Patents

Literature

91results about How to "Restored" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

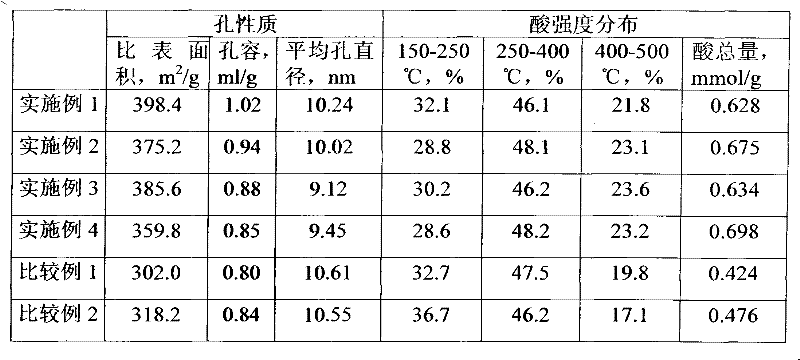

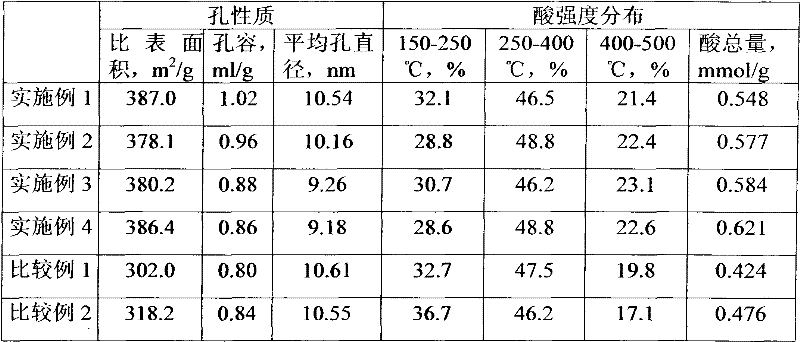

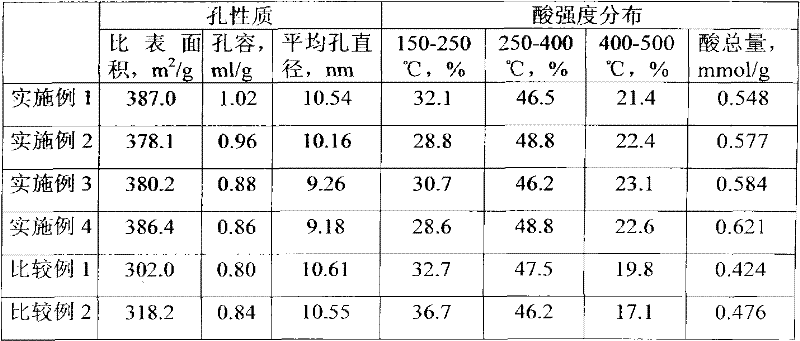

Preparation method for composite oxide carrier

ActiveCN102451765AGood dispersionLarge specific surface areaCatalyst carriersRefining to eliminate hetero atomsAluminium hydroxideAqueous solution

The present invention discloses a preparation method for a composite oxide carrier. According to the method of the present invention, a composite oxide dry glue is prepared by the following steps, wherein the steps comprise: firstly preparing an aluminum hydroxide wet filter cake and an aqueous solution containing an IVB group metal complex; adding the wet filter cake to the complex solution, andstrongly stirring; carrying out filtering and drying to obtain the composite oxide dry glue. With the composite oxide dry glue prepared by the method, most of the IVB group metal oxide can be distributed on the surface of aluminum oxide so as to reduce the influence on the pore structure of the aluminum oxide, improve the assistant catalysis effect of the IVB group metal oxide, and improve the pore structure and the surface performance of the composite oxide carrier. In addition, with the present invention, the sulfurization performance of the catalyst adopting the composite oxide carrier as the carrier can be improved, and the loaded active metal is easy to reduce.

Owner:CHINA PETROLEUM & CHEM CORP +1

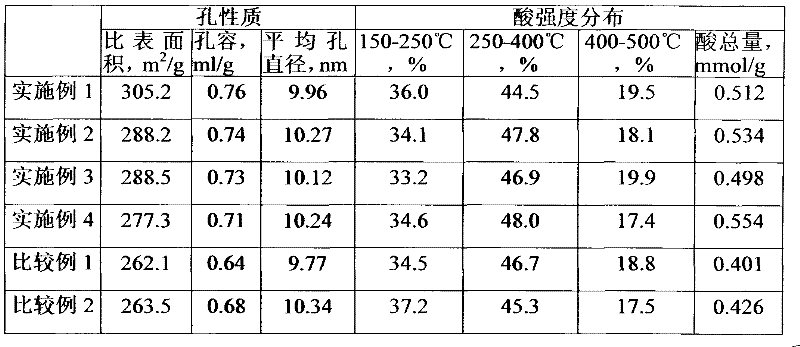

Bimetal methanation catalyst and preparation method thereof

InactiveCN101703933ARestoredGood dispersionHydrogen separation using solid contactCatalyst activation/preparationLow loadMethanation

The invention discloses a bimetal methanation catalyst for the removal of micro carbon monoxide from a hydrogen-rich gas and a preparation method thereof. The bimetal methanation catalyst contains active components, namely nickel oxide and ferric oxide, loaded on an oxide carrier and an assistant, wherein the assistant is at least one element selected from the main group I, the main group II, the subgroup I, the subgroup III, the subgroup VI and the subgroup VIII of the periodic table, and the oxide carrier is alumina, titanium dioxide, zirconium dioxide and silicon dioxide or a mixture thereof. The catalyst of the invention can allow the micro carbon monoxide to be removed from the hydrogen-rich gas at a relatively low temperature and has the advantages of low load, high activity, relatively low cost and wide application prospect.

Owner:SHANXI UNIV

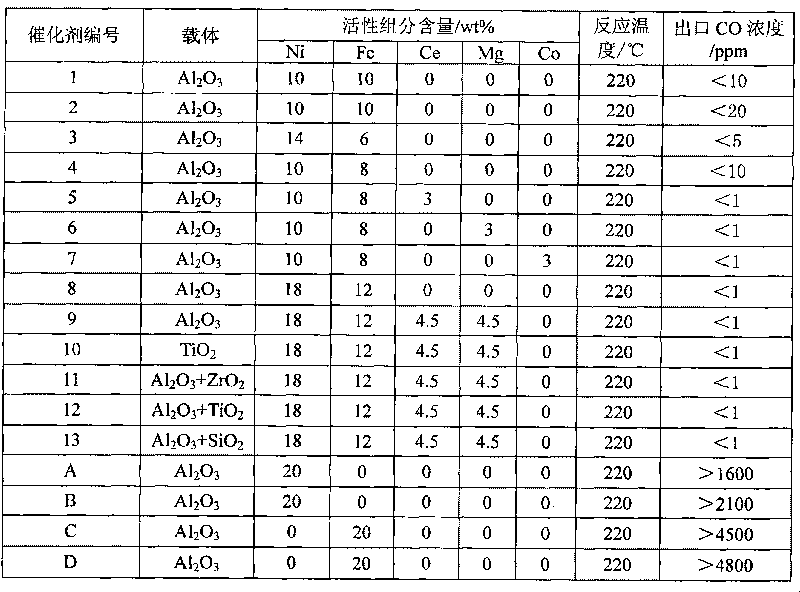

Resource recycling application of heavy metals in wastewater

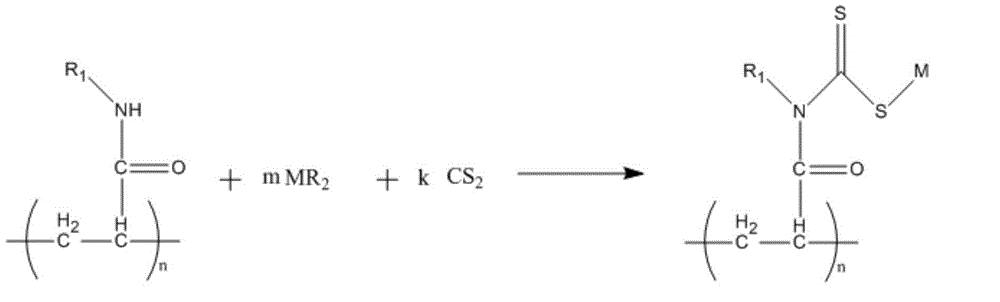

InactiveCN104558324AEasy to separate and recycleGood oil solubilityWater/sewage treatment by flocculation/precipitationCross-linkAryl

A heavy metal ion recycling agent is characterized by comprising a compound represented as a structural formula shown in the specification, wherein R1 is selected from an alkyl group, a derivative of the alkyl group, an amino group, a derivative of the amino group, an aryl group and a derivative of the aryl group, and the number of hydrogen atoms in the components and the number of carbon atoms in the components are smaller than 6; n is an integer larger than or equal to 50; M adopts K, Na, Li or NH4. The heavy metal ion recycling agent in water can form a stable heavy metal ion chelate in a cross-linked network shape with divalent and / or trivalent heavy metal ions, and flocculent precipitate is formed to facilitate separation and recycling, that is, the heavy metal ions in the wastewater can be recycled. Besides, the wastewater containing the heavy metal ions can be discharged up to the standard, and heavy metal can be recycled from the separated heavy metal ion chelate after reduction treatment.

Owner:上海源育节能环保科技有限公司

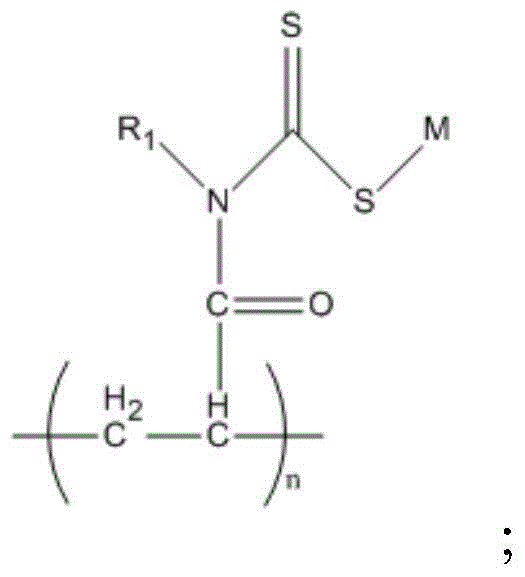

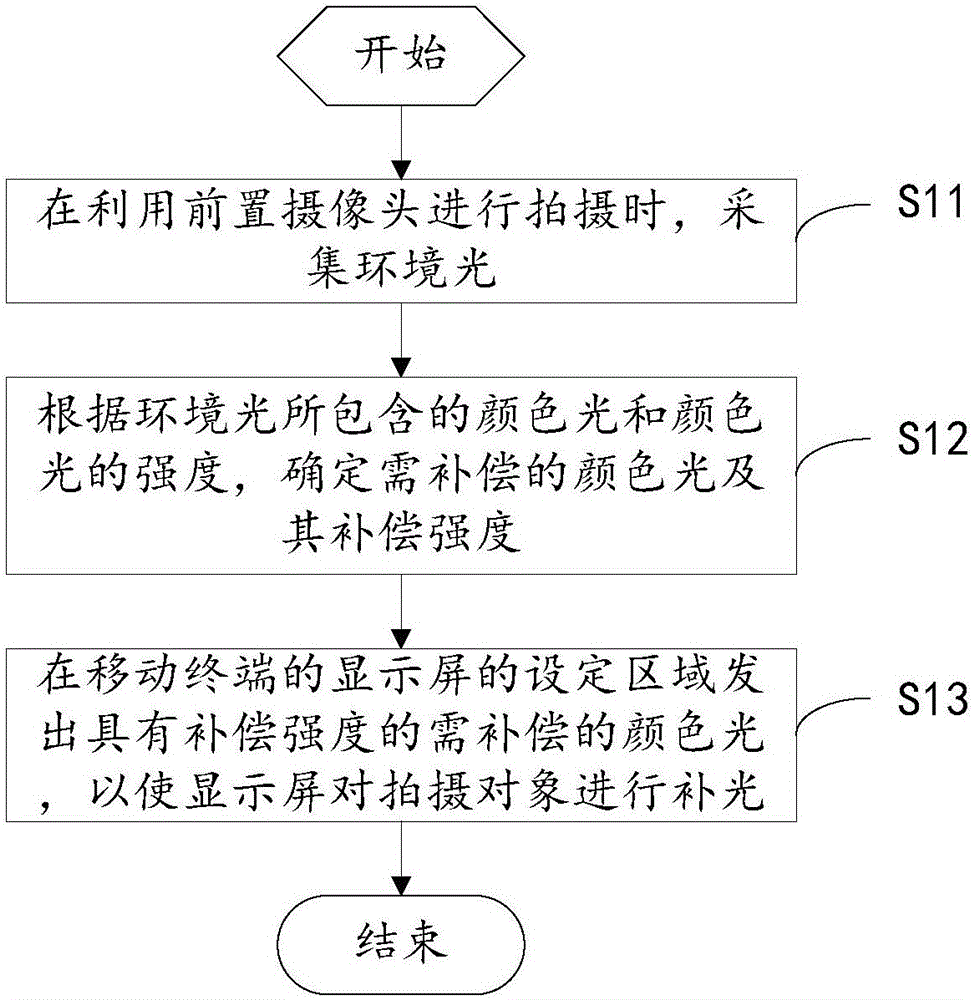

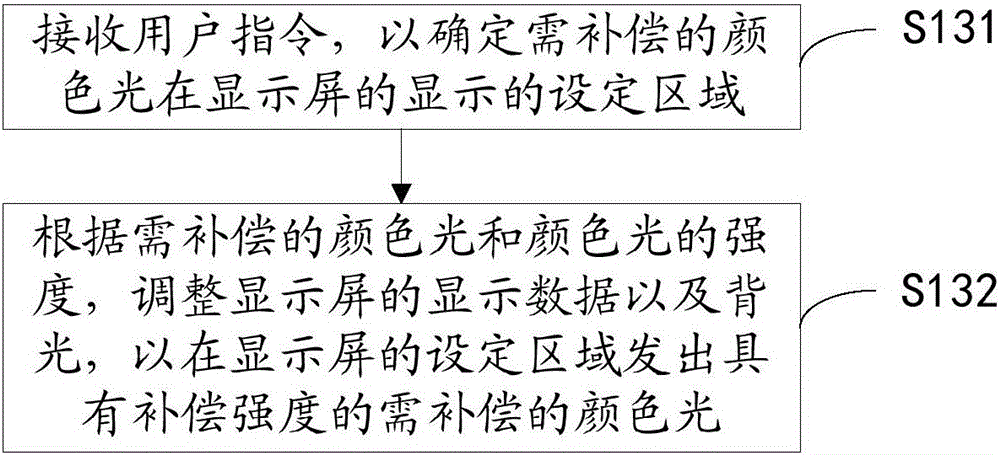

Mobile terminal and shooting light compensation method thereof

InactiveCN106791468AQuality improvementRestoredTelevision system detailsColor television detailsPhysicsCompensation methods

Owner:SHENZHEN TINNO WIRELESS TECH

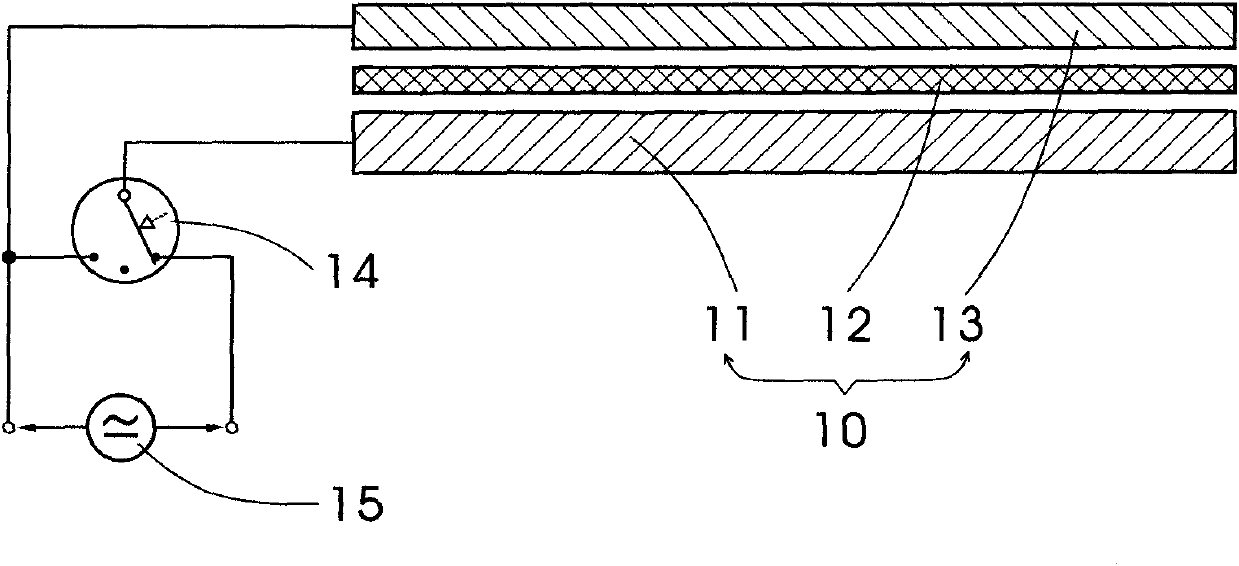

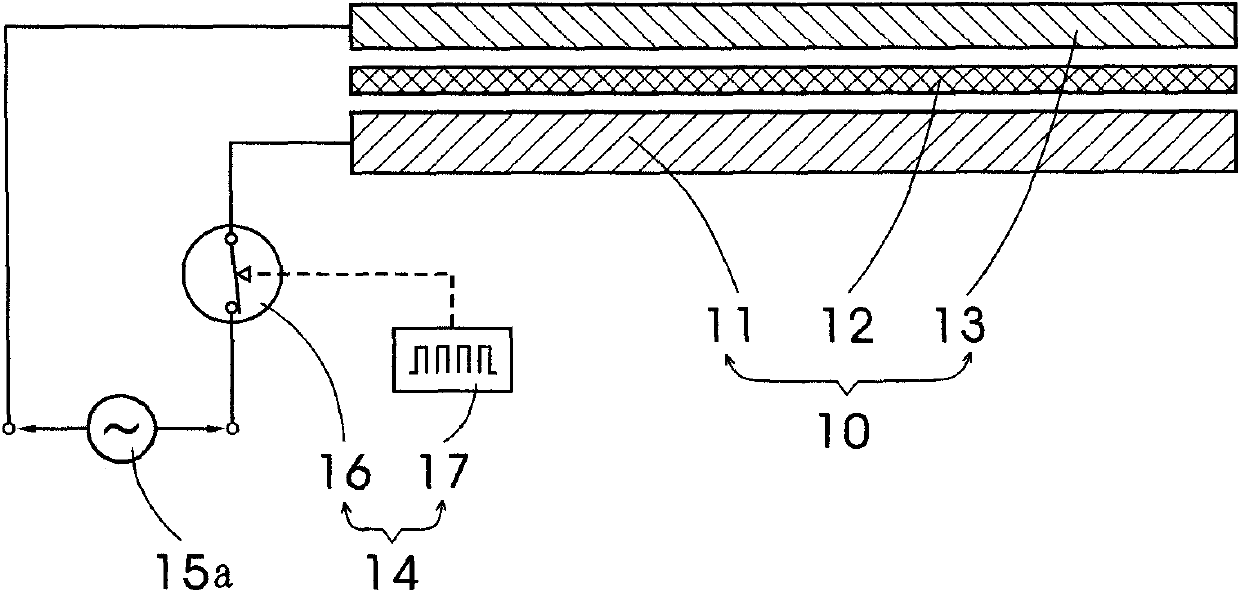

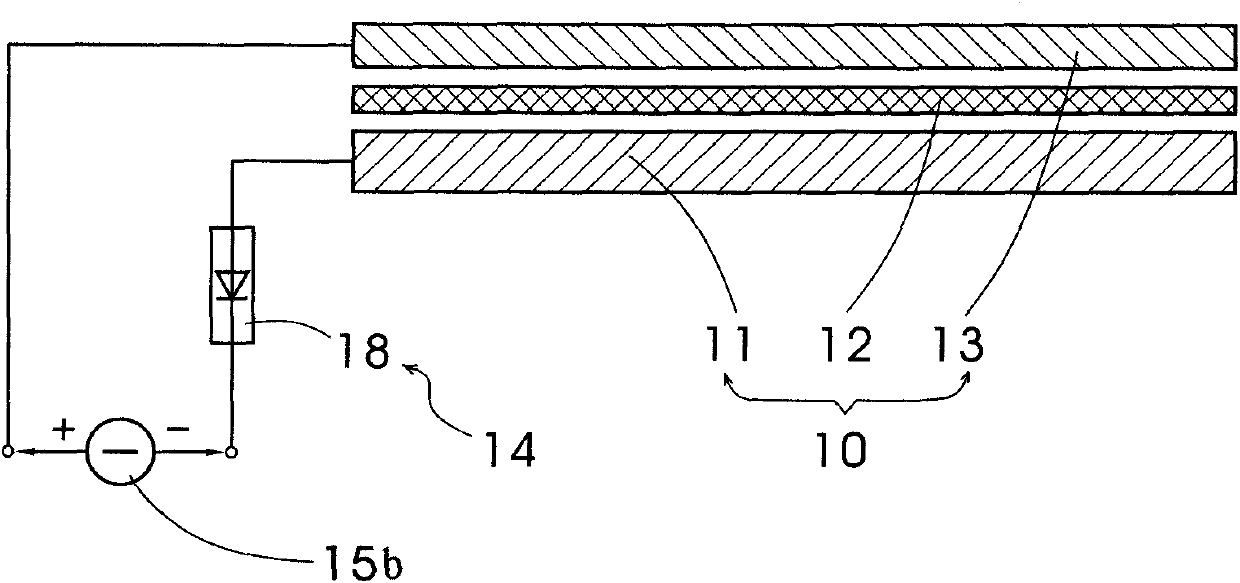

Negative oxygen ion generator

InactiveCN101771242AHigh activityHigh purityElectrical apparatusDeodrantsCapacitanceSemiconductor materials

The invention provides a negative oxygen ion generator which comprises an assembly (10) and a loader (14). The assembly (10) has the characteristics of a capacitor, and the loader (14) provides or loads ultra-low voltage for the assembly. The assembly (10) which has the characteristics of charging, energy storing and discharging of the capacitor is composed of a first electrode (11), a second electrode (13) and an electric insulating medium (12). The first electrode (11) and the second electrode (13) are oppositely arranged, and the electric insulating medium (12) is arranged between the first electrode and the second electrode. Semiconductor materials which are sensitive to oxygen gas are adhered on the surface of the first electrode (11), the assembly (10) uses low voltage, the loader has the functions of switching on and off, and the assembly (10) and the loader (14) are correspondingly connected with each other. By combining the voltage loading technology and applying the characteristics of the capacitor and the semiconductor materials that are sensitive to the oxygen gas, the negative oxygen ion generator can generate high-activity genitive oxygen ions under the condition of low voltage without generating ozone; moreover, the production rate of the negative oxygen ions can be conveniently adjusted. The negative oxygen ion generator can be made into an independent device or can be applied in an instrument, an electrical appliance, equipment and a device that need to generate the negative oxygen ions.

Owner:马骧彬

Process for preparing ceramic filter element with desulfuration function

InactiveCN1629099AUniform adhesionRestoredDispersed particle separationCombustible gas purificationZincFilm-coated tablet

The invention provides a process for preparing ceramic filter element with desulfuration function which comprises, mixing aggregate, agglutinant and bonding agent with water proportionally, grinding to obtain mixed paste, then charging -100 mesh composite pore former and gum Arabic, mixing uniformly, adjusting pH to 9-10, obtaining porous ceramic paper stock, slip casting moulding through vacuum treatment, demoulding to obtain ceramic element, (2) preparing ferrum acid zinc sol suitable for heat gas desulfurizing by means of sol-gel method, then carrying out desulfurizing agent film coating to the filtering element, sintering at 500 deg. C.

Owner:SHANDONG UNIV OF TECH

Method of cultivating selenium-enriched garlic plant material

InactiveCN102511280AImprove bioavailabilityHigh selenium cultivationFertilising methodsHorticultureSe-methylselenocysteineCell culture media

The invention discloses a method of cultivating a selenium-enriched garlic plant material. The selenium content of the selenium-enriched garlic plant material is 3mg / kg-1500mg / kg, and selenium existing in a form of Se-methylselenocysteine accounts for more than 80% of the content of total selenium. The method is characterized by including: adding a selenium source into garlic growth medium in growth of garlic, using the selenium source to adjust the selenium content of the growth medium to be 0.2-100mg / kg, and adding alkaline matter to adjust the overall or local environmental pH value of the growth medium to be 7-8. By the method, the selenium source is obtained from different selenium concentration gradients, a good selenium form result is obtained, and the shortages that persistence of plant material selenium in the prior art is poor, the selenium is easy to be reduced in the environment, the utilization rate of the selenium is limited and the like are overcome.

Owner:SUZHOU SETEK

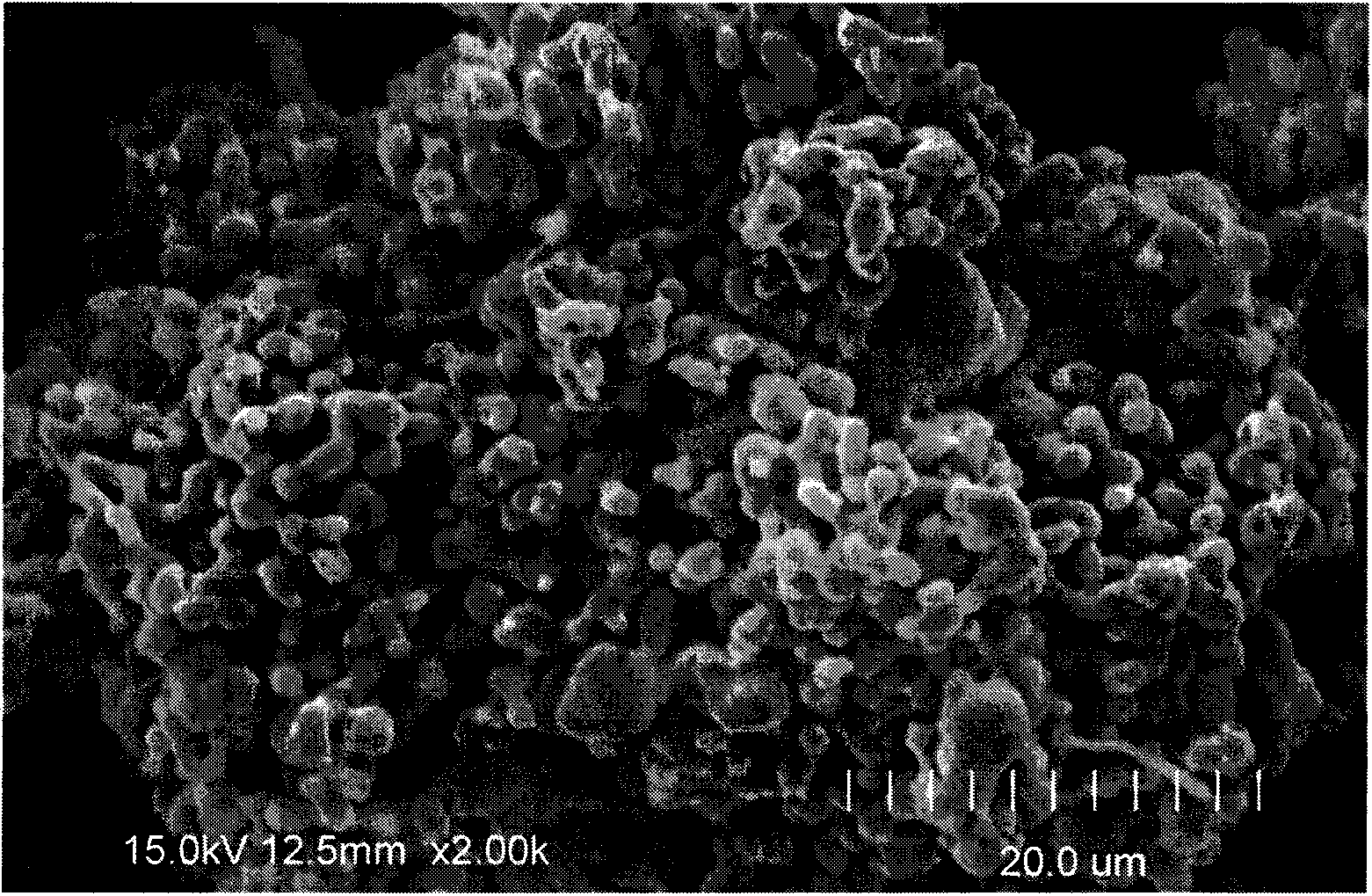

Manufacturing method of high-green-strength atomized copper powder

The invention discloses a manufacturing method of high-green-strength atomized copper powder. The manufacturing method includes steps of smelting, specifically, placing solid-state pure-copper materials into a smelter and smelting to obtain liquid-state copper, and oxygenating during smelting; atomizing, ejecting atomized copper powder by a closed type V-shaped nozzle under the condition of high pressure when the liquid-state copper flows out of the smelter; drying, to be specifically, drying the copper powder subjected to atomization; reduction, reducing the dried copper powder by reducing gas; after-treatment, more specifically, coarsely crushing the reduced copper powder by a hammer mill, then finely crushing by a turbo type mill, finally screening by an ultrasonic screening machine with copper granularity of 150-600 meshes to obtain high-green-strength atomized copper powder. The manufacturing method of the high-green-strength atomized copper powder can manufacture copper powder in various and complicated shape, green strength of the copper powder is effectively improved, and loose-packed density of the copper powder is reduced.

Owner:铜陵国传电子材料科技有限公司

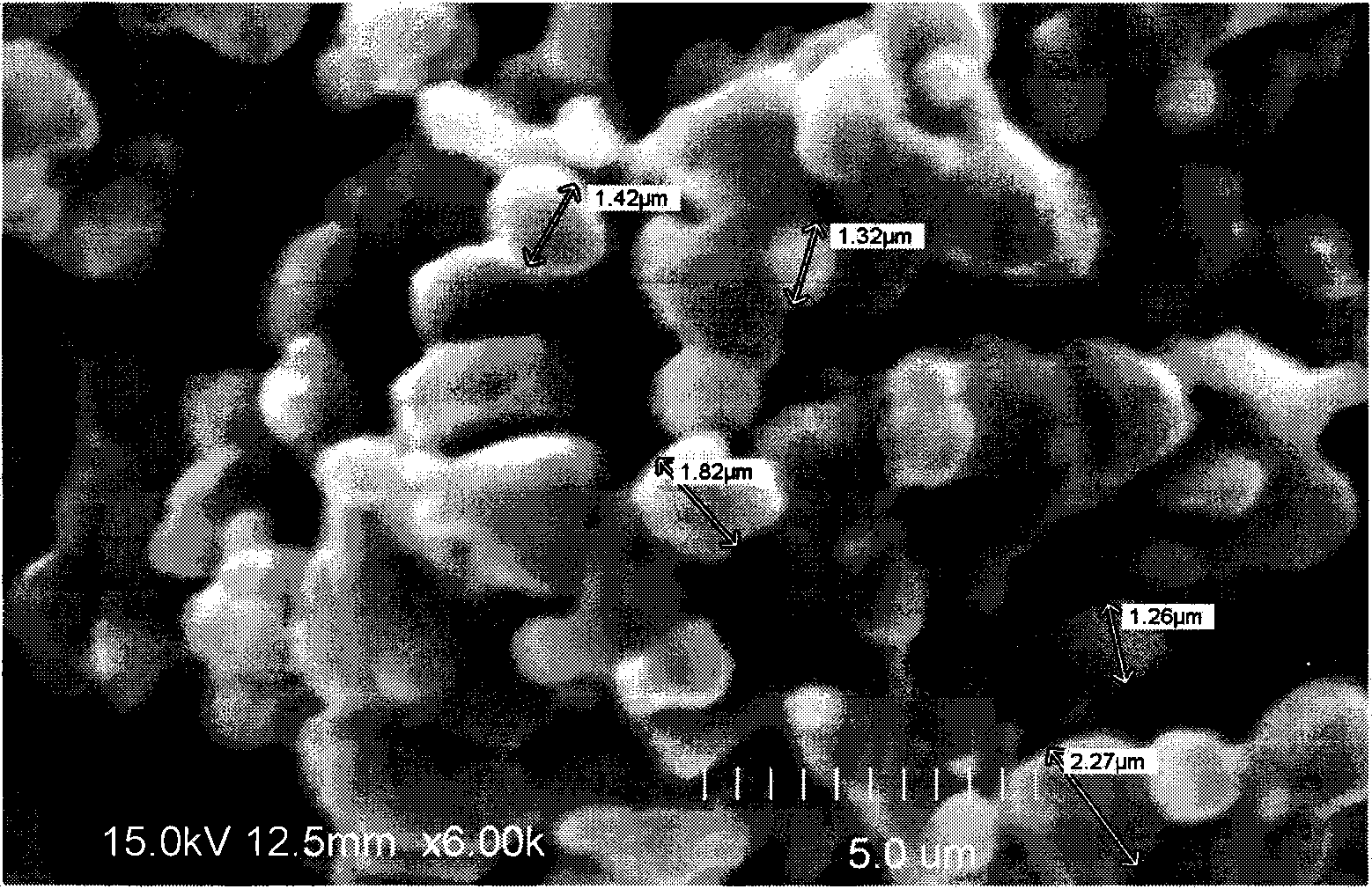

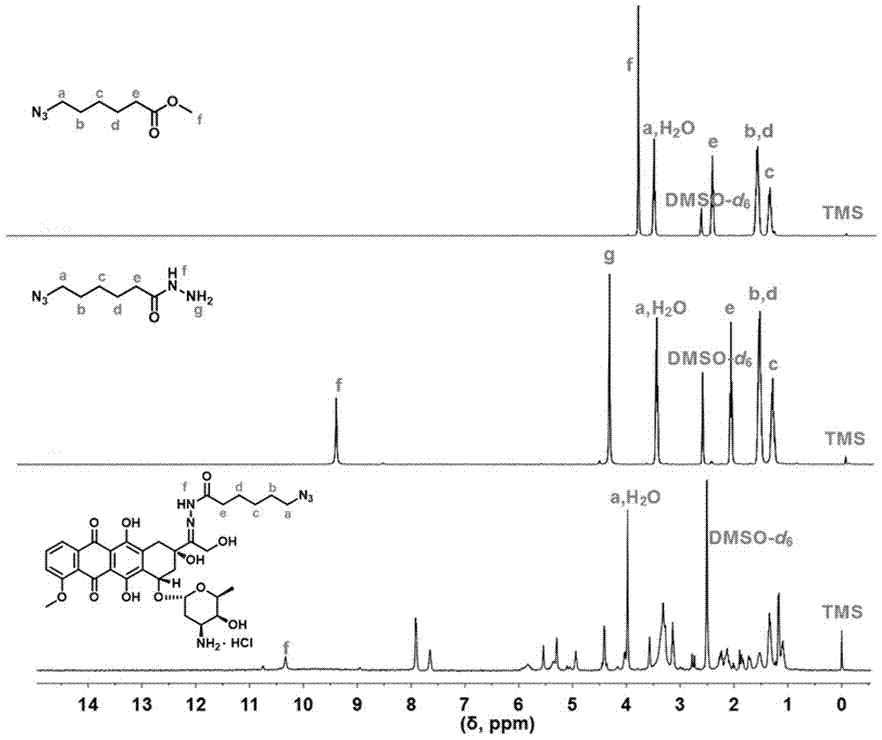

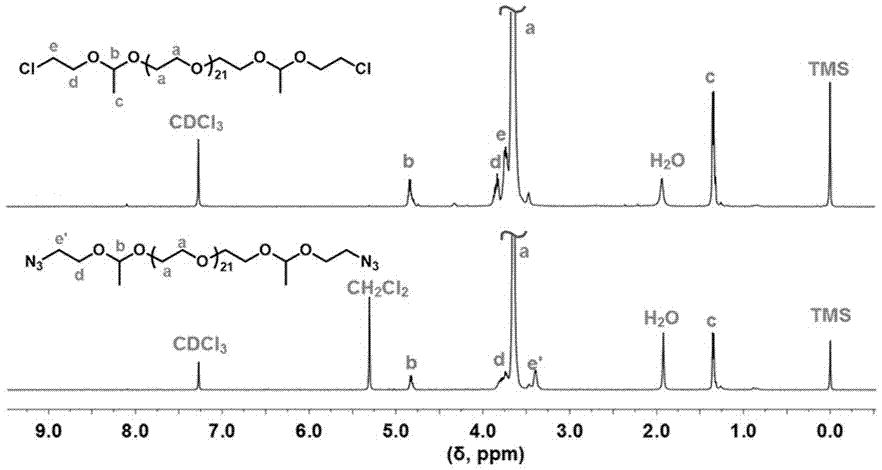

Reduction/pH double response adriamycin prodrug and preparation method and application thereof

ActiveCN107141323ANew synthetic methodThe synthesis method is simpleOrganic active ingredientsSugar derivativesChemical reactionPolyethylene glycol

The invention discloses a reduction / pH double response adriamycin prodrug and a preparation method and application thereof. The specific preparation method comprises the steps of performing a chemical reaction by using a small molecule compound 3,3'-dithio diyne butyl dipropionate (B-ss-B) endcapped with alkynyl and a compound diazide ethyl diacetal polyethyleneglycol (N3-a-PEG-a-N3) endcapped with an azide group, so as to prepare a reduction / pH double response polymer poly(SS-alt-A)n endcapped with alkynyl; and then connecting adriamycin derivatives at two ends of a polymer chain, so as to obtain the reduction / pH double response adriamycin prodrug DOX-hyd-poly(SS-alt-A)n-hyd-DOX. The reduction / pH double response water-soluble adriamycin prodrug has good biocompatibility and characteristics of controlled-release drugs, so that the reduction / pH double response water-soluble adriamycin prodrug can be used as a stimulating sensitive antitumor prodrug.

Owner:SUZHOU UNIV

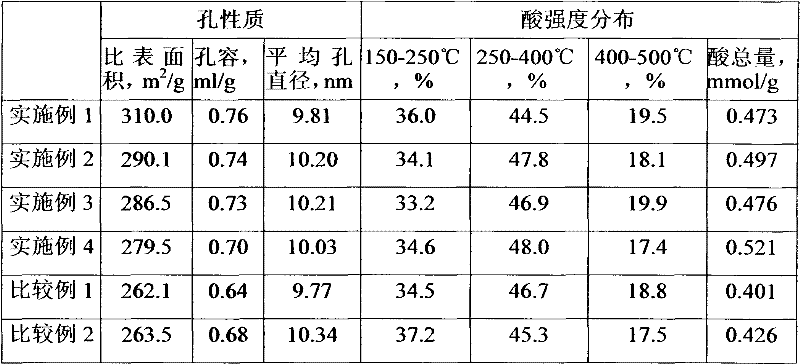

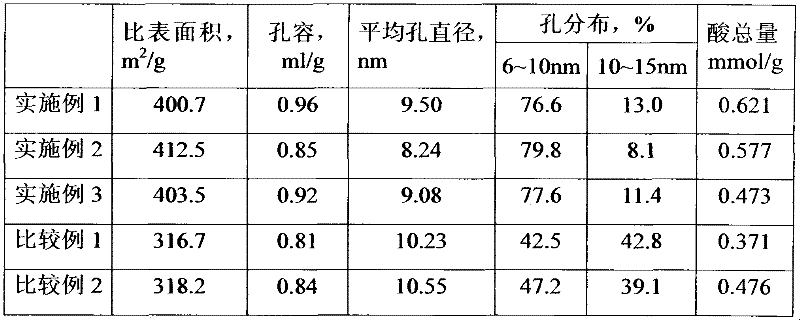

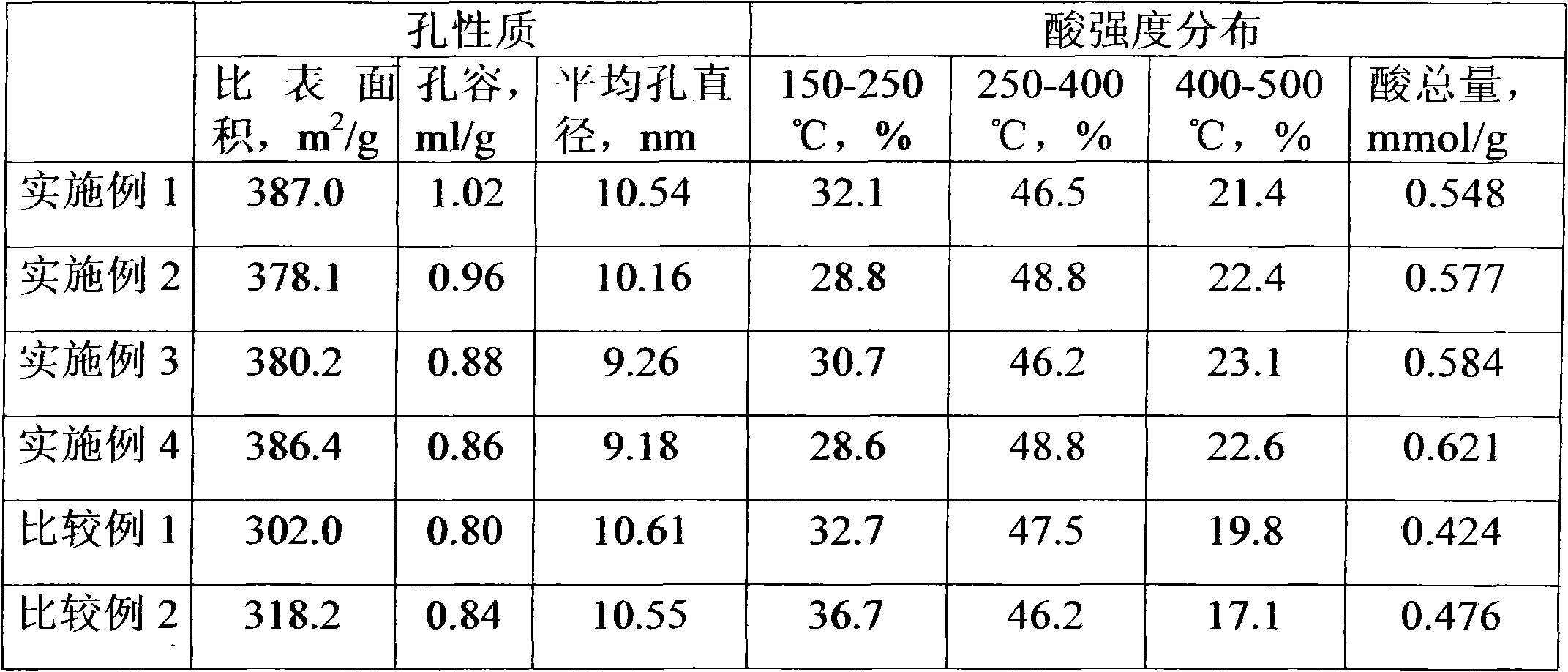

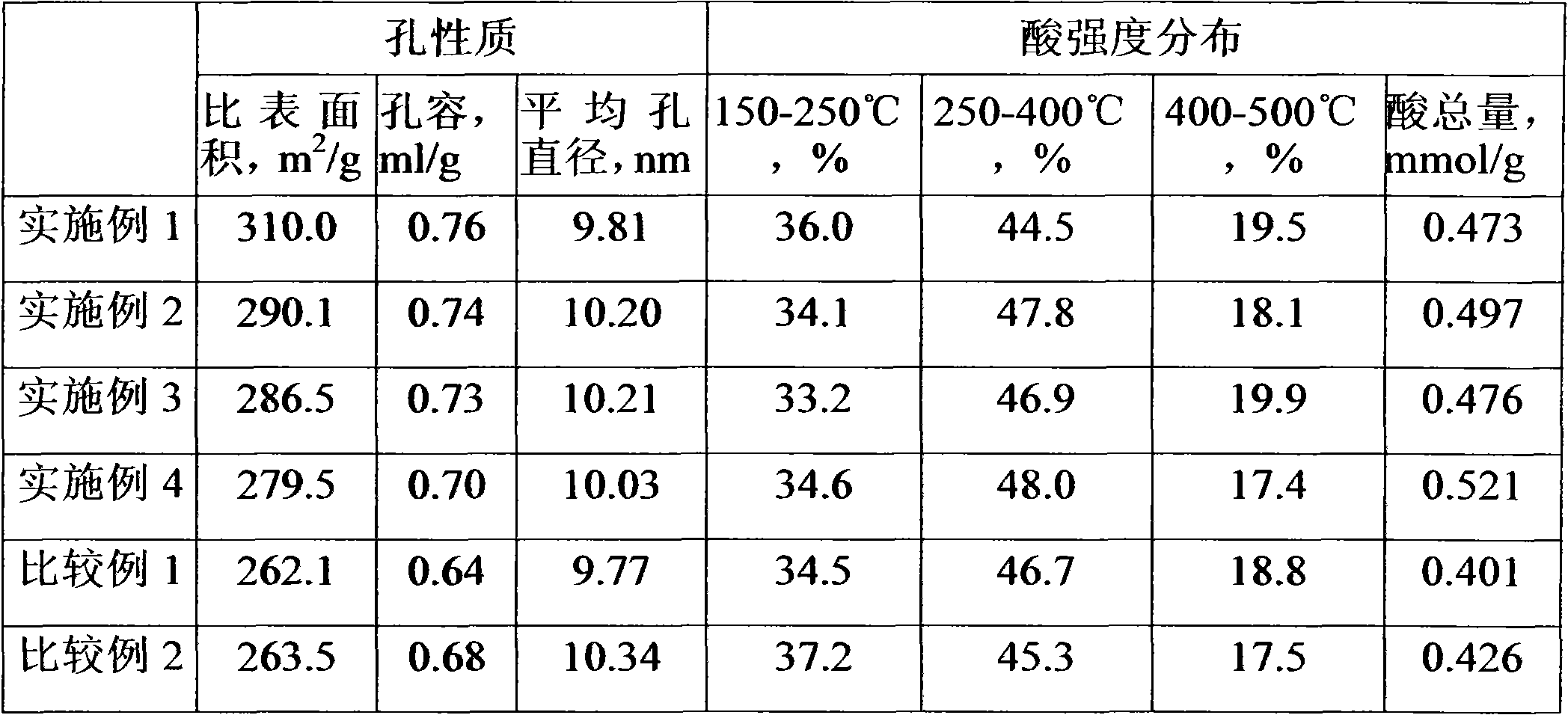

Preparation method of composite oxide carrier

ActiveCN102451766ALarge hole volumeHigh specific surface areaCatalyst carriersRefining to eliminate hetero atomsComposite oxideMetal

The invention discloses a preparation method of a composite oxide carrier. A composite oxide gel adopted in the method of the invention is obtained by the steps of: first preparing an aluminum hydroxide sol and a water solution containing a group IVB metal complex, then mixing the sol and the water solution, adding dropping a hydrolysis promoter so as to obtain a mixed precipitate, which is then subjected to aging, washing, filtering and drying. The composite oxide gel obtained by the method can make most of group IVB metal oxides distributed on an alumina surface so as to weaken influence onan alumina pore structure, enhance the catalysis assisting effect of group IVB metal oxides, and improve the pore structure and surface performance of the composite oxide carrier. Therefore, the vulcanizing property of a catalyst with the carrier of the invention can be improved, and loaded active metals are easy for reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of composite oxide adhesive

ActiveCN102451769ALarge specific surface areaGive full play to the catalytic performanceCatalyst carriersRefining to eliminate hetero atomsAdhesiveAluminium hydroxide

The present invention discloses a preparation method of composite oxide adhesive. The method comprises the following steps: preparing aluminum hydroxide sol and aqueous solution containing IVB family metal complexes, mixing the aluminum hydroxide sol and the aqueous solution, dripping hydrolyzation accelerant to obtain mixed sediment, and carrying out aging, washing, filtering and drying treatments to obtain the composite oxide adhesive. According to the preparation method, most IVB family metal oxides are distributed on a surface of alumina, influence on an alumina pore structure is weakened, catalytic action of the IVB family metal oxides is raised, advantages of the alumina and the IVB family metal oxides are fully played, and the obtained composite oxide adhesive has the characteristics of large hole capacity, high specific surface area, controllable acidity, and is suitable for being a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

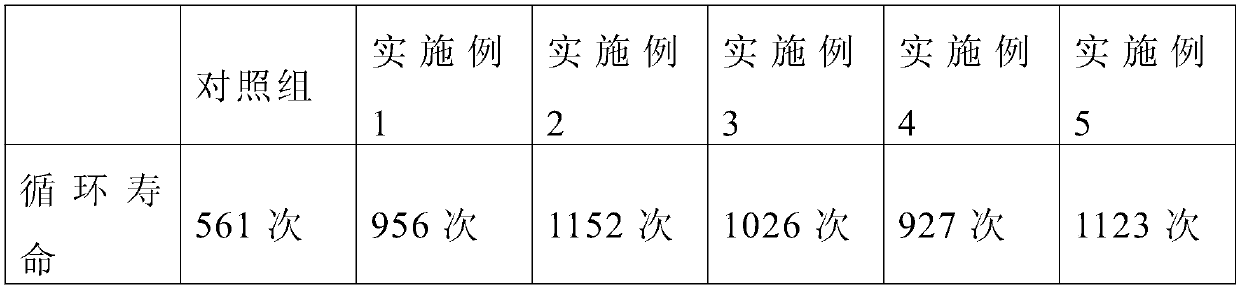

Positive grid lead-calcium alloy for lead-acid storage battery

The invention relates to a novel positive grid lead-calcium alloy for a lead-acid storage battery. The alloy is prepared from components in percentage by weight as follows: 0.05%-0.12% of calcium, 0.5%-1.5% of tin, 0.06%-0.11% of bismuth, 0.07%-0.15% of rare earth elements and the balance of lead, wherein the rare earth elements are one or more of ytterbium, gadolinium and lanthanum. The ingredients of the grid alloy are improved by adding tin, bismuth, the rare earth elements and other additives, and a novel deep-cycle and maintenance-free grid alloy material for the lead-acid storage batterywhich is corrosion-resistant, good in charging property and mechanical property and long in cycle life is obtained.

Owner:WUHAN YIWEIDENG TECH DEV

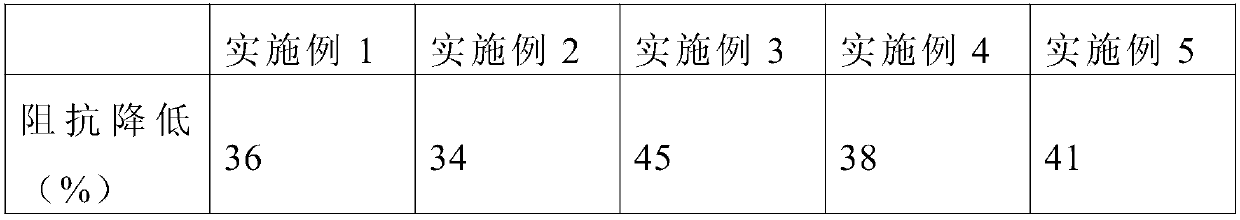

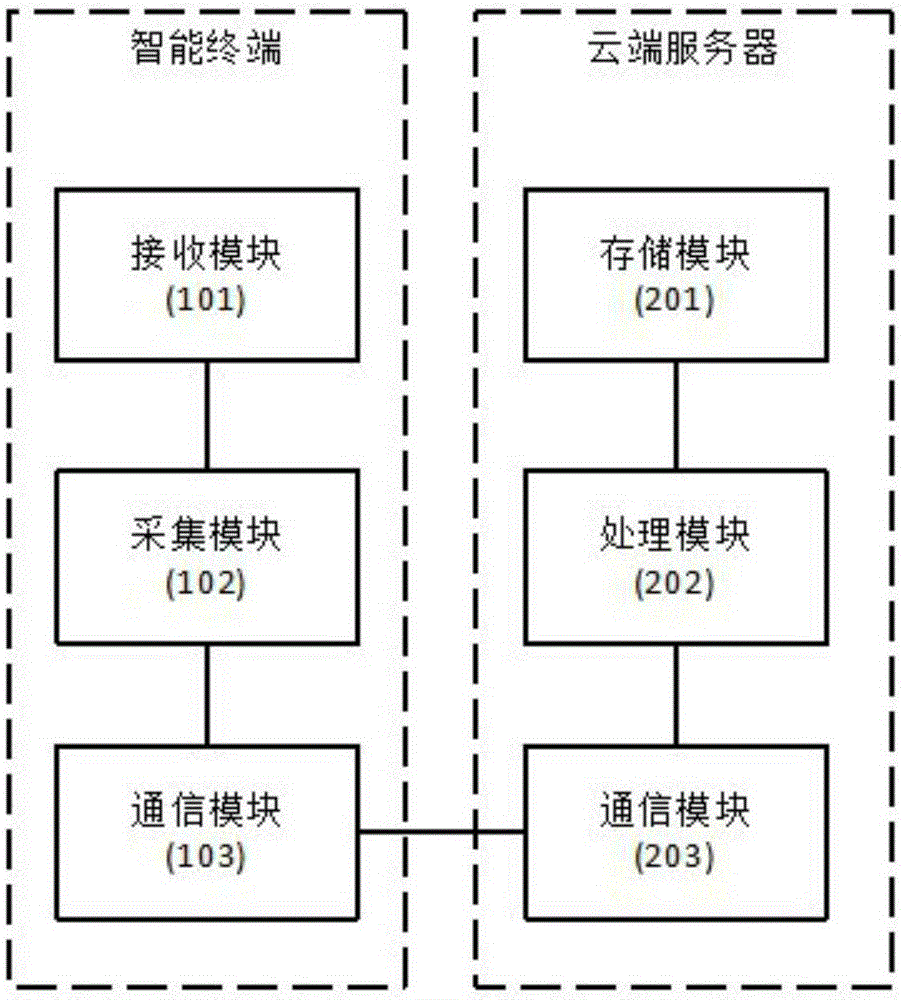

Method and system for recording help-seeking and rescue evidences

InactiveCN105357282AGood restorationRestoredTelevision system detailsColor television detailsUnique identifierReal-time computing

The invention relates to a method and system for recording help-seeking and rescue evidences. The method for recording the help-seeking and rescue evidences is characterized by comprising the following steps: generating a unique identifier UID for the help-seeking this time by a server; and respectively automatically collecting videos, audios or pictures of a rescue process by an intelligent terminal of a help seeker and an intelligent terminal of a rescuer. The invention further relates to a system for recording the help-seeking and rescue. The system for recording the help-seeking and rescue evidences is characterized by comprising an intelligent terminal and the server, wherein the server is used for receiving the help-seeking, receiving geographical location information of the help seeker, generating the unique identifier UID for the help-seeking, and distributing a help-seeking message for rescue; receiving a response of the rescuer to the help-seeking and receiving the geographical location information of the rescuer; and recording. The method and system for recording the help-seeking and rescue evidences provided by the invention solve the problem that in the prior art, the evidences of the whole help-seeking and rescue process cannot be recorded.

Owner:SHANGHAI JIUYAOJIU INFORMATION TECH CO LTD

Method for preparing zirconia-alumina composite oxide xerogel

InactiveCN102451768ALarge specific surface areaMaintain skeleton structureCatalyst carriersZirconia aluminaComposite oxide

The invention discloses a method for preparing a zirconia-alumina composite oxide xerogel. An aluminum hydroxide sol and a zirconium-containing sol are prepared firstly, and then are mixed, aged, washed, filtrated and dried to obtain the composite oxide xerogel. In the method, most of zirconia is distributed on the surface of alumina, the impact on a pore structure of the alumina is weakened, the co-catalysis of the zirconia is improved, the advantages of the alumina and the zirconia are fully utilized, and the obtained composite oxide xerogel has the characteristics of large pore volume, high specific surface area, concentrated pore size distribution and controllable acidity, and is suitable for being used as a hydrogenation catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

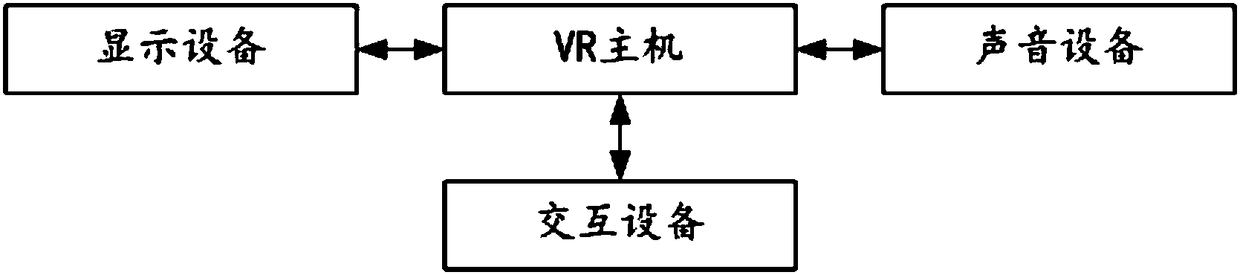

Power transmission and distribution construction safety education and training system based on VR technology and construction method thereof

PendingCN108399805AAchieve transformationImprove immersionElectrical appliancesElectric power transmissionDisplay device

The invention relates to the technical field of power transmission and distribution construction, in particular to a power transmission and distribution construction safety education and training system based on the VR technology and a construction method thereof. The system includes a VR host, a display device, a sound device and an interaction device, the display device is used for displaying image data in the VR host, the sound device is used for playing sound data in the VR host, and the interaction device is used for interacting with the VR host. The construction method is used for building the power transmission and distribution construction safety education and training system based on the VR technology. The system can better train construction personnel.

Owner:ANHUI ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG +1

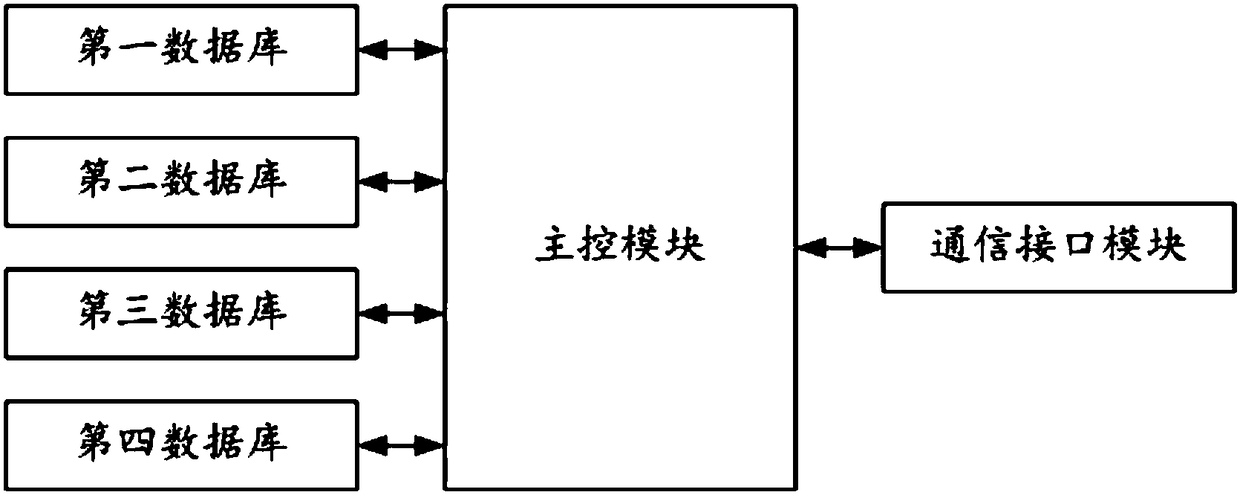

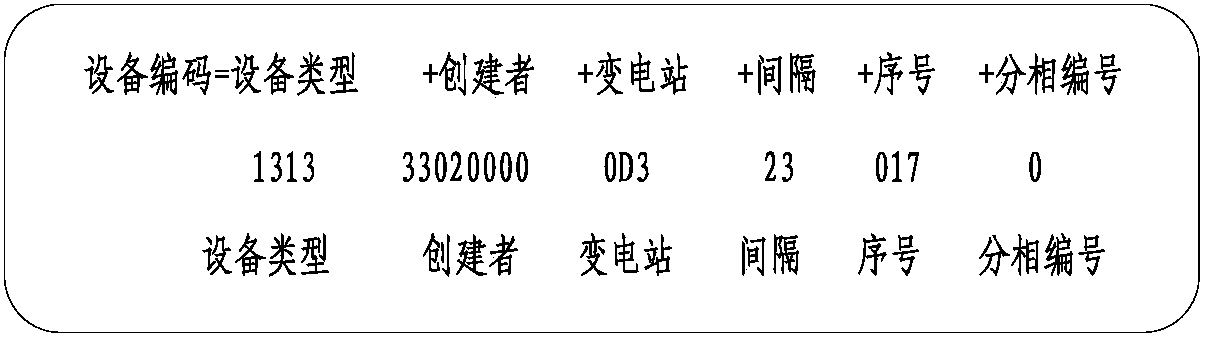

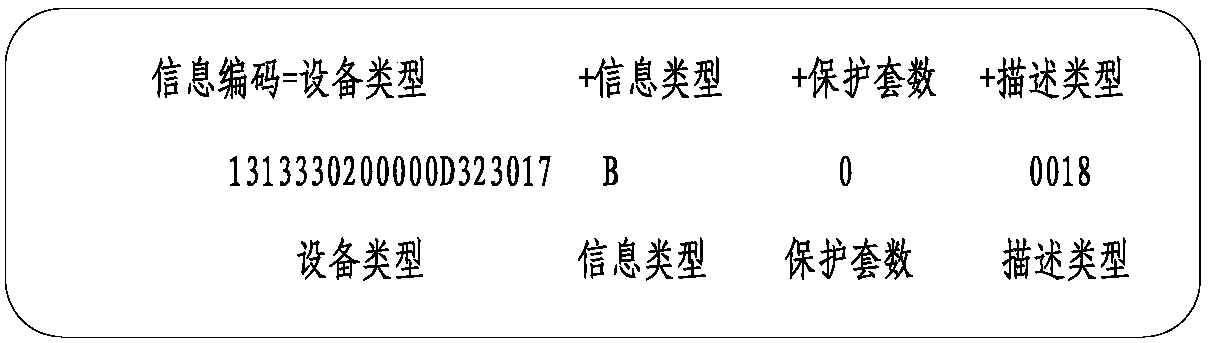

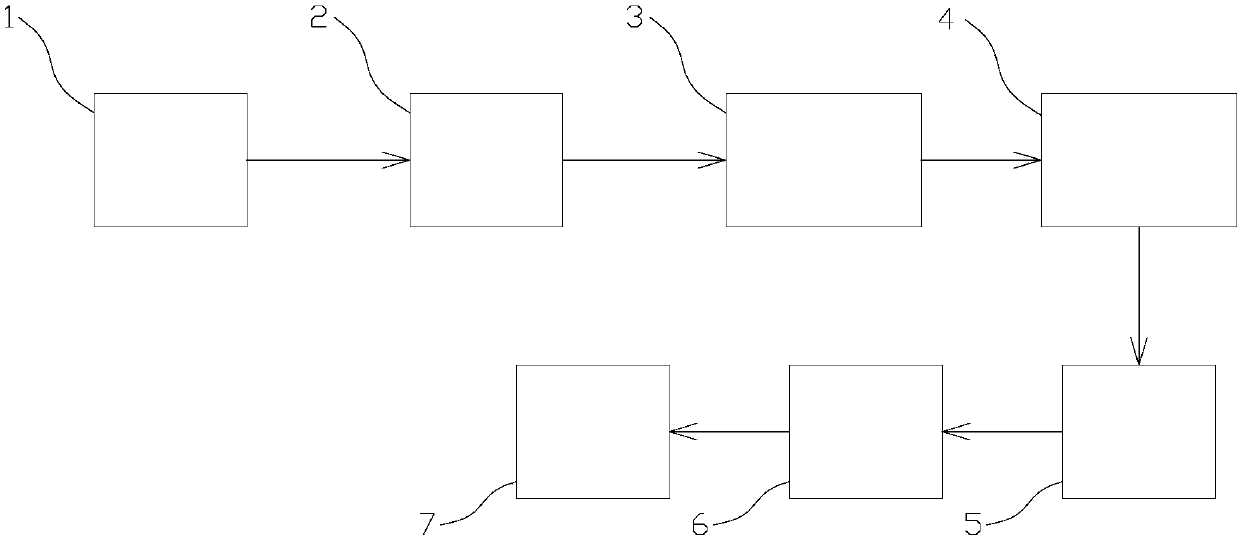

Power grid monitoring information storage and interactive coding processing method and apparatus

InactiveCN107748767AImprove query efficiencyImprove monitoring efficiencySource coding adaptationSpecial data processing applicationsLow speedInstability

The invention relates to the field of power equipment monitoring, in particular to a power grid monitoring information storage and interactive coding processing method and apparatus. For the problem of upper-level application system instability caused by quick information change and low speed and efficiency of monitoring data query in the field of existing power grid equipment monitoring, the invention provides the power grid monitoring information storage and interactive coding processing method and apparatus. The apparatus comprises a first receiving module, a first processing module, a monitoring information coding module, a comprehensive monitoring management module and a second processing module which are connected. By performing coding, query and contrast analysis and statistics on equipment type information input by a user or a system, the monitoring data query and monitoring efficiency is improved, and the stability of the upper-level application system is enhanced; informationof equipment attribution and the like can be easily restored under the condition of not performing a table association query; patrol is performed for retrieving associated data; and even if the datafalls into other systems, the data can be restored and traced, so that the retrieval efficiency is improved and the operation cost is reduced.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +3

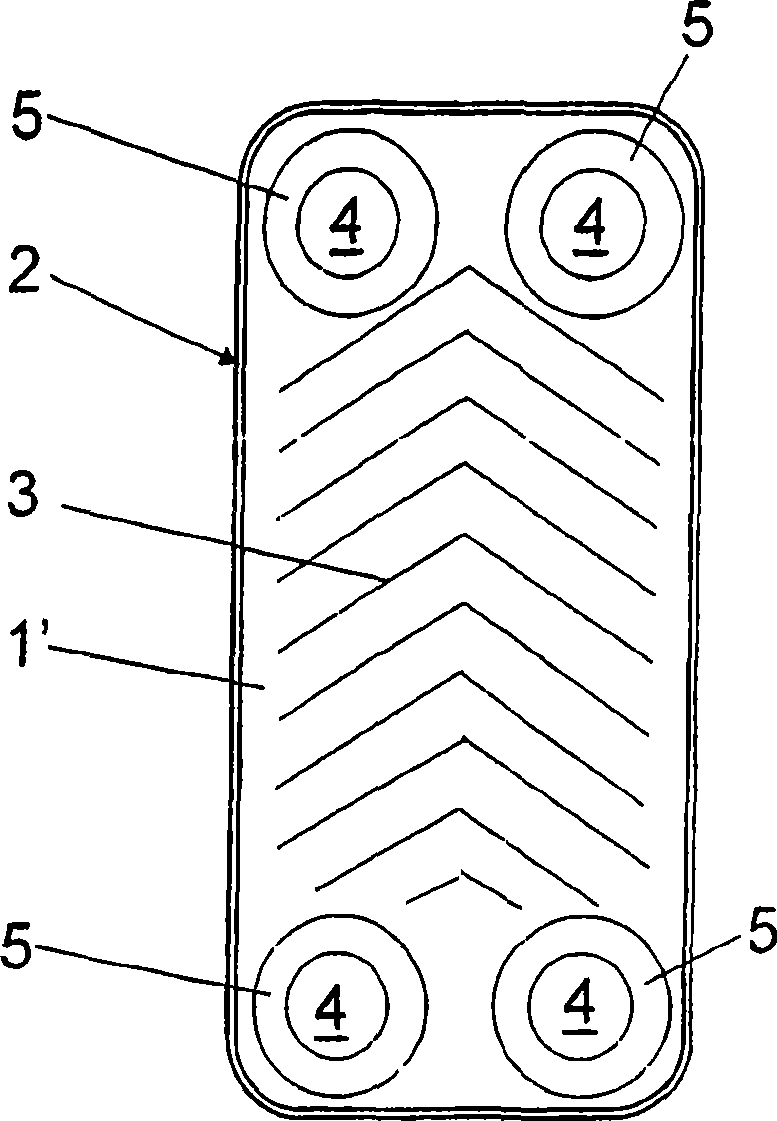

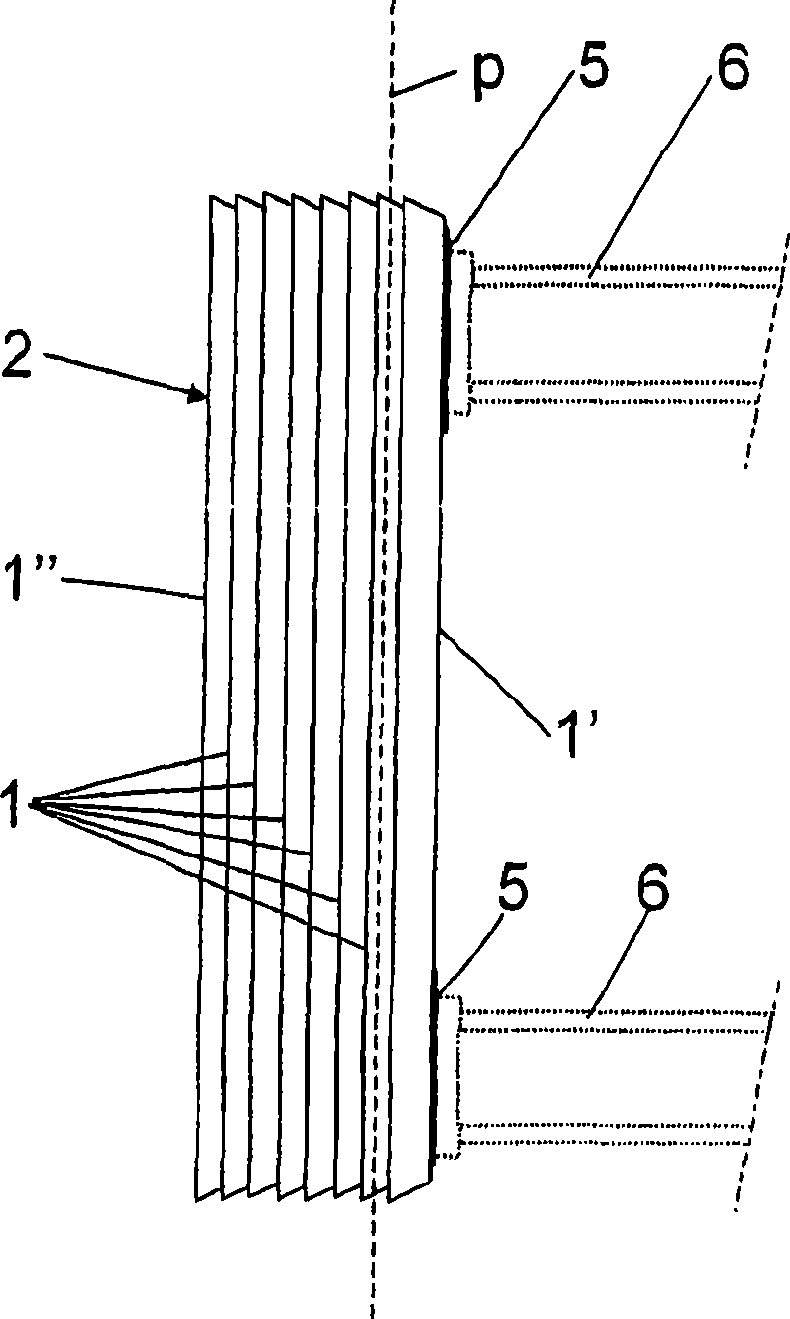

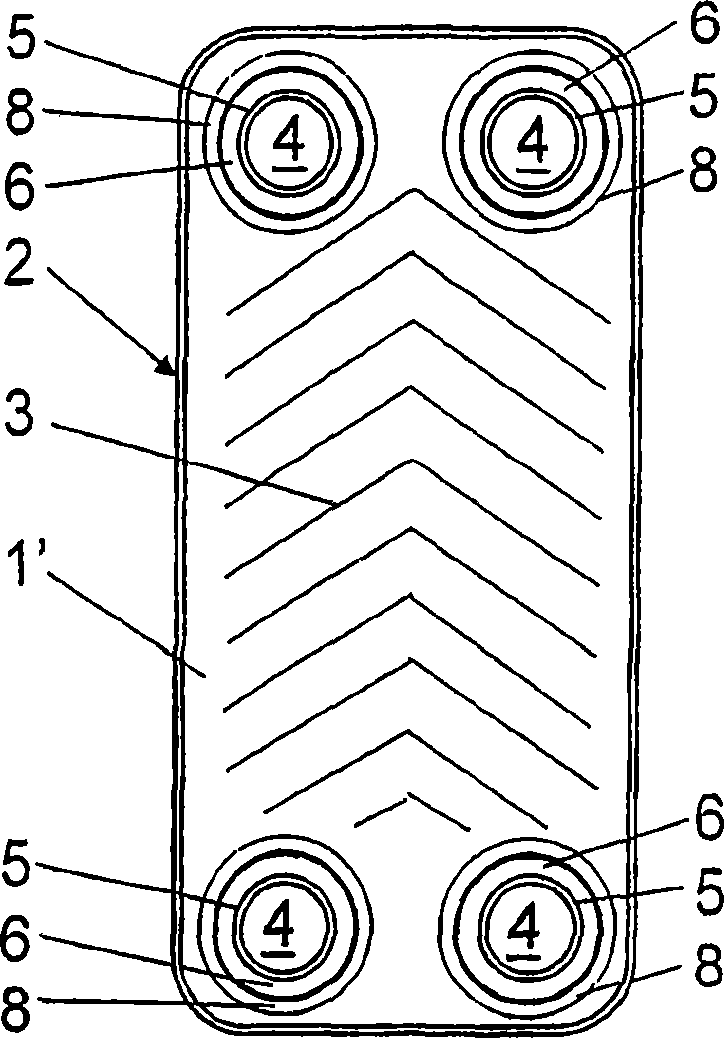

A plate heat exchanger

InactiveCN1867807APromote reductionRestoredSoldering apparatusHeat exchanger casingsPlate heat exchangerMechanical engineering

The invention relates to a plate heat exchanger and a method of manufacturing a plate heat exchanger. The plate heat exchanger includes a number of heat exchanger plates (1, 1', 1'') which are provided beside each other and connected to each other by means of a braze connection. The heat exchanger plates are substantially manufactured in stainless steel containing chromium. The plate heat exchanger includes a number of port channels extending through at least some of the heat exchanger plates. Each port channel is surrounding by a connection surface (5) for connection of the port channel to a pipe member (6). The connection surface includes a material permitting brazing of the pipe member to the connection surface in a more easy manner than stainless steel.

Owner:ALFA LAVAL CORP AB

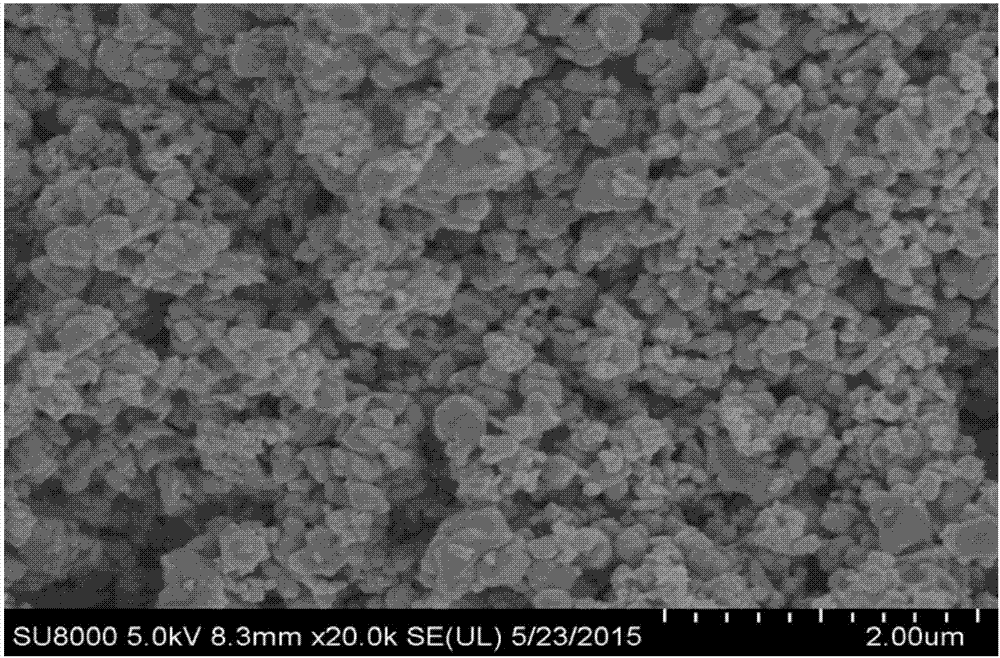

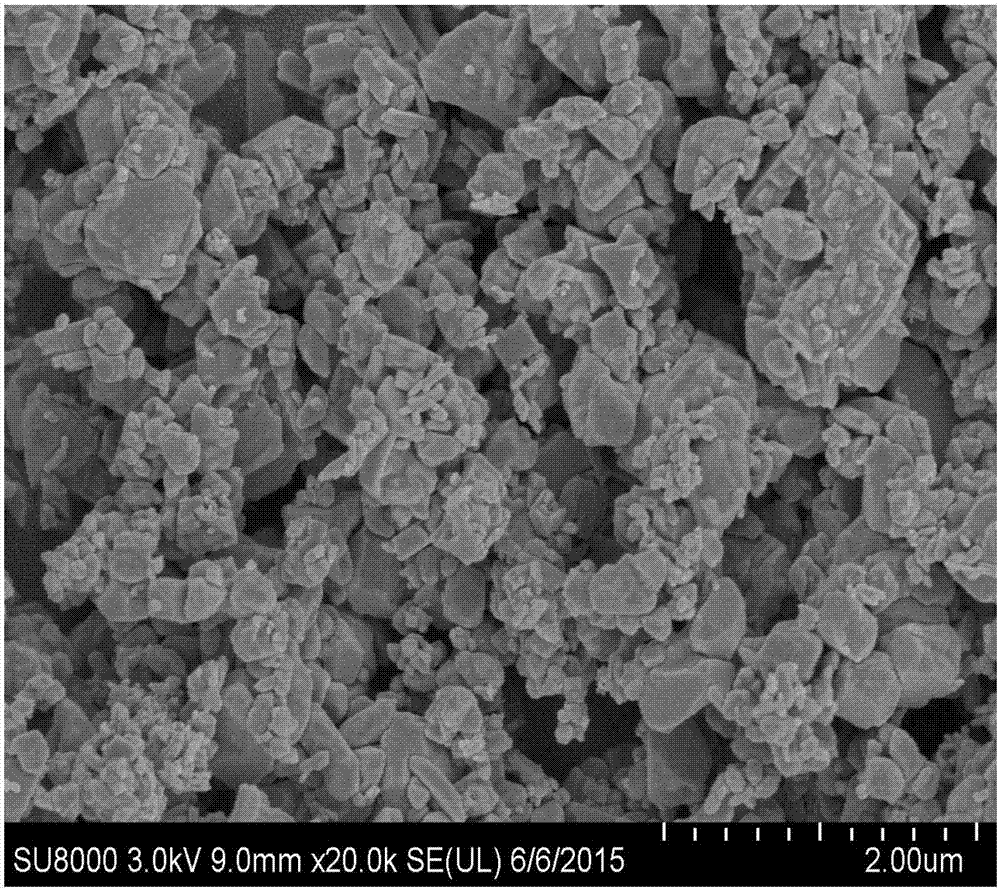

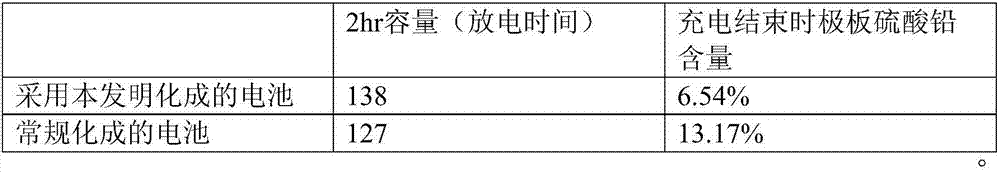

Magnetic force internal formation method of power-type lead accumulator

ActiveCN107204490AIncrease speedIncrease profitFinal product manufactureSecondary cells charging/dischargingMagnetic tension forceElectronic transmission

The invention discloses a magnetic force internal formation method of a power-type lead accumulator. The magnetic force internal formation method of the lead accumulator applies generation of a low-energy magnetic field to influence on intensity of lead accumulator in chemical reaction, charge transfer in solution and metal medium and transmission rate. At the early period of the discharge of the formation battery, the magnetic field system current is also influenced by an external physical magnetic field, its frequency and power are adjusted to reduce the polarization degree; at the post period of the formation discharge, the magnetic field intensity is modulated to change electronic transmission rate and intensity; formation of a large lead sulfate grain can play very good suspending effect; moreover, electromagnetic fields with different intensities are modulated generally to generate waves with low frequency and high frequency so as to increase the mobility of sulfuric acid solution; thus the acid liquid stratification in the battery formation process is solved.

Owner:CHAOWEI POWER CO LTD

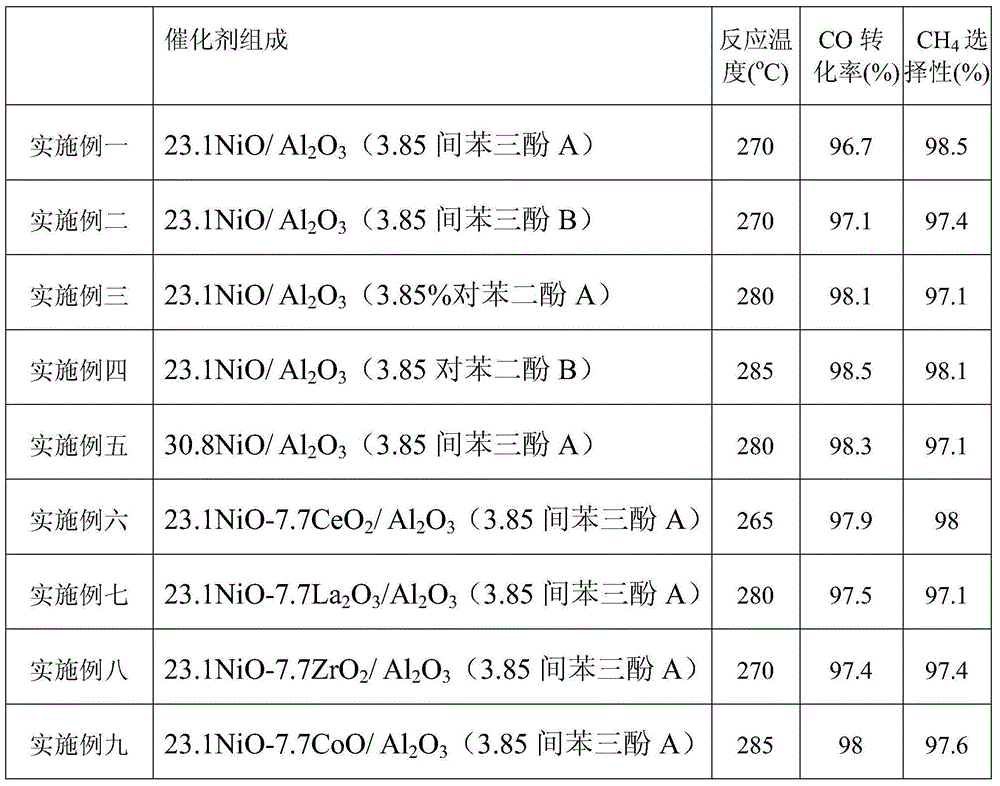

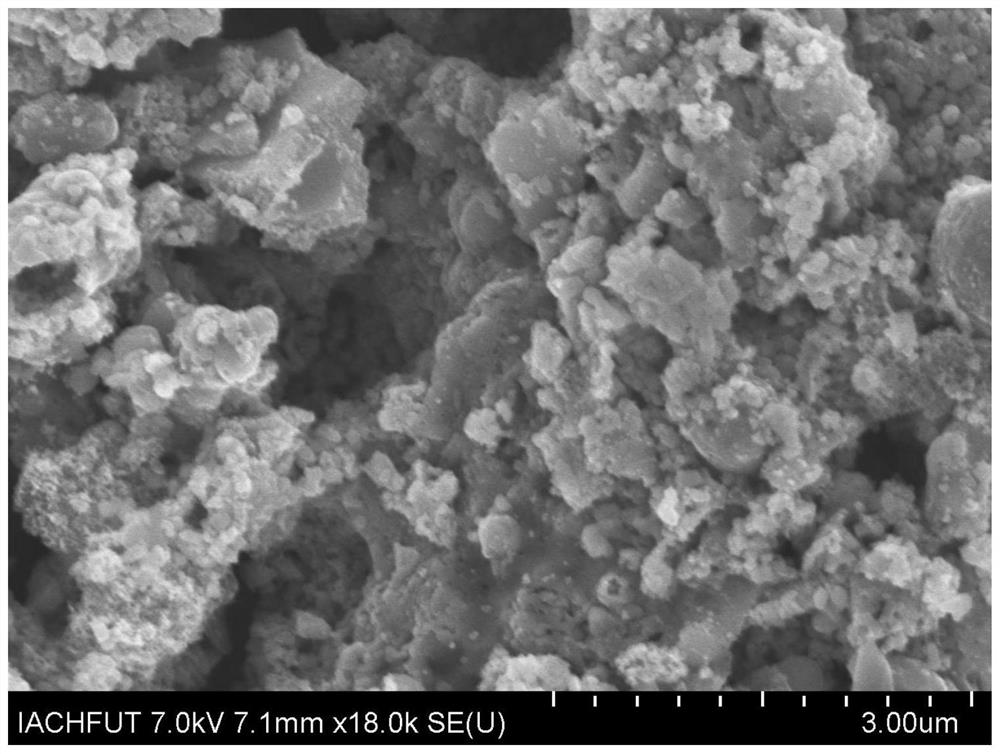

Preparation method of polyhydroxy phenyl improved type methanation catalyst

ActiveCN104525205AUniform surface distributionConsistent sizeHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereMethanation

The invention discloses a preparation method of a polyhydroxy phenyl improved type methanation catalyst. The preparation method comprises the following steps: firstly, adding an ethanol dispersant into aluminum oxide or pseudo-boehmite, and performing ball milling on a ball mill to prepare activated aluminum oxide or pseudo-boehmite microsphere particles; secondly, preparing a nickel nitrate-polyhydroxy phenyl solution by using polyhydroxy phenyl and nickel nitrate, or preparing a nickel nitrate / M nitrate-polyhydroxy phenyl solution by using polyhydroxy phenyl, nickel nitrate and nitrate corresponding to an auxiliary agent M, and dipping to an activated aluminum oxide or pseudo-boehmite microsphere particles carrier; and finally, drying overnight at room temperature, and calcining at a nitrogen atmosphere or air atmosphere to prepare a NiO / Al2O3 catalyst or NiO-M / Al2O3 catalyst. By adopting the preparation method disclosed by the invention, the activity, selectivity and thermal stability of the catalyst are improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

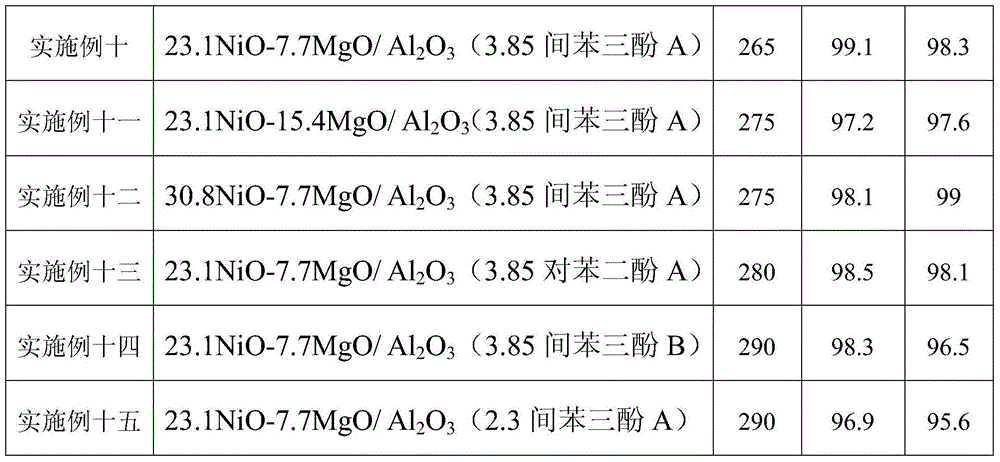

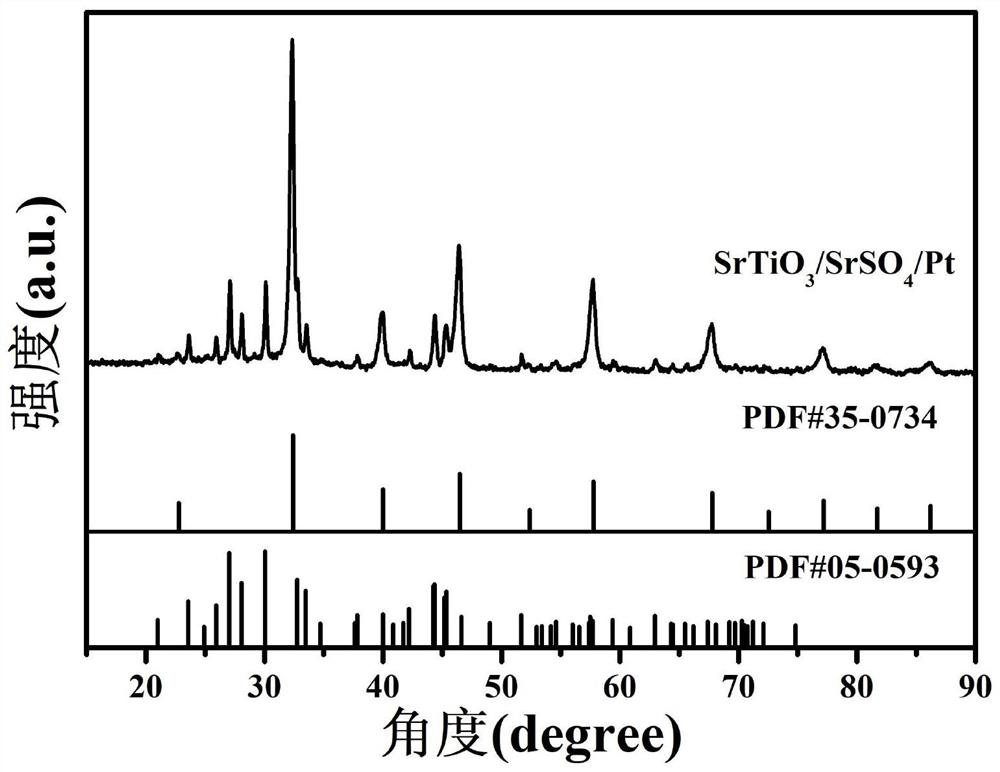

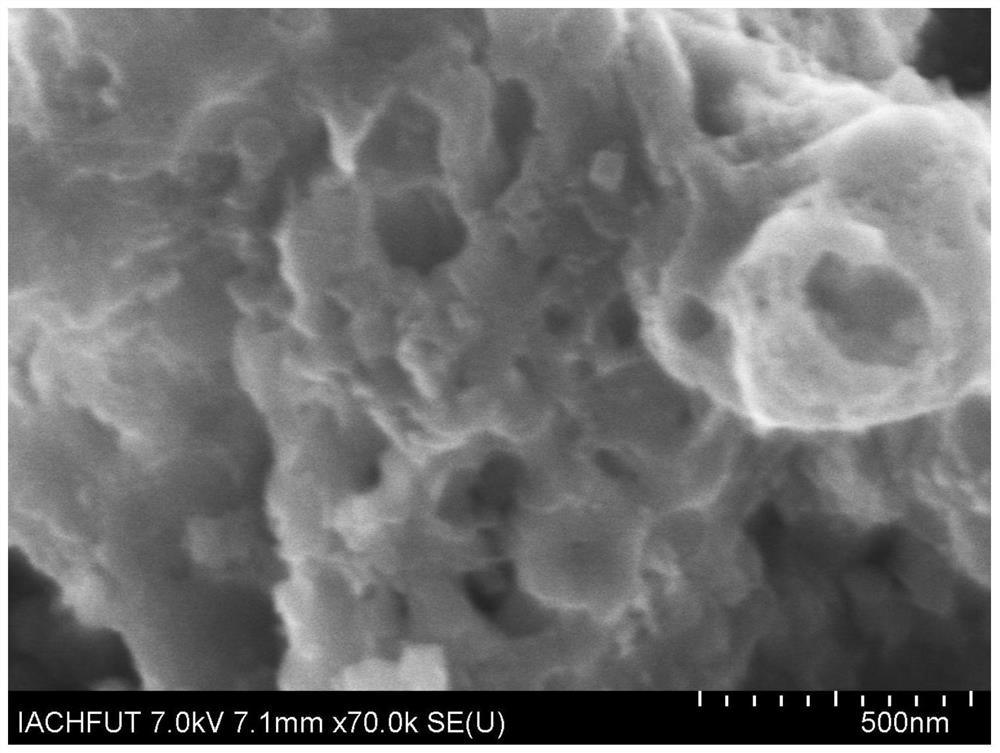

Preparation method of SrTiO3/SrSO4/Pt double-heterojunction nano material

ActiveCN111905770ALow costReduce generationCatalyst activation/preparationHydrogen productionHeterojunctionStrontium titanate

The invention discloses a preparation method of a SrTiO3 / SrSO4 / Pt double-heterojunction nano material. The preparation method comprises the following specific steps: preparing deionized water, glacialacetic acid and absolute ethyl alcohol as solvents and preparing strontium nitrate and tetrabutyl titanate respectively as a strontium source and a titanium source, wherein the added cysteine not only serves as a chelating agent, but also serves as a sulfur source; then preparing a precursor by adopting a sol-gel method, drying theprecursor in a drying box at low temperature for 48 hours, grinding the precursor, and annealing the precursor in a muffle furnace to obtain composite powder of strontium titanate and strontium sulfate; and finally, depositing a layer of platinum on the surface through a photodeposition method to form as a cocatalyst, and thereby the SrTiO3 / SrSO4 / Pt double-heterojunction nano material is obtained. The SrTiO3 / SrSO4 / Pt double-heterojunction nano material disclosedby the invention has a porous structure and a relatively large specific surface area, and can provide more active sites for a photocatalytic reaction; besides, the SrTiO3 / SrSO4 / Pt has very high activity on the precipitation of H2 under the illumination. The nano-material shows great development prospect in the field of photocatalysis.

Owner:HEFEI UNIV OF TECH

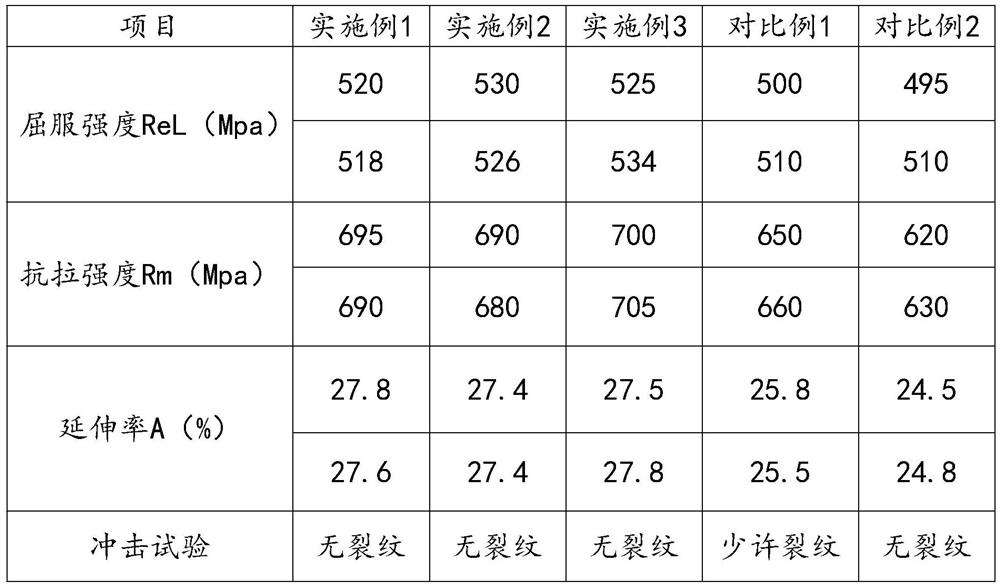

High-strength H-shaped steel for prefabricated buildings and production technology of high-strength H-shaped steel

InactiveCN112593152AImprove qualityEasy to filterBlast furnace detailsProcess efficiency improvementArchitectural engineeringCoke

The invention discloses high-strength H-shaped steel for prefabricated buildings. The high-strength H-shaped steel is prepared from the raw materials including, by weight, 1,500-1,600 parts of iron ore raw material, 300-400 parts of coke, 120-160 parts of pulverized coal and 100-120 parts of a modified refining agent. The invention further discloses a production technology of the high-strength H-shaped steel for the prefabricated buildings. Through a bottom blowing mode, the smelting time can be shortened, the power consumption can be reduced, the desulfurization and dephosphorization conditions can be improved, the residual manganese content in the steel can be increased, the yield of the steel can be increased, the temperature uniformity of molten steel and the uniformity of components can be improved, and the quality of the steel can be improved; through cooperation of stirring and bottom blowing, the diffusion rate of reactants and products is increased, then the floating removal rate of inclusions is increased exponentially, and the quality of the steel is improved; through addition of the modified refining agent, the slagging effect and the slagging rate are increased, moltensteel impurities are adsorbed, the smelting cost per ton of steel is obviously reduced, phosphorus removal is facilitated, and the quality of the steel is improved.

Owner:ANHUI KINGYOUNG STRUCTURAL METAL WORK

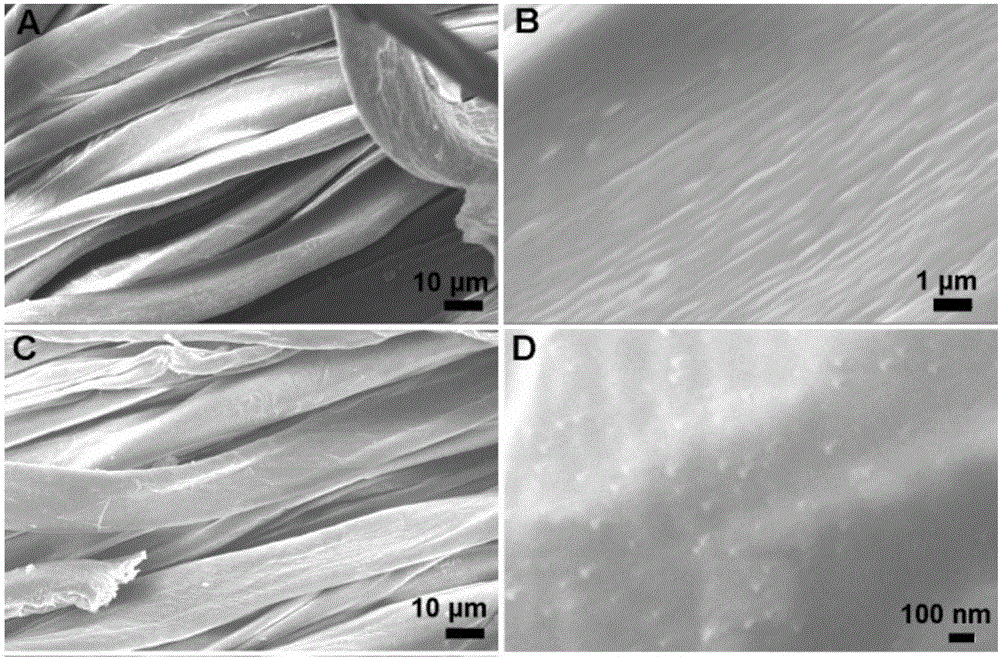

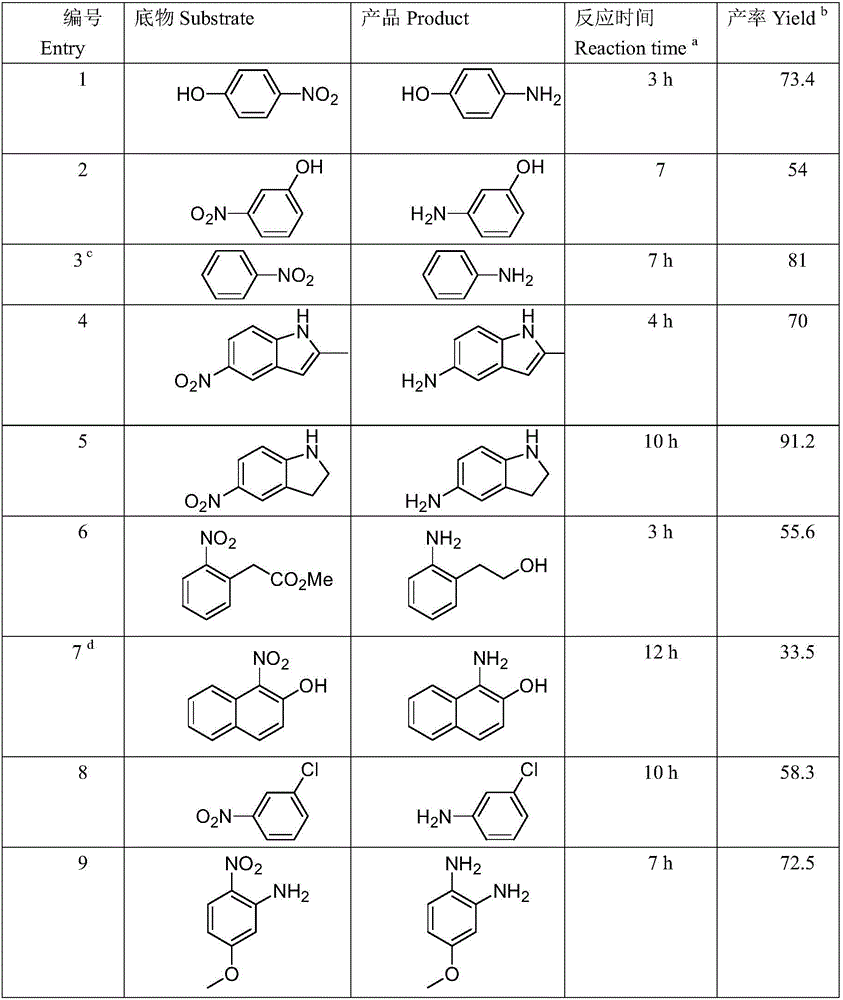

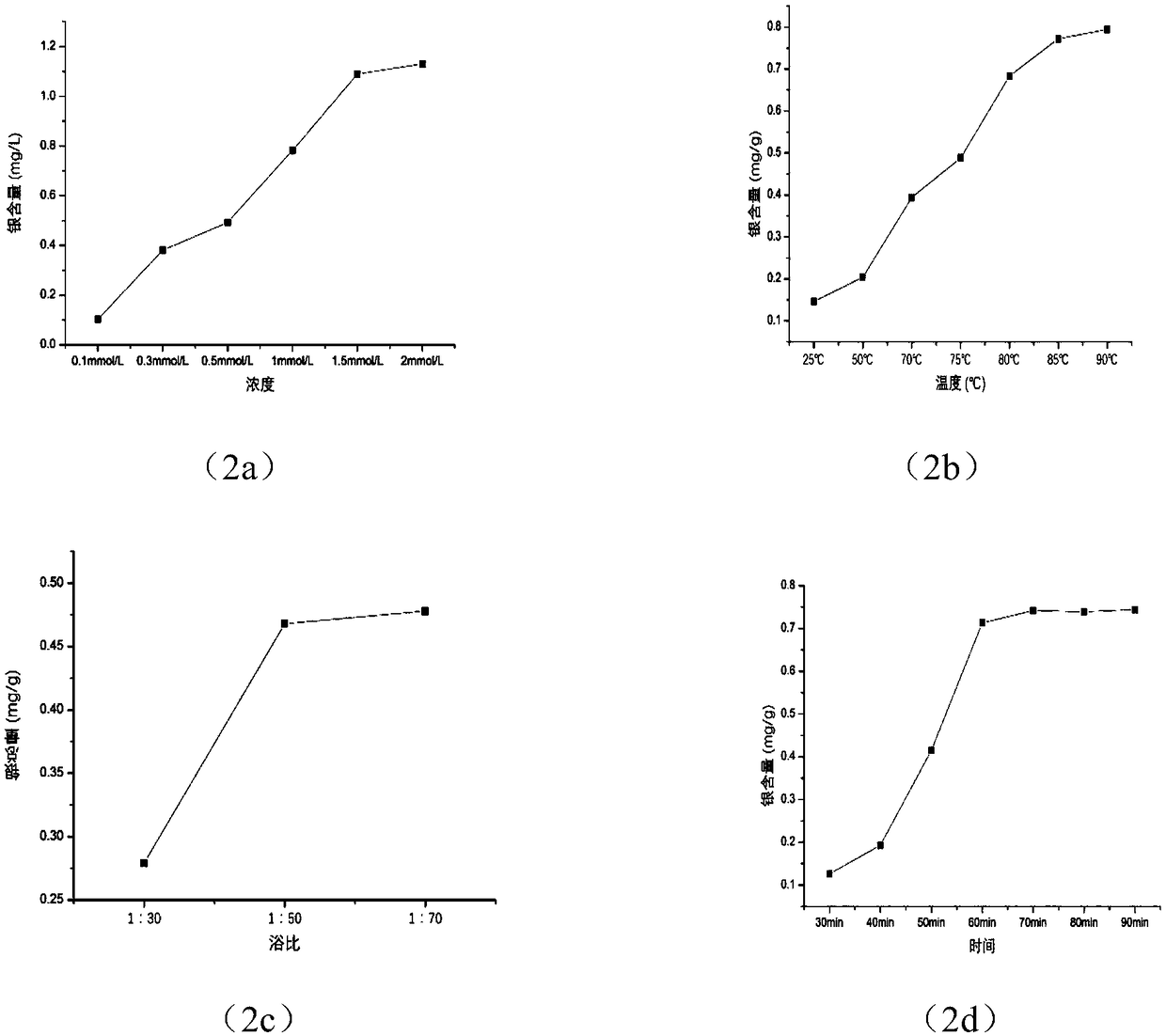

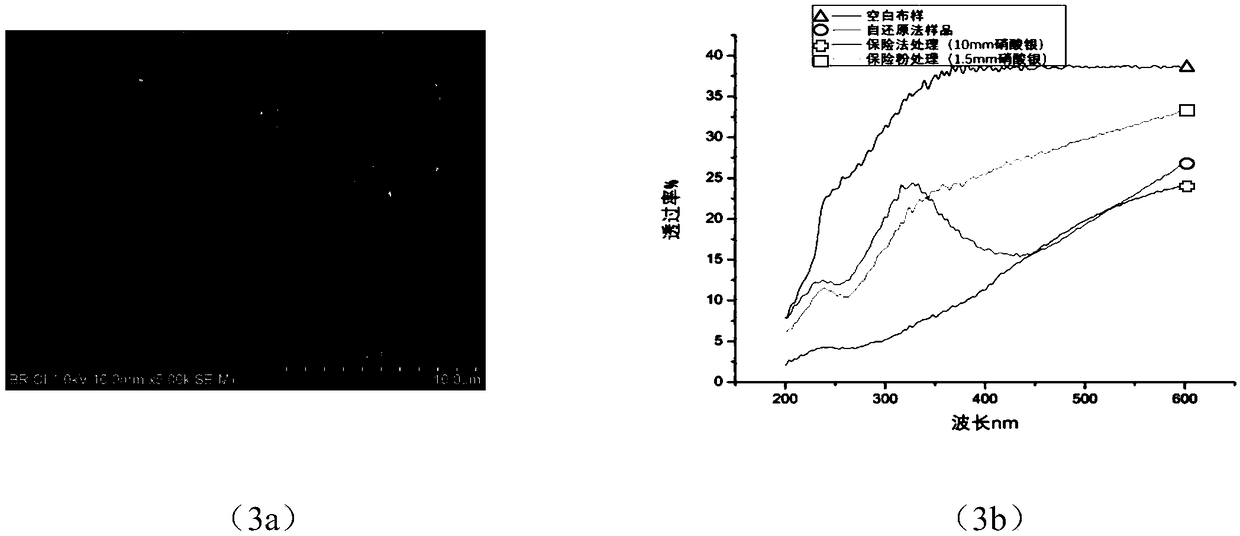

Nano-silver composite textile catalyst and application thereof

ActiveCN105921173AEasy to manufactureLow priceOrganic reductionCarbamic acid derivatives preparationTextile fiberNitro compound

The invention discloses a nano-silver composite textile catalyst and an application thereof. The nano catalyst is prepared by loading nano-silver to the surface of a textile material. Nano-silver particles are loaded on the surfaces of textile fibers by virtue of an in-situ growth method, and the particle size of the nano-silver particles is between 1-50nm; the nano-silver composite textile material shows a good catalytic effect, and can quickly reduce a nitro-compound and an ester compound under a room temperature condition, thereby effectively solving the problem of a severe condition for a reduction reaction of the ester compound at present; and the nano-silver composite textile catalyst is easy to prepare, can be used repeatedly, is low in price, and can be used for large-scale production. The nano-silver composite textile catalyst can quickly reduce an aromatic nitro-compound into aromatic amine at room temperature, and can reduce the ester compound into alcohol by taking an aqueous solvent as a reaction medium at room temperature. The nano-silver composite textile catalyst disclosed by the invention can also be recycled.

Owner:HENAN UNIVERSITY

Catalyst for preparing gamma-butyrolactone by normal-pressure gas-phase dehydrogenation of 1,4-butanediol and preparation method thereof

ActiveCN103877981BRestoredHigh activityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalysts1,4-ButanediolGas phase

The invention relates to a catalyst for preparing gamma-butyrolactone by gaseous phase dehydrogenation of 1, 4-butanediol under normal pressure and a preparation method thereof. The catalyst is composed of CuO, ZnO, Al2O3 and SiO2, and the unreduced catalyst is prepared from the following ingredients by weight percentage: 30-60% of CuO, 15-50% of Zn, 5-25% of Al2O3 and 10-30% of SiO2. The grain diameter of the catalyst is phi 5*5mm, and the catalyst is easy to restore, and has high activity and high selectivity, and long service life under a reaction process condition; the conversion rate of 1, 4-butanediol is greater than or equal to 99%, and the selectivity of the 1,4-butanediol for generating gamma-butyrolactone is greater than or equal to 96.5%.

Owner:MAIQI CHEM CO LTD

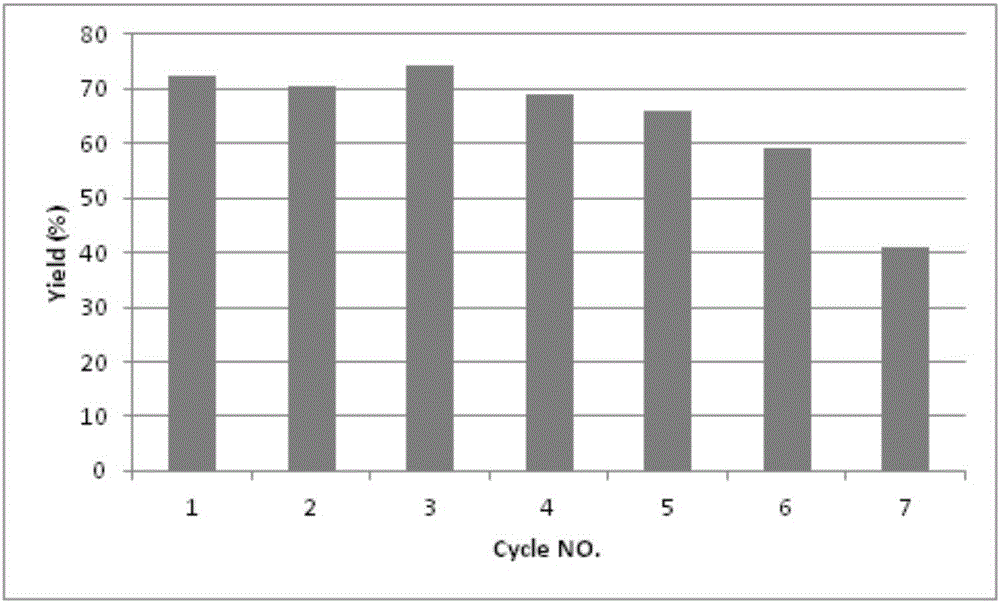

Method for preparing nano-silver antibacterial cotton fabric by self-reduction

InactiveCN108774880ACraft greenRestoredBiochemical fibre treatmentVegetal fibresEnvironmentally friendlySelf reduction

The invention discloses a method for preparing a nano-silver antibacterial cotton fabric by self-reduction. The method comprises the following steps: pretreating a cotton fabric in a NaOH solution under the condition of a water bath, then immersing the pretreated cotton fabric in a silver nitrate solution, carrying out immersing under the condition of a constant temperature, taking the immersed cotton fabric out of the silver nitrate solution, placing the immersed cotton fabric in clear water, carrying out washing, repeatedly carrying out stirring with a top-mounted stirrer under the conditionof a normal temperature, and carrying out natural air-drying. According to the invention, nano-silver is prepared by utilizing the absorption action of a hydroxyl group and the reduction action of analdehyde group in cellulose fibers, and addition of a reducing agent and an absorbent in a conventional process is not needed, so the preparation method for the nano-silver antibacterial cotton fabric provided by the invention is relatively more environmentally-friendly and greener and is a simple process.

Owner:ZHEJIANG ACAD OF SCI & TECH FOR INSPECTION & QUARANTINE

Architectural decoration material and method for realizing custom-made modular indoor fitment system

InactiveCN101158211AMeet needsAvoid secondary pollutionCovering/liningsResource utilizationEngineering

The invention provides a method for the realization of the modularized customization and the assembly of room furniture and fitment system, comprising the steps that: a. the construction decorative materials are customized according to the room area and structure; b. the customized construction decorative materials are arranged in an appropriate position in the room; c. the construction decorative materials are dissembled and folded to be assembled into the required furniture and to realize the required fitment effect, wherein the construction decorative materials comprise a construction decorative demi-body module, and a demountable and foldable room furniture demi-body module jointed with the construction decorative demi-body module. The customized construction decorative materials can satisfy the requirements of different consumers with convenient transportation, and can complete the room decorative process through dissembling and assembling after arriving at the room. The invention is economy, highly efficient, environment-friendly, simplifies the room decorative process, increases the space and resource utilization ratio, and leads a new development direction of the room decoration industry.

Owner:苏运升

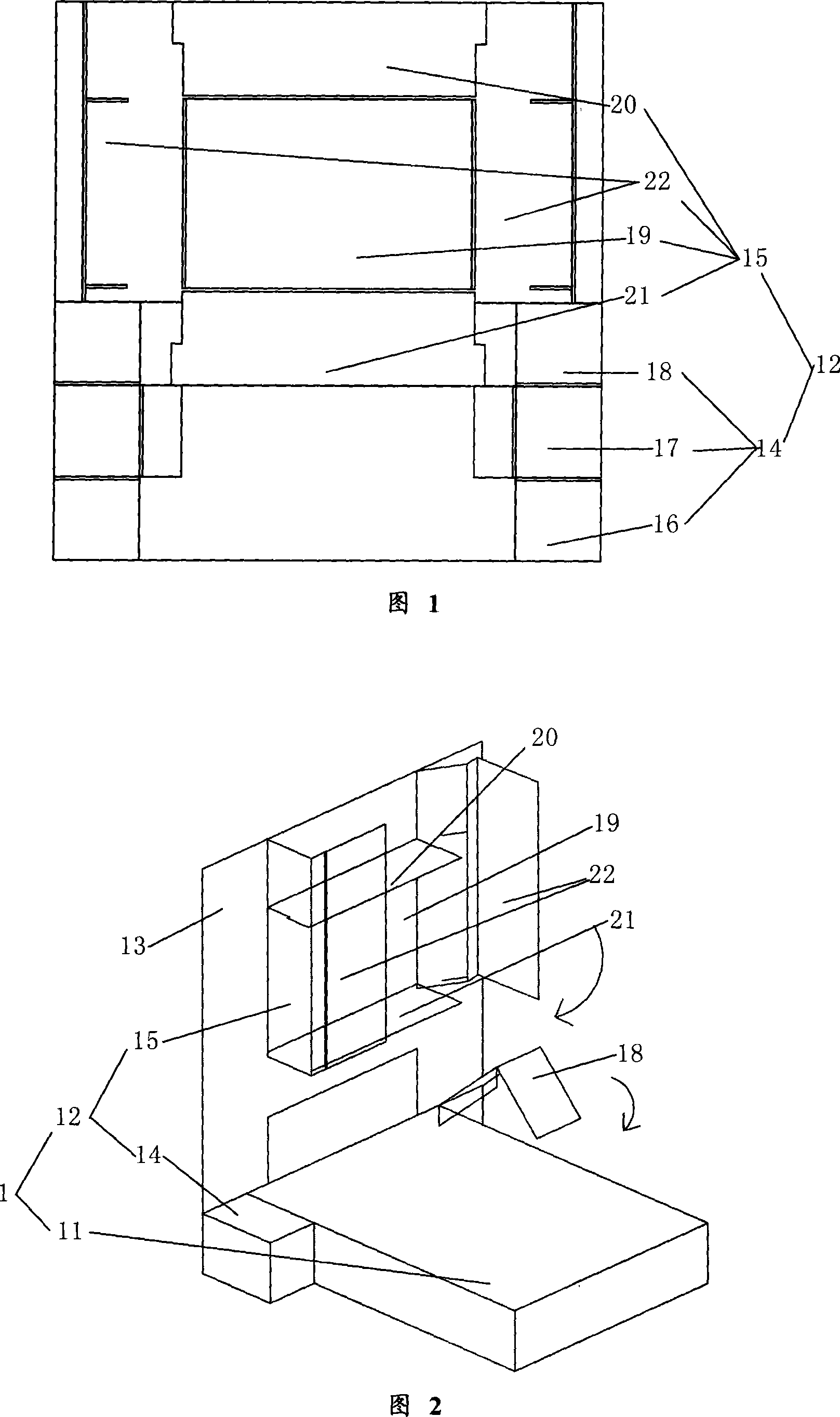

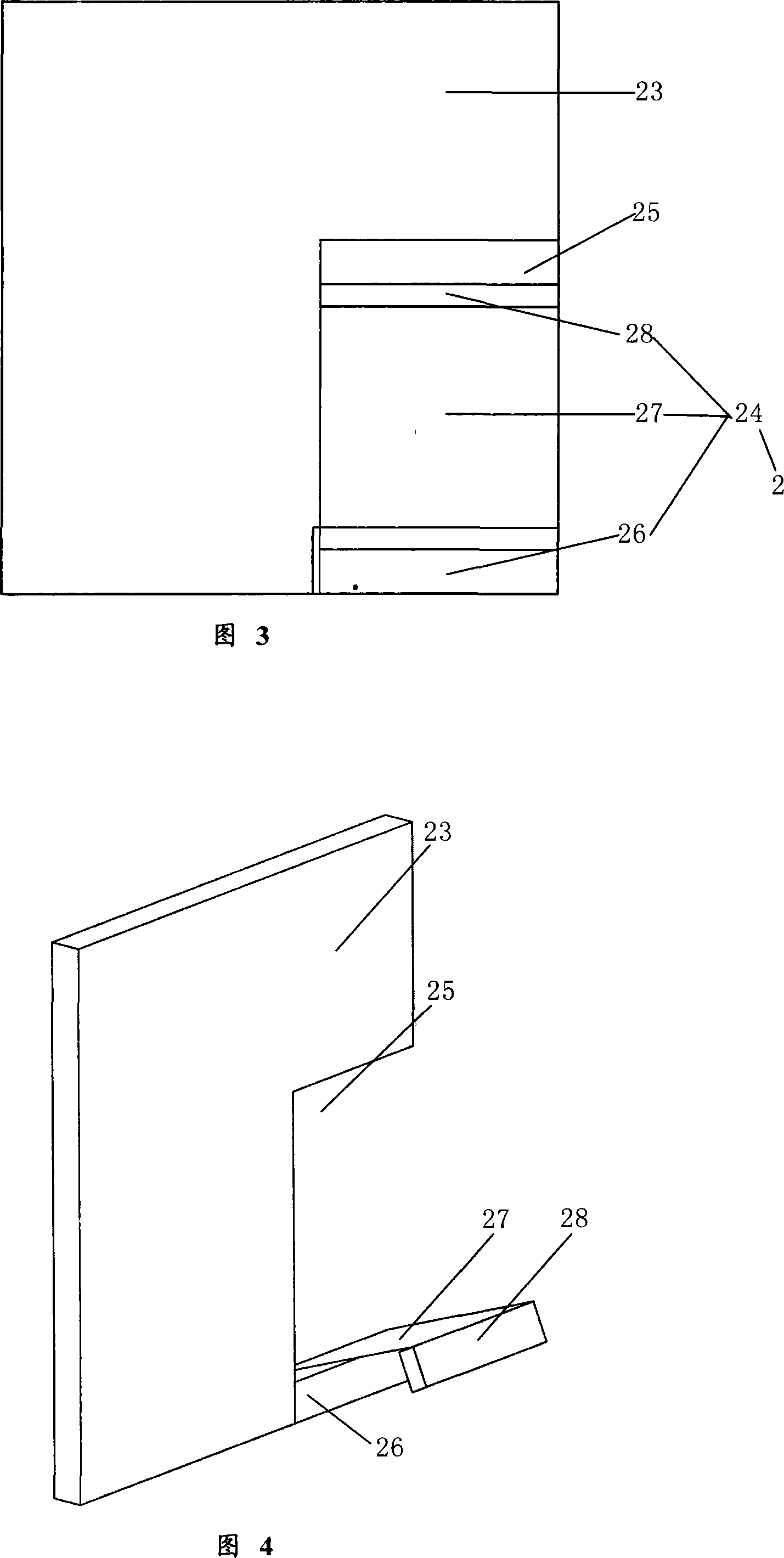

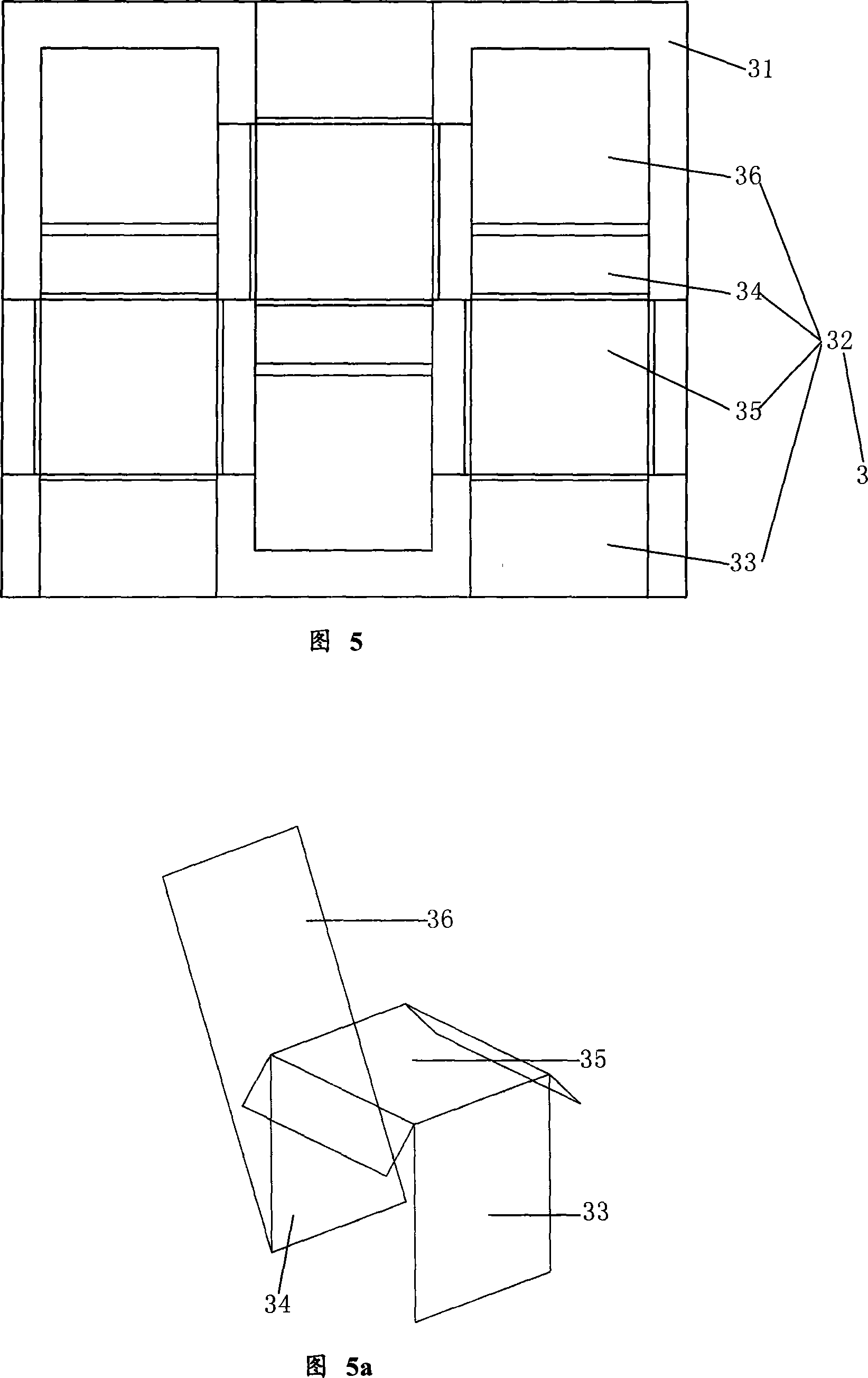

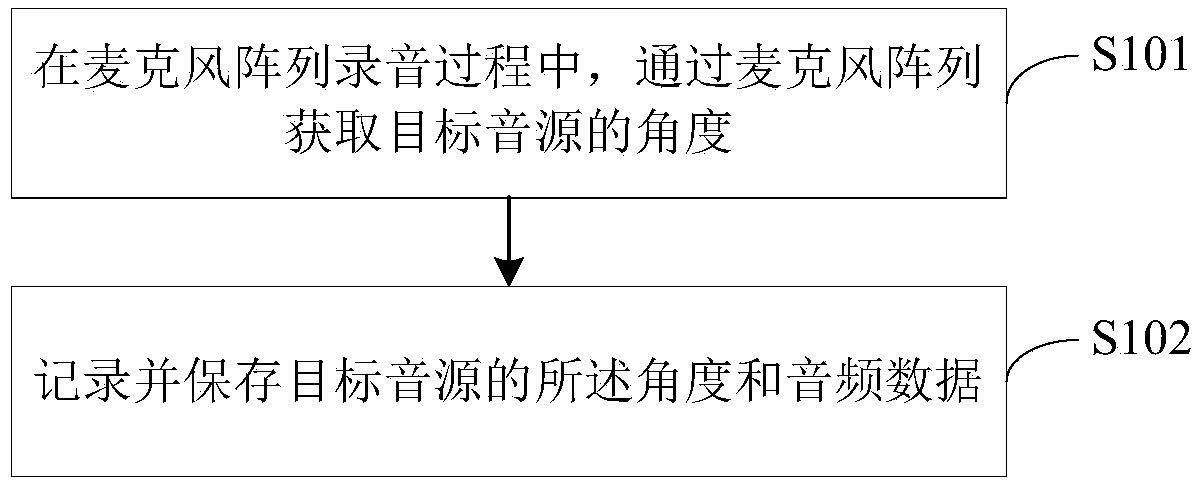

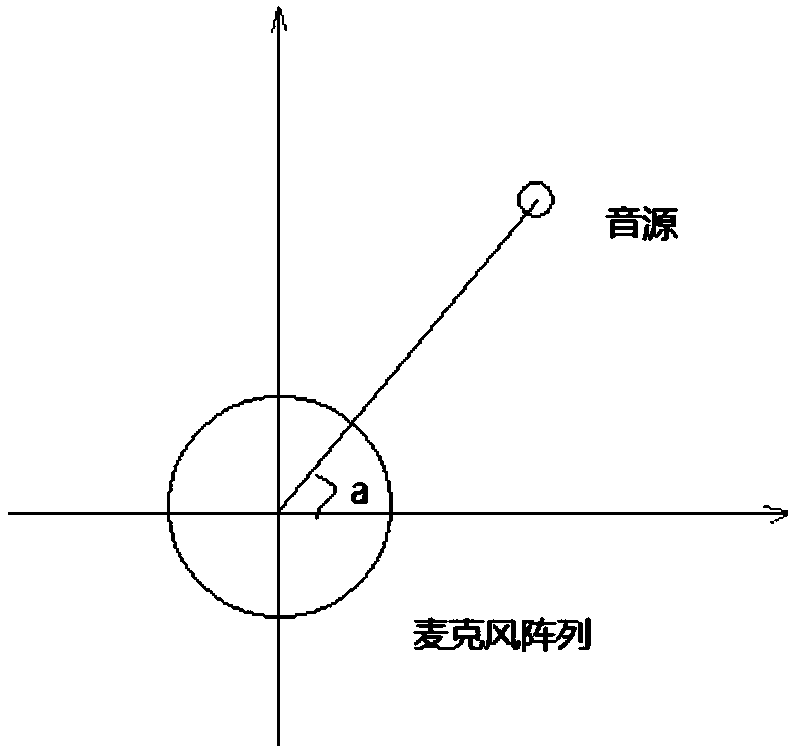

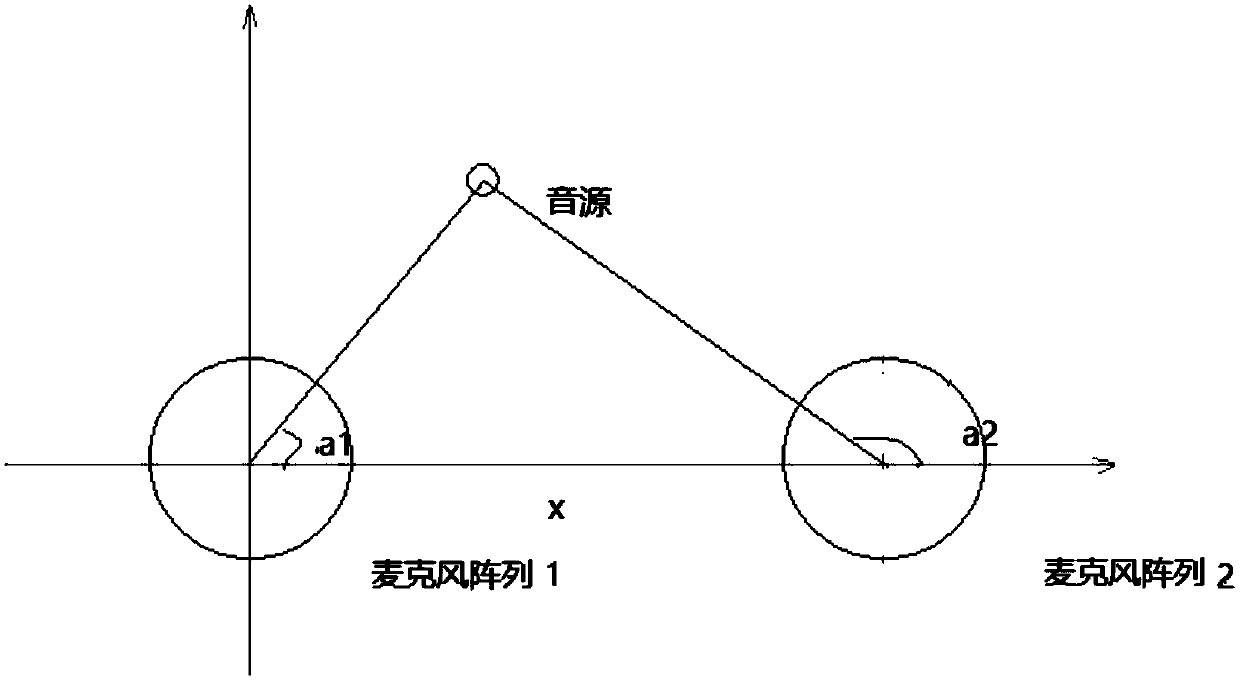

Holographic sound recording method and device and recording equipment

ActiveCN111312295ARestoredStrong practicality and ease of useRecord information storageDigital storageAudio frequencyTerminal equipment

The invention is suitable for the technical field of multichannel recording, and provides a holographic sound recording method and device and terminal equipment, and the method comprises the steps: obtaining the angle of a target sound source through a microphone array in a recording process of the microphone array; and recording and storing the angle and audio data of the target sound source. According to the invention, the problem that the sound information of a continuous or moving sound source cannot be accurately recorded in the process of changing the sound along with time is solved.

Owner:SHENZHEN GRANDSUN ELECTRONICS

Preparation method of composite oxide carrier

ActiveCN102451766BGood dispersionLarge specific surface areaCatalyst carriersRefining to eliminate hetero atomsAluminium hydroxideAqueous solution

The invention discloses a preparation method of a composite oxide carrier. A composite oxide gel adopted in the method of the invention is obtained by the steps of: first preparing an aluminum hydroxide sol and a water solution containing a group IVB metal complex, then mixing the sol and the water solution, adding dropping a hydrolysis promoter so as to obtain a mixed precipitate, which is then subjected to aging, washing, filtering and drying. The composite oxide gel obtained by the method can make most of group IVB metal oxides distributed on an alumina surface so as to weaken influence onan alumina pore structure, enhance the catalysis assisting effect of group IVB metal oxides, and improve the pore structure and surface performance of the composite oxide carrier. Therefore, the vulcanizing property of a catalyst with the carrier of the invention can be improved, and loaded active metals are easy for reduction.

Owner:CHINA PETROLEUM & CHEM CORP +1

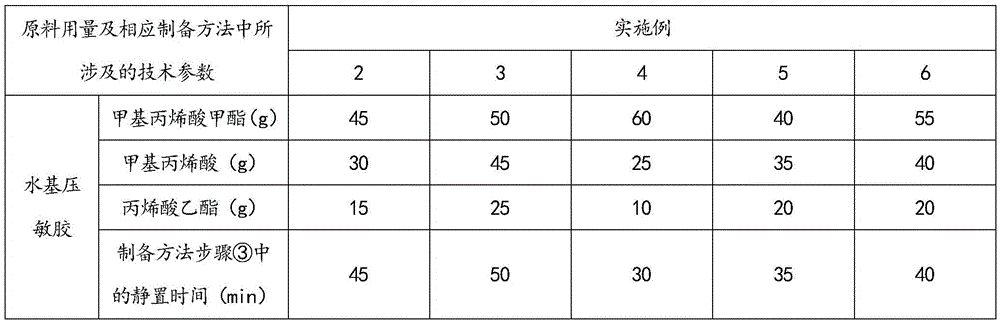

Bopp antirust adhesive tape, its preparation method and application

InactiveCN104479578BReduce viscosityNot subject to wear and tearNon-macromolecular adhesive additivesLamination ancillary operationsOxidation resistantPlastic film

Owner:SHANGHAI SANTAI WRAPPER

Synthetic gas conversion catalyst, and preparation method and applications thereof

ActiveCN103769109AReduce hydroxyl concentrationReduce strong interactionsLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsSyngasSurface modification

The invention discloses a synthetic gas conversion catalyst. According to the synthetic gas conversion catalyst, modified silica gel is taken as a carrier; cobalt is taken as an active component, and accounts for 5 to 35wt% of the synthetic gas conversion catalyst; and the modified silica gel is modified with a zinc-containing aqueous solution with a pH value of 3 to 4.5 via excessive immersion treatment. The invention also discloses a preparation method of the synthetic gas conversion catalyst. The preparation method comprises following steps: silica gel is taken as the carrier, and is subjected to surface modification, wherein excessive immersion treatment with the zinc-containing aqueous solution with a pH value of 3 to 4.5 is used for surface modification of the silica gel carrier; and loading of the active component Co is carried out via immersion method. The invention also discloses applications of the synthetic gas conversion catalyst in Fischer-Tropsch synthetic reaction. The preparation method is simple; and the synthetic gas conversion catalyst is high in activity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

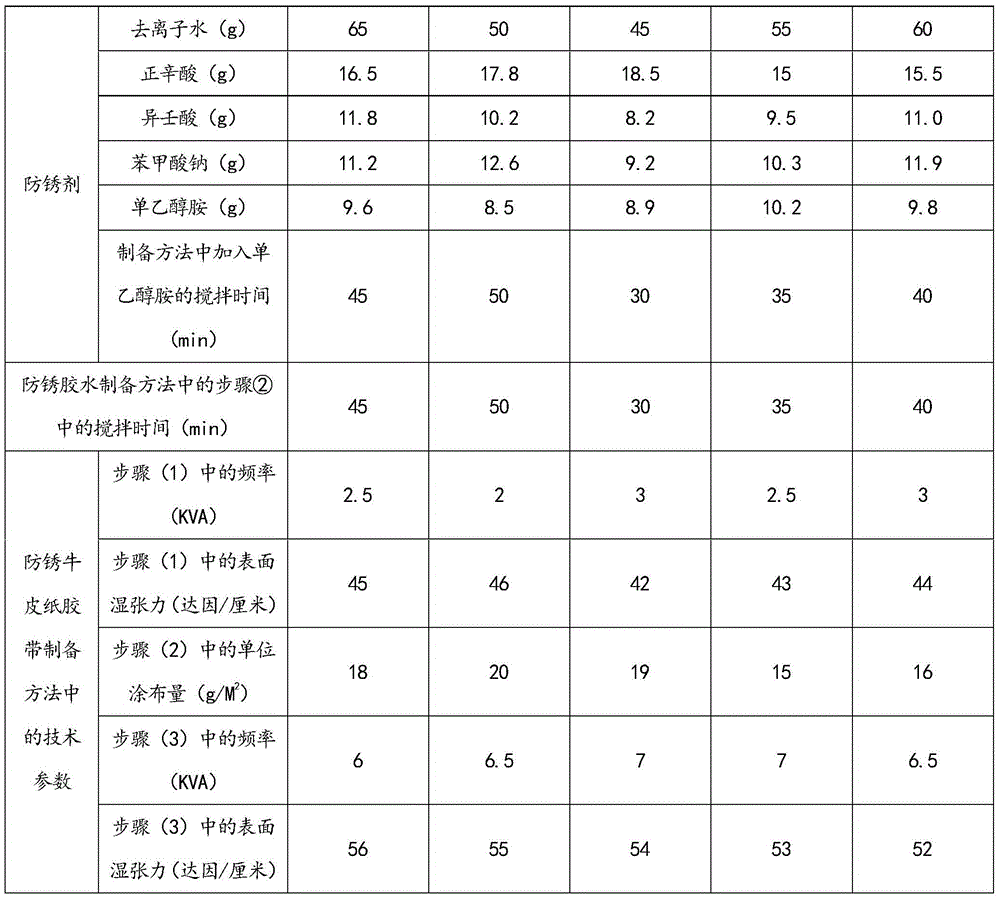

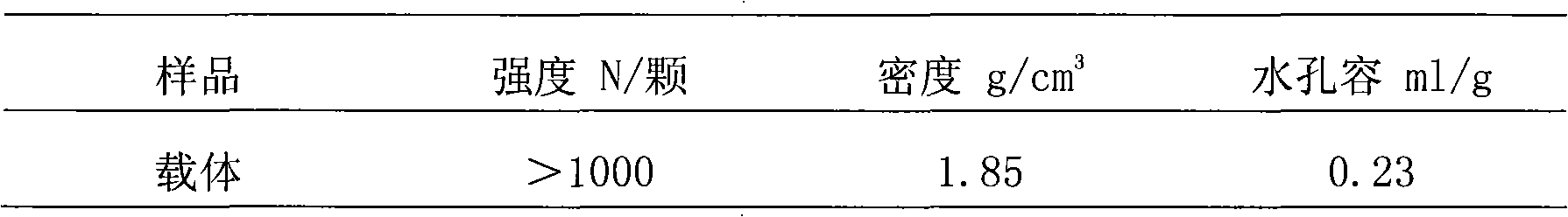

Catalyst for producing city gas with natural gas intermittent conversion and method of producing the same

InactiveCN101402040ASmall and stable differential pressureHigh strengthHydrogenMetal/metal-oxides/metal-hydroxide catalystsMass ratioHigh carbon

The invention discloses a catalyst for preparing city gas through intermittently converting natural gas, which mainly consists of a carrier and an active component, wherein the carrier is a SiO2-Al2O3 composite oxide carrier; counted on Al2O3 and SiO2, the mass ratio of the Al2O3 to the SiO2 in the carrier is between 1 to 0.05 and 1 to 0.50, and the phase of the carrier mainly comprises alpha-Al2O3 and Al6Si2O13; the active components is NiO; auxiliary agents are selected from one or more of Al2O3 and rare earth oxides; and the mass percentage of various component is as follows: 5 to 20 percent of the active component, and 80 to 95 percent of the carrier. The catalyst has the advantages of higher strength and wear resistance, stronger oxidation resistance, excellent heat resistance, higher carbon-separation resisting capability and conversion activity and the like. The invention also discloses a method for preparing the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com