Patents

Literature

300 results about "High pressure pulse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high pulse rate of more than 100 beats per minutes is called tachycardia. Normal blood pressure is defined as having a systolic pressure that ranges from 90 to 140 mmHg (millimetres of mercury), and a diastolic pressure that ranges from 60 to 90 mmHg.

Method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection

ActiveCN102155254AChange mechanical propertiesImprove breathabilityFluid removalGas removalPulse pressureDischarge rate

The invention relates to a method for extracting gas in low air permeability coal layer by pulse fracture anti-reflection, comprising the following steps: firstly using the blast-proof pulse-type coal layer high pressure water injector with adjustable frequency and pressure from the coal layer, high tunnel or low tunnel; using the pulse water effect generated by the periodical change of high pressure pulse water inside the drill hole of coal body, wherein the maximum pulse pressure is 35 MPa, the flow is about 300 L / min, and the pulse frequency is 0-1460 times / min; forcing the macroscopic fracture in the coal layer to be expanded and communicated; promoting the micro-pore fracture to be formed and extended; forming a new regeneration fracture net; providing a permeable channel of water inthe coal layer so as to achieve the effects of improving the mechanical property of the coal body, reducing the stress of the coal body in front of the working face and improving the discharge rate of the gas. Through the method, the pressure releasing range of the coal layer is enlarged, the whole pressure is adequately released, the radius of influence range of fracture can reach 10-40 m, and the air permeability of the coal body can be improved by 100-1000 times; and the method is simple, easy to operate and good in effect.

Owner:CHINA UNIV OF MINING & TECH

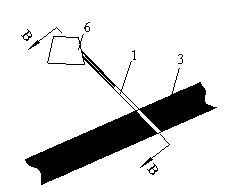

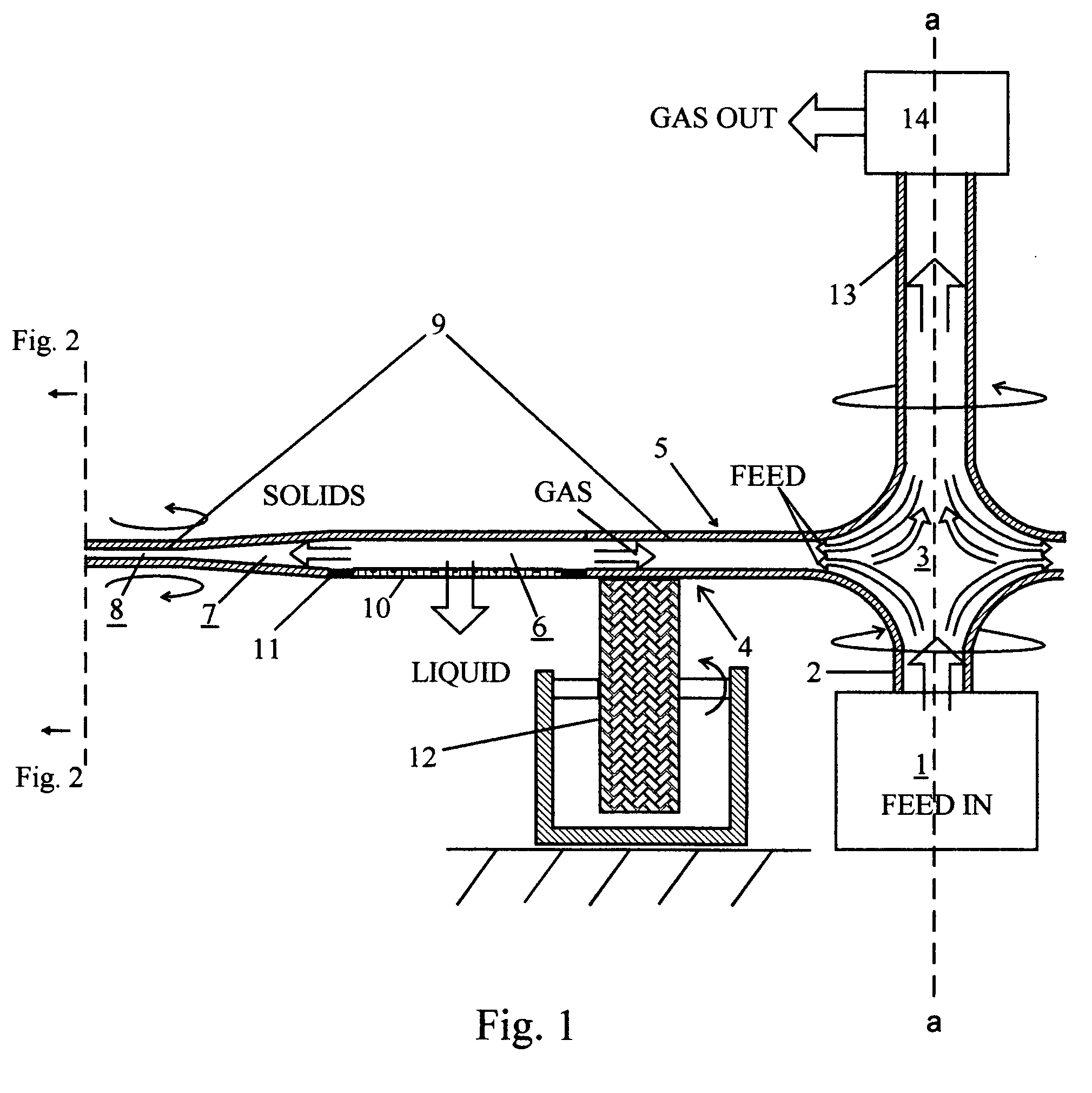

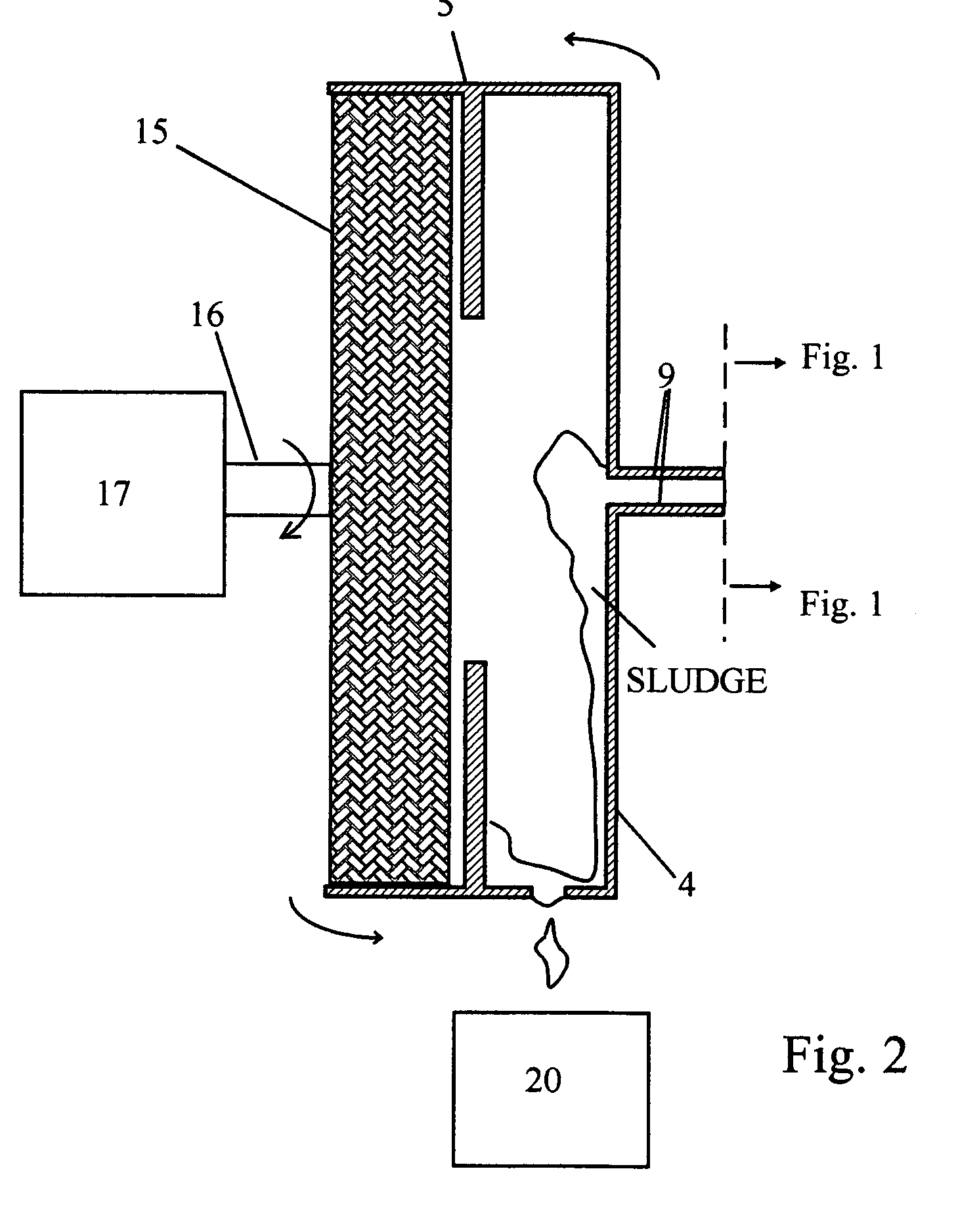

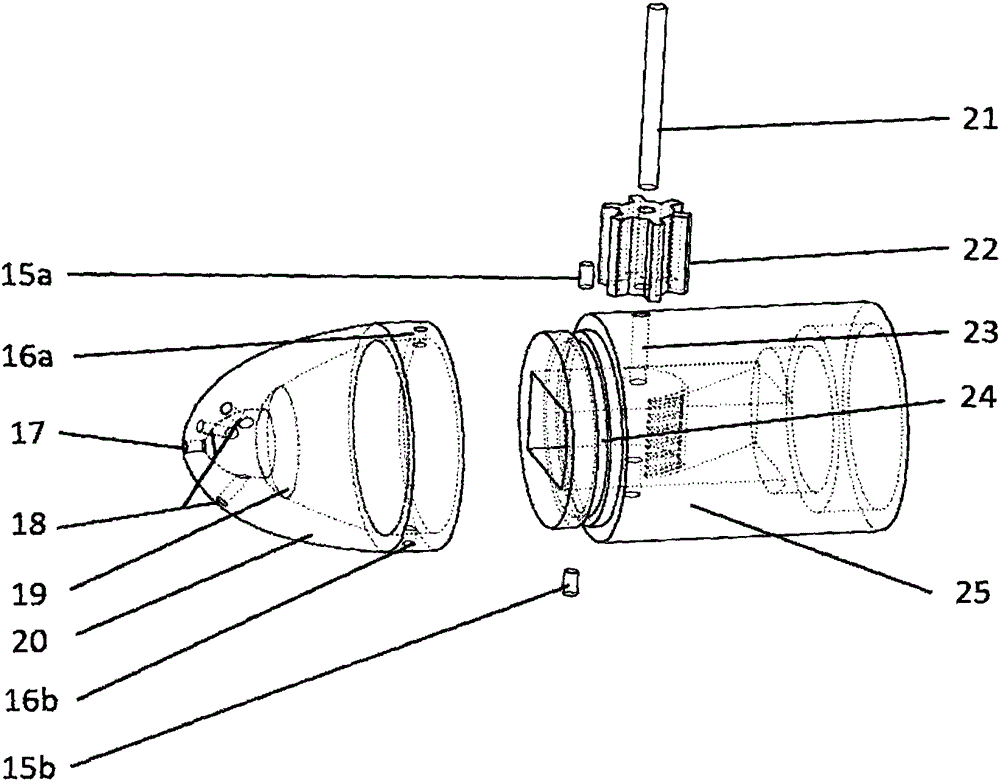

Rotary annular crossflow filter, degasser, and sludge thickener

ActiveUS20090159523A1Accelerate scrubbing reactionAvoid emissionsLiquid degasificationSludge treatmentHigh energySludge

A rotating annular crossflow filter shears radially outward flowing axial feed between counter-rotating coaxial centrifugal impellers. A radial impedance of flow at the impeller periphery slows the radially outward flow and increases residence time of feed between the impellers. Shear lift ejects solids from the boundary layer at the filter surface, and ejected solids collect by centrifugation at the impeller periphery, where they thicken into a sludge and are extruded. Gases, oils, floating solids, and fractions having a specific gravity less than water evolve into radial vortices and are sucked radially inward and out from between the impellers by an axial pump. Three way phase separation proceeds continuously in one pass through a simple mechanical device having a long residence time for feed in the processing zone.Opposing rugose portions of counter-rotating impeller surfaces cause audio frequency pressure pulses. At the impeller periphery, the pressure pulses milk liquid out of sludge. At the portion of the radial passage prior to the filter, pressure pulses evolve gases and degassed cavitation bubbles inactivate microbes. Degassing of the high energy forced periodic cavitation bubbles between the impellers removes the cushion of noncondensibles which would otherwise absorb energy on compression, therefore implosion becomes extremely violent and a barrage of high pressure pulses and ultraviolet light pulses inactivates microbes.Applications include field water purification, municipal and industrial wastewater degassing and sludge thickening, swimming pool filtration, effluent dewatering, wine and beverage degassing and clarification, fruit crushing, olive oil dewatering, produced brine and drilling mud processing, manure slurry dewatering and degassing, and recovery of solvents and fine suspended solids from fluid mixtures such as wastewater from machining operations.

Owner:VORSANA INC

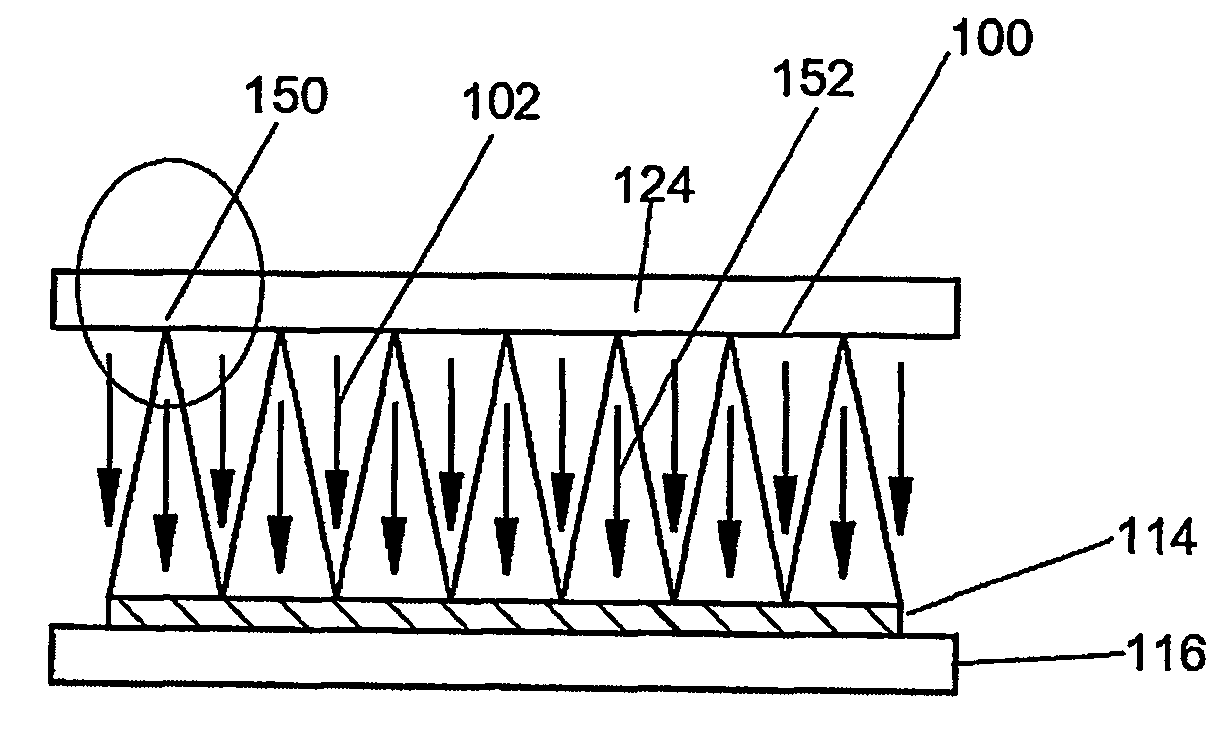

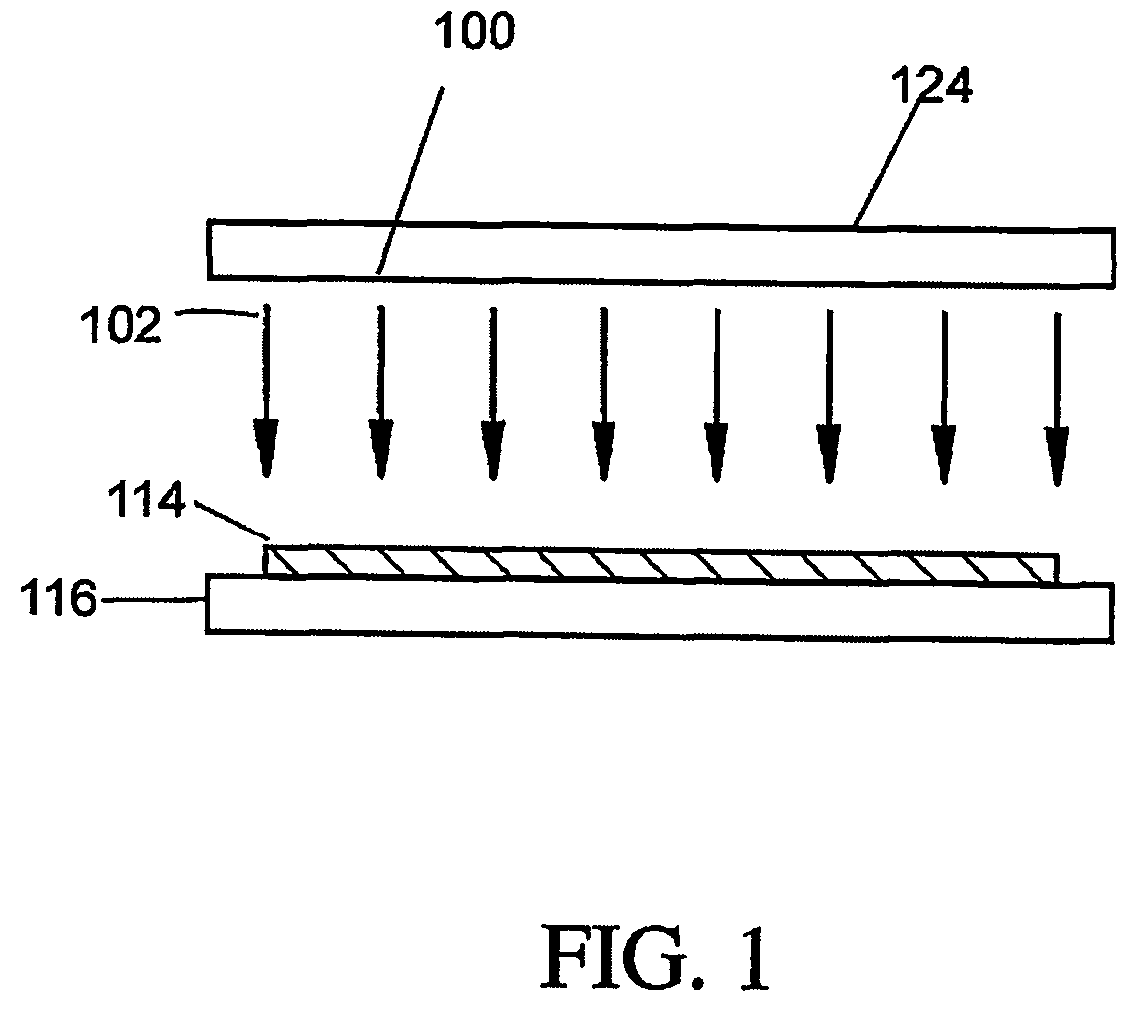

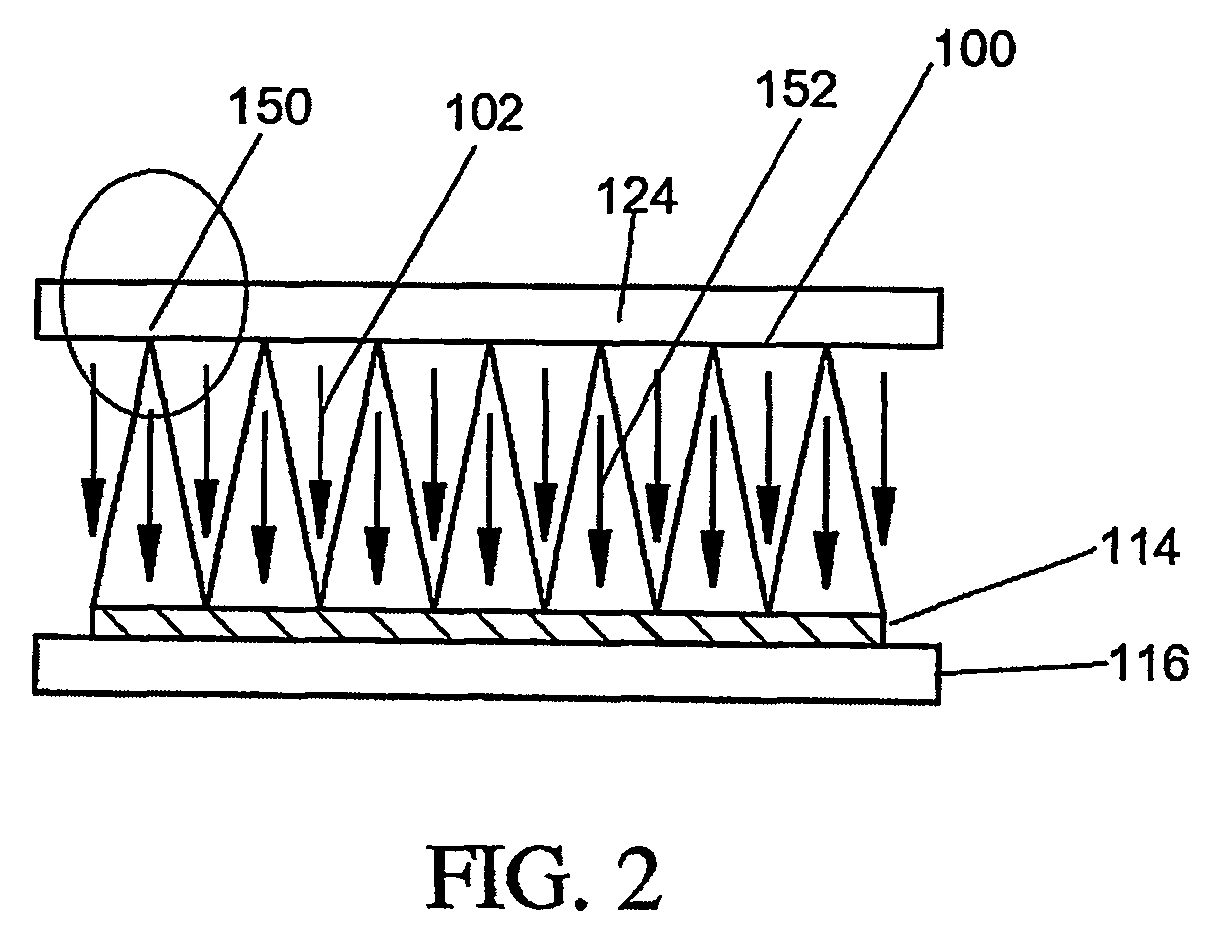

Shower head gas injection apparatus with secondary high pressure pulsed gas injection

InactiveUS20040123803A1Electric discharge tubesChemical vapor deposition coatingCombined useEngineering

A plasma-processing chamber including pulsed gas injection orifices / nozzles utilized in combination with continous flow shower head injection orifices is described. The continous flow shower head injection orifices introduce a continous flow of gas while the pulsed gas injection orifices / nozzles cyclically inject a high-pressure gas into the chamber. In one embodiment, a central computer may monitor and control pressure measurement devices and utilize the measurements to adjust processing parameters (e.g. pulse duration, pulse repetition rate, and the pulse mass flow rate of processing gases).

Owner:TOKYO ELECTRON LTD

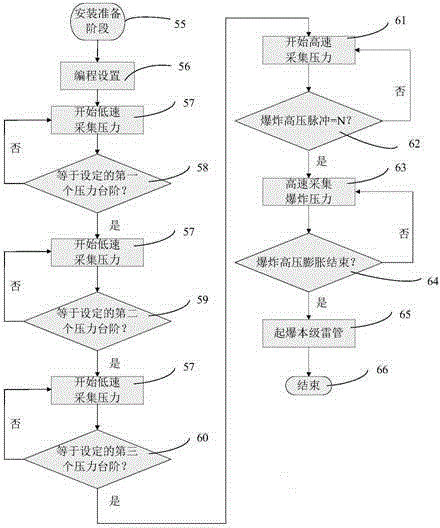

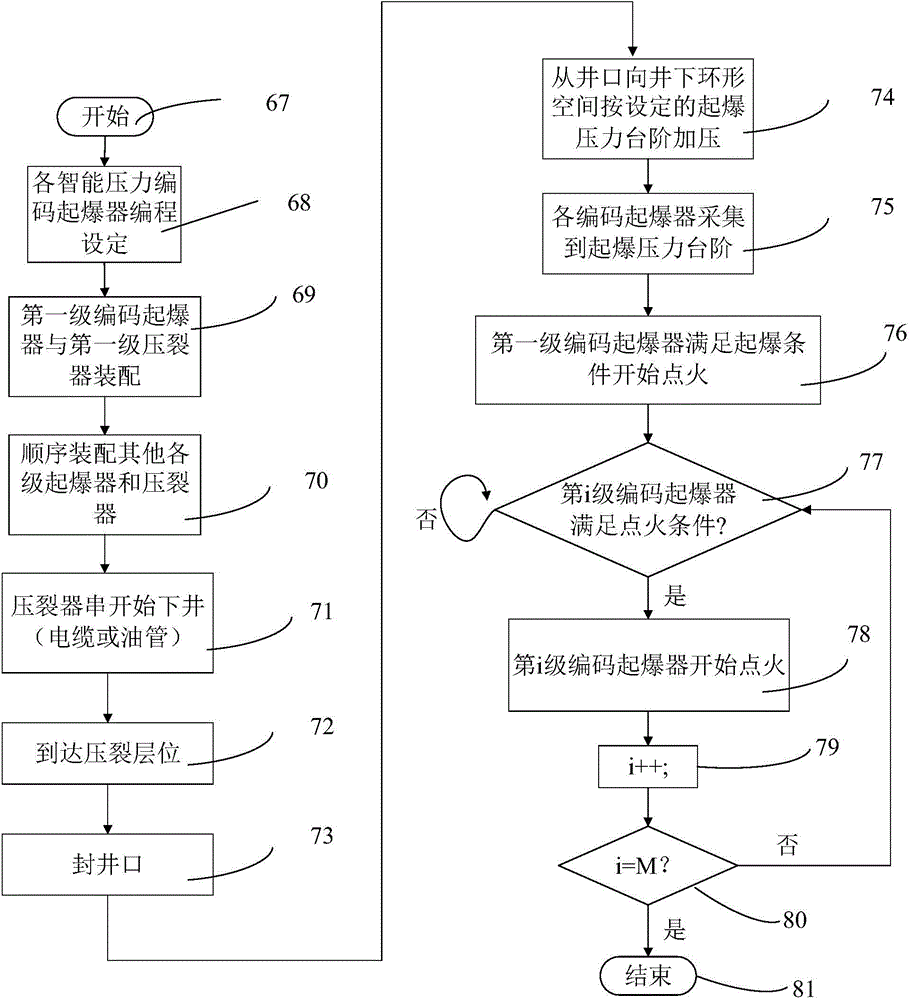

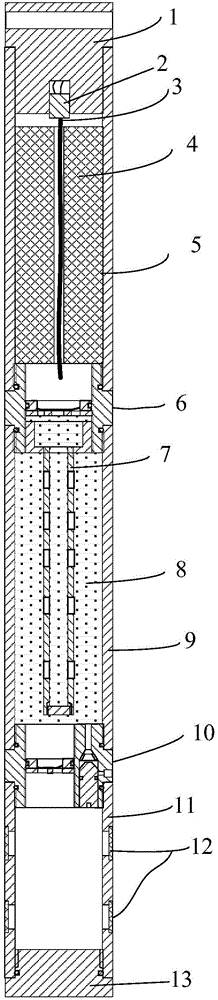

Underground multi-stage intelligent high pressure gas pulse formation fracturing device and method thereof

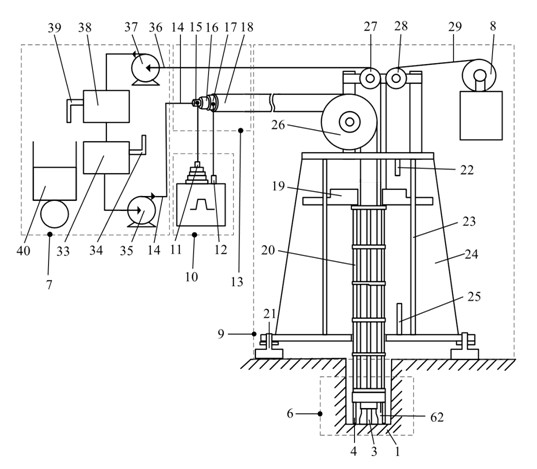

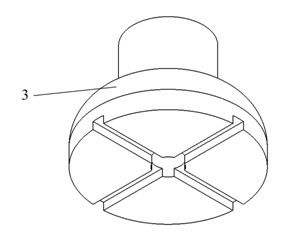

The invention discloses an underground multi-stage intelligent high pressure gas pulse formation fracturing device and a method thereof, belongs to the technical field of fracturing completion of oil and gas wells, and particularly relates to two technical sachems of the device and the method. The method is used for fracturing the underground layer by the underground multi-stage intelligent high pressure gas pulse formation fracturing device. The device is controlled by each stage of intelligent pressure encoding detonator to gradually detonate by stages at proper time to generate a large amount of high pressure gas according to the set working mode, the dynamic high pressure pulse pressure is formed in the well or holes of a formation, the formation is fractured to form a plurality of cracks, and the permeability of fluid in the formation is increased, so the oil and gas are easily produced. The device and the method have the advantages that the cyclic multiple pressure pulses which are controlled at proper pressure can be generated, so the formation can generate the compression-expansion-compression alternating 'resonance', the cracks are promoted to effectively extend, and a new fracturing network is formed, so the permeability of the formation is improved; the pollution to the formation and environment in the fracturing process is avoided; the method is suitable for the water-sensitive and acid-sensitive formation; the construction cycle is short, the cost is low, the equipment is simple and convenient, and the limitation by terrain and water sources is avoided.

Owner:ZHONGBEI UNIV

Electric pulse assisted hydrofracture unconventional gas reservoir permeability increasing method

InactiveCN104832149AOvercome speedOvercome timeFluid removalVibration devicesCavitationHydraulic fracturing

The invention relates to unconventional gas reservoir permeability increasing methods, in particular to an electric pulse assisted hydrofracture unconventional gas reservoir permeability increasing method. The electric pulse assisted hydrofracture unconventional gas reservoir permeability increasing method comprises the following steps that a hole is drilled in an unconventional gas reservoir, and a discharge electrode is descended to the position of the reservoir with permeability to be increased through a winch; the drilled hole of the reservoir is sealed, and water is injected into the drilled hole of the reservoir through a water injection pipe to achieve the preset static pressure; discharge equipment is used for pulse discharge through the discharge electrode; after the discharge process is finished, the water in the drilled hole of the reservoir is drained, natural gas exhausting and mining equipment is connected, and then natural gas is collected through the natural gas exhausting and mining equipment. The high pressure pulse discharge and hydrofracture technology are integrated creatively, the cavitation effect of the high pressure pulse discharge and the instantaneous loading function of water shock are used for achieving the purposes of changing the existence state of natural gas, increasing the reservoir fracture, reducing weakening intensity, improving permeability and improving the exhausting and mining efficiency of natural gas. The electric pulse assisted hydrofracture unconventional gas reservoir permeability increasing method also has very wide application prospects on the aspect of unconventional gas exhausting and mining.

Owner:TAIYUAN UNIV OF TECH

Method for extracting coal bed gas from circulating pulse type low temperature freeze-thawed anti-reflection coal

ActiveCN106337672AImprove anti-reflection efficiencyImprove gasification expansion efficiencyFluid removalGas removalFreeze thawingUltrasound attenuation

The invention discloses a method for extracting coal bed gas from circulating pulse type low temperature freeze-thawed anti-reflection coal. Firstly, a borehole and multiple rows of guiding slots are constructed in a coal bed, the guiding slots are communicated with the borehole and extend to two sides of the borehole in the direction perpendicular to the borehole in the coal bed, and coal bed gas extraction boreholes are formed at the outer ends of the guiding slots. A liquid low-temperature medium is injected into the borehole and the guiding slots in a high-pressure pulse mode, the coal bed is freeze-thawed by adopting a pulse circulating low temperature freeze-thawing method to fracture for increasing reflection, and a coal bed gas extraction fracture network is thus formed. Coal bed gas is extracted via the coal bed gas extraction boreholes. By combining freeze-thawing erosion with coal bed gas extraction and combining pulse circulating injection of the liquid low-temperature medium with freeze-thawing phase change fracture, the method significantly improves the anti-reflection efficiency of coal. The method is simple, feasible and low in construction cost, can effectively improve the single-pore extraction quantity and extraction concentration of coal bed gas and prolong the attenuation time of gas concentration, and is particularly suitable for coal bed gas extraction in low-osmosis and high-gas bearing coal beds.

Owner:CHINA UNIV OF MINING & TECH

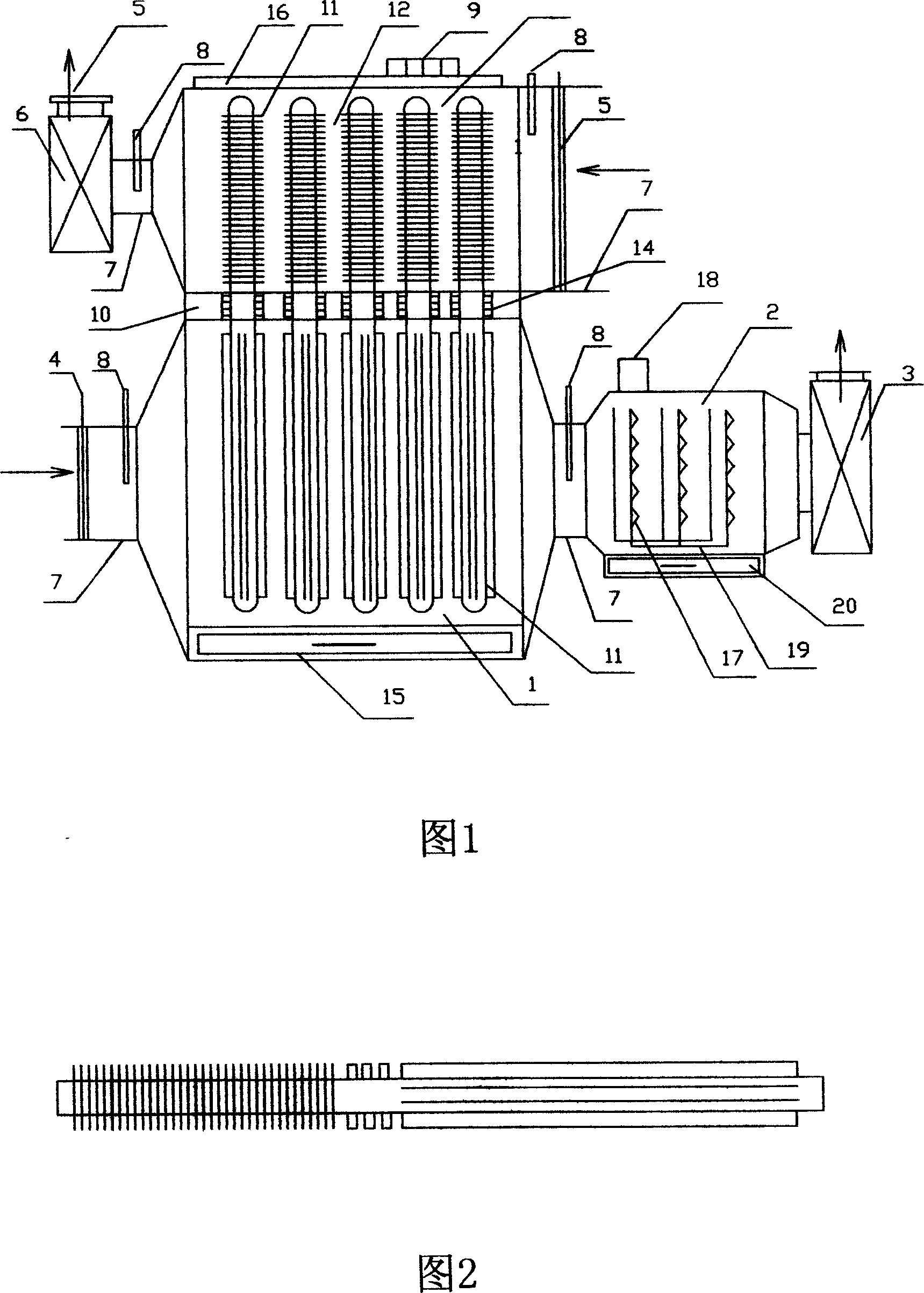

Heat shaped machine exhaust heat air purification heat energy utilized heat pipe exchanger

InactiveCN101113877AAvoid oil plugging sceneGuaranteed recyclingElectrostatic separationSteam/vapor condensersThermal energyEngineering

A heat pipe heat exchanger for waste heat air purifying and heat energy utilization of heat setting equipment is a heat pipe heat exchanger that is provided with heat pipes of different working mediums. An exothermic section of an air side heat pipe is of a spiral fin structure, and an endothermic section of a waste heat air side heat pipe is of a longitudinal fin structure. 50 percent of heat energy is recycled when the temperature of the waste heat air falls from 180 DEG C to 70-80 DEG C. At the same time, a waste heat air inlet tube and a heated air inlet tube are provided with a slot with a detachable and replaceable yarn dust filtering netting; the steamed and liquidized air that is condensed and discharged from the waste heat air with the heat absorbed by the heat pipe of longitudinal fin structure flows into an oil sump tank along the longitudinal fin, enters a low temperature electrostatic pulse oil fume staticizer, and the oil molecular is ionized in the high pressure pulse positive-negative electrode electric field. The waste heat air discharged from the heat setting equipment fundamentally reaches the requirements of environment protective of low temperature, dust free and oil free.

Owner:吴江市普天热管技术推广应用研究所

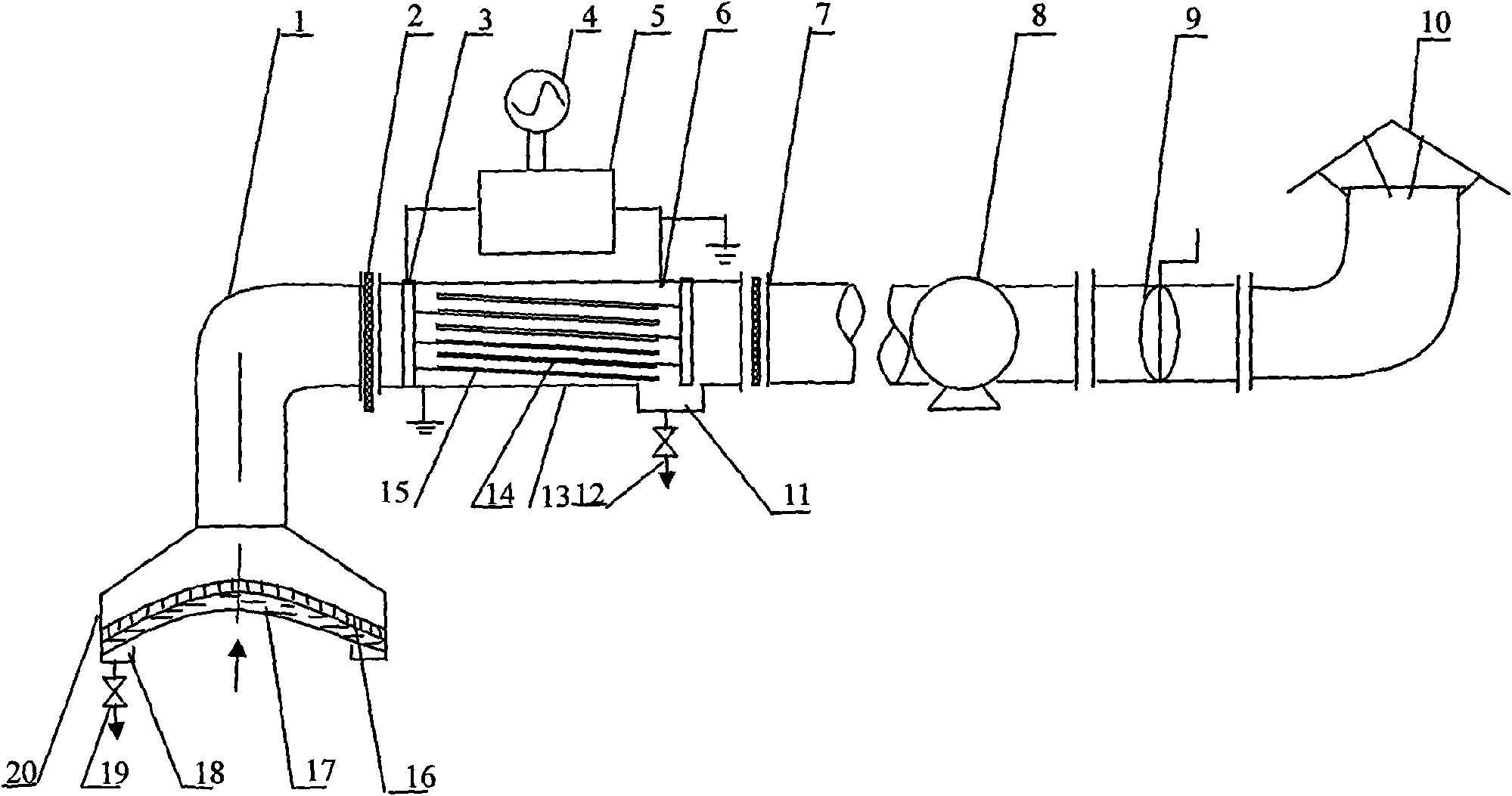

Oil and smoke purifier of low-temperature plasma synergistic modified filtering membrane

InactiveCN101653683AEfficient captureImprove lipophilicityCombination devicesDomestic stoves or rangesFuel tankPlasma generator

The invention relates to an oil and smoke purifier of a low-temperature plasma synergistic modified filtering membrane in purification catering. The oil and smoke purifier comprises a gas-collecting hood, a vent pipe and a fan, wherein a working surface of the gas-collecting hood is provided with a stainless steel mesh and a filtering membrane in sequence, and a trough-shaped oil-collecting tank is arranged at the lower edge of the working surface of the gas-collecting hood; a secondary oil-collecting tank is arranged on the vent pipe in series, more than one pair of anode plate and cathode plate which are parallel to each other are arranged in the secondary oil-collecting tank, and a high-pressure pulse plasma generator is arranged between an anode terminal and a cathode terminal in series; an oil outlet is arranged at one side of the bottom of the second oil-collecting tank; and a blast volume adjusting valve is arranged at an outlet of the vent pipe. The invention has the advantagesthat the synergistic effect between filtering materials and a plasma has unique advantages for removing flue gas in a kitchen; the structure is simple, the removal ratio is high, the maintenance is convenient, and the treated gas has no odors; and the device is unnecessary to be rinsed, belongs to a technology for purifying flue gas in the kitchen by adopting a dry method, and not only can be used for purifying oil and smoke in hotels, restaurants and dining halls, but also can be applied to gas purification of a large-size central air-conditioning system.

Owner:陈明功

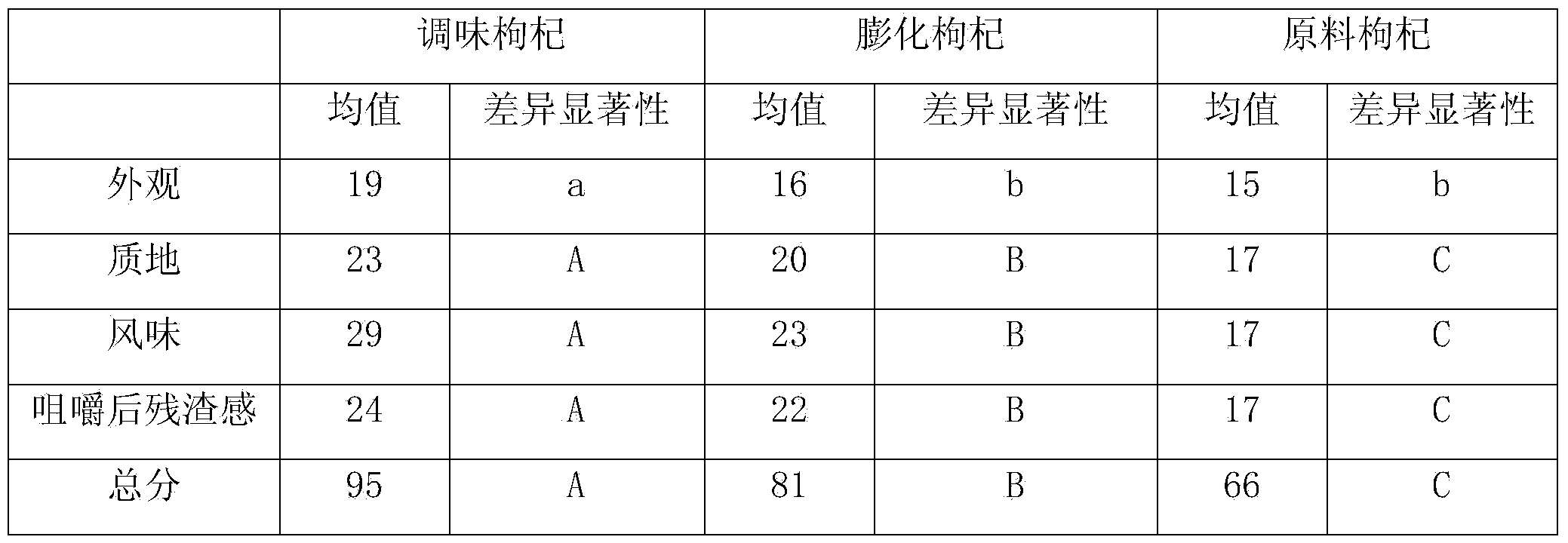

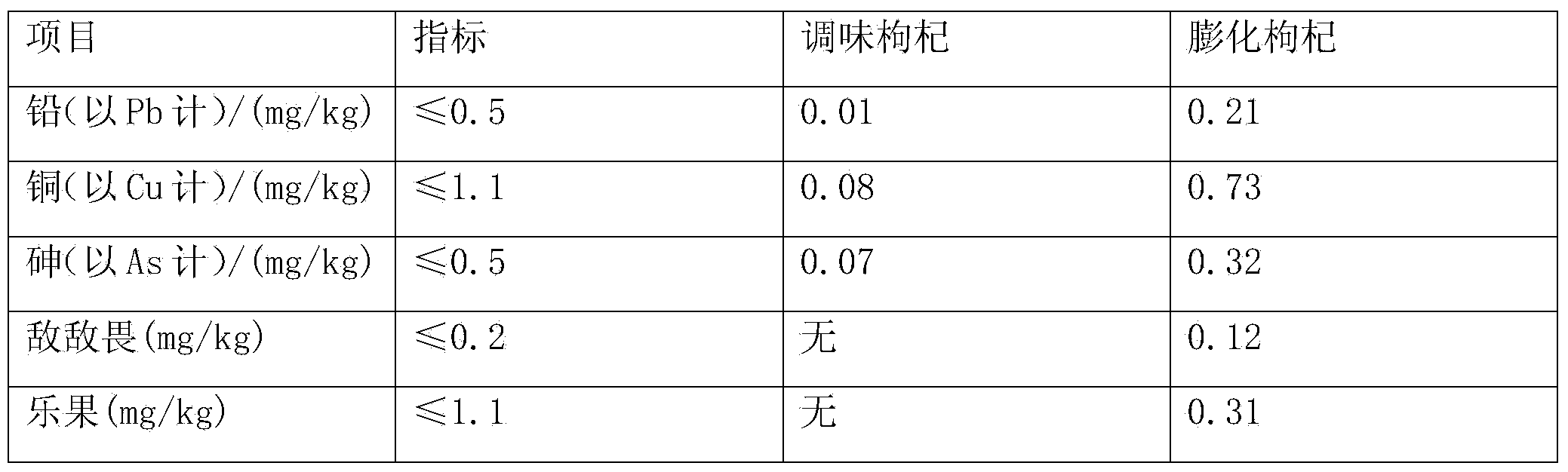

Preparation method for seasoning medlar

ActiveCN104012919AImprove permeabilityNatural colorFood shapingFood ultrasonic treatmentBalancing dietSnack food

The present invention discloses a preparation method for flavoring medlar, and belongs to the technical field of snack food processing. High-pressure pulsed electric field and ultrasound wave are synergically applied to moderately break the wall of medlar fruits, so that permeation solution is facilitated to fully penetrate into the medlar fruit grain. Medlar, extract of flavoring materials and other functional food materials are scientifically compounded and fuse as a whole without destroying the natural shape, color and texture of medlar fruits, not only can balance diet, but also can serve for leisure and health. The prepared flavoring medlar has natural color, delicious taste and crisp mouthfeel, is easy to digest and absorb without suffering from excessive internal heat after eating, is suitable for all types of people, and is a safe, nutritional and healthy functional snack food truly consistent with the development directions of international and domestic snack food. The present invention has a simple process and is easy to operate, the whole process is conducted at low temperature such that the nutrient loss is low. The preparation method has high efficiency and can achieve large-scale and industrialized production.

Owner:玺赞庄园枸杞有限公司

Coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method

InactiveCN105464638AIncrease drilling speedShorten working timeFluid removalFracturing fluidCoiled tubing

Disclosed is a coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method and a whole construction scheme. Equipment matched with the method includes a continuous coiled tubing unit, a high pressure pump, a pulsating pump set, a guider, a pulse generator and a porous nozzle. In a coal bed gas well, the pulse generator and the porous nozzle are utilized to generate high-pressure pulse jets to drive a high-pressure hose to quickly drill into a coal bed to form a radial hole of certain length; a ball is cast into a coiled tubing for maintaining pressure, and a pin is cut off to separate the porous nozzle; the high pressure pump and the pulsating pump set are utilized to pump fracturing fluid in at the same time from the coiled tubing and an oil jacket annulus, the pulse generator generates high-frequency low-amplitude pressure fluctuation, the pulsating pump set generates low-frequency high-amplitude pressure fluctuation, double-pulsating fracturing construction with low-frequency hammering and high-frequency oscillating effects is formed to impact and damage the coal bed, size fracturing is realized finally, and the objectives of substantially improving permeability of the coal bed and increasing yield of a single coal bed gas well are achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

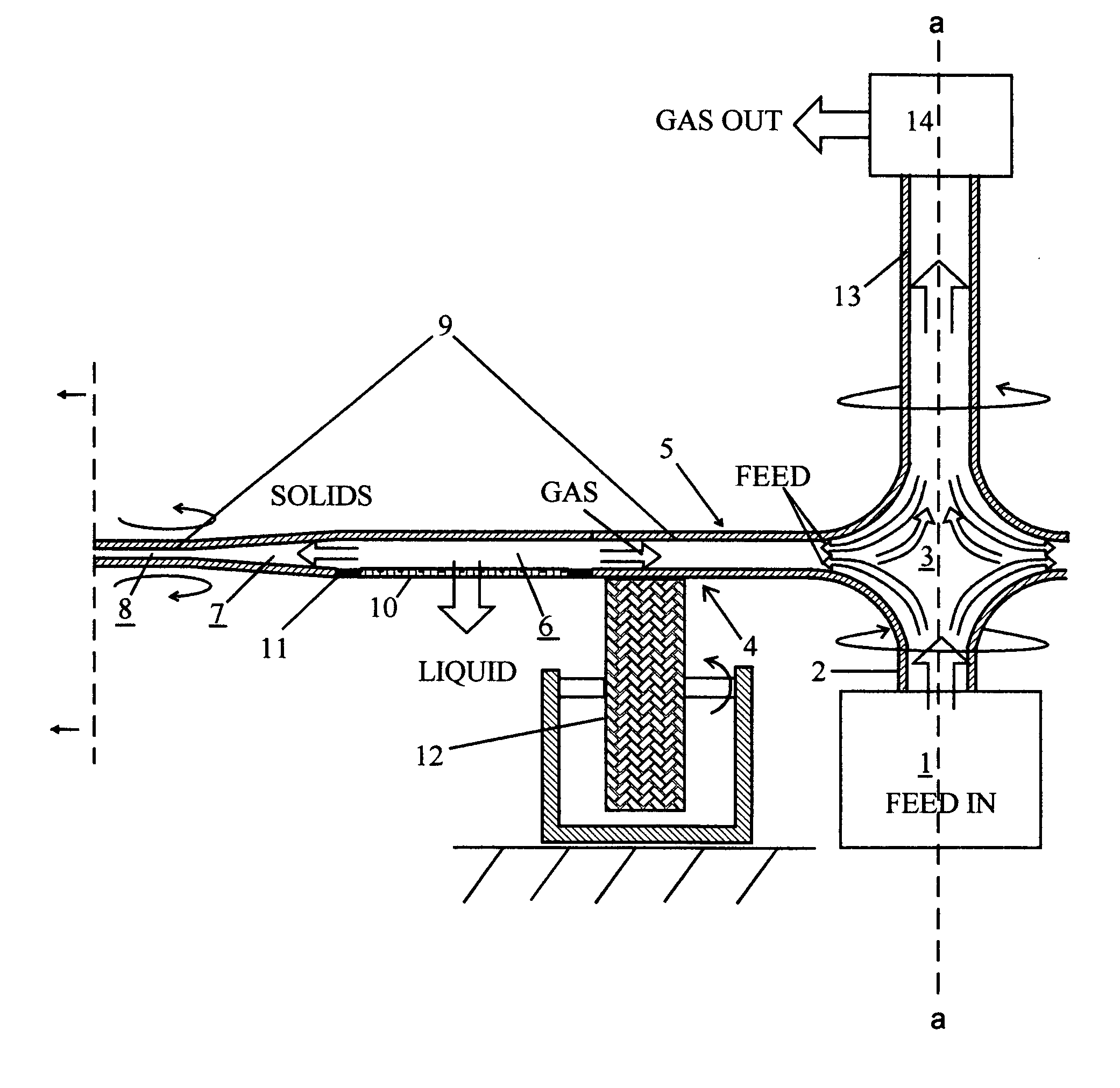

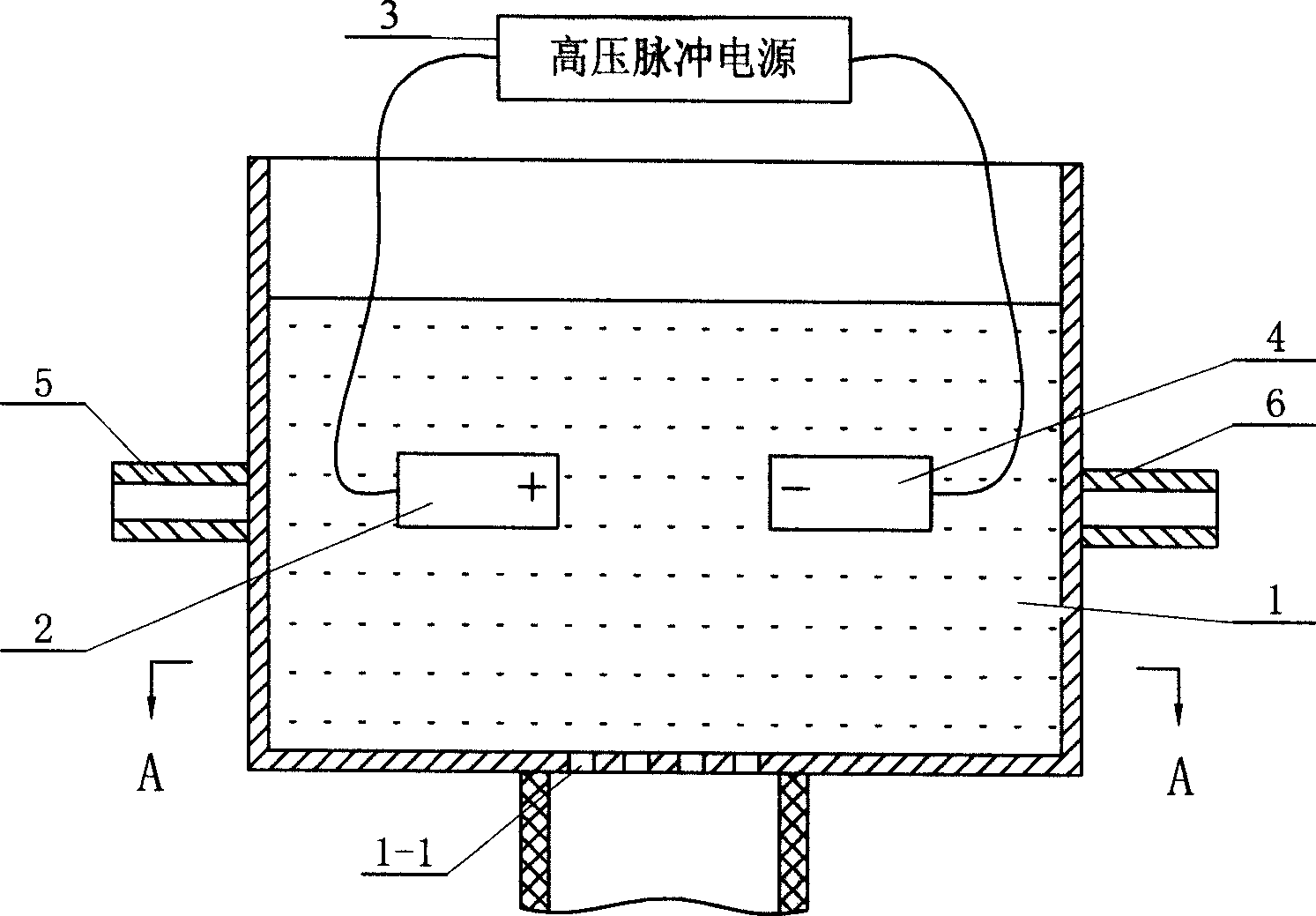

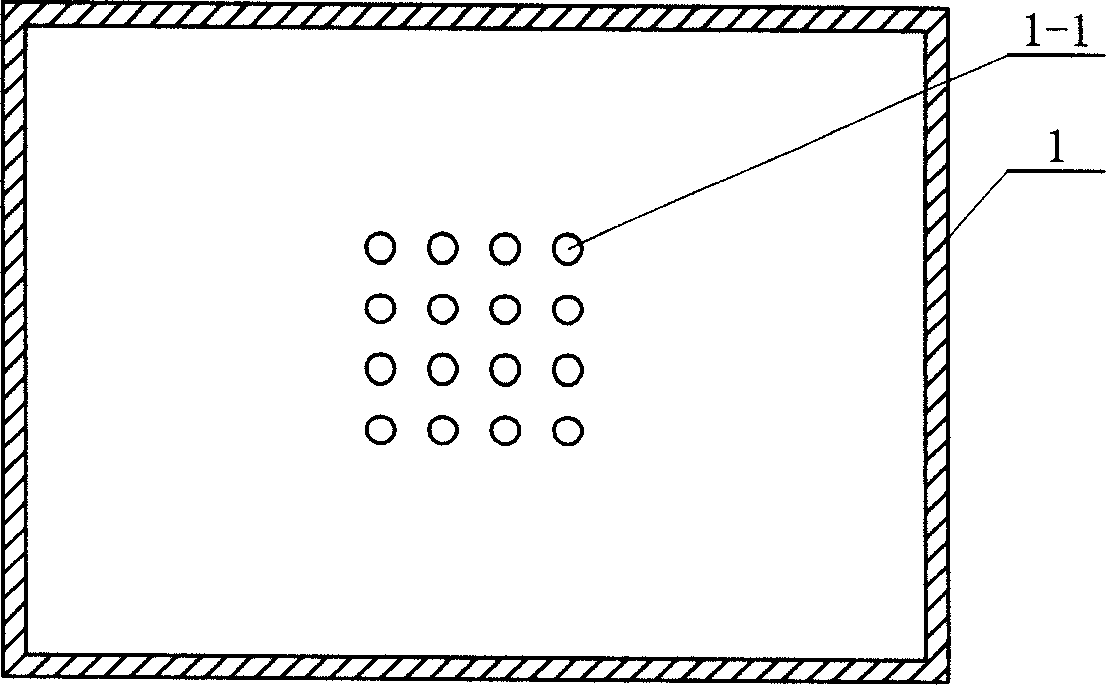

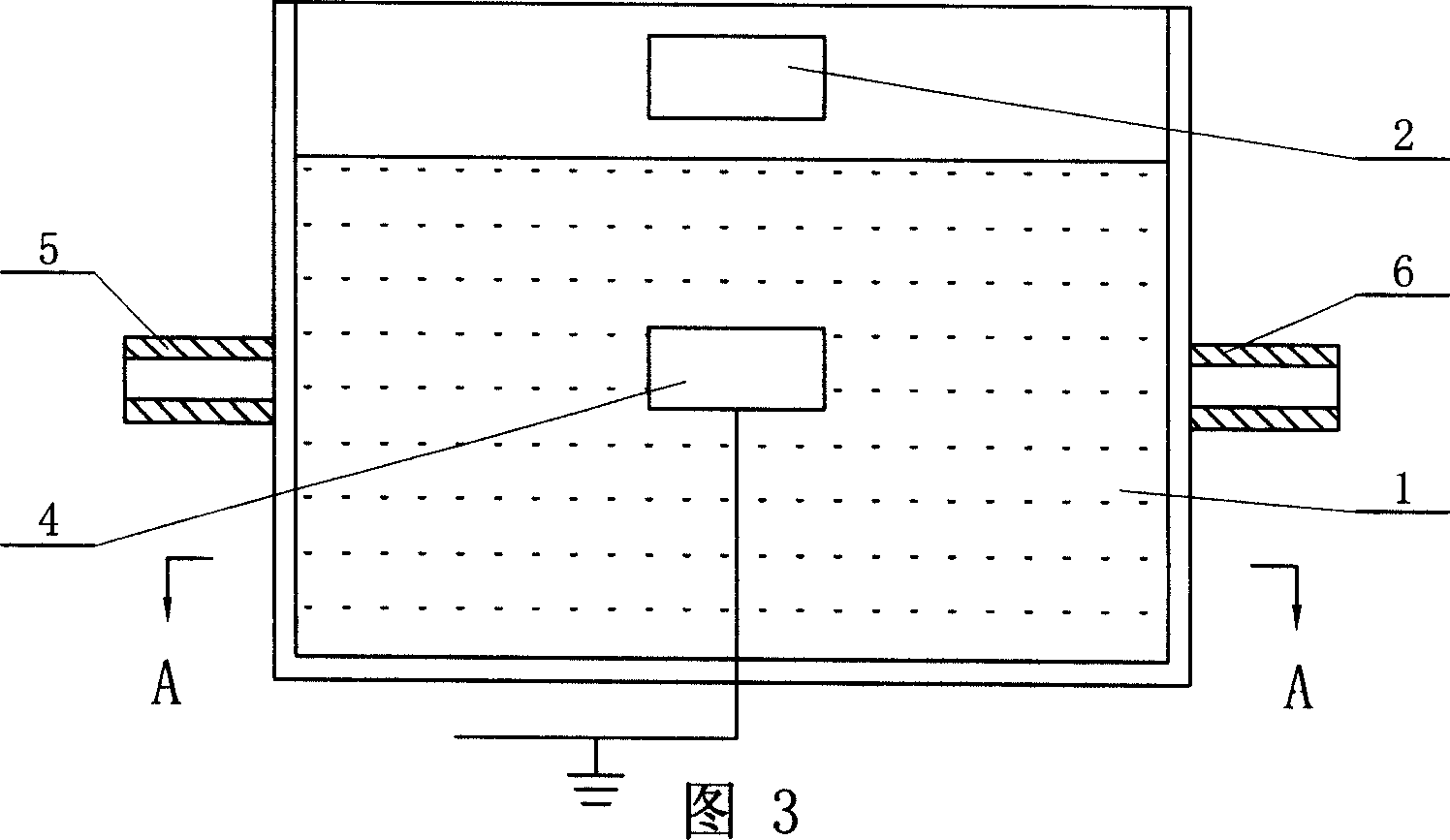

High-pressure pulse discharge catalytic oxidation method for removal of undegradable organic substances in water

InactiveCN1663916AImprove oxidation efficiencyImprove processing efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by magnetic/electric fieldsCatalytic oxidationOxygen

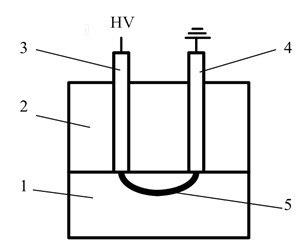

The invention discloses a method of removing the non-degradable organic substance in the water by catalyzed oxidation with high-voltage discharging, comprising applying the high-voltage pulse between the high voltage electrode 2 and earth electrode 4 in the reaction container with water by high voltage impulse power source 3, and at the same time adding oxygen, ozone, powdered activated carbon, transition metal oxide, hydrogen dioxide or transition metal ion to catalyze and oxygenize the organics. The process of removal of non-degradable organic is reinforced because of the existing of diverse catalyst and the efficiency of removal is greatly improved.

Owner:HARBIN INST OF TECH

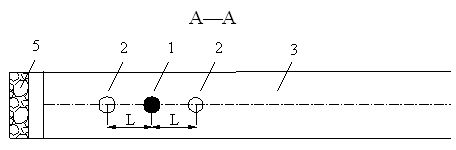

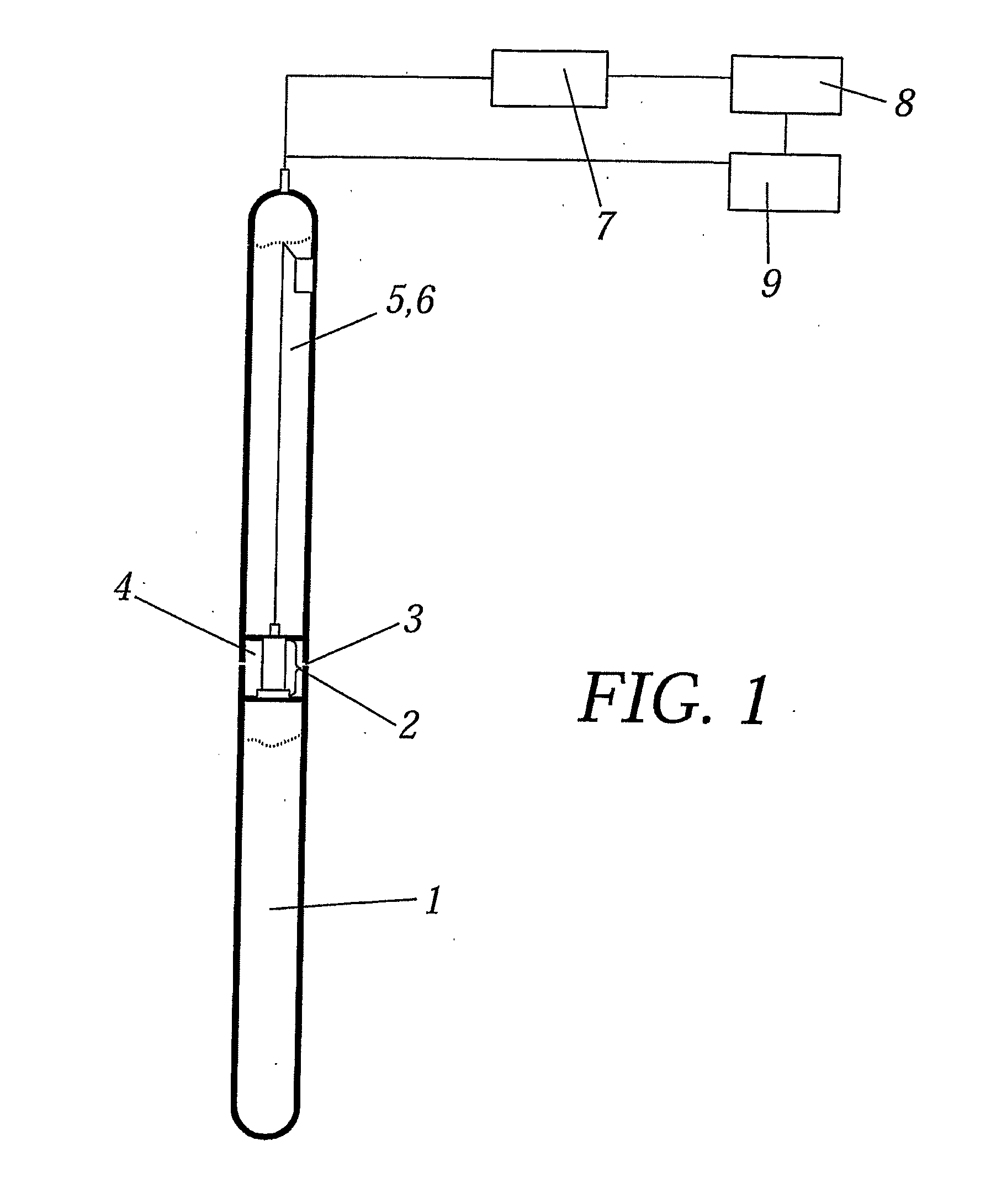

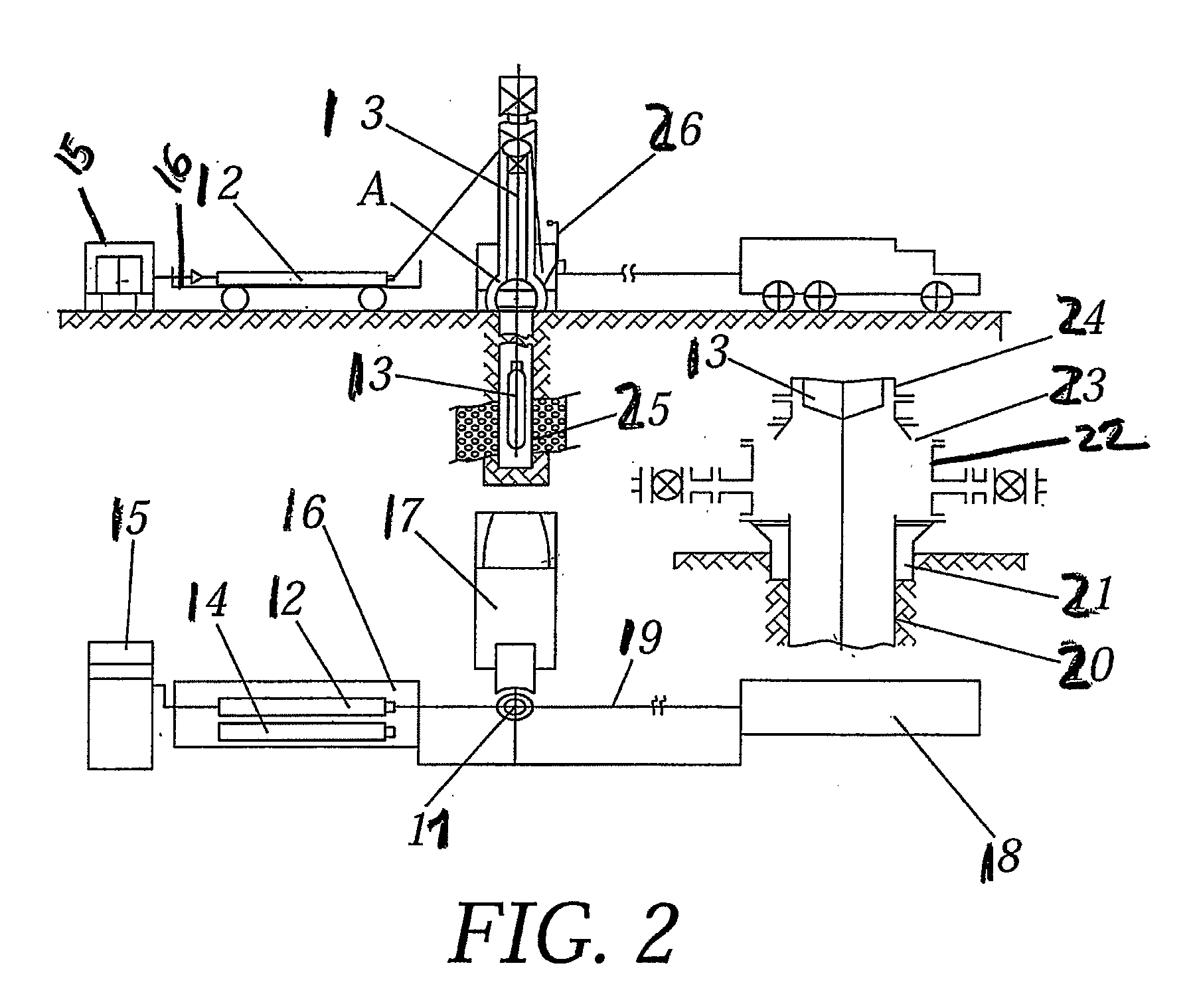

Well drilling rod and pulse plasma drilling machine system

InactiveCN102678044AAvoid problems such as collapseSimple structureDrilling rodsDrilling casingsWell drillingHigh pressure

The invention discloses a well drilling rod and a pulse plasma drilling machine system. The well drilling rod comprises at least one well drilling rod unit, wherein each well drilling rod unit comprises at least two open-close type support rings and a connecting rod; two adjacent support rings are fixedly connected through one connecting rod; the well drilling rod units are connected in sequence; and two adjacent support rings of two adjacent well drilling units are fixedly connected. The well drilling machine system comprises a well drilling mechanism comprising the well drilling rod, a high-pressure pulse power supply, a high-pressure low-wave impedance coaxial water cable, a water circulating device and a drill bit electrode for discharging towards rock stone, so that the drill bit electrode can be always contacted with the rock stone and keep drilling vertically downwards, and the problems of collapse of a water pipe and a cable and the like occurring during deep drilling in the conventional plasma drilling machine are avoided simultaneously; and moreover, the length of the well drilling rod is adjusted by increasing or decreasing the well drilling rod units, so that well drilling of different depths can be realized.

Owner:ZHEJIANG UNIV

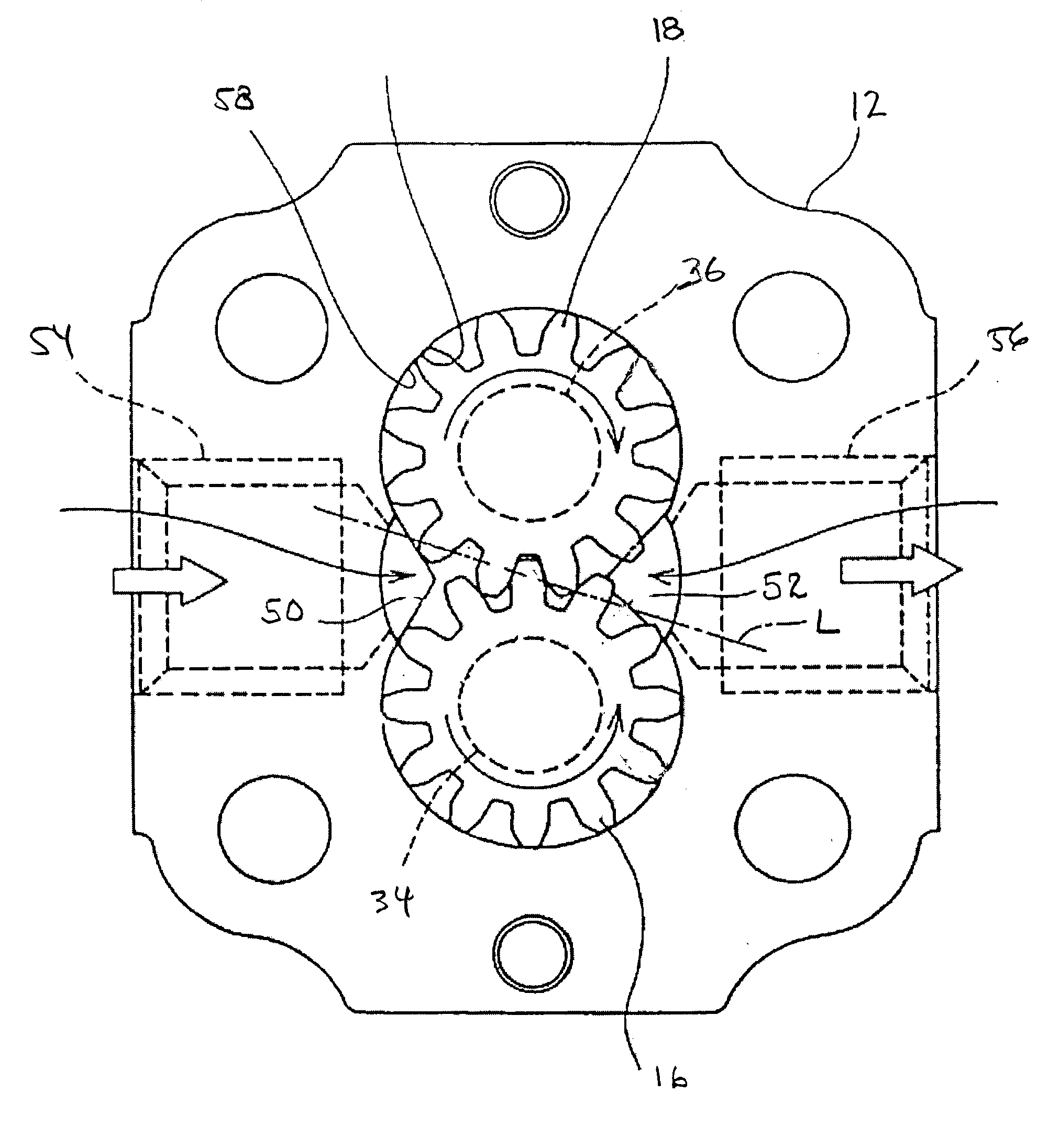

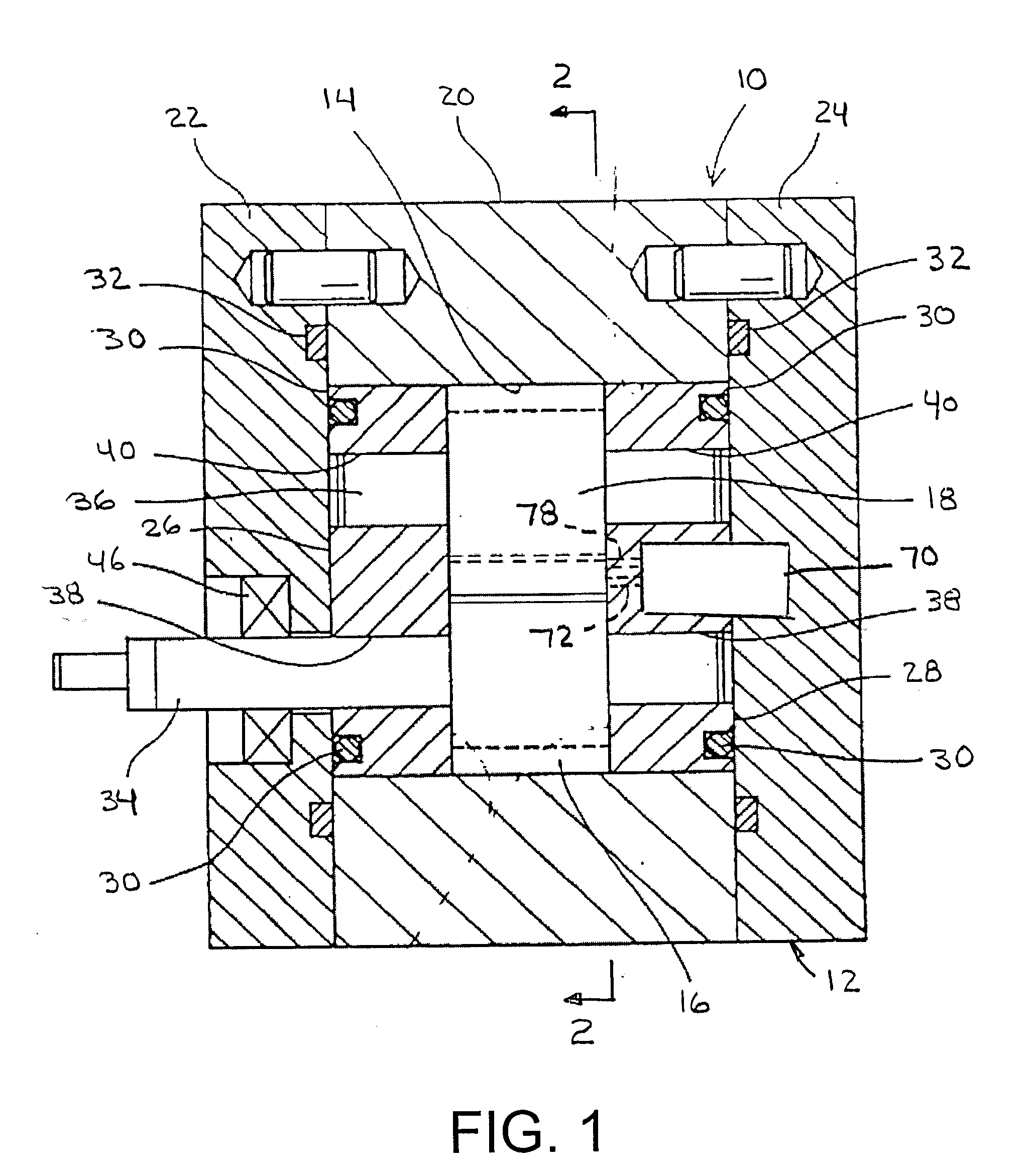

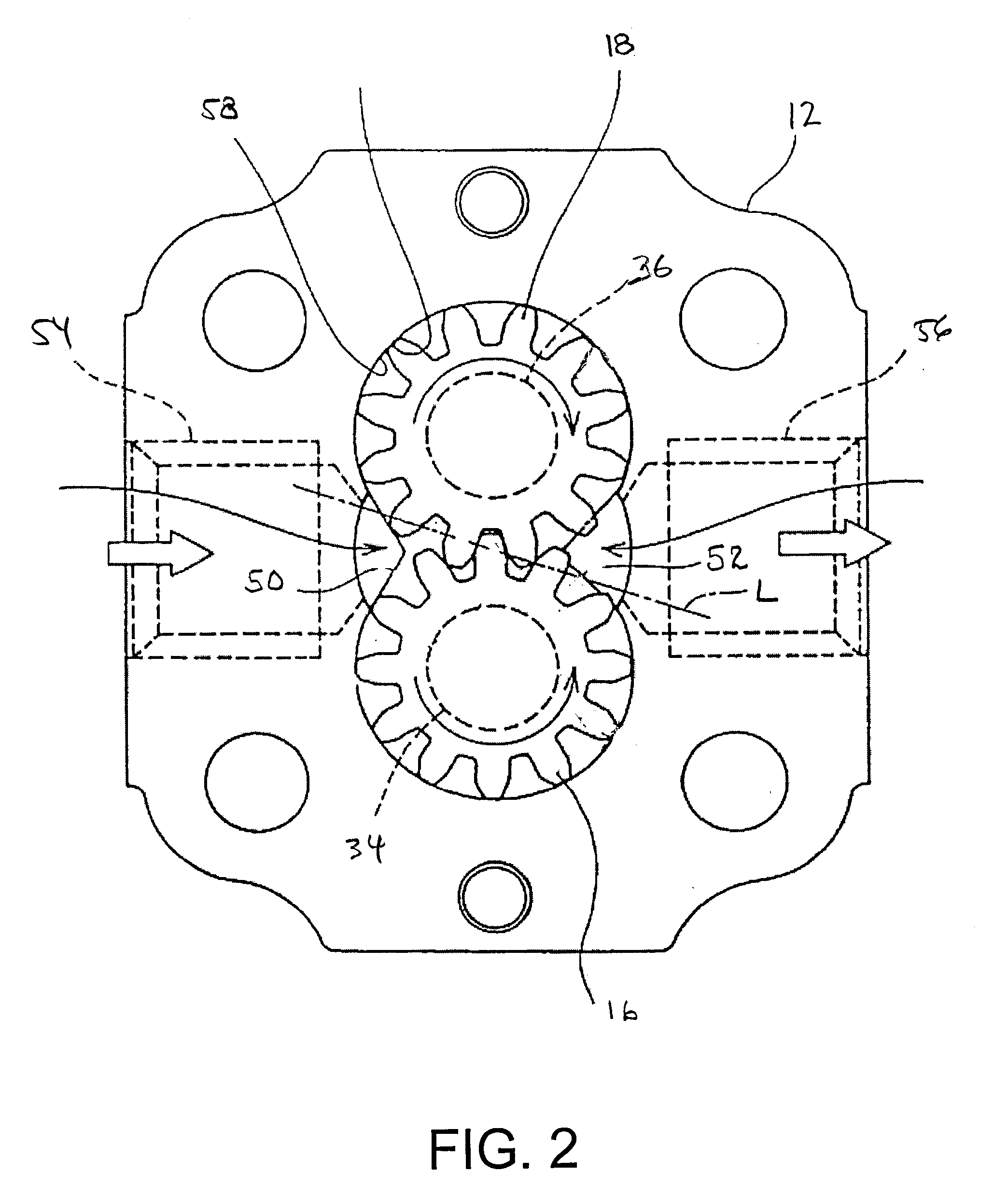

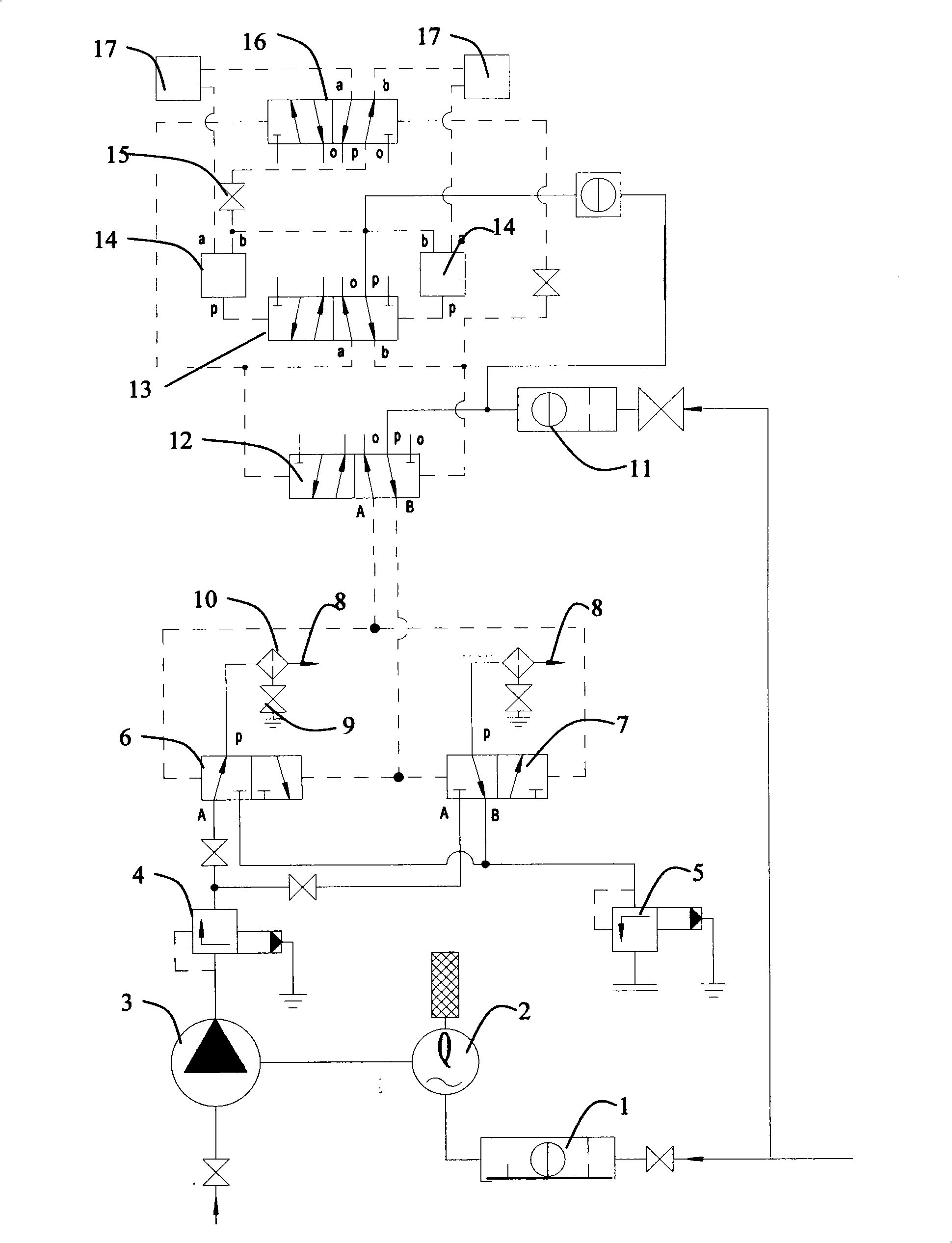

Gear pump with ripple chamber for low noise and pressure ripples

InactiveUS20070178003A1Oscillating piston enginesEngine of counter-engagement typeLow noiseGear pump

A gear pump comprising a gear chamber having opposite side walls; a pair of gears disposed within the gear chamber with teeth thereof meshed with one another, the meshed teeth forming a trap region in which fluid becomes entrapped during rotation of the gears; inlet and outlet chambers on opposite sides of the meshed teeth of the gears and separated from one another by the meshed teeth of the gears; a ripple chamber; and a first passage connecting the ripple chamber to the trap region, whereby the trapped high pressure fluid will flow from the trap region to the ripple chamber to dampen the otherwise generated high pressure pulse.

Owner:PARKER HANNIFIN CORP

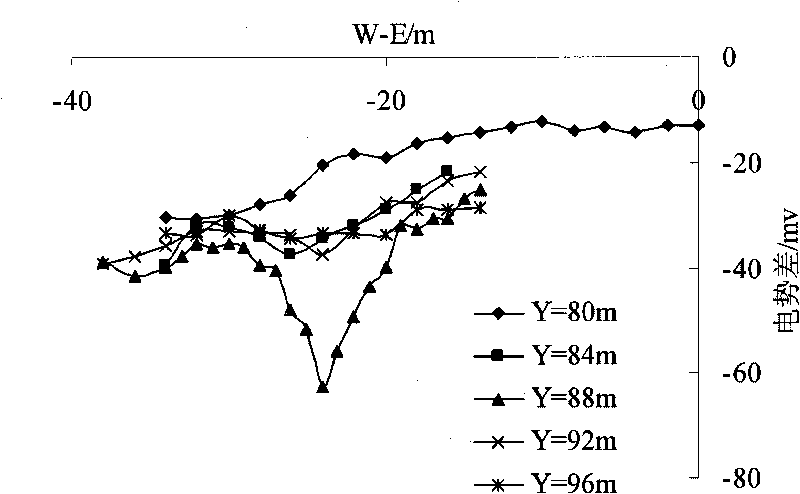

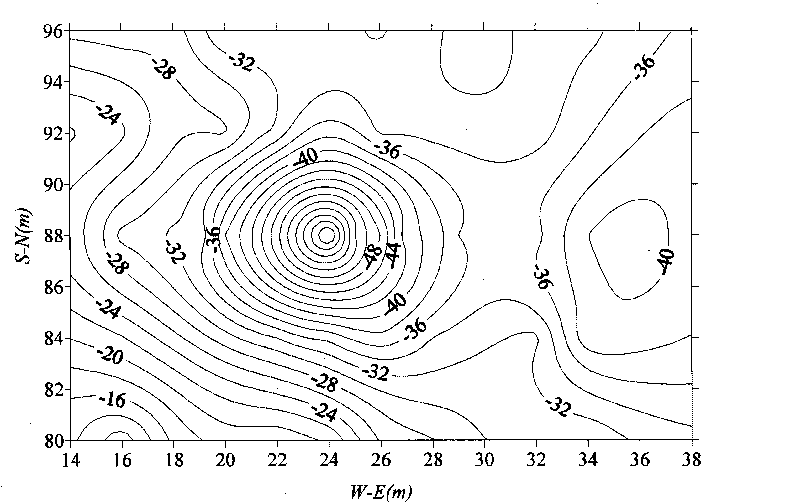

Method for detecting anti-seepage effect of anti-seepage film

InactiveCN101706354AEasy to measureEasy to masterFluid-tightness measurement using electric meansEngineeringHigh pressure

The invention discloses a method for detecting the anti-seepage effect of an anti-seepage film, belonging to the anti-seepage detection field of anti-seepage films. The method comprises the following steps: adopting a high-pressure pulse power supply to apply electric potentials onto the upper side and the lower side of the anti-seepage film by current electrodes the positions of which are fixed; arranging a fixed electrode and a movable electrode in an upper detection region of the anti-seepage film, wherein the position of the fixed electrode is fixed; and distributing detection points at 1-5m *1-5m intervals by the movable electrode. In measurement, a high-pressure pulse is applied onto the current electrodes to measure an electric potential difference between the movable electrode and the fixed electrode until all measuring points are measured; and the distribution of the electric potential differences is distorted in loophole positions so as to judge the existence and the positions of leakage. The invention is a nondestructive measurement method and has high detection precision and simple and convenient operation.

Owner:HOHAI UNIV

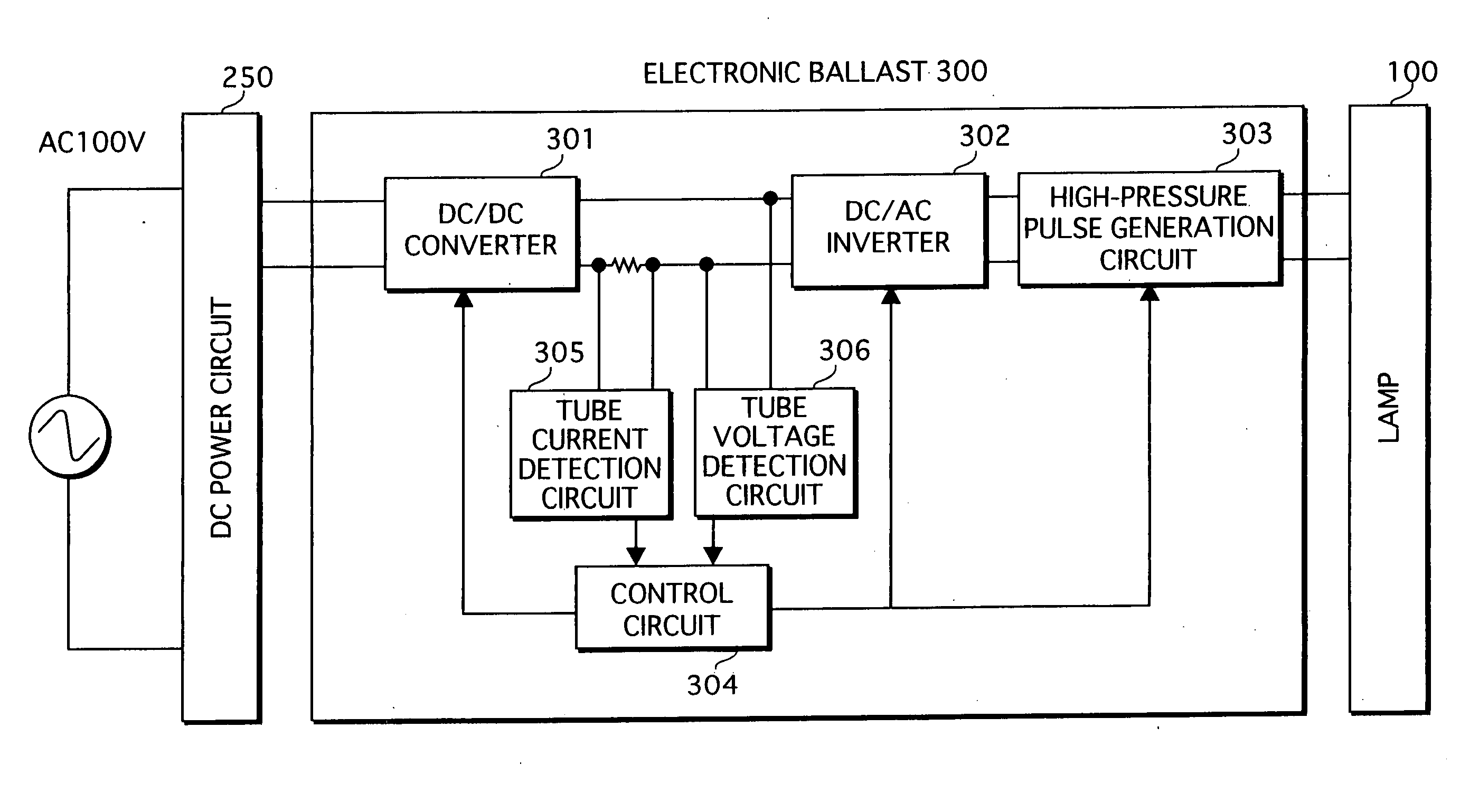

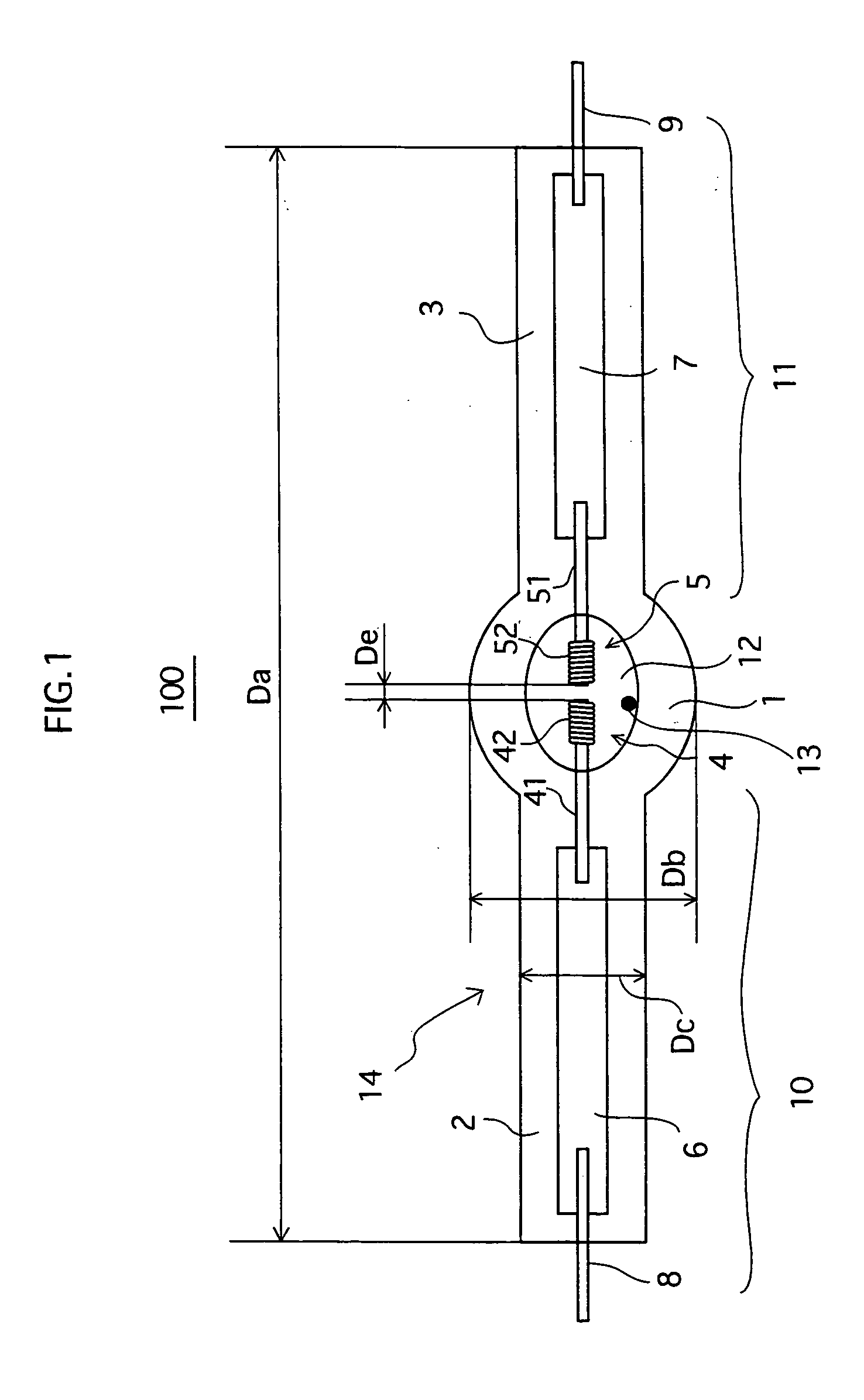

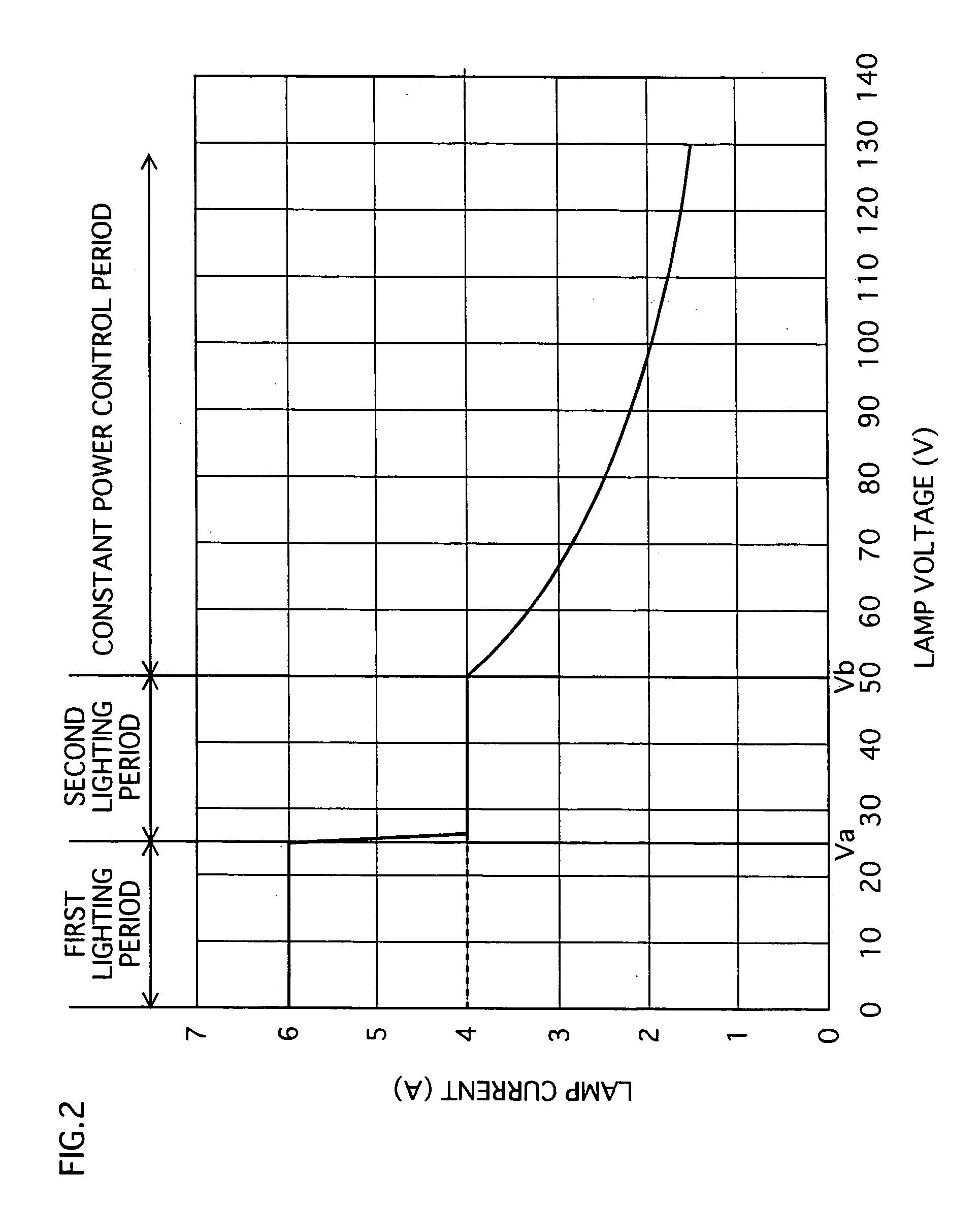

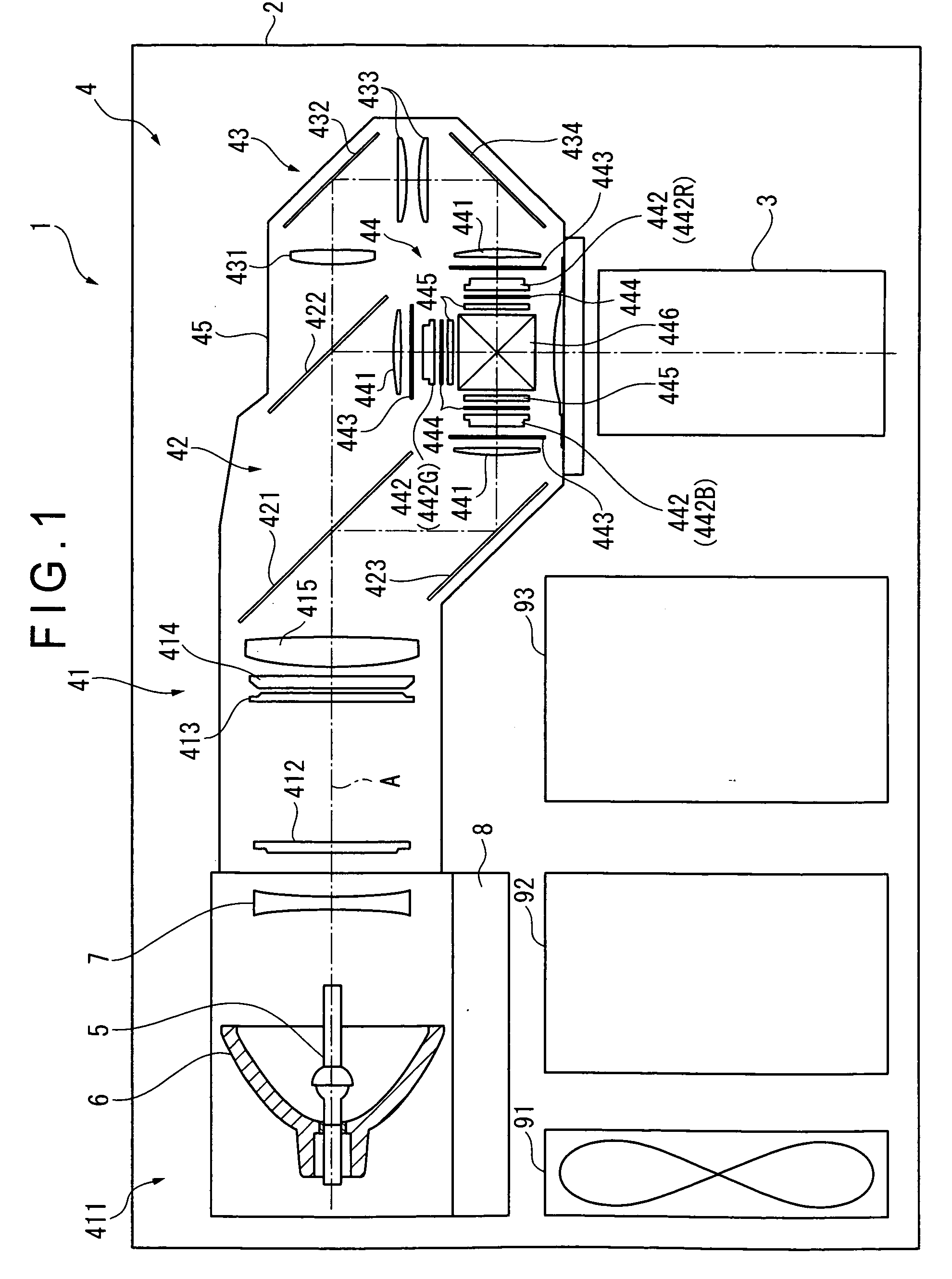

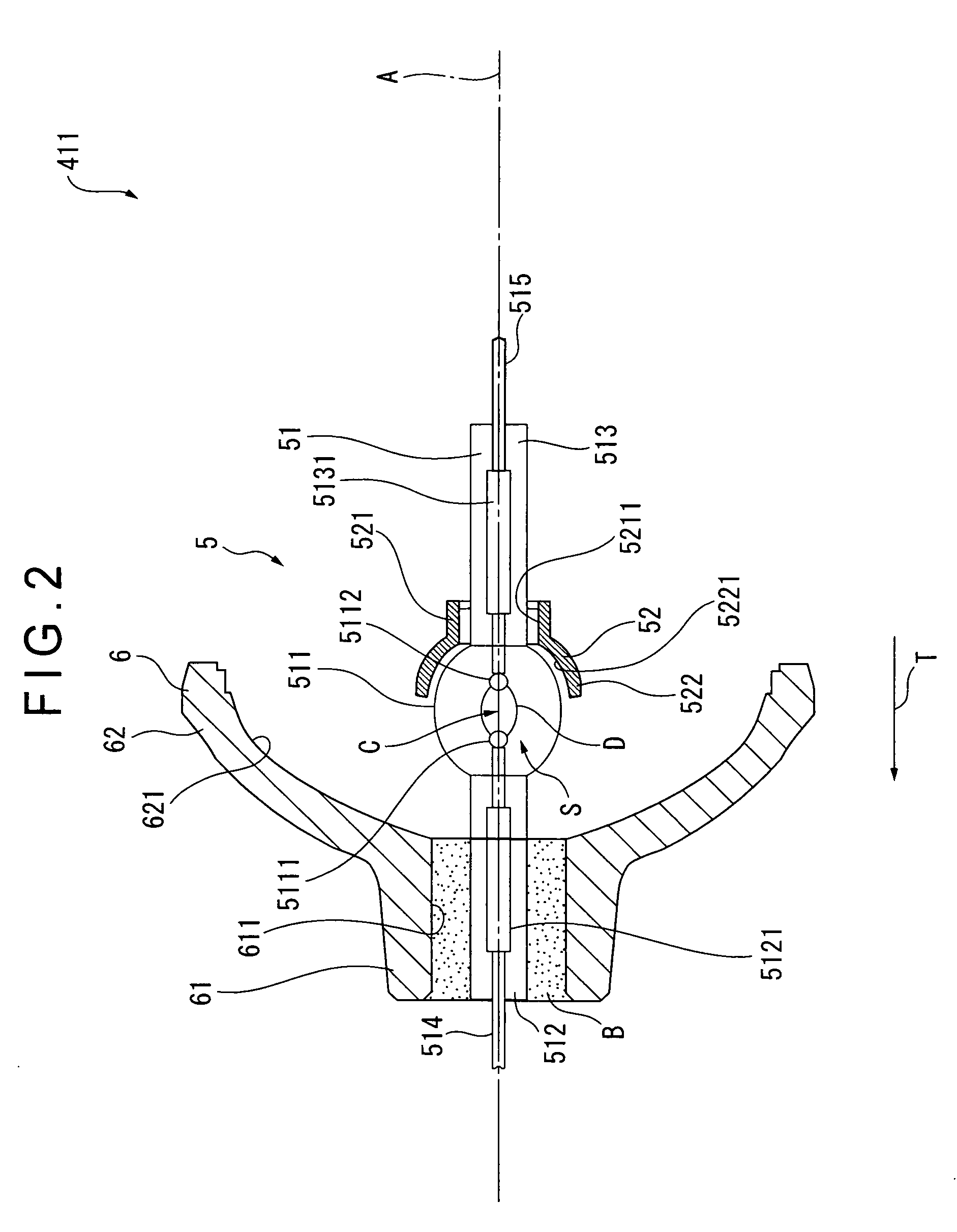

Method and apparatus for lighting high pressure discharge lamp, high pressure discharge lamp apparatus, and projection-type image display apparatus

ActiveUS20050023993A1Reduced light rise timeLight rise timeElectrical apparatusElectric light circuit arrangementConstant powerAmpere

A lighting method for a high pressure discharge lamp in which a high-pressure pulse is applied to cause a dielectric breakdown, and then in step S1, it is judged whether the lamp voltage is higher than 25 volts as the current switching voltage. If it is judged negatively in step S1, the control circuit 304 performs a constant current control with the current limiting level set to 6 amperes (step S2). If it is judged that the lamp voltage is higher than 25 in step S1, the control circuit 304 performs a constant current control with the current limiting level set to 4 amperes (step S3). When the lamp voltage rises and reaches 50 volts, the control circuit 304 performs a constant power control so that the lamp power remains to be 200W.

Owner:PANASONIC CORP

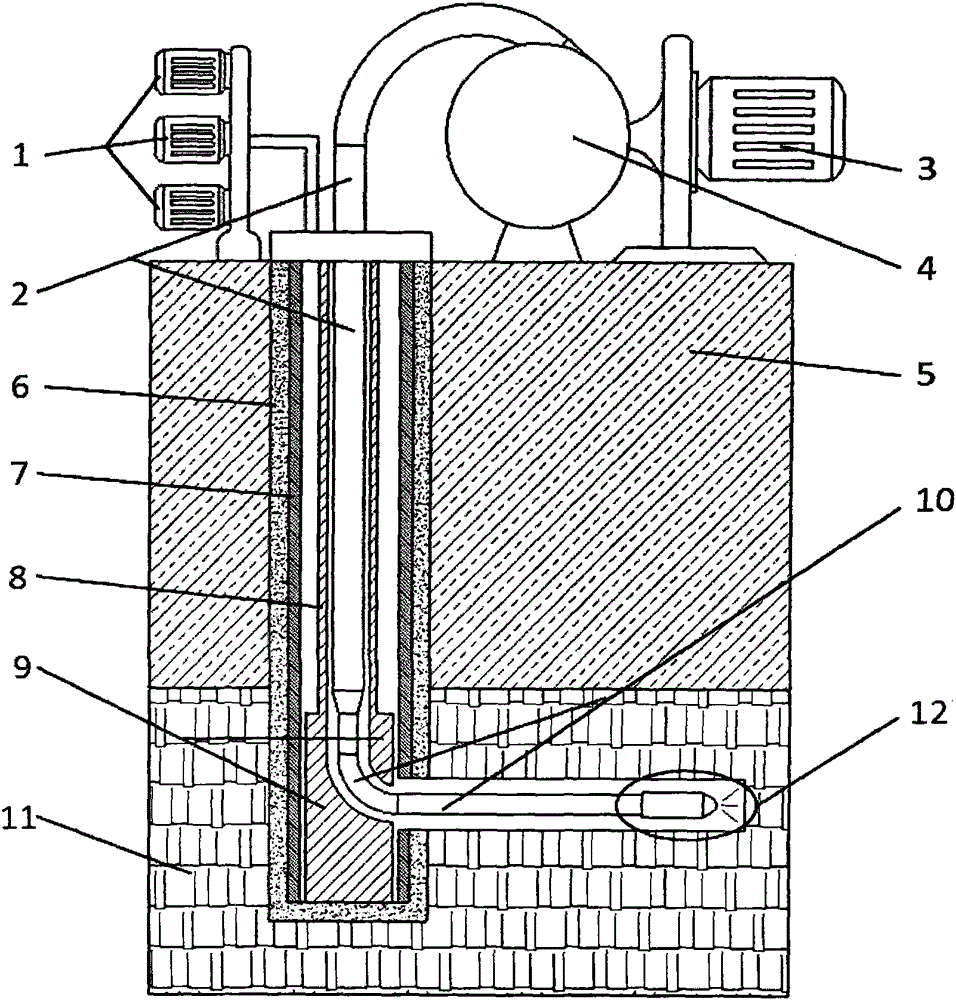

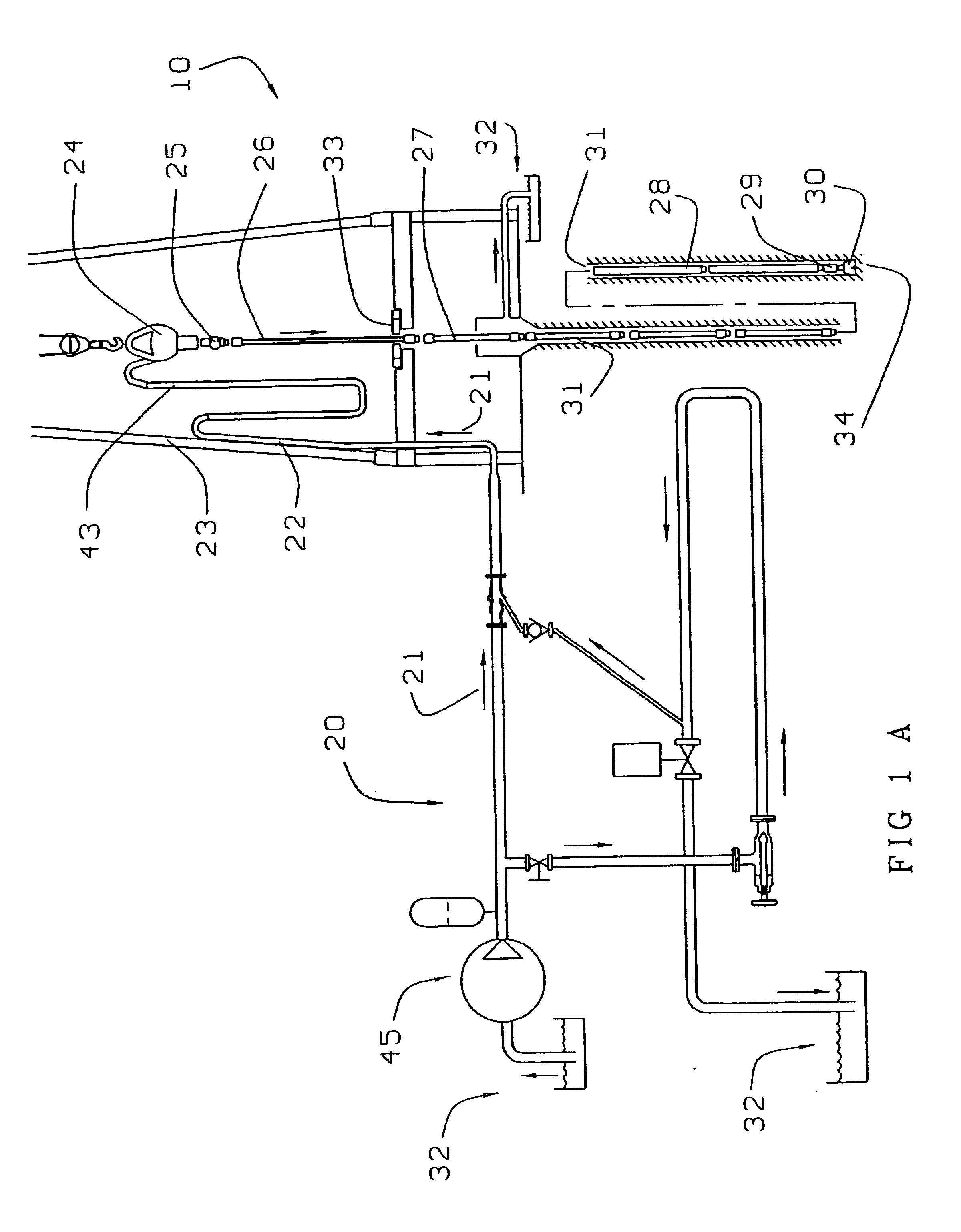

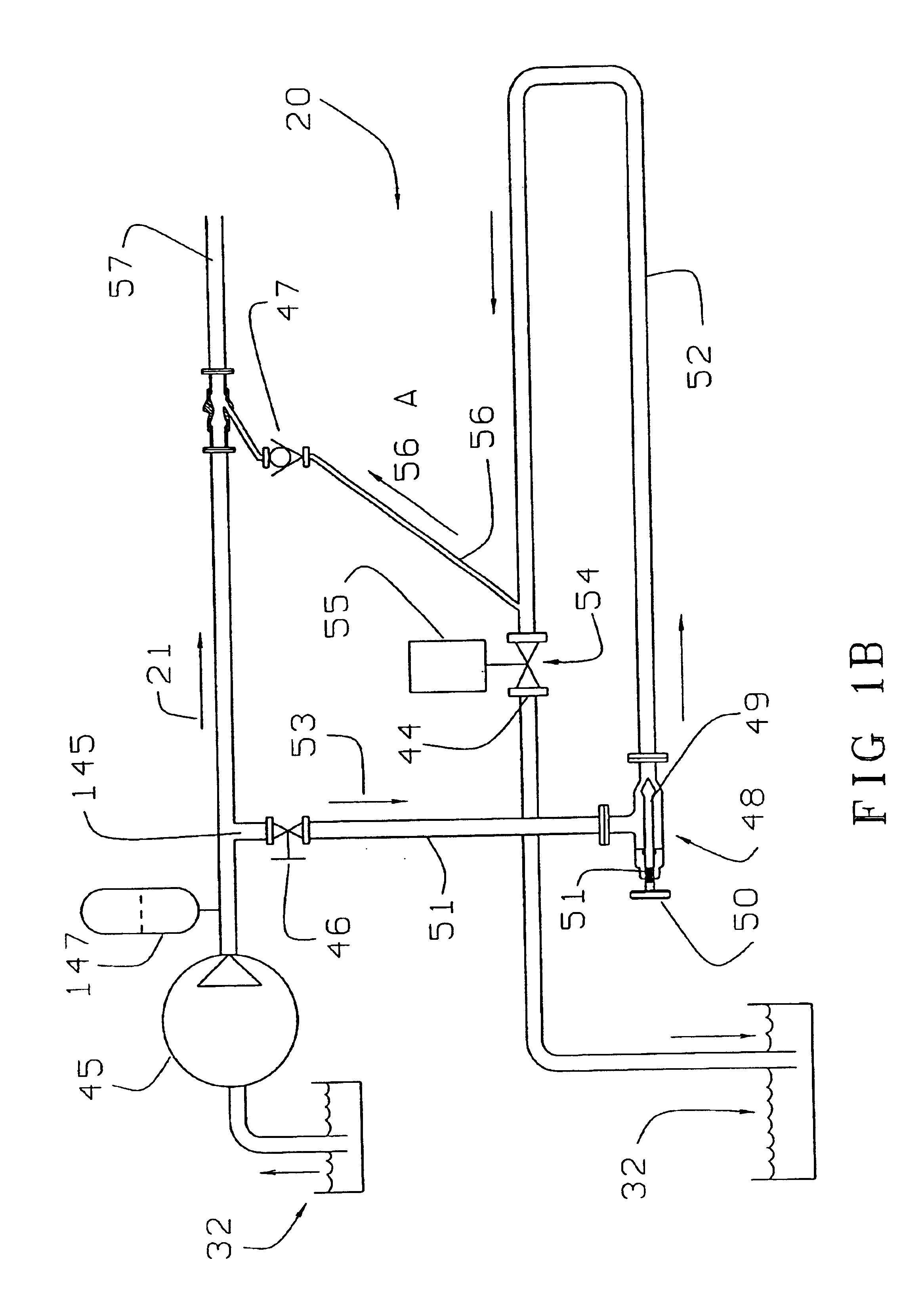

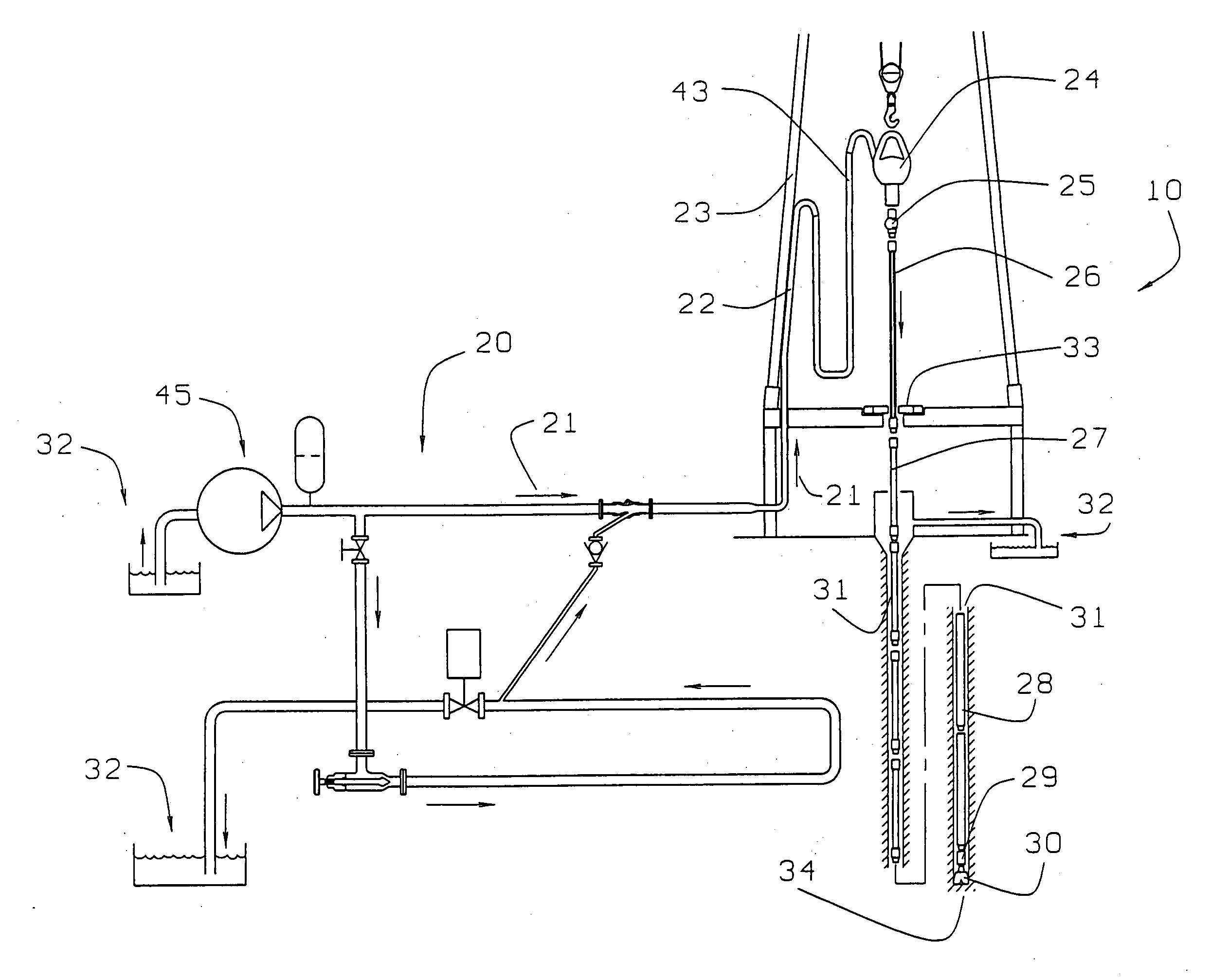

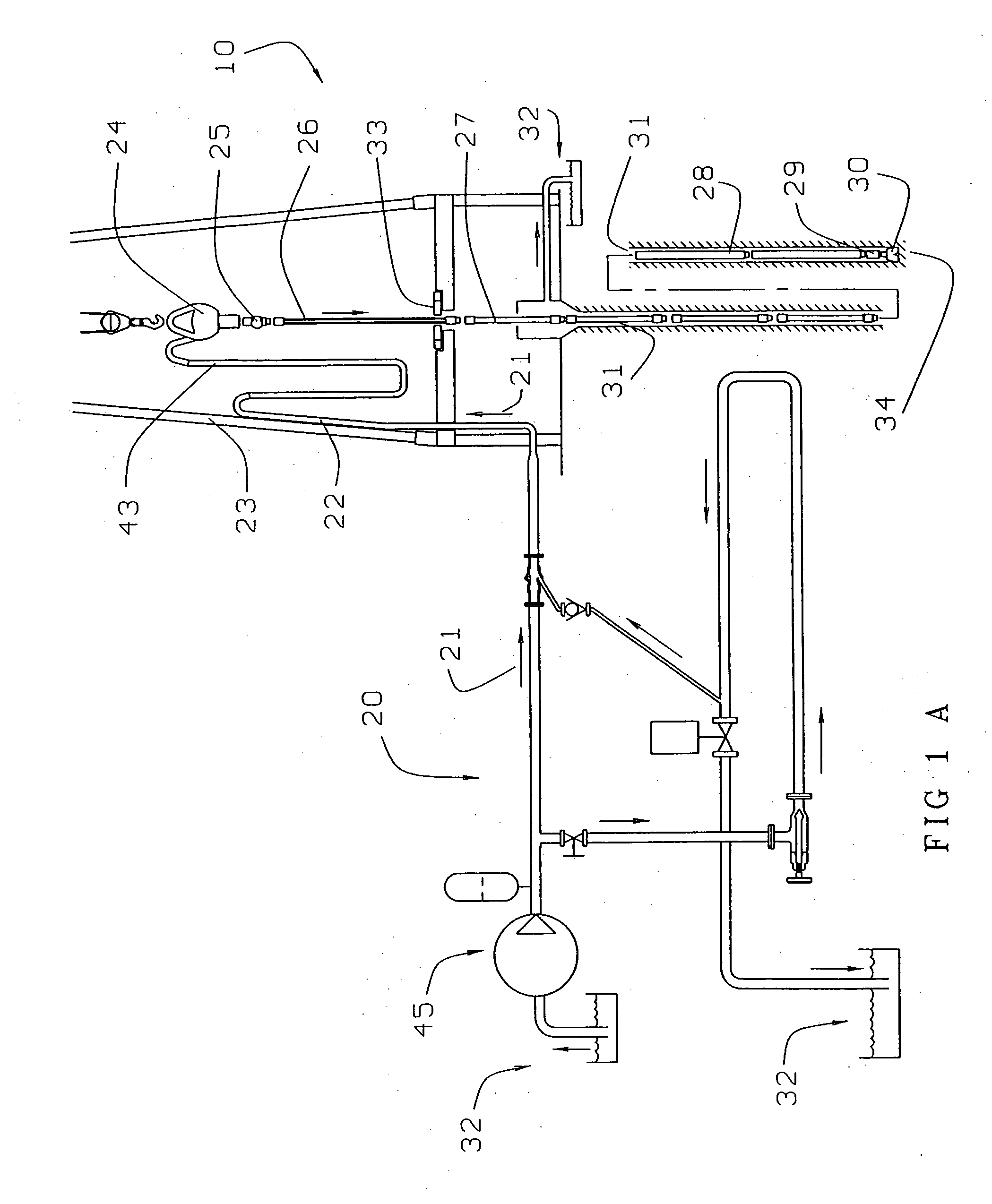

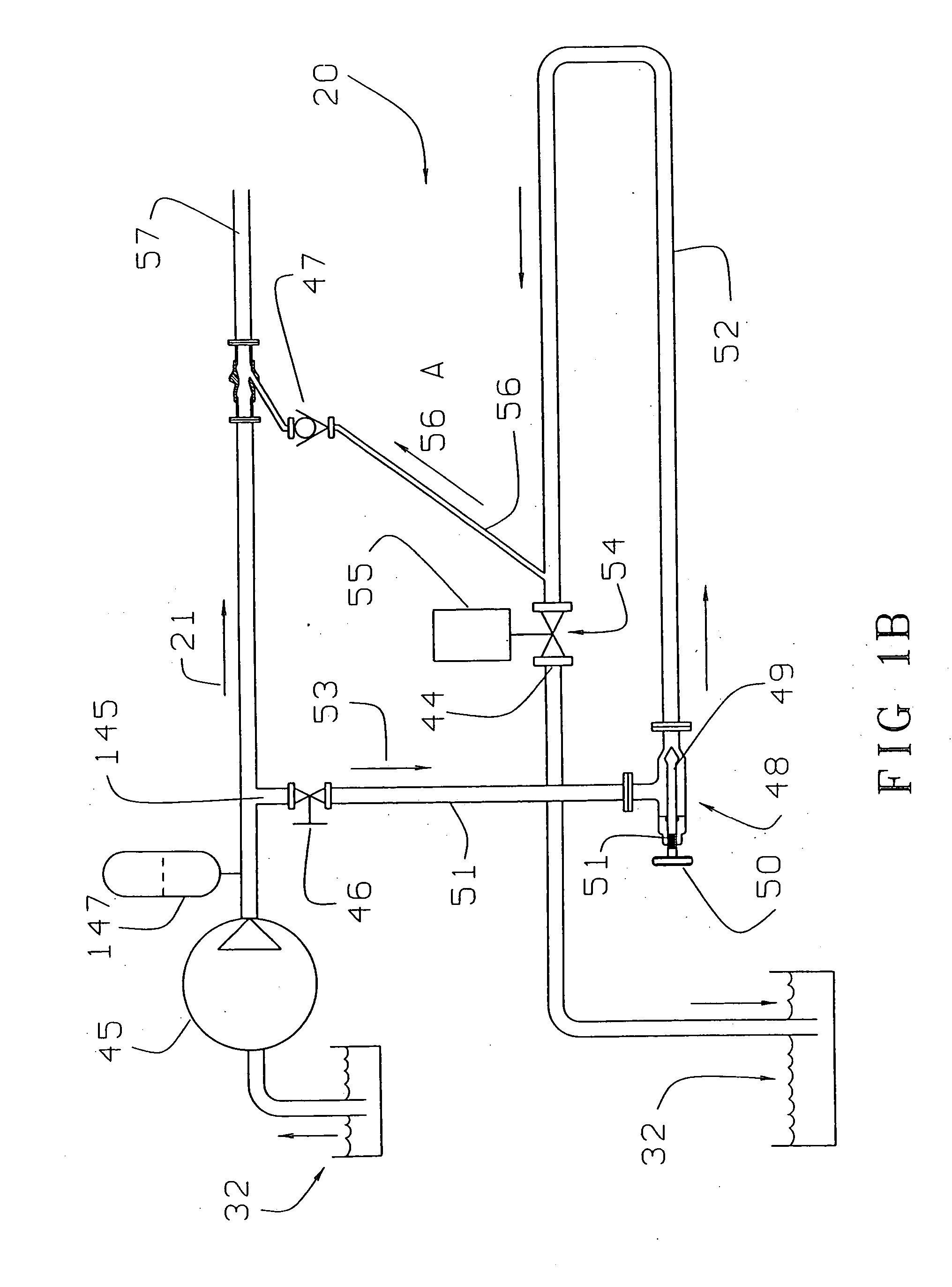

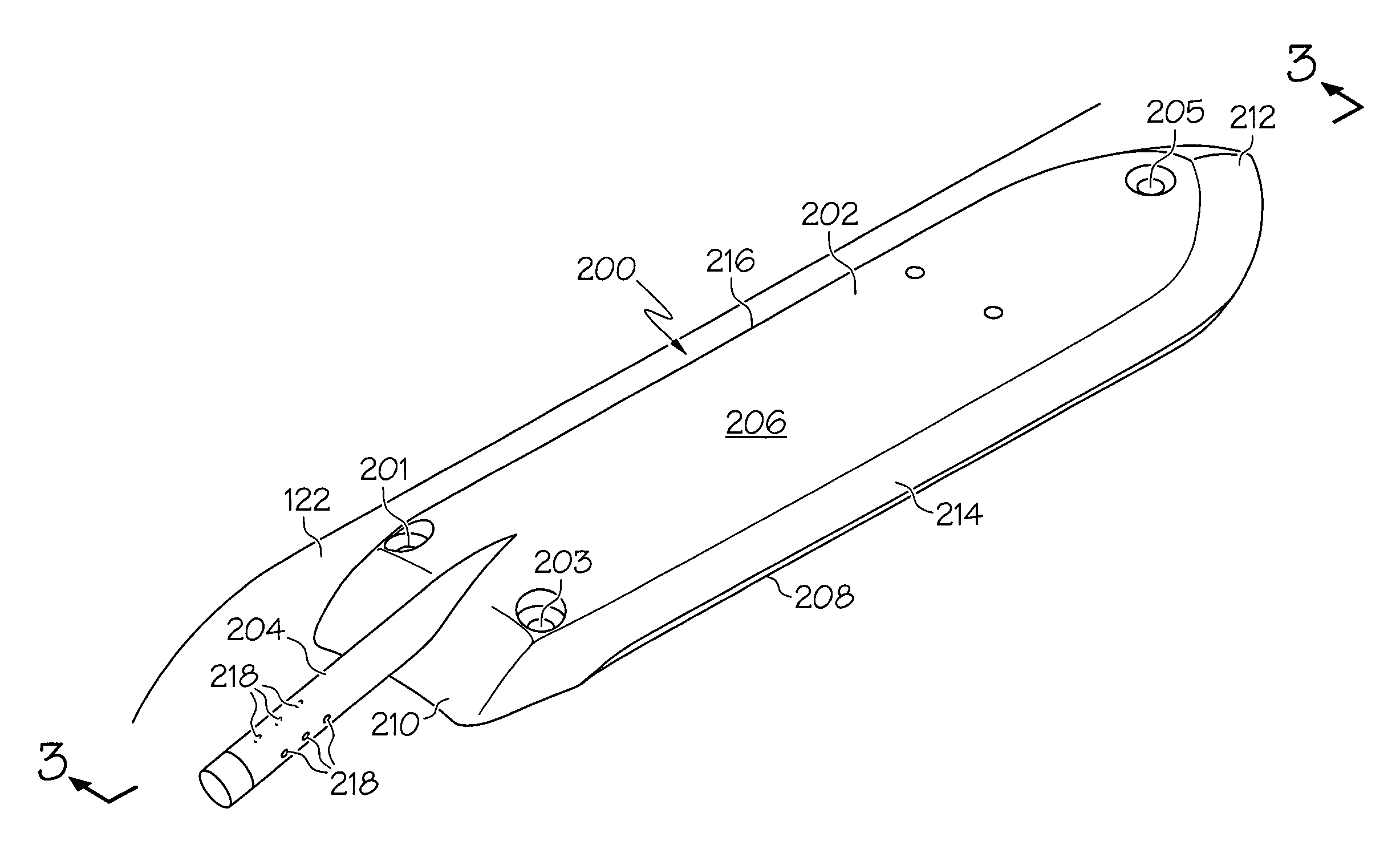

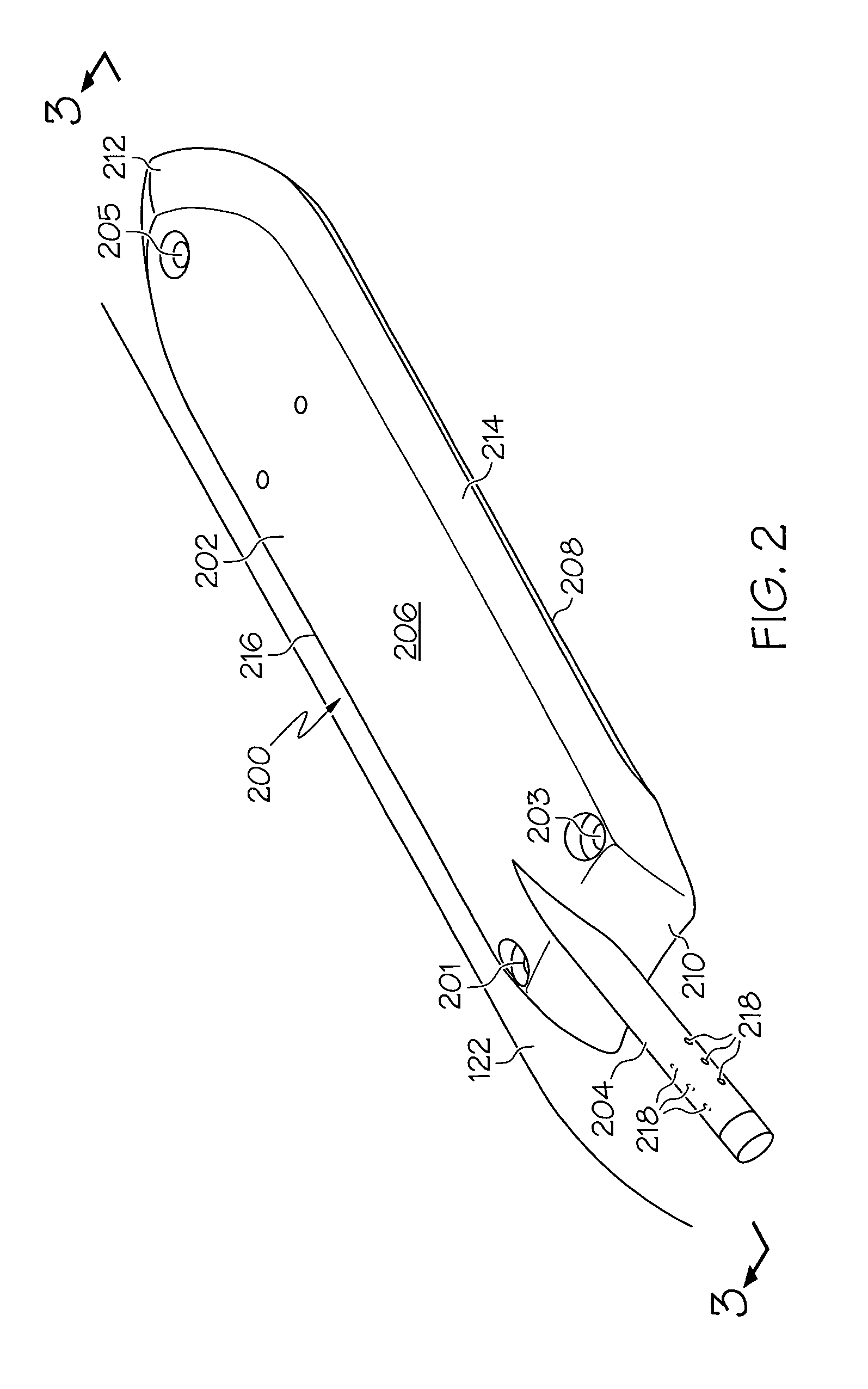

Acoustic flow pulsing apparatus and method for drill string

An underground drilling method and apparatus generates intense pressure pulses at a location at the surface. The pressure pulses propagate down through a drill string to a drill bit. The pulses may be generated by creating water hammer in flowing drilling mud. Intensity of the acoustic pulses is increased in the bit nozzles. Vigorous pulsing of the fluid exiting the bit nozzles results in better cleaning of the hole bottom and faster drilling. The pulses may be used to drive the operation of various down hole tools. One type of tool has multiple pistons arranged in series. High pressure pulses move the pistons to generate strong mechanical vibration in the drill string. Vibration of the drill string may also reduce the friction between the drill string and the hole, resulting in lower torque requirements.

Owner:LEWAL DRILLING

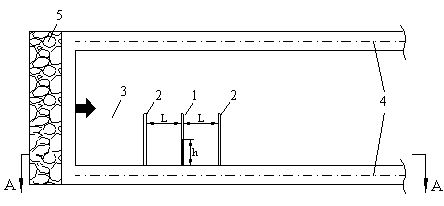

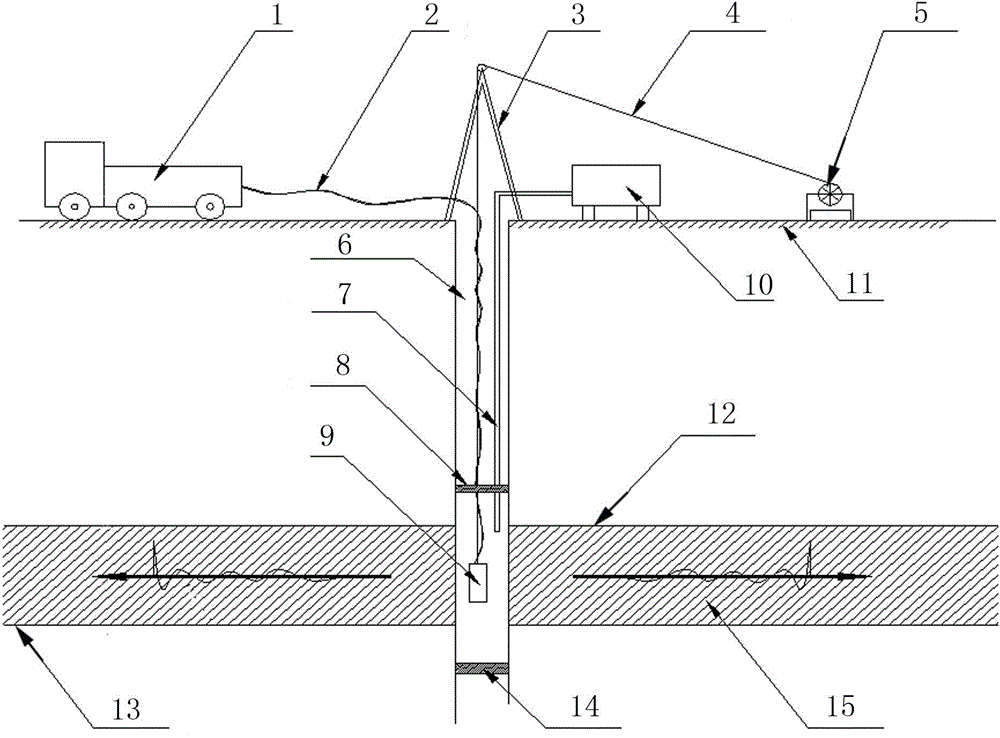

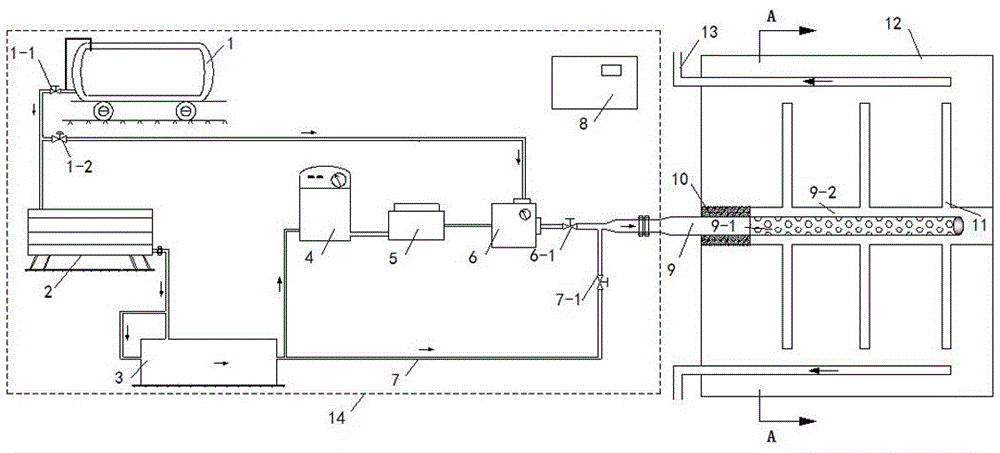

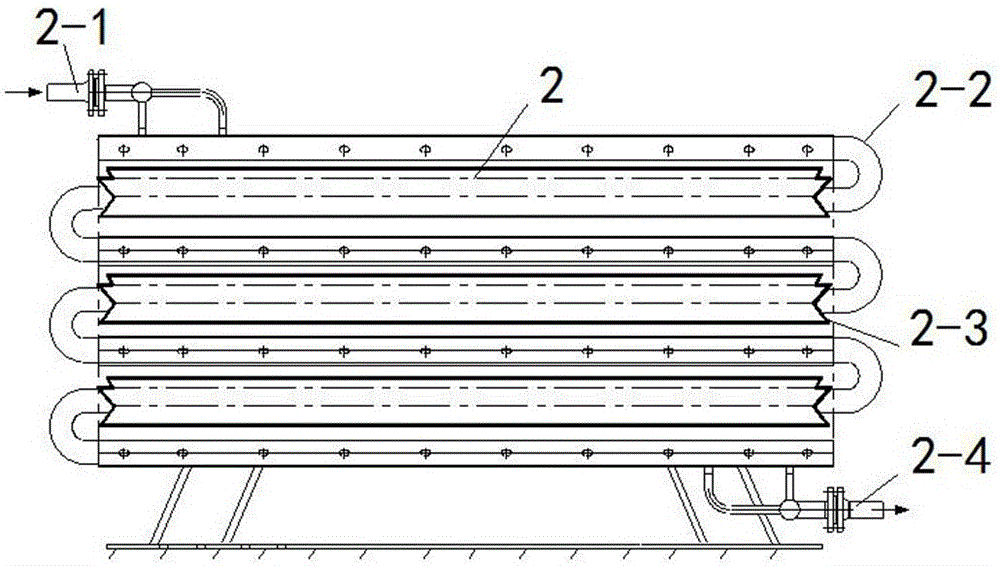

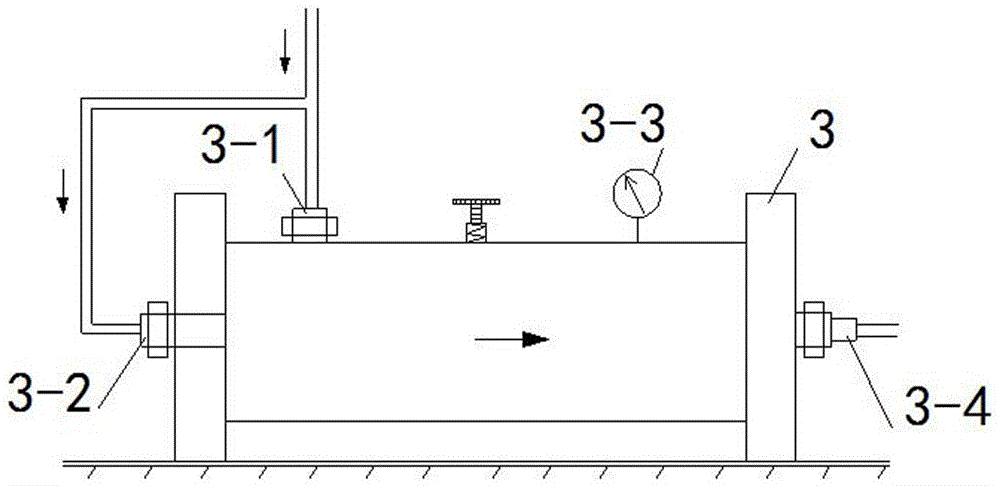

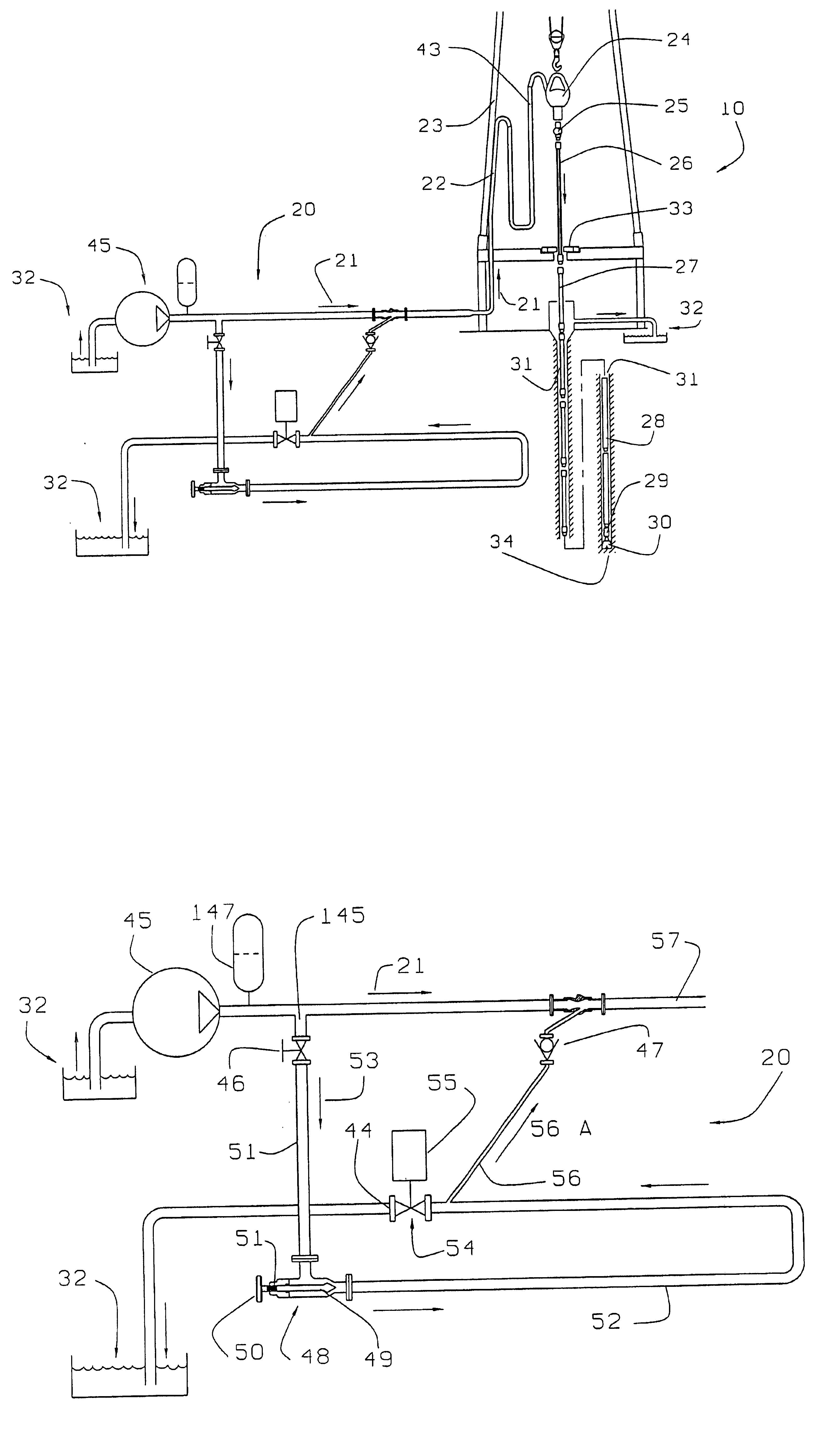

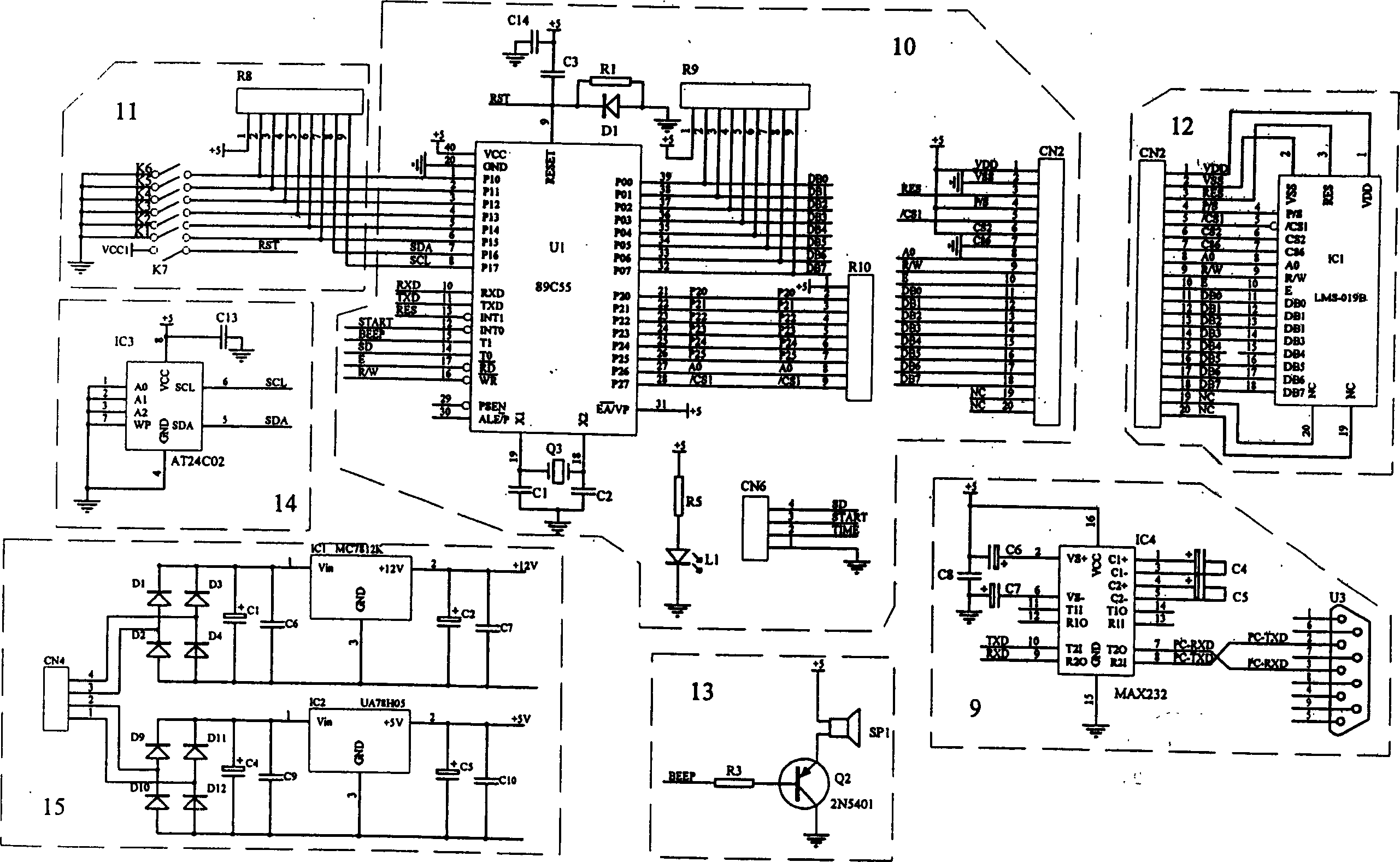

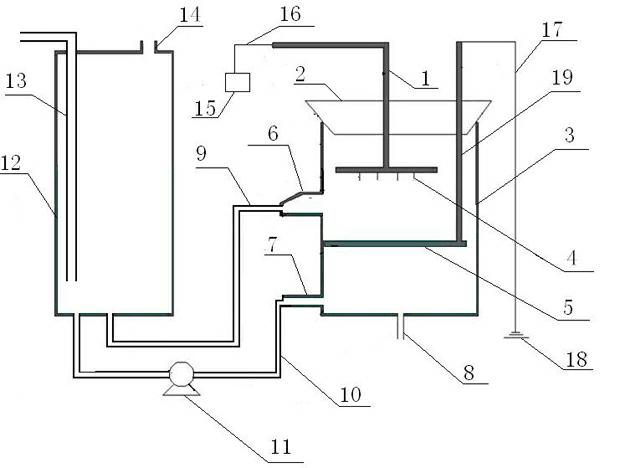

Method and apparatus for preventing and controlling coal or rock dynamic disaster by high-pressure pulse water injection

InactiveCN101539028AChange the physical and mechanical propertiesReduce or eliminate the riskGas removalWater filterPulse pressure

The invention discloses a method and an apparatus for preventing and controlling coal or rock dynamic disaster by high-pressure pulse water injection. The apparatus comprises a high-pressure water supply system, a pulse pressure water output system and a pneumatic frequency modulation control system. The pulse pressure water output system is controlled by the pneumatic frequency modulation control system and injects high-pressure water in boreholes in a pulsation manner. Water injection pressure is changed such that water filters into different gaps and pores by injecting pulse high-pressure water in coal beds, namely, by injecting water with the pressure changed periodically, so as to change the mechanical property of the coal body furthest. The pulse high-pressure water is used for discharging free high-pressure mash gas so as to reduce mash gas content in the coal body, improve safety, and reduce or eliminate coal bed outburst and shock hazard. The invention has a simple technology and good control efficiency, and is suitable for preventing and controlling coal or rock dynamic disaster in all coal mines.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Acoustic flow pulsing apparatus and method for drill string

An underground drilling method and apparatus generates intense pressure pulses at a location at the surface. The pressure pulses propagate down through a drill string to a drill bit. The pulses may be generated by creating water hammer in flowing drilling mud. Intensity of the acoustic pulses is increased in the bit nozzles. Vigorous pulsing of the fluid exiting the bit nozzles results in better cleaning of the hole bottom and faster drilling. The pulses may be used to drive the operation of various down hole tools. One type of tool has multiple pistons arranged in series. High pressure pulses move the pistons to generate strong mechanical vibration in the drill string. Vibration of the drill string may also reduce the friction between the drill string and the hole, resulting in lower torque requirements.

Owner:LEWAL DRILLING

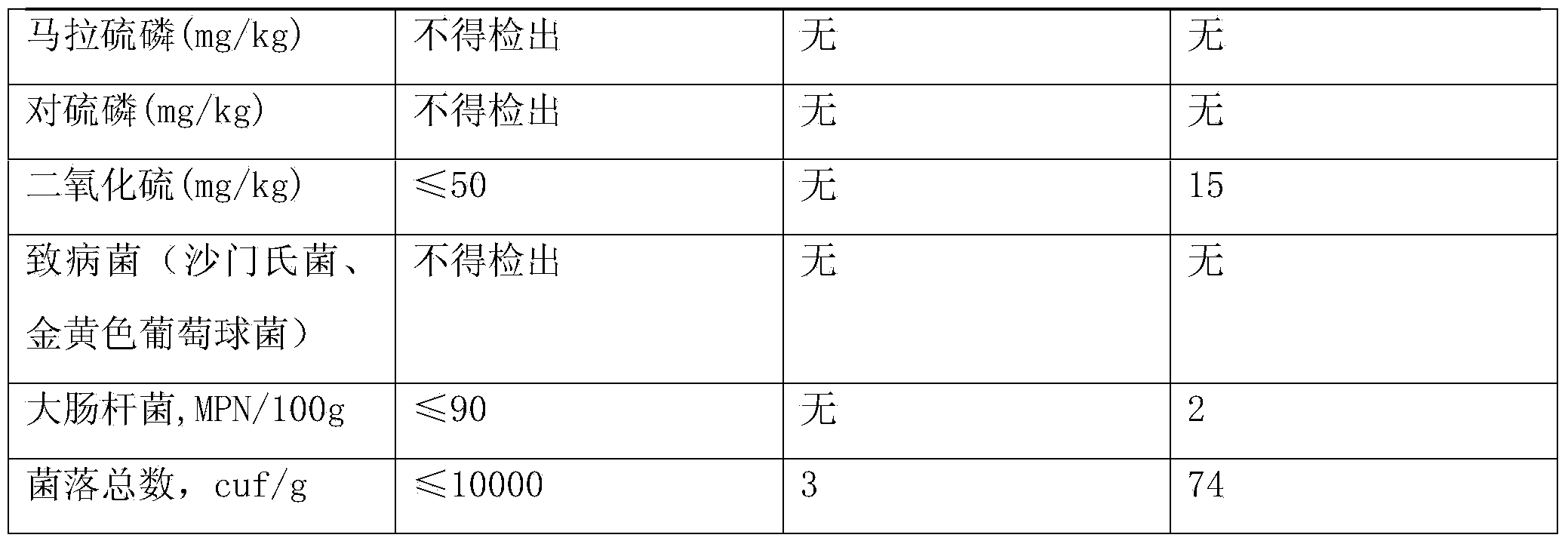

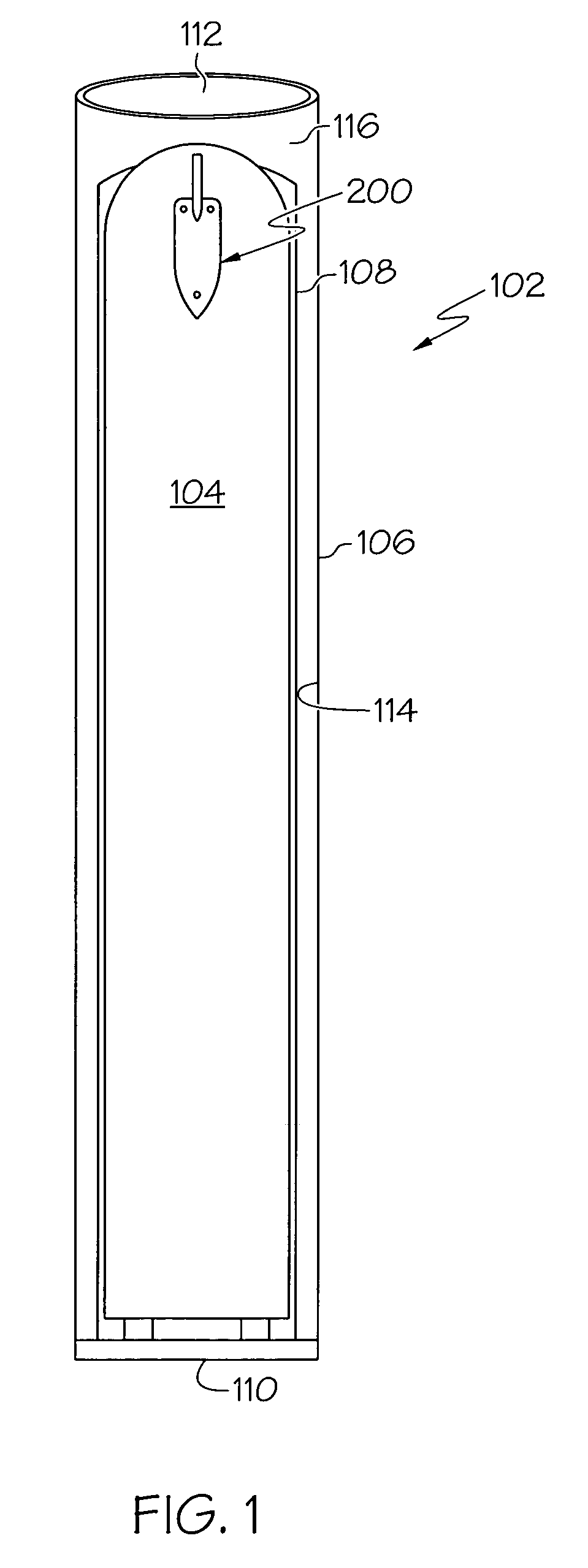

Method for the Treatment of the Obstructed Zones of the Parent Rock of Hydrocarbon-Producing Strata Adjacent to a Gas and Oil Well Drilling Zone in Order to Increase Productivity

The invention relates to a device and method for treating the backfilled area of the productive stratum adjacent to the drilling area of oil and gas wells using high pressure pulses. The technological equipment consists of a submersible cylindrical container which is equipped with a high pressure section for accumulating the gaseous working agent, a high pressure one-way electromagnetic valve for dispensing the gaseous agent, a low pressure section where gamma radiation and material solidity detectors and data transmission equipment are located, an intermediate section where at least two one-way nozzles are located, specially arranged radially for injecting the working agent into the areas to be treated, and the technical control and operating equipment.

Owner:BLACH SERVERA PEDRO

Air data module that ensures sufficient air data performance after exposure to relatively high overpressure

InactiveUS7334467B1Low costLow powerIndication/recording movementNavigation instrumentsComputer moduleEngineering

An air data module is provided that is relatively small, lightweight, low cost, uses relatively low power, and is relatively easy to install, test, and maintain. The air data module includes a housing that is adapted to be mounted to an external surface of an aircraft, and includes at least a sensor compartment and an interface electronics compartment formed therein. A pitot-static probe is coupled to the housing and extends therefrom, and has a static pressure passageway that is in fluid communication with the sensor compartment. A plurality of static pressure ports are formed in the pitot-static probe and are in fluid communication with the static pressure passageway. A pitot pressure inlet port is formed in a distal end of the pitot-static probe. A static pressure sensor and a differential impact or absolute pitot pressure sensor, for example, may be mounted within the module and used to sense static pressure and impact or pitot pressure, respectively. The disclosed configuration makes the module less sensitive to a relatively high pressure pulse.

Owner:HONEYWELL INT INC

High-voltage pulse resistance voltage divider

InactiveCN1731195AReduce step response timeMeet the needs of different measurementsVoltage dividersElectrical resistance and conductanceVoltage pulse

The invention relates to a high pressure pulse resistance voltage divider which can reduce the reaction time of the resistance voltage divider and improve the function of the voltage divider. The outer shield radar dome (9) of the voltage divider is a hollow pipe-type which possesses a first stage high pressure arm resistance (1); the insulated bushing (2) is covered out the first stage high pressure arm resistance (1); the pad electrode (3) is covered on one end of the insulated bushing (2); the high pressure arm frame (4) on the two ends of the insulated bushing (2) is supported inside the outer shield radar dome (9); the high pressure input end (10) is connected with the out end of the first stage high pressure arm resistance; the pad electrode (3) is connected with the inner end of the first stage high pressure arm resistance; the first stage low pressure arm resistance, the second stage high pressure arm resistance, the second stage low pressure arm resistance, and the divider output end are positioned between the outer shield radar dome (9) and the high pressure arm frame (4).

Owner:SOUTHEAST UNIV

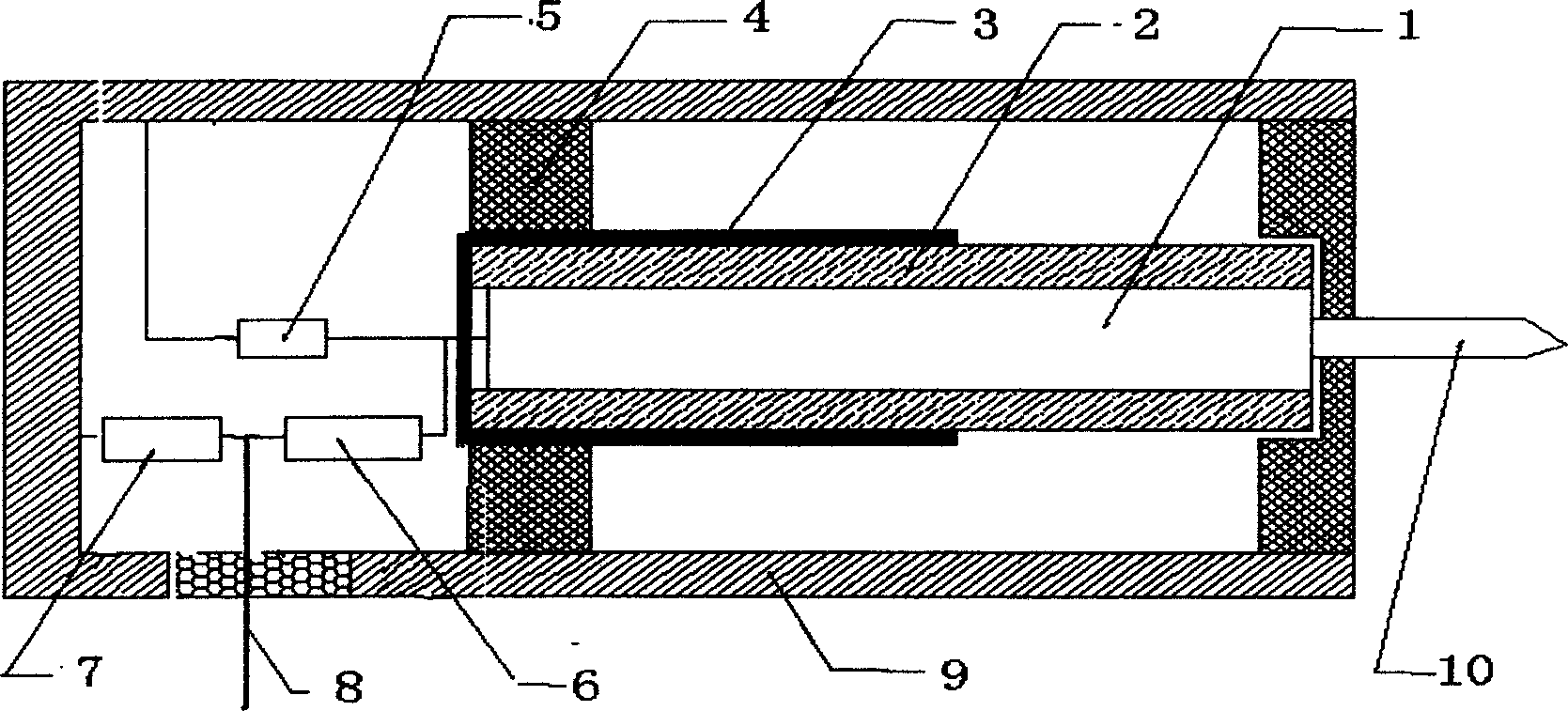

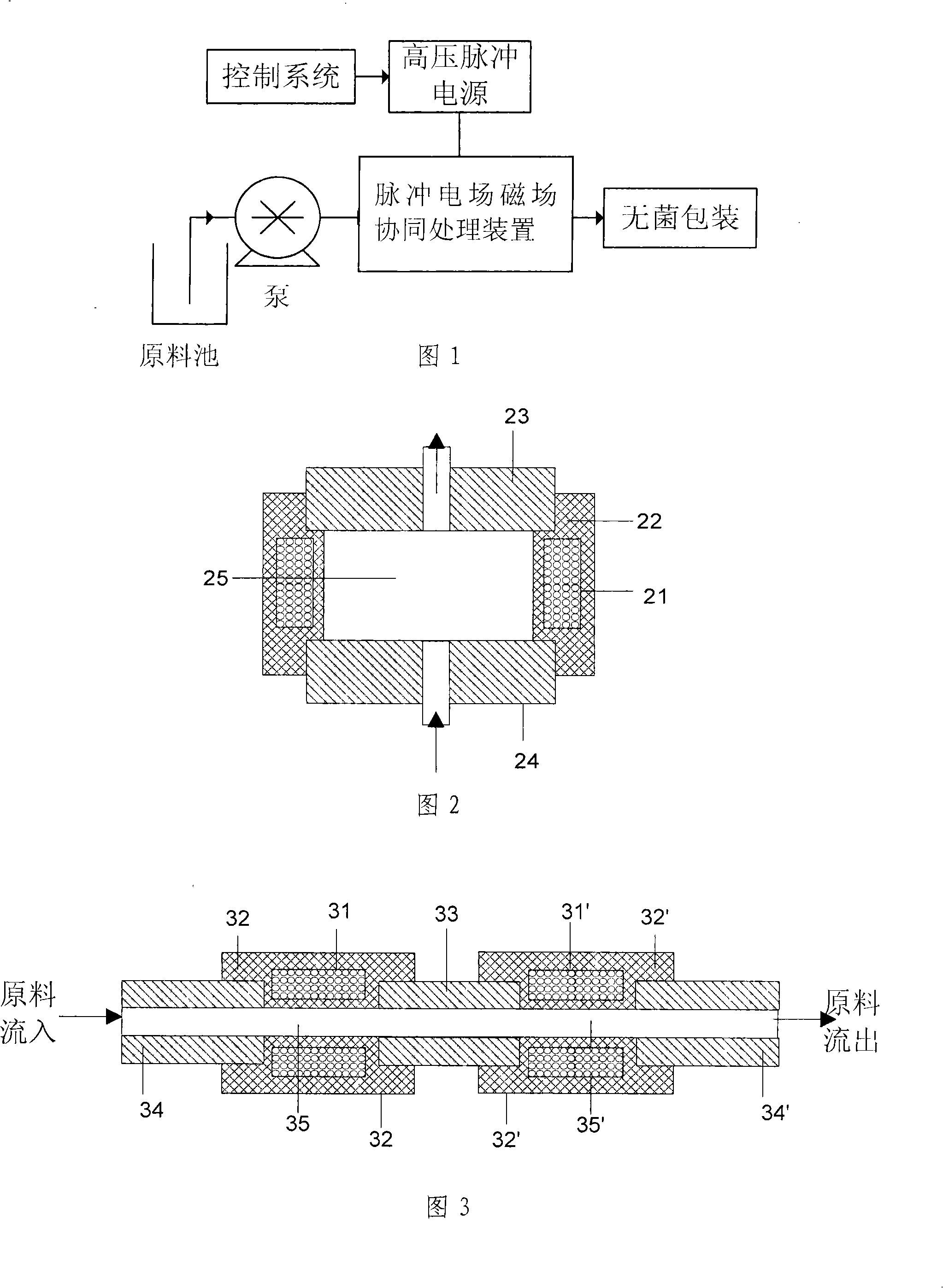

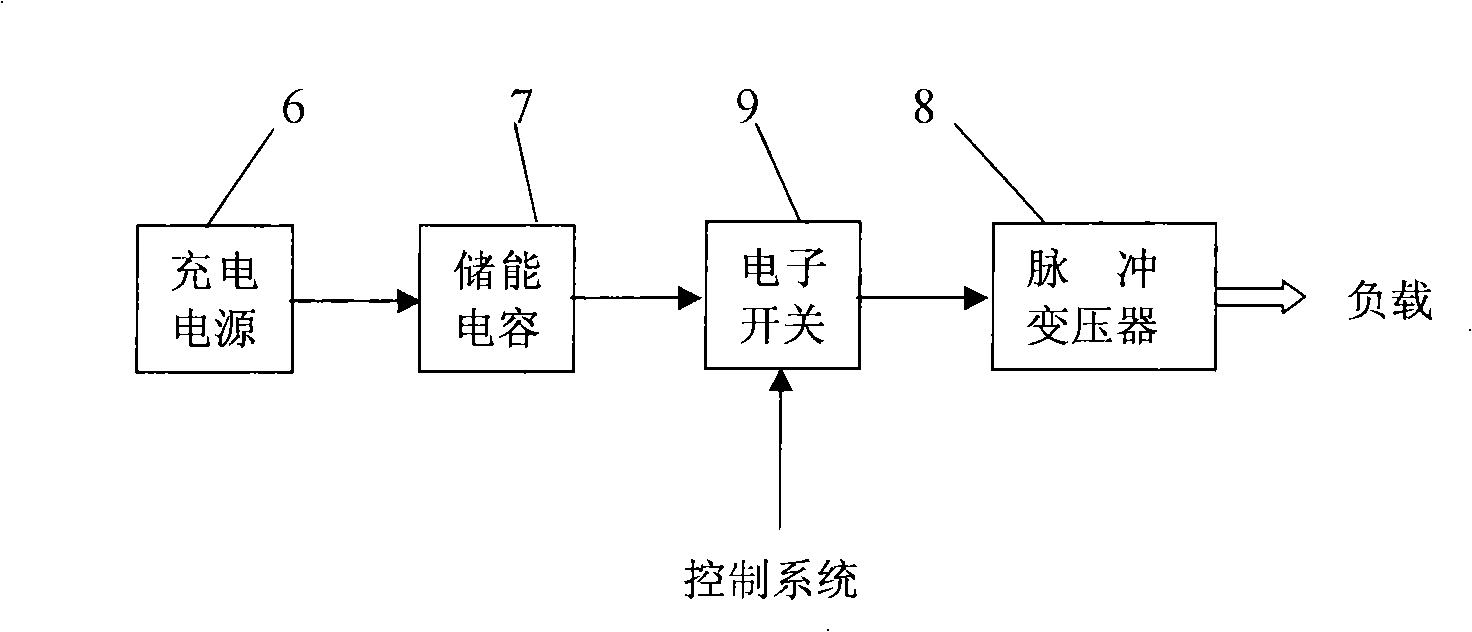

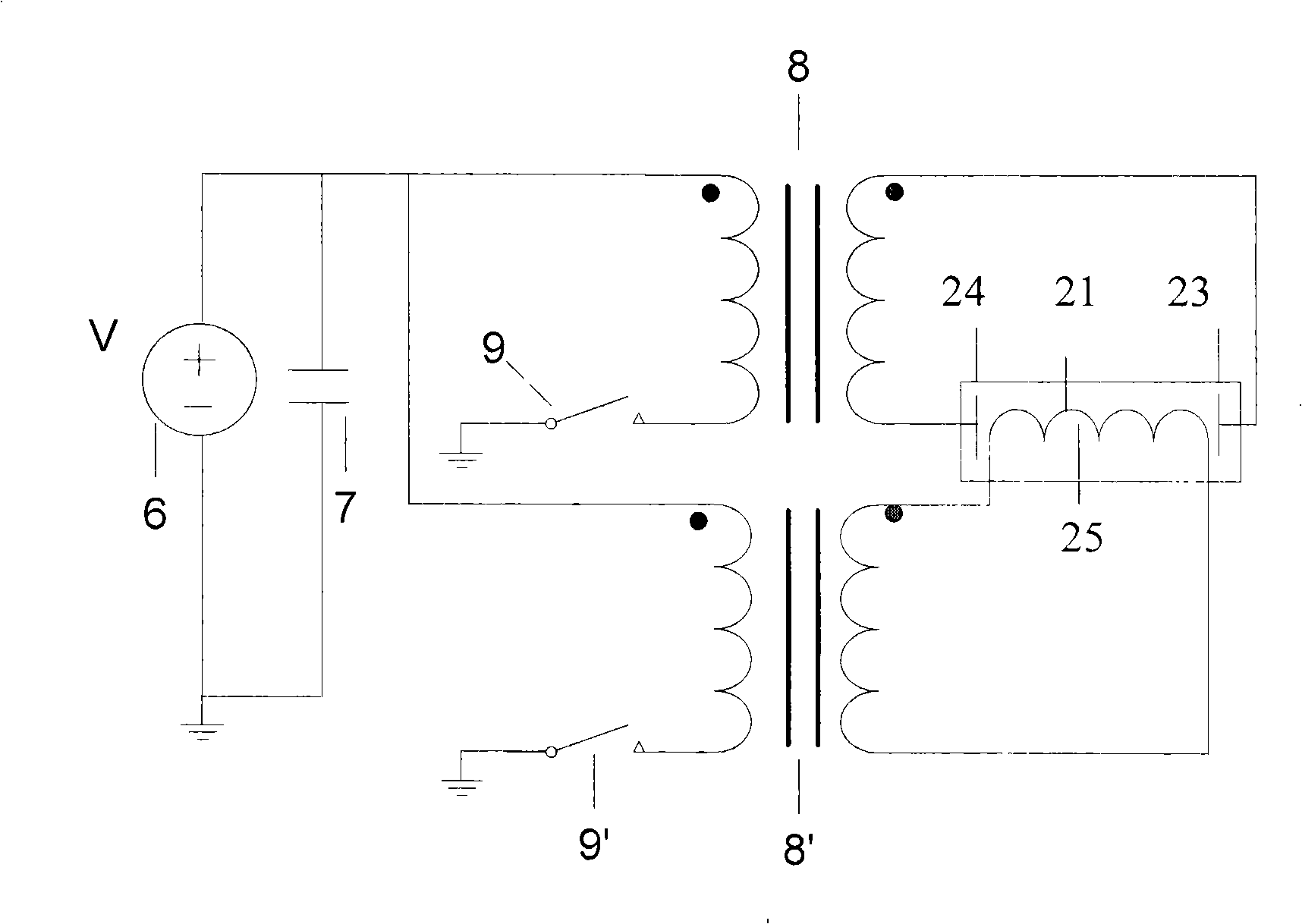

Method and apparatus for materials cooperation disinfection and enzyme dulling with impulse electric field and magnetic field

InactiveCN101292769AMaintain nutritional valueKeep the flavorMilk preservationFood preservationNutritive valuesElectromagnetic field

The invention provides a method that a pulsed electric field and a magnetic field cooperatively sterilize materials and inactivate enzyme and a device. The method comprises: materials to be processed continuously or discontinuously flow through the processing area of the cooperative processing device with the pulsed electric field and the magnetic field; a high pressure pulse power source imposes a pulsed magnet field of 0.1T-50T by the field coils which circle the processing area and a pulsed electric field of 5-100kV / cm by electrode plates at two sides of the processing area to carry out electric-magnetic-field cooperative processing of the materials in the processing area; the electric-magnetic-field cooperative processing device has novel conception, combines the magnetic field and the pulsed electric field, is convenient in installation and application and suitable for being adapted and used in a food sterilization processing system; the cooperative processing of materials by the pulsed electric field and the magnetic field takes a short time; the temperature of materials rises a little during the whole sterilizing course; the effect of sterilization and enzyme inactivation is increased, meanwhile, the original nutritive value and flavor of food are preserved to the maximum degree.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

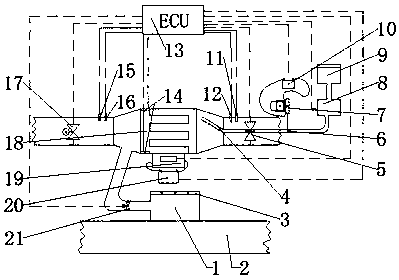

Diesel particle filter regenerating unit and control method thereof

ActiveCN107420159AEfficient removalReduce energy consumptionInternal combustion piston enginesExhaust apparatusThermal energyEngineering

The invention relates to a diesel particle filter regenerating unit and a control method for the regenerating unit, and belongs to the technical field of diesel particle filter regenerating. The diesel particle filter regenerating unit and a control method for the regenerating unit are characterized in that an regenerating electric control unit (ECU) judges the regenerating opportunity according to the a exhausting pressure difference and a temperature difference of the upstream and the downstream of the diesel particle filter; while regenerating, the ECU controls a magnetic valve, a sewage tank magnetic valve, a high pressure pump, a rotary motor and a high pressure pulse rotary undershoot nozzle at the two ends of the diesel particle filter to conduct high pressure water pulse jet cleaning; water is injected into the inner cavity of the diesel particle filter, and ultrasonic generator is started to conduct ultrasonic vibration cleaning; and regenerating sewage flows into an sewage tank, exhausting thermal energy is utilized to evaporate the regenerating sewage, and centralized harmless treatment is conducted on soot accumulation. According to the regenerating control method for the regenerating unit, through high pressure rotary jet, combined with the ultrasonic vibration, regenerating of the diesel particle filter is achieved, and the service life can be prolonged effectively.

Owner:KUNMING UNIV OF SCI & TECH

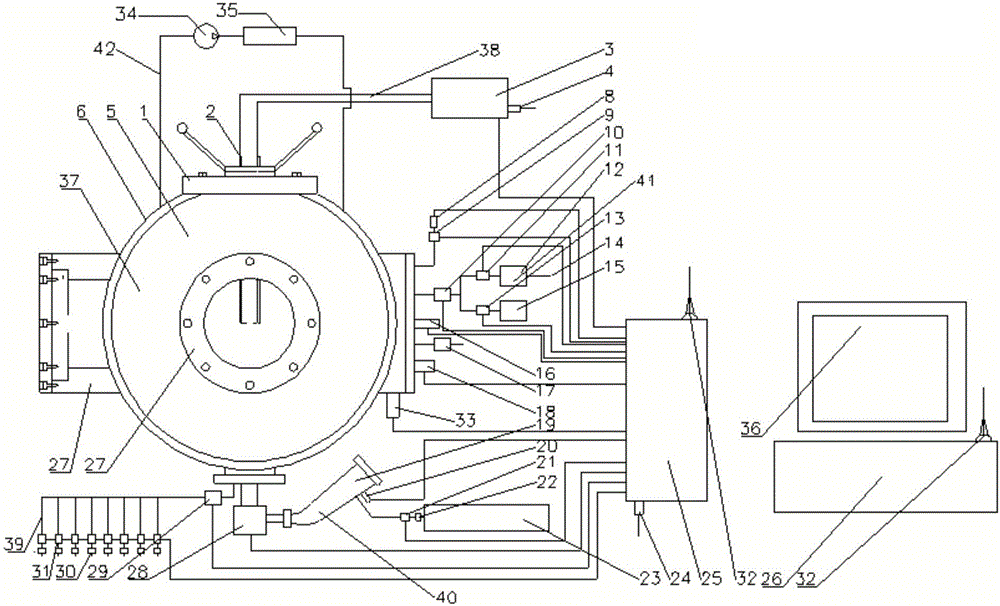

Multi-window multifunctional gas and dust explosion inhibition experiment system

ActiveCN106248733AMeet Synchronous ApplicationsSatisfy synchronous testing requirementsMaterial exposibilityEngineeringHigh pressure

The invention provides a multi-window multifunctional gas and dust explosion inhibition experiment system, and aims to meet a high-transparency quartz window characterized in that a plurality of external triggering connectors are available for externally connecting devices and a plurality of advanced optical testers are synchronously used, and to achieve a comprehensive explosion experiment testing system for preparing multiple gases. The multi-window multifunctional gas and dust explosion inhibition experiment system comprises a testing control system, an explosion container, an ignition system, a gas distribution system, a powder spraying system, a vacuuming system, a heating constant-temperature system as well as at least two optical diagnosis windows, an ignition external triggering connector and a powder spraying external triggering connector, wherein the ignition system is connected with the explosion container; the optical diagnosis windows are formed in side surfaces of the explosion container; the ignition external triggering connector is arranged on an energy-adjustable high-pressure pulse igniter; the powder spraying external triggering connector is arranged on a system testing and control main machine.

Owner:XIAN UNIV OF SCI & TECH +1

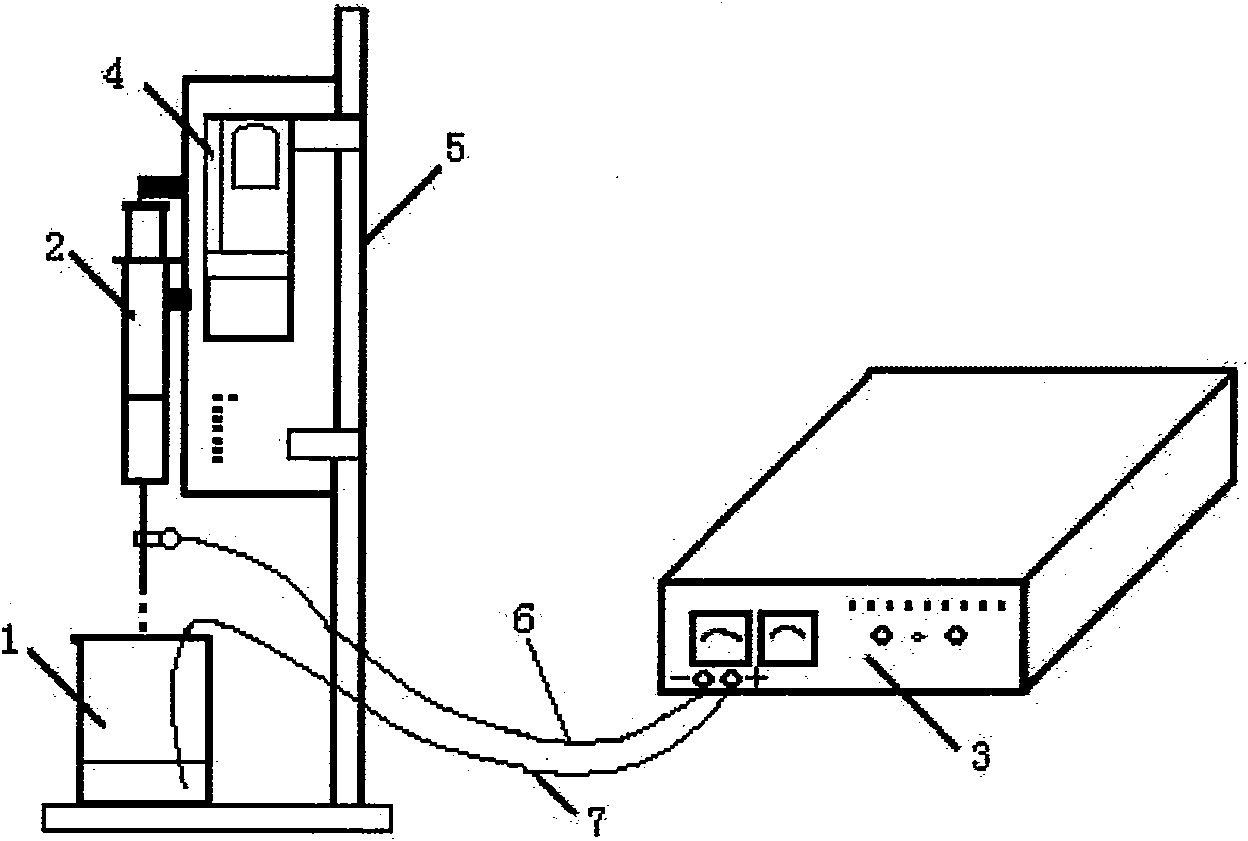

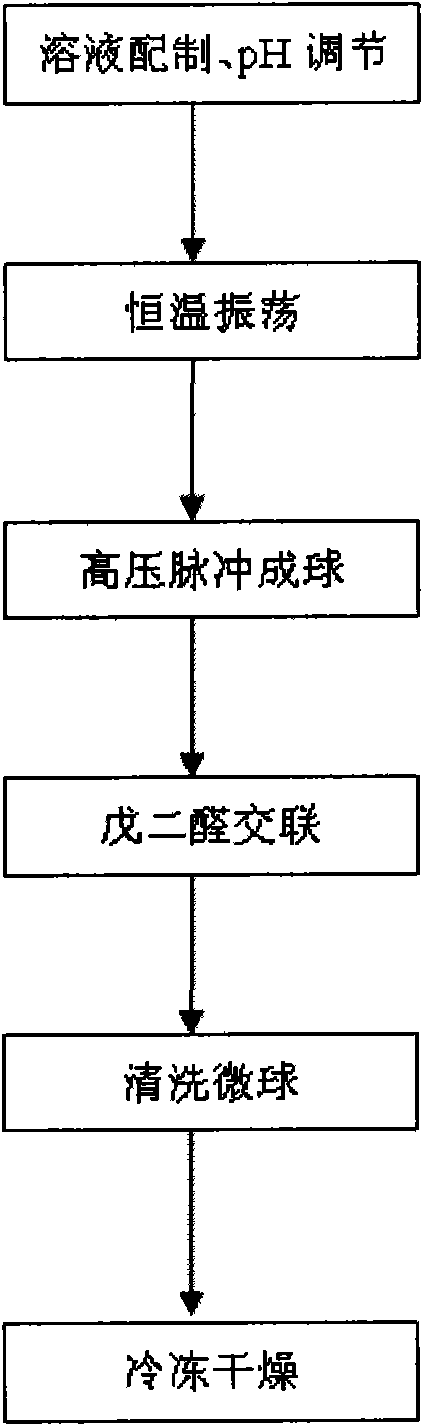

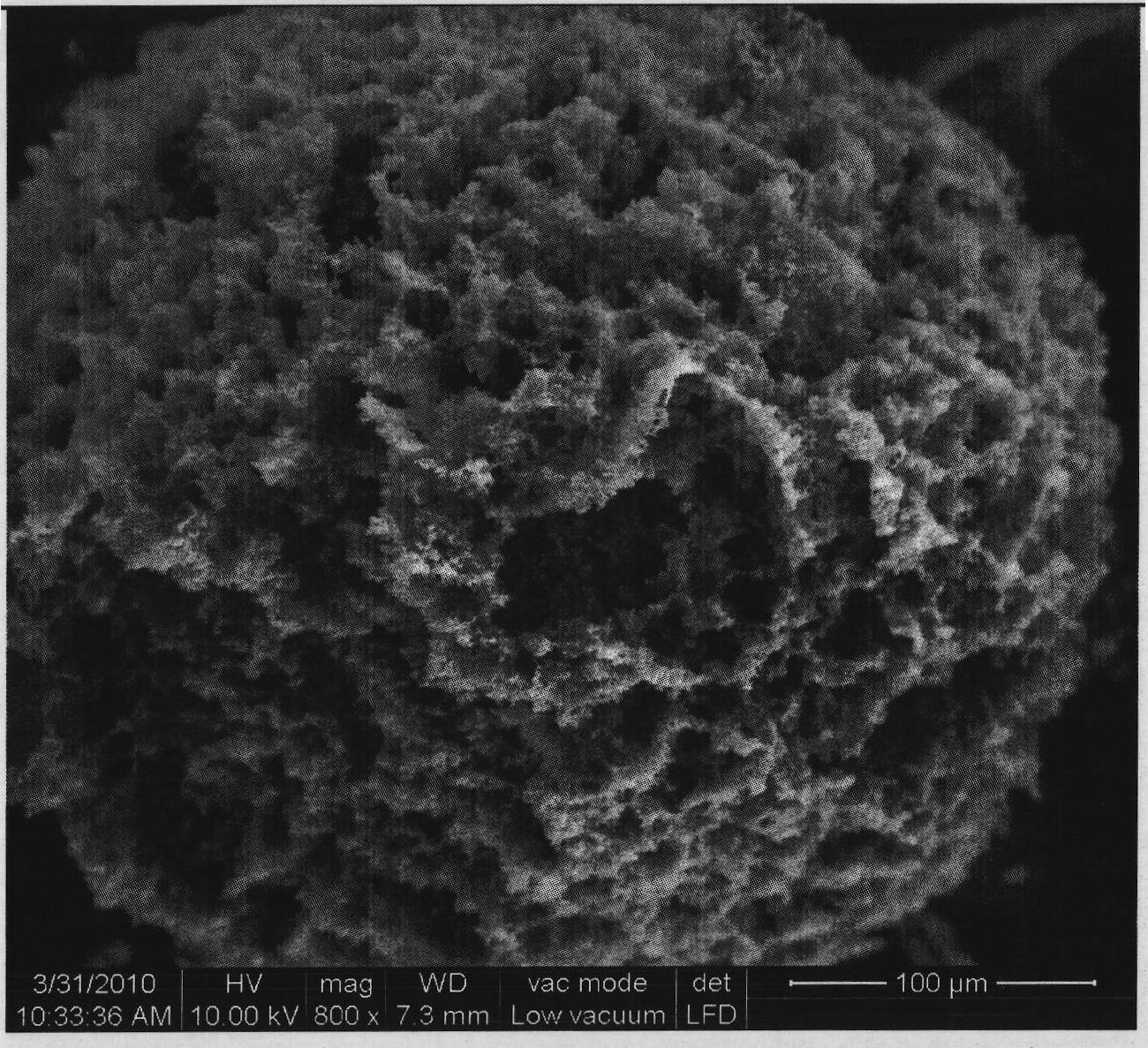

Preparation method of chitosan/sodium polyphosphate porous microcarrier

InactiveCN101844059AImprove water absorptionImprove roundnessAnimal cellsMicroballoon preparationCross-linkPorosity

The invention discloses a preparation method of chitosan / sodium polyphosphate porous microcarrier, which comprises the following steps: dropping chitosan into sodium polyphosphate solution under high pressure through a high-pressure pulse microcapsule forming device to form microspheres, cross-linking the microspheres with glutaric dialdehyde, and freezing-drying, thereby forming the chitosan / sodium polyphosphate porous microcarrier of a three-dimensional structure. The chitosan / sodium polyphosphate porous microcarrier prepared in the method has the advantages of good roundness and uniform particle size distribution. In addition, due to the adoption of the freezing-drying technology under the condition that the pH of the sodium polyphosphate is ensured during the preparation of the chitosan / sodium polyphosphate porous microcarrier, the particle size of the prepared chitosan / sodium polyphosphate porous microcarrier is 15-20 mum, the porosity thereof is close to 90 percent, and the water absorbing capacity thereof is up to 8 times.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

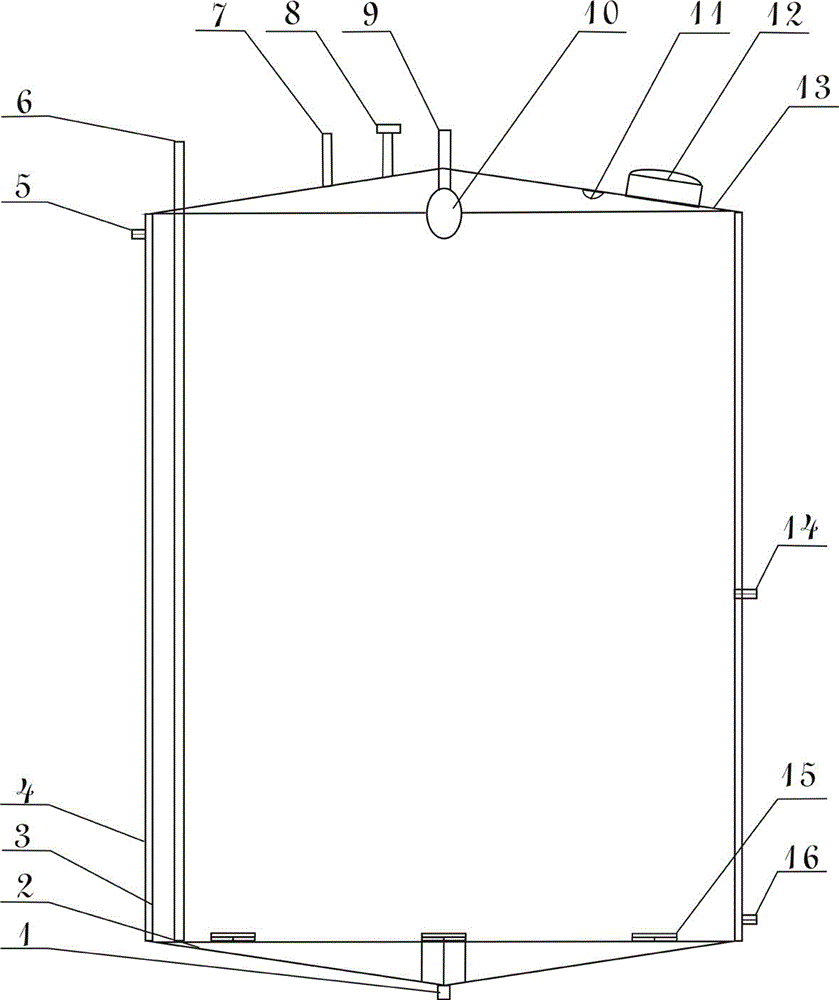

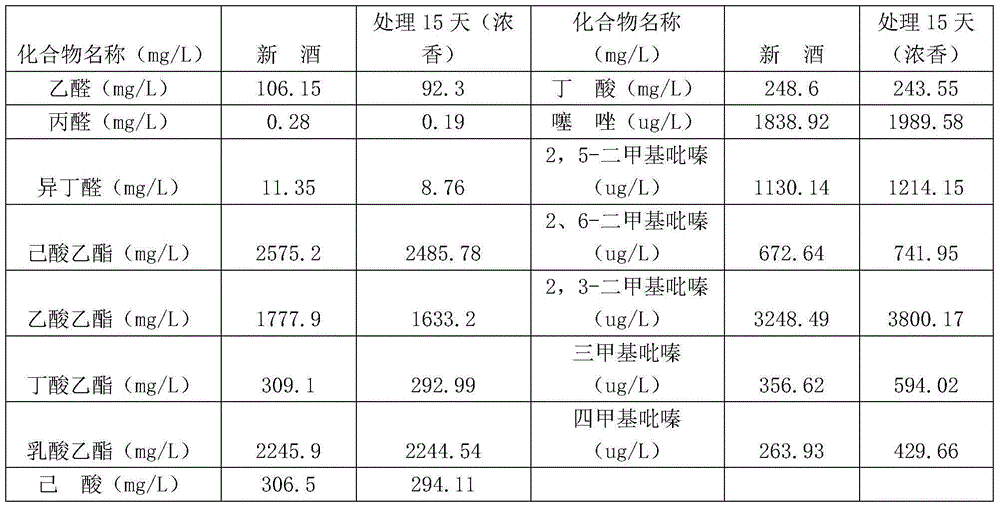

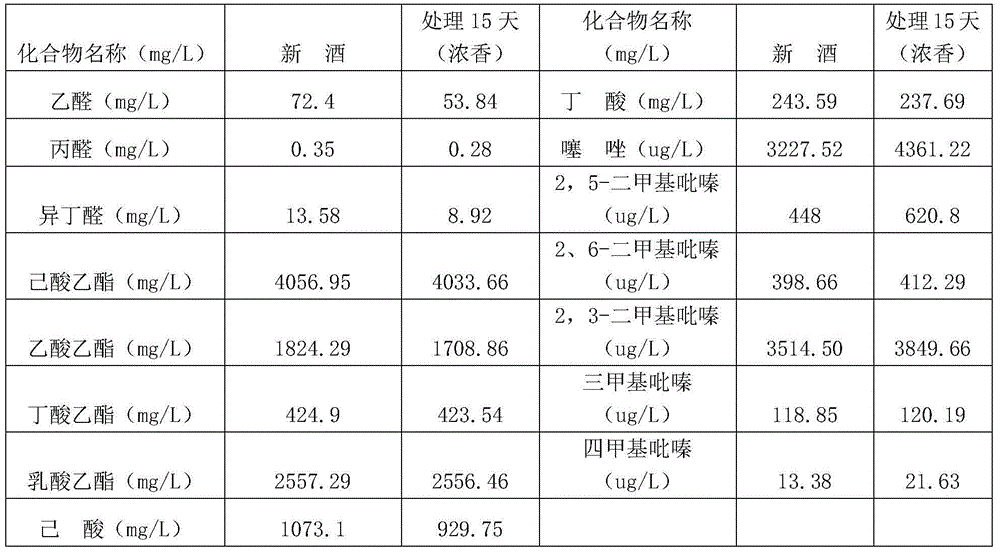

Device and method for accelerating aging of white wine by utilizing heat source and air

ActiveCN104593214AElegant aromaMeet the needs of large-scale agingAlcoholic beverage preparationHigh pressure pulseWater pipe

The invention discloses a device and a method for accelerating aging of white wine by utilizing a heat source and air. The device comprises a tank body, wherein the upper part of the tank body is provided with an upper conical body, and the lower part of the tank body is a lower conical body; the upper part of the tank body is provided with a feeding hole and the lower part of the tank body is provided with a discharging hole; the upper part of the tank body is provided with a water feeding pipe; the outer wall of the tank body is provided with a heating interlayer; a hot-water inlet at the lower part of the tank body and a hot-water outlet at the upper part of the tank body are communicated with the heating interlayer; the lower part of the tank body is provided with a stirrer; and an air inlet pipe enters the bottom part of the tank body. The device and the method disclosed by the invention have the advantages that the aging of the white wine is accelerated by utilizing temperature-control heating, high-pressure pulse air is introduced for stirring wine liquor while heating, so that the heating of the wine liquor is uniform. The method has the obvious characteristics of short aging-acceleration time, low cost, simplicity in operation and suitability for large-scale application of the white wine. The white wine treated by short-time aging acceleration is as the same as the white wine obtained after more than one year of natural aging.

Owner:HUBEI ZHIJIANG LIQUOR INDUSTRY CO LTD

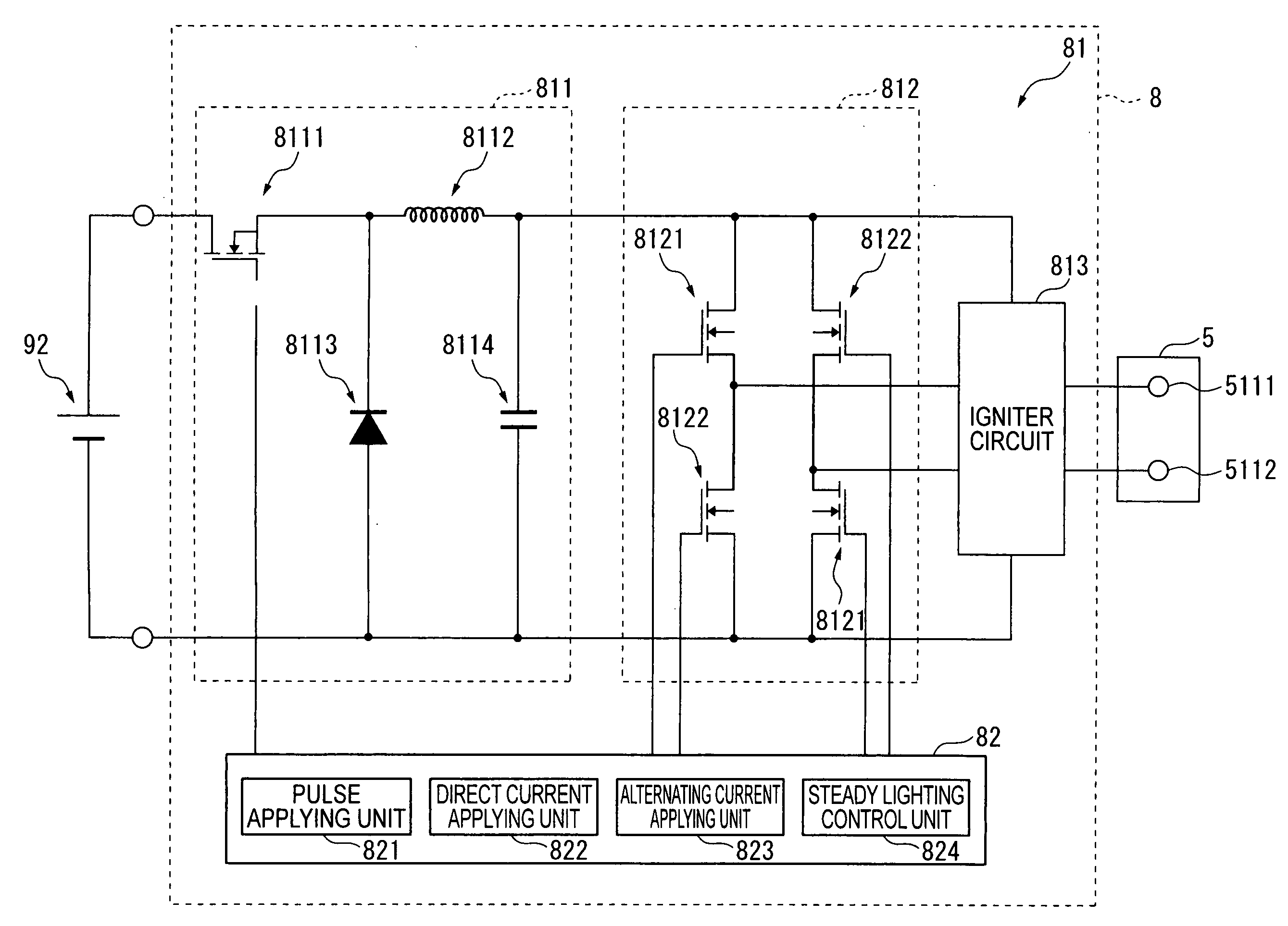

Ignition controller, light source, projector and ignition control method

ActiveUS20090001904A1Avoid damageImprove discharge efficiencyElectrical apparatusElectric light circuit arrangementEngineeringHigh pressure

An ignition controller that controls ignition of a discharge lamp discharging and emitting light between a pair of electrodes provided therein, the controller includes: an ignition device that ignites the discharge lamp, and a controller that controls a drive of the ignition device, in which the controller includes: a pulse applying unit that applies a high pressure pulse to the pair of electrodes by the ignition device, a direct current applying unit for applying a direct current to the pair of electrodes for a first period after applying the high pressure pulse, and an alternating current applying unit for applying a first alternating current to the pair of electrodes for a second period after the first period.

Owner:SEIKO EPSON CORP

Composite ceramic resistor and manufacture method thereof

ActiveCN101702357ANo failureImprove reliabilityResistor manufactureNon-adjustable resistorsComposite ceramicHigh pressure

The invention relates to a composite ceramic resistor and a manufacture method thereof, belonging to the field of power electronics. The manufacture method of the composite ceramic resistor is suitable for a breaker switch-on resistor, a high-pressure pulse line, a laser, a particle accelerator, and the like. The composite ceramic resistor is manufactured by adopting bauxite, kaolin, talc powder and carbon as main materials through ball-milling, mixing with water and a binding agent, rotting, curing, granulating, compression moulding for forming a raw blank, sintering and metal electrode coating. The composite ceramic resistor comprises the following raw materials in percentage by weight: 50-70 percent of bauxite, 10-40 percent of kaolin, 1-10 percent of talc powder, 1-15 percent of carbon, 1-3 percent of binding agent and 4-8 percent of water.

Owner:NANJING ZHAONENG ELECTRIC

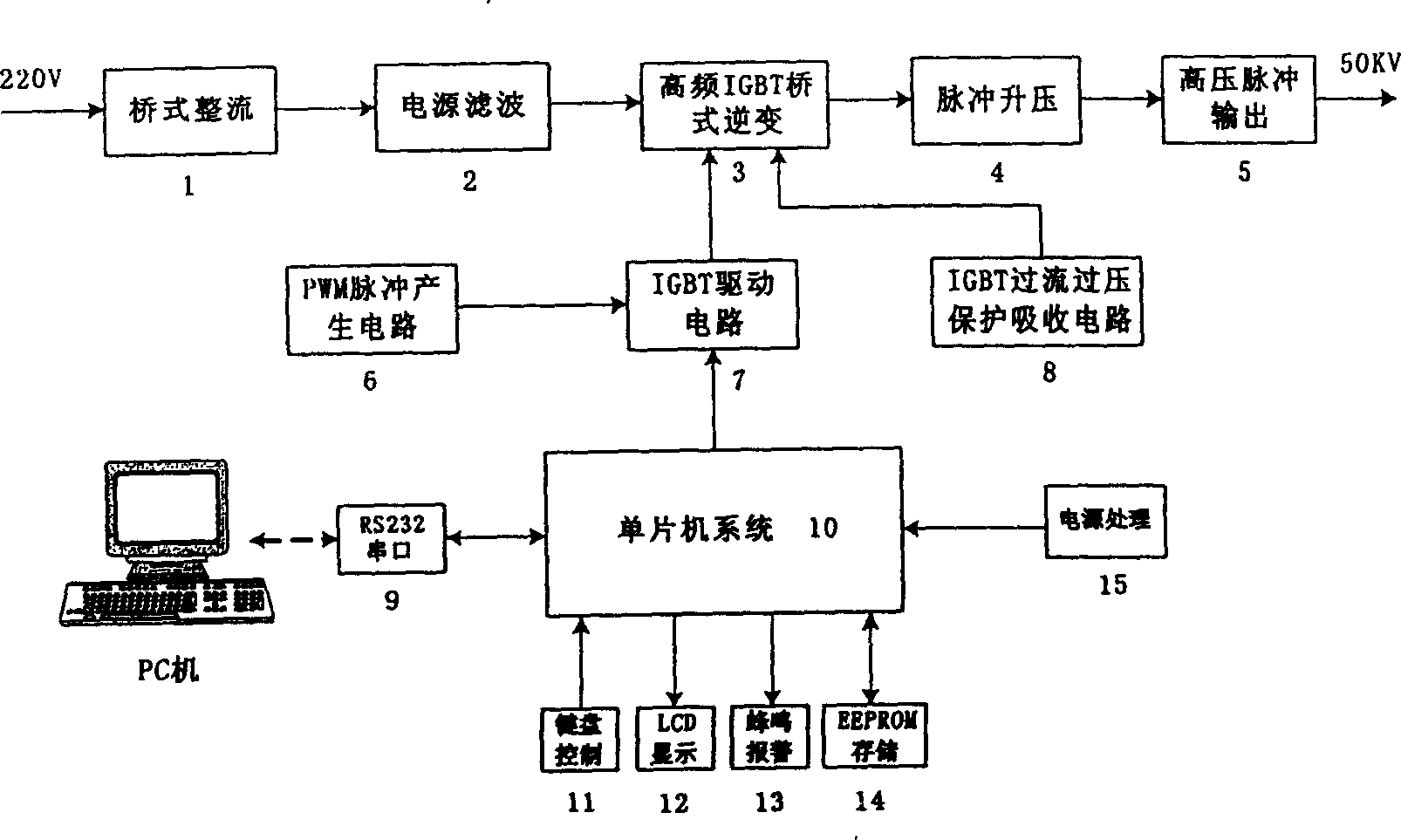

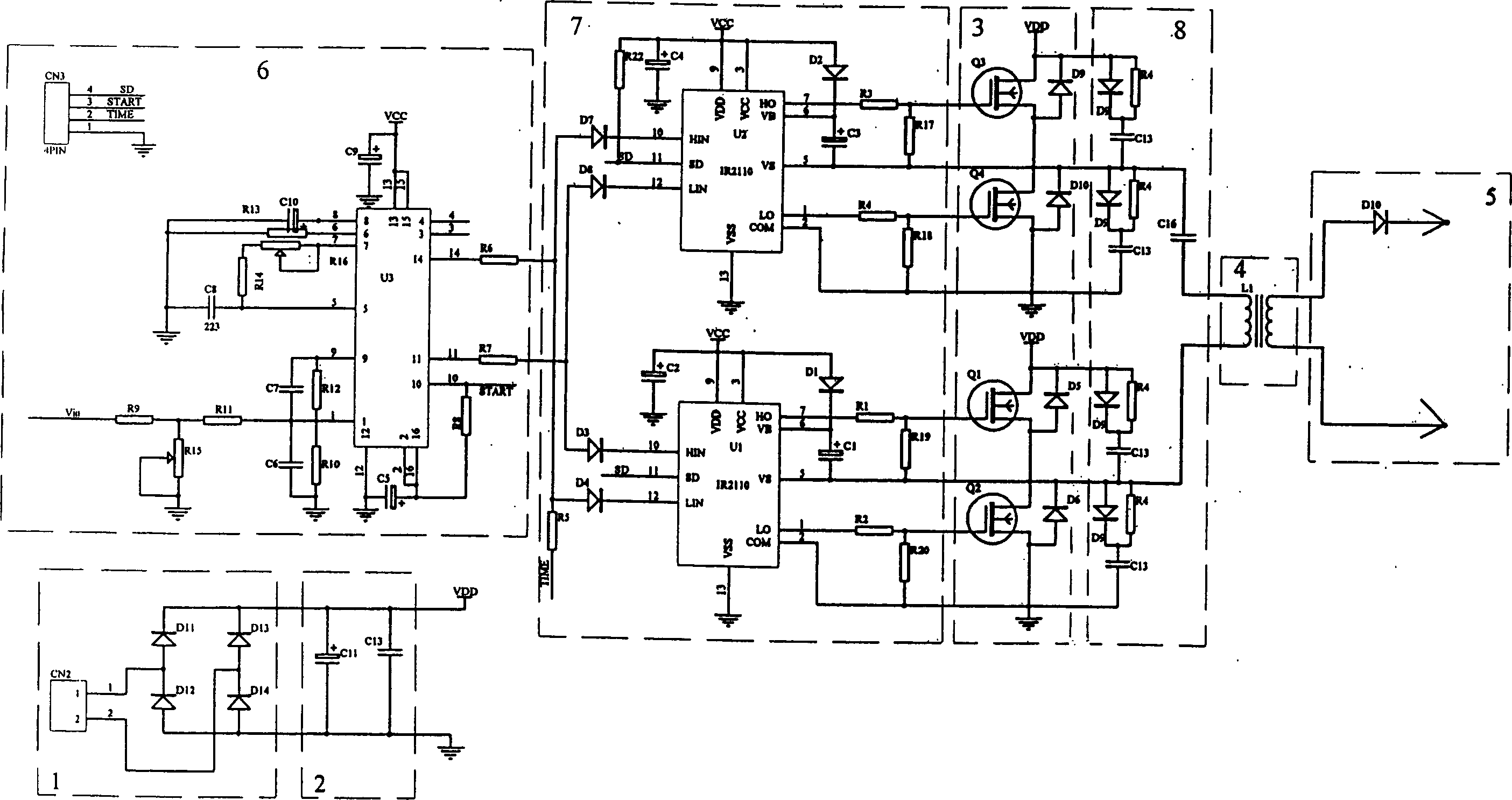

Intelligent high pressure pulse generator

InactiveCN1785072AEasy to shapeEasy to operateFood preservationElectric pulse generatorMicrocontrollerEngineering

Owner:ZHEJIANG UNIV

Gas-phase high pressure pulse discharge device and method for catalytically degrading organic dyes in water by same

InactiveCN102190352ASolve the problem of secondary useLarge amount of processingWater/sewage treatment by electrochemical methodsWater/sewage treatment by sorptionGas phaseOrganic dye

The invention discloses a gas-phase high pressure pulse discharge device and a method for catalytically degrading organic dyes in water by the same. A reaction device comprises a tubular rector and a gas inlet pipe at the bottom thereof, a liquid storage tank and a gas outlet on the top thereof, a high pressure electrode and a ground electrode which are respectively hung on the upper part and thelower part of the reactor through fixed guide rods, and an external high pressure pulse power supply. Nonequilibrium plasmas generated through gas-phase high pressure pulse discharge degrade the organic dyes; and the design structure inside the reactor makes gas and liquid flowing directions fixed, can make contact time of the generated oxidative particles and pollutants prolonged, and improves the conversion efficiency of the reactor. Meanwhile, an adsorptive catalyst is put into the upper part of the reactor or into the liquid storage tank to improve the concentration of organic matters at the liquid level, so that the contact between high-activity substances and the organic matters is enhanced and the treatment efficiency can be improved. By the invention, the organic pollutants are degraded into carbon dioxide, water and nontoxic byproducts, and the invention has the advantages of high efficiency, low cost, simple process, simple operation, no secondary pollution on environment and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com