Patents

Literature

45results about How to "High volumetric space velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

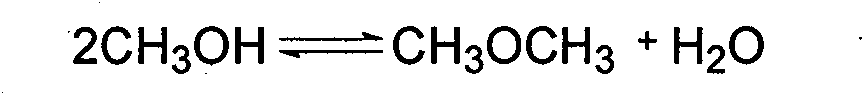

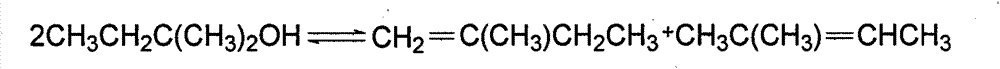

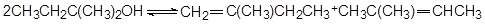

Catalyst in preparation of isobutene by methyl tertbutyl ether pyrolysis

ActiveCN1853772AHigh activityImprove stabilityCatalystsHydrocarbon preparation catalystsEtherHigh selectivity

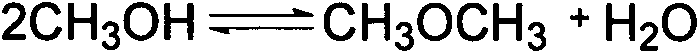

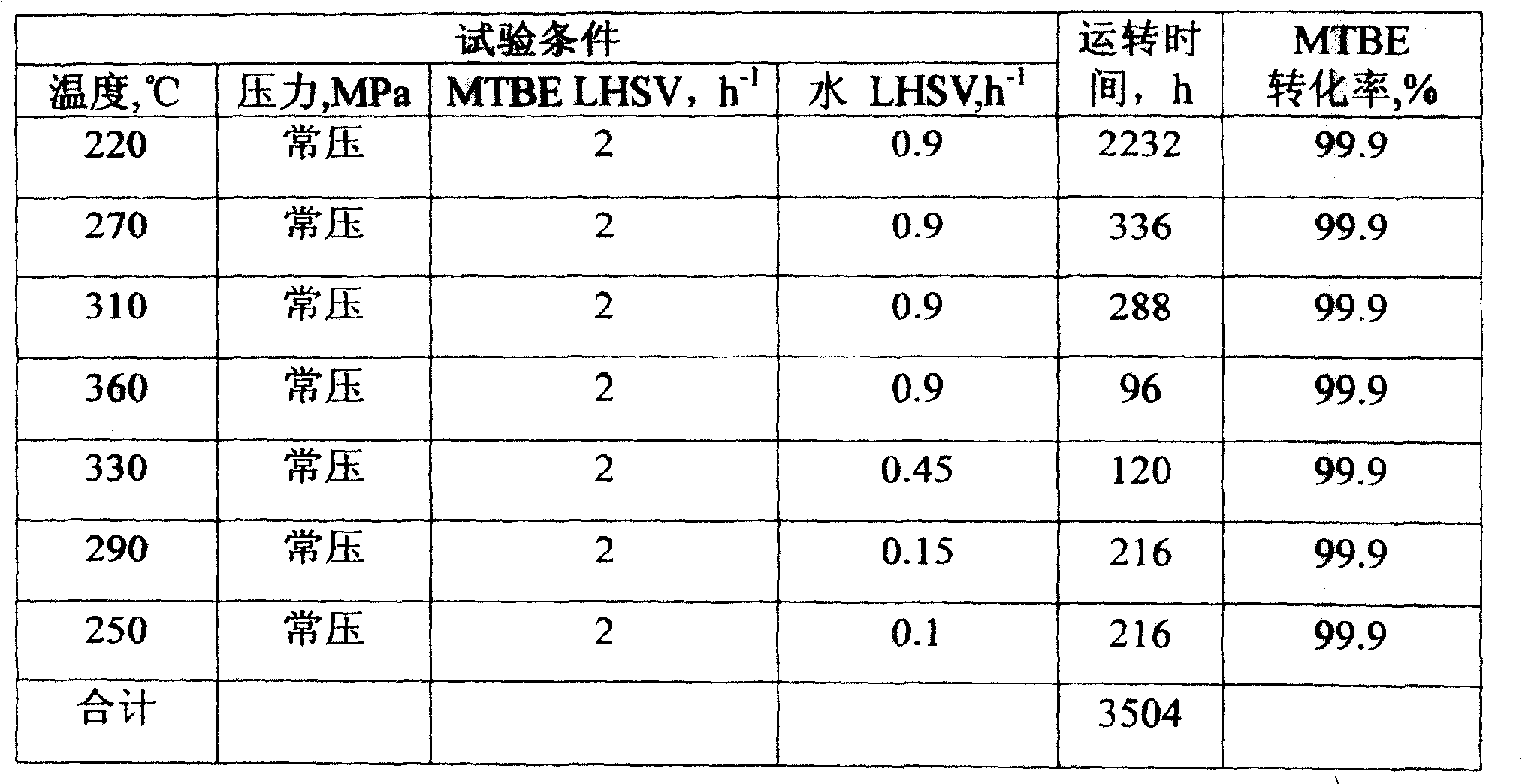

A catalyst for preparing isobutene by cracking methyl turt-butyl ether (MTBE) is prepared from the amorphous SiAl through treating by saturated steam at 100-600 deg.C for 1-10 hr. Its advantages are high conversion rate of MTBE, high selectivity to isobutene, and long service life (at least 3504 hr).

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process for producing catalytically cracked material

ActiveCN101020843AImprove processing depthExpand sourceRefining to eliminate hetero atomsHydrogenation processResidual oil

The hydrogenation process for producing catalytically cracked material includes the successive contacting and reaction of the mixture of material oil and hydrogen with hydrogenation protecting agent, residual oil hydrogenating and demetallizing agent and residual oil hydrogenating and desulfurizing agent, cooling the reaction resultants, and separating obtain hydrogen-rich liquid and gas products. The catalyst includes hydrogenation protecting agent in 2-10 vol%, residual oil hydrogenating and demetallizing agent in 5-70 vol%, and residual oil hydrogenating and desulfurizing agent 20-93 vol%. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

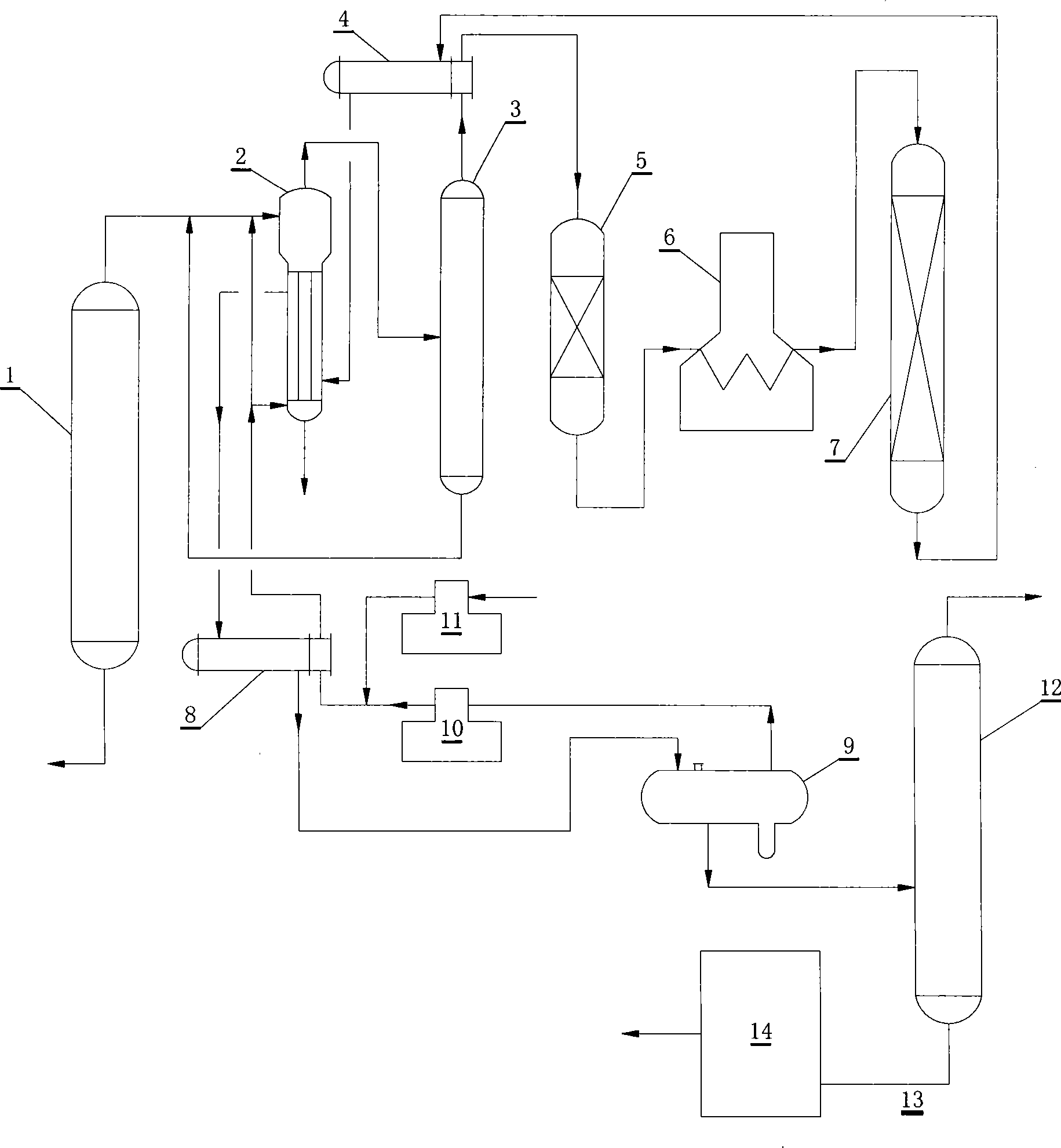

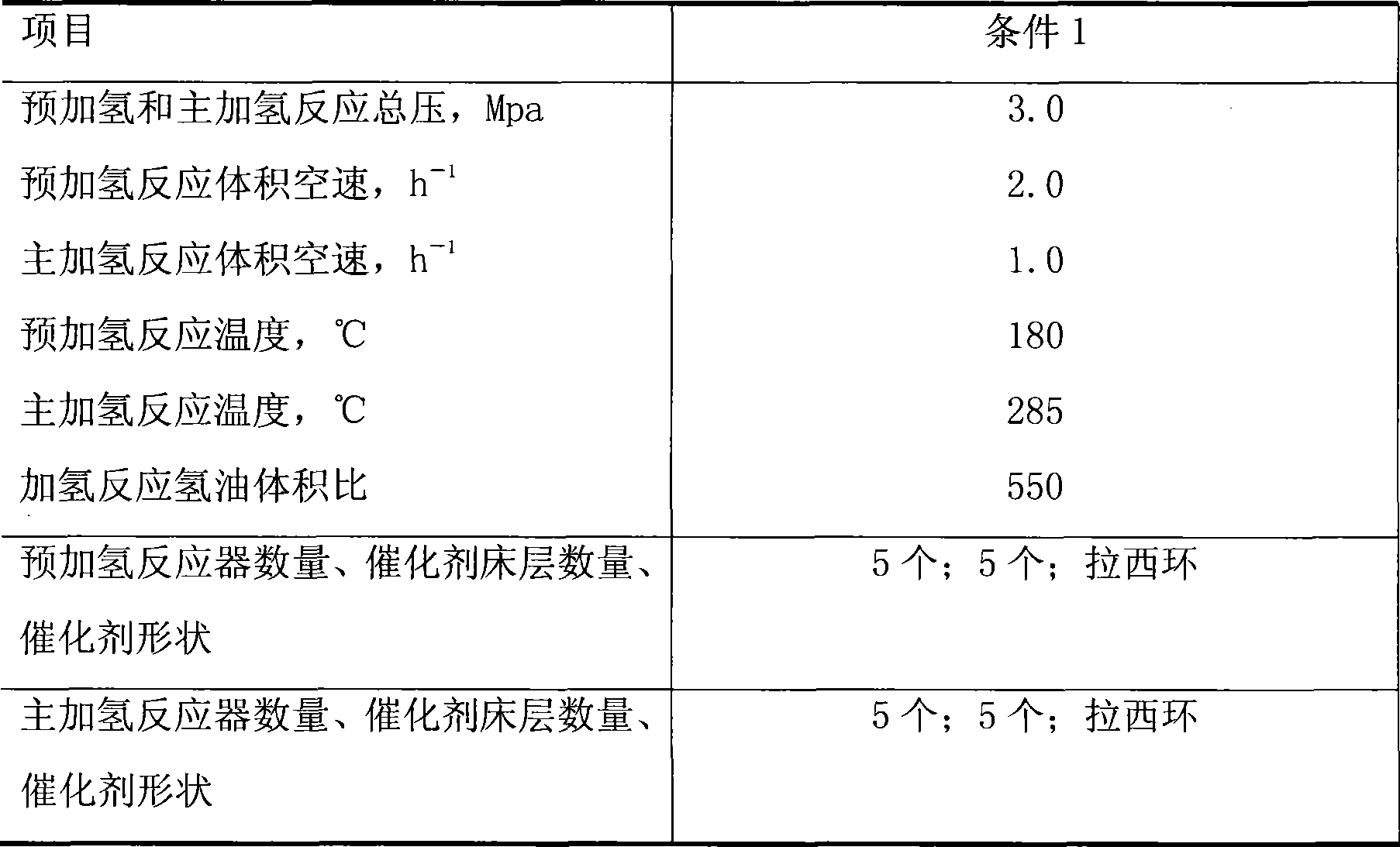

Hydrofinishing method for crude benzol

InactiveCN101486623ASmall diameterFully contactedHydrocarbon purification/separationHydrocarbonsGas phaseBoiling point

The invention relates to the production field of high purity benzene, toluene and mixed xylene, in particular to a method for treating a hydrorefining crude benzene. The method takes coking crude benzene as raw material, after pretreatment, heavy aromatics are removed directly through a vacuum and de-heavy tower with the pressure at the top of the tower between 0.01MPa and 0.1MPa; pre-hydrotreating reaction and main-hydrotreating reaction are carried out, gas phase material enters a high pressure flash drum after hydrotreating reaction, hydrogen-rich gases are separated, liquid phase material enters a stabilizer and low boiling point hydrocarbon is removed; liquid phase material removed from the low boiling point hydrocarbon enters an aromatics extraction device and high purity benzene, toluene and mixed xylene are obtained through extraction. Under the premise of guaranteeing the yield of benzene, toluene and mixed xylene, the method not only effectively reduces investment cost and the operation cost of devices, but also has the advantages of good product quality, long device running cycle, etc.

Owner:胜帮科技股份有限公司

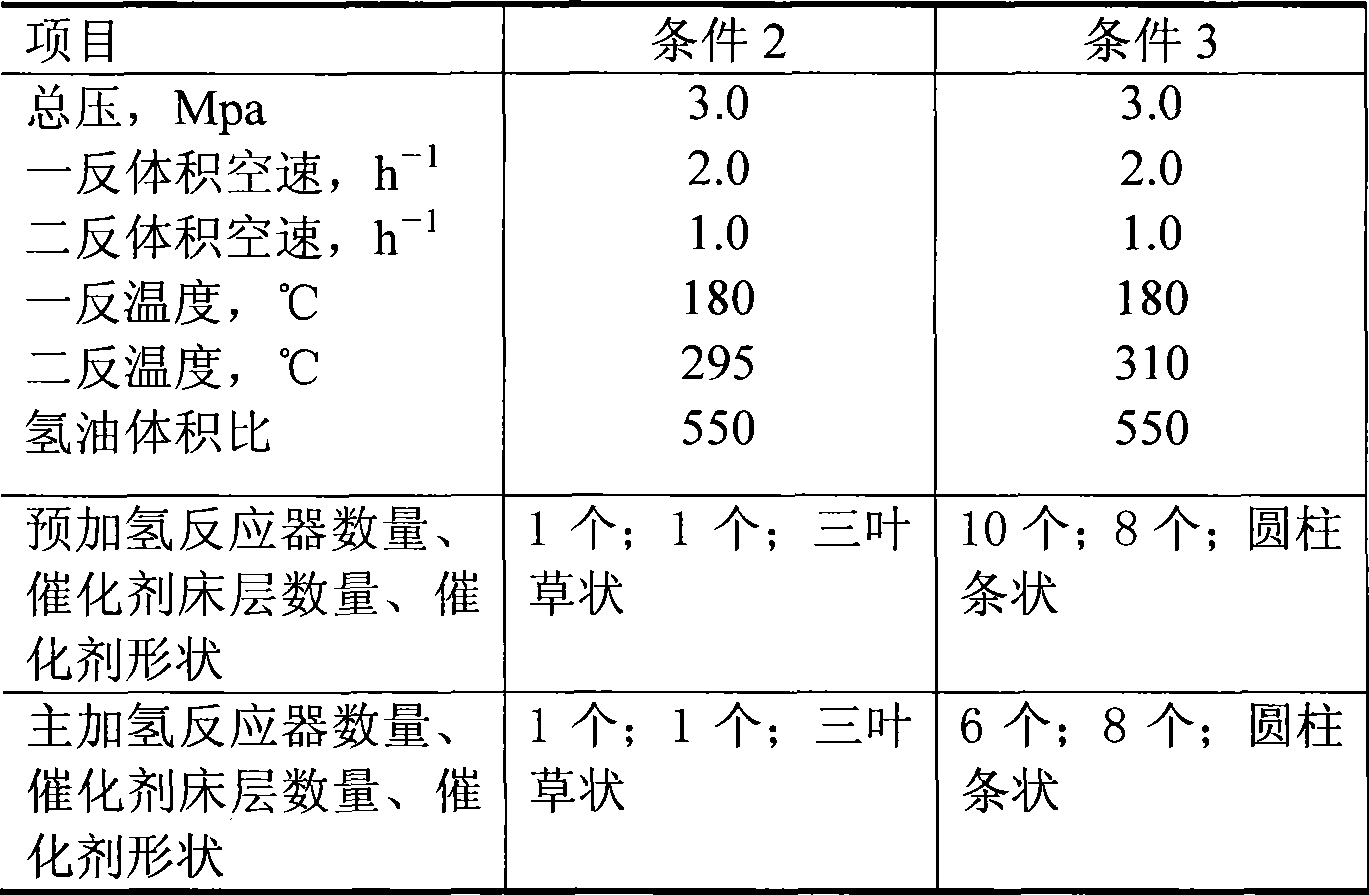

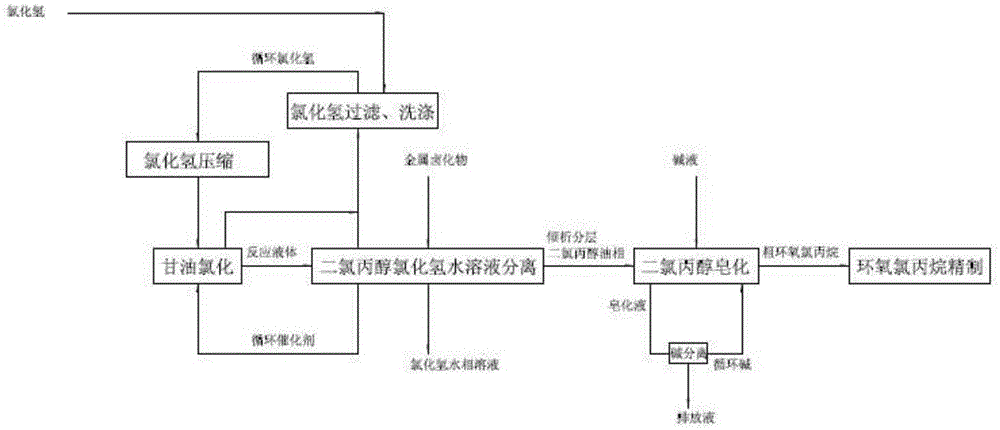

Method for producing epoxy chloropropane

The invention provides a method for producing epoxy chloropropane. The method comprises the following steps of chlorination of glycerin, separation of a dichloropropanol-hydrogen chloride aqueous solution, compression of hydrogen chloride, and purification of dichloropropanol saponification and epoxy chloropropane. A dichloropropanol oil phase is decanted and layered through the separation of the dichloropropanol-hydrogen chloride aqueous solution and directly enters the saponification step; gas-phase hydrogen chloride escaped during the separation of the dichloropropanol-hydrogen chloride aqueous solution is pressurized and introduced into a reactor; and hydrogen chloride is subjected to filtration and washing operations, so that the content of water and impurities in hydrogen chloride raw material is reduced; and selective scope of the hydrogen chloride compressor is broadened. The method is advantaged by guaranteeing that volume space velocity of the reactor is not smaller than 0.1; conversion rate of glycerin is not lower than 98% and selectivity for dichloropropanol is not lower than 99%, by optimizing a catalyst proportion, a reaction pressure and reaction temperature during the chlorination of glycerin.

Owner:CHINA TIANCHEN ENG +1

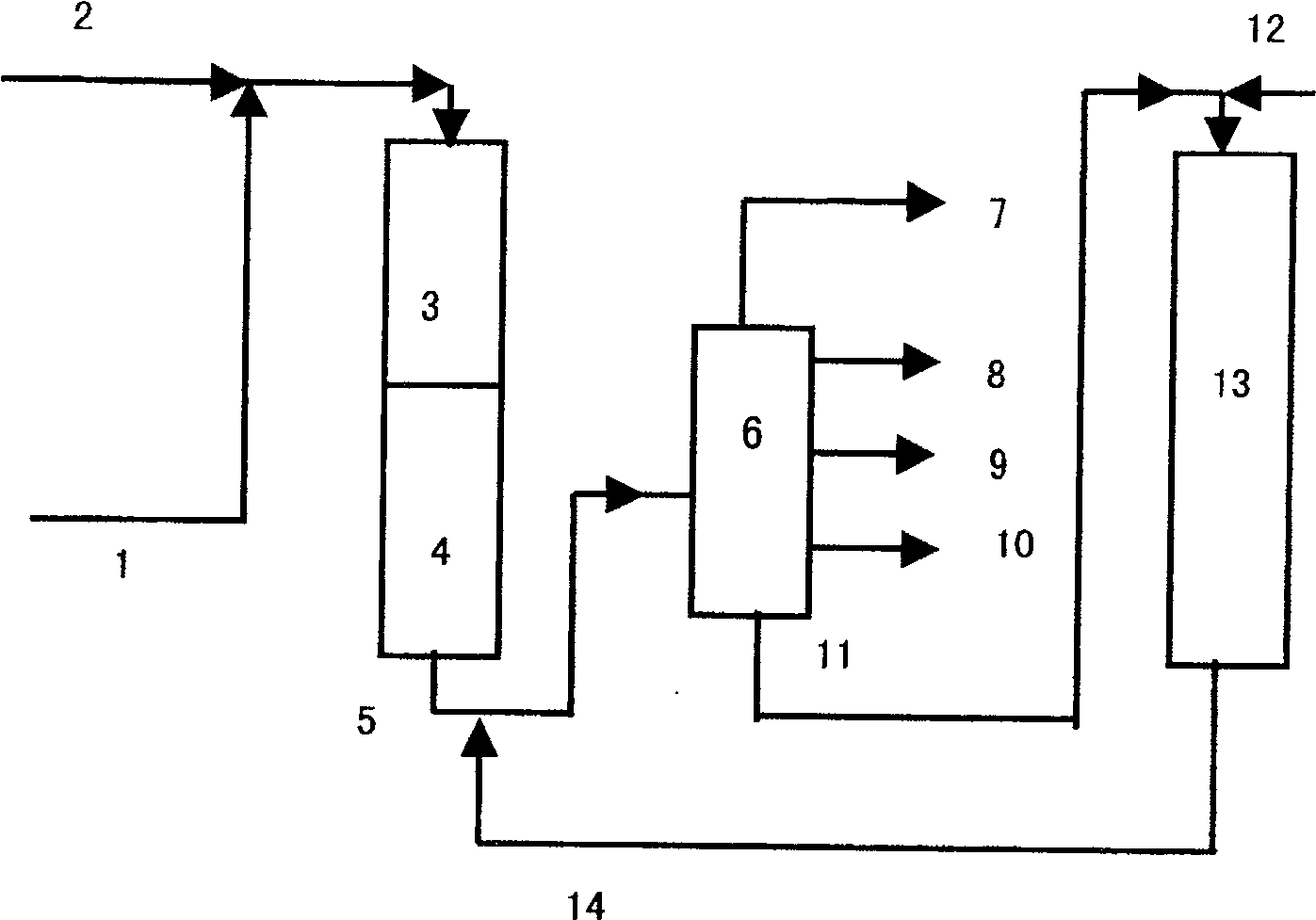

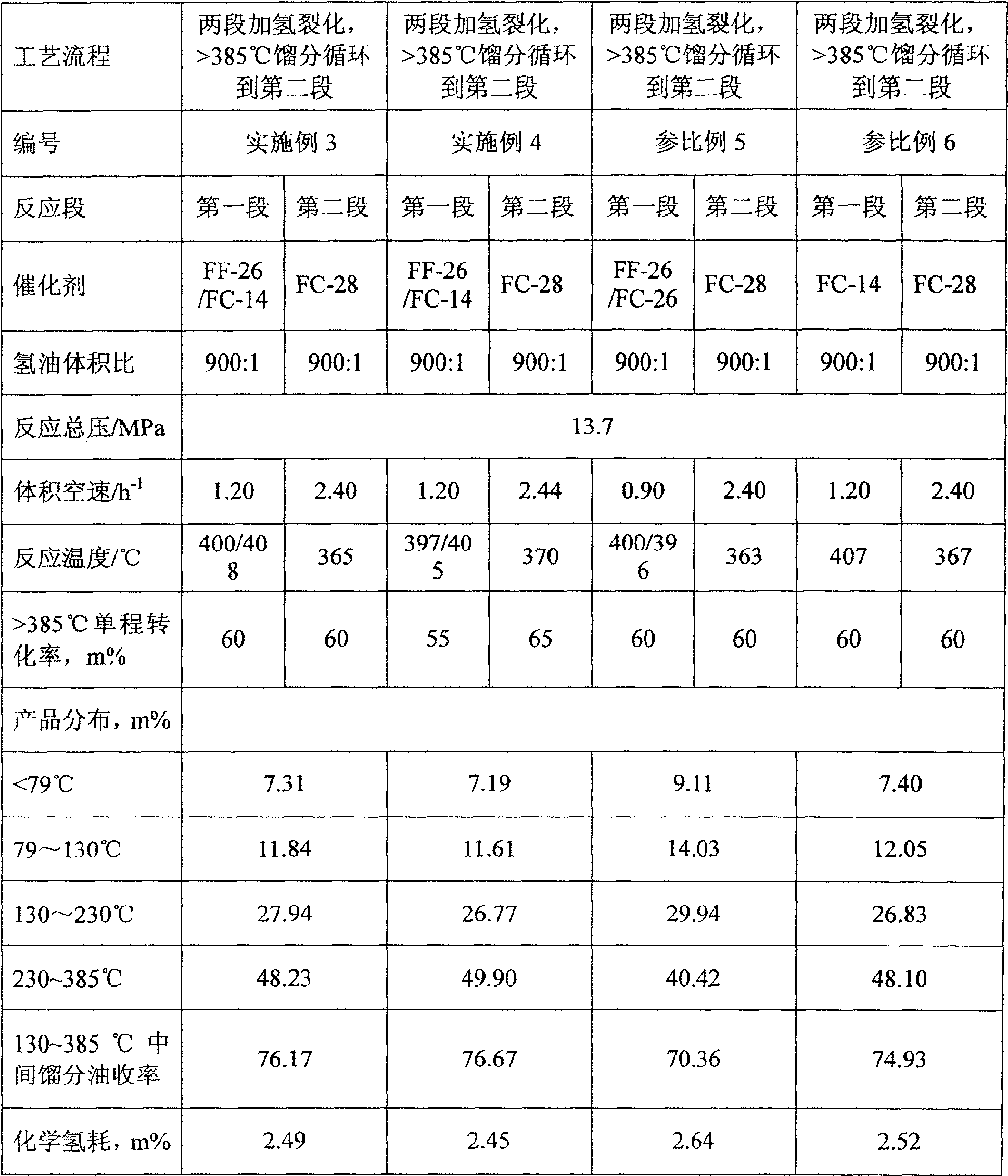

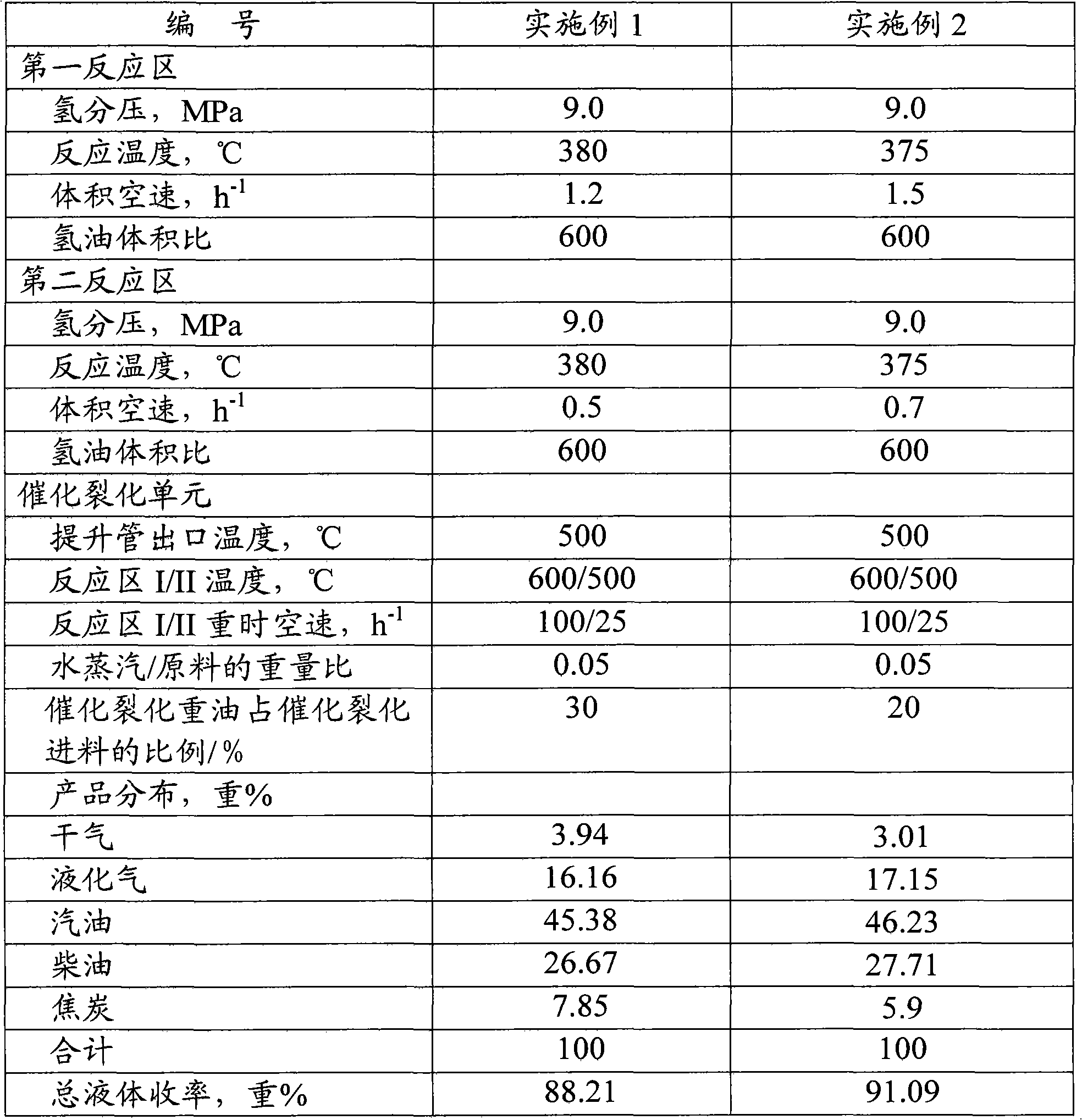

Two-segment hydrocracking method

ActiveCN100526433CSimple processHigh volumetric space velocityTreatment with hydrotreatment processesSingle stageLow load

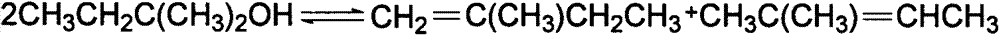

The invention discloses a two-stage hydrocracking method for producing high-quality middle distillate oil. The feedstock oil is mixed with hydrogen and directly enters the first-stage hydrocracking reactor. The first-stage hydrocracking reactor adopts two catalysts in one stage, that is, two catalysts are used in the single-stage hydrocracking process, and the upper part is filled with refined agents , the lower part is filled with cracking agent, and the tail oil of the first stage is recycled to the inlet of the hydrocracking reactor of the second stage. The method of the present invention uses a set of circulating hydrogen system and separation system. Compared with the prior art, the method of the present invention not only maintains the advantages of high middle distillate oil yield, low chemical hydrogen consumption and less total catalyst cost of the single-stage two-agent hydrocracking technology, but also possesses the single-stage serial hydrocracking technology It has the characteristics of strong adaptability to raw oil, long catalyst operation period and good quality of hydrocracking products. The method of the invention is mainly used in the hydrocracking process for producing high-quality middle distillates by using various heavy distillates as raw materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

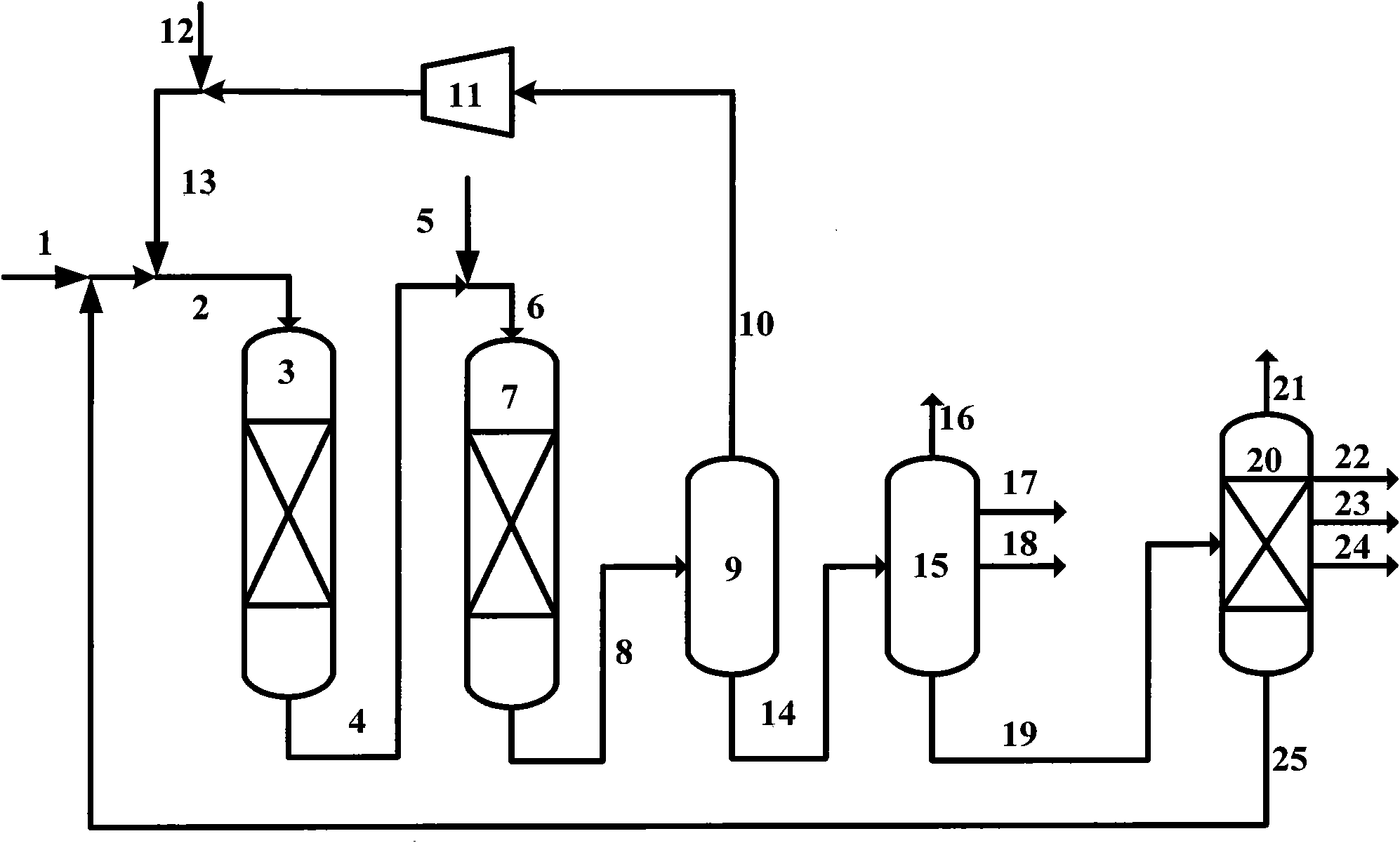

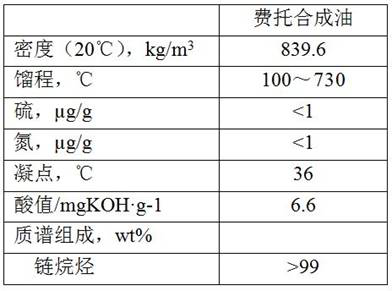

Gas oil and residual oil hydrotreating process for producing catalytically cracked material

ActiveCN101020845AImprove processing depthExpand sourceTreatment with hydrotreatment processesHydrogenResidual oil

The process of hydrogenating gas oil and residual oil to produce catalytically cracked material includes the following steps: contacting and reacting the mixture of gas oil and hydrogen with optional hydrogenation protecting agent and hydrogenation refining catalyst in the first reaction area; directly mixing the produced oil with residual oil, contacting and reacting the mixture with hydrogenation protecting agent, hydrogenating and demetallizing catalyst and hydrotreating catalyst successively in the second reaction area; cooling and separating the reacted products to obtain hydrogen-rich liquid and gas products. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

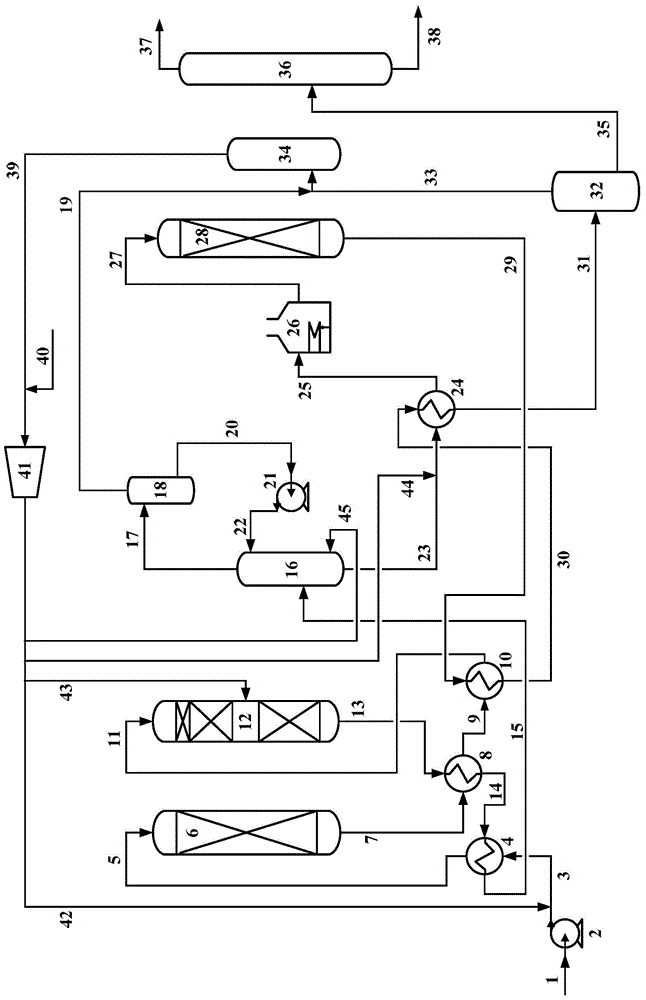

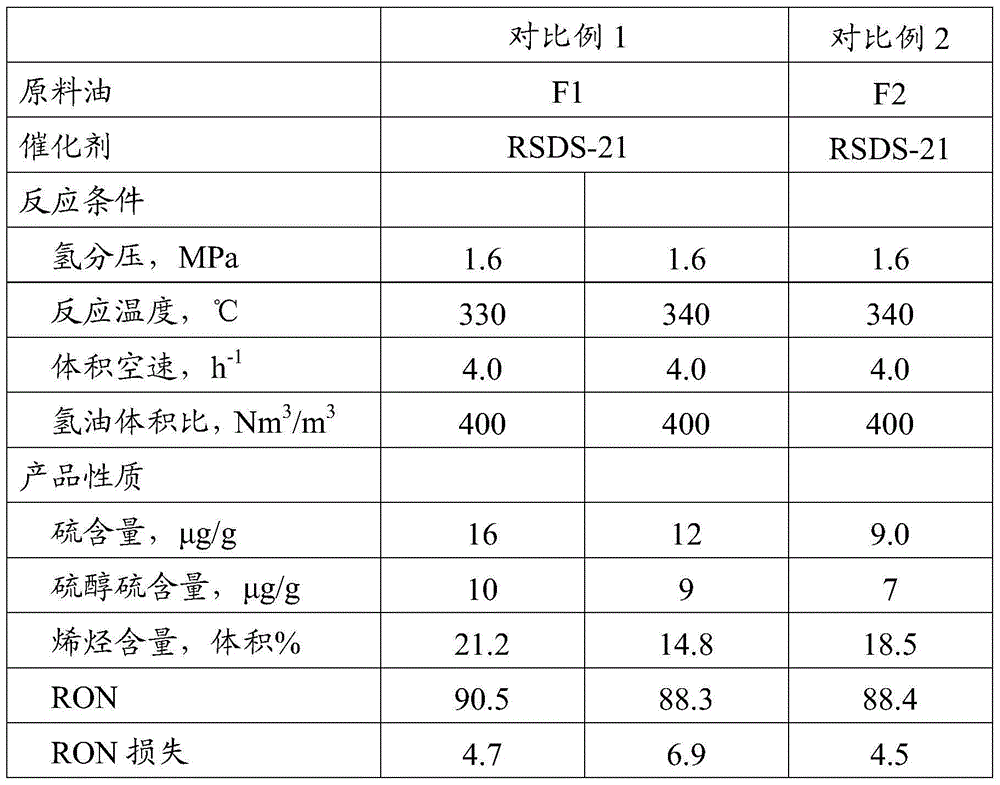

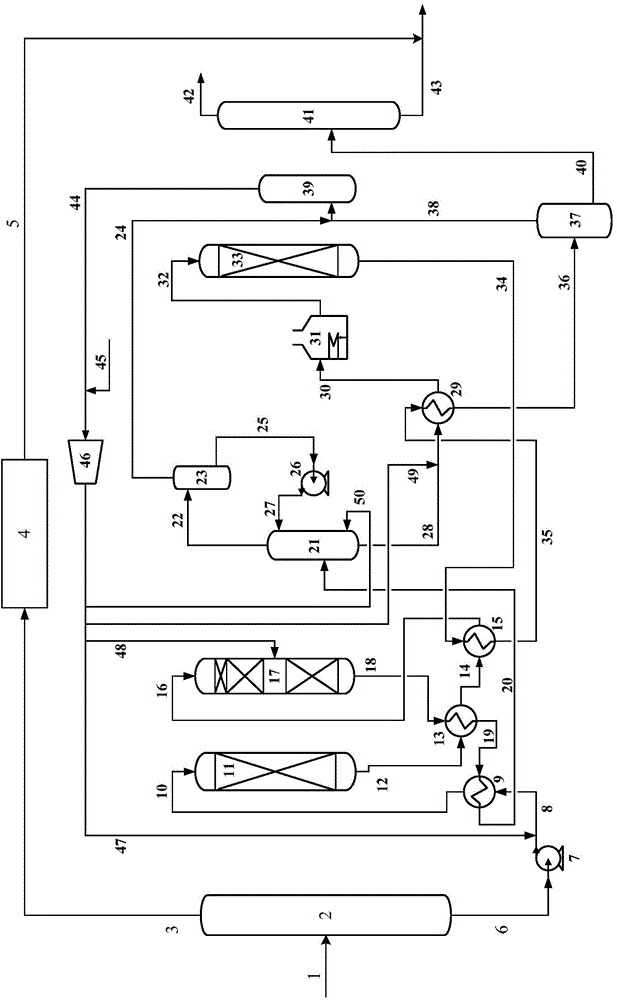

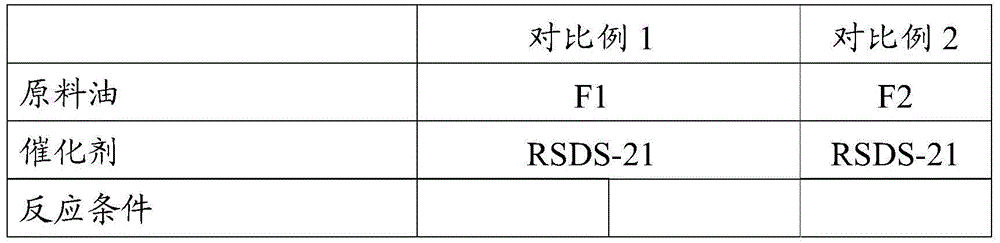

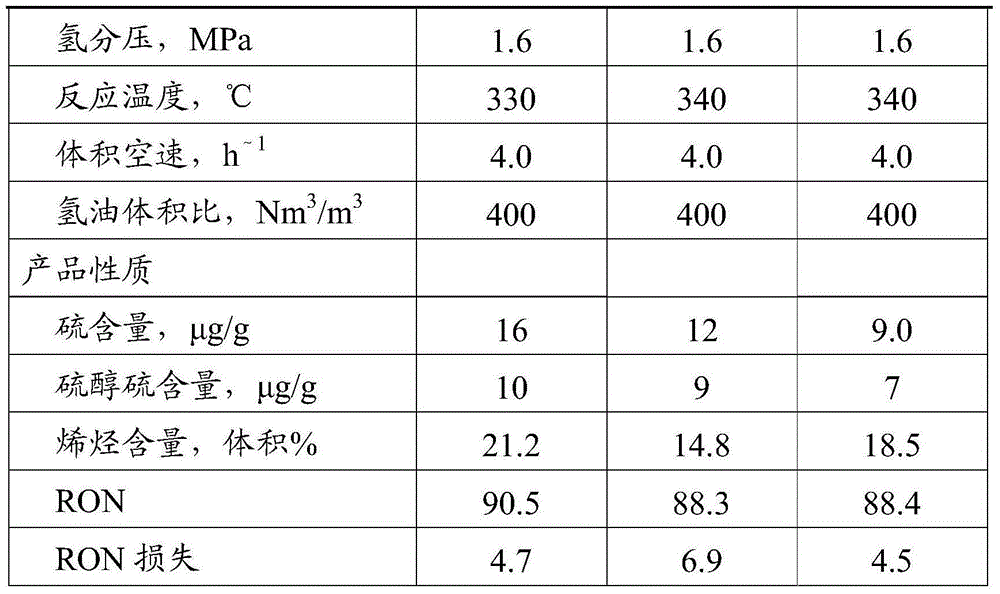

Hydrogenation method for producing ultralow-sulfur gasoline

ActiveCN106147844AReduce lossesReduce sulfur contentTreatment with hydrotreatment processesHydrogenGasoline

Provided is a hydrogenation method for producing ultralow-sulfur gasoline. After full-range gasoline and / or a heavy gasoline fraction and hydrogen are mixed, the mixture enters a first hydrogenation reactor to be in contact with a selective hydrogenation diene removal catalyst I for reacting, and effluent of the first hydrogenation reactor enters a second hydrogenation reactor and is in contact with a selective hydrogenation desulfurization catalyst II regulated and controlled selectively for reacting; effluent of the second hydrogenation reactor enters a third hydrogenation reactor after hydrogen sulfide is removed through a flash column and is in contact with a selective hydrogenation desulfurization catalyst III regulated and controlled selectively for reacting, and reaction effluent of the third hydrogenation reactor is separated to obtain an ultralow-sulfur hydrogenation gasoline fraction. High-sulfur high-olefin catalytically cracked gasoline can be treated, the sulphur content of the product is smaller than 10 micrograms / gram, the octane value loss is small, and the gasoline yield reaches 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

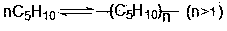

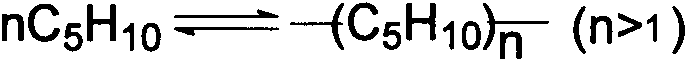

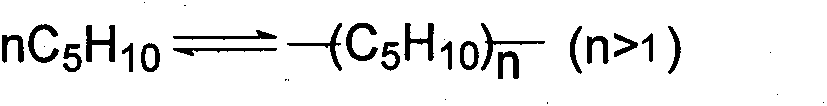

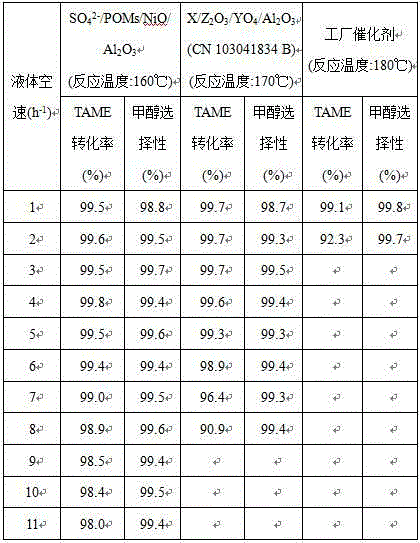

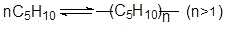

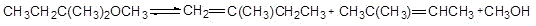

Catalyst for preparing isopentene by cracking of tertiary amyl methyl ether, as well as preparation method and applications of catalyst

ActiveCN103846098AHigh selectivityLow reaction temperaturePhysical/chemical process catalystsOrganic compound preparationAlcoholCracking reaction

The invention discloses a multi-component X / Z2O3 / POMs / Al2O3 type catalyst for preparing high-purity isopentene, and a preparation method of the catalyst. According to the method, the catalyst contains the following components in percentage by weight: 20-95% of Al2O3, 0.01-20% of Z2O3, 0.01-50% of POMs and 0.01-25% of X. The catalyst can be used for preparing isopentene by cracking of tertiary amyl methyl ether at temperature (140-160 DEG C) lower than that of other similar catalysts, the selectivity of high-purity isopentene and methyl alcohol is ensured, the cracking of tertiary amyl methyl ether approximates complete transformation, the airspeed of the reacted liquid in use of the catalyst is enhanced by 2-5 times than that in use of other similar industrial catalysts, and inert substances such as water are not required to be added in a tertiary amyl methyl ether cracking reaction system; under the condition that the existing reaction equipment is not changed, the energy consumption in industrial production can be lowered and the utilization rate of equipment can be multiplied.

Owner:EAST CHINA UNIV OF SCI & TECH

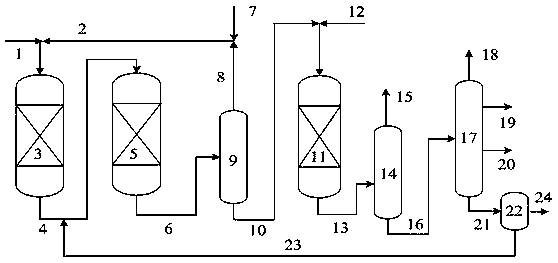

Hydrocracking technological method for processing inferior raw material

ActiveCN103059944AReduced volumetric space velocityHigh volumetric space velocityTreatment with hydrotreatment processesLiquid productLow nitrogen

The invention relates to a hydrocracking method for processing an inferior raw material. The method comprises: passing the inferior raw material through a first hydrotreating area, and subjecting the liquid product to fractionation in a first fractionating tower; passing the obtained heavy distillate oil through a second hydrotreating area, and passing the obtained effluent and intermediate distillate generated by the fractionation to a hydrocracking area together; and leaving the cracking liquid product and light distillate generated in the fractionation to enter a second fractionating tower, thus obtaining the product. Compared with the prior art, the invention makes use of fractionation to separate out the light and intermediate distillate with a low nitrogen content from the hydrotreating product, thus reducing the space velocity of feed entering the second hydrotreating area, and also being able to properly mitigating the operation severity of the first hydrotreating area. Therefore, while meeting the demand for long-period operation treatment of the inferior raw material, the method provided in the invention also enhances the device processing capacity to the utmost. On the basis of improving the product quality, the method can achieve an ideal comprehensive processing effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

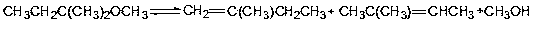

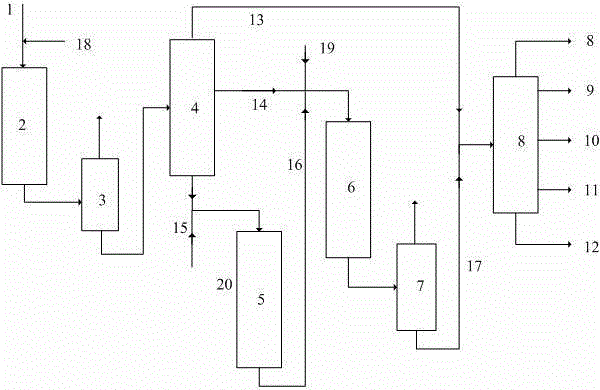

Method for purifying 1,4-butanediol

ActiveCN107778141ALess impuritiesReduce chromaOrganic-compounds/hydrides/coordination-complexes catalystsHydroxy compound separation/purificationHydrogenButanediol

The invention discloses a method for purifying 1,4-butanediol. The method comprises the following step of enabling crude 1,4-butanediol containing aldehyde compound and / or acetal compound impurities to contact a silver-loaded resin catalyst under the hydrogen contacting condition, so as to obtain the purified 1,4-butanediol with color degree smaller than 10APHA. The method has the advantage that the crude 1,4-butanediol containing the aldehyde compound and / or acetal compound impurities can be purified, so that the color degree of the 1,4-butanediol is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ultralow-sulfur gasoline

ActiveCN106147838AReduce lossesReduce sulfur contentTreatment with hydrotreatment processesHydrogenGasoline

The invention discloses a method for producing ultralow-sulfur gasoline. Gasoline raw materials are fractionated into a light gasoline fraction and a heavy gasoline fraction, the light gasoline fraction enters an alkali extraction unit, and a refined light gasoline fraction is obtained. After the heavy gasoline fraction is mixed with hydrogen, the mixture sequentially enters a first hydrogenation reactor and a second hydrogenation reactor and is in contact with a selective hydrogenation diene removal catalyst I and a selective hydrogenation desulfurization catalyst II for reacting, effluent of the second hydrogenation reactor enters a third hydrogenation reactor after hydrogen sulfide is removed through a flash column, the product is in contact with a selective hydrogenation desulfurization catalyst III for reacting, and reaction effluent of the third hydrogenation reactor is separated to obtain a hydrogenation heavy gasoline fraction. The refined light gasoline fraction and the hydrogenation heavy gasoline fraction are mixed to obtain an ultralow-sulfur gasoline product. According to the method, high-sulfur high-olefin catalytically cracked gasoline can be treated, the sulfur content of the product is smaller than 10 micrograms / gram, the octane value loss is small, and the gasoline yield reaches 99% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing isoamylene by splitting decomposition of t-amyl-methyl ether and preparation method and application thereof

ActiveCN103041834AHigh selectivityLow reaction temperaturePhysical/chemical process catalystsOrganic compound preparationDecompositionChemistry

The invention discloses a multicomponent (X / Z2O3 / YO4 / Al2O3) catalyst for preparing isoamylene and a preparation method thereof. According to the method, the catalyst comprises the following components by weight percent: 20% to 95% of Al2O3, 0.1% to 20% of Z2O3, 0.1% to 50% of YO4 and 0.1% to 40% of X. The catalyst can take a reaction to prepare the isoamylene by the splitting decomposition of t-amyl-methyl ethe at a temperature lower than that of the existing catalyst of the same type. Under the condition that the high selection on the isobutene and the methanol and the high conversion rate of the splitting decomposition of the t-amyl-methyl ether are guaranteed, as compared with the existing catalyst of the same type, the catalyst provided by the invention has the effects that the space velocity of liquids in the reaction is improved exponentially, and water and other inert substances are not required to be added into a splitting decomposition reaction system of the t-amyl-methyl ether. Therefore, under the condition of unchanging the existing reaction equipment, the energy consumption in the industrial production is lowered, and the equipment utilization rate is improved exponentially.

Owner:EAST CHINA UNIV OF SCI & TECH

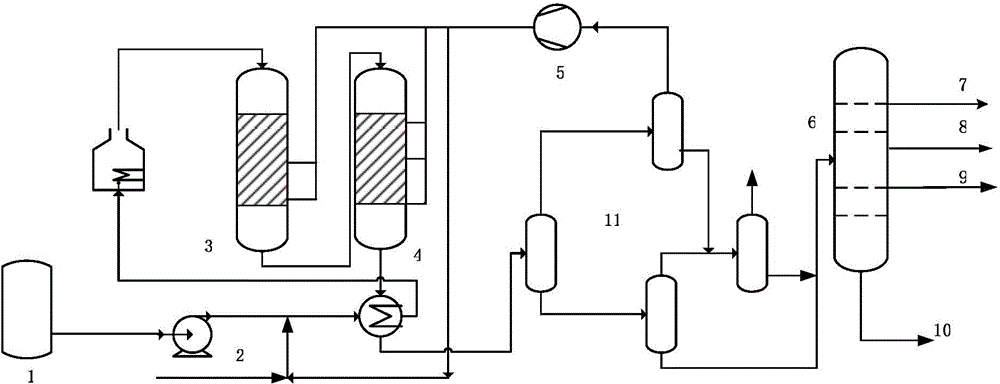

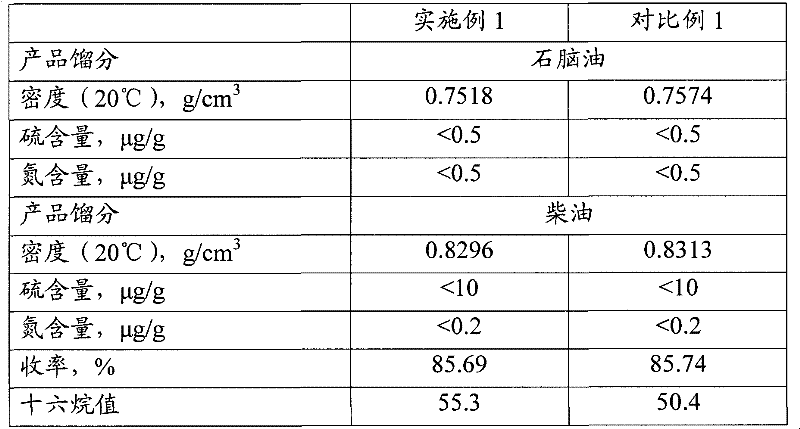

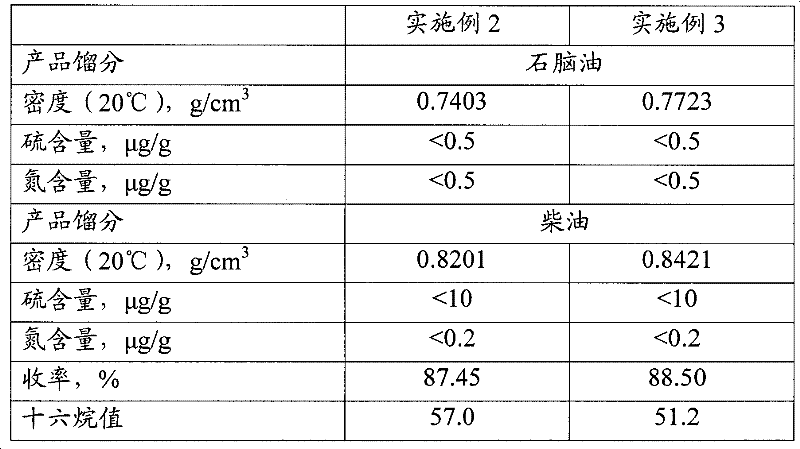

Hydrocracking method for producing chemical materials

InactiveCN104560160AHigh volumetric space velocityFang QiangaoTreatment with hydrotreatment processesHydrogenNaphtha

The invention discloses a hydrocracking method for producing chemical materials. The method comprises the steps of entering raw material oil and hydrogen into a hydrorefining reactor for performing hydrodesulfurization, hydro-denitrification, olefin saturation and partial aromatic saturation under the action of a hydrorefining catalyst; and carrying out contact reaction on the obtained effluent and a hydrocracking catalyst in a hydrocracking reactor. According to the method provided by the invention, the required transformation depth can be reached under a relatively mild reaction condition; heavy naphtha is good in selectivity; and long-term operation of a device is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

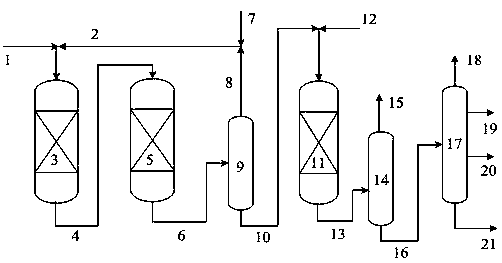

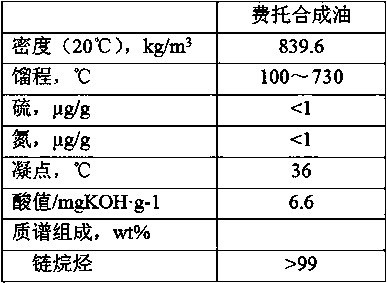

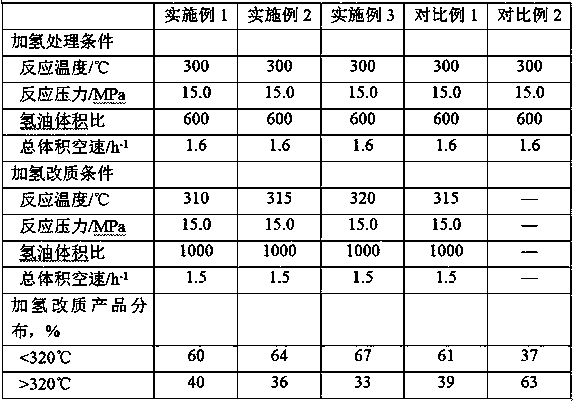

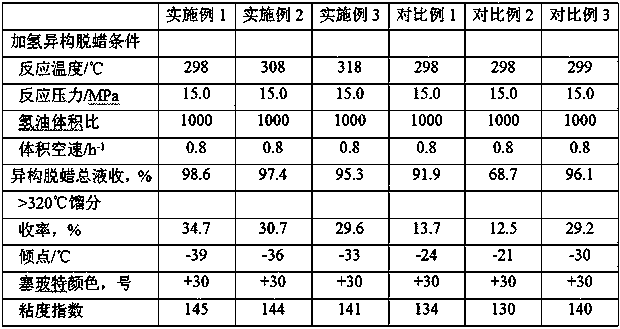

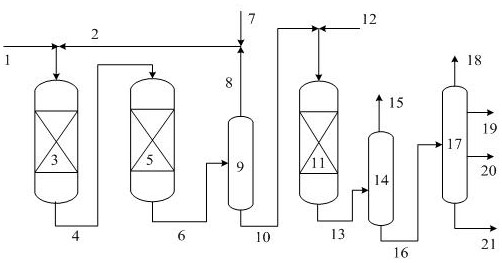

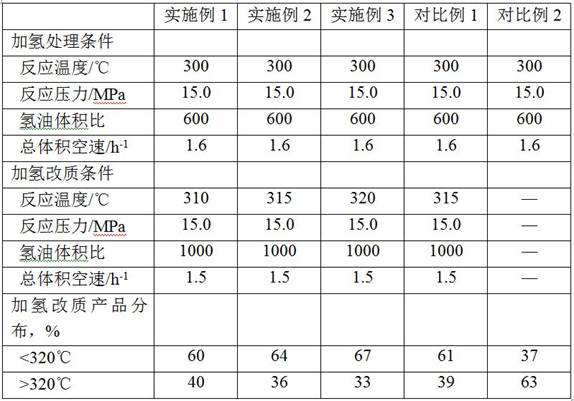

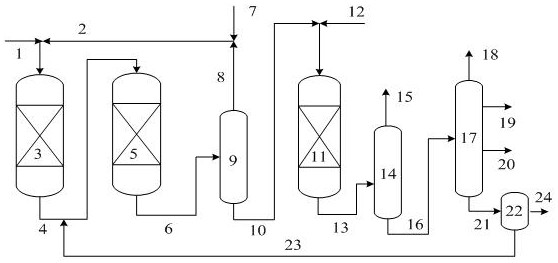

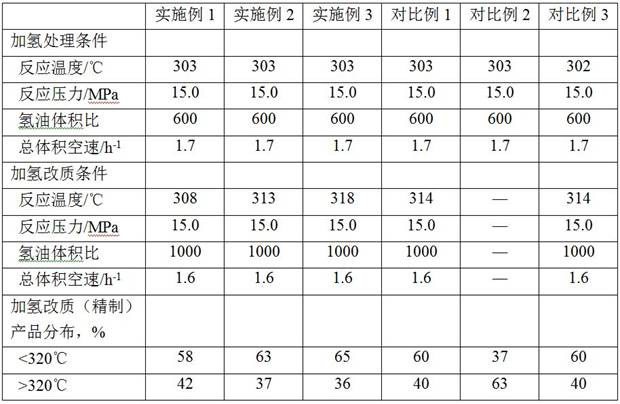

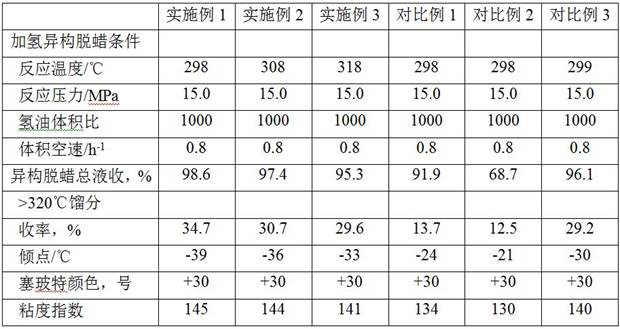

Hydrogenation method for producing API III <+> base oil from Fischer-Tropsch synthetic oil

ActiveCN111378495ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Fischer-Tropsch synthetic oil is used as a raw material, and a two-stage hydrogenation process of hydrofining-hydro-upgrading-isodewaxing is adopted to produce API III <+> lubricating oil base oil. Generated oil obtained through separation of a hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reactionzone, and different types of API III <+> lubricating oil base oil products are obtained through separation and fractionation of an isodewaxing reaction effluent. The method has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthetic oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing isoamylene by splitting decomposition of t-amyl-methyl ether and preparation method and application thereof

ActiveCN103041834BHigh selectivityLow reaction temperaturePhysical/chemical process catalystsOrganic compound preparationPolymer scienceDecomposition

The invention discloses a multicomponent (X / YO4= / Z2O3 / Al2O3) catalyst for preparing isoamylene and a preparation method thereof. According to the method, the catalyst comprises the following components by weight percent: 20% to 95% of Al2O3, 0.1% to 20% of Z2O3, 0.1% to 50% of YO4 and 0.1% to 40% of X. The catalyst can take a reaction to prepare the isoamylene by the splitting decomposition of t-amyl-methyl ethe at a temperature lower than that of the existing catalyst of the same type. Under the condition that the high selection on the isobutene and the methanol and the high conversion rate of the splitting decomposition of the t-amyl-methyl ether are guaranteed, as compared with the existing catalyst of the same type, the catalyst provided by the invention has the effects that the space velocity of liquids in the reaction is improved exponentially, and water and other inert substances are not required to be added into a splitting decomposition reaction system of the t-amyl-methyl ether. Therefore, under the condition of unchanging the existing reaction equipment, the energy consumption in the industrial production is lowered, and the equipment utilization rate is improved exponentially.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst in preparation of isobutene by methyl tertbutyl ether pyrolysis

ActiveCN100448527CHigh activityImprove stabilityCatalystsHydrocarbon preparation catalystsEtherHigh selectivity

A catalyst for preparing isobutene by cracking methyl turt-butyl ether (MTBE) is prepared from the amorphous SiAl through treating by saturated steam at 100-600 deg.C for 1-10 hr. Its advantages are high conversion rate of MTBE, high selectivity to isobutene, and long service life (at least 3504 hr).

Owner:CHINA PETROLEUM & CHEM CORP +1

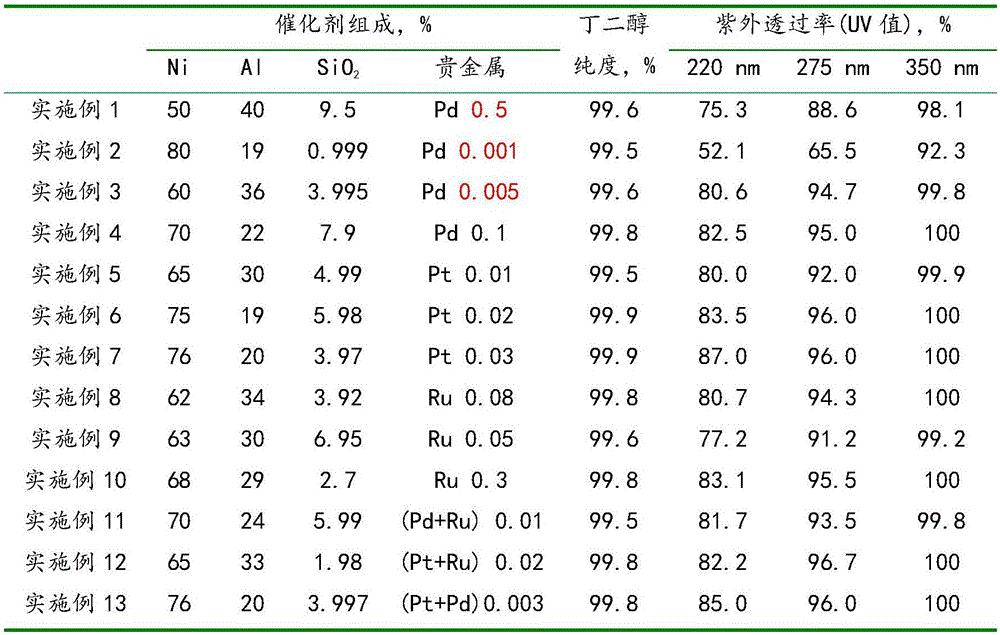

Supplementing refining catalyst for preparing 1,4-butanediol, preparation method and application thereof

ActiveCN105797747AEfficient removalHigh purityOrganic compound preparationHydroxy compound preparationTransmittanceChemistry

The invention discloses a supplementing refining catalyst for preparing 1,4-butanediol, a preparation method and application thereof. Compared with the prior art, the catalyst provided by the invention can be used for effectively removing colored impurities in 1,4-butanediol. Under the reaction condition according to the invention, the ultraviolet transmittance (UV value) of 1,4-butanediol under 220nm, 275nm and 350nm is increased to be more than or equal to 80%, 92% and 99% from 0.1%, 0.3% and 34.0%; the purity of the products can reach 99.8%; the polymer grade requirement is met; the reaction condition of the supplementing refining catalyst is mild; the pressure, temperature and hydrogen consumption are ultralow; the volume airspeed is ultrahigh; compared with rectifying purification, the supplementing refining catalyst is beneficial to the reduction of production cost.

Owner:SINOPEC YANGZI PETROCHEM +1

Preparation method and application of catalyst for preparing isoamylene

ActiveCN104689853AHigh volumetric space velocityEasy to makeOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from oxygen organic compoundsHalogenHigh selectivity

The invention discloses a multicomponent SO42- / POMs / NiO / Al2O3 catalyst for preparing high-purity isoamylene through cracking of tert-amyl methyl ester and a preparation method thereof. According to the preparation method of the multicomponent SO42- / POMs / NiO / Al2O3 catalyst, the multicomponent SO42- / POMs / NiO / Al2O3 catalyst is composed of, by weight percentage, 20-95% of Al2O3, 1-50% of NiO, 0.1-20% of POMs and 0.5-35% of SO42-. The multicomponent SO42- / POMs / NiO / Al2O3 catalyst is prepared through an impregnation method and is simple in operation and low in prices, and compared with existing similar catalysts, can achieve the reaction of preparing the isoamylene through cracking of the tert-amyl methyl ester under a lower temperature, thereby ensuring high selectivity of isoamylene and methanol and meanwhile approximately fully converting the tert-amyl methyl ester; the liquid space velocity ratio of the reaction can be increased by 2-10 times compared with that of reactions with similar industrial catalysts; meanwhile, without adding of halogen, cleanliness and environmental protection can be achieved.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of method of producing epichlorohydrin

The invention provides a method for producing epoxy chloropropane. The method comprises the following steps of chlorination of glycerin, separation of a dichloropropanol-hydrogen chloride aqueous solution, compression of hydrogen chloride, and purification of dichloropropanol saponification and epoxy chloropropane. A dichloropropanol oil phase is decanted and layered through the separation of the dichloropropanol-hydrogen chloride aqueous solution and directly enters the saponification step; gas-phase hydrogen chloride escaped during the separation of the dichloropropanol-hydrogen chloride aqueous solution is pressurized and introduced into a reactor; and hydrogen chloride is subjected to filtration and washing operations, so that the content of water and impurities in hydrogen chloride raw material is reduced; and selective scope of the hydrogen chloride compressor is broadened. The method is advantaged by guaranteeing that volume space velocity of the reactor is not smaller than 0.1; conversion rate of glycerin is not lower than 98% and selectivity for dichloropropanol is not lower than 99%, by optimizing a catalyst proportion, a reaction pressure and reaction temperature during the chlorination of glycerin.

Owner:CHINA TIANCHEN ENG +1

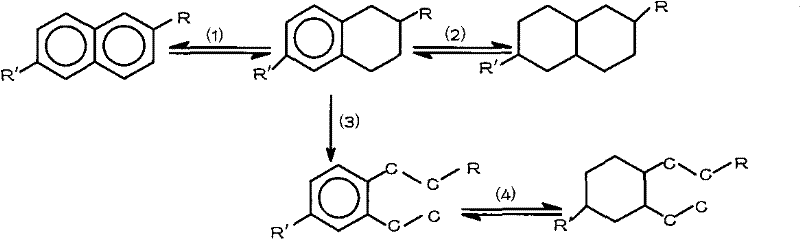

Hydrogenation method for increasing cetane number of diesel oil

ActiveCN102206510AReduce side chain scission reactionIncrease cetane numberTreatment with hydrotreatment processesAlkaneSide chain

Disclosed is a hydrogenation method for increasing cetane number of diesel oil. According to the invention, a reaction unit is provided with three sequentially arranged reaction zones; in a first reaction zone, a hydrobon catalyst I is filled and a hourly space velocity is 0.5 to 5.0 h <-1>; in a second reaction zone, a hydroupgrading catalyst is filled and a hourly space velocity is 1.0 to 8.0 h <-1>; in a third reaction zone, a hydrobon catalyst II is filled and a hourly space velocity is 1.5 to 12.0 h <-1>; the acidity of the hydrobon catalyst I is less than that of the hydrobon catalyst II. With the utilization of the method provided in the invention, cracking of open loops of annular aromatic hydrocarbons with more than two rings in the raw materials can be realized and the reaction of long-chain alkane cracking into short-chain alkane and the scission reaction of annular hydrocarbon with long side chains can be reduced; therefore, cetane number of diesel oil can be greatly increased under the condition that high yield of diesel oil is maintained.

Owner:CHINA PETROLEUM & CHEM CORP +1

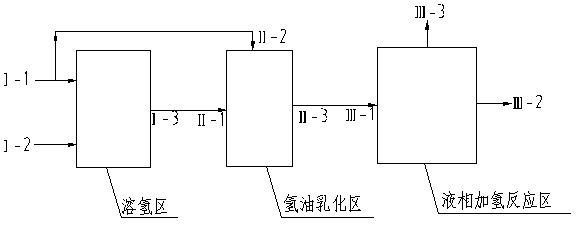

Efficient hydrogenation process and system for producing hydrogen peroxide through anthraquinone method

ActiveCN109678121AIncrease profitHigh volumetric space velocityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemistryAnthraquinone process

The invention discloses an efficient hydrogenation process and system for producing hydrogen peroxide through an anthraquinone method. The efficient hydrogenation process comprises the following contents: (1) total hydrogen of the hydrogenation process is divided into two paths, namely hydrogen I and hydrogen II; the hydrogen I and a working solution enter hydrogen dissolving equipment, and thus the hydrogen I is dissolved in the working solution to obtain a hydrogen-dissolved working solution; (2) the hydrogen-dissolved working solution and the hydrogen II enter a mixer containing a ceramic membrane tube bundle, wherein the hydrogen-dissolved working solution enters the shell side outside the tube bundle, the hydrogen II enters the tube pass side inside the tube bundle, the hydrogen II radially passes through the tube wall of the ceramic membrane tube bundle to be dispersed into nano-sized / micron-sized minute bubbles, and the nano-sized / micron-sized minute bubbles act with the hydrogen-dissolved working solution on the shell side to obtain a microemulsion fluid; and (3) the microemulsion fluid enters a liquid phase hydrogenation reactor filled with a hydrogenation catalyst, a hydrogenation reaction is conducted, and a hydrogenation reaction product enter into the next procedure. According to the efficient hydrogenation process, by controlling the two different states of hydrogen in the working solution, the whole hydrogenation reaction is conducted in the liquid phase, the uniformity of the reaction is ensured while the hydrogenation reaction efficiency is improved, the side reaction is effectively controlled, and the anthraquinone consumption is greatly lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation process for producing API III < + > base oil from Fischer-Tropsch synthetic oil

ActiveCN111378493ASlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a hydrogenation process for producing API III < + > lubricating oil base oil from Fischer-Tropsch synthetic oil. The Fischer-Tropsch synthetic oil is used as a raw material, and a hydrofining-hydro-upgrading-isodewaxing two-stage hydrogenation process is adopted to produce API III + lubricating oil base oil. The generated oil obtained by separation of hydrofining-hydro-upgrading reaction effluent enters an isodewaxing reaction zone; and the process further includes separating and fractionating the isodewaxing reaction effluent to obtain different types of API III + lubricating oil base oil products, cooling fractionated vacuum bottom oil to obtain an incompletely converted wax component, and returning the incompletely converted wax component to the hydro-upgrading reactor to continue the upgrading reaction. The invention has the advantages of simple process flow and wide raw material adaptability, and can be suitable for the process of producing special oil products with good stability by Fischer-Tropsch synthesis oil fraction hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas oil and residual oil hydrotreating process for producing catalytically cracked material

ActiveCN100577773CImprove processing depthExpand sourceTreatment with hydrotreatment processesHydrogenResidual oil

The process of hydrogenating gas oil and residual oil to produce catalytically cracked material includes the following steps: contacting and reacting the mixture of gas oil and hydrogen with optional hydrogenation protecting agent and hydrogenation refining catalyst in the first reaction area; directly mixing the produced oil with residual oil, contacting and reacting the mixture with hydrogenation protecting agent, hydrogenating and demetallizing catalyst and hydrotreating catalyst successively in the second reaction area; cooling and separating the reacted products to obtain hydrogen-rich liquid and gas products. The present invention makes it possible to produce high quality catalytically cracked material via adding residual oil in 5-50 wt% into gas oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of a catalyst for preparing olefins

ActiveCN106955687BHigh volumetric space velocityEasy to makeHeterogenous catalyst chemical elementsHydrocarbonsEtherMethanol

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst for preparing isopentene by cracking methyl tert-amyl ether, preparation method and application

ActiveCN103846098BHigh selectivityLow reaction temperaturePhysical/chemical process catalystsOrganic compound preparationAlcoholCracking reaction

The invention discloses a multi-component X / Z2O3 / POMs / Al2O3 type catalyst for preparing high-purity isopentene, and a preparation method of the catalyst. According to the method, the catalyst contains the following components in percentage by weight: 20-95% of Al2O3, 0.01-20% of Z2O3, 0.01-50% of POMs and 0.01-25% of X. The catalyst can be used for preparing isopentene by cracking of tertiary amyl methyl ether at temperature (140-160 DEG C) lower than that of other similar catalysts, the selectivity of high-purity isopentene and methyl alcohol is ensured, the cracking of tertiary amyl methyl ether approximates complete transformation, the airspeed of the reacted liquid in use of the catalyst is enhanced by 2-5 times than that in use of other similar industrial catalysts, and inert substances such as water are not required to be added in a tertiary amyl methyl ether cracking reaction system; under the condition that the existing reaction equipment is not changed, the energy consumption in industrial production can be lowered and the utilization rate of equipment can be multiplied.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation method and application of catalyst for preparing olefins

ActiveCN106955687AHigh volumetric space velocityEasy to makeHeterogenous catalyst chemical elementsHydrocarbonsEtherAlkene

The invention discloses a multi-component NiO / SiO2 / F<-> / SO4<2-> / Al2O3 catalyst for preparing high-purity olefins by ether cracking and a preparation method thereof. According to the method, the catalyst comprises the following components in percentage by weight: 20-95% of Al2O3, 1-50% of NiO, 0.1-20% of SiO2, 0.1-10% of F<-> and 0.5-35% of SO4<2->. The catalyst is prepared by using an impregnation method, the operation is simple, the price is low, the catalyst can be used for preparing olefins by ether cracking at a lower temperature over present congeneric catalysts, the ether cracking is close to complete conversion while high olefin and methanol selectivity is guaranteed, and the air speed ratio of the reaction liquid is improved by 2-10 times over congeneric industrial catalysts.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing light fuel by using gas oil and residual oil

ActiveCN102373086BImprove processing depthHigh yieldTreatment with hydrotreatment processesHydrogenation reactionGas phase

The invention discloses a method using gas oil and residual oil to process light fuel. The gas oil, catalytic cracking heavy oil and hydrogen are mixed to enter a first hydrogenation reaction area to react, the produced oil after the reaction and residual oil raw materials are mixed to react in a second hydrogenation reaction area, the obtained product after the reaction is separated to obtain a liquid phase product and a gas phase product, wherein the gas phase product is purified and pressurized to be fed back to the first hydrogenation reaction area for cycle use, the hydrogenation residual oil in the liquid phase product enters a catalytic cracking device to react, and the catalytic cracking heavy oil in a reaction product is circulated to the first hydrogenation reaction area. The method organically combines the heavy oil hydrotreatment and the catalytic cracking device, can translate inferior gas oil and residual oil into light fuel to the maximum extent, so the liquid yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Fischer-Tropsch synthetic oil production api Ⅲ + Hydrogenation method of base oil

ActiveCN111378495BSlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrogenation processProcess engineering

The invention discloses a processing method of Fischer-Tropsch synthetic oil. Using Fischer-Tropsch synthetic oil as raw material, the two-stage hydrogenation process of hydrorefining-hydro-upgrading-isomerization dewaxing is used to produce API III + Lubricant base oil. Hydrofining - The resulting oil obtained from the separation of the hydrogenation upgrading reaction effluent enters the isomerization dewaxing reaction zone, and the isomerization dewaxing reaction effluent is separated and fractionated to obtain different types of API III + Lubricant base oil products. The invention has simple technological process and wide adaptability of raw materials, and can be applied to the process of producing special oil products with good stability through hydrogenation of Fischer-Tropsch synthetic oil distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation process for producing API III+ base oil from Fischer-Tropsch synthetic oil

ActiveCN111378493BSlow cokingLowering the freezing pointTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationHydrogenation process

The invention discloses a method for producing API III from Fischer-Tropsch synthetic oil + Hydrogenation process of lube base oil. Using Fischer-Tropsch synthetic oil as raw material, adopt the two-stage hydrogenation process of hydrofining-hydro-upgrading-isomerization dewaxing to produce API III + Lubricant base oil. Hydrofining - The resulting oil obtained from the separation of the hydrogenation upgrading reaction effluent enters the isomerization dewaxing reaction zone, and the isomerization dewaxing reaction effluent is separated and fractionated to obtain different types of API III + The lubricating oil base oil product, the incompletely converted wax component obtained by cooling the fractionated reduced bottom oil is returned to the hydrogenation reforming reactor to continue the reforming reaction. The invention has simple technological process and wide adaptability of raw materials, and can be applied to the process of producing special oil products with good stability through hydrogenation of Fischer-Tropsch synthetic oil distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

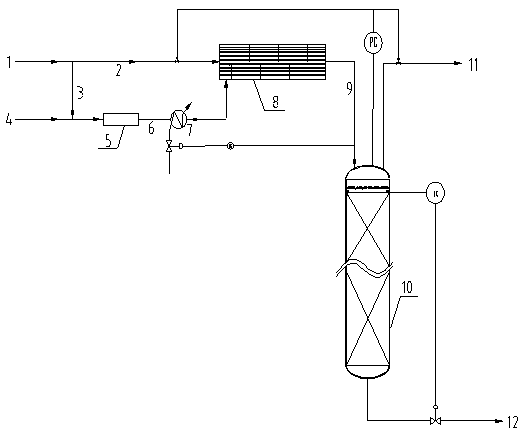

Diesel oil fraction hydrogenating modification process

ActiveCN1986747BSimple processLow investment costHydrocarbon oils refiningPolycyclic aromatic hydrocarbonLiquid product

The diesel oil fraction hydrogenating modification process includes the contact of the mixture of material oil and hydrogen with the hydrotreating catalyst or the contact of the mixture of material oil and hydrogen with the hydrorefining catalyst and the hydrotreating catalyst successively, cooling and separating the reacted effluent, reusing the hydrogen-rich gas circularly, and fractionating the liquid product in the fractionating system to obtain diesel oil fraction and naphtha fraction. The process makes it possible to process inferior diesel oil fraction with banal boiling point in mild operation condition and can raise the cetane number greatly, lower the content of polycyclic aromatic hydrocarbon, S and N and reduce the density. In addition the process has high volume space velocity, low operation cost and high product yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com