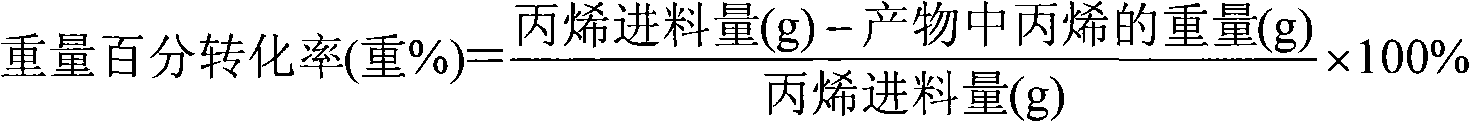

Catalytic conversion method for improving productivity of low carbon olefin hydrocarbon

A catalytic conversion method and a carbon olefin yield technology, applied in the field of low carbon olefins, can solve problems such as a decrease in propylene yield, and achieve the effects of improving yield, wide application range and wide source.

Active Publication Date: 2008-10-29

CHINA PETROLEUM & CHEM CORP +1

View PDF6 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the inventors have found through laboratory research that under the reaction conditions for preparing low-carbon olefins by catalytic conversion of hydrocarbon oils and the presence of acidic zeolites, propylene can be converted into other hydrocarbons, hydrogen and coke in large quantities and rapidly after generation, and then lead to Propylene yield decreased significantly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Solidifying point | aaaaa | aaaaa |

Login to View More

Abstract

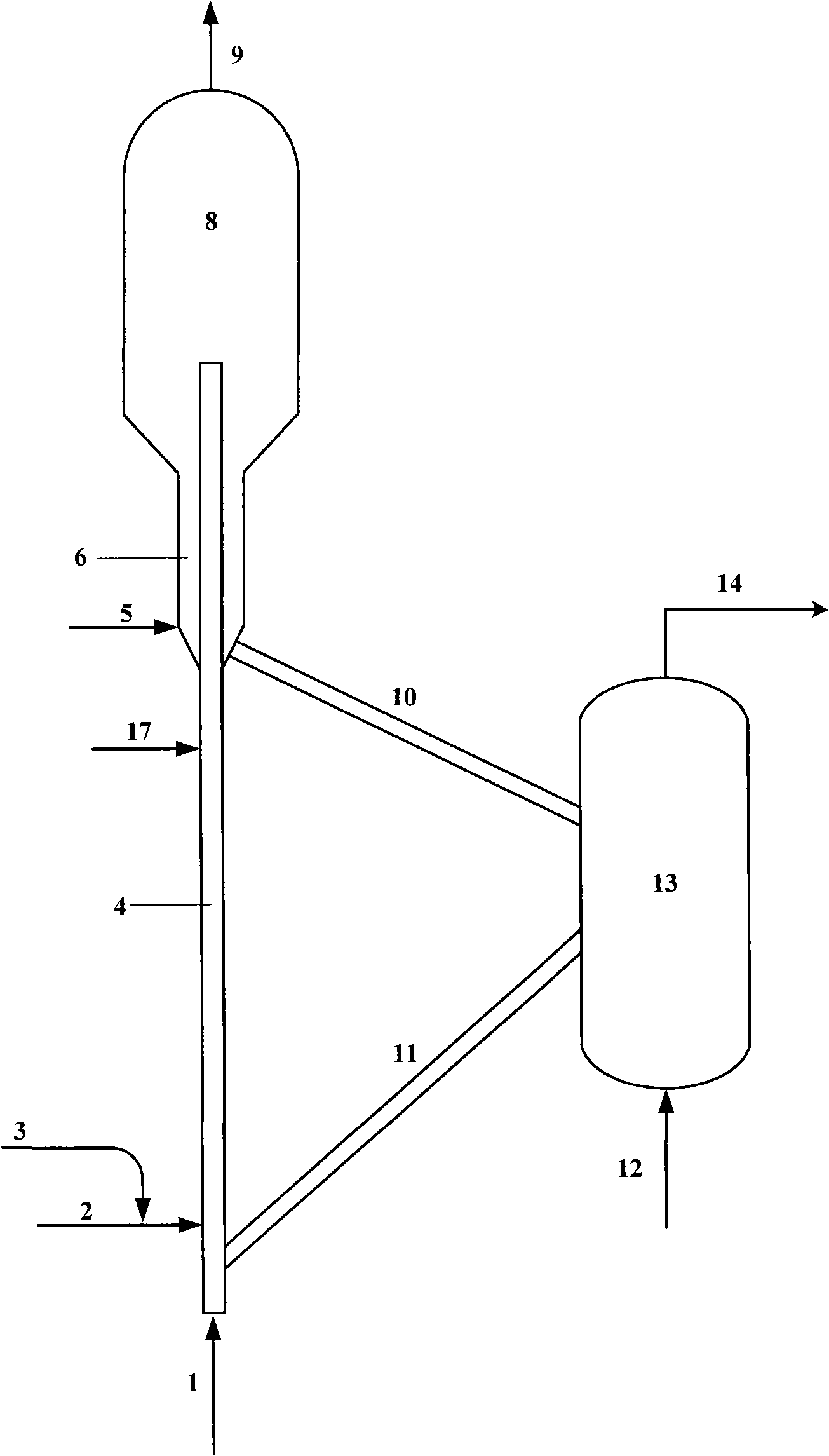

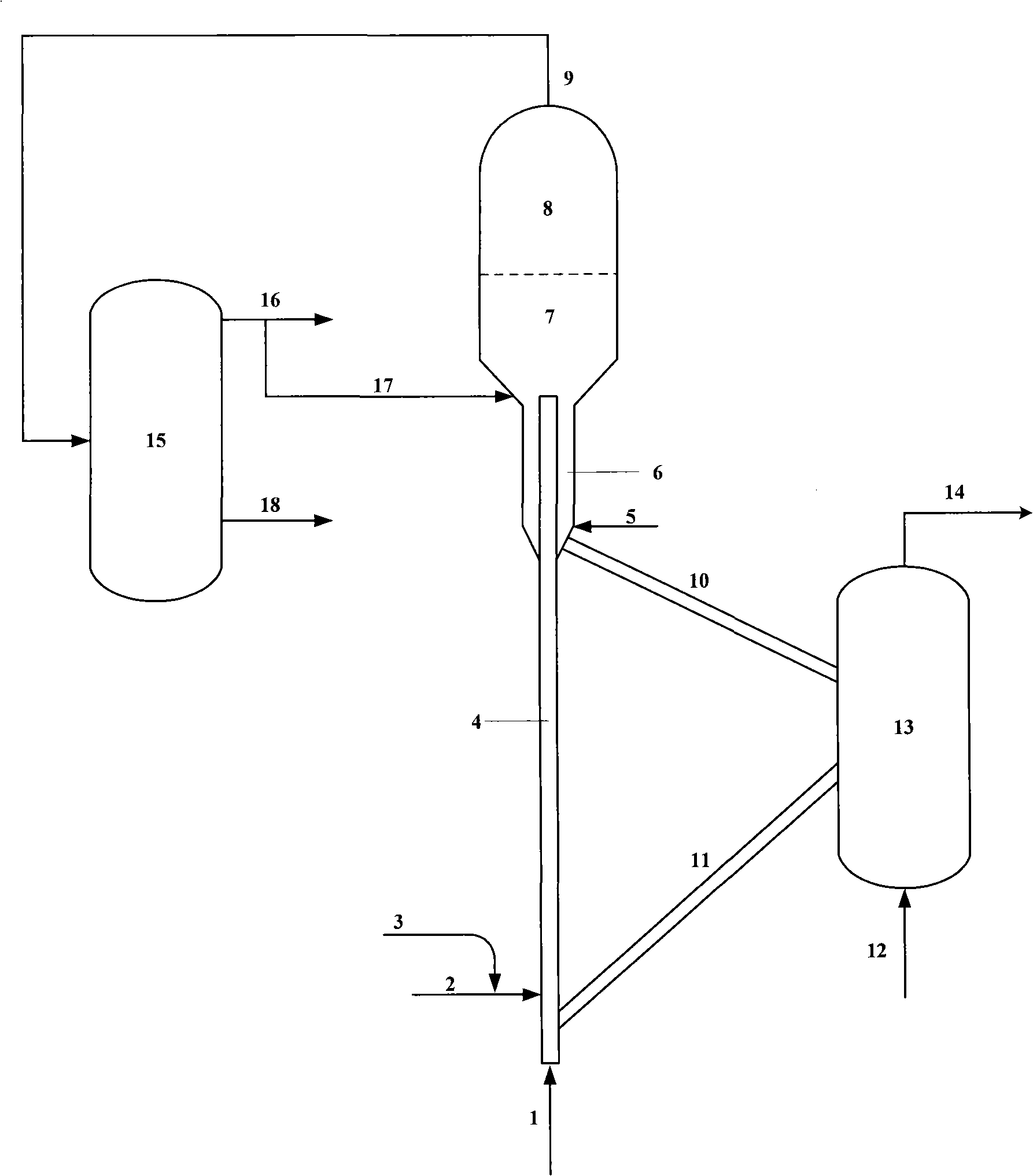

A catalytic conversion method for improving the yield of low-carbon olefin comprises the following steps: hydrocarbon oil raw material is injected into a riser or / and a fluidized bed reactor via a feed nozzle, comes into contact with catalyst containing shape-selective zeolite with an average pore size being smaller than 0.7 nm and reacts; gas rich in hydrogen is injected into the reactor; reaction oil gas and carbon deposited catalyst after reaction are separated, wherein the reaction oil gas is separated to obtain a target product containing ethylene and propylene; and the carbon deposited catalyst is returned to the reaction for reutilization after being stripped and regenerated. By injecting gas rich in hydrogen, the method can remarkably inhibit reconversion reaction of the generated low-carbon olefin to improve the yield of low-carbon olefin, particularly of propylene. When vacuum gas oil is adopted as raw material and double risers combined with a fluidized bed reactor are adopted, ethylene yield reaches 8.97 wt%, and propylene yield reaches 31.38 wt%, which are respectively improved by 2.93% and 6.81% in comparison with a process without injection of gas rich in hydrogen.

Description

technical field The invention belongs to a method for catalytic conversion of hydrocarbon oil, more specifically, a method for preparing low-carbon olefins such as ethylene and propylene through catalytic conversion of hydrocarbon oil under the action of a catalyst. Background technique At present, the traditional method of producing low-carbon olefins is the tube furnace steam cracking method, and the suitable raw materials for this method are light petroleum hydrocarbons such as ethane, propane, butane, naphtha or light diesel oil. As crude oil becomes heavier, the supply of light petroleum hydrocarbons is limited, forcing researchers to turn their attention to using a wider range of raw materials including heavy petroleum hydrocarbons to produce light olefins. In recent years, some patent documents have disclosed the method of producing light olefins by using raw materials such as heavy petroleum hydrocarbons, naphtha and C4-C6 light hydrocarbons by catalytic cracking re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C11/02C10G47/16

CPCY02P20/584

Inventor 李正龙军谢朝钢侯栓弟朱根权张执刚陈昀

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com