Intelligent high pressure pulse generator

A high-voltage pulse and generator technology, applied in pulse generation, pulse technology, electric pulse generation, etc., can solve problems such as side effects and difficulty in achieving predetermined effects, and achieve the effects of simple and convenient operation, small and exquisite equipment, and reduced product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

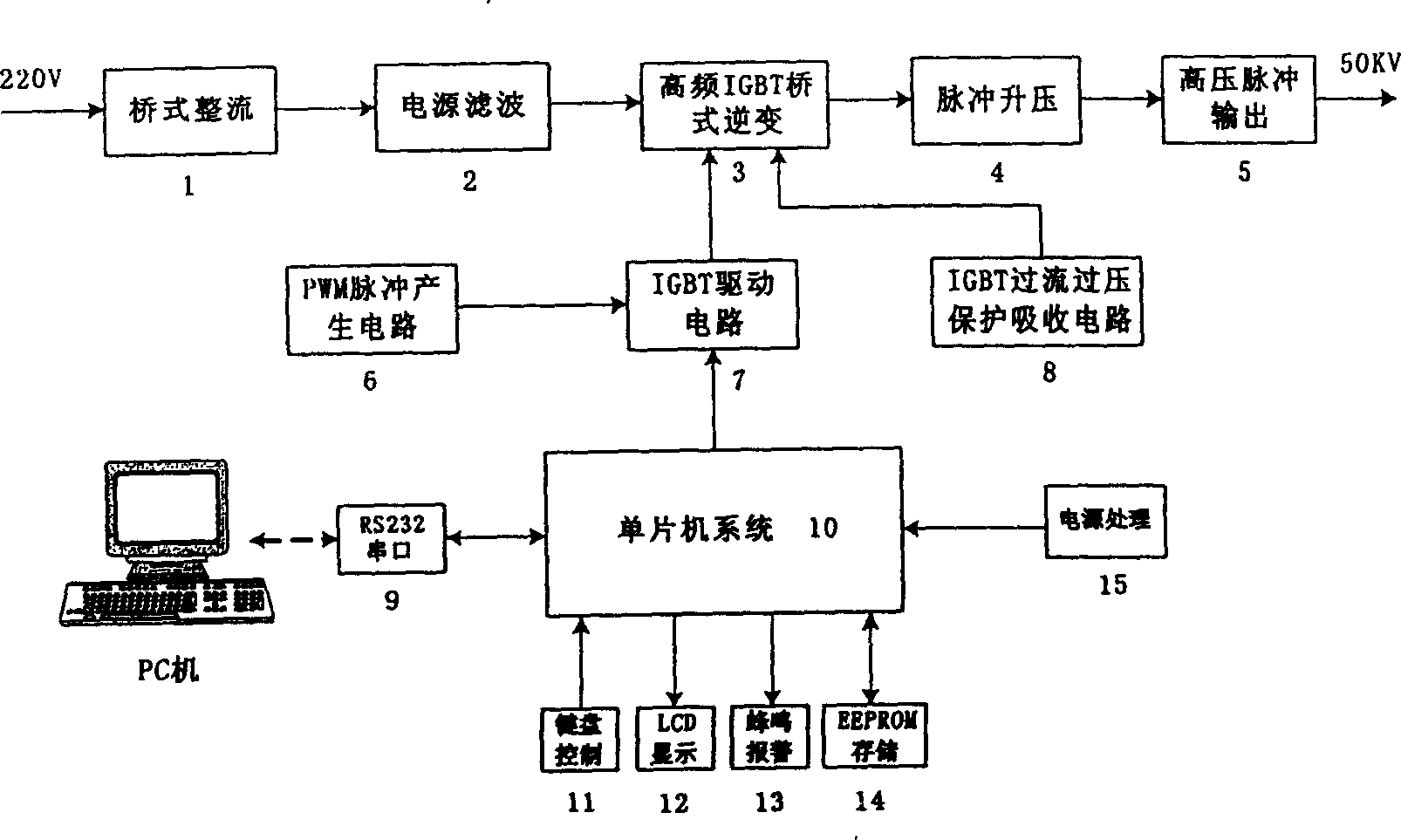

[0014] like figure 1 As shown, the present invention includes a main circuit and a control circuit, wherein:

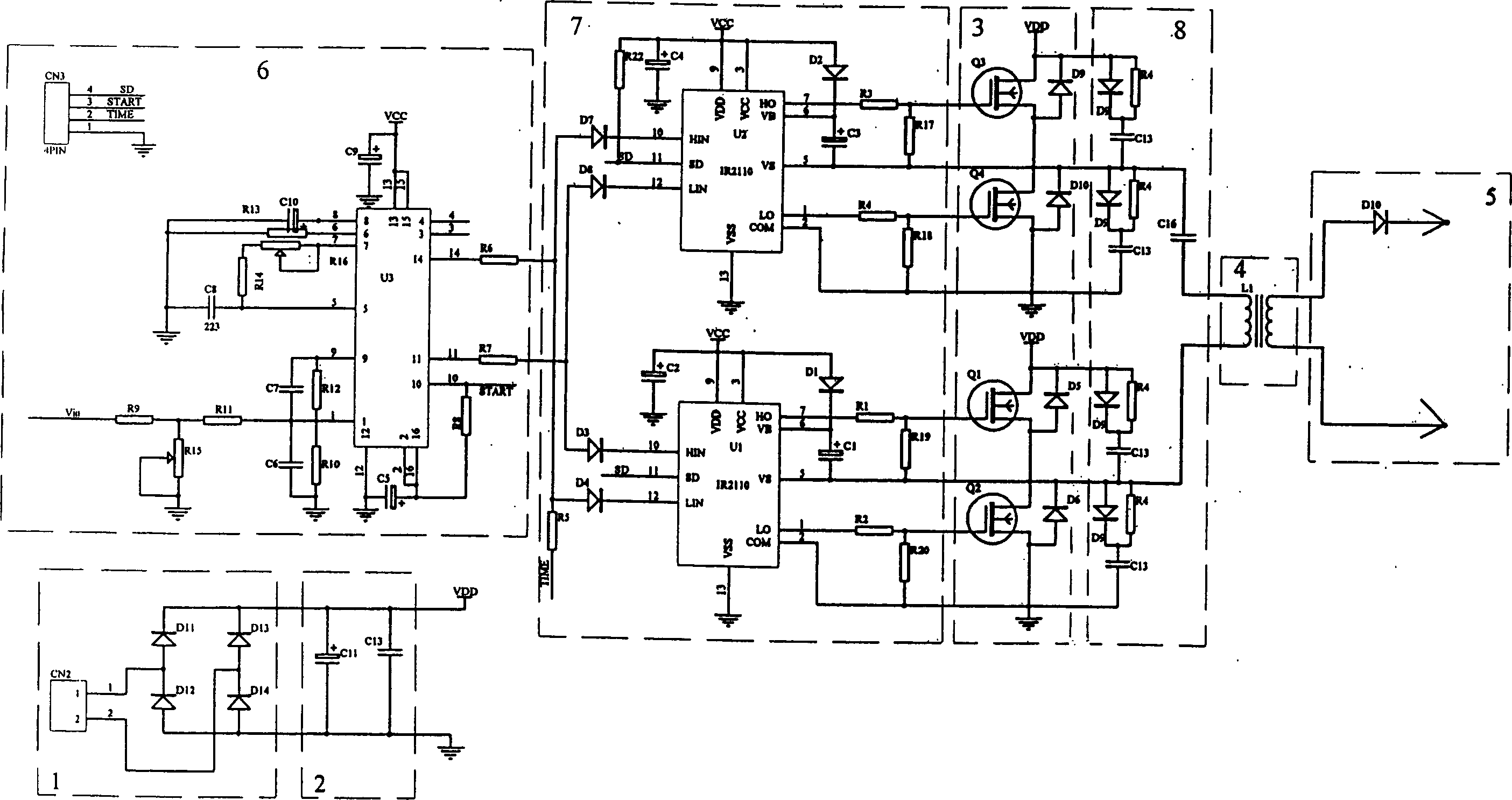

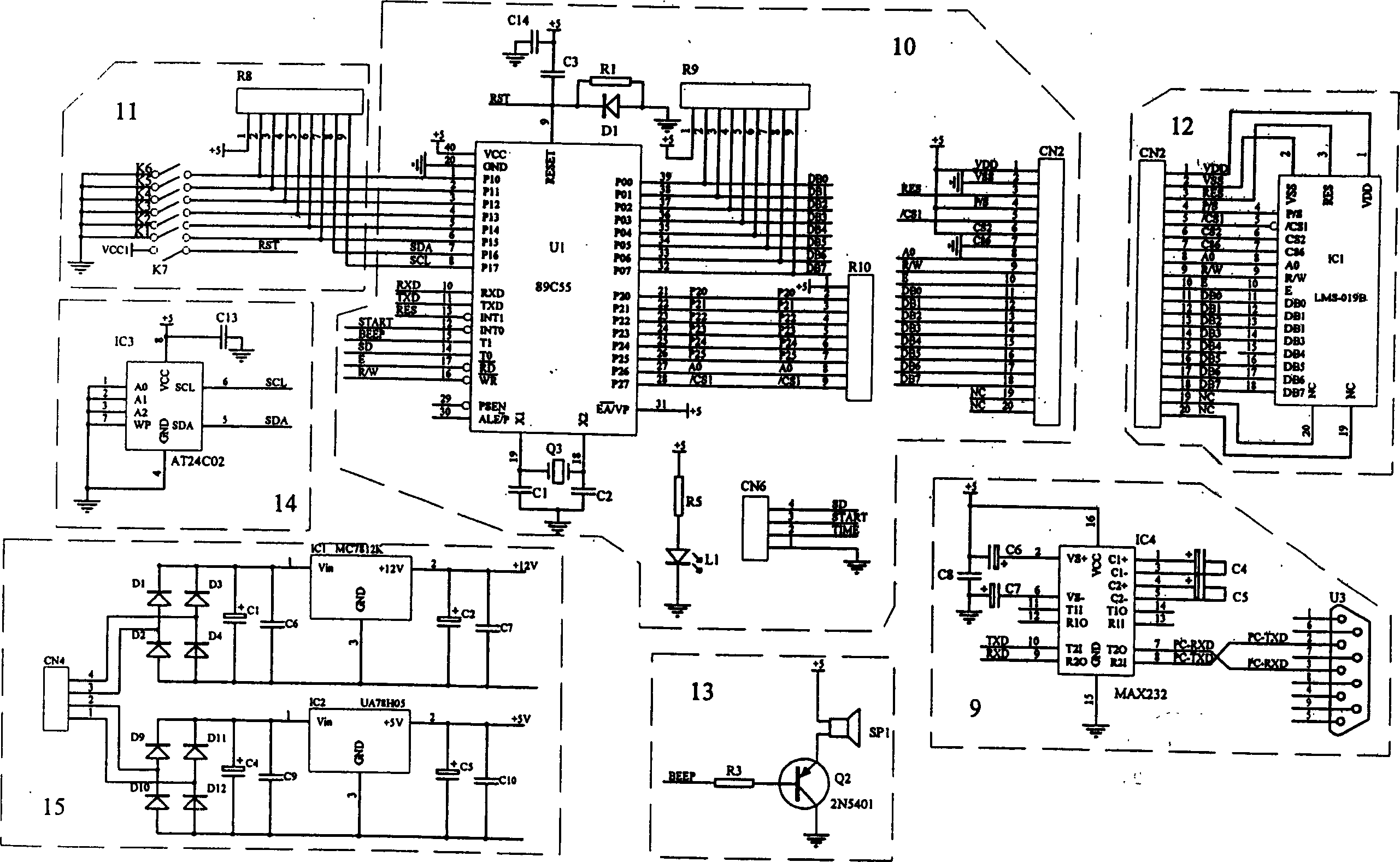

[0015] 1) Main circuit: including bridge rectifier circuit 1, power filter circuit 2, high frequency IGBT bridge inverter circuit 3, pulse boost circuit 4 and high voltage pulse output circuit 5. The AC 220V becomes about 300V DC after passing through the bridge rectifier circuit 1 and the power filter circuit 2, and then connected to the high-frequency IGBT bridge inverter circuit 3, the pulse boost circuit 4 and the high-voltage pulse output circuit 5 in sequence;

[0016] 2) Control circuit: including microcontroller system circuit 10, PWM pulse width generation circuit 6, IGBT drive circuit 7, RS232 serial port circuit 9, IGBT overcurrent and overvoltage protection absorption circuit 8, keyboard control circuit 11, LCD display circuit 12, buzzer Alarm ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com