Poly (3, 4-ethylenedioxythiophene)/nickel cobaltate/carbon cloth flexible electrode

A technology of ethylenedioxythiophene and dioxythiophene, which is applied in the direction of hybrid capacitor electrodes and electrolytic capacitors, can solve the problems of easy agglomeration specific capacitance, etc., and achieve the effects of improving specific capacitance, avoiding surface dead gas, and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

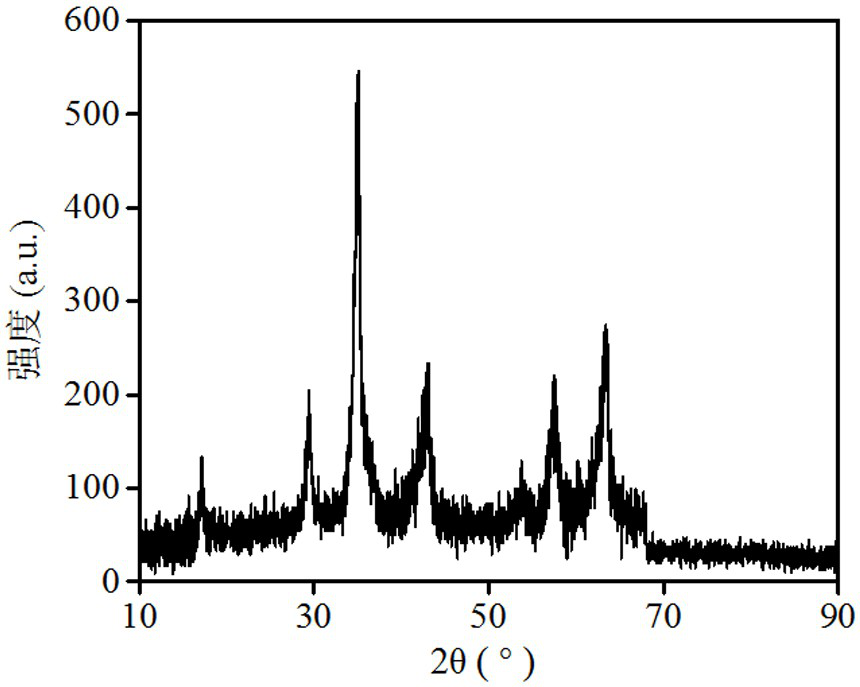

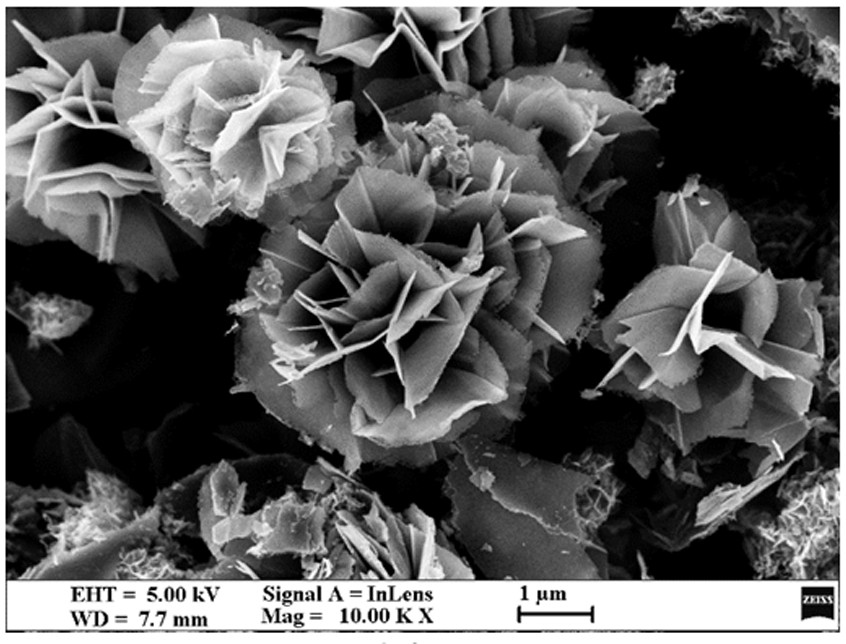

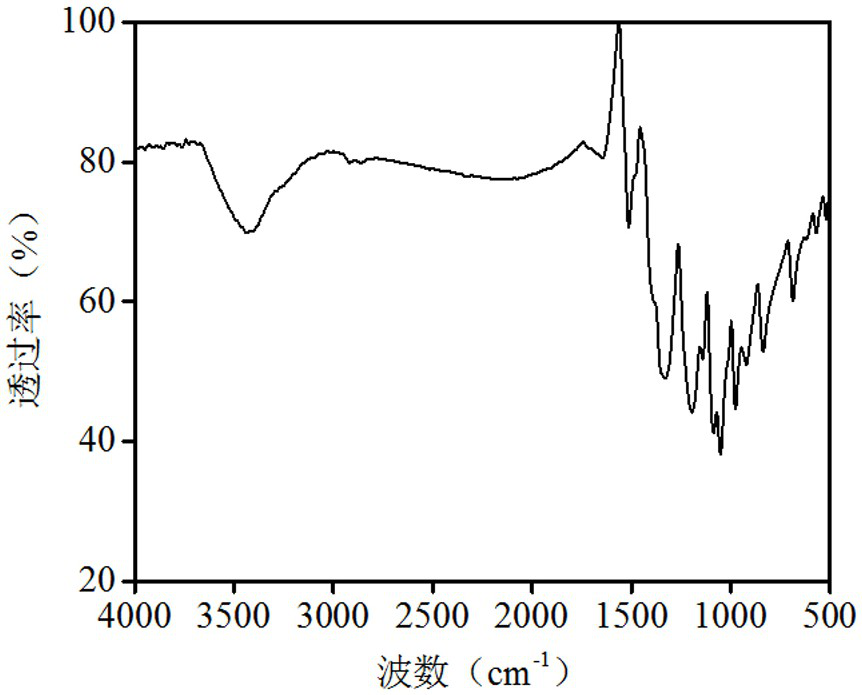

[0026] (1) At room temperature, add 1 g of cobalt nitrate hexahydrate and 0.3 g of nickel nitrate hexahydrate into 80 mL of methanol. After magnetic stirring for 20 min, add 1.5 g of hexamethylenetetramine and continue magnetic stirring for 15 min. The temperature was raised to 160 °C, magnetically stirred for 12 h, cooled to room temperature naturally, first centrifuged, washed, vacuum dried at 60 °C for 24 h, and then annealed at 330 °C for 3 h to prepare nickel cobaltate.

[0027] (2) Add 60 mg of ammonium persulfate to 20 mL of deionized water, stir magnetically at room temperature for 8 min, and add 1 mL of hydrochloric acid solution dropwise at a rate of 15 drops / min under magnetic stirring to prepare mixed solution A ; Add 50 mg of nickel cobaltate to 30 mL of deionized water, stir magnetically at room temperature for 20 min, then sonicate for 20 min, add 80 mg of 3,4-ethylenedioxythiophene, stir magnetically for 20 min, and sonicate for 45 min , to prepare a mixed disp...

Embodiment 2

[0034](1) At room temperature, add 0.5 g of cobalt nitrate hexahydrate and 0.2 g of nickel nitrate hexahydrate into 50 mL of ethanol, stir magnetically for 10 min, add 1 g of hexamethylenetetramine, and continue magnetic stirring for 10 min. The temperature was raised to 140 °C, magnetically stirred for 16 h, cooled to room temperature naturally, first centrifuged, washed, vacuum dried at 60 °C for 24 h, and then annealed at 300 °C for 4 h to prepare nickel cobaltate.

[0035] (2) Add 40 mg ammonium persulfate to 10 mL deionized water, stir magnetically at room temperature for 5 min, and add 0.5 mL hydrochloric acid solution dropwise at a rate of 10 drops / min under magnetic stirring to prepare mixed solution A ; Add 20 mg of nickel cobaltate to 10 mL of deionized water, stir magnetically at room temperature for 10 min, then sonicate for 10 min, add 50 mg of 3,4-ethylenedioxythiophene, stir magnetically for 10 min, and sonicate for 30 min , to prepare a mixed dispersion B; put ...

Embodiment 3

[0038] (1) At room temperature, add 2 g of cobalt nitrate hexahydrate and 0.4 g of nickel nitrate hexahydrate into 100 mL of ethanol. After magnetic stirring for 30 min, add 2 g of hexamethylenetetramine and continue magnetic stirring for 20 min. Raise the temperature to 180 °C, stir magnetically for 8 h, cool to room temperature naturally, centrifuge, wash, and vacuum dry at 60 °C for 24 h, then anneal at 360 °C for 2 h to prepare nickel cobaltate.

[0039] (2) Add 80 mg ammonium persulfate to 30 mL deionized water, stir magnetically at room temperature for 10 min, and add 2 mL hydrochloric acid solution dropwise at a rate of 20 drops / min under magnetic stirring to prepare mixed solution A ; Add 80 mg of nickel cobaltate to 50 mL of deionized water, stir magnetically at room temperature for 30 min, then sonicate for 30 min, add 100 mg of 3,4-ethylenedioxythiophene, stir magnetically for 30 min, and sonicate for 60 min , to prepare a mixed dispersion B; place the acidified car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com