Method for preparing nano-silver antibacterial cotton fabric by self-reduction

A technology of antibacterial cotton and nano-silver, which is applied in the field of antibacterial cotton fabric preparation and self-reduction preparation of nano-silver antibacterial cotton fabric, which can solve the problems of low preparation rate, waste, and fast preparation speed, and achieve the effect of green technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

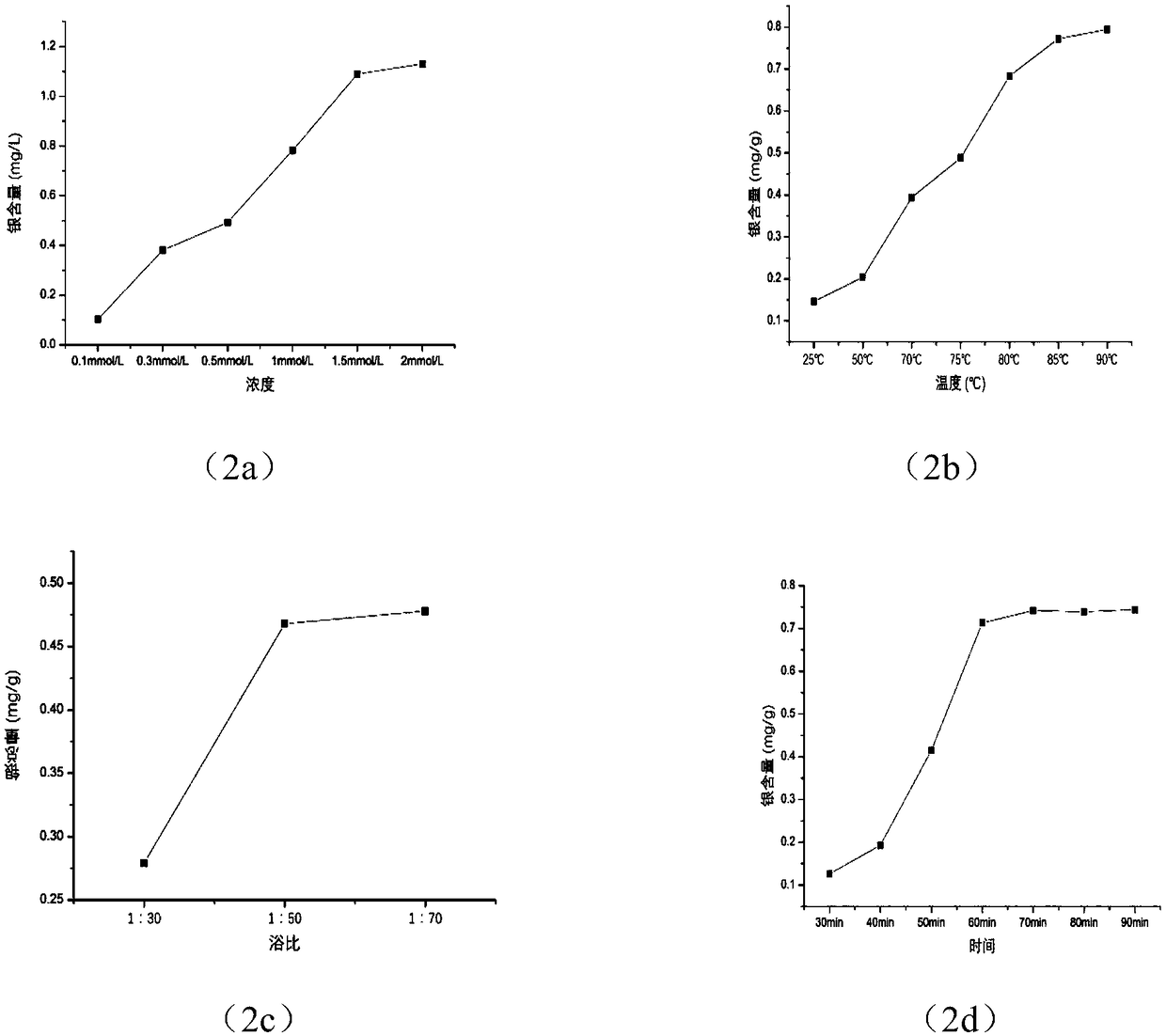

[0024] The pretreated cotton fabrics were immersed in silver nitrate solutions of 0.1mmol / L, 0.3mmol / L, 0.5mmol / L 1mmol / L, 1.5mmol / L and 2mmol / L respectively, the bath ratio was 1:50, and then After soaking for 60 minutes at a constant temperature of 85°C, take it out, wash it in clean water, and stir it with an overhead stirrer at a speed of 300r / min at room temperature for 5 minutes, repeat the stirring 3 times, and then dry it naturally.

[0025] Analysis of results:

[0026] Such as figure 1 Shown are the results of cold field emission scanning electron microscopy on the surface of antibacterial cotton fabrics obtained by self-reduction method. figure 1 a is untreated cotton fiber, figure 1 B is the fiber that 0.5mmol / L silver nitrate solution has processed, figure 1 c is the fiber treated with 2mmol / L silver nitrate solution. For untreated cotton fabrics, the fiber surface has the inherent longitudinal stripes of cotton fibers, while the fiber surface of the cotton fa...

Embodiment 2

[0030] Immerse the pretreated cotton fabric in 1.5mmol / L silver nitrate solution with a bath ratio of 1:50, and then under the temperature conditions of 25°C, 50°C, 70°C, 75°C, 80°C and 85°C respectively After soaking at a constant temperature for 60 minutes, take it out and wash it in clean water. At room temperature, stir it with an overhead stirrer at a speed of 300r / min for 5 minutes. Repeat the stirring 3 times and then dry it naturally.

[0031] Analysis of results:

[0032] Such as figure 2 As shown in b, when the temperature is higher than 85°C, the increase in temperature has little effect on the increase of silver element content, indicating that when the temperature reaches 85°C, the reduction of nano-silver tends to be saturated. Therefore, it can be known that the preparation of nano-antibacterial For cotton fabrics, the optimum reaction temperature is 85°C.

Embodiment 3

[0034] Immerse the pretreated cotton fabric in 1.5mmol / L silver nitrate solution under the condition of bath ratio 1:30, 1:50 and 1:70 respectively, after soaking at 85℃ for 60min, take it out and put it in clean water Cleaning, at room temperature, stir with an overhead stirrer at a speed of 300r / min for 5min, repeat the stirring for 3 times, and let it dry naturally.

[0035] Analysis of results:

[0036] Such as figure 2 As shown in c, when the bath ratio is higher than 1:50, the increase of the bath ratio has little effect on the silver content, indicating that when the bath ratio is 1:50, the reduction of nano-silver tends to be saturated. When preparing nano-antibacterial cotton fabrics by reduction method, the optimum bath ratio is 1:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com