Patents

Literature

926 results about "Heat pipe heat exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Answer Wiki. A double pipe heat exchanger (also sometimes referred to as a 'pipe-in-pipe' exchanger) is a type of heat exchanger comprising a 'tube in tube' structure. As the name suggests, it consists of two pipes, one within the other.

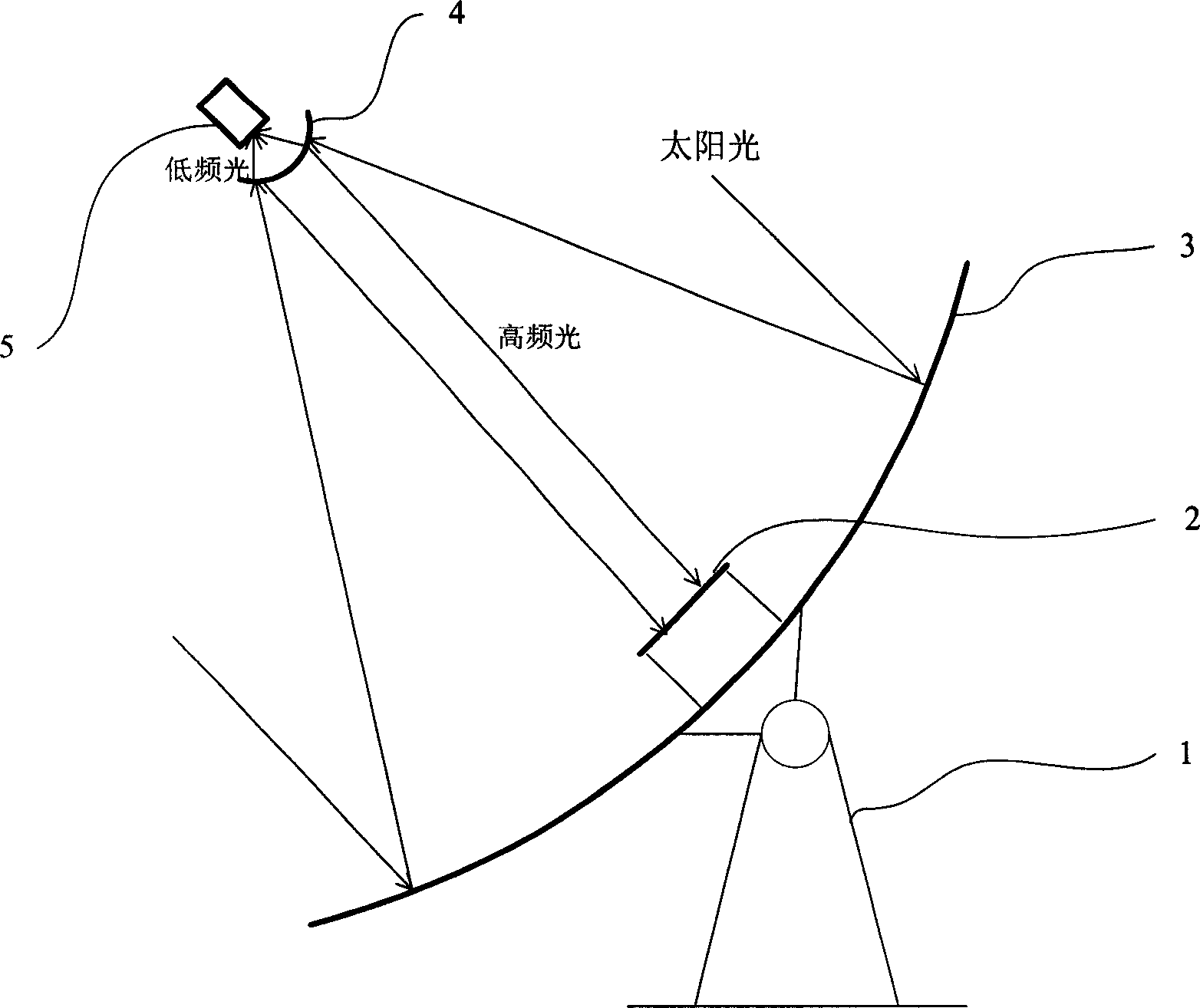

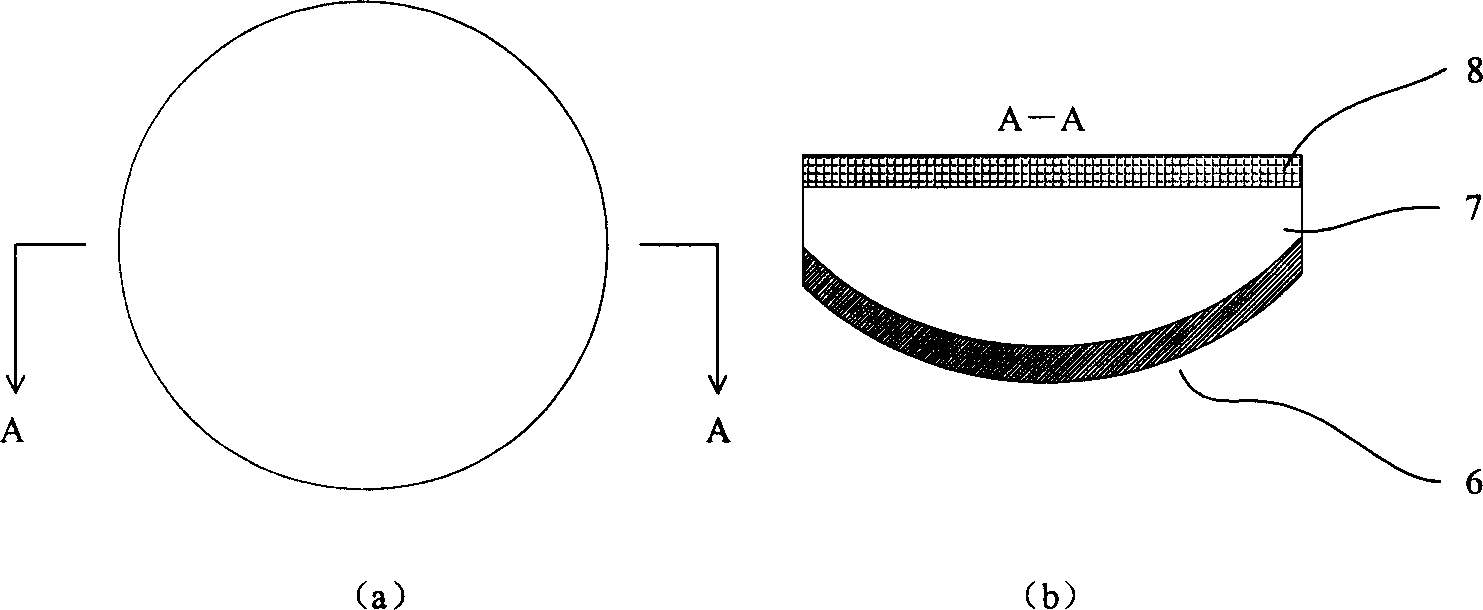

Solar energy thermoelectric co-supply system

InactiveCN1773190AImprove utilization efficiencyImprove photoelectric conversion efficiencySolar heating energySolar heat collector controllersControl systemEngineering

The present invention relates to a solar heating and power generation combined supply system. Said system includes the following several components: rotating parabolic saucer condenser, rotating hyperbolic spectral control system, light-gathering photovoltaic group battery and hot-pipe type water heater. Said invention also provides the concrete structure of the above-mentioned every portion and the working principle of said system.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

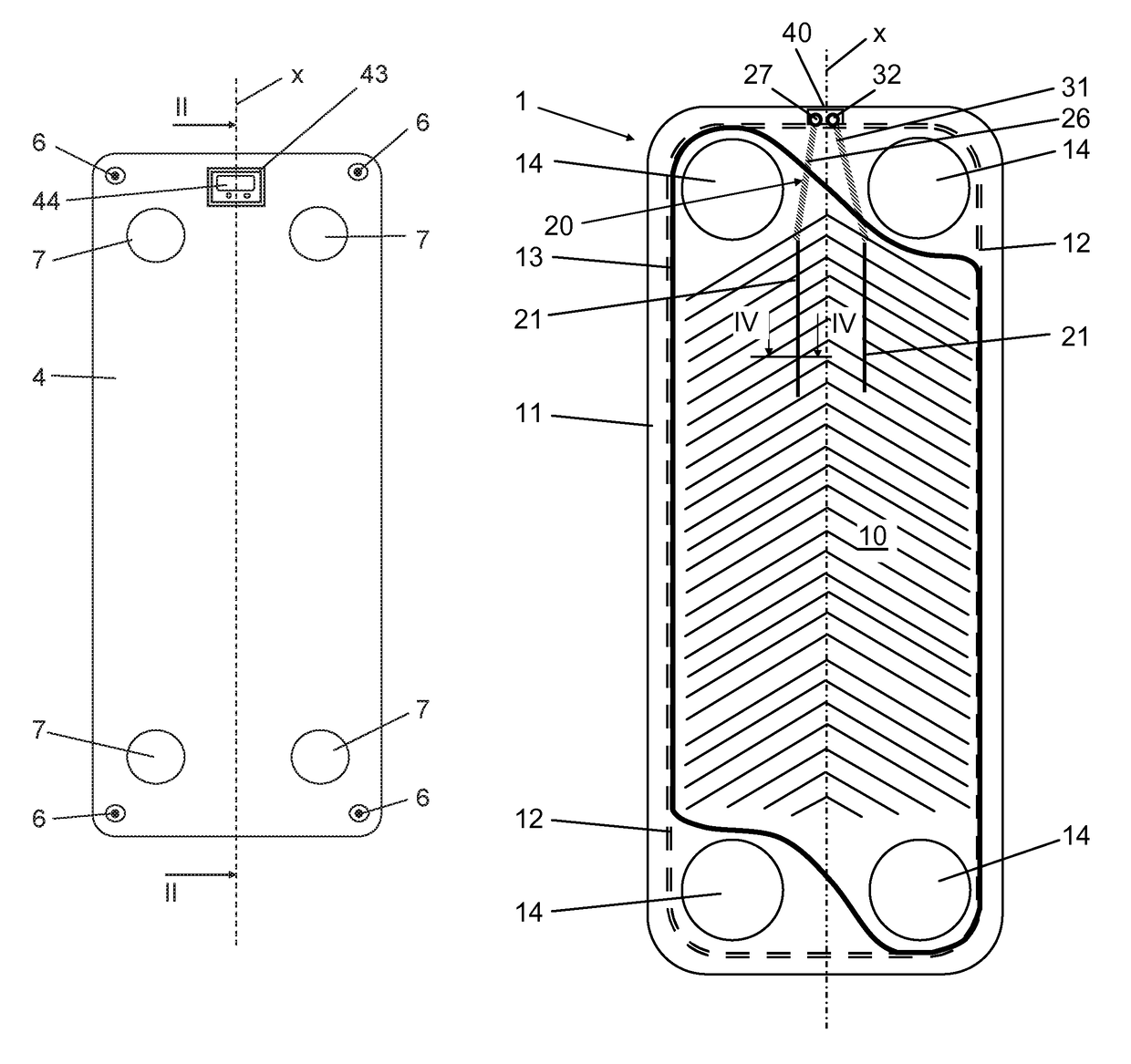

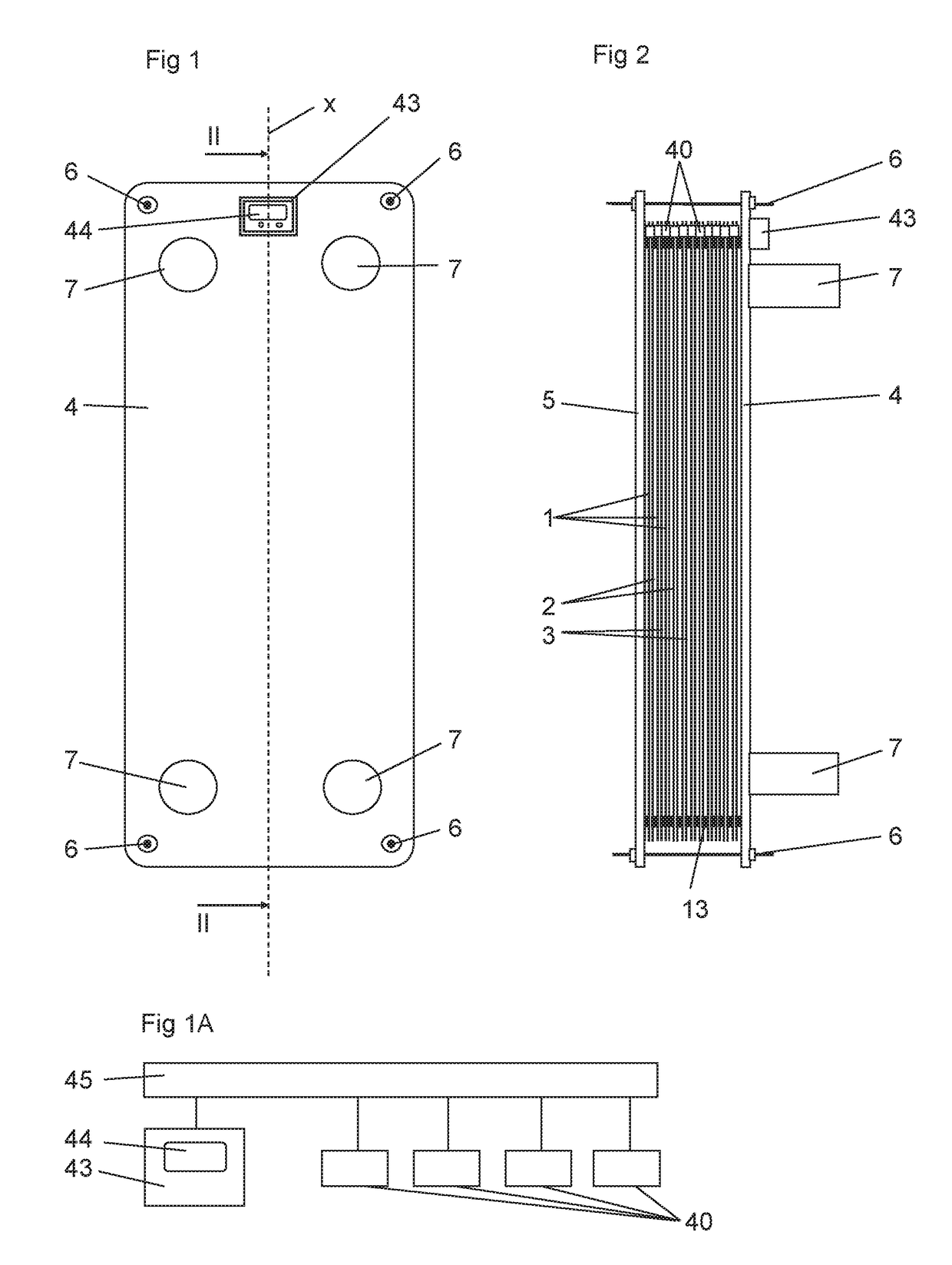

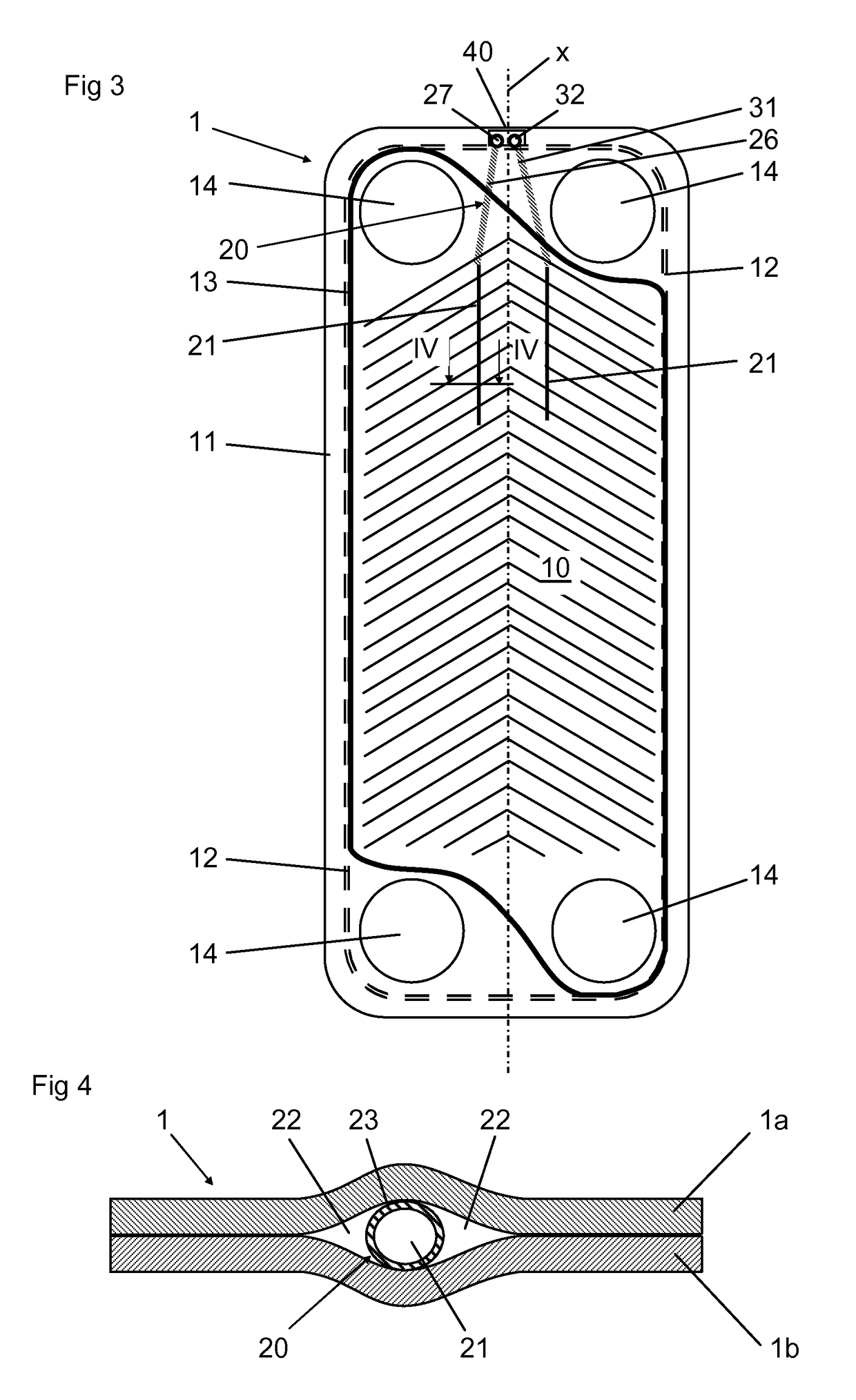

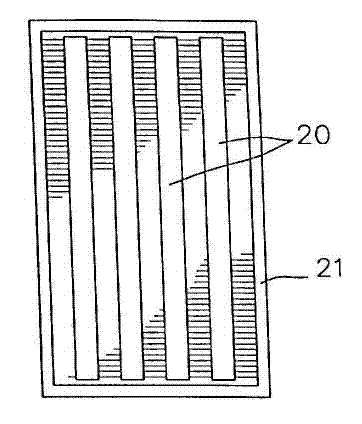

Heat exchanger plate and a plate heat exchanger with insulated sensor internal to heat exchange area

ActiveUS9739546B2Raise the possibilityDetection of leakageDetection of fluid at leakage pointAir-treating devicesDouble wallEngineering

A plate heat exchanger includes a heat exchanger plate having a heat transfer area and an edge area, extending around the heat transfer area. The heat exchanger plate is a double wall plate formed by two adjoining plates compressed to be in contact with each other. A sensor configured to sense at least one parameter and to produce a signal depending on the parameter includes a sensor probe that is provided between the adjoining plates.

Owner:ALFA LAVAL CORP AB

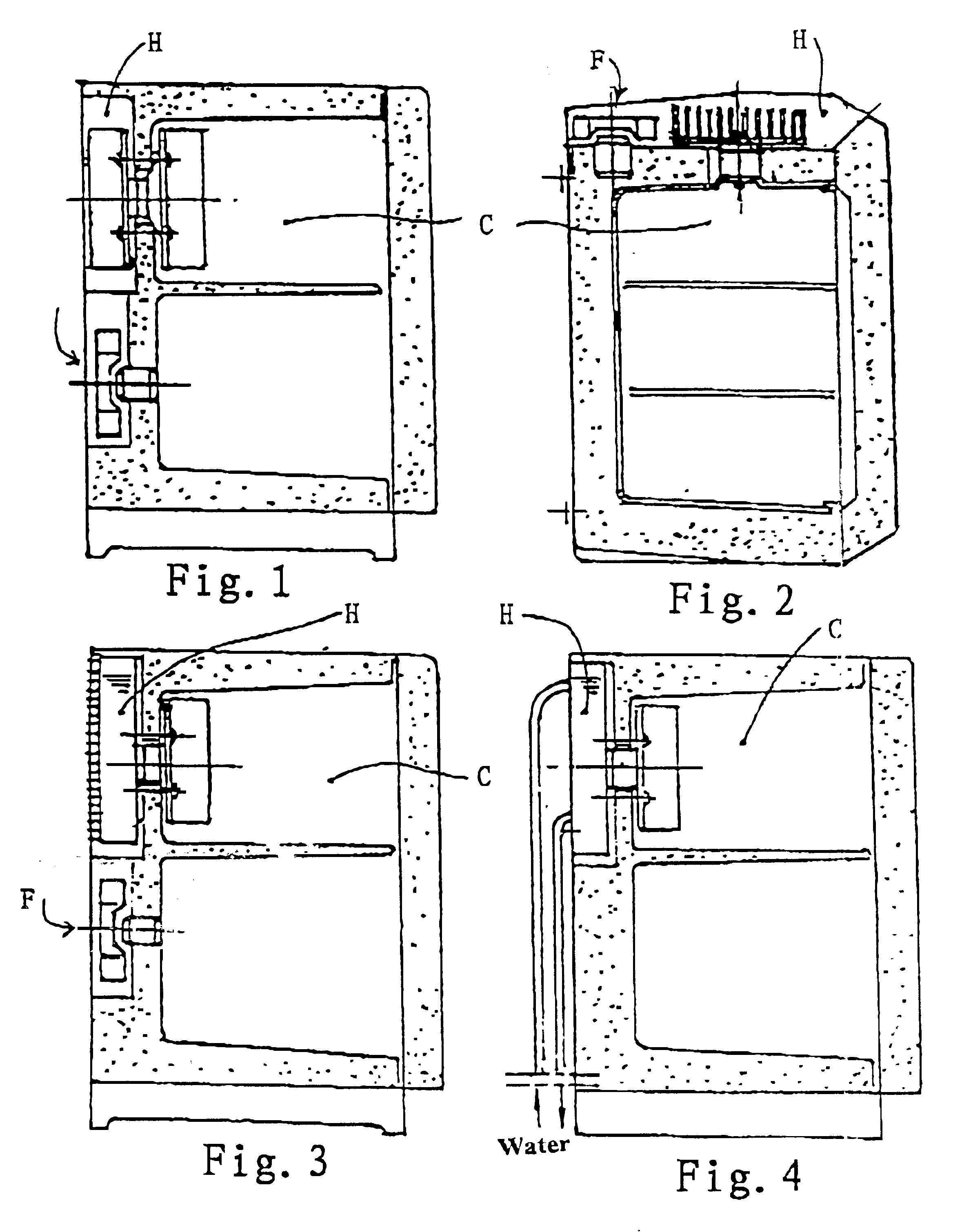

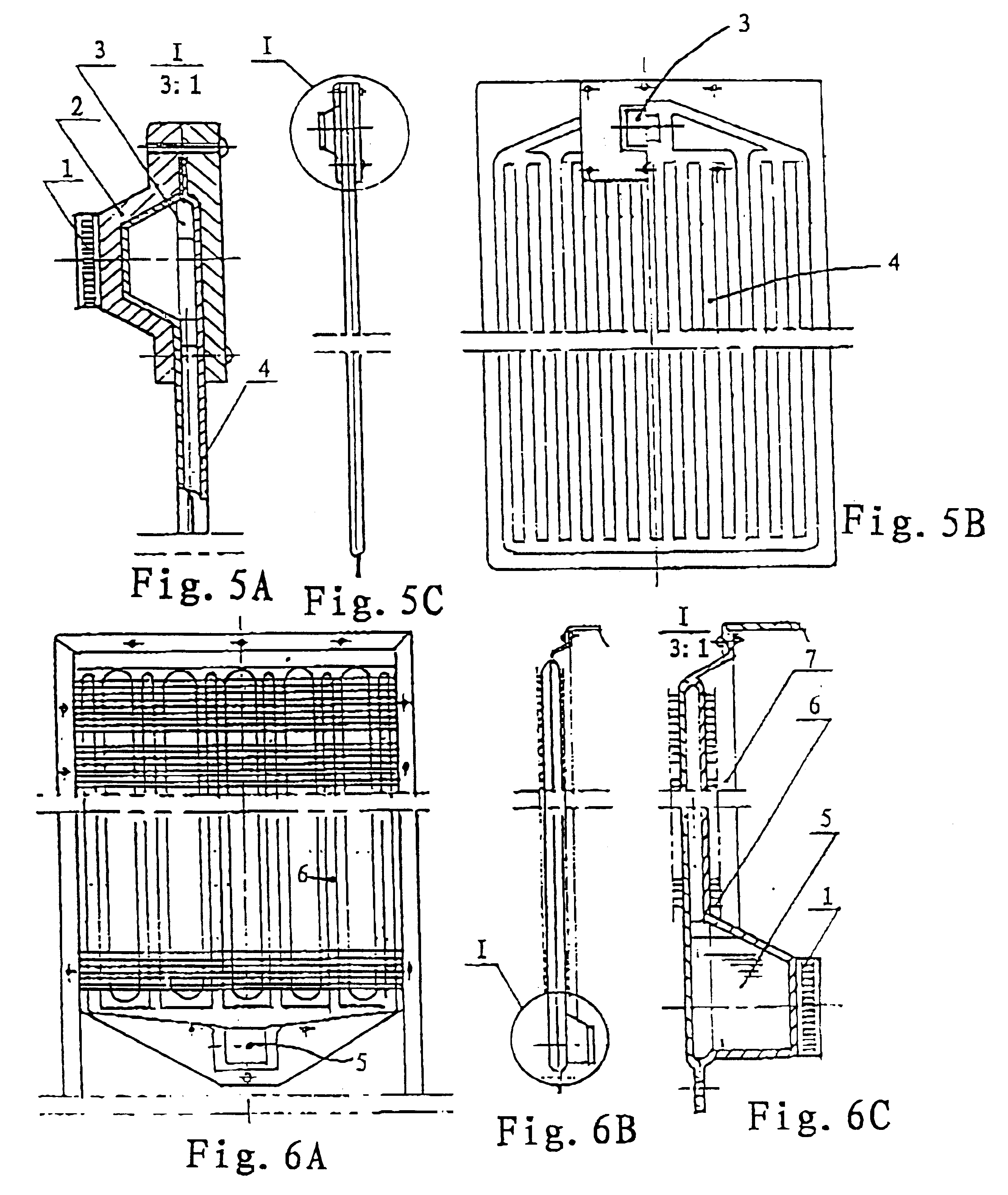

Thermoelectric cooling device using heat pipe for conducting and radiating

InactiveUS6351951B1Efficient and large conductionEfficient and large and dispersionHeat exhanger conduitsDomestic refrigeratorsThermoelectric coolingHeat conducting

A thermoelectric cooling device using heat pipes for heat conducting and dispersing, comprising a multi-bundle of the heat pipe conducting plates installed at the cold end of the thermoelectric cooling member and converged to condenser, a multi-bundle of the heat pipe heat exchangers installed at the hot end of the thermoelectric cooling member with fin plates or fin stripes and converged to the evaporator. It performs a fast cooling and heat dispersing by heat pipes and high efficient phase change and heat transport of the working medium. It can eliminate the heat exchange produced by the heat accumulation on the cold and hot ends, so as to run at the minimum operation temperature differences in order to obtain the maximum cooling capacity.

Owner:LUQUAN JIWEI ELECTRICAL APPLIANCE

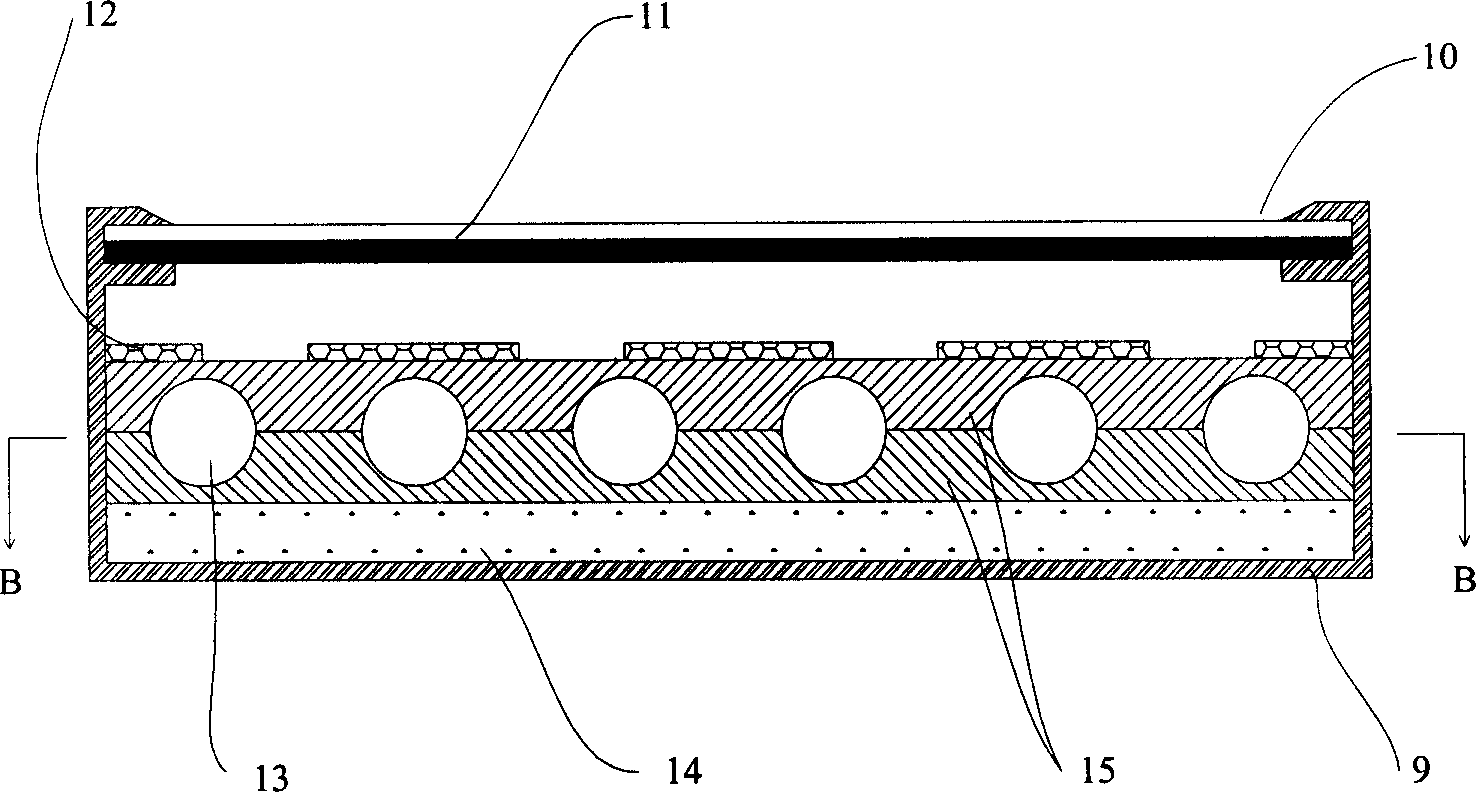

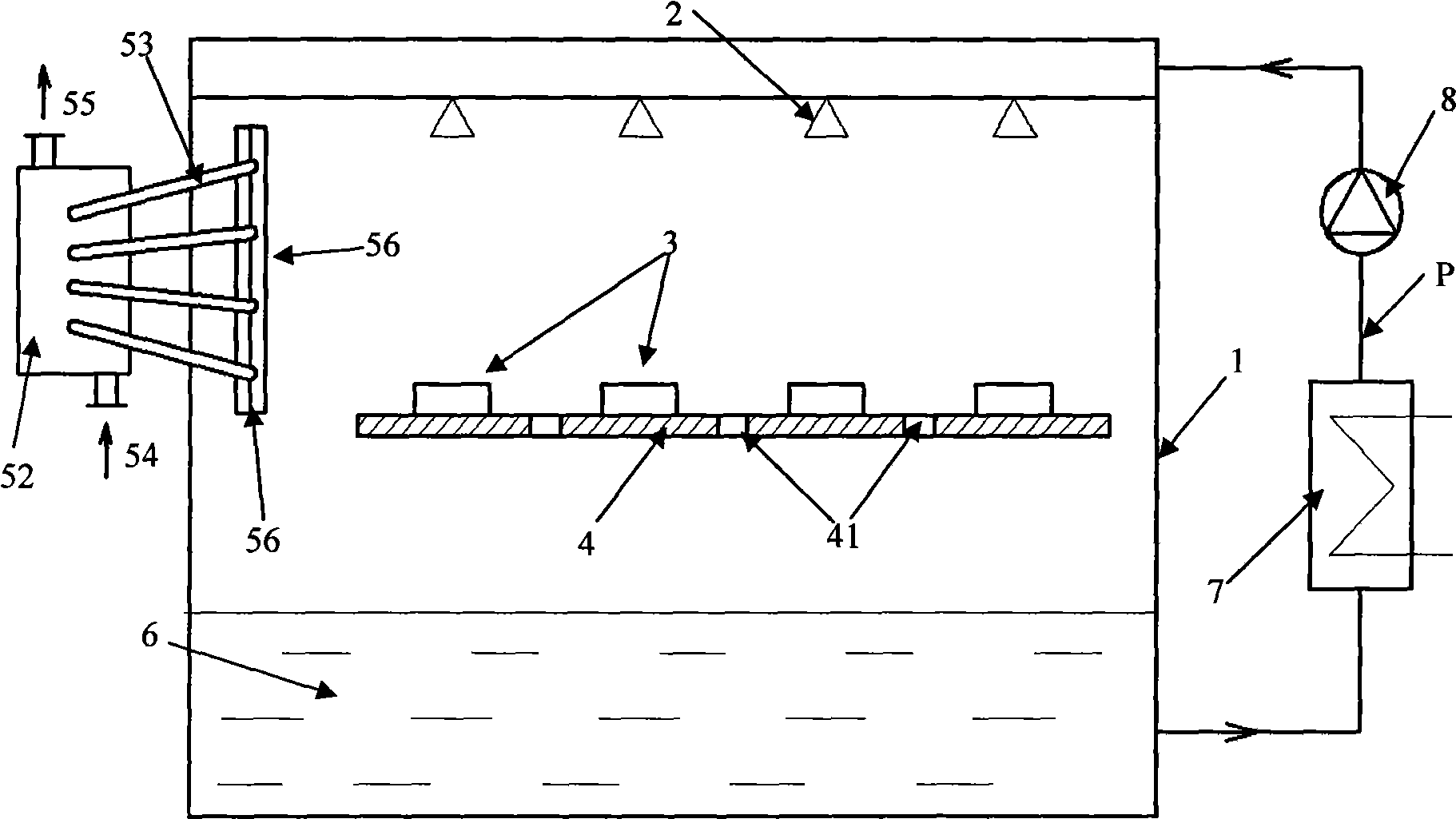

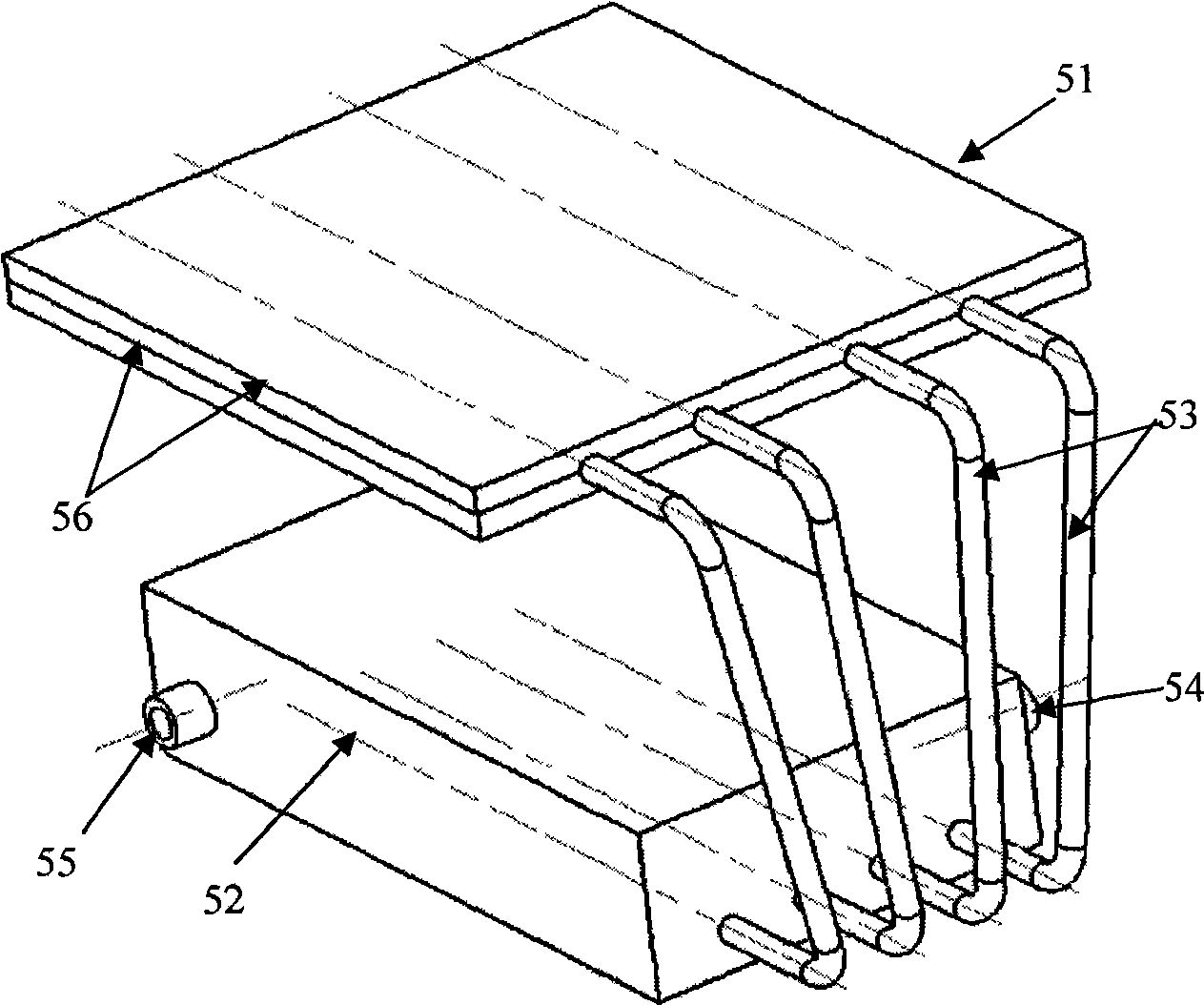

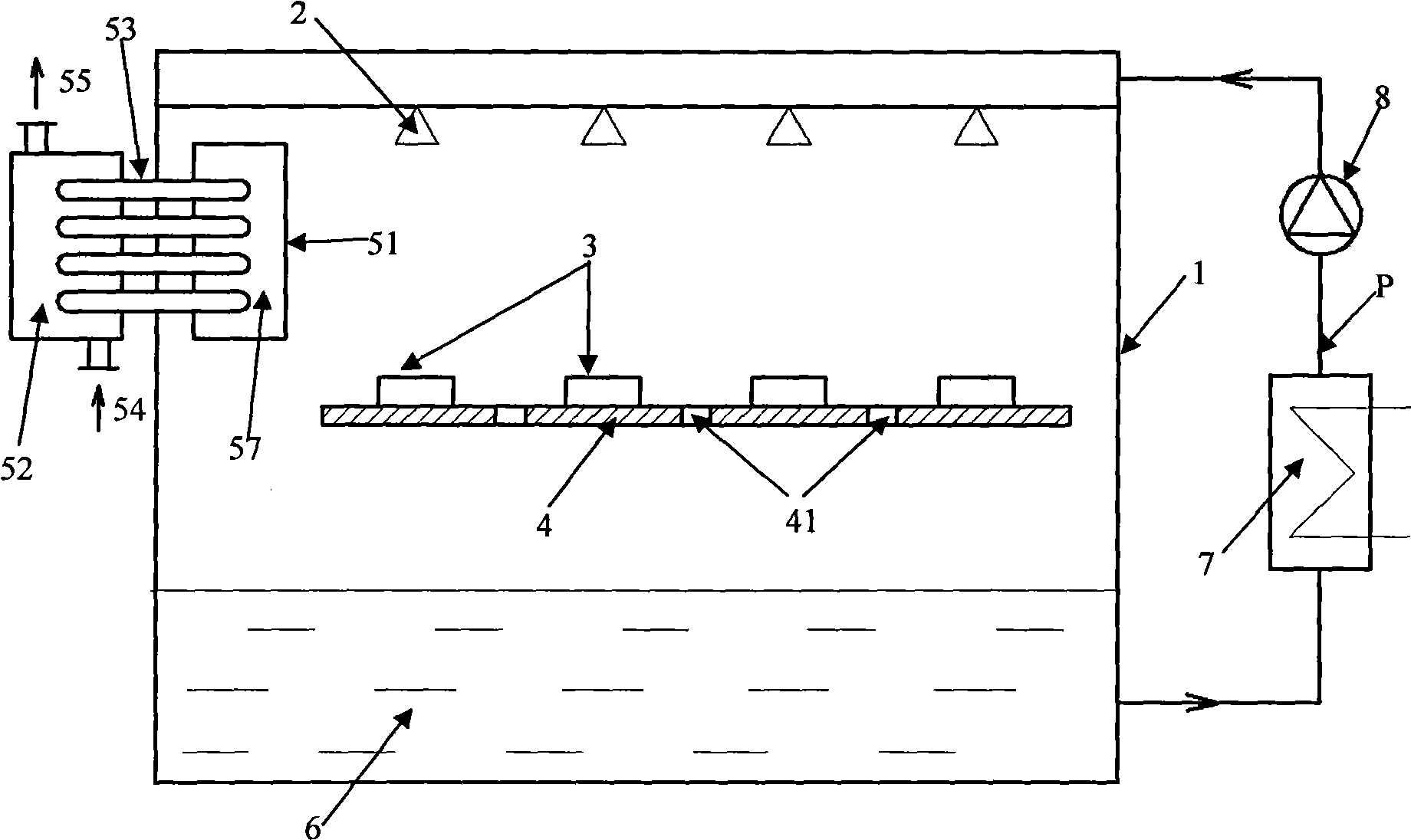

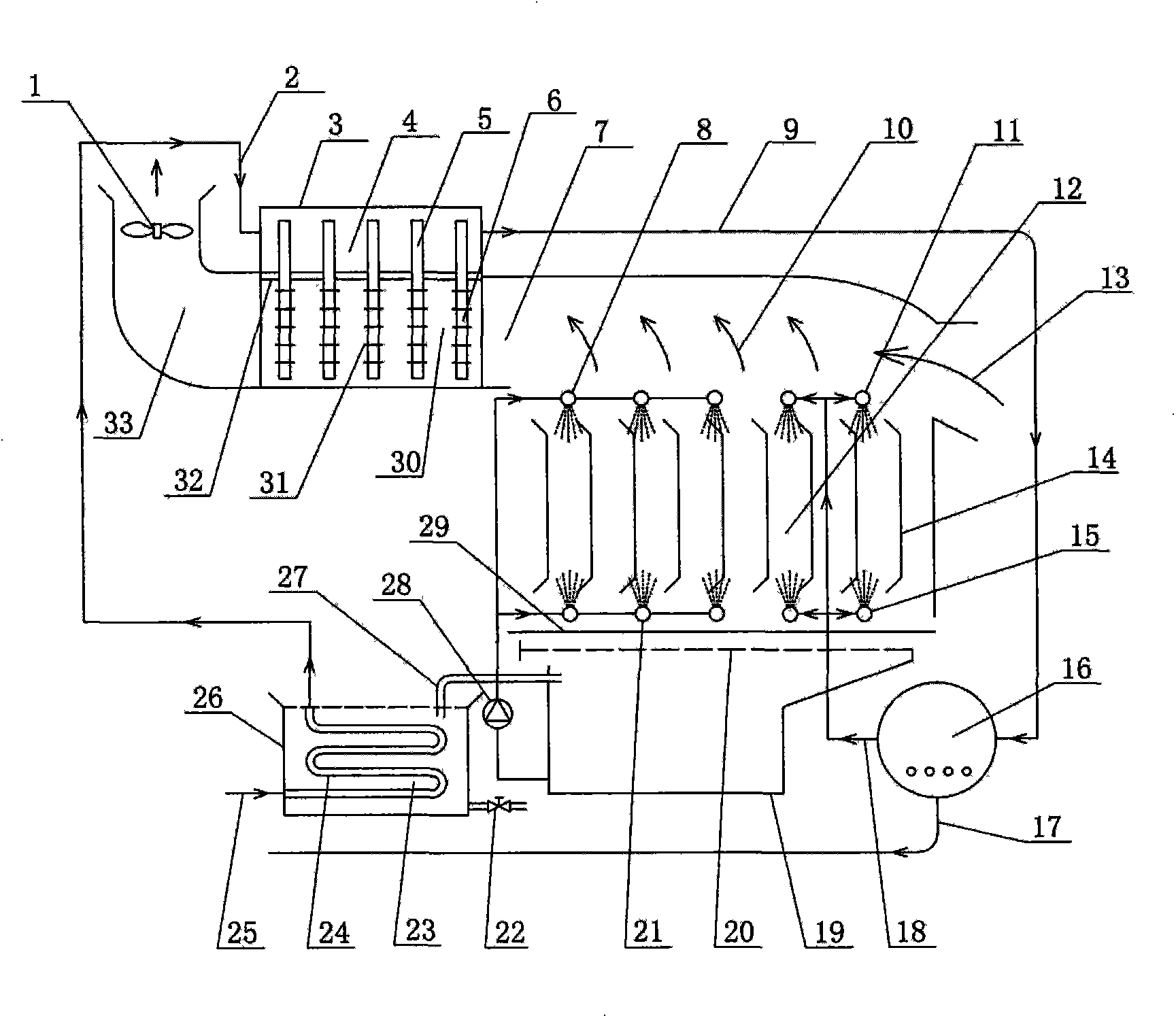

High-effective integral spray cooling system

InactiveCN101534627AReduce heat transfer areaCompact structureSemiconductor/solid-state device detailsSolid-state devicesEvaporationEngineering

The invention relates to a high-effective integral spray cooling system, which solves heat dissipation problem in field such as high power electron or laser system. The spray cooling system includes a spray cavity, a heat exchanger, a cooler, a circulating pump and a system working medium circulation pipeline, wherein the heat exchanger is a heat pipe heat exchanger; one end of the heat pipe of the heat pipe heat exchanger is a condensation end, and the other end is an evaporation end; the evaporation end is arranged in the spray cavity and is a steam condenser, and the condensation end is arranged in a water cooling shell-and-tube heat exchanger outside the spray cavity. The invention separates steam cooling and liquid cooling, which is beneficial to respectively increase heat transfer effect in condensation and cooling process; employs the heat pipe condenser to further increase heat transfer performance in condensation process and reduce heat exchange area of the condenser; and arranges the condenser in the spray cavity for making spray cooling structure more compact and reducing flow resistance of working medium steam, thereby reducing operating pressure of the spray cavity and being beneficial to increase general heat dispersion performance of spray cooling.

Owner:UNIV OF SCI & TECH OF CHINA +1

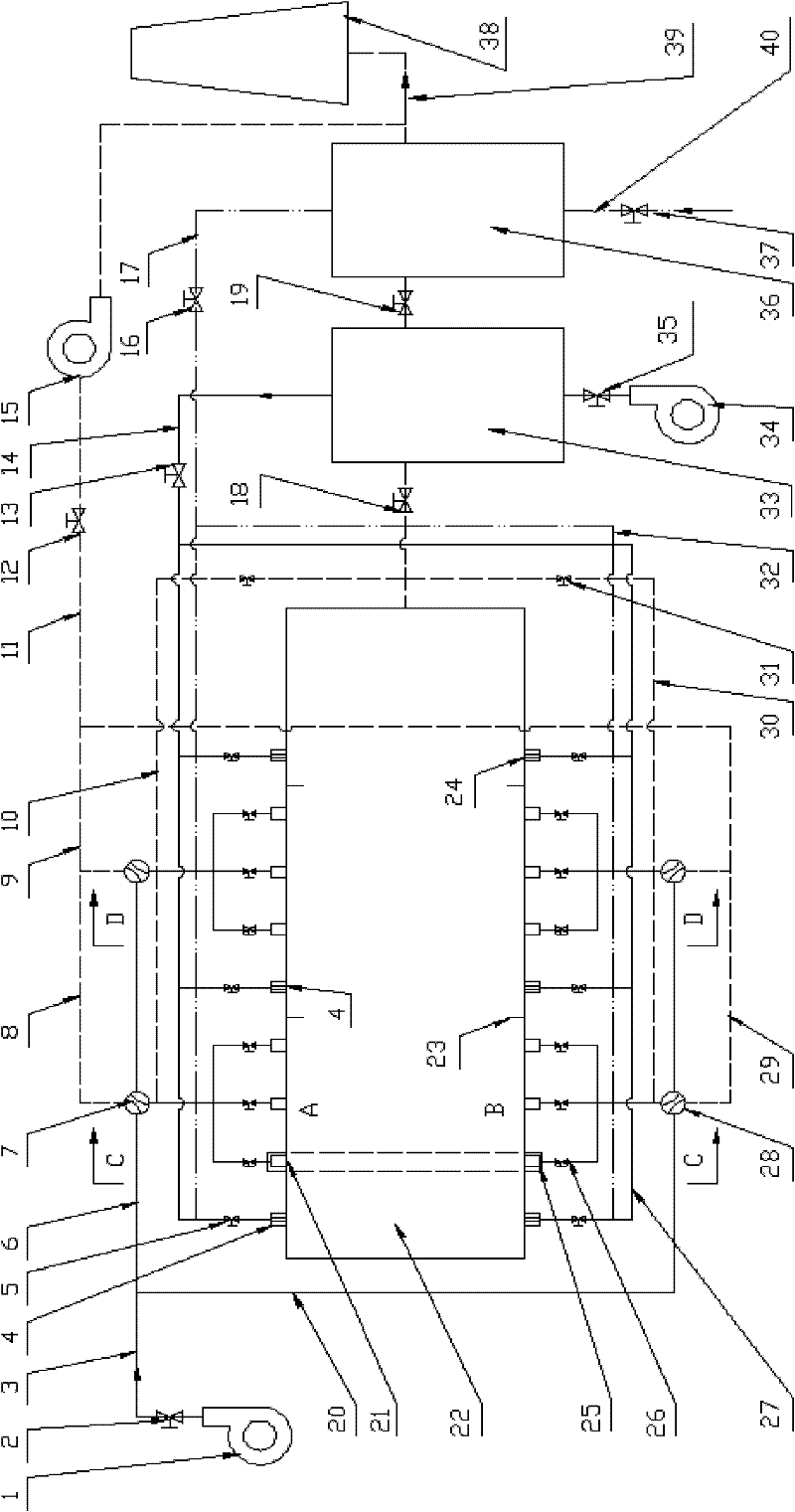

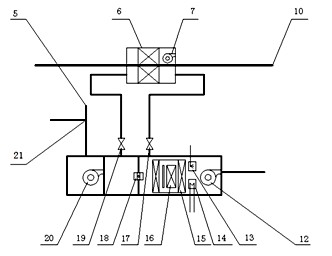

Heating device for improving heating quality of steel billets and using method thereof

ActiveCN102242249AImprove heating uniformityImprove uneven flow fieldFurnace typesHeat treatment furnacesHeat pipe heat exchangerGas pipeline

The invention relates to a heating device for improving heating quality of steel billets and a using method thereof. The heating device comprises a heating furnace, a heat storage system blower, a flat flame system blower, a combustion-supporting air pipeline, a gas pipeline, a heat storage system draught fan, an air heat exchanger, a gas heat pipe exchanger, a smoke exhaust pipeline and a chimney. 2-4 ignition burners are arranged at a preheating section of a heating furnace, and 12-30 pairs of heat storage type burners and 4-12 flat flame burners are respectively arranged at a heating section and a soaking zone. The using method comprises the following steps of reasonable distribution of combustion-supporting air and gas flow rate of the heat storage type burners and the flat flame burners, sectional configuration of furnace temperature and heating time, preheating of combustion-supporting air and gas temperature through a high-temperature smoke gas and furnace tail gas in grades, alternative furnace feeding of cold and heat steel billets, intermittent movement of the steel billets, and vaporization cooling of the steel billets. The flow field in the furnace is modified through the system, the optimal configuration of flow rates of air and gas in the burner is realized through reasonable arrangement of gas and air pipeline systems, and the waste heat of high-temperature smoke gas of the heating furnace is gradiently utilized, thus the in-furnace time is shortened, the uniformity of heating the steel billets is improved, and the high-efficiency heating of the steel billets is realized.

Owner:SHOUGANG CORPORATION

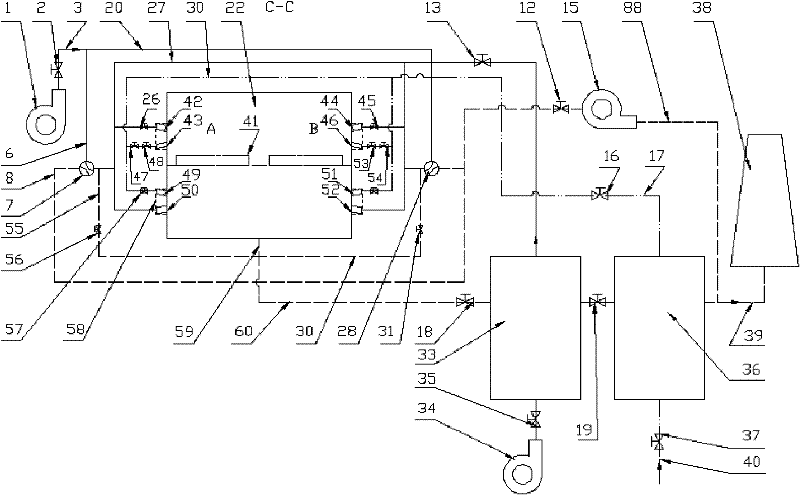

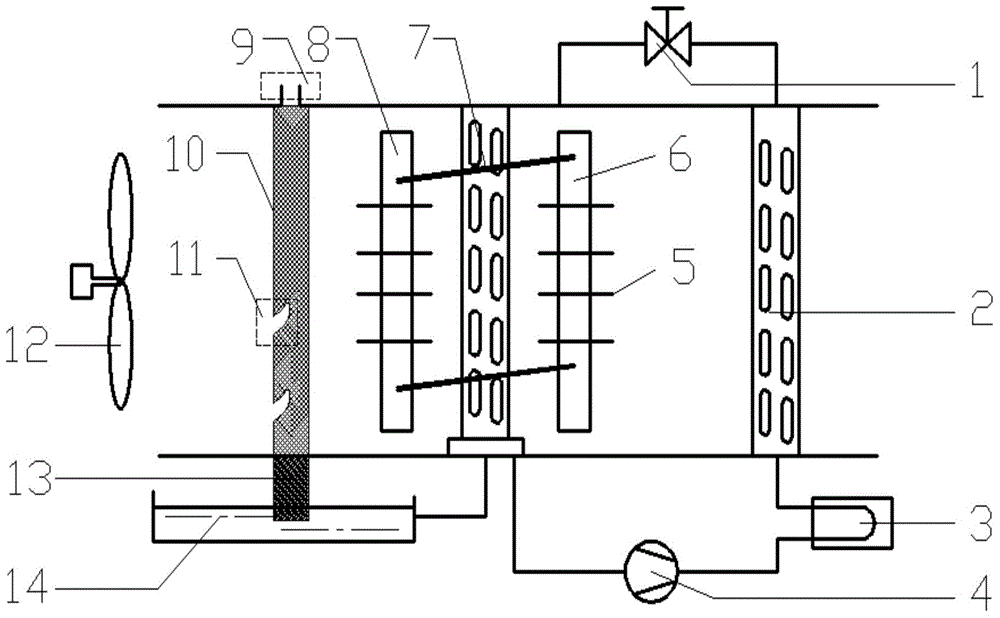

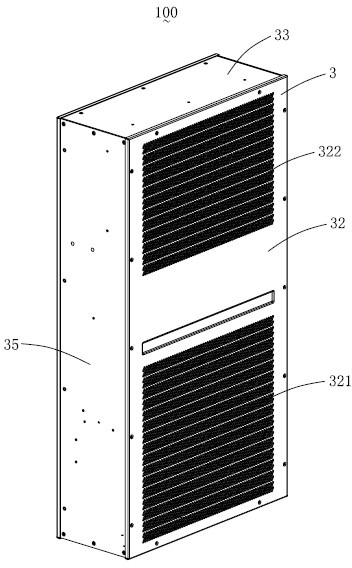

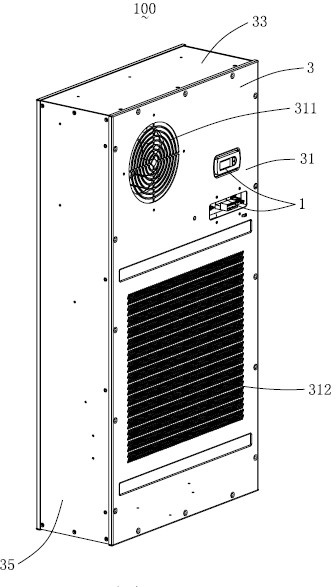

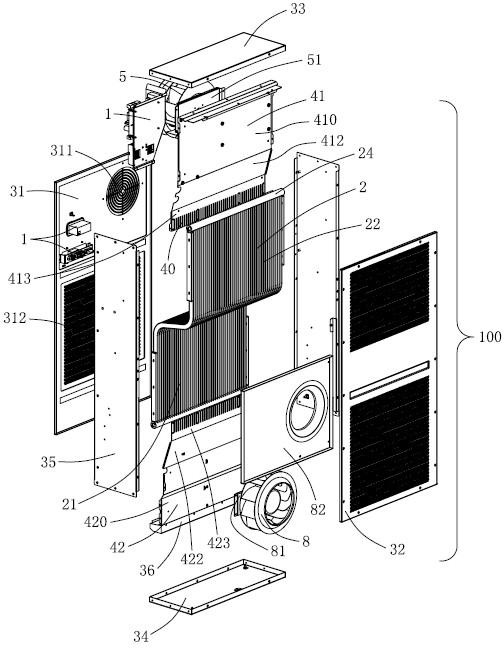

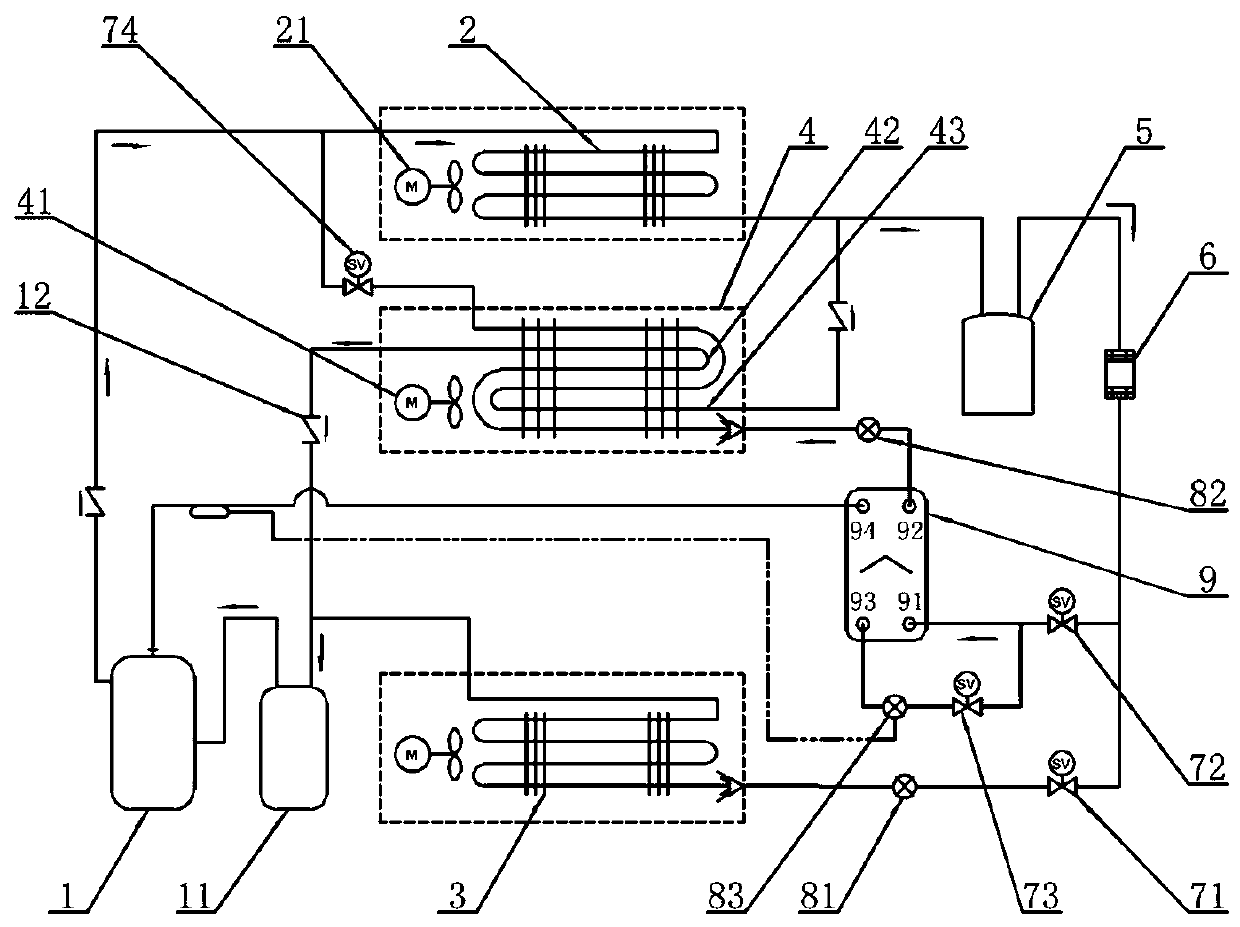

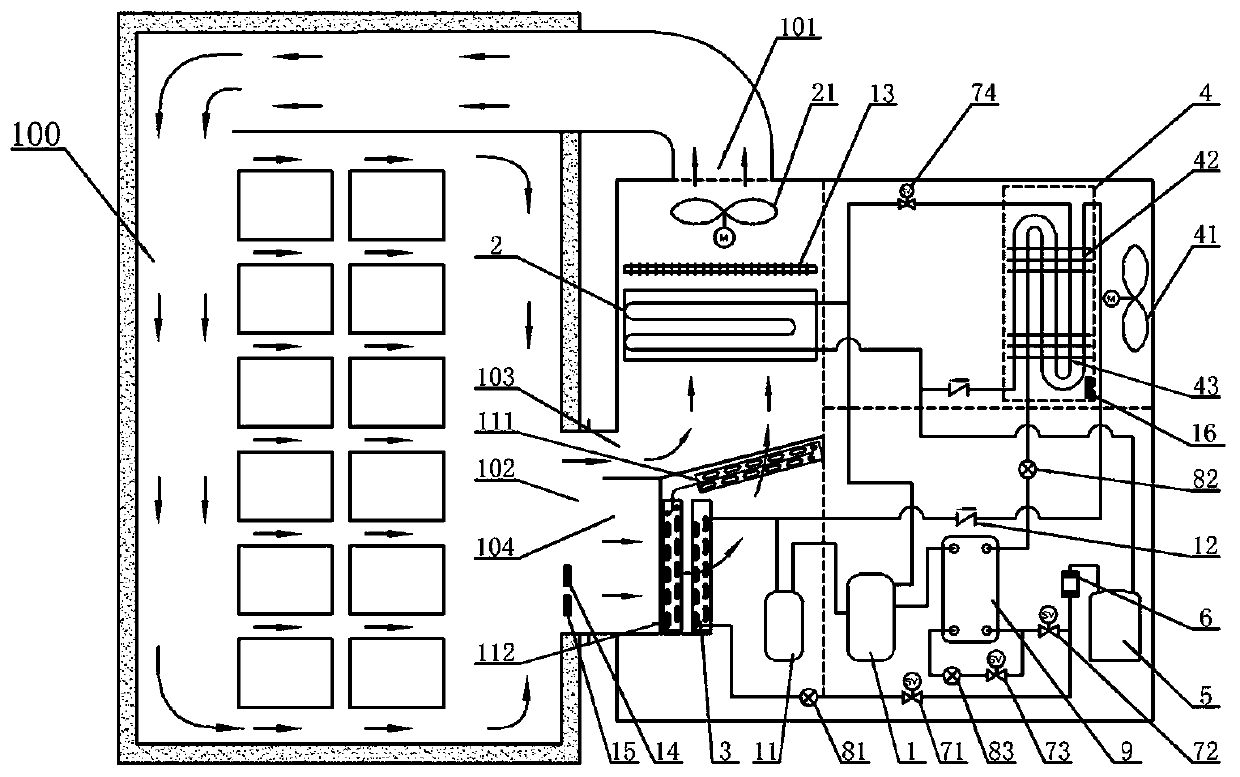

Energy saving device suitable for accurate control air conditioner in machine room

ActiveCN102425828AAvoid enteringReduce loadEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsAutomatic controlEngineering

The invention discloses an energy saving device suitable for an accurate control air conditioner in a machine room; the energy saving device comprises a refrigerating compression unit, a hot and humidity control device, a loop heat pipe device, separating air flue type heat pipe exchangers, an air valve, a fan, an air flue and an electronic control system. In transitional seasons and winter, the electronic control system automatically controls the opening and closing of the valve so that indoor air passes through a separating air flue inside the room and outdoor cold air passes through a separating air flue outside the room; and air inside the machine room is cooled by using the cold energy of outer air through the arrangement of a middle separating air flue type heat pipe exchanger. The separating air flue type heat pipe exchangers are used for recycling the part of cold energy of exhaust air in a summer working condition through the arrangement of an air supply / exhaust pipeline to precool new air. Loop heat pipe devices arranged before and after an evaporator can recycle the part of energy consumption of electric heating, thereby the energy is saved. According to the energy saving device, the energy saving scheme of the air conditioner in the machine room is further perfected and provides a very good reference value for energy saving of the air conditioner in the machine room.

Owner:合肥万豪环境科技有限责任公司

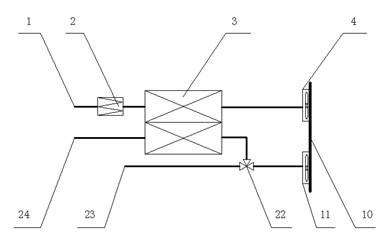

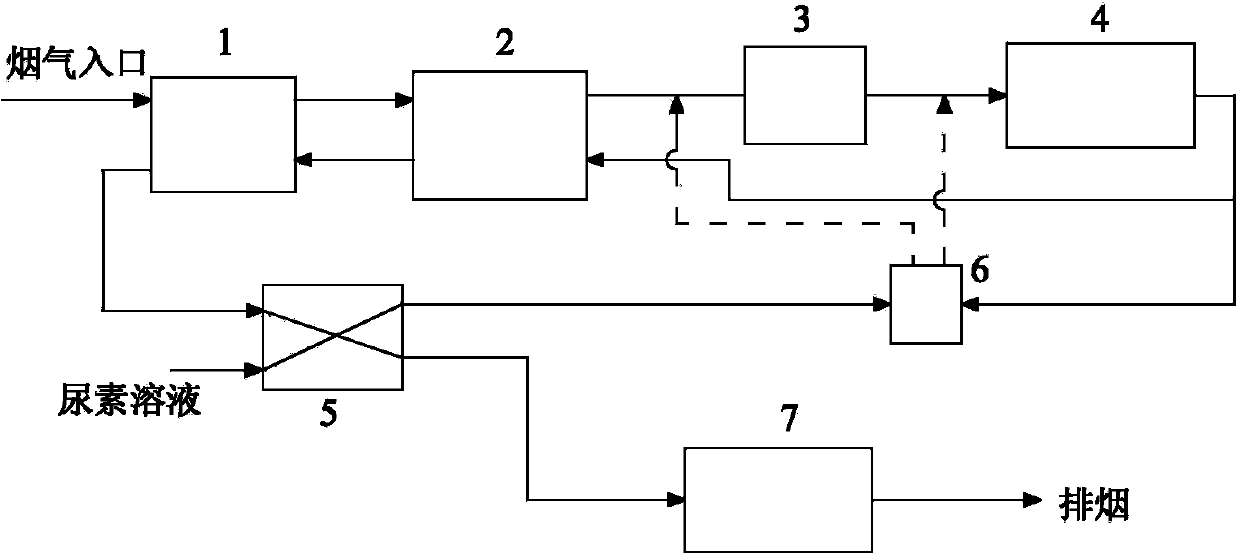

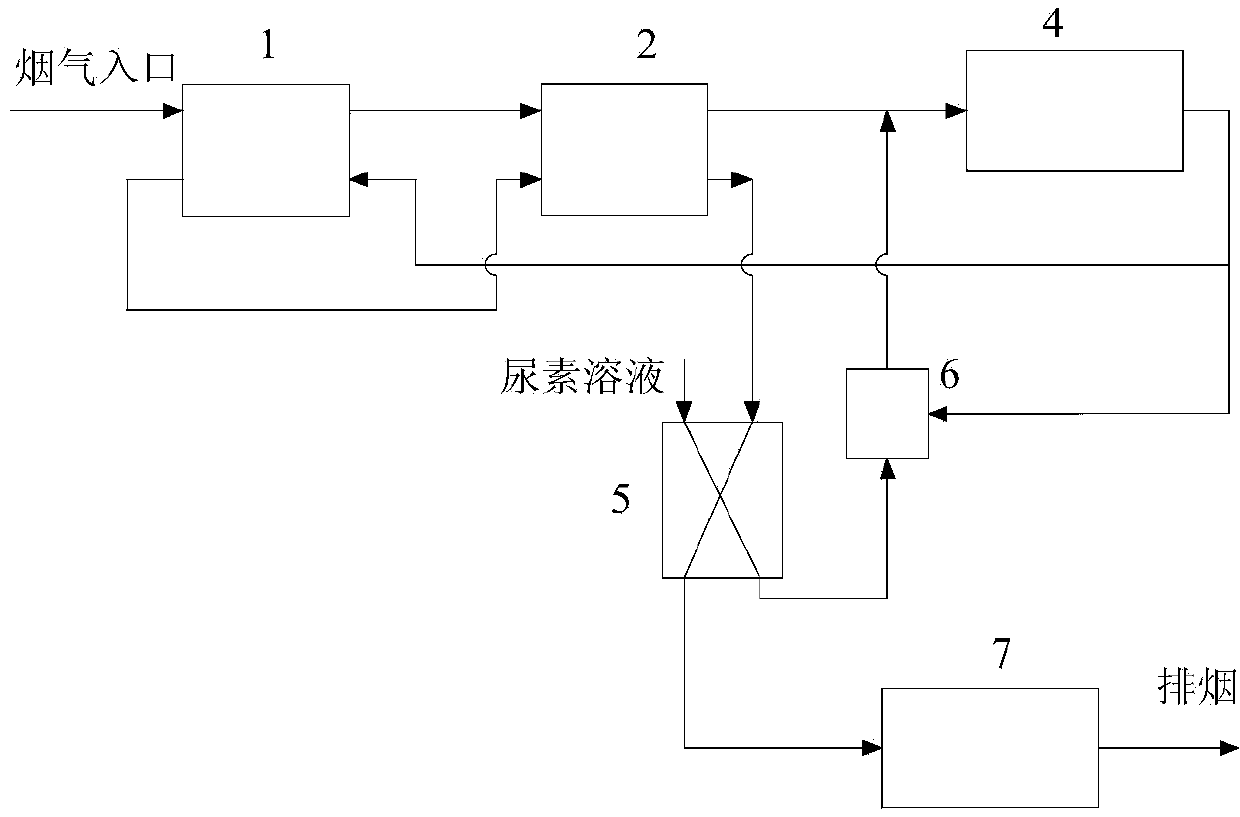

Flue gas desulphurization and denitration method as well as its apparatus

ActiveCN103585867AIncrease temperatureReduce electric heating energy consumptionDispersed particle separationAmmonia productionAtmospheric air

The invention relates to a flue gas desulphurization and denitration method as well as its apparatus, and especially relates to a desulphurization and denitration technology system for flue gas from large-scale mobile facilities such as ships. The method comprises the following steps: flue gas is passed through a heat pipe exchanger and a heat pump in order for increasing temperature of flue gas, and flue gas is selectively passed through an electric heater for heating to the temperature of 340-350 DEG C, an urea solution is used for preparing ammonia gas in a hydrolysis reactor, ammonia gas is diluted by partial high temperature flue gas at an outlet of a SCR reactor and then mixed for injecting flue gas which is undenitrated, the mixed flue gas enters into the SCR reactor for a flue gas denitration reaction, the flue gas after denitration is passed through the heat exchanger, the heat pump and the hydrolysis reactor and cooled, and then enters into a desulfurization tower, flue gas after desulphurization is directly discharged into atmosphere, and an absorption liquid adds alkali and seawater for regeneration and cycle usage. In the method, the heat exchanger and the heat pump are used for recovering waste heat of flue gas, and the energy consumption is greatly reduced. The ammonia production method through hydrolysis is capable of increasing the mixing degree of ammonia and flue gas, so that denitration efficiency can be further increased.

Owner:湖州旧馆頔南污水处理有限公司

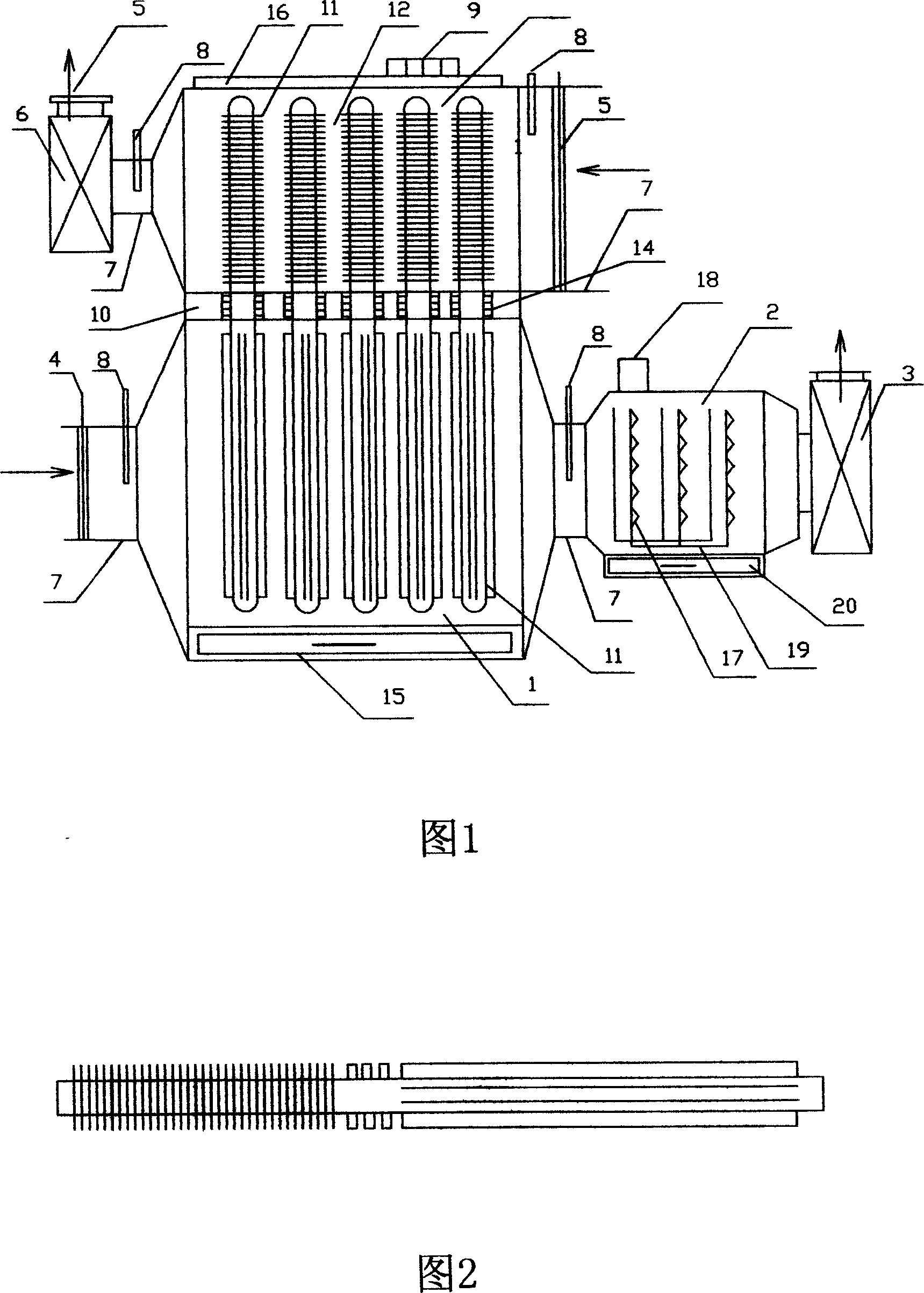

Heat shaped machine exhaust heat air purification heat energy utilized heat pipe exchanger

InactiveCN101113877AAvoid oil plugging sceneGuaranteed recyclingElectrostatic separationSteam/vapor condensersThermal energyEngineering

A heat pipe heat exchanger for waste heat air purifying and heat energy utilization of heat setting equipment is a heat pipe heat exchanger that is provided with heat pipes of different working mediums. An exothermic section of an air side heat pipe is of a spiral fin structure, and an endothermic section of a waste heat air side heat pipe is of a longitudinal fin structure. 50 percent of heat energy is recycled when the temperature of the waste heat air falls from 180 DEG C to 70-80 DEG C. At the same time, a waste heat air inlet tube and a heated air inlet tube are provided with a slot with a detachable and replaceable yarn dust filtering netting; the steamed and liquidized air that is condensed and discharged from the waste heat air with the heat absorbed by the heat pipe of longitudinal fin structure flows into an oil sump tank along the longitudinal fin, enters a low temperature electrostatic pulse oil fume staticizer, and the oil molecular is ionized in the high pressure pulse positive-negative electrode electric field. The waste heat air discharged from the heat setting equipment fundamentally reaches the requirements of environment protective of low temperature, dust free and oil free.

Owner:吴江市普天热管技术推广应用研究所

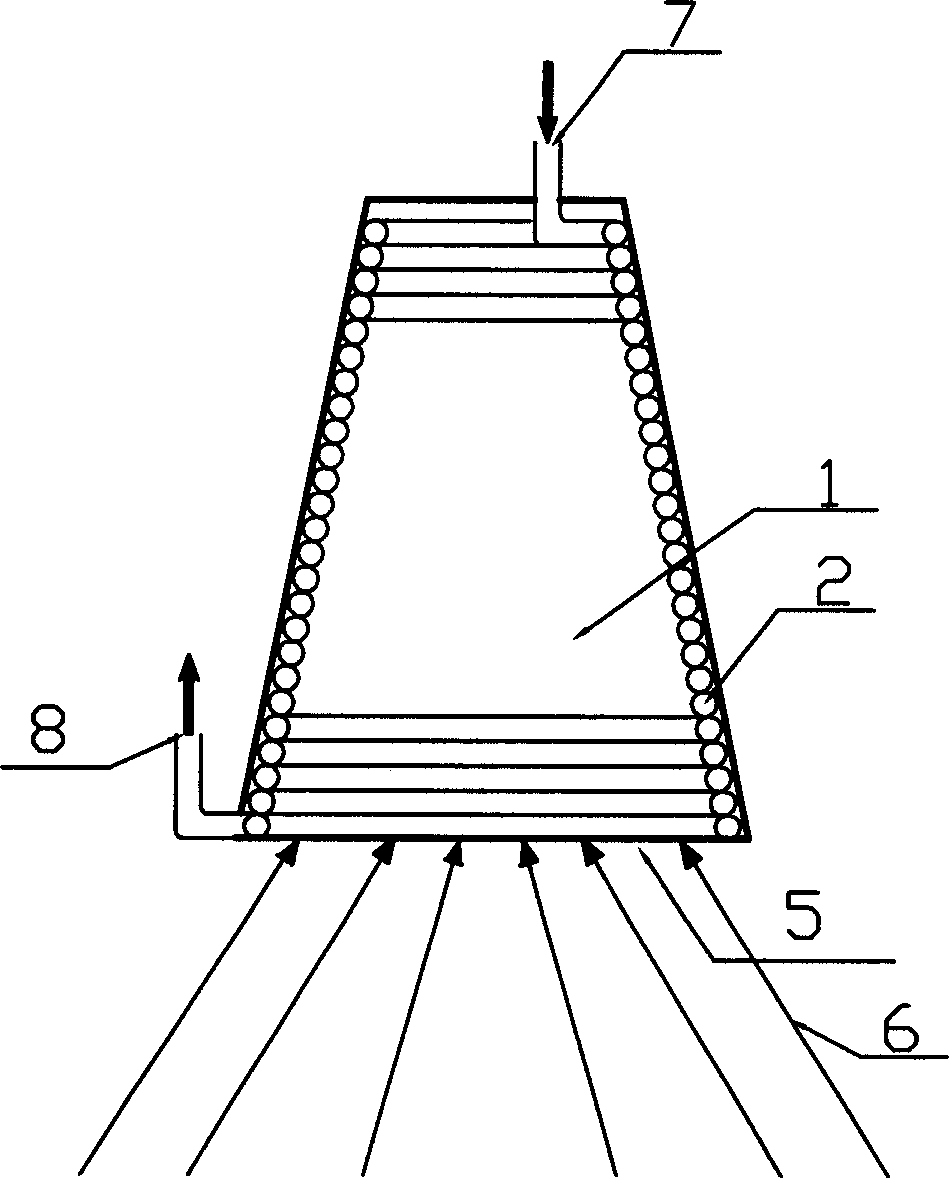

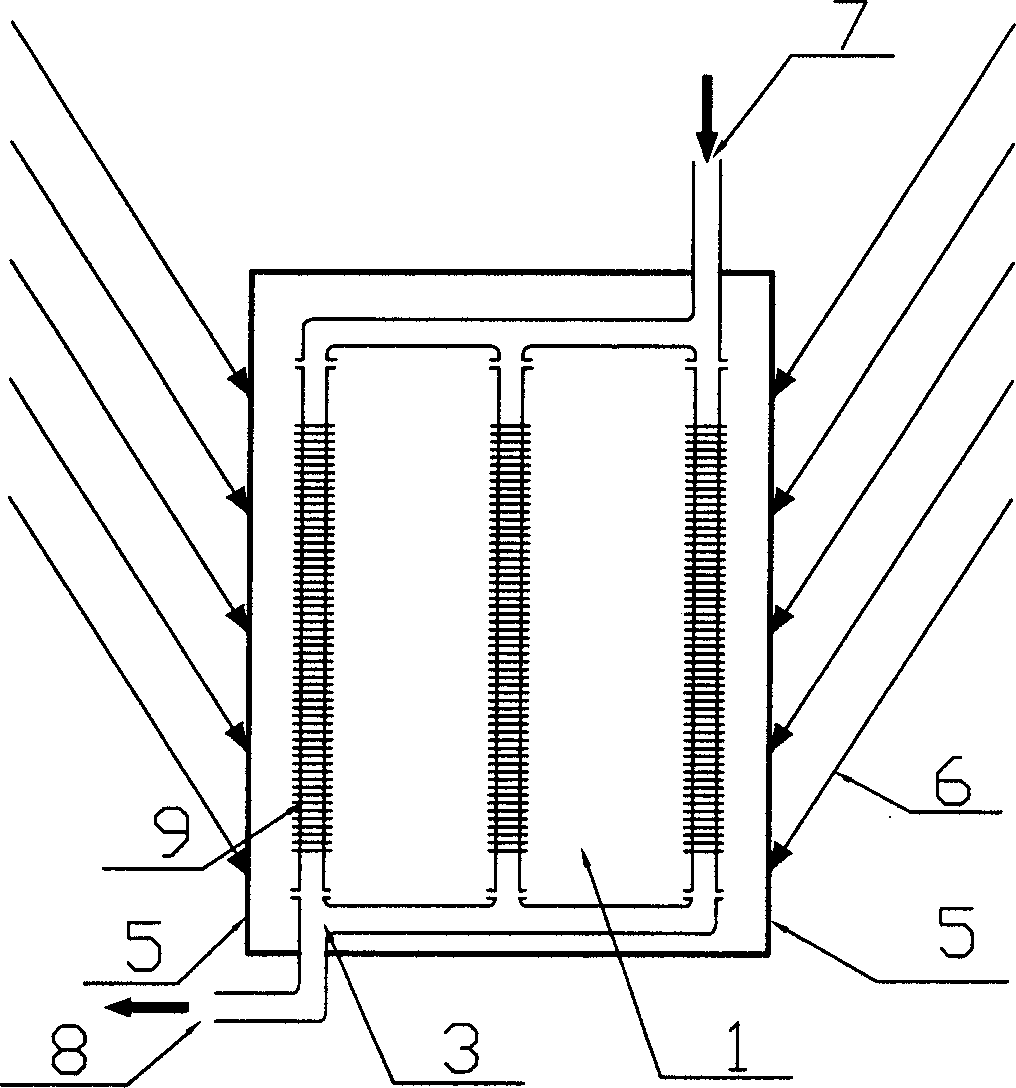

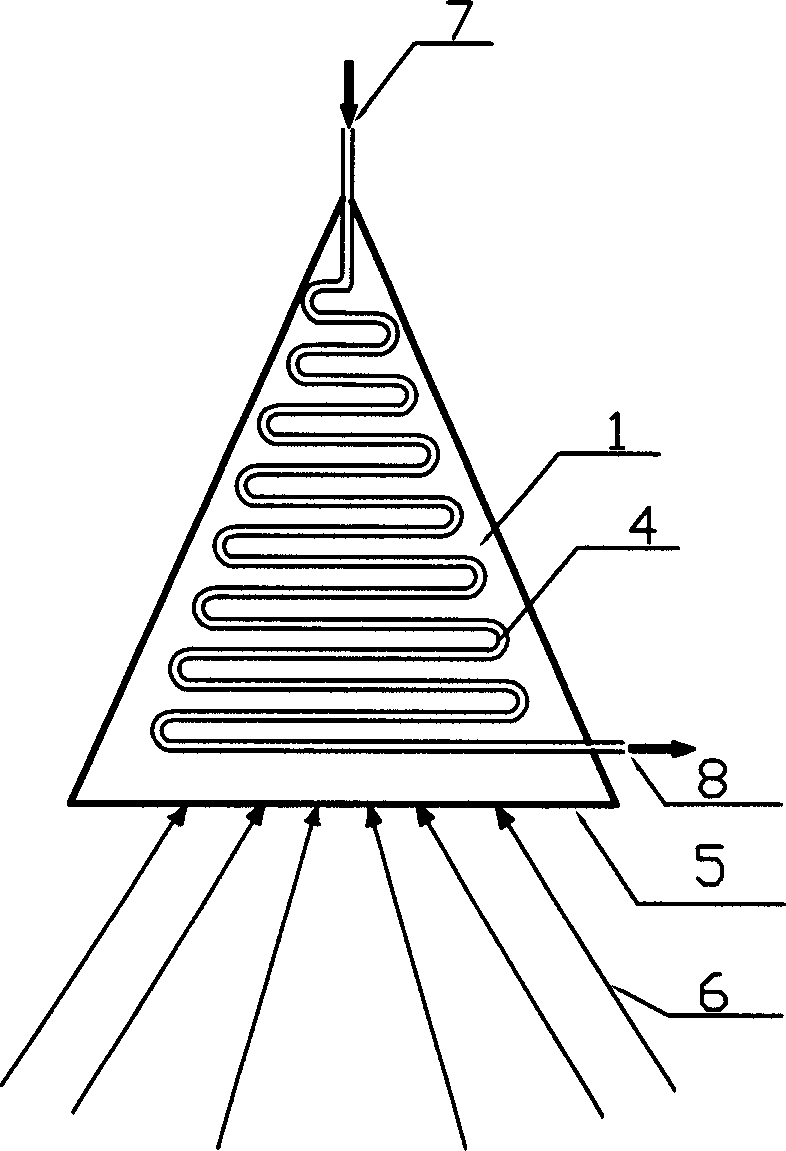

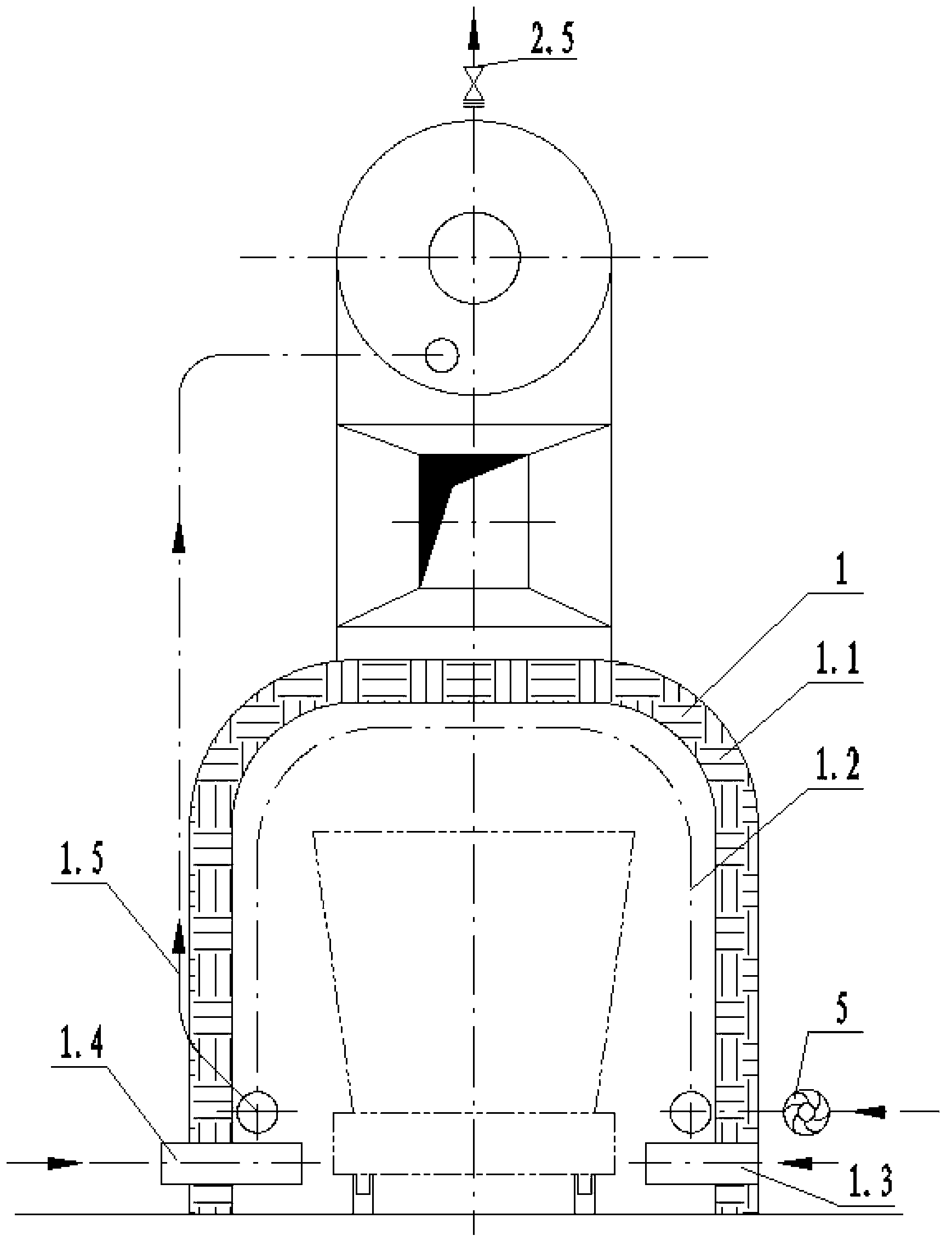

Binary medium solar high temperature heat absorption/storage device

InactiveCN1776322AGuaranteed to workReduce heat lossSolar heating energySolar heat devicesMolten saltEngineering

The heat absorber / heat storage includes cavity, heat exchanger, heat absorbent surface, and cycle working-medium inside the heat exchanger. Characters are that the heat absorber / accumulator also includes heat storage working medium. Filled between the heat exchanger and case, heat storage working-medium and the heat exchanger are in same case. Obtaining quantity of heat from heat absorbent surface, the heat storage working-medium stores energy and passes part of quantity of heat to cycle working-medium. The heat exchanger is metal coil pipe in single helix or dual helixes, or heat exchanger of ribbing heat pipe etc. Heat storage working-medium is molten salt of phase change in high temperature. Air, gas or water is adopted as cycle working-medium. Heat absorber / heat storage is in shape of circular truncated cone or taper. Heat absorption coating in high temperature is coated on heat absorbent surface. Features are: low cost and high thermal efficiency.

Owner:BEIJING UNIV OF TECH

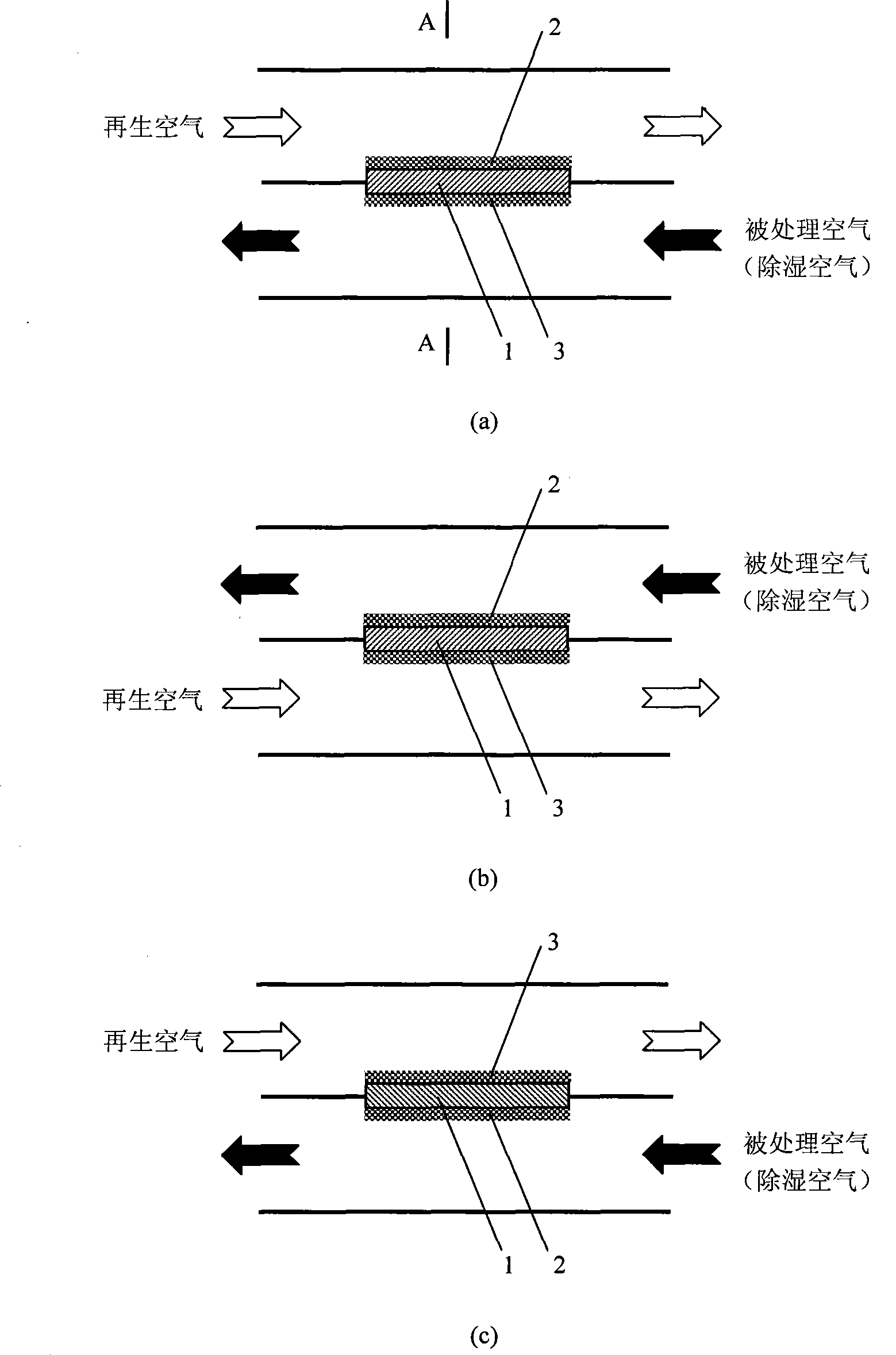

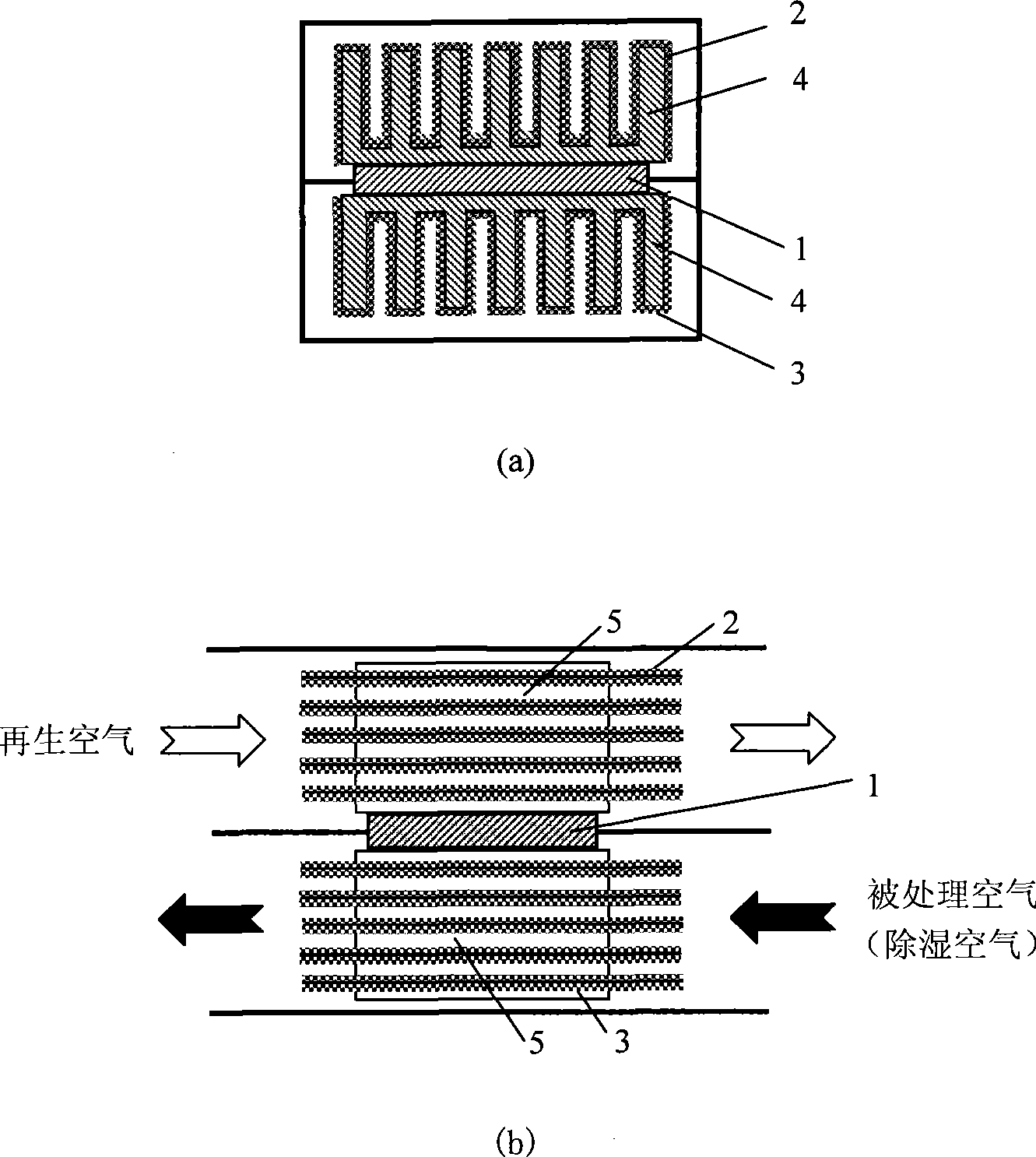

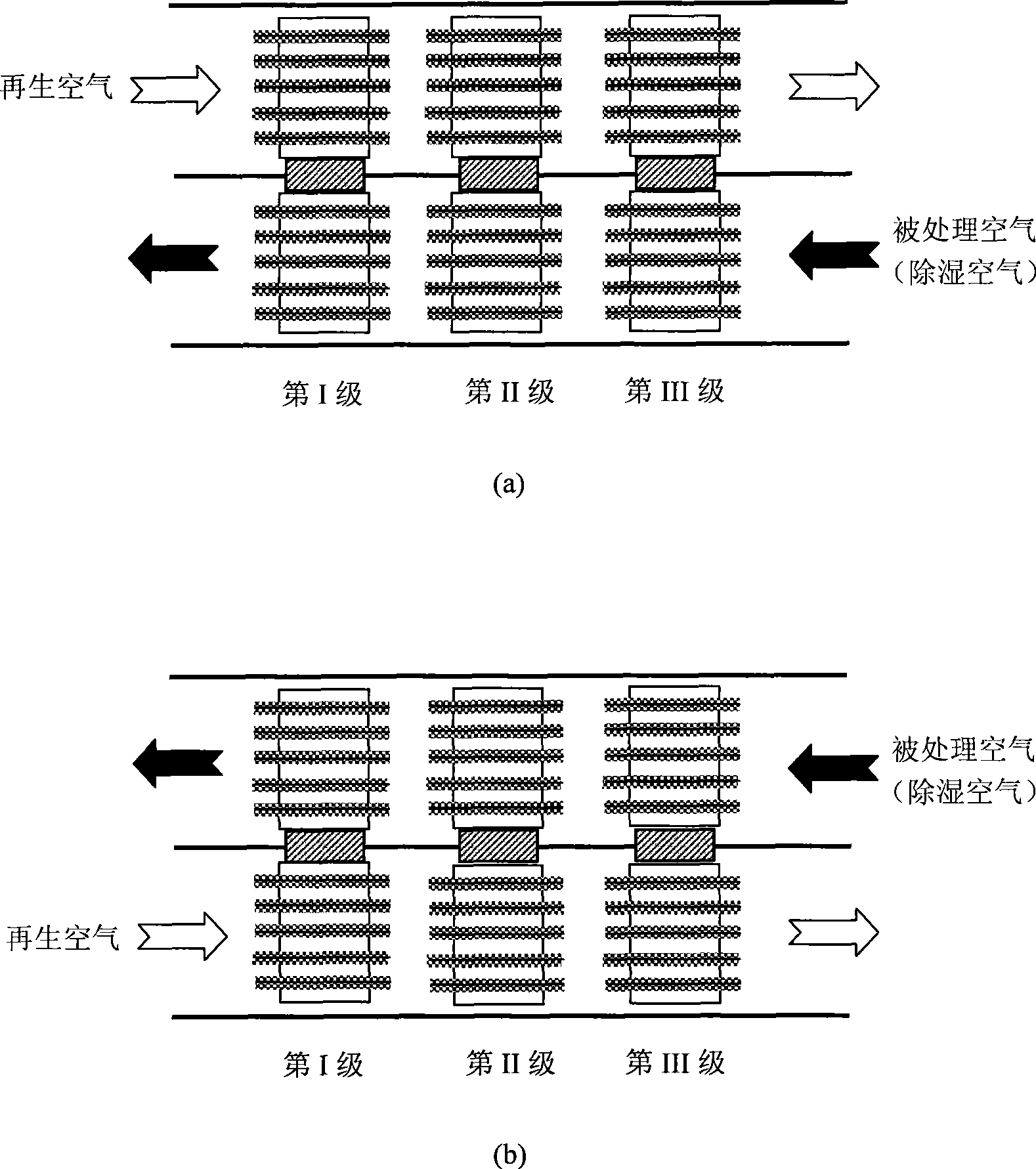

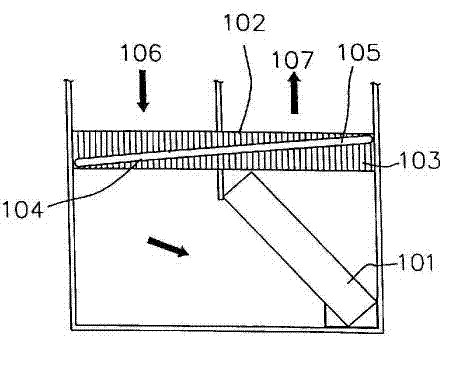

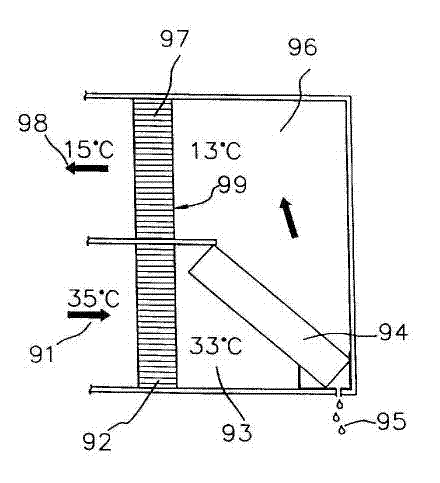

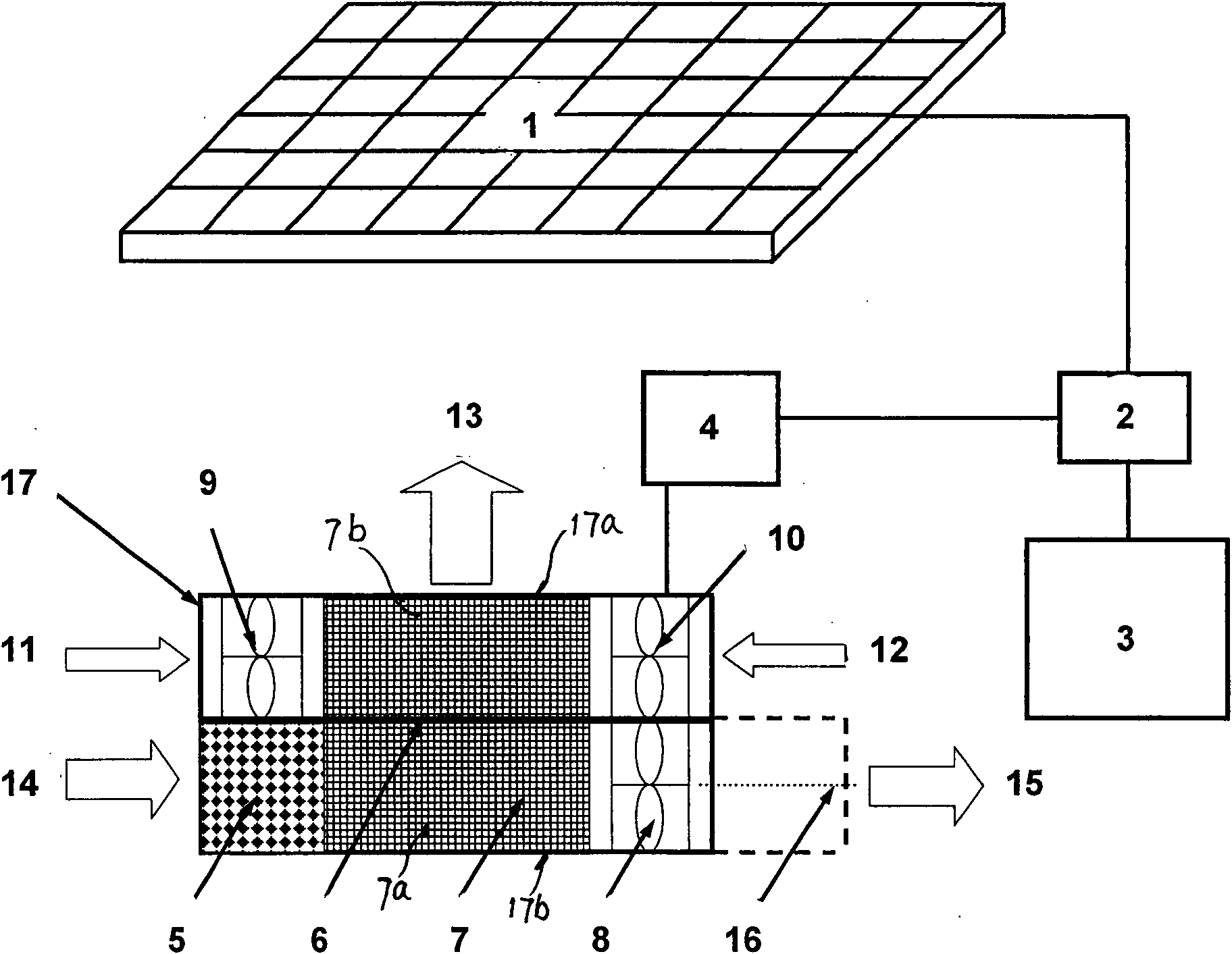

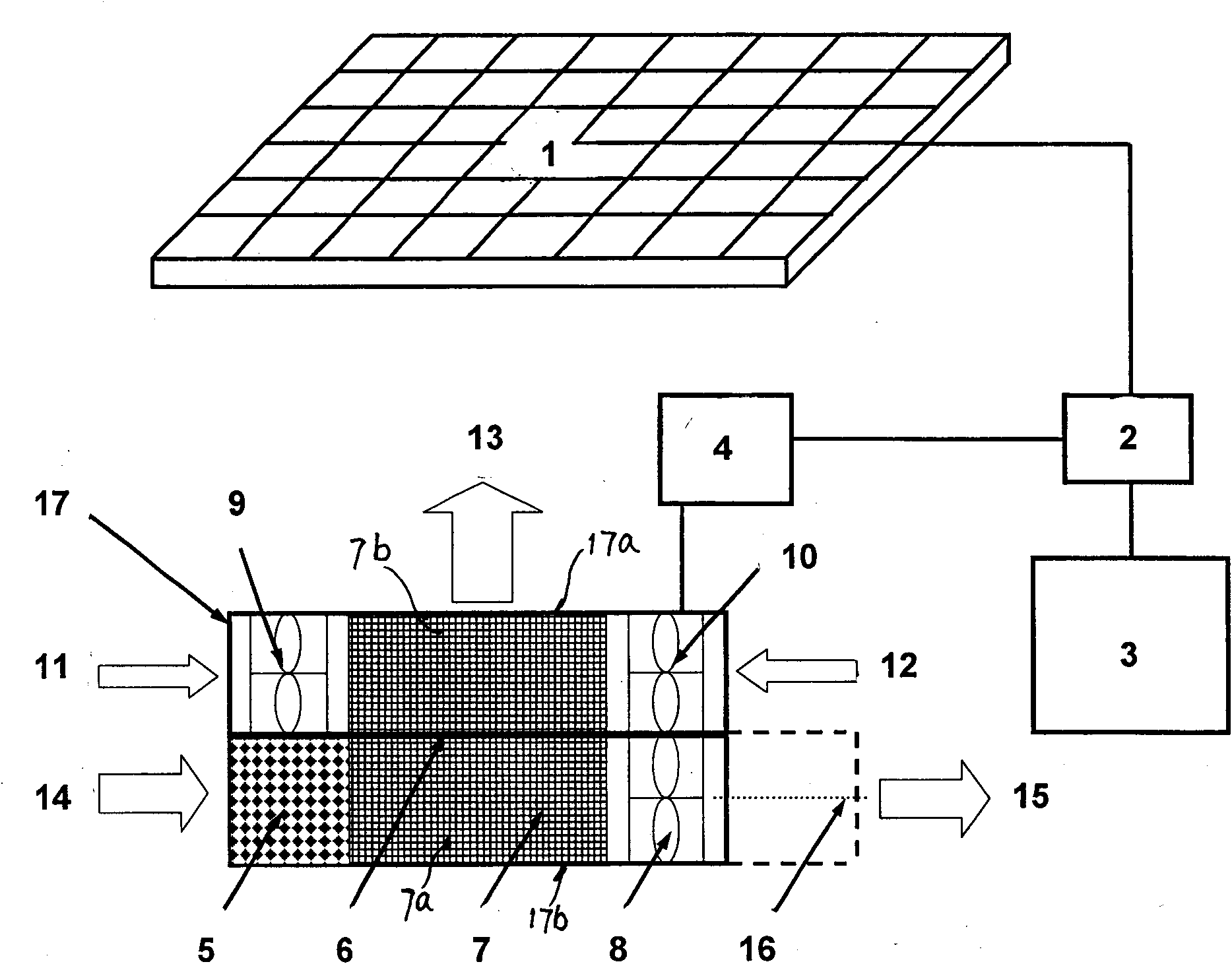

Solid adsorption moisture eliminator based on semiconductor refrigeration

InactiveCN101476757AImprove cooling efficiencyImprove performanceDispersed particle separationMachines using electric/magnetic effectsRefrigerationMoisture

The invention relates to a semiconductor refrigeration-based solid absorption dehumidifier and belongs to the technical field of air dehumidifiers. The dehumidifier is characterized by comprising a semiconductor cooler, a first solid hygroscopic agent adhered on a cold end of the semiconductor cooler for dehumidifying processed air and a second solid hygroscopic agent adhered on the hot end of the semiconductor cooler for regenerated air to carry away the water absorbed by the second solid hygroscopic agent. After a half period, under a condition of constant air ducts used by the process air and the regenerated air, the semiconductor cooler is rotated 180 degrees and the direction of the current in the semiconductor cooler is changed at the same time, or an air valve changes instead of the rotation of the semiconductor cooler. Meanwhile, the solid hygroscopic cooler can be adhered on the cold end and the hot end of the semiconductor cooler indirectly through the fin extended surface heat exchanger or a heat tube exchanger. A plurality of the dehumidifiers can be connected serially to form a multistage dehumidifier. The application has the advantages of greatly improving the efficiency of semiconductor refrigeration.

Owner:TSINGHUA UNIV

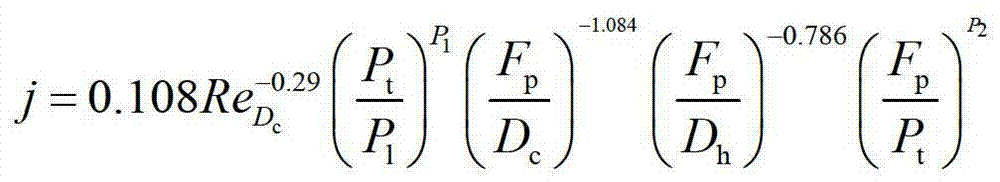

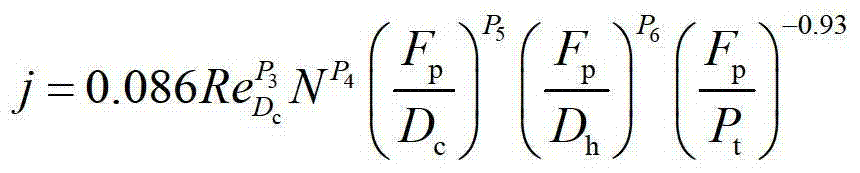

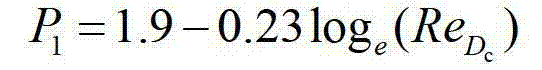

Design method of general combination pipe diameter air conditioner heat exchange equipment fluid passage

ActiveCN103542621AOptimizing Geometry ParametersImprove general performanceEvaporators/condensersSpace heating and ventilation detailsPhysical modelEngineering

The invention discloses a design method of a general combination pipe diameter air conditioner heat exchange equipment fluid passage. Firstly, a proper combination pipe diameter air conditioner heat exchanger type and a proper installation manner are selected, and a general heat exchanger physical model is set up by referring to the geometric construction parameters and the using conditions of a combination pipe diameter air conditioner heat exchanger; secondly, grid division is performed on a heat exchanger based on the heat exchanger model, and calculation models of different pipe diameter fluid passage connection networks of the heat exchanger of the type are achieved according to different configuration of the fluid passage of a pipe-diameter-changing heat exchanger; thirdly, a method for accurately positioning a phase change interface of a working medium in a pipe to be changed into two phases from a single phase and into the single phase from the two phases is designed; finally, based on correction of flowing of the single phase and the two phases and a heat exchange correlation formula of the side provided with a plurality of fins and the inner side of the pipe, the flowing and heat exchange performances of the fin side of the combination pipe diameter air conditioner heat exchanger and the temperature, the pressure, the dryness and the heat exchange performance of any position on the fluid passage of the inner side of the pipe are obtained through the iterative computation.

Owner:XI AN JIAOTONG UNIV

Comprehensive energy-saving device for recovery of waste heat of ultrasonic dish-washing machine

InactiveCN103519764ATake advantage ofReduce energy consumptionTableware washing/rinsing machine detailsHome appliance efficiency improvementEvaporationEngineering

The invention discloses a comprehensive energy-saving device for recovery of waste heat of an ultrasonic dish-washing machine. The comprehensive energy-saving device is composed of a flushing and cleaning segment, a round pipe heat exchanger, a heat pipe exchanger, an exhaust outlet, a hot air inlet, a hot water outlet pipe, a flushing water tank and an overflow pipe. Inflow water of the dish-washing machine enters the round pipe heat exchanger first and then enters the efficient phase-change heat-exchange heat pipe exchanger after being heated by overflow water in the round pipe heat exchanger, and the inflow water absorbs heat of hot steam and hot exhaust air from the air side of the evaporation segment on the condensation segment and flows out of the hot water outlet pipe after being further heated. Feedwater is heated by heating pipes in an electric heater to reach a specified temperature after undergoing secondary heat recovery heat exchange by the utilization of waste heat resources, and then the feedwater respectively flows to a cleaning pipe spray nozzle and a water inlet pipe of an ultrasonic washing segment through two paths, so that the requirements for hot water supply and supplement of hot water to the ultrasonic washing segment are met. The comprehensive energy-saving device fully utilizes the waste heat resources of the dish-washing machine, reduces electric heating power, obviously reduces energy consumption of the dish-washing machine, achieves hot water cooling and hot air humidity reducing discharge and is simple in structure and easy to implement.

Owner:YANGZHOU POLYTECHNIC INST

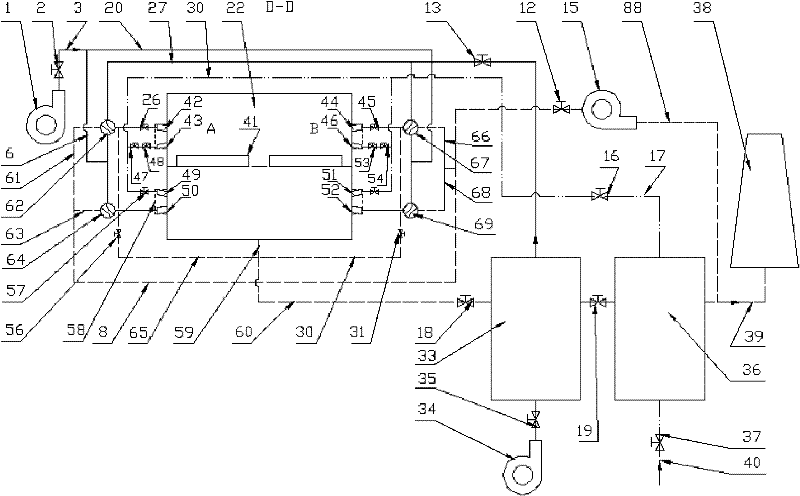

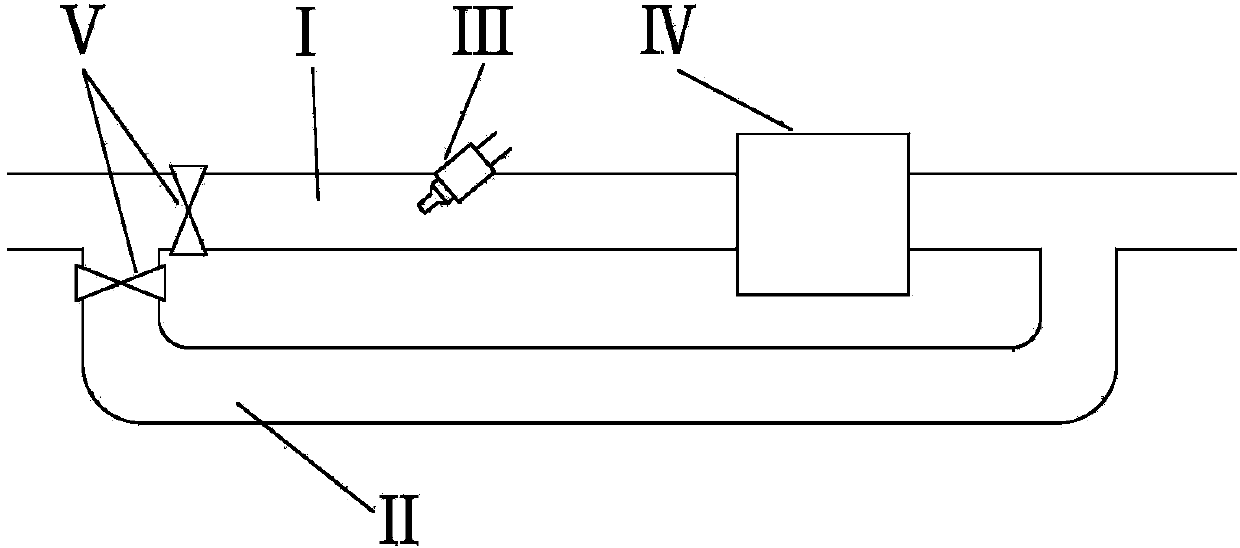

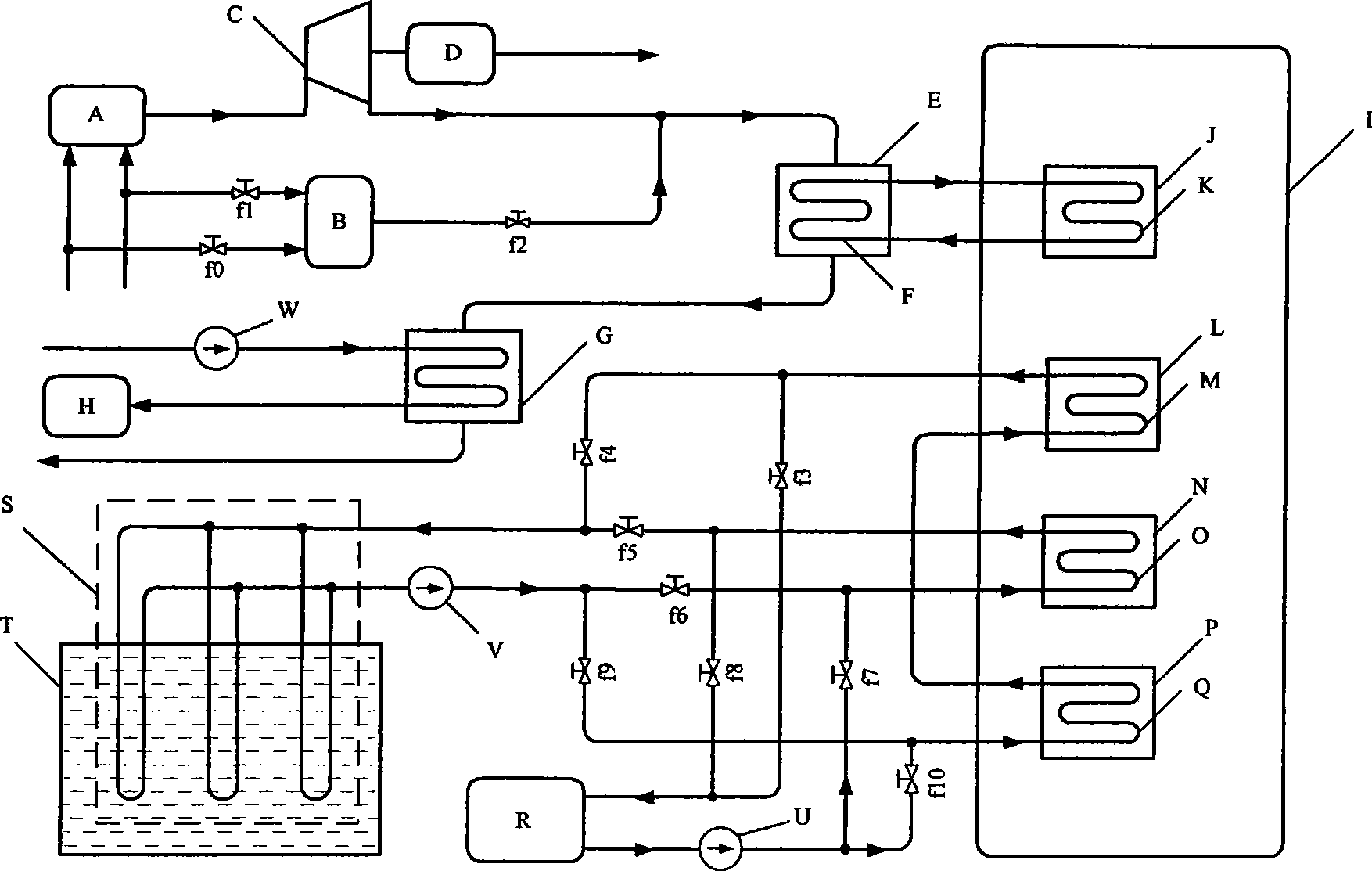

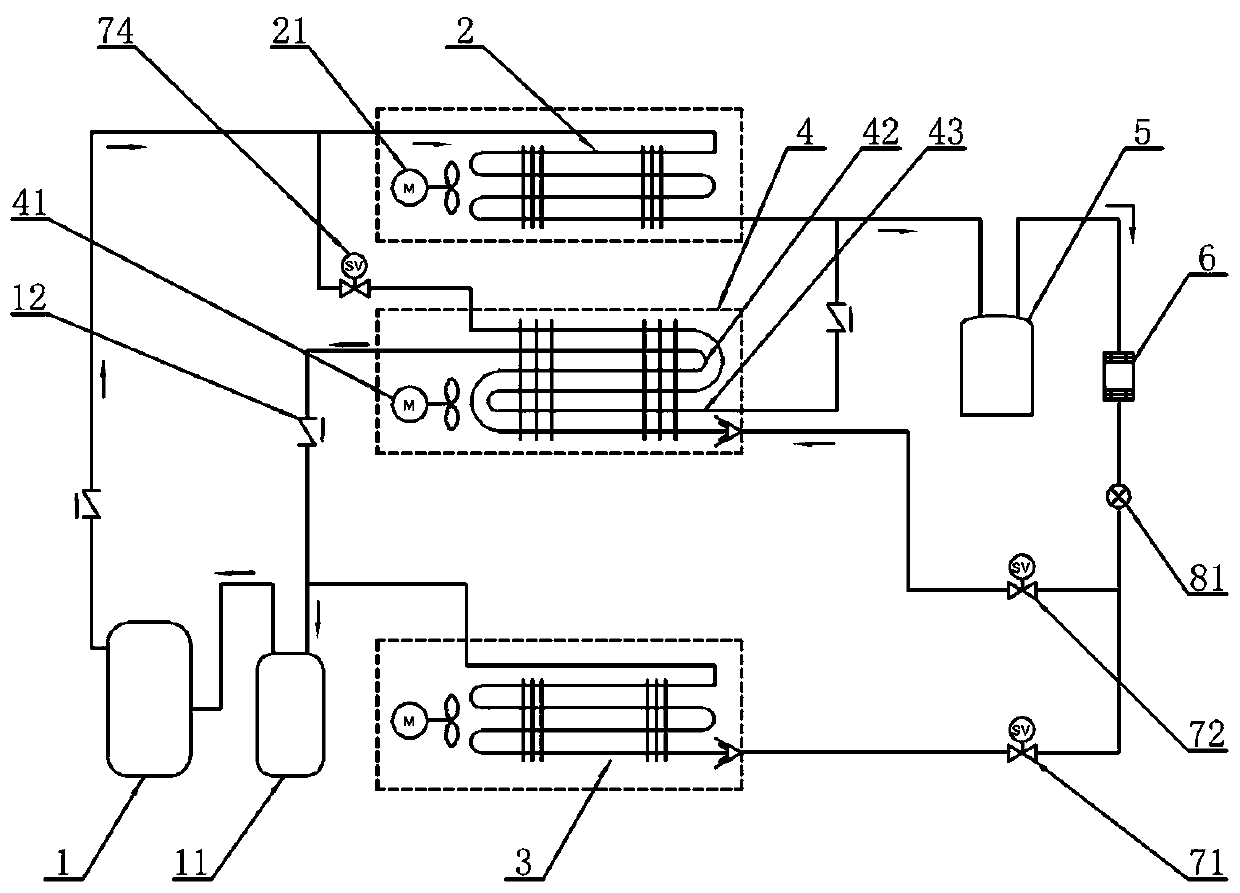

Combined cold, heat and power supply apparatus and method with utilization of earth source absorption type refrigeration heat pump

InactiveCN101498524AImprove utilization efficiencyImprove consumption structureHeat pumpsEnergy efficient heating/coolingCombustion chamberEvaporation

The invention discloses a combined cooling heat and power supplying device and a method for a ground source absorption type refrigeration-heat pump. The invention takes natural gas (or other combustible gases) as fuel, after high-temperature flue gas generated by the combustion of the fuel in a combustion chamber drives a gas turbine to generate power, the exhausted flue gas is firstly taken as compensation energy for an absorption type refrigeration-heat pump device, and then heat is supplied to a hot water heat exchanger. The hot water heat exchanger can supply domestic hot water to the external all the year round. The device comprises a power supply part, a refrigeration-heat part and a domestic hot water supply part, wherein the power supply part comprises the combustion chamber (A), the gas turbine (C) and a generator (D); the refrigeration-heat part comprises an afterburning chamber (B), the absorption type refrigeration-heat pump device (I), a split type heat pipe heat exchanger evaporation section (F), a split type heat pipe heat exchanger condensation section (K), a geothermal source buried pipe heat exchanger (S) and an air conditioning user pump (U); the absorption type refrigeration-heat pump device (I) comprises a generator (J), a condensator (L), an evaporator (N) and an absorber (P); the domestic hot water supply part comprises a hot water heat exchanger (G) and a water supply pump (W) of the hot water heat exchanger.

Owner:SOUTHEAST UNIV

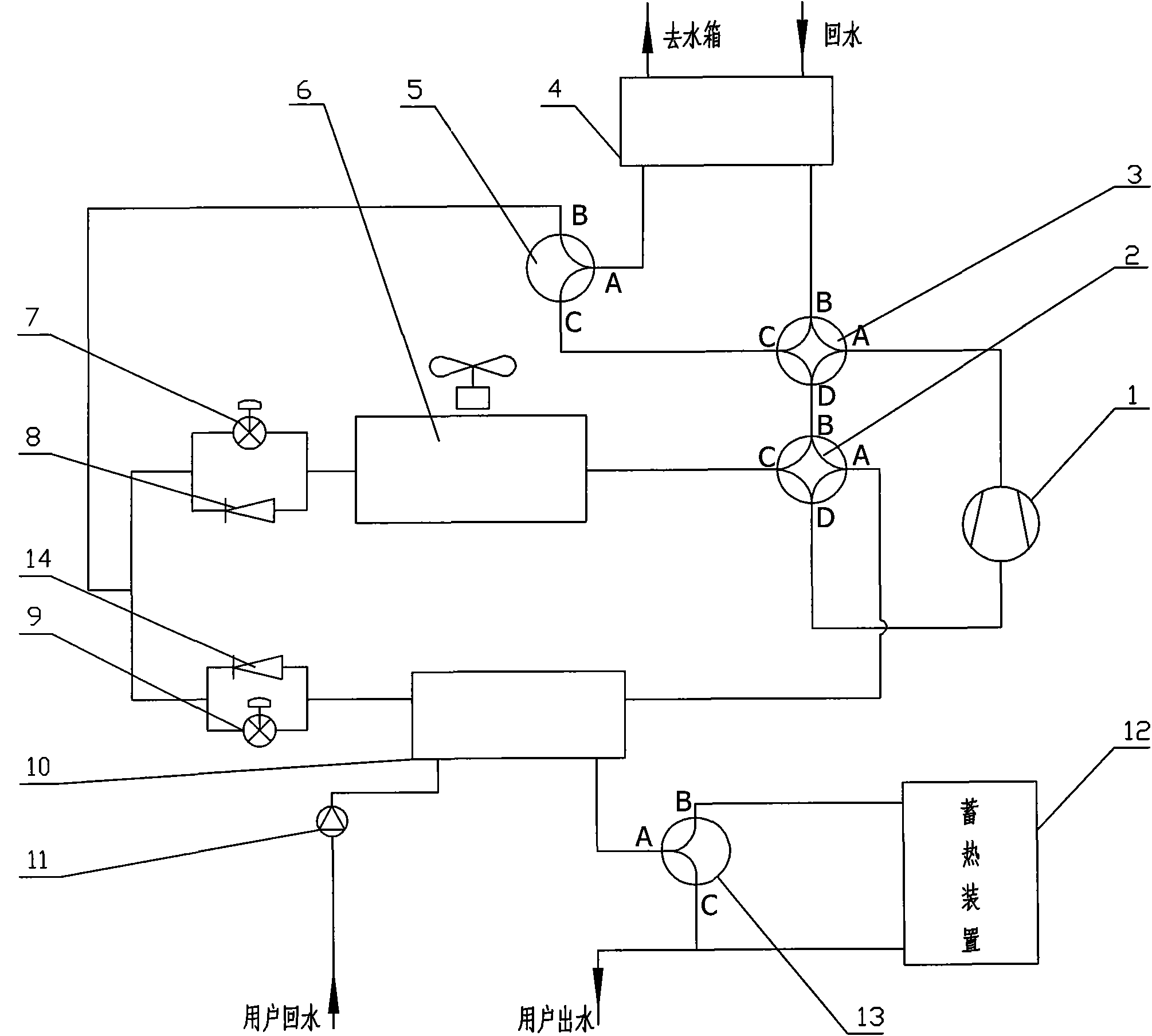

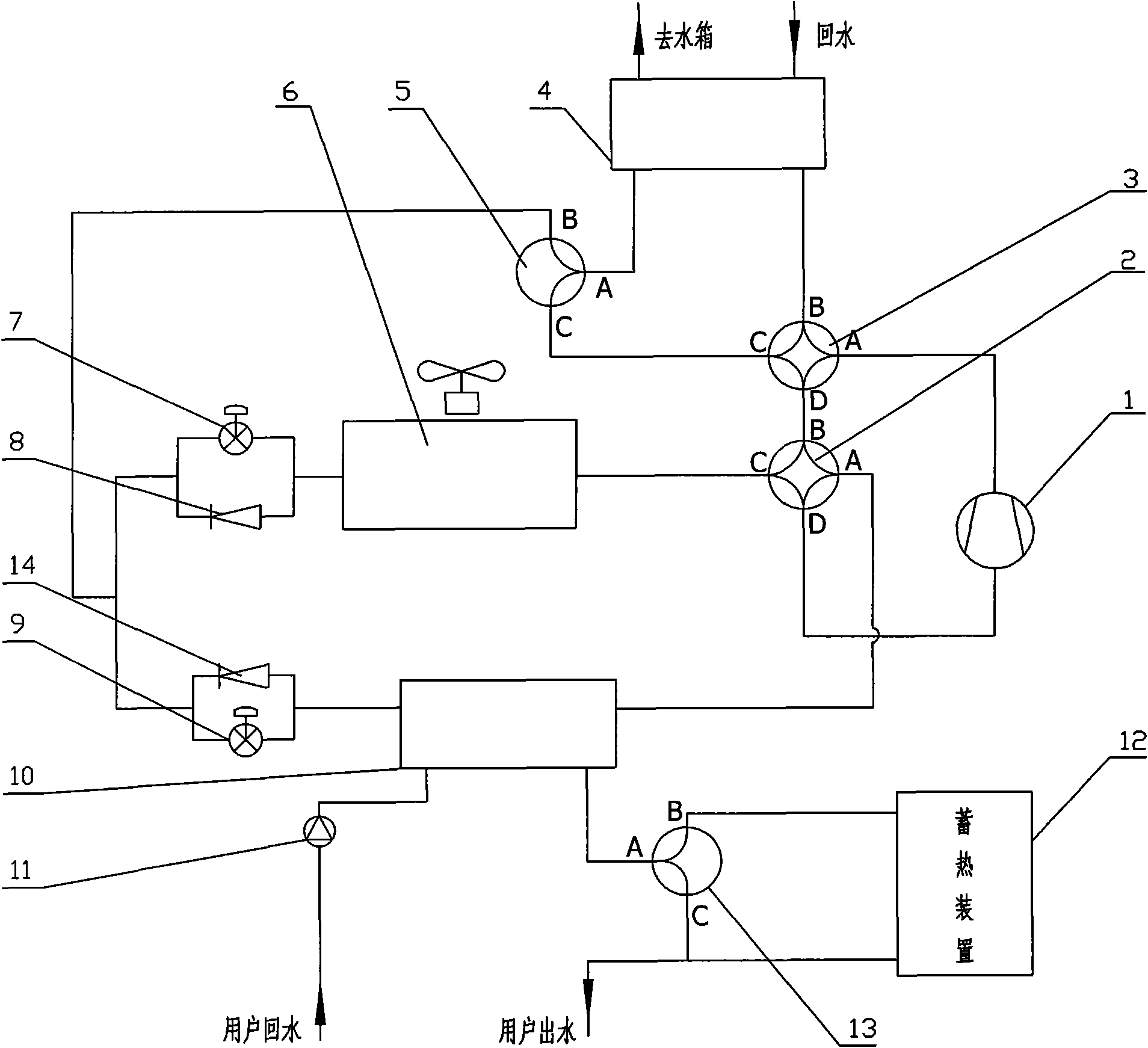

Energy-saving air-conditioning/hot water triple-supply system

InactiveCN101813401AOvercome efficiencyOvercome stabilityEnergy industryHeating and refrigeration combinationsBusiness efficiencyWater quality

The invention discloses an energy-saving air-conditioning / hot water triple-supply system, comprising a compressor (1), a hot water heat exchanger (4), an air heat exchanger (6), an air conditioning heat exchanger (10) and other parts; using main components of a heat pump system, the system adopts a structure with three heat exchangers interconnected in a mixed manner and double four-way reversing valves and has four working modes including refrigeration and water heating, water heating, heating and water heating, and defrosting, thus the triple supply of refrigeration, heating and clean hot water can be realized; the system has high heat exchange efficiency and simultaneously enhances energy efficiency ratio of system as well; by adopting the heat pipe exchangers, the system solves the problem that the heat exchanger is liable to leakage so as to pollute water, and overcomes the deficiency of large resistance when a plurality of heat exchangers are connected with each other in series.

Owner:江乐新

Two-stage precooling dehumidification device and method

InactiveCN103982958AReduce cooling loadIncrease the dehumidification capacity per unit input powerEnergy recovery in ventilation and heatingLighting and heating apparatusEngineeringWater cooling

The invention discloses a two-stage precooling dehumidification device and method, which break through a traditional dehumidification system form. The two-stage pre-cooling dehumidification device comprises an indirect evaporative circular tube surface heat exchanger, a heat pipe heat exchanger, a refrigeration dehumidification system and a condensed water collecting device, all of which sequentially form a primary fresh air precooling section, a secondary precooling section, a dehumidification section and a coolant recovery section. According to the two-stage precooling dehumidification device and method, cooling capacity of high-graded exhaust air and condensed water is sufficiently used for precooling fresh air, so that the cooling load of an evaporator of a dehumidification unit is reduced, and thus the unit input power can be less when the unit achieves the same dehumidification workload. Therefore, economic and better selection can be realized on accessory model selection of the unit.

Owner:NANJING NORMAL UNIVERSITY

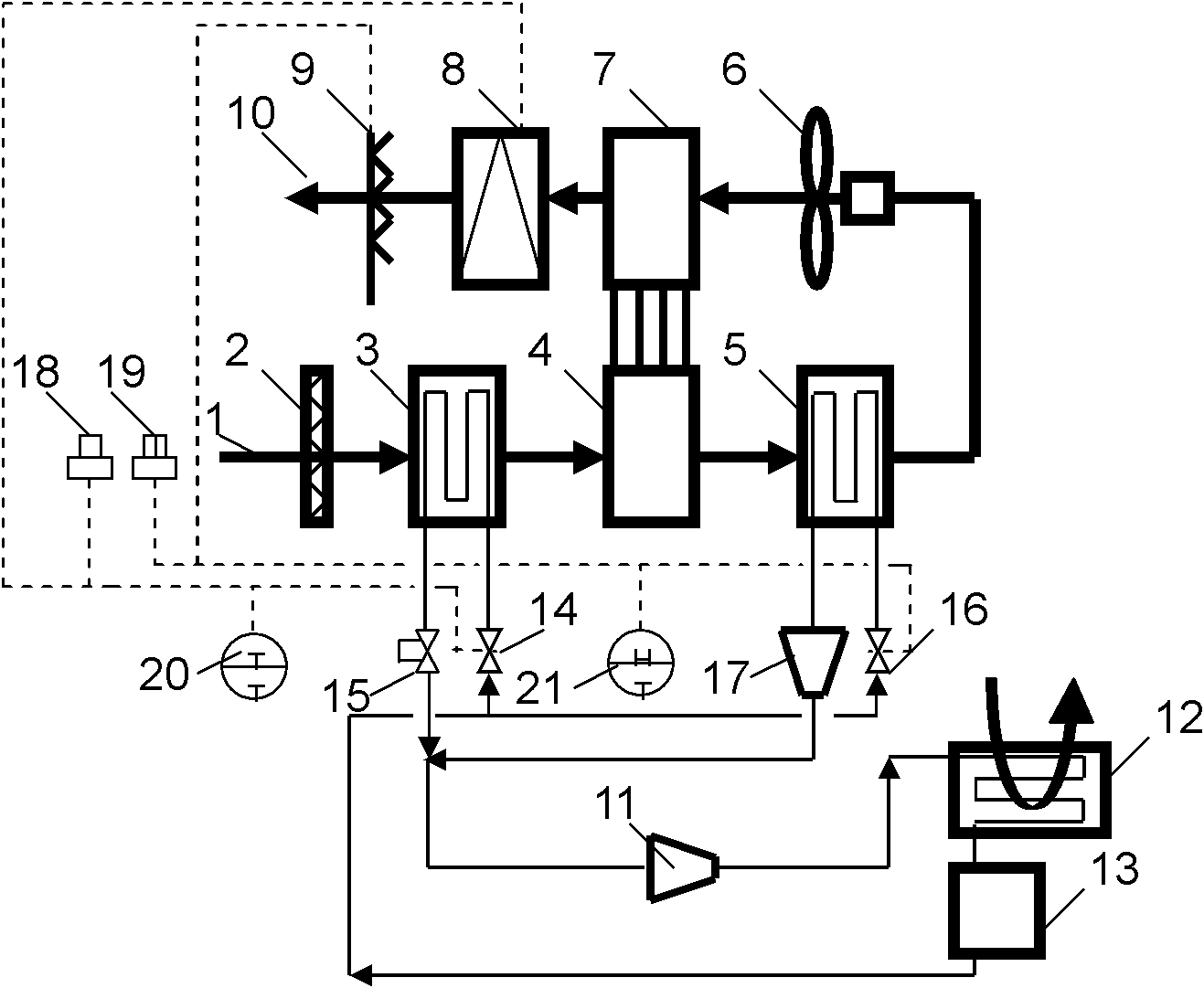

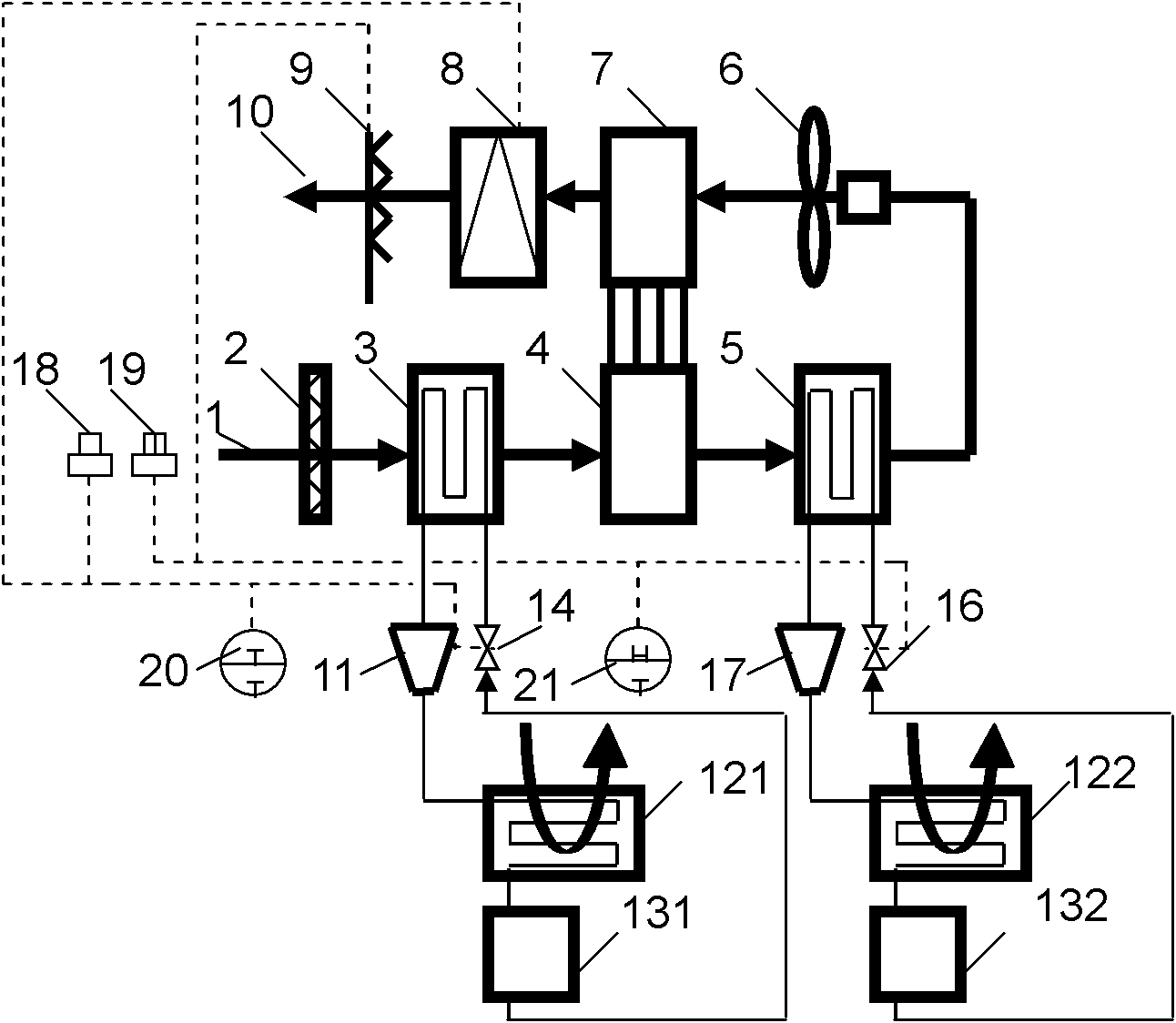

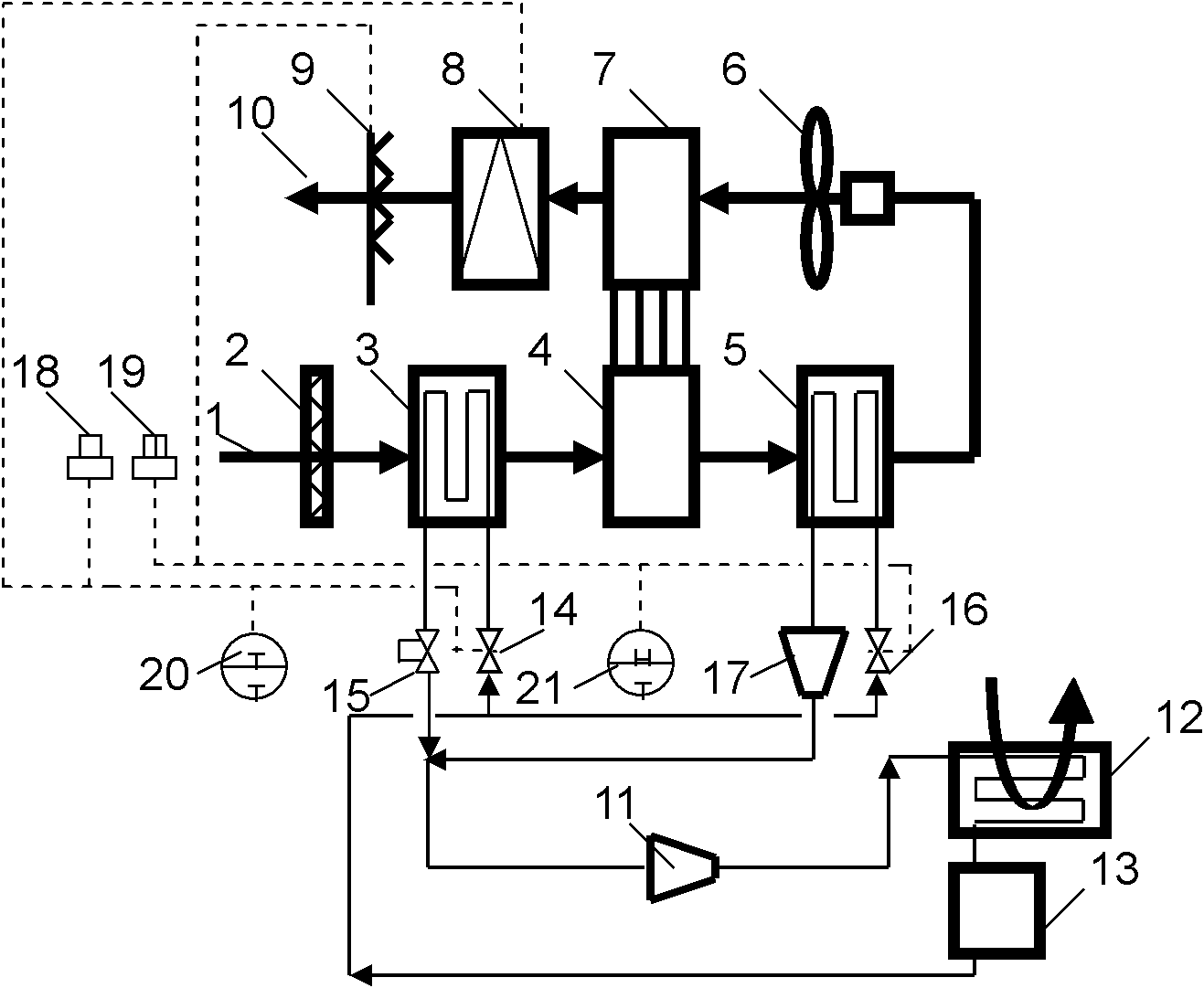

Dual-temperature-heat-pipe constant-temperature and constant-humidity air-conditioning unit

InactiveCN102121731AReduce reheat energy consumptionEliminate sensible heatEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsLow voltageEvaporation

The invention discloses a dual-temperature-heat-pipe constant-temperature and constant-humidity air-conditioning unit, comprising an air treatment circulating system and a dual-temperature refrigeration circulating system which are coupled through a high-temperature evaporator (3) and a low-temperature evaporator (5), wherein the air treatment circulating system comprises an air inlet (1), a filter (2), the high-temperature evaporator (3), a heat pipe exchanger evaporation section (4), a low-temperature evaporator (5), an air blower (6), a heat pipe exchanger condensation section (7), an electric heater (8), an electrode-type steam humidifier (9) and an air supply outlet (10) which are arranged in sequence according to the air flowing path; and the dual-temperature refrigeration circulating system consists of a high-voltage level refrigeration circulating loop and a low-voltage level refrigeration circulating loop. The dual-temperature-heat-pipe constant-temperature and constant-humidity air-conditioning unit also comprises a temperature sensor (18), a temperature controller (20), a humidity sensor (19) and a humidity controller (21). The dual-temperature-heat-pipe constant-temperature and constant-humidity air-conditioning unit disclosed by the invention can be used for effectively solving the problem of the common cold-hot offset and has greater energy-saving potential.

Owner:ZHEJIANG SCI-TECH UNIV

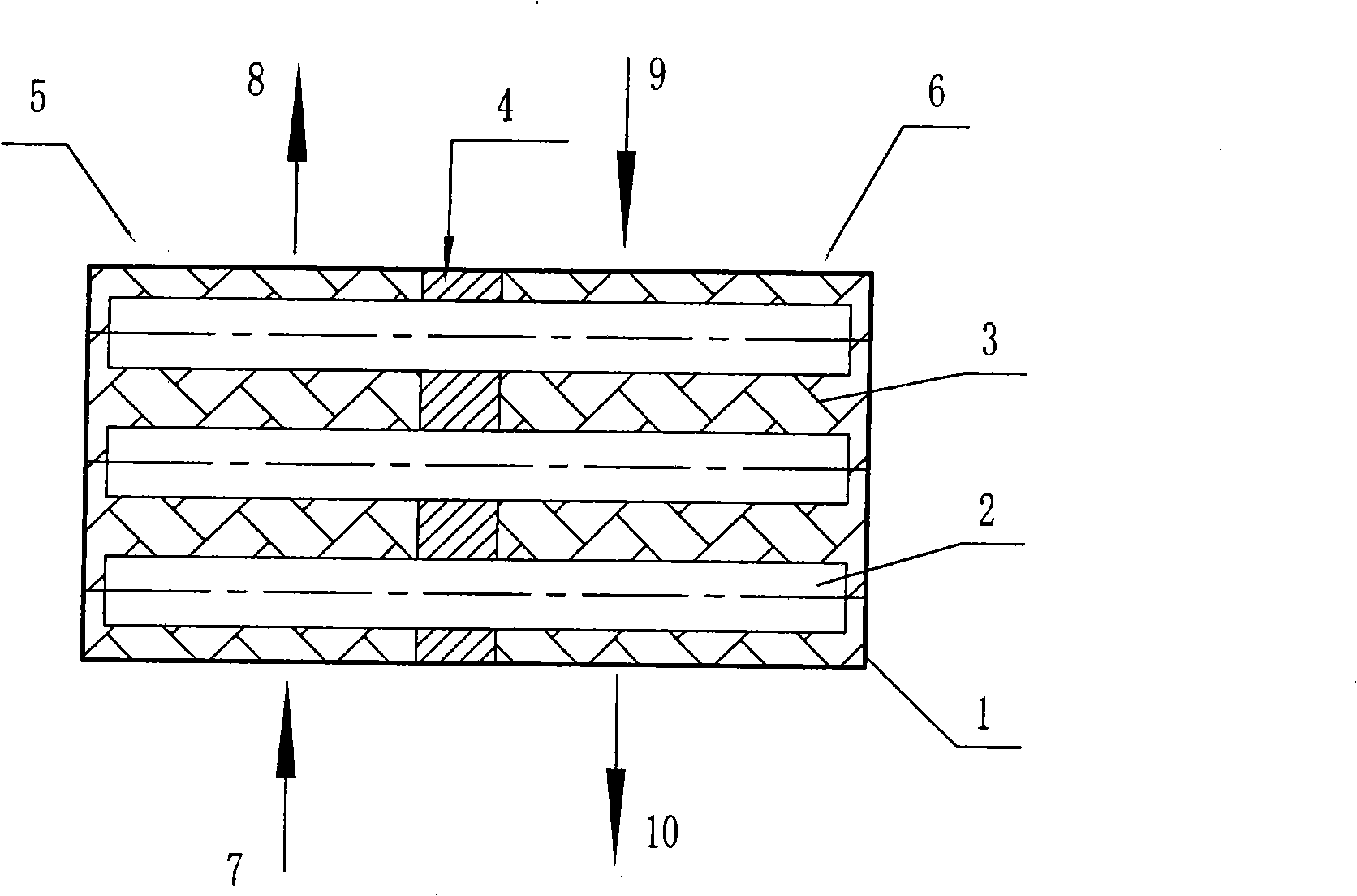

Three-dimensional heat-pipe heat exchanger and production method thereof

The invention discloses a three-dimensional heat-pipe heat exchanger. A plurality of pipes are combined into an S-shaped heat pipe by a U-shaped elbow, and the heat-pipe heat exchanger connected by the U-shaped elbow can form a completely continuous coiled pipe. The S-shaped heat pipe and the heat exchanger can be configured into an integrative heat exchanger, wherein a condensing end and an evaporating end are isolated by a heat insulation section, or can be configured into a split type heat exchanger, wherein the evaporating end and the condensing end are connected by an evaporating pipe and a reflowing pipe. The three-dimensional heat-pipe heat exchanger can form a continuous closed loop, in this way, the heat exchanger works no matter whether the reflowing is implemented with the aid of gravity. A plurality of U-shaped pipes are needed to interconnect in the production of the S-shaped pipe to form one S-shaped heat pipe loop, wherein one pipe has an opening end, each of all the pipes can work as one independent heat pipe only by injecting enough refrigerant from the opening end at one time. The three-dimensional heat-pipe heat exchanger can be used for the aspects of enhancement of dehumidification effect of the air conditioner, energy recovering, heat radiation of partial space, and the like.

Owner:苏州浩佳节能科技有限公司

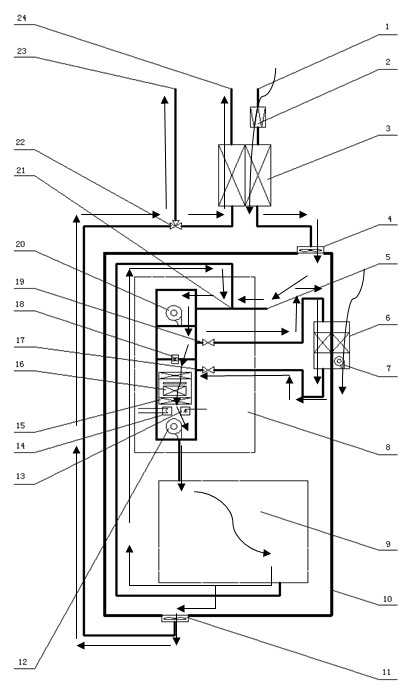

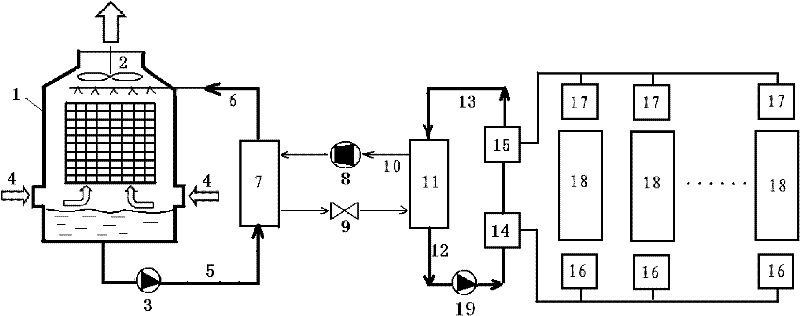

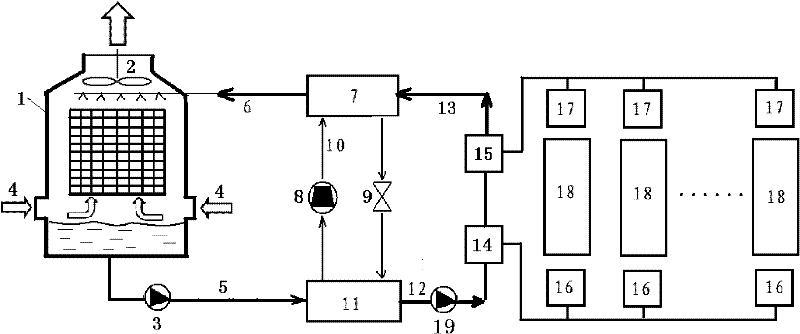

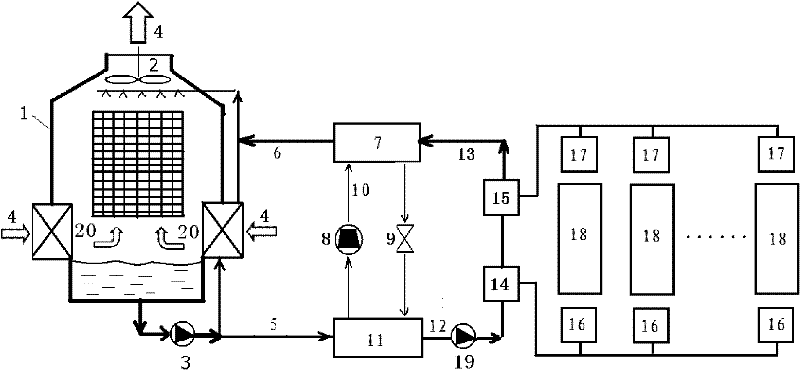

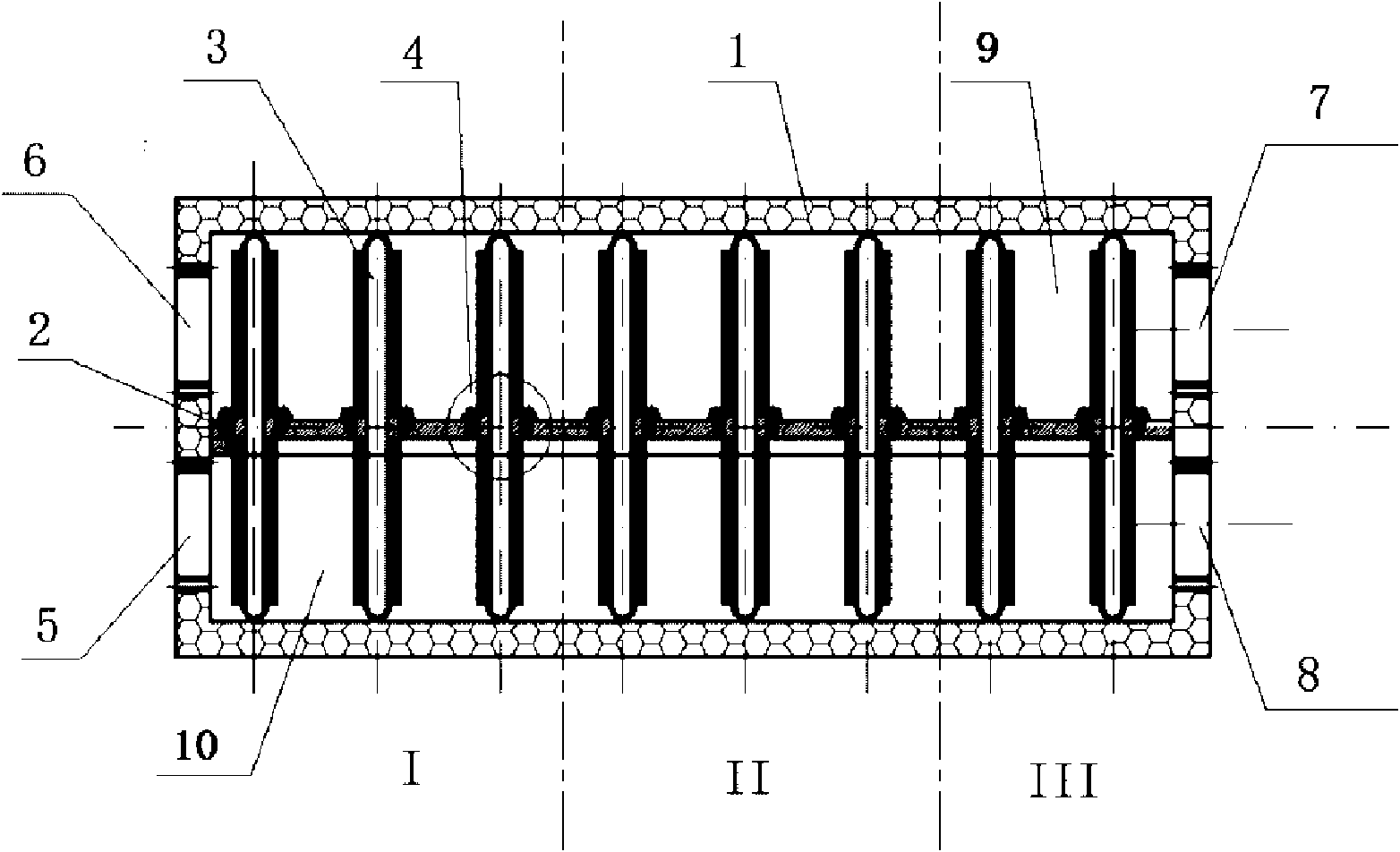

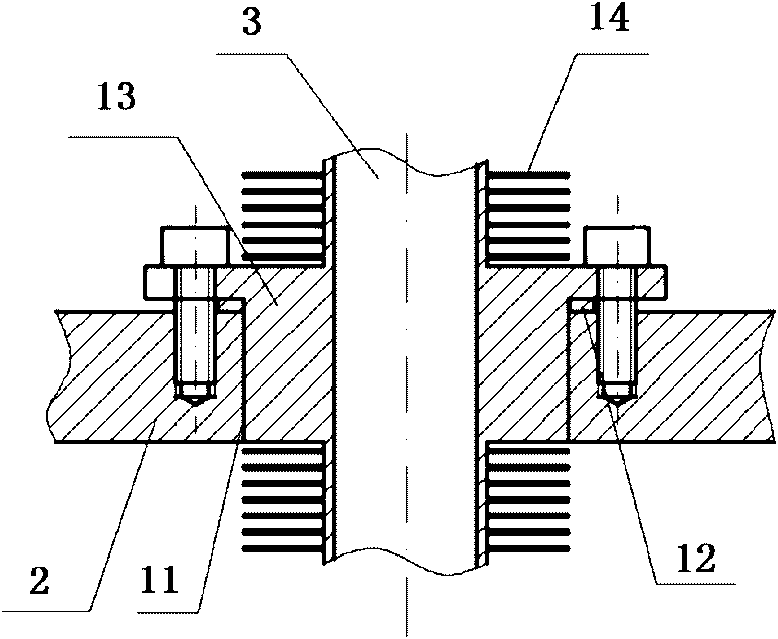

Thermal environmental control system

InactiveCN102213466AReduce loadReduce energy consumptionCompressorSpace heating and ventilation detailsCooling towerControl system

The invention relates to a thermal environmental control system which comprises a cooling tower, a cooling tower fan, a water pump, a cooling tower water outlet pipe, a cooling tower water return pipe, a refrigerant circulating system, a low-temperature freezing water pipe, a high-temperature freezing water pipe, two water-heat pipe exchangers and two paths of air-heat pipe exchangers, wherein the refrigerant circulating system consists of a condenser, a compressor, a throttling device and an evaporator; each path of air-heat pipe exchangers is connected with one water-heat pipe exchanger and provided with a plurality of air-heat pipe exchangers which are arranged in parallel, the two water-heat pipe exchangers are serially connected between the low-temperature freezing water pipe and the high-temperature freezing water pipe, and the lower part of the cooling tower is provided with an outdoor air inlet. The thermal environment control system is characterized in that a shell inlet of the evaporator is connected with the cooling tower water outlet pipe, a shell outlet of the evaporator is connected with the high-temperature freezing water pipe; and a shell inlet of the condenser is connected with the high-temperature freezing water pipe, and a shell outlet of the condenser is connected with the cooling tower water return pipe. According to the invention, power consumption of the compressor in the process of reducing environment sensible heat is effectively reduced.

Owner:TSINGHUA UNIV +1

Combined heat pipe exchanger

ActiveCN101666589AImprove transmission efficiencyReduce lossesIndirect heat exchangersHeat exchanger casingsHeat conductingEngineering

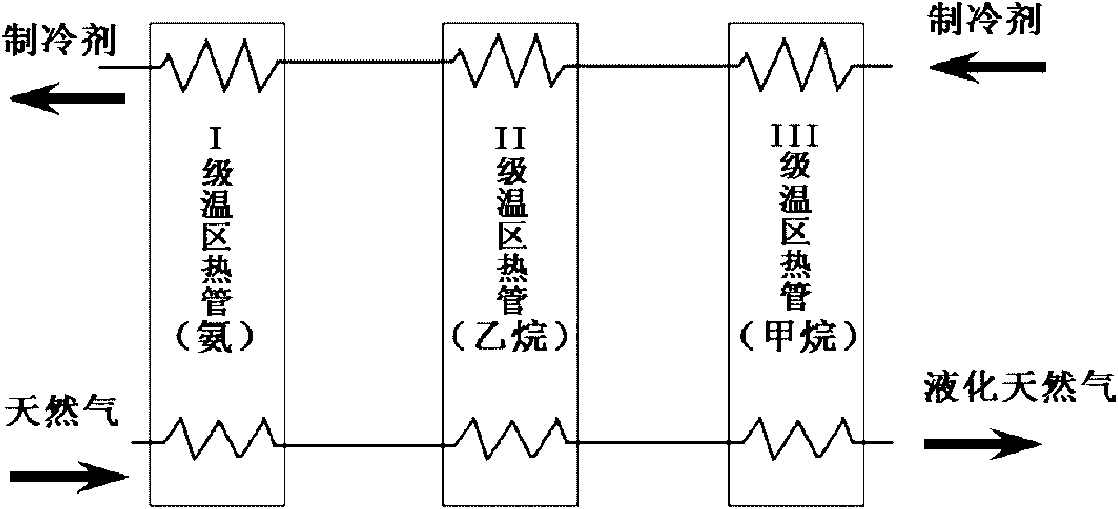

The invention relates to a combined heat pipe exchanger in the technical field of refrigeration, which comprises a box body, a clapboard, a plurality of heat pipes and a heat pipe fixing structure, wherein two ends of the box body are respectively and correspondingly provided with a natural gas inlet pipeline, a refrigerant outlet pipeline, a refrigerant inlet pipeline and a liquefied natural gasoutlet pipeline; one end of the clapboard is fixedly arranged between the natural gas inlet pipeline and the refrigerant outlet pipeline which are at one end in the box body; the other end of the clapboard is fixedly arranged between the refrigerant inlet pipeline and the liquefied natural gas outlet pipeline which are at the other end in the box body; the heat pipe fixing structure is fixedly arranged on the clapboard; and the heat pipes are connected with the heat pipe fixing structure and vertical to the clapboard. The combined heat pipe exchanger integrates the characteristic of high-thermal conductivity of the heat pipes and overcomes the defect of poor heat-conducting property of the common heat exchanger material in the current industry.

Owner:合肥万豪能源设备有限责任公司

Method and device for heat supply of rotary hearth furnace

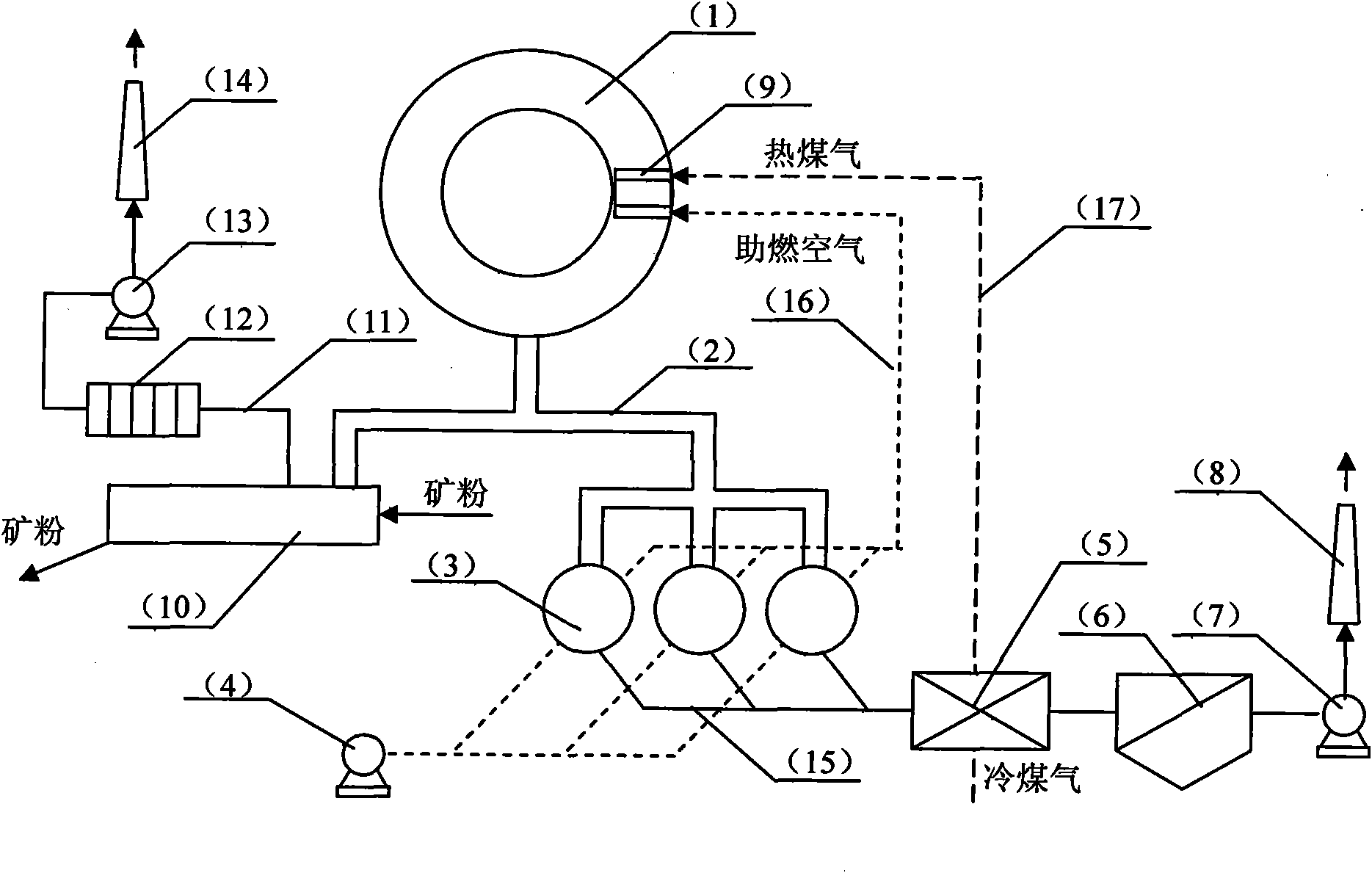

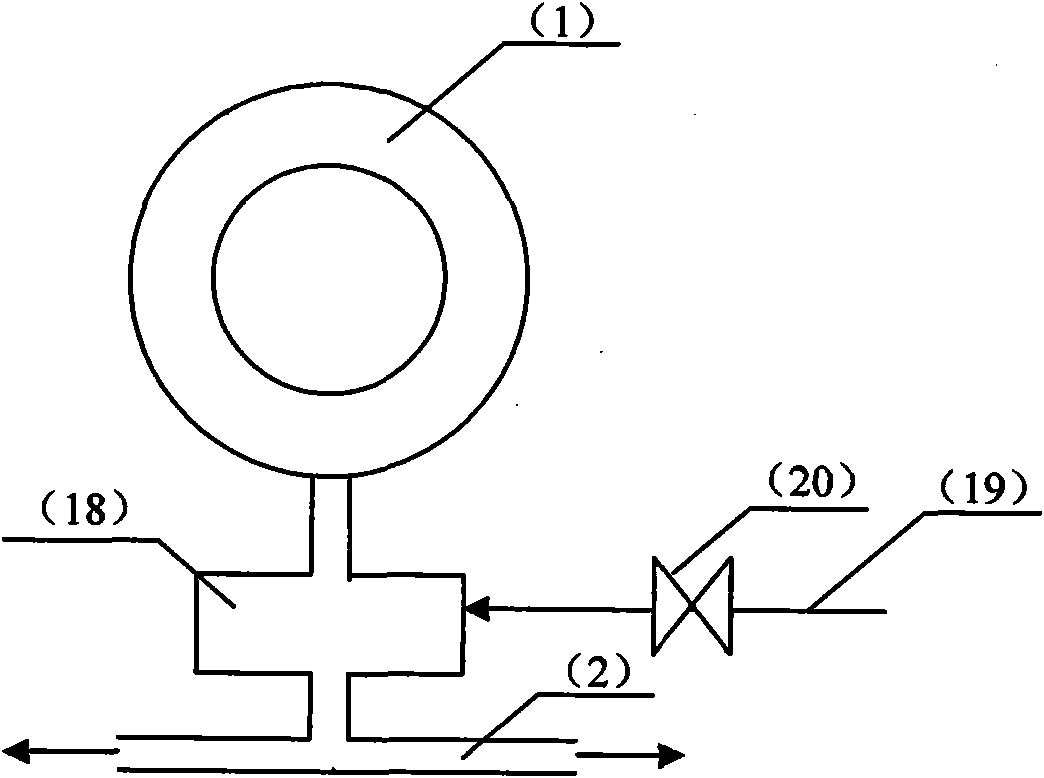

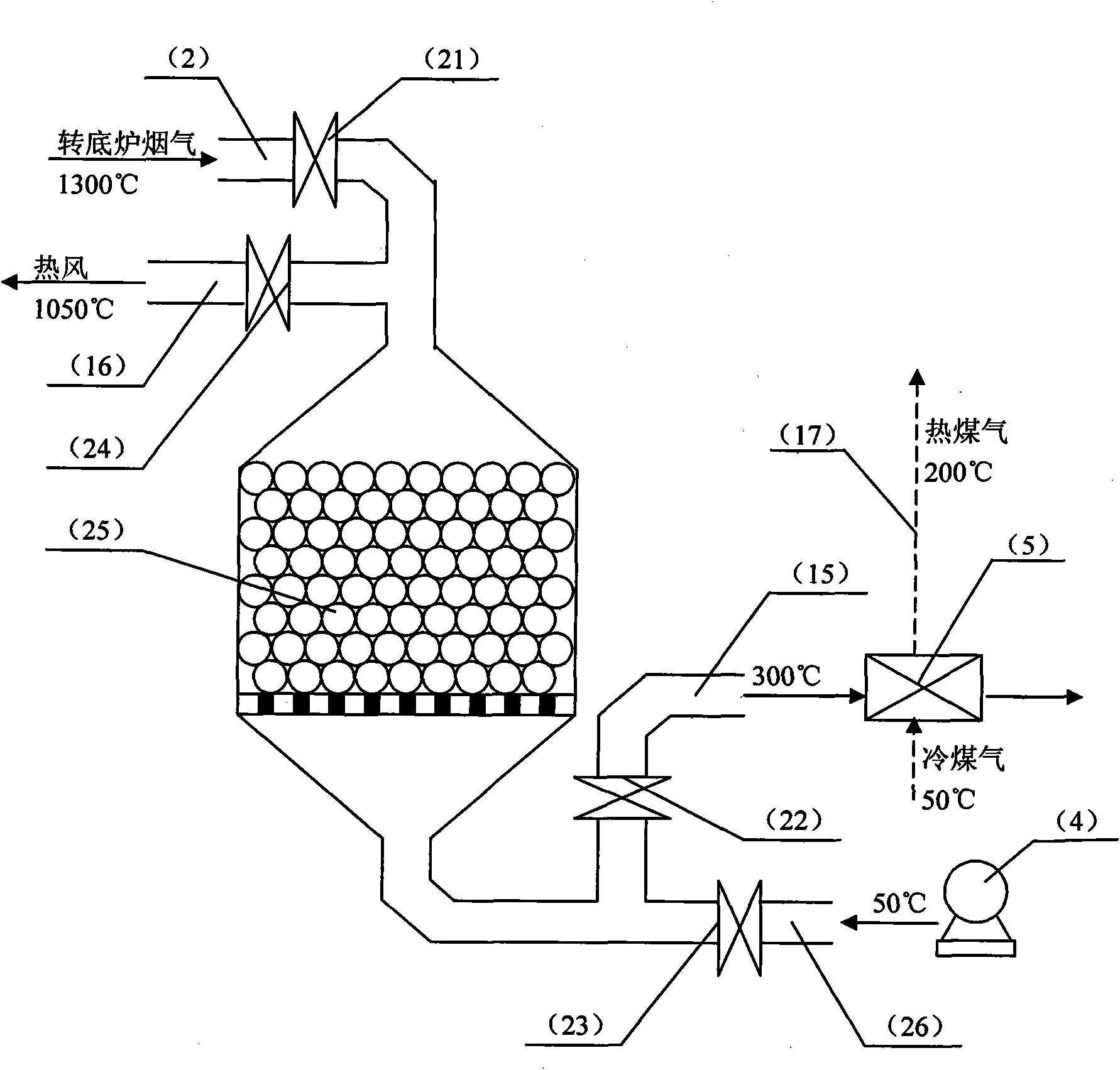

ActiveCN102062534ABreakthrough in heating methodsRestoration of economic rationalityIncreasing energy efficiencyFurnace typesCombustion chamberEngineering

The invention discloses a method and a device for the heat supply a rotary hearth furnace. Smoke afterheat generated by the rotary hearth furnace is firstly heated up through a rear combustion chamber to 1300 DEG C and then respectively introduced into a ball-type hot blast furnace and a fire tube-type rotary dryer which are interconnected in parallel, double preheating and staged heat exchange of the fuel for gas generator and the combustion-supporting air are realized by means of the coordinative operation of combined afterheat utilization devices which are mutually connected, such as ball-type hot blast furnace, heat pipe exchanger, fire tube-type rotary dryer and the like, thus the temperature of combustion flame at a combustion nozzle of the rotary hearth furnace is guaranteed to be not less than 2200 DEG C and drying iron ore powder is performed while high temperature reduction is implemented. The novel high-temperature smoke afterheat recycling technology of the rotary hearth furnace is especially suitable for plants in the area without natural gas and coke-oven gas which require coal-based direct reduction rotary hearth furnace to generate high reduction temperature ranging from 1300 to 1400 DEG C, the technology is advanced, the economical benefit is considerable, the top-quality fuel is saved, the expenditure for cooling high temperature smoke is avoided, and the CO2emission and the production cost are lowered.

Owner:SICHUAN LOMON MINING & METALLURGY

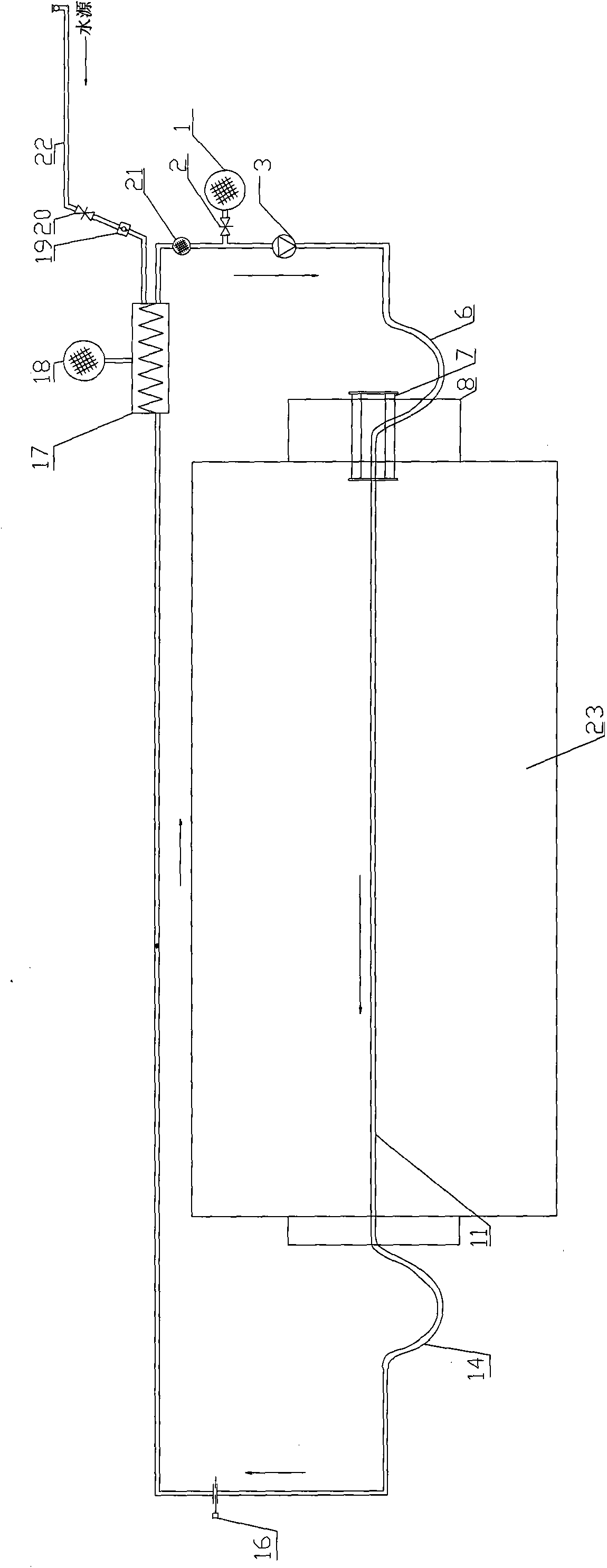

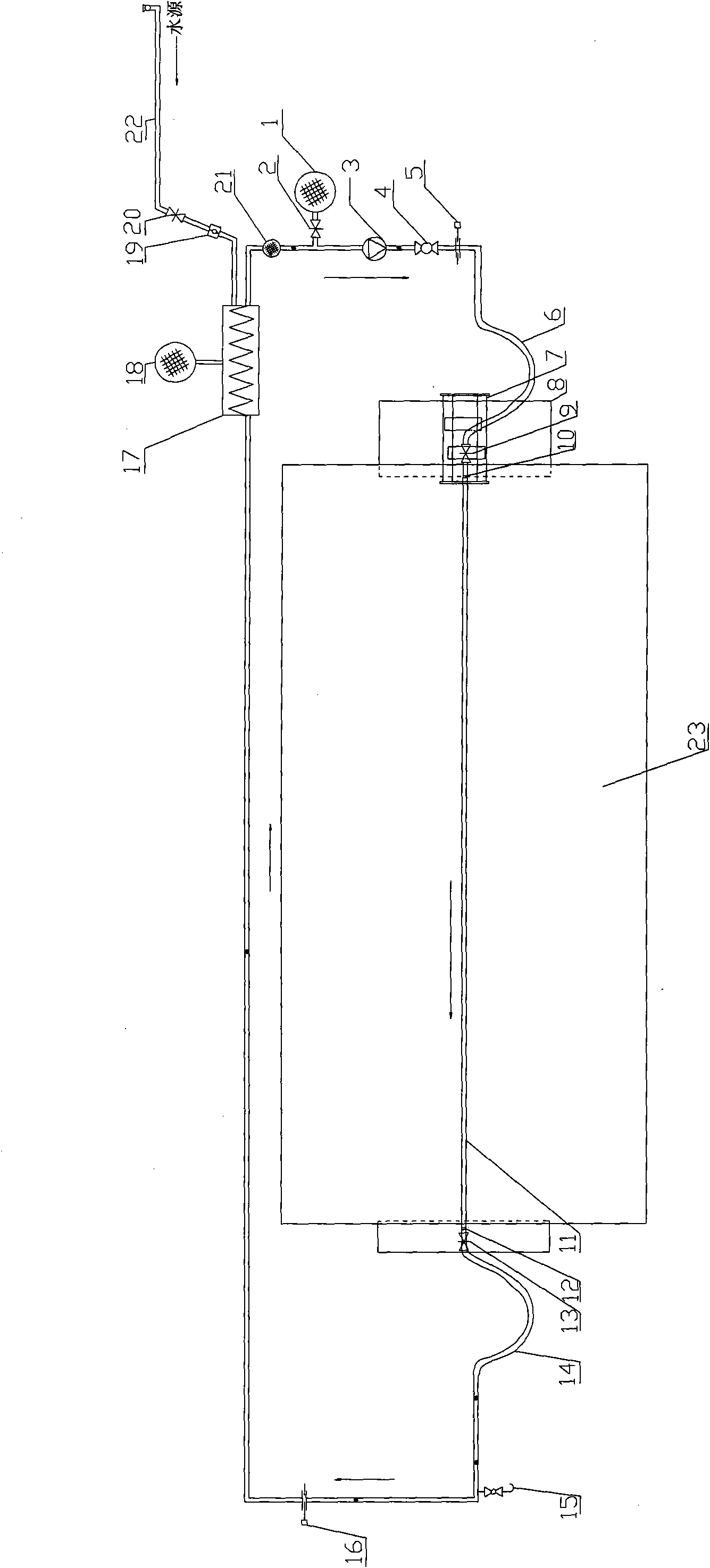

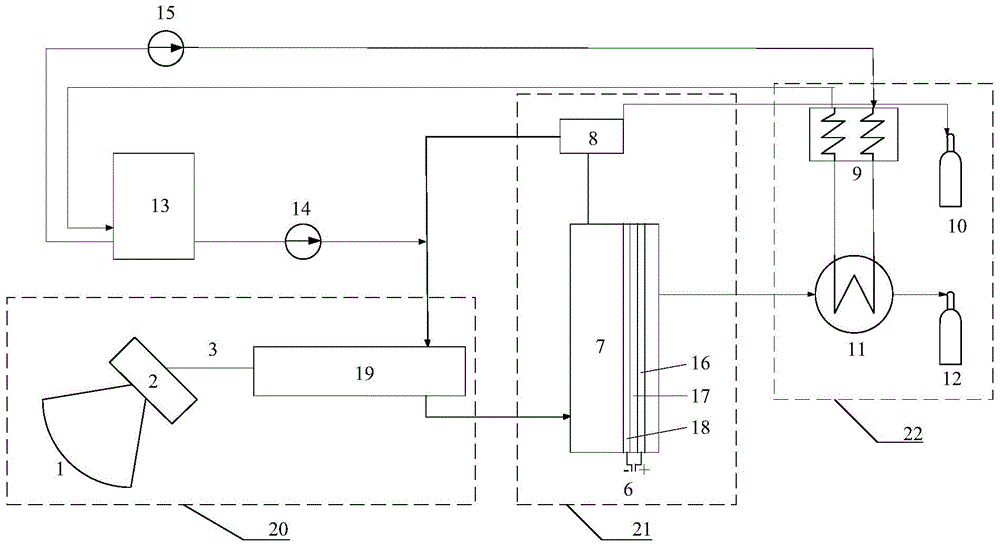

Quick test device and method for performances of trough type solar thermal collector

ActiveCN101666704AQuick measurementSimple structureTesting optical propertiesExpansion tankFast measurement

The invention discloses a quick test device for performances of a trough type solar thermal collector, which comprises a fuel tank, a valve arranged at the port of the fuel tank, a fuel pump, a thermal collector, a heat interchanger, a vapor tank, an expansion tank, a water pipe and a direct radiometer which is fixed with the thermal collector in the same direction, wherein the focusing point of the thermal collector is provided with a thermal collecting pipe; the fuel tank is filled with heat conducting fuel; the thermal collector, the heat interchanger and the expansion tank are connected bypipelines in sequence to form a loop; the thermal collecting pipe is connected on the left of the valve, and the expansion tank is connected on the right thereof; and the water pipe and the vapor tank are respectively connected at the inlet and the outlet of the heat interchanger. The quick test device has the advantages of simple and easily-implemented structure and capability of realizing quicktest of performances of the thermal collector. The invention also discloses a quick test method for the performances of the trough type solar thermal collector.

Owner:深圳市汇元佳实业发展有限公司

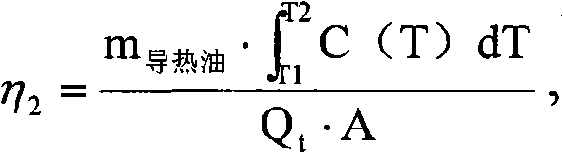

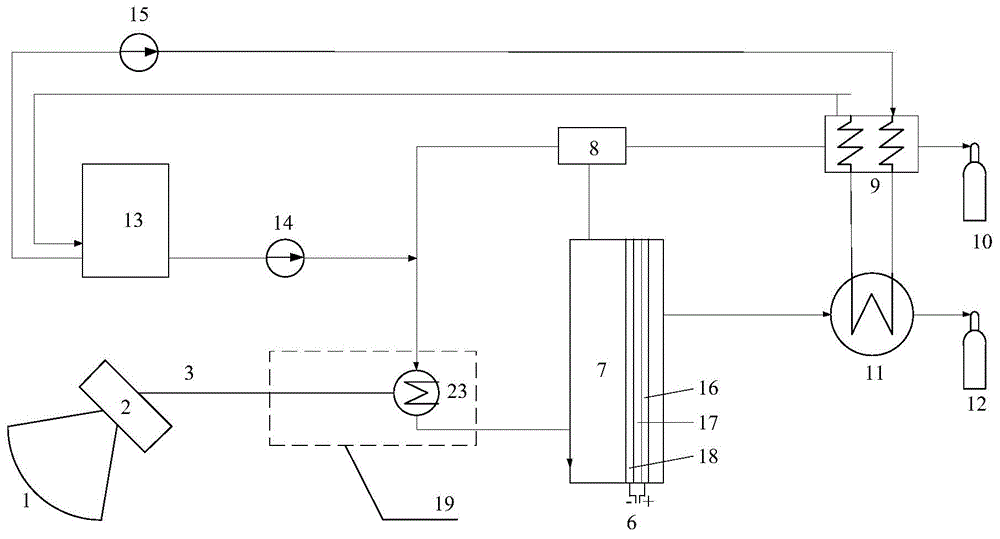

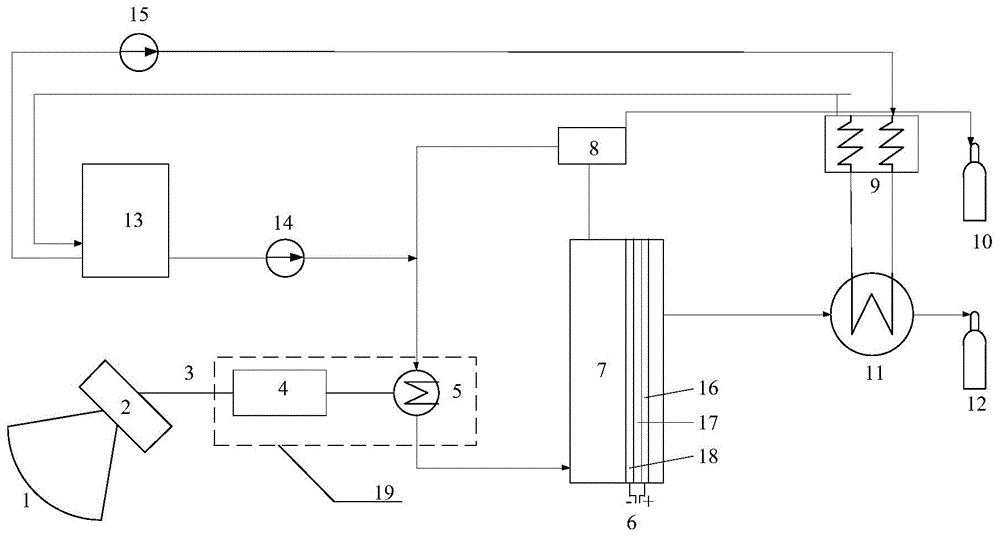

Solar optothermal coupled high-temperature water electrolysis hydrogen production system

ActiveCN104694950AResolve unstable situationsProduction environmental protectionCellsThermal energyProcess engineering

The invention provides a solar optothermal coupled high-temperature water electrolysis hydrogen production system. The system comprises a heat energy supply module, a hydrogen production and separation module and a storage module which are sequentially connected; the heat energy supply module comprises a condensation device, a heat collection device, a heat storage high-temperature heat pipe heat exchanger and a heat exchanger unit which are sequentially connected, and hydrogen and hydrogen are separated through electrolysis after a water and hydrogen mixture in the hydrogen production and separation module is heated into a steam and hydrogen mixture above 800 DEG C. Compared with the prior art, the hydrogen production system has the advantages that fossil energy does not need to be consumed, the productive process is more green and environmentally friendly, and the power consumption is greatly reduced; a stable heat source is provided through the system, the problem that a photo-thermal system is not stable due to changes in the weather is solved, the availability of the system is improved, and meanwhile the electrolytic efficiency of the system is improved.

Owner:STATE GRID CORP OF CHINA +1

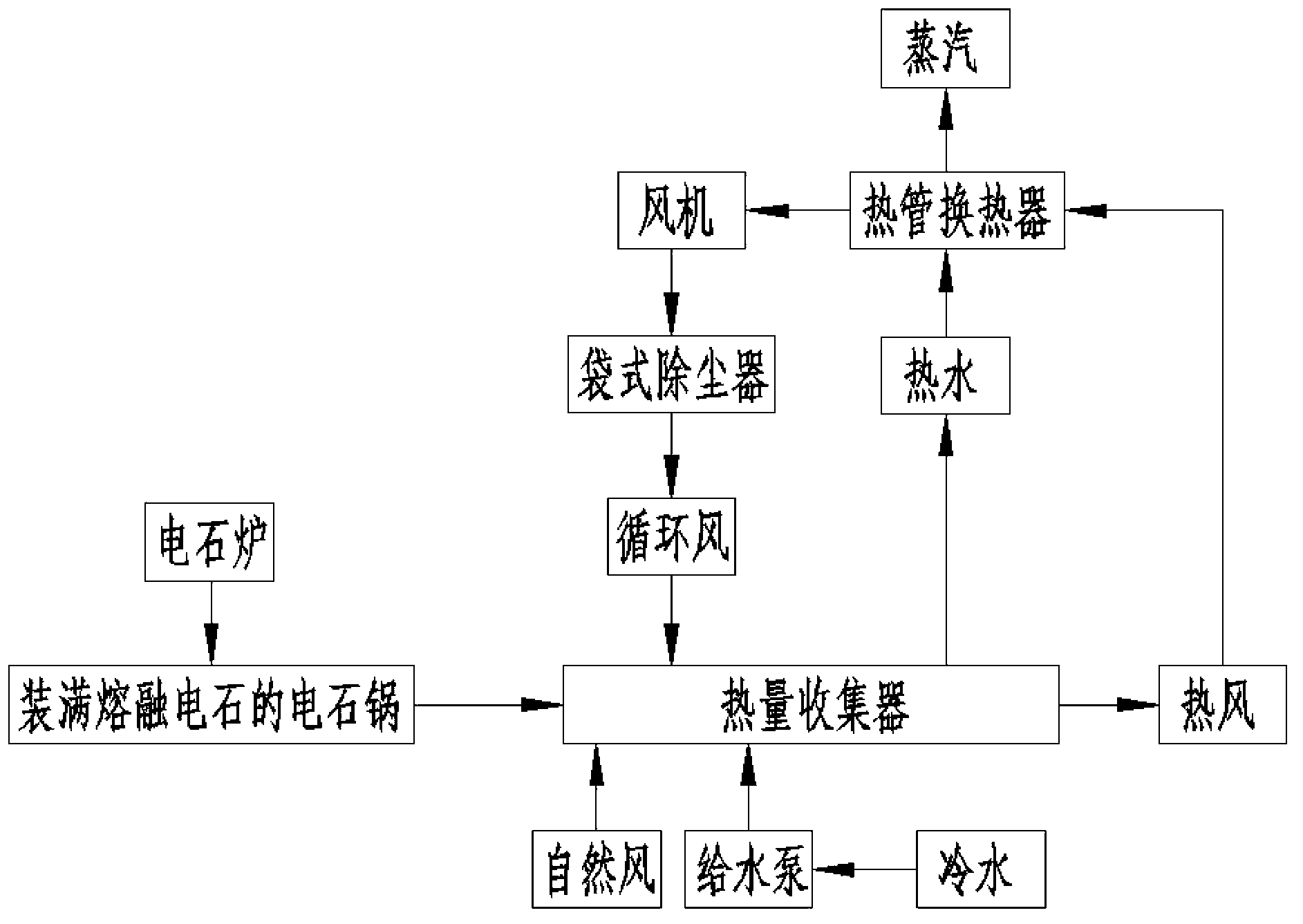

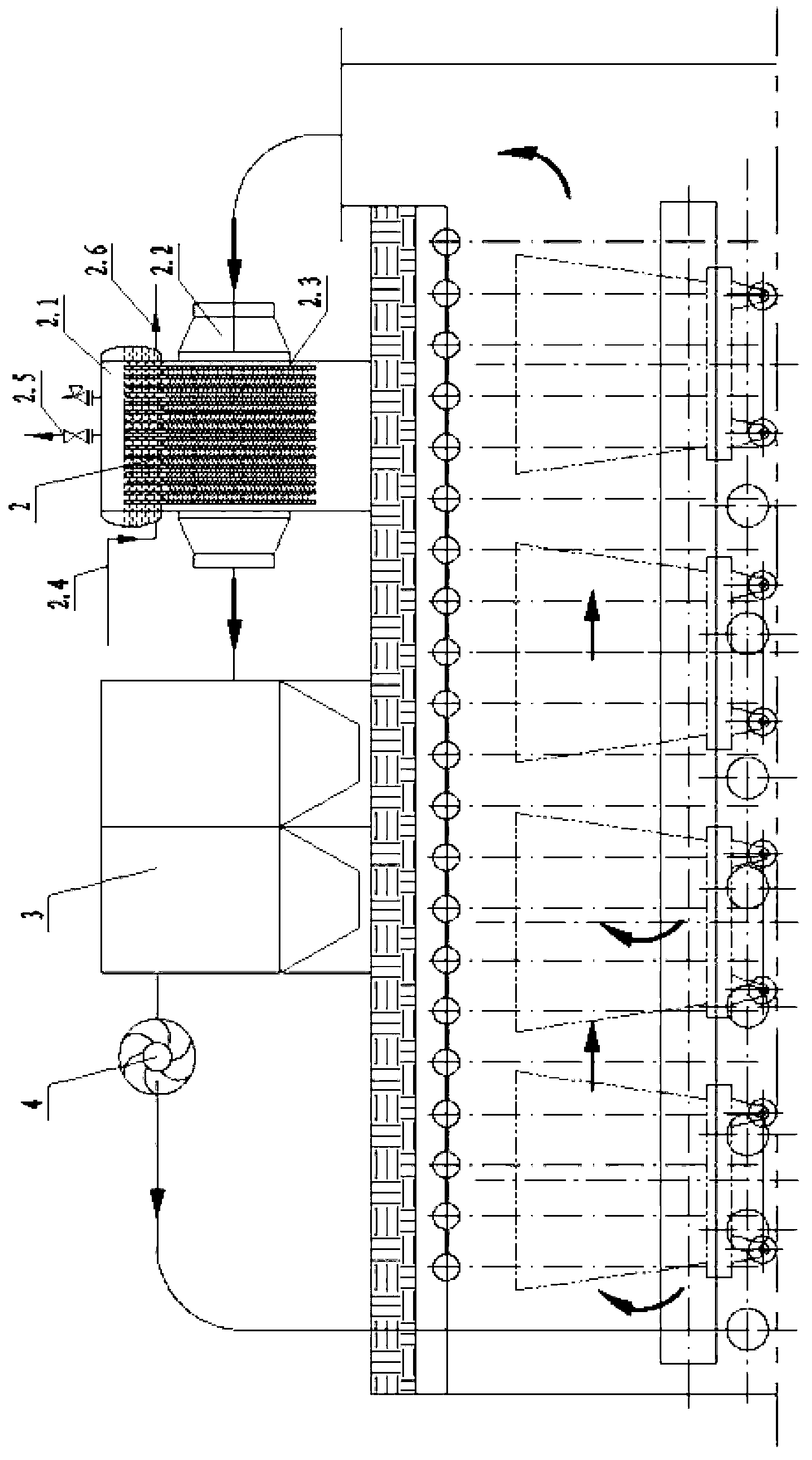

Waste heat recovery device and waste heat recovery method during condensation of molten calcium carbide

InactiveCN103307894AHigh efficiency of waste heat recoveryIncrease temperatureEnergy industryIncreasing energy efficiencyRecovery methodWaste heat recovery unit

The invention relates to a waste heat recovery device and a waste heat recovery method during condensation of molten calcium carbide. The device comprises a heat collector, a heat pipe exchanger, a duster, a fan and a feed water pump, wherein the heat collector is a closed box arranged on calcium carbide pot transport trolley tracks; sealing doors are arranged at the two ends of the box; a heat insulating material is arranged outside the box; a membrane wall pipe is arranged at the top of the box and on the inner faces of two side walls; a water inlet and a water outlet of the membrane wall pipe are connected with the feed water pump and a water inlet of a heat exchange pipe of the heat pipe exchanger respectively; an air suction port and an air inlet are formed at the lower part of the box; an air outlet is formed at one end of the box; an air inlet of the heat pipe exchanger is connected with an air outlet of the heat collector; an air outlet of the heat pipe exchanger is connected with the duster; the duster is connected with the fan; the fan is connected with an air inlet of the heat collector; the heat pipe exchanger is provided with a steam port; and the steam port supplies gas to a user. The device and the method have the benefits that heat exchange effects of radiation and convection are made full use of, the efficiency is high, the gas is purified, the cooling time is shortened, and the production cost is lowered.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

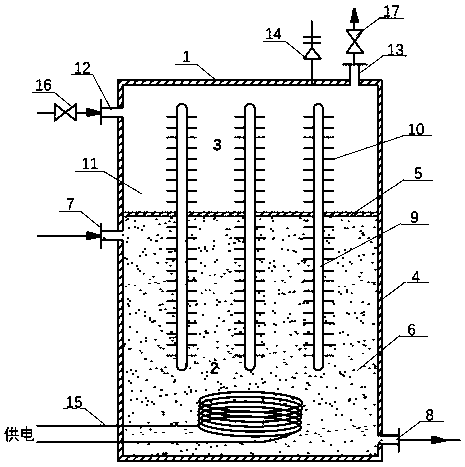

Fuse salt phase-change heat storage electric boiler

InactiveCN108150986ACompact structureSmall footprintStorage heatersIndirect heat exchangersWorking temperatureMolten salt

The invention discloses a fuse salt phase-change heat storage electric boiler. The fuse salt phase-change heat storage electric boiler comprises a boiler tank body, the interior of the boiler tank body is portioned into a heat transferring cavity and a heat storage cavity through a partition plate, and a heat storage medium is arranged in the heat storage cavity. A heat transferring medium is arranged in the heat transferring cavity, an immersed-type electric heater is arranged in the heat storage cavity, and the heat storage cavity is connected with a heat storage medium inlet and a heat storage medium outlet. The heat transferring cavity is connected with a heat transferring medium inlet and a heat transferring medium outlet, and a set of heat tubes penetrating through the partition plate are arranged in the boiler tank body. According to the fuse salt phase-change heat storage electric boiler, a heat tube exchanger is adopted, compared with an ordinary exchanger, the heat transferring performance is better, storage heat can be rapidly extracted, and efficient heat transferring is achieved; through the diode characteristic of the heat tubes, heat one-way transferring is ensured,and heat back flowing is prevented; and through the heat switch characteristic of the heat tubes, the work temperature range of the heat storage medium is controlled, it is ensured that solid-liquid phase-change circulation occurs near fused points, and the phase-change energy storage characteristic of fuse salt is maintained.

Owner:SOUTHEAST UNIV

Evaporation type automobile parking ventilating and cooling system

InactiveCN101898498AIngenious ideaNovel structureAir-treating devicesLighting and heating apparatusHeat pipe heat exchangerAerospace engineering

The invention discloses an evaporation type automobile parking ventilating and cooling system, which comprises a working power supply. In the system, a partition board is arranged in a shell to divide the inner cavity of the shell into an upper cavity and a lower cavity, the evaporation section and condensation section of a heat pipe exchanger are arranged in the upper and lower tow cavities respectively, two circulating fans are arranged on the left and right sides of the evaporation section in the upper cavity respectively, two interior dry and hot air inlets for the air exhaust of the circulating fans are formed on the left and right lateral plates of the shell and positioned above the partition board respectively; and an interior dry and cold air exhaust hole is formed on the top plate of the shell; a water-absorbing porous honeycomb ceramic body is arranged in an air intake channel on the left side of the condensation section in the lower cavity, the ceramic body is arranged in the water tank and an exhaust fan is arranged on the right side of the condensation section in the lower cavity; and an interior dry and hot air first inlet is formed on the left lateral plate of the shell and positioned below the partition board, and an interior wet and hot air outlet is formed on the right lateral plate of the shell and positioned below the partition board. The system has ventilation and cooling functions and has the characteristics of simple structure, convenient installation and low energy consumption.

Owner:XIHUA UNIV

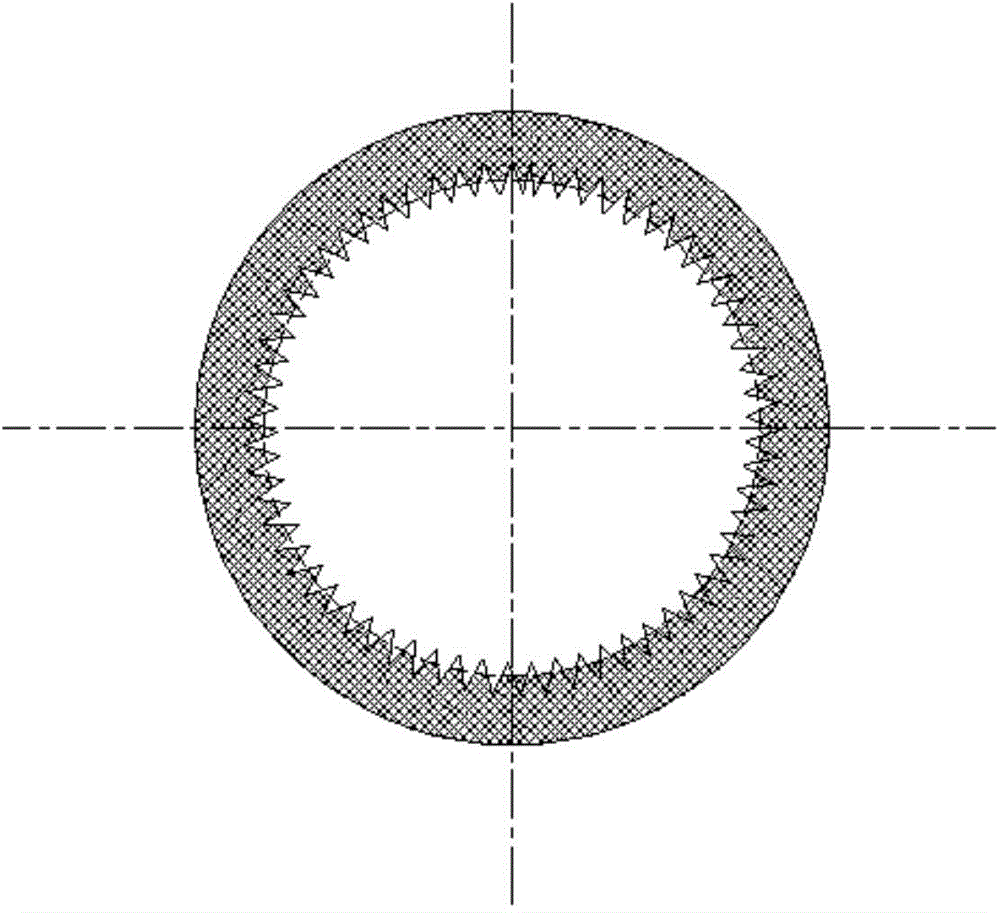

Integral heat pipe heat exchanger

InactiveCN102607304ASmall resistanceImprove heat transfer efficiencyStationary conduit assembliesHeat exchanger casingsEvaporationEngineering

The invention relates to an integral heat pipe heat exchanger, comprising an outer shell, a heat pipe heat exchanger device contained in the outer shell and a separator fixedly connected with the outer shell. The heat pipe heat exchanger device comprises an evaporation end and a condensation end. The integral heat pipe heat exchanger is divided into an inner circulation heat exchange system and an outer circulation heat exchange system by the separator and the outer shell. The heat pipe heat exchanger device comprises a connection part which extends along the horizontal direction by leaning a certain angle. The connection part is connected with the condensation end and the evaporation end, and the separator penetrates through the connection part so as to divide the connection part into a first connection part and a second connection part. The first connection part and the evaporation end are together located in the inner circulation heat exchange system; and the second connection part and the condensation end are together located in the outer circulation heat exchange system. The integral heat pipe heat exchanger provided by the invention has the advantages of simple structure, high heat transmission efficiency, small fluid resistant loss and large power-heat ratio.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

Combined opening and closing type circulating heat pump drying system

PendingCN109539762AFree from pollutionStable temperatureFluid heatersMechanical apparatusVapor–liquid separatorEvaporation

The invention discloses a combined opening and closing type circulating heat pump drying system. The combined opening and closing type circulating heat pump drying system comprises a drying room, a heat pump drying subsystem and a drying air circulation subsystem, wherein the heat pump drying subsystem comprises a compressor, a main condenser, an indoor evaporator, an outdoor heat exchanger, a liquid storage device, a drying filter and a gas-liquid separator; the drying air circulation subsystem comprises an air supply port and an air return port, wherein the air supply port and the air returnport communicate with the drying room through an air duct, the main condenser is arranged at the position corresponding to the air return port, and an air supply fan is arranged at the air supply port; the air return port comprises a bypass air duct and a dehumidifying air duct, wherein the dehumidifying air duct communicates to the position where the main condenser is located by sequentially passing through an evaporation section of a heat pipe heat exchanger and a condensation section of the heat pipe heat exchanger from the drying room; and the bypass air duct communicates with the position where the main condenser is located through the drying room. According to the system, the working efficiency is high, the structure is simple, the size is small, working is carried out more stably,an open type function and a closed type function are provided, the heating speed of the system is fast, and dehumidification is still carried out in the defrosting process.

Owner:河南中瑞制冷科技有限公司

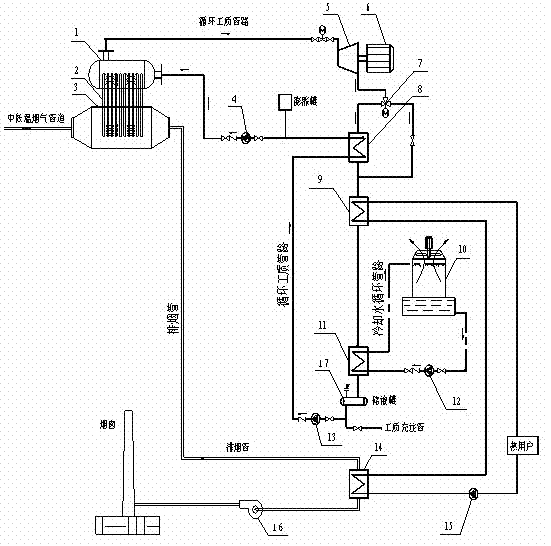

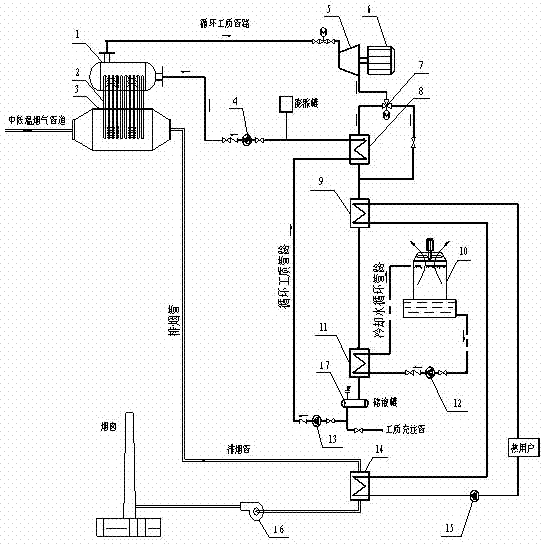

Power generation system for waste heat of medium and low temperature flue gas with heat pipe heat exchanger organic medium Rankine cycle

InactiveCN102401590AEasy to replaceImprove heat transfer performanceIndirect heat exchangersSteam engine plantsDichlorodifluoromethaneOrganic Rankine cycle

The invention provides a power generation system for waste heat of medium and low temperature flue gas with heat pipe heat exchanger organic medium Rankine cycle, and belongs to the technical field of energy and environment. The invention comprises a heat pipe heat exchanger system, a working medium circulation loop of organic Rankine cycle, a medium and low temperature flue gas exhausting pipeline, a heating hot water loop and a cooling water loop, wherein an ascending pipe and a descending pipe of a boiler are replaced by heat pipes, the heat pipe heat exchanger system is formed by a heat pipe, a flue gas heat exchanger and a boiler cylinder, evaporating section of the lower end of the heat pipe is arranged in flue gas heat exchanger, condensing section of the upper end is arranged in the boiler barrel, toluene, dichlorodifluoromethane, propane and pentafluoropropane are used as working medium, 20% volume of the softening desalted water is used as the heat pipe fluid. The invention has advantages of high efficiency of heat exchange, convenient replacement of heat pipe, being capable of avoiding corrosion and uneasy-change of the heat exchanger pipe, affecting the heat transfer efficiency and leakage of the working medium and other advantages, and being capable of adjusting exhaust heat of the organic Rankine cycle according to the demand for heating load of users.

Owner:KUNMING UNIV OF SCI & TECH

Hot pipe type porous foamed metal heat exchanger

InactiveCN101338985ALarge specific surface areaReduce weightIndirect heat exchangersHeat flowHeat pipe heat exchanger

The invention discloses a heat pipe multihole foam metal heat exchanger with multihole foam metal as expanded transfer area based on the heat pipe principle, in order to solve the problems of the prior heat pipe heat exchanger with expanded transfer area, namely, large volume, large weight, consuming much metal and so on. The heat pipe multihole foam metal heat exchanger solves the problem of small heat interchanging area of heat pipes through filling multihole foam metal around the heat pipes in a shell. Cold and hot fluid involving in transfer of heat flows through multihole foam metal passages. Therefore, the heat exchanger is lighter, smaller and more compact with less metal consumed under the precondition of the same heat exchange effect.

Owner:NANJING UNIV OF TECH

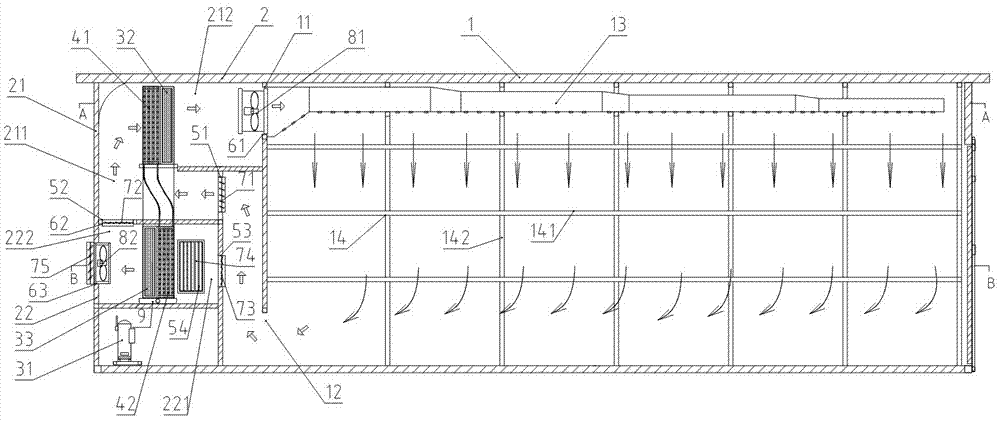

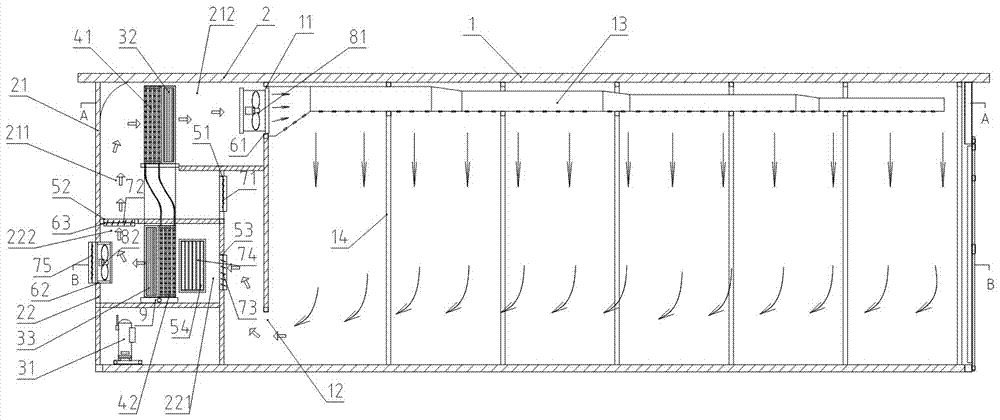

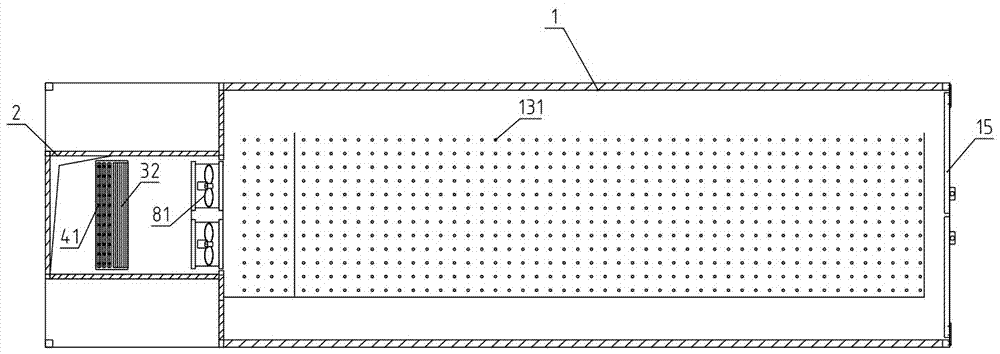

Heat pump tobacco drying room using closed type humidity elimination and open type hot air in combined mode

The invention discloses a heat pump tobacco drying room using closed type humidity elimination and open type hot air in a combined mode. The heat pump tobacco drying room comprises a drying chamber and a heat controlling chamber, the heat controlling chamber comprises a heating unit and a dehumidification and backheating unit, the heat controlling chamber is internally provided with a heat pump and a separate type heat pipe exchanger, the heat pump comprises a compressor, a condenser and an evaporator; the separate type heat pipe exchanger comprises a heat pipe condensation section and a heat pipe evaporation section, the condenser and the heat pipe condensation section are arranged in the heating unit side by side and divide the heating unit into a first air inlet cavity and a first air outlet cavity, condensate water collectors are arranged at the bottom end of the condenser and the bottom end of the heat pipe condensation section, the evaporator and the heat pipe evaporation section are arranged in the dehumidification and backheating unit side by side and divide the dehumidification and backheating unit into a second air inlet chamber and a second air outlet chamber, the first air inlet chamber and the second air outlet chamber and the drying chamber are controlled to be connected or disconnected through valves, switching of the closed type and the open type is achieved in structure, the requirements of all stages of tobacco drying are met, and the quality of dried products is improved.

Owner:河南芳捷农业发展有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com