Patents

Literature

68results about How to "Good cycle stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

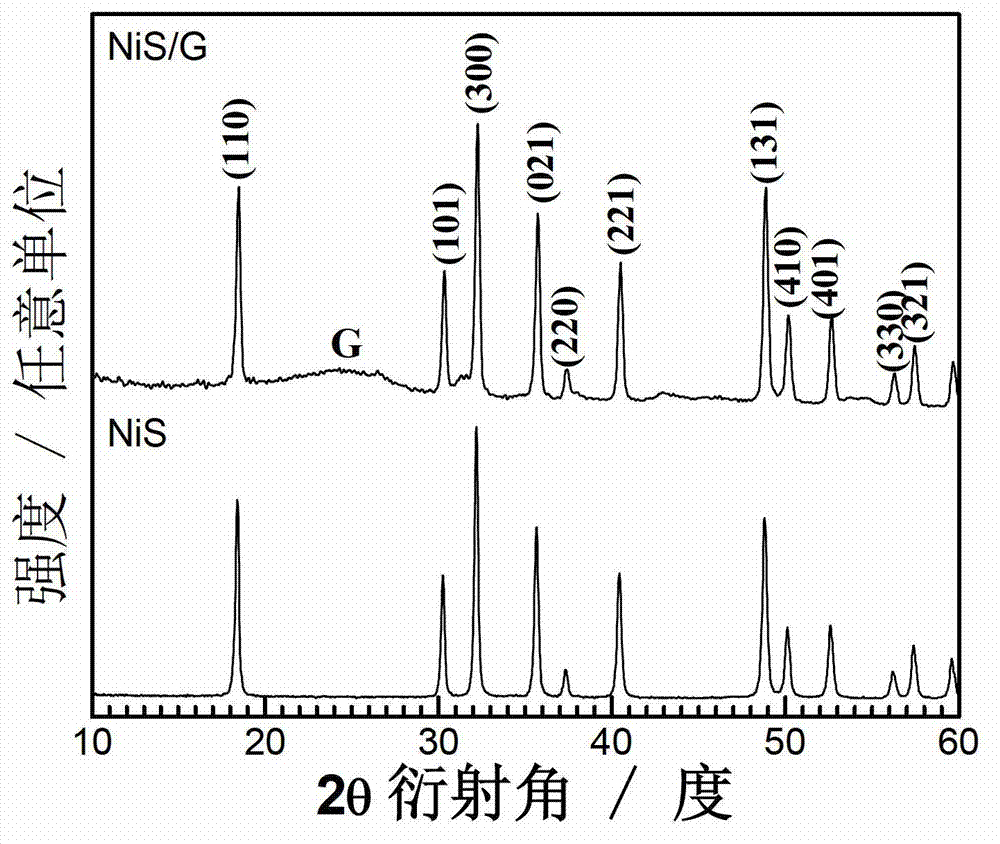

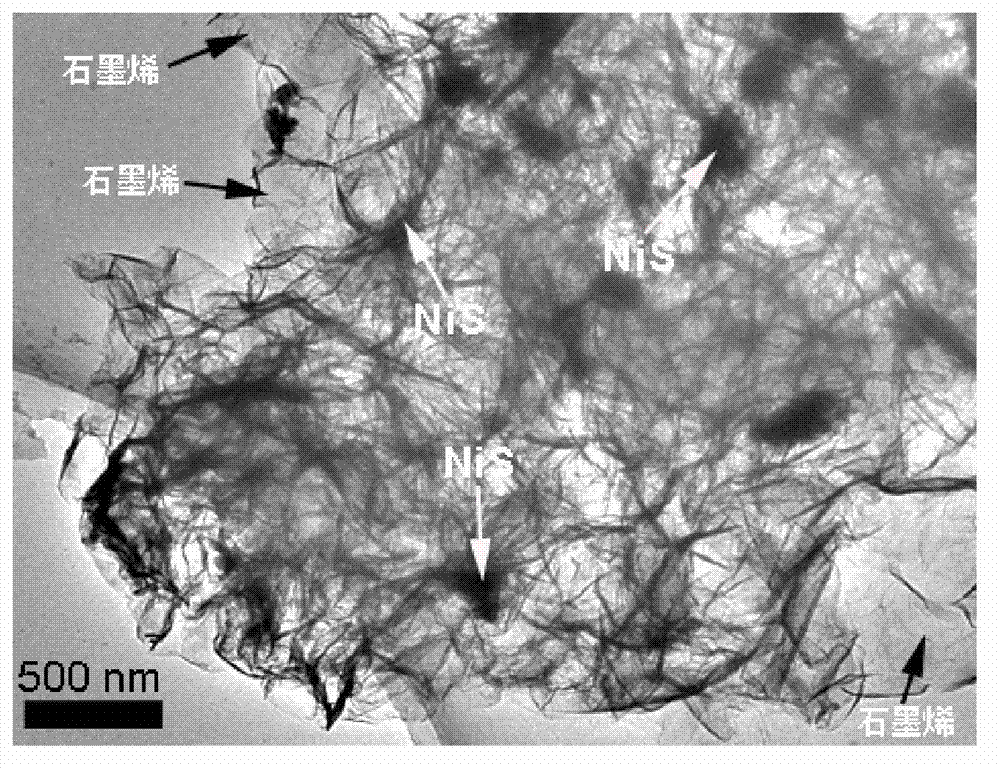

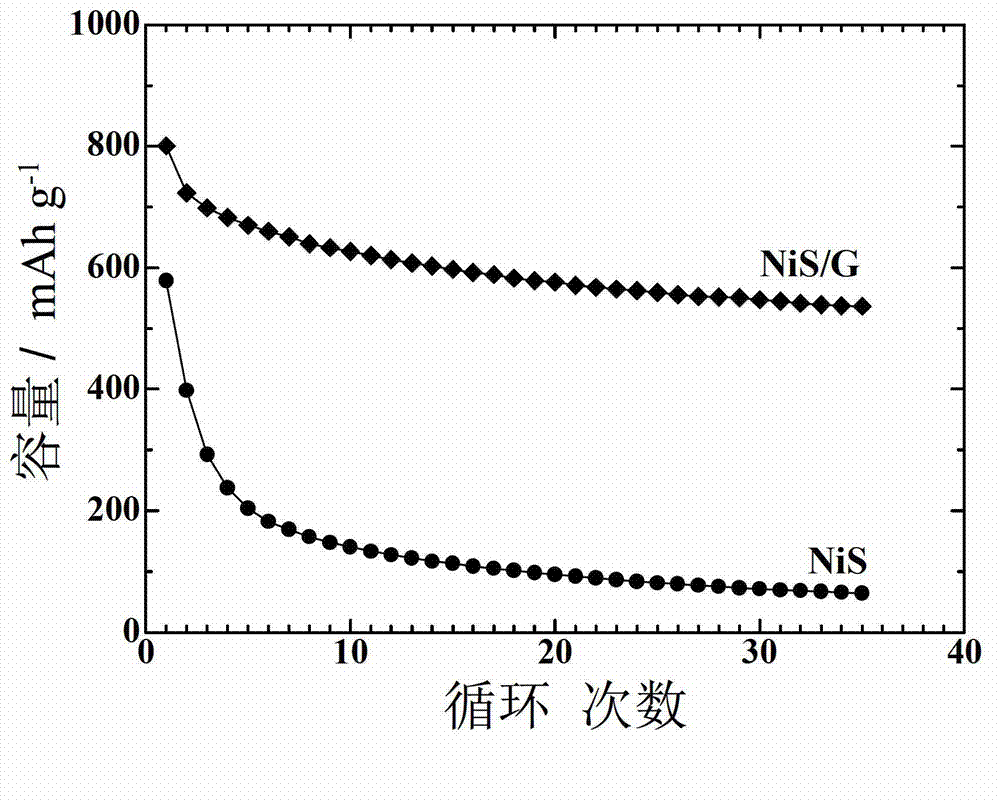

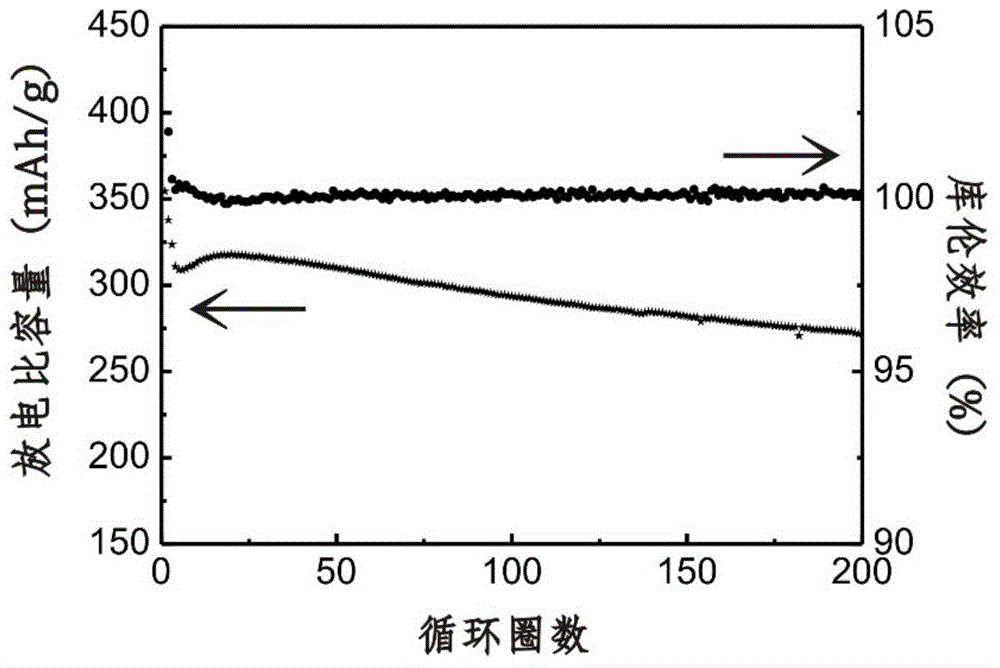

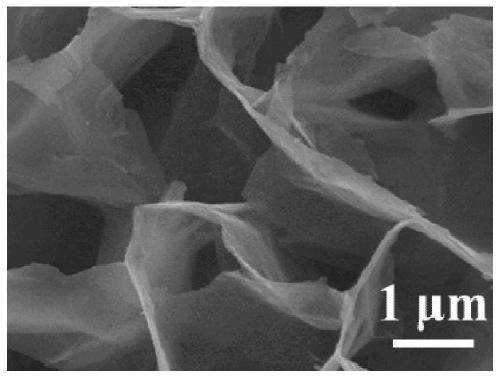

Nickel sulfate sheet/graphene composite material as well as preparation method and application thereof

InactiveCN103035914AGood electrochemical stabilityGood cycle stabilityCell electrodesCvd grapheneCharge and discharge

The invention discloses a nickel sulfate sheet / graphene composite material as well as a preparation method and application thereof. The nickel sulfate sheet / graphene composite material comprises nanoscale nickel sulfate and graphene, wherein NiS takes a sheet shape. Nickel sulfate sheets in the composite materials can be evenly arranged due to the dispersing and bearing effects of the graphene and have small sizes, so that the stability and the circulating stability of the nickel sulfate in the charge and discharge process can be effectively improved, and the composite material can be used as a lithium ion battery cathode material. The preparation method of the composite material is a one-step low-temperature preparation method, has the advantages of simple technique, low cost, short circle, low energy consumption and the like, and is suitable for large-scale industrial production. The nickel sulfate sheet / graphene composite material can be used as the lithium ion battery cathode material.

Owner:ZHEJIANG UNIV

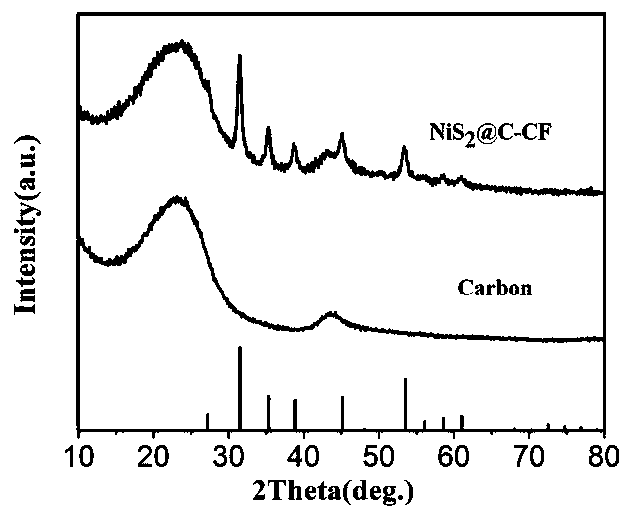

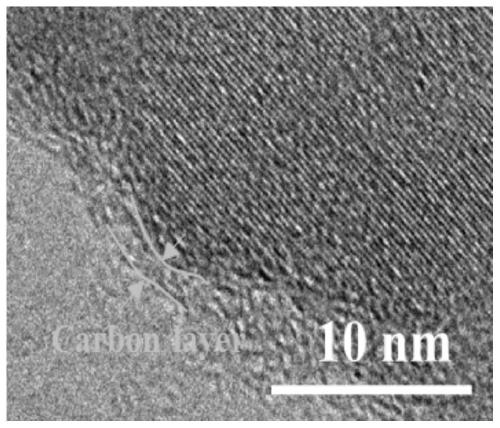

Transition metal sulfide coated with carbon, preparation method and application

InactiveCN104835961AGood electrical conductivityGood cycle stabilityCell electrodesSecondary cellsCarbon coatingCarbon source

A transition metal sulfide coated with carbon, a preparation method and an application relate to transition metal sulfide. The transition metal sulfide coated with the carbon comprises a nucleus and a coating layer on the surface of the nucleus, wherein the nucleus is a transition metal sulfide nucleus, and the coating layer is a carbon coating layer. The preparation method comprises the steps as follows: dissolving the transition metal sulfide in water, adding a carbon source, and coating the surface of the transition metal sulfide with carbon. The transition metal sulfide coated with the carbon is applied to preparation of an electrode material, and the electrode material could be a battery electrode material or the like, and is specifically used as an electrode active material to be applied in a secondary battery. The transition metal sulfide coated with the carbon is greatly improved in conductive performance, further improved in charge and discharge capacity and rate capability, greatly improved in coulombic efficiency and cycle performance, and low in material cost and simple in preparation process. The composite material used as an electrode material of a secondary lithium battery has high energy density, excellent cyclicity, and especially excellent rate capability, and is safe and reliable.

Owner:XIAMEN UNIV

Hybrid super capacitor

ActiveCN107910195AIncrease energy densityGood cycle stabilityHybrid capacitor electrolytesCurrent collectorSmart grid

The invention discloses a hybrid super capacitor. The capacitor comprises an electrolyte, a positive electrode, a negative electrode and an isolation film, wherein the positive electrode and the negative electrode are disposed in the electrolyte; a mixture of a positive electrode active substance, a positive electrode conductive agent and a positive electrode binder coats a positive electrode current collector, so that the positive electrode can be prepared; the positive electrode active substance contains a carbon material; the negative electrode active substance of the negative electrode contains a zinc element; and the electrolyte includes zinc salt and a non-proton high-polarity organic solvent. The prices of the materials of the hybrid super capacitor of the invention are relatively low; and the capacitor has high energy density and cycle stability and can be widely applied to fields such as new energy storage, smart grid, electric bus and automobiles start-stop fields.

Owner:刘小林

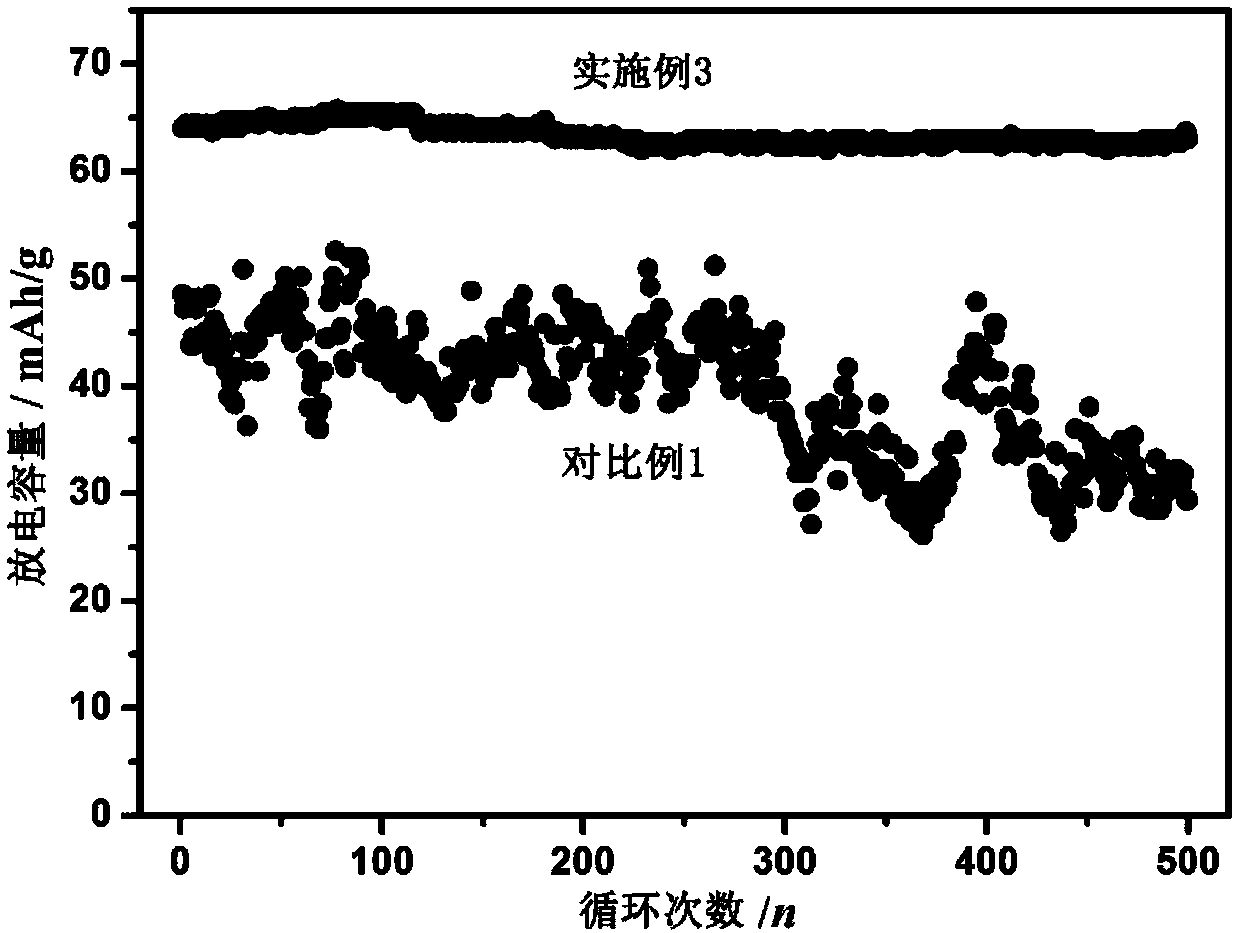

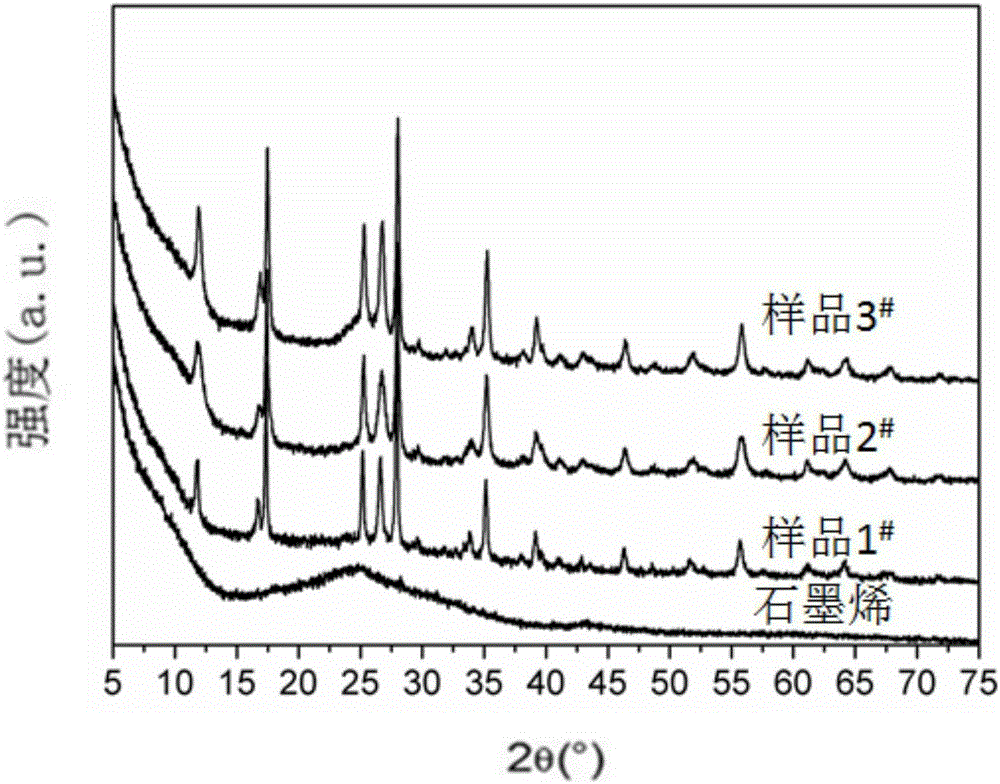

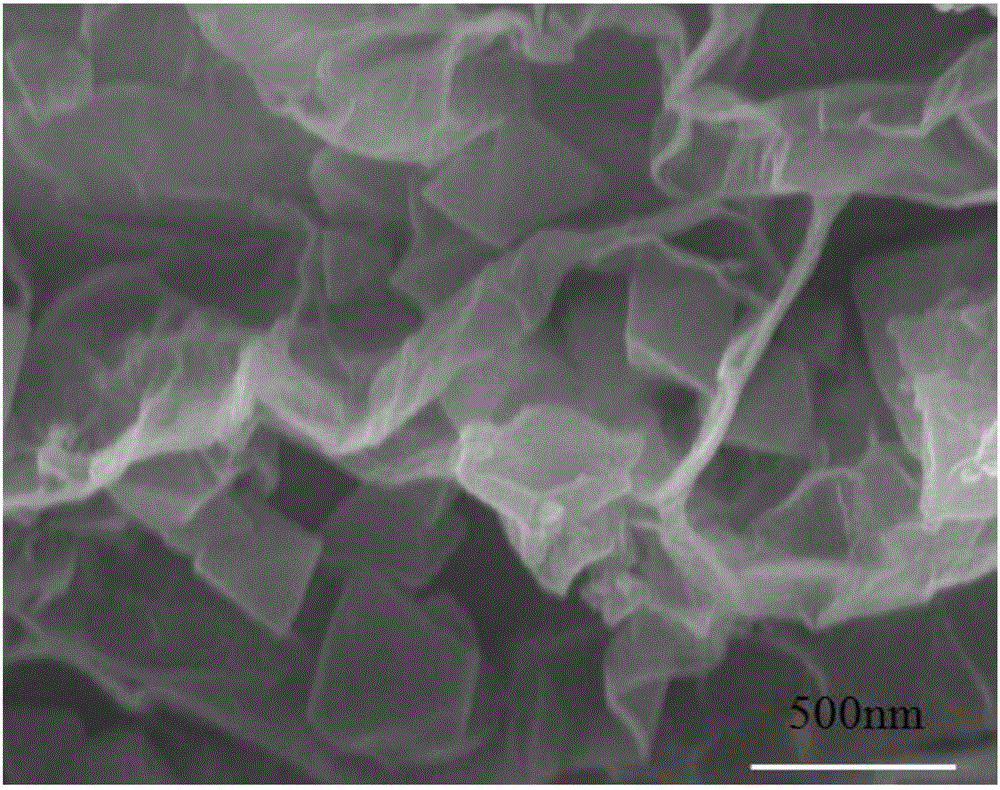

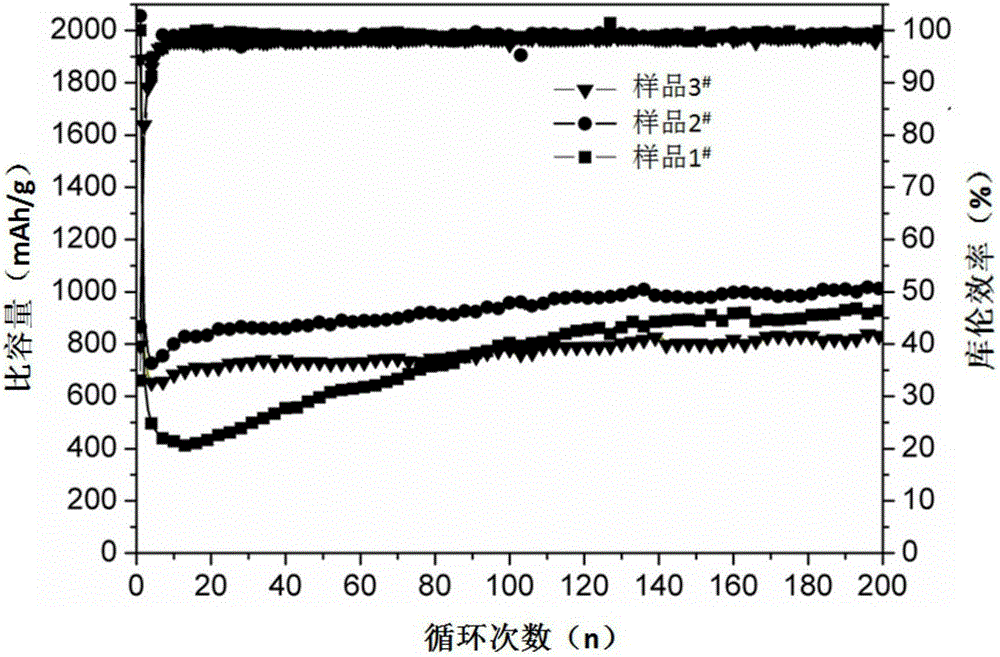

Iron based metal organic framework compound / graphene composite and application thereof

ActiveCN105355873AIncrease capacityGood cycle stabilityCell electrodesSecondary cellsCyclic stabilityMetal-organic framework

The application discloses an iron based metal organic framework compound, an iron based metal organic framework compound / graphene composite formed by the compound and graphene, and application thereof in a lithium ion battery as a negative active material. The iron based metal organic framework compound and the iron based metal organic framework compound / graphene composite are used as the negative electrode active material for the lithium ion battery, and have the advantages of high capacity and good cycle stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

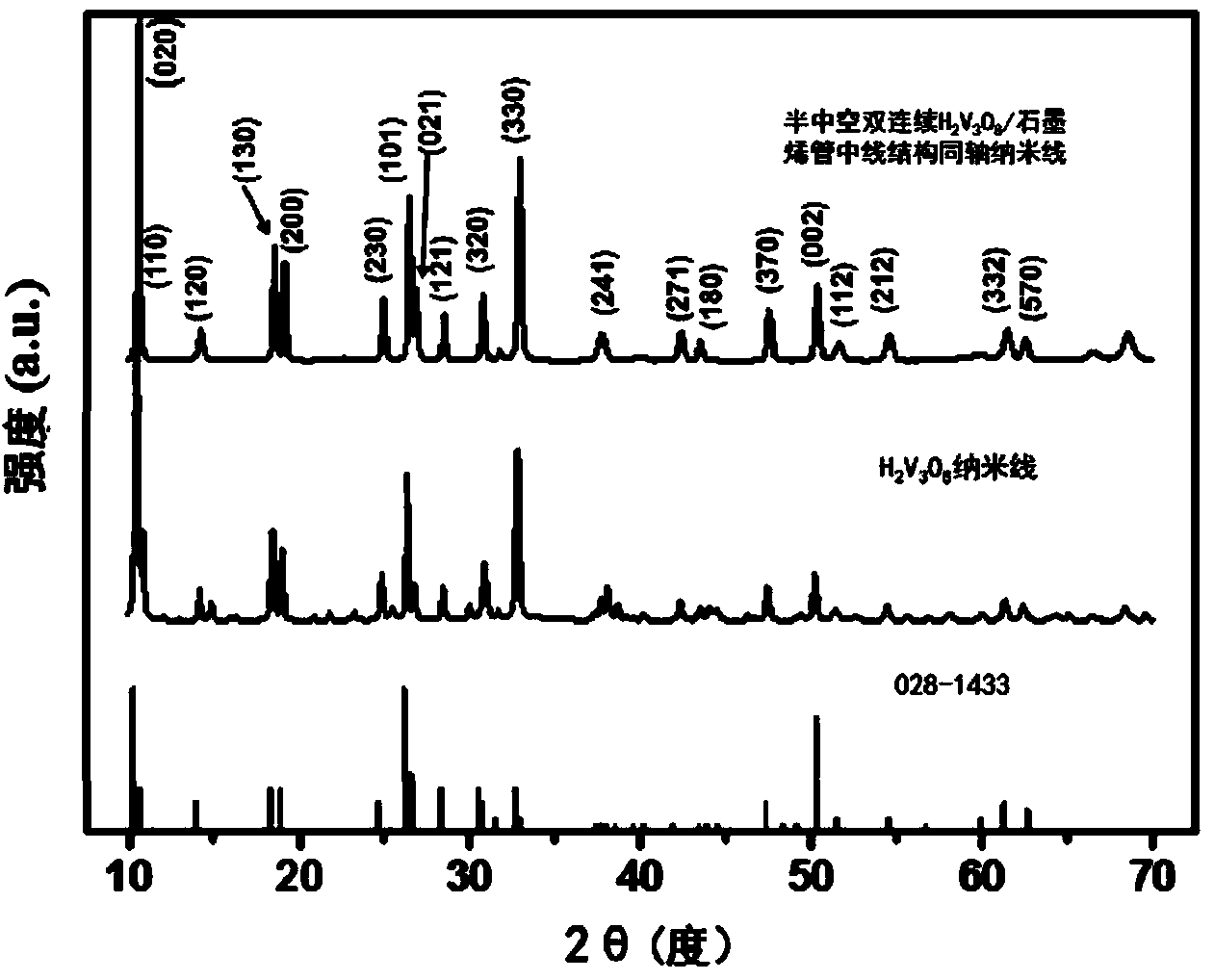

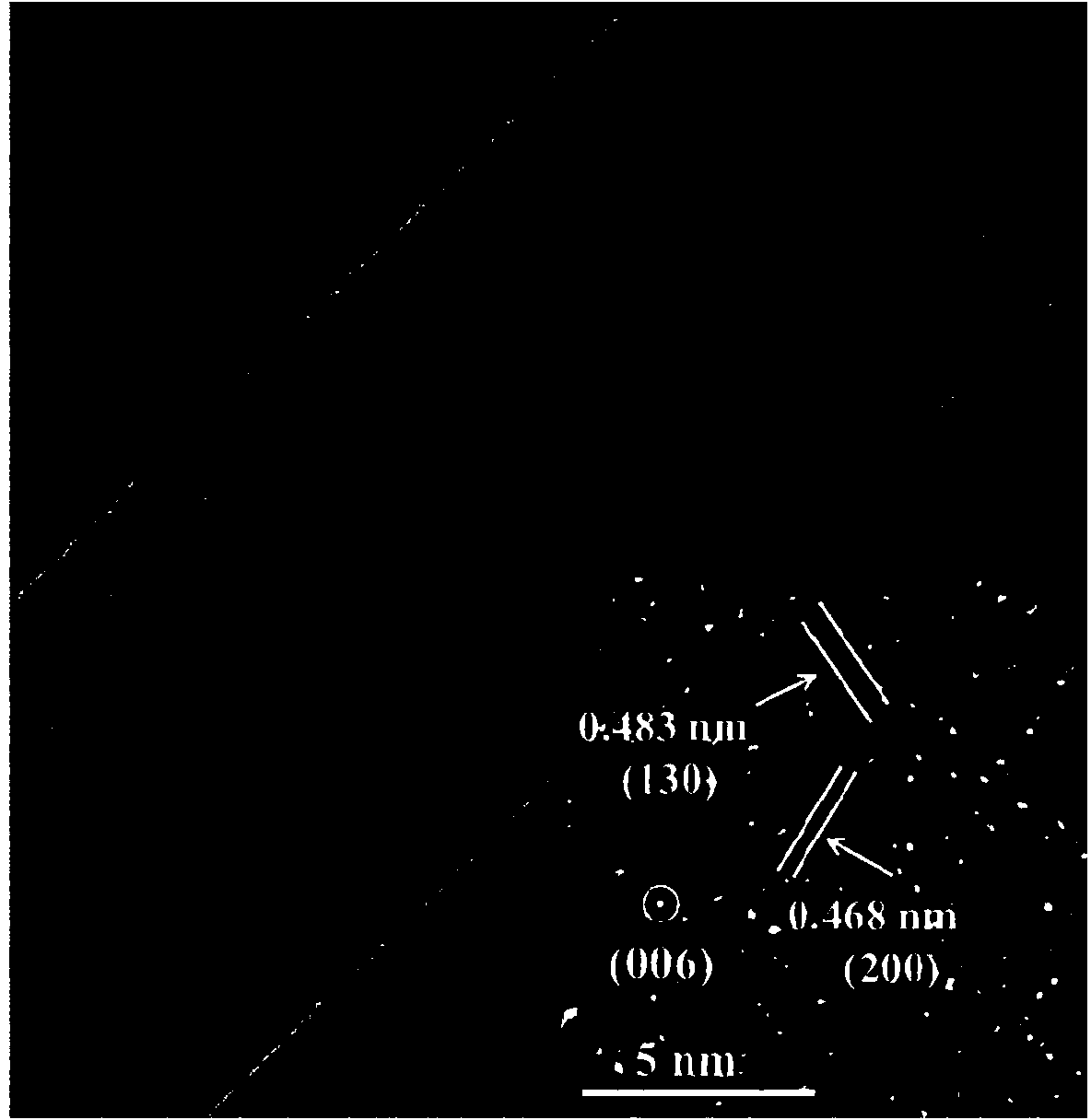

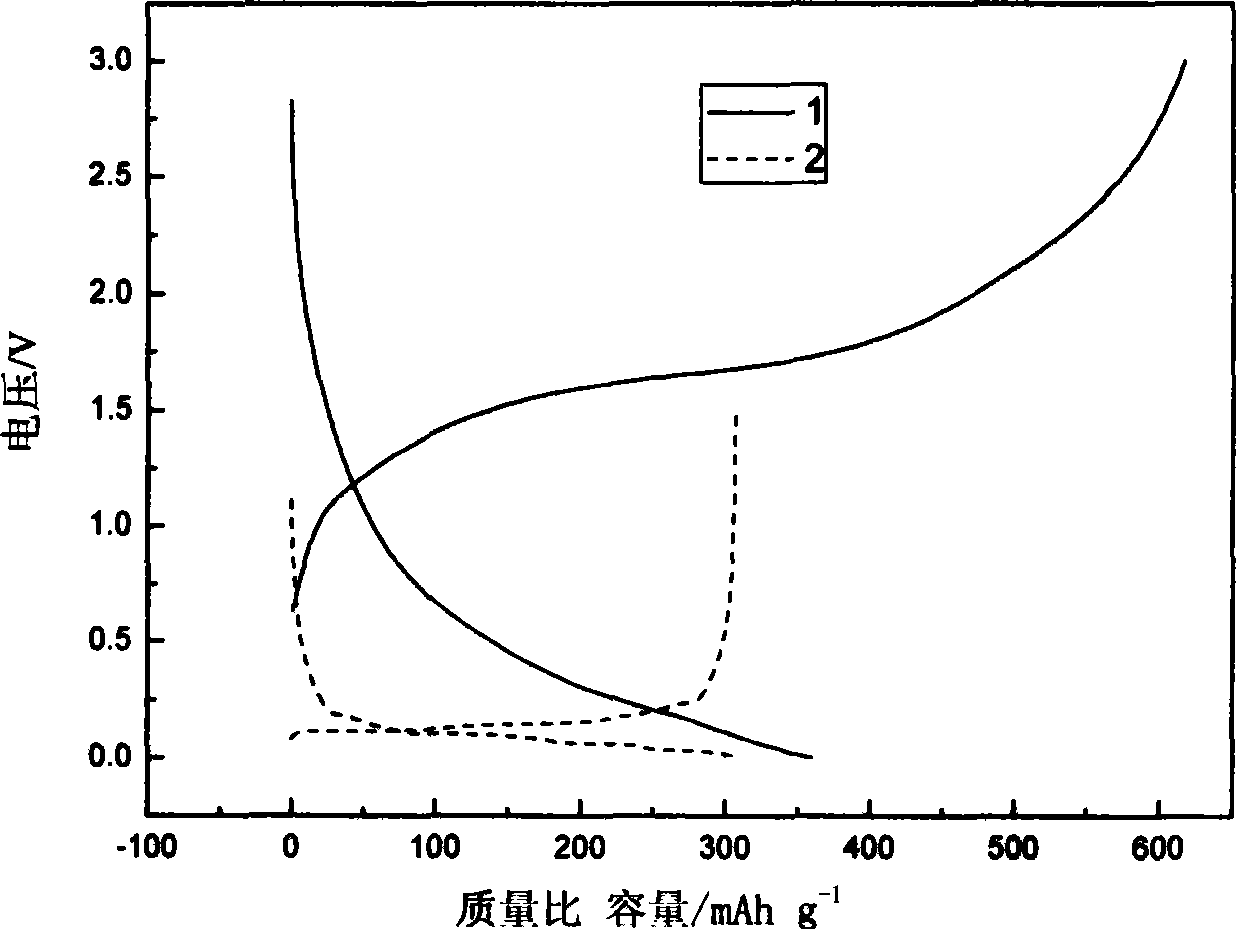

Semi-hollow bicontinuous line-structure coaxial nanowire material in H2V3O8/graphene tube, as well as preparation method and application of material

ActiveCN103474629AGood cycle stabilityExcellent electrochemical performanceMaterial nanotechnologyCell electrodesCvd grapheneCyclic stability

The invention relates to a semi-hollow bicontinuous line-structure coaxial nanowire material in a H2V3O8 / graphene tube, a preparation method and application of the material. The nanowire material is formed by coating a H2V3O8 nanowire by self curling of graphene, a gap is formed between a H2V3O8 nanowire and graphene curl formed by self curling of the graphene, wherein the diameter of the H2V3O8 nanowire is 20-80nm. The nanowire material can be used as a positive electrode active material of a lithium ion battery. The nanowire material has the advantages of simple process, low cost and the like, and the battery formed by the electrode material has the characteristics of good cycling stability, excellent electrochemical performance under high current, and the like.

Owner:安徽国芯新材料有限公司

Lithium nitride/ceramic base composite material with high activity lithiation/delithiation performance

The invention belongs to the field of lithium ion batteries and super-capacitors, and in particular relates to a lithium nitride / ceramic-based composite anode material and a preparation method thereof, wherein the lithium nitride / ceramic-based composite anode material is prepared by a mechanochemical method and has high specific capacity, electrochemical lithium intercalation-detercalation reversibility and steady cycle performance. The composite material is a composite material which takes lithium nitride as an activity reinforced body and ceramic powder containing silicon element as a matrix; in the composite material, the chemical bonding is taken as a main interfacial bonding mode between the reinforced body and the matrix, the reinforced body and the matrix have good structural stability, and the mol ratio of the reinforcement body to the matrix is 1: 1-9: 1. The material has better electrochemical cycle performance and rate performance; and the material has a wider voltage window, has good ionic conductivity and cyclicity, and has potential application value in novel super-capacitor electrode materials. The preparation method is simple and easy to control, and the needed raw materials do not contain heavy metal elements and have the advantages of environmental protection and low cost.

Owner:DALIAN MARITIME UNIVERSITY

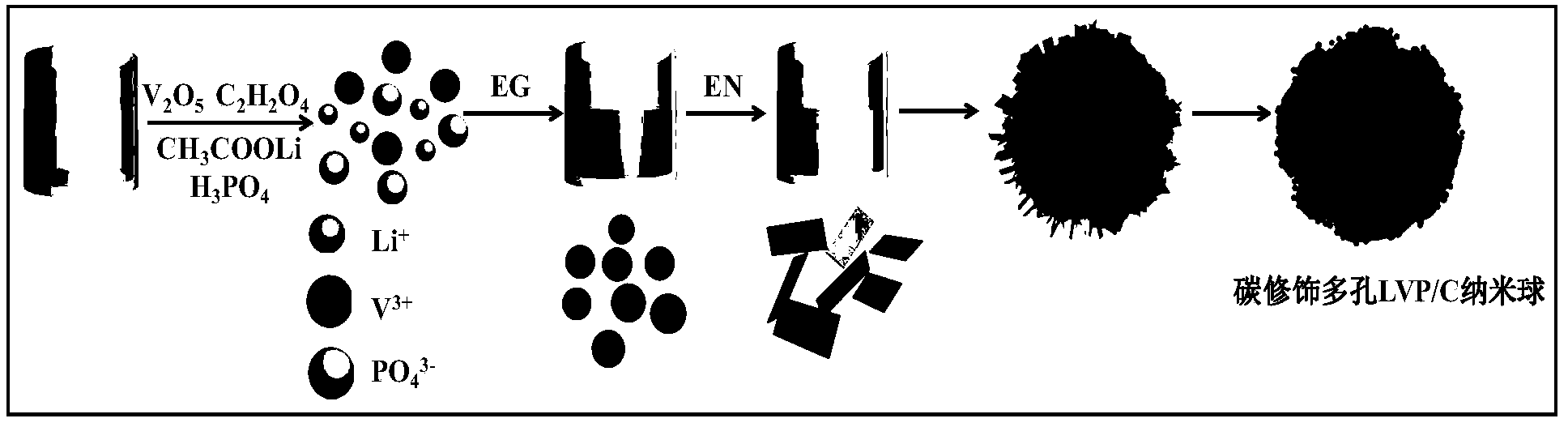

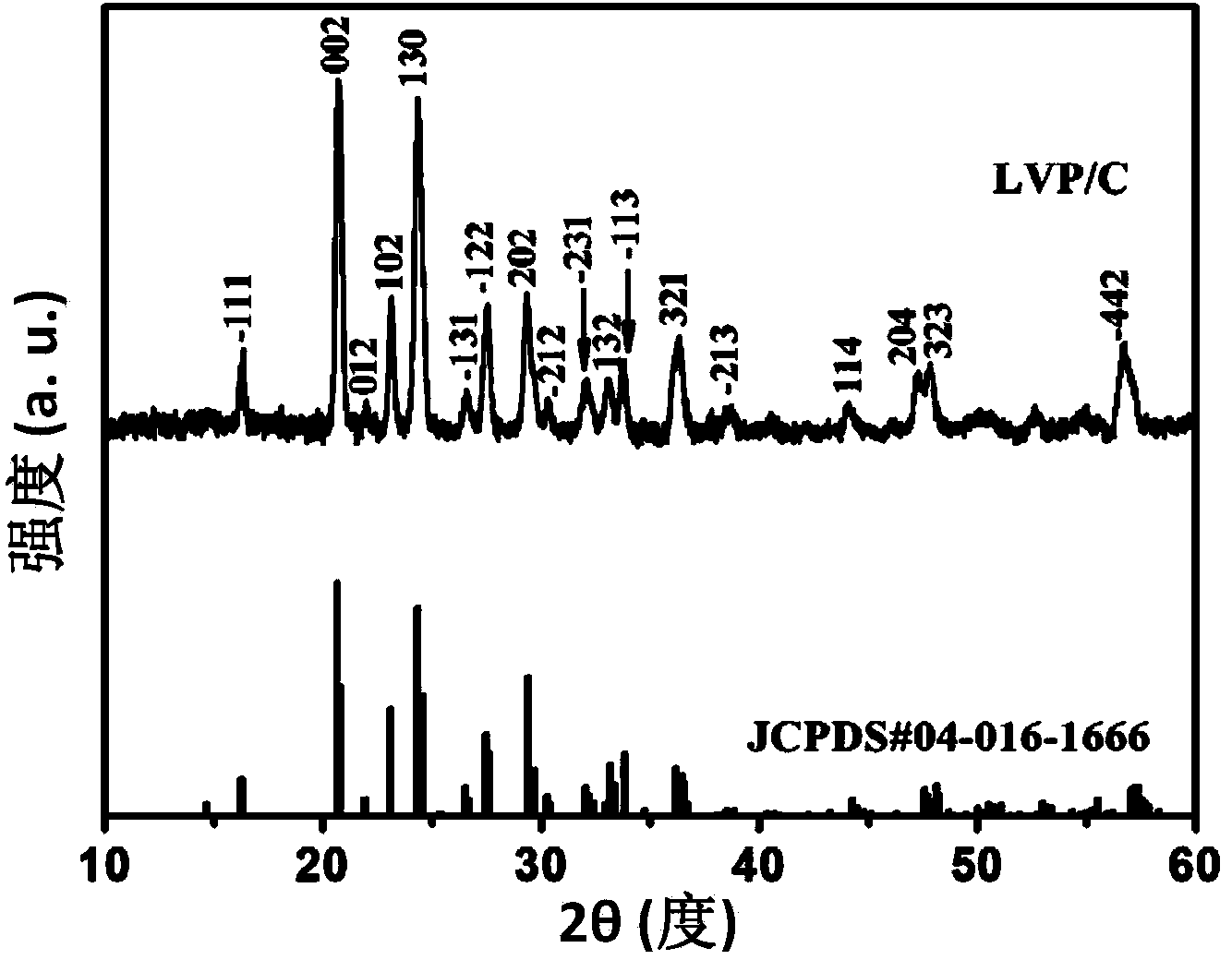

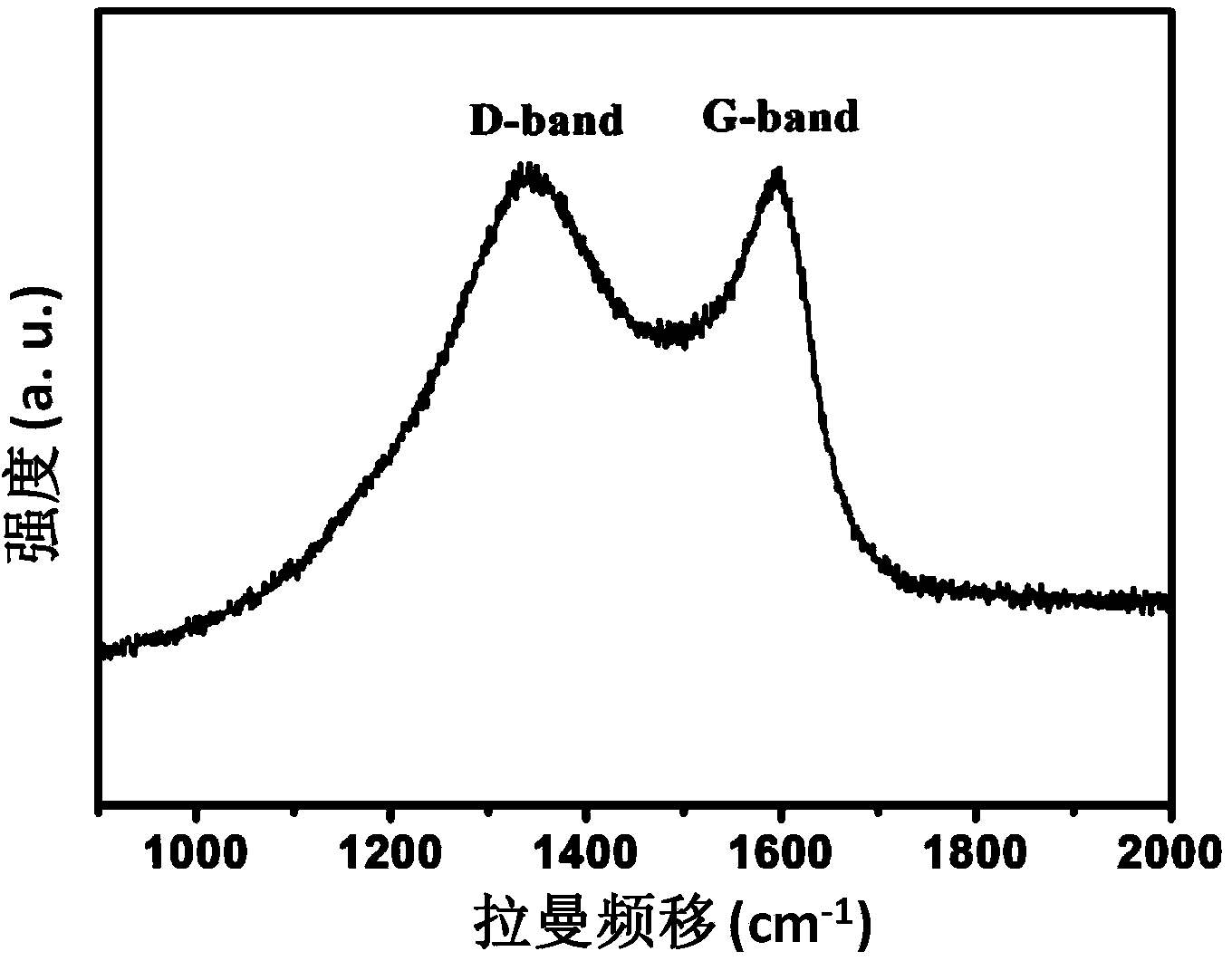

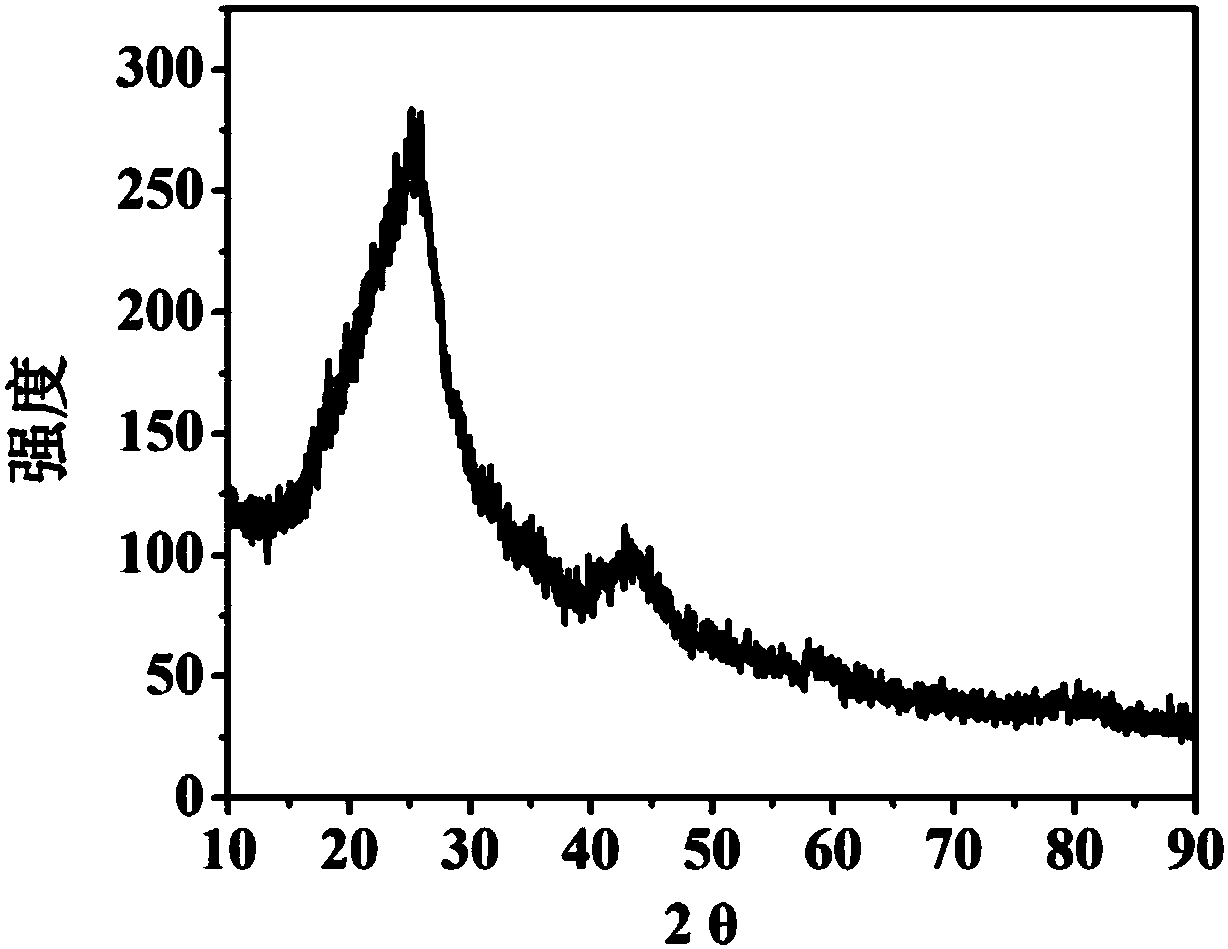

Carbon-decorated porous lithium vanadium phosphate nanosphere material as well as preparation method and application thereof

ActiveCN104134799AIncrease powerGood cycle stabilityMaterial nanotechnologyCell electrodesLithium electrodeOxalate

The invention discloses a carbon-decorated porous lithium vanadium phosphate nanosphere material as well as a preparation method and application thereof. Lithium vanadium phosphate particles coated with a carbon layer are connected with one another to form the carbon-decorated porous lithium vanadium phosphate nanosphere material which is characterized in that lithium vanadium phosphate particles are connected with one another by a three-dimensional carbon net, and the three-dimensional carbon net covers lithium vanadium phosphate. The preparation method comprises the following steps: adding a vanadium source, namely vanadium pentoxide, and oxalic acid into distilled water, and agitating until vanadium pentoxide and oxalic acid are dissolved; sequentially adding a phosphorus source, a lithium source, glycol and ethylenediamine; carrying out hydrothermal reaction on the materials to obtain a precursor solution; drying the precursor solution to obtain a red brown solid; and grinding, pre-sintering, grinding and calcining the solid to finally obtain the black three-dimensional carbon-decorated porous lithium vanadium phosphate nanosphere material. When being used as a positive active material of a lithium ion battery, the carbon-decorated porous lithium vanadium phosphate nanosphere material has the characteristics of high power and high cycling stability; the preparation process is simple, and the nanosphere material can be obtained by combining a hydrothermal method with a solid-state sintering method; the nanosphere material is high in feasibility and easy to amplify, meets the requirements of green chemistry, and is suitable for market popularization.

Owner:皮玉强

Nitrogen-doped hollow carbon sphere composite and preparation method and application thereof

InactiveCN108417803AAlleviate volume expansionGood cycle stabilityNegative electrodesSecondary cellsChemistryCarbon coated

The invention belongs to the field of lithium-ion battery materials and discloses a nitrogen-doped hollow carbon sphere composite and a preparation method and application thereof. Manganese acetate and ammonium bicarbonate are dissolved in ethylene glycol, solvothermal reaction is carried out at 180-220 DEG C to obtain manganese carbonate; the manganese carbonate is subjected to reaction with dopamine hydrochloride to obtain manganese carbonate / polydopamine composite; the manganese carbonate / polydopamine composite is calcined in an inert atmosphere to obtain nitrogen-doped carbon-coated manganese oxide composite; the nitrogen-doped carbon-coated manganese oxide composite is treated with an acid solution; washing and drying are performed to obtain the nitrogen-doped hollow carbon sphere composite. The preparation method herein is simple, low in cost and environmentally friendly. The prepared nitrogen-doped hollow carbon sphere composite has stable structure and good conductivity and hasexcellent cycle stability when acting as a lithium-ion battery anode material.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application for nanosheet formed by carbon-coated titanium dioxide nanotube

ActiveCN105355864AGood cycle stabilityEasy to operateCell electrodesSecondary cellsPotassium permanganateCarbon coated

The invention relates to a preparation method and an application for a nanosheet formed by a carbon-coated titanium dioxide nanotube, and belongs to the technical field of lithium ion battery electrode material preparation. The preparation method comprises the steps of preparing the nanosheet formed by the titanium dioxide nanotube firstly; then performing a hydrothermal reaction between the nanosheet formed by the titanium dioxide nanotube and a glucose solution, and performing carbonization to obtain the nanosheet formed by the carbon-coated titanium dioxide nanotube; makingthe nanosheet formed by the carbon-coated titanium dioxide nanotube react with a potassium permanganate solution to obtain the manganese dioxidecoated nanosheet formed by the carbon-coated titanium dioxide nanotube; performing a hydrothermal reaction between the manganese dioxidecoated nanosheet formed by the carbon-coated titanium dioxide nanotube and a ferric salt-containing solution, and then performing annealing to obtain the nanosheet formed by the carbon-coated titanium dioxide nanotube loaded with iron trioxide. The nanosheet prepared by the invention is used as the lithium battery positive electrode material for assembling batteries and the prepared lithium ion battery is relatively high in the specific discharge capacity.

Owner:KUNMING UNIV OF SCI & TECH

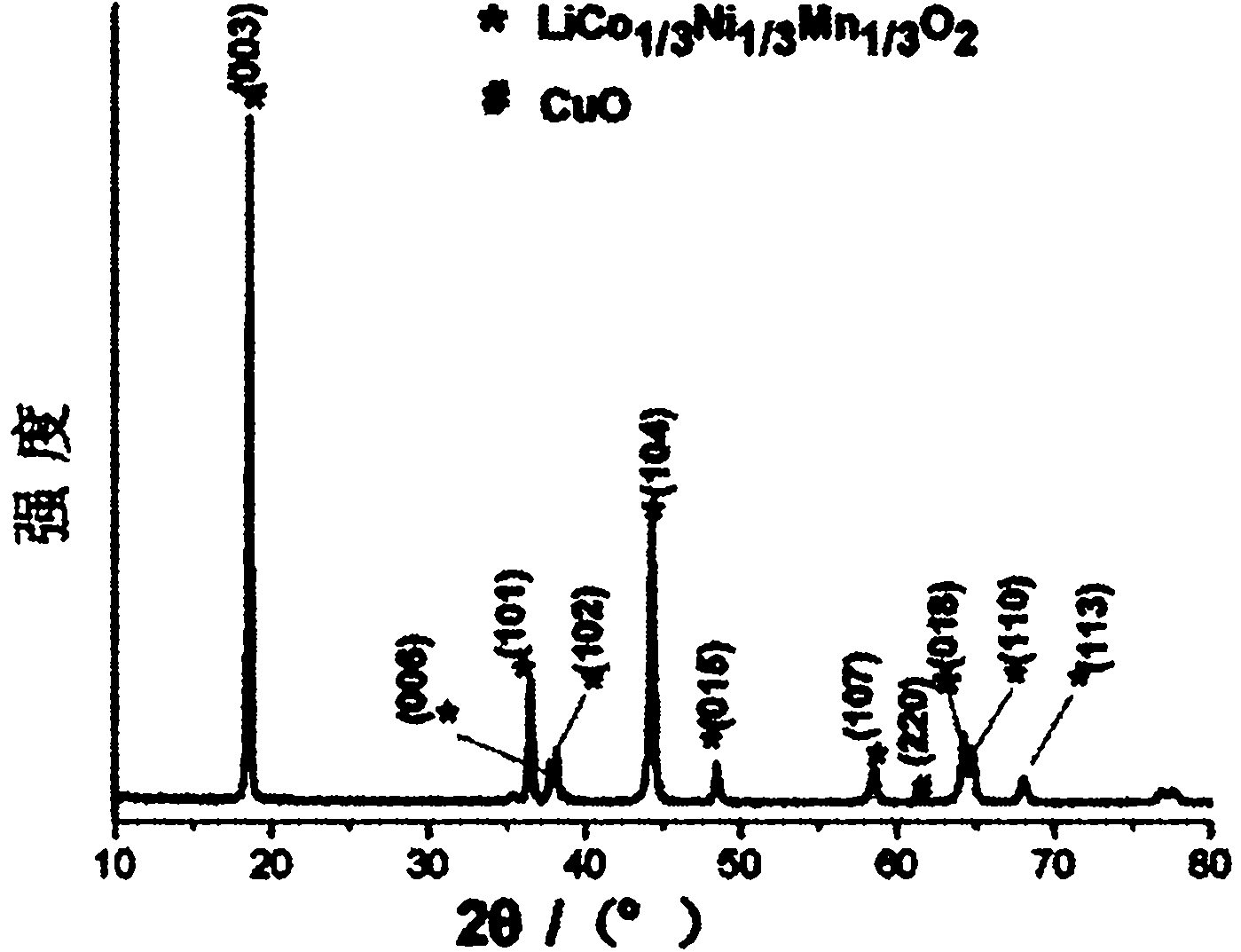

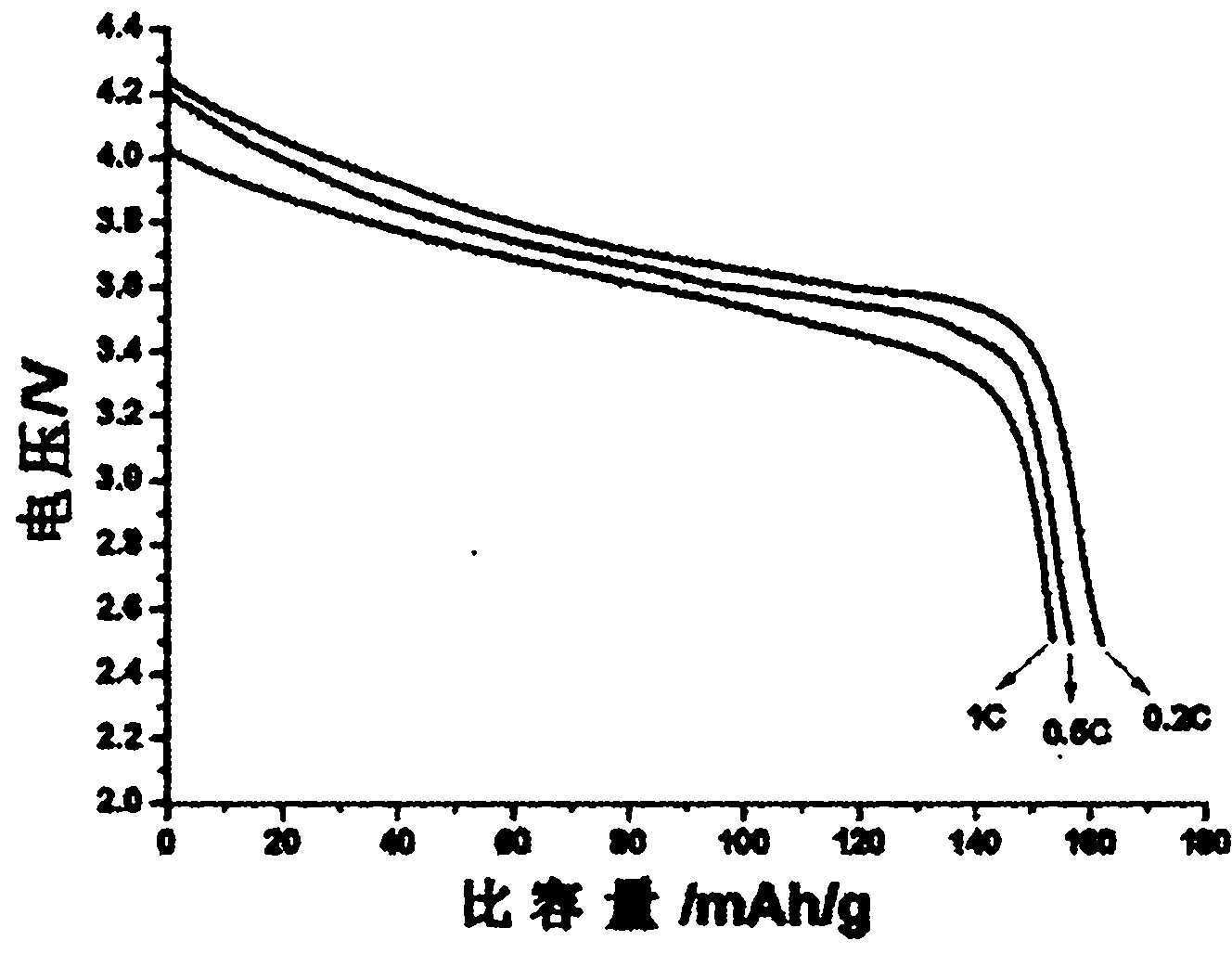

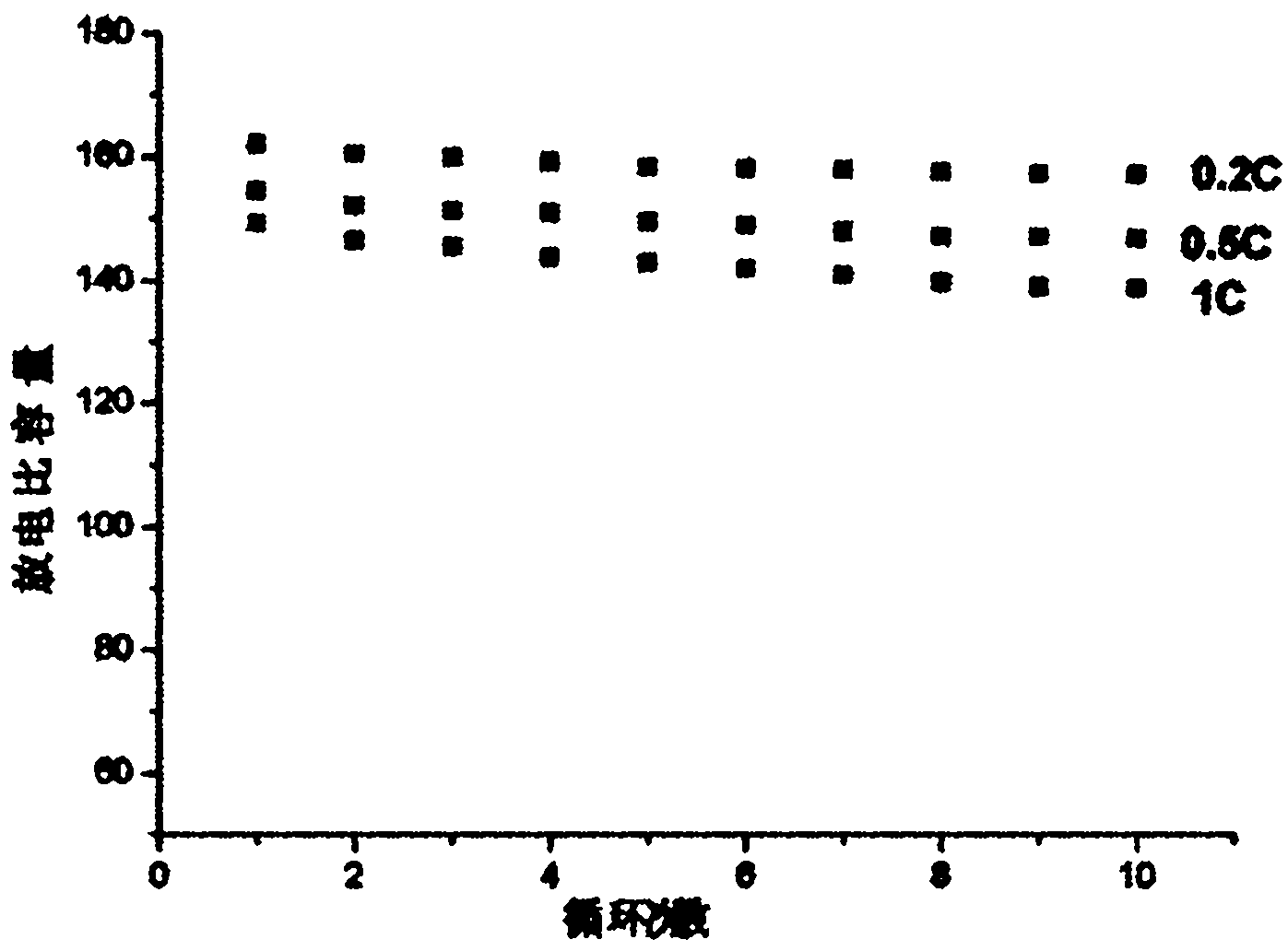

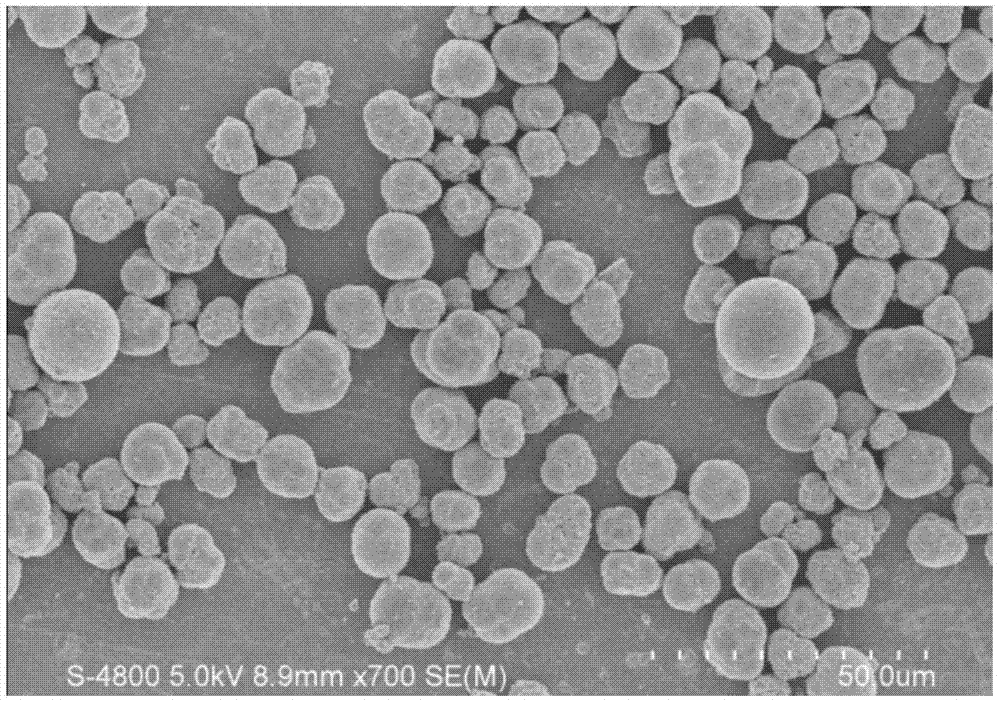

Cobalt nickel manganese lithium oxide-cooper oxide compound positive material for lithium ion battery and preparation method thereof

InactiveCN102163709AGood cycle stabilityExcellent high magnification performanceCell electrodesNickelLithium electrode

The invention discloses a cobalt nickel manganese lithium oxide-cooper oxide compound positive material for a lithium ion battery and a preparation method thereof. The compound positive material is obtained by coating cooper oxide on the surface of cobalt nickel manganese lithium oxide; and the chemical general formula of the compound positive material is LiCoxNiMn(1-x-y)O2 / CuO, wherein x is large than or equal to 0.2 and less than or equal to 0.4, and y is more than or equal to 0.3 and less than or equal to 0.7. The preparation method comprises the following steps: preparing cobalt nickel manganese lithium oxide ternary compound oxide lithium salt by a high temperature solid method; and then coating the copper oxide on the surface of the cobalt nickel manganese lithium oxide through high-temperature sintering so as to obtain the cobalt nickel manganese lithium oxide-cooper oxide compound positive material for the lithium ion battery. The material provided by the invention has the advantages of high specific capacity, good circulation characteristic, short production period and the like, is suitable for industrial production, and can be applied to the fields of electromobiles, energy storing equipment, electric power tools and the like.

Owner:HEFEI UNIV OF TECH

Lithium and manganese-rich cathode material of lithium ion battery and preparation method of cathode material

ActiveCN104241634AImprove Coulombic efficiencyGood cycle stabilityCell electrodesSecondary cellsLithium compoundSolvent

The invention relates to a lithium and manganese-rich cathode material of a lithium ion battery and a preparation method of the cathode material. The lithium and manganese-rich cathode material is a Li2TiO3-coated xLi2MnO3.(1-x)LiNi[0.5-a / 2]Mn[0.5-a / 2]AlaO2 (wherein x is not less than 0.1 and not more than 0.9 and a is not less than 0.002 and not more than 0.1) material. The preparation method comprises the following steps: preparing a nickel manganese aluminum compound carbonate precursor by a coprecipitation method, sintering at the high temperature to obtain spherical or quasi-spherical nickel manganese aluminum compound oxide, adding into a solvent, uniformly dispersing, adding tetrabutyl titanate, hydrolyzing to obtain a nickel manganese aluminum titanium compound, mixing with a lithium compound, and calcining to obtain the lithium and manganese-rich cathode material. The lithium and manganese-rich cathode material prepared by the method is high in first coulombic efficiency, good in circulation stability and high in rate performance.

Owner:CHERY AUTOMOBILE CO LTD

Preparation method of growing needle-shaped network-structure nickel cobalt flexible electrode by taking carbon fiber as support body

InactiveCN109449011AGood electrochemical performance and lifetimeGood cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureElectrospinningUrea

A preparation method of growing a needle-shaped network-structure nickel cobalt flexible electrode by taking carbon fiber as a support body comprises the steps of preparing a carbon fiber precursor from a PAN solution by an electrospinning method, performing pre-oxidization processing, and performing low-temperature carbonization to obtain a flexible carbon fiber; immersing the flexile carbon fiber in a mixed solution of a nickel salt and a cobalt salt, performing hydrothermal reaction by taking urea as a precipitant, and performing calcination. The preparation method is simple to operate andis low in cost, the prepared carbon fiber substrate is good in flexibility, the space among the fibers is larger, residual surface treatment is not needed due to an oxygen-containing functional group,the needle-shaped nickel cobalt is grown to form a unique network structure and is uniformly distributed in a flexible carbon fiber framework structure, the flexible electrode material is combined with favorable cycle stability of the carbon material and high energy density and specific capacity of the nickel cobalt, the electrochemical performance of the electrode is integrally improved, and theservice lifetime also can be remarkably prolonged.

Owner:SHAANXI UNIV OF SCI & TECH

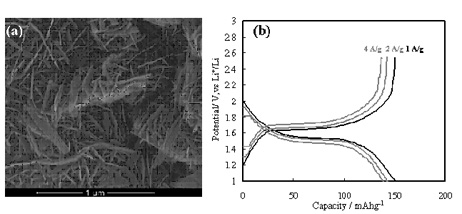

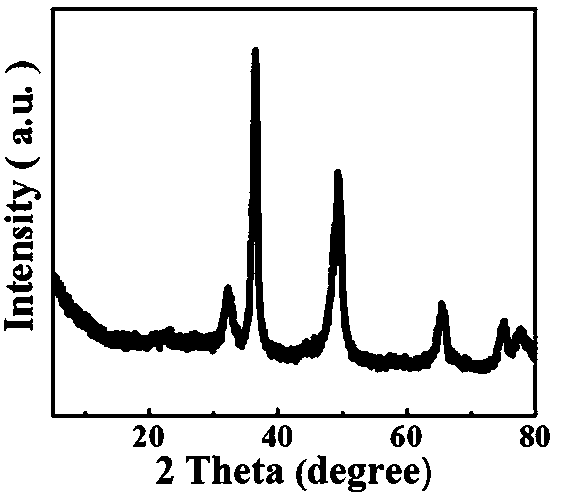

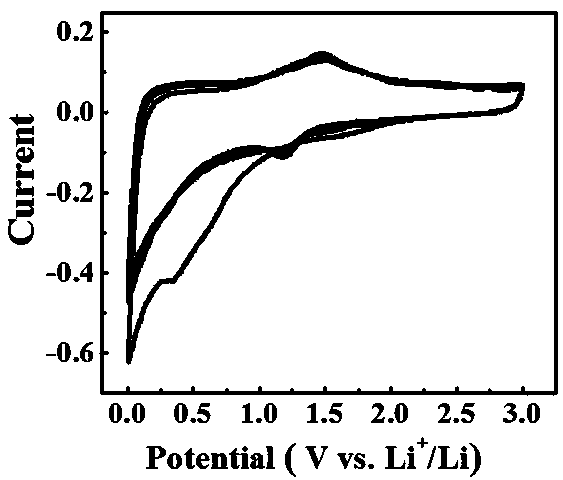

Method for preparing spinel lithium titanate nano piece and application of spinel lithium titanate nano piece in lithium battery

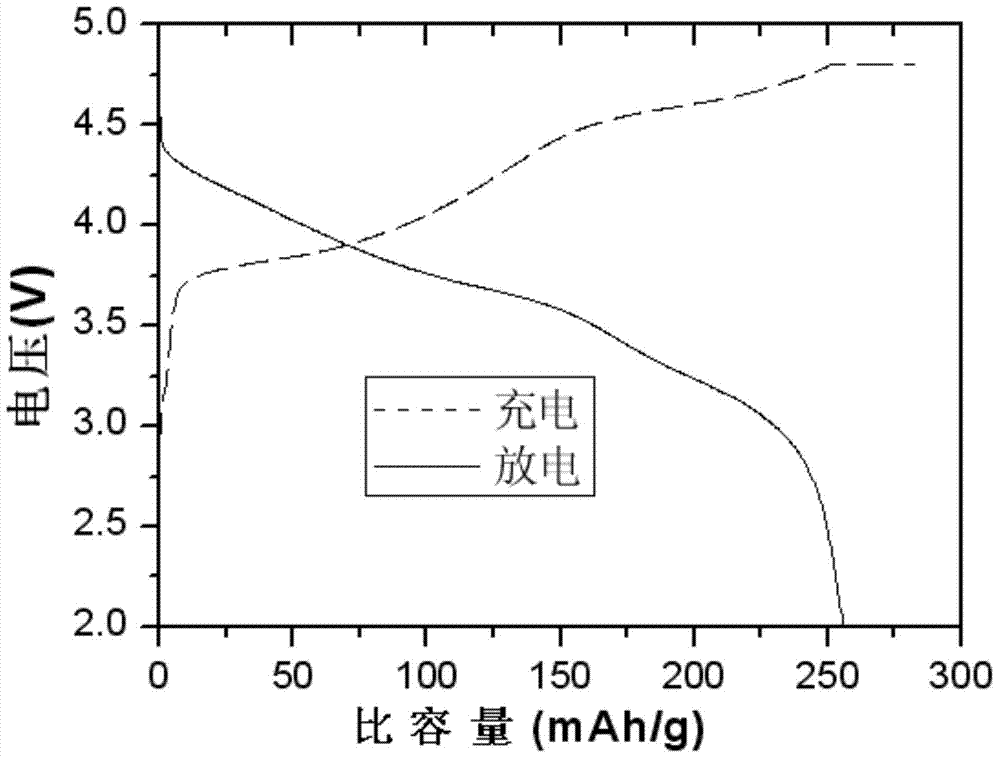

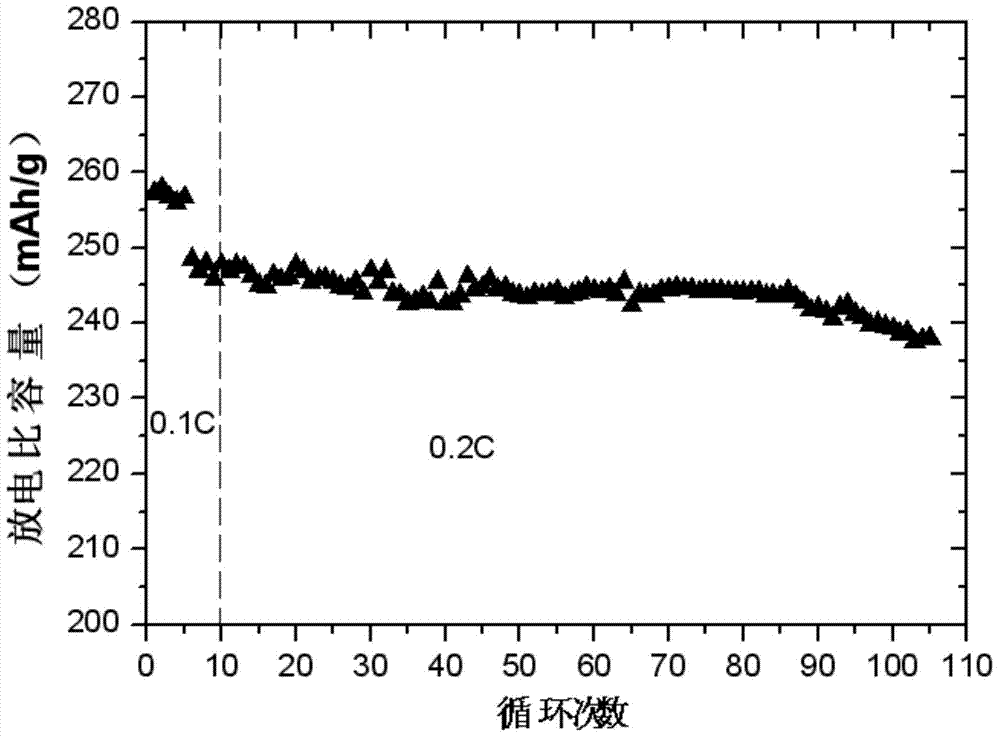

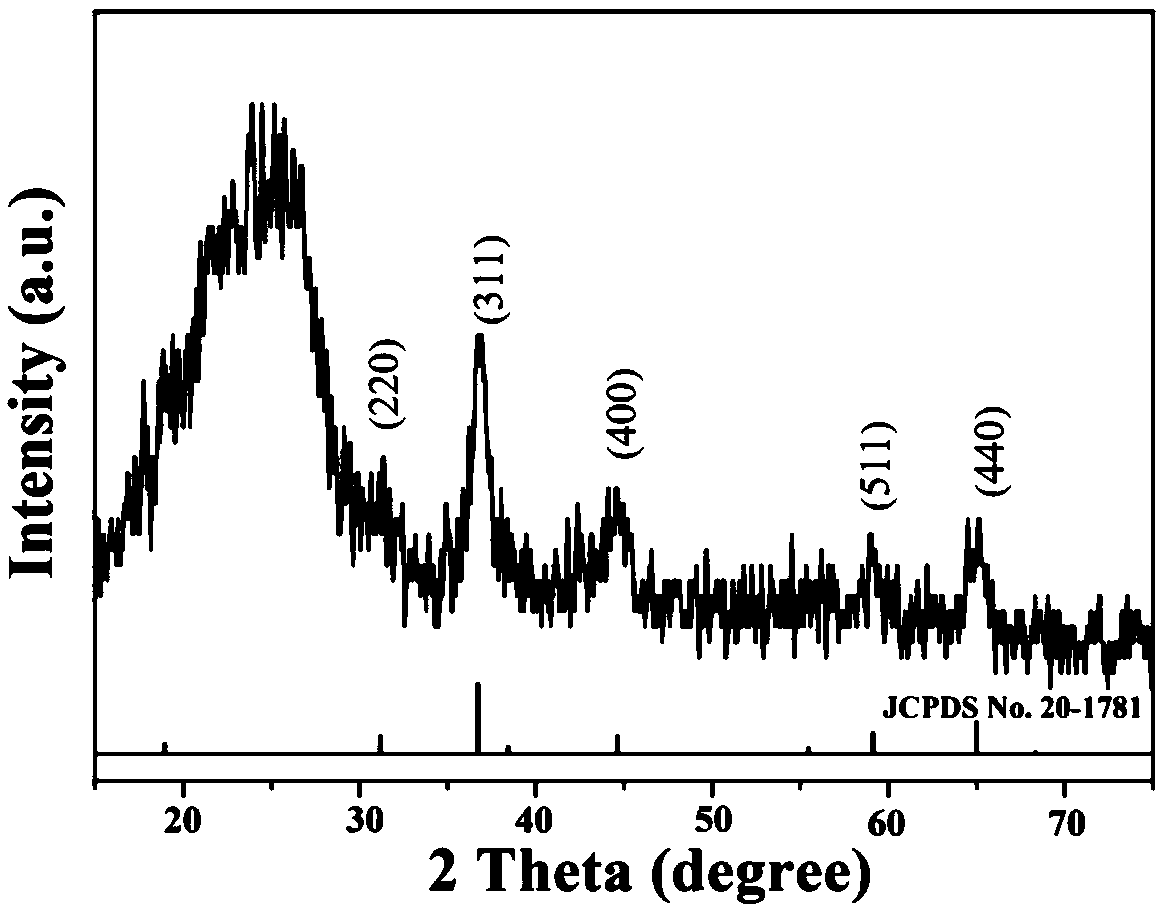

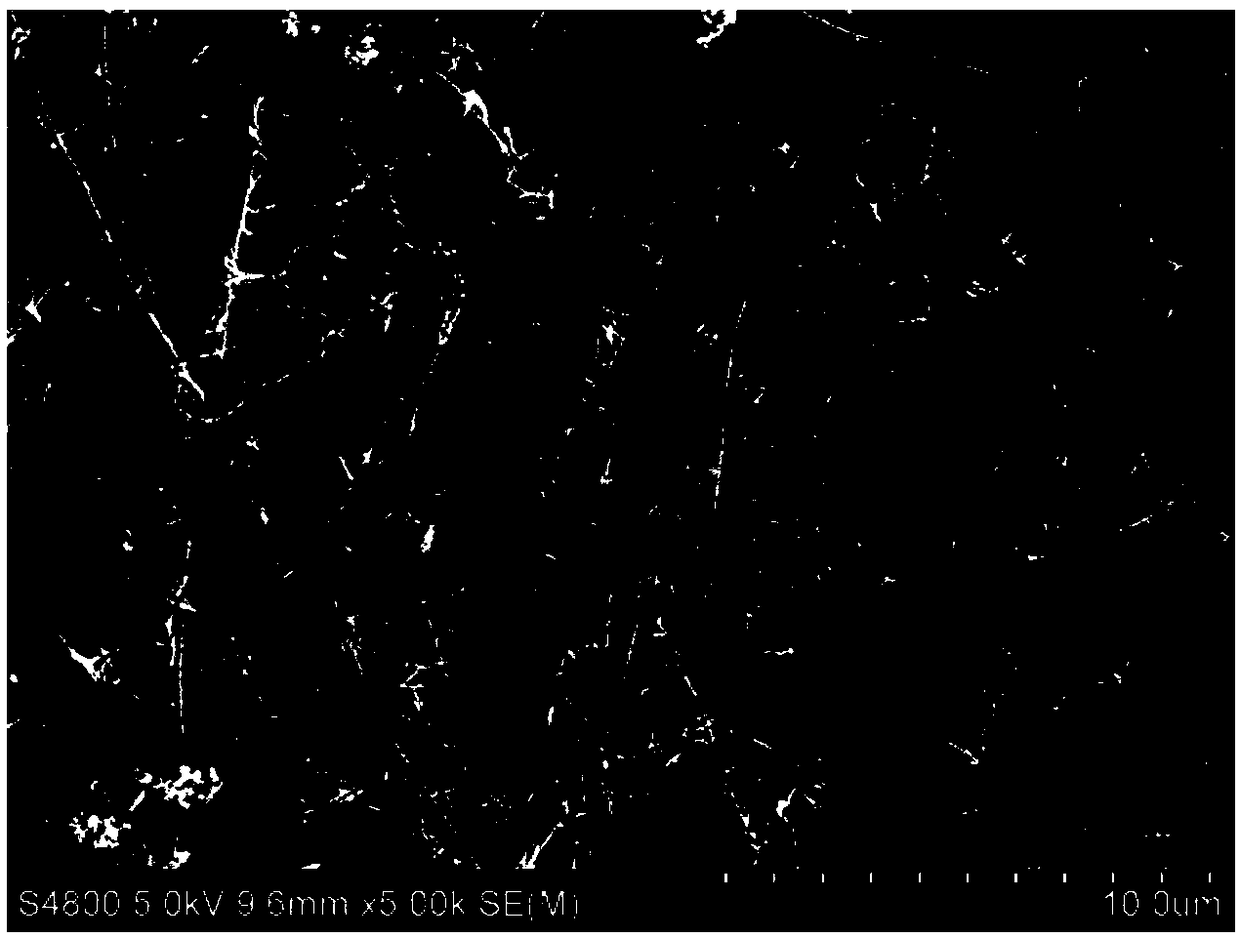

InactiveCN102064315ASuperior fast charge and discharge performanceGood cycle stabilityCell electrodesNanotechnologyCharge and dischargeCyclic stability

The invention relates to a method for preparing a spinel lithium titanate nano piece and application of the spinel lithium titanate nano piece in a lithium battery. In the method, a high-purity (more than 95 percent) spinel Li4Ti5O12 nano piece is synthesized for the first time, the length is about dozens of to hundreds of nano, and the width is about dozens of nano. When the high-purity spinel Li4Ti5O12 nano piece is use as the anode material of the lithium battery, results indicate that the high-purity spinel Li4Ti5O12 nano piece has favorable rapid charge and discharge performance and high circulating stability.

Owner:FUZHOU UNIVERSITY

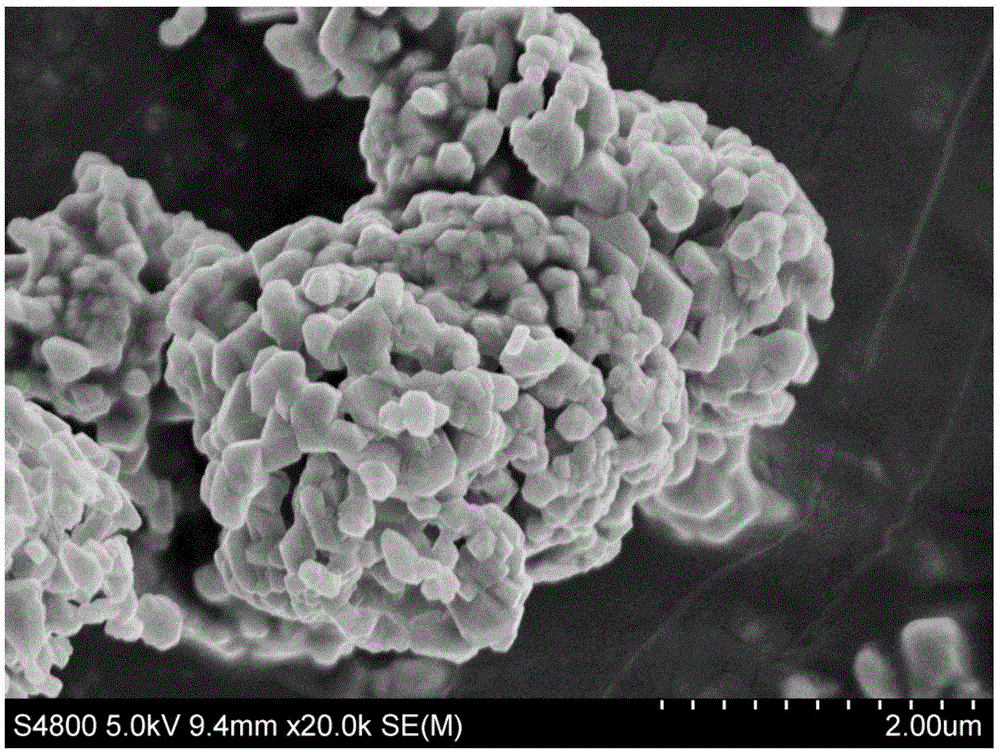

Carbon-supported porous spherical MoN formed by nanosheets, and application of porous spherical MoN as negative material in lithium batteries

ActiveCN108777294AGood cycle stabilityExcellent high magnification performanceCell electrodesSecondary cellsTube furnaceLithium electrode

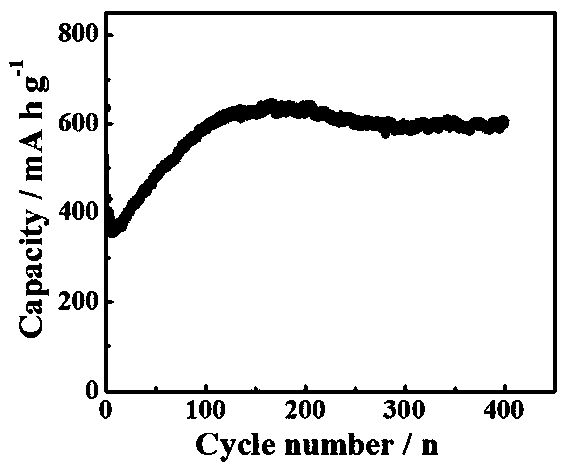

The invention relates to a carbon-supported porous spherical MoN lithium battery negative material formed by nanosheets. A preparation method of the material comprises the following steps: adding 0.1gof MoO2(acac)2, 0.2g of CH4N2S and 0.1g of glucose into 20ml of H2O and stirring for 1h, then placing in an oven at 200 DEG C for 12h, then taking out, centrifuging the product when the product is cooled to the room temperature, washing with ethanol and deionized water for a plurality of times, and placing in the oven at 70 DEG C to obtain a precursor of MoN; then, placing the obtained precursorin a tube furnace, and calcining for 4h at 800 DEG C in an ammonia atmosphere to obtain the carbon-supported porous spherical MoN material formed by the nanosheets. The prepared spherical MoN nanosheets having sizes of 500nm have good cycle stability and high rate performance as negative electrodes of lithium ion batteries, and has a specific capacity of 600mAh / g after 400 cycles of charge and discharge when the current density is 1A.

Owner:FUZHOU UNIVERSITY

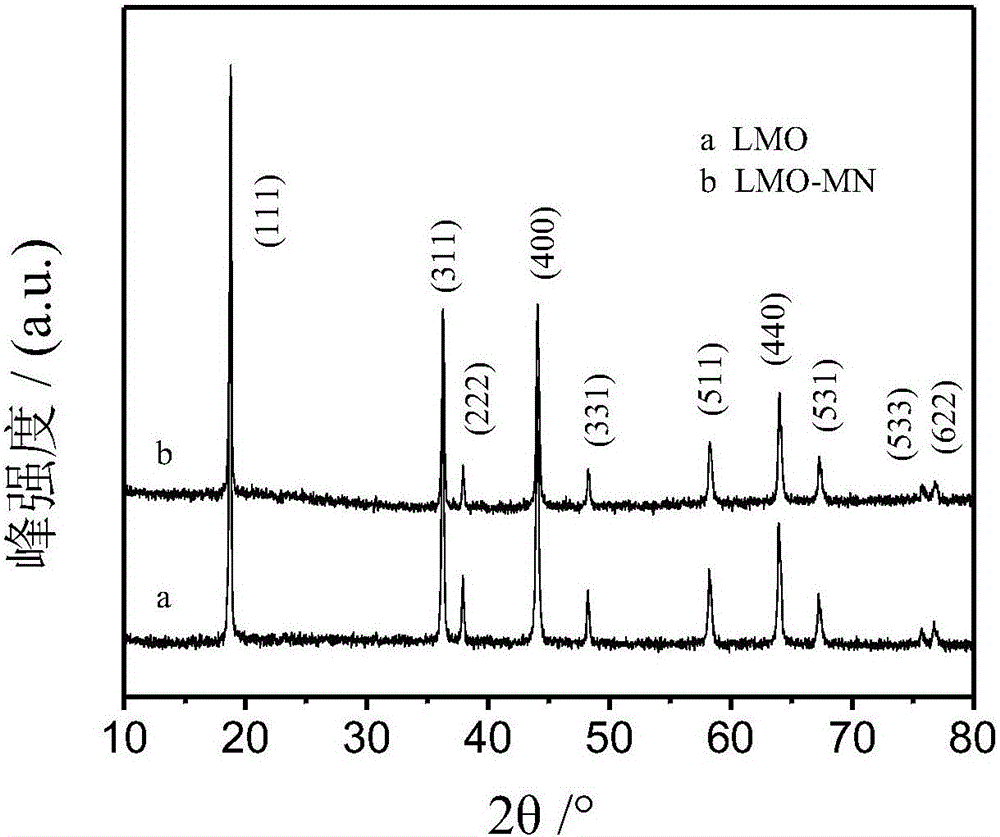

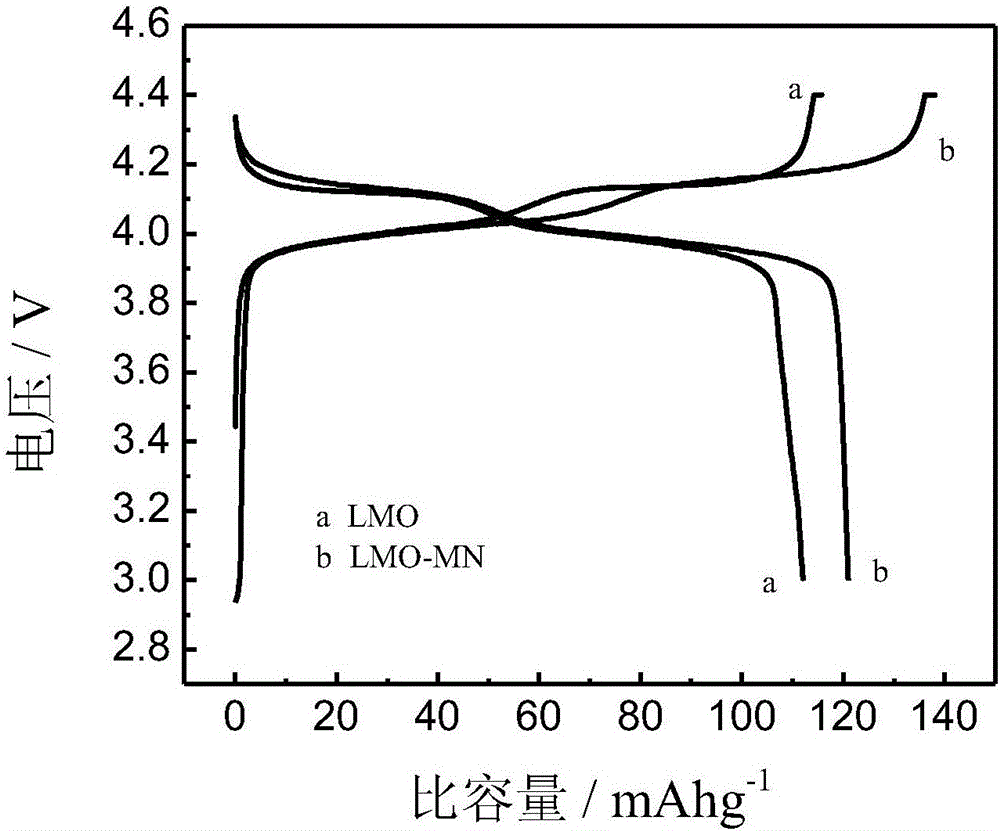

Preparation method capable of increasing electrochemical performance of magnesium-sodium-doped lithium permanganate anode material

InactiveCN106450285AGood cycle stabilityImprove electrochemical performanceCell electrodesSecondary cellsElectrochemistryPrecipitation

The invention discloses a preparation method capable of increasing the electrochemical performance of a magnesium-sodium-doped lithium permanganate anode material. The preparation method includes the steps of firstly, dissolving manganese sulfate monohydrate into deionized water, and dropwise adding anhydrous ethanol; secondly, dissolving ammonium bicarbonate into deionized water; thirdly, mixing the obtained solutions, stirring, aging, performing precipitation and suction filtration, washing, and drying to obtain manganese carbonate; fourthly, pre-sintering the manganese carbonate, washing with hydrochloric acid, performing suction filtration, washing, and drying to obtain manganese dioxide; fifthly, grinding a lithium source, the manganese dioxide, a magnesium ion doping source and a sodium ion doping source, sintering, and cooling to obtain the magnesium-sodium-doped lithium permanganate anode material Li1-xNaxMgyMn2-yO4, wherein x=0.01-0.2, and y=0.01-0.2. The preparation method has the advantages that the method is simple in process, environmentally friendly, low in cost and capable of preparing the well-crystallized magnesium-sodium-doped lithium permanganate anode material even in distribution, and the electrochemical performance of the material is increased evidently.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

A silicon-based negative electrode material with heterostructure, a preparation method thereof and a lithium ion battery are disclosed

ActiveCN109273689AGood cycle stabilityExcellent rate performanceCell electrodesGrapheneCarbon sourceOrganosilicon

The invention provides a heterostructure silicon-based negative electrode material, a preparation method thereof and a lithium ion battery. The negative electrode material comprises carbon nanotubes,silicon distributed on the surface of the carbon nanotubes, and graphene coated on the silicon. 1) mixing that carbon nanotube and the acid, condensing and reflux, and then solid-liquid separation toobtain the carbon oxide nanotube; 2) after that carbon oxide nanotube is dispersed in wat, mixing with an organosilicon source, heating and reacting, and then solid-liquid separation; 3) mixing the product and the magnesium powder, crushing the mixture in an inert atmosphere, heating the mixture in an inert atmosphere, and heat treating the mixture; 4) under vacuum or inert atmosphere, taking carbon source as raw material to produce graphene by chemical vapor deposition on that product of the step 5) pickling to obtain the negative electrode material. The negative electrode material provided by the invention has good cycle stability and rate performance.

Owner:EVE ENERGY CO LTD

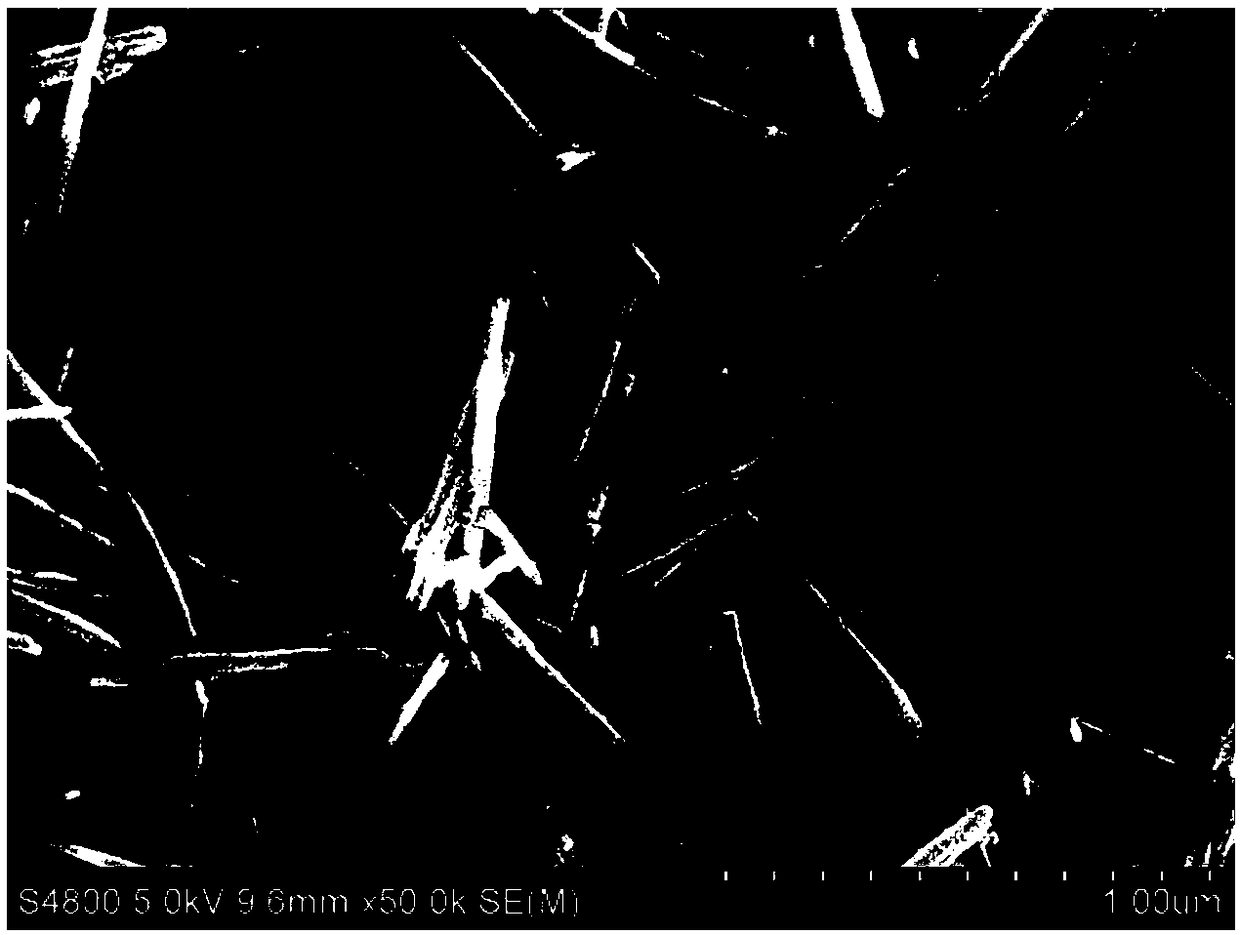

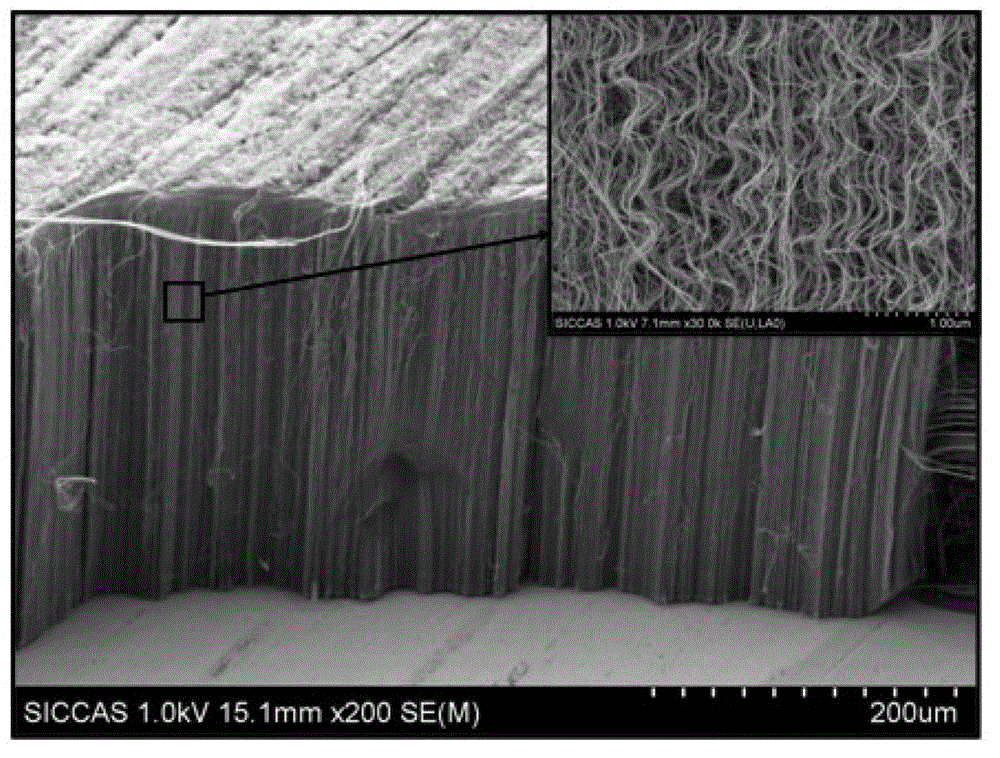

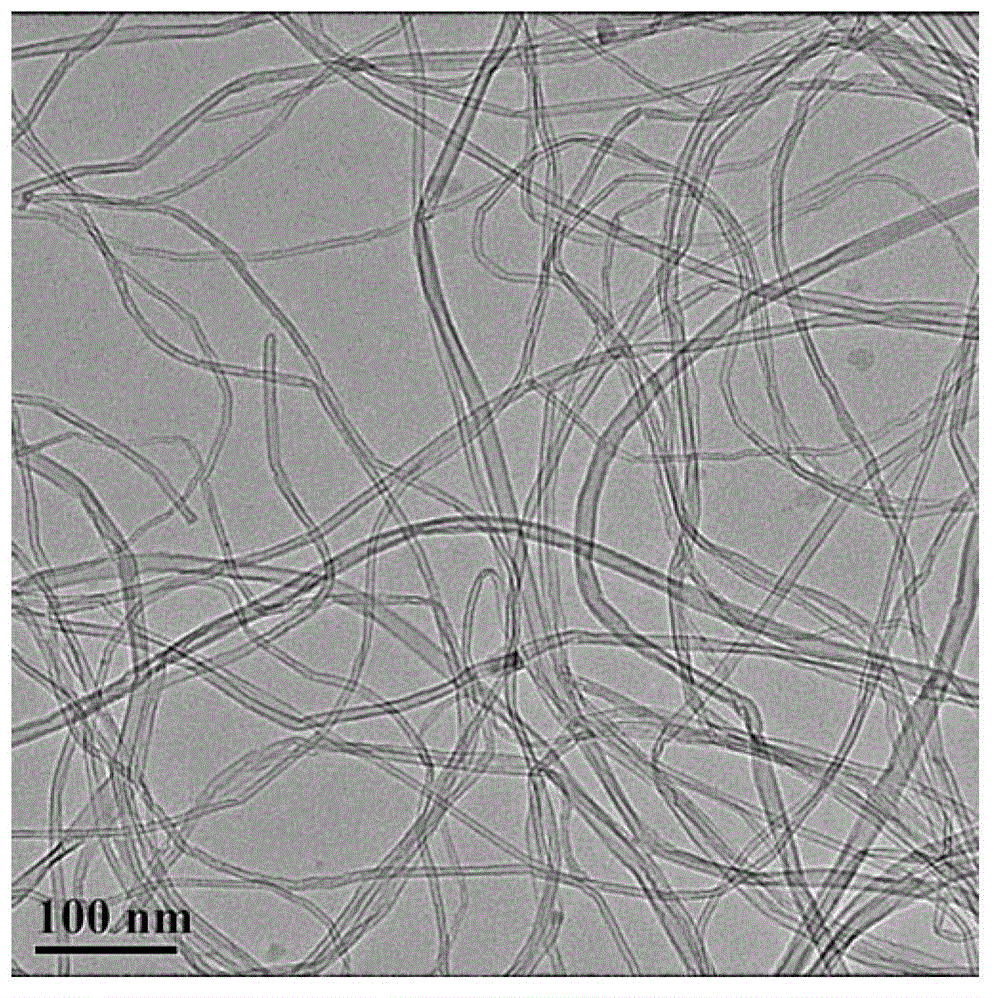

Method for in-situ growth of carbon nanotube array on metal current collector

The invention discloses a method for in-situ growth of a carbon nanotube array on a metal current collector. The method includes the steps: preparing a substrate with a catalyst layer, a buffer layer and a metal foil layer; and growing the carbon nanotube array on the substrate by a hot CVD (chemical vapor deposition) method. The height of the carbon nanotube array grown by the method can reach 80-300 micrometers, the diameter of the carbon nanotube array reaches 6-20 nanometers, the carbon nanotube array has fewer walls, and each carbon nanotube is directly and firmly combined with the current collector. From experiments, negative electrode materials of the prepared carbon nanotube array have high specific capacity and fine cyclic stability under low-speed and high-speed charge-discharge conditions. The method has the advantages of simple process, low equipment requirement and the like, and the prepared carbon nanotube array has a huge potential of serving as a support for loading other active materials for preparing high-performance composite electrode materials, and has a quite wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Vanadium-lithium phosphate composite material for positive electrode of lithium ion battery and preparation method thereof

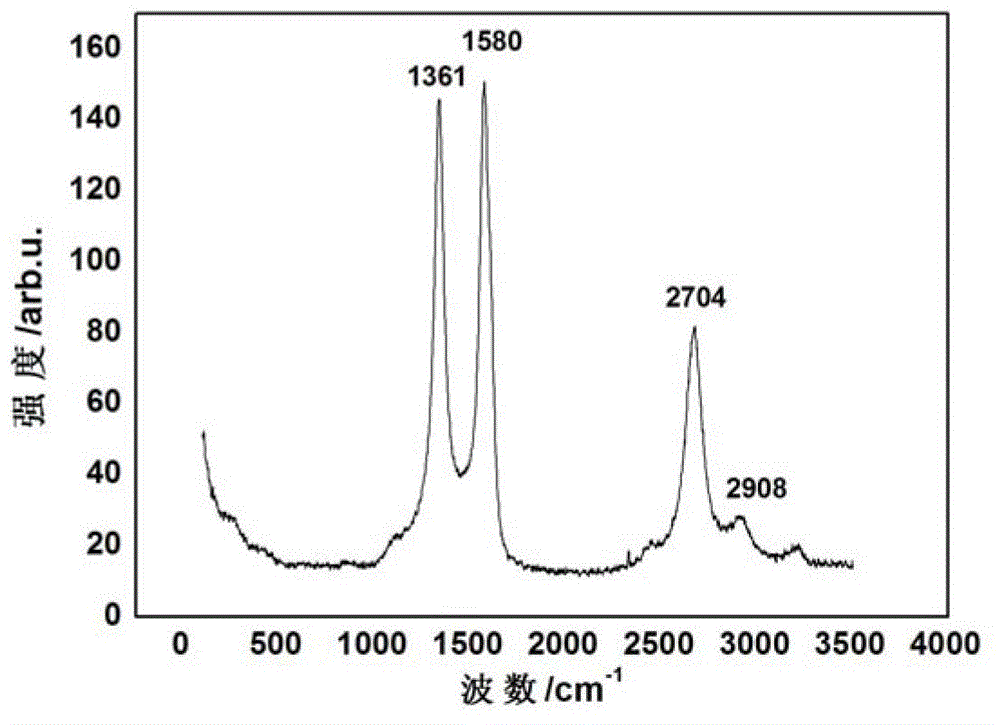

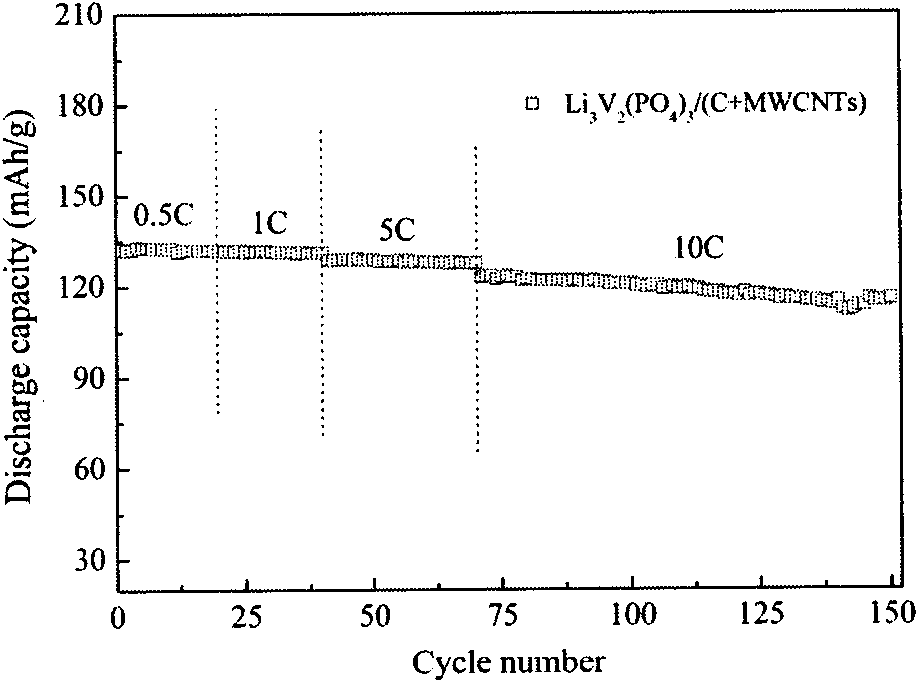

InactiveCN101937986AHigh charge and discharge capacityGood cycle stabilityCell electrodesCarbon nanotubeLithium electrode

The invention discloses a vanadium-lithium phosphate composite material for a positive electrode of a lithium ion battery. The material is powder which is formed by coating surface of Li3V2(PO4)3 with multi-wall carbon nanotube-modified amorphous carbon in situ; and the material comprises 95 to 98 mass percent of Li3V2(PO4)3 and 2 to 5 mass percent of carbon. A preparation method of the material comprises the following steps of: mixing Li2CO3, NH4H2PO4 and NH4VO3 serving as raw materials according to a stoichiometric ratio of the Li3V2(PO4)3; adding the multi-wall carbon nanotubes and polyvinyl alcohol into the mixture; adding anhydrous alcohol into the mixture and mixing the mixture by ball milling on a ball mill; and calcining the mixture in an argon atmosphere to obtain the material. The vanadium-lithium phosphate composite material of the invention is used for the positive electrode of the lithium ion battery, has the advantages of high charging and discharging capacity, high cyclical stability, superior high-rate performance and high material conductivity and is suitable for providing a power energy source for portable electric tools, electric motorcycles, electric automobiles and the like.

Owner:ZHEJIANG GODSEND POWER TECH +1

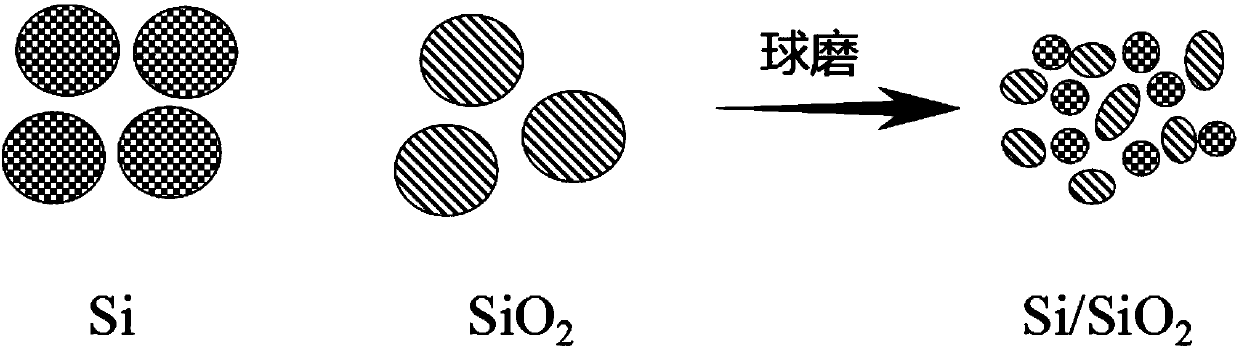

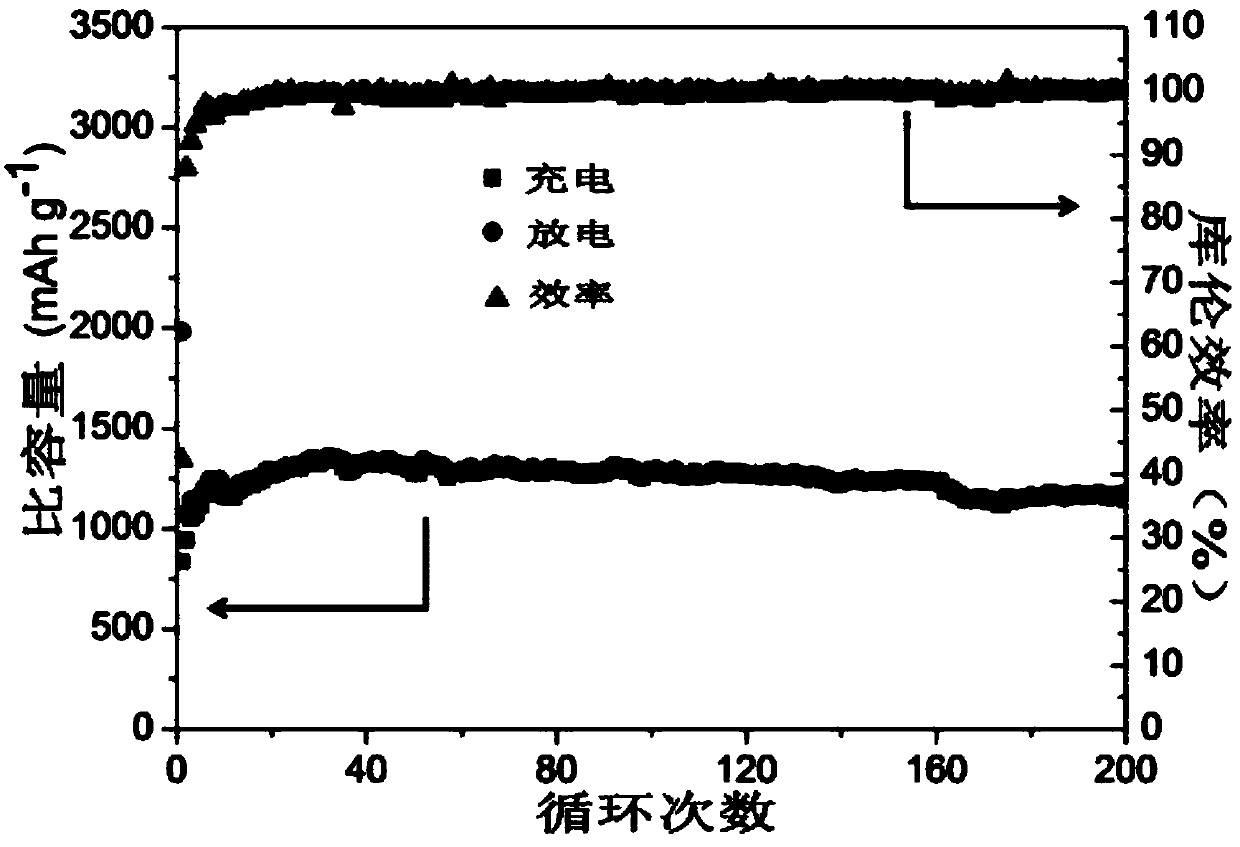

Silicon-based negative electrode material for lithium ion battery and preparation method of silicon-based negative electrode material

InactiveCN109524626AGood cycle stabilityHigh specific capacityMaterial nanotechnologyCell electrodesLithium electrodeVolume expansion

The invention relates to a silicon-based negative electrode material for a lithium ion battery and a preparation method of the silicon-based negative electrode material and belongs to the field of lithium ion battery negative electrode materials. The silicon-based negative electrode material is prepared by taking silicon and silica as raw materials by a ball-milling method, and is a composite material formed by mutually contacting the silicon and silica particles and uniformly distributing the particles in a three-dimensional space on a micro scale, wherein the particle size of the two kinds of particles is 50-300nm. In the ball milling process, the particle size is obviously reduced when the two raw materials are uniformly mixed, and compared with a bulk material, the material disclosed by the invention is capable of effectively releasing stress produced by lithium insertion. Meanwhile, the electrochemical activity of the silica in the grinding process is improved. The capacity of thenegative electrode material is maintained at 800-2000mAhg<-1> under the current density of 0.5Ag<-1> after 200 cycles. The composite material fully achieves the characteristics of high specific capacity of the silicon material and excellent cycling stability of the silica, the respective advantages of the two materials are complemented, and volume expansion of the silicon-based material in the charging and discharging process is buffered by an irreversible phase produced in the lithium insertion process by utilizing the silica material.

Owner:ZHEJIANG UNIV OF TECH

Preparing method and application of high-purity lithium manganate anode material

InactiveCN105514416AHigh specific capacityGood cycle stabilitySecondary cellsPositive electrodesIonElectrochemistry

The invention belongs to the field of lithium ion batteries, and particularly relates to a preparing method and application of a high-purity lithium manganate anode material. A lithium ion battery prepared from the high-purity lithium manganate anode material is also disclosed. Manganese dioxide is embedded into lithium ions by means of the electrochemical method, and then annealing is conducted to generate the high-purity lithium manganate material. The proportion of lithium to manganese can be accurately controlled by controlling discharge electric quantity, so that the high-purity lithium manganate material is obtained. The lithium manganate material prepared with the method has extremely high cycle performance as the anode of the lithium ion battery.

Owner:SHANDONG YUHUANG NEW ENERGY TECH

Method for preparing tin-carbon composite negative electrode material

InactiveCN104577079AHigh specific capacityGood cycle stabilityCell electrodesSecondary cellsMuffle furnaceCarbon source

The invention provides a method for preparing a tin-carbon composite negative electrode material. The tin-carbon composite negative electrode material is prepared by adopting a method for combining mechanochemistry and high-temperature hot carbon reduction. The method for preparing the negative electrode material comprises the following steps: 1, uniformly mixing graphite and a tin salt; 2, adding a solid alkaline substance into the mixture in the step 1 so as to carry out a mechanochemical reaction; 3, adding a certain amount of organic carbon source into the mixture in the step 2 for mixing; 4, sintering the mixture in the step 3 in a muffle furnace; and 5, washing, filtering and drying the tin-carbon mixture in the step 4, thereby obtaining the tin-carbon composite material. According to the negative electrode material prepared by the method disclosed by the invention, the capacity and cycle performance of the battery can be obviously improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

Method for preparing surface-coated anode material of lithium battery

The invention discloses a method for preparing a surface-coated anode material of a lithium battery. The method comprises the steps of: mixing an anode material, namely lithium iron phosphate, with lithium nickel cobaltate, magnesium nitrate and cobalt oxide, heating an obtained mixture to the temperature above a melting point of the magnesium nitrate for reaction, and then cooling; performing ball milling for crushing, and sieving; placing a lithium hydroxide saturated solution in a spraying system, controlling the spraying system to spay in a mixing drying kettle, continuously starting a mixer, placing aluminum sulfate which is in exact complete reaction with the lithium hydroxide into the spraying system, controlling the spraying system to spray into the mixing and drying kettle, continuously mixing after spraying to complete hydrolysis reaction uniformly; drying a mixture obtained after hydrolysis reaction; and carrying out thermal treatment, crushing and sieving to obtain the surface-coated anode material of the lithium battery. The surface-coated anode material prepared according to the invention is uniform in coating and thus has good cyclic stability and high-quality specific capacity, and is high in capacity, good in cyclic stability and long in service when applied to the lithium ion battery.

Owner:ZHEJIANG MEIDU HITRANS LITHIUM BATTERY TECHNOLOGY CO LTD

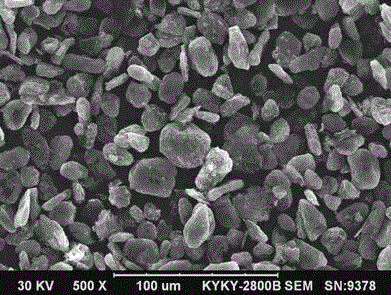

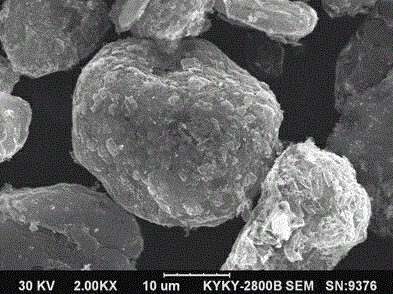

Carbon cloth-loaded carbon-coated nickel disulfide nanosheet composite material and preparation method and application thereof

InactiveCN111584840AGood cycle stabilityHigh magnificationMaterial nanotechnologySecondary cellsNickel sulphideComposite material

The invention relates to a carbon cloth-loaded carbon-coated nickel disulfide nanosheet composite material and a preparation method thereof. A carbon cloth-loaded nickel precursor nanosheet is prepared through a hydrothermal in-situ growth method, the precursor is coated with polyaniline, and vulcanizing is conducted in a nitrogen sealed atmosphere to obtain the carbon cloth-loaded carbon-coated nickel disulfide nanosheet composite material. The nickel disulfide nanosheet is formed by assembling small nickel disulfide particles of 10-15 nanometers, and the thickness of the nanosheet is 10-50 nanometers. The composite material shows good electrochemical performance when being used as an aluminum ion positive electrode material, and can be used as a potential application material of the aluminum ion battery positive electrode material with long service life, excellent cycling stability and high rate.

Owner:WUHAN UNIV OF TECH

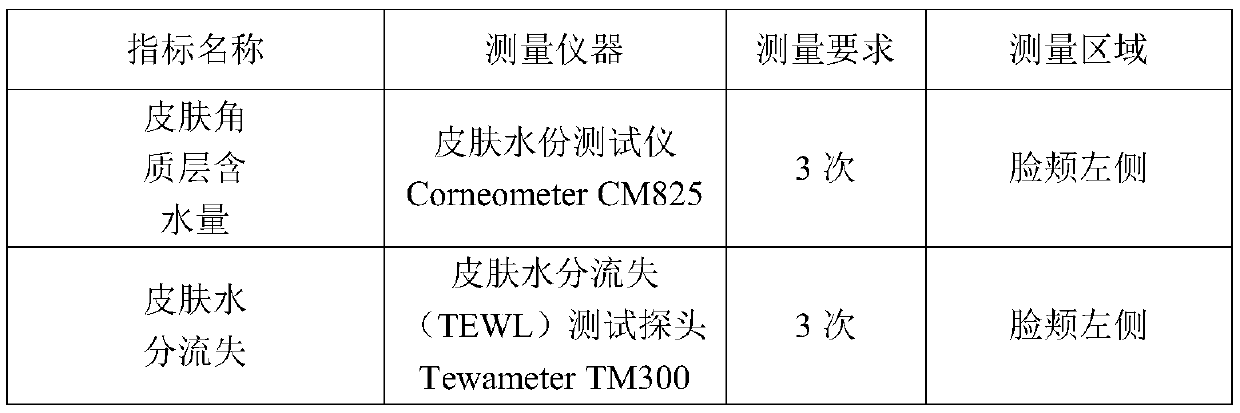

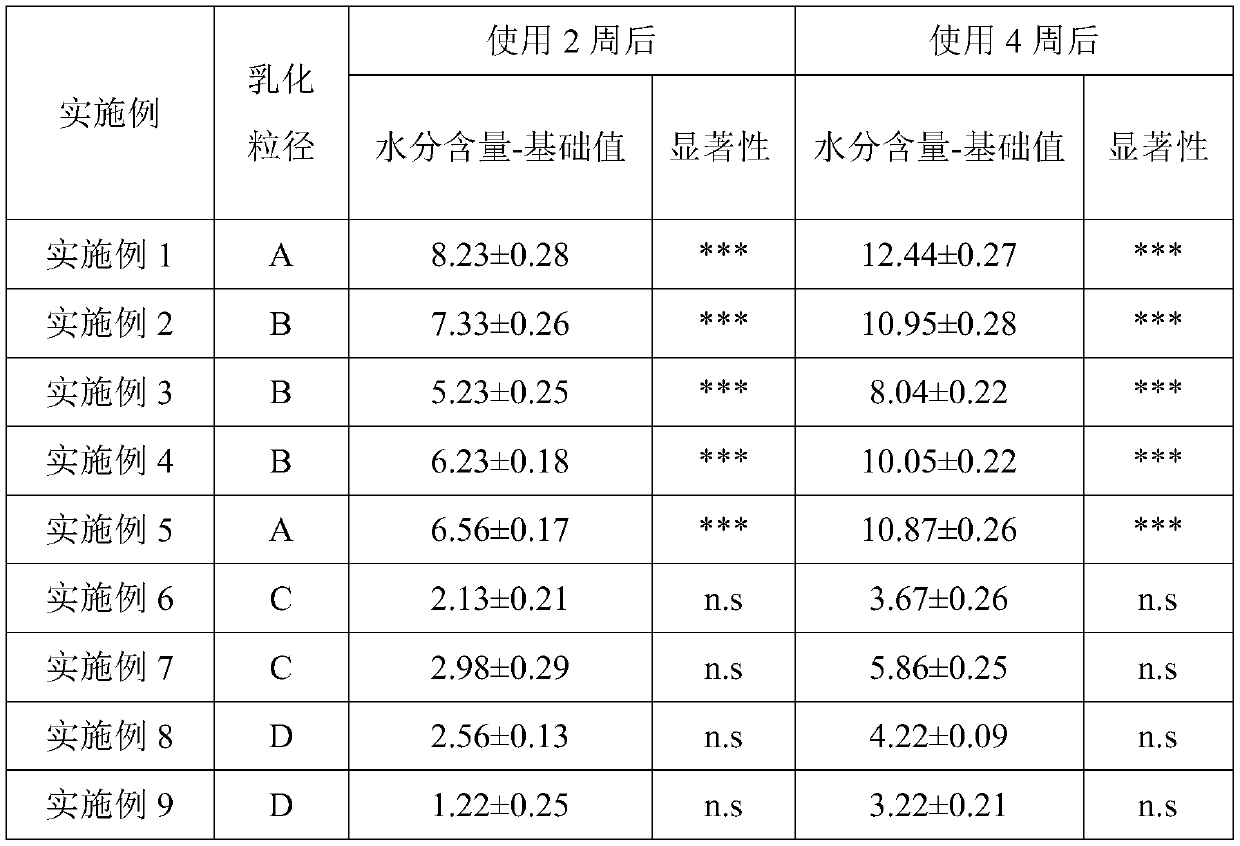

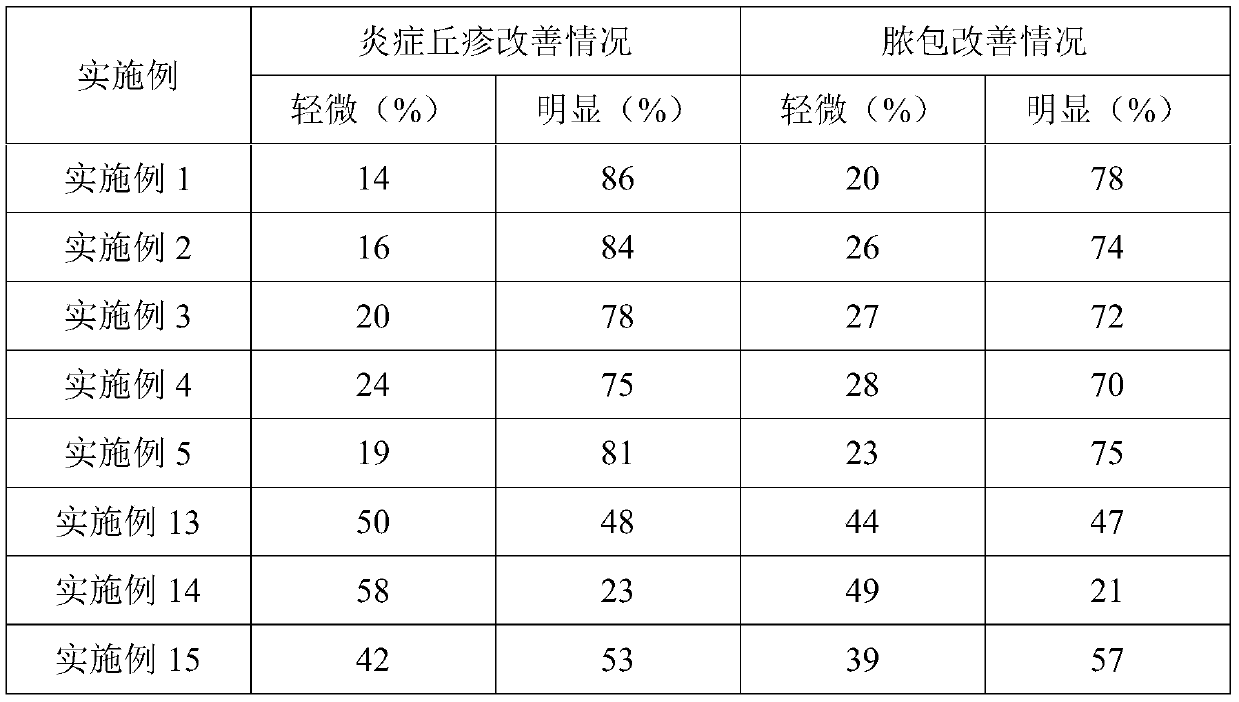

Traceless repair composition containing mineral hot spring

ActiveCN110025513AGood cycle stabilityPromote absorptionCosmetic preparationsToilet preparationsSolventHumectant

The invention relates to the field of skin care products, and provides a traceless repair composition containing mineral hot spring. The composition at least comprises the following components: a solvent, a chelating agent, a humectant, a thickening agent, a skin conditioner and a pH regulator. The skin conditioner comprises a combination of one or more of p-hydroxyacetophenone, asiatic pennywortherb extract, panthenol and a plant composite anti-allergy agent.

Owner:伊犁弥玥泉生物科技有限公司

Nitrogen-rich foam carbon electrode material for super capacitor and preparing method of nitrogen-rich foam carbon electrode material

InactiveCN104036973AReduce loss rateGood cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureComposite materialCyanate ester

The invention provides a nitrogen-rich foam carbon electrode material for a super capacitor and a preparing method of the nitrogen-rich foam carbon electrode material. The preparing method includes: taking foamed nickel subjected to acid treatment as an auxiliary template, taking cyanate ester as a raw material, and obtaining the nitrogen-rich foam carbon electrode material for the super capacitor via pre-polymerizing, moulding by casting, curing, carbonizing and template removing technologies. The prepared foam carbon electrode material is uniform in pore diameters, high in nitrogen content, good in electrical conductivity, high in porosity and aperture ratio, large in specific capacity, good in cycling performance and capable of realizing complex structure forming without a foaming technology.

Owner:FUZHOU UNIVERSITY

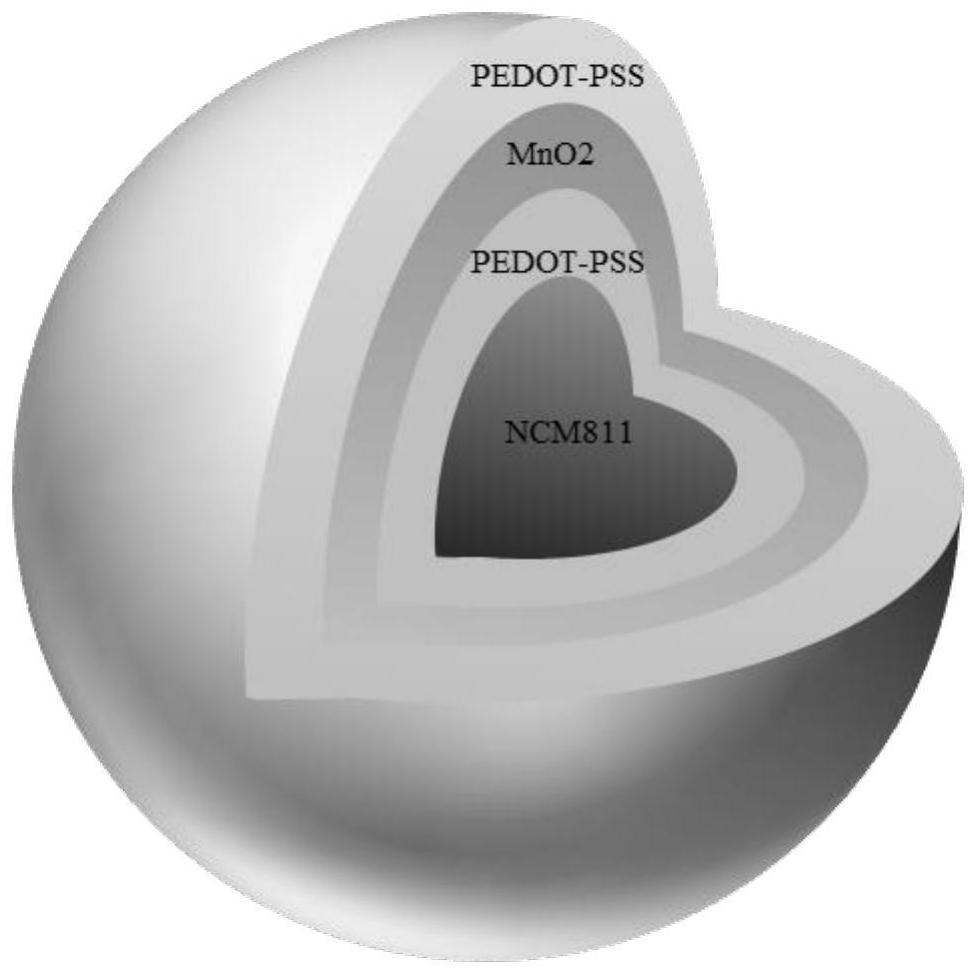

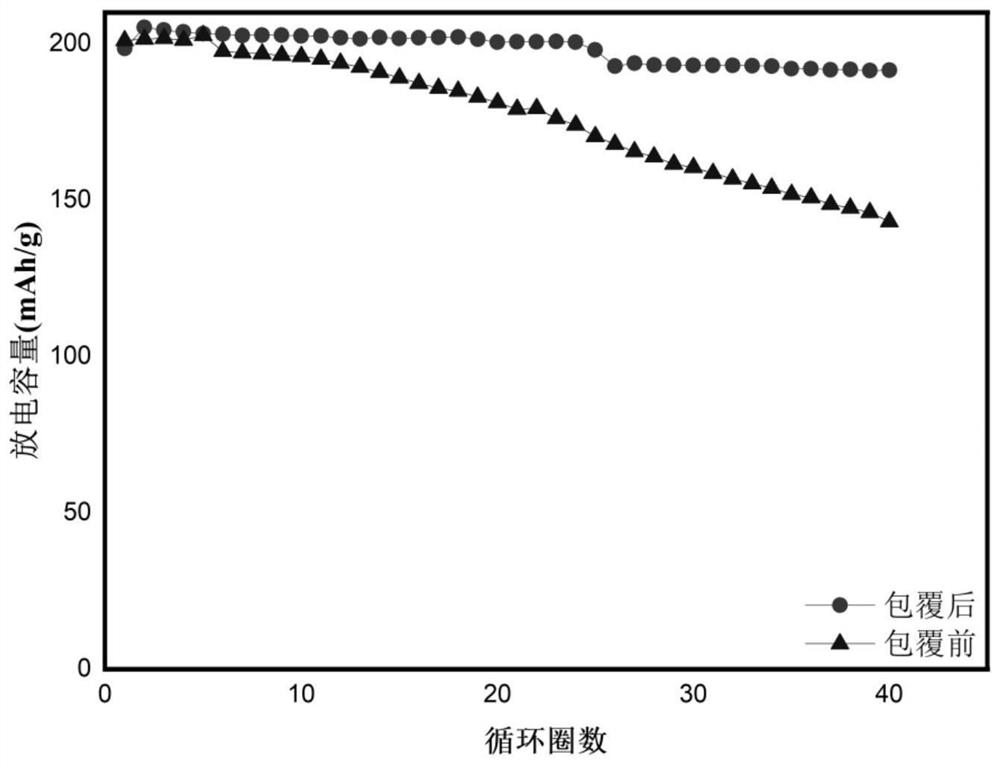

Conductive polymer and transition metal oxide coated high-nickel positive electrode material and method

ActiveCN112758994AImprove discharge capacityGood cycle stabilityMaterial nanotechnologyElectrolysis componentsPoly ethyleneCentral layer

The invention provides a conductive polymer and transition metal oxide coated high-nickel positive electrode material and a preparation method thereof. A central layer is a spherical high-nickel ternary material, the surface of the central layer is a coating layer, and the coating layer comprises a three-layer structure composed of poly(3,4-ethylene dioxythiophene) / polystyrene sulfonate PEDOT-PSS, MnO2, and poly(3,4-ethylene dioxythiophene) / polystyrene sulfonate PEDOT-PSS. The chemical formula of the high-nickel ternary material is Li Ni<x>Co<y>Mn<1 x y>O2, wherein the conditons are 0.75<=x<=0.85, 0.075<=y<=0.125, and 1.0<=z<=1.1. The conductive polymer has higher discharge capacity and better cycle stability and rate performance, and the surface coating layer can effectively reduce the residual quantity of lithium ions on the surface of the cathode material, so that the propagation of LiF and HF in the cycle process is greatly inhibited, and the dissolution of transition metal ions and the formation of cycle electrode cracks are reduced.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

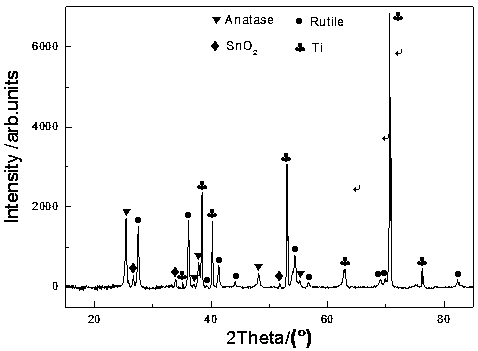

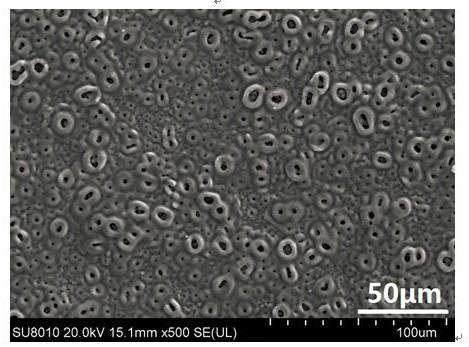

Preparation method for titanium oxide/tin oxide composite membrane for sodium ion battery cathode

ActiveCN109537021AHigh specific capacityGood cycle stabilityCell electrodesSurface reaction electrolytic coatingIonSodium silicate

The invention provides a method of preparing a TiO2 / SnO2 cathode material of a sodium ion battery by using a plasma electrolytic oxidation technique. An electrolyte is prepared from 1-10 ml / l phosphoric acid (85wt.%), 1-10 g / L sodium silicate, 5-30 g / L sodium stannate and 5-30 ml / L glycerol separately. The method comprises the following steps: by taking foamed titanium as an anode and stainless steel as a cathode, immersing the anode and the cathode into a special electrolyte solution containing phosphoric acid, sodium silicate, sodium stannate, glycerol and deionized water; applying a bipolarpulse voltage between the two electrodes at constant temperature and constant pressure, wherein plasma discharge happens on the surface of the foamed titanium; turning off a power supply after discharge for a period of time to prepare the TiO2 / SnO2 composite membrane on the surface of the foamed titanium. The composite membrane can be used as a cathode material of the sodium ion battery. The TiO2 / SnO2 cathode material makes full use of a high capacity characteristic and high cyclic stability of TiO2. The method is simple in preparation process, low in production cost and suitable for industrial production.

Owner:TIANJIN NORMAL UNIVERSITY

Preparation method for positive electrode material lithium cobalt iron phosphate for lithium ion battery

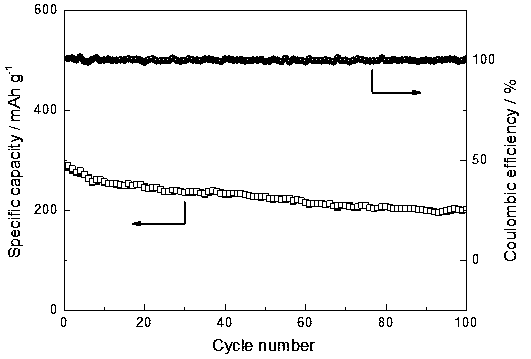

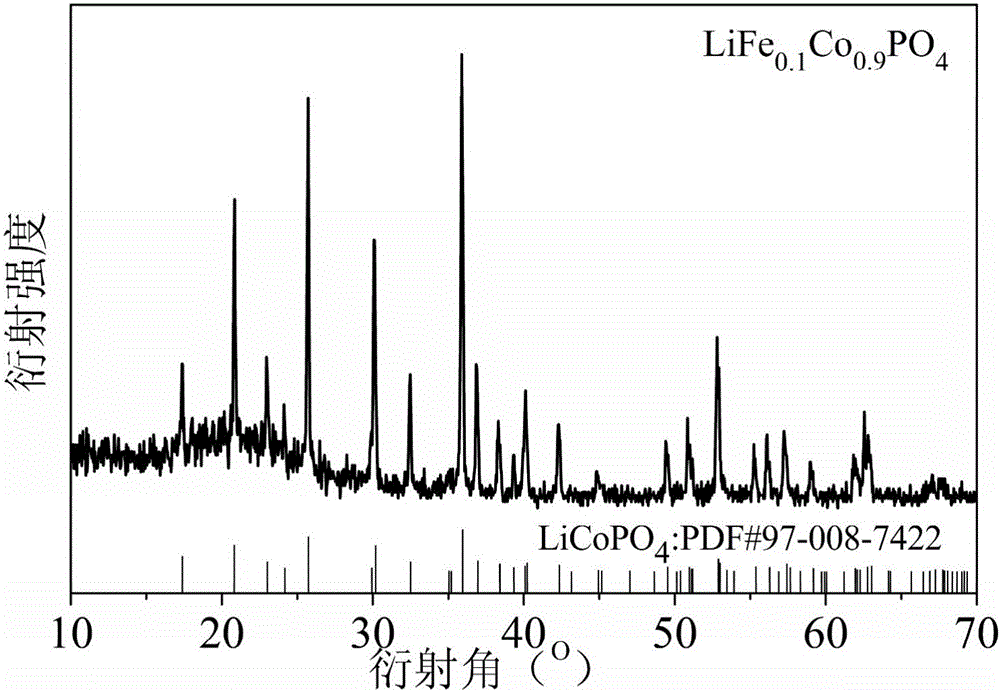

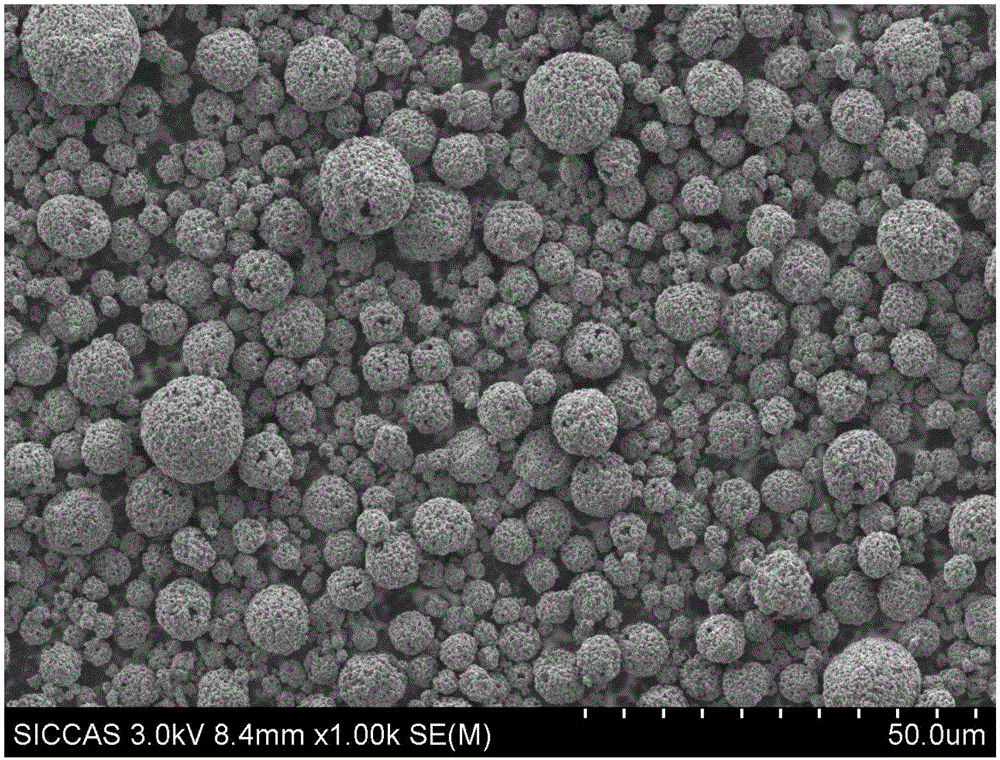

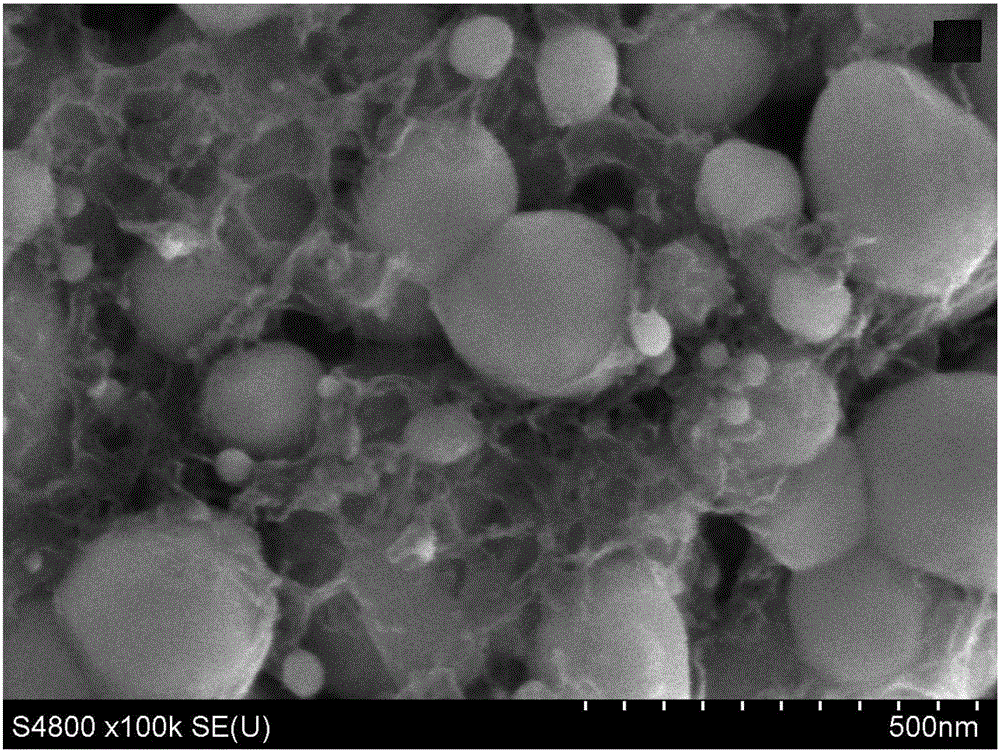

InactiveCN105958066AIncrease energy densityGood cycle stabilityCell electrodesSecondary cellsCobalt hydroxideNitrogen atmosphere

The invention provides a preparation method for a positive electrode material lithium cobalt iron phosphate for a lithium ion battery. The chemical formula of lithium cobalt iron phosphate is LiFe<x>Co<1-x>PO<4> / C, wherein x is greater than or equal to 0.1 and less than or equal to 0.2; the preparation method comprises the steps of adding phosphoric acid into deionized water to prepare a phosphoric acid solution; adding reduced iron powder under a stirring state, enabling the mixture to be reacted to obtain a clear mixed solution; adding a lithium hydroxide solution to the mixed solution; after the solution is cooled, adding the cooled solution to a nanometer ball mill, and adding cobalt hydroxide; carrying out ball milling on the mixture, and then adding a caramel solution, stirring uniformly the ball-milled product, and spraying and drying the product to obtain a spherical lithium cobalt iron phosphate / carbon composite material precursor powder; and calcining the precursor powder at a temperature of 600-700 DEG C under a nitrogen atmosphere to obtain the positive electrode material for the lithium ion battery. The positive electrode material for the lithium ion battery obtained by the invention has relatively high energy density and high cycle performance, and can be expected to be the new generation of high-energy-density positive electrode material for the lithium ion battery.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

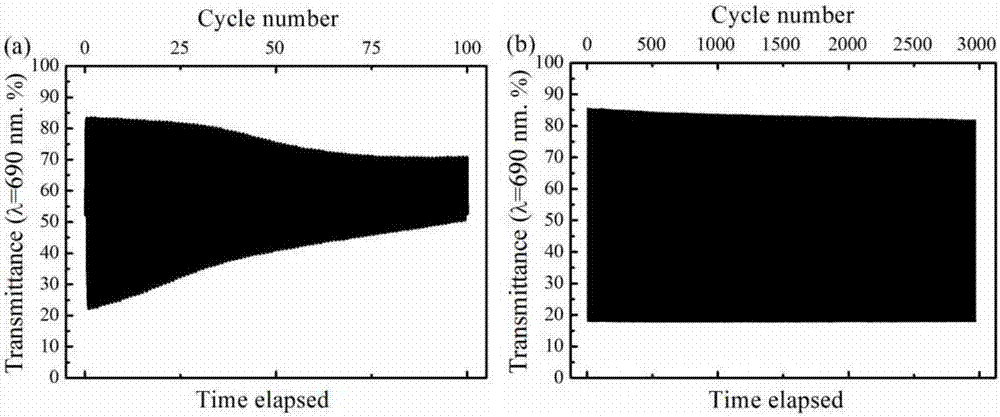

Method for improving cycling stability of prussian-blue electrochromic film in LiClO4/PC electrolyte

ActiveCN107991819AStable transmittanceGood cycle stabilityNon-linear opticsCyclic stabilityOleic Acid Triglyceride

The invention discloses a method for improving the cycling stability of a prussian-blue electrochromic film in a LiClO4 / PC electrolyte, and belongs to the field of function-material technology application. Weak acid (acetic acid, oleic acid, oxalic acid and the like can be selected) is dropped into the configured LiClO4 / PC electrolyte, the prussian-blue electrochromic film is put into the electrolyte and subjected to electrochromism. The cycling stability can be improved, and the service life is prolonged.

Owner:BEIJING UNIV OF TECH

Fluorination modification method for AB3-type hydrogen storage alloy

InactiveCN103920871AEasy to operateGood cycle stabilityCell electrodesVacuum induction meltingCyclic stability

The invention discloses a fluorination modification method for AB3-type hydrogen storage alloy. An AB3-type (Mm0.78 Mg0.22 Ni2.48 Mn0.09 Al0.23 Co0.47) parent alloy ingot is prepared in a vacuum induction smelting method, wherein Mm is misch metal and comprises, by weight, 82.3% of La and 17.7 % of Nd. After the parent alloy ingot is smashed mechanically, ball milling is carried out for 60-90 minutes at the rotation speed of 250-300 turns per minute, then the ground alloy ingot is screened to be AB3-type alloy powder of 200-300 meshes, the prepared alloy powder is placed in fluorination liquid, the fluorination liquid comprises 0.02-0.10 ml of HF and 0.15 g of NaF each liter, the mixture is stirred for 8-15 minutes at the temperature of 40-60 DEG C, and NaBH4 solution of 0.04-0.06 mol / L is added until hydrogen bubbles disappear completely. The obtained alloy powder is washed sequentially by deionized water and absolute ethyl alcohol and is dried for 6-10 hours at the temperature of 60 DEG C in a vacuum environment, and the modified alloy is prepared. An electrode made by the modified alloy has good circulating stability and excellent dynamic performance.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com