Hydrogenation method for increasing cetane number of diesel oil

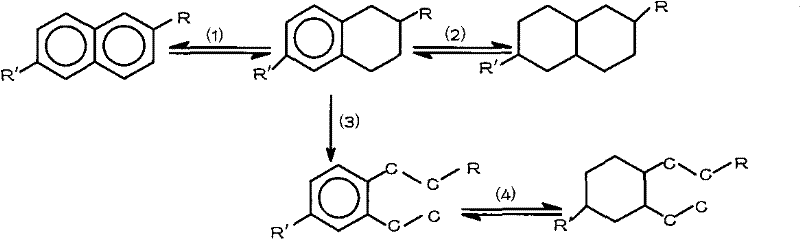

A technology for cetane number and diesel oil, which is applied in the field of hydrogenation and upgrading to improve the cetane number of diesel oil, can solve the problems of not mentioning the properties of the product diesel, achieve high product yield, high volume space velocity, and reduce aromatic hydrocarbons. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

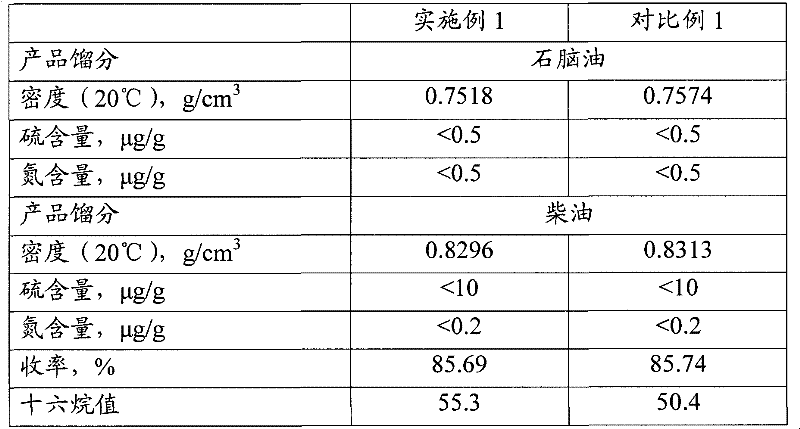

Embodiment 1

[0041] Mixed raw material oil H is a mixture of low-quality catalytic cracking diesel oil with high sulfur, nitrogen content and aromatics content and a straight-run diesel oil with low sulfur and nitrogen content and good properties at a mass ratio of 7:3. The properties of the oil are shown in Table 1. It was carried out on a 3L fixed-bed medium-scale experimental device.

[0042] The mixed raw material oil H is mixed with hydrogen, and enters the first reaction zone after being preheated by the heating furnace, and successively contacts and reacts with the hydrogenation protection agent and the hydrofinishing catalyst I. The loading volume ratio of the hydrogenation protection agent and the hydrofinishing catalyst I is 1:10. The liquid effluent from the first reaction zone enters the second reaction zone without intermediate separation, and quickly contacts and reacts with the hydrogenation upgrading catalyst, and the reaction product in the second reaction zone enters the...

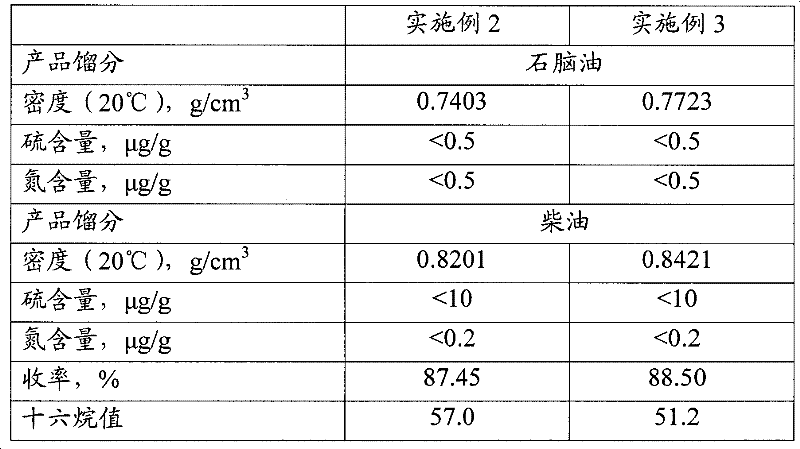

Embodiment 2

[0049] The mixed raw material oil F is a mixture of a low-quality catalytic cracking diesel oil with high sulfur, nitrogen content and aromatics content and a straight-run diesel oil with low sulfur and nitrogen content and good properties according to the mass ratio of 1:1. The properties of the oil are shown in Table 1. It was carried out on a 3L fixed-bed medium-scale experimental device.

[0050] The mixed raw material oil F is mixed with hydrogen, and enters the first reaction zone after being preheated by the heating furnace, and successively contacts and reacts with the hydrogenation protection agent and the hydrofinishing catalyst I. The loading volume ratio of the hydrogenation protection agent and the hydrofinishing catalyst I is 1:10. The liquid effluent from the first reaction zone enters the second reaction zone without intermediate separation, and quickly contacts and reacts with the hydrogenation upgrading catalyst, and the reaction product in the second reacti...

Embodiment 3

[0053] The raw material oil J is a kind of low-quality catalytic cracking diesel oil, and the properties of the raw material oil are shown in Table 1. It was carried out on a 3L fixed-bed medium-scale experimental device.

[0054] The raw material oil J enters the first reaction zone after being preheated by the heating furnace, and successively contacts and reacts with the hydrogenation protection agent and the hydrofinishing catalyst I. The loading volume ratio of the hydrogenation protection agent and the hydrofinishing catalyst I is: 1:10. The liquid effluent from the first reaction zone enters the second reaction zone without intermediate separation, and quickly contacts and reacts with the hydrogenation upgrading catalyst, and the reaction product in the second reaction zone enters the third reaction zone to contact and react with the hydrogenation refining catalyst II, After cooling, the final liquid effluent enters the cold high fraction for oil and gas separation, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com