Patents

Literature

3468 results about "Nickel oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel oxide may refer to: Nickel oxide, NiO, green, well-characterised oxide Nickel oxide, Ni₂O₃, black, not well-characterised oxide

Method of depositing nanolaminate film for non-volatile floating gate memory devices by atomic layer deposition

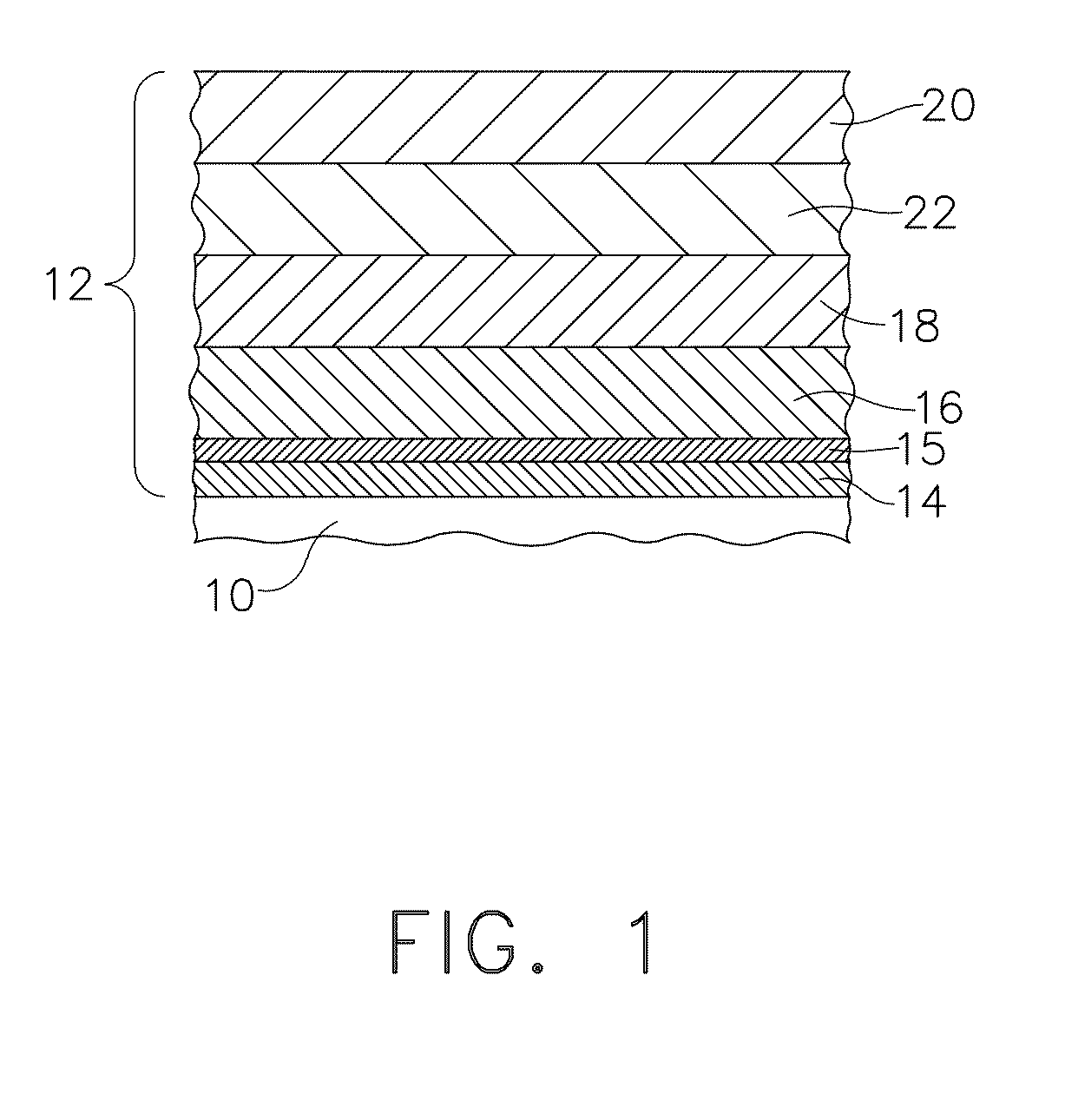

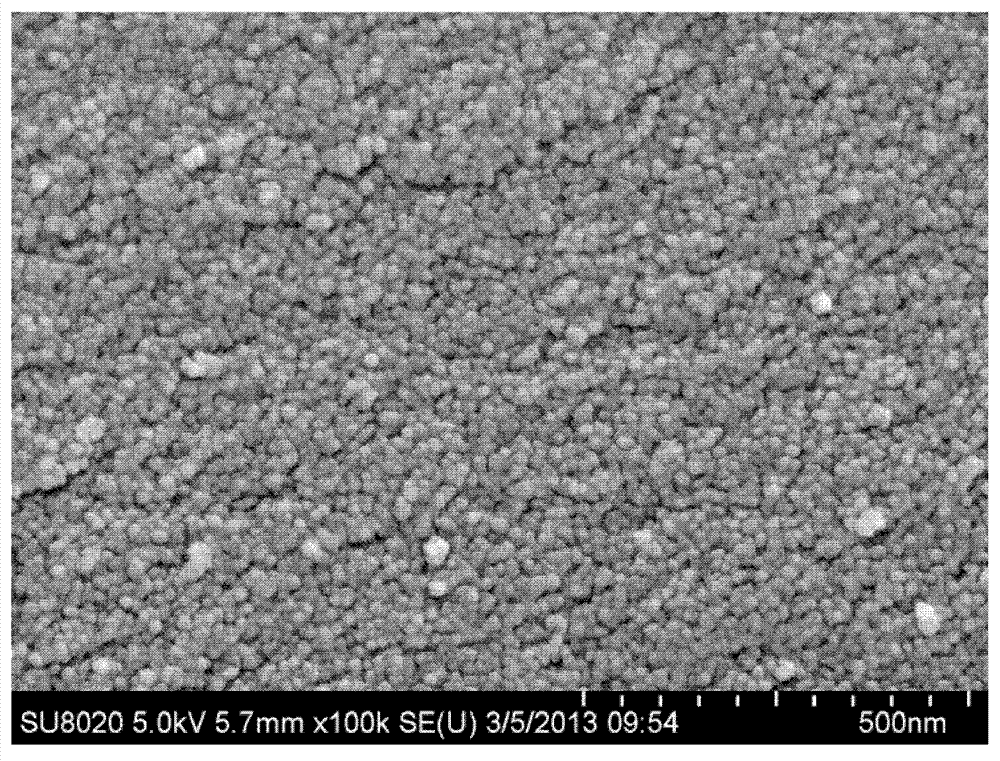

Disclosed herein is a method of depositing a nanolaminate film for next-generation non-volatile floating gate memory devices by atomic layer deposition. The method includes the steps of: introducing a substrate into an atomic layer deposition reactor; forming on the substrate a first high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source; forming on the first high-dielectric-constant layer a nickel oxide layer by alternately supplying a nickel source and an oxygen source; and forming on the nickel oxide layer a second high-dielectric-constant layer by alternately supplying an oxygen source and a metal source selected from among an aluminum source, a zirconium source and a hafnium source. The nanolaminate film deposited according to the method shows good memory window characteristics compared to those of memory devices fabricated using nanocrystal floating gates according to the prior physical vapor deposition methods, and thus can be applied to non-volatile floating gate memory devices.

Owner:KOREA RES INST OF CHEM TECH

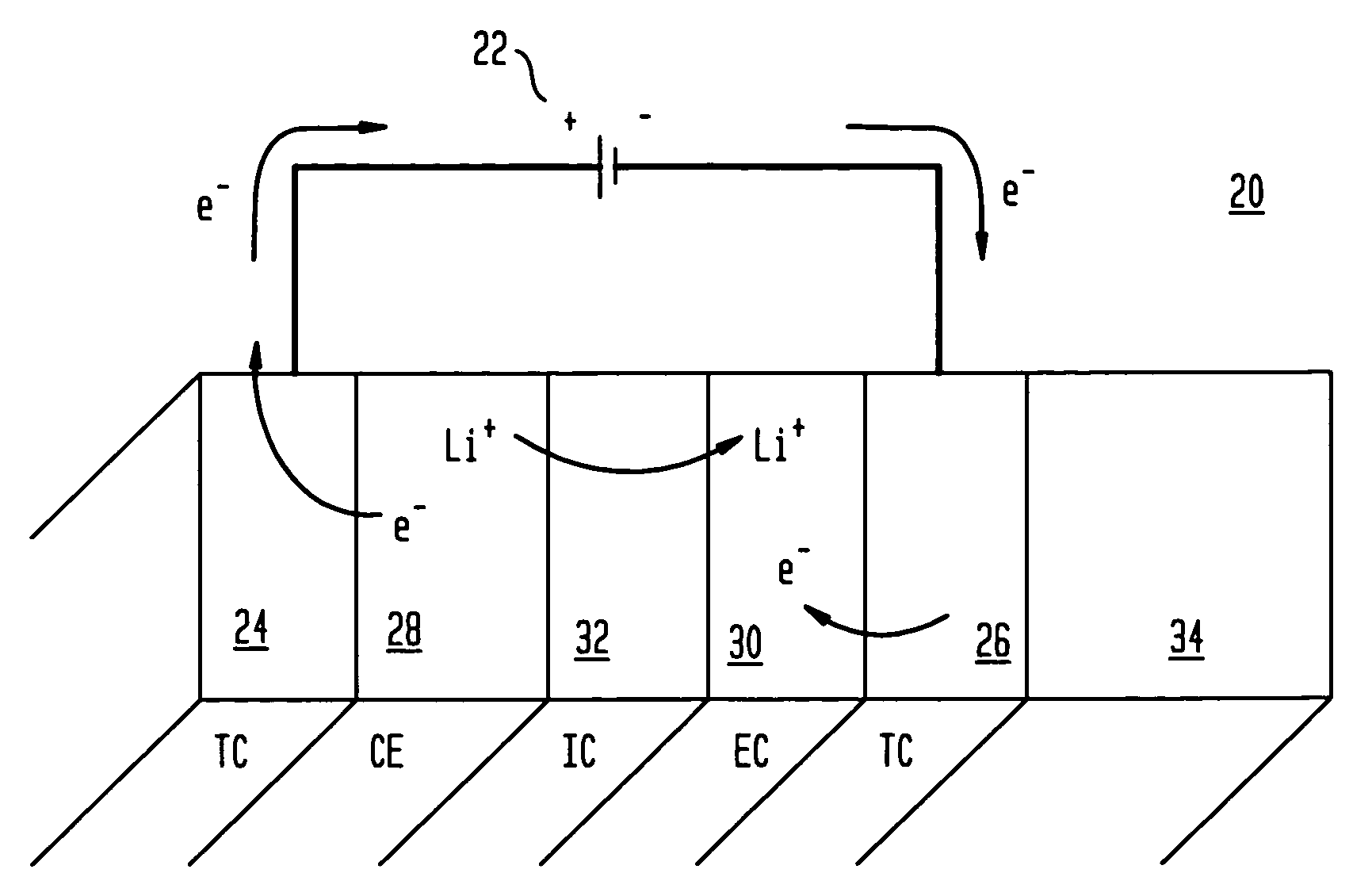

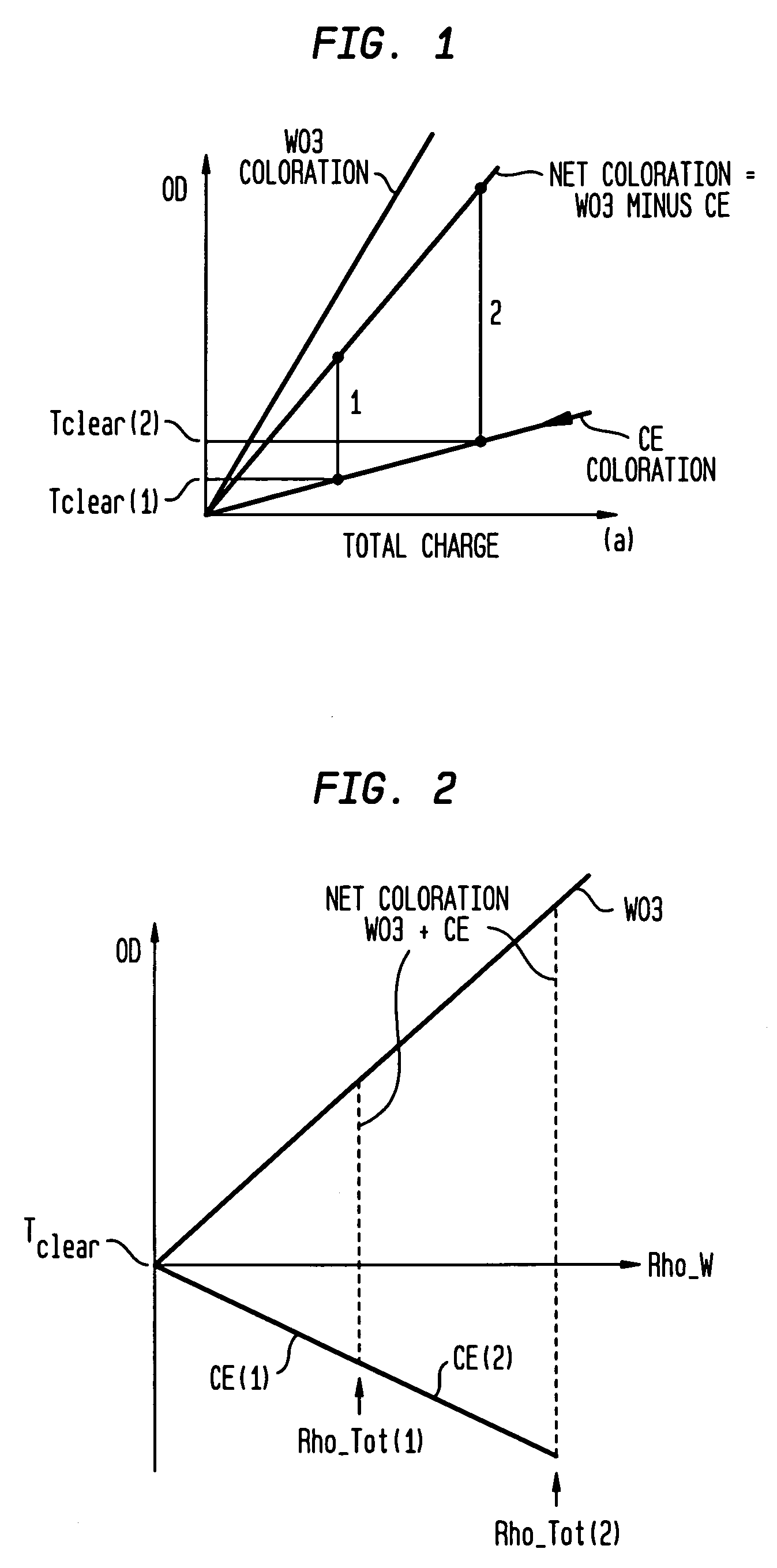

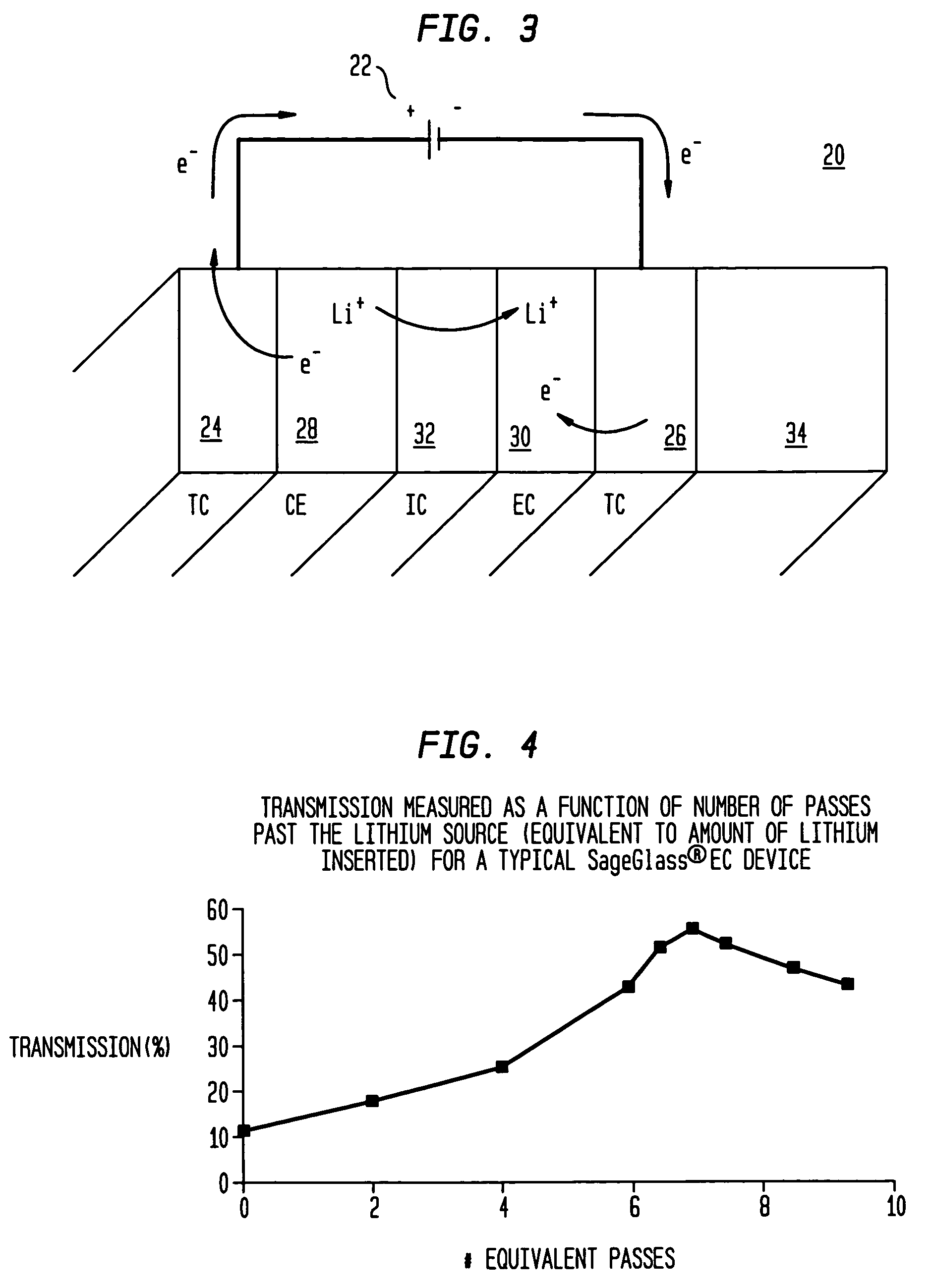

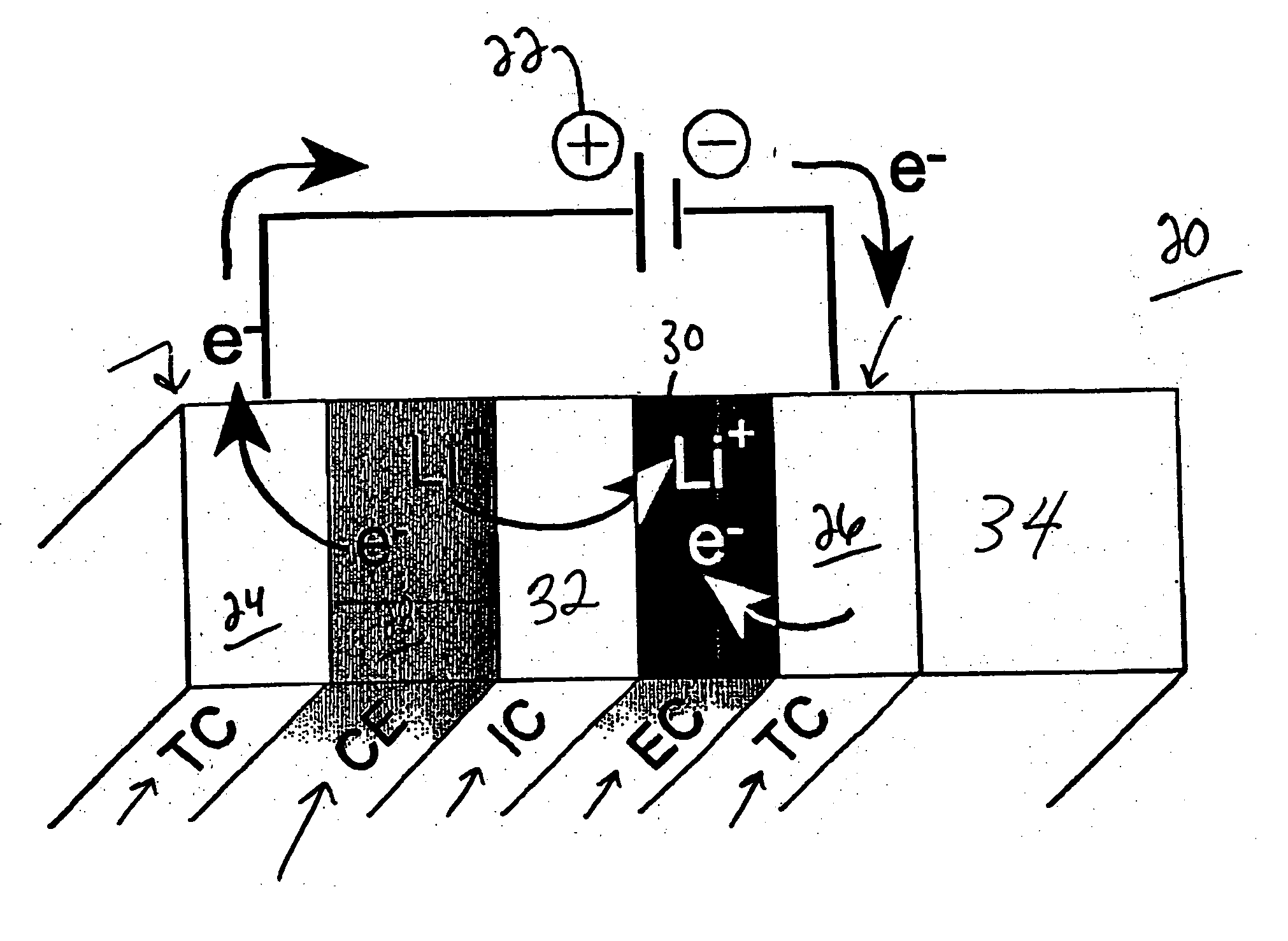

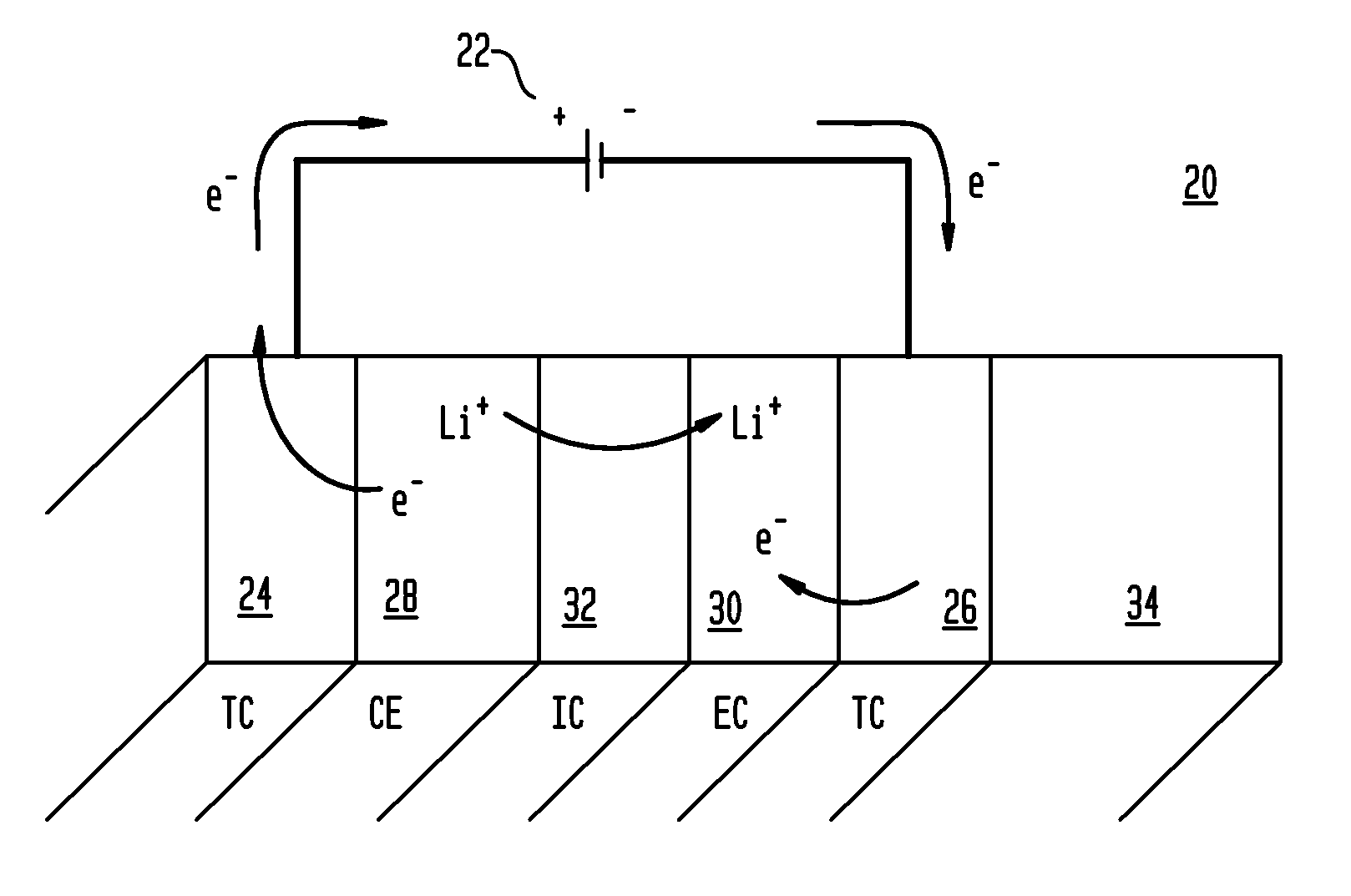

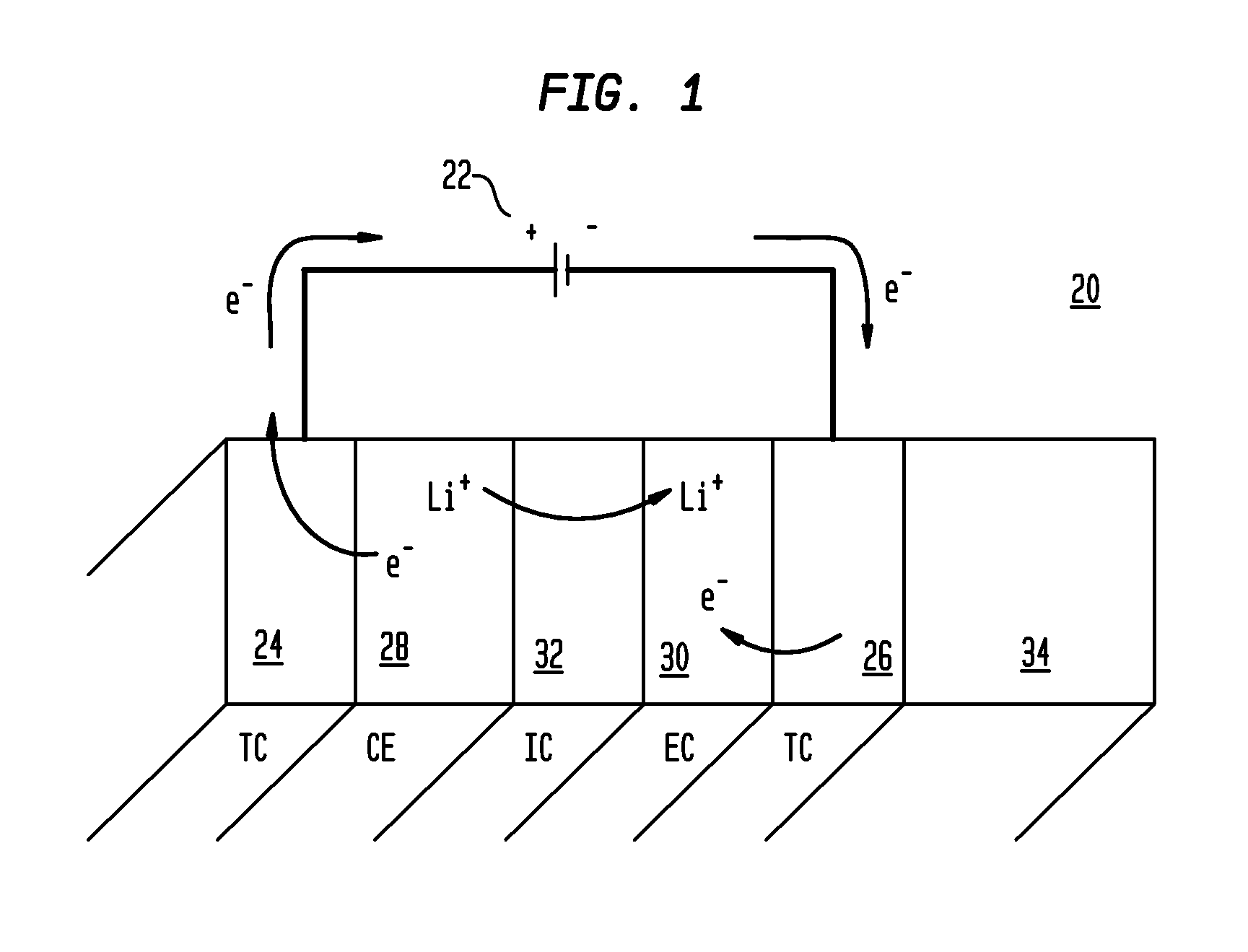

Electrochromic devices and methods

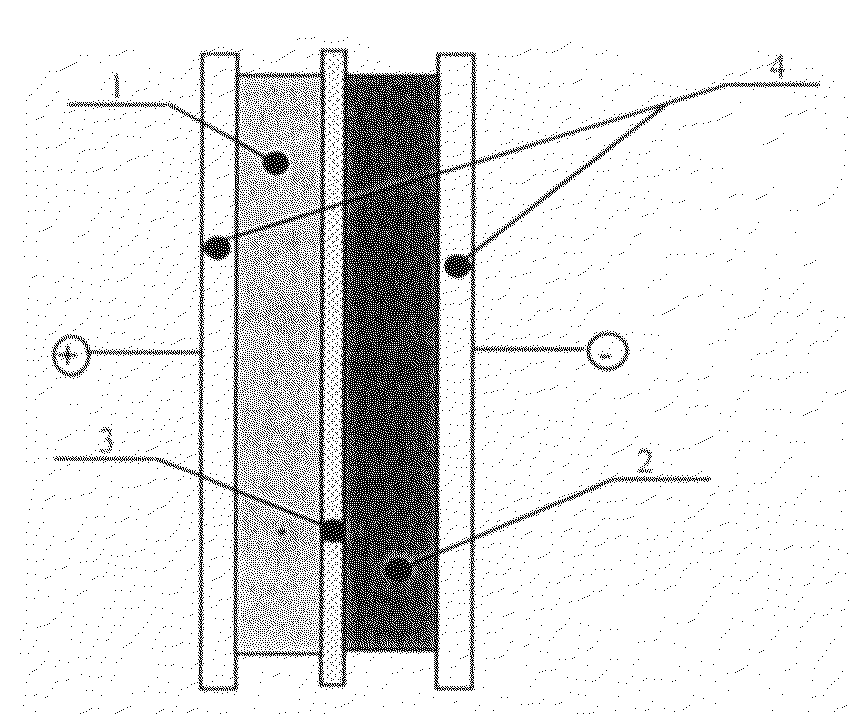

A heat treated electrochromic device comprising an anodic complementary counter electrode layer comprised of a mixed tungsten-nickel oxide and lithium, which provides a high transmission in the fully intercalated state and which is capable of long term stability, is disclosed. Methods of making an electrochromic device comprising an anodic complementary counter electrode comprised of a mixed tungsten-nickel oxide are also disclosed.

Owner:SAGE ELECTROCHROMICS

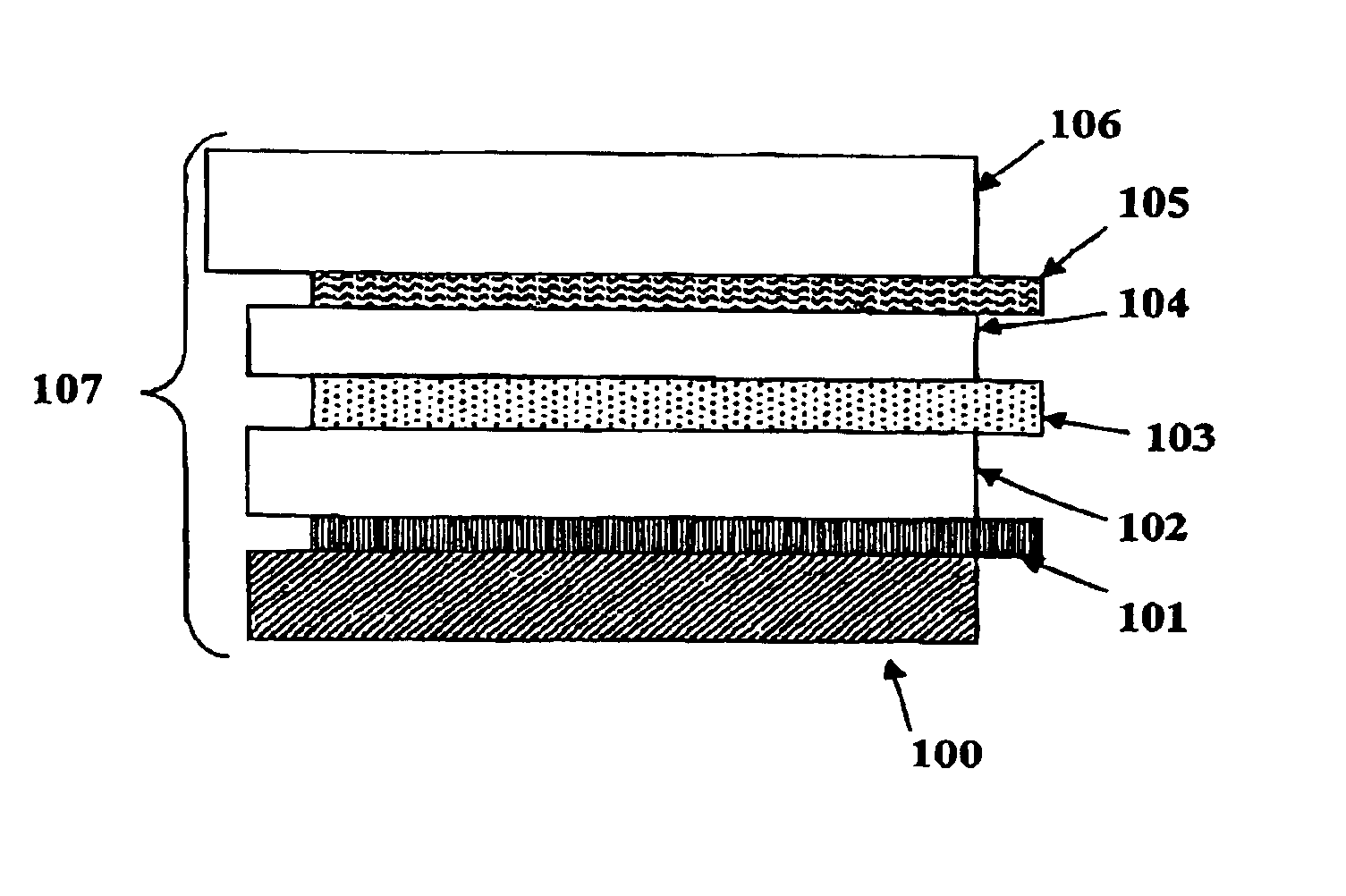

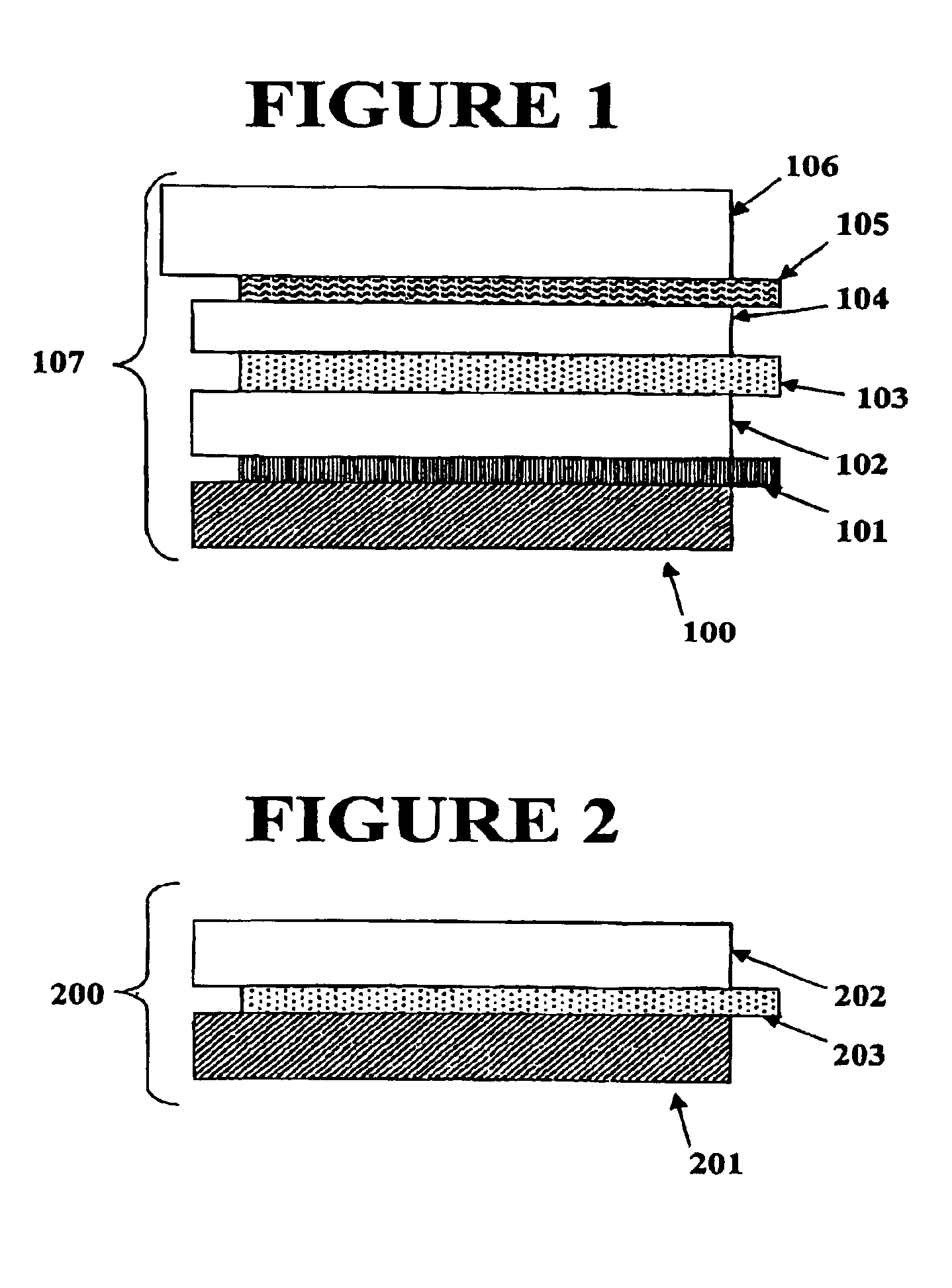

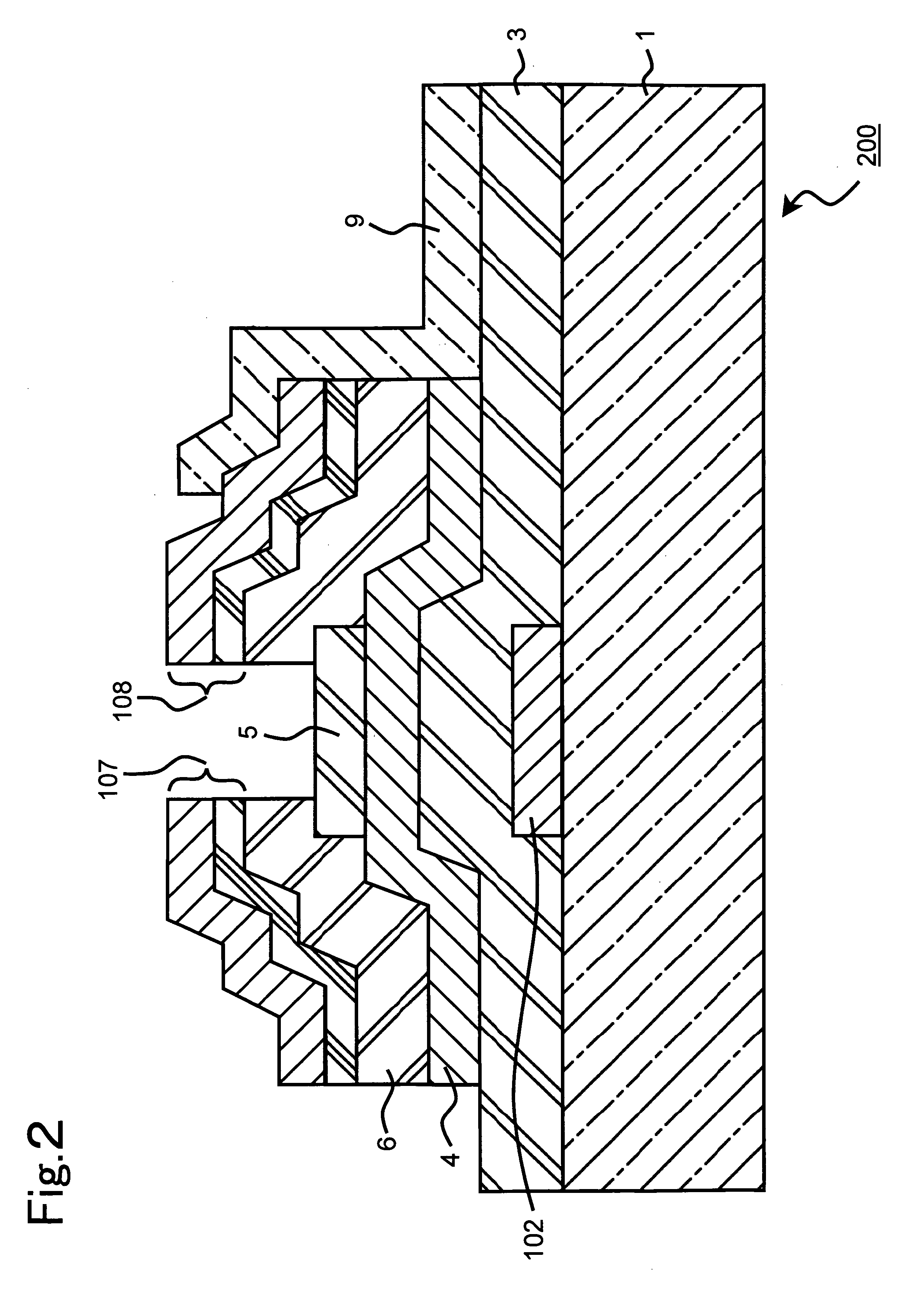

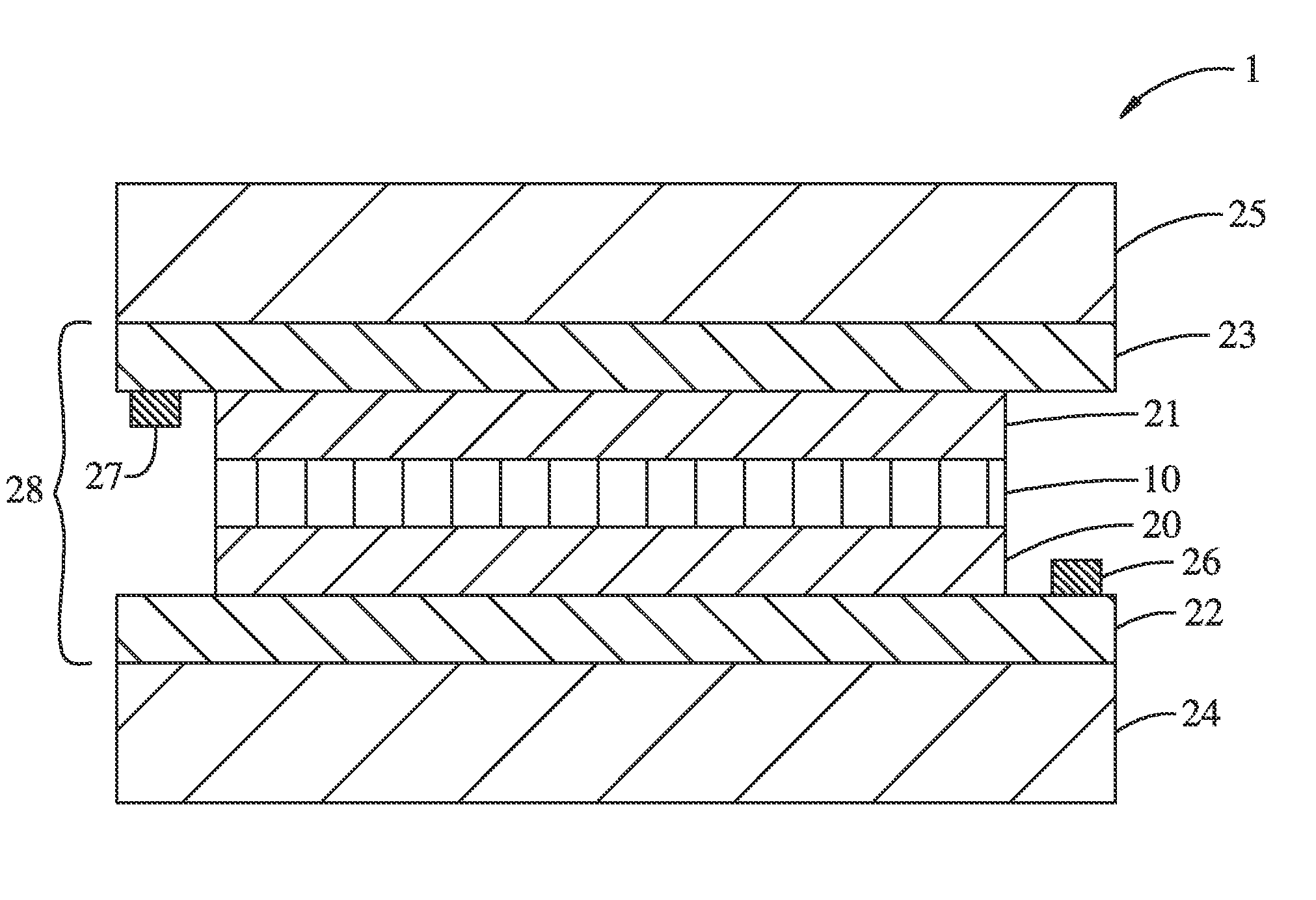

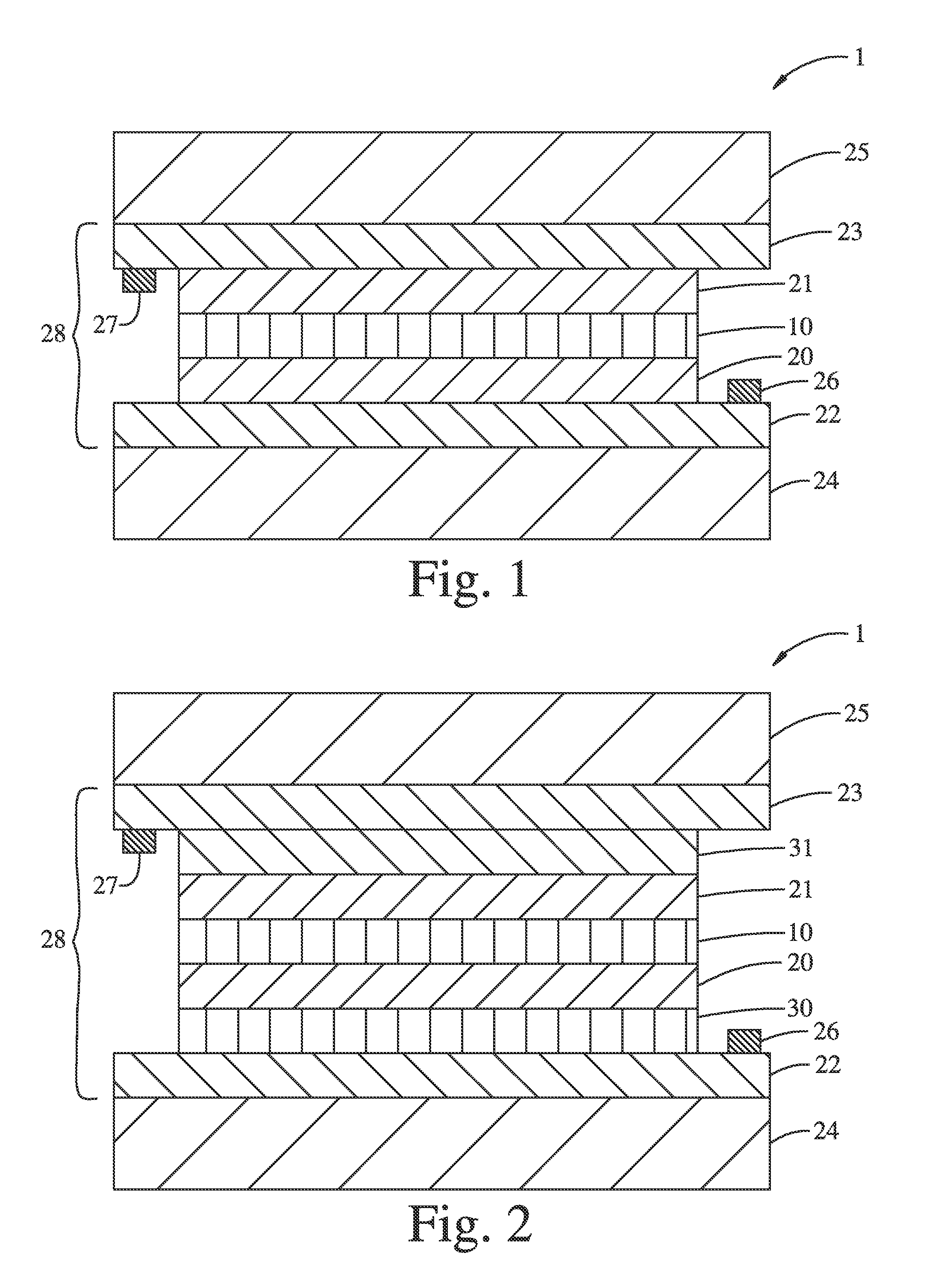

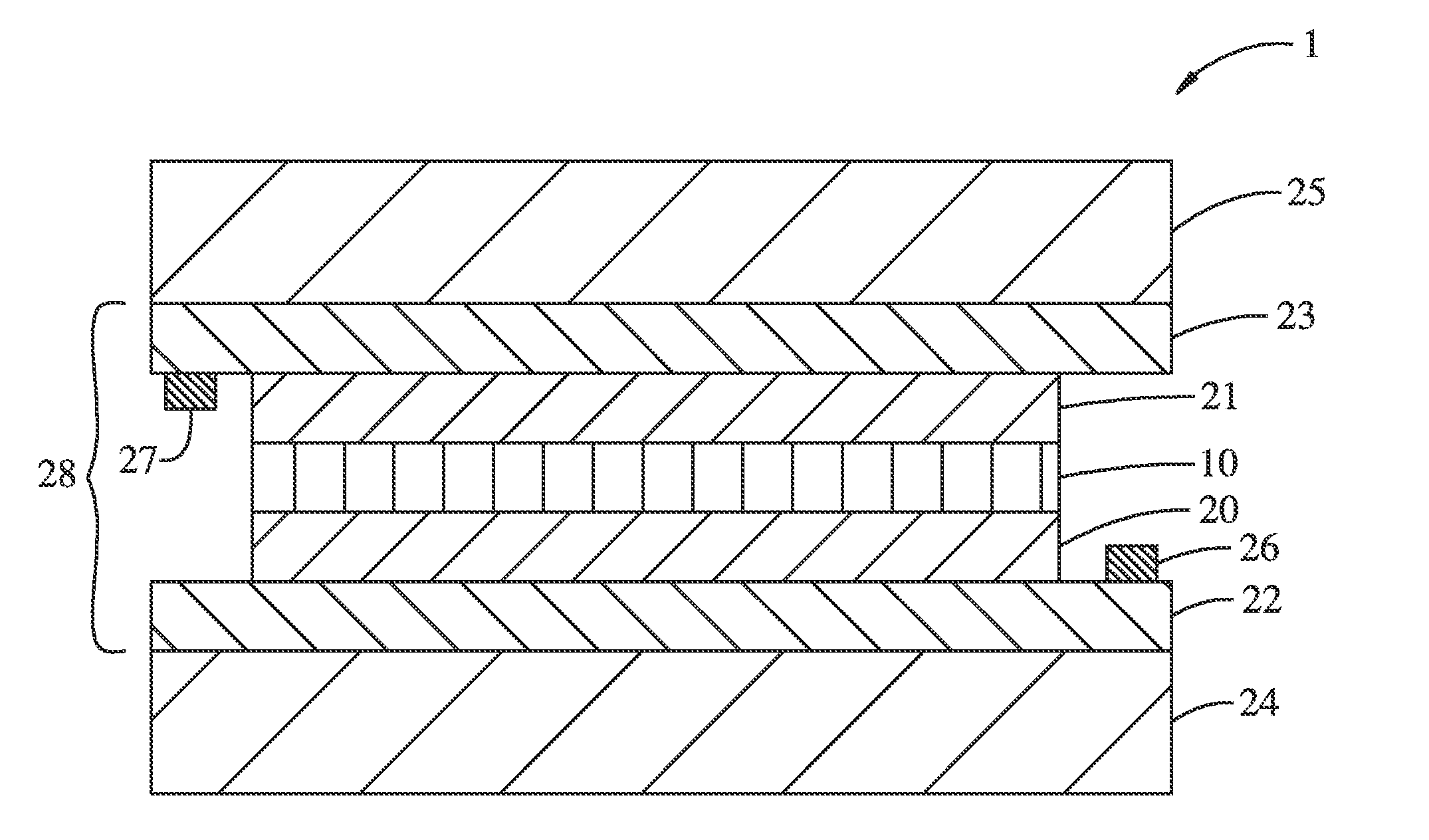

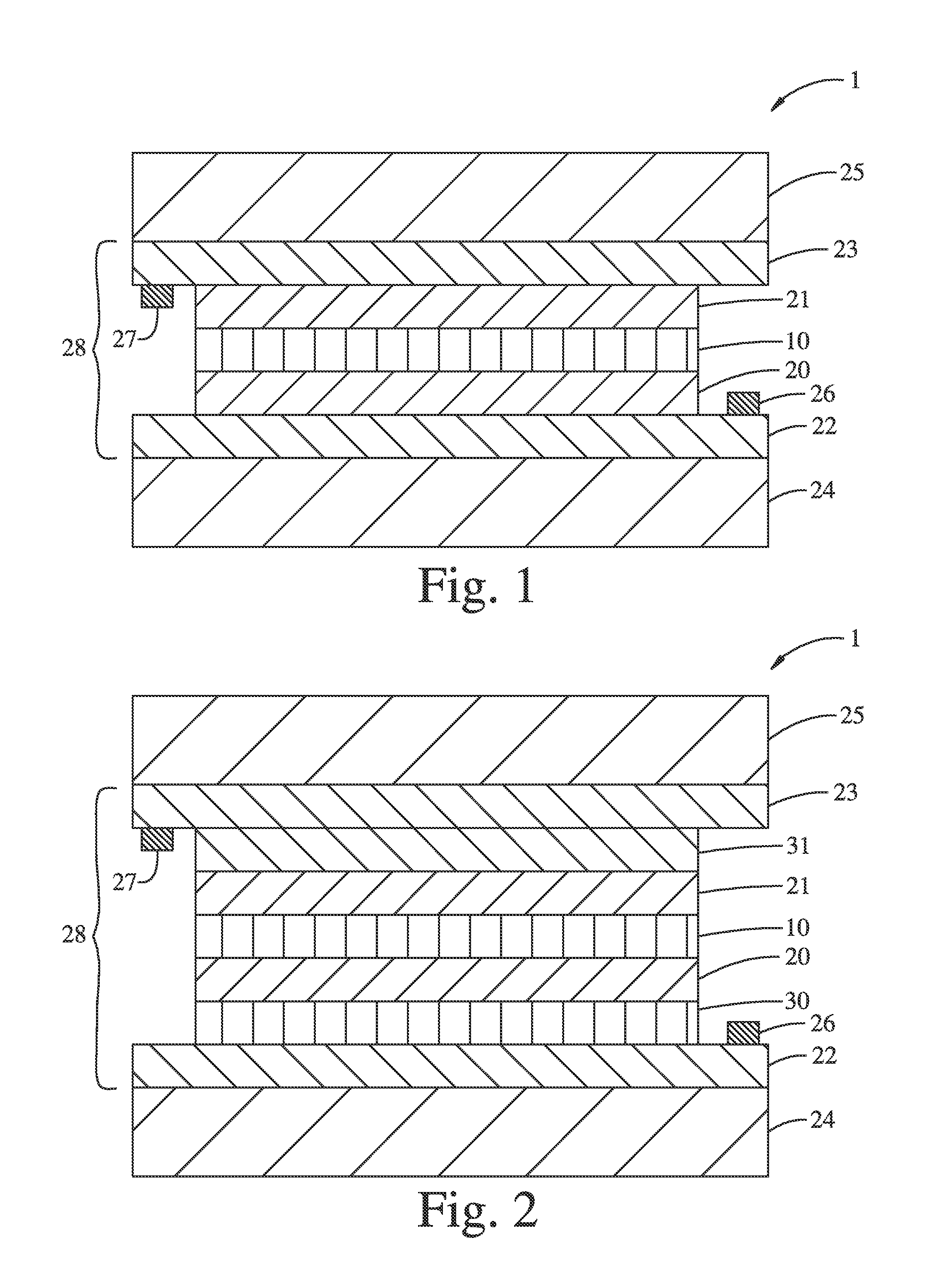

Electrochromic counter electrode

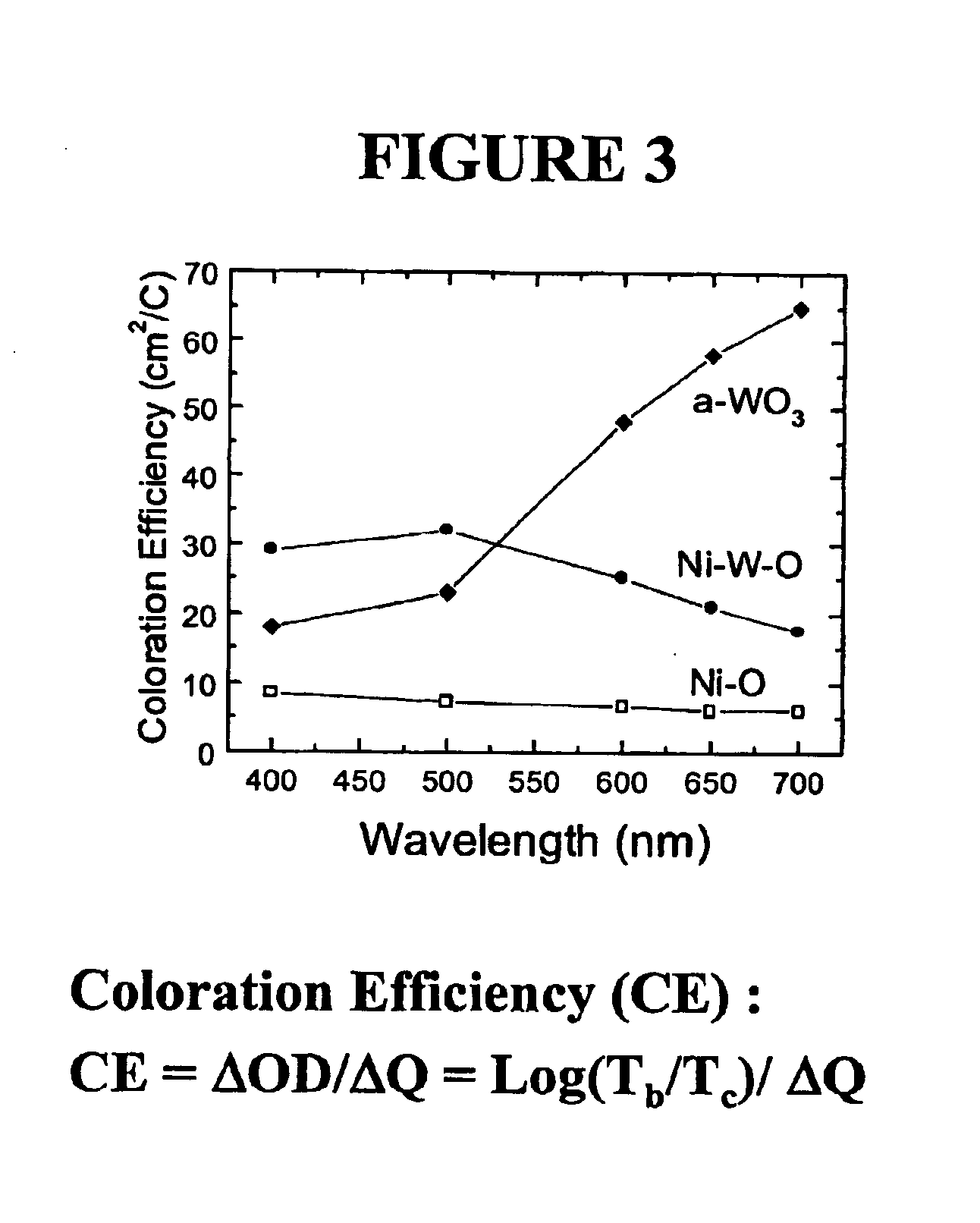

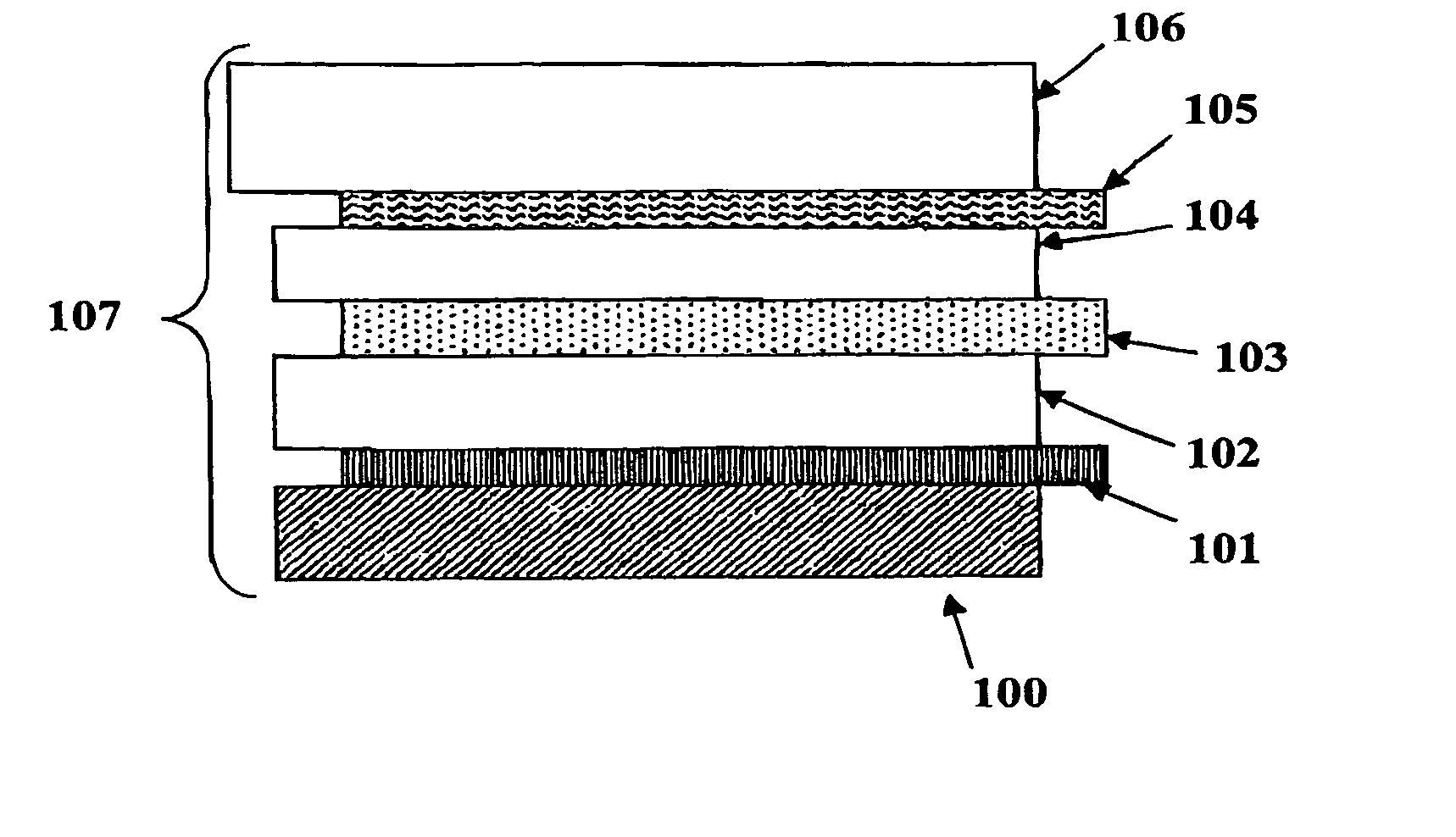

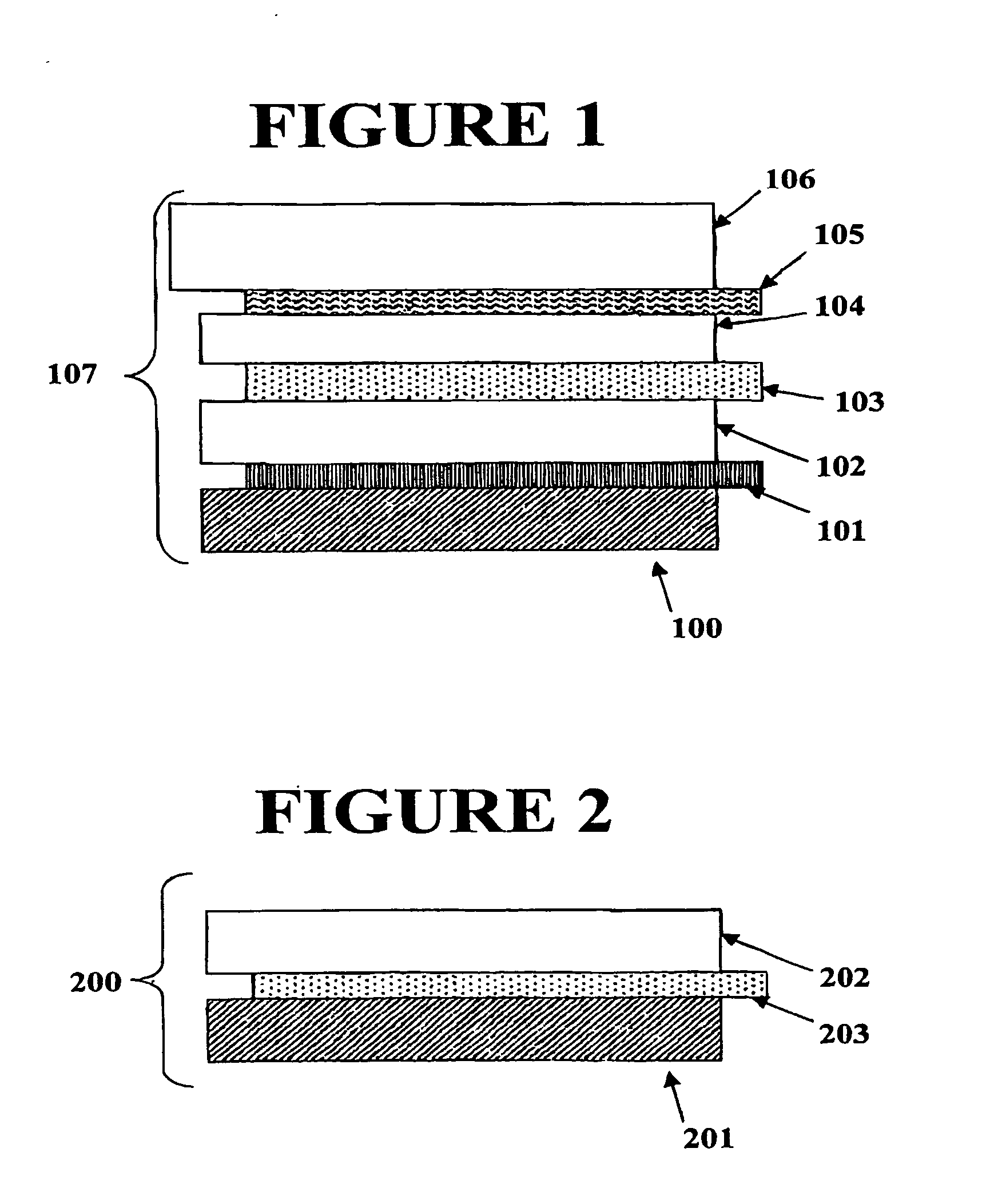

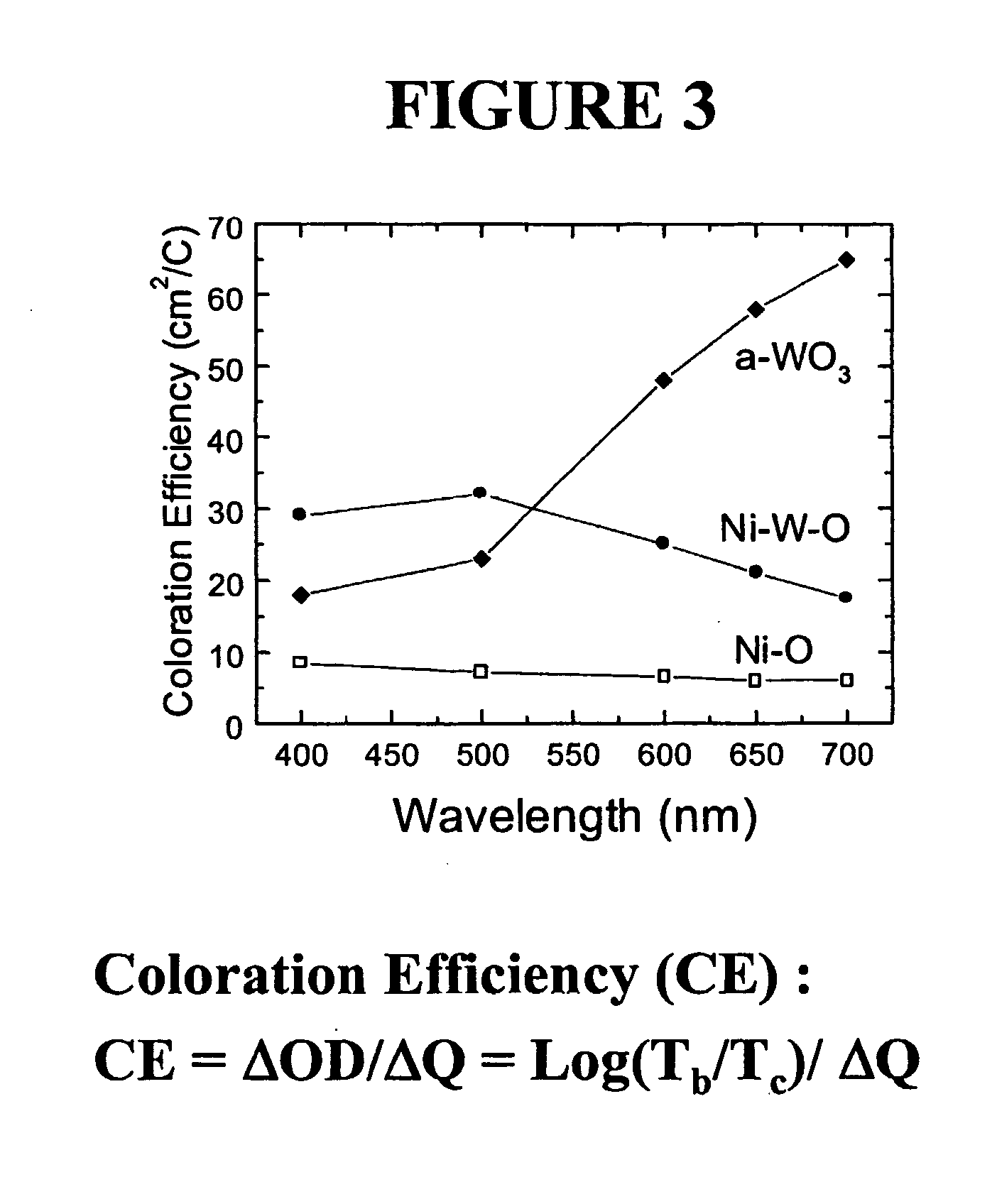

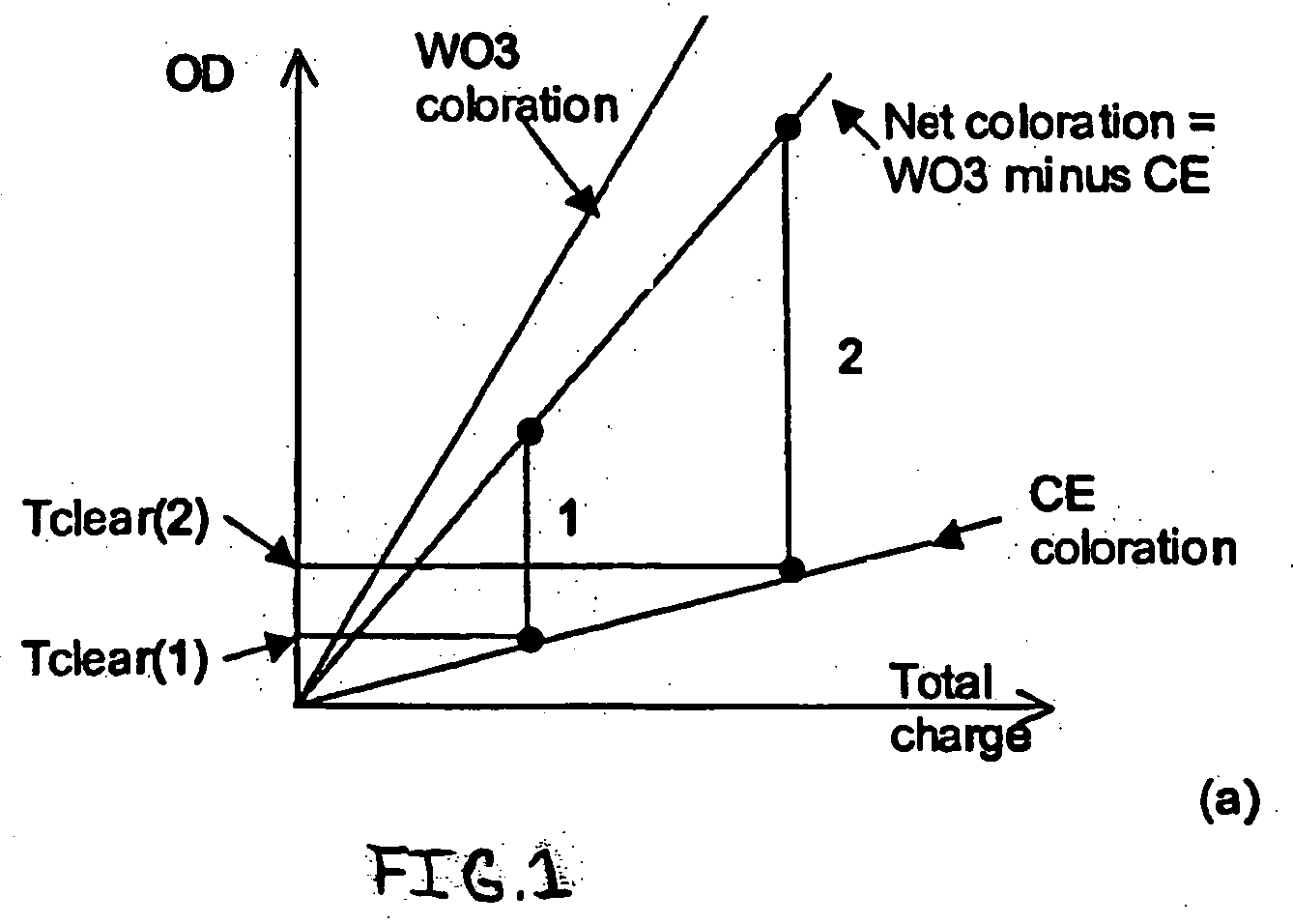

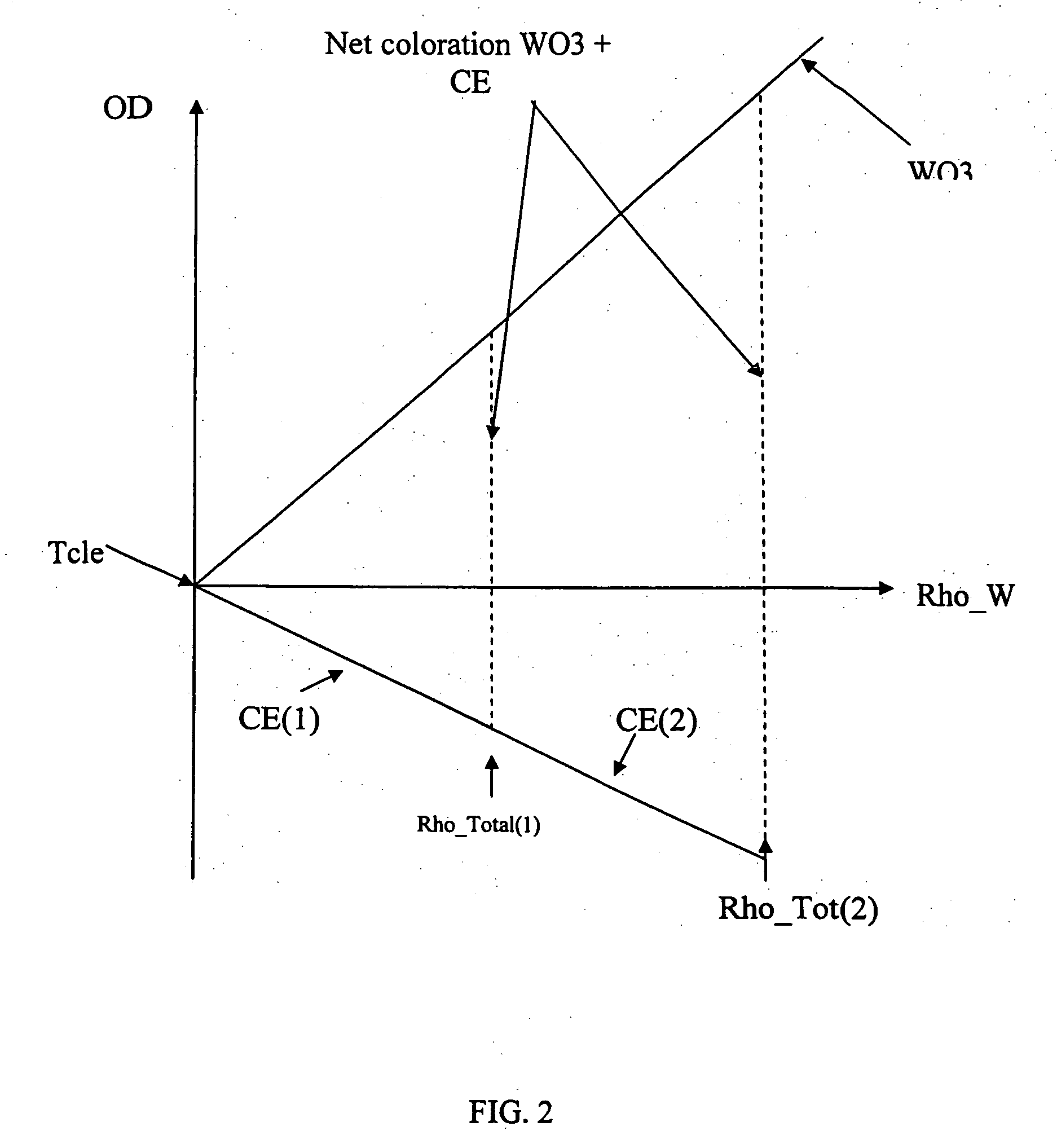

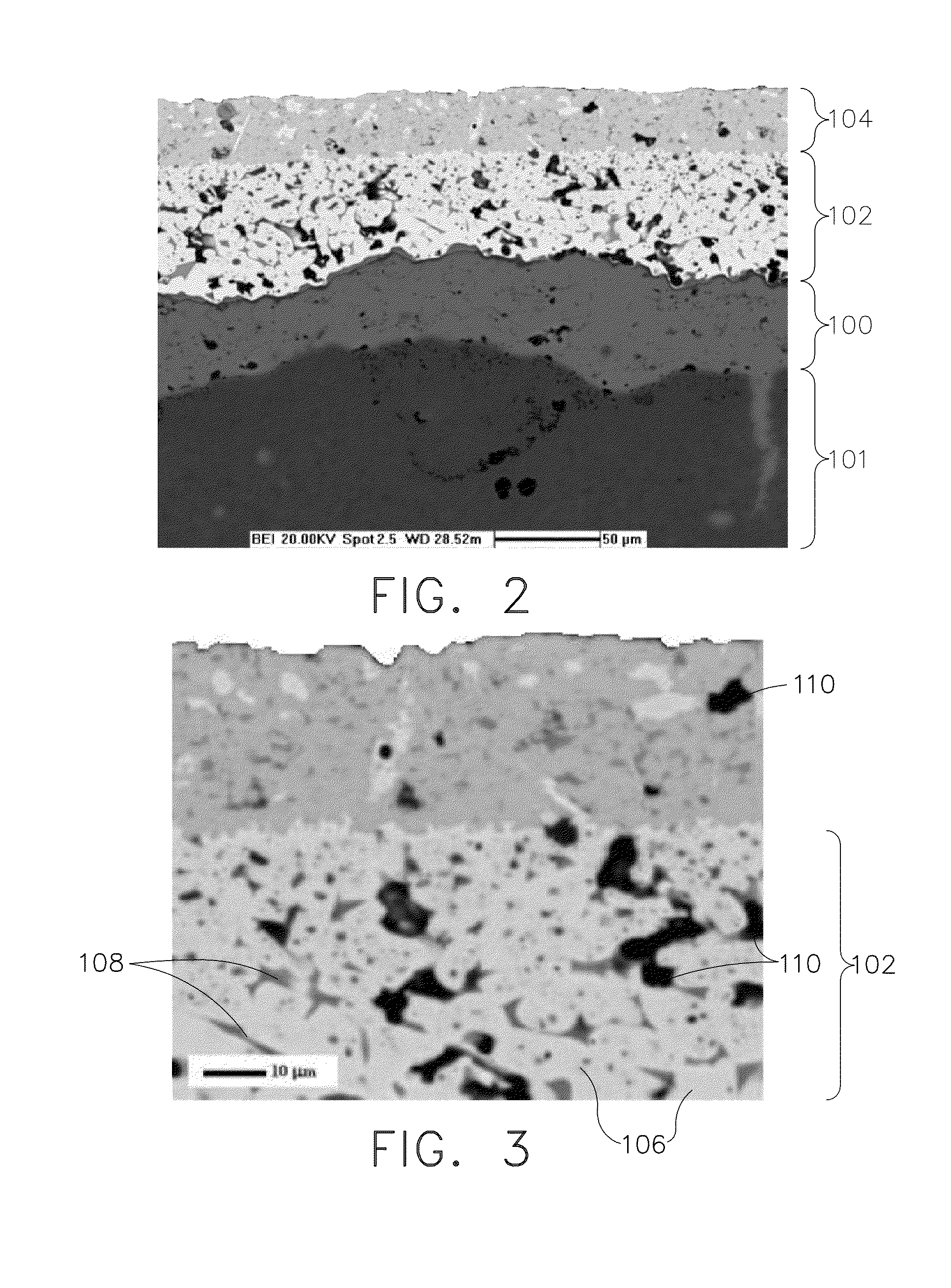

The present invention discloses an amorphous material comprising nickel oxide doped with tantalum that is an anodically coloring electrochromic material. The material of the present invention is prepared in the form of an electrode (200) having a thin film (202) of an electrochromic material of the present invention residing on a transparent conductive film (203). The material of the present invention is also incorporated into an electrochromic device (100) as a thin film (102) in conjunction with a cathodically coloring prior art electrochromic material layer (104) such that the devices contain both anodically coloring (102) and cathodically coloring (104) layers. The materials of the electrochromic layers in these devices exhibit broadband optical complimentary behavior, ionic species complimentary behavior, and coloration efficiency complimentary behavior in their operation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

Electrochromic counter electrode

InactiveUS20040150867A1Easy to calculateSpeed of coloring/bleaching can be alteredNon-linear opticsElectricityElectrochromism

The present invention discloses an amorphous material comprising nickel oxide doped with tantalum that is an anodically coloring electrochromic material. The material of the present invention is prepared in the form of an electrode (200) having a thin film (202) of an electrochromic material of the present invention residing on a transparent conductive film (203). The material of the present invention is also incorporated into an electrochromic device (100) as a thin film (102) in conjunction with a cathodically coloring prior art electrochromic material layer (104) such that the devices contain both anodically coloring (102) and cathodically coloring (104) layers. The materials of the electrochromic layers in these devices exhibit broadband optical complimentary behavior, ionic species complimentary behavior, and coloration efficiency complimentary behavior in their operation.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

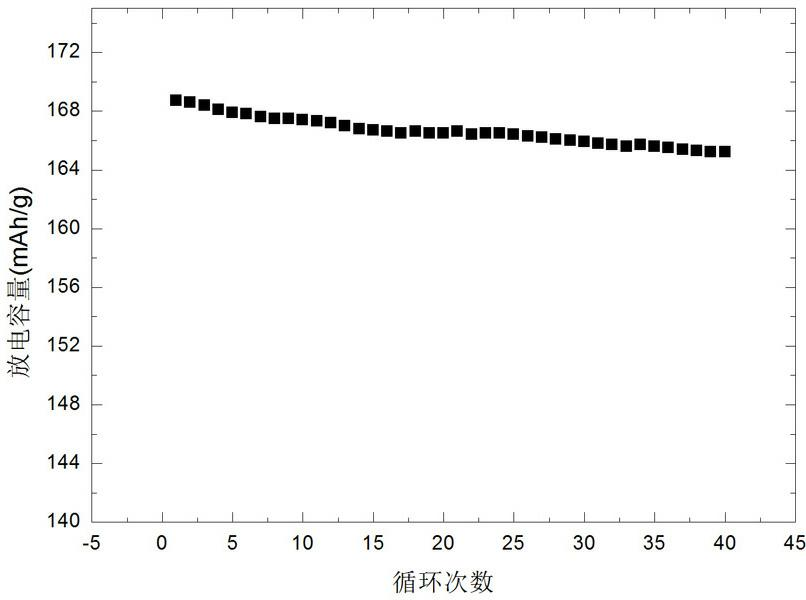

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

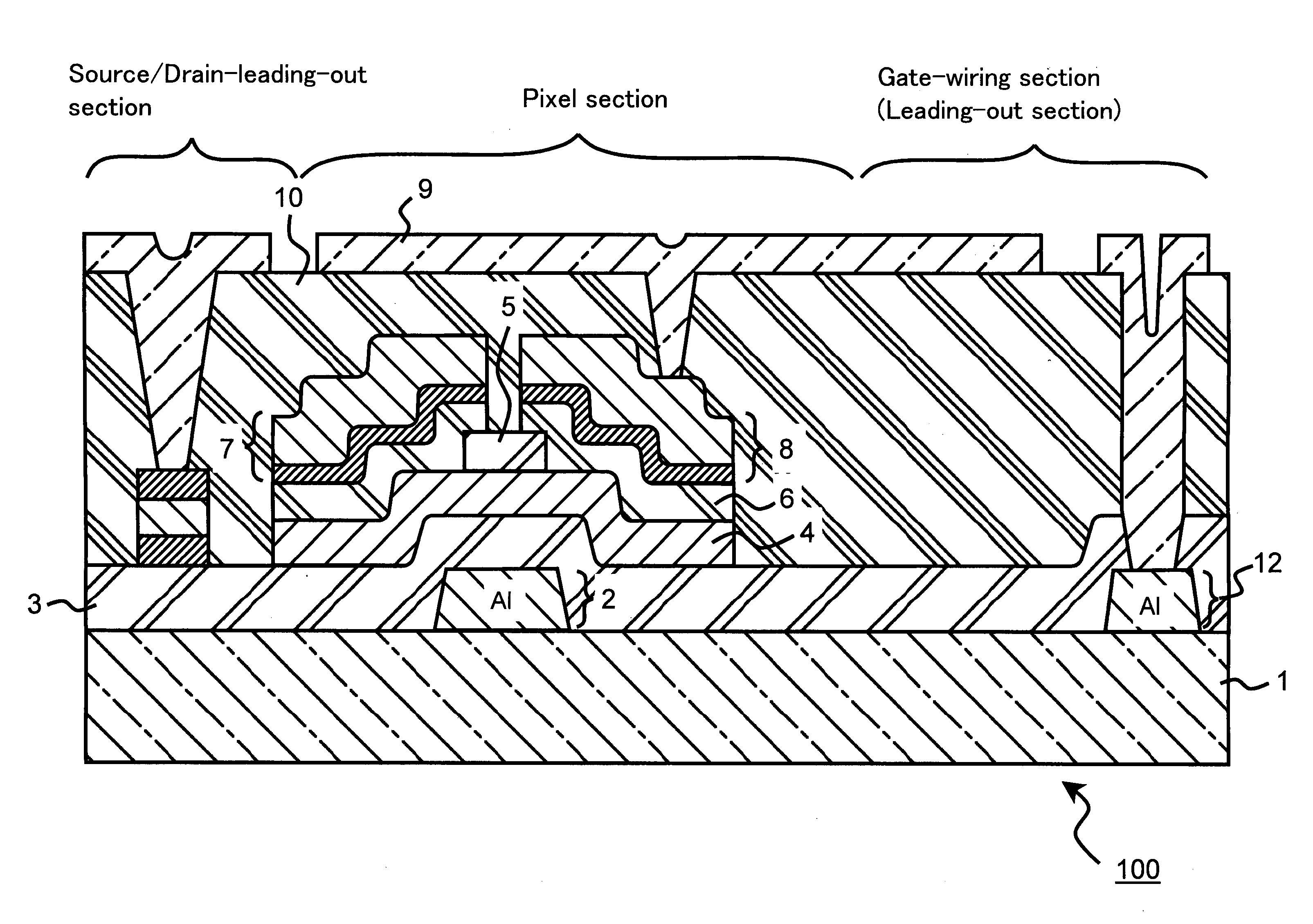

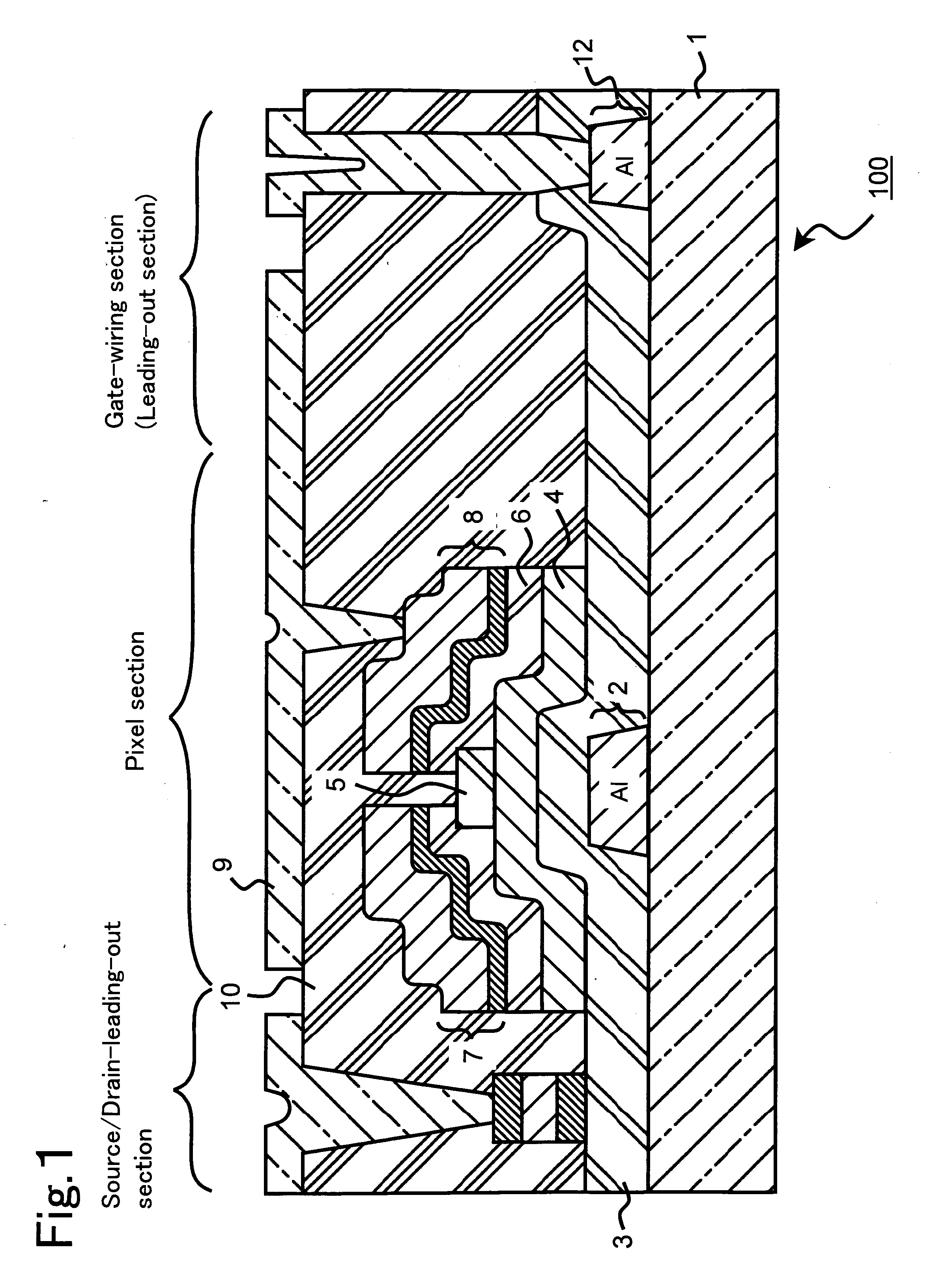

Thin film transistor, thin film transistor substrate, processes for producing the same, liquid crystal display using the same, and related devices and processes; and sputtering target, transparent electroconductive film formed by use of this,transparent electrode, and related devices and processes

InactiveUS20070170434A1Reduce light transmittanceConductive layers on insulating-supportsSemiconductor/solid-state device detailsIndiumLiquid-crystal display

Provided are a thin film transistor substrate having a transparent electroconductive film in which residues and so on resulting etching are hardly generated; a process for producing the same; and a liquid crystal display using this thin film transistor substrate. A thin film transistor substrate, comprising a transparent substrate, a source electrode formed over the transparent substrate, a drain electrode formed over the transparent substrate, and a transparent pixel electrode formed over the transparent substrate, wherein the transparent pixel electrode is a transparent electroconductive film which is made mainly of indium oxide, and further comprises one or two or more oxides selected from tungsten oxide, molybdenum oxide, nickel oxide and niobium oxide, and the transparent pixel electrode is electrically connected to the source electrode or the drain electrode; a process for producing the same; and a liquid crystal display using this thin film transistor substrate.

Owner:IDEMITSU KOSAN CO LTD

Electrochromic devices and methods

A heat treated electrochromic device comprising an anodic complementary counter electrode layer comprised of a mixed tungsten-nickel oxide and lithium, which provides a high transmission in the fully intercalated state and which is capable of long term stability, is disclosed. Methods of making an electrochromic device comprising an anodic complementary counter electrode comprised of a mixed tungsten-nickel oxide are also disclosed.

Owner:SAGE ELECTROCHROMICS

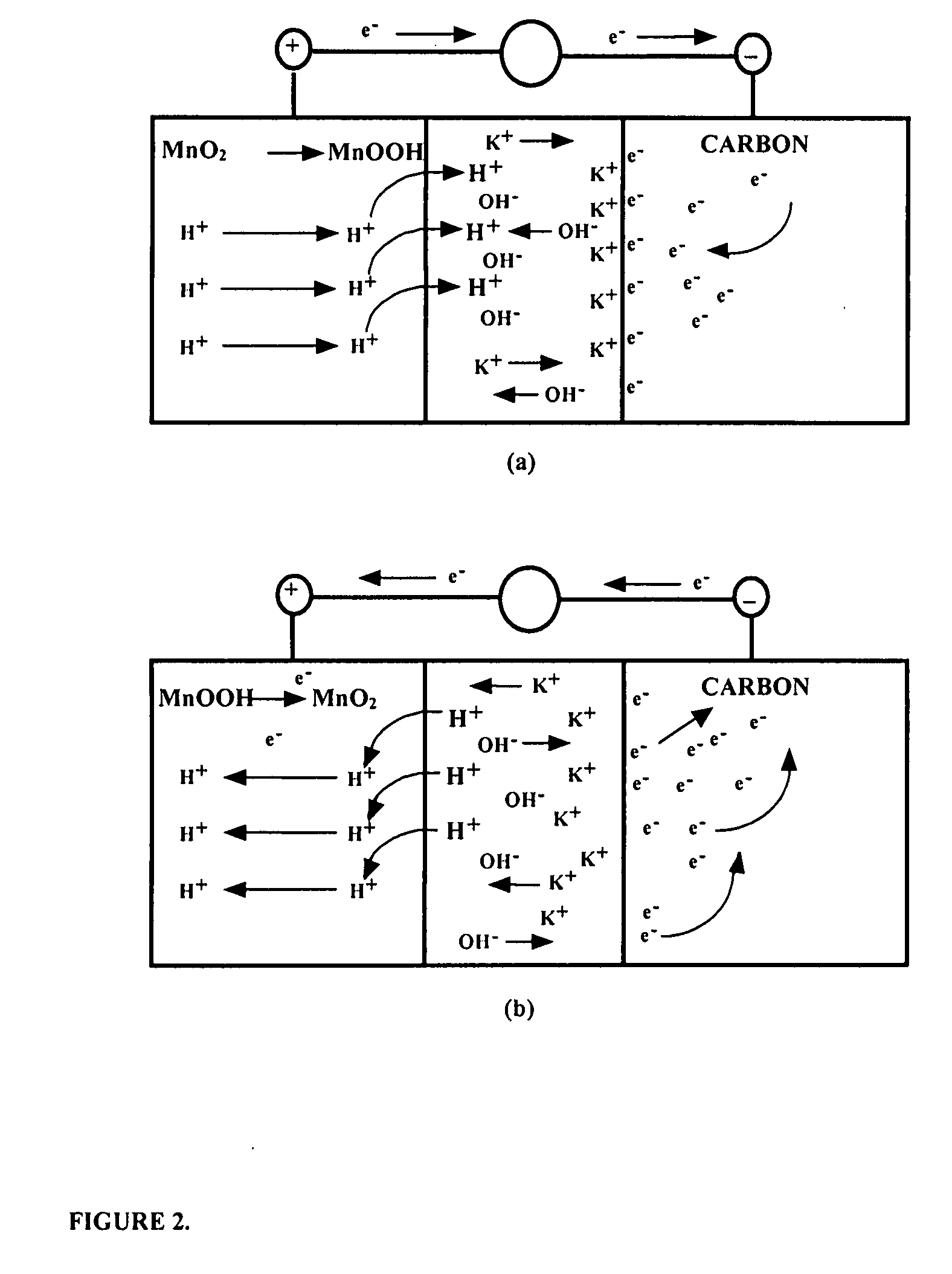

Asymmetric electrochemical supercapacitor and method of manufacture thereof

InactiveUS20080158778A1Increase energy densityImprove power densityHybrid capacitor electrodesLiquid electrolytic capacitorsAqueous electrolyteLithium manganese oxide

Asymmetric supercapacitors comprise: a positive electrode comprising a current collector and a first active material selected from the group consisting of manganese dioxide, silver oxide, iron sulfide, lithium manganese oxide, lithium cobalt oxide, lithium nickel oxide, lithium iron phosphate, and a combination comprising at least one of the foregoing active materials; a negative electrode comprising a carbonaceous active material; an aqueous electrolyte solution selected from the group consisting of aqueous solutions of hydroxides of alkali metals, aqueous solutions of carbonates of alkali metals, aqueous solutions of chlorides of alkali metals, aqueous solutions of sulfates of alkali metals, aqueous solutions of nitrates of alkali metals, and a combination comprising at least one of the foregoing aqueous solutions; and a separator plate. Alternatively, the electrolyte can be a non-aqueous ionic conducting electrolyte or a solid electrolyte.

Owner:U S NANOCORP

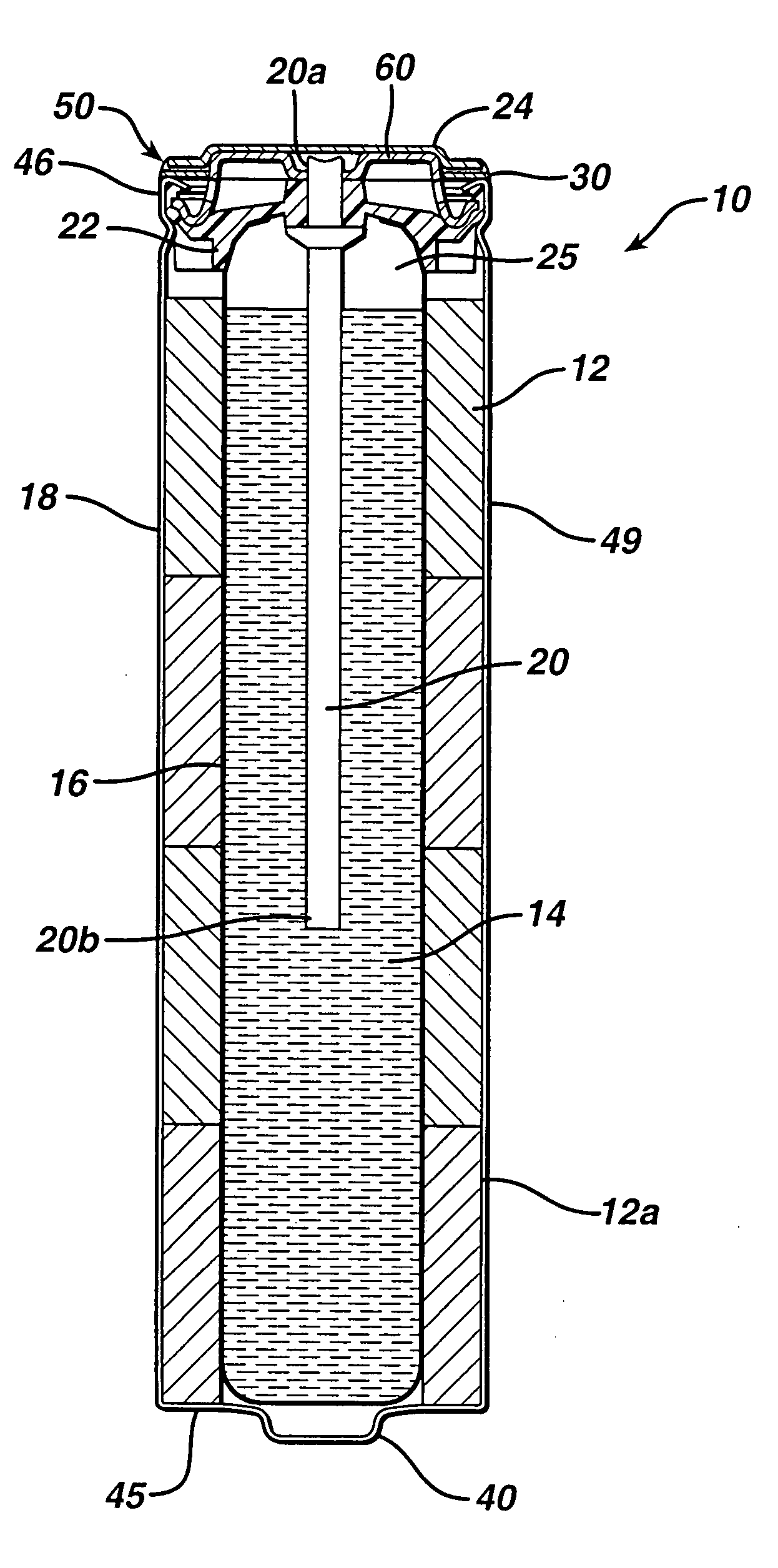

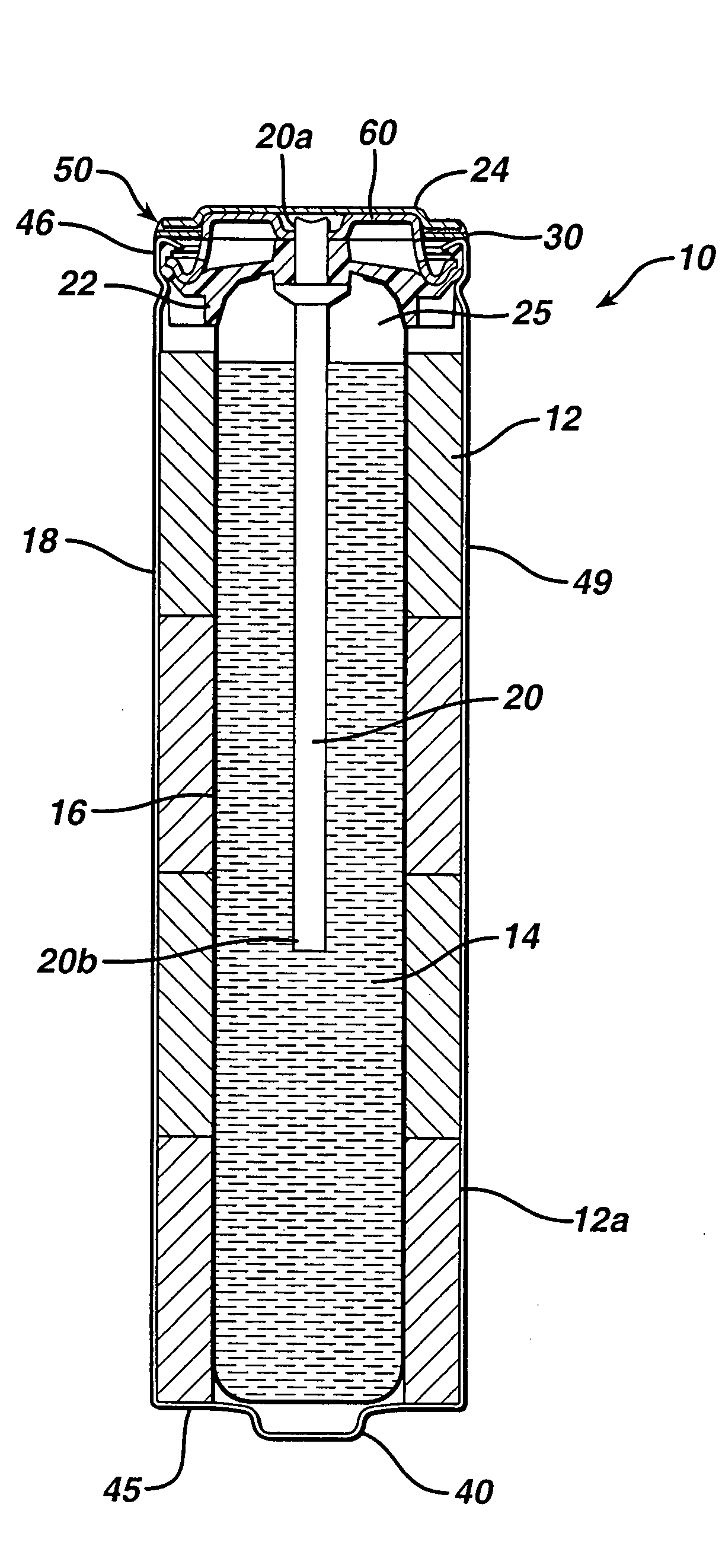

Alkaline battery including nickel oxyhydroxide cathode and zinc anode

InactiveUS20070248879A1Improve discharge performanceHigh capacity retentionActive material electrodesJackets/cases materialsConductive coatingZinc alloys

A primary alkaline battery includes a cathode including a nickel oxyhydroxide and an anode including zinc or zinc alloy particles. Performance of the nickel oxyhydroxide alkaline cell is improved by adding zinc fines to the anode and by including an oxidation resistant graphite in the cathode as well as in a conductive coating applied to the inside surface of the cell housing.

Owner:THE GILLETTE CO

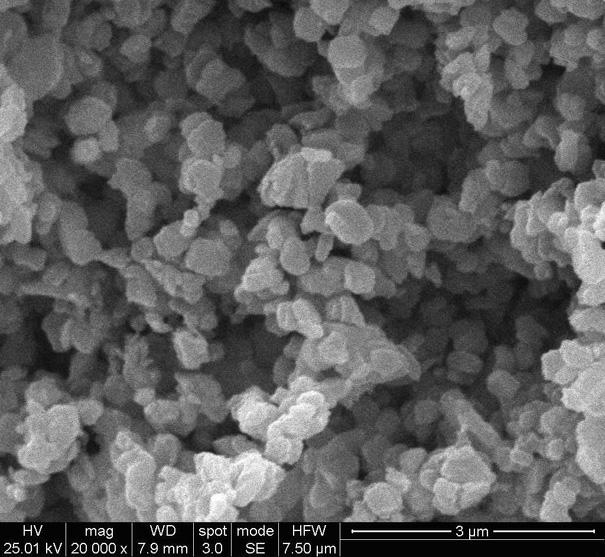

Nanometer grade low carbon paraffin dehydrogen catalyst

InactiveCN1911502ALarge specific surface areaHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsAlkaneCarbon nanotube

The present invention relates to one kind of nanometer level low carbon alkane dehydrogenating catalyst, and features that the C3-C5 low carbon alkane dehydrogenating catalyst comprises carrier of single wall or multiple wall carbon nanotube and two active components selected from chromic oxide in 2-30 wt%, alumina in 2-25 weight and nickel oxide in 2-30 wt%. The catalyst has high catalysis activity, increased active structures, long service life, low catalytic dehydrogenation reaction temperature, high conversion rate, high selectivity and other advantages.

Owner:DAQING PETROLEUM ADMINISTRATION

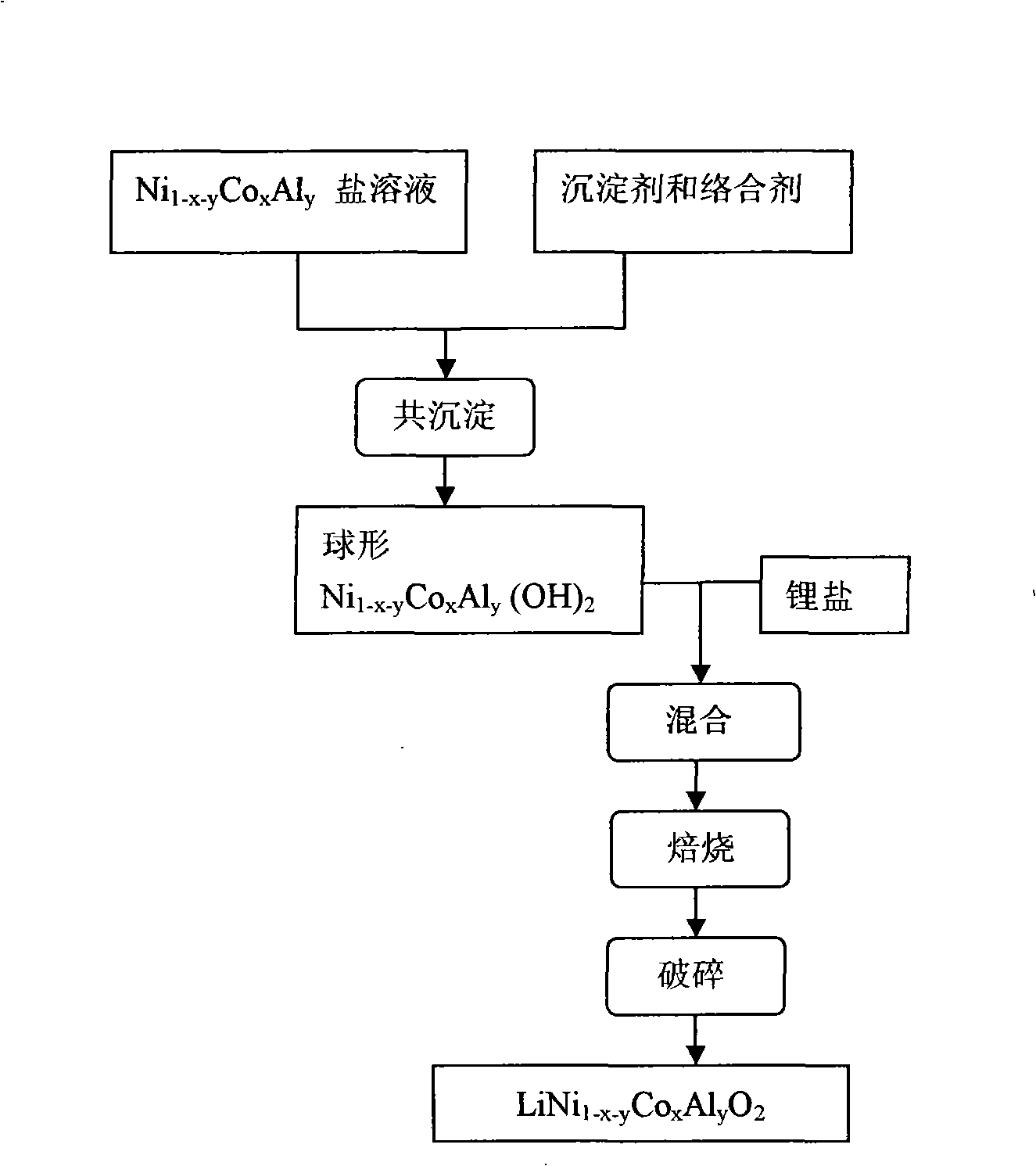

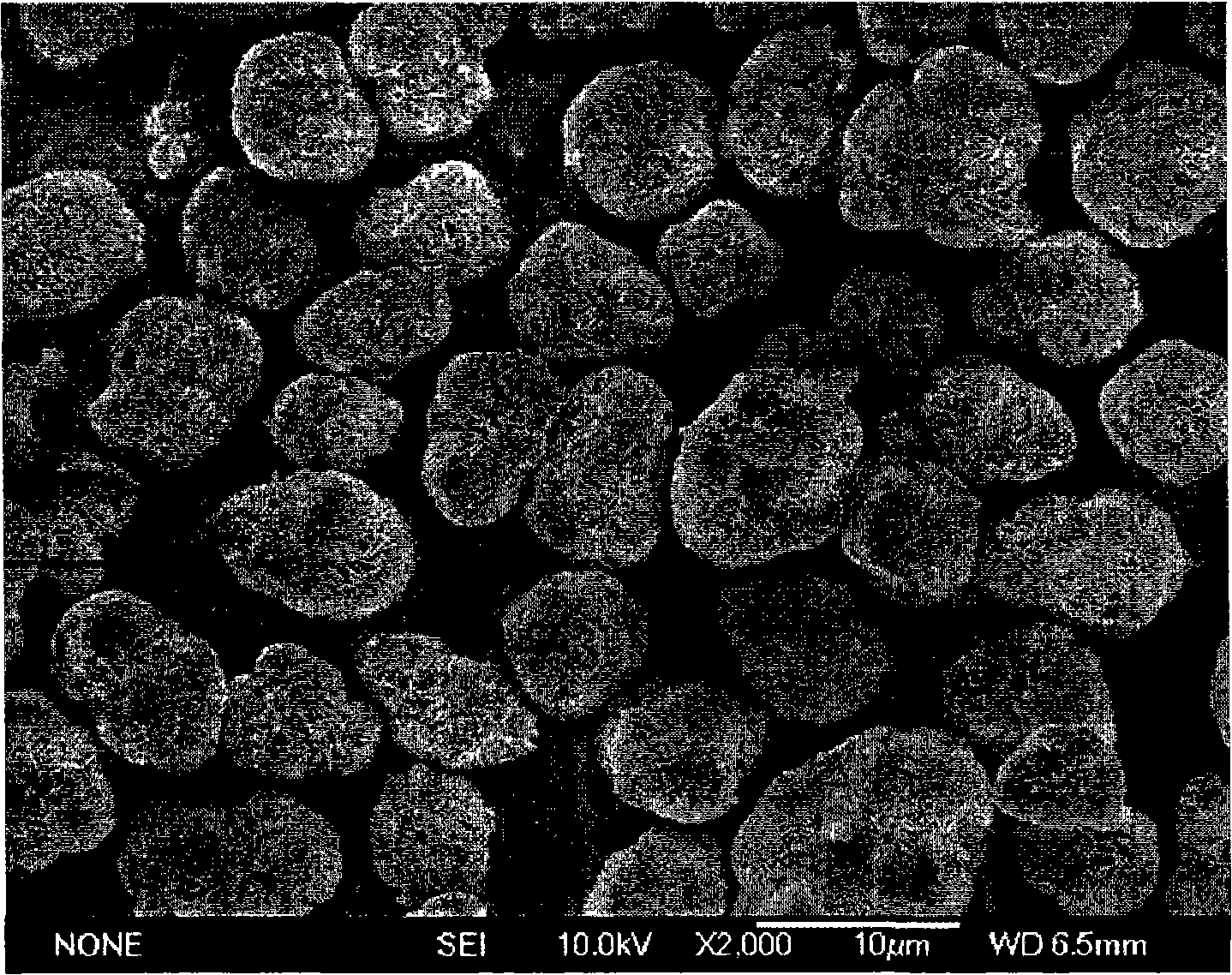

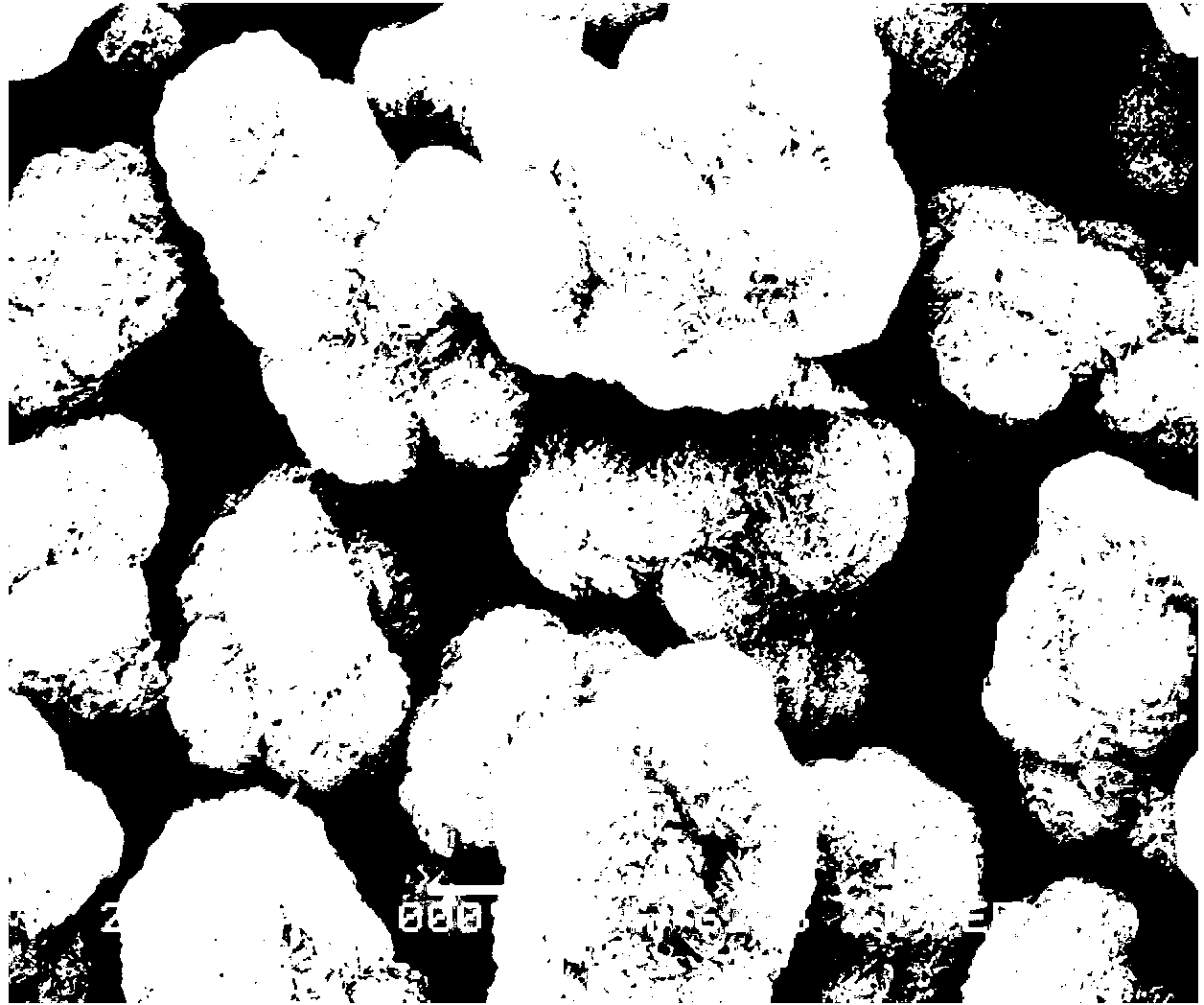

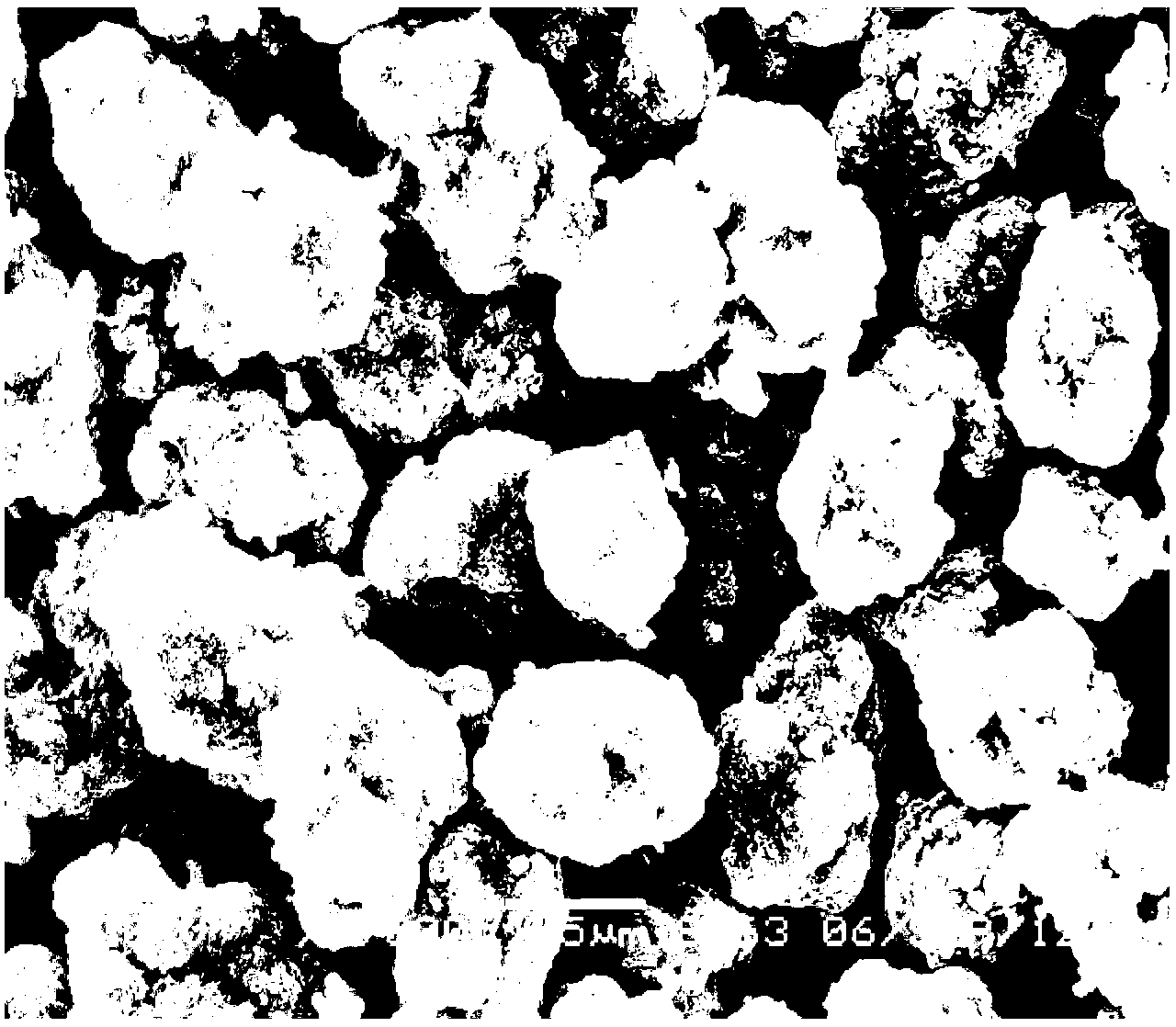

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

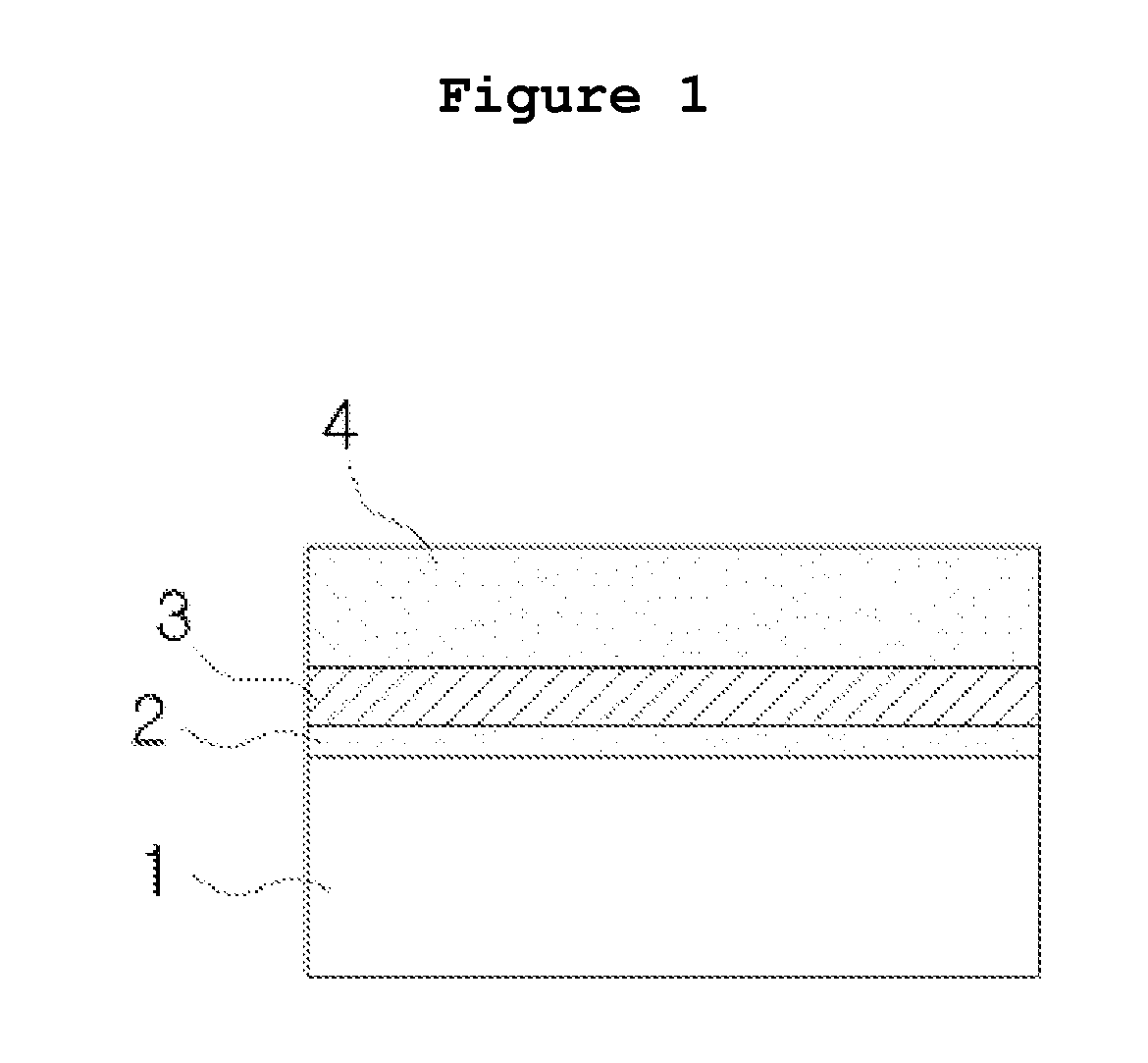

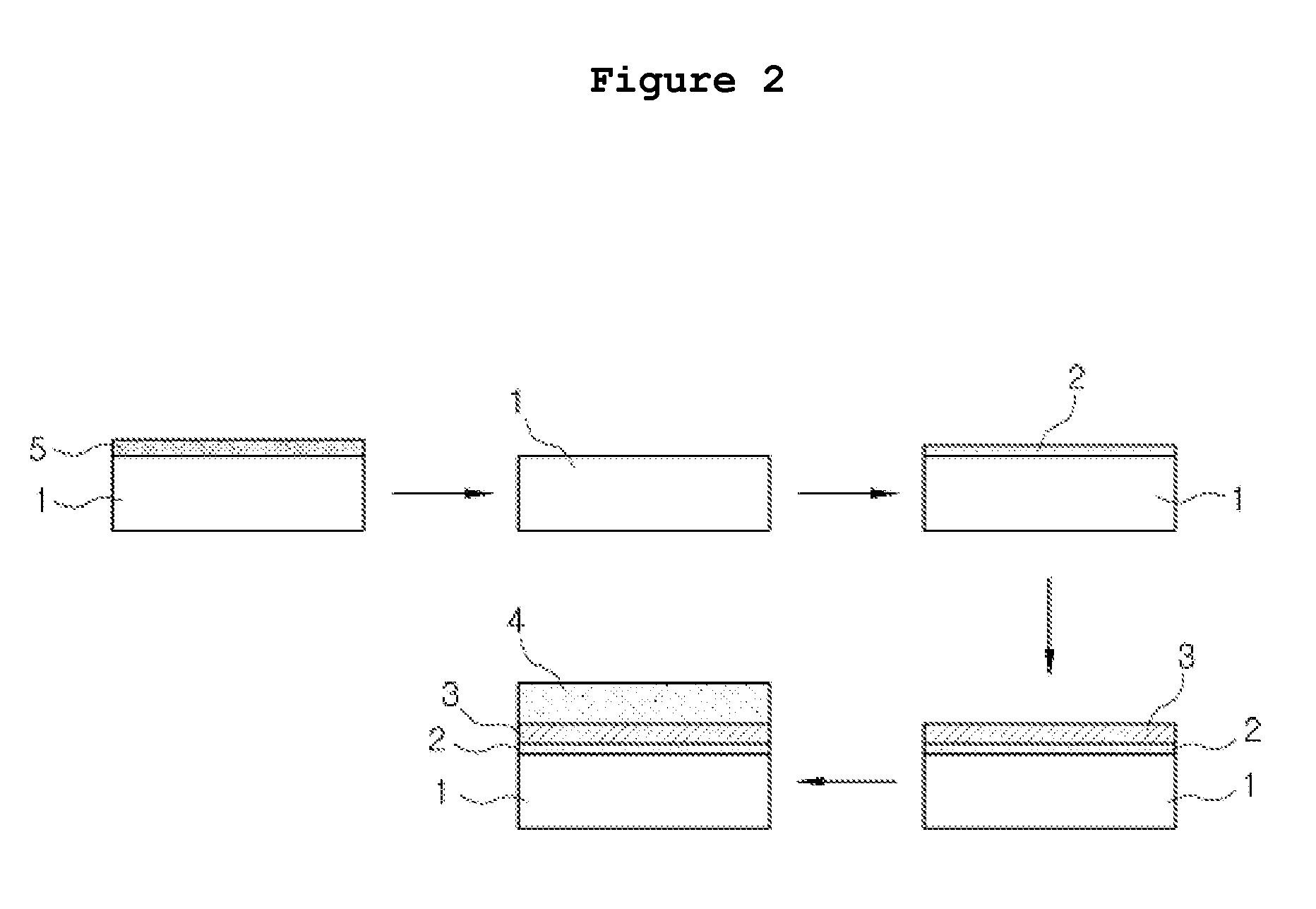

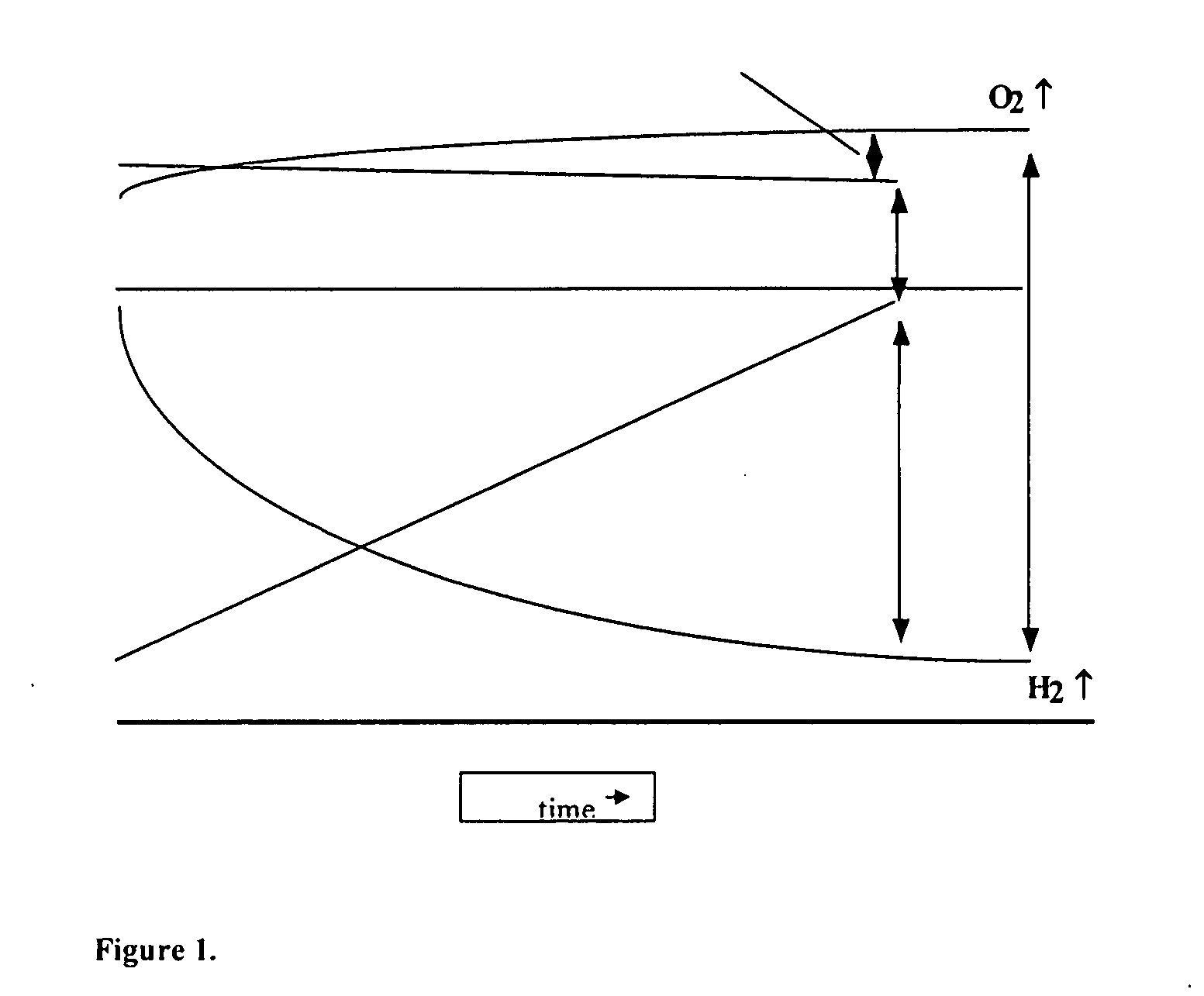

Process for preparing a multi-layer electrochromic structure

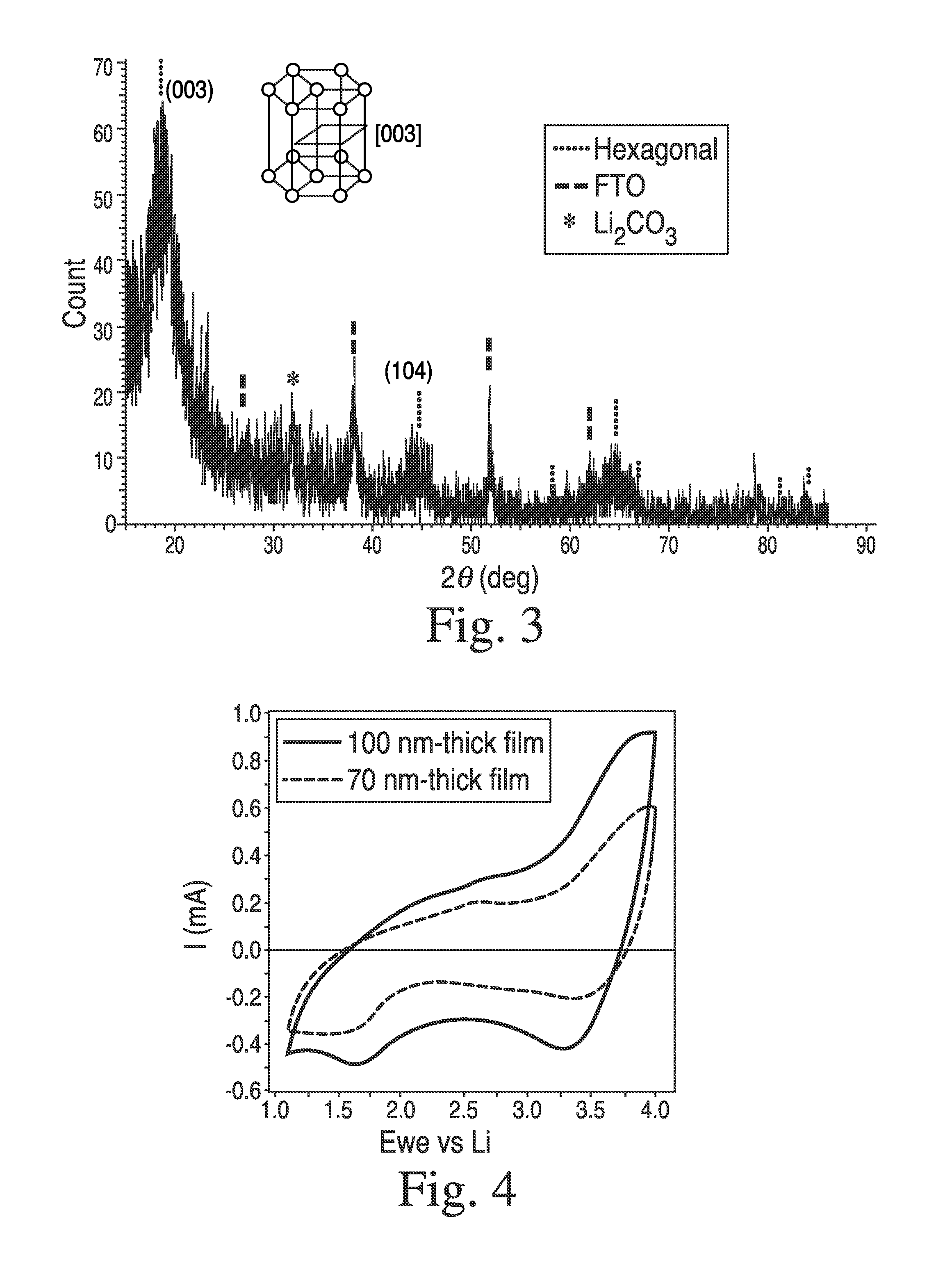

Process for preparing a multi-layer electrochromic structure comprising depositing a film of a liquid mixture onto a substrate and treating the deposited film to form an anodic electrochromic layer comprising a lithium nickel oxide composition, the anodic electrochromic layer comprising lithium, nickel and the bleached state stabilizing element(s) wherein in the film (i) the ratio of lithium to the combined amount of nickel and the bleached state stabilizing element(s) is at least 0.4:1, (ii) the ratio of the combined amount of the bleached state stabilizing element(s) to the combined amount of nickel and the bleached state stabilizing elements in the lithium nickel oxide composition is at least about 0.025:1, and (iii) the bleached state stabilizing element(s) is / are selected from the group consisting of Y, Ti, Zr, Hf, V, Nb, Ta, Mo, W, B, Al, Ga, In, Si, Ge, Sn, P, Sb and combinations thereof.

Owner:KINESTRAL TECH

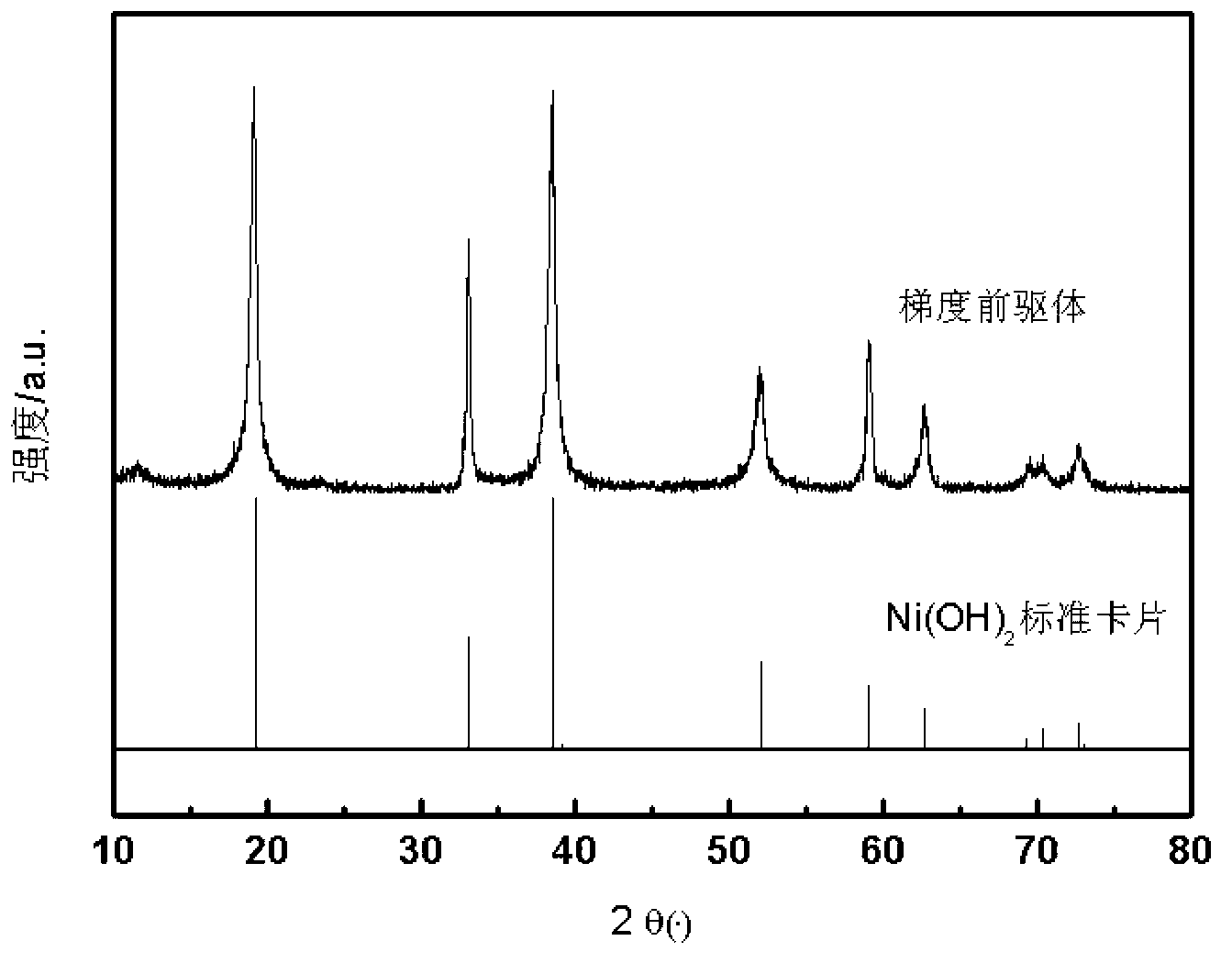

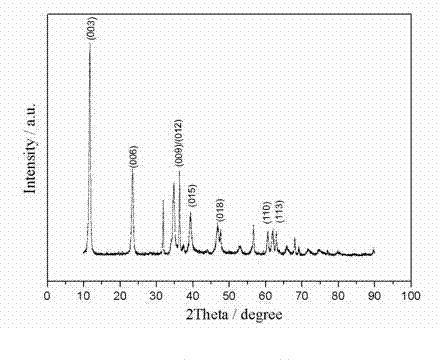

Gradient coated LiNiO2 material and preparation method

InactiveCN103078109AHigh electrochemical capacityInhibit sheddingCell electrodesSource materialManganese

The invention discloses a preparation method for gradient coated LiNiO2 for lithium ion battery positive pole material, so as to solve the problem of bad circulating performance of conventional LiNiO2. The molecular formula of the LiNiO2 is LiNi 1-xMxO2, wherein, the x is less than or equal to 0.3 and greater than 0, the M is adulterated metal ions and is one or more selected from magnesium, nickel, Fe, titanium, zinc, Co, manganese, aluminum, Nb and vanadium, the gradient coat refers to that concentration gradient hydroxide coprecipitate provided with nickel and other metallic elements is coated on the surfaces of spherical nickelous hydroxide material, and then the precursor is mixed with lithium-source material and roasted under high temperature in an oxygen atmosphere furnace, so as to obtain high-performance modified LiNiO2. The gradient coated LiNiO2 obtained in the invention has the characteristics of high specific capacity, excellent circulating performance, excellent high-temperature property and the like, and is suitable for the application field of high- capacity lithium ion batteries.

Owner:CENT SOUTH UNIV

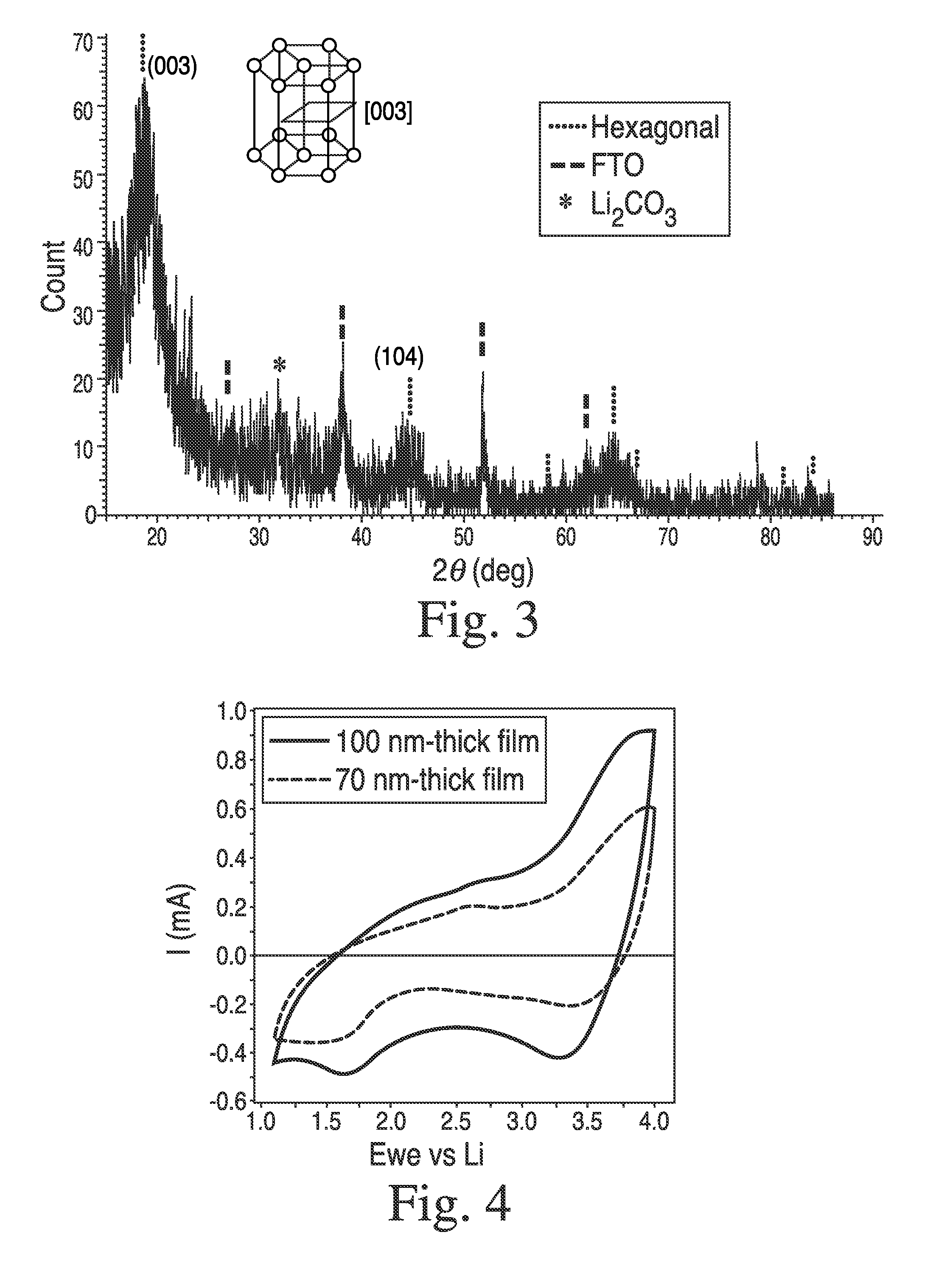

Electrochromic nickel oxide simultaneously doped with lithium and a metal dopant

An electrochromic device comprising a counter electrode layer comprised of lithium metal oxide which provides a high transmission in the fully intercalated state and which is capable of long-term stability, is disclosed. Methods of making an electrochromic device comprising such a counter electrode are also disclosed.

Owner:SAGE ELECTROCHROMICS +1

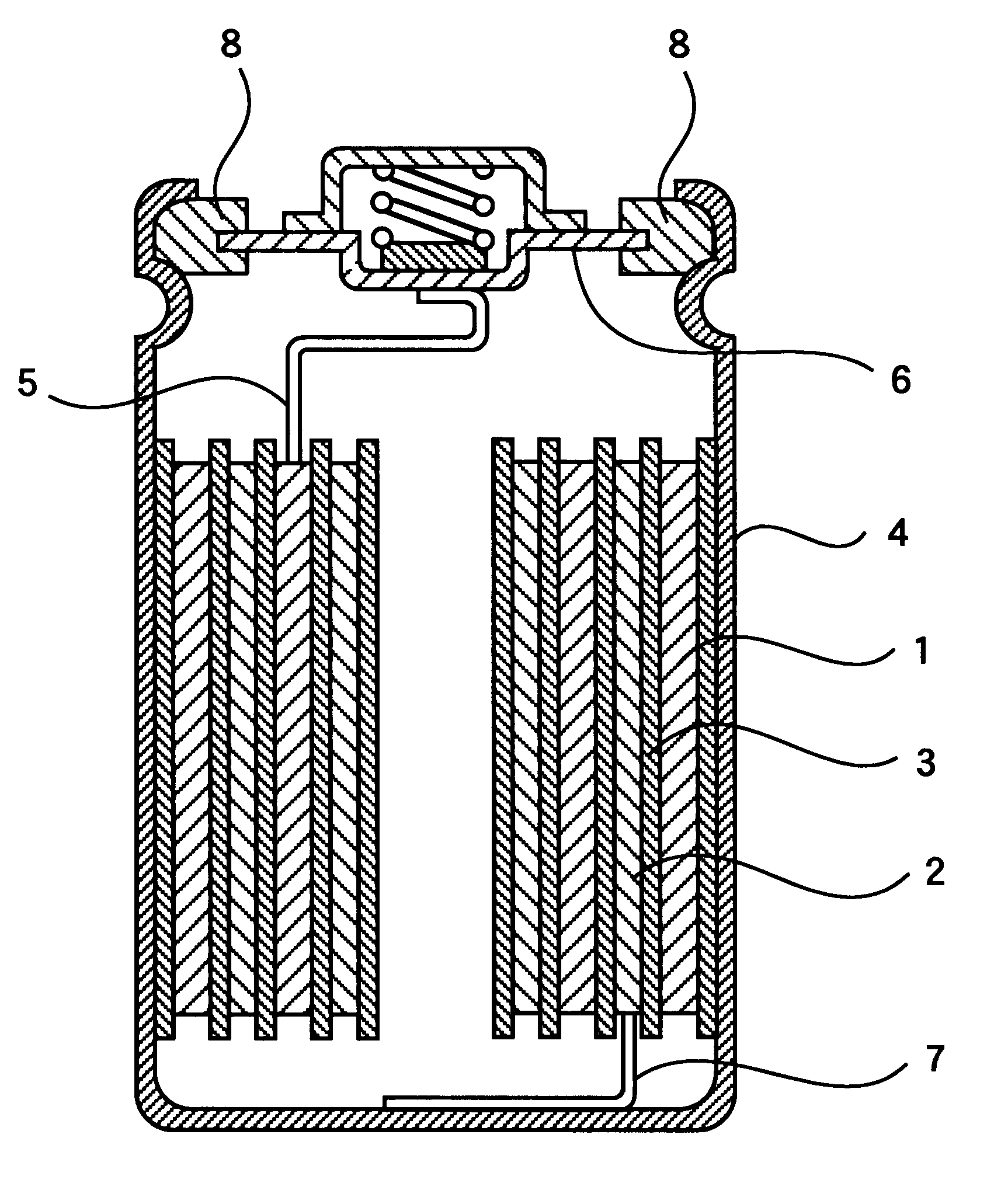

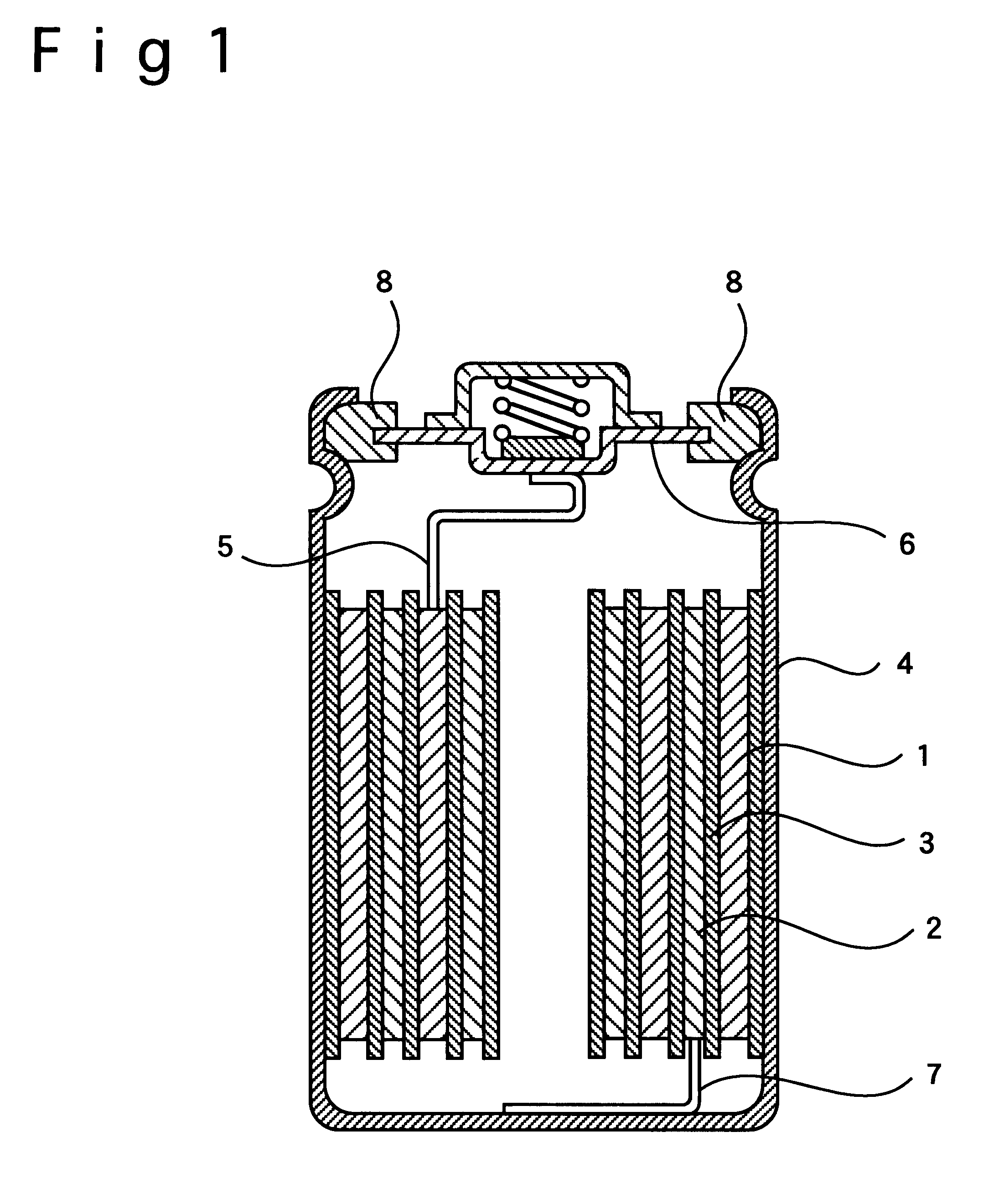

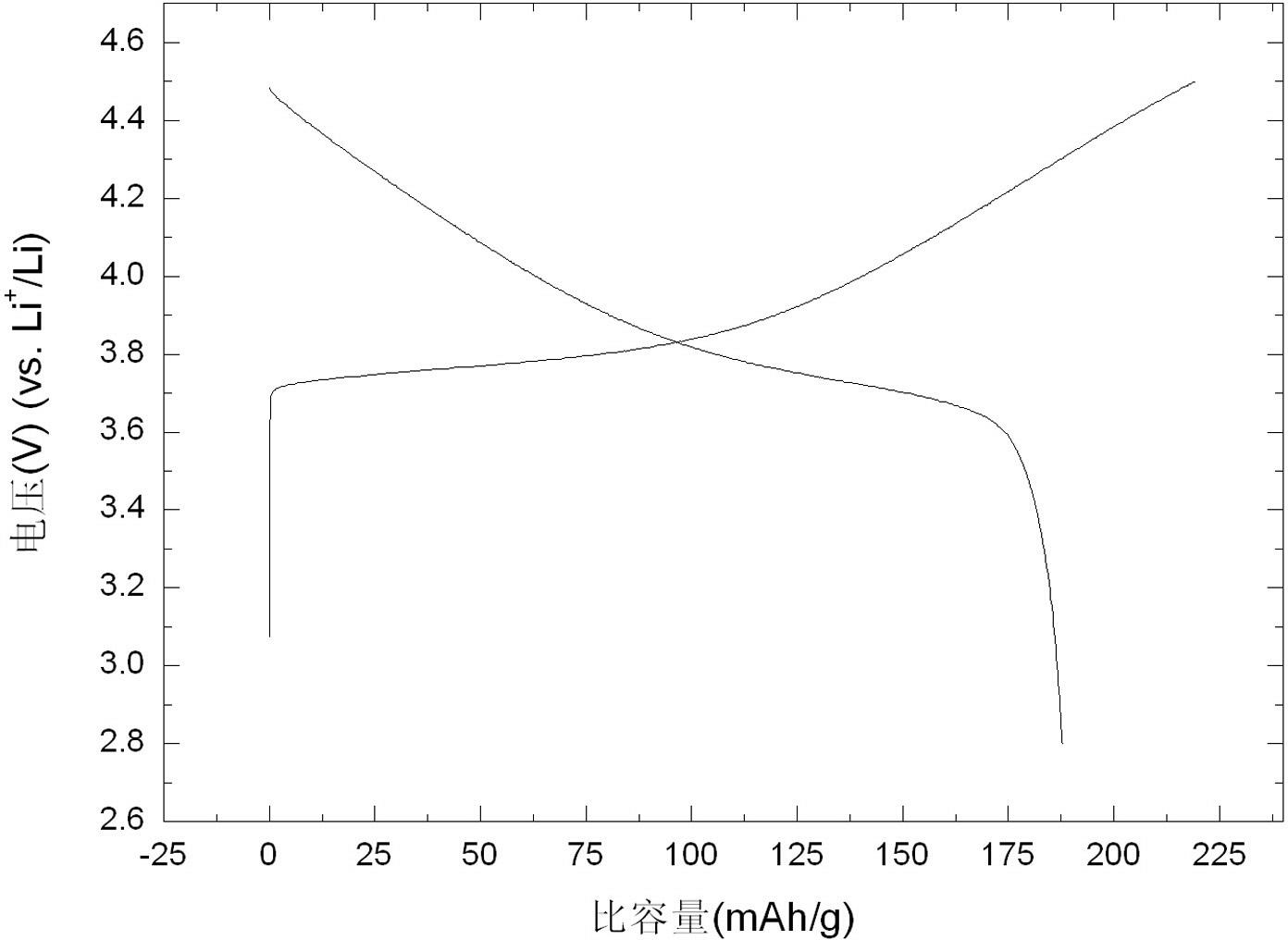

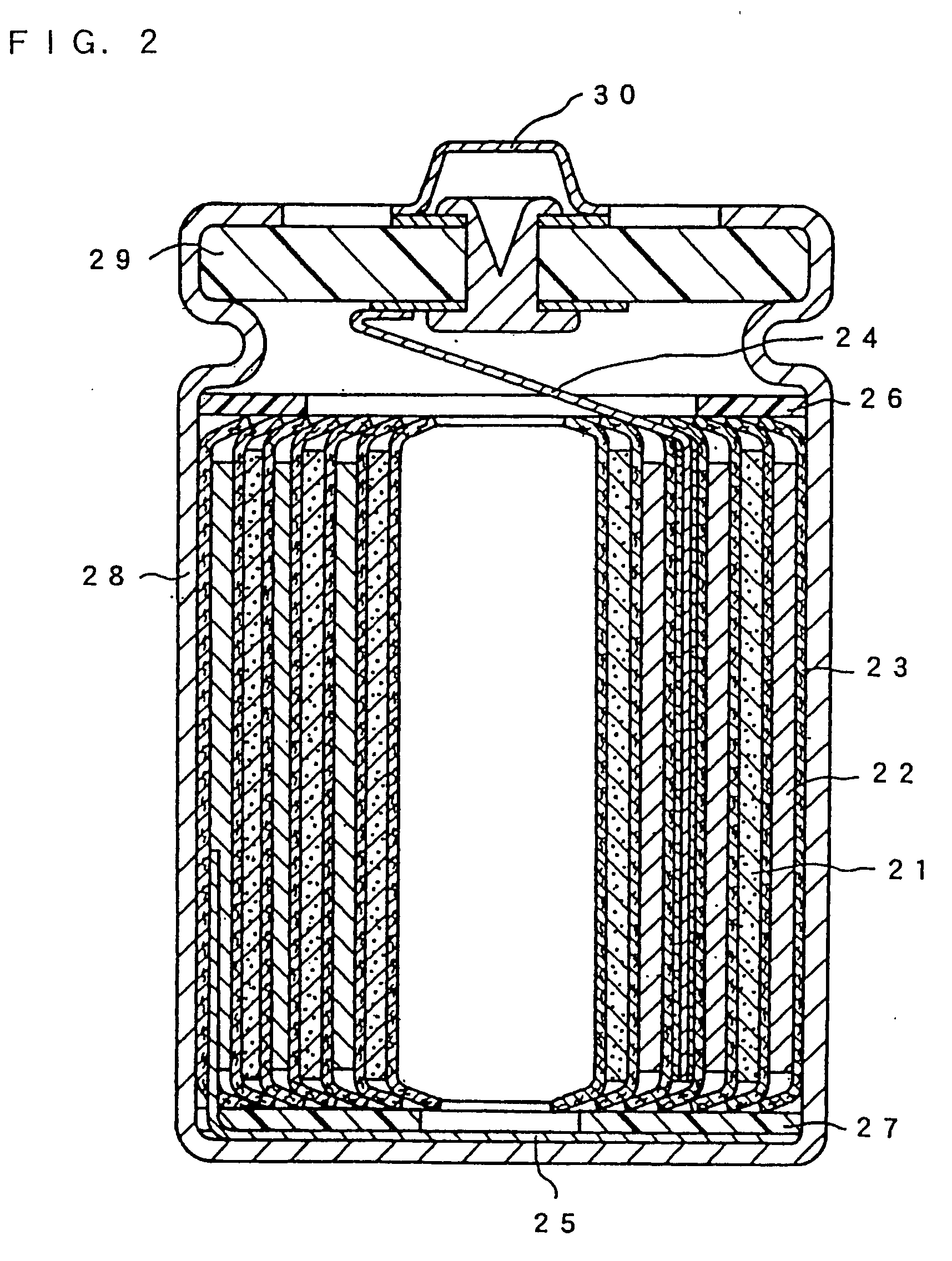

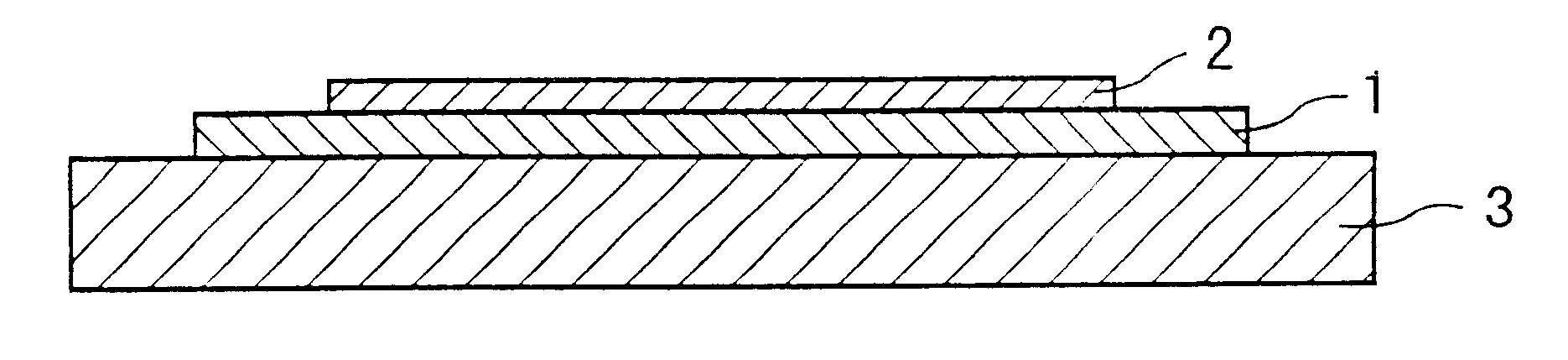

Non-aqueous electrolytic secondary cell

InactiveUS6436577B1Improve cycle performanceLow viscosityNon-aqueous electrolyte accumulatorsOrganic electrolyte cellsSolventTitanium oxide

In a non-aqueous electrolyte secondary battery provided with a positive electrode 1, a negative electrode 2, and a non-aqueous electrolyte solution, a lithium-containing composite nickel oxide is used as a chief component of the positive electrode material for the positive electrode, a lithium-containing titanium oxide is used as a chief component of the negative electrode material for the negative electrode, and the solvent of the non-aqueous electrolyte solution contains a cyclic carbonic ester and a chain carbonic ester in such a manner that the cyclic carbonic ester and chain carbonic ester are contained in amounts of not less than 10% by volume of the whole solvent, respectively, and the total content of the cyclic carbonic ester and the chain carbonic ester is not less than 60% by volume of the whole solvent.

Owner:SANYO ELECTRIC CO LTD

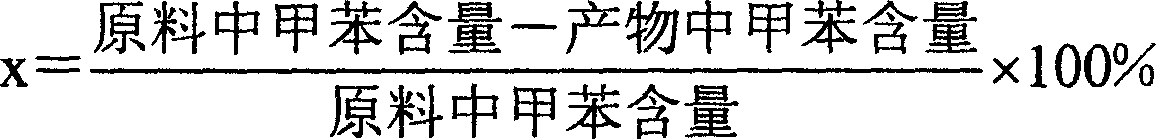

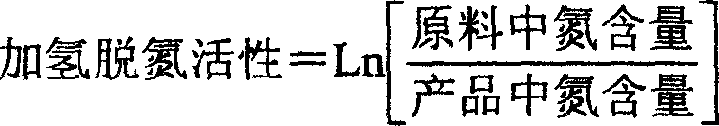

Hydrogenation catalyst of containing fluorin with alumina being as carrier, and preparation

ActiveCN1872959AHigh activityImprove denitrification activityRefining to eliminate hetero atomsDenitrificationAluminium oxide

This invention provides a method for preparing hydrogenation catalyst containing fluorine supported by aluminum oxide. The catalyst is composed of nickel oxide 1-10 wt.%, molybdena oxide and tungsten oxide 10-50 wt.%, fluorine 1-10 wt.%, and aluminum oxide. The method comprises introducing nickel oxide, molybdena oxide, tungsten oxide and fluorine into aluminum oxide carrier. The catalyst has such advantage as high hydrogenation and denitrification activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of nano positive material for lithium ion battery

InactiveCN102386381AShort heat treatment timeReduce energy consumptionNanostructure manufactureCell electrodesNickel saltElectrical battery

The invention belongs to the field of preparation techniques of nanophase materials and green energy resources, and relates to a preparation method of a nano positive material LiNi1 / 3Mn1 / 3Co1 / 3O2 applied to a lithium ion battery. By using the method, the defects that the calcining temperature needed by a current synthetic material is high, the calcining time is long, the particle sizes of a product are not uniform, and the like, are mainly solved. The preparation method comprises the following steps: adding a certain amount of template agent in a mixed aqueous solution of a nickel salt, a manganese salt and a cobalt salt, and then, dripping a precipitant and a complexing agent into the obtained mixture to form a precipitate; subjecting the precipitate and the mixed aqueous solution to a high-pressure thermal reaction in a hydrothermal kettle, cleaning and baking the obtained product to be dry, so as to obtain a nickel manganese cobalt oxide; and finally, uniformly mixing the nickel manganese cobalt oxide with the lithium salt to prepare a final product by calcining and cooling. By using the preparation method, the product with favorable electrochemical performance can be obtained within a shorter calcining time; the energy consumption is decreased; and the preparation method has obvious economic benefit in the large-scale application of industrial synthesis.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

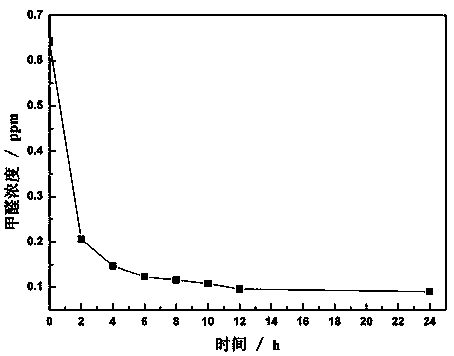

Preparation of room temperature formaldehyde catalyst

Belonging to the technical field of adsorption catalysis and air pollution control, the invention relates to preparation of a room temperature formaldehyde catalyst. The invention is characterized in that: zeolite, sepiolite, a porous activated carbon material, cordierite or a self-made carrier is adopted as the catalyst carrier, one or more non-noble metal oxides, like magnesium oxide, aluminum oxide, silicon oxide, manganese oxide, iron oxide, cobalt oxide, nickel oxide, copper oxide, zinc oxide, zirconium oxide, lanthanum oxide or cerium oxide are taken as active components, and an impregnation technique is employed to prepare the catalyst, which can be powdery, strip, blocky, spherical or honeycomb. The loading amount of the non-noble metal oxides is 2-15wt%, and the content of the catalyst carrier is 85-98%. Under normal temperature and ambient humidity conditions, the catalyst has the capacity of catalytic oxidation of formaldehyde into non-toxic and harmless CO2 and H2O up to over 95%, no intermediate product is generated, and the catalyst has the characteristics of high catalytic oxidation activity, strong moisture resistant ability, stable operation, long service life and the like, thus being suitable for formaldehyde purification treatment in offices, office buildings, living rooms, shopping malls, hospitals, hotels and other places.

Owner:江苏瑞丰科技实业有限公司

Exhaust gas catalyst

InactiveUS6180075B1Favorable degree of conversionExceptional heat and aging resistanceNitrogen compoundsInternal combustion piston enginesZirconium hydrideCerium(IV) oxide

A single-layered three-way catalytic converter containing palladium as the only catalytically active noble metal, with high activity and heat resistance. The catalyst contains, in addition to finely divided, stabilized aluminum oxide, at least one finely divided cerium / zirconium mixed oxide and optionally finely divided nickel oxide as well as highly dispersed amounts of cerium oxide, zirconium oxide and barium oxide. The palladium is distributed largely uniformly throughout the entire catalyst.

Owner:DMC2 DEGUSSA METALS +1

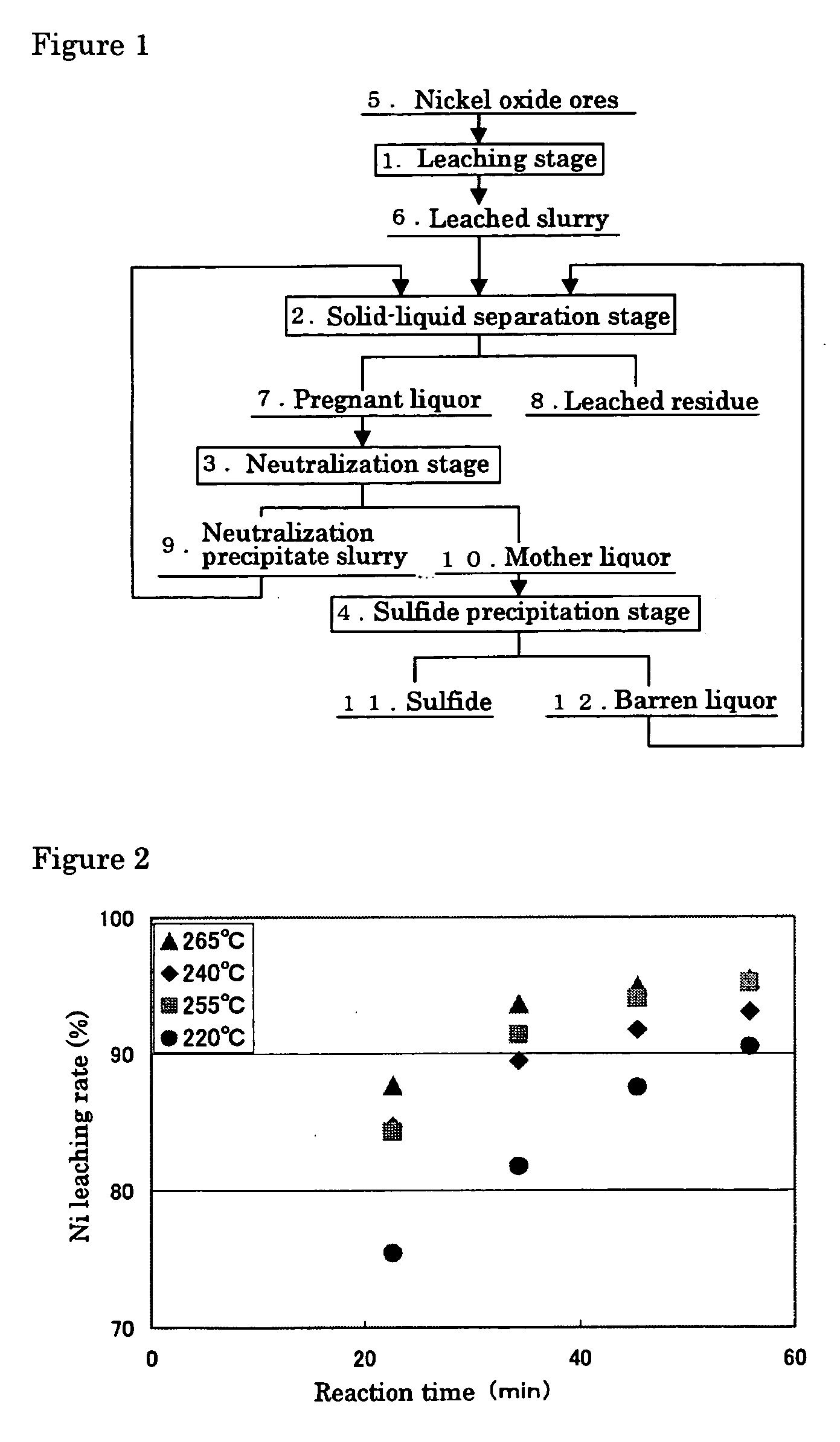

Hydrometallurgical process of nickel oxide ore

InactiveUS20050265910A1Simple and efficient processSimplified leaching stageSolvent extractionIron compoundsSlurryHydrometallurgy

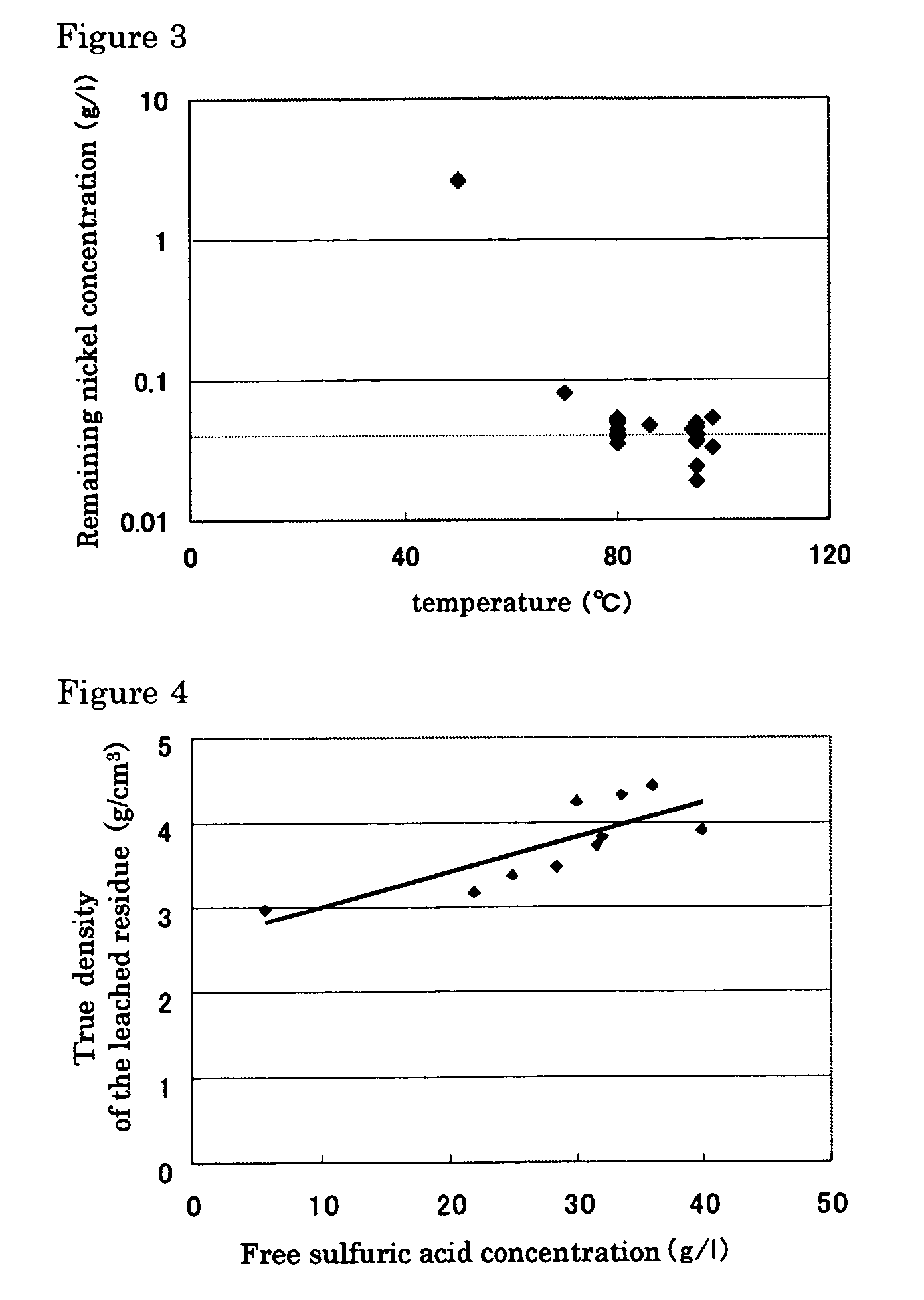

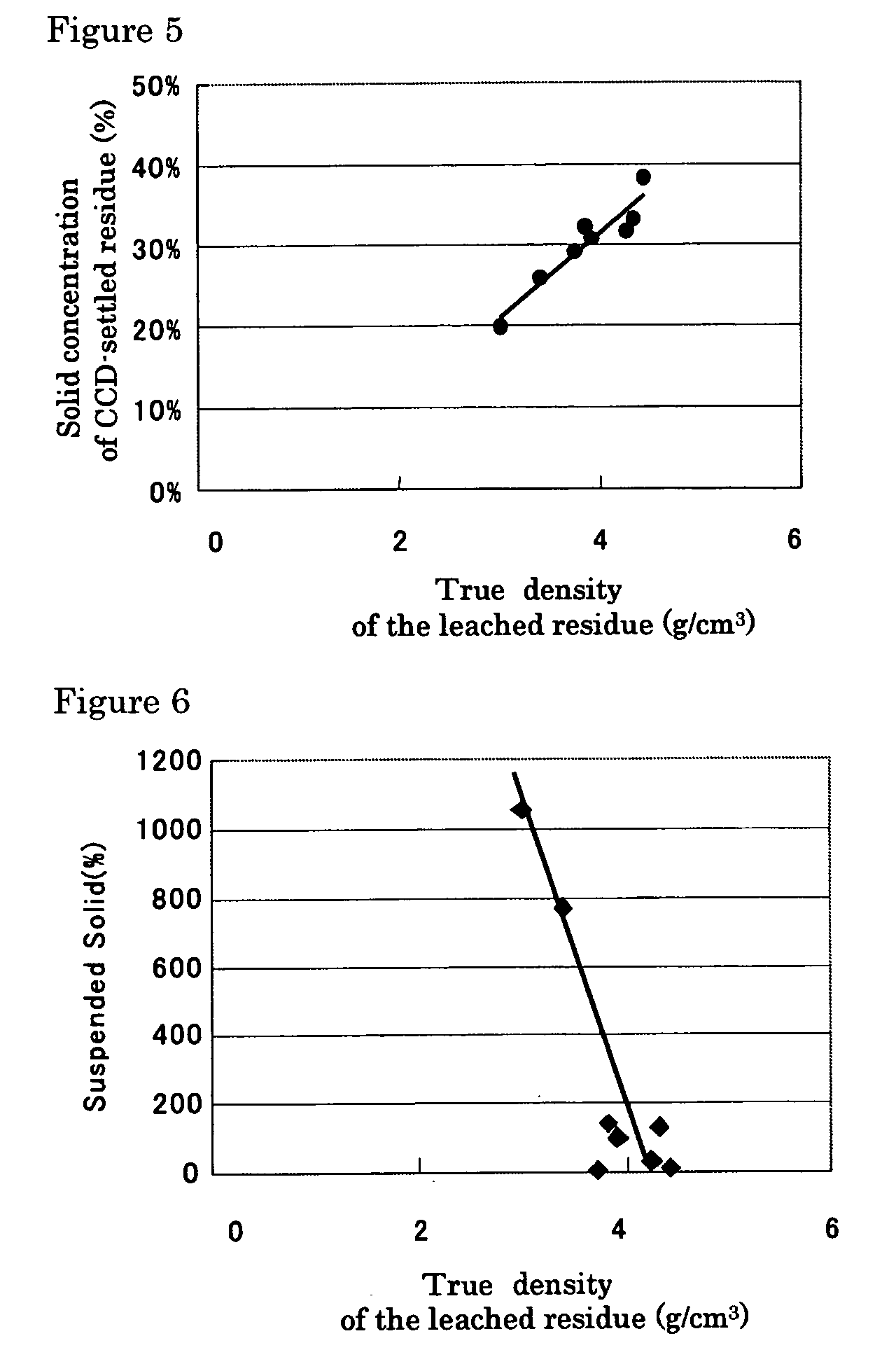

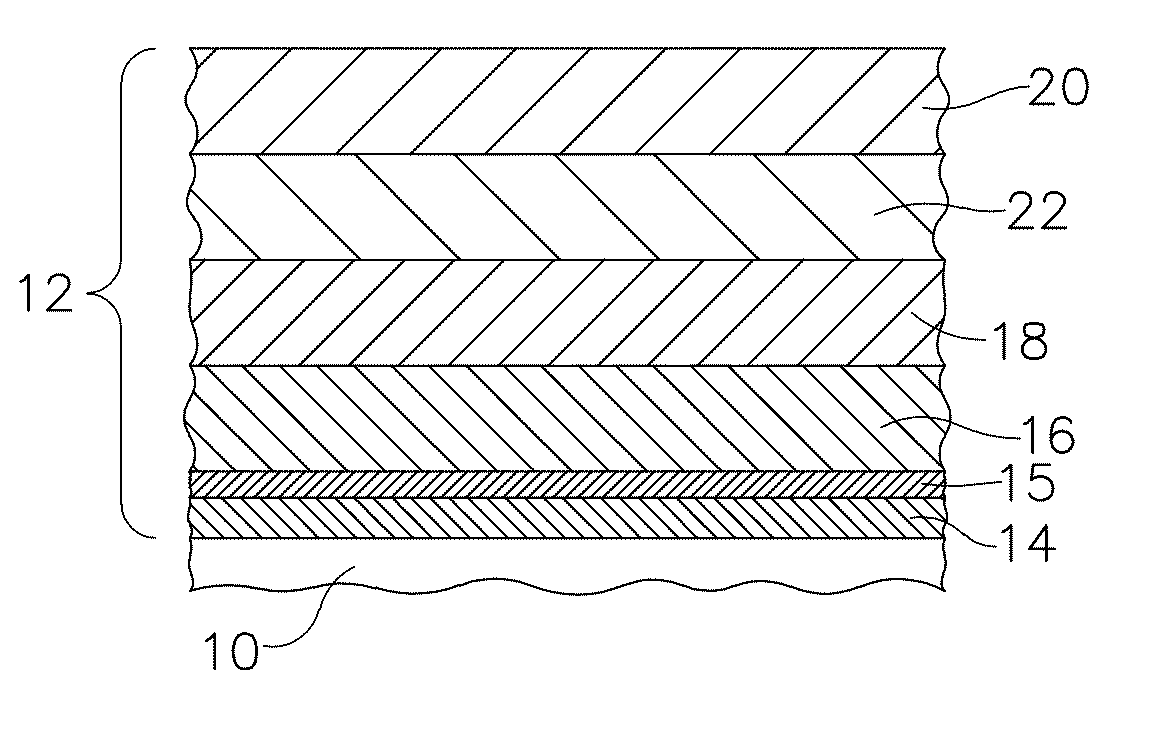

A hydrometallurgical process based on pressure leaching at elevated temperature for recovering nickel from nickel oxide ores, characterized by a simplified and efficient process as a whole, realizing a simplified leaching stage, reduced neutralizer consumption and precipitate production in the neutralization stage, and efficient use of recycled water. The hydrometallurgical process of the present invention, comprising a leaching stage which stirs the slurried ore in the presence of sulfuric acid at 220 to 280° C. to produce the leached slurry; solid-liquid separation stage which washes the leached slurry in multi-stages to produce the pregnant liquor and leached residue, the former containing nickel and cobalt; neutralization stage which treats the pregnant liquor in the presence of calcium carbonate incorporated to keep the pH level at 4 or less, while suppressing oxidation of the liquor, to produce the neutralization precipitate slurry and mother liquor for nickel recovery, the former containing trivalent iron; and a sulfide precipitation stage which blows hydrogen sulfide gas into the mother liquor to produce the sulfide solution and barren liquor, the former containing nickel and cobalt.

Owner:SUMITOMO METAL MINING CO LTD

Water based environmental barrier coatings for high temperature ceramic components

Environmental barrier coatings for high temperature ceramic components including: a bond coat layer; an optional silica layer; and at least one transition layer including: from about 85% to about 100% by volume of the transition layer of a primary transition material selected from a rare earth disilicate, or a doped rare earth disilicate; and from 0% to about 15% by volume of the transition layer of a secondary material selected from Fe2O3, iron silicates, rare earth iron oxides, Al2O3, mullite, rare earth aluminates, rare earth aluminosilicates, TiO2, rare earth titanates, Ga2O3, rare earth gallates, NiO, nickel silicates, rare earth nickel oxides, Lnb metals, Lnb2O3, Lnb2Si2O7, Lnb2SiO5, borosilicate glass, alkaline earth silicates, alkaline earth rare earth oxides, alkaline earth rare earth silicates, and mixtures thereof; where the transition layer is applied to the component as a slurry including at least water, the primary transition material and at least one slurry sintering aid, and where a reaction between the slurry sintering aid and the primary transition material results in the transition layer having a porosity of from 0% to about 15% by volume of the transition layer.

Owner:GENERAL ELECTRIC CO

Low temperature denitration catalytic addictive and preparation method thereof

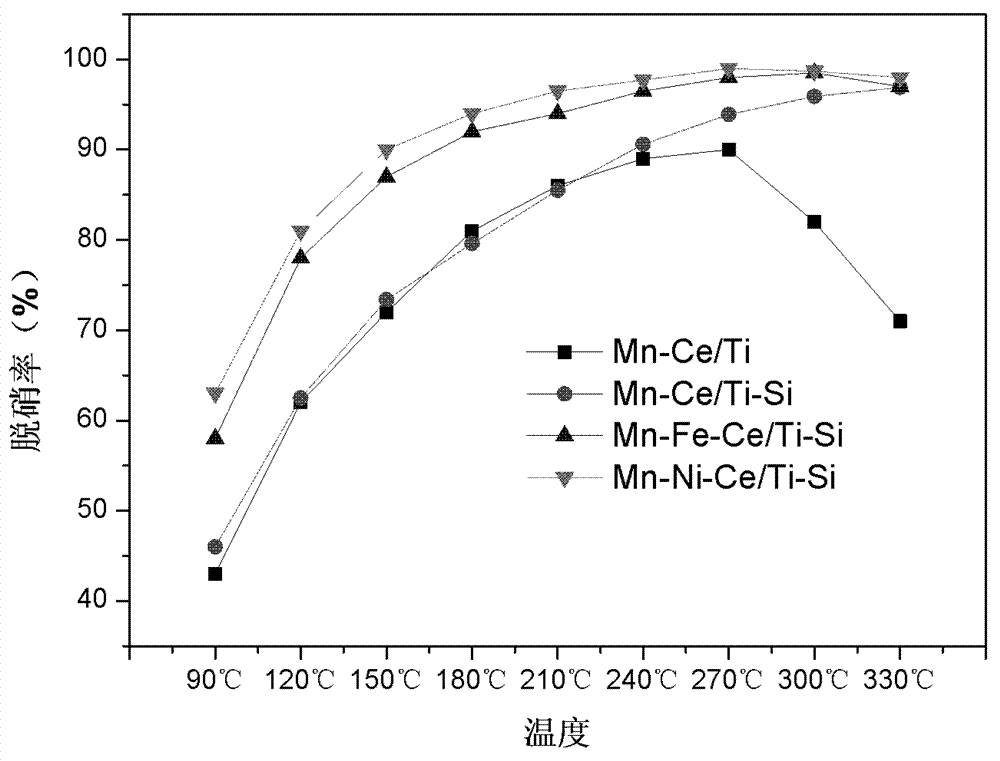

ActiveCN103537279ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganese oxideCement kiln

The invention discloses a low temperature denitration catalytic addictive and a preparation method thereof, and belongs to the field of low temperature denitration catalyst. According to the low temperature denitration catalytic addictive, TiO2-SiO2 is taken as carrier, manganese oxide (MnOx) is taken as active substance, and cerium oxide (CeO2), nickel oxide (NiO) and iron oxide (FeOx) are taken as auxiliary agents. The preparation method comprises following steps: TiO2-SiO2 composite carrier is prepared by sol-gel method; loading of CeO2, NiO or FeOx is realized by one-step dipping; and then the low temperature denitration catalytic addictive is obtained by calcination. The low temperature denitration catalytic addictive possesses high low-temperature denitration catalytic efficiency, wide active temperature window, and relatively high alkali metal poisoning resistance. TiO2-SiO2 is low in cost, and specific area of TiO2-SiO2 is larger than that of pure TiO2 carrier, so that it is beneficial for dispersion of active substances on the surface of TiO2-SiO2, and stability of the active substances. Auxiliary agent NiO or FeOx are capable of increasing low-temperature activity and alkali metal poisoning resistance of the low temperature denitration catalytic addictive, so that the low temperature denitration catalytic addictive is suitable for denitration in dedusted cement kiln at low temperature or even under conditions with unstable temperature.

Owner:BEIJING UNIV OF TECH

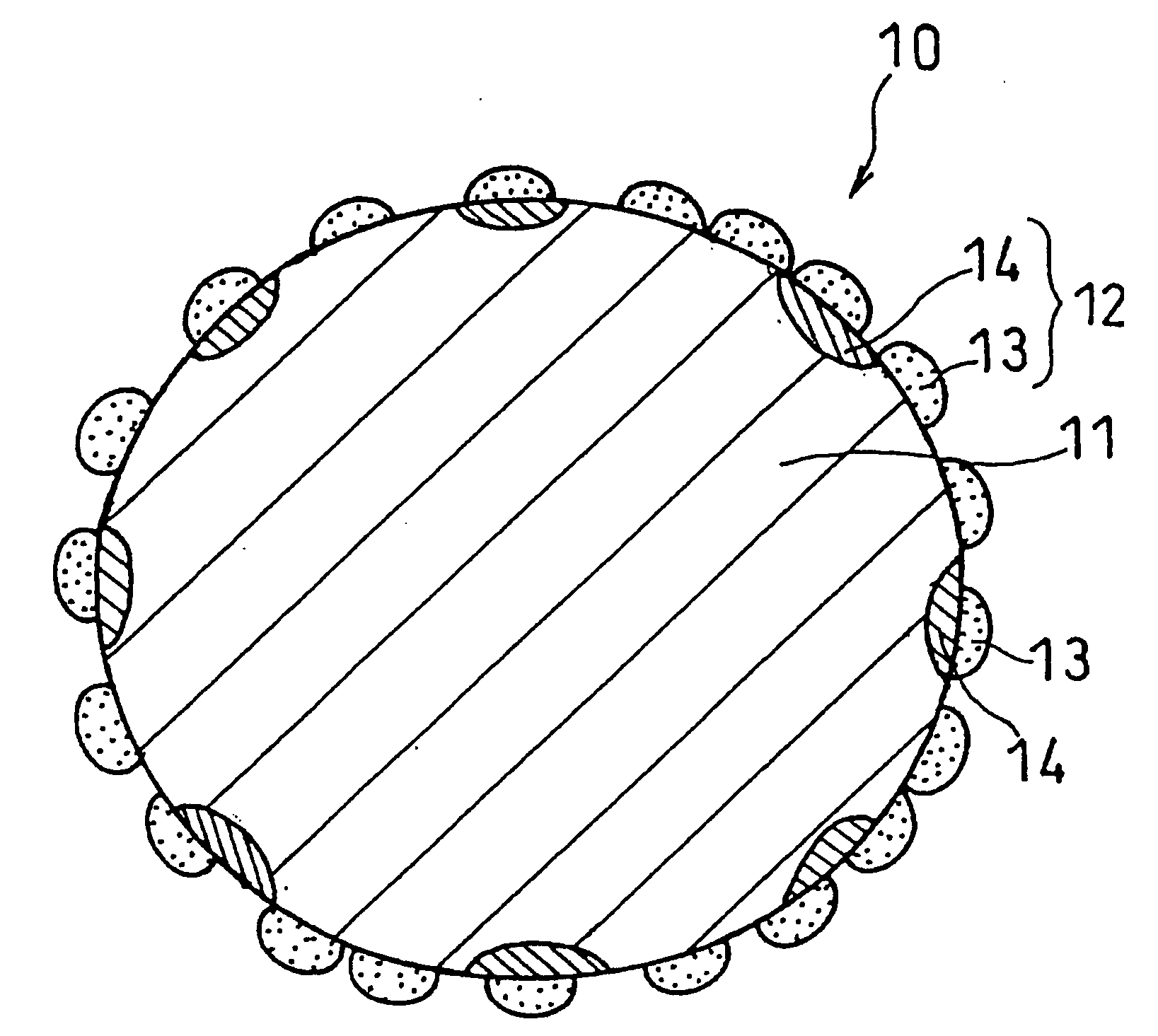

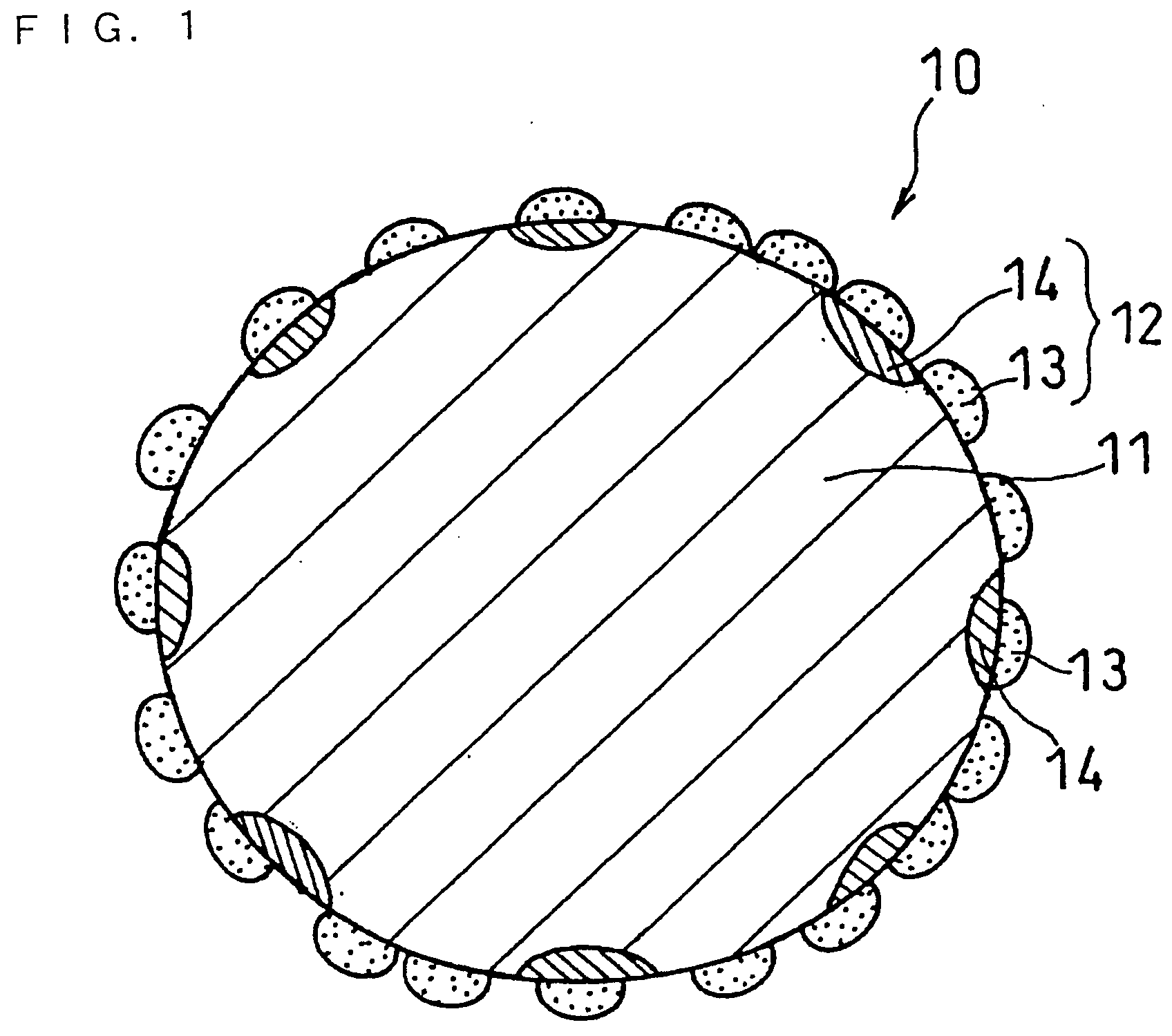

Lithium Ion Secondary Battery And Manufacturing Method Therefor

ActiveUS20080090150A1Extension of timeImprove securityElectrode manufacturing processesPrimary cellsSurface layerCrystal structure

Active material particles of a lithium ion secondary battery includes at least a first lithium-nickel composite oxide: LixNi1-y-zCoyMezO2 (where 0.85≦x≦1.25, 0<y≦0.5, 0≦z≦0.5, 0<y+z≦0.75, and element Me is at least one selected from the group consisting of Al, Mn, Ti, Mg, and Ca) forming a core portion thereof. The surface layer portion of the active material particles includes nickel oxide having the NaCl-type crystal structure or a second lithium-nickel composite oxide, and further includes element M not forming the crystal structure of the first lithium-nickel composite oxide. Element M is at least one selected from the group consisting of Al, Mn, Mg, B, Zr, W, Nb, Ta, In, Mo, and Sn.

Owner:PANASONIC CORP

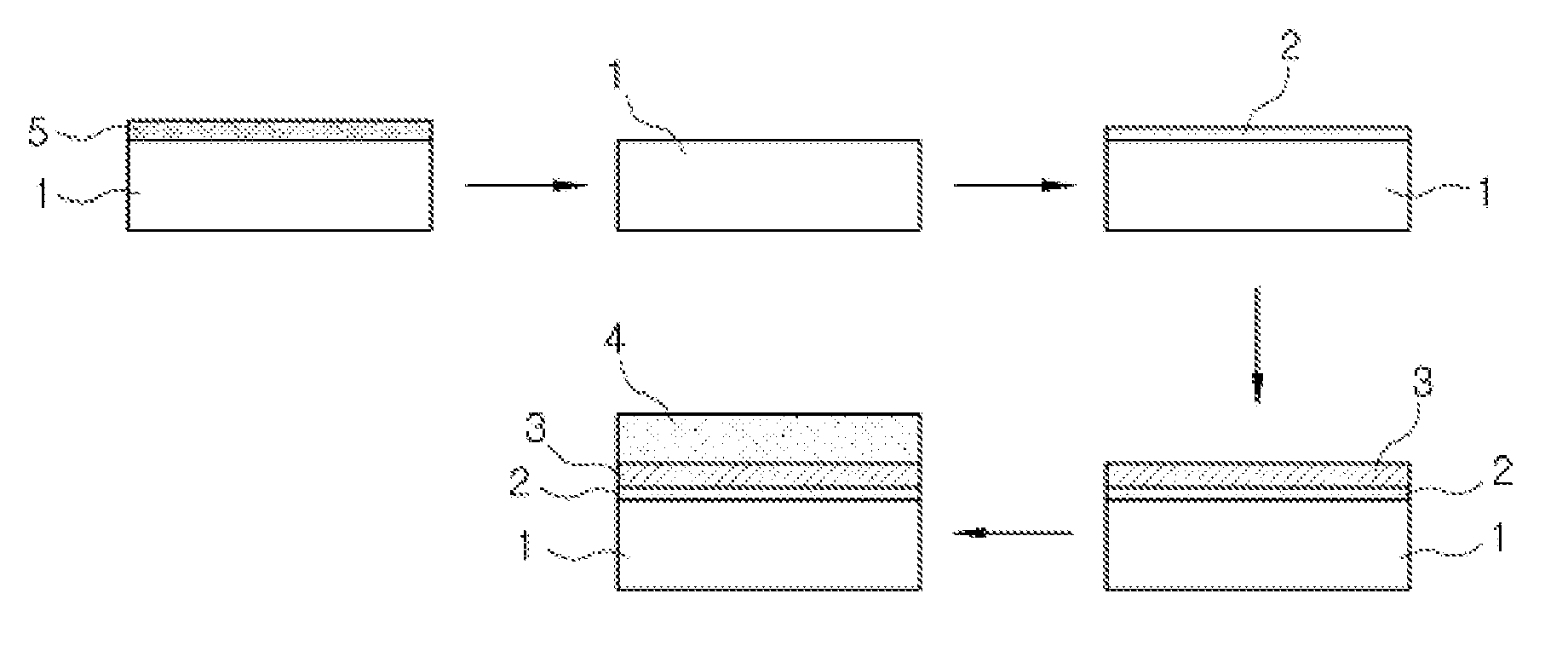

Process for preparing a multi-layer electrochromic structure

Process for preparing a multi-layer electrochromic structure comprising depositing a film of a liquid mixture onto a substrate and treating the deposited film to form an anodic electrochromic layer comprising a lithium nickel oxide composition, the anodic electrochromic layer comprising lithium, nickel and the bleached state stabilizing element(s) wherein in the film (i) the ratio of lithium to the combined amount of nickel and the bleached state stabilizing element(s) is at least 0.4:1, (ii) the ratio of the combined amount of the bleached state stabilizing element(s) to the combined amount of nickel and the bleached state stabilizing elements in the lithium nickel oxide composition is at least about 0.025:1, and (iii) the bleached state stabilizing element(s) is / are selected from the group consisting of Y, Ti, Zr, Hf, V, Nb, Ta, Mo, W, B, Al, Ga, In, Si, Ge, Sn, P, Sb and combinations thereof.

Owner:KINESTRAL TECH

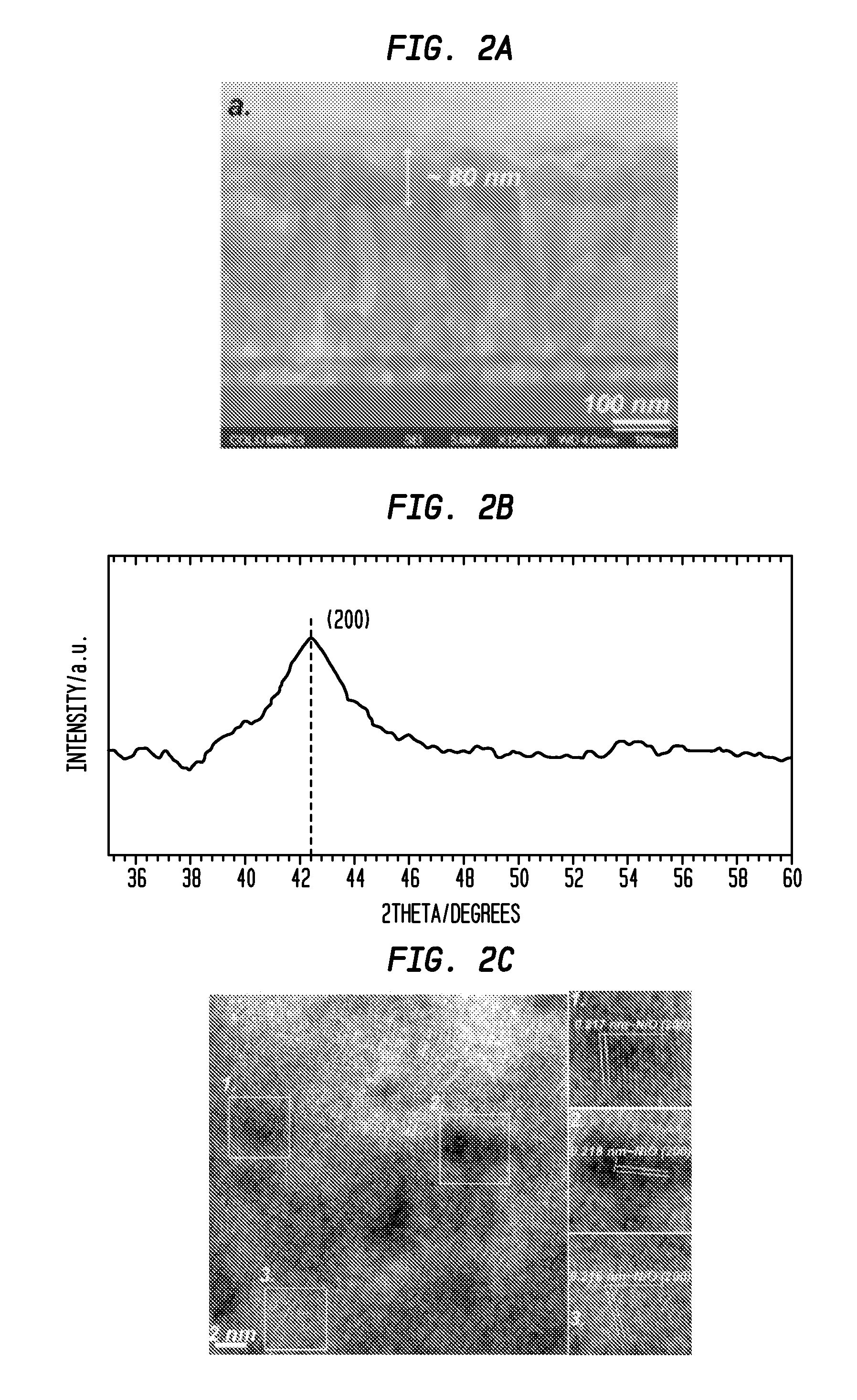

Porous ceramic sheet, process for producing the same, and setter for use in the process

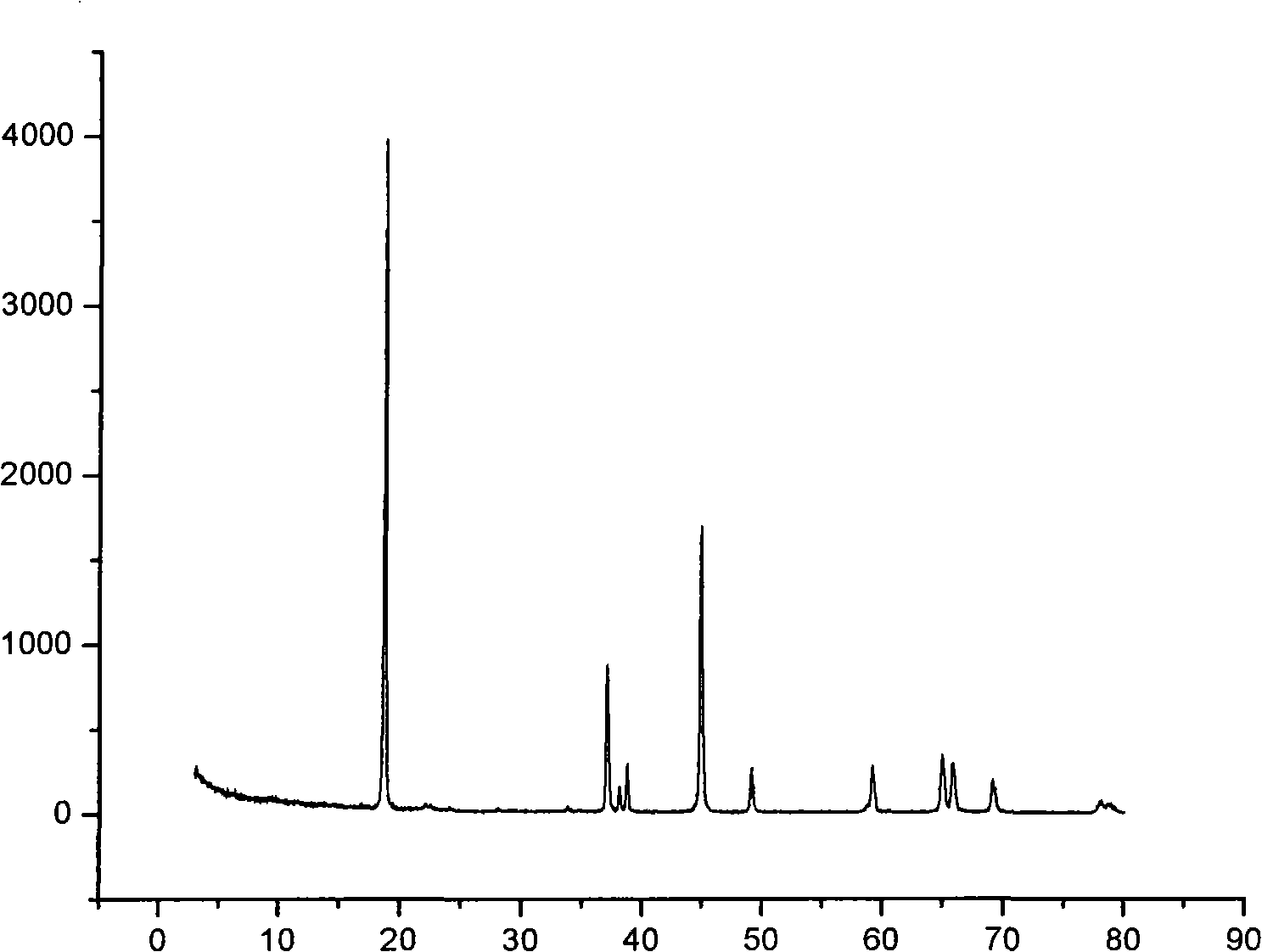

InactiveUS6344426B1Low mechanical strengthReduce electrical conductivityRoof covering using sealantsCell electrodesX-rayPeak intensity

The invention provides a setter which comprises a sheet ceramic containing 40% to 90% by weight of an [NiO] unit; a process for producing a porous ceramic sheet containing nickel oxide and stabilized zirconia, by the use of the setter; and a porous ceramic sheet having a ratio X of a ratio Xa relative to a ratio Xb ranging from 0.85 to 1.18, where the ratio Xa is a ratio of an X-ray diffraction peak intensity of the (200) line of nickel oxide relative to an X-ray diffraction peak intensity of the (111) line of the stabilized zirconia on one side of the sheet, and the ratio Xb is a ratio of an X-ray diffraction peak intensity of nickel oxide in the (200) line relative to an X-ray diffraction peak intensity of the (111) line of the stabilized zirconia on the other side, where the ceramic sheet is mainly produced by the process.

Owner:NIPPON SHOKUBAI CO LTD

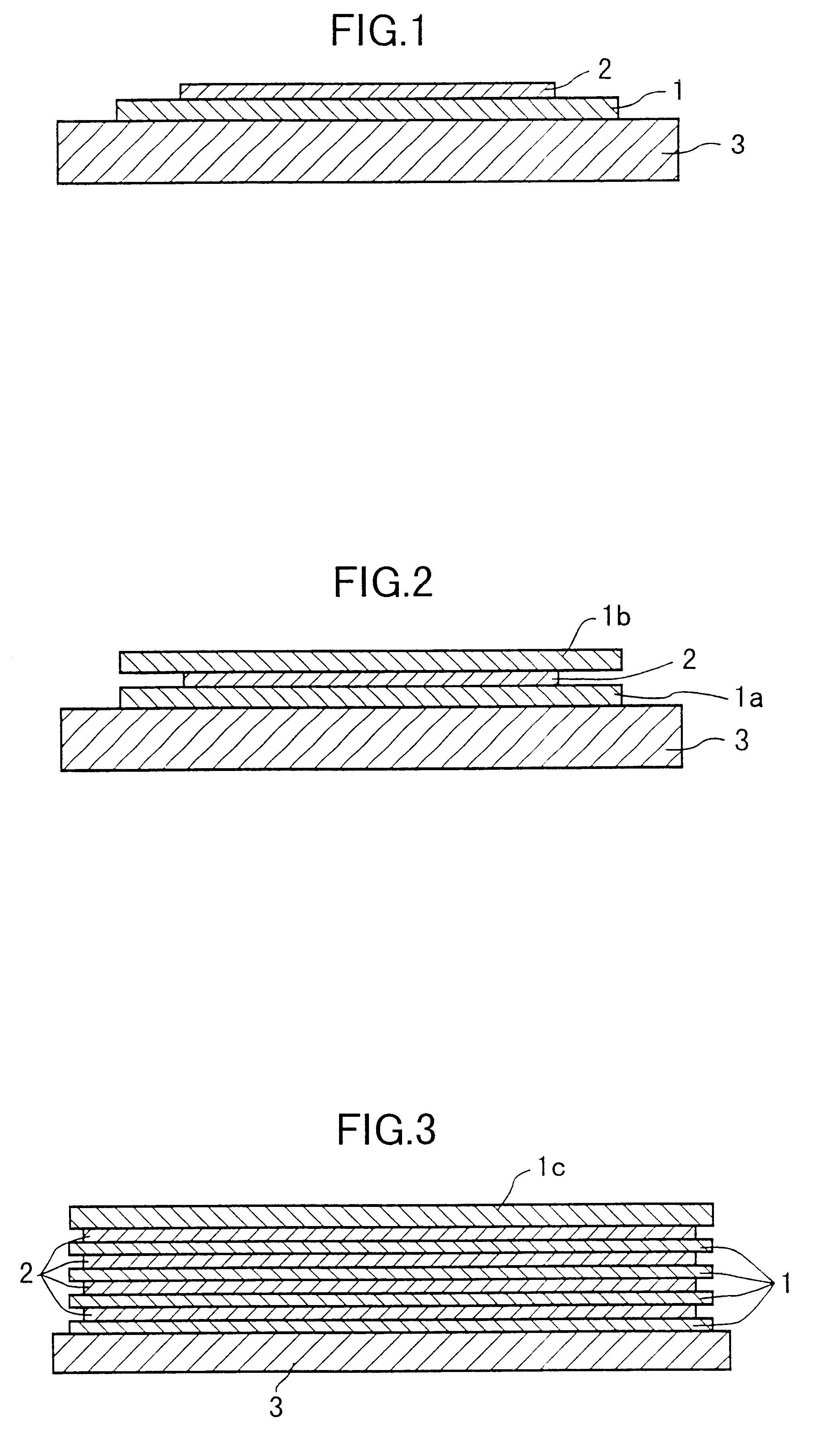

Bimetal methanation catalyst and preparation method thereof

InactiveCN101703933ARestoredGood dispersionHydrogen separation using solid contactCatalyst activation/preparationLow loadMethanation

The invention discloses a bimetal methanation catalyst for the removal of micro carbon monoxide from a hydrogen-rich gas and a preparation method thereof. The bimetal methanation catalyst contains active components, namely nickel oxide and ferric oxide, loaded on an oxide carrier and an assistant, wherein the assistant is at least one element selected from the main group I, the main group II, the subgroup I, the subgroup III, the subgroup VI and the subgroup VIII of the periodic table, and the oxide carrier is alumina, titanium dioxide, zirconium dioxide and silicon dioxide or a mixture thereof. The catalyst of the invention can allow the micro carbon monoxide to be removed from the hydrogen-rich gas at a relatively low temperature and has the advantages of low load, high activity, relatively low cost and wide application prospect.

Owner:SHANXI UNIV

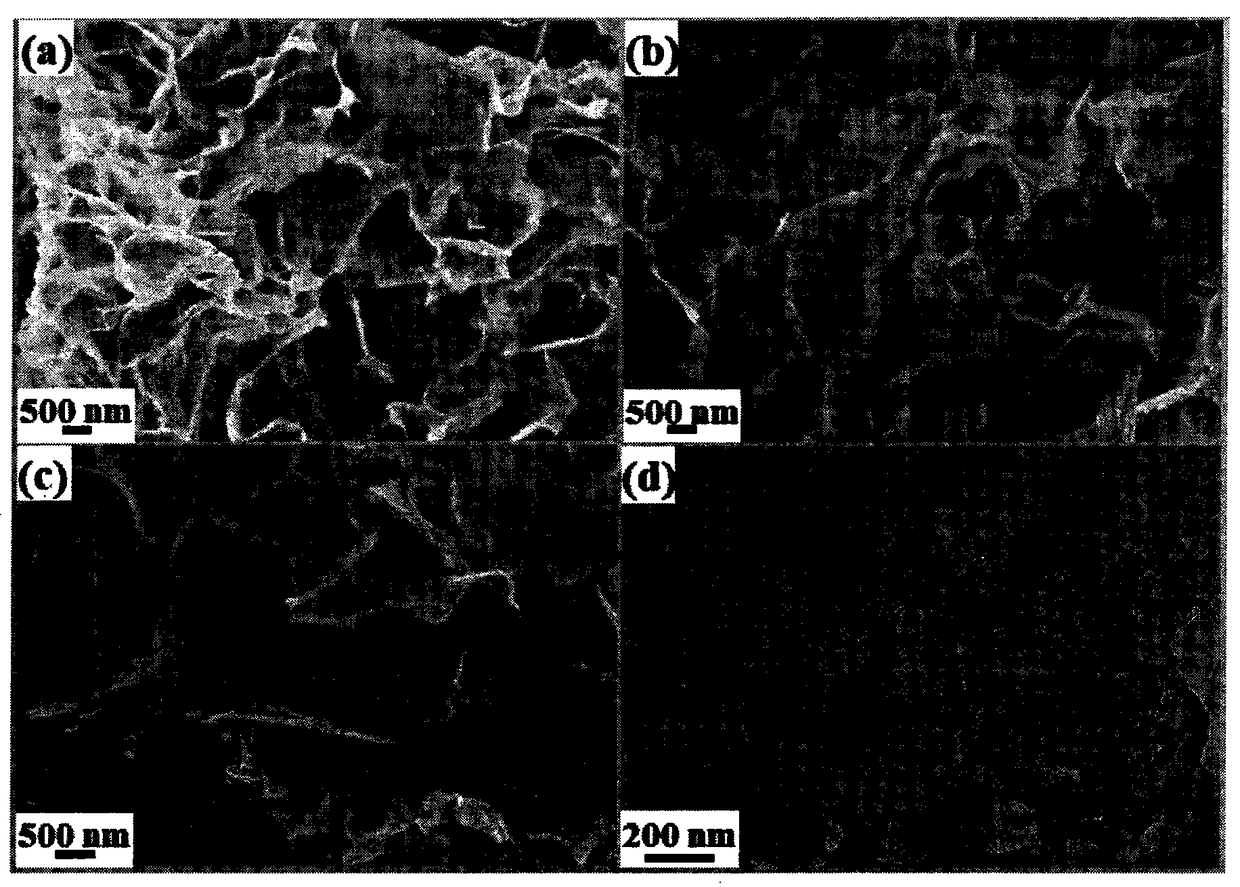

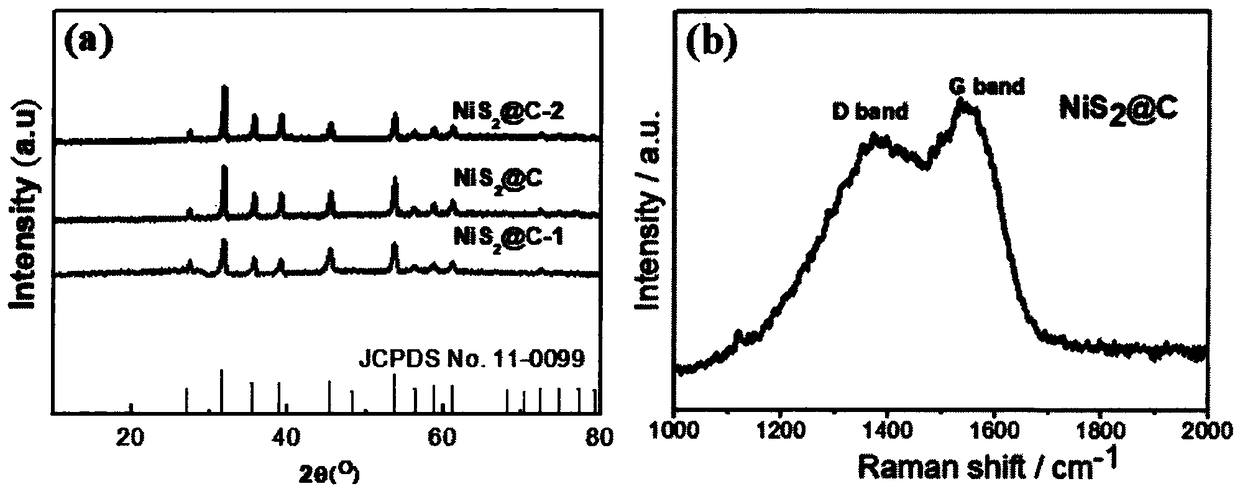

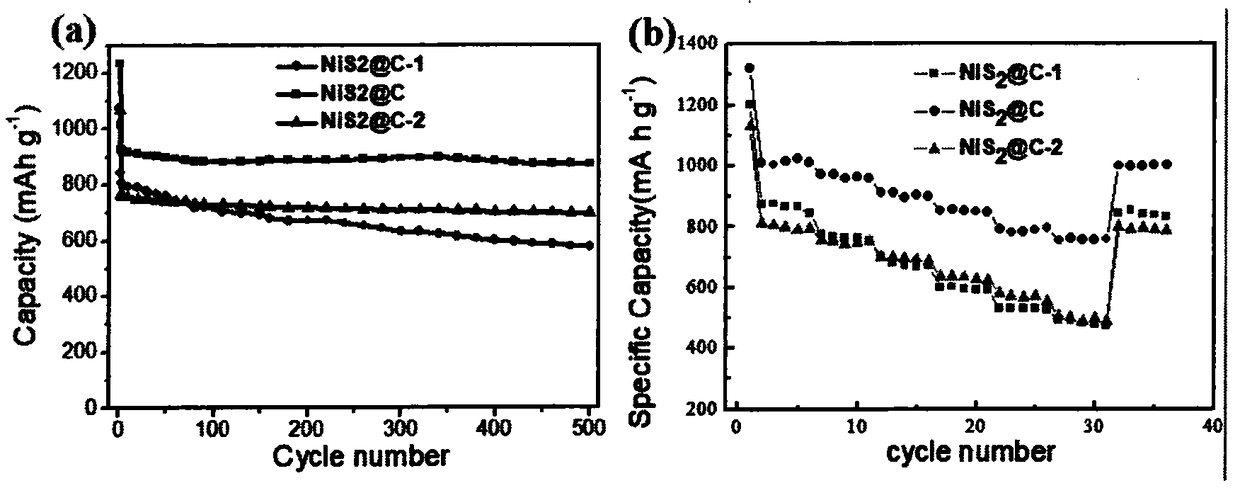

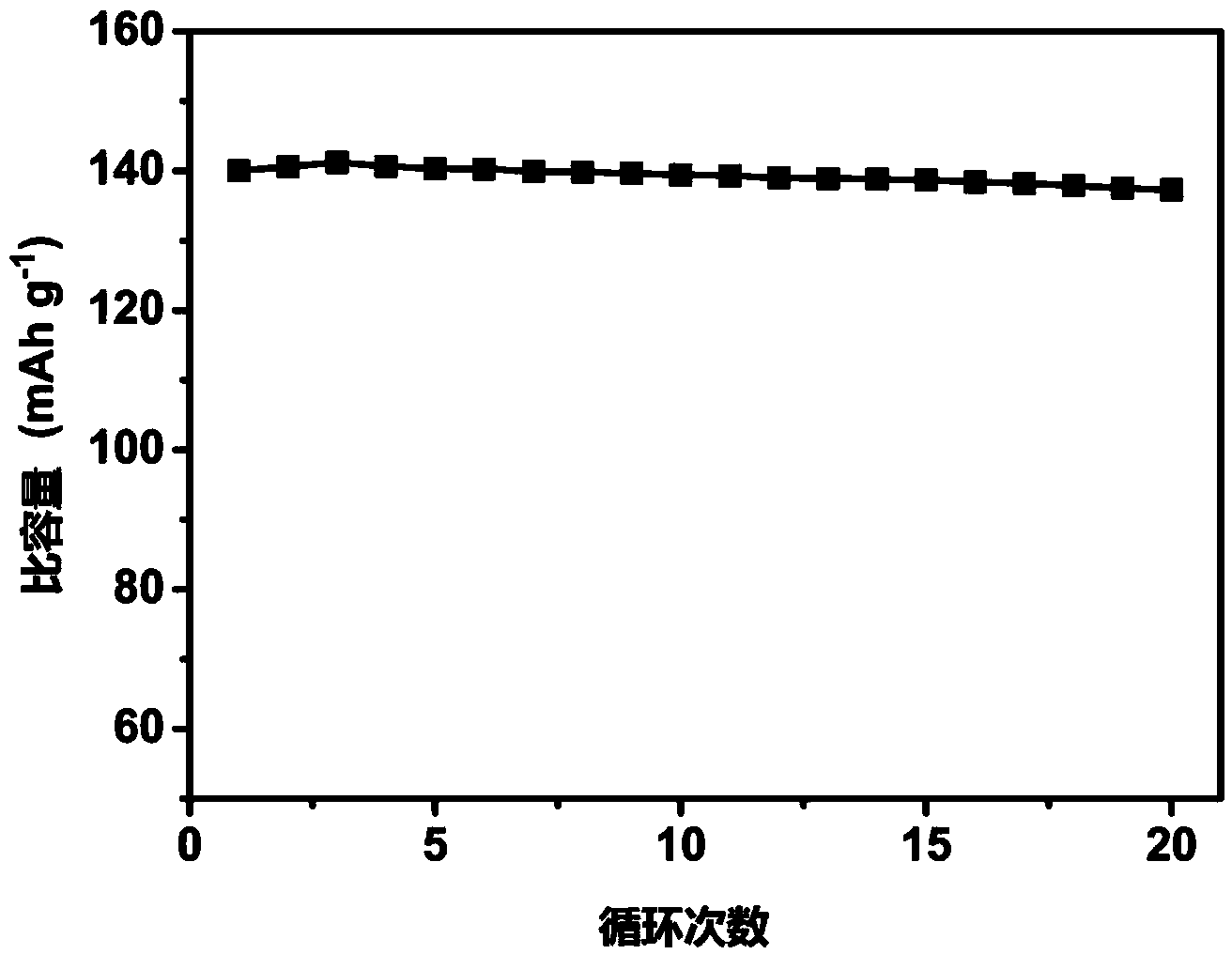

Nickel disulfide carbon nano composite material and preparation method and application thereof

InactiveCN108832097AGood biocompatibilityStrong adhesionMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesCarbon layer

The invention relates to a nickel disulfide carbon nano composite material and a preparation method and an application thereof, wherein the composite material is formed by coating a nickel disulfide nanosheet with a carbon layer. The preparation method comprises the following steps of preparing a nickel hydroxide nanosheet precursor by a hydrothermal method, performing magnetic stirring and dispersing in deionized water to obtain a uniform dispersion liquid of the nickel hydroxide nanosheet precursor, adding a buffering agent tris(hydroxymethyl) aminomethane hydrochloride, and adjusting the pHvalue to be 8.5 by adopting an alkali solution with the pH value of 13, adding dopamine hydrochloride, and magnetically stirring at room temperature for in-situ polymerization, and carrying out washing and centrifugally drying to obtain a nickel hydroxide nanosheet precursor / polydopamine composite material, and carrying out heat treatment and vulcanization with sublimed sulfur powder in a tubularfurnace in nitrogen atmosphere at a certain temperature to obtain the composite material. The preparation process is simple, easy to operate, green and non-toxic and friendly in material preparationprocess; and the prepared nickel disulfide carbon nano composite material is stable in structure, uniform in morphology and high in dispersion. The obtained nickel disulfide carbon nano composite material can be an ideal electrode material of a high-performance lithium ion battery, a supercapacitor and other new energy devices.

Owner:DONGHUA UNIV

Active carbon desulfurization catalyst and preparation method thereof

InactiveCN101954284ANo pollution in the processHigh yieldDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNickel compoundsCopper oxide

The invention provides an active carbon desulfurization catalyst and a preparation method thereof. The catalyst consists of carrier activated carbon and an active ingredient metal oxide mixture, wherein the metal oxide mixture is the mixture of copper oxide, iron oxide, aluminum oxide, nickel oxide, manganese oxide, cobalt oxide and zinc oxide. The preparation method comprises the following steps of: mixing a copper-containing compound, an iron-containing compound, an aluminum-containing compound, a nickel-containing compound, a manganese-containing compound, a cobalt-containing compound and a zinc-containing compound; dissolving the mixture; dispersing the active carbon into the mixed solution; and filtering, washing, drying and calcining the mixture. The preparation method is simple and the obtained catalyst has high desulfurization efficiency.

Owner:DONGHUA UNIV

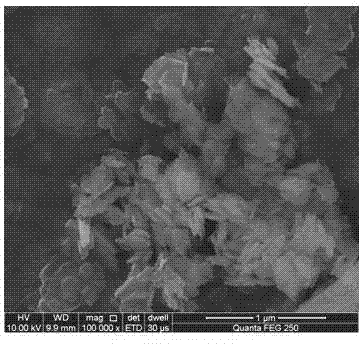

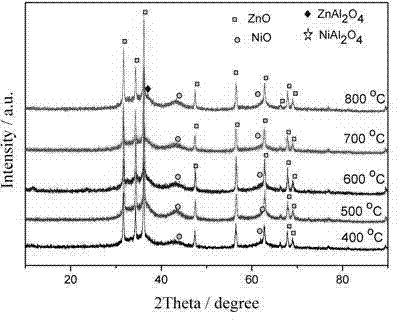

Preparation method for photocatalytic material with strong adsorption and high visible light degradation of performance

The invention discloses a gahnitem, zinc oxide and nickel zinc nano-composite photocatalytic material which has a high specific surface area and a mesoporous structure and is prepared by roasting at high temperature by taking ternary hydrotalcite as a precursor. The material is used for the adsorption and the degradation of organic pollutants. The photocatalytic material is prepared by taking zinc nitrate, nickel nitrate, aluminum nitrate, sodium carbonate, sodium hydroxide and the like as raw materials; preparing the raw materials into salt solutions and alkali solutions respectively; mixing the solutions by using a constant-flow pump at the temperature of 80 DEGC with magnetic stirring, transferring the mixed solution into a hydrothermal reaction kettle; performing hydrothermal treatment at 130 to 180 DEG C; performing suction filtration, washing and drying to the precursor; roasting the precursor in Muffle furnace for 2 to 6 hours at the temperature of 400 to 600 DEG C to obtain the product, wherein the specific surface area is greater than 150 m<2>.g<-1>. The photocatalyst disclosed by the invention has regular shape, large specific surface area, and super-high capacity for adsorbing and degrading organics, and can be reused; the raw materials for preparing the composite photocatalyst are abundant, the cost is low, and the process is simple.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

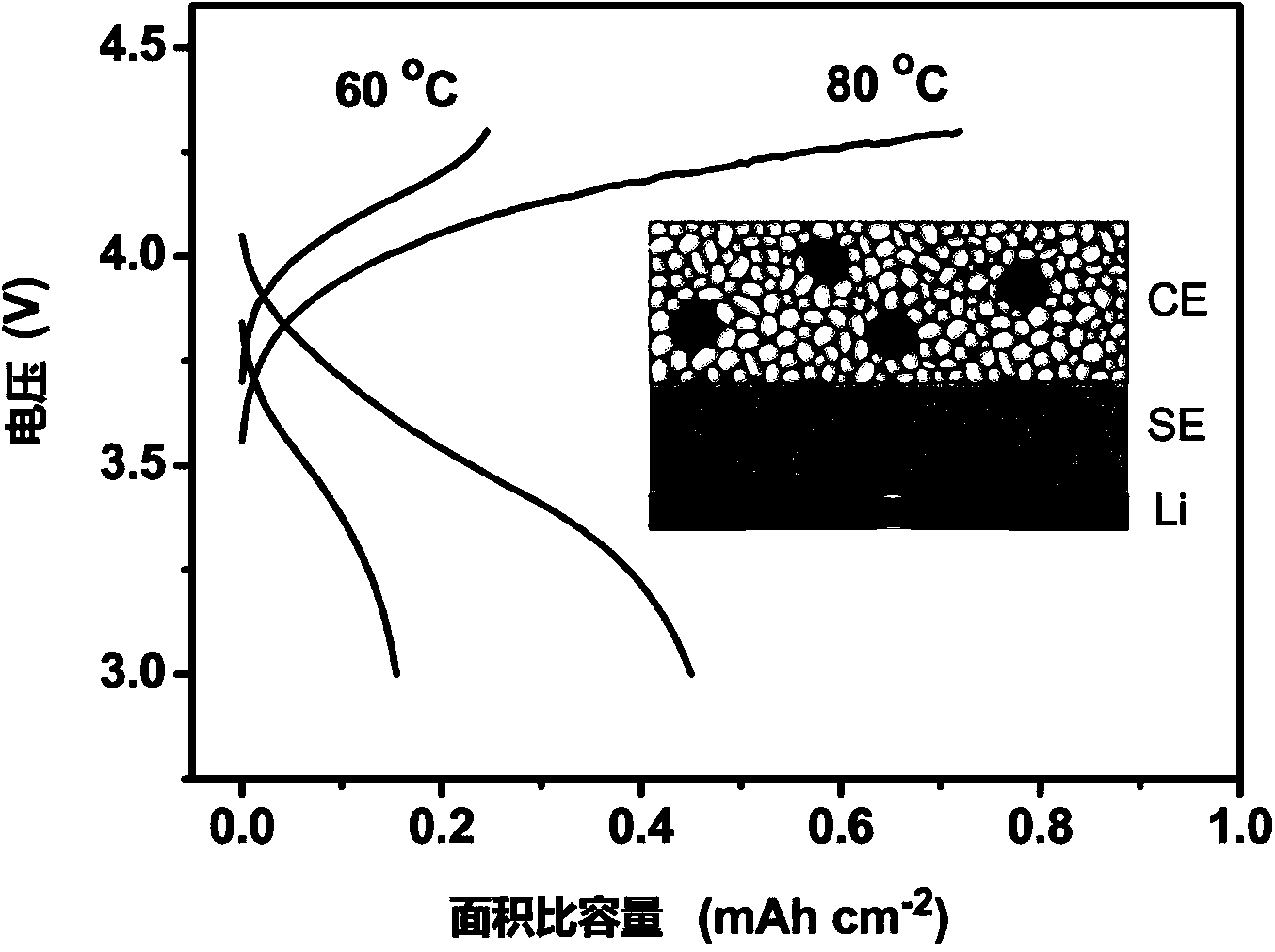

Composite positive electrode of lithium ion battery as well as preparation method and application to all-solid-state battery thereof

ActiveCN103956458AShorten migration distanceIncrease energy densityCell electrodesSecondary cellsSolid state electrolyteTin dioxide

The invention discloses a composite positive electrode of a lithium ion battery as well as a preparation method and application to an all-solid-state battery thereof. The composite positive electrode of the lithium ion battery comprises a positive active material, inorganic solid electrolyte and a conductive oxide additive, wherein the positive active material is any one of lithium cobaltate, lithium manganate, lithium iron phosphate and nickel-cobalt-manganese ternary material; the inorganic solid electrolyte is at least one of lithium borate, lithium metaborate and lithium fluoride; the conductive oxide additive is any one of indium tin oxide, indium oxide, tin dioxide, zinc oxide, nickel oxide and ferroferric oxide. The method comprises the steps of (1) mixing the positive active material, the inorganic solid electrolyte and the conductive oxide additive, carrying out ball milling, drying, and carrying out tabletting to obtain a ceramic piece; and (2) sintering the ceramic piece to obtain the composite positive electrode. The composite positive electrode is good in mass ratio capacity, area ratio capacity and cycle performance, can be used for preparing the all-solid-state lithium ion battery, and can be used at high temperature.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com