High-voltage all-solid-state lithium battery electrolyte and preparation method therefor

An all-solid-state, electrolyte technology, applied in the direction of solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte, etc., can solve the problems of limiting the energy density of the battery system, difficult NCM material pairing, PEO oxidation, etc., to achieve good cycle stability and low cost , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. The present invention discloses an electrolyte for an all-solid-state lithium-ion battery, which consists of 0.345g LiTFSI, 1gPVDF (Mn=300000) and 0.1g SiO 2 composition.

[0048] 2. A preparation method for an all-solid-state lithium-ion battery electrolyte: 0.345g LiTFSI, 1g PVDF (Mn=300000) and 0.1g SiO 2 Put it into a vacuum oven to heat at 70°C after fully grinding, then take out the powder and put it in a hot press, and press it at 70°C with a pressure of 10MPa to obtain a uniform composite polymer electrolyte.

[0049] 3. An all-solid-state lithium-ion battery, comprising a positive electrode, a negative electrode, and the electrolyte prepared in this embodiment; the positive electrode includes: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , acetylene black, PVDF and aluminum foil, of which LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The mass ratio of acetylene black and PVDF is 8:1:1; the negative pole is metal lithium foil.

Embodiment 2

[0051] 1. The present invention discloses an electrolyte for an all-solid-state lithium-ion battery, which consists of 0.345g LiTFSI, 1gPVDF (Mn=300000) and 0.1g Al 2 o 3 composition.

[0052] 2. A preparation method for an all-solid-state lithium-ion battery electrolyte: 0.345g LiTFSI, 1g PVDF (Mn=300000) and 0.1g SiO 2 Put it into a vacuum oven to heat at 70°C after fully grinding, then take out the powder and put it in a hot press, and press it at 70°C with a pressure of 10MPa to obtain a uniform composite polymer electrolyte.

[0053] 3. An all-solid-state lithium-ion battery, comprising a positive electrode, a negative electrode, and the electrolyte prepared in this embodiment; the positive electrode includes: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , acetylene black, PVDF and aluminum foil, of which LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The mass ratio of acetylene black and PVDF is 8:1:1; the negative pole is metal lithium foil.

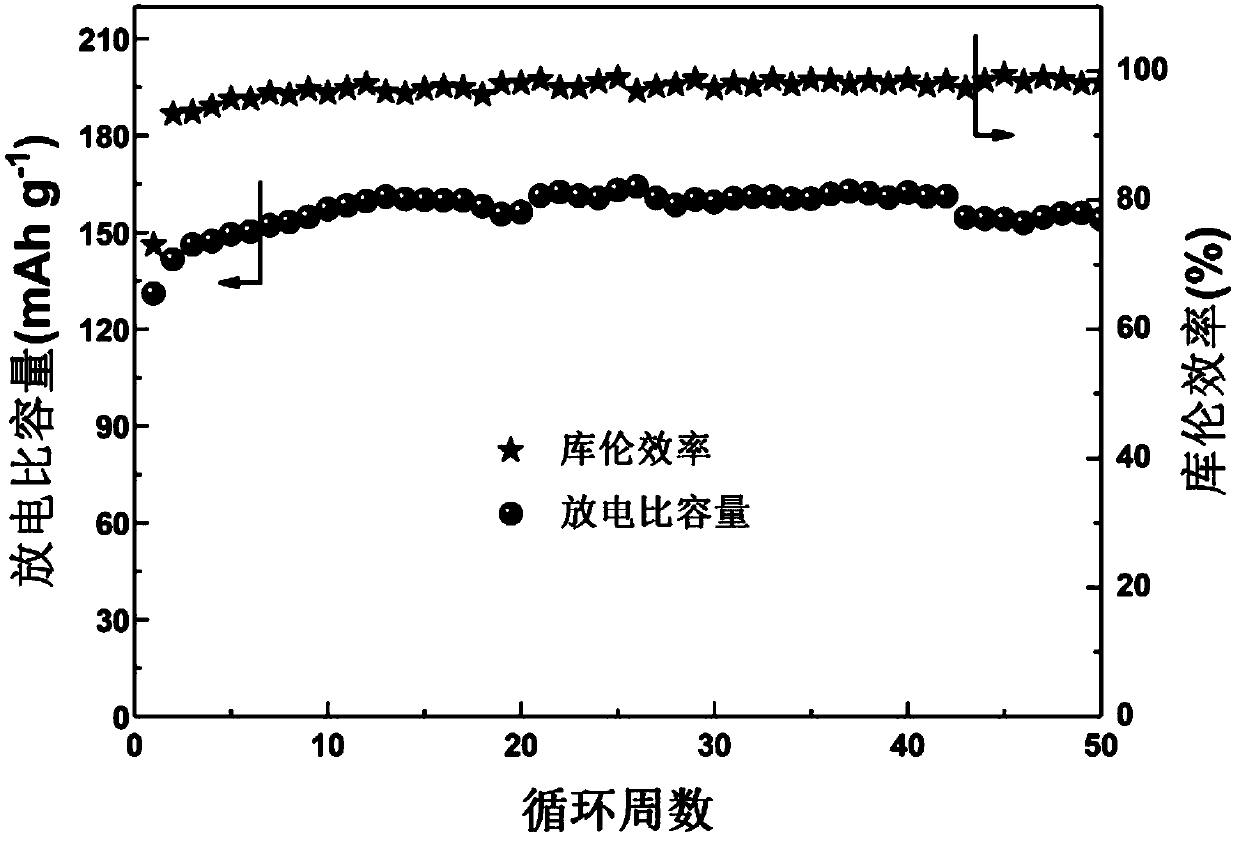

[0054] 4. Cycle test at 50°C: battery test condition i...

Embodiment 3

[0056] 1. The present invention discloses an electrolyte for an all-solid-state lithium-ion battery, which consists of 0.345g LiTFSI, 1gPVDF (Mn=300000) and 0.1g TiO 2 composition.

[0057] 2. A preparation method for an all-solid-state lithium-ion battery electrolyte: 0.345g LiTFSI, 1g PVDF (Mn=300000) and 0.1g SiO 2 Put it into a vacuum oven to heat at 70°C after fully grinding, then take out the powder and put it in a hot press, and press it at 70°C with a pressure of 10MPa to obtain a uniform composite polymer electrolyte.

[0058] 3. An all-solid-state lithium-ion battery, comprising a positive electrode, a negative electrode, and the electrolyte prepared in this embodiment; the positive electrode includes: LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 , acetylene black, PVDF and aluminum foil, of which LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 The mass ratio of acetylene black and PVDF is 8:1:1; the negative pole is metal lithium foil.

[0059] 4. Cycle test at 50°C: battery test condition is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com