Method for improving productivity of low carbon olefin hydrocarbon in biological oil and fat catalytic conversion reaction

A carbon olefin yield and bio-oil technology, which is applied in the field of catalytic conversion of bio-oil, can solve the problem of low-carbon olefin yield decline, and achieve the effects of inhibiting re-conversion reaction, increasing yield, and high and low-carbon olefin yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example illustrates: using the method provided by the present invention, the catalytic reaction activity of low-carbon olefins on a small fixed fluidized bed experimental device when hydrogen is injected into the reactor.

[0039] The composition of the catalyst used in Example 1 is as follows: based on the total weight of the catalyst, the content of the zeolite with MFI structure and modified β zeolite are 20% by weight, 10% by weight, and 20% by weight, respectively Al 2 O 3 , 50% by weight kaolin. Among them, β zeolite is modified by phosphorus and Zn (P 2 O 5 The weight content of ZnO and ZnO are 1.5% and 1.6% respectively).

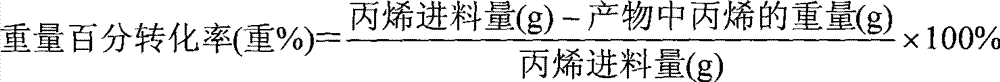

[0040] The experiment uses raw material A as the raw material and adopts a batch operation mode. The raw materials, hydrogen and atomized steam are heated to about 350°C in the preheating furnace, and then enter the bottom of the fluidized bed reactor through the feed nozzle, and contact the hot catalyst for catalytic conversion reaction . ...

Embodiment 2

[0046] This example illustrates the result of the catalytic conversion reaction of bio-oil when hydrogen is injected into the reactor using the method provided by the present invention.

[0047] The composition of the catalyst used in Example 2 is the same as that of Example 1.

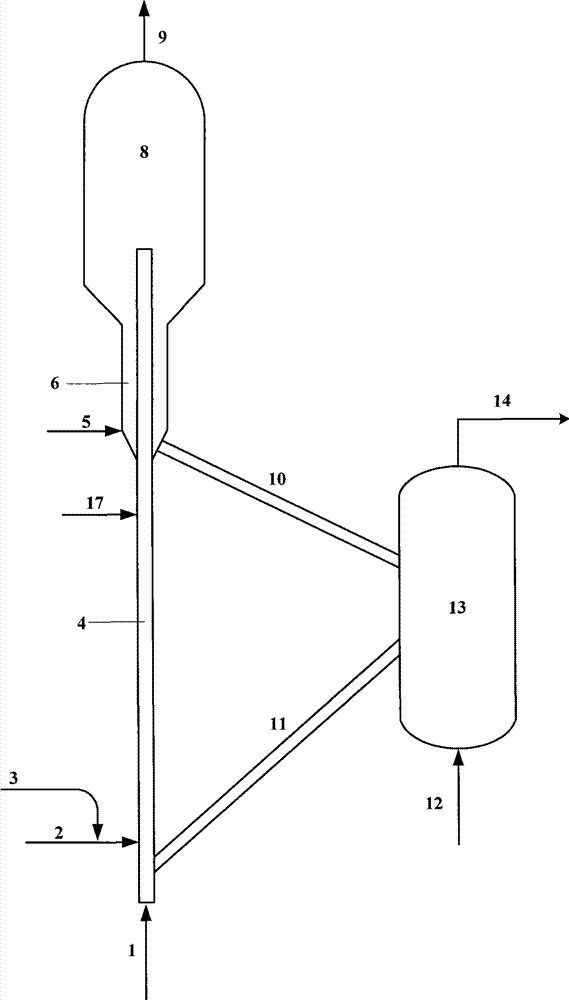

[0048] The experiment uses palm oil as raw material B and is carried out on a medium riser device with continuous reaction-regeneration operation. The riser has an inner diameter of 16 mm and a height of 6 meters. Take the raw material nozzle of the riser as a starting point, and define the effective length of the riser as 100% along the flow direction of the raw material, and the hydrogen injection position is 40% of the riser.

[0049] The experiment adopts a single pass operation mode. The regenerated catalyst with a temperature of about 700°C enters the bottom of the riser reaction section through the regeneration inclined pipe, and flows upward under the action of the pre-lift steam. Palm oil raw mat...

Embodiment 3

[0056] This example illustrates: using the method provided by the present invention, the catalytic cracking dry gas produced by the device is used as a hydrogen-rich gas, and the hydrogen-rich gas is recycled and injected into the bottom of the fluidized bed. .

[0057] The composition of the catalyst used in Example 3 is as follows: based on the total weight of the catalyst, the content of the zeolite with MFI structure and the modified β zeolite are 25% by weight, 15% by weight, and 15% by weight, respectively SiO 2 And Al 2 O 3 , 45% by weight kaolin. Among them, β zeolite is modified by phosphorus and Mn (P 2 O 5 The weight content of MnO and MnO are 1.5% and 1.5% respectively).

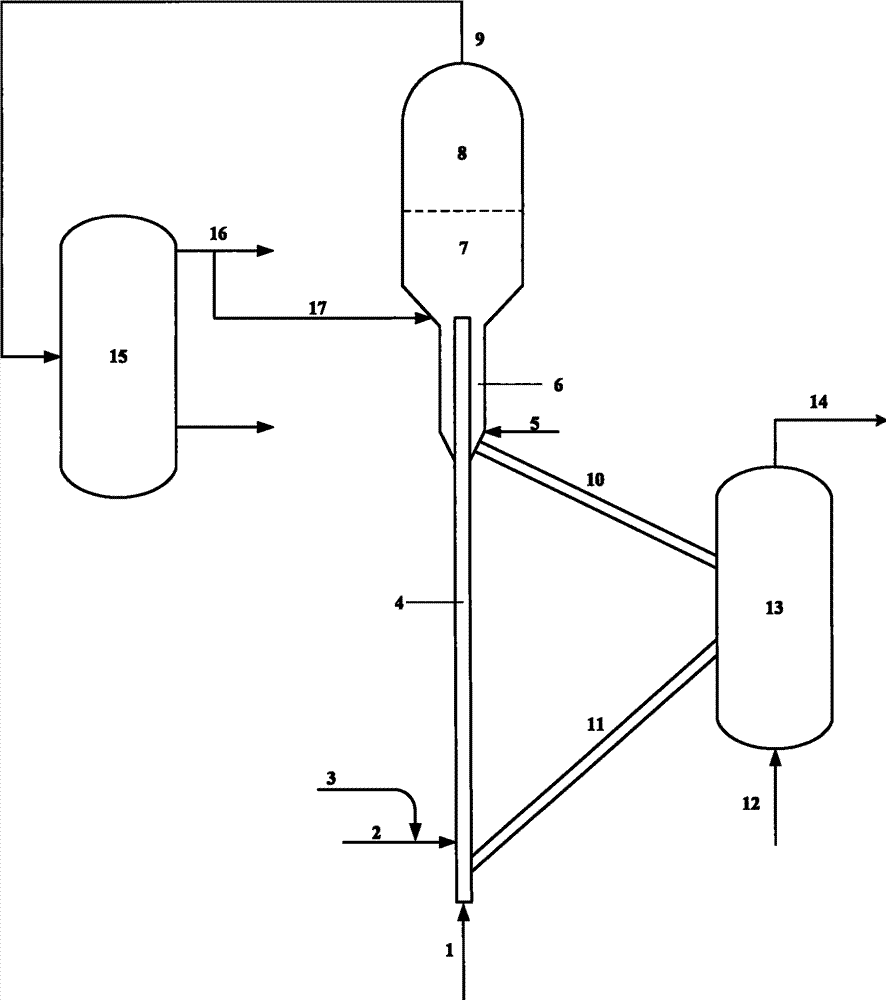

[0058] The experiment uses lard as raw material C, and is carried out on a medium riser + fluidized bed device with continuous reaction-regeneration operation. The inner diameter of the riser is 16 mm and the height is 6 meters. Above the outlet of the riser is a fluidized bed. The inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com