Patents

Literature

157results about How to "Improve electrochemical cycle stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

NANO silicon-carbon composite material and preparation method thereof

ActiveUS20140302396A1Improve cycle stabilityShort production processMaterial nanotechnologyElectrolysis componentsCarbon compositesSilicon dioxide

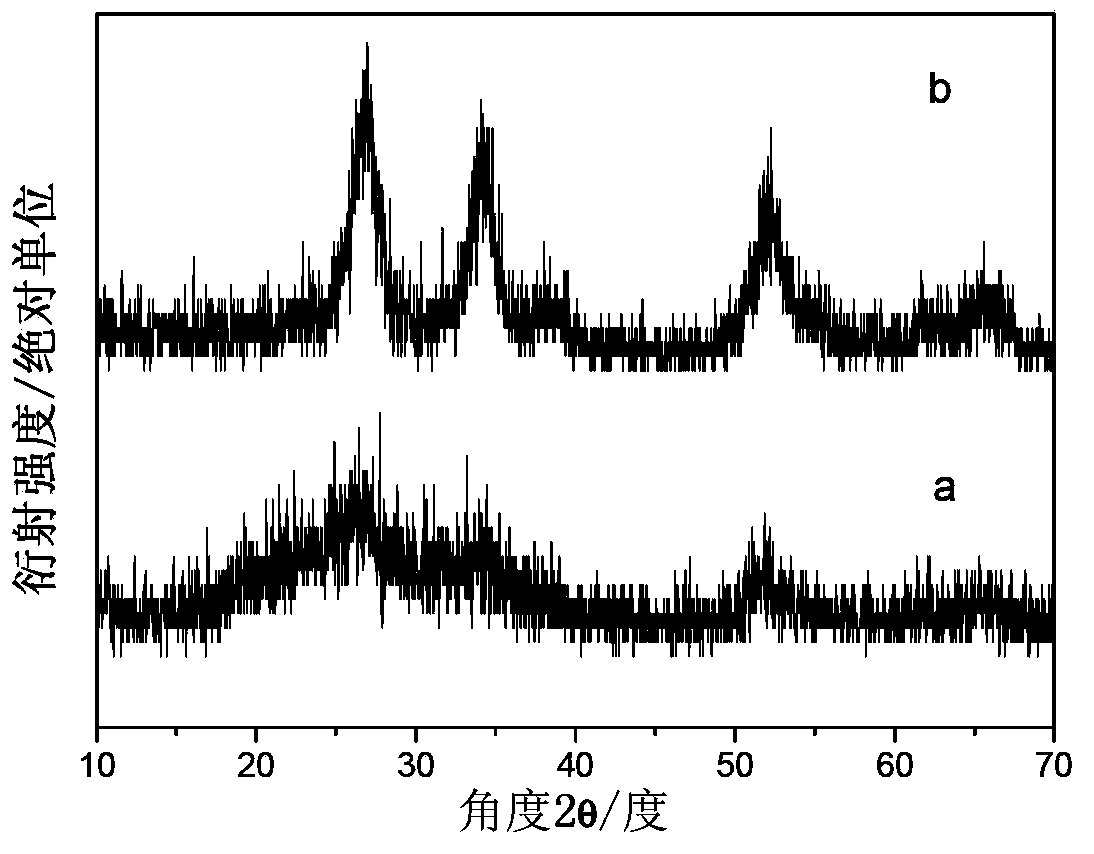

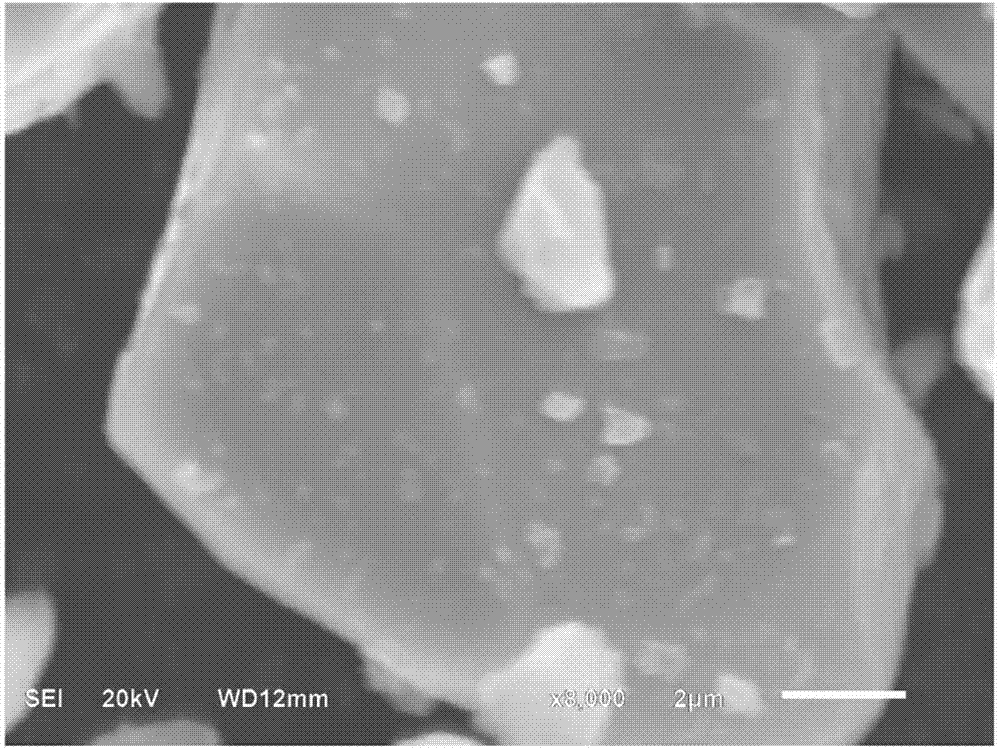

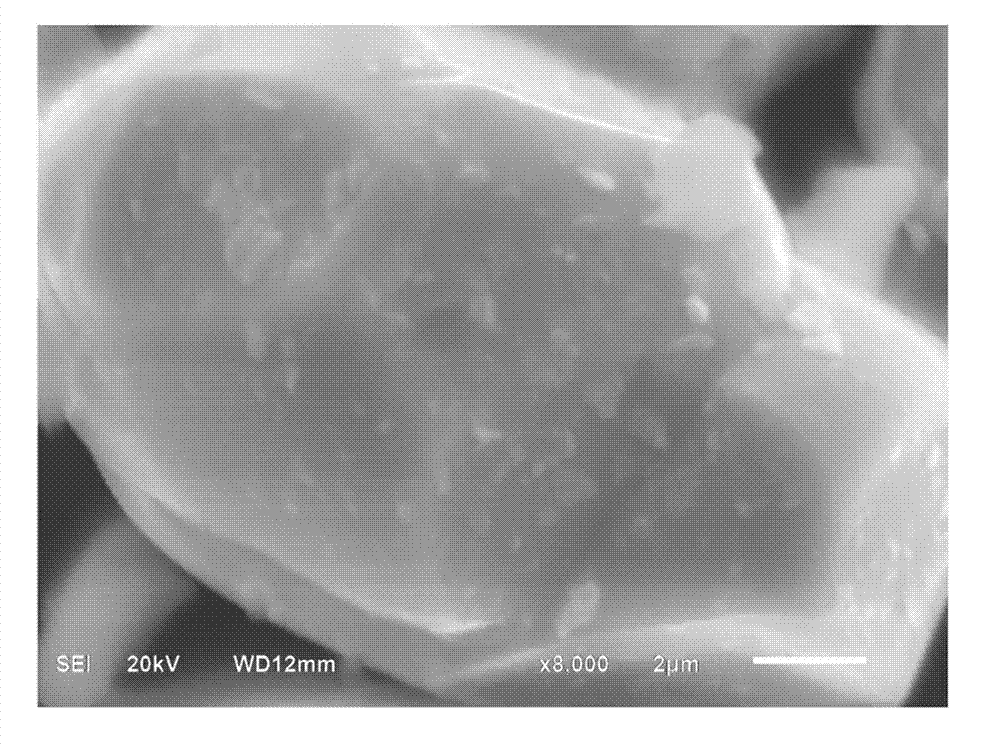

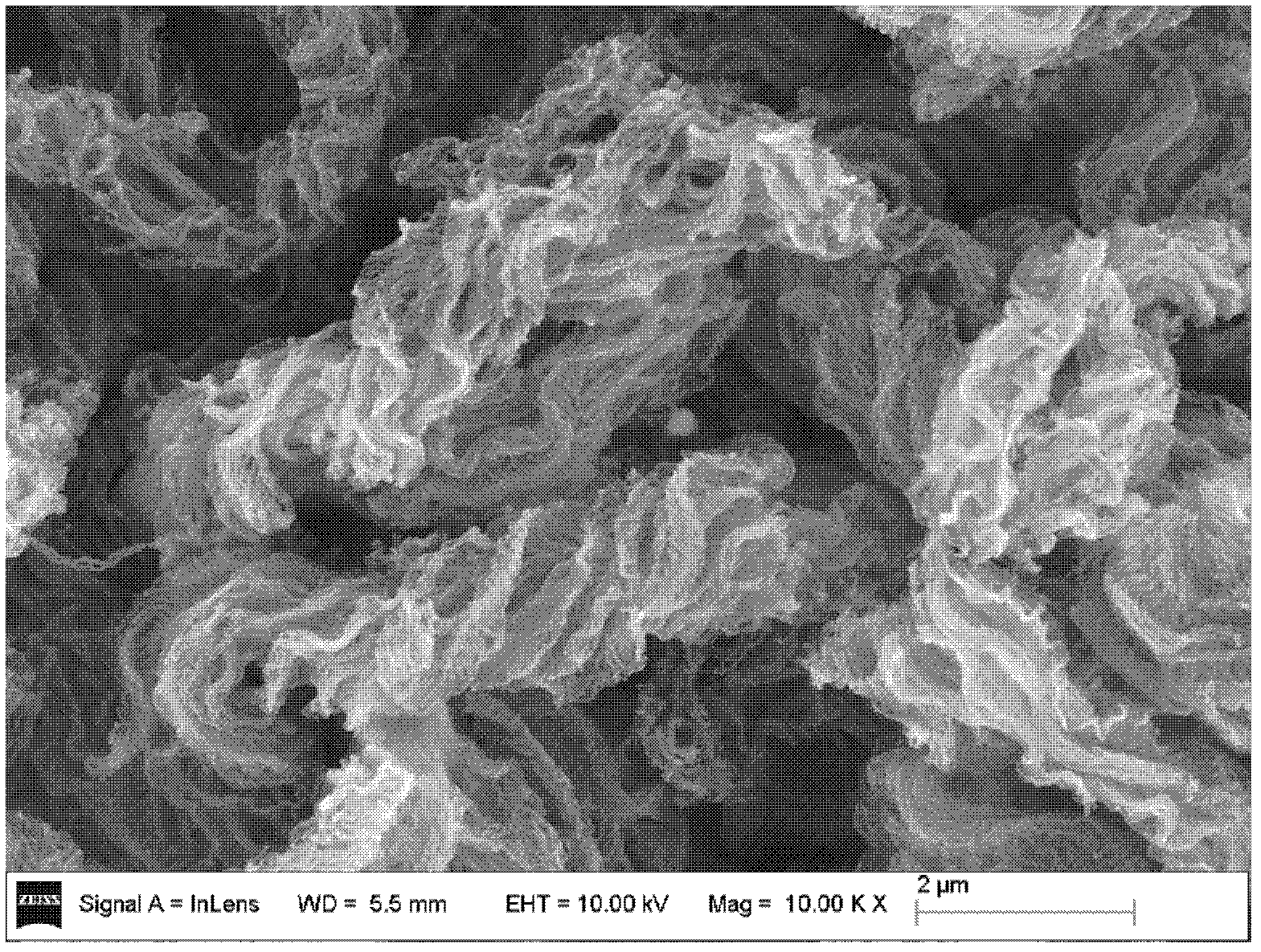

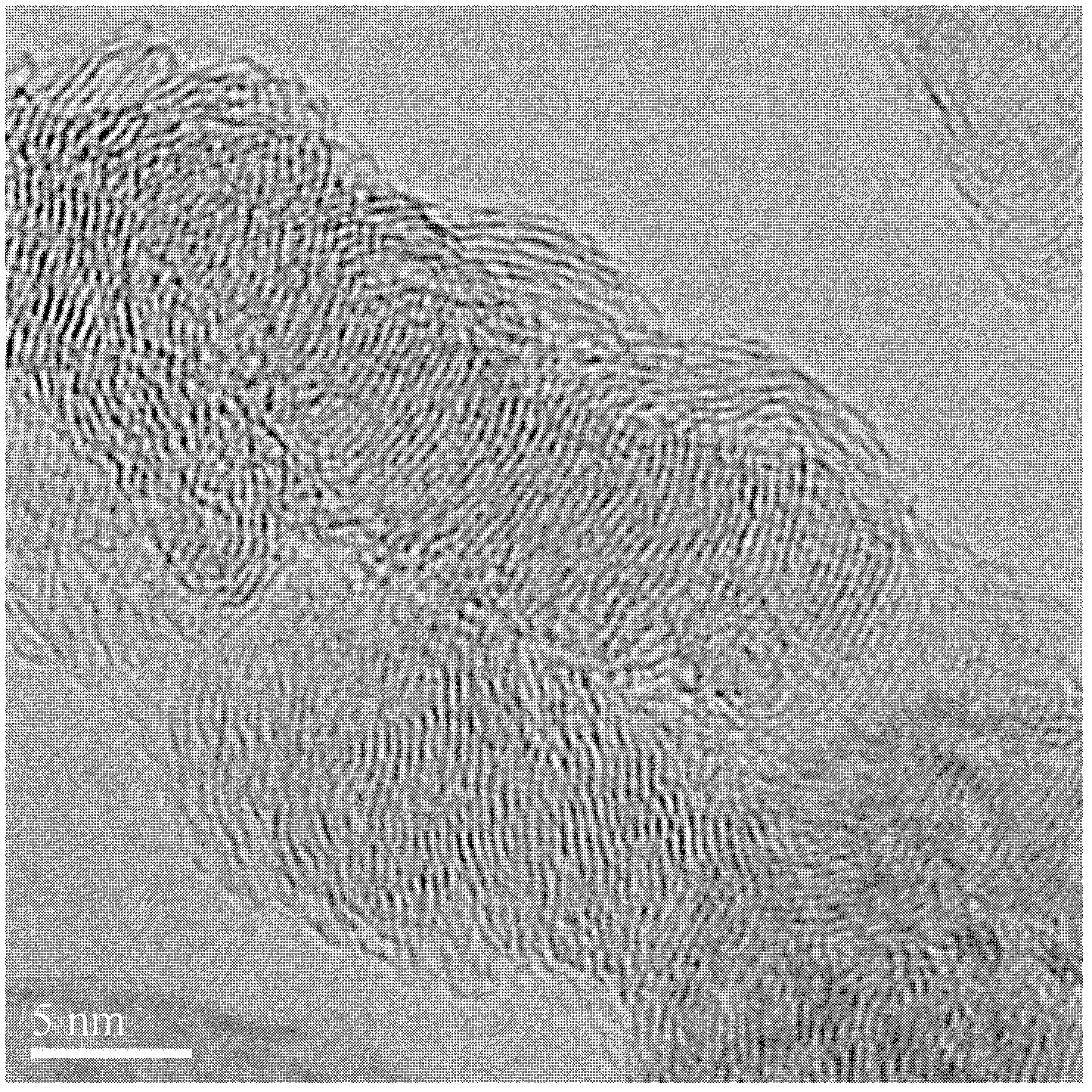

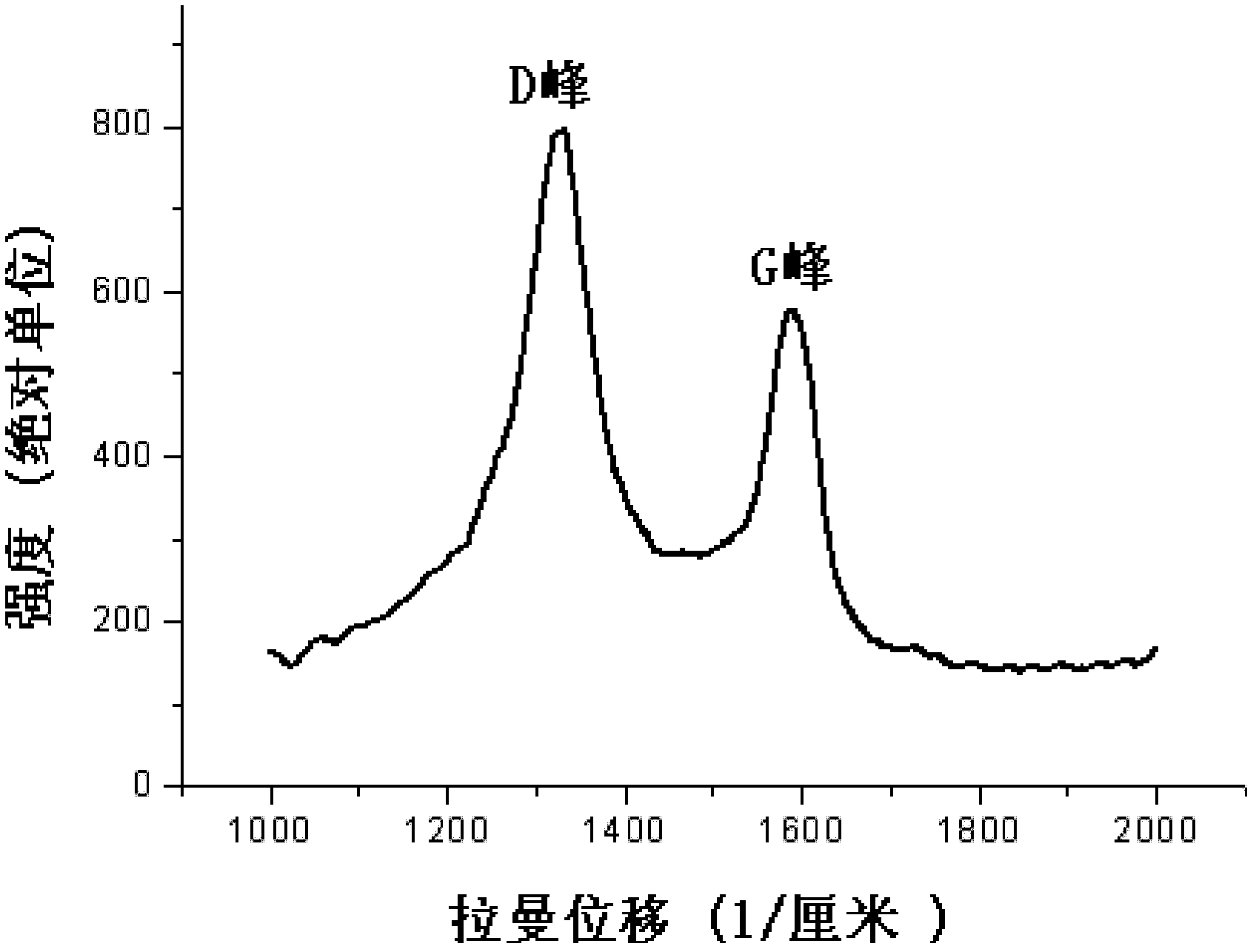

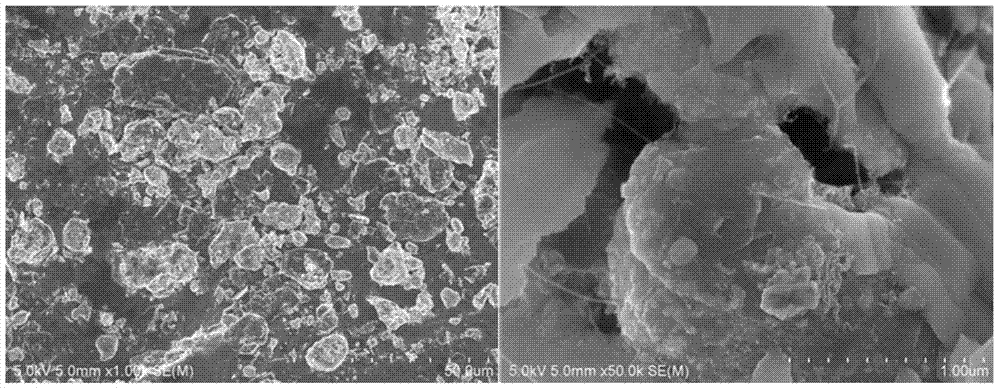

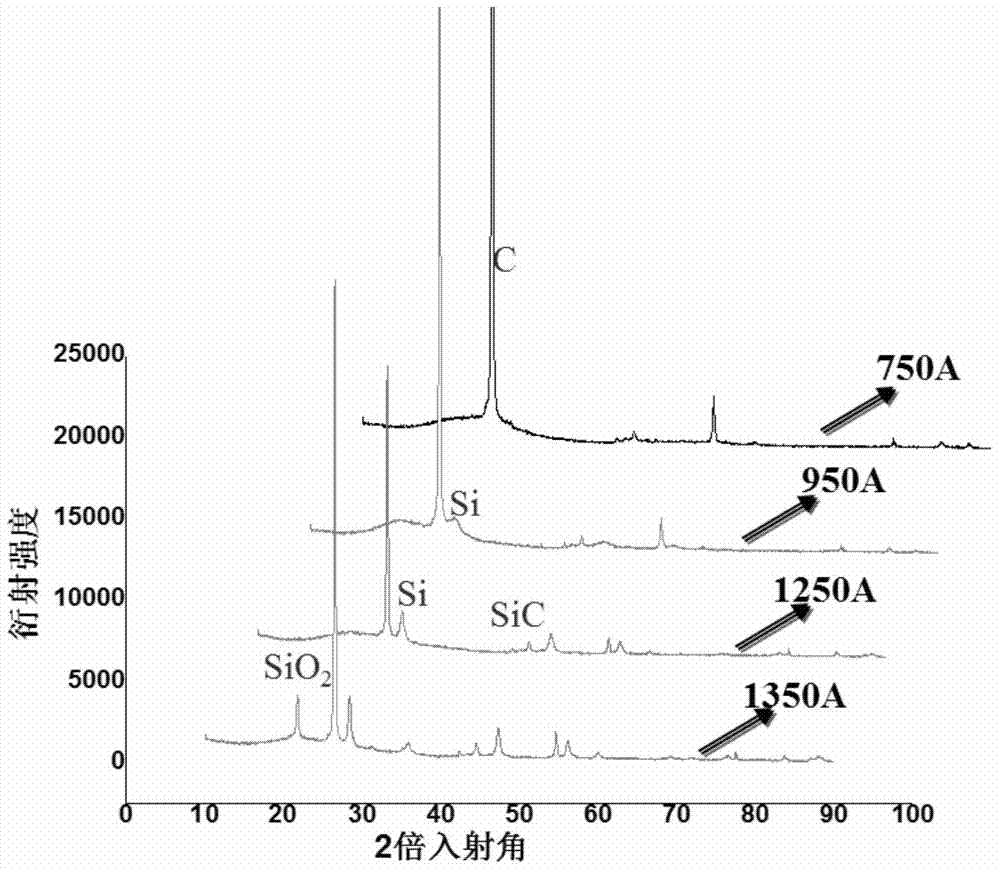

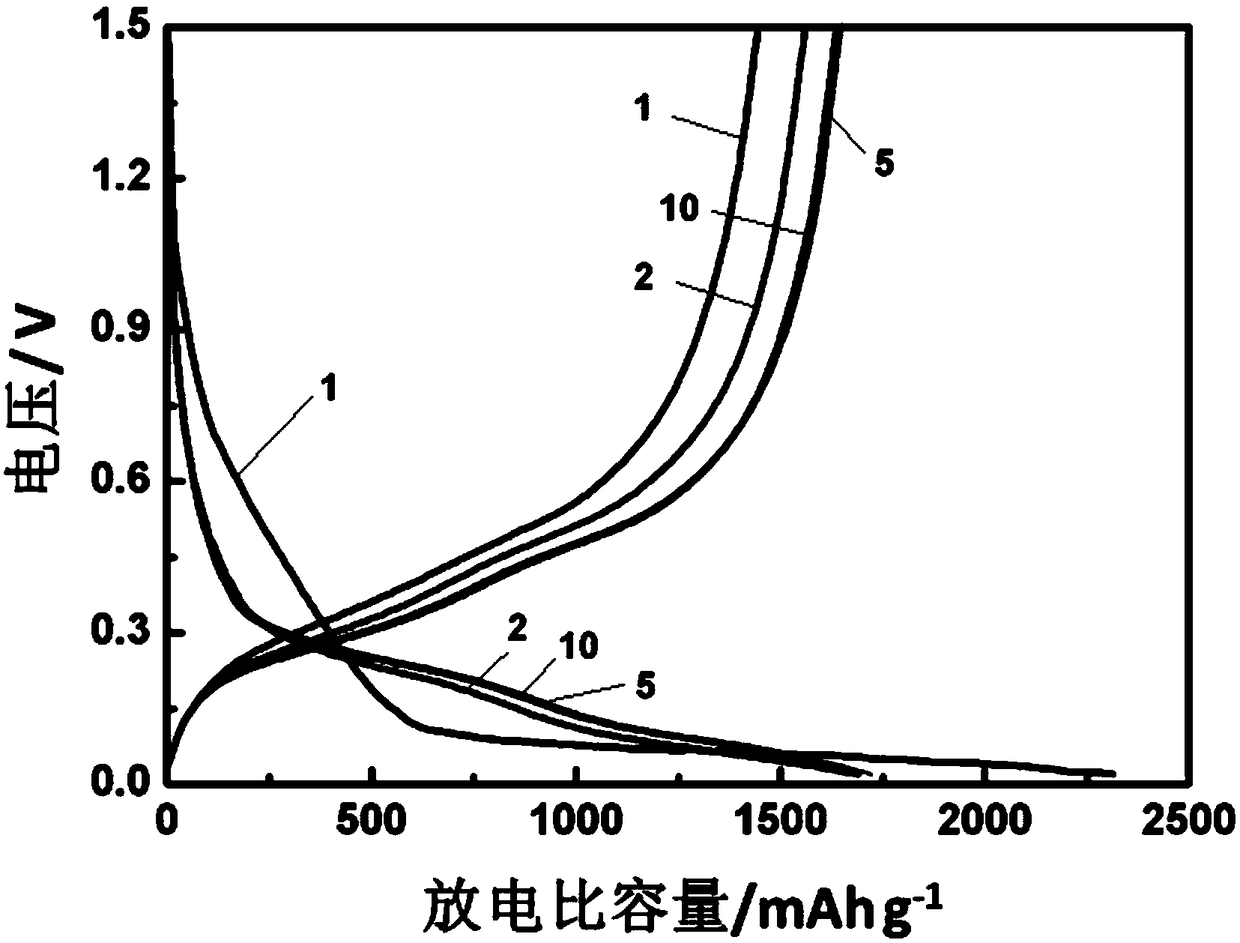

The invention relates to a nano silicon-carbon composite negative material for lithium ion batteries and a preparation method thereof. A porous electrode composed of silica and carbon is taken as a raw material, and a nano silicon-carbon composite material of carbon-loaded nano silicon is formed by a molten salt electrolysis method in a manner of silica in-situ electrochemical reduction. Silicon and carbon of the material are connected by nano silicon carbide, and are metallurgical-grade combination, so that the electrochemical cycle stability of the nano silicon-carbon composite material is improved. The preparation method of the nano silicon-carbon composite material provided by the invention comprises the following steps: compounding a porous block composed of carbon and silica powder with a conductive cathode collector as a cathode; using graphite or an inert anode as an anode, and putting the cathode and anode into CaCl2 electrolyte or mixed salt melt electrolyte containing CaCl2 to form an electrolytic cell; applying voltage between the cathode and the anode; controlling the electrolytic voltage, the electrolytic current density and the electrolytic quantity, so that silica in the porous block is deoxidized into nano silicon by electrolytic reduction, and the nano silicon-carbon composite material for lithium ion batteries is prepared at the cathode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

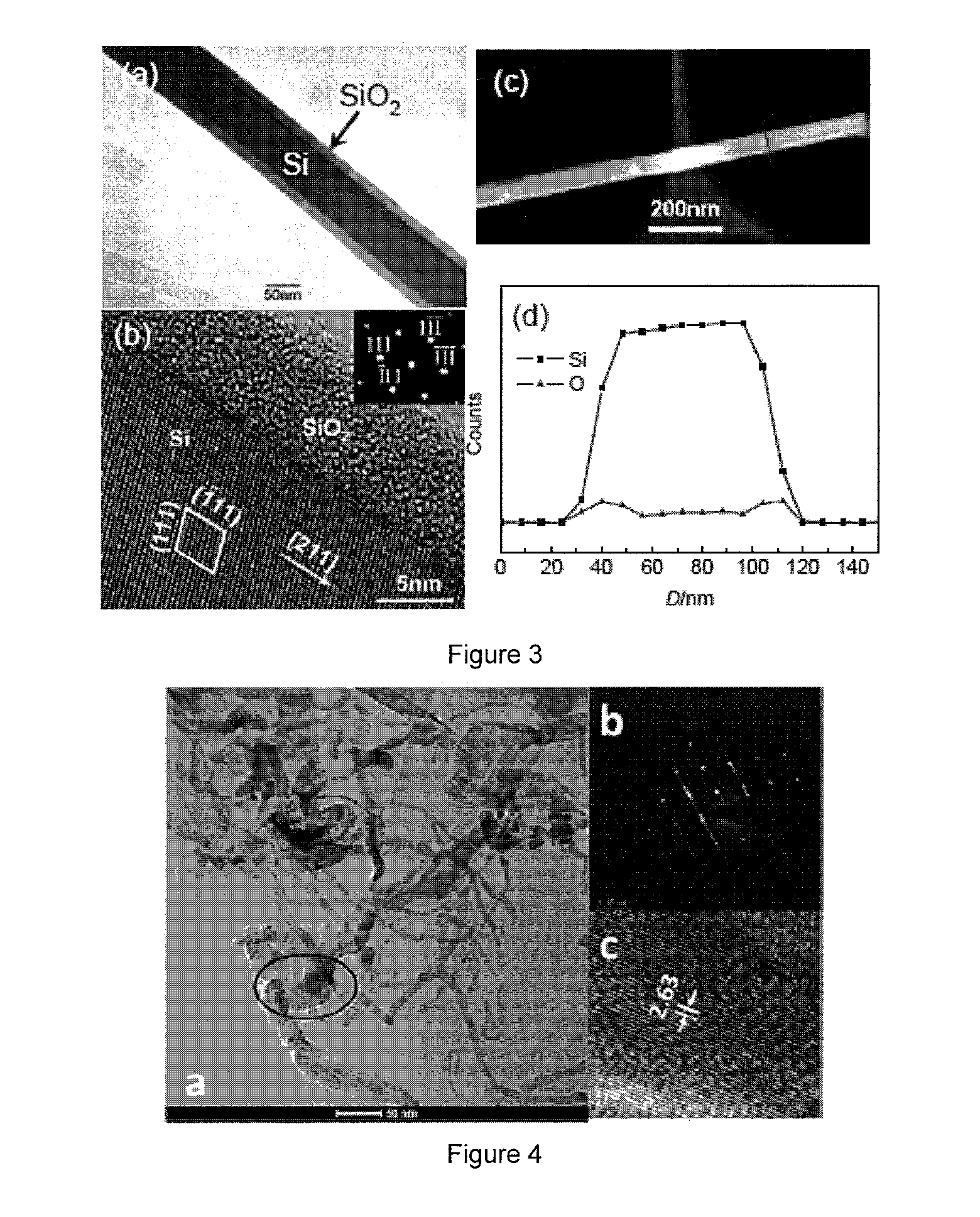

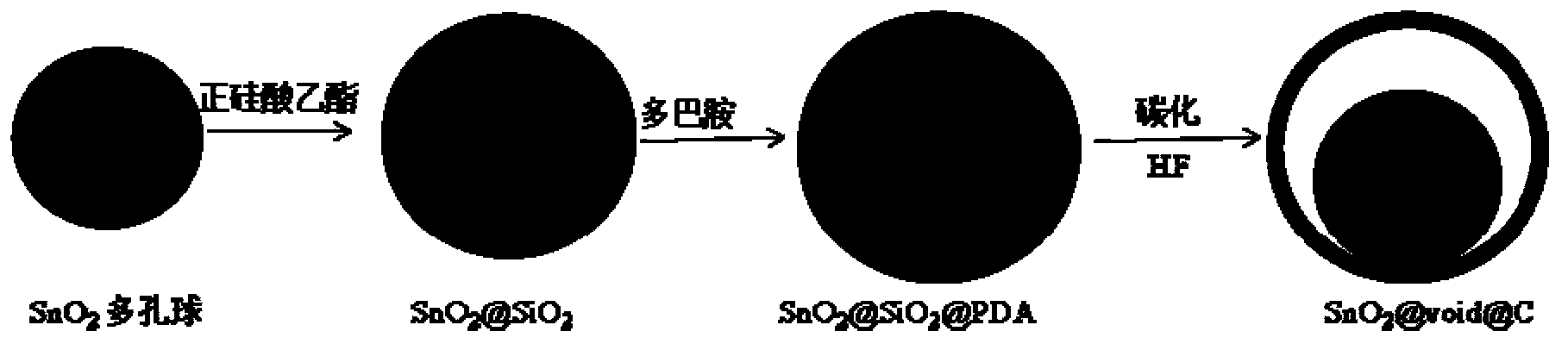

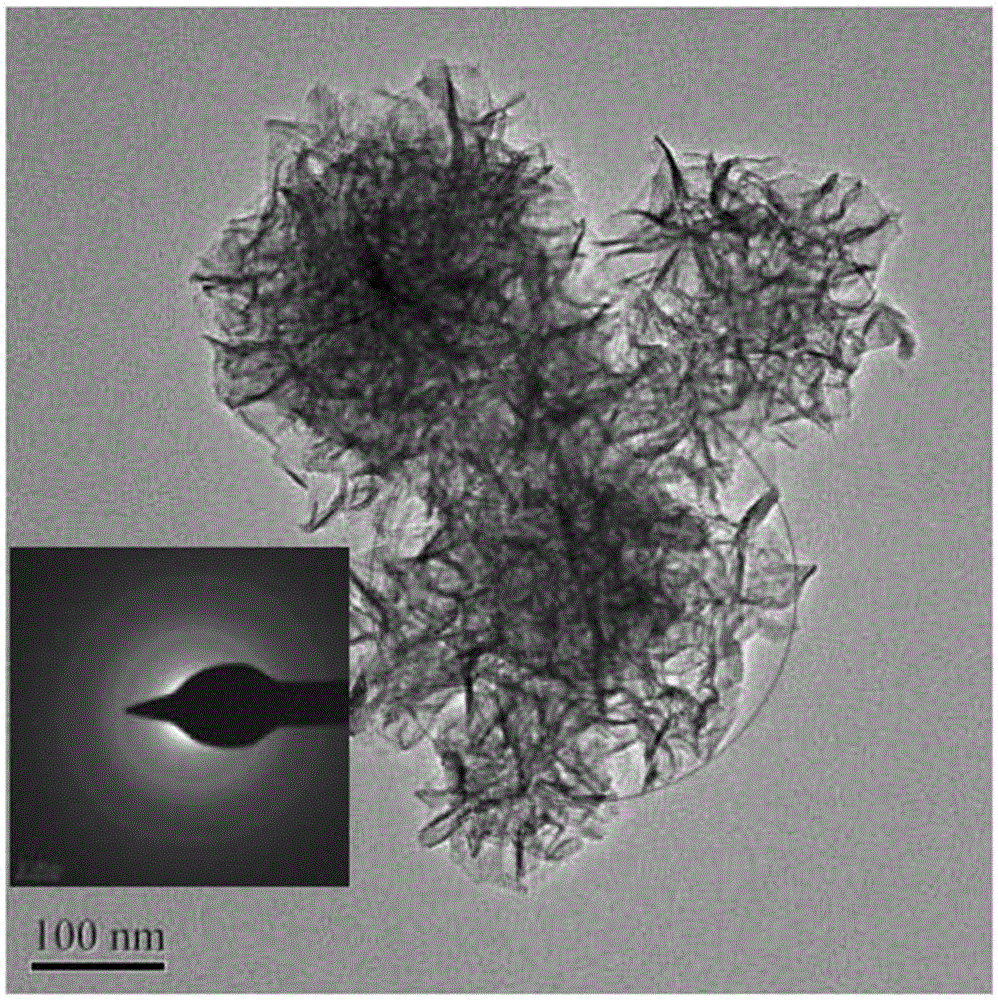

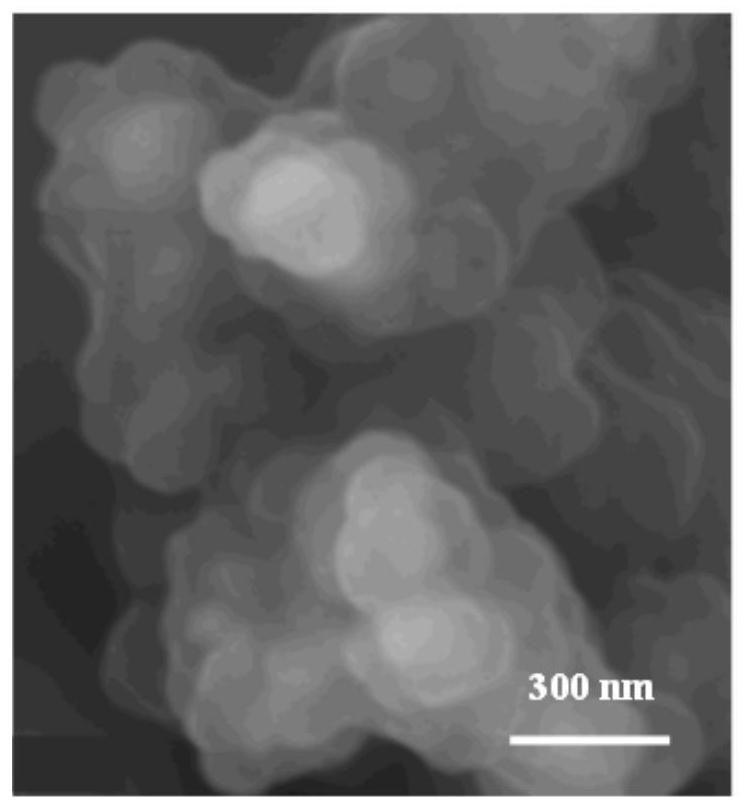

Yolk-shell structure tin dioxide-nitrogen-doped carbon material and preparation method thereof

ActiveCN103367719AImprove conductivityImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesTin dioxideYolk

The invention relates to a yolk-shell structure tin dioxide-nitrogen-doped carbon material and a preparation method thereof, belonging to the technical field of lithium ion battery electrode material. The yolk-shell structure SnO2@void@N-C material takes porous submicron tin dioxide SnO2 as a core and has the diameter of 200-400 nanometers; nitrogen-doped carbon (N-C) is taken as a shell, and the thickness of the shell is 15-20 nanometers; a cavity has the inner diameter of 300-500 nanometers; in the N-C shell, the mass percent of N element is 8-12%. The porous SnO2 core shortens the lithium ion diffusion path; the volume change of SnO2 can be effectively buffered by a gap between the SnO2 core and a carbon layer in the charge-discharge process, and the N-C can effectively improve the electrical conductivity of the material, so that the yolk-shell structure tin dioxide-nitrogen-doped carbon material has excellent electrochemical cycle stability. The thickness of the carbon layer can be regulated and controlled by controlling the concentration of dopamine or the auto-agglutination time, and the size of the gap can be regulated and controlled by controlling the quantity of tetraethoxysilane; the preparation method can well control the structure of the material, and is simple in technology and convenient to operate.

Owner:BEIJING UNIV OF CHEM TECH

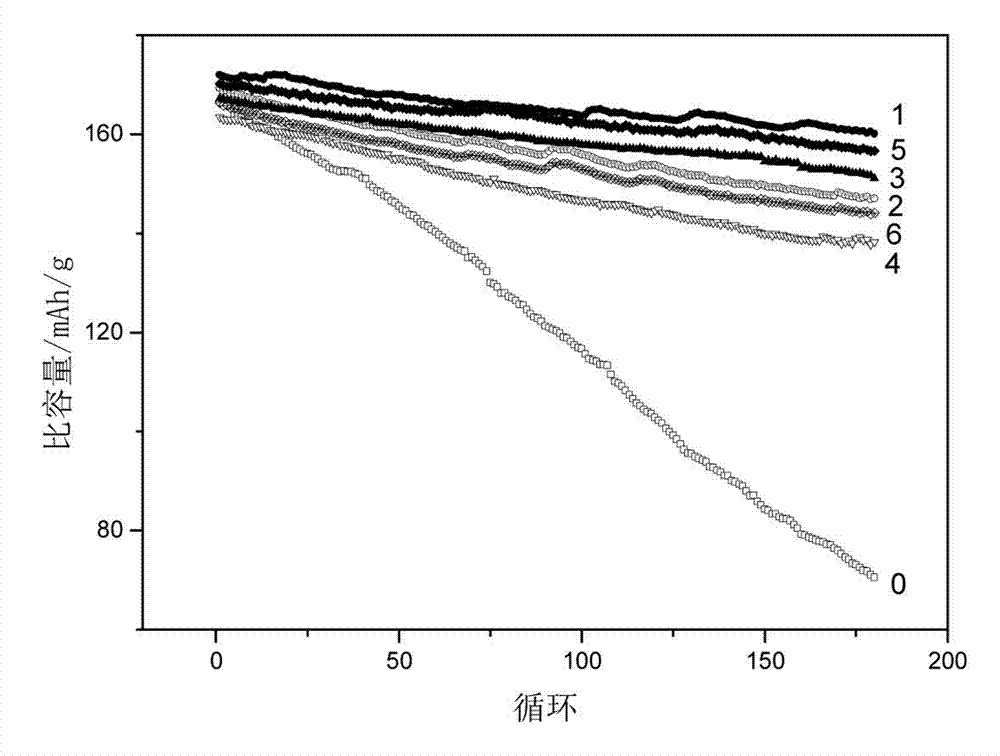

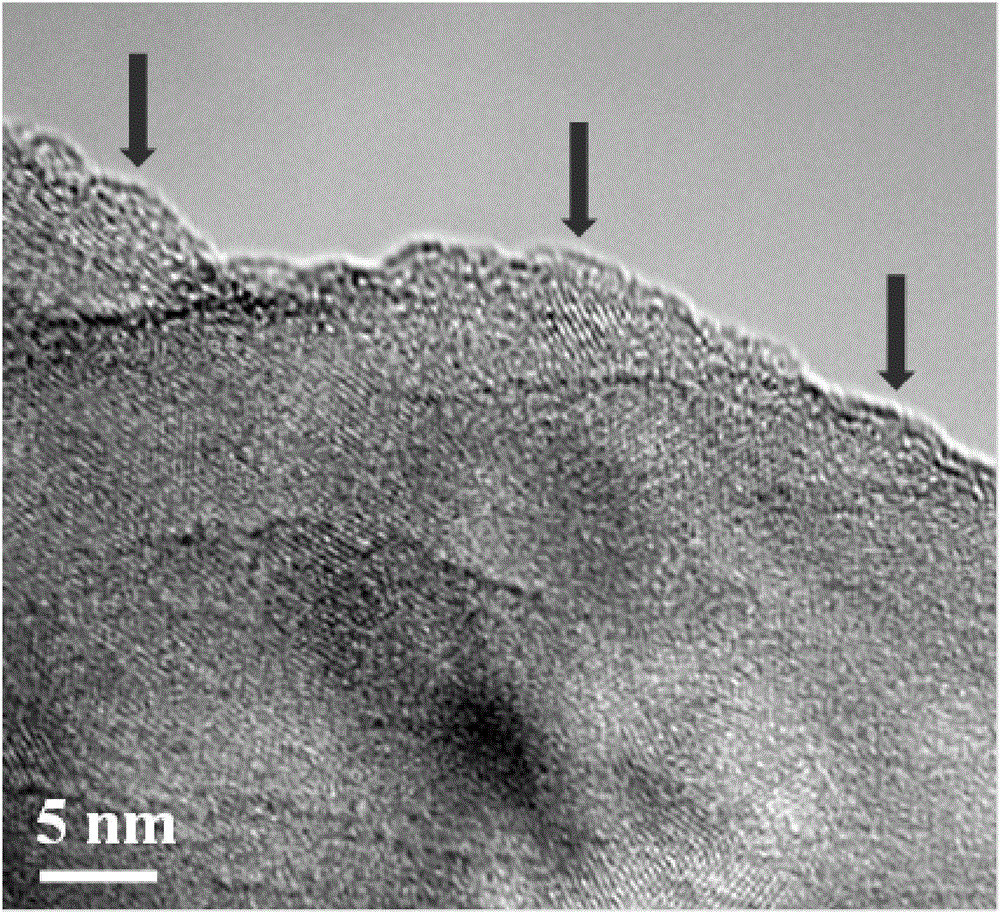

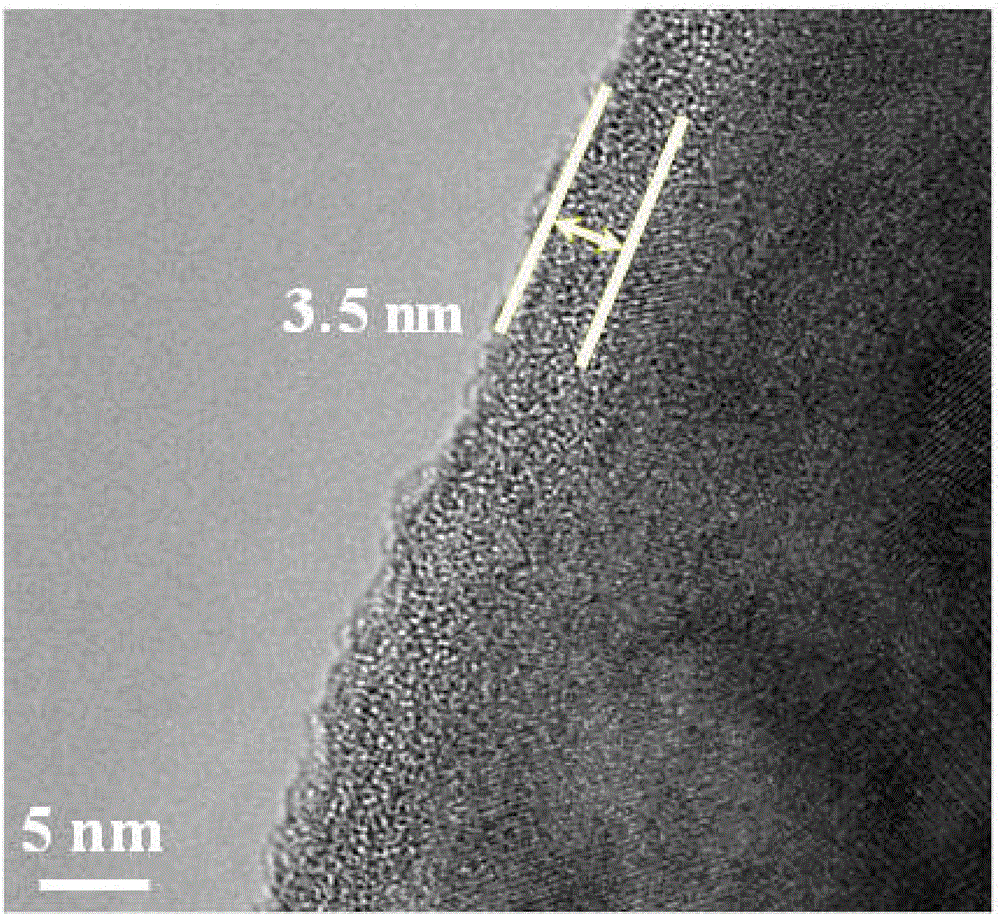

Preparation method of alumina coated lithium cobaltate positive electrode material

ActiveCN104201323AAvoid direct contactImprove electrochemical cycle stabilityElectrode manufacturing processesSecondary cellsAluminium hydroxideVapor phase

The invention discloses a preparation method of an aluminum oxide coated lithium cobaltate positive electrode material, and the lithium cobaltate surface is evenly coated with an alumina thin film by vapor phase deposition method. The preparation process is as follows: mixing evenly an aluminum-containing compound and lithium cobaltate in a converter, heating the aluminum-containing compound for vaporization, then introducing water vapor to allows the aluminum-containing compound to be hydrolyzed into aluminum hydroxide for deposition onto the lithium cobaltate surface, and heating to obtain the aluminum oxide coated lithium cobaltate positive electrode material. The method has the advantages that the preparation process is simple and suitable for large-scale production, the synthesized aluminum oxide coated lithium cobaltate positive electrode material is coated evenly with the alumina and excellent in cycle stability.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

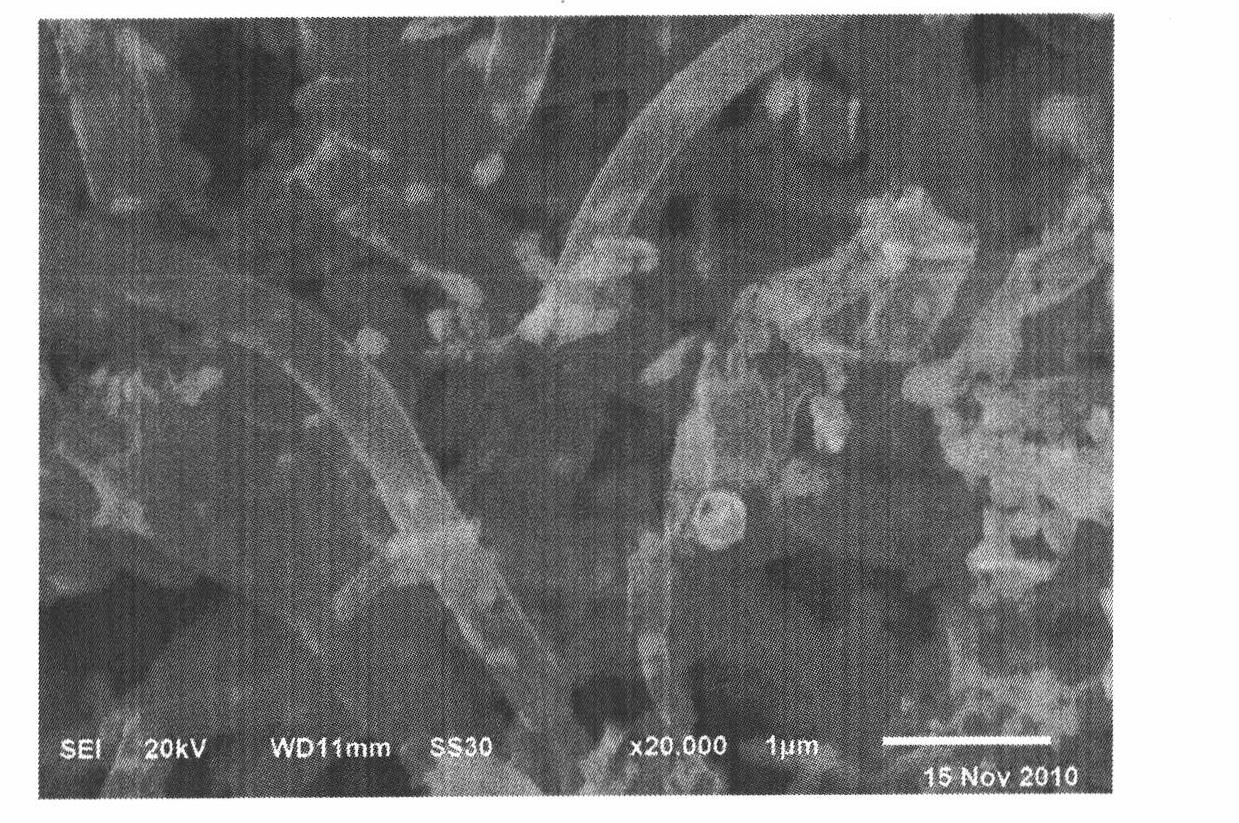

Method for preparing lithium ion battery cathode material ZnFe2O4/C nano fibers

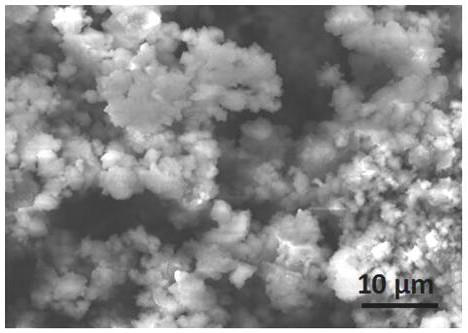

InactiveCN102154739AControl diameterSolve reunionCell electrodesFilament/thread formingFiberCyclic process

The invention discloses a method for preparing lithium ion battery cathode material ZnFe2O4 / C nano fibers. The method has the advantages that: 1, the preparation process flow is short, the diameter of the nano fibers can be controlled more effectively, nano fiber precursors with regular structure are obtained, and the lithium ion battery cathode material ZnFe2O4 / C nano fibers with uniform structure are prepared by combining different change of two polymers in the calcining process; and 2, the prepared lithium ion battery cathode material ZnFe2O4 / C nano fibers are apparently nano fibers, the diameter of the nano fibers is about 200 to 400 nanometers, ZnFe2O4 nano granules are distributed in the continuous phase of carbon in the internal structure, and meanwhile, because of the carbon, the volume change in the electrode circulating process is greatly relieved, the problem of granule agglomeration in the circulating process is solved and the electrochemical circulating stability is improved.

Owner:XIANGTAN UNIV

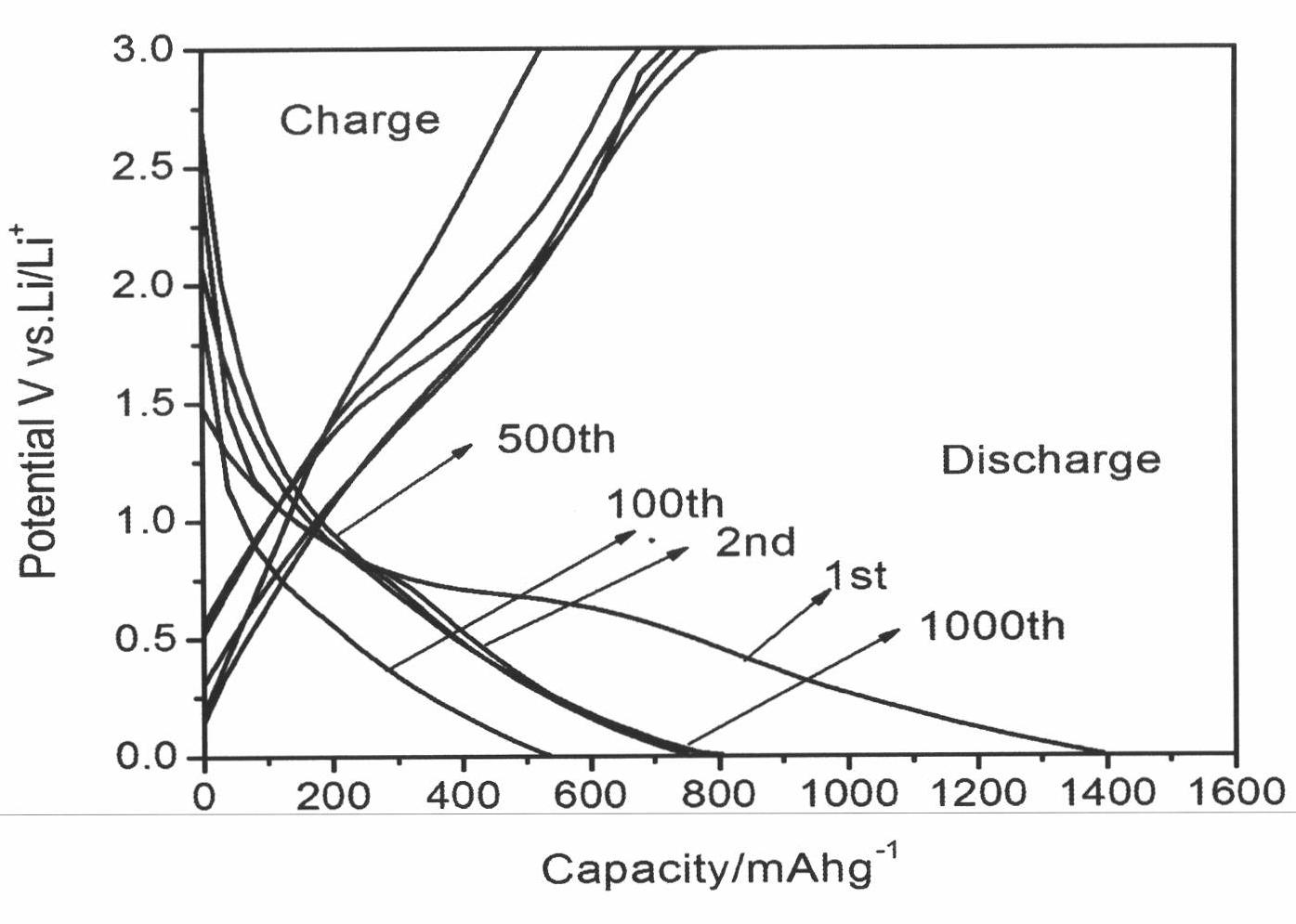

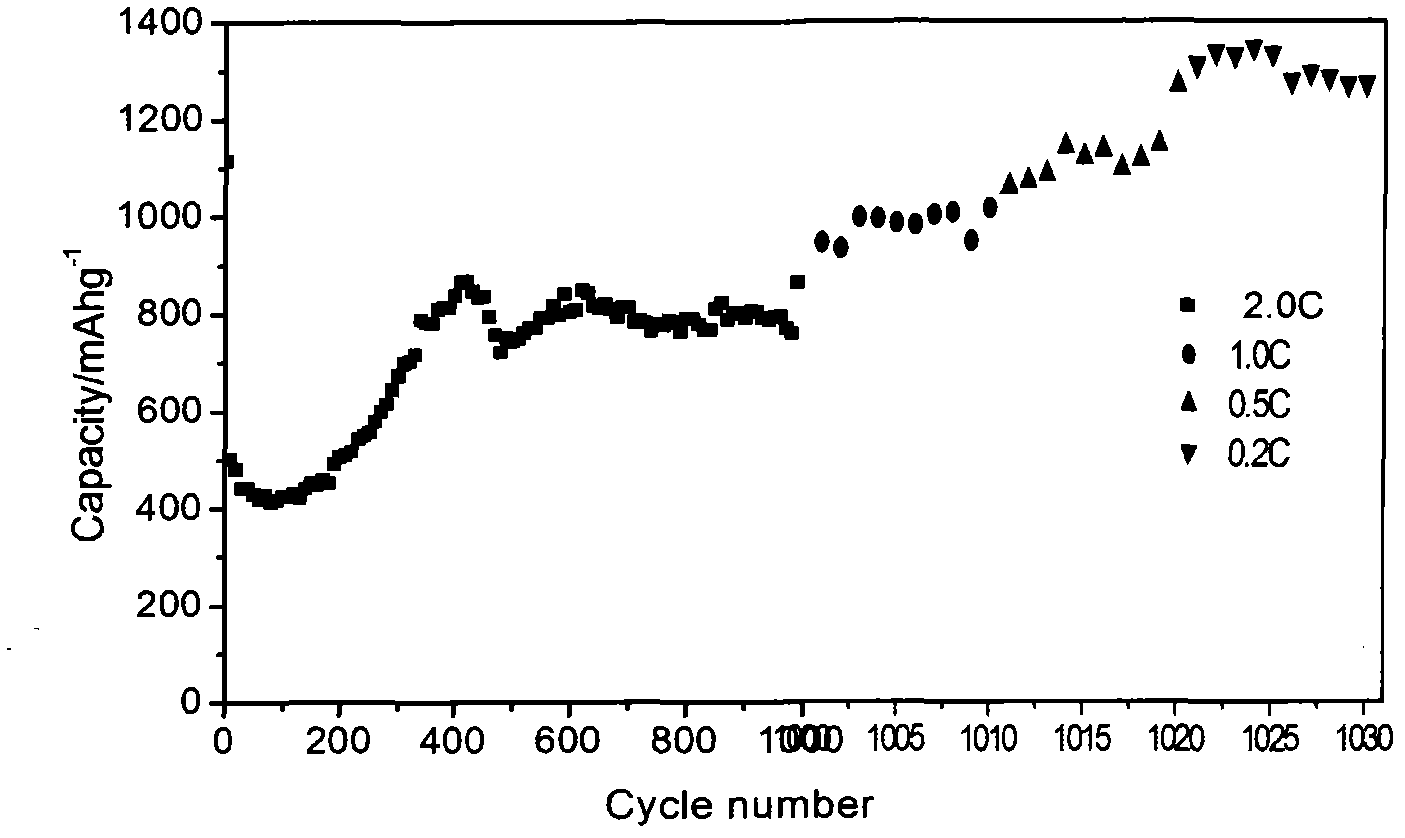

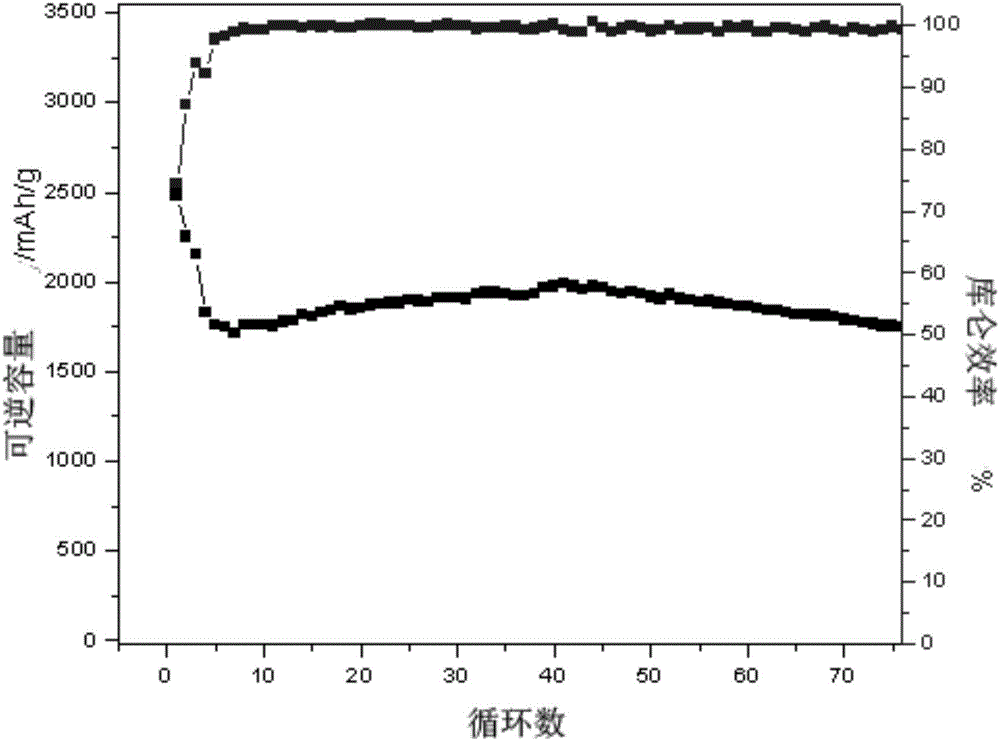

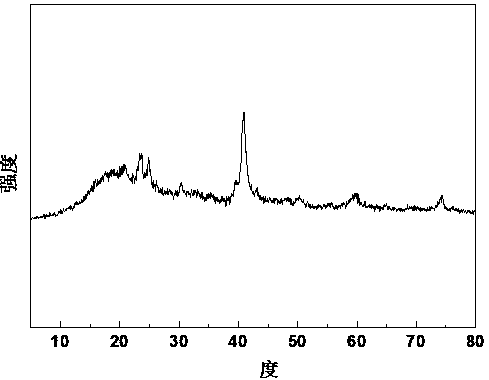

Phosphorus/carbon composite negative electrode material of lithium ion battery and preparation method thereof

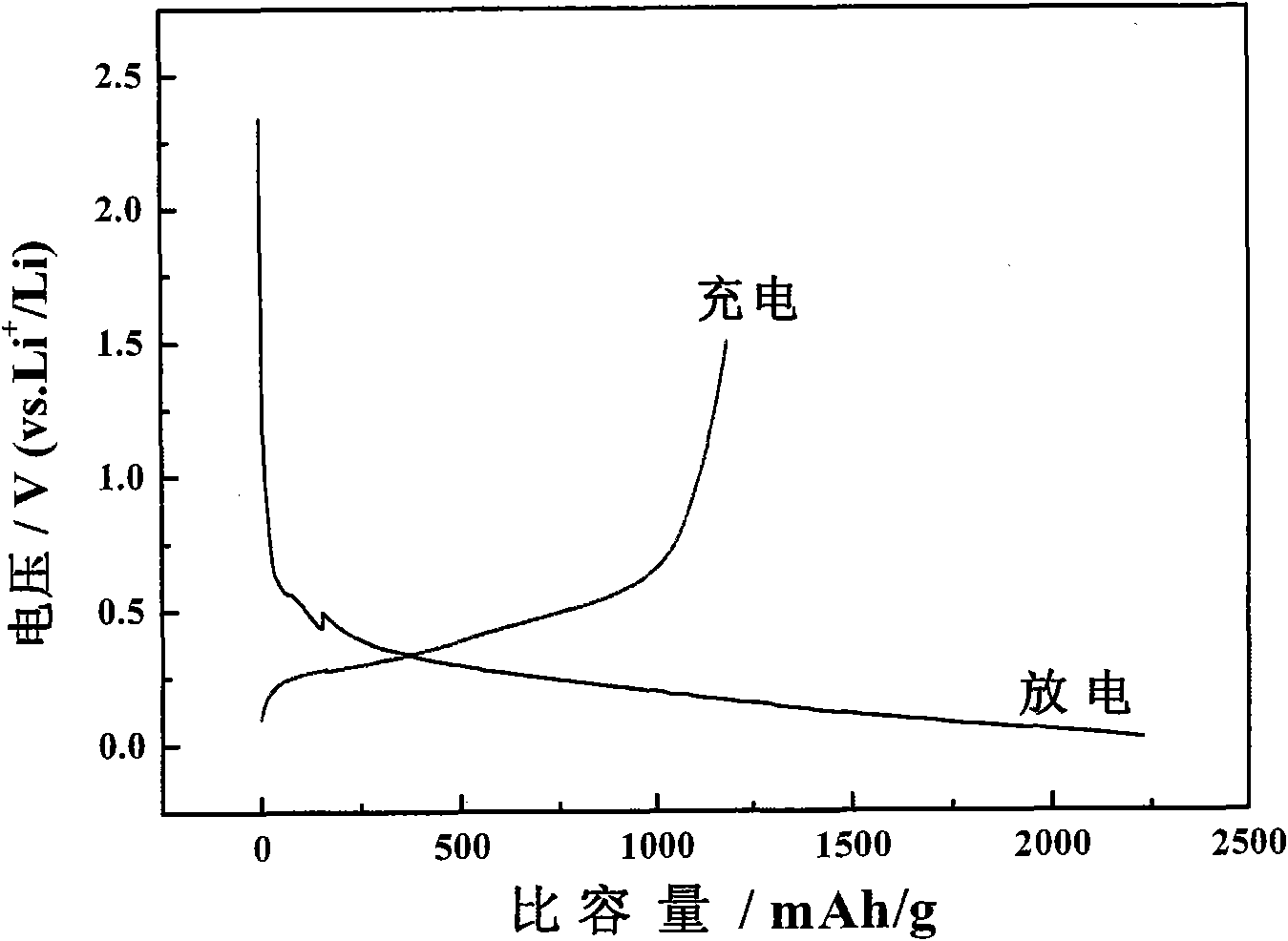

InactiveCN101604752AHigh reversible specific capacityGood electrochemical cycle stabilityElectrode manufacturing processesSource materialCarbon source

The invention discloses a phosphorus / carbon composite negative electrode material of a lithium ion battery and a preparation method thereof, which belong to the technical field of electrode materials of the lithium ion batteries and preparation thereof. In the composite material, the mass ratio of P to C is 8 / 2-4 / 6, and the composite material has an amorphous structure containing P-C chemical bonds. A phosphorus source material and a carbon source material are mixed according to the mass ratio of the P to the C of 8 / 2-4 / 6; then the mixed material is added into a stainless steel tank; stainless steel balls are added into the mixed material according to the mass ratio of the mixed material and the stainless steel balls of 1:20-1:80; and the ball milling is performed for 5 to 30 hours under the protection of nitrogen to obtain the phosphorus / carbon composite material. The phosphorus / carbon composite material has higher reversible specific capacity and good electrochemical cycle stability; and the material has simple process and convenient operation, and is easy to realize mass industrial production.

Owner:BEIJING UNIV OF CHEM TECH

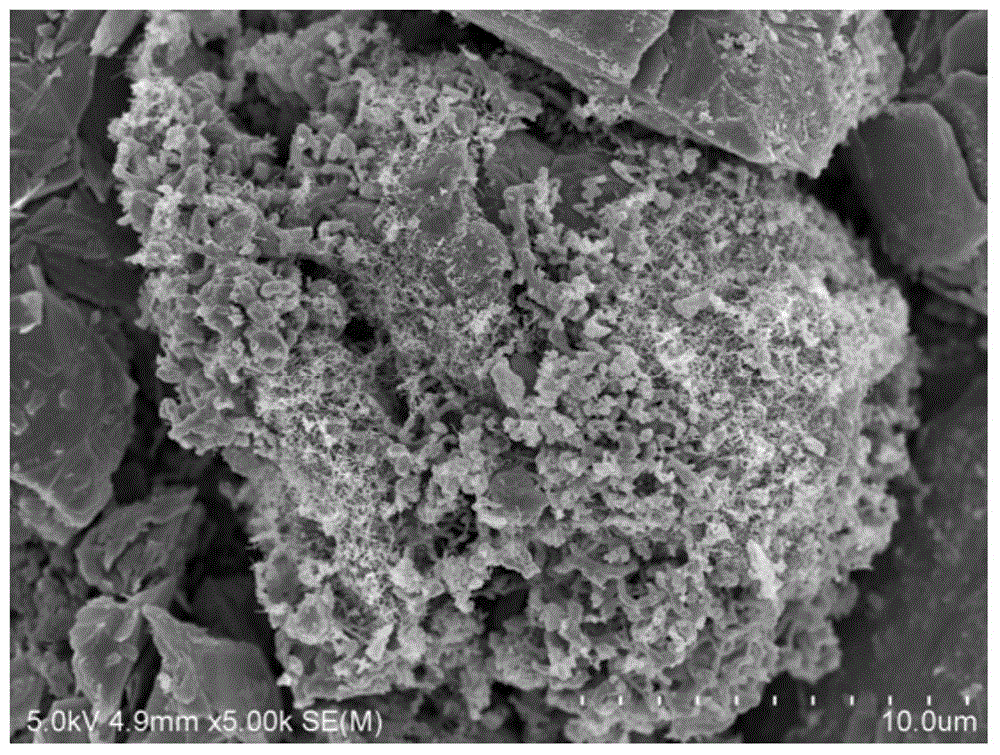

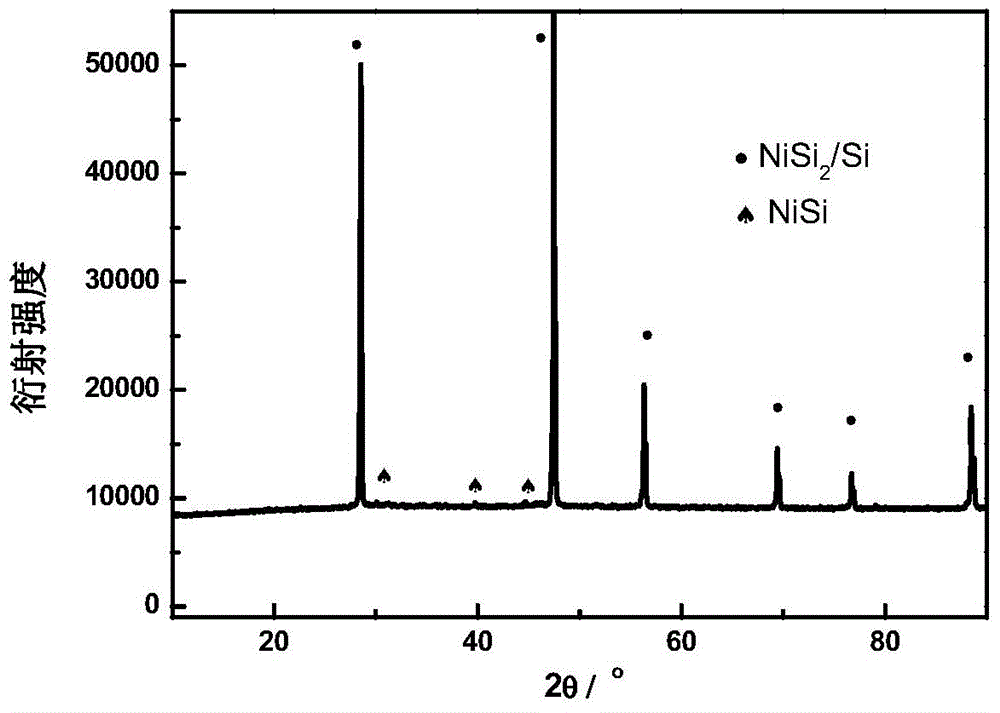

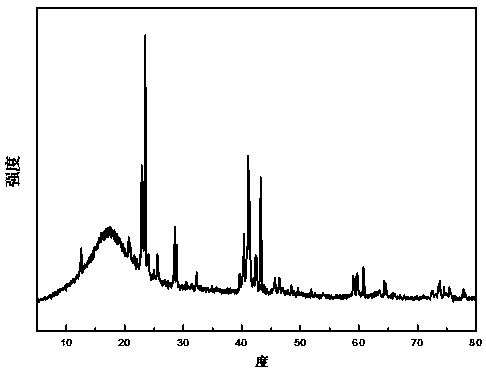

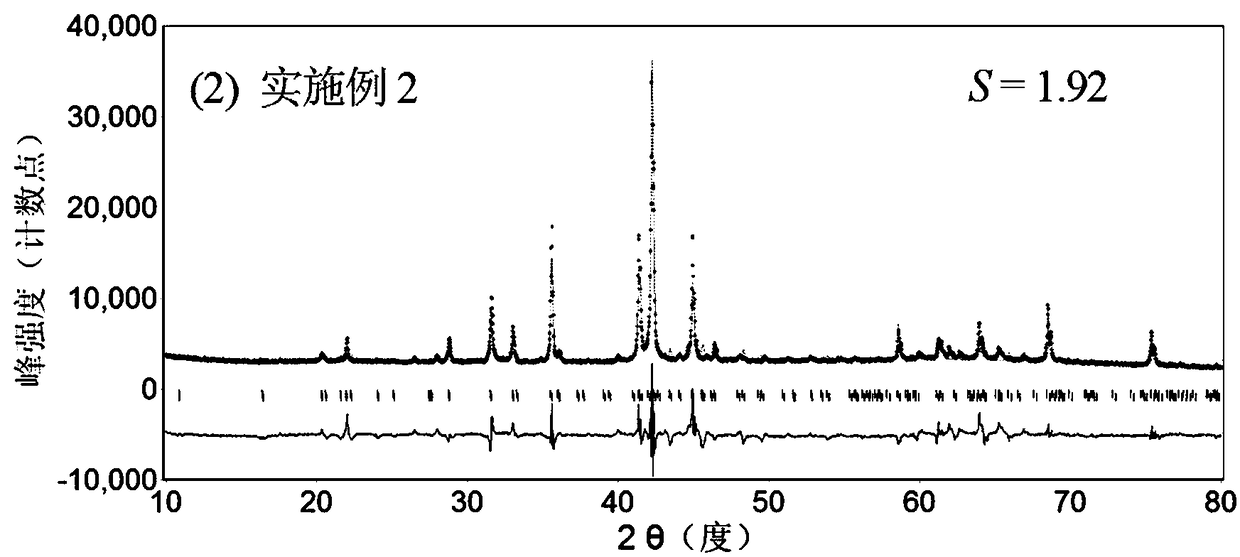

Nano silicon metal composite material and preparation method thereof

ActiveCN104617278AControl the degree of metallurgical bondingImprove electrochemical cycle stabilityMaterial nanotechnologyCell electrodesElectrolysisSilicon oxygen

A nano silicon metal composite used for a negative electrode of a lithium ion battery comprises the following parts: (a) the first component part is simple substance silicon with the content accounting for 5-75mol% of the nano silicon metal composite; (b) the second component part contains a metal element, a compound formed and a silicon oxygen compound formed by the metal element and silicon, the second component part content accounts for 25 to 95mol% of the nano silicon metal composite; and (c) the third component part is simple substance carbon with the content accounting for 0-70mol% of the nano silicon metal composite. The preparation method is as follows: a porous block, comprising silica and metal or metal oxide and the like, and a conductive negative electrode current collector are compounded as a negative electrode, graphite or an inert positive electrode is used as a positive electrode, the negative electrode and the positive electrode are placed in a mixed salt melt electrolyte using CaCl2 or CaCl2 as the main components, voltage is applied between the negative electrode and the positive electrode, current density and electrolytic quantity are controlled, silica in the porous block is electrolyzed and reduced into nano silicon, and a nano silicon metal composite material is prepared on the negative electrode.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

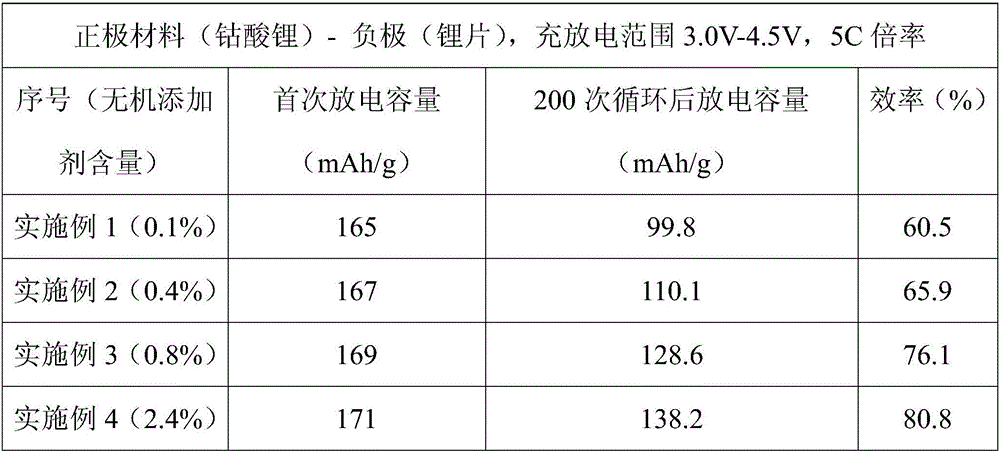

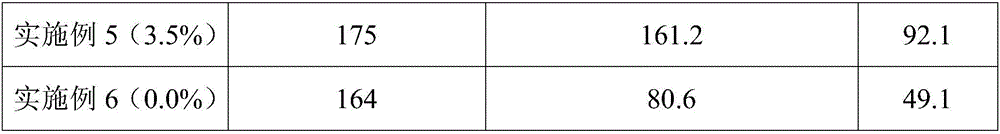

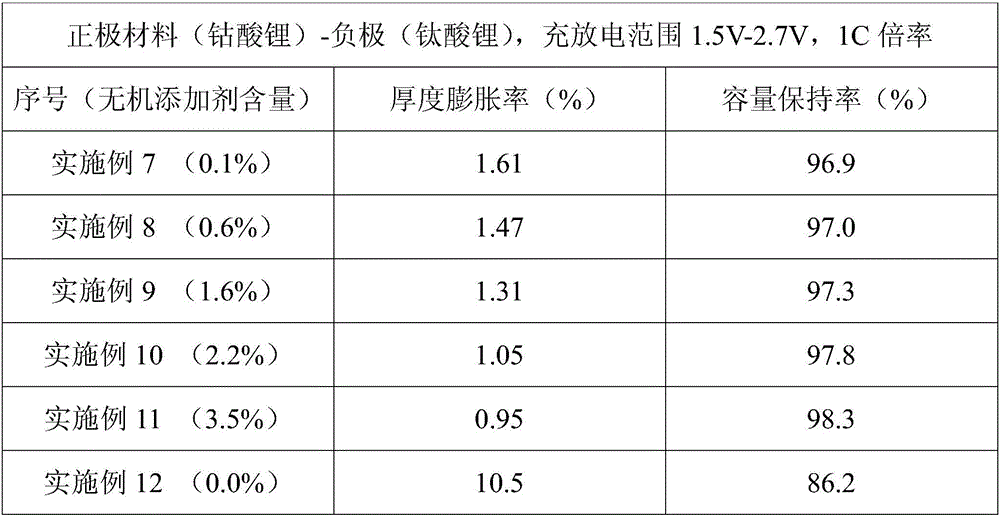

Electrolyte containing inorganic additive and lithium-ion battery containing electrolyte

InactiveCN105938919AExtend your lifeImprove cycle performanceSecondary cellsSilicon oxideSide reaction

The invention discloses an electrolyte containing an inorganic additive and a lithium-ion battery containing the electrolyte. The electrolyte comprises an organic solvent, a lithium salt electrolyte, the inorganic additive and an organic additive; the inorganic additive is one or a mixture of two or more of dry aluminum oxide, dry silicon oxide, dry magnesium oxide, dry zinc oxide and dry titanium dioxide and has the particle size less than 100 nm. The electrolyte provided by the invention can reduce the surface activity of a cathode material, thereby suppressing side reaction between an electrode material and the electrolyte, increasing a battery charging voltage and improving the cycle comprehensive performance of the electrolyte, can improve wettability and good imbibition of the electrolyte for a diaphragm and suppress a micro-short circuit, can efficiently improve the electrochemical performance of a lithium battery for neutralizing free harmful gases such as hydrogen fluoride and fluorine gas, and can reduce water content in the electrolyte.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Surface modification method for silicon negative electrode material of lithium ion battery, silicon negative electrode material and application

ActiveCN106328913AImprove electrochemical cycle stabilityImprove bindingCell electrodesSecondary cellsCyclic processEffective surface

The invention relates to a method for improving the surface performance of a lithium ion battery silicon negative electrode material. By performing effective surface modification on a silicon negative electrode material, a layer of continuous, uniform and dense silicon oxidizing film can be formed on the surface, so as to form a rich hydroxyl functional group on the surface of the silicon oxidizing film, and by selecting a binder with a specific functional group, the functional group in the binder and the hydroxyl functional group on the surface of the silicon oxidizing film can form a hydrogen bond with relatively strong acting force, so that the binder can be firmly attached to the surfaces of silicon particles, and therefore, on the one hand, the complete conductive network of an electrode can be maintained in the cyclic process, and on the other hand, contact between an electrolyte and the silicon particles can be prevented, thus reducing decomposition of the electrolyte and further improving the electrochemical cyclic stability of the silicon negative electrode.

Owner:江苏载驰科技股份有限公司

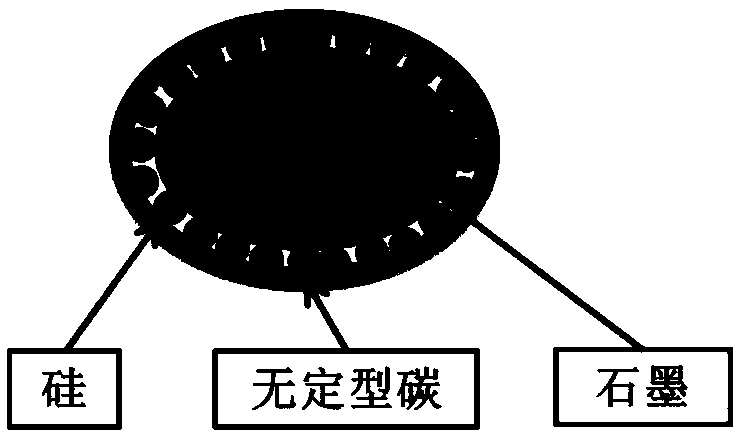

Preparation method of silicon-carbon anode material and lithium ion battery

The invention discloses a preparation method of a silicon-carbon anode material and a lithium ion battery. The preparation method includes: mixing nano-silicon with graphite solid phase, sieving the mixture, mixing the mixture with an amorphous carbon precursor solid phase, sieving the mixture, performing vibrating shaping, and sintering the product to obtain the silicon-carbon anode material. Bymeans of sieving, the graphite, nano-silicon and amorphous carbon precursor are dispersed, so that the surface of graphite can be uniformly coated with the nano-silicon and the surface of nano-siliconcan be uniformly coated with the amorphous carbon precursor; through the vibrating shaping, surface-to-surface contact between the amorphous carbon precursor and the nano-silicon and between the nano-silicon and the graphite is achieved without existence of a gap; through the sintering step, a volatile substance can be slowly volatilized from interior to exterior, so that a problem of forming pores since a huge gas pressure is generated from the volatile substance can be avoided. The silicon-carbon anode material, when being used for producing the lithium ion battery, shows excellent electrochemical cyclic stability.

Owner:湖北融通高科先进材料集团股份有限公司

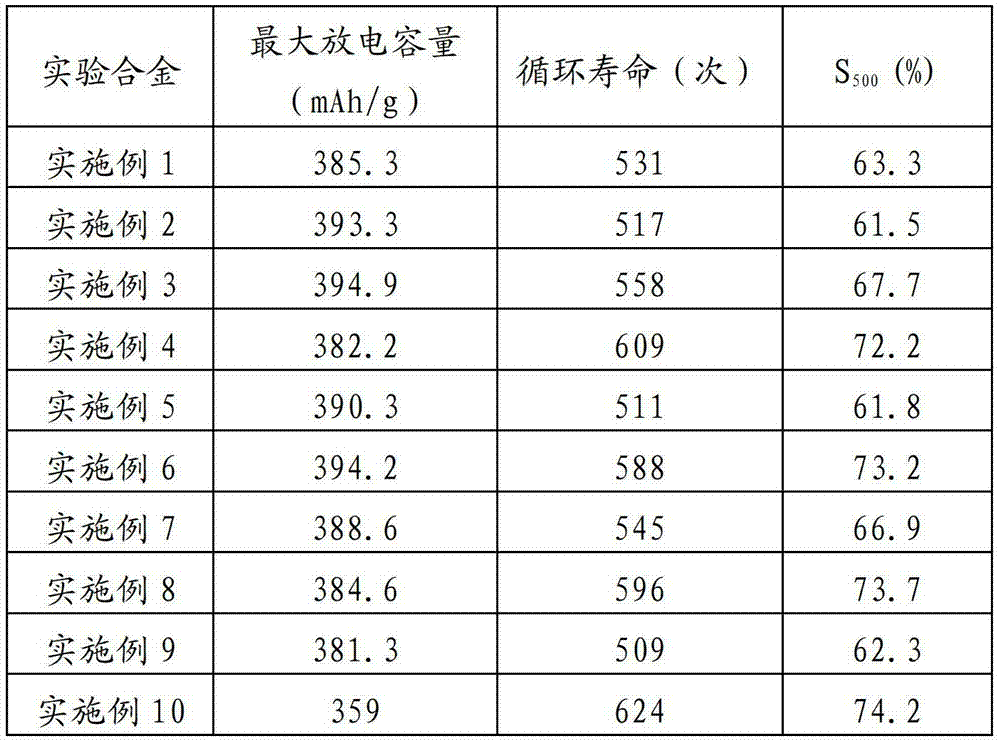

Power battery hydrogen storage electrode alloy and preparation method thereof

ActiveCN103165873AImprove electrochemical cycle stabilityStrong anti-powdering abilityAlkaline accumulator electrodesRare-earth elementElectrochemistry

The invention provides a power battery hydrogen storage electrode alloy and a preparation method of the power battery hydrogen storage electrode alloy. The power battery hydrogen storage electrode alloy is formed by low magnesium multi-rare-earth components, the chemical formula is RE1-xMgxNiyAlz, wherein 0.15<=x<=0.2, 3.3<=y<=3.8, and 0.05<=z<=0.15, and the rare earth elements (RE) are at least two elements selected from La, Ce, Sm, Y and Nd. The preparation method is that in inert gas shielding, induction heating smelting is adopted, melting alloy is poured into a tundish and sprayed on the surface of a water-cooling copper roller rotating at a certain speed through a nozzle at the bottom of the tundish to obtain rapid-quenching alloy, and then vacuum annealing is carried out in a vacuum heat treatment furnace. Combined action of the rare earth elements is fully used, the power battery hydrogen storage alloy is prepared by adoption of vacuum melting, the inert gas shielding and the rapid-quenching technology, electrochemical cycling stability of the alloy is improved, and the power battery hydrogen storage electrode alloy and the preparation method of the power battery hydrogen storage electrode alloy have the advantages that the technology is easy to master and suitable for mass production.

Owner:CENT IRON & STEEL RES INST

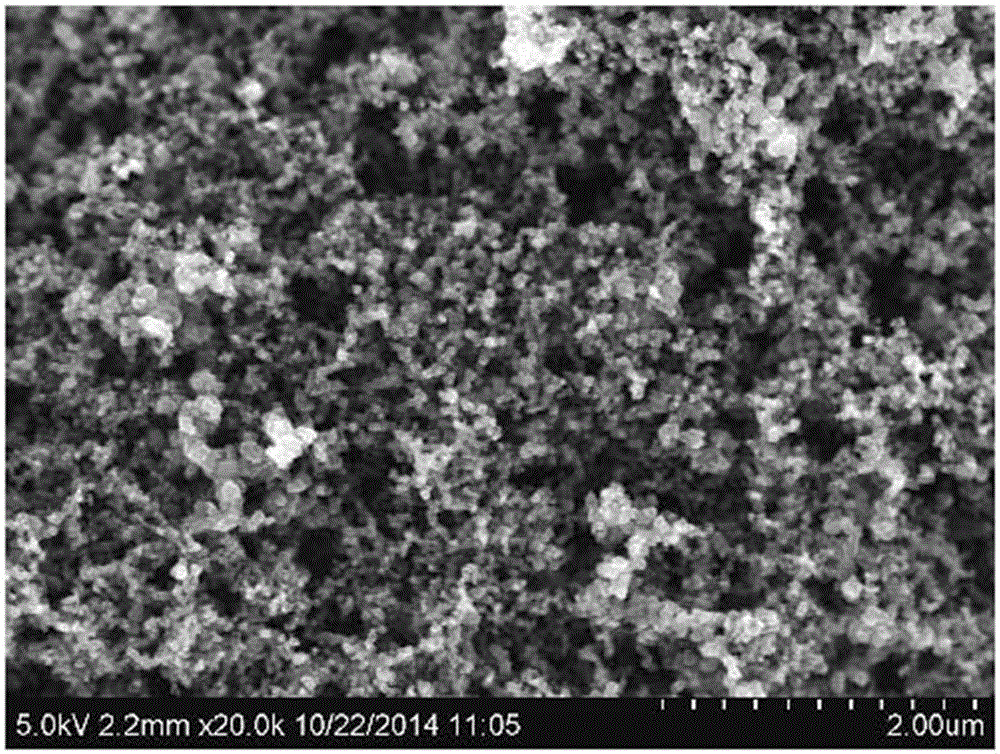

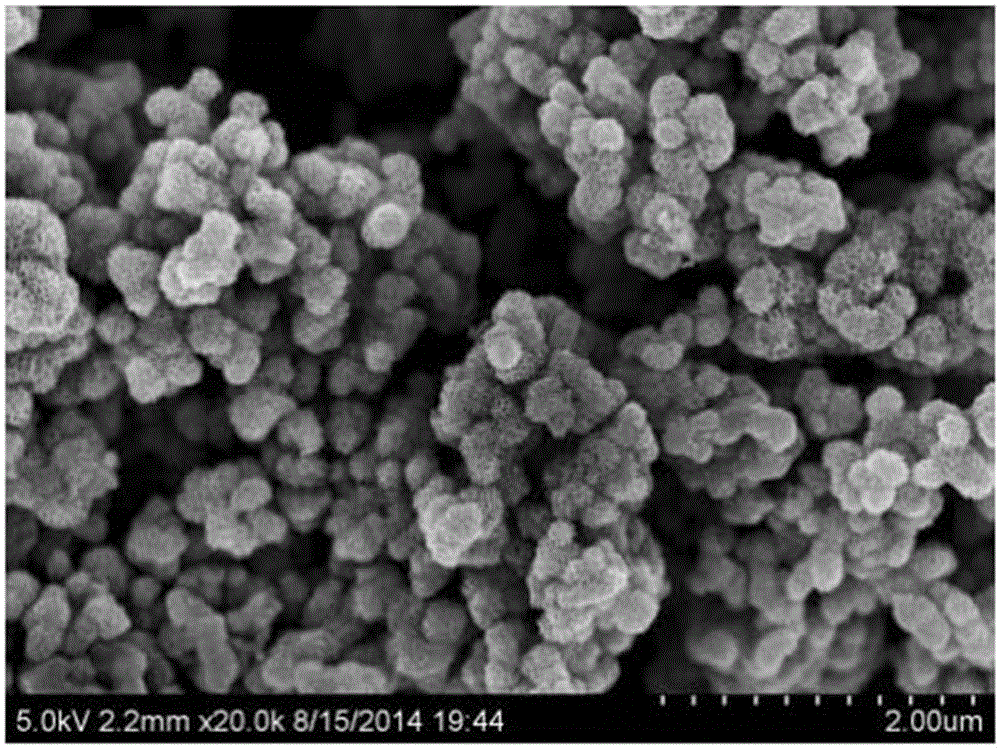

Manganese dioxide/carbon composite electrode material and preparation method thereof, and super capacitor

ActiveCN105047419AEfficient conductionHigh specific capacitanceHybrid capacitor electrodesHybrid/EDL manufactureCarbon compositesManganese

The invention provides a manganese dioxide / carbon composite electrode material. The manganese dioxide / carbon composite electrode material is a core-shell structure and comprises carbon black particles, and a plurality of manganese dioxide nanosheets. The grain diameter of the carbon black particle is 3 to 8 nm. The manganese dioxide nanosheets are extended out from the surface of the carbon black particle and are connected with each other to form a coralloid porous shell to coat the carbon black particles. The invention further provides a preparation method of the manganese dioxide / carbon composite electrode material and a super capacitor.

Owner:TSINGHUA UNIV

Preparation method of high-efficiency negative active material for lithium ion secondary battery

ActiveCN109786670AImprove first week coulombic efficiencyImprove electrochemical cycle stabilityCell electrodesSecondary cellsSilicon alloyHigh energy

The invention relates to a preparation method of a high-efficiency negative active material for a lithium ion secondary battery. Lithium-silicon alloys Li4.4Si, Li3.25Si and Li1.71Si are prepared by high-energy ball milling. The preparation method is simple, pollution-free and high in safety. At the same time, a suitable solvent is added in the high-energy ball milling to serve as a lubricant, thereby greatly improving the efficiency of an alloying reaction. A composite material is prepared from a lithium-silicon alloy together with pre-ball-milling silicon powder, graphite and carbon has a unique structure, which inhibits the volume expansion of materials during charging and discharging. Moreover, LixSi has high capacity and higher conductivity than pure silicon, and contains lithium, which can inhibit the formation of an SEI film in the first week and improve the first week coulombic efficiency of materials. Secondly, the experimental results of the invention show that the synthesized LixSi can be transformed into amorphous silicon after lithium removal, thereby effectively alleviating the volume change during charging and discharging, and exhibiting cycle performance far exceeding that of crystalline silicon. The high-efficiency negative active material is environmentally friendly, simple and feasible in preparation method and instrument and equipment, high in safety, and suitable for industrial production.

Owner:NANKAI UNIV

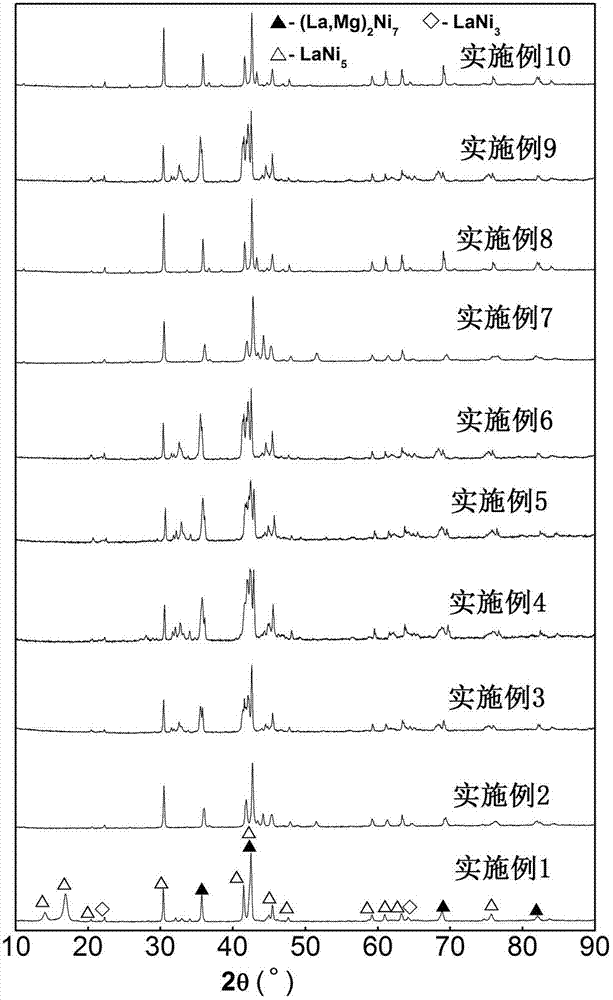

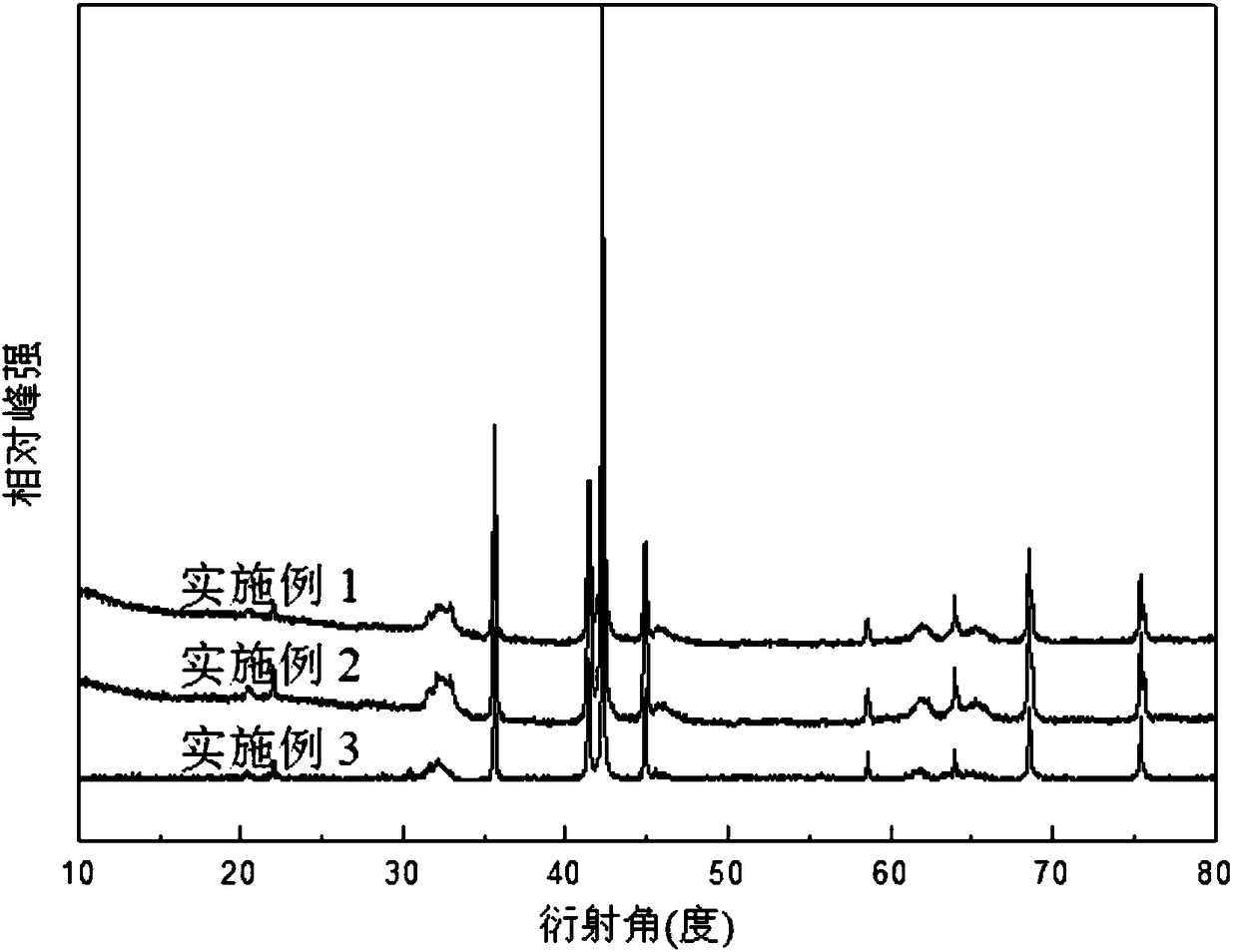

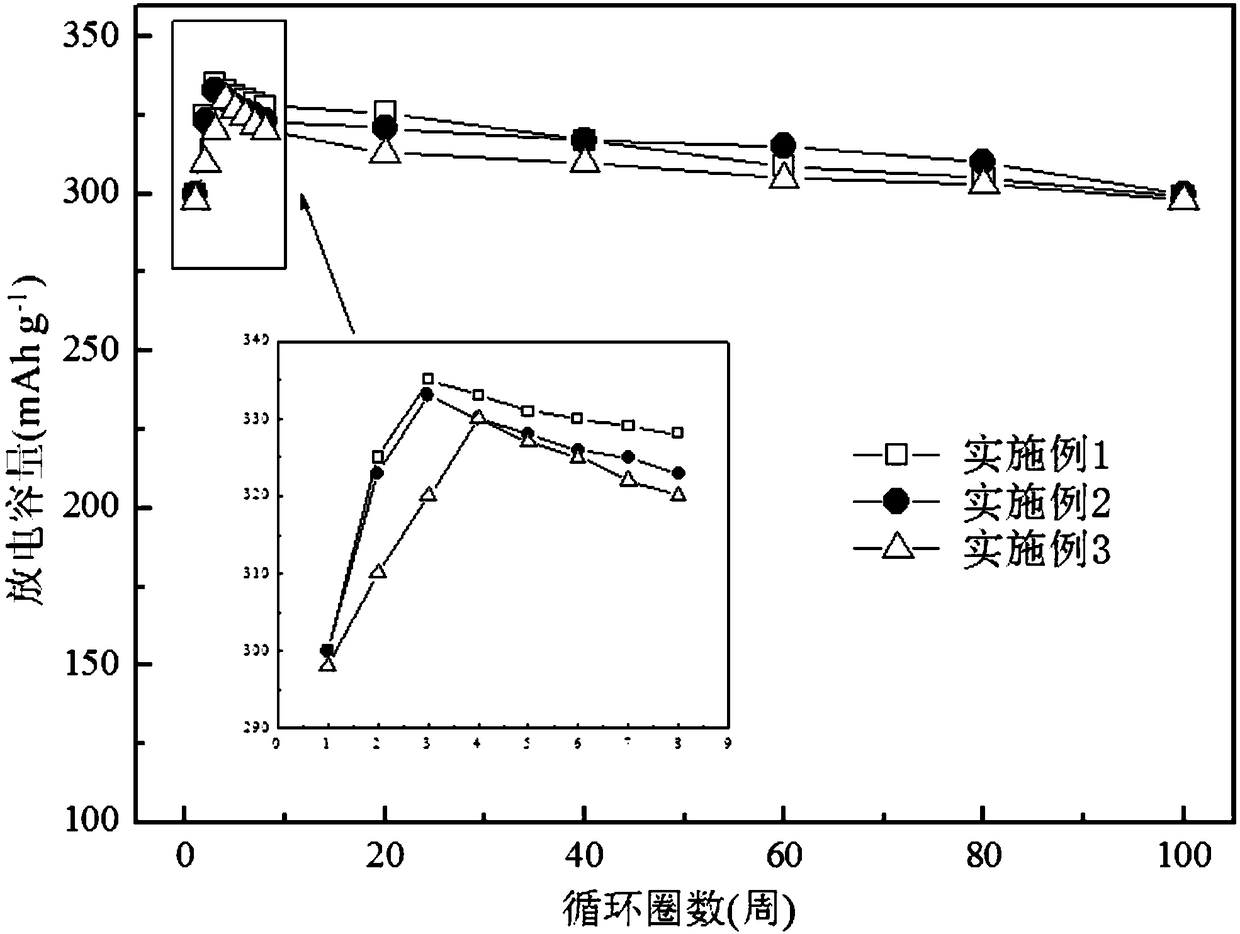

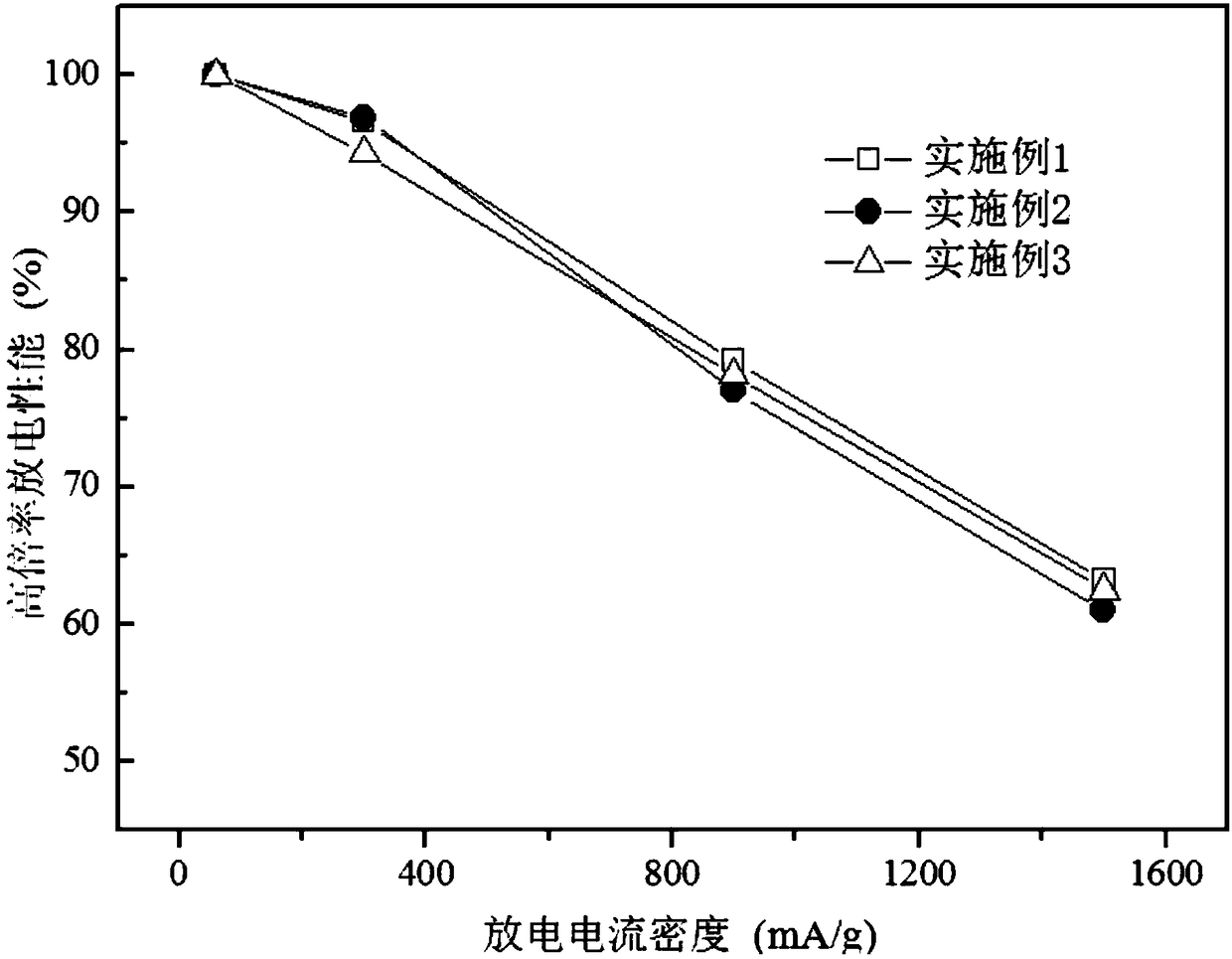

Multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material and preparation method thereof

ActiveCN108172807AImprove electrochemical performanceImprove discharge capacityCell electrodesNickel accumulatorsHigh rateChemical composition

The present invention discloses a multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material. The chemical composition of the material is La<1-a-b-c-d-e>PrNdSm<c>Gd<d>Mg<e>Ni<k-x-y-z>Co<x>Al<y>Mn<z>. The alloy has relatively high discharge capacity, good electrochemical cycling stability and high rate discharge performance, wherein the maximum discharge capacity >=363 mAh / g, capacity retention ratio >=88.8% after 100 charging and discharging cycles, and HRD1500 >=58.2%. The present invention also provides a preparation method of the multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material. A cast alloy is prepared via an induction melting method, and then the alloy is subjected to heat treatment. The method has the advantages of simplicity, stable conditions and good repeatability. The prepared alloy has the advantages of uniform composition, small crystalline grain, intact crystal form, stable structure, application in large-scale production and short preparation period. The present invention can be applied to the preparation of the multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material.

Owner:包头中科轩达新能源科技有限公司

Polyaniline-based MOF nanocomposite flexible supercapacitor and preparation method thereof

ActiveCN107731545AExtended conduction pathImprove electrochemical cycle stabilityMaterial nanotechnologyHybrid capacitor electrodesFiberSlurry

The invention discloses a polyaniline-based MOF nanocomposite flexible supercapacitor and a preparation method thereof. MIL-101 is one of MOF materials with excellent acid-resistance stability. The method provided by the invention comprises the steps that a PANI / MIL-101 composite material is prepared; the PANI / MIL-101 composite material, acetylene black and polyvinylidene fluoride (PVDF) are uniformly dispersed in N-methyl-2-pyrrolidone (NMP) in a certain proportion to form a slurry, and the slurry is coated on carbon fiber cloth to form electrodes; a gel electrolyte is used to symmetrically stack two electrodes, and the middle space is separated by a diaphragm; and the electrodes are packaged to prepare the flexible supercapacitor. The specific capacity of the electrode material is up to1197 F / g. The prepared supercapacitor has only 10% attenuation of the specific capacity after 1000 times of bending. The cyclic stability test 10000 cycles can maintain more than 90% of the specific capacity. Four supercapacitors are connected in series to light up a 1.8V red LED. The flexible supercapacitor prepared by the invention has good flexibility and electrochemical performance, and has agood application prospect in the aspects of flexible electronic devices and energy storage.

Owner:SHAANXI UNIV OF SCI & TECH

Membrane electrode based on spiral carbon nanofiber bundle and preparation method thereof

InactiveCN102306749AHigh reversible specific capacityImproved magnification performanceCell electrodesFiberGas phase

The invention discloses a membrane electrode based on a spiral carbon nanofiber bundle and a preparation method thereof, belonging to the technical field of lithium ion batteries. The membrane electrode comprises a copper coil current collector and the spiral carbon nanofiber bundle growing on the surface of the copper coil current collector, wherein the spiral carbon nanofiber bundle is formed by spirally winding a plurality of carbon nanofibers, and a graphite layer of the carbon nanofibers is vertical to the axial direction of the carbon nanofibers. The preparation method of the membrane electrode comprises the following steps: loading a nickel-based catalyst on the surface of a copper coil; and then growing the spiral carbon nanofiber bundle on the surface of the copper coil by adopting a chemical vapor deposition method. The membrane electrode and the preparation method provided by the invention have the advantages that the unique structure of the membrane electrode enables the membrane electrode to have higher reversible specific capacity, good electrochemical cycle stability and higher multiplying power performance; and the preparation technology is simple, convenient to operate, and easy to implement large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

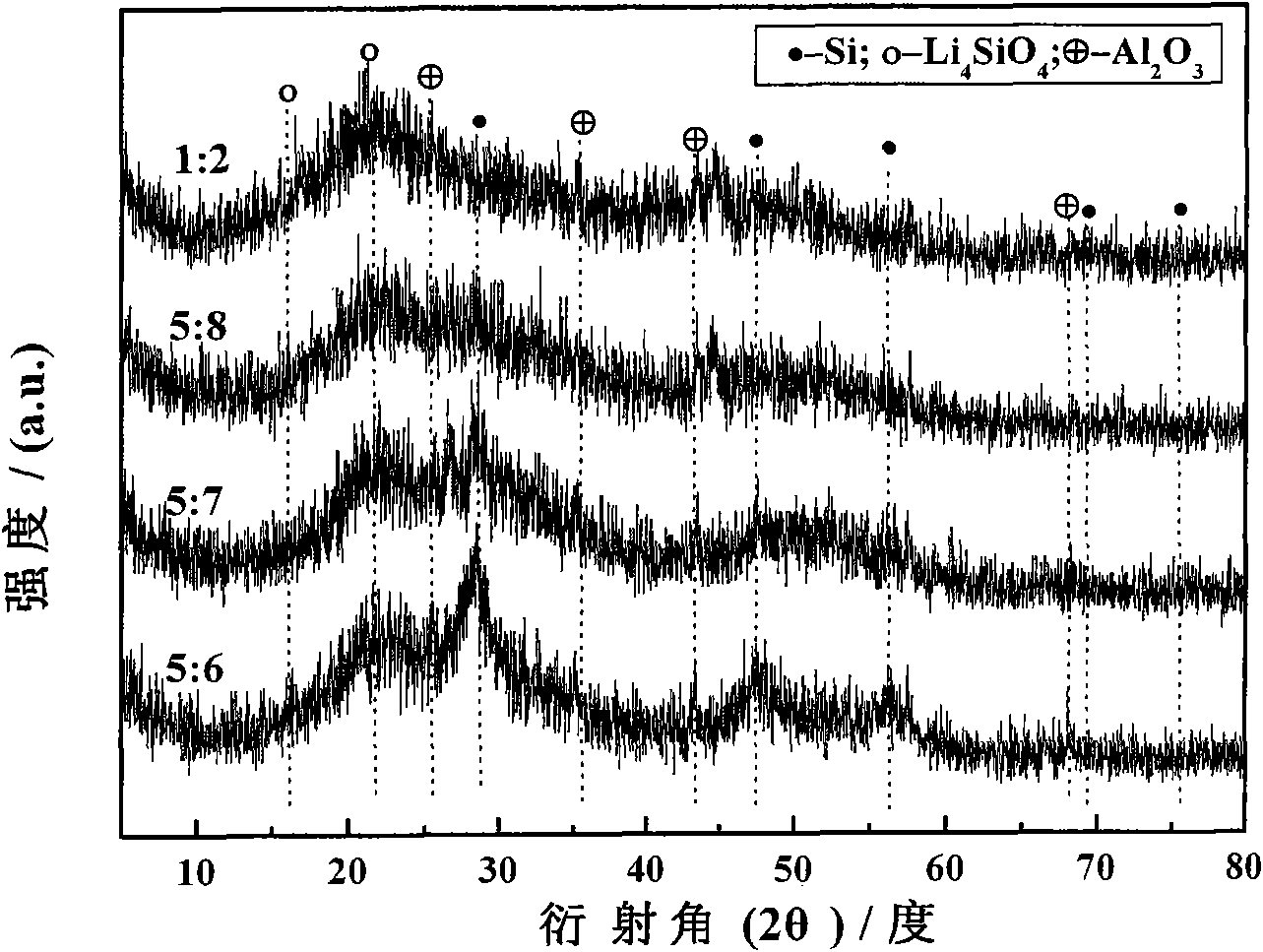

Lithium ion battery silicon oxide composite negative electrode material and preparation method thereof

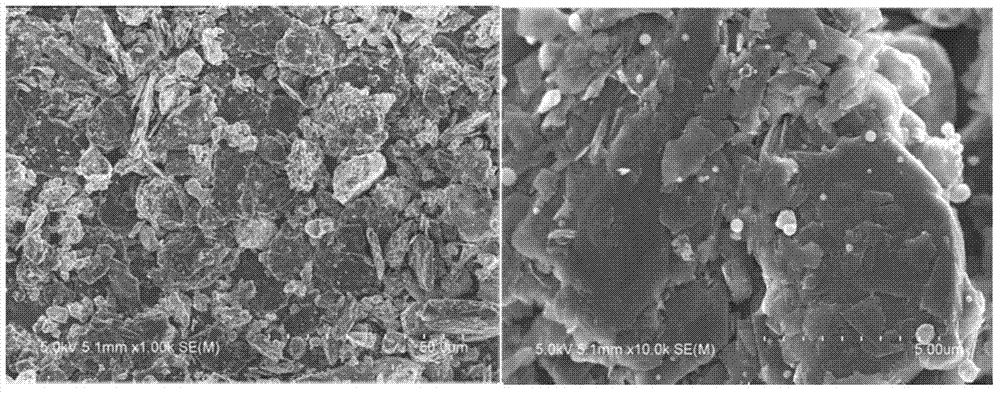

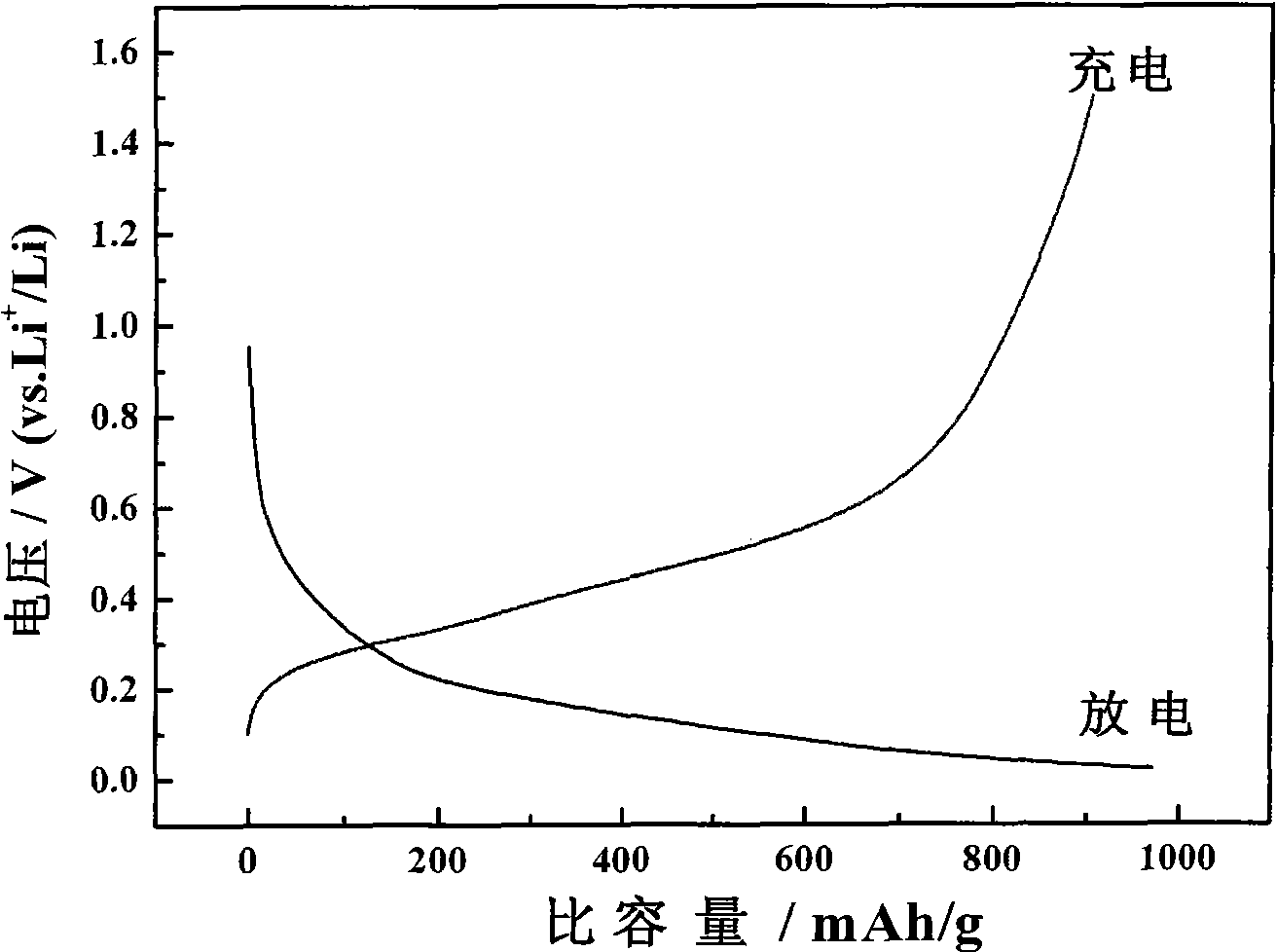

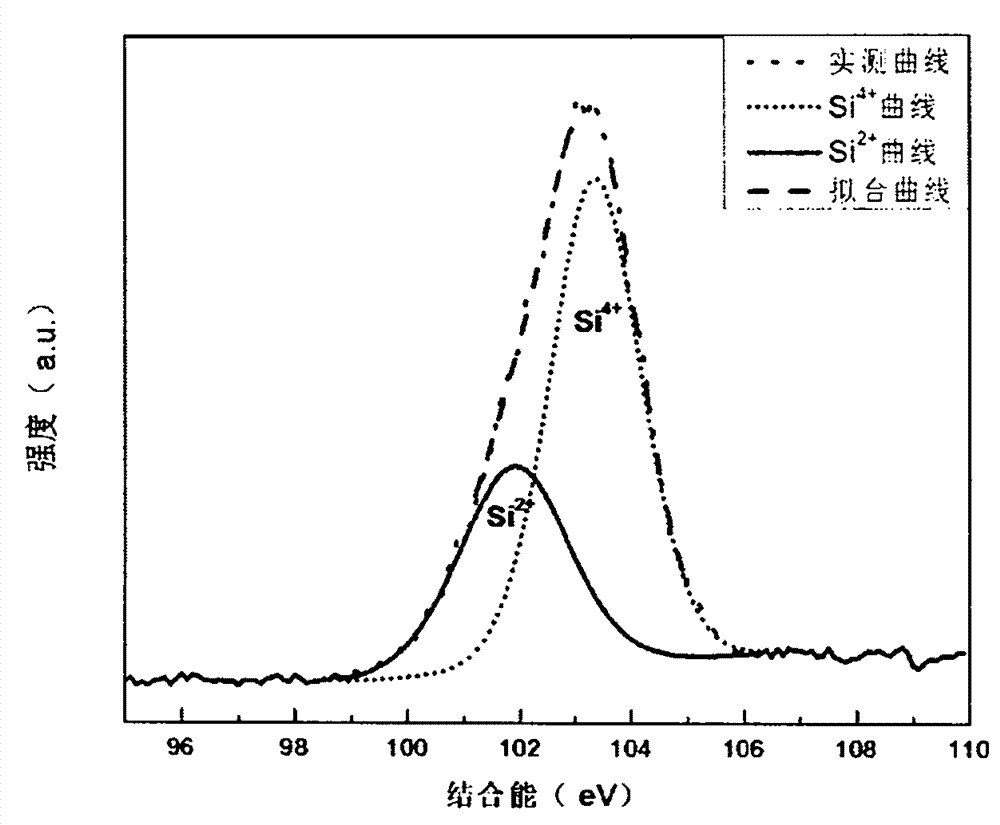

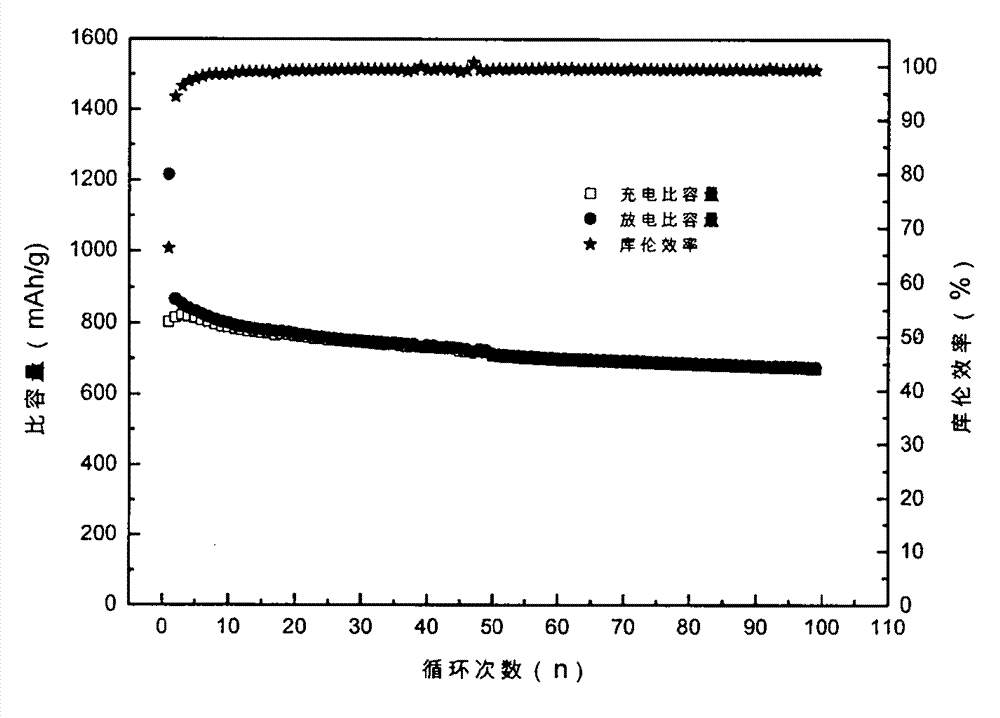

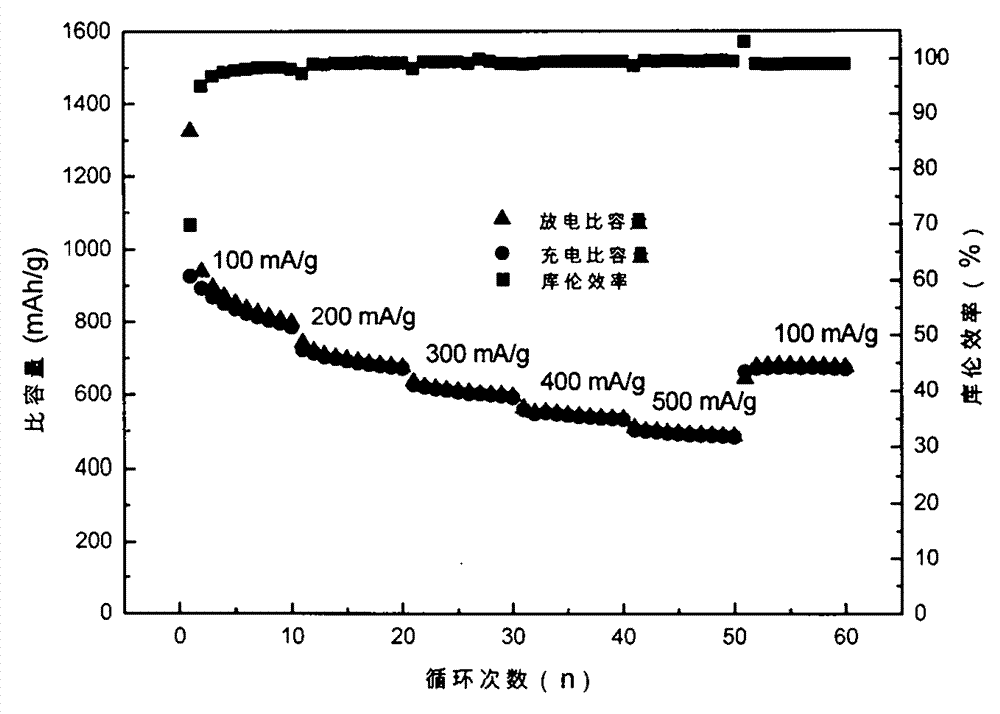

InactiveCN104852020AReduce formation rateImprove electrochemical cycle stabilityCell electrodesSilica nanoparticlesCarbon coating

The invention discloses a preparation method of a lithium ion battery silicon oxide composite negative electrode material, the method includes the following steps: (1) weighting a certain amount of silicon oxide SiOx, organic carbon and a graphite oxide precursor raw material for ball milling for 0.5-24 h to fully mix the precursor raw material; and (2) calcining the mixed precursor raw material in a protective atmosphere at 600-1400 DEG C for 0.5-12 h, and performing post-processing to obtain the silicon oxide composite negative electrode material. Through silicon oxide disproportionation, silica nanoparticles are distributed evenly in silicon dioxide, by organic carbon splitting decomposition, carbon coating is obtained, the probability of the formation of a SEI (solid electrolyte interphase) film in the material charge and discharge process can be reduced, the material electrochemical cycle stability can be improved, and by addition of graphite, good conductivity and ratio stability performance can be provided for the material. The production process is simple, raw material is cheap and easy to obtain, equipment is general, and mass production is easy.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Composite cathode material for lithium ion battery and preparation method thereof

ActiveCN101789506ASimple preparation processEasy to operateElectrode manufacturing processesSource fieldSodium-ion battery

The invention relates to composite cathode material for a lithium ion battery and a preparation method thereof, belonging to the chemical power source field. The invention aims to solve the problems that the first lithium ion insertion process of oxide cathode material performs an irreversible reaction, the first coulombic efficiency is low, etc. The preparation method comprises the following steps: using precursor MO, reducing agent metal lithium and a defined amount of organic solvent to perform wet mechanochemical in situ reduction and obtain power, heating the obtained power under vacuum atmosphere to remove organic solvent, and obtaining the composite material. The method of the invention has simple process, low cost and wide application range; and the first efficiency of the prepared composite cathode material is more than 80%, the maximum is more than 95%, and the composite cathode material also has good electrochemical cycle stability.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Silicon oxide/carbon composite negative electrode material of lithium ion secondary battery and preparation method of silicon oxide/carbon composite negative electrode material

InactiveCN103594689AIncrease capacityPromote circulationCell electrodesSecondary cellsCarbon compositesMass ratio

The invention relates to a silicon oxide / carbon composite negative electrode material of a lithium ion secondary battery and a preparation method of the silicon oxide / carbon composite negative electrode material. The preparation method comprises the steps of by taking silicon oxide containing a carbon source as a raw material, preparing SiO2 and a xerogel precursor consisting of SiO and pyrolytic carbon by adopting a sol-gel method, supplementing the carbon source to perform high-energy ball milling mixing and high-temperature solid phase pyrolysis, carbonizing and partially reducing the silicon oxide, performing ball milling crushing to obtain a final composite material product, wherein the mass ratio of SiO2 to SiO in the silicon oxide / carbon composite material is (2-6):1, and the pyrolytic carbon accounts for 40-70% of the total weight of the composite material. The composite material of SiO2, SiO and the pyrolytic carbon, prepared by the preparation method disclosed by the invention, is high in capacity, long in cycle life and good in rate capability, is applied to the lithium ion secondary battery, and can significantly improve the specific energy. The preparation method disclosed by the invention is simple in equipment, easy in operation, easily-controllable in process condition and suitable for large-scale production.

Owner:NANKAI UNIV

2H type A5B19 superstacked La-M-Mg-Ni based quaternary hydrogen storage alloy electrode material and preparation method thereof

ActiveCN108493436AEasy to prepareFlexible and controllable operationCell electrodesNickel accumulatorsRare-earth elementHigh rate

The invention relates to a 2H type A5B19 superstacked La-M-Mg-Ni based quaternary hydrogen storage alloy electrode material. The material has a chemical composition of LaxMyMgzNir, wherein x, y, z andr are atomic ratios, and x is greater than or equal to 0.6 and smaller than or equal to 0.7, y is greater than or equal to 0.1 and smaller than or equal to 0.2, z is greater than or equal to 0.1 andsmaller than or equal to 0.20, r is greater than or equal to 3.70 and smaller than or equal to 3.85, and M is one of the rare earth elements Pr, Nd, Sm or Gd. The preparation method of the quaternaryhydrogen storage alloy electrode material mainly consists of compounding, ball milling, tabletting and sintering, and sintering is divided into two temperature rise periods and two cooling periods. The preparation method is simple, the process is easy to control, the prepared material has a stable structure and few defects, the alloy composition is uniform, the crystal structure is complete, the grain size is uniform, the alloy electrode material has excellent electrochemical cyclic stability and high rate discharge performance, the HRD1500 (high rate discharge performance under a discharge current density of 1500mA / g) is up to 65%, and the capacity retention rate can be as high as 90% after 100 charge / discharge cycles.

Owner:YANSHAN UNIV

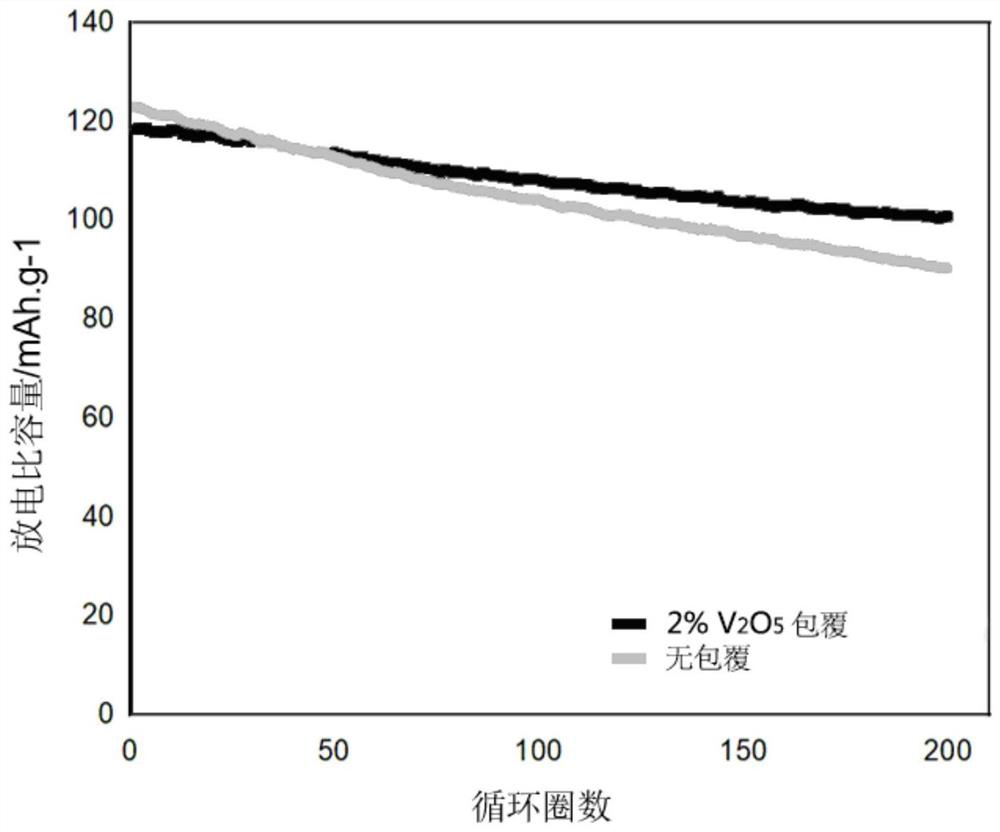

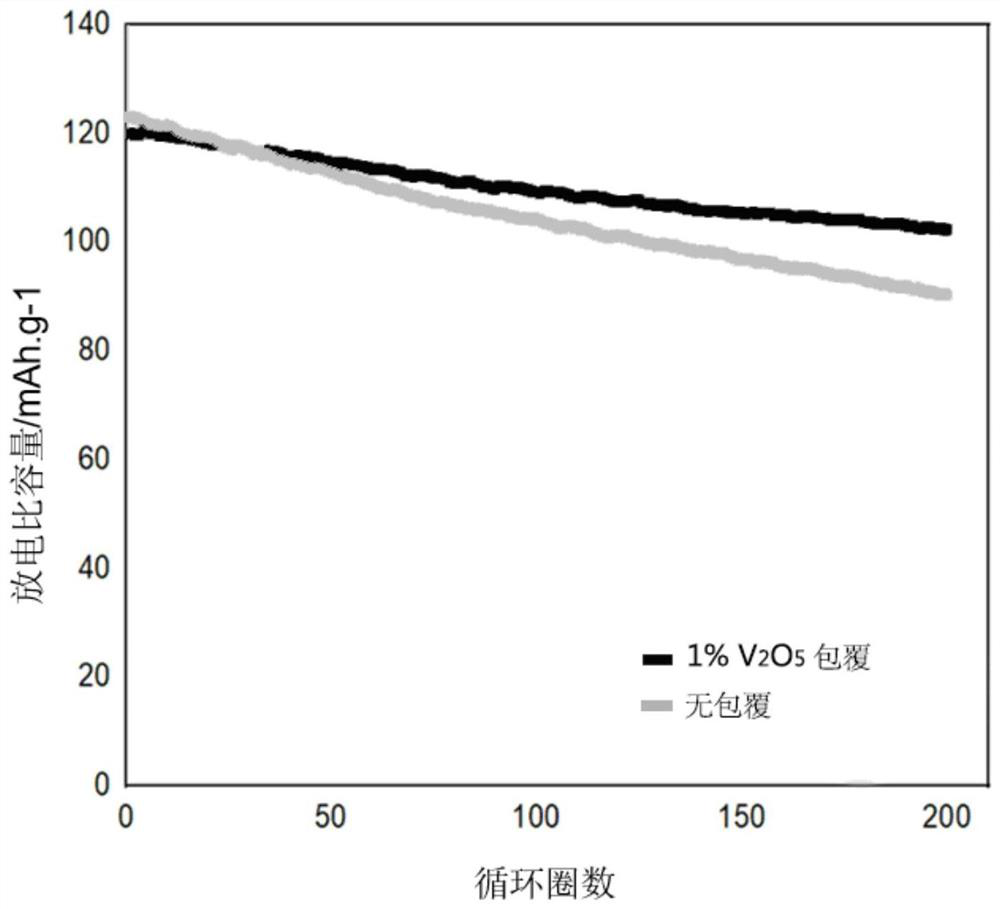

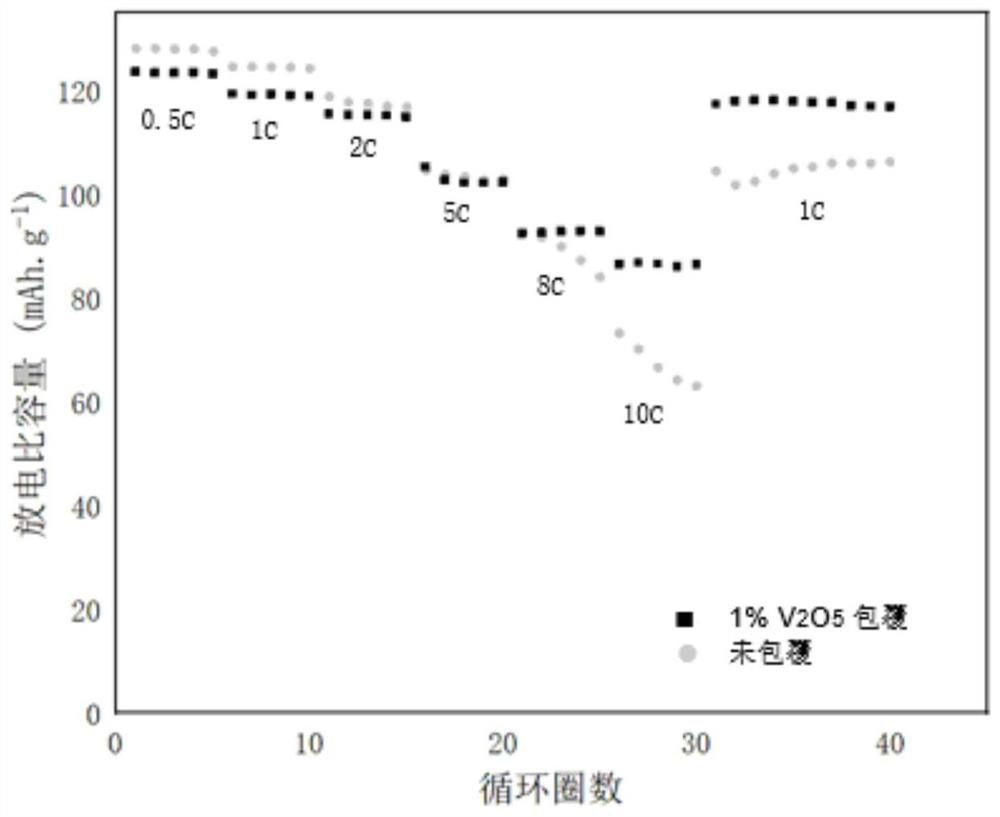

Preparation method of sodium ion battery positive electrode material with coating structure

InactiveCN112456567AEvenly distributedTightly boundMaterial nanotechnologyCell electrodesCharge and dischargeCyclic stability

The invention discloses a preparation method of a sodium ion battery positive electrode material with a coating structure, wherein the preparation method is characterized by comprising the steps: dissolving or dispersing a metal source into a volatile solvent to prepare a solution / suspension, adding the sodium ion battery positive electrode material or a positive electrode material precursor, anduniformly mixing, and drying and calcining to decompose the metal source into active oxide to coat the surface of the sodium ion battery positive electrode material or the positive electrode materialprecursor. A vanadium source precursor is dispersed and suspended in the medium, the active oxide is coated in the process of synthesizing the sodium ion positive electrode material, and a coating layer is uniformly distributed on the surface of the positive electrode material and is tightly combined, so that the cycling stability of the sodium ion battery positive electrode material is improved;and the surface nano-layer active oxide has good stability to CO2 / H2O and an electrolyte in the air, so the air storage stability and the charge-discharge cycle life of the positive electrode materialare effectively improved, the method is simple, the cost is low, and the positive electrode material can be used for large-scale production.

Owner:浙江钠创新能源有限公司

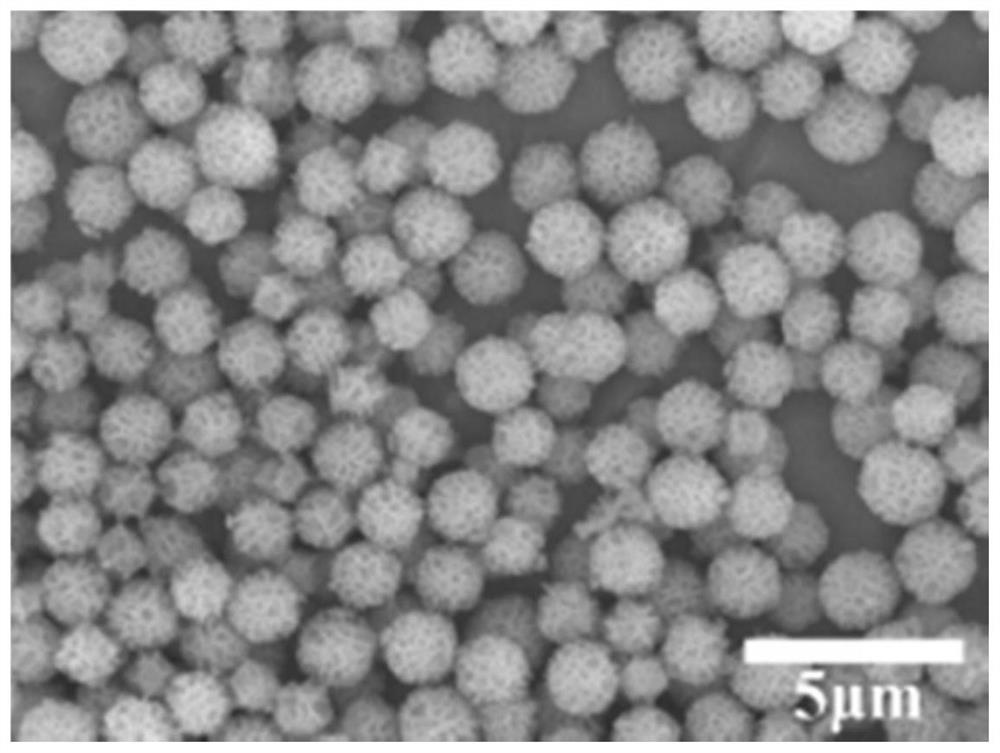

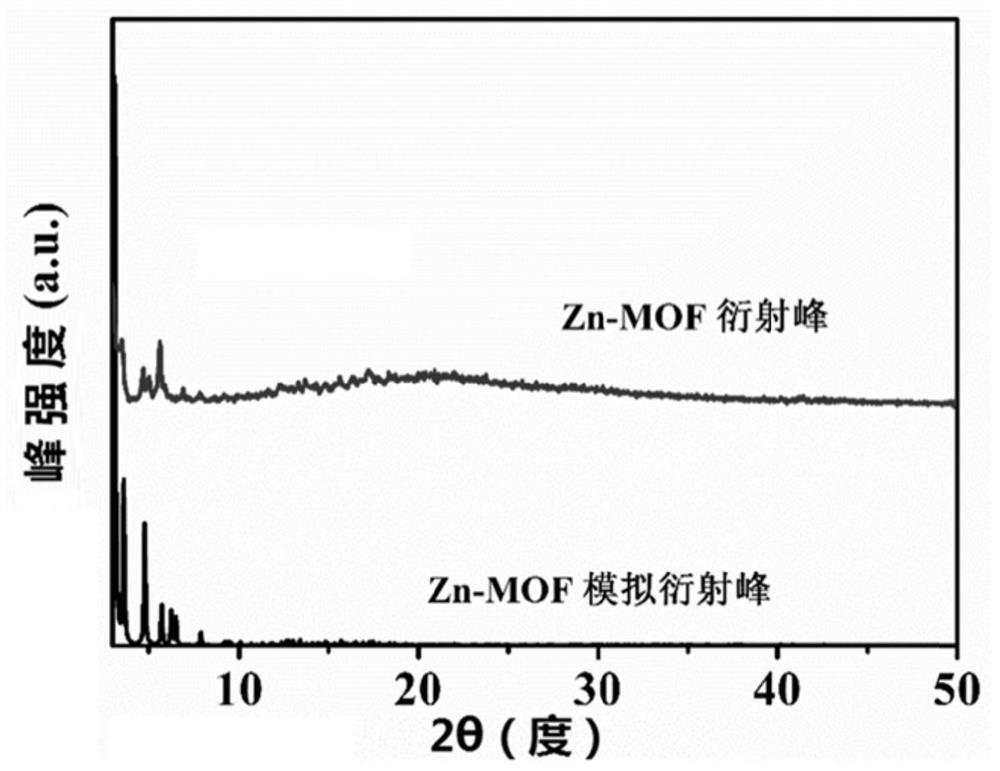

Double-coating diaphragm capable of simultaneously inhibiting lithium dendrites and shuttle effect and preparation method thereof

ActiveCN111682147AEffective and uniform precipitationCyclic stabilityLi-accumulatorsCell component detailsElectrical batteryLithium sulfur

The invention belongs to the technical field of battery diaphragm materials, and particularly relates to a double-coating diaphragm capable of simultaneously inhibiting lithium dendrites and shuttle effect and a preparation method thereof. The double-coating diaphragm comprises a diaphragm and coating materials coating the two sides of the diaphragm. The coating materials comprise a Zn-MOF material and a ZnNC carbon material. The preparation method comprises the following steps: preparing a Zn-MOF powder material and a ZnNC carbon material; respectively blending a Zn-MOF powder material and aZnNC carbon material into slurry, and coating two sides of a battery diaphragm with the slurry. The double-coating diaphragm has a protection effect on a lithium negative electrode and an inhibition effect on shuttling of lithium polysulfide at the same time, and when the double-coating diaphragm is applied to a lithium-sulfur battery, the double-coating diaphragm has relatively excellent electrochemical cycling stability through electrochemical detection.

Owner:SOUTH CHINA NORMAL UNIVERSITY

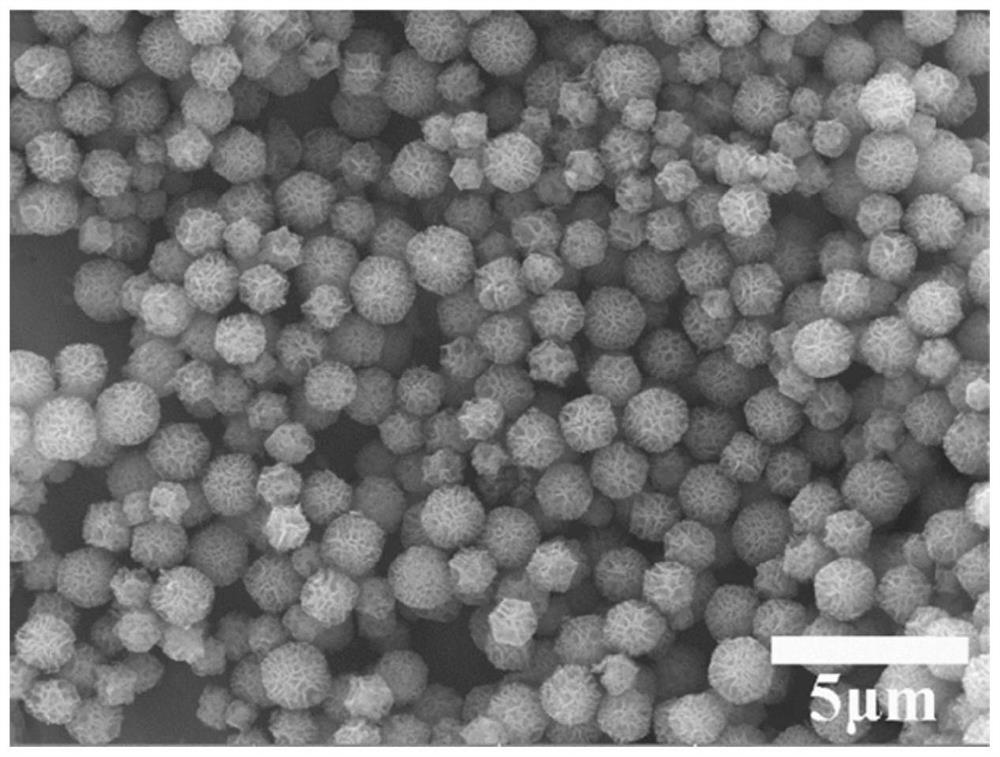

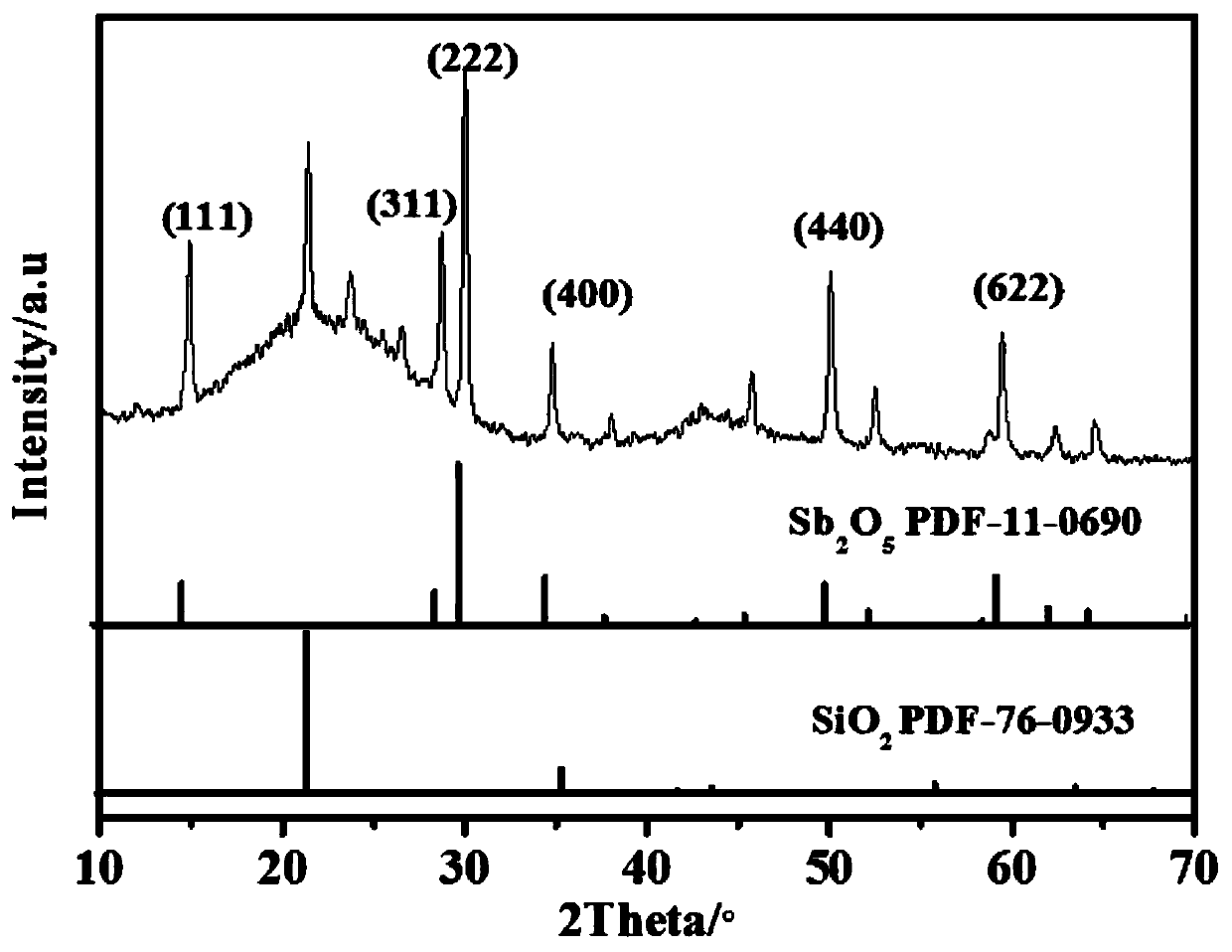

Preparation of antimony pentoxide/silicon dioxide/carbon cloth flexible material and application thereof as negative electrode of sodium-ion battery

The invention discloses preparation of an antimony pentoxide / silicon dioxide / carbon cloth flexible material and an application thereof as a negative electrode of a sodium-ion battery, which comprisesthe following steps: grinding silicon dioxide, adding the silicon dioxide into deionized water for dissolution to obtain a solution A; adding antimony trichloride into the ethanol solution for dissolution to obtain an antimony trichloride solution, and adding a sodium hydroxide aqueous solution into the antimony trichloride solution to adjust the pH value of the antimony trichloride solution to obtain a solution B; adding the solution A into the solution B and stirring to obtain a solution C; impregnating the activated carbon cloth in the solution C, transferring the solution C and the carboncloth into a reaction kettle for hydrothermal reaction, cooling the carbon cloth to room temperature, moving out the carbon cloth, and cleaning and drying the carbon cloth to obtain the antimony pentoxide / silicon dioxide / carbon cloth flexible sodium ion battery negative electrode material. The method is simple to operate and low in cost, and the silicon material can be applied to the negative electrode material of the sodium-ion battery.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of Co3S4 nanosheet array modified by CeO2 nanoparticles

ActiveCN112164592AKeep porousRetain multiple active sitesHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel substrate

The invention provides a preparation method of a Co3S4 nanosheet array modified by CeO2 nanoparticles. The method comprises the following steps: mixing a cobalt salt, an imidazole ligand and a solvent, adding foamed nickel, and growing a zeolite imidazolate framework CoZIFL nanosheet array on a foamed nickel substrate through a reaction; then, adding the CoZIFL nanosheet array into a sulfur sourcesolution, and generating a Co3S4 nanosheet array through hydrothermal vulcanization; and adding cerium salt, a precipitator and a solvent into the precursor, and obtaining a CeO2 nanoparticle modified Co3S4 nanosheet array through solvothermal reaction. The CeO2 nanoparticle modified Co3S4 nanosheet array prepared by adopting the method can be directly used as an electrode of a supercapacitor, and compared with a Co3S4 nanosheet array precursor, the specific capacitance of the CeO2 nanoparticle modified Co3S4 nanosheet array prepared by adopting the method is improved by 114.8% (under the condition of 0.5 A / g).

Owner:宁波市大学科技园发展有限公司

Method for manufacturing a polyacrylonitrile-sulfur composite material

InactiveUS20150129810A1Improve electrochemical cycle stabilityHigh rateNon-metal conductorsCell electrodesHigh rateSulfur

A method is described for manufacturing a polyacrylonitrile-sulfur composite material, including the following method steps: a) providing a matrix material; b) optionally adding sulfur to the matrix material; c) adding polyacrylonitrile to the matrix material to produce a mixture made of sulfur and polyacrylonitrile; and d) reacting sulfur and polyacrylonitrile. A composite material manufactured in this way may be used in particular as an active material of a cathode of a lithium-ion battery and offers a particularly high rate capacity. In addition, methods are provided for manufacturing an active material for an electrode.

Owner:ROBERT BOSCH GMBH

Preparation method of spinel-type LiMn2O4 cathode material coated by cobalt-aluminum composite metal oxide

ActiveCN101847715AGood electrochemical cycle stabilityImprove electrochemical cycle stabilityCell electrodesColloid millAluminum composites

The invention relates to a preparation method of a spinel-type LiMn2O4 cathode material coated by a cobalt-aluminum composite metal oxide, belonging to the technical field of electrode materials of a lithium ion battery. The preparation method comprises the following steps of: simultaneously dripping a cobalt-aluminum mixed salt solution and an LiOH solution to an LiMn2O4 suspension to obtain an LiMn2O4 precursor coated by cobalt-aluminum houghite; simultaneously adding cobalt-aluminum mixed salt solution and the LiOH solution to a colloid mill to obtain a cobalt-aluminum houghite suspension; adding the prepared LiMn2O4 precursor coated by the cobalt-aluminum houghite to the cobalt-aluminum houghite suspension; and crystallizing, filtering, drying and roasting to obtain an LiMn2O4 cathode material coated by the cobalt-aluminum composite metal oxide. The invention has the advantages that not only larger LiMn2O4 crystal grains are evenly coated, secondary grains formed by piling fine LiMn2O4 crystal grains can also be evenly coated so that the coated LiMn2O4 cathode material has better electrochemical cyclical stability.

Owner:BEIJING UNIV OF CHEM TECH

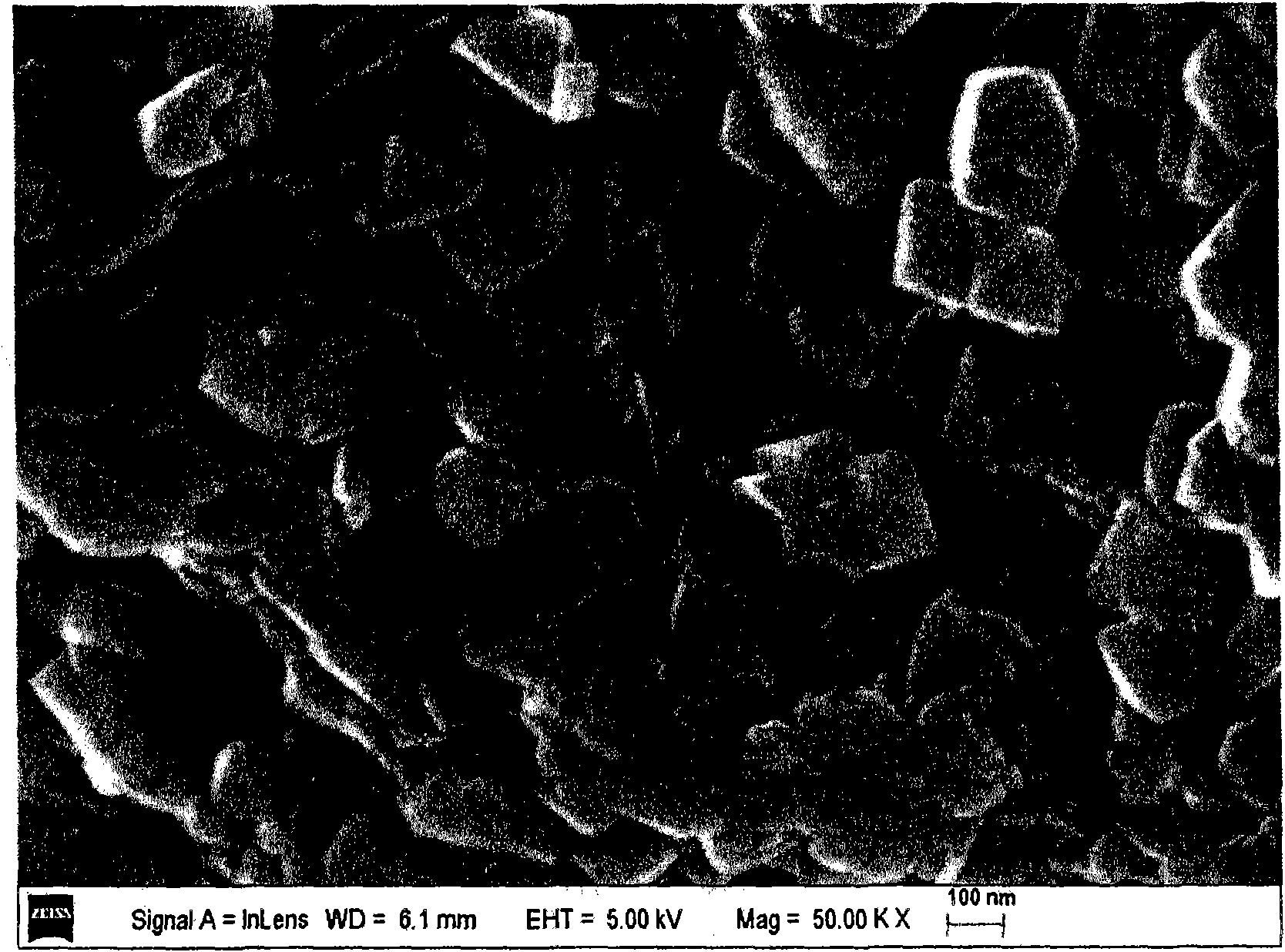

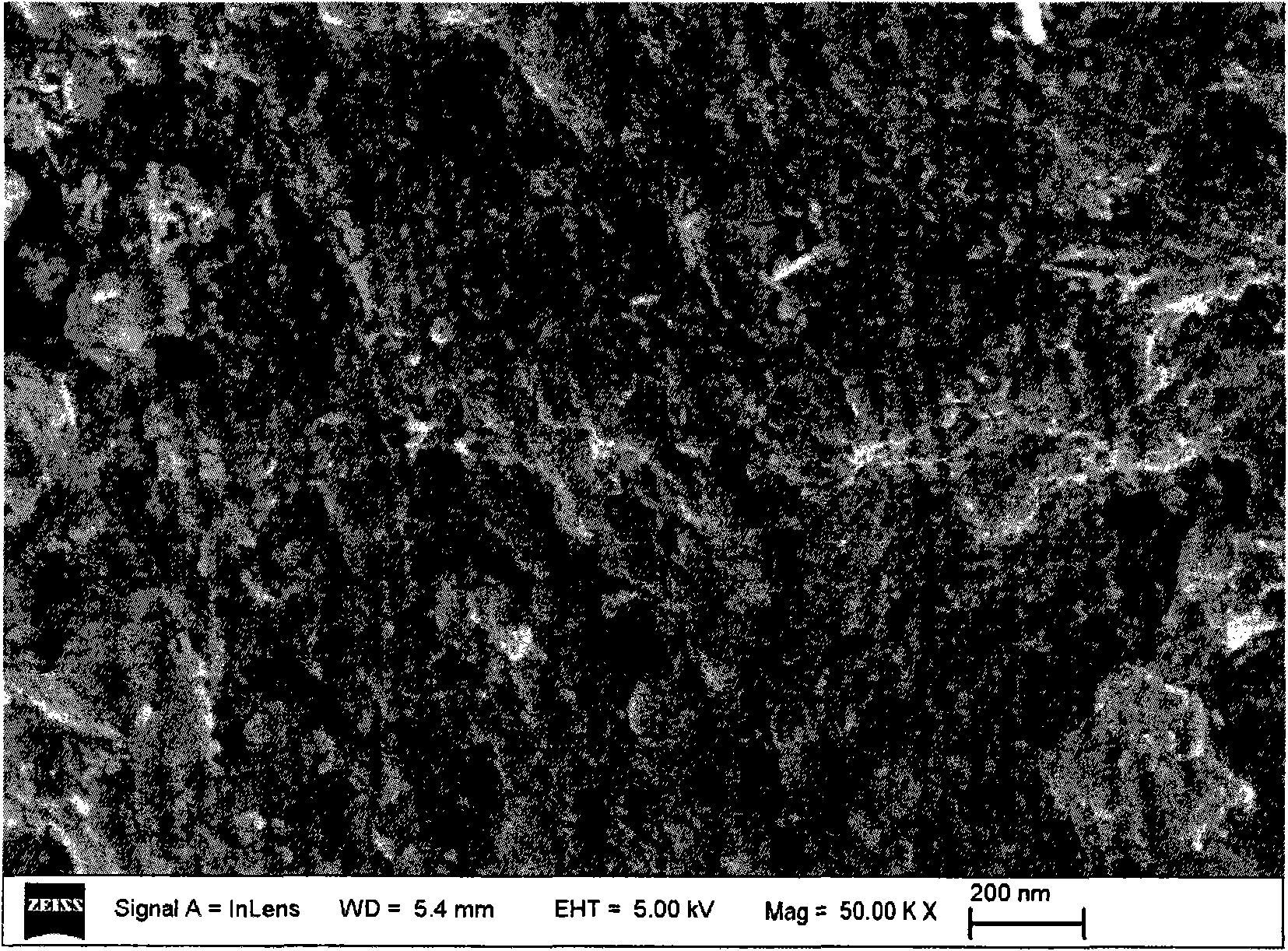

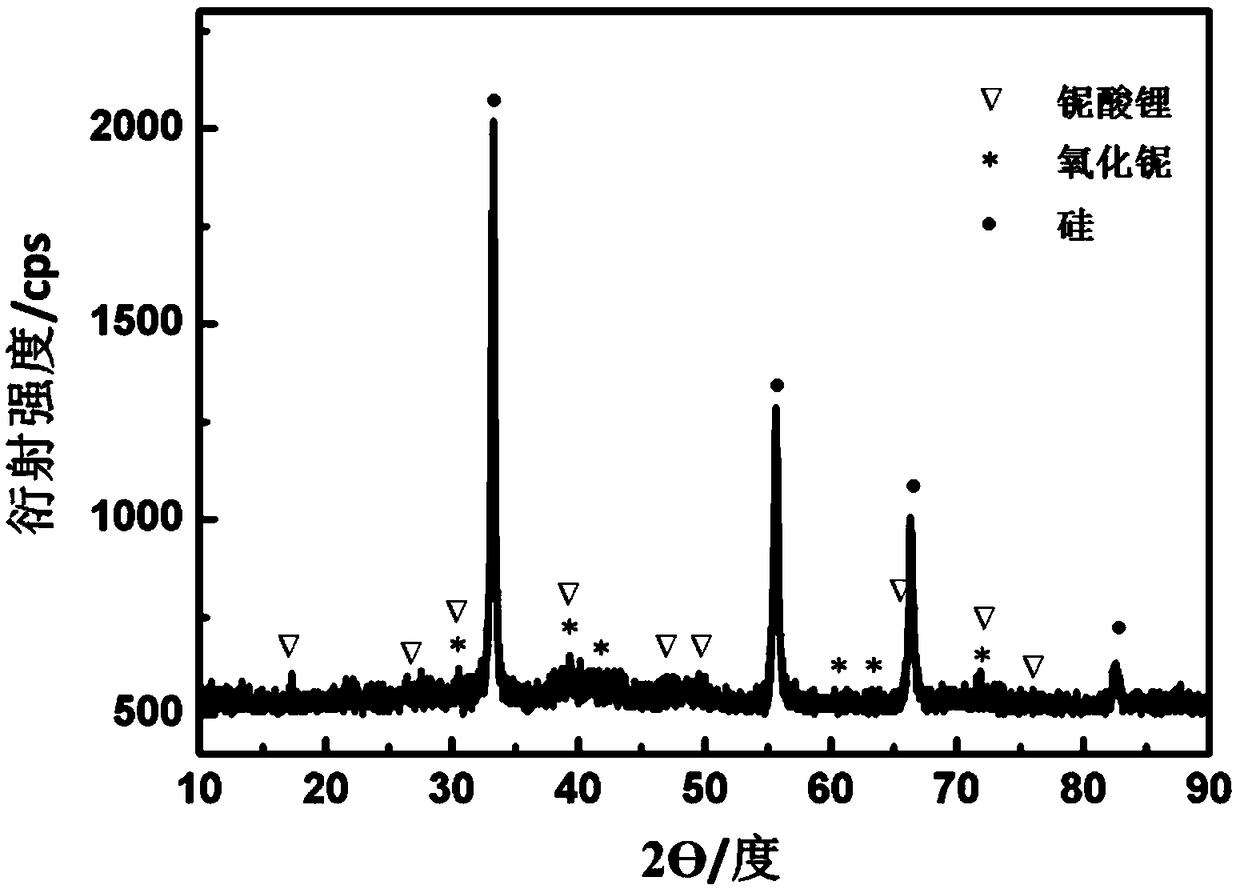

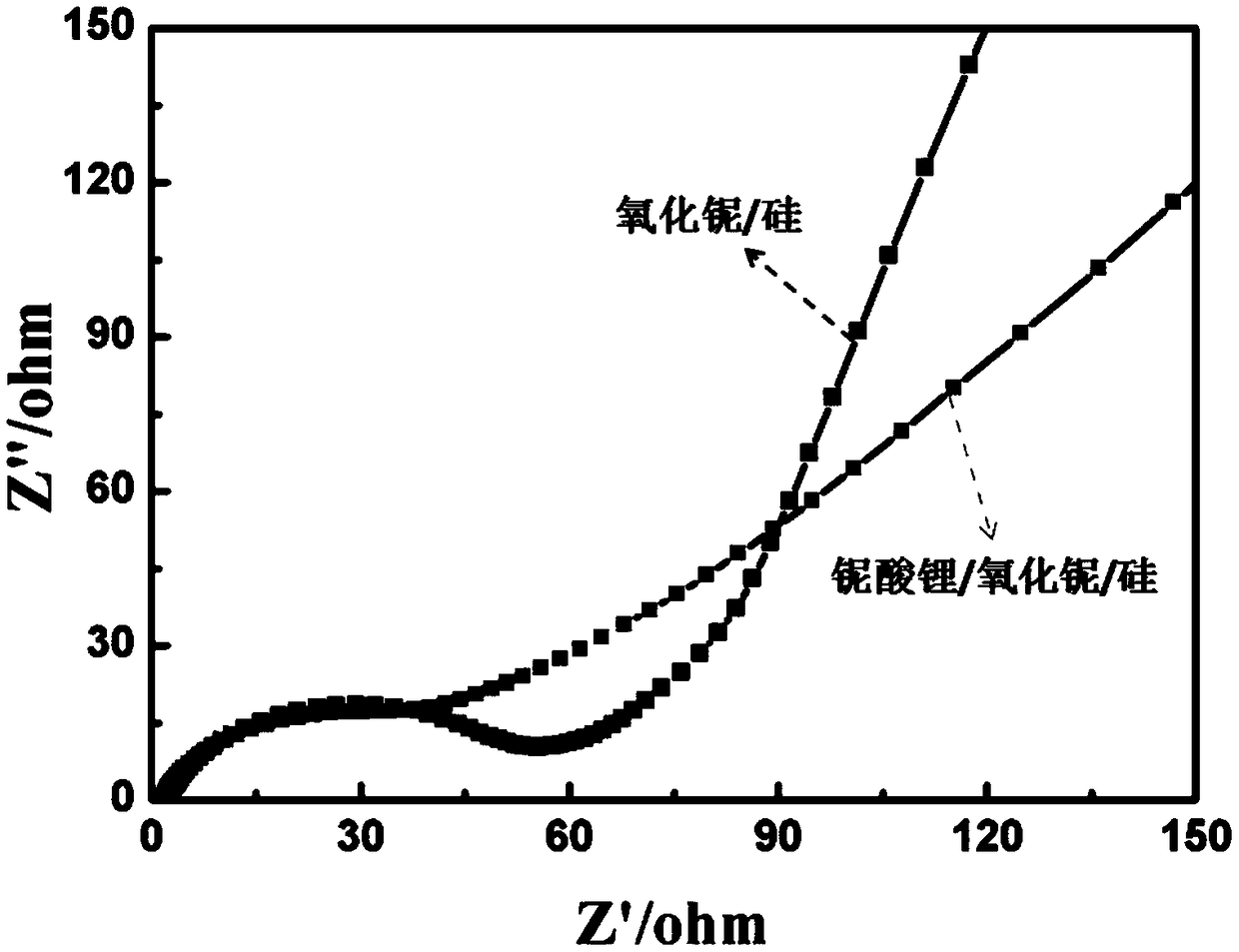

Lithium niobite/niobium-base oxide/silicon compound cathode material, preparation method and application thereof

ActiveCN108899517ASimple structureImprove surface stabilityCell electrodesSecondary cellsElectrochemical responseNiobium

The invention discloses a lithium niobite / niobium-base oxide / silicon compound cathode material, a preparation method and an application thereof. The lithium niobite / niobium-base oxide / silicon compoundcathode material comprises a silicon active center and a lithium niobite / niobium-base oxide mixed shell layer uniformly coated on the surface of the silicon active center. The lithium niobite / niobium-base oxide / silicon compound cathode material provided by the invention takes lithium niobite as a fast ion conductor, so that the rapid transferring of lithium ions under room temperature and even high temperature can be effectively guaranteed; the synergic alloying effect of the lithium niobite and the niobium-base oxide is beneficial to the structure and surface stability of the silicon duringan electrochemical reaction process, so that the lithium niobite / niobium-base oxide mixed shell layer can be used as a stress buffer layer, an ionic conduction layer and a surface stabilizing layer; the lithium niobite / niobium-base oxide / silicon compound cathode material has high initial coulombic efficiency and excellent electrochemical circling stability performance.

Owner:DALIAN MARITIME UNIVERSITY

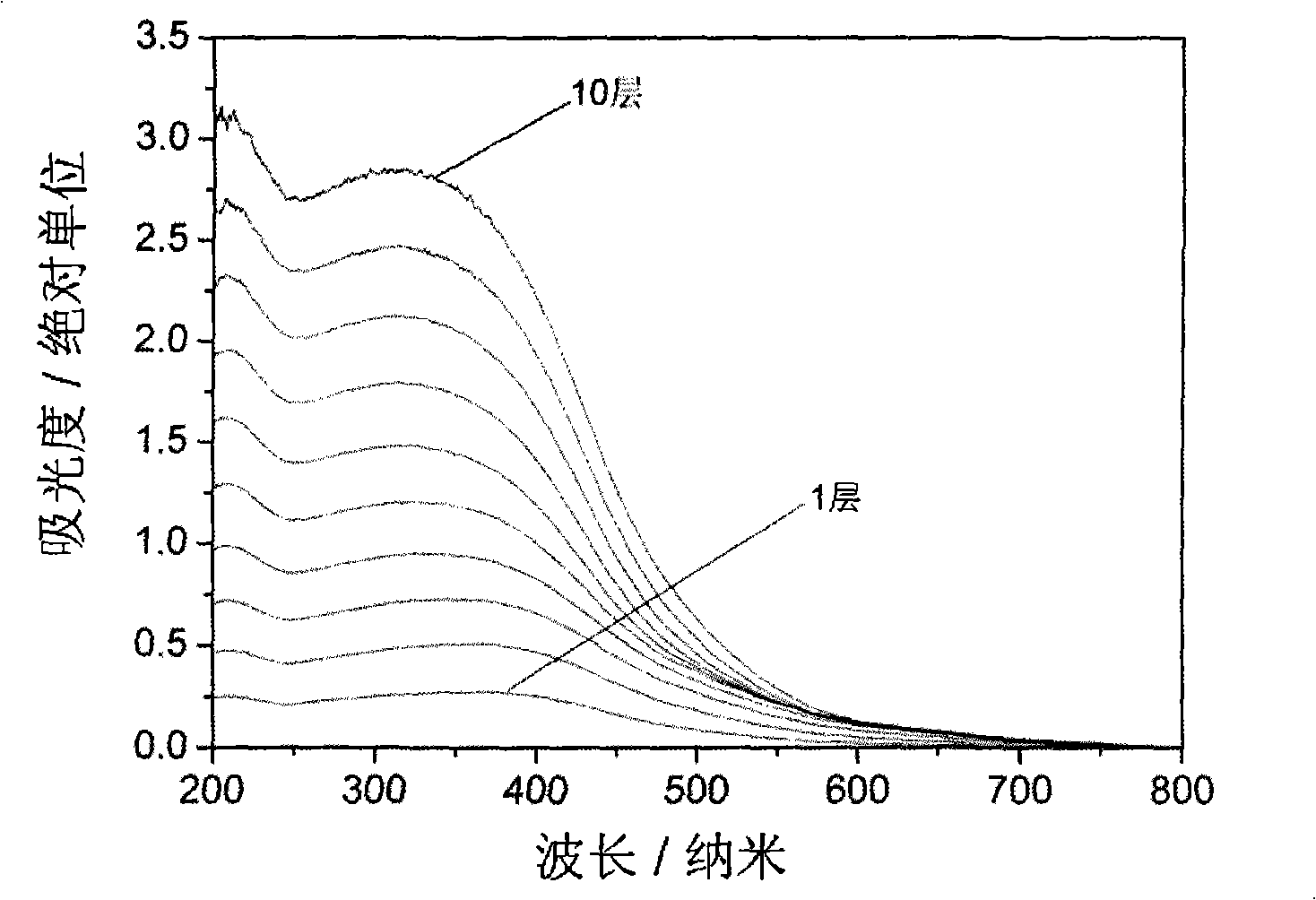

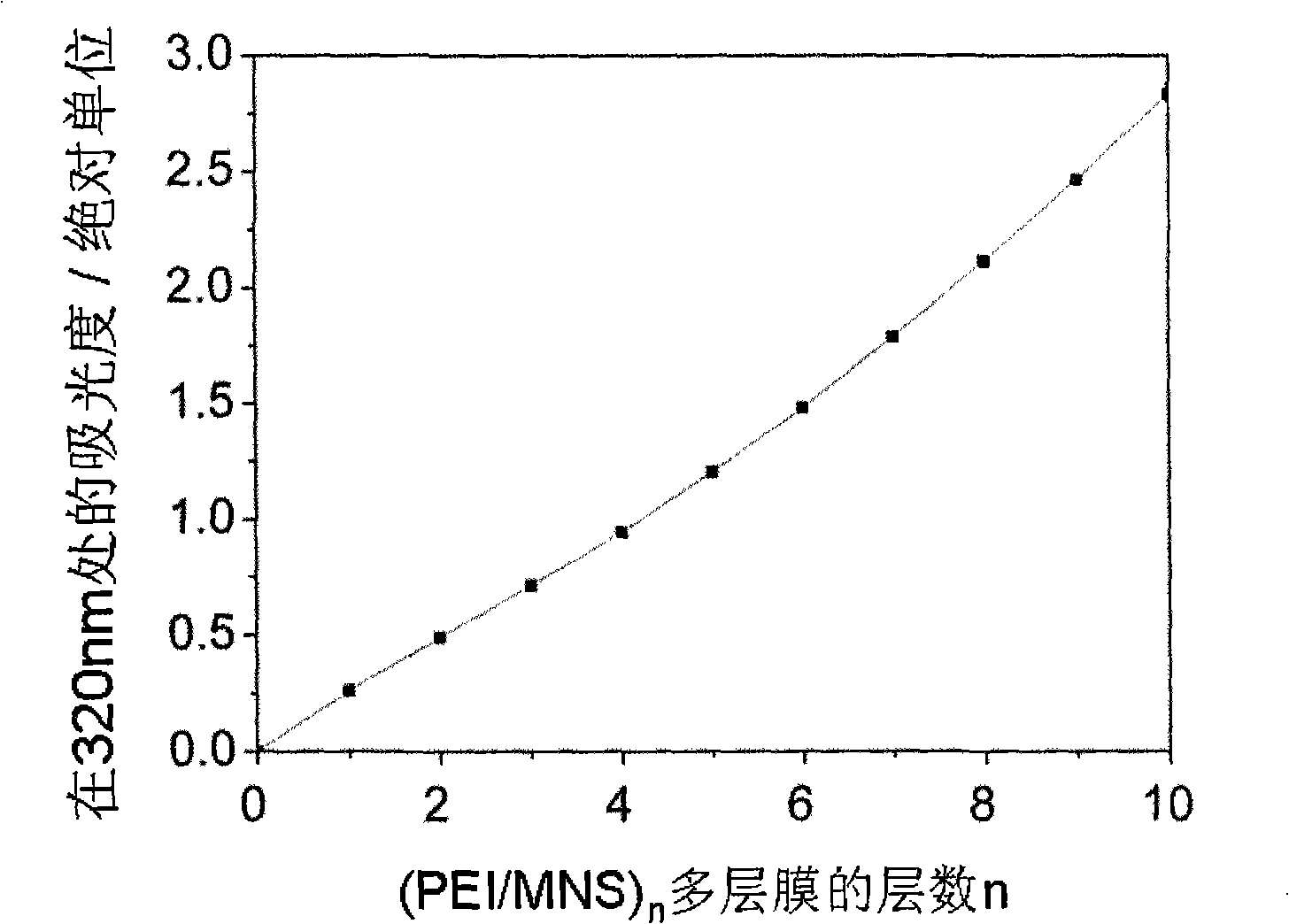

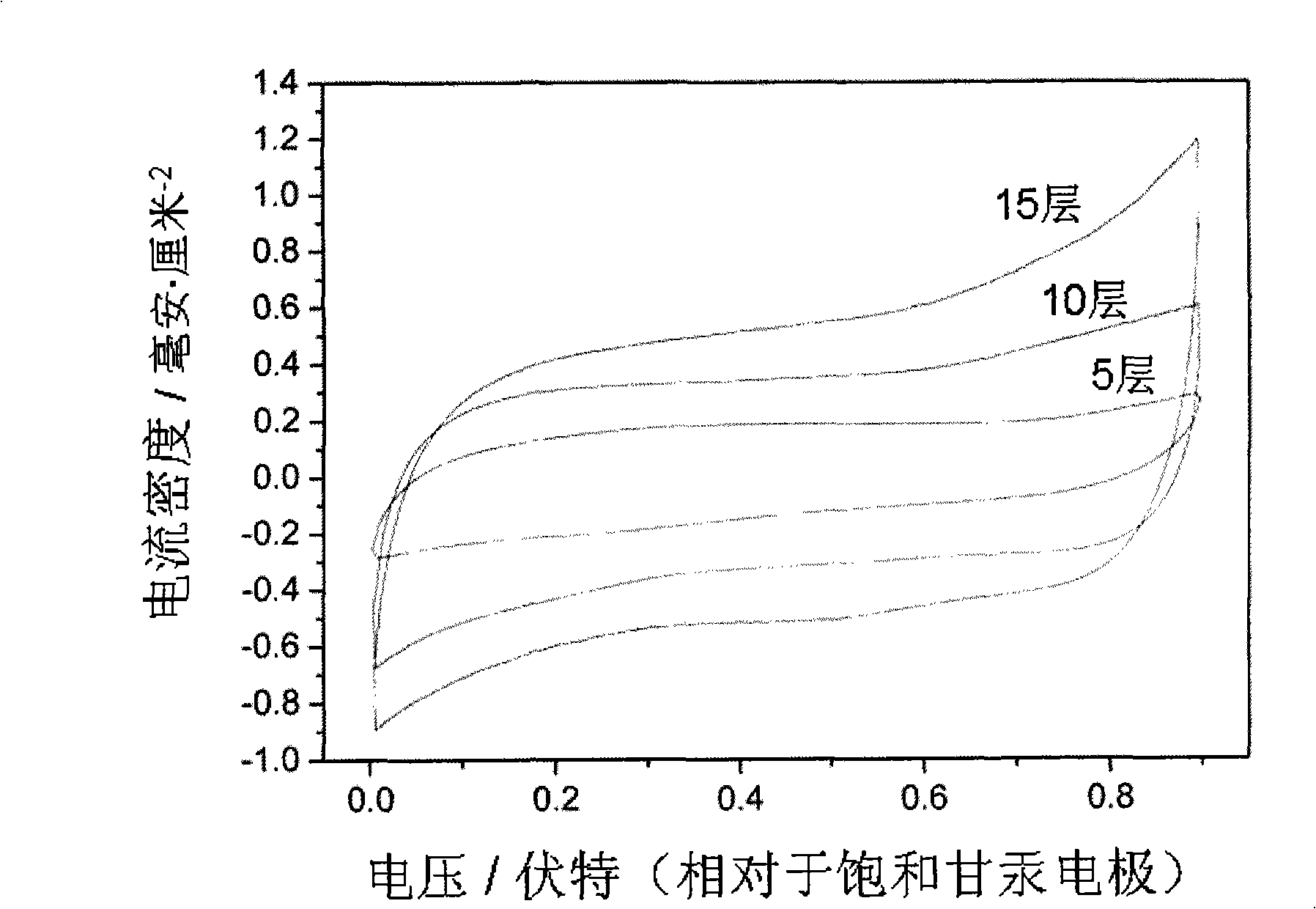

Polyethylene imine/manganese dioxide nano sheet multiple-layer composite film and preparation method thereof

InactiveCN101255261AIncrease profitHigh specific capacityLamination ancillary operationsSynthetic resin layered productsCapacitanceComposite film

The invention provides a polyethyleneimine / manganese dioxide nm multilayer composite membrane and preparation method, belonging to super capacitor electrode material technical field. The chemical composition of multilayer composite membrane is PEI / MNS)n, wherein PEI is polyethyleneimine, MNS is manganese dioxide nm sheet with negative charge, n is number of layers of multilayer composite membrane and 3<=n<=20. The polyethyleneimine with positive charge and managanese dioxide nm sheet with negative charge are recurrently deposited in turn on a substrate after surface treatment by static self-assembly technique. The multilayer composite membrane as electrode material of super capacitor has features of high specific capacitance, good magnification characteristic and excellent electrochemical cycle performance, in addition, the preparation method can perform at room temperature and under solution system. The dear device is not necessary and the operation is convenient and material cost is low.

Owner:BEIJING UNIV OF CHEM TECH

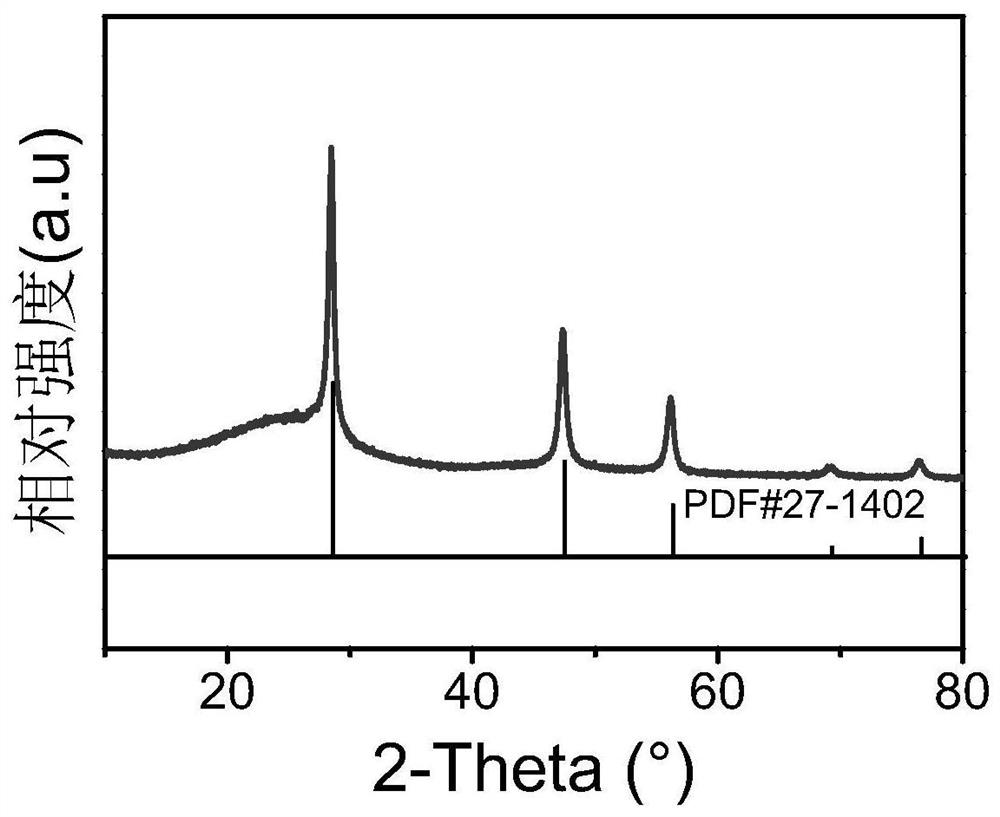

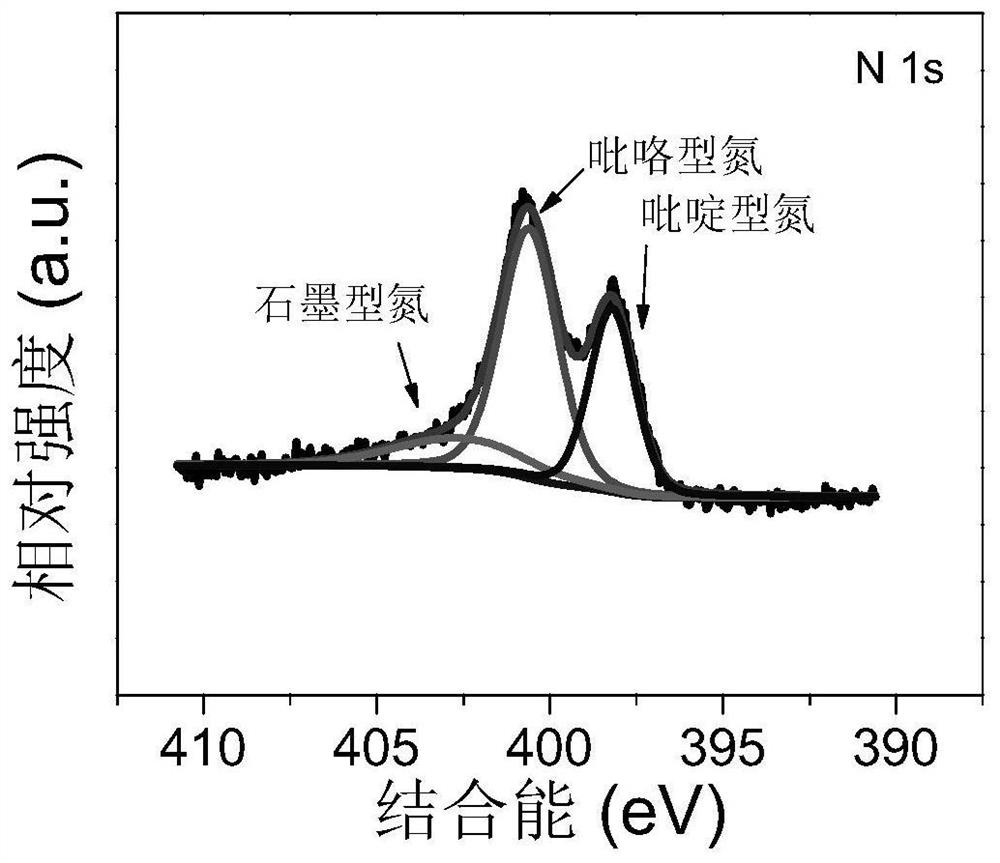

Nitrogen-doped carbon/nano-silicon composite negative electrode material and preparation method thereof

InactiveCN112110448AImprove the first charge and discharge efficiencyImprove electrochemical cycle stabilityMaterial nanotechnologySiliconElectrical batteryNew energy

The invention discloses a preparation method of a nitrogen-doped carbon / nano-silicon composite negative electrode material, belonging to the field of new energy materials and electrochemistry. The method comprises the following steps: (1) putting nano-silicon powder into a solvent, conducting ultrasonic dispersion, adding an initiator solution, and conducting sufficient stirring and mixing to obtain a dispersion liquid A, wherein the particle size of the nano-silicon powder is 30-80 nm; (2) adding a carbon source into the dispersion liquid A obtained in the step (1), conducting stirring and mixing, carrying out a polymerization reaction, performing filtering, and washing and drying the obtained solid to obtain a precursor B, wherein the carbon source comprises at least one selected from pyrrole, dopamine and aniline, and a ratio of the mass of the nano-silicon powder to the volume of the carbon source is 0.15-0.25 g: 400-800 [mu]L; and (3) heating and calcining the precursor B obtainedin the step (2) and then conducting cooling to obtain the nitrogen-doped carbon / nano-silicon composite negative electrode material. The invention also provides the nitrogen-doped carbon / nano-siliconcomposite negative electrode material prepared by using the method and a lithium ion battery containing the nitrogen-doped carbon / nano-silicon composite negative electrode material.

Owner:SUN YAT SEN UNIV

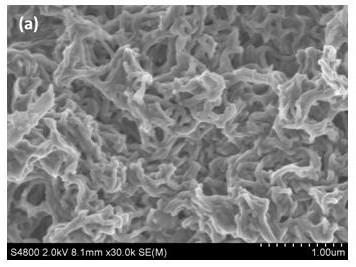

Preparation method of porous network structure graphene/polyaniline composite dry gel

Relating to a preparation method of a nano composite energy storage dry gel, the invention provides a preparation method of a porous network structure graphene / polyaniline composite dry gel. The method includes: preparation of graphene oxide (GO), preparation of a cross-linked polyaniline conductive slurry (gel), and preparation of a high-strength three-dimensional porous network structure graphene / polyaniline composite dry gel: directly mixing the polyaniline conductive slurry with a GO dispersion liquid to prepare a GO and polyaniline slurry blended composite slurry so as to obtain a graphene / polyaniline composite hydrogel, repeatedly soaking the obtained graphene / polyaniline composite hydrogel in hot alcohol and water for dialysis until the solution becomes colorless, and performing freeze-drying to obtain the high-strength three-dimensional porous network structure graphene / polyaniline dry gel. The dry gel prepared by the method provided by the invention has the characteristics ofgood conductivity, high specific capacitance, good electrochemical cycling stability, high mechanical strength, easily available raw materials, simple preparation process and low cost, has positive impact on development of novel supercapacitor electrode materials, and at the same time, the high-strength porous structure lays a research foundation for the development of all solid-state supercapacitors in the future.

Owner:SHENYANG UNIV

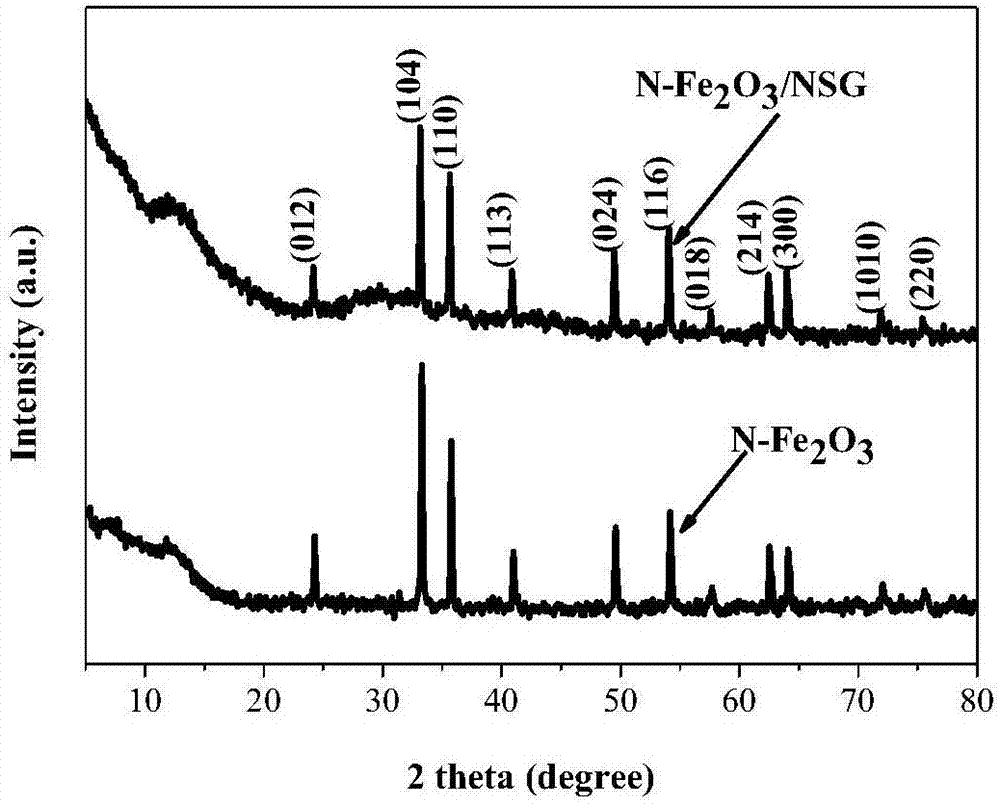

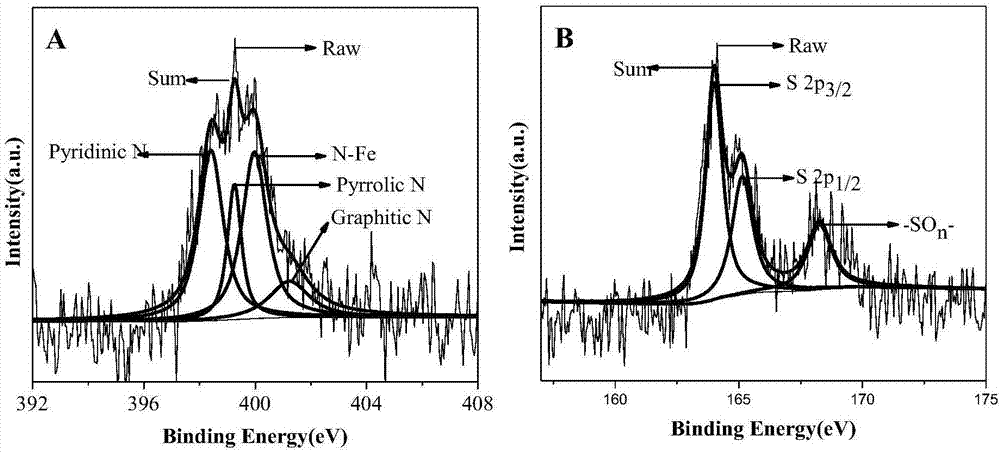

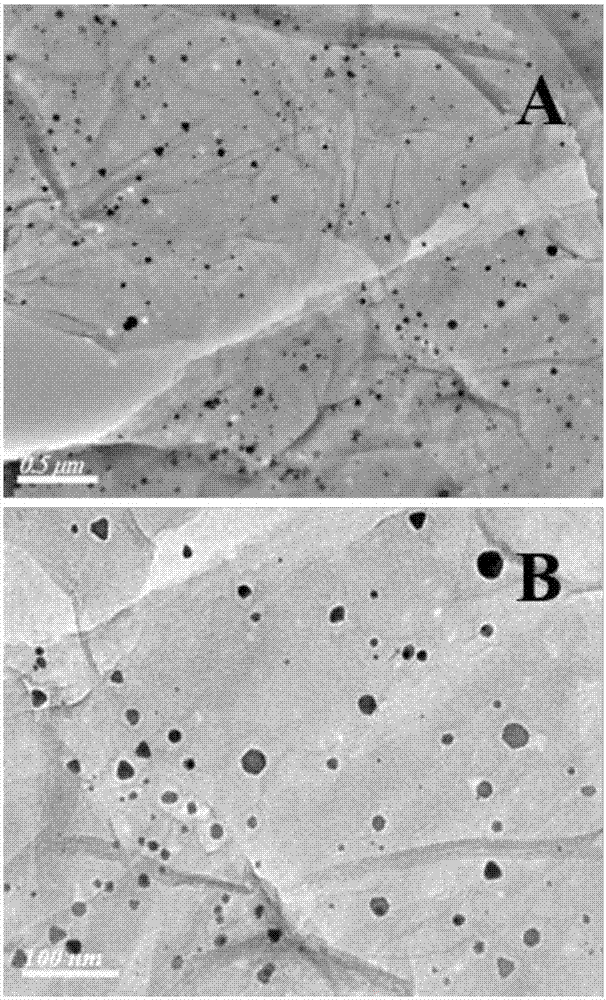

N-Fe2O3/nitrogen-sulfur double-doped graphene composite electrode material and preparation method thereof

InactiveCN107045949ASmall particle sizeTo achieve the perfect combinationHybrid capacitor electrodesHybrid/EDL manufactureDoped grapheneFiltration

The invention provides an N-Fe2O3 / nitrogen-sulfur double-doped graphene composite electrode material and a preparation method thereof. The method comprises: step one, oxidized graphene is added into a mixed solution of ethyl alcohol and ethylene glycol and ultrasonic dispersion is carried out to obtain a stable homogeneous dispersion solution A of oxidized graphene; step two, ferric nitrate nonalydrate and a nitrogen-sulfur source are added into the dispersion solution A obtained at the step one, and stirring is carried out uniformly to obtain a mixed solution B; step three, the mixed solution B obtained at the step two is transferred to a polytetrafluoroethylene hydrothermal reactor to carry out constant-temperature hydrothermal reaction, and after completion of reaction, a mixed solution C is obtained; and step four, suction filtration is carried out on the mixed solution B obtained at the step three and then cleaning and drying are carried out successively, thereby obtaining a product of N-Fe2O3 / nitrogen-sulfur double-doped graphene composite electrode material. According to the invention, the N-Fe2O3-nano-particle loaded double-doped graphene material is obtained by synthesis based on a one-step hydrothermal method for nano particle synthesis. The raw materials are available easily; green and environment-friendly effects are good; and the synthesis process is simple without any pollution.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com