Patents

Literature

224 results about "Industrial catalysts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

T<Sou rakan M7 he first time a catalyst was used in the industry was in 1746 by J. Hughes in the manufacture of lead chamber sulfuric acid. Since then catalysts have been in use in a large portion of the chemical industry. In the start only pure components were used as catalysts, but after the year 1900 multicomponent catalysts were studied and are now commonly used in the industry.

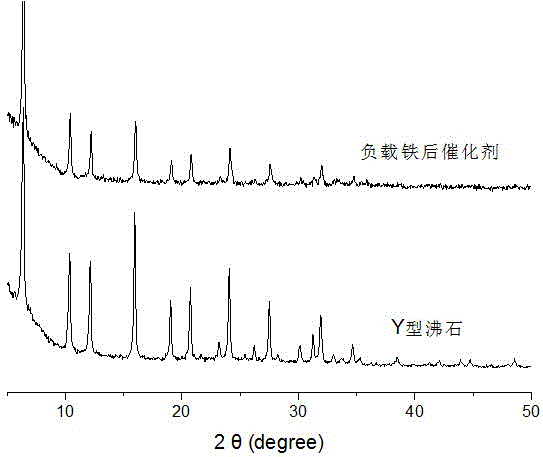

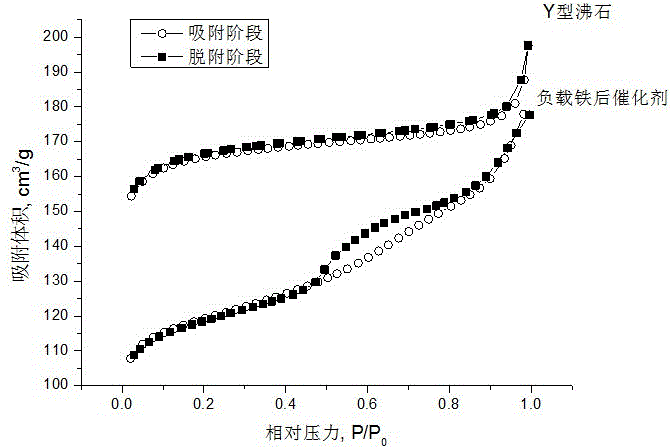

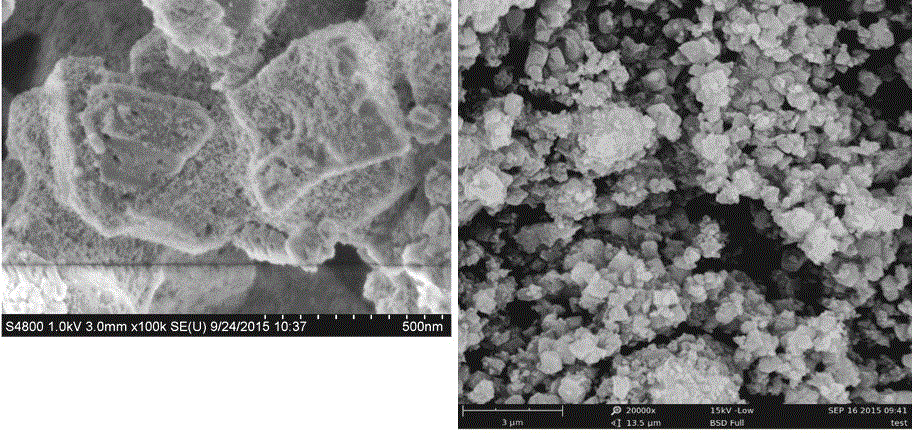

Regenerable heterogeneous Fenton catalyst, and preparation method and application thereof

ActiveCN105478155AImprove stabilityGood regeneration performanceMolecular sieve catalystsWater treatment compoundsPhenolPollution

The invention specifically relates to a regenerable heterogeneous Fenton catalyst, and a preparation method and application thereof, which belongs to the technical field of industrial catalysts. The catalyst provided by the invention uses commercial zeolite as a carrier and is prepared through the following steps: surface modification of the carrier with a high polymer; loading of an active component Fe or Co; and roasting so as to form an iron or cobalt compound-valence oxide on the surface of zeolite. The catalyst shows high-efficiency degradability to industrial intractable organic waste water containing phenols, dyes or the like, and the degradation rate of organic matters in waste water is up to more than 90% at room temperature (less than 30 DEG C) under an almost neutral condition (wherein a pH value is in a range of 6 to 8); and the catalyst has good regeneration performance. According to the method, the heterogeneous Fenton catalyst is used for oxidation removal of organic matters like phenols and dyes in waste water, so cost is low and no secondary pollution is produced; and a process for treating waste water with the Fenton catalyst is a promising organic waste water treatment process.

Owner:FUDAN UNIV

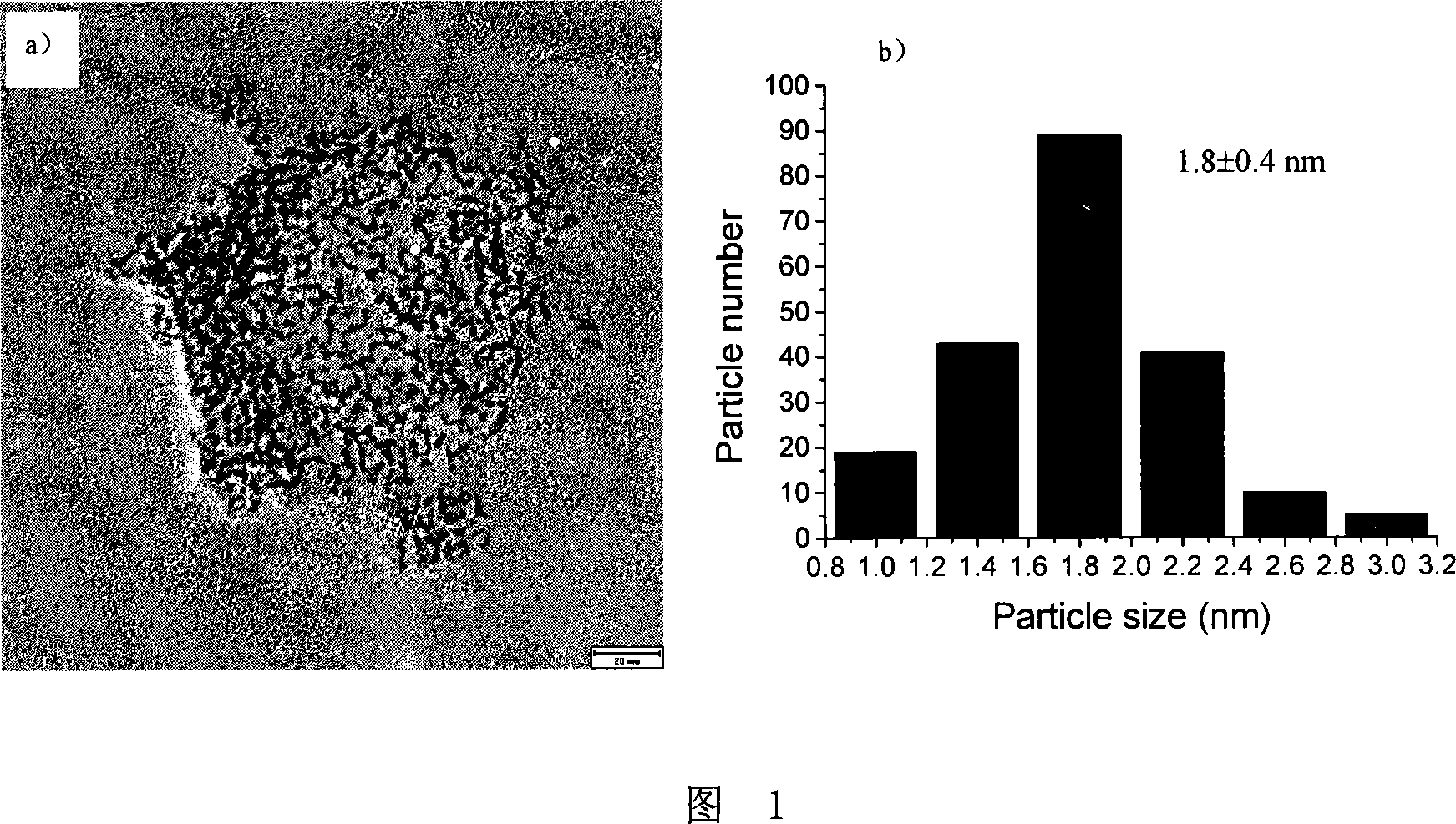

Method for proceeding Feituo Synthesizing reaction and catalyst specially for the same

ActiveCN101045206ASmall particle sizeNarrow distributionHydrocarbon from carbon oxidesOrganic-compounds/hydrides/coordination-complexes catalystsNano catalystLiquid medium

Owner:SYNFUELS CHINA TECH CO LTD

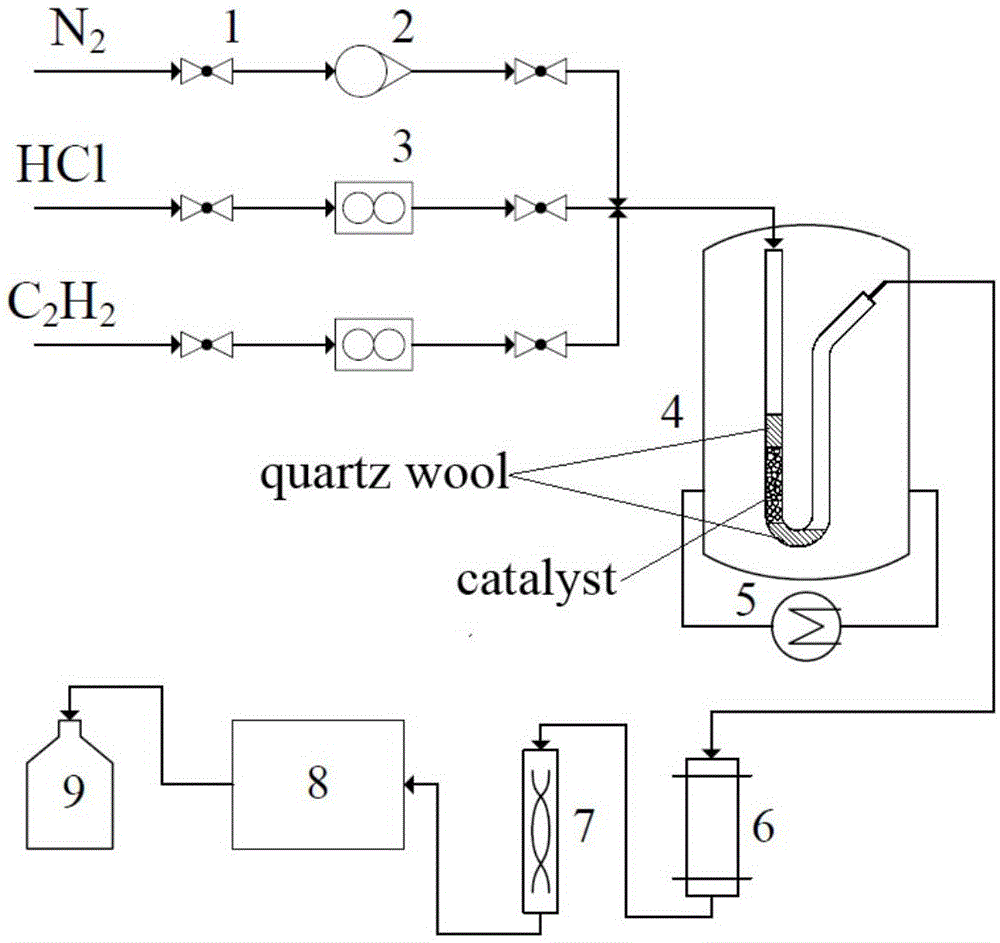

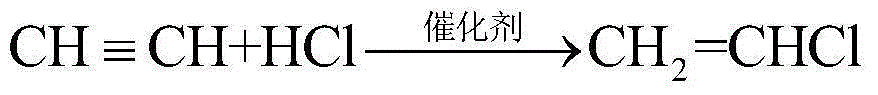

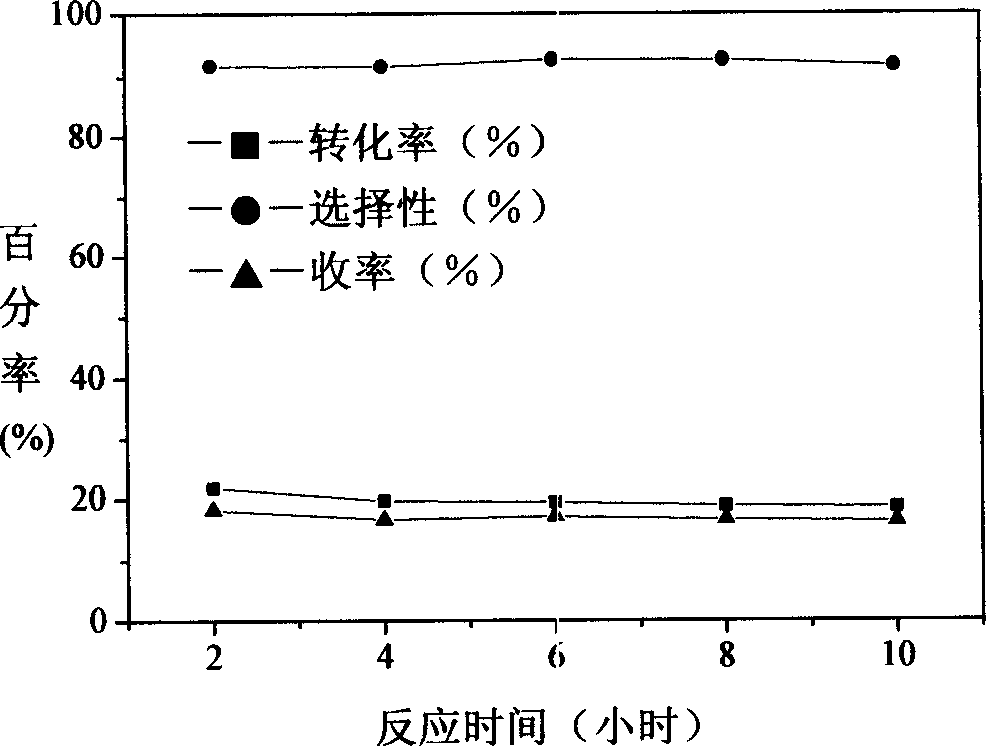

Composite metal salt catalyst for acetylene hydrochlorination

ActiveCN105126878AKeep aliveImprove stabilityPreparation by halogen halide additionOrganic-compounds/hydrides/coordination-complexes catalystsActive componentCopper salt

Belonging to the technical field of industrial catalysts, the invention in particular relates to a composite metal salt catalyst for acetylene hydrochlorination. The catalyst takes a copper salt loaded on a carbon-based carrier as the main active component, and a synergistic metal or anionic ligand is added to enhance the catalytic activity and stability of the catalyst. In the catalyst, the mass fraction of the copper salt is 1-10%, and the mass fraction of the synergistic metal is 0.5-11.0%. On the basis of maintaining the activity, the prepared catalyst has greatly improved stability, and realizes the purpose of maintaining excellent catalyst performance under the premise of reducing the cetylene hydrochlorination catalyst cost.

Owner:TSINGHUA UNIV +1

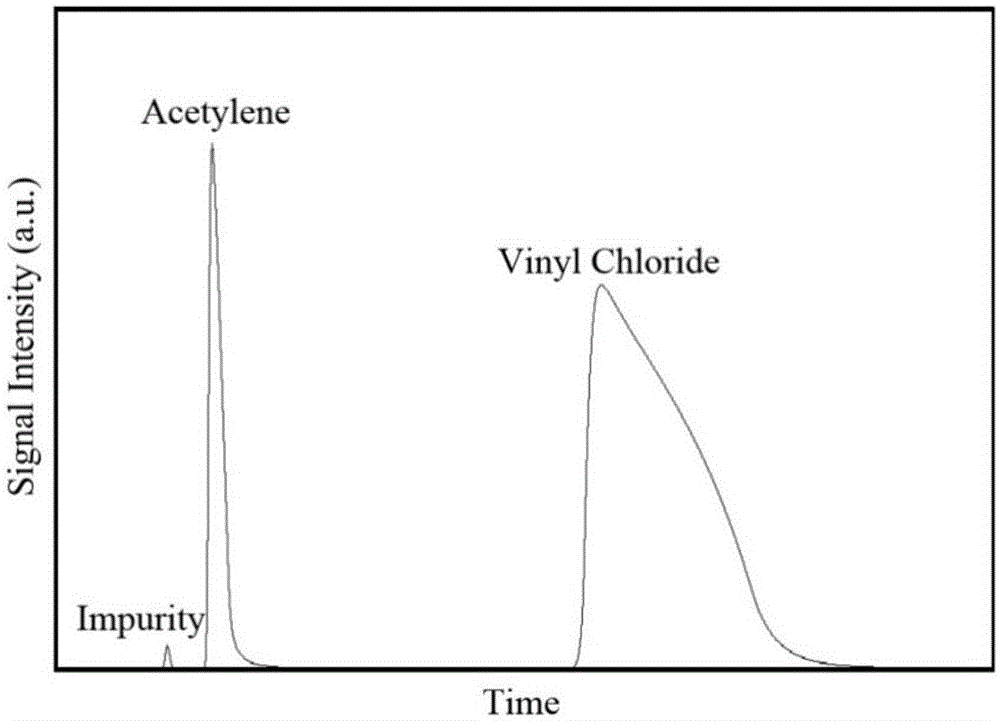

Gold-containing catalyst for preparing vinyl chloride by using acetylene method as well as preparation method and application of catalyst

InactiveCN102327777ANo pollution in the processThere will be no deactivationMolecular sieve catalystsPreparation by halogen halide additionMicro structureEthyl Chloride

The invention discloses a gold-containing catalyst for preparing vinyl chloride by using an acetylene method as well as a preparation method and application of the catalyst. The catalyst contains a gold element, a lanthanum element, a cobalt element, a co-catalytic metal element and a carrier with a porous micro-structure. The gold accounts for 0.3%-2% by mass of the catalyst; the gold element in the catalyst comes from gold chlorides or gold nitrates; the cobalt element comes from chlorides of the cobalt or cobalt nitrates; and the lanthanum element comes from lanthanum chlorides or lanthanum nitrates. The catalyst disclosed by the invention in use is free from inactivation phenomenon caused by sublimation of industrial catalyst mercury chloride, has no pollution to the environment, overcomes defects of high toxicity and high pollution of the conventional industrial catalyst mercury chloride, has the characteristics of simple preparation method, high conversion rate of the acetylene and selectivity of the vinyl chloride, long service life up to 1000 hours or more, high temperature resistance, and high intensity and is renewable, and the conversion rate of the acetylene and selectivity of the vinyl chloride approximate to or exceed the technical indexes of the mercury chloride catalyst.

Owner:TIANJIN UNIV +1

Catalyst for synthesizing para diethyl benzene by ethanol and ethyl benzene combination reaction and its preparation method

InactiveCN1605390AHigh yieldGood choiceOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to catalyst for alkylating ethanol and ethyl benzene into p-diethylbenzene and its preparation process. The industrial catalyst for efficient synthesis of p-diethylbenzene is prepared with the H-ZSM-5 molecular sieve with Si / Al ratio of 50 as basic matter and through surface acidity and tunnel regulation with B, Mg and Co, and has ideal pore size distribution and in-tunnel acidity distribution and strong coking resisting capacity. The precursor of B is boric acid, that of Mg is magnesium nitrate and that of Co is cobalt nitrate. The mass ratio between B and H-ZSM-5 molecular sieve is 1-3 %, that between Mg and H-ZSM-5 molecular sieve is 0.1-1 % and that between Co and H-ZSM-5 molecular sieve is 1-3 %. Compared with available similar catalyst, the present invention has the features one simple preparation process, low cost, high selectivity and yield of p-diethylbenzene, etc.

Owner:NANKAI UNIV

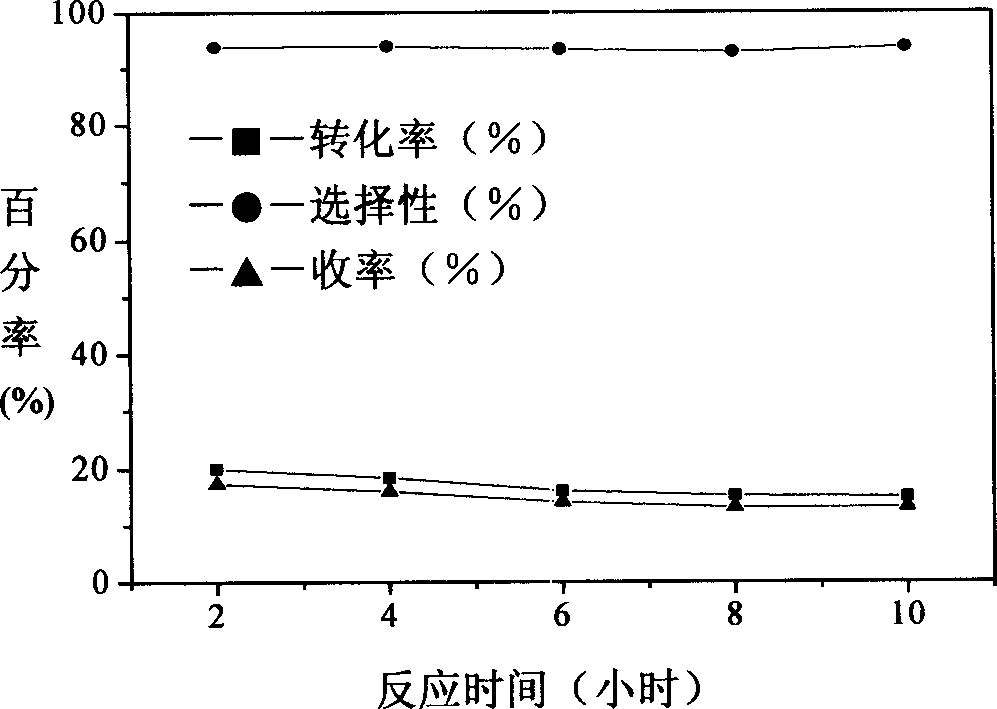

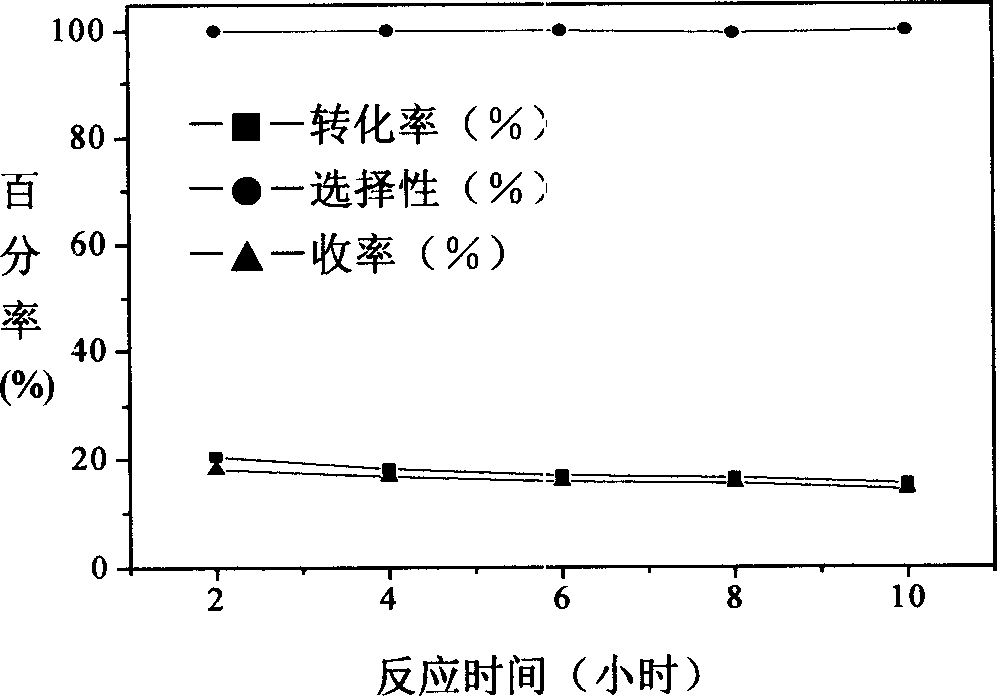

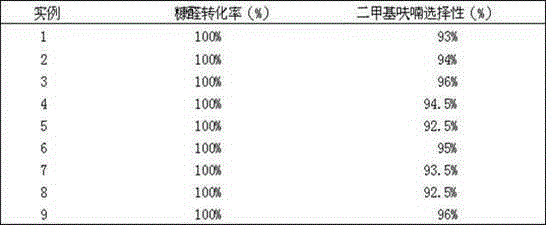

Environment-friendly 2-methyl furan catalyst and preparation method thereof

InactiveCN102614883AGood dispersionImprove performanceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranPtru catalyst

The invention provides an environment-friendly 2-methyl furan catalyst and a preparation method thereof and relates to a hydrogenation catalyst and a preparation method thereof. The catalyst is prepared by a colloid precipitation method and the active component Cu is dispersed highly. The catalyst mainly comprises the following components as per percentage by weight: 15 to 50 percent of CuO and 40 to 80 percent of silicon oxide or aluminum oxide. The catalyst is applied to preparation of 2-methyl furan through furfural gas phase hydrogenation, wherein the conversion rate of the furfural is 100 percent and the selectivity of the 2-methyl furan reaches over 92 percent. By the colloid precipitation method, sol can be effectively bound with Cu and aid; the Cu can be dispersed on the surface of the carrier highly; and the catalyst has high activity and stability in the reaction of synthesizing the 2-methyl furan by hydrogenating the furfural. The catalyst applied to preparation of the 2-methyl furan by hydrogenating the furfural has simple components and does not comprise Cr so as to avoid the environmental pollution caused by pretreatment on the Cr-containing industrial catalyst and treatment on the waste catalyst.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for preparing anhydrous formaldehyde industrial catalyst by methanol dehydrogenation

InactiveCN101147872ALow costReduce resistancePhysical/chemical process catalystsOrganic compound preparationSodium bicarbonateSodium Bentonite

The present invention discloses a preparation method of industrial catalyst for producing anhydrous formaldehyde by utilizing methyl alcohol dehydrogenation. Said preparation method includes the following steps: using (by wt%) 40%-60% of industrial sodium hydrogen carbonate as raw material, using 30%-20% of active carbon as adjuvant and using 30%-20% of bentonite as carrier, uniformly mixing them, then adding 5% of Na2SiO3 solution adhesive according to the solid-liquid ratio of 20:1, further uniformly mixing them, tabletting, drying, calcining, pulverizing and screening so as to obtain the invented product.

Owner:TAIYUAN UNIV OF TECH

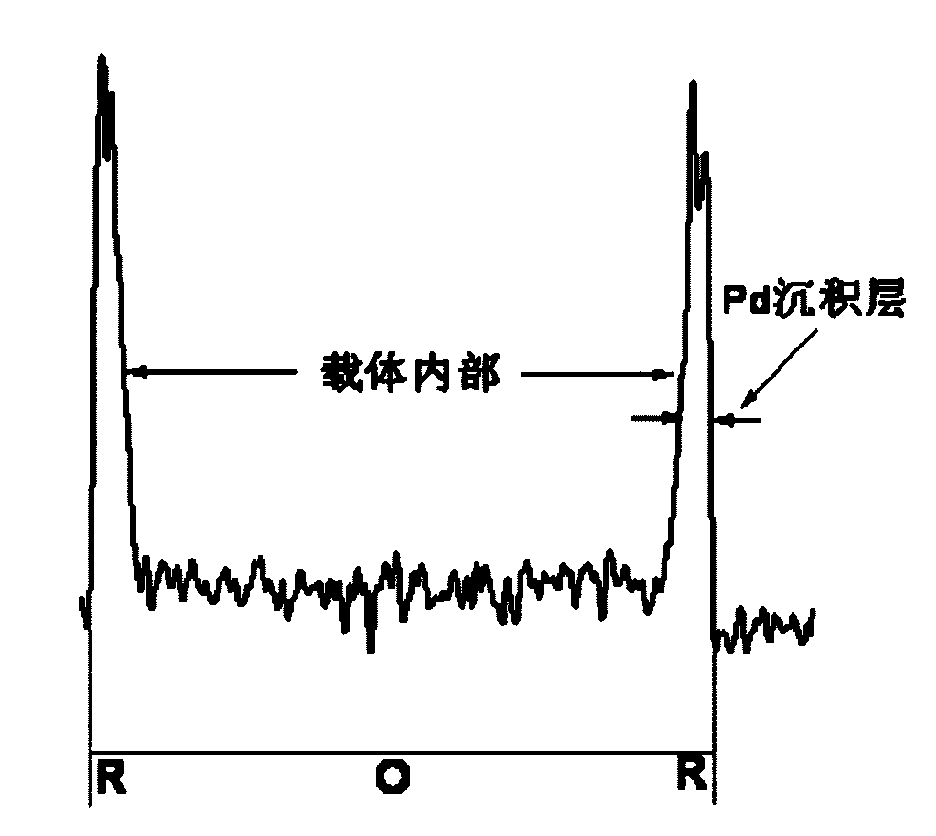

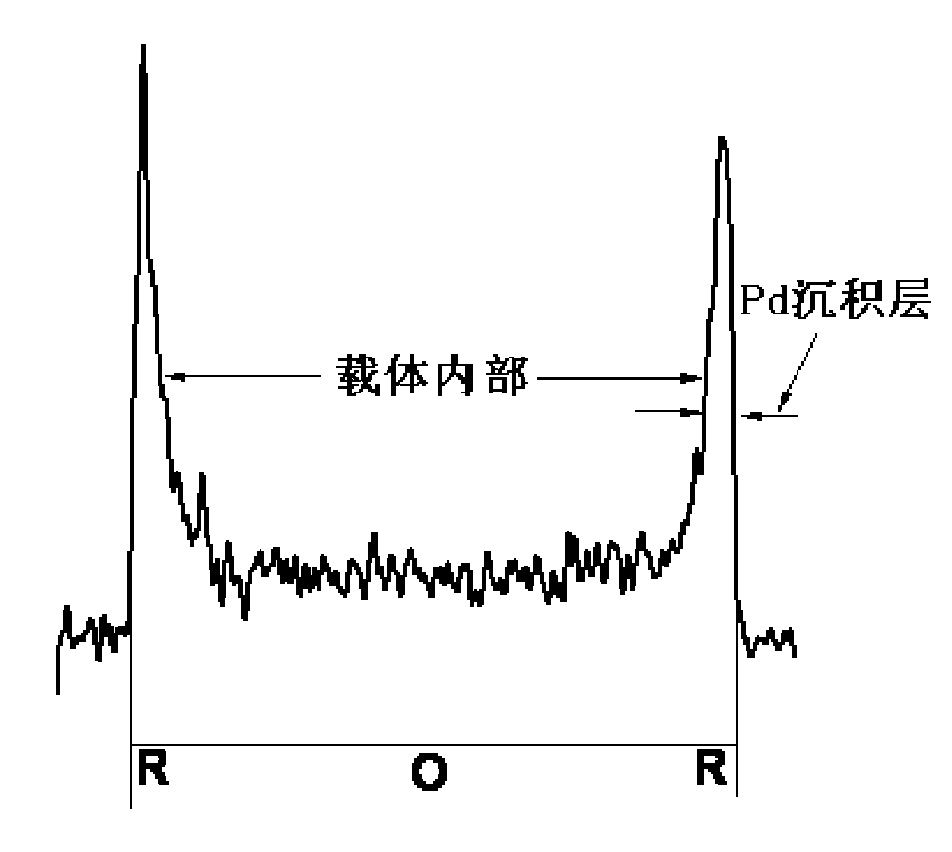

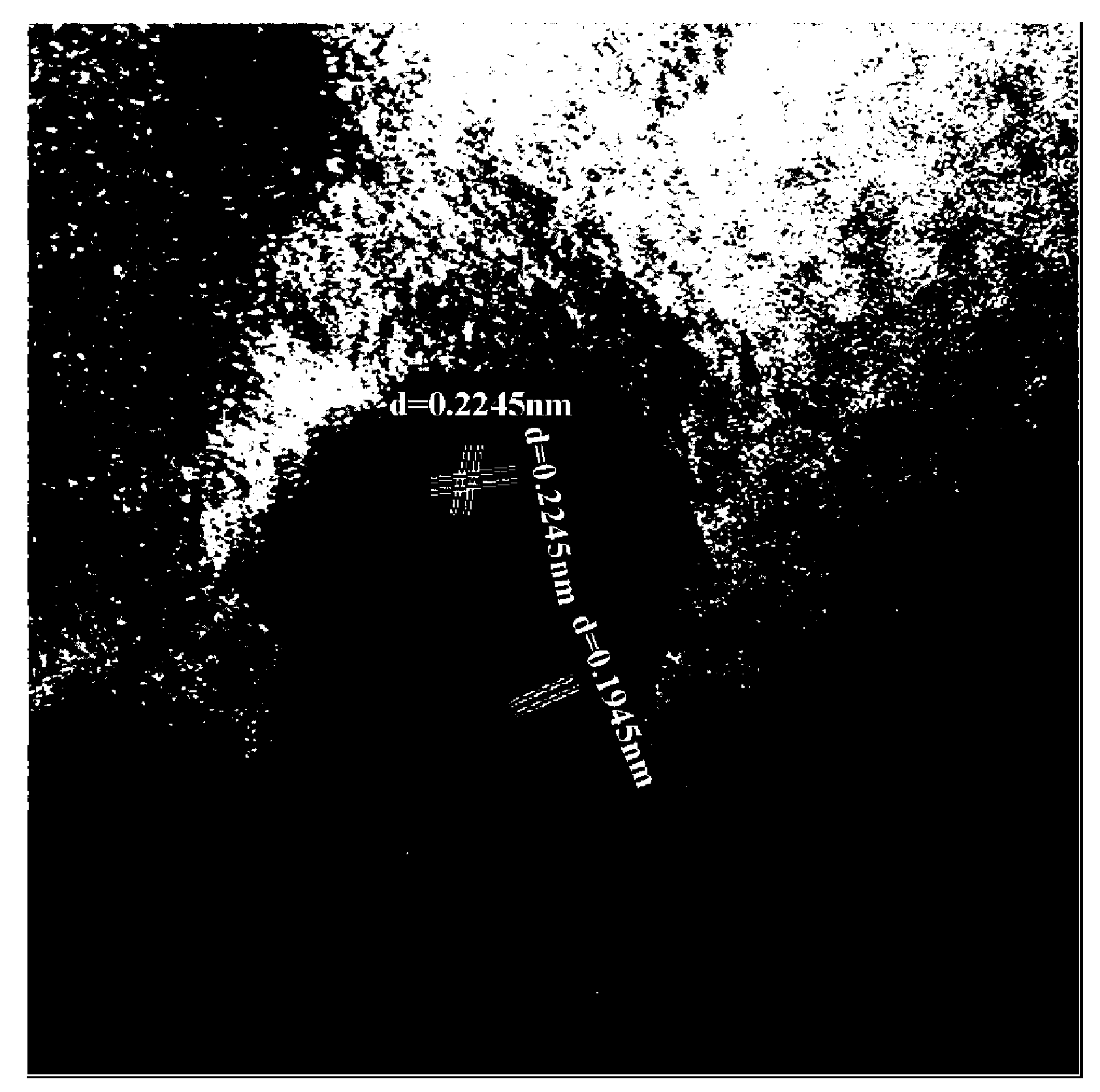

Eggshell type Pd catalyst prepared by reaction deposition method

ActiveCN101618320AImprove performanceReduce dosageOrganic compound preparationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesEggshellMetal salts

The invention discloses an eggshell type Pd catalyst prepared by a reaction deposition method, which belongs to the technical field of industrial catalysts. The method comprises the following steps: adding a carrier into Pd metal salt solution; controlling the deposition of Pd on the surface of the carrier by a rapid reduction reaction; and carrying out filtering, washing as well as heating and drying in inert atmosphere to form a stable eggshell type Pd catalyst. The eggshell type Pd catalyst has the advantages of simple process, controllable structure, low energy consumption process and the like; Pd particles in the prepared eggshell type Pd catalyst are evenly distributed on the surface of the carrier, thus the eggshell type Pd catalyst reduces the consumption of noble metal Pd, effectively reduces the cost of the catalyst and has favorable industrial application prospect. The eggshell type Pd catalyst can be used for enyne hydrocarbon selective hydrogenation, cracking ethylene C9 fraction selective hydrogenation, olefin aldehyde selective hydrogenation, anthraquinone catalytic hydrogenation in H2O2 synthesis and other reactions.

Owner:成都大研科技产业发展有限公司

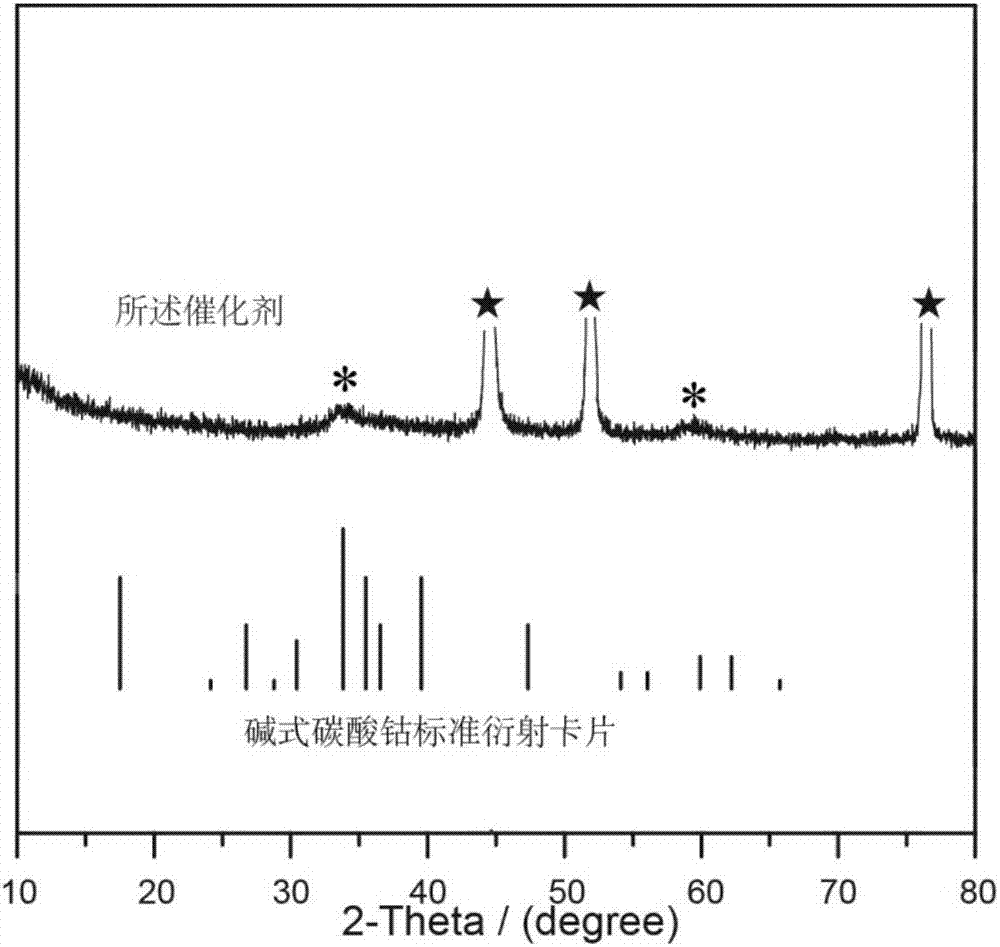

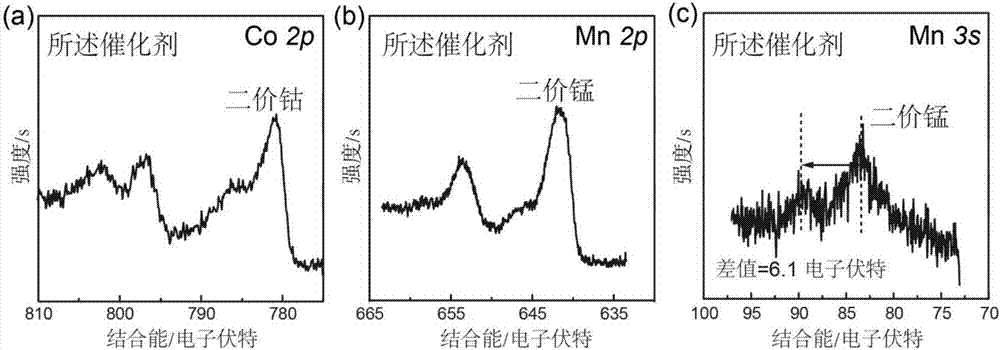

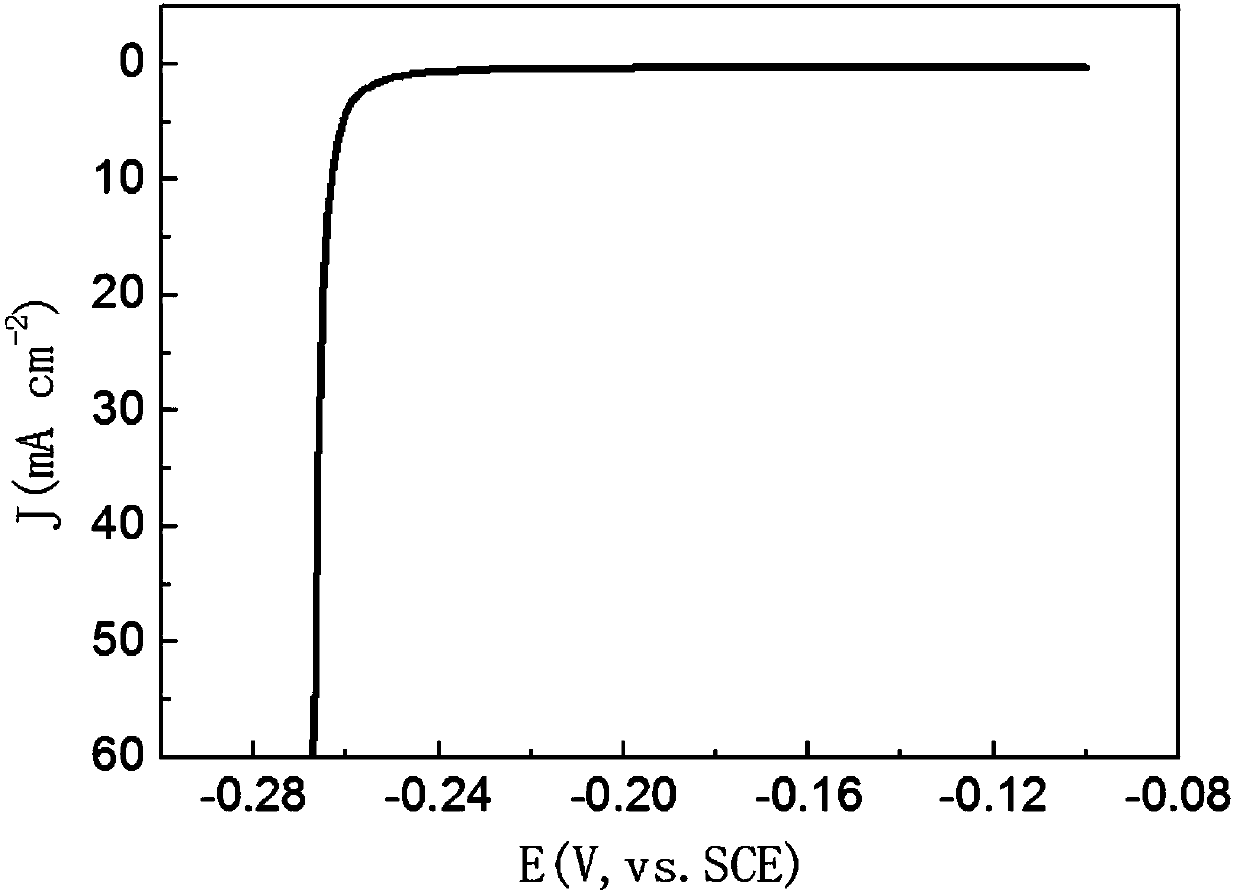

High-performance subcarbonate electrolyzed water catalyst as well as preparation method and application thereof

InactiveCN107051565AExcellent electrolytic water hydrogen evolution performanceExcellent electrolytic water oxygen evolution performancePhysical/chemical process catalystsElectrodesElectrolysisDecomposition

The invention discloses a high-performance subcarbonate electrolyzed water catalyst as well as a preparation method and application thereof. The catalyst is an electrolyzed water catalyst, is a transition metal cobaltous dihydroxycarbonate nanosheet array which directly grows on a foam metal substrate by a solvothermal method and has excellent electrolyzed water hydrogen evolution property and electrolyzed water oxygen evolution property; the subcarbonate electrolyzed water catalyst can be directly used for a hydrogen evolution electrode and an oxygen evolution electrode in a water electrolyzing device; the electrolyzed water catalyst prepared by the preparation method disclosed by the invention has excellent catalytic performance; compared with other traditional non-noble metal catalysts reported in the literature, the high-performance subcarbonate electrolyzed water catalyst has higher total water decomposition activity. The method disclosed by the invention has the advantages of simple process, economy, convenience in operation, easiness in large-scale production and huge potential application value in many industrial catalyst fields or other scientific fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

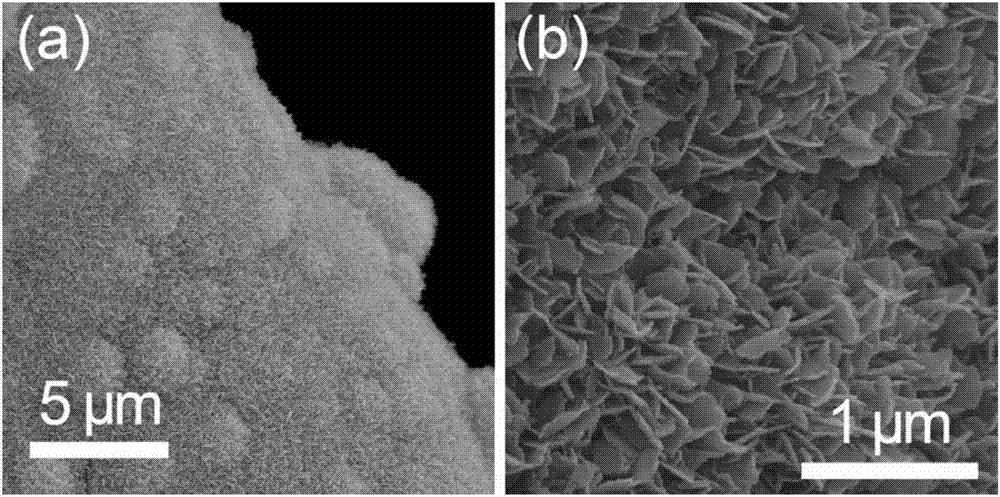

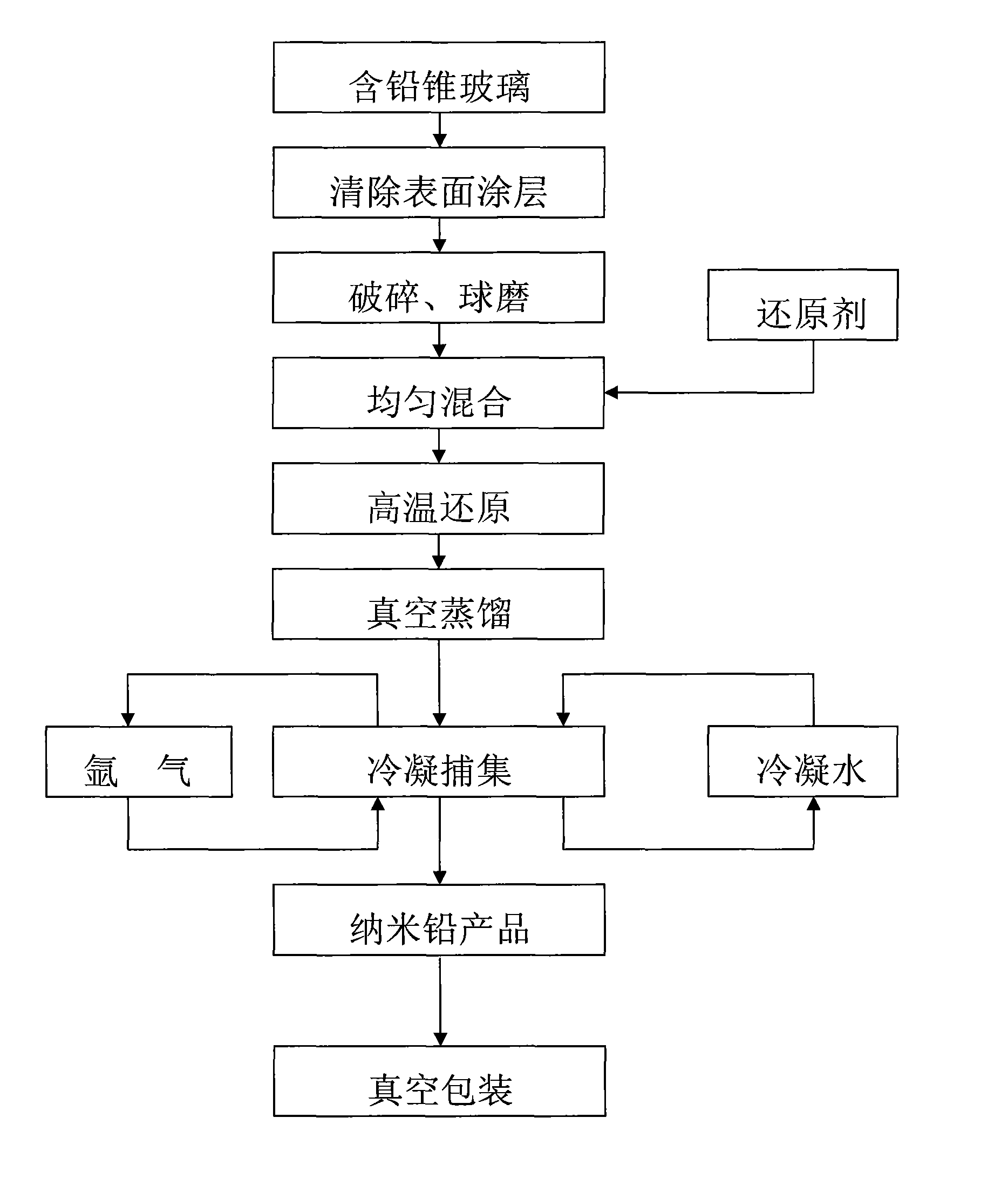

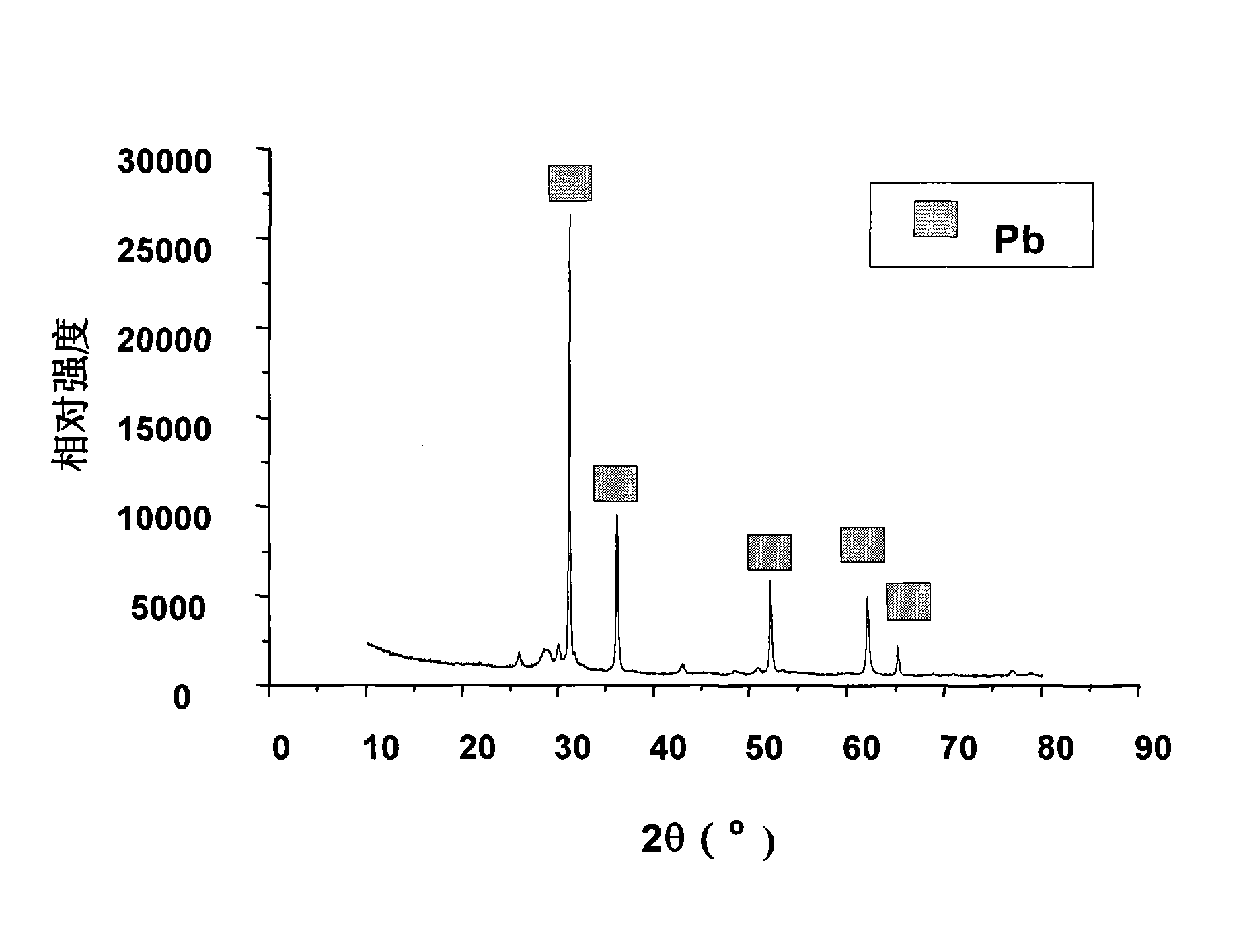

Process for synthesizing nano-lead from waste cathode-ray tube (CRT) lead-containing glass by one-step method

InactiveCN102002593APrevent oxidative spontaneous combustionProcess efficiency improvementNanoparticleElectronic waste

Aiming at the current situations that in the electronic waste treatment process, high lead-containing cathode-ray tube (CRT) cone-glass is short of recycling technologies, is optionally discarded and stacked and severely pollutes the environment, the invention provides a process for removing lead in the lead-containing cone-glass, enabling the lead-containing cone-glass to be harmless and simultaneously preparing nano-lead particles with high added values. The invention is characterized by comprising the following steps: properly pre-treating the lead-containing glass, and then, adding a reducing agent; removing the lead in the cone-glass under certain atmospheric conditions; and condensing and collecting the removed lead on a special collector to form nano-lead, thereby realizing the purposes of removing the lead and synthesizing the nano-lead in one step. The process has the characteristics of controllable particle diameter of nano-particles and low cost and is simple and convenientin operation, and the lead removing rate can reach more than 95%, the purity of the prepared nano-lead is more than 95%, and the particle diameter is 5nm-15nm. The product has wide application prospects in production of high radiation protection materials, superconducting materials and special industrial catalysts.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

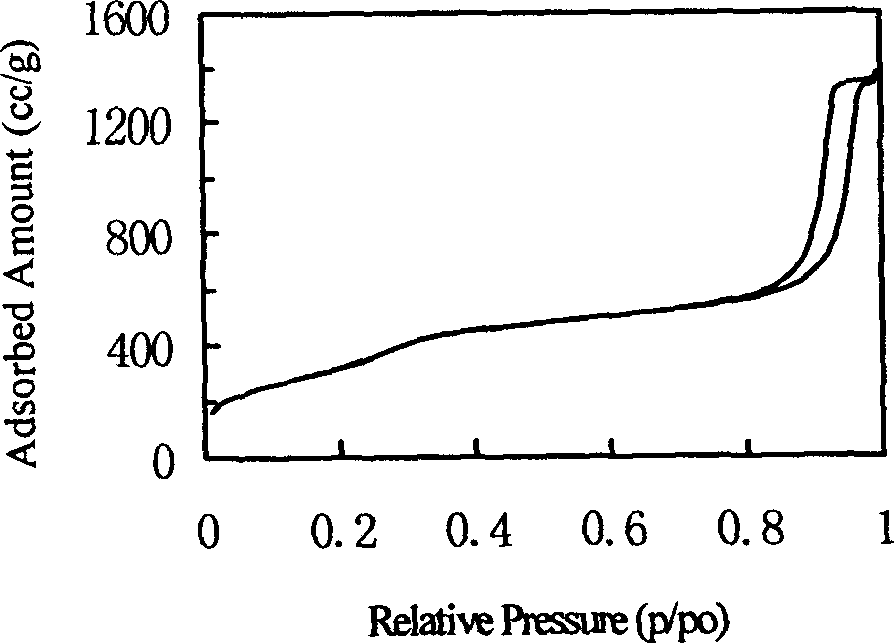

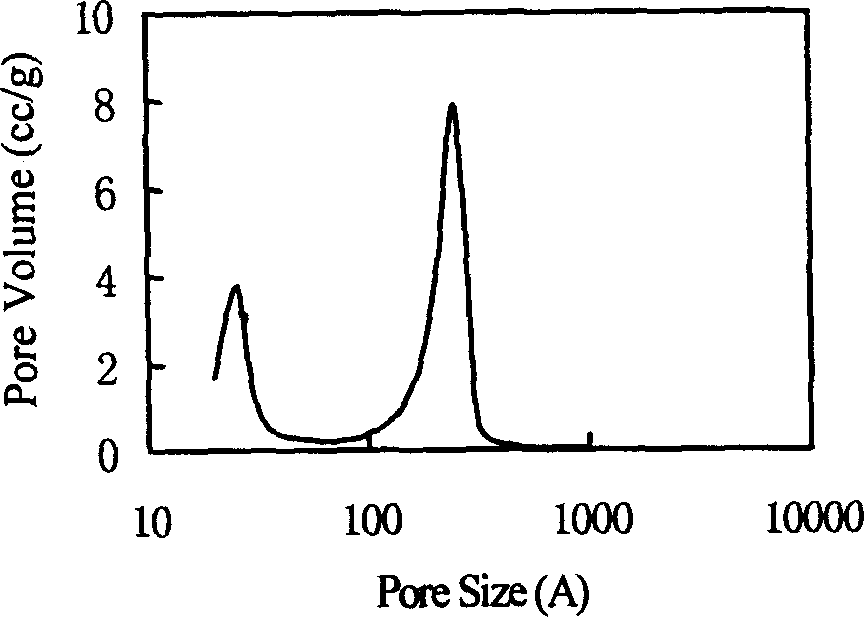

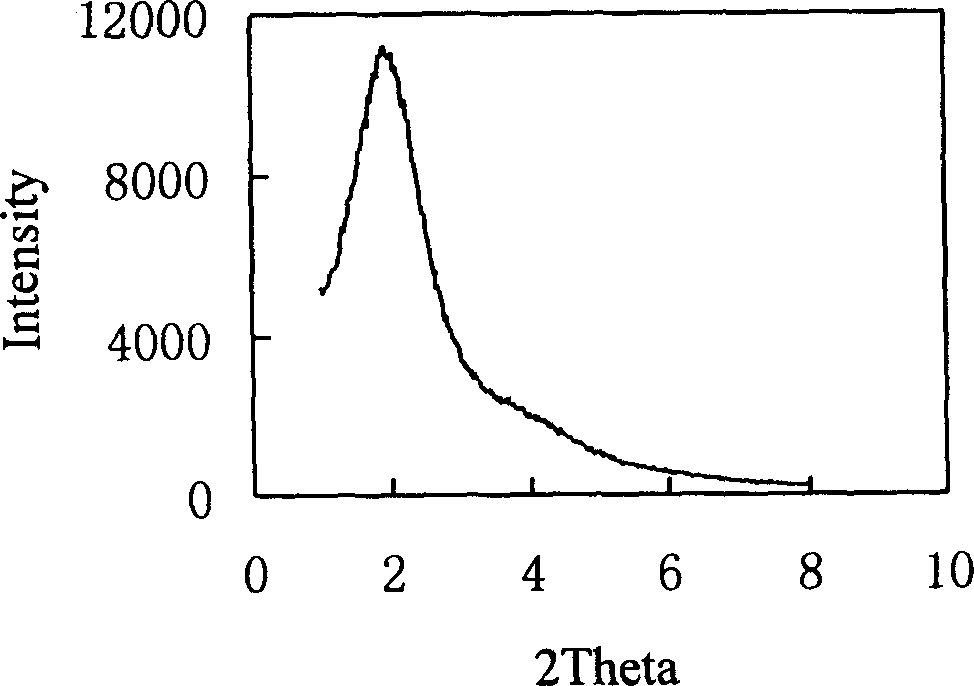

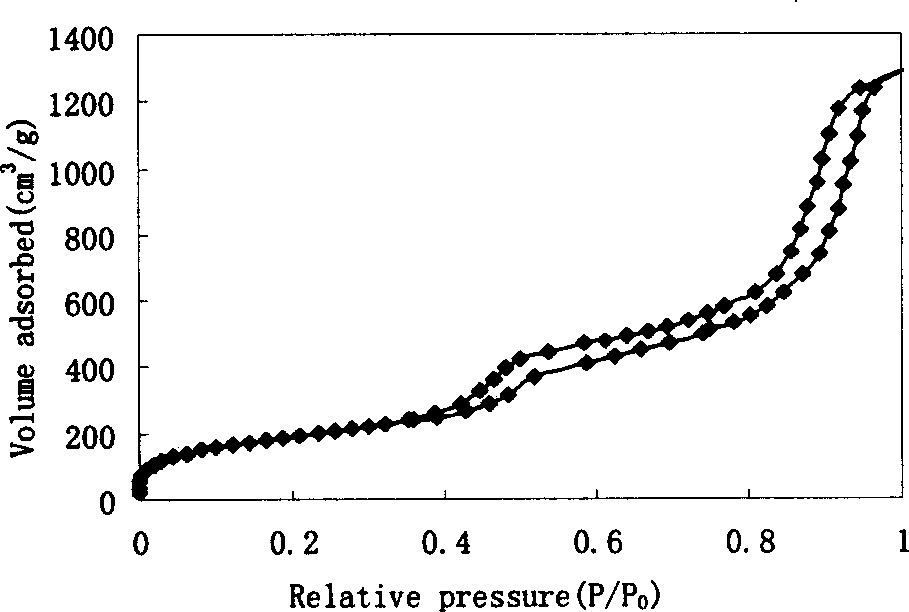

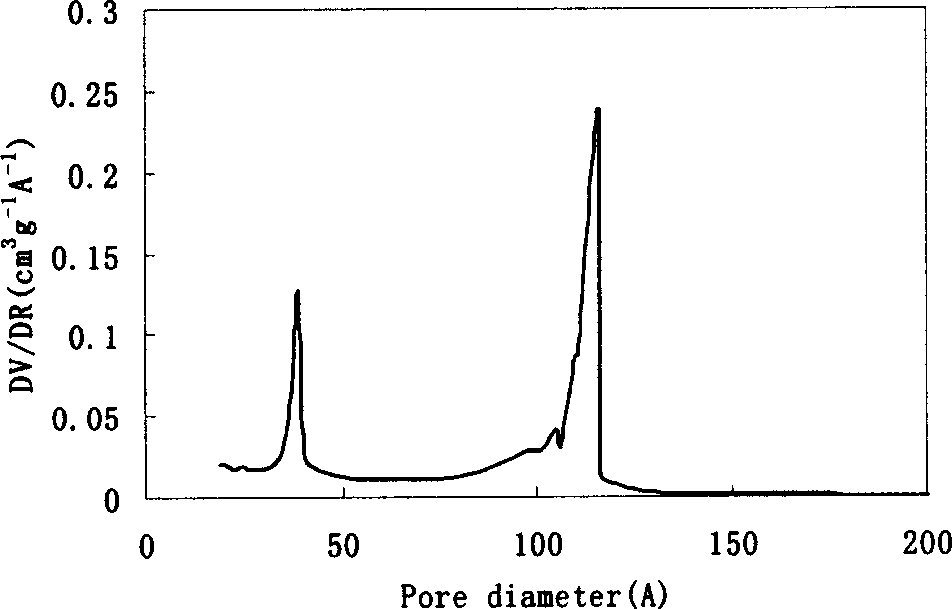

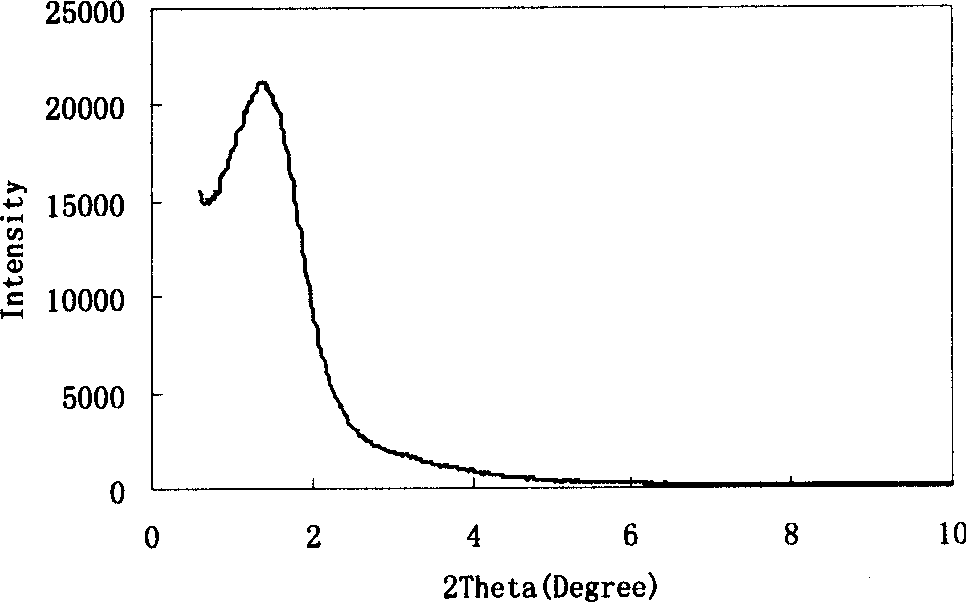

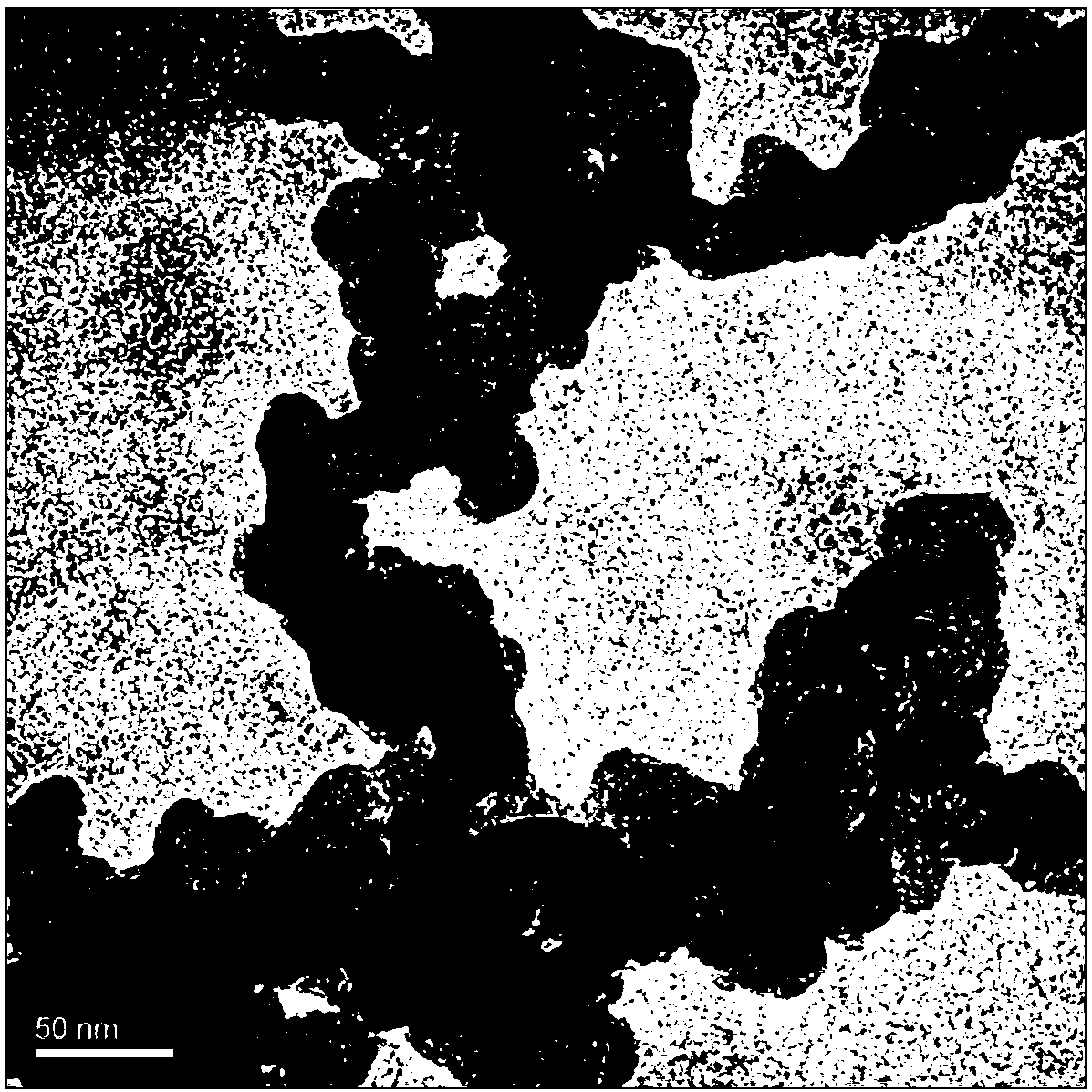

Double mesopore molecular sieve and its preparation method

InactiveCN1380250ARich varietyIncreased diffusion sitesSilicaMolecular-sieve silica-polymorphsChemical synthesisMolecular sieve

The present invention relates to a double-mesopore molecular sieve and its preparation method, belonging to the field of chemical synthesis technology, and is characterized by that the double-pore pore size distributions of said material are being in the mesopore zone, so that said material can effectively meet the requirements to the catalyst pore size distribution for macromolecualr shape selection and diffusion effect, and is a potential industrial catalyst and catalyst carrier. Its preparation method uses quaternary ammonium salt cationic surfactant as template agent, and in the weak alkaline system utilizes the room-temp. hydrolysis and condensation polymerization of ethyl metasilicate to synthesize the invented double-mesopore distribution molecular sieve.

Owner:TAIYUAN UNIV OF TECH

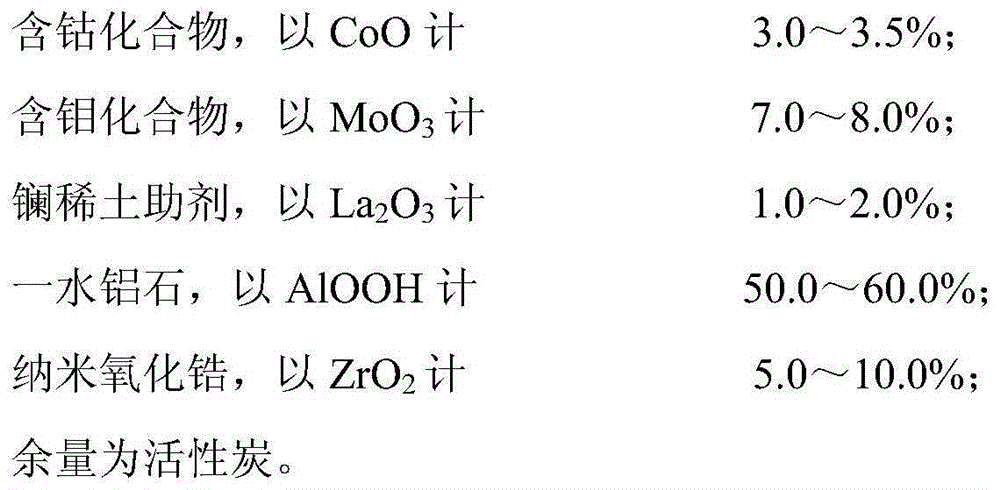

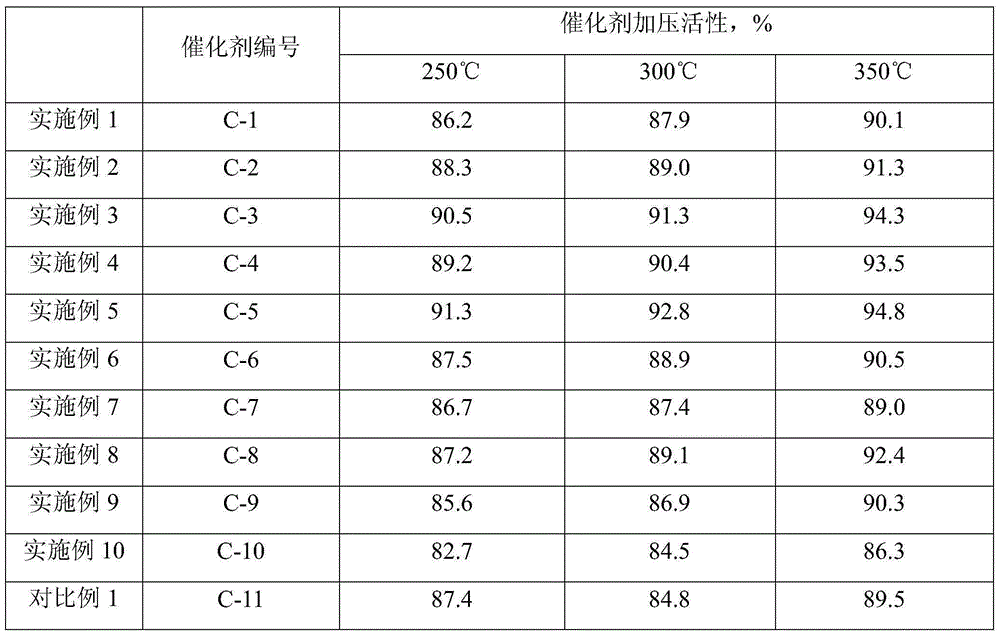

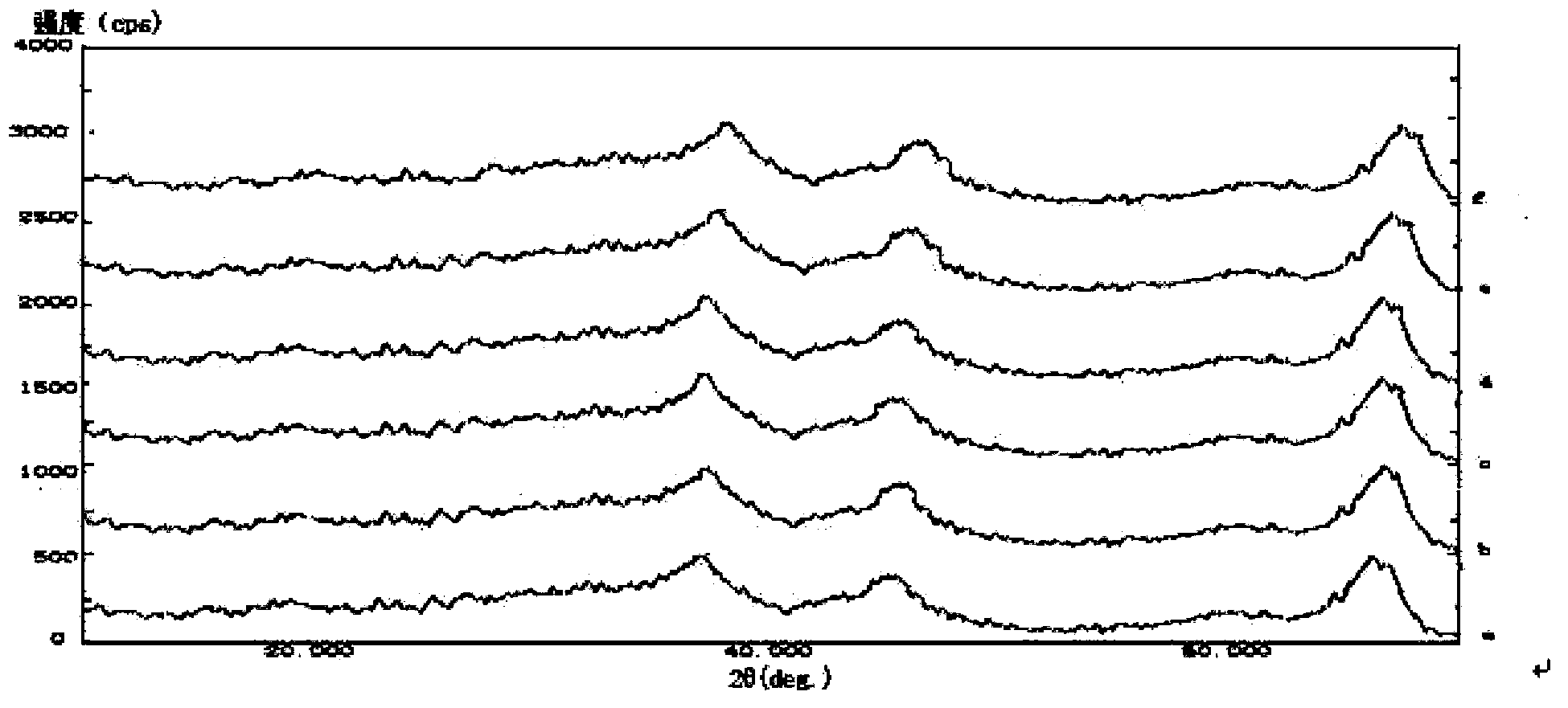

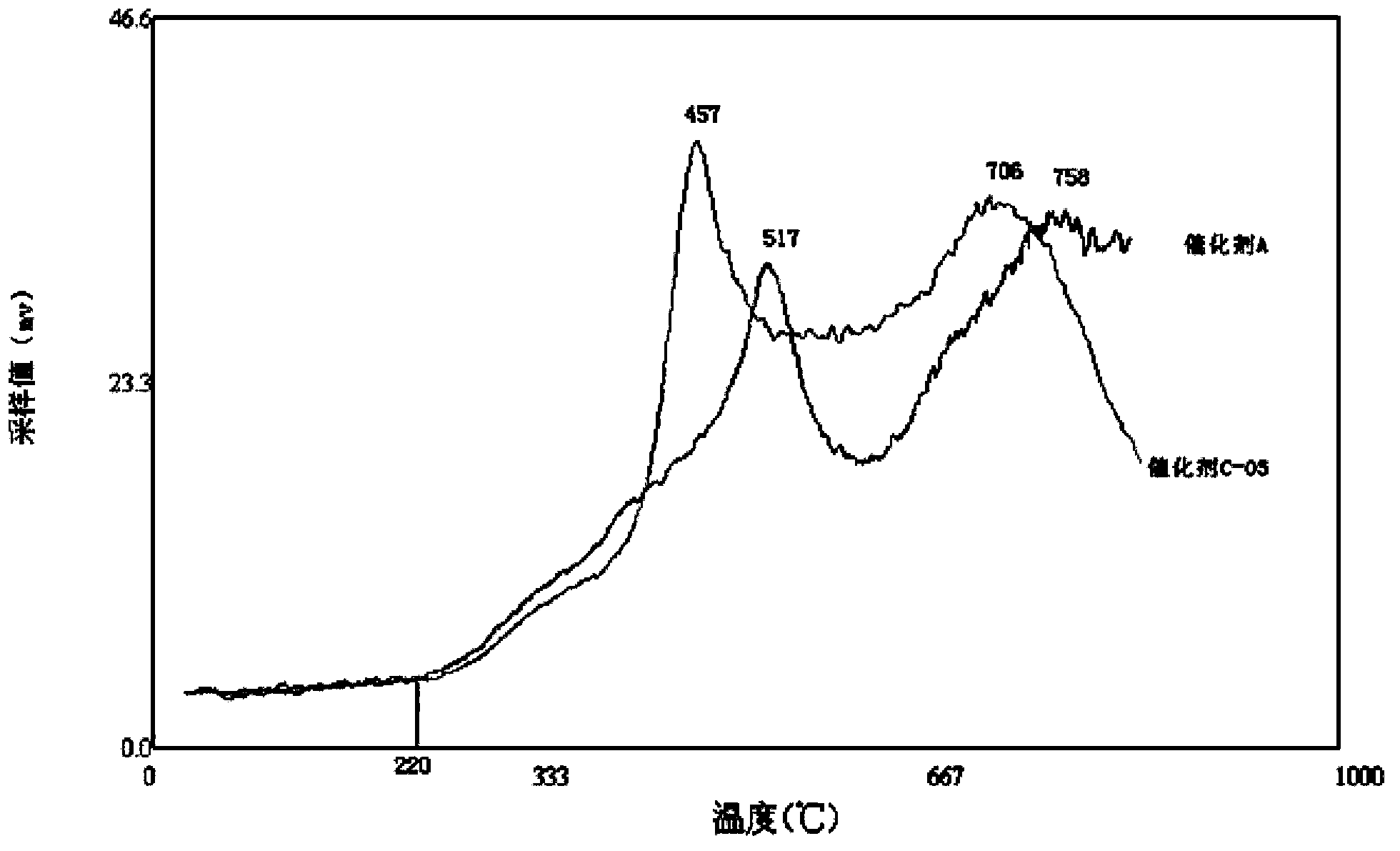

Cobalt-molybdenum low-temperature sulfur tolerant shift catalyst and preparation method thereof

ActiveCN106552637AHigh surface areaImprove adsorption capacityHydrogenMetal/metal-oxides/metal-hydroxide catalystsCrack resistanceRare earth

The invention relates to a cobalt-molybdenum low-temperature sulfur tolerant shift catalyst and a preparation method thereof and belongs to the technical field of carbon monoxide shifting. The catalyst comprises active ingredients, an accessory ingredient and carriers, wherein the active ingredients include a cobaltiferous compound and a molybdenum-containing compound, the accessory ingredient is a lanthanum rare earth accessory ingredient, and the carriers include boehmite, nano zirconium oxide and activated carbon. According to cobalt-molybdenum low-temperature sulfur tolerant shift catalyst, AlOOH is utilized to replace an Al2O3 ingredient commonly used in an industrial catalyst, so that the problem that a catalyst containing a gamma-Al2O3 carrier is subjected to phase transformation caused by soaking in water due to working condition changes during operation at a temperature approximate to the dew point can be avoided; the activated carbon ingredient has relatively high specific surface and adsorptive properties, is beneficial to uniform distribution of the active ingredients, and is capable of enhancing adsorptive collection of hydrogen sulfide, so that the shift activity is improved; nano zirconium oxide is capable of improving the crack resistance and tenacity of a common activated carbon carrier; the rare earth accessory ingredient can be used for improving the activity stability and structural stability of the shift catalyst; the preparation method is simple and practical and is easy in production.

Owner:CHINA PETROLEUM & CHEM CORP

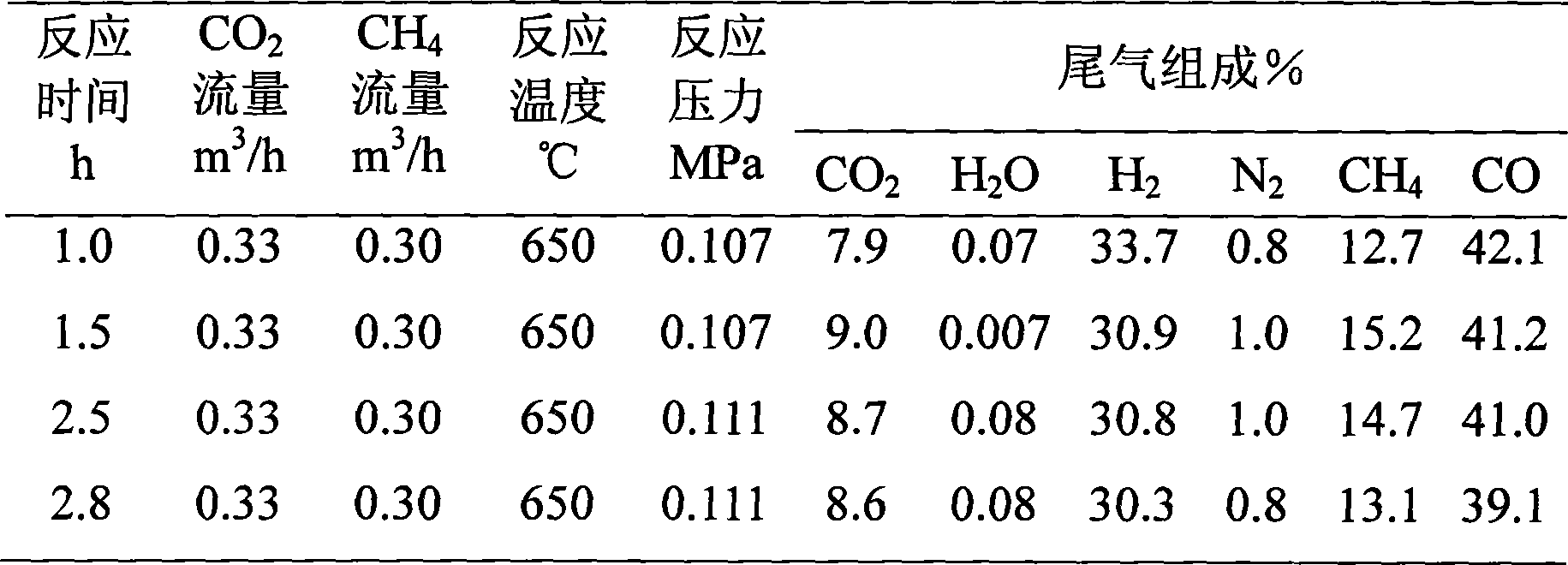

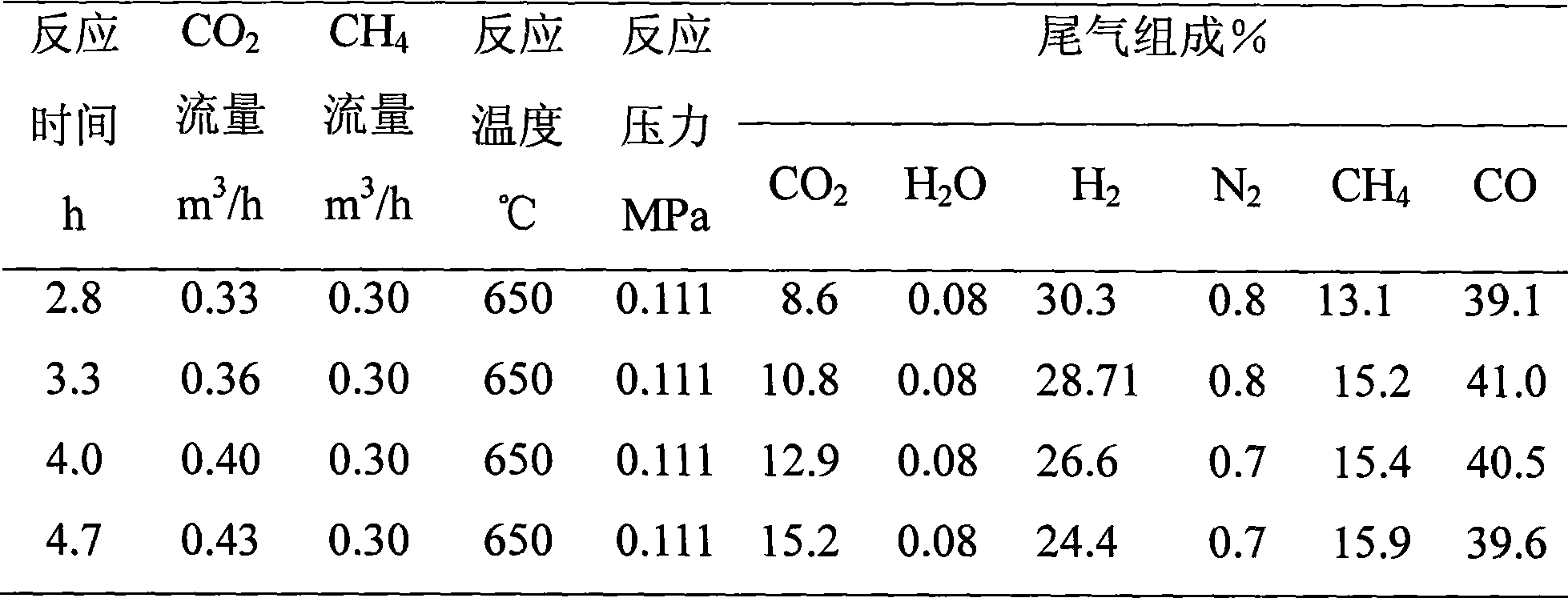

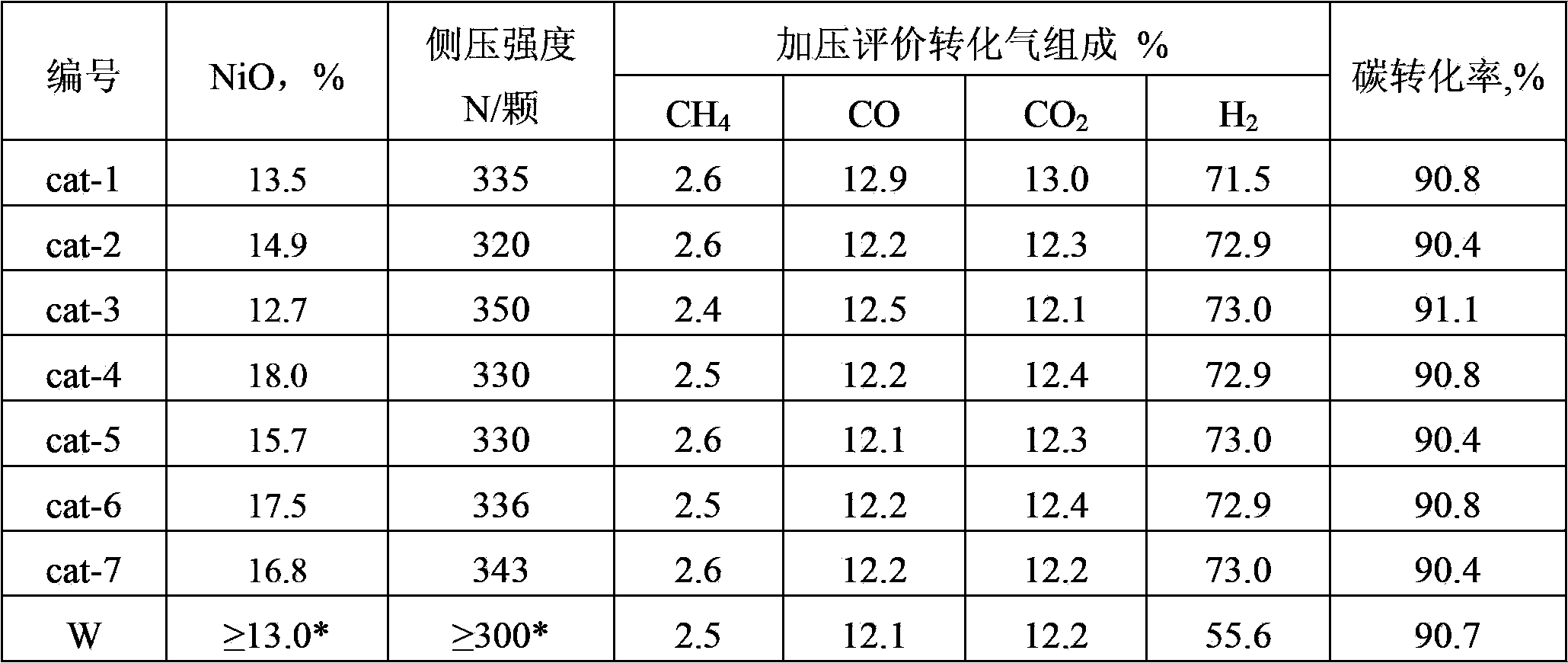

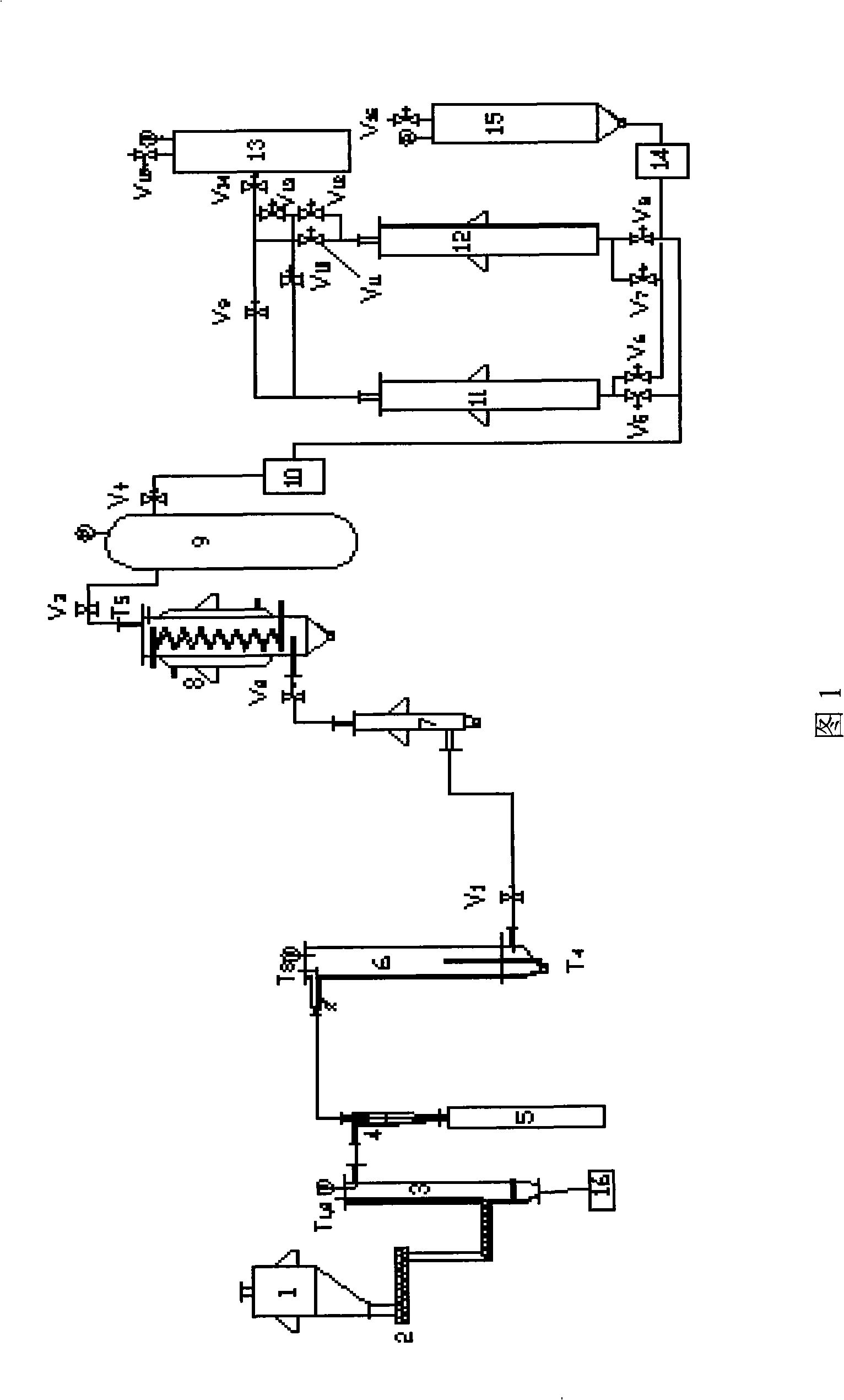

Catalyst for producing synthesis gas by reforming natural gas-carbon dioxide for industry

ActiveCN101462058AImprove performanceHigh catalytic activityHydrogenMolecular sieve catalystsCoalChemistry

The invention provides an industrial catalyst for producing synthesis gas by natural gas-carbon dioxide reforming. The catalyst comprises the following components in percentage by weight: 5 to 19 percent of Ni, 20 to 70 percent of La, and 0 to 2 percent of precious metal; and the catalyst is prepared by powder molding or the impregnation of a carrier by an active constituent, and the carrier is amolecular sieve and a molding additive. The catalyst has high catalytic activity through a micro-reactor and pilot magnification activity evaluation; and compared with other catalysts, the catalyst has strong carbon deposition resistance and steady performance. The catalyst is suitable to produce the synthesis gas by reforming natural gas and carbon dioxide, and also is suitable to produce the synthesis gas by reforming combined raw materials such as flue gas, coke-oven gas and coal bed gas of fuel electric plants, dry gas of oil refineries and the like.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

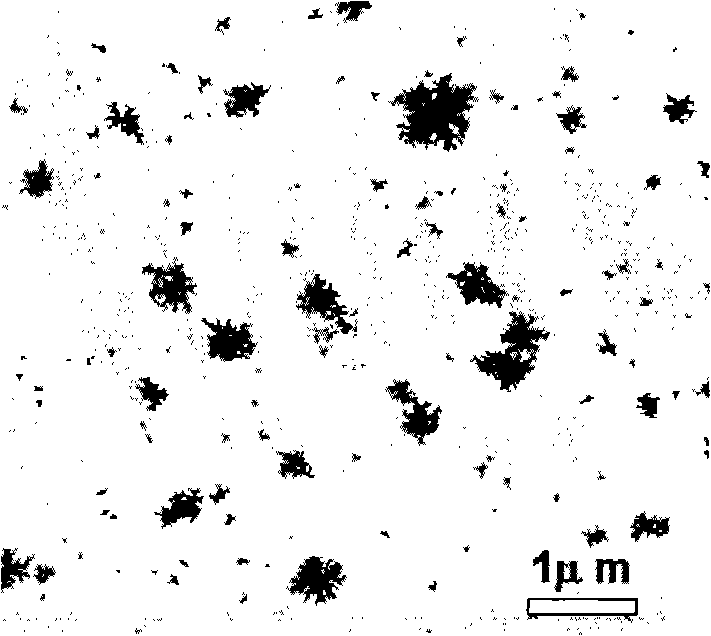

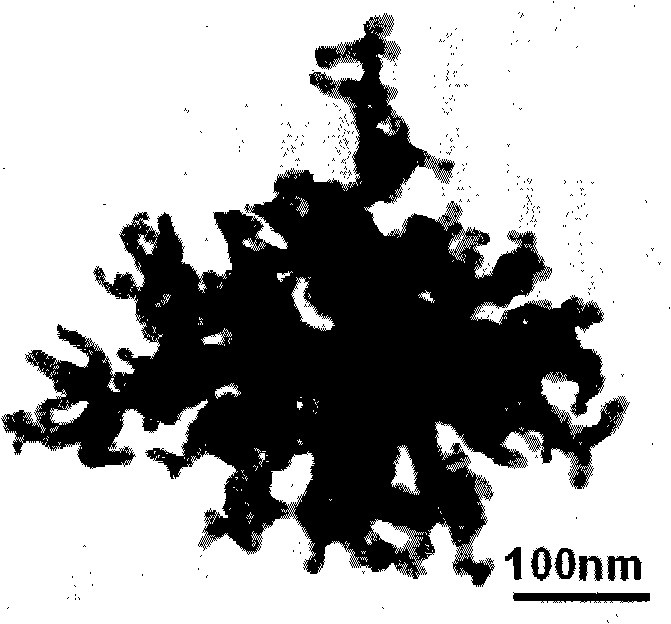

Dendritic golden nanophase material and preparation method thereof

InactiveCN101538736ASimple processProcess safetyPolycrystalline material growthFrom normal temperature solutionsAmmonium formatePolyvinylpyrrolidone

The invention relates to a dendritic golden nanophase material and a preparation method thereof. The gold nanophase material is dendritic, and all golden branches are formed by mutually stuck and fused golden nano particles or formed in a twin-crystal structure for growing. The preparation method comprises the following steps: pure water is added with chloroauric acid or chloraurate, ammonium formate and polyvinyl-pyrrolidone stabilizer and then transferred to a hydro-thermal reaction vessel after even ultrasonic mixing; after heating is carried out for 1-6 hours, a black mixturei is obtained after natural cooling; and the obtained product naturally subsides for 24-48 hours with ethyl alcohol or acetone or centrifugally subsides for at least 30 minutes, and after the liquid on the upper layer is removed, the product is added with absolute ethyl alcohol or acetone for dilution, and the black dendritic golden nanophase material deposition is obtained after centrifugal settling; and the ethyl alcohol or acetone washing process is repeated for 2-3 times, and finally, the black dendritic golden nanophase material coated with the polyvinyl-pyrrolidone is obtained. The dendritic golden nanophase material can be used as a commercial catalyst, a surface enhanced Raman substrate material, and the like. The method has the advantages of simple process and device and safe operation; and large-scale production can be performed by the method.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

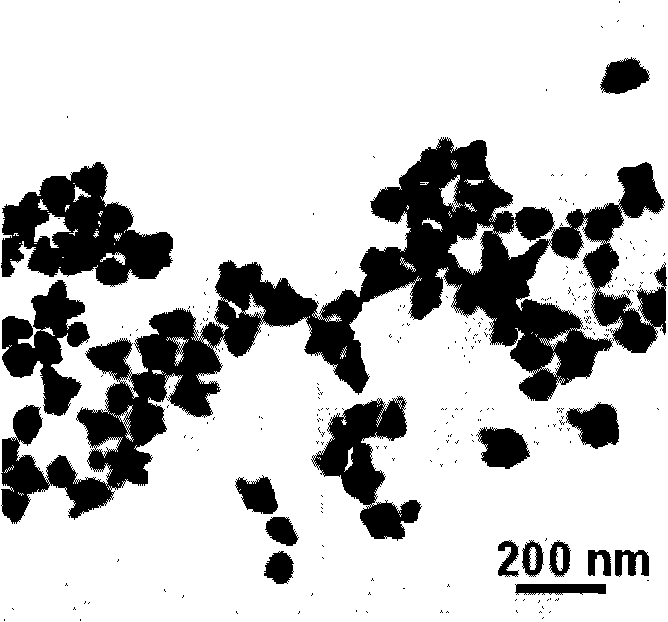

Cyclohexane ionic liquid catalyst prepared from benzene and hydrogen and preparation method thereof

InactiveCN101602015ANo pollution in the processMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon by hydrogenationHydrogenChloride

The invention relates to a cyclohexane ionic liquid catalyst prepared from benzene and hydrogen and a preparation method thereof, belonging to the development field of industrial catalysts. The prior supported catalyst pollutes the environment during production and has a high price, and the Ziegler catalyst has hidden danger in the production and storage processes. The Cl in the ionic liquid catalyst Cl / is chlorine N-methyl-N-normal-butyl-imidazole and has a molar percentage of 75-99; and the is ruthenous chloride and has a molar percentage of 1-25. The preparation method comprises the following steps: (1), reducing RuCl3 into RuCl2; (2), using N-butyl-imidazole and chloro-normal butane as raw materials and using phenylethane as a solvent to prepare the Cl; and (3), using the Cl and the as raw materials to prepare the Cl / . The catalyst has the advantages of high activity, good selectivity, environment-friendly preparation process, no hidden danger, and the like.

Owner:BEIJING UNIV OF CHEM TECH

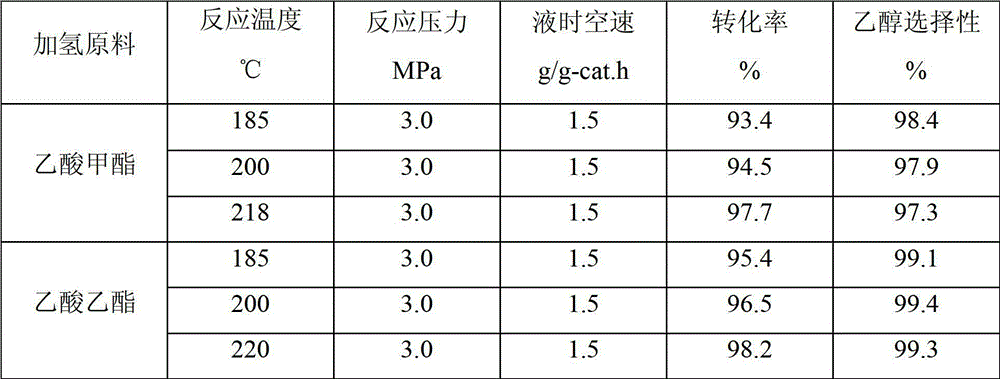

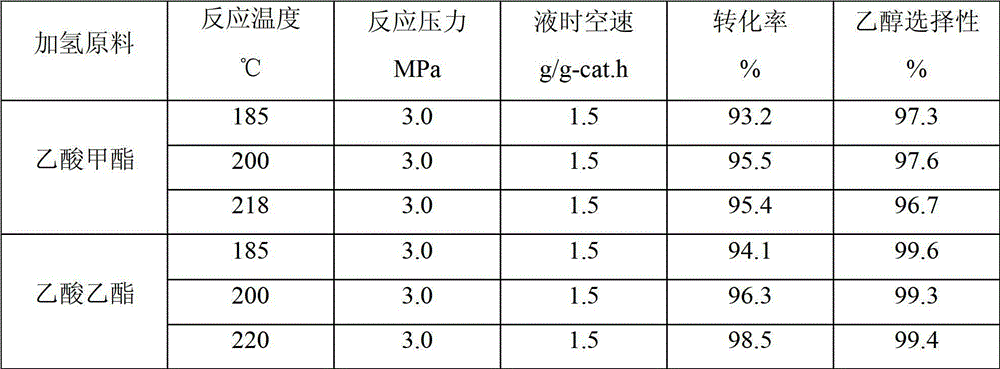

Industrial catalyst for preparing ethanol with acetic ester by hydrogenation, preparation method of industrial catalyst and application

ActiveCN102941097ALow priceReduce pollutionOrganic compound preparationHydroxy compound preparationAcetic acidCopper

The invention relates to an industrial catalyst for preparing ethanol with acetic ester by hydrogenation. The catalyst comprises, in weight percent, 20-50% of CuO, 10-30% of ZnO, 1-10% of M oxide and 10-69% of SiO2, wherein the M is selected from IIA group or VIII group metals, the SiO2 is amorphous silicon dioxide, the specific surface area of the catalyst is 100-300m<2> / g, and the specific surface area of active copper is 10-20m<2> / g. The preparation process of the catalyst includes the steps: firstly, mixing precursors of metal Cu, Zn and M to prepare water solution I, mixing a Si precursor and a precipitator to prepare water solution II and then mixing and precipitating the solution; and secondly, performing washing, filtering, drying, preforming, roasting, crushing and reducing to obtain the catalyst. The obtained catalyst has high catalytic activity for hydrogenation of the acetic ester and has a certain water resistance and acid resistance, the ethanol has high selectivity, and the service life of the catalyst is prolonged.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

Low-cost hydrogen production catalyst and preparation method thereof

The invention belongs to the technical field of hydrogen production realized trough hydrocarbon steam conversion, relates to a preparation method of a low-cost hydrogen production catalyst and particularly relates to a method for preparing a new catalyst by recovering waste nickel hydrocarbon steam conversion catalyst. The method can be used for preparing the new catalysts of a same type by recycling a waste catalyst as a part of raw materials. The method disclosed by the invention can not only be used for completely recovering the nickel oxide contained in the catalyst, but also be used for reusing the Al2O3 contained in a carrier, thereby effectively recycling the waste catalyst, reducing the preparation cost of the catalyst and eliminating the environment pollution caused by waste residues. The catalyst prepared through the method is suitable for a natural gas steam conversion catalyst and is equivalent to an industrial catalyst prepared through the conventional method in physical and chemical property, activity and activity stability.

Owner:CHINA PETROLEUM & CHEM CORP

Supported type nickel catalyst for producing hydrogen via decomposition of ammonia and preparation method

InactiveCN101352686APromote resource utilizationLess investmentHydrogenMetal/metal-oxides/metal-hydroxide catalystsHydrogen purityCatalytic reforming

The invention relates to a catalyst applied to catalyst hydrogen generation and a method of the catalyst hydrogen generation. The catalyst comprises industrial catalyst YWC-95 and CaO. The catalyst is used in steam catalytic reforming reaction of the catalyst hydrogen generation, the technical process of the catalyst hydrogen generation is shortened, hydrogen purity and production rate are improved and no secondary pollutant is generated in the production process.

Owner:EAST CHINA UNIV OF SCI & TECH

Sulfur-tolerant CO converting Co-Mo catalyst and its carrier and prepn

InactiveCN1548228AHigh activityHigh strengthCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsCobaltAlkali metal

The Co-Mo catalyst for sulfur-tolerant CO conversion has carrier component comprising one or two of Al2(OH)3, gamm-Al2O3, delta-Al2O3, alpha-Al2O3 or pseudo-thin diasphore; and active component comprising oxide of Co and Mo. The preparation process includes preparing carrier via mixing main carrier material with active assistant, kneading after adding efficient extrusion assistant, extruding into strip and roasting; soaking the carrier inside the soaking liquid containing active components Co, Mo and alkali metal and subsequent drying or roasting. The catalyst of the present invention may be used in the pressure range 1-5 MPa and has strength, strength stability, chalking resistance and conversion activity under different temperature higher than common industrial catalyst.

Owner:青岛联信催化材料有限公司

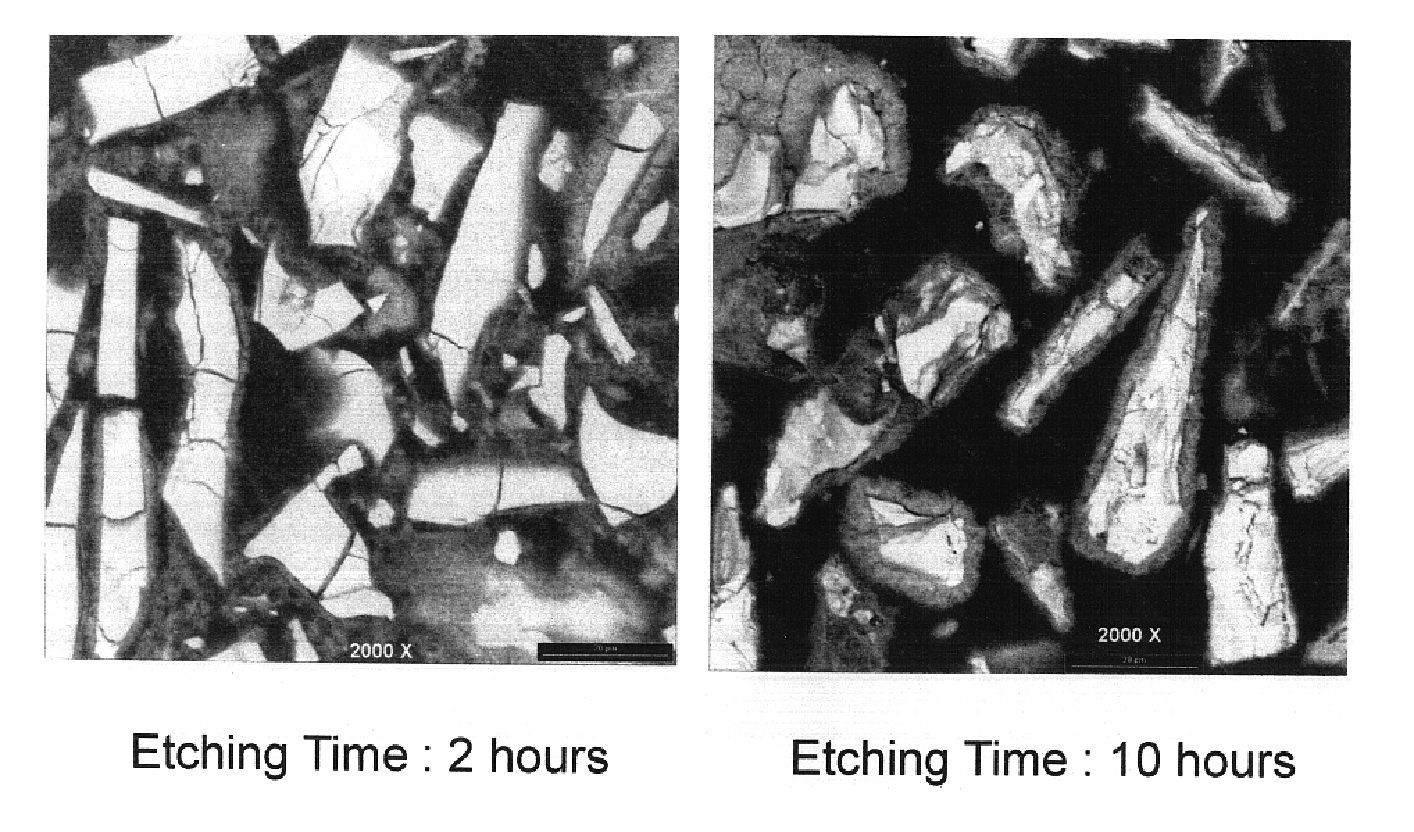

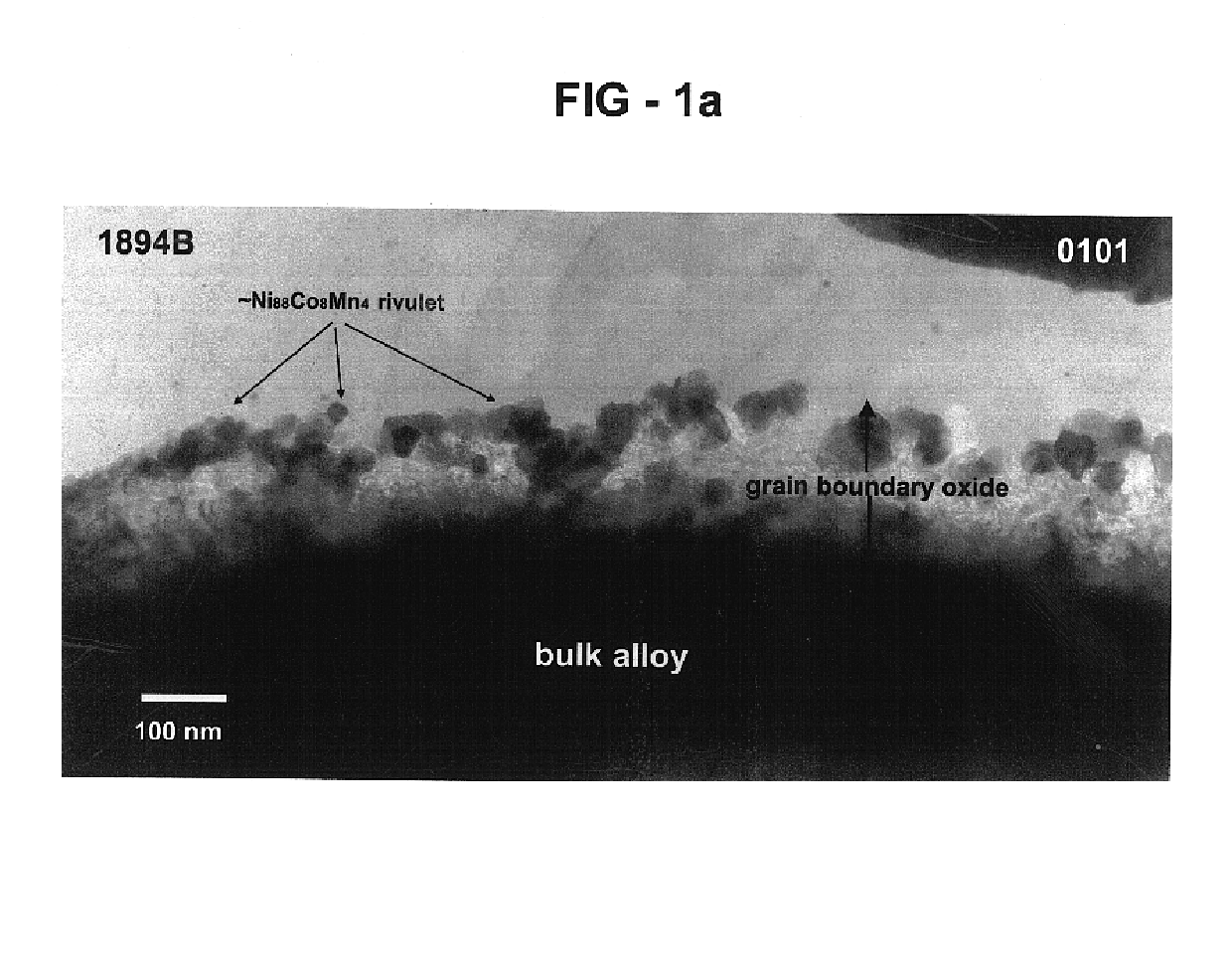

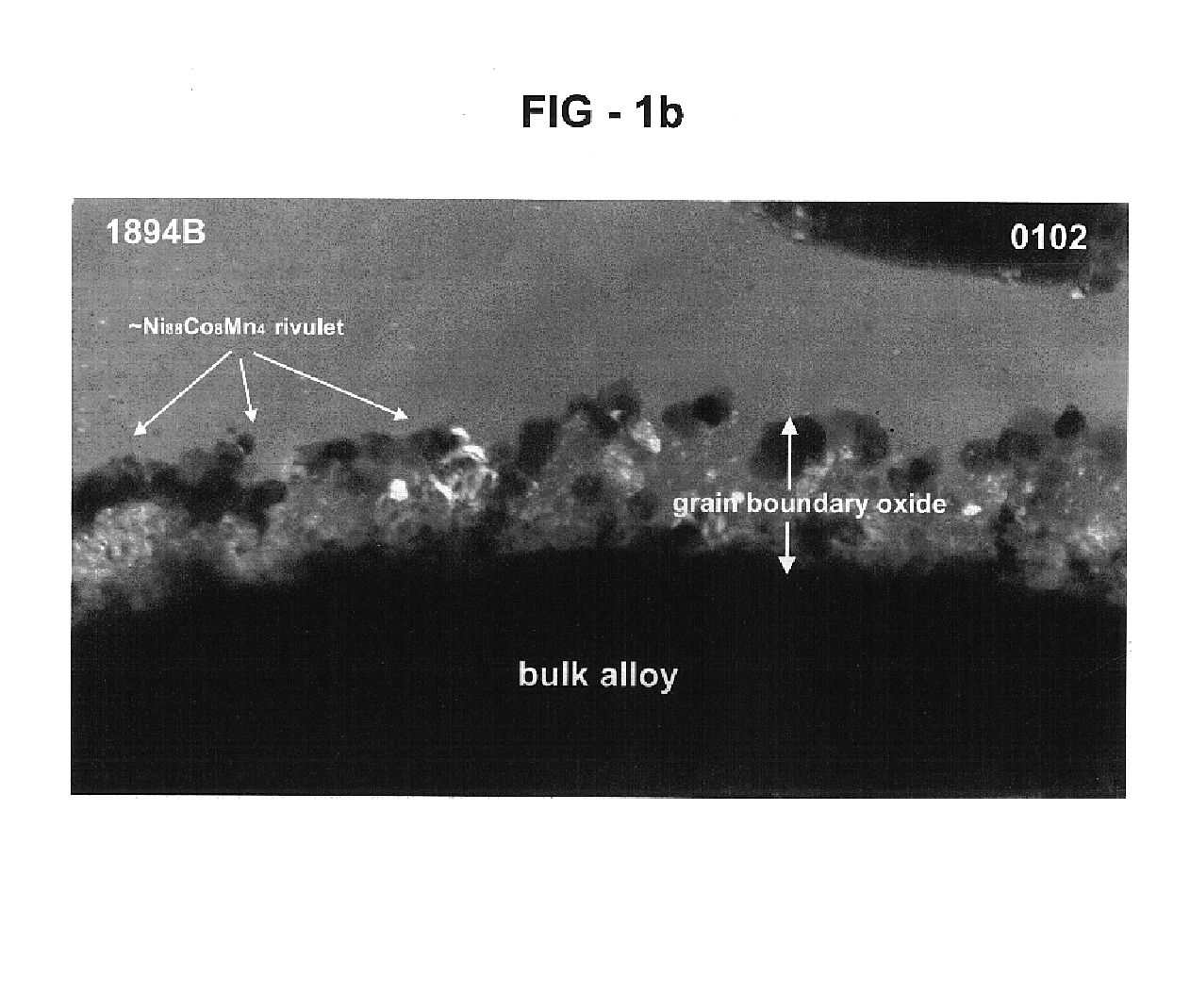

Coated catalytic material with a metal phase in contact with a grain boundary oxide

InactiveUS6964826B2Molecular sieve catalystsCatalyst activation/preparationParticulatesNon noble metal

An industrial catalyst having: a support; a plurality of metallic particulates distributed throughout the support; and a metal at least partially covering the surface of the support.A method for making a catalyst including the steps of: forming a support with non-noble metal particulates distributed throughout the support; and at least partially covering the surface of the support with a metal.

Owner:CHEVRONTEXACO TECH VENTURES

Double metaporous silicon dioxide material and its preparing method

InactiveCN1648044AWide pH rangeAvoid damageSilicaPhysical/chemical process catalystsSolubilityMesoporous silica

The double mesoporous silicon dioxide material has small pore diameter of 3.2-3.9 nm, great pore diameter of 9.4-24.5 nm, specific surface area of 408.6-718.2 sq cm / g, and pore volume of 0.53-1.8 cu cm / g. The material can meet the requirement of macromolecular shape selecting and diffusing effect on catalyst pore diameter distribution, and is one kind of latent industrial catalyst and catalyst carrier. The preparation process is one hydrolysis and condensation process with low solubility double alkyl chain quaternary ammonium salt as surfactant, dioctadecyl dimethyl ammonium chloride as template agent and ethyl silicate as silicon source and under wide pH value range and certain temperature. The preparation process is mild inreaction condition, simple and novel.

Owner:SHANXI UNIV

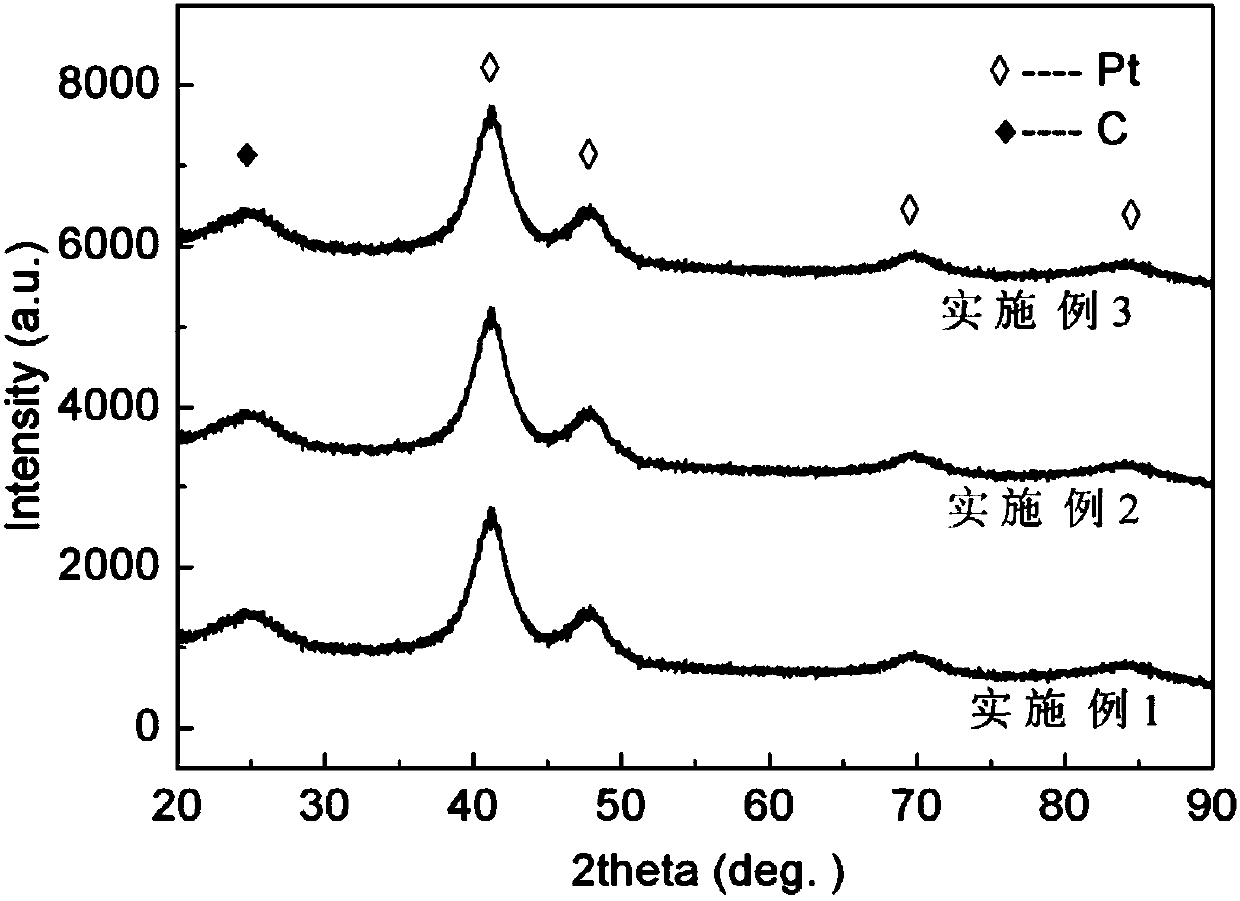

Preparation method for efficiently plaining noble metal and improving electro-catalytic performance thereof

ActiveCN107552044AGood dispersionGood adhesionMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectricityPorous carbon

The invention belongs to the technical field of nano materials and electro-chemical catalysis, and particularly relates to a preparation method for efficiently plaining a noble metal and improving electro-catalytic performance thereof. The preparation method comprises the following steps: uniformly mixing raw materials in a certain element molar ratio, placing into a closed reaction kettle to perform in-situ reduction and loading growth reaction on platinum-based alloy to obtain platinum-based alloy nanoparticles which are uniformly loaded on porous carbon; plaining platinum alloy nano-crystalto obtain a platinum nano-crystalline catalyst which only contains platinum element and is rich in hole and lattice imperfection. The plained platinum nano-particles have the catalytic effect remarkably superior to that of a carbon-loaded platinum catalyst in current commercial application. The nano-crystalline noble metal platinum has the advantages of simple process steps, short flow, adjustable platinum nano-crystalline appearance structure and the like, is easy for large-scale production, and has an important value in the fields of industrial catalyst or other subjects.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

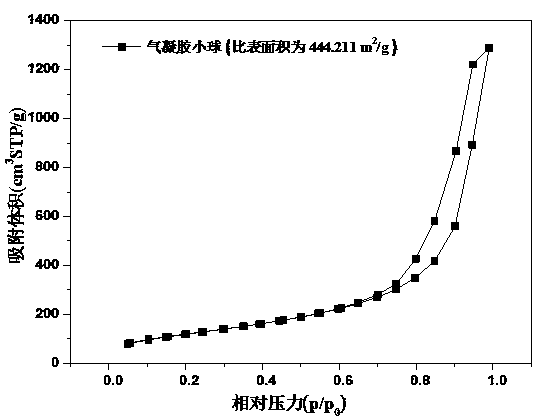

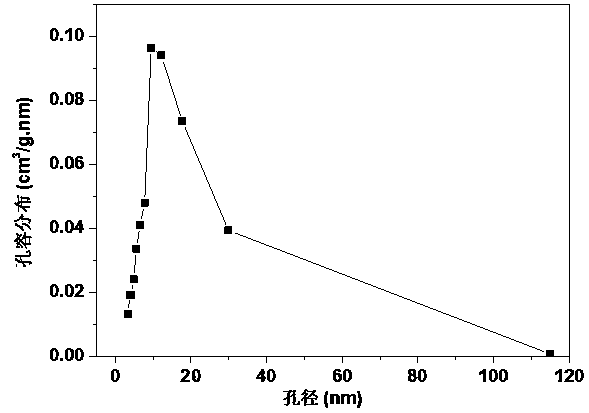

Method for preparing silicon oxide aerogel pellet at normal pressure at normal pressure

InactiveCN103880025ASimple processLow costSilicaOther chemical processesPtru catalystPhysical chemistry

The invention belongs to the technical field of new material preparation, and particularly relates to a simple and convenient method for preparing a silicon oxide aerogel pellet at normal pressure by utilizing water glass. The diameter of the silicon oxide aerogel pellet is 3-9 mm, the bulk density of the silicon oxide aerogel pellet is 0.142 g / cm<3>, and the specific surface of the silicon oxide aerogel pellet is 419.475-539.627 m<2> / g. The silicon oxide aerogel pellet is fast in adsorption velocity, large in adsorption capacity and convenient to use and can be used for the sewage treatment and the air purification. The preparation process disclosed by the invention is stable and provides the feasible raw material source for massively producing a heat-insulating material, an industrial catalyst and a chromatographic column filling material because the silicon oxide aerogel pellet is low in cost.

Owner:JIANGSU UNIV

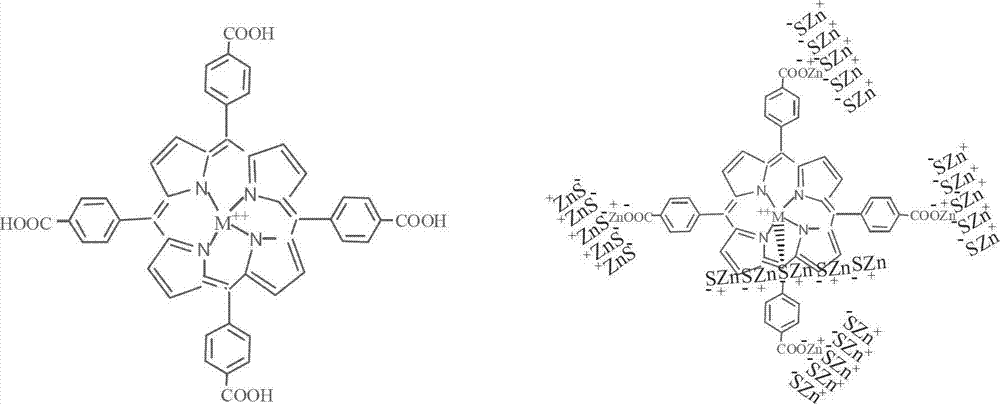

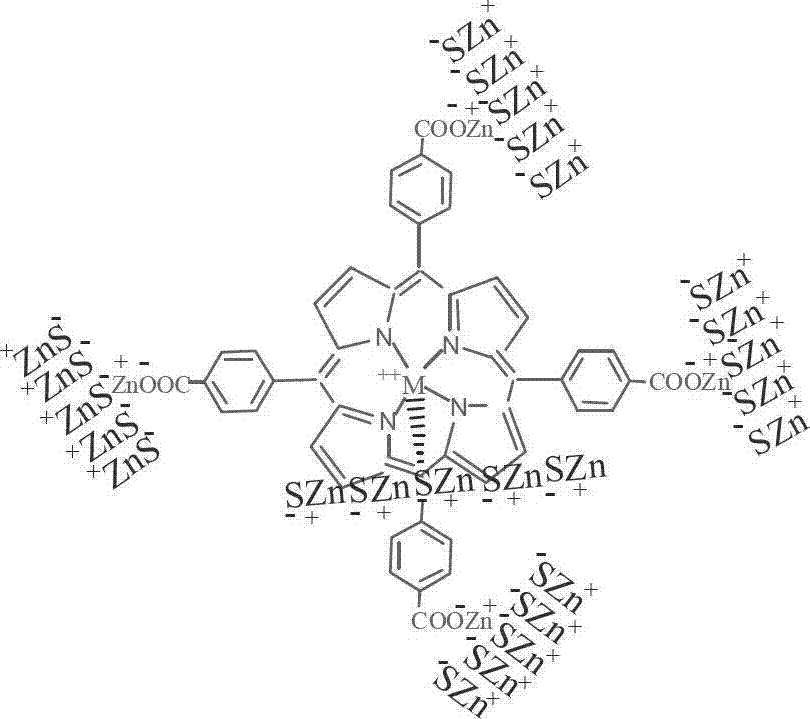

Nano zinc sulfide metalloporphyrin catalyst and preparation method and application thereof

InactiveCN102921463AIncrease conversions per passHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsOxygen compounds preparation by hydrocarbon oxidationPorphyrinRaw material

The invention discloses a nano zinc sulfide metalloporphyrin catalyst and a preparation method and application thereof. The method comprises the following steps of: reacting zinc vitriol and sodium sulfide to obtain zinc sulfide precipitation, and reacting the zinc sulfide and metalloporphyrin to prepare the nano zinc sulfide metalloporphyrin catalyst, wherein the catalyst comprises the the following main raw materials in parts by weight: 16.198 parts of zinc vitriol, 13.529 parts of sodium sulfide, 0.006 part of metalloporphyrin, 26.350 to 32.297 parts of organic solvent and a proper quantity of deionized water. The catalyst can be used for obviously improving the conversion per pass of cyclohexane and the yield of primary products, wherein the conversion rate of the cyclohexane is 72.9 percent, the turn over number of the catalyst is 9.4*105, and the yield of ketol is 27.0 percent. The catalyst can be repeatedly recycled, the preparation method is simple, the cost is low, the metalloporphyrin is less in quantity and easy to separate, and the catalyst is an ideal bionic industrial catalyst and has good economic benefits and social benefits.

Owner:GUANGXI UNIV

Preparing technology for production of EPT rubber vanadium catalyst

Ternary rubber vanadium series catalysts are prepared by: taking the V2O5, NaVO3 ore as start materials, organic phosphorus monoacid as extracting reagent, fatty carboxylic acid being as aided extracting reagent, and saturated alkane as solvent. By cross current extracting method, stable saturated alkane vanadium (IV) or vanadium (V) compounds used as catalyst for EPDM production directly can be obtained. This invention has the features of preparation simple, condition moderation, low cost, large scale production, without toxic and harm chlorine, good for environment protection. The prepared catalyst saturated alkane solution is high homogeneous stability, and non-sensitive to water and air ,which overcomes shortages of present catalysts sensitive to water and air, meanwhile, reduces the storing and transporation cost. The catalysts prepared has higher catalyzed activity than catalyst VOCl3, and the obtained rubber having similar molecular chain structure, monomer unit sequence structure and third monomer contents.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

CO sulfur tolerant shift catalyst in cobalt-molybdenum system and preparation method

ActiveCN103447049APromote reductionAccelerated vulcanizationHydrogenCatalyst carriersCobaltChemistry

The invention provides a CO sulfur tolerant shift catalyst in a cobalt-molybdenum system. The CO sulfur tolerant shift catalyst comprises a carrier and active components, wherein the carrier is aluminium-titanium-based surficial magnesium-aluminium spinel; the active components are cobalt and molybdenum. The catalyst is ball-shaped. A preparation method comprises the following steps: introducing titanium on aluminium oxide to prepare the aluminium-titanium composite carrier; uniformly introducing magnesium on the aluminium-titanium composite carrier, and carrying out roasting and phase inversion to form the aluminium-titanium-based surficial magnesium-aluminium spinel; introducing the active components into the aluminium-titanium-based surficial magnesium-aluminium spinel to prepare the catalyst. The CO sulfur tolerant shift catalyst provided by the invention has the advantages that the low-temperature activity and the low-sulfur activity are good, the stability is strong, the adaptability to the demanding conversion condition of synthesized gas with high CO content (more than or equal to 60%) is stronger, the difficulties of poor stability, easy inactivity and short service life when the existing industrial catalyst is used for shifting of the synthesized gas with high CO content as a shifting or pre-shifting catalyst are solved, and the application range of the traditional CO sulfur tolerant shift catalyst is greatly expanded.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

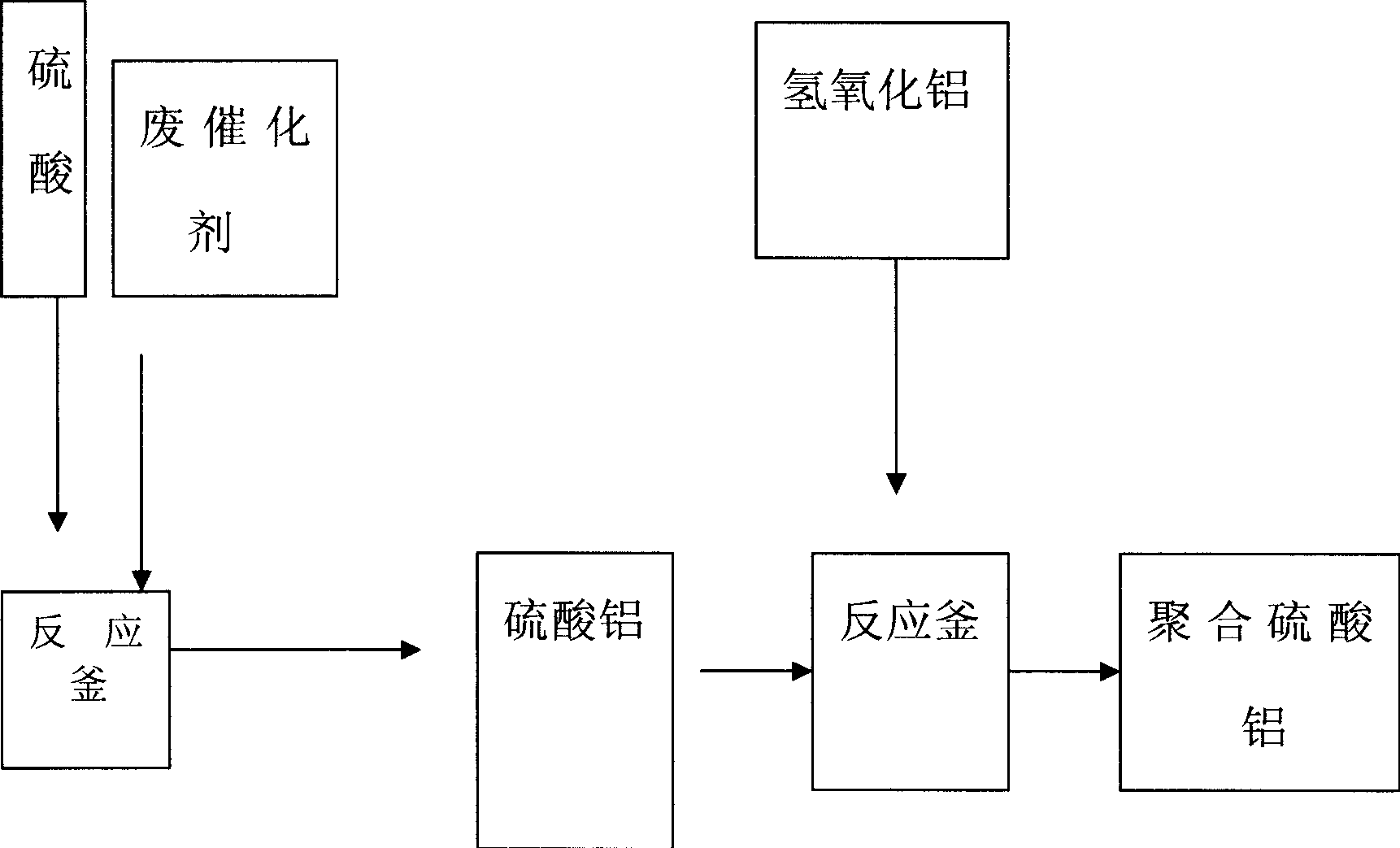

Method for preparing synthesized polymer aluminum sulphate through spent catalyst

ActiveCN1727282APollution controlOvercoming the lack of pollutionAluminium sulfatesAluminium sulfateAluminium hydroxide

A process for preparing the polymerized aluminium sulfate by used of the used catalyst includes such steps as dissolving the used industrial catalyst in sulfuric acid to prepare aluminium sulfate, and polymerizing aluminium hydroxide with aluminium sulfate to obtain the polymerized aluminium sulfate used as flocculant.

Owner:PETROCHINA CO LTD

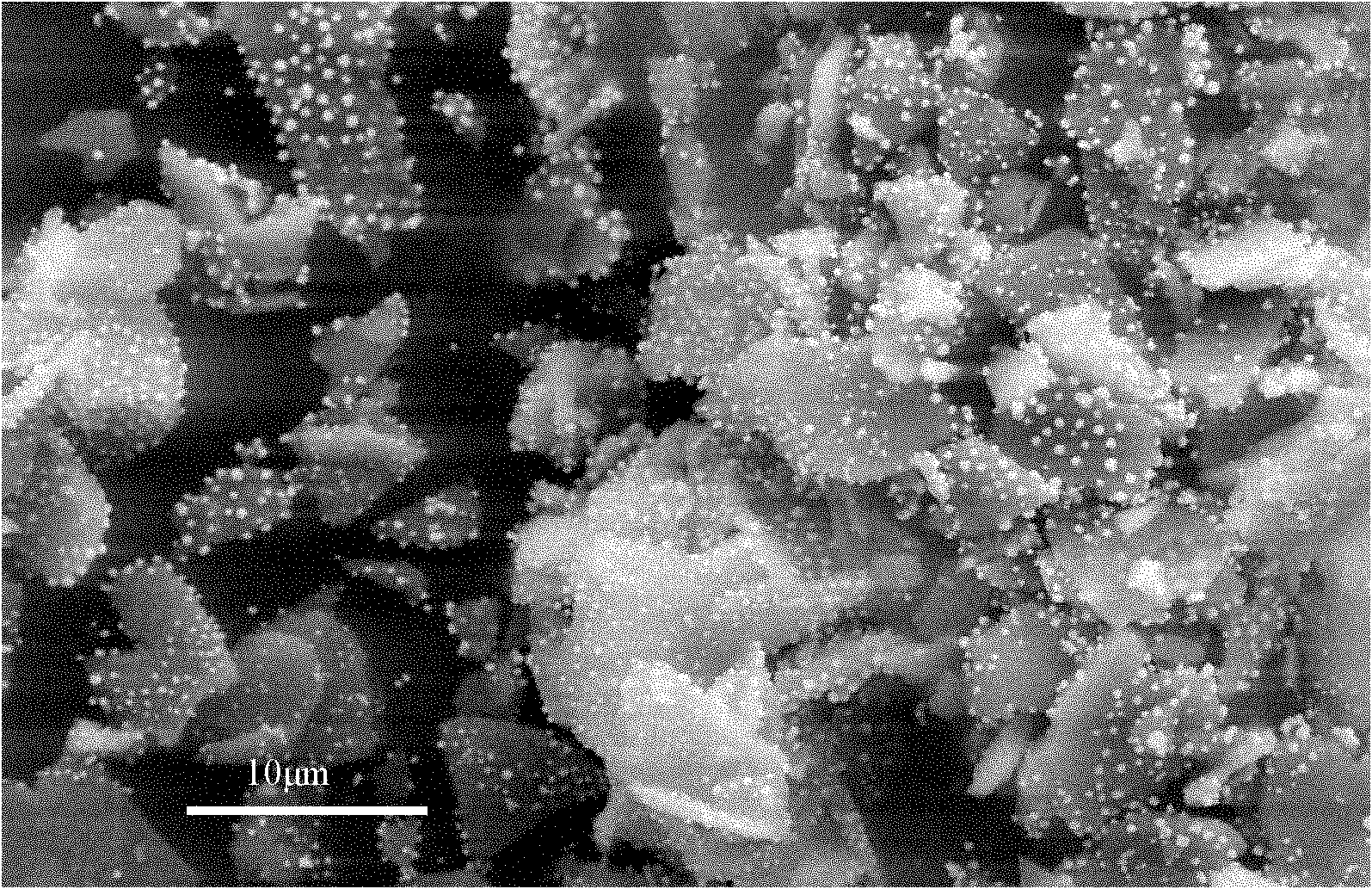

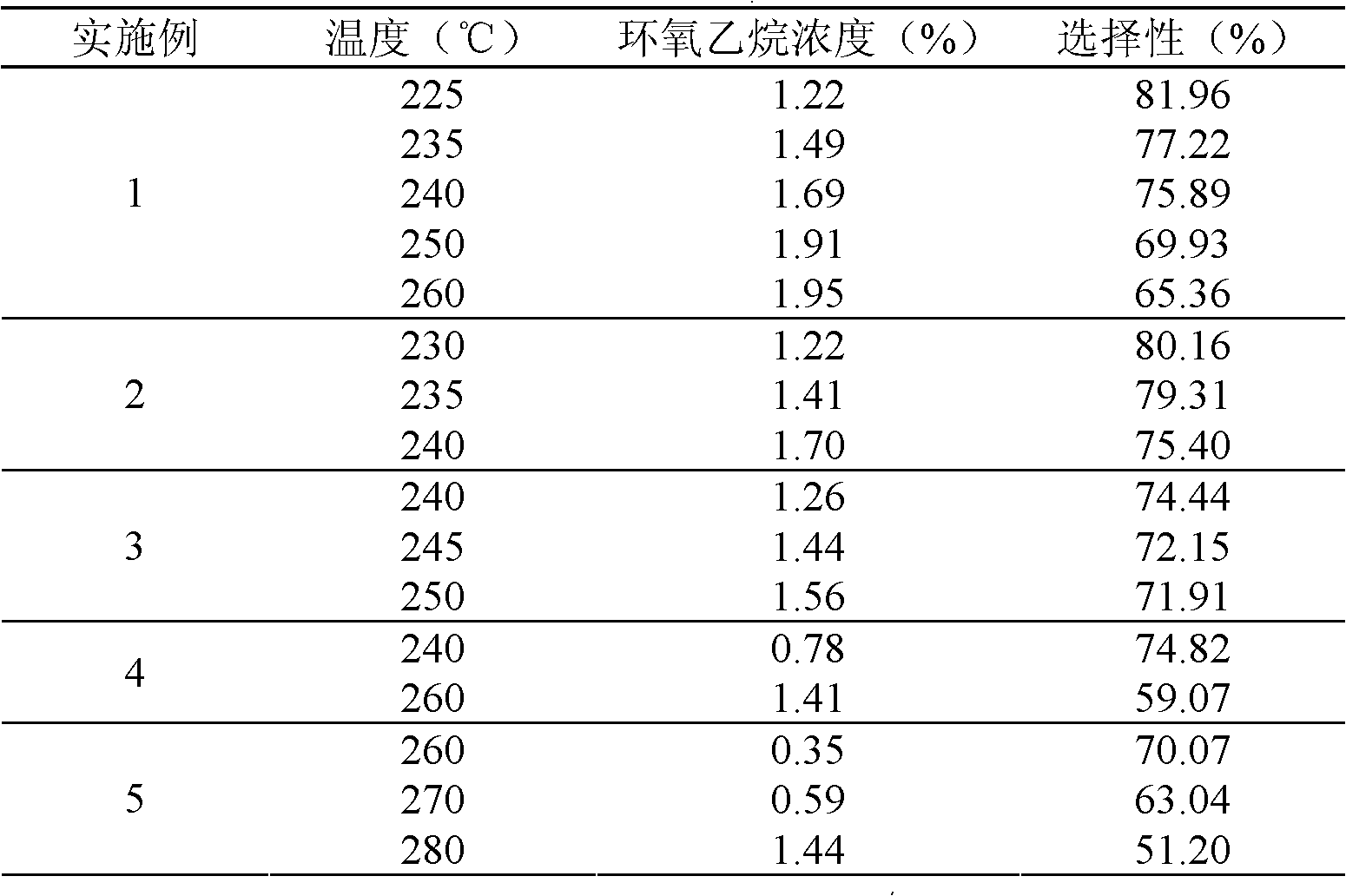

Plant reduction preparation method of load-type silver catalyst

InactiveCN101898132AGreen preparationEvenly distributedCatalyst carriersOrganic chemistrySilver particlesSolvent

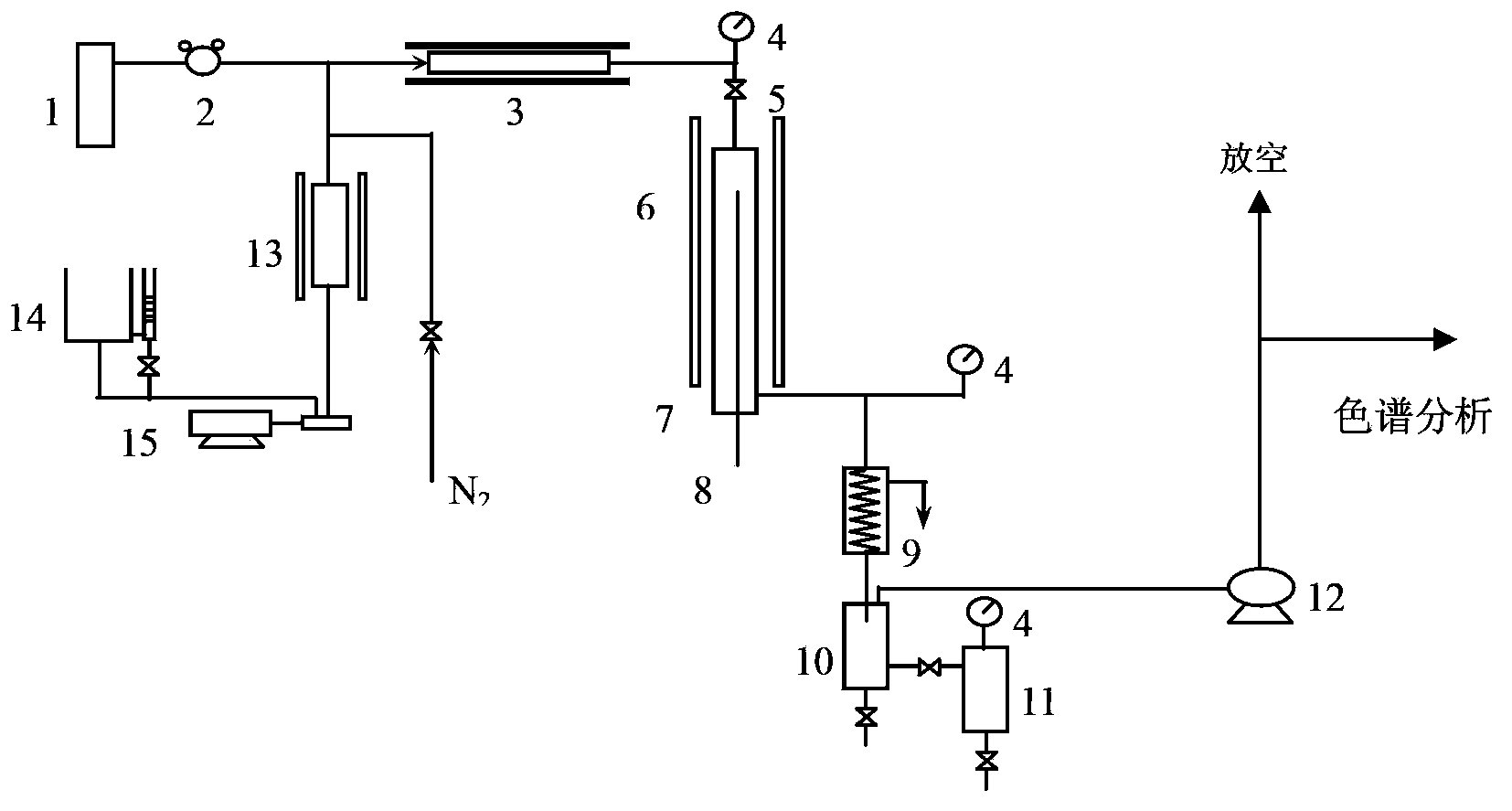

The invention discloses a plant reduction preparation method of a load-type silver catalyst, relating to a silver catalyst and providing a plant reduction preparation method of a load-type silver catalyst. The method comprises the following steps of: drying and crushing plant blades into powder, mixing with water and leaching, and removing residues to obtain a plant extract; dissolving silver salts in the plant extract, preparing into a dipping solution, soaking a vector with the dipping solution, and reacting to obtain the catalyst; and carrying out drying and activation on the catalyst to prepare the load-type silver catalyst which can be used for ethylene epoxidation. In the invention, the natural plant blade extract is adopted as a reducing agent without adding other solvents and reducing agents and loading a cocatalyst, an inhibitor is not added in reaction feed gas, and under the simulated industrial reaction conditions with the lower temperature of 225 DEG C, the selectivity of the catalyst to ethylene oxide reaches 81.96 percent which approaches to the index of an industrial catalyst. The preparation process of the catalyst is green; and silver particles on the catalyst vector are evenly distributed.

Owner:XIAMEN UNIV

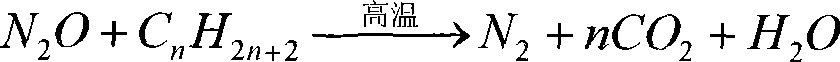

Catalyst for decomposing laughing gas and preparation method thereof

InactiveCN101480615ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentCatalytic decomposition

The invention relates to a catalyst for catalytic decomposition of nitrous oxide in industrial waste gas and the preparation method of the catalyst, belonging to the field of development of industrial catalysts. The prior catalysts have the disadvantages of sensitivity for impurities in waste gas, easy loss of activity caused by poisoning, short service life and expensive price. The catalyst for catalytic decomposition of the nitrous oxide in the industrial waste gas belongs to a carrying type catalyst, wherein Al2O3 or dichroite is used as a carrier, one of or a plurality of metallic oxides of IIA, IIB and VIII are used as active components, Ni and Pt are preferably selected as the main active components of the catalyst, and Co and Mg are preferably selected as the auxiliary active components of the catalyst; the content of the main active components of the catalyst is 0.01 to 15.0 percent (wt) of the total content of the catalyst, and the content of the auxiliary active components of the catalyst is 0.0 to 20.0 percent (wt) of the total content of the catalyst. The method of immersion is used for preparing the catalyst in the following steps: firstly, the carrier is used for immersing the auxiliary active components of the catalyst, and then, the main active components of the catalyst after being dried are immersed; finally, the catalyst is obtained after the processes of drying and roasting. The catalyst for catalytic decomposition of the nitrous oxide in the industrial waste gas has the advantages of highly effective decomposability, high stability, low price and the like.

Owner:BEIJING UNIV OF CHEM TECH

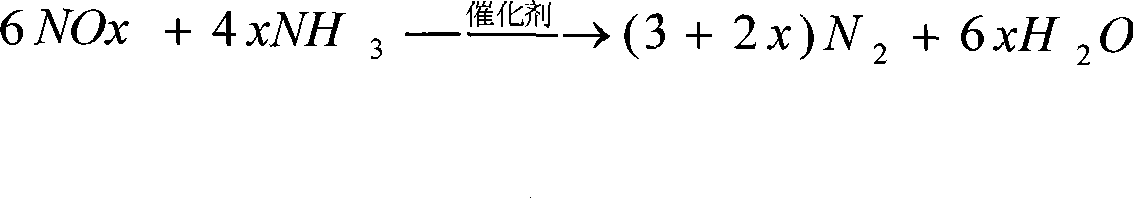

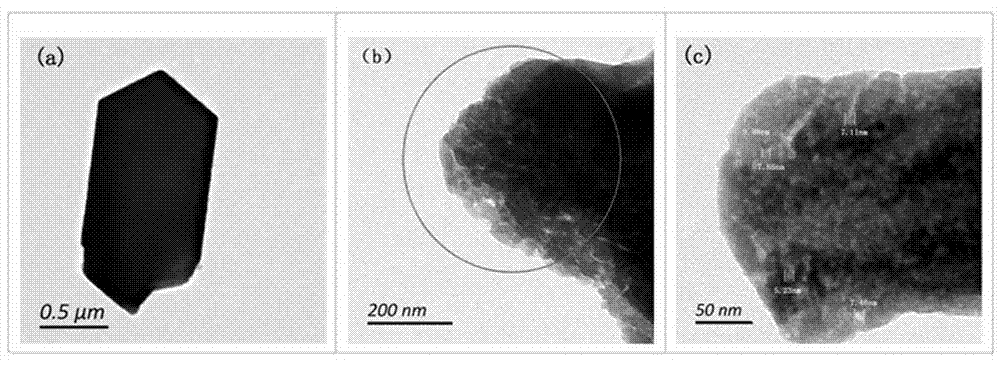

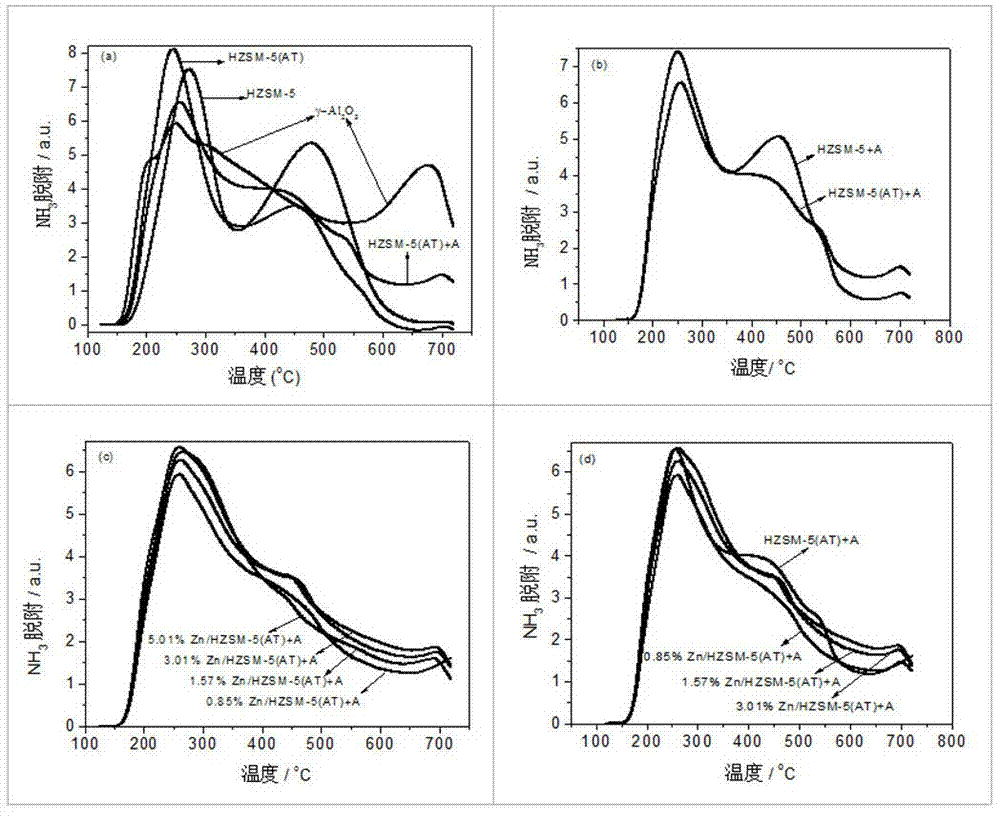

Zn-modified multi-level pore HZSM-5 catalyst and application thereof in liquefied gas aromatization

ActiveCN104759290AHigh activityImprove stabilityMolecular sieve catalystsLiquid hydrocarbon mixtures productionMolecular sievePtru catalyst

The invention relates to a Zn modified multi-level pore HZSM-5 catalyst, a NaOH solution is used for alkali treatment of HZSM-5 molecular sieve to prepare the HZSM-5 (AT), the the HZSM-5 (AT) is mixed with binder pseudo-boehmite mixed stone and roasted to obtain industrial catalyst HZSM-5 (A-T) + A, and finally Zn (NO3) 2 modification of the HZSM-5 (A-T) + A is performed by equivalent-volume impregnation method to obtain Zn / (HZSM-5 (A-T) + A). The alkali modified industrial catalyst is used in liquefied gas aromatization reaction, due to the formation of a small amount of mesopores, the stability is improved; and after combination of alkali modification and Zn modification, the stability is improved, at the same time due to the existence of proper amount of Zn-L medium-strong acid center, he synergetic catalysis effect of B and L acid and strong and weak acids can be improved, splitting action of strong B acid and the generation of C9 + in liquid aromatic hydrocarbons can be reduced, and the BTEX selectivity can be improved.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com