Patents

Literature

600 results about "Alloy electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

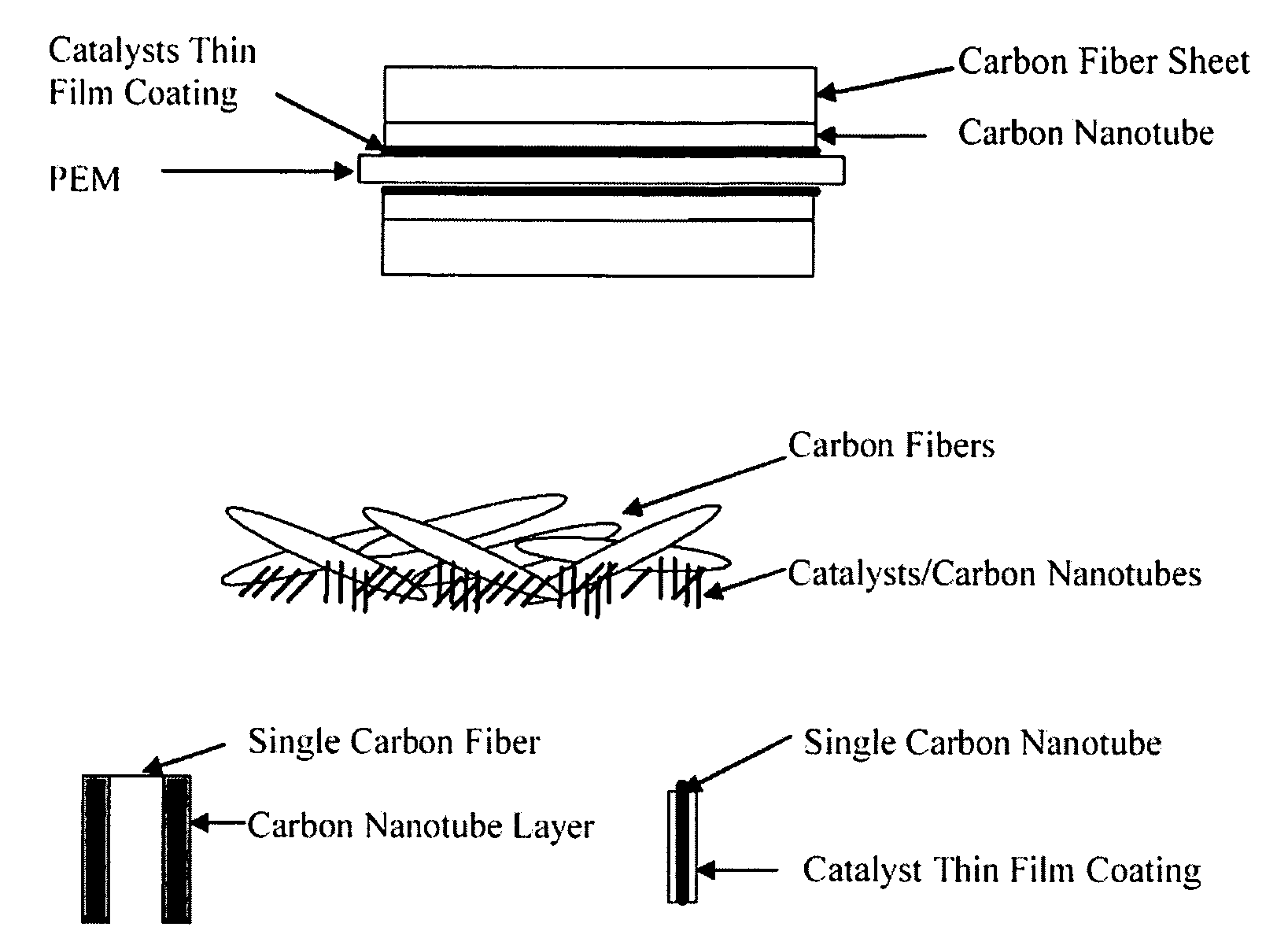

Low platinum fuel cells, catalysts, and method for preparing the same

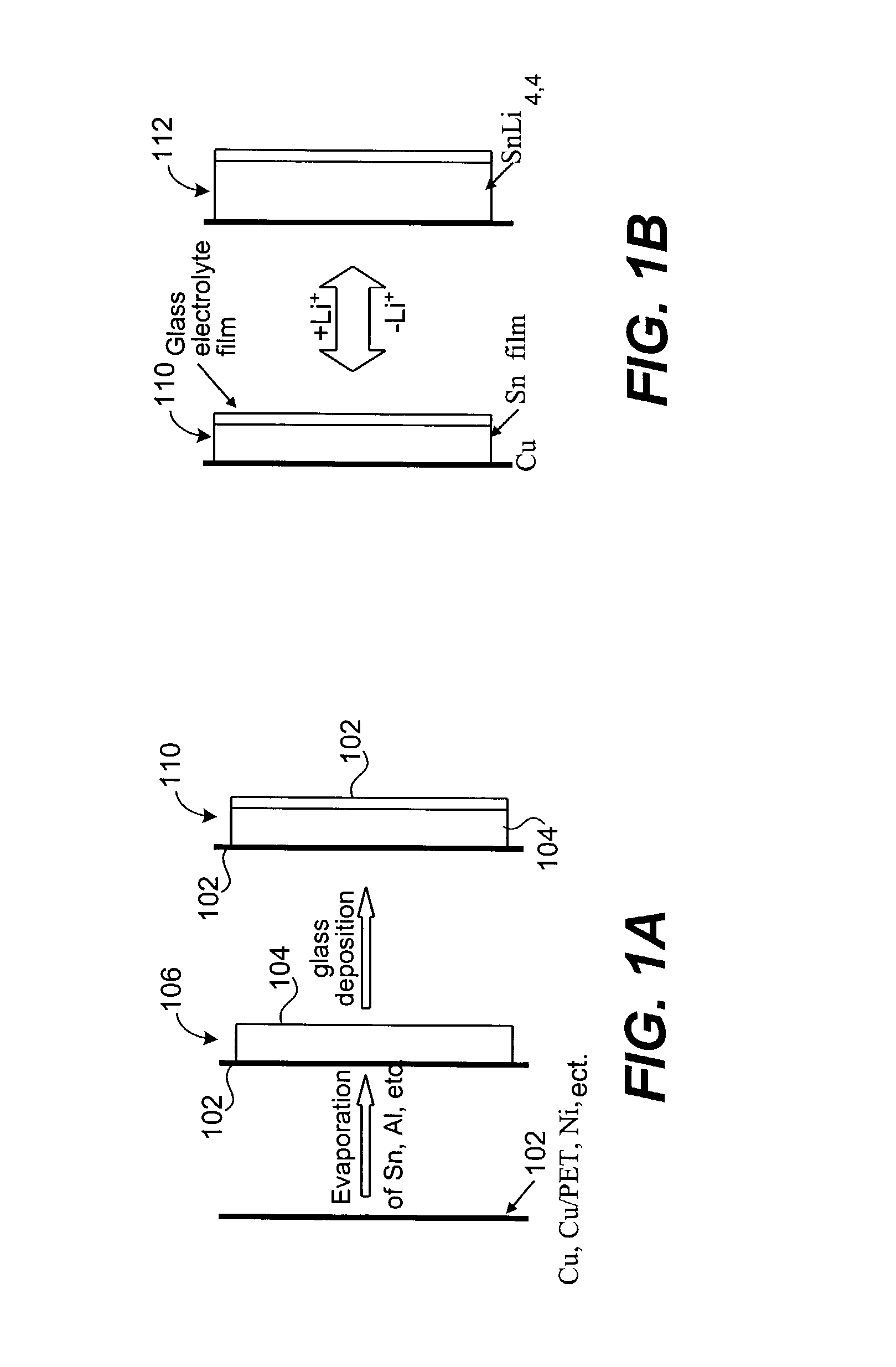

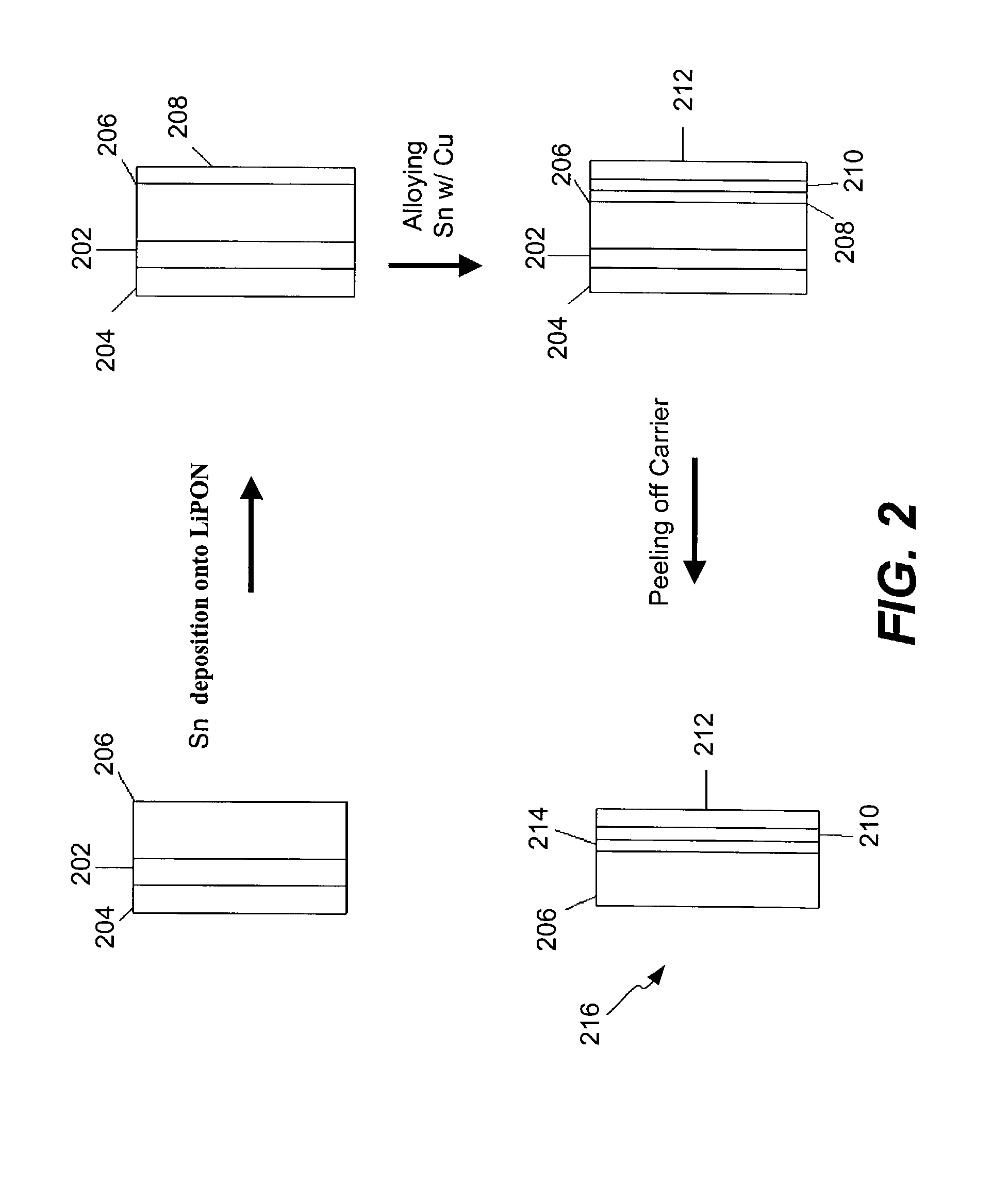

InactiveUS20060172179A1Efficient processingImprove throughputMaterial nanotechnologyConductive materialFiberCarbon fibers

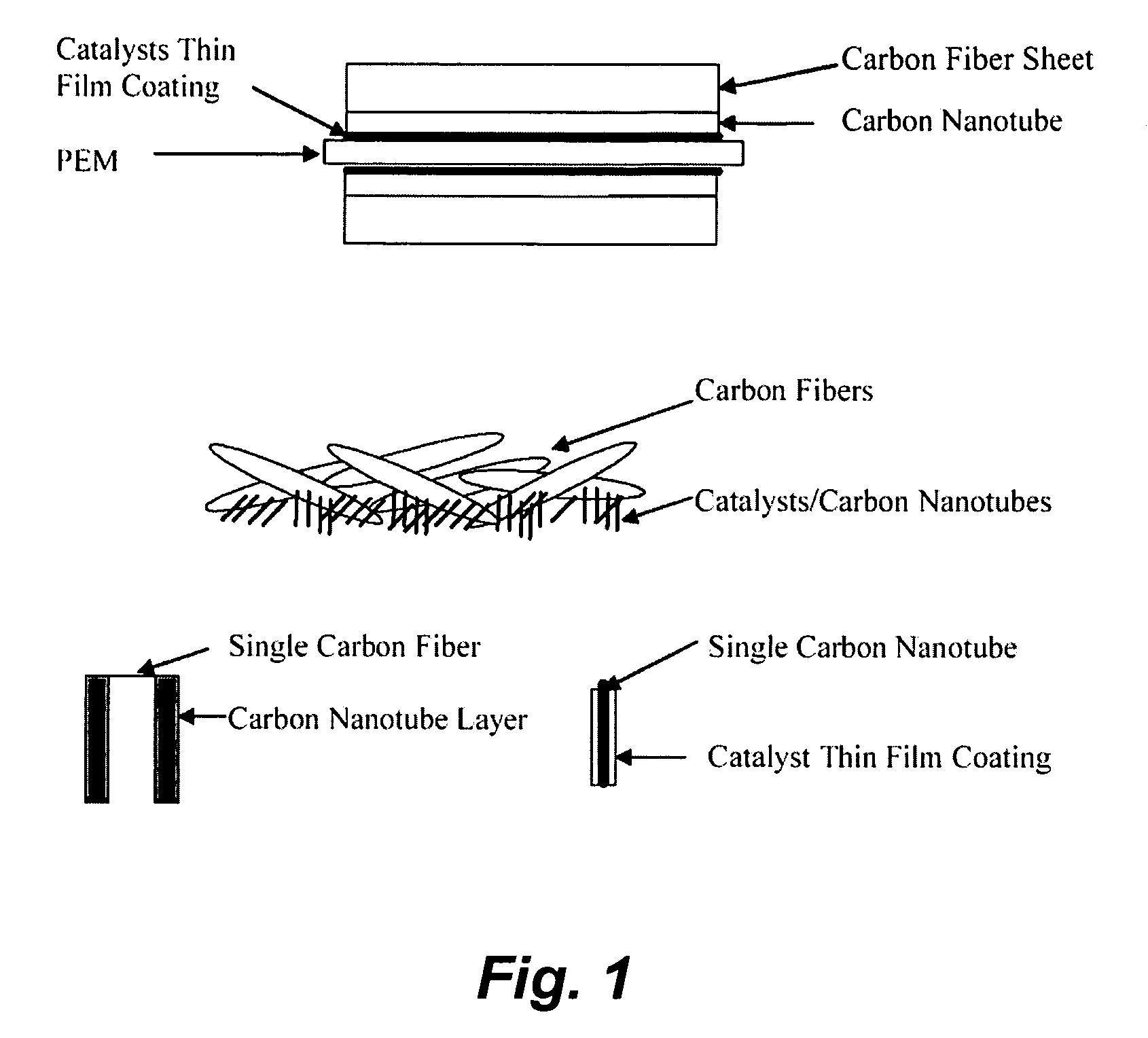

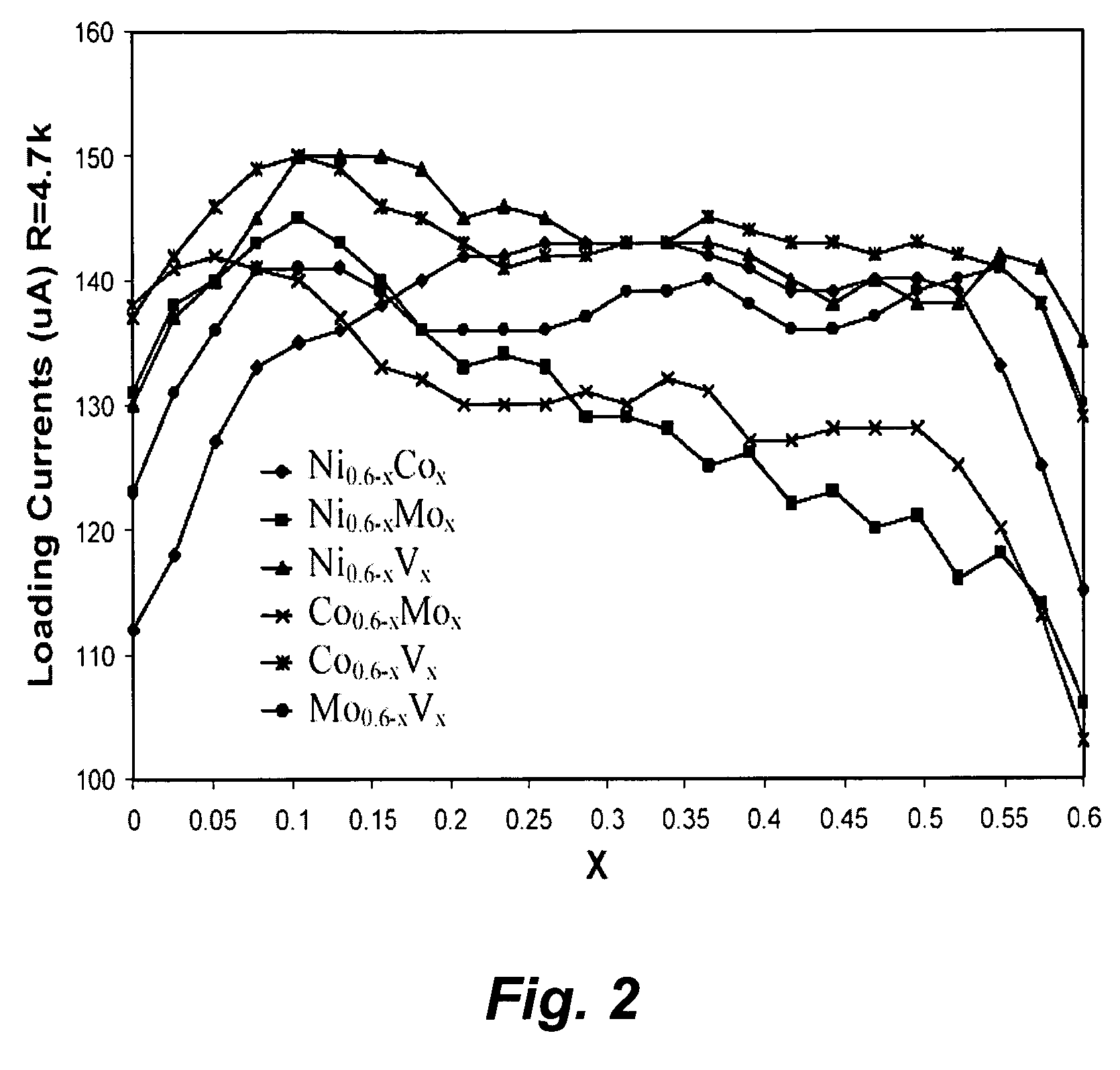

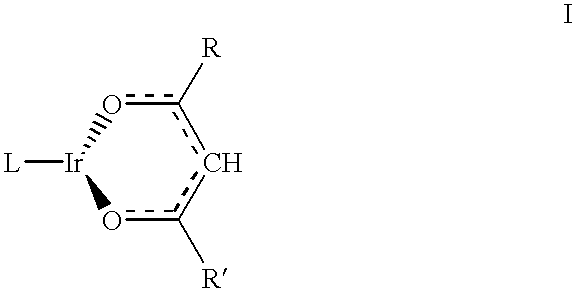

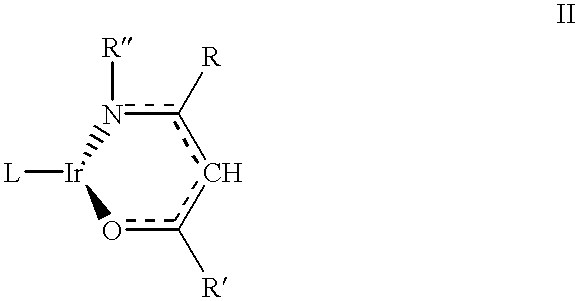

This invention provides novel fuel cell electrodes and catalysts comprising a series of catalytically active thin-film metal alloys with low platinum concentration supported on nanostructured materials (nanoparticles). Processing of the electrodes and catalysts can include electrodeposition methods, and high-pressure coating techniques. In certain embodiments, an integrated gas-diffusion / electrode / catalyst layer can be prepared by processing catalyst thin films and nanoparticles into gas-diffusion media such as Toray or SGL carbon fiber papers. The catalysts can be placed in contact with an electrolyte membrane for PEM fuel cell applications.

Owner:INTEMATIX

Chemical vapor deposition process for fabrication of hybrid electrodes

InactiveUS6284654B1Solid-state devicesSemiconductor/solid-state device manufacturingGas phaseChemical vapor deposition

A method of fabricating an electrode structure for a ferroelectric device structure including a ferroelectric material, involving chemical vapor deposition of a hybrid electrode constituting a multilayer electrode structure or an alloyed electrode structure, using either bubbler delivery or liquid delivery chemical vapor deposition.

Owner:ENTEGRIS INC

Fluxless heat-and wear-resistant cast iron alloy surfacing welding electrodes and manufacture thereof

InactiveCN1530201AReduce labor intensityImprove welding productivityArc welding apparatusWelding/cutting media/materialsWear resistantRefractory

An uncoated refractory antiwear welding cast iron alloy electrode for build-up welding contains C (2.5-6.5 wt.%), Si (0.8-2.5), Mn (0.4-1.5), Cr (16-35), Nb (0-1.5), Mo (0-3.5), Ni (0-2.0), W (0-2.5), V (0.1-2.0), Ti (0-0.8), Cu (0-1.0), S (0-0.08), P (0-0.1), O (0-0.08), N (0-0.08), Al (0-0.1) and Fe (rest), and is made up by casing method. Its advantages are high hardness of welded layer (more than 42 HRC), and low cost.

Owner:攀钢集团钢城企业总公司溶解乙炔厂

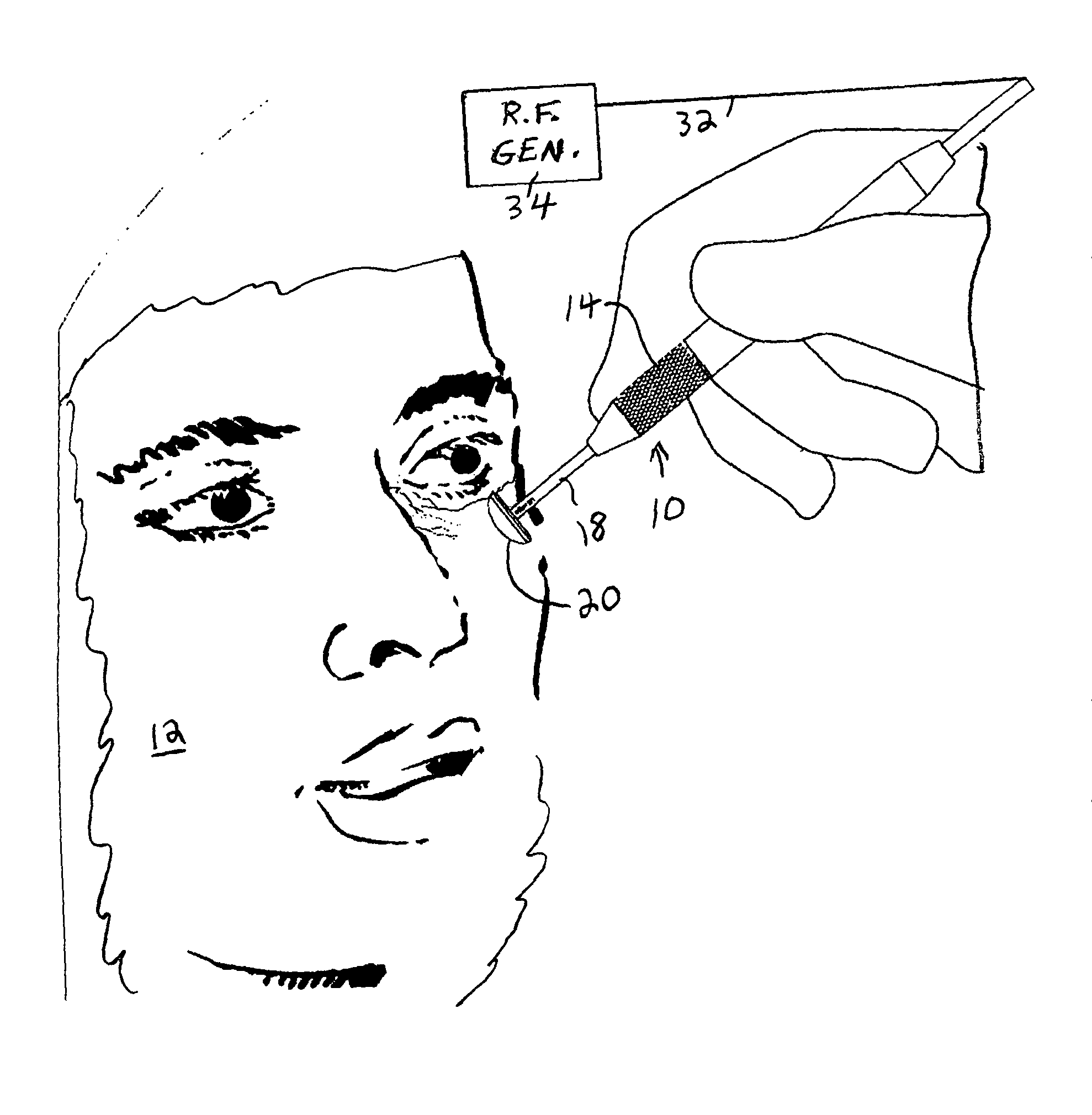

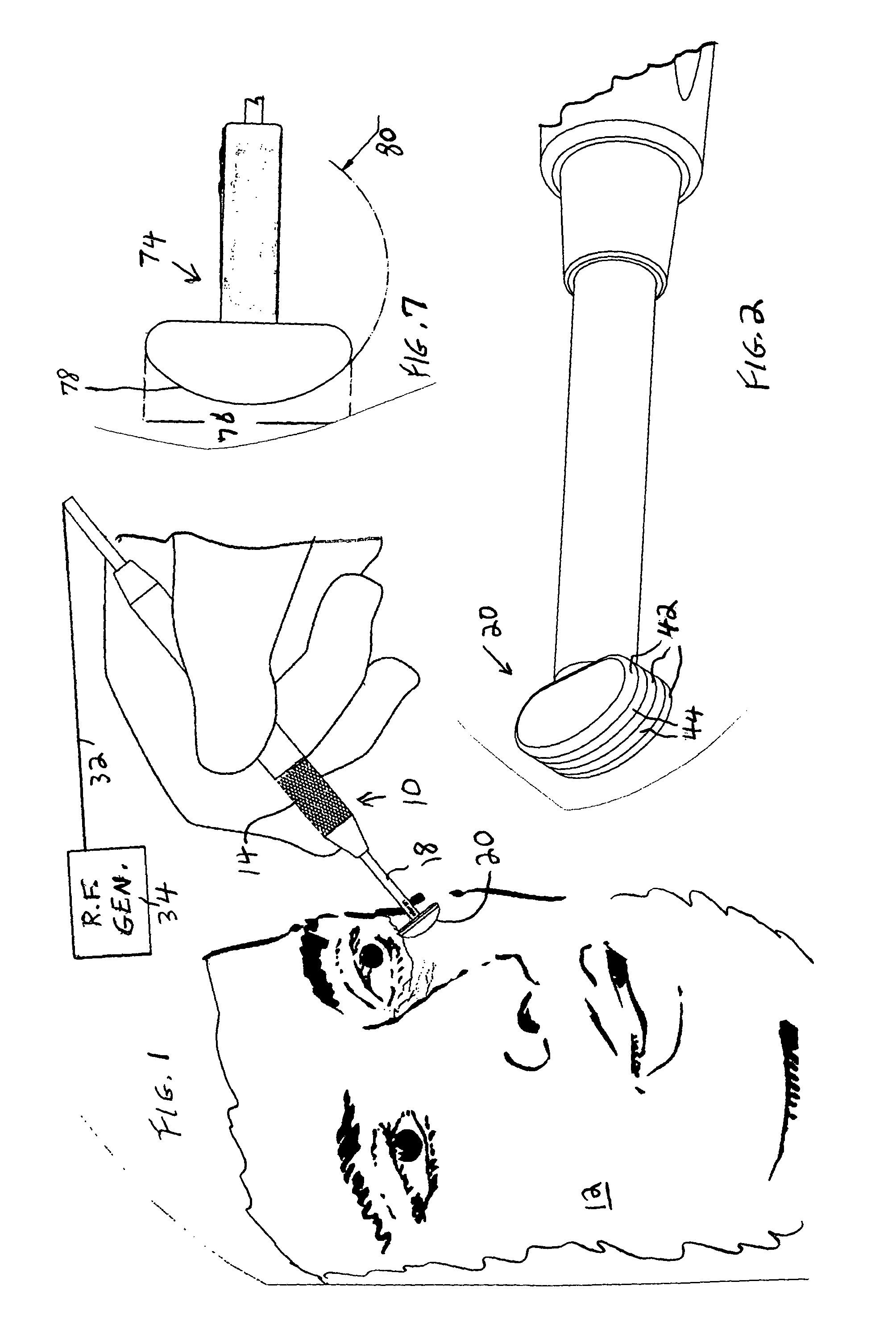

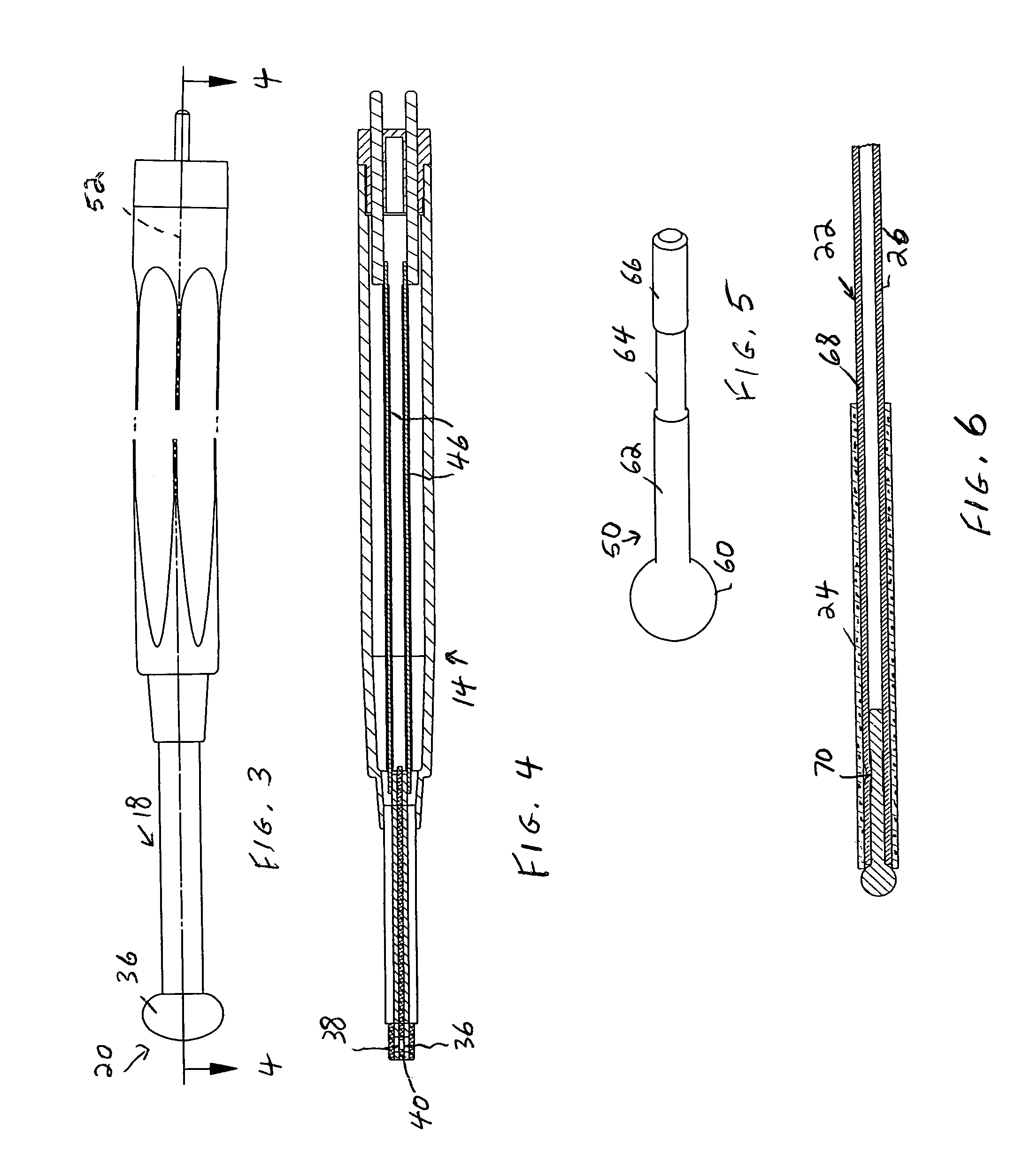

Non-ablative radio-frequency treatment of skin tissue

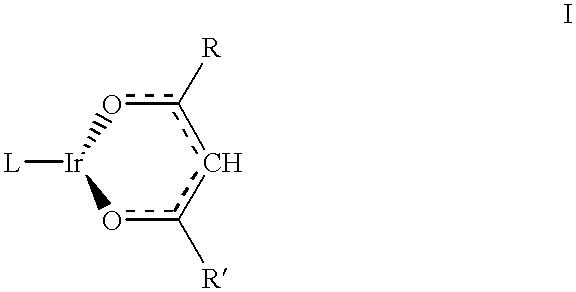

ActiveUS8317782B1Increase temperatureAlleviate the conditionSurgical instruments for heatingTherapeutic coolingAdditive ingredientConductive materials

A radio-frequency electrode that is specially configured to provide a reasonably uniform electric field distribution at the skin surface of a patient being treated to improve the skin appearance. Harmful burning is avoided by employing one of the following four features: pre-applying to the skin a thermal gel, a known thermally and electrically-conductive material, using low radio-frequency power at 3.8-4 MHz, relying on the natural cooling provided by a highly conductive electrode material, and continuously moving the electrode while in contact with the skin. Preferably, all four features are combined in carrying out the cosmetic procedure of the invention. In a preferred embodiment, the highly conductive electrode material is an alloy comprised mainly of silver with a small percentage of ingredients added to strengthen the silver alloy electrode and preserve its luster and the active surface of the electrode is configured as a section of a sphere, or as dome shaped.

Owner:CYNOSURE

Copper, copper/molybdenum, or copper/molybdenum alloy electrode etching solution for use in liquid crystal display system

ActiveCN101684557AWith purityGood straightnessSemiconductor/solid-state device manufacturingNon-linear opticsPhosphateMaterials science

The invention relates to a copper, copper / molybdenum, or copper / molybdenum alloy electrode etching solution, comprising: based on the total weight of the etching solution, 12-35 wt% of hydrogen peroxide, 0.5-5 wt% of sulfate, 0.5-5 wt% of phosphate, 0.0001-0.5 wt% of fluorine ion, 0.1-5 wt% of first water-soluble cyclic amine, 0.1-5 wt% of chelating agent, 0.1-5 wt% of second water-soluble cyclicamine, 0.1-5 wt% of diol, and deionized water, the total weight of the etching solution being 100 wt%. The invention relates to the copper, copper / molybdenum, or copper / molybdenum alloy electrode layer etching solution for use in the process of etching gate electrode, source electrode, or collecting electrode of the thin film transistor (TFT) in the liquid crystal display device or etching metallic wire.

Owner:SOULBRAIN CO LTD

Method for melting nickel-base high temperature alloy with electro-slag furnace

The invention relates to a method for melting a nickel-base high temperature alloy with an electro-slag furnace. The method includes the following methods: loading materials, welding a high temperature alloy electrode and a false electrode to be smelted together, and placing slag materials at the bottom of a crystallizer; blowing the welded electrodes with inert gases, and closing a protection cover; protecting a smelting closing smoke exhaust valve, and feeding an Ar gas into the crystallizer and the protection cover; striking an arc and melting slag; cleaning smelting slag materials, starting a smelting period, and swinging a slag resistor for less than 0.5 m omega during the smelting process; adding oxidizing agents, and adding metal aluminum powder continuously or at intervals to serve as deoxidizing agents during an electro-slag re-melting process; adopting feeding thorough three stages, power feeding is decreased rapidly, power feeding is decreased slowly, and finally heat is preserved at constant power; and casting a die, cooling and demolding the die. According to the method for melting the nickel-base high temperature alloy with the electro-slag furnace, the surface of a nickel-base high temperature steel ingot has no slag groove defect, and the burning losses of Al and Ti are less than or equal to 5%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

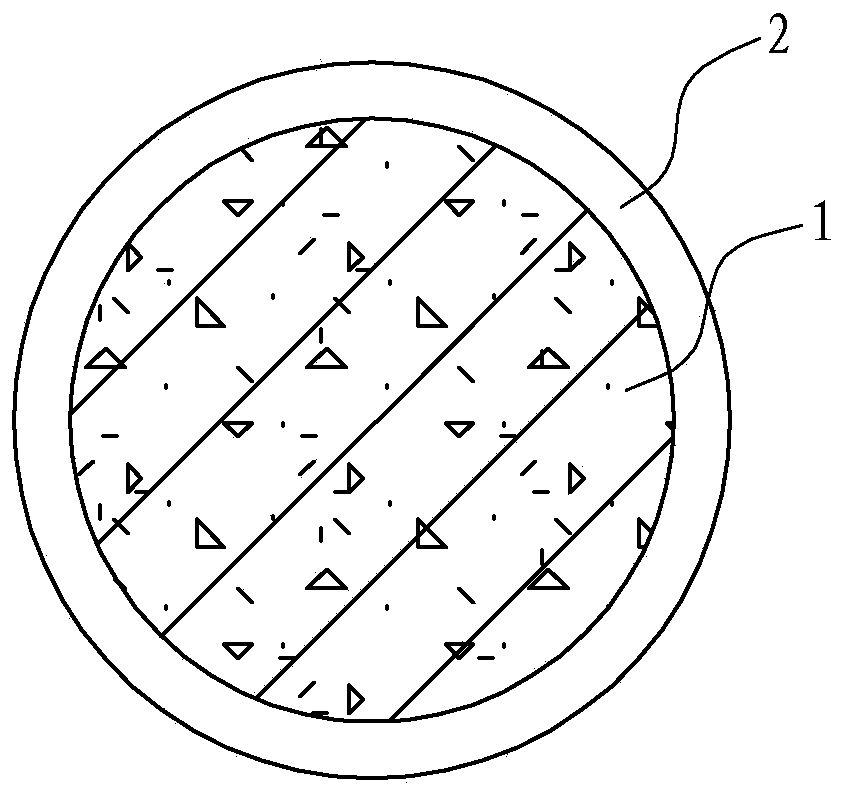

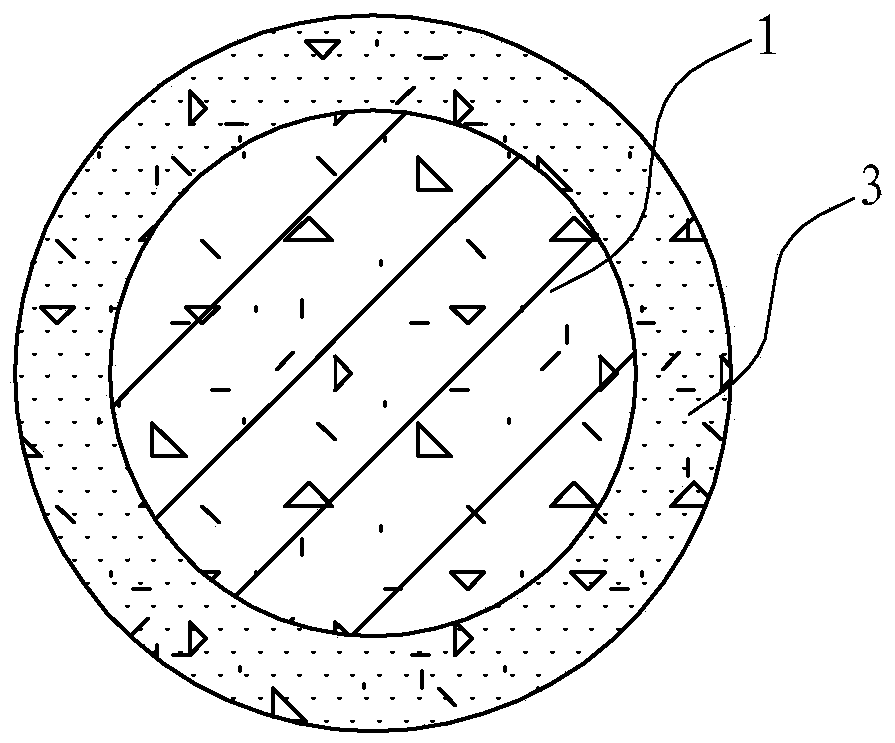

A nanometer porous high-entropy alloy electrode, a preparing method thereof and applications of the electrode

The invention belongs to the technical field of catalytic and energy storage applications of high-entropy alloys, and particularly relates to a nanometer porous high-entropy alloy catalytic electrode,a preparing method thereof and applications of the electrode in bi-functional catalytic water splitting to produce hydrogen and oxygen. The electrode includes, by mole, 15-50% of Ni, 5-20% of a transition metal A, 15-50% of Mo, 5-25% of a transition metal B and 5-40% of Mn, wherein the transition metal A is Fe or Cu, and the transition metal B is one of Co, Ti or W. The alloy electrode has a porous structure, pore diameters range from 2 nm to 500 nm, and the specific surface area is 10-80 m<2> / g. The alloy electrode has advantages of 1) capability of being three-dimensional, porous, self-supporting and no need of any support or adhesive; 2) a large specific surface area and good electrical conductivity; 3) a simple material structure of the non-noble-metal porous high-entropy electrode, rich raw material sources, low prices and controllable preparation conditions; and 4) excellent catalytic performance.

Owner:宁波杰士兄弟工具有限公司

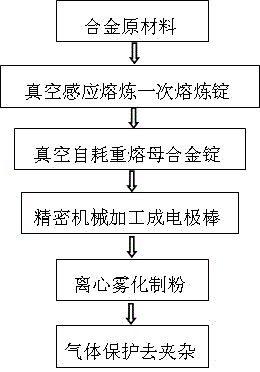

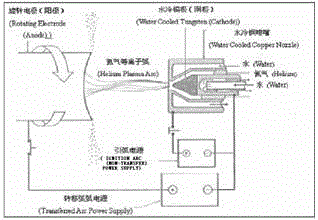

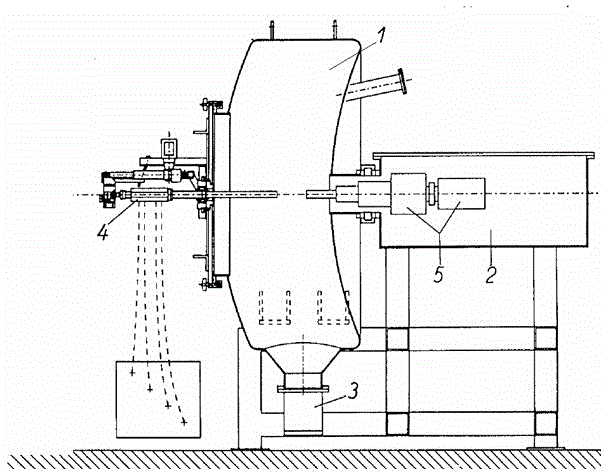

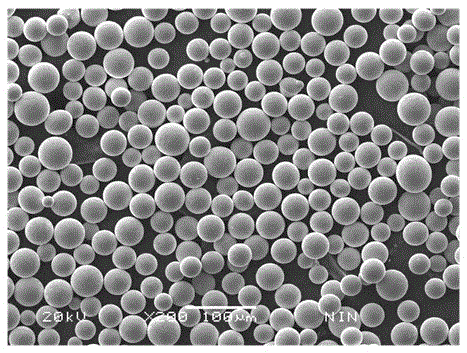

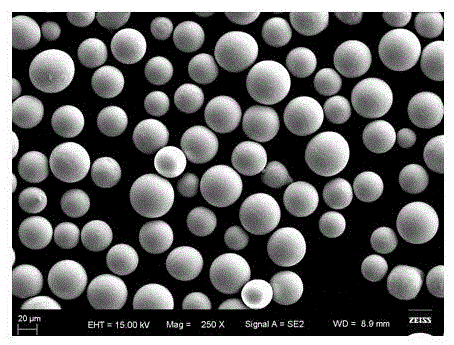

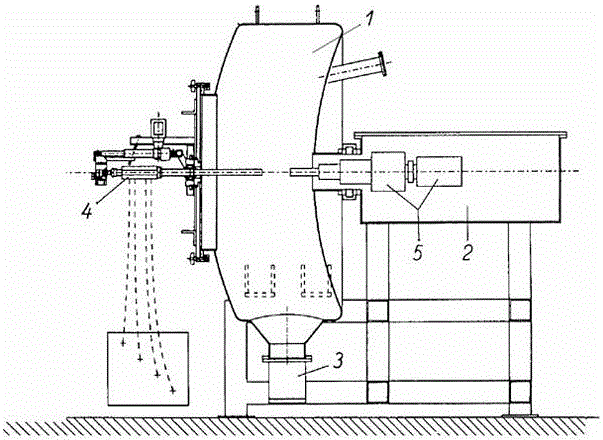

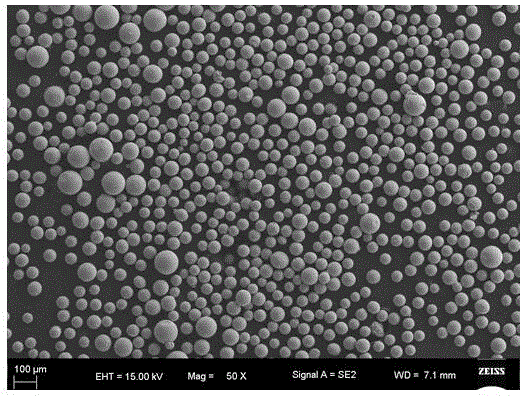

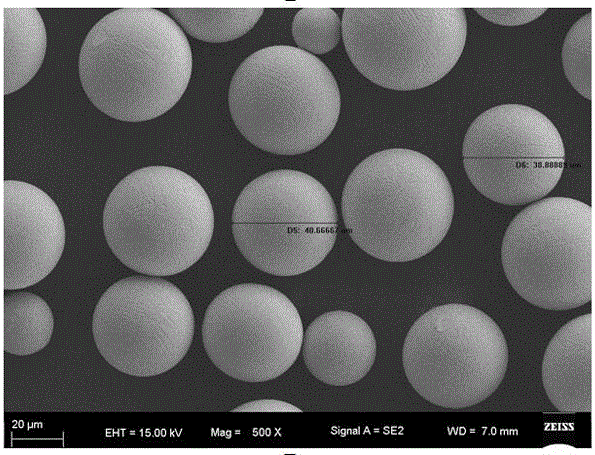

Preparation method of IN718 alloy spherical powder

InactiveCN104308167AReduce oxygen contentReduce contentElectrostatic separationNon-metallic inclusions

The invention discloses a preparation method of IN718 alloy spherical powder. The method comprises the following steps of step 1, smelting an IN718 alloy master ingot; step 2, processing the IN718 alloy master ingot into an IN718 alloy electrode bar with the diameter of 50 to 90mm and the length of 600 to 800mm, wherein the straightness of the electrode bar is controlled to be smaller than or equal to 0.1mm / m; step 3, placing the IN718 alloy electrode bar in a sealed furnace chamber protected by inert gas, rotating the IN718 alloy electrode bar at high speed, and heating the end part of the electrode bar by using a plasma gun to melt the electrode bar; step 4, atomizing the melted metal under the action of centrifugal force to enable melted metal to fly to form fine liquid droplets, wherein the liquid droplets are quickly cooled in inert gas to form spherical particles, and the spherical particles fall into a collector at the bottom of the furnace chamber to form the IN718 alloy spherical powder; step 5, under the protection of the inert gas, performing electrostatic separation processing on the prepared IN718 alloy spherical powder to remove non-metal impurities from the powder to obtain the pure IN718 alloy spherical powder. The method has the characteristics of good sphericity degree, fine particle size, low oxygen content and few impurities.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

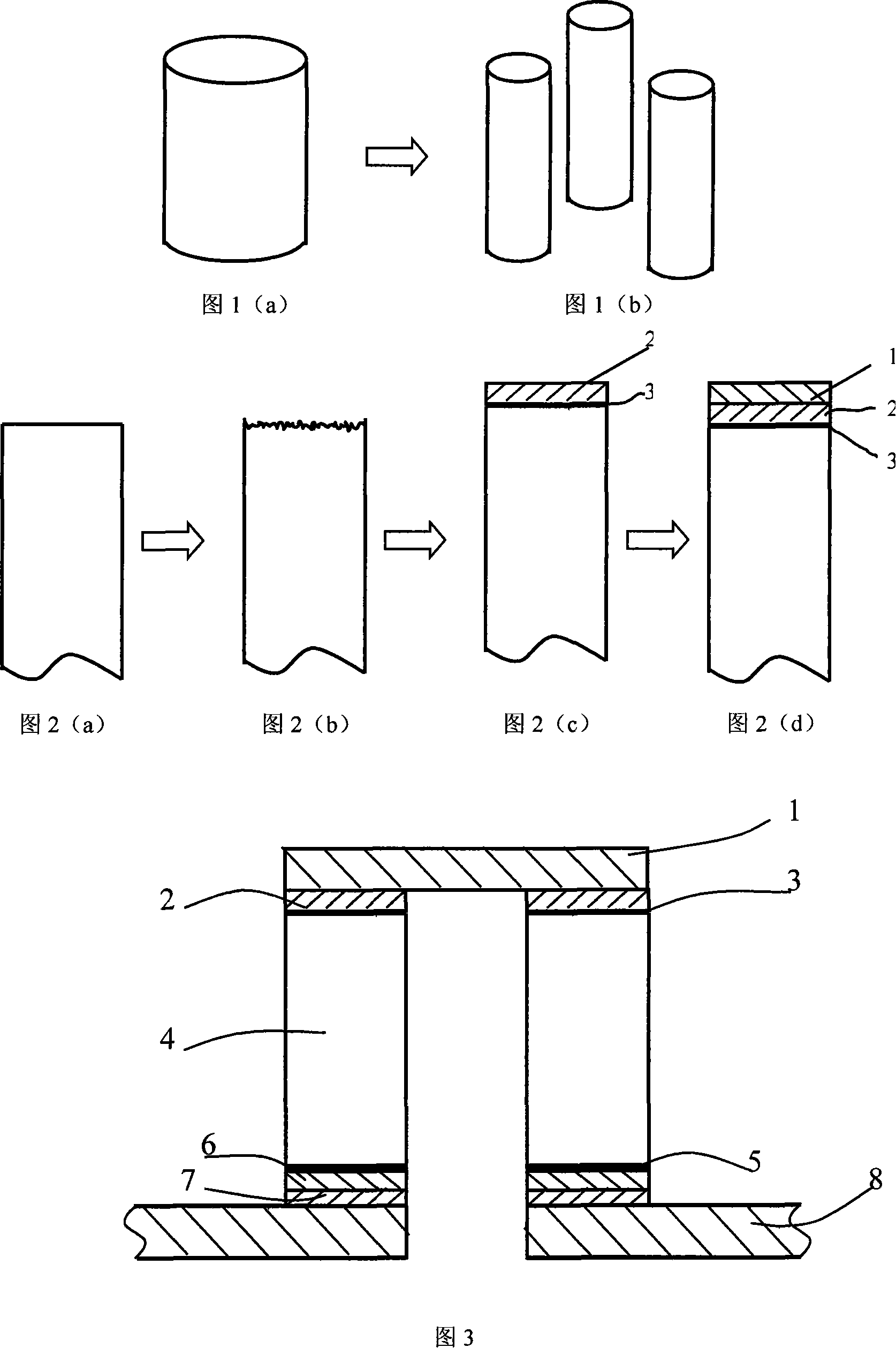

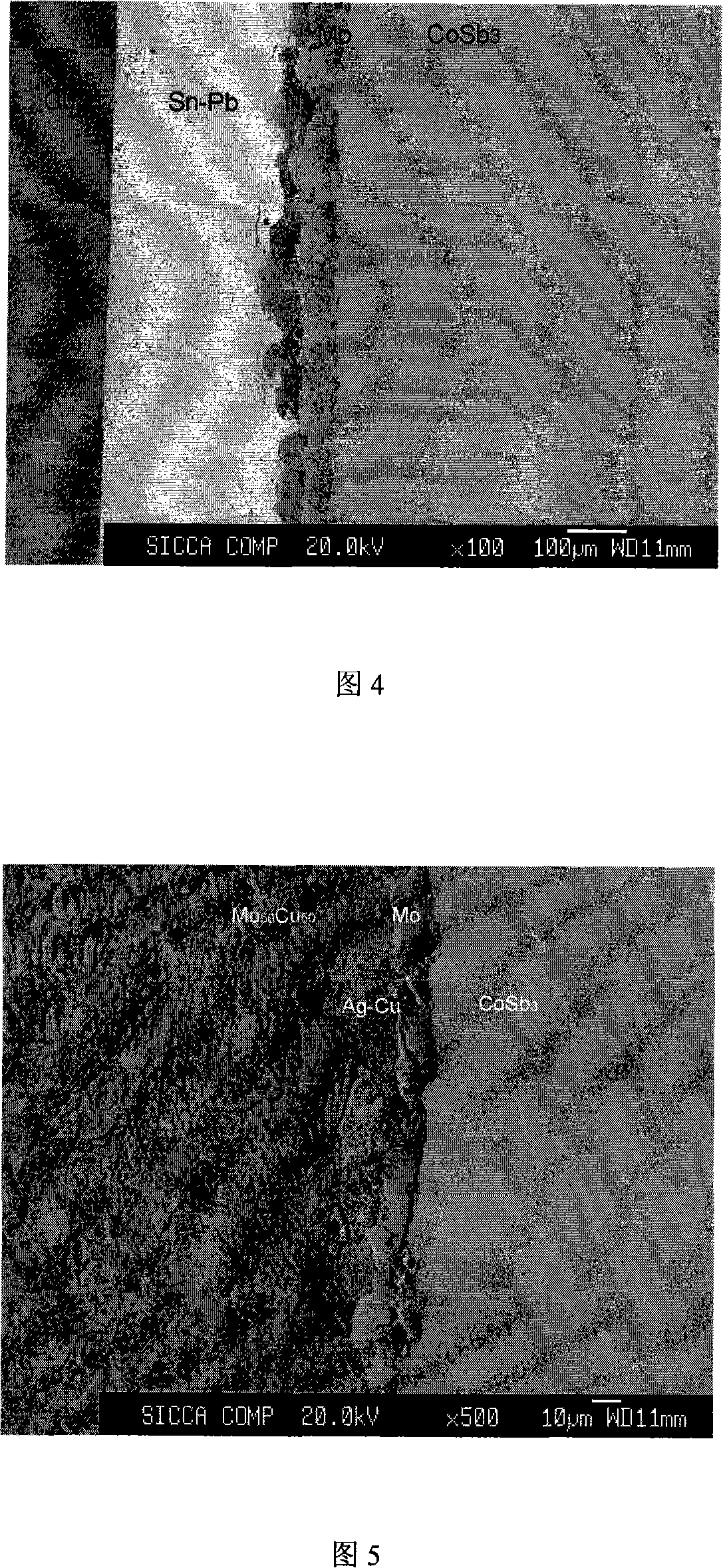

Pi type CoSb3 based thermoelectric converting device and method for producing the same

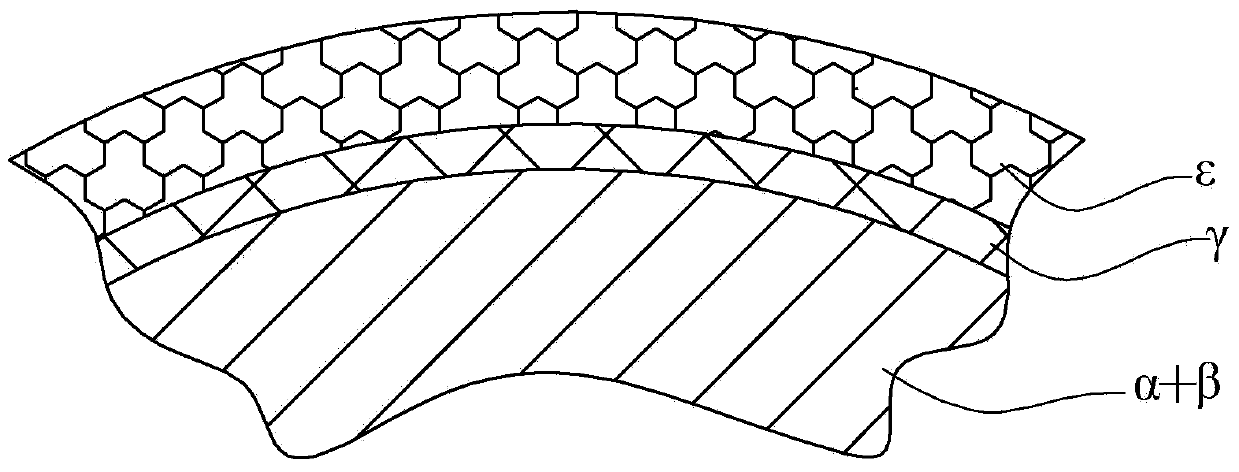

ActiveCN101136450AReliable Thermal PerformanceEasy to weldThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsDiffusion barrier

This invention relates to a Pa-type CoSb3-base thermoelectric converting device including: a Mo-Cu alloy electrode at an end of high temperature, a welding layer of the high temperature end, a diffusion blocking layer, thermoelectric pins, a metal layer, a welding layer and an electrode of the low temperature end, in which, the thermoelectric pins are made of P or N-type CoSb3-base thermoelectric material and are connected with the Mo-Cu alloy electrode into one unit by the welding layer of the high temperature end to form a high temperature end, the low temperature end of the pins are connected with the electrode of its end by the metal layer and the welding layer of the low temperature end, which utilizes a SPS quick welding technology to realize heat match as much as possible and no obvious crack exists at the high temperature end.

Owner:中科西卡思(苏州)科技发展有限公司

Method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder

The invention provides a method for preparing Ti-6Al-7Nb medical titanium alloy spherical powder. The preparation method comprises the following steps: preparing materials of alloy components according to ASTM F1295 standards and carrying out two times of vacuum melting on a mother alloy ingot; preparing the mother alloy ingot into an alloy electrode bar through forging and machining; carrying out pre-vacuumizing treatment on atomization equipment and introducing mixed inert protective gas; conveying the electrode bar into an atomization chamber through a feeding system and heating the end face of the electrode bar by using a plasma torch; preparing metal liquid drops by using a centrifugal effect of a rotary electrode and instantly condensing the metal liquid drops into spherical metal powder; after cooling the high-nitrogen stainless steel spherical powder, removing non-metal impurities through an electrostatic impurity removing device; and finally, carrying out powder package by adopting multilayered vacuum heat sealing. The method provided by the invention has the characteristics of high production efficiency, strong batch stability, high fine powder yield and the like; and the Ti-6Al-7Nb medical titanium alloy spherical powder with high sphericity degree, good purity, strong mobility and smooth and clean surface can be easily prepared.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

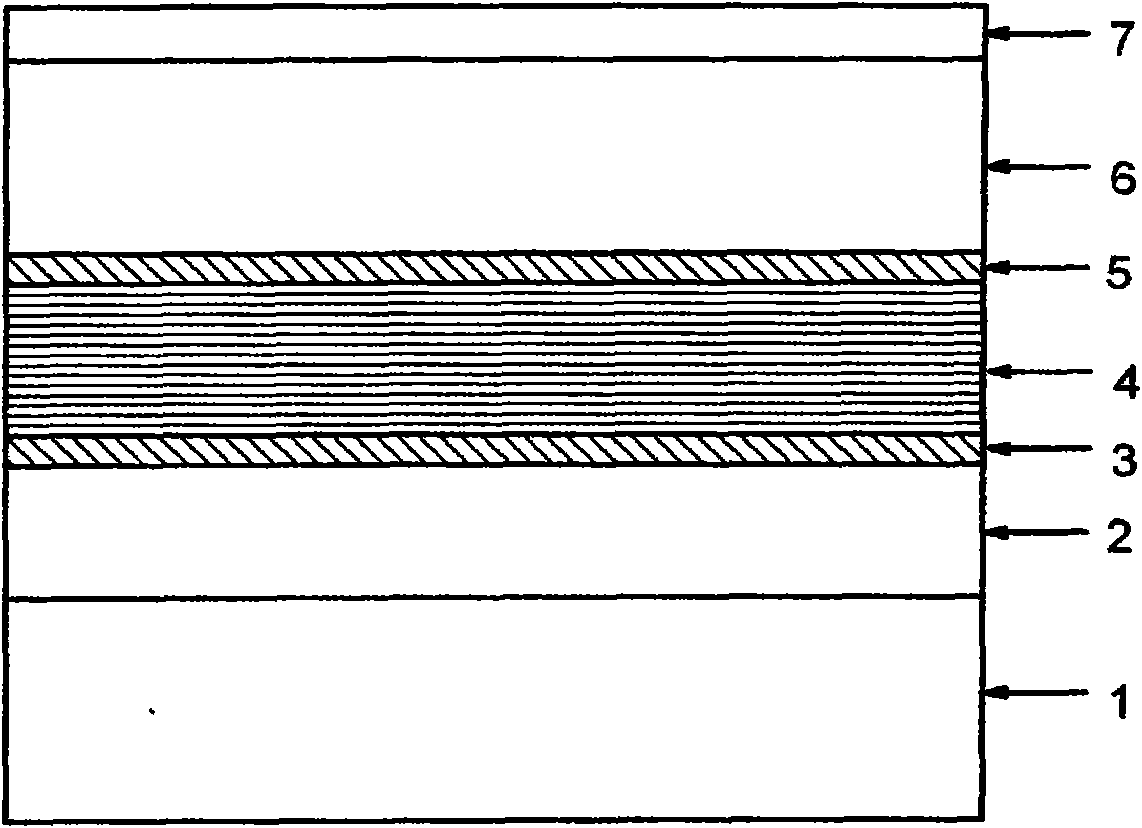

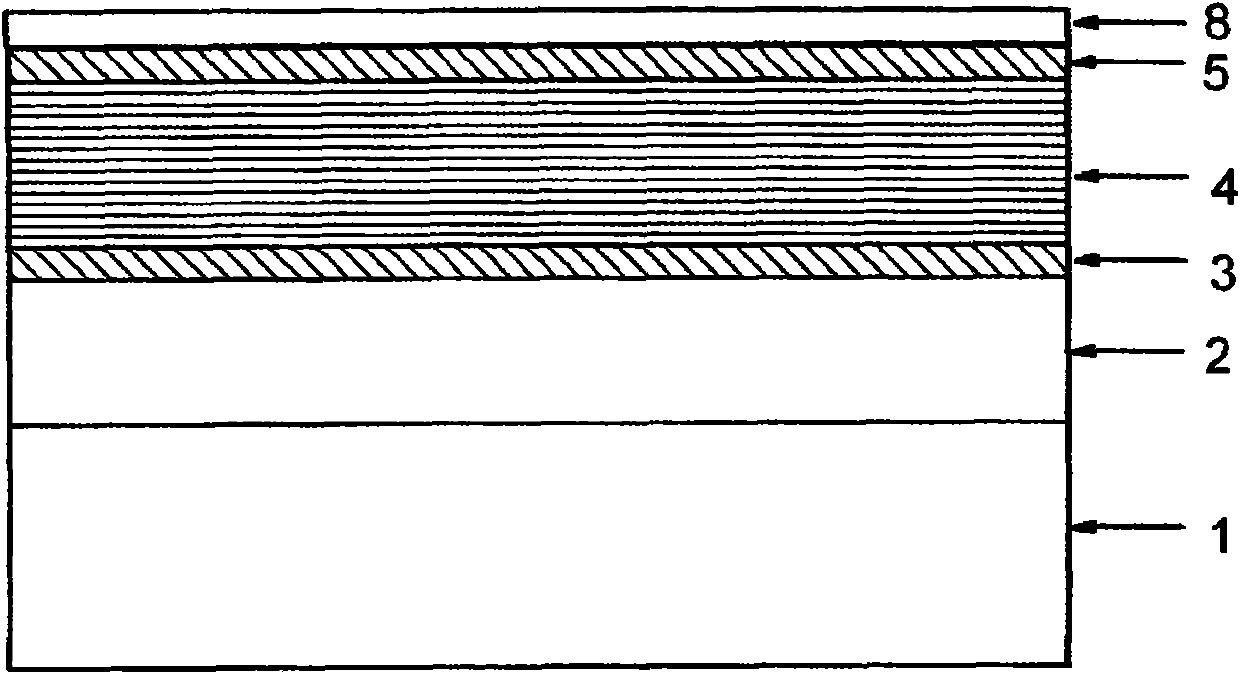

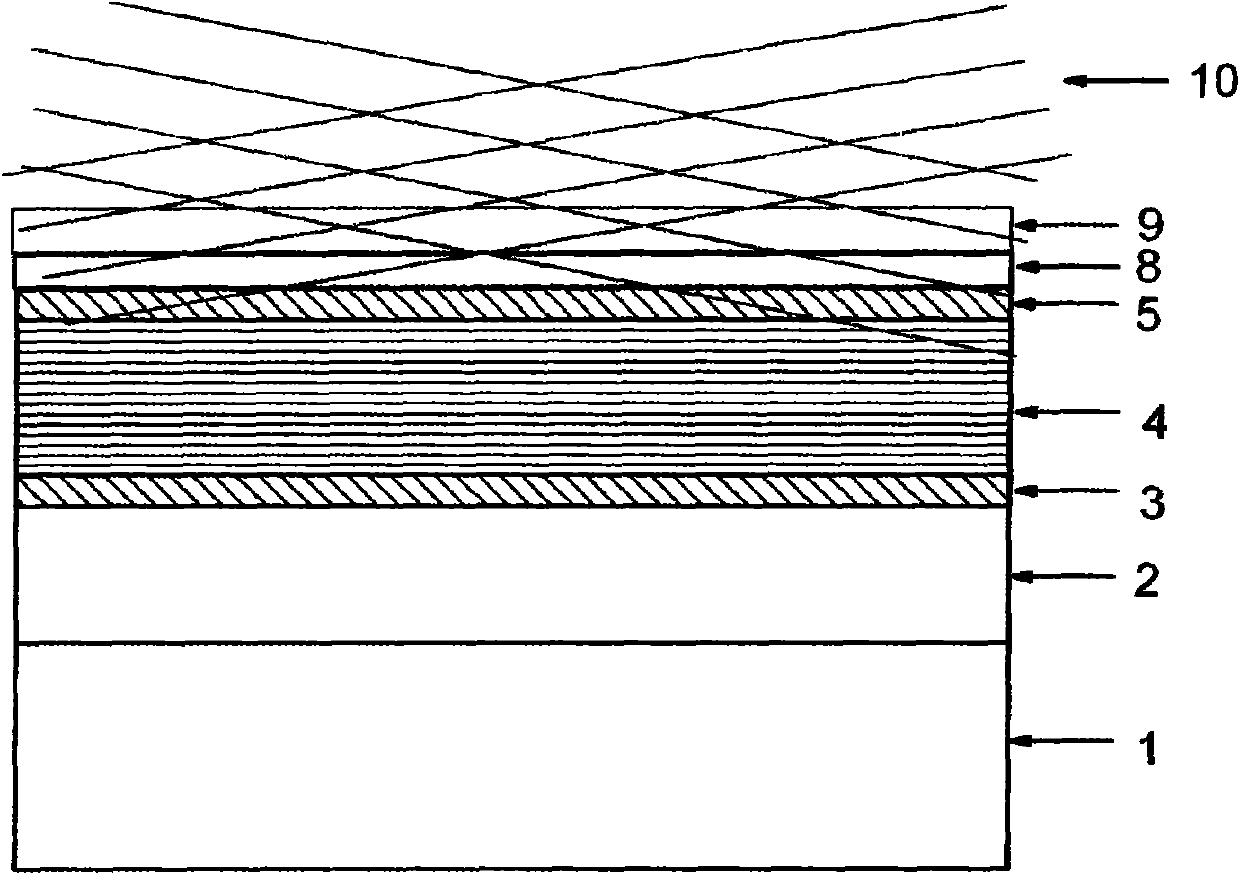

Inclined cavity surface two-dimensional photonic crystal distribution feedback quantum cascade laser and preparation method

InactiveCN102025110AImprove performanceSimple processLaser detailsLaser active region structureDot matrixPhotonic crystal

The invention discloses an inclined cavity surface two-dimensional photonic crystal distribution feedback quantum cascade laser and a preparation method. The inclined cavity surface two-dimensional photonic crystal distribution feedback quantum cascade laser comprises an InP substrate, an InP waveguide limit layer manufactured on the InP substrate, an InGaAs lower waveguide layer manufactured on the InP waveguide limit layer, a strain compensation active layer manufactured on the InGaAs lower waveguide layer, an InGaAs upper waveguide layer manufactured on the strain compensation active layer, a two-dimensional rectangular photonic crystal dot matrix graph manufactured on the InGaAs upper waveguide layer, an InP cover layer manufactured on the InGaAs upper waveguide layer, a contact layer manufactured on the cover layer for forming a secondary epitaxial wafer, V-shaped double channels etched downward from the surface of the secondary epitaxial wafer to the limit layer for forming a slant ridge waveguide, a silicon dioxide layer which is manufactured on the surfaces of the V-shaped double channels and the contact layer, a front electrode manufactured on the surface of the etched secondary epitaxial wafer, a metal layer which is manufactured on the front electrode and fills up the two V-shaped double channels and an alloy electrode manufactured on the backside of the InP substrate, wherein a current injection window is formed in the middle of the silicon dioxide layer on the surface of the contact layer.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Preparation method of Waspalloy spherical powder for additive manufacturing

InactiveCN106623959AFast pure meltingReduce the introductionAdditive manufacturing apparatusTransportation and packagingVacuum pumpingElectrostatic separation

A preparation method of Waspalloy spherical powder for additive manufacturing includes the steps of conducting alloy component compounding according to AMS 5706 standards and subjecting master ingots to vacuum melting twice; producing the master ingots into alloy electrode bars by means of forging and machining; subjecting an atomizing unit to pre-vacuum-pumping treatment, and feeding the atomizing unit with mixed inert protective gas; feeding the electrode bars into an atomizing chamber by a feeding system, heating electrode bar end faces by a plasma torch, preparing metal liquid droplets under the centrifugal action of a rotating electrode, and making the metal liquid droplets form spherical metal powder by flash setting; using a powder collecting device comprising an electrostatic separation component for removing inclusions of the spherical metal powder and collecting purified powder. The preparation method has the advantages of high production efficiency, high batch stability and high -270-mesh powder yield and can be used for easily preparing the Waspalloy spherical powder high in purity, sphericity and fluidity.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

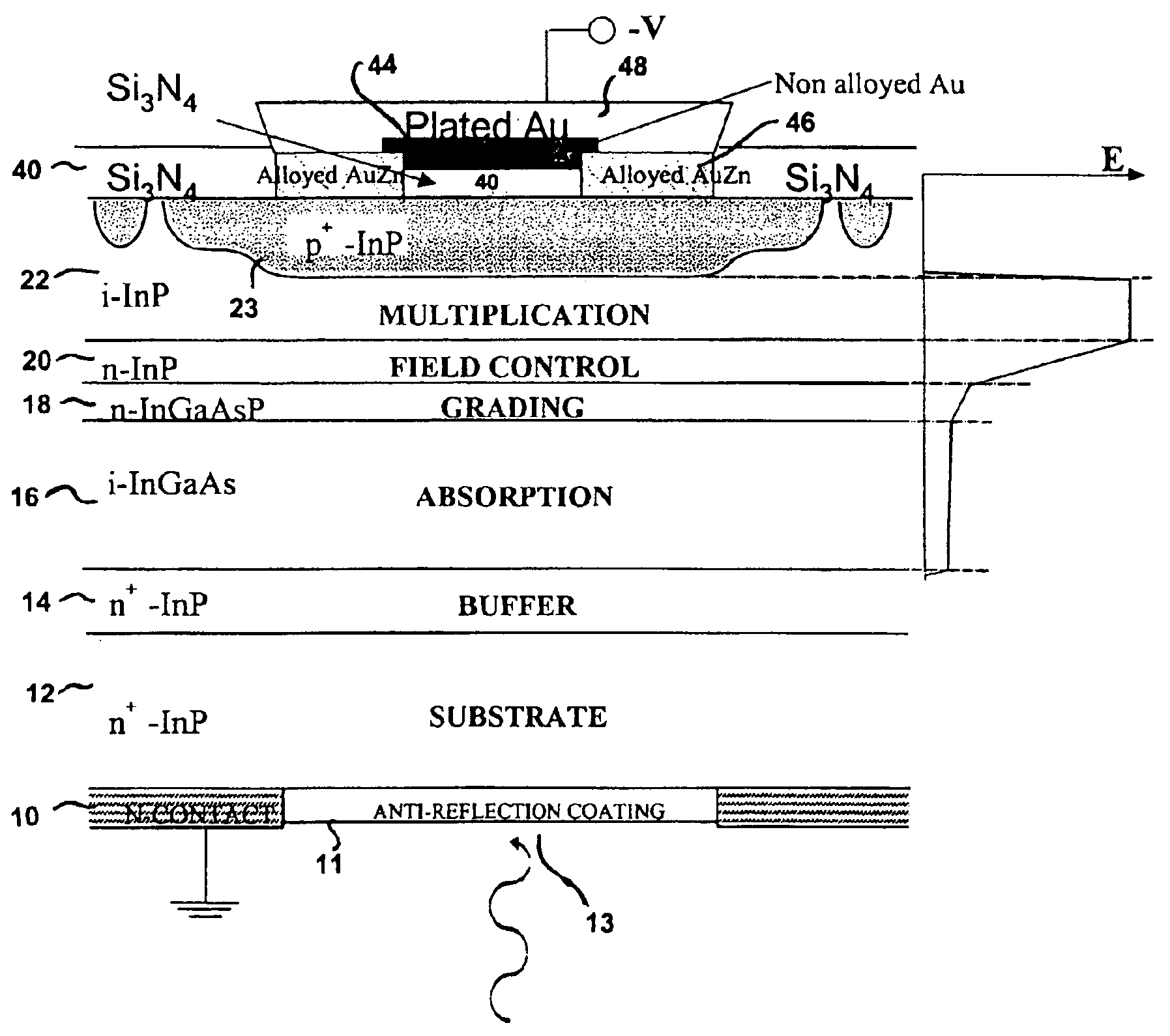

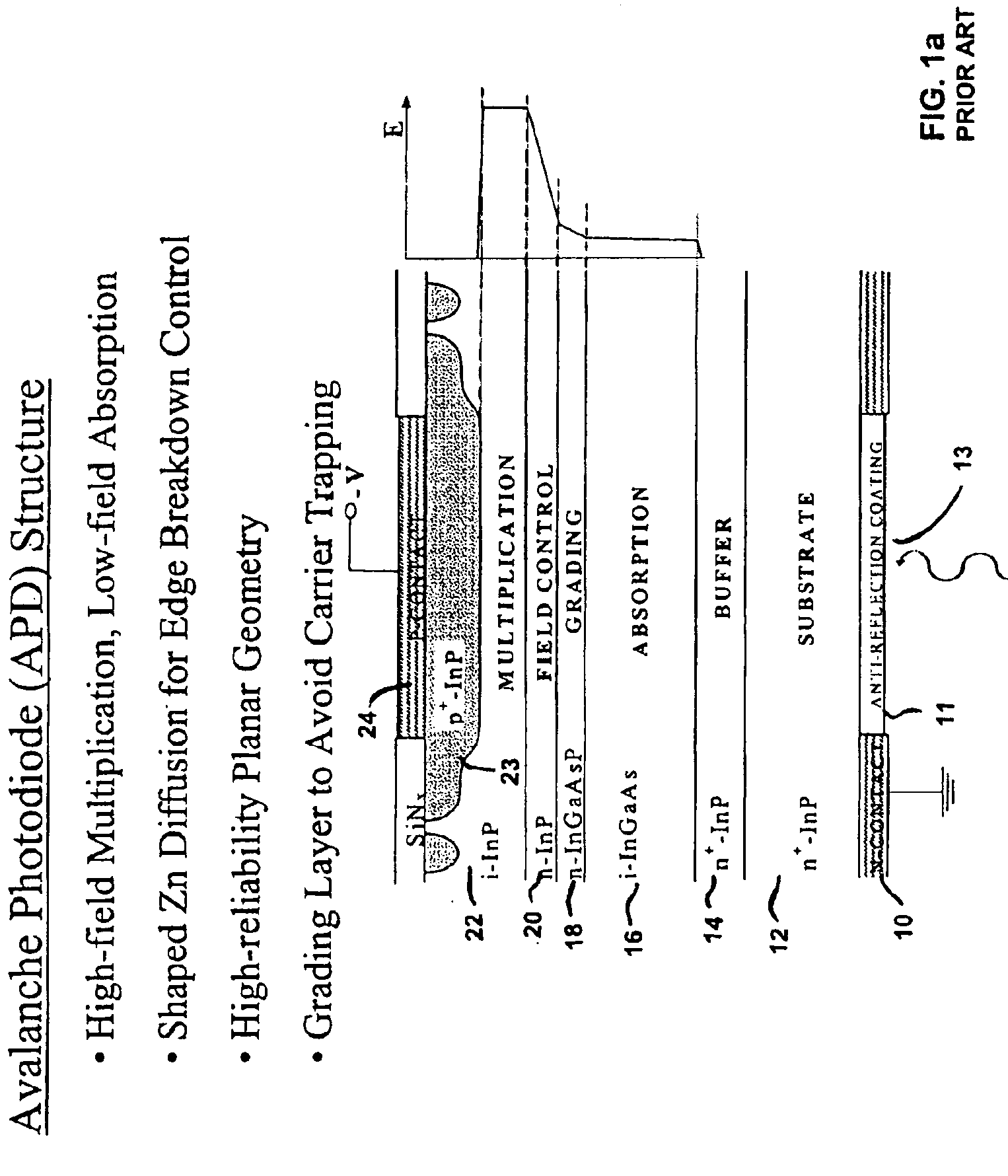

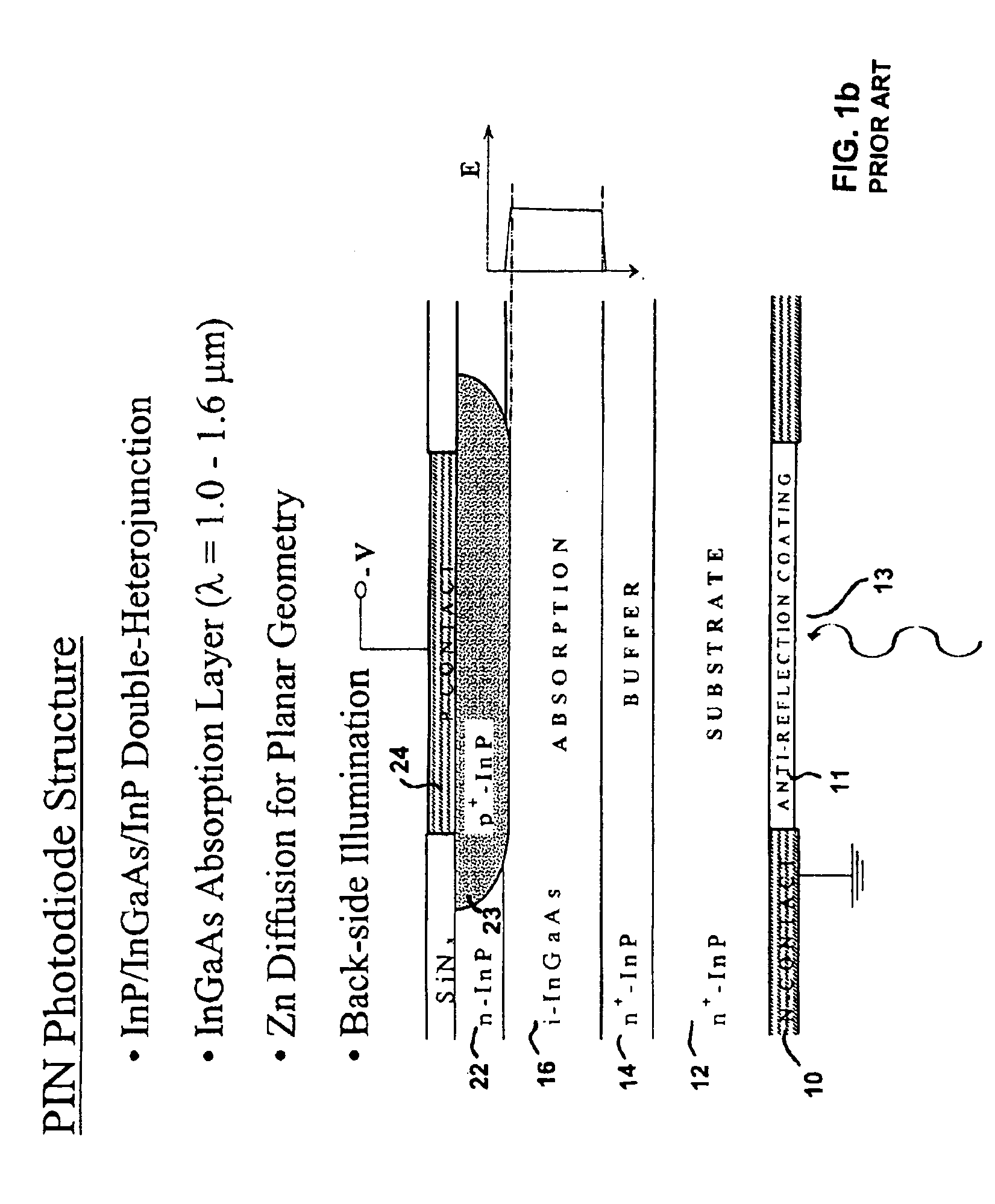

Back illuminated photodiodes

InactiveUS6894322B2Improve reflectivityIncrease reflective surfaceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotodiodeSemiconductor

A highly reflecting back illuminated diode structure allows light that has not been absorbed by a semiconductor absorbing region to be back reflected for at least a second pass into the absorbing region. The diode structure in a preferred embodiment provides a highly reflecting layer of gold to be supported in part by a conducting alloyed electrode ring contact and in part by a passivation layer of SixNy. Conveniently this structure provides a window within the contact which allows light to pass between the absorbing region and the reflecting layer of gold.

Owner:LUMENTUM OPERATIONS LLC

High-accuracy zinc base alloy electrode wire and preparing method thereof

ActiveCN104191056AGood for taking awayCutting discharge mitigationElectrical-based machining electrodesSurface finishImpurity

The invention relates to a high-accuracy zinc base alloy electrode wire. Components in a shell layer comprise, by weight, 70.5%-95% of Zn, 2.5%-27% of Cu, 0.02%-4.0% of X, 0.002%-0.4% of Y and inevitable impurities brought in by raw materials. X is any two kinds of metal from Ni, Ag, Cr, Si and Zr, the content ranges of the two kinds of metal are both 0.01%-2.0%, Y is any two kinds of elements of Ti, Al, Co, B and P, and the content range of the two elements are both 0.001%-0.2%. The epsilon phase content in the shell layer structure is over 80% by weight, the balance is a gamma phase or an eta phase, and epsilon phases are evenly distributed on the surface of core materials. Meanwhile, the invention relates to a preparing method of the electrode wire. Compared with the prior art, a metal workpiece subjected to cutting processing by the electrode wire is high in surface smoothness and good in surface quality, accordingly, cutting accuracy is high, meanwhile, the electrode wire preparing technology is simple, operability is high, the number of manufacturing steps is small, and large-scale and automatic production can be achieved easily.

Owner:NINGBO BODE HIGHTECH CO LTD

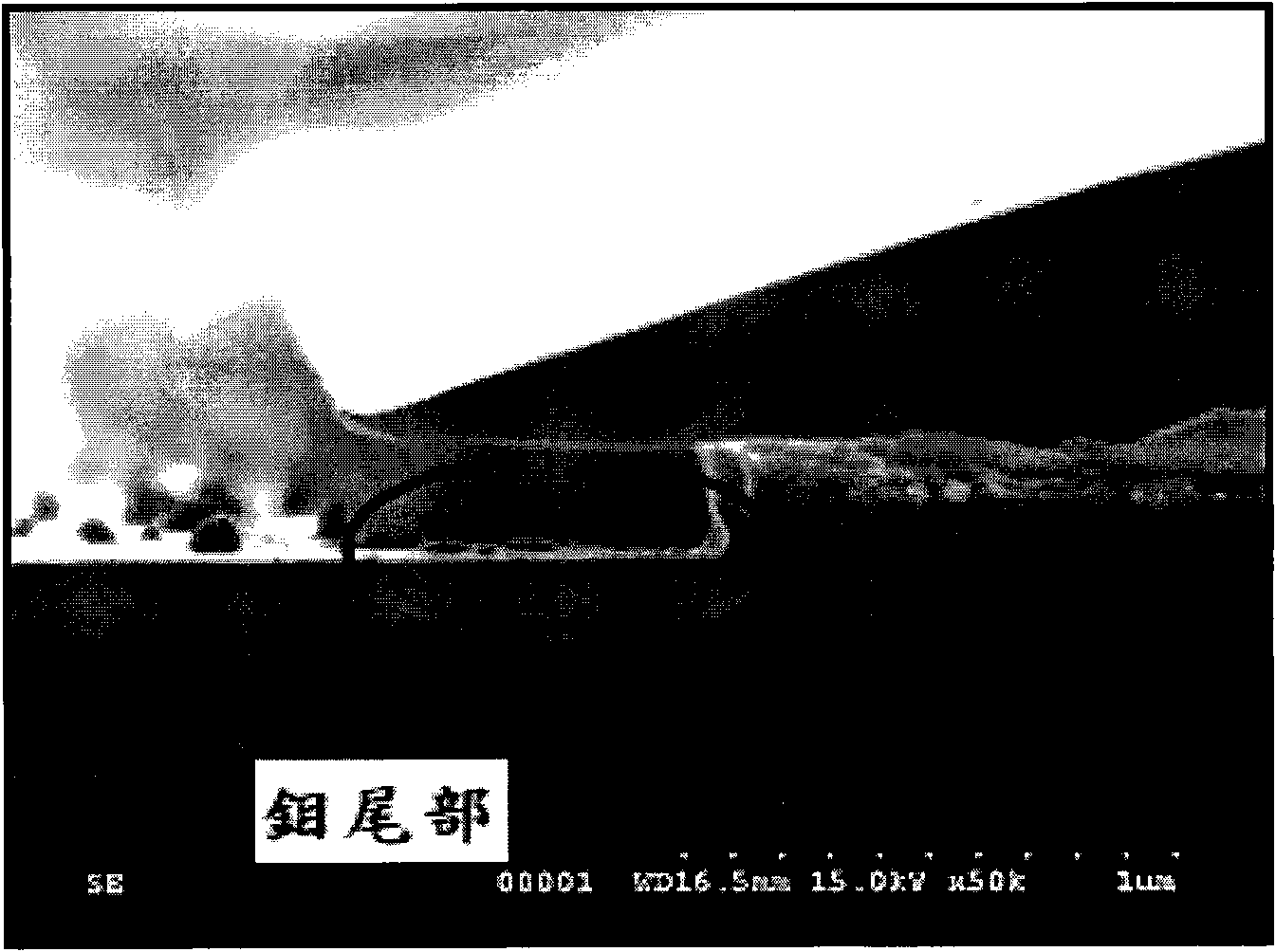

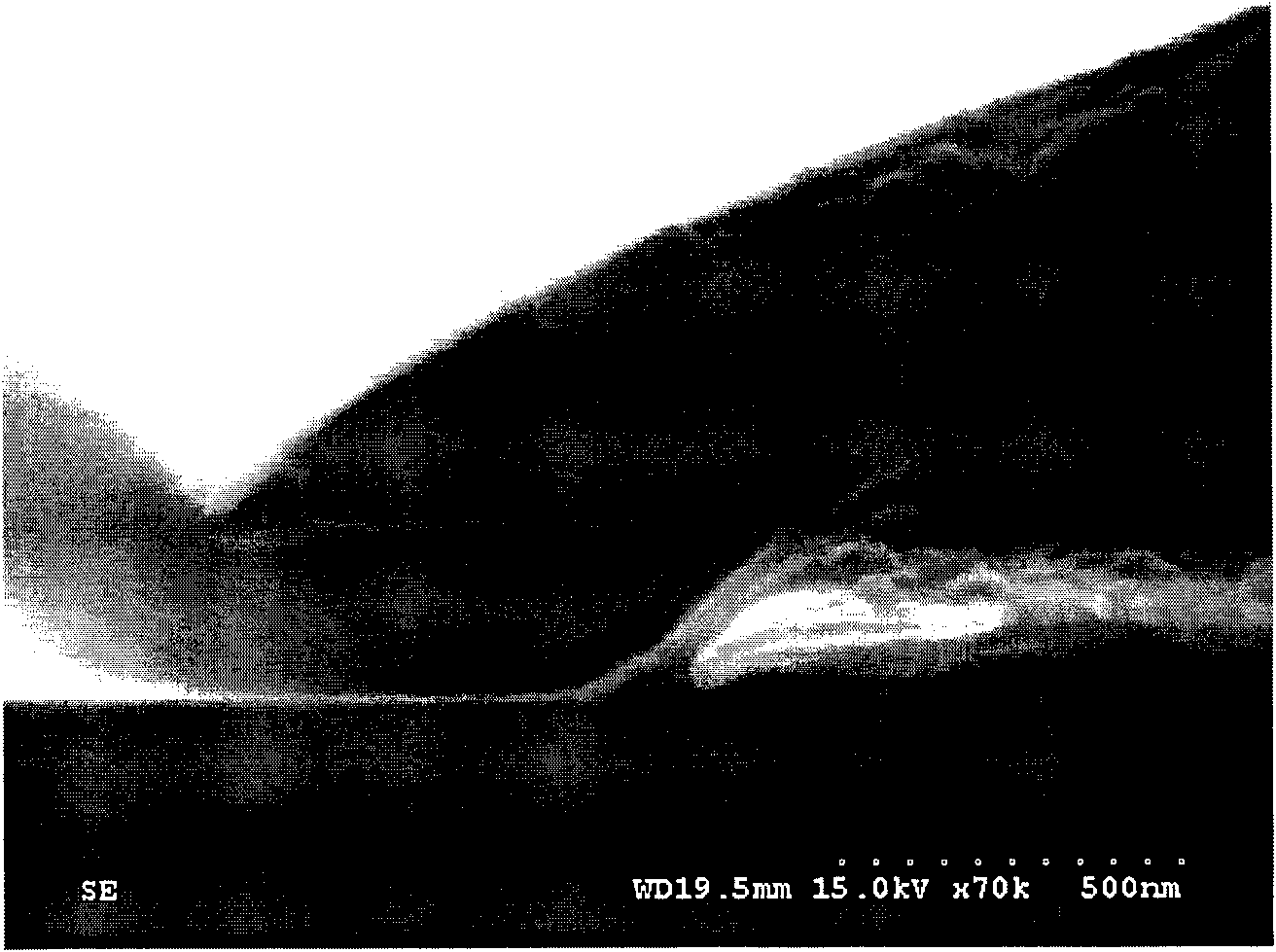

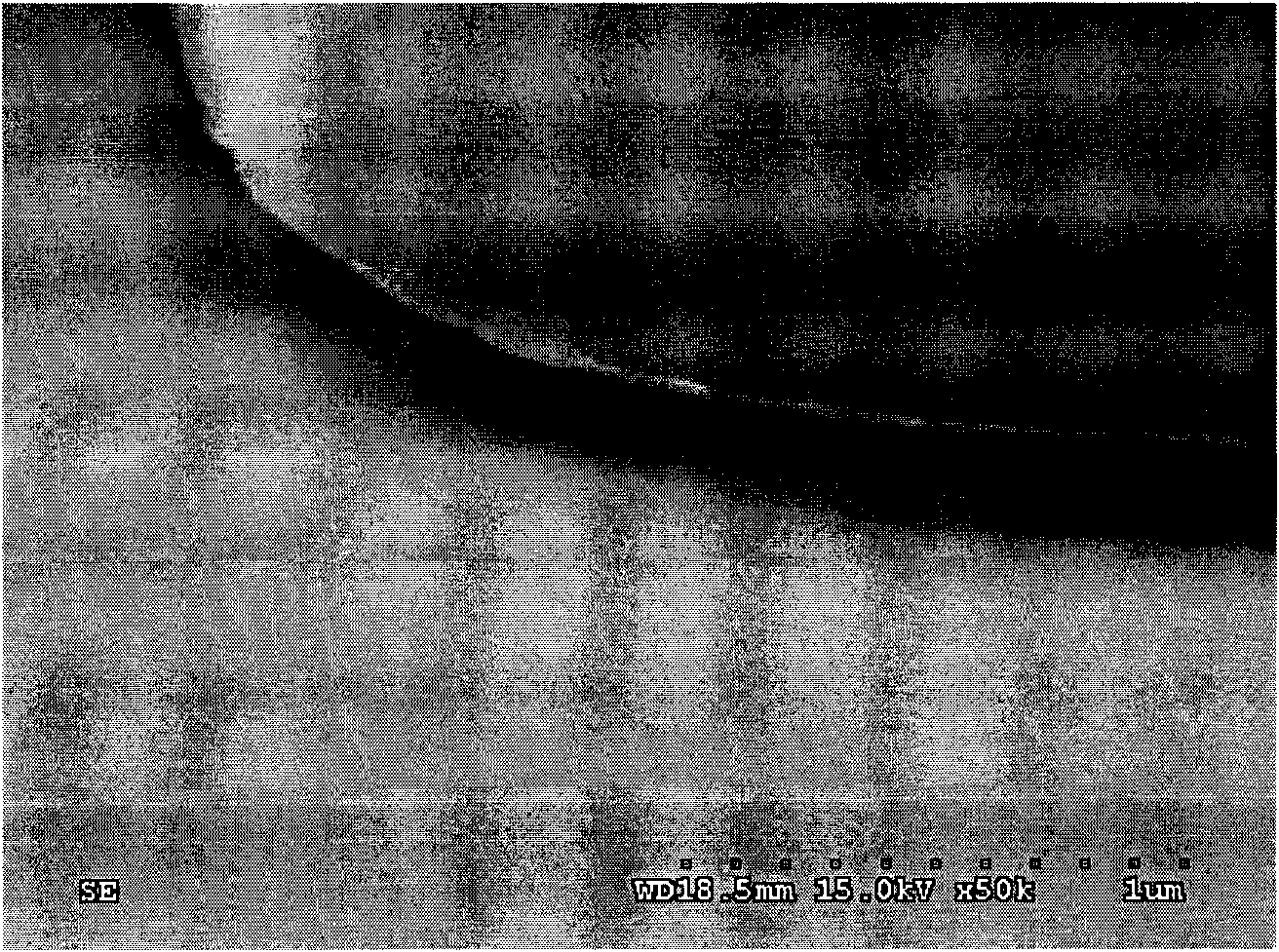

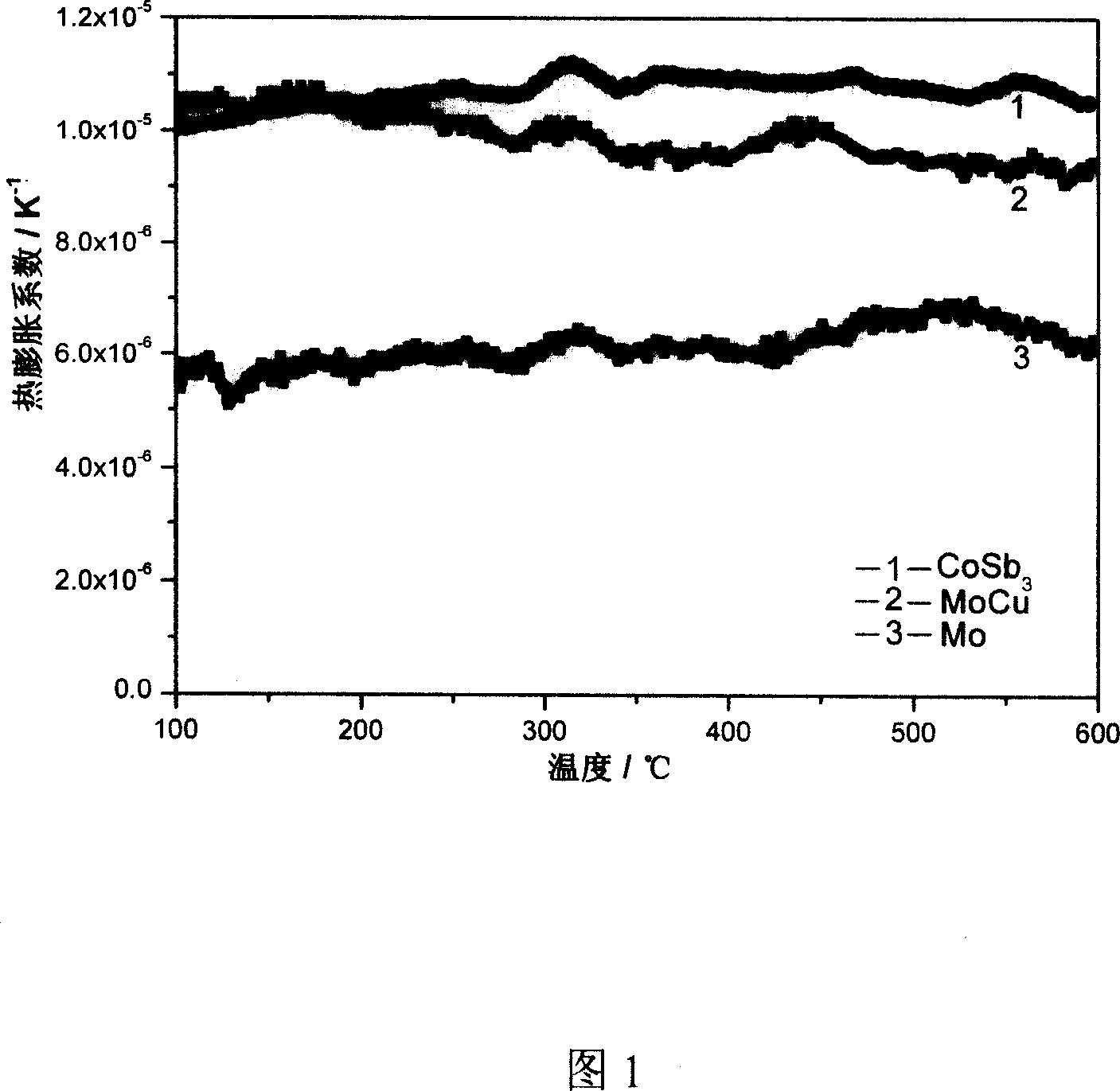

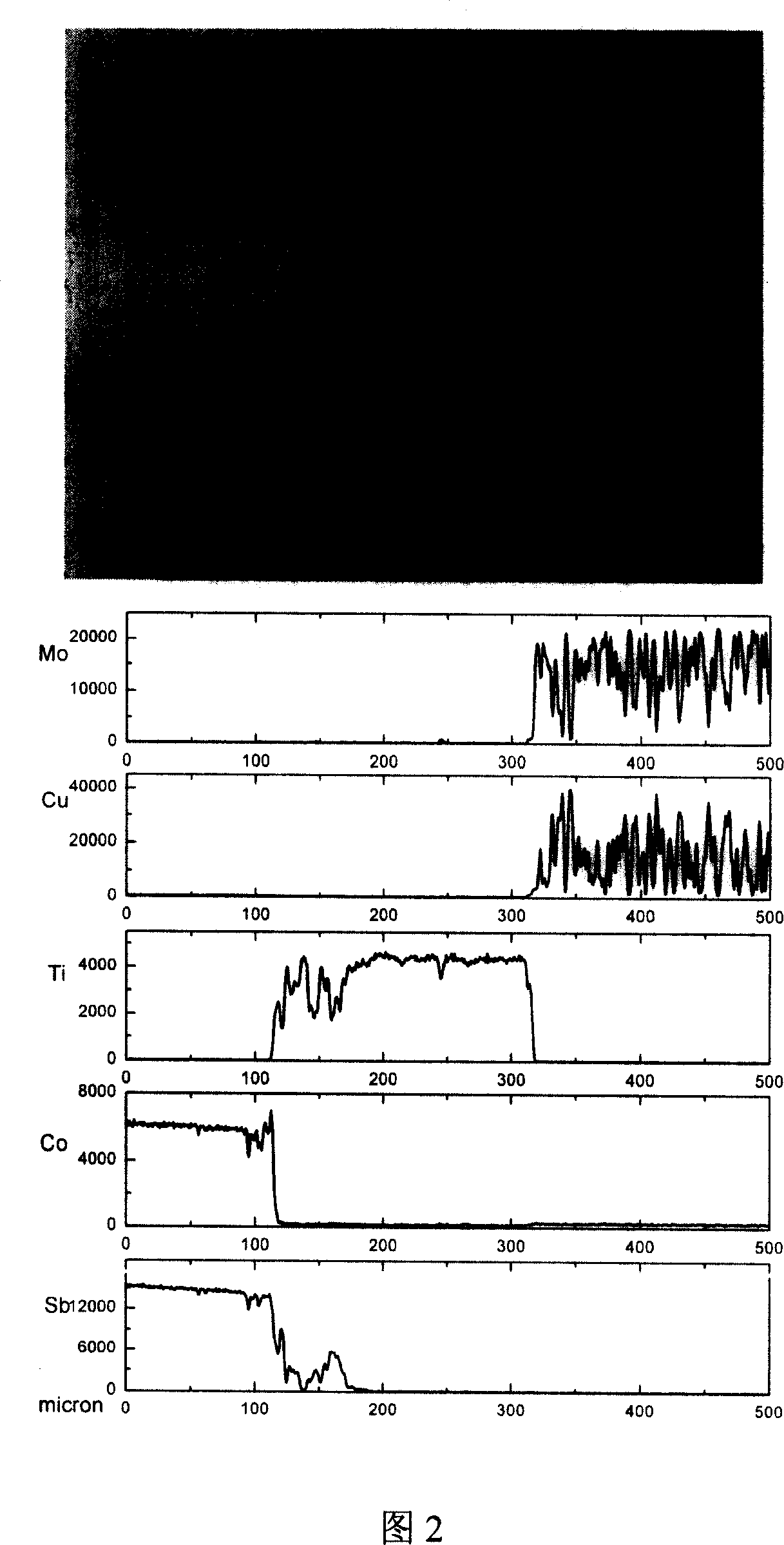

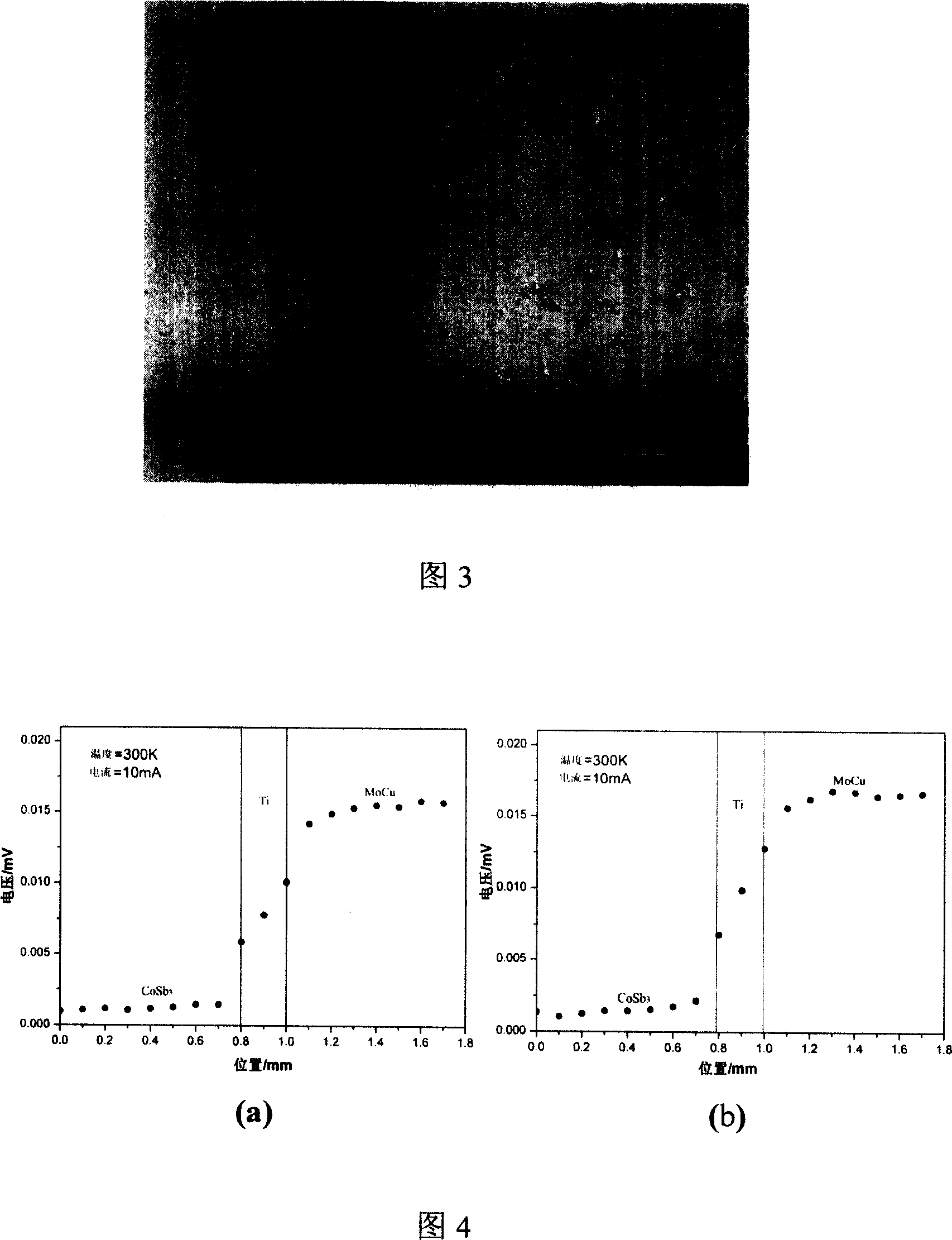

Alloy electrod matched with cobalt antimonide thermoelectric component and one-step process connecting technology

ActiveCN101022149AReduce thermal stressEnhanced interface bindingThermoelectric device manufacture/treatmentThermoelectric device detailsThermoelectric materialsAlloy

This invention relates to a one-step connection technology for the thermoelectric element of CoSb base and an alloy electrode (flow connector) matched to it characterizing that said alloy electrode is made of Mo-Cu serial alloy advantaged that related CTE can be designed freely, the electrode is made of Mo-Cu alloy in the thickness of 0.5-3mm, and the preparation character is a one-step connection method by utilizing discharge plasma sinter to connect a MoCu alloy electrode material and a CoSb thermoelectric material at a Ti transition layer with the grain size of 30-75mum to connect the interfaces very well without evident resistance transition.

Owner:中科西卡思(苏州)科技发展有限公司

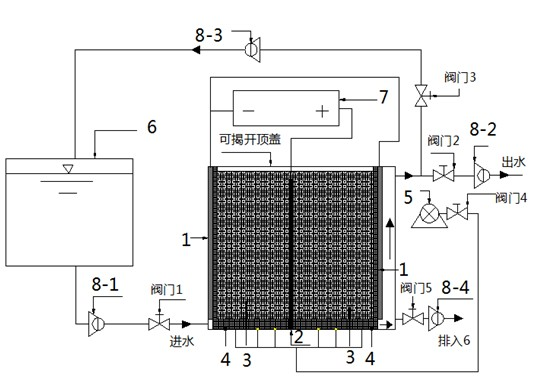

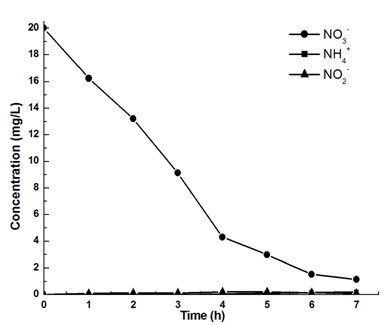

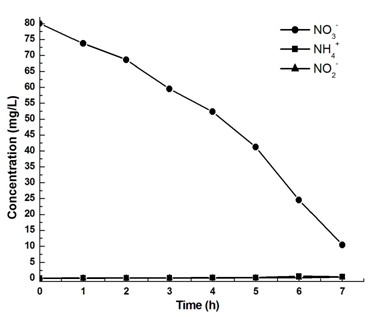

Compound three-dimensional electrode reactor and application thereof in treatment of nitrogenous organic wastewater

InactiveCN102020342AIncreased Joint Processing CapabilitiesLow stratificationWater/sewage treatmentIridiumPolyvinyl alcohol

The invention belongs to the technical field of environmental engineering, and relates to a device for treating wastewater, in particular to a three-dimensional electrode reactor which can effectively degrade nitrogenous organic wastewater and a treating process thereof. The main electrodes of the reactor respectively consist of two copper-zinc alloy electrodes and a titanium-iridium-platinum steady-state anode; active carbon is filled between the main electrodes; a part of active carbon is made into insulated particles through coating polyvinyl alcohol gel; and the proportion of the insulated active carbon particles to conductive active carbon particles is between 1: 6 and 6: 1. After a certain voltage is applied, the cathode undergoes nitrate reduction reaction, and the anode oxidizes ammonia nitrogen into nitrogen and mineralizes or converts COD into a simple organic matter. The existence of the filler can effectively strengthen the current efficiency of the reactor, reduce the energy consumption and improve the mass transfer efficiency; and therefore, the invention provides wastewater denitrification device and process with high current efficiency, simple operation, and capabilities of efficiently removing nitrate, ammonia nitrogen and COD and keeping energy consumption at an acceptable level.

Owner:NANJING UNIV

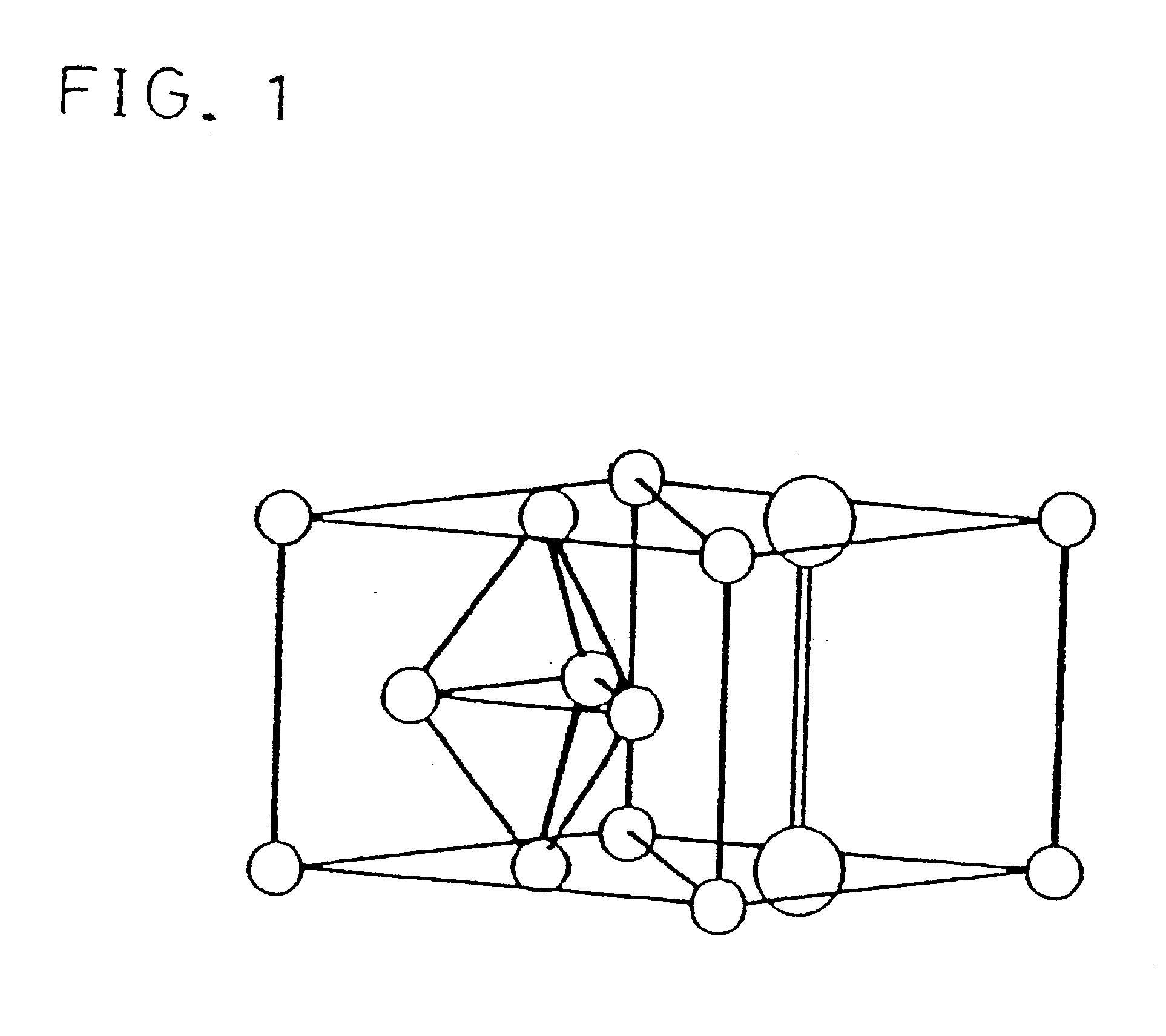

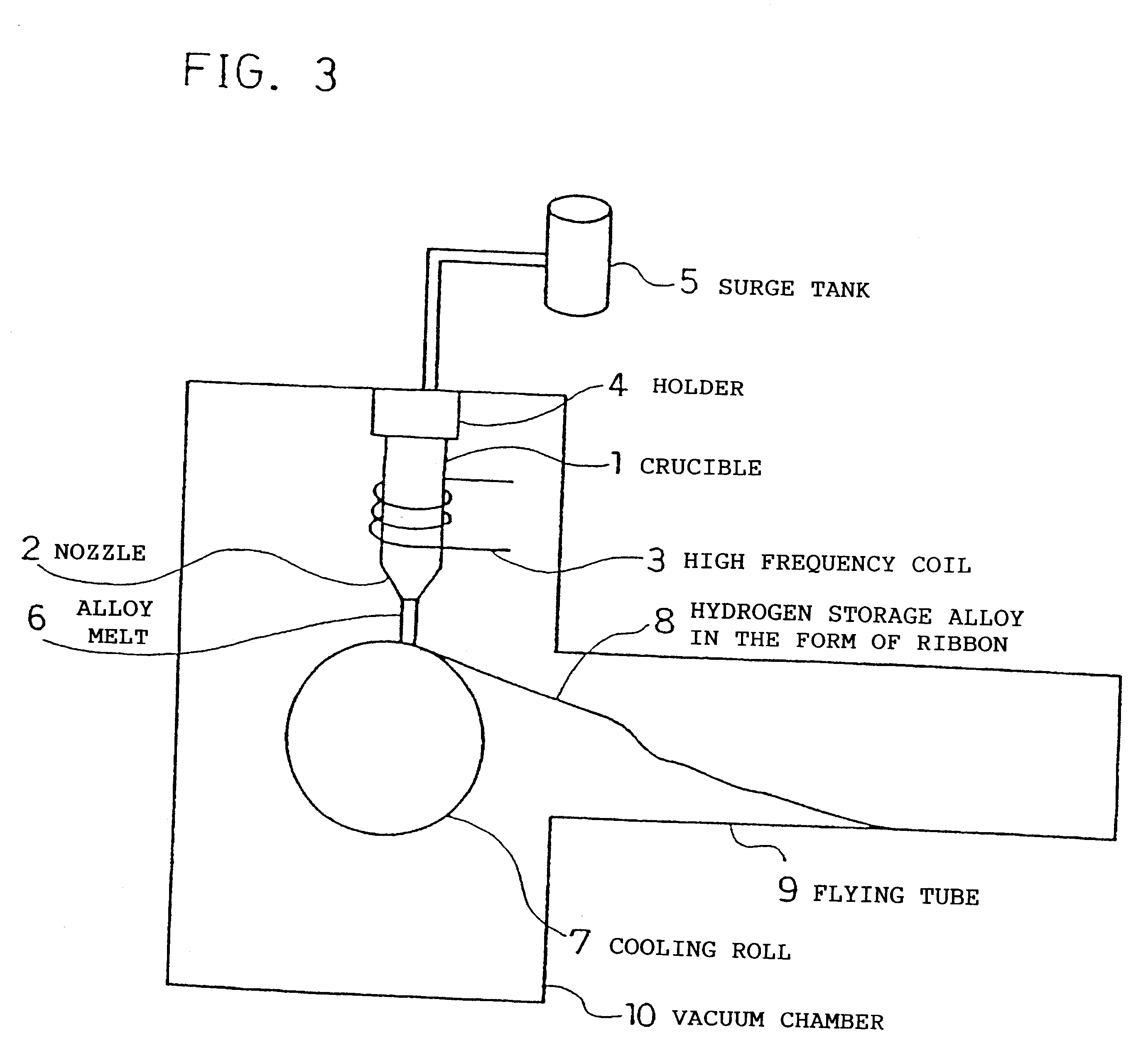

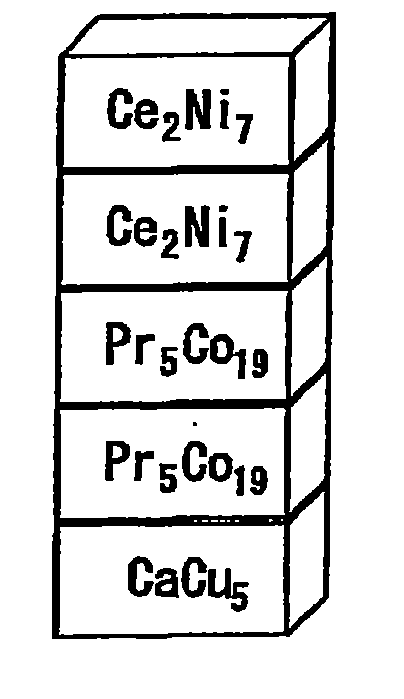

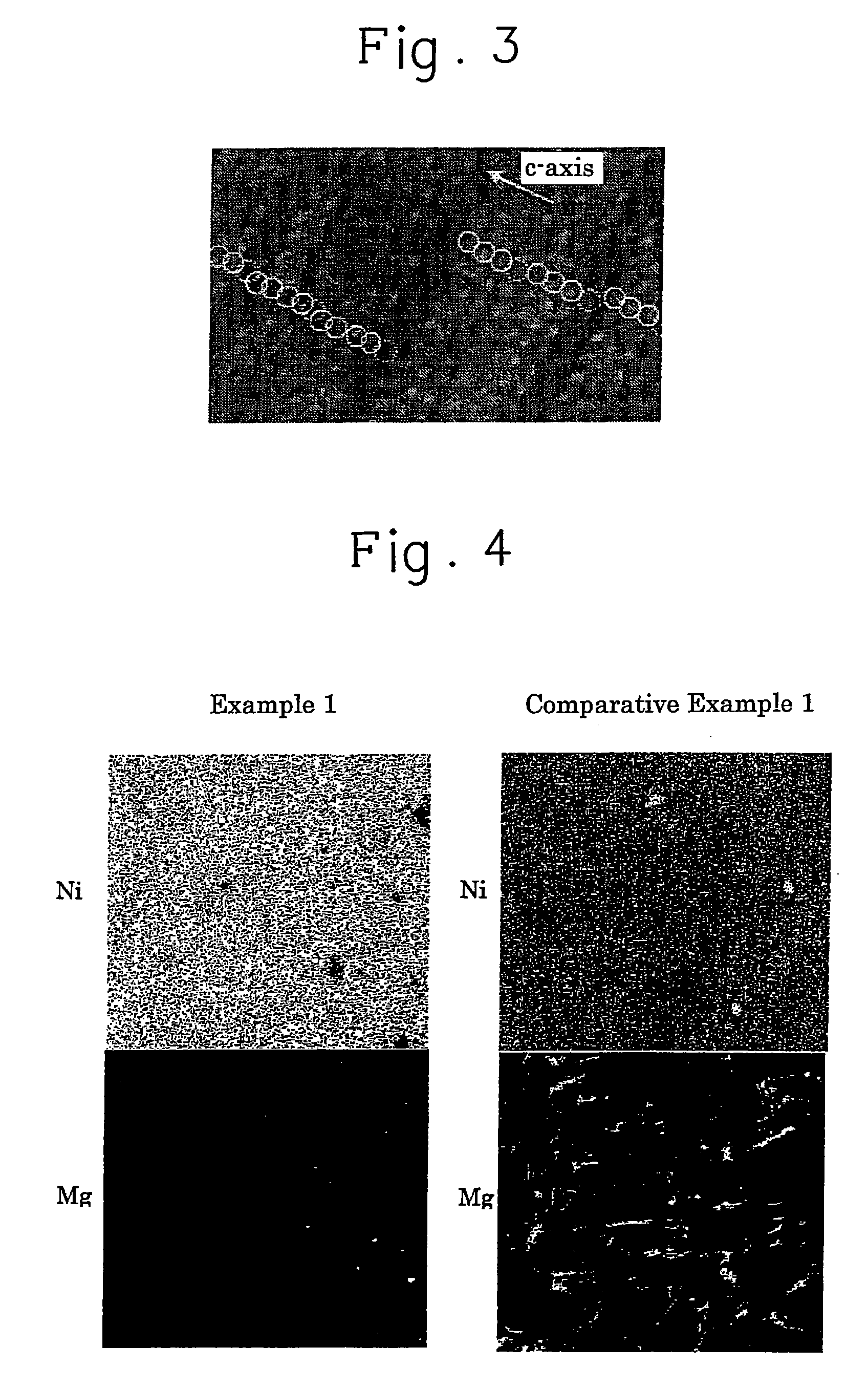

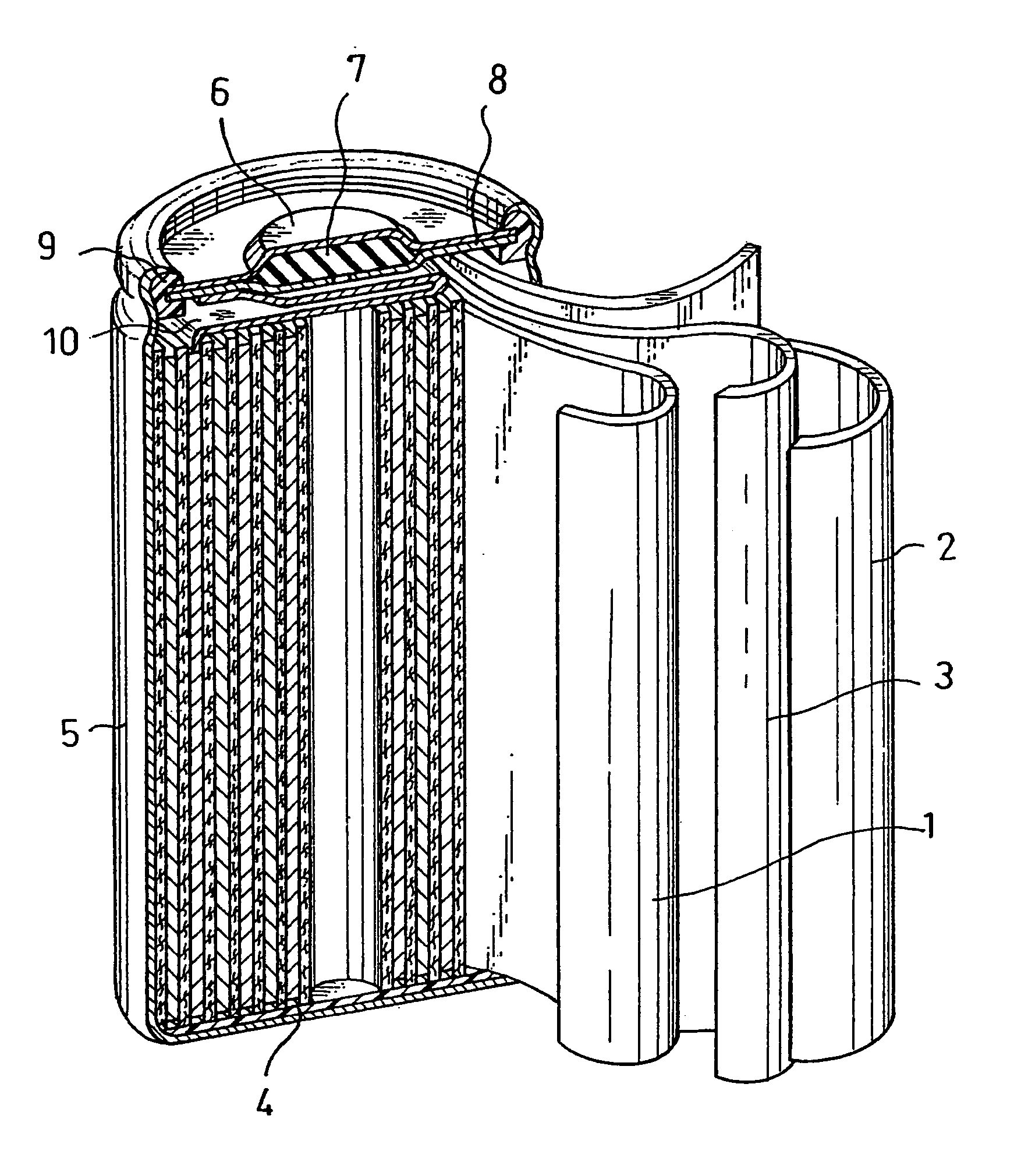

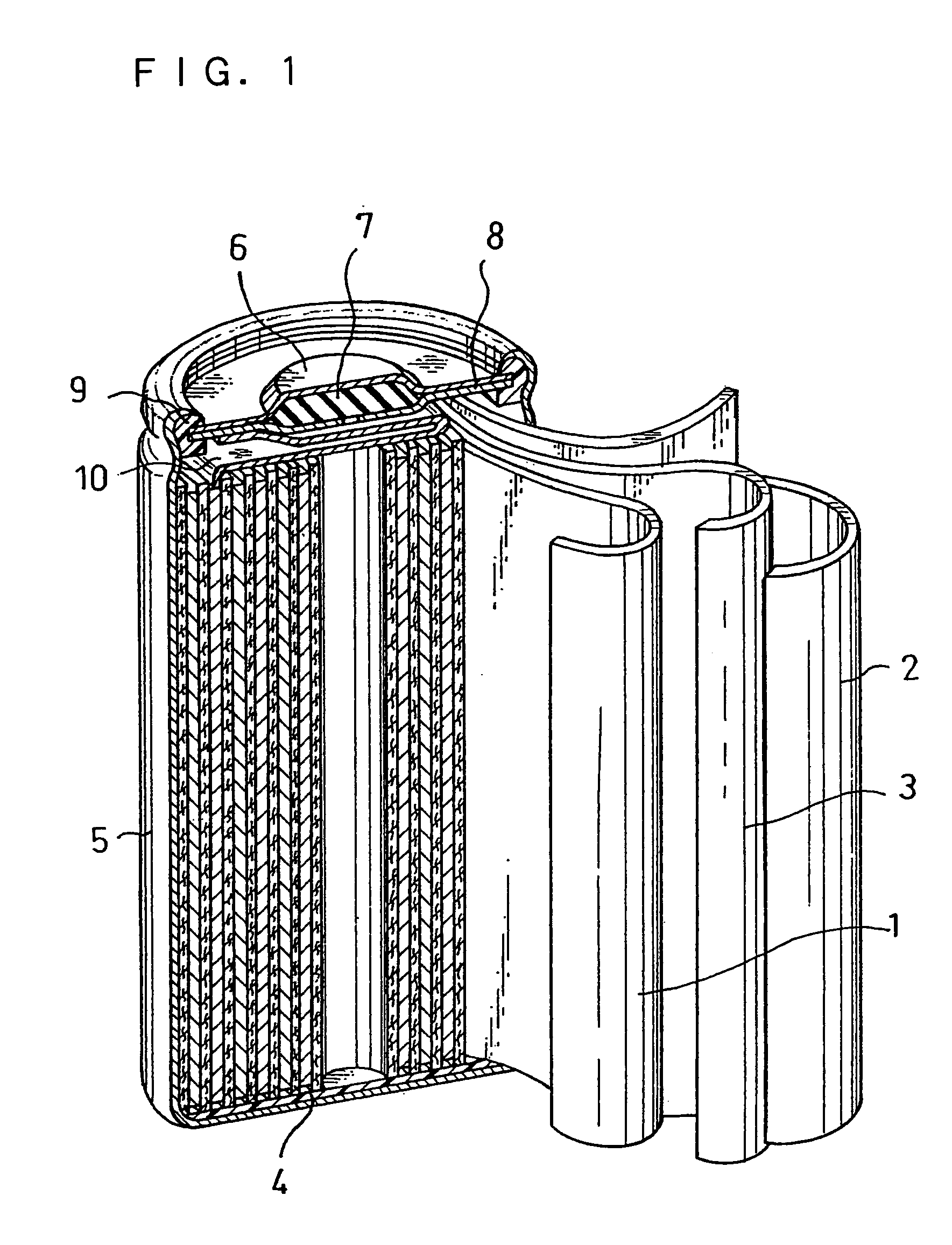

Hydrogen absorbing alloy electrode, electrode producing method and alkali storage battery

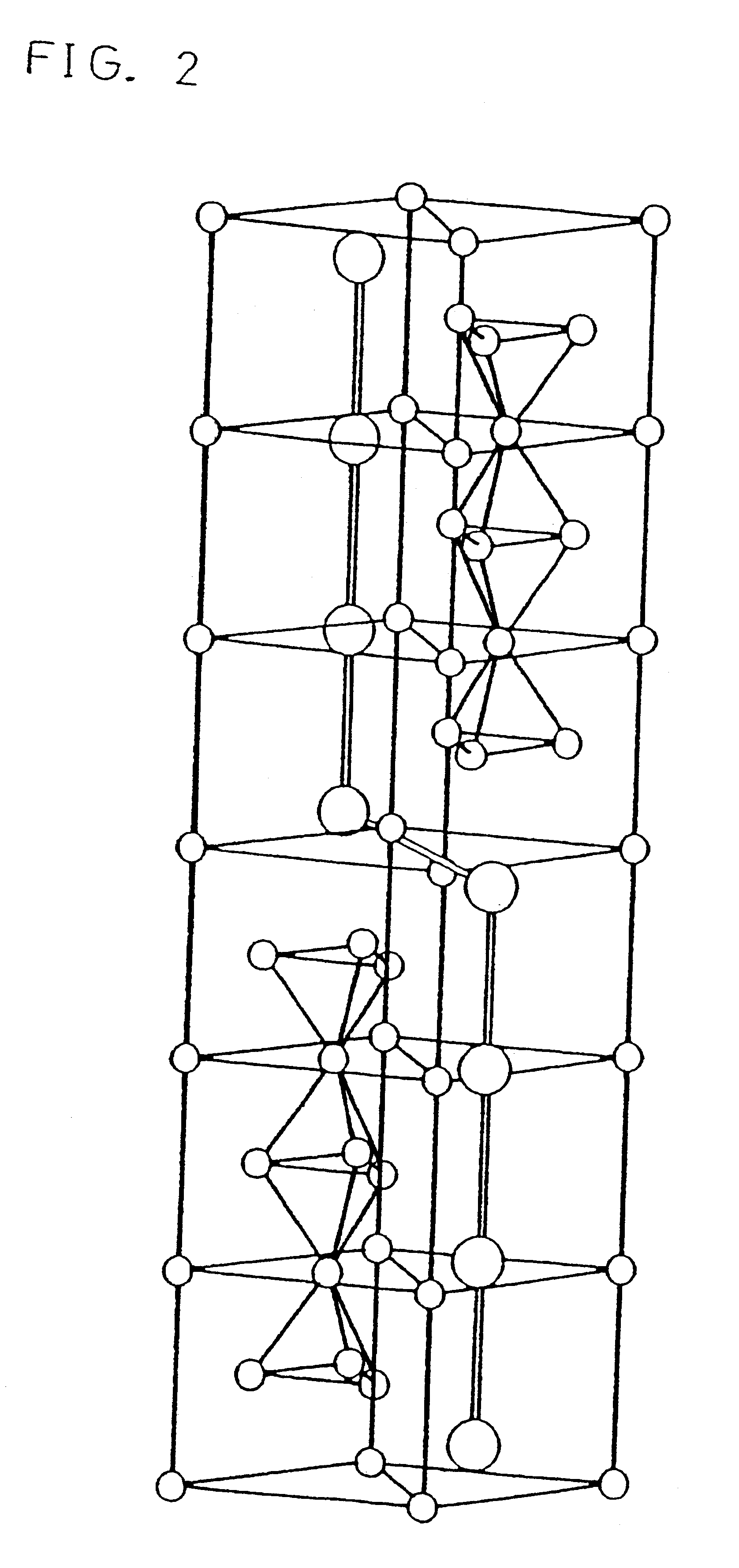

InactiveUS6660431B1Alkaline accumulator electrodesSecondary cell gas removalCrystal structureLarge capacity

The present invention relates to a hydrogen storage alloy electrode composed of a hydrogen storage alloy having a CaCu5 region and a Ce2Ni7 region in the crystal structure and satisfies the relational formula: p:q=1:(4+a), where p is the sum of the mole fraction of an element occupying the Ca site of the CaCu5 region and the mole fraction of an element occupying the Ce site of the Ce2Ni7 region, q is the sum of the mole fraction of an element occupying the Cu site of the CaCu5 region and the mole fraction of an element occupying the Ni site of the Ce2Ni7 region, and -0.2<=a<=0.4. Accordingly, although the hydrogen storage alloy electrode contains a little or no Co, it is possible to obtain an electrode having little deterioration due to pulverization of the alloy and a high capacity.

Owner:PANASONIC CORP

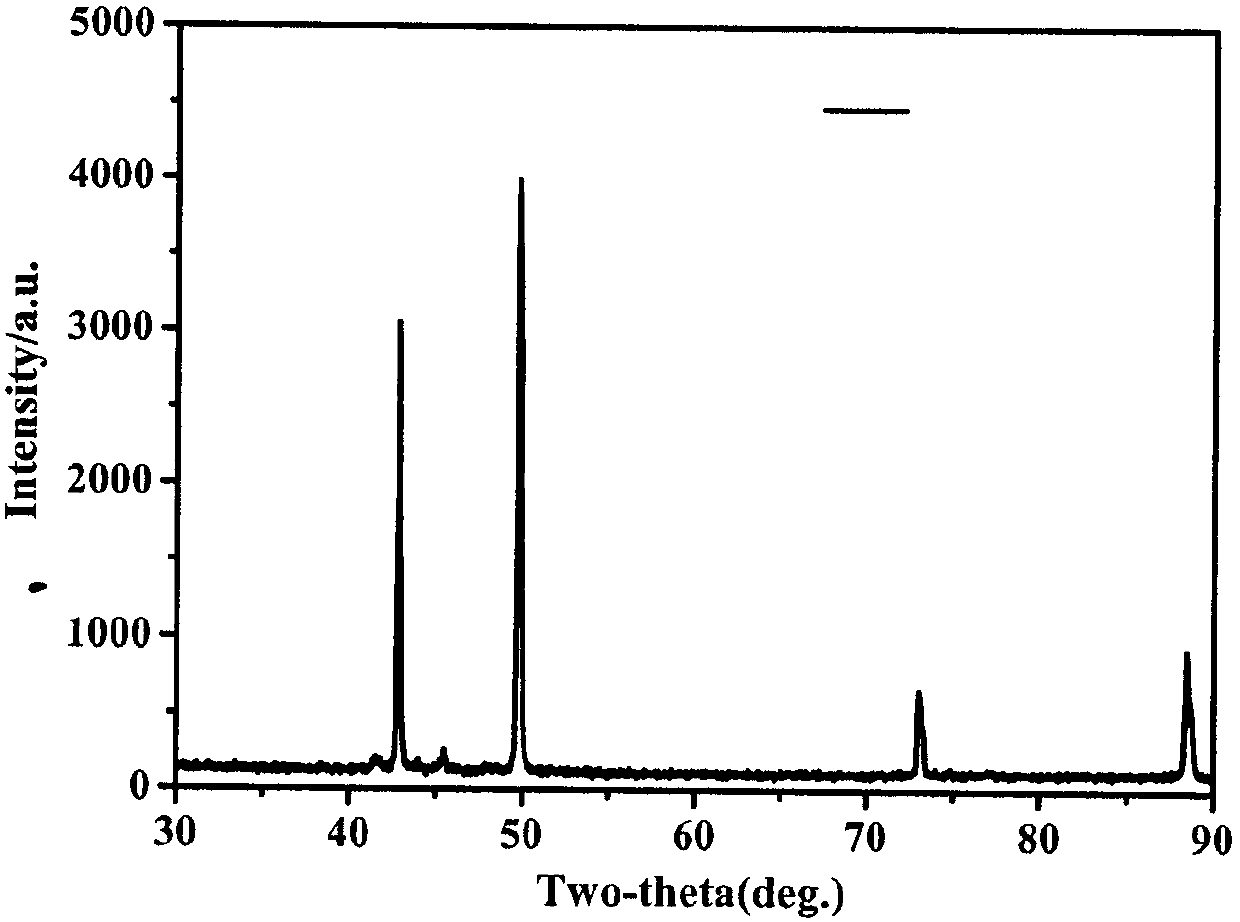

A kind of preparation method of nano rare earth oxide doped molybdenum alloy electrode material

The invention relates to a preparation method of a molybdenum alloy electrode material doped with nano rare oxides. According to the preparation method, molybdenum powder is used as a raw material, the molybdenum powder and nano rare oxide powder are uniformly mixed by adopting a solid-solid doping method, wherein the nano rare oxides are lanthana oxide, cerium oxide or mixed rare earth oxide; and then the molybdenum alloy electrode material doped with different kinds and contents of nano rare earth oxides is prepared through adopting the processes of sieving, pressing and forming, sintering,forging and vacuum annealing heat treatment under certain temperature. The preparation method disclosed by the invention and the heat treatment process are simple and feasible; and the molybdenum alloy electrode material doped with the nano rare earth oxides, which is prepared by using the method disclosed by the invention, has the characteristics of uniform tissues, high compactness, high strength, high recrystallization temperature, high elongation rate, favorable deep processing performance, and the like.

Owner:XIAN FULAI ELECTRICAL ALLOY

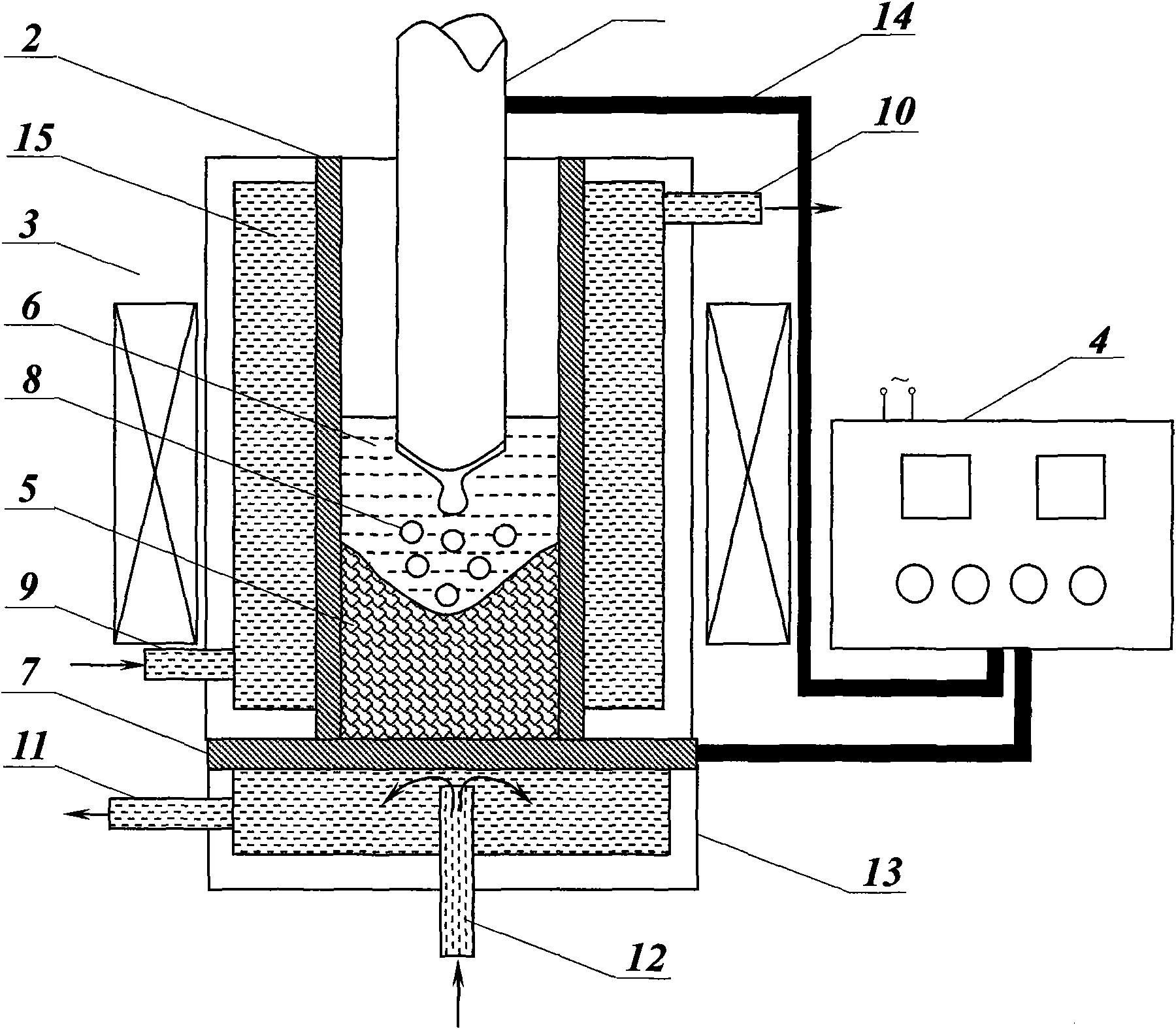

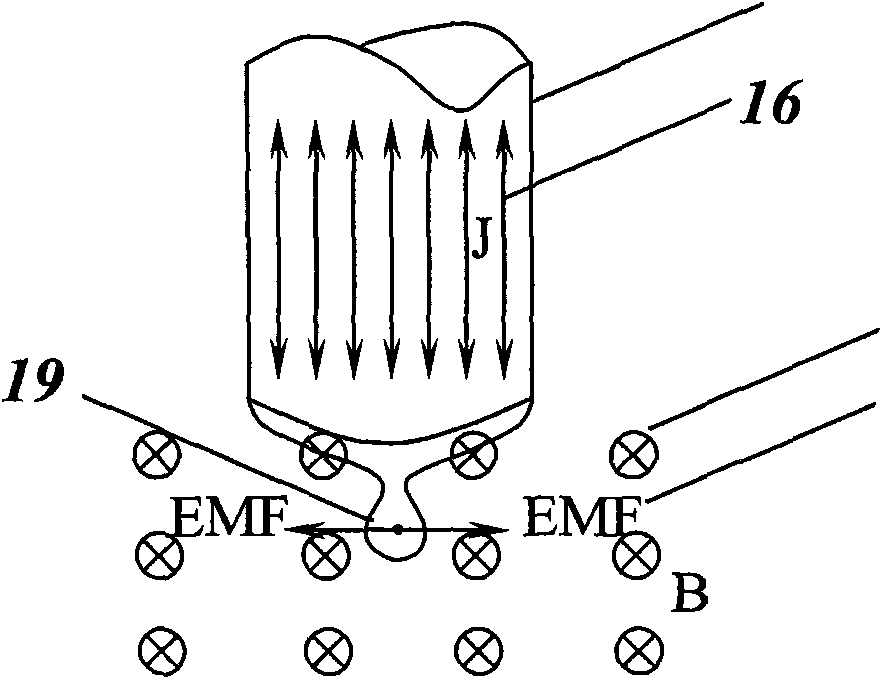

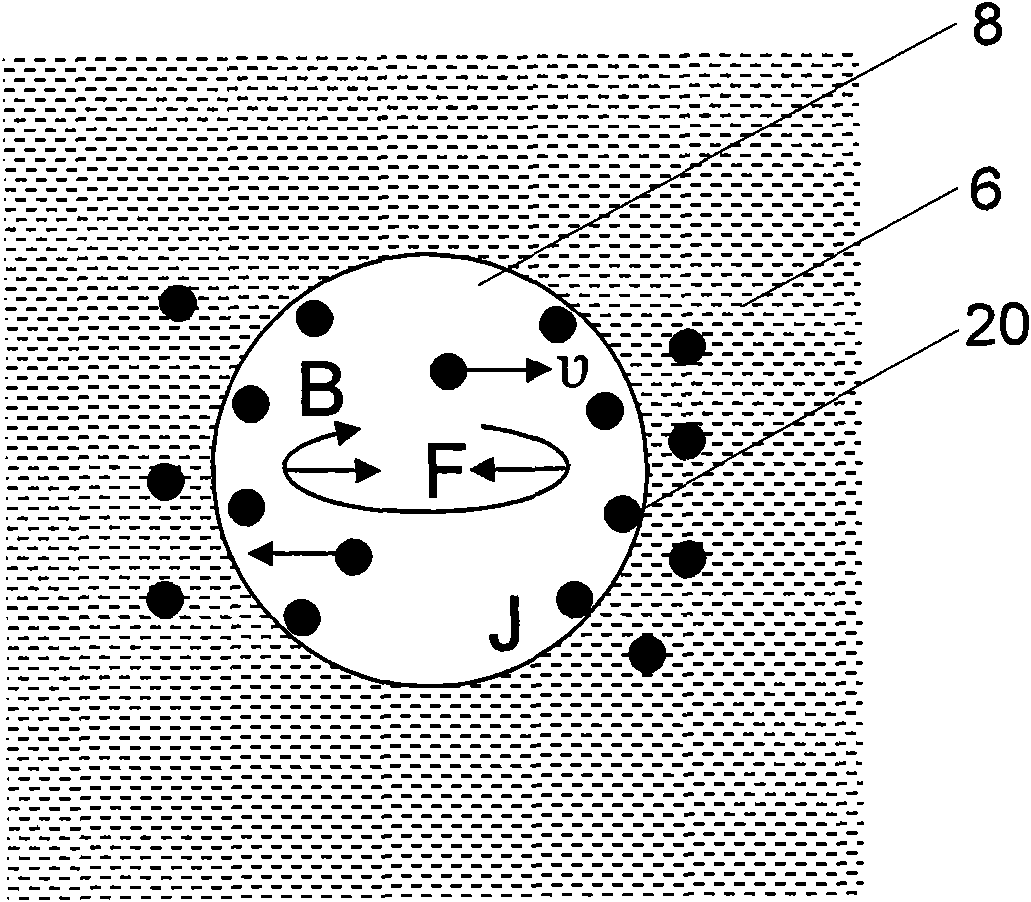

Method for magnetic control electroslag remelting and high-efficiency refining high temperature alloy and device therefor

The invention relates to a method for magnetic control electroslag remelting and high-efficiency refining high temperature alloy and a device therefor. The method utilizes electromagnetic shock excitation effect for thinning molten drop and solidification structure, so as to improve the refining effect and reduce segregation. The device comprises a copper mould crystallizer, a water jacket, a high temperature alloy electrode bar, a water-cooled copper plate bottom electrode and a power supply. The invention is characterized in that a magnetic field generator is arranged at the periphery of the water-cooling copper mould crystallizer to generate magnetic field which is compounded with current of electroslag melting, thus generating oscillating lorentz force. The invention is used for electroslag remelting and refining the high temperature alloy, can improve the refining effect and reduce segregation of cast ingot.

Owner:SHANGHAI UNIV

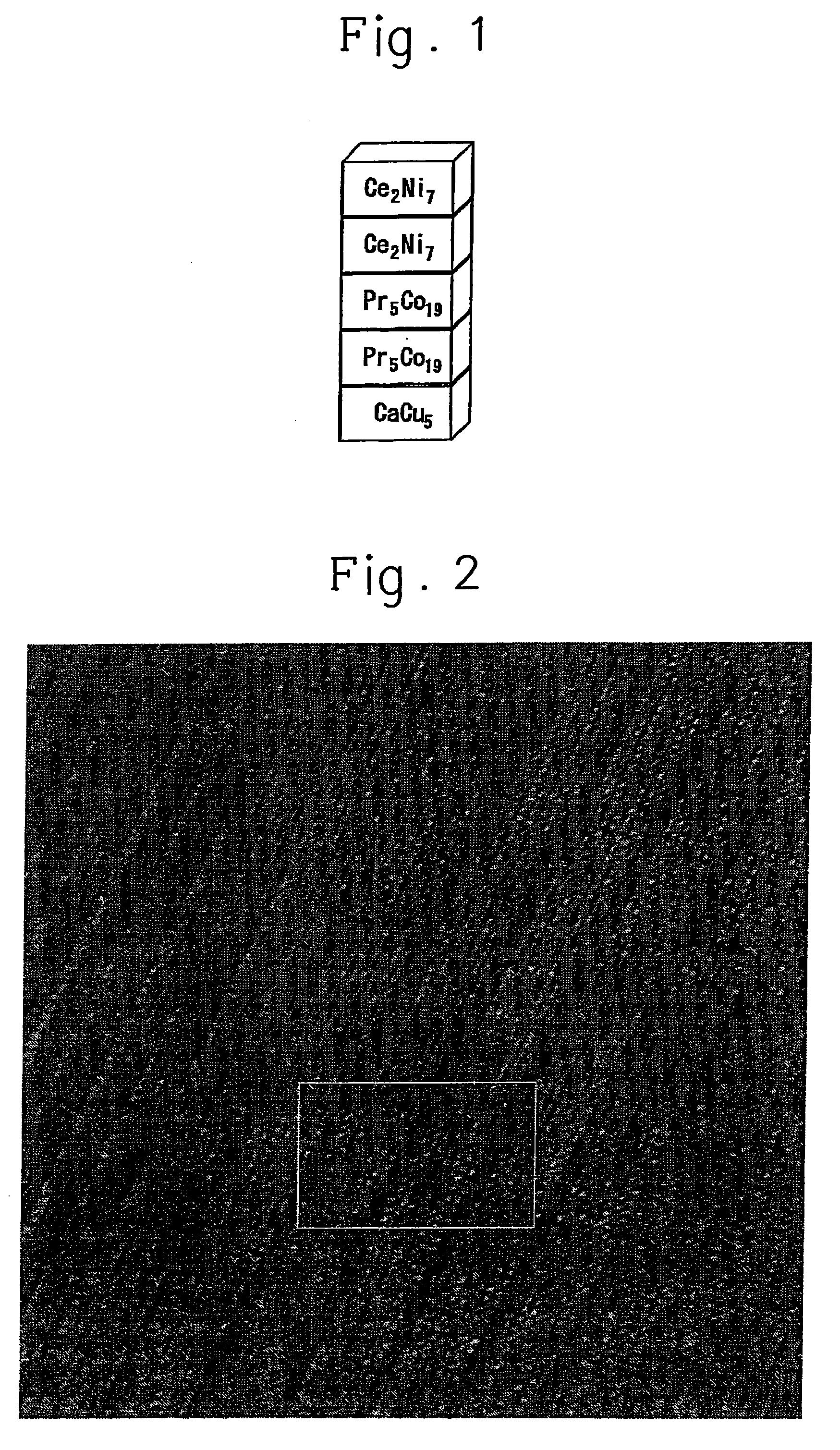

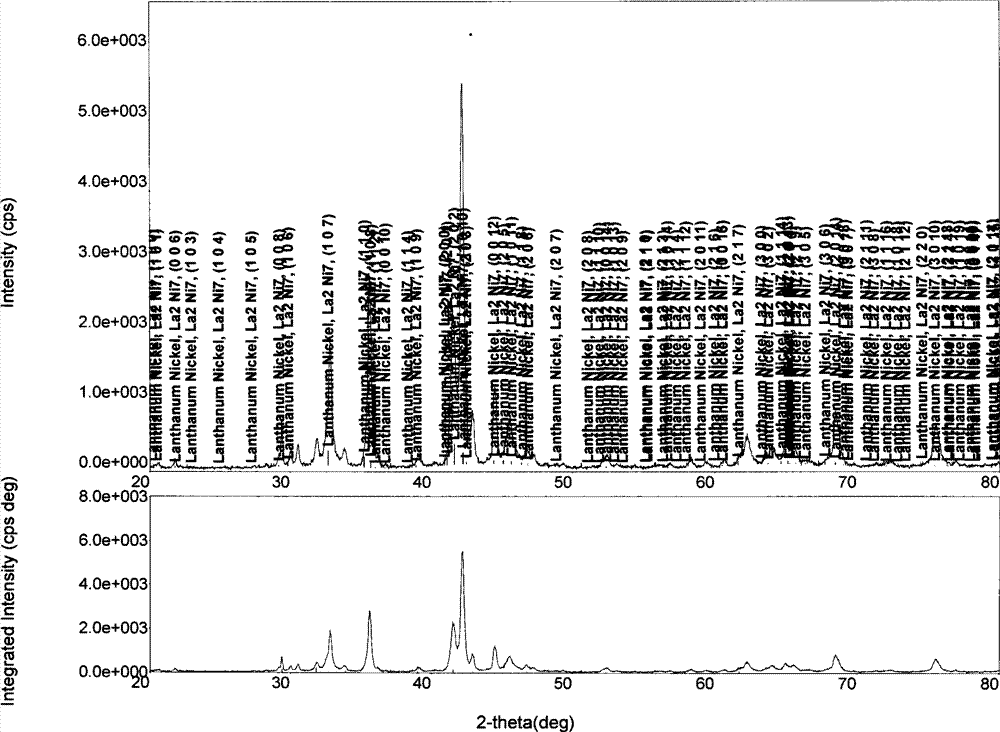

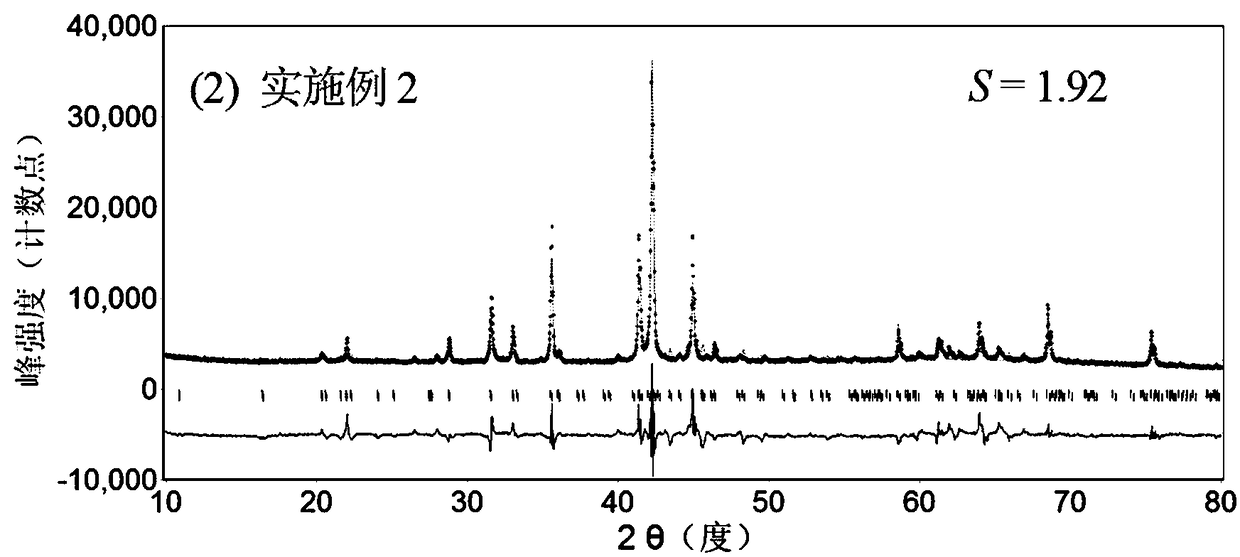

Hydrogen Storage Alloy, Hydrogen Storage Alloy Electrode, Secondary Battery, And Method For Producing Hydrogen Storage Alloy

ActiveUS20100178561A1Inhibit deteriorationImprove cycle lifeNegative electrodesSecondary cellsCrystal structureLattice constant

Provided is a hydrogen storage alloy which is characterized in that two or more crystal phases having different crystal structures are layered in a c-axis direction of the crystal structures. The hydrogen storage alloy is further characterized in that a difference between a maximum value and a minimum value of a lattice constant a in the crystal structures of the laminated two or more crystal phases is 0.03 Å or less.

Owner:GS YUASA INT LTD +1

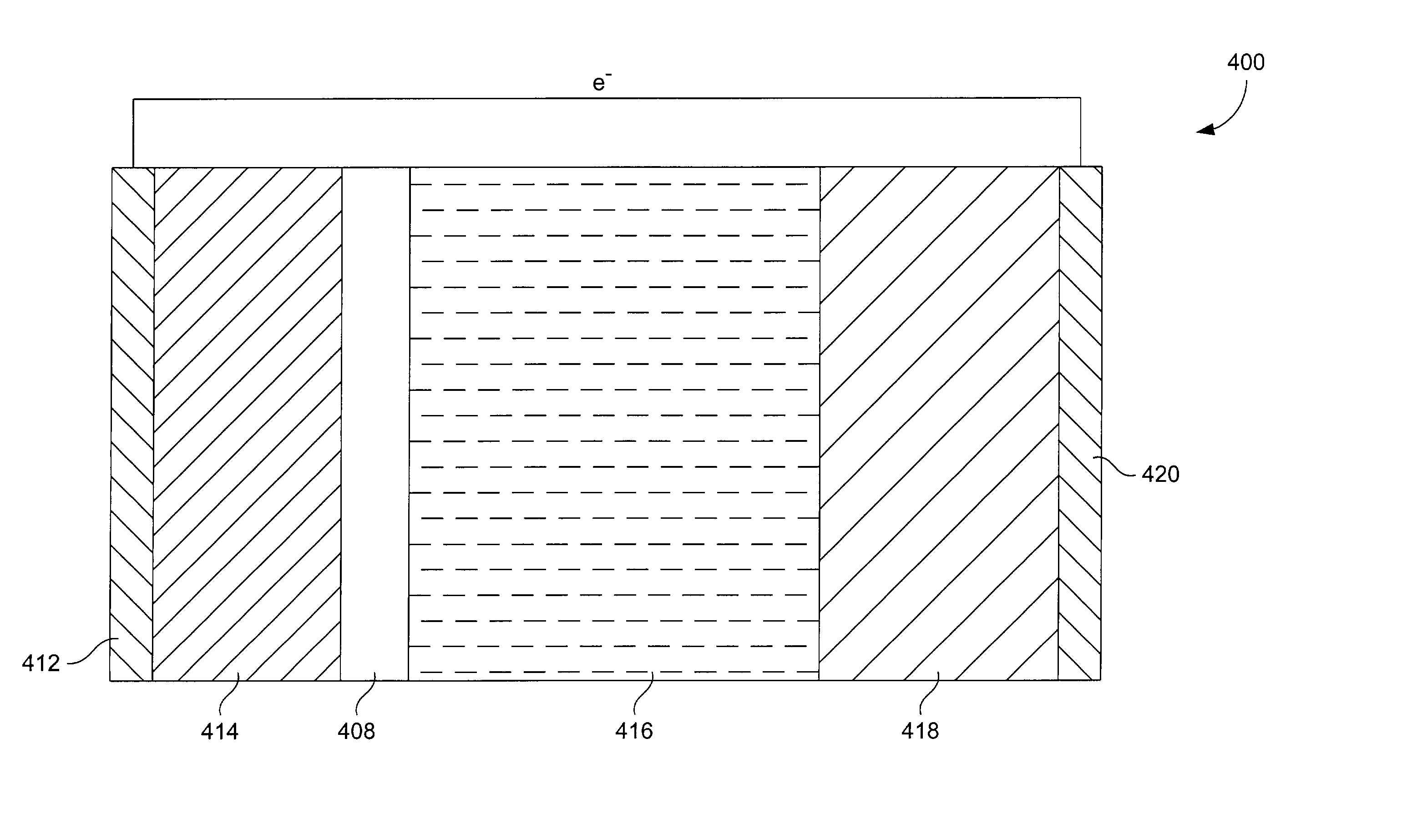

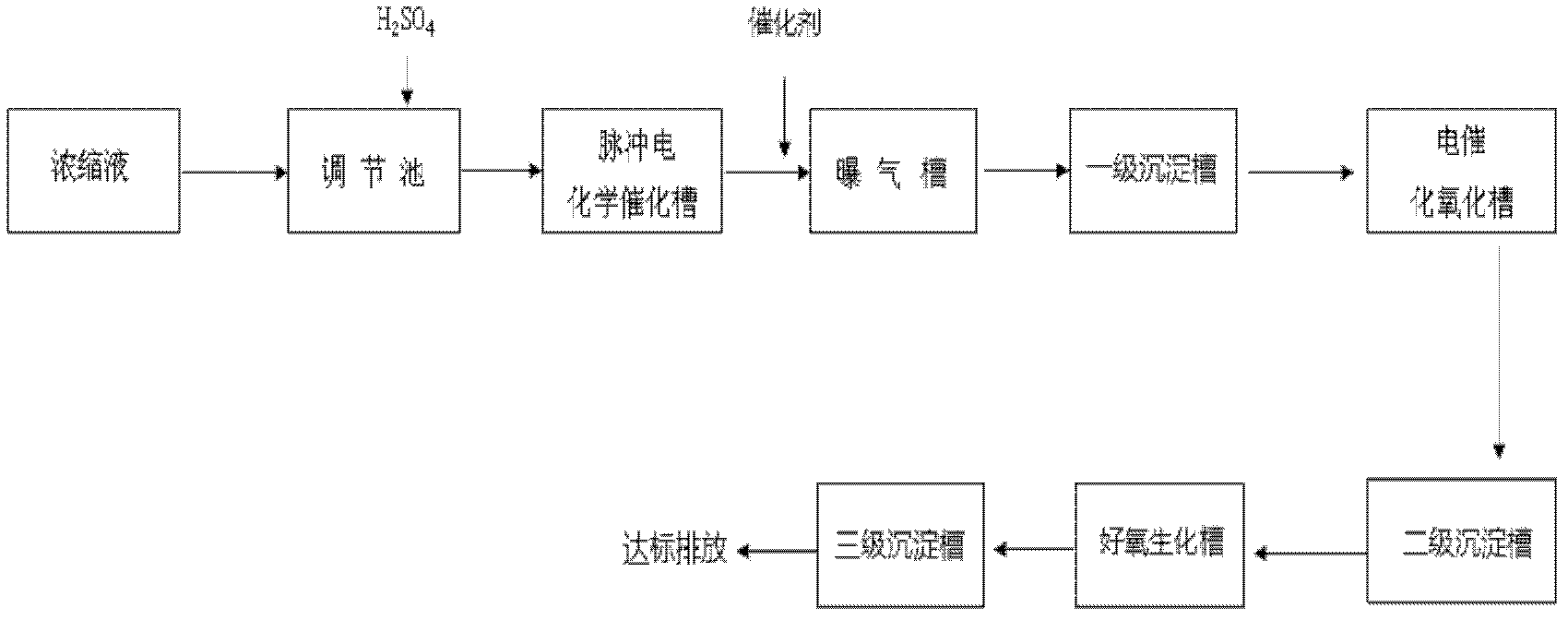

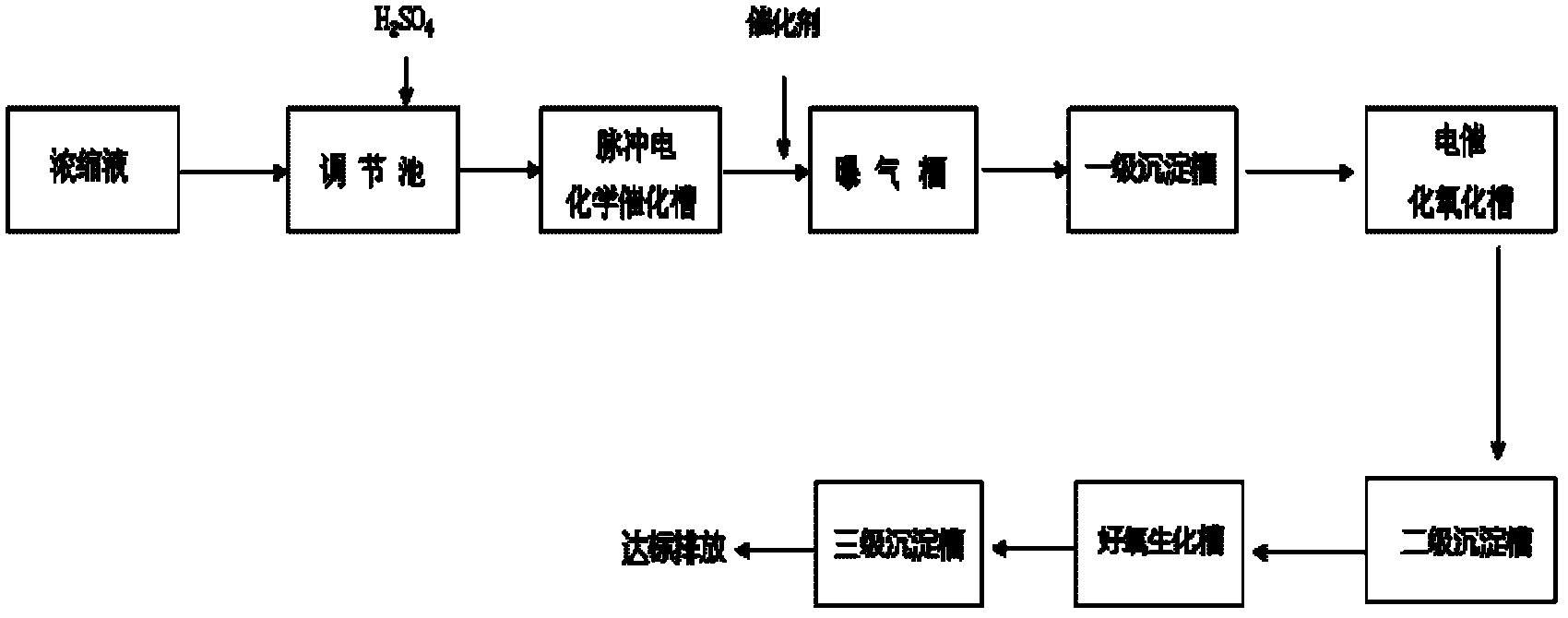

Electrochemical method for processing garbage percolate concentrated solution

ActiveCN102701515ALow biological toxicityReduce salt contentWater/sewage treatment by electrochemical methodsMultistage water/sewage treatmentChemical treatmentFenton reaction

The invention discloses an electrochemical method for processing garbage percolate concentrated solution. The electrochemical method includes adjusting pH value of the garbage percolate concentrated solution to 2-4, conducting primary electrochemical processing on the garbage percolate concentrated solution by utilizing a high voltage pulse power supply and an alloy electrode, then adding an oxidation accelerator and a catalyst for further conducting fenton reaction, utilizing the high voltage pulse power supply and an advanced oxidation electro catalysis electrode to conduct secondary electrochemical processing, namely the anode electro catalysis oxidation reaction and the cathode electro catalysis reduction reaction, on supernate till the ratio of BOD5 / CODcr of the supernate is larger than or equal to 0.35 to obtain modified garbage percolate concentrated solution capable of conducting aerobic biochemical degradation. The electrochemical method conducts non-selective oxidation degradation and reduction modification on different organic molecules with different structures in the concentrated solution, effectively eliminates biotoxicity of the concentrated solution, reduces salt content, reduces pollutant density and accordingly lays foundation for standardized discharge of processed garbage percolate concentrated solution.

Owner:中钢集团武汉安全环保研究院有限公司 +1

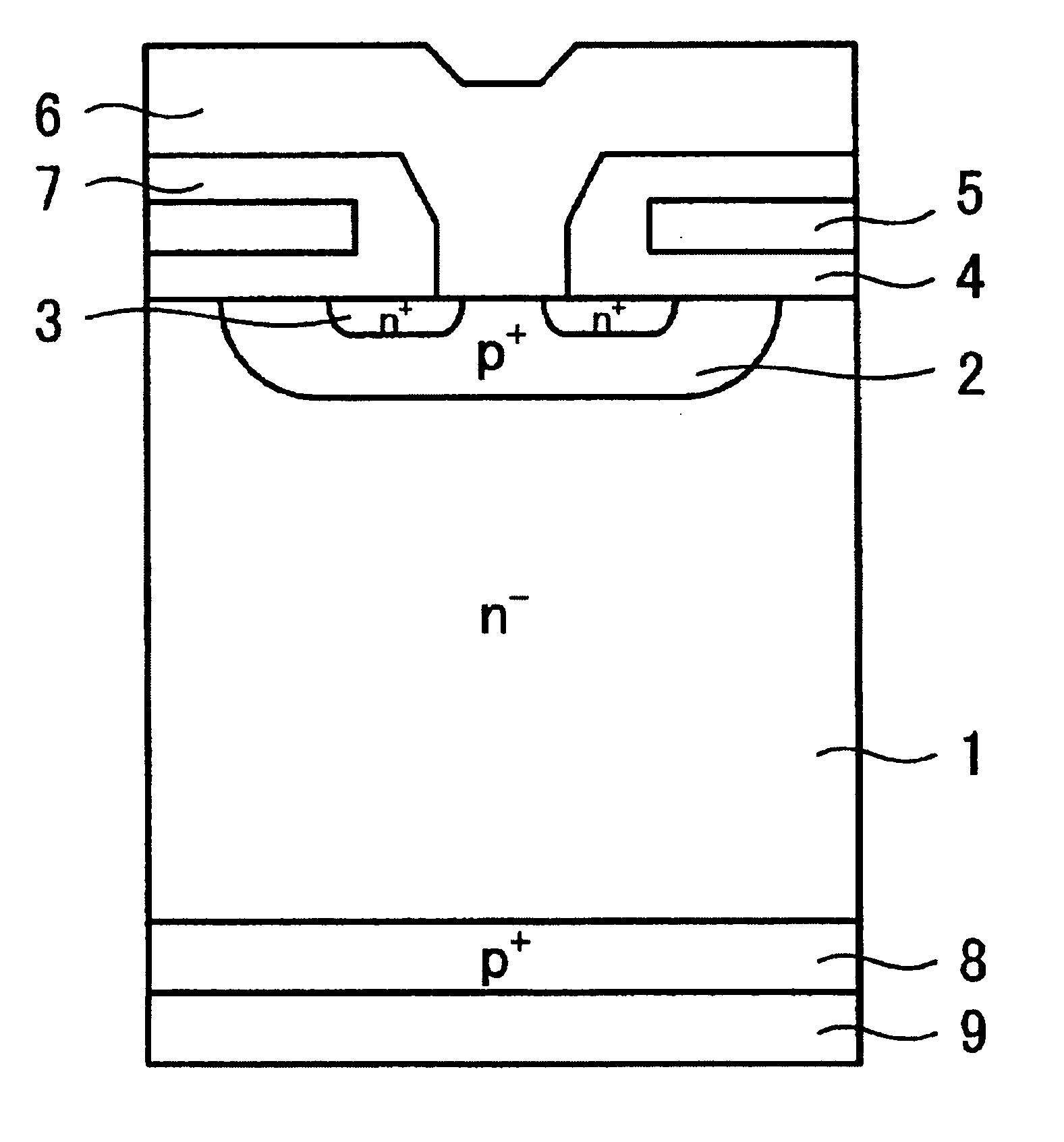

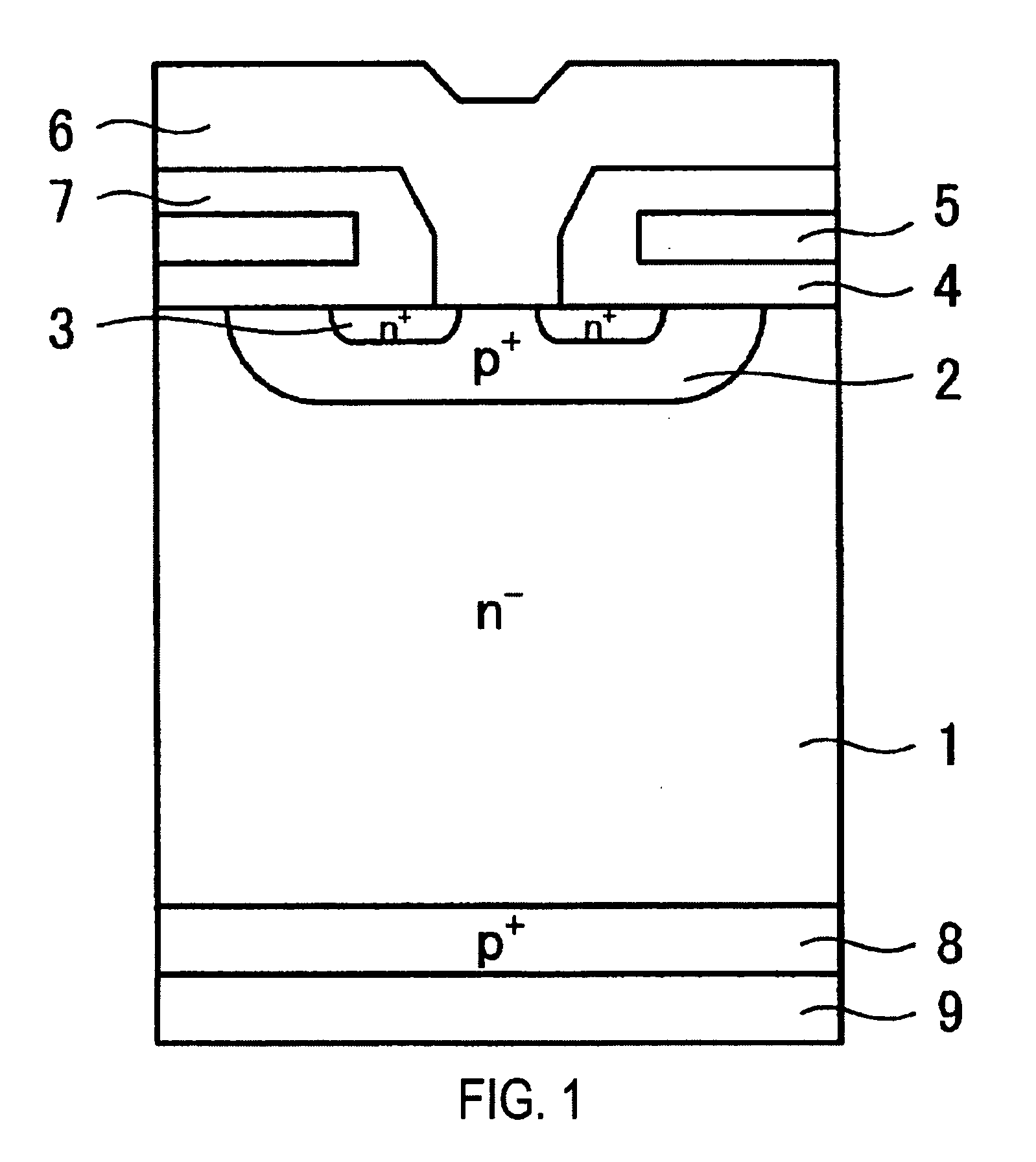

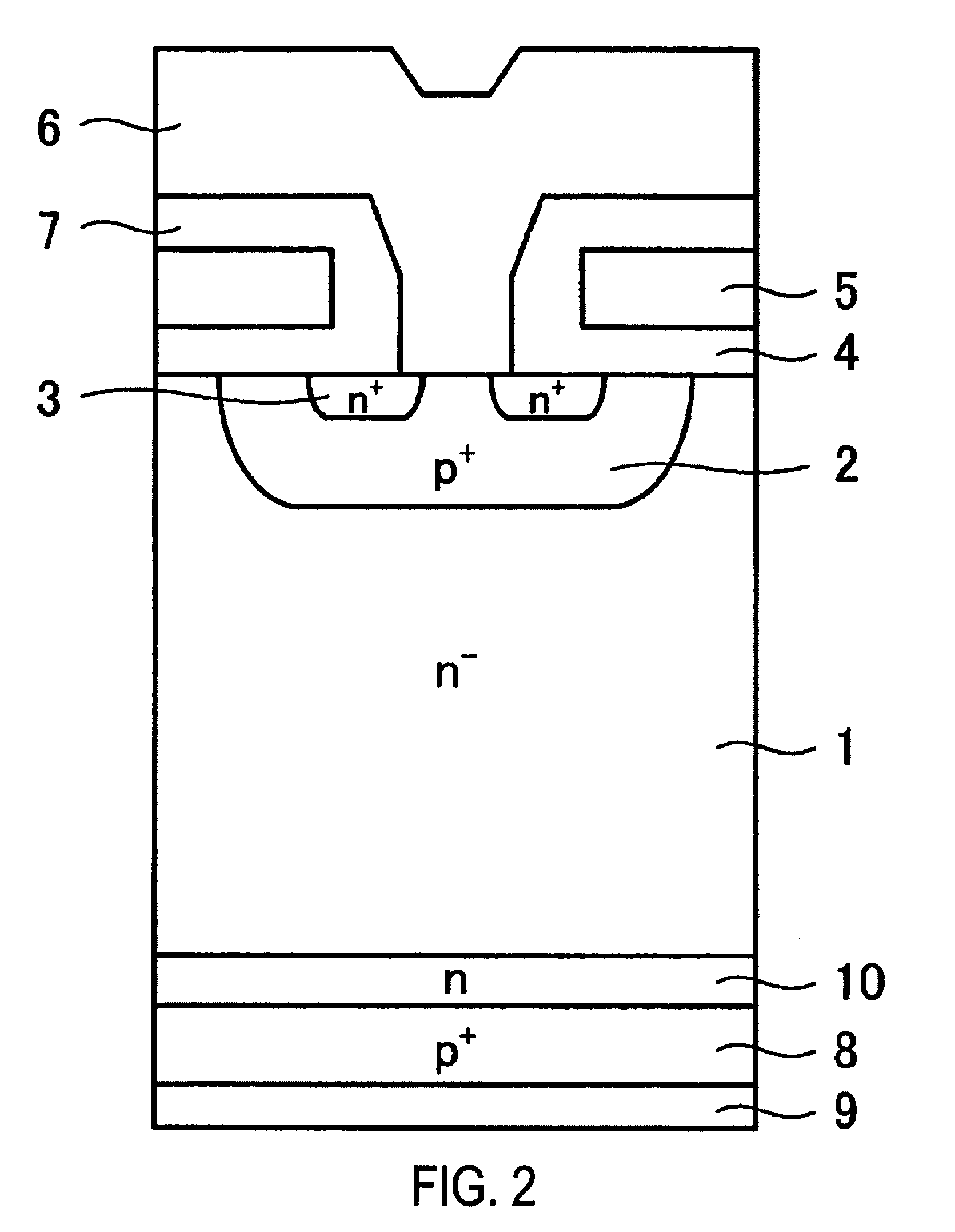

Method of producing a semiconductor device with an aluminum or aluminum alloy electrode

InactiveUS20070004098A1Avoid it happening againHigh proportionTransistorSemiconductor/solid-state device manufacturingSilicon electrodeDevice material

A method of producing a semiconductor device having a thickness of 90 μm to 200 μm and with an electrode on the rear surface, which achieves a high proportion of non-defective devices by optimizing the silicon concentration and thickness of the aluminum-silicon electrode. A surface device structure is formed on a first major surface of a silicon substrate. A buffer layer and a collector layer are formed on the second major surface after grinding to reduce the thickness of the substrate. On the collector layer, a collector electrode is formed including a first layer of an aluminum-silicon film having a thickness of 0.3 μm to 1.0 μm and a silicon concentration of 0.5 percent to 2 percent by weight, preferably not more than 1 percent by weight.

Owner:FUJI ELECTRIC CO LTD

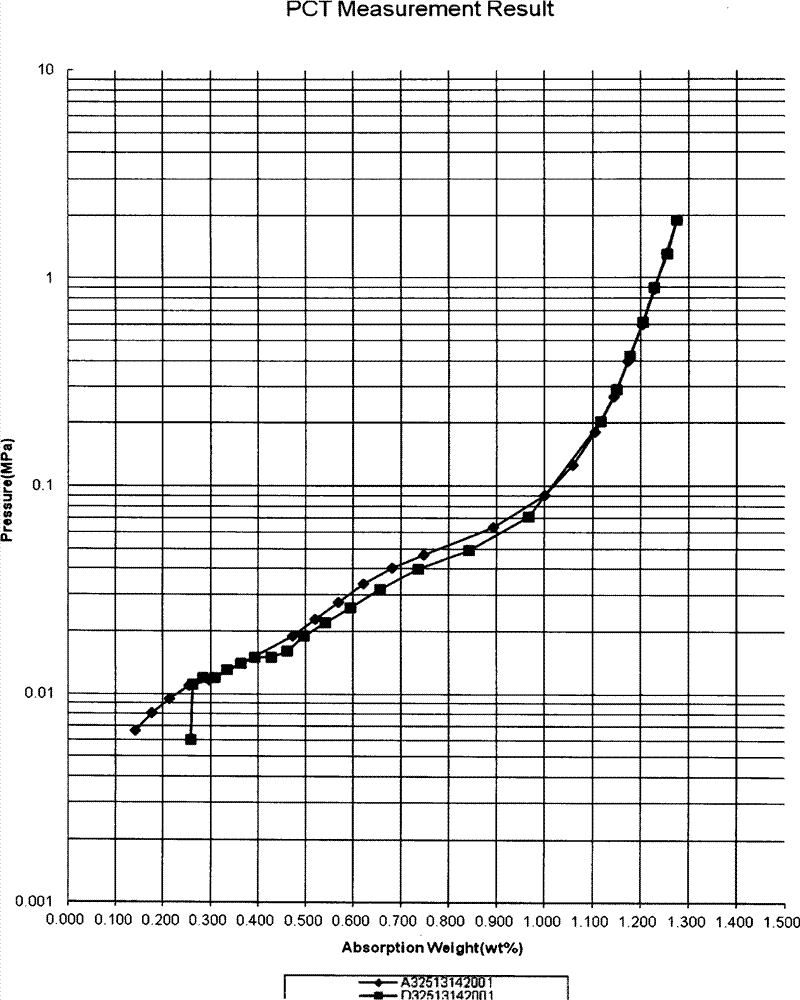

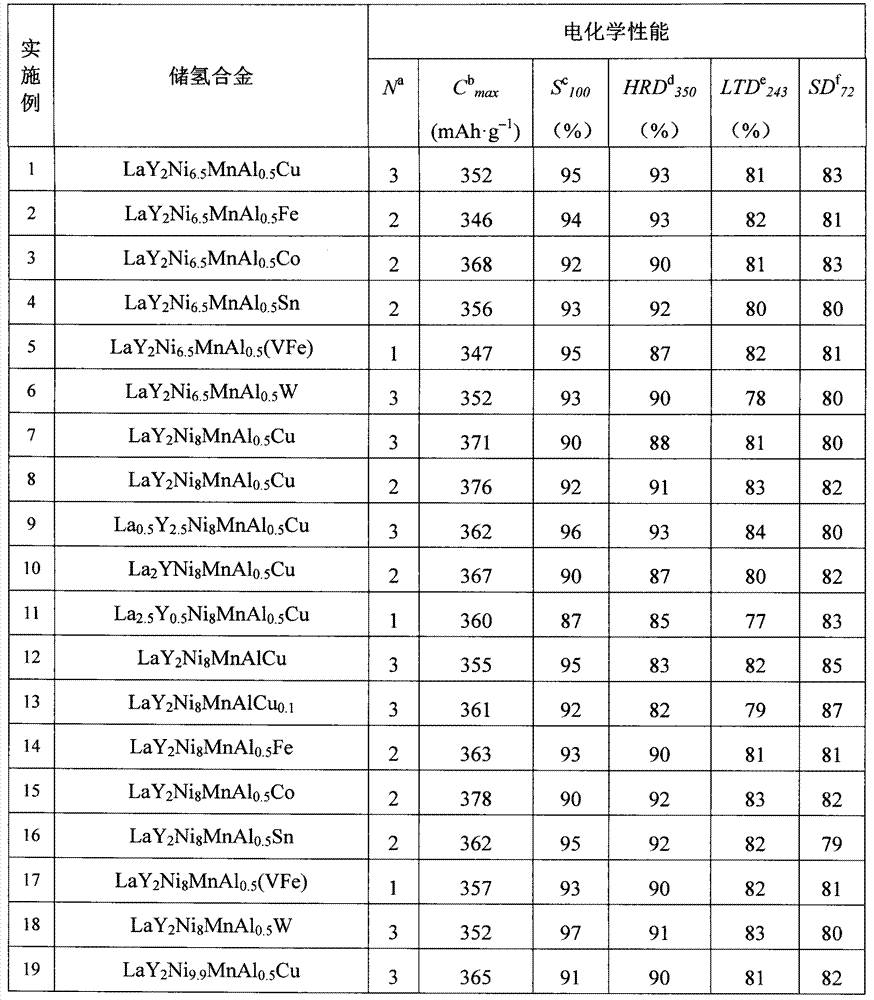

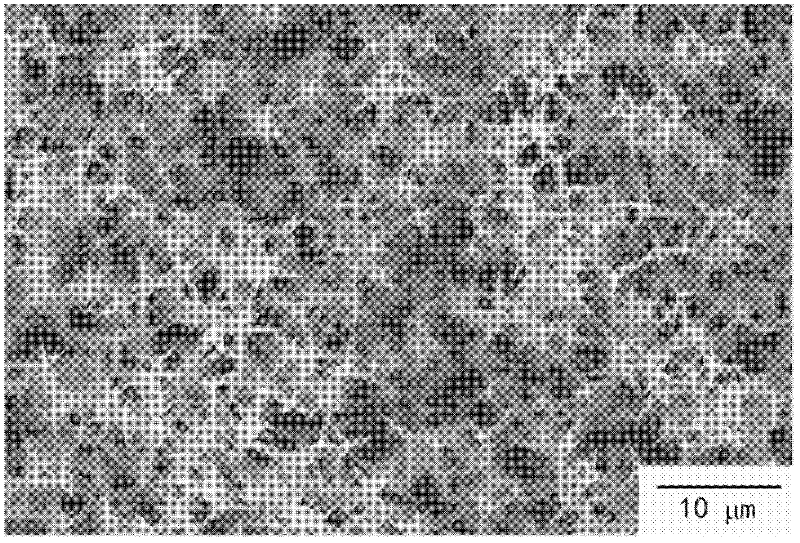

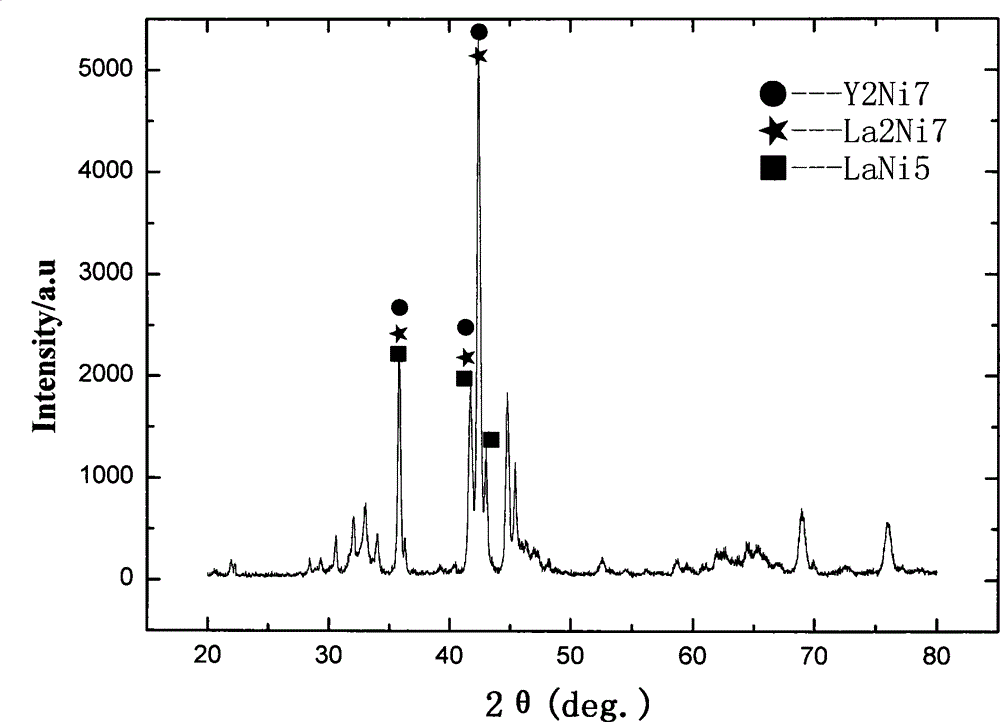

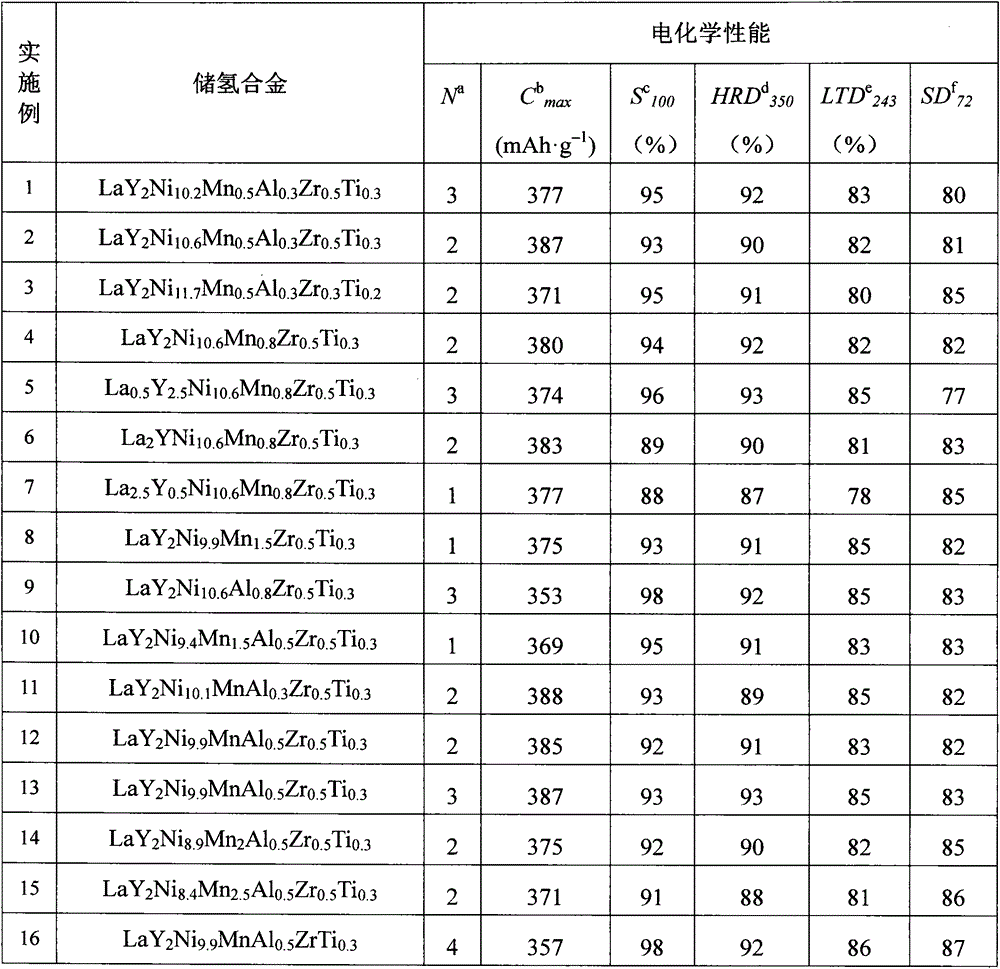

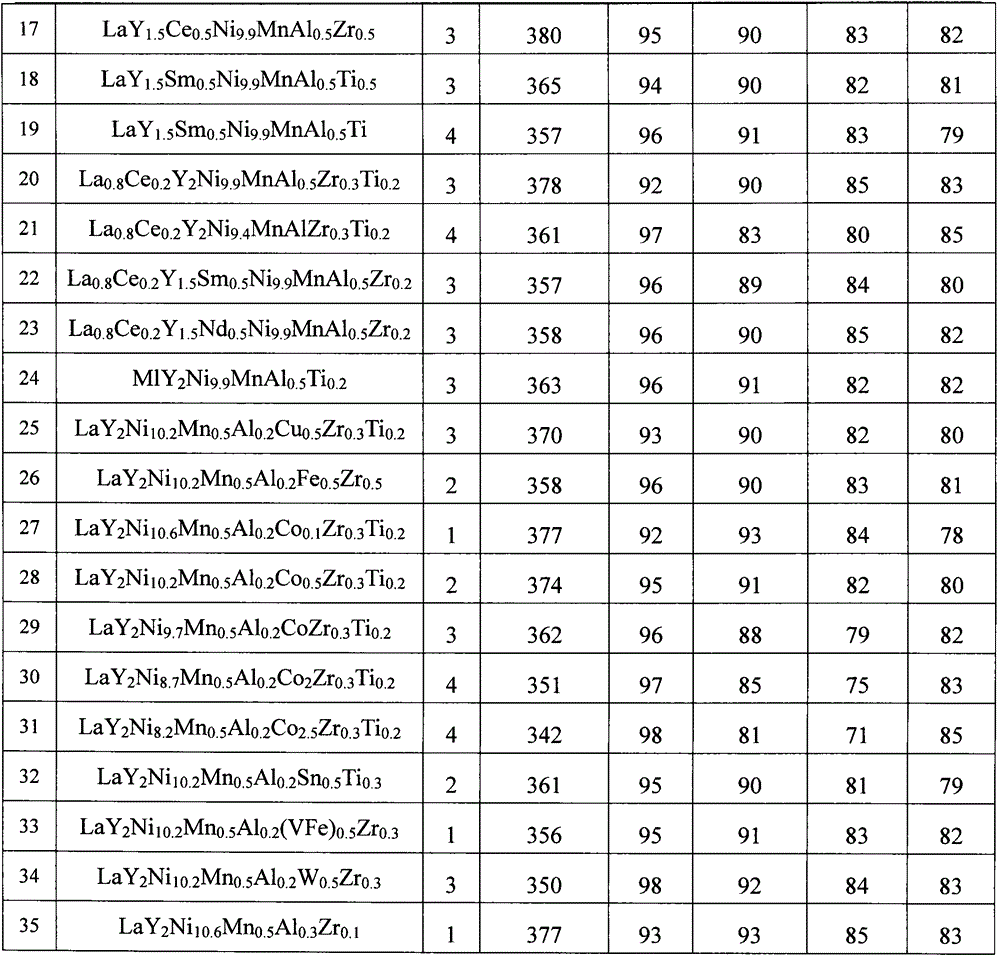

Rare earth-yttrium-nickel family hydrogen storage alloy, and secondary battery containing hydrogen storage alloy

ActiveCN104518204AIncrease capacityThe manufacturing method is simple and safeAlkaline accumulator electrodesNickel accumulatorsAlkaline earth metalRare earth

The invention relates to a rare earth family hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMc. The alloy treats the rare earth Y as one of main components, contains Mn and Al elements or one of Mn and Al, also contains one or more of Cu, Fe, Co, Sn, V and W, contains no alkali earth metals, and is simple and safe to produce. The hydrogen storage alloy has a good compression-composition-isothermal characteristic and a large hydrogen storage amount reaching above 1.28wt% under usual conditions; the highest capacity of the above hydrogen storage alloy electrode is higher than that of LaNi5 type hydrogen storage alloy; and the rare earth family hydrogen storage alloy has good activation performances, rate discharge ability, and charge and discharge or hydrogen absorption and desorption cycle stability, can be used in a wide temperature range, and has small self discharge.

Owner:BAOTOU RES INST OF RARE EARTHS +2

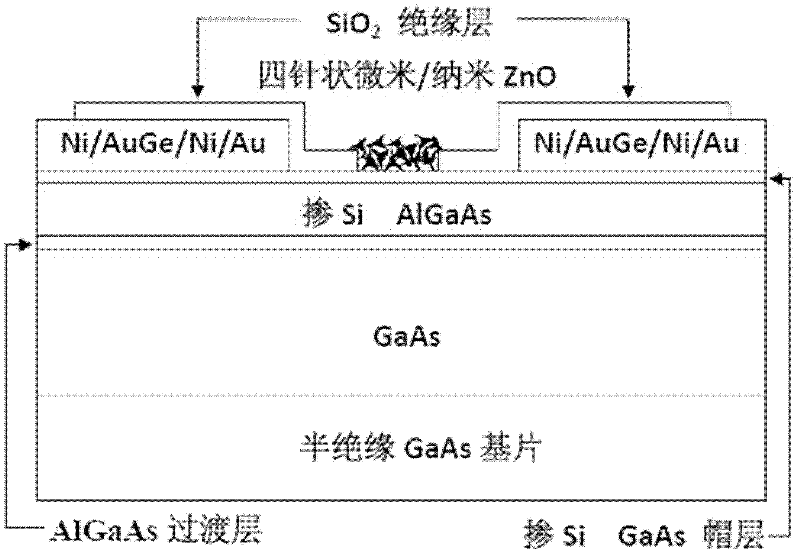

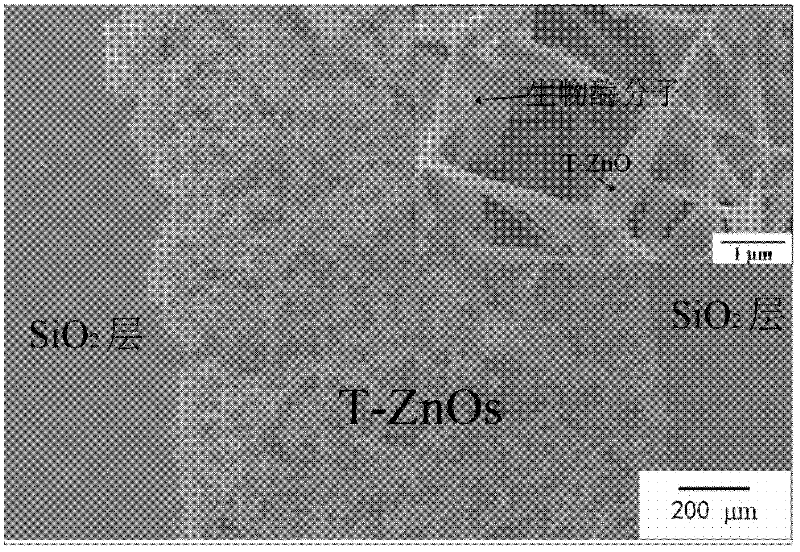

Biosensor base on zinc oxide and high electron mobility transistor and its preparation method

InactiveCN102313765ASimple manufacturing processShort response timeMaterial electrochemical variablesSilicon dioxideMaterials science

The invention provides a biosensor base on zinc oxide and high electron mobility transistor and its preparation method, which belongs to the nano-material application field. The invention is characterized by using a molecular beam epitaxy (MBE) system to prepare an AlGaAs / GaAsHEMT layered structure. A method of heat vapor plating is used to prepare a nickel / gold-germanium / nickel / gold alloy electrode, a silica insulating layer is deposited on the surface of the device to obtain the AlGaAs / GaAsHEMT. A gas-solid method is used for preparing T-ZnO. T-ZnO is modified on a grid electrode of HEMT and a bio-enzyme solution and a Nafion solution are added add drop by drop on a T-ZnO layer. The prepared device is placed at the low temperature for a period of time and then can detect the concentration of the solution to the corresponding biological solution. The invention has the advantage that the prepared device is capable of modifying different biological enzyme through the grid electrode to detect the concentration of the solution to the corresponding biological solution, and has the merits of high sensitivity, low detection limitation, wide detection scope, fast response speed, simple structure and stable performance, so that the biosensor provides the possibility to an practical application.

Owner:UNIV OF SCI & TECH BEIJING

A5B19 type rare earth-yttrium-nickel system hydrogen storage alloy added with zirconium and titanium elements

ActiveCN104152749AIncrease capacityThe manufacturing method is simple and safeCell electrodesRare earthTitanium

The invention relates to rare earth system hydrogen storage alloy with the general formula of RExYyNiz-a-b-cMnaAlbMcZrATiB. The peak capacity of an alloy electrode is higher than that of LaNi5 type hydrogen storage alloy, and the manufacturing method is simple and safe. The hydrogen storage alloy has the good activation property, the rate discharge capability, and charging and discharging or hydrogen absorption and desorption circular stability, can be used in the wider temperature range, and is small in self discharging. The method can be used for manufacturing a cathode of an alkaline rechargeable battery and a rechargeable battery with the hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

Method for cryogenic treatment of galvanized steel sheet resistance spot welding electrode

InactiveCN1435505AExtend working lifeLow cryogenic processing costsElectrode featuresWelding/cutting media/materialsOperating lifeMaterials science

A process for deep cold treatment of the spot-welding electrode for the galvanized steel plate in order to elongate its service life includes putting the Cu-alloy electrodes in a container full of deep cold medium in a deep cold treater layer by layer, setting parameters, deep cold treating, and naturally raising their temp to ordinary temp. Its advantages are long service life elongated by 4 times, no splash on welding, and high welding quality.

Owner:TIANJIN UNIV

Alkaline storage battery and method for producing the same

InactiveUS20050186478A1Improve cycle lifeSmall self-dischargeCell seperators/membranes/diaphragms/spacersFinal product manufactureCross-linkMethacrylate

An alkaline storage battery includes: a positive electrode containing nickel hydroxide; a negative electrode; a separator layer intervening between the positive electrode and the negative electrode; and an alkaline electrolyte. The separator layer includes a water-absorbing polymer, a water repellent, an alkaline aqueous solution, and a scavenger capable of trapping an element which leaches from the negative electrode into the alkaline aqueous solution. The scavenger comprises an oxygen-containing metal compound. The negative electrode is a hydrogen storage alloy electrode, a cadmium electrode or a zinc electrode. The water-absorbing polymer comprises a cross-linked polymer having at least one kind of monomer unit selected from the group consisting of an acrylate unit and a methacrylate unit.

Owner:PANASONIC CORP

Multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material and preparation method thereof

ActiveCN108172807AImprove electrochemical performanceImprove discharge capacityCell electrodesNickel accumulatorsHigh rateChemical composition

The present invention discloses a multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material. The chemical composition of the material is La<1-a-b-c-d-e>PrNdSm<c>Gd<d>Mg<e>Ni<k-x-y-z>Co<x>Al<y>Mn<z>. The alloy has relatively high discharge capacity, good electrochemical cycling stability and high rate discharge performance, wherein the maximum discharge capacity >=363 mAh / g, capacity retention ratio >=88.8% after 100 charging and discharging cycles, and HRD1500 >=58.2%. The present invention also provides a preparation method of the multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material. A cast alloy is prepared via an induction melting method, and then the alloy is subjected to heat treatment. The method has the advantages of simplicity, stable conditions and good repeatability. The prepared alloy has the advantages of uniform composition, small crystalline grain, intact crystal form, stable structure, application in large-scale production and short preparation period. The present invention can be applied to the preparation of the multi-element single-phase A5B19-type super-lattice hydrogen storage alloy electrode material.

Owner:包头中科轩达新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com