Preparation method of Waspalloy spherical powder for additive manufacturing

A spherical powder, additive manufacturing technology, applied in additive processing, metal processing equipment, transportation and packaging, etc., can solve the problems of production difficulty and procurement cost increase, improve production efficiency, reduce satellite powder and hollow powder. Formation, high sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: A preparation method of Waspalloy spherical powder for additive manufacturing, including the following steps:

[0033] The mass percentages of the main elements used are: Cr-18.3%, Co-12.5%, Mo-3.8%, Al-1.2%, Ti-2.8%, Fe-0.5%, Mn-0.03%, S-0.007%, P- 0.006%, Si-0.08%, Cu-0.03%, B-0.004%, Zr-0.03%, C-0.003%, Ni-balance balance, put the raw materials in a vacuum induction furnace with a vacuum of 0.1 Pa for one time Smelting; remove the surface oxide scale of the primary smelting, and carry out the second vacuum consumable remelting, and the vacuum degree is 0.05 Pa to obtain the Waspalloy master alloy secondary smelting ingot blank with a relative density of 95%;

[0034] Waspalloy alloy rods with a density of 99.6% were obtained by isothermal free forging, and processed by lathes and precision CNC lathes into Waspalloy alloy rods with a diameter of 75mm and a length of 850mm;

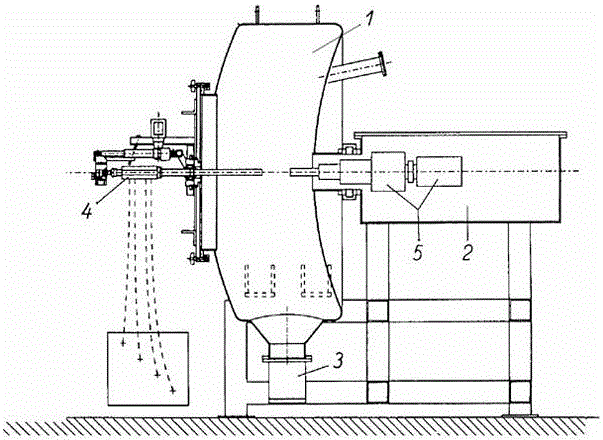

[0035] Place the Waspalloy alloy electrode rod in the electrode rod installation chamber ...

Embodiment 2

[0039] Example 2: Preparation of Waspalloy alloy spherical powder

[0040] The mass ratio of the main elements used is: Cr-19.8%, Co-13.5%, Mo-4.4%, Al-1.4%, Ti-2.98%, Fe-1.3%, Mn-0.6%, S-0.011%, P -0.0010%, Si-0.12%, Cu-0.07%, B-0.007%, Zr-0.05%, C-0.006%, Ni-balance balance, the raw materials are placed in a vacuum induction furnace with a vacuum of 0.05 Pa Primary smelting; remove the surface oxide scale of the primary smelting, and carry out the second vacuum consumable remelting. The vacuum degree is 0.01Pa to obtain the Waspalloy master alloy secondary smelting ingot blank with a relative density of 91%;

[0041] The Waspalloy master alloy is re-smelted ingot-shaped billet, and the Waspalloy alloy rod with a density of 99.5% is obtained by isothermal free forging, and processed into a Waspalloy alloy electrode rod with a diameter of 85mm and a length of 500mm;

[0042] Place the alloy electrode in the electrode rod installation chamber 2 and evacuate the inert protective gas a...

Embodiment 3

[0047] The mass ratio of the main elements used is: Cr-20.7%, Co-14.9%, Mo-4.7%, Al-1.6%, Ti-3.16%, Fe-1.8%, Mn-0.9%, S-0.015%, P -0.0013%, Si-0.14%, Cu-0.10%, B-0.009%, Zr-0.08%, C-0.009%, Ni-balance balance, put the raw materials in a vacuum induction furnace with a vacuum of 0.05 Pa Primary smelting; remove the surface oxide scale of the primary smelting, and carry out the second vacuum consumable remelting. The vacuum degree is 0.01Pa to obtain the Waspalloy master alloy with a relative density of 91%.

[0048] The Waspalloy master alloy is re-smelted ingot-shaped billet, and the Waspalloy alloy bar with a density of 99.5% is obtained by isothermal free forging, and processed into a Waspalloy alloy electrode bar with a diameter of 10mm and a length of 100mm;

[0049] Place the alloy electrode in the electrode rod installation chamber 2, and evacuate the inert protective gas atomization chamber 1 until the vacuum degree of the equipment reaches 9×10 -3 When Pa is filled with arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com