Production method of moisture-absorbing and sweat-discharging fabric

A technology of moisture absorption and perspiration production method, which is applied in the directions of fabrics, textiles, textiles and paper making, etc., can solve the problems of not very obvious capillary effect, limited functionality of fabrics, and the effect of moisture absorption and perspiration can not further meet the requirements of wearing. , to achieve the effect of good moisture absorption and quick drying effect, good skinny, good moisture absorption and quick drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

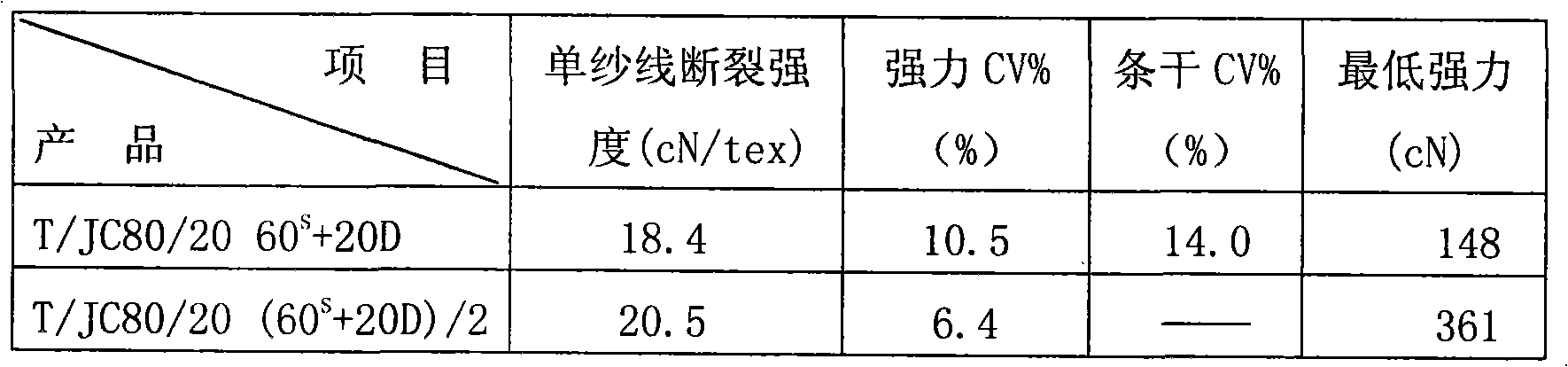

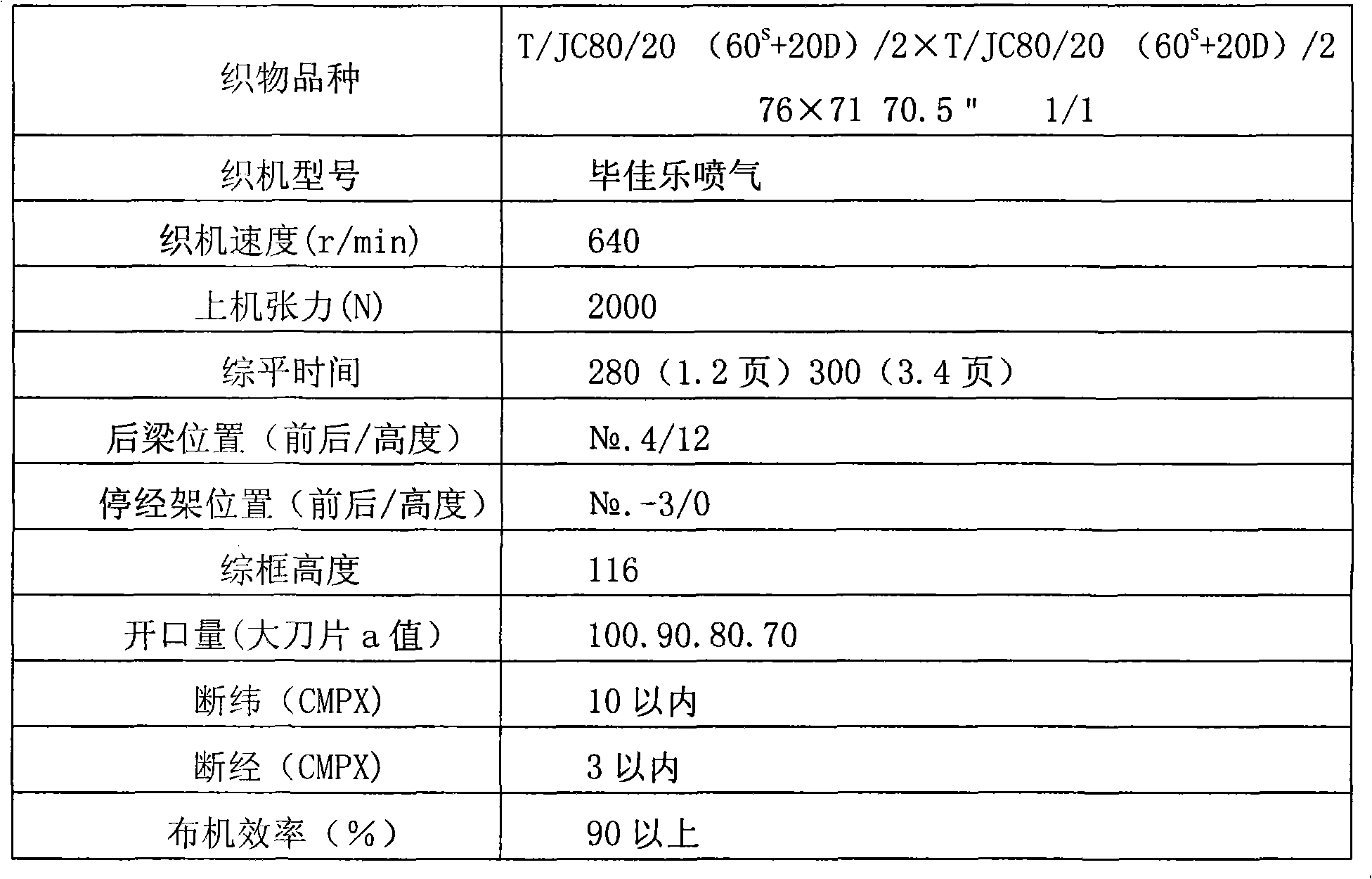

[0043] The present invention selects 80% honeycomb hygroscopic quick-drying fiber and 20% cotton fiber as covering fiber, and 20D ordinary polyester filament is used as core yarn to produce polyester-cotton core-spun yarn, thereby producing T / JC80 / 20 (60 S +20D) / 2×T / JC80 / 20(60 S +20D) / 2 76×7170.5″1 / 1 Moisture-absorbing and sweat-wicking functional fabric. The honeycomb moisture-absorbing and quick-drying fiber adopts Zhejiang Hongqiang honeycomb moisture-absorbing and quick-drying fiber. The specific steps are as follows:

[0044] 1. Spinning production, the specific steps are as follows:

[0045] 1. The cleaning, carding, and combing of cotton fibers are the same as the production methods of ordinary cotton yarn.

[0046] 2. Opening, cleaning, carding, and pre-merging of honeycomb moisture-absorbing and quick-drying fibers:

[0047] 1) Start cleaning process

[0048] Since the moisture-absorbing and sweat-wicking fibers have good length uniformity and do not contain impuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powerful | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com