Patents

Literature

2297 results about "Carbon deposit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

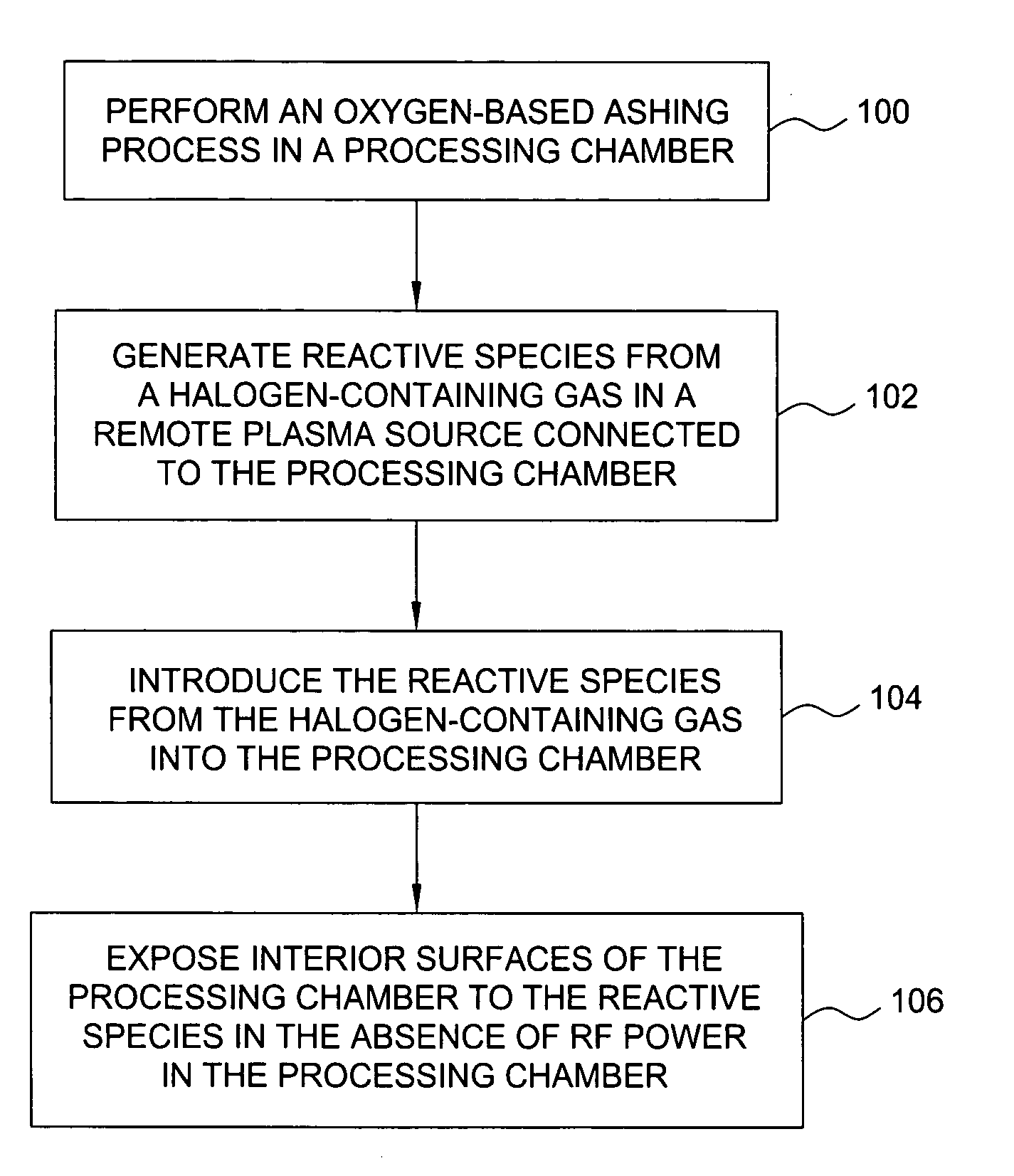

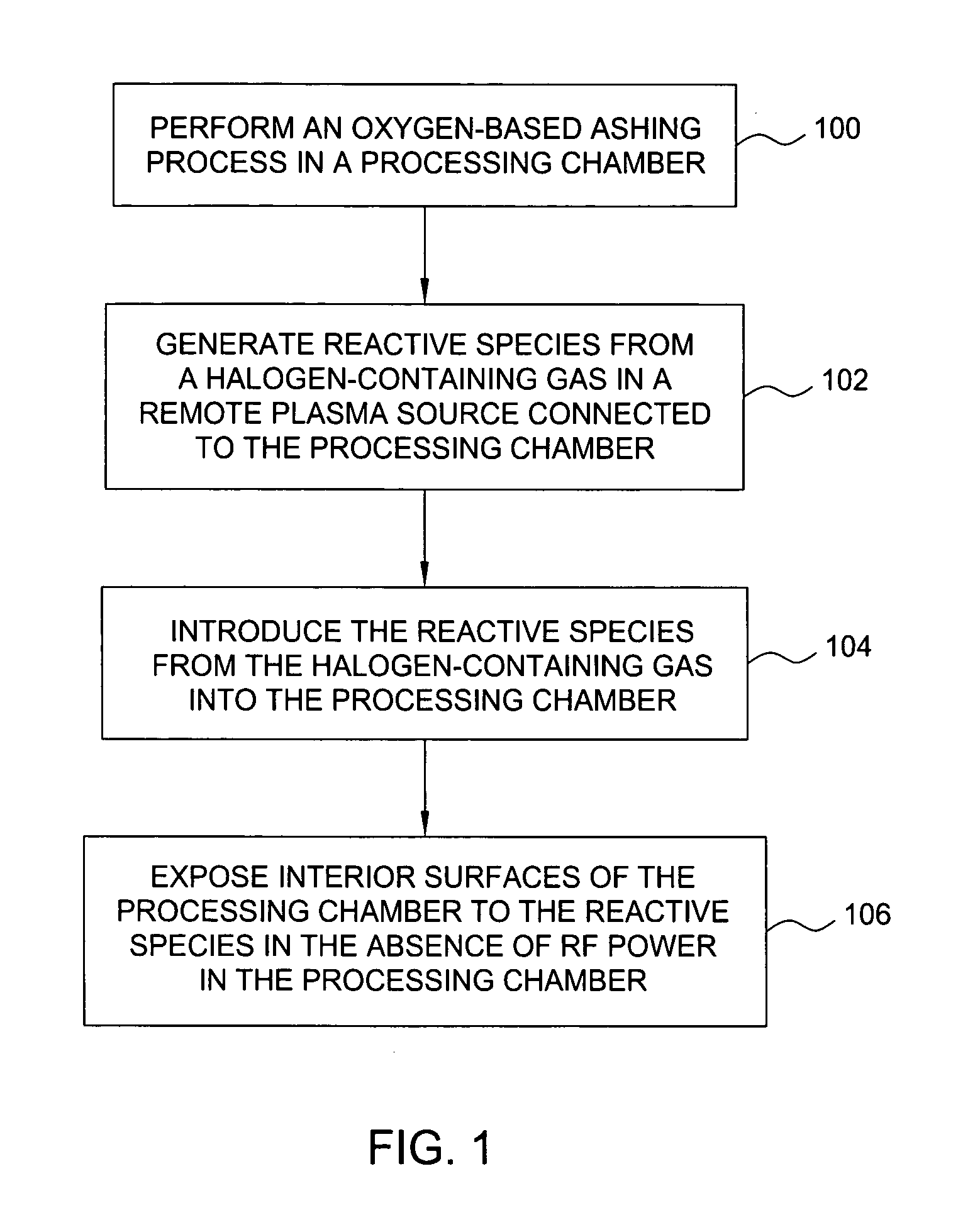

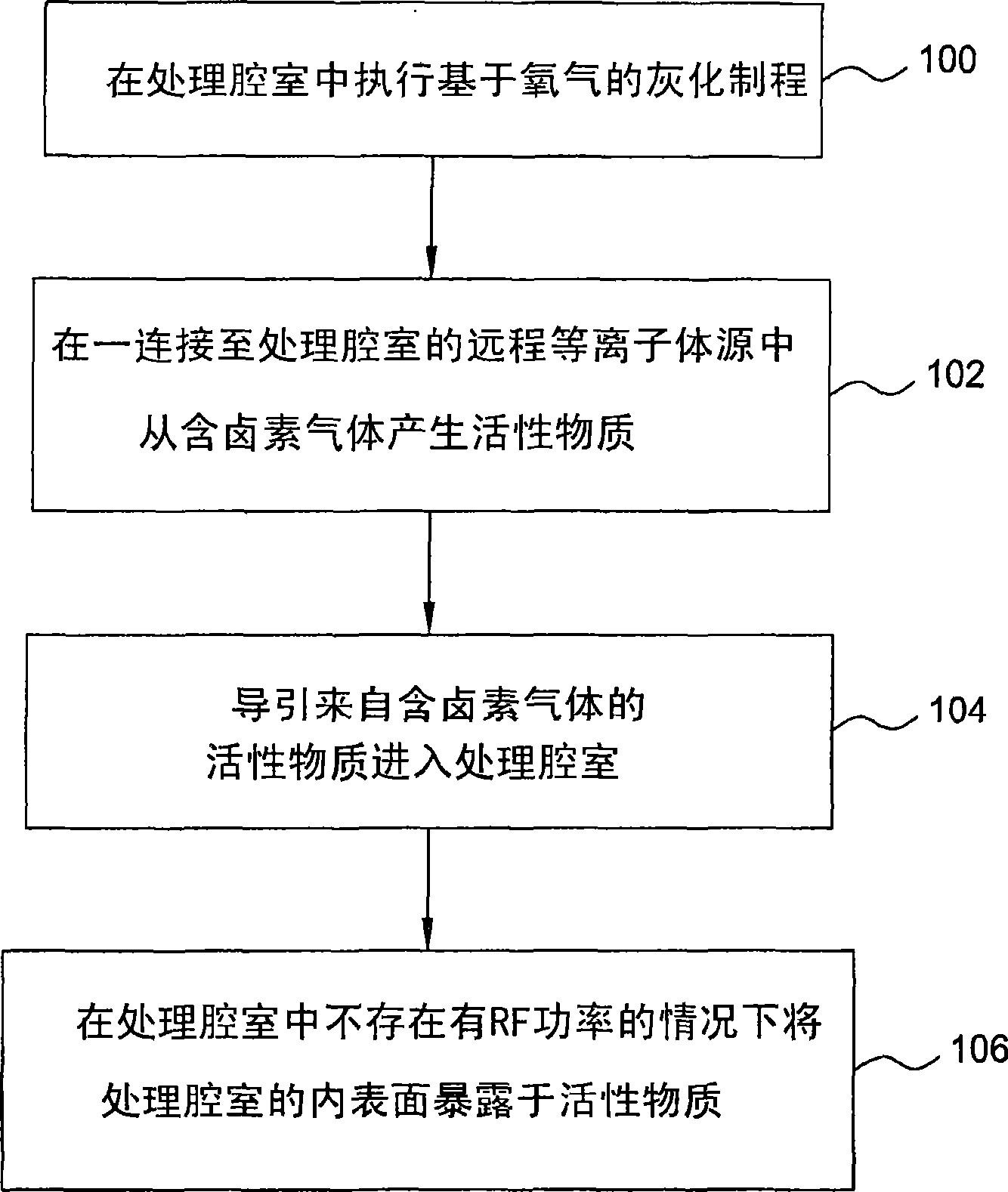

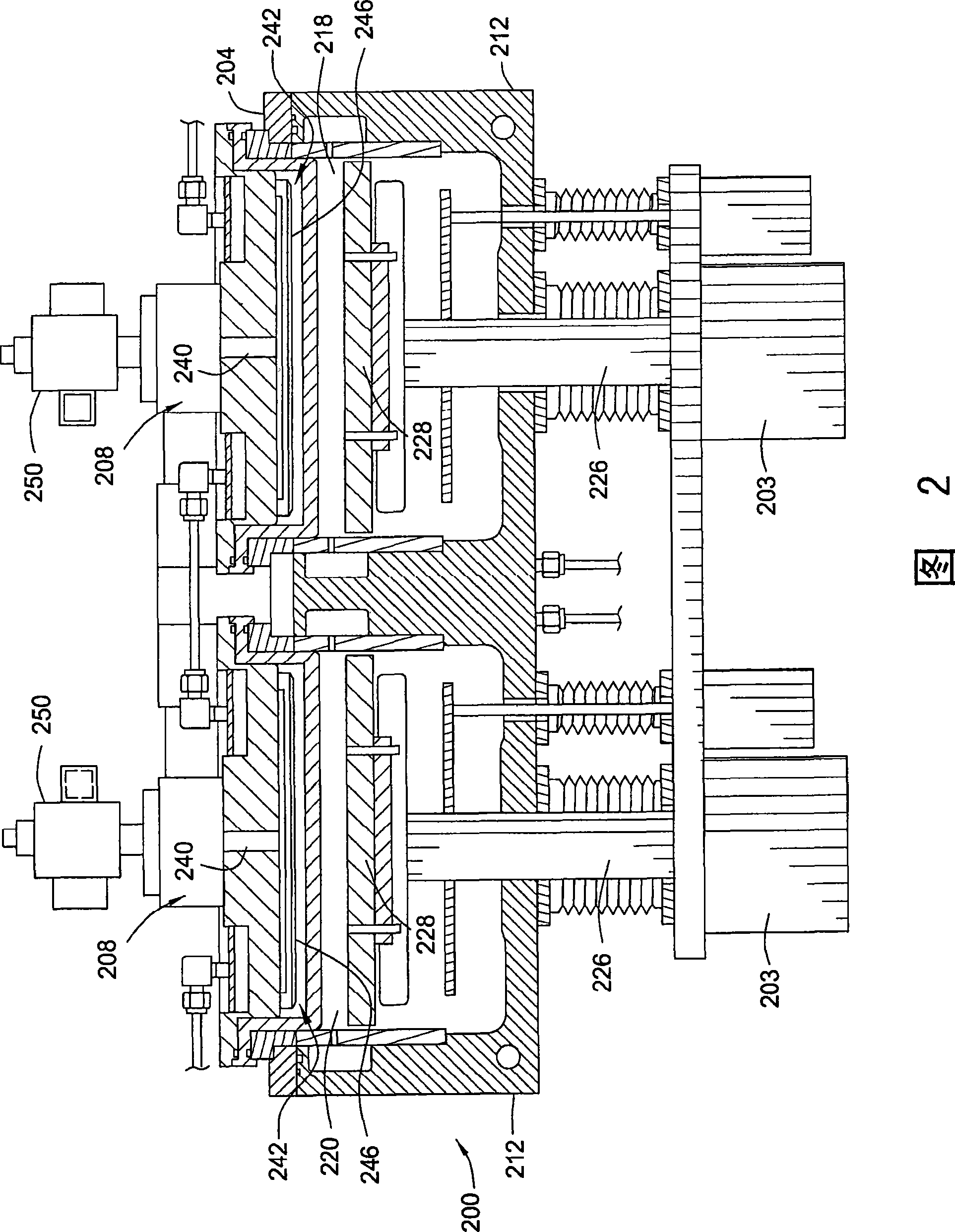

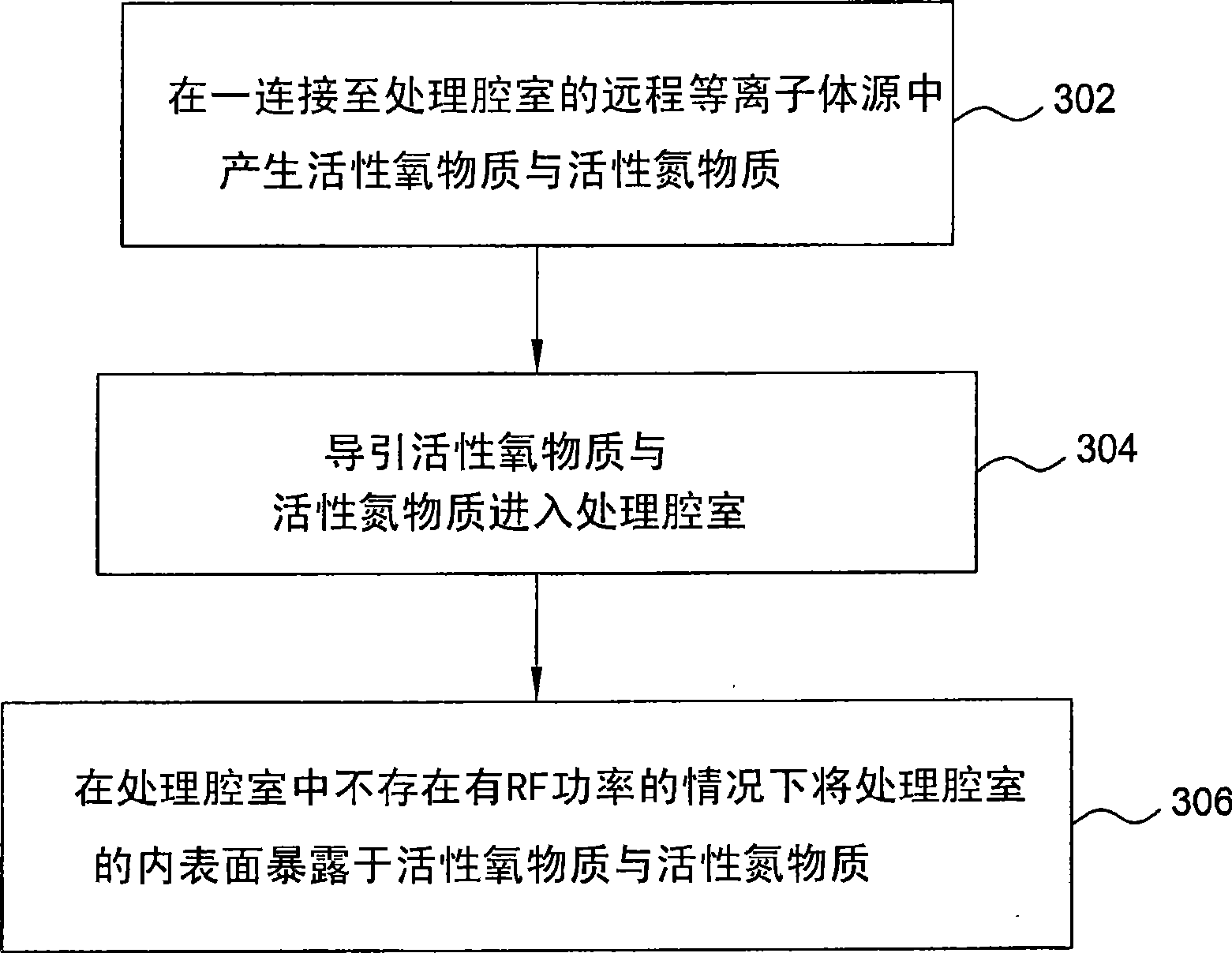

Enhancement of remote plasma source clean for dielectric films

Methods for cleaning semiconductor processing chambers used to process carbon-containing films, such as amorphous carbon films, barrier films comprising silicon and carbon, and low dielectric constant films including silicon, oxygen, and carbon are provided. The methods include using a remote plasma source to generate reactive species that clean interior surfaces of a processing chamber in the absence of RF power in the chamber. The reactive species are generated from an oxygen-containing gas, such as O2, and / or a halogen-containing gas, such as NF3. An oxygen-based ashing process may also be used to remove carbon deposits from the interior surfaces of the chamber before the chamber is exposed to the reactive species from the remote plasma source.

Owner:APPLIED MATERIALS INC

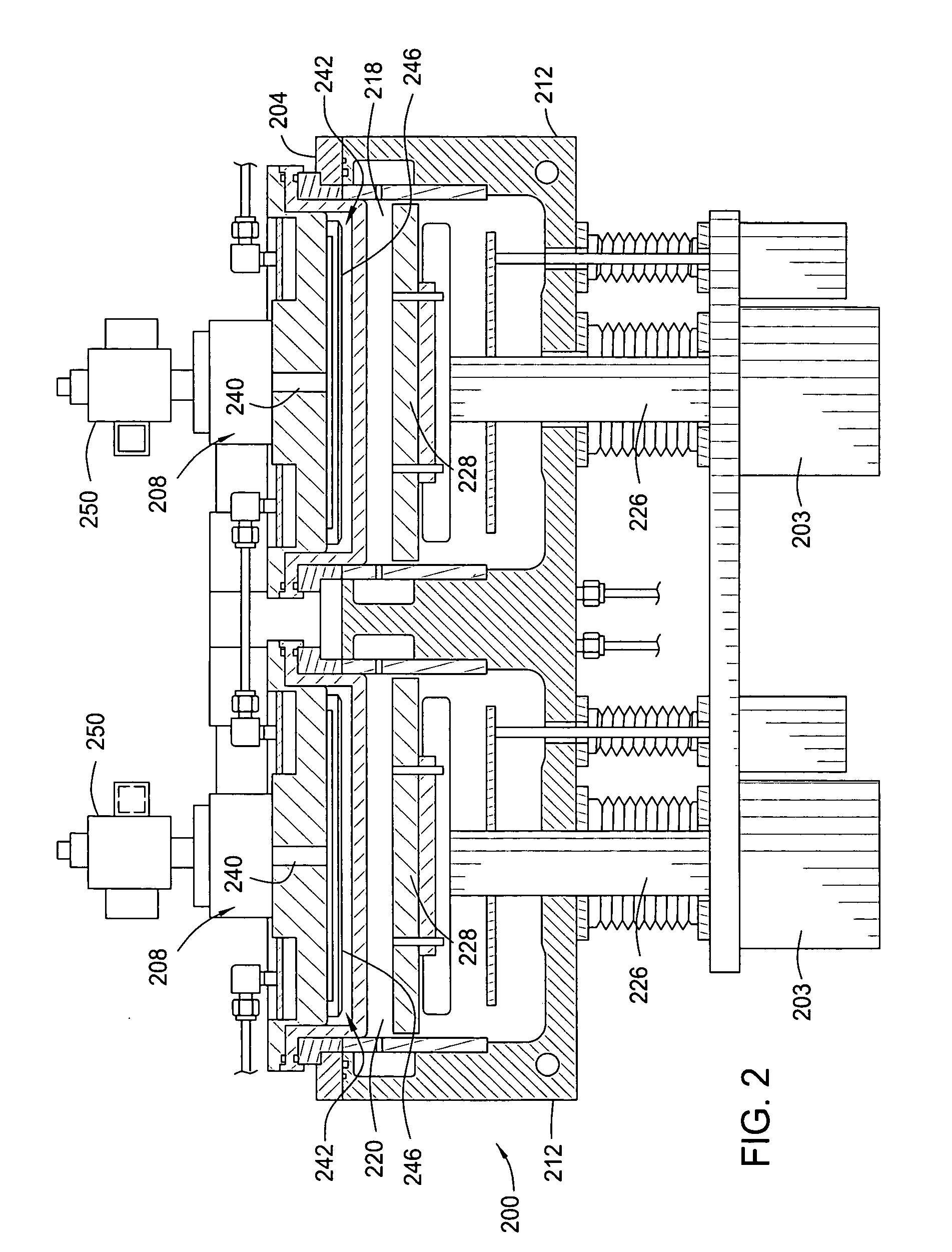

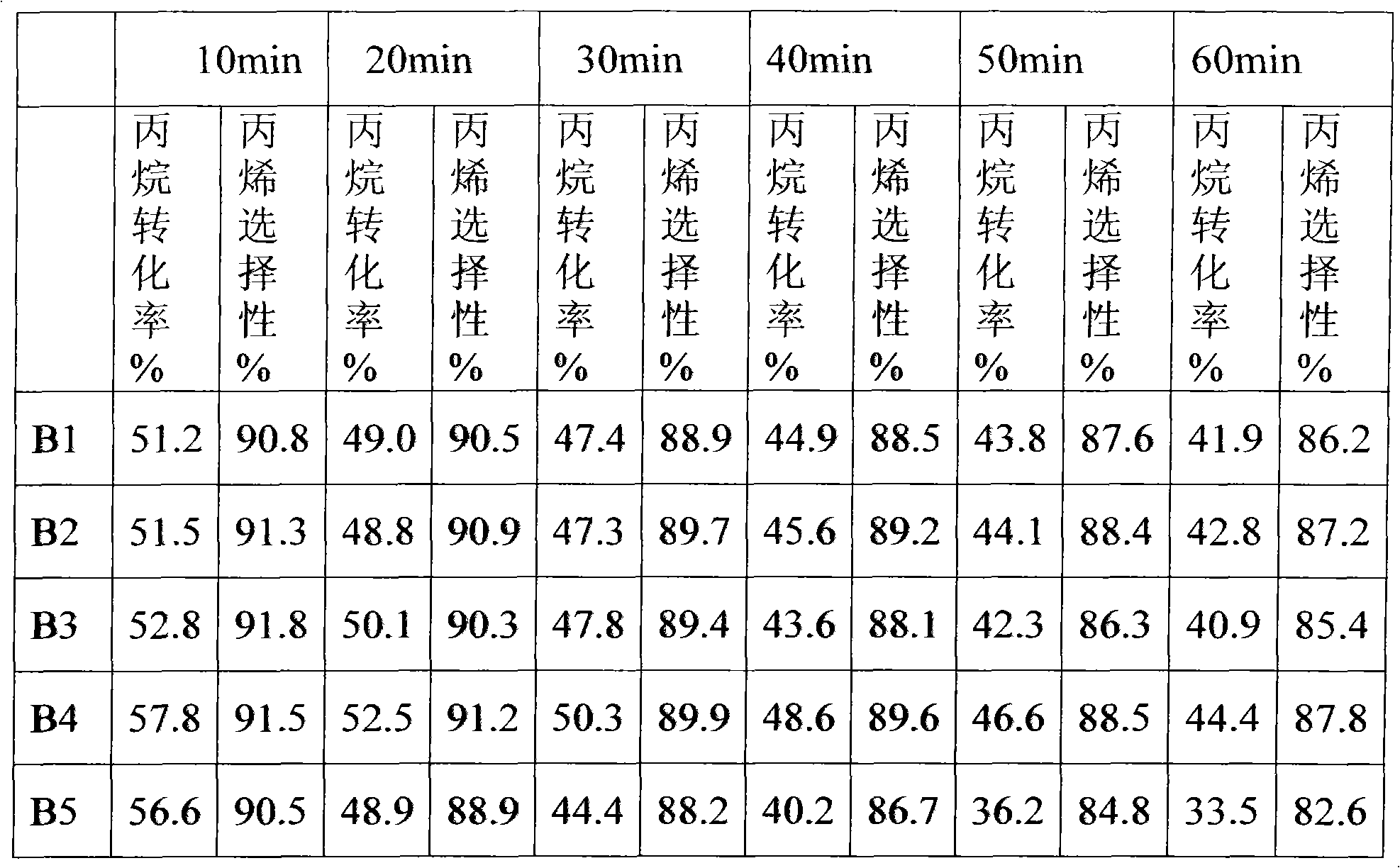

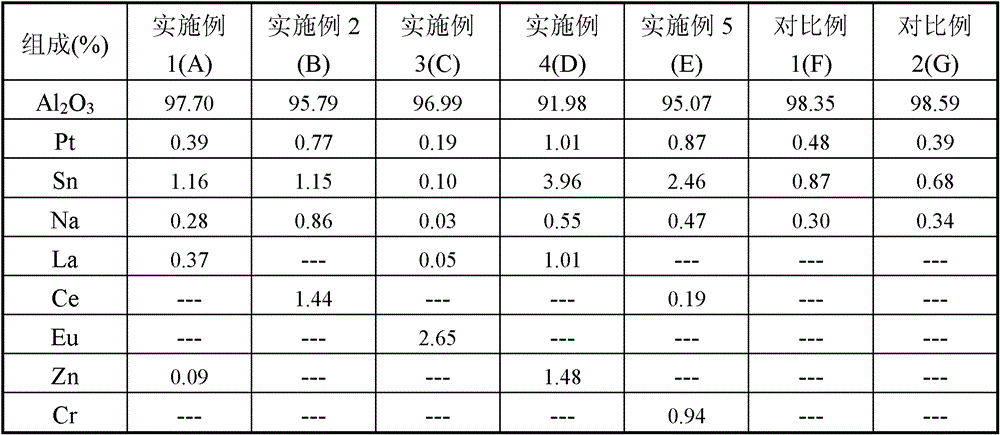

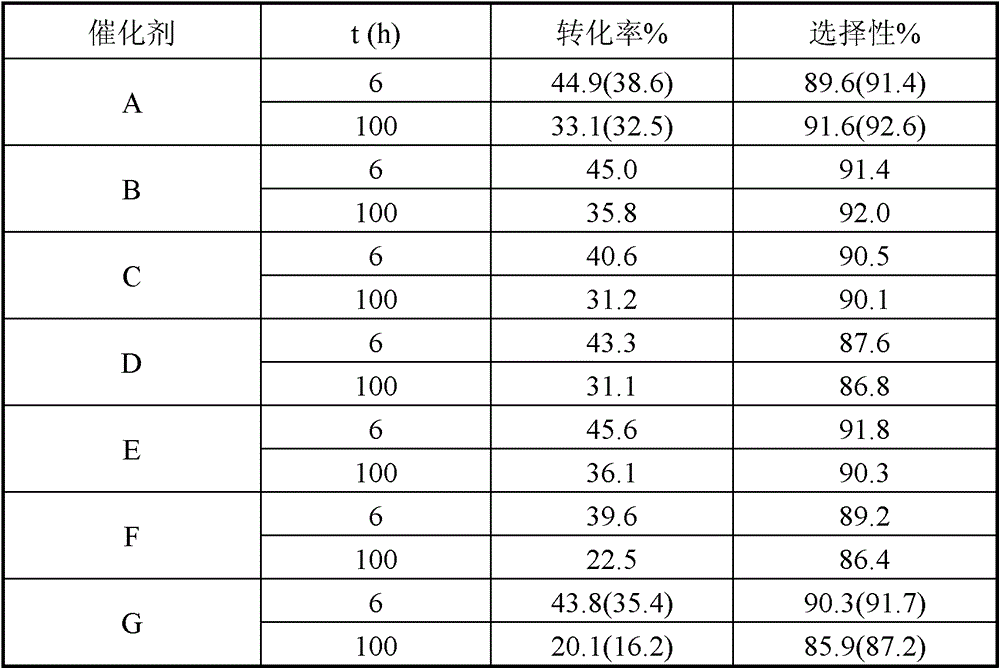

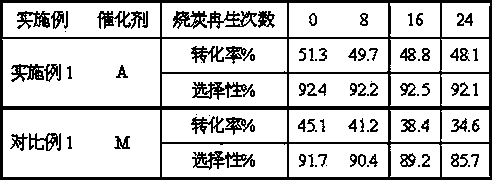

Low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN101940922AEvenly distributedEnhanced charcoal capacityCatalyst activation/preparationHydrocarbonsAlkaneDehydrogenation

The invention discloses a low-carbon alkane dehydrogenation catalyst and a preparation method thereof. The catalyst is prepared from chromium serving as an active metal ingredient, alkali metal serving as an auxiliary catalytic ingredient and chromium-containing aluminum oxide serving as a carrier, wherein the weight content of the chromium oxide in the carrier is 2.0 to 15.0 percent. In the method, the active metal ingredient, namely chromium, is introduced into the aluminum oxide carrier by partially using a kneading method and partially using an immersion method; pseudo-boehmite mixed with chromium is processed by adopting a three-step roasting method and a hydrothermal method; and thus, the porous structure and the surface character of the carrier can be improved, the content and the distribution of the active metal chromium in the carrier and the mutual effect between the active metal and the aluminum oxide are further modulated, the activity and the stability of the catalyst are improved, the carbon depositing resistance of the catalyst is enhanced, and the service life of the catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Enhancement of remote plasma source clean for dielectric films

Methods for cleaning semiconductor processing chambers used to process carbon-containing films, such as amorphous carbon films, barrier films comprising silicon and carbon, and low dielectric constant films including silicon, oxygen, and carbon are provided. The methods include using a remote plasma source to generate reactive species that clean interior surfaces of a processing chamber in the absence of RF power in the chamber. The reactive species are generated from an oxygen-containing gas, such as O2, and / or a halogen-containing gas, such as NF3. An oxygen-based ashing process may also be used to remove carbon deposits from the interior surfaces of the chamber before the chamber is exposed to the reactive species from the remote plasma source.

Owner:APPLIED MATERIALS INC

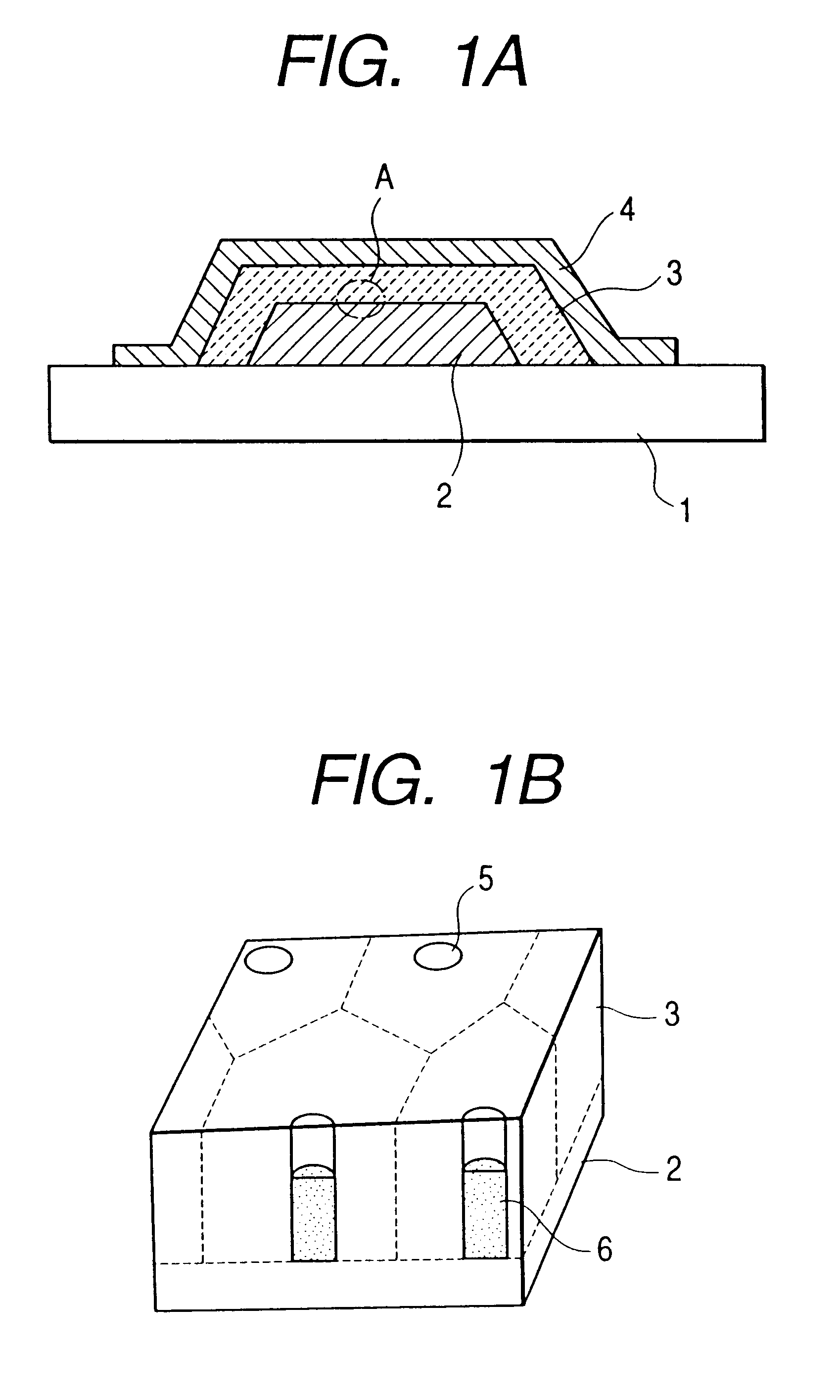

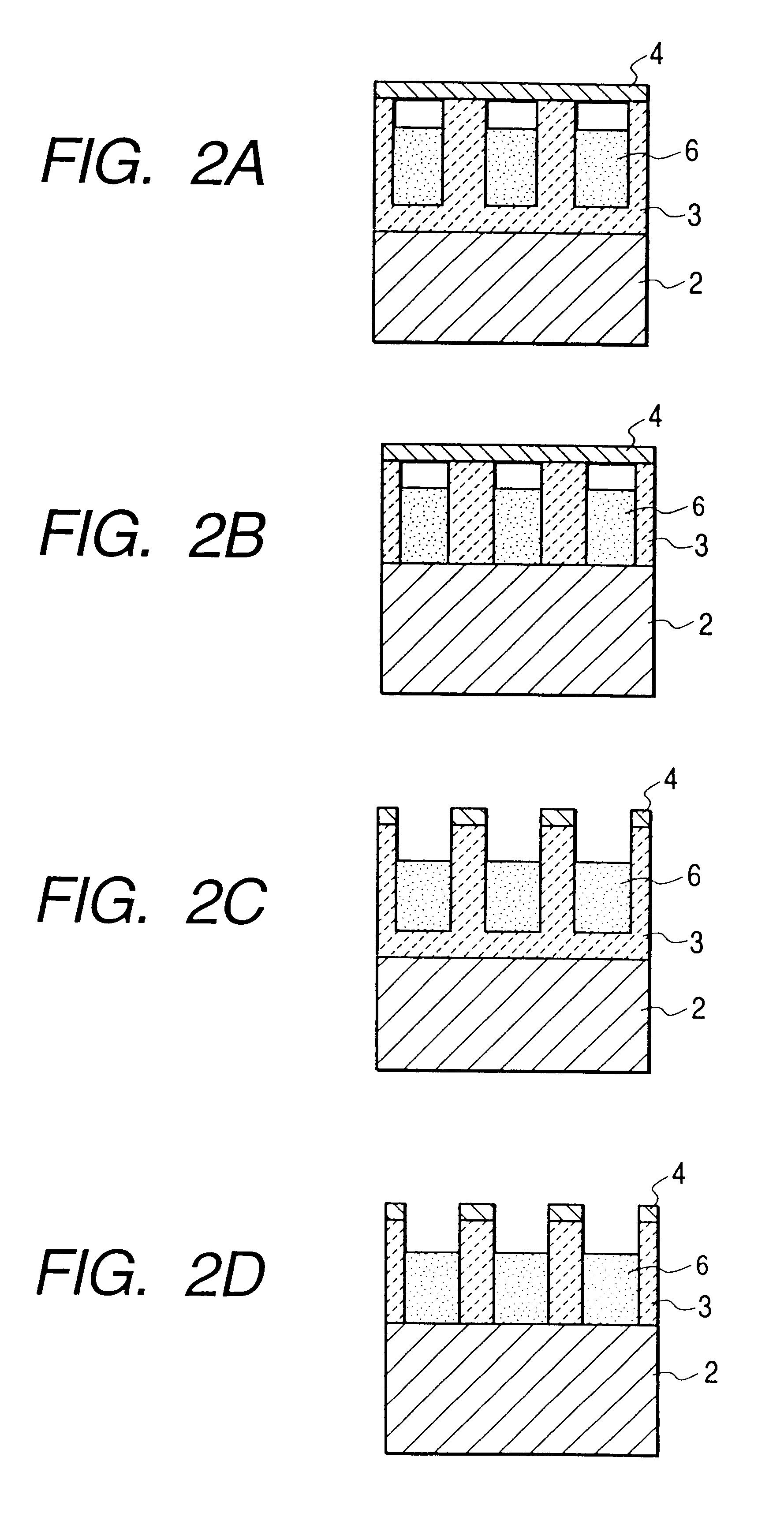

Electron-emitting device provided with pores that have carbon deposited therein

An electron-emitting device disclosed has stable electron emission characteristics with little variation, in high electron emission efficiency, in high definition, and at low driving voltage. The electron-emitting device disclosed is constructed in such structure that on a substrate there are a lower electrode, an insulating layer having pores, and an upper electrode stacked in this order, the insulating layer is an anodic oxide layer, and a carbon deposit is formed in the pores.

Owner:CANON KK

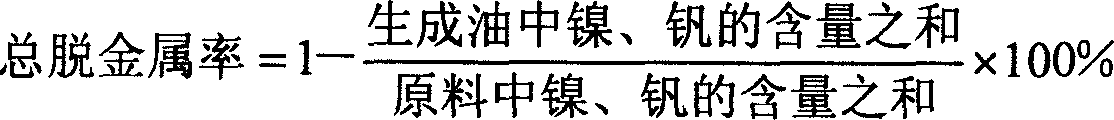

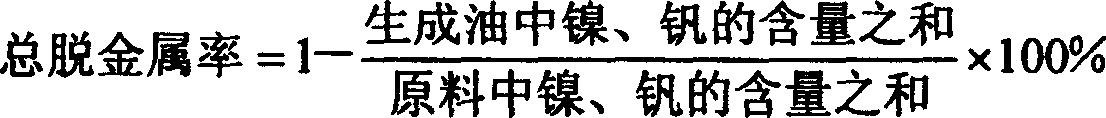

Demetallization catalyst of addig hydrogen to residual oil and preparation method

ActiveCN1626625ALess carbon depositHigh hydrodemetallization activityRefining to eliminate hetero atomsHalogenHydrogen

A hdyrocatalyst for removing metals from residual oil is composed of a macroreticular aluminium carrier and the Mo and / or W and Co and / or Ni, which are carried by said carrier. It features that said carrier contains aluminium oxide (95-99 wt%) and halogen (1-5) and has lower acidity, resulting in high demetallizing activity and low carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

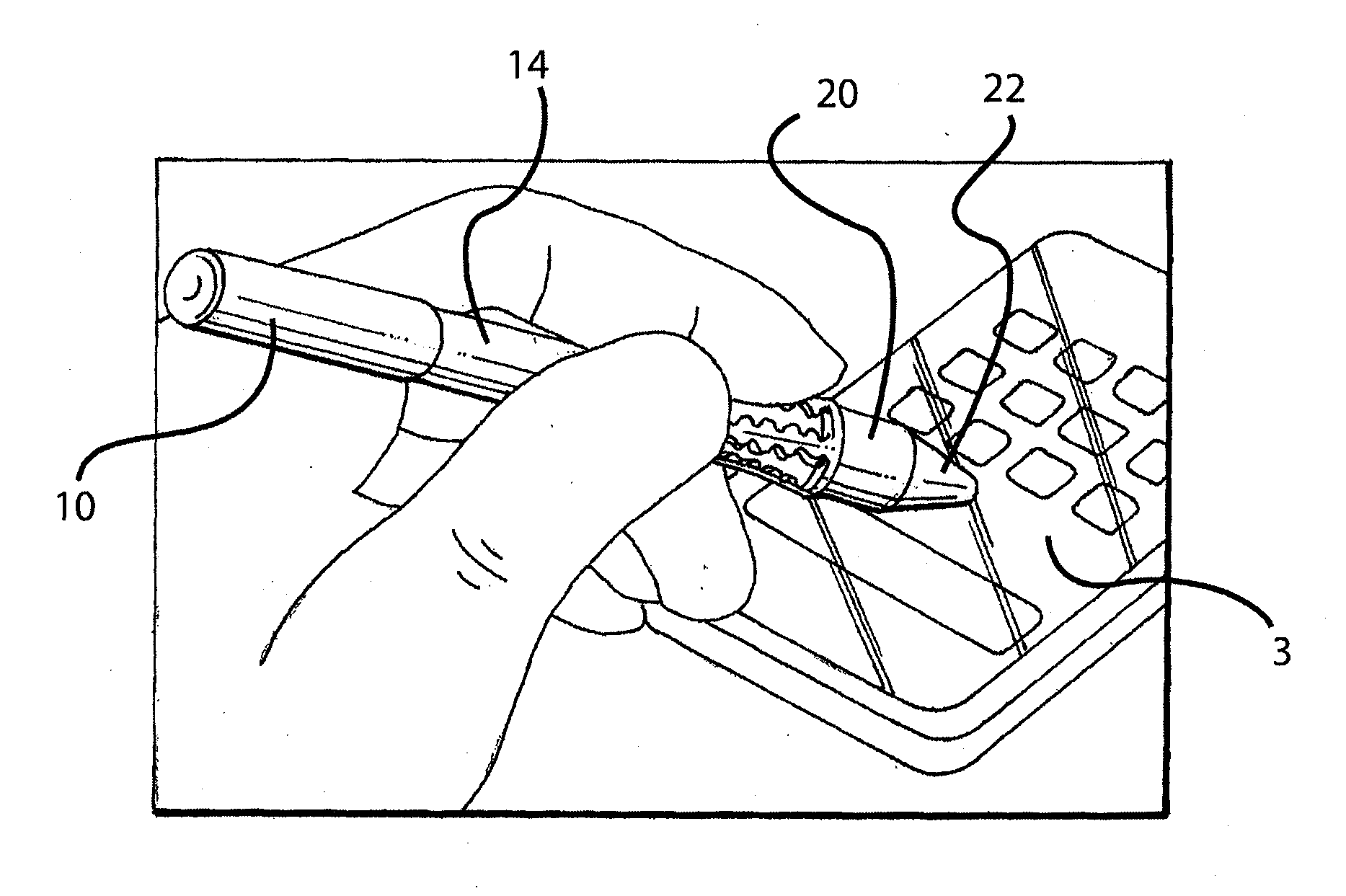

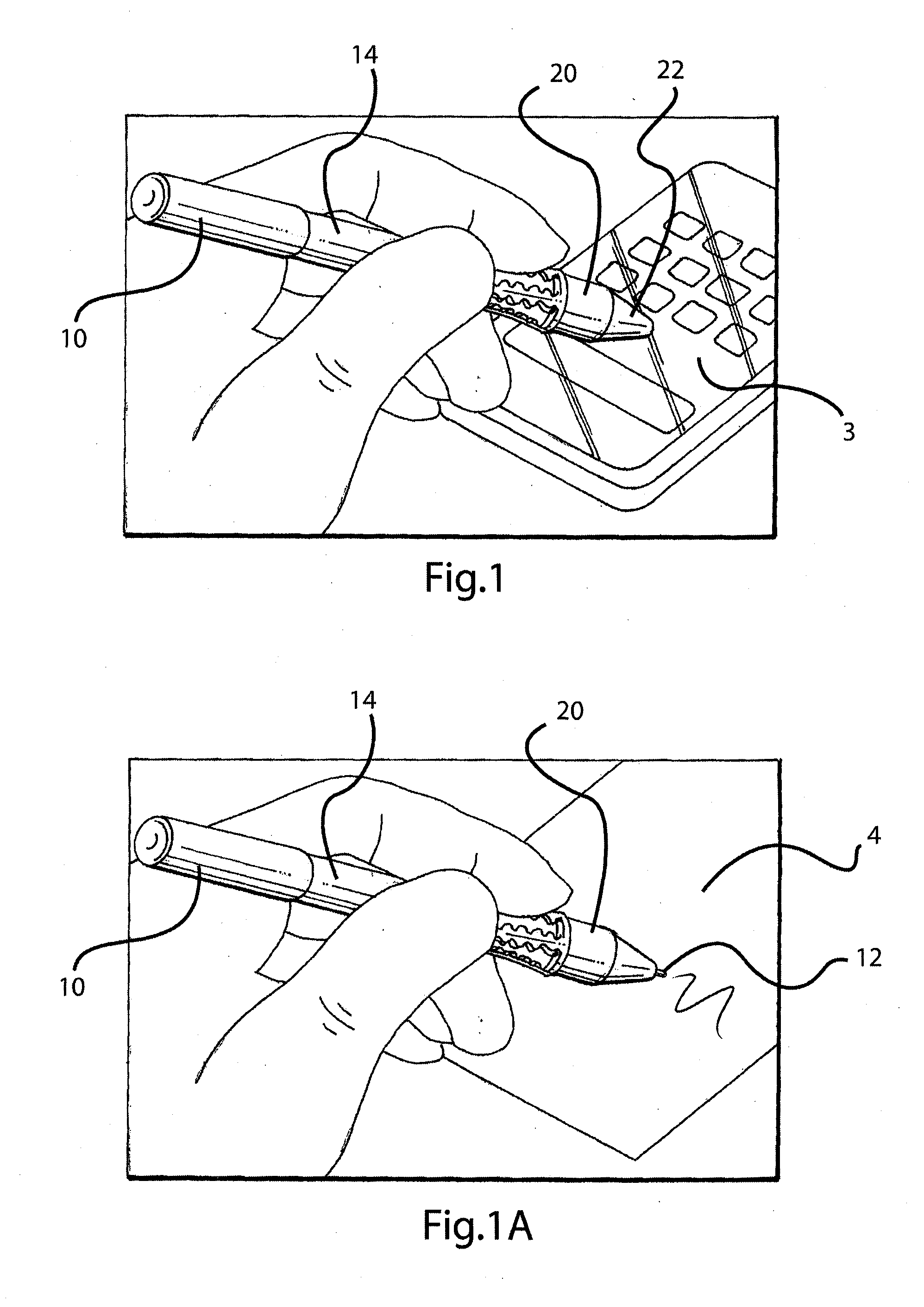

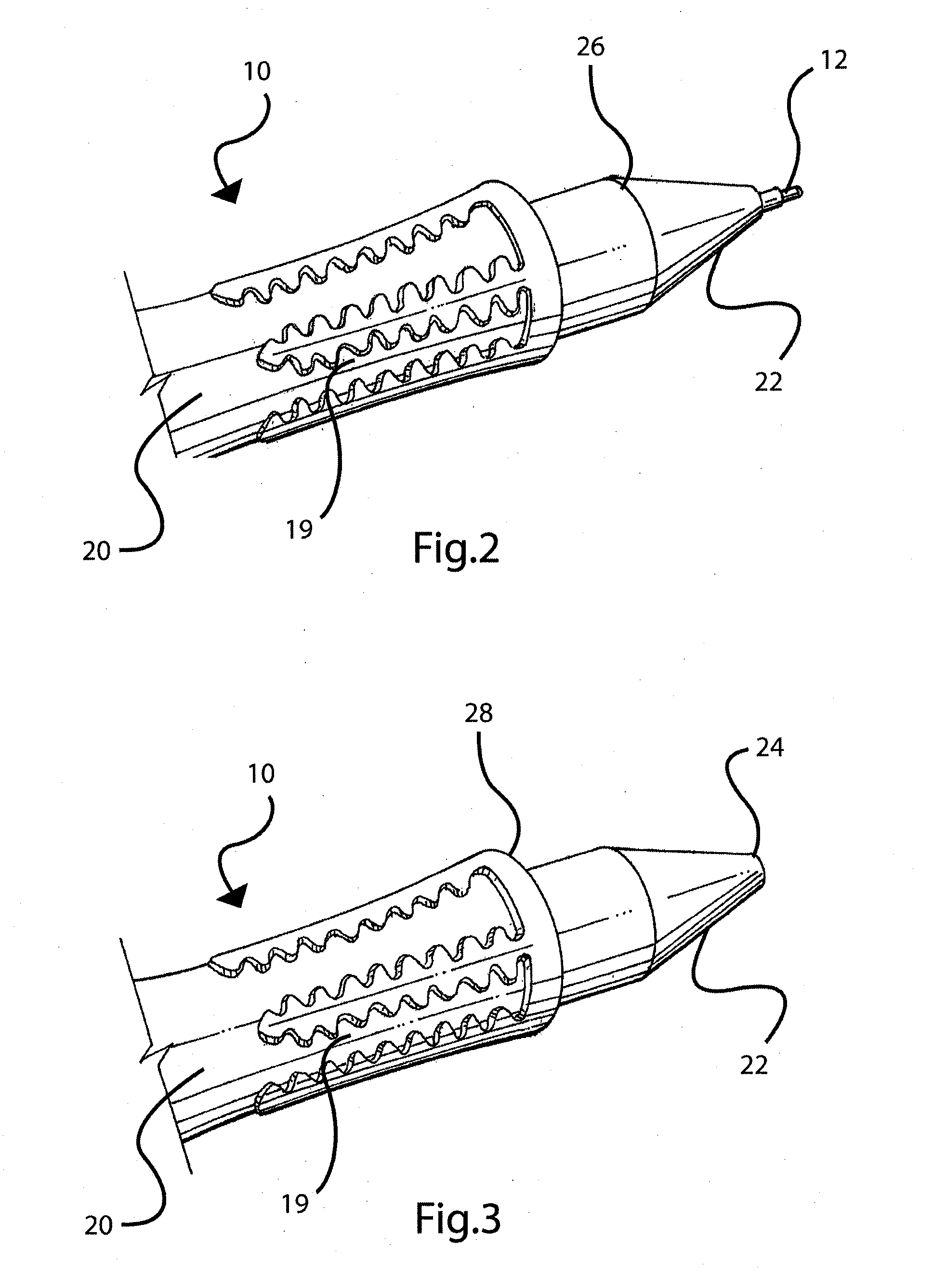

Electrically conductive touch pen

ActiveUS20130038579A1Easy to useEffective insulationWriting connectorsBall-point pensEngineeringTouchscreen

A combination writing pen and stylus is disclosed. The device has an internal ink cartridge deployable through a hole in the stylus tip. The stylus tip extends from a sleeve that is formed of a conductive elastomeric material. The sleeve extends up a rigid shaft of the device such that it contacts a sufficient ground. The stylus tip may be coated with a protective material that adjusts the coefficient of friction and prevents carbon deposits on the touch screen. A sufficient contact patch is achieved to simulate a human finger so as to overcome false positives from common touch screen logic. This is done by altering tip geometries around an air cavity within the sleeve.

Owner:PIXEL PEN LLC

Demetallization catalyst of addig hydrogen to residual oil and preparation method

ActiveCN1267537COvercome the disadvantage of high carbon depositionLess carbon depositRefining to eliminate hetero atomsHalogenHydrogen

A hdyrocatalyst for removing metals from residual oil is composed of a macroreticular aluminium carrier and the Mo and / or W and Co and / or Ni, which are carried by said carrier. It features that said carrier contains aluminium oxide (95-99 wt%) and halogen (1-5) and has lower acidity, resulting in high demetallizing activity and low carbon deposit.

Owner:CHINA PETROLEUM & CHEM CORP +1

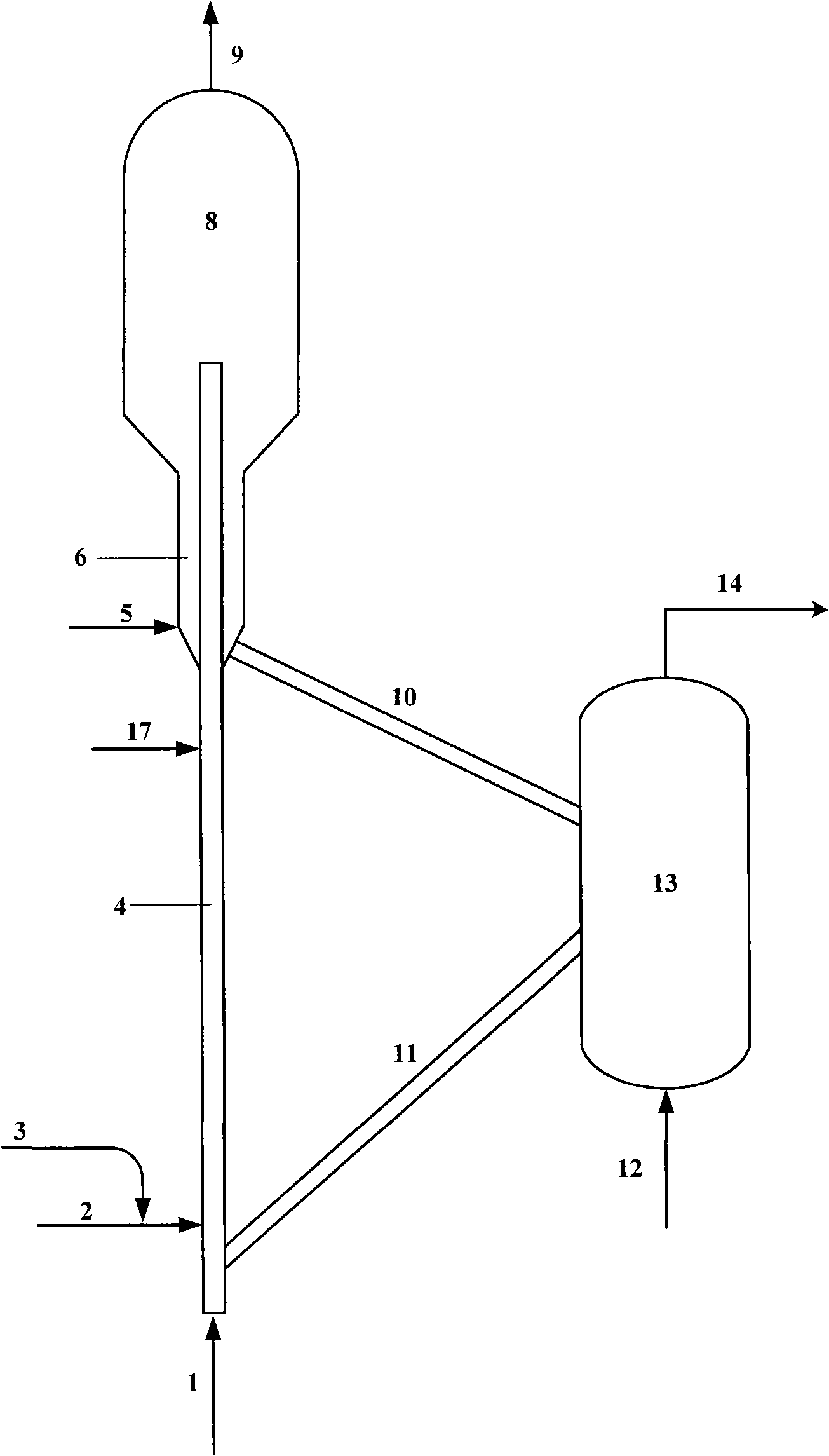

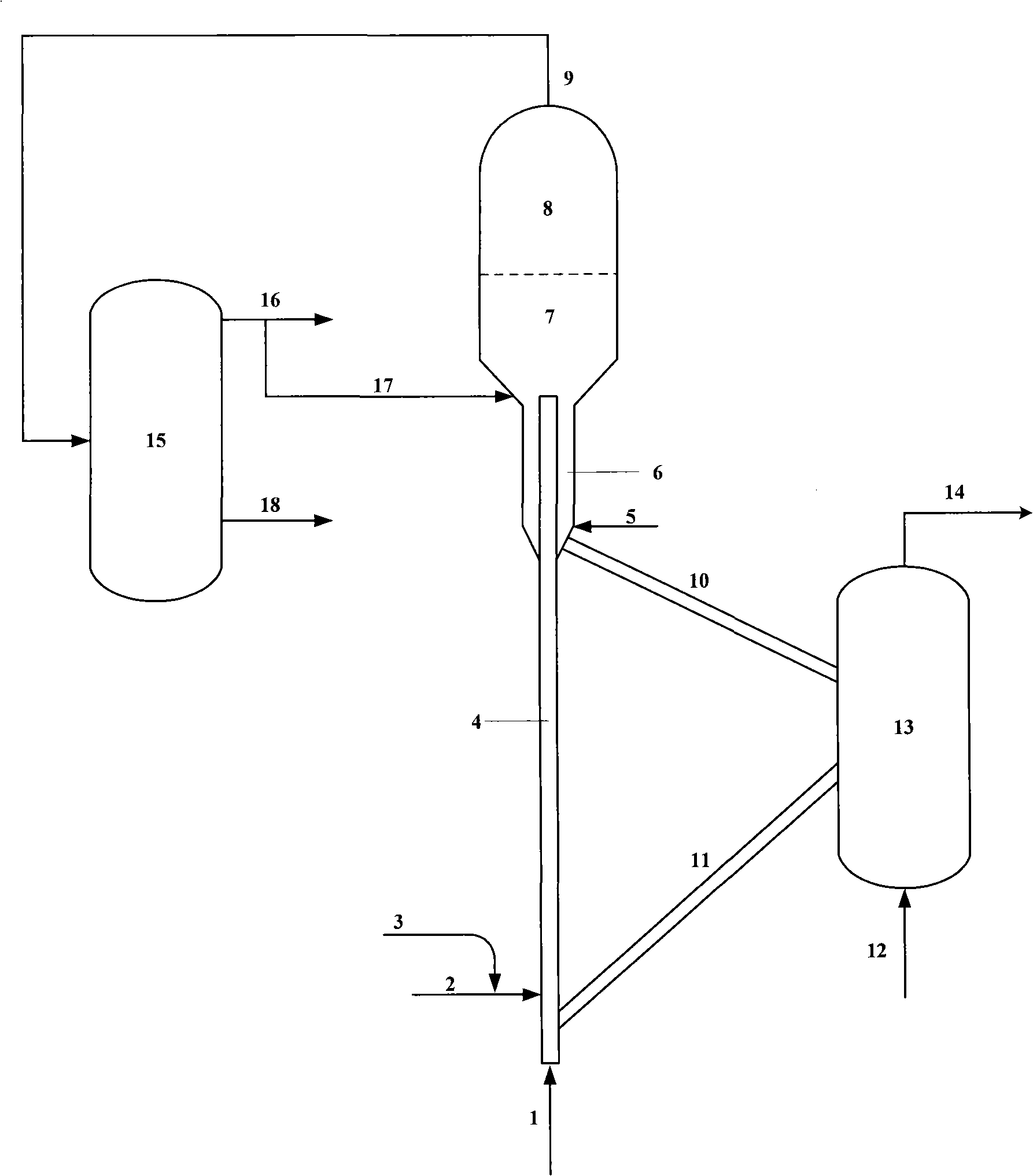

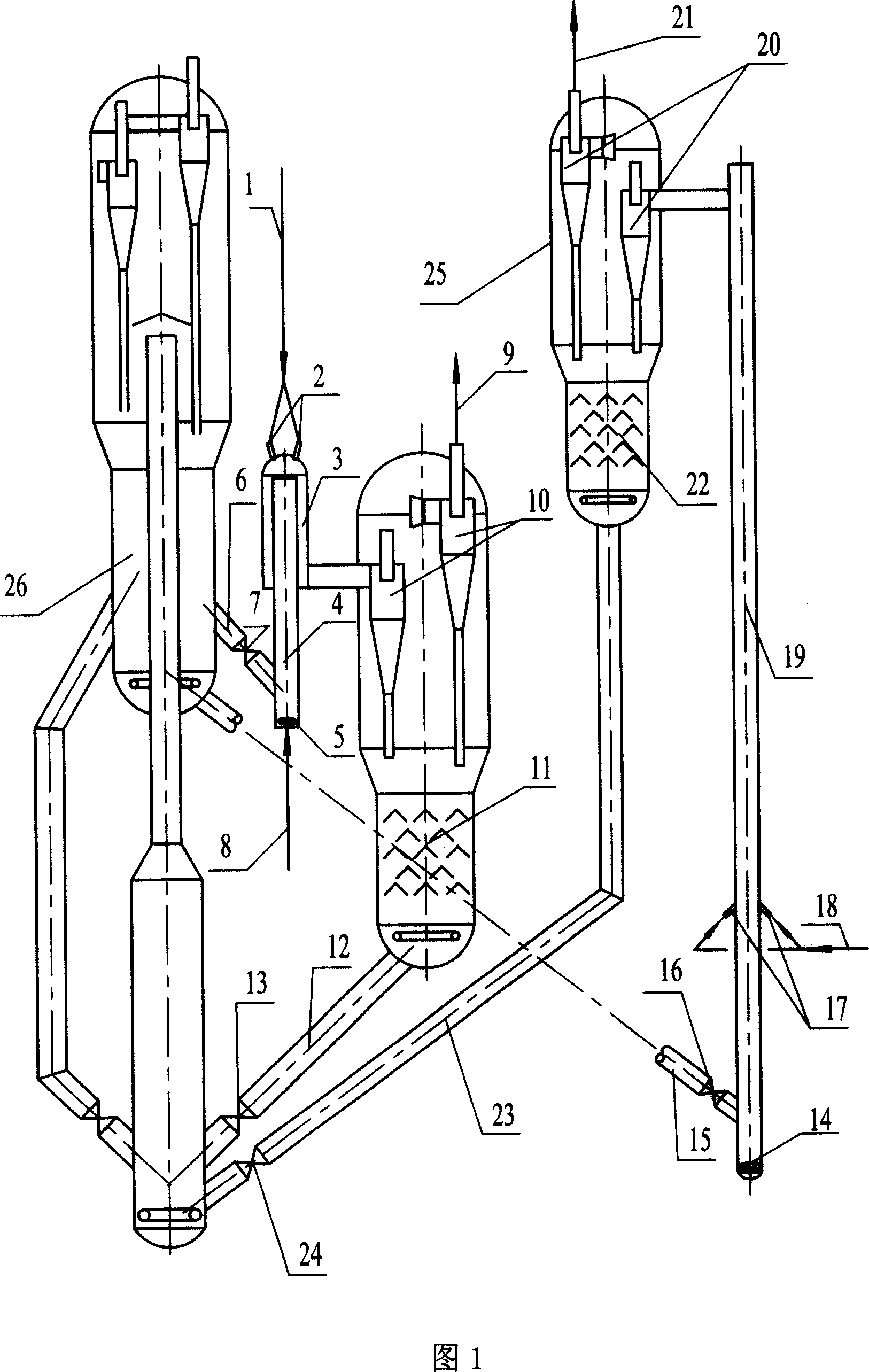

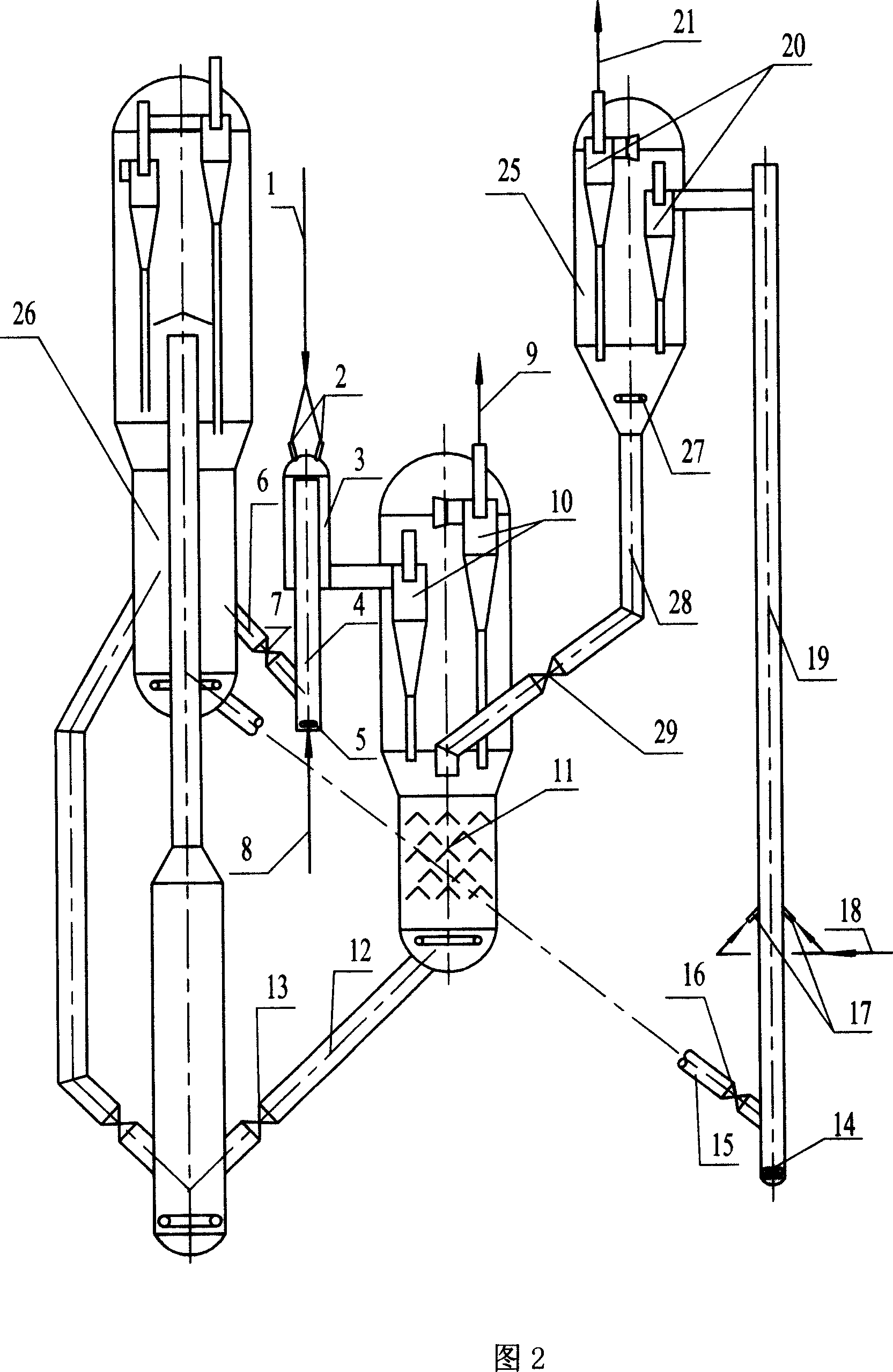

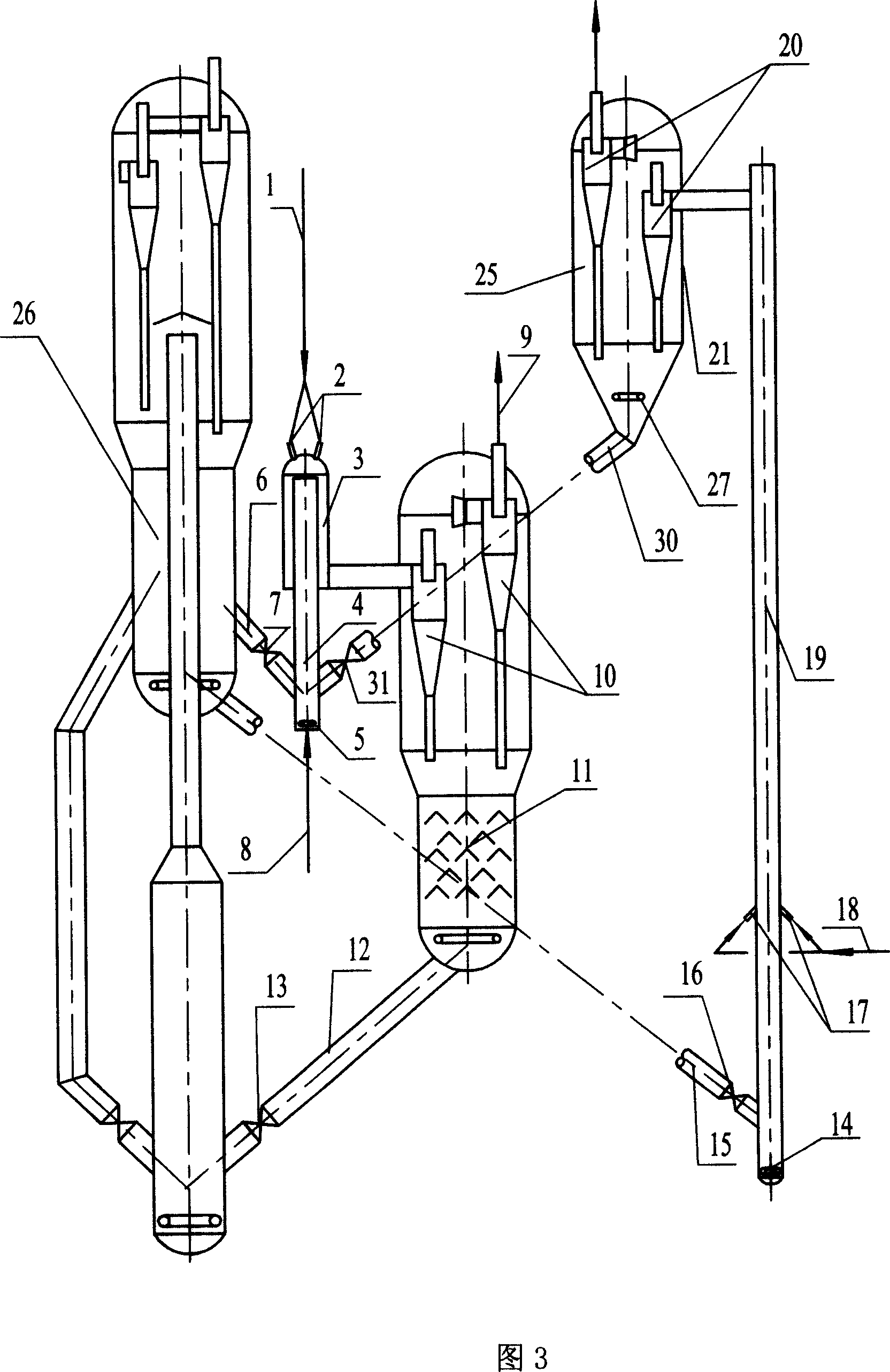

Hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon

ActiveCN104560154AInhibition of hydrogen transfer reactionsFast carbanion cracking reactionTreatment with plural serial stages onlyCarbon depositAromatic hydrocarbon

The invention relates to a hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon. The method comprises steps as follows: a heavy hydrocarbon raw material and a cracking catalyst are contacted in a first reactor and have a catalytic cracking reaction, a first carbon deposit catalyst and a first reaction product are obtained through separation; a light hydrocarbon raw material is injected from the upstream part of a second reactor, a medium hydrocarbon raw material is injected from the middle of the second reactor, and the mixture has a catalytic cracking reaction; a reaction mixture produced in the second reactor is introduced to the third reactor and continuously has a reaction, and a second carbon deposit catalyst and a second reaction product are obtained through separation; the cracking catalyst adopts a cracking catalyst containing modified beta zeolite, and the modified beta zeolite adopts phosphorus and transition metal M modified beta zeolite. With adoption of the method, higher propylene yield and light aromatic hydrocarbon yield can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

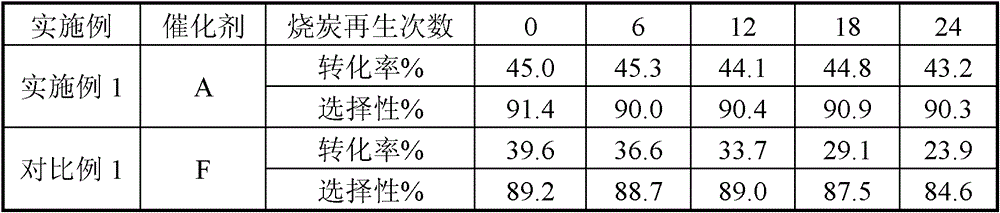

Catalyst for low-carbon alkane dehydrogenation and preparation method thereof

ActiveCN103055857AImprove performanceHigh selectivityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDehydrogenation

The invention relates to a catalyst for preparing low-carbon alkenes by low-carbon alkane dehydrogenation and a preparation method thereof. The invention mainly solves the problems of high inactivation tendency of carbon deposit and poor stability of the catalyst in the high-temperature service process in the prior art. The technical scheme is as follows: metal tin and other transition metal assistants are introduced into the supporter in the alumina supporter precursor kneading process, and extruded to form the composite metal oxide supporter; and an impregnation method is utilized to support the platinum compound, i.e. a platinum-impregnated soluble salt water solution is roasted by drying and treated with steam to obtain the platinum-tin catalyst. The technical scheme well solves the problems, and can be used in industrial production of the catalyst for preparing low-carbon alkenes by low-carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

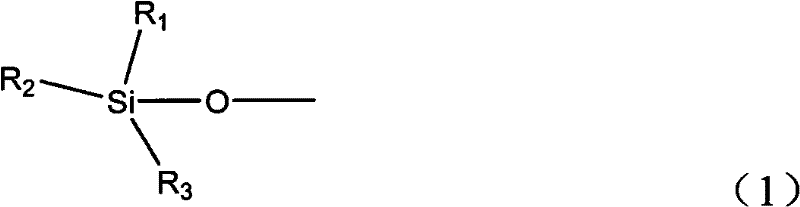

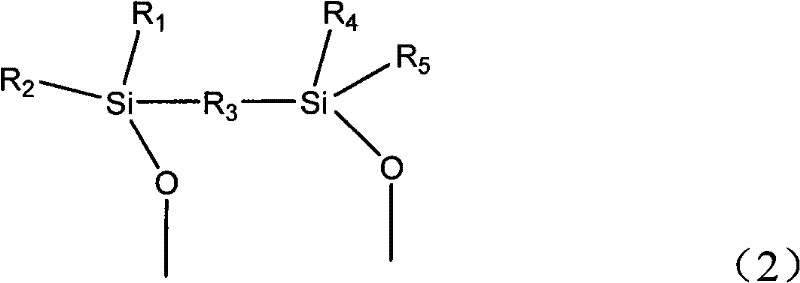

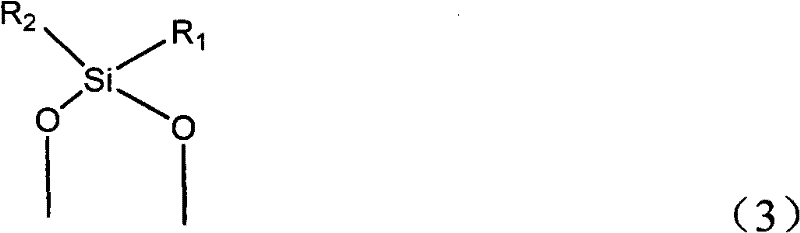

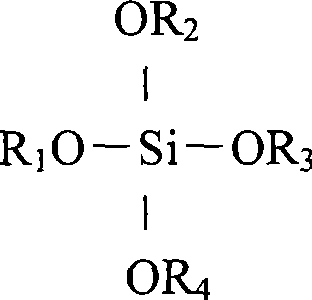

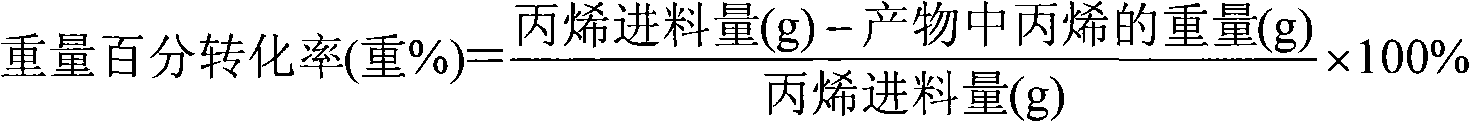

Method for preparing alcohols by selectively hydrogenating aldehydes

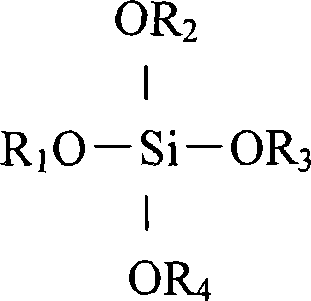

ActiveCN102408304AHigh selectivityHydrophobicOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesReaction temperature

The invention relates to a method for preparing alcohols by selectively hydrogenating aldehydes, belonging to hydrogenation technologies. In order to meet the requirements of people on two aspects, i.e. the improving of the selectivity on preparing the alcohols by hydrogenating the aldehydes and the prolonging of the service life of a catalyst currently, the method proposes that: the aldehydes are taken as raw materials; the reaction temperature is 20-300 DEG C; the reaction pressure is 0.1-7.0 MPa; the weight space velocity of the aldehydes is 0.02-20 h<-1>; the aldehydes and hydrogen gas are in contact with a hydrogenation catalyst; and the aldehydes are produced into corresponding alcohols through selectively hydrogenating. In the method, the hydrogenation catalyst comprises a carrier, a metal active component and silane groups; the silane groups are grafted through a silylanizing treatment; and the content of the silane groups in the total weight of the catalyst is 0.05 wt% to 25 wt%. Compared with the existing method, with the adoption of the catalyst in the method provided by the invention, the selectivity is high, the amount of byproducts, such as ethers, esters and acetals is greatly lowered; and meanwhile, the generation amount of carbon deposit is little, so that the catalyst has longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

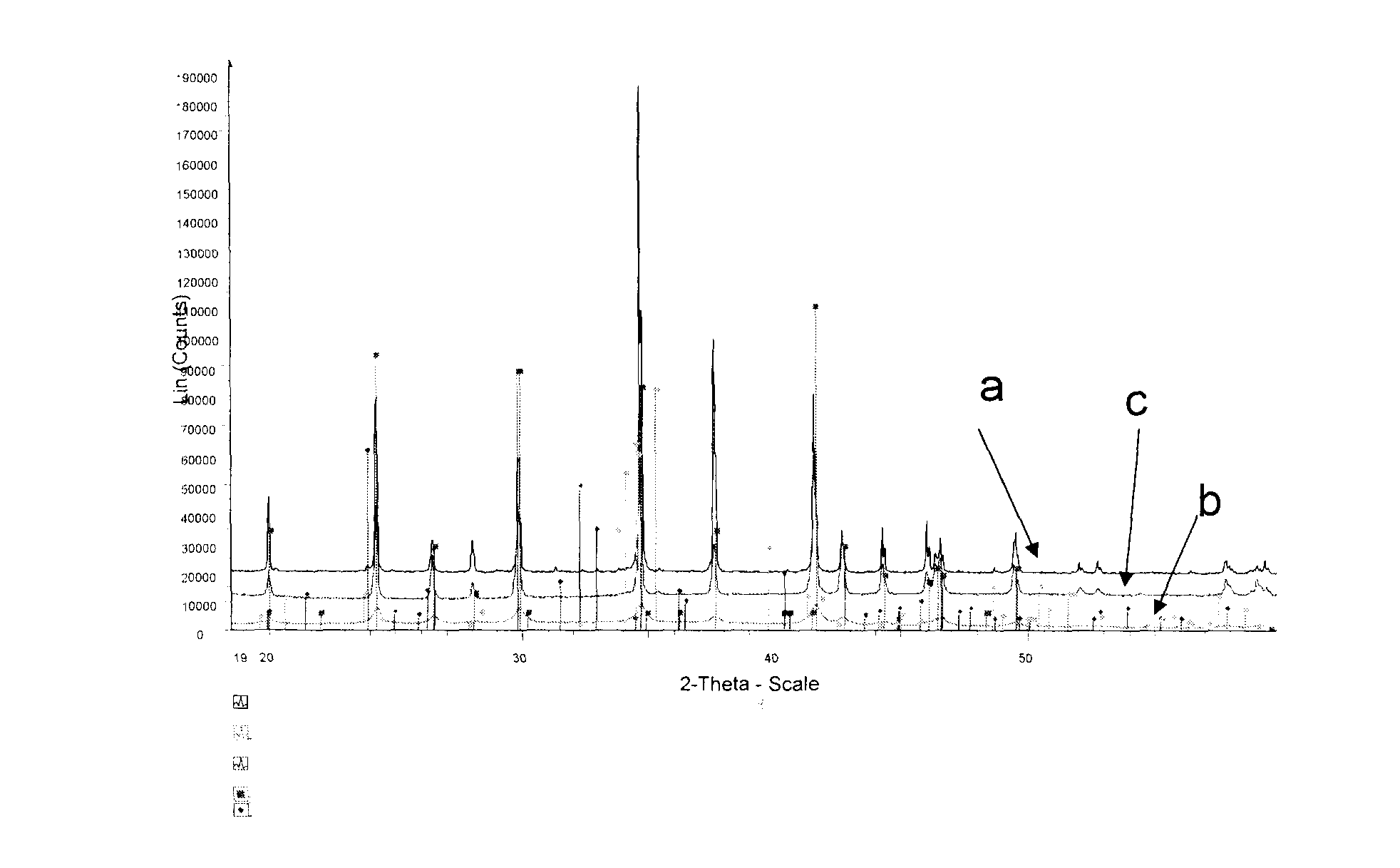

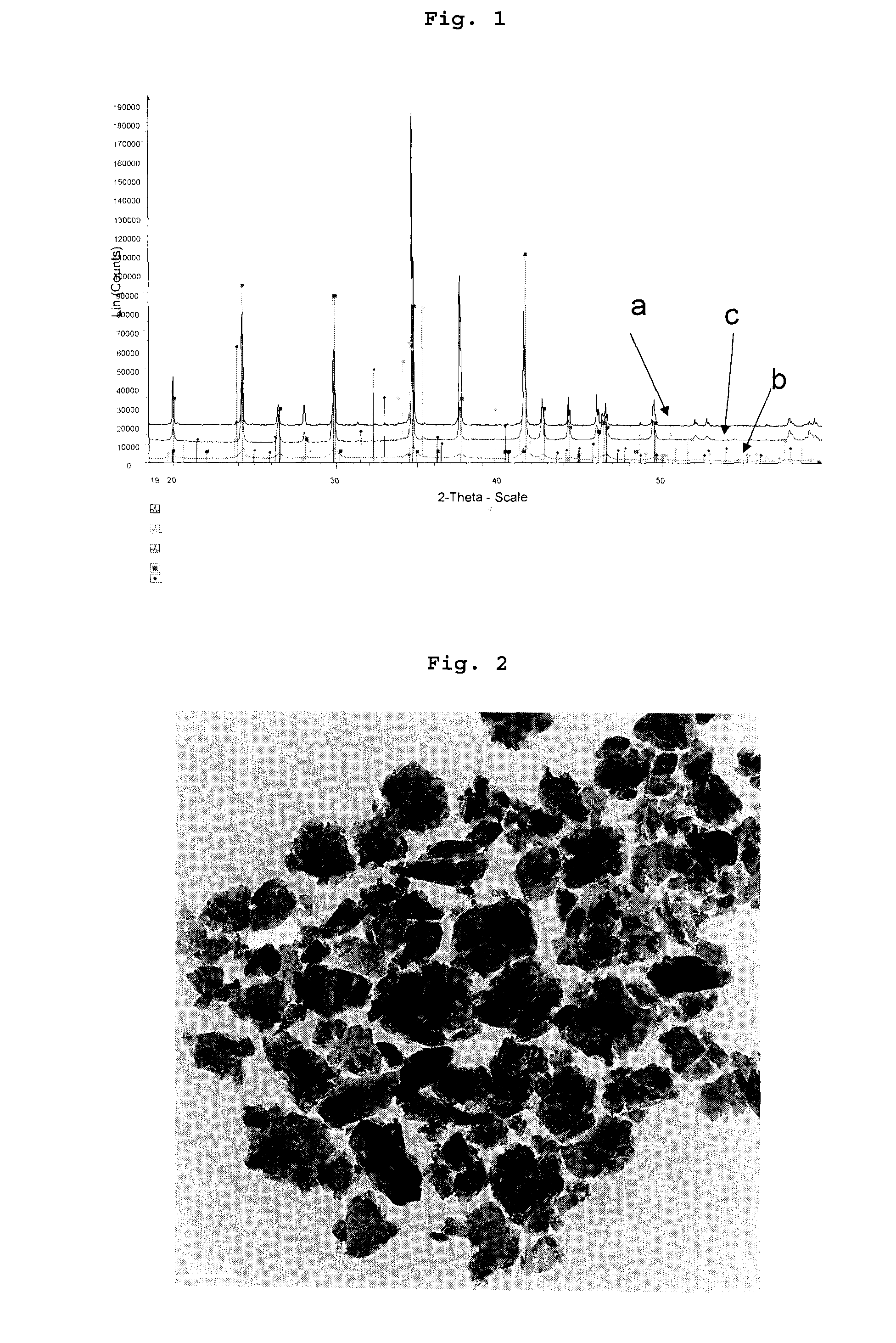

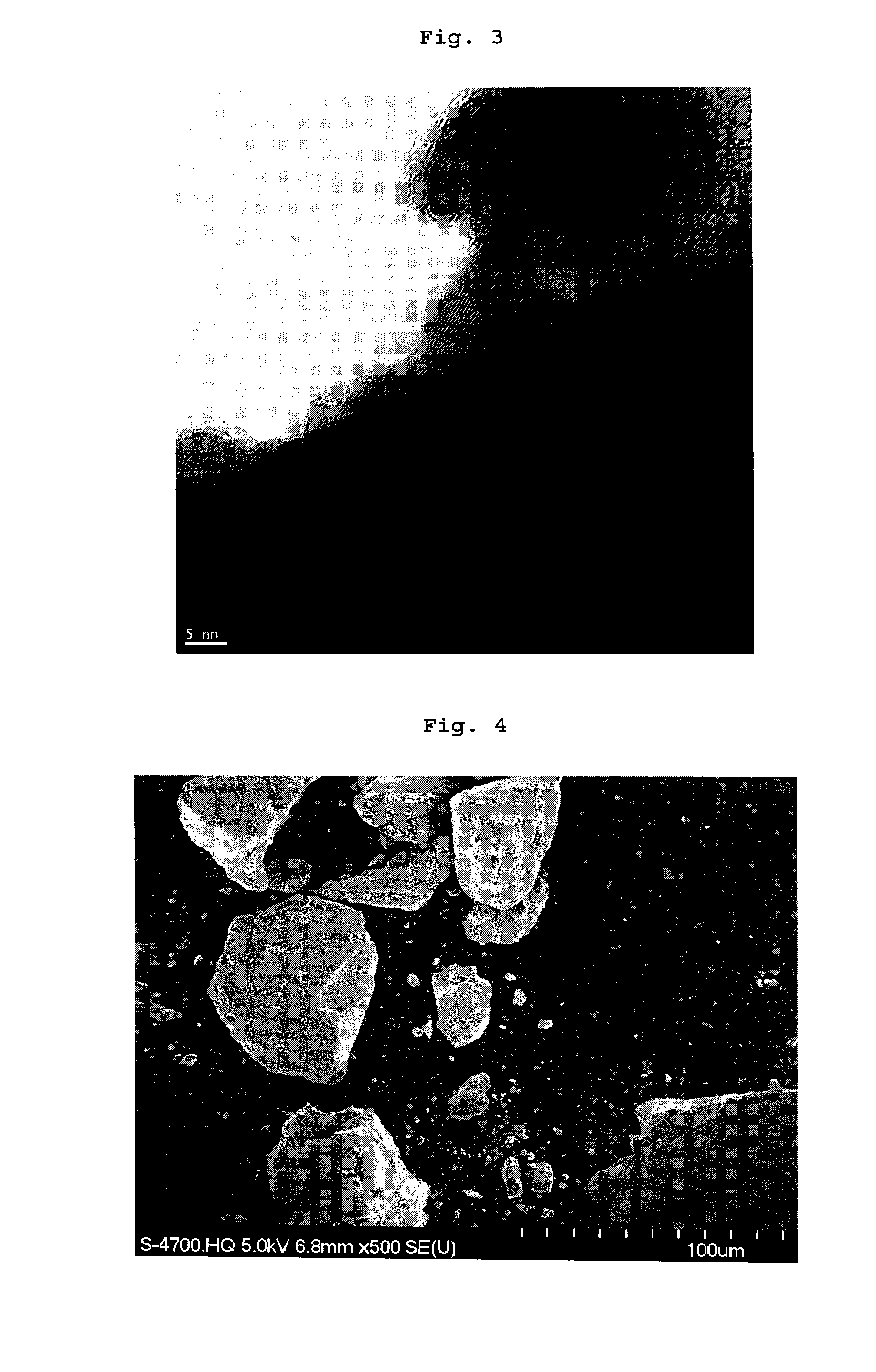

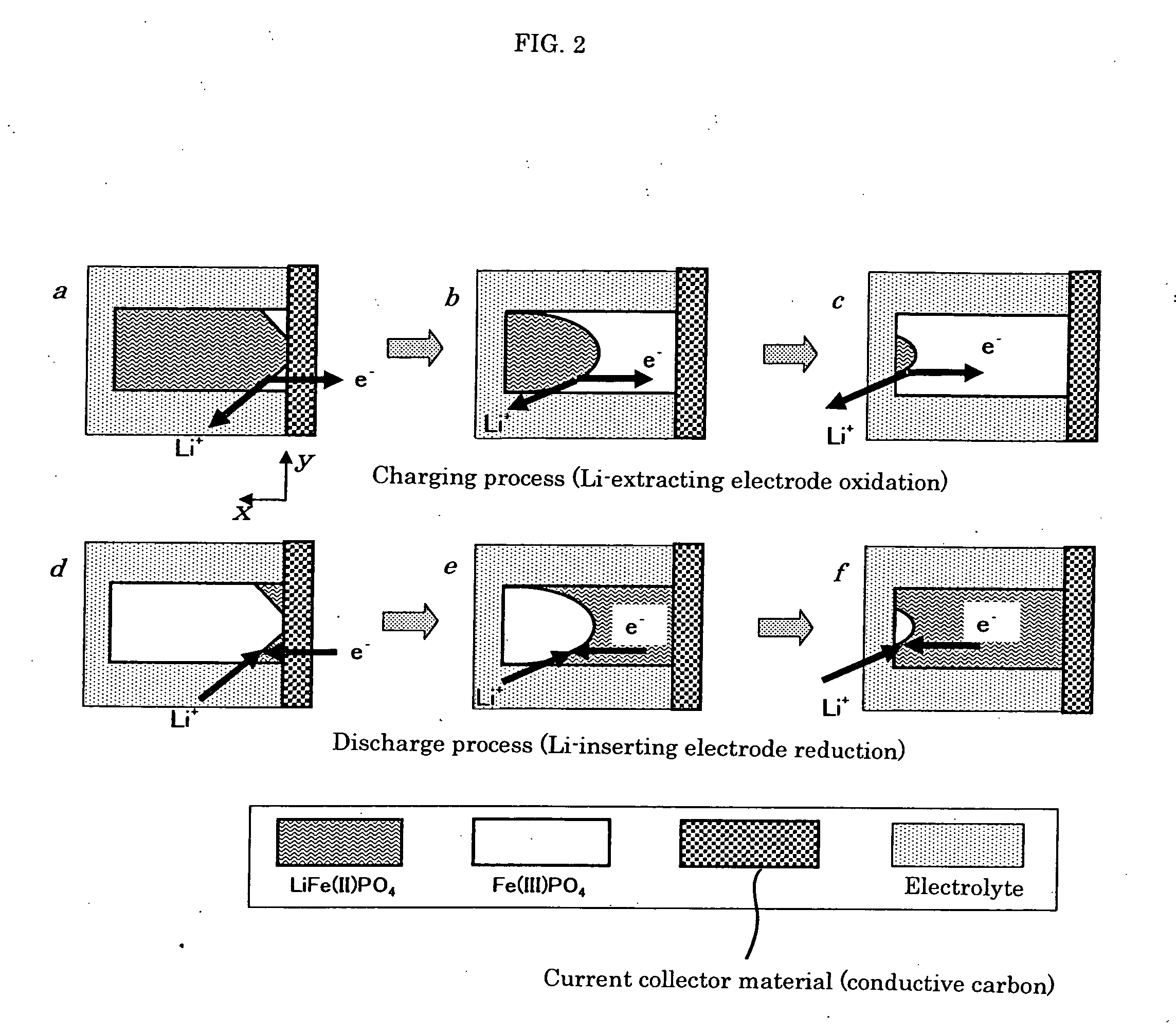

A method for preparing a particulate cathode material, and the material obtained by said method

Disclosed are a method for preparing a complex oxide particle composition, the so-prepared particle composition and its use as electrode material. This composition comprises complex oxide particles having a non powdery conductive carbon deposit on at least part of their surface. Its method of preparation comprises nanogrinding complex oxide particles or particles of complex oxide precursors, wherein an organic carbon precursor is added to the oxide particles or oxide precursor particles before, during or after nanogrinding, and pyrolysing the mixture thus obtained; a stabilizing agent is optionally added to the oxide particles or oxide precursor particles before, during or after nanogrinding; and the nanogrinding step is performed in a bead mill on particles dispersed in a carrier solvent.

Owner:CLARIANT (CANADA) INC

Low carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN104107692AImprove stabilityCarbon deposit deactivation rate is slowHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkane

The invention relates to a noble metal catalyst used for preparing low carbon olefin by dehydrogenating low carbon alkane, and a preparation method thereof. A problem of the influence of likely carbon deposit inactivation of present catalysts under high temperature conditions on the one way stability of the catalysts is mainly solved. The catalyst comprises a certain amount of a noble metal component distributed on a porous alumina carrier, a composite assistant composed of IIA group element components, IIB group element components and rare earth elements, and a certain amount of an alkali metal / alkali earth metal component. A technical scheme adopted in the invention is characterized in that a dipping process is adopted to load noble metals, that is, an aqueous solution of a soluble salt is adopted to dip platinum and other components, and the platinum-tin catalyst is obtained after drying, roasting and water vapor treatment .The preparation method well solves the problem, and can be used in the industrial production of the catalyst for preparing low carbon olefin by using low carbon alkane.

Owner:CHINA PETROLEUM & CHEM CORP +1

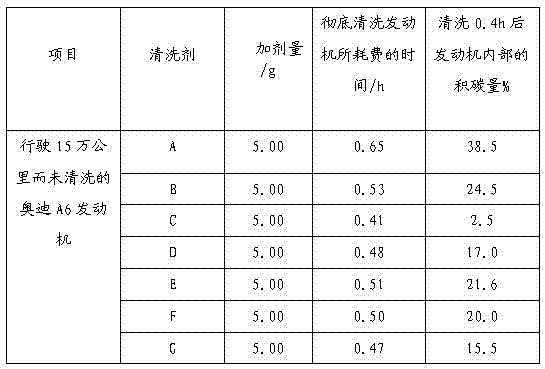

Engine carbon deposition cleaning agent and preparation method thereof

ActiveCN102965206ARapid and efficient penetrationClean up thoroughlyAnionic surface-active compoundsDetergent compounding agentsOrganic solventActive agent

The invention relates to the technical field of engine cleaning agents, and particularly relates to an engine carbon deposition cleaning agent. The engine carbon deposition cleaning agent is composed of the following components in parts by weight: 5-20 parts of surfactant, 5-10 parts of penetrant, 5-15 parts of dispersant, 5-20 parts of emulsifier and 35-80 parts of organic solvent. The cleaning agent has the advantages of high cleaning efficiency, high safety and practicability, environment friendliness and the like.

Owner:临沂星火知识产权服务有限公司

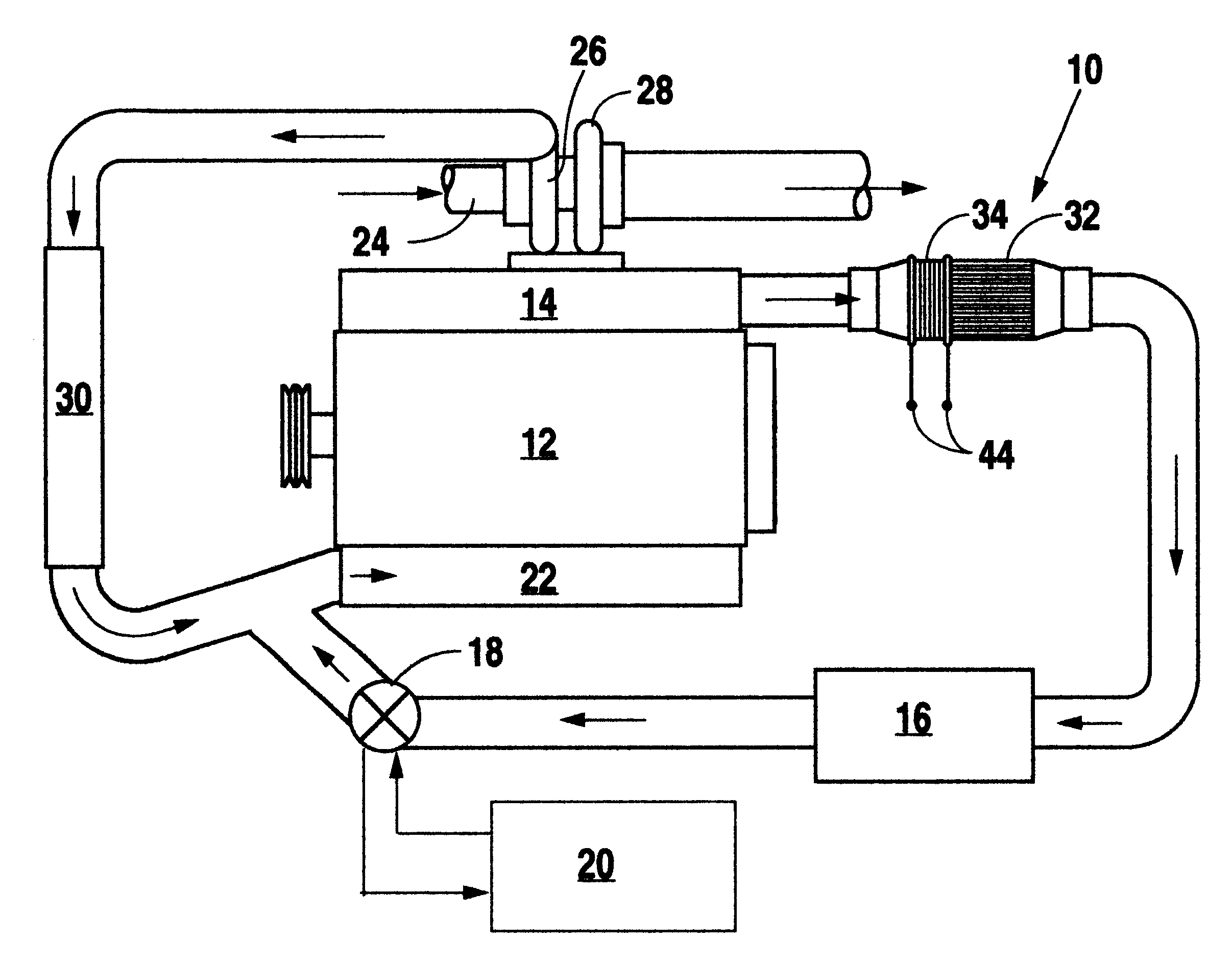

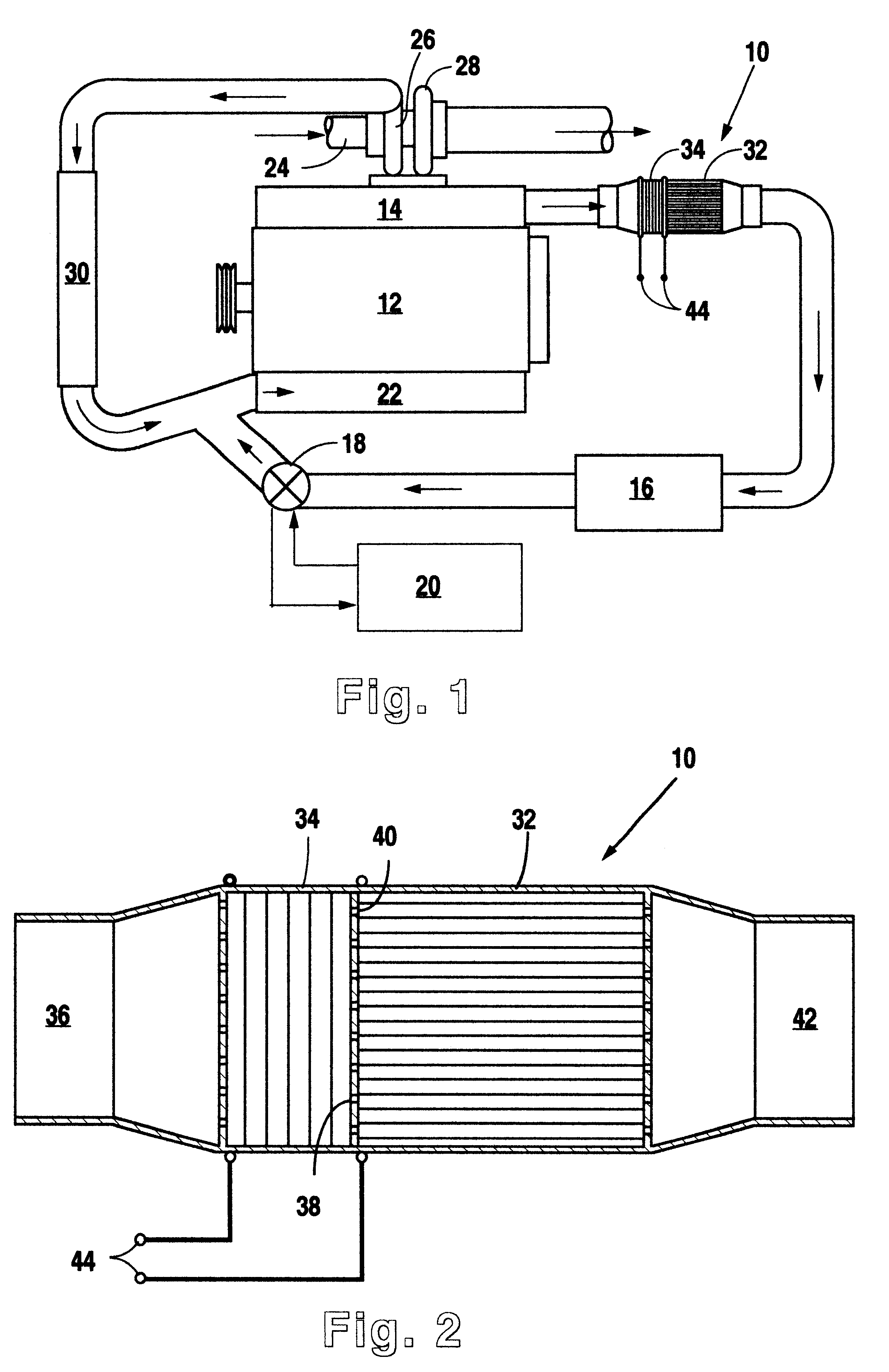

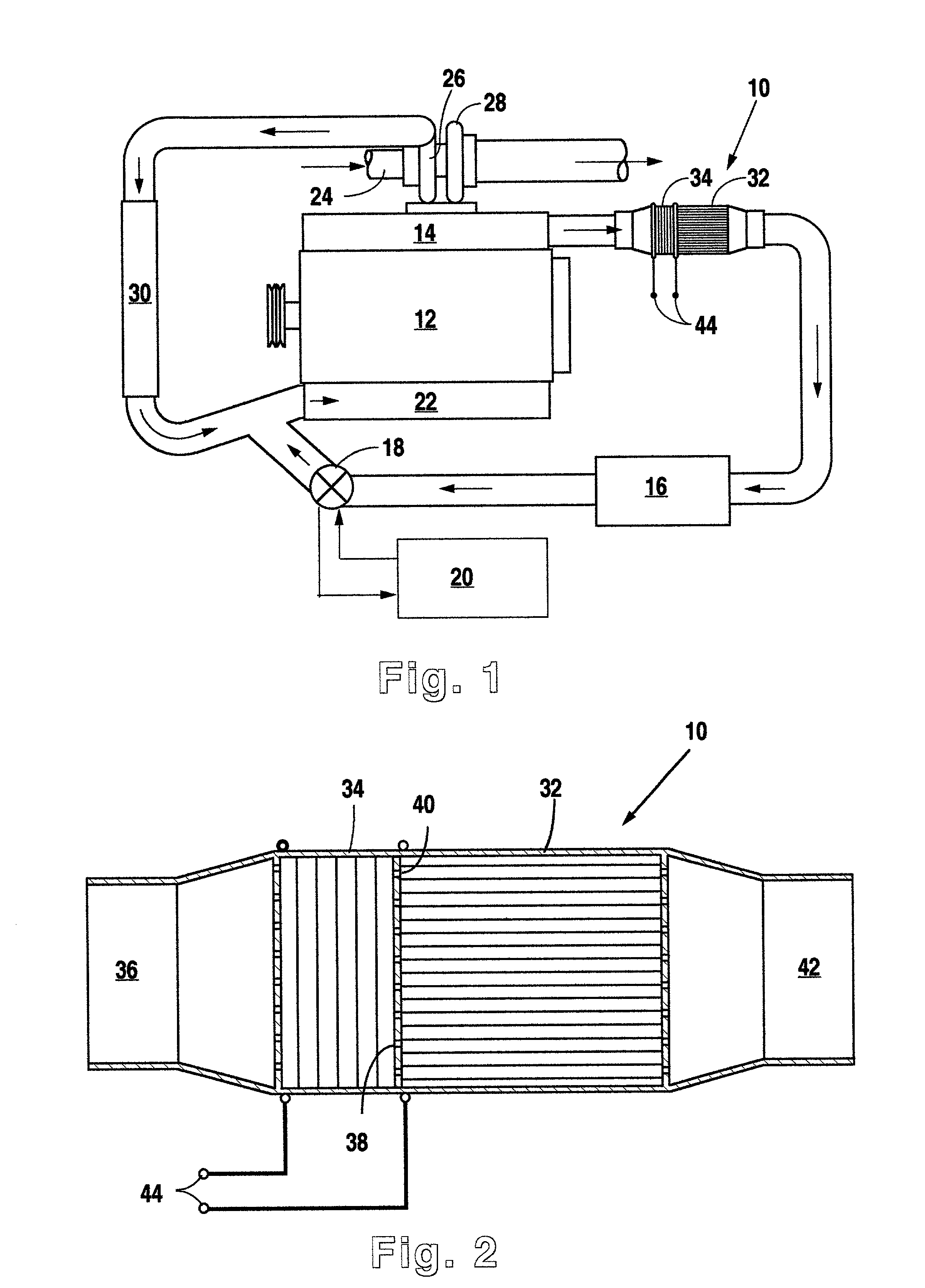

Exhaust gas recirculation filtration system

InactiveUS6474060B2Non-fuel substance addition to fuelInternal combustion piston enginesExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

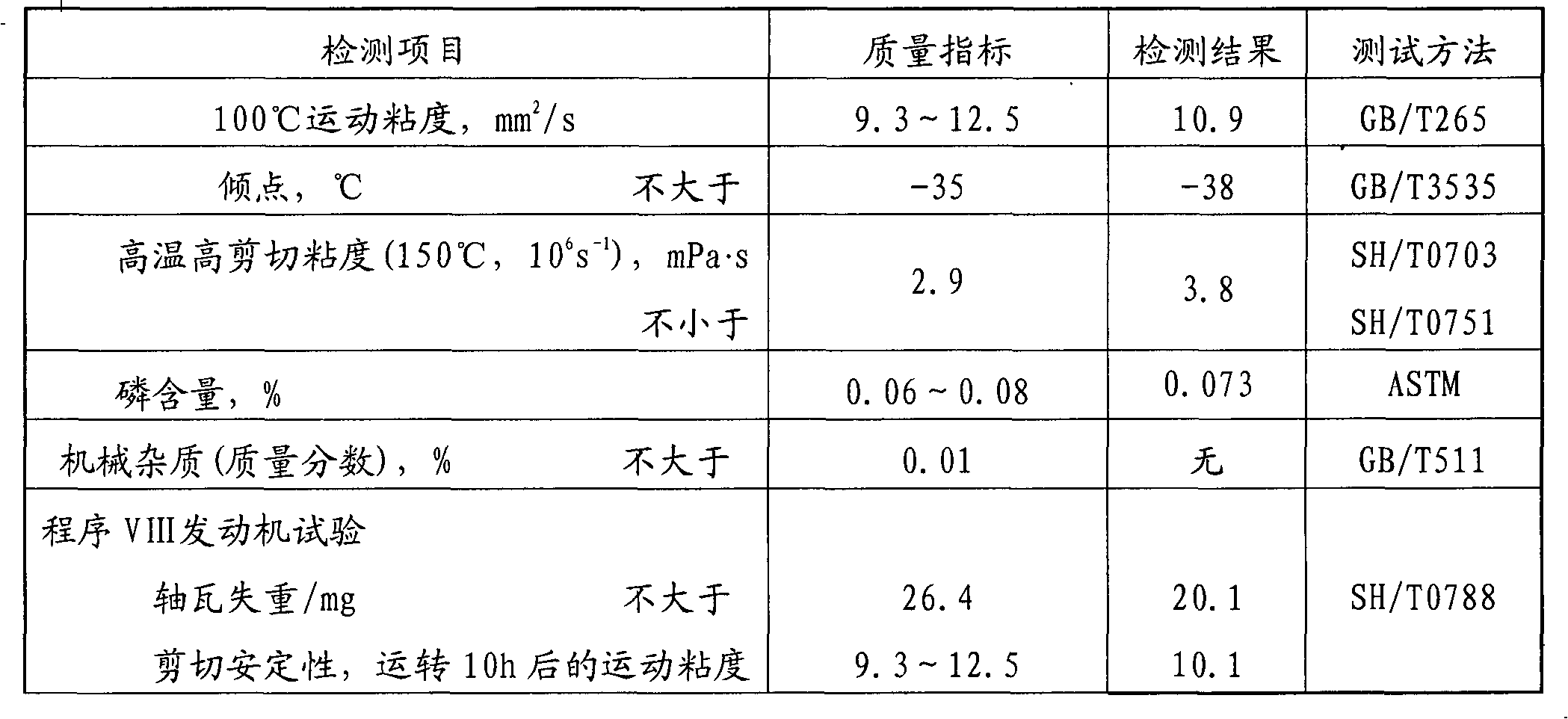

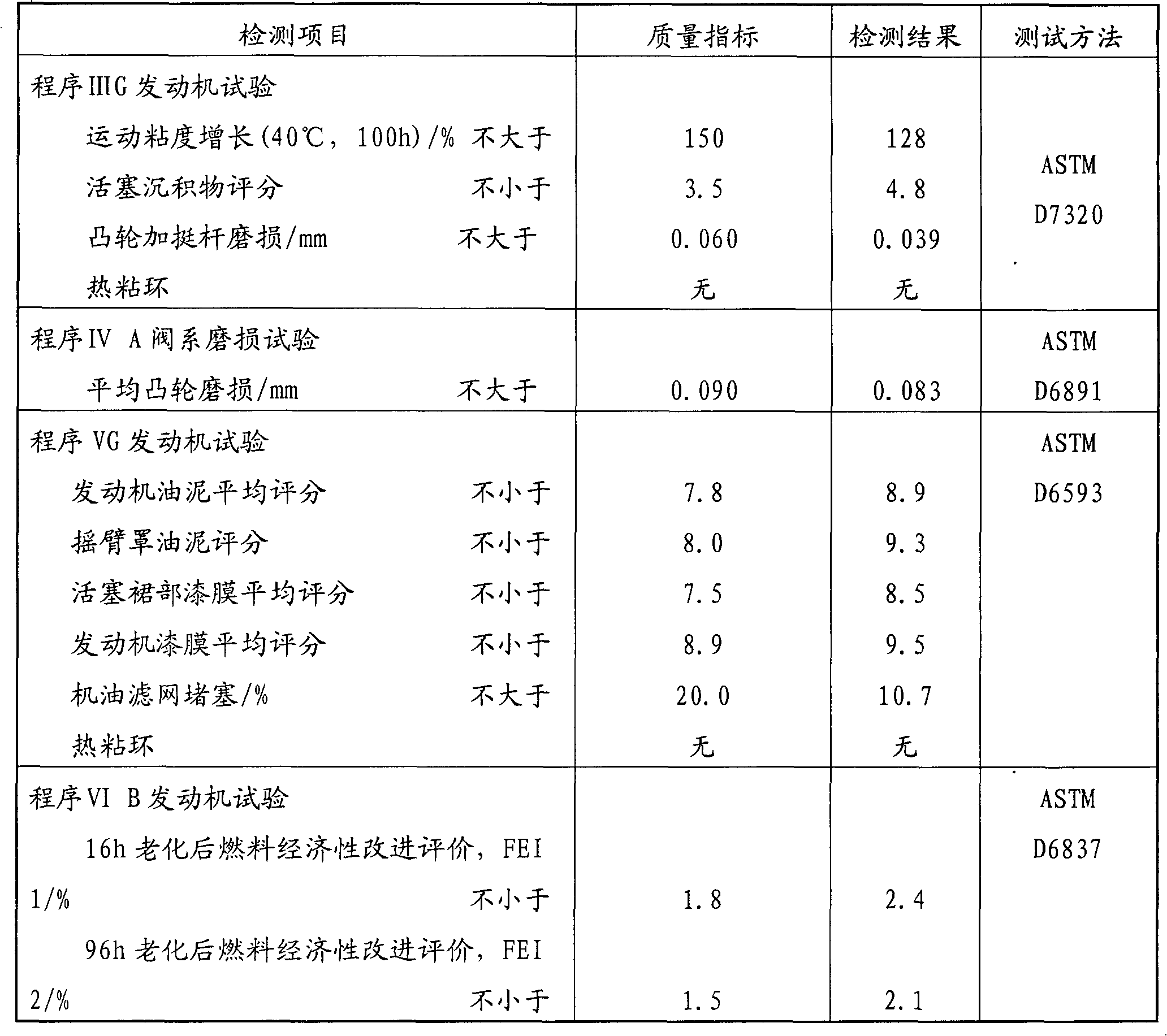

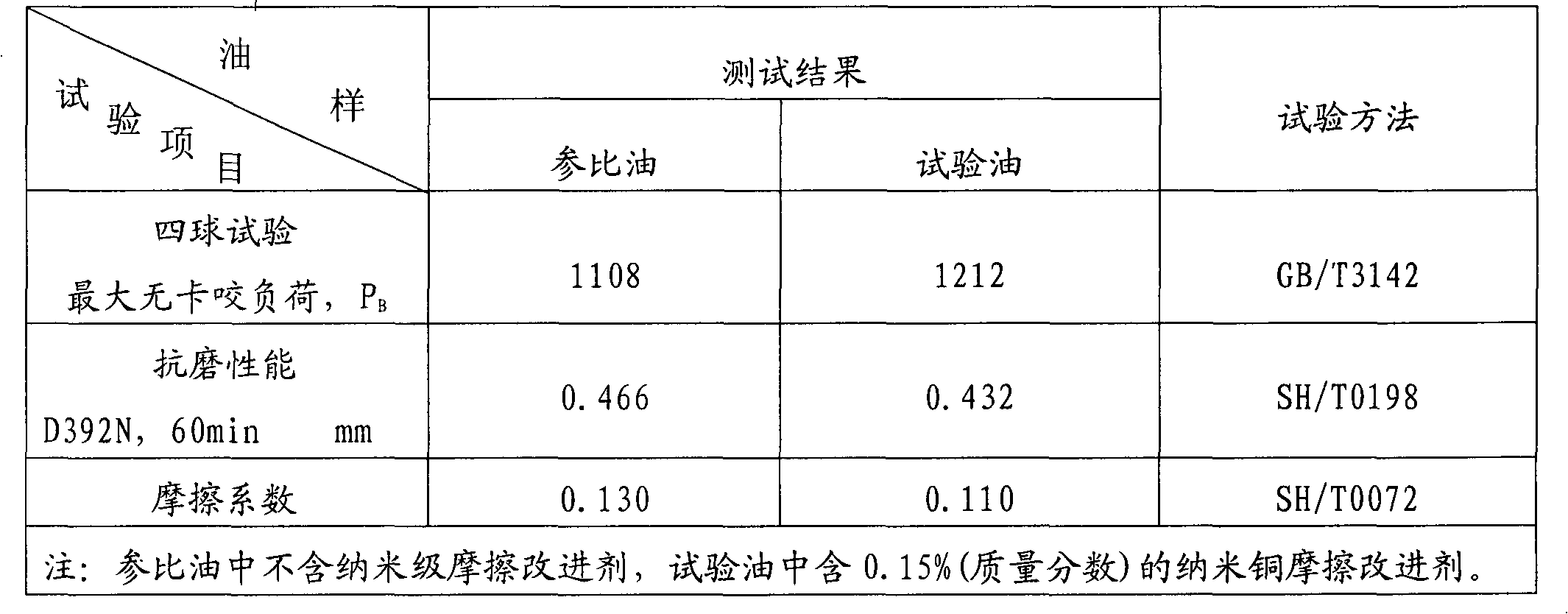

Energy-efficient long-life gasoline engine oil

InactiveCN101982534AReduce sulfur and phosphorus contentImprove carrying capacityLubricant compositionEcological environmentOil sludge

The invention discloses energy-efficient long-life gasoline engine oil prepared from the following components: synthetic base oil, a composite antioxygen, a metal cleaning agent, an ashless dispersant, a nano-level friction improver, a viscosity improver and a pour point reducer. The gasoline engine oil provided by the invention has the following advantages: requirements of API SM, ILSAC GF-4 and SAEJ300 are met and the service life is long; the complete synthetic base oil features low pour point, high viscosity index, good economy of fuel, degradability and reduced harm to the ecological environment; the phenol type antioxygen is combined with ZDDP, the anti-oxygen and antifriction properties are good and the catalyst poisoning in a tail gas processing unit is prevented; the acid neutralization capacity is good, the cleaning dispersibility is good and the oil sludge and carbon deposit are prevented from being generated; and the nano-level friction improver is added, the frictional factor is low, and the oil film features high carrying capacity and can automatically repair abraded surface and lengthen the service life of the engine.

Owner:GUANGDONG SANVO CHEM IND TECH

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1472181AImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

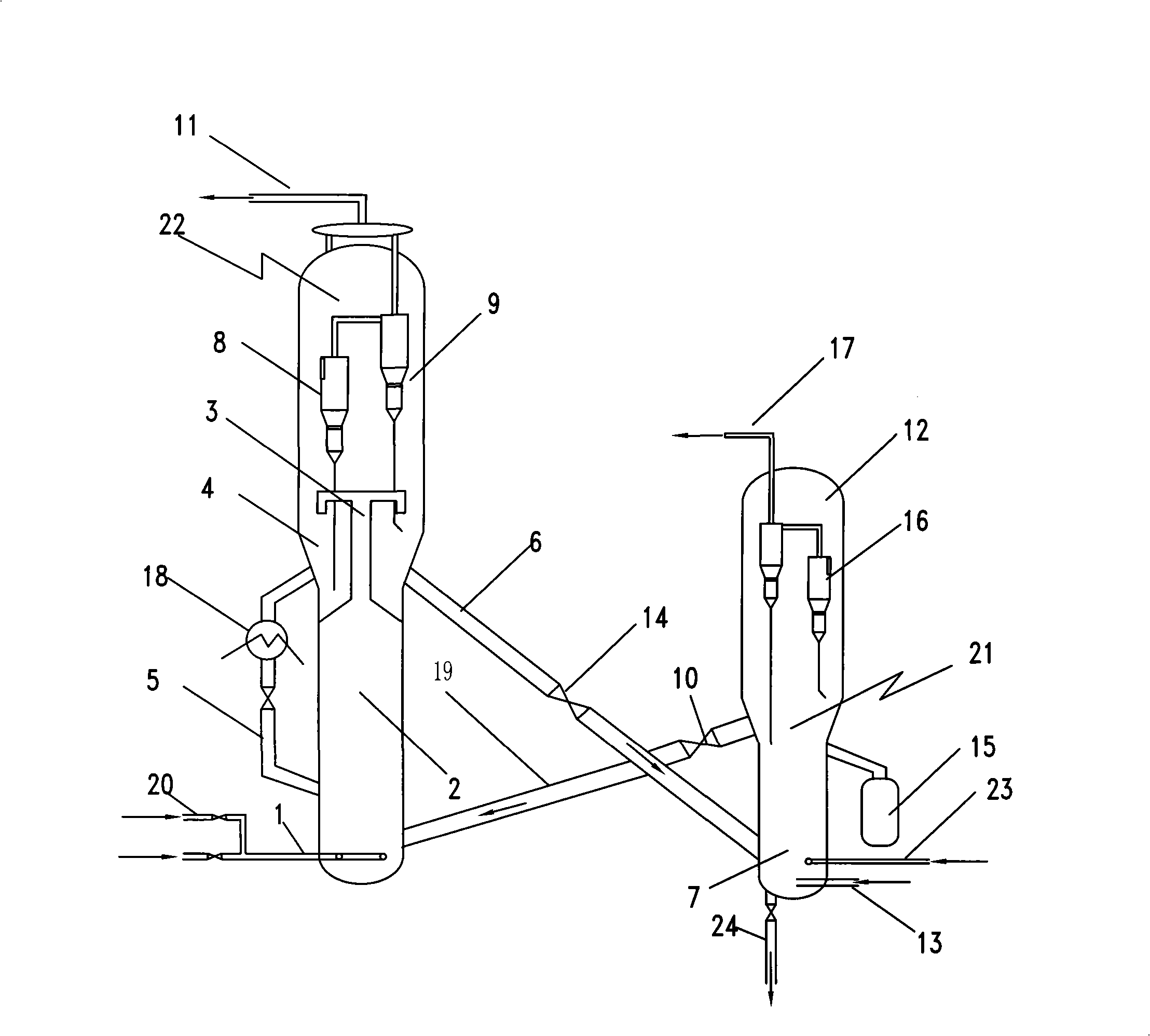

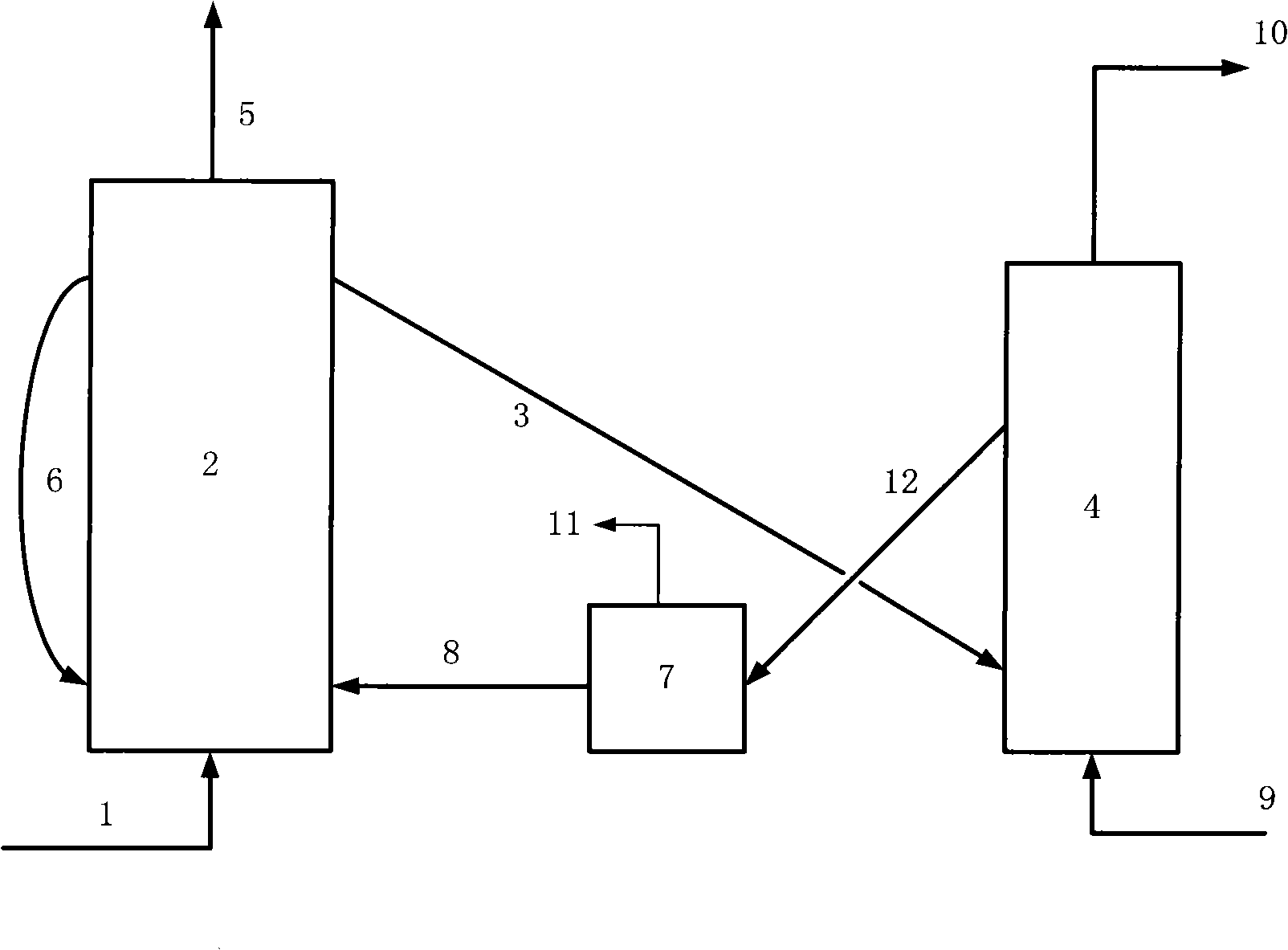

Starting method of reaction-regenerative device for preparing low carbon olefin form methanol

ActiveCN101333142AImprove technical effectMolecular sieve catalystsCatalyst regeneration/reactivationCombustion chamberReaction zone

The invention relates to a starting method for a reaction-regeneration device which uses methanol to prepare low-carbon olefin, mainly comprising the following steps: a. using an auxiliary combustion chamber to heat air, and then entering the reaction-regeneration device; heating the dense phase temperature of a regenerator to 400-600 DEG C, and heating the temperature of a reactor reaction zone to 150-350 DEG C; b. switching the catalyst from a catalyst storage tank into the regenerator, and injecting the combustion oil to maintain the temperature of the regenerator; c. switching the catalyst from the regenerator into the reactor, and establishing reaction catalyst circulation between the reactor and the regenerator; d. heating the reactor reaction zone to a temperature not less than 350 DEG C, and putting the raw materials containing the methanol in the reactor to contact with the catalyst so as to generate the products containing low-carbon olefin and also form a carbon deposit on the catalyst; e. stop injecting combustion oil to the regenerator; f. stop using the auxiliary combustion chamber. The method has short starting period and light catalyst damage degree, which can be used for low-carbon olefin industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Deposited carbon cleaning agent for internal-combustion engine

InactiveCN101760345ALow costStrong decontaminationInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCarbon stainResource saving

The invention discloses a deposited carbon cleaning agent for an internal-combustion engine, which relates to an environmentally-friendly, safe and resource saving carbon deposit cleaning agent and comprises the following matters: 5 to 16 weight percent of polyoxyethylene ether surfactant, 5 to 10 weight percent of emulsifier, 0 to 5 weight percent of inorganic alkali, 0 to 4 weight percent of corrosion inhibitor and 65 to 90 weight percent of water. In the invention, the polyoxyethylene ether surfactant is used to soften the deposited carbon to make the attached deposited carbon loose and deformed; the emulsifier makes liquid penetrate the contact parts between the deposited carbon and parts easily, so that the deposited carbon can be stripped and the softening and cleaning effects of the product on the deposited carbon stains are improved; the inorganic alkali can decompose part of lipoid substance in the deposited carbon, so the cleaning effect is improved; and the corrosion inhibitor can reduce the corrosion of the parts in the cleaning process. The cleaning agent has excellent washing effect on deposited carbon on parts made of various materials. The cleaning agent uses water as a solvent instead of toxic solvent such as benzenes, phenol aromatic hydrocarbons and halogenated hydrocarbon. The prepared deposited carbon cleaning agent for the internal-combustion engine has the advantages of low cost, high detergency, quick deposited carbon removal and good effect.

Owner:YANGZHOU POLYTECHNIC INST

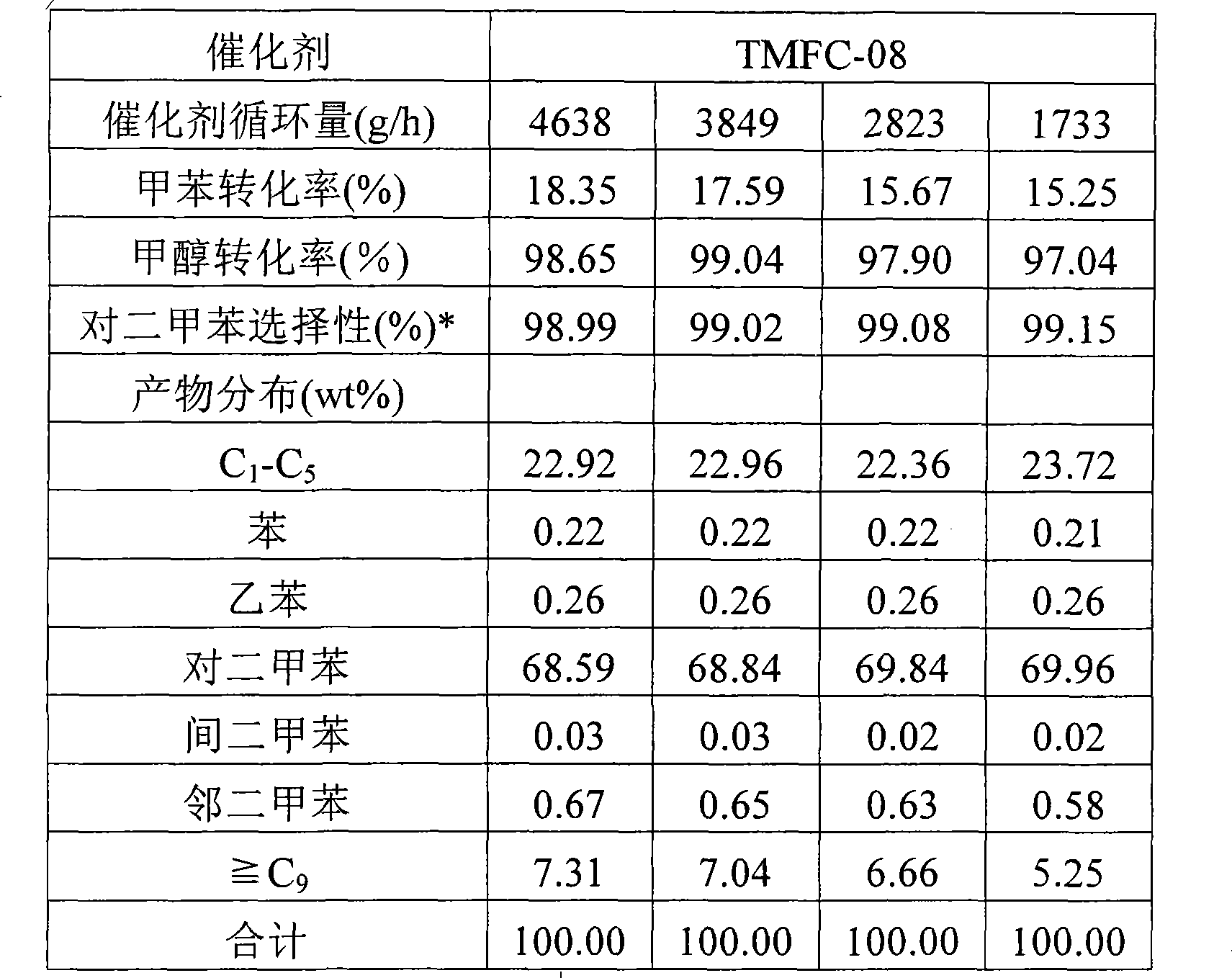

Method for preparing p-xylene and co-producing light olefins by toluene and methylating reagent

ActiveCN101456786AHigh activitySimple processMolecular sieve catalystsHydrocarbonsBiological activationCarbon deposit

The invention relates to a fluidized bed reaction method for preparing para-xylene and coproducing low-carbon olefin with high selectivity by reacting toluene and a methylated reagent. The method adopts fluidized bed reaction technology and uses a catalyst to highly selectively produce the para-xylene and simultaneously highly selectively coproduce ethylene and propylene. The method is characterized in that the raw materials, namely the toluene and the methylated reagent enter a vaporizer for mixing and gasification, pass through a distribution plate, enter a fluidized bed reactor, and are taken as a fluidizing medium and subjected to catalysis with a fluidized catalyst; and gaseous mixture products after reaction are exhausted from the top of a tower and separated. The selectivity of the para-xylene in products in a xylene isomer is more than 99 weight percent, and the selectivity of the ethylene and the propylene in low-carbon hydrocarbon between C1 and C5 is more than 90 weight percent. The carbon deposit catalyst in the reactor continuously enters a regenerator for regeneration and activation and enters the reactor for recycling, can be continuously regenerated and has stable activity; and the method has simple technological flow and is easy to realize large-scale industrialization.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

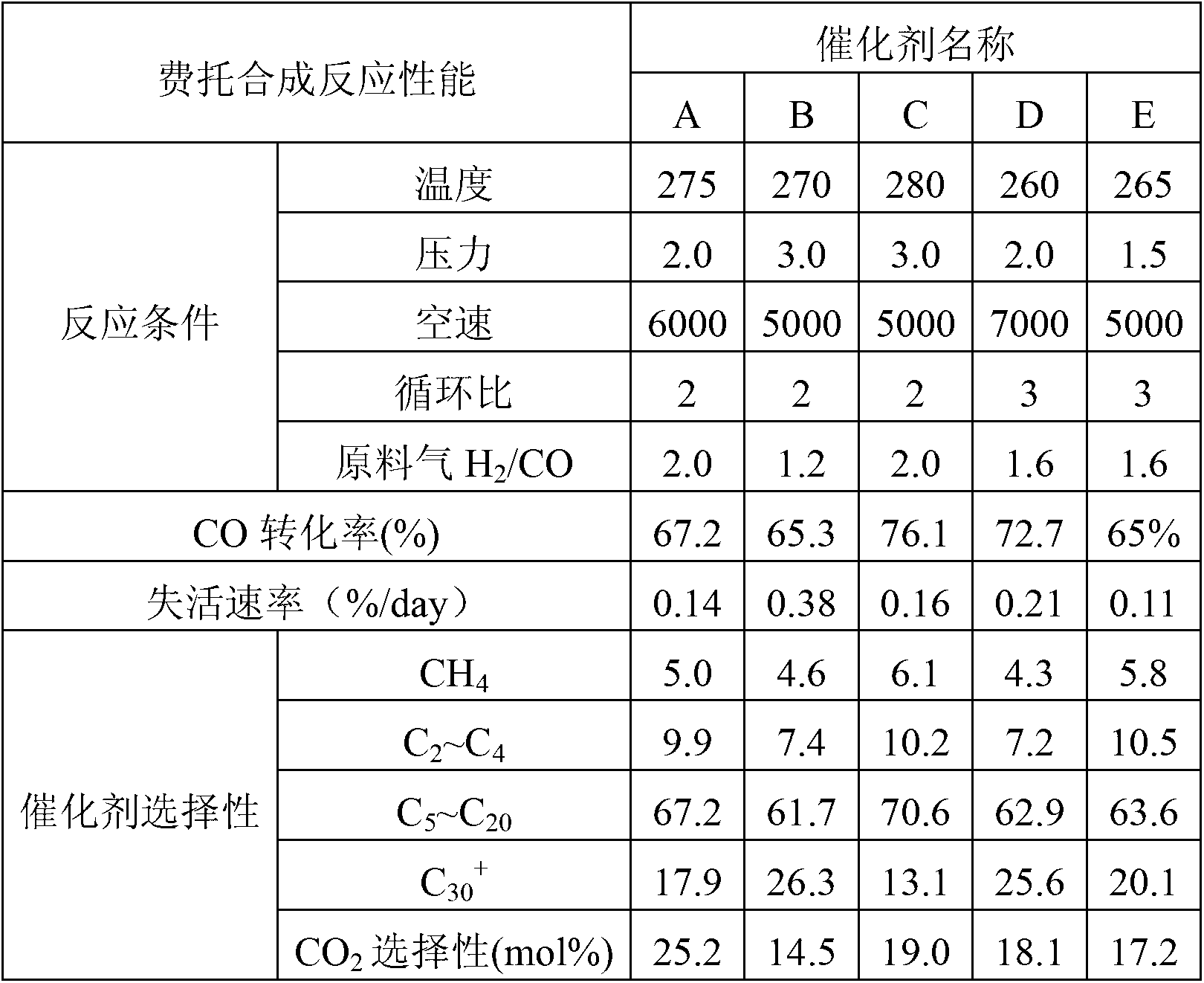

Reduction method for iron-based catalyst for Fischer-Tropsch synthesis in fixed bed

ActiveCN103071543AReduce carbon depositionHigh activityCatalyst activation/preparationLiquid hydrocarbon mixture productionHydrogenFixed bed

The invention discloses a reduction method for an iron-based catalyst for Fischer-Tropsch synthesis in a fixed bed. The method comprises the following steps: adding the iron-based catalyst into a fixed bed reactor; and introducing gaseous hydrocarbon or mixed gas of hydrogen and gaseous hydrocarbon into the fixed bed reactor for reduction reaction to reduce the iron-based catalyst. The reduction method has the advantages that (1) the reduced catalyst has a little carbon deposit, so the catalyst has high activity and stability; (2) the product selectivity of the catalyst can be effectively modulated, and the selectivity for C5-30 in products is high; and (3) the reduced catalyst has a little carburization, so the catalyst has high wear resistance.

Owner:SYNFUELS CHINA TECH CO LTD

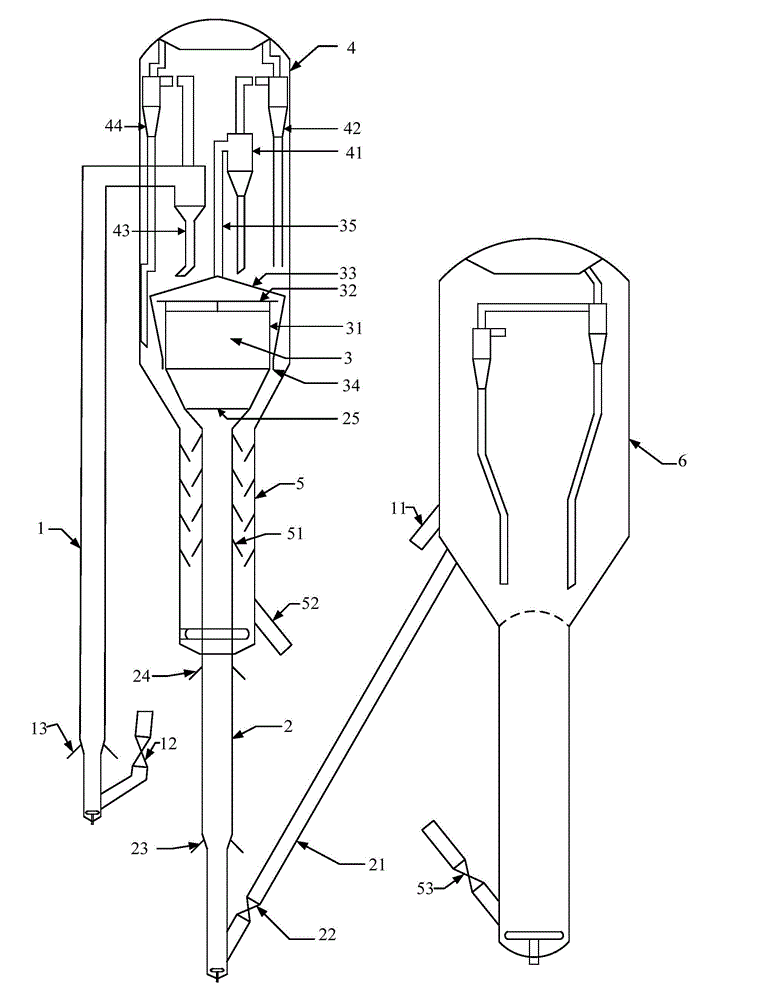

Catalytic conversion method for improving productivity of low carbon olefin hydrocarbon

ActiveCN101293806AInhibition of the retransformation reactionHigh yieldOrganic chemistryHydrocarbon oil crackingHydrogenFluidized bed

A catalytic conversion method for improving the yield of low-carbon olefin comprises the following steps: hydrocarbon oil raw material is injected into a riser or / and a fluidized bed reactor via a feed nozzle, comes into contact with catalyst containing shape-selective zeolite with an average pore size being smaller than 0.7 nm and reacts; gas rich in hydrogen is injected into the reactor; reaction oil gas and carbon deposited catalyst after reaction are separated, wherein the reaction oil gas is separated to obtain a target product containing ethylene and propylene; and the carbon deposited catalyst is returned to the reaction for reutilization after being stripped and regenerated. By injecting gas rich in hydrogen, the method can remarkably inhibit reconversion reaction of the generated low-carbon olefin to improve the yield of low-carbon olefin, particularly of propylene. When vacuum gas oil is adopted as raw material and double risers combined with a fluidized bed reactor are adopted, ethylene yield reaches 8.97 wt%, and propylene yield reaches 31.38 wt%, which are respectively improved by 2.93% and 6.81% in comparison with a process without injection of gas rich in hydrogen.

Owner:CHINA PETROLEUM & CHEM CORP +1

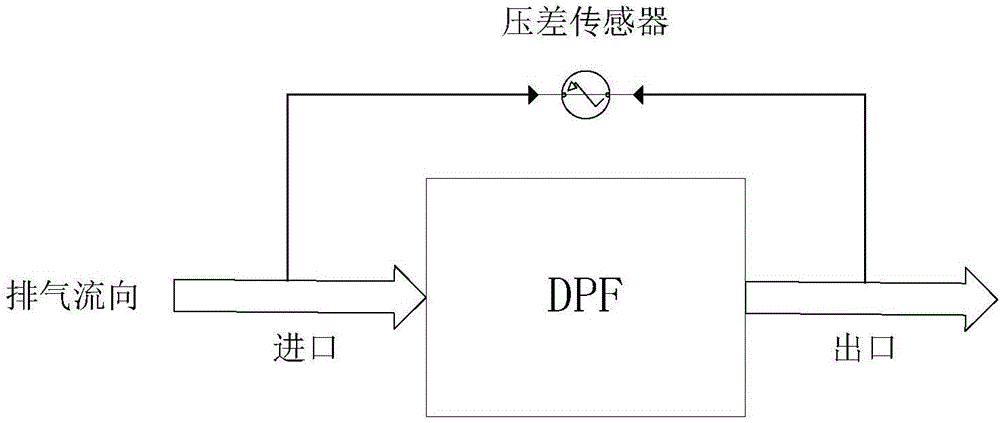

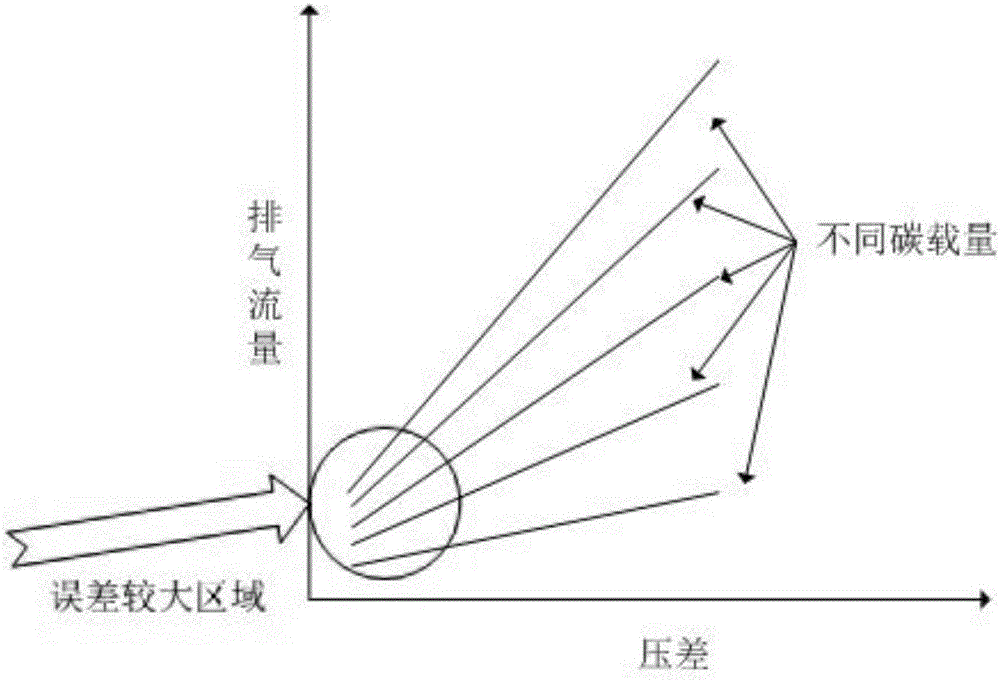

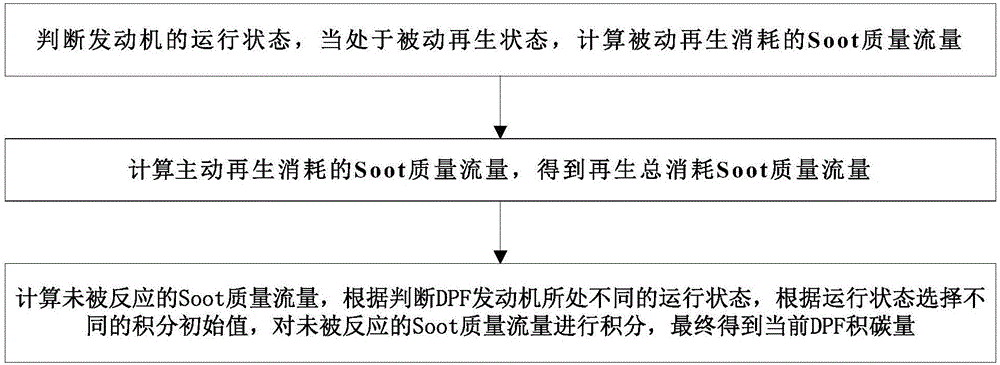

Carbon deposit amount calculation method of diesel engine particulate filter

ActiveCN106481419AReduce economyReduce riskInternal combustion piston enginesExhaust treatment electric controlCarbon depositSoot

The invention discloses a carbon deposit amount calculation method of a diesel engine particulate filter. The method comprises following steps: the running state of an engine is judged, and when the engine is in the passive regeneration state, the Soot mass flow consumed by passive regeneration is calculated; the Soot mass flow consumed by initiative regeneration is calculated, and the Soot mass flow totally consumed by regeneration is obtained; the non-reaction Soot mass flow is calculated, according to judgment of the different running states of a DPF engine and the running state, the different integral initial values are selected, the non-reaction Soot mass flow is subject to integral operation, and the current DPF carbon deposit amount is obtained; the work state of an aftertreatment system is represented through exhaust substance components and exhaust physical parameters, and therefore the DPF carbon deposit amount is identified, and the identification result is more precise.

Owner:清华大学苏州汽车研究院(吴江) +1

Combined catforming of high-production low carbon alkene

ActiveCN101045667AReduce backmixingHigh selectivityChemical recyclingBulk chemical productionCarbon depositAlkene

A combined catalytic converting process for preparing low-carbon olefin with high output includes such steps as contacting between heavy oil as raw material, regenerated catalyst and carbon deposited catalyst in flow-down tube reactor, cracking reaction, separating the cracked product from the catalyst to be regenerated, separating low-carbon olefin from cracked product, contacting between rest of said product and regenerated catalyst in flow-up tube reactor, reaction, separating oil gas from catalyst, separating low-carbon olefin from oil gas, and regenerating the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving selectivity of light olefin hydrocarbon

ActiveCN101270023AHigh yieldMolecular sieve catalystsHydrocarbon from oxygen organic compoundsCarbon depositOxygen

The present invention relates to a method used for improving the yield of light olefins and mainly solves the problem of the low yield of the products when oxygen-containing compounds are used for preparing the light olefins. In the technical proposal, two reactors are used; zeolite catalysts with carbon deposit are prepared in the first reactor; the regenerated catalysts are optimized again in the second reactor; thus the problem can be well solved. The method can be used for the industrial production of the light olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultra quick quenching oil and preparation method thereof

InactiveCN102212662AFast coolingFast medium temperature cooling speedQuenching agentsPolybutyleneAntioxidant

The invention relates to ultra quick quenching oil and a preparation method thereof. The ultra quick quenching oil comprises the following raw materials in percentage by weight: 80 to 97 percent of refined mineral oil, 1 to 10 percent of cooling catalyst, 1 to 5 percent of antioxidant and 1 to 6 percent of anionic surfactant. The kinematic viscosity of the refined mineral oil at the temperature of 40 DEG C is 6 to 9 mm<2> / s; the cooling catalyst is a mixture of oily phenolic resin and polybutylene; the antioxidant is alkylated diphenylamine; and the anionic surfactant is petroleum sodium sulfonate. The preparation method of the ultra quick quenching oil is simple and convenient; the obtained quenching oil has the advantages of ultra high cooling speed, good thermal oxidation stability, long service life and continuous and stable property retention; little peculiar smell, smog and carbon deposit are produced, and the take-out consumption of a workpiece is low; and after the workpiece is quenched by adopting the quenching oil, the workpiece has the advantages of high and uniform surface hardness, deep quenching layer, low deformation, metallographic structure, good mechanical property and good brightness, the surface of the workpiece does not become black, and the workpiece is easily cleaned.

Owner:上海德润宝特种润滑剂有限公司

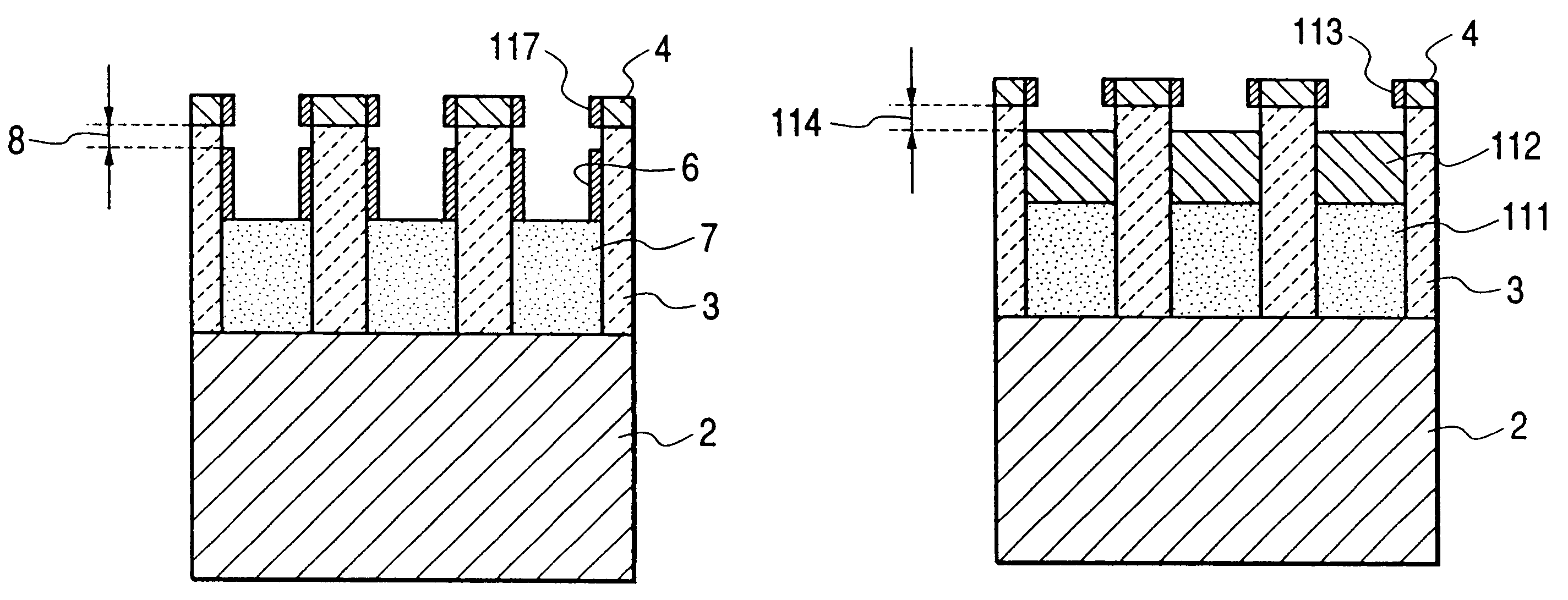

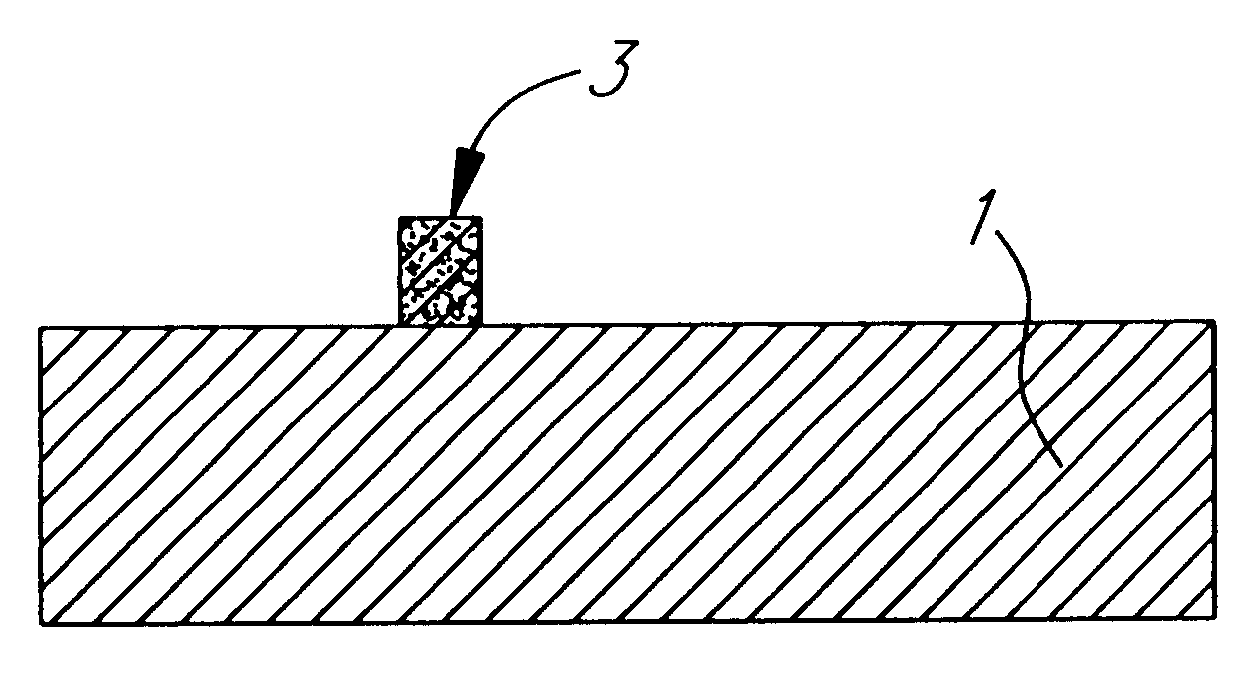

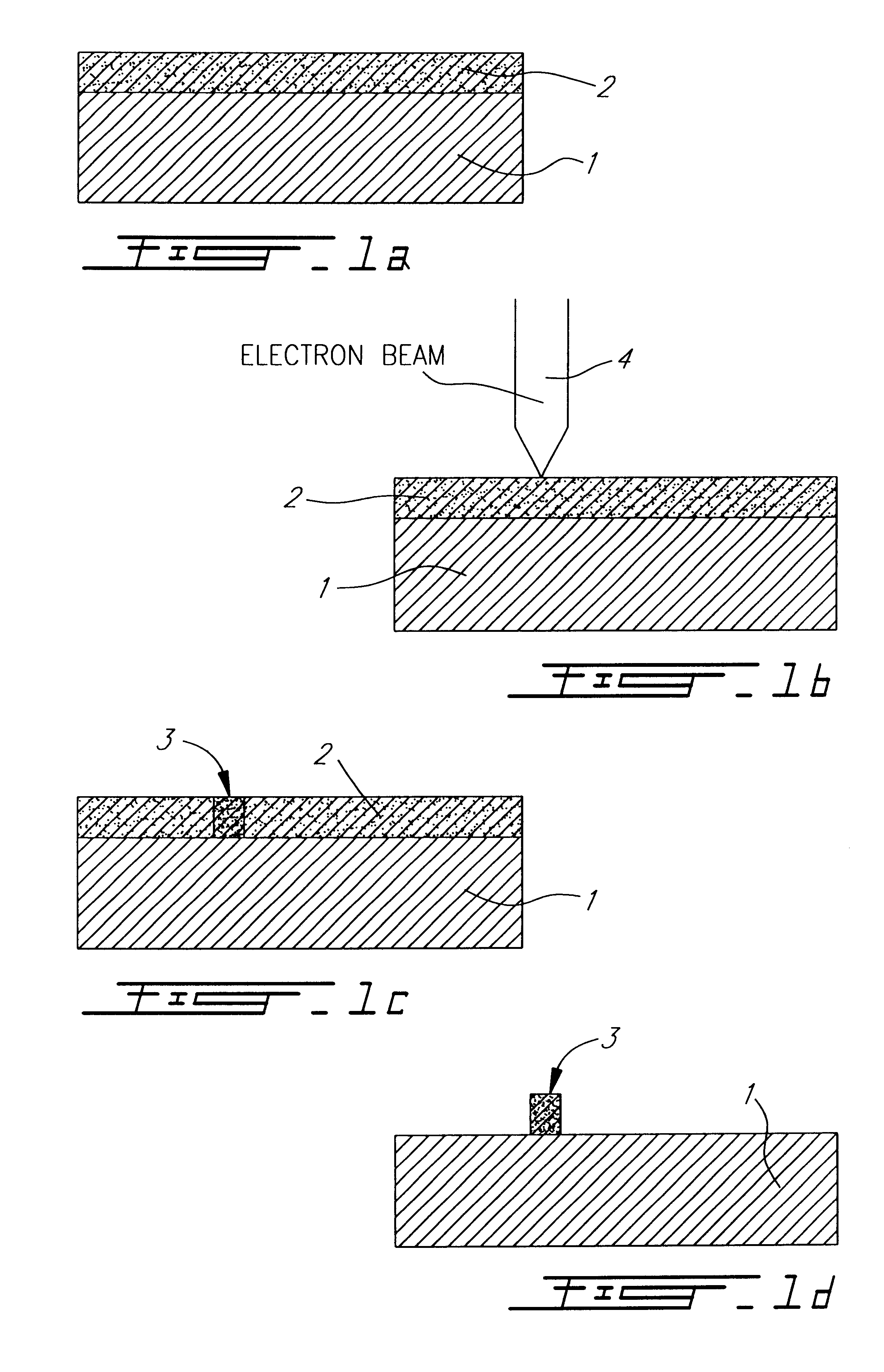

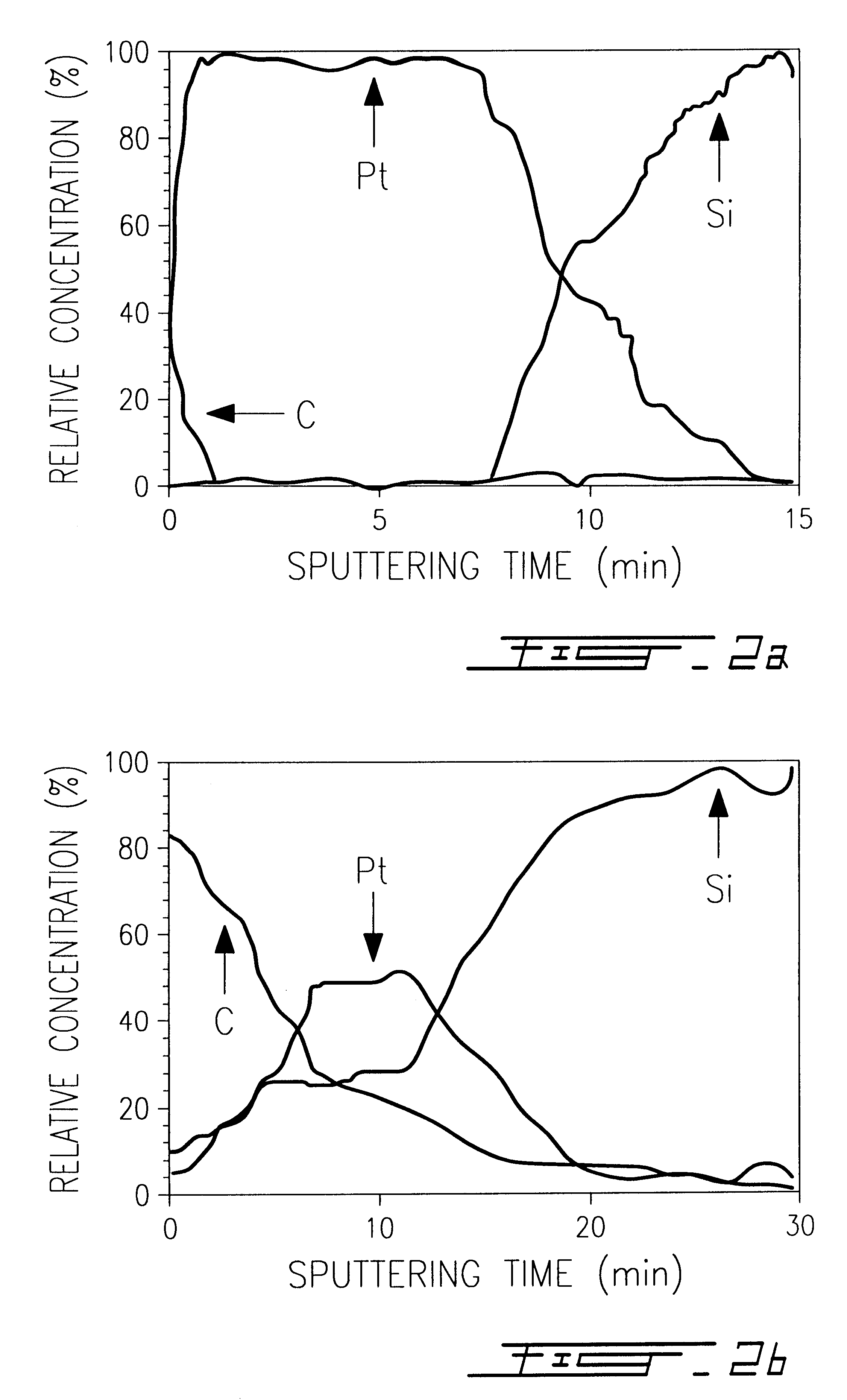

Fabrication of sub-micron etch-resistant metal/semiconductor structures using resistless electron beam lithography

InactiveUS6261938B1NanoinformaticsSemiconductor/solid-state device manufacturingSemiconductor materialsSemiconductor structure

A method for fabricating a sub-micron structure of etch-resistant metal / semiconductor compound on a substrate of semiconductor material comprises the step of depositing onto the substrate a layer of metal capable of reacting with the semiconductor material to form etch-resistant metal / semiconductor compound, and the step of producing a focused electron beam. The focused electron beam is applied to the layer of metal to locally heat the metal and semiconductor material and cause diffusion of the metal and semiconductor material in each other to form etch-resistant metal / semiconductor compound. The focused electron beam is displaced onto the layer of metal to form the structure of etch-resistant metal / semiconductor compound. Finally, the layer of metal is wet etched to leave on the substrate only the structure of metal / semiconductor compound. Following wet etching of the layer of metal, an oxygen plasma etch can be conducted to remove a carbon deposit formed at the surface of the structure of etch-resistant metal / semiconductor compound. Also, the substrate may be subsequently etched to remove a thin layer of metal rich semiconductor material formed at the surface of the substrate by reaction, at room temperature, of the metal and semiconductor material with each other.

Owner:SCOPRA SCI & GENIE SEC

Exhaust gas recirculation filtration system

InactiveUS20010042372A1Internal combustion piston enginesNon-fuel substance addition to fuelExternal combustion engineFiltration

A filtration system adapted to prevent diesel soot carried with recirculated exhaust gas from being recirculated through internal combustion engine. The filtration system provides continuous elimination of soot, thus reducing its negative impact on engine life, lubrication oil quality, and on components in the exhaust gas recirculation system. The filtration system comprises a non-thermal plasma generator that periodically, or continuously, oxidizes carbon deposited, or trapped, within a carbon filter disposed downstream of the non-thermal plasma generator.

Owner:SOUTHWEST RES INST

Modified alumina catalyst for synthetizing dimethyl ether

InactiveCN1613558APhysical/chemical process catalystsEther preparation by compound dehydrationSulfateCarbon deposit

A modified alumina catalyst for preparing dimethylether by dewatering methanol is prepard by adding sulfate to ordinary gamma-Al2O3. Its advantages are high transform rate and selectivity at lower temp and no carbon deposit at higher temp.

Owner:NANJING UNIV

Catalyst for preparing mixing alcohol with low carbon from synthesis gas and its preparing method

InactiveCN1431049AGuaranteed stabilityGuaranteed lifeOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammoniumsulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

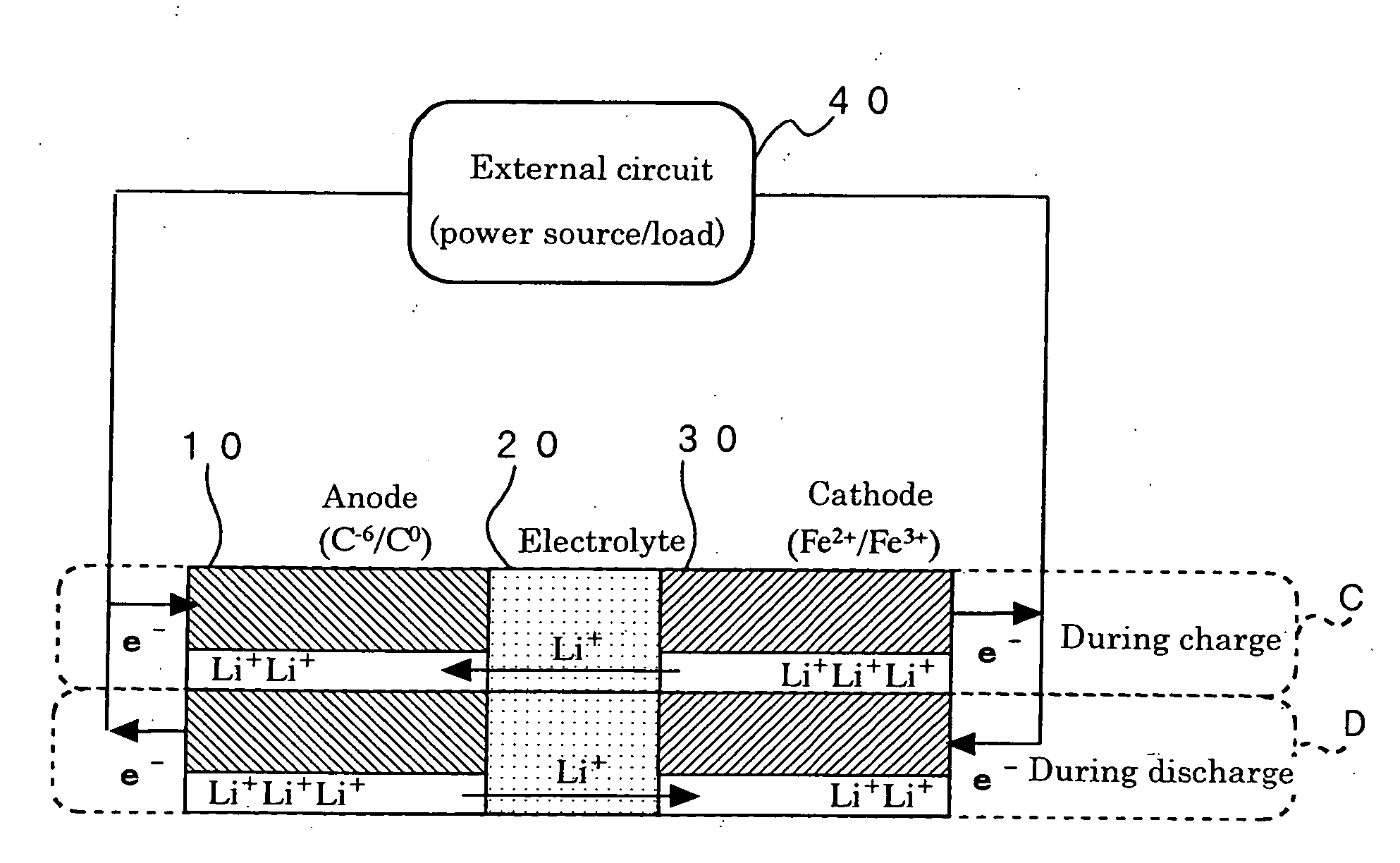

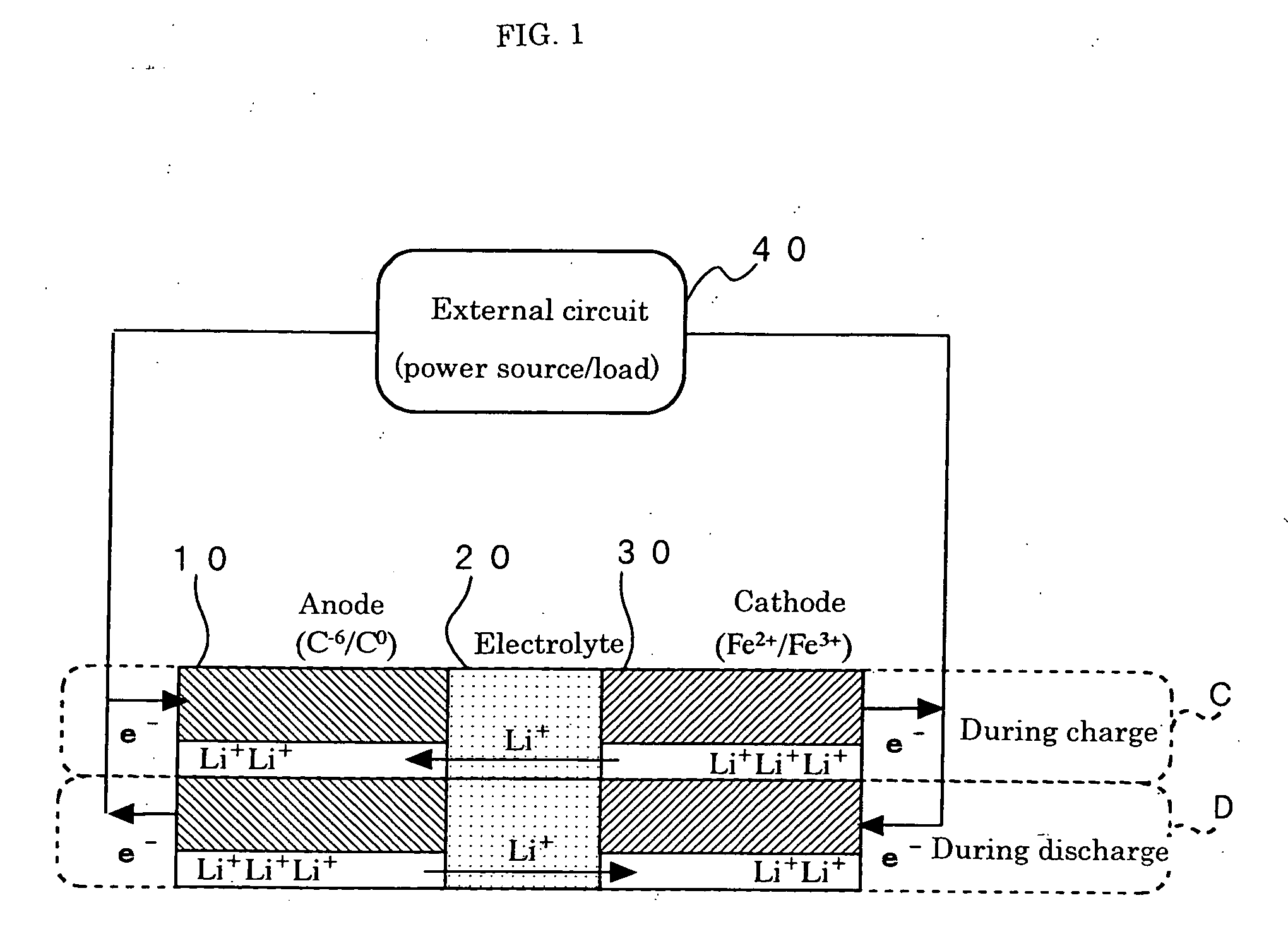

Cathode Material For Secondary Battery, Method For Producing Same, and Secondary Battery

InactiveUS20080138709A1Easy to getUniform depositionElectrode manufacturing processesNon-aqueous electrolyte accumulatorsCarbon depositPrimary component

A cathode material for a secondary battery containing a cathode active material represented by the general formula LinFePO4 (wherein n represents a number from 0 to 1) as a primary component and molybdenum (Mo), wherein the cathode active material LinFePO4 is composited with the Mo. In a preferred embodiment, the cathode material has conductive carbon deposited on the surface thereof.

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com