Multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material and preparation method thereof

An A5B19, hydrogen storage alloy technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems that the sintering method is difficult to meet the large-scale industrial production, the operation steps are complicated, and the temperature is difficult to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 A multi-element single-phase A 5 B 19 Type Superlattice Hydrogen Storage Alloy Electrode Material

[0040] The chemical composition of the alloy prepared in this embodiment is: La 0.78 Mg 0.22 Ni 3.75 Al 0.05 , the preparation method is carried out according to the following steps:

[0041] (11) Ingredients

[0042] Select metal elemental La, Mg, Ni and Al as raw materials, carry out batching according to the alloy chemical composition of this embodiment, consider the volatilization loss in smelting, supplement and increase the volatilization amount of corresponding elements when batching, and then put other raw materials except Mg into into the crucible of the vacuum induction melting furnace, and the Mg is put into the secondary feeding bin;

[0043] (12) Smelting

[0044] Induction smelting of ingredients by conventional induction smelting method, in which Mg is added by secondary feeding, and then poured and cooled to obtain alloy ingots;

[0045]...

Embodiment 2

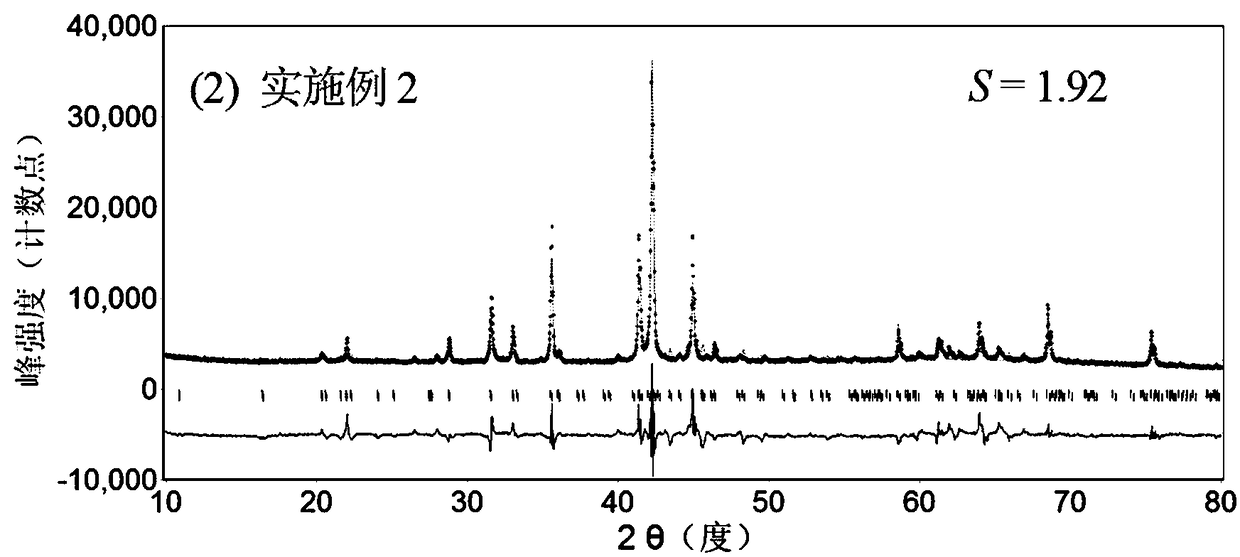

[0051] Example 2 A multi-element single-phase A 5 B 19 Type Superlattice Hydrogen Storage Alloy Electrode Material

[0052] The alloy composition of this embodiment is: La 0.84 Mg 0.16 Ni 3.60 co 0.04 Al 0.12 , the preparation method is carried out according to the following steps:

[0053] (21) Ingredients

[0054]Select metal elemental La, Mg, Ni, Co and Al as raw materials, carry out batching according to the above alloy chemical composition, consider the volatilization loss during smelting, increase the volatilization of corresponding elements when batching, and then put other raw materials except Mg into the crucible of the vacuum induction melting furnace, and the Mg is put into the secondary feeding bin;

[0055] (22) Smelting

[0056] Induction smelting of ingredients by conventional induction smelting method, in which Mg is added by secondary feeding, and then poured and cooled to obtain alloy ingots;

[0057] (23) Heat treatment

[0058] Place the alloy in...

Embodiment 3

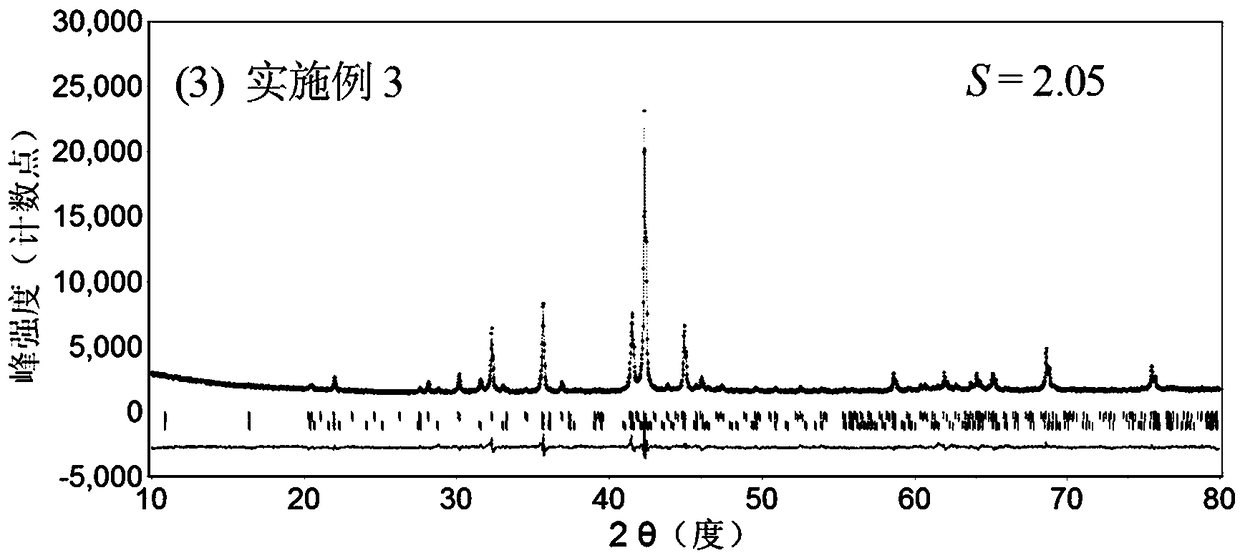

[0063] Example 3 A multi-element single-phase A 5 B 19 Type Superlattice Hydrogen Storage Alloy Electrode Material

[0064] The alloy composition of the present embodiment is: La 0.65 Nd 0.07 SM 0.08 Mg 0.20 Ni 3.50 Al 0.15 , the preparation method is carried out according to the following steps:

[0065] (31) Ingredients

[0066] Select metal elemental La, Nd, Sm, Mg, Ni and Al as raw materials, carry out batching according to the above-mentioned alloy chemical composition, consider the volatilization loss during smelting, increase the volatilization amount of corresponding elements when batching, and then add other elements except Mg The raw materials are put into the crucible of the vacuum induction melting furnace, and the Mg is put into the secondary feeding bin;

[0067] (32) Smelting

[0068] Induction smelting of ingredients by conventional induction smelting method, in which Mg is added by secondary feeding, and then poured and cooled to obtain alloy ingots;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com