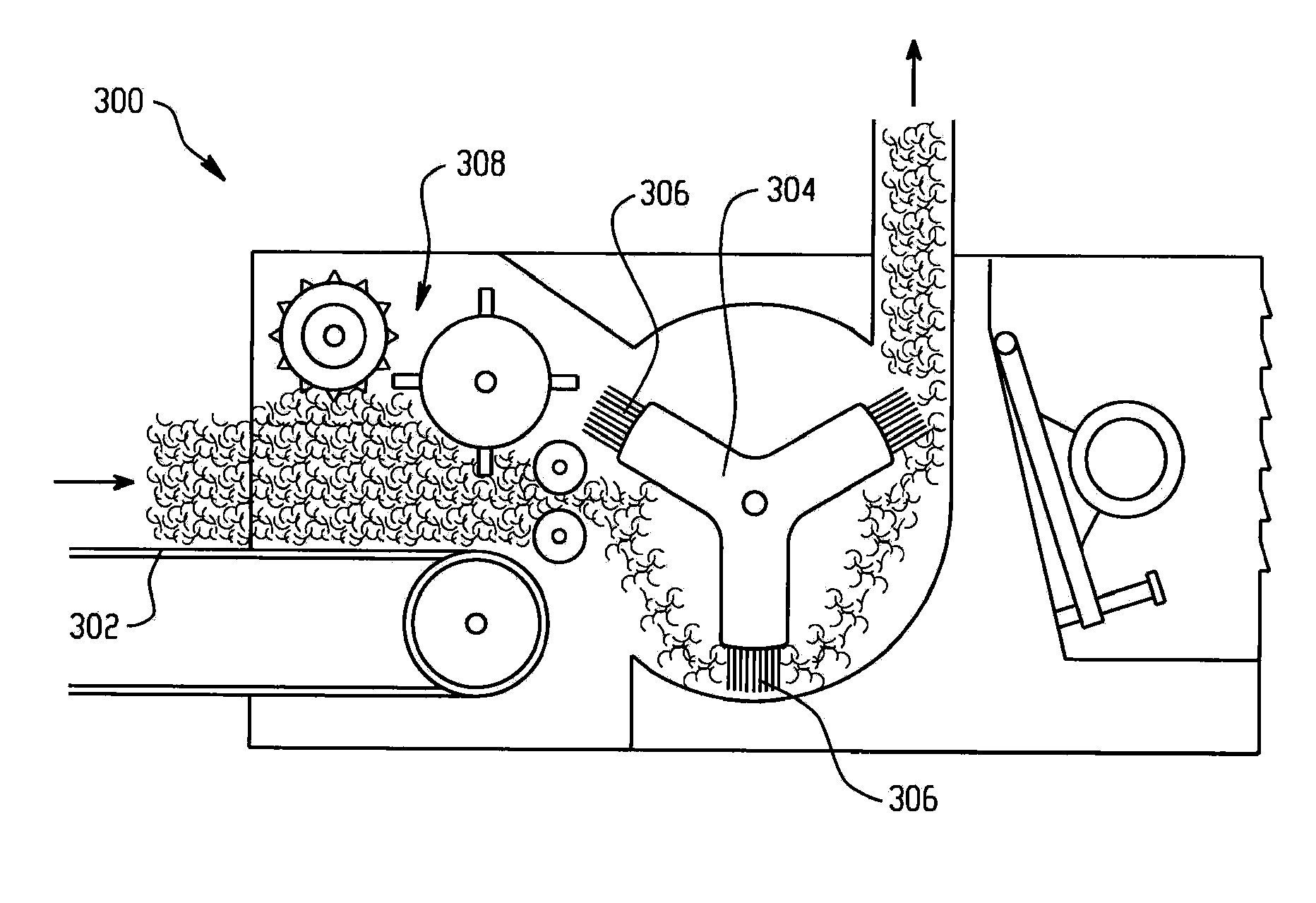

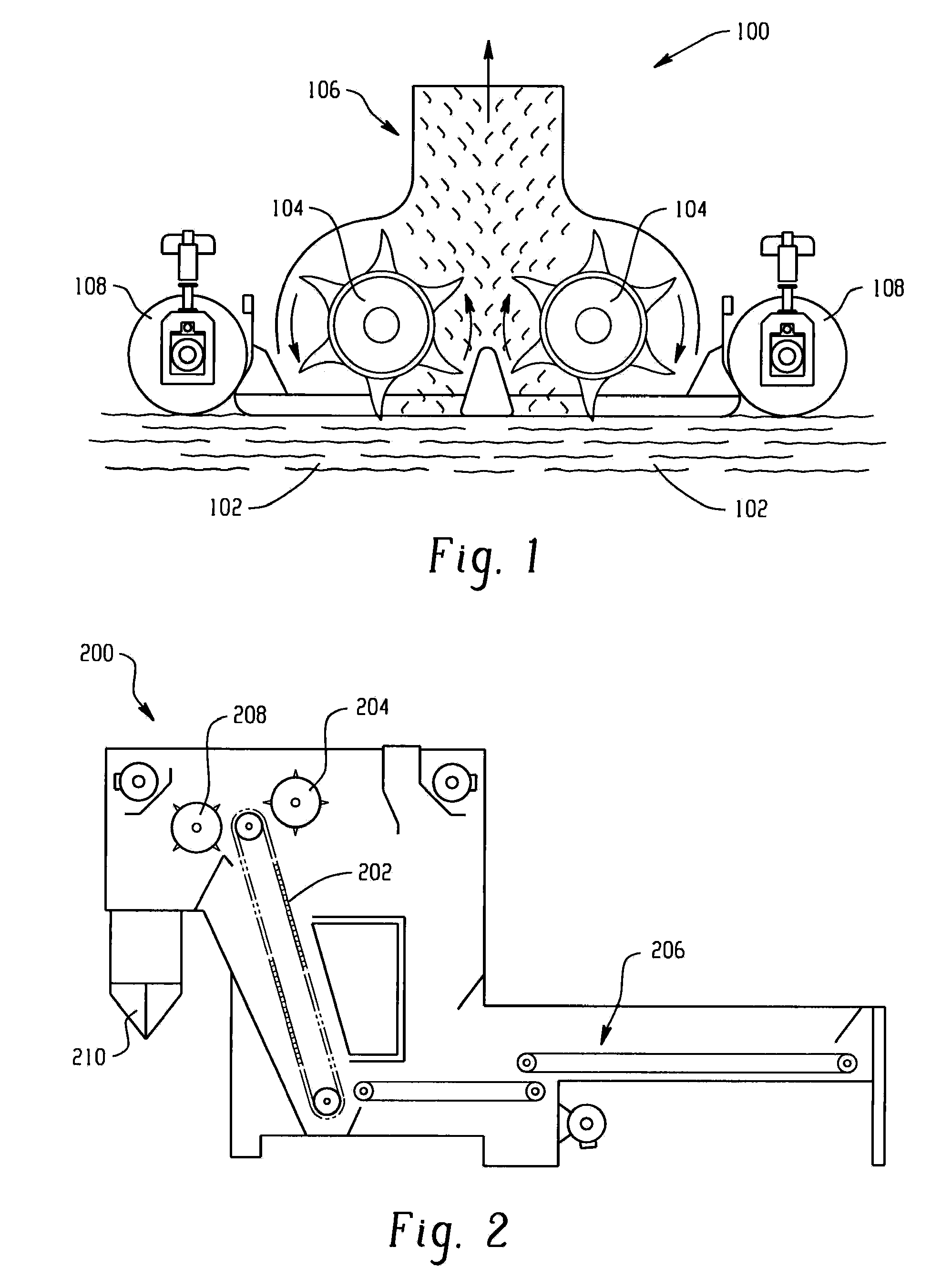

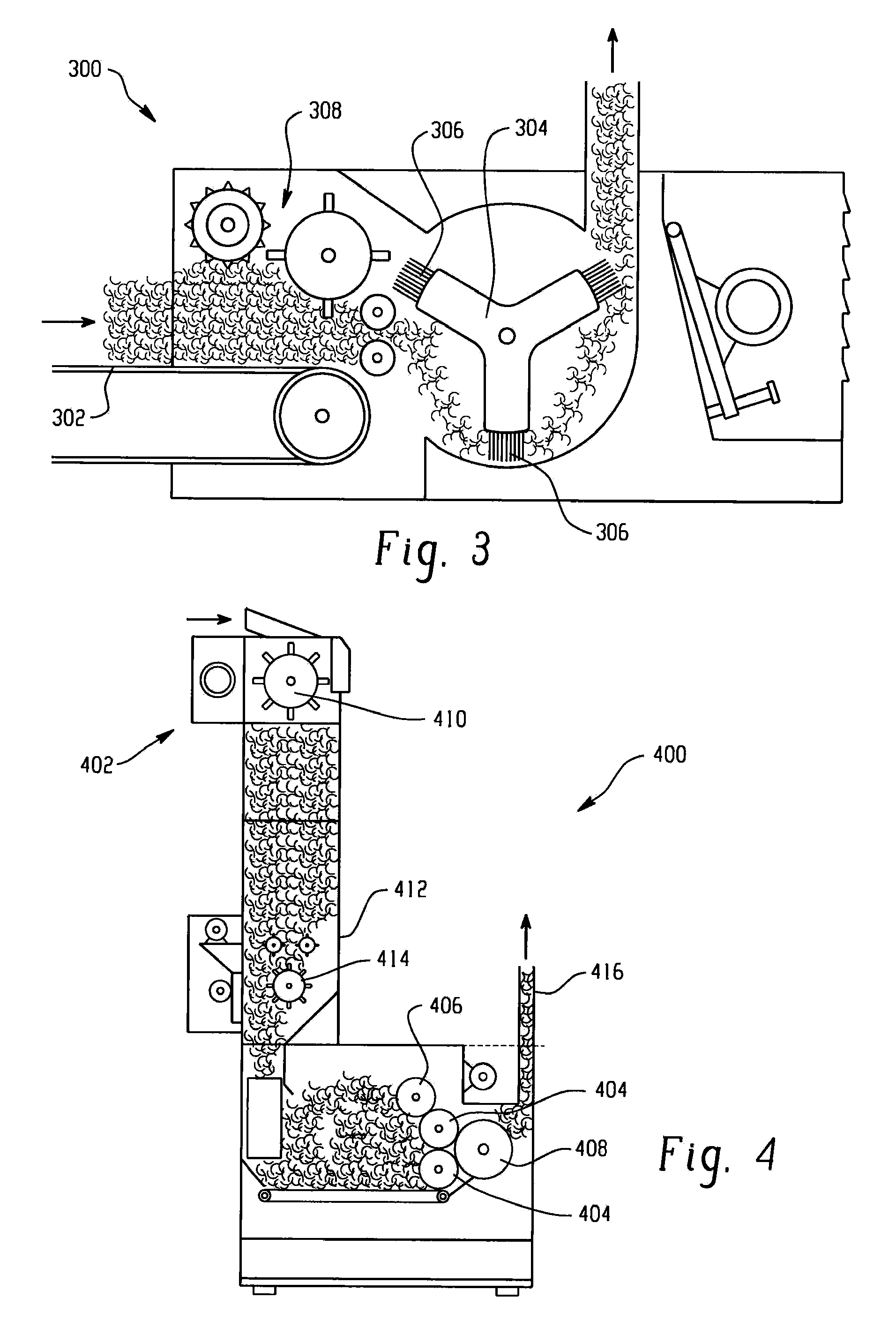

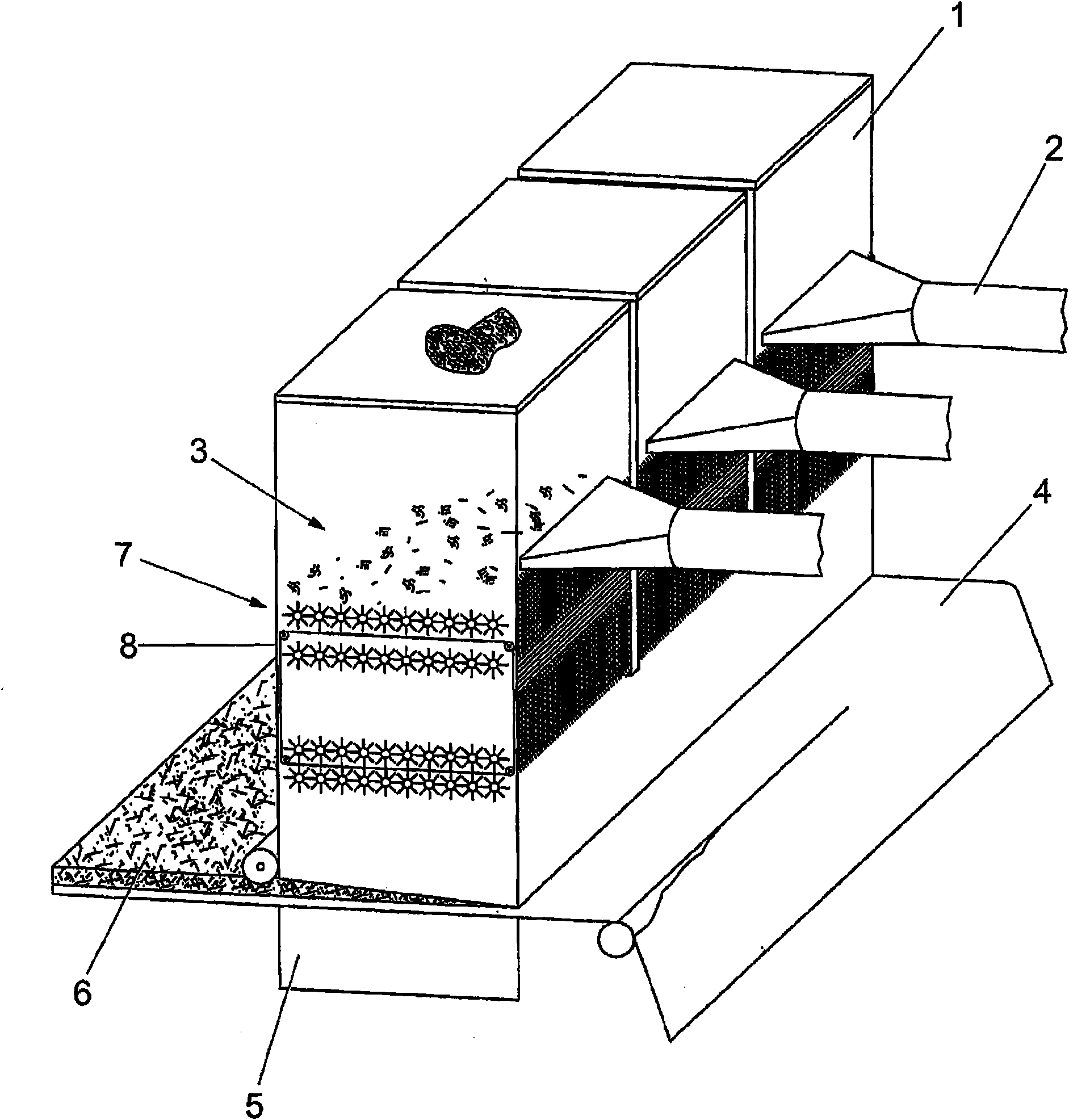

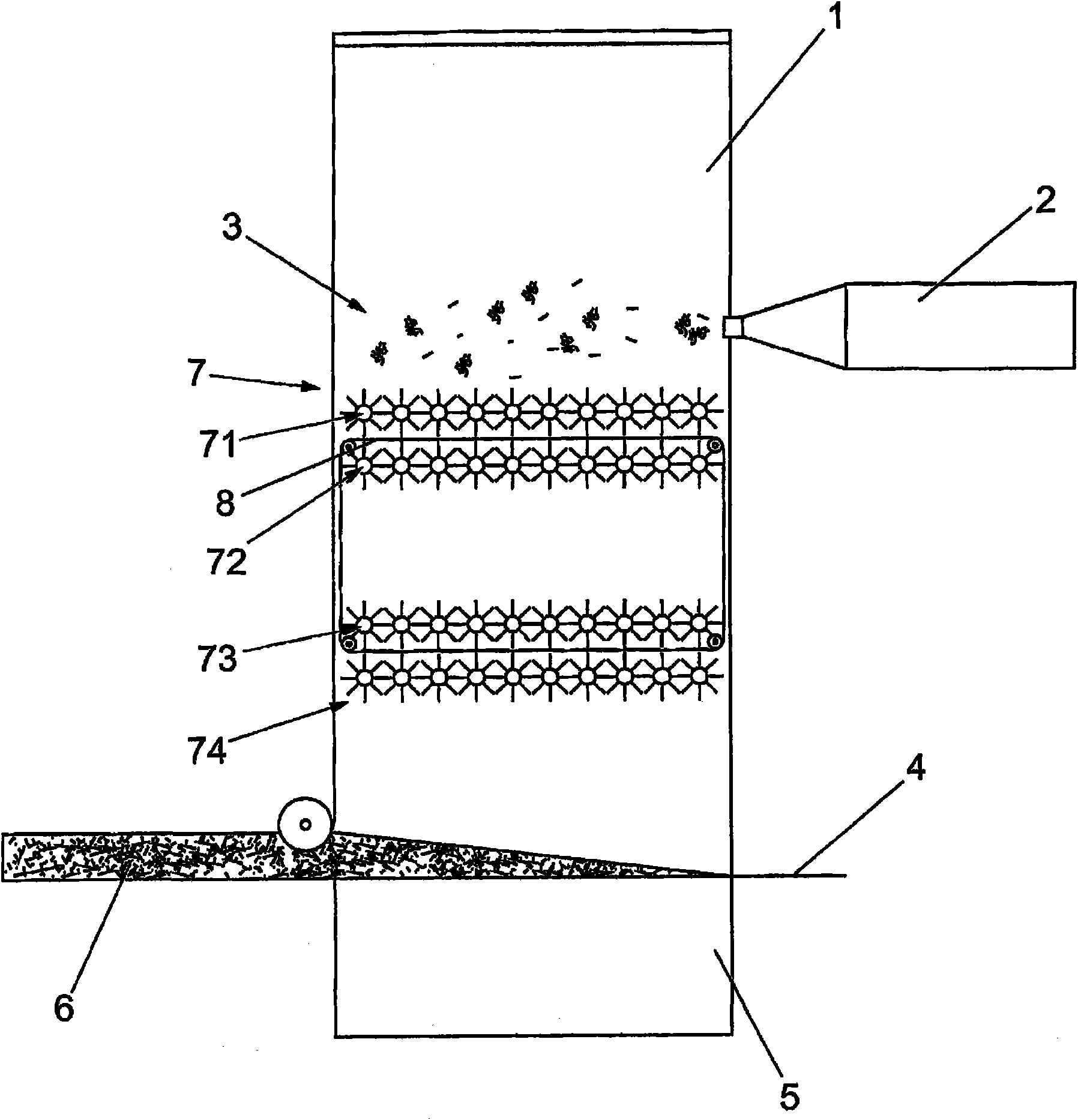

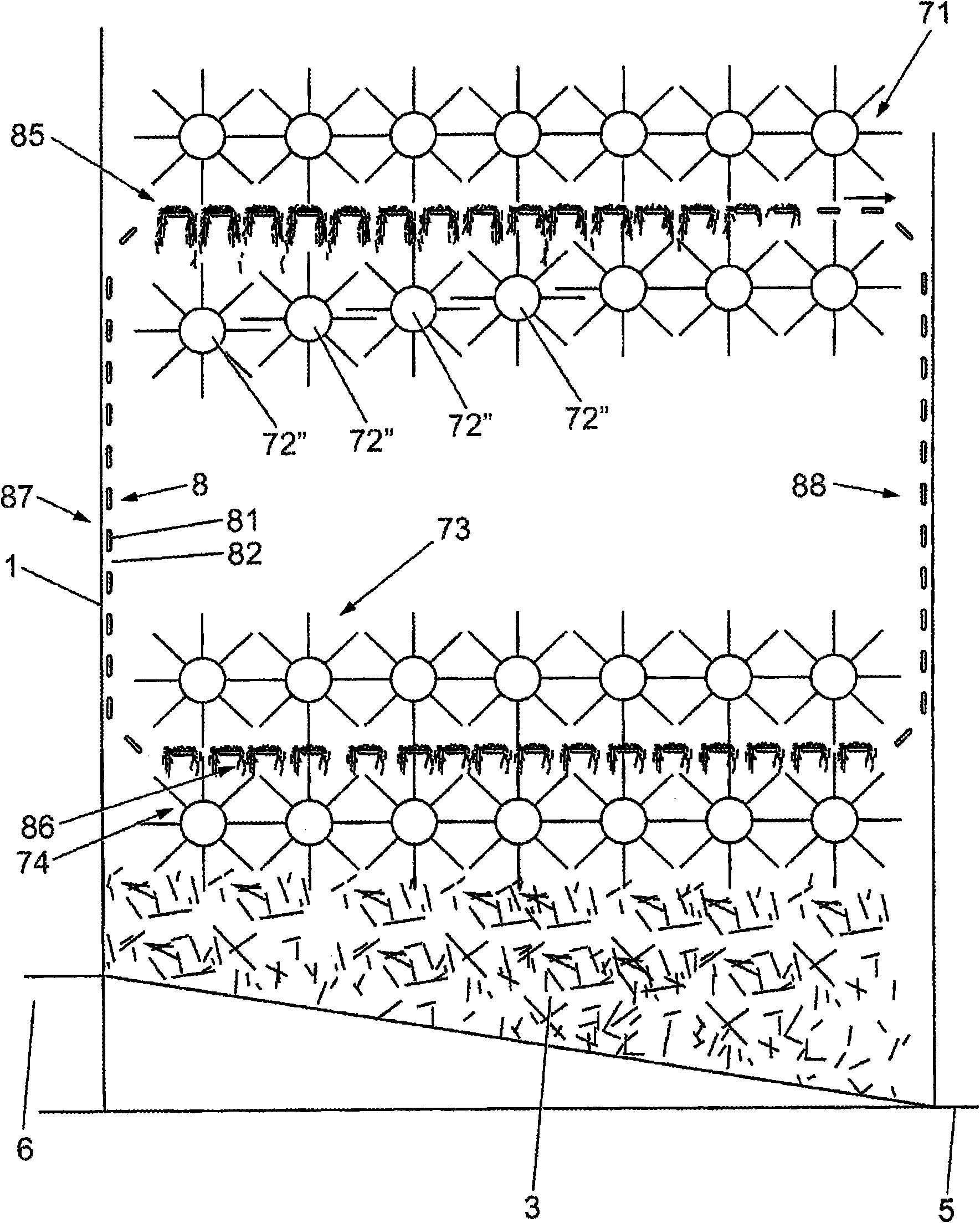

Method of making mounting mats for mounting pollution control element

InactiveCN101821070AEasy to prepareEasy to manufactureFibre cleaning and opening machine combinationsSilencing apparatusFiberMechanical engineering

The present invention relates to a method of making mounting mats for use in pollution control device. The method comprises the steps of: (i) supplying inorganic fibers through an inlet of a forming box having an open bottom positioned over a forming wire to form a mat of fibers on the forming wire, the forming box having a plurality of fiber separating rollers arranged in at least one row in the housing between the inlet and housing bottom for breaking apart clumps of fibers and an endless belt screen; (ii) capturing clumps of fibers on a lower run of the endless belt beneath fiber separating rollers and above the forming wire; (iii) conveying captured clumps of fibers on the endless belt above fiber separating rollers to enable captured clumps to release from the belt and to contact and be broken apart by the rollers; (iv) transporting the mat of fibers out of the forming box by the forming wire; and (v) compressing the mat of fibers and restraining the mat of fibers in its compressed state thereby obtaining a mounting mat having a desired thickness suitable for mounting a pollution control element in the housing of a catalytic converter.

Owner:3M INNOVATIVE PROPERTIES CO

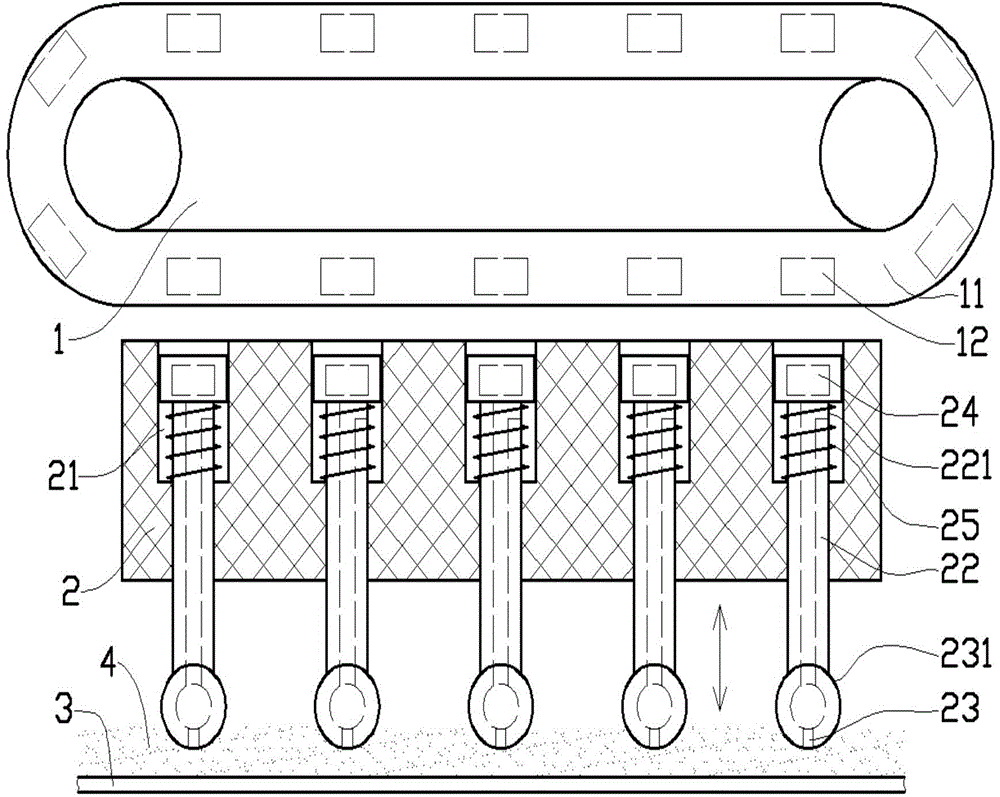

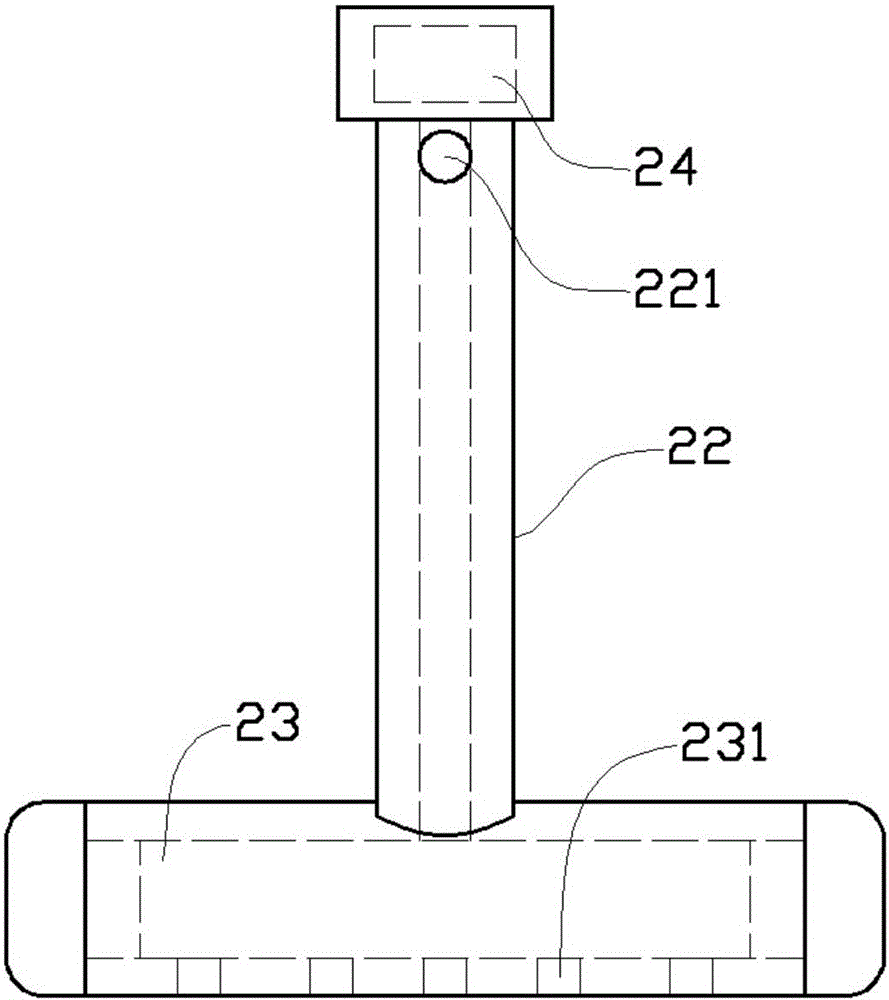

Cotton loosening knocking device

ActiveCN104611790AEasy to passUniform percussionFibre cleaning/opening machinesForce linesComputer module

The invention provides a cotton loosening knocking device. The cotton loosening knocking device comprises a driving module, a positioning and knocking module and a conveying module, wherein the positioning and knocking module is assembled at the lower part of the driving module; two or more positioning holes are formed in the positioning and knocking module in a front-and-back sequential arranging manner, and are vertically through; a sliding rod is assembled in each positioning hole; a horizontal knocking rod is arranged at the lower part of each sliding rod; lower magnet blocks of which the magnetic force line direction is vertical and the upper magnetic poles and the lower magnetic poles face the same direction; outwards upper magnet blocks of which magnetic poles are the same are arranged on the surface of a driving belt on the driving module; the movement direction of the driving belt at the lower part of a driving structure of the device is perpendicular to the movement directions of the sliding rod and the knocking rod; the device is driven by magnetic force; the energy utilization rate is high; the elastic transfer effect is achieved by magnetic force transmission; therefore, a knocking process is more flexible, and the knocking effect is better.

Owner:桐乡市立明喷织股份有限公司

Cotton dust removal recycling equipment for producing colored spun yarns

InactiveCN107245780AWith rotation functionImprove dust removal effectUsing liquid separation agentCarding machinesYarnSuction stress

The invention discloses cotton dust removal recycling equipment for producing colored spun yarns, and relates to the field of technologies for producing colored spun yarns. The cotton dust removal recycling equipment comprises a base tank. A first motor is fixedly connected with the bottom of the inner wall of the base tank, a transmission shaft is fixedly connected with an output shaft of the first motor by a coupling, a first conical gear is fixedly connected with the end, which is far away from the first motor, of the transmission shaft, a second conical gear meshes with the top of the first conical gear, a rotary shaft is fixedly connected with the axis of the second conical gear, a rotary tank is fixedly connected with the top of the rotary shaft, and suction fan blades are fixedly connected with an output shaft of a second motor. The cotton dust removal recycling equipment for producing the colored spun yarns has the advantages that strong suction can be generated by the cotton dust removal recycling equipment, suction of fans can be optimally utilized, cotton dust in contact with water can settle without blocking machines after the cotton dust is sucked into the machines, accordingly, effects of quickly removing the dust can be realized, and the work efficiency of the machines can be greatly improved.

Owner:响水县嘉禾纺织制衣有限公司

Novel cotton slitting machine

InactiveCN103993391ANo leakageSimple structureFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineeringRotating drum

The invention discloses a novel cotton slitting machine. The novel cotton slitting machine comprises a feeding area and a cotton slitting area. A feeding opening is formed in the upper left side of the feeding area, a filer screen is arranged below the feeding opening, and a vibrating shaft is arranged below the filter screen. A feeding device is arranged on the lower right portion of the filter screen, and a raw material inlet is formed in the right side of the feeding device. A rotating drum is arranged in the middle of the cotton slitting area, cotton slitting cloths are arranged on the surface of the rotating drum at intervals, and the cotton slitting cloths are trapezoidal. Sawtooth notches are formed in the upper surface and the two inclined planes of each trapezoid, and toothlike pull troughs are formed in the two sides of each notch and the two sides of each cotton slitting block. Cotton slitting rakes which are the same as the cotton slitting area in shape are arranged on the upper portion of the inner side of a circular housing of the cotton slitting area, and the cotton slitting rakes and the cotton slitting blocks are crossed and staggered. A suction fan is arranged at a discharging opening, so that cotton is sucked into a pipeline to be conveyed to the next working procedure, and an air nozzle is arranged above the discharging opening. The novel cotton slitting machine is simple in structure, convenient to operate, capable of filtering the dust in the cotton, high in yield, high in efficiency, even in cotton slitting, free of dust and flock leakage, and small in noise for the reason that drum-type rotating sawteeth are used for cotton slitting in a crossed mode.

Owner:JIANGSU SHUANGYING TEXTILE TECH

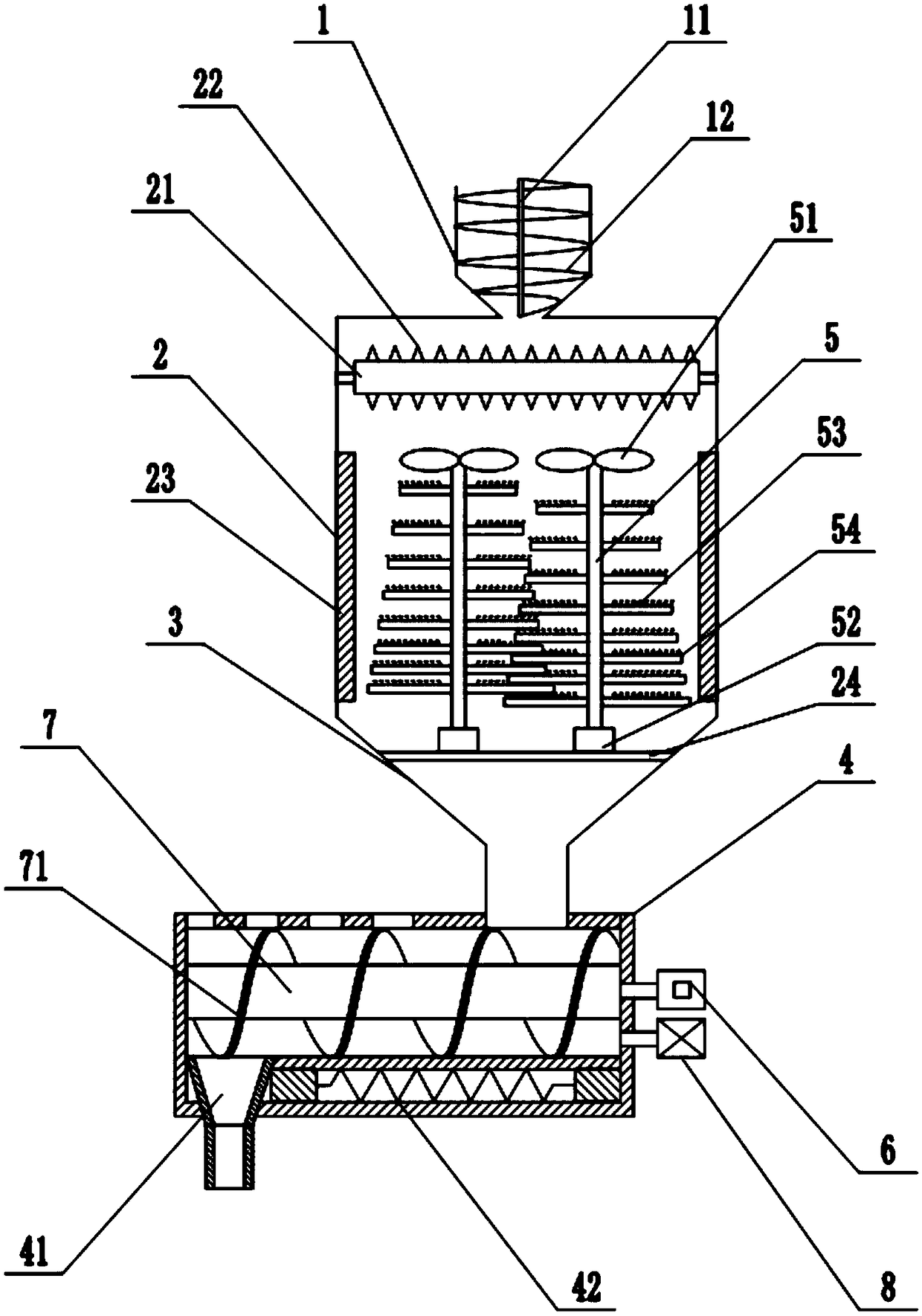

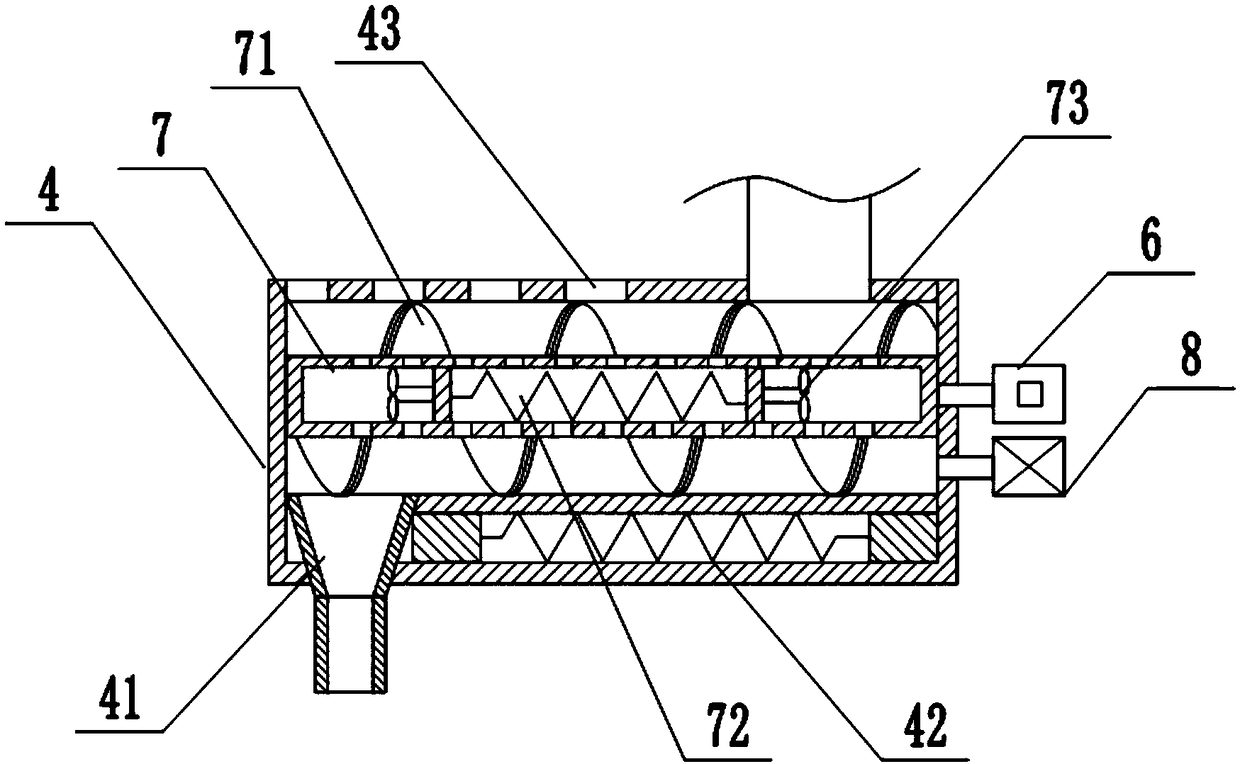

Cotton fluffing equipment

InactiveCN108950745AFast fallSpeed up the flowFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineering

The invention relates to the technical field of spinning equipment, and discloses cotton fluffing equipment. The cotton fluffing equipment comprises a feeding hopper, a fluffing box, a conical guidinghopper and a discharging device; a rotary roller and rotary rods are arranged in the fluffing box, barbs are densely arranged on the rotary roller, fixing plates are arranged on the rotary rods, andbent hooks are densely arranged on the fixing plates; the discharging device comprises a box body, a rotary cylinder is rotatably connected into the box body, a second motor is connected to the rotarycylinder, a spiral pushing belt is arranged on the outer wall of the rotary cylinder, and a heating layer is arranged at the bottom of the box body. When the cotton fluffing equipment is in use, therotary roller in the fluffing box rotates to preliminarily tear cotton, and under the effect of the bent hooks on the fixing plates, the cotton is torn again, so that the cotton is torn into pieces, and gets soft and fluffy. The cotton fluffing equipment is novel in structure, and solves the problem existing in the prior art that when a fluffing cotton filler conducts cotton fluffing, fine floccules in the cotton easily drift away.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

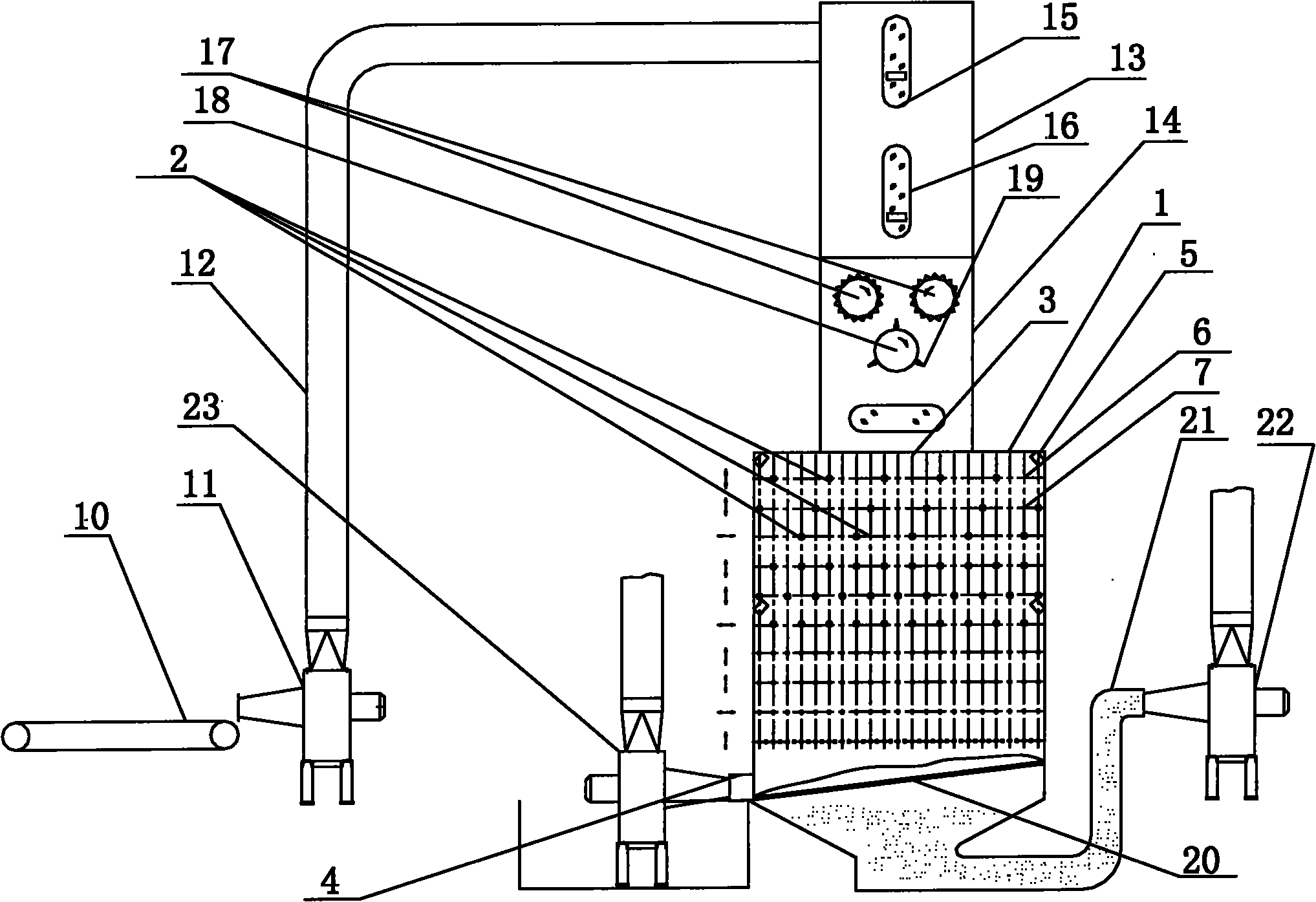

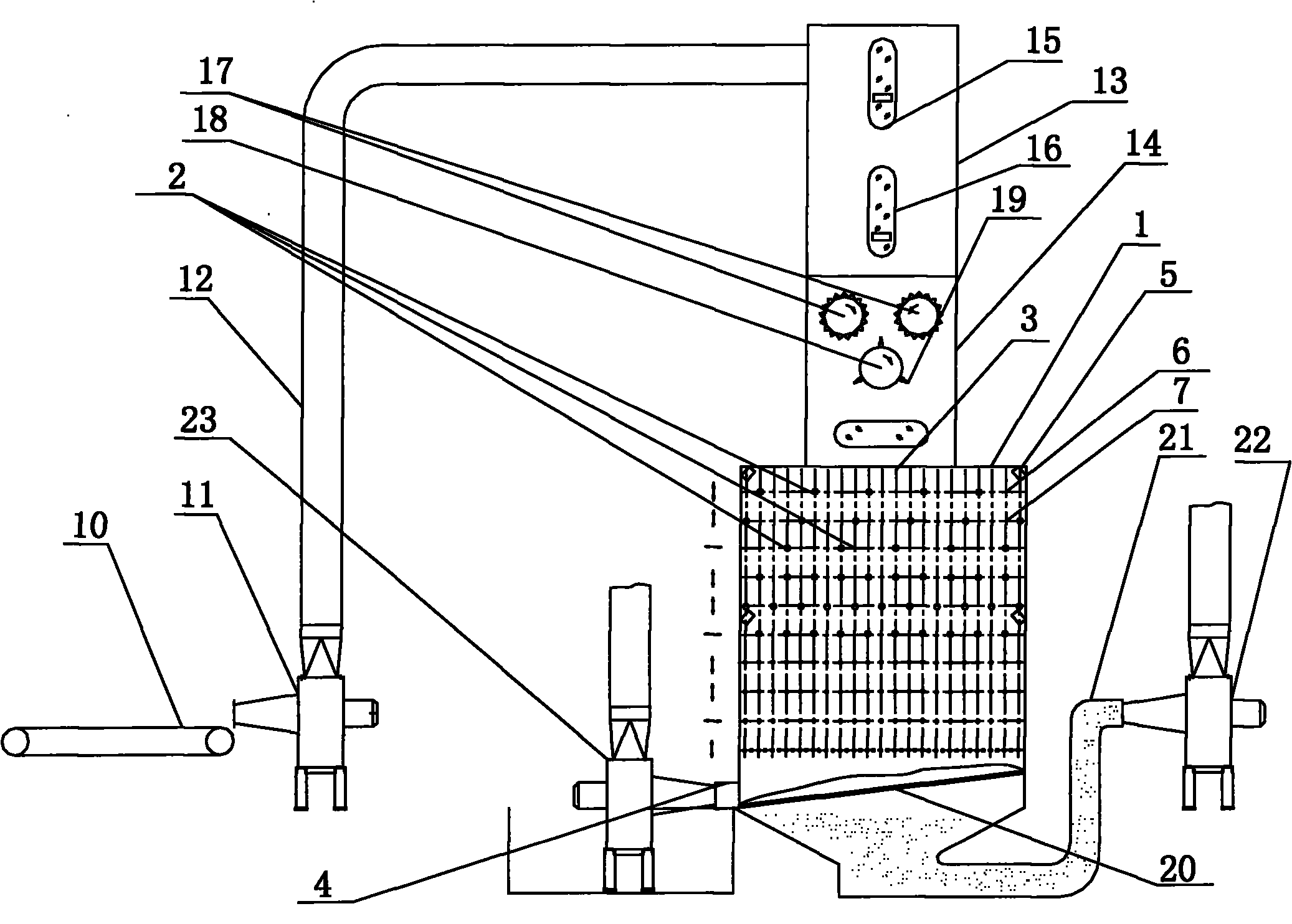

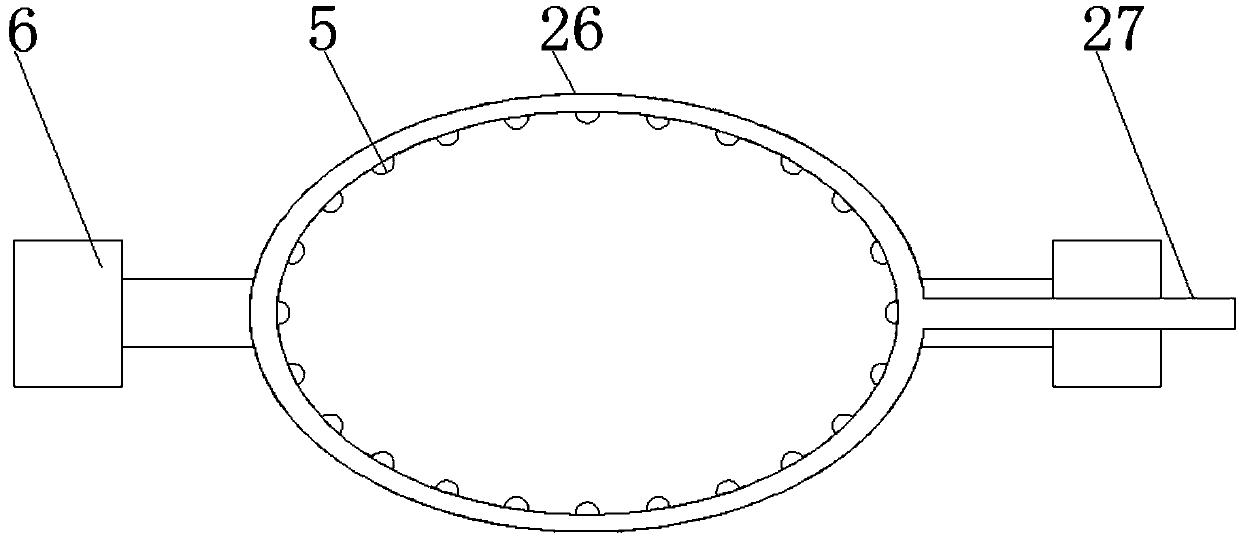

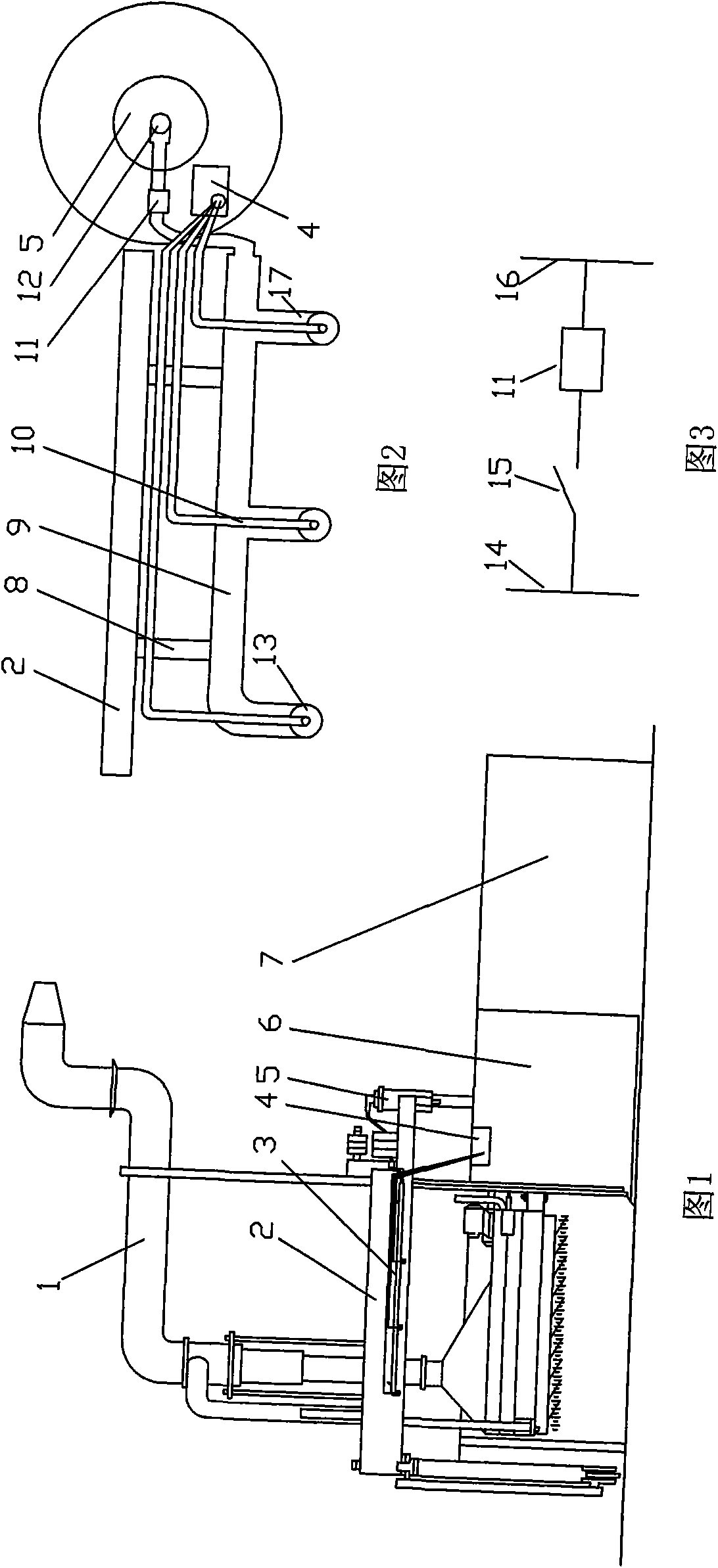

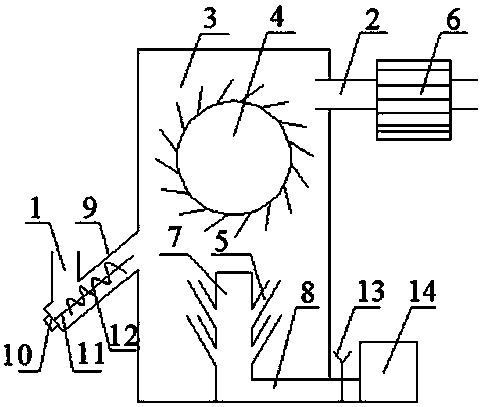

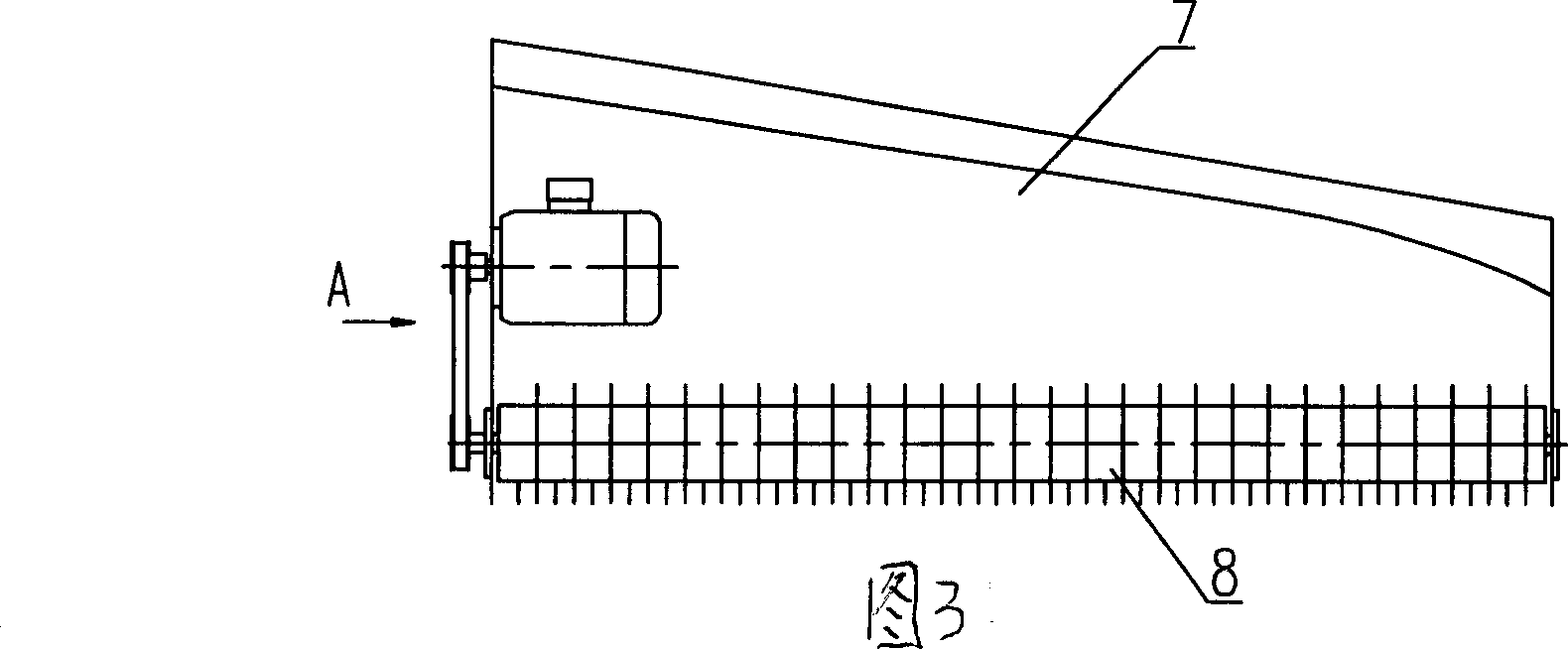

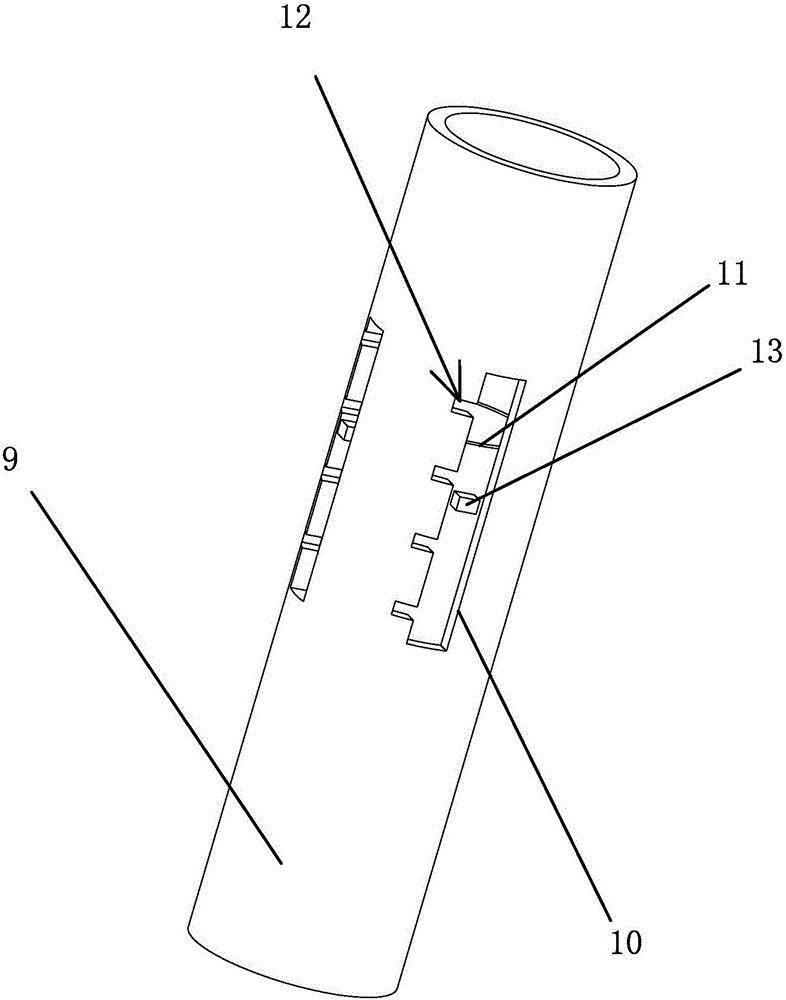

Spray humidifier for bale plucker disk

InactiveCN101629749AUniform humidificationSimple structureLighting and heating apparatusFibre cleaning/opening machinesArchitectural engineeringAir pump

The invention discloses a spray humidifier for an A002 type bale plucker disk, which is characterized in that the left side of an A002 type bale plucker wall panel (2) is provided with two screw holes, an air pipe (9) is fixed on the screw holes of the wall panel through a bracket (8), one end of the air pipe (9) is connected with a nozzle (13), and the other end of the air pipe is connected with an electromagnetic valve (11); the electromagnetic valve (11) is connected to a universal rotary head (12) through another section of air pipe, and the universal rotary head (12) is fixed on a slip ring (5) and connected to an air compressor air pump through the air pipe; one end of a water pipe (10) is connected to the nozzle (13) respectively, and the other end of the water pipe (10) is arranged at the bottom of a water tank (4) respectively; and the water tank (4) is welded on an inner wall panel (6). The humidifier has the advantages of reasonable structure design, low production cost, convenient and even humidification, not only reduces the intensity of labor, but also increases the production efficiency of enterprises.

Owner:JIHUA 3542 TEXTILE CO LTD

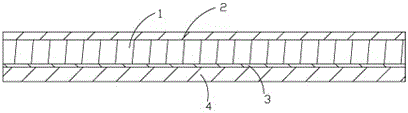

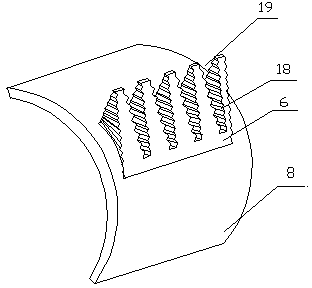

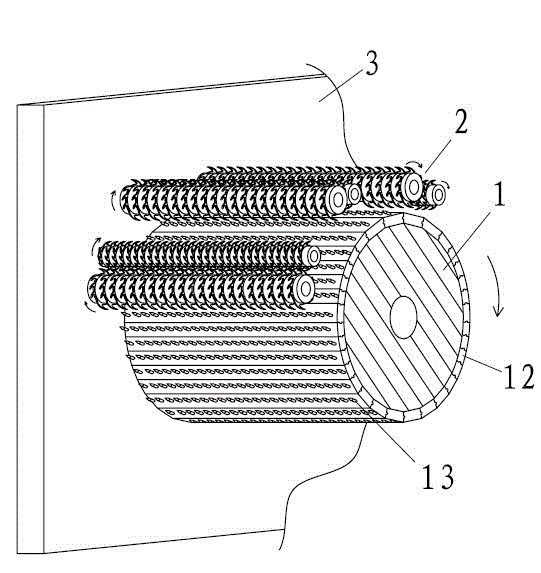

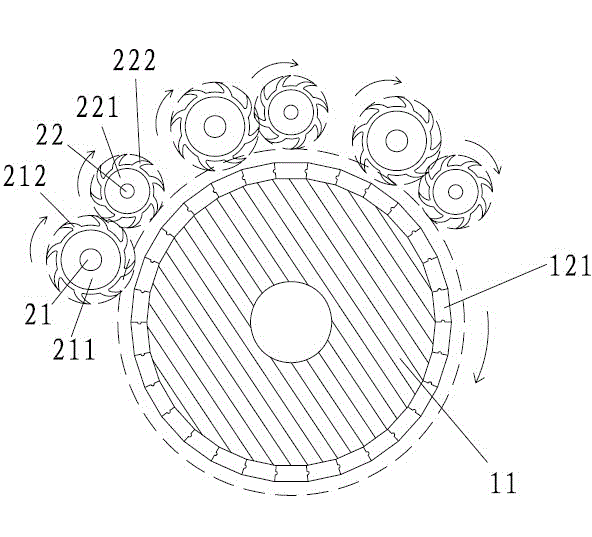

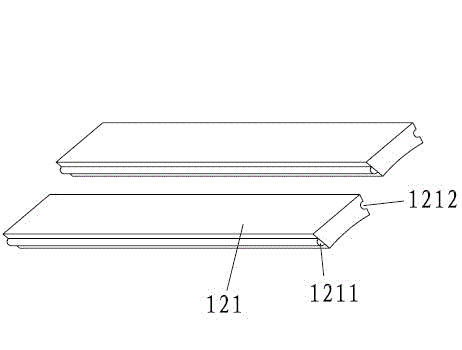

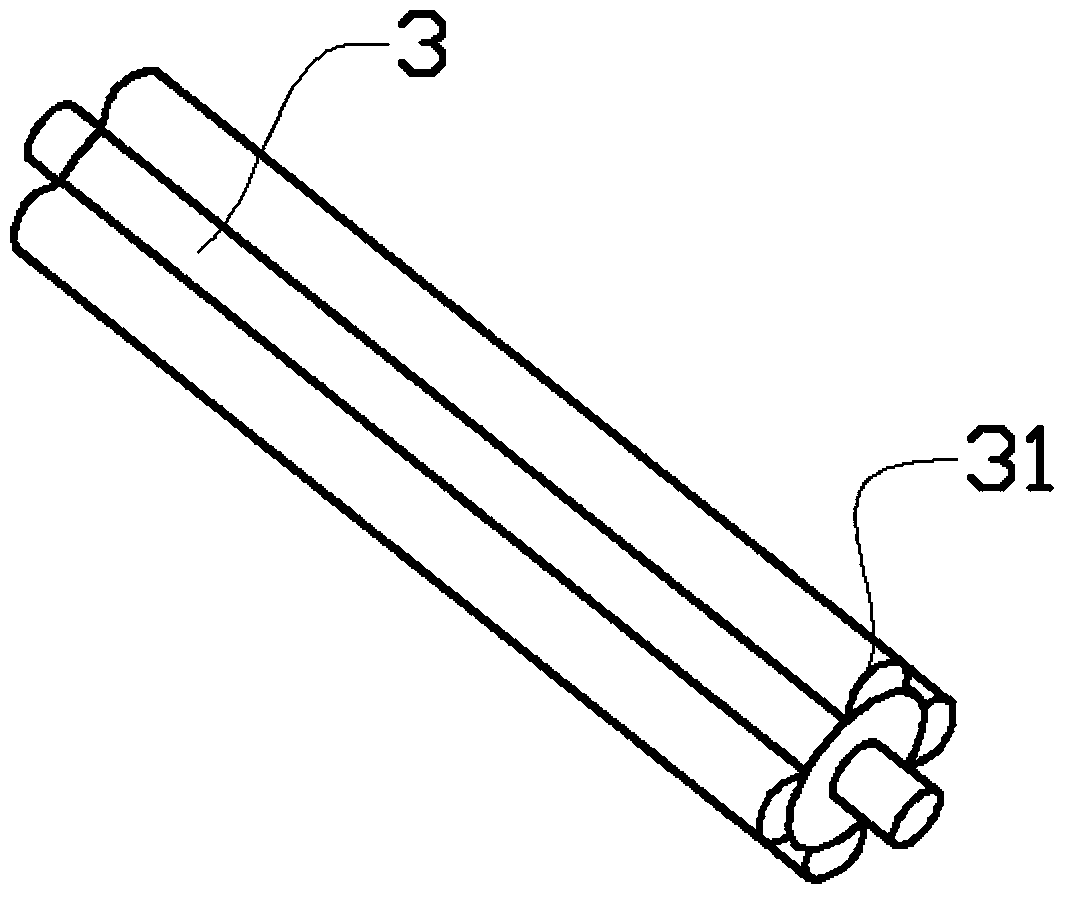

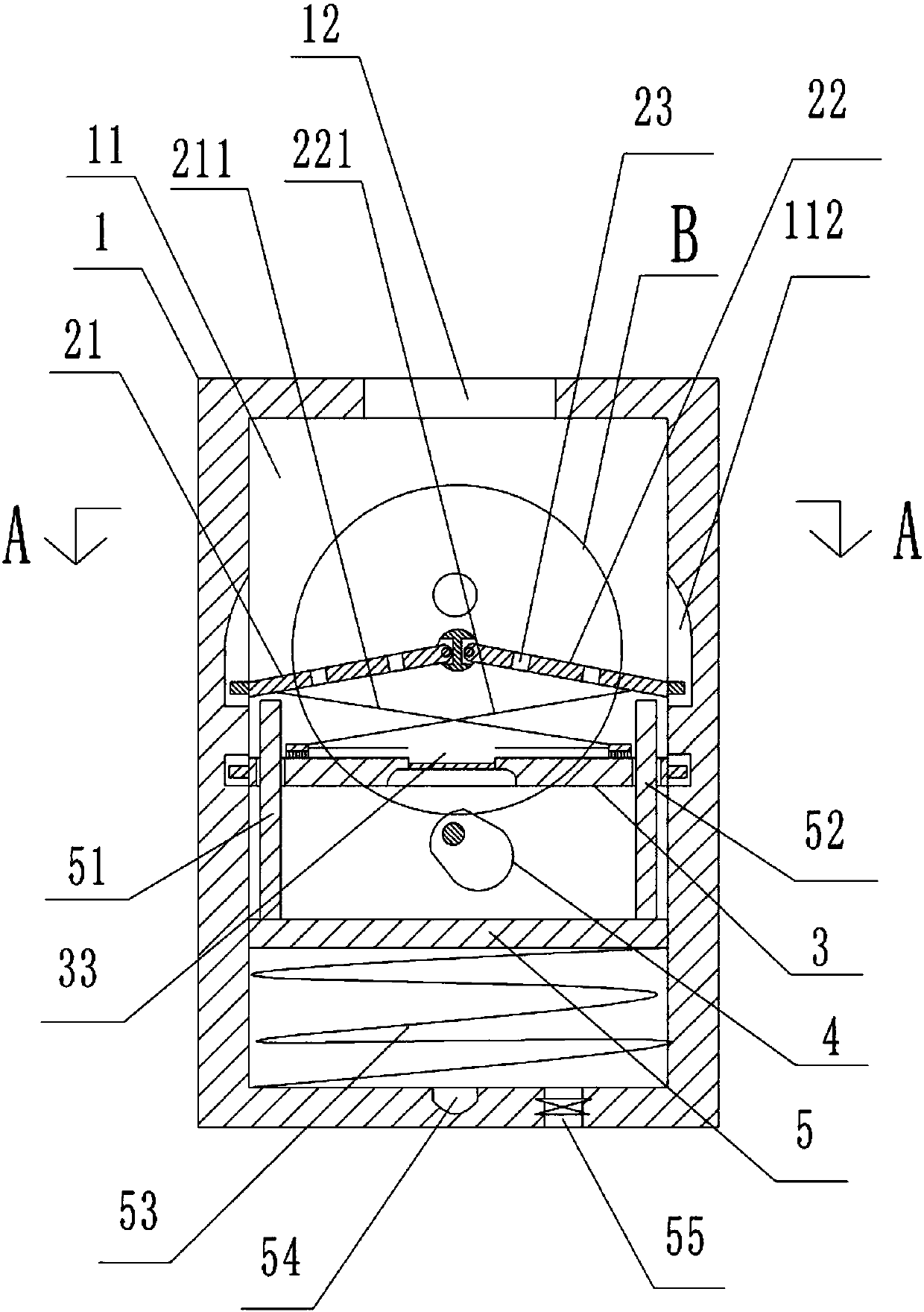

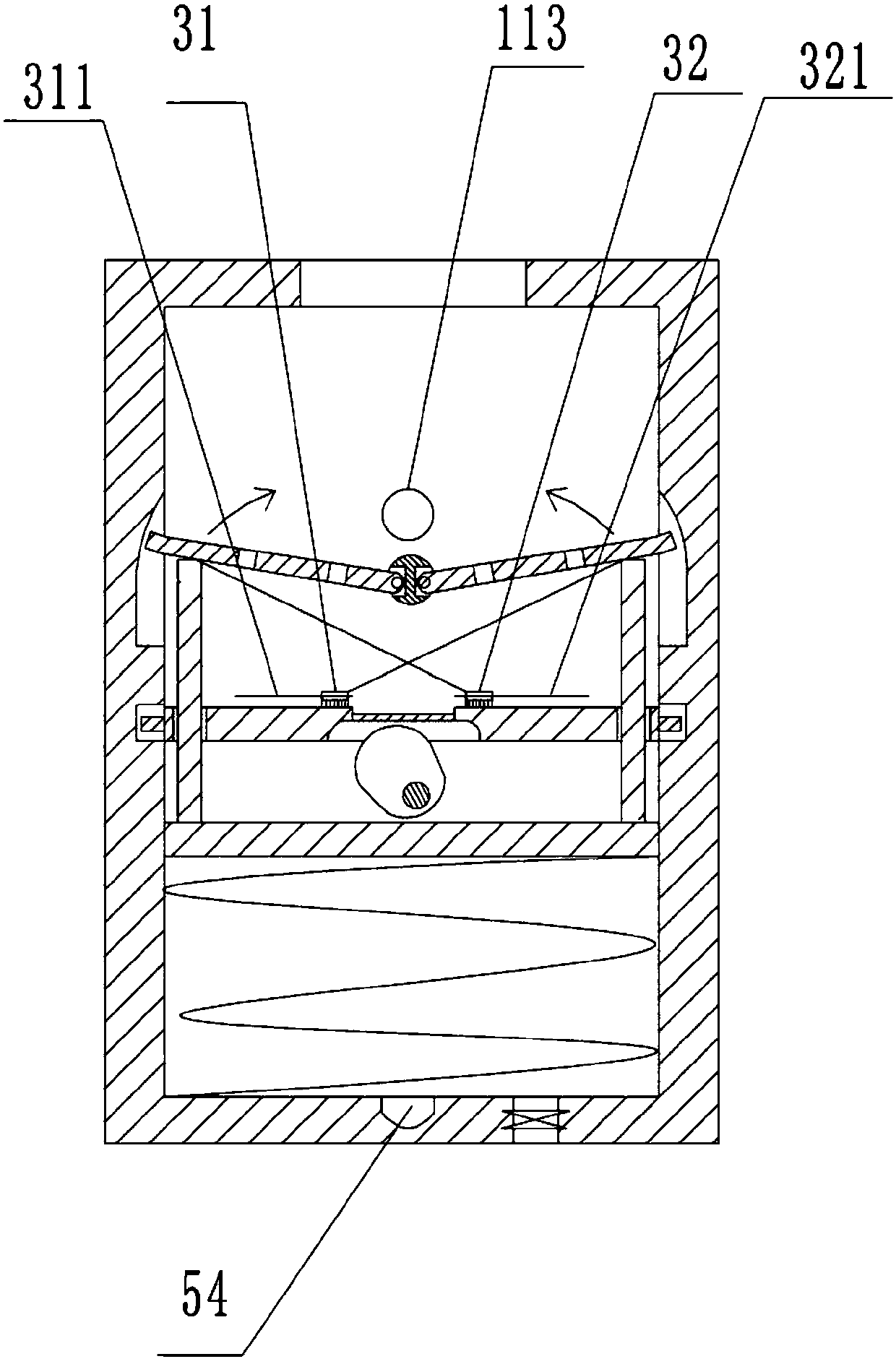

Opening mechanism and opener comprising same

InactiveCN102747458AEasy maintenanceNot easy to damageFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineeringMechanical engineering

The invention relates to an opening mechanism and an opener comprising the same, relates to cashmere production equipment and particularly relates to an opening and carding unit for raw cashmere. According to the technical scheme, the opening mechanism comprises a cylinder and at least one opening roller set. The cylinder comprises a drum, a mounting layer and a needle loop. The mounting layer fixed to the outer wall of the drum is composed of a plurality of plates. The cylinder has the advantages of convenience to maintenance, labor saving, and low potential safety hazard.

Owner:湖州珍贝羊绒制品有限公司

Scutcher

InactiveCN103526339AImprove adaptabilitySimple structureFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesFiberGranularity

The invention relates to equipment in the technical field of scutchers, in particular to a scutcher. The scutcher comprises a scutching bin, a cotton inlet formed in the lateral wall of the scotching bin and a beater arranged in the scotching bin, and is characterized in that an air passage in the vertical direction is arranged at the bottom inside the scutching bin, is externally connected with an air supply device through a transverse pipe and is provided with an air spraying head, and the air spraying head inclines upwards at an angle. After the structure is adopted, cotton fibers fed by a feeding mechanism into the scutching bin are jacked up through the air sprayed by the air spraying head, the heavier cotton fibers will fall on the bottom of the scutching bin, the structure is simple, and realization is convenient. The granularity of separated-out impurities can be controlled by controlling the flow amount of the air inside the transverse pipe, the quality of products has larger controllability, and the adaptability of the products on the market is improved.

Owner:WUJIANG KESHIDA TEXTILE

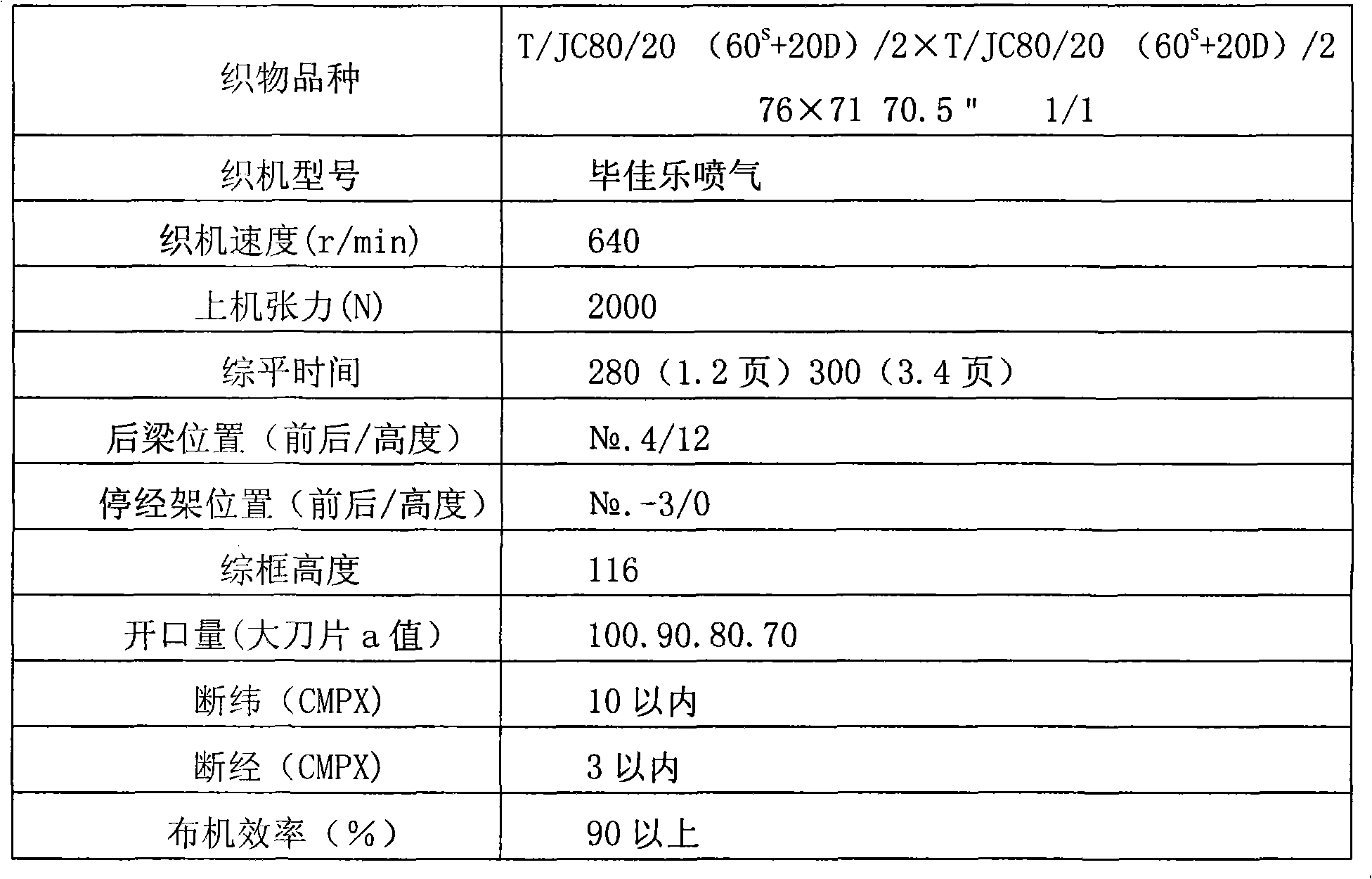

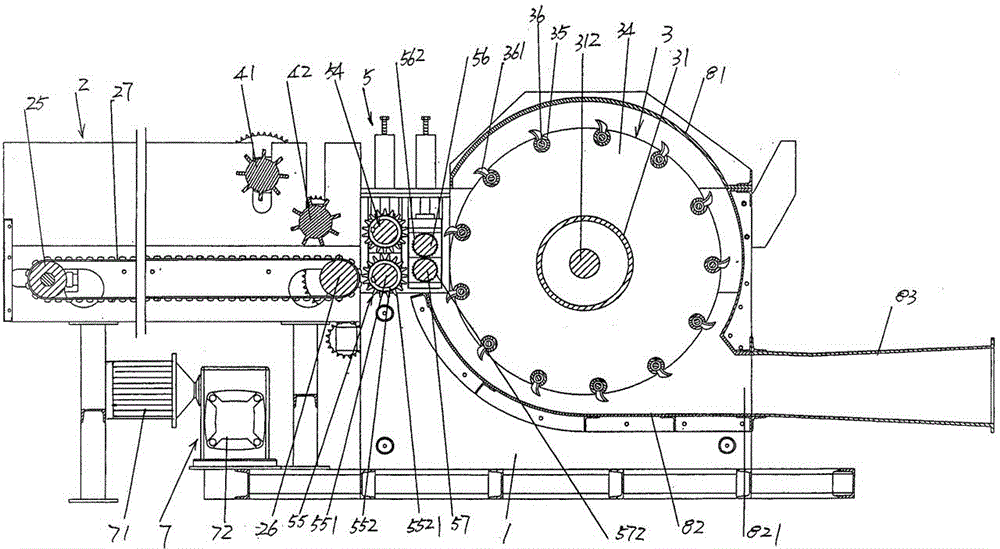

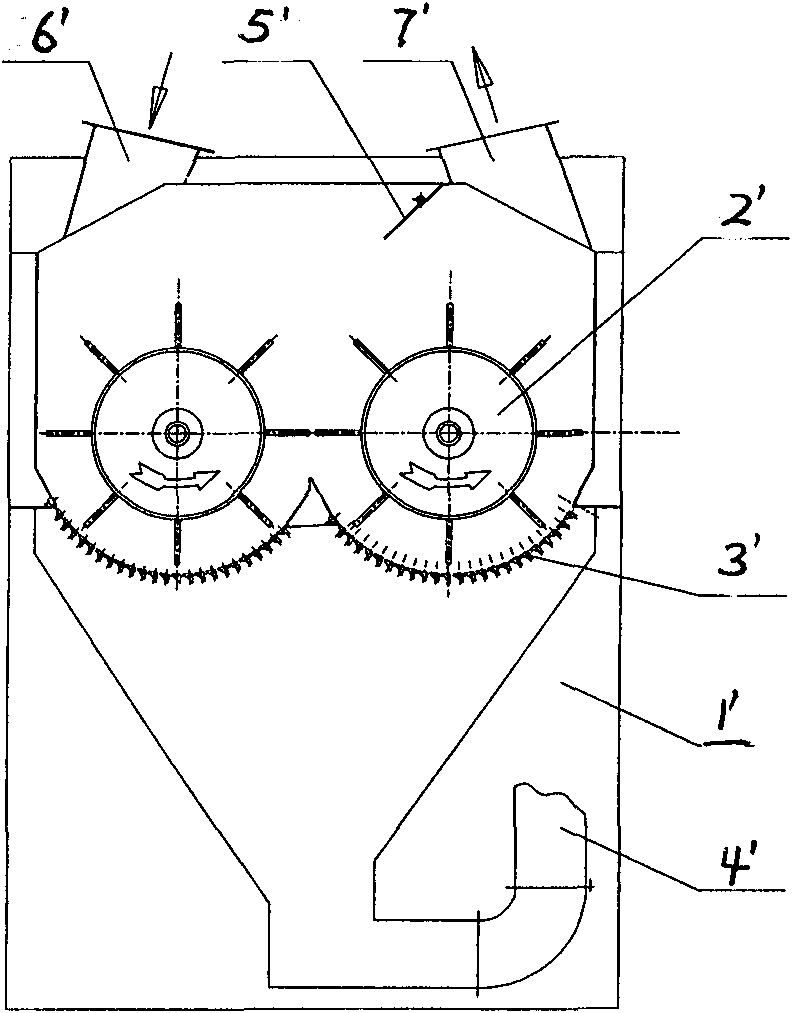

Opening and cleaning method for axial flow opener for opening picking or blowing carding process and special composite beater device thereof

ActiveCN101812745AMeet free strikeSatisfy the weak first and then the strongFibre cleaning/opening by toothed membersFibre cleaning/opening machinesState of artFiber

The invention provides an opening and cleaning method for an axial flow opener for opening picking or blowing carding process, and a special composite beater device. The method comprises the step that a cotton block to be opened makes spiral movement along beaters under common action of the beaters and air flow after the cotton block to be opened is fed into a beater chamber. The method is characterized in that the cotton block is subjected to opening and cleaning in different beating modes in turns when the cotton block makes spiral movement from a cotton inlet to a cotton outlet. The special composite beater device comprises beater cylinders, and is characterized in that the beater cylinders are provided with a blade region, a bar-shaped brad region and a V-shaped brad region in sequence from the inlet end to the outlet end. A reducing mode that the beater outer diameter is reduced from the inlet to the outlet in turns is adopted, so distances between beaters and grid bars are increased from the inlet to the outlet in turns to adapt to the condition that the cotton block is gradually opened and expanded in the forwarding process. The method has reasonable opening mode, high cleaning efficiency and fiber destruction prevention, and achieves the effect of developing strong points and avoiding weak points compared with the prior art.

Owner:CHTC HEAVY IND +1

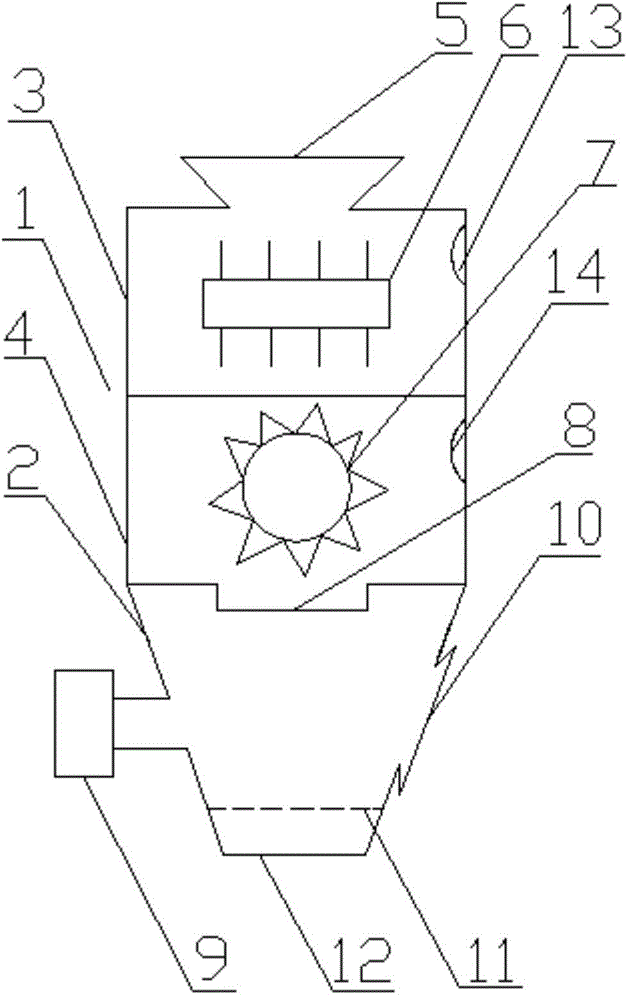

Cotton cleaning machine

InactiveCN105019061AEfficient removalThe opening process is sufficientFibre cleaning/opening by air draught arrangementsFibre cleaning/opening by toothed membersFiberPulp and paper industry

The invention provides a cotton cleaning machine, comprising a cotton loosening device and an impurity removing device, wherein the cotton loosening device comprises a first cotton loosening chamber and a second cotton loosening chamber, a feed port is formed in the top of the first cotton loosening chamber, a needle licker-in is arranged inside the first cotton loosening chamber, the second cotton loosening chamber is arranged at the bottom of the first cotton loosening chamber, a breaking roller is arranged inside the second cotton loosening chamber, an outlet is formed in the bottom of the second cotton loosening chamber and communicated with the impurity removing device, the left side of the impurity removing device is connected with a draught fan, a discharge port is formed in the right side of the impurity removing device, and a filter screen and a sundry box are sequentially arranged at the bottom of the impurity removing device from top to bottom. The cotton cleaning machine has the advantages that after being primarily loosened through the needle licker-in in the first cotton loosening chamber, cotton bales enter the second cotton loosening chamber to be secondarily loosened through the breaking roller, and therefore the cotton loosening process is more sufficient; moreover, impurities are removed through air flow, impurities mixed in cotton fibers are effectively removed, and therefore cotton bundles suitable for spinning are obtained.

Owner:TIANJIN JINGLONG TEXTILE RUBBER

Novel scutcher

ActiveCN105970361ASufficiency of increase or decreaseQuality improvementFibre cleaning/opening by toothed membersFibre cleaning/opening machinesEngineering

The invention provides a novel scutcher. The novel scutcher comprises a scutching box, an initial scutching mechanism, a fine scutching mechanism and a dust removal mechanism. A feed port, a discharge port and an impurity output opening are formed in one side of the scutching box. The initial scutching mechanism comprises at least two small hitting rollers and a cotton guide plate. Prods are arranged on the small hitting rollers. The cotton guide plate is obliquely installed in the scutching box. Multiple impurity guide holes are obliquely formed in the cotton guide plate. The fine scutching mechanism comprises a cotton output plate, a dust removal knife, a large hitting roller and a cotton return plate. A prod is arranged on the large hitting roller. The dust removal mechanism comprises a dust removal cover, a dust removal box and a draught fan. The dust removal cover is communicated with the upper end of the scutching box. The communicating positions of the dust removal cover and the scutching box are located on the two sides of the large hitting roller, the dust removal cover is in pipeline communication with the dust removal box, the dust removal box is in pipeline communication with an air inlet of the draught fan, an outlet of the draught fan is communicated with the scutching box, and the communicating position of the air outlet of the draught fan and the scutching box and the discharge port are located in the same side of the scutching box, and the communicating position is located below the discharge port. Cotton bales can be efficiently subjected to disassembly, impurity removal and dust removal.

Owner:WANGJIANG RUNHUA TEXTILE

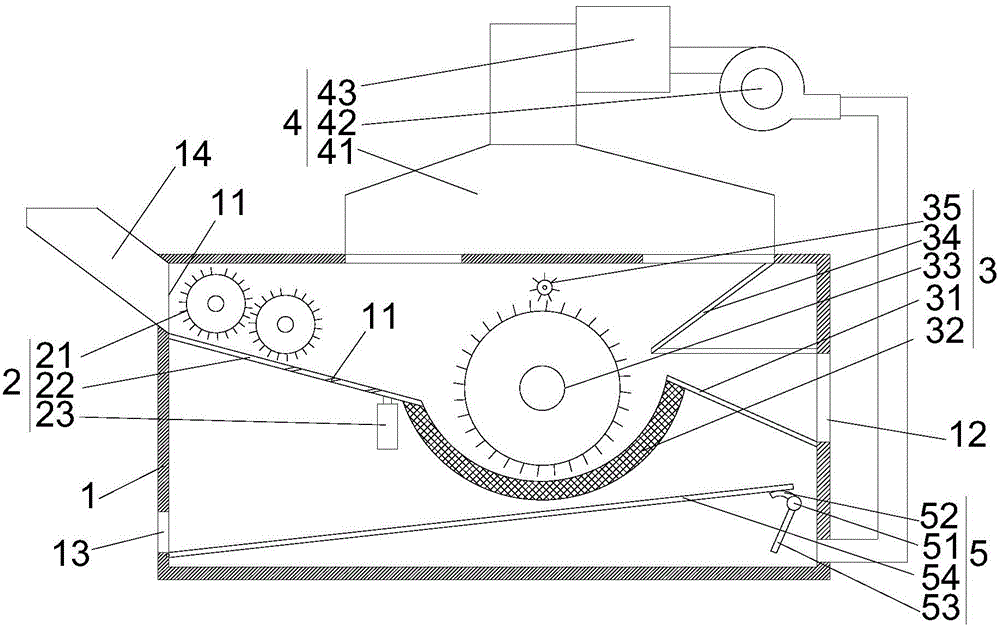

Oscillation beating type impurity removal device

InactiveCN104073921AEasy to sendSimple structureFibre cleaning/opening machinesEngineeringConveyor belt

The invention provides an oscillation beating type impurity removal device. The oscillation beating type impurity removal device comprises a conveyor belt, conveyor rollers, protruding head beaters and an oscillation roller; the surface of the conveyor belt is in a mesh shape and is formed by elastic materials; the conveyor rollers are utilized in a paired mode and assembled at the front end and the rear end of the inner side of the conveyor belt respectively; the conveyor rollers are placed on the higher portion and the lower portion respectively; the conveyor belt is assembled in an inclined mode; each protruding head beater is in a long stick shape, is assembled above the conveyor belt and is parallel to the cross section of the conveyor belt; long-strip-shaped protruding beating strips are machined on the roller surface of each protruding head beater in a uniformly distributed mode; the oscillation roller is assembled between the upper plane and the lower plane of the conveyor belt; the oscillation roller is driven by a transmission mechanism to rotate and is in periodic abutting contact with the surface of the inner side of the upper portion of the conveyor belt. According to the oscillation beating type impurity removal device, the oscillation on cotton which is located on the upper portion of the conveyor belt is achieved through the periodic arching deformation of the conveyor belt and meanwhile the loosening machining on the cotton is achieved through the protruding head beaters which are arranged above the conveyor belt.

Owner:WUJIANG TEXTILE SCI & TECH CENT

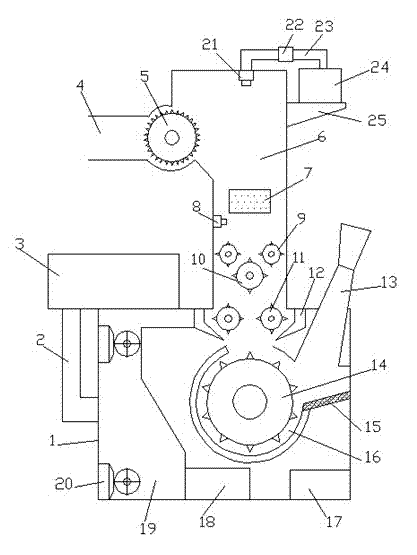

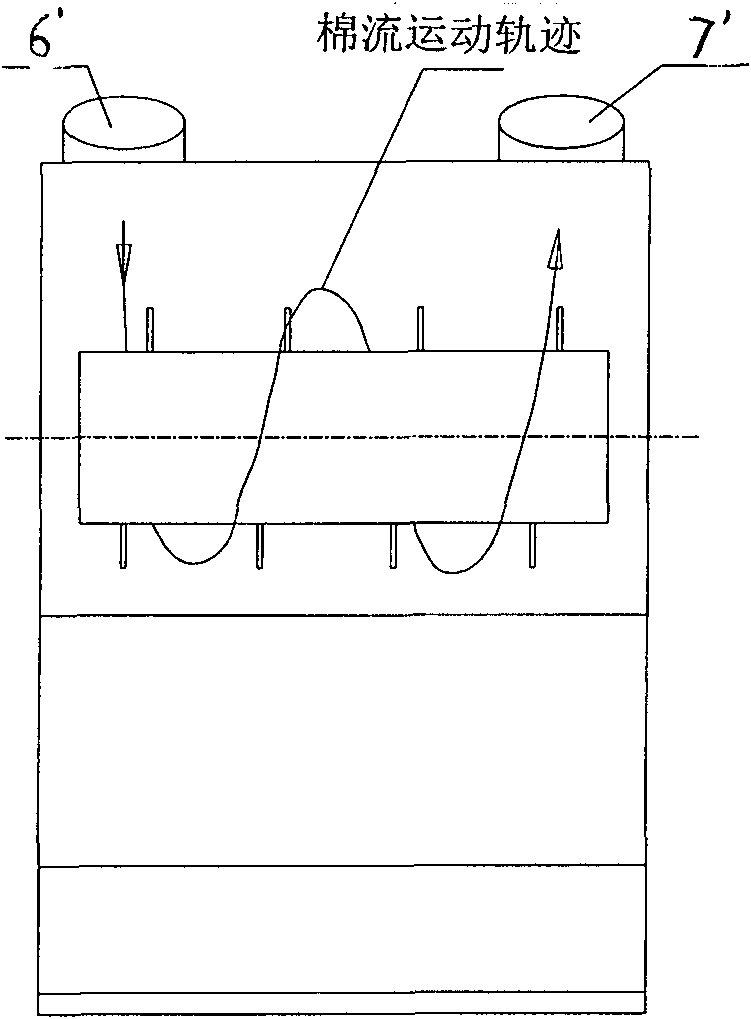

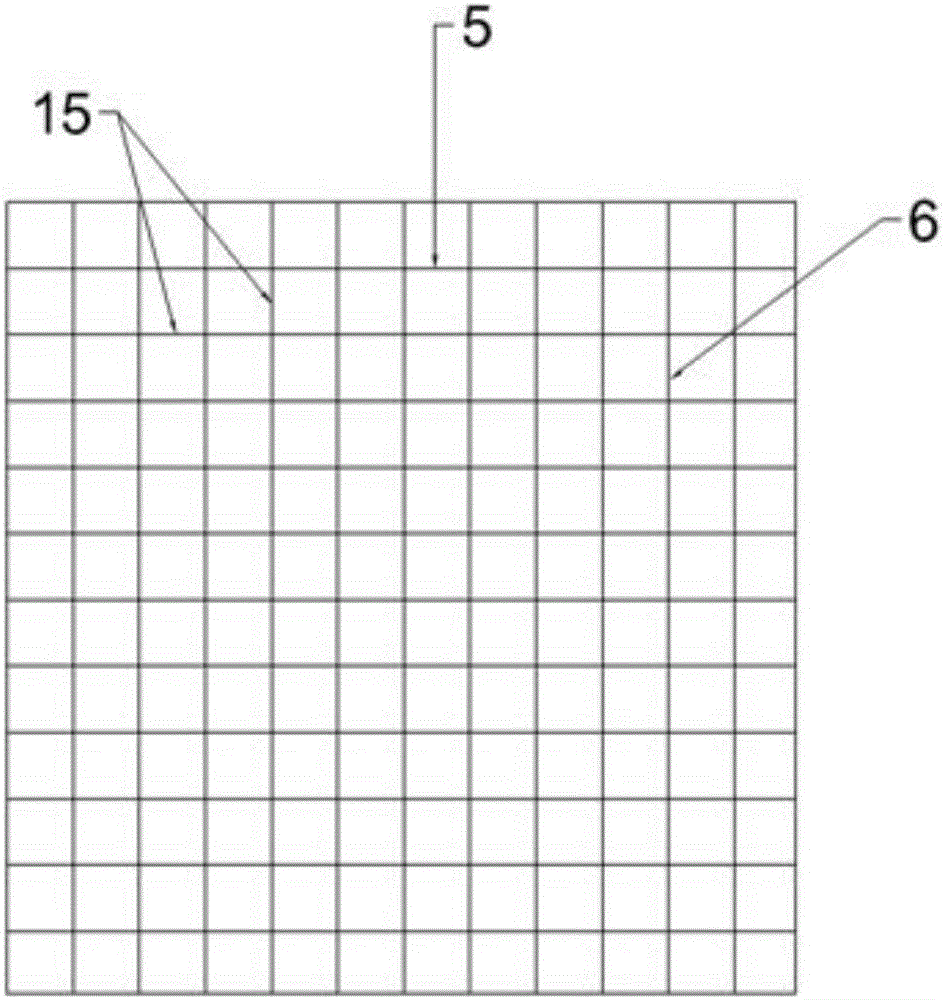

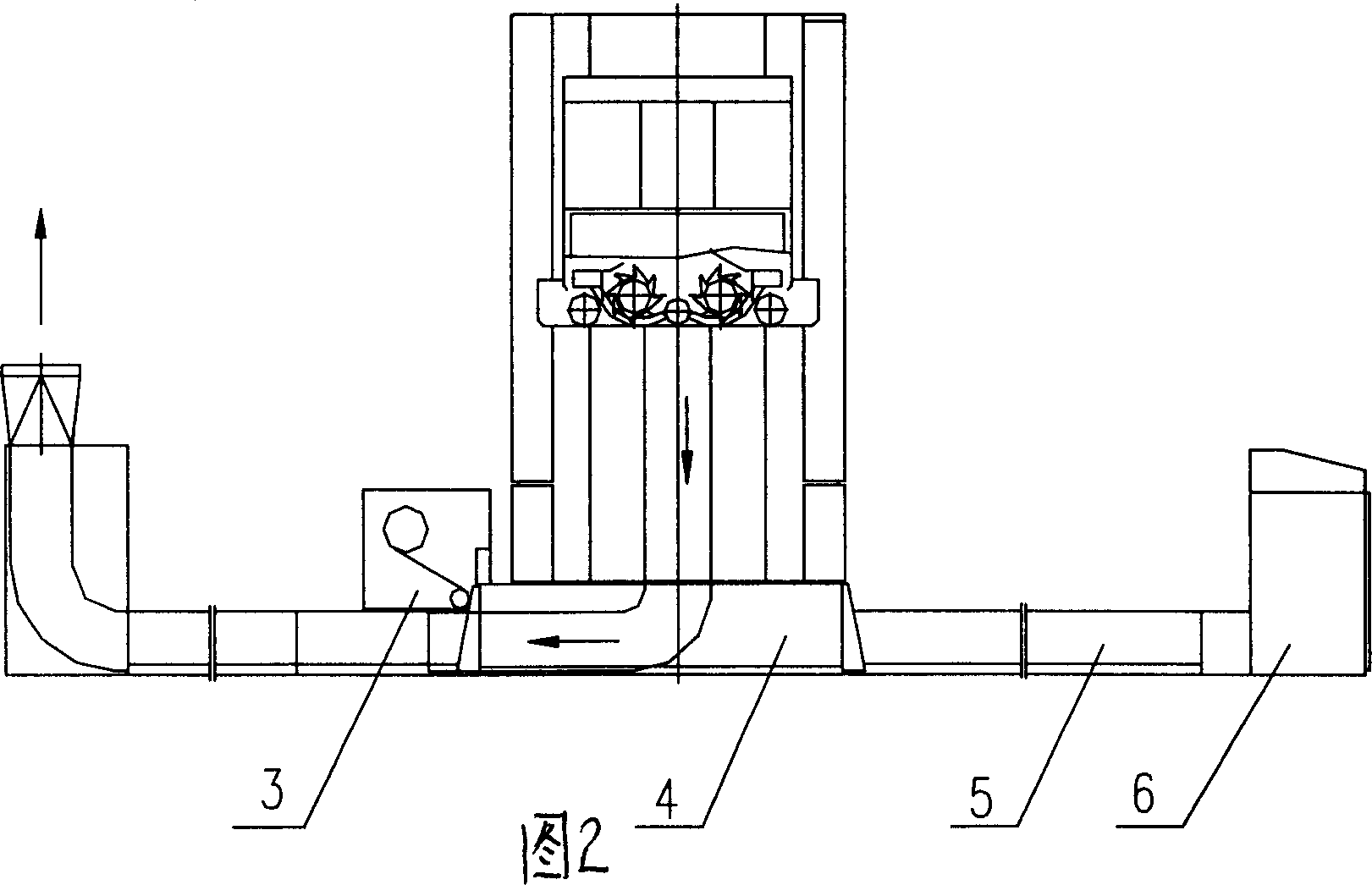

Cotton feed box adapted for blowing-carding process

InactiveCN101177805AUniform, continuous and stable deliveryTo achieve the use ofFibre cleaning/opening machinesFibre feedersEngineeringCommunicating cavity

The invention relates to a chute feeder applicable to blowing-carding process, which comprises a chute feeder body, a dust exhaust pipeline (1) arranged above the chute feeder body and communicated with the inner cavity of the chute feeder through a pipeline, a cotton feeding pipeline (4) arranged above the chute feeder body, an upper cotton path (5) arranged inside the chute feeder body, the upper nozzle of which is communicated with the lower nozzle of the cotton feeding pipeline and the lower nozzle of which is communicated with a lower cotton path (7), and a feed roller (2) and an opening and scotching beater (6) which are arranged inside a communicating cavity which is arranged between the upper cotton path (5) and the lower cotton path (7). A pair of air return boxes (8) is arranged at the two sides at the lower end of the lower cotton path (7) and a pair of delivery rollers (9) is arranged at the delivery orifice of the lower cotton path (7); a cotton shedding plate (10) is arranged below the delivery rollers (9). The air return inlets where two air return boxes (8) are communicated with the lower cotton path (7) are respectively provided with shade boards (18); the inner cavities of two air return boxes (8) are respectively communicated with an air inlet of an air circulator (3) through a pipeline.

Owner:CHTC HEAVY IND +1

Fiber opening equipment

InactiveCN106835370AReduce damageImprove the opening effectFibre cleaning/opening by toothed membersFibre cleaning/opening machinesFiberEngineering

The invention relates to a fiber opening device, comprising a cotton conveying fan, a conveying pipeline and a pre-opening box, the cotton conveying fan is connected to the top of the pre-opening box through a conveying pipeline, and the pre-opening box is an upper small The lower large round table and cylinder are composed of a pre-opening device in the pre-opening box; the lower end of the pre-opening box is fixedly connected with the opening box, and several layers of left and right vibrating opening layers are arranged in the opening box. A front and rear vibration opening layer is arranged below the left and right vibration opening layer. The beneficial effect of the present invention is that a pre-opening device is provided to pre-open the fiber raw materials, which improves the opening effect of the fiber raw materials; the vibration device is used to realize the oscillating wave on the silk thread, and quickly bounces the fiber raw materials, so that the fibers are fully Opening reduces the degree of damage to fibers. The invention has the advantages of reasonable structural design, convenient use, good opening effect, etc., and has certain popularization and application value.

Owner:安徽谢佑圣电子科技有限公司

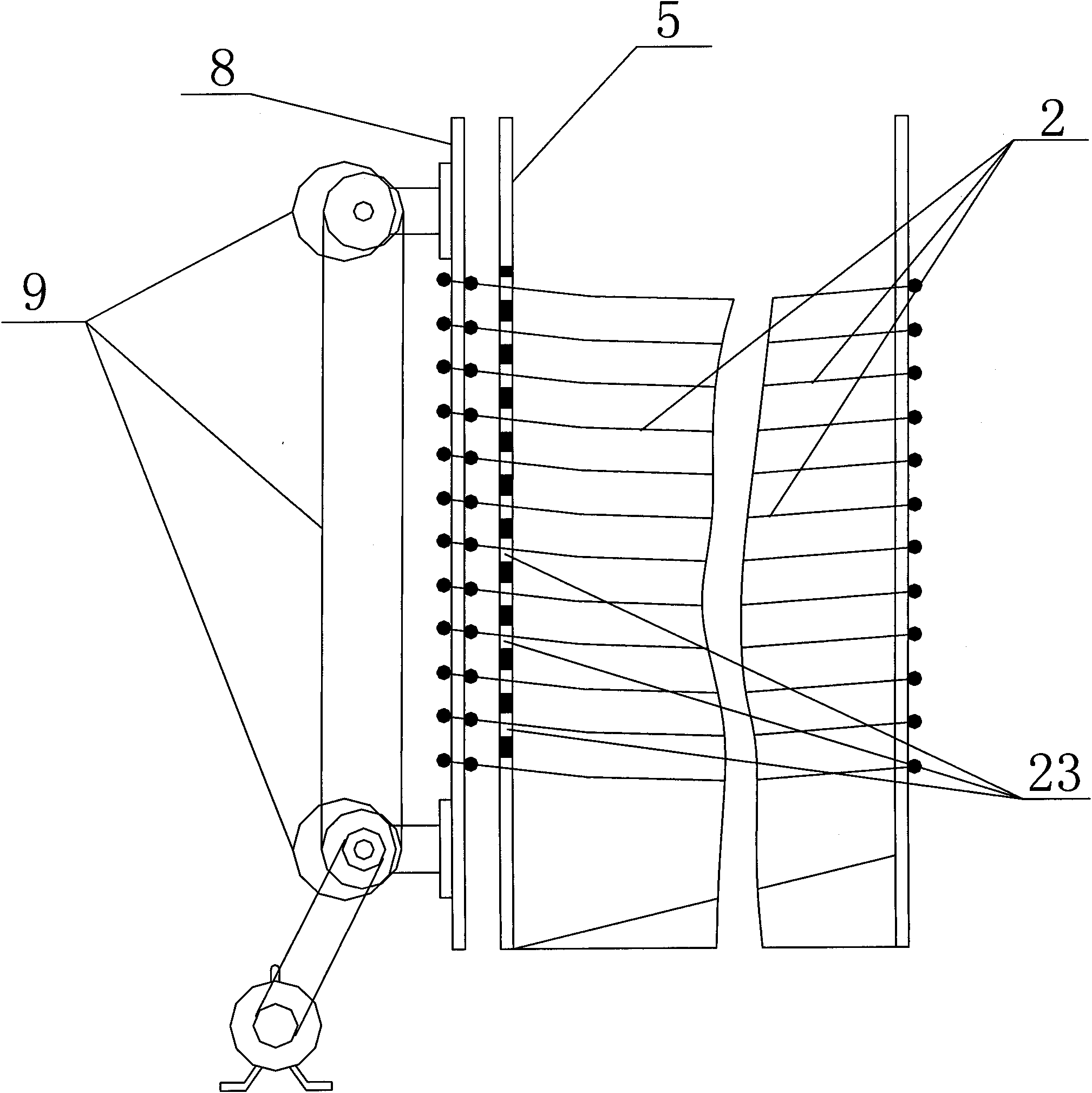

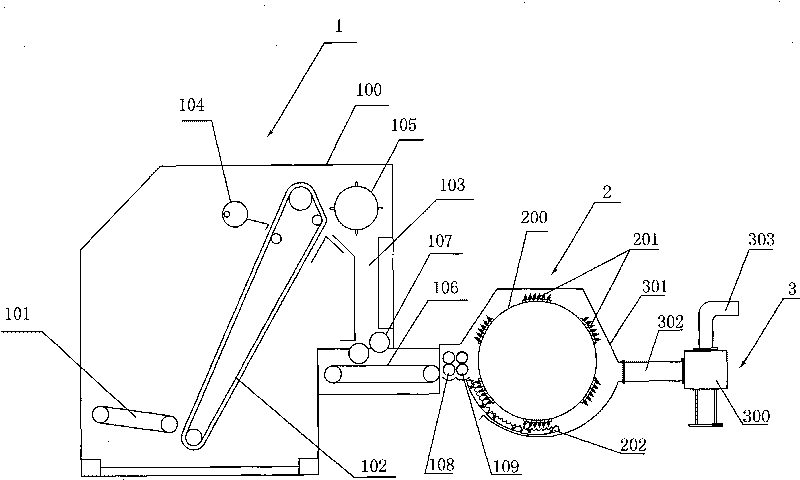

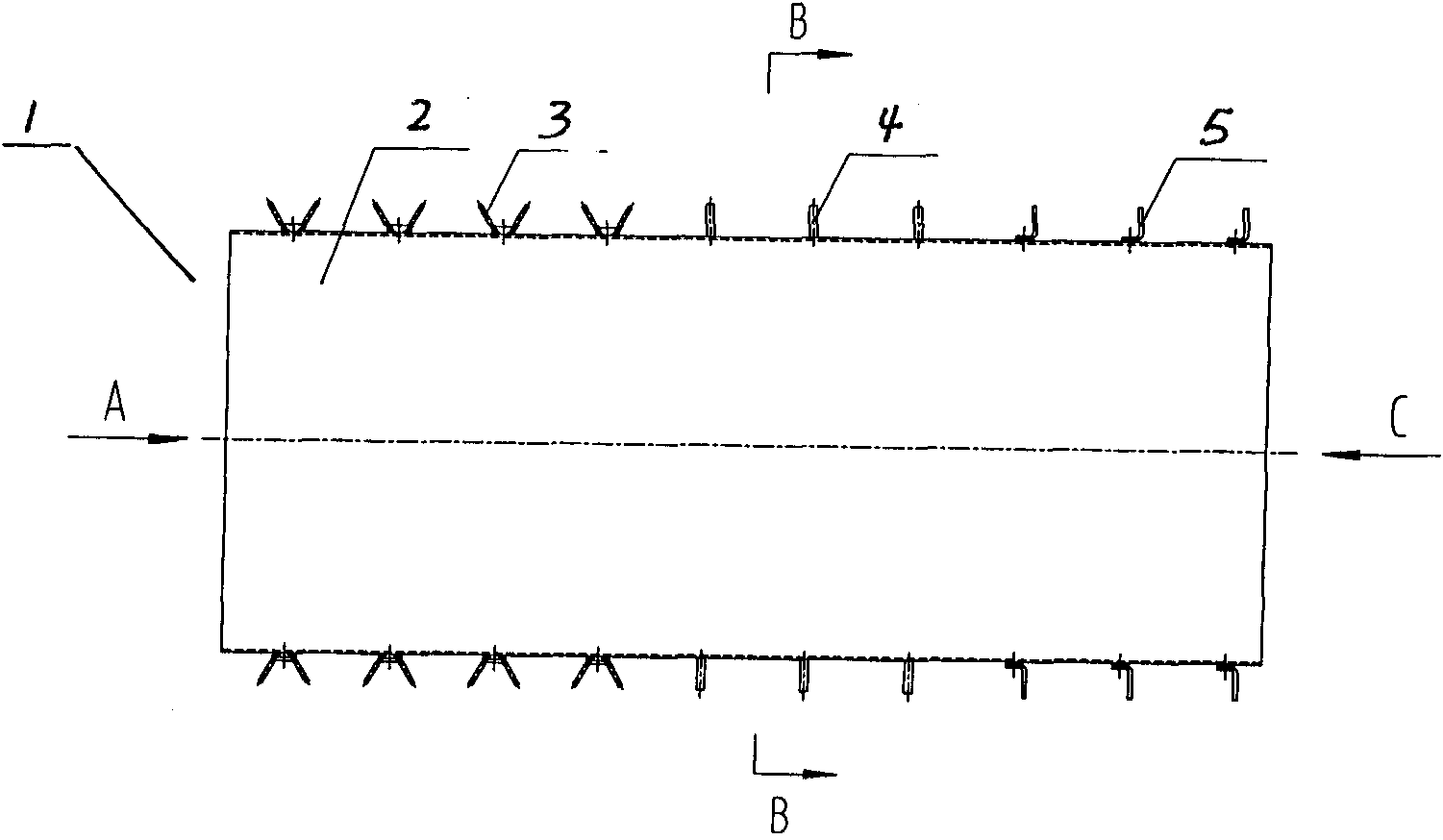

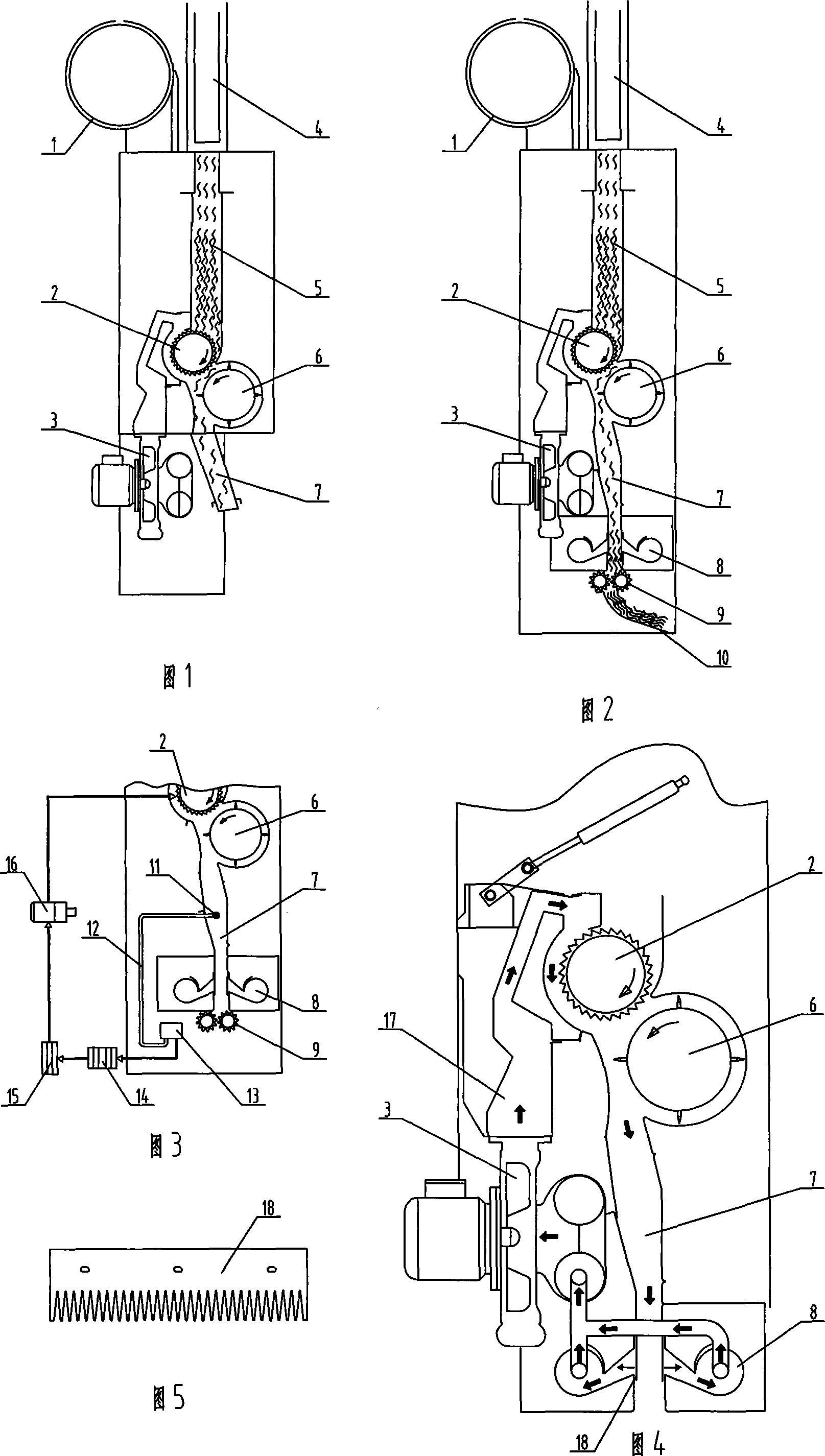

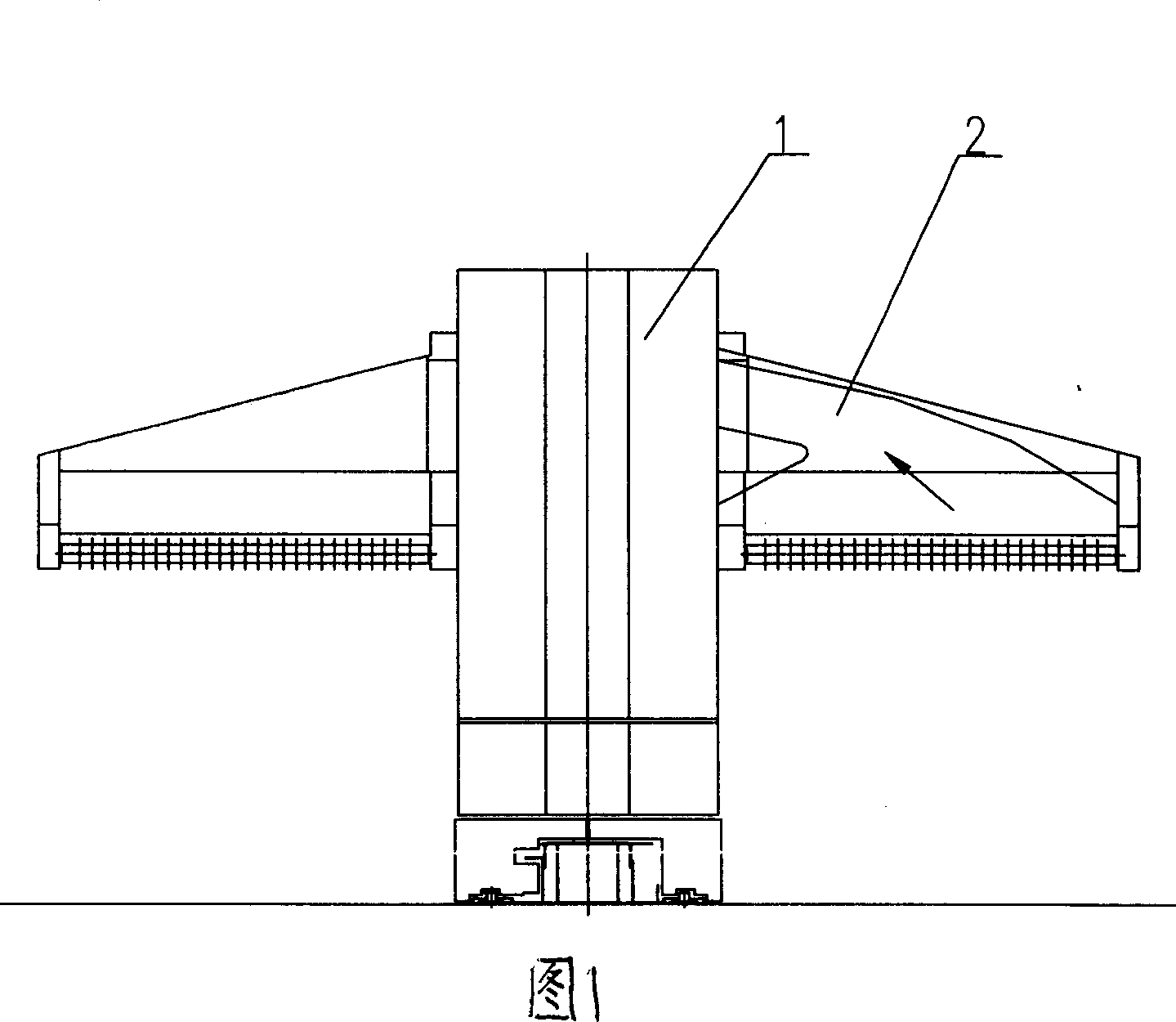

Cotton grasp mechanism adapted for reciprocation bale plucker

The invention relates to a cotton picker used in reciprocated cotton picking machine, wherein it comprises cotton picking arm frame (7) combined with rotational tower; under the frame (7), along the length direction, via the longitudinal vibrator (13), two swing rods (16) are parallel suspended; two ends of each swing rod (16) are both fixed with supports (14) for mounting beater; the left and right supports (14) at same end of two swing rods (16) via hinged connectors form the four bar linkage; two beaters (8) are individually arranged in two independent beater cotton picking areas formed by arm frame protect plate (18), inner baffle plate (17) and rib (12), while they are parallel mounted under two swing rods (160 via four bar linkage; and the transmission device for rotating two beaters (8) synchronously at same direction is arranged at the outer end of cotton picker.

Owner:ZHENGZHOU HONGDA NEW TEXTILE MACHINERY +1

Cotton cleaning machine for spinning

InactiveCN107794602AEasy to dropPromote withdrawalFibre cleaning/opening machinesEngineeringLED lamp

The invention discloses a cotton cleaning machine for spinning. The cotton cleaning machine for spinning comprises a feed inlet, a control panel, a tank body, a dust collecting tank and acoustic baffles, the control panel is installed at one side of the tank body, a waste material chamber is formed in the bottom inside the tank body, slide grooves are formed in both ends of the bottom inside the waste material chamber, smashing rolls are evenly fixed to a belt pulley mechanism, and smashing heads are evenly arranged on the smashing rolls. Through the installation of the dust collecting tank, by making the top of the dust collecting tank connected with the dust collecting head through a dust collecting pipe, when a cotton material is smashed, generated dust is collected; through the installation of an LED lamp, when illumination is poor, illumination can be provided; through the installation of a fan, the clean processed cotton material can be blown out through the effect of gravity, impurities fall into the lower portion, and the cotton material is output from a material outlet; by arranging the acoustic baffles at both sides of a second cotton breaking and opening chamber, noise pollution can be reduced.

Owner:丽水遂智科技咨询有限公司

Opening and picking machine

ActiveCN105155043ASimple structureEasy to implementFibre cleaning/opening by toothed membersFibre cleaning/opening machinesYarnAir volume

The invention provides an opening and picking machine and belongs to the technical field of weaving equipment. The opening and picking machine comprises a housing having a cavity. A feeding port communicated with the cavity is formed in the upper end of the housing; two horizontally arranged breaking rollers are rotationally connected in the cavity; a needling roller is arranged under the breaking rollers; a motor driving the breaking rollers and the needling rollers to rotate at the same time is fixed on the outer wall of the housing; the lower end of the housing is in a trapezoidal shape; a first air inlet is formed in the bottom of the housing; a discharging port and a second air inlet are formed in the side wall of the housing; the discharging port faces the second air inlet; the air inlet part is provided with an air inlet pipe connected with the cavity, and a first air draught fan; one end of the air inlet pipe extends into the housing; an outlet end of the air inlet pipeline in the cavity is sealed and a lateral air exhaust port is arranged on the side part of the outlet end; an adjusting structure adjusting air volume is arranged on the lateral air exhaust port; and the second air inlet is provided with a second air draught fan. Product quality can be controlled and suitability of products to the market can be enhanced; and cotton yarn waste in the opening and picking machine can be reduced.

Owner:东营慈母坊家纺有限责任公司

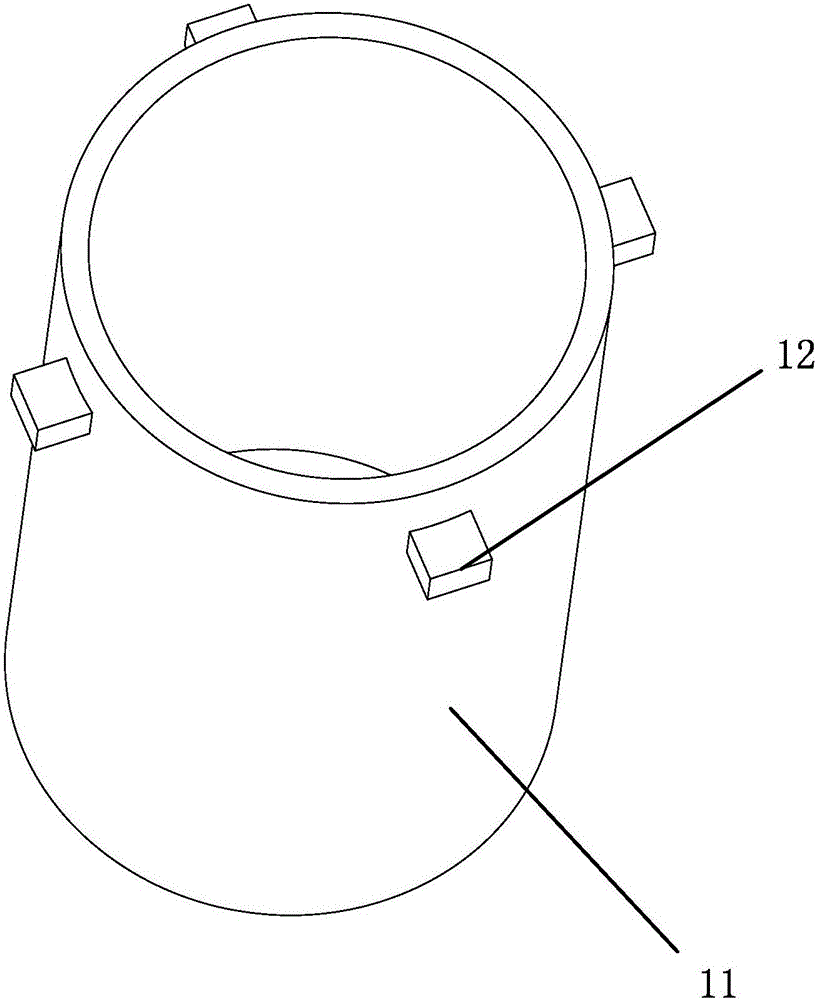

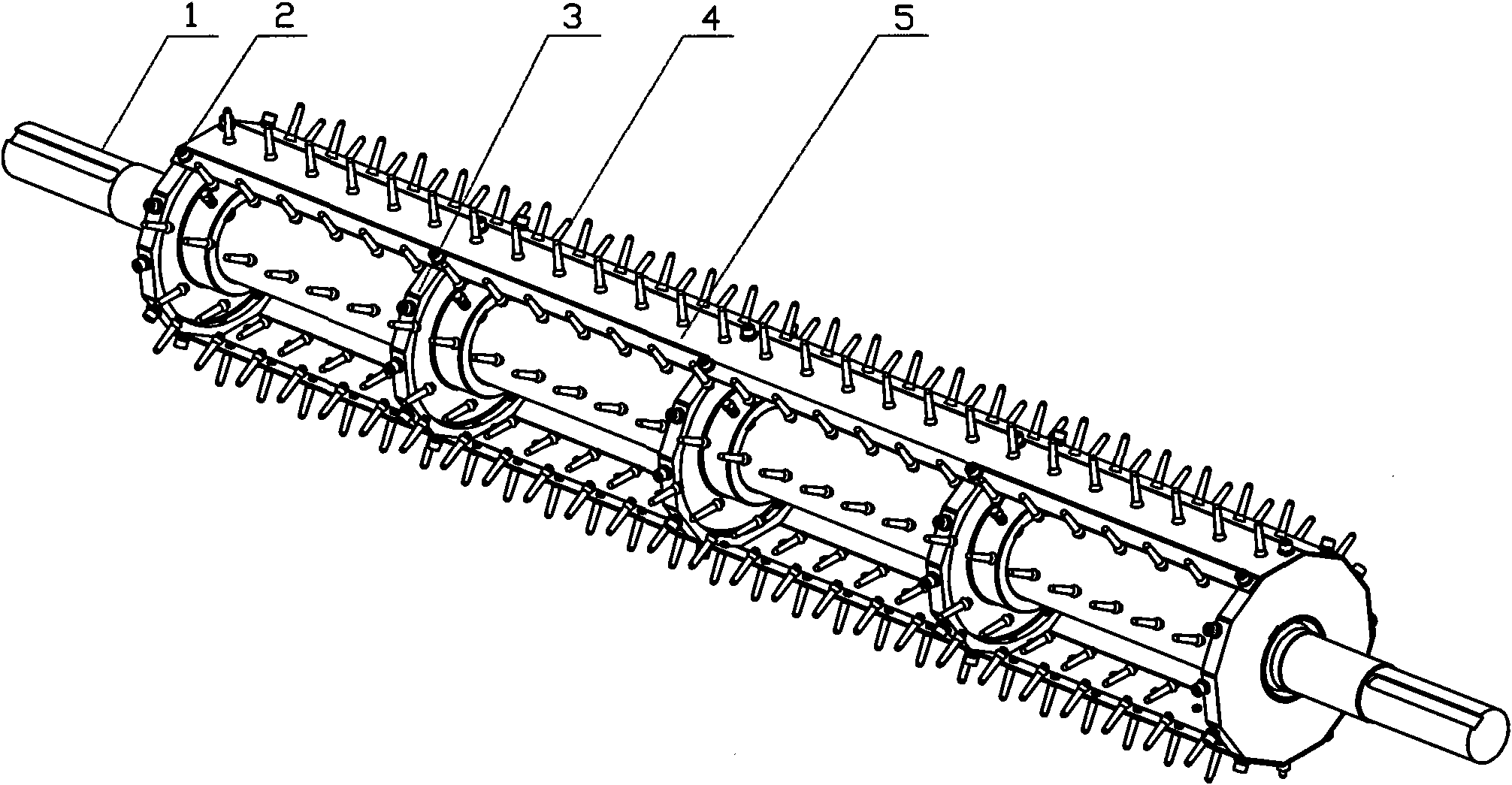

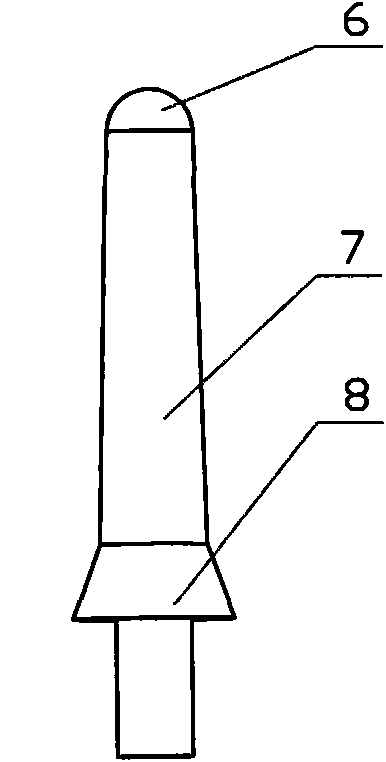

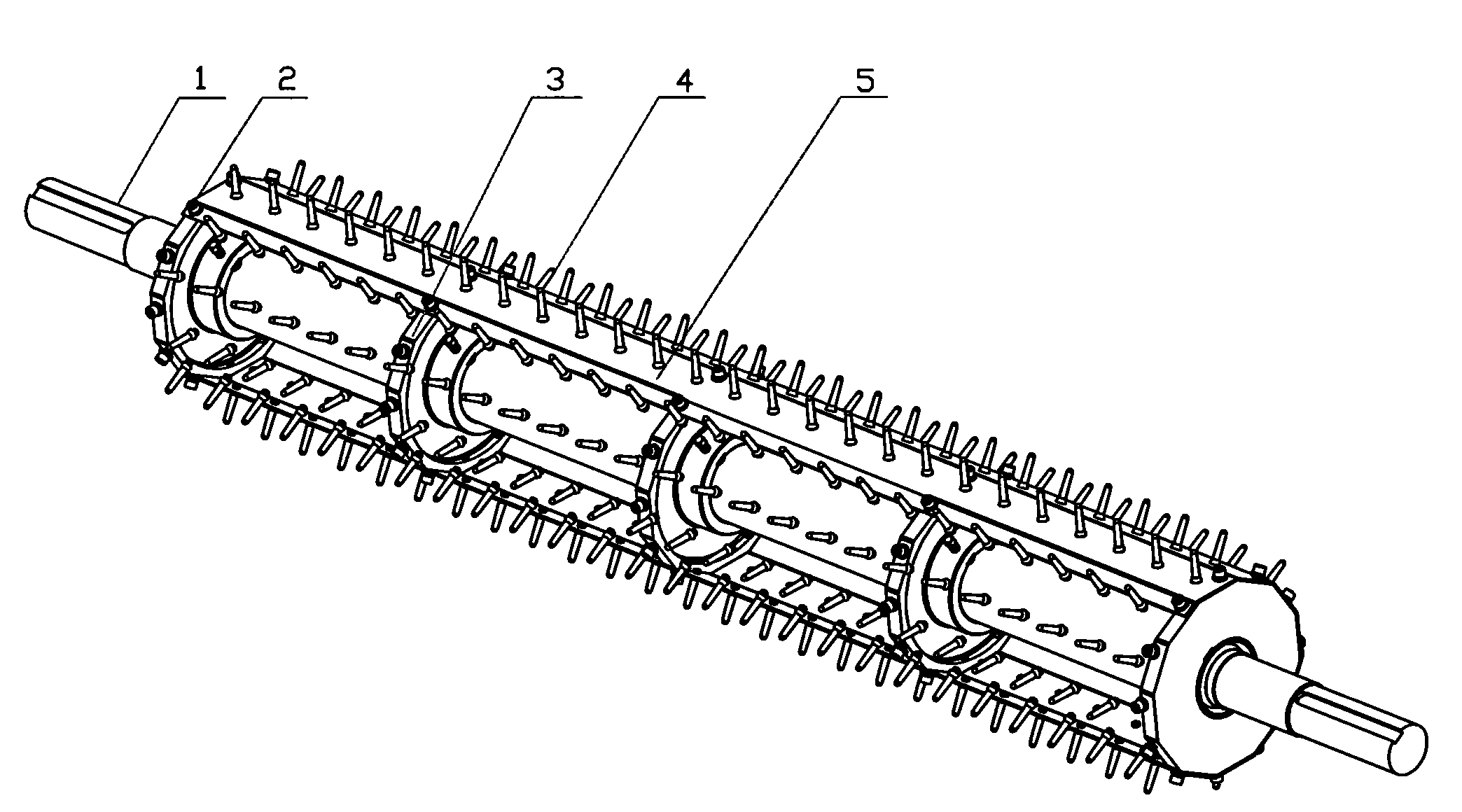

Barbed nail roller assembly

The invention discloses a barbed nail roller assembly which comprises a pipe shaft, a group of flanges and a wrapping plate, wherein the flanges are arranged along with axial direction of the pipe shaft and are coaxial with the pipe shaft; the wrapping plate is fixed on the flanges to form a cylinder; barbed nails are uniformly arranged on the wrapping plate; each flange has a regular pyramid structure; the wrapping plate comprises a plurality of split bodies which are exactly divided by the arris number of the regular pyramid; the split blocks are used for forming the side surface of the cylinder; and the barbed nails are spherical crown tapered barbed rivets. The barbed nail roller assembly has high motion precision, high reliability and long service life.

Owner:SHANDONG SWAN COTTON INDAL MACHINERY STOCK

Cotton cleaning machine

ActiveCN108018622AAchieve dischargeEasy to sweep awayFibre cleaning/opening machinesEngineeringMechanical engineering

The invention relates to the technical field of spinning, in particular to a cotton cleaning machine. The cotton cleaning machine includes a cotton cleaning machine body, and a cleaning cavity and a feeding inlet are formed in the cotton cleaning machine body. The cleaning cavity is internally provided with an impurity filtering plate, a cleaning plate, a cam and a piston from top to bottom; the cam is connected with a motor, the inner wall of the cleaning cavity is fixedly provided with a rotating shaft, the impurity filtering plate includes a first folding plate and a second folding plate rotatably connected with the two sides of the rotating shaft, and the connection portion of the first folding plate and the rotating shaft and the connection portion of the second folding plate and therotating shaft are provided with torsional springs, and the first folding plate and the second folding plate are provided with filtering holes; a first cleaning brush, a second cleaning brush and a cleaning channel are arranged / formed on / in the cleaning plate; the upper surface of the piston is fixedly provided with a first push rod and a second push rod; a reset spring is arranged between the piston and the bottom surface of the cleaning cavity; the bottom surface of the cleaning cavity is provided with an air inlet pipe and an air blow pipe, and the upper portion of the rotating shaft is provided with a air-blowing port communicated with the air blow pipe. According to the scheme, after scattered materials are gathered, the materials can be scattered again through blowing, and impurities can be cleaned away and discharged.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com