Method for preparing nanometer chromium dioxide

A technology of chromium dioxide and chromium hydroxide, applied in the direction of chromium dioxide, chromium oxide/hydrate, etc., can solve the problems of Cr6+ pollution reaction temperature, harsh reaction conditions, long reaction time, etc., and meet the requirements of green process and sealing Low, the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

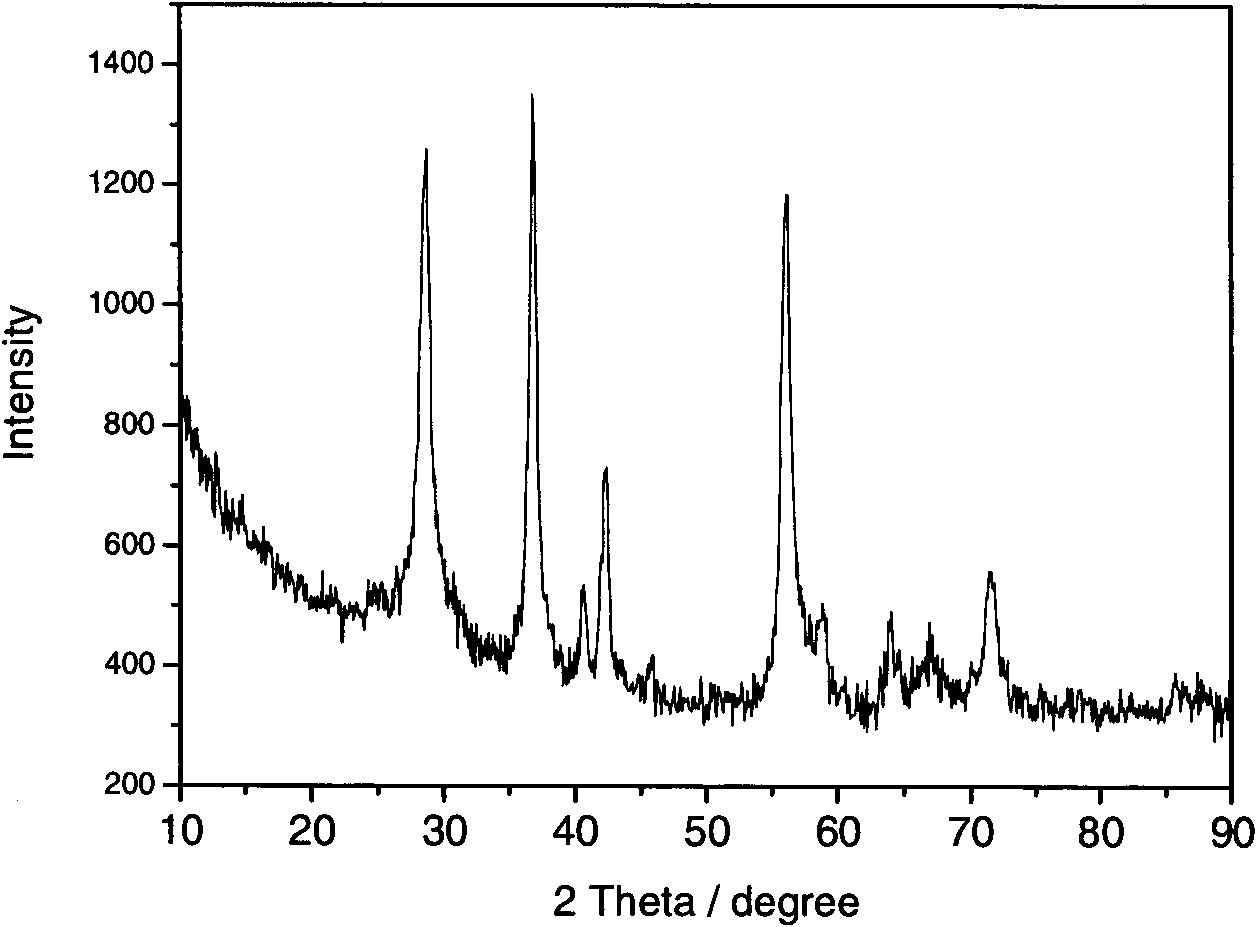

Image

Examples

Embodiment 1

[0025] Take 0.2 g of dry chromium hydroxide hydrate after ball milling for 2-3 hours, put it into a corundum crucible, and then add 0.4 g of deionized water. Put the crucible in the high-pressure reactor, seal it, then feed oxygen, evacuate and ventilate until the air pressure in the reactor is lower than the original 1 / 1000, and then adjust O 2 pressure, so that the initial pressure of oxygen is 7MPa. Close the valve, program temperature rise in a closed system, set the reaction temperature at 390°C, keep it at 390°C for 6h, and then cool down to room temperature. Then, the kettle was opened, and the reactant was taken out to obtain 69.1nm nano-chromium dioxide.

Embodiment 2

[0027] Take 0.2 g of dry chromium hydroxide hydrate after ball milling for 2-3 hours, put it into a corundum crucible, and then add 0.4 g of deionized water. Put the crucible in the high-pressure reactor, seal it, then feed oxygen, evacuate and ventilate until the air pressure in the reactor is lower than the original 1 / 1000, and then adjust O 2 pressure, so that the initial pressure of oxygen is 6MPa. Close the valve, program temperature rise in a closed system, set the reaction temperature at 350°C, keep it at 350°C for 10min, and then cool down to room temperature. Then, the kettle was opened, and the reactant was taken out to obtain 76.75nm nano-chromium dioxide.

Embodiment 3

[0029] Take 0.4 g of dry chromium hydroxide hydrate after ball milling for 2-3 hours, put it into a corundum crucible, and then add 0.4 g of deionized water. Put the crucible in the high-pressure reactor, seal it, then feed oxygen, evacuate and ventilate until the air pressure in the reactor is lower than the original 1 / 1000, and then adjust O 2 pressure, so that the initial pressure of oxygen is 4MPa. Close the valve, program temperature rise in a closed system, set the reaction temperature at 370°C, keep it at 370°C for 3 hours, and then cool down to room temperature. Then open the kettle, take out the reactants, and obtain 60.81nm nano-CrO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com