Carbon fiber strand

a carbon fiber and strand technology, applied in the direction of yarn, transportation and packaging, coating, etc., can solve the problems of insufficient adhesion between sizing agent and carbon fiber, difficult later handling, and insufficient strength of the composite material in the fiber axis direction, and achieve the effect of superior interlaminar shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0058] Physical properties were measured according to the following methods.

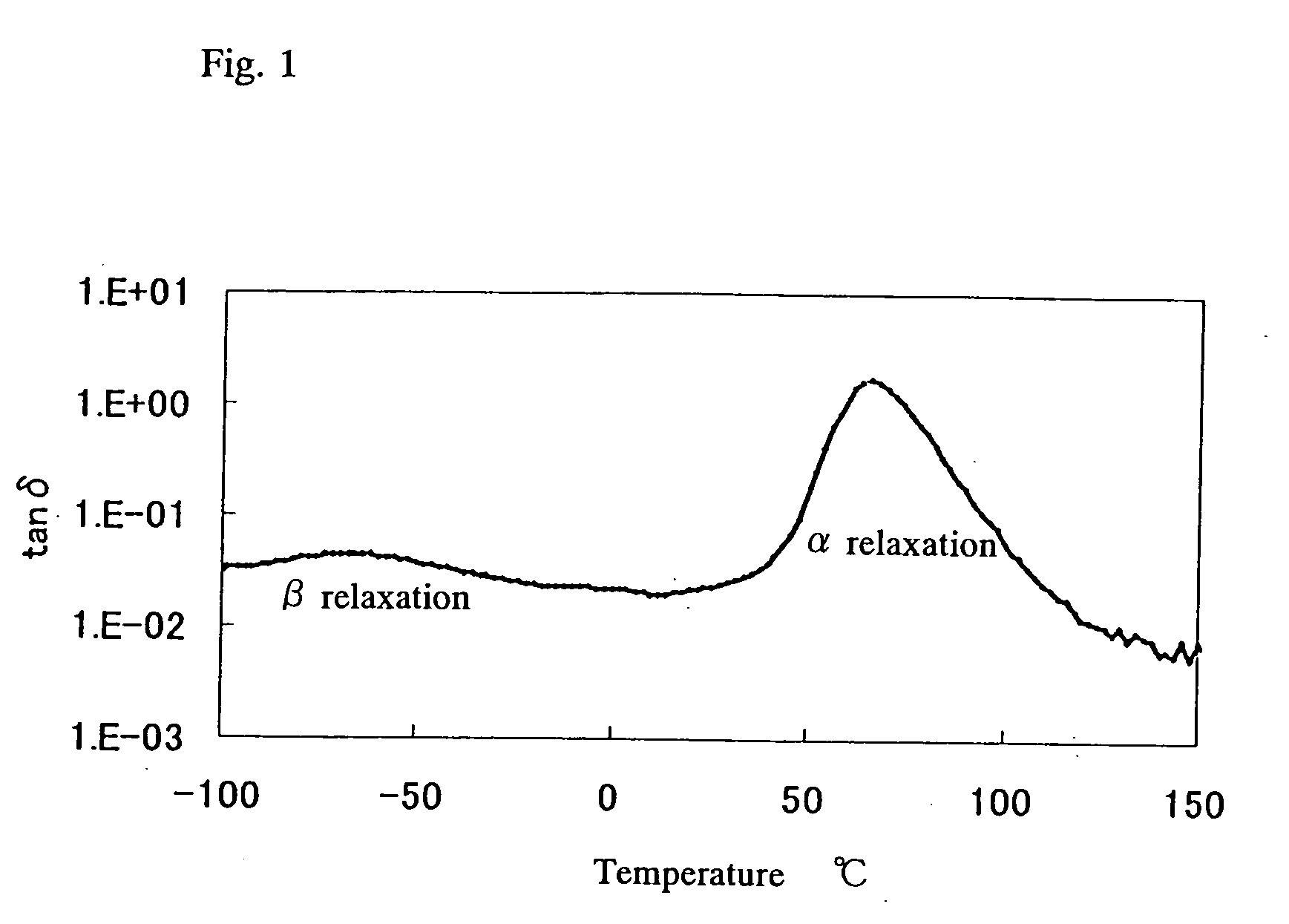

[0059] 100 parts by mass of a sizing agent and 30 parts by mass of a curing agent (Kayahard MCD, a product of Hitachi Chemical Company, Ltd.) were mixed to prepare a composition for estimation; the composition was molded and cured at 130° C. for 2 hours in a mold to obtain a cured material for estimation. This cured material for estimation was cut into a size of 30 mm (length)×6 mm (width)×3 mm (thickness) to obtain a test piece for measurement of dynamic viscoelasticity.

[0060] The test piece was measured for dynamic viscoelasticity using a dynamic mechanical analyzer (Model Rhogel E-4000, a product of UBM). The measurement conditions were temperature elevation rate: 4° C. / min, frequency: 10 Hz; and measurement temperature range: −100 to 200° C.

[0061] From the dynamic viscoelasticity curve obtained (an example of the curve is shown in FIG. 1), a tan δ of a relaxation peak (αtan δ) and a tan δ of β relaxat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tan δ | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com