Patents

Literature

37results about How to "Improve conversion depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and preparation method thereof

ActiveCN103120955AReduced inactivation rateIncrease unsaturationMolecular sieve catalystsHydrocarbonsMolecular sievePolycyclic aromatic hydrocarbon

The invention relates to a catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and a preparation method thereof, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the monocyclic aromatic hydrocarbon yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the catalyst and the preparation method thereof. The catalyst comprises 34.5-60wt% of mixture of FAU type zeolite and at least one molecular sieve from MOR, BEA, MFI and MCM-22, 39.5-65wt% of at least one of gamma-alumina, eta-alumina and pseudo-boehmite as a binder and 0.05-0.9wt% of at least one metal from Pt, Pd and Ir. The catalyst can be used in the industrial production of converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

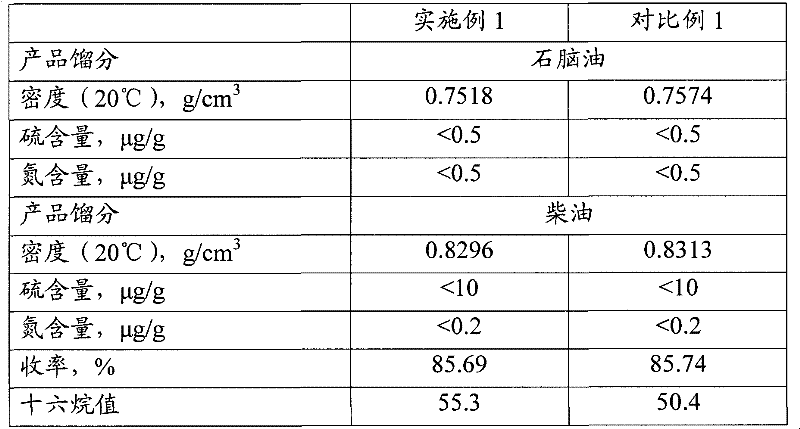

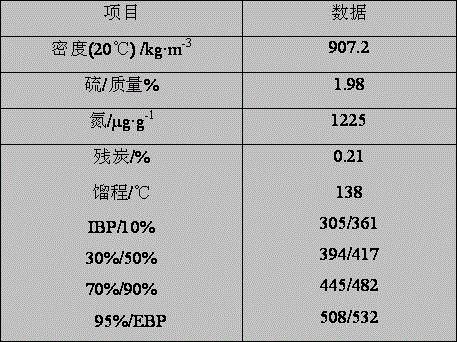

Coal tar hydrogenating modified method by two-stage method

ActiveCN101307257AGood Ring Opening Cracking PerformanceGood nitrogen resistanceTreatment with hydrotreatment processesGas phaseDistillation

The invention discloses a two-stage method coal tar hydro-upgrading method. Coal tar is subject to the atmospheric distillation and / or the reduced pressure distillation and is cut into coal tar light cut and coal tar heavy cut; after the coal tar light cut and optional distillate oil are mixed with hydrogen, the mixture enters a first hydrogeneration reaction zone and performs the contact reaction with hydrorefining catalyst; gas phase impurities of a reaction effluent is removed through an intermediate flash distillation column or a high-pressure stripping tower, and then the reaction effluent enters a second hydrogeneration reaction zone to perform the contact reaction with the hydro-upgrading catalyst or the hydrocracking catalyst; and the obtained reaction effluent is cooled, separated and fractionated to produce diesel fraction and naphtha cut. The invention provides a clean and effective coal tar processing and utilizing method, the coal tar light cut is hydro-upgraded to produce diesel oil for vehicles, the sulfur content of the obtained diesel product is less than 50 mu g / g, the content of polycyclic aromatic hydrocarbon is less than 11 weight percent, and the diesel oil cetane number of the product is improved by not less than 20.

Owner:CHINA PETROLEUM & CHEM CORP +1

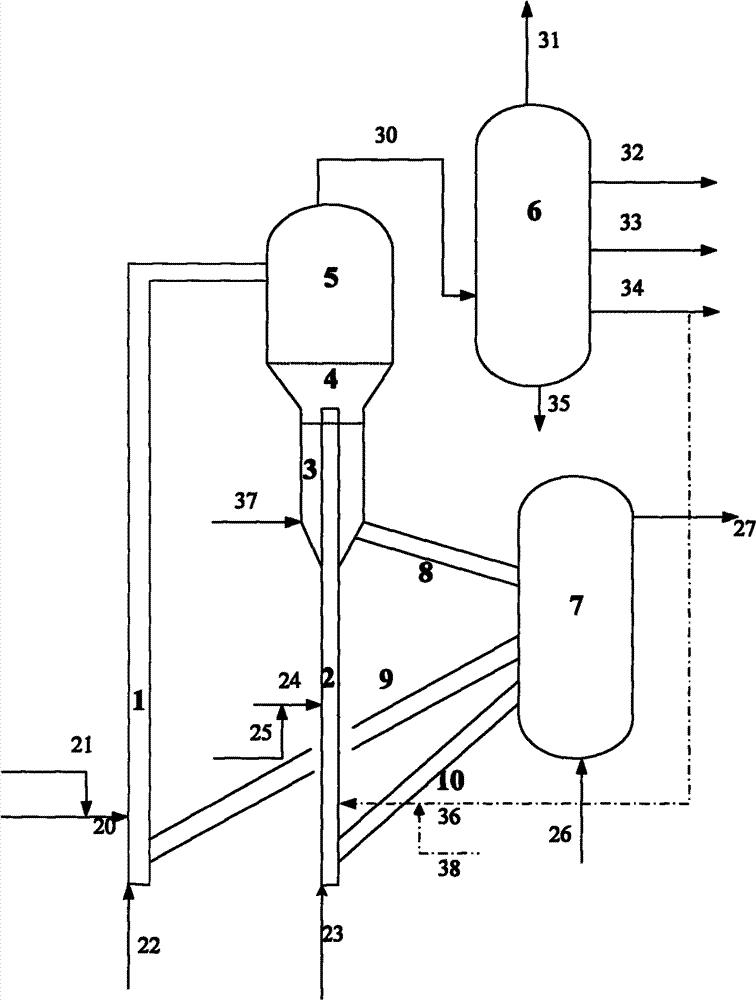

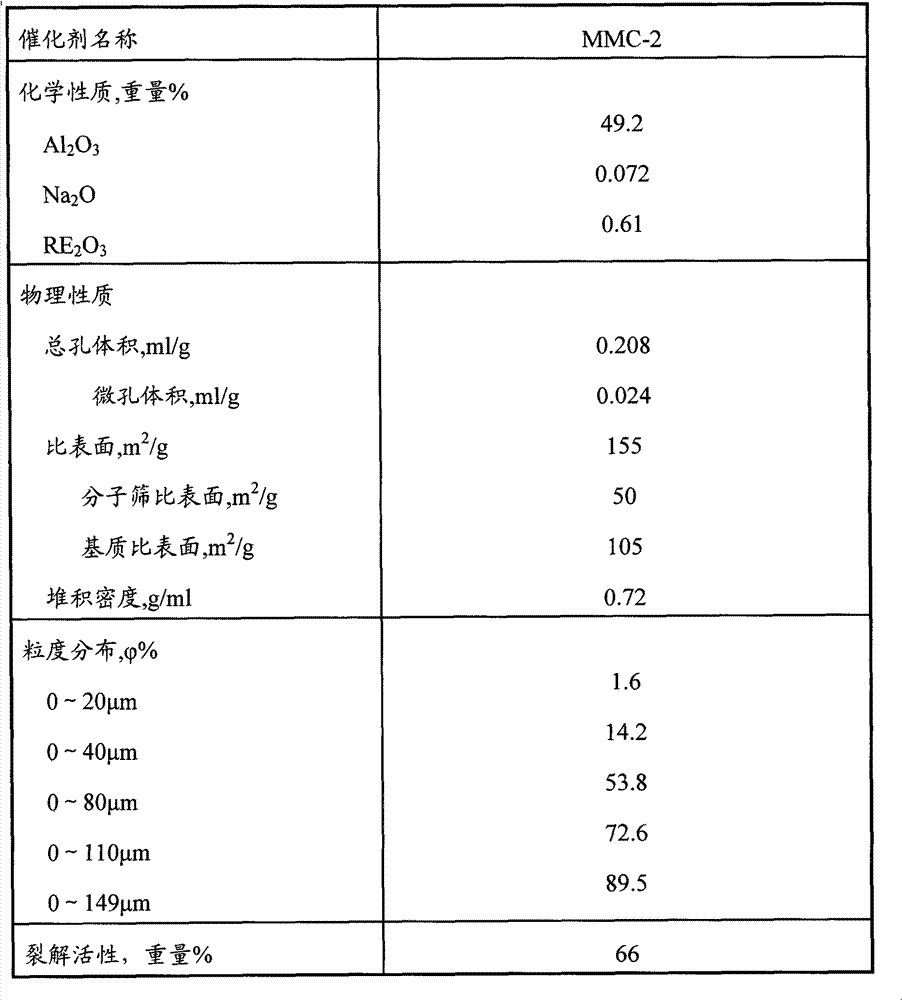

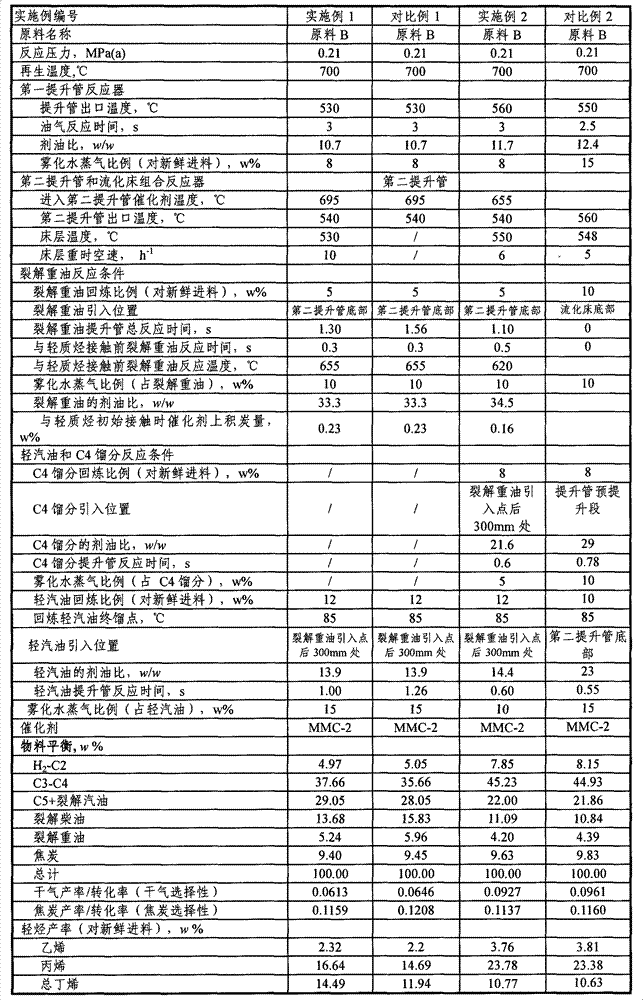

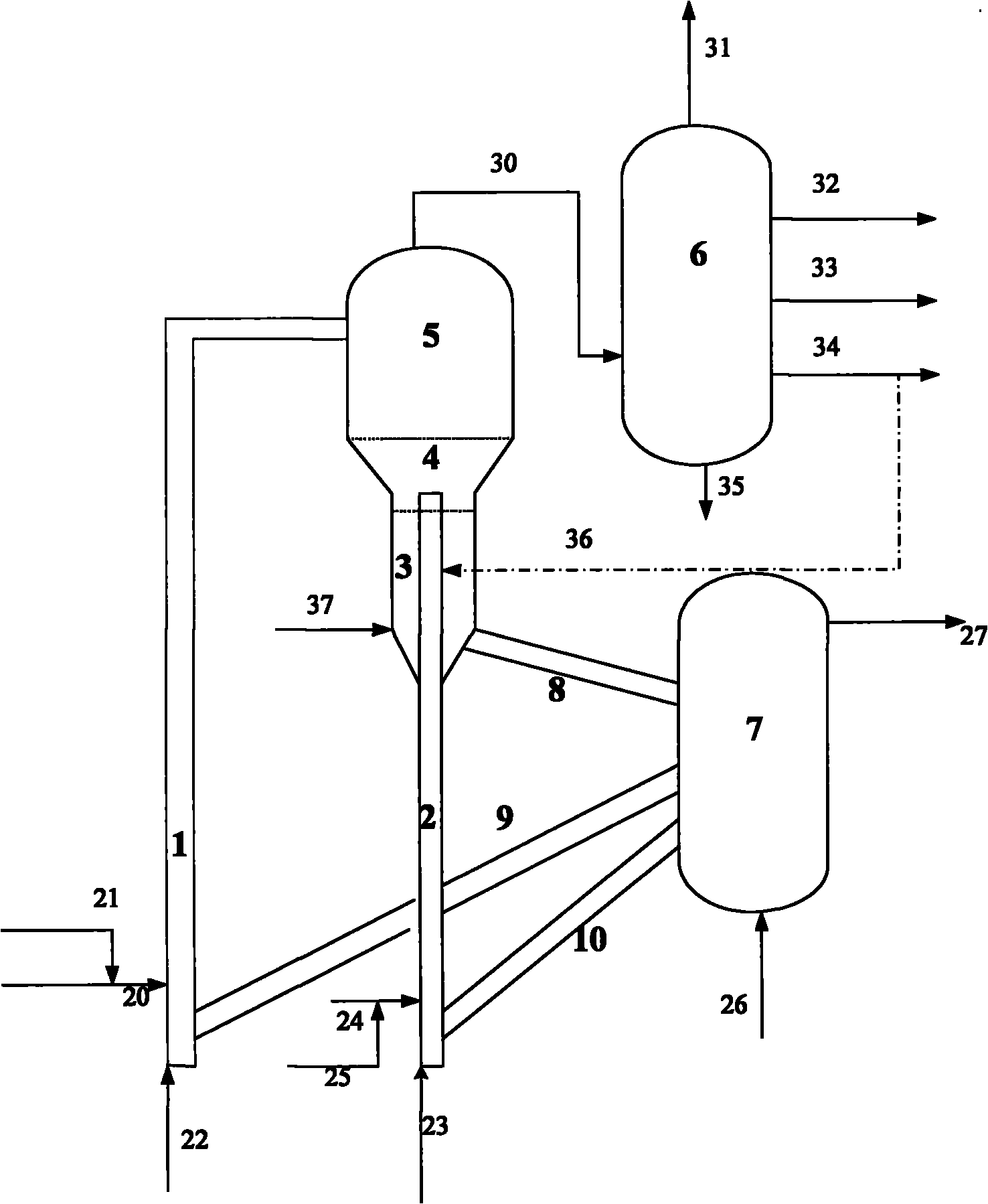

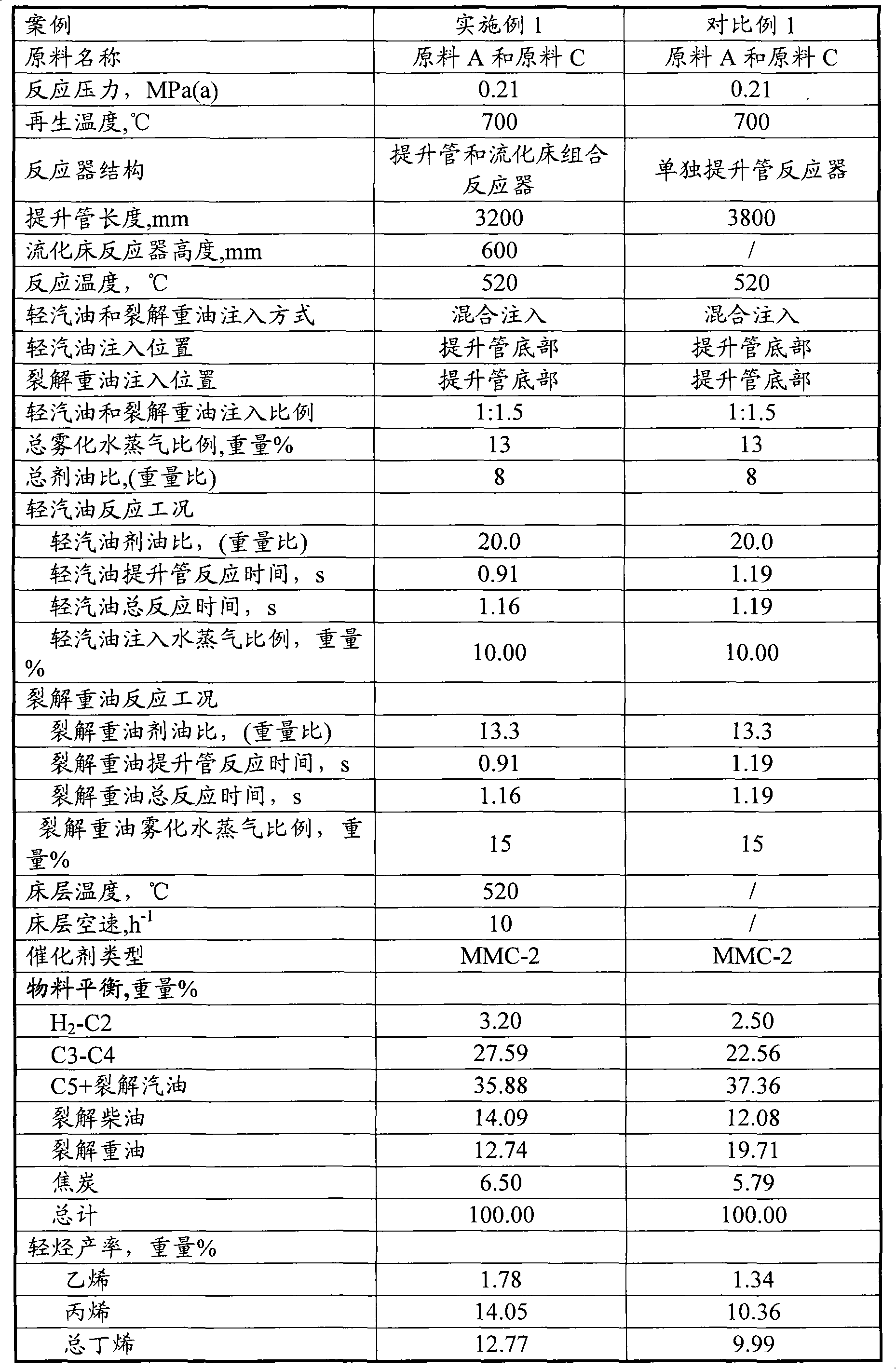

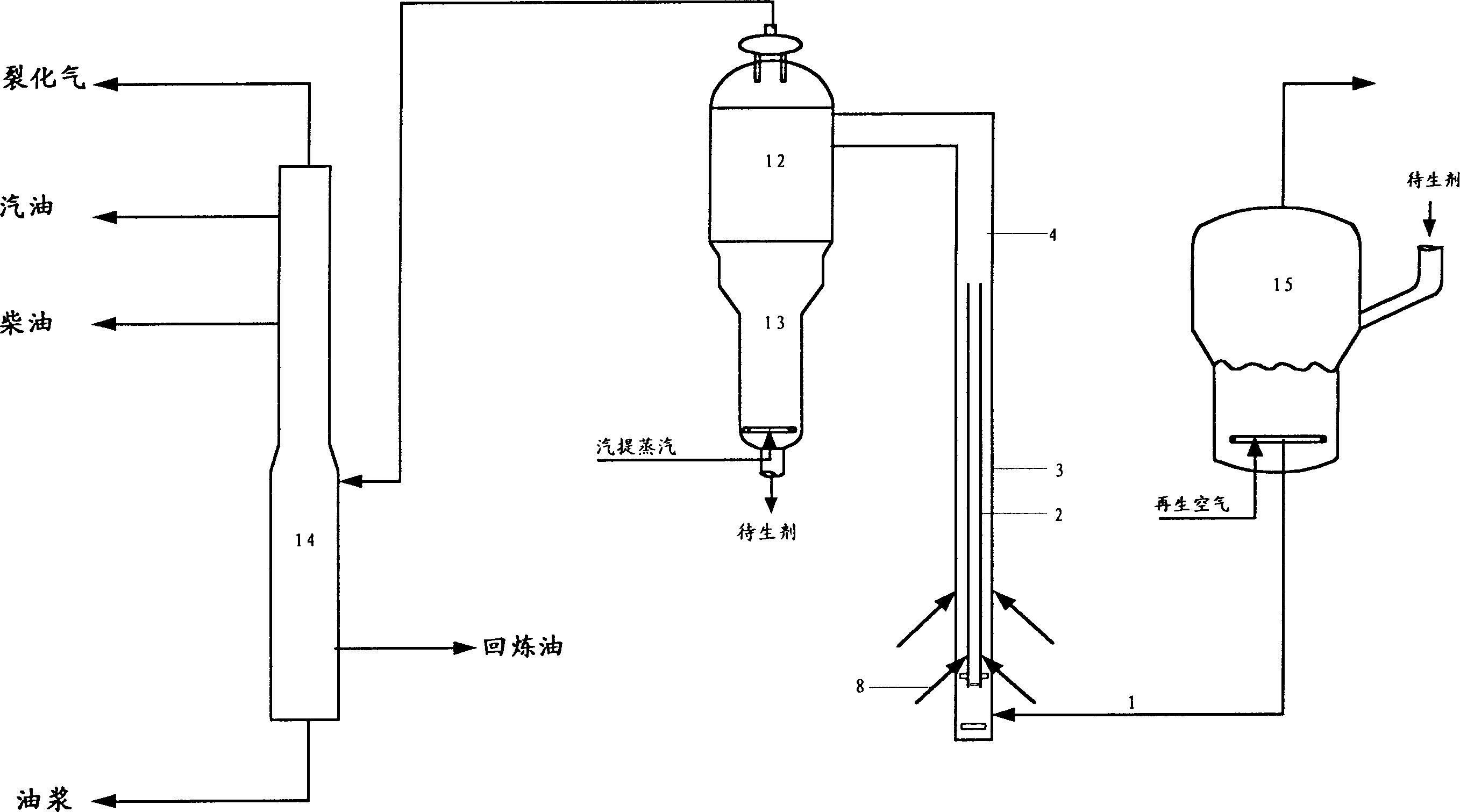

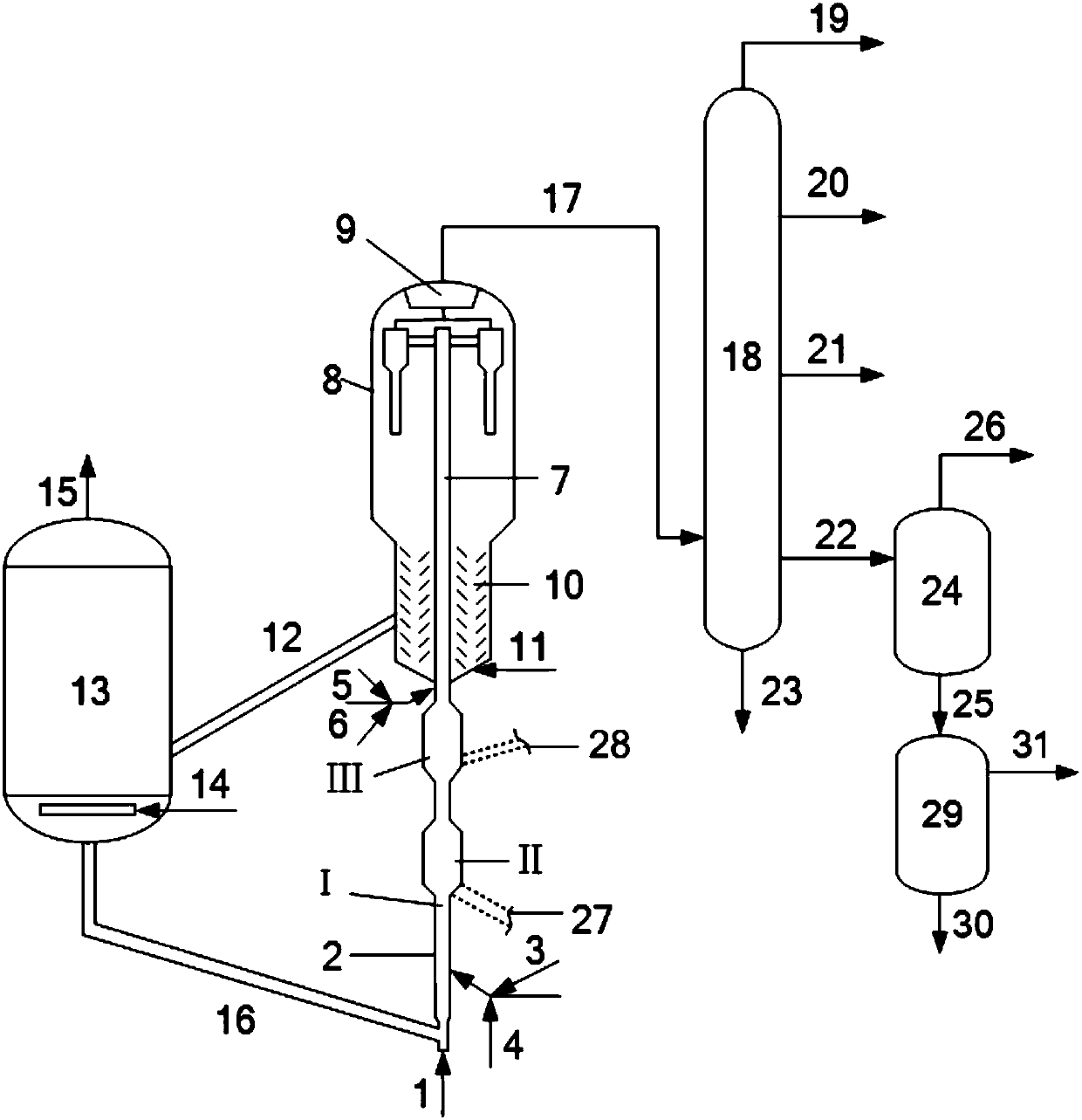

Catalytic cracking method for producing propylene

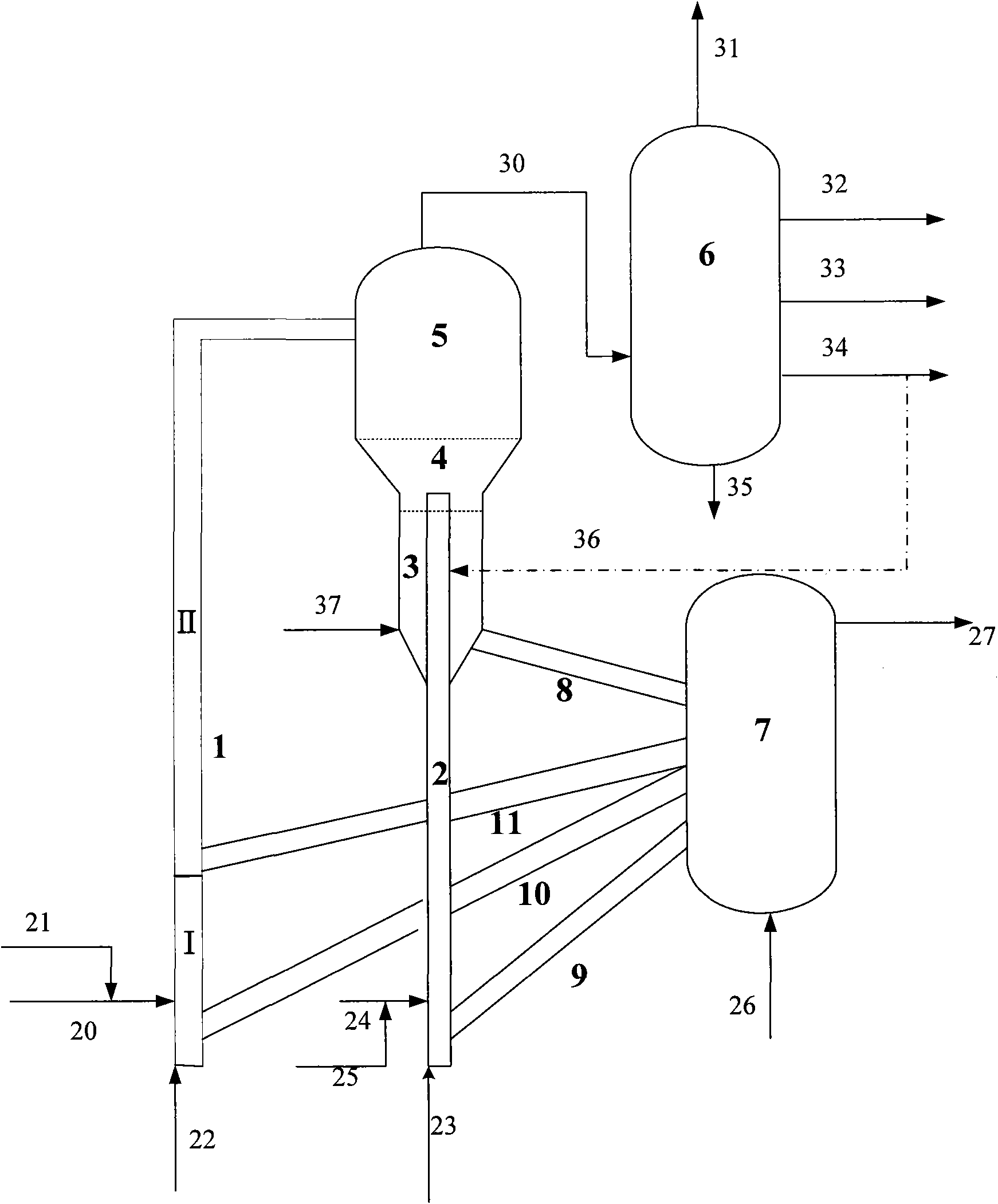

ActiveCN102899078AImprove conversion depthHigh yieldCatalytic crackingTreatment with plural serial stages onlyButeneFluidized bed

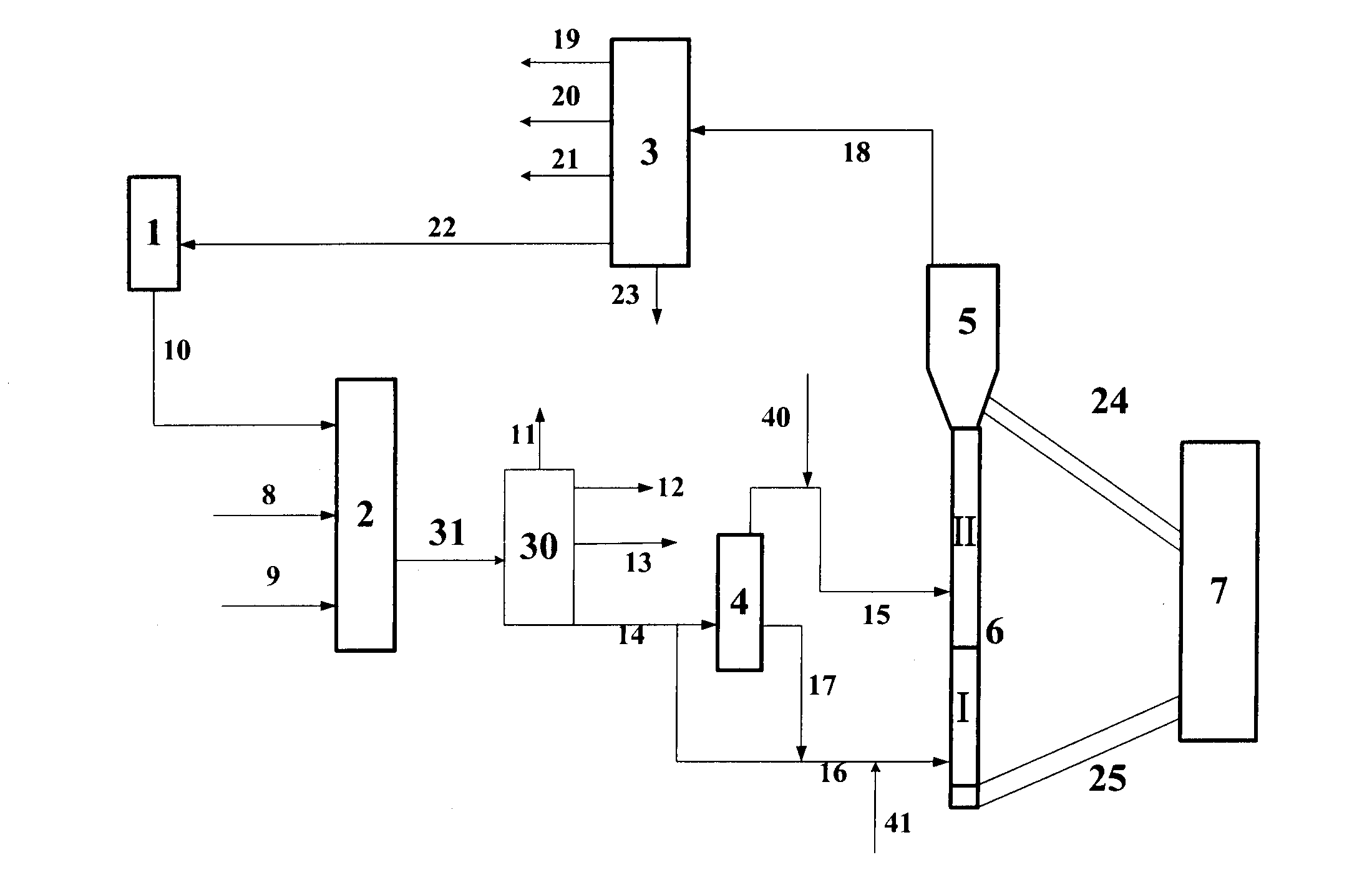

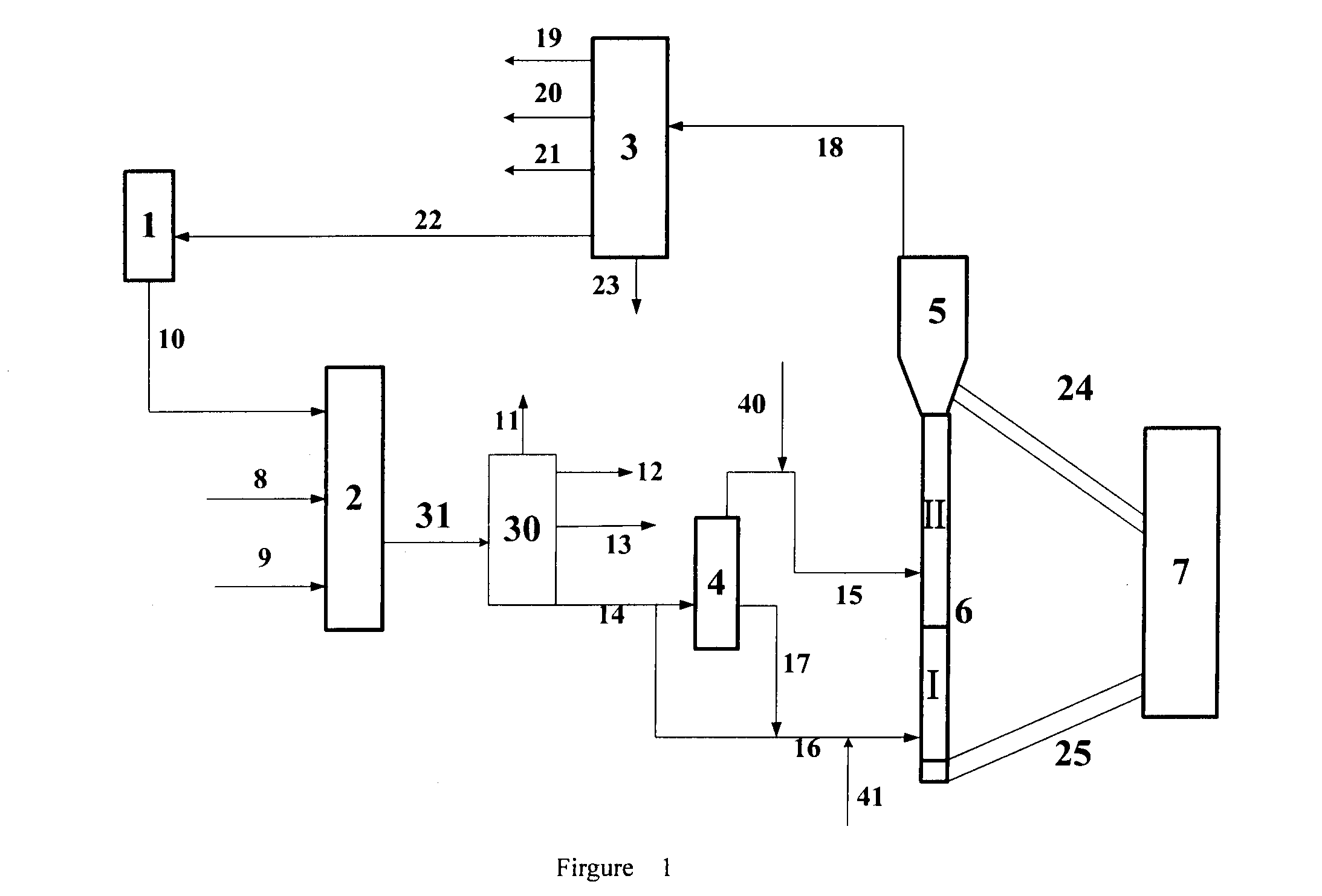

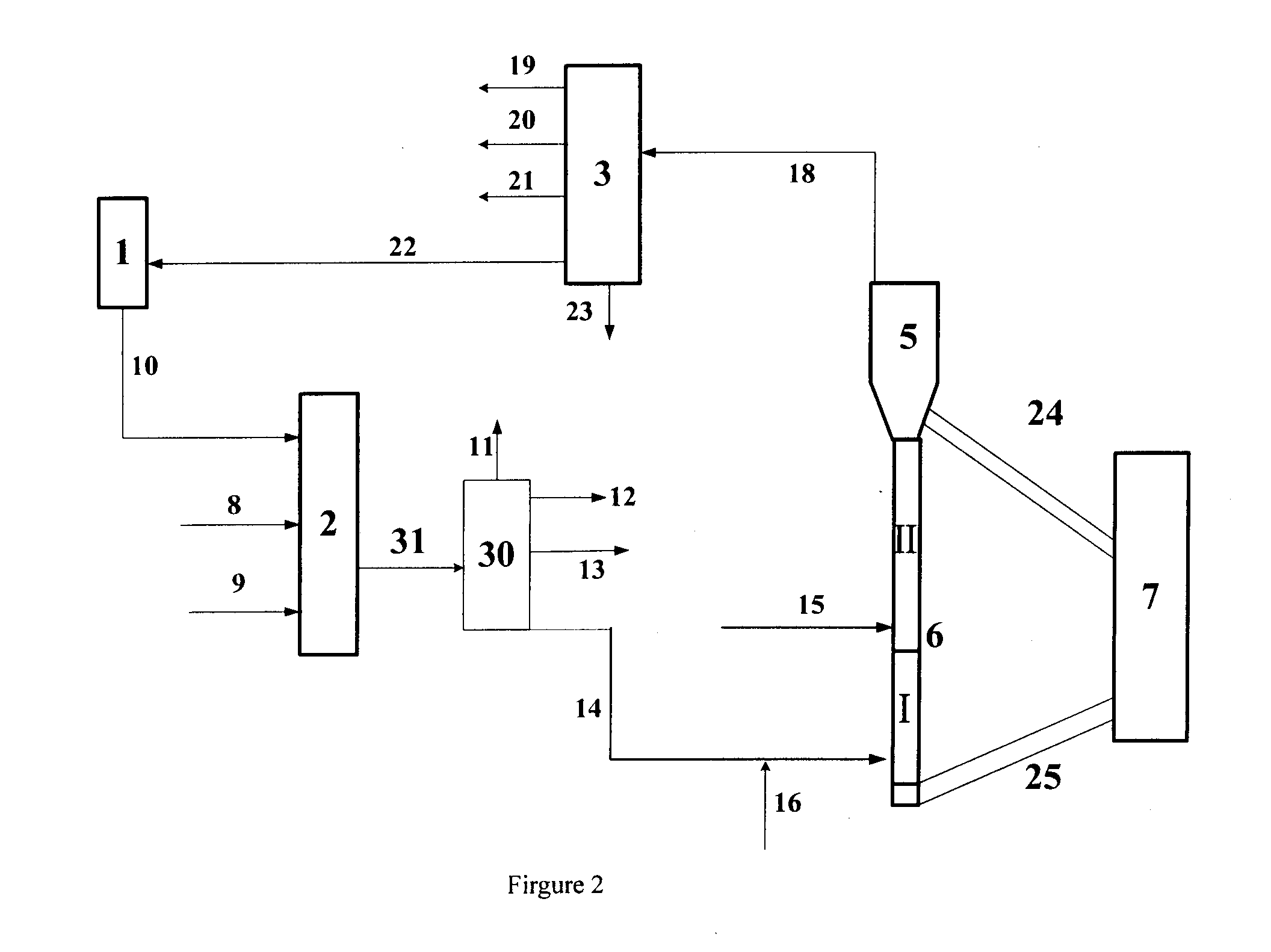

The invention discloses a catalytic cracking method for producing propylene, comprising the following steps: contacting heavy feed stock with a first stream of a catalyst containing shape-selective zeolite with an average pore size being less than 0.7nm in a first riser reactor to conduct cracking reaction, then separating the oiling agent, introducing oil gas into a product separation system, and introducing the catalyst into a stripper or a fluidized bed reactor; contacting the recycled cracking heavy oil with a second stream of the catalyst containing shape-selective zeolite with an average pore size being less than 0.7nm in a second riser reactor to conduct cracking reaction, then letting the obtained oiling agent mixture and the light hydrocarbon introduced into the second riser reactor be subject to contact reaction, then introducing the reaction mixture into a fluidized bed combined reactor for reacting, introducing the reacted oil gas into the product separation system, and introducing the reacted catalyst into the stripper. According to the invention, the method is used for heavy oil catalytic cracking, the heavy oil conversion rate is high, the yields of propylene and butene are high, and the selectivity of dry gas and coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

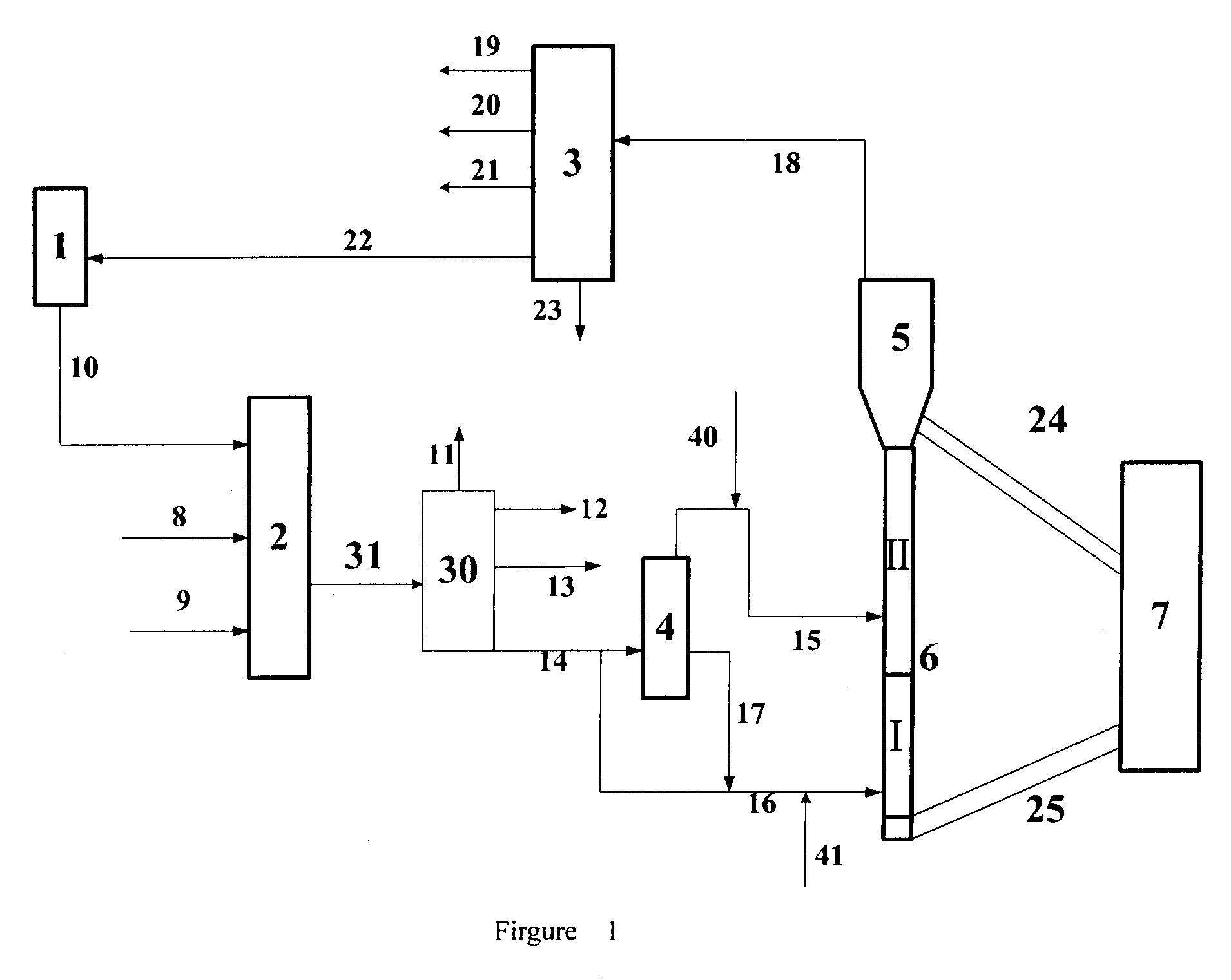

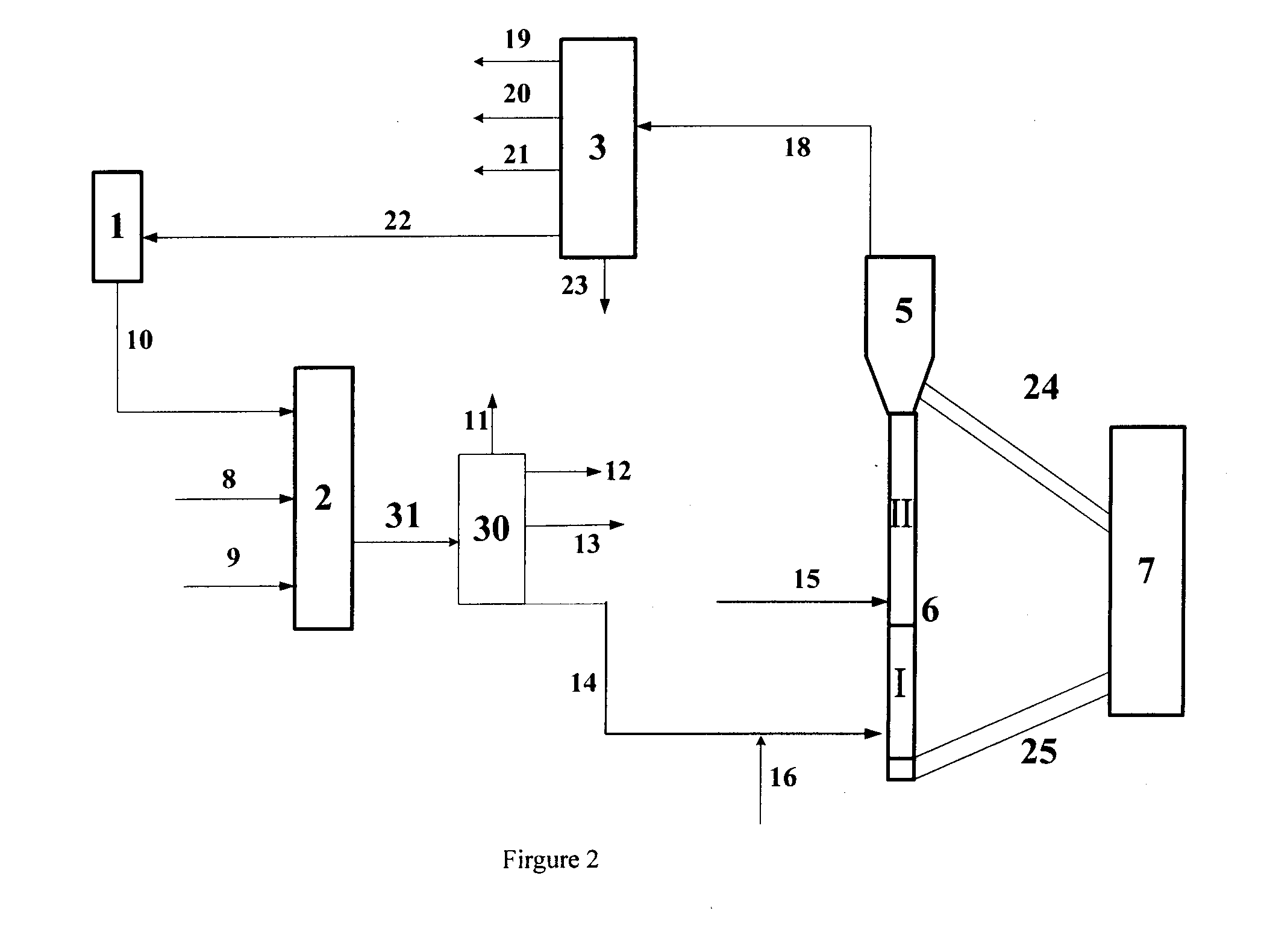

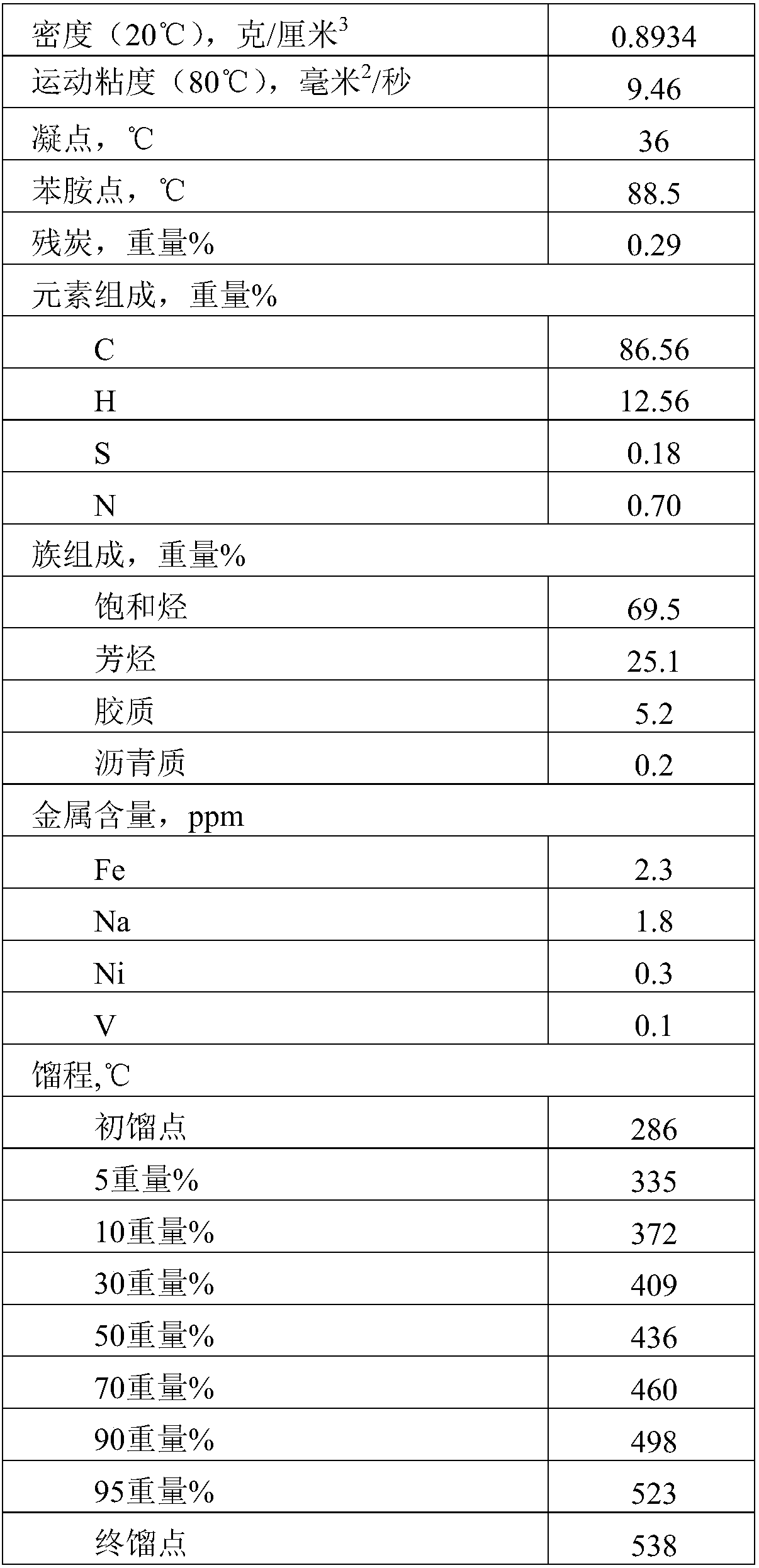

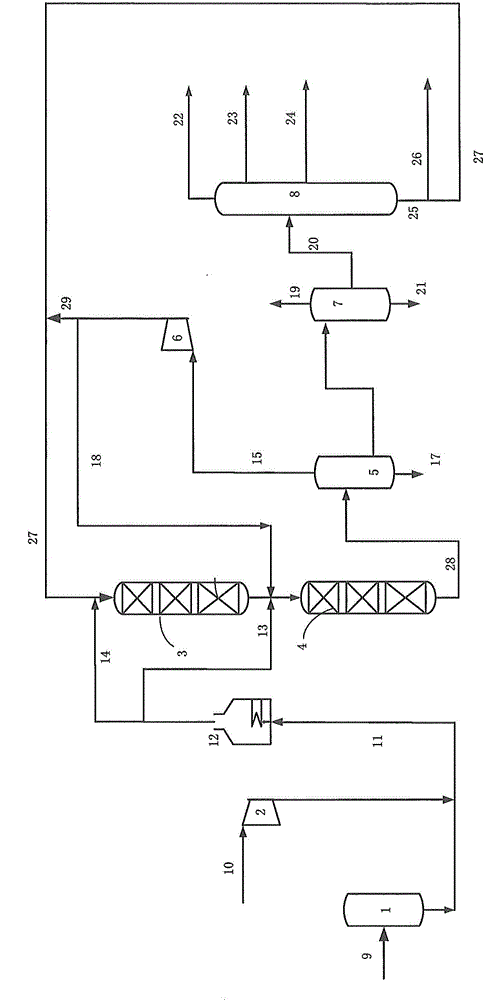

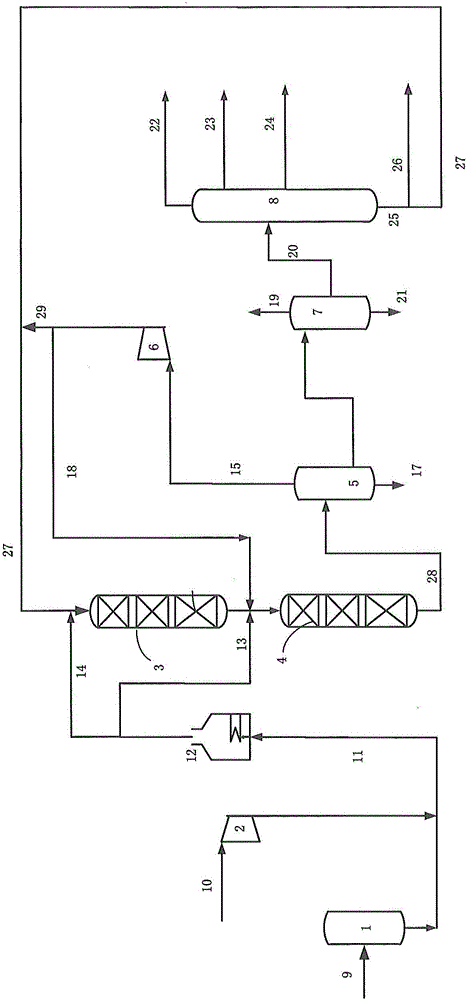

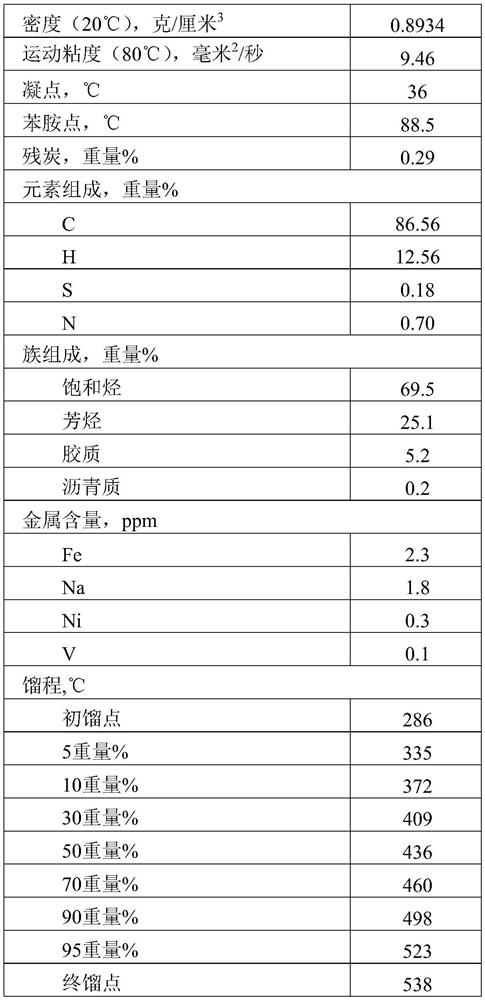

Improved integrated process for hydrogenation and catalytic cracking of hydrocarbon oil

ActiveUS20110062054A1Improve conversion depthIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyQuantum gasNatural gas

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain gas, hydrogenated naphtha, hydrogenated diesel oil, and hydrogenated tail oil; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products to obtain dry gas, hydrogenated naphtha, liquefied petroleum gas, catalytic cracked gasoline, catalytic cracked diesel oil, and catalytic cracking cycle oil; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions, the light and the heavy fractions or normal catalytic cracking heavy feedstock oil and normal catalytic cracking light feedstock oil, prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst. The process according to the present invention is especially suitable for conversion of hydrocarbon oils to produce more products of gasoline or diesel oil.

Owner:CHINA PETROCHEMICAL CORP +1

Catalytic cracking method

ActiveCN102071054AHigh yieldImprove conversion depthCatalytic crackingTreatment with plural parallel cracking stages onlyFluidized bedCracking reaction

The invention relates to a catalytic cracking method which comprises the following steps of: enabling heavy raw materials to be in contact with a catalyst containing shape selective zeolite with average hole diameter of less than 0.7nm in a first raising pipe reactor for performing cracking reaction, and enabling light raw materials and cracked heavy oil to be in contact with the catalyst containing the shape selective zeolite with the average hole diameter of less than 0.7nm in a second raising pipe reactor and a fluidized bed reactor for performing the cracking reaction. The method is used for catalytic cracking of the heavy oil, the conversion rate of the heavy oil and the yield of propylene are high, and the yield of dry gas and coke is low.

Owner:CHINA PETROLEUM & CHEM CORP

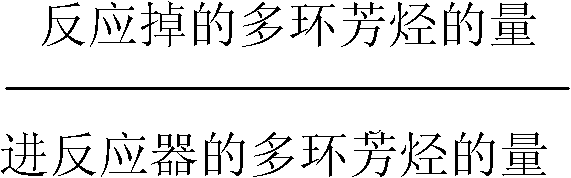

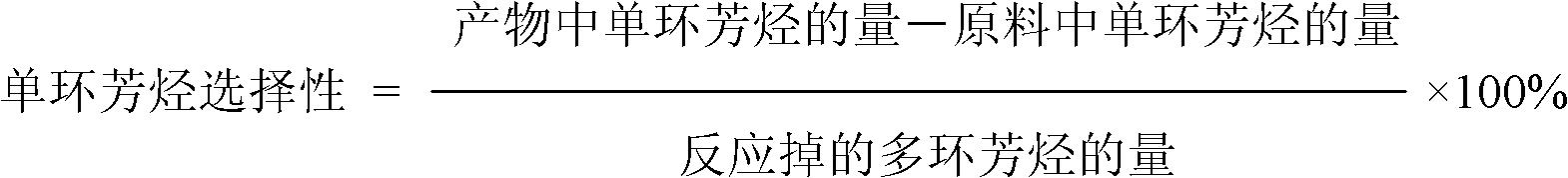

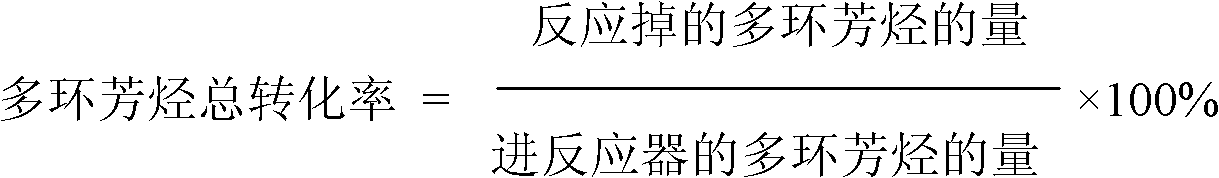

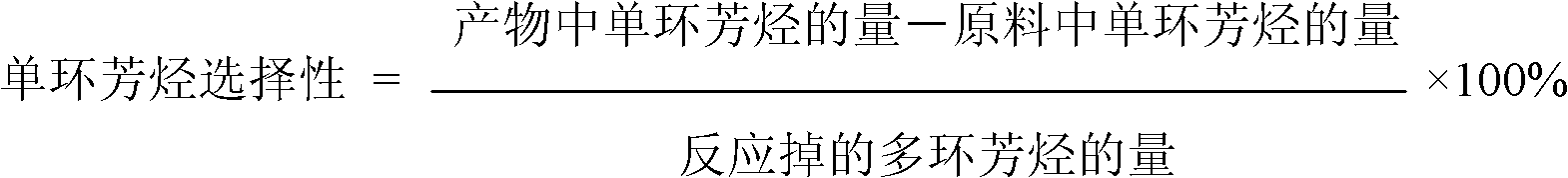

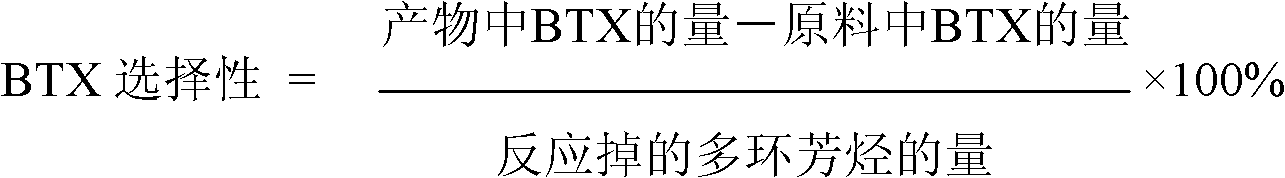

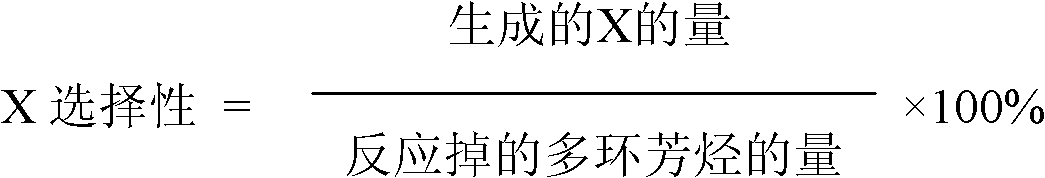

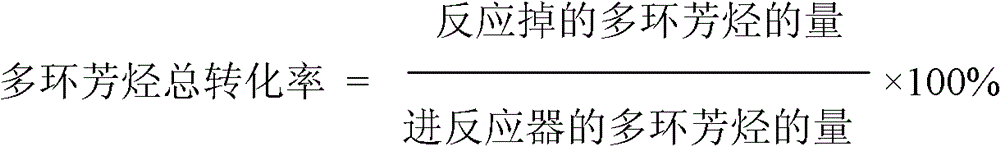

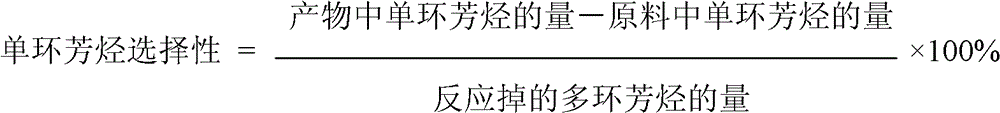

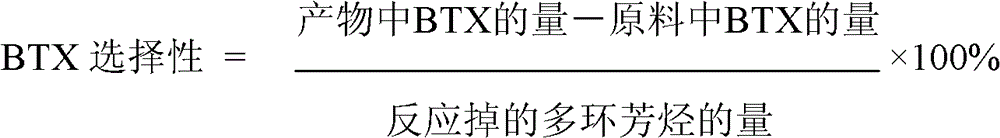

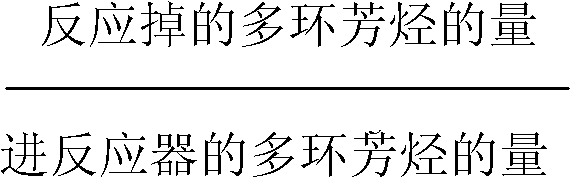

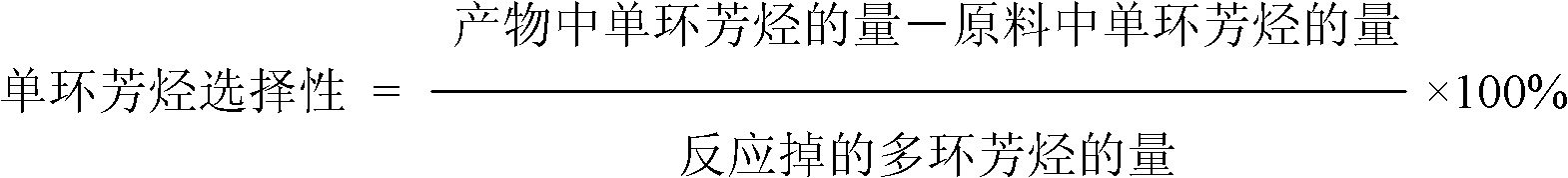

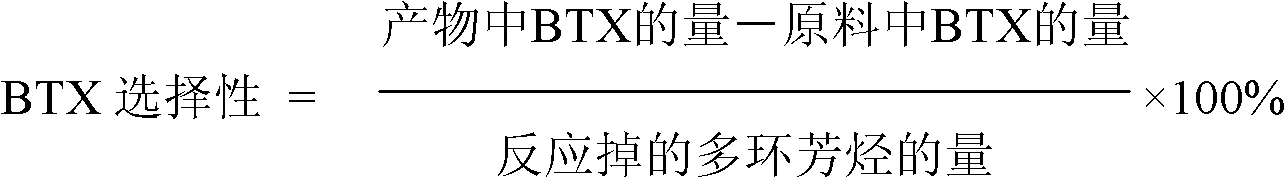

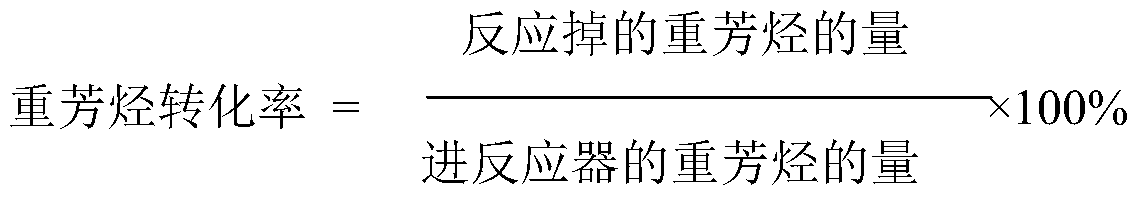

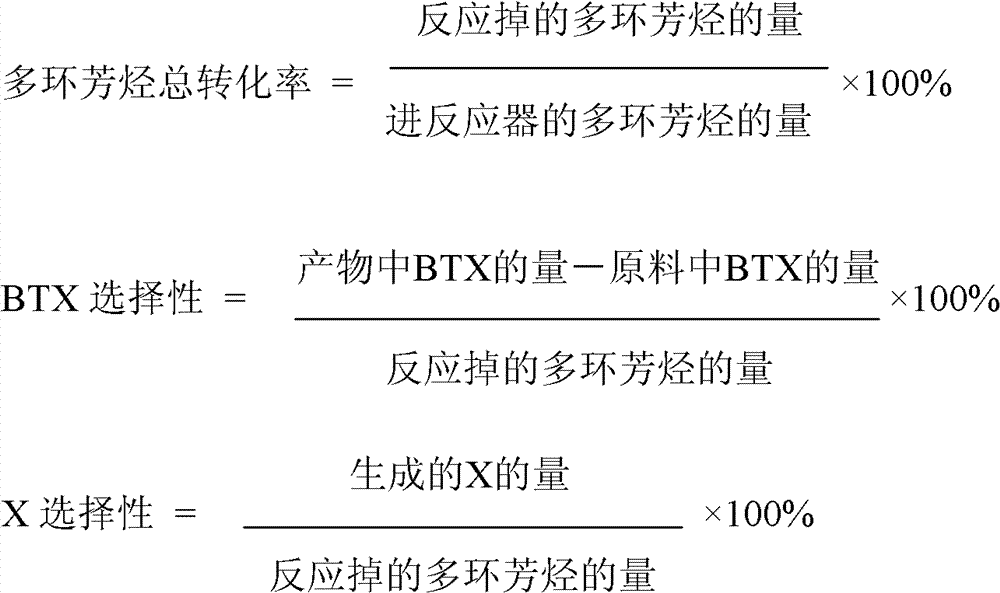

Method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons

ActiveCN103121896AReduced inactivation rateIncrease unsaturationMolecular sieve catalystsHydrocarbonsPolycyclic aromatic hydrocarbonHydrogen

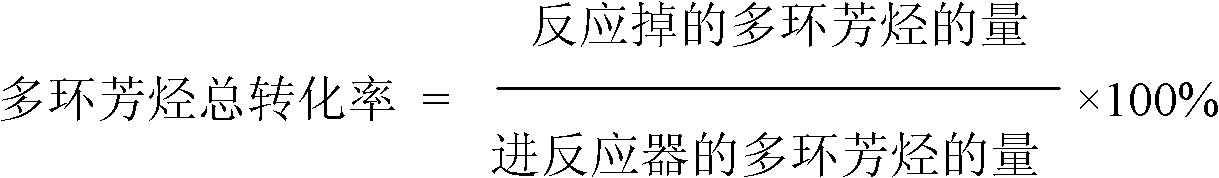

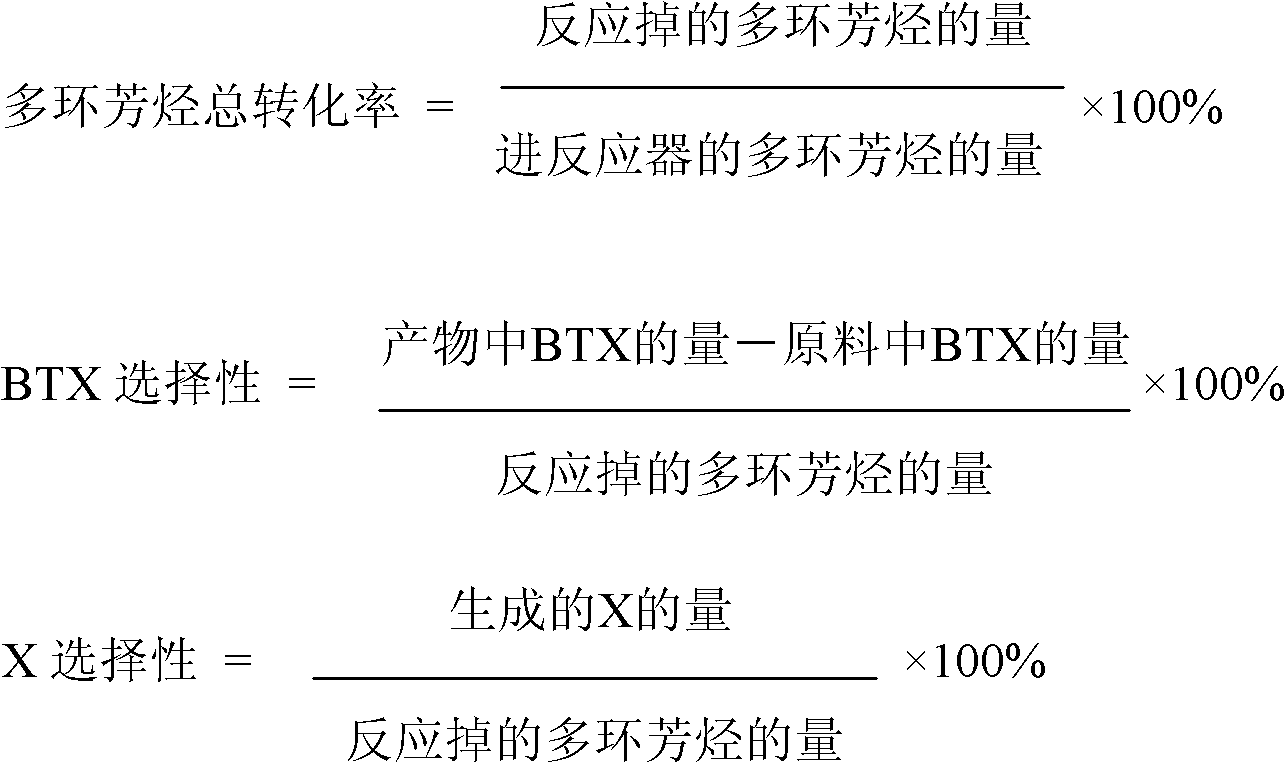

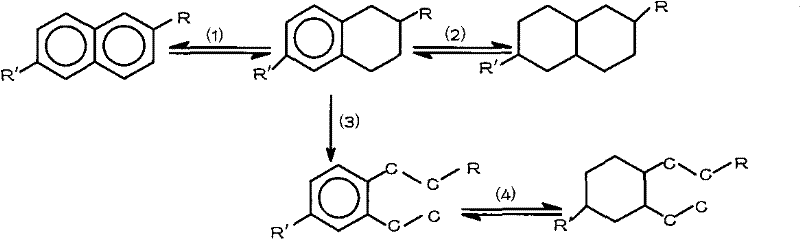

The invention relates to a method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the monocyclic aromatic hydrocarbon yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the technical scheme that polycyclic aromatic hydrocarbon mixtures and hydrogen are taken as the raw materials and are contacted with a catalyst in a fixed bend reactor to react under the conditions that the reaction temperature is 335-440 DEG C, the pressure is 4-7MPa, the weight hourly space velocity is 1-3hr<-1> and the hydrogen / hydrocarbon mole ratio is 4.0-8.0 to generate monocyclic aromatic hydrocarbon mixtures. The method can be used in the industrial production of converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

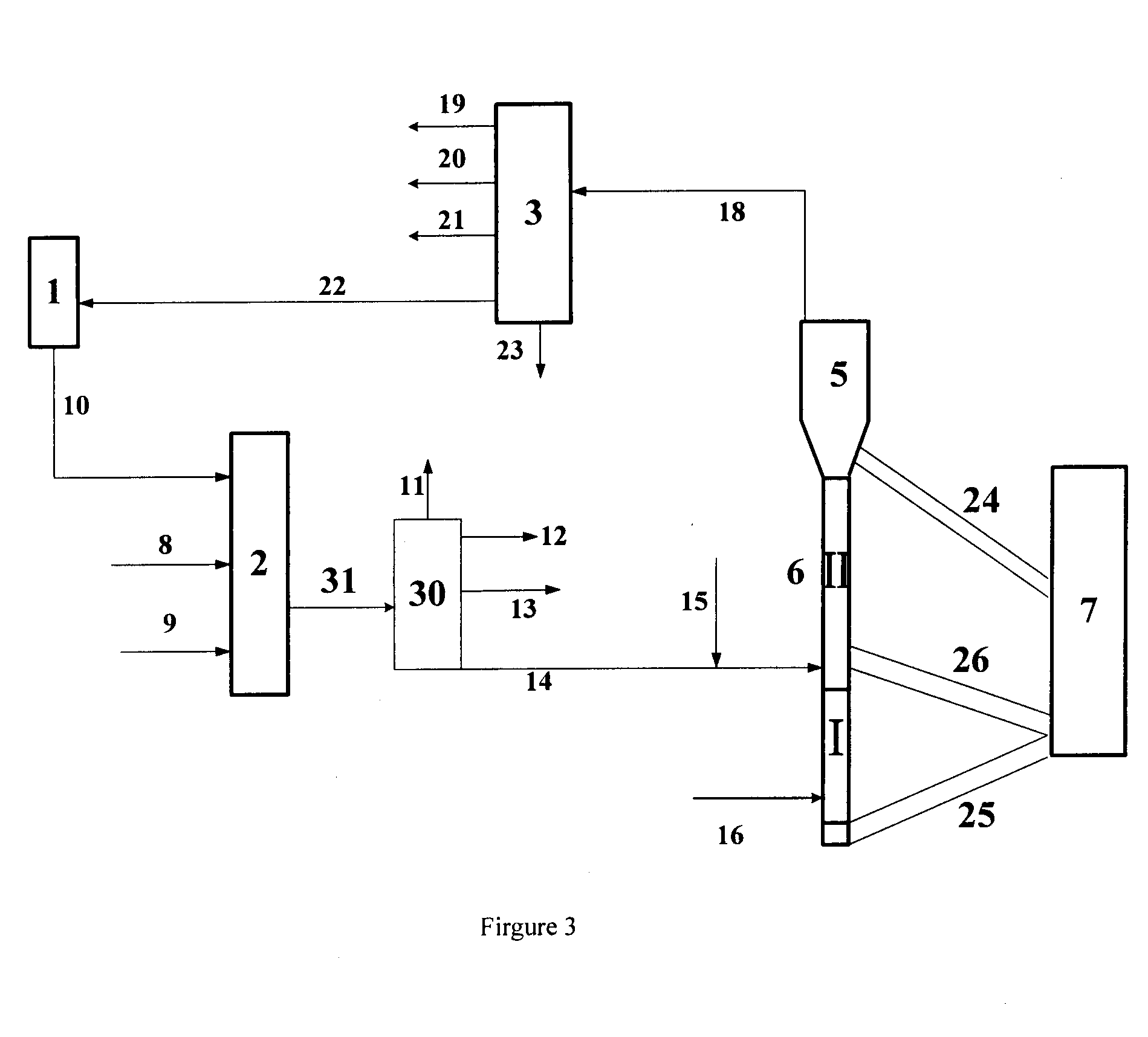

Combined process of hydrotreating and catalytic cracking of hydrocarbon oils

ActiveUS20130062250A1Big ratioIncrease productionCatalytic crackingTreatment with plural parallel cracking stages onlyHydrogenResidual oil

Disclosed is a combination process for improved hydrotreating and catalytic cracking of hydrocarbon oils, including: contacting residual oil, catalytic cracking cycle oil, and optional distillate oil with a hydrotreating catalyst under hydrotreating conditions in the presence of hydrogen followed by separation of the reaction products to obtain hydrogenated tail oil and other products; contacting the hydrogenated tail oil and optional normal catalytic cracking feedstock oil with a cracking catalyst under catalytic cracking conditions followed by separation of the reaction products; wherein the hydrogenated tail oil and / or normal catalytic cracking feedstock oil are separated into at least two fractions prior to contacting the hydrogenated tail oil and / or normal catalytic cracking feedstock oil with the cracking catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

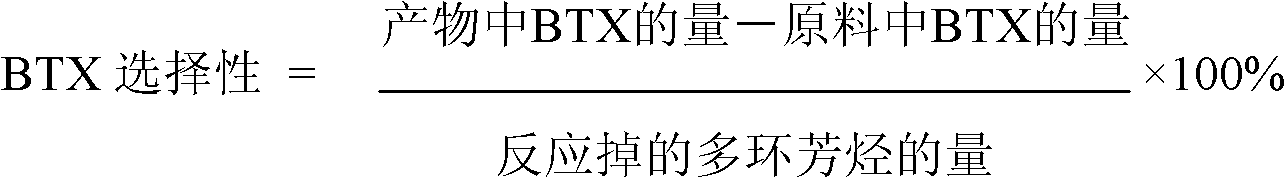

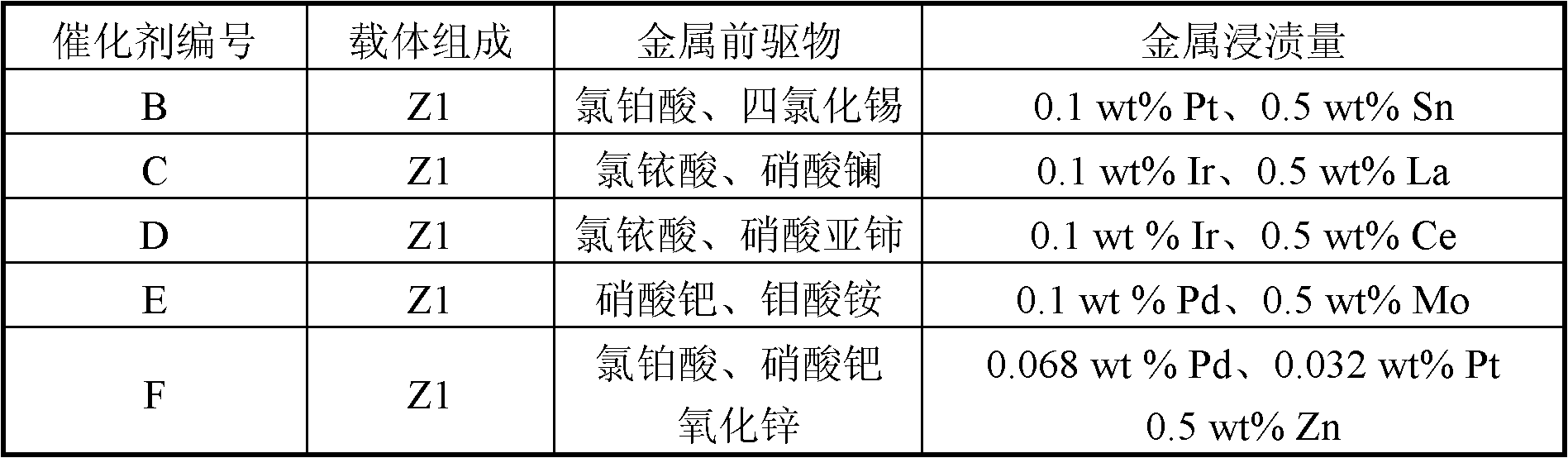

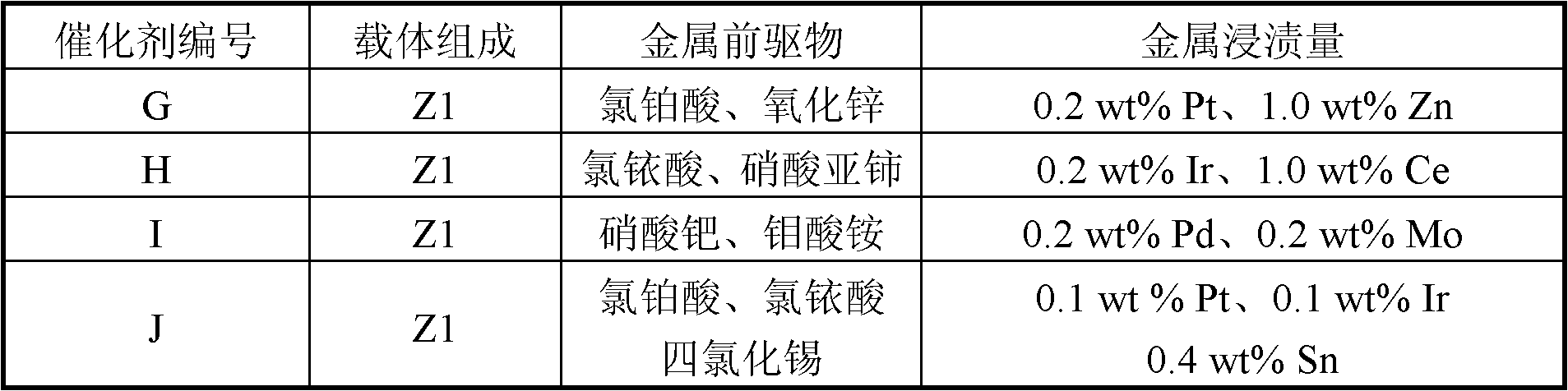

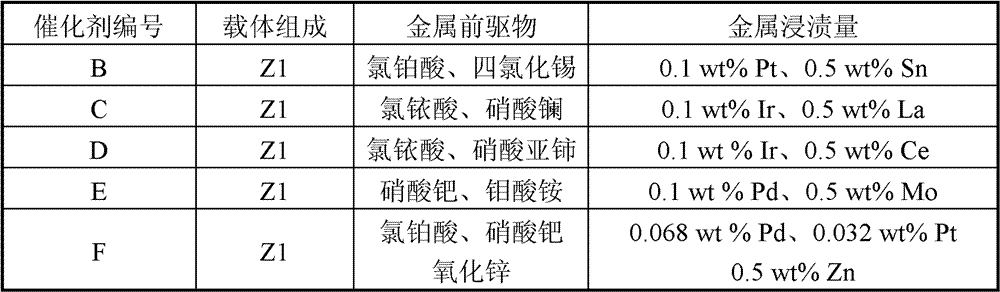

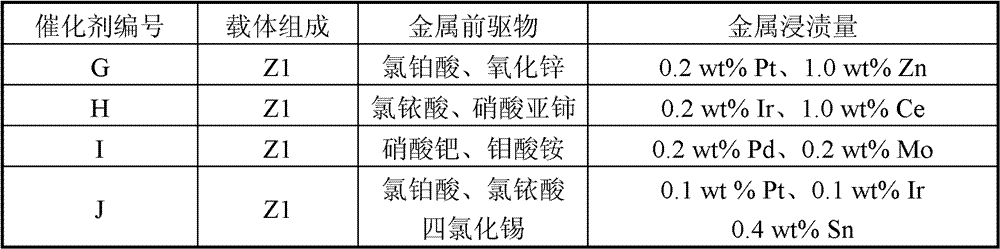

Catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene and preparation method thereof

ActiveCN103120956ADelay inactivationLow depth of conversionMolecular sieve catalystsHydrocarbonsMolecular sievePolycyclic aromatic hydrocarbon

The invention relates to a catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene and a preparation method thereof, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the dimenthylbenzene yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the catalyst and the preparation method thereof. The catalyst comprises 30-60wt% of mixture of FAU type zeolite and at least one molecular sieve from MOR, BEA, MFI and MCM-22, 38-69.9wt% of at least one of gamma-alumina, eta-alumina and pseudo-boehmite as a binder, 0.04-0.9wt% of at least one metal from Pt, Pd and Ir and 0.1-1wt% of at least one of Zn, Sn, La, Ce and Mo. The catalyst can be used in the industrial production of increasing production of dimethylbenzene by converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons

ActiveCN103121896BLow depth of conversionImprove conversion depthMolecular sieve catalystsHydrocarbonsPolycyclic aromatic hydrocarbonHydrogen

The invention relates to a method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the monocyclic aromatic hydrocarbon yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the technical scheme that polycyclic aromatic hydrocarbon mixtures and hydrogen are taken as the raw materials and are contacted with a catalyst in a fixed bend reactor to react under the conditions that the reaction temperature is 335-440 DEG C, the pressure is 4-7MPa, the weight hourly space velocity is 1-3hr<-1> and the hydrogen / hydrocarbon mole ratio is 4.0-8.0 to generate monocyclic aromatic hydrocarbon mixtures. The method can be used in the industrial production of converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

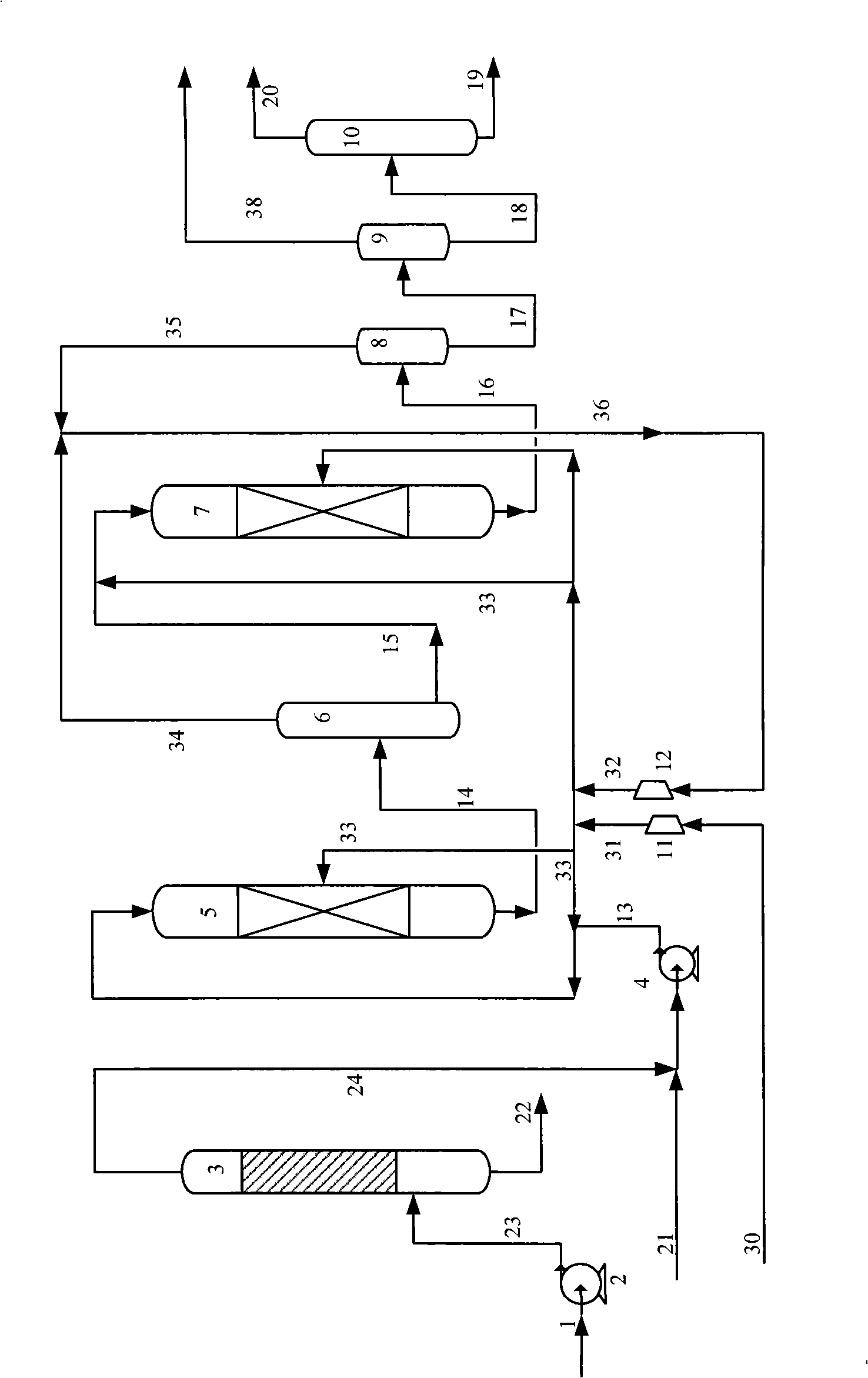

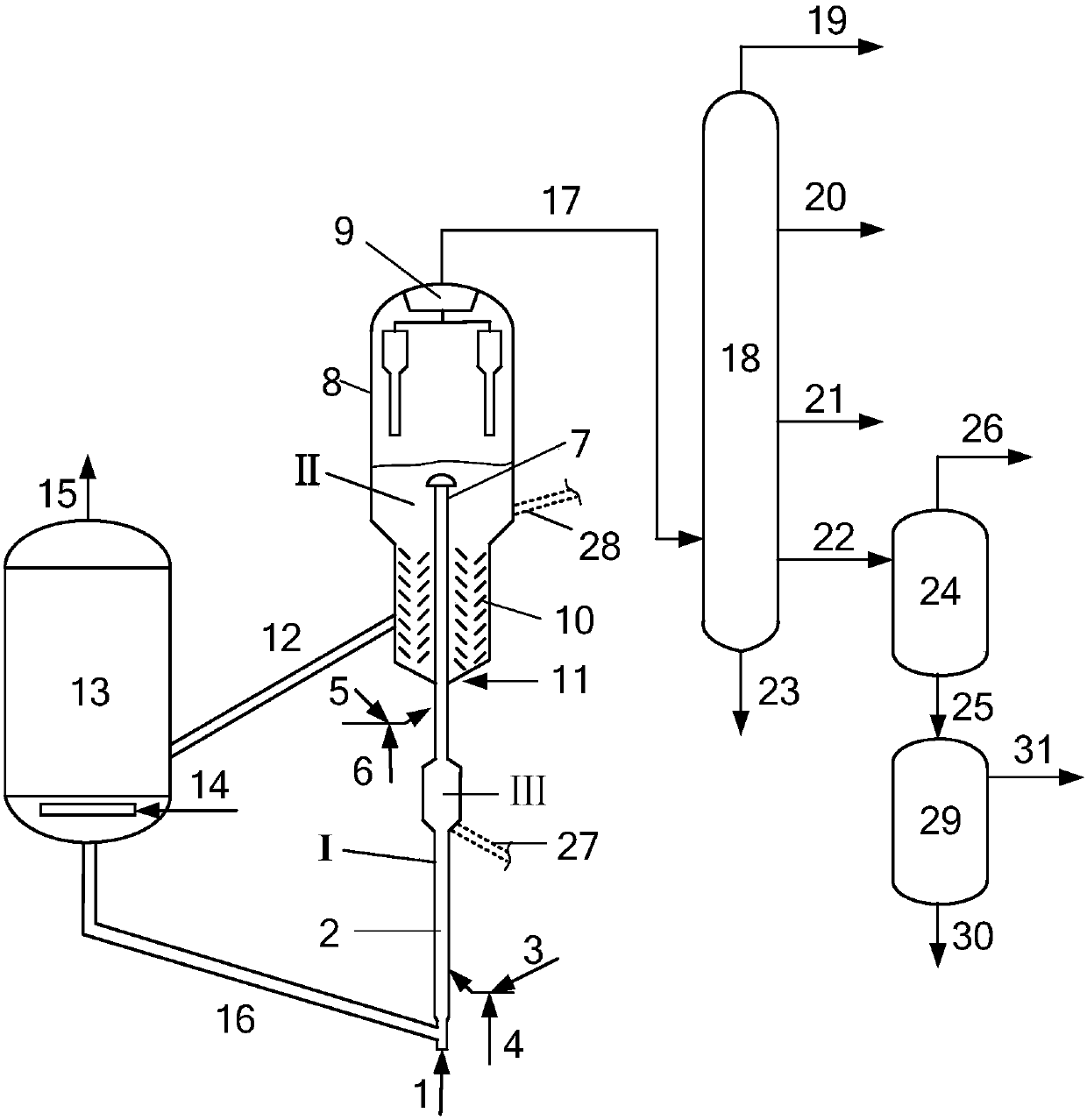

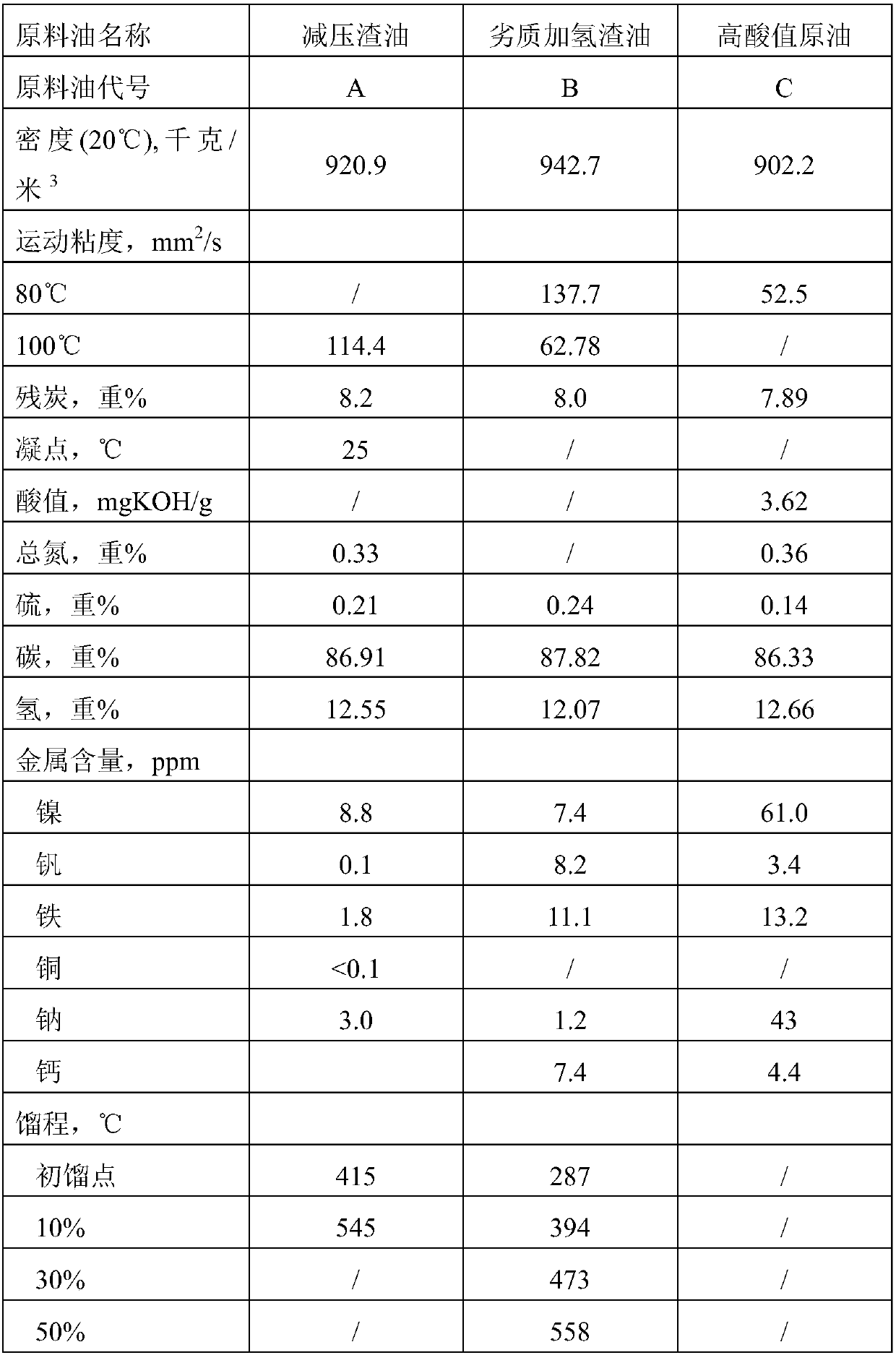

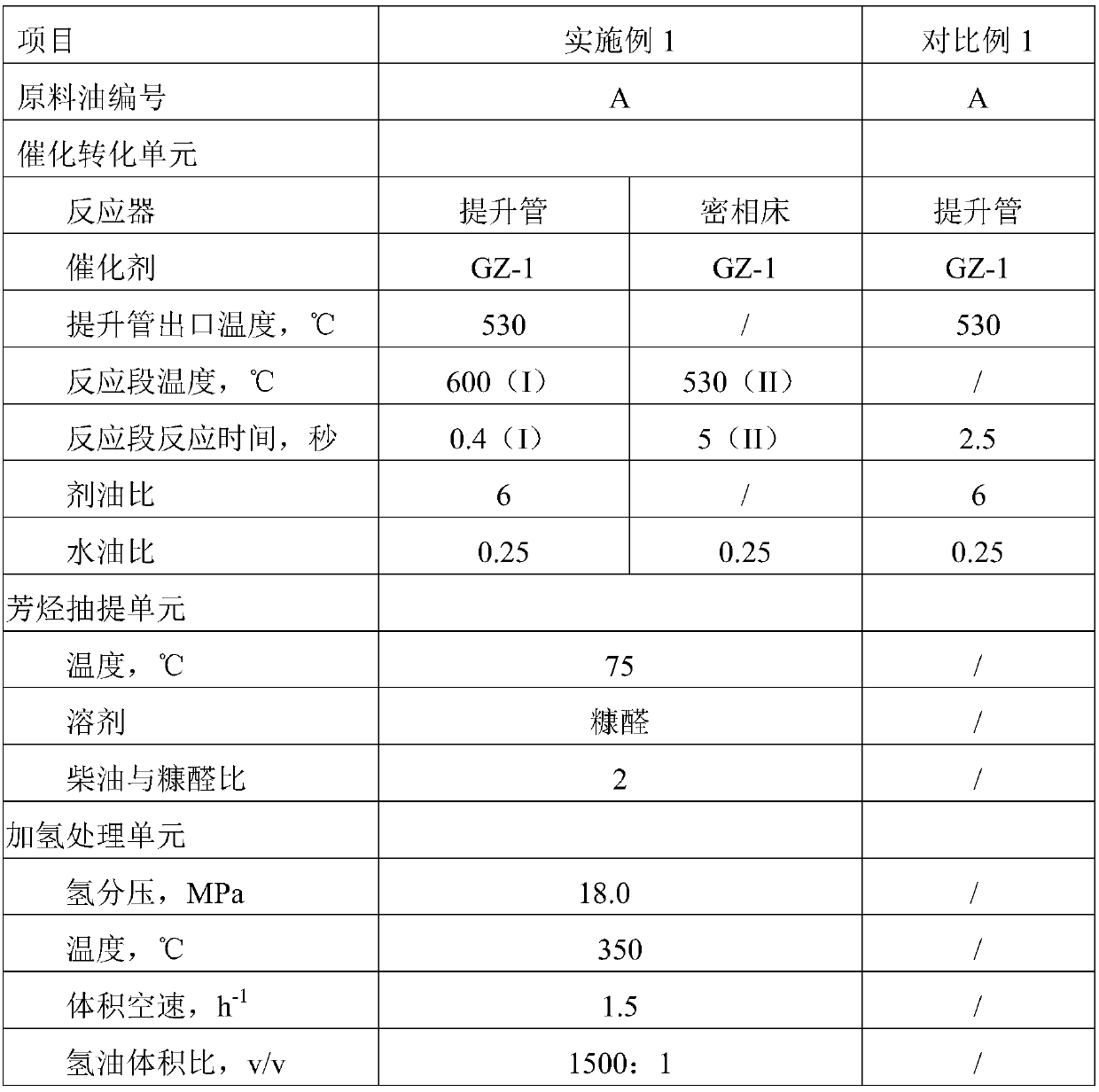

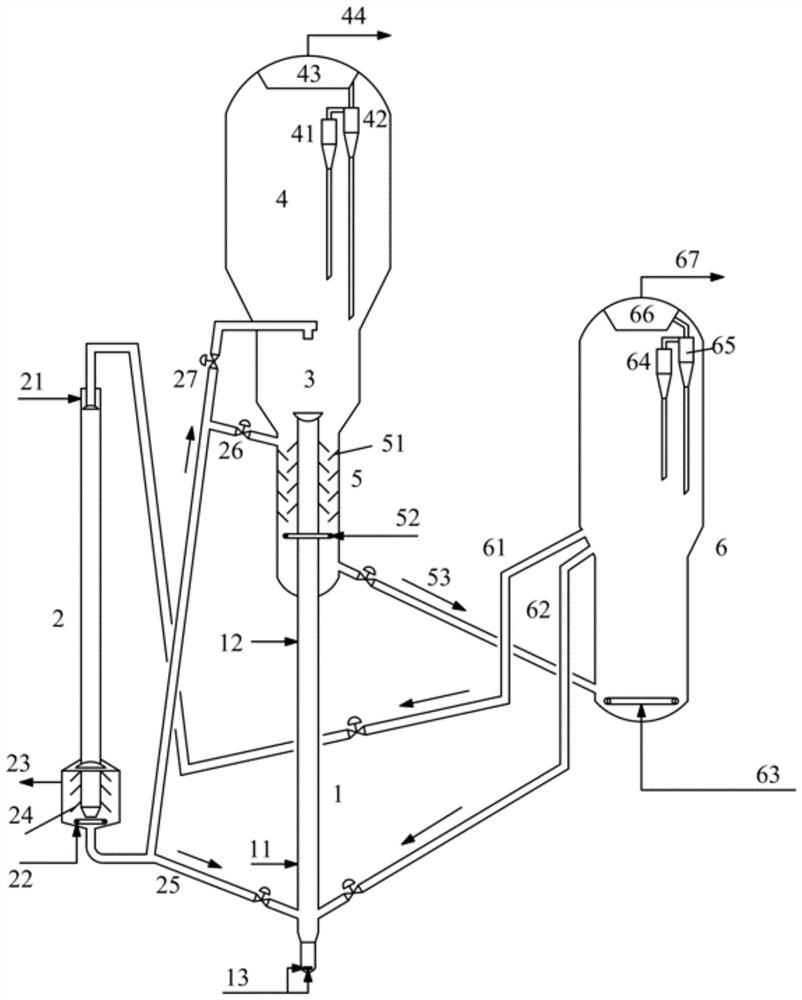

Method and system for catalytic conversion of poor quality raw material oil

ActiveCN107557067AHigh activityImprove conversion depthTreatment with hydrotreatment processesLighter fuelAromatic hydrocarbon

The invention discloses a method and a system for catalytic conversion of poor quality raw material oil. The method comprises: carrying out a catalytic conversion reaction on poor quality raw materialoil sequentially with a riser reactor and a settler, feeding the obtained reaction product into a product separation unit, separating, and sequentially carrying out aromatic hydrocarbon extraction and hydrogenation treatment on the obtained diesel oil, wherein the partial catalyst is taken out from the diameter expanding section at the middle portion of the riser reactor, and the partial regeneration catalyst is fed into the settler. According to the present invention, by organically combining the catalytic conversion, the aromatic hydrocarbon extraction, the hydrogenation treatment and otherprocesses and the process apparatuses, the low carbon olefins, the light fuel oil and the heavy aromatic hydrocarbons are produced from the poor quality raw material oil at a maximum so as to achievethe efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

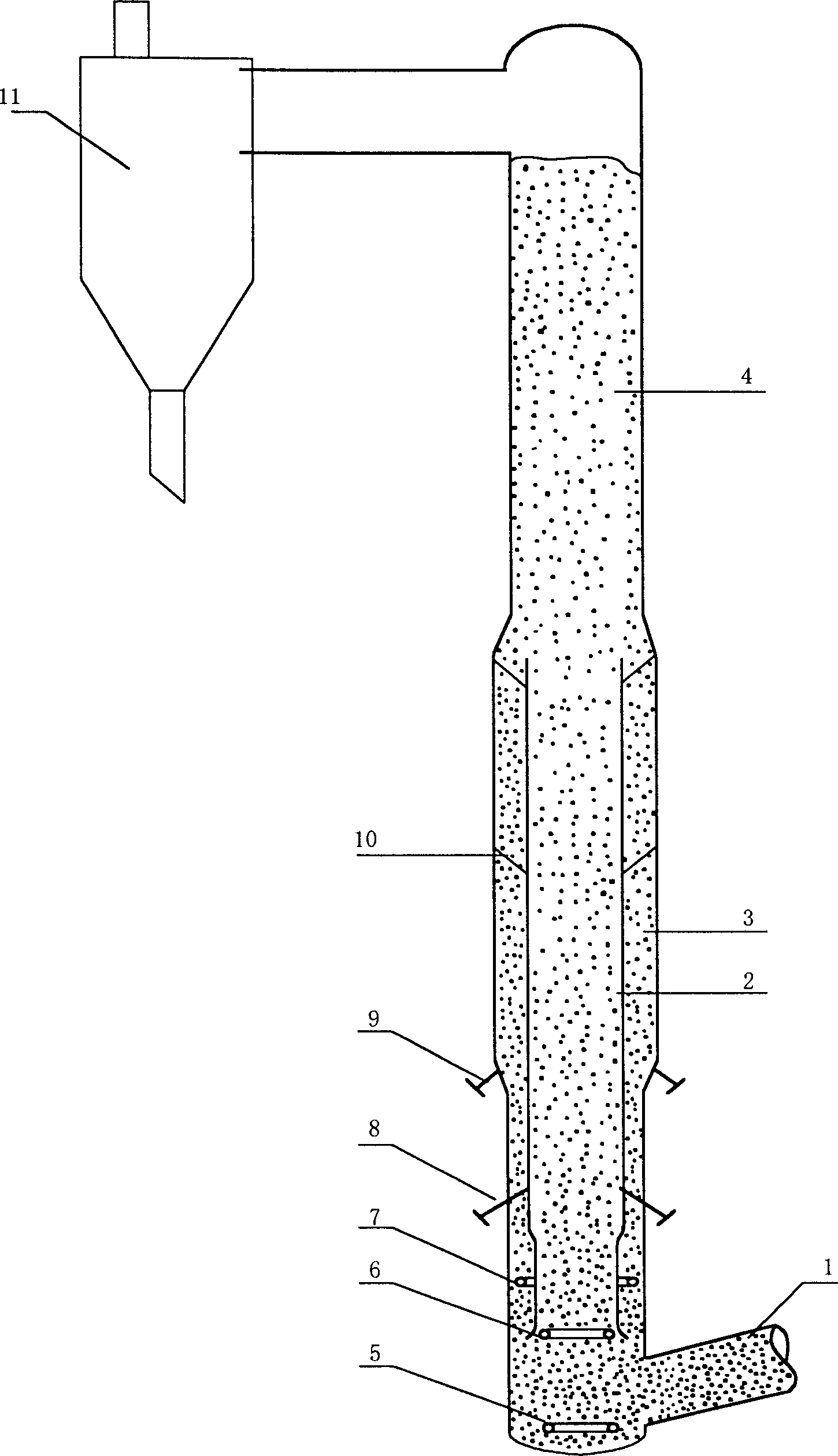

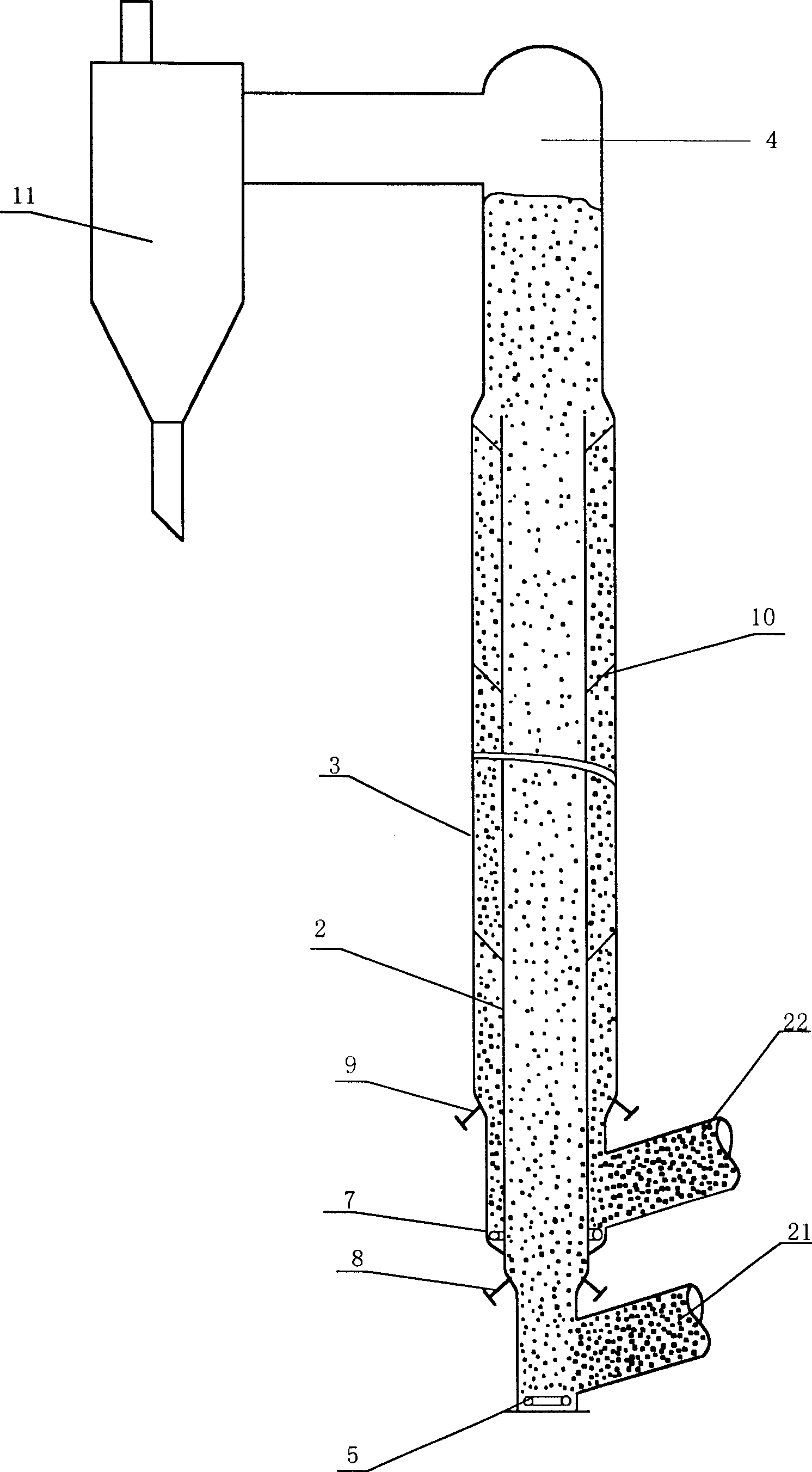

Method for catalyzing and cracking petroleum hydrocarbon in relaying mode

InactiveCN1415701ALow construction costLow operating costCatalytic crackingChemical/physical processesEngineeringPetroleum

A relay-type catalytic cracking process for pertroleum hydrocarbon includes such steps as feeding the regenerating agent in the internal tube and the ring reactino space between internal and external tubes of reactor while flowing upward, feeding raw hydrocarbon oil in internal tube, contacting with catalyst for reaction, flowing the rsultant upward, aggregating the resultant with the regenerating agent from internal tube, reaction, gas-solid separation, feeding oil gas iater separating system, and regenerating catalyst for cyclic use. Its advantage is high reaction activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

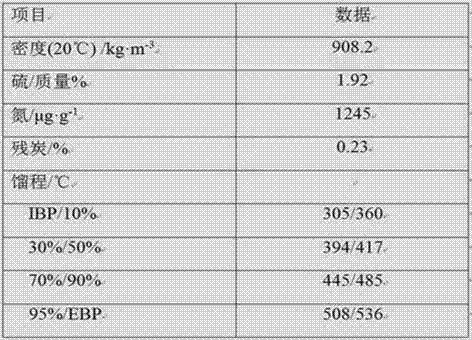

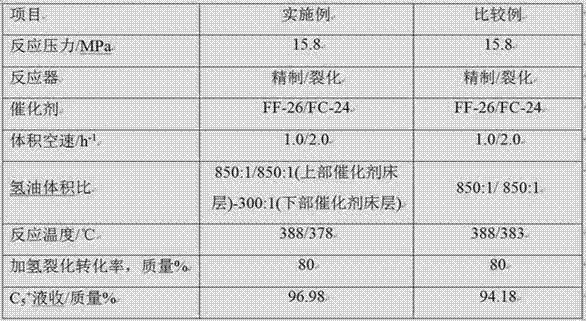

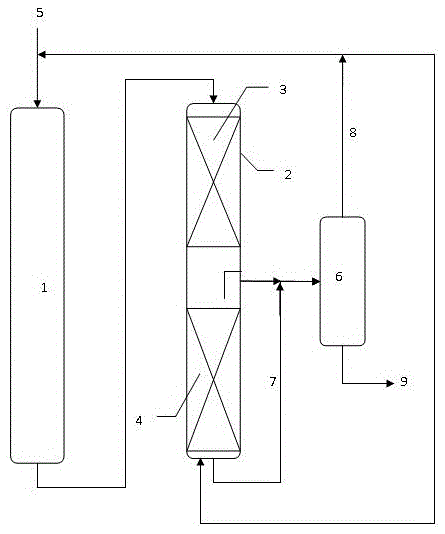

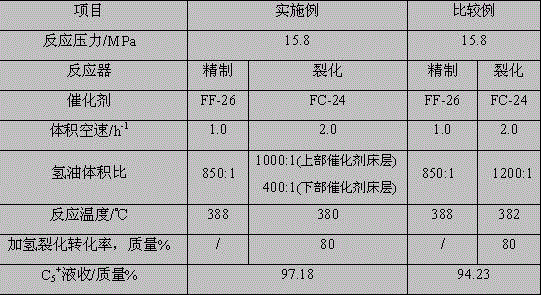

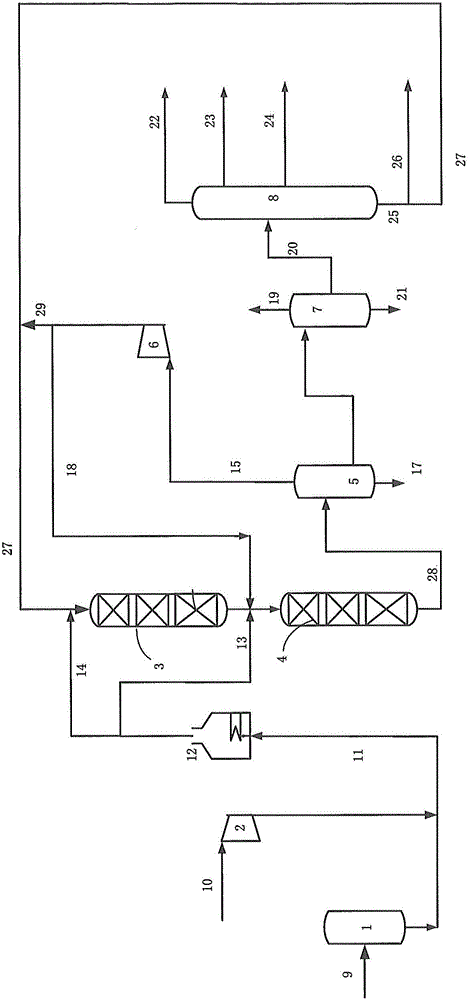

Method for reverse hydrocracking

ActiveCN105733674ASimple processEasy to transformTreatment with hydrotreatment processesLiquid productHydrogen

The invention discloses a method for reverse hydrocracking. The method comprises the following steps that: a raw material, hydrogen and oil produced after hydrocracking are mixed and the obtained mixture enters a hydrofinishing reactor for a reaction; hydrofinishing effluent enters a separator and a fractionation system so as to obtain a product and cycle oil; cycle oil and hydrogen are mixed and then the obtained mixture enters a hydrocracking reactor and undergoes a cracking reaction in the presence of a hydrocracking catalyst; the hydrocracking reactor is provided with at least two catalyst beds and a gas phase leading-out pipeline is arranged between two adjacent catalyst beds; and a gas phase material flow is lead out to a high-pressure separator via the gas phase leading-out pipeline, and a liquid phase passes through the underneath catalyst beds and contacts with hydrogen in a countercurrent way for a hydrocracking reaction, wherein the hydrogen enters from the bottom of the reactor. The method provided by the invention is simple and is easy to operate; and since a cracked gas-phase light component is extracted and directly enters the high-pressure separator, secondary or multitime cracking reaction of the light component is reduced, so the yield of a hydrocracking liquid product can be effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system for catalytic conversion of poor quality raw material oil

ActiveCN107557066AImprove conversion depthHigh selectivityTreatment with hydrotreatment processesGasolineAromatic hydrocarbon

The invention discloses a method and a system for catalytic conversion of poor quality raw material oil. The method comprises: feeding poor quality raw material oil into a riser reactor, carrying outa catalytic conversion reaction, feeding the obtained reaction product into a product separation unit, separating, and carrying out aromatic hydrocarbon extraction on the obtained diesel oil, whereinthe partial regeneration catalyst is added to the second diameter expanding section after the partial semi-spent catalyst is taken out from the first diameter expanding section at the middle portion of the riser reactor. According to the present invention, with the method and the system, the poor quality raw material oil is converted into high octane number gasoline and propylene while the yieldsof dry gas and coke are greatly reduced so as to achieve the efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

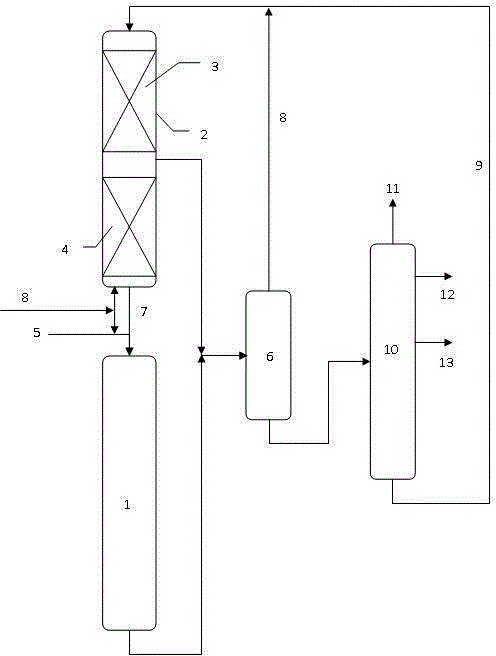

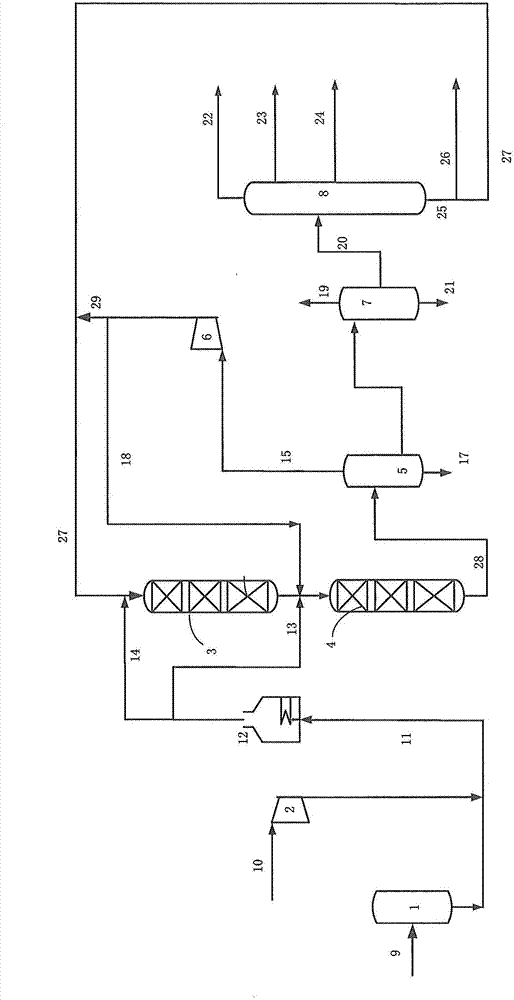

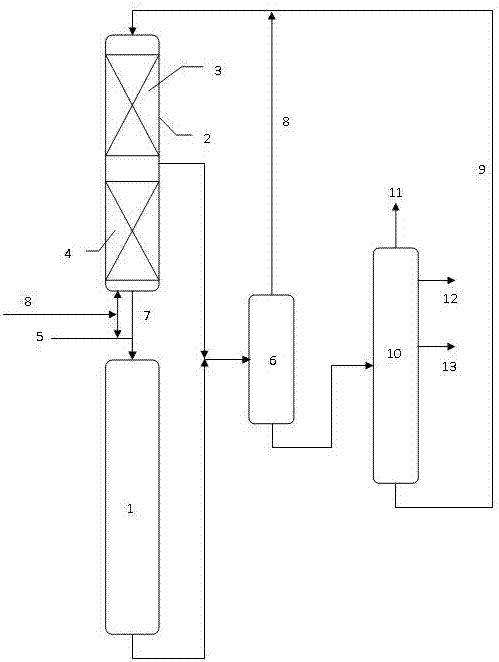

Hydrocracking method for increasing production of high-quality middle distillates

ActiveCN102807898AHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaChemistry

The invention relates to a hydrocracking method for increasing production of high-quality middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with a hydrofining catalyst and a zeolite hydrocracking catalyst; a reaction effluent from the hydrofining reactor is separated to obtain light naphtha fractions and tail oil fractions; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking method

The invention relates to a catalytic cracking method which comprises the following steps: a heavy raw material is in contact with a catalyst containing shape-adaptive zeolite with the average pore size of less than 0.7nm in a first riser reactor with at least two reaction zones to perform cracking reaction; and a light raw material and cracked heavy oil are in contact with the catalyst containing shape-adaptive zeolite with the average pore size of less than 0.7nm in a second riser reactor and a fluidized bed reactor to perform cracking reaction. The method is used for the catalytic cracking of heavy oil; and the conversion rate of heavy oil and the yield of propylene are higher, and the yields of dry gas and coke are low.

Owner:CHINA PETROLEUM & CHEM CORP

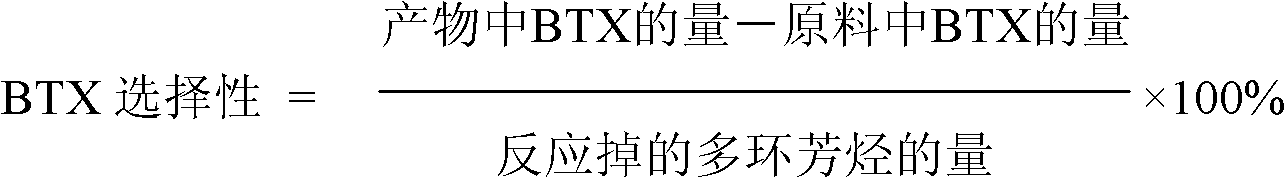

Method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene

ActiveCN103121907AReduced inactivation rateExtended service lifeMolecular sieve catalystsBulk chemical productionPolycyclic aromatic hydrocarbonHydrogen

The invention relates to a method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the dimenthylbenzene yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the technical scheme that polycyclic aromatic hydrocarbon mixtures and hydrogen are taken as the raw materials and are contacted with a catalyst in a fixed bend reactor to react under the conditions that the reaction temperature is 330-420 DEG C, the reaction pressure is 4-7MPa, the weight hourly space velocity is 1-3hr<-1> and the hydrogen-hydrocarbon mole ratio is 5.0-8.0 to generate monocyclic aromatic hydrocarbon mixtures producing more dimethylbenzene. The method can be used in the industrial production of increasing production of dimethylbenzene by converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

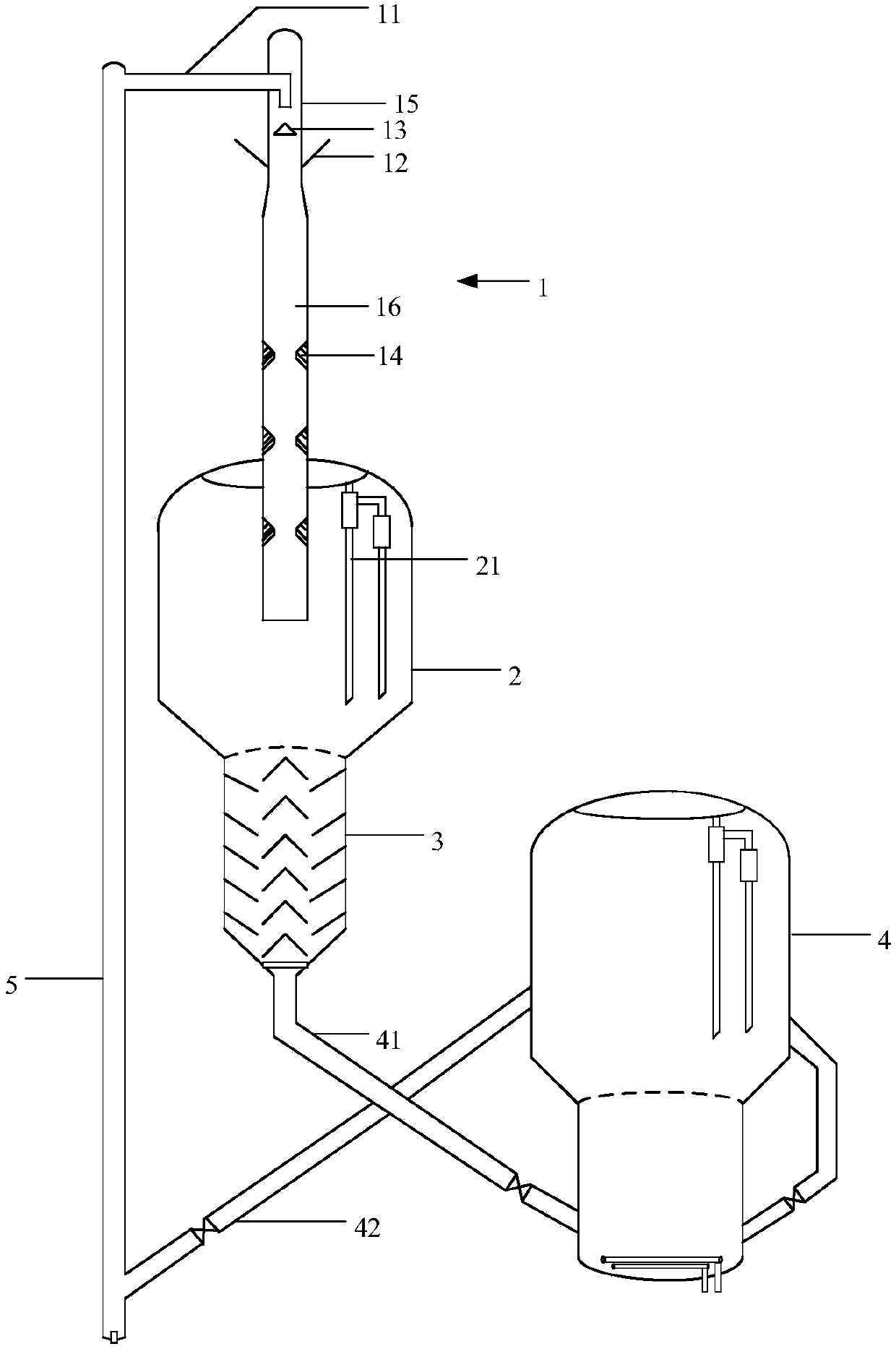

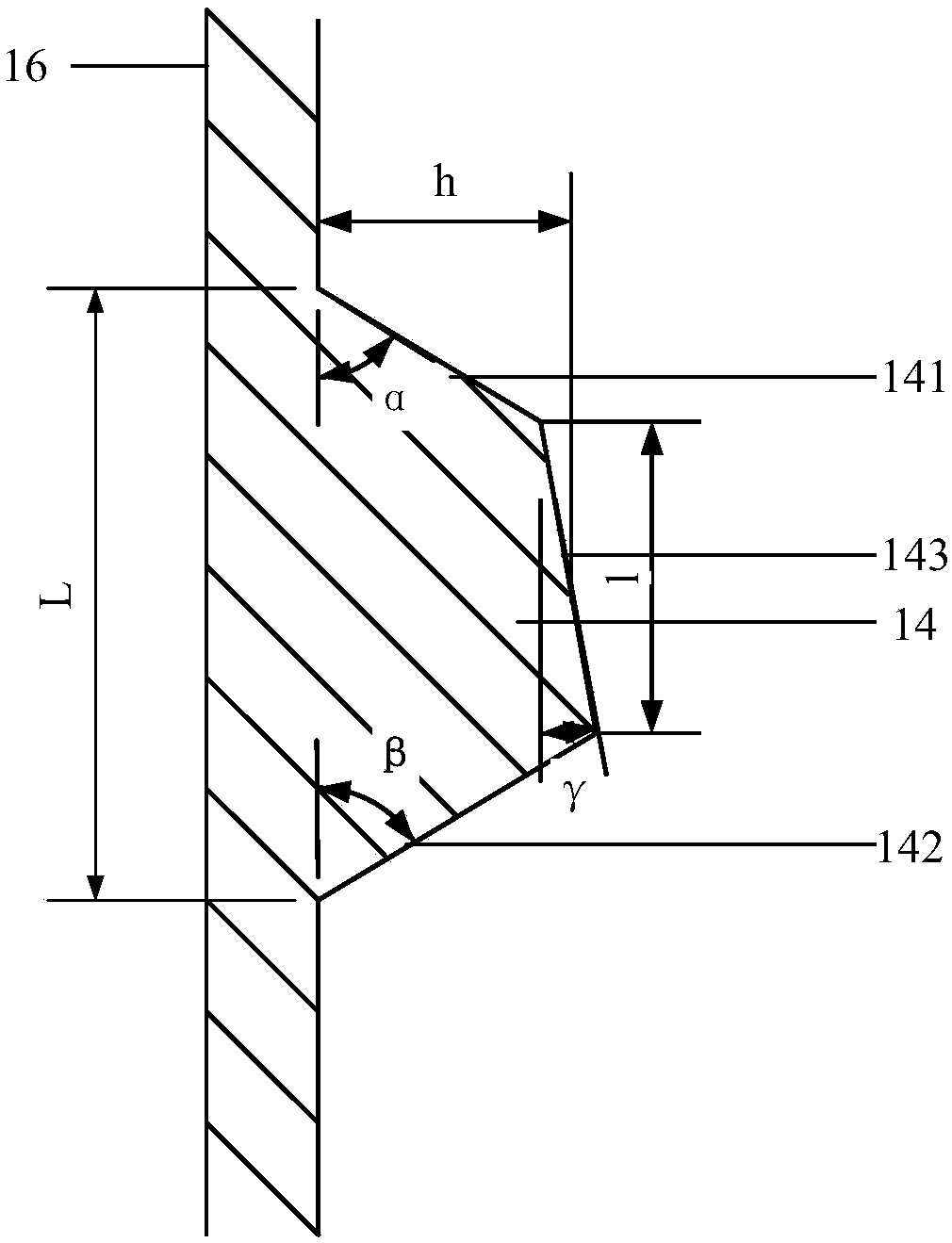

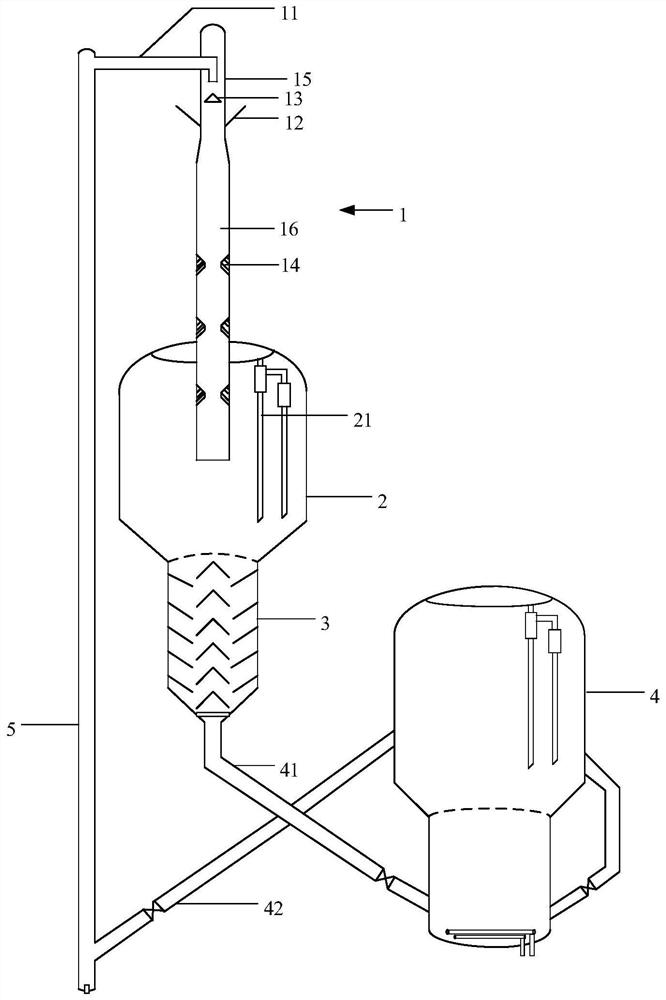

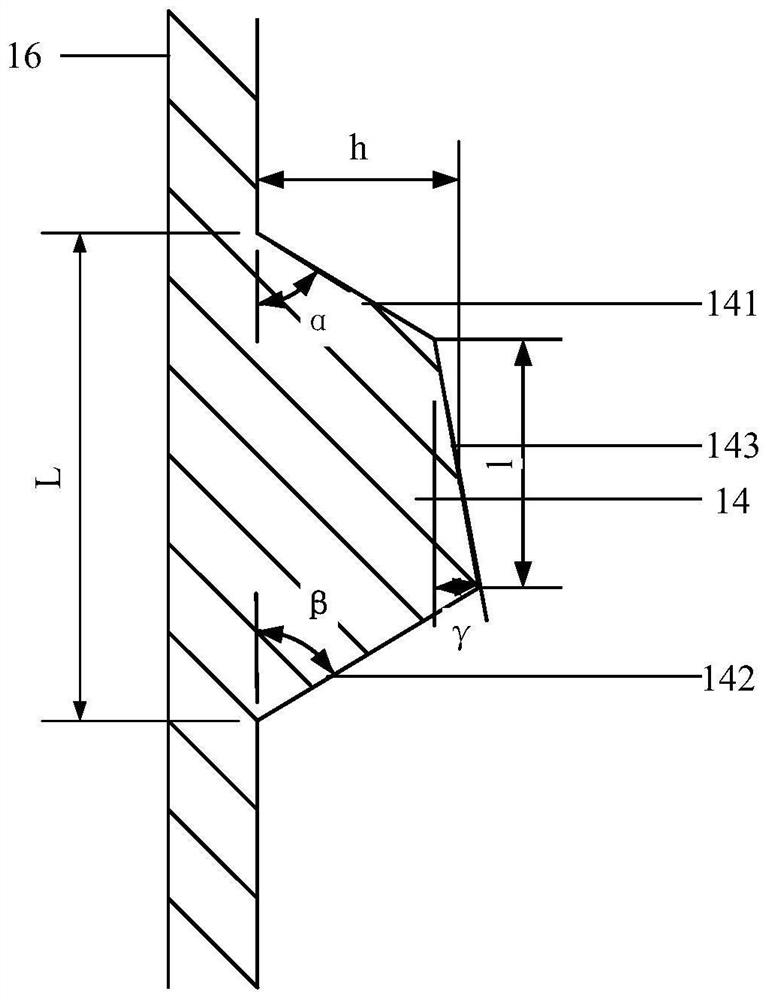

Downer reactor and catalytic conversion method

ActiveCN109666503AHigh selectivityImprove distributionCatalytic crackingChemical/physical processesCatalytic transformationSpray nozzle

The present invention relates to a downer reactor and a catalytic conversion method. The downer reactor (1) sequentially comprises an agent-oil contact section (15) and a main reaction section (16) from top to bottom, wherein the agent-oil contact section (15) and the main reaction section (16) are coaxially arranged and are fluidly communicated, the agent-oil contact section (15) is sequentiallyprovided with a catalyst inlet and a raw material oil spraying nozzle (12) from top to bottom, and the inner wall of the main reaction section (16) is provided with at least an annular baffle (14) coaxial with the main reaction section (16). The catalytic conversion method using the downer reactor of the present invention has high low-carbon olefin yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for increasing production of high-quality middle distillates

ActiveCN102807898BHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesNaphthaChemistry

The invention relates to a hydrocracking method for increasing production of high-quality middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with a hydrofining catalyst and a zeolite hydrocracking catalyst; a reaction effluent from the hydrofining reactor is separated to obtain light naphtha fractions and tail oil fractions; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

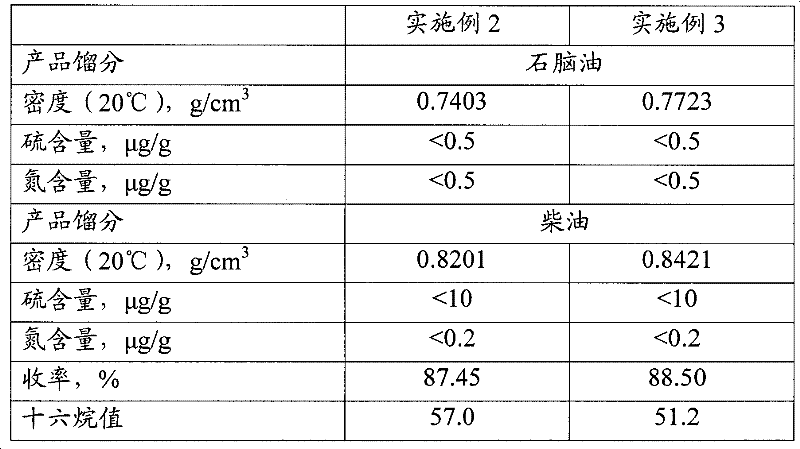

Hydrogenation method for increasing cetane number of diesel oil

ActiveCN102206510AReduce side chain scission reactionIncrease cetane numberTreatment with hydrotreatment processesAlkaneSide chain

Disclosed is a hydrogenation method for increasing cetane number of diesel oil. According to the invention, a reaction unit is provided with three sequentially arranged reaction zones; in a first reaction zone, a hydrobon catalyst I is filled and a hourly space velocity is 0.5 to 5.0 h <-1>; in a second reaction zone, a hydroupgrading catalyst is filled and a hourly space velocity is 1.0 to 8.0 h <-1>; in a third reaction zone, a hydrobon catalyst II is filled and a hourly space velocity is 1.5 to 12.0 h <-1>; the acidity of the hydrobon catalyst I is less than that of the hydrobon catalyst II. With the utilization of the method provided in the invention, cracking of open loops of annular aromatic hydrocarbons with more than two rings in the raw materials can be realized and the reaction of long-chain alkane cracking into short-chain alkane and the scission reaction of annular hydrocarbon with long side chains can be reduced; therefore, cetane number of diesel oil can be greatly increased under the condition that high yield of diesel oil is maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and preparation method thereof

ActiveCN103120955BDelay inactivationLow depth of conversionMolecular sieve catalystsHydrocarbonsMolecular sievePolycyclic aromatic hydrocarbon

The invention relates to a catalyst for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons and a preparation method thereof, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the monocyclic aromatic hydrocarbon yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the catalyst and the preparation method thereof. The catalyst comprises 34.5-60wt% of mixture of FAU type zeolite and at least one molecular sieve from MOR, BEA, MFI and MCM-22, 39.5-65wt% of at least one of gamma-alumina, eta-alumina and pseudo-boehmite as a binder and 0.05-0.9wt% of at least one metal from Pt, Pd and Ir. The catalyst can be used in the industrial production of converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

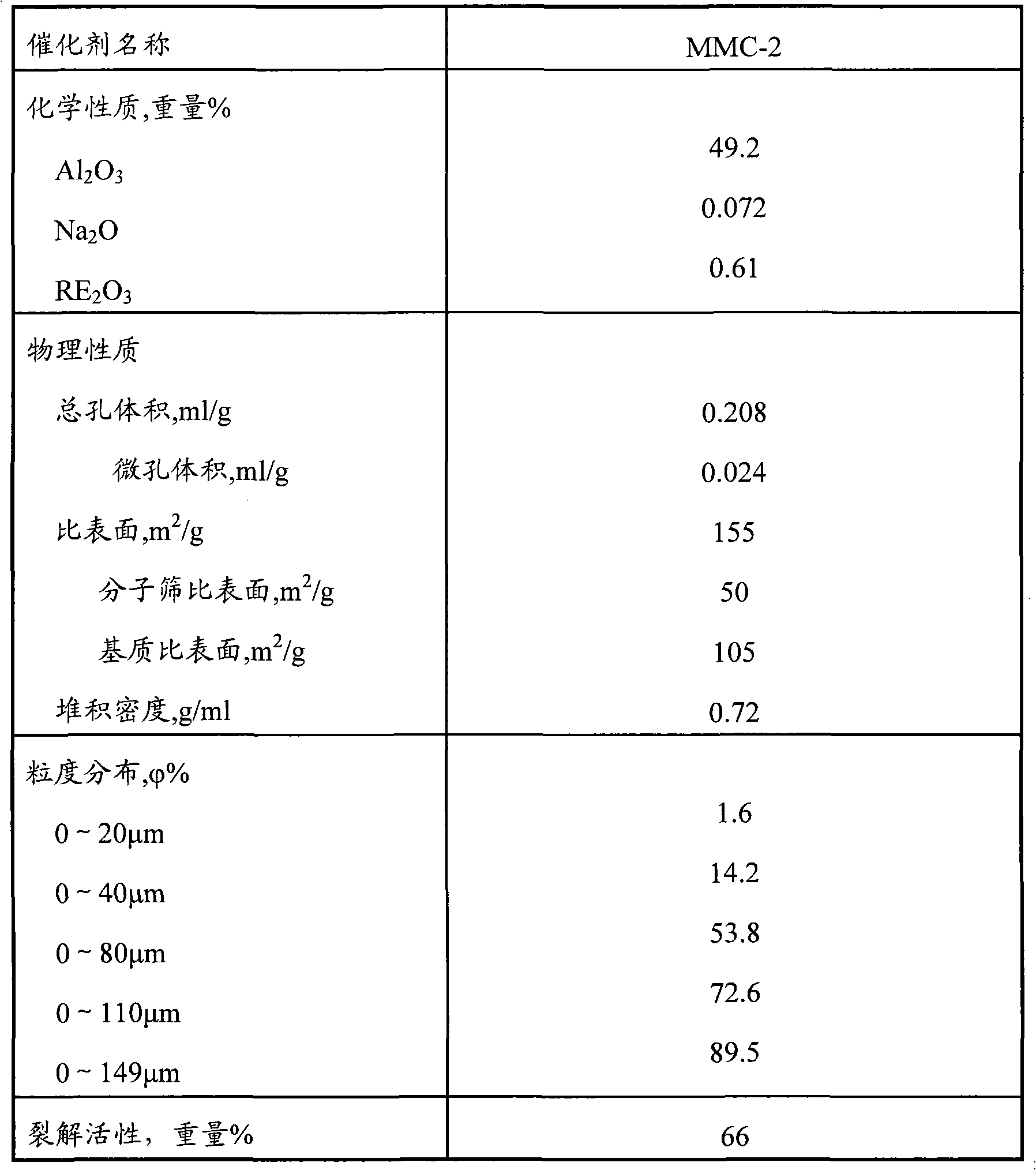

Alloy type catalyst for lightening heavy aromatics and preparation method thereof

ActiveCN106582780BImprove conversion depthDelay inactivationMolecular sieve catalystsHydrocarbon oil crackingPolycyclic aromatic hydrocarbonAlloy

The invention relates to an alloy type heavy aromatic hydrocarbon lightening catalyst and a preparation method thereof to mainly solve the problems of low conversion level of heavy aromatic hydrocarbon, low yield of monocyclic aromatic hydrocarbon, and high catalyst deactivation rate in the prior art. The technical scheme is that the catalyst provided by the invention comprises the following components in percentage by weight: 44-60.9% of at least one of FAU, BEA, MOR or MFI type zeolite, 10-30% of pseudo-boehmite, 0.1-0.5% of noble metal Ir, 2-6% of metal Ni and 0.5-3% of at least one of Zn and Bi. By adopting the technical scheme, the problems are well solved. The alloy type heavy aromatic hydrocarbon lightening catalyst is suitable for the chemical refining field of lightening heavy aromatic hydrocarbon into monocyclic aromatic hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method and catalytic conversion device for producing low-carbon olefins

PendingCN112745900AImprove conversion rateHigh selectivityLiquid hydrocarbon mixture productionChemical recyclingCatalytic transformationPtru catalyst

The invention provides a catalytic conversion method and a catalytic conversion device for producing low-carbon olefins. The method comprises the following steps: carrying out contact reaction on a heavy raw material and a cracking catalyst in a riser reactor to obtain a first oil agent mixture; enabling the first oil agent mixture to enter a fluidized bed reactor for reaction; and carrying out a contact reaction on the light raw material and a cracking catalyst in a down reactor to obtain a second oil agent mixture. According to the catalytic conversion method and device thereof, the light raw material is introduced into the downstream reactor, and the conversion rate of the light raw material and the selectivity of low-carbon olefin can be improved under the conditions of high temperature, short contact time and large catalyst-oil ratio, so that the yields of ethylene and propylene are further improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for producing middle distillates to maximum extent

ActiveCN102807897BHigh selectivityAvoid secondary crackingTreatment with hydrotreatment processesMolecular sieveReactor system

The invention provides a hydrocracking method for producing middle distillates to the maximum extent. The method comprises the following steps of: simultaneously leading fresh raw oil to a hydrorefining reactor and a hydrocracking reactor in a mode of parallel flow; filling a hydrorefining catalyst and an amorphous hydrocracking catalyst in the hydrorefining reactor in sequence; filling a molecular sieve hydrocracking catalyst in the hydrocracking reactor; separating reactor effluent of the hydrorefining reactor to obtain light fraction and tail oil fraction; and sending all or partial tail oil fraction to the hydrocracking reactor, and simultaneously sending reactor effluent of the hydrocracking reactor and partial raw oil to the hydrorefining reactor. The hydrocracking method for producing middle distillates to the maximum extent can process heavy distillates and produce middle distillates to maximum extent. Because partial raw oil is sent to the hydrocracking reactor, over high cracking activity of the hydrocracking catalyst is avoided under the non-ammonia environment of the hydrocracking reactor system, and the secondary cracking phenomenon of more middle distillates is also avoided, so that the yield of the middle distillates is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for reverse sequence hydrocracking

ActiveCN105733674BSimple processEasy to transformTreatment with hydrotreatment processesLiquid productReverse order

The invention discloses a method for reverse sequence hydrocracking. After the raw material, hydrogen and hydrocracking oil are mixed, they enter the hydrorefining reactor for reaction; the hydrofinishing effluent enters the separator and fractionation system to obtain the product and circulating oil; the circulating oil is mixed with hydrogen and enters the hydrocracking reaction The cracking reaction is carried out in the presence of a hydrocracking catalyst; at least two catalyst beds are arranged in the hydrocracking reactor, and a gas phase extraction pipeline is set between two adjacent catalyst beds; the gas phase stream is drawn to the In the high-pressure separator, the liquid phase passes through the catalyst bed below and is in countercurrent contact with the hydrogen entering from the bottom of the reactor to carry out the hydrocracking reaction. The process of the present invention is simple and easy to operate; since the cracked gas-phase light components are drawn out and directly enter the high-pressure separator, the secondary or multiple cracking reactions of this part of the light components are reduced, thereby effectively increasing the hydrocracking efficiency. Liquid product yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

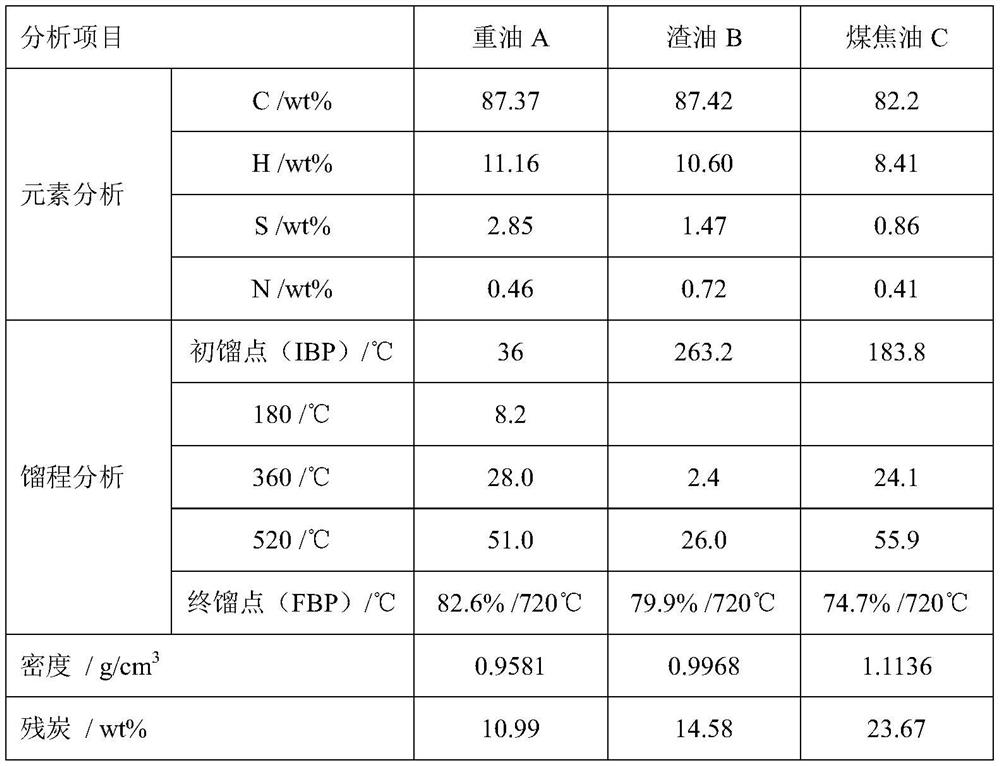

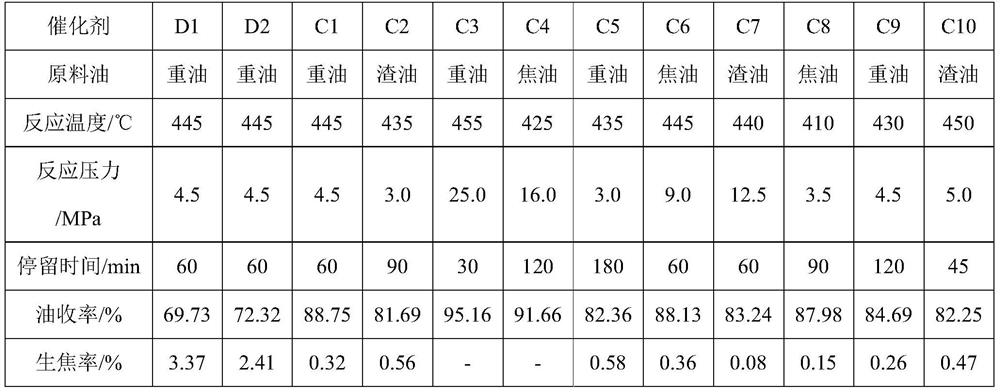

Pretreatment method of heavy and/or inferior oil slurrybed hydrogenation upgrading iron-based catalyst

ActiveCN113058612AThe preprocessing method is simpleImprove hydrogenation activityTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPretreatment method

The invention discloses a pretreatment method of a heavy and / or inferior oil slurry bed hydrogenation upgrlading iron-based catalyst. According to the method, a fresh iron-based catalyst is mixed with a pretreatment regulator, and then the catalyst is pretreated under the conditions of specific pretreatment airflow, pressure and the like, so that the hydrogenation activity of the iron-based catalyst is improved. The pretreatment method provided by the invention is controllable in condition, and the treated catalyst has the characteristics of high activity, strong coke inhibition capability and high distillate oil yield, and is beneficial to long-period stable operation of a device, so that the economical efficiency of a heavy and / or inferior oil slurry bed hydrogenation process is improved.

Owner:SYNFUELS CHINA TECH CO LTD

A kind of descending reactor and catalytic conversion method

ActiveCN109666503BHigh selectivityImprove distributionCatalytic crackingChemical/physical processesCatalytic transformationPtru catalyst

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrocracking method for increasing product liquid yield

ActiveCN104650969BSimple processEasy to operateTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a hydrocracking method increasing liquid yield of products. A gas-phase lead-out pipeline is disposed in a catalyst bed layer of a hydrocracking reactor. A gas-phase material flow in a reactor is leaded-out to a high-pressure separator through the gas-phase lead-out pipeline in the catalyst bed layer, while a liquid phase is counter-current contacted with hydrogen fed from the bottom of the reactor through a lower catalyst bed layer to perform a hydrocracking reaction. The hydrocracked gas-phase light fraction is directly fed into the high-pressure separator so that secondary or multiple cracking reactions are reduced. The hydrocracking method can increase the liquid yield of the products, can reduce the consumption of hydrogen and can prolong the service life of a catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating method for maximum production of middle distillates

The invention relates to a hydrotreating method for maximum production of middle distillates. The method comprises the following steps that: fresh feedstock oils are simultaneously introduced into a hydrofining reactor and a hydrocracking reactor in a co-current flow way; the hydrofining reactor is sequentially filled with a hydrofining catalyst and an amorphous hydrocracking catalyst; the hydrocracking reactor is sequentially filled with an amorphous hydrocracking catalyst and a zeolite hydrocracking catalyst; and all or part of the tail oil fractions are introduced into the hydrocracking reactor, and a reaction effluent from the hydrocracking reactor and part of the feedstock oils are introduced into the hydrofining reactor together. According to the method provided by the invention, the heavy distillates can be treated, and the maximum production of the middle distillates can be realized. Only the tail oil fractions are introduced into the hydrocracking reactor, so that the selectivity of middle distillates is improved; and part of the feedstock oils is introduced into the hydrocracking reactor, so that the phenomenon that more middle distillates are cracked secondarily in an ammonia-free environment in the hydrocracking reactor is avoided, and thus the yield of the middle distillates is effectively improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene

ActiveCN103121907BImprove conversion depthHigh yieldMolecular sieve catalystsBulk chemical productionPolycyclic aromatic hydrocarbonPtru catalyst

The invention relates to a method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the dimenthylbenzene yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the technical scheme that polycyclic aromatic hydrocarbon mixtures and hydrogen are taken as the raw materials and are contacted with a catalyst in a fixed bend reactor to react under the conditions that the reaction temperature is 330-420 DEG C, the reaction pressure is 4-7MPa, the weight hourly space velocity is 1-3hr<-1> and the hydrogen-hydrocarbon mole ratio is 5.0-8.0 to generate monocyclic aromatic hydrocarbon mixtures producing more dimethylbenzene. The method can be used in the industrial production of increasing production of dimethylbenzene by converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

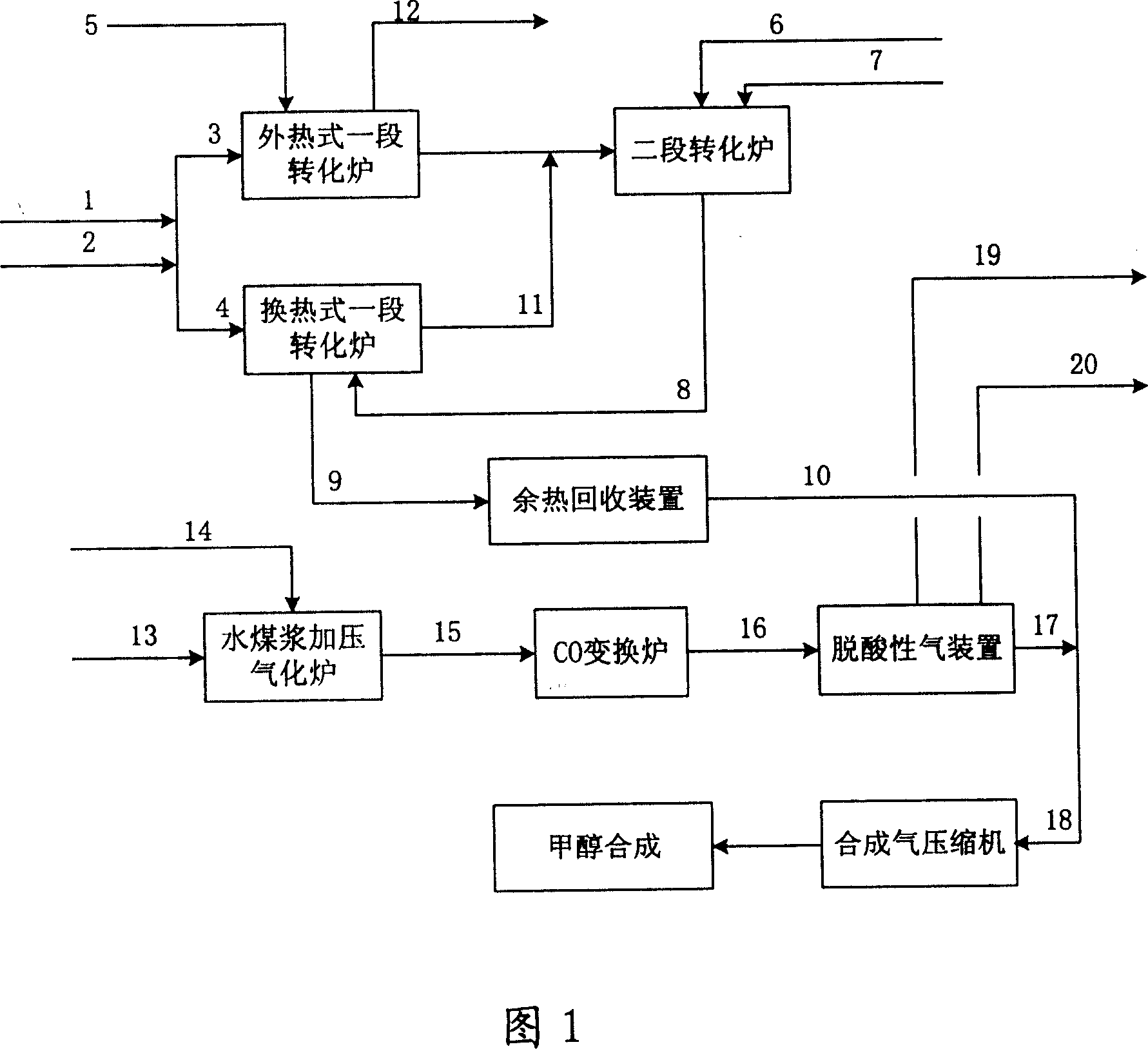

Method for producing methanol synthetic gas with hydrocarbon gas and coal as raw materials

ActiveCN100358851CReduce loadControl conversion loadHydrogenOrganic compound preparationSyngasProcess conditions

Disclosed is a method for producing methanol synthetic gas with hydrocarbon gas and coal as raw materials, which comprises preparing methanol synthetic gas using gaseous hydrocarbon and coal as raw material, mixing by the following proportion, 0.5-1 part of methanol synthetic gas by using gaseous hydrocarbon as the raw material, 1 part of methanol synthetic gas by using coal as the raw material, making the hydrogen-carbon ratio of the obtained methanol raw material gas to be (H2-CO2) / (CO+CO2)=2.0-2.1, compressing and loading into methanol synthesizing procedure.

Owner:庞玉学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com