Method for producing carbon/carbon skid of magnetic suspension train

A technology for maglev trains and manufacturing methods, which is applied in the field of manufacturing carbon/carbon composite materials for maglev train skids, can solve the problems of skid function failure, small thermal conductivity, and low interlayer shear strength, and achieve improved interlayer Effects of shear strength, improvement of wear resistance, improvement of interlayer shear strength and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

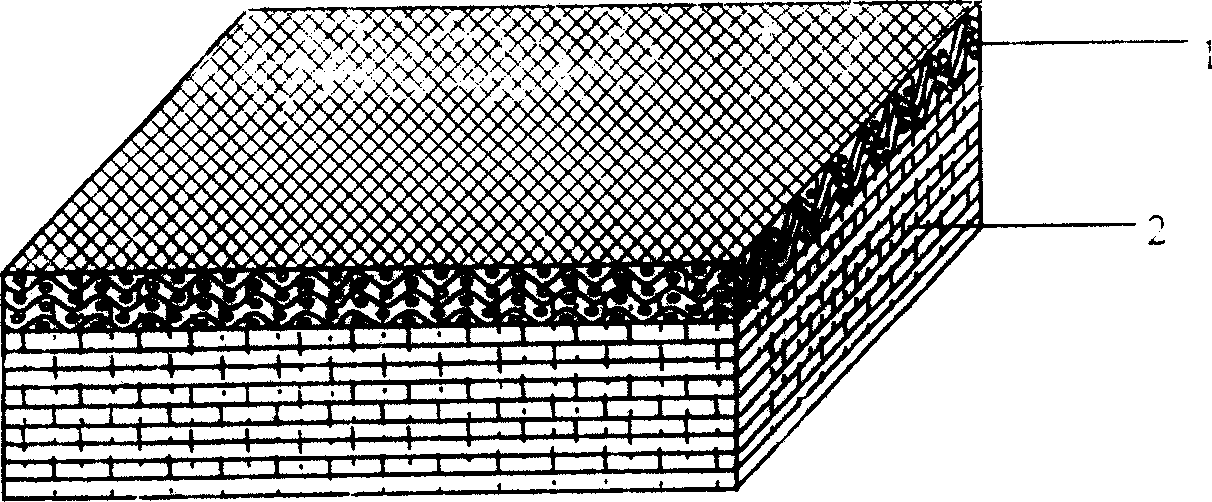

[0024] (1) Acupuncture carbon cloth and carbon fiber composite structure quasi-three-dimensional structure preform is used. The thickness of the acupuncture carbon cloth is 2-4mm, and the remaining thickness is acupuncture long fibers. In the preform, long carbon fibers and mesh short fibers are used. The weight percentage is about 75%: 25%.

[0025] (2) The preform is loaded into the negative pressure directional flow gas phase carbon deposition furnace, and the isothermal CVI densification process is adopted. The temperature is 1000 ° C, the pressure in the furnace is 10 KPa, and the carbon source gas (C 3 H 6 ) at a flow rate of 100 L / h, and after 300 hours of densification treatment, a pyrolytic carbon matrix was formed.

[0026] (3) The porous carbon / carbon body is impregnated in a vacuum-pressure impregnation tank, and the weight of the furfurone resin is 120kg, and the SiC ultrafine powder with a weight percentage of 6kg (5% of the furfurone resin) is added, and the ne...

Embodiment 2

[0030] (1) Acupuncture carbon cloth and carbon fiber composite structure quasi-three-dimensional structure preform is used. The acupuncture carbon cloth and fiber mesh are alternately laminated, with a thickness of 6-8mm, and the remaining thickness is acupuncture long fiber and fiber mesh. The tires are alternately laminated, the thickness is 25mm, and the weight percentage of the long carbon fibers and the short fibers of the mesh tire in the preform is 78%: 22%.

[0031] (2) The preform is loaded into the negative pressure directional flow gas phase carbon deposition furnace, and the isothermal CVI densification process is adopted. The temperature is 900-1100 ° C, the pressure in the furnace is 5KPa, and the carbon source gas (C 3 H 6 ) at a flow rate of 2000 L / h, and after 500 hours of densification treatment, a pyrolytic carbon matrix was formed.

[0032] (3) Put the porous carbon / carbon body in a vacuum-pressure impregnation tank, the furfurone resin weighs 100kg, and a...

Embodiment 3

[0036] (1) Acupuncture carbon cloth and carbon fiber composite structure quasi-three-dimensional structure preform is used. The acupuncture carbon cloth and fiber mesh are alternately laminated. The thickness is 8-10mm, and the rest is acupuncture long fiber and fiber mesh. The tires are alternately laminated, and the thickness is 30 mm. The weight percentage of long carbon fibers and short fibers of the mesh tire in the preform is about 85%: 15%.

[0037] (2) The preform is loaded into the negative pressure directional flow gas phase carbon deposition furnace, and the isothermal CVI densification process is adopted. The temperature is 950-1200 ° C, the pressure in the furnace is 5KPa, and the carbon source gas (C 3 H 6 ) at a flow rate of 3000L / h, and after 300-500 hours of densification treatment, a pyrolytic carbon matrix is formed.

[0038] (3) The porous carbon / carbon body was impregnated with 80 kg of furfurone resin in a vacuum-pressure impregnation tank, and 4% by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com