Nickel sulfate sheet/graphene composite material as well as preparation method and application thereof

A composite material, nickel sulfide technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of capacity decay and large volume change, and achieve the effects of small size, simple process and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] NiCl 2 ·6H 2 O as a raw material, it was dissolved in deionized water to prepare 80 ml of Ni 2+ The concentration is 0.01mol / L solution, then add 32 mg GO and make mixed solution after fully stirring and dispersing; then thiourea (the molar dosage of thiourea is NiCl 2 ·6H 2 (3 times of the molar weight) is added to the above mixed solution, and then trisodium citrate is added (the molar amount of trisodium citrate is NiCl 2 ·6H 2 (1 times of molar weight), then transferred to a capacity of 100 milliliters of autoclave (filling degree 80%, percent by volume), then the reactor was sealed, reacted at 180 ° C for 24 hours, naturally cooled to room temperature; Solid reaction product, the product was washed alternately and repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C to obtain 0.085g NiS flake / graphene composite material, wherein the weight percentage of graphene was 15.2%.

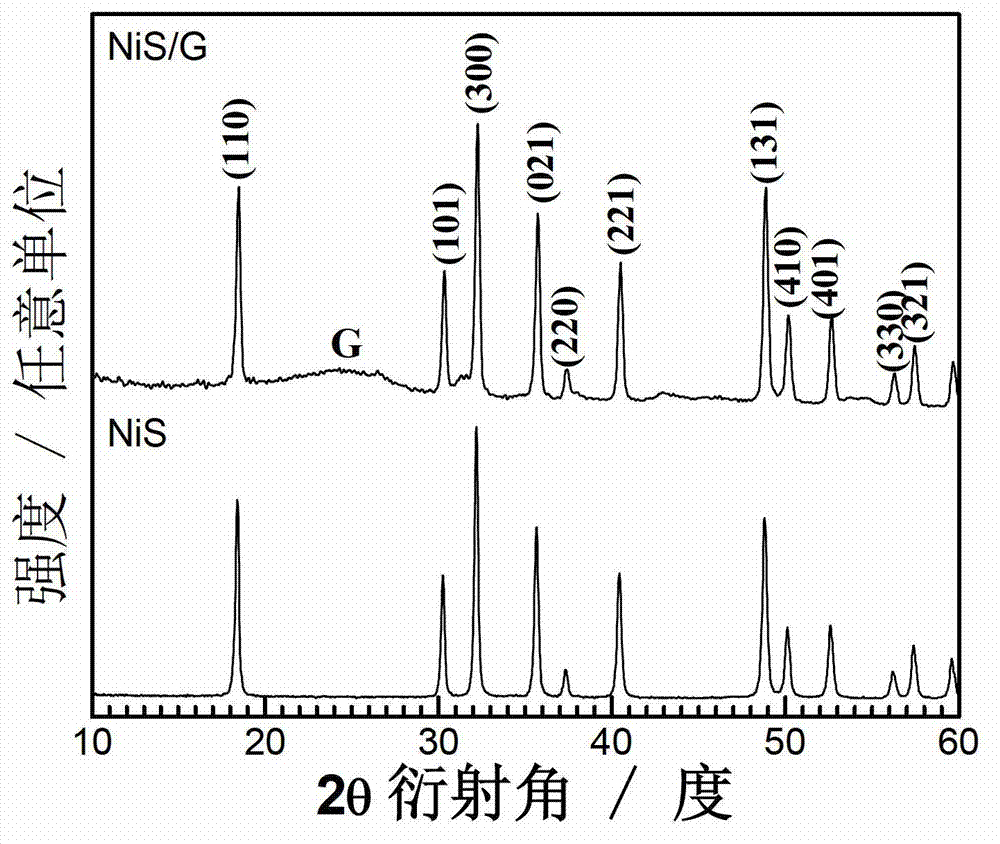

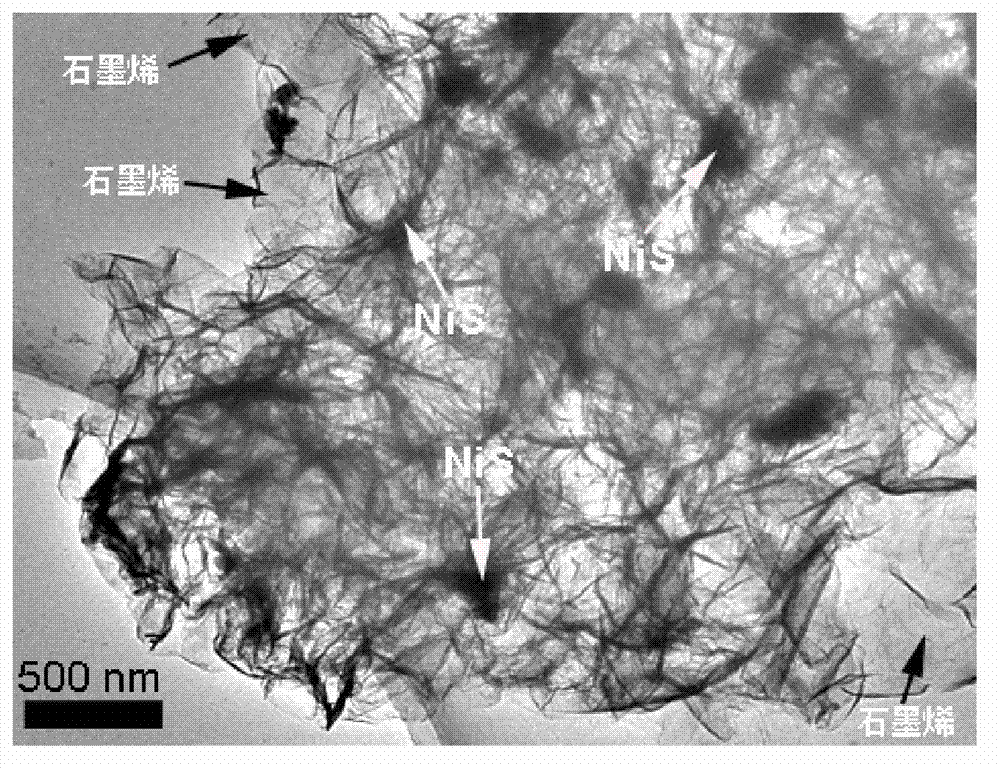

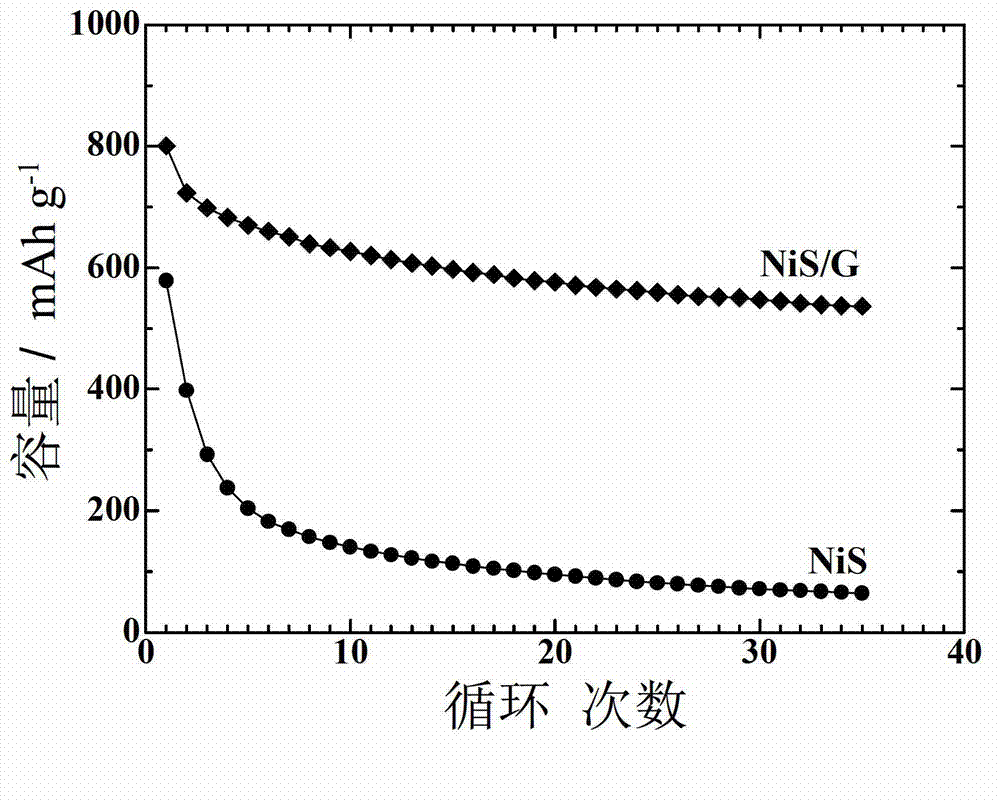

[0035] The X-ray diffraction spectrum and transmission elect...

Embodiment 2

[0047] NiC 2 o 4 2H 2 O as raw material, dissolved in ethanol, prepared 80 ml with Ni 2+ A solution with a concentration of 0.04mol / L was added, and 87 mg of GO was added to obtain a mixed solution after fully stirring and dispersing; then Na 2 S (Na 2 The molar amount of S is NiC 2 o 4 2H 2 2 times of the molar weight) is added to the above mixed solution, and then trisodium citrate is added (the molar usage of trisodium citrate is NiC 2 o 4 2H 2 (2 times of the molar weight), then transferred to a capacity of 100 milliliters of autoclave (filling degree 80%, percent by volume), then the reactor was sealed, reacted at 220 ° C for 12 hours, naturally cooled to room temperature; Solid reaction product, the product was washed alternately and repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C to obtain 0.32g NiS flake / graphene composite material, wherein the weight percentage of graphene was 10.7%.

[0048] It can be seen from the X-ray diffr...

Embodiment 3

[0060] With Ni(NO 3 ) 2 ·6H 2 O as a raw material, it is dissolved in ethylene glycol, and prepared into 80 ml with Ni 2+ The concentration is 0.06mol / L solution, then add 108 milligrams of GO and make mixed solution after fully stirring and dispersing; 3 ) 2 ·6H 2 (4 times of 2 molar weight) joins above-mentioned mixed solution, then adds trisodium citrate (the molar use amount of trisodium citrate is Ni(NO 3 ) 2 ·6H 2 (3 times of molar weight), then transferred to a capacity of 100 milliliters of autoclave (filling degree 80%, percent by volume), then the reactor was sealed, reacted at 170 ° C for 48 hours, naturally cooled to room temperature; Solid reaction product, the product was washed alternately and repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C to obtain 0.47g NiS flake / graphene composite material, wherein the weight percentage of graphene was 9.1%.

[0061] It can be seen from the X-ray diffraction pattern and transmission ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com