Patents

Literature

138results about How to "Craft green" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyacrylonitrile (PAN)-base microporous membrane

ActiveCN102806022AAchieving melt processabilityReduce defectsSemi-permeable membranesPolymer scienceAcrylonitrile

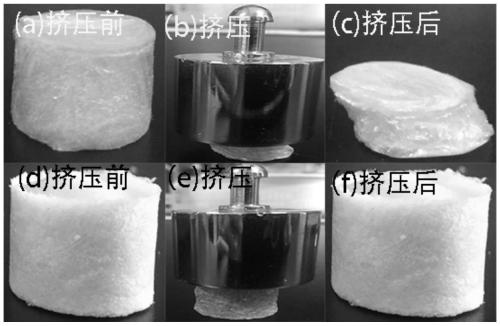

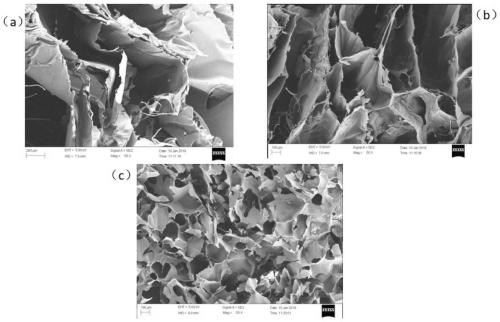

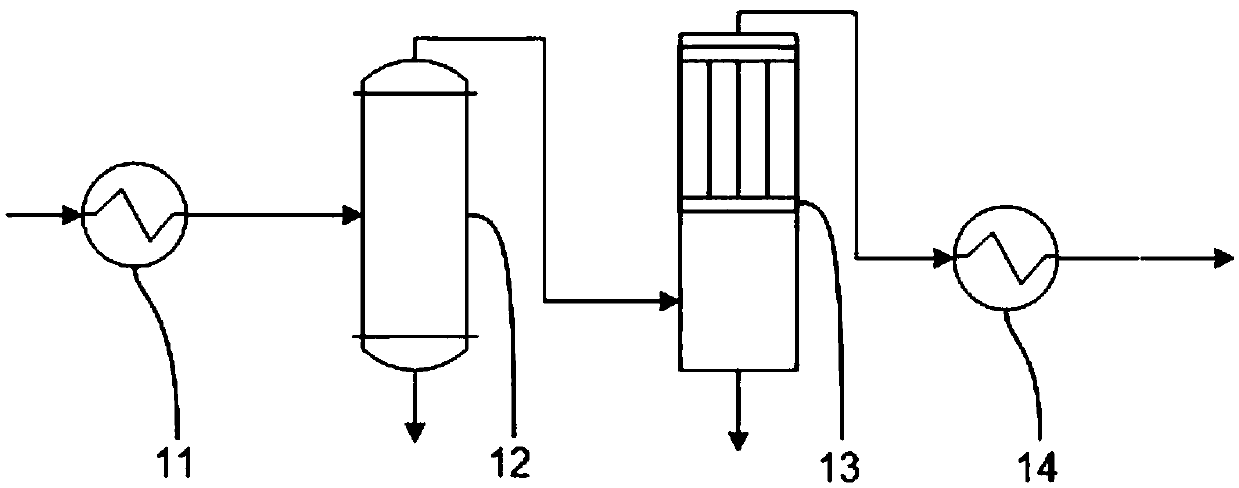

The invention discloses a method for preparing a polyacrylonitrile (PAN)-base microporous membrane, which adopts a thermally induced phase separation (TIPS) technology and comprises the steps of: 1, preparing meltable acrylonitrile-base copolymer: adopting a mixture of acrylonitrile monomer and second monomer, which has the mixing molar ratio of 95:5-70:30, and preparing the meltable acrylonitrile-base copolymer through a polymerization technology; 2, preparing acrylonitrile-base casting film liquid: adding the copolymer and diluent into a reactor according to a weight ratio of 1:9-5:5wt%, heating to 140-230 DEG C, forming the uniform solution, then defoaming for 10-60 minutes, and producing PAN-base casting film liquid; and 3, preparing a microporous membrane: adopting a flat membrane preparation method which comprises of pouring the casting film liquid into a mould which is preheated to 150-230 DEG C, calendaring molding, cooling, solidifying, and extracting to obtain the product; adopting a hollow membrane preparation method which comprises of pouring the casting film liquid into a spinning machine, extruding at 150-230 DEG C, and extracting the diluent to obtain the product.

Owner:TIANJIN POLYTECHNIC UNIV

Comprehensive energy grass recycling method

ActiveCN103752588ACraft greenBio-organic fraction processingSolid waste disposalAgricultural scienceResource utilization

The invention discloses a comprehensive energy grass recycling method. The method comprises the following production steps: preparing biogas from energy grass, producing edible fungi from biogas residues, producing mushroom bran feed through mushroom bran, feeding livestock by using the mushroom bran feed, and producing organic fertilizers through feces of livestock and poultry. The grass, biogas, fungi, feed, livestock and fertilizer are organically connected, five different commodities including the biogas, edible fungi, feed, livestock and organic fertilizer are produced, high-efficiency resource utilization and additional value improvement are realized, and a high-efficiency agricultural compressive recycling system is constructed.

Owner:XIAMEN 139 BIOTECH CO LTD

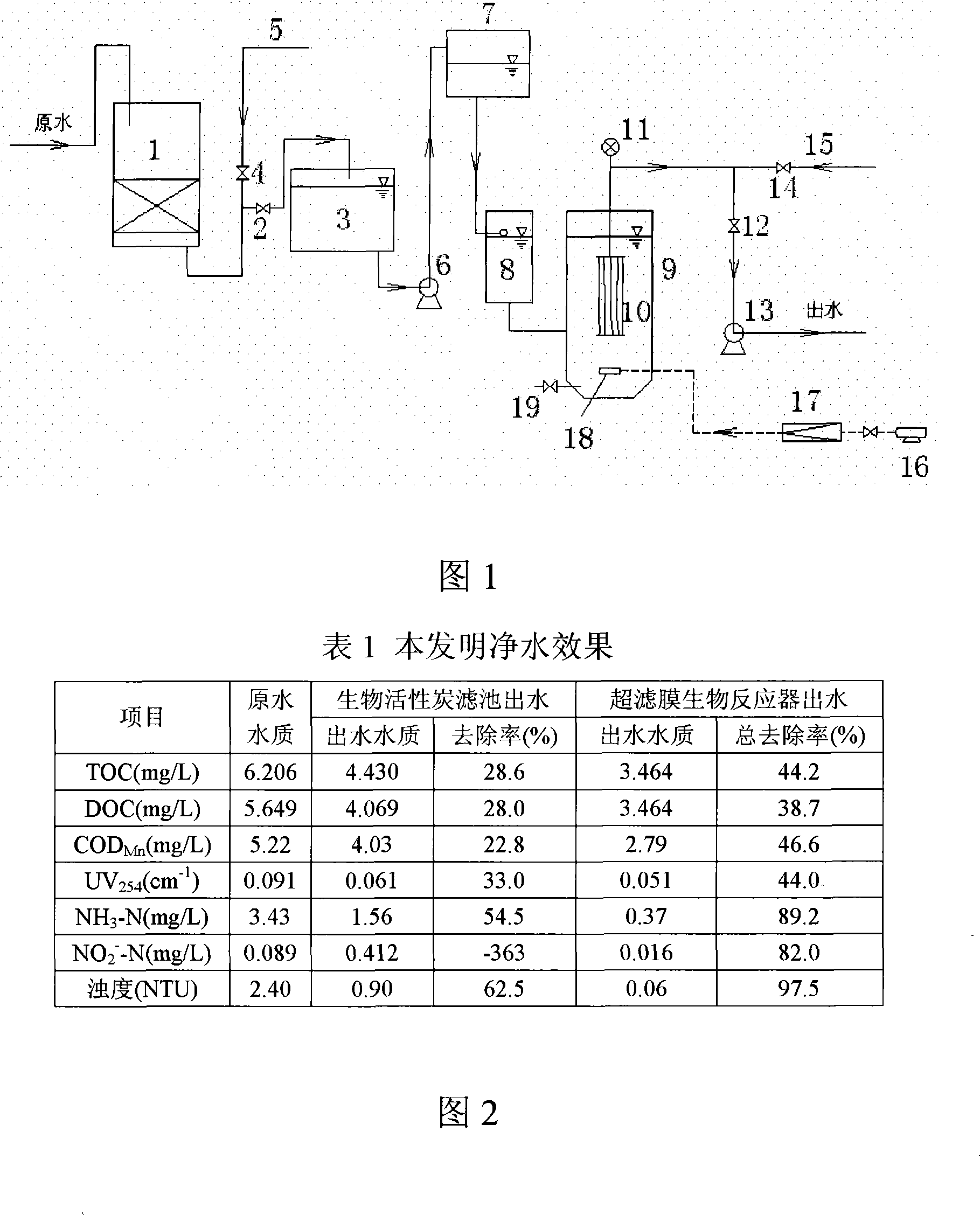

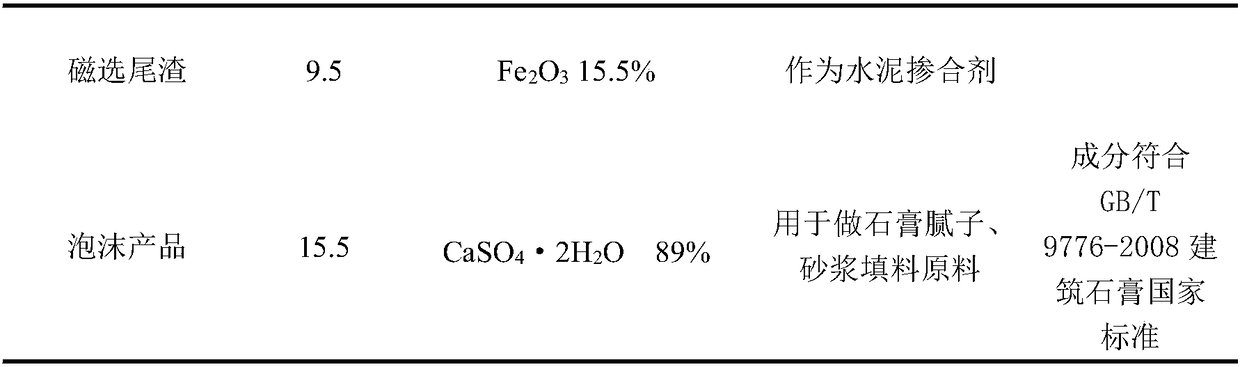

Drinking water deeply purifying method and device

ActiveCN101219848AWater quality impactCraft greenUltrafiltrationMultistage water/sewage treatmentUltrafiltrationChemistry

The invention discloses an advanced purification method for drinking water and a device thereof. The advanced purification process for drinking water is explored aiming at generally existing micro-polluted source water and the process combines a biological activated carbon filter and an ultrafiltration membrane biological reactor to purify the drinking water in an advanced way. After the raw water being treated enters the biological activated filter first, the particulate matters in the water being partly intercepted; pollutants like organic matters and ammonia nitrogen and so on are partly degraded and the water quality is purified to some degree; load of the ultrafiltration membrane biological reactor is reduced; the water in the filter is discharged into the ultrafiltration membrane biological reactor; the activated sludge in the reactor biologically treats the water from the filter and the pollutants ammonia nitrogen and the organic matters in the water are degraded again; at last, the water after two-level biodegradation is drawn form ultrafiltration membrane component by a draw-suck pump and the remarkable effect of removal of particulate matters as well as interception of two insects, daphnia, red worms, alga, bacteria and even virus of the ultrafiltration membrane can be brought into play.Therefore, the safe and clean drinking water with excellent quality can be prepared.

Owner:东营工大水环境技术有限公司

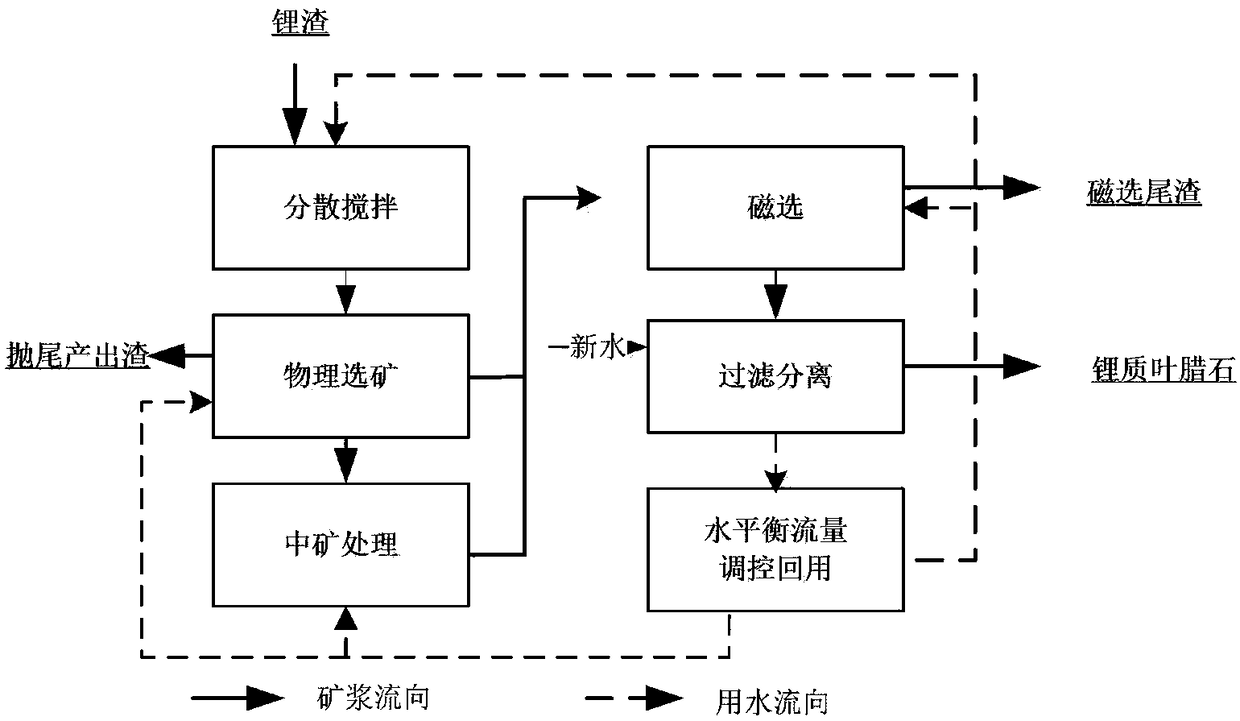

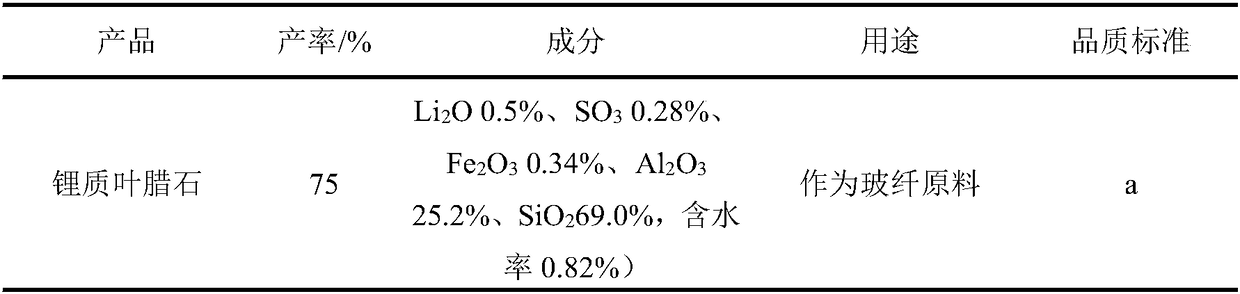

High-valued comprehensive utilization method of lithium slag

The invention provides a high-valued comprehensive utilization method of lithium slag, in particular to mineral waste residues obtained by lithium extraction of spodumene by a sulfuric acid method. The high-valued comprehensive utilization method comprises the following steps: firstly, carrying out size mixing and stirring on the lithium slag and enabling sulfate mineral in the lithium slag to bein a dispersed suspension state; secondly, carrying out desulfurizing treatment on a product obtained in the first step by using a physical ore dressing mode to obtain desulfurized slurry and tailingdiscarding produced slag and enabling the sulfur content of slag phase in the desulfurized slurry to be smaller than or equal to 0.5 percent; thirdly, under the condition that the magnetic field strength is 0.5 to 2.0T, carrying out magnetic separation on the desulfurized slurry obtained in the second step to obtain magnetic separation slurry and magnetic separation tailings and reducing the content of ferric oxide in the magnetic separation slurry to be smaller than or equal to 0.05 percent; then concentrating, filtering and drying the obtained magnetic separation slurry to obtain a pyrophyllite raw material for glass fibers. The treatment method of the lithium slag, disclosed by the invention, has the advantages of greenness and environmental protection, obvious economic benefits and capability of realizing the leap of high-valued recycling of the lithium slag.

Owner:TIANQI XINLONG CO LTD

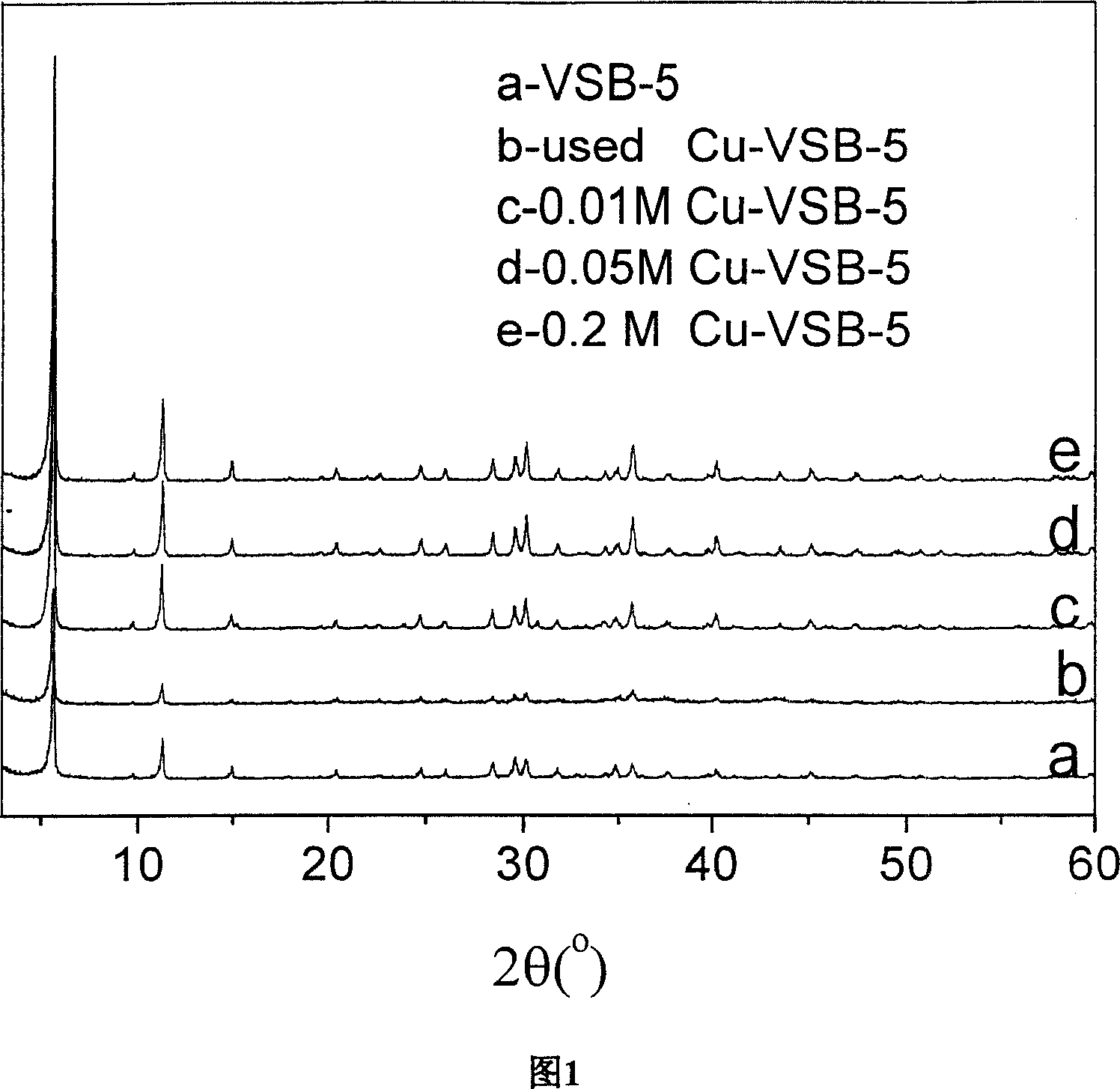

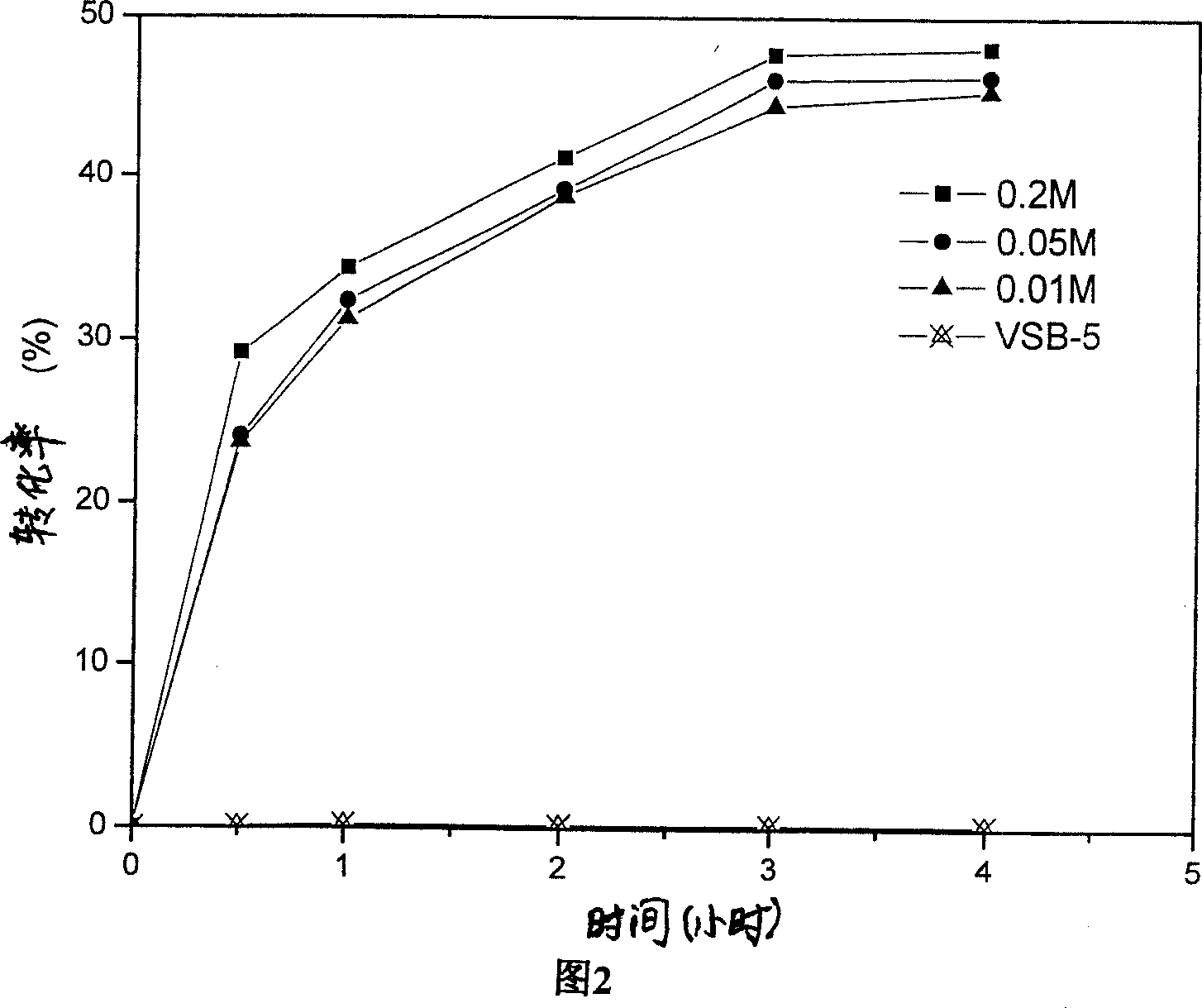

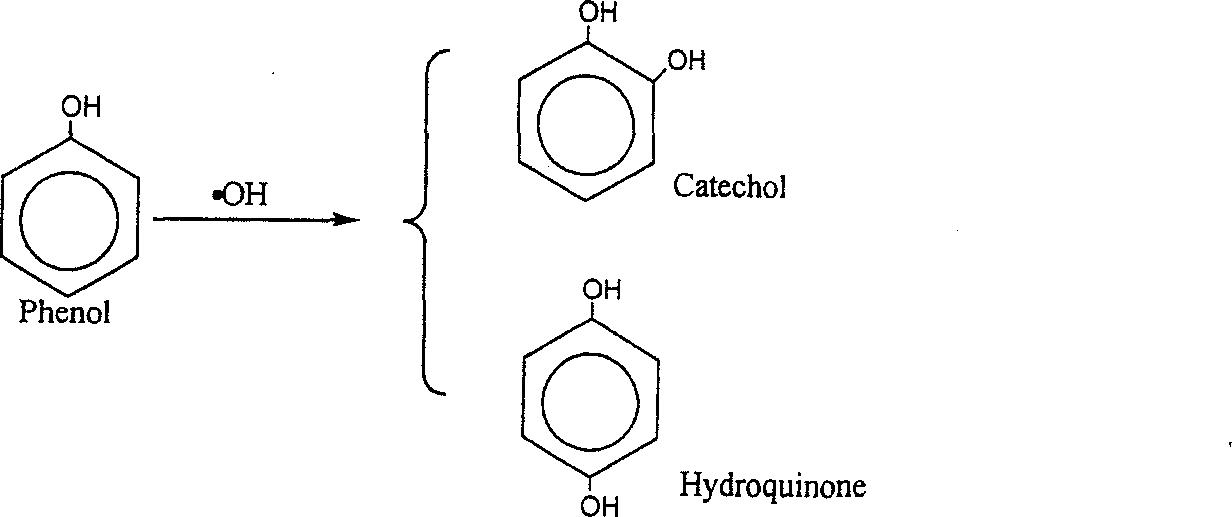

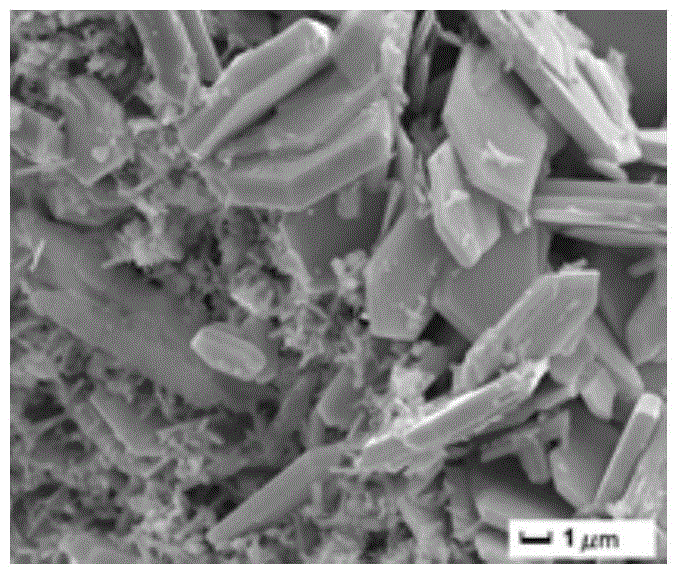

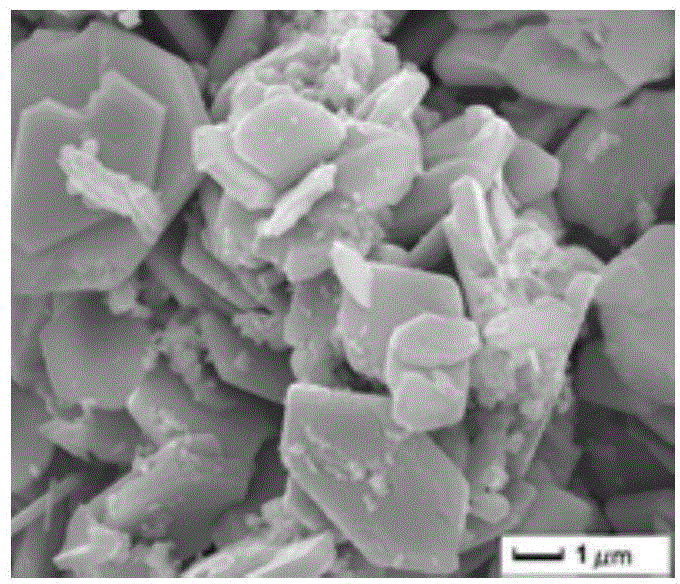

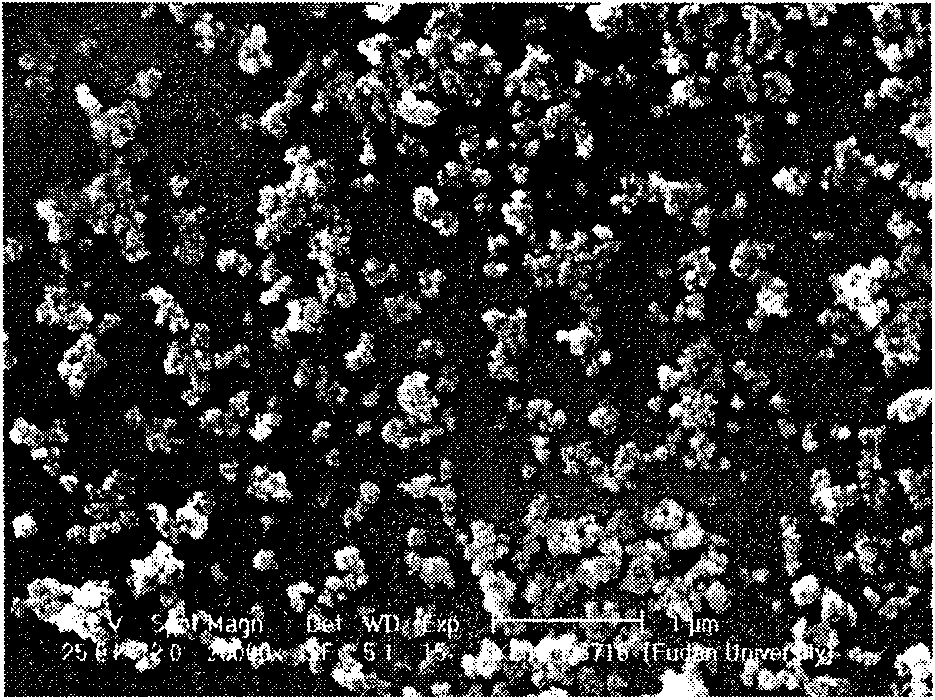

Cu-VSB 5 catalyst for hydroxylation of phenol, and preparation method

InactiveCN1958160ALow costEasy to makePhysical/chemical process catalystsOrganic chemistryNickel phosphateIon exchange

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

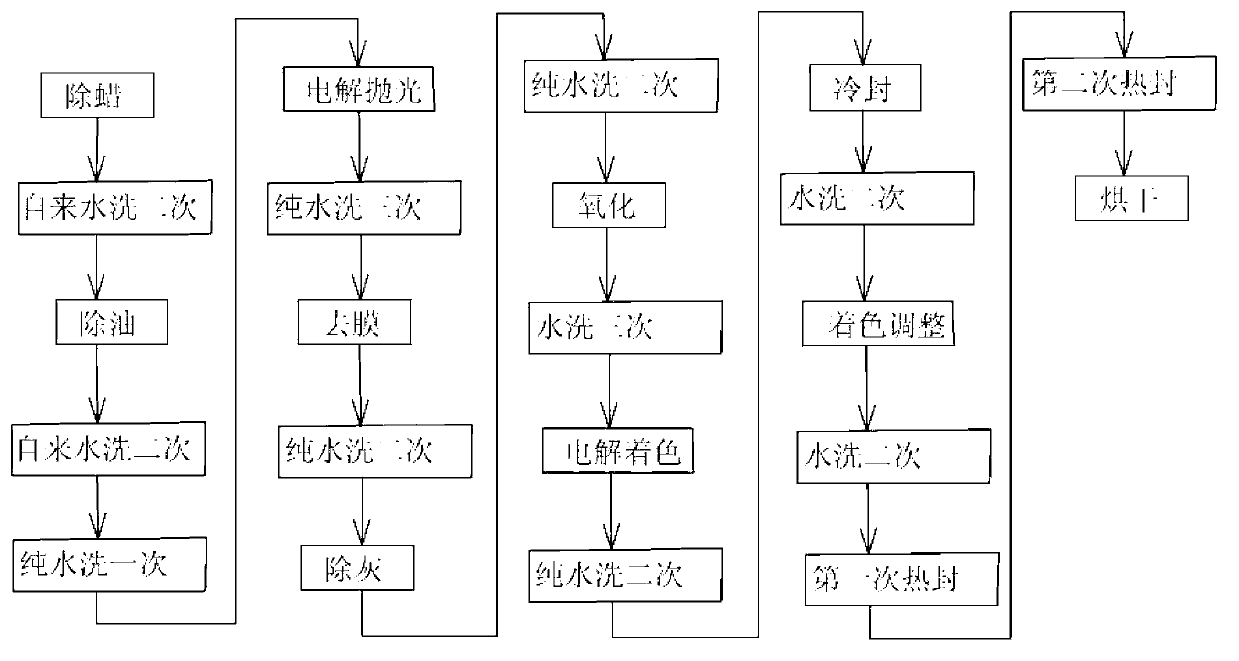

Oxidation process of aluminum alloy titanium-color-imitated anode

The invention belongs to the technical field of surface treatment and provides an oxidation process of an aluminum alloy titanium-color-imitated anode. The oxidation process is used for manufacturing a titanium-color-imitated aluminum alloy workpiece by the steps including wax-removing, water-washing, oil-removing, electrolytic polishing, stripping, ash-removing, oxidizing, electrolytic coloring, cold-sealing, coloring adjustment, hot-sealing, drying and the like. The oxidation process of the aluminum alloy titanium-color-imitated anode has the advantages that the whole process is green, environment-friendly and safe; each process step is simple; the yield and the qualification rate are improved; the production cost is lowered; the maintenance is easy; the treated aluminum alloy workpiece surface has a titanium-color-imitated color, a smooth and bright surface, a uniform color without mixed color; and an oxidation film and a base body are firmly combined, so that the surface hardness is higher and the corrosion resistance is good.

Owner:JIANGSU HEXING AUTOMOTIVE TECH

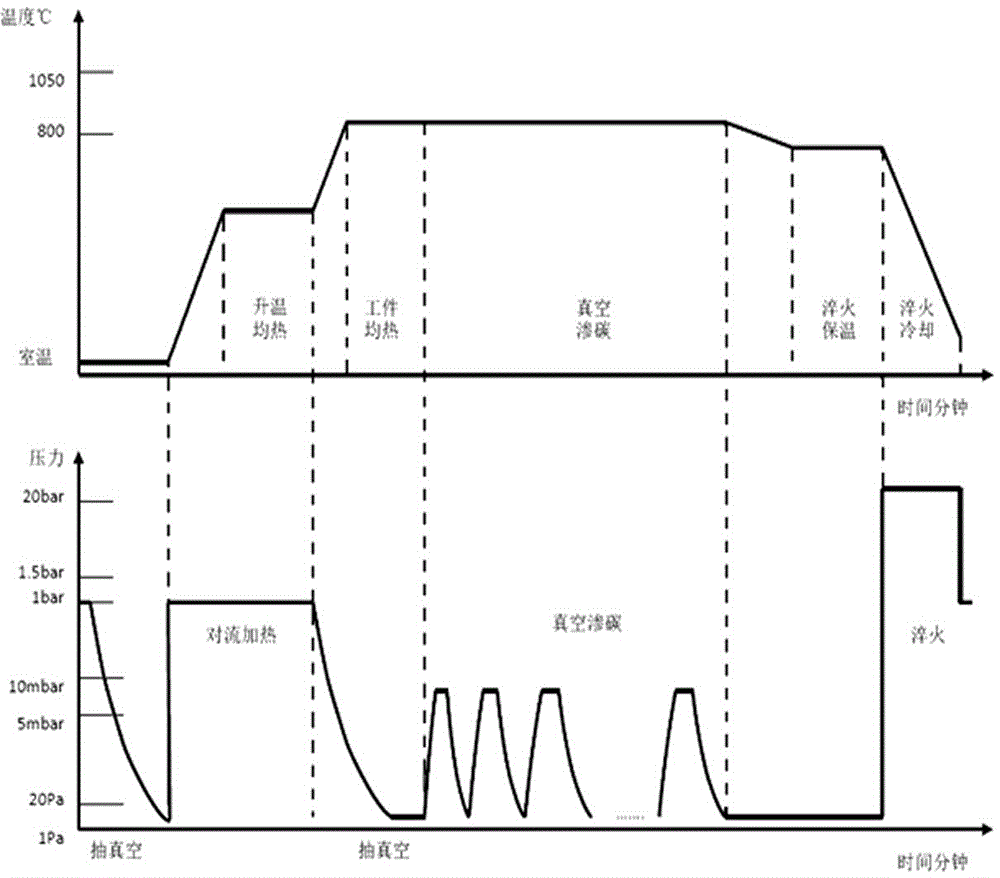

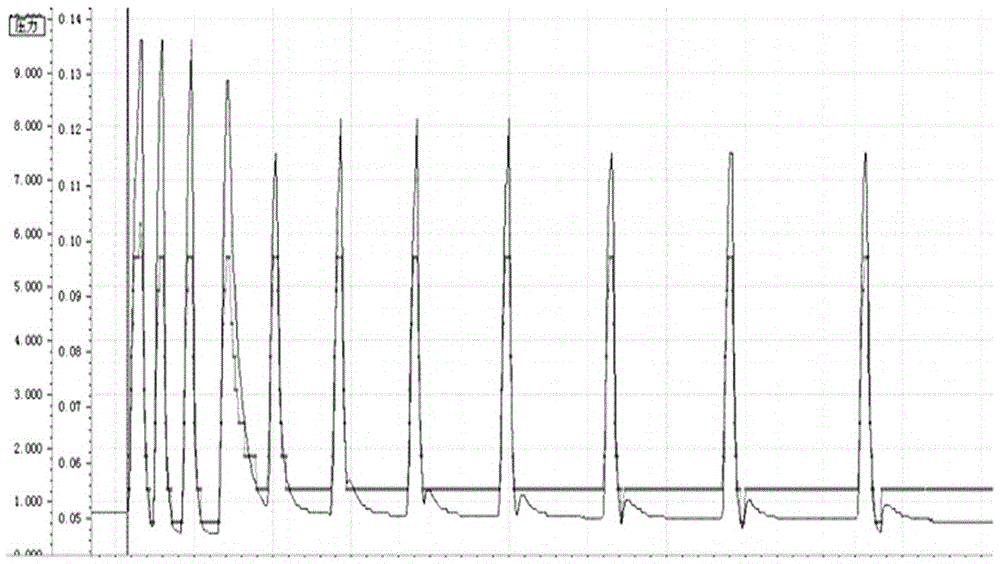

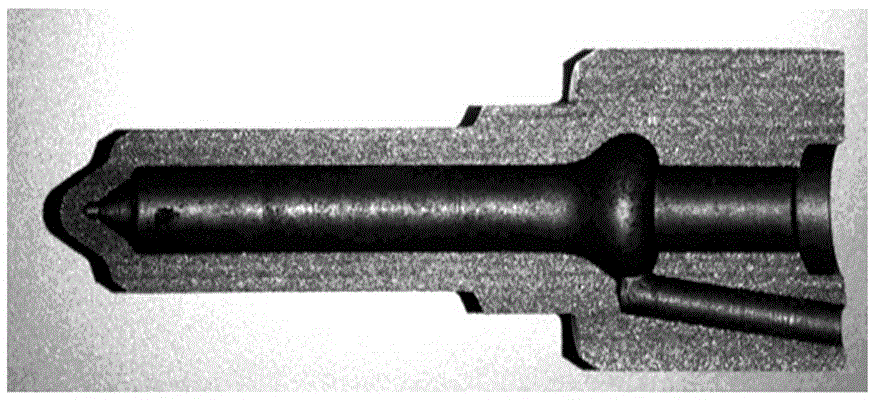

Low-pressure vacuum carburizing process

InactiveCN106756752AEffective control of surface carbon contentEffective control depthSolid state diffusion coatingMetallurgyPulse period

The invention discloses a low-pressure vacuum carburizing process. The low-pressure vacuum carburizing process comprises a temperature rising stage, a carburizing stage, a diffusing stage and a precooling stage. The temperature rising stage comprises the steps that a workpiece is vacuumized, and the vacuum degree is controlled within 1 Pa-20 Pa; and after vacuumizing is completed, heating is started, and the carburizing temperature ranges from 800 DEG C to 1050 DEG C. The carburizing stage comprises the steps that after the temperature of the workpiece reaches the set temperature of the process, acetylene gas is introduced into a furnace to maintain the carburizing gas partial pressure, which is named as a carburizing gas inflation pulse stage; after the carburizing gas inflation pulse stage is kept for a set time, vacuumizing is started, a certain time is kept under vacuum, which is named as a vacuumizing diffusion stage, and the carburizing gas inflation pulse stage and the vacuumizing diffusion stage are combined to serve as a carburizing pulse period; the whole carburizing stage is composed of a plurality of carburizing pulse periods; and when the carburized layer depth reaches the carburized layer depth set by the process, the carburizing pulse is stopped. The low-pressure vacuum carburizing process can effectively control the surface carbon content and the carburized layer depth of the workpiece, and the optimal carburizing effect of the workpiece is achieved.

Owner:上海先越冶金技术股份有限公司

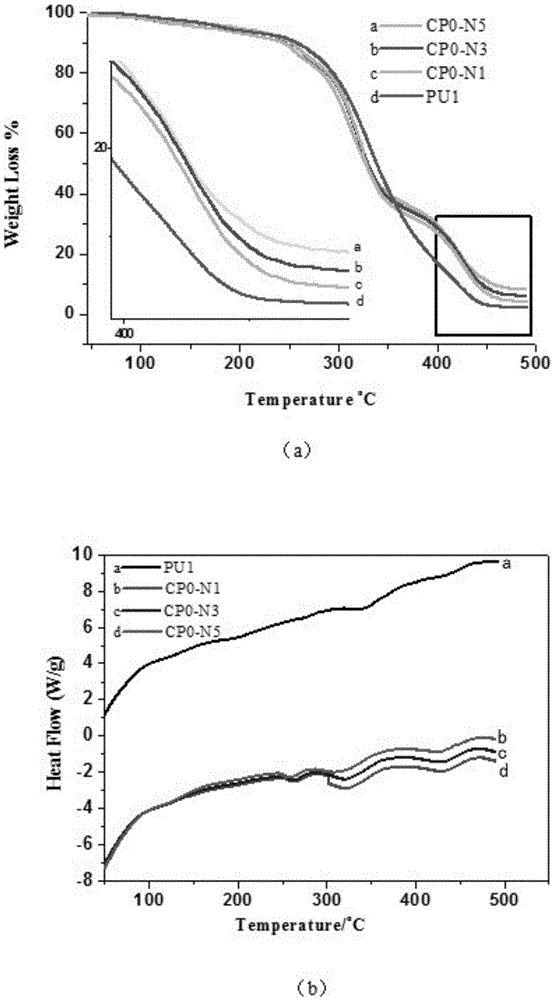

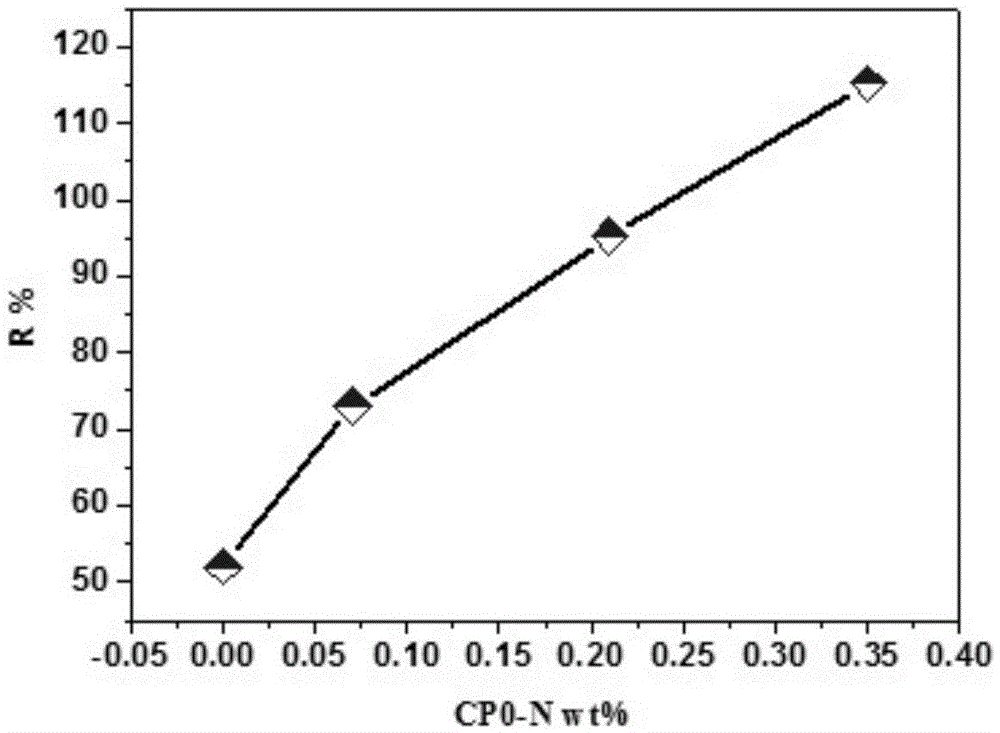

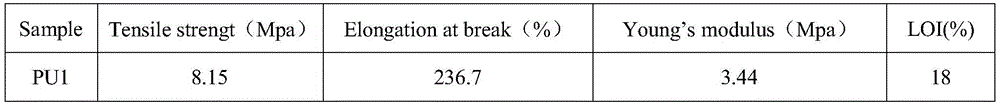

Preparation method of bio-based polyurethane flame-retardant coating

ActiveCN105754467AIncrease layer spacingGood dispersionPolyurea/polyurethane coatingsButanediolPolyurethane coating

The invention discloses a preparation method of a bio-based polyurethane flame-retardant coating. The bio-based polyurethane flame-retardant coating is prepared from the raw materials polyalcohol, diisocyanate, ammonium polyphosphate (APP), phytic acid, layered dihydroxyl compound, dimethylolpropionic acid, 1,4-butanediol and triethylamine by the steps of prepolymerization, neutralization, emulsifying and forming. In the invention, the phytic acid and layered dihydroxyl compound are pretreated and serve as flame-retardant additives which cooperate with an intumescent flame retardant APP for flame retardance of waterborne polyurethane so as to obtain the bio-based polyurethane flame-retardant coating with excellent comprehensive properties.

Owner:JINHU JINLING NEW MATERIAL SCI & TECH

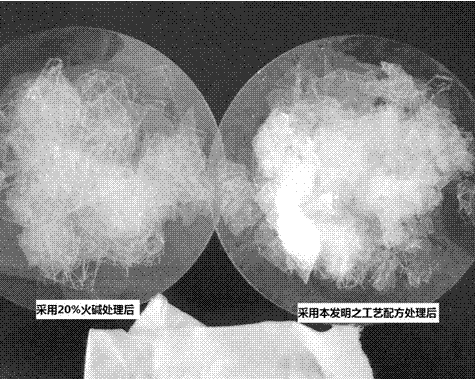

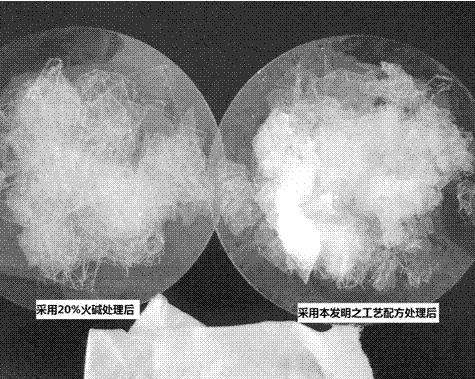

Method for removing surface coating of reflective PET (Polyethylene Terephthalate) aluminium plating film

The invention relates to a PET (Polyethylene Terephthalate) reflective film, in particular to a method for removing the surface coating of a reflective PET aluminium plating film. The method is characterized by comprising the steps of: immersing the reflective PET aluminium plating film into a cleaning solution, and heating at the temperature of 40-100 degrees centigrade, rinsing by using clean water to remove the coating adhered on the PET surface, and airing to obtain the recyclable PET film. The recycled PET film is colourless and transparent on the appearance and has the intrinsic viscosity being about 0.723; the melt strength of the recycled PET film can satisfy requirements of PET extrusion-blown molding (bottle) or even extrusion blown film; and in the same extrusion technological conditions, the intrinsic viscosity of the PET film, which has a yellow appearance and is recycled by using the traditional method of hermetically boiling by using 20% caustic soda at high temperature for more than 24 hours, is reduced to about 0.564 and cannot satisfy the requirements of the extrusion-blown molding (bottle). The test in the invention proves that the method has the advantages of high-efficiency technology, time / water / electricity-saving performance, environment friendliness, zero discharge of waste water and practicability, is benefiical to realization of recycle of the reflective PET aluminium plating film, and is suitable for recycling and practical.

Owner:CHANGZHOU VOCATIONAL INST OF ENG +1

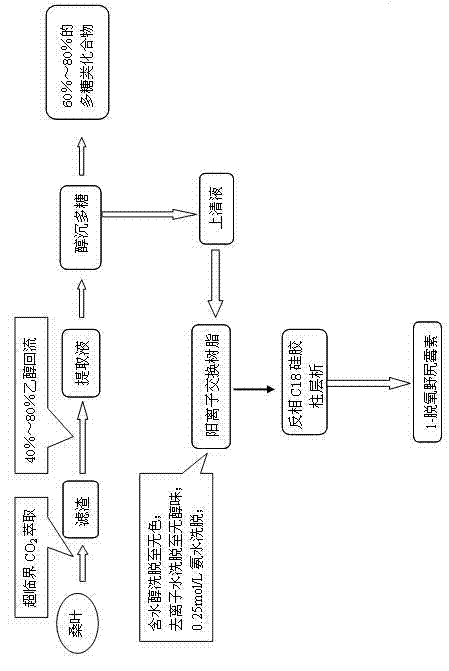

Method for continuously extracting and separating polysaccharides and 1-deoxynojirimycin from mulberry leaves

InactiveCN102964460AHigh dissolution rateResidue reductionOrganic chemistryBulk chemical productionSilica gelBULK ACTIVE INGREDIENT

The invention relates to a method for continuously extracting and separating polysaccharides and 1-deoxynojirimycin from mulberry leaves. The method comprises the following steps: grinding the mulberry leaves, carrying out supercritical CO2 extraction under certain conditions and collecting mulberry leaf dregs; after drying the mulberry leaf dregs, carrying out extraction through ethanol refluxing; concentrating the extracting solution, standing and drying the precipitate, thus obtaining a polysaccharide compound with the content being 60-80%; concentrating the supernatant and adsorbing active ingredients on resins via cation exchange resins; eluting the resins with water-containing ethanol and ammonia water; and concentrating the ammonia water eluent with a reversed-phase C18 silica gel based chromatographic column and drying the concentrated products, thus obtaining alkaloids in the mulberry leaves, wherein the content of 1-deoxynojirimycin in the alkaloids in the mulberry leaves is 80-86%. The detailed method refers to the specification. The method has the advantages that the process is simple, the extraction rate is high, the obtained products have higher purity, and the resins and silica gel used for purification are renewable, low in costs and beneficial to industrial popularization and application.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

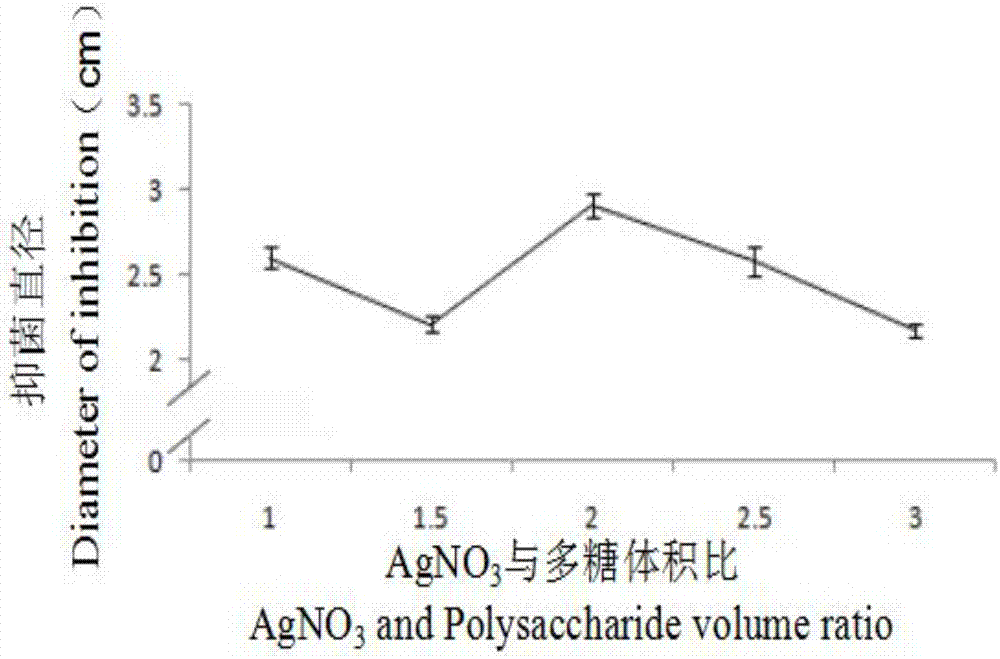

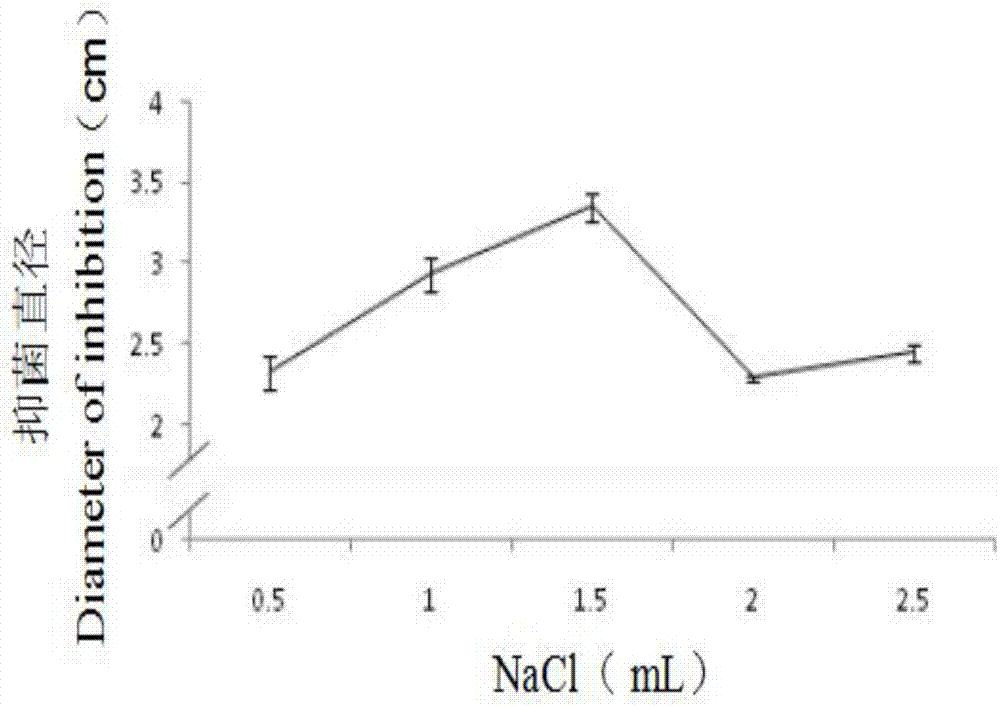

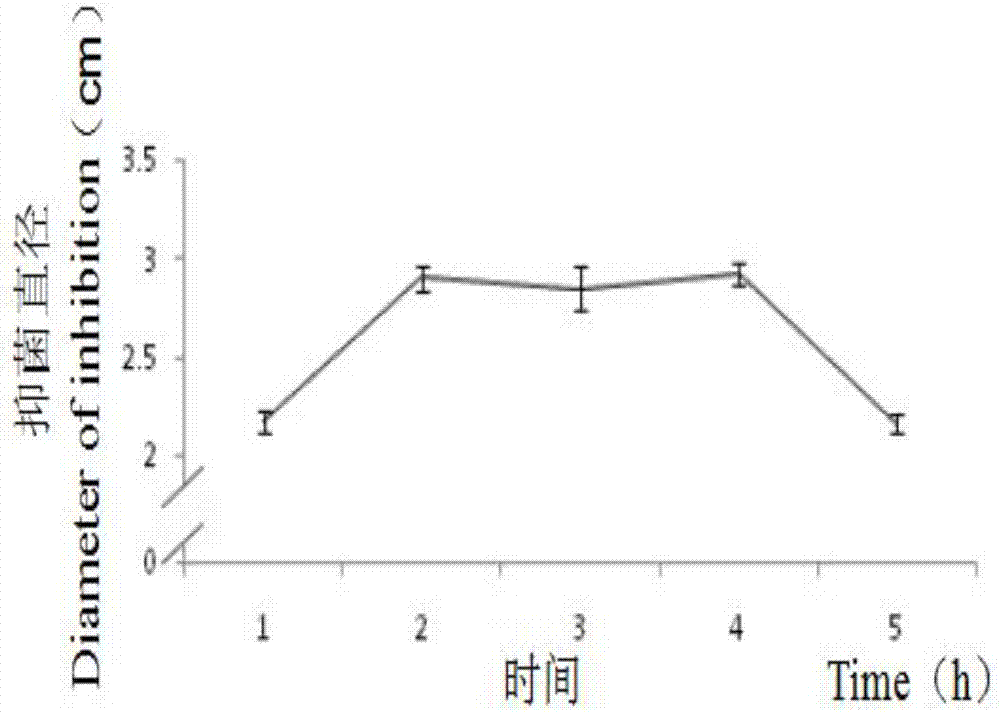

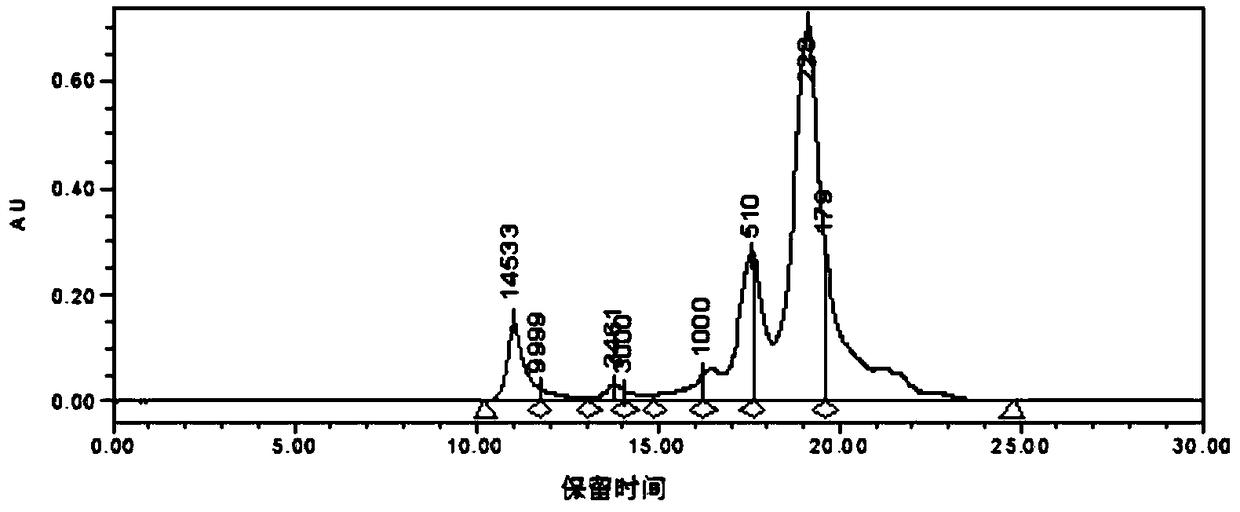

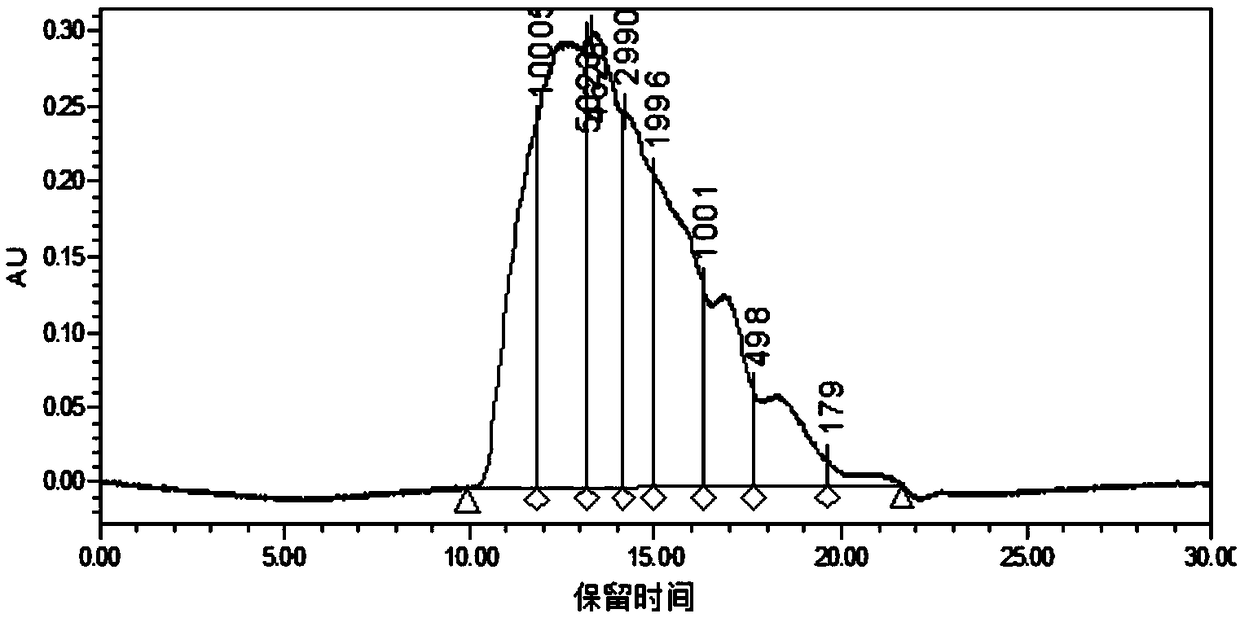

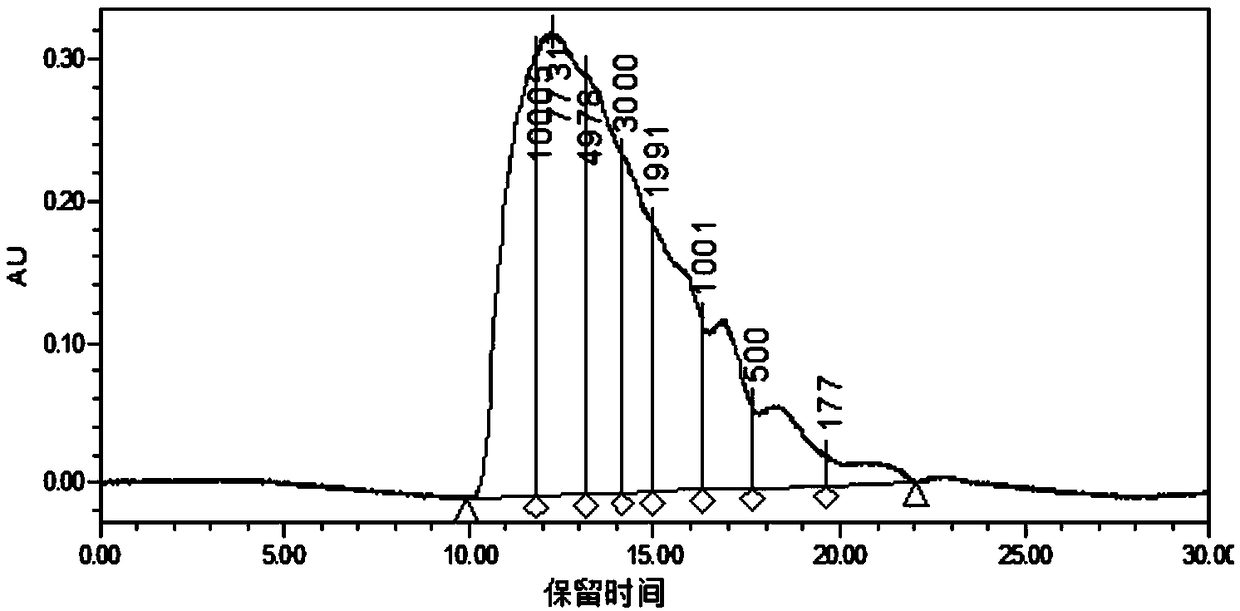

Method for preparing nano-silver composite particles from emblica polysaccharide

The invention provides a method for preparing nano-silver composite particles from emblica polysaccharide and belongs to the technical field of nanometer materials. The method comprises the steps of preparation of emblica polysaccharide and preparation of nano-silver. According to the prepared composite particles, the diameter, measured through bacteria inhibition experiments, of inhibition zones is 27.9+ / -0.01 mm; a theoretical value and an experimental value are basically equal. This shows that the process for preparing AgNPs through a response surface optimization method is green and reliable.

Owner:FUJIAN AGRI & FORESTRY UNIV

Rare earth metal ionic liquid, preparation method and application thereof

InactiveCN103073500AEasy to getEasy to manufactureOrganic chemistryMagnetic liquidsHigh concentrationMetal nitrate

The invention relates to a novel ionic liquid of nitryl rare earth metal acid salt anion, a preparation method and an application thereof, and belongs to the fields of rare earth functional materials, preparations and applications thereof. According to the method, a rare earth metal nitrate solution is added into a corresponding imidazole or pyridine nitrate ionic liquid solution in a mole ratio of 1:3, a solvent is removed after a reaction, and the rare earth metal ionic liquid is obtained. The prepared ionic liquid of the nitryl rare earth metal acid salt anion has good stability, is provided with characteristics of the ionic liquid as well as advantages of the rare earth metal simultaneously, and can be provided with characteristics of luminescence and magnetism; and the required cost is low, the preparation is simple and convenient, the product purity is high, the ionic liquid is suitable for large-scale production and application, and liquid luminescent materials / liquid magnetic materials with high-concentration rare earth can be prepared through the provided process which is simple, efficient and environment-friendly.

Owner:SICHUAN UNIV

Comprehensive utilization method of energy grass

The invention discloses a comprehensive utilization method of energy grass. With energy grass as a raw material, biogas, paper pulp and a plant cultivation nutrient solution are generated. Grass, biogas residues and biogas slurry are organically connected with one another, the biogas is prepared from the energy grass, the paper pulp is produced from the biogas residues, and a soilless culture nutrient solution is produced by the biogas slurry, so that efficient utilization of resources and improvement of additional value are realized, and an efficient agricultural comprehensive utilization is constructed.

Owner:福州市惠达天下生物科技有限公司

Preparation method of ultralow molecular weight yak collagen peptide

InactiveCN109295145ASimple processImprove efficiencyConnective tissue peptidesPeptide preparation methodsMacrophage proliferationPeptide

Belonging to the technical field of nutritional health products, the invention discloses a preparation method of an ultralow molecular weight yak collagen peptide. The preparation method of the ultralow molecular weight yak collagen peptide includes: conducting dilute alkali soaking, high temperature and high pressure pulping, filtration, enzymolysis, concentration, spray drying and other processes on yak hide to obtain yak hide collagen peptide hydrolysate, the ultralow molecular weight collagen peptide (less than 300D) content of which is greater than 75%. The ultralow molecular weight yak collagen peptide prepared by the method provided by the invention can combine with a mannose receptor on macrophage to stimulate macrophage proliferation and enhance immunity.

Owner:西藏银美科技股份有限公司

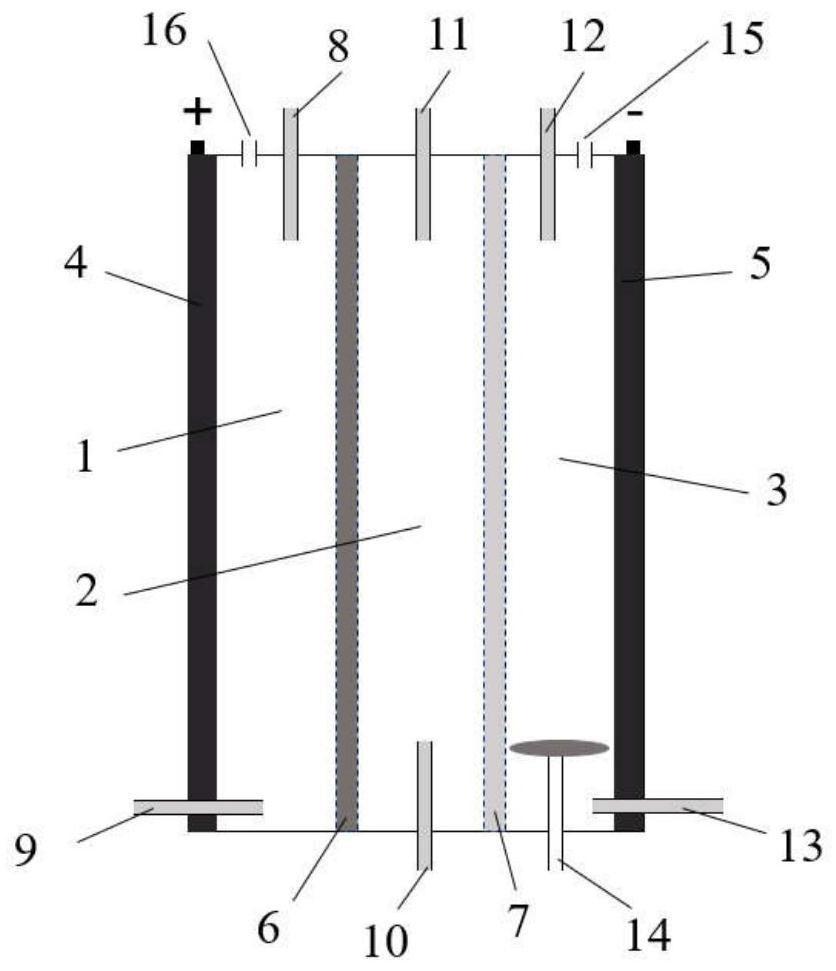

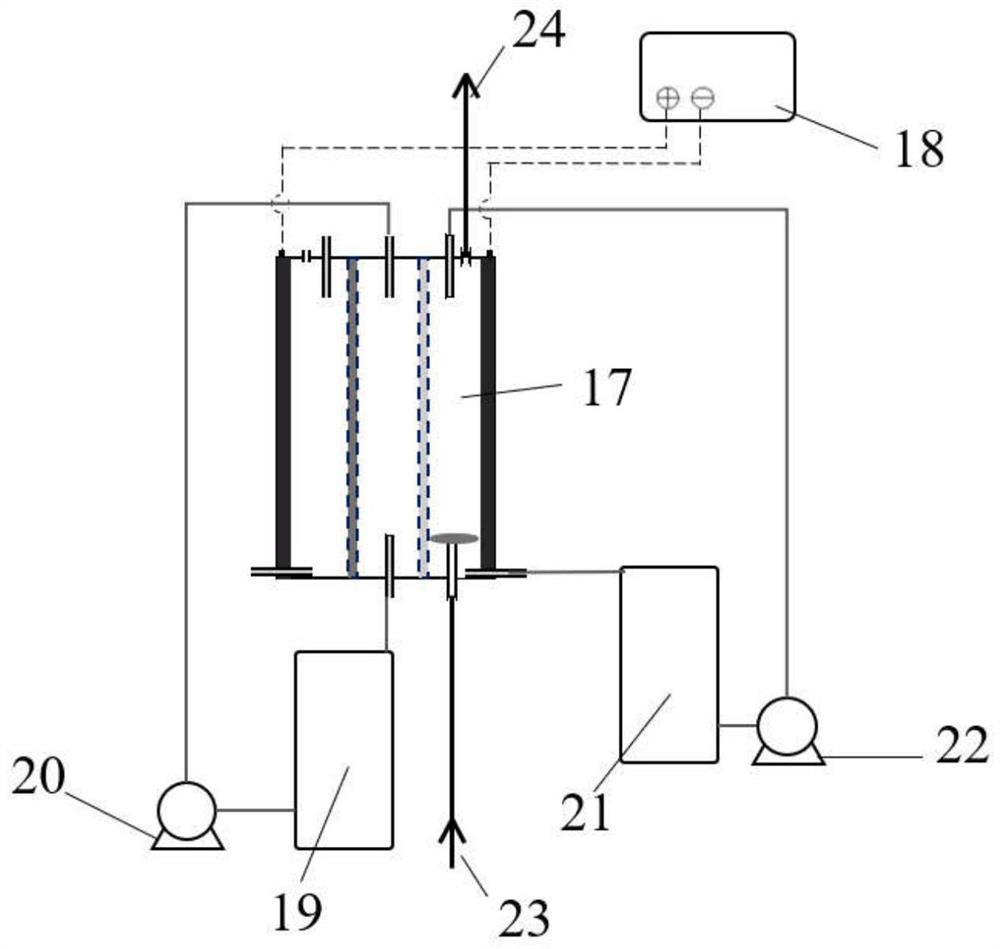

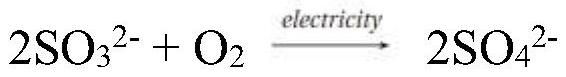

Method and device for capturing carbon dioxide and simultaneously producing sulfuric acid by sodium bisulfate

The invention belongs to the field of flue gas purification, and discloses a method and a device for capturing carbon dioxide and simultaneously producing sulfuric acid by using sodium bisulfate. According to the method, a desulfurization byproduct (NaHSO4) is converted into H2SO4 by using a three-grid electrodialysis device, and CO2 in flue gas is captured in a cathode chamber. Under the action of electric field driving and an ion exchange membrane, HSO4<-> enters an anode chamber to generate H2SO4 and is concentrated, and Na<+> enters the cathode chamber to generate NaOH; and CO2 containinggas to be treated is introduced from the cathode chamber and is absorbed and captured by NaOH. The technology is simple, green and economical, carbon dioxide in the flue gas is captured in the comprehensive utilization process of the sodium bisulfate solution, good environmental benefits are achieved, updating and upgrading of the flue gas treatment technology in China are promoted, and the treatment pressure of desulfurized gypsum is relieved.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Catalyst for preparing pentanediol from biomass, and preparation method and application thereof

InactiveCN108620122ASimple processMild conditionsMolecular sieve catalystsOrganic compound preparationMolecular sieveBiomass

The invention relates to a supported platinum-cobalt catalyst and a preparation method thereof, and a method for producing pentanediol from biomass and biomass derivatives by using the supported catalyst. In the supported platinum-cobalt catalyst, different contents of platinum and cobalt are loaded on a carrier, and a weight ratio of platinum to cobalt is in a range of 1: 20 and 10: 1; and the carrier may be at least one selected from the group consisting of an acidic molecular sieve, activated carbon, ZrO2, Nb2O5 and Al2O3. The preparation method for catalyst is simple in process. The methodfor preparing pentanediol from biomass and the derivatives thereof by using the catalyst can realize high-selectivity preparation of 1,2-pentanediol or 1,5-pentanediol. Compared with traditional routes, the method provided by the invention has the obvious advantages of renewability of raw materials green, reaction process and the like, and has good application prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

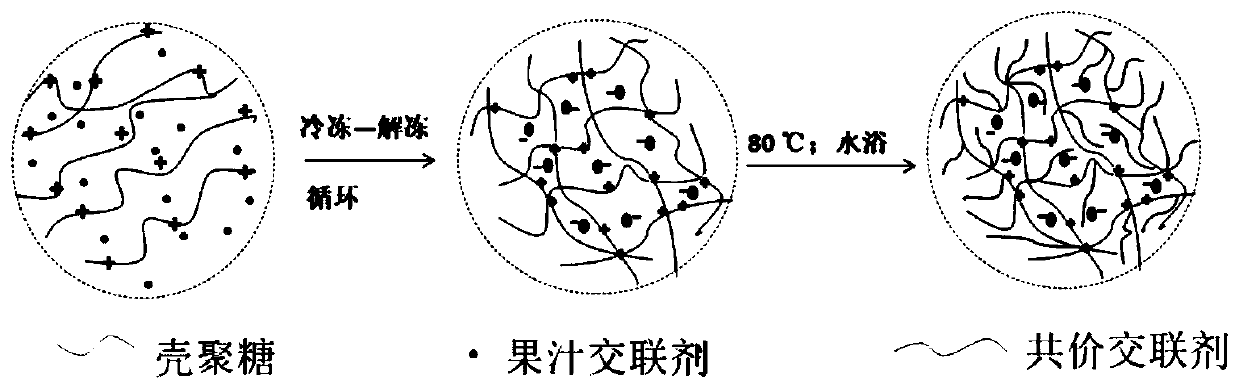

Preparing method of edible chitosan elastic sponge with aromatic odor

The invention discloses a preparing method of an edible chitosan elastic sponge with an aromatic odor. According to the method, juice replaces an existing cross-linking agent to be subjected to a cross-linking reaction with chitosan, then a reaction product is subjected to a covalent cross-linking reaction with aldehydes from an edible plant to prepare the edible chitosan elastic sponge with the aromatic odor. The edible chitosan elastic sponge with the aromatic odor has the advantages of edibility, aromatic odor, high tensile strength, high elasticity moduli, high breaking tenacity, rapid self-recovery capability, good fatigue resistance, high gas permeability, high adsorption capacity, biocompatibility, bacterial resistance, environmental protection performance (the material is free of pollution) and the like; besides, the process has the advantages that the process is environmentally friendly, easy to operate and safe, the materials are recycled, and no secondary pollution is causedaccordingly; the prepared sponge can be applied to the field of artificial meat food, perfume satchels, chewing gum, hemostasis dressings, tissue engineering scaffolds, oil-water separation, heavy metals, dyestuff adsorbents and the like.

Owner:GUANGDONG OCEAN UNIVERSITY

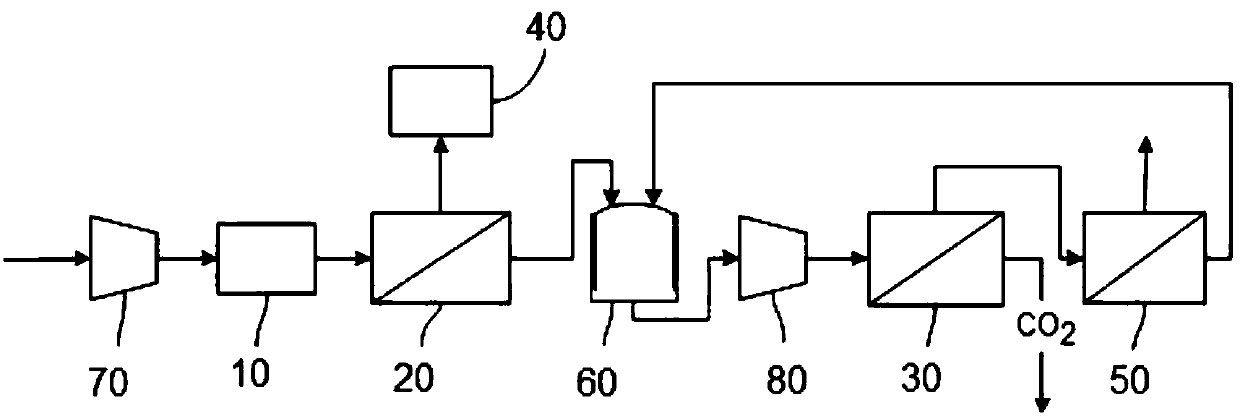

Device and method for capturing and recovering carbon dioxide in flue gas

PendingCN107899377AAffect separation efficiencyAffect the degree of enrichmentCombination devicesProductsFlue gasProduct gas

The invention provides a device and method for capturing and recovering carbon dioxide in flue gas. The device comprises a flue gas treatment system, a first membrane separation unit, a second membrane separation unit and a high-pressure energy recovery device, wherein the flue gas treatment system is provided with a treatment inlet and a treatment outlet and used for treating the flue gas; the first membrane separation unit is provided with a first gas inlet, a first carbon dioxide enriched gas outlet and a first high-pressure impermeable gas outlet, and the first gas inlet is connected withthe treatment outlet; the second membrane separation unit is provided with a second gas inlet, a carbon dioxide product gas outlet and a second high-pressure impermeable gas outlet, and the second gasinlet is connected with the first carbon dioxide enriched gas outlet; the high-pressure energy recovery device is connected with the first high-pressure impermeable gas outlet and used for recoveringpressure energy of the high-pressure gas produced by the first high-pressure impermeable gas outlet. The device provided by the invention can capture CO2 in recovered flue gas more effectively.

Owner:北京集封环能科技有限责任公司

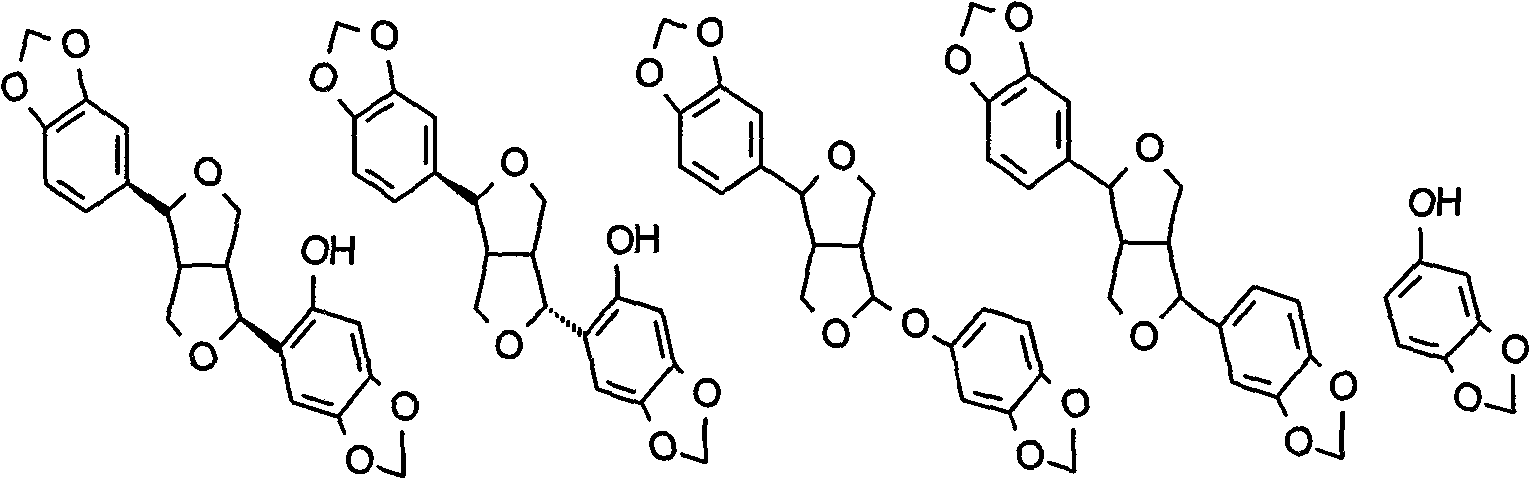

Preparation method of sesamin phenol

InactiveCN101648957AEasy to separate and purifyThe separation and purification method is simpleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSesamolinSolvent

The invention relates to a preparation method of esamin phenol. Sesamolin reacts in a benzene series solvent under the action of a catalyzer at the temperature of 70-110 DEG C for 1-6h, and sesamin phenol is obtained after a reaction solution is treated, wherein the catalyzer is an H-type strongly acidic styrene which is cation exchange resin. Compared with the traditional methods, the preparationmethod has the advantages of available raw material, stable conversion process, high sesamin phenol yield, simple separation and purification, green process and the like.

Owner:河南省农科院农副产品加工研究所

Preparation method of niobium diselenide or niobium disulphide/carbon wear-resistant nano composite material

InactiveCN104962235AReduce pollutionReduce the difficulty of preparationMaterial nanotechnologyOther chemical processesSolid phasesNiobium

The invention relates to a preparation method of a niobium diselenide (NbSe2) or niobium disulphide (NbS2) / carbon wear-resistant nano composite material. According to the preparation method, solid-phase method is adopted to prepare the niobium diselenide or niobium disulphide / carbon wear-resistant nano composite material. The preparation method comprises following steps: niobium powder, selenium powder or sulfur powder, and graphite powder are weighed and added into a dispersion medium, and an obtained mixture is mixed via magnetic stirring; the mixture is allowed to stand, a supernatant is removed, and an obtain product is dried; the product is heated at a temperature increasing speed of 10 DEG C / min, thermal preservation reaction is carried out, the product is collected, and is subjected to natural cooling to room temperature so as to obtain the NbSe2 / graphite composite material or the NbS2 / graphite composite material. Beneficial effects are that: the niobium diselenide or niobium disulphide / carbon wear-resistant nano composite material is prepared via solid-phase method, so that pollution caused by traditional liquid-phase method is reduced, and the preparation method is green and friendly to the environment; preparation difficulty of NbSe2 or NbS2 is reduced, nano material preparation cost is reduced effectively, and application prospect of NbSe2 or NbS2 in machinery industry is improved; the prepared niobium diselenide or niobium disulphide / carbon wear-resistant nano composite material possesses excellent antifriction performance.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

Frozen pork unfreezing technology

InactiveCN106259827AThaw fitReduce reproductionMeat/fish preservation by freezing/coolingPork meatCarboxymethyl-chitosan

The invention relates to a frozen pork unfreezing technology. The frozen pork unfreezing technology includes the steps that an unfreezing solution is prepared, wherein chitosan or carboxymethyl chitosan is dissolved in water to obtain the unfreezing solution; unfreezing is conducted, wherein frozen pork is placed in the unfreezing solution to be unfrozen. According to the frozen pork unfreezing technology, the frozen pork is placed in the unfreezing solution prepared from chitosan / carboxymethyl chitosan in the unfreezing process, bacterial reproduction in the unfreezing process is effectively reduced under the unfreezing condition near normal temperature, the whole technology is environmentally friendly and natural, the operation process is simple and convenient, unfreezing time is greatly shortened, and the technology is very suitable for unfreezing the unfrozen pork in industrial food processing.

Owner:湖南华乐食品有限公司

Preparation method of intumescent flame retardant synergist adopting saccharide derivatives

The invention discloses a preparation method of an intumescent flame retardant synergist adopting saccharide derivatives and belongs to the technical field of flame retardant materials. The method comprises steps as follows: 1) a high-carbon graft polymer is prepared from chitosan graft polyacrylic acid; 2) N-acetylated chitosan graft polyacrylic acid is prepared, that is, solid chitosan graft polyacrylic acid is dissolved in an acetic acid aqueous solution, 1,2-propylene glycol is added, the mixture is left to stand at the room temperature for degassing for 1 days, and a degassed mixed liquid is obtained; an acetylated solution is slowly added to the degassed mixed liquid through a constant-pressure dropping funnel, the mixture is stirred at the room temperature to react for 5 h, the obtained solution is adjusted to be alkaline with 1 mol / L of sodium hydroxide after the reaction, and an N-acetylated chitosan graft polyacrylic acid aqueous solution is obtained; 3) solid N-acetylated chitosan graft polyacrylic acid, namely, the intumescent flame retardant synergist adopting saccharide derivatives, can be obtained through evaporative crystallization and drying. The preparation method adopts the simple and green process, and the prepared flame retardant synergist is efficient and environment-friendly.

Owner:SOUTHEAST UNIV

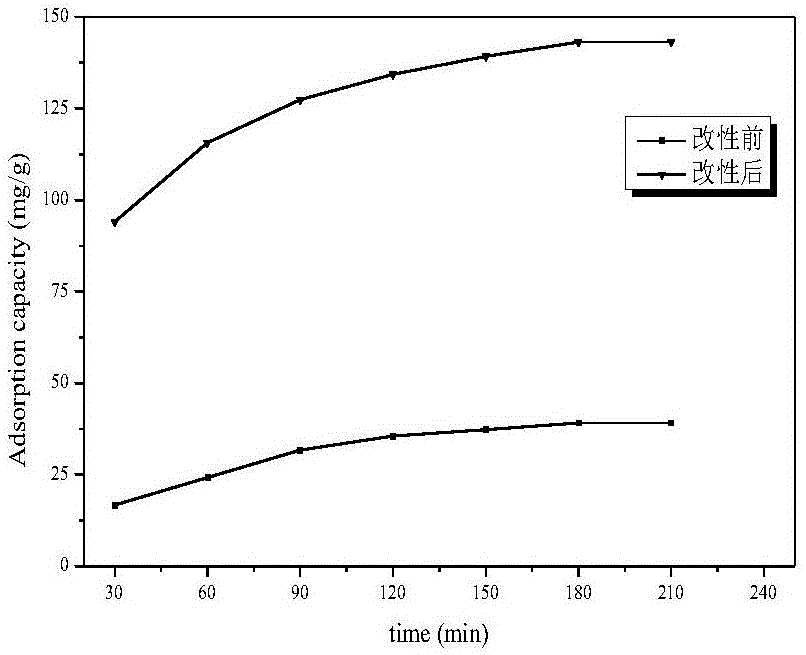

Modifying method capable of increasing methylbenzene adsorption quantity of carbon sphere-activated carbon composites

InactiveCN106732398AIncrease the number ofIncrease the adsorption capacity of tolueneOther chemical processesActivated carbonD-Glucose

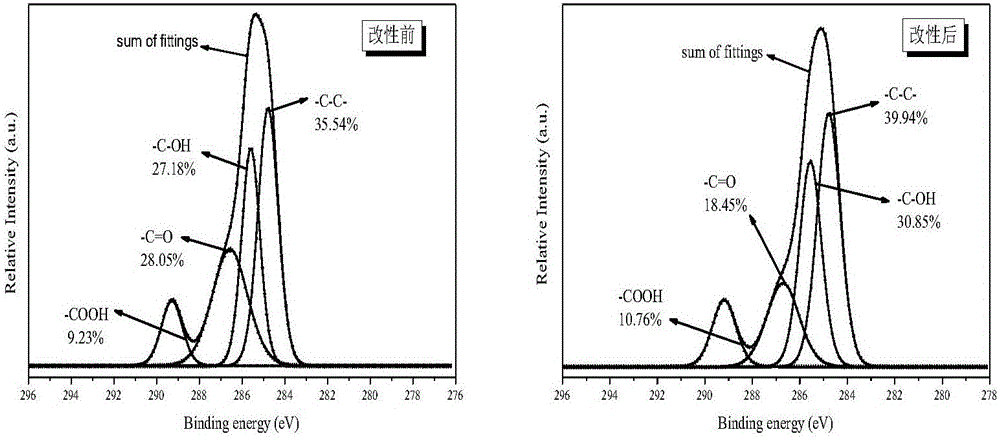

The invention discloses a modifying method capable of increasing the methylbenzene adsorption quantity of carbon sphere-activated carbon composites. The modifying method includes preparing to obtain the carbon sphere-activated carbon composites through a hydrothermal method, wherein a glucose solution serves as a hydrothermal reaction medium; weighing a specific quantity of dried carbon sphere-activated carbon composites, mixing the dried carbon sphere-activated carbon composites with nitric acid according to a specific mass ratio, adding the mixture into a conical flask with a cover and performing ultrasonic technical treatment. The modifying method is green and efficient in modifying technology and enables the methylbenzene adsorption quantity of the carbon sphere-activated carbon composites to be increased from 39.19 mg / g to 143.15 mg / g, the surface hydroxyl group content thereof to be increased from 27.18% to 30.85% and the carboxyl group content thereof to be increased from 9.23% to 10.7%.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

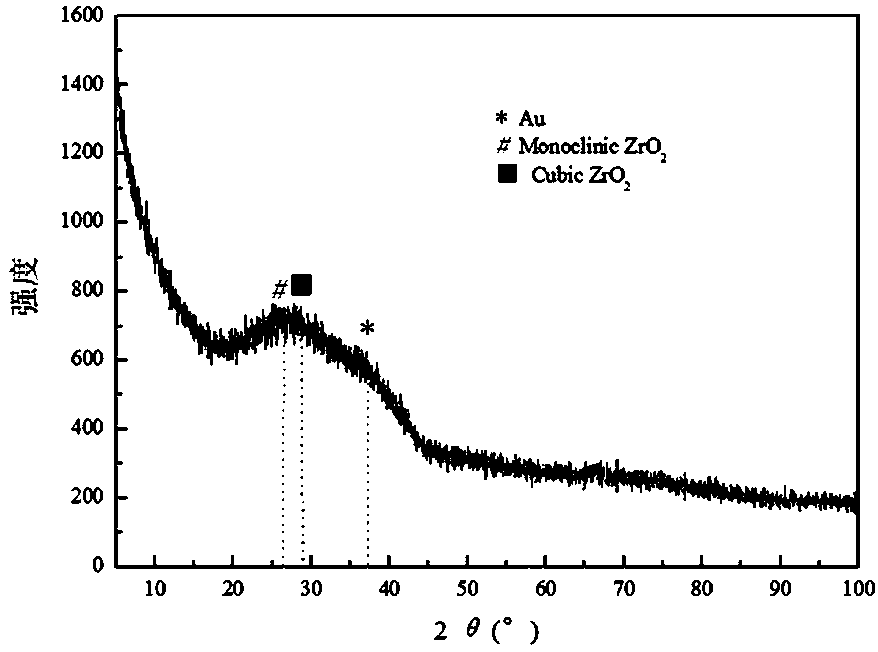

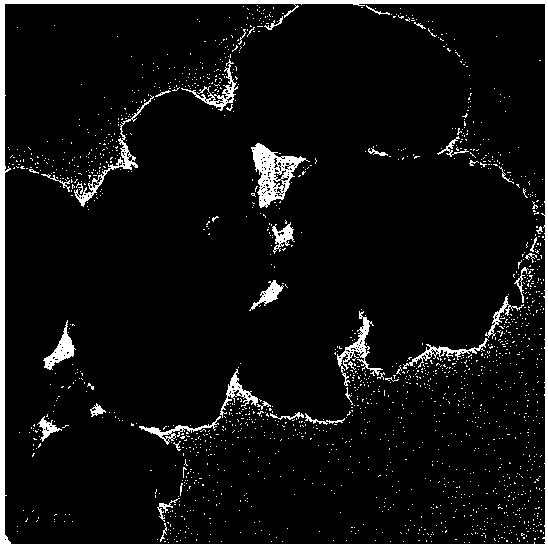

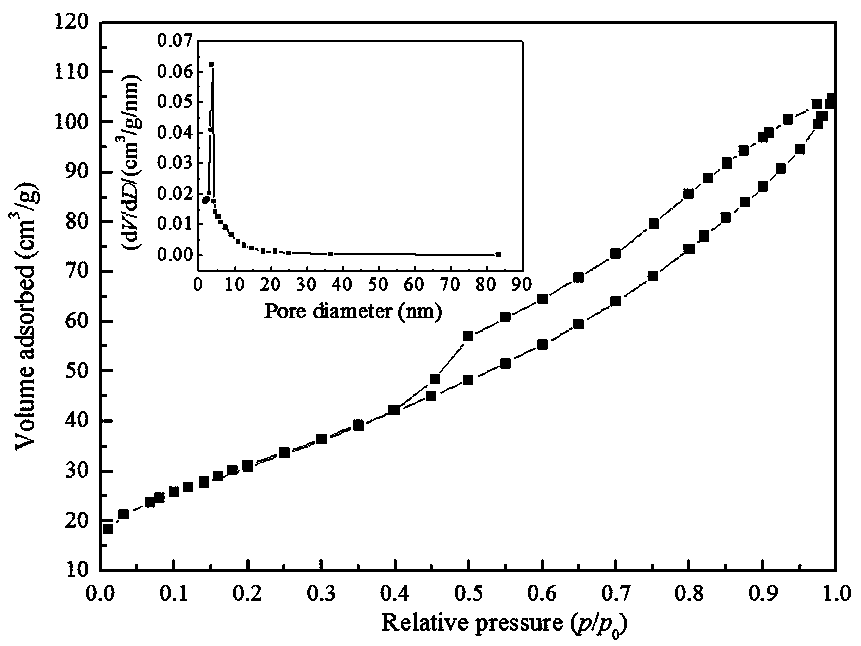

arsenic-removing adsorbent with IB group metal nanoparticles loaded on zinc zirconium composite oxide and preparation method thereof

ActiveCN107551986ALarge specific surface areaHigh removal rateOther chemical processesWater contaminantsCooking & bakingSorbent

The invention discloses an arsenic-removing adsorbent with IB group metal nanoparticles loaded on a zinc zirconium composite oxide and a preparation method thereof. The method comprises the followingsteps: firstly, preparing an IB group metal salt solution, a zinc salt solution and a zirconium salt solution into a mixed metal salt solution; with the deionized water with pre-regulated pH value asa base solution, adding the mixed metal salt solution and a precipitant solution for co-precipitating and controlling an end point pH value within a range of 7-10; ending the dropwise adding, continuously stirring, heating and hydrolyzing the precipitate; centrifugally separating, thereby acquiring a hydrolysis product; washing, centrifuging, drying and baking, thus obtaining the arsenic-removingadsorbent. The arsenic-removing adsorbent prepared according to the invention is high in specific surface area and narrow in pore size distribution; the metal nanoparticles are highly dispersed and loaded onto an amorphous composite oxide carrier, so that the arsenic-removing adsorbent has the characteristics of high removal rate, high adsorption capacity, less dosage, high adsorption rate, and the like; the arsenic-removing adsorbent can be used for deeply treating the low-concentration arsenic pollutants in underground water and surface water and the low-concentration arsenic-bearing industrial wastewater.

Owner:FUZHOU UNIV

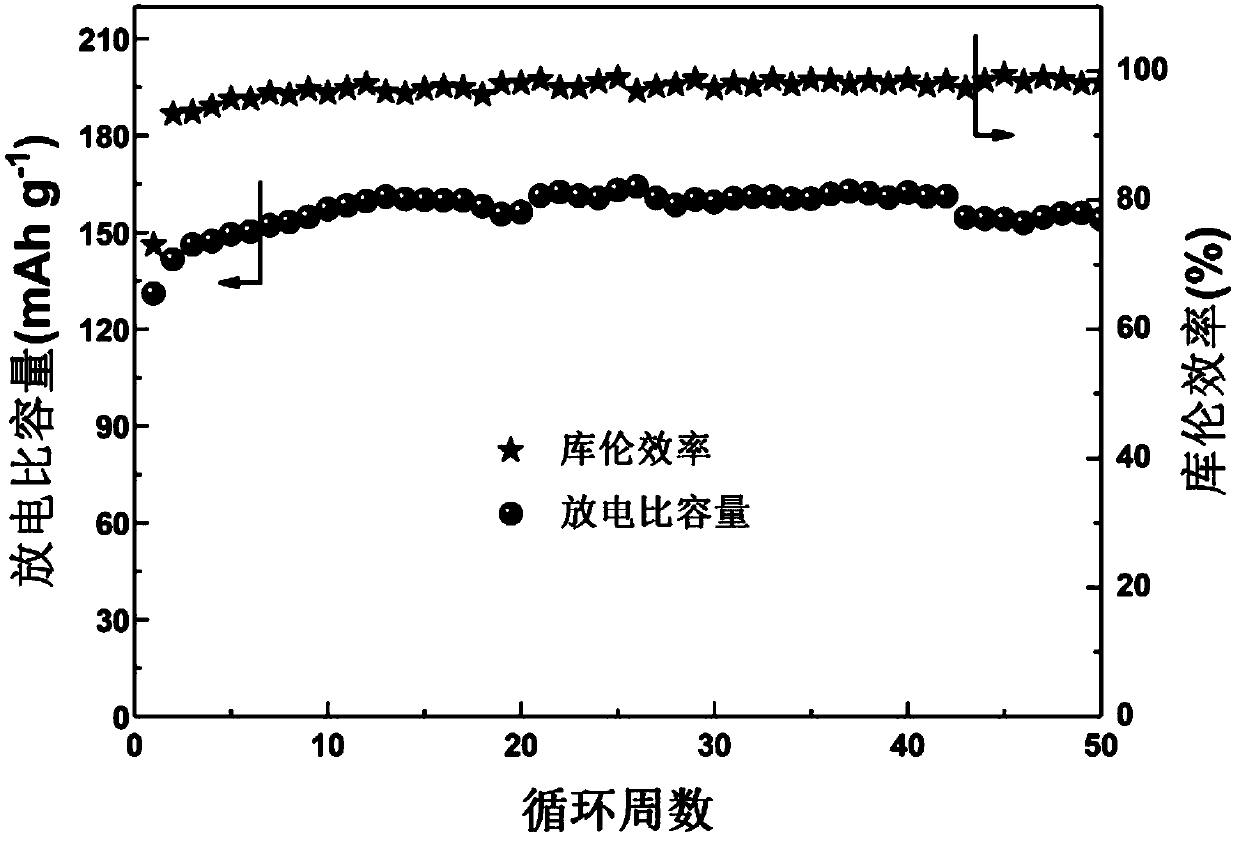

High-voltage all-solid-state lithium battery electrolyte and preparation method therefor

ActiveCN109546210AImprove ionic conductivityLow costMaterial nanotechnologySolid electrolytesPolyvinylidene fluorideNanometre

The invention relates to a high-voltage all-solid-state lithium battery electrolyte and a preparation method therefor, and belongs to the field of solid-state electrolyte preparation. The electrolytecomprises 50%-85% of a lithium ion-conducting polymer, 15%-50% of lithium salt, and 0%-50% of a nano inorganic particle filler. The nanofiller contains one or two of SiO2, TiO2 and Al2O3. The lithiumion-conducting polymer is polyvinylidene fluoride (PVDF). The solid electrolyte prepared by the method adopts the PVDF with high voltage resistance and high ionic conductivity as an ion transport phase, and the prepared solid electrolyte has the advantages of good compatibility with the positive electrode, high voltage resistance and environmental friendliness.

Owner:SHANDONG UNIV

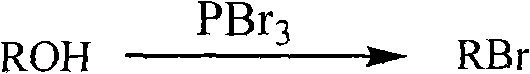

Method for preparing halogenated hydrocarbons from strong acidic ionic liquid

InactiveCN101768045ACraft greenMild reaction conditionsHalogenated hydrocarbon preparationSolventIonic liquid

The invention discloses a new method for preparing halogenated hydrocarbons, which belongs to the technical field of fine chemical synthesis. In the method, strong acidic ionic liquid is used as a halogenated agent, a catalyst and a solvent and reacts for 30 to 120 minutes at the temperature of between 60 and 100 DEG C to generate the halogenated hydrocarbons. Compared with the current methods, the method has the advantages of green preparation process, high product yield, short technological flow, mild reaction conditions, simple process, easy isolation of the product from the ionic liquid, easy recovery of the ionic liquid from a reaction system, recycling and the like, is favorable for saving energy resources, lowering investment, reducing environmental pollution and the like, and has a good application prospect.

Owner:ZHENGZHOU UNIV

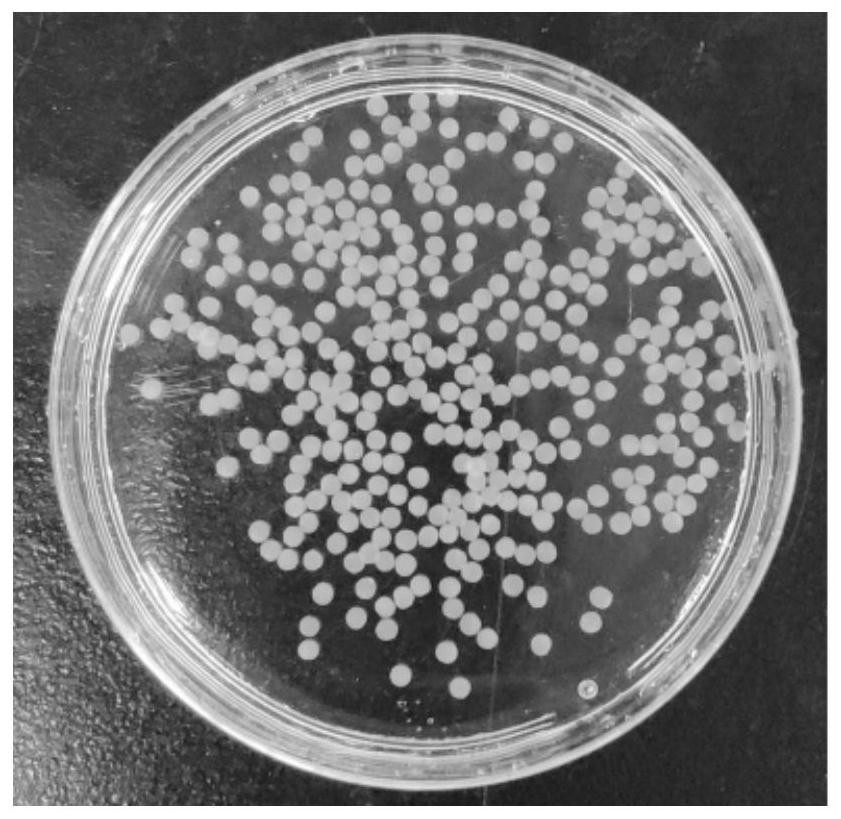

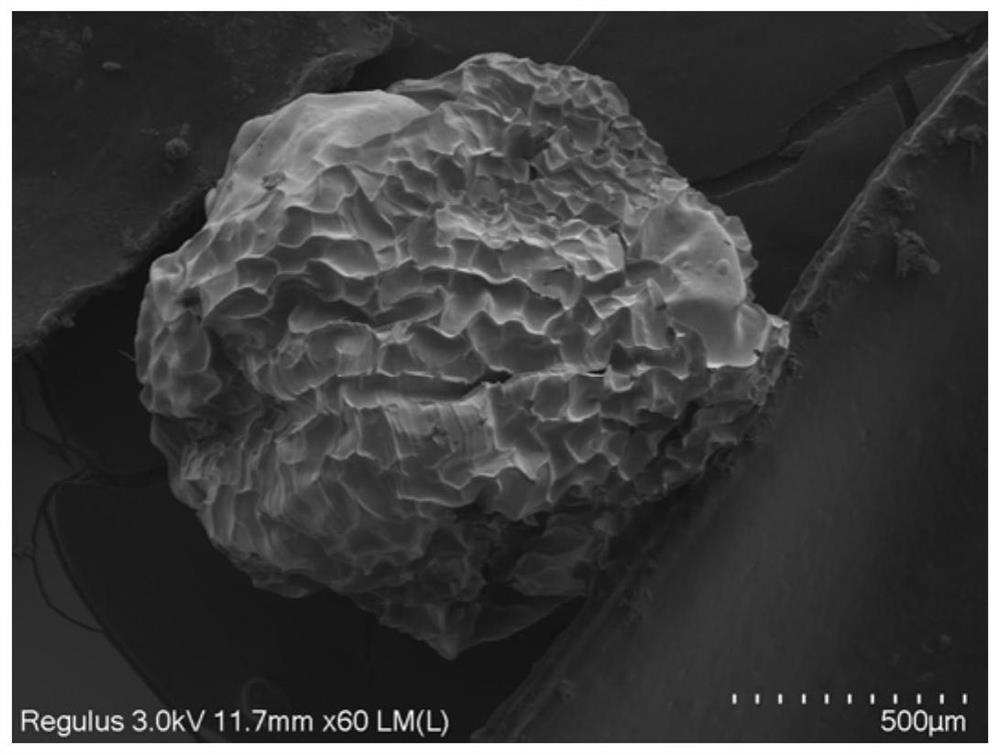

Preparation method of pH response type carboxymethyl chitosan/sodium alginate hydrogel ball

PendingCN113372578AGood pH responsivenessStable structureAerosol deliveryOintment deliveryPharmaceutical drugWater soluble drug

The invention belongs to the field of high-molecular polymer hydrogel, and relates to a preparation method of a pH response type carboxymethyl chitosan / sodium alginate hydrogel ball. The preparation method of the hydrogel ball comprises the following steps: respectively dissolving carboxymethyl chitosan and sodium alginate in water under stirring at room temperature, carrying out filtering to remove insoluble substances, and performing ultrasonic degassing to respectively obtain transparent carboxymethyl chitosan and sodium alginate solutions; adding a certain amount of the carboxymethyl chitosan solution into the sodium alginate solution, carrying out quick stirring to form a uniform solution, and conducting degassing; and dropwise adding a mixed solution obtained in the previous step into a cross-linking agent by using a disposable syringe with a volume of 1 mL, conducting curing, taking out the hydrogel ball, and washing the hydrogel ball with water. According to the invention, release of protein in simulated gastric juice can be effectively reduced; a preparation process is simple, safe and non-toxic; raw materials are low in price; the hydrogel ball is stable in structure and good in pH response characteristics, and wide application prospects are achieved in the aspect of oral protein and water-soluble drug delivery.

Owner:JIANGNAN UNIV

Method for preparing nanometer chromium dioxide

InactiveCN101684002AReduce the temperatureRelieve pressureChromium dioxideReaction temperatureInorganic materials

The invention relates to a method for preparing nanometer chromium dioxide, belonging to the preparation field of inorganic materials, in particular to a method for preparing the nanometer chromium dioxide with an oxidation process; the method is characterized in that: chromium hydroxide hydrate is taken as raw material and is mixed with water according to the proportion that water / chromium hydroxide hydrate (w / w) is 0.001-5 after being crushed by a ball-milling method or other ways, the initial oxygen pressure is 0.001-7MPa, constant reaction temperature with 350-390 DEG C generally is kept, and the mixture is reacted for less than 60min, so as to obtain purified nanometer CrO2. The method has simple process and the reaction condition is mild compared with the existing process, thereby having promotional value.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

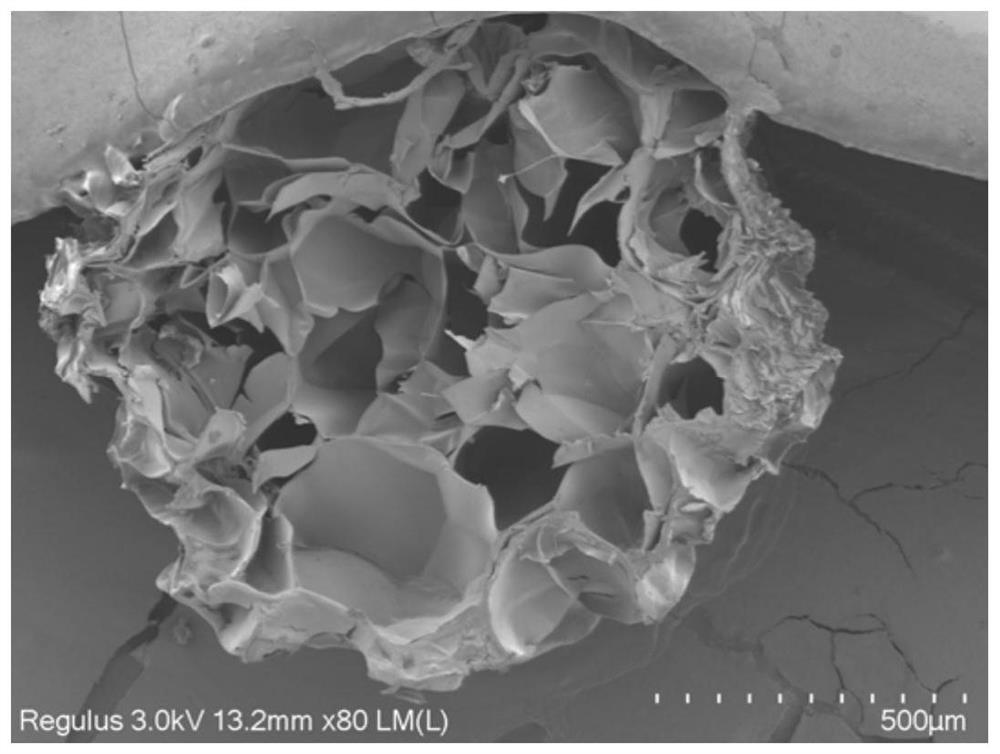

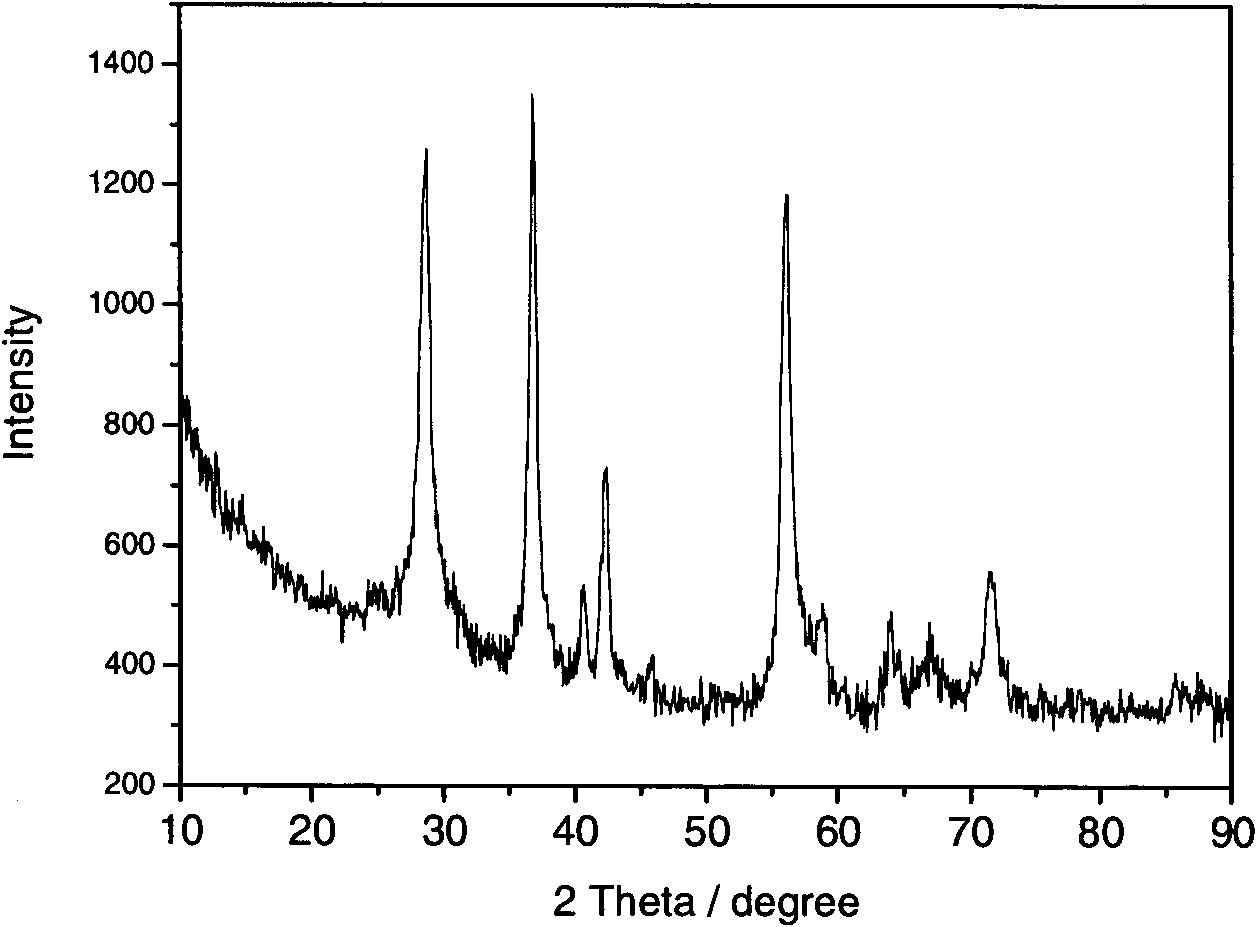

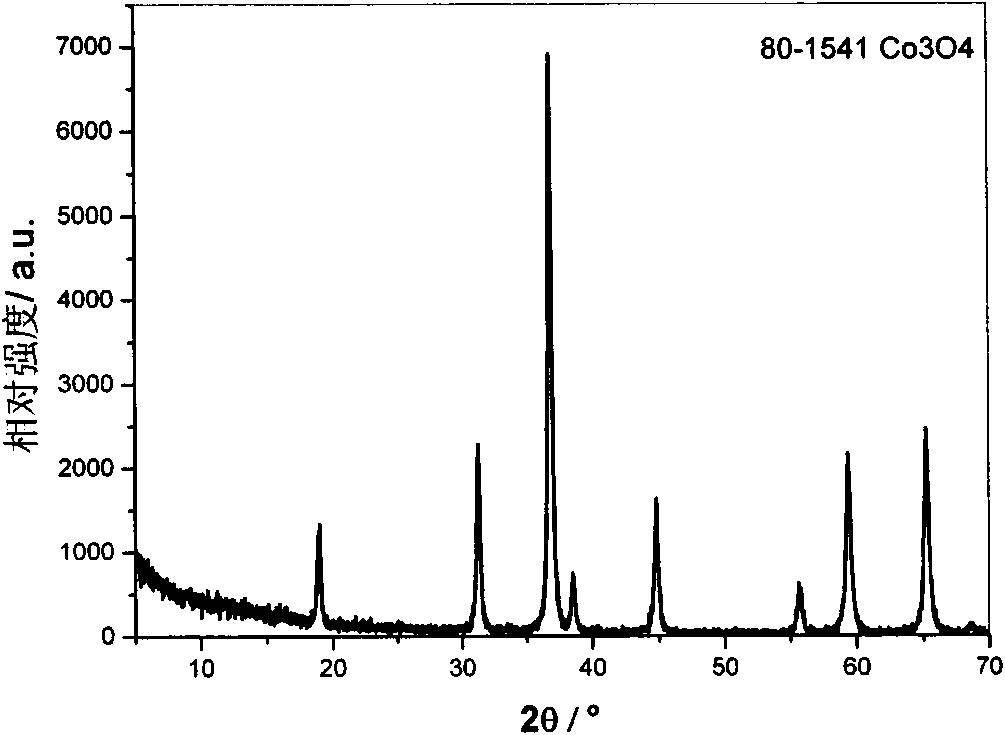

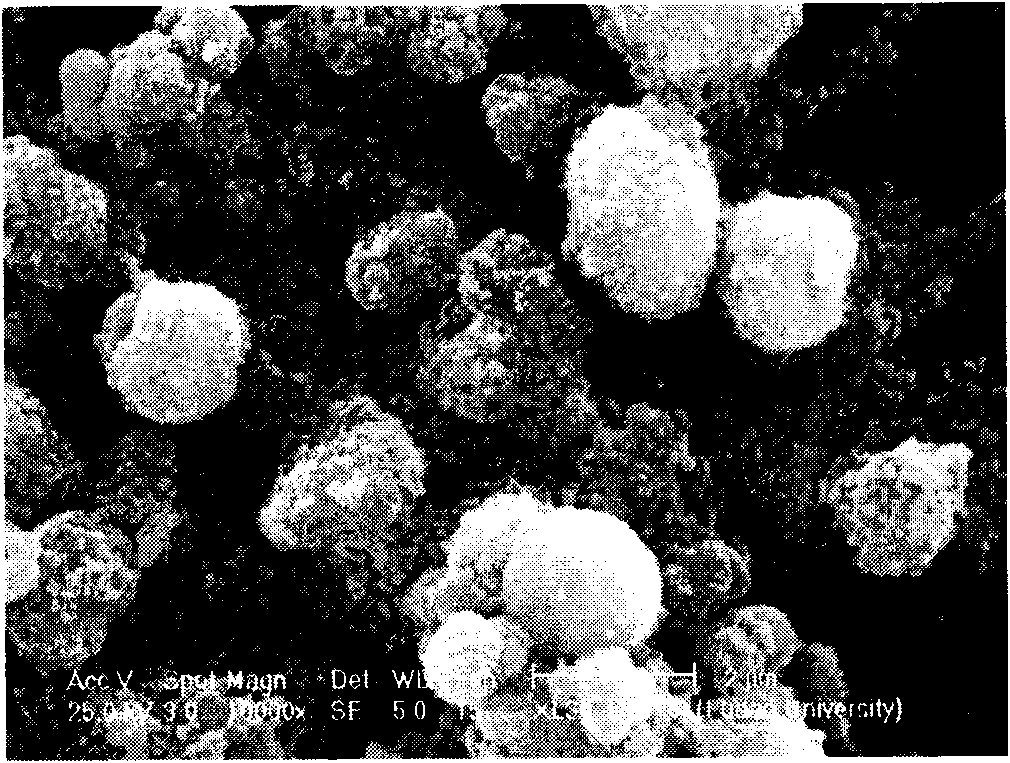

Method for preparing Co3O4 nano material by Co2O3 powder

InactiveCN101654285ASimple ingredientsLow raw material costNanostructure manufactureCobalt oxides/hydroxidesSolventIon

The invention discloses a method for preparing a Co3O4 nano material by Co2O3 powder, comprising the following steps: taking the Co2O3 powder as a precursor, wherein, if deionized water and ethanol are taken as solvents, the volume ratio of the deionized water to the ethanol of absolute ethanol is 9:1 to 0:10; or when the water solution of glucose is taken as the solvent, the mass fraction of theglucose is between 5-30 percent; mixing and stirring 0.1-0.2mol / 1 Co2O3 powder and deionized water and ethanol or glucose aqueous solution solvent to form a uniform mixed material; putting the mixedmaterial in a container, then putting the container in a constant temperature cabinet, raising the temperature at a speed of 8.5-11.5 DEG C / min, and heating the mixed material within the temperaturerange of 120-160 DEG C for 6-24h; taking the container out for cooling to the room temperature; alternately washing a synthetic product by the deionized water and the absolute alcohol, and drying at low temperature to obtain the Co3O4 nano material. The Co3O4 nano material prepared by the method has easily controlled shape and granularity, high purity, good crystallinity and environment-friendly production process.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

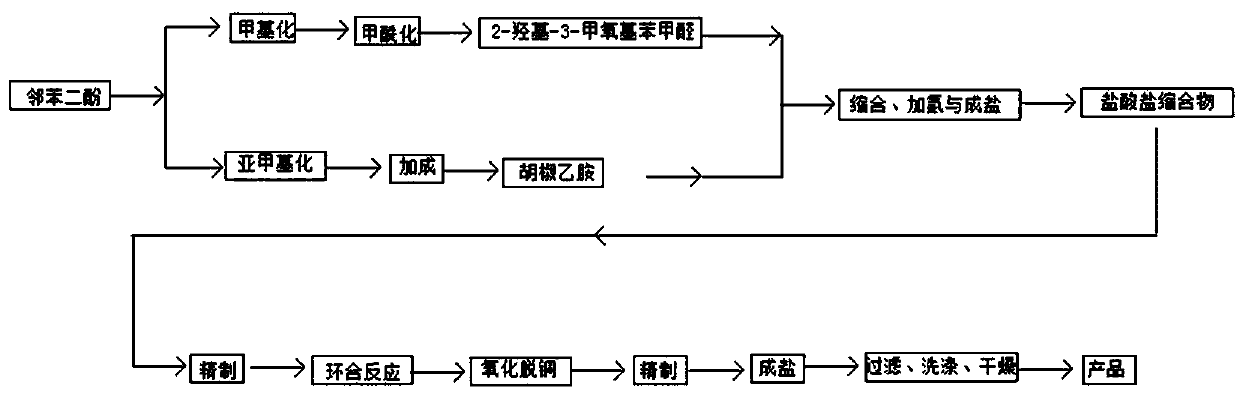

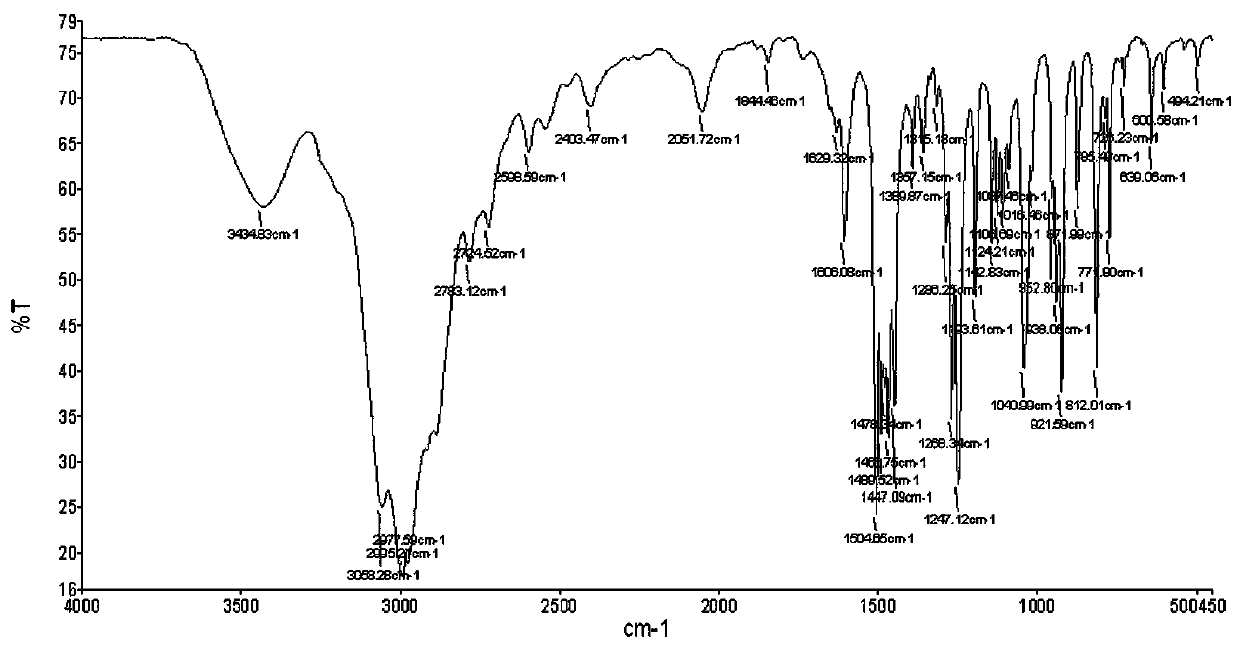

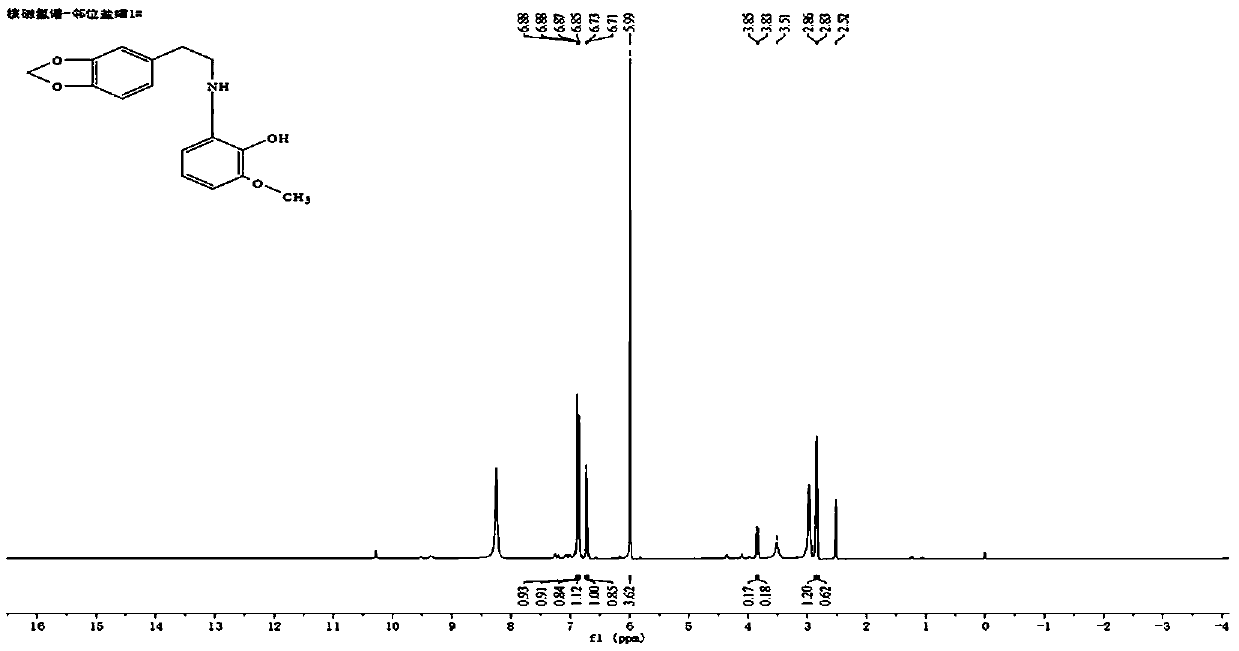

Method for totally synthesizing berberrubine from catechol

InactiveCN109705113AFew synthetic stepsReduce usageOrganic chemistryChemical synthesisFormylation reaction

The invention relates to a method for synthesizing a drug, and concretely relates to a method for synthesizing berberrubine from catechol. The method comprises the following steps: carrying out a selective methylation reaction on the raw material catechol and 2-chloromethane to obtain o-methoxyphenol, and carrying out a selective formylation reaction to obtain 2-hydroxy-3-methoxybenzaldehyde; carrying out a methylenation reaction on catechol and 2-chloromethane to obtain piperidine, and carrying out a catalytic addition reaction on the piperidine and 2-chloroethylamine to obtain homopiperonylamine; carrying out a one-pot condensation hydrogenation reaction on the homopiperonylamine and 2-hydroxy-3-methoxybenzaldehyde under the action of a nickel-based catalyst, adding hydrochloric acid tothe obtained reaction product, cooling obtained crystals, and performing filtration to obtain a hydrochloride condensate; and refining the hydrochloride condensate, carrying out a cyclization reactionon the refined hydrochloride condensate and glyoxal under the action of a copper-based catalyst, refining the obtained reaction product, adding hydrochloric acid, performing cooling for crystallization, and filtering and washing obtained crystals to obtain the product berberrubine. The method realizes industrial total synthesis of the berberrubine, and opens up a chemical synthesis method for berberrubine drugs.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com