Patents

Literature

3471results about "Grip property fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabric care compositions comprising aminosilicone

InactiveUS20050170994A1Good flexibilityEliminate negative effectsCationic surface-active compoundsOrganic detergent compounding agentsEmulsionAminosilochrome

Fabric care compositions comprise aminosilicone having an amino content ratio defined by a ratio of the amine containing units to the total number of units, wherein the amino content ratio is from about 1:11 to about 1:269, emulsifier, and fabric softening active. The aminosilicone materials in fabric care compositions can provide a number of benefits including improved fabric softness, wrinkle reduction after drying, ease of ironing, in-wear shape retention, fabric elasticity, fabric tensile strength, fabric tear strength, and / or color protection. A process of making an aminosilicone emulsion comprises the step of mixing an aminosilicone having an amino content ratio of from about 1:11 to about 1:269 with a cationic emulsifier. The invention further relates to a process of making the fabric care compositions.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions

ActiveCN104294583ASimple methodGood antibacterial, anti-ultraviolet and deodorizing propertiesLight resistant fibresWrinkle resistant fibresStaphylococcusHydrogen

The invention discloses a preparation method of a composite functional fabric with antimicrobial, anti-ultraviolet, deodorization and self-cleaning functions. The preparation method comprises the steps of preparing an activated modified treatment liquid, preparing a nano-titania dispersion liquid, processing fabrics by virtue of the activated modified treatment liquid, processing the fabrics by virtue of the nano-titania dispersion liquid, and the like. After the composite functional fabric is processed, the UPF value is more than 100, the deodorization rate is more than 95%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 96.7%, and the antibacterial rate (to staphylococcus) is 98.6%; after the composite functional fabric is washed for ten times in families, the UPF value is more than 50, the deodorization rate of the composite functional fabric to substances (including ammonia gas, formaldehyde, acetaldehyde, sulfureted hydrogen, nicotine and trimethylamine) is more than 90%, the photocatalysis self-cleaning fading rate of the composite functional fabric to chili oil is 93.9%, and the antibacterial rate (to staphylococcus) is 95.8%.

Owner:江苏巧雅纺织科技有限公司

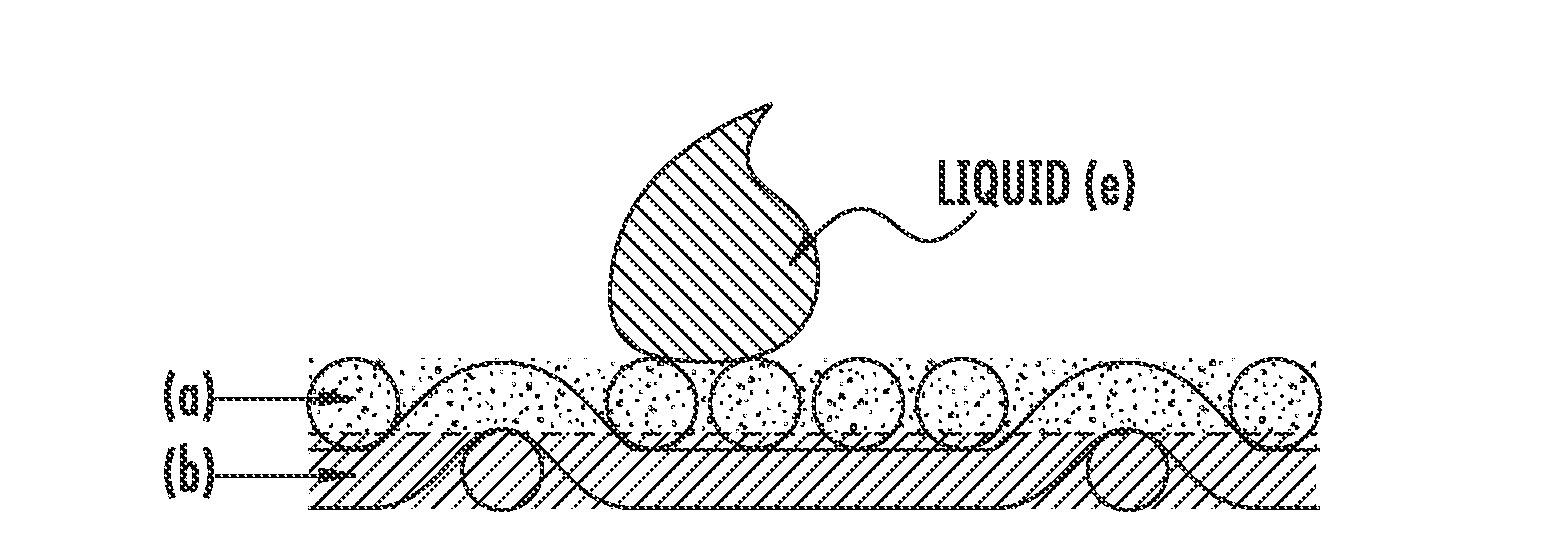

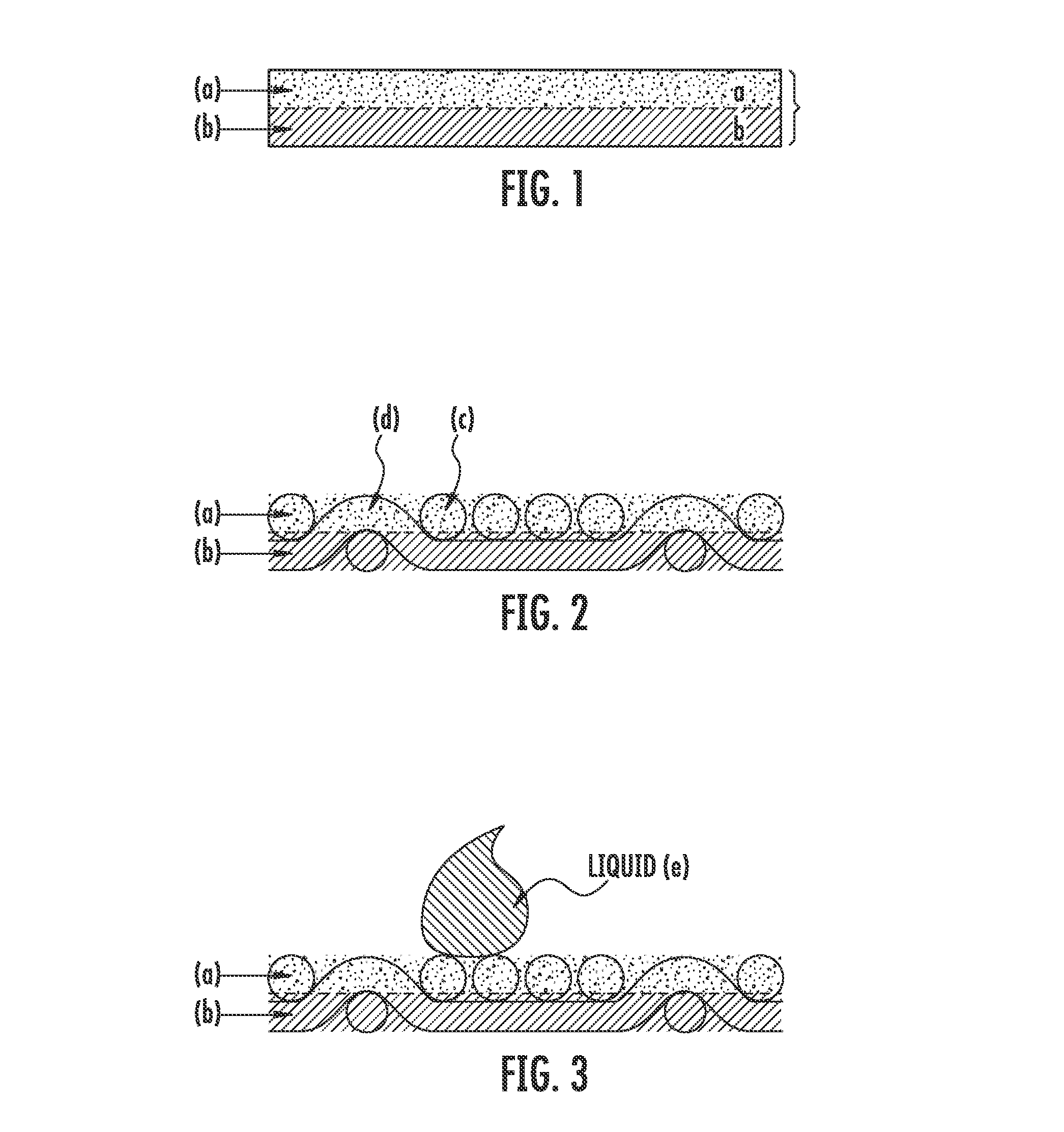

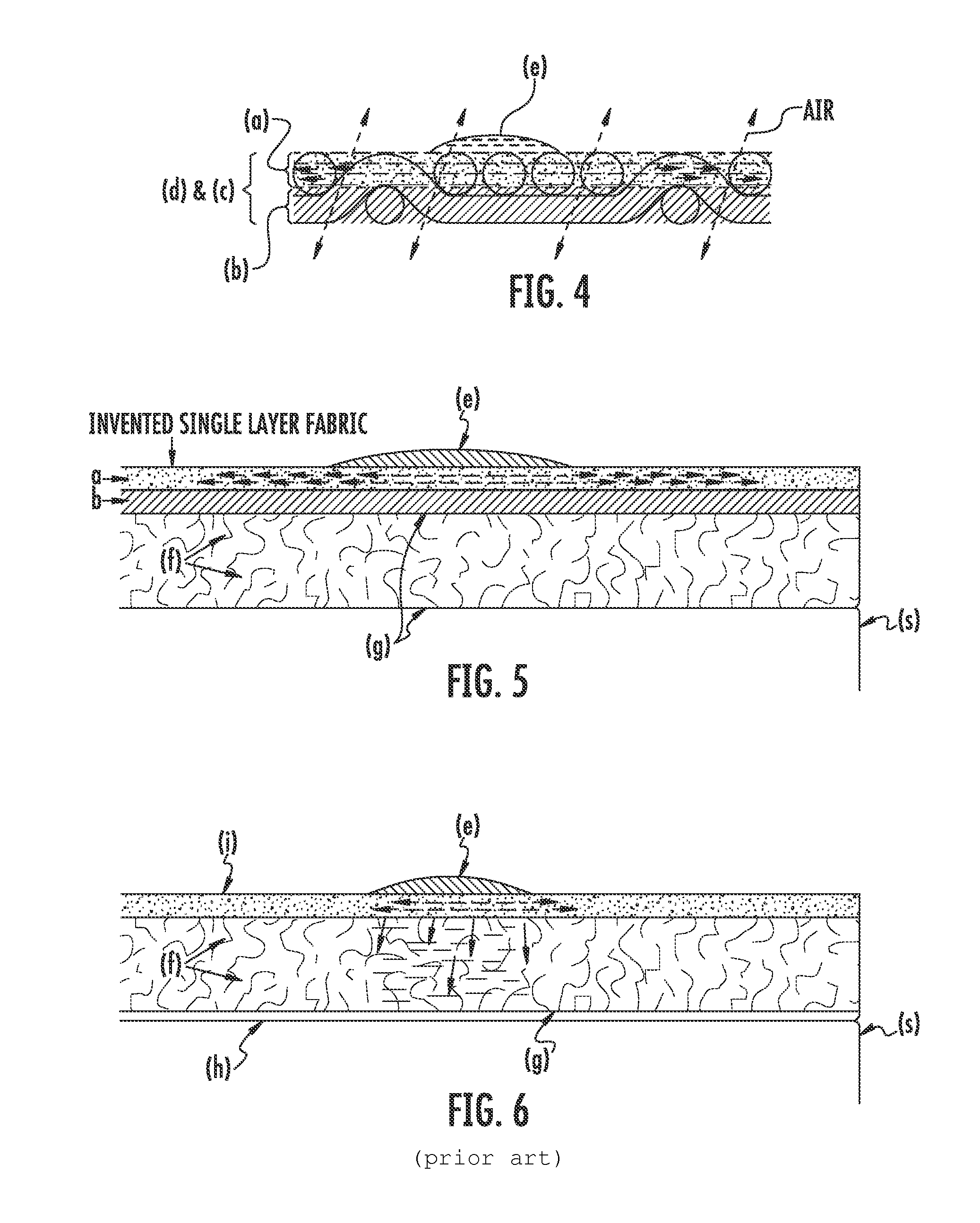

Semi-absorbent, semi-resistant, breathable fabric

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

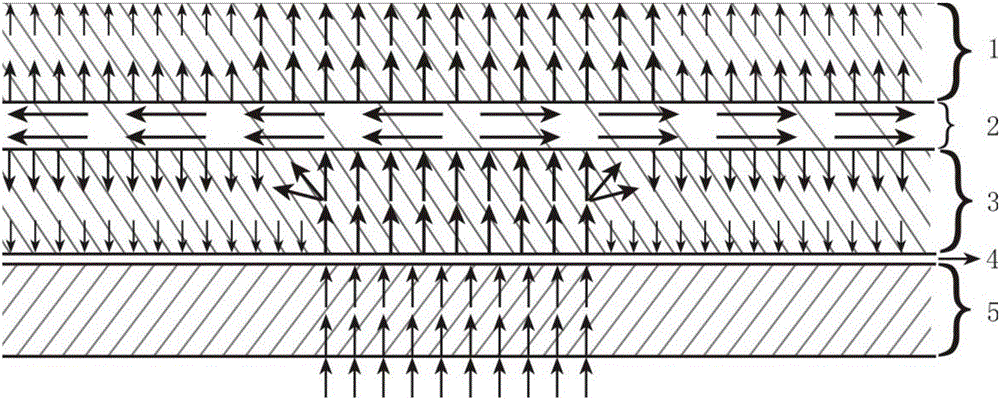

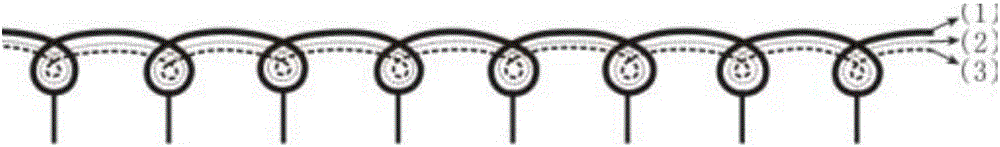

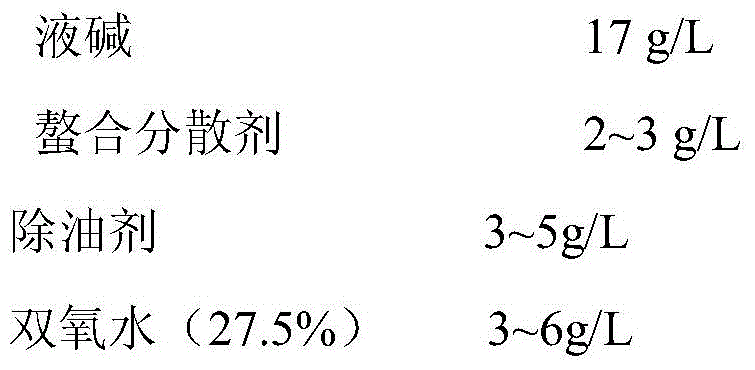

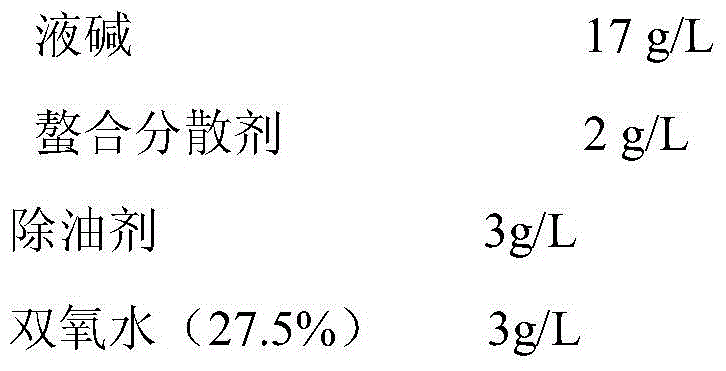

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

Preparation method of soft and durable anti-penetrating material

ActiveCN107815870AIncreased durabilityGood flexibilityUltrasonic/sonic fibre treatmentGrip property fibresFiberEngineering

The invention discloses a preparation method of a soft and durable anti-penetrating material. The preparation method is characterized by comprising the following steps: (1) preparing shearing thickening liquid; (2) preparing a high performance fiber fabric with a special tissue structure, namely preparing a fabric from high performance fibers by virtue of a special tissue structure weaving process, putting the fabric into a vacuum drying oven, and drying at 120-150 DEG C for 2-3 hours; and (3) preparing the anti-penetrating material. According to the method, by virtue of reasonable tissue structure configuration on the fabric and plasma treatment on the shearing thickening liquid and the fabric, the shearing thickening liquid and the fabric are adequately compounded, so that the durabilityand flexibility of the anti-penetrating material are improved, and the soft and durable anti-penetrating material suitable for multiple environments of daily protective clothes of military police, armored military equipment, civil and industrial protection and the like is prepared.

Owner:江苏威之盾安防科技有限公司

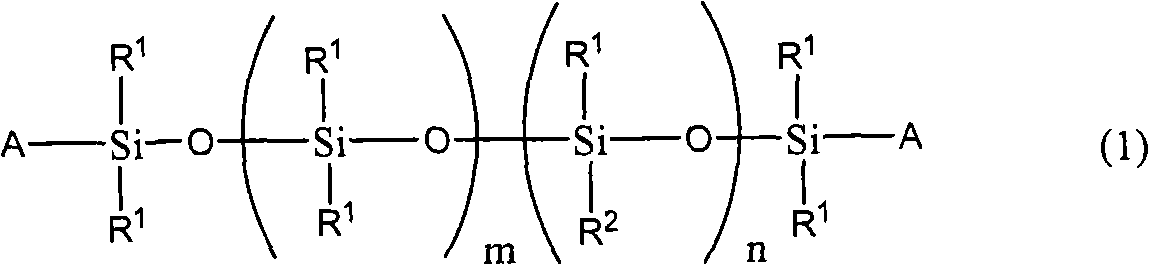

Branched polyorganosiloxane polymers

InactiveUS7390479B2Preventing and reversing creaseCosmetic preparationsOrganic detergent compounding agentsPolymer chemistryCopolymer

Owner:BAYER AG

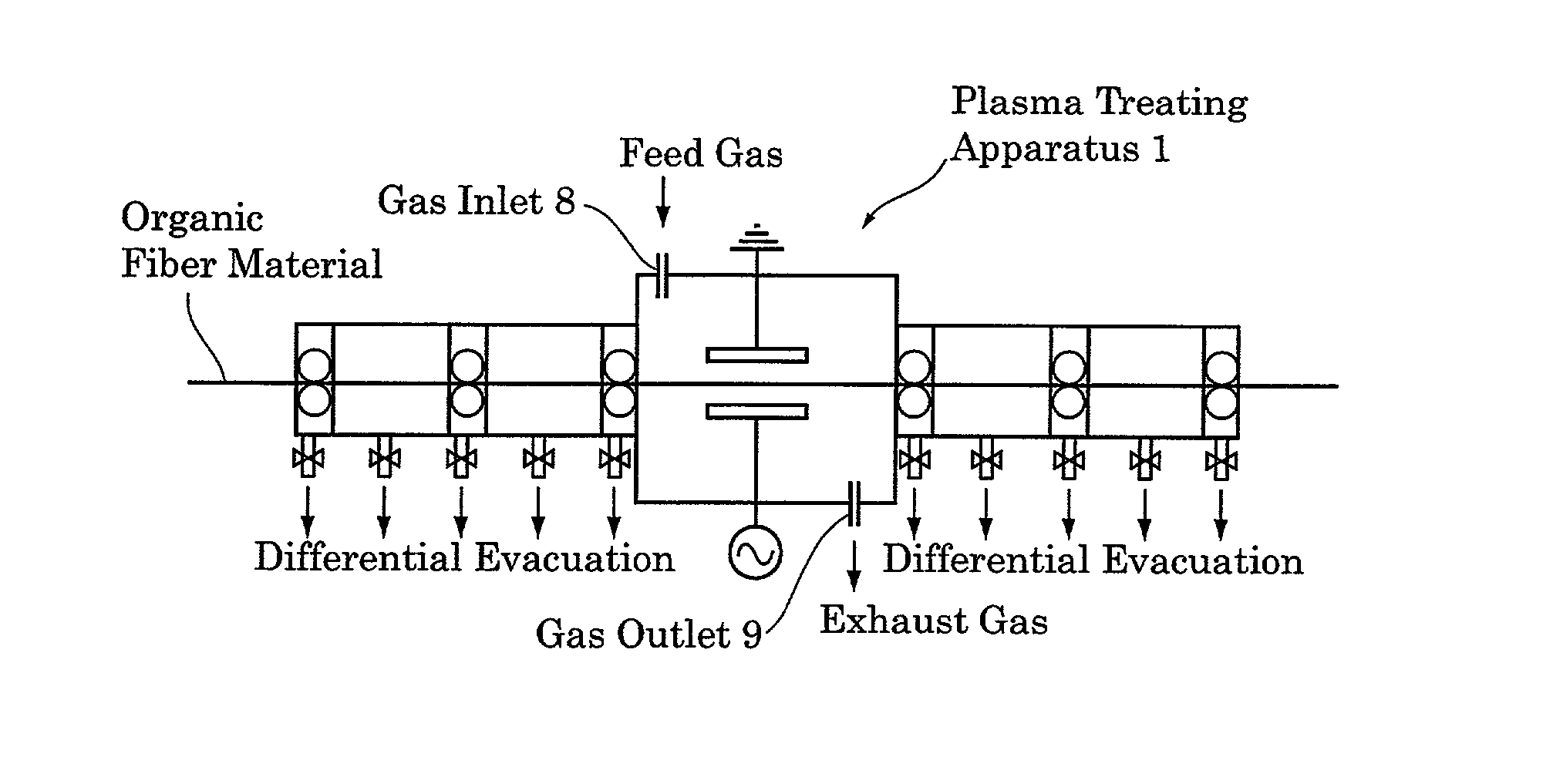

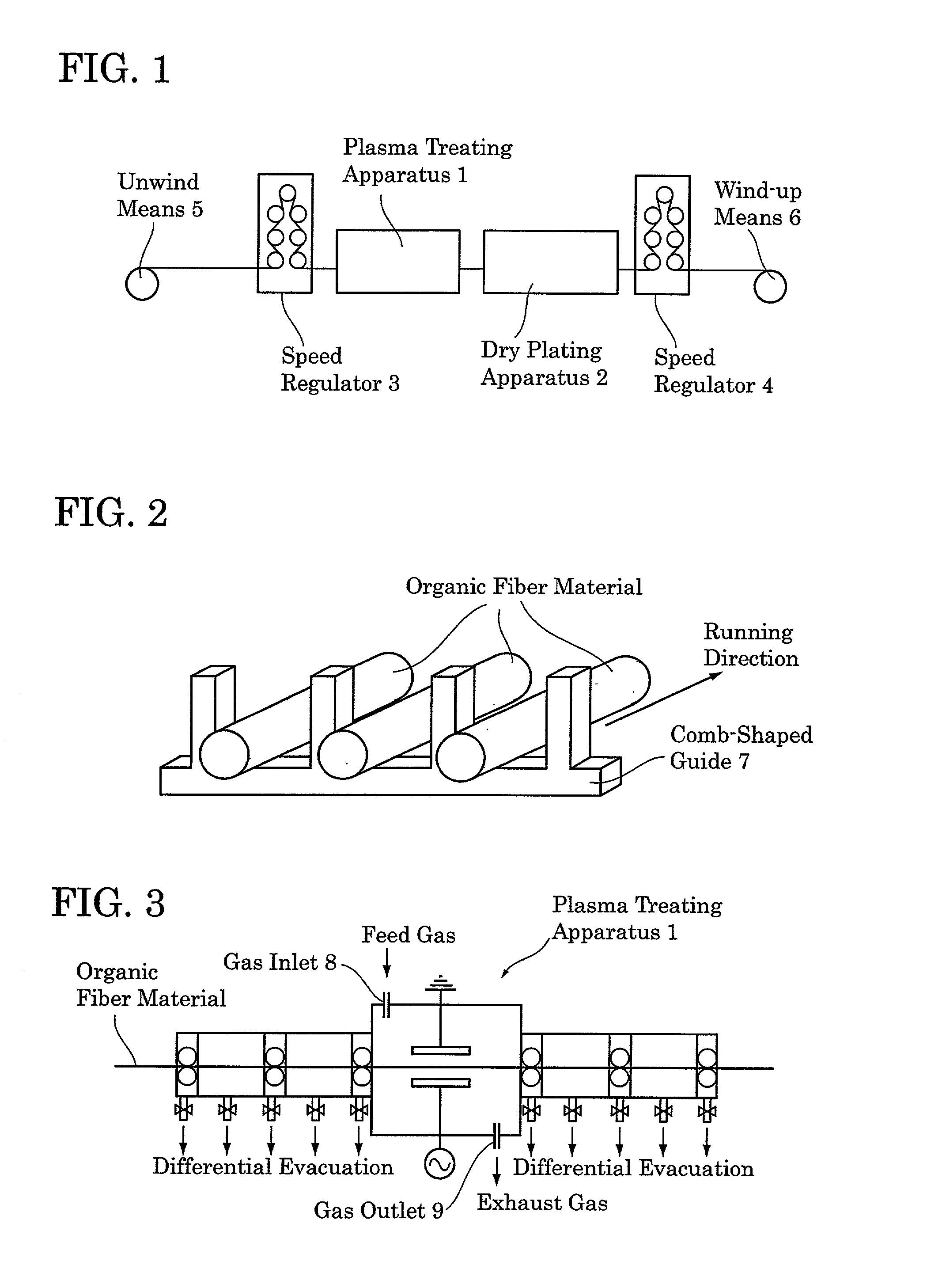

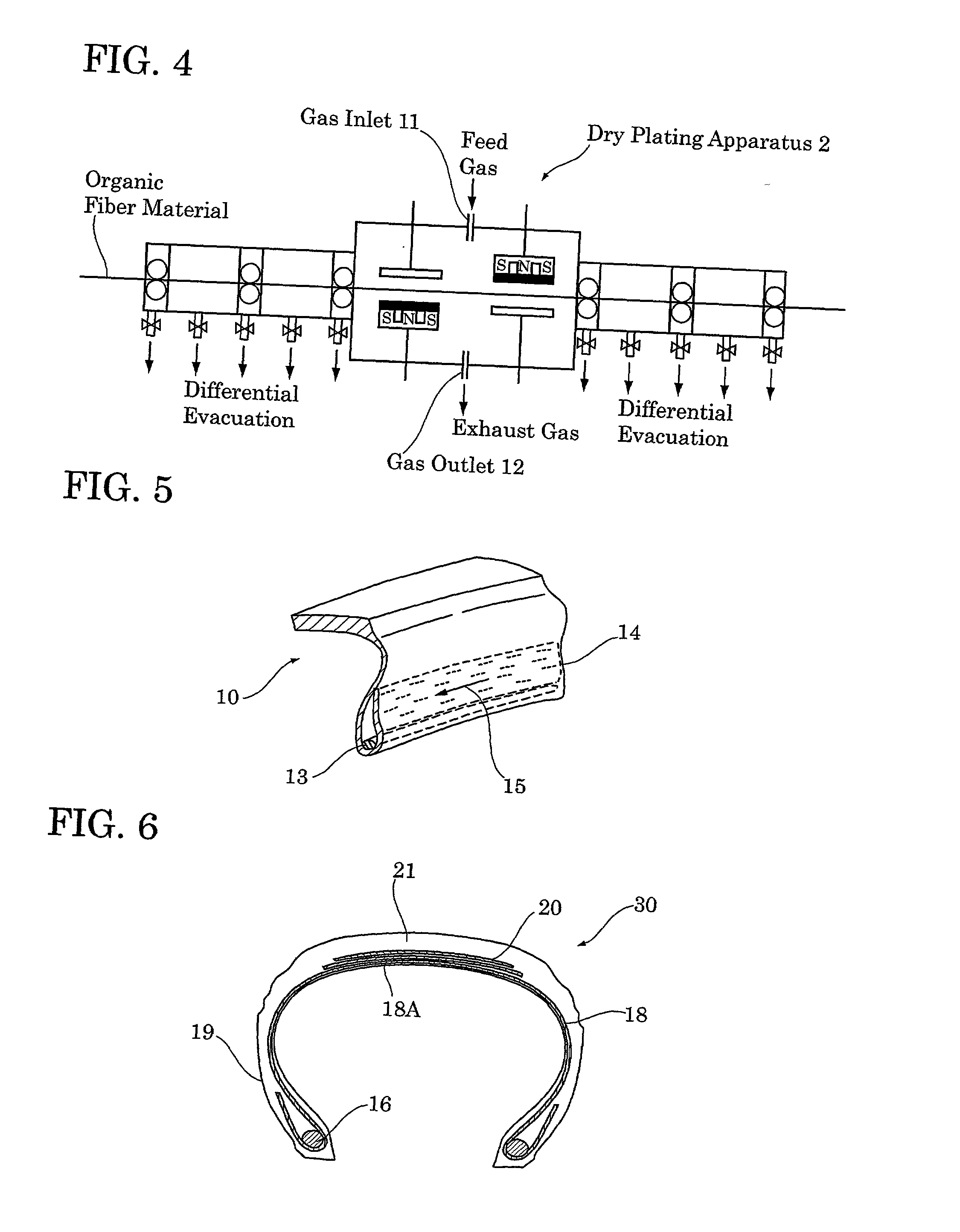

Rubber-reinforcing fiber, process for producing the same, and rubber product and pneumatic tire each made with the same

InactiveUS20030000619A1Sufficient fatigue resistanceSolve the lack of resistanceLiquid surface applicatorsTyresFiberTitanium

The rubber-reinforcing fiber of the present invention is provided with a coating layer of a thickness of 10 Å to 40 mum. The coating layer is formed by dry plating and contains at least one metal and / or metal compound selected from the group consisting of cobalt, zinc, copper, titanium, silver, nickel and compounds of the aforesaid metals. With such a coating layer, the rubber-reinforcing fiber of the present invention forms a firm adhesion to a rubber component and drastically improves the fatigue resistance and durability of a rubber article, particularly, a pneumatic tire.

Owner:BRIDGESTONE CORP

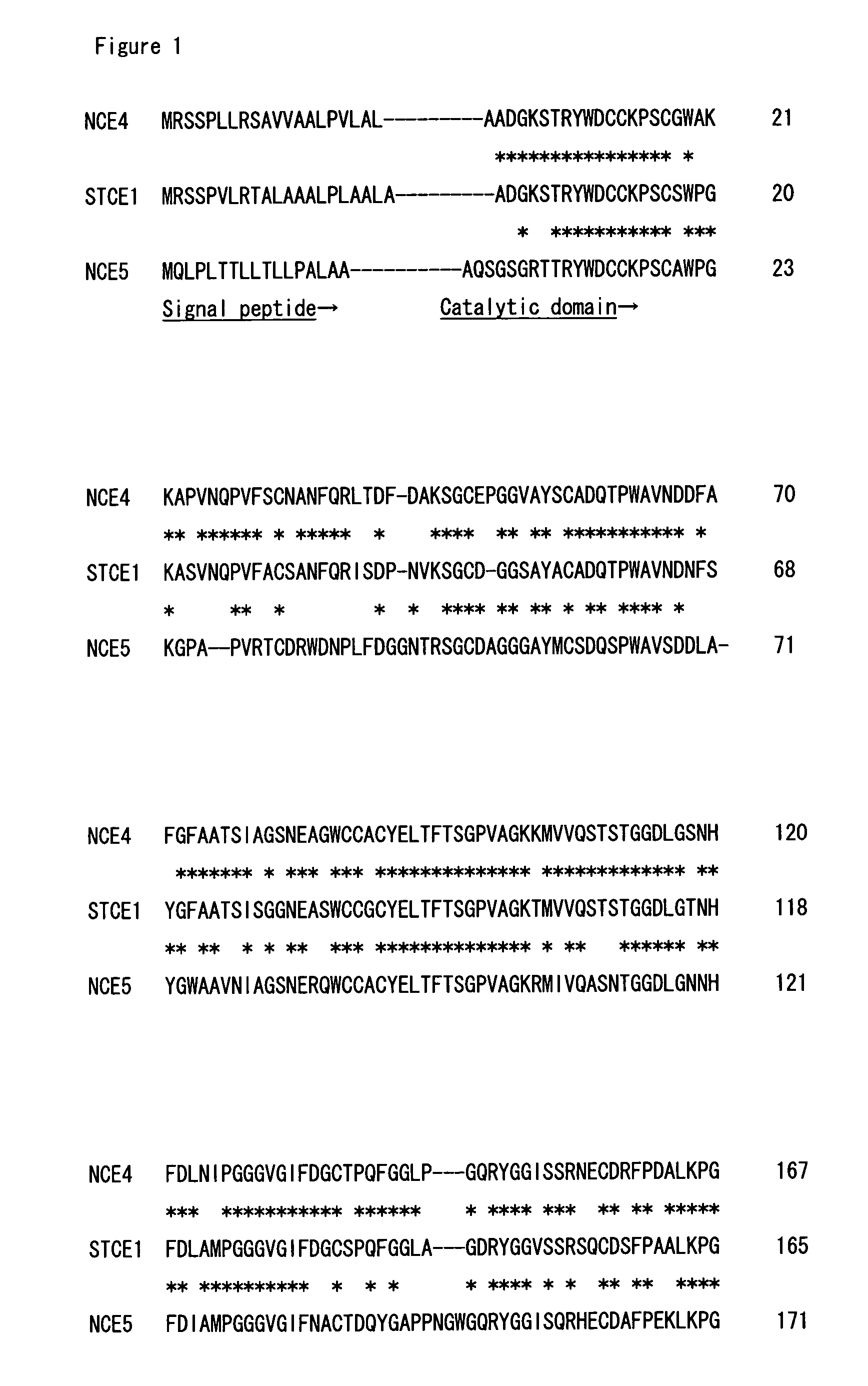

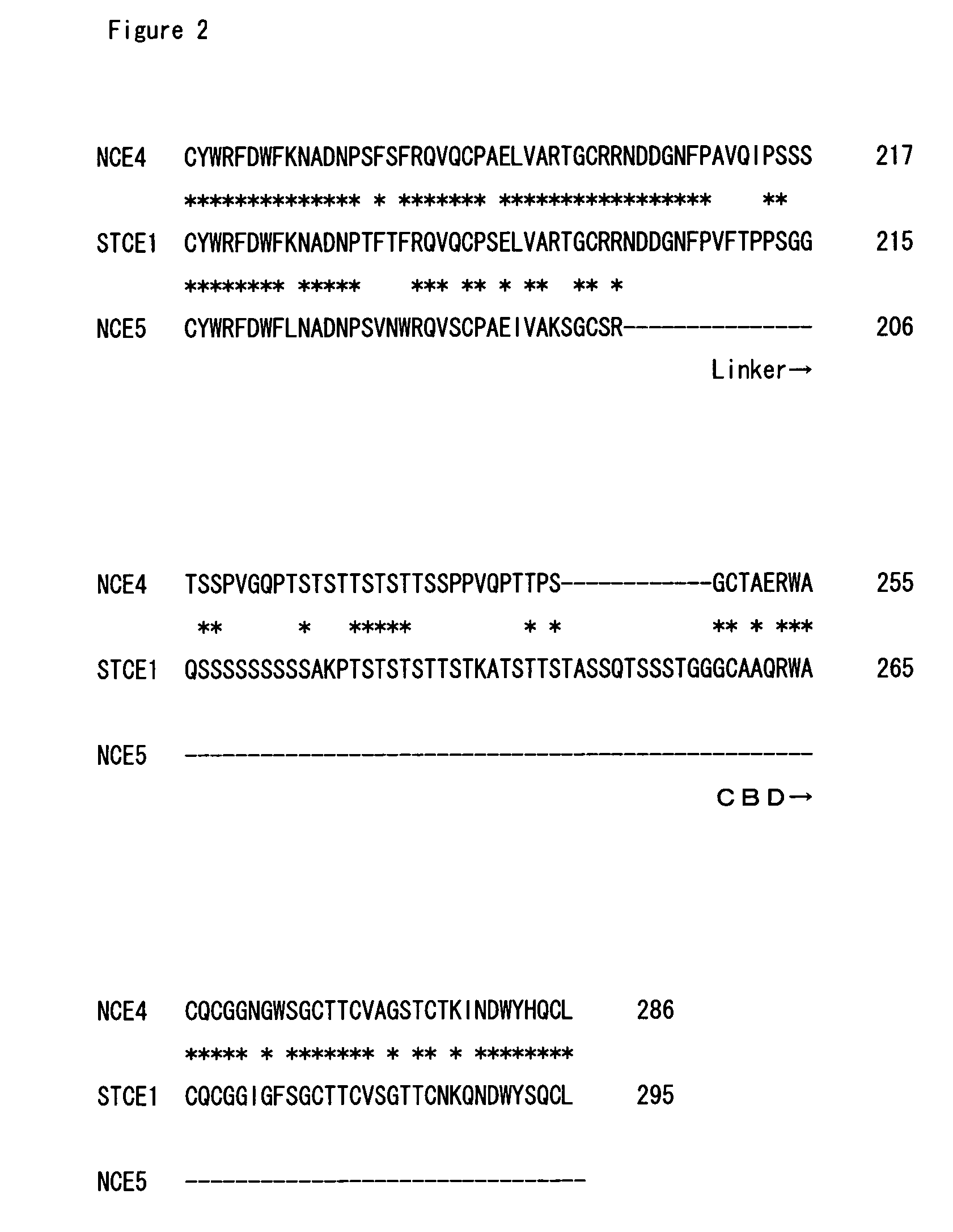

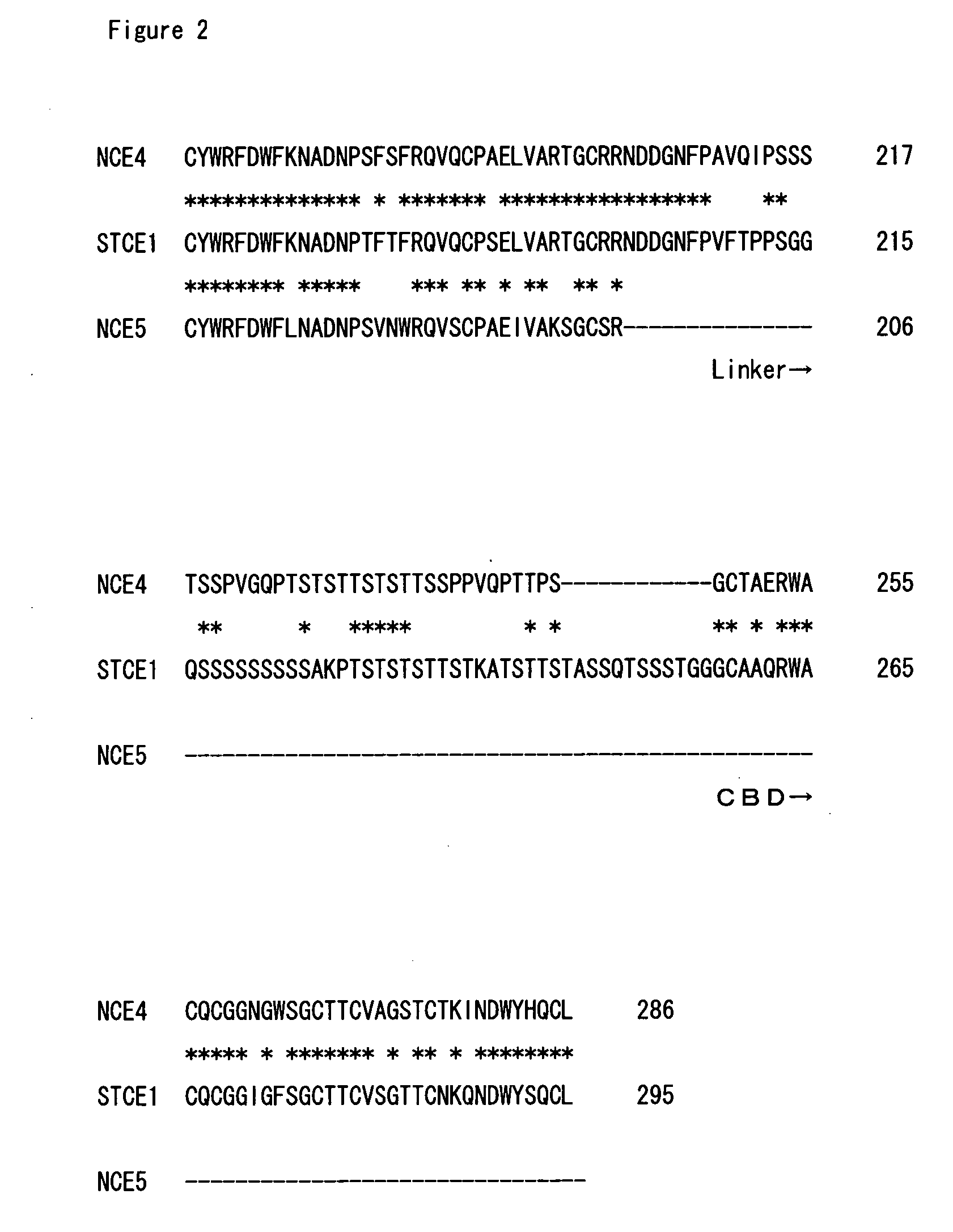

Endoglucanase STCE and cellulase preparation containing the same

ActiveUS7595182B2Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseColor changes

Owner:MEIJI SEIKA KAISHA LTD

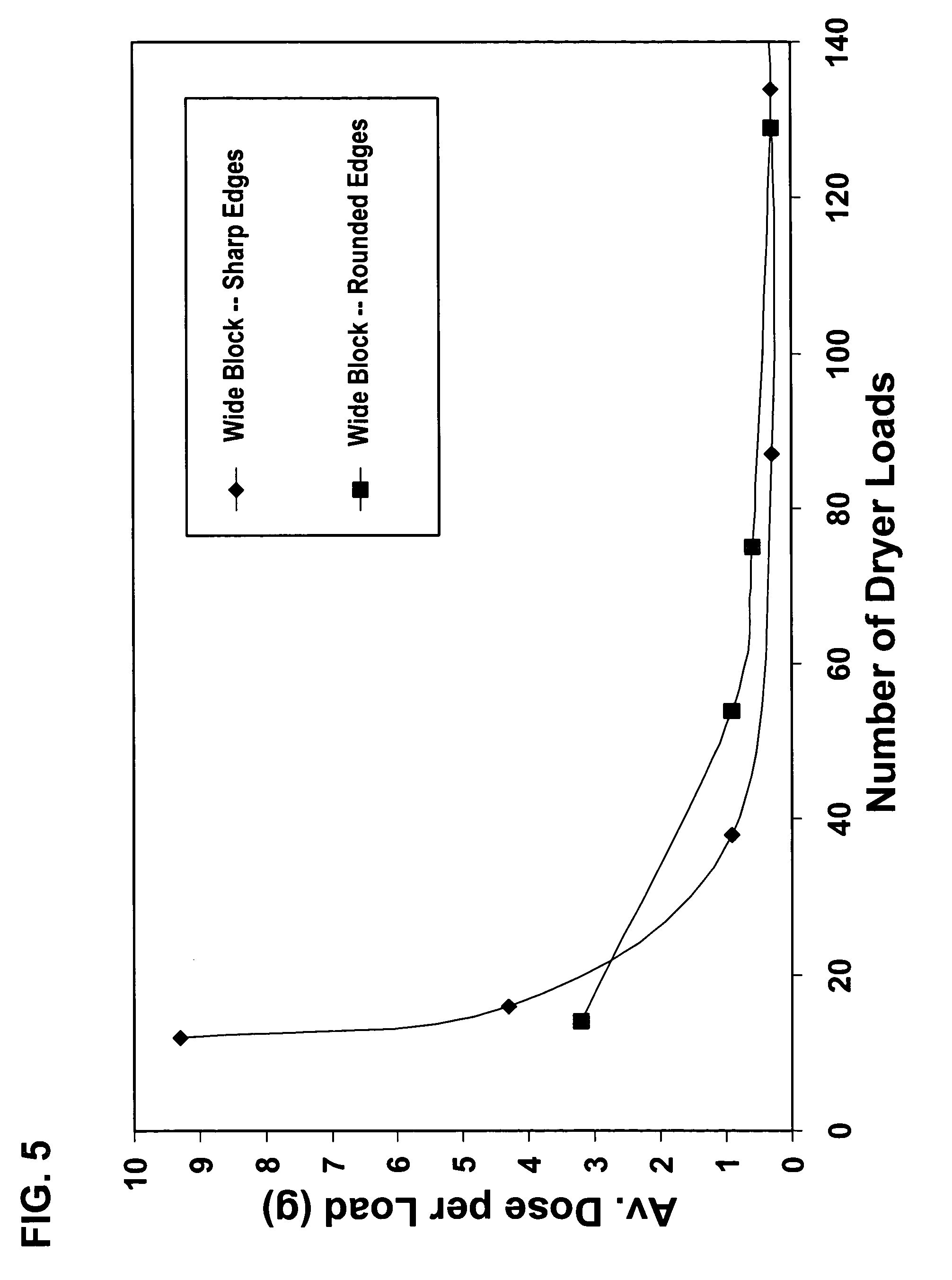

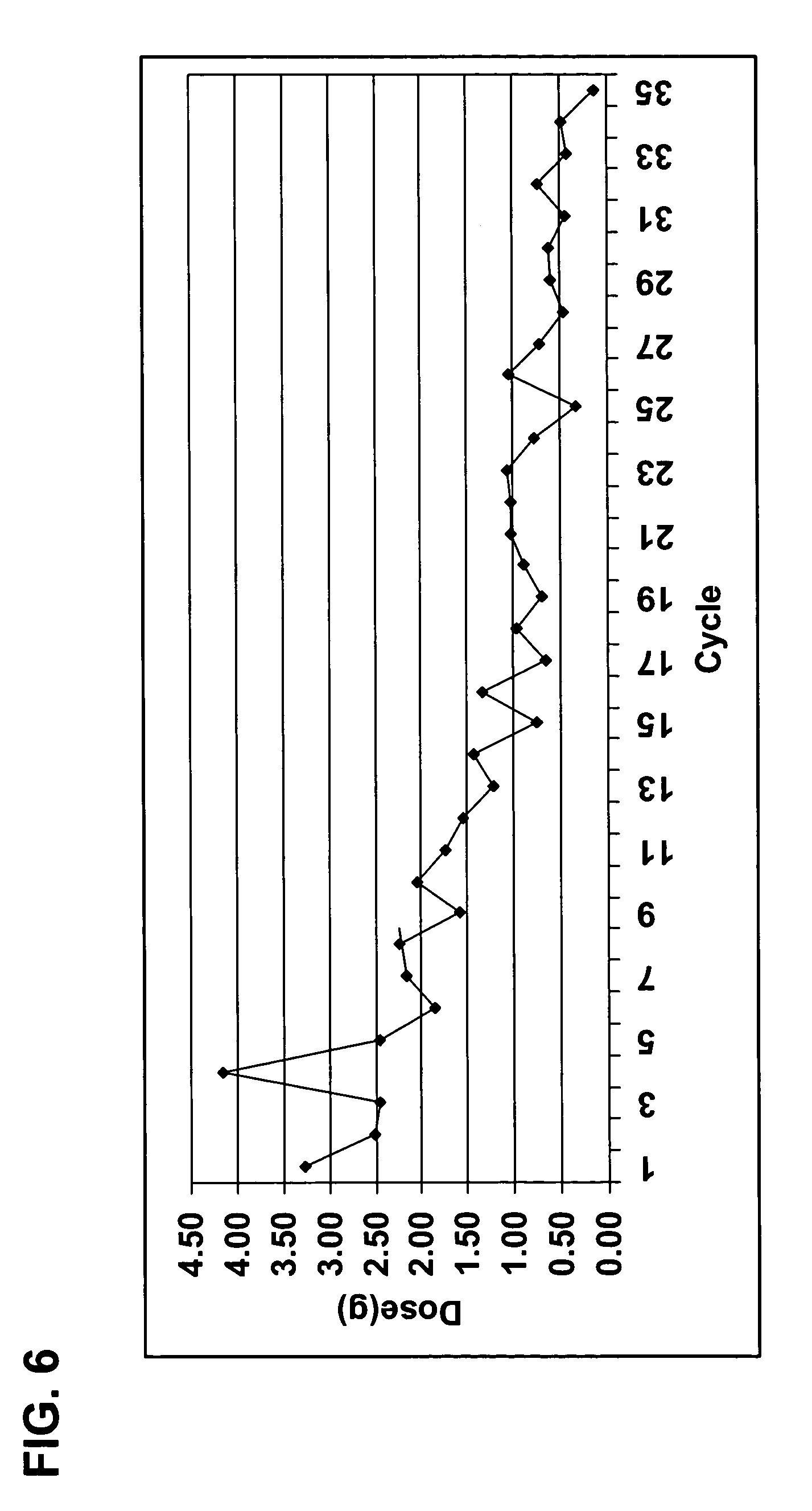

Fabric treatment compositions and methods for treating fabric in a dryer

InactiveUS7087572B2Low transfer rateCationic surface-active compoundsOrganic detergent compounding agentsMedicineOperant conditioning

A fabric treatment composition is provided. The fabric treatment composition includes a fabric treatment agent and a carrier component for containing the fabric treatment agent in a solid form during operation conditions in a dryer. The fabric treatment composition is constructed for transferring the composition to wet fabric as a result of solubilizing the fabric treatment composition by contacting the fabric treatment composition with the wet fabric during a drying operation in a dryer. A method for treating fabric is provided.

Owner:ECOLAB USA INC

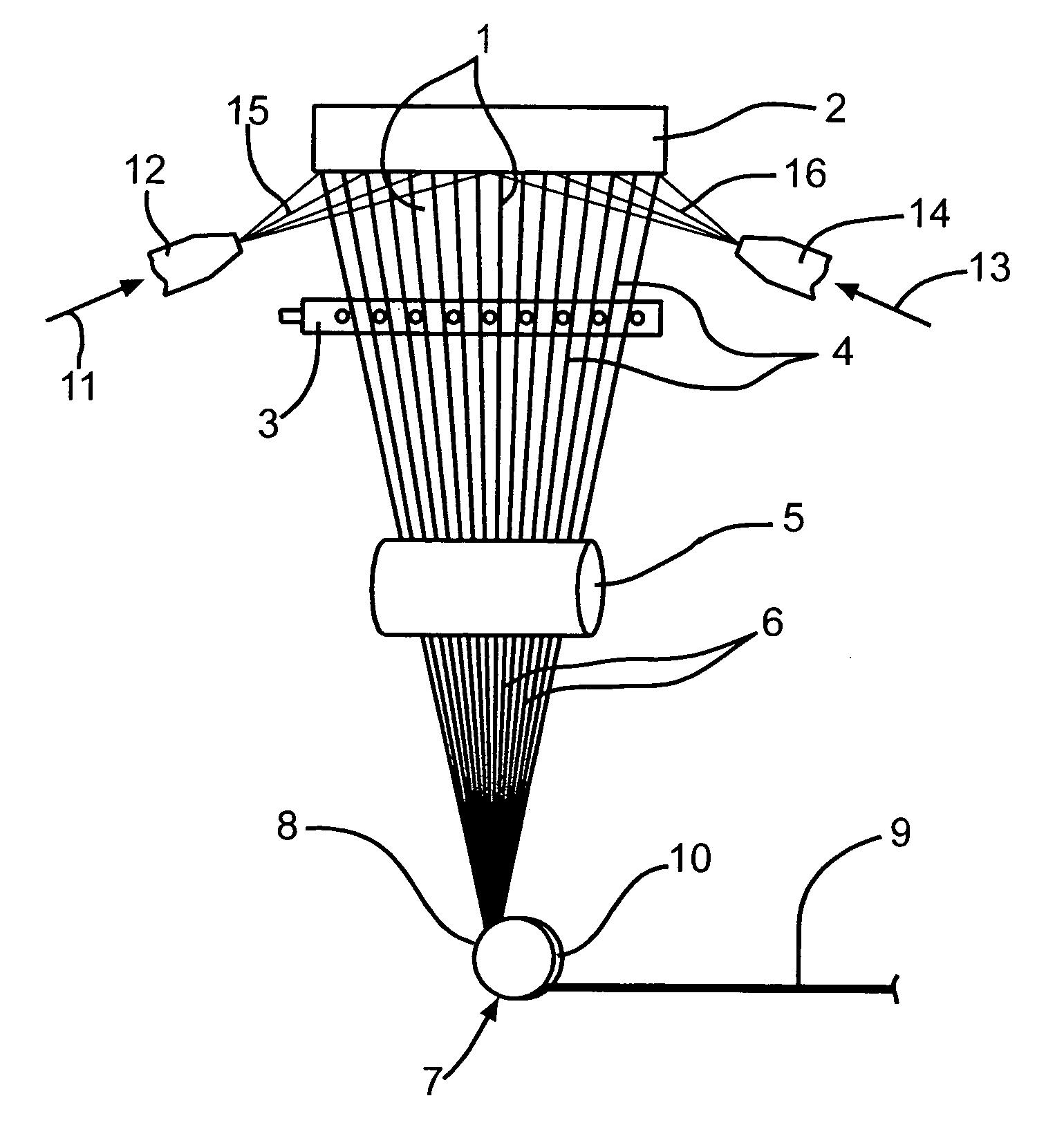

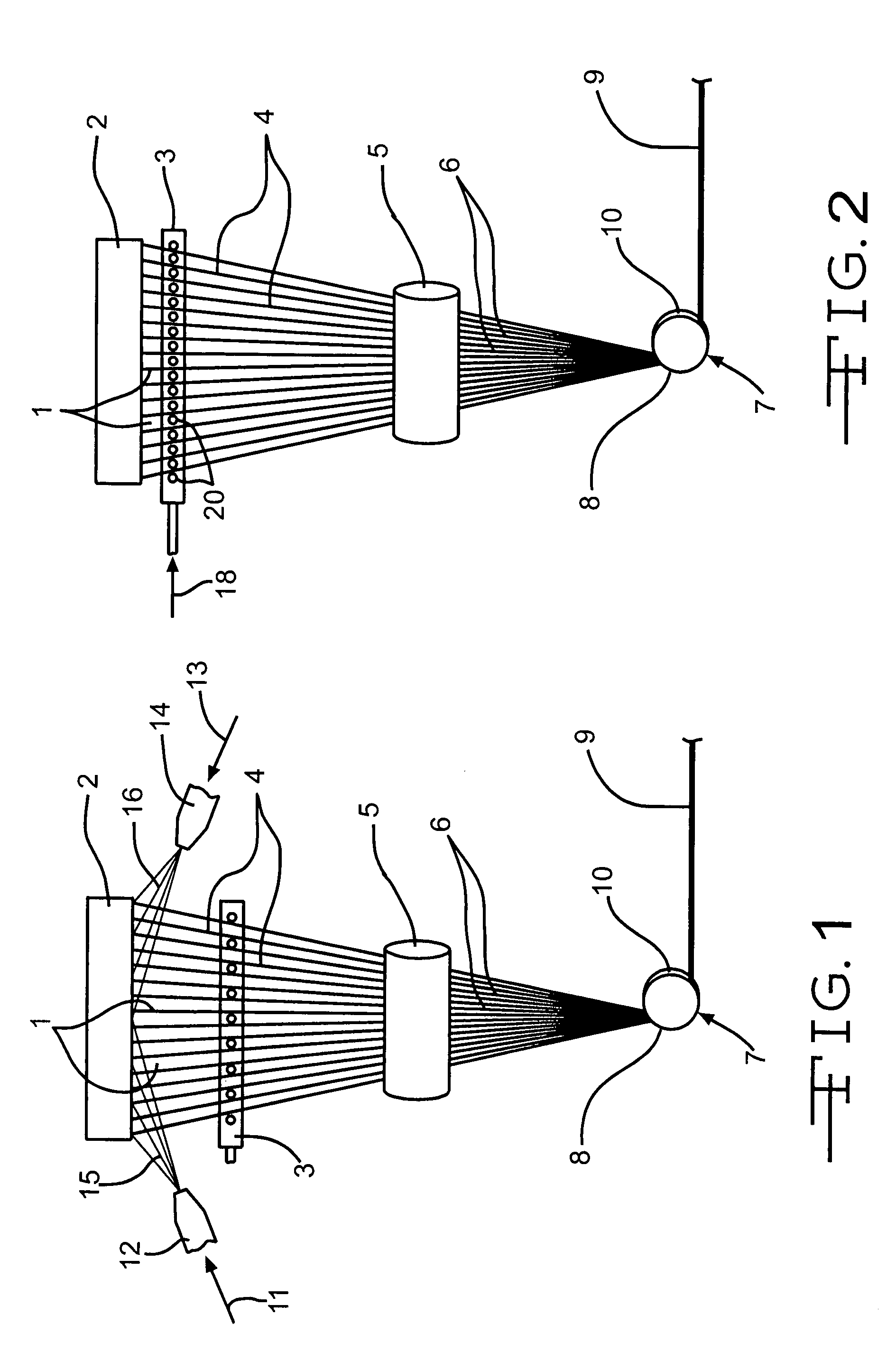

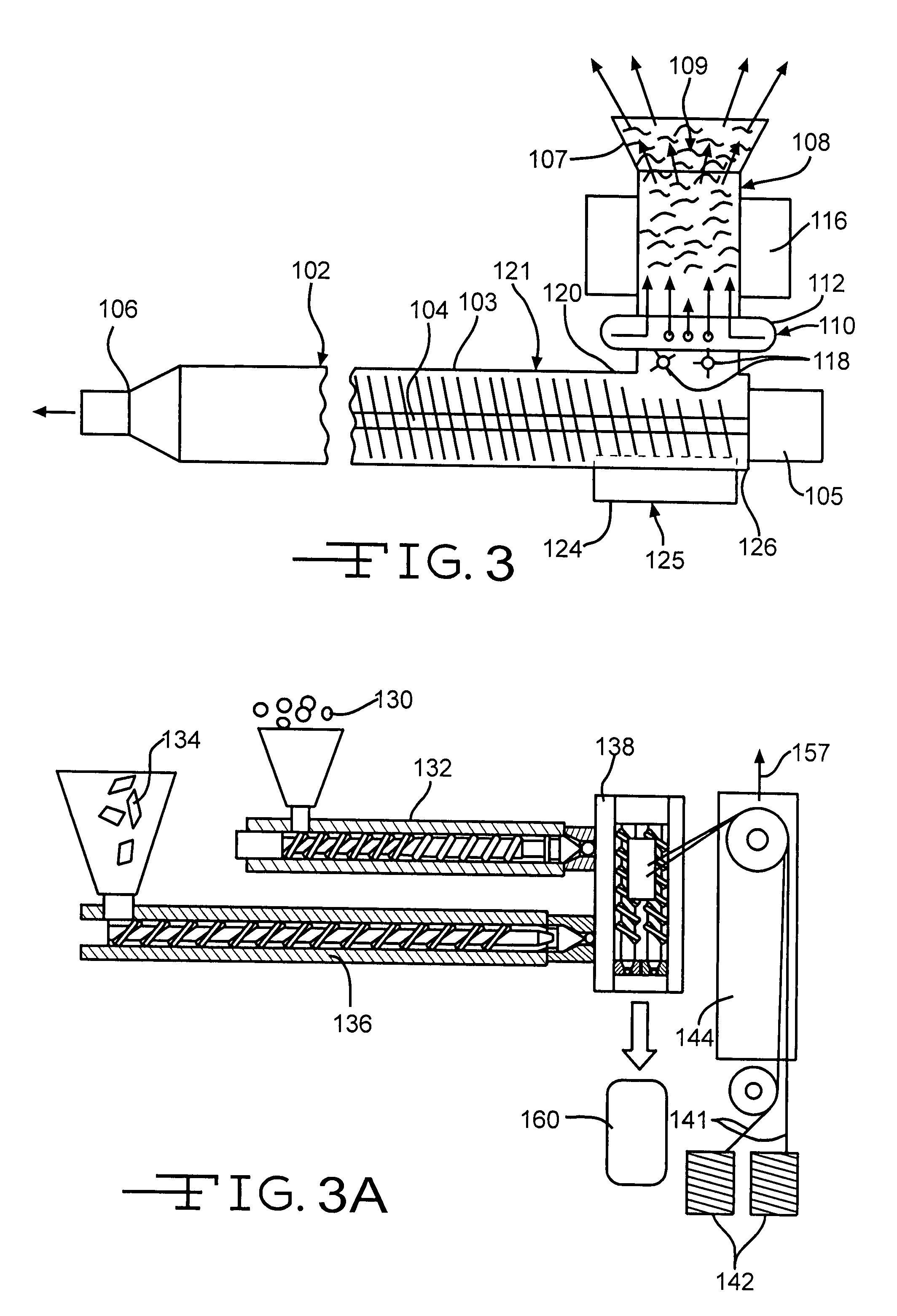

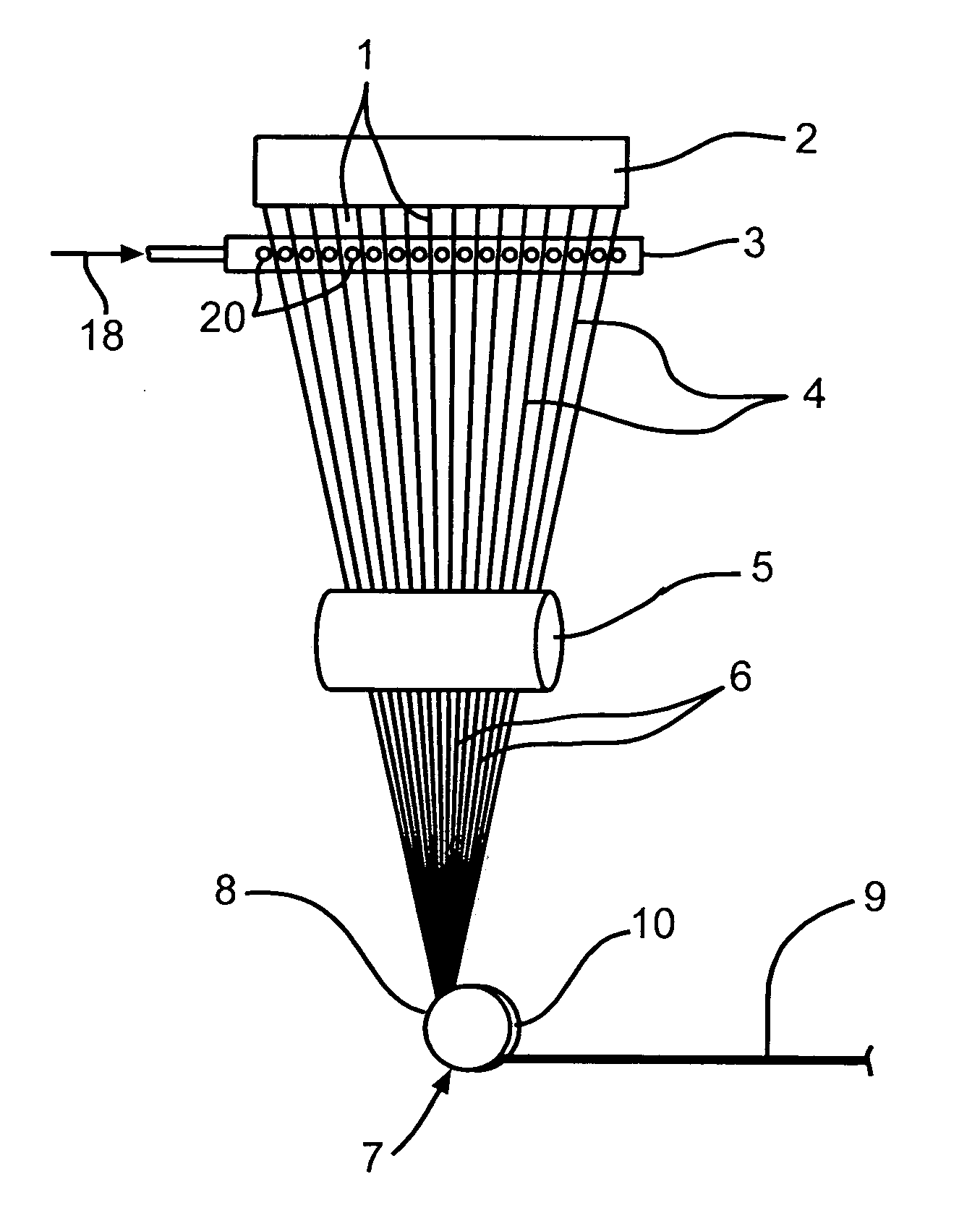

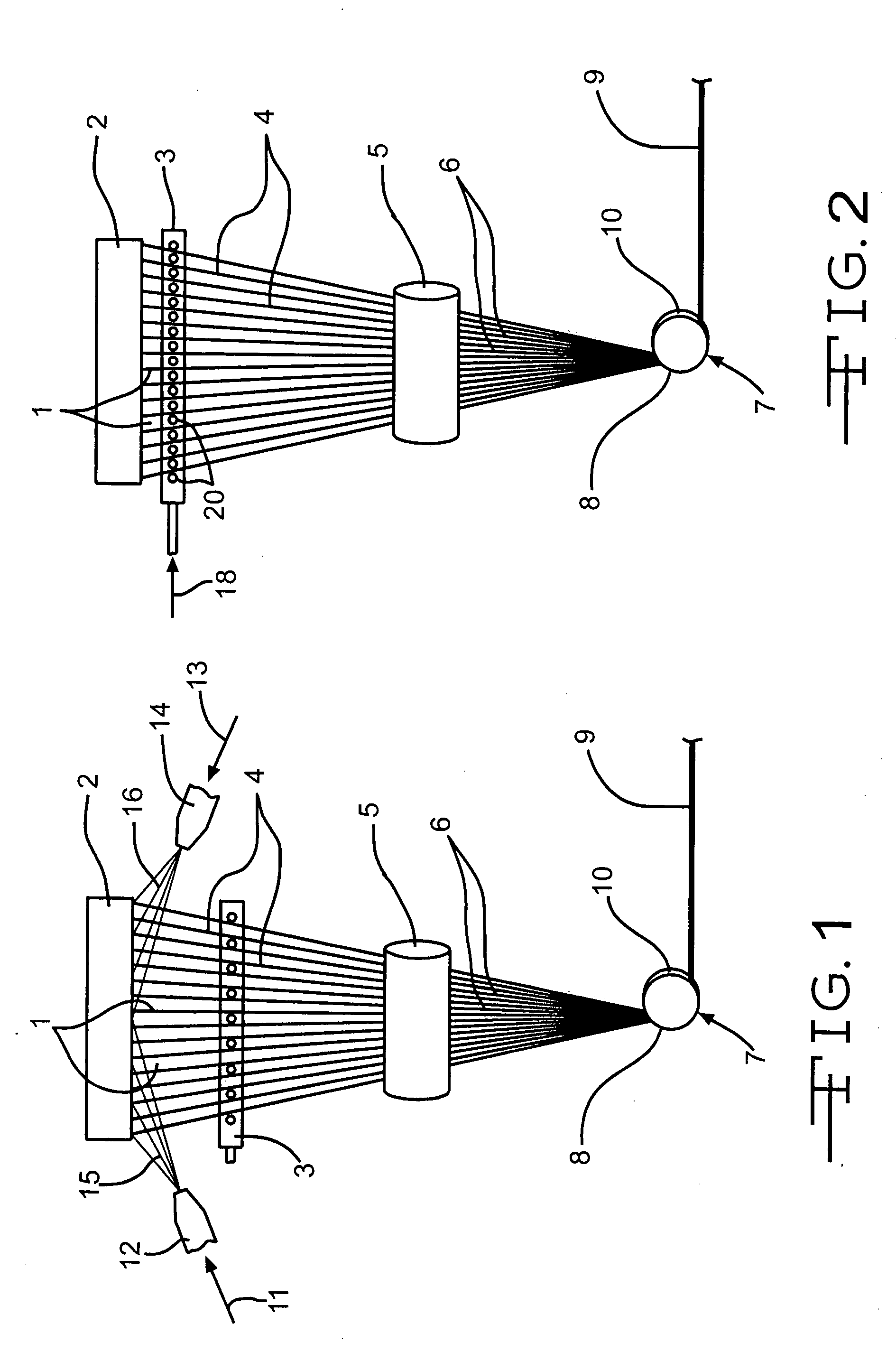

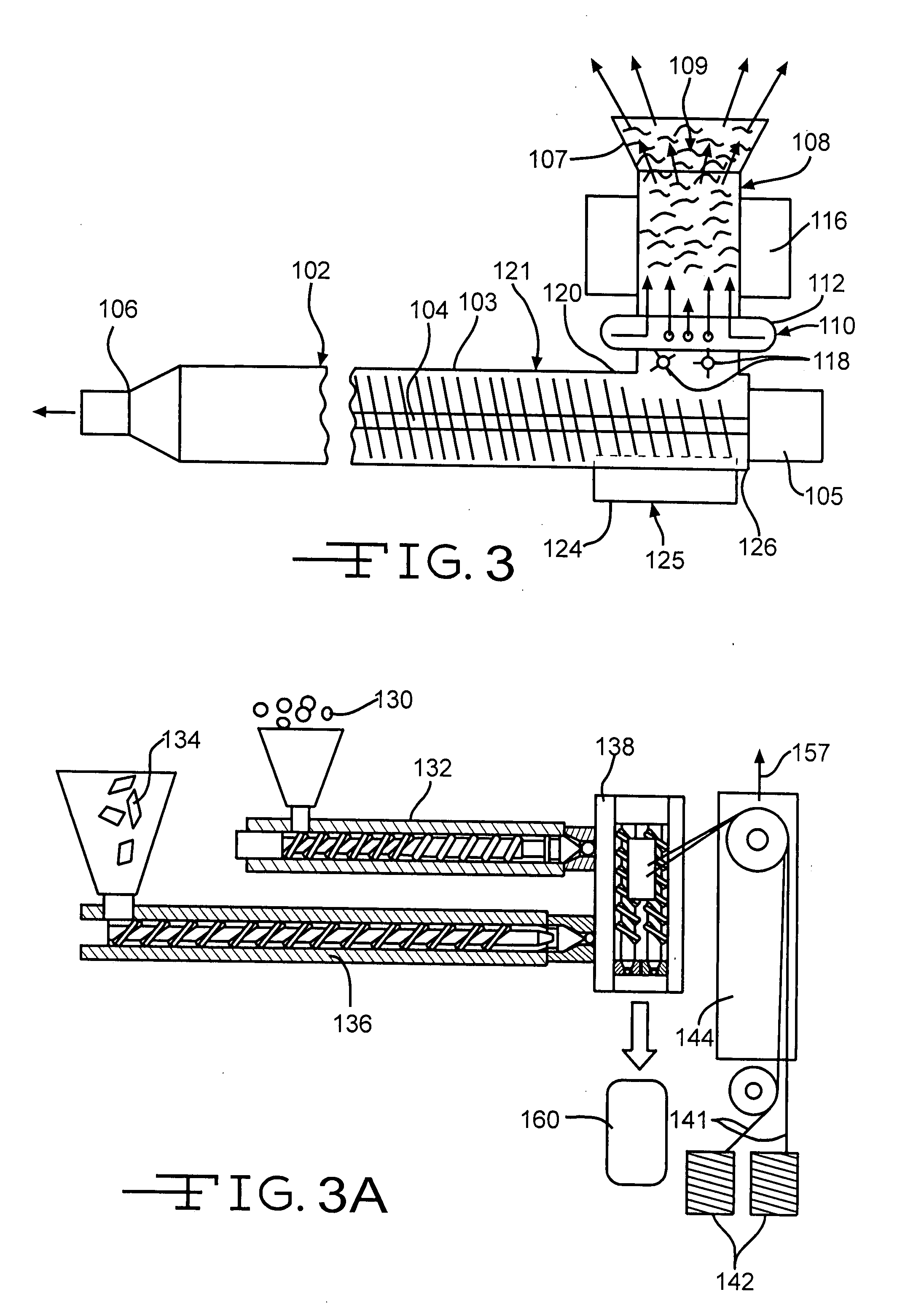

Method and system for forming reinforcing fibers and reinforcing fibers having particulate protuberances directly attached to the surfaces

Reinforcing fibers with small particles having a longest average dimension of approximately 0.01 nanometer to approximately 30 micrometers physically and / or chemically bonded directly to their surfaces to form protuberances thereon and a method and system for making these modified fibers are disclosed. The particles directly bonded to the surfaces of the fibers, serve to enhance physical properties of composite articles which incorporate such fibers as reinforcement.

Owner:JOHNS MANVILLE CORP

Method and system for forming reinforcing fibers and reinforcing fibers having particulate protuberances directly attached to the surfaces

Reinforcing fibers with small particles having a longest average dimension of approximately 0.01 nanometer to approximately 30 micrometers physically and / or chemically bonded directly to their surfaces to form protuberances thereon and a method and system for making these modified fibers are disclosed. The particles directly bonded to the surfaces of the fibers, serve to enhance physical properties of composite articles which incorporate such fibers as reinforcement.

Owner:JOHNS MANVILLE CORP

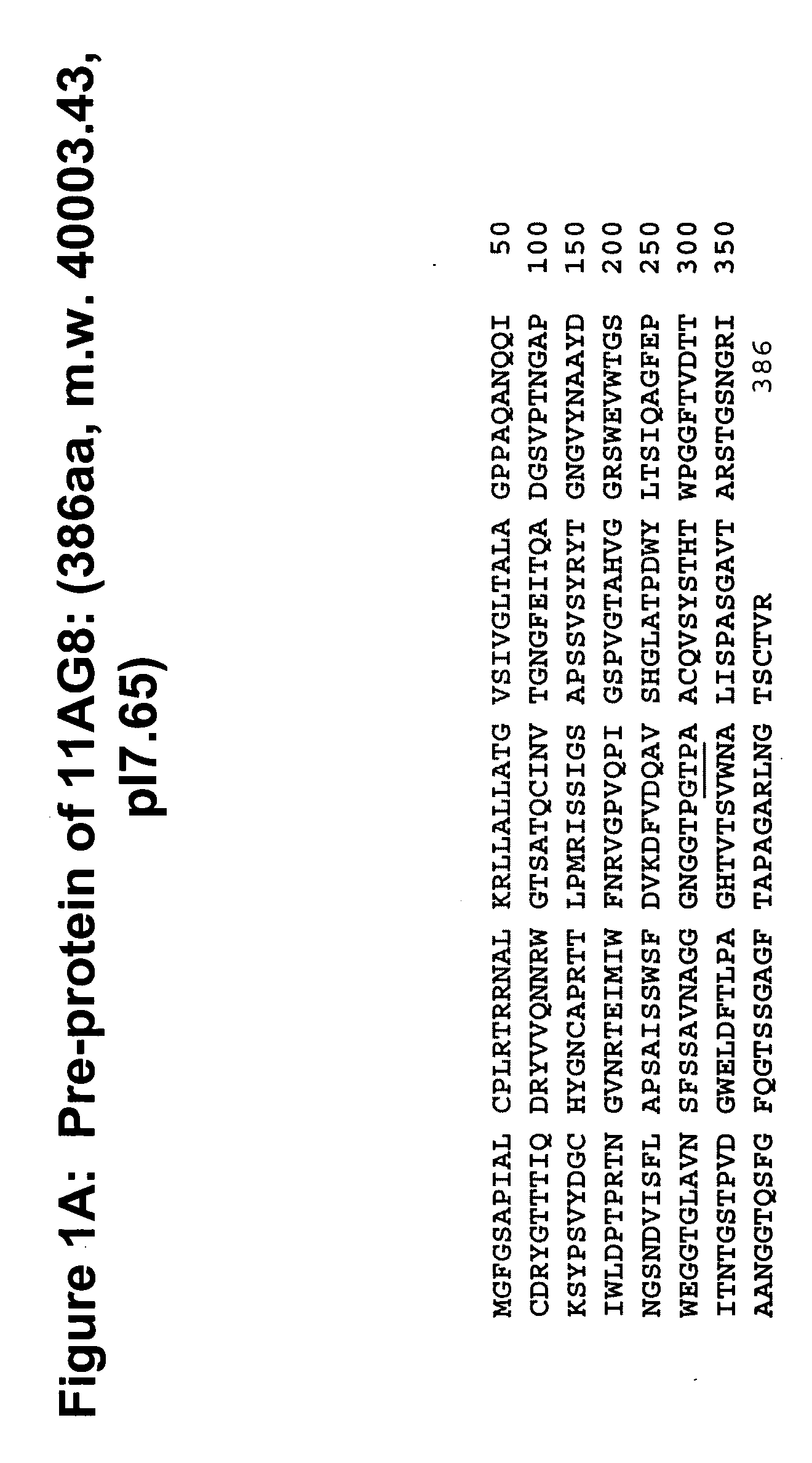

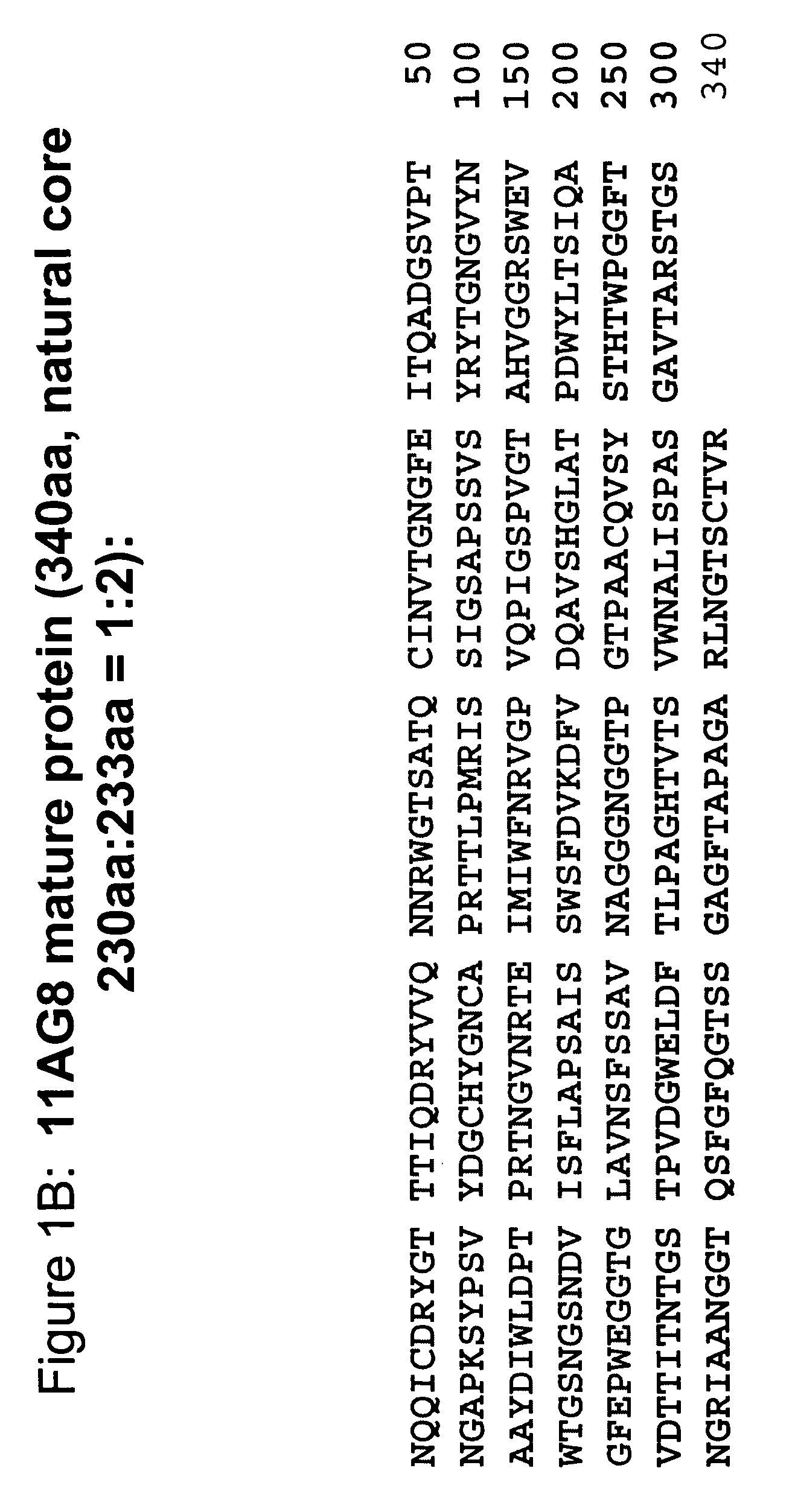

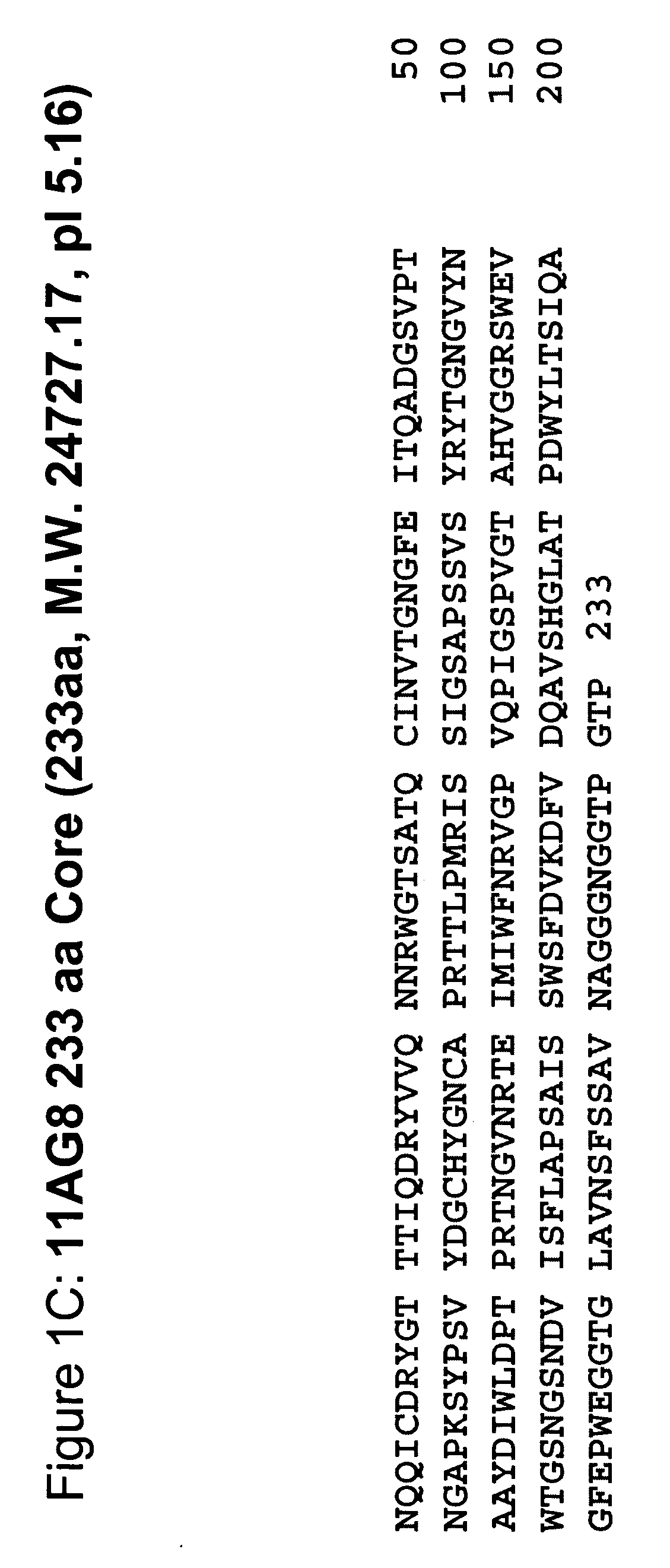

Neutral cellulase catalytic core and method of producing same

InactiveUS20060154843A1Reduce redepositionEasy to wearBacteriaFermentationHigh level expressionCellulose breakdown

The present invention relates to the cloning and high level expression of novel cellulase proteins or derivatives thereof in the in a host cell. Further aspects of the present invention relate to transformants that express the novel cellulases, and expression vectors comprising the DNA gene fragments or variants thereof that code for the novel cellulases derived from Actinomycete using genetic engineering techniques. The present invention is also directed to novel cellulase compositions and methods of use therefore in industrial processes. In particular, the present invention is related to treating textiles with a novel cellulase derived from Actinomycete spp. The present invention also relates to the use of cellulase derived from Actinomycete spp. to enhance the digestibility of animal feed, in detergents, in the treatment of pulp and paper and in the production of starch and treatment of by-products thereof.

Owner:GENENCOR INT INC

Water-repellent and soil-resistant finish for textiles

InactiveUS6855772B2Improve wear resistanceGood water solubilityPretreated surfacesOrganic dyesYarnEmulsion

The present invention is directed to polymeric treatment preparations for textiles and other fibrous substrates that impart water and oil repellency to fibers, yarns, textiles, or other fibrous substrates. More particularly, this invention comprises an aqueous solution, emulsion or suspension of (a) a fluorinated polymer that contains reactive groups that can complex with metal atoms that have a formal charge of 2 or greater, and (b) one or more metal atoms that have a formal charge of 2 or greater. The invention is further directed to the process for treating fibrous substrates with textile preparations in one step that provide water / soil repellency that is durable to repeated cleanings and to abrasion. This invention is further directed to the yarns, fibers, fabrics, textiles, webs, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “fibrous substrates”) treated with the textile-reactive water- and soil-resistant preparation of the invention. Such fibrous substrates exhibit a greatly improved, durable water and soil repellency or resistance, even after multiple launderings.

Owner:NANO TEX

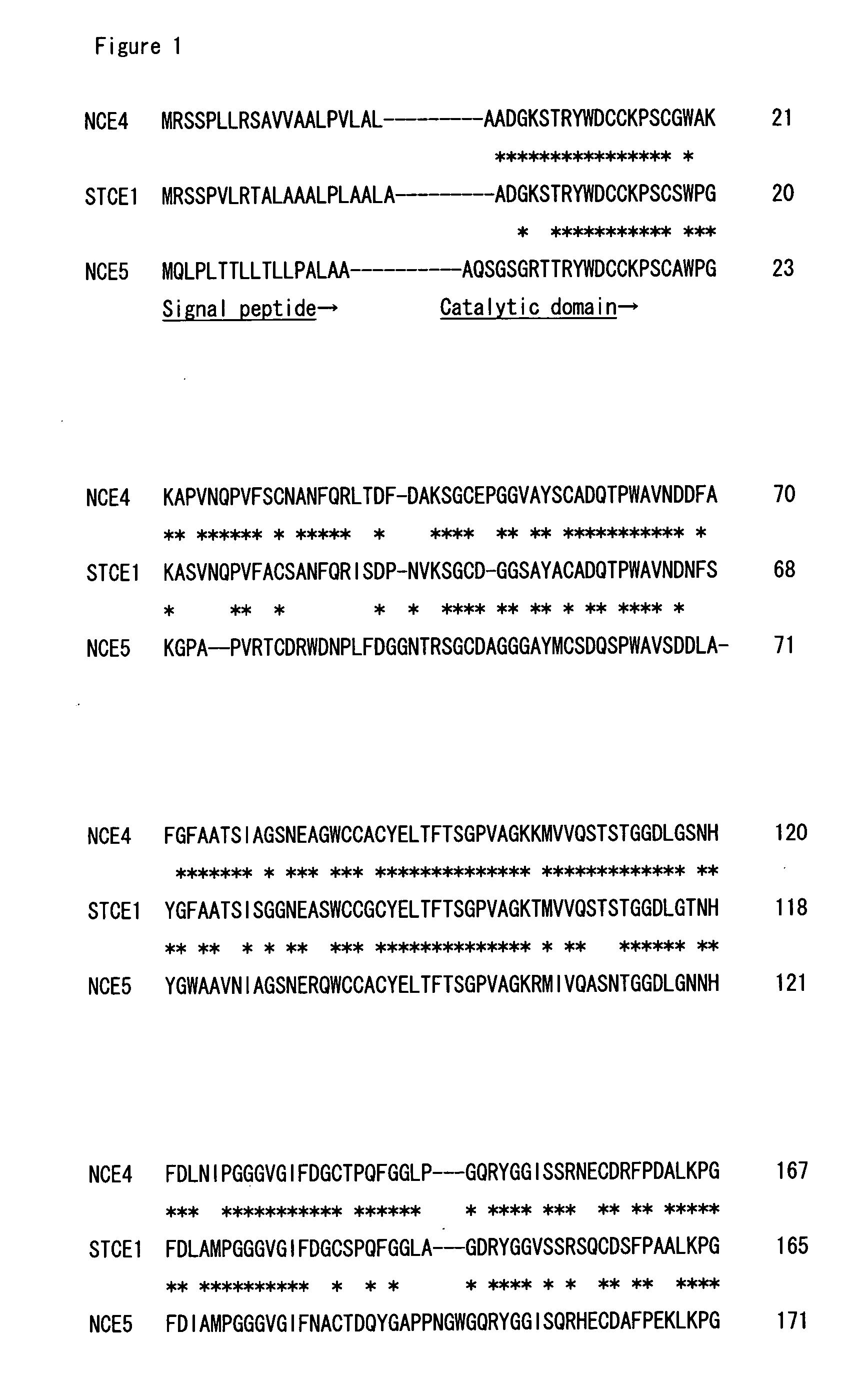

Endoglucanase stce and cellulase preparation containing the same

ActiveUS20070111278A1Improvement of touch feel and appearance of fabricReduction of fuzzFungiBacteriaGlucanaseStaphylococcus aureus

A novel endoglucanase derived from Staphylotrichum coccosporum, a polynucleotide encoding the endoglucanase, and a cellulase preparation containing the endoglucanase are disclosed. The endoglucanase or cellulase preparation is available for a washing use or fabric processing, such as a color clarification of a cellulose-containing fabric, a reduction of fuzz, an improvement of the touch feel and appearance of the fabric, providing a localized color change to the fabric, or a reduction of stiffness.

Owner:MEIJI SEIKA KAISHA LTD

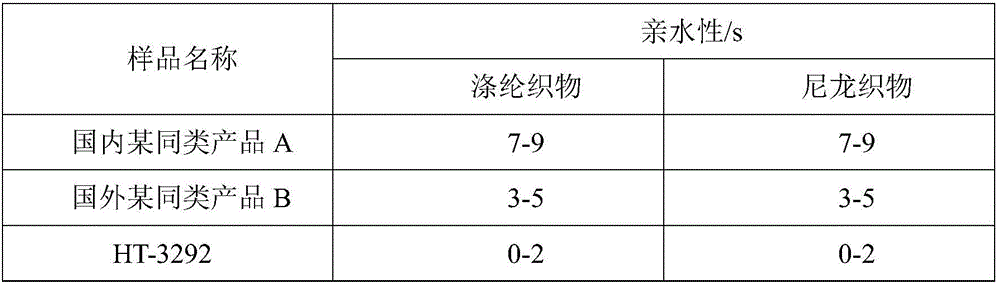

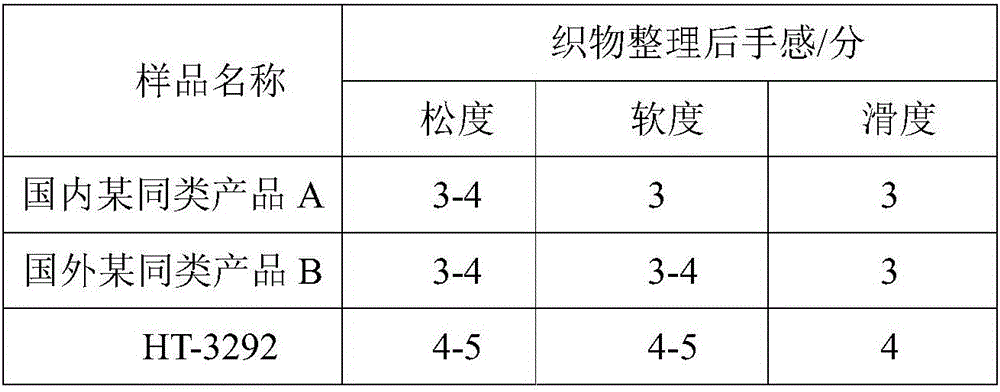

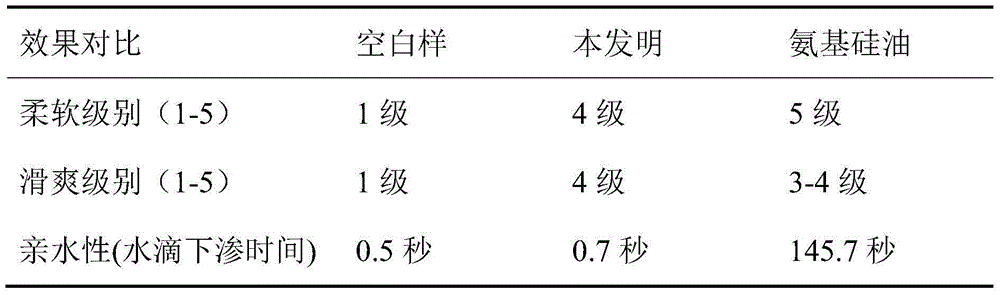

Terpolymer block hydrophilic amino silicone oil and preparation method and application thereof

The invention provides terpolymer block hydrophilic amino silicone oil and a preparation method and application thereof. The terpolymer block hydrophilic amino silicone oil is prepared by: reflux-reacting epoxy-terminated polyether silicone oil, amino-terminated polyether and isopropanol at 80-83 DEG C for 8-10 hours, adding a quaternization reagent for modifying, and distilling a modified product under reduced pressure. The terpolymer block hydrophilic amino silicone oil, as a chemical fiber fabric softener, can improve handle characteristics of bulkiness, softness and smoothness to chemical fiber fabric, is good in permeability and can go hydrophilic instantly on nylon fabric; the terpolymer block hydrophilic amino silicone oil has low influence on fabric yellowing and discoloration; the terpolymer block hydrophilic amino silicone oil has excellent chemical stability in resistance to acids, alkalis and salts, has good compounding stability with the aids such as a brightener, saves cost for customers in terms of energy conservation and emission reduction, and provides conveniences.

Owner:HT FINE CHEM CO LTD +1

Hydrophilic ice-cold skin touch finishing agent for cotton fabric and preparation method of hydrophilic ice-cold skin touch finishing agent

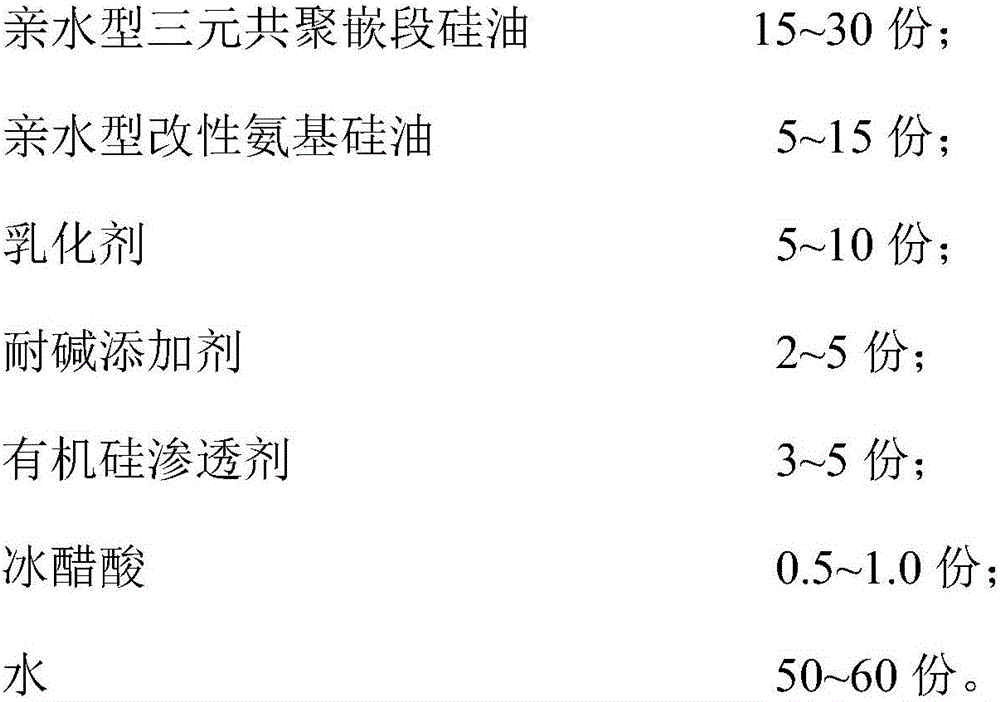

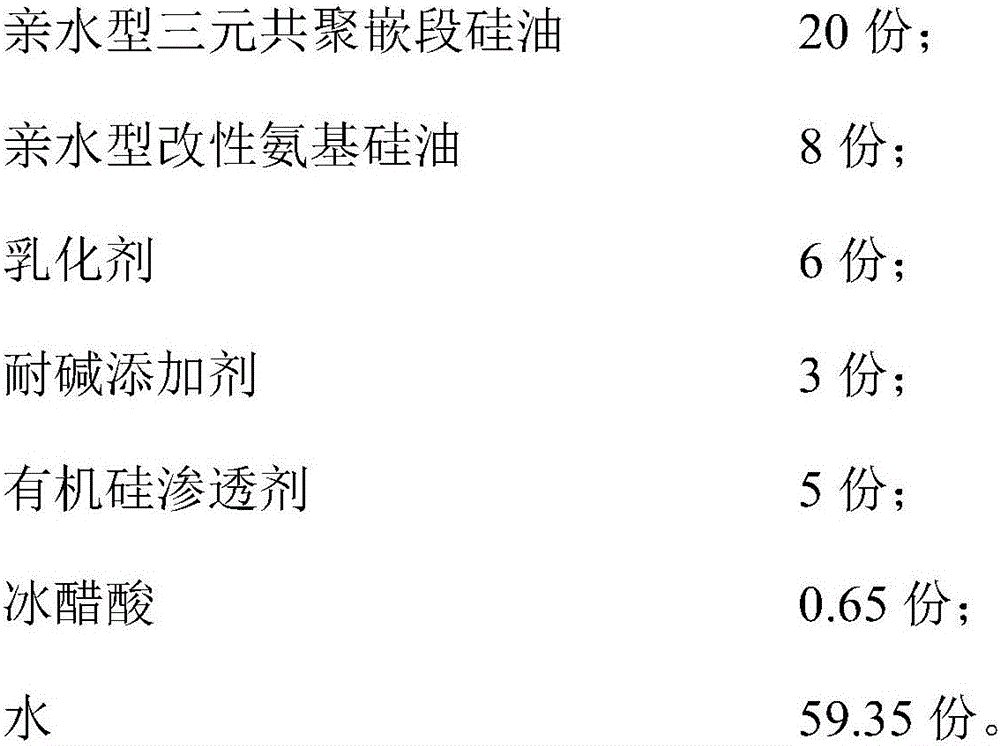

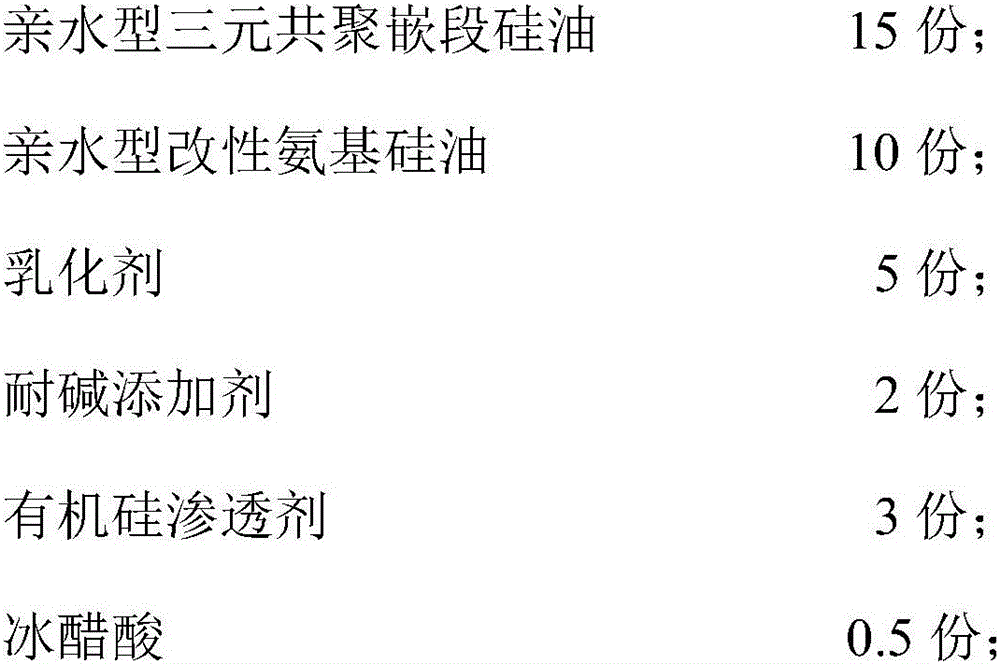

ActiveCN106319975AImprove performanceIncrease elasticityGrip property fibresVegetal fibresAcetic acidAlkylphenol

The invention discloses a hydrophilic ice-cold skin touch finishing agent for a cotton fabric and a preparation method of the hydrophilic ice-cold skin touch finishing agent. The finishing agent is prepared from the following raw material formula in parts by weight: 15 to 30 parts of hydrophilic ternary polymerization block silicone oil, 5 to 15 parts of hydrophilic modified amino silicon oil, 5 to 10 parts of emulsifying agent, 2 to 5 parts of alkali-resisting additive, 3 to 5 parts of organosilicon penetrant, 0.5 to 1.0 part of glacial acetic acid and 50 to 60 parts of water. The finishing agent disclosed by the invention has a good hydrophilic effect on the cotton fabric, and can endow the cotton fabric with excellent softness, exquisite smoothness, ice-cold touch and good resilience effect; in addition, the raw material formula does not contain harmful components polluting the environment and components which are strictly prohibited by China such as APEO (Alkylphenol Ethoxylates). The preparation method has the advantages of simple process, convenience in operation and control, stable quality, high production efficiency and capability of realizing large-scale industrial production.

Owner:HT FINE CHEM CO LTD

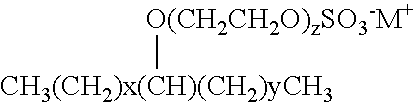

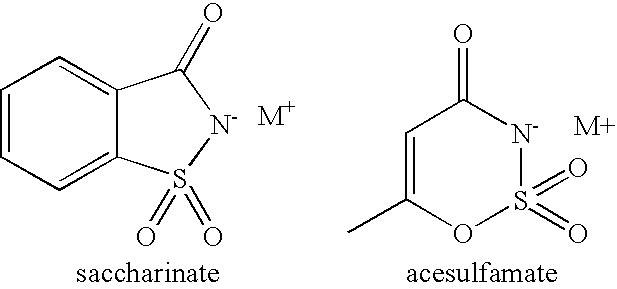

Process for improving processability of a concentrate and compositions made by the same

InactiveUS20060094621A1Easy to processCationic surface-active compoundsDetergent mixture composition preparationIonic liquidViscosity

Methods for improving the processability of an active concentrate are disclosed. Specifically, an ionic liquid is incorporated into the diluting process to lower the viscosity and avoid the formation of a viscosity-increasing gel phase. Moreover, the ionic liquid may comprise an ion active capable of delivering a desired benefit, which accompanies and / or enhances the benefit provided by the active in the concentrate. The present invention also encompasses a dilution process for forming a product composition from a conventional active concentrate or an ionic liquid containing composition. The present invention further comprises compositions made by these processes.

Owner:THE PROCTER & GAMBLE COMPANY

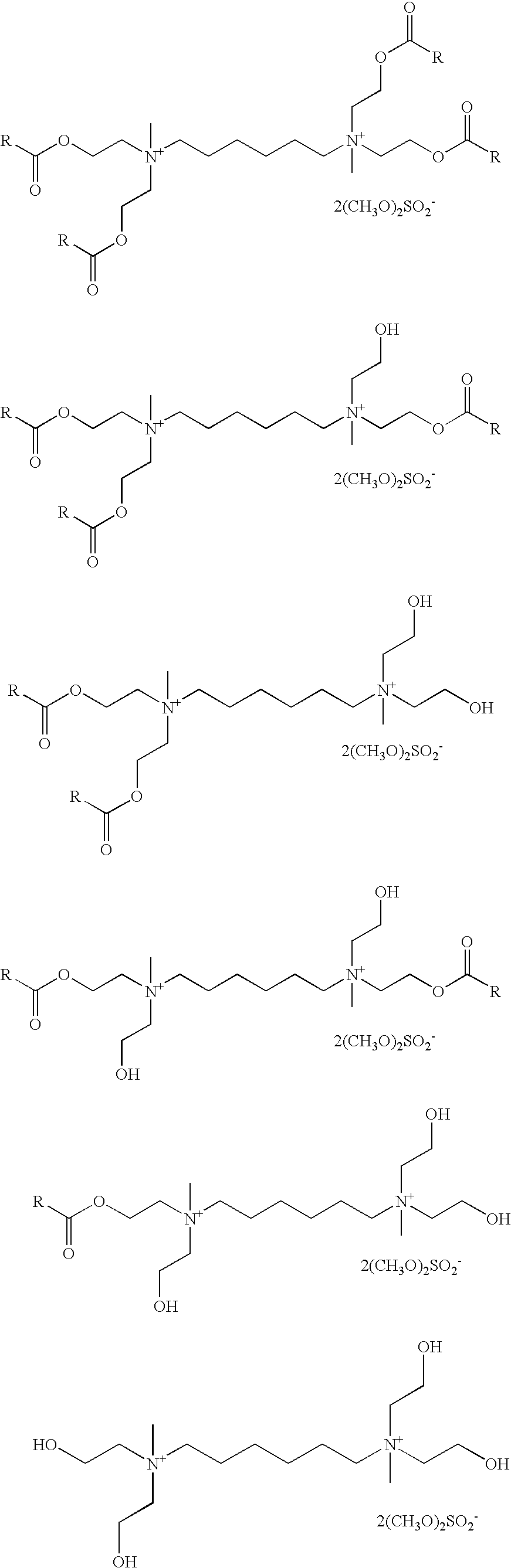

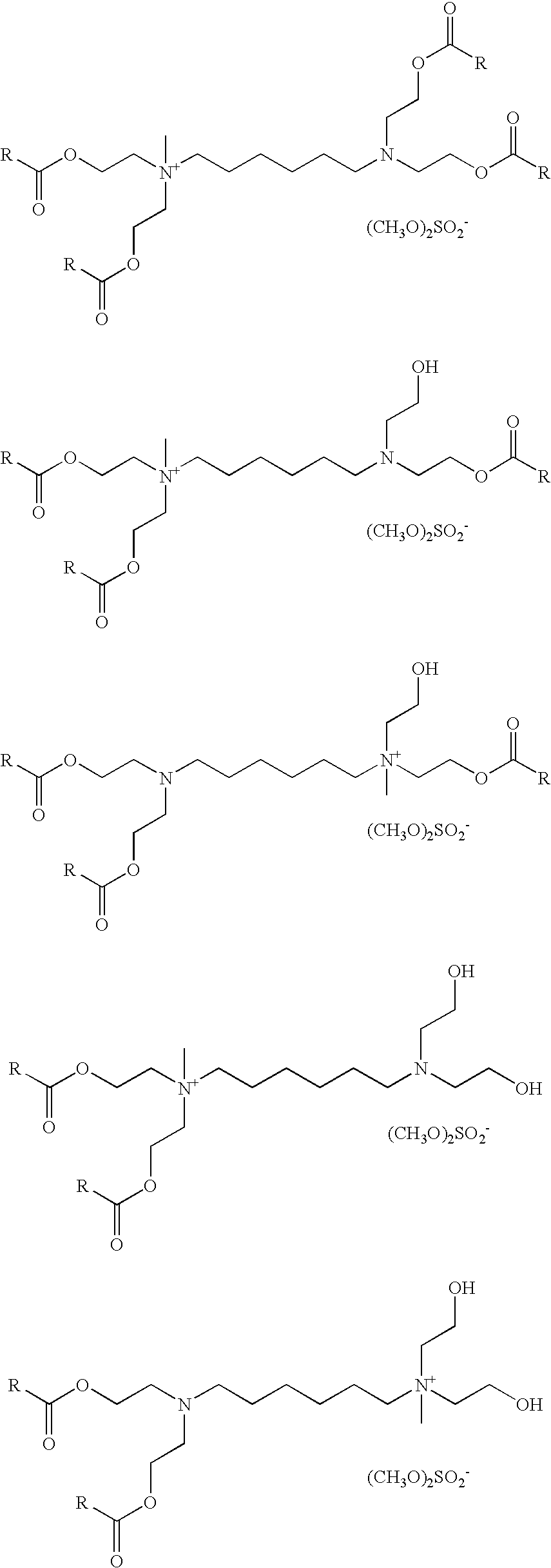

Highly concentrated fabric softener compositions and articles containing such compositions

InactiveUS6958313B2Cationic surface-active compoundsNon-ionic surface-active compoundsPolyvinyl alcoholPolymer chemistry

An article comprising a polyvinyl alcohol film encapsulating a fabric care composition is useful for conditioning laundry.

Owner:PROCTER & GAMBLE CO

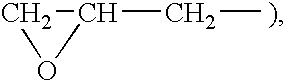

Preparation method of polyurethane modified organic silicon multipolymer fabric softening agent

ActiveCN103951809AImprove hydrophilicityImprove wearing moisture absorptionGrip property fibresEpoxyPolyethylene glycol

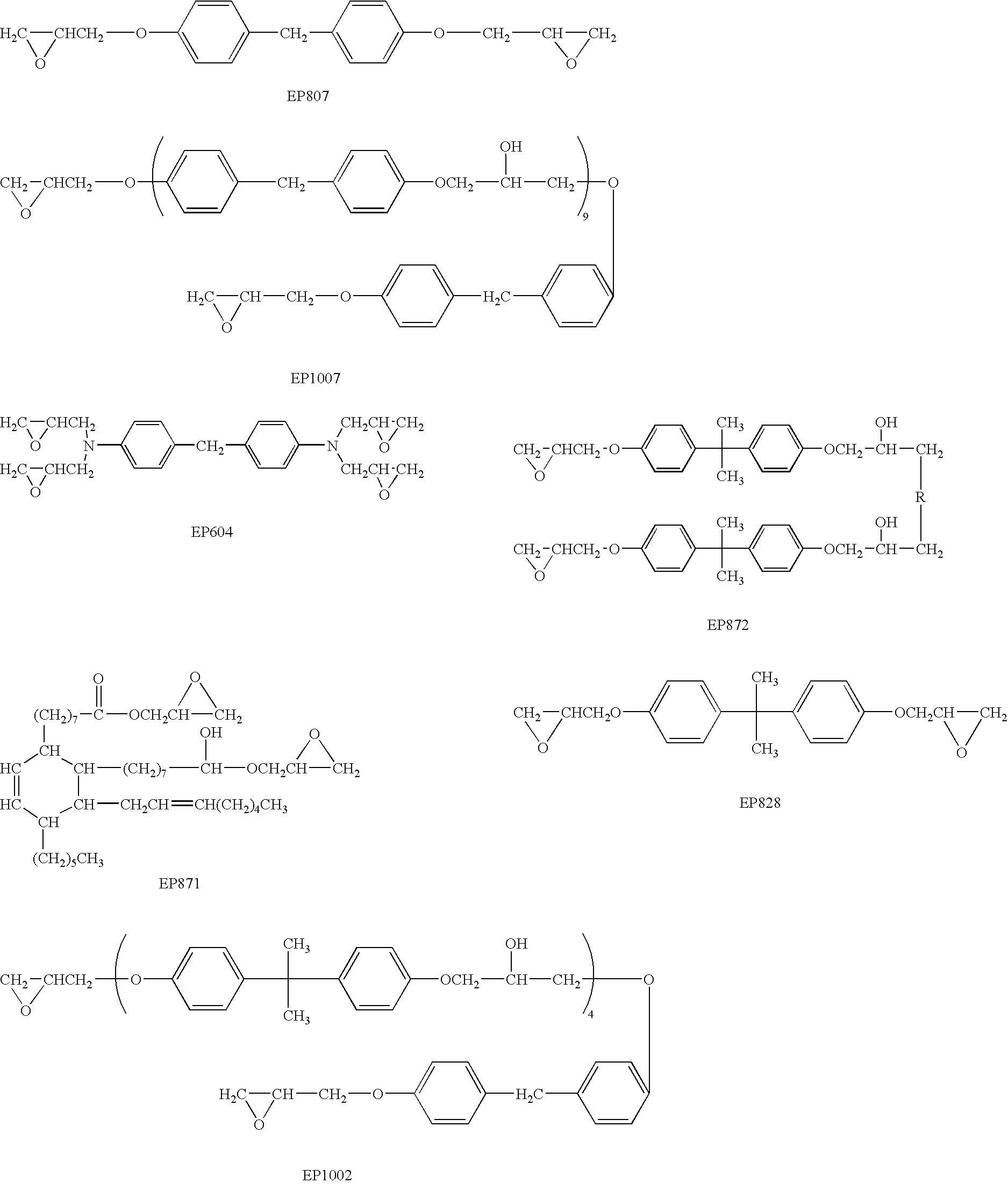

The invention discloses a preparation method of a polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method comprises the following steps: firstly preparing a polyurethane prepolymer by using polyethylene glycol 2000 and isophorone diisocyanate; then preparing alkylhydroxyl-containing silicone oil by using di-n-butyl amine, epoxy 1,3-bis(3-glycidoxypropyl)-1,1,3,3-tetramethyldisiloxane and octamethyl cyclotetrasiloxane; reacting the polyurethane prepolymer with the alkylhydroxyl-containing silicone oil so as to obtain a polyurethane organic silicon multipolymer; and finally adding deionized water, and emulsifying so as to obtain the polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method of the polyurethane modified organic silicon multipolymer fabric softening agent has the beneficial effects that urethane groups and urethane are introduced into organic silicon and serve as hard chain segments for generation of physical crosslinking, meanwhile, polyether is introduced and serves as a hydrophilic chain segment, the problem that as an amino silicon oil softening agent is easy to yellow and demulsify, oil patches are formed on fabrics, is solved, the hydrophilic performance of the fabrics subjected to soft finish is improved, the wearing hygroscopicity of the fabrics is improved, and the durability of the fabrics is good.

Owner:佛山市澳棉纺织有限公司

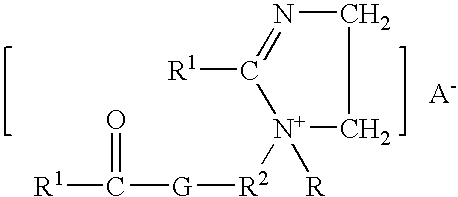

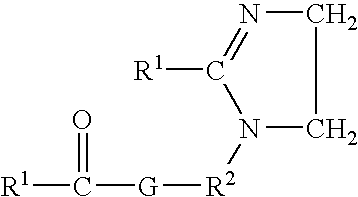

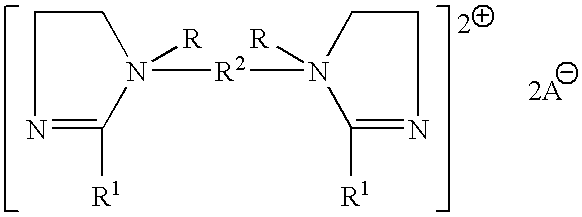

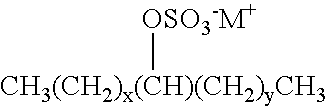

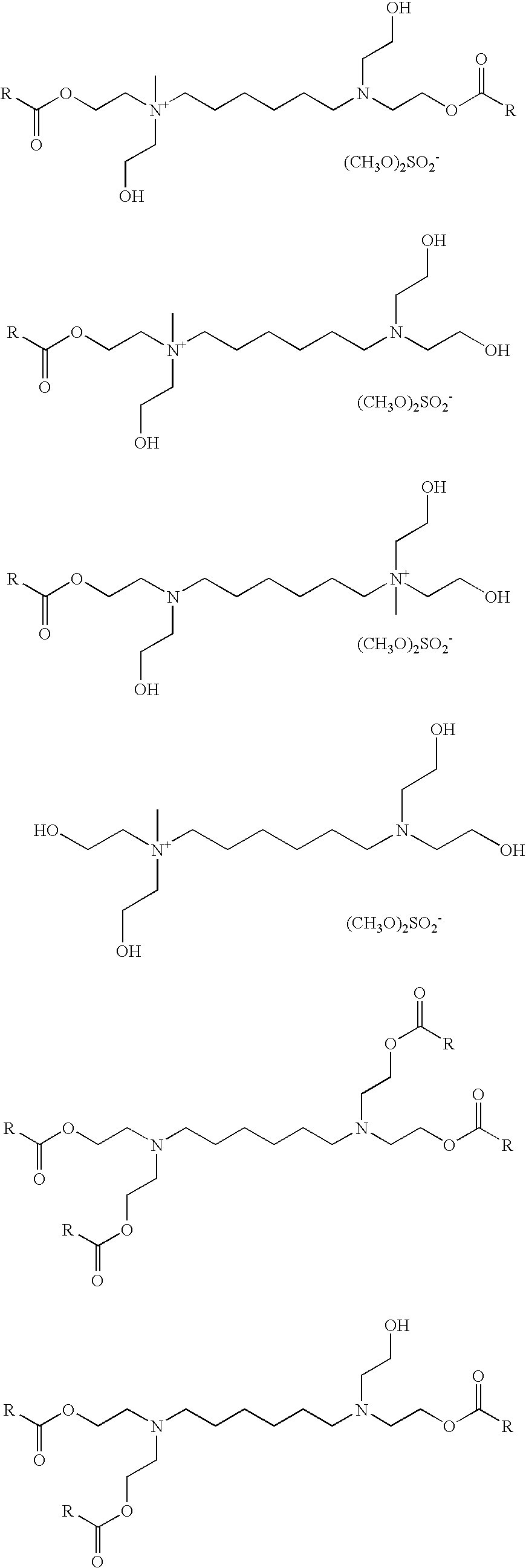

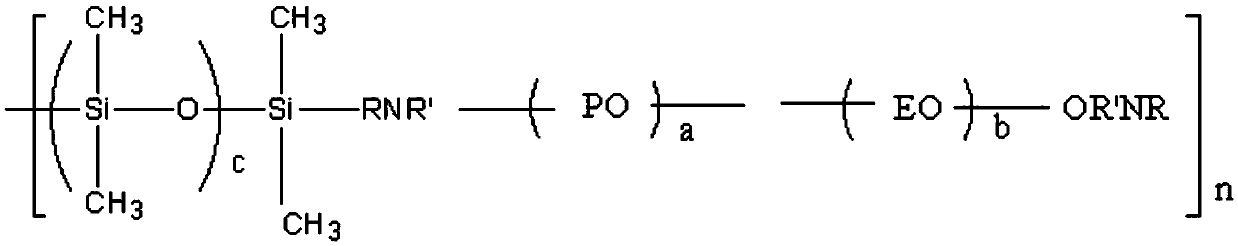

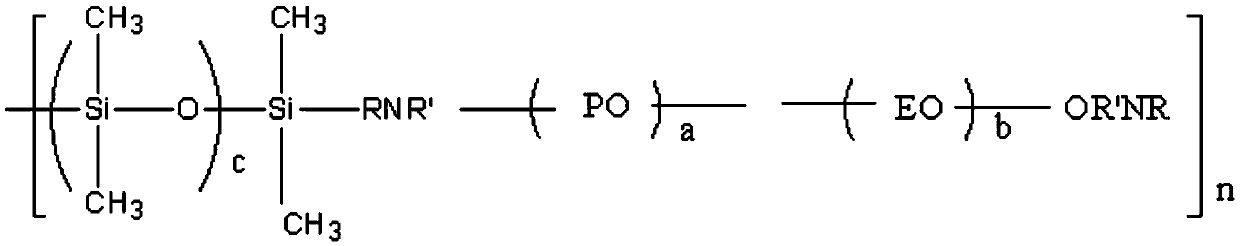

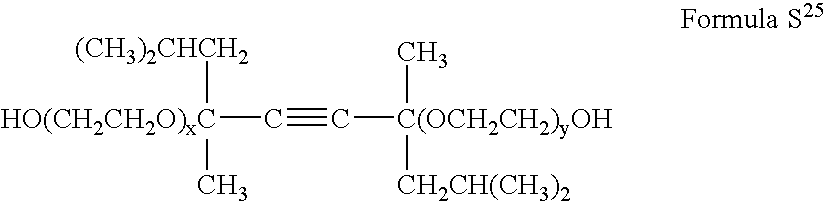

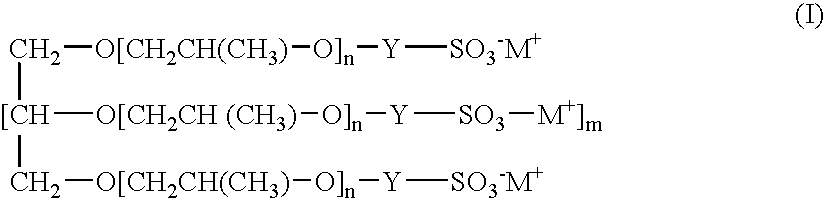

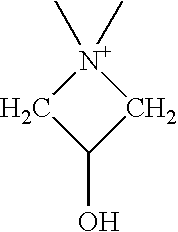

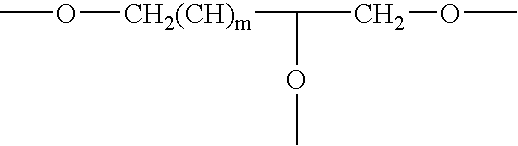

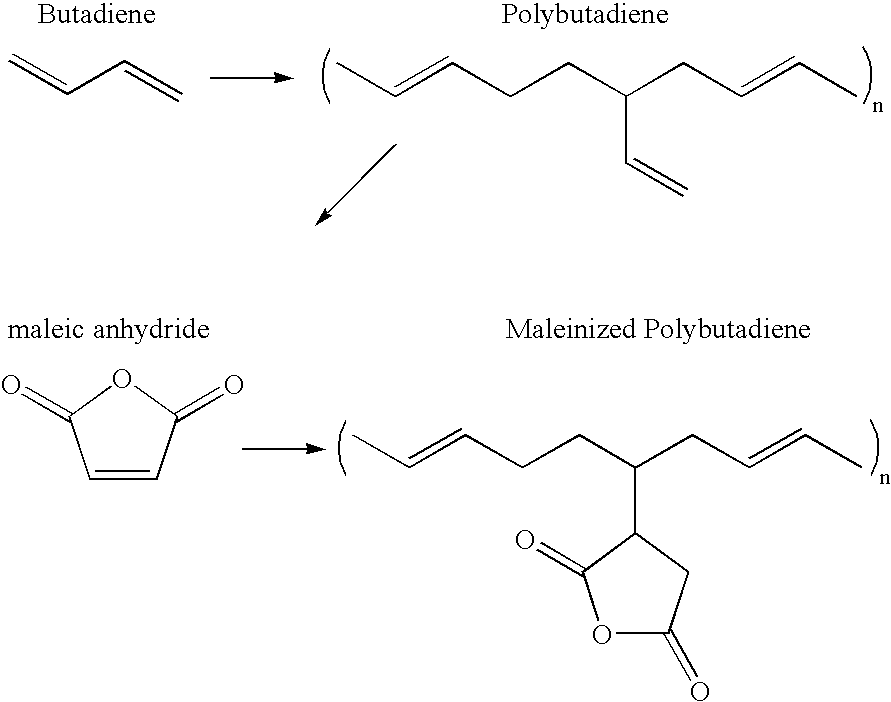

Ternary polymerization block polyether amino silicon oil softening agent and preparing method thereof

InactiveCN105504298AHydrophilicImprove hydrophilicityLight resistant fibresLiquid repellent fibresPolyesterAlkane

The invention relates to the technical field of softening agents, in particular to a ternary polymerization block polyether amino silicon oil softening agent. The structural formula is shown in the description, wherein R=-CH2CH2CH2, -CH3 or -CH2CH3, R'=C1-22 alkane, PO=OC3H6, EO=OC2H4, a and b are any integer from 5 to 24, c is any integer from 10 to 60, and n is any integer from 10 to 60. Yellowing, instability and hydrophobicity of ordinary amino silicon oil are overcome, fabric has excellent hand feeling, hydrophilia, washability and stability, and the softening agent is suitable for various kinds of pure cotton fabric, cotton-polyester blended fabric, wool and other kinds of fabric.

Owner:上海氟聚化学产品股份有限公司

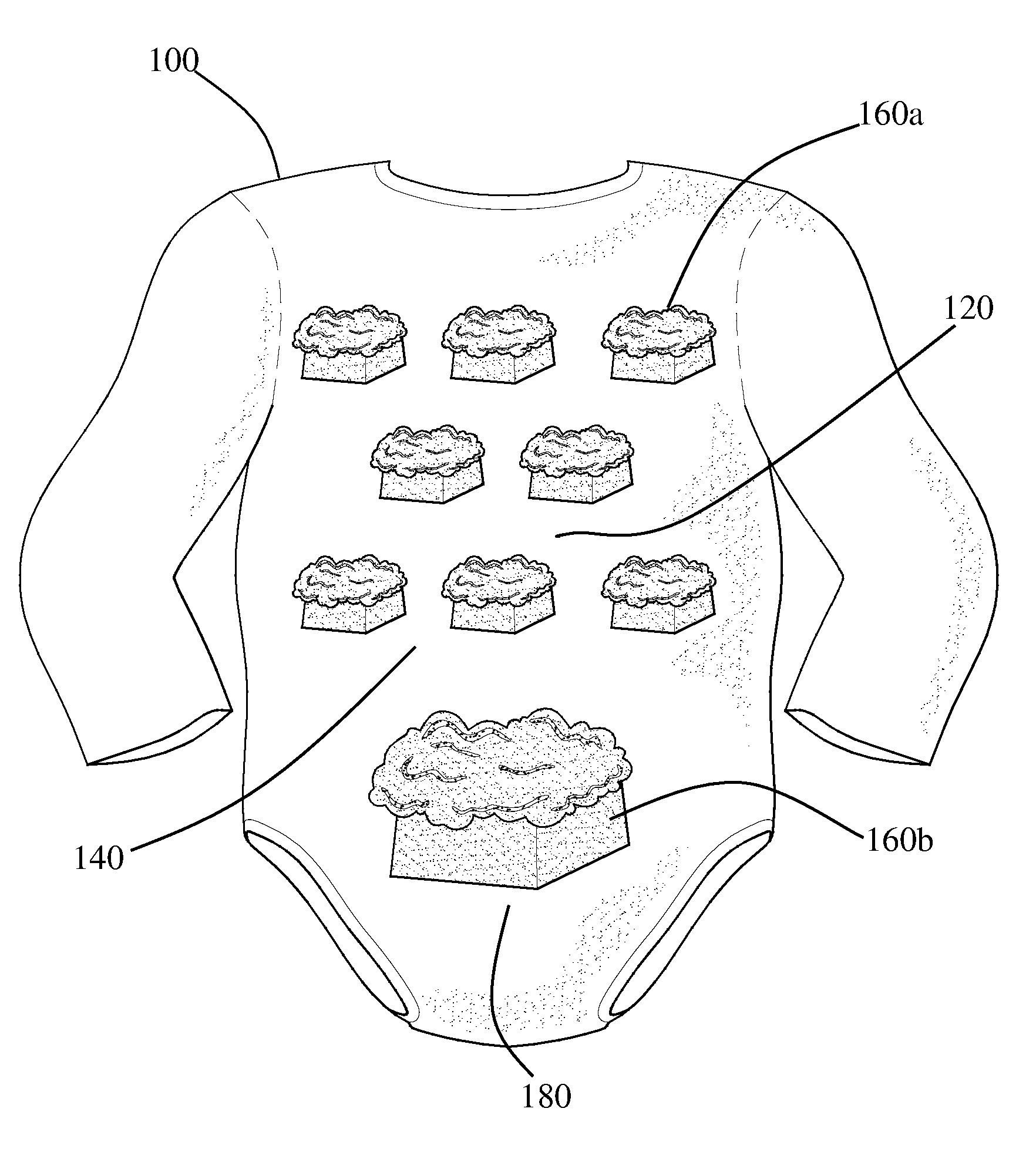

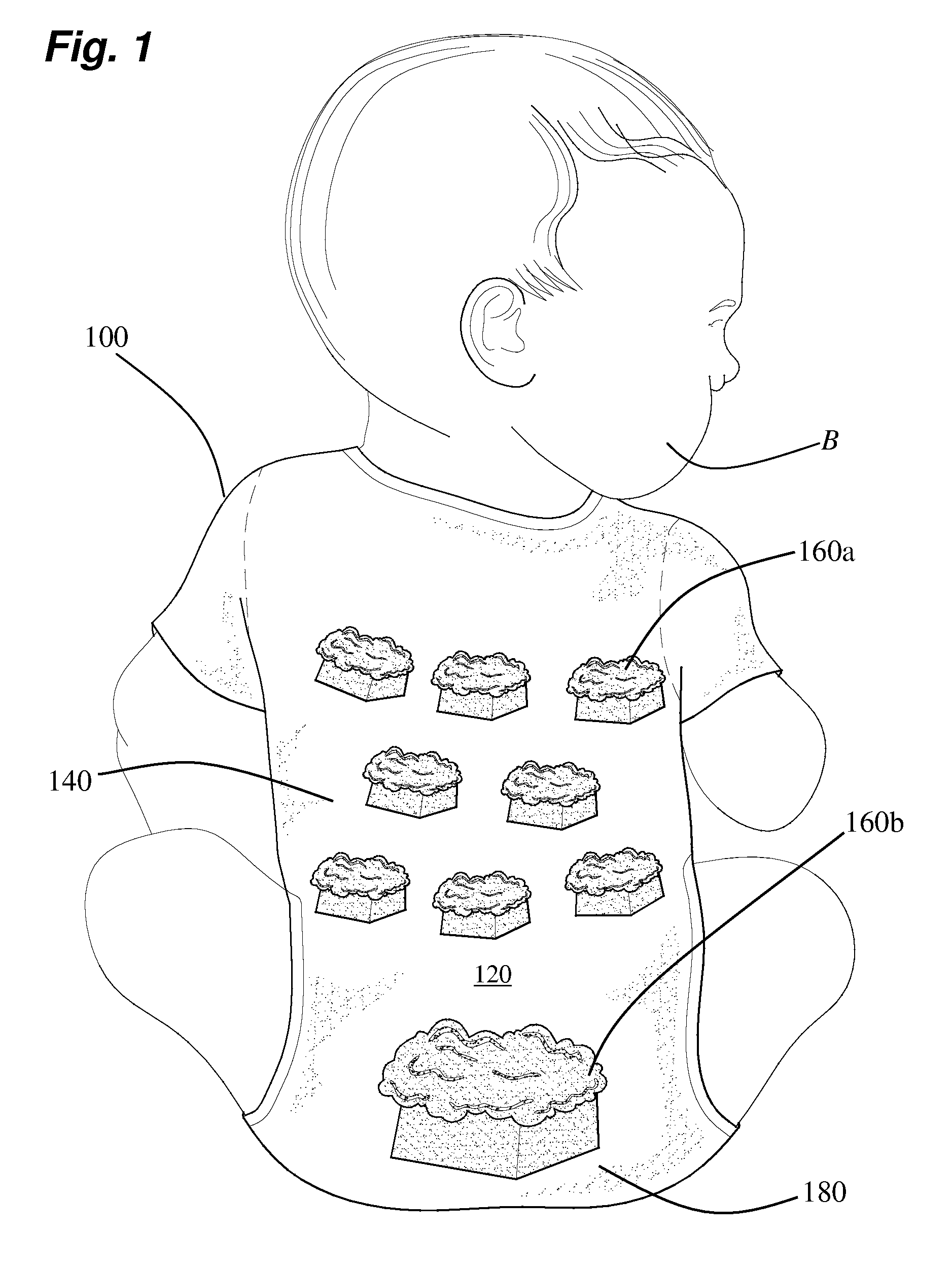

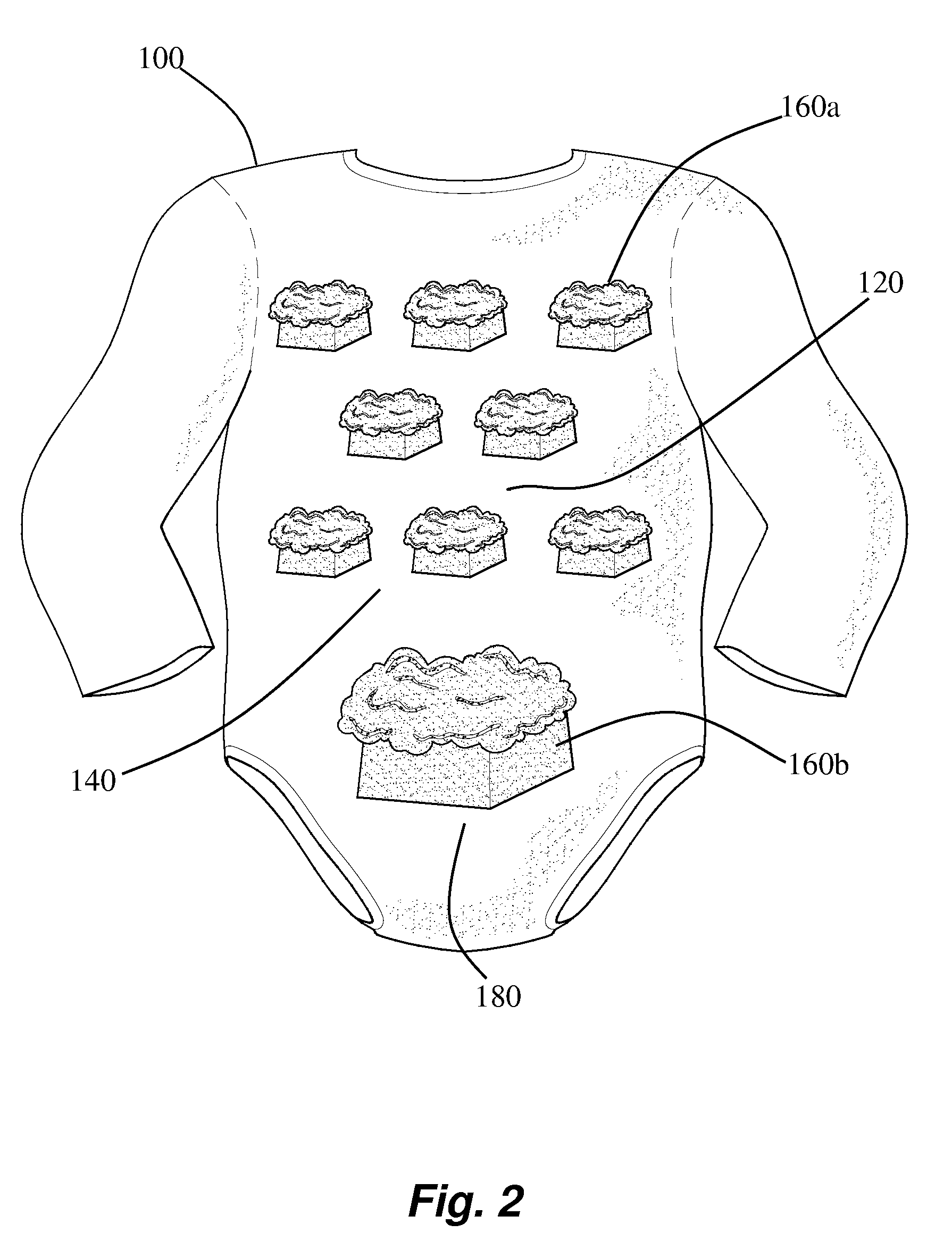

Non-slip emblems and their application to baby clothing

InactiveUS20090100566A1Low viscosityGarment special featuresScreen printersScreen printingEngineering

A non-skid means for helping prevent slip accidents with respect to infants in which a baby garment is provided having front and rear sides, the rear side comprising an external fabric surface, the external fabric surface of the rear side comprising thereon a plurality of non-slip rubber emblems each having an overall predetermined decorative shape, wherein each of the plurality of non-slip rubber emblems comprises at least one layer of cured low viscosity silicone rubber applied by a silk screen printing process in which low viscosity liquid silicone rubber is used in place of ink.

Owner:SCHIAVINO SHANNON +1

Carbon fiber strand

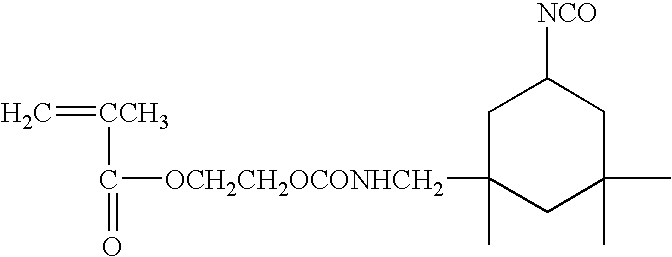

InactiveUS20050271874A1Increased interlaminar shear strengthCarbon fibresGrip property fibresFiberAlcohol

A sizing agent for carbon fiber consisting of a reaction products containing an unsaturated urethane compound as the principal component obtained by reacting an unsaturated alcohol with an isocyanate compound is disclosed in claim 1.

Owner:TOHO TAYON CO LTD

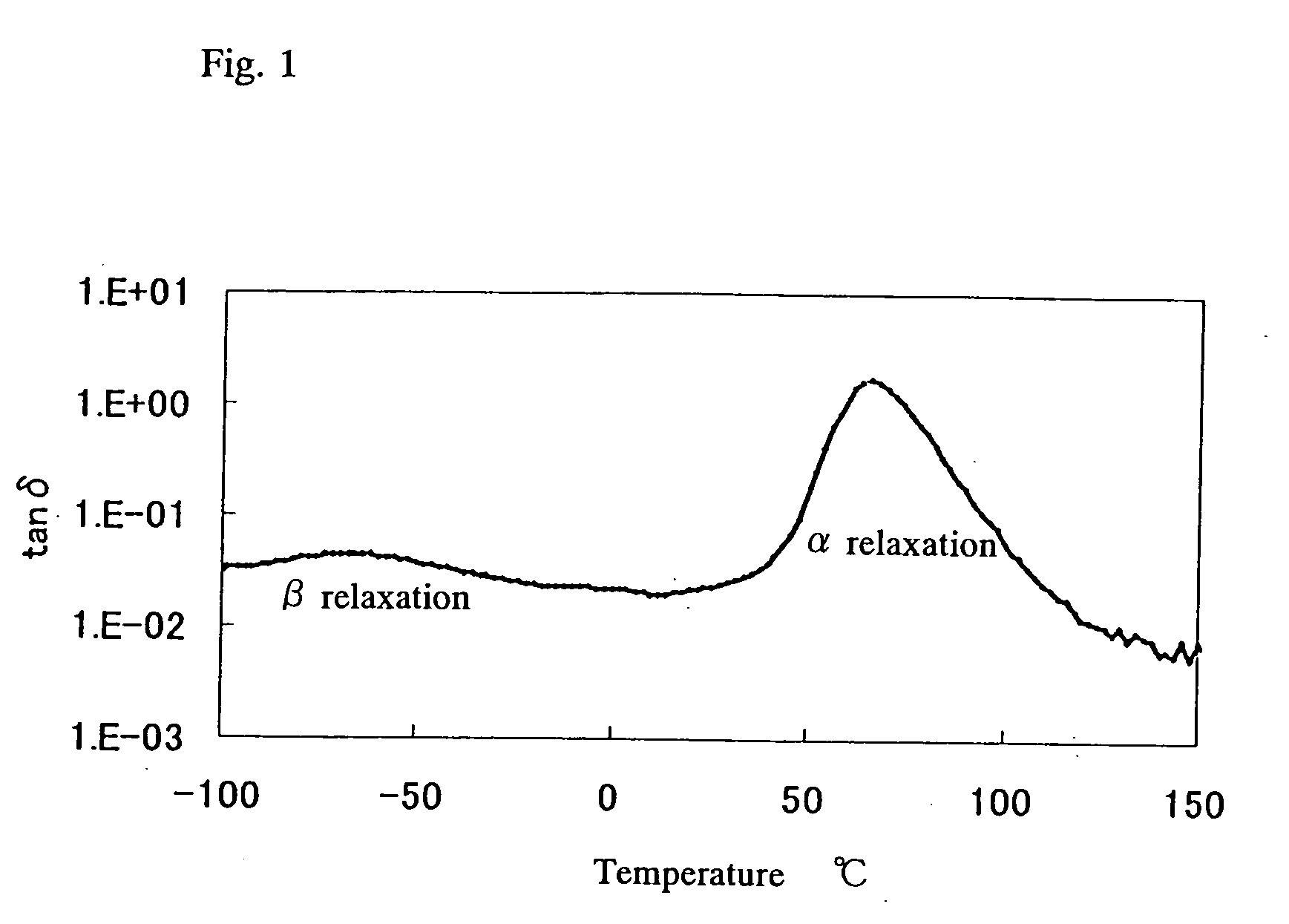

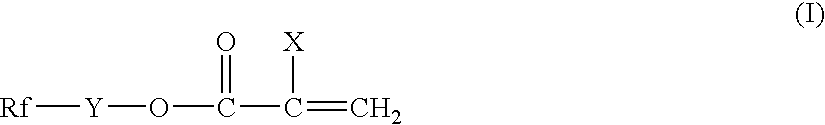

Water and oil repellent composition

InactiveUS20050267241A1Other chemical processesFilm/foil adhesivesPhotopolymerGlass transition point

A water and oil repellent composition having excellent durability, which can impart excellent water and oil repellency to an object, even in a process at low temperatures, and which enables water and oil repellent treatment providing a soft hand. A water and oil repellent composition which comprises, as an essential component, a copolymer containing polymerization units of the following monomer (a) and polymerization units of the following monomer (b): monomer (a): an Rf group-containing monomer which forms a photopolymer having no melting point or a melting point of at most 55° C. attributable to fine crystals derived from the Rf groups and having a glass transition point of at least 20° C. monomer (b): a monomer having no Rf group and having a cross-linkable functional group.

Owner:ASAHI GLASS CO LTD

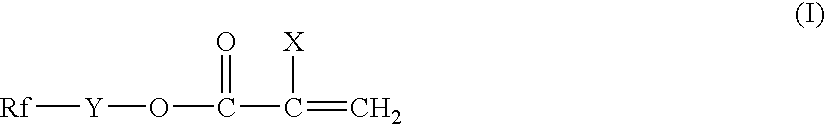

Silicon-containing fluorochemical surface-treating agent

ActiveUS20060134439A1Improve soil resistancePowerful shearing energyOther chemical processesLiquid repellent fibresPolymeric surfacePolymer science

There is provided a surface treatment agent which comprises a fluoropolymer having repeating units derived from a fluorine-containing monomer of the formula: wherein (a) the fluoropolymer contains a silicon atom, and / or (b) the surface treatment agent contains a fluorine-free polymer which is different from the fluoropolymer and which is a silicon-containing polymer. The surface treatment agent imparts excellent water- and oil-repellency and soil resistance to textiles while retaining the feeling of the textiles, even if the surface treatment agent contains a fluorine-containing acrylate polymer substituted at its α-position by a fluorine atom, a chlorine atom or the like.

Owner:DAIKIN IND LTD

Fabric care composition

InactiveUS20040023836A1Increase the rate of moisture transport through the fabricImprove comfortOrganic detergent compounding agentsGrip property fibresCelluloseCross-link

Polymers which are capable of self-cross-linking and / or of reacting with cellulose can be used in the treatment of fabric comprising cellulosic fibres to enhance the feeling of comfort when a garment comprising the fabric is worn. The enhanced feeling of comfort is due, at least in part, to an increase in the rate of moisture transport through the fabric. The polymers may be used in conjunction with a liquid or soft solid derivative of a cyclic polyol or of a reduced saccharide resulting from 35 to 100% of the hydroxyl groups in the polyol or the saccharide being esterified or etherified.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Dyeing and finishing process for improving color fastness to light of light-colored fabric of FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile

ActiveCN105696385AShrink evenlyNot prone to wrinklesGrip property fibresDyeing processAcetic acidDisperse dye

The invention discloses a dyeing and finishing process for improving the color fastness to light of a light-colored fabric of an FDY (Fully Drawn Yarn) polyester filament yarn warp and weft four-way elastic textile. The dyeing and finishing process comprises a dyeing process; a formula of a dyeing auxiliary adopted in the dyeing process comprises the following components: 0.5g / L to 1g / L of high-efficiency dispersant, 2g / L to 3g / L of chelating dispersant, 0.3g / L to 0.5g / L of 99 percent glacial acetic acid, X percent (o.w.f.) (on Weight the Fabric) of disperse yellow AM-2R, Y percent (o.w.f.) of disperse red AM-SLR and Z percent (o.w.f.) of disperse blue AM-SLR, wherein the sum of X, Y and Z is not more than 0.5, and a bath ratio is 1: (3 to 4). According to the dyeing and finishing process, the light-colored fabric of the FDY polyester filament yarn warp and weft four-way elastic textile which does not contain a fluorescent whitening agent and is obtained by being dyed by a disperse dye with color fastness to high sunlight is used as greige cloth; the color fastness to light which is up to a rating of 5 to 6 is realized through the specific dyeing and finishing process.

Owner:杭州天宇印染有限公司

Graphene/fiber fabric preparation method, graphene/fiber fabric and sensor

InactiveCN105951427AImprove mechanical propertiesEfficient compositePhysical treatmentLiquid/gas/vapor removalFiberRoom temperature

The invention relates to a graphene / fiber fabric preparation method, which is characterized by comprising the following steps of 1) immersing fiber fabric in a bovine serum albumin solution at a room temperature, drying the fiber fabric, and cleaning the fiber fabric by utilization of deionized water so as to obtain cationized fiber fabric; 2) immersing the cationized fiber fabric obtained in the step 1) into a graphene oxide solution, and drying to obtain graphene oxide / fiber fabric; 3) immersing the graphene oxide / fiber fabric obtained in the step 2) into a reducing agent, cleaning by utilization of the deionized water, and drying to obtain the graphene / fiber fabric. The preparation method provided by the invention has the advantages that the technology is simplified, the graphene / fiber fabric prepared according to the preparation method is well compounded with graphene, and the effects of stable resistance, high sensitivity, security and environmental friendliness are achieved.

Owner:SHENZHEN MICRO & NANO INTEGRATED CIRCUITS & SYST RES INST

Modified fibers for use in the formation of thermoplastic fiber-reinforced composite articles and process

ActiveUS20130040108A1Secure bondingImprove mechanical propertiesMaterial nanotechnologyPretreated surfacesRough surfaceGlass fiber

A surface-modified fibrous material is provided for incorporation in a thermoplastic matrix to form a fiber-reinforced composite article. Good binding between the fibrous material and the thermoplastic matrix is achieved through the presence of finely roughened surfaces on the fibers of nanoparticles of an inorganic material. Such nanoparticles are provided from an alkaline aqueous size composition containing the nanoparticles dispersed therein (as described). The fibrous material may be provided in continuous or discontinuous form. In a preferred embodiment glass fibers are initially provided in continuous form followed by cutting into discontinuous lengths and drying with the retention of the nanoparticles on the surfaces of the fibers. The surface-roughened fibrous material is incorporated in a thermoplastic matrix as fibrous reinforcement with the application of heat whereby the thermoplastic matrix is rendered melt processable. In preferred embodiments injection or compression molding is utilized. Improved long-fiber thermoplastics also may be formed to advantage.

Owner:JOHNS MANVILLE CORP

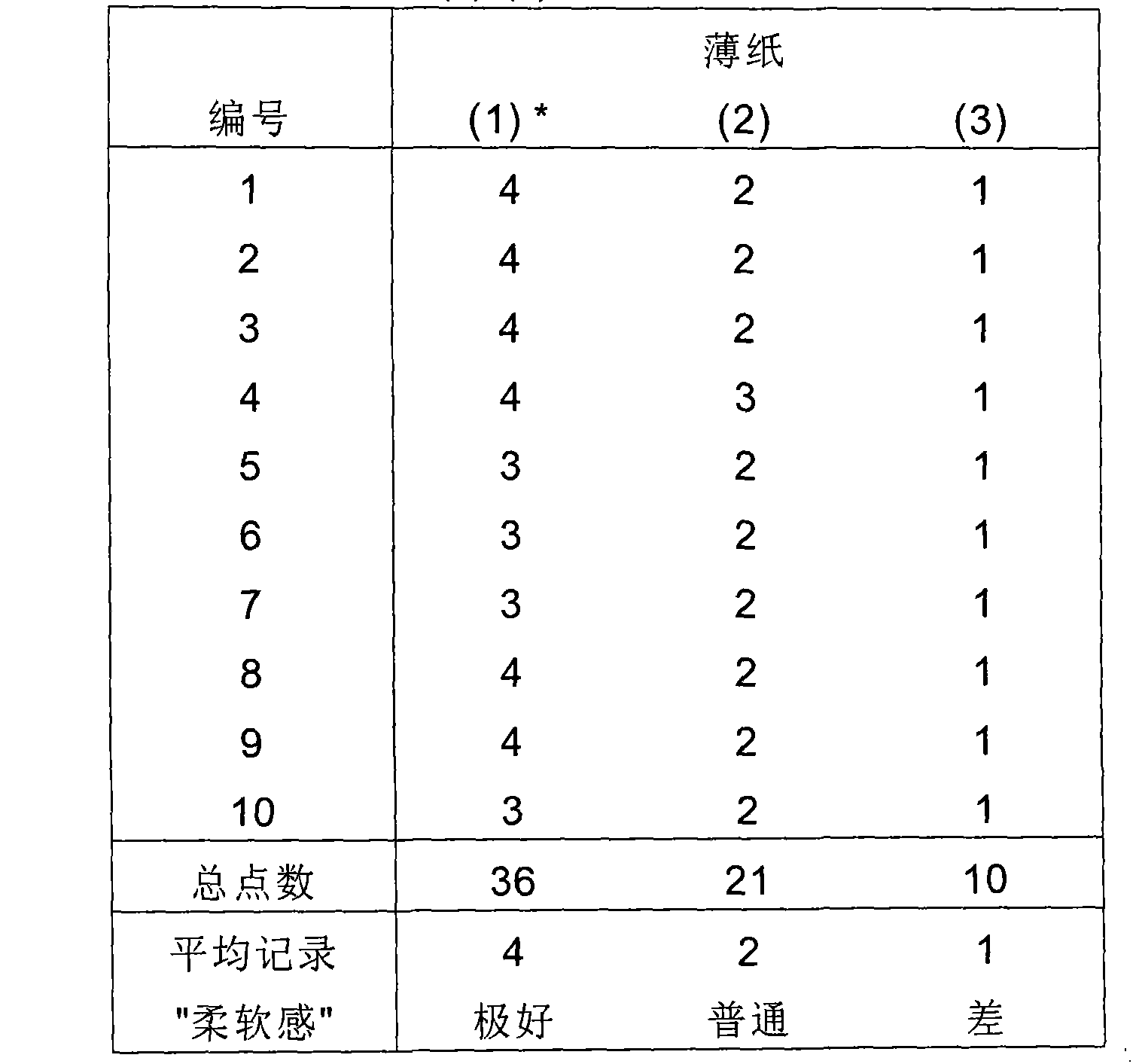

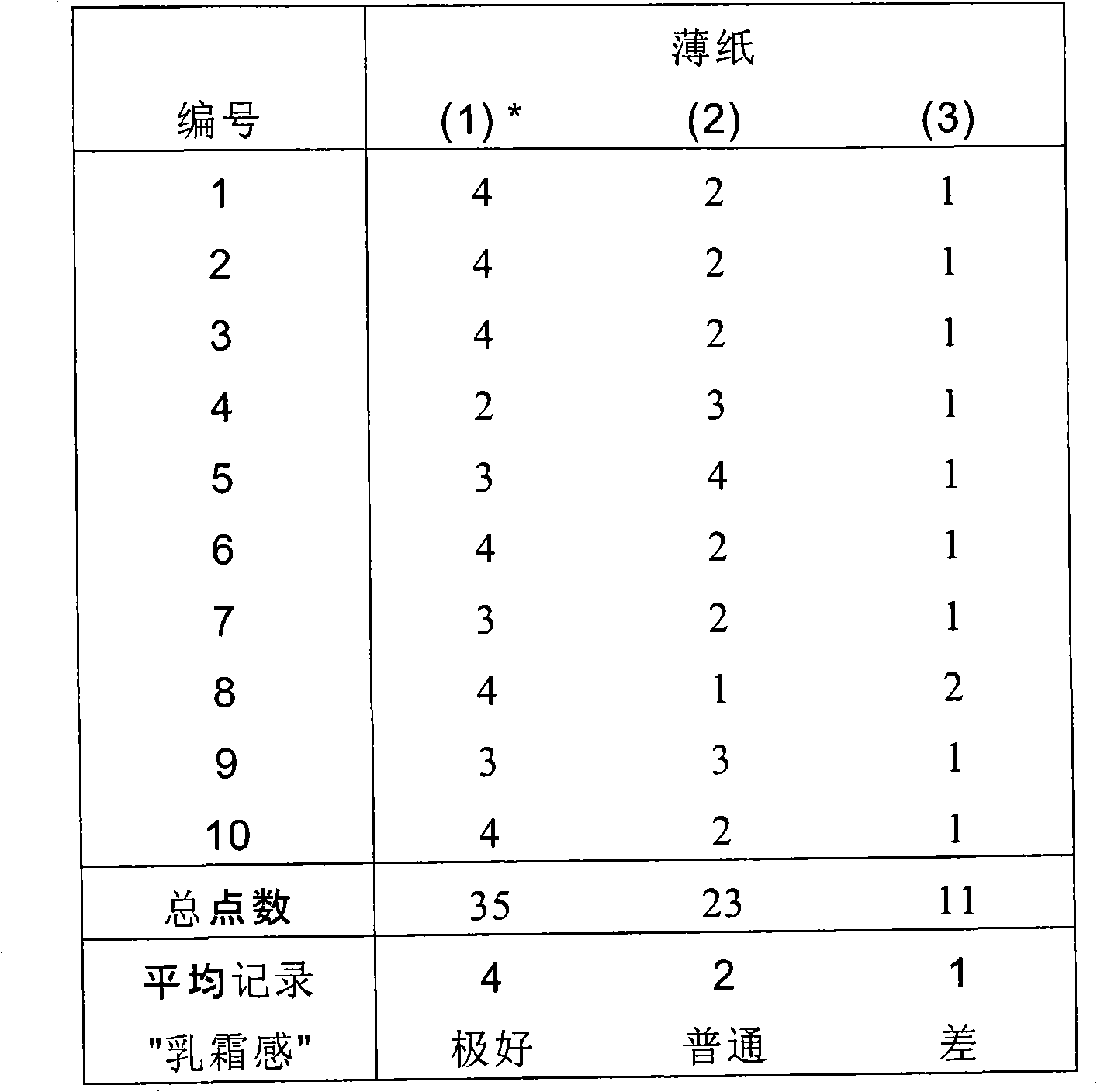

Emulsion composition, method for softening fiber structure and fiber containing base material

Owner:DOW CORNING SHANGHAI

Durable finishes for textiles

InactiveUS6872424B2Improve stabilityGood water solubilitySynthetic resin layered productsPretreated surfacesTextile fiberAlcohol

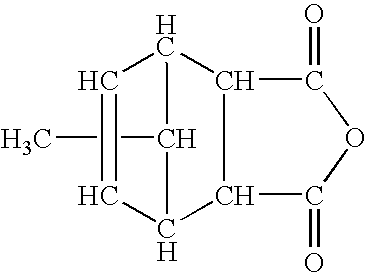

The present invention relates to textile treatment compositions for imparting desirable characteristics durably to textile fibers and fabrics, including softness, hydrophobicity, oleophobicity, surface lubricity, abrasion resistance, tear resistance, improved drape, and pilling resistance. More particularly, in one embodiment, the invention is directed to preparations that comprise a carboxylate-functionalized fluorinated polymer and a catalyst that is capable of forming reactive anhydride rings between carboxyl groups on the polymer. In another embodiment, the invention is directed to preparations comprising a polymeric softener having at least one anhydride functional group or at least one reactive group capable of forming an anhydride functional group, together with a catalyst for forming anhydrides from the reactive group or groups. In either embodiment, the resulting reactive anhydride rings bind to substrates, such as textiles and other webs, having free sulfhydryl, alcohol, or amine groups. The invention is further directed to the process for treating textiles and other webs with desirable finishes durable to repeated cleanings. This invention is further directed to the yarns, fibers, fabrics, textiles, finished goods, or nonwovens (encompassed herein under the terms “textiles” and “webs”) treated with the textile-reactive preparations of the invention. Such textiles and webs exhibit a greatly improved, durable characteristics, such as softness and / or hydrophobicity, even after multiple launderings.

Owner:NANO TEX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com