Heat shaped machine exhaust heat air purification heat energy utilized heat pipe exchanger

A technology of heat pipe heat exchanger and hot air, which is applied in chemical instruments and methods, steam/steam condensers, lighting and heating equipment, etc., and can solve problems such as large pressure loss, environmental pollution, and polluted environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

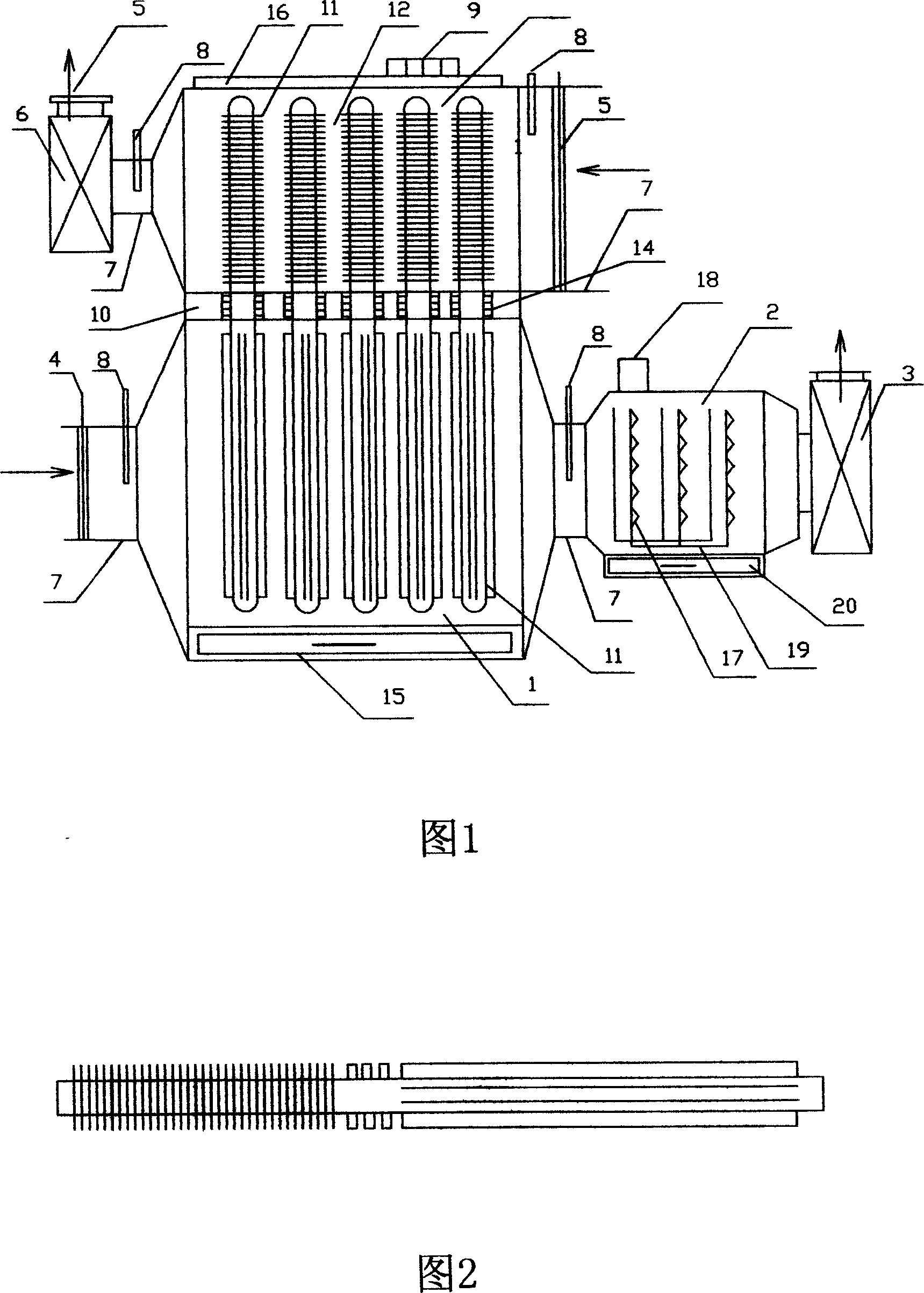

[0012] In figure (1), the top of the tube plate (10) of the heat pipe heat exchanger (1) is an air heating chamber (12) with a top cover (16), the bottom is a waste heat air heat absorption chamber (13), and the heat pipe (11 ) is inserted into the fork hole of the tube plate (10) with a tapered snap ring (14) asbestos climbing root, and under the action of the induced draft fan (3), the waste hot air containing yarn dust oil vapor is inserted through the detachable dust filter. The tank (4) temperature sensor (8) passes through the air inlet and outlet pipe (7) to the waste heat air absorption chamber (13), and the heat absorbed by the heat absorption section of the longitudinal finned heat pipe (11) is phase-transformed and transferred to the upper air of the tube sheet (10) In the heat release section of the spiral fins in the heating chamber (12), the temperature of the waste heat air drops rapidly, and the oil vapor is condensed on the longitudinal fins and removed, and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com