Low-cost hydrogen production catalyst and preparation method thereof

A catalyst and low-cost technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as inability to achieve recycling and reuse, and achieve elimination of waste residue pollution , the effect is remarkable, the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

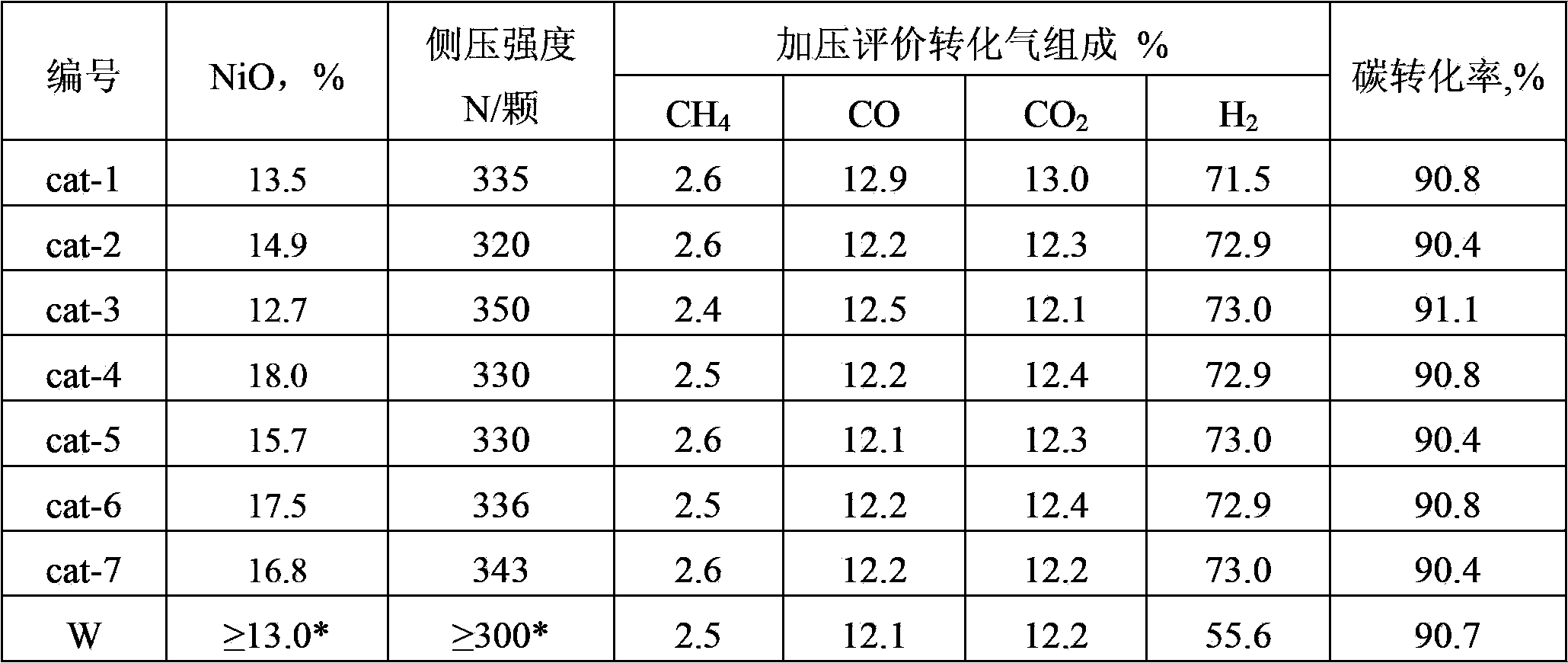

Examples

Embodiment 1

[0028] Recycled waste NiO / Al 2 o 3 After the type natural gas steam-to-catalyst is screened to remove impurities and broken particles, it is blown with compressed air to remove the powder and cleaned with dilute nitric acid with a mass concentration of 5%. The acid-washed catalyst was dried, crushed, and ball-milled until all of it passed through a 280-mesh sieve to obtain raw material A.

[0029] Mix 2000mL of nickel nitrate solution with a concentration of 3mol / L and 2500mL of magnesium nitrate solution with a concentration of 3mol / L, heat and stir in the reaction tank, and when the temperature rises to 75°C, slowly add carbonic acid with a concentration of 3mol / L 5000mL of sodium solution was used for precipitation, and 310g of raw material A was added with stirring during the precipitation process. After the precipitation is complete, filter and wash with deionized water until there is no NO3 - 、Na + residual. The washed filter cake was dried at 120°C for 12 hours and...

Embodiment 2

[0032] Recycled waste NiO / Al 2 o 3 After the type hydrocarbon steam-to-catalyst is screened to remove impurities and broken particles, the powder is blown off with compressed air and washed with dilute sulfuric acid with a mass concentration of 8%. The acid-washed catalyst was dried, crushed, and ball-milled until all of it passed through a 280-mesh sieve to obtain raw material A.

[0033] Mix 2000mL of nickel nitrate solution with a concentration of 3mol / L and 3000mL of magnesium nitrate solution with a concentration of 3mol / L, heat and stir in the reaction tank, and when the temperature rises to 75°C, slowly add carbonic acid with a concentration of 3mol / L 5500mL of sodium solution was used for precipitation, and 180g of raw material A was added with stirring during the precipitation process. After the precipitation is complete, filter and wash with deionized water until there is no SO 4 - , NO 3 - 、Na + residual. The washed filter cake was dried at 120°C for 12 hour...

Embodiment 3

[0036] Recycled waste NiO / Al 2 o 3 After the type hydrocarbon steam-to-catalyst is screened to remove impurities and broken particles, it is blown with compressed air to remove the powder and washed with dilute hydrochloric acid with a mass concentration of 8%. The acid-washed catalyst was dried, crushed, and ball-milled until all of it passed through a 280-mesh sieve to obtain raw material A.

[0037]Mix 1000g nickel nitrate hexahydrate crystals with 5000g magnesium nitrate hexahydrate crystals and add 5000mL deionized water to dissolve. Pour the above mixed solution into a reaction tank, heat and stir. When the temperature rises to 70°C, slowly add 8000 mL of sodium carbonate solution with a concentration of 3 mol / L for precipitation. During the precipitation, stir and add 500 g of raw material A. After the precipitation is complete, filter and wash with deionized water until there is no Cl - , NO 3 - 、Na + residual. The washed filter cake was dried at 120°C for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com